Patents

Literature

579results about How to "Avoid splitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rolling circle replication of padlock probes

InactiveUS6558928B1Avoid splittingStrong specificitySugar derivativesMicrobiological testing/measurementNucleic acid hybridisationOligonucleotide

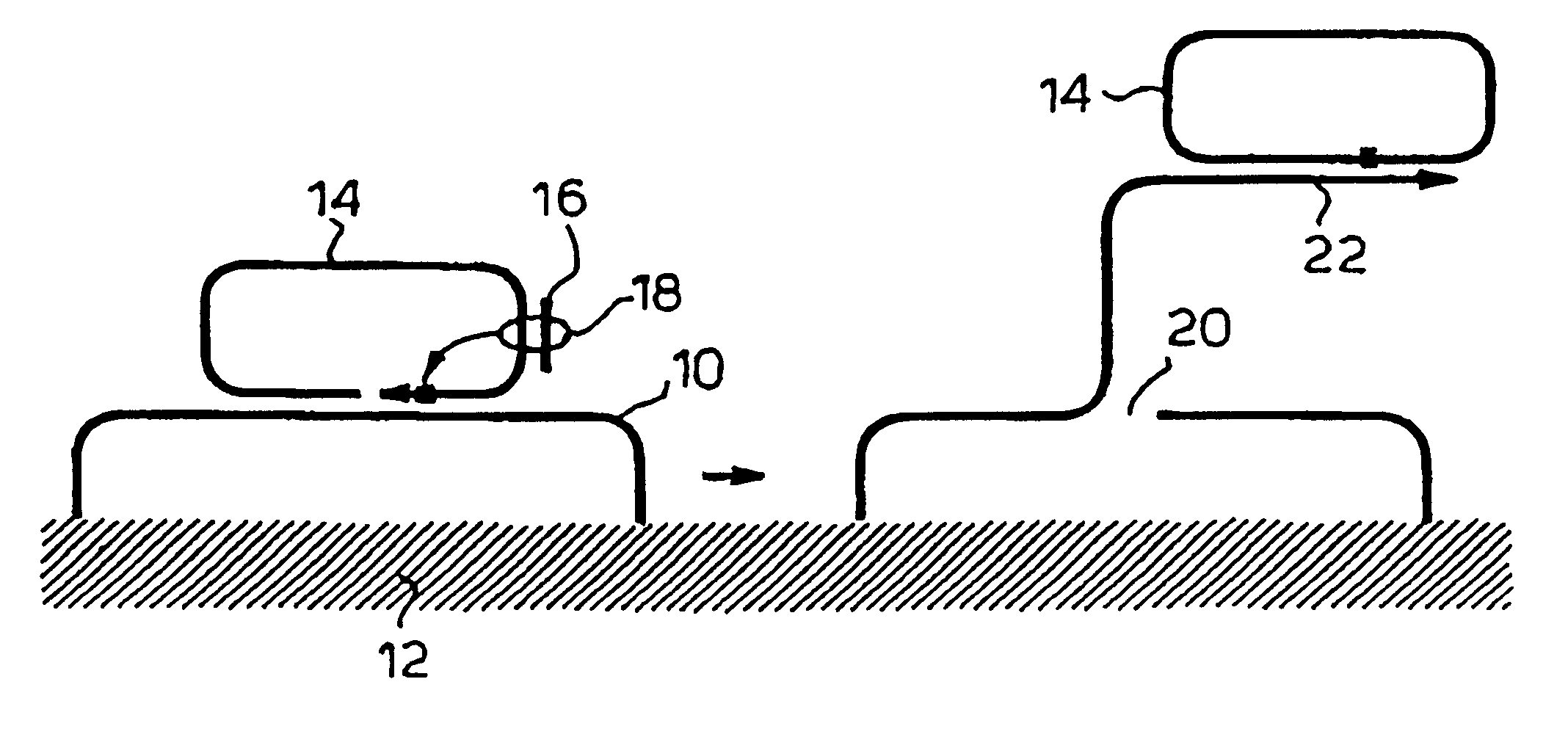

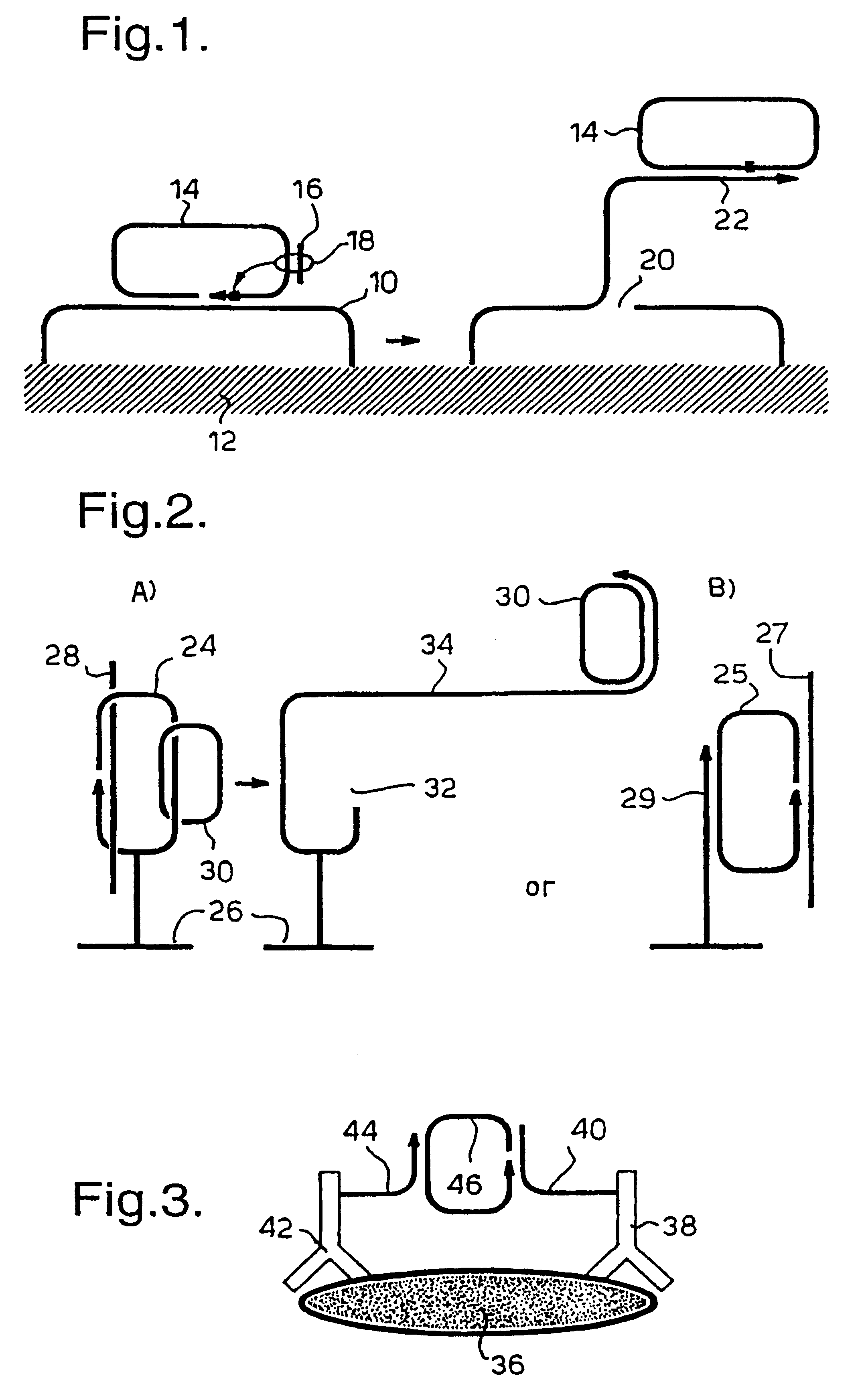

