Patents

Literature

264results about How to "Improve the tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

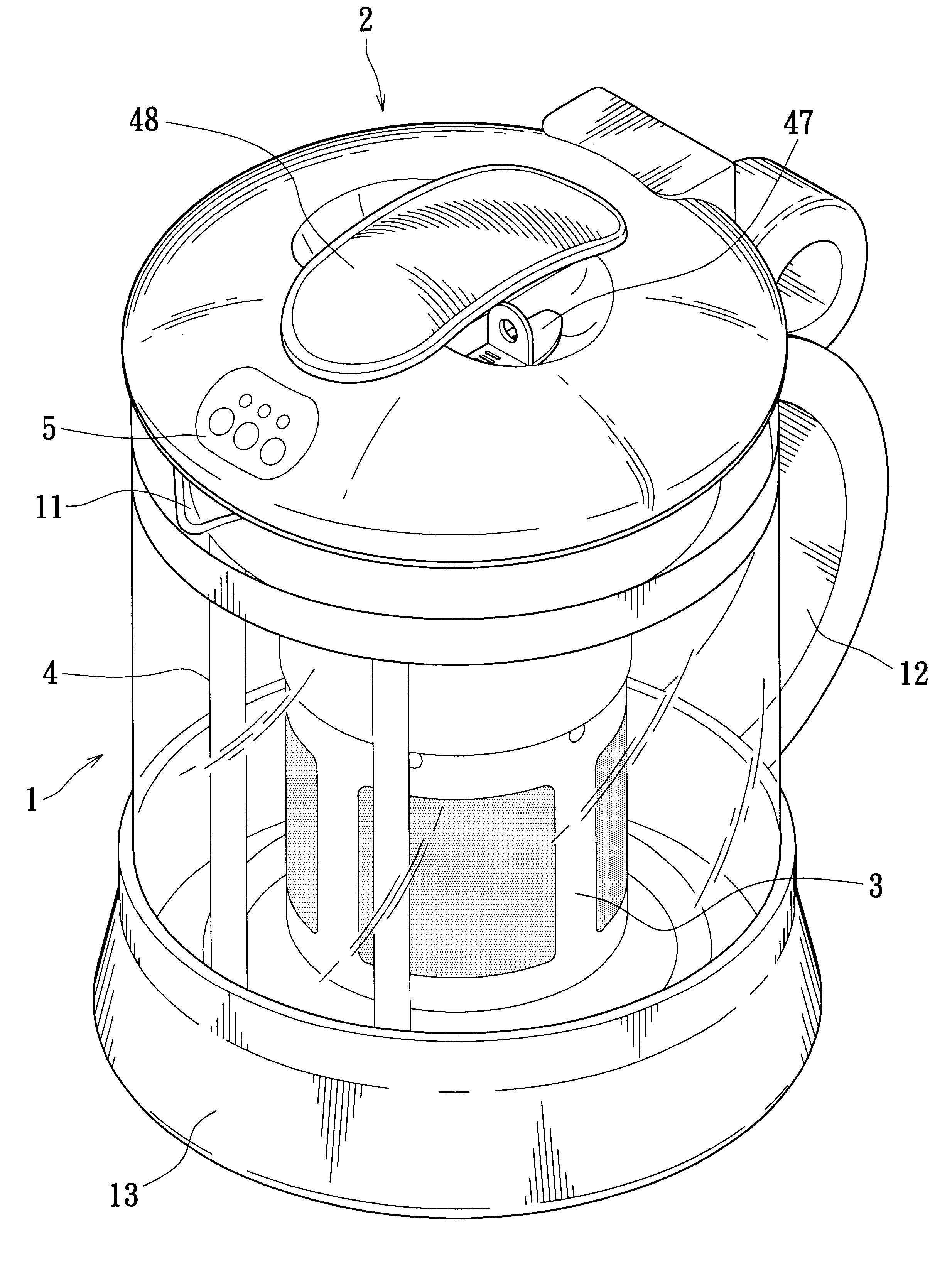

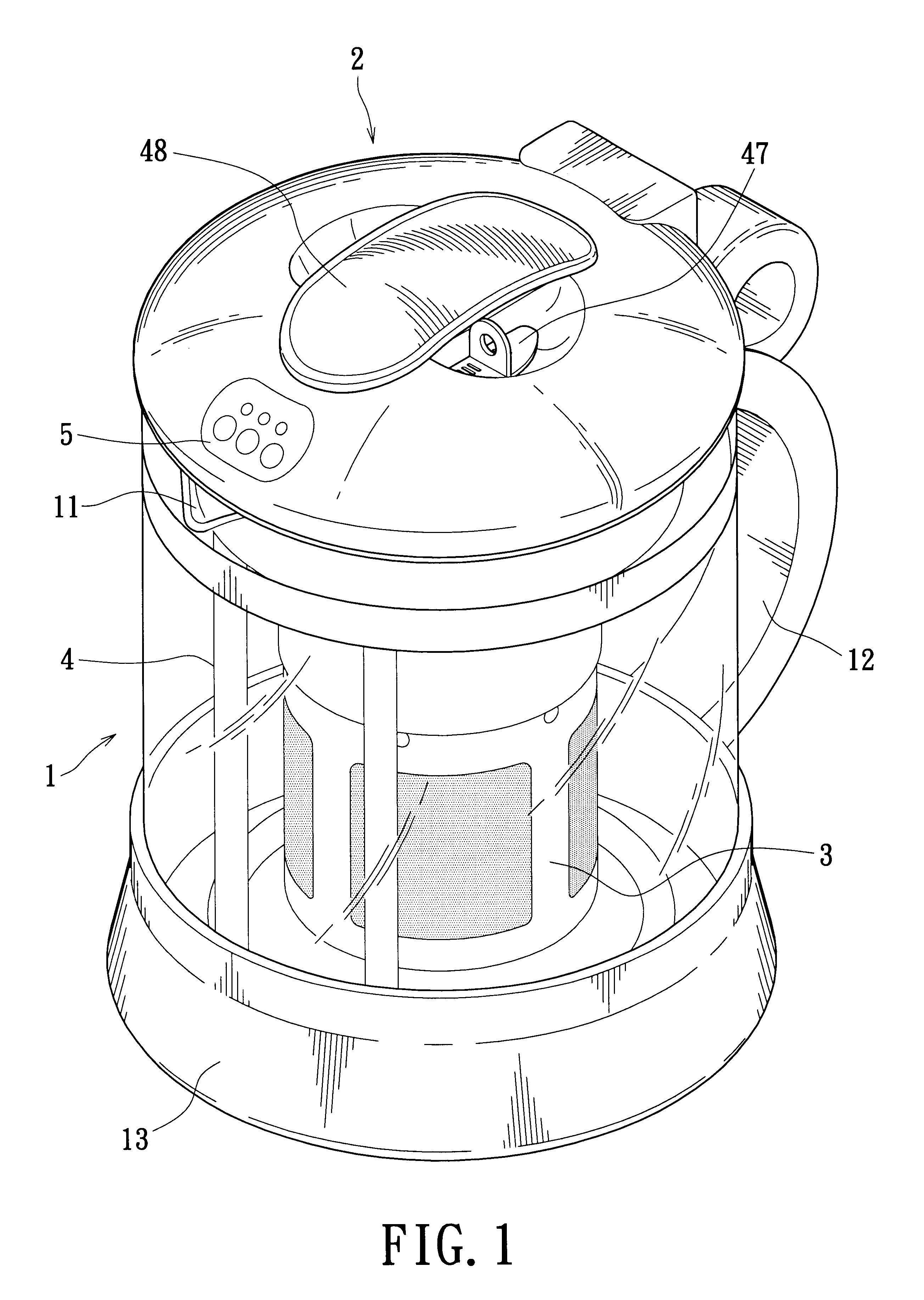

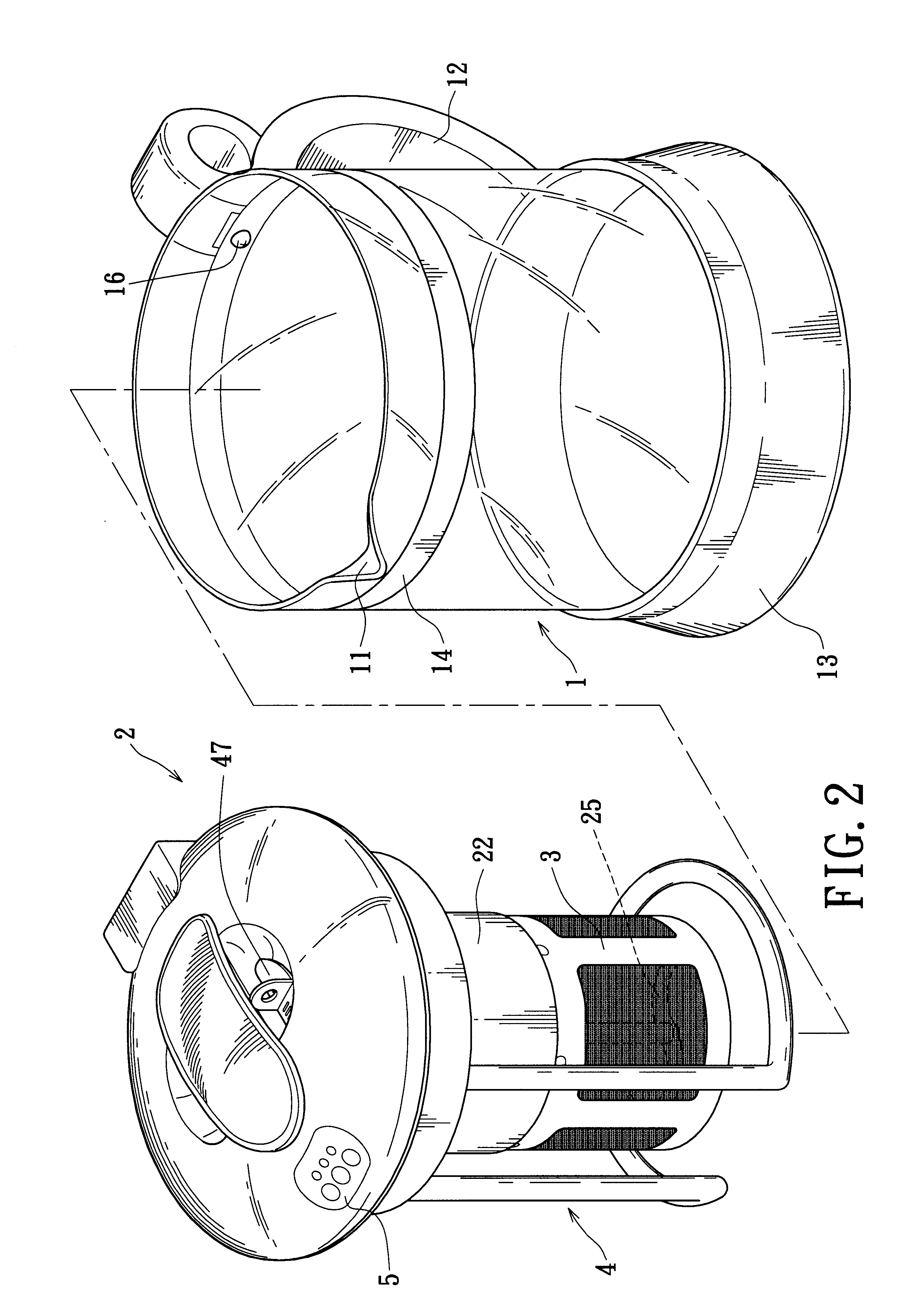

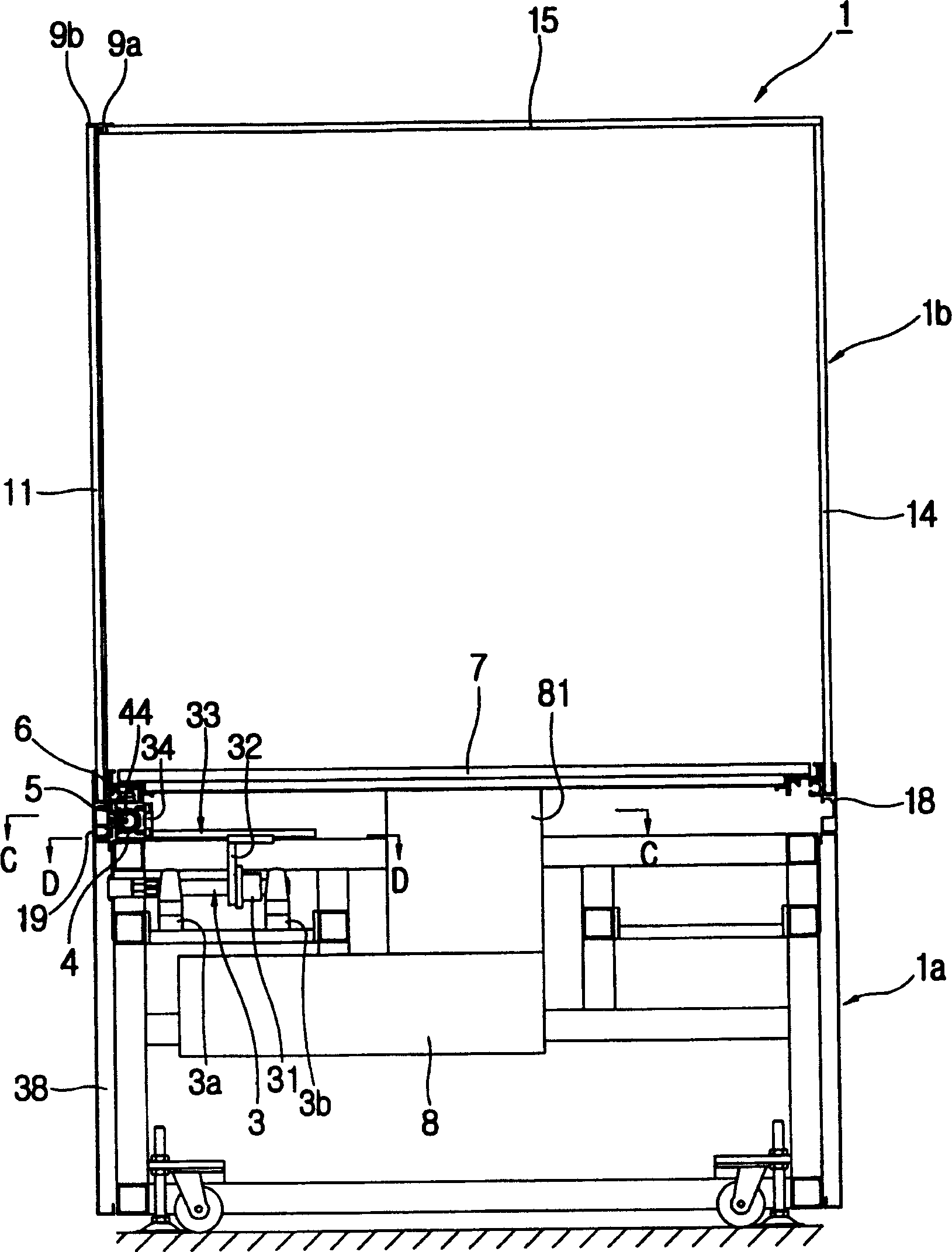

Means for making soybean milk

InactiveUS6247393B1Safe and hygienic useImprove the tightnessJuice extractionRotary stirring mixersMechanical engineeringSoybean meal

The present invention proposes an apparatus for making soybean milk, wherein a cover body is connected to the opening of a container, and a fixing tank is extended form the cover body toward the inside of the container. A motor is installed in the fixing tank. A reaming blade is extended from the motor. A through passage is installed downwards from a position away from the center of the cover through the fixing tank to a cup-shaped component. A fixedly-joining device is installed at the inner edge of the opening of the cup-shaped component to be correspondingly joined with a fixedly-joined device installed at the bottom end of the peripheral surface of the fixing tank. The reaming blade is placed in the cup-shaped component. The periphery of the cup-shaped component is formed to be a filtering net. An electro-thermal tube is connected from the bottom edge of the cover into the container. When soybeans are guided in via the through passage, a small sealing cap is used to cover on the opening of the through passage. After the apparatus is turned on, the soybeans are reamed by the reaming blade, and soybean juice flows into the container while soybean lees is left in the cup-shaped component. After water is added and boiled, the cover is removed and a sealing cap is covered on the container. The sealing cap has a filtering net at a position corresponding to that of the conduct mouth of the container such that soybean can be filtered and poured out.

Owner:CHANG KWEI TANG

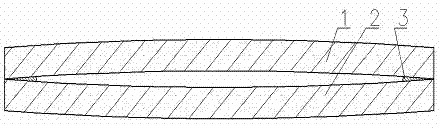

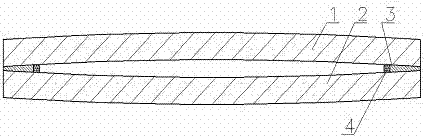

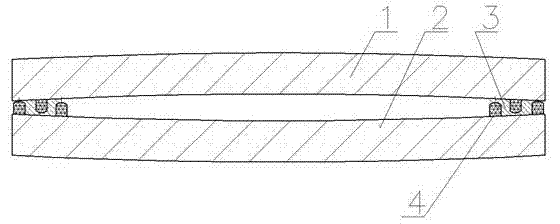

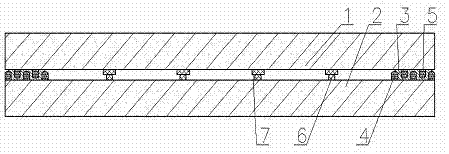

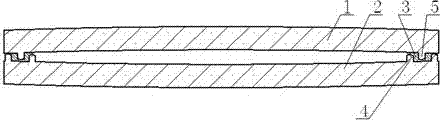

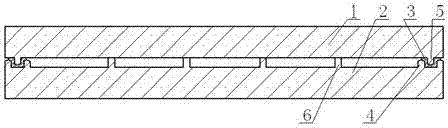

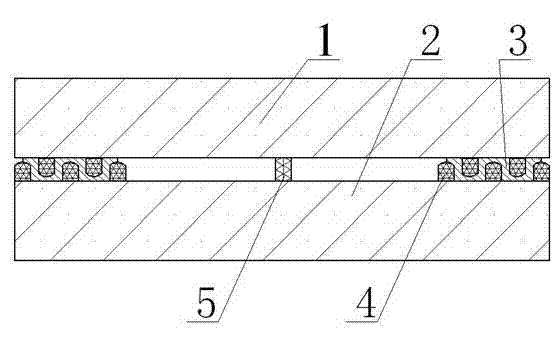

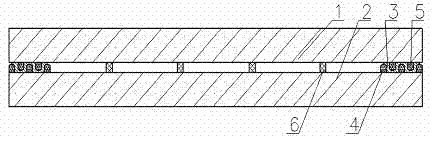

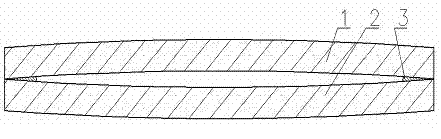

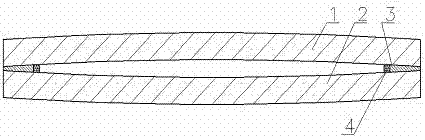

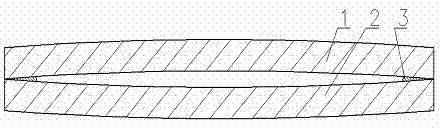

Convex-sided vacuum heat-insulating board, flattened vacuum heat-insulating board and preparation methods thereof

InactiveCN102953441AHigh compressive strengthSimple manufacturing processClimate change adaptationInsulation improvementConvex sideEngineering

The invention provides a vacuum heat-insulating board which comprises an upper heat-insulating board and a lower heat-insulating board, wherein the peripheries of the upper heat-insulating board and the lower heat-insulating board are welded together through using a welding flux, a closed vacuum layer is formed between the upper heat-insulating board and the lower heat-insulating board, the upper heat-insulating board and the lower heat-insulating board are flattened heat-insulating boards or convex-sided heat-insulating boards, and the convex side of each convex-sided heat-insulating board faces outwards. The production method of the vacuum heat-insulating board provided by the invention is simple in process, and the prepared vacuum heat-insulating board overcomes the defects of the existing heat-insulating board, so that the tightness of a vacuum layer of the vacuum heat-insulating board can be effectively guaranteed, the service life of the vacuum heat-insulating board is prolonged, and the strength and heat insulation, sound insulation and fire prevention properties of the vacuum heat-insulating board can be increased.

Owner:戴长虹

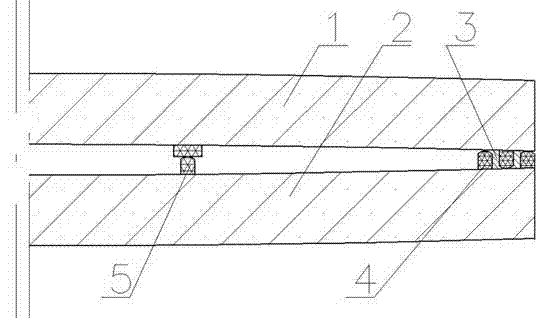

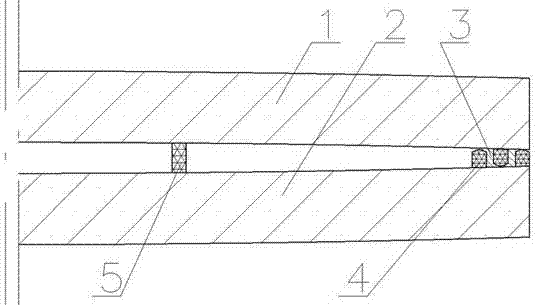

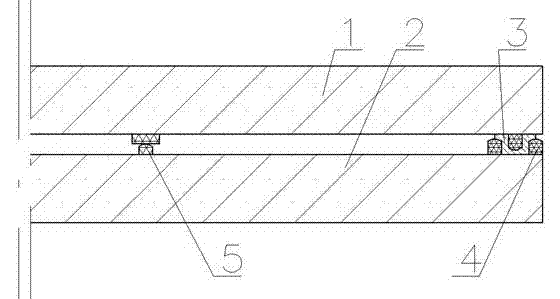

Flat vacuum glass welded by using metal welding material and provided with strip frame edge sealing, and manufacturing method thereof

InactiveCN102976592AExtend your lifeGuaranteed tightnessGlass reforming apparatusGlass productionAlloyGlass manufacturing

The present invention relates to a vacuum glass, which is characterized in that peripheries of an upper glass and a lower glass of the vacuum glass comprise edge sealing strip frames, and a metal welding material or an alloy welding material is adopted to integratedly weld the upper glass and the lower glass in a vacuum edge sealing furnace, such that vacuum glass manufacturing is simple, and a sealing effect is ensured through engagement of the upper edge sealing strip frame and the lower edge sealing strip frame. The manufacturing method has characteristics of simple process, low cost, high production efficiency, reliable sealing and good sealing effect. With the technology, large mass manufacturing of the vacuum glass with no gas exhaust port through the one-step method can be achieved. In addition, with the method, the universal vacuum glass can be manufactured, and the tempered vacuum glass can be manufactured.

Owner:戴长虹

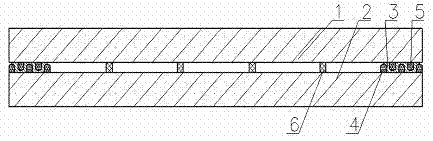

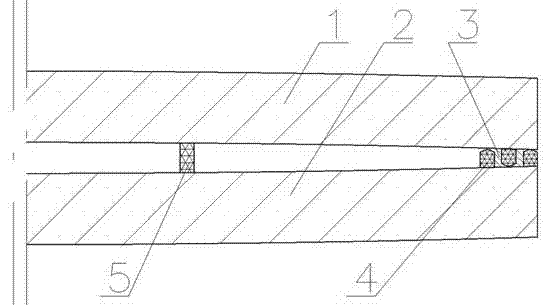

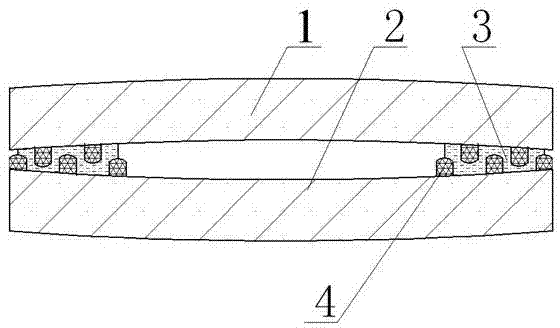

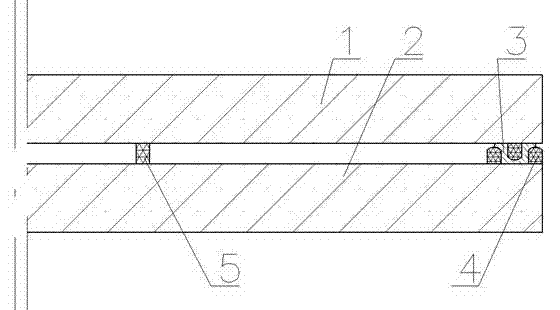

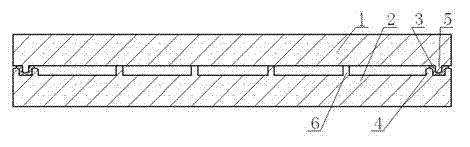

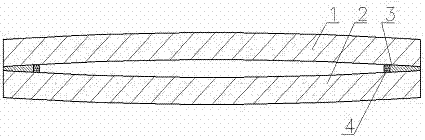

Metal solder-welded and strip frame-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951826AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMetalEdge banding

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex surface glass, edge sealing strip frames are arranged at the welded peripheries of the upper glass and the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the upper and the lower edge sealing strip frames can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

