Silicon-carbon anode paste and preparation method thereof

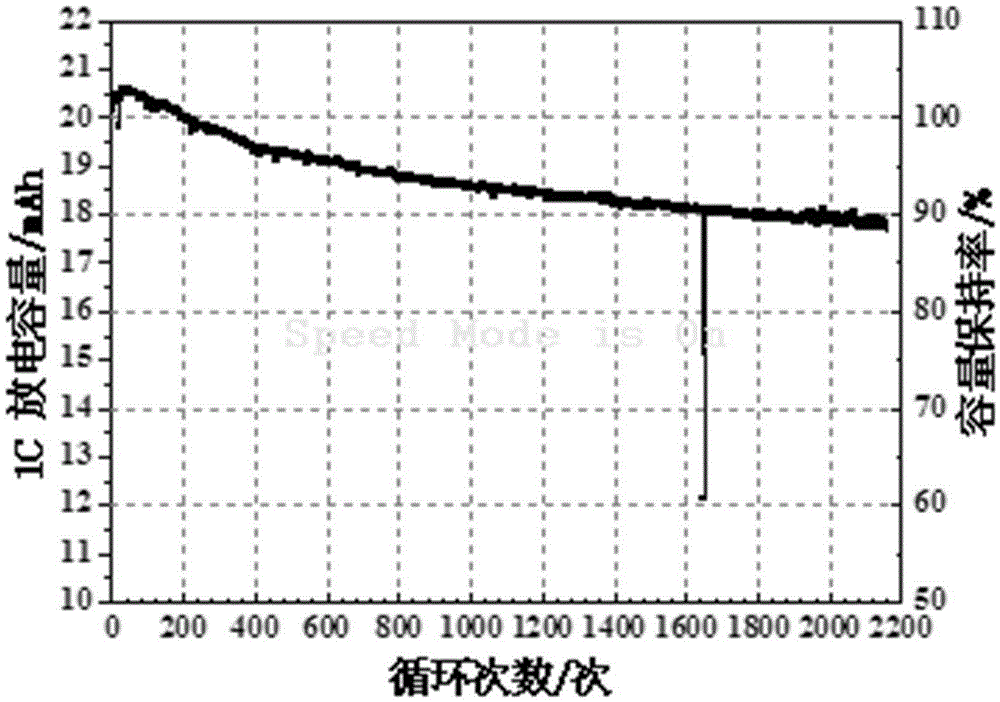

A technology of negative electrode slurry and negative electrode material, applied in battery electrodes, nanotechnology for materials and surface science, electrical components, etc., can solve the problem of material and current collector shedding, low lithium storage capacity, poor electrical conductivity and cycle performance and other problems, to achieve the effect of improving compaction density and electrical conductivity, improving cycle performance, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Mix 25±0.005kg of acrylonitrile multi-polymerized LA-type water-based electrode binder LA133 (Chengdu Yindile Power Technology Co., Ltd.) with a solid content of 15.0±0.2% and 62.5±0.005kg of deionized water into a planetary mixer (Guangzhou Hongyun Mixer Equipment Co., Ltd. HY-DLH (100L)) was stirred for 1~2h, the revolution speed was 10~20r / min, the rotation speed was 500~800r / min, and the binder solution was prepared and set aside for later use.

[0028] 1±0.005kg of carbon black Super-p conductive agent powder (Shanghai Huipu Industrial Chemicals Co., Ltd.) and 55±0.005kg of single-armed carbon nanotube suspension emulsion with a solid content of 0.2±0.01% (European OCSiAl company TUBALLSWCNT) were averaged Put the mixture into the planetary ball mill (MITR-QM-QX-100L of Changsha Miqi Instrument Equipment Co., Ltd.) and wet mix the ball mill in four alumina ball mill tanks. The diameter of the alumina ball is 3mm, the total mass of the ball is 50±0.1kg, and the revol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com