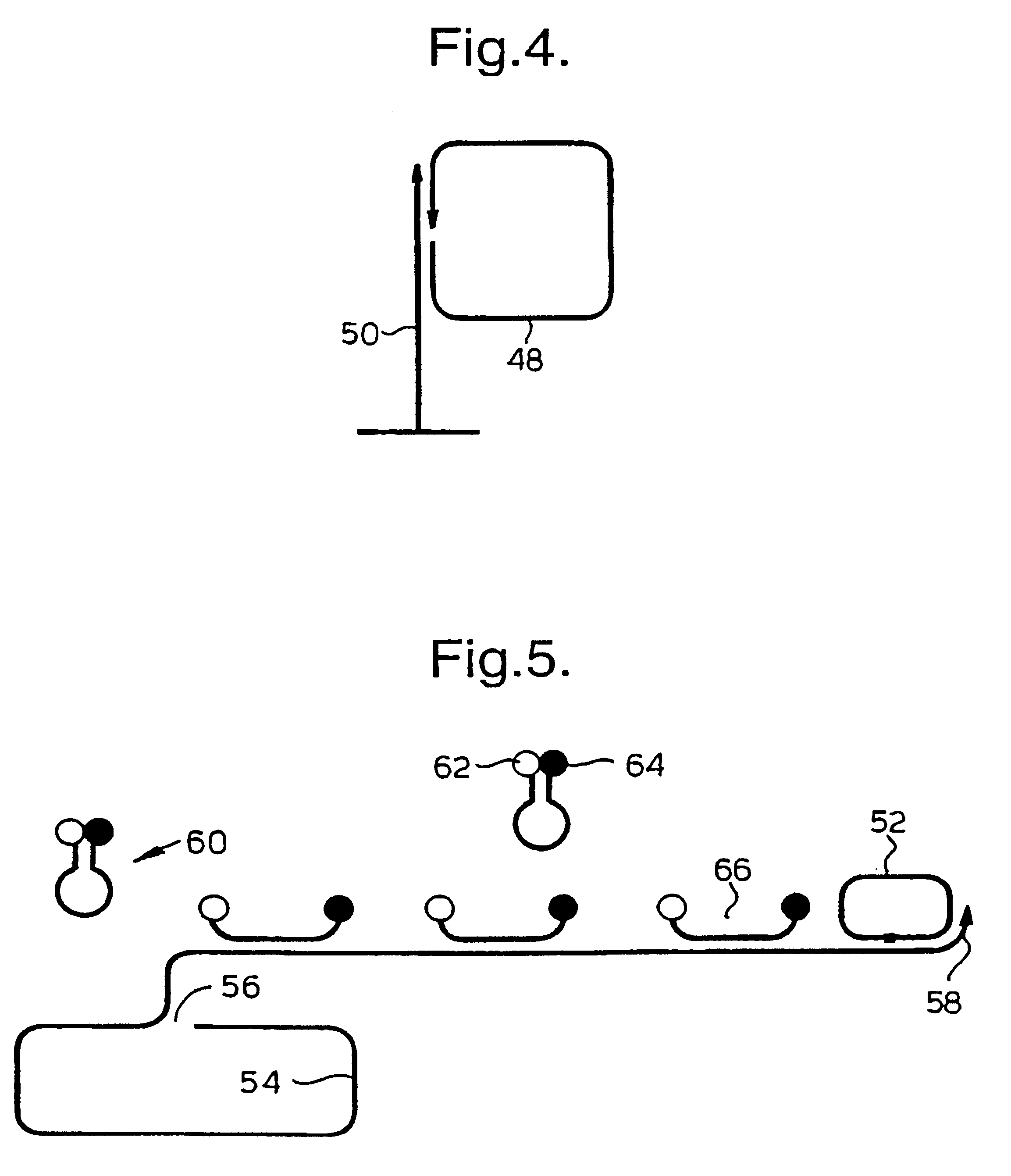

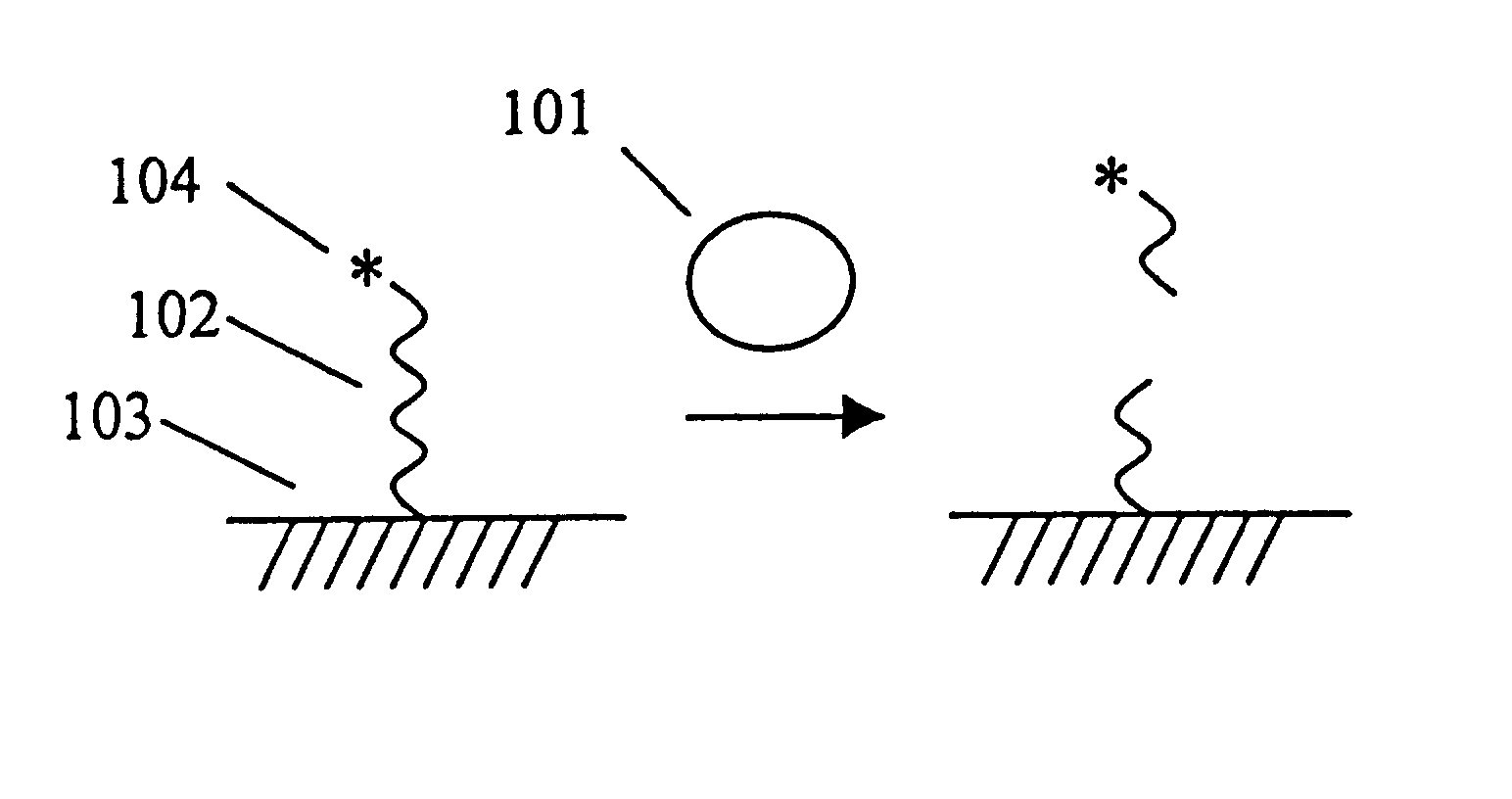

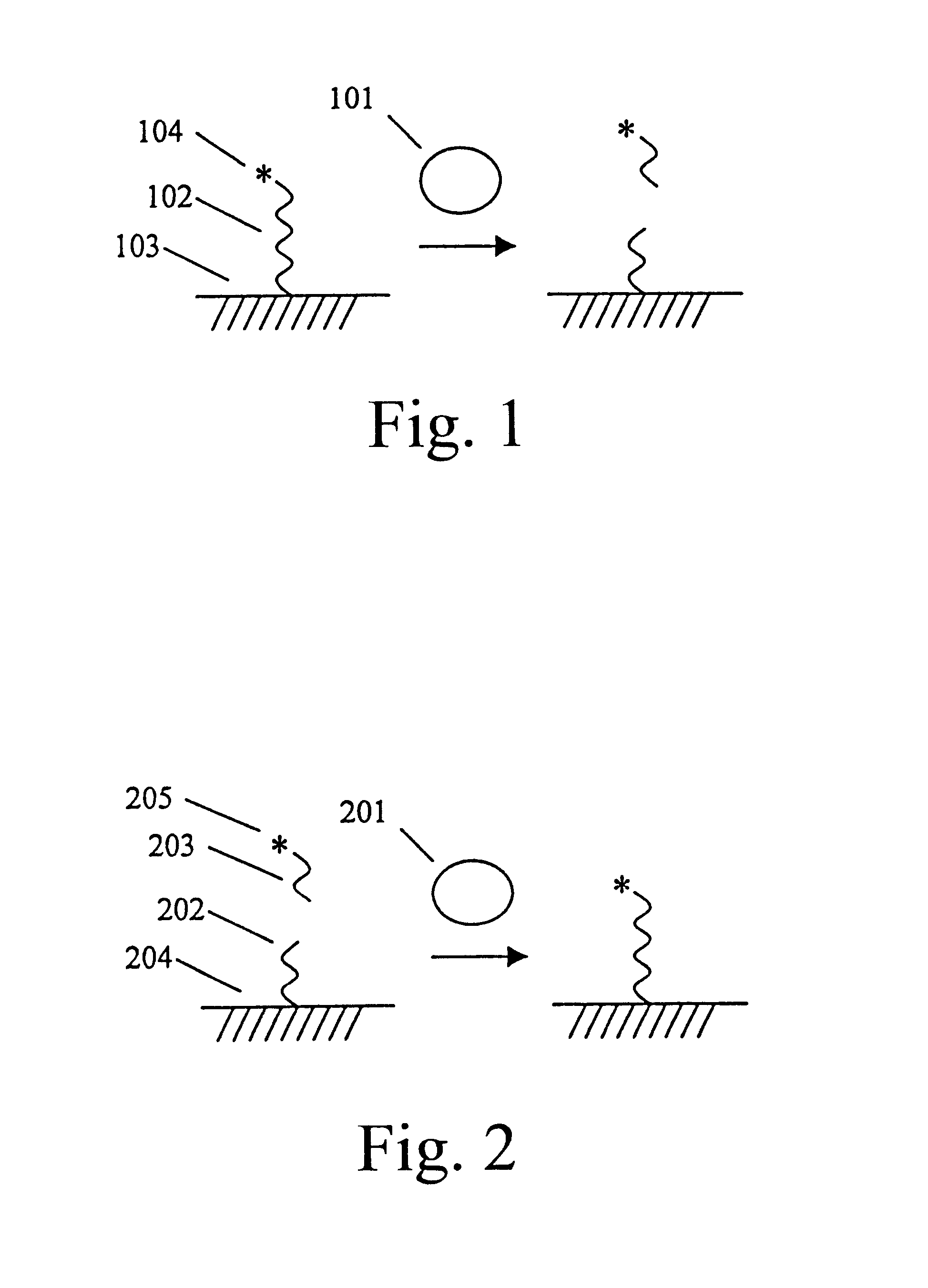

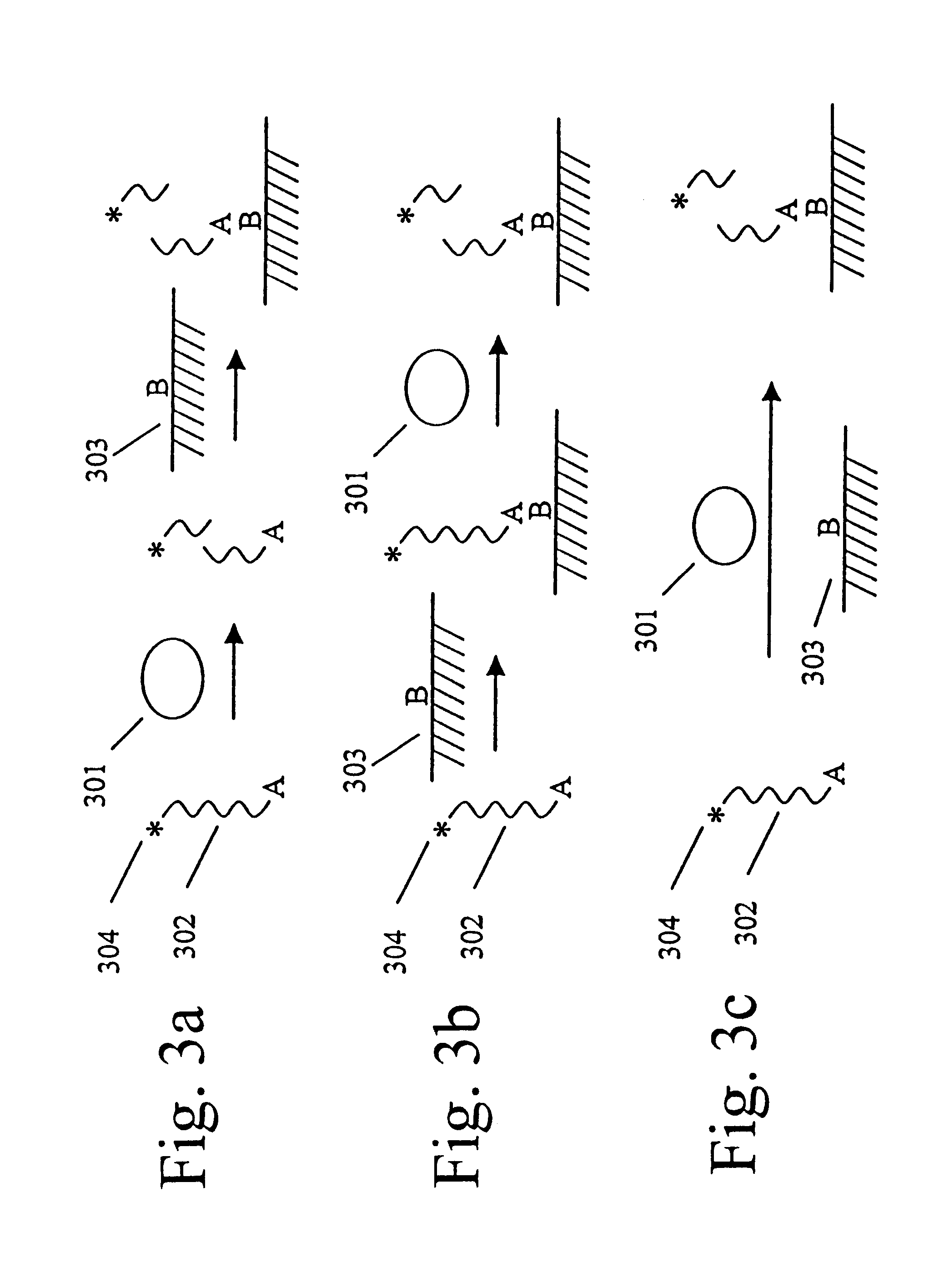

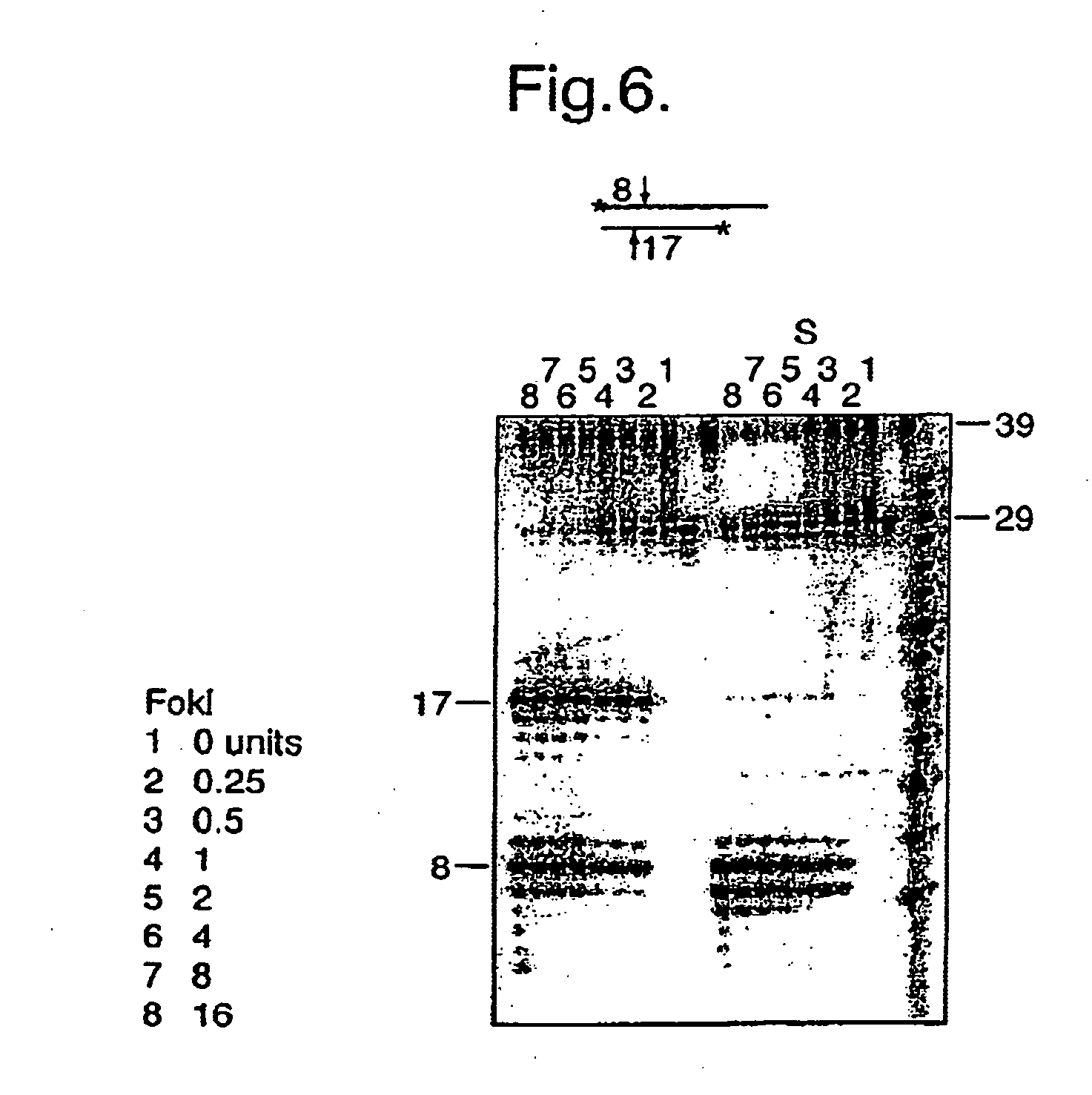

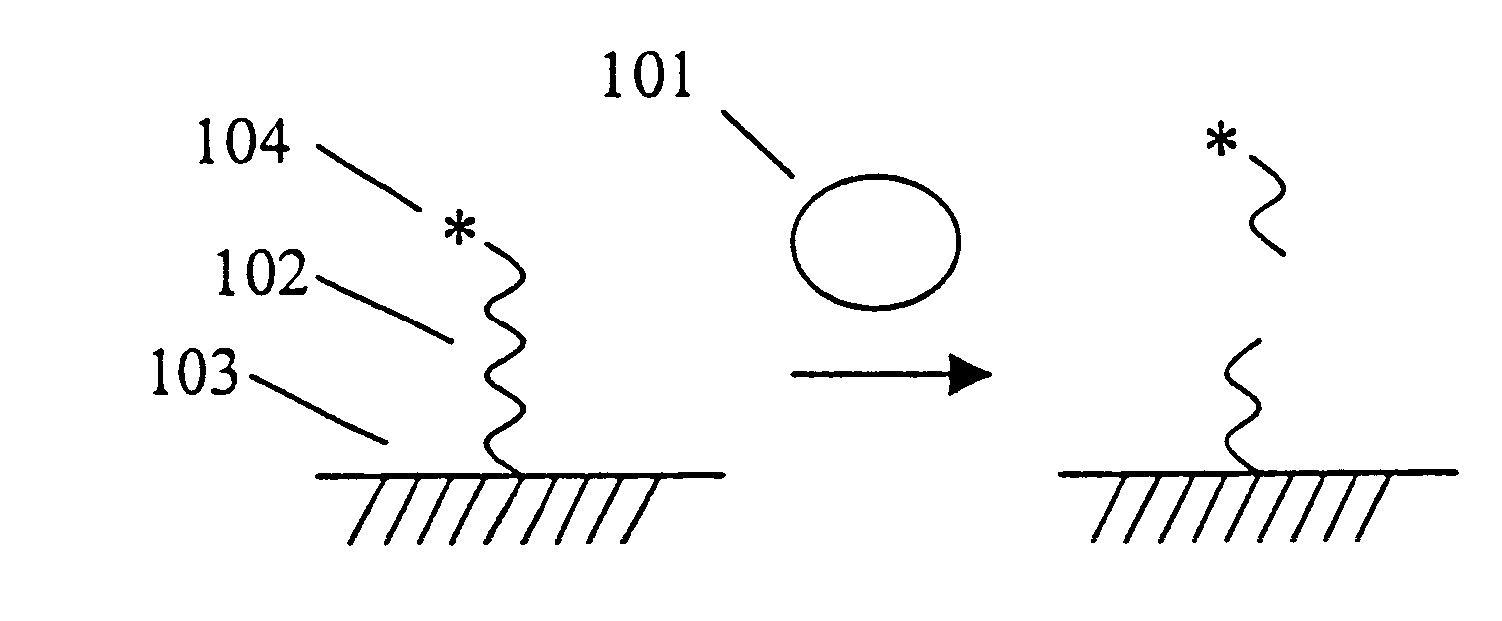

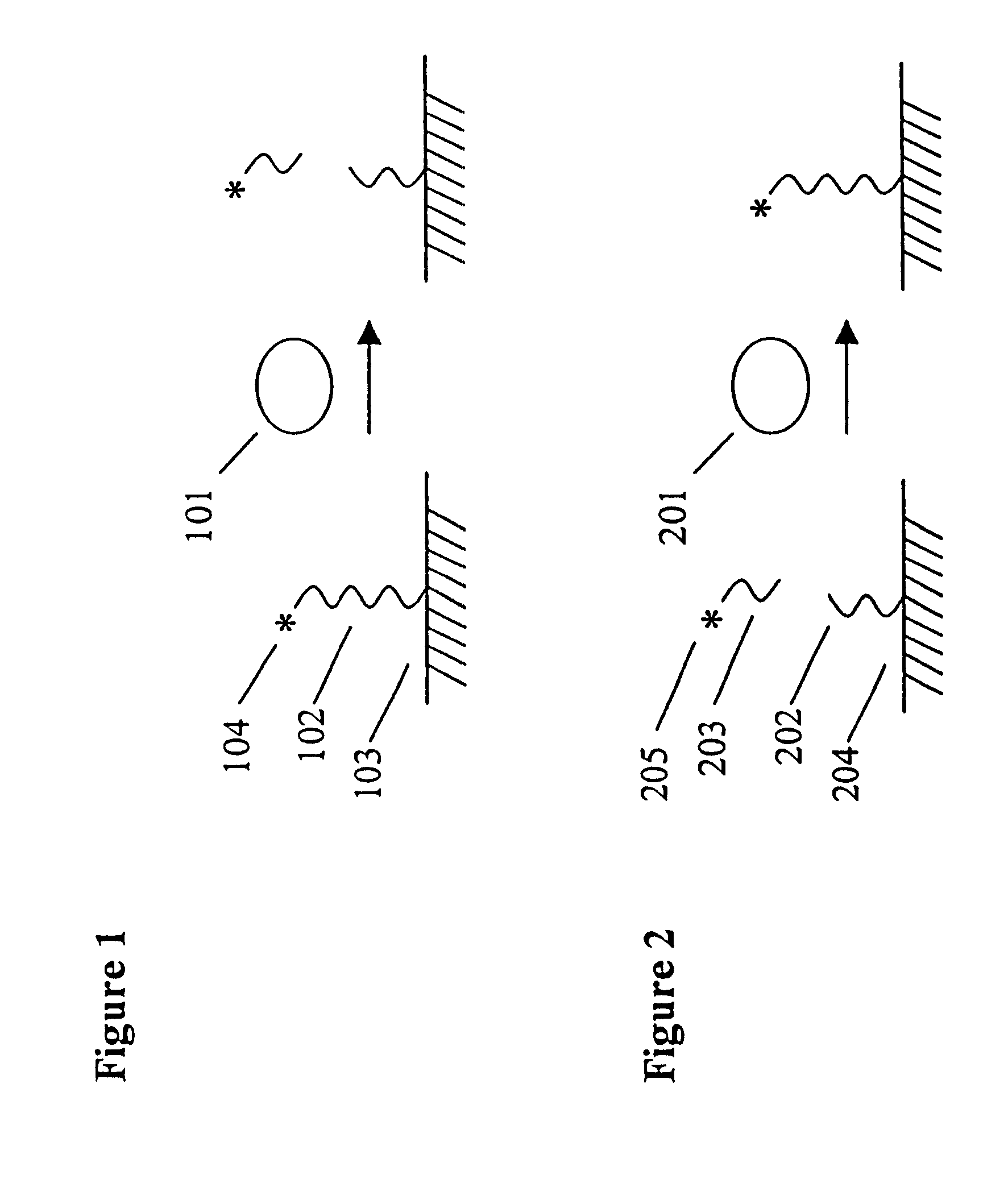

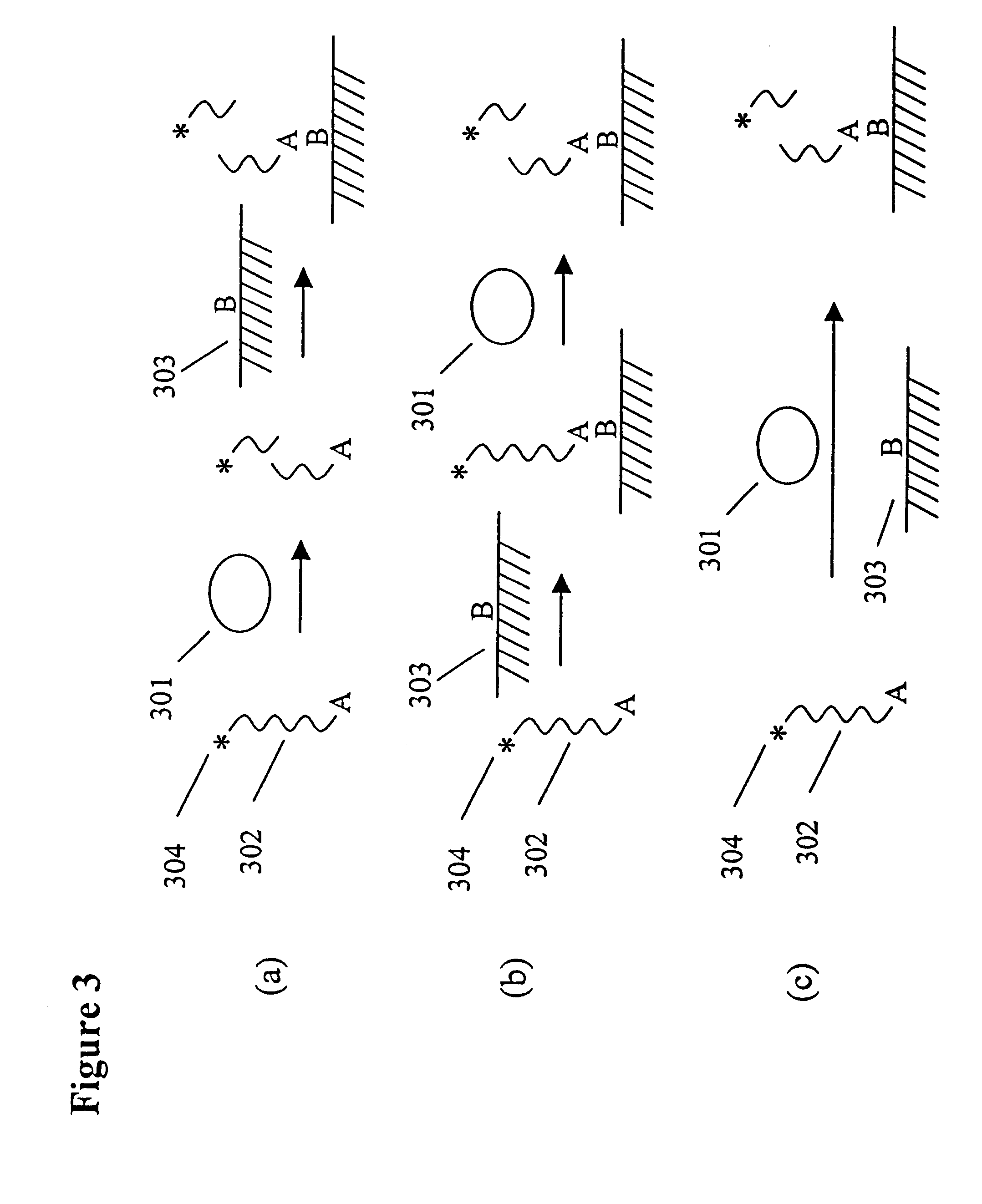

Rolling circle replication of a padlock primer is inhibited when it is hybridized to a target nucleic acid that is long or circular. The invention provides methods of addressing this problem including cutting the target nucleic acid near or preferably at the site which hybridizes with the padlock probe, whereby a 3'-end of the cut target nucleic acid acts as a primer for rolling circle replication of the padlock probe. Also included is a method of assaying for a polyepitopic target by the use of two affinity probes each carrying an oligonucleotide tag and of a padlock probe for rolling circle replication in association with the two affinity probes

Owner:SIGMA ALDRICH CO LLC

Assays for measuring nucleic acid damaging activities

InactiveUS6214552B1Simple and accurate and reliable assayEfficient transferSugar derivativesMicrobiological testing/measurementElectrochemiluminescenceDouble strand

