Patents

Literature

775results about "Baking plants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

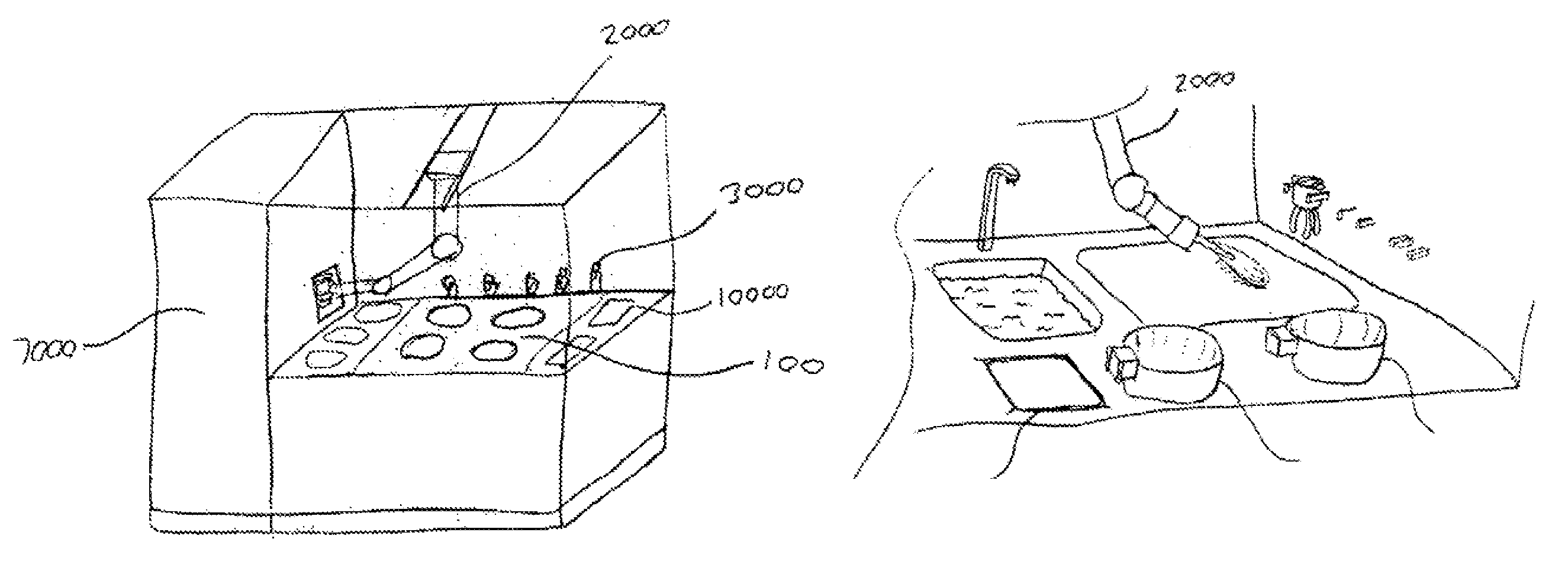

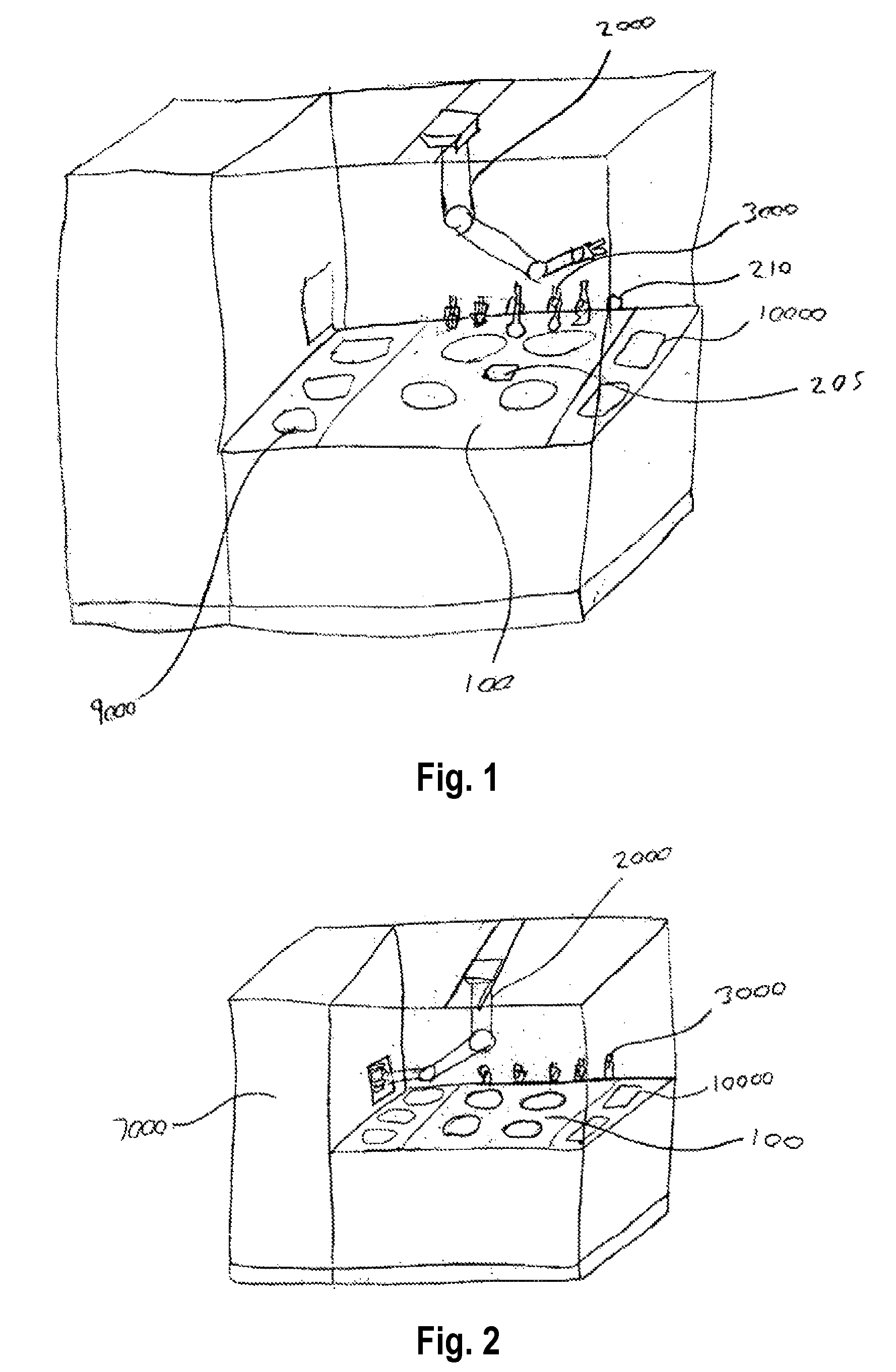

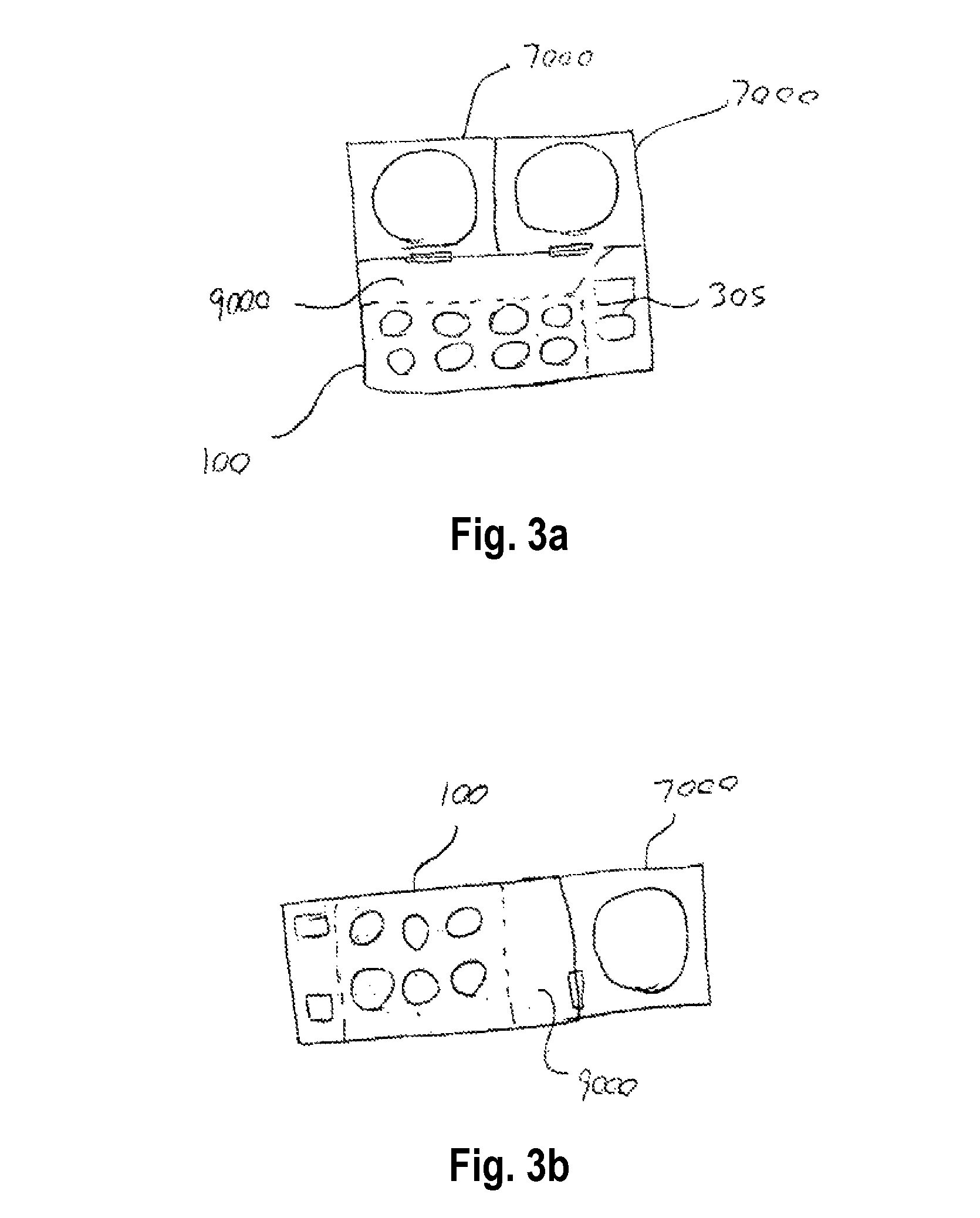

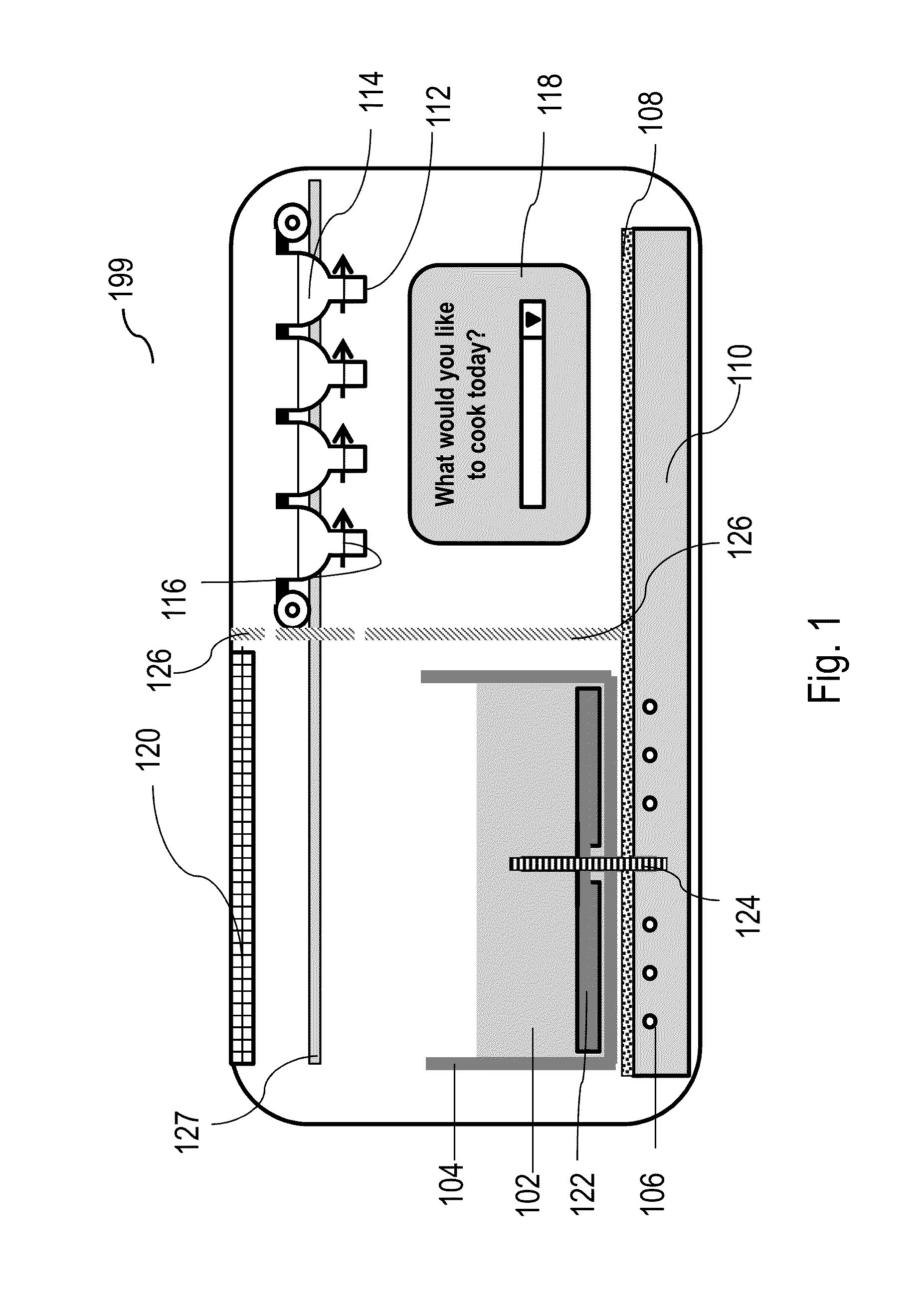

Food preparation system

InactiveUS20050193901A1Eliminate all packaging materialGood for foodFeeding apparatusRoasters/grillsAdditive ingredientControl system

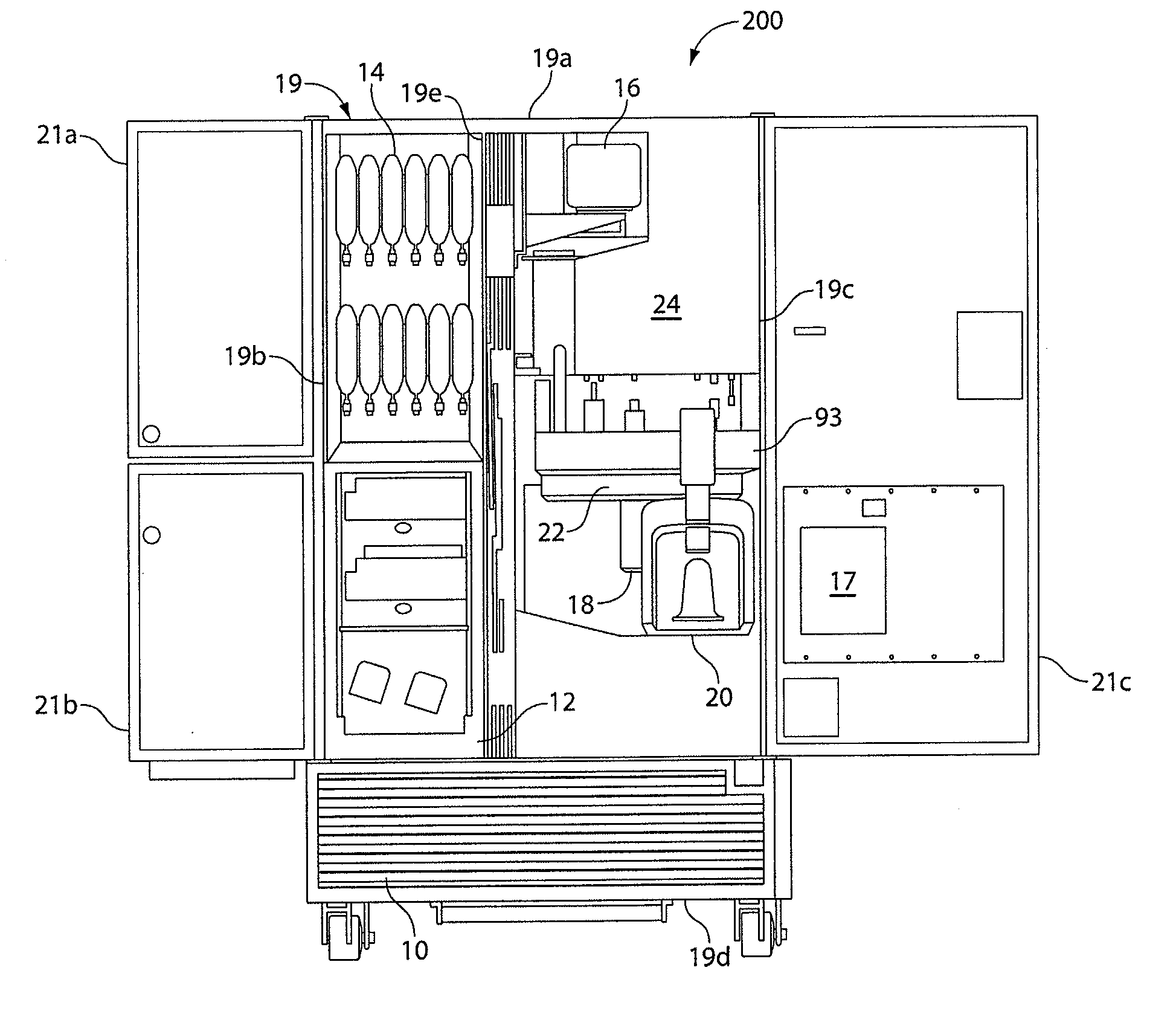

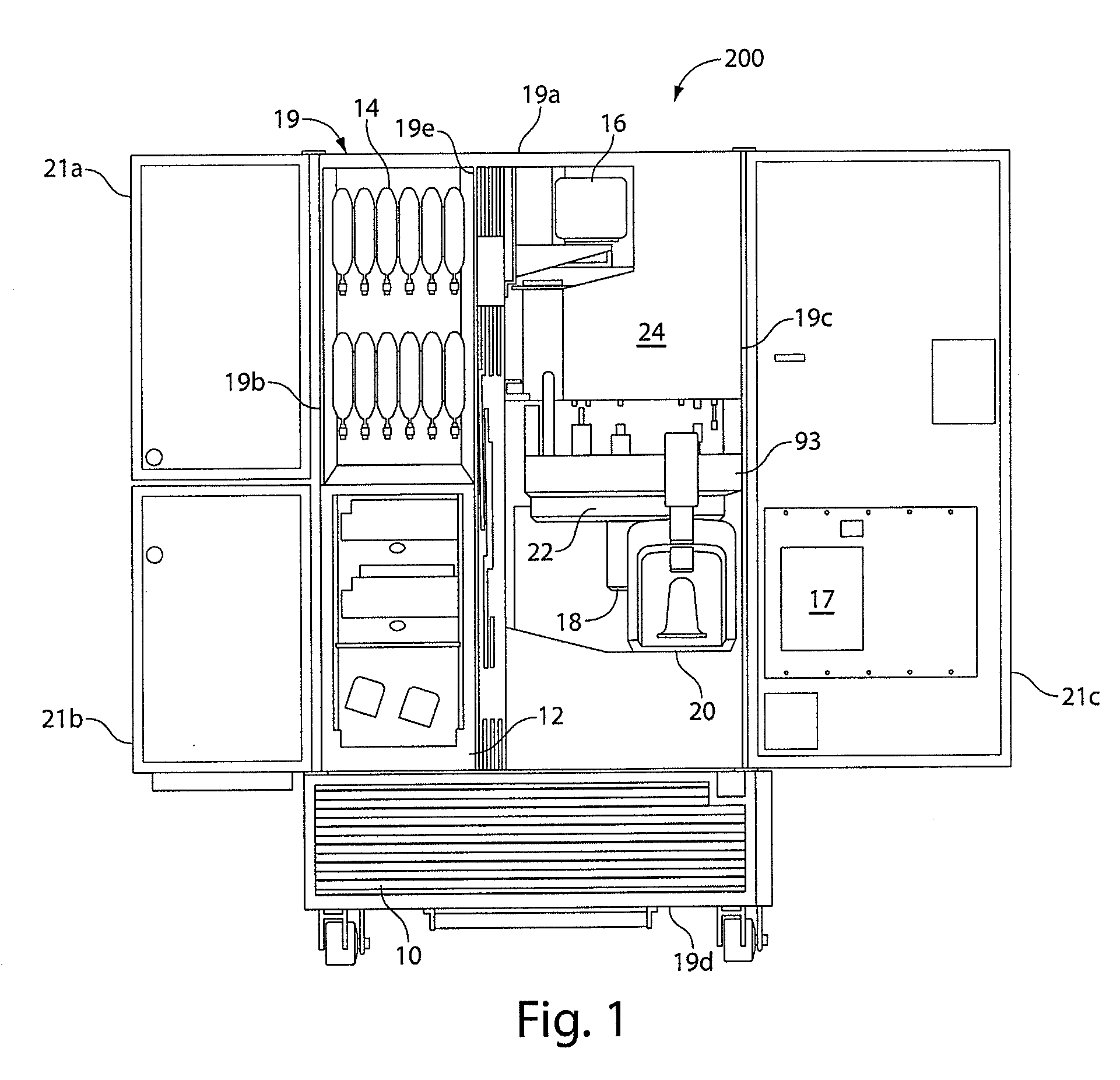

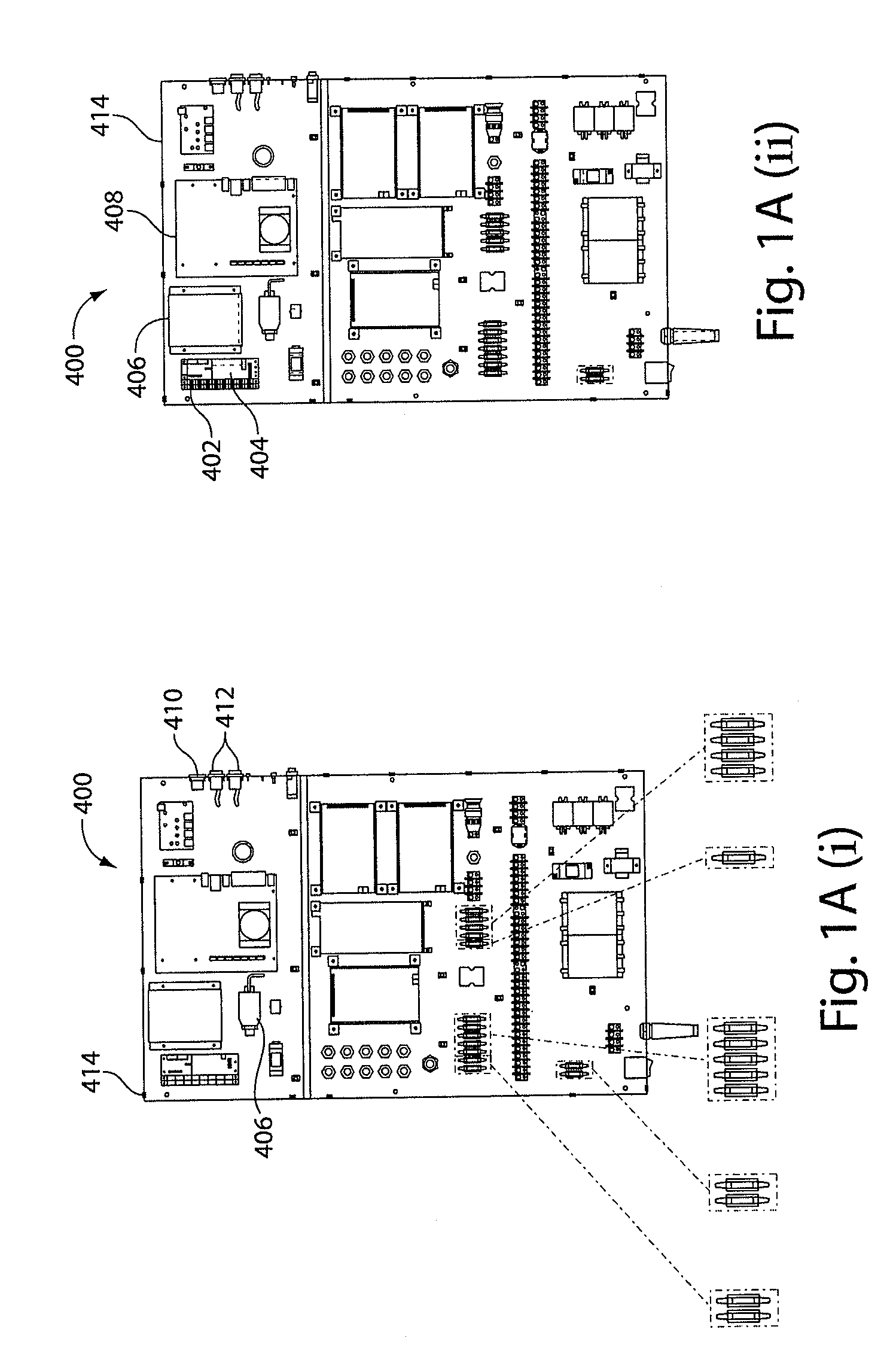

An automated food preparation system is described. It allows precise, automated control of the food preparation process, and has the ability to perform an automated cleanup. It comprises at least one manipulator to process and move ingredients, a control system, an autonomously accessible ingredient storage system, and at least one cooking receptacle.

Owner:BUEHLER DAVID BENJAMIN

Stir-frying Apparatus with Overhead Heating Device

InactiveUS20050223906A1Free handsEnvironmentally friendlyRoasters/grillsBaking plantsFresh airKnife blades

A stir-frying apparatus (100) with an overhead-heating device (128). Apparatus (100) comprises a container (102) for holding foods, a lid (120) covering on top of container (102), a bottom heating device (118) installed underneath container (102) and an overhead heating device installed on lid (120), a stirring blade (136) rotatably and removably installed inside container (102) for stirring foods, a power-drive assembly (140) operationally coupled with blade (136) for driving blade (136) through repeating stirring cycles, a coupling device (134) for coupling assembly (140) and blade (136), a venting device (200) for filtering and deodorizing cooking fumes, a blowing device (202) for forcing fresh air into apparatus (100) for the removal of moisture from therein-side, and an ingredient adding conduit (250) for use of adding ingredients during a frying process.

Owner:XU ZHAOXIA +1

Air Fryer

InactiveUS20080206420A1Improve heat transfer performanceProvide taste and texture and appearance characteristicDomestic stoves or rangesElectrical heating fuelProduct gasProcess engineering

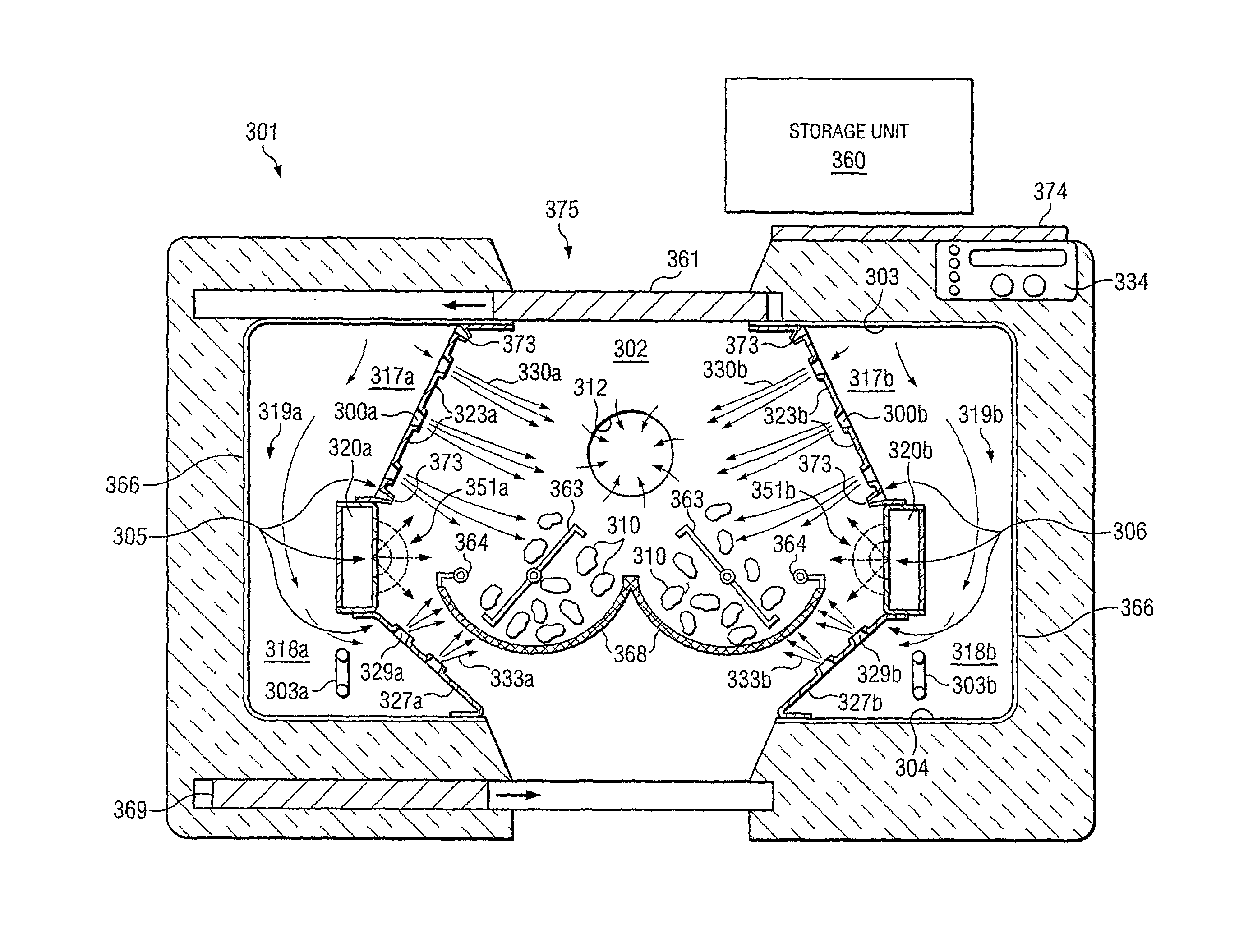

An accelerated cooking air fryer is disclosed comprising a cavity, controller, thermal heating source, blower assembly, gas directing means and a vent assembly. Hot gas is circulated by the blower motor assembly into the air fryer cavity where the hot air is directed in a manner wherein a conflicting, colliding turbulent gas flow is directed at a food product providing for the accelerated cooking of the food product.

Owner:TURBOCHEF TECH INC

Fryer with Automatic Coating of Fat

ActiveUS20080213447A1Easy to useEasy maintenanceMilk preservationRoasting apparatusEngineeringFood products

Owner:SEB SA

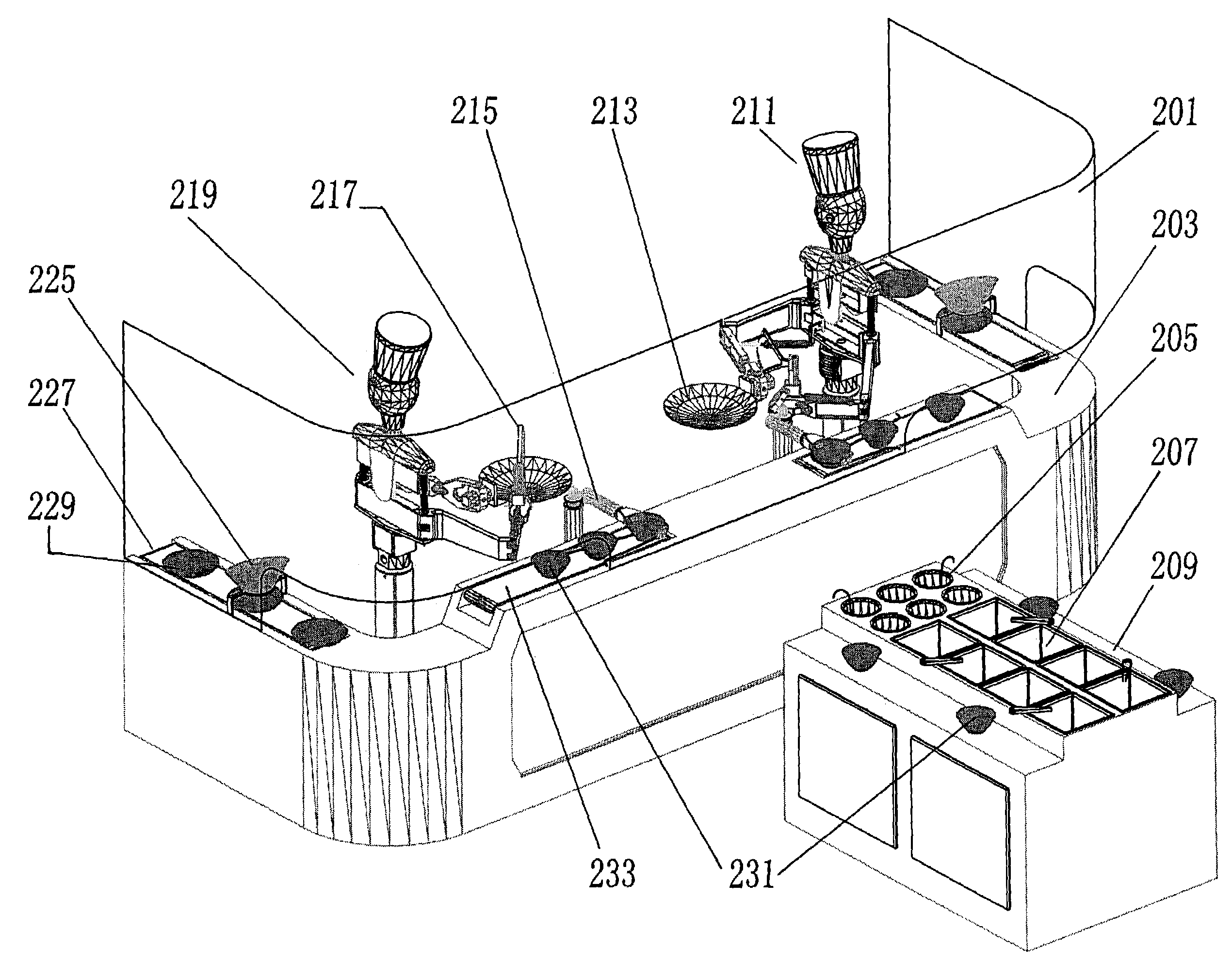

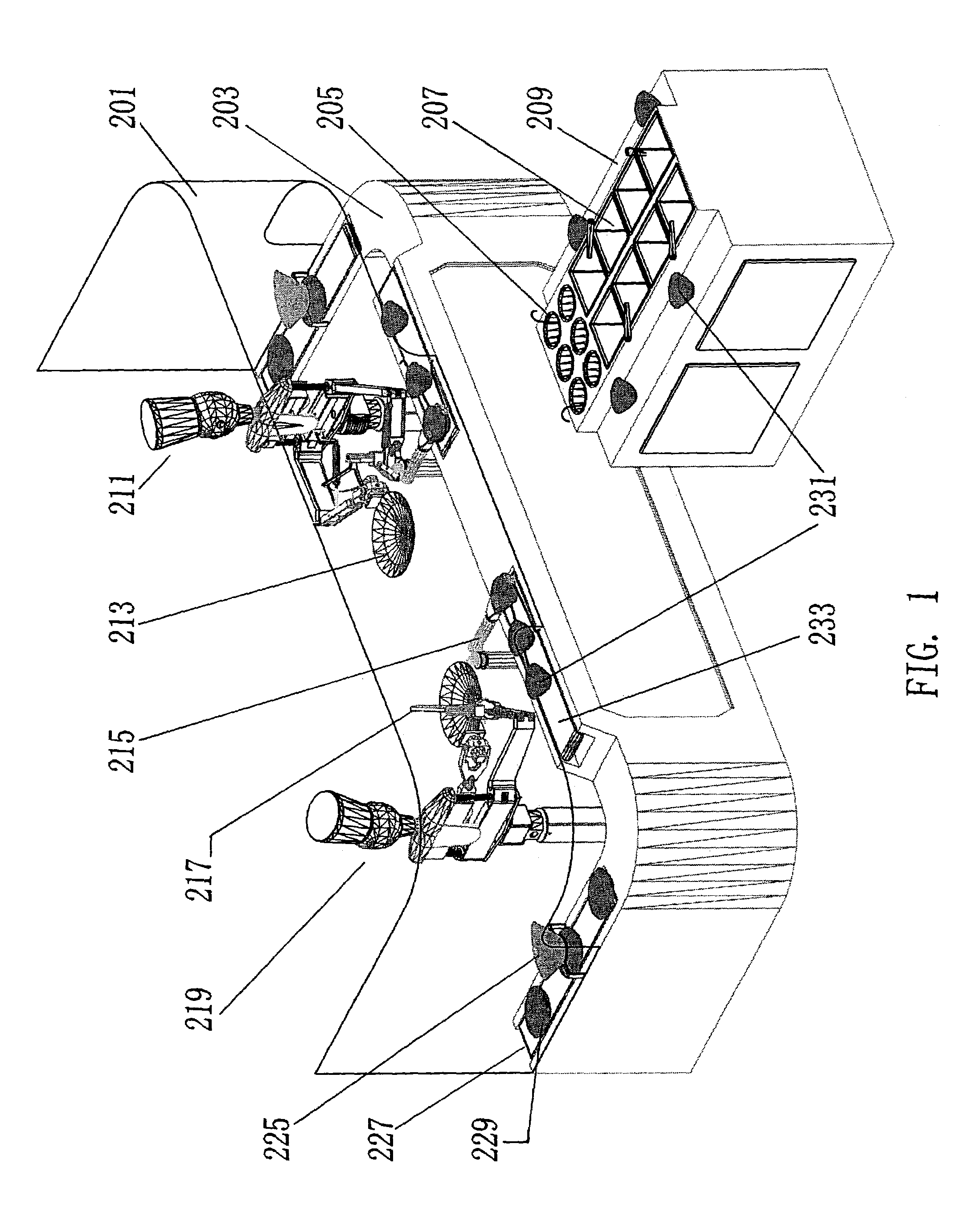

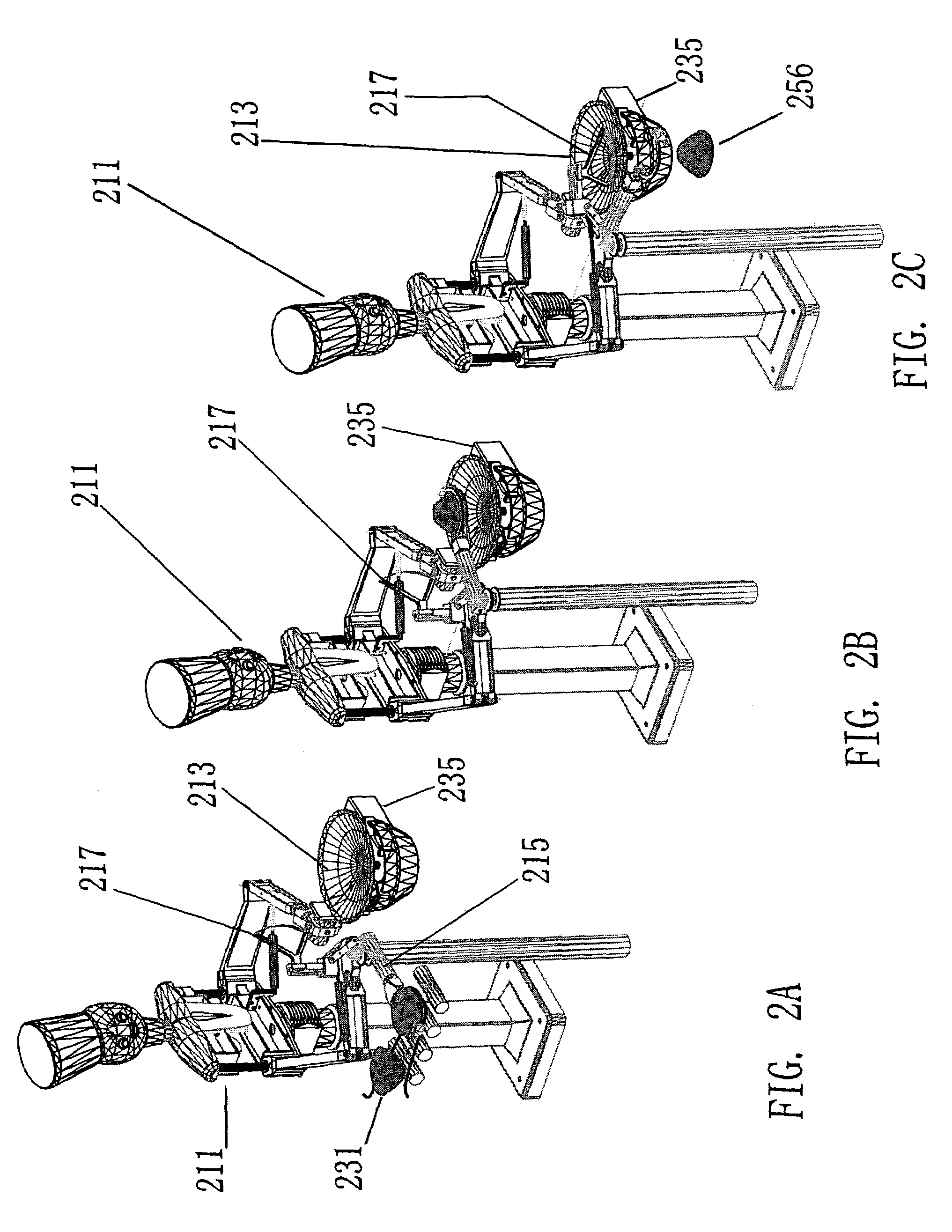

Robotic cooking system

InactiveUS7174830B1Reduce stepsReduce manpowerProgramme-controlled manipulatorMeat/fish preservationProcess engineeringHeating element

An automated system of preparing food designed with the preparation of Chinese food in mind, the system can be adapted to whatever type of food is desired by the user. The system uses one or more robots as the “chefs”. A heating element heats a cooking pan to a desired temperature. The cooking pan includes a temperature sensing element to monitor heating of the pan and cooking of the food. When the pan is fully heated, a delivery arm empties the contents of the bowl into the cooking pan to being the actual cooking. When the contents of the pan have reached the correct temperature to be “done”, the robot empties the contents into a serving dish, and the food is ready to be eaten.