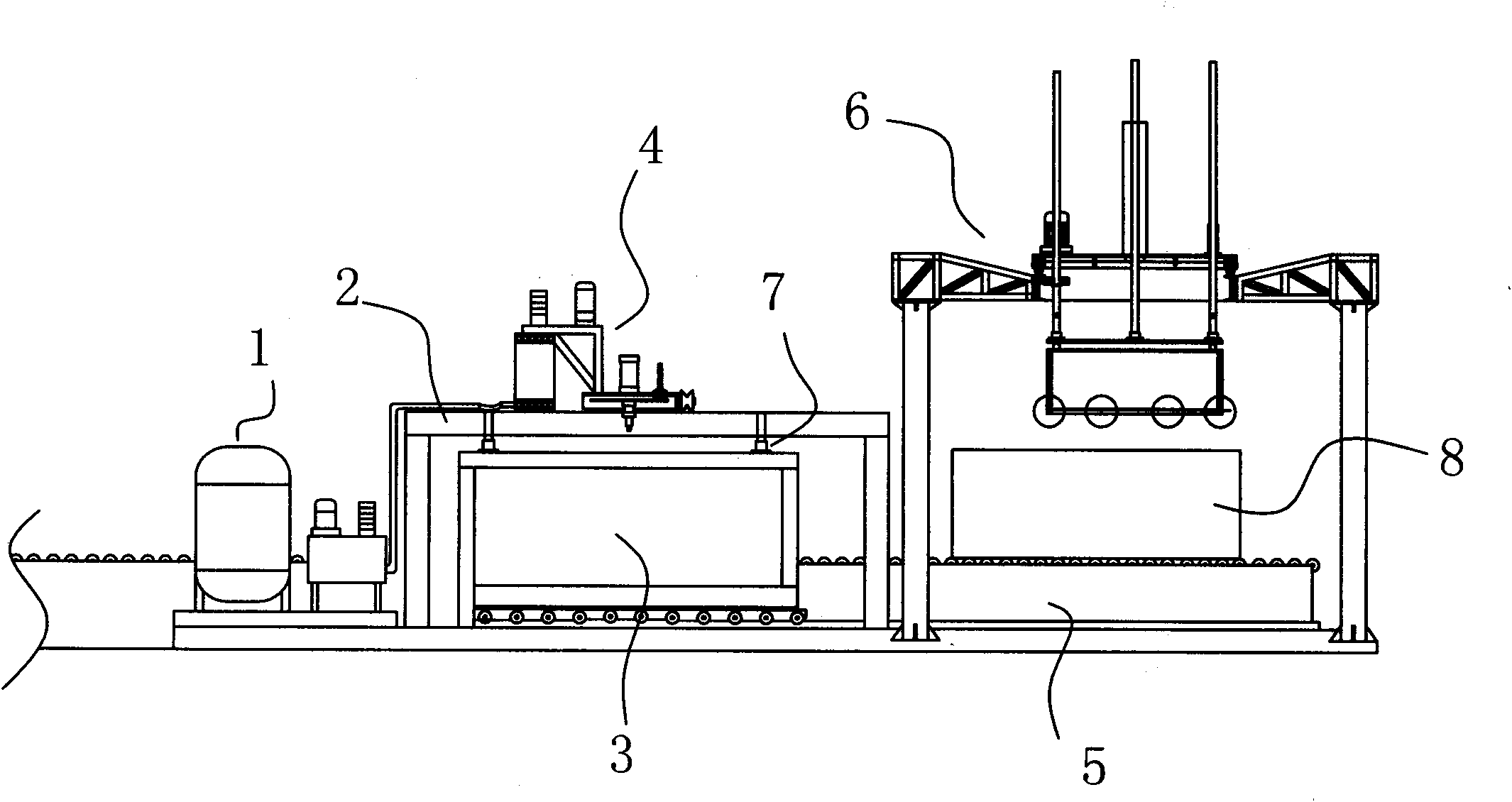

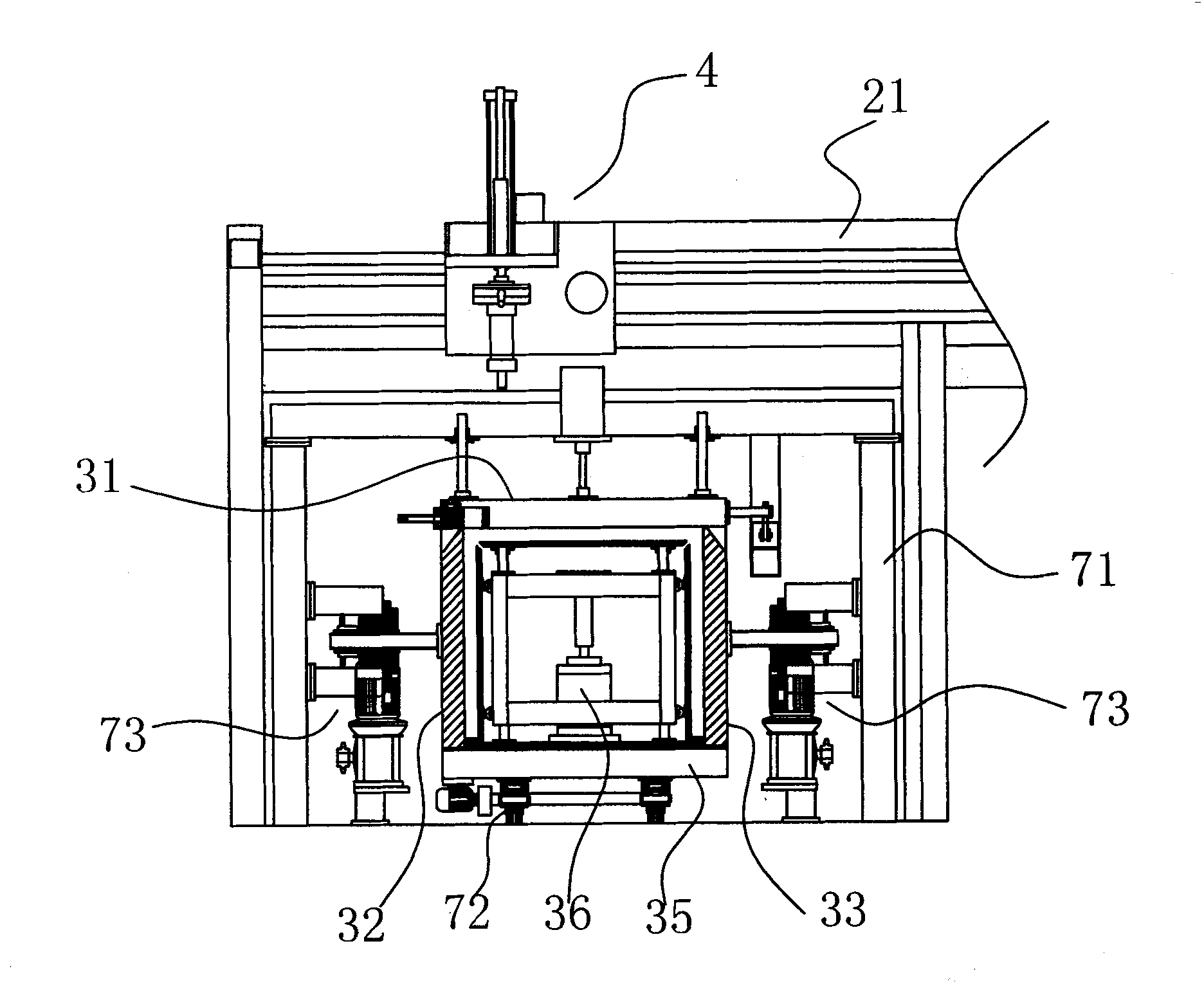

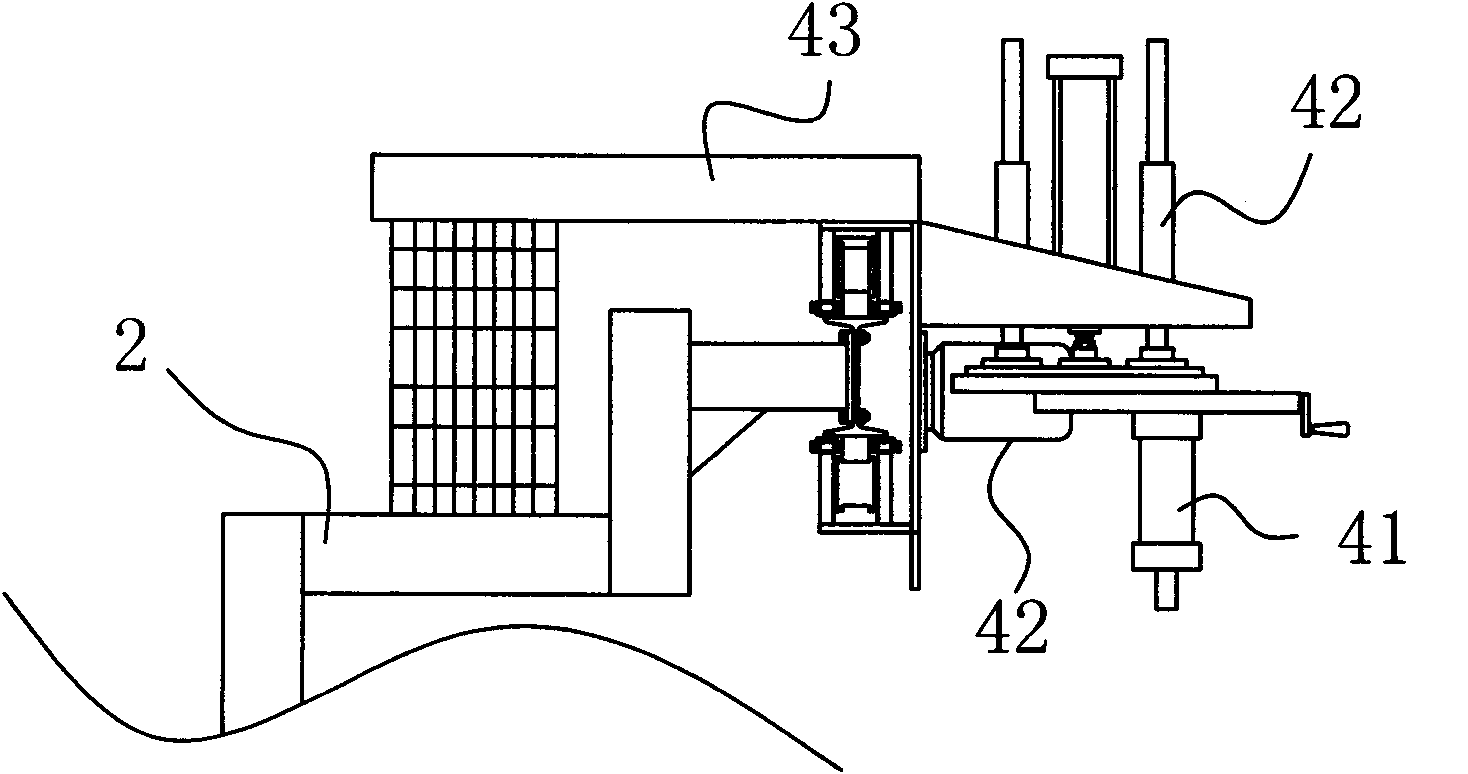

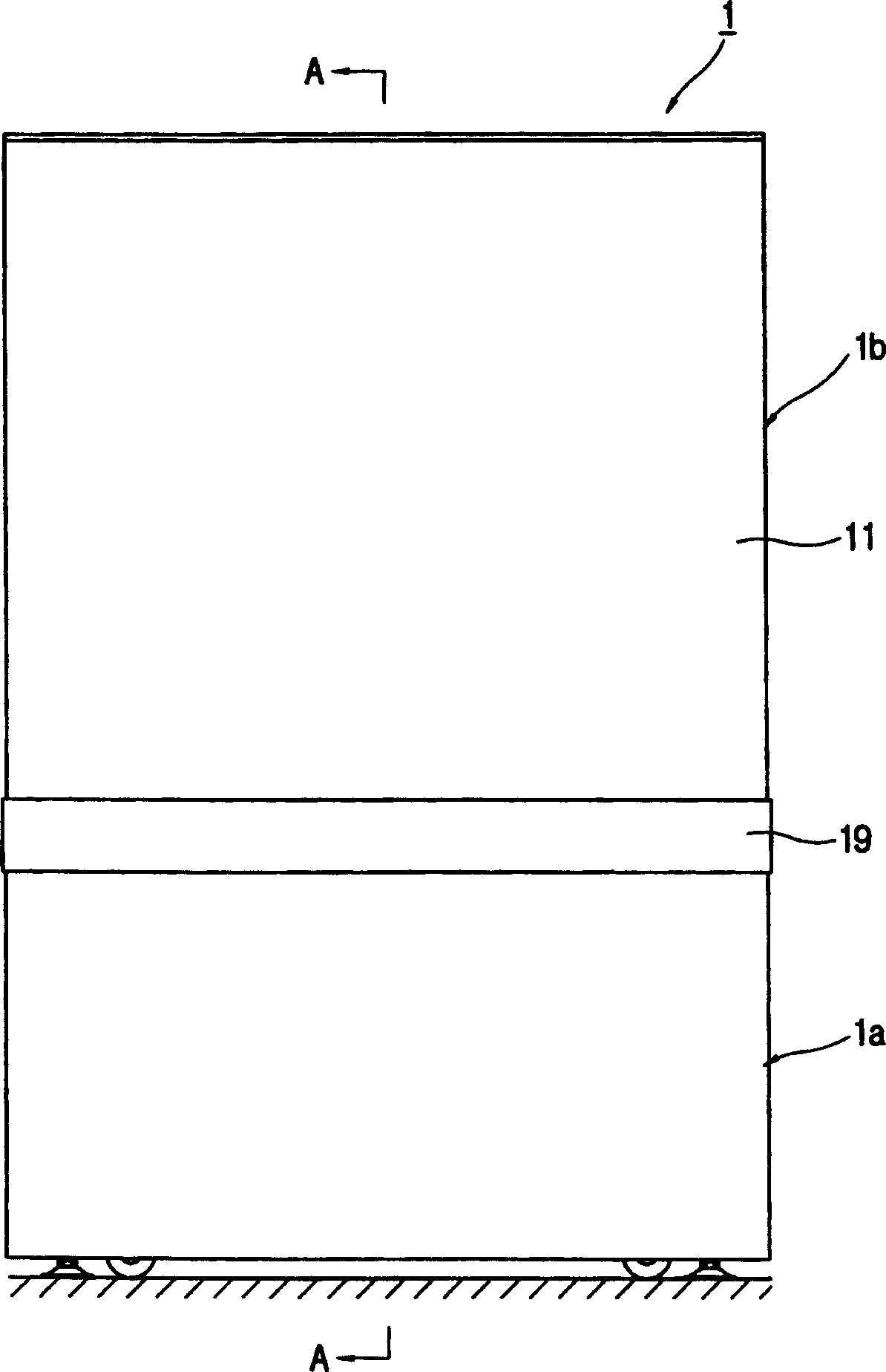

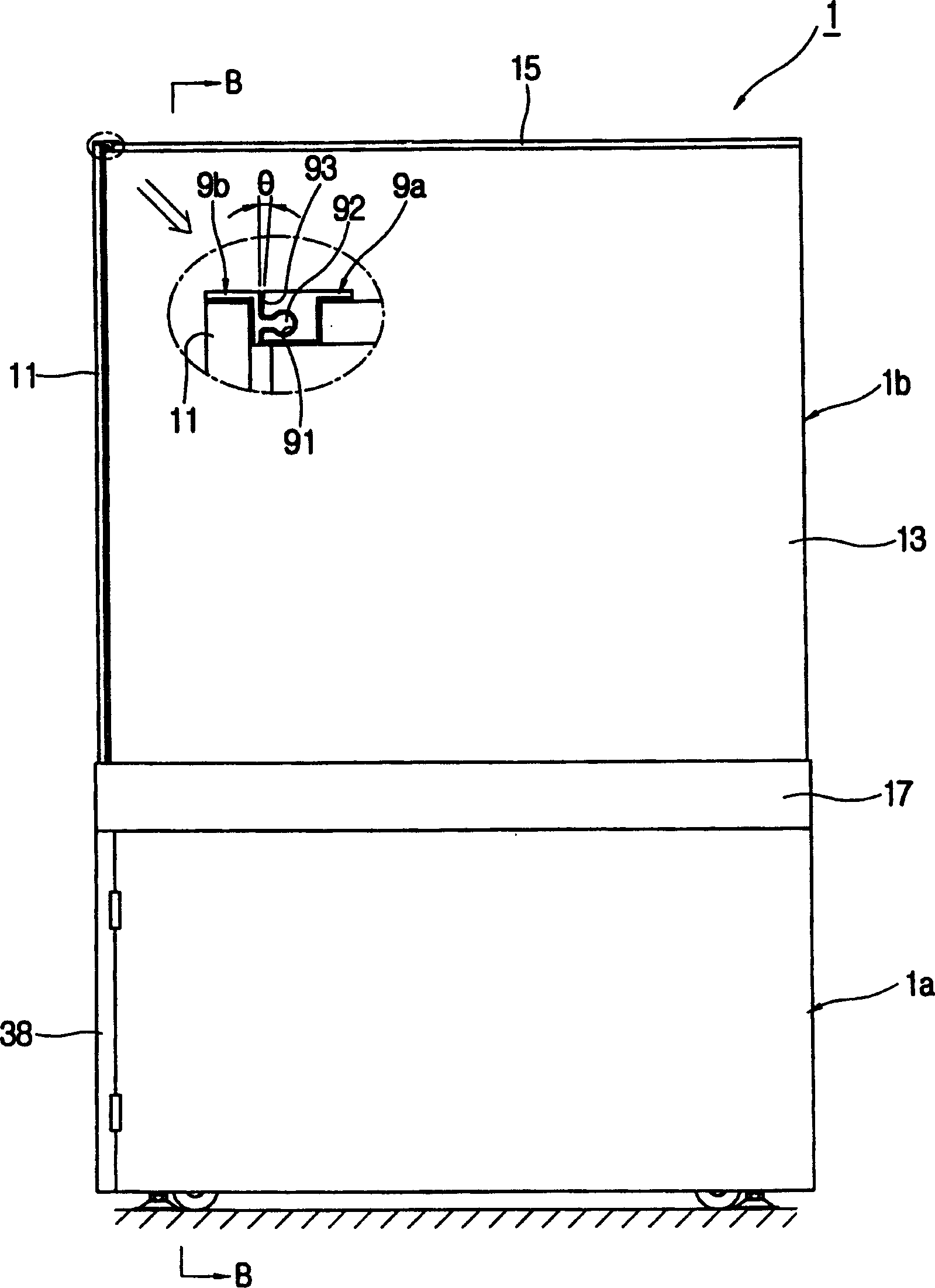

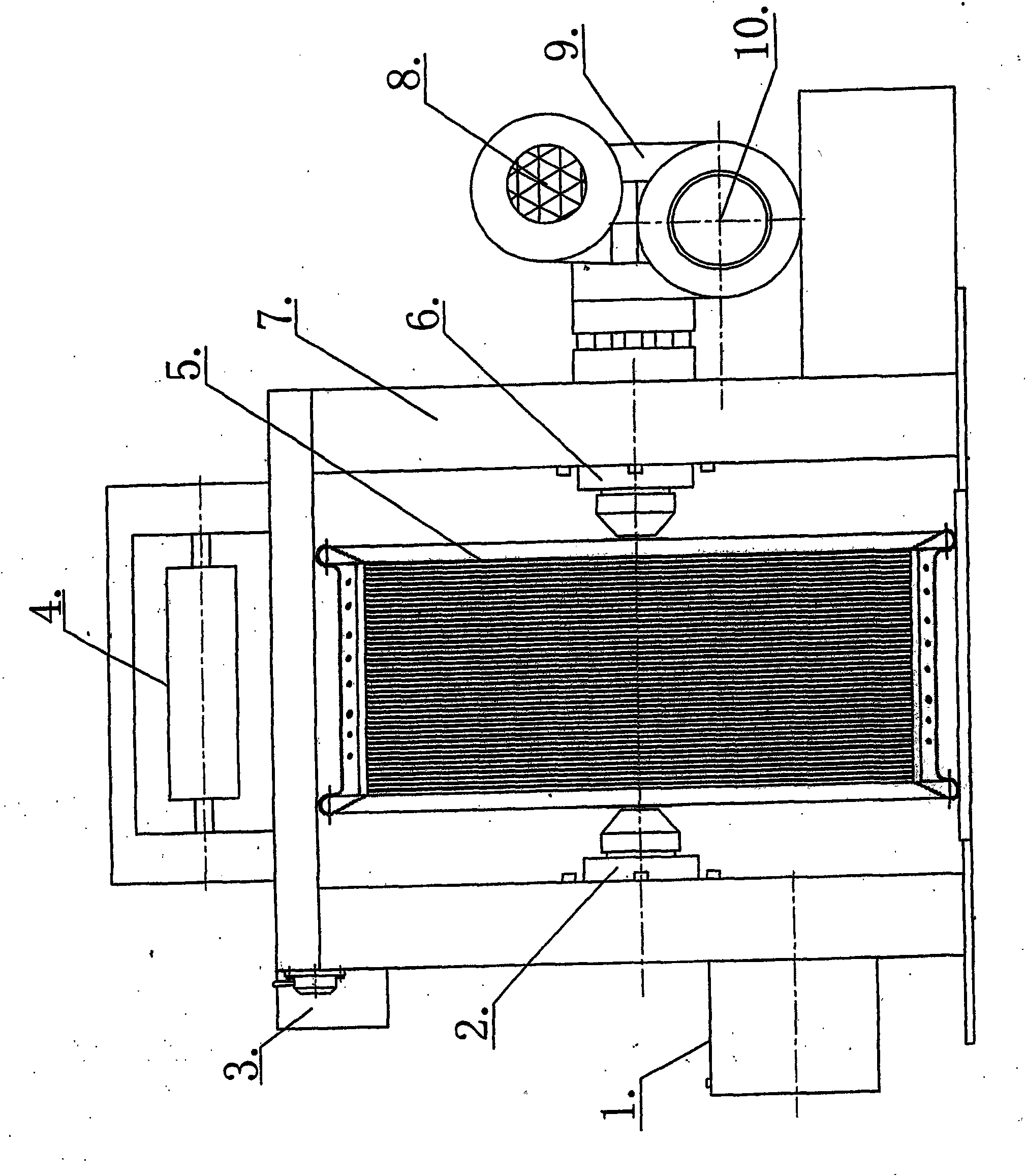

Full-automatic production method of multi-station mobile fixed foaming freezer body and system thereof

InactiveCN101913223AFlexible adjustment of specificationsReduce investmentDomestic articlesAutomatic controlRobot hand

The invention discloses a full-automatic production method of a multi-station mobile fixed foaming freezer body, comprising the following steps of: (1) setting foaming equipment and an automatic foaming control system capable of controlling the work state of the foaming equipment; (2) setting a foaming mould frame with a slide at the top; (3) arranging multiple fixed foaming moulds below the slide juxtaposedly; and (4) setting a pouring manipulator which is controlled by the automatic foaming control system. The invention also discloses a system for implementing the method. The invention employs a mobile fixed foaming technology and an automatic control technology and has simple production process and automated process, thereby effectively decreasing the supervisor, making the operation convenient, greatly reducing the labour intensity, saving the manpower and material resources, and reducing the production cost; furthermore, a multi-station batch production technology with rapid production speed, short period and guaranteed product quality is added, thereby greatly improving the production efficiency and the product qualification rate and strengthening the enterprise competitiveness.