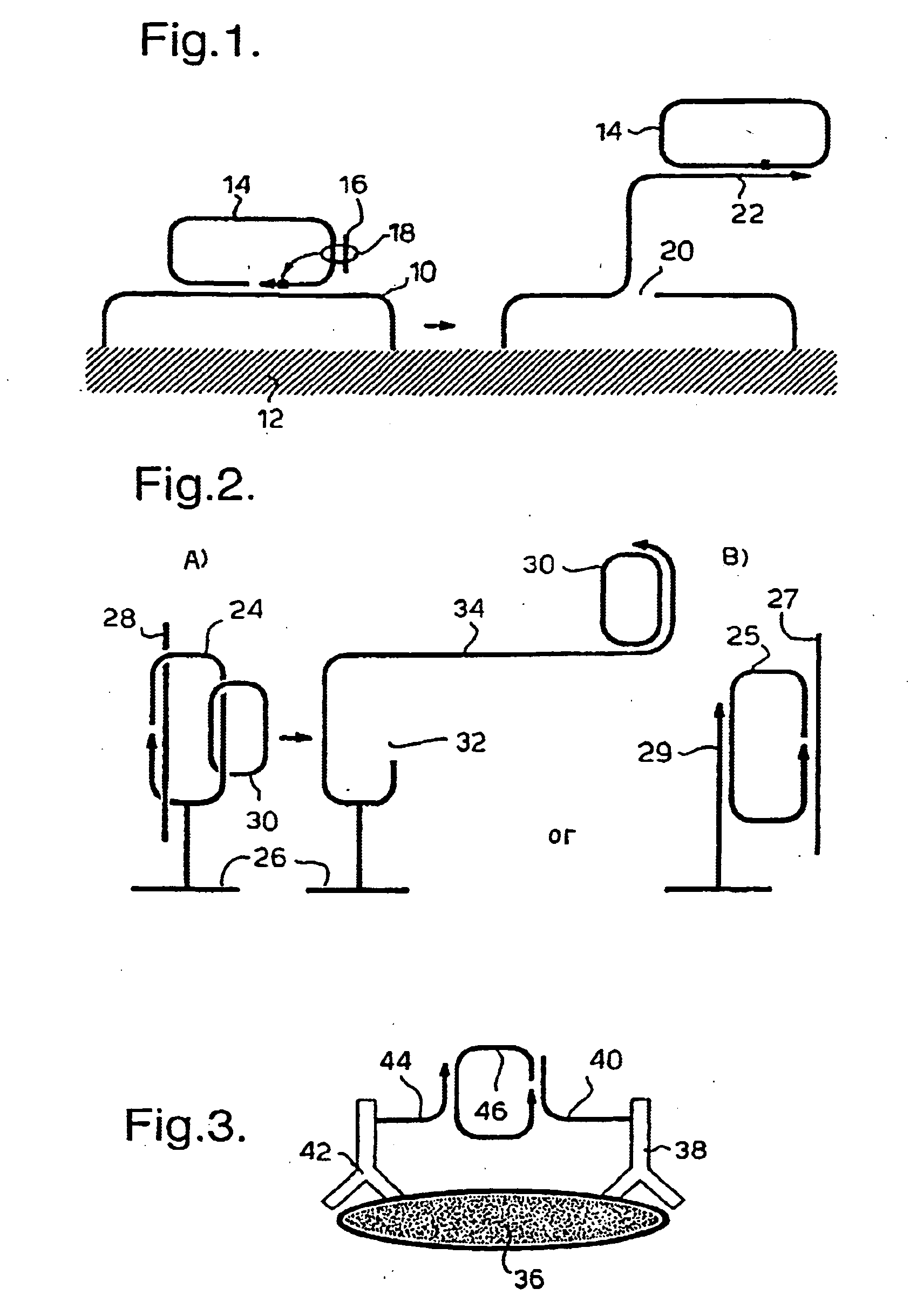

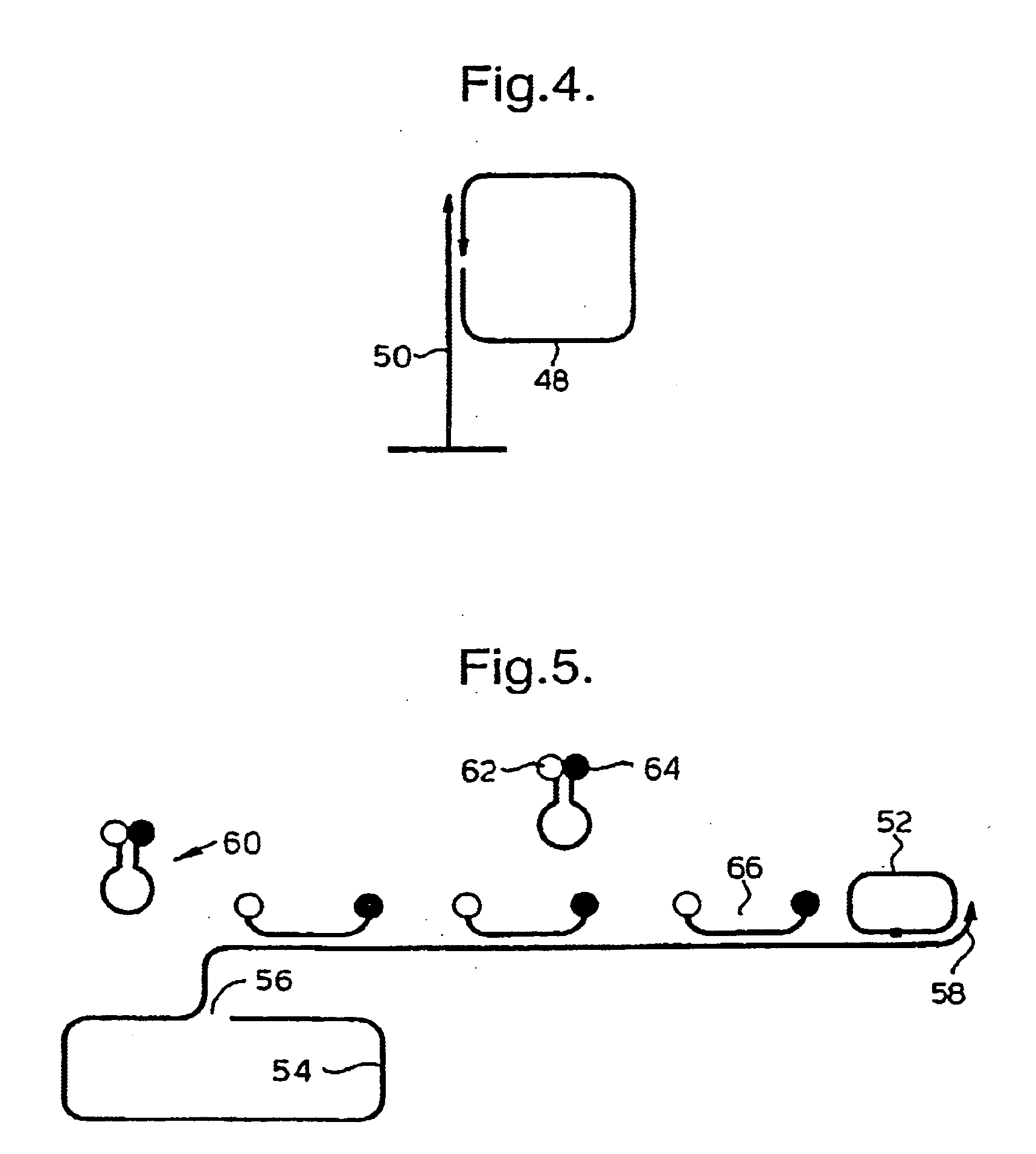

A method for assaying a sample for a nucleic acid damaging activity using at least one singular double-stranded nucleic acid with at least one electrochemiluminescent label, and a method for measuring an inhibitor of a nucleic acid damaging activity with at least one singular double-stranded nucleic acid using at least one electrochemiluminescent label, are disclosed.

Owner:BIOVERIS CORP

Rolling circle replication of padlock probes

InactiveUS20050282158A1Limited amplificationInhibition of replicationMicrobiological testing/measurementRecombinant DNA-technologyOligonucleotideRolling circle replication

Rolling circle replication of a padlock primer is inhibited when it is hybridised to a target nucleic acid that is long or circular. The invention provides methods of addressing this problem including cutting the target nucleic acid near or preferably at the site which hybridises with the padlock probe, whereby a 3′-end of the cut target nucleic acid acts as a primer for rolling circle replication of the padlock probe. Also included is a method for assaying for a polyepitopic target by the use of two affinity probes each carrying an oligonucleotide tag and of padlock probe for rolling circle replication in association with the two affinity probes.

Owner:SIGMA ALDRICH CO LLC

Assays for measuring nucleic acid binding proteins and enzyme activities

InactiveUS6312896B1Simple and accurate and reliable assayEfficient transferSugar derivativesMicrobiological testing/measurementProtein insertionNucleic acid binding protein