Owner:DONG DAWEI

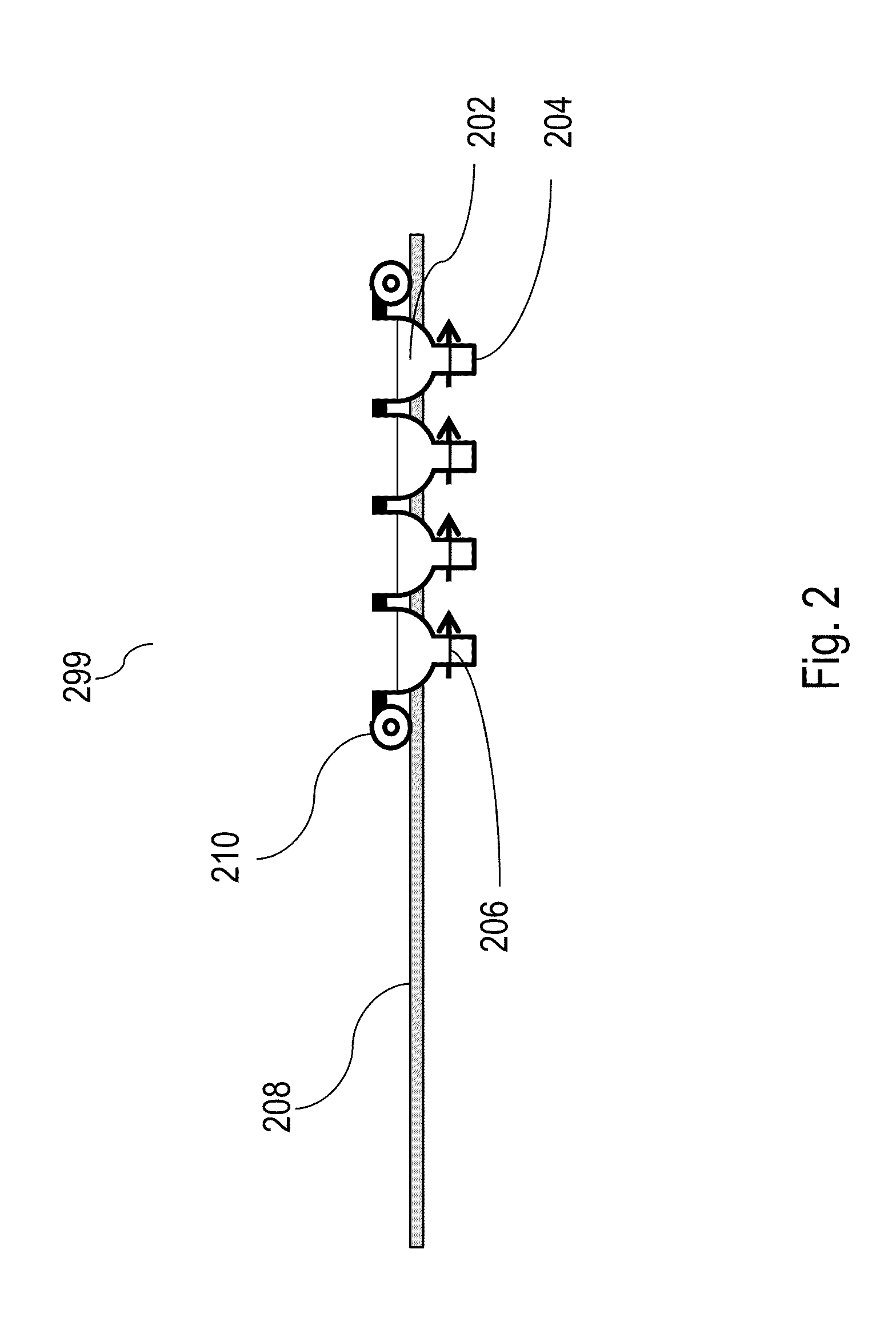

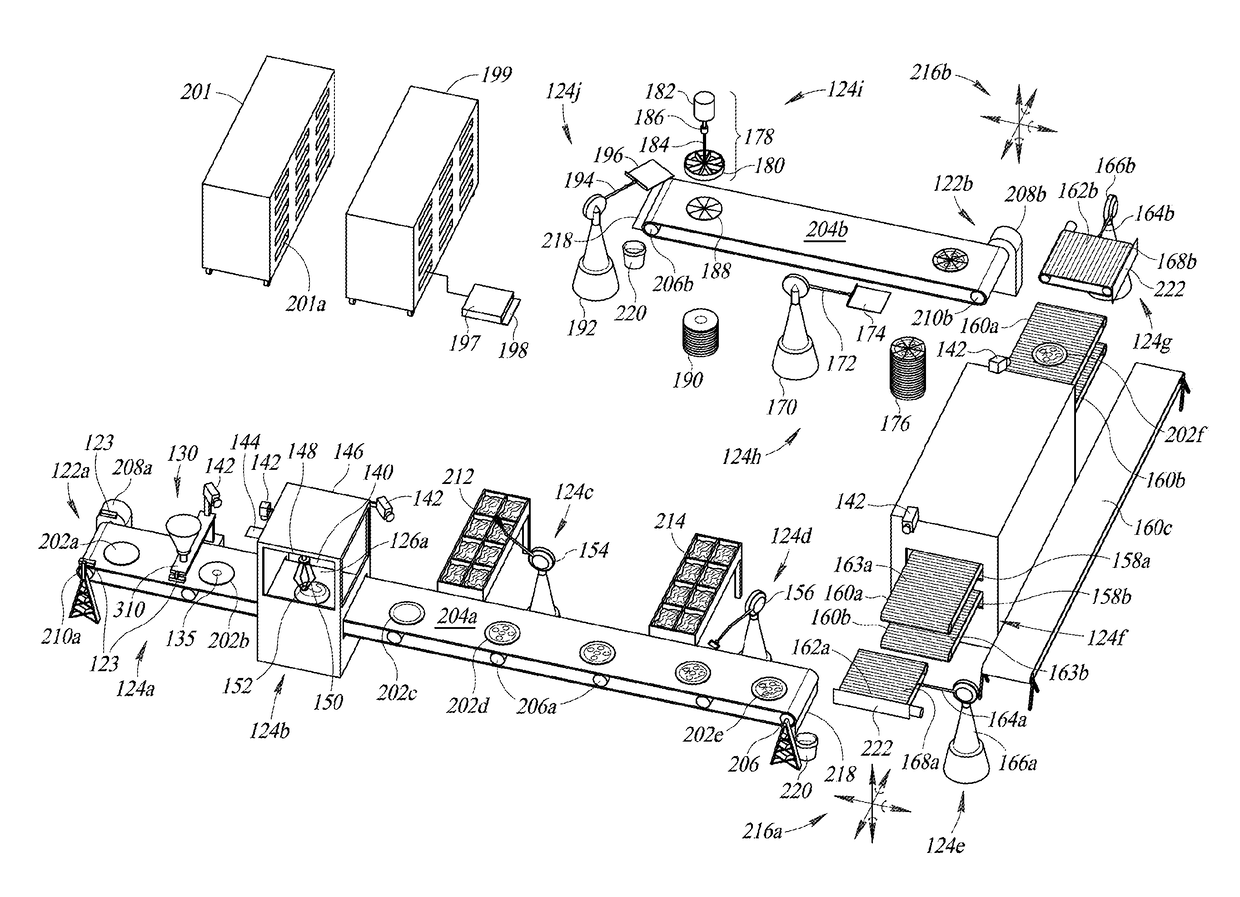

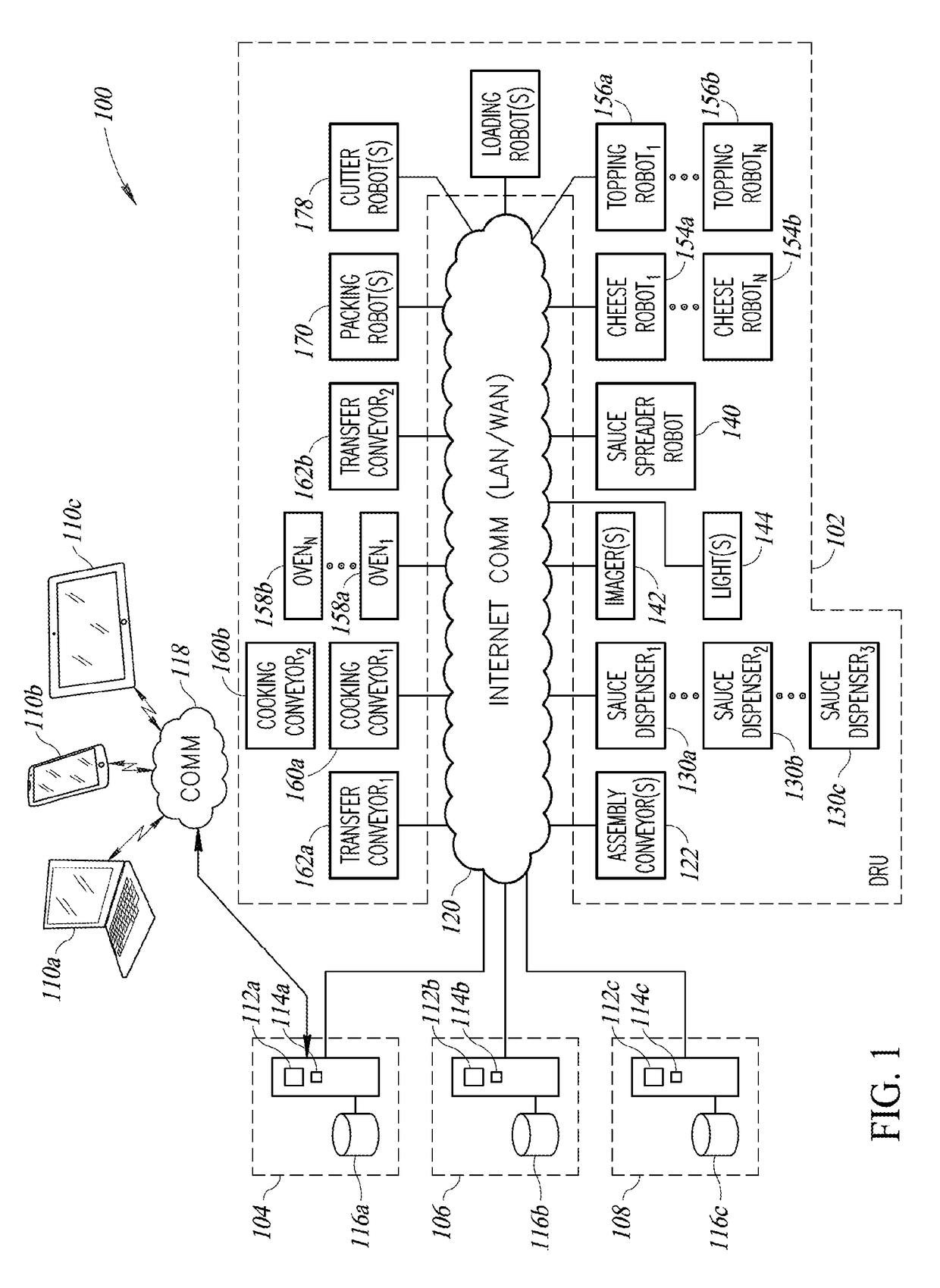

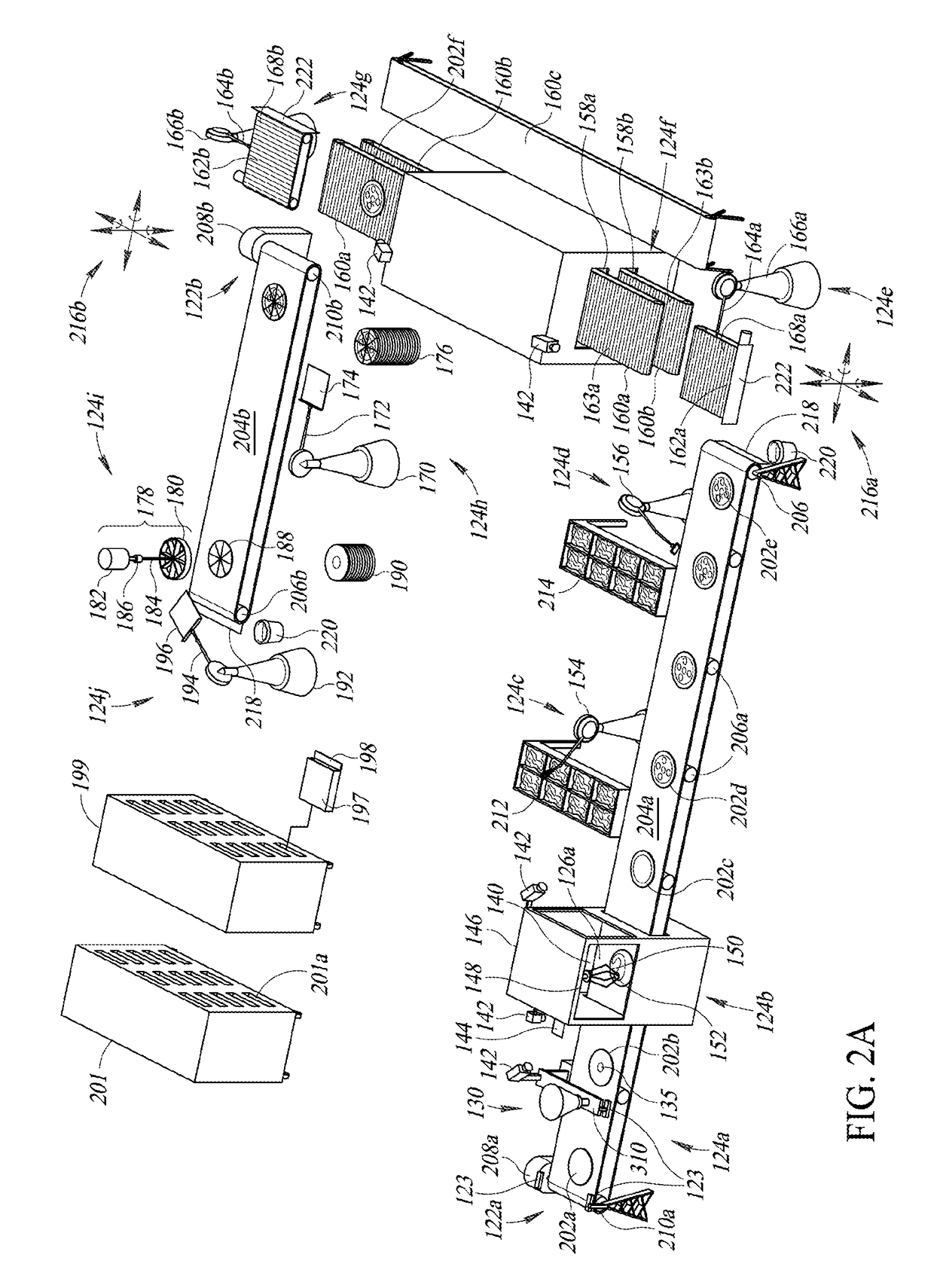

On-demand robotic food assembly and related systems, devices and methods

An on-demand robotic food assembly line can include one or more conveyors and one or more robots, operable to assemble food items in response to received orders for food items, and one or more ovens operable to, for example, partially cook assembled food items. The on-demand robotic food assembly line can optionally package the assembled and partially cooked food items in packaging, and optionally load the packaged partially cooked food items into portable cooking units (e.g., ovens) that are optionally loaded into racks that are, in turn, optionally loaded into delivery vehicles, where the food items are individually cooked under controlled conditions while en route to consumer destinations, such the cooking of each food item is completed just prior to arrival at the consumer destination location. A dynamic fulfillment queue for control of assembly is maintained based at least in part on estimated transit time for orders.

