Patents

Literature

741results about How to "Increase tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

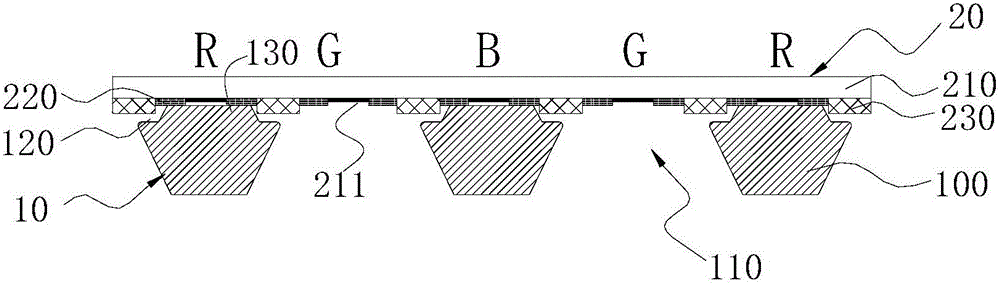

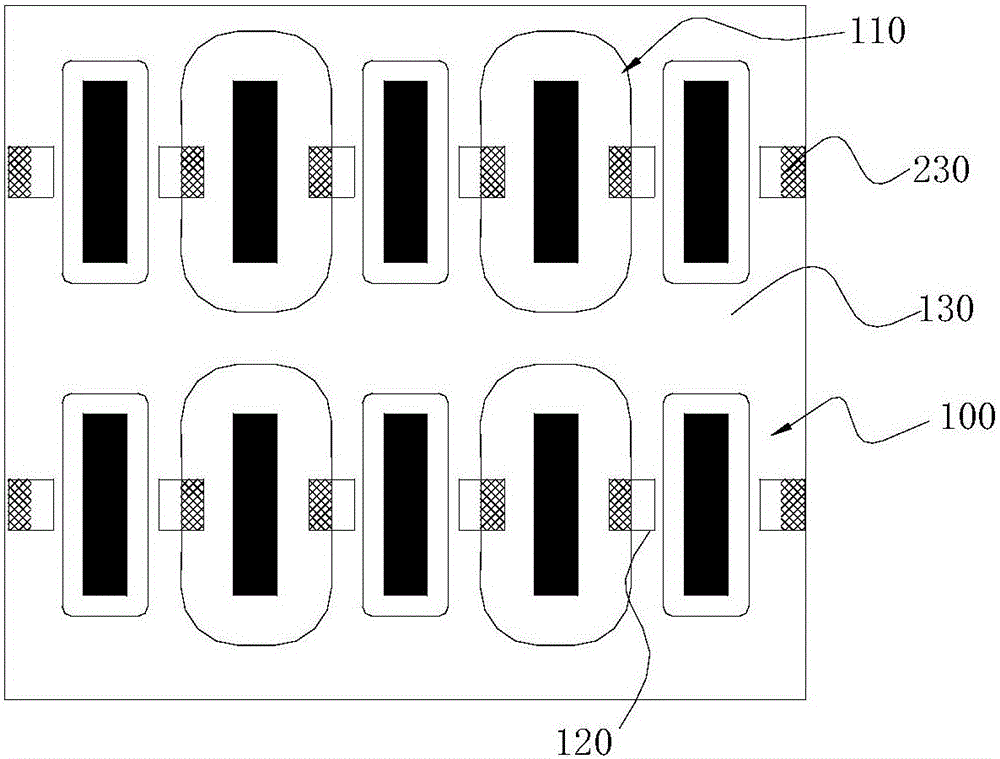

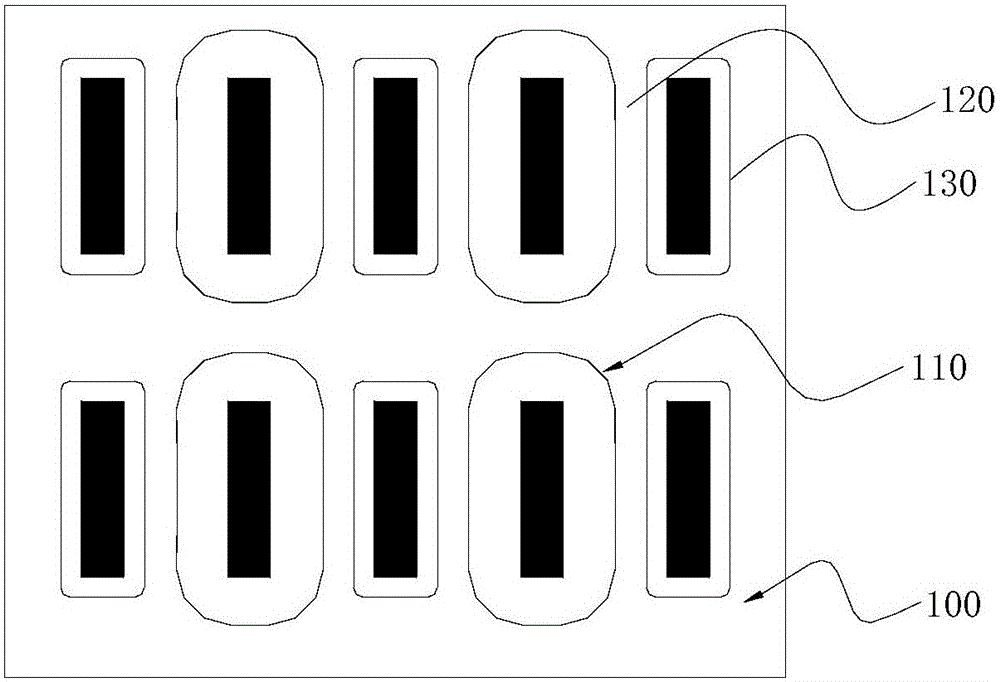

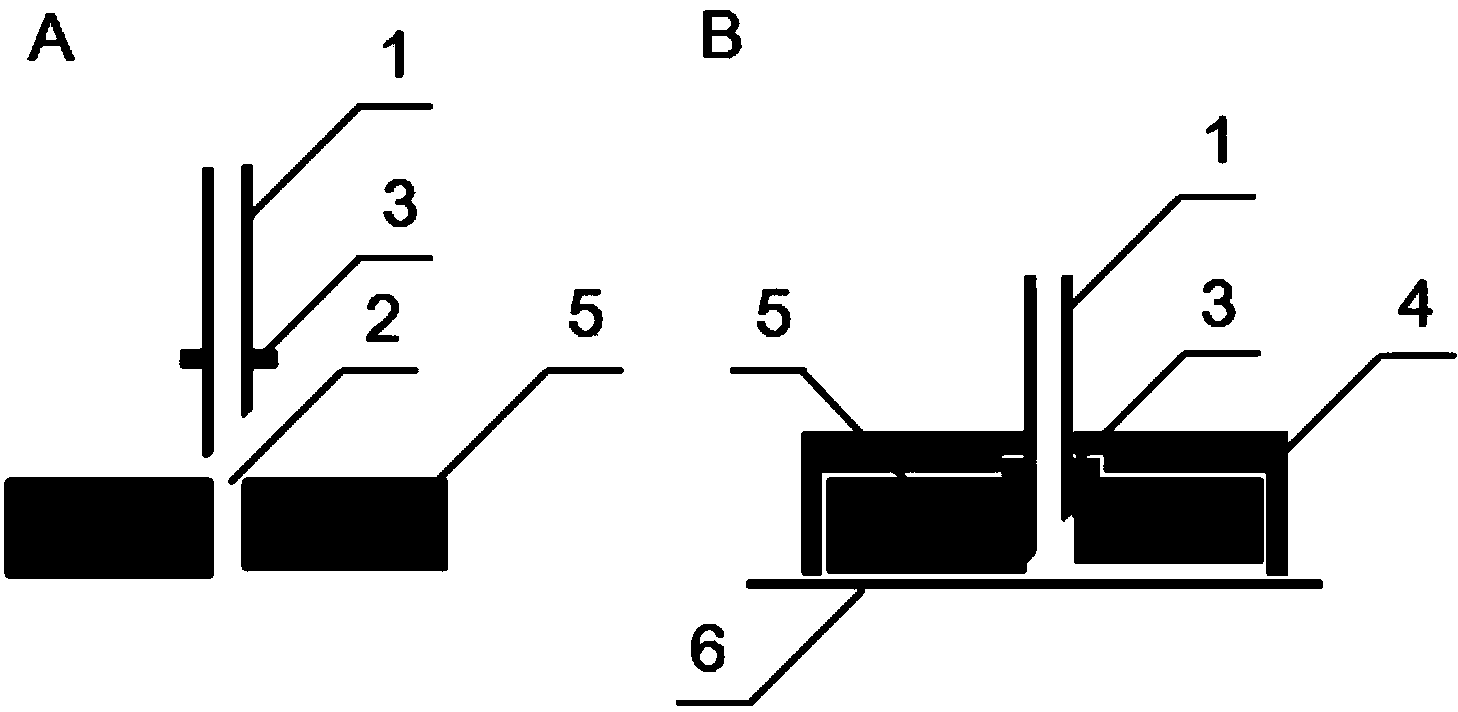

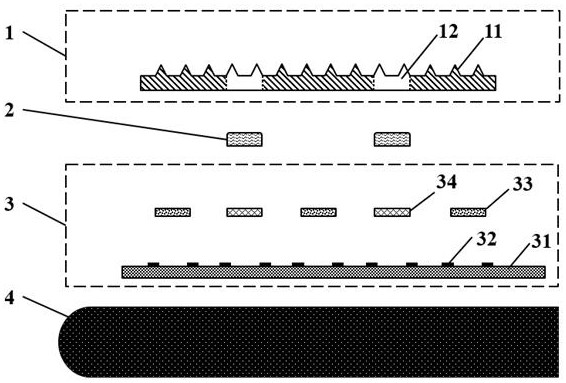

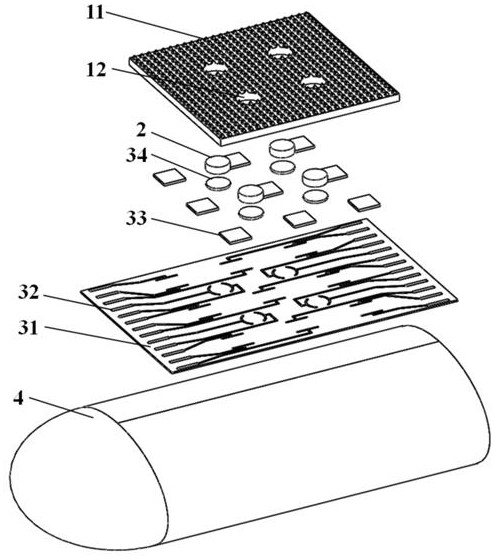

Evaporation masking plate and manufacturing method thereof

ActiveCN105154823AEliminate gapsIncrease tightnessVacuum evaporation coatingSolid-state devicesColor mixingThinning

The invention discloses an evaporation masking plate. The evaporation masking plate is used for evaporating a pixel region on a display panel. The display panel comprises a substrate, a pixel limiting layer arranged on the substrate, and cushion blocks arranged on the pixel limiting layer. The substrate is divided by the pixel limiting layer into a plurality of sub-pixel regions, and the sub-pixel regions include the evaporation sub-pixel regions and the non-evaporation sub-pixel regions. The evaporation masking plate comprises a masking plate body and evaporating holes formed in the masking plate body, and the evaporating holes penetrate the masking plate body. A thinning region is arranged at the portion, corresponding to the cushion blocks on the display panel, of the masking plate body so that the thickness of the position, corresponding to the cushion blocks on the display panel, of the masking plate body can be smaller than the whole thickness of the masking plate body. By means of the evaporation masking plate, a gap between the evaporation masking plate and the substrate can be removed, the attachment compact degree can be increased, the color mixing risk can be reduced, and the evaporation quality can be improved.

Owner:TRULY HUIZHOU SMART DISPLAY

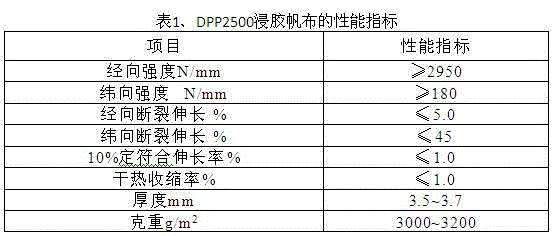

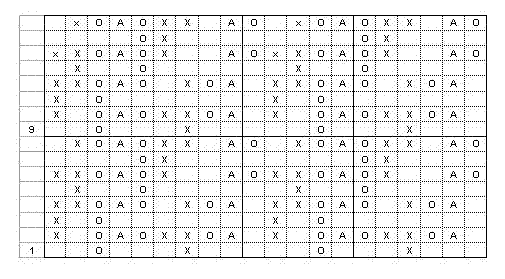

Aramid rubber canvas fabric structure for high-strength conveyor belts and production process of aramid rubber canvas fabric structure

InactiveCN104611819AEasy to weaveGood physical and mechanical propertiesConveyorsMulti-ply fabricsYarnEngineering

The invention discloses an aramid rubber canvas fabric structure for high-strength conveyor belts and a production process of the aramid rubber canvas fabric structure. The aramid rubber canvas fabric structure comprises warps and wefts, aramid materials are adopted in the warps, at least four warps are paved in the belt length direction, nylon industrial yarns are adopted in the wefts which are crisscrossly paved on upper end faces and lower end faces of the warps, the wefts on upper and lower layers are tightly crisscrossly bonded to the warps by adopting bundling yarns, and a canvas fabric structure is obtained after secondary bath gum dipping; the production process includes single-layer canvas knitting, secondary bath gum dipping and reeling. Single-layer structures of the warps adopting the aramid materials and the weft adopting the nylon materials are knitted through bundling yarns, the high-strength conveyor belts with the strength higher than 2500N / mm are produced after secondary bath gum dipping, mechanical physical properties of the conveyor belts are improved, layer reduction and weight reduction of the conveyor belts are realized during the production process, the conveyor belts are adaptively high strengthened, less layered and lightweight, energy consumption is reduced, the production process is further simplified, and production efficiency is higher.

Owner:浙江尤夫科技工业有限公司

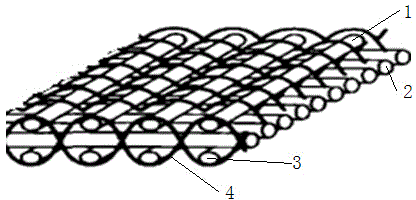

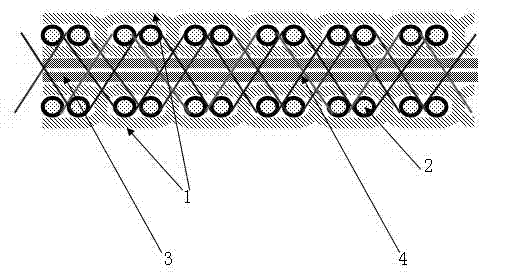

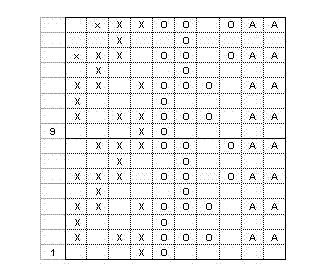

Dipped canvas fabric structure in three-dimensional structure for heavy-duty conveyor belt and production process thereof

ActiveCN102212917ASolve production technical problemsGood physical and mechanical propertiesFibre treatmentTwo or more solvent application treatmentPolyesterEngineering

The invention discloses a dipped canvas fabric structure in a three-dimensional structure for a heavy-duty conveyor belt and a production process thereof. The dipped fabric structure is characterized in that an upper layer and a bottom layer adopt ground-facing warps (1) in the plain weave structure and weft (2) interwoven with the ground-facing warp, a straight warp (3) in the straight warp structure is utilized as an intermediate layer, a bundling warp (4) is connected with the weft (2), and the upper layer, the intermediate layer, the bottom layer and the bundling warp form the three-dimensional structure. The production process comprises the following processes: the process of weaving a fabric on a machine: adopting double warp shafts to send a warp woven cloth; and the process of stipulating a dipping formula and preparing, wherein a dipping solution is a mixture of an RF (resorcinol-formaldehyde) resin water solution generated by virtue of condensation polymerization of hydroxyphenol and formaldehyde and VP (vinyl pyridine) latex (L), the total content of solids is 18-22%, the pH value is 9-11, and the ratio of the RF to the L is (1:5)-(1:7). Polyester dipped canvas in the three-dimensional structure is especially applicable to production of the heavy-duty rubber conveyor belts and has the characteristics of tear resistance, puncture resistance and impact resistance.

Owner:浙江尤夫科技工业有限公司

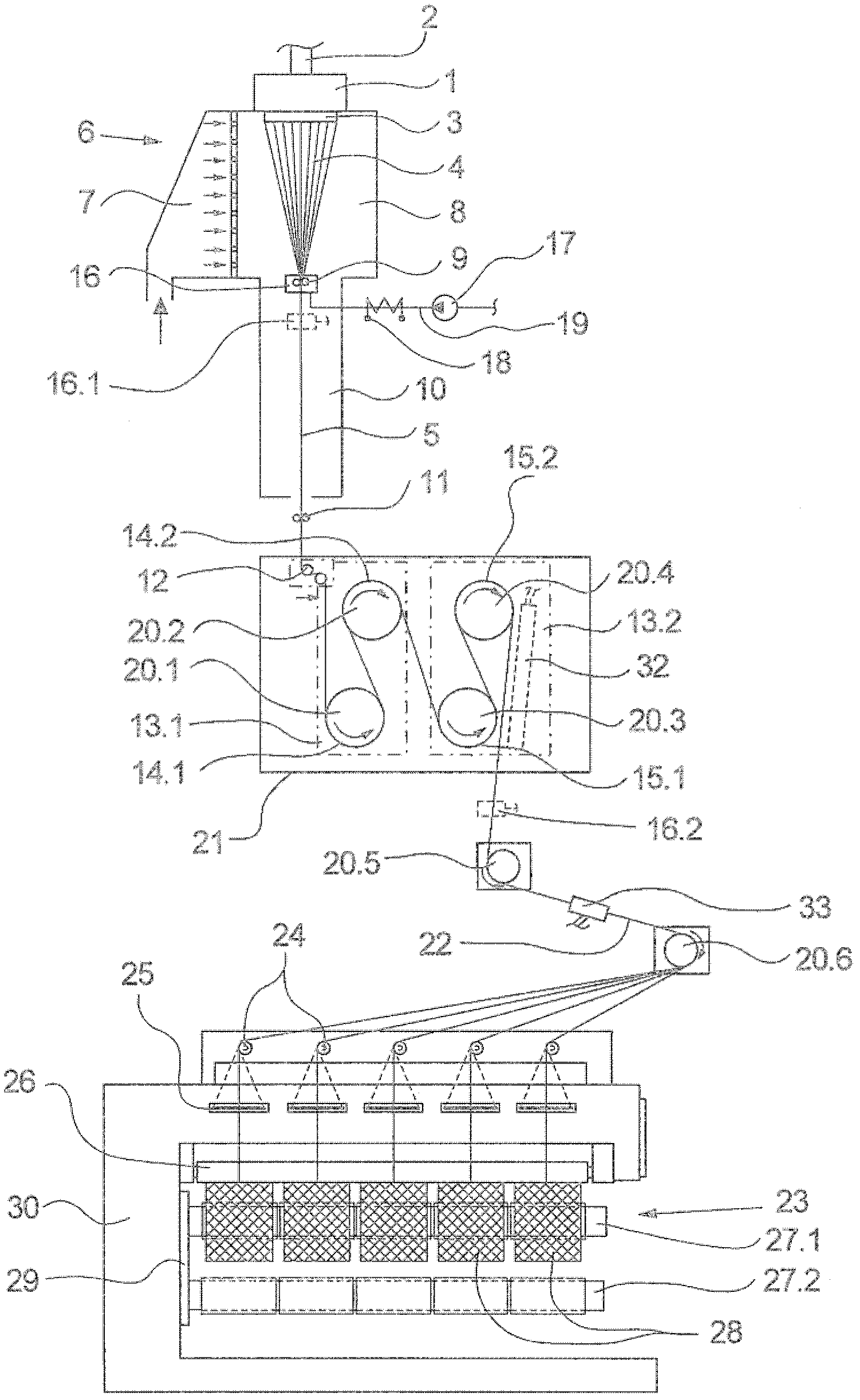

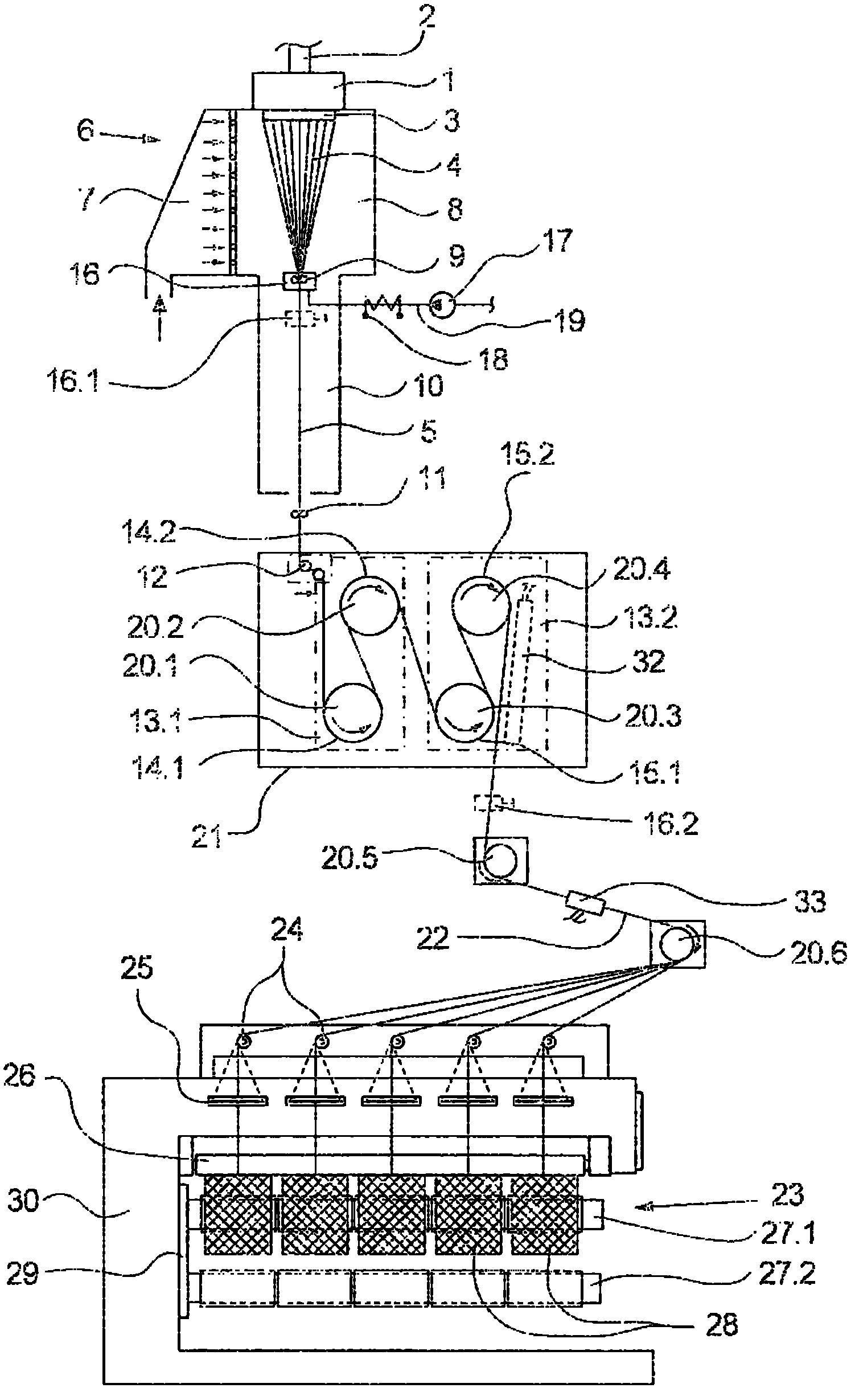

Method for melt-spinning, drawing, and winding a multifilament thread and a device for performing the method

ActiveCN102471936ACompact Stretch and RelaxImprove thread tightnessArtificial filament physical treatmentStretch-spinning methodsWater contentMelt spinning

The invention relates to a method for melt-spinning, drawing, and winding a multifilament thread to form a fully-drawn yarn and to a device for performing the method. First, a plurality of filaments are extruded from a thermoplastic melt, cooled to a temperature below the glass transition temperature of the thermoplastic material, and joined to form a filament bundle by supplying a preparation oil having a water content of at most 8%. Then, the filament bundle is removed by a simple partial wrapping on optionally heated guiding jackets of several driven galettes at a speed above 1,200 m / min. For drawing and subsequent relaxation, the filament bundle is guided at a drawing speed above 3,500 m / min by a simple partial wrapping on the circumference of further heated guiding jackets of driven galettes. For this purpose, the device according to the invention comprises two galette groups having several driven galettes, wherein the first galette group guides the filament bundle in order to remove and / or heat the filament bundle by simple partial wrapping and the second galette group guides the filament bundle in order to draw the filament bundle by simple partial wrapping.

Owner:OERLIKON TEXTILE GMBH & CO KG

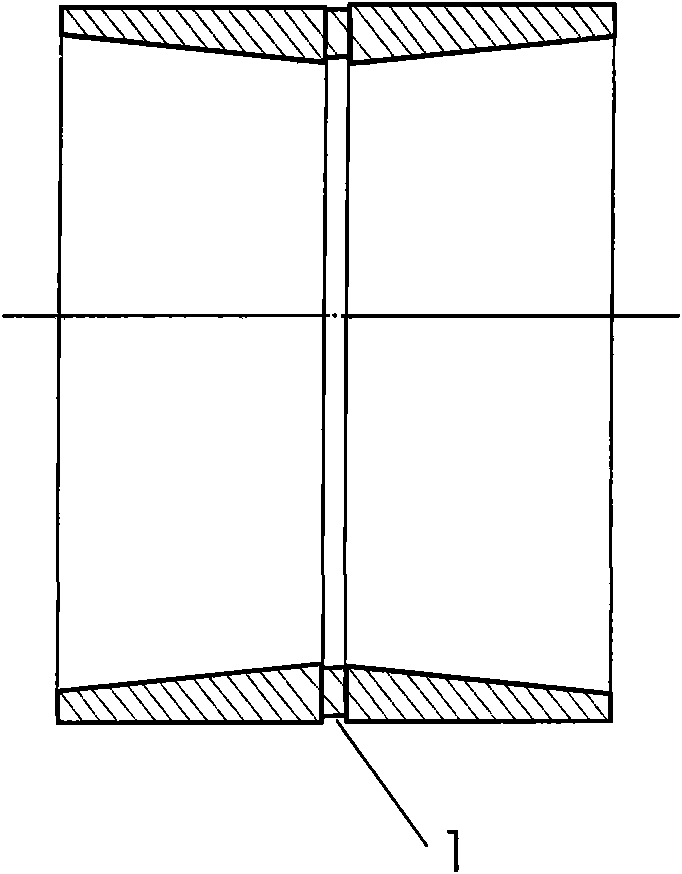

Method for manufacturing outer ring of tapered roller bearing

The invention discloses a method for manufacturing an outer ring of a tapered roller bearing, comprising the following steps of: a: taking a material: setting the quality of the finished product outer ring as M, setting the outer diameter as D, taking a bearing steel pipe with the outer diameter of D1 as the raw material, taking the bearing steel pipe with the quality of M1 and meeting the condition that one half of D is less than or equal to D1 which is less than D, and M1 is equal to 2M plus M2 plus 2M3, wherein M2 is the margin of quality by cutting, and M3 is the margin of quality of single outer ring by grinding process; b: cold rolling: rolling on the bearing steel pipe taken in the step a for obtaining a combined blank of the outer ring; c. cutting: cutting the combined blank at the connecting ring for obtaining a single blank of the two outer rings; d: thermal processing; and e: finish machining: grinding the single blank of the outer ring. The proposal leads the outer ring of the tapered roller bearing to realize the cold rolling for shaping, has the advantages of small material loss, saved energy consumption, simple process, high production efficiency and the like, and simultaneously ensures the product quality.

Owner:NINGXIA QINCHANG ROLLING BEARING MFG

Forging process of bearing ring

ActiveCN104827245AEliminate Inherent DefectsIncrease tightnessBearing componentsEngine componentsPunchingMedium frequency

The invention relates to a forging process of a bearing ring. The process includes following steps that: 1) in first firing, a medium-frequency induction heating furnace is adopted to heat an ingot to 1200 DEG C, dead head pressing, chamfering and sprue filing are performed; 2) in second firing, re-heating, upsetting and drawing out are performed on the machined ingot; 3) in third firing, re-heating, upsetting, rotary flattening, punching and reaming are performed on the machined ingot; 4) in fourth firing, the machined ingot is re-heated, and upsetting is performed on the machined ingot in a mold ring, so that the machined ingot can be in a technique size, the mold is removed, and reaming is performed on the machined ingot, so that the machined ingot can be in a technique size, and total forging ratio is controlled to be larger than 5; 5) groove turning is performed, the machined ingot is subjected to cold rolling and reeling on a closed shaping and reaming machine, and rolling paths and chamfered angles are molded with one step, truing is performed, and two end surfaces are subjected to soft grinding; 6) the machined ingot is pre-heated to 800 DEG C to 850 DEG C, after crack detection is performed, when the temperature of the machined ingot is lower than 450 DEG C, the machined ingot is put into the furnace so as to pre-heated to 600 DEG C to 650 DEG C, and heat preservation is performed on the machined ingot, and the machined ingot is put in to the furnace of which the temperature ranges from 950 DEC C to 1000 DEC and is rapidly heated to 1140 DEC C to 1200 DEC C, and water quenching is performed, and instantly, tempering from 550 DEC C to 600 DEC C is performed on the machined ingot, and the machined ingot is cooled to 400 DEC C to 450 DEC C in the furnace, and the machined ingot is taken out from the furnace and cooled. With the forging process adopted, inherent defects of metal can be eliminated, and the service life of a bearing can be prolonged.

Owner:JIANGSU JINYUAN FORGE

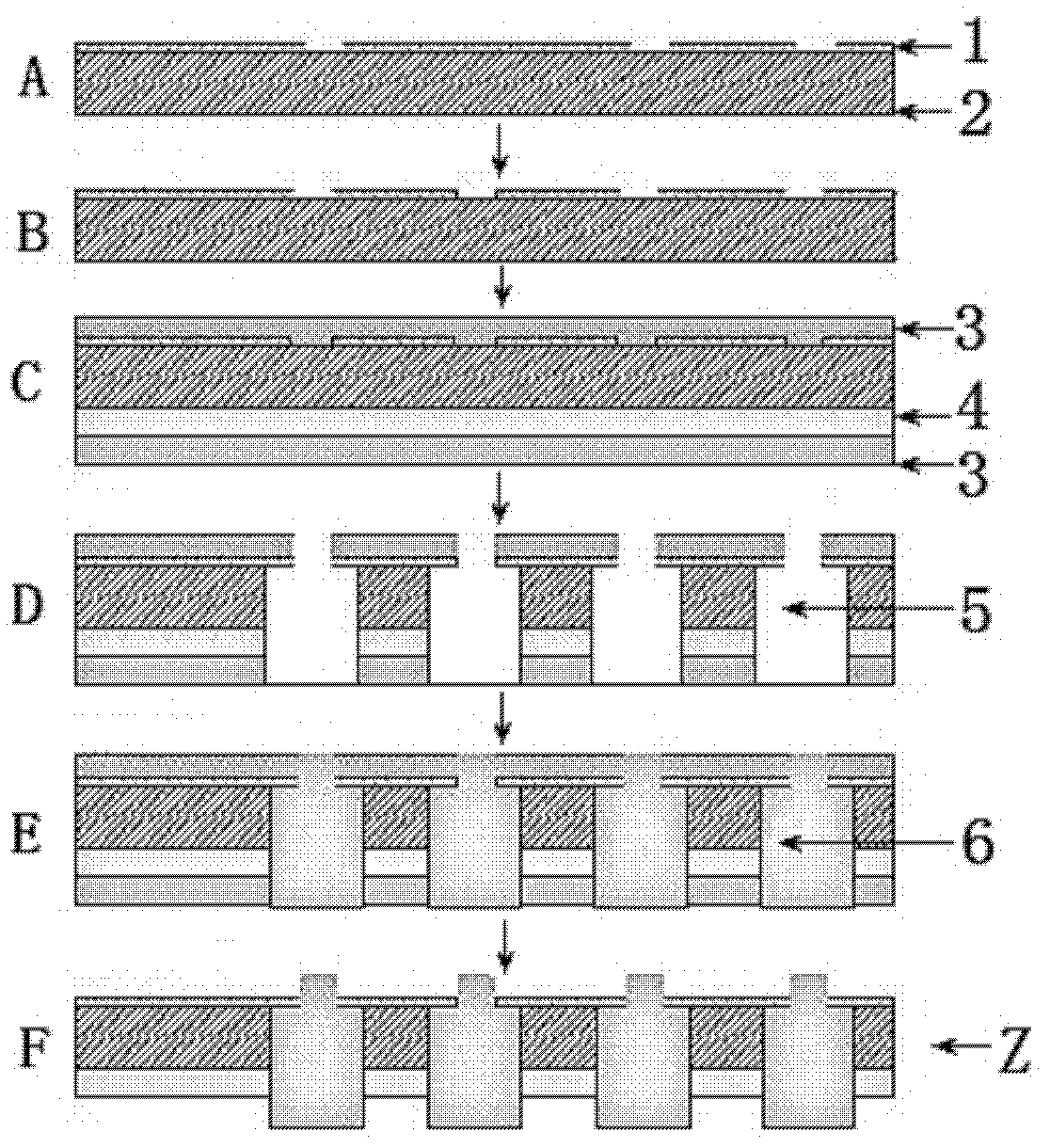

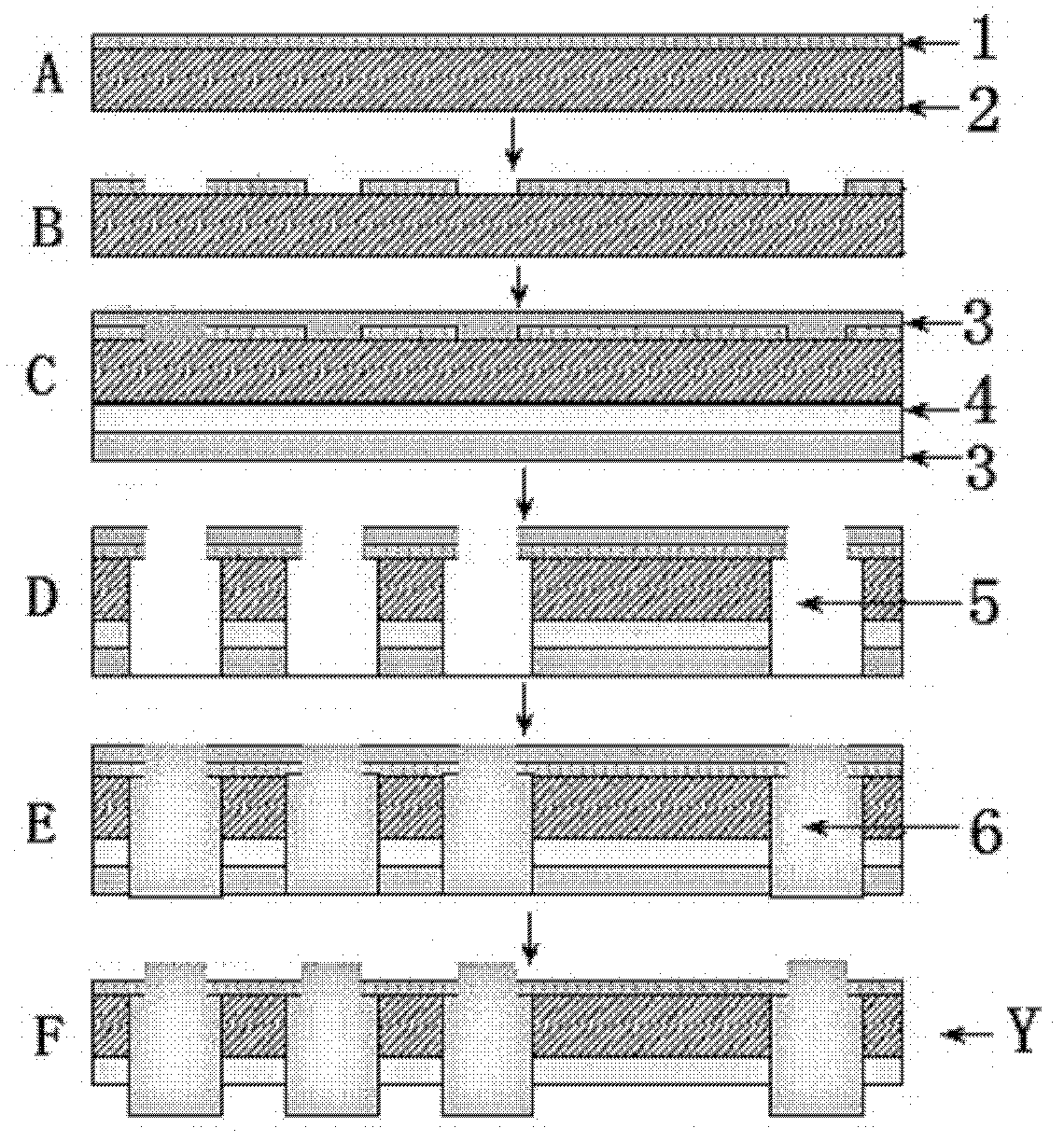

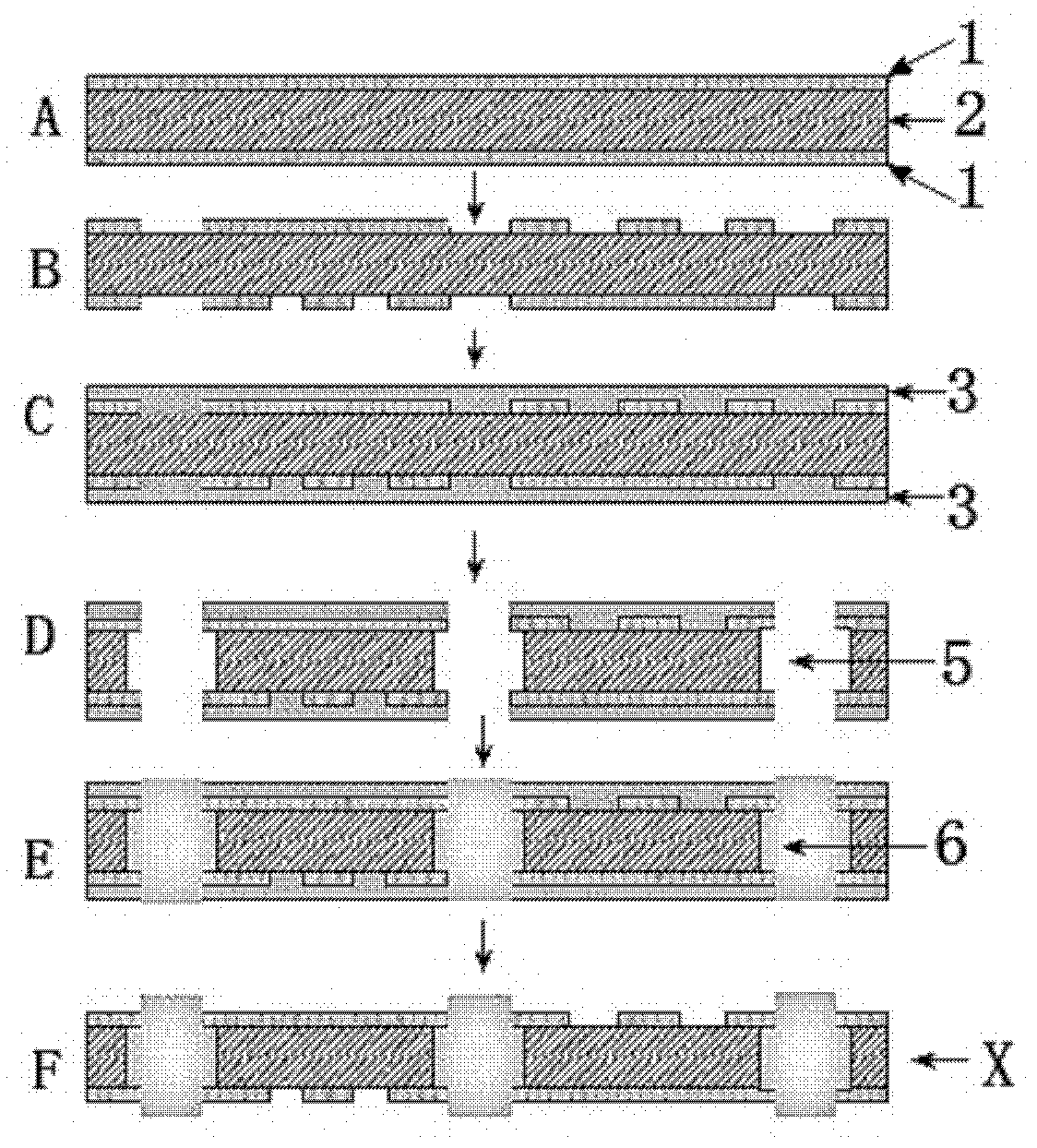

Manufacturing method of high-density interconnected printed circuit board

ActiveCN102595799AAvoid damageAvoid pollutionNon-metallic protective coating applicationPrinted element electric connection formationTectorial membraneConductive paste

The invention discloses a manufacturing method of a high-density interconnected printed circuit board, which mainly comprises the following steps that: the high-density interconnected printed circuit board is divided into a core layered structure, an outer layered structure and a plurality of middle layered structures which are respectively manufactured and finally pressed in; and the method for manufacturing the core layered structure, the outer layered structure and each middle layered structure is to press protective films onto copper foil base plates with made lines, drill through holes, fully fill conductive paste into the through holes and remove the protective films, so that the conductive paste is protruded out of the surfaces of the copper foil base plates. According to the method, the processing procedures are simple, the repeat of electroplating and hot pressing is reduced, the energy is saved, the environment is protected, and the production efficiency and the yield are high.