Owner:BIOVERIS CORP

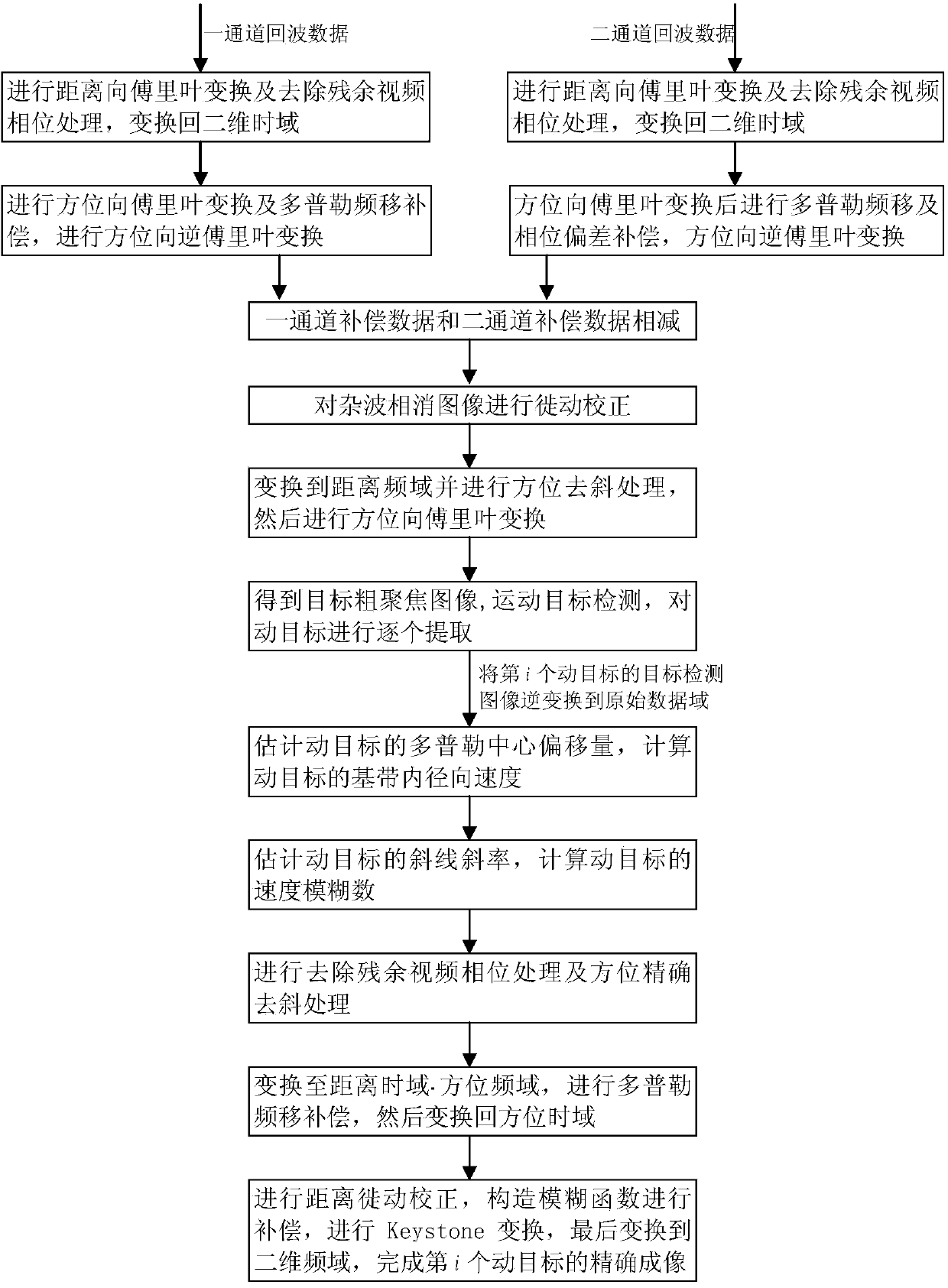

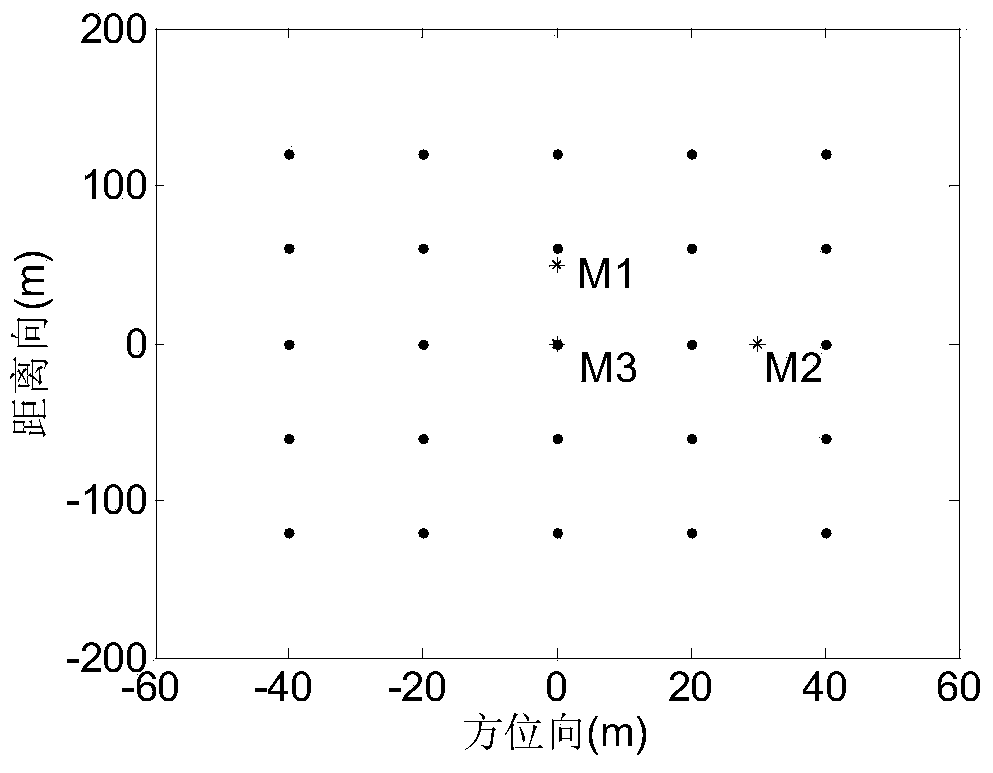

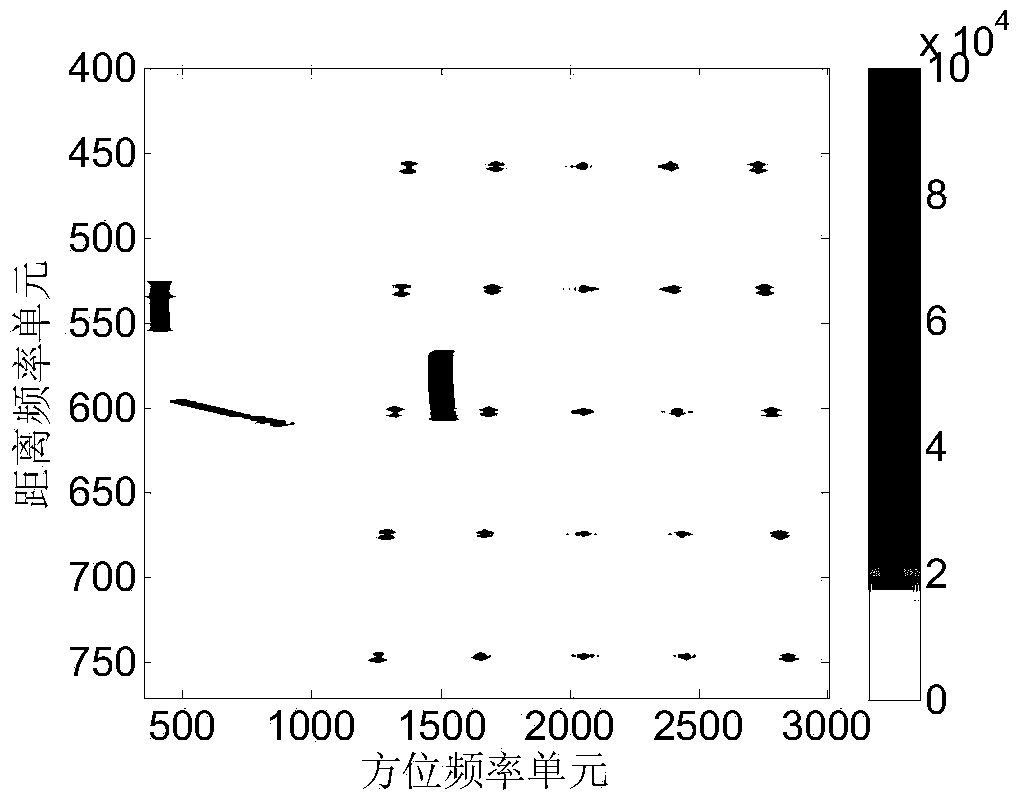

Moving target detection imaging method of dual-channel frequency modulation continuous wave SAR system

ActiveCN103744068AEfficient detectionAvoid splittingRadio wave reradiation/reflectionPattern recognitionRadar systems

A moving target detection imaging method of a dual-channel frequency modulation continuous wave SAR system comprises the steps of recording echo data by a radar system, performing residual video phase removing processing on the echo data, performing Doppler frequency shift compensation on the data, performing phase deviation compensation on two-channel conversion data, and performing subtraction processing on the two-channel data; performing migration correction and direction dechirping processing on an image with clutter cancellation to realize the rough imaging of a target, and detecting the moving target and extracting one by one; performing inverse transformation on the extracted targets to an original data domain, estimating motion parameters to construct a precise direction dechirping function of the moving target, performing residual video phase removing processing, precise direction dechirping processing and distance migration correction, constructing a fuzzy function for compensation, and then performing Keystone transformation to finish the precise image of the moving target. The moving target detection imaging method solves the imaging problem of the fast moving target when motion parameters are unknown under the continuous wave system, so the signal-to-noise rate and the target detection probability are greatly improved.