Owner:ZUME INC

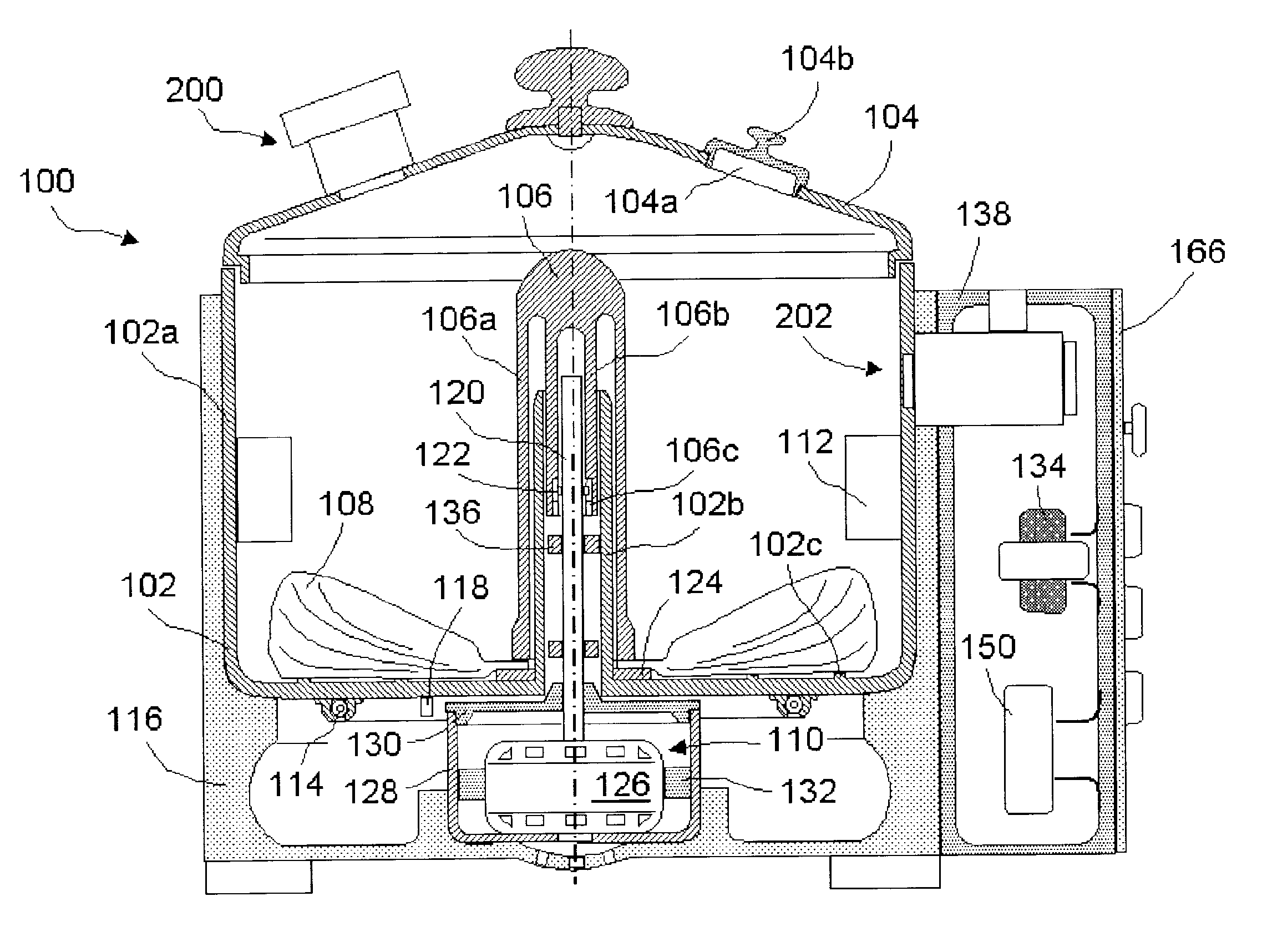

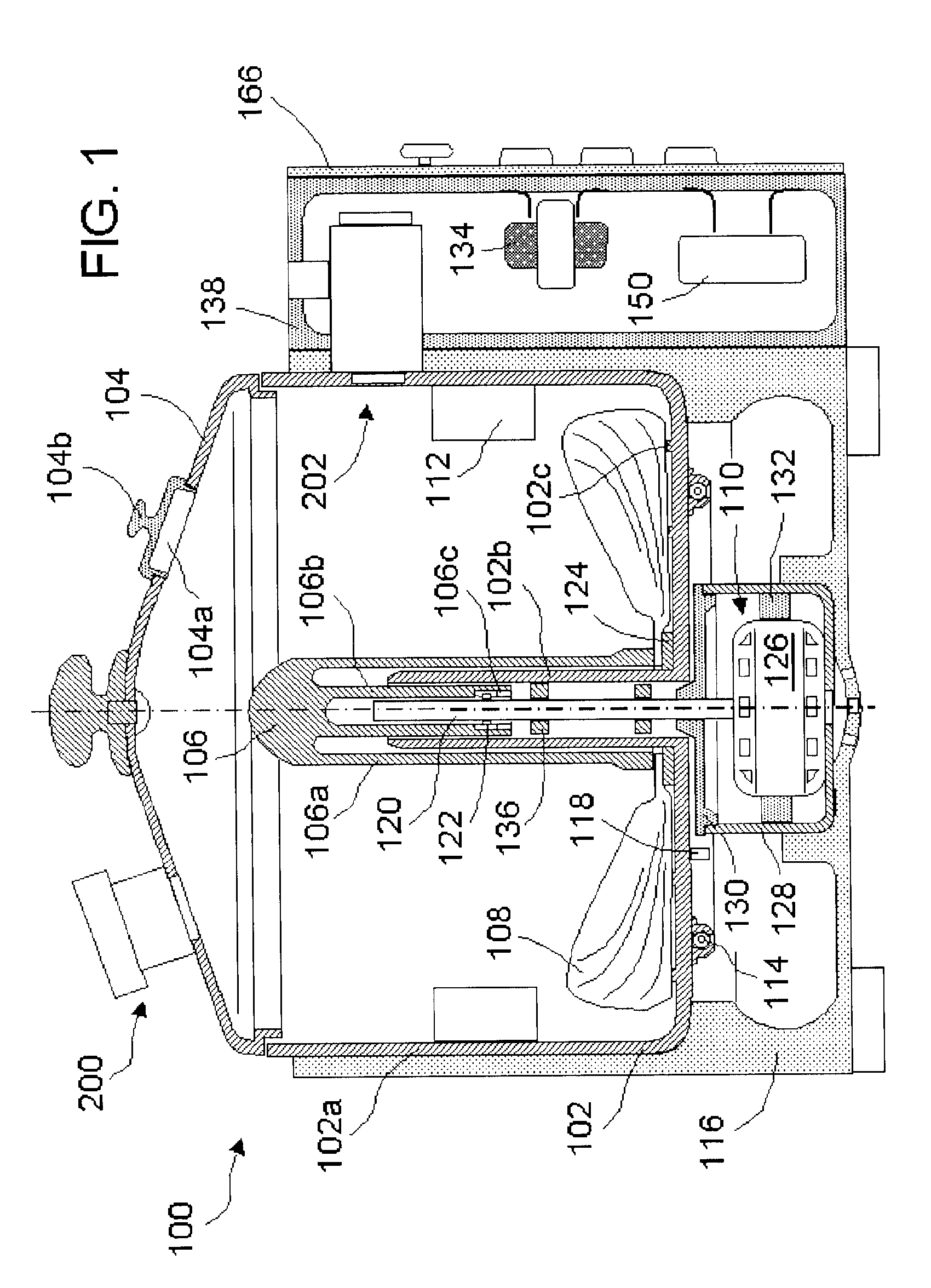

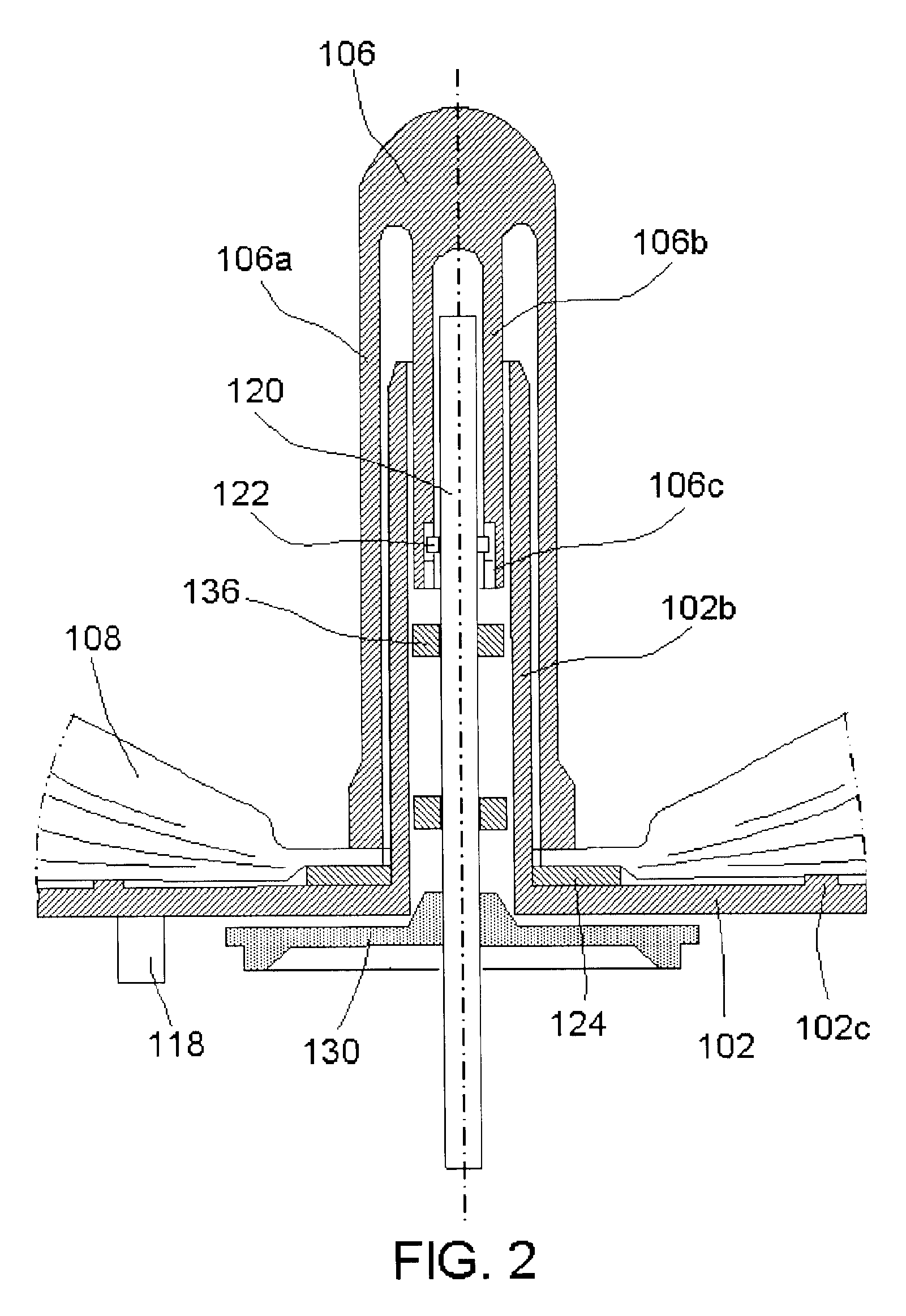

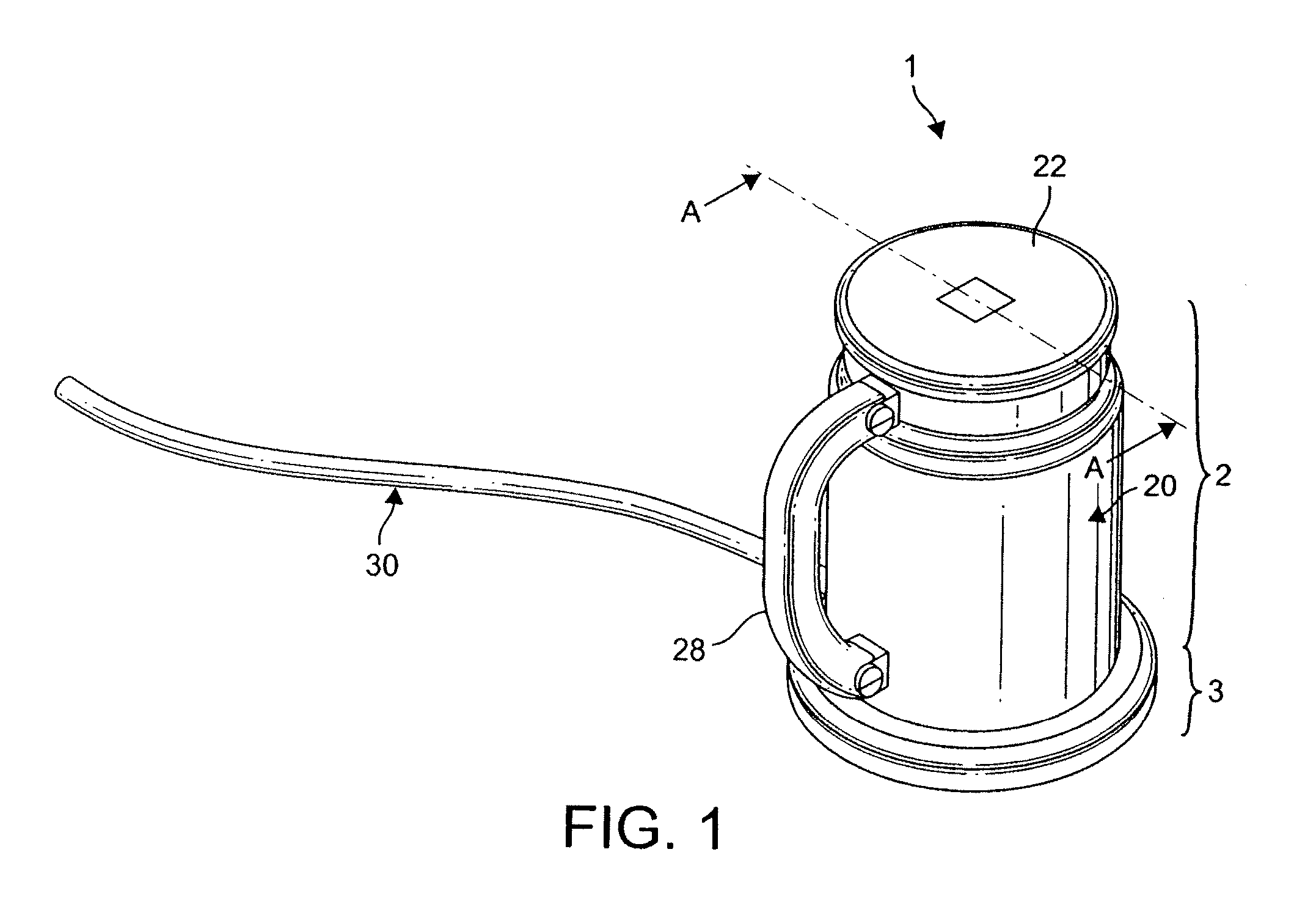

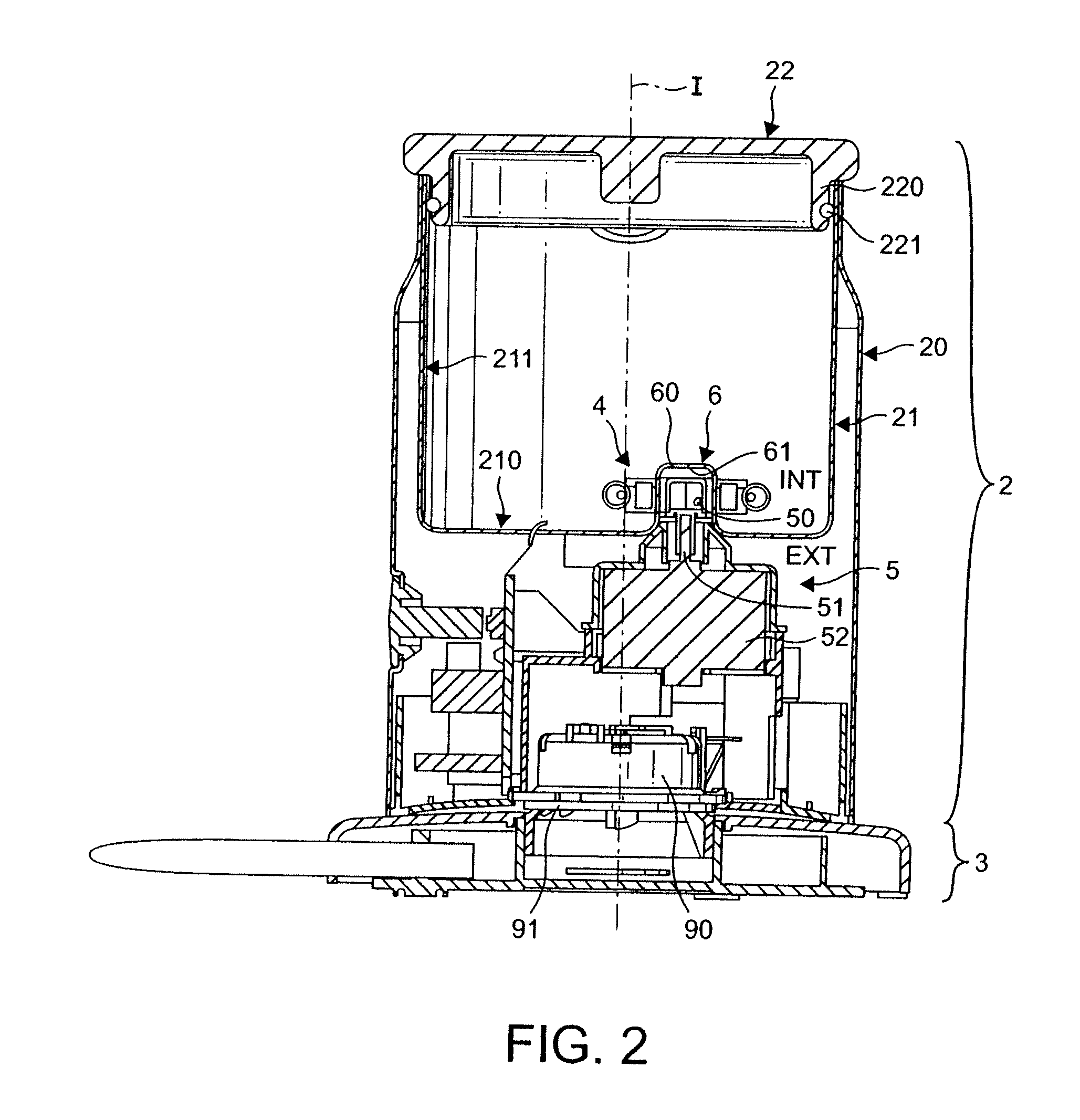

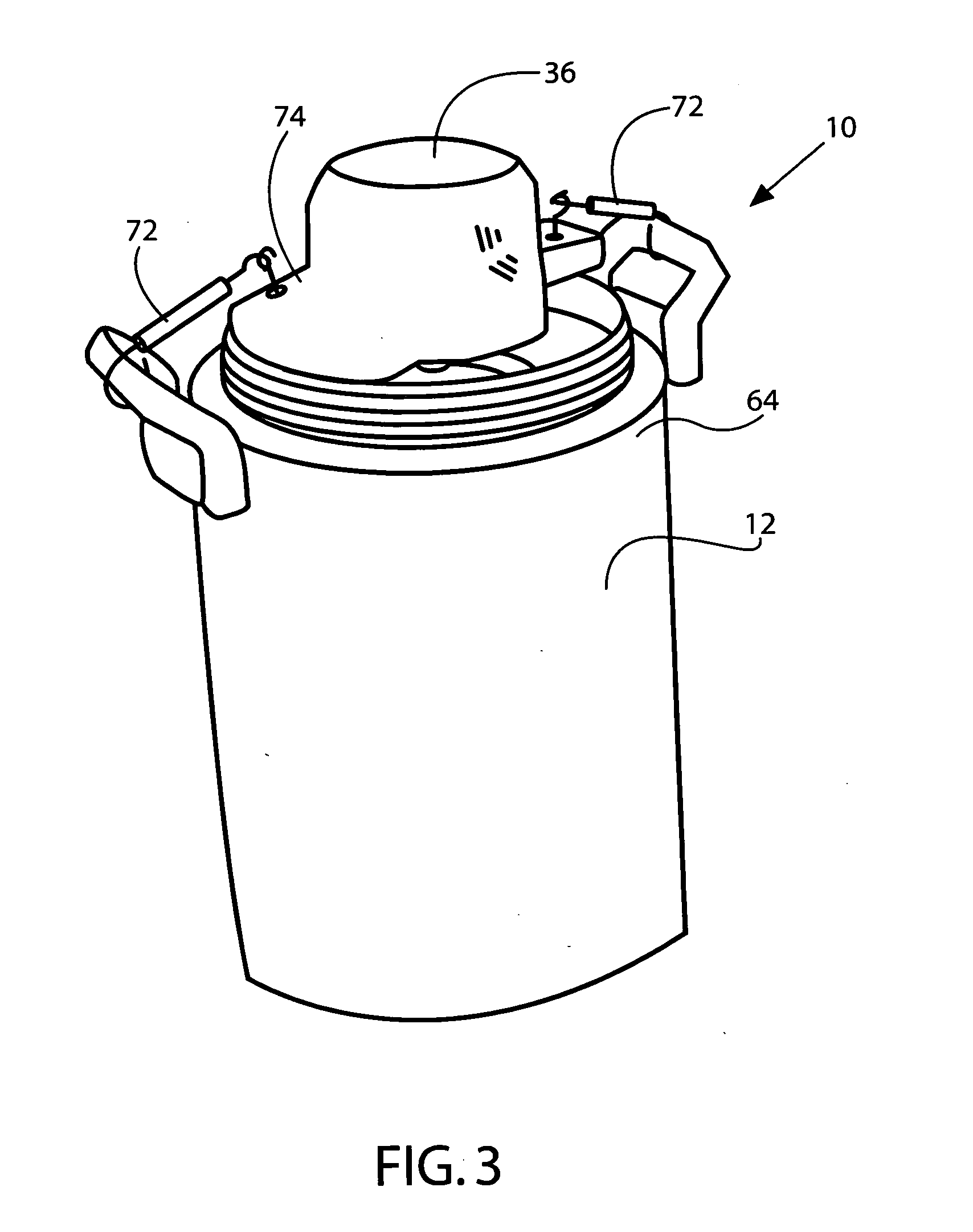

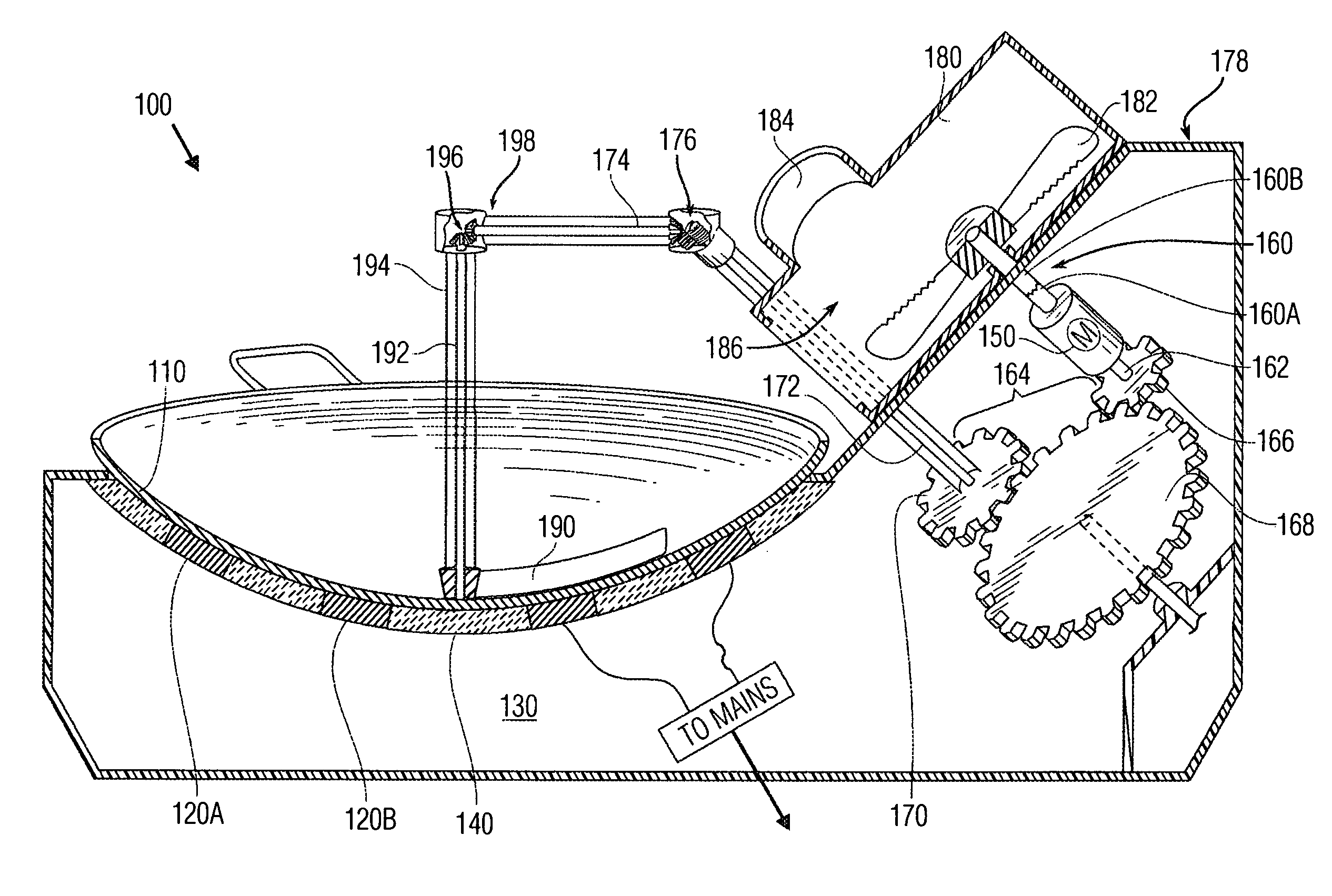

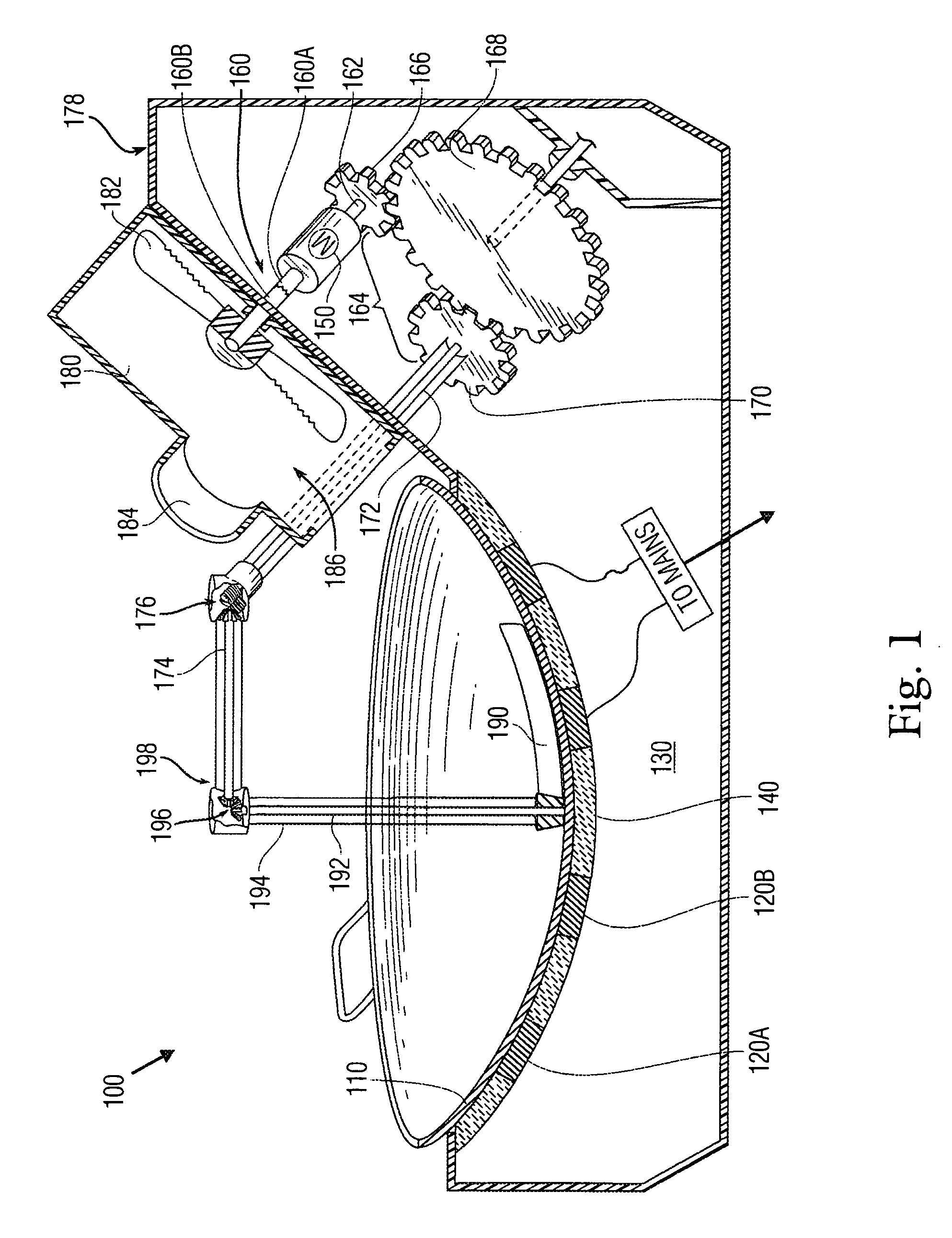

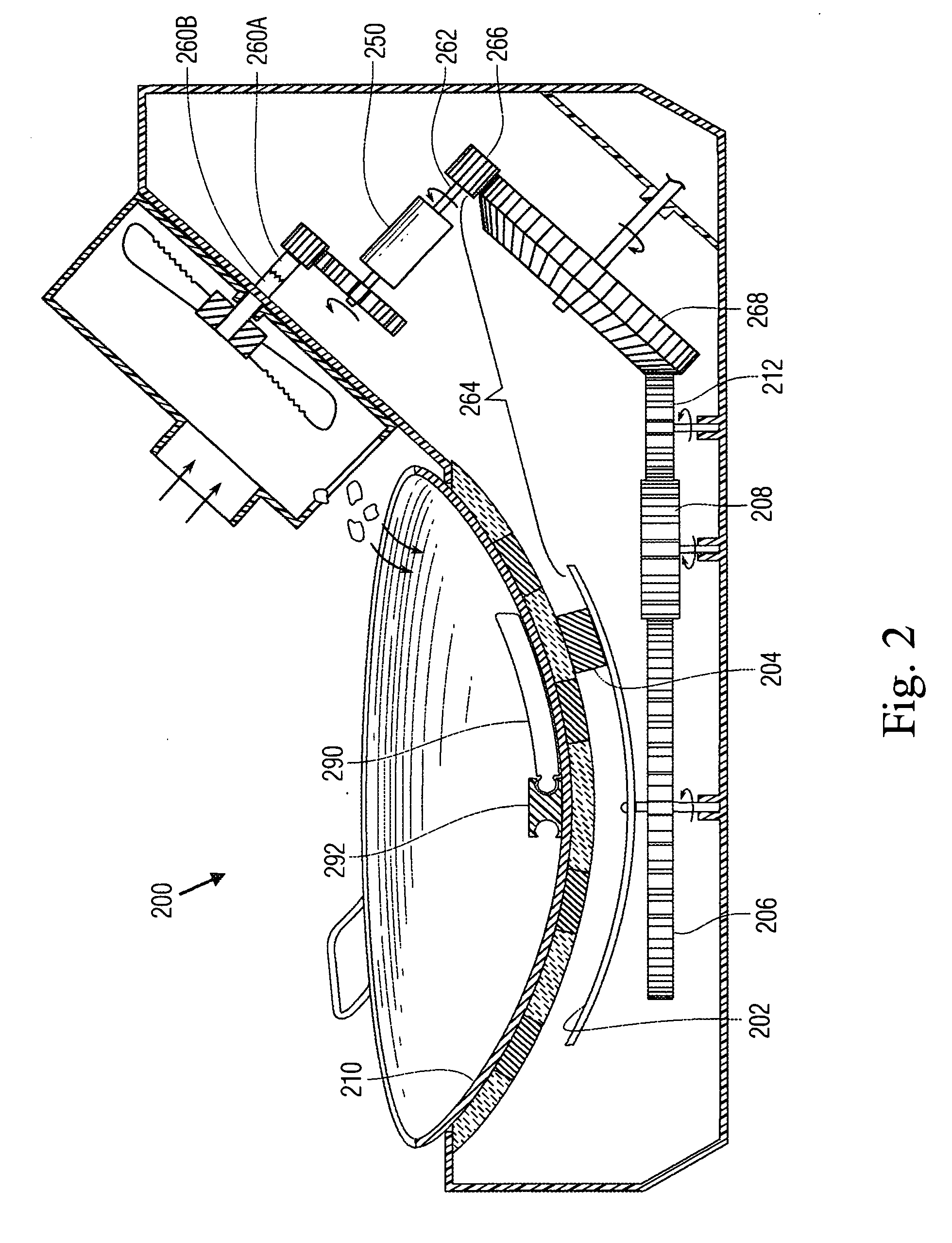

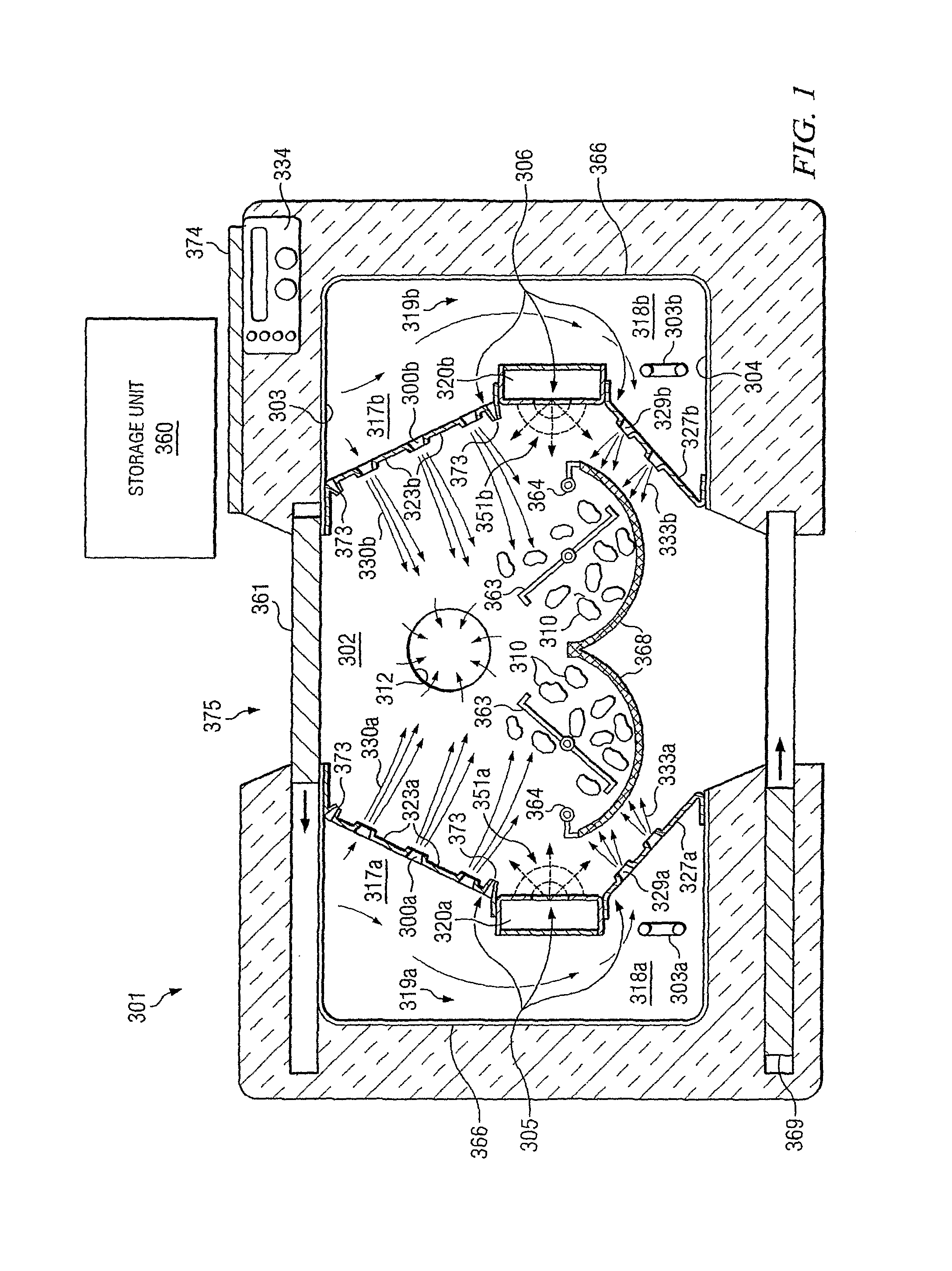

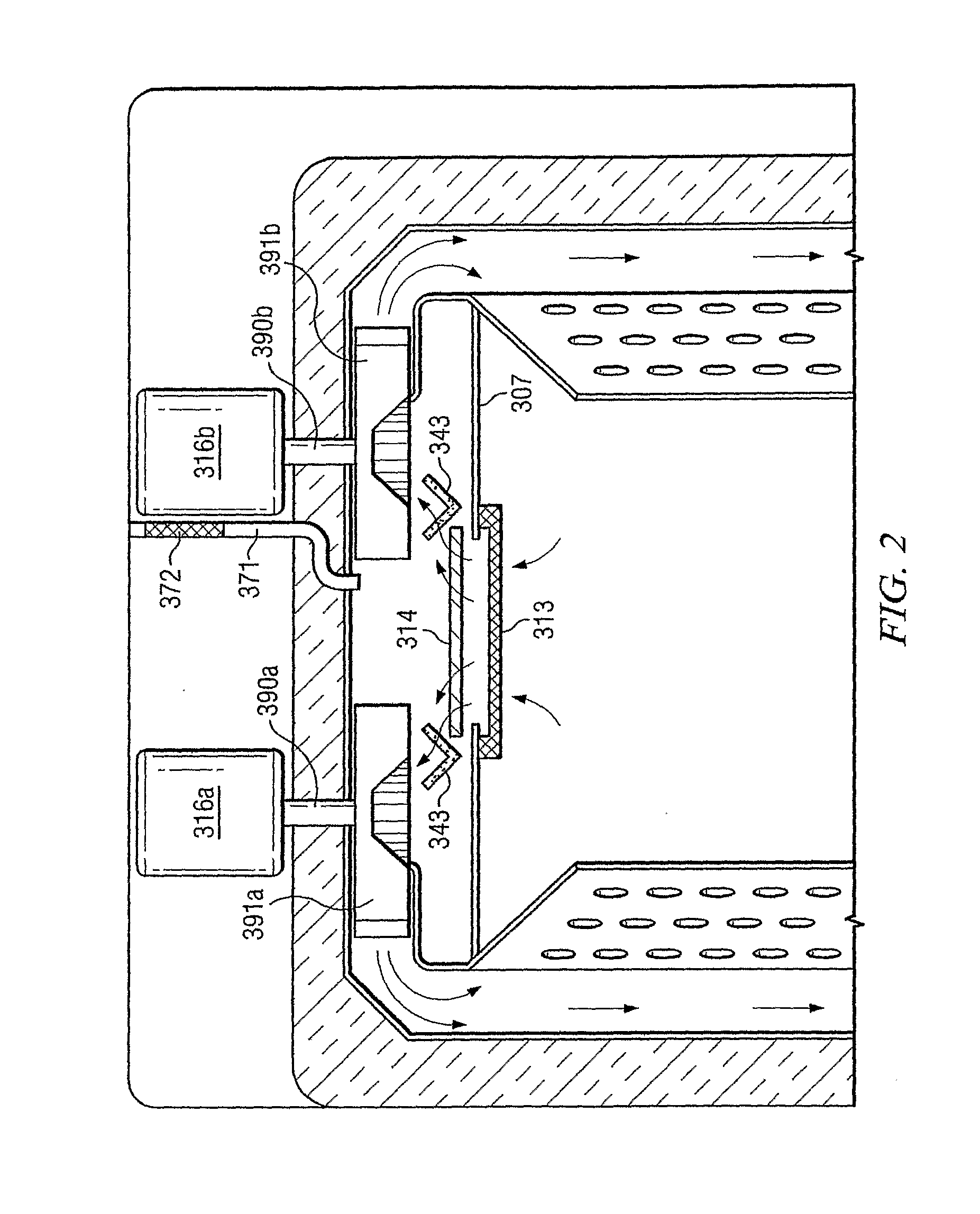

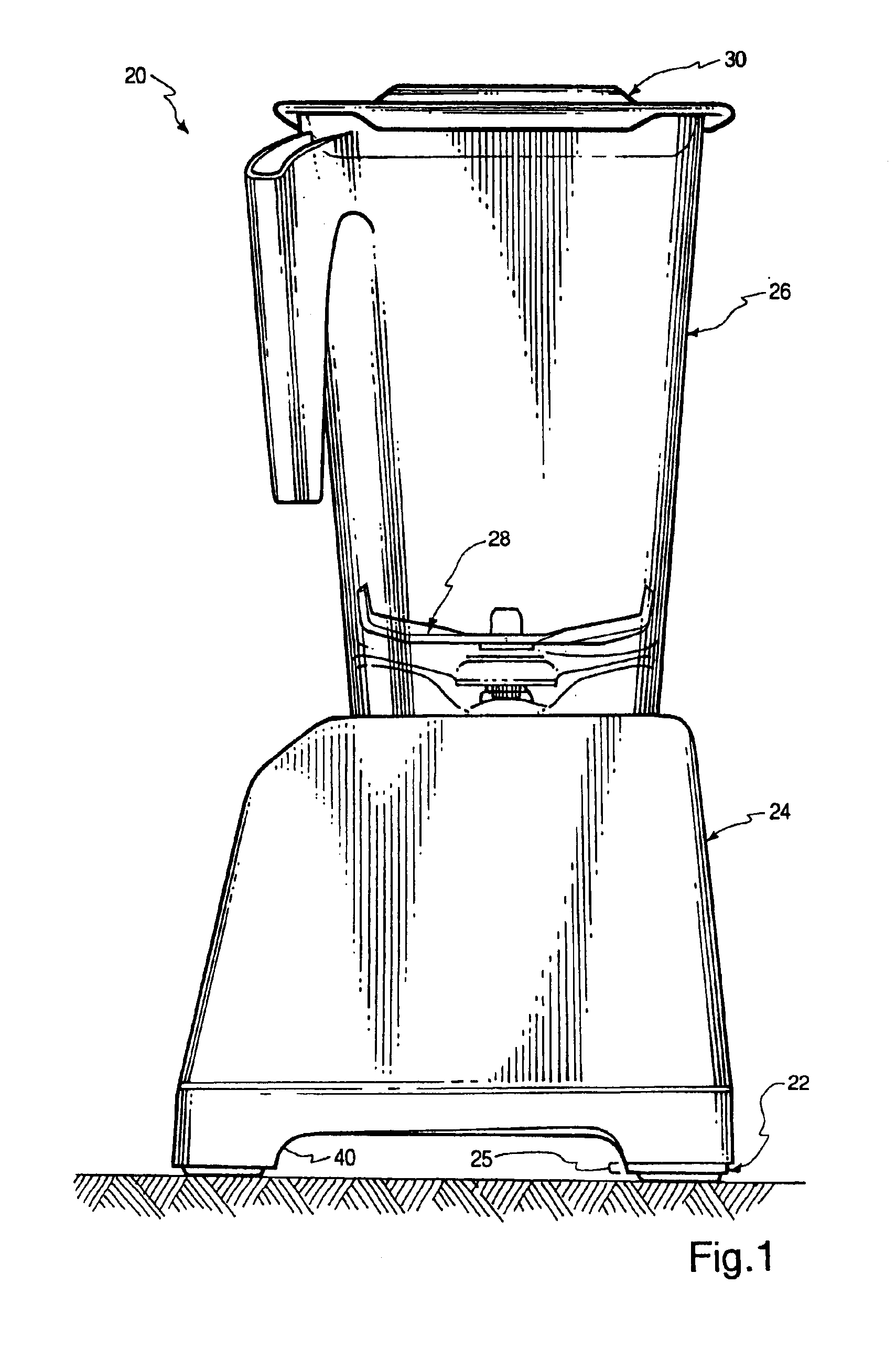

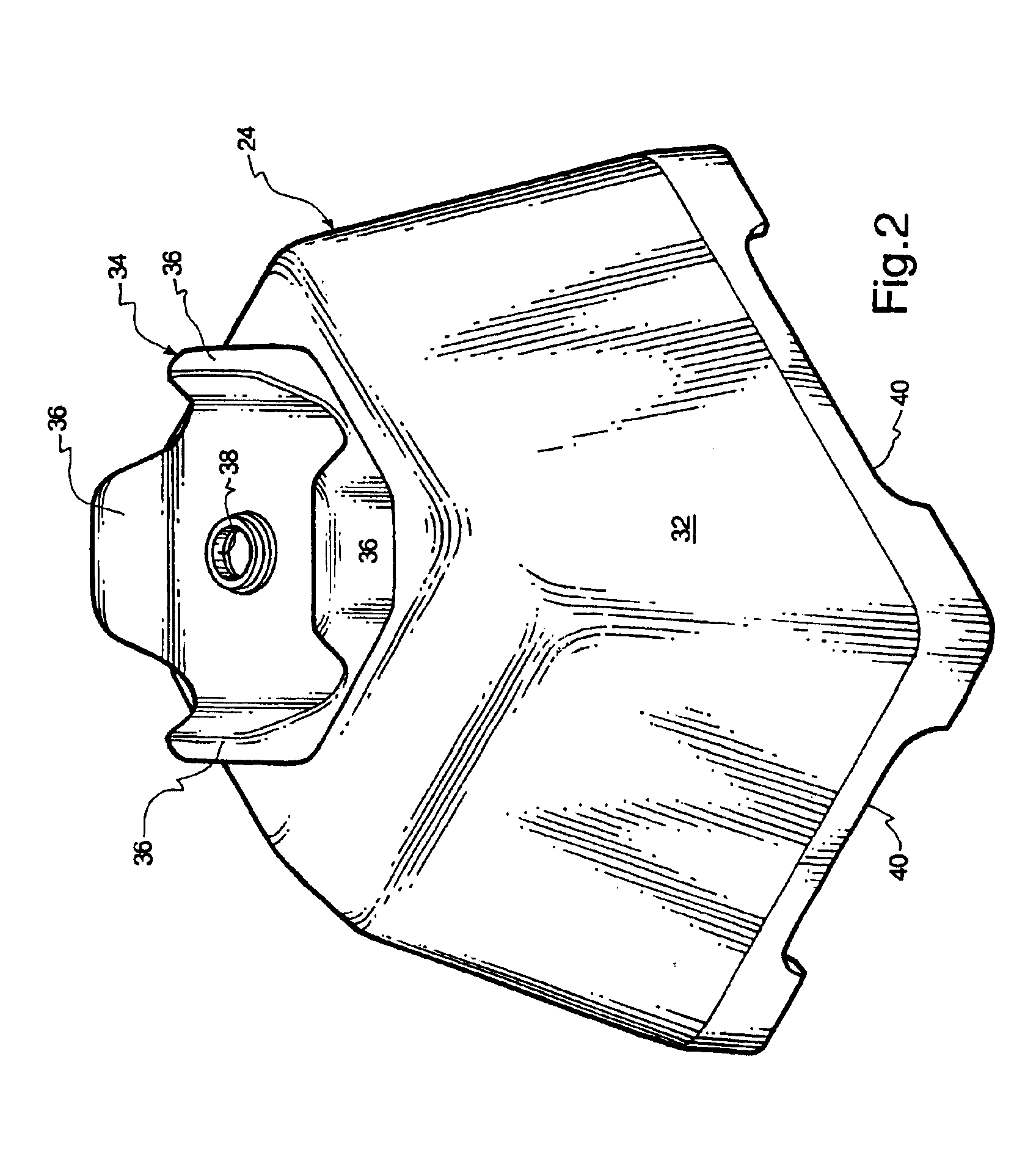

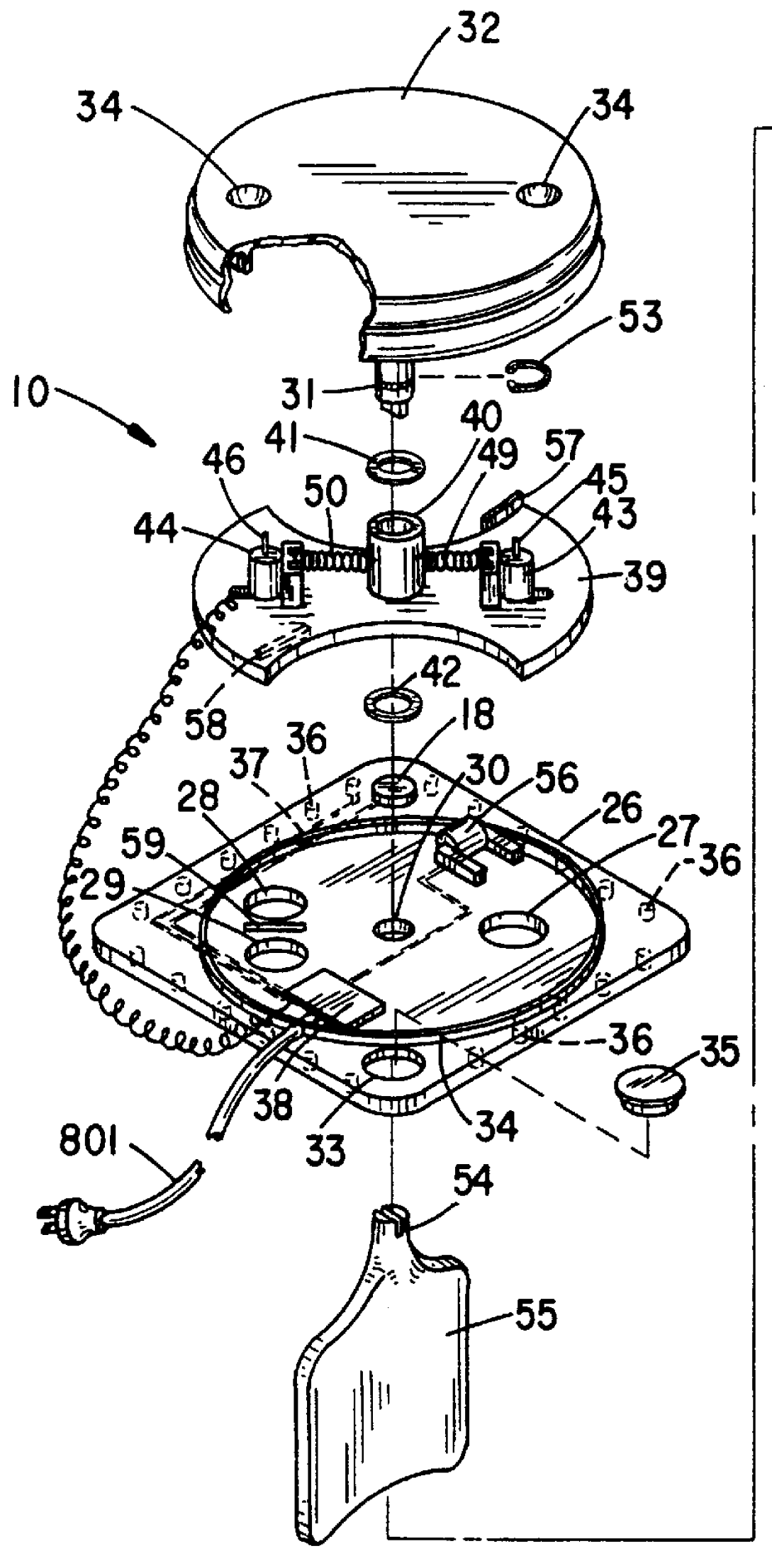

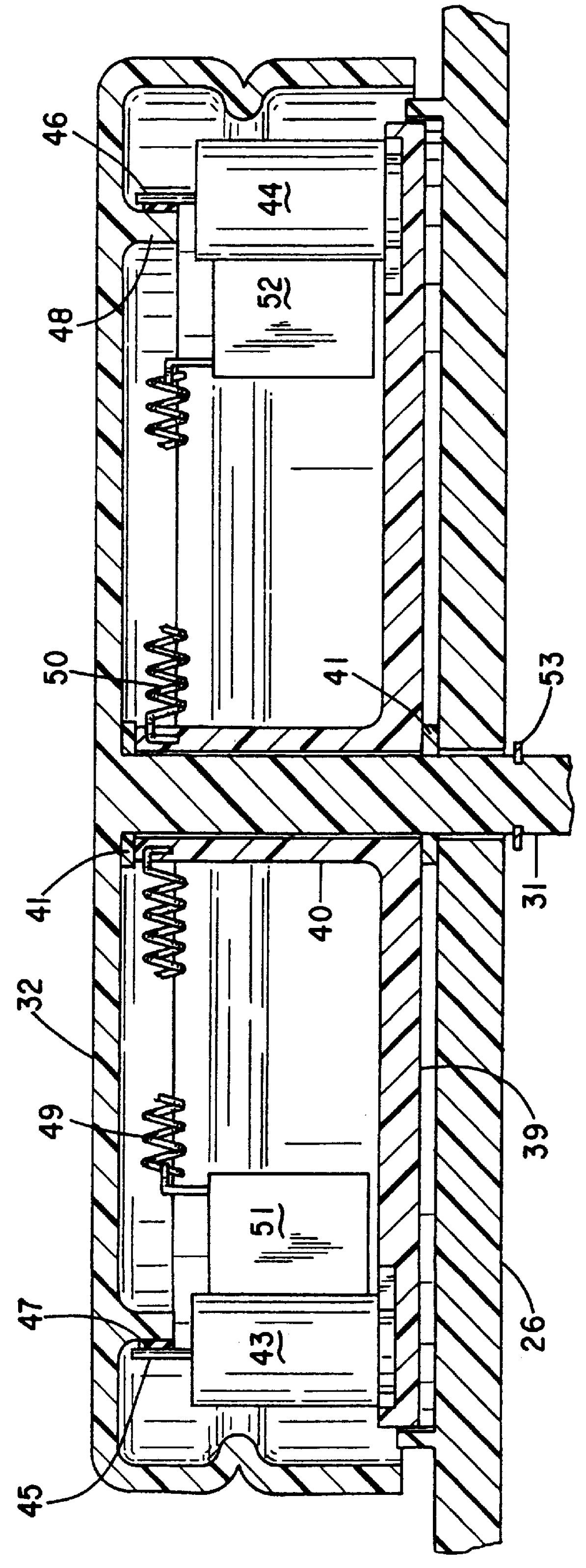

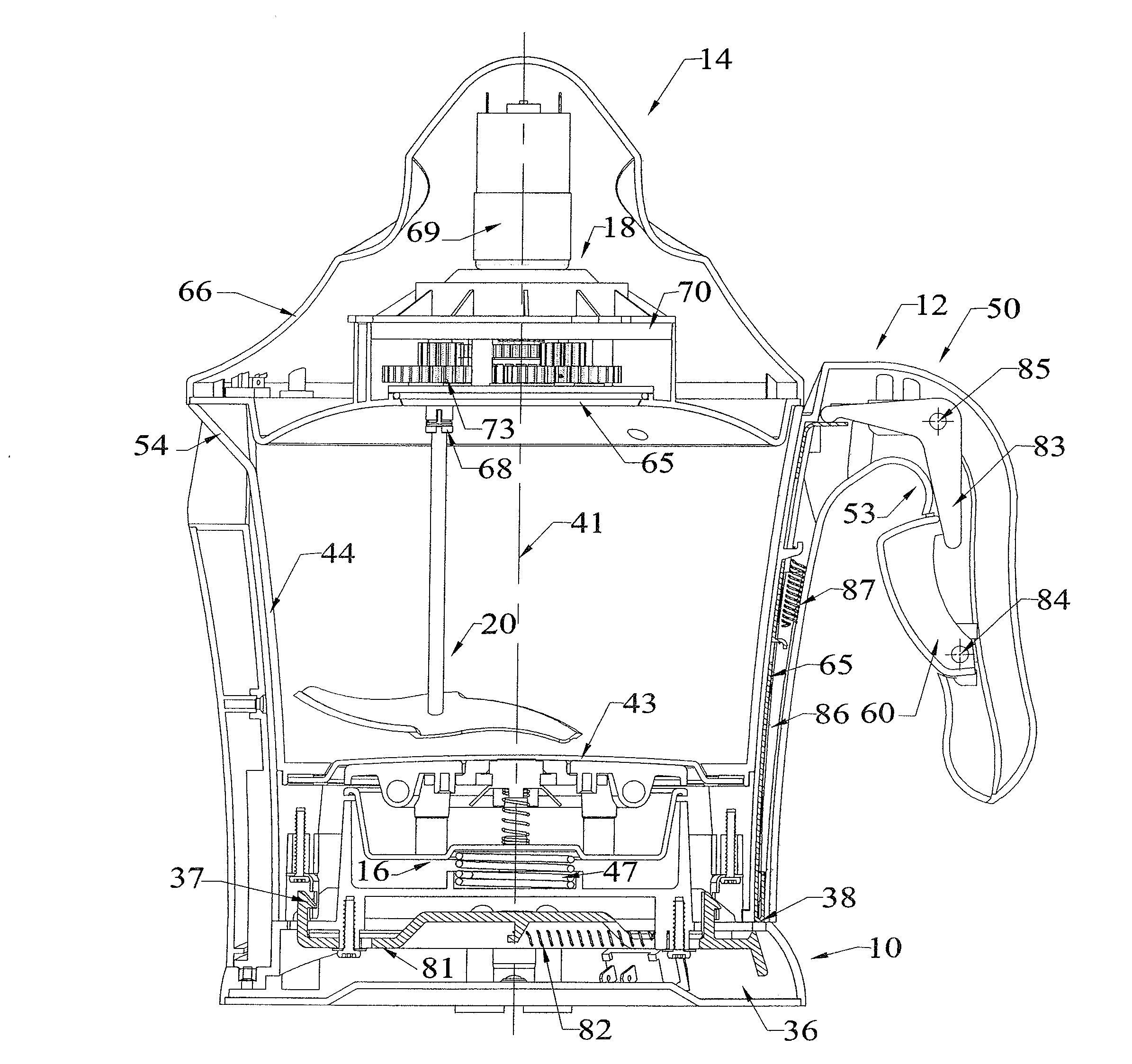

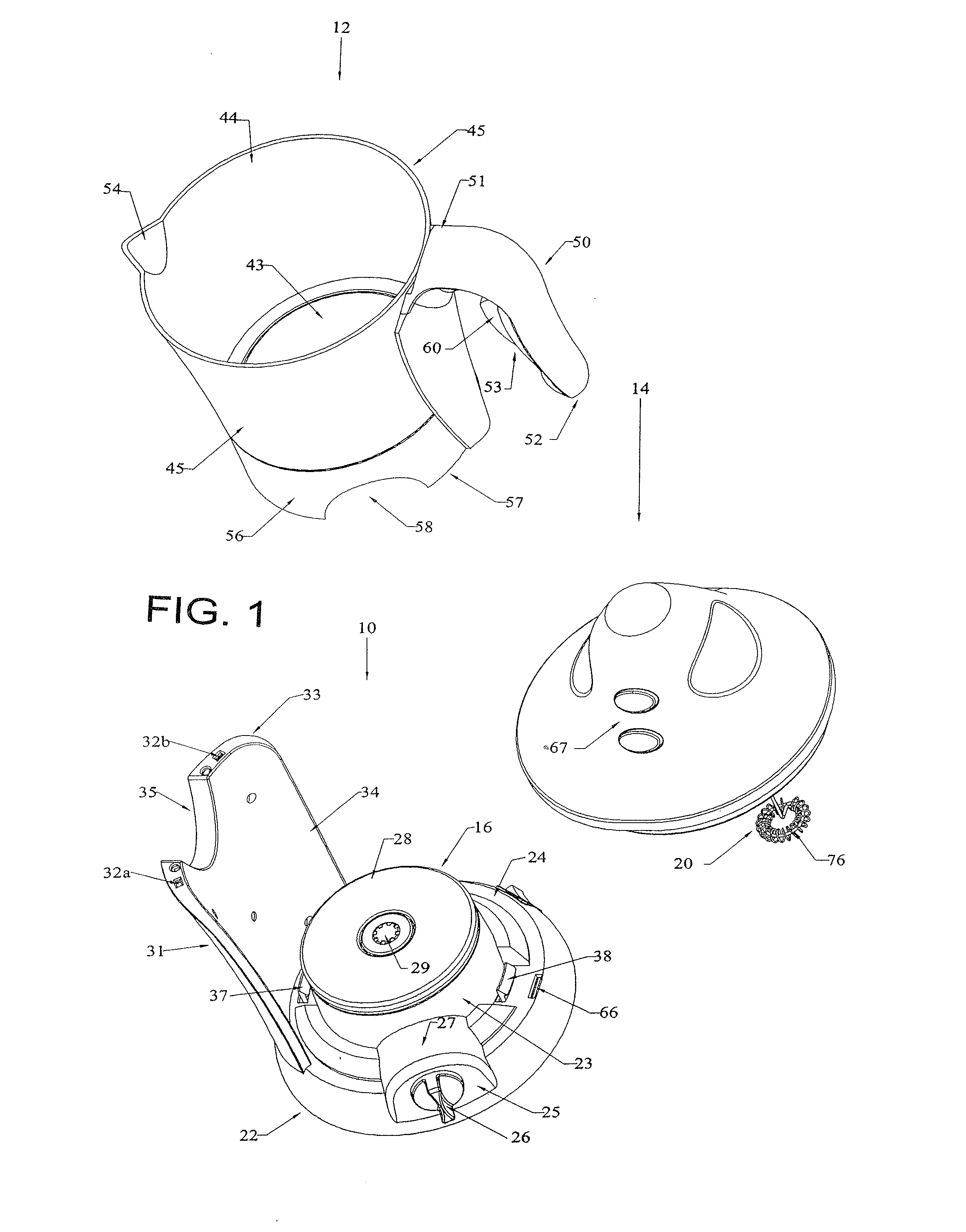

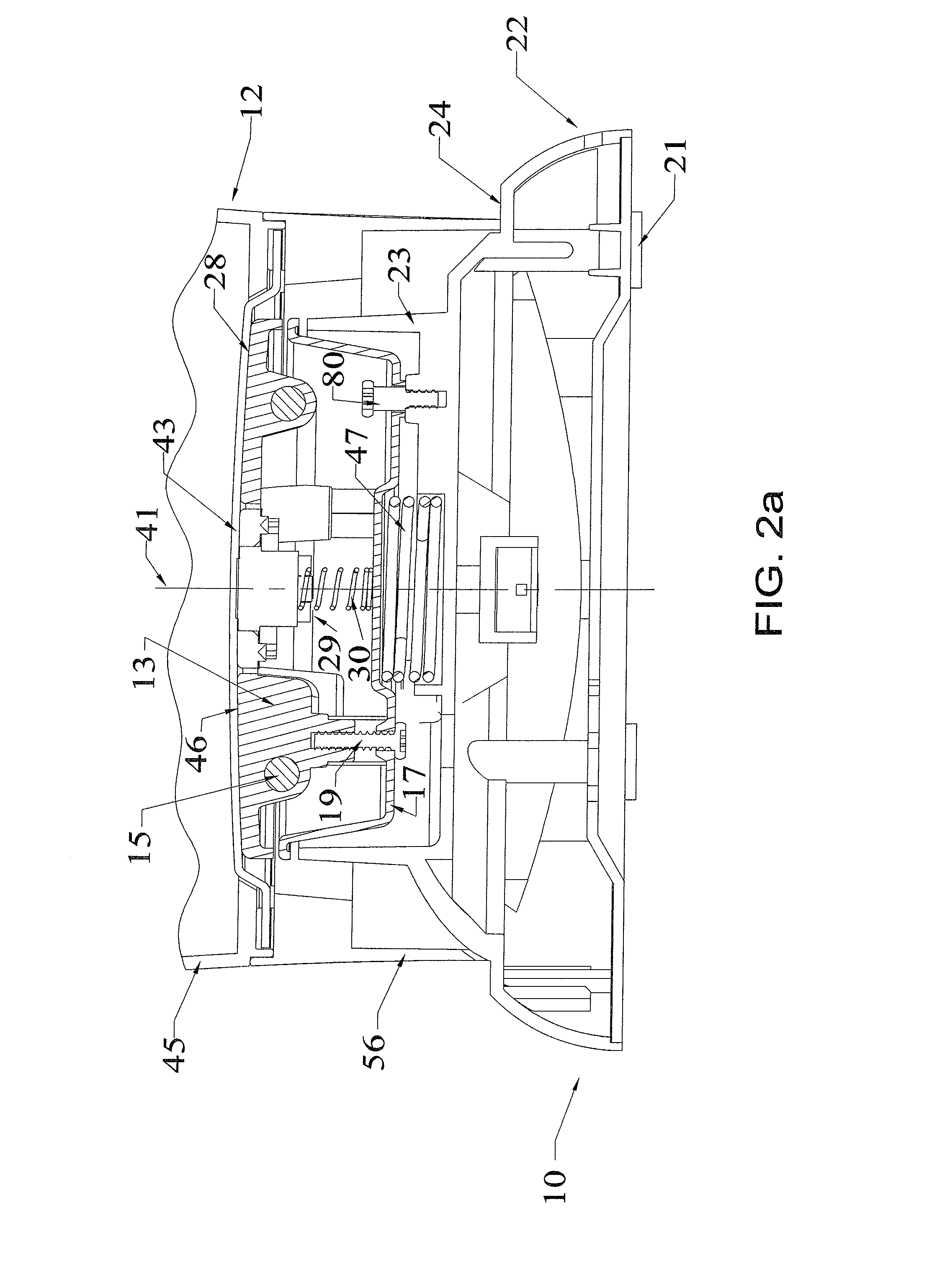

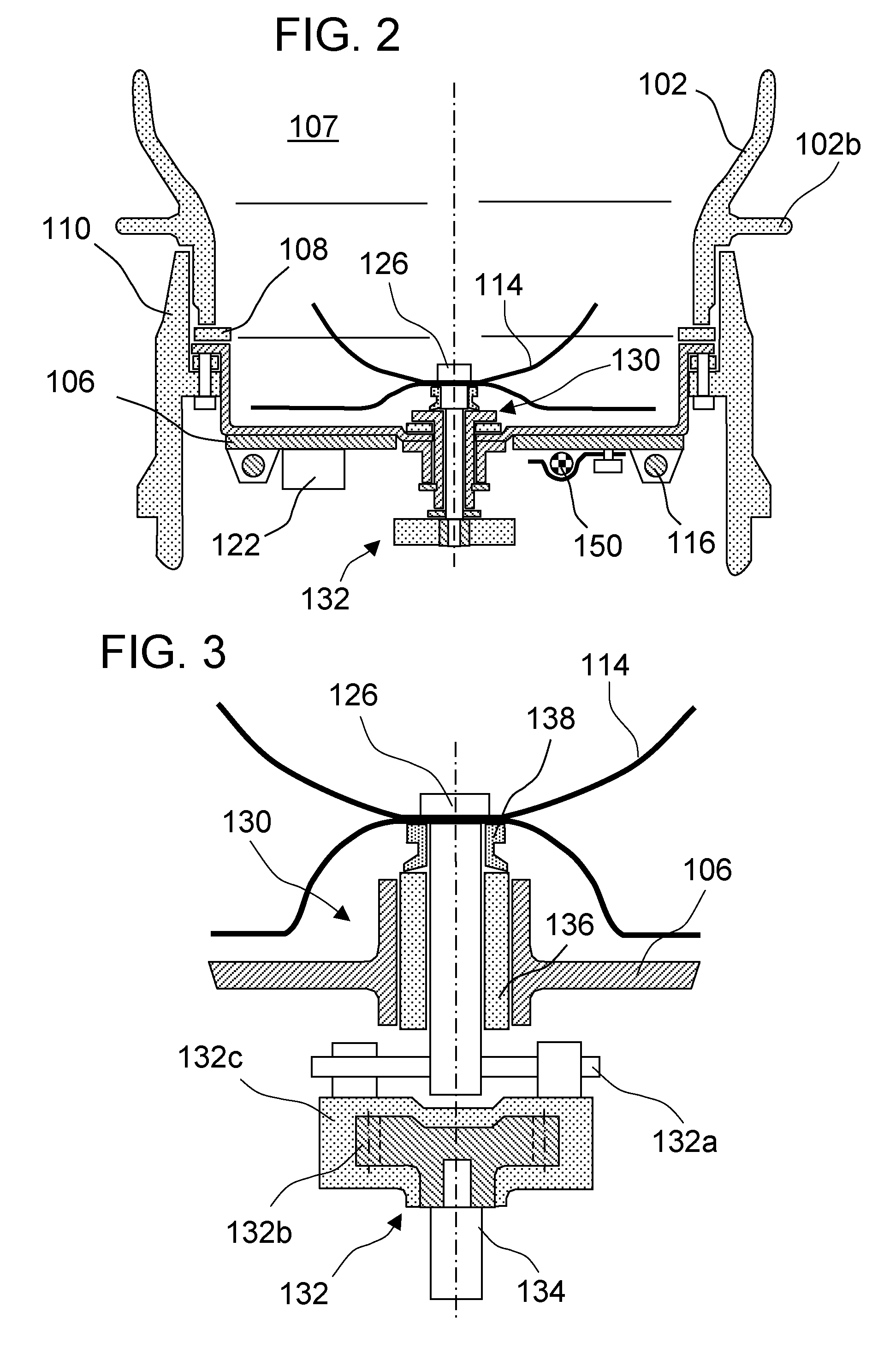

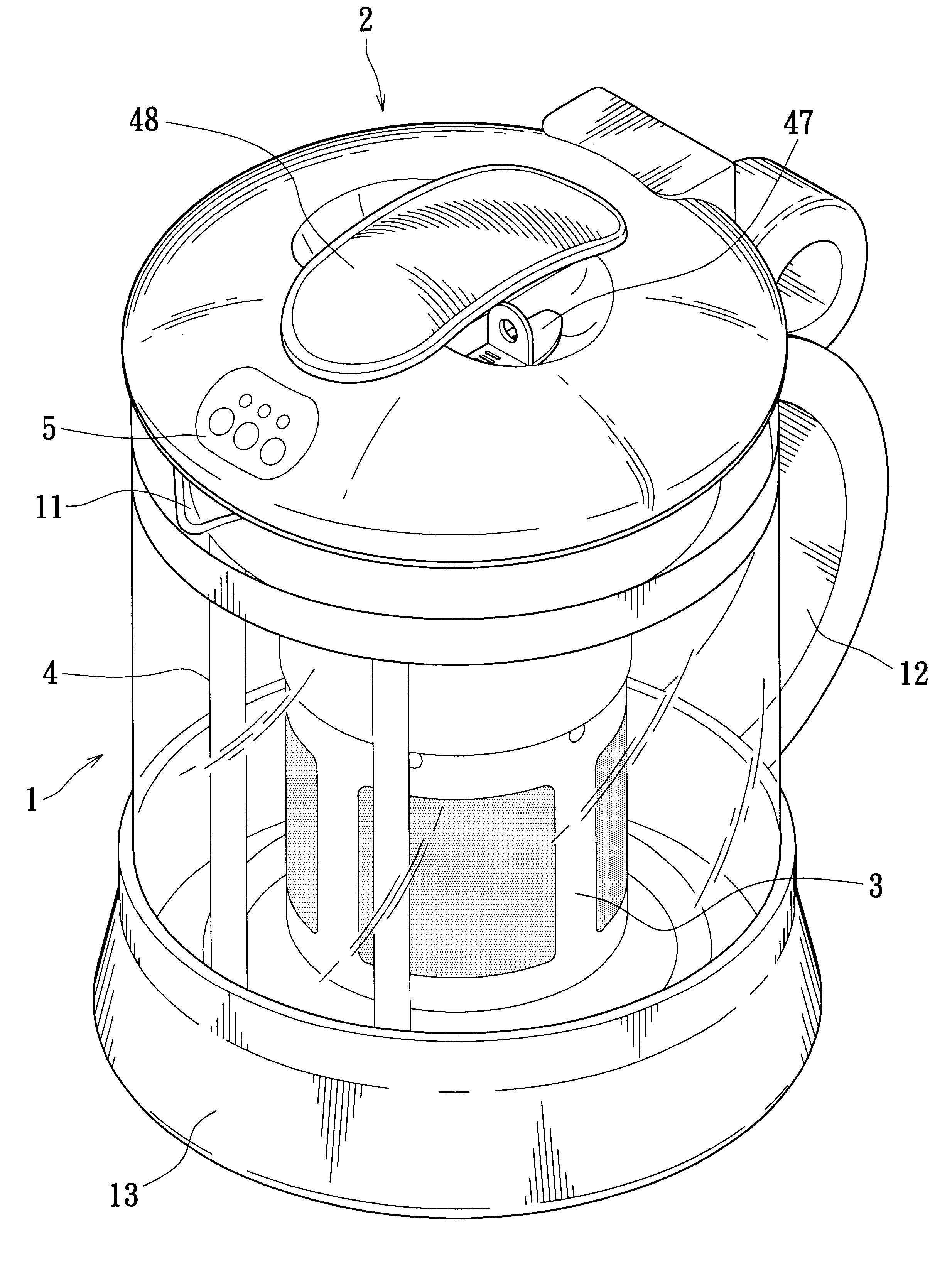

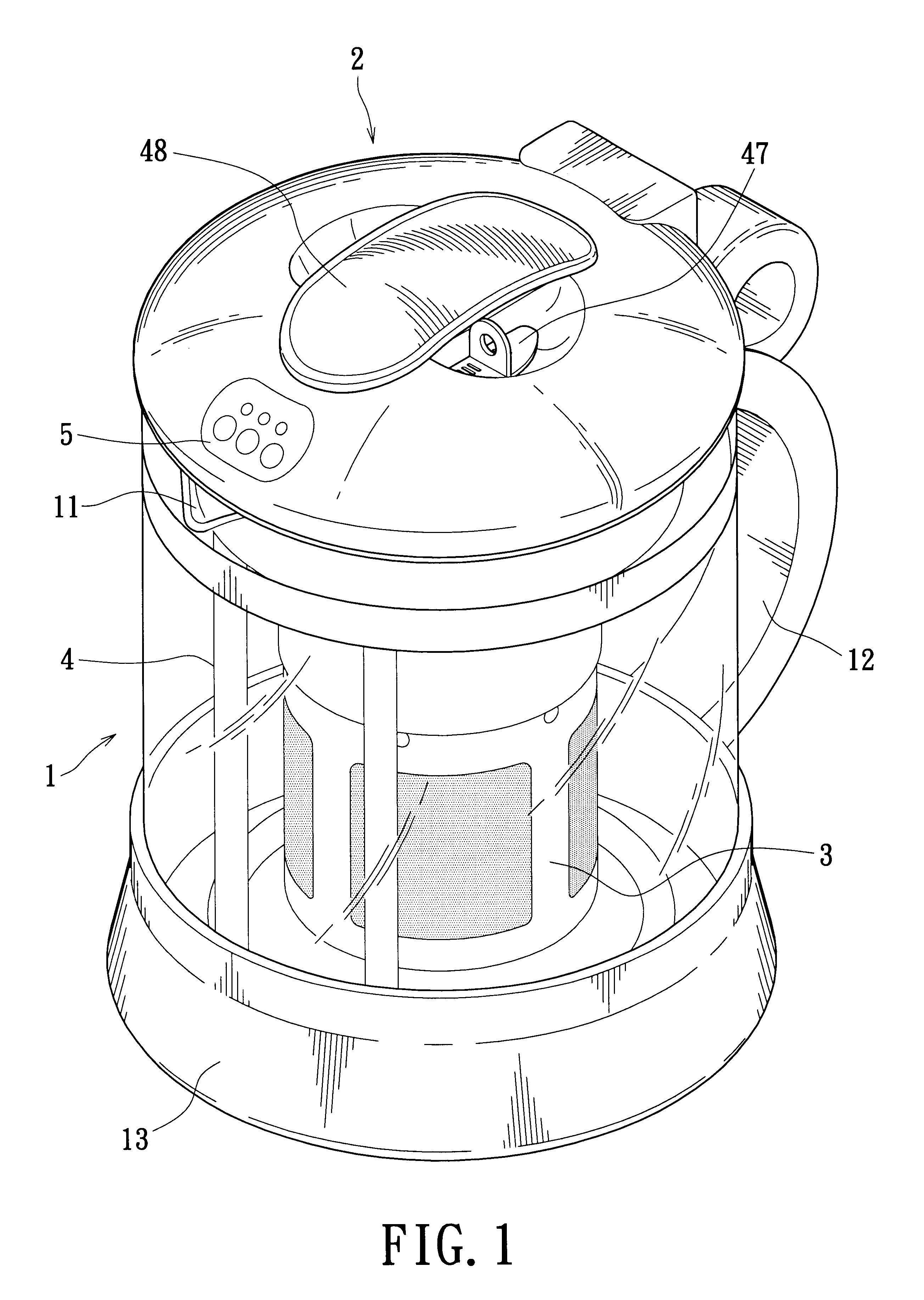

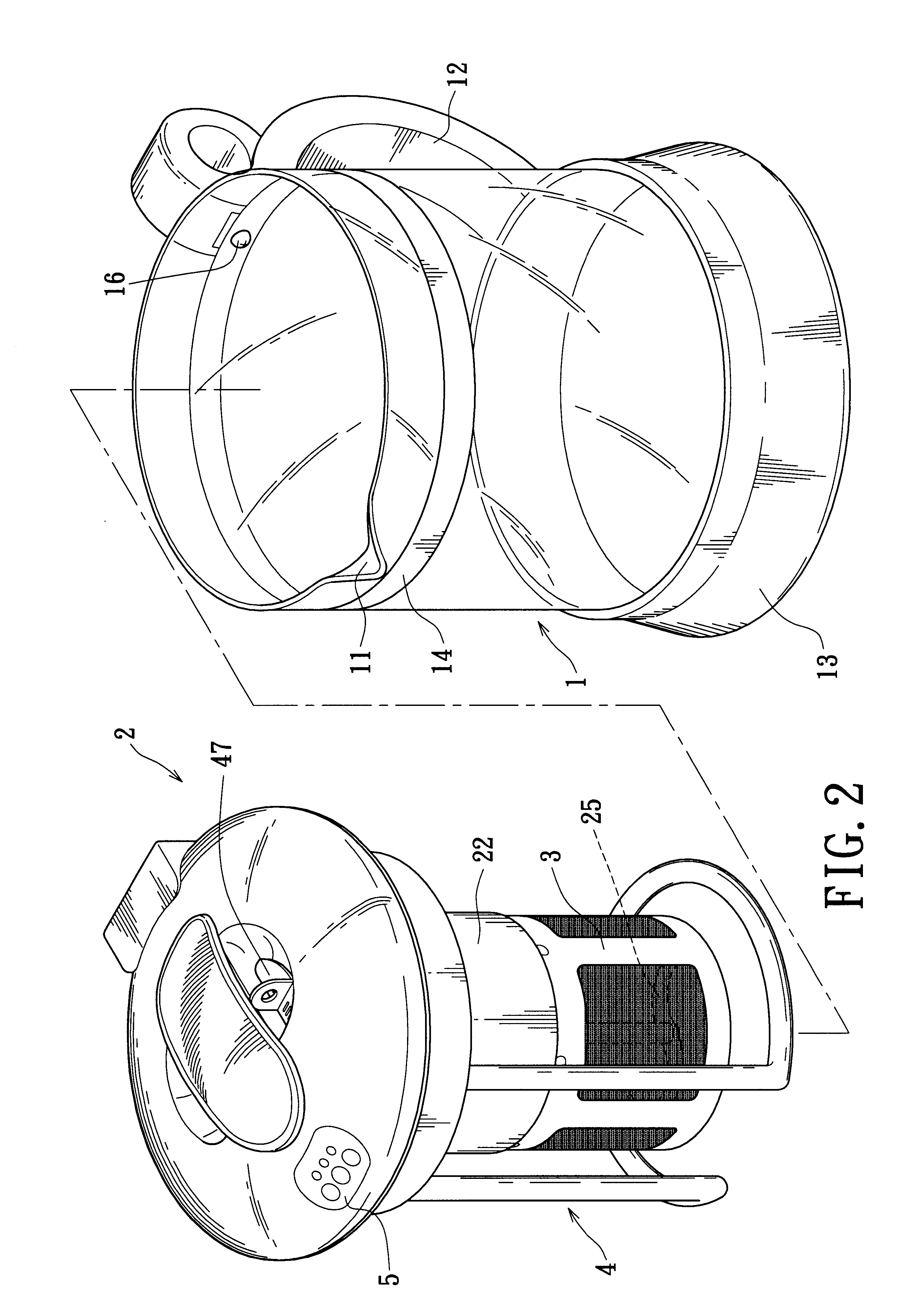

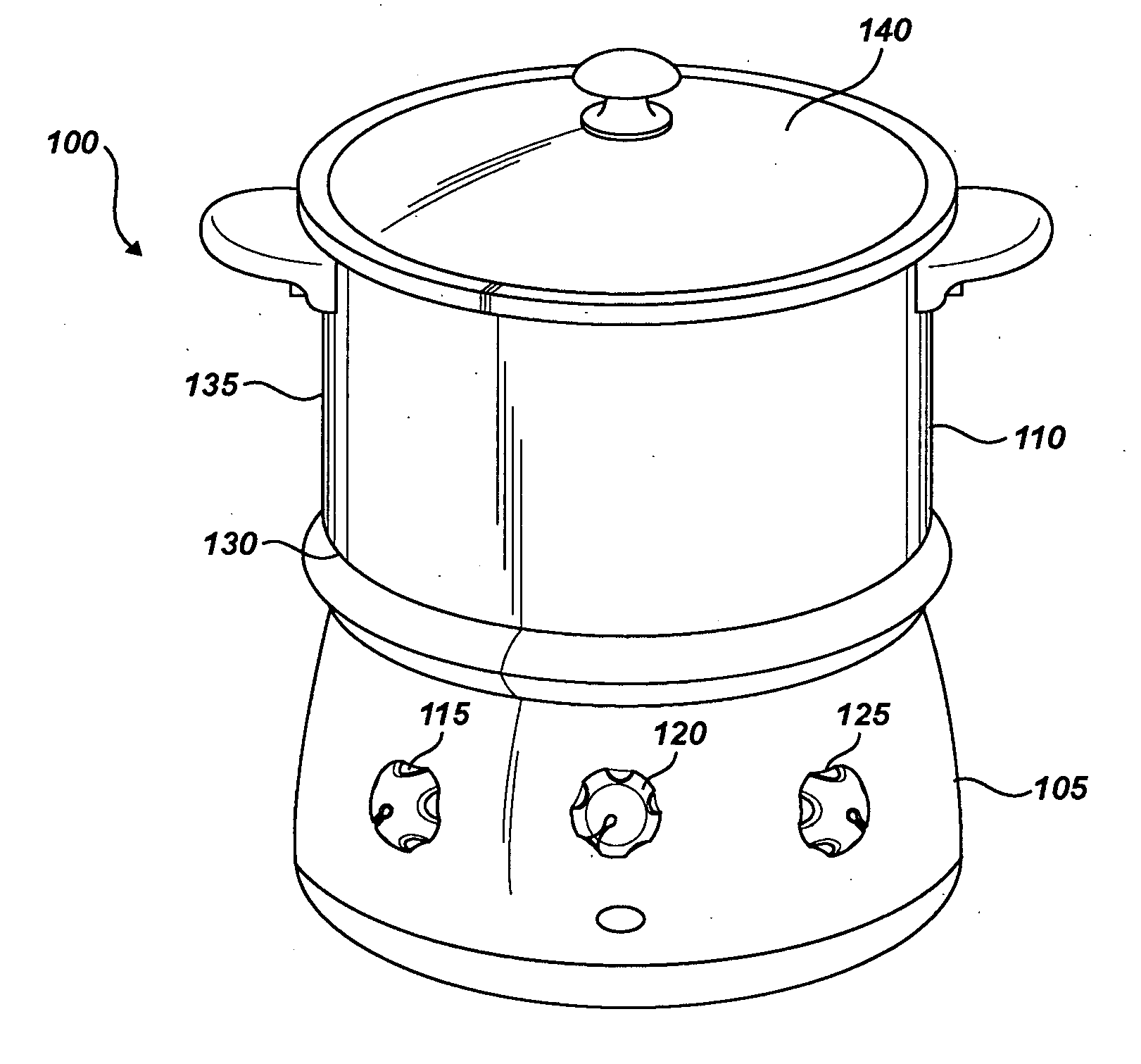

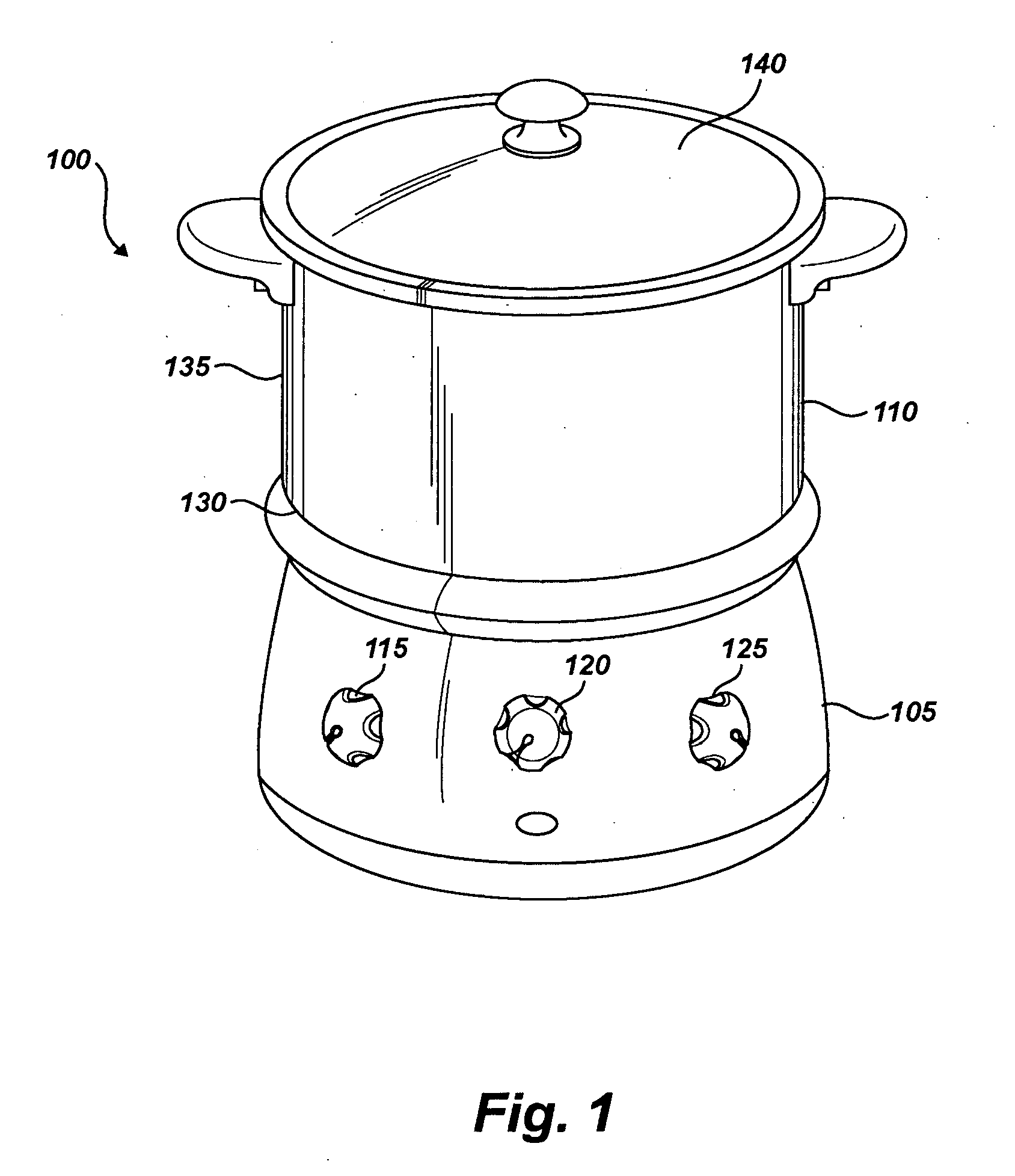

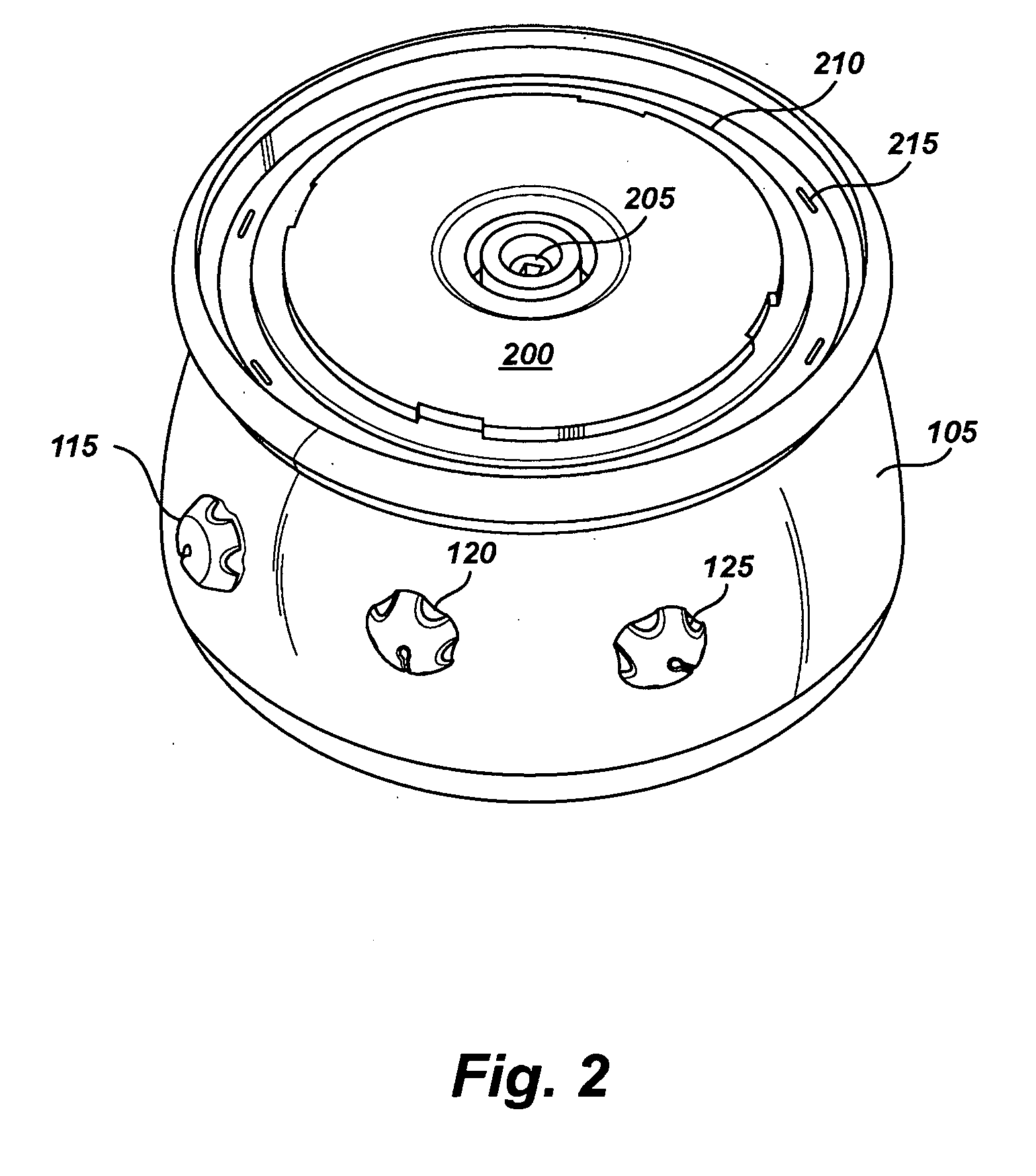

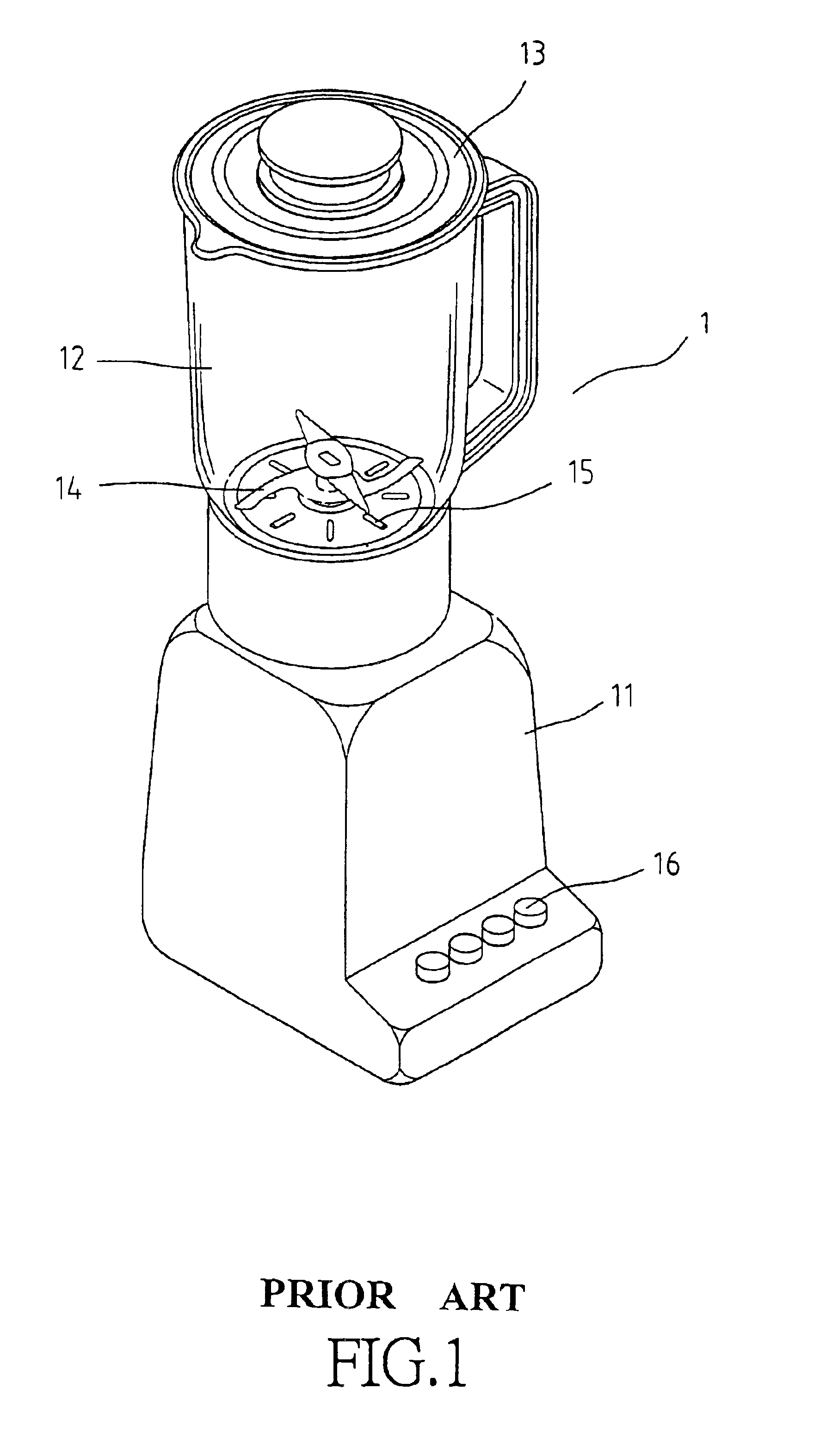

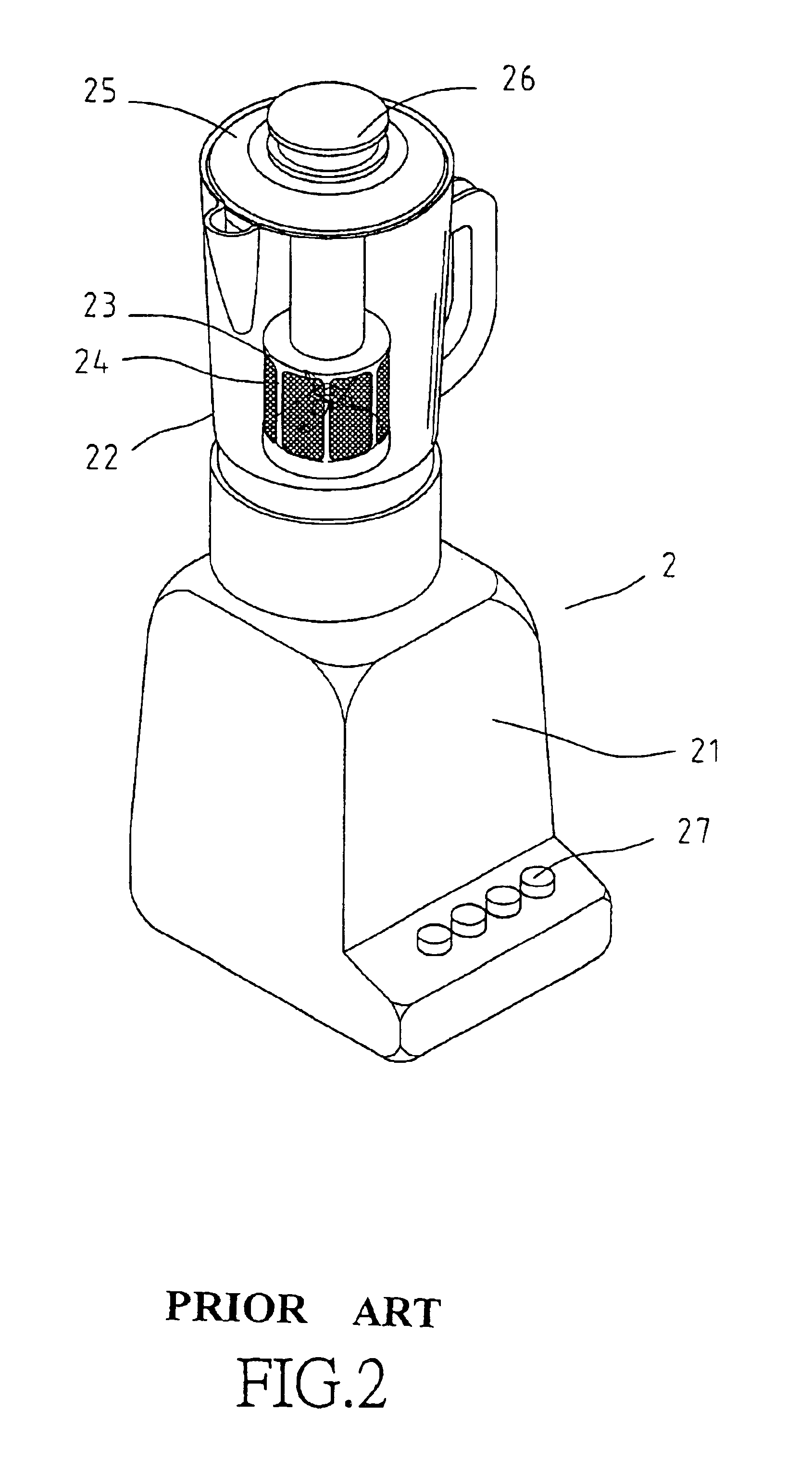