Owner:PLOTECH TECH KUNSHAN CO LTD

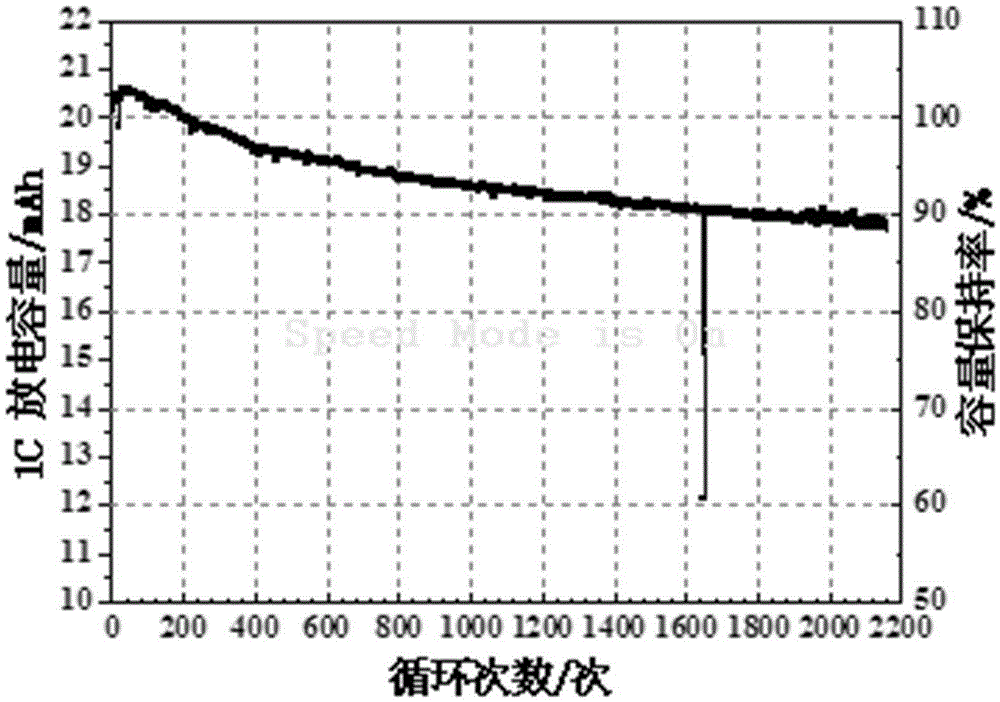

Silicon-carbon anode paste and preparation method thereof

ActiveCN105406039AIncrease tightnessImproved compaction density and electrical conductivityMaterial nanotechnologyCell electrodesEmulsionCarbon nanotube

The invention relates to a silicon-carbon anode paste and a preparation method thereof, and belongs to the technical field of lithium-ion batteries. The silicon-carbon anode paste comprises an acrylonitrile multi-component copolymerized LA-type water-based electrode binder, a carbon black Super-p conductive agent, a single-arm carbon nanotube suspension emulsion, a silicon-carbon / carbon nanotube composite anode material and deionized water. The preparation method of the anode paste comprises the following steps: (1) adding the acrylonitrile multi-component copolymerized LA-type water-based electrode binder and the deionized water to a planetary stirrer for stirring, preparing a binder solution and standing the binder solution for later use; (2) putting the carbon black Super-p conductive agent and the single-arm carbon nanotube suspension emulsion to the planetary stirrer for ball-milling and wet mixing; (3) putting the mixed two conductive agents and the silicon-carbon / carbon nanotube composite anode material into the planetary stirrer for carrying out thick material stirring; and (4) adding the binder solution for mixing and stirring, finally adding the deionized water to adjust the viscosity of the anode paste and sieving the paste.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

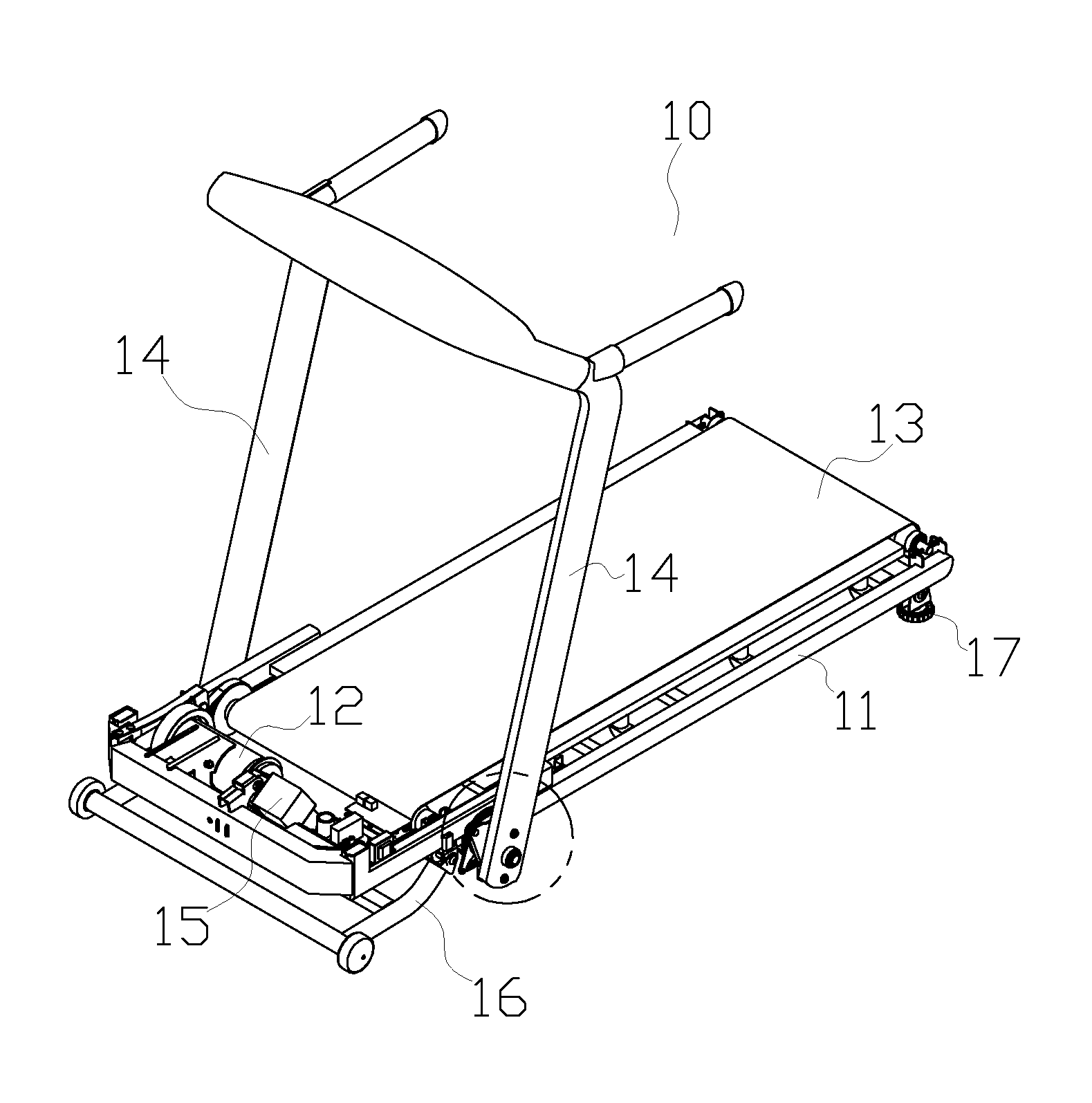

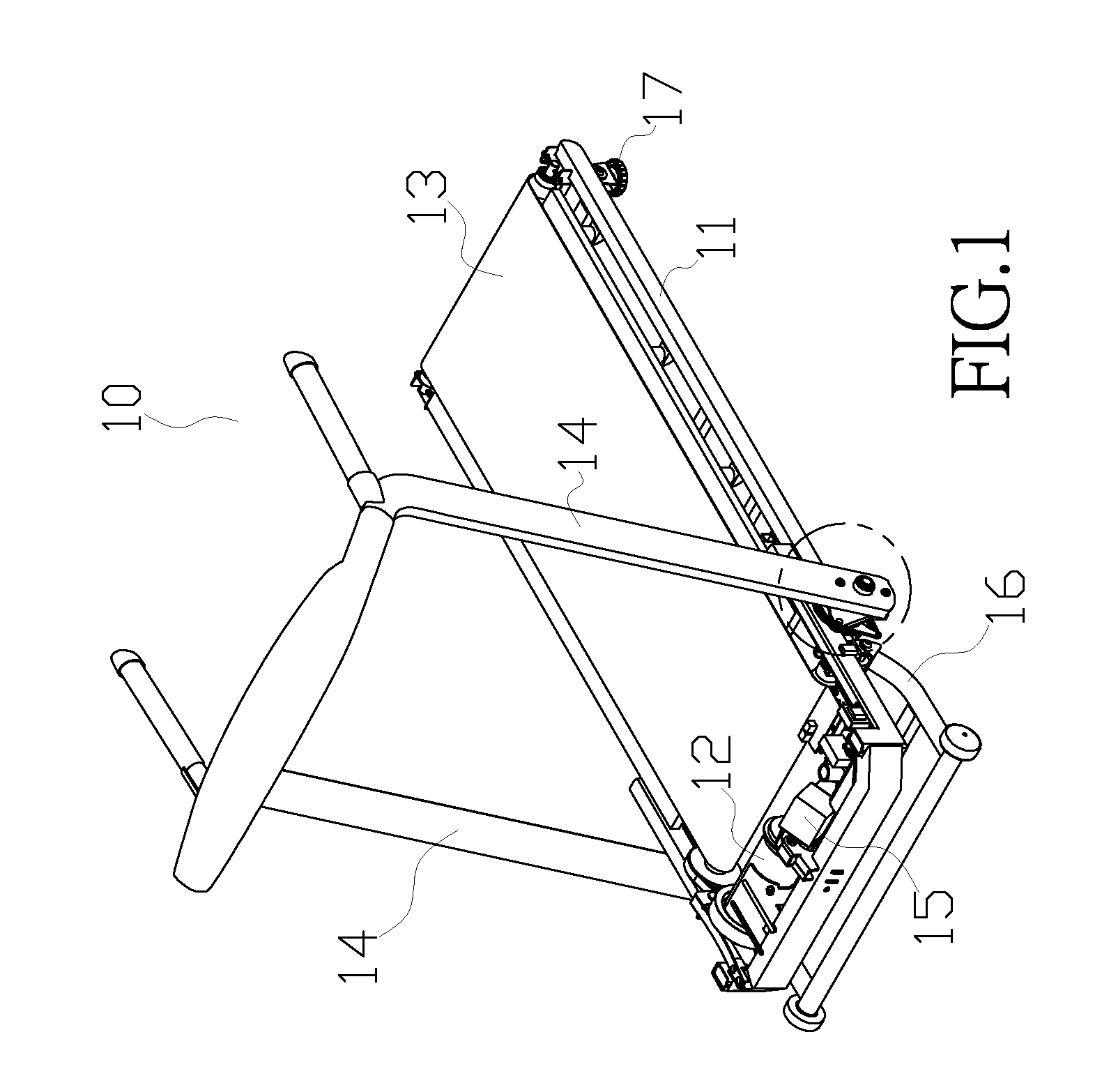

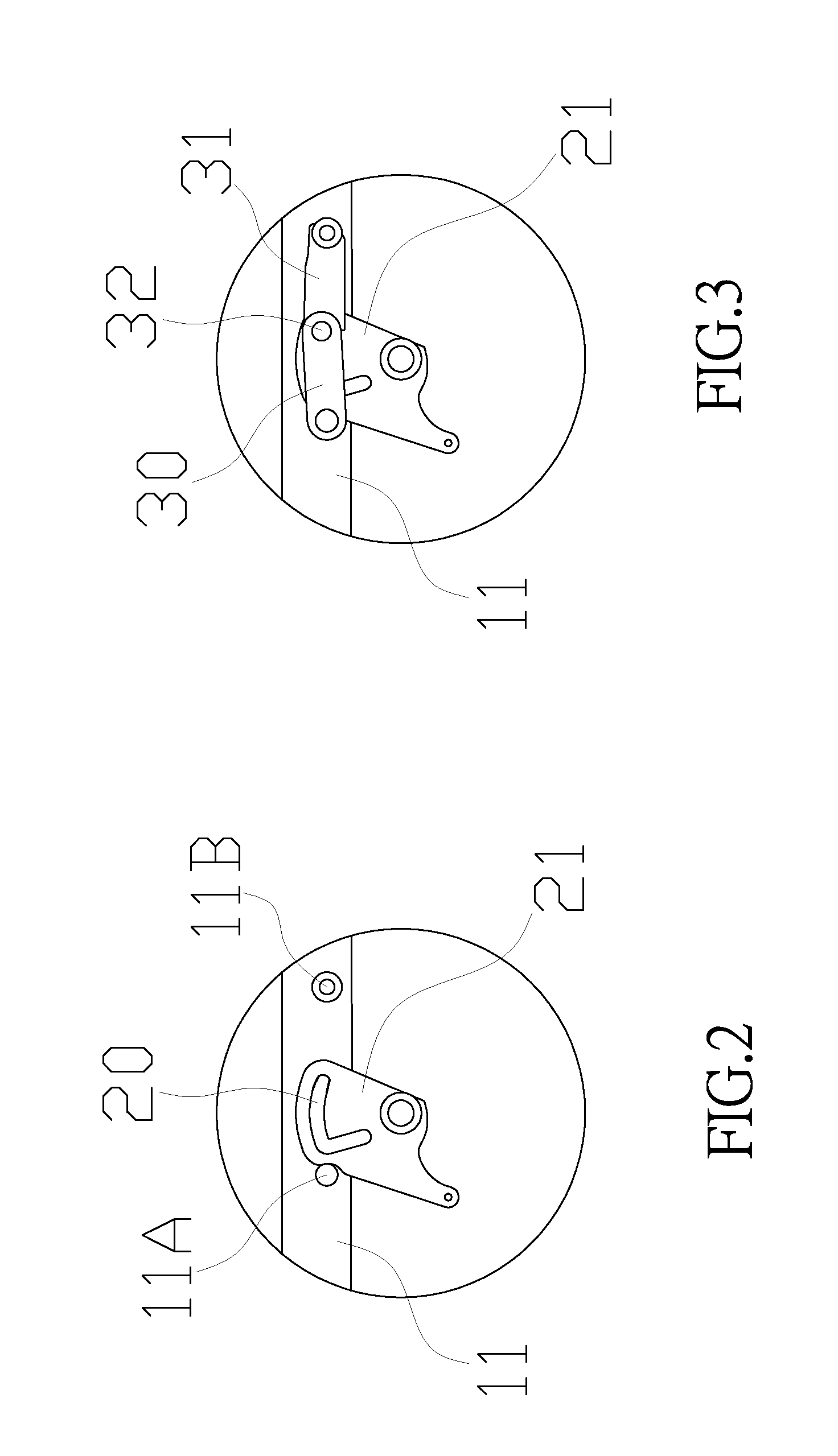

Electric treadmill with a folding mechanism

InactiveUS20130203560A1Increase tightnessReduce vibrationSpace saving gamesMovement coordination devicesHandrailEngineering

An electric treadmill with a folding mechanism includes a handrail frame pivotably mounted at both sides of the front end of the base frame. A guide plate having a sliding groove, two link plates, and a positioning plate attached to the handrail frame are provided between both sides of the base frame and the handrail frame. The guide plate is connected to a sliding support of a ground-touching roller. The sliding support is pivotably coupled to the bottom of the base frame. According to the assembly of the above-mentioned components, when the base frame is lifted in a folded position, a slide pin of the link plates is movable in the sliding groove of the guide plate until the base frame is folded in an upright position.