Owner:东莞市百利电器有限公司 +1

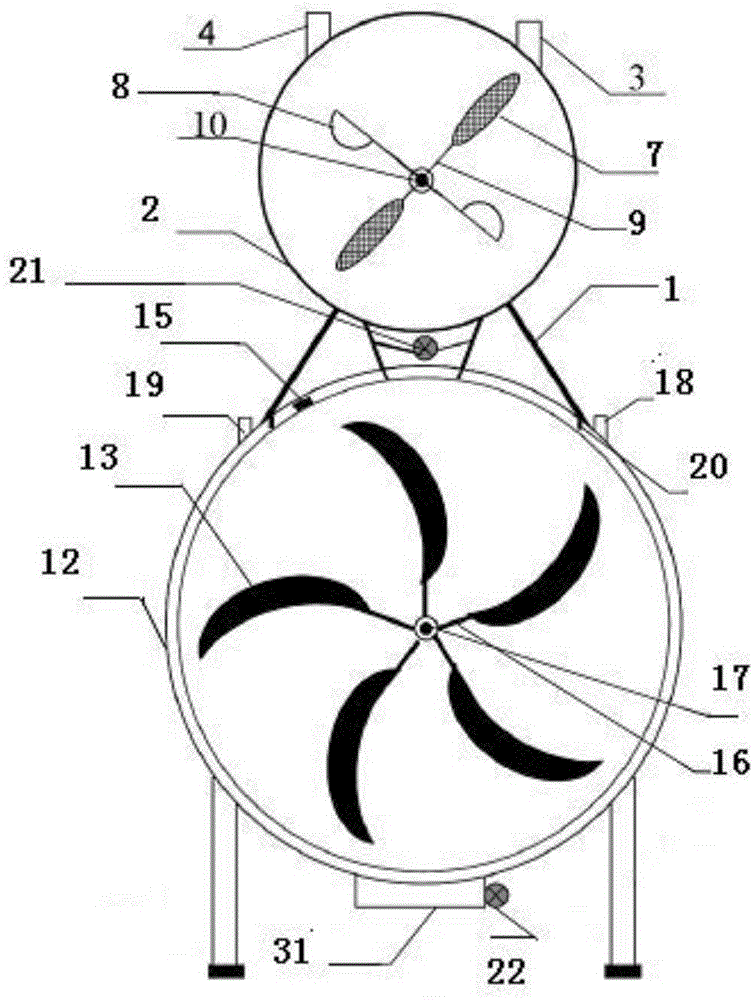

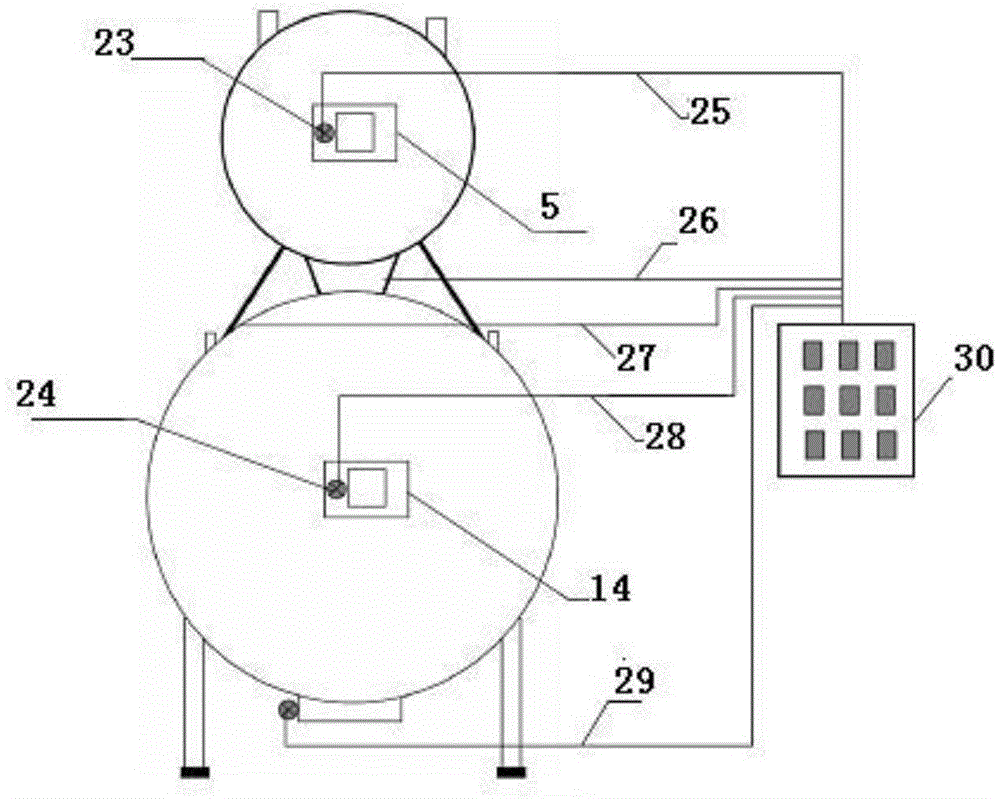

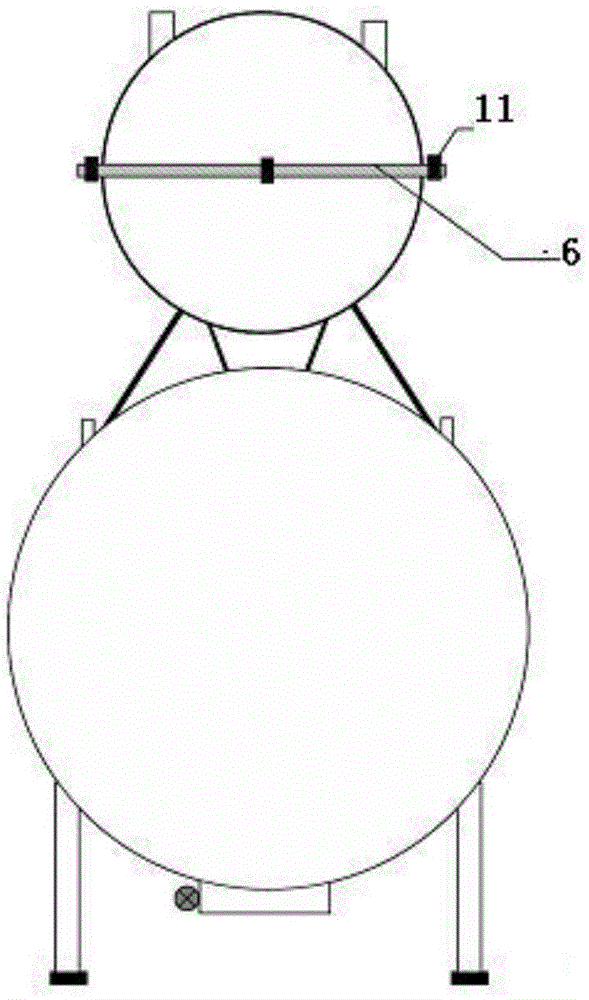

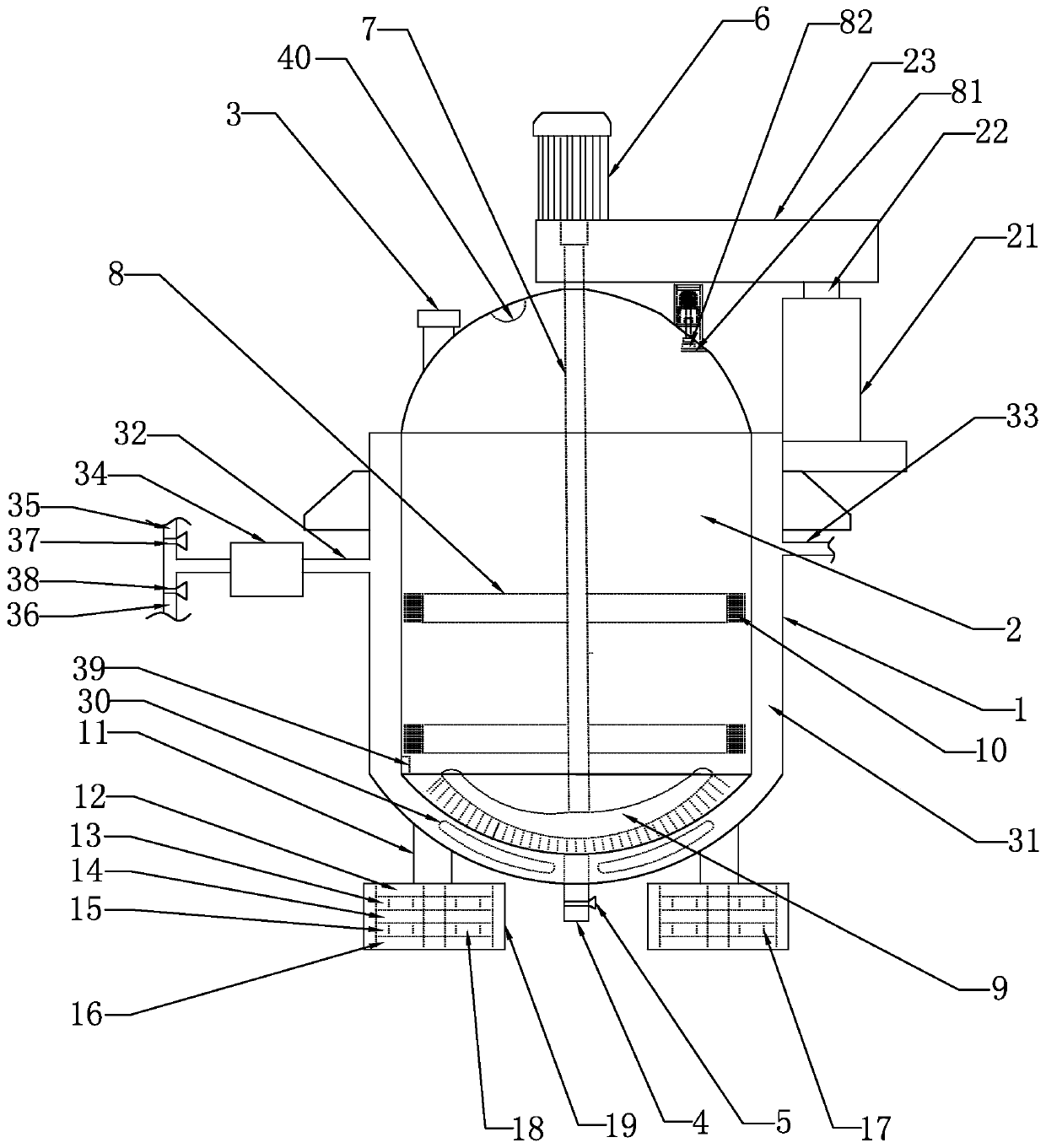

Automatic mixing device for mixed feed additive

ActiveCN105536586AImprove the tightnessQuality improvementFeeding-stuffTransportation and packagingHybrid typeAutomatic control

The invention discloses an automatic mixing device for a mixed feed additive. The automatic mixing device comprises four parts, namely a premixing system, a mixing system, a temperature control system and an automatic control system, wherein the premixing system comprises a premixing bin body, a main and auxiliary material feeding hole, a mixing blade, an adjustable motor and a fixed sealing flange; the mixing system comprises a mixing bin body, a mixing blade, an adjustable motor and a vibrator; the temperature control system comprises an internally inlet / outlet, a seal sheet and an interlayer; and the automatic control system comprises a relay switch gear, a connecting circuit and an automatic control board. The automatic mixing device has the characteristics of high automation, convenience in use, high main / auxiliary material mixing strength and obviously improved mixing degree, is high in device sealing degree, is capable of lowering the pollution rate and the material loss rate, reducing damage to human bodies, decreasing heat produced by machine operation and improving the activity and heat-labile component quality of the mixed feed additive, and is beneficial to quality stability of products in different batches.

Owner:FUJIAN BRADY PHARMA CO LTD

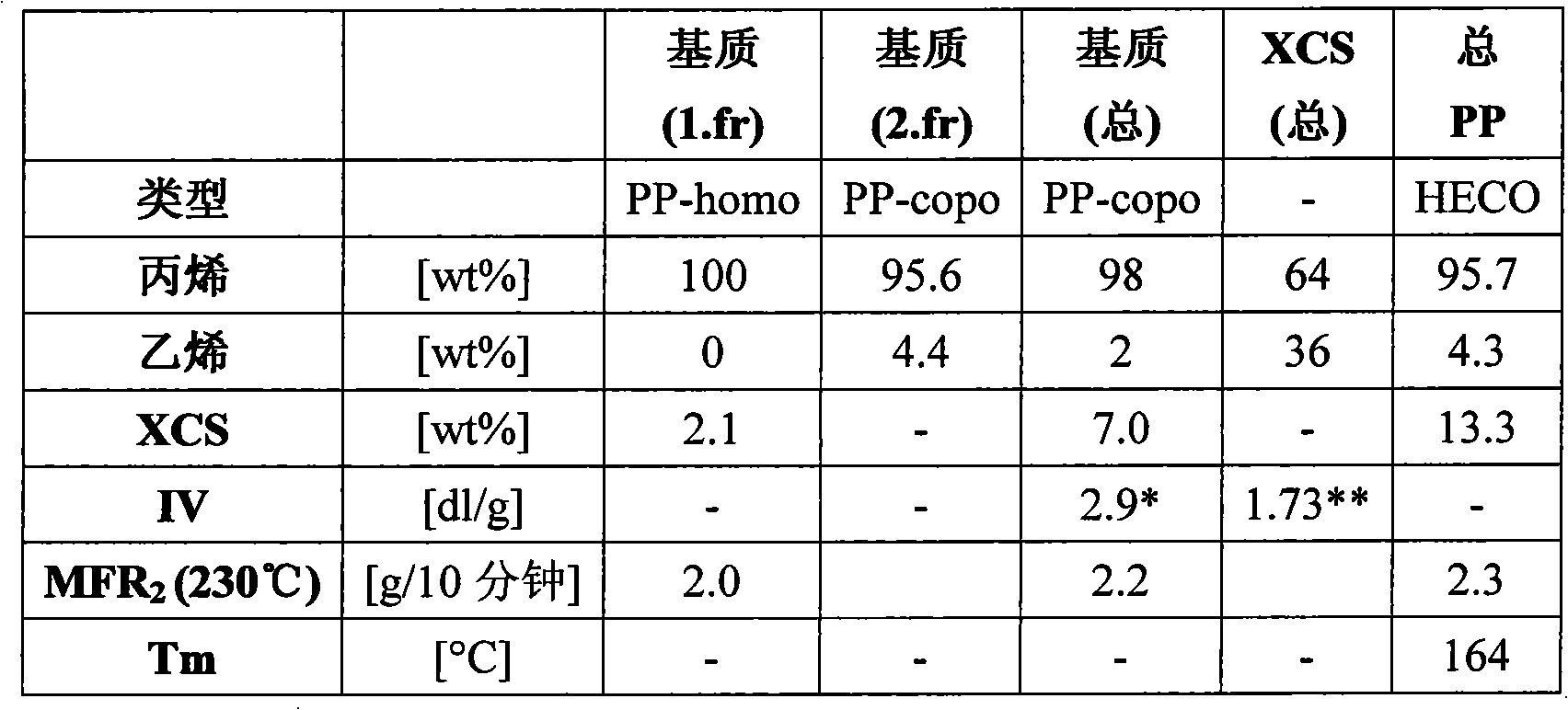

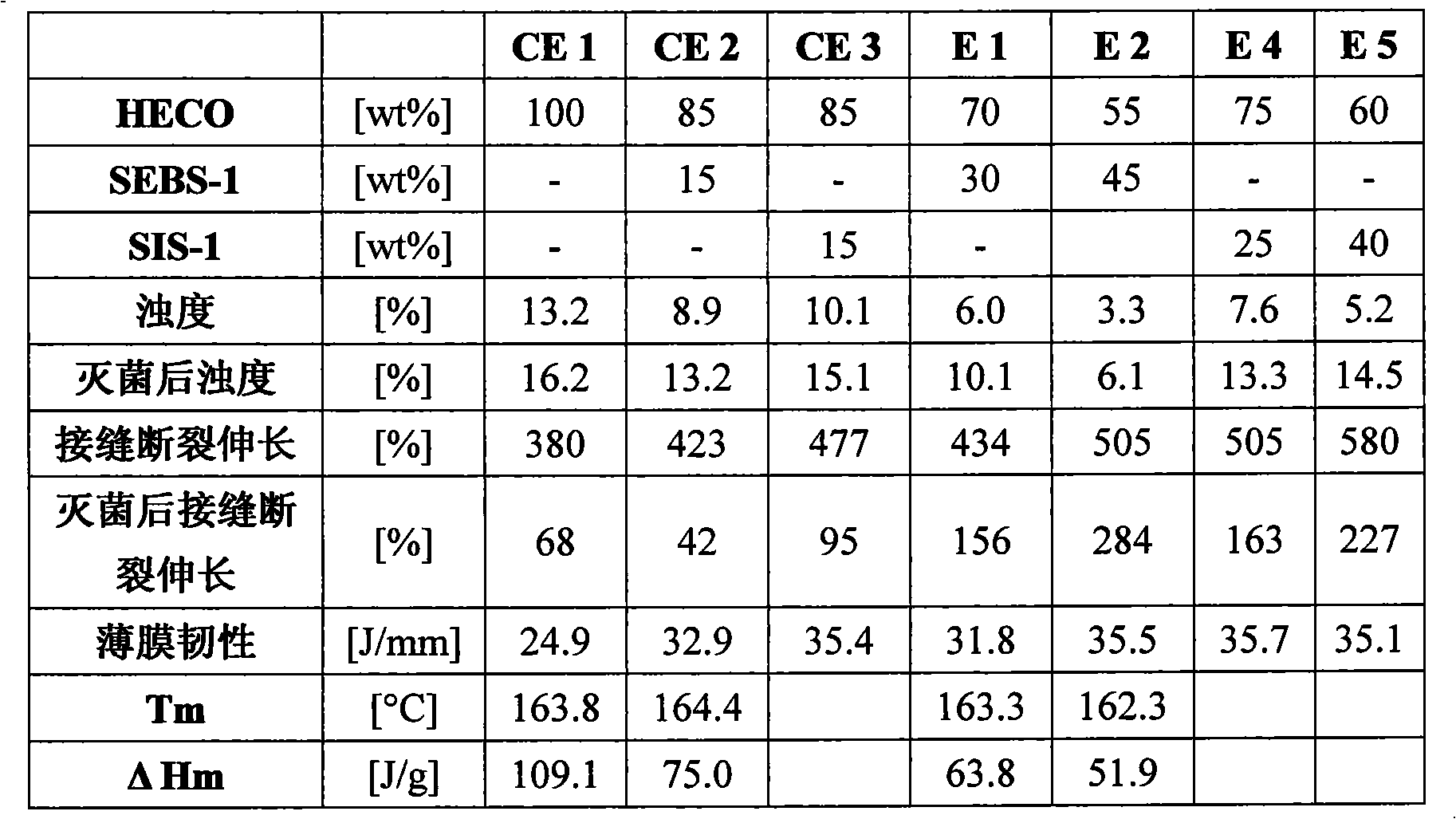

Composition based on polypropylene compounds with styrenic based elastomers

ActiveCN102112541AImprove the tightnessImprove toughnessThin material handlingLayered productsElastomerBenzene

Polymer composition comprises: a heterophasic propylene copolymer comprising a polypropylene matrix and an elastomeric propylene copolymer comprising at least one comonomer selected from the group consisting of ethylene and C4-C20 alpha-olefine, and - a styrenic based elastomer(s) (B), wherein the styrene content in each styrenic based elastomer (B) is equal or below 15 wt.%, and the total amount of the styrenic based elastomer(s) (B) based on the total amount of polymers present in the polymer composition is of 16.0 to 46.0 wt.%.

Owner:BOREALIS AG

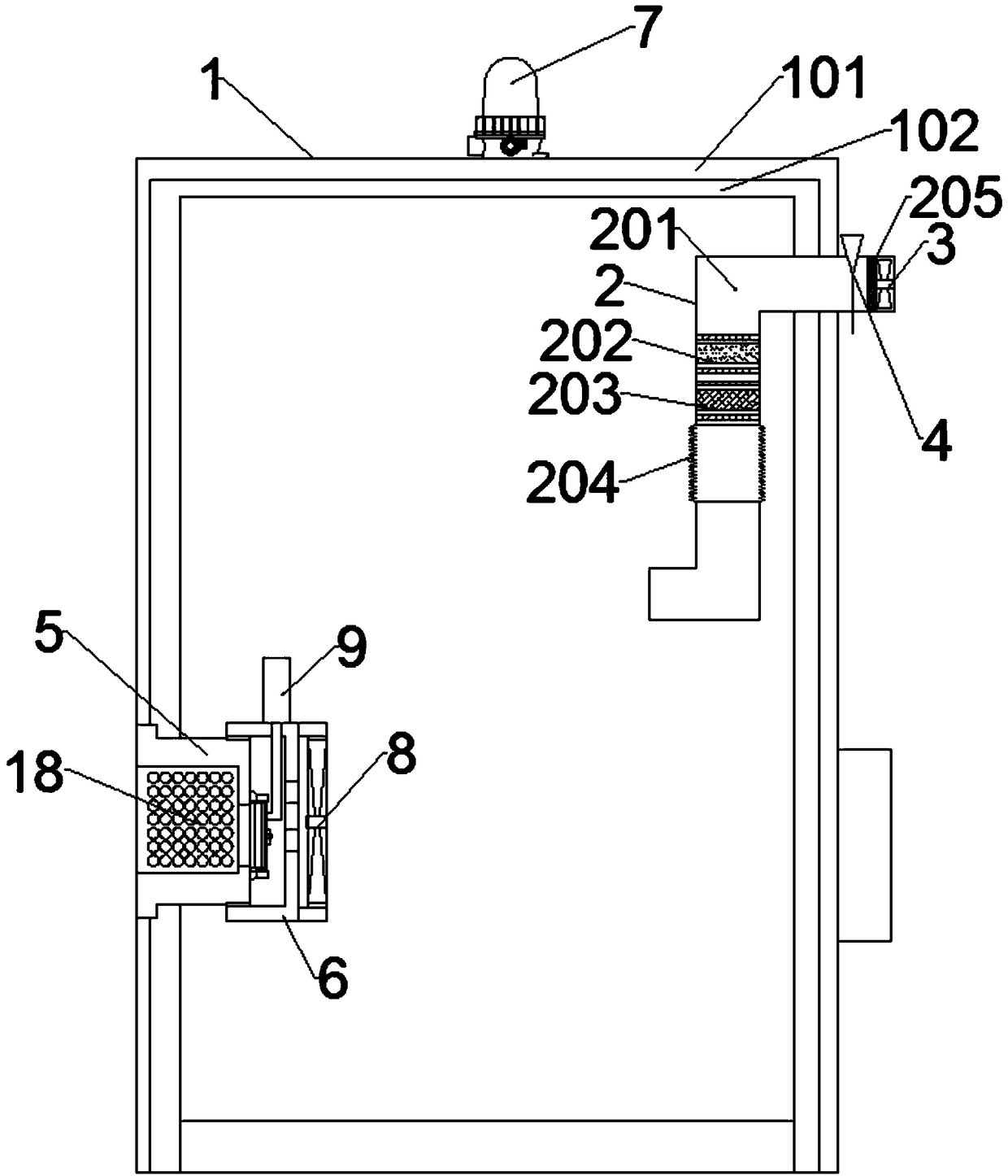

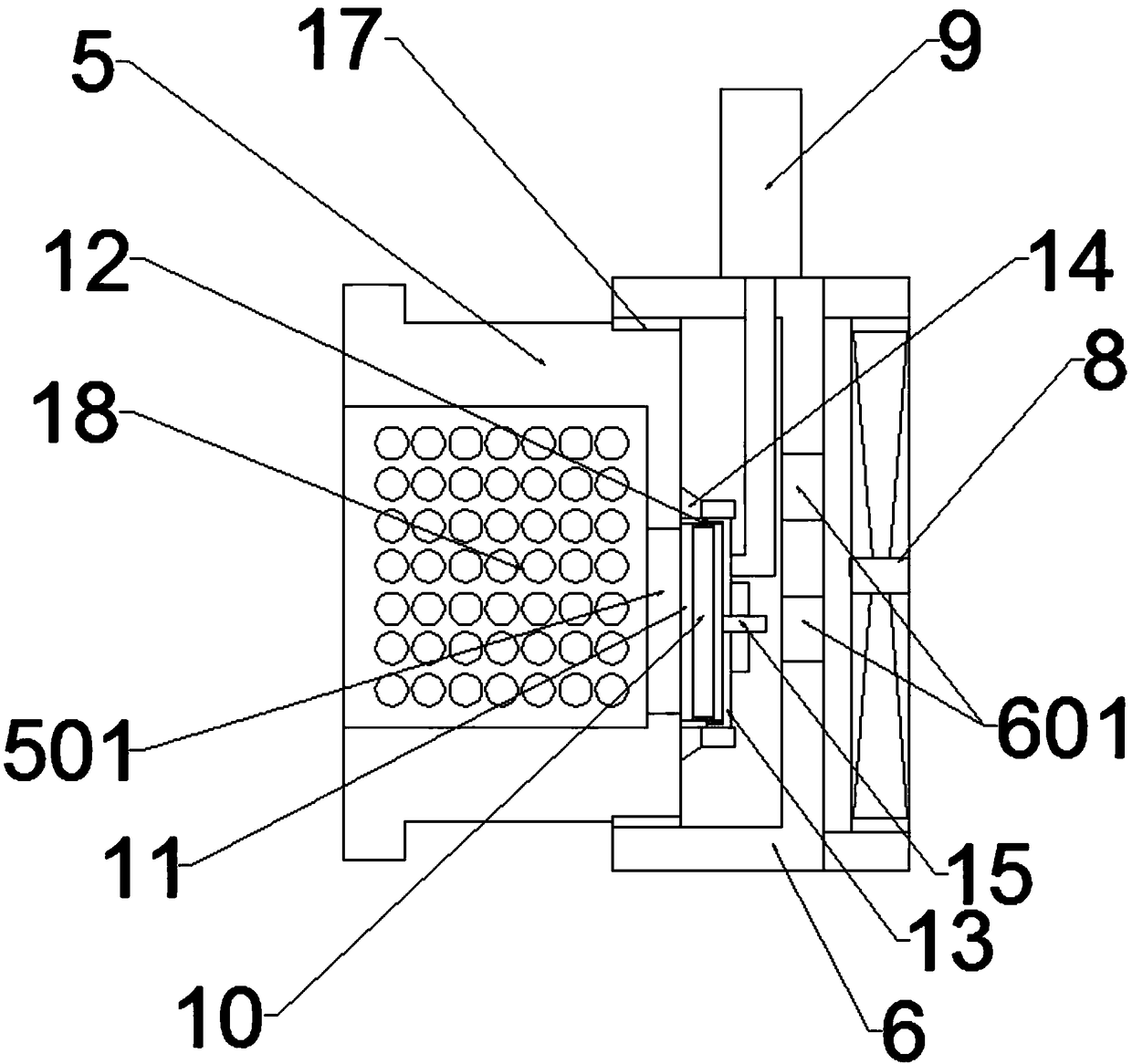

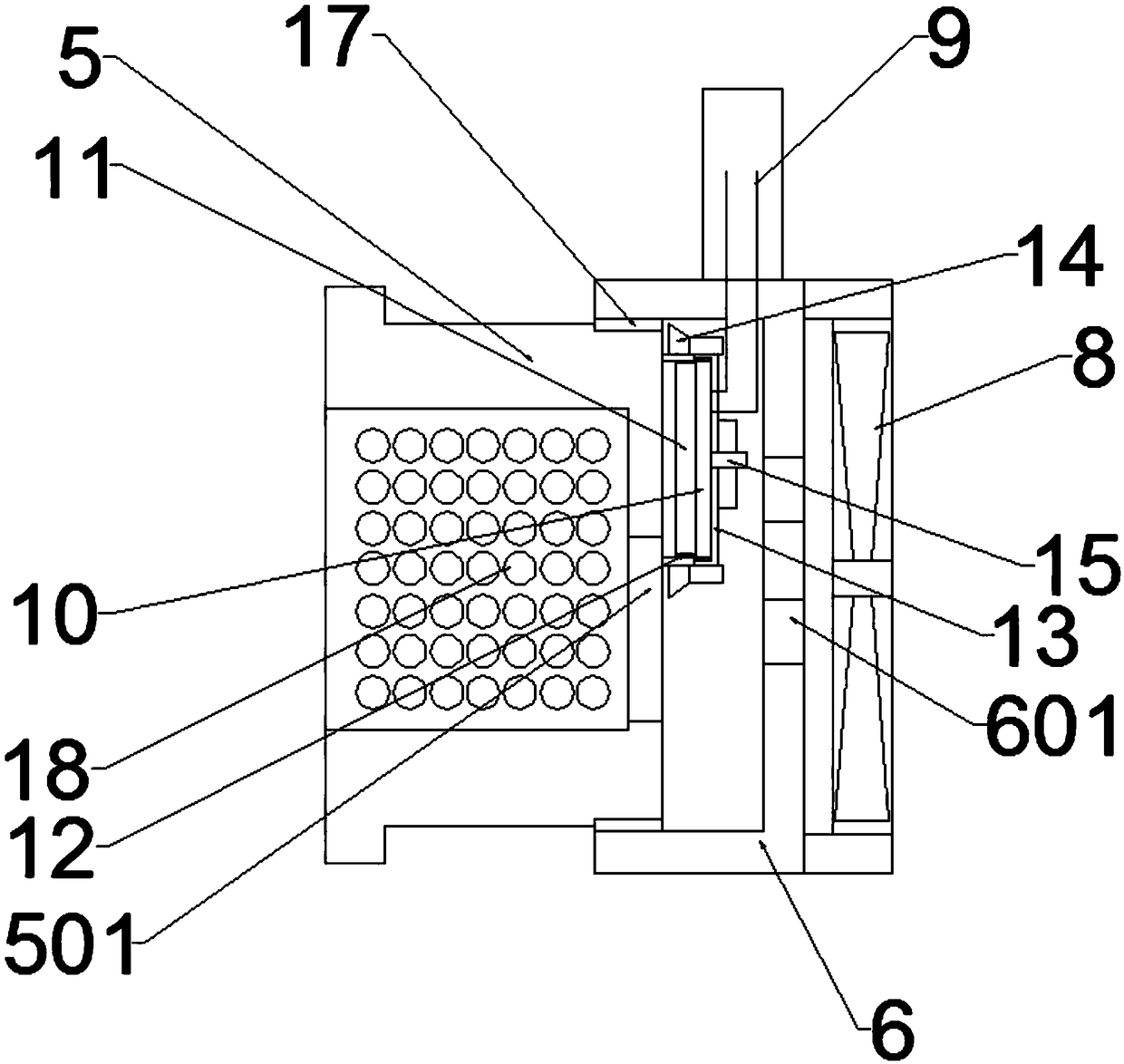

Explosion-proof positive pressure power distribution cabinet

ActiveCN108321704AAchieve sealingRealize heat dissipationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsPositive pressureMoisture

The invention discloses an explosion-proof positive pressure power distribution cabinet. The explosion-proof positive pressure power distribution cabinet comprises: a housing, an air inlet and an airoutlet which are formed in the housing, an air inlet pipe assembly disposed at the air inlet, and an explosion-proof deflation assembly disposed at the air outlet; the air inlet pipe assembly comprises: an air inlet pipe, a first suction fan disposed at an inlet of the air inlet pipe, and an electromagnetic valve disposed on the air inlet pipe; the explosion-proof deflation assembly includes a ventilating box which is fixed on the air outlet and having a first through hole, a ventilating cover which is corresponding to the first through hole and has a second through hole, a second suction fandisposed on the ventilating cover, a sealing assembly for sealing the first through hole, and an electronic telescopic rod for controlling the opening and closing of the first through hole and connected to the sealing assembly. The invention can seal the power distribution cabinet, can prevent external moisture, flammable and explosive gas, and dust from entering the power distribution cabinet, can monitor the pressure and the temperature of the power distribution cabinet in real time, and can automatically realize explosion-proof decompression and heat dissipation; the safety is improved, theautomatic level is improved, and the manpower burden is reduced.

Owner:CHINA HELON EXPLOSION PROOF ELECTRIC

Vacuum ceramic thermal baffle welded by metal solders and manufacturing method of thermal baffle

InactiveCN102953509AGood heat insulationGood sound insulationCovering/liningsLaminationUltimate tensile strengthAir tightness

The invention provides a vacuum ceramic thermal baffle. The thermal baffle comprises an upper thermal baffle and a lower thermal baffle, wherein the peripheries of the upper and lower thermal baffles are welded together by metal or alloy solders; a closed vacuum layer is formed between the upper thermal baffle and the lower thermal baffle; and the upper and lower thermal baffles can be flat, flat externally and concave internally, or convex. A manufacturing method of the vacuum ceramic thermal baffle is simple in process. According to the invention, the manufactured vacuum ceramic thermal baffle can overcome defects of the conventional thermal baffle, the air tightness of the vacuum layer of the thermal baffle can be effectively ensured, the service life of the thermal baffle can be prolonged, the strength, sound insulation and fireproof performance of the thermal baffle can be improved, and the thermal baffle also can achieve a good decoration effect.

Owner:戴长虹

Five side independent showcase for diplaying cultural heritage

ActiveCN1600200AImprove the tightnessShow cabinetsBurglary protectionMechanical engineeringEngineering

Owner:SIGONG TECH

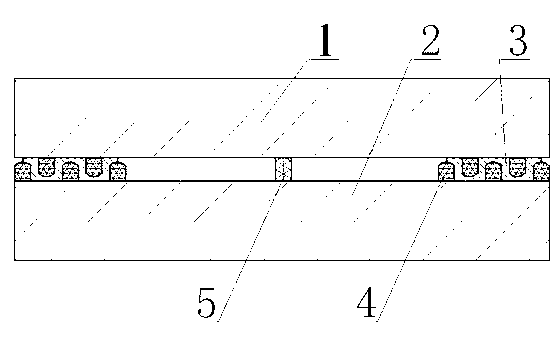

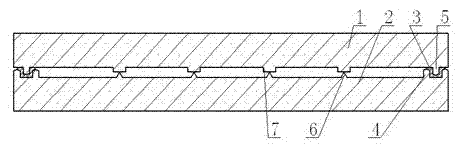

Convex vacuum glass welded by glass solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951806AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention discloses vacuum glass. The vacuum glass is characterized in that upper glass and lower glass are convex; the peripheries of the upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by low-temperature glass solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing common vacuum glass and tempered vacuum glass.

Owner:戴长虹

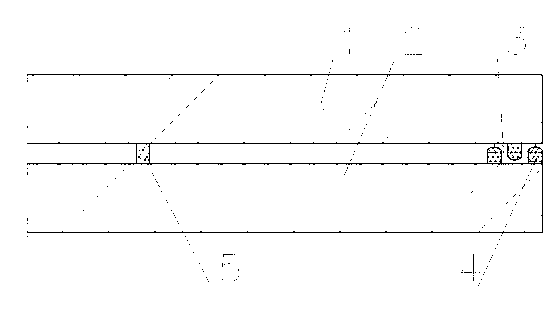

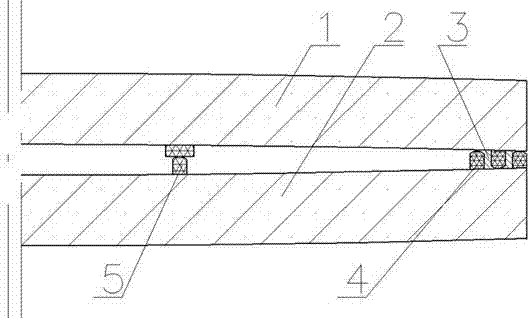

Planar vacuum glass welded by glass solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951817AEasy edge bandingExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention discloses vacuum glass. The vacuum glass is characterized in that the peripheries of the upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by low-temperature glass solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without special extraction openings in mass by virtue of a one-step method, and can be used for manufacturing common vacuum glass and tempered vacuum glass.

Owner:戴长虹

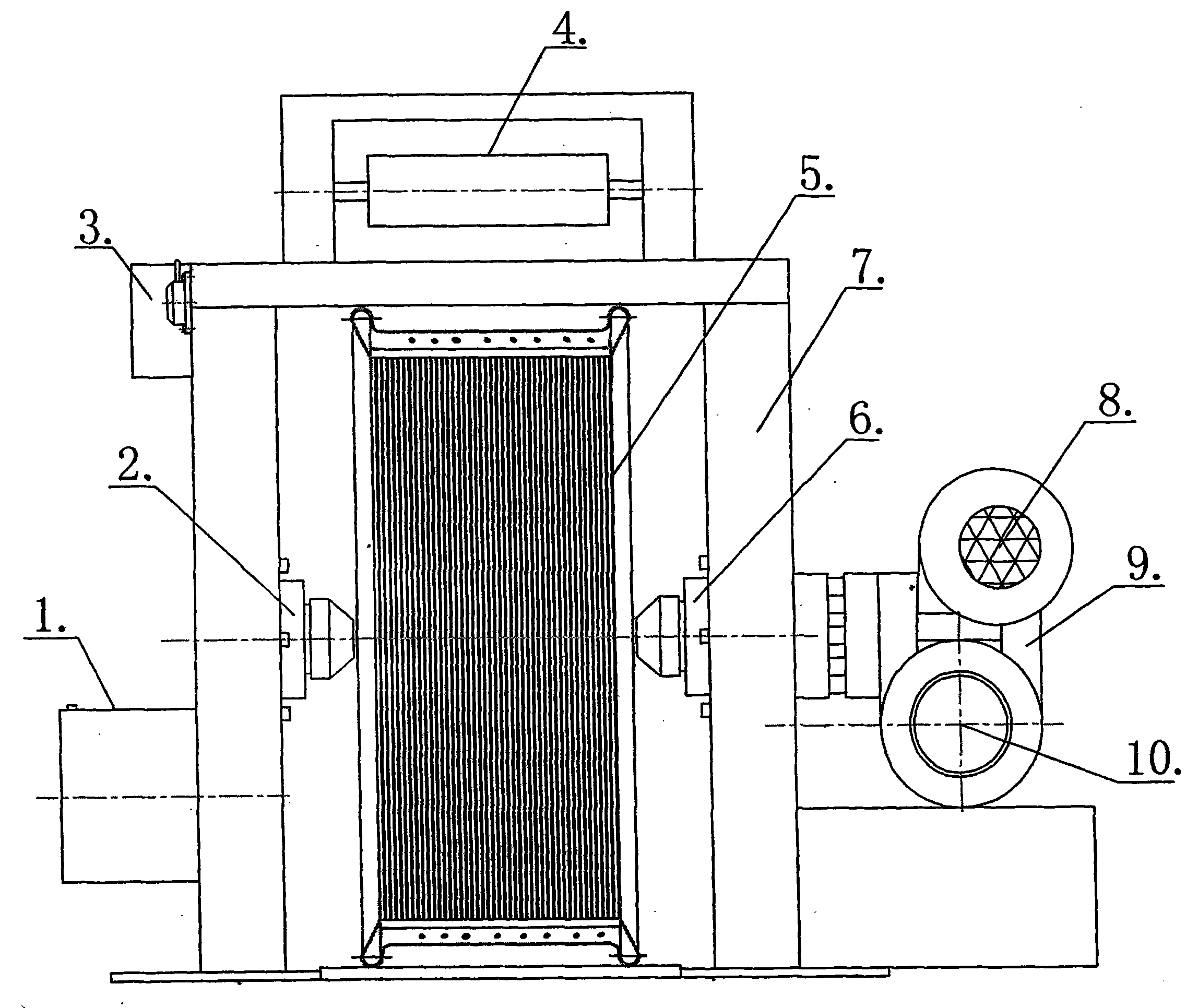

Bobbin packager

The invention discloses a bobbin packager, which is characterized in that the top end of a frame is provided with a preservative film; one side of the top end of the frame is provided with a control cabinet; one side on the bottom of the frame is provided with a cylinder; a clamping tip and a fixing tip are respectively arranged in the frame; the fixing tip is connected to a reducer; the reducer is connected to a driving motor; and the top end of the reducer is provided with a cooling fan. Through the technical scheme, the preservative film of the bobbin packager of the invention has higher tightness.

Owner:SHANDONG DAYE

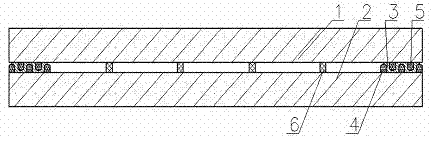

Vacuum ceramic thermal baffle and manufacturing method of vacuum ceramic thermal baffle

ActiveCN102953444AEasy edge bandingExtend your lifeClimate change adaptationInsulation improvementThermal insulationAir tightness

The invention provides a vacuum ceramic thermal baffle comprising an upper thermal baffle and a lower thermal baffle which are of flat plates, wherein the peripheries of the upper thermal baffle and the lower thermal baffle are welded together by welding fluxes, a closed vacuum layer is formed between the upper thermal plate and the lower thermal plate, and supports are arranged in the vacuum layer in a dot matrix manner. According to a manufacturing method of the vacuum ceramic thermal baffle, the process is simple, the manufactured vacuum ceramic thermal baffle overcomes the defects of the existing thermal baffle, the air tightness of the vacuum layer of the vacuum ceramic thermal baffle can be effectively ensured, the service life of the vacuum ceramic thermal baffle is prolonged, the strength, the thermal insulation, sound insulation and fire resistance of the vacuum ceramic thermal baffle are enhanced, and simultaneously, the vacuum ceramic thermal baffle has an excellent decorative effect.

Owner:海宁市袁花镇工业投资有限公司

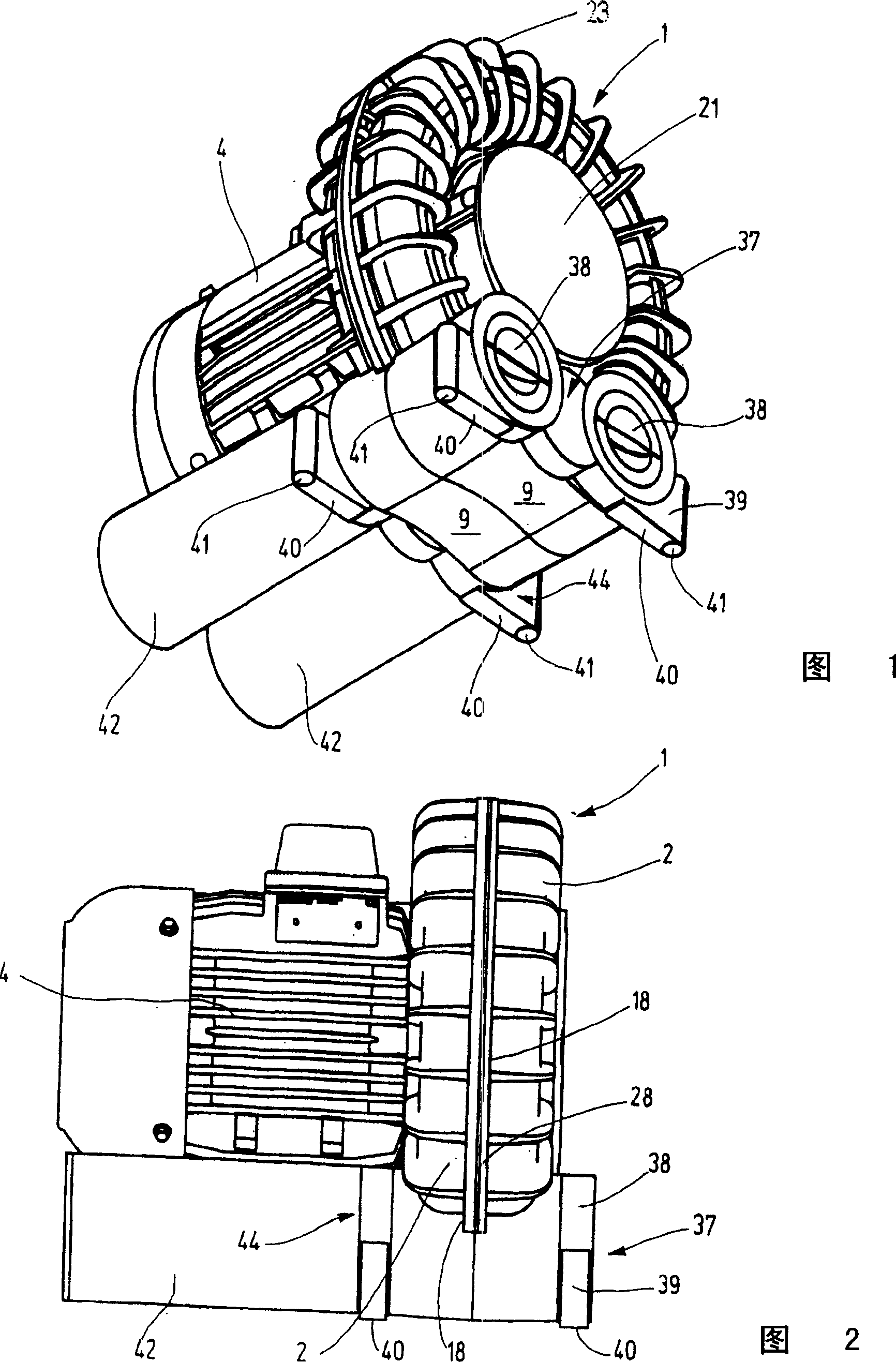

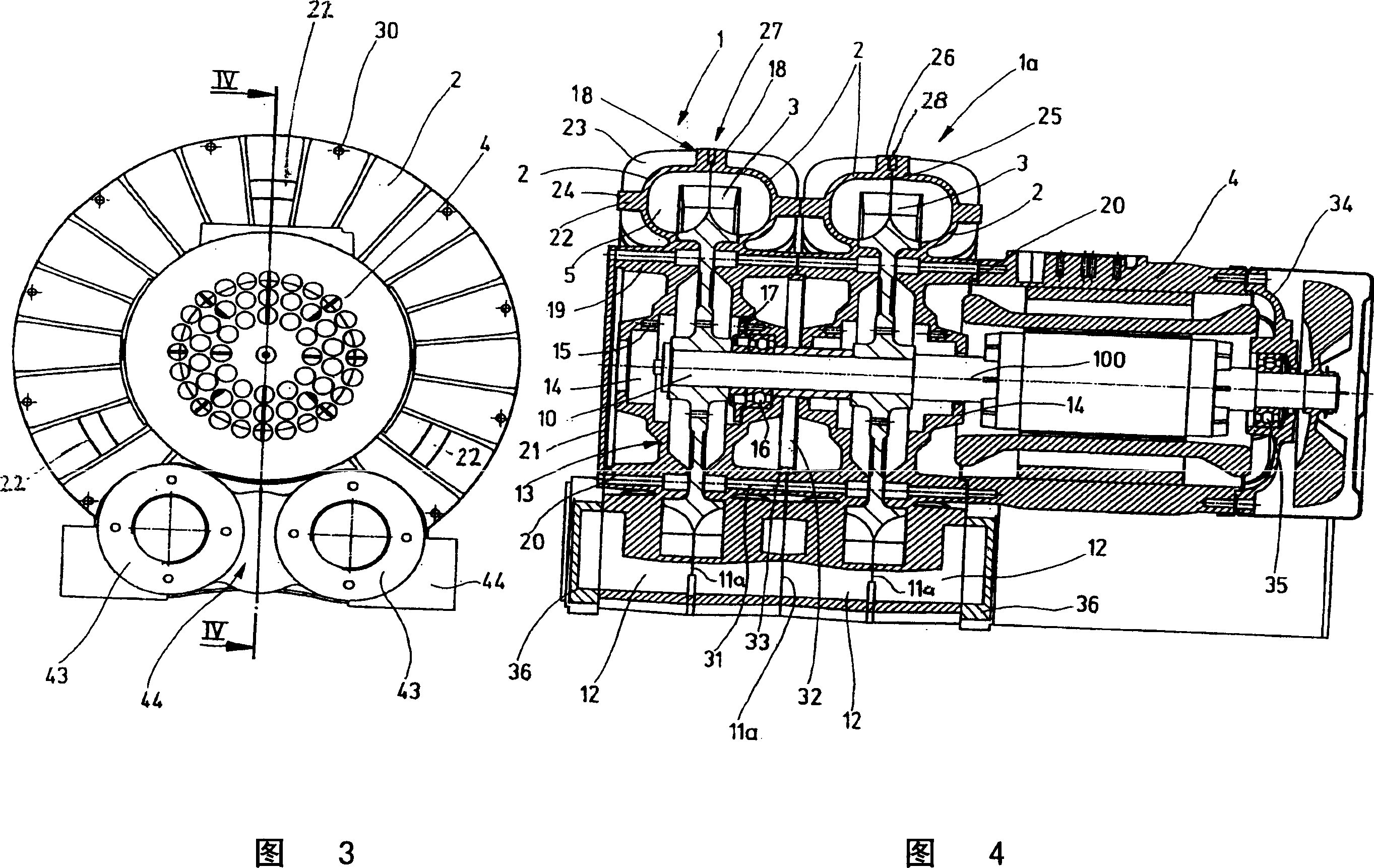

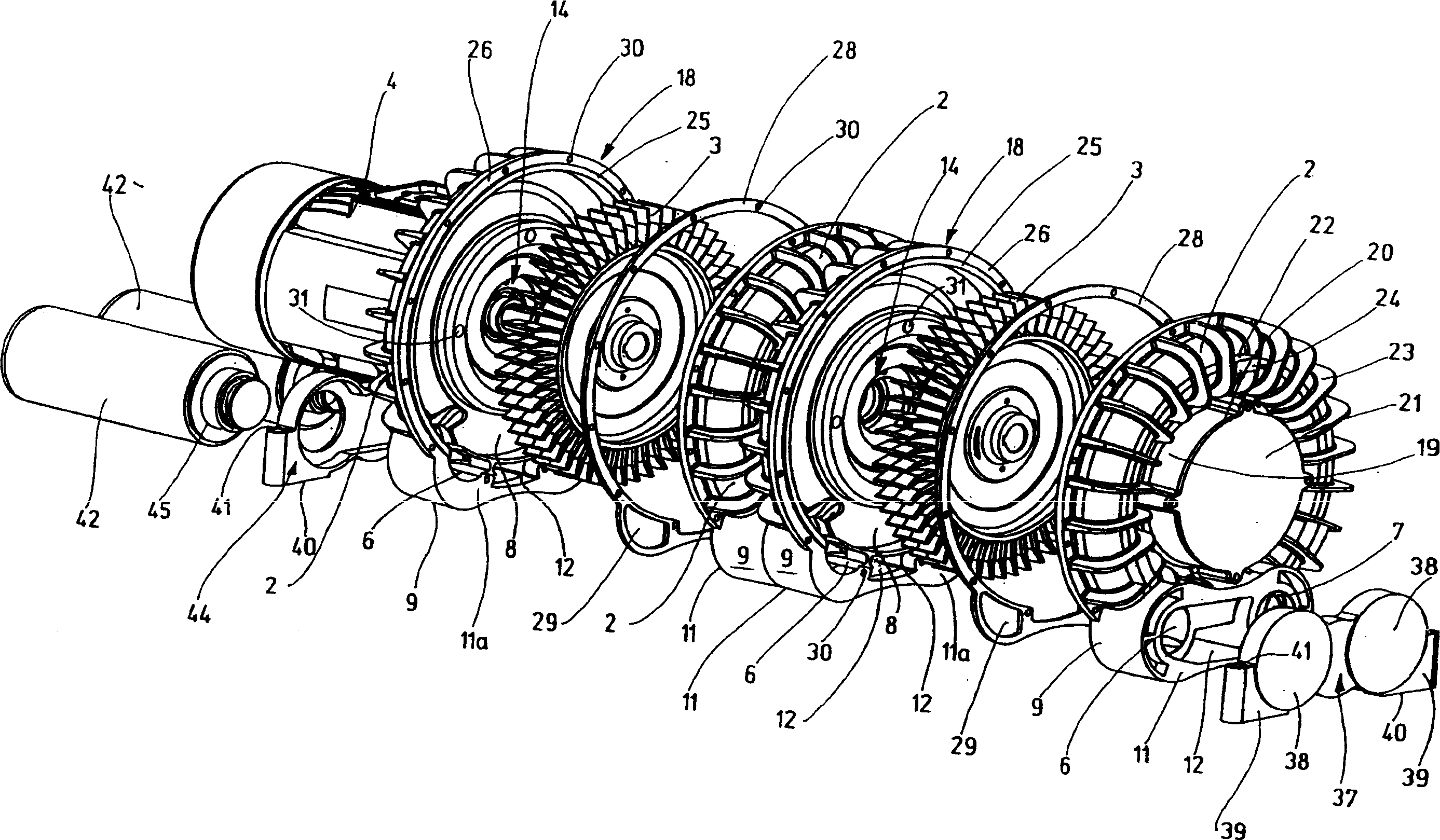

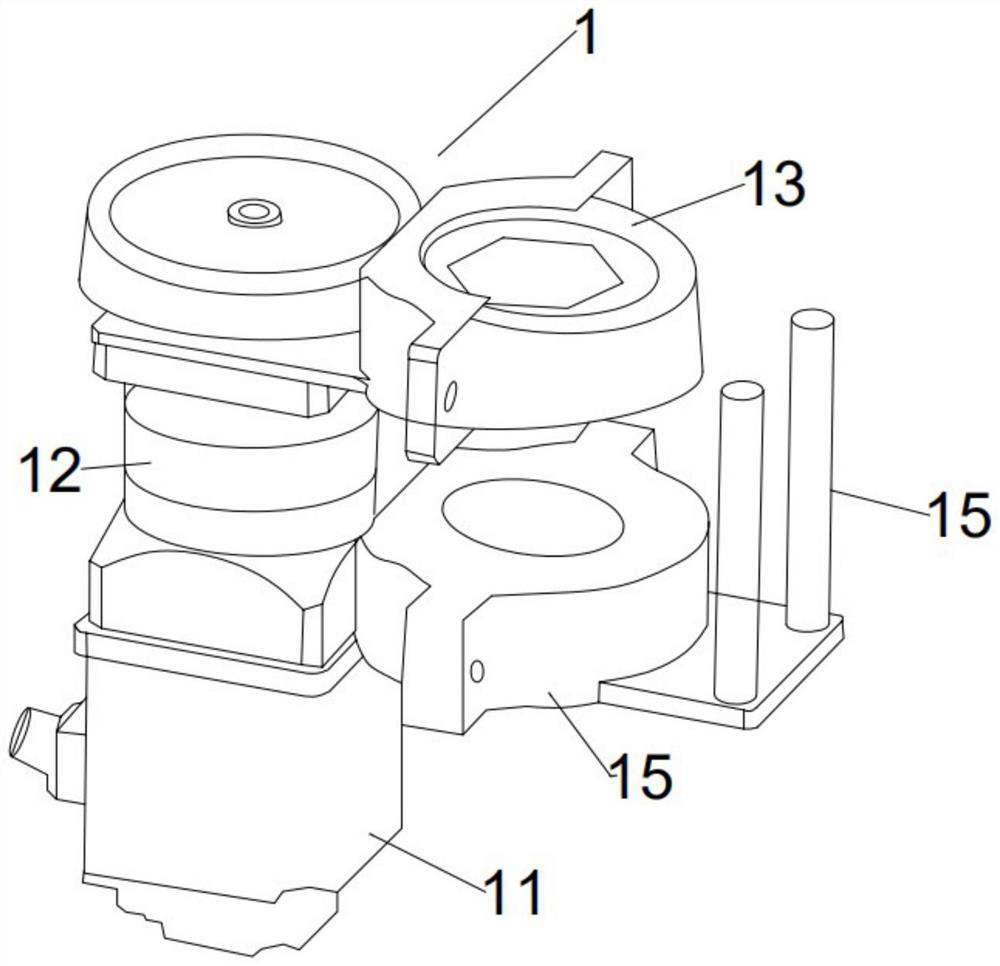

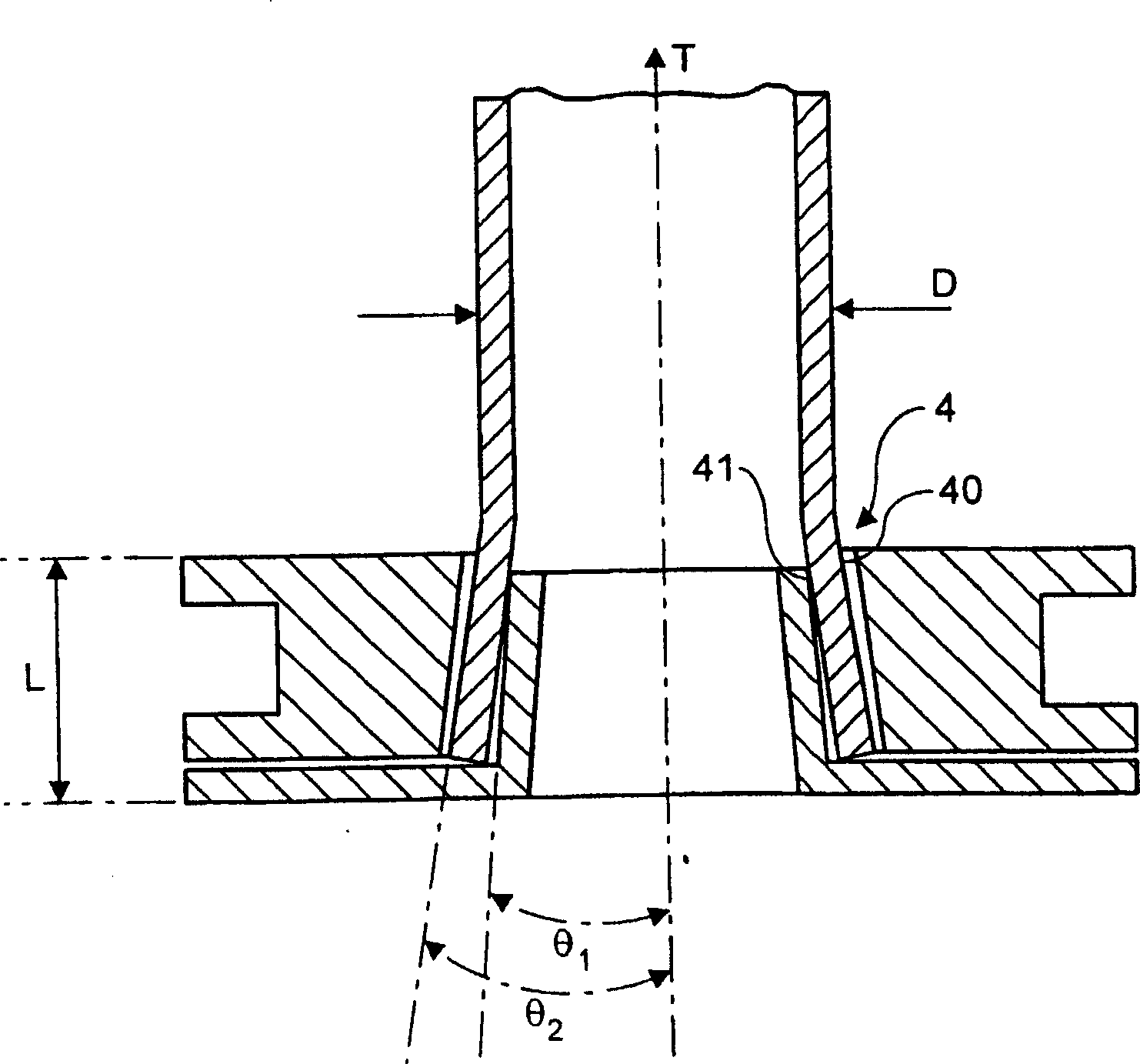

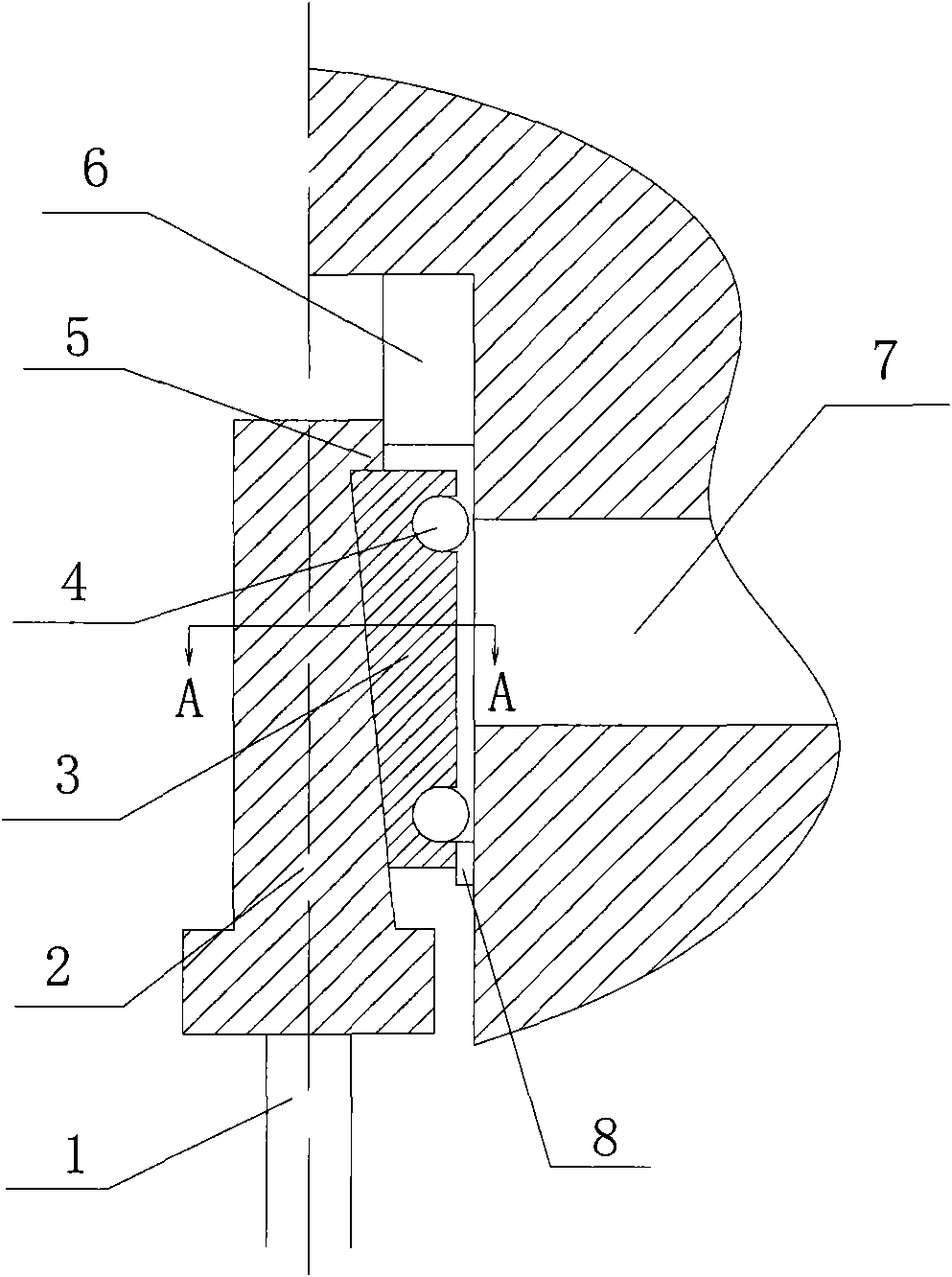

Side channel compressor

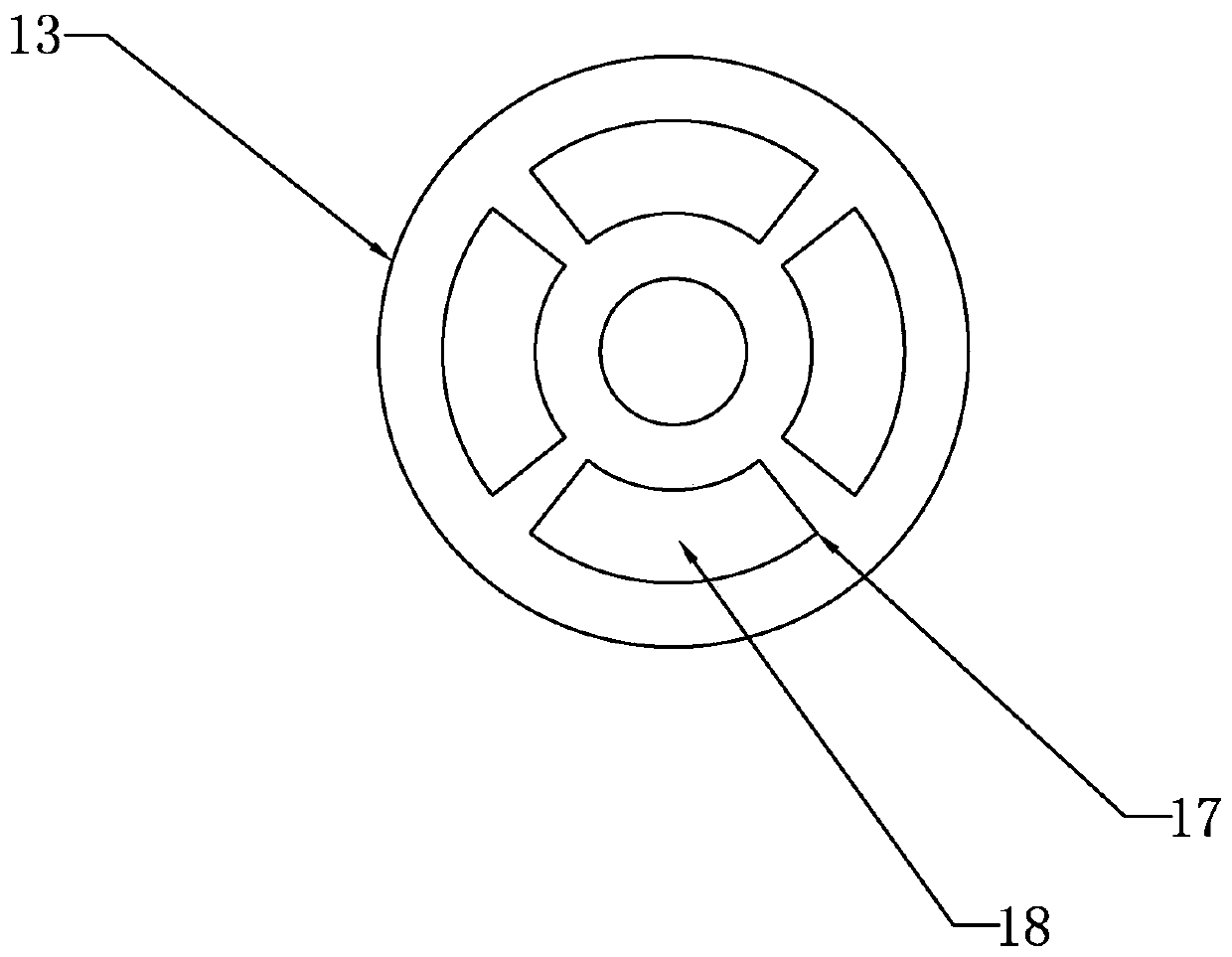

InactiveCN1601113AImprove the tightnessPump componentsRotary non-positive displacement pumpsImpellerTurbine wheel

A side channel compressor comprises at least one annular and two semi-shell type housing (1) which encloses a rotary turbine wheel (3) supported therein and is provide with an air intake and an air discharge pipes (6, 7), the housing of the turbine wheel is provided with two same semi-housings (2) joined together at planes (25) via planar separation surfaces at right angles to the rotation axis (10) of the turbine wheel (3), an annular ring (28) is arranged in the plane (25), and the two semi-housings (2) are aligned by the ring.

Owner:M.米勒电气有限责任公司

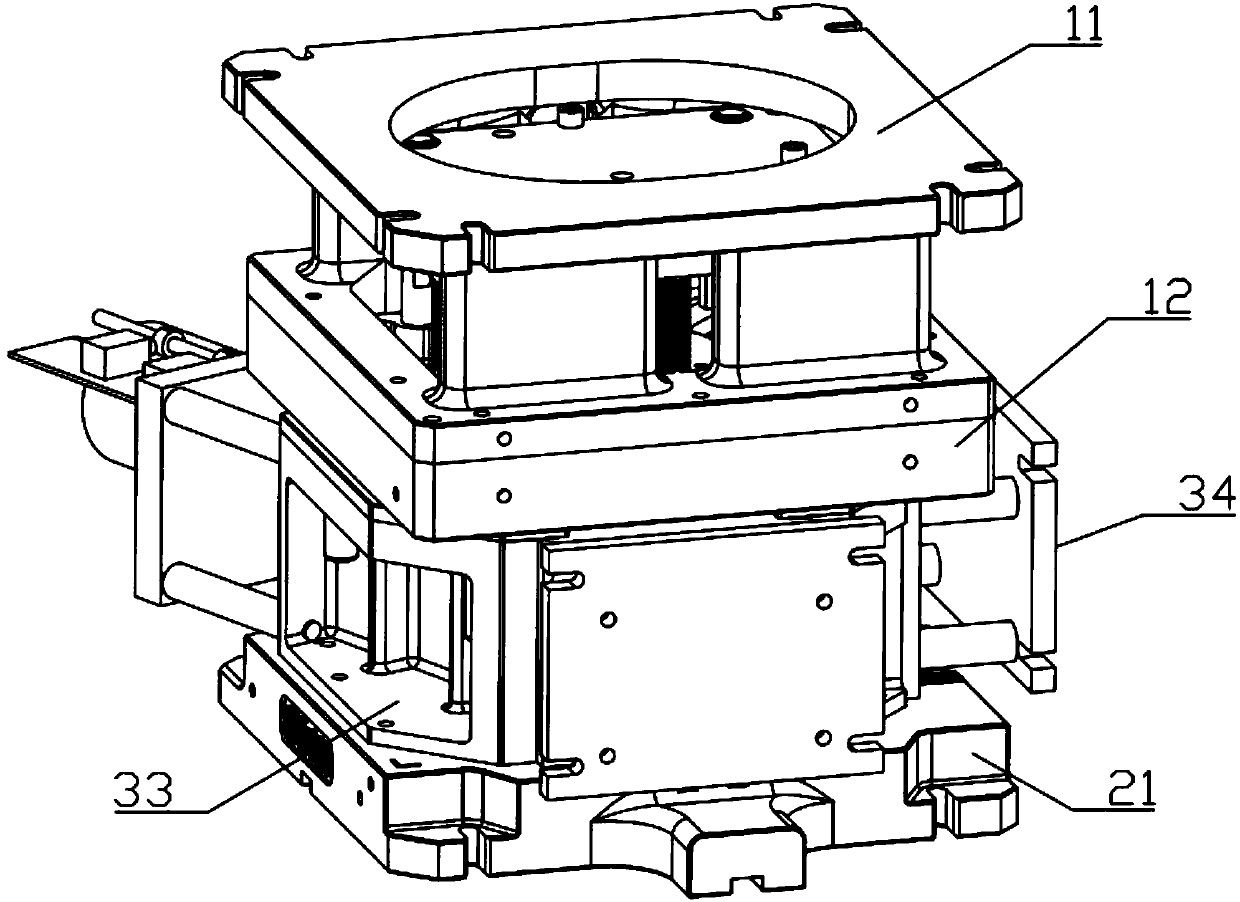

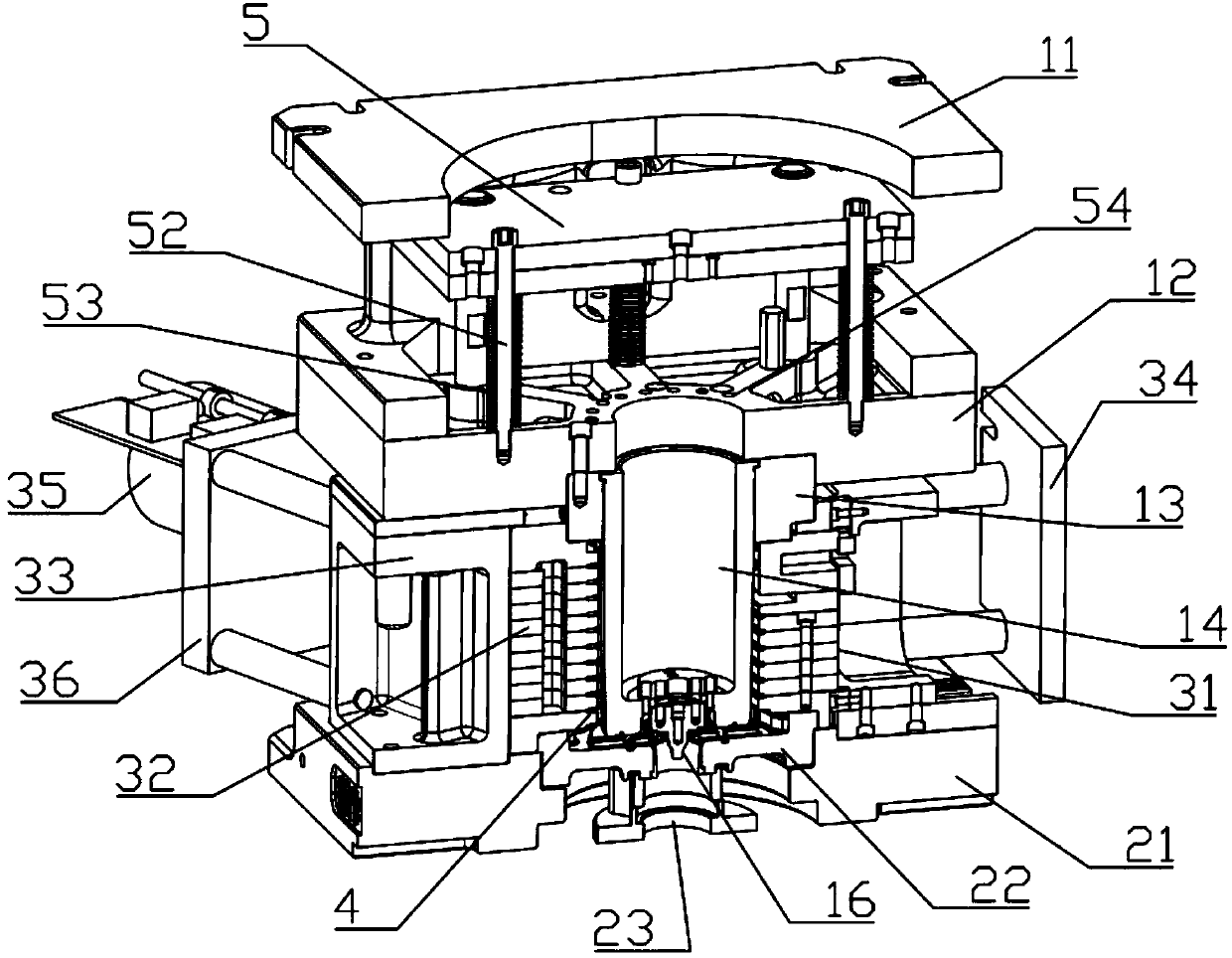

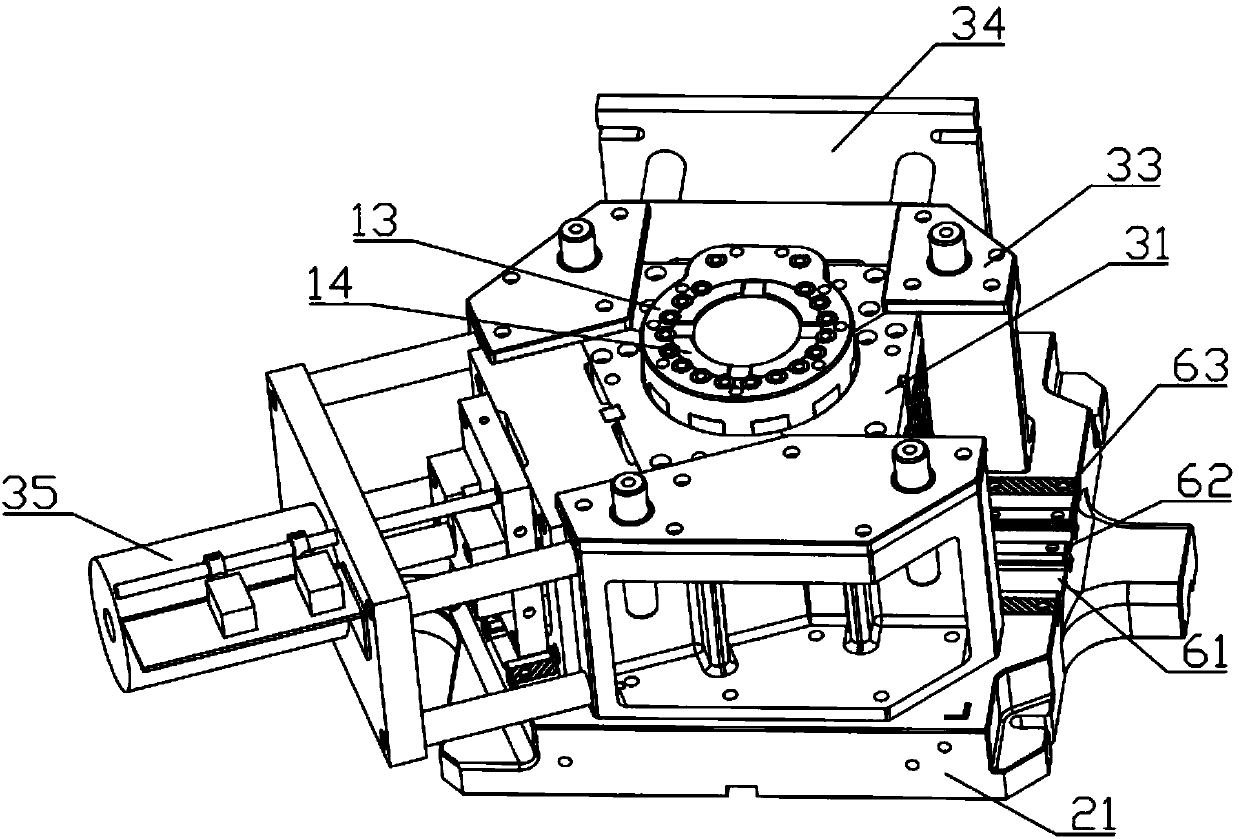

Low-pressure casting die for new energy automobile motor shell with end cover

The invention belongs to the technical field of casting machining, and particularly designs a low-pressure casting die for a new energy automobile motor shell with an end cover. The low-pressure casting die comprises an upper die, a side die set and a lower die. The upper die comprises an upper die base, an upper die head and an upper die core set. The upper die base and an upper die core set arefixedly connected through the upper die head. The lower die comprises a lower die base and a lower die core which are fixedly connected. The side die set is formed by three mutually-matched side dies.When the upper die, the side die set and the lower die are assembled, a motor shell pouring cavity is defined by the upper die core set, the side dies and the lower die core. By adoption of the abovescheme, the low-pressure casting die has the beneficial effects that the whole set of die is divided into three parts, meanwhile, the side die with the largest size is divided into three parts, the size of each part is greatly reduced, the structure is simplified, and machining is convenient.

Owner:CHONGQINGZHICHENG MACHINERY CO LTD

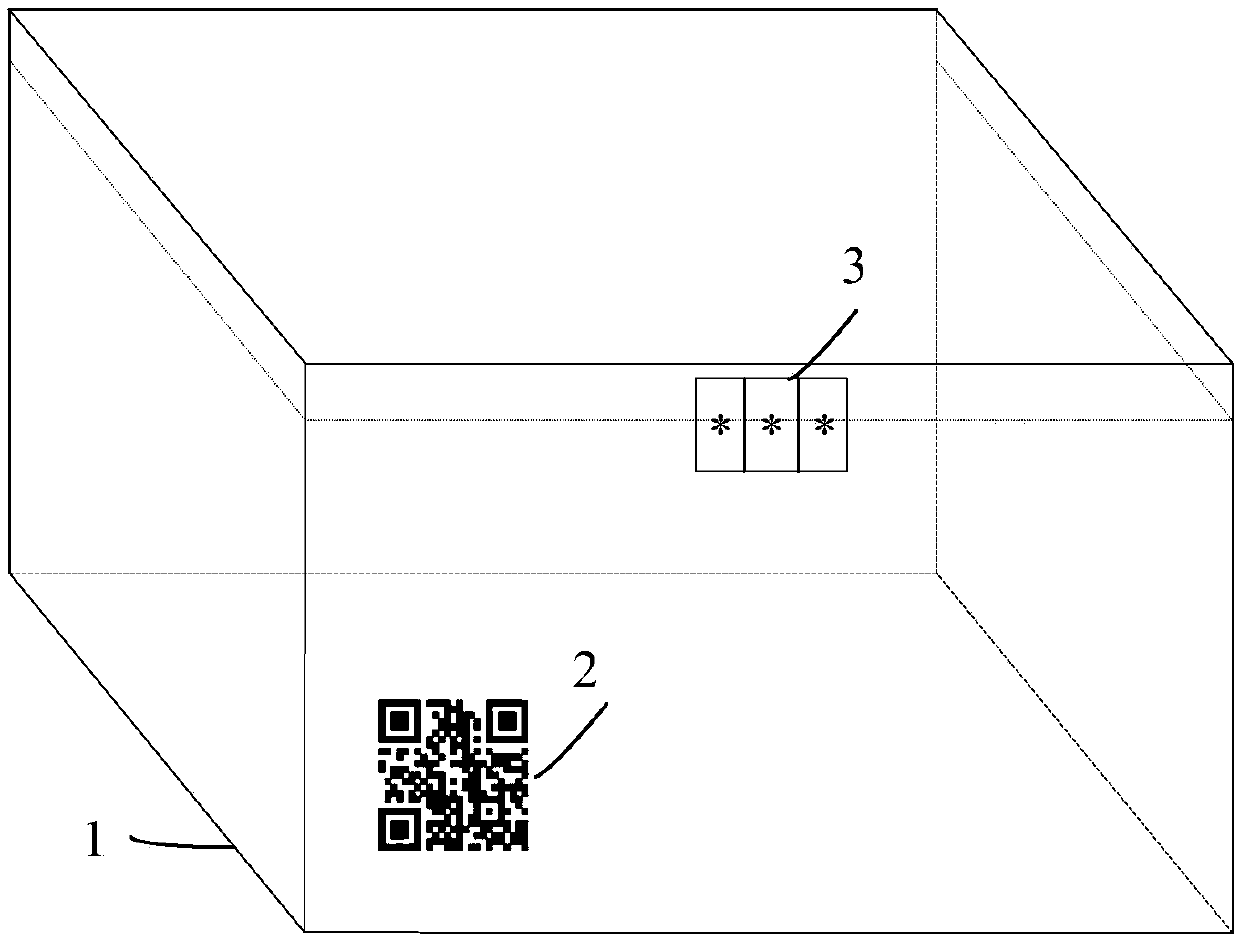

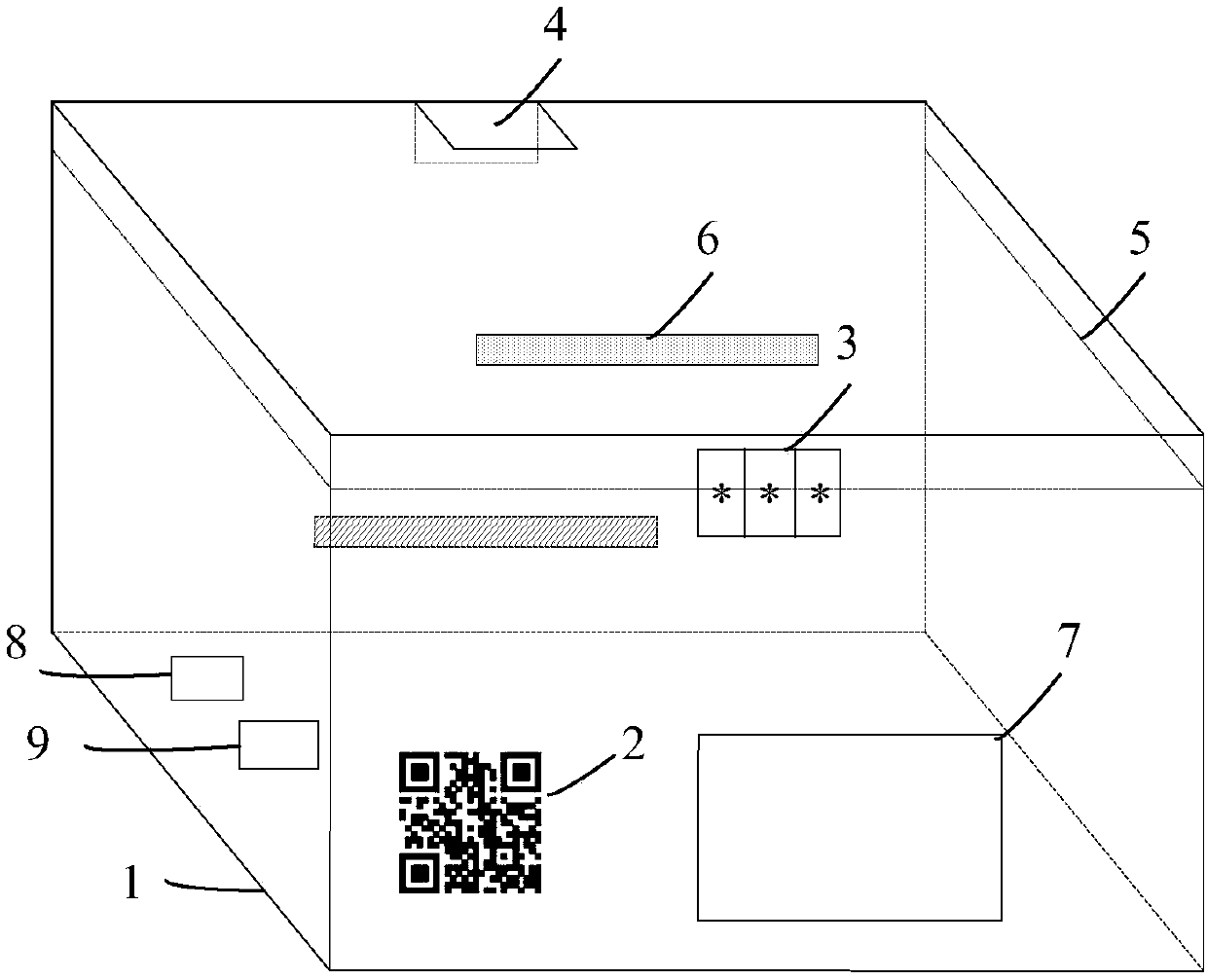

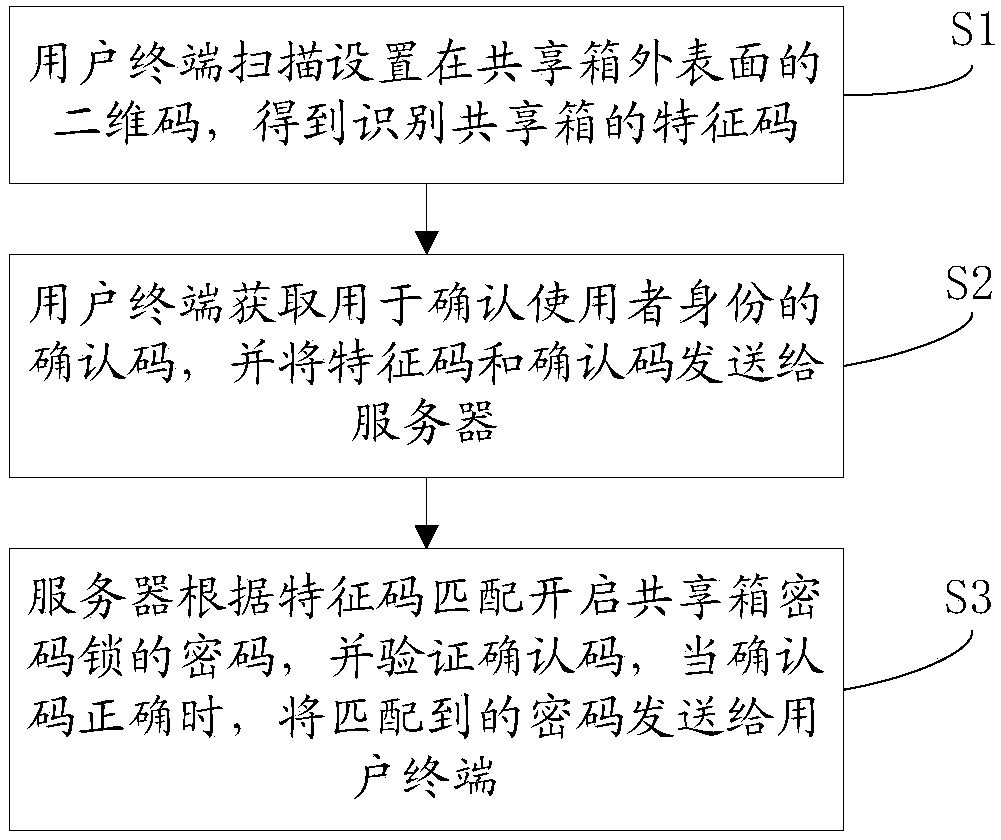

Shared box, sharing method and sharing system

InactiveCN107622593AImprove securityEnsure safetyCo-operative working arrangementsApparatus for meter-controlled dispensingComputer hardwarePassword

The invention relates to a shared box, a sharing method and a sharing system. The sharing box comprises a box body, at least one two-dimensional code and at least one coded lock, wherein the two-dimensional codes are arranged on the outer surface of the box body, and the two-dimensional codes are used for identifying characteristic codes, identical to one another, of the shared box; the characteristic codes are used for matching passwords for opening the coded locks from a database of a server, and each coded lock is arranged at an opening of the box body. According to the shared box, the sharing method and the sharing system, the passwords for opening the coded locks on the box body are obtained through the two-dimensional codes arranged on the box body, an express box can be repeatedly used, the sharing effect is achieved, the use of disposable cartons is reduced, and resources are saved; by arranging the coded locks, the safety of the shared box can be improved, and the safety of articles in the box can be guaranteed.