Owner:XIDIAN UNIV

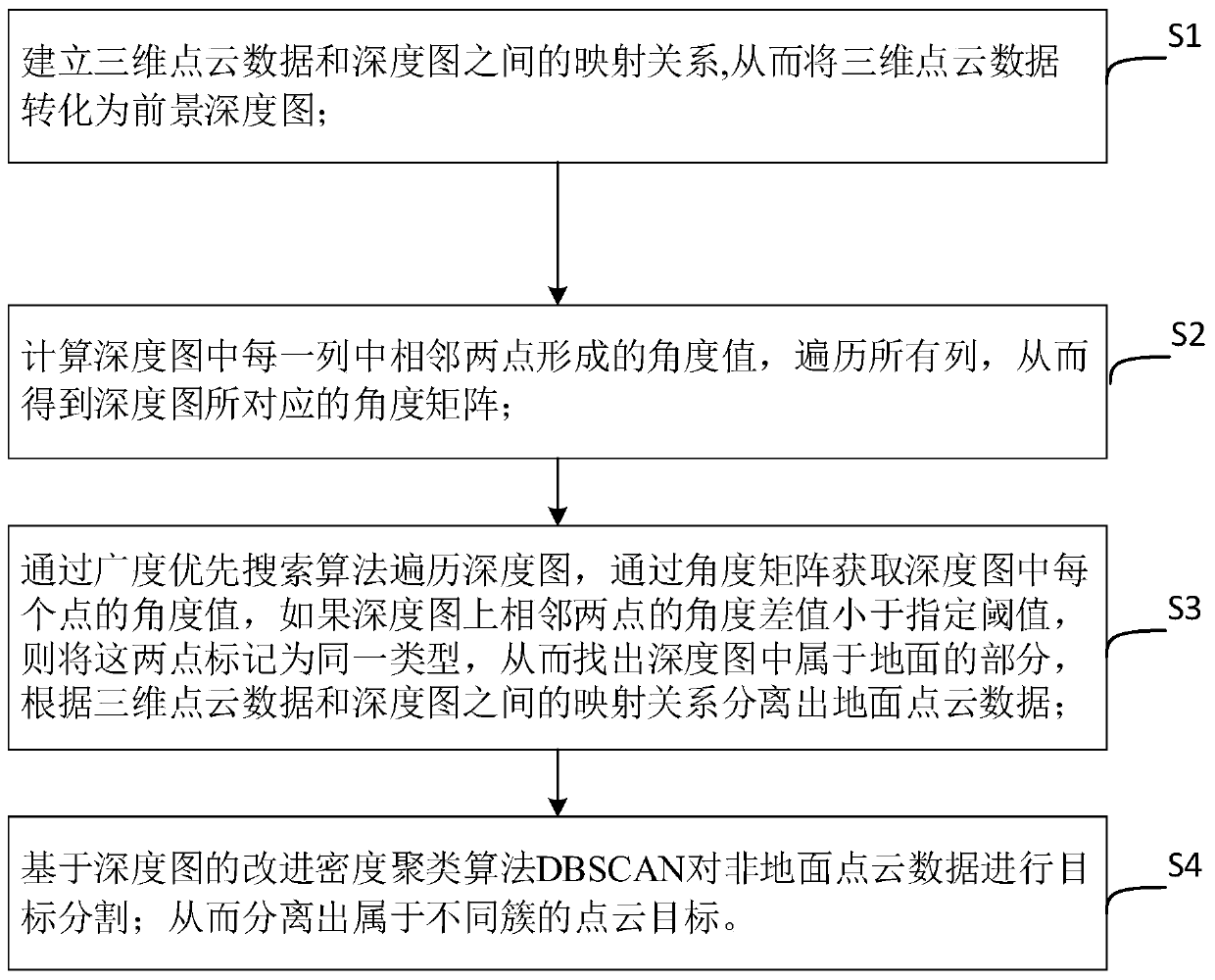

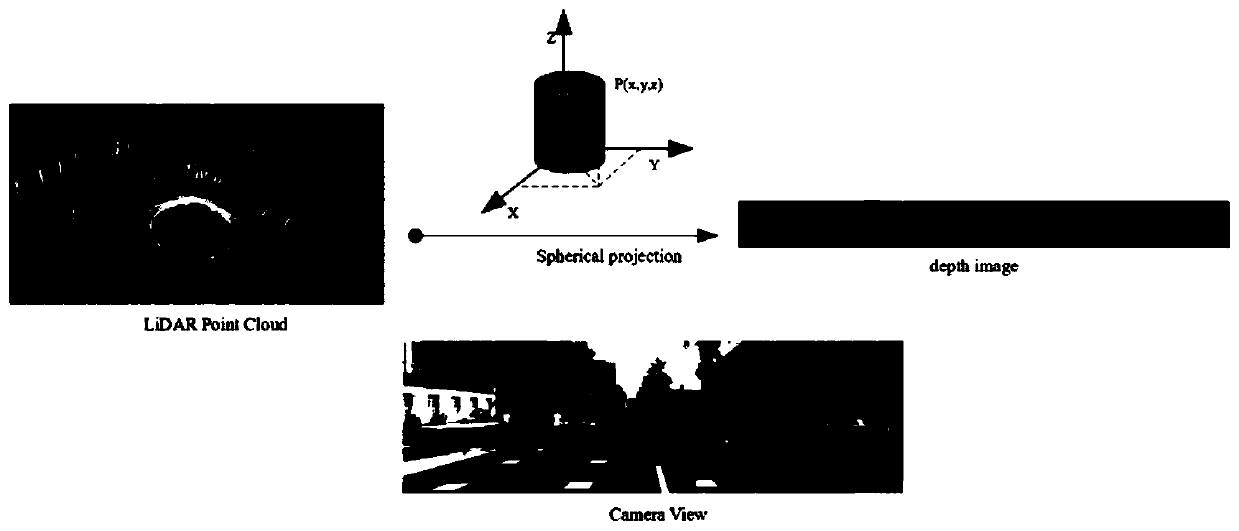

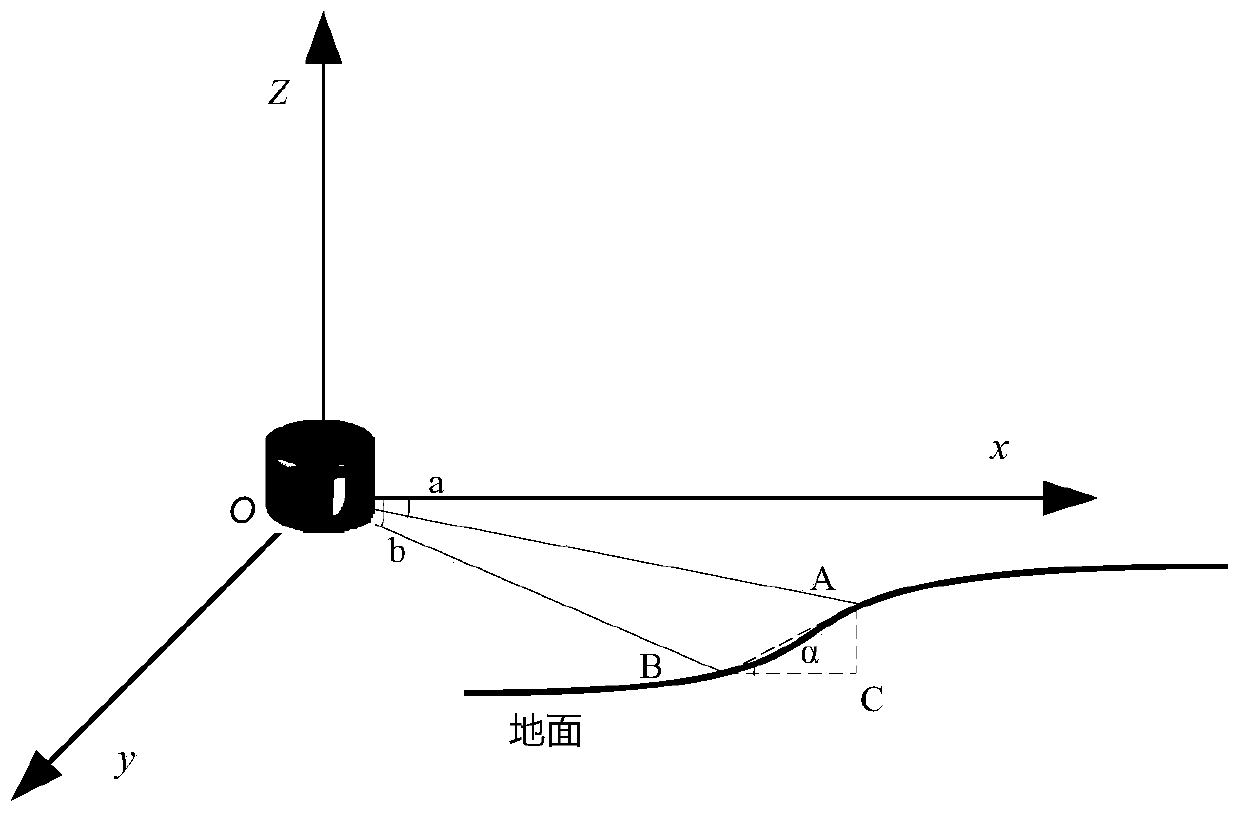

Three-dimensional laser radar point cloud target segmentation method based on depth map

ActiveCN109961440AAvoid splittingImprove real-time performanceImage enhancementImage analysisPoint cloudRadar

