Vacuum isolating valve

A technology for isolating valves and vacuum, which is applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of high maintenance and repair costs, damage to the isolation effect, and short service life of electron microscopes, and achieve good isolation effects and safe and reliable isolation , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

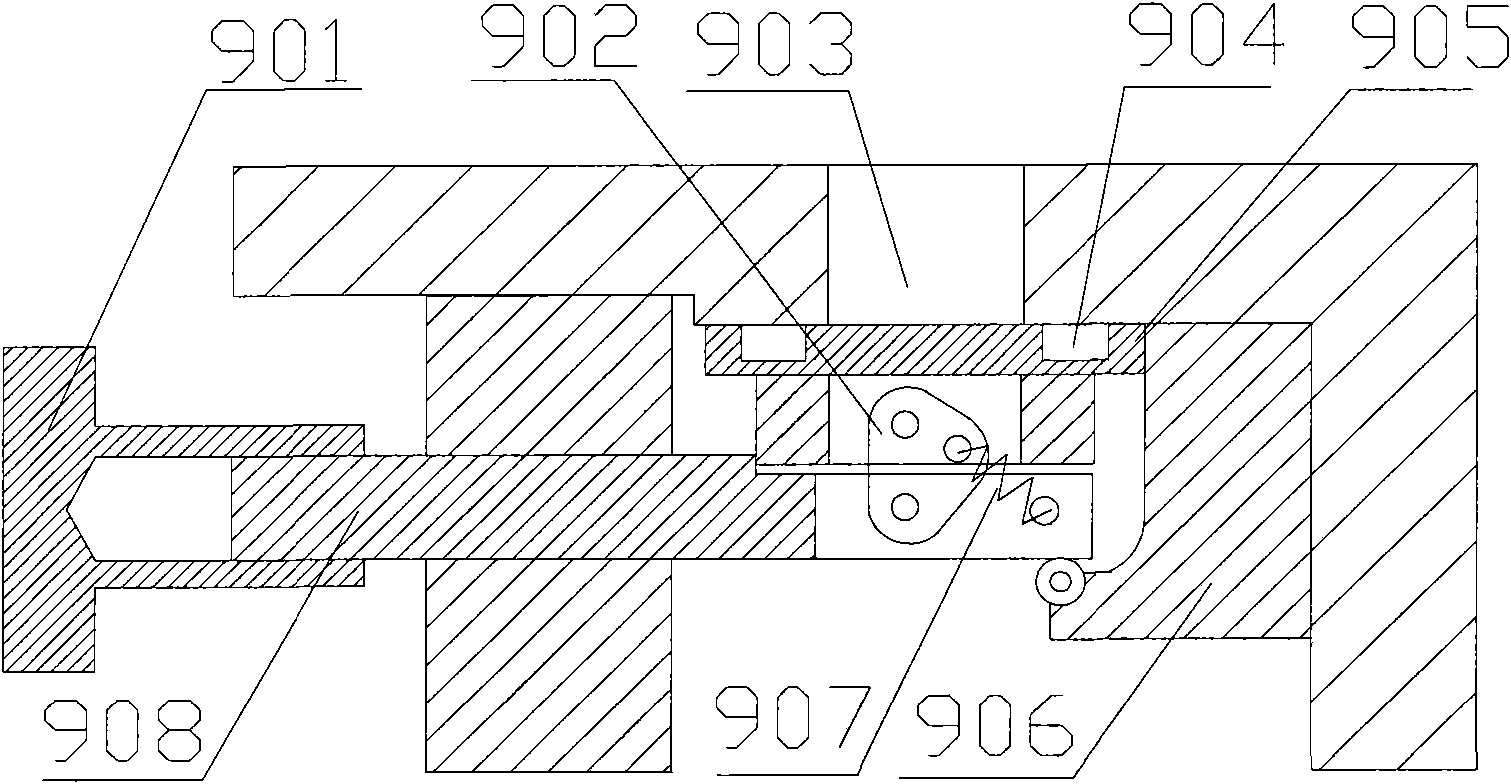

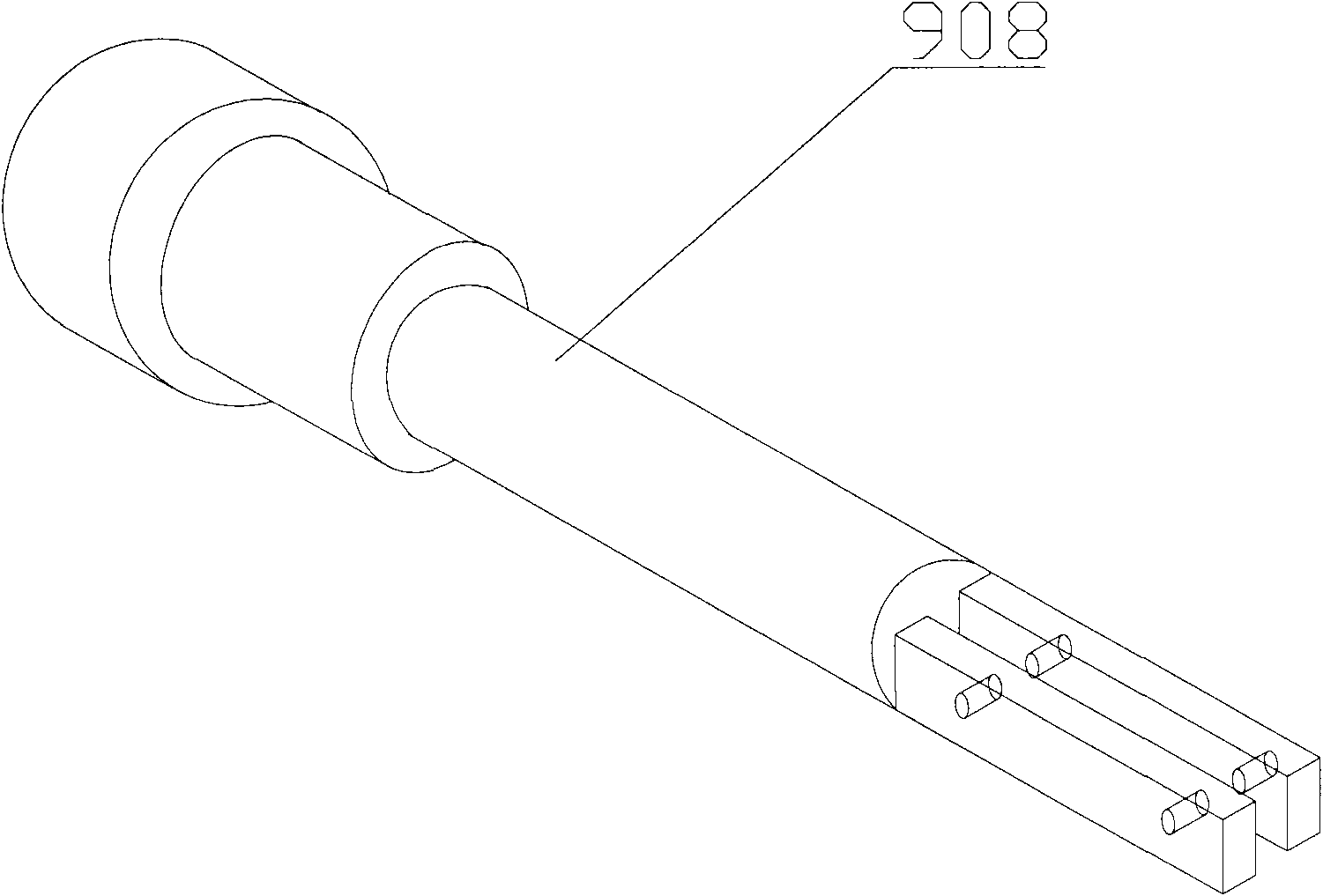

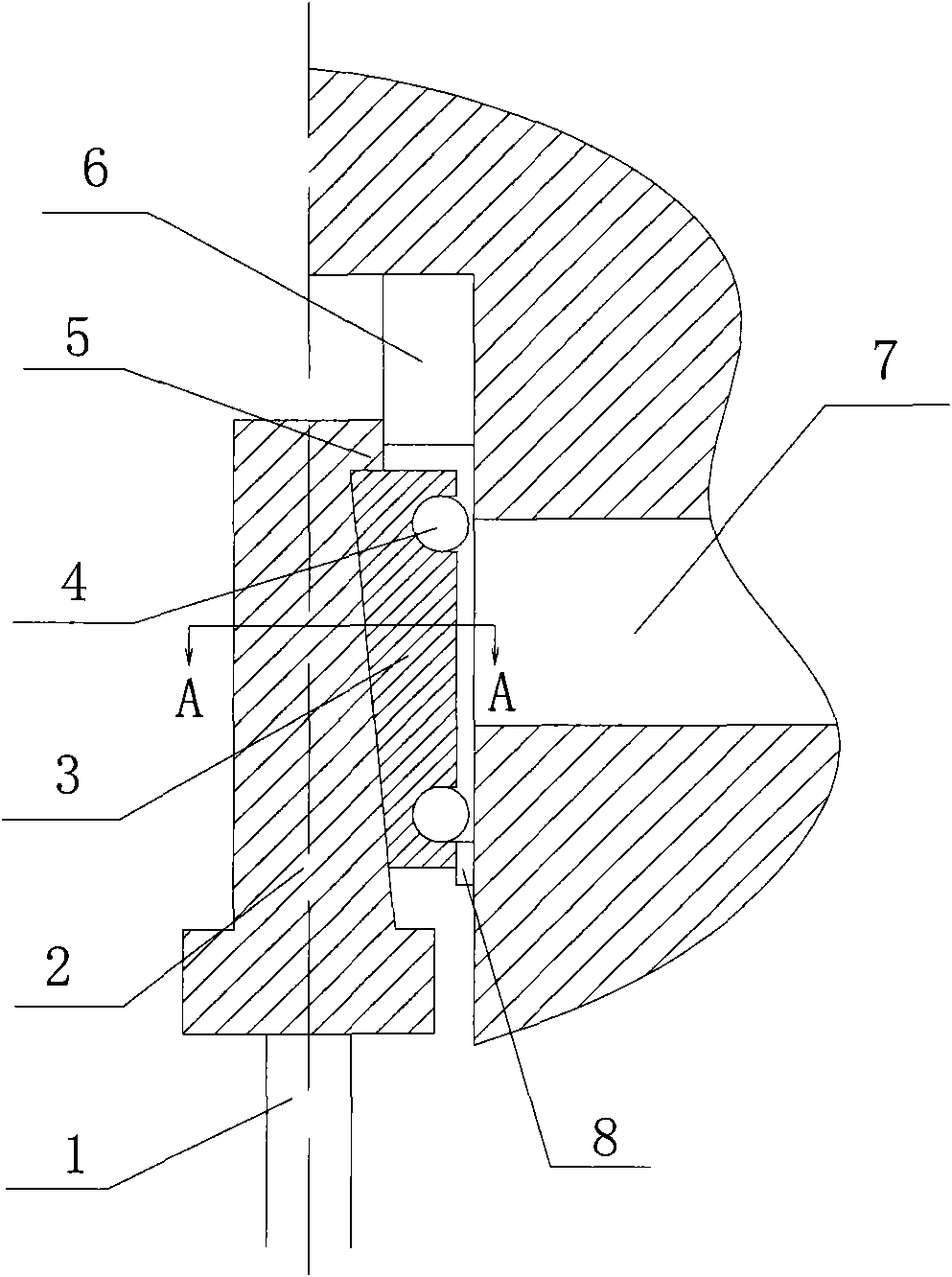

[0031] Such as image 3 As shown, the main components of the vacuum interrupting valve of the present invention include a drive rod 1, a drive mechanism 2 with a wedge-shaped slope, a stopper 5 arranged at the front end of the drive rod 1 along the slope, a sealing plate 3, and a first stopper. Advance the limit stopper 6, and the second limit stopper is the retreat limit stopper 8. The drive mechanism 2 is a wedge-shaped component with a slope, the extended surface of the slope of the drive mechanism 2 intersects the axis extension line of the drive rod, wherein the end with a larger axial distance from the slope to the drive rod 1 is its high end, and the end from the slope