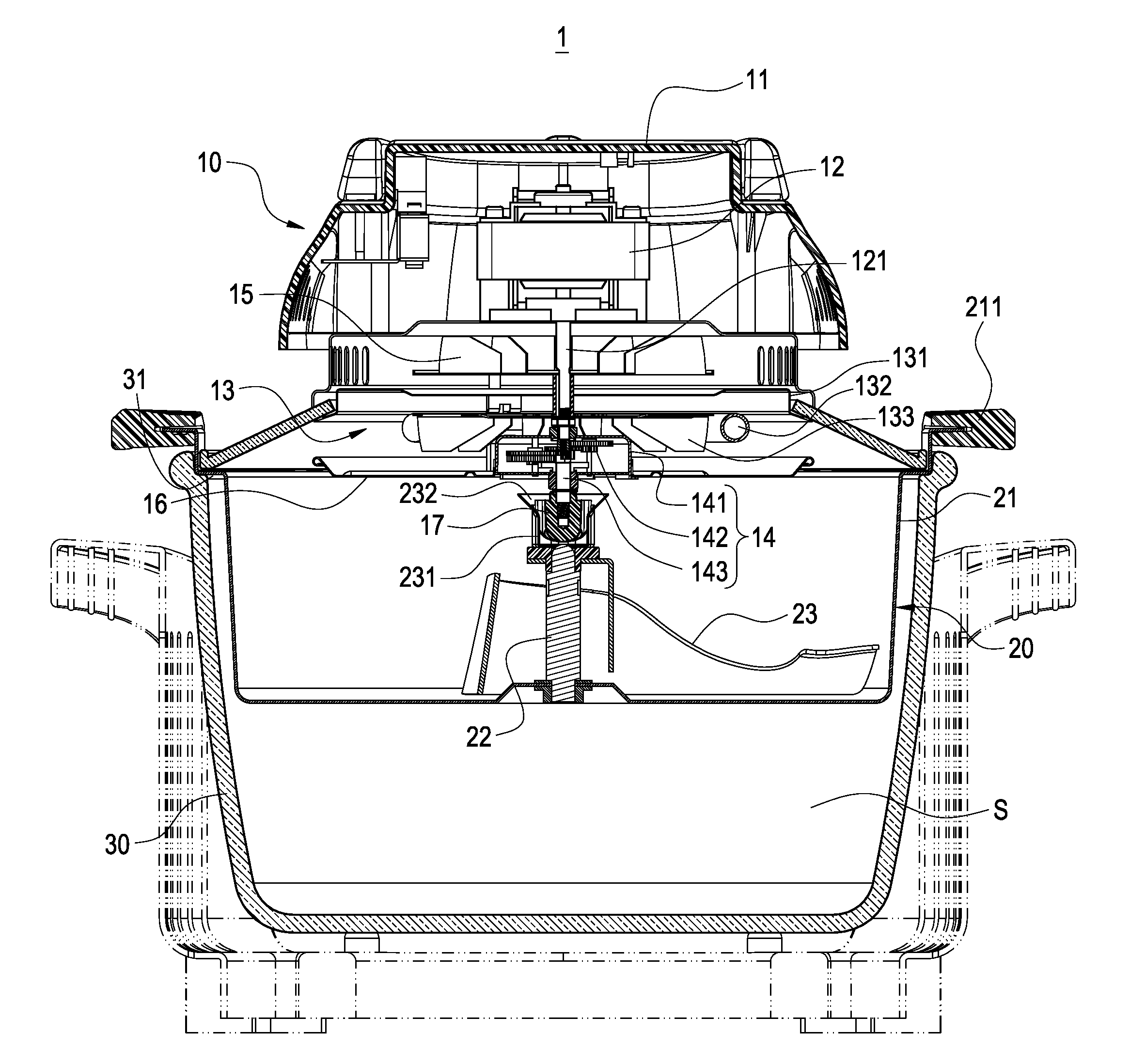

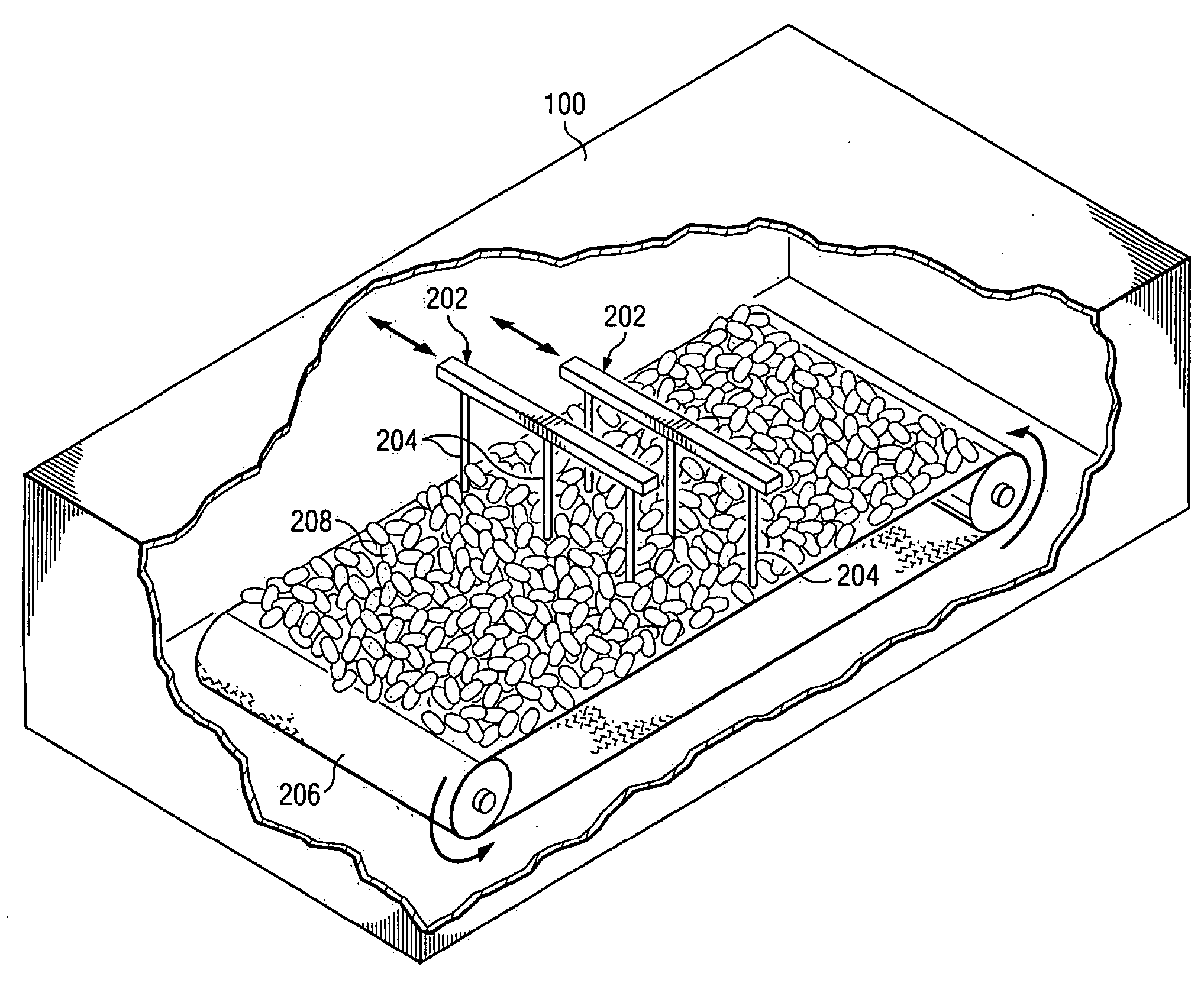

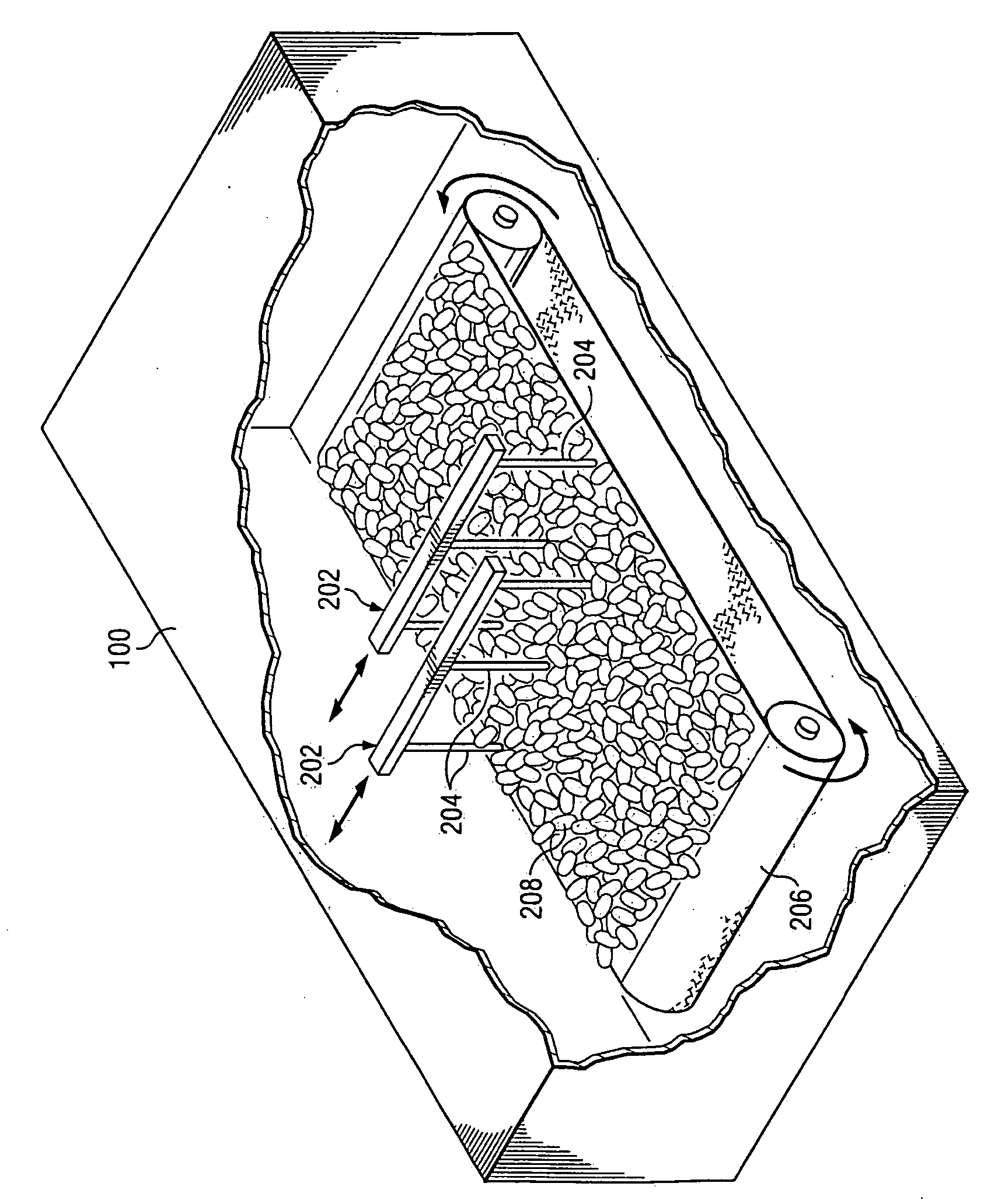

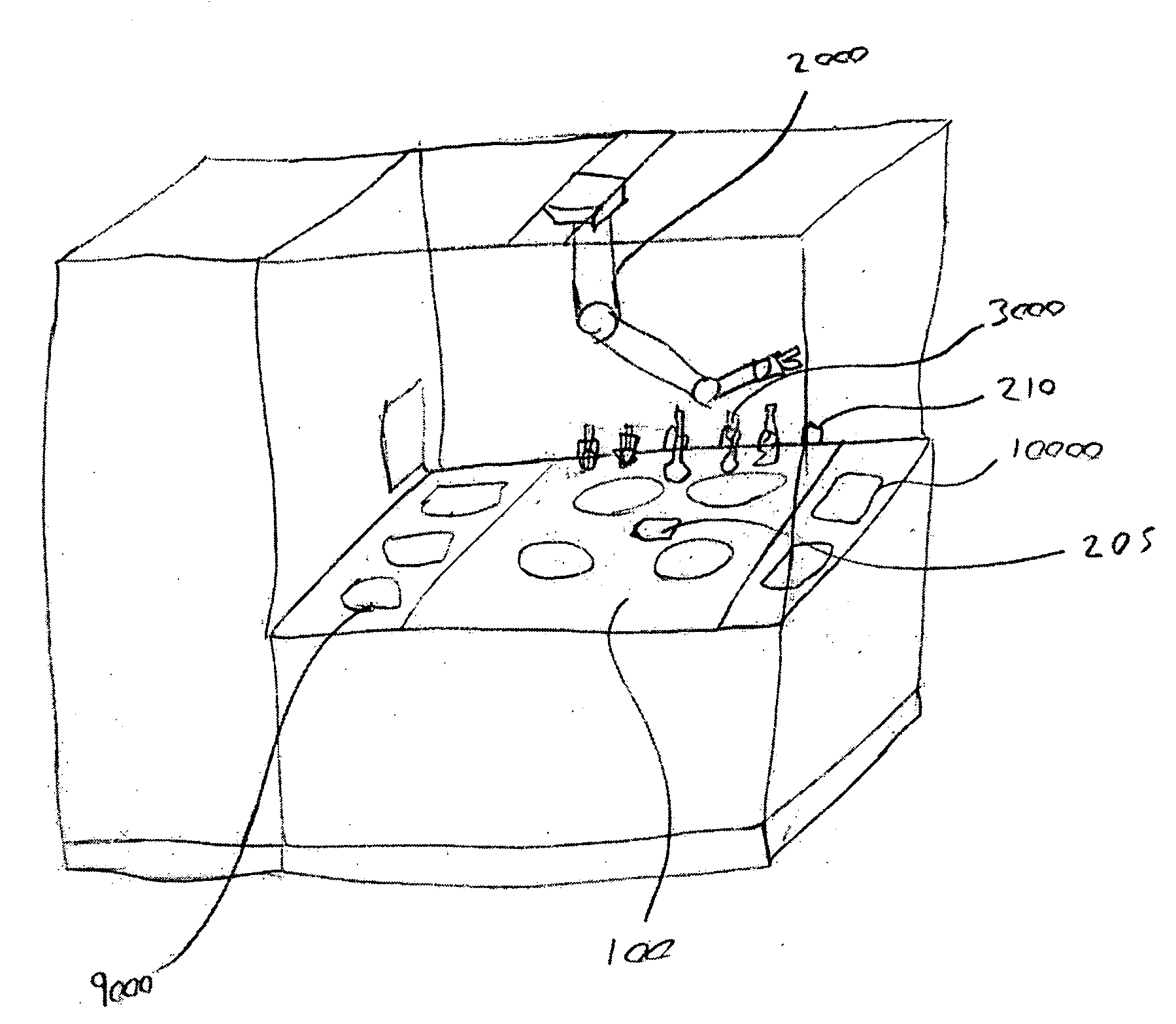

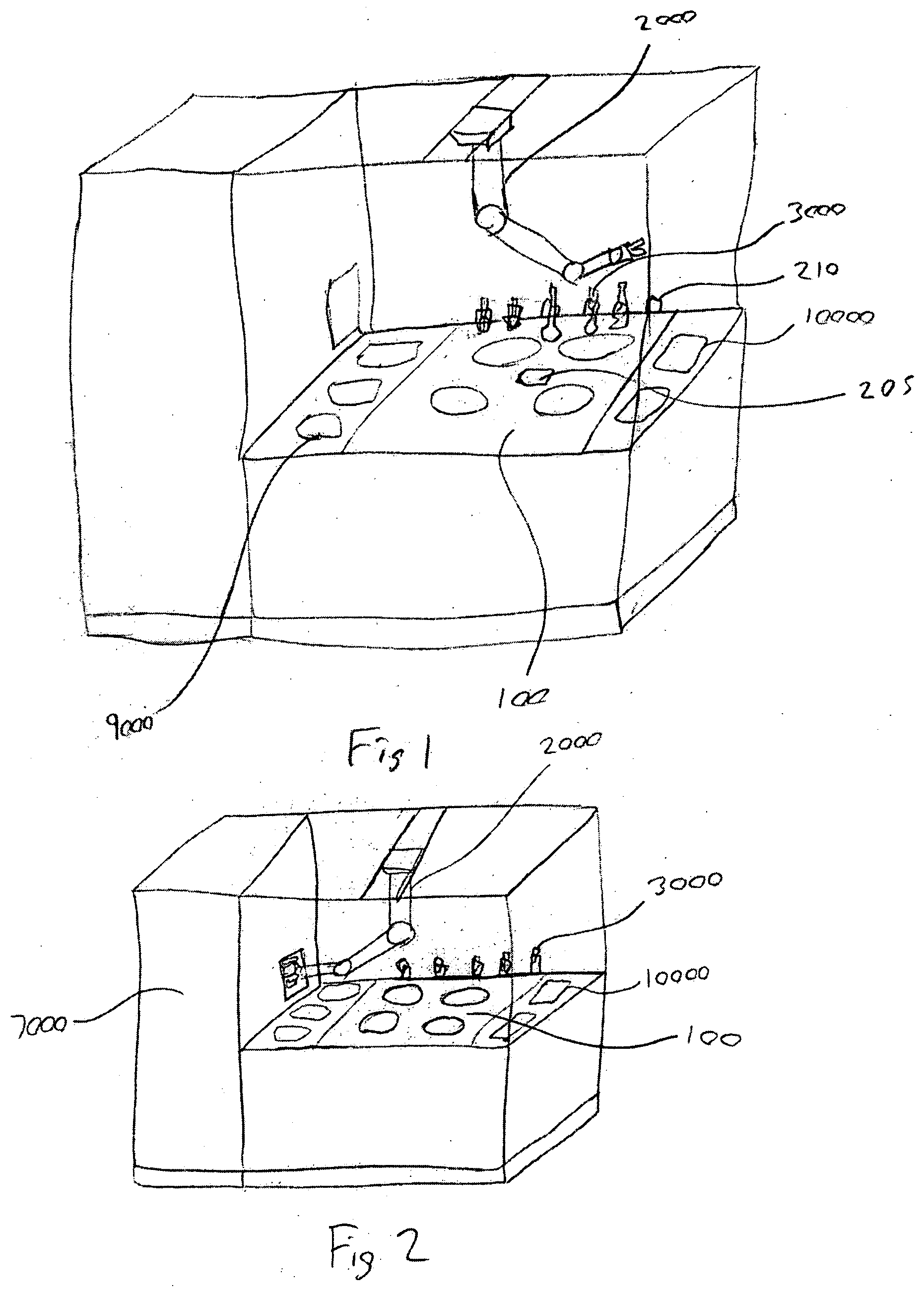

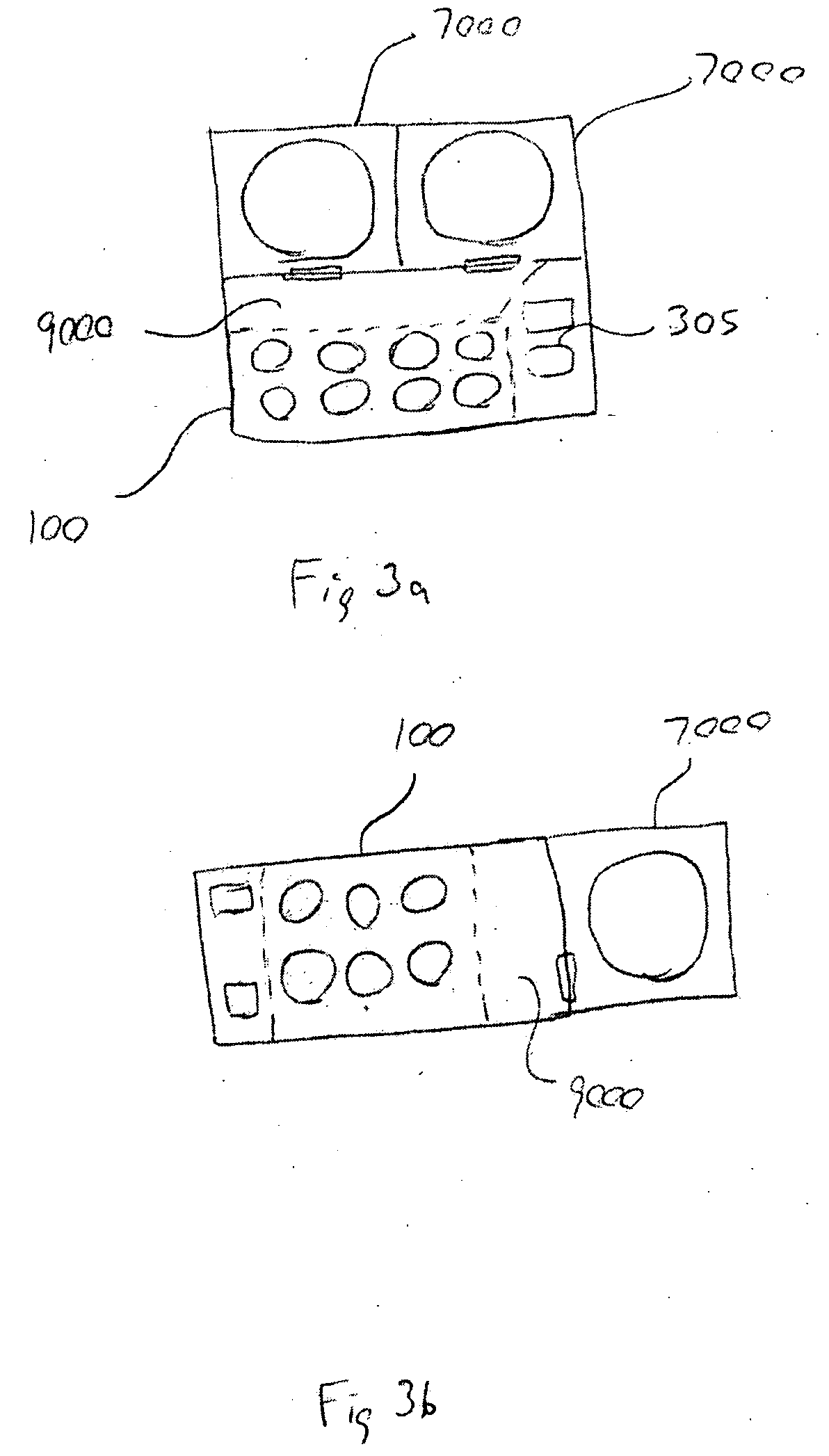

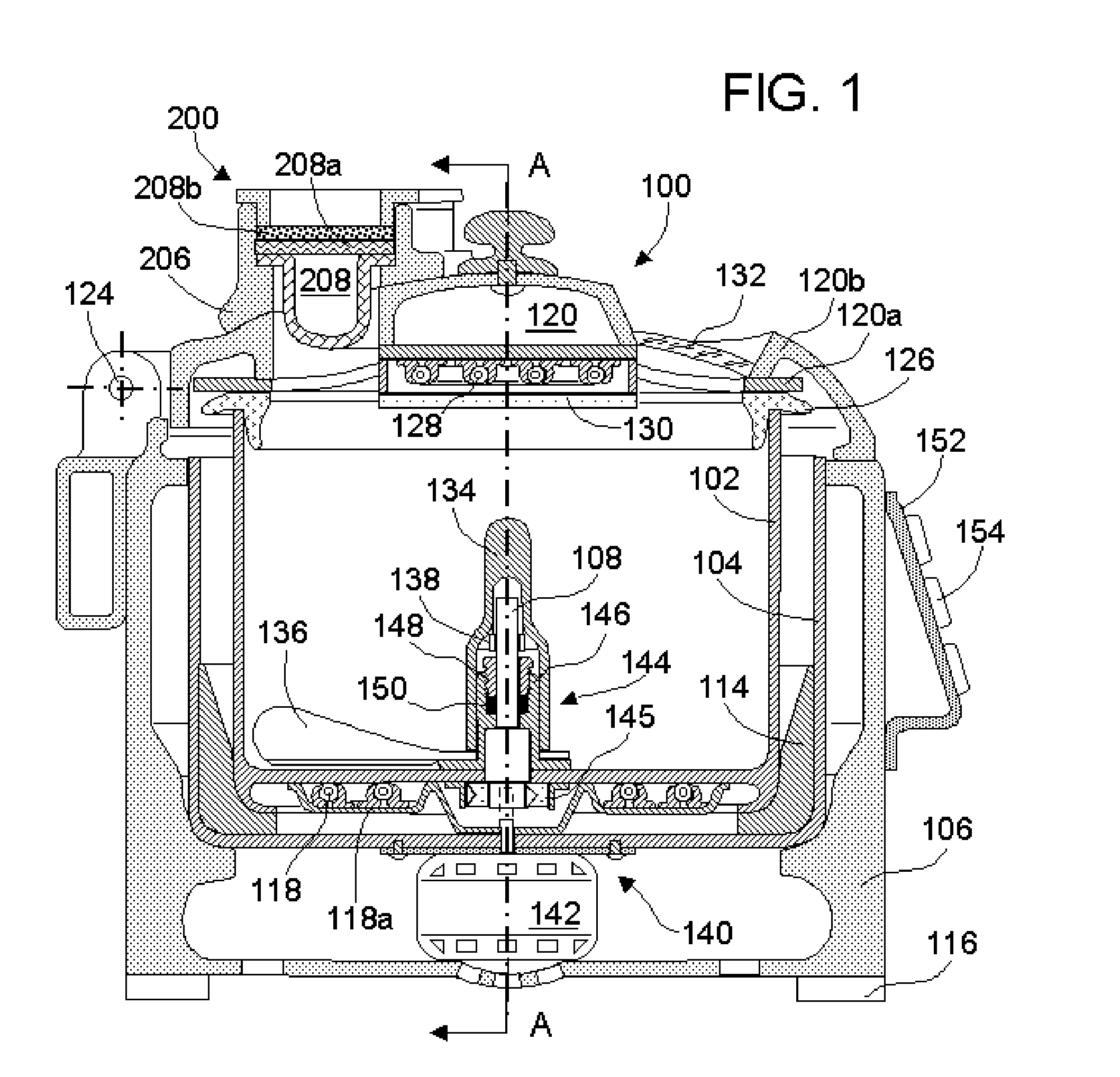

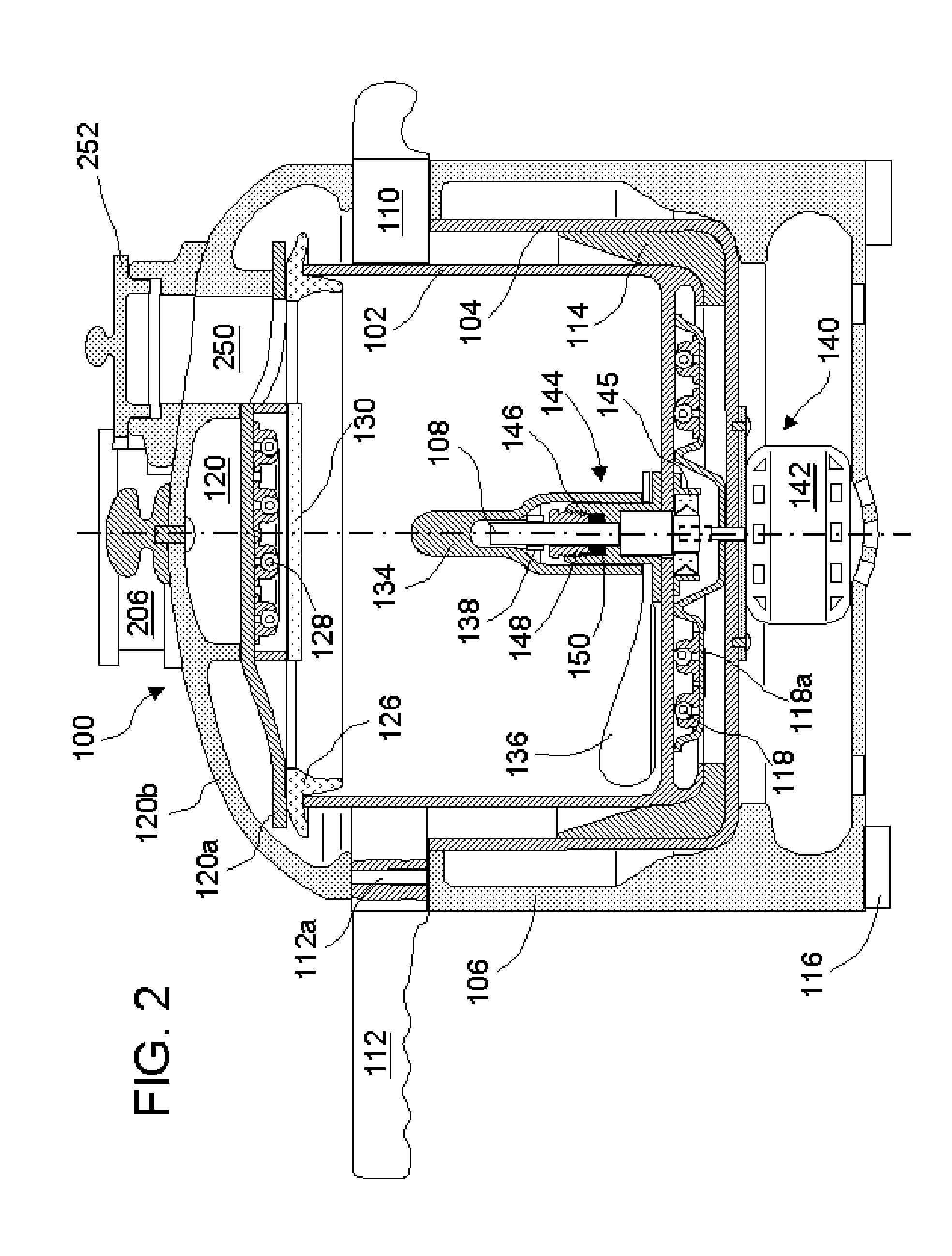

[automatic frying apparatus for both deep and shallow frying]

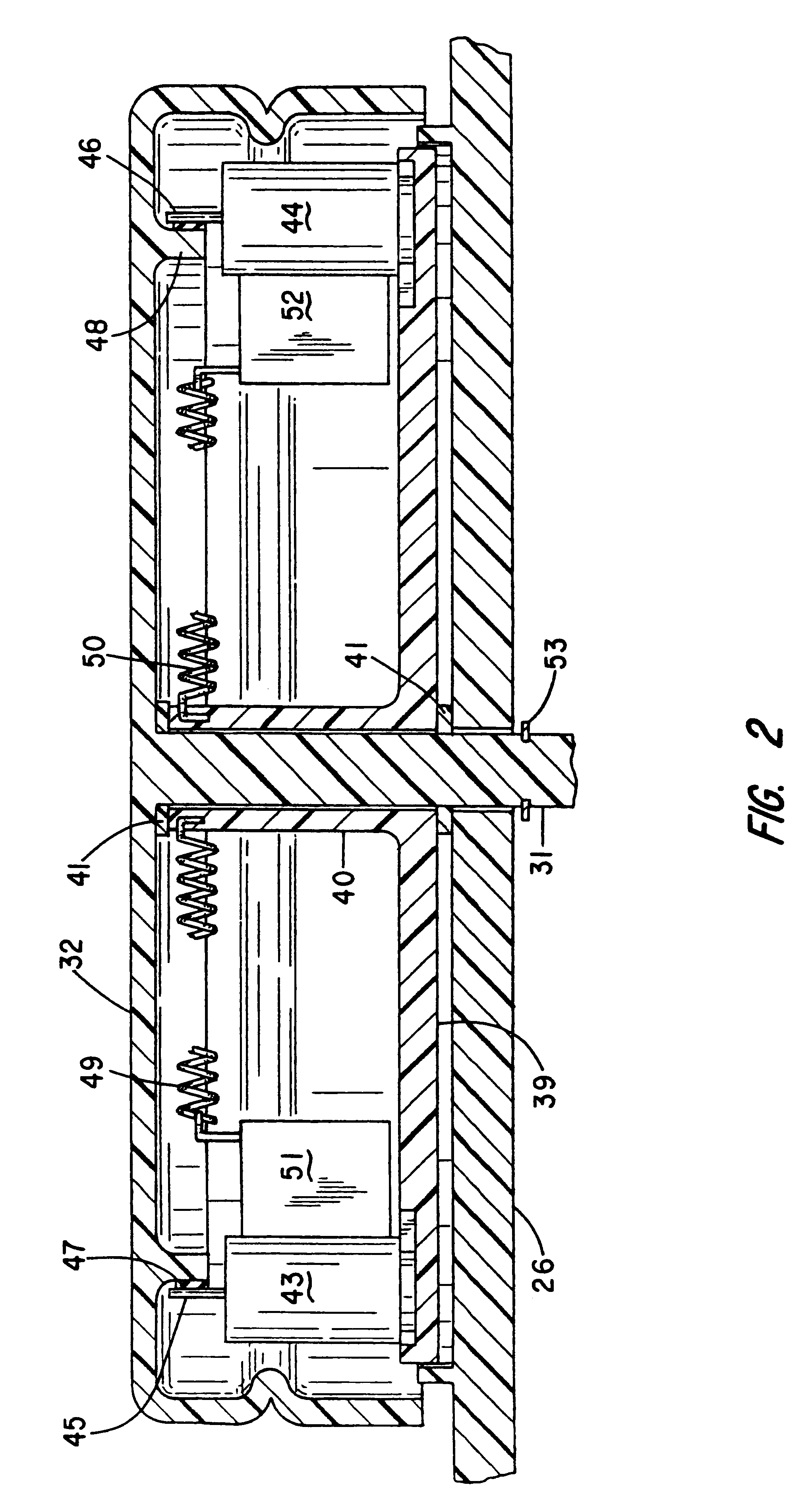

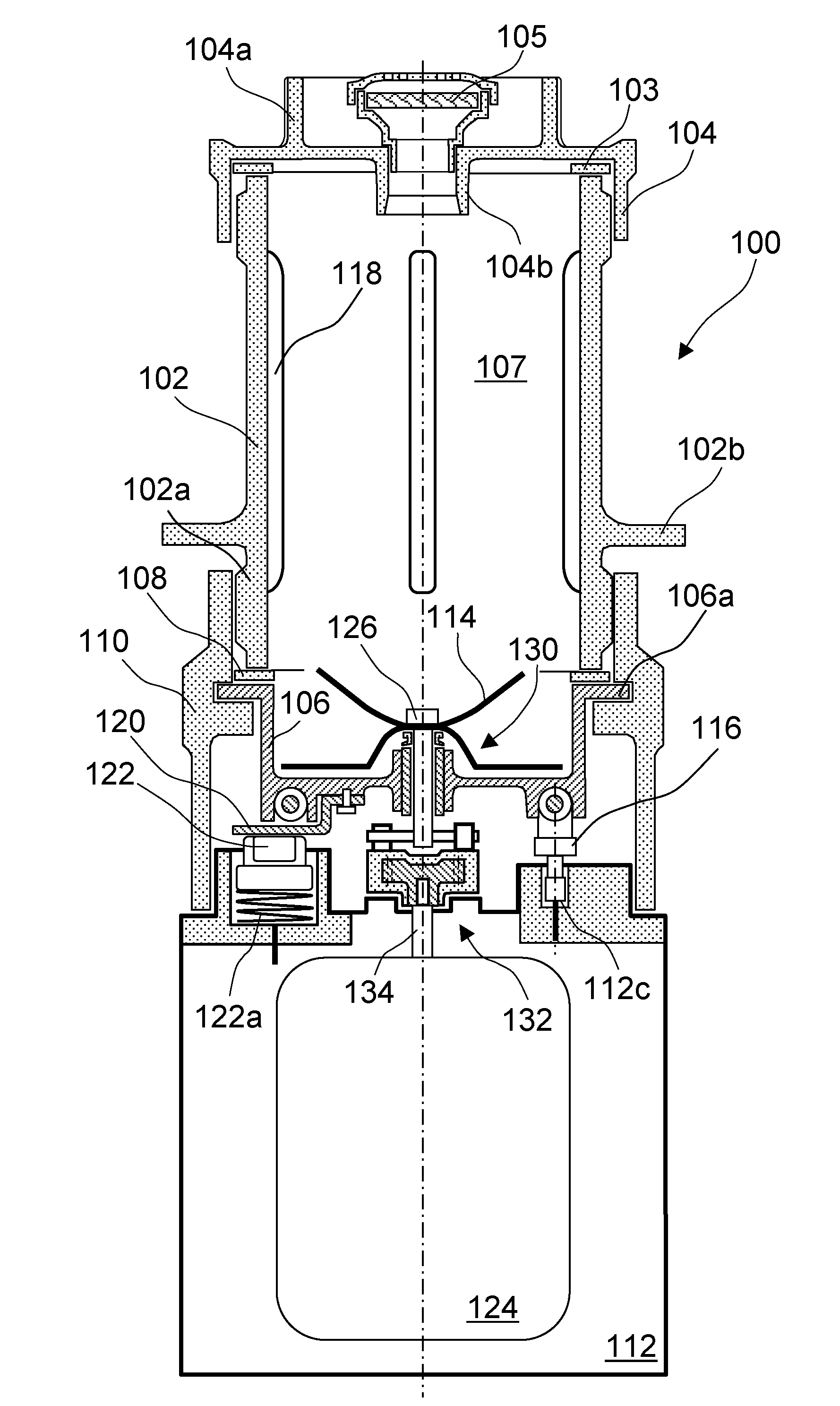

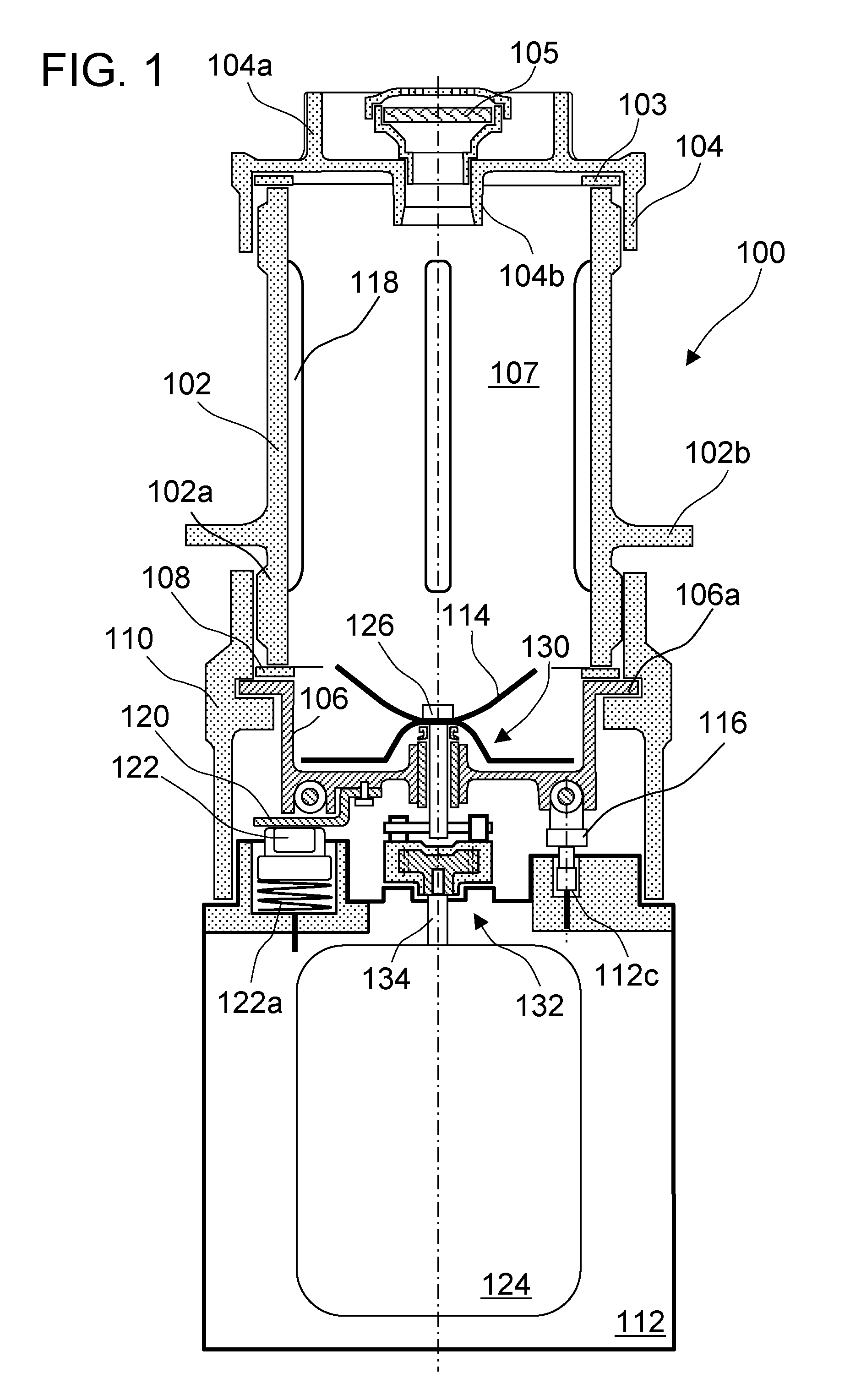

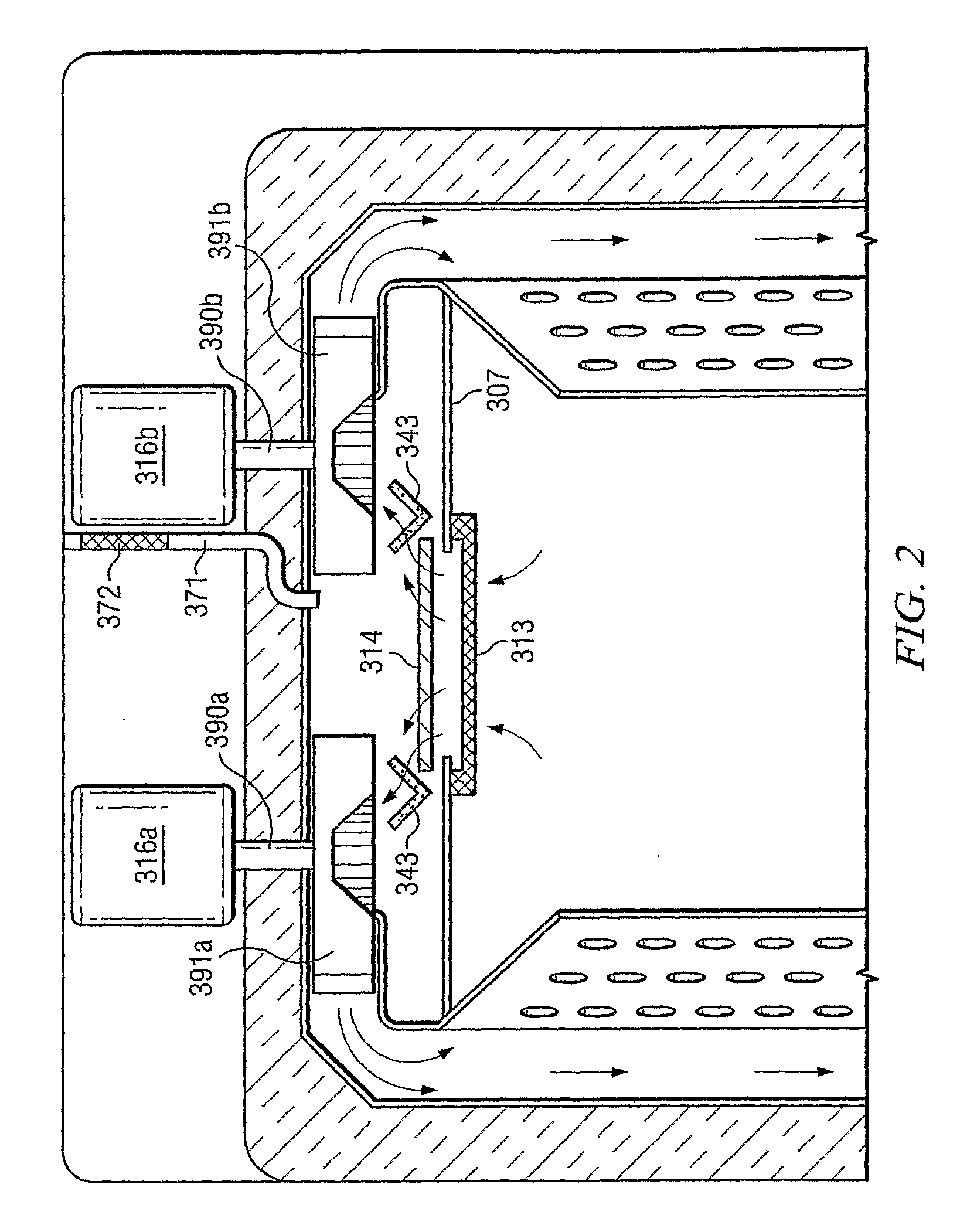

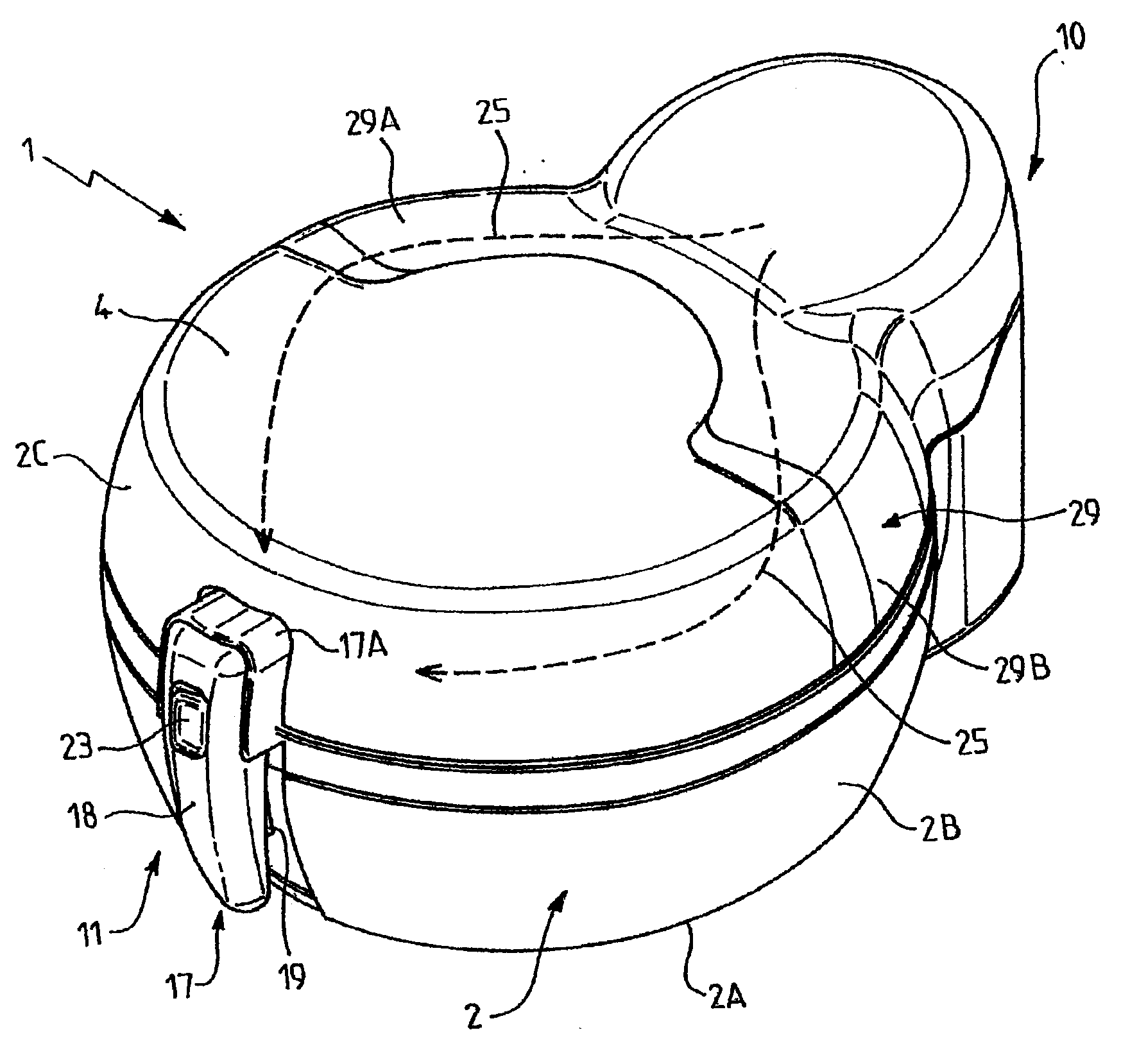

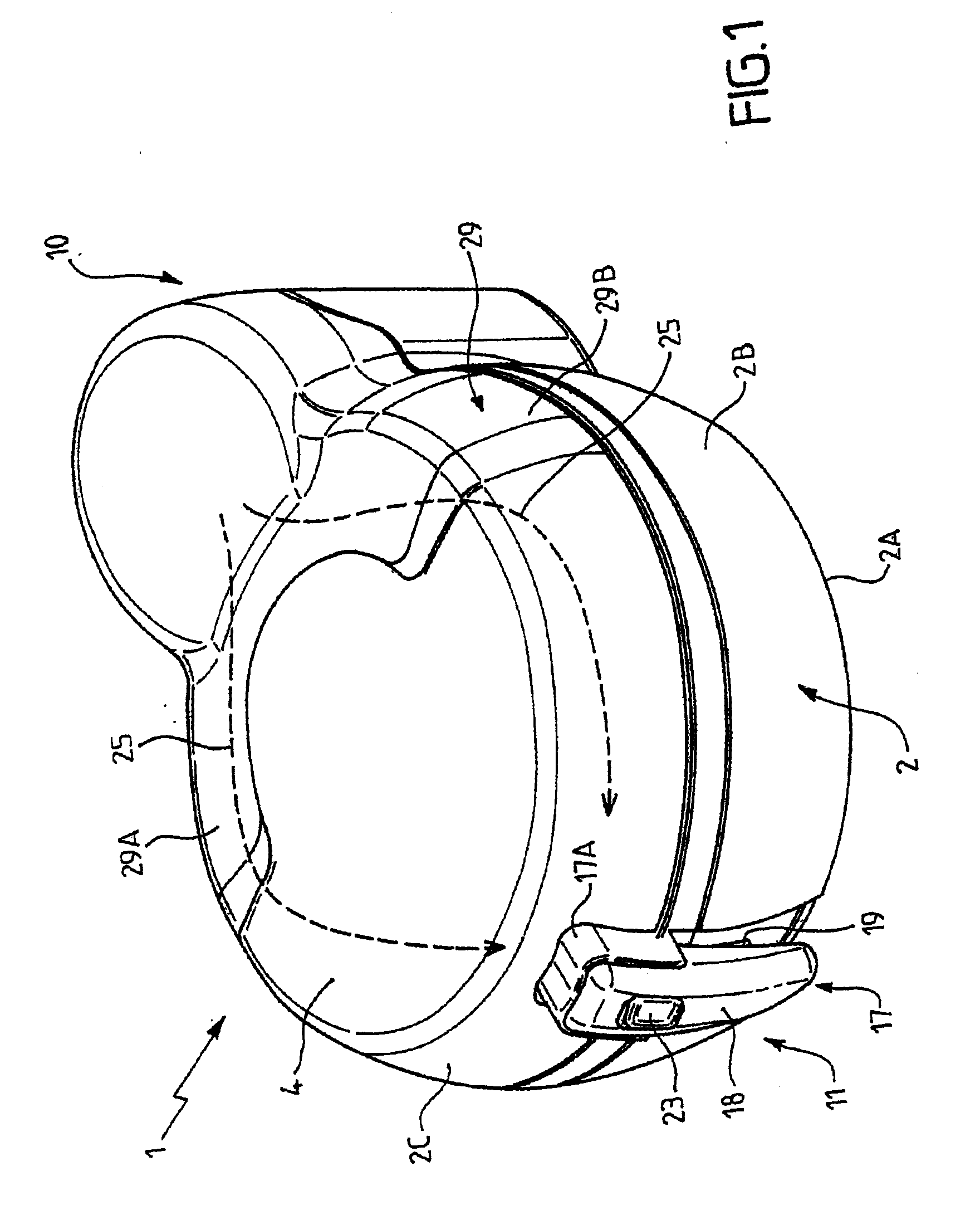

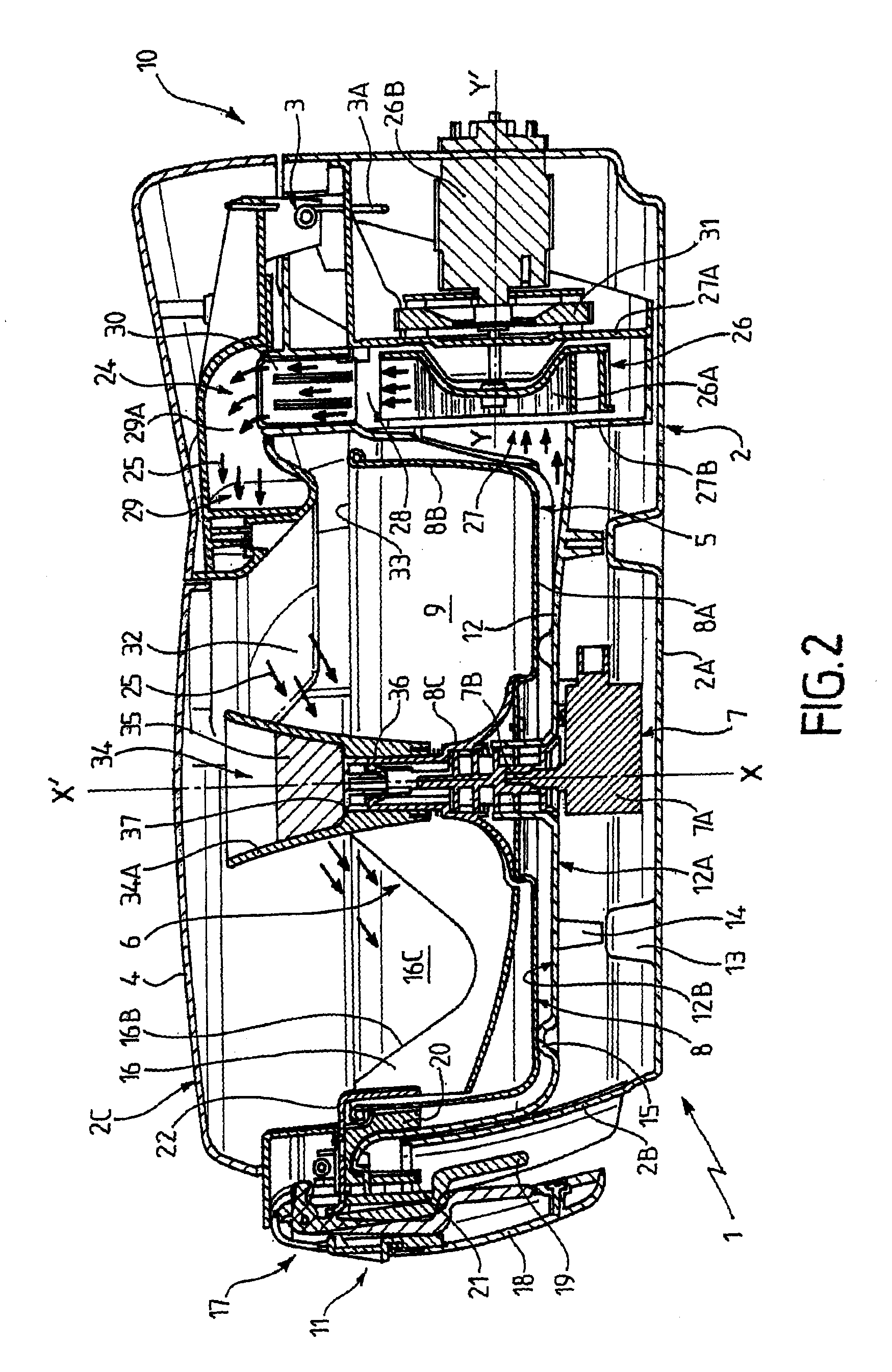

InactiveUS20050011370A1Free handsEnvironmentally friendlyAir-treating devicesBaking plantsFresh airFully automatic

An automatic frying apparatus (100) for both deep and shallow frying. Frying apparatus (100) comprises a container (102) having an inner cylindrical wall (102b) installed on the central bottom thereof, so as to emanate from the bottom to substantially the upper portion of container (102) for holding foods and oil, a lid (104) covering on top of container (102), a plurality of stirring blades (108) rotatably and removably installed inside container (102) for stirring foods, a power-drive assembly (110) operationally coupled with blades (108) for driving blades (108) through repeating stirring cycles, a coupling device (106) for coupling in between assembly (110) and blades (108), a venting device (200) for filtering and deodorizing cooking fumes, and a blowing device (202) for forcing fresh air into frying apparatus (100) for moisture removal from thereinside. Blades (108) sweep across food pieces intermittently, such that blades (108) dwell for a predetermined dwell period starting near the end of each stirring cycle. This intermittent operation favors better agitation of food pieces and affords relief from constant stirring of food pieces at a higher speed. Food pieces are partially immersed in the boiling oil, and therefore, less oil is required for frying foods, thereby, causing less energy consumption, less fat absorption by the food, less time for cooking, and less used oil for disposal. The frying process is fully automatic and requires minimal human involvement and chore.

Owner:XU ZHAOXIA +1

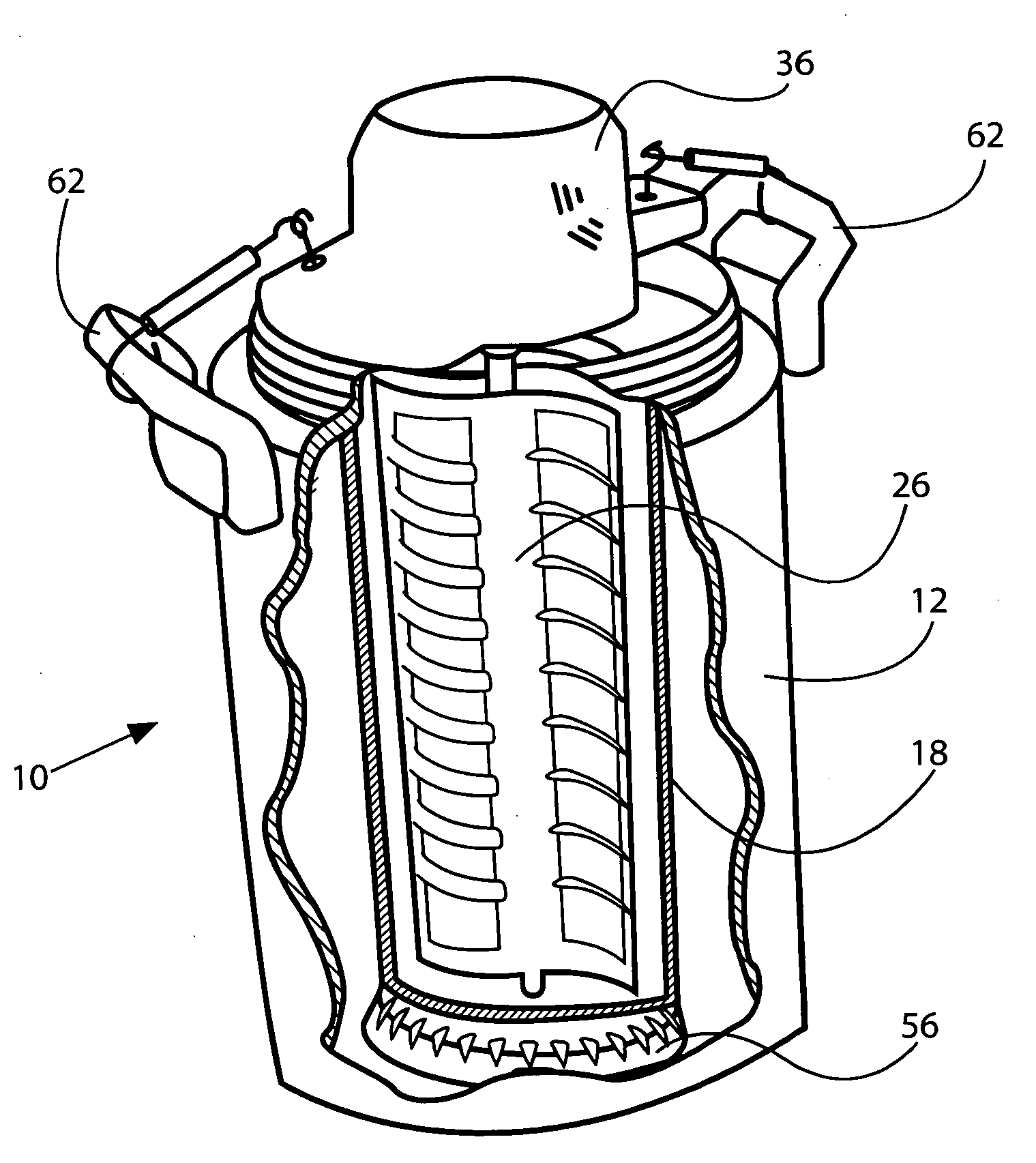

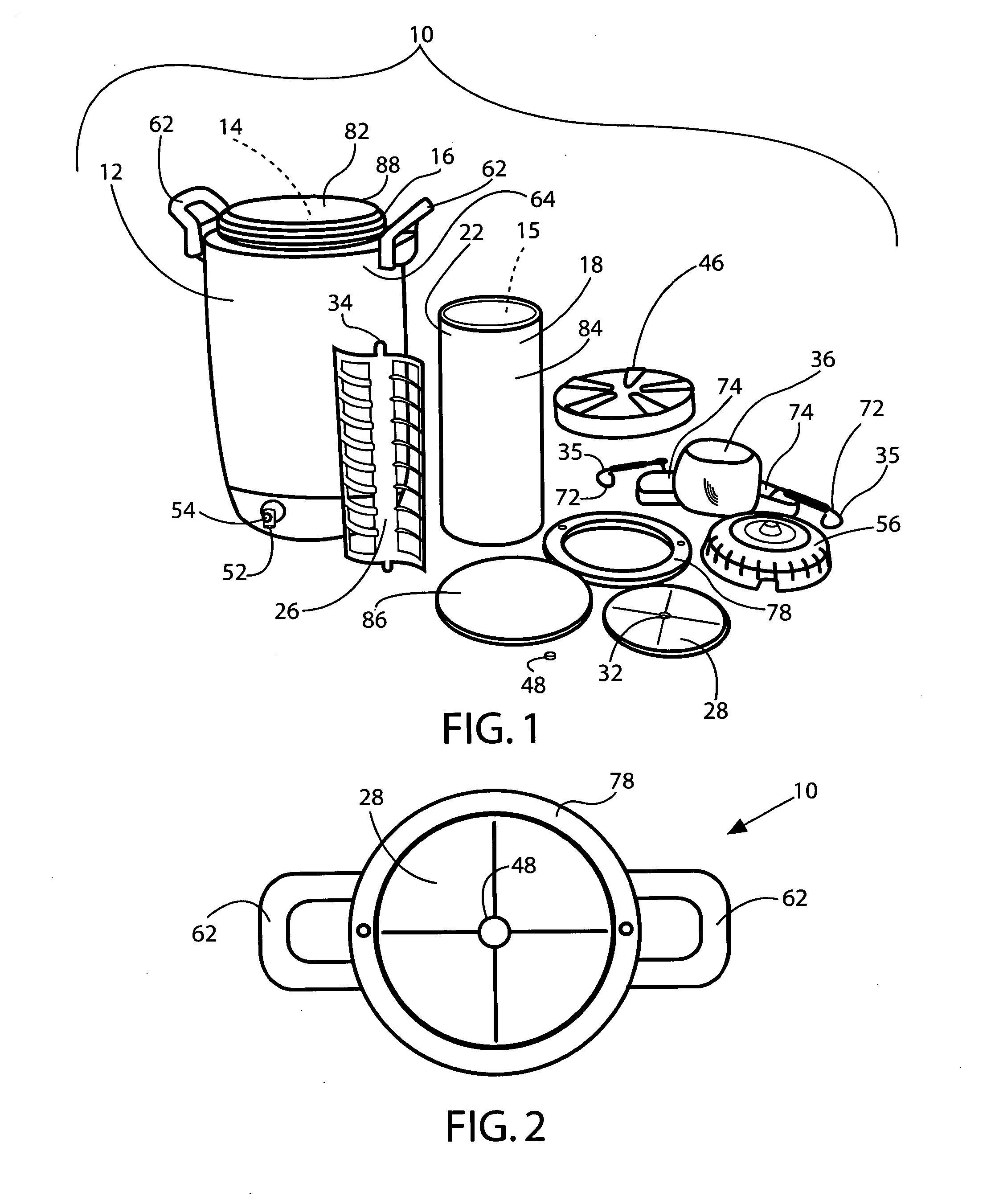

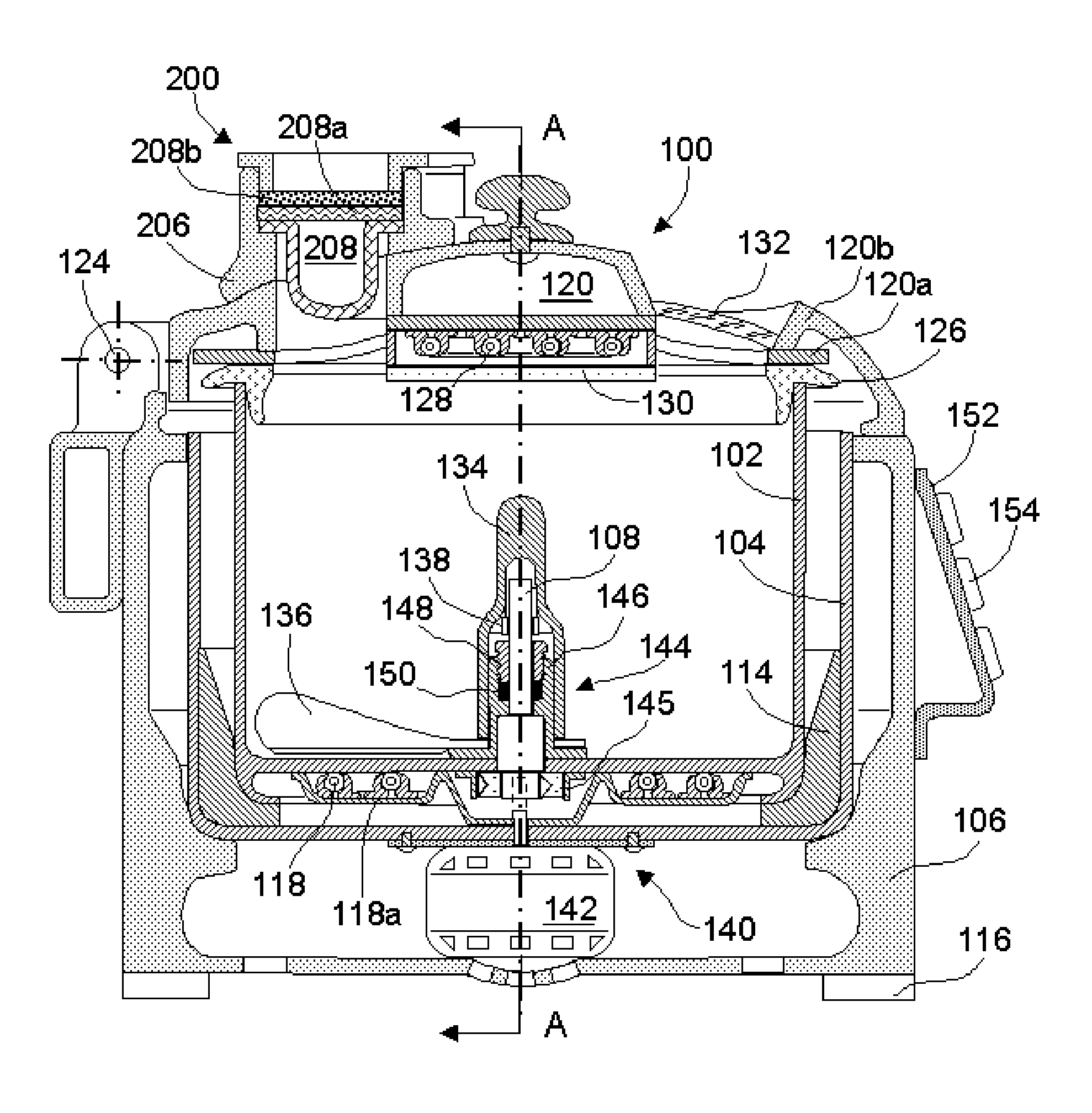

Automatic frying apparatus for both deep and shallow frying

InactiveUS6845707B1Easy to operateReduce manufacturing costAir-treating devicesBaking plantsFresh airEnergy expenditure

An automatic frying apparatus (100) for both deep and shallow frying. Frying apparatus (100) comprises a container (102) having an inner cylindrical wall (102b) installed on the central bottom thereof, so as to emanate from the bottom to substantially the upper portion of container (102) for holding foods and oil, a lid (104) covering on top of container (102), a plurality of stirring blades (108) rotatably and removably installed inside container (102) for stirring foods, a power-drive assembly (110) operationally coupled with blades (108) for driving blades (108) through repeating stirring cycles, a coupling device (106) for coupling in between assembly (110) and blades (108), a venting device (200) for filtering and deodorizing cooking fumes, and a blowing device (202) for forcing fresh air into frying apparatus (100) for moisture removal from thereinside. Blades (108) sweep across food pieces intermittently, such that blades (108) dwell for a predetermined dwell period starting near the end of each stirring cycle. This intermittent operation favors better agitation of food pieces and affords relief from constant stirring of food pieces at a higher speed. Food pieces are partially immersed in the boiling oil, and therefore, less oil is required for frying foods, thereby, causing less energy consumption, less fat absorption by the food, less time for cooking, and less used oil for disposal. The frying process is fully automatic and requires minimal human involvement and chore.

Owner:XU ZHAOXIA +1

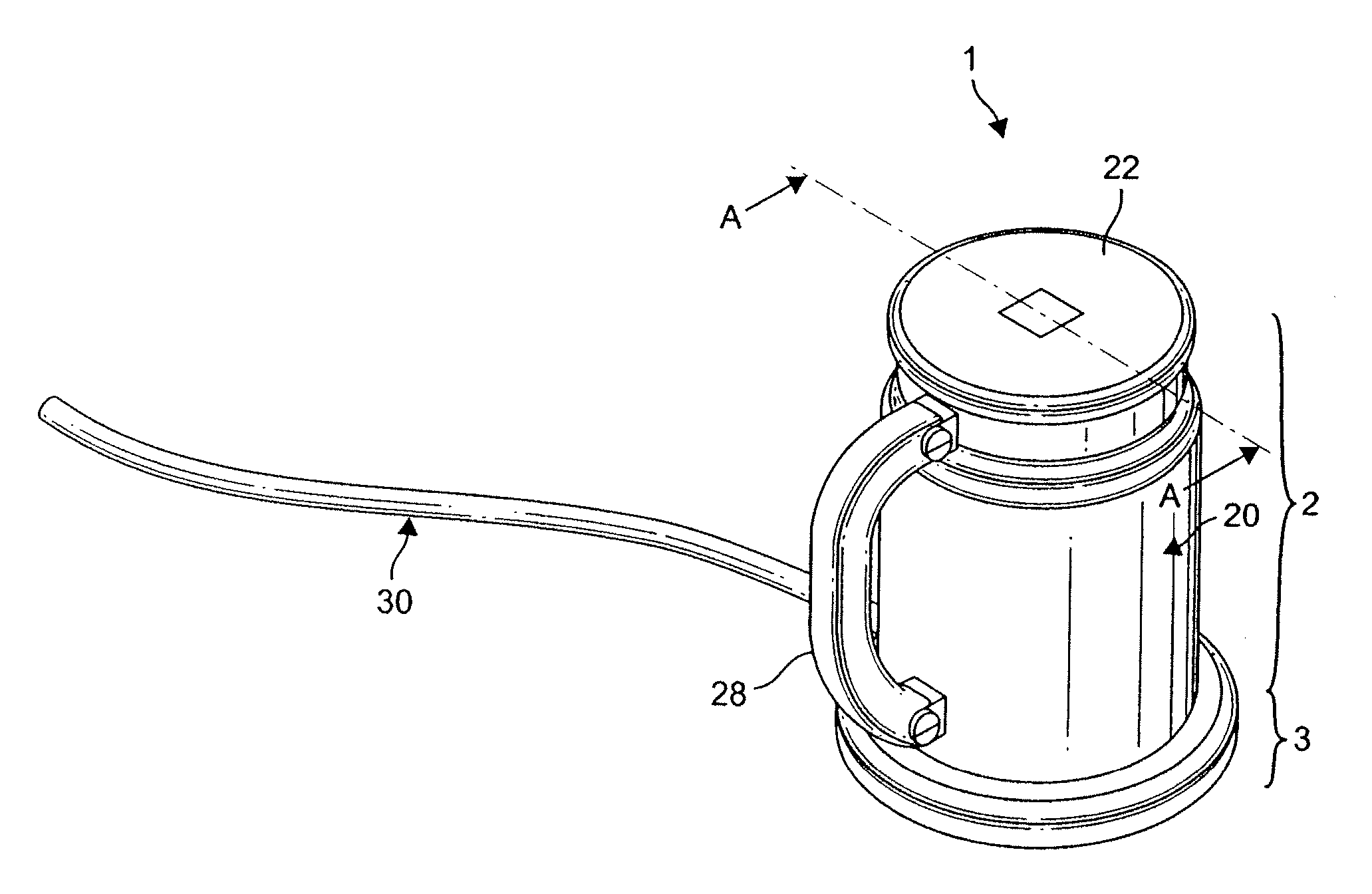

Appliance and method for preparing a froth from a food liquid

ActiveUS20070221068A1Design moreEasy to useMilk preparationMilk preservationMechanical engineeringVertical axis

Owner:SOC DES PROD NESTLE SA

Apparatus for making, storing, and transporting frozen confections and method

ActiveUS20090223386A1Solve the lack of spaceRotating receptacle mixersDomestic cooling apparatusAdditive ingredientEngineering

Owner:EDWARDS DEBRA +1

Food preparation system

An automated food preparation system is described. It allows precise, automated control of the food preparation process, and has the ability to perform an automated cleanup. It comprises at least one manipulator to process and move ingredients, a control system, an autonomously accessible ingredient storage system, and at least one cooking receptacle.

Owner:BUEHLER DAVID BENJAMIN

Electric wok having food processor with automatic feed

A device for processing and cooking food comprises a base housing a heating element for a food cooking function and a controllable motor for a food processing function. A container seatable on the base has an inlet for introducing food and an outlet for processed food. A blade is rotatably mounted within the container and driven by the controllable motor to process any food that is introduced into the container. A removable pan is seatable on the base proximate to the heating element to define a cooking surface. The outlet is positioned relative to the removable pan so that any food introduced into the container exits the outlet directly onto the cooking surface. A spatula can be coupled to the base and positioned within the removable pan for movement across the cooking surface to stir the processed food as it is cooked. A method is also disclosed.

Owner:LEASON HLDG

Air fryer

InactiveUS9351495B2Improve heat transfer performanceProvide taste and texture and appearance characteristicMilk preservationBaking ovenProcess engineeringFood products

An accelerated cooking air fryer is disclosed comprising a cavity, controller, thermal heating source, blower assembly, gas directing means and a vent assembly. Hot gas is circulated by the blower motor assembly into the air fryer cavity where the hot air is directed in a manner wherein a conflicting, colliding turbulent gas flow is directed at a food product providing for the accelerated cooking of the food product.

Owner:TURBOCHEF TECH INC

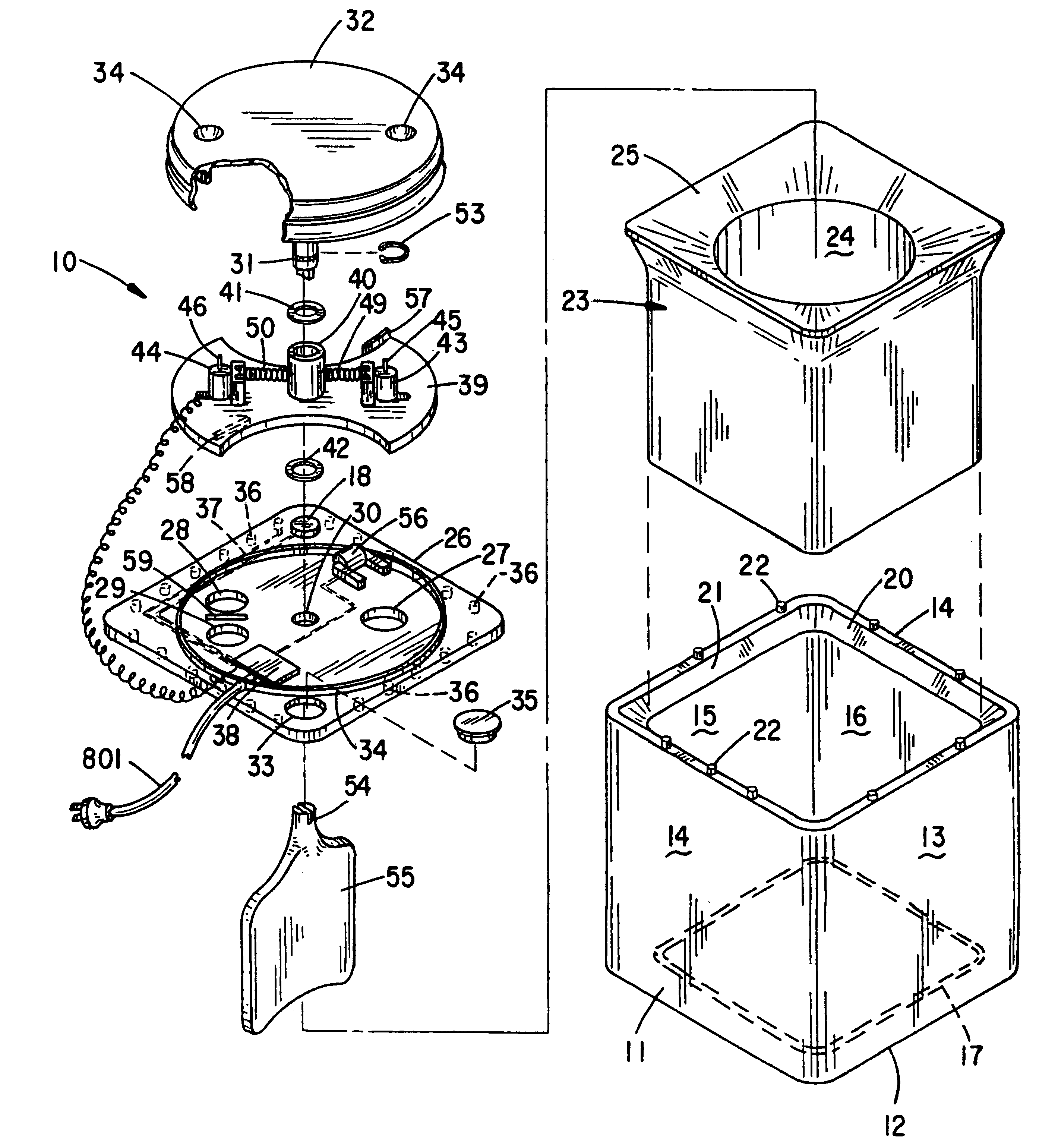

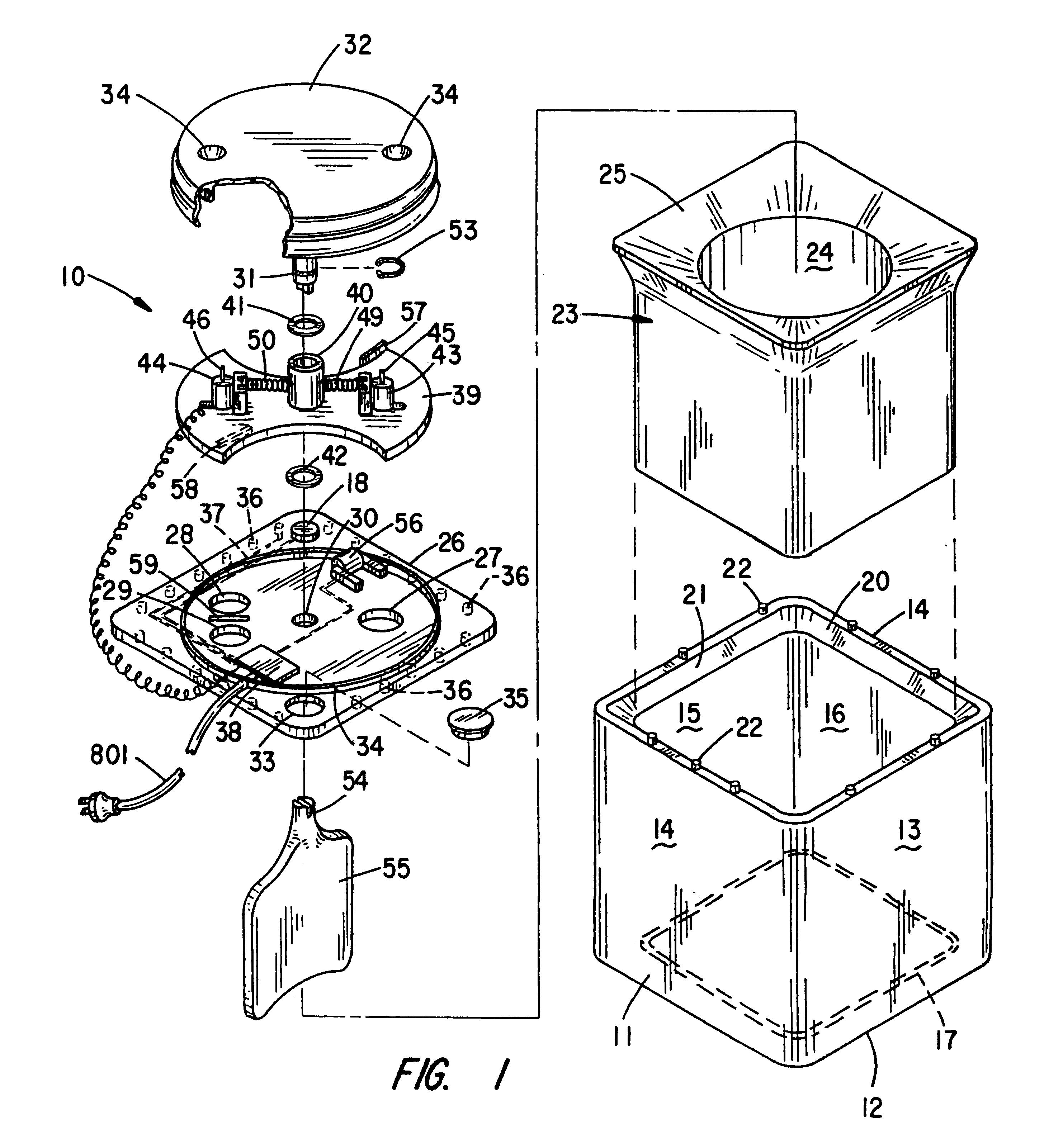

Home yogurt/cheese making machine

InactiveUS6213007B1Improve the immunityAutomatic control devicesMilk preservationCheesemakingMotor drive

A kitchen appliance for preparing yogurt, soft frozen yogurt and ice cream, hard frozen yogurt and ice cream, and cheese. The appliance includes a housing having a base and side walls defining an open top. A motor-driven paddle device is rotationally journaled with respect to the cover and base and the motor therefor is adapted to be driven either continuously or with a predetermined duty cycle, dependent upon the product being made. Also mounted on either the cover or the base is a vent hole occluder that is normally positioned to block the vent holes in the cover or base, but which shifts to a second position uncovering those vent holes when the consistency of the product being produced, as tested by the paddle motion or other apparatus reveals that a predetermined cultured state has been reached. Shifting of the occluding device from the covering position to the open position also actuates a switch to shut off the drive motor and a warming element. When a frozen yogurt product is desired, a pre-chilled freezing bowl can be placed in the housing and the paddle used to scrape the frozen yogurt from the walls of the freezing bowl.

Owner:LANDE ARNOLD J

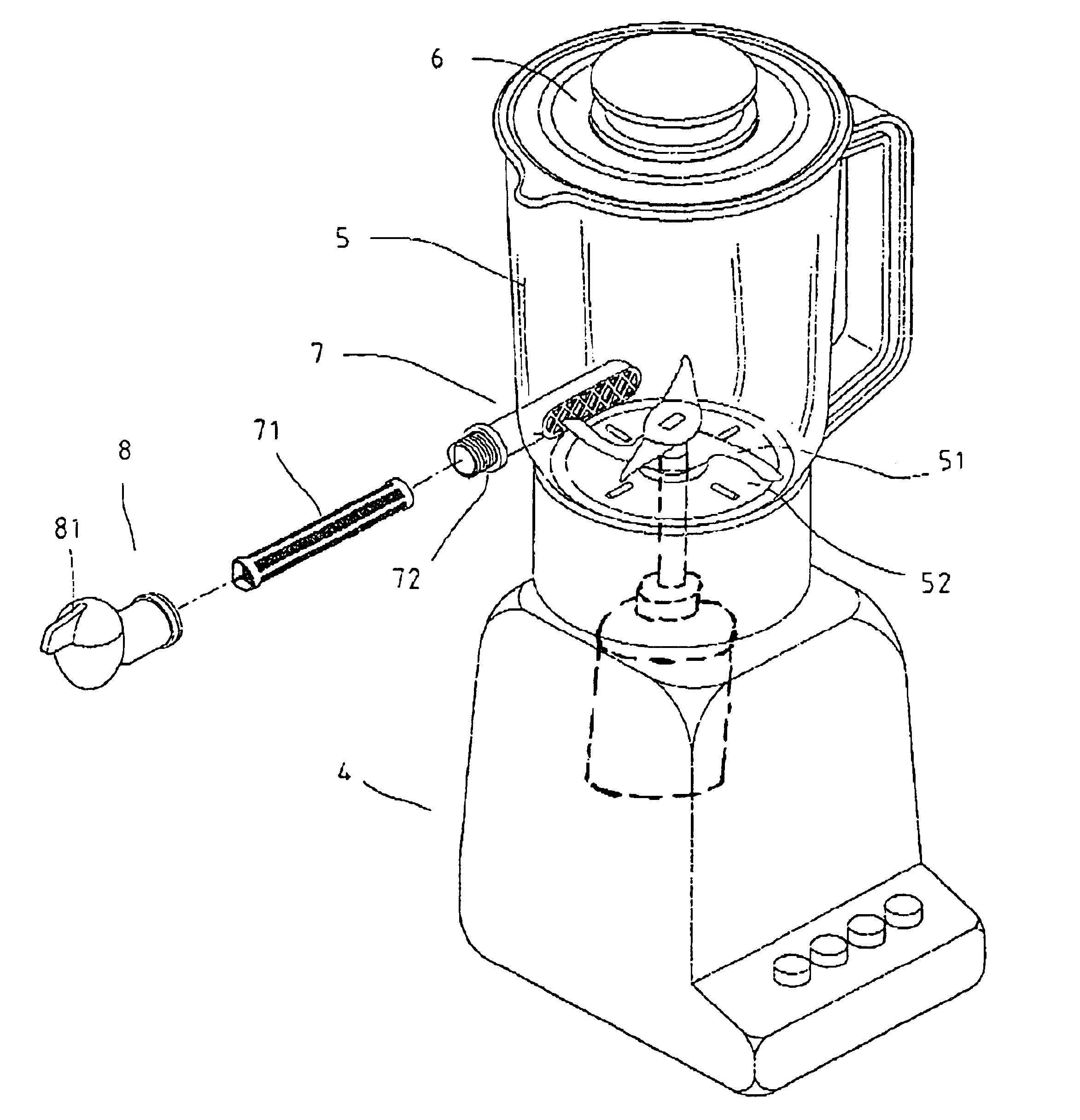

Blend soup maker

InactiveUS20080198688A1Efficient heat transferSave energyTransportation and packagingMixing methodsMechanical engineeringEngineering

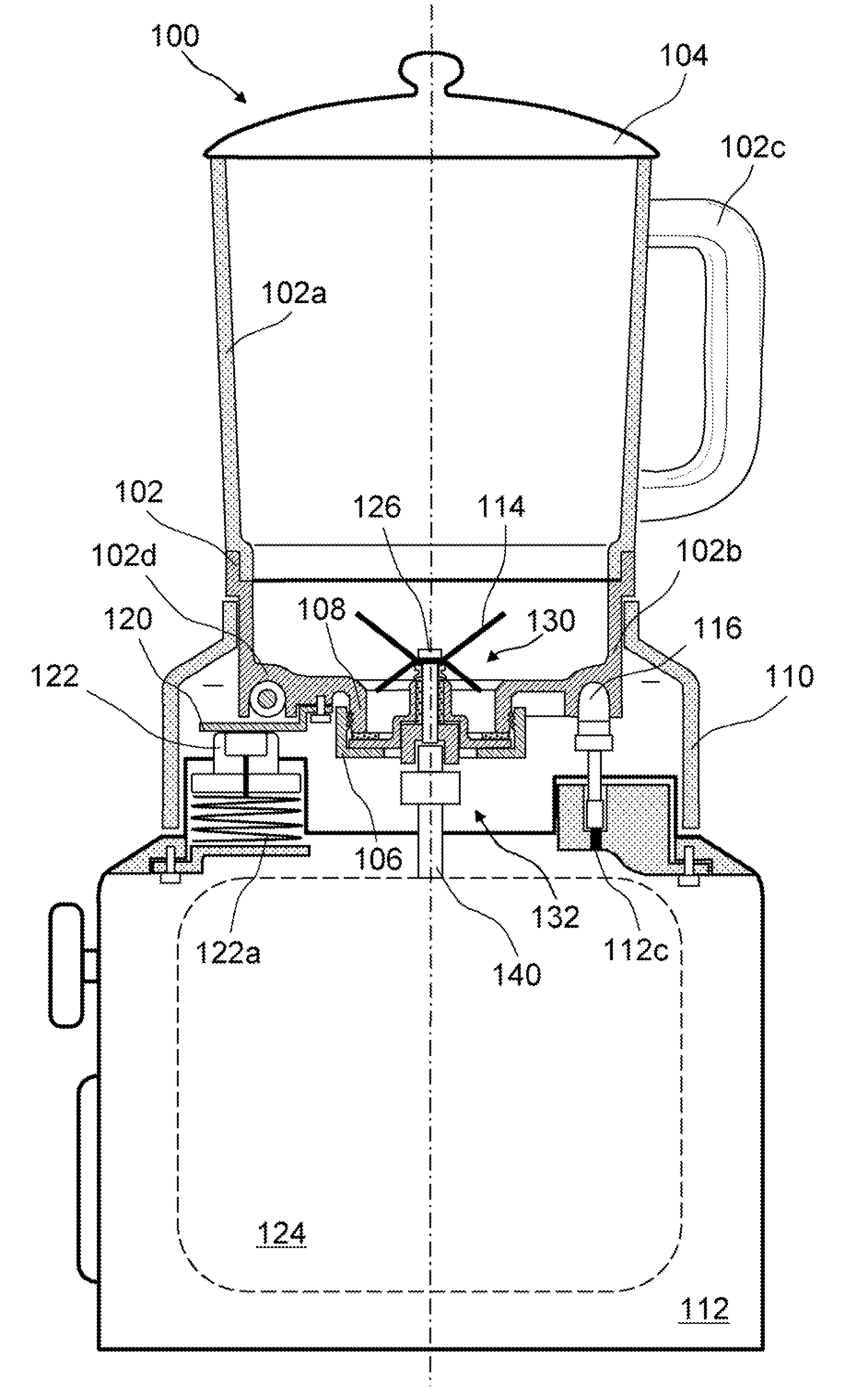

A blend soup maker (100). Soup maker (100) comprises a jar (102) having an open top and an open bottom for holding food, a lid (104) for closing the open top of jar (102), a bottom cap (106) for closing the open bottom of jar (102), a blending blade (114) installed inside jar (102) for blending food, an electrical heating tube (116) fixedly installed on the bottom of jar (102) for heating food, a base support (112) disposed underneath jar (102) for supporting jar (102), a blending motor (124) installed inside support base (112) and removably coupled with blade (114) for driving blade (114) to blend food, and a support member (110) engaged with the lower portion of jar (102) for adapting jar (102) to stand on base support (112).

Owner:PENG ZHENG

Systems and methods for dispensing product

InactiveUS20070251260A1Facilitated releaseReduce flowDomestic cooling apparatusIce productionEngineeringIngested food

An apparatus for producing a food product includes a frame, a first module coupled to the frame and operative to provide a first food product, a second module coupled to the frame and operative to provide a second food product, a selection assembly coupled to the frame and having an outlet and a plurality of inlets, each inlet operative to receive a portion of the second food product, the selection assembly operative to allow passage of the portion of the second food assembly from an inlet to the outlet, a tube kit having a proximal end including a first opening coupled to the first module and a second opening for receiving air, the tube kit having a distal end coupled to the outlet of the selection assembly, the tube kit operative to combine the first food product, air and the portion of the second food product to produce a product mix, and a food preparation assembly coupled to the frame and adapted to receive the product mix from the distal end of the tube kit and to prepare food from the product mix.

Owner:MOOBELLA ACQUISITION +2

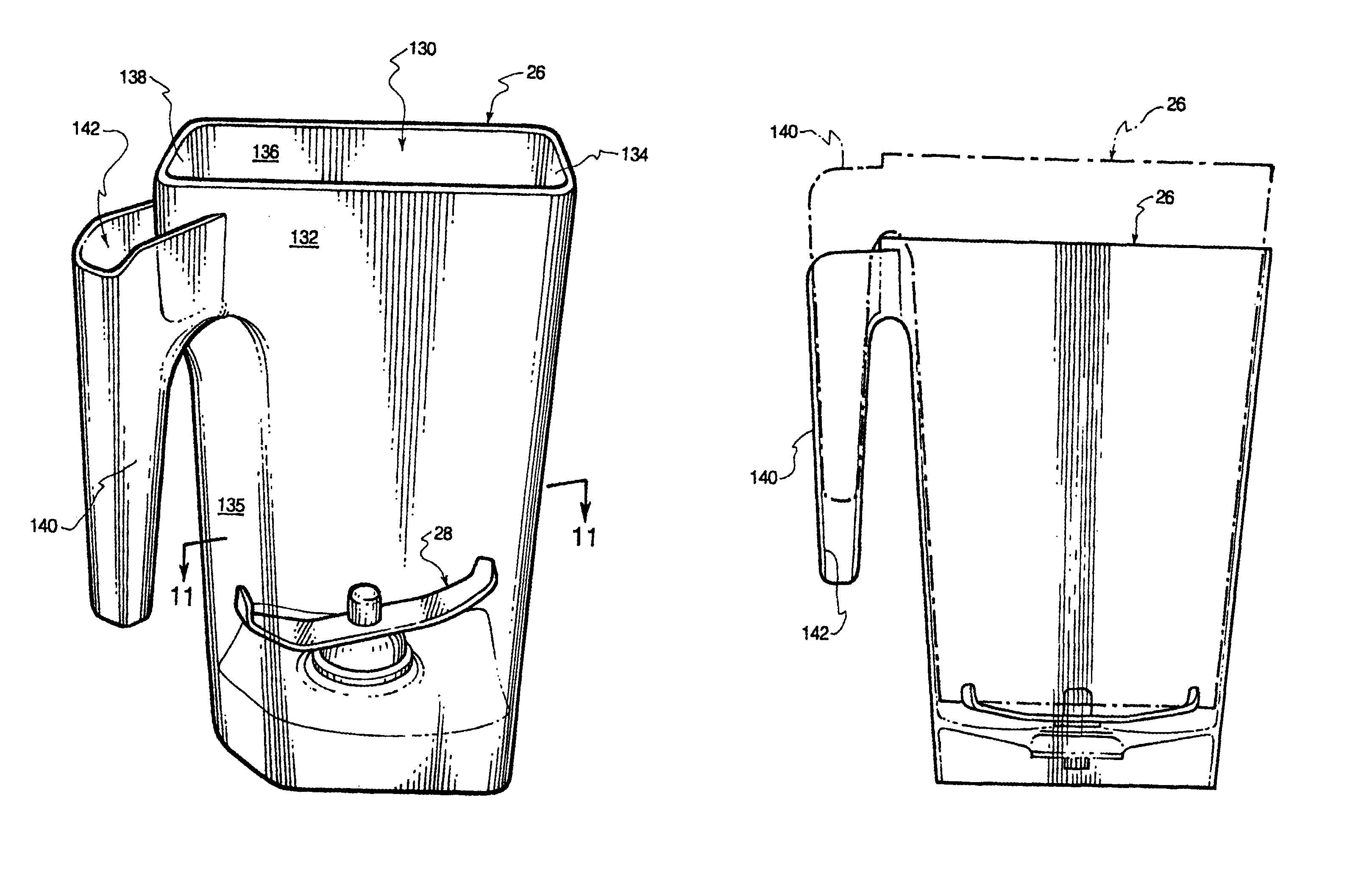

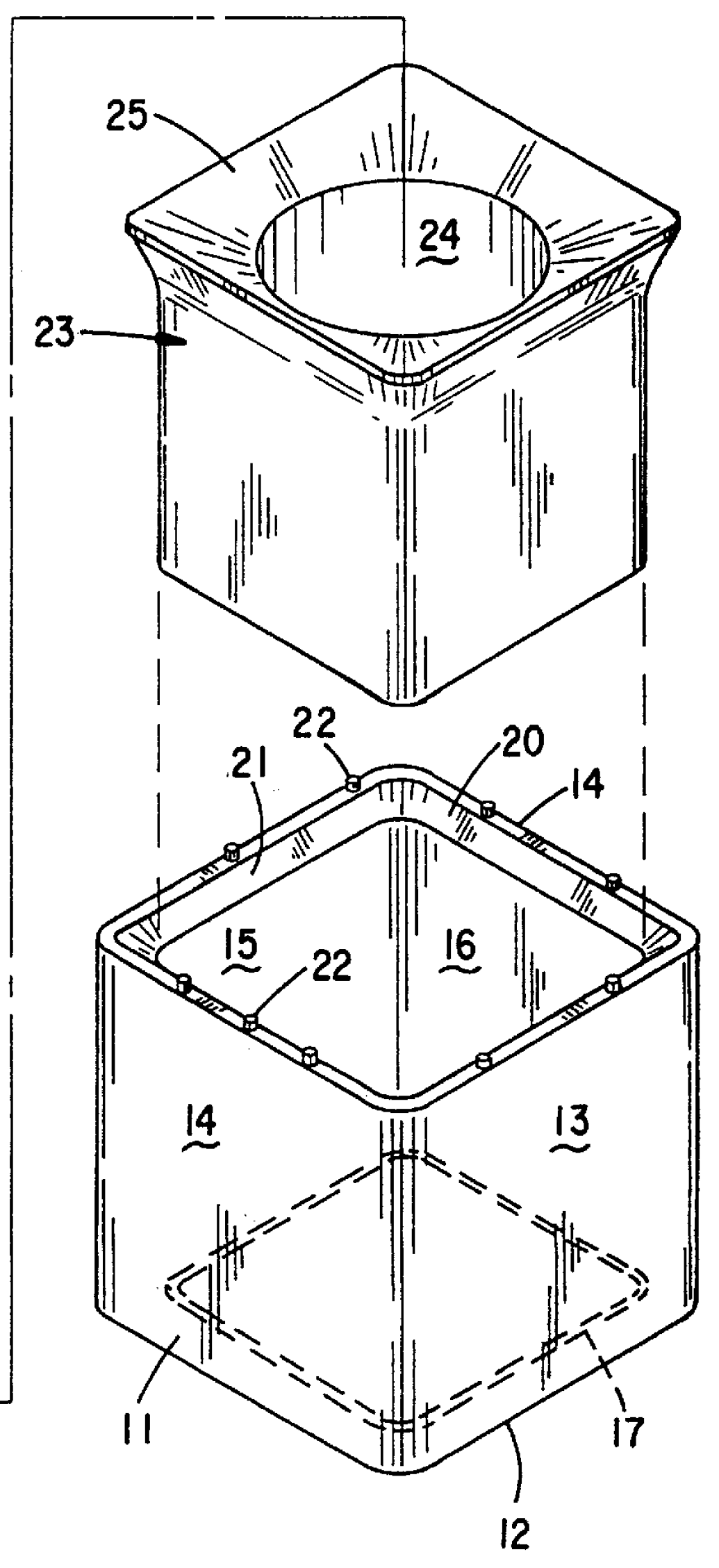

Nestable blending jar apparatus

A blending jar apparatus is disclosed and includes a plurality of walls and a handle secured to one of the plurality of walls. The handle includes an aperture receptive of a handle of another blending jar apparatus. One of the plurality of walls may include a truncated wall, to which the handle is secured.