Owner:全春益

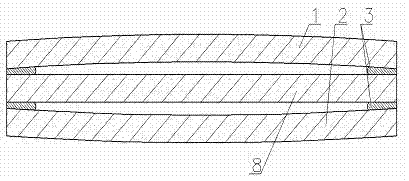

Convex vacuum thermal baffle and manufacturing method thereof

InactiveCN102953439ASimple manufacturing processReduce manufacturing costClimate change adaptationInsulation improvementThermal insulationConvex side

The invention provides a vacuum thermal baffle plate comprising an upper thermal baffle and a lower thermal baffle, wherein the peripheries of the upper thermal baffle and the lower thermal baffle are welded together by welding fluxes, a closed vacuum layer is formed between the upper thermal baffle and the lower thermal baffle, the upper thermal baffle and the lower thermal baffle are both convex, and the convex sides of the convex thermal plates face to the outer side. According to a manufacturing method of the vacuum thermal baffle provided by the invention, the process is simple, the manufactured vacuum thermal baffle overcomes the defects of the existing thermal baffle, the air tightness of the vacuum layer of the vacuum thermal baffle can be effectively ensured, the service life of the vacuum thermal baffle is prolonged, the strength, the thermal insulation, the sound insulation and the fire resistance of the vacuum thermal baffle are enhanced, and meanwhile, the vacuum thermal baffle has an excellent decorative effect.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

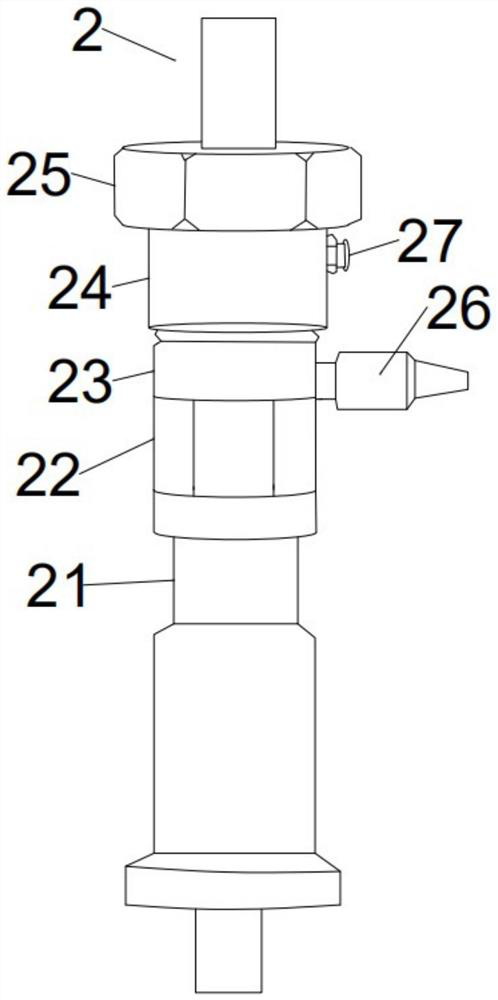

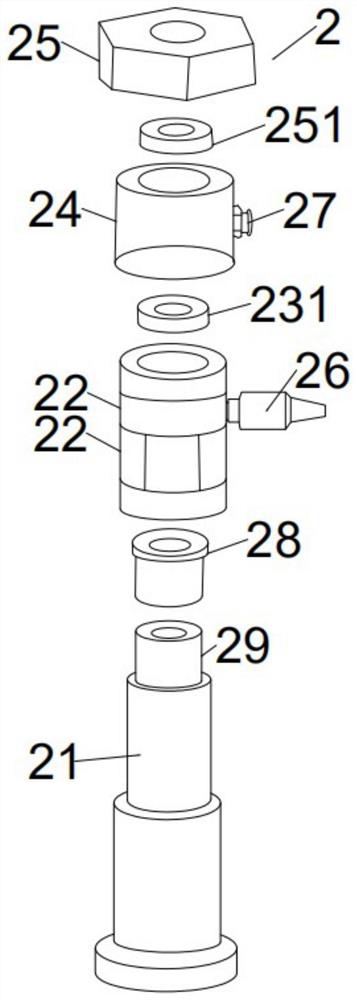

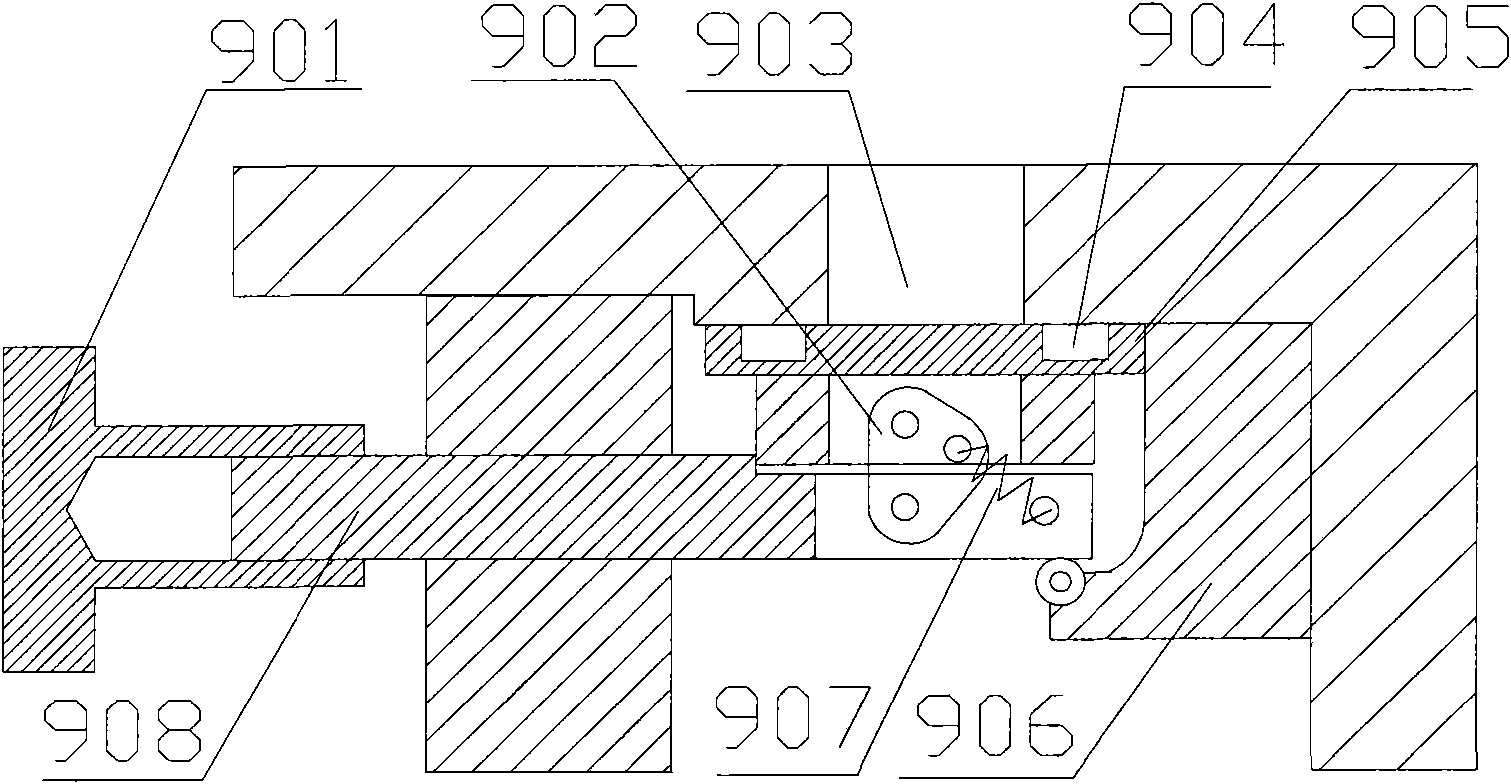

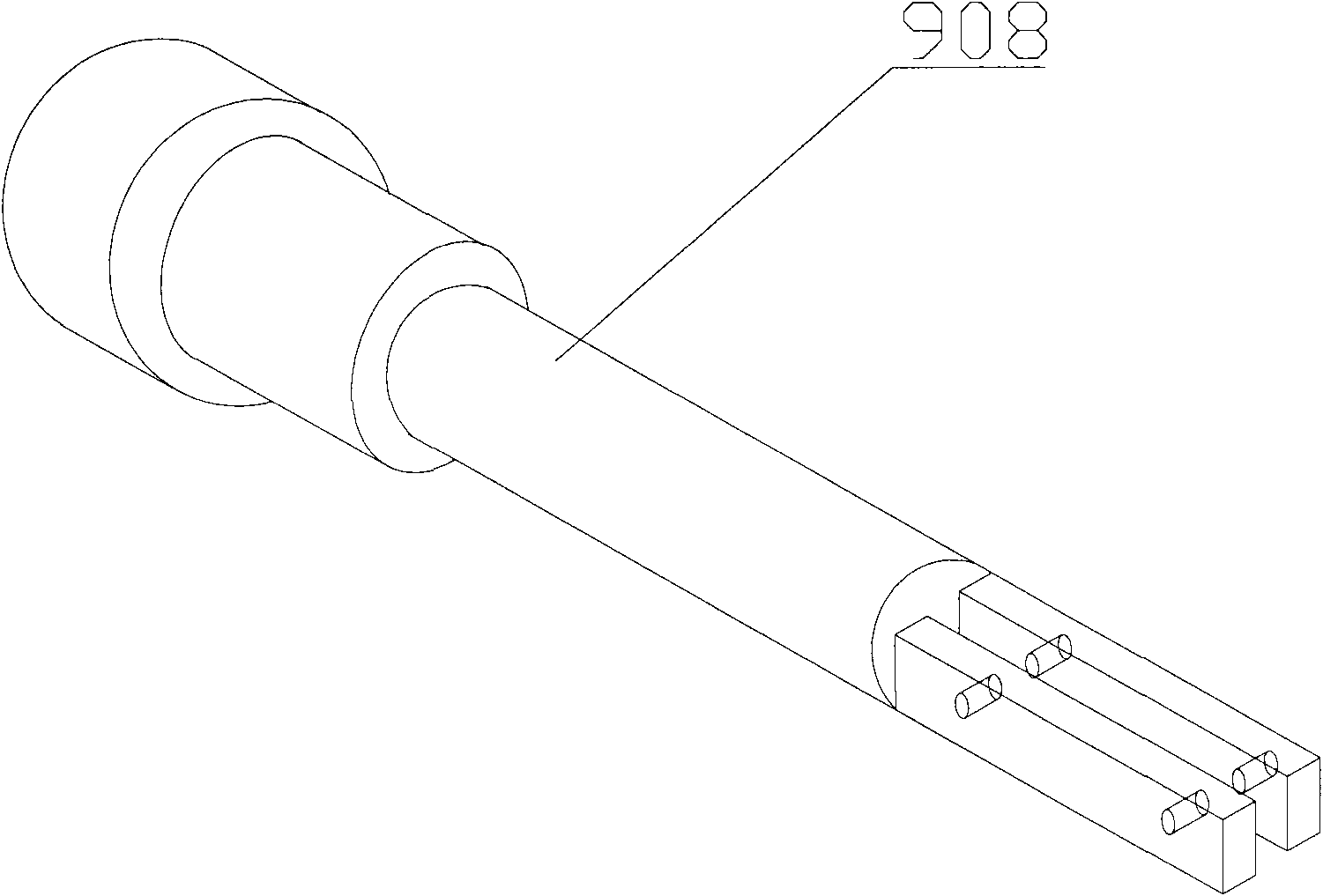

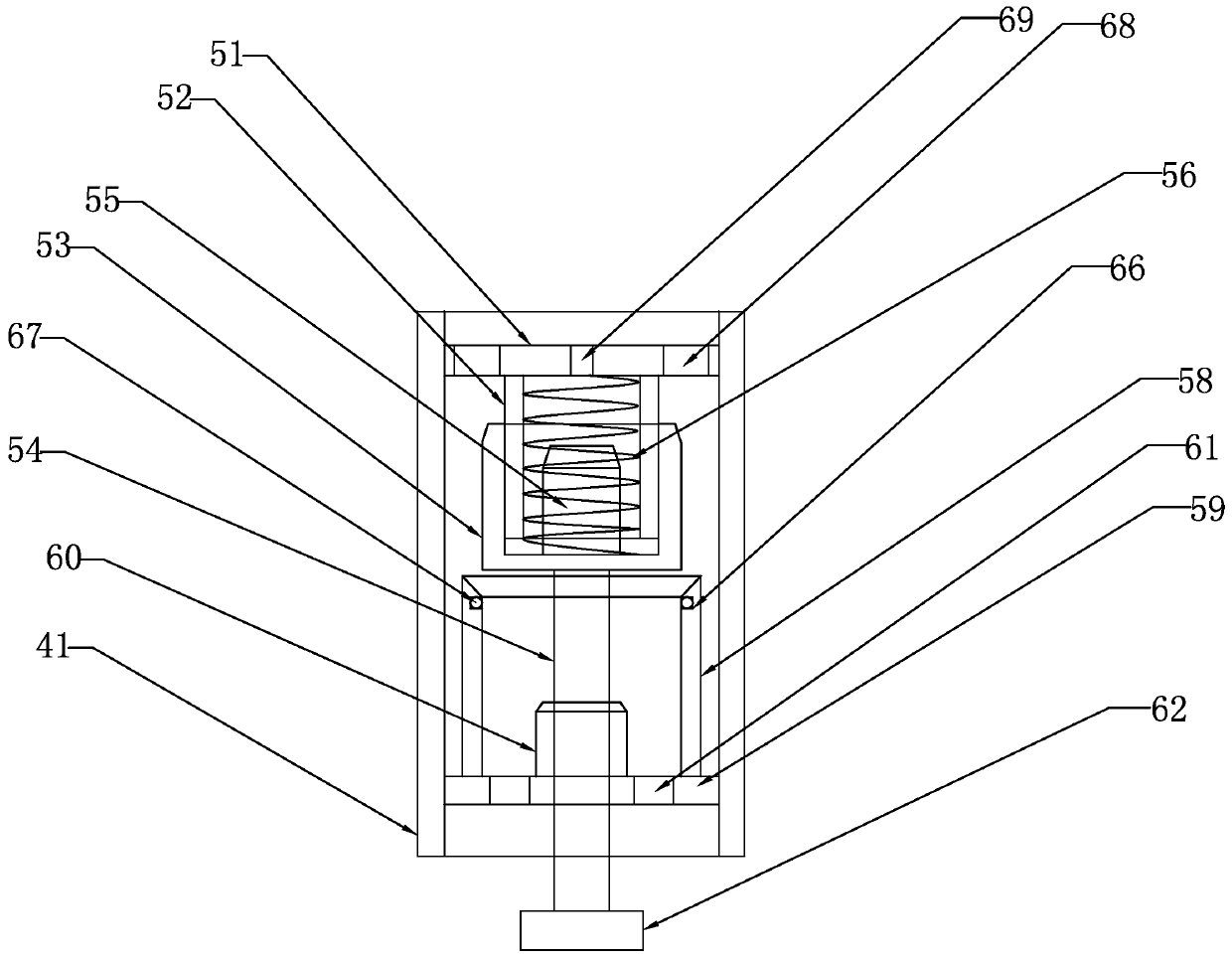

Multi-stage detection self-tightening protection system for preventing wellhead packing from leaking

InactiveCN113701956AIncrease productionSolve environmental problemsMachine part testingSurveyControl systemTorque regulation

The invention relates to a multi-stage detection self-tightening protection system for preventing wellhead packing from leaking, which comprises a packing gland automatic tightening mechanism, a three-stage novel packing gland and a control system, the control system is respectively connected with the packing gland automatic tightening mechanism and the three-stage novel packing gland, and the control system is connected with the packing gland automatic tightening mechanism and the three-stage novel packing gland. The packing gland automatic tightening mechanism is used for automatically tightening packing according to set torque, the three-level type novel packing gland is used for preventing an oil and gas wellhead from being directly connected with the outside, and the control system is used for remotely controlling the packing gland automatic tightening mechanism and the three-level type novel packing gland to work so as to prevent the wellhead packing from leaking. Therefore, oil well mouth oil gas leakage can be firstly prevented and then treated through the pressure sudden change value and the torque adjusting amount, the environmental protection problem of oil well mouth oil gas leakage is thoroughly solved, and oil gas yield increasing and green and clean production are achieved.

Owner:孙文海

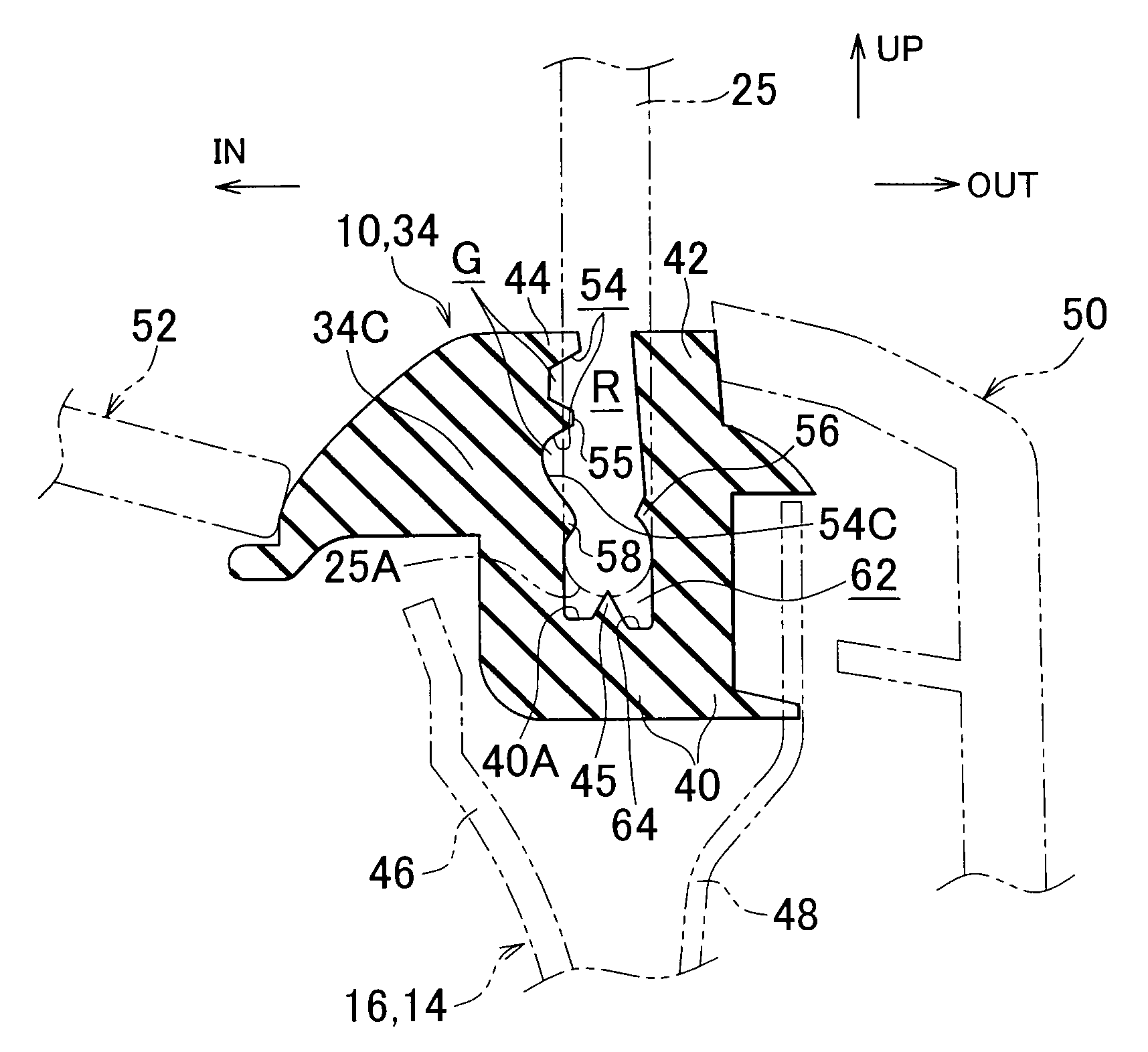

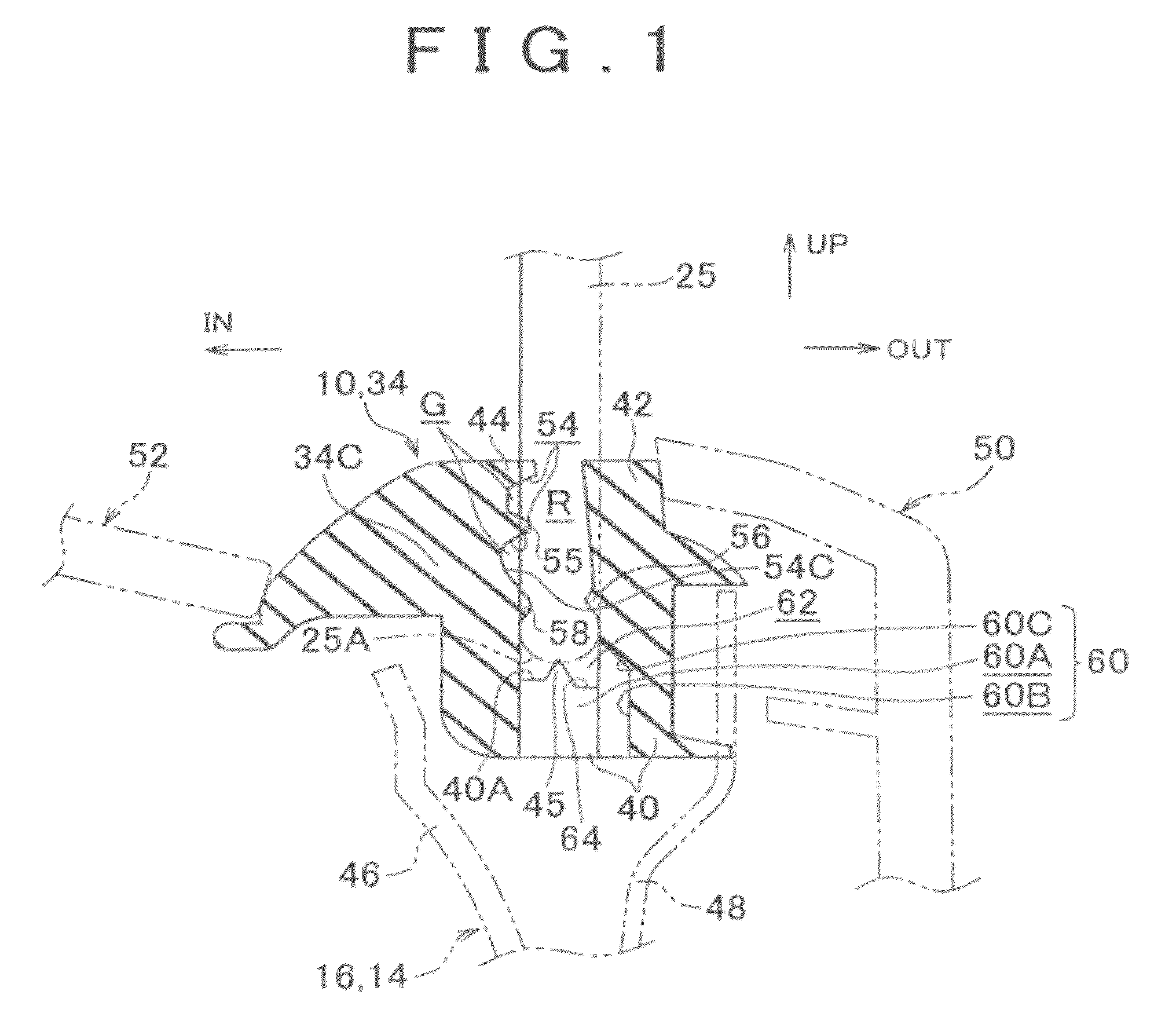

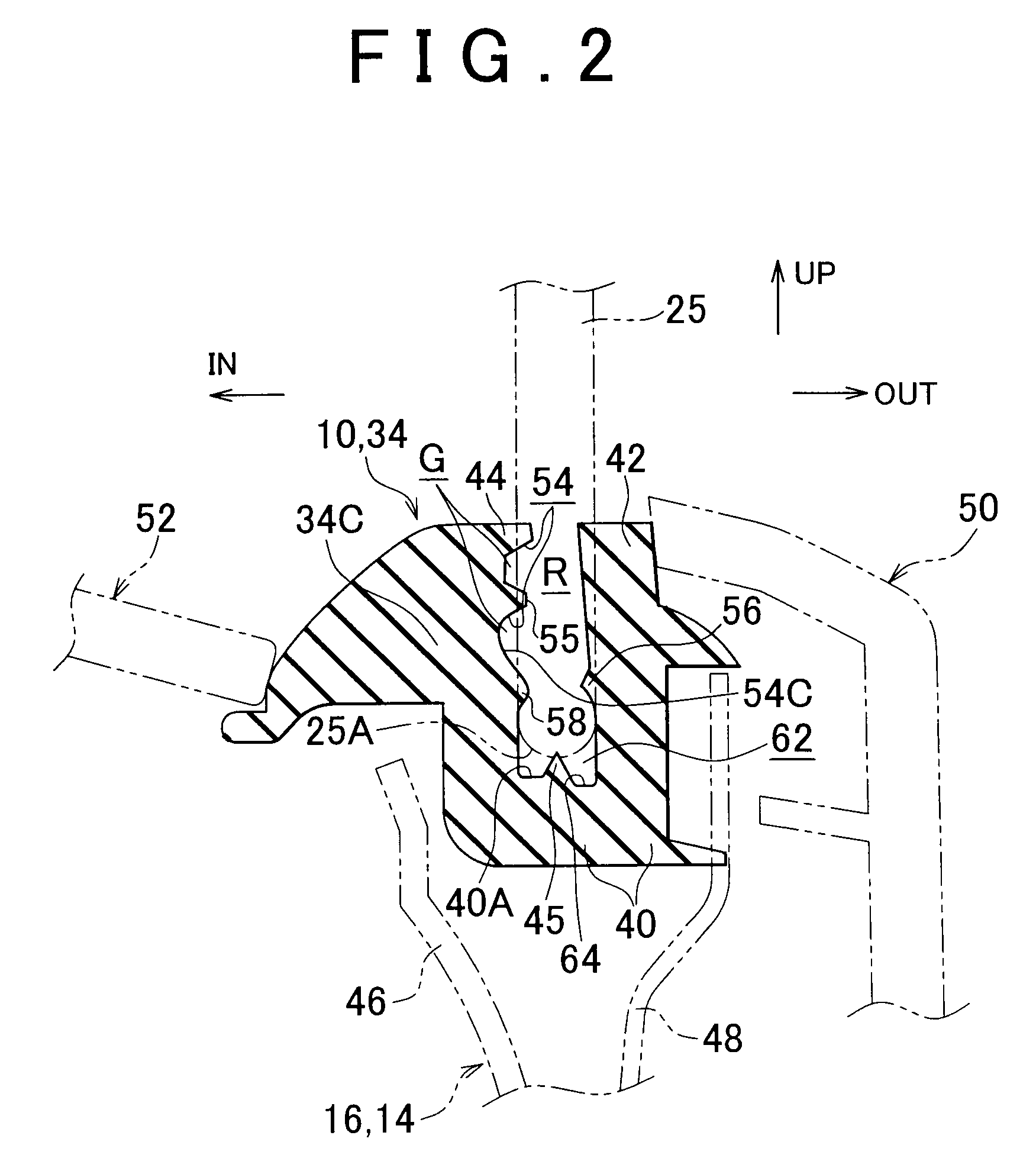

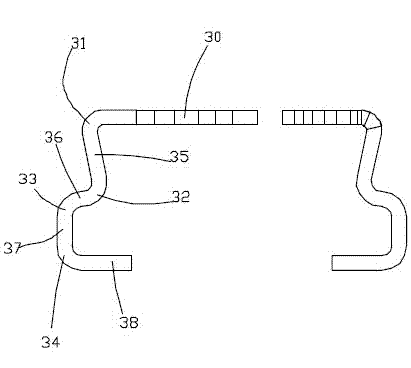

Weather strip structure

ActiveUS8312689B2Effectively prevent enteringAvoid enteringWindowsWindscreensWindow openingEngineering

A weather strip includes a bottom wall that faces or is in contact with an end face of a fixed window glass that closes a window opening of a side door. An outer wall extends from the bottom wall on an outer side of the vehicle body with respect to the fixed window glass, and an inner wall extends from the bottom wall on an inner side of the vehicle body with respect to the fixed window glass so that the inner wall and the outer wall sandwich a peripheral portion of the fixed window glass in a thickness direction. The inner wall is provided with a spacing groove for creating a space between the fixed window glass and the inner wall.

Owner:TOYOTA JIDOSHA KK

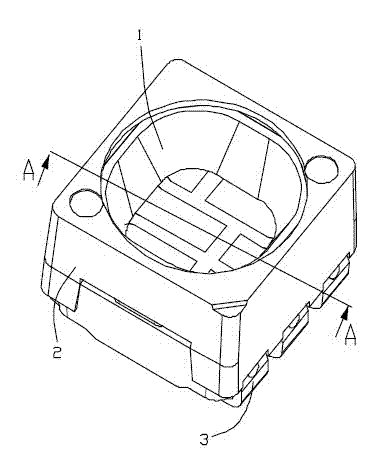

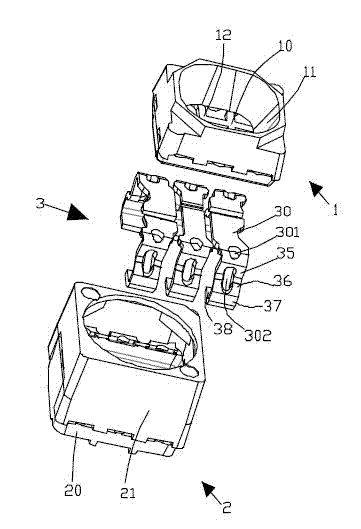

LED (light-emitting diode) support and manufacturing method thereof

ActiveCN102655203AImprove the tightnessIncrease holding powerSemiconductor devicesMoistureLight-emitting diode

The invention discloses an LED (light-emitting diode) support which comprises at least one pair of electric conducting terminals, a first insulation body and a second insulation body, wherein the first insulation body and the electric conducting terminals are molded into a whole; the second insulation body is molded outside the first insulation body; the first insulation body is provided with a containing cavity which is used for packaging an LED chip; each electric conducting terminal comprises a fixed welding region, a first extending part, a second extending part and a welding part, wherein the fixed welding part is exposed out of the bottom surface of the containing cavity; the first extending part is formed in the way that the fixed welding part is bent from the tail end to form a first bent part and then extends inwards at a certain inclined angle; the second extending part is formed in that way that the first extending part is bent from the tail end to form a second bent part and then extends outwards; the welding part is formed in the way that the second extending part is bent to form a third bent part and then extends; the fixed welding region is close to one end of the first bent part and is integrally molded into the first insulation body; and the first extending part and the second bent part are integrally molded in the second insulation body. The LED support and the manufacturing method thereof can effectively improve the waterproof and moisture-proof performances.

Owner:东莞智昊光电科技有限公司

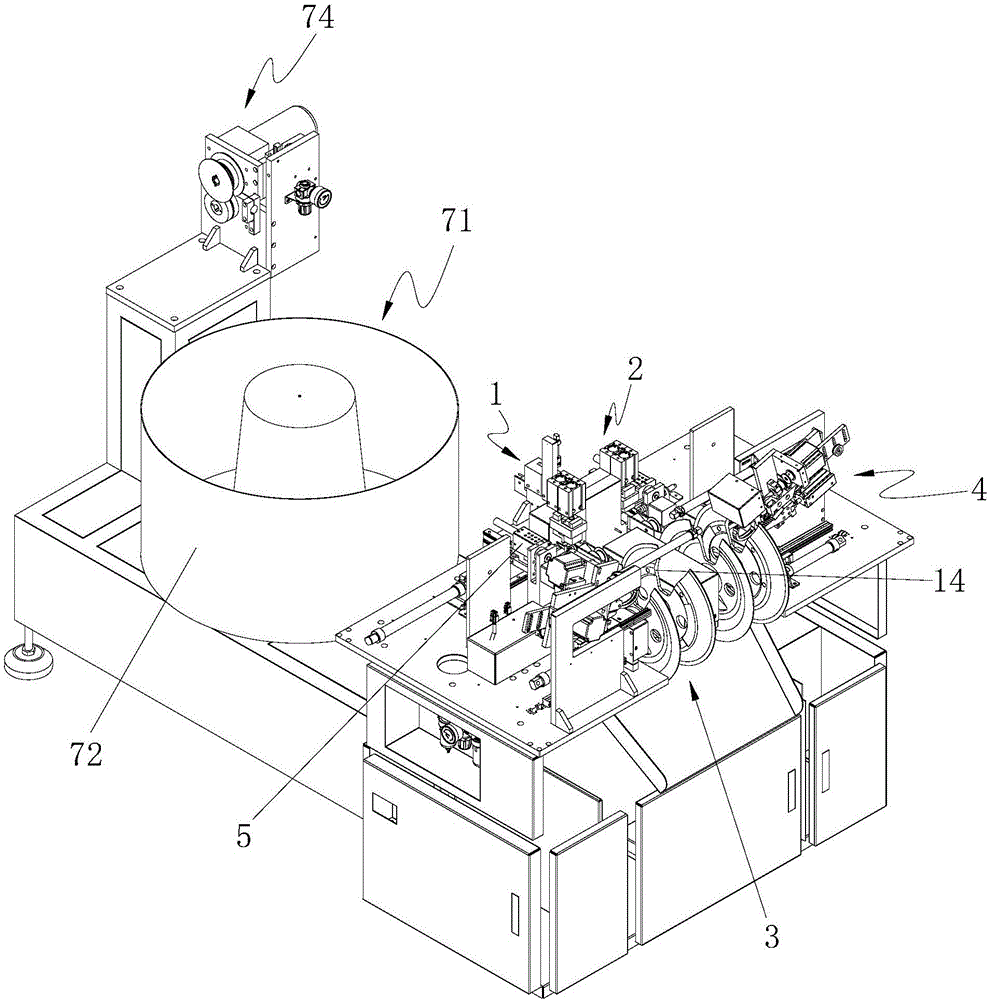

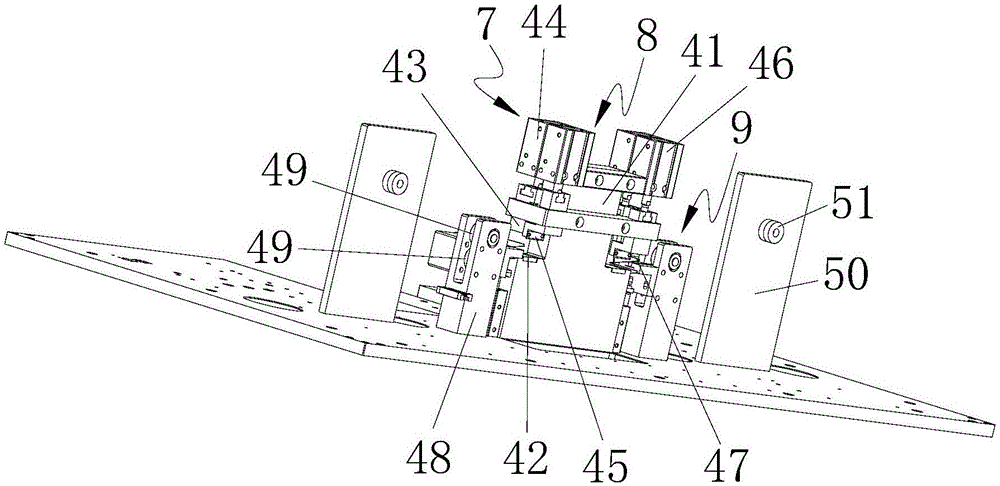

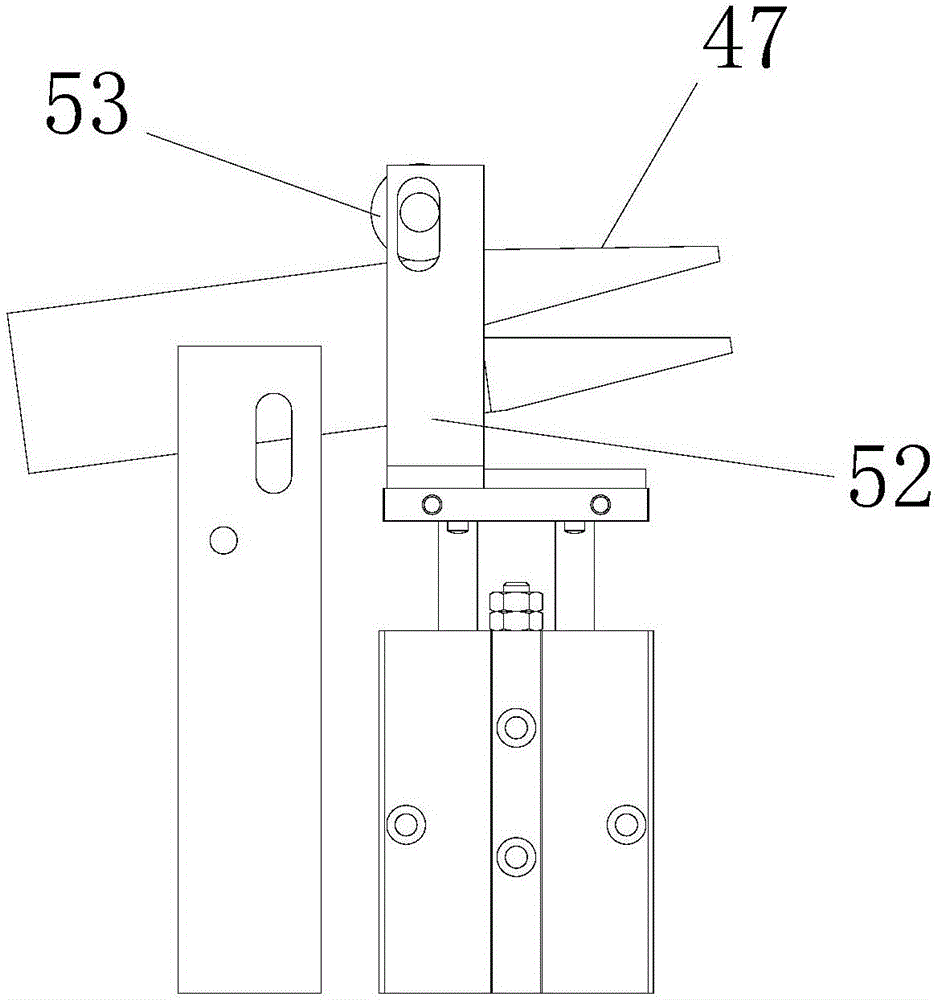

Full-automatic detonator tube end-capping, labeling and winding machine

ActiveCN106428844AImprove the tightnessImprove work efficiencyBinding material applicationBundling machine detailsWinding machineDetonator

The invention discloses a full-automatic detonator tube end-capping, labeling and winding machine which comprises a detonator tube feeding mechanism, a label feeding and cutting device, a tube winding rotary table device, a bundling mechanism and an end-capping device used for heat-sealing detonator tubes. The detonator tube feeding mechanism is used for feeding the detonator tubes into the label feeding and cutting device and the tube winding rotary table device sequentially. The tube winding rotary table device is used for winding the detonator tubes fed by the detonator tube feeding mechanism. The bundling mechanism is used for bundling the detonator tubes wound to a certain length through the tube winding rotary table device. The label feeding and cutting device comprises a tube pressing mechanism, a cutting mechanism used for cutting off the detonator tubes and a label feeding mechanism used for feeding labels into the tube pressing mechanism. The tube pressing mechanism is used for applying pressure to the detonator tubes and the labels during detonator tube cutting and detonator tube heat-sealing. The full-automatic detonator tube end-capping, labeling and winding machine can achieve full-automatic operation of feeding, fixed-length cutting, label fixing, end capping, bundling and discharging.

Owner:GUANGDONG MINGHUA MACHINERY

Bristle binding method of painting brush or writing brush

The invention discloses a bristle binding method of a painting brush or writing brush, relating to the technical field of production processes of Chinese painting brushes. The method comprises the following steps of: firstly, prebinding the root of a bristle bundle by using a rope; then, melting the root of the bristle bundle by using an electric iron; and tightening the rope after the root of the bristle bundle is melted because of heated. Through the melting of the electric iron, the root of the bristle bundle is heated, melted and bonded so that the roots of bristles in the bristle bundle are mutually adhered to be not easy to fall off. In addition, the bristle bundle is heated and softened so as to be beneficial to the secondary tightening of the rope to improve the binding degree. Therefore, the method provided by the invention can be used for easily binding the rope and ensuring that the painting brush or writing brush has no bristle falling phenomenon in the using process, the service life of the painting brush or writing brush is prolonged, and the handwriting or painting quality can be improved.

Owner:石庆鹏

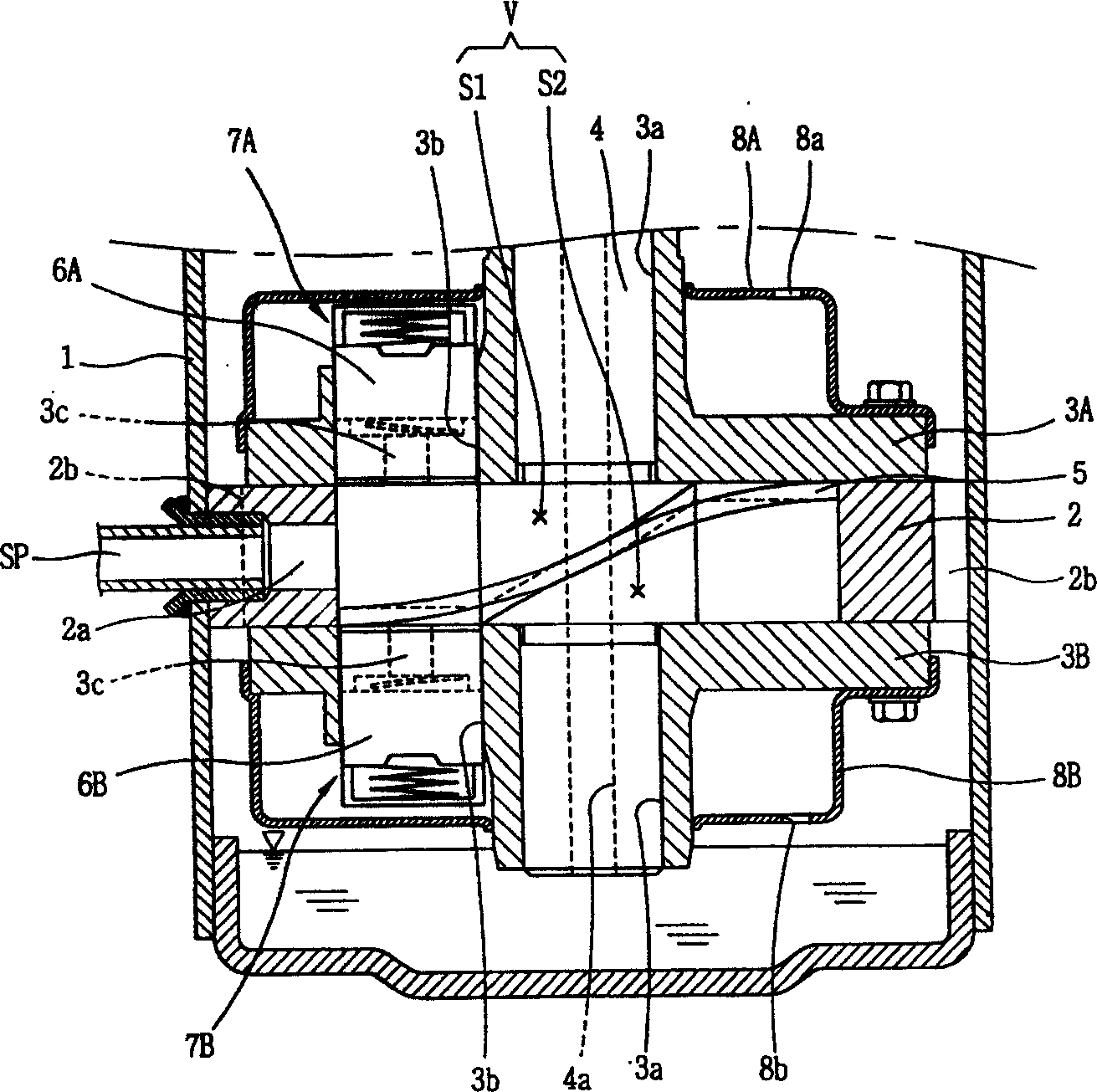

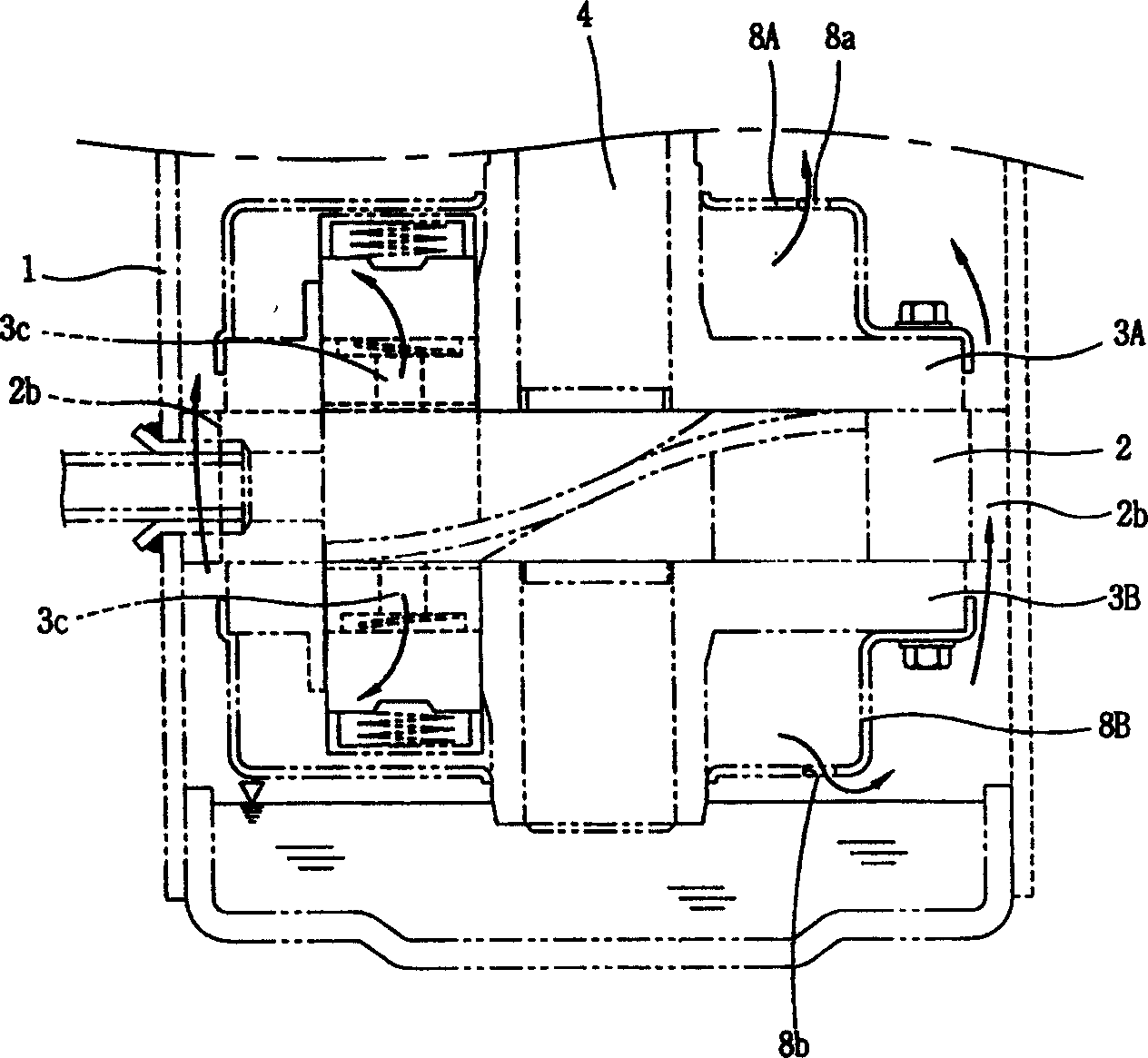

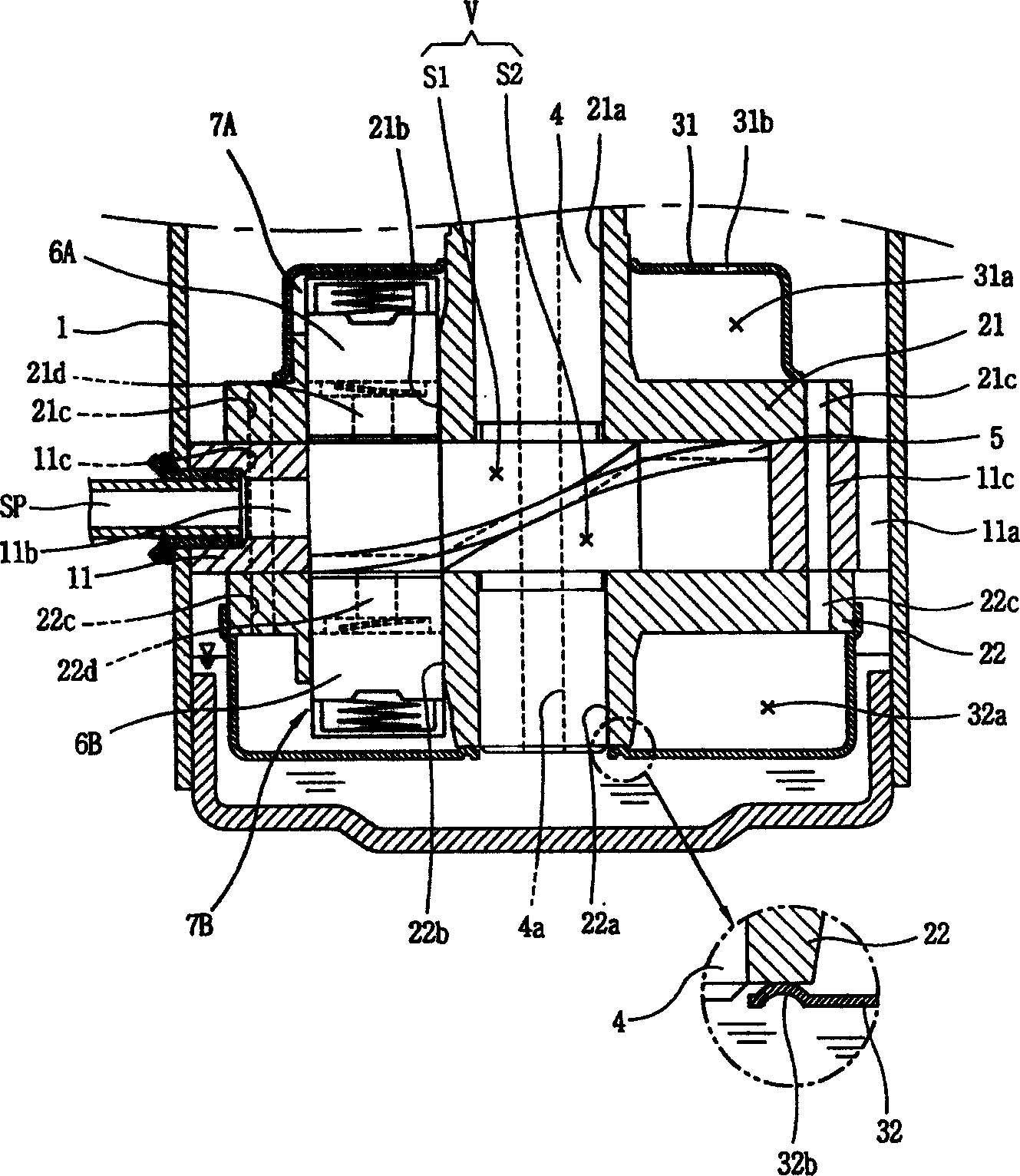

Exhaust gas quide structure of closed compressor

InactiveCN1532409AReduce vibration and noiseShorten the lengthRotary piston pumpsRotary piston liquid enginesManufacturing cost reductionEngineering

The present invention discloses a kind of gas exhaust guiding structure of closed compressor, and features that the lower bearing board has at least one formed first gas flow path, the upper board has at least one formed third gas flow path, and the cylinder wall in the engine recovering flow path side has at least one formed second gas flow path communicated with the first gas flow path and the third gas flow path, so that the compressed gas from the lower silencer may be exhausted to the inner cavity of compressor casing through the first gas flow path, the second gas flow path and the third gas flow path successively. The advantages of the present invention include reduced length of rotating compressor shaft, reduced input power, lowered manufacture cost and decreased vibration noise of compressor.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

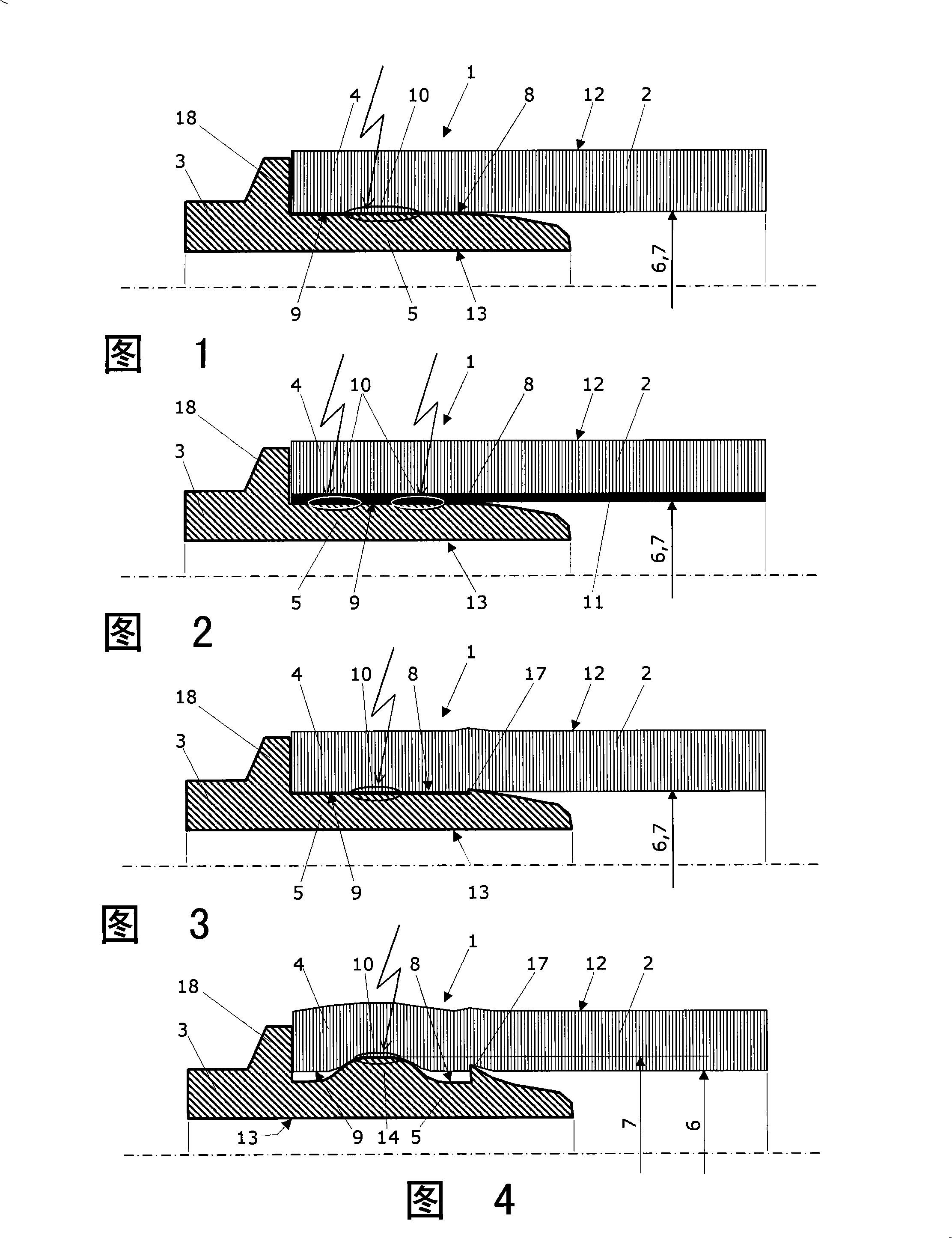

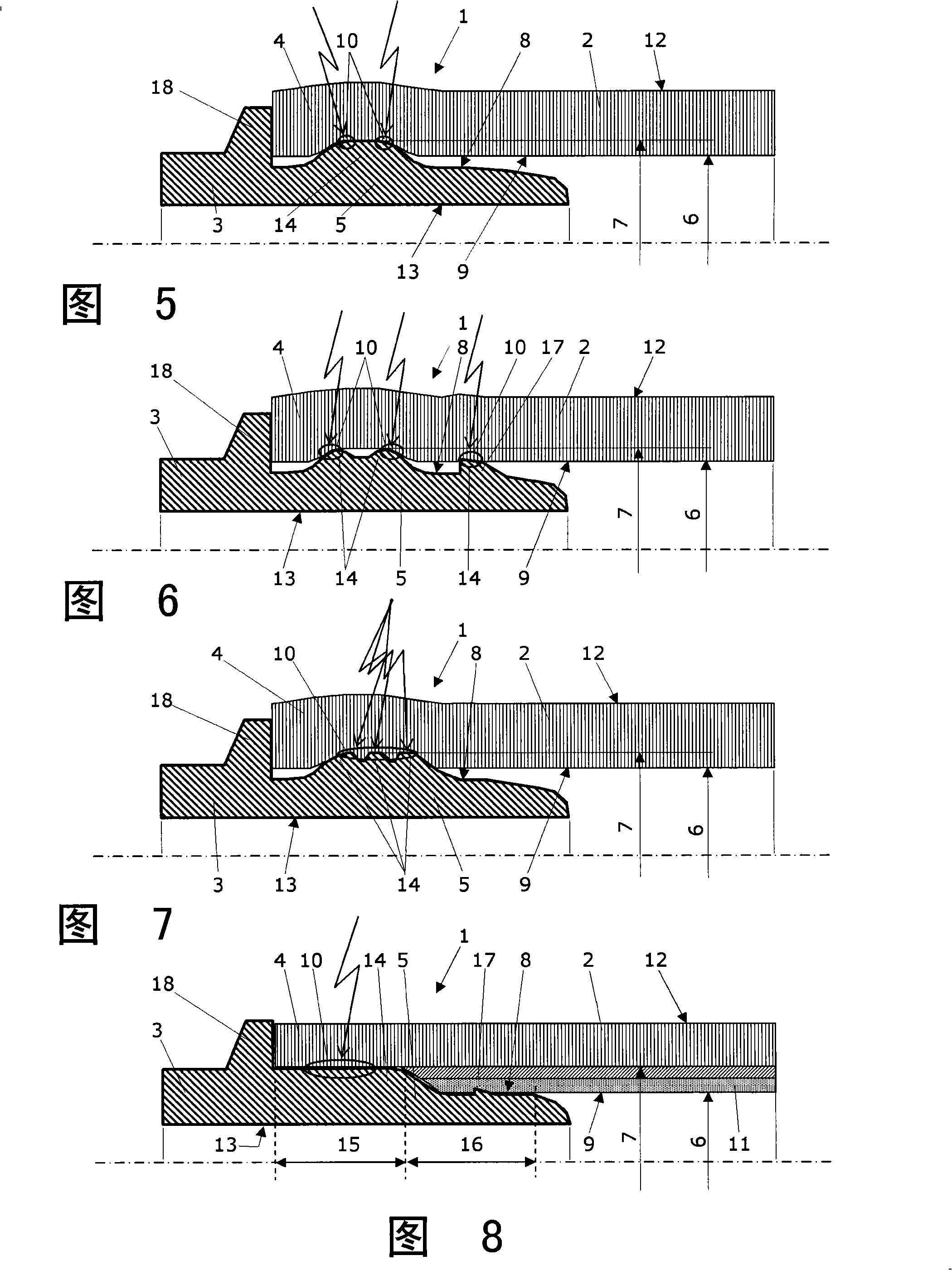

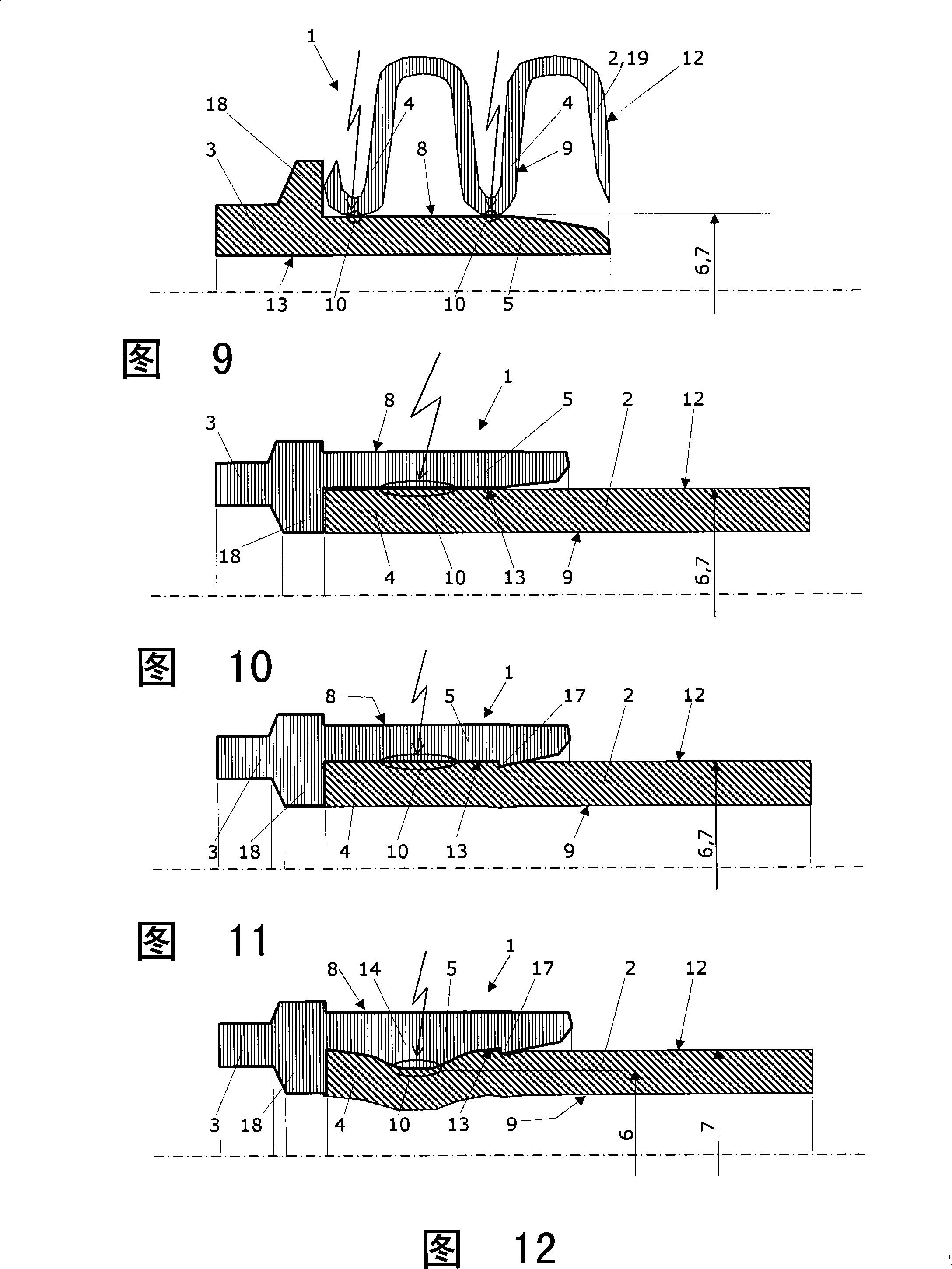

Laser welding connection of plastic pipe and other plastic parts

InactiveCN101332672AImprove the tightnessIncrease joint tear forceDomestic articlesPipe connection arrangementsPolyamideLaser beams

Owner:EHMS PARTEN

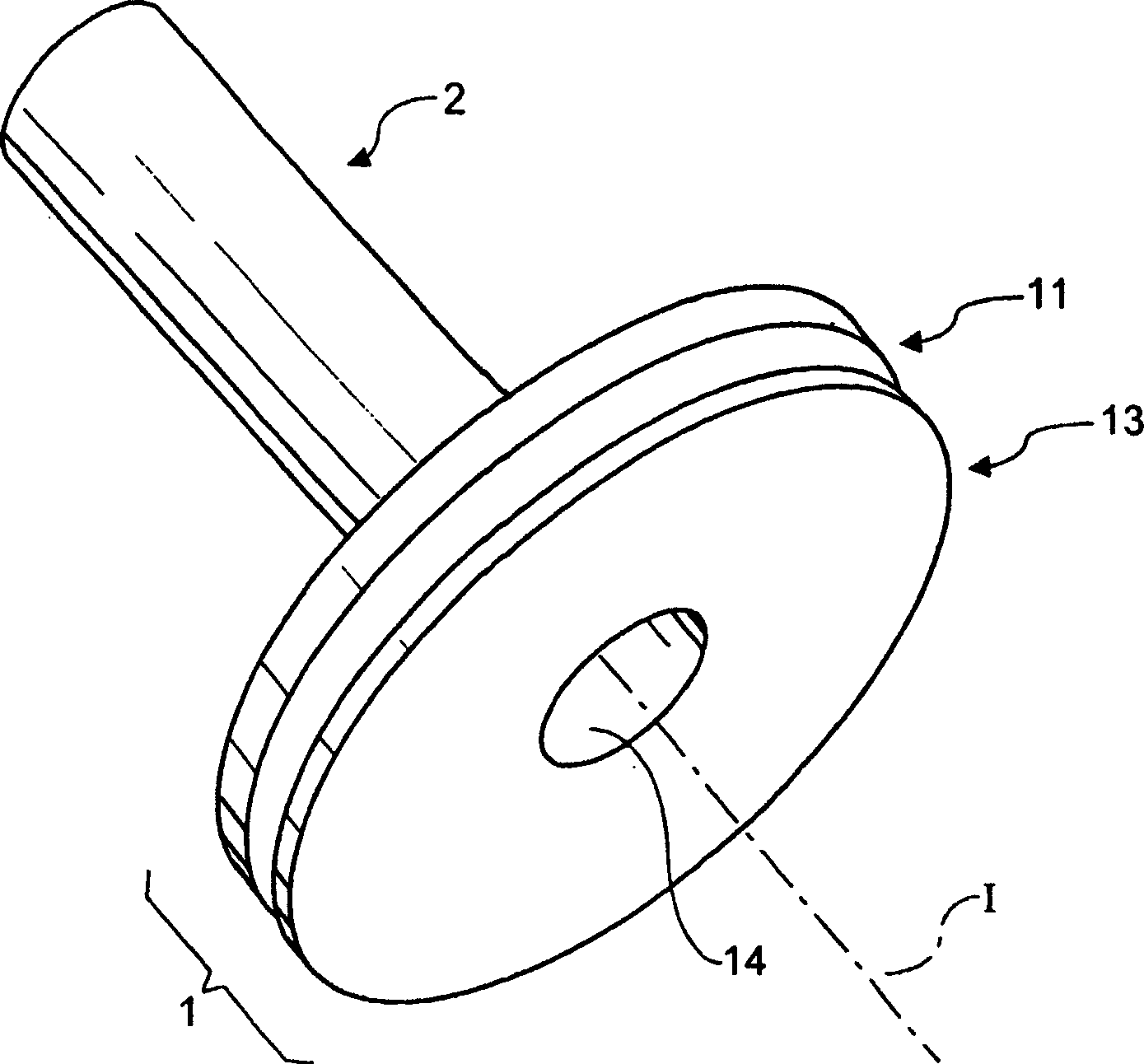

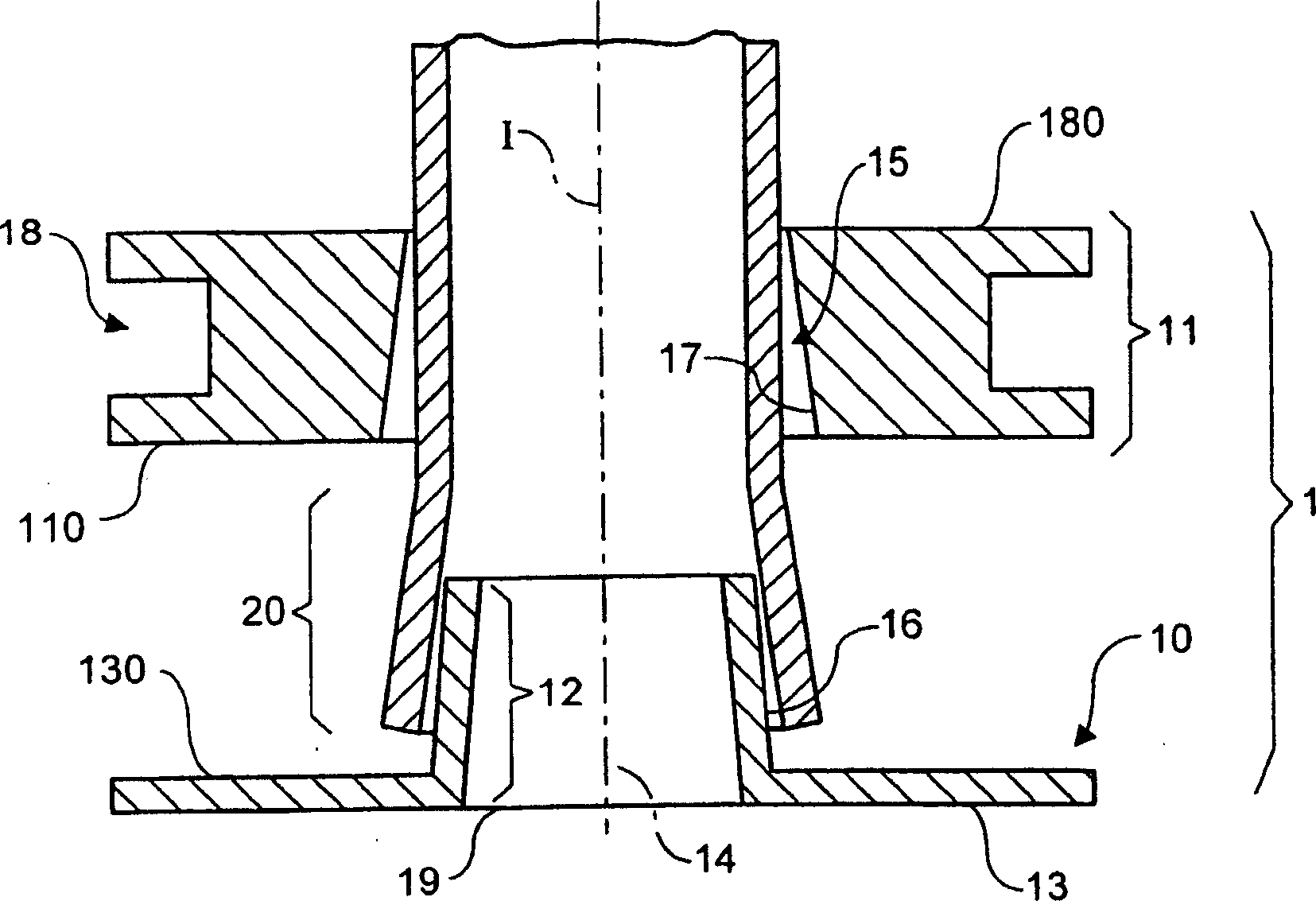

Hose fitment for disposable food container

InactiveCN1666057AFew contact surfacesImprove the tightnessPipe couplingsLiquid transferring devicesEngineeringMechanical engineering

Owner:SOC DES PROD NESTLE SA

Convex-sided low-altitude heat-insulating board, flattened low-altitude heat-insulating board and preparation methods thereof

The invention provides a low-altitude heat-insulating board which comprises an upper heat-insulating board and a lower heat-insulating board, wherein the peripheries of the upper heat-insulating board and the lower heat-insulating board are welded together through using a welding flux, a closed low-altitude layer is formed between the upper heat-insulating board and the lower heat-insulating board, the upper heat-insulating board and the lower heat-insulating board are flattened heat-insulating boards or convex-sided heat-insulating boards, and the convex side of each convex-sided heat-insulating board faces outwards. The production method of the low-altitude heat-insulating board provided by the invention is simple in process, and the prepared low-altitude heat-insulating board overcomes the defects of the existing heat-insulating board, so that the tightness of a low-altitude layer of the low-altitude heat-insulating board can be effectively guaranteed, the service life of the low-altitude heat-insulating board is prolonged, and the strength and heat insulation, sound insulation and fire prevention properties of the low-altitude heat-insulating board can be increased.

Owner:戴长虹

Vacuum isolating valve

ActiveCN101604609AReduce frictionReduce wearOperating means/releasing devices for valvesElectric discharge tubesMoving parts

Owner:KYKY TECH

Preparation method of easy-to-clean anti-fouling water-based automobile leather treating agent

InactiveCN111410903AImprove product qualityPrevent leakageAntifouling/underwater paintsRotary stirring mixersPolymer scienceEmulsion

The invention relates to a preparation method of an easy-to-clean anti-pollution water-based automobile leather treatment agent. The preparation method comprises the following steps: preparing the following reaction raw materials in parts by weight for later use: 30-50 parts of waterborne polyurethane resin, 5-20 parts of self-extinction resin, 1-3 parts of a leveling agent, 1-5 parts of a wax emulsion, 1-5 parts of a hand feeling agent, 1-5 parts of silicon dioxide extinction powder, 1-3 parts of a thickener and 30-50 parts of deionized water; adding 30-50 parts of waterborne polyurethane resin and 5-20 parts of self-extinction resin into a reaction kettle, increasing the temperature to 60-90 DEG C at the rotating speed of 50-80 rpm, and performing heat preservation for 10-50 min; adding1-5 parts of silicon dioxide matting powder, increasing the rotating speed to 85-100 rpm, and performing stirring for 10-50 minutes; adding 1-3 parts of a leveling agent, 1-5 parts of a wax emulsion,1-5 parts of a feeling agent and 1-3 parts of a thickener, increasing the rotating speed to 105-120 rpm, and performing stirring for 10-50 min; and adding 30-50 parts of deionized water, performing stirring for 20-40 minutes, and performing cooling and discharging. The preparation process is simple, and the preparation process is stable.

Owner:浙江新诺高分子材料有限公司

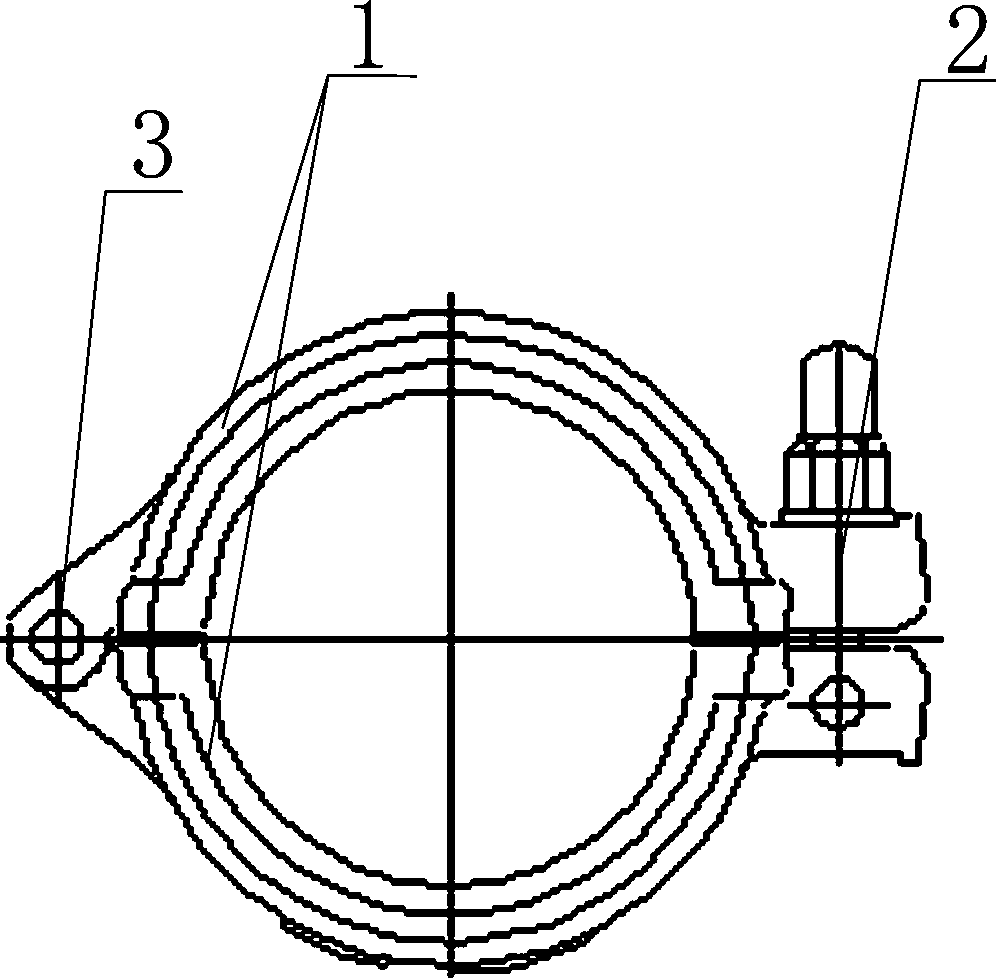

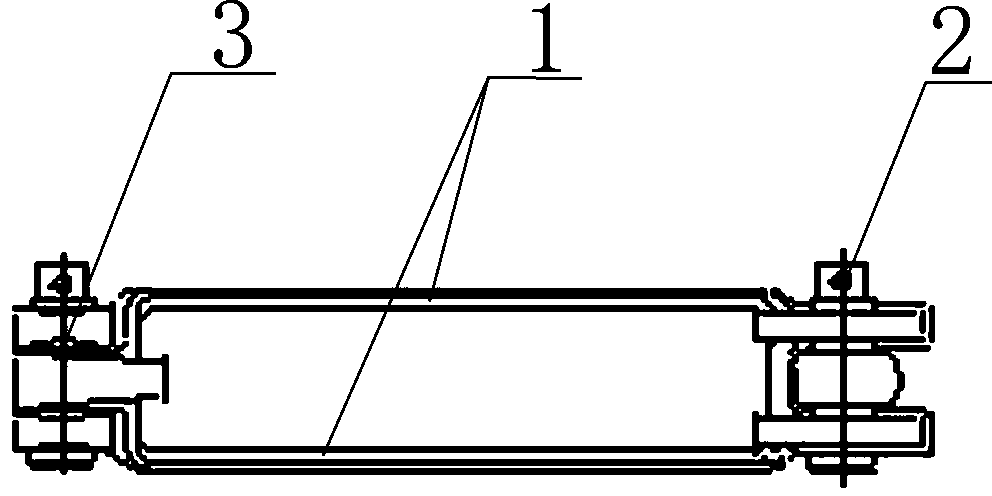

Forging hoop

InactiveCN103807529AFlexible disassemblyImprove the tightnessSleeve/socket jointsEngineeringHeat treated

The invention discloses a forging hoop. One end of one of two semicircular fixed rings is hinged to one end of the other semicircular fixed ring, and the other ends of the two semicircular fixed rings are fixed by a fastening bolt; one end of one semicircular fixed ring and one end of the other semicircular fixed ring are respectively provided with a hole; a pin penetrates through the holes; the two semicircular fixed rings rotate by adopting the pin as a rotary shaft. The fastening bolt comprises a screw rod and a nut, the screw rod penetrates through the other ends of the two semicircular fixed rings and is fixed by the nut, and the two semicircular fixed rings form a hollow circle after being fixed. The forging hoop disclosed by the invention has the advantages that the high-quality steel is adopted, a high-tech heat treatment technology is utilized, and one-time forging and forming is achieved; a product is flexible in disassembly and assembly, high in sealing degree and long in service life.

Owner:宜都市万鑫精密铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com