Owner:WANG LEAO

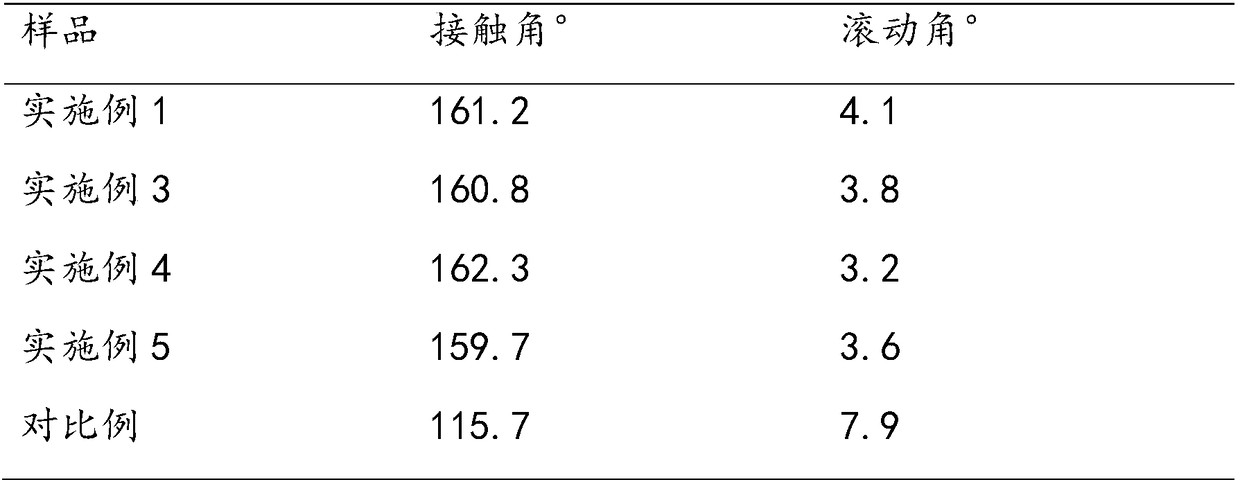

Processing technology of UV-curing fluorine-containing wear-resistant hydrophobic coating

ActiveCN108587381AHas hydrophobic and oleophobic propertiesImprove waterproof performanceCoatingsWear resistantLipophobicity

The invention discloses a processing technology of a UV-curing fluorine-containing wear-resistant hydrophobic coating. The processing technology comprises the following steps: a, preparing hydrophobicnano SiO2 / TiO2 particles; b, preparing an organic silicone fluorine-containing acrylate emulsion; c, preparing a bottom-layer hydrophobic coating emulsion; e, spraying the bottom-layer hydrophobic coating emulsion; and f, spraying a surface hydrophobic coating. The processing technology disclosed by the invention has the beneficial effects that a double-layer cooperation manner of the bottom-layer hydrophobic coating and the surface hydrophobic coating is adopted, so that the coating has the properties of hydrophobicity and lipophobicity while adhesion of the waterproof coating and a target material is ensured, and water resistance of the target material is improved; the bottom-layer hydrophobic coating is cured by acrylate, so that contact strength of the bottom-layer hydrophobic coatingand the surface of the target material can be provided, and the compactness of the waterproof coating can be improved; and a structure of a nano material is stabilized through the organic silicone modified fluorine-containing acrylate, fluorine-containing silane and fluorine-containing acrylate are also used, so that hydrophobicity of the surface-layer hydrophobic coating is improved.

Owner:GUANGZHOU SUN EMPEROR INTELLIGENT TECH +1

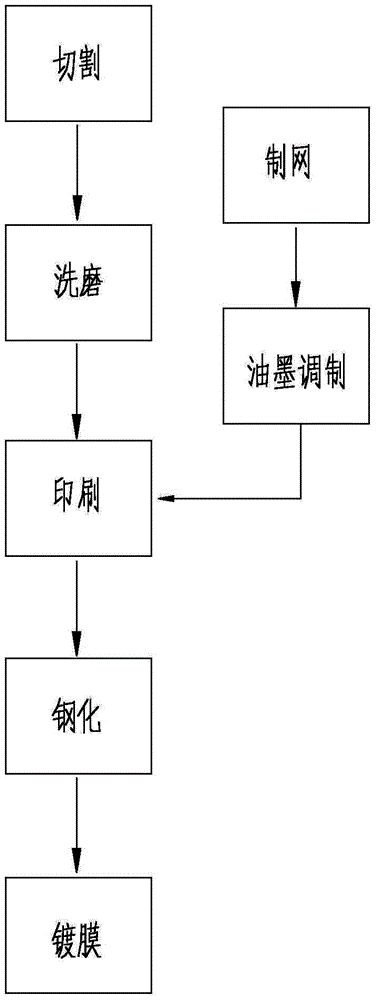

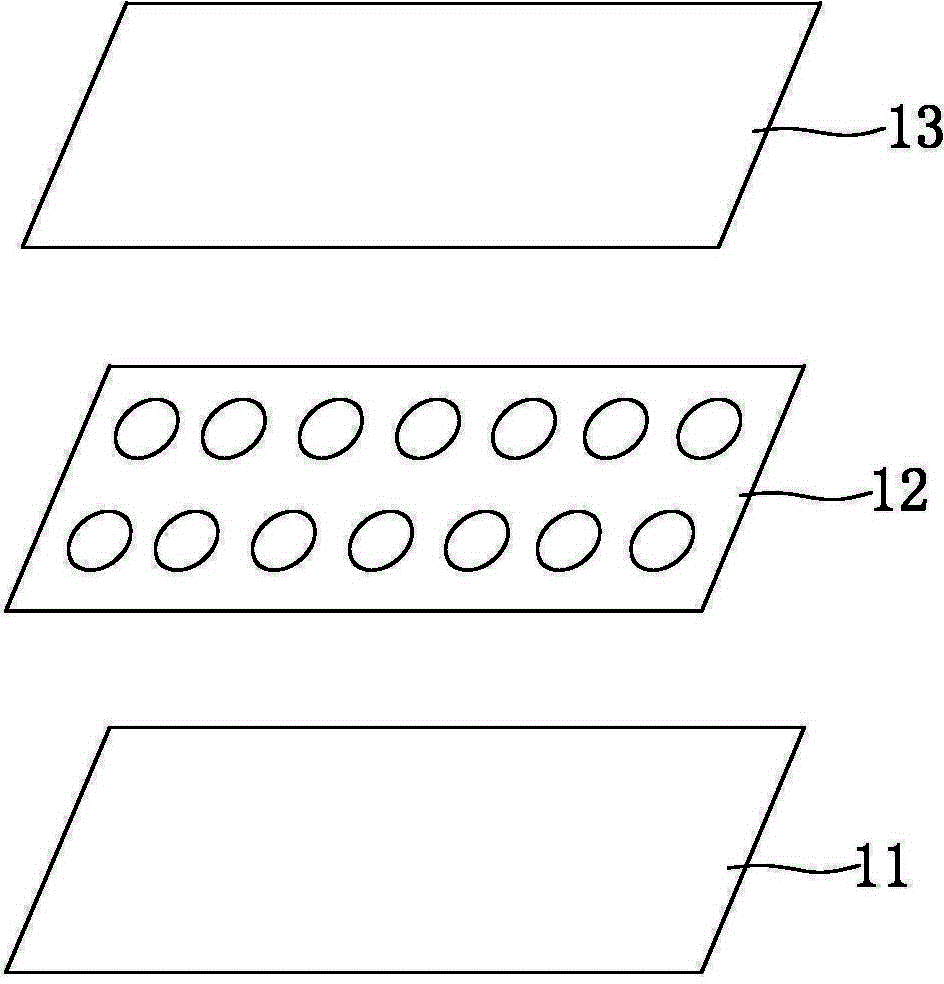

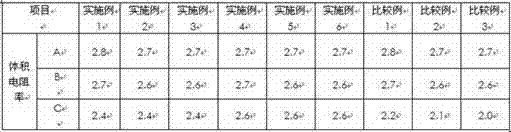

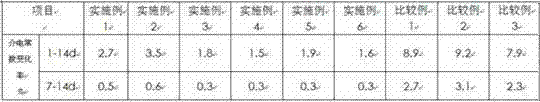

Manufacturing method for color glaze coated glass and color glaze coated glass

ActiveCN105271808AIncrease tightnessSimple processGlass tempering apparatusGlass productionScreen printingWear resistant

The invention belongs to the glass manufacturing technology field, and discloses a manufacturing method for color glaze coated glass and color glaze coated glass. The manufacturing method comprises steps: a cutting procedure is carried out, namely, a glass original sheet is selected and cut; a washing and grinding procedure is carried out, namely, the glass original sheet is ground and washed; a printing procedure is carried out, namely, a screen printing plate is selected and washed, printing oil is blended, and a pattern is printed on the surface of the glass original sheet; a toughening procedure is carried out, namely, the surface of the glass original sheet is cleaned, the glass original sheet is conveyed to a toughening furnace and heated, then is outputted after heating and cooled rapidly to a normal temperature, and glaze layer is formed; a coating procedure is carried out, namely, coating layers with different colors are plated on the glaze layer according to needs. The color glaze coated glass is manufactured through the above manufacturing method. The manufacturing method is simple, and the production efficiency is high. The color glaze coated glass manufactured through the method has good acid-base resistance, has a good adhesive force, and is durable and wear-resistant. The color is changeable, the sunshade effect is raised, and usage requirement of the coated glass are met.

Owner:XINYI GLASS ENG (DONGGUAN) CO LTD

Polyamide yarn production technology

InactiveCN104674366AImprove performanceImprove dyeing effectFilament forming substance formingMelt spinning methodsPolyamidePulp and paper industry

The invention discloses a polyamide yarn production technology. The polyamide yarn production technology comprises the following steps of treating raw materials, drying, preparing POY yarns, preparing DTY yarns, carrying out net treatment, classifying and packaging. According to the technology, an anti-oxidant, an anti-static agent and an antibacterial agent are added in the raw materials, so that the performances of a chinlon 66 finished product is improved, and the produced chinlon yarns have the anti-bacterial and anti-static effects; a easily dyeable agent is also added in the raw materials, so that the dyeing performance of the finished product is improved; by utilizing the production processes of the POY and DTY net yarns, yarn floating is prevented, and net breaking is low, so that the fluffy property and the good elasticity of the chinlon yarns are kept, the chinlon yarns also have the cycle property and net points, the stability is good, the compactness of the long yarns is improved, and the handfeel and the comfort of the finished product are effectively improved.

Owner:ZHEJIANG YINAN FIBER TECH

Waterproof and flame-retarded PVC (polyvinyl chloride) cable material for data cable and preparation method thereof

ActiveCN102952357AImprove performanceLong-term usePlastic/resin/waxes insulatorsPolymer scienceKaolin clay

The invention relates to a waterproof and flame-retarded PVC (polyvinyl chloride) cable material for a data cable. The material comprises the following components in part by weight: 100 parts of PVC resin, 32 to 38 parts of trioctyl trimellitate, 4 to 6 parts of stabilizer, 8 to 10 parts of fire retardant and 8 to 12 parts of waterproof modifier, wherein the waterproof modifier is prepared by cladding 2 to 3 parts of nano-barium sulfate, 4 to 7.5 parts of calcined kaolin and 2 to 3 parts of nanosilicon dioxide by using 0.3 to 0.5 parts of silane coupling agent. The material can adapt to a complex using environment and resist water for a long time, and excellent electrical insulation property, mechanical property and flame resistance are also kept.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

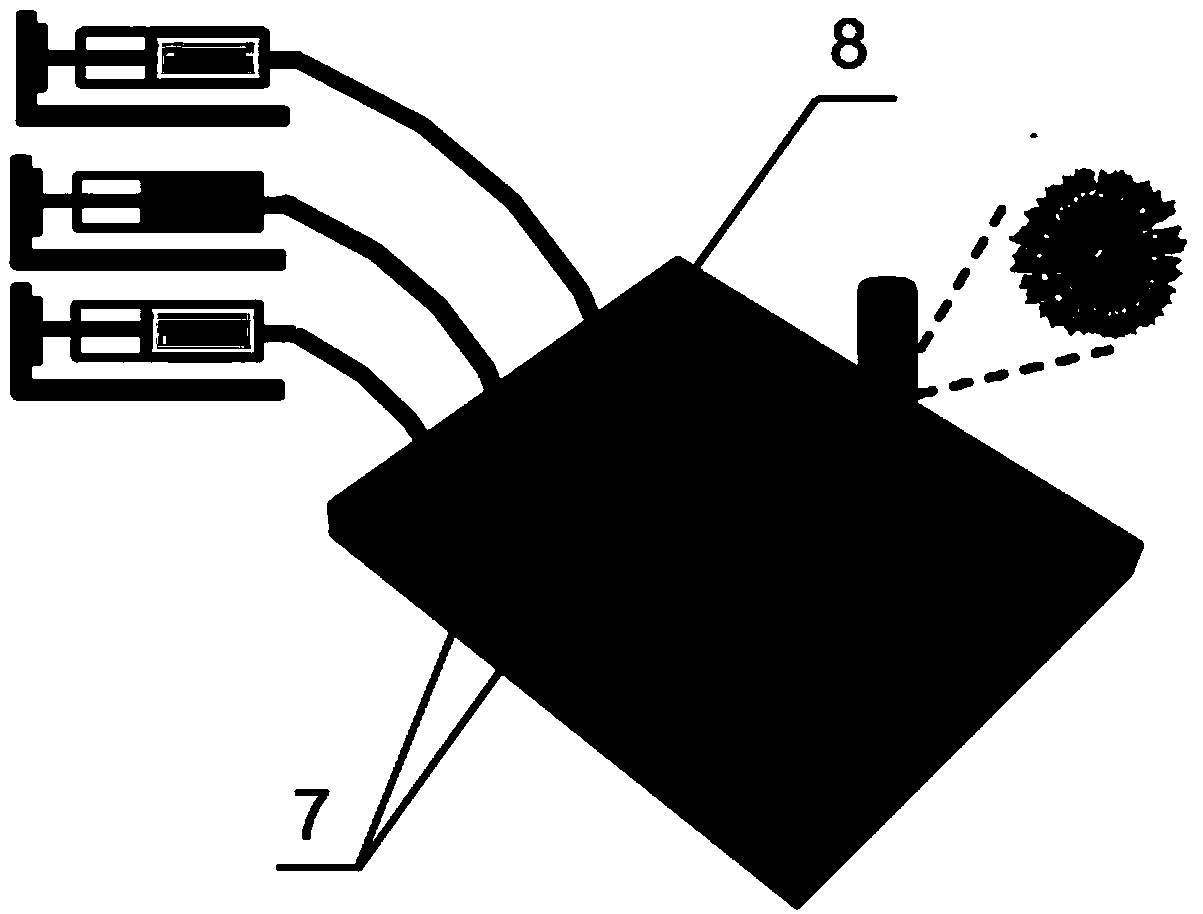

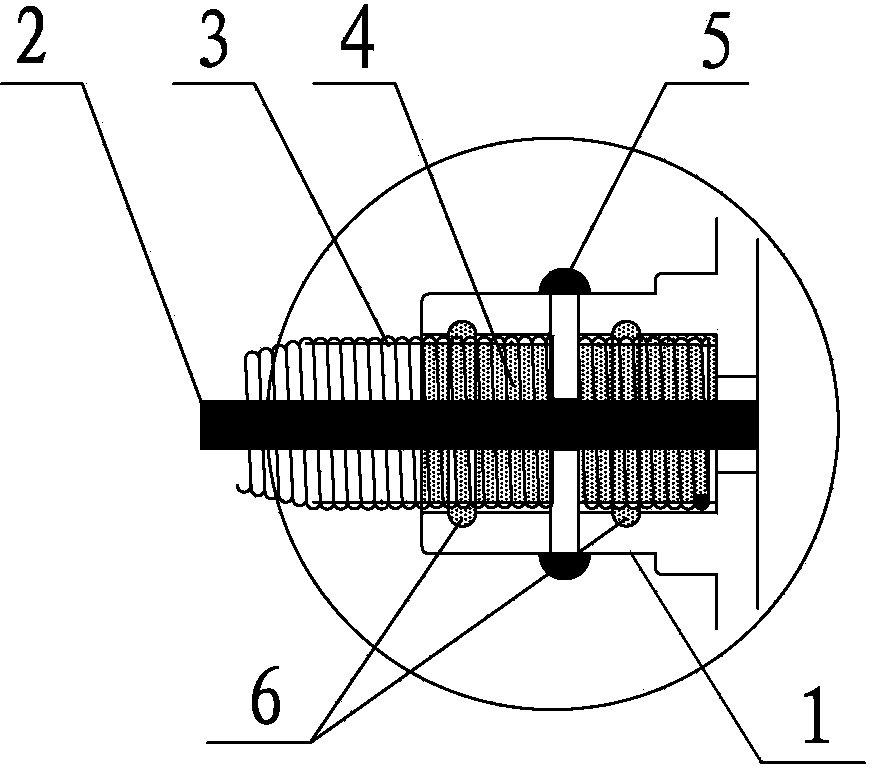

Interface structure of micro-fluidic chip, and manufacturing method and application thereof

InactiveCN103816950AGuaranteed StrengthGuaranteed tightnessLaboratory glasswaresInterference fitHigh flux

The invention relates to an interface structure of a micro-fluidic chip, and a manufacturing method and an application thereof. The interface structure of the micro-fluidic chip comprises a drainage tube, a micro-fluidic channel inlet / outlet, a first seal layer and a second seal layer, wherein the drainage tube is inserted into the micro-fluidic channel inlet / outlet to form an interference fit; the first seal layer is sealant; the sealant bonds the drainage tube and the micro-fluidic channel inlet / outlet; the material of the second seal layer is the same as that of the micro-fluidic chip; the second seal layer covers the first seal layer and is adhered with the micro-fluidic chip and the drainage tube. The interface structure provided by the invention has the characteristics of firm seal and high pressure resistance, and can meet experiment requirements of high throughput synthesis of the micro-fluidic chip with relatively high flow speed.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

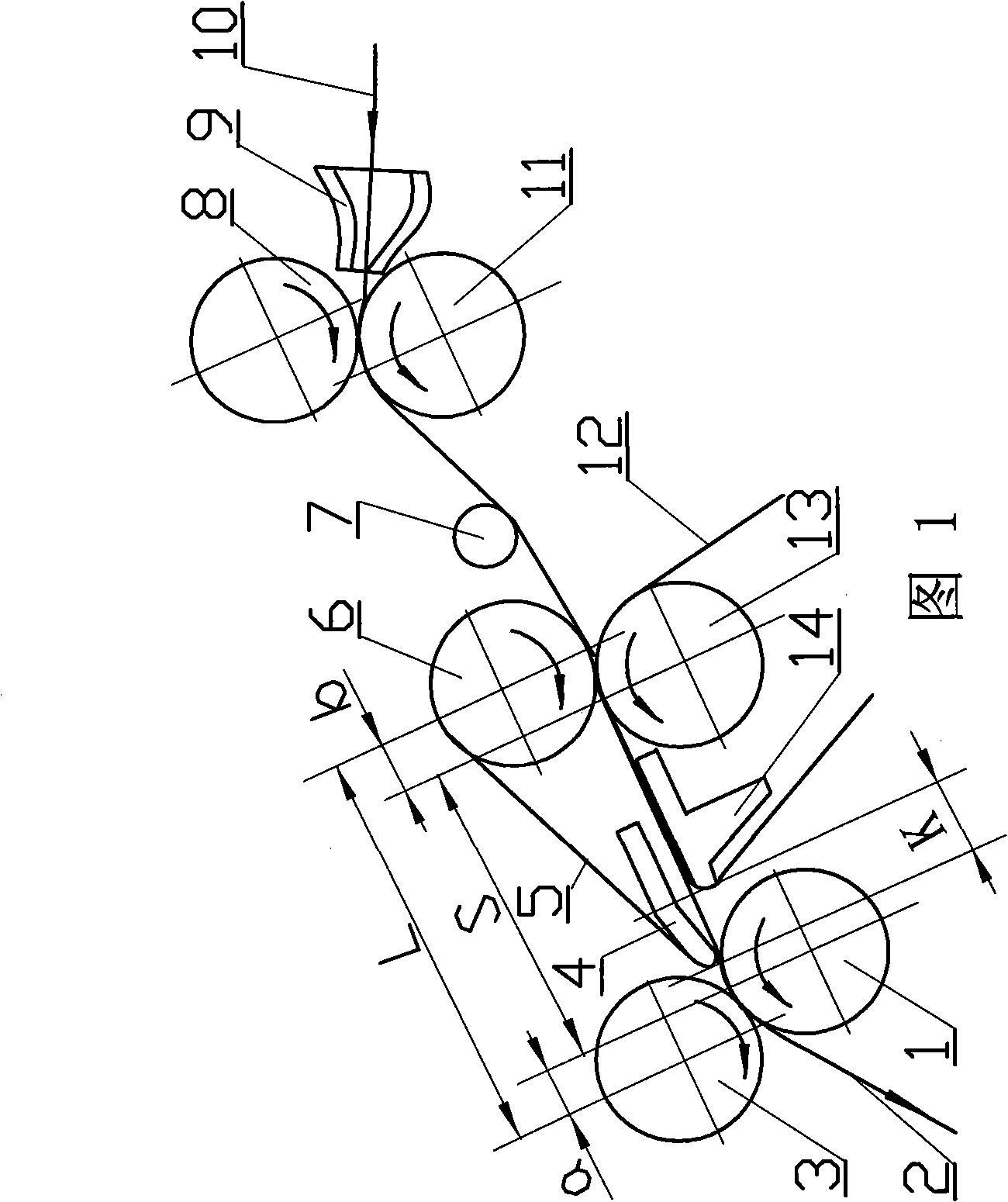

High power drafting device for ring spinning frame

InactiveCN101307515AShorten the lengthExpand the range of the friction fieldDrafting machinesFiberEngineering

The invention discloses a high-power drafting assembly used for a ring spinner, comprising a front drafting roller pair with a front roller and a front belt roller, and a rear drafting roller pair with a rear roller and a rear belt roller, wherein, a middle roller and an upper middle roller are arranged between the front drafting roller pair and the rear drafting roller pair, an upper pin is arranged between the upper middle roller and the front belt roller, while a lower pin is arranged between the middle roller and the front roller, an upper apron is sleeved on the upper middle roller and the upper pin, a lower apron is sleeved on the middle roller and the lower pin, the forward setting distance K between the upper pin front edge and the lower pin front edge is at least 3 millimeters, the ratio of the setting distance L from the upper middle roller to the front belt roller and the setting distance S from the roller to the front roller is between 1.1 and 1.6. The high-power drafting assembly can shorten the freestream flow zone length to the utmost extent, extend the control area of the apron, effectively increase the drafting multiple of the drafting assembly and guarantees the quality of the completed filament.

Owner:DONGTAI TEXTILE MASCH CO LTD

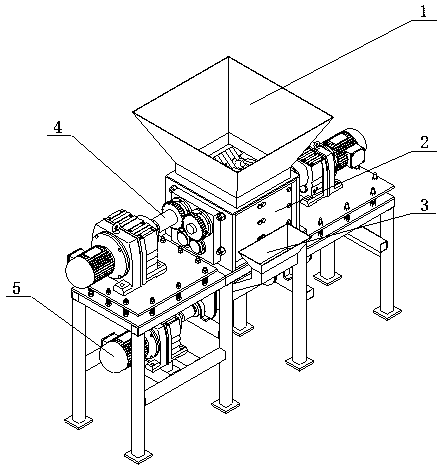

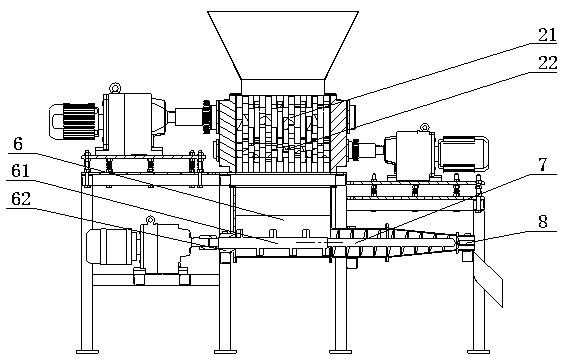

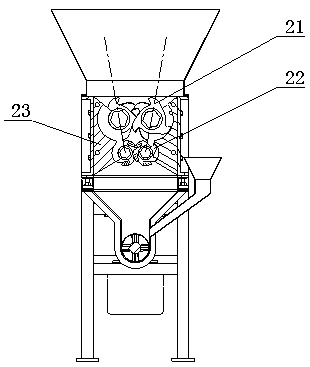

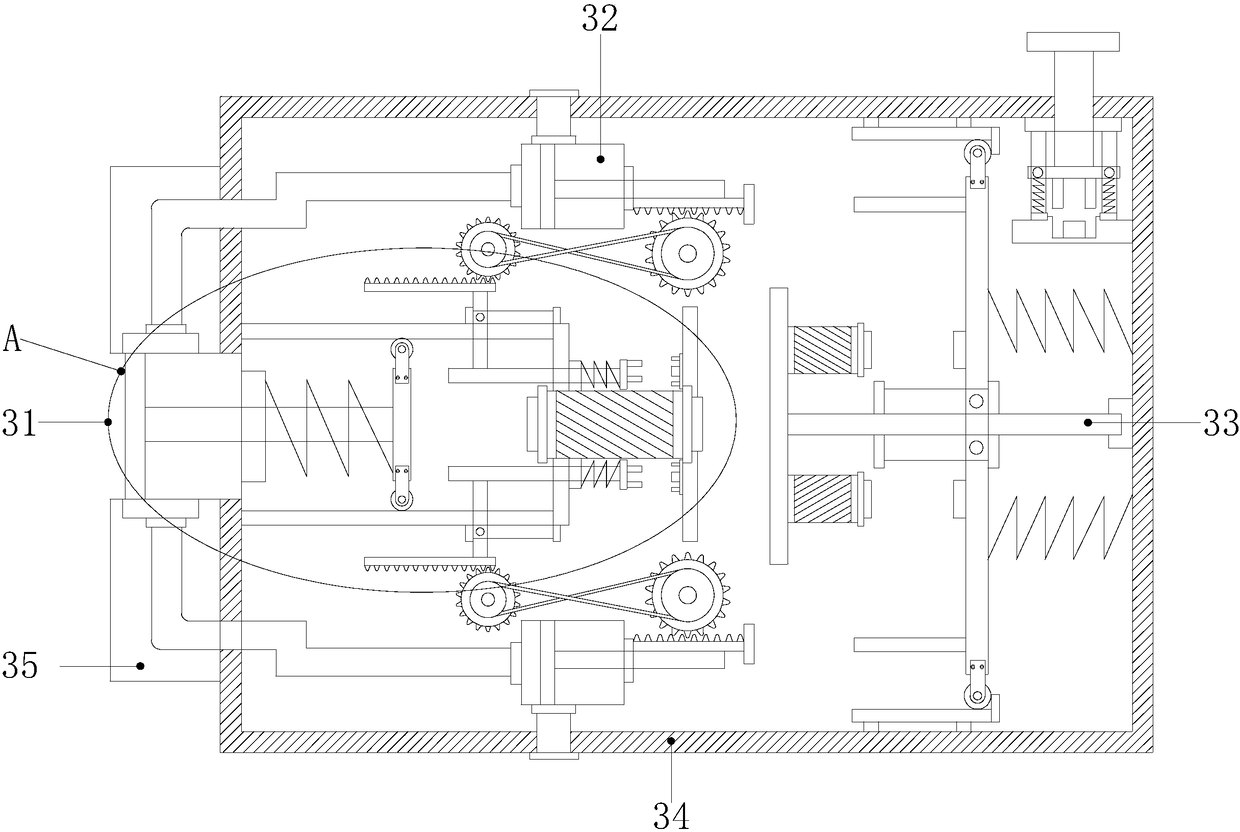

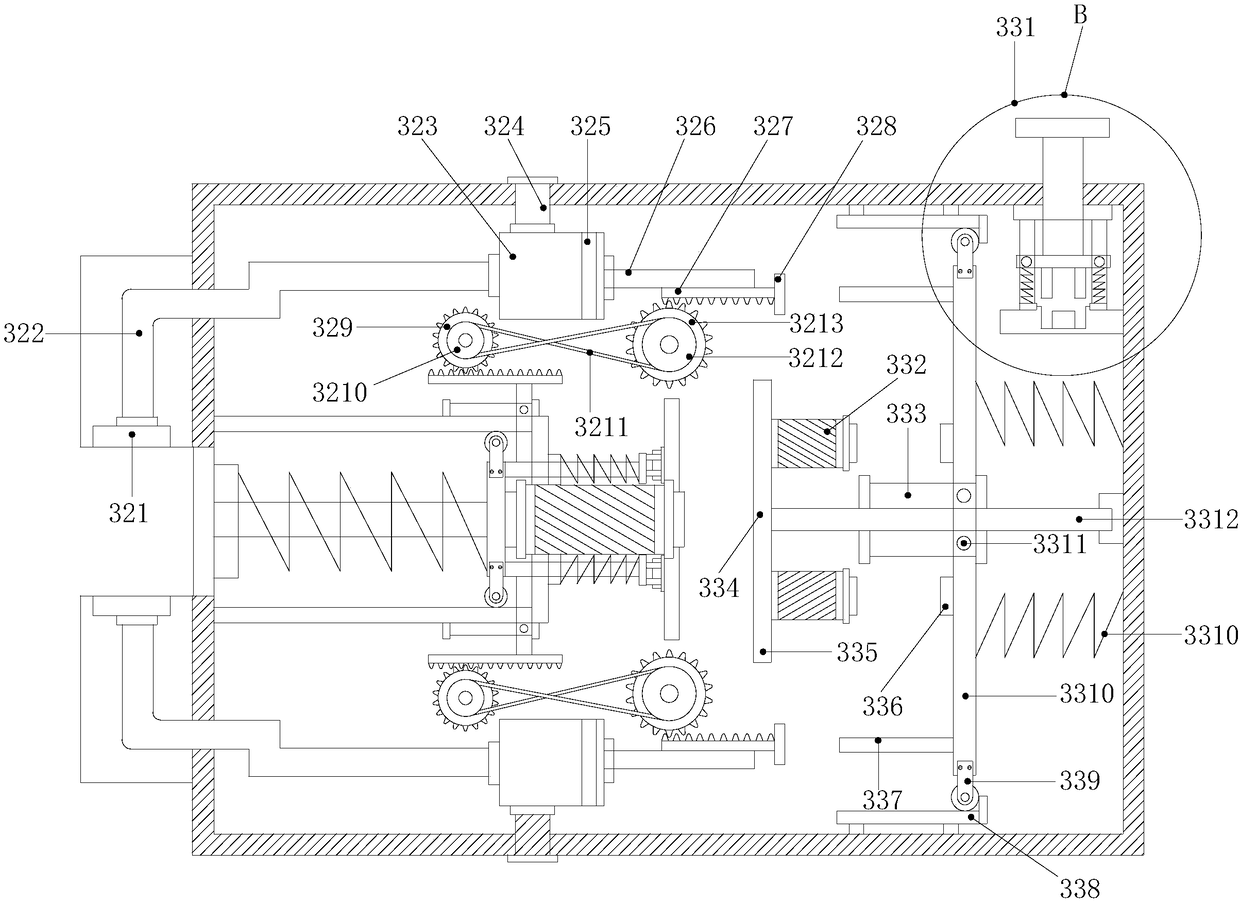

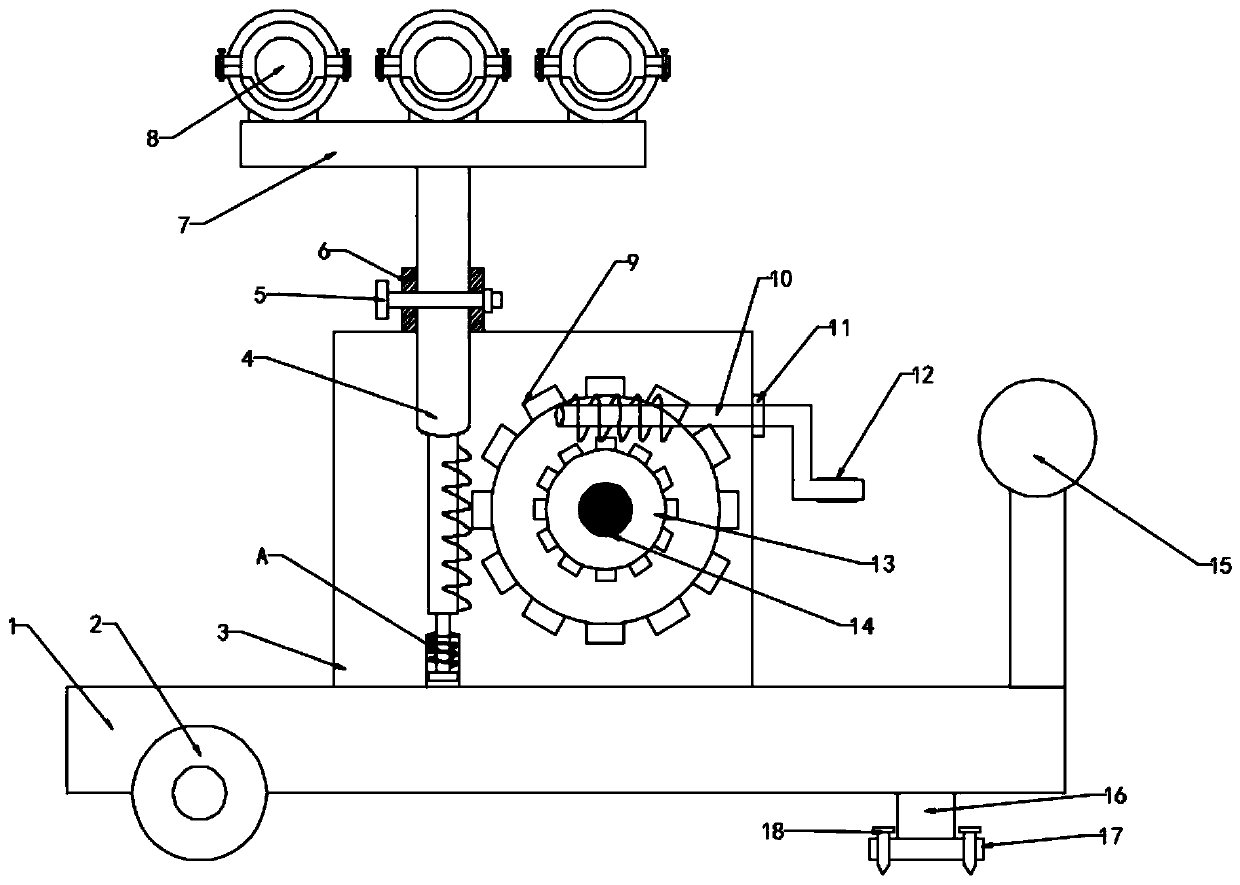

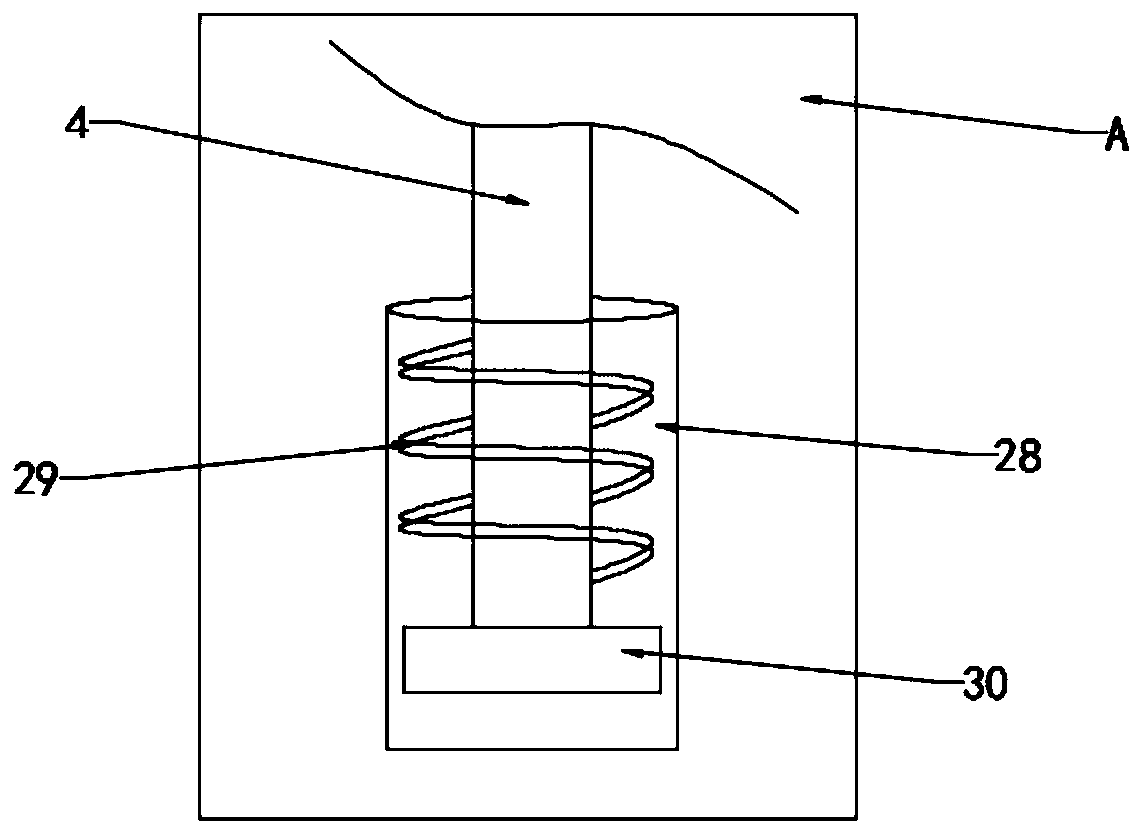

RDF production equipment and RDF preparation method

InactiveCN109022095AEvenly dispersedIncrease the calorific value of combustionTransportation and packagingBiofuelsRefuse-derived fuelCombustion

The invention discloses RDF (refuse derived fuel) production equipment. The equipment includes a crushing box internally equipped with a crushing mechanism, the top of the crushing box is equipped with a feed inlet, the bottom of the crushing box is equipped with a crushing discharge port, and a mixing box communicated with the crushing discharge port is disposed under the bottom of the crushing box. The box wall of the mixing box is equipped with an additive feed inlet, the mixing box is internally equipped with a stirring shaft, one end of the stirring shaft extends out of the box wall of the mixing box and is in power connection with a stirring motor, and the other end of the stirring shaft is connected to a screw conveying extrusion moulding machine. The screw conveying extrusion moulding machine includes a shell communicated with the mixing box and a screw conveying shaft coaxially connected to the stirring shaft. The equipment also includes a heating device for heating the mixingbox or the shell of the screw conveying extrusion moulding machine. The invention also provides an RDF preparation method using the RDF preparation equipment. The equipment and method provided by theinvention can increase the combustion heat of refuse derived fuel, have no need for an adhesive, are beneficial to environmental protection and are convenient for storage and transportation.

Owner:CHONGQING UNIV OF TECH

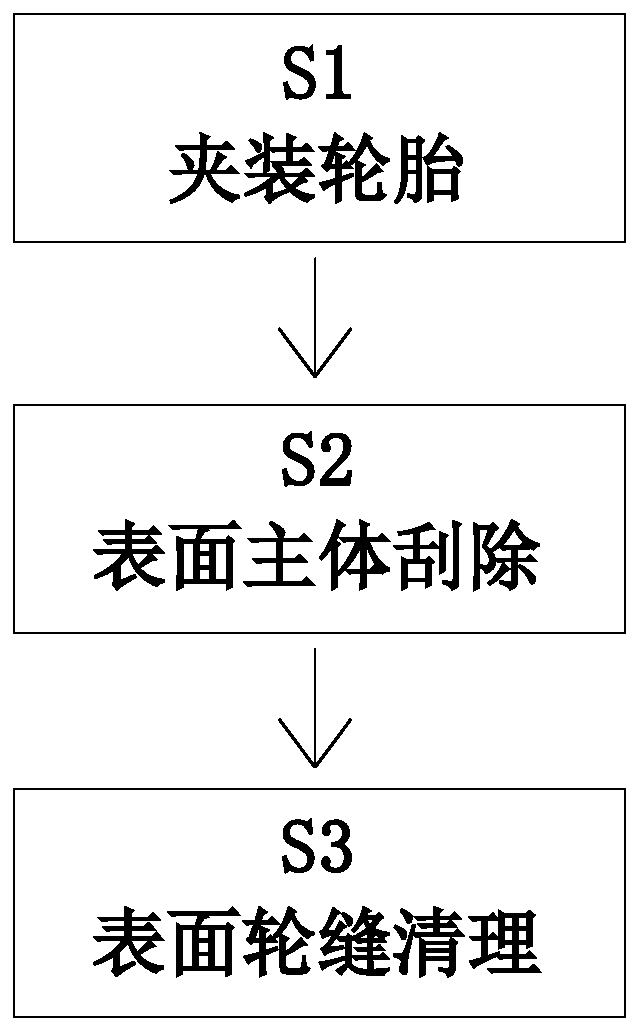

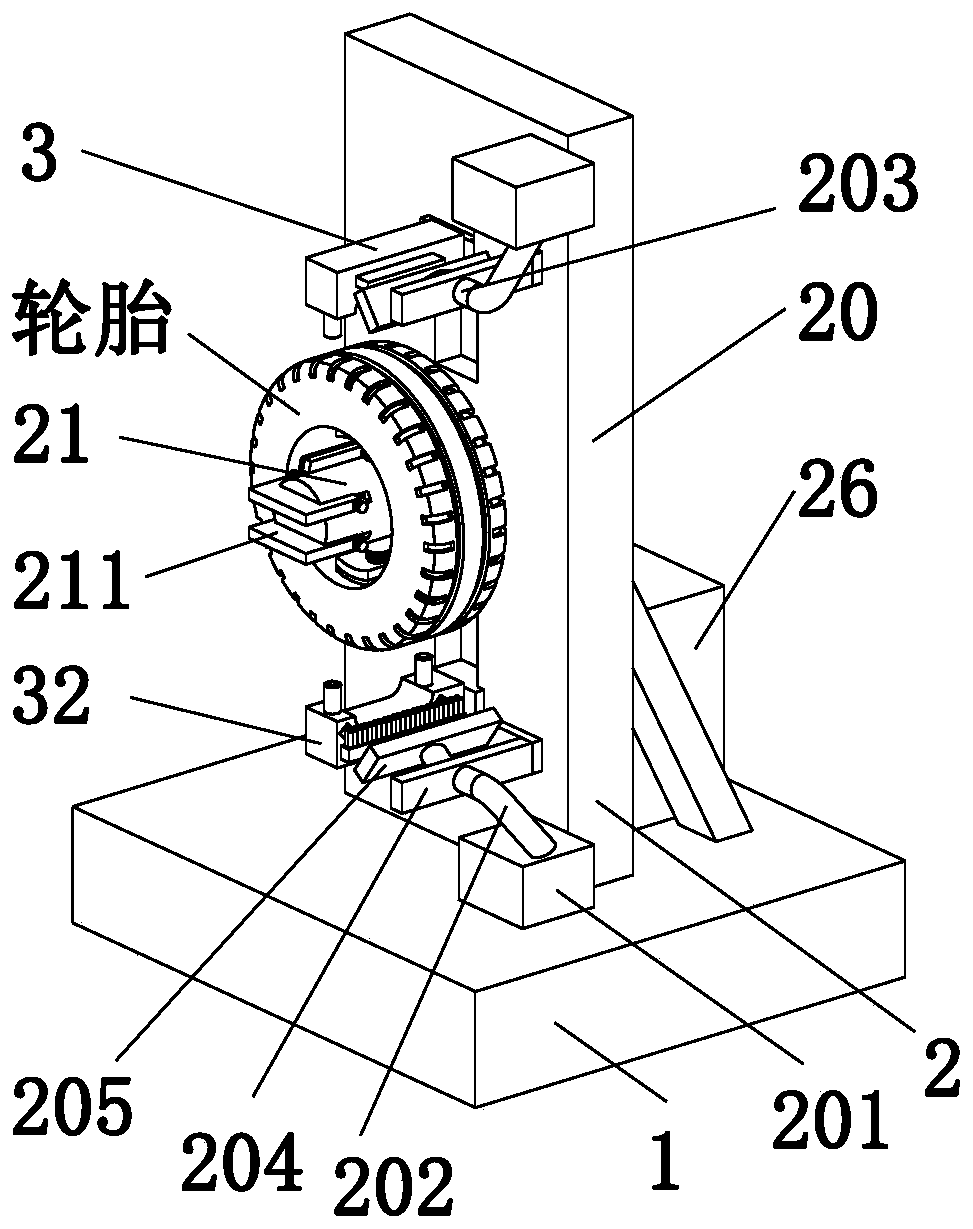

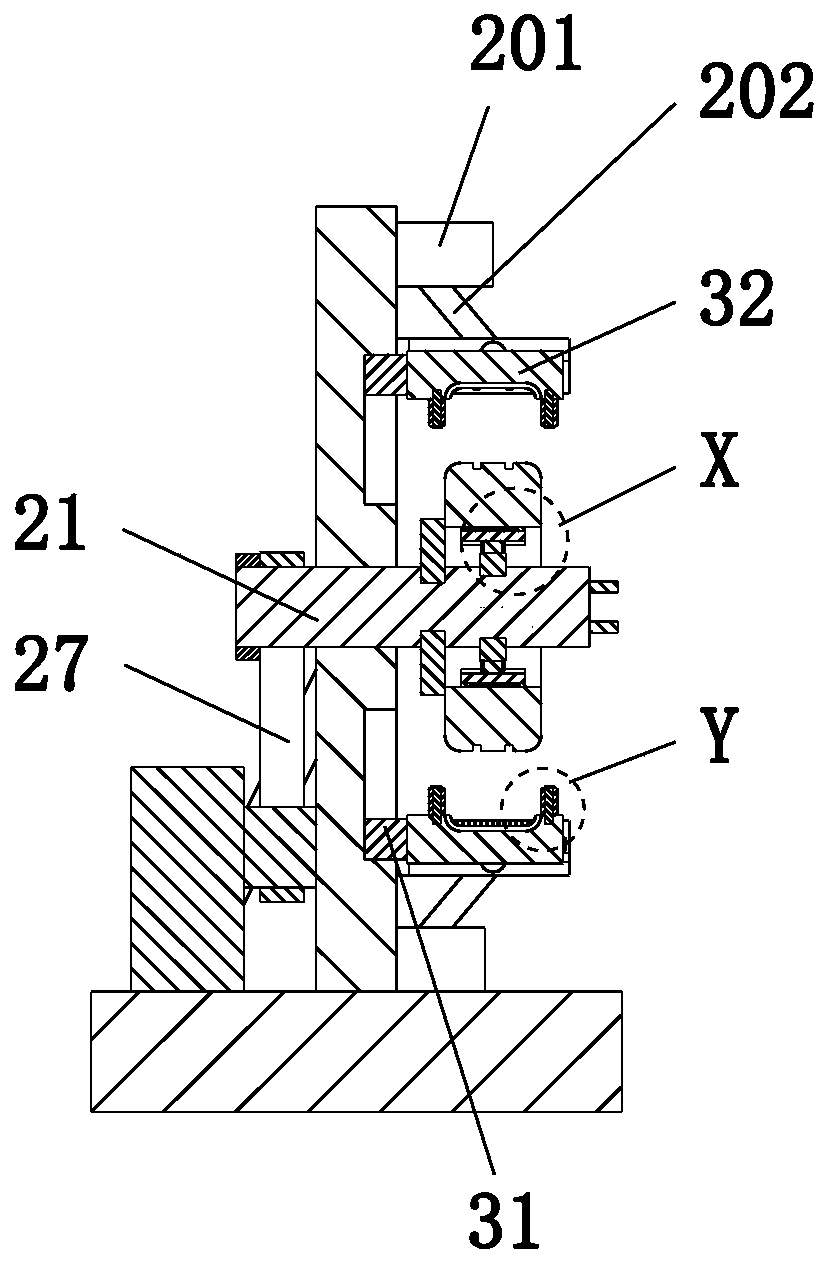

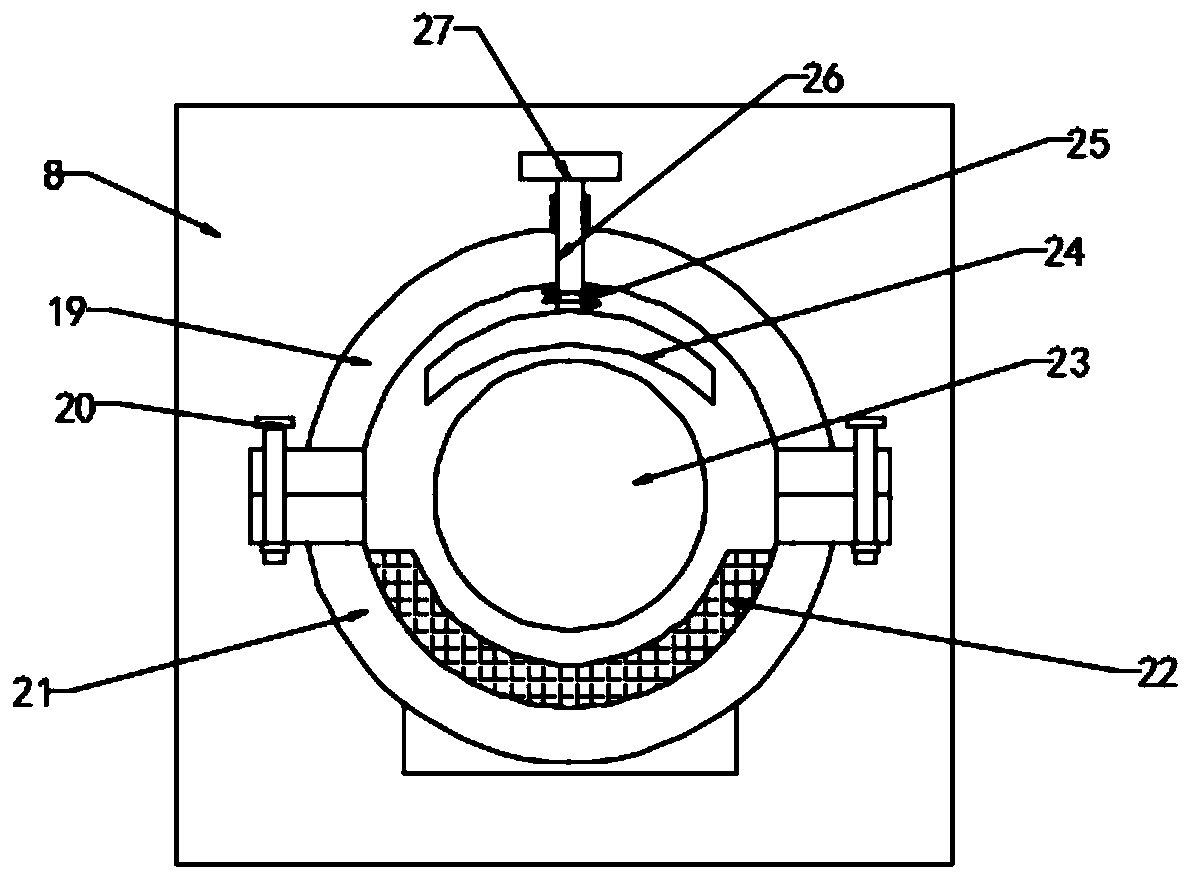

Method for detection processing of rubber tire after molding

ActiveCN111408557AImprove the stabilityImprove cleanlinessEdge grinding machinesRevolution surface grinding machinesMechanical engineeringAutomotive engineering

The invention relates to a method for detection processing of a rubber tire after molding, which uses a device for detection processing of a rubber tire after molding, wherein the device for detectionprocessing of the rubber tire after molding comprises a pedestal, a clamping mechanism and a scraping mechanism, the clamping mechanism is mounted at an upper end of the pedestal, and the scraping mechanisms are symmetrically mounted up and down on a front end face of the clamping mechanism. According to the method and the device provided by the invention, a design concept of a clamping-cleaningintegrated controllable structure is adopted for performing detection processing of the rubber tire after molding, a plurality of structures with functions of scraping away defects, such as burrs, ofthe tire are used, so that cleanness degree of a surface of the tire is improved, moreover, the structures aim at cleaning of different parts of the surface of the tire, meanwhile, a plurality of auxiliary fixing and limiting structures are added on the basis of arrangement of the structure playing a leading role in clamping, and thus, relative stability of entirety of the tire is improved.

Owner:QINGDAO FULUN TECH

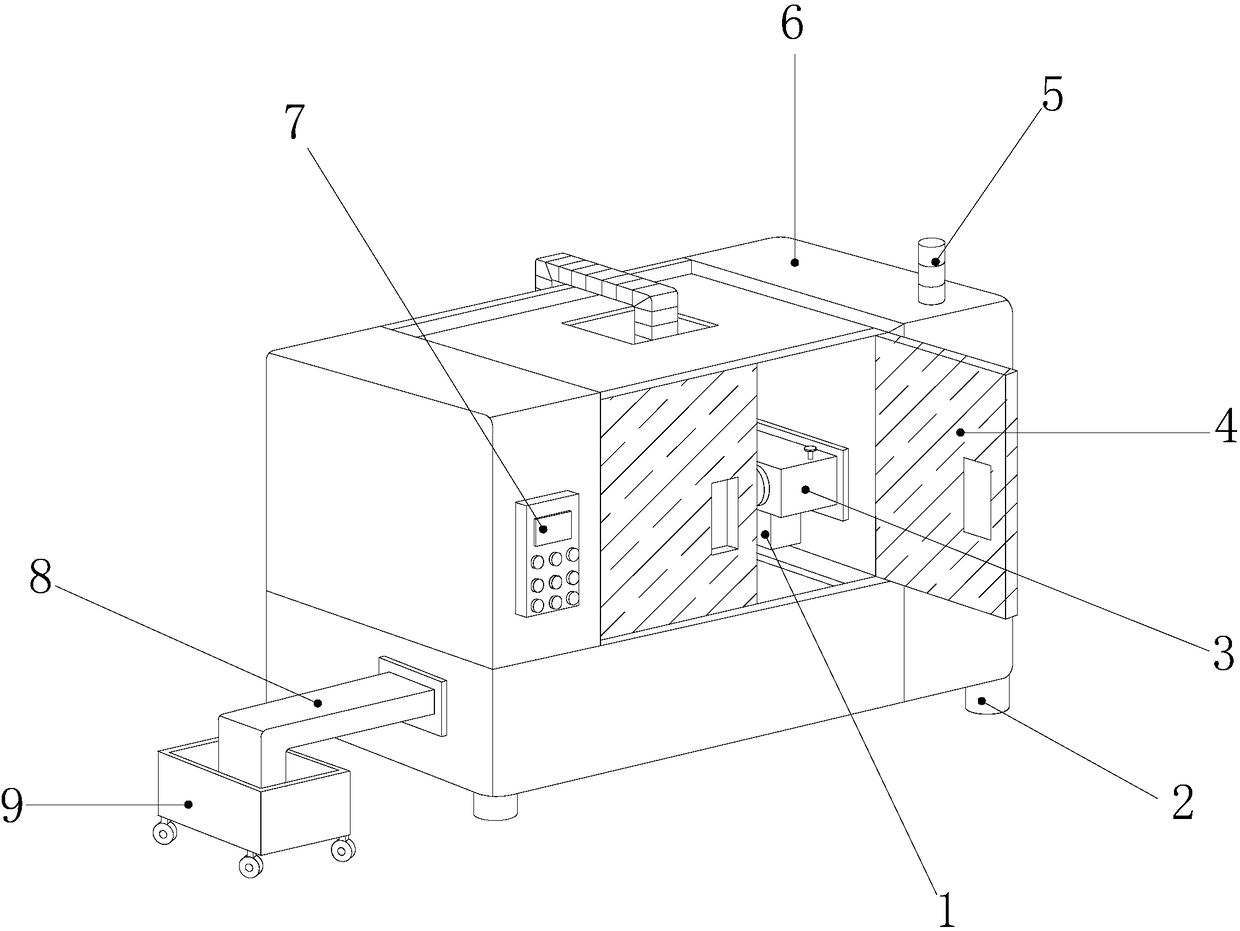

Double-spindle core moving type numerical control lathe

InactiveCN108515191AIncrease tightnessIncrease the degree of fixationWork clamping meansPositioning apparatusNumerical controlEngineering

The invention discloses a double-spindle core moving type numerical control lathe. The numerical control lathe structurally comprises a fixture rotating driving motor, support legs, a workpiece adsorption fixing device, a double-open glass door, a three-color warning lamp, a double-spindle numerical control lathe body, a controller, a cuttings guide pipe and a movable cuttings storage frame. The workpiece adsorption fixing device is arranged in the double-spindle numerical control lathe body. The fixture rotating driving motor is arranged at the bottom of the workpiece adsorption fixing deviceand is in clearance fit with the workpiece adsorption fixing device. According to the double-spindle core moving type numerical control lathe, the workpiece adsorption fixing device inserts one end of a workpiece into a fixture axle hole; at the moment, a driving mechanism can be triggered; the workpiece adsorption fixing device automatically fixes the workpiece to the interior of the axle hole through cooperation of a vacuum adsorption mechanism and an electromagnetic reinforcement mechanism; accordingly, the workpiece is fixed automatically, and the manual material changing speed is increased.

Owner:珠海大金卷贸易有限公司

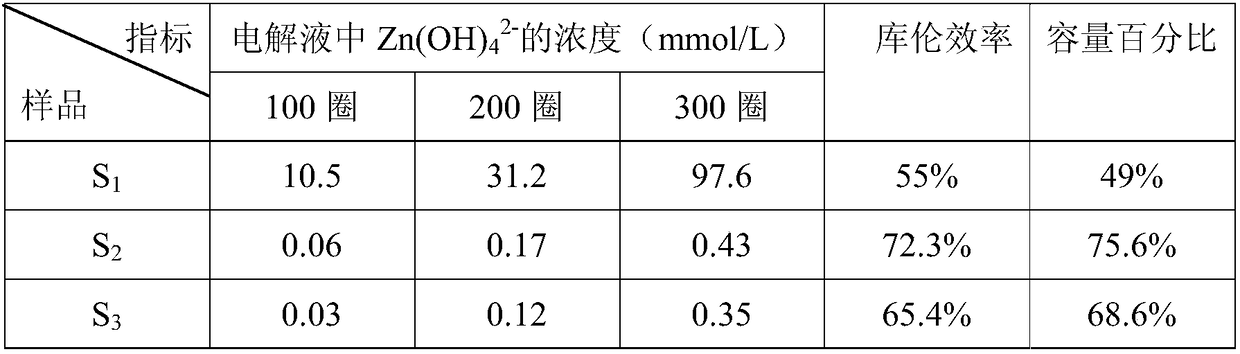

Negative electrode material of zinc-based secondary batteries and preparation method thereof

InactiveCN108288695AChange wrappingCoated evenlyAlkaline accumulatorsCell electrodesResin coatingMetal particle

The invention relates to a negative electrode material of zinc-based secondary batteries and a preparation method thereof. According to the method, a modification reagent is added to make positive charges evenly distributed on the surface of zinc oxide, cationic resin uniformly coats zinc oxide through electrostatic adsorption, and the thickness is 5-50 nm. The zinc oxide coated with the cationicresin is put into a mixed metal salt solution and stirred, metal ions are uniformly adsorbed in a cationic resin coating layer, and a reducing agent is added to make the metal ions reduced to metal elementary substances of 3-7 nm. The cationic resin coating the zinc oxide can effectively inhibit Zn(OH)42- from diffusing into an electrolyte solution and prevent or release the deformation and dendrite growth of zinc negative electrodes in charging and discharging circulation; nanoscale metal particles adsorbed in the cationic resin layer can improve hydrogen evolution overpotential and coulombicefficiency and reduce hydrogen evolution corrosion and dendrite growth. By means of the method, the cycle performance of the zinc negative electrodes can be improved, and the marketization of the zinc-based secondary batteries is facilitated.

Owner:CENT SOUTH UNIV

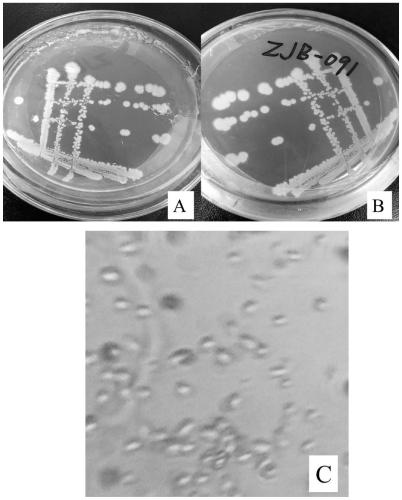

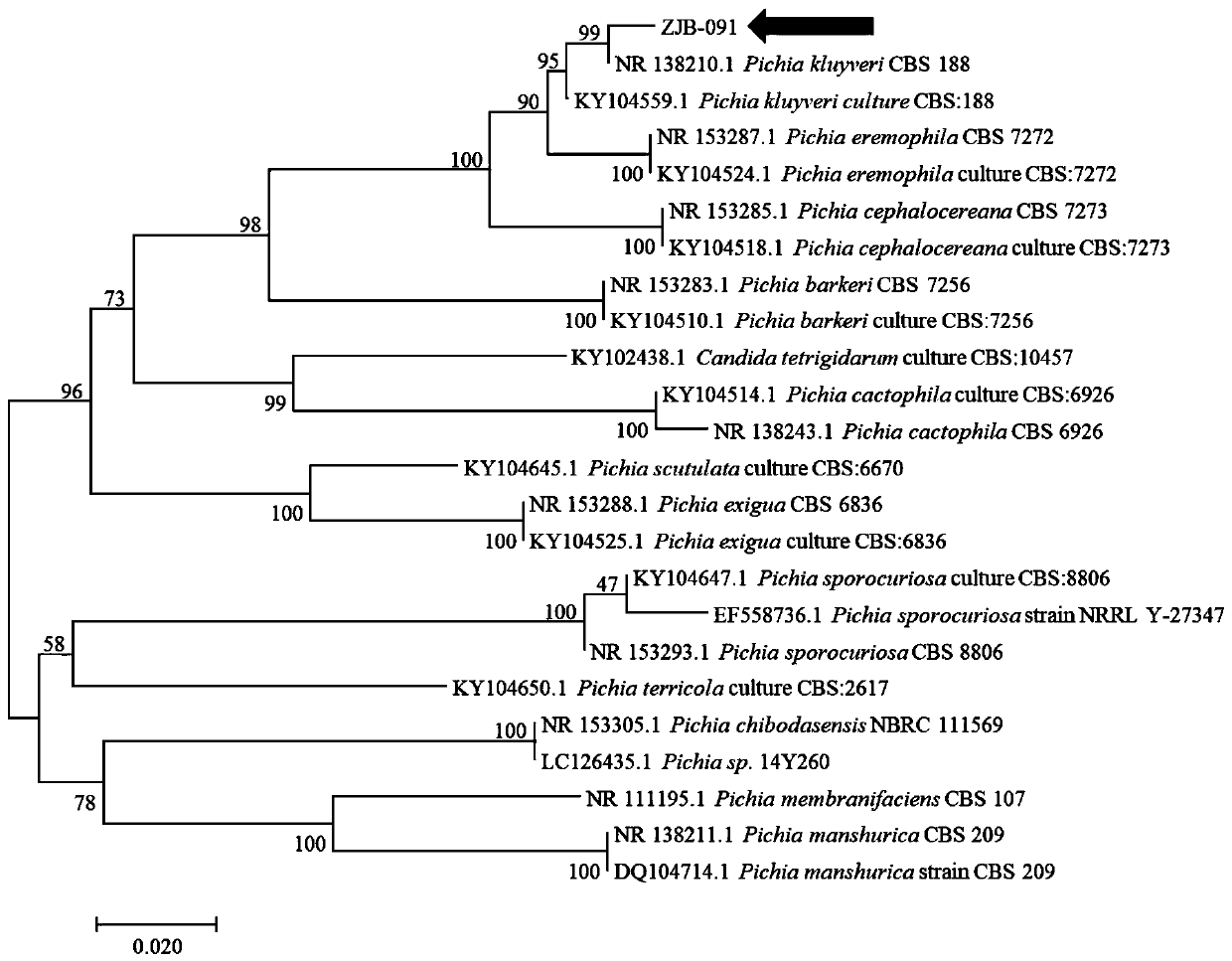

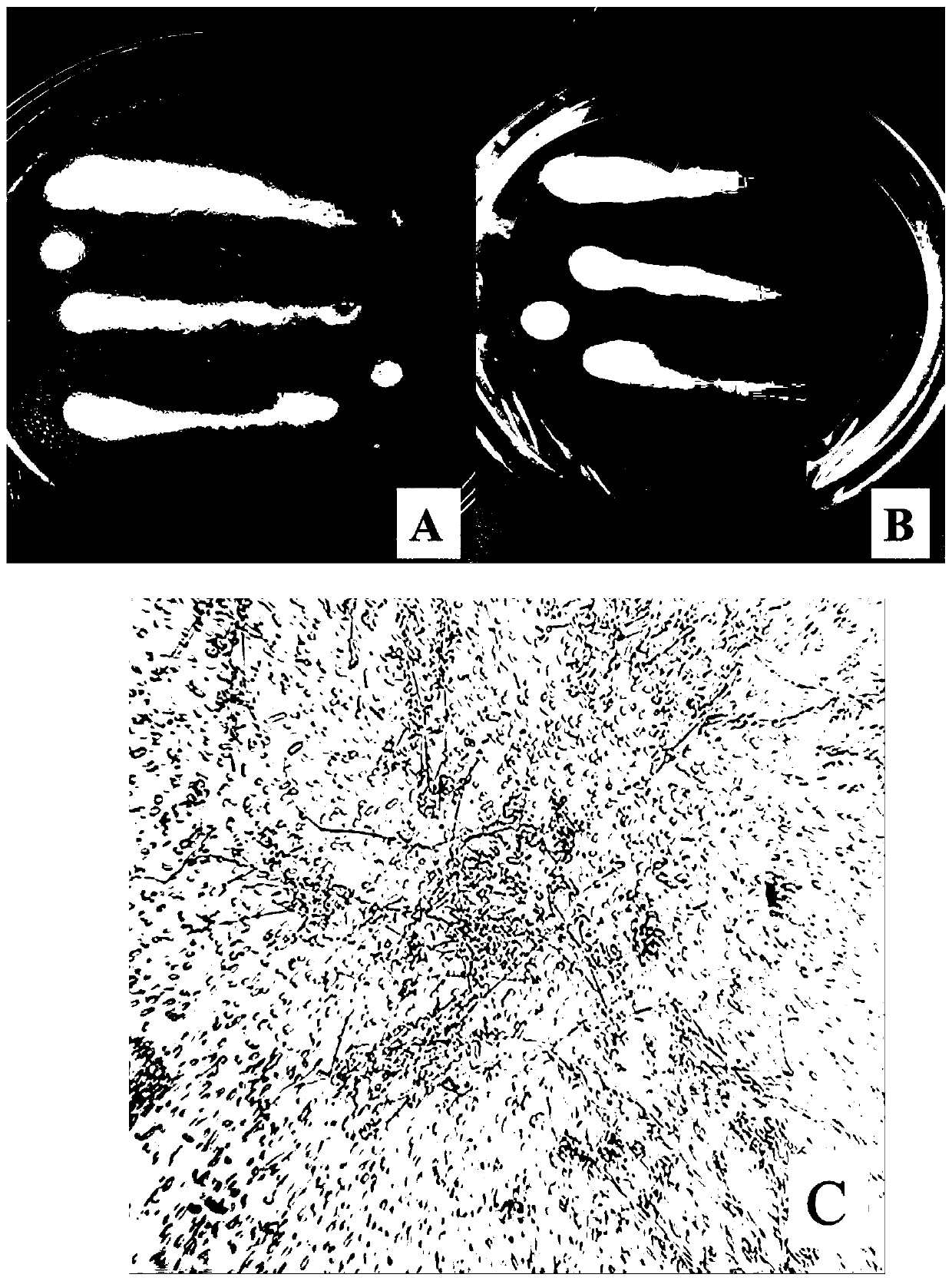

Preparation method of immobilized microbial agent for kitchen waste treatment and application thereof

ActiveCN110257365AHigh viable countAvoid lostTransportation and packagingSolid waste disposalHigh densityGeotrichum silvicola

The invention discloses a preparation method of an immobilized microbial agent for kitchen waste treatment and an application thereof. The method comprises the following steps: respectively performing high-density liquid fermentation on Kluyer pichia yeast and geotrichum silvicola, and mixing the bacterial liquids in proportion; after concentrating a composite bacterial solution, adding the composite bacterial solution to a modified carrier, mixing the materials, adding a crosslinking agent during a mixing process, and then performing constant temperature aeration culture; and after constant temperature aeration, performing low temperature drying to obtain the immobilized microbial agent. The method of the invention not only significantly increases the amount of carrier immobilized thalline, but also makes the binding between the carrier and the thalline tight, prevents the living bacteria from being lost in the preparation process and the preservation, improves the live bacteria of the unit mass of the microbial agent, and reduces the amount of the microbial agent; The prepared microbial agent has strong capability for decomposing the kitchen waste, the odor generated in the process of degrading the kitchen waste can be eliminated, the amount of the thalline immobilized in the carrier is large, the binding between the carrier and the thalline is closer, and the biomass of the living bacteria is large.

Owner:ZHEJIANG UNIV OF TECH

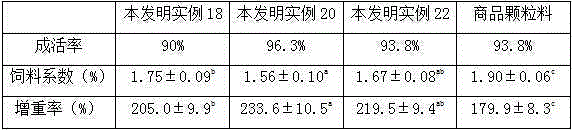

Slowly-sinking puffed compound feed for misgurnus anguillicaudatus and production process thereof

InactiveCN105010738AIncrease profitPromote healthy growthAnimal feeding stuffFood shapingBiotechnologyAnimal science

The invention relates to slowly-sinking puffed compound feed for misgurnus anguillicaudatus and a production process thereof, and belongs to the technical field of misgurnus anguillicaudatus feed. The feed comprises 5-10 parts of fish meal, 3-10 parts of pork meal, 10-25 parts of bean meal, 3-8 parts of peanut meal, 5-15 parts of cottonseed meal, 5-20 parts of rapeseed meal, 3-10 parts of corn DDGS, 5-15 parts of rice bran, 15-20 parts of flour, 2-4 parts of soybean oil, 1-3 parts of monocalcium phosphate, 2-5 parts of bentonite, 0.2-1.5 parts of vitamin premix, 1-3 parts of microelement premix, 0.05-0.5 part of choline chloride, 0.05-0.1 part of antioxidant and 0.05-0.1 part of mould inhibitor. The utilization rate of the slowly-sinking puffed compound feed is increased for the misgurnus anguillicaudatus, healthy growth of the misgurnus anguillicaudatus is promoted, and pollution of remnant feed and metabolic waste to aquatic water is reduced. The volume weight of the produced slowly-sinking puffed compound feed is kept between that of granular feed and that of puffed feed, the feed has the characteristic of sinking slowly in water like the granular feed and further has the advantage of being long in water resisting time like the puffed feed, and therefore the feed meets the feeding characteristics of misgurnus anguillicaudatus.

Owner:TONGWEI

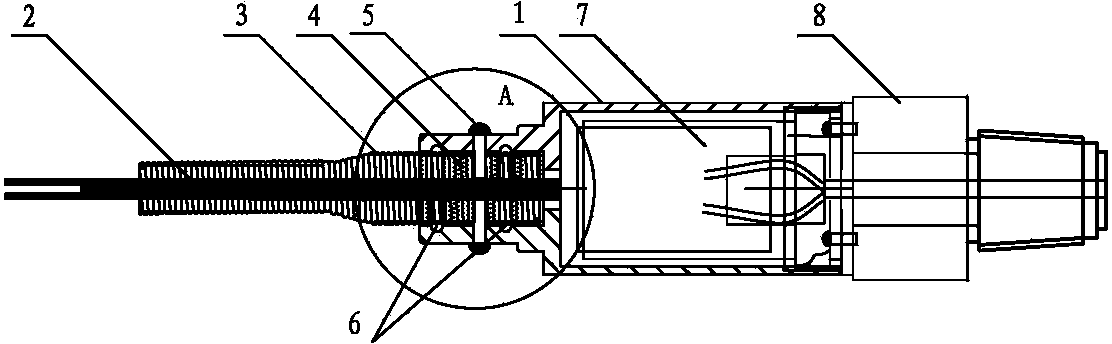

Fixing device of leading-out cable of pressure sensor

InactiveCN103471763AIncrease tightnessMeeting Industrial NeedsForce measurementFluid pressure measurementEngineeringSealant

The invention relates to a fixing device of a leading-out cable of a pressure sensor, and aims to solve the problems that the existing pressure sensor is damaged or measure failure is caused due to the fact that the leading-out cable is not fixed. A fastening spring screw is arranged between an outer cover of the pressure sensor and a leading-out terminal of the leading-out cable and is near to the leading-out cable after passing through the outer cover of the pressure sensor, a cable-protecting spring and a pouring sealant. Furthermore, a fastening spring screw pouring sealant ring groove is formed in the inner wall of a part in which the pouring sealant is filled, of the outer cover of the pressure sensor. Based on the arrangement of the fastening spring screw and the fastening spring screw pouring sealant ring groove, the outer cover, the cable-protecting spring and the pouring sealant of the pressure sensor and the leading-out cable are fixed into a whole after the pouring sealant is solidified, so that the leading-out cable can be firmly connected with a transmitting circuit board always no matter the pressure sensor is used under a severe environment or a vibration environment. Thus, the normal use of the pressure sensor is ensured.

Owner:QINGDAO AEROSPACE SEMICON RES INST

Pipeline supporting device for hydraulic engineering

InactiveCN110260051AEasy to moveIncrease tightnessPipe supportsPipe supportArchitectural engineering

The invention relates to the field of hydraulic engineering pipeline erecting, and specifically discloses a pipeline supporting device for hydraulic engineering. The device comprises a base, a fixing box, a gear guide rod, a fixing platform and three fastening assemblies, wherein the fixing box is fixedly mounted at the upper end of the base; the lower end of the gear guide rod extends into the fixing box, and the upper end of the gear guide rod penetrates through the fixing box and then is connected to the fixing platform; and the three fastening assemblies are fixedly welded on the fixing platform. The device is reasonable in structure design, and high in practicability; a transmission assembly is operated to adjust the height of the gear guide rod, thus the height position of the fastening assembly is changed based on the mounting demand; the operation is simple; the height position is accurately adjusted; in addition, limiting assemblies arranged on the fastening assemblies are capable of further improving the fastening degree of the fastening assemblies to hydraulic engineering pipelines.

Owner:焦新建

Metal plate asynchronous rolling method

InactiveCN101524707ASimple methodImprove metallographic structureMetal rolling arrangementsRoll speed control deviceMetalCrystal

The invention discloses a metal plate asynchronous rolling method which adopts a rolling pair roller for rolling, and an upper rolling roller and a lower rolling roller of the rolling pair roller adopt different linear velocity when rolling metal plates. The invention has simple method, and rolled products have good metallurgical structure, fine and uniform crystal grains, strong intensity, favorable tightness and good quality.

Owner:江苏包罗铜材集团股份有限公司

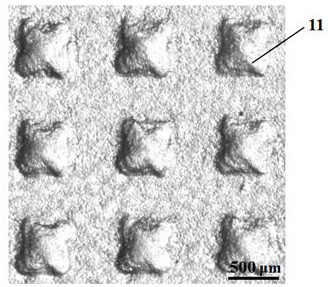

Multifunctional flexible tactile sensor and preparation method thereof

ActiveCN112179410AHigh detection sensitivityImprove real-time detection performanceMeasurement devicesPlanar electrodeTactile sensor

The invention discloses a multifunctional flexible tactile sensor and a preparation method thereof. The multifunctional flexible tactile sensor with a novel structure is obtained by introducing the elastic layer and the flexible sensing layer and adopting a multi-layer fitting assembly method, the elastic layer is provided with the micro-bulge array for conducting mechanical information and the through hole array for conducting temperature information, the flexible sensing layer comprises a pressure sensing unit array, a temperature sensing unit array and a flexible insulating substrate, and the surface of the flexible insulating substrate is provided with a planar electrode array. The structure can realize multifunctional detection of tactile information such as pressure, sliding and temperature by the sensor, realizes real-time detection of spatial distribution of the tactile information by the sensor, and overcomes the defect of single measurement function of a tactile sensing device in the prior art. The sensor can be directly worn at the tail end of a finger of the manipulator and acquire tactile information of the manipulator in real time, and has the characteristics of array, multiple functions, wearable performance, low cost and customizability.

Owner:ZHEJIANG LAB

Preparation of zircite tube

The invention relates to a preparation method for a zirconia tube. The method comprises the following steps: firstly, the preparation of ceramic slurry: ceramic powder, microcrystalline wax, polyethylene or polypropylene and oleic acid are fully mixed; secondly, injection molding: suitable particles required for injection molding are produced through a granulating machine, and finally the blank of the zirconium tube of an oxygen sensor is produced; thirdly, low-temperature dewaxing: low-temperature heating treatment is performed for a long term, in order to discharge the paraffine resin adhesive; fourthly, isostatic cool pressing: the stress to the blank is uniform in all directions, in order to eliminate the gap reserved in the blank after dewaxing; fifthly, high temperature sintering: the zirconia tube is sintered. The invention provides a preparation method which can effectively enhance the compactness of the zirconia tube with high rate of finished products.

Owner:浙江通源环保科技有限公司

Regenerated environmental-friendly yarn label strap and manufacturing method thereof

ActiveCN103572468AIncrease tightnessGood orientationHeating/cooling textile fabricsWoven fabricsYarnGram

The invention relates to a label strap and a manufacturing method of the label strap, in particular to a regenerated environmental-friendly yarn label strap and a manufacturing method of the regenerated environmental-friendly label strap. The thickness of the label strap is 0.11-0.15mm, the hardness is 2.8-3.7, and the gram weight is 120-180g / m<2>; base cloth is made of PET material, the specification of yarns for manufacturing the base cloth is 50-150D, the warp density is 90-130 roots / cm, and the weft density is 36-45 roots / cm. The manufacturing method includes the step of beaming, slashing and weaving, the step of pretreatment for dyeing and finishing; the step of dyeing, the step of sizing in a continuous and segmented mode, the step of calendering for the first time at the temperature of 150-170 DEG C, pressure of 5-15MPa and speed of 5-15m / min, the step of calendering for the second time at the temperature of 190-210 DEG C, pressure of 10-15MPa and speed of 10-16m / min and the step of slitting. The manufactured regenerated environmentally-friendly yarn label strap functionally defined to be suitable for a double-faced TTR hot transfer printing mode, the color fastness to soaping meets the GB / T3921 textile color fastness test standard, environmental requirements meet the OEKO-TEX primary standard, and the label strap is suitable for dry ink printing and wet ink printing modes.

Owner:HUZHOU SINY LABEL MATERIAL

Gypsum-based heat-insulation mortar and preparation method thereof

The invention discloses gypsum-based heat-insulation mortar and a preparation method thereof. The gypsum-based heat-insulation mortar is prepared from the following ingredients in parts by weight: 15to 25 parts of Portland cement, 30 to 40 parts of building plaster, 10 to 20 parts of glass bead, 10 to 30 parts of converter steel slag, 10 to 20 parts of coal ash, 5 to 15 parts of nano silicon dioxide powder, 15 to 25 parts of ash calcium powder, 5 to 10 parts of modified pulpified starch, 2 to 8 parts of dispersible latex powder, 5 to 15 parts of cellulose ether, 3 to 8 parts of crack-resistant fiber, 5 to 15 parts of modified talcum powder, 4 to 10 parts of binder, 0.3 to 0.7 part of air entraining agent, 0.2 to 0.6 part of water repellent, 0.1 to 0.5 part of water reducing agent and 40 to 60 parts of water. The gypsum-based heat-insulation mortar disclosed by the invention has the advantages of high strength, good heat insulation, small drying shrinkage, no easiness in cracking and the like. The gypsum-based heat-insulation mortar can meet a requirement of building industry to mortar performance indexes and can be widely applied to projects of heat insulation and the like of outer walls and inner walls of buildings.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

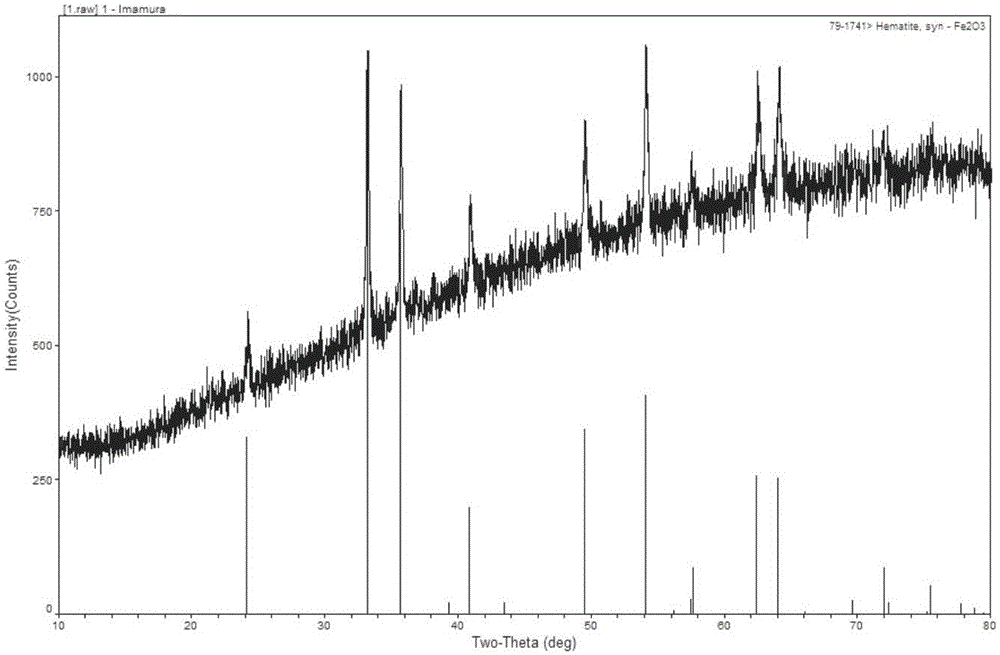

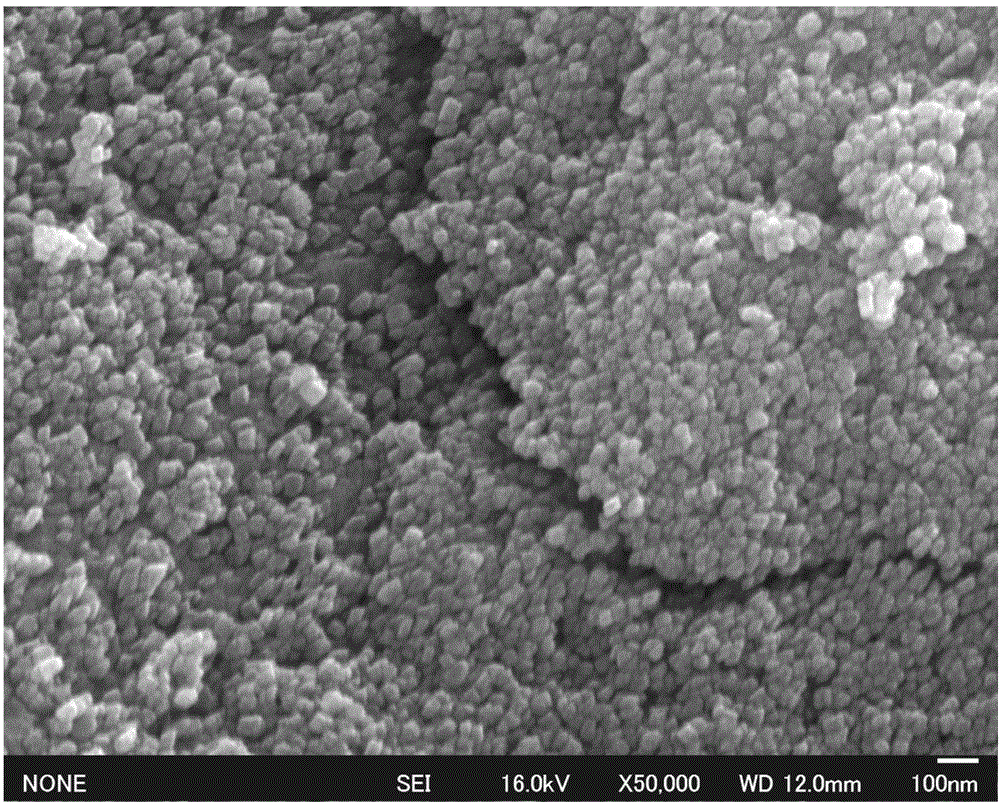

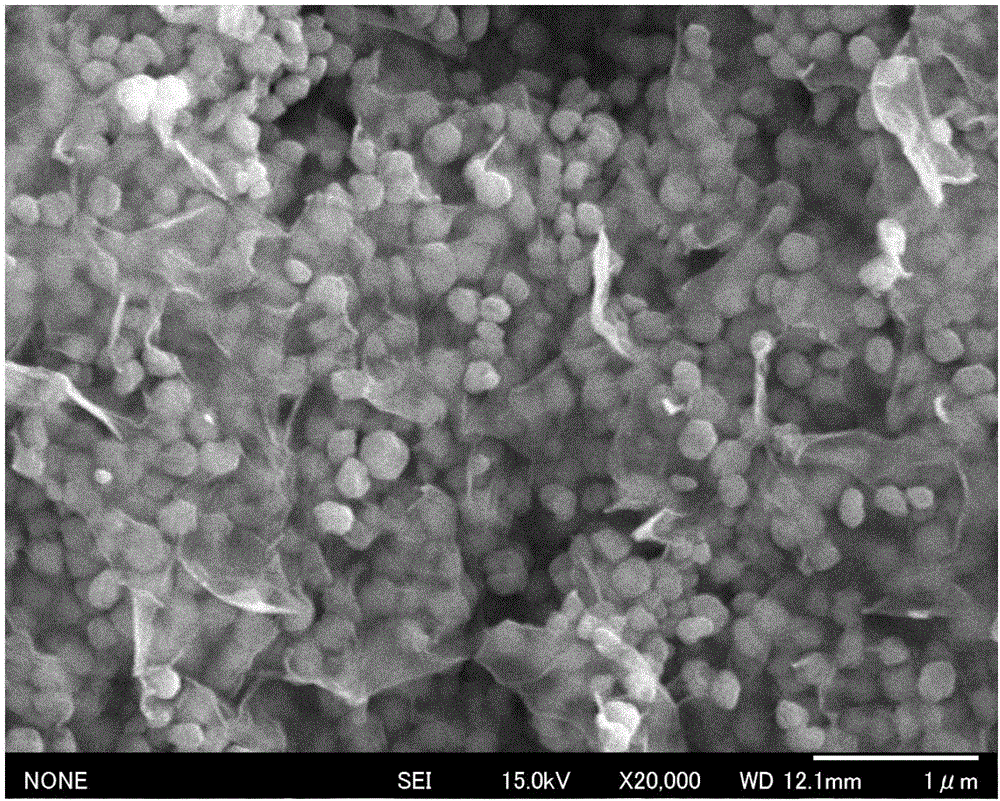

Method for preparing graphene-ferric oxide-graphene composite structure battery negative electrode material

ActiveCN106848220AImprove conductivityIncrease tightnessCell electrodesWater bathsBlack ferric oxide

The invention discloses a method for preparing a graphene-ferric oxide-graphene composite structure battery negative electrode material. The method comprises the following steps: preparing graphene loaded Fe2O3 through a first-step pyrolysis method; covering a graphene layer on the surface of Fe2O3 through a water bath method; and finally forming a graphene-ferric oxide-graphene sandwich structure. According to the structure, the electrical conductivity and charge and discharge stability of the ferric oxide can be obviously improved. Meanwhile, the equipment used in the method is simple and easy to realize.

Owner:SHAANXI UNIV OF SCI & TECH

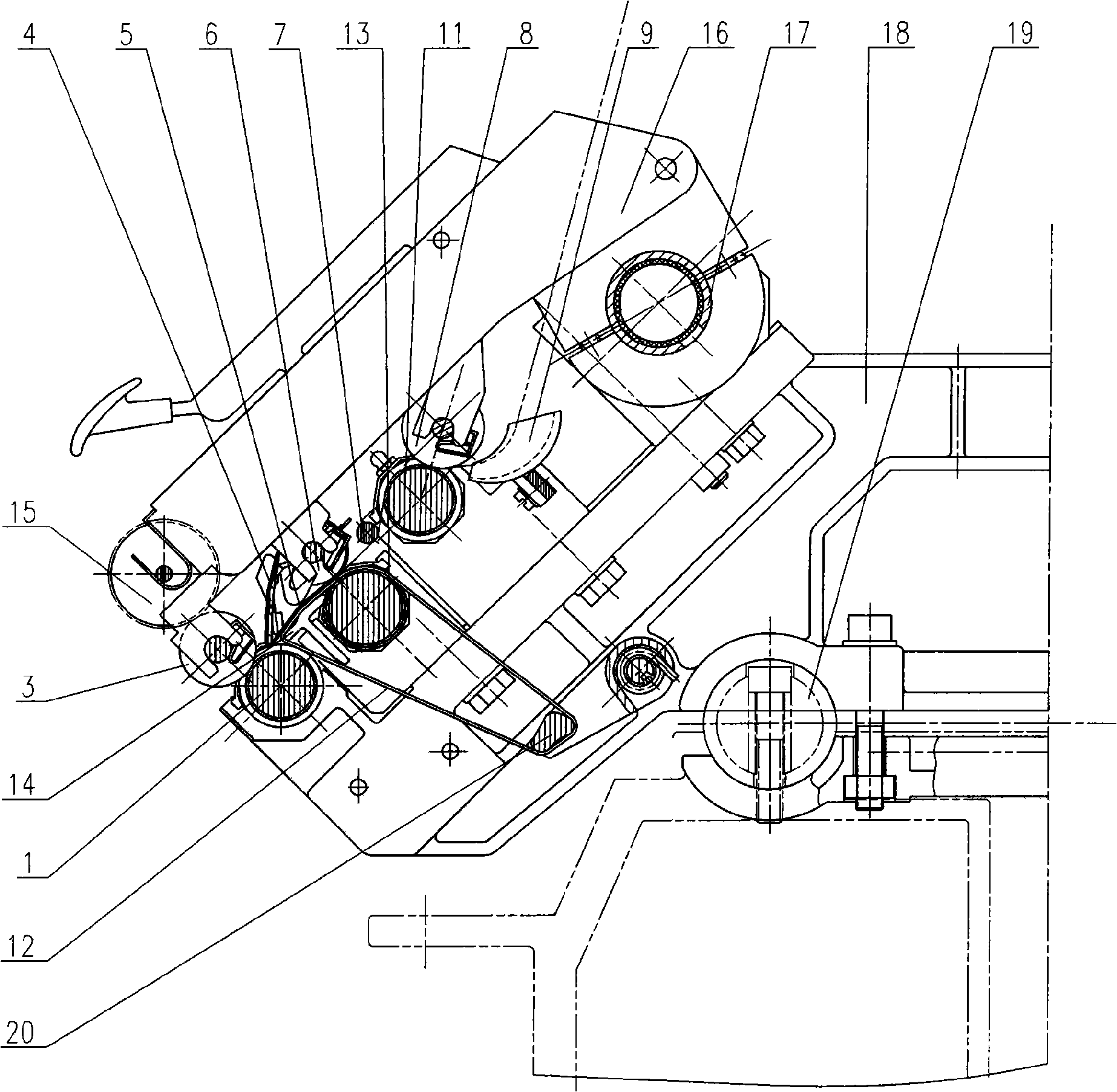

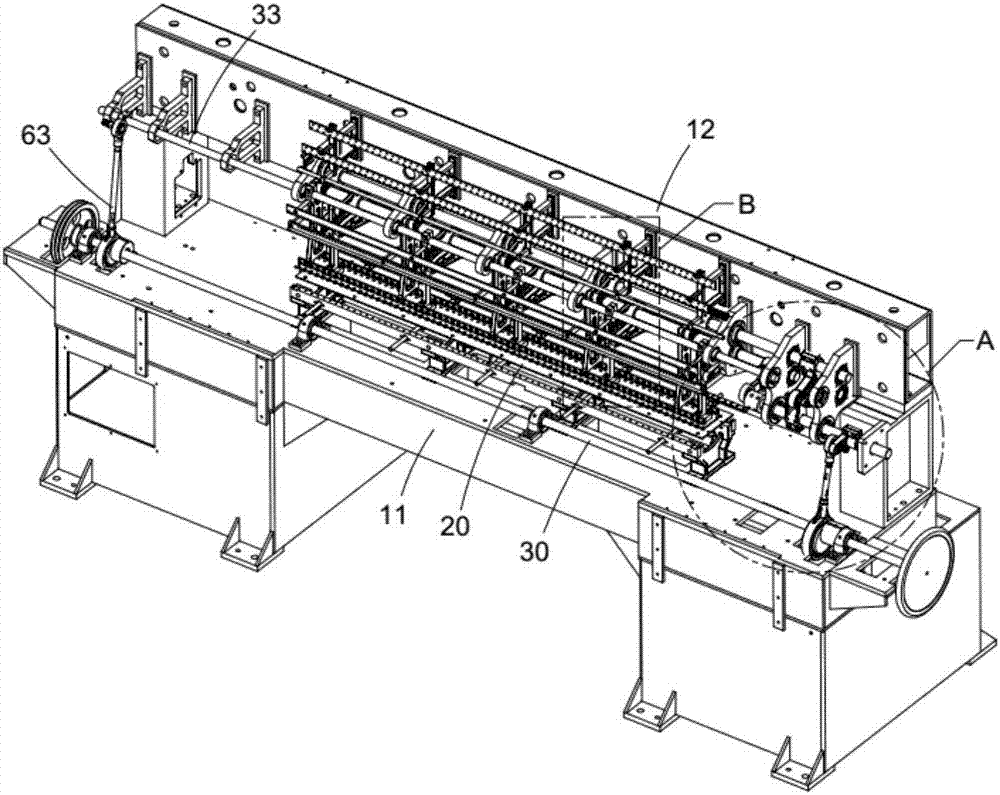

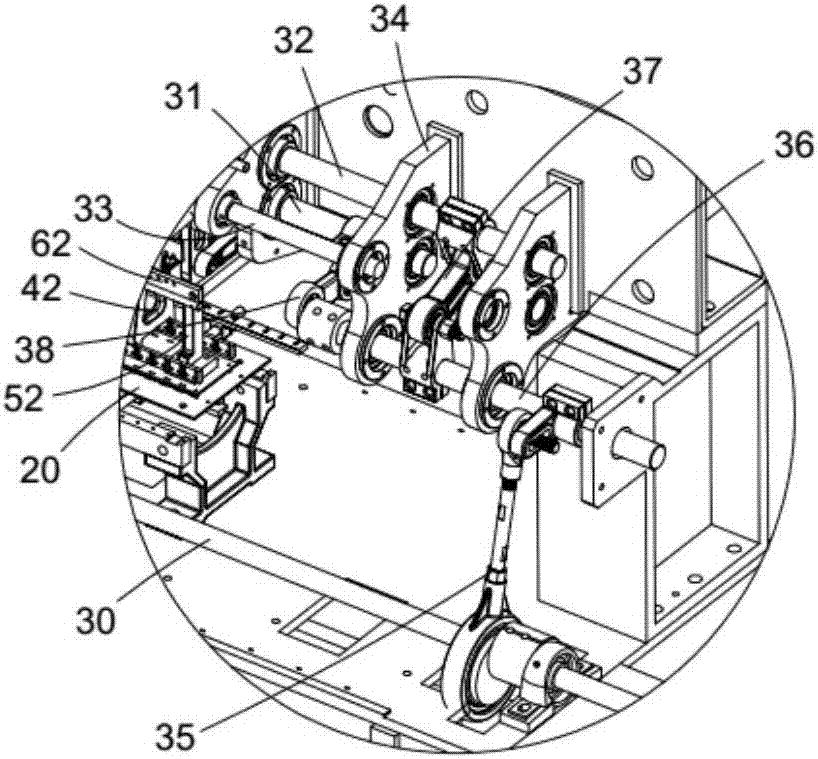

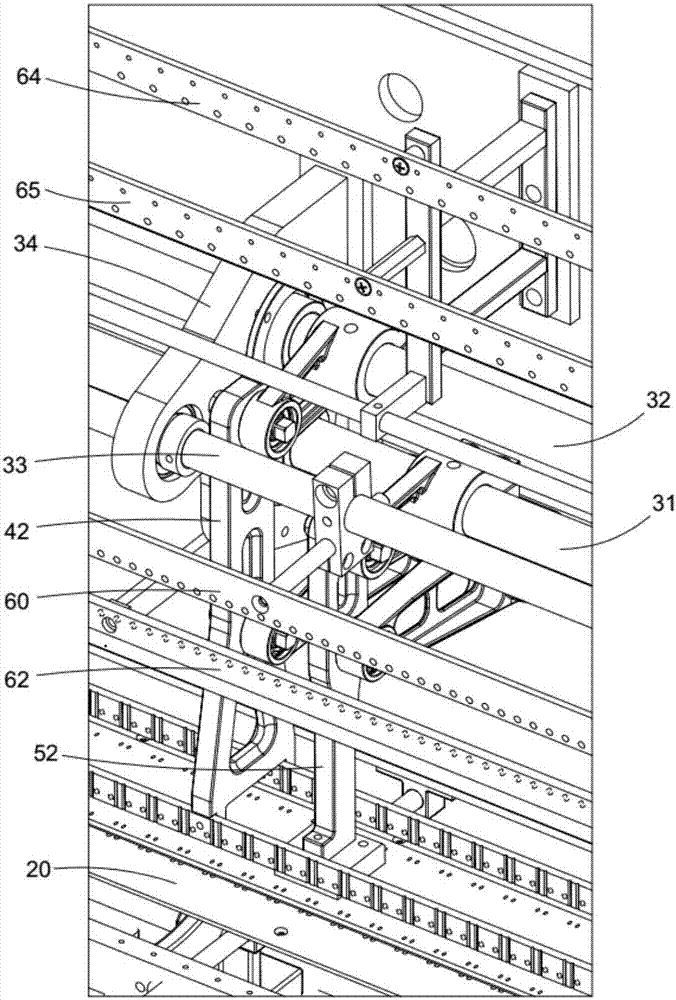

Quilting machine

ActiveCN107237050AImprove coordinationImprove stabilityFinal product manufactureSewing-machine control devicesDrive shaftEngineering

A quilting machine comprises a working platform and a quilting machine head. The quilting machine head comprises a pressing plate pressing a product, a needle frame provided with multiple quilting needles, a thread supplying module supplying quilting threads to the quilting needles and a power system driving the pressing plate, the needle frame and the thread supplying module to be linked, the power system comprises a pressing plate transmission shaft connected with the pressing plate, a quilting transmission shaft connected with the needle frame, a thread supplying transmission shaft connected with the thread supplying module and a main shaft connected with a power source, the main shaft is connected with a middle rotating shaft through a first cam-linkage mechanism, and the middle rotating shaft is connected with the quilting transmission shaft and the pressing plate transmission shaft through an ordinary linkage mechanism and a second cam-linkage mechanism separately. Accordingly, on the condition that the pressing plate keeps pressing the product, the product is sewn through the quilting needles, the tradition of synchronous lifting of the pressing plate and the quilting needles is broken through, the phenomenon that quilting threads on the product obtained after quilting is conducted are likely to loose is avoided, and the compact degree of the quilting threads on the textile product is increased.

Owner:东莞市钰腾机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com