Quilting machine

A technology for a quilting machine and a quilting head, which is applied to sewing machine components, sewing machines for sewing quilts, and control devices for sewing machines, etc., can solve the problems of loose quilting threads, etc. Improves coordination and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

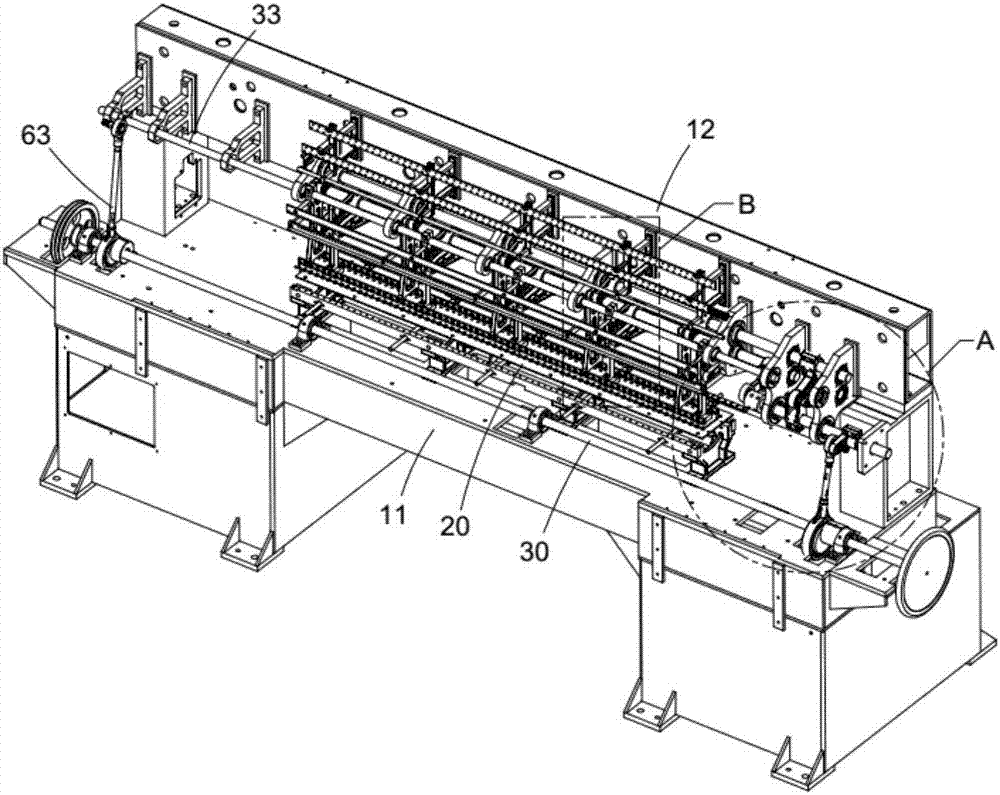

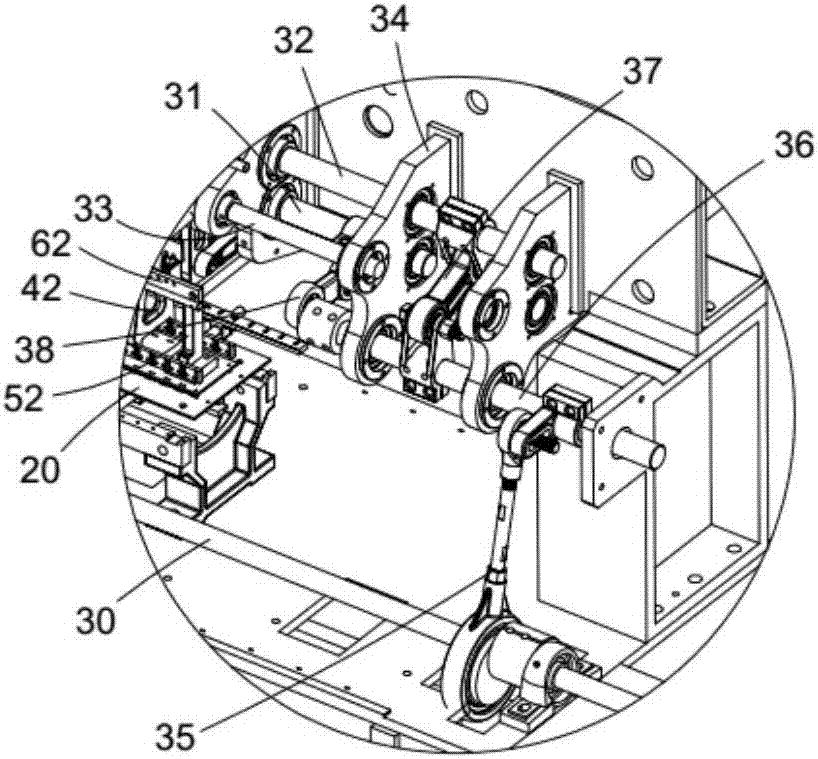

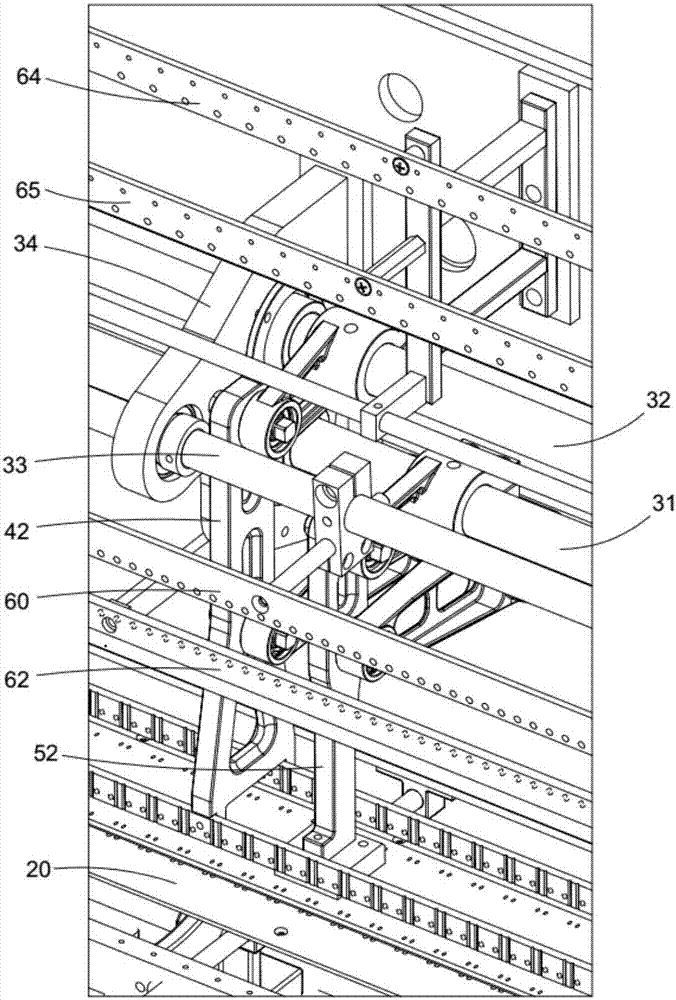

[0040] refer to Figure 1 to Figure 3 , a quilting machine, comprising a working platform 20 installed on a frame for receiving processed products, a quilting head positioned above the working platform, the quilting head includes a pressing plate lifting module for pressing products, a device There are quilting lifting modules for several quilting needles, a thread supply module for supplying quilting threads to the quilting needles, a power system that drives the platen lifting module, the quilting lifting module and the thread supply module, and the power system includes The platen drive shaft 31 connected to the platen lifting module, the quilting drive shaft 32 connected to the quilting lift module, the line supply drive shaft 33 connected to the line supply module, the main shaft 30 connected to the power source, the main shaft drives the platen drive shaft, quilting Seam drive shaft and line feed drive shaft linkage.

[0041] The main shaft 30 is pivotally connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com