Owner:BLENDTEC

Home yogurt/cheese making machine

A kitchen appliance for preparing yogurt, soft frozen yogurt and ice cream, hard frozen yogurt and ice cream, and cheese. The appliance includes a housing having a base and side walls defining an open top. A motor-driven paddle device is rotationally journaled with respect to the cover and base and the motor therefor is adapted to be driven either continuously or with a predetermined duty cycle, dependent upon the product being made. Also mounted on either the cover or the base is a vent hole occluder that is normally positioned to block the vent holes in the cover or base, but which shifts to a second position uncovering those vent holes when the consistency of the product being produced, as tested by the paddle motion or other apparatus reveals that a predetermined cultured state has been reached. Shifting of the occluding device from the covering position to the open position also actuates a switch to shut off the drive motor and a warming element. When a frozen yogurt product is desired, a pre-chilled freezing bowl can be placed in the housing and the paddle used to scrape the frozen yogurt from the walls of the freezing bowl.

Owner:LANDE ARNOLD J

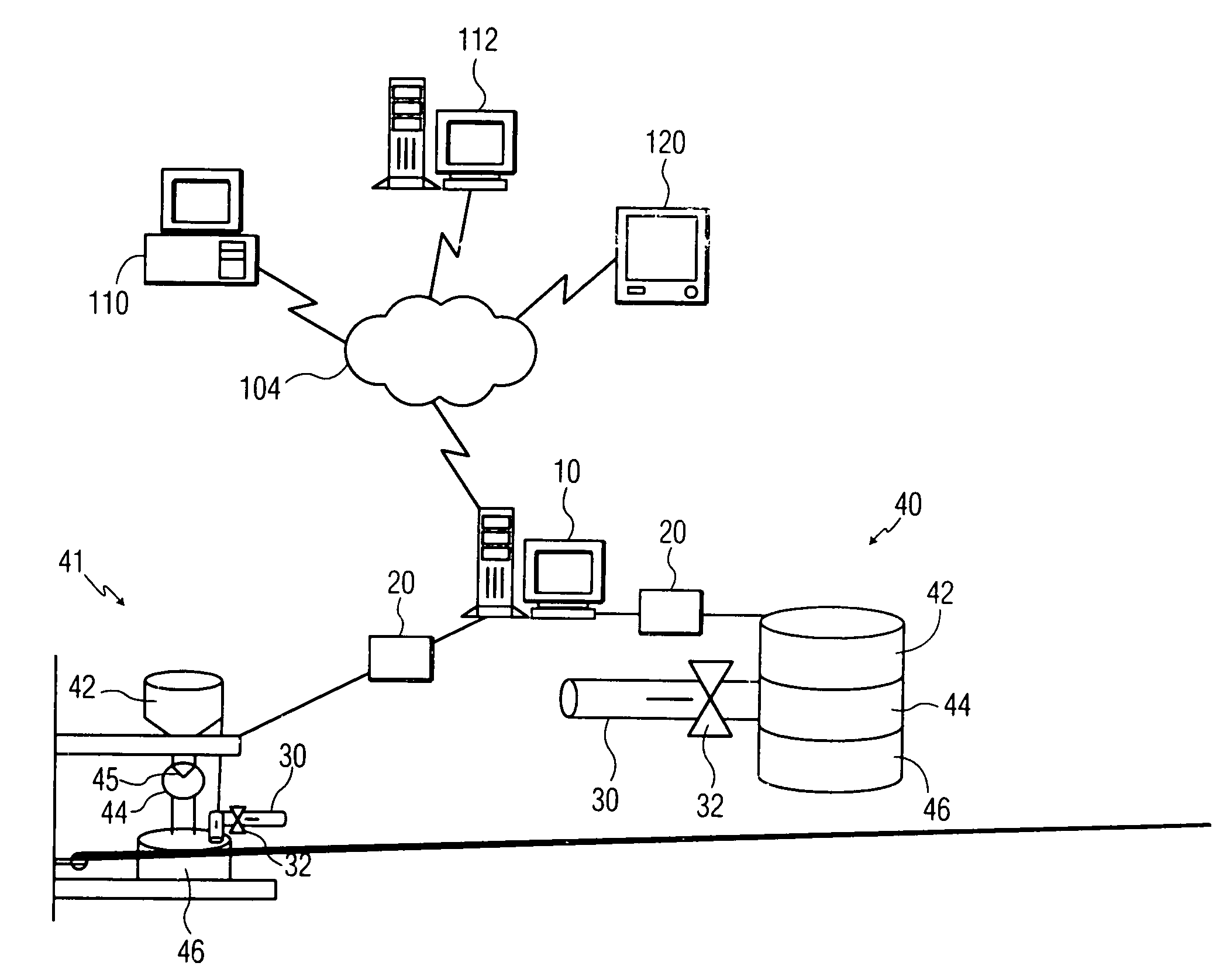

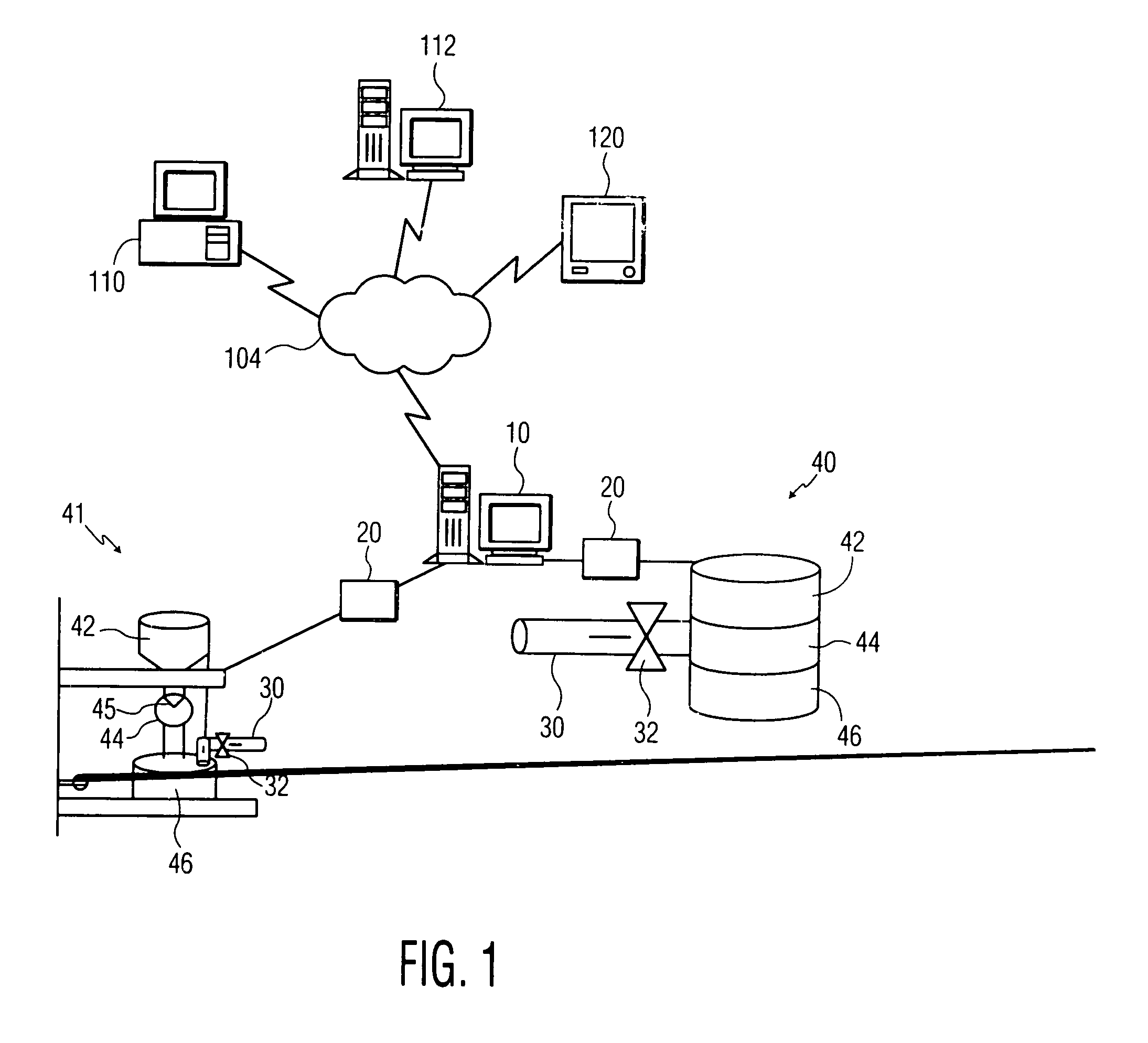

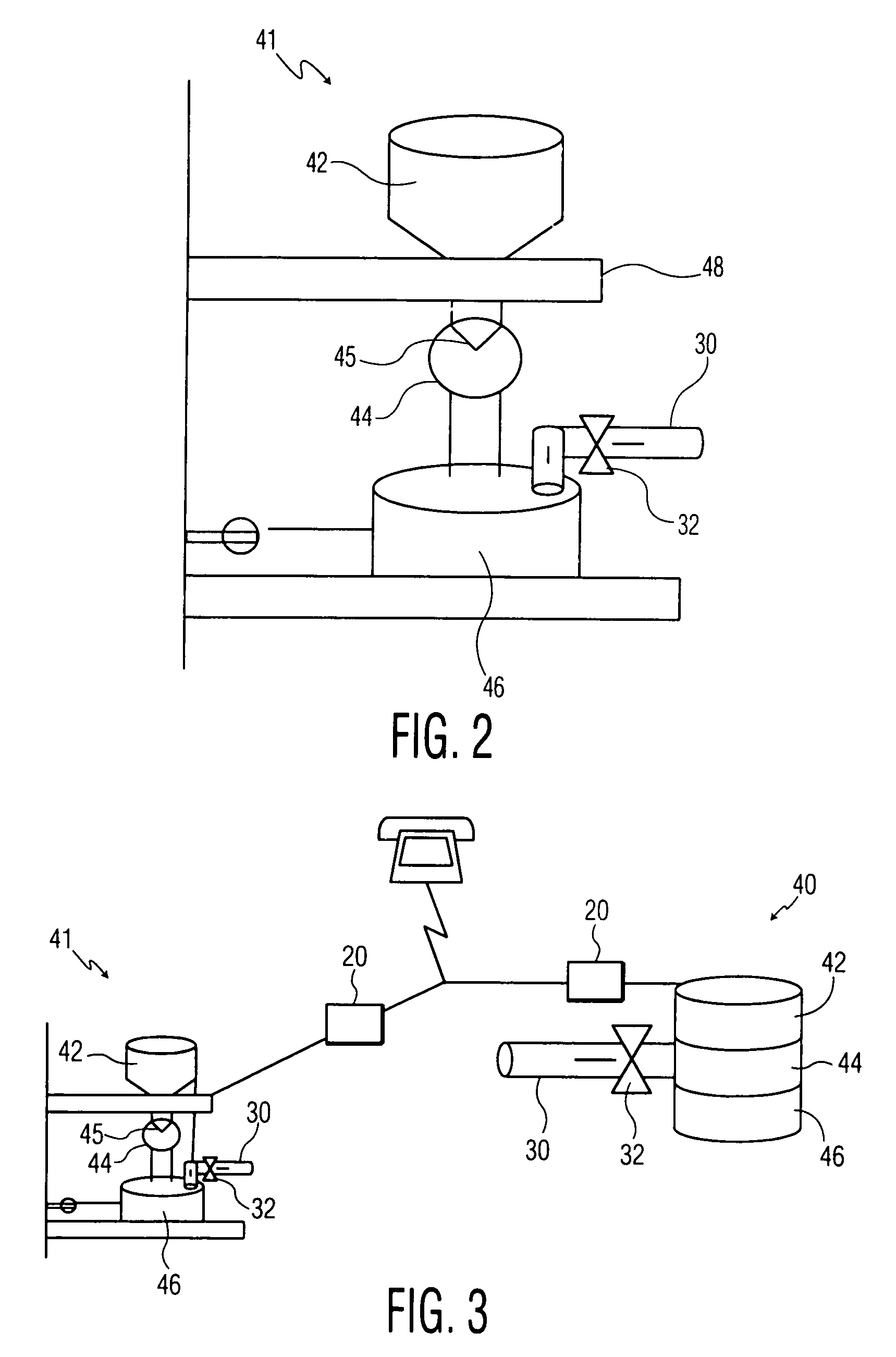

Automated system for cooking and method of use

The present invention comprises an improved device and method for automated cooking foods with a liquid such as water. In a preferred embodiment, the system comprises a cooking chamber (46); a controller (20); a residential home gateway server (10) comprising a memory and a communications interface operatively connected to the controller (20) and to the Internet (104); a hopper (42) for containing food; a stopper (44) in communication with the cooking chamber (46) and the hopper (42), the stopper (44) operatively connected to and selectively controllable by the controller (20) to provide a predetermined portion of the food from the hopper (42) into the cooking chamber (46); the stopper having at least one position in which it is sealingly engaged against the cooking chamber (46) and the hopper (42) to prevent steam generated by the cooking process from entering into the hopper (42) during cooking; a conduit (30) in communication with the cooking chamber (46) for providing liquid into the cooking chamber (46); and a valve (32) disposed intermediate the conduit (30) and the cooking chamber (46) and operatively connected to and selectively controllable by the controller (20). The method comprises receiving data from a remote source, the data comprising a desired amount of servings of the food and a starting time for preparation of the food; determining the cooking characteristics of the food, comprising liquid needs for the food and cooking time; providing food into the cooking chamber (46) from the hopper (42) in a quantity sufficient to satisfy the desired servings; providing liquid into the compartment from the conduit (30) sufficient to satisfy liquid requirements of the food for the number of serving requirements; and engaging a cooking element accessible to the cooking chamber (46) sufficient to satisfy cooking time requirements for the desired number of servings.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Appliance for simultaneous cooking and stirring

InactiveUS20130074700A1Effective and efficient in operational useVersatile convenient and safe to useRotary stirring mixersCooking-vessel lids/coversGear wheelAgitator

A cooking appliance includes a base upon which a pot is supported, with a stirrer configured as a lid, for closing an open top of the pot. A tool coupled to a motorized drive of the stirrer extends downwardly into the pot. A heating element is coupled to the base and resiliently biased outwardly from the base to engage the base of the pot. A latch mechanism is provided for releasably connecting the pot to the base. The motorized drive includes a planetary gear set mounted coaxially with a pot axis, and a tool coupling is connected to a planet gear of the planetary gear set to drive the stirring tool in an orbital motion.

Owner:HANG SHUN HING

Automated cooking machine using a cartesian bot

InactiveUS20160067866A1Reduce in quantityProgramme-controlled manipulatorRobotRobotic systemsIntelligent agent

Owner:DOORDASH INC

Blender

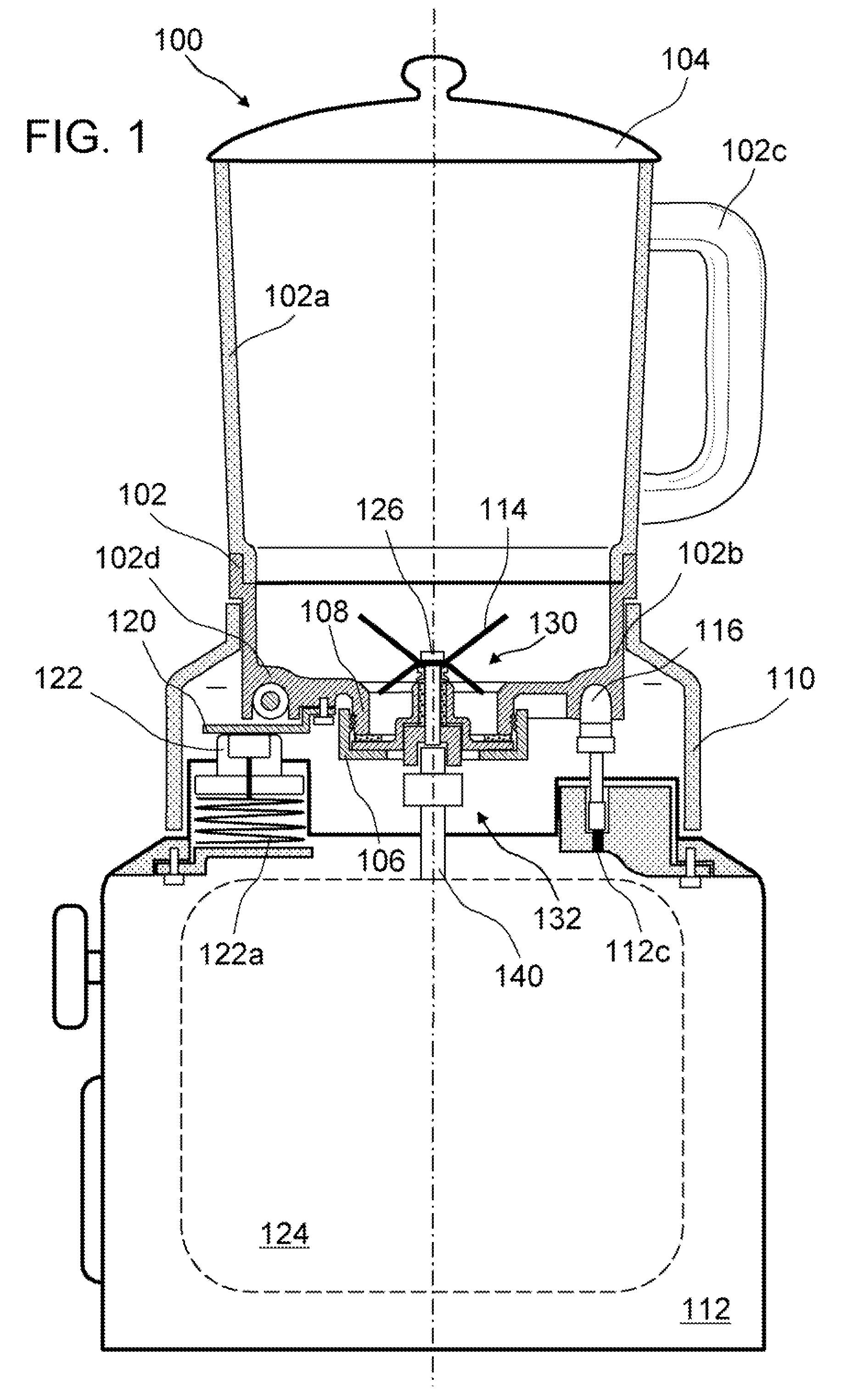

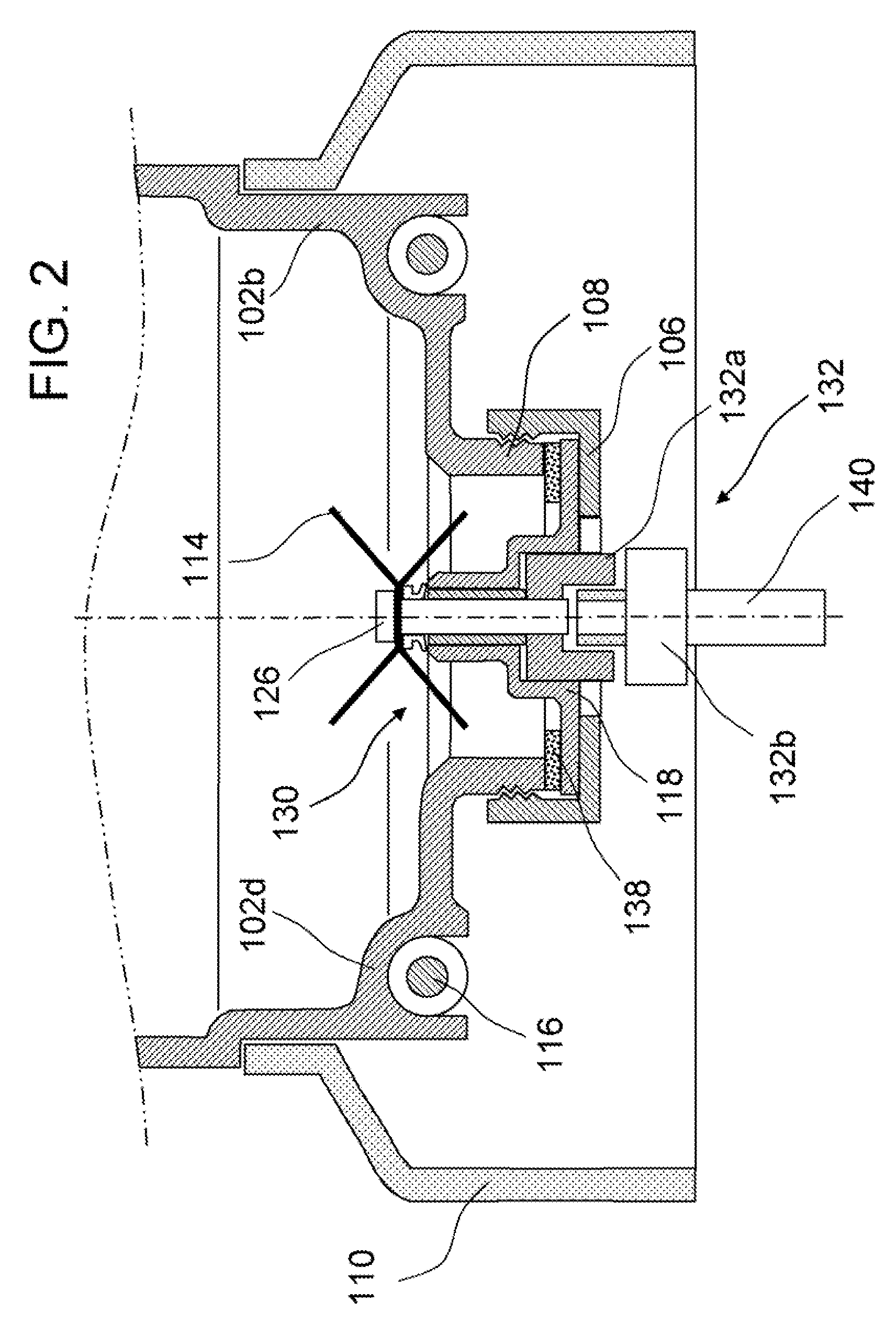

InactiveUS20090260523A1Easy to cleanOperational securityMixer accessoriesBaking plantsMechanical engineeringPosition detector

A blender (100). Blender (100) comprises a jar (102) having an open top and an open bottom for holding food, a top cap (104) for closing the open top of jar (102), a heated bottom (106) sealingly engaged with the lower end of jar (102) for forming a cooking chamber (107), blending or stirring device (114) installed inside cooking chamber (107) for blending / stirring food, a heating tube (116) fixedly installed on the bottom of heated bottom (106) for heating food, a blender base (112) disposed underneath cooking chamber (107) for supporting cooking chamber (107), a motor (124) installed inside blender base (112) and removably coupled with device (114) for driving device (114) to blend or to stir food, a jar base (110) engaged with the lower portion of jar (102) for adapting cooking chamber (107) to stand on blender base (112), and an in-position detector (128) installed inside blender base (112) for user safety protection.

Owner:PENG ZHENG

Means for making soybean milk

InactiveUS6247393B1Safe and hygienic useImprove the tightnessJuice extractionRotary stirring mixersMechanical engineeringSoybean meal

The present invention proposes an apparatus for making soybean milk, wherein a cover body is connected to the opening of a container, and a fixing tank is extended form the cover body toward the inside of the container. A motor is installed in the fixing tank. A reaming blade is extended from the motor. A through passage is installed downwards from a position away from the center of the cover through the fixing tank to a cup-shaped component. A fixedly-joining device is installed at the inner edge of the opening of the cup-shaped component to be correspondingly joined with a fixedly-joined device installed at the bottom end of the peripheral surface of the fixing tank. The reaming blade is placed in the cup-shaped component. The periphery of the cup-shaped component is formed to be a filtering net. An electro-thermal tube is connected from the bottom edge of the cover into the container. When soybeans are guided in via the through passage, a small sealing cap is used to cover on the opening of the through passage. After the apparatus is turned on, the soybeans are reamed by the reaming blade, and soybean juice flows into the container while soybean lees is left in the cup-shaped component. After water is added and boiled, the cover is removed and a sealing cap is covered on the container. The sealing cap has a filtering net at a position corresponding to that of the conduct mouth of the container such that soybean can be filtered and poured out.

Owner:CHANG KWEI TANG

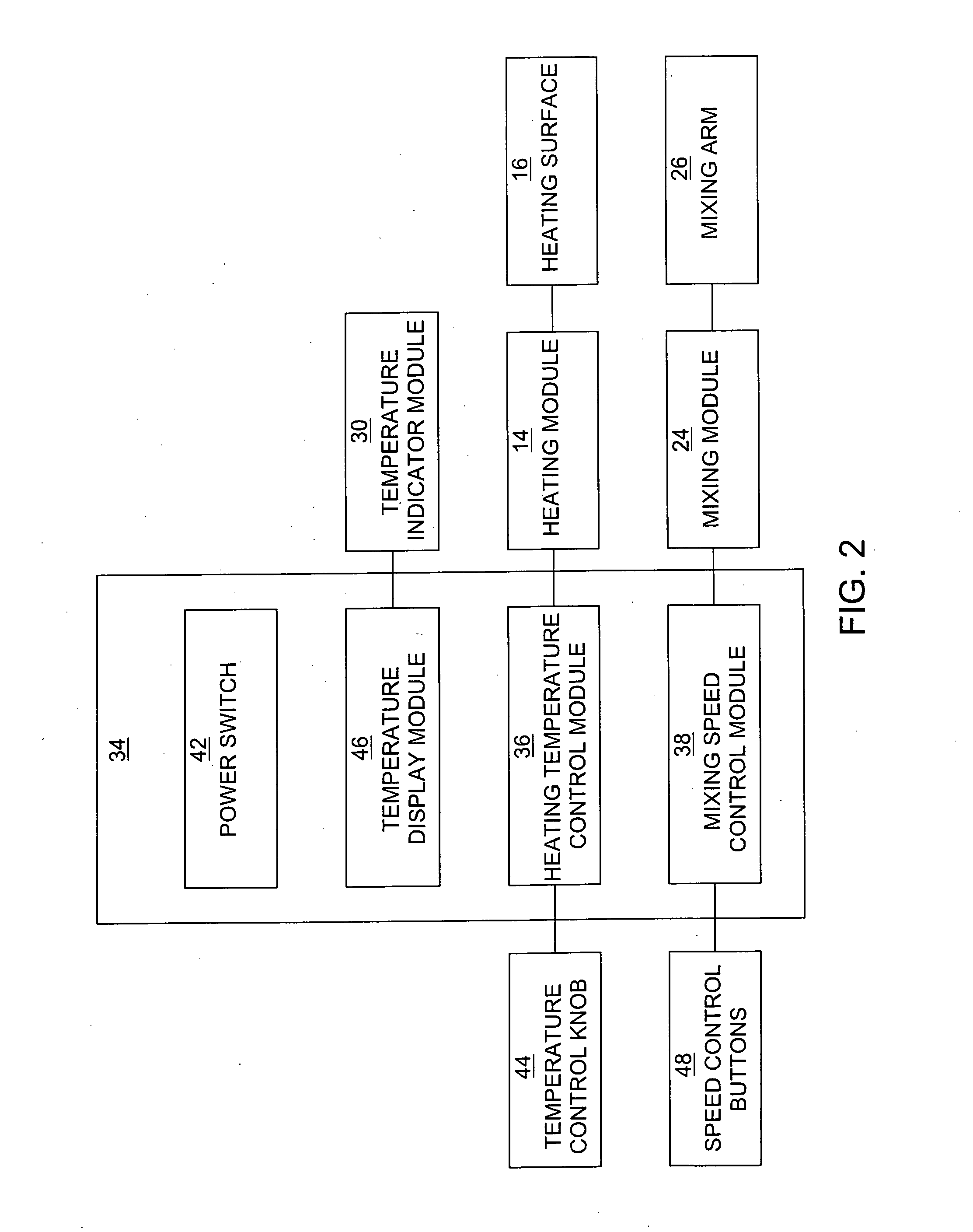

Self stirring, heating and cooking assembly having interchangeable stirring devices

A self stirring cooking assembly including a container defined by a bottom surface and a side surface extending up from the bottom surface, a stirring device having an arm positioned to rotate along the bottom surface of the container, the arm having a non-rectangular cross-section, and a motor configured to rotate the stirring device. The self stirring cooking assembly may have a base having a motor control for controlling the motor, where the motor is positioned in the base. The self stirring cooking assembly may also have a heating element coupled to the base or positioned within the container. That is, the heating element may be positioned on the base or within the stirring device.

Owner:ROTO COOKWARE +1

Structure of a fruit and vegetable processor

Owner:CHANG CHIEN SUNG SHAN

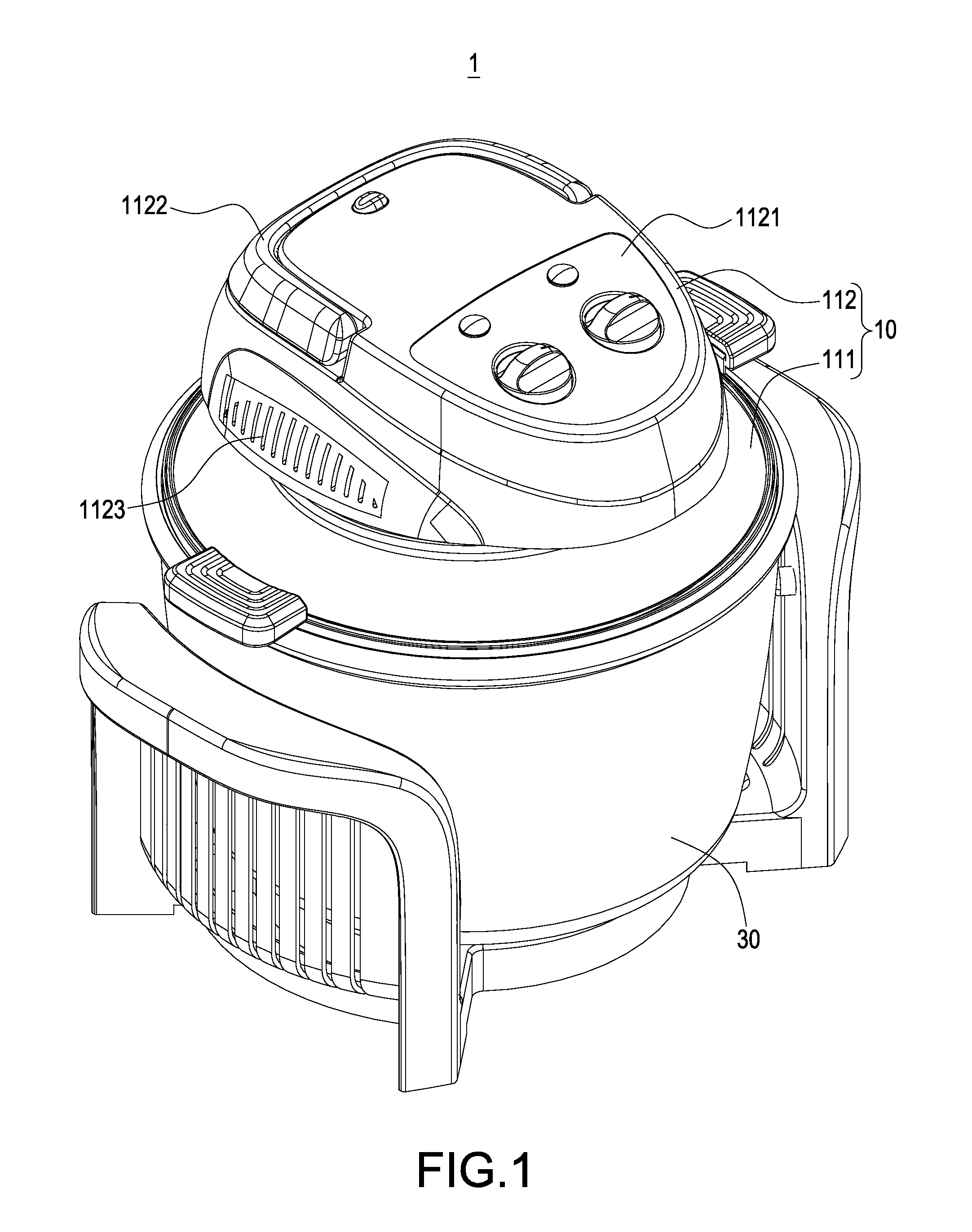

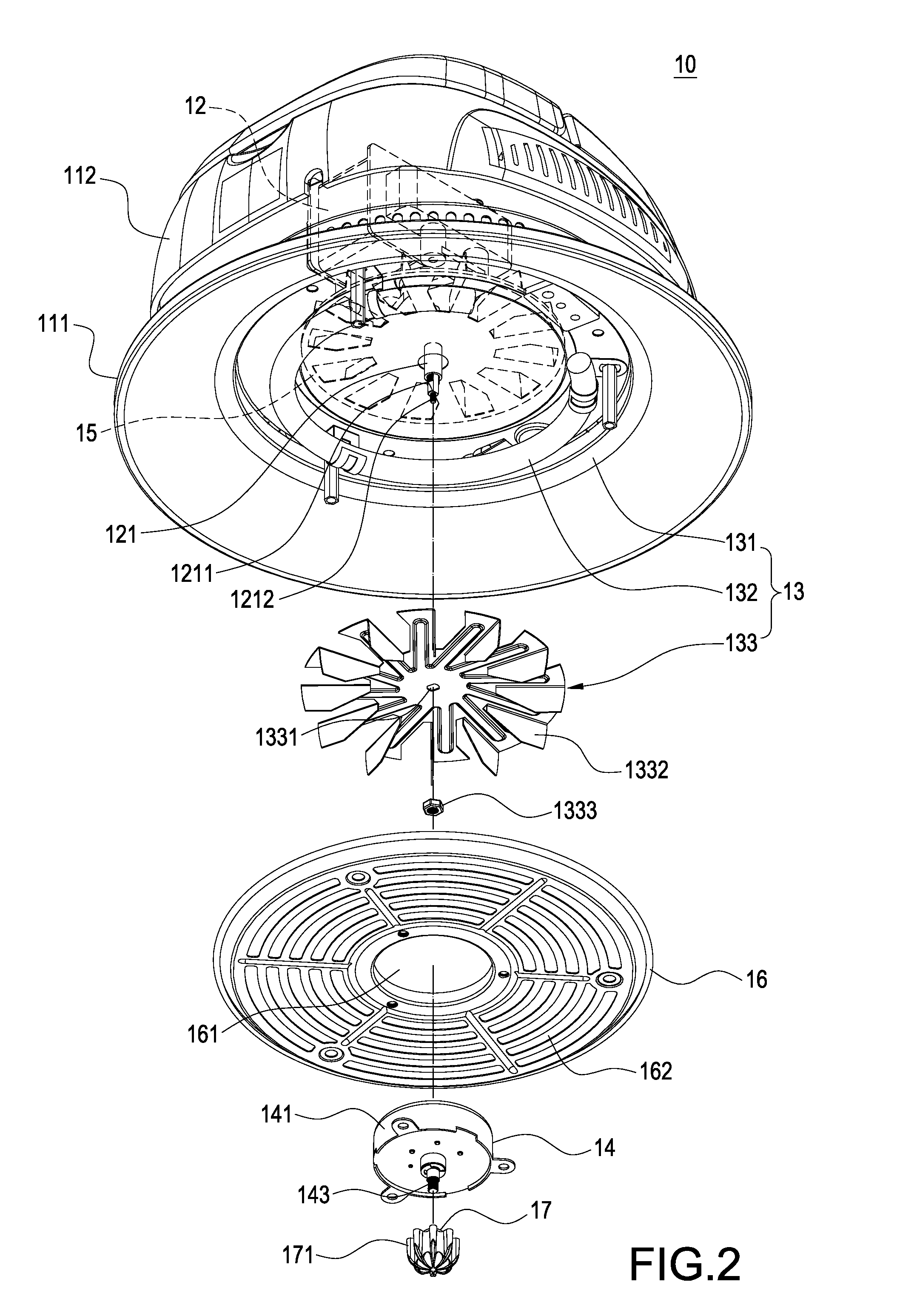

Frying-and-baking oven and heating cover assembly thereof

InactiveUS20110214574A1Improve convenienceImprove functionalityDomestic stoves or rangesDrying solid materials with heatCooking & bakingImpeller

A frying-and-baking oven includes a baking outer pot, a heating cover assembly covering the outer pot, and a frying inner pot disposed between the outer pot and the heat cover assembly. The heating cover assembly includes a cover, an actuator, a hot-air supplying module, and a speed-reducing mechanism. The actuator has a driving shaft. The hot-air supplying module has an air-blowing impeller and a heating element. The driving shaft drives the air-blowing impeller to blow the hot airflow generated by the heating element. The driving shaft also drives a transmission shaft of the speed-reducing mechanism and in turn a stirring member to rotate at a low speed, thereby stirring food materials in the inner pot. With this arrangement, the food materials received in the inner pot can be stirred automatically and cooked sufficiently. Further, the oven can cook the food materials by baking or frying, which increases the functionality and convenience thereof.

Owner:TALL & STOUT INDAL CORP

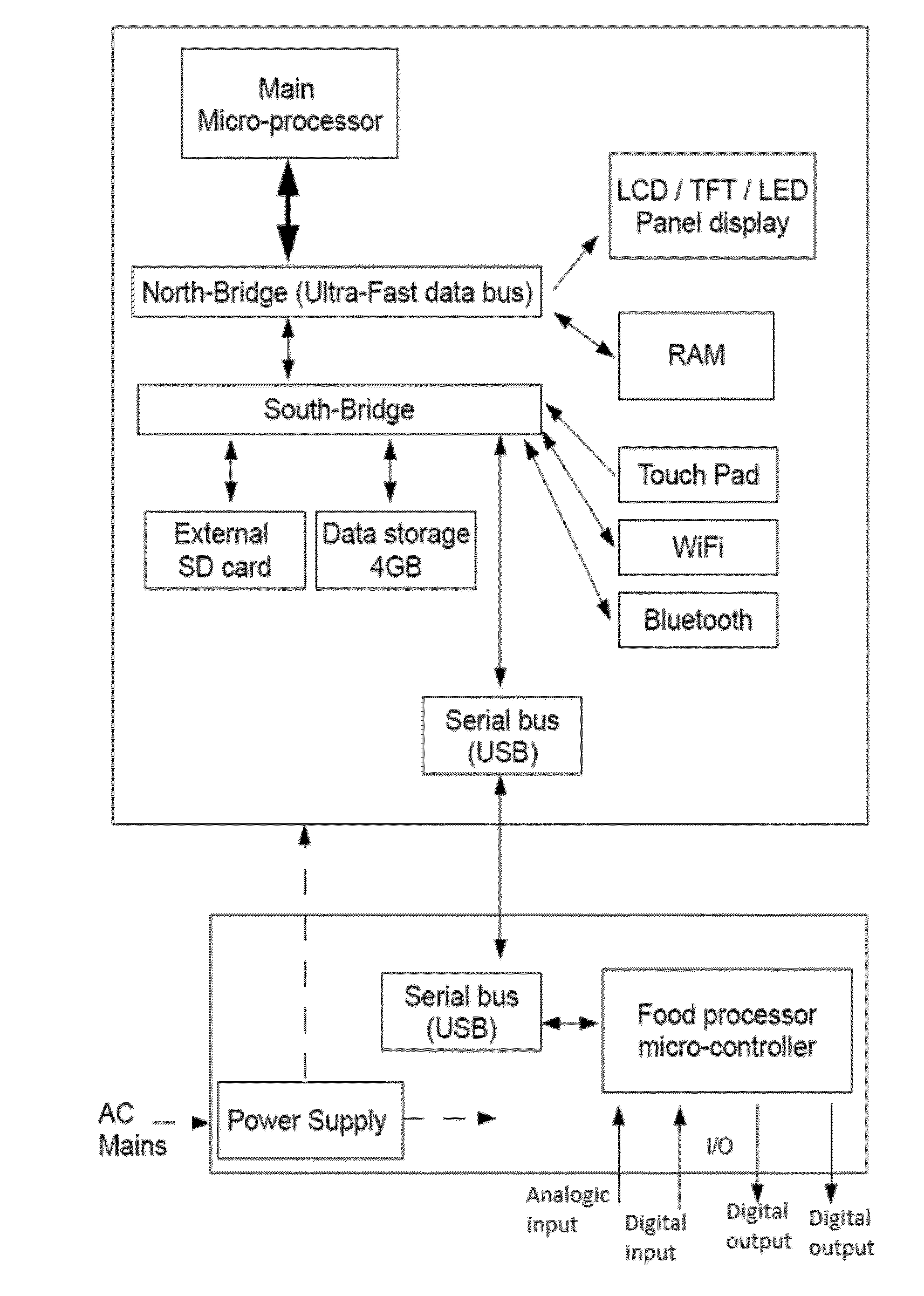

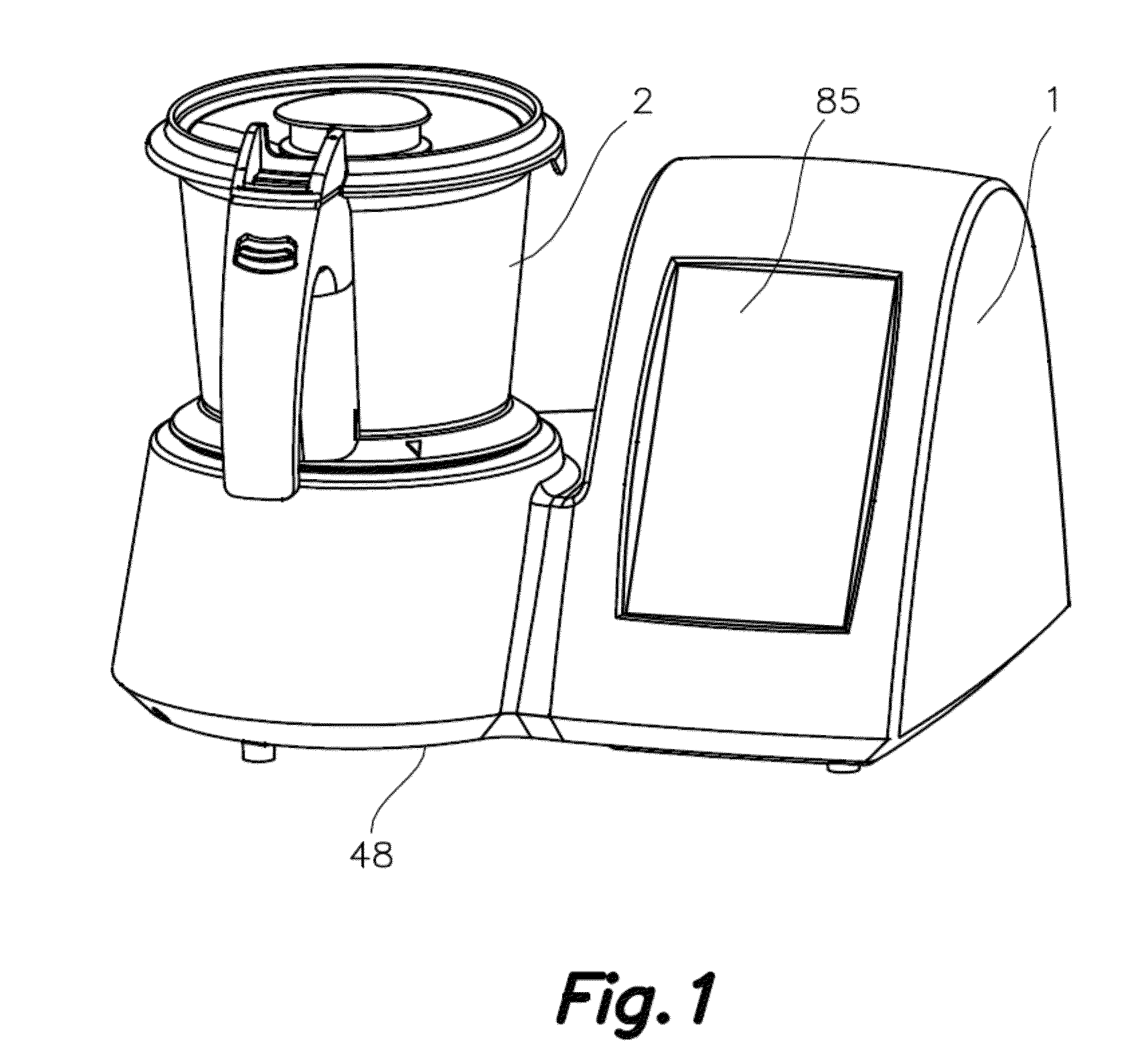

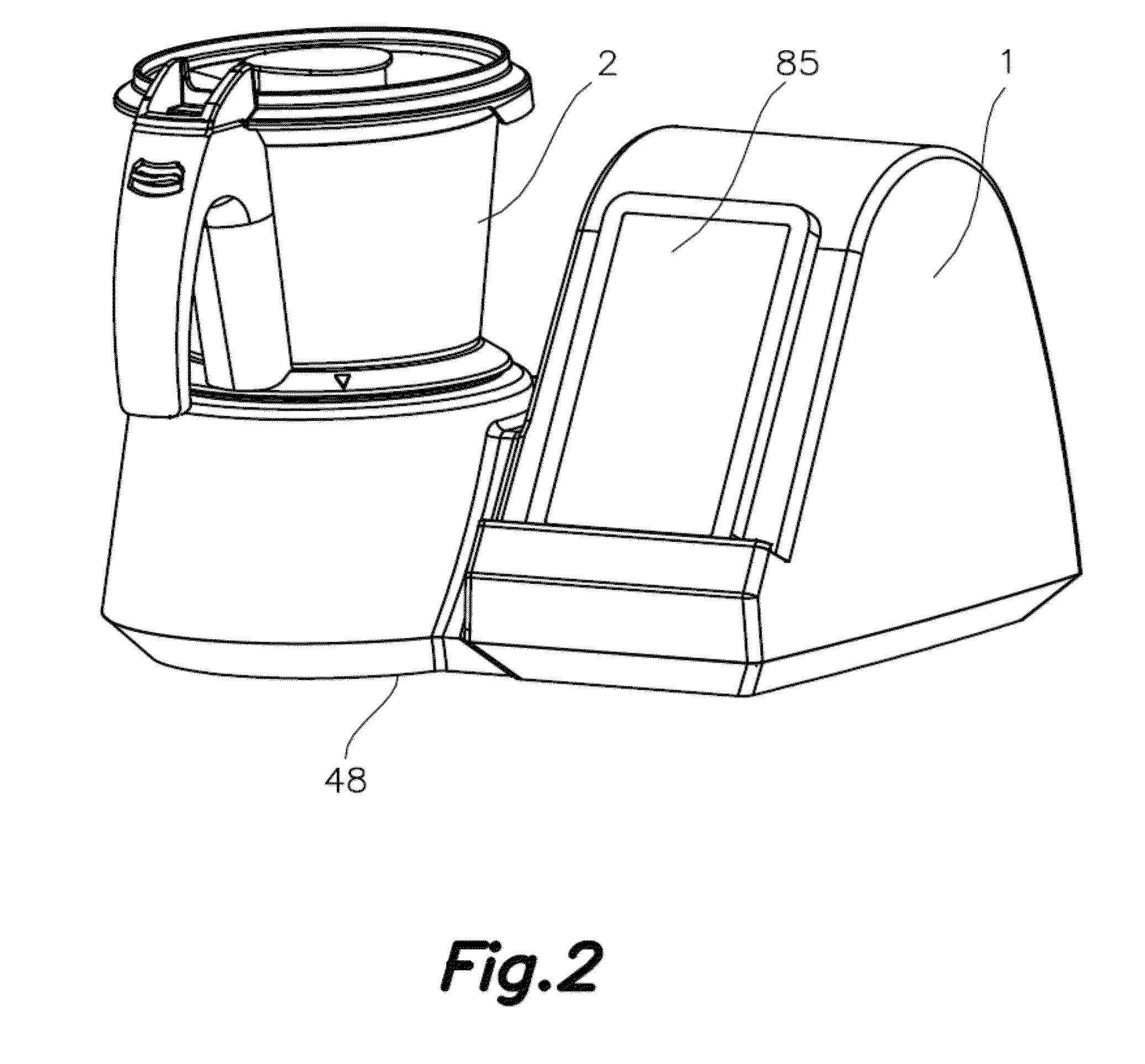

Cooking appliance for processing and preparing foods

InactiveUS20140345474A1Digital data information retrievalBoiling over preventionMicrocontrollerHeat energy

A cooking appliance for processing and preparing foods that includes a base structure (48) on which a support suitable for holding a container (2) containing foods to be processed is assembled, a motorized driving device suitable for rotating a detachable stirring or cutting device inside the container (2), an electronic circuit for powering and controlling the driving device and a heat energy transferring device which is controlled by an appliance microcontroller, and a dedicated computing device (85) integrating a user interface and a telecommunication interface, which, depending on the instructions provided by a user, is suitable for at least sending instructions containing cooking parameters and / or programs to the appliance microcontroller through a data bus and for displaying any anomaly detected by the appliance microcontroller through a multifunction touch screen.

Owner:COMPANIA ESPANOLA DE ELECTROMENAJE

Preparation of individually coated edible core products

A method and apparatus for producing individually coated, baked, edible core products is disclosed. Individual edible cores are coated with a farinaceous dough and baked. The coated cores are agitated as their coatings expand to prevent them from clumping or agglomerating during baking. The baked, coated cores are individual core pieces with an expanded, crispy coating.

Owner:FRITO LAY TRADING CO GMBH

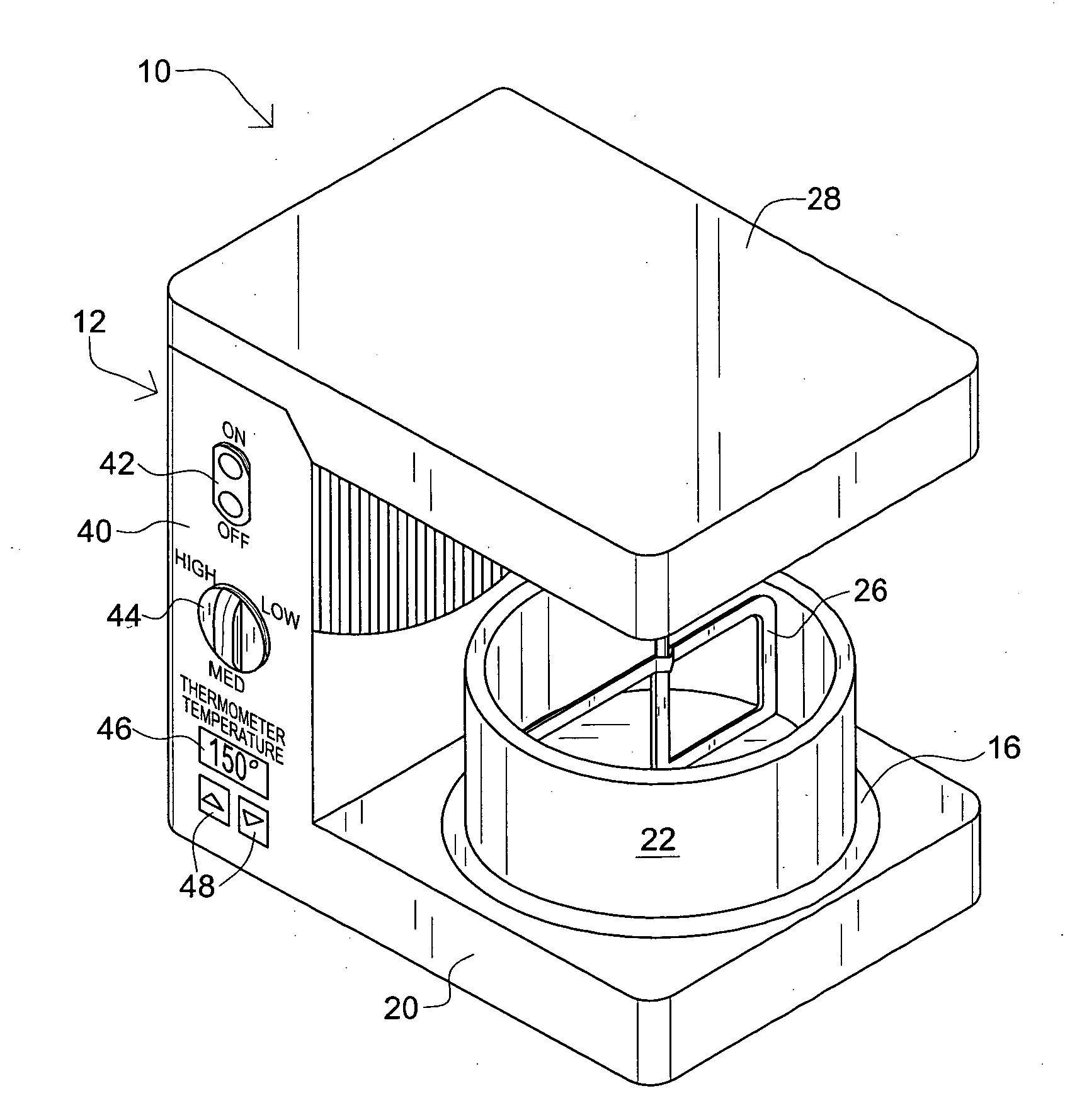

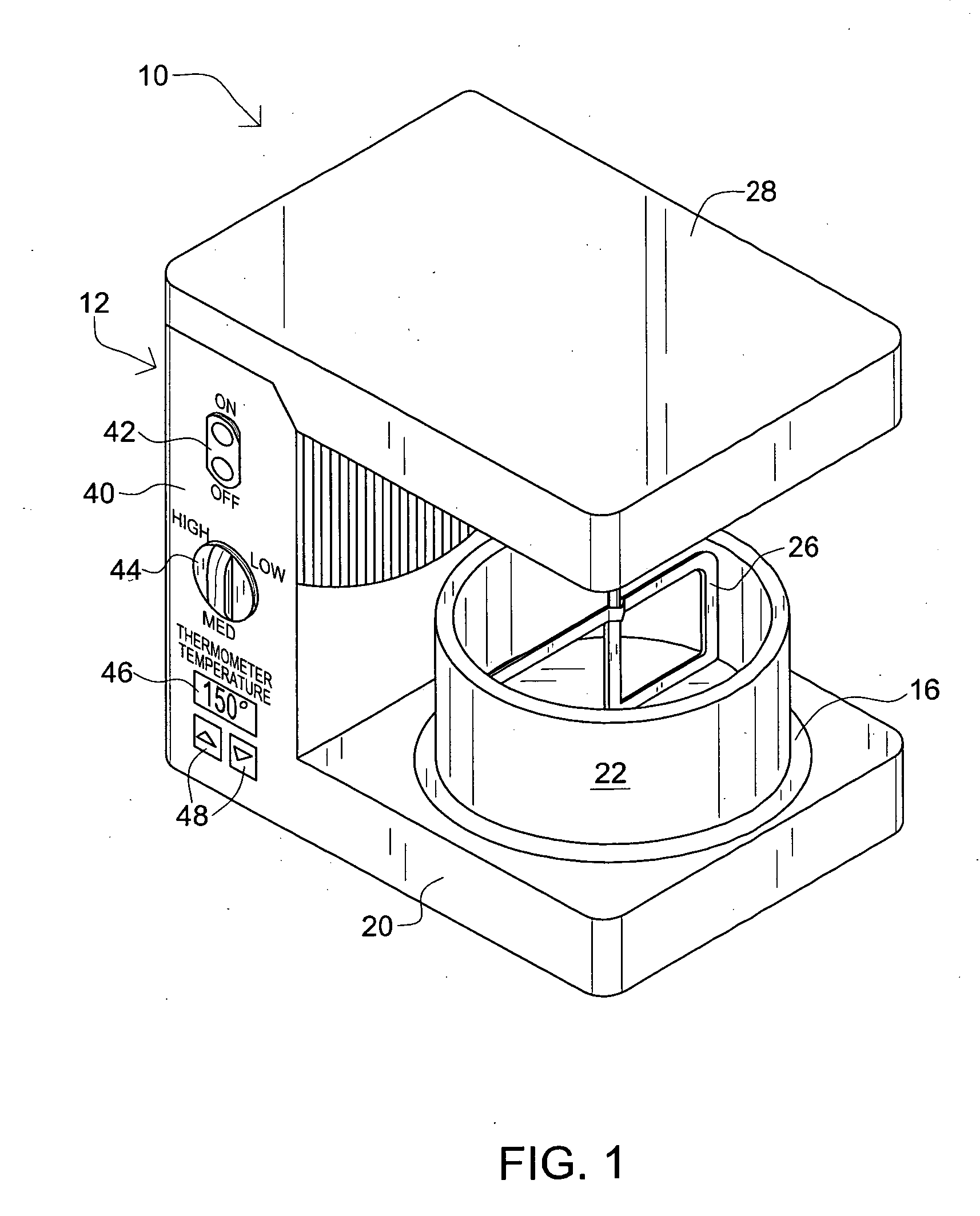

Cooking Device

InactiveUS20090120301A1Boiling over preventionRoasters/grillsMechanical engineeringHeating temperature

A cooking device for making candy. The device includes: a U-shaped base member, a heating module, a container, a mixing module, a temperature indictor module, and a control module. The heating module includes a heating surface coupled to an interior surface of a first arm of the U-shaped base member. The container contains ingredients. The mixing module mixes ingredients in the container. The temperature indictor module indicates a temperature. The control module includes a heating temperature control module, and a mixing speed control module. The heating temperature control module controls a temperature of the heating module. The mixing speed control module controls a speed of the mixing module. A second arm of the U-shaped base member is hingedly coupled to the U-shaped base member member.

Owner:SEVERNAK TERI L

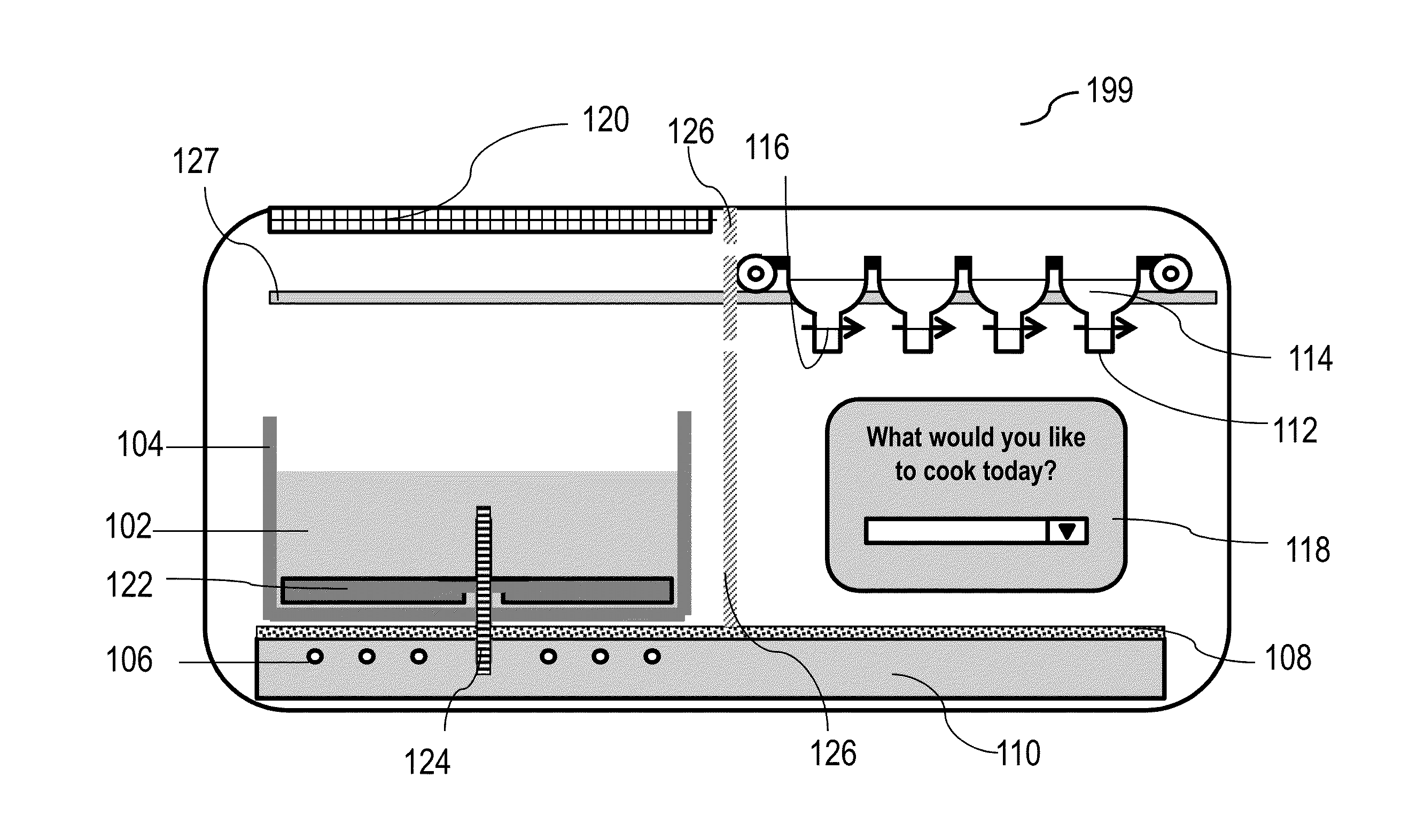

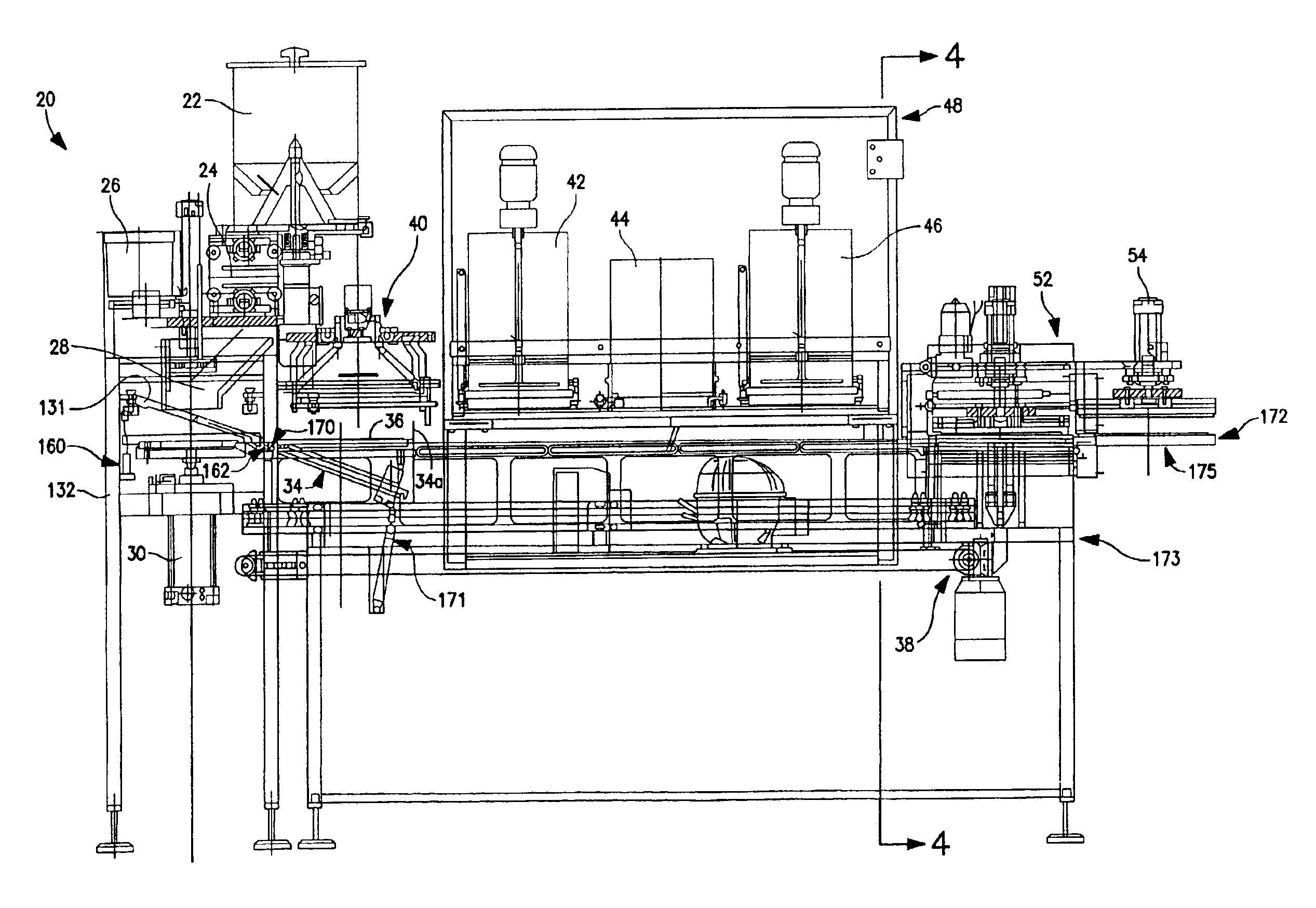

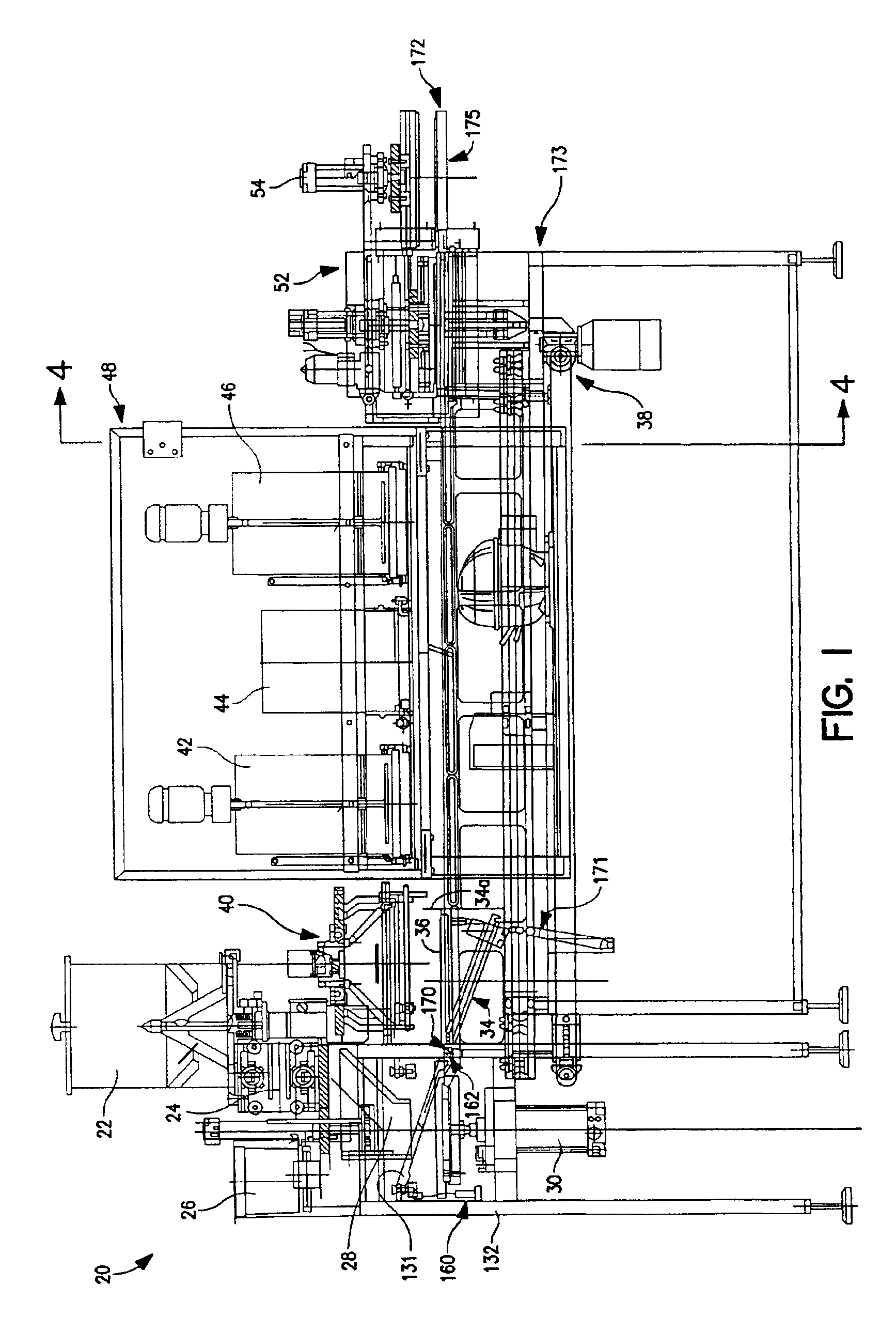

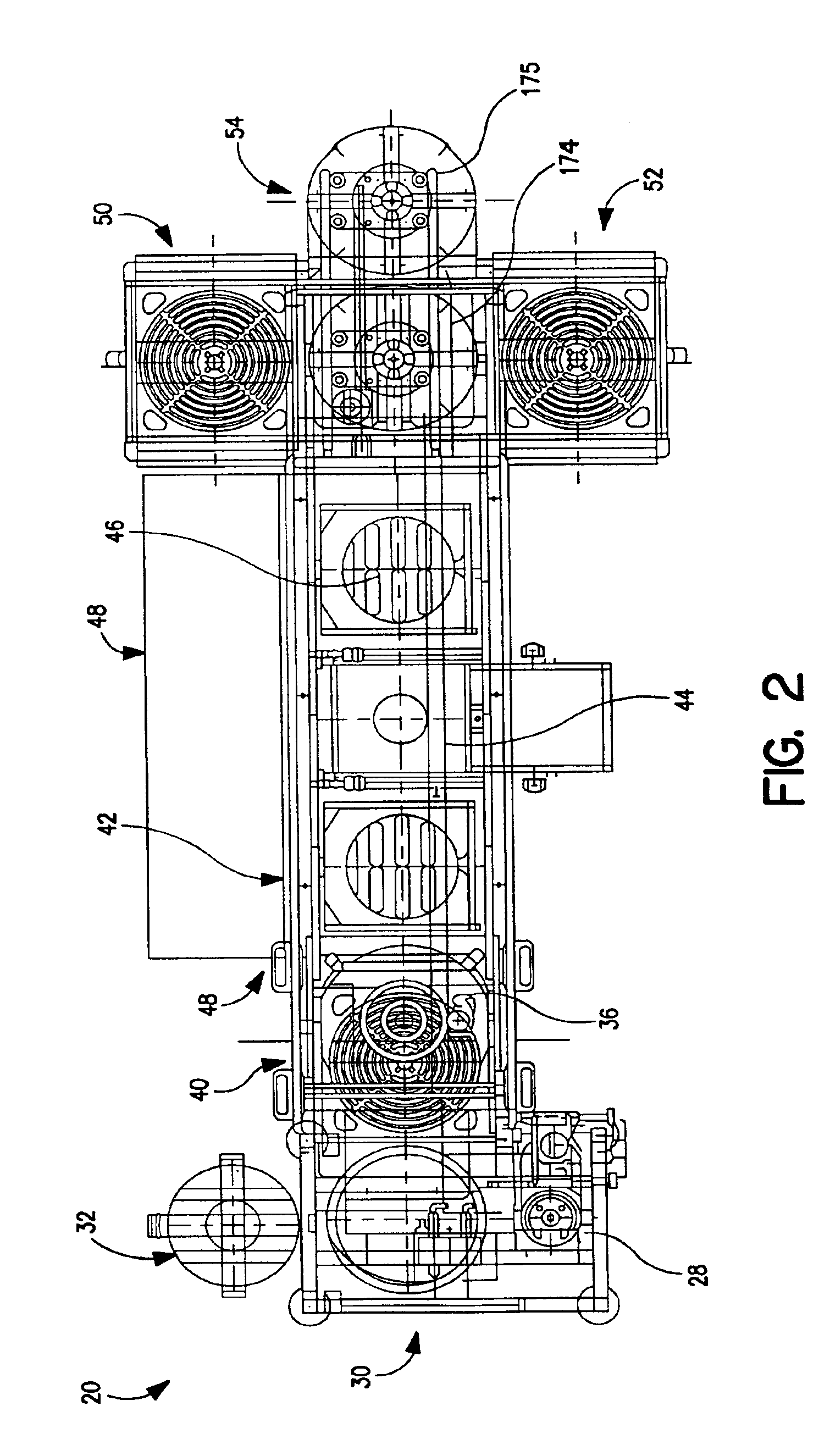

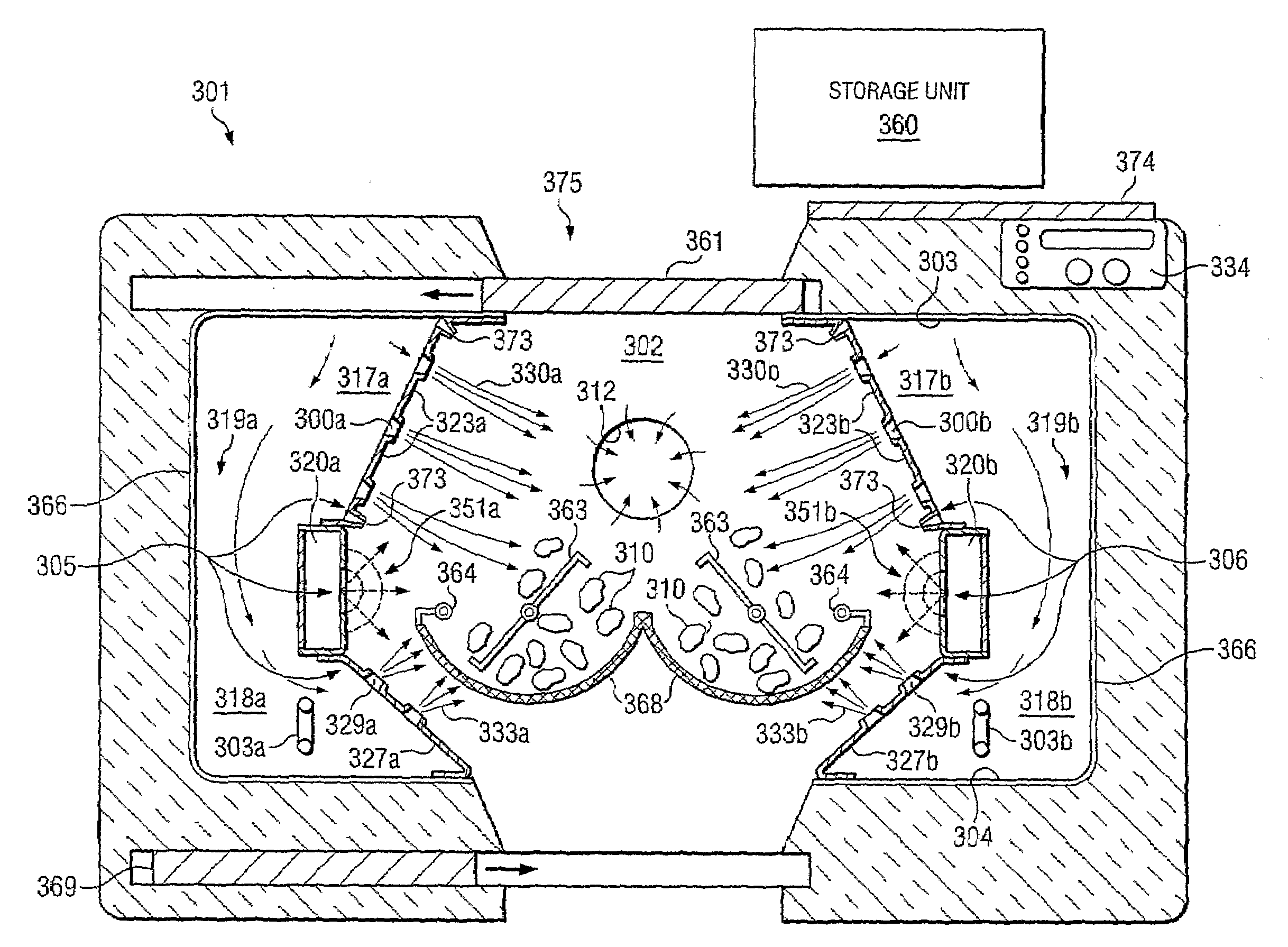

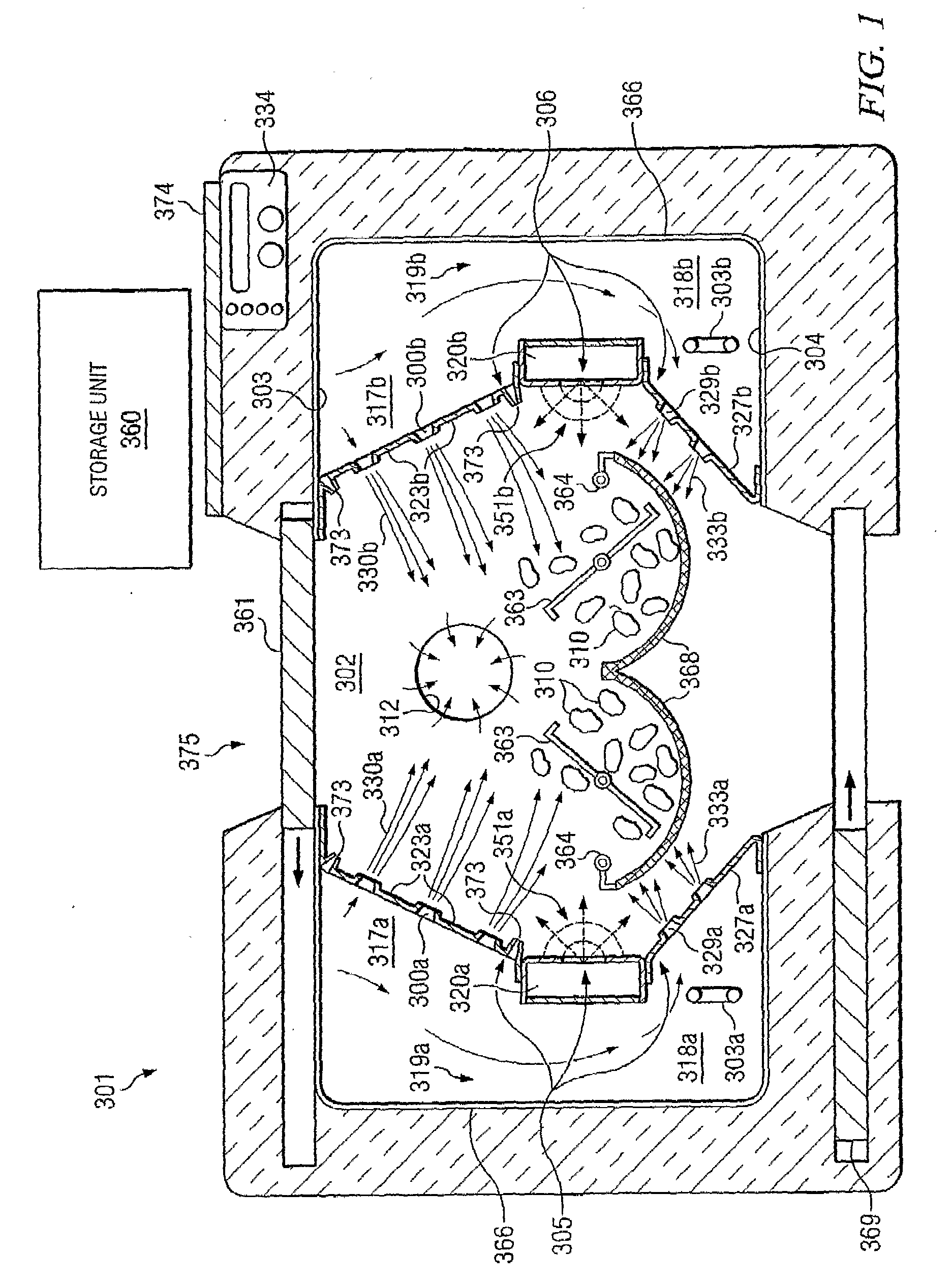

Pizza making method and system

InactiveUS6915734B2Simple and compact designMeet actual needsTransportation and packagingRotary stirring mixersCooking & bakingAdditive ingredient

The invention provides an automated method and apparatus for pizza production which is initiated by individual order placement and uses only fresh ingredients (no ingredients are frozen, pre-prepared or pre-cooked). Each dough portion is individually and mechanically prepared from flour and other fresh, pre-proportioned ingredients. The dough portion passes through a series of shaping and pre-heating processing stations to prepare a flattened and partially baked pizza base. Using a preheated or continuously heated conveying tray, the pizza base passes under a number of metering and distribution devices for selected application of tomato sauce and / or various other toppings according to the order. Baking occurs in one of multiple ovens to complete pizza preparation. Multiple ovens are provided to facilitate the automated preparation of multiple pizzas at any given time. A tray conveying system transports one or more trays through the various processing stations to accommodate multiple orders at the same time.

Owner:SITOS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[automatic frying apparatus for both deep and shallow frying] [automatic frying apparatus for both deep and shallow frying]](https://images-eureka.patsnap.com/patent_img/ed52a9a0-2e0c-483c-b780-14d21b19312c/US20050011370A1-20050120-D00000.png)

![[automatic frying apparatus for both deep and shallow frying] [automatic frying apparatus for both deep and shallow frying]](https://images-eureka.patsnap.com/patent_img/ed52a9a0-2e0c-483c-b780-14d21b19312c/US20050011370A1-20050120-D00001.png)

![[automatic frying apparatus for both deep and shallow frying] [automatic frying apparatus for both deep and shallow frying]](https://images-eureka.patsnap.com/patent_img/ed52a9a0-2e0c-483c-b780-14d21b19312c/US20050011370A1-20050120-D00002.png)