to the drive rod 1 The side with the smaller axis distance is its lower end. Such as image 3 As shown, the low end of the slope is close to the front end of the drive rod 1, and its low end is close to the tail end of the drive rod 1. The sealing plate 3 is slidably arranged on the slope, such as Fi...

Embodiment 2

[0036] Such as Figure 7 Shown is the cross-sectional view of this embodiment, which is different from the first embodiment in that the vacuum isolation valve of this embodiment adopts two-way sealing, and the driving mechanism 2 at the front end of the driving rod 1 is a wedge-shaped structure with two opposite slopes Correspondingly, the vacuum isolation valve of this embodiment further includes a second sealing plate 12 on which a sealing ring 4 is also arranged. The second sealing plate 12 is arranged opposite to the sealing plate 3 . The extended surfaces of the two slopes all intersect with the extension line of the drive rod 1, and the low end is close to the front end of the drive rod 1, and the high end is close to the tail end. Different from the previous embodiments, in this embodiment, the slope of the driving mechanism 2 and the two sealing plates are slidably connected through the bearing 9 , and a tension spring 11 is provided between the sealing plate 3 and th...

Embodiment 3

[0041] Such as Figure 8 Shown is a partial cross-sectional view of this embodiment. The difference from the previous two embodiments is that this embodiment uses a cylinder to drive the drive rod 1 to move. The vacuum isolation valve components of this embodiment also include components such as a cylinder 23 and a piston 24. . Wherein the piston 24 is installed in the cylinder 23, and the cylinder 23 is divided into a cylinder chamber 25 and a cylinder chamber 28, and the cylinder chamber 25 and the cylinder chamber 28 are connected with the pneumatic interface 26 and the pneumatic interface 29 respectively; On the piston 24, in order to ensure the airtightness between the two cylinders, a sealing ring 31 is also installed on the piston 24.

[0042] The difference between this embodiment and the second embodiment is that it also includes a positioning block 14 for guiding the sealing plate 3 and the second sealing plate 12 to complete the vacuum channel isolation and opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com