Owner:CHONGQING UNIV OF POSTS & TELECOMM

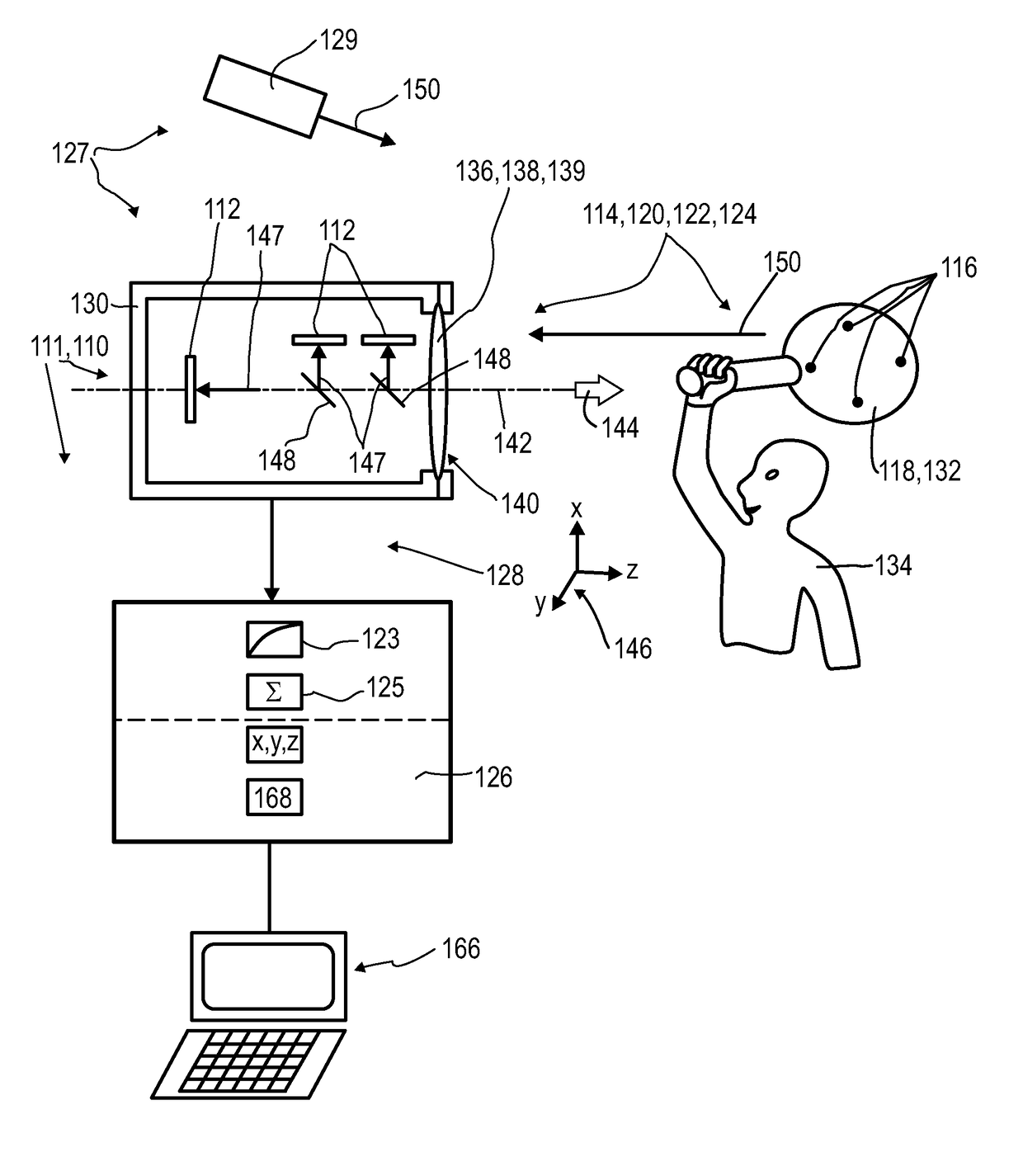

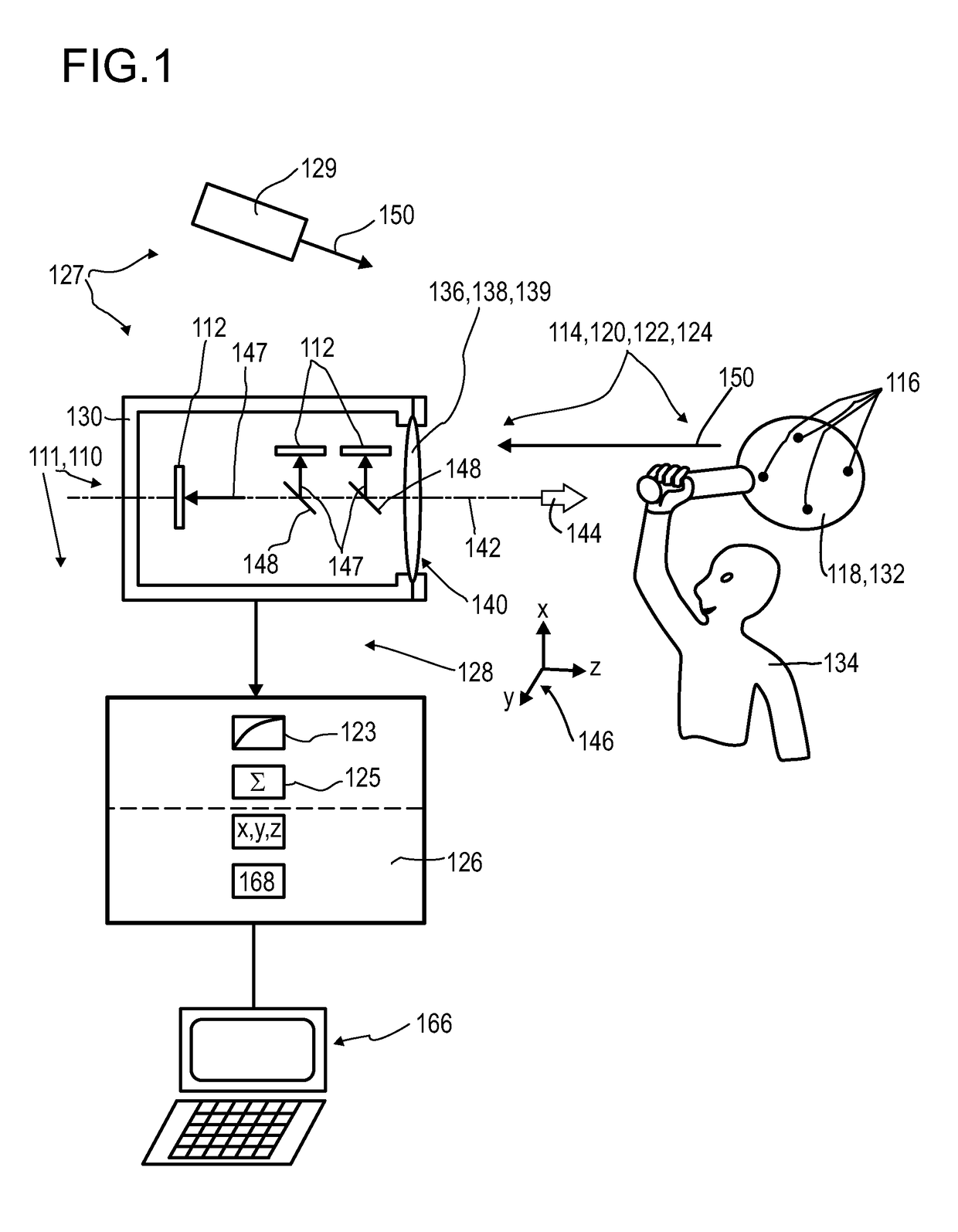

Detector for optically detecting at least one object

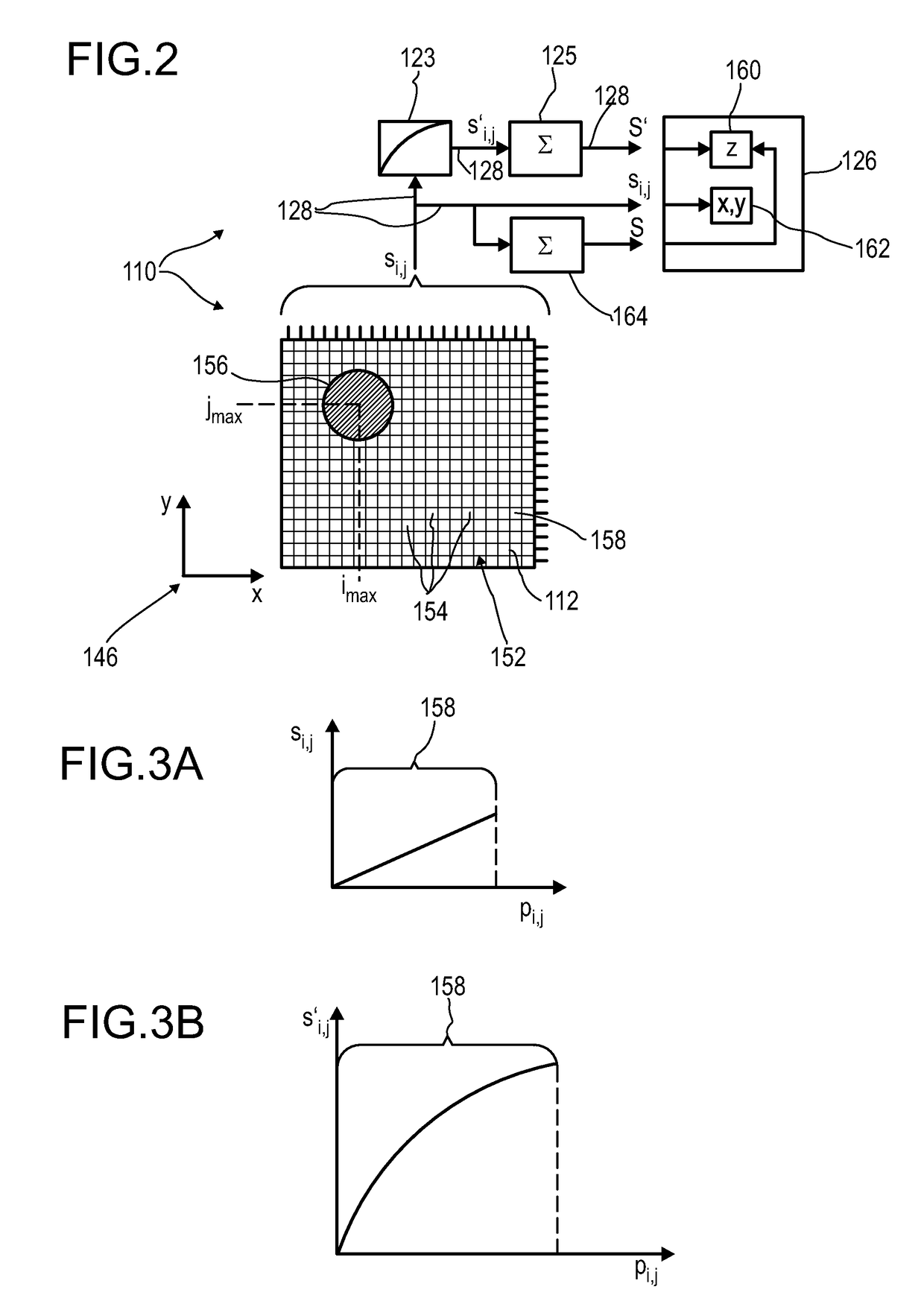

ActiveUS20180210064A1Avoid splittingRaise the ratioImage enhancementImage analysisNon linear functionsOptics

A detector (110) for determining a position of at least one object (118) is proposed. The detector (110) comprises: —at least one optical sensor (112), the optical sensor (112) being configured to detect at least one light spot (156) generated by at least one light beam (150) propagating from the object (118) towards the detector (110), the optical sensor (112) having at least one matrix (152) of pixels (154), each pixel (154) being adapted to generate at least one pixel signal si,j in response to an illumination of the pixel (154) by the light beam (150); —at least one non-linearization device (123) configured to transform the pixel signals si,j of all pixels (154) i, j or of at least one group of pixels (154) into nonlinear pixel signals s′i,j, the nonlinear pixel signals s′i,j each being a nonlinear function of the power of the illumination pi,j of the respective pixel (154); —at least one summing device (125) configured to add up the nonlinearpixel signals s′i,j of all pixels (154) i, