Laser welding connection of plastic pipe and other plastic parts

A plastic parts, laser welding technology, applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, household components, etc., can solve the problem of removing the mandrel, etc., to strengthen the welding seam and/or welding point, increase joint tear Crack force, increase the effect of fastening degree

Inactive Publication Date: 2008-12-31

EHMS PARTEN

View PDF9 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method is used to weld straight pipes or tubular bodies to heads or plastic parts, but has the disadvantage that the m

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

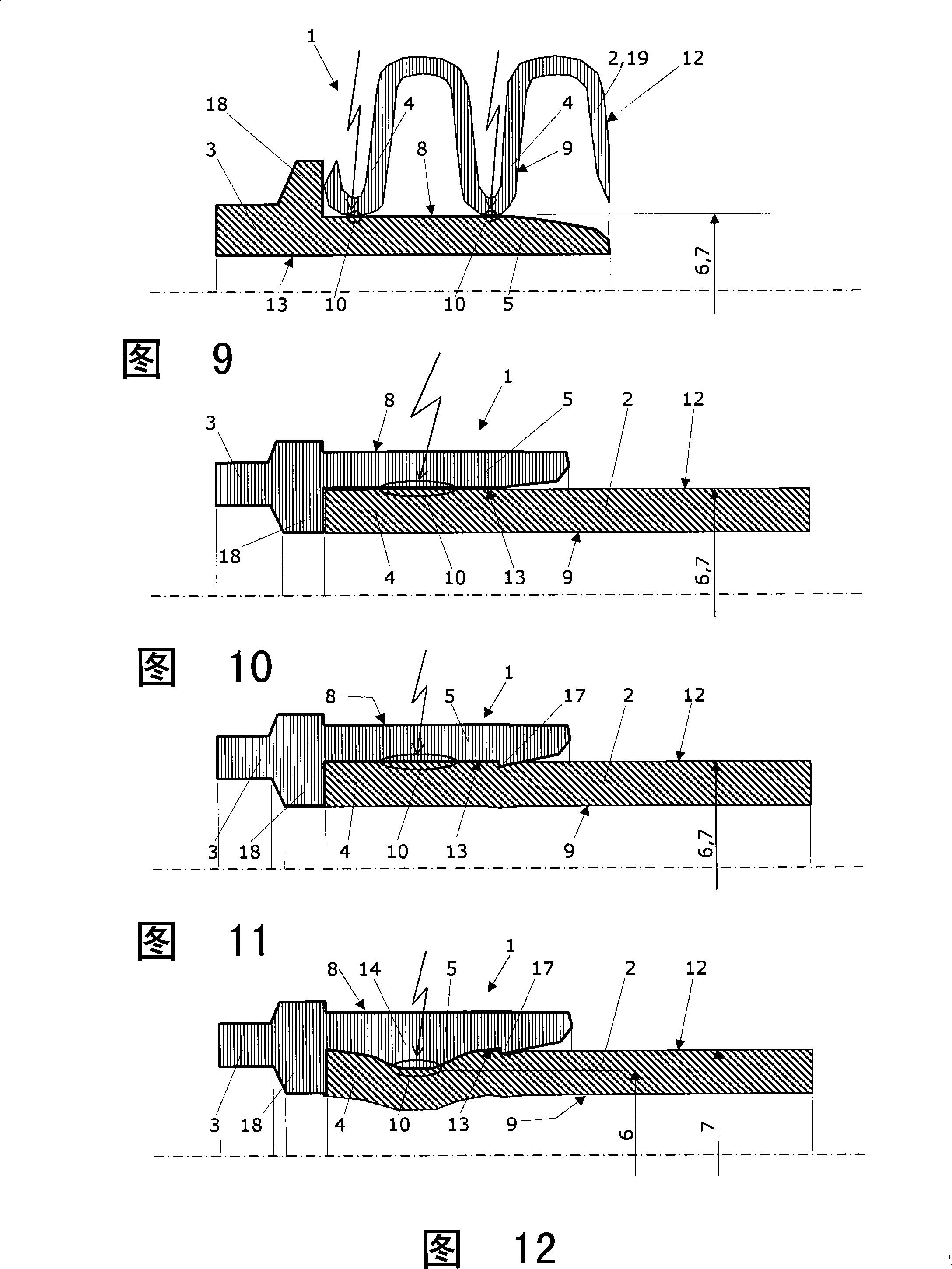

The present invention relates to a laser welding method for establishing connection of plastic pipe (2) with plastic part (3), the method involves sticking together an end (4) of a plastic pipe (2) with an end (5) of a plastic part (3) in an overlapping manner, where the ends respectively exhibit an inner dimension (6) and/or outer dimension (7) in the area of connection of the plastic pipe with the plastic part, largest outer dimension of the ends lying inside the area of connection is larger than lowest inner dimension of the ends lying outside the area of connection, a contact pressure is formed between the ends, thus heat contact each other in the laser welding process is reinforced. According to the invention, the laser welding method is characterized in that installation ends (4) of the plastic pipe (2) and the plastic part (3) is mainly composed of polyamide without core shaft fixation, simultaneously the laser beam for welding is guided around the fixed pipe contact.

Description

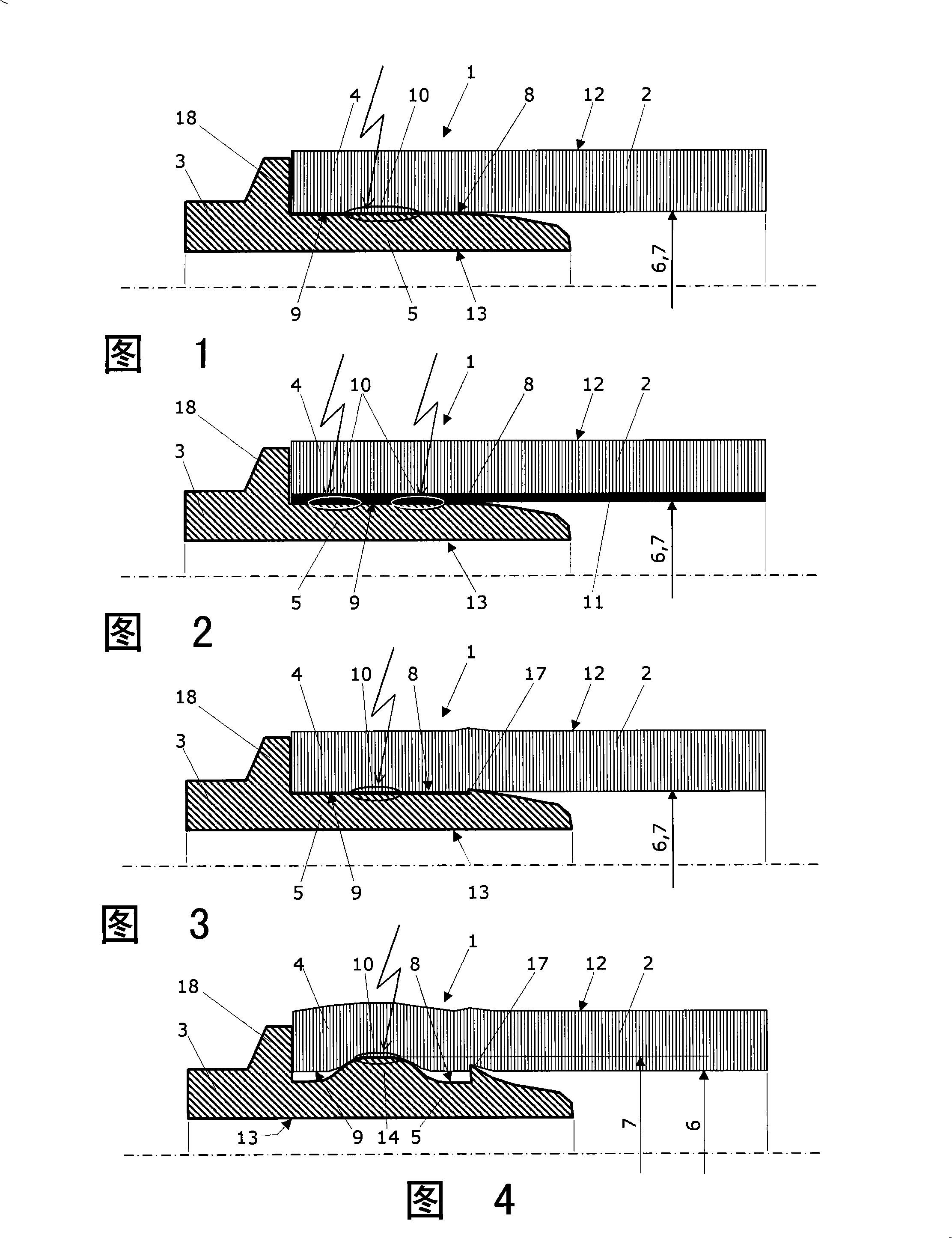

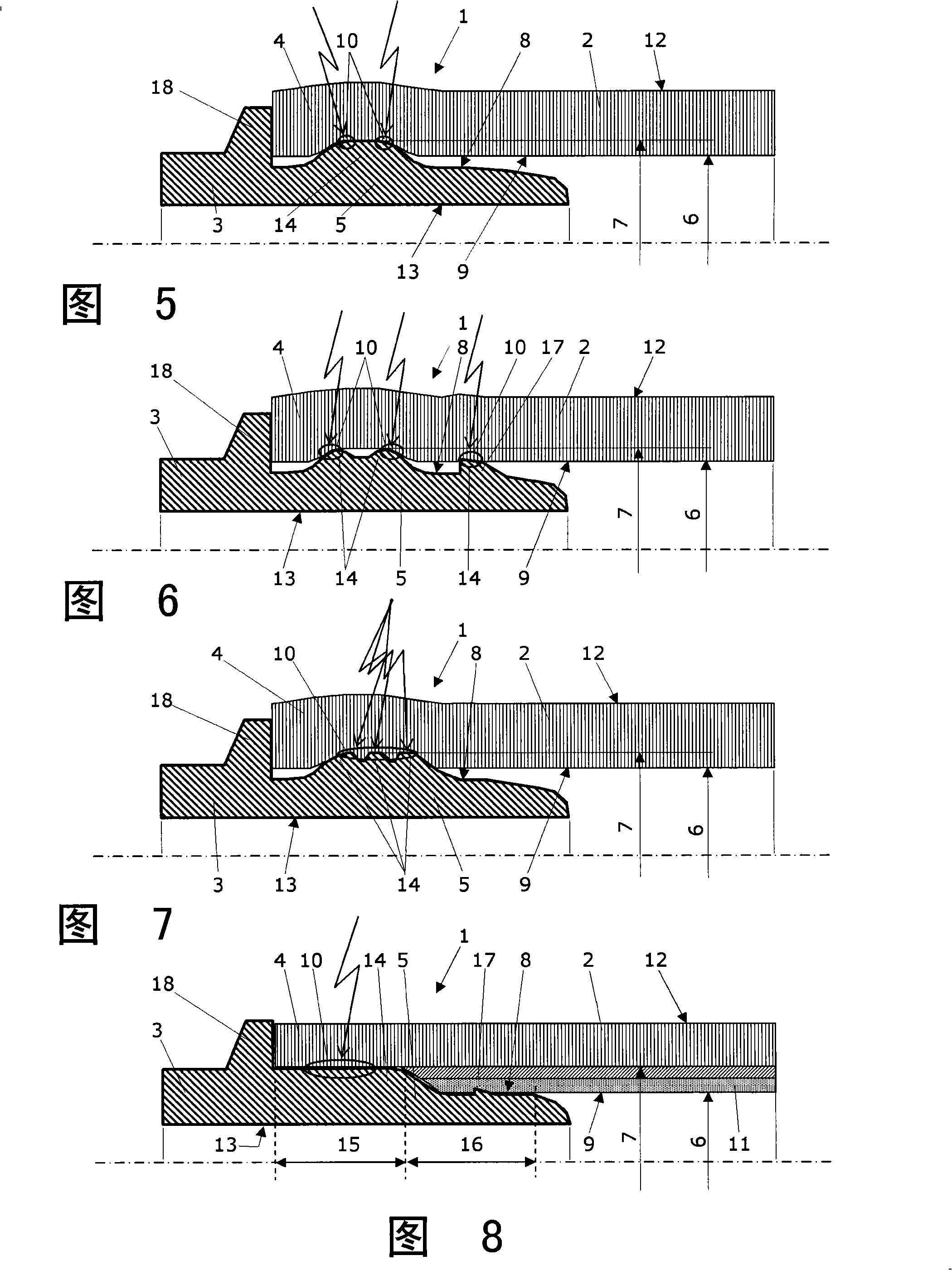

technical field [0001] The invention relates to a laser welding method for preparing a connection of a plastic pipe to another plastic part, wherein one end of the plastic pipe is mounted overlappingly on the tubular end of the other plastic part, the end of the plastic pipe and the end of the plastic part being in the area of the connection have inner or outer dimensions respectively, and the largest outer dimension of the inner end in the connection area is larger than the smallest inner dimension of the outer end in this area, thereby forming a contact pressure between the two ends, which strengthens mutual thermal contact during laser welding. Background technique [0002] Connections between plastic pipes and other plastic parts are known, for example, in the automotive industry. In particular fuel lines, which must be connected in a sealed and safe manner to the fittings and / or joints of the plastic pipes used to transport the fuel. Due to the increased ethanol cont...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C65/16B29K77/00

CPCB29C65/1616B29C65/1635B29C65/1677B29C65/1683B29C65/58B29C65/72B29C65/8207B29C66/1122B29C66/1222B29C66/1224B29C66/21B29C66/232B29C66/30223B29C66/5344B29C66/55B29C66/612B29C66/71B29C66/7212B29C66/723B29C66/73921B29C66/8262B29K2077/00B29K2101/12B29K2105/12B29K2105/126B29K2305/12B29K2307/00B29K2995/0005B29K2995/0027B29L2009/00B29L2023/18B29L2031/7172F16L47/02B29C65/00B29K2309/08B29C65/14B29C65/16

Inventor T·恩贝勒R·凯特尔W·卡吉

Owner EHMS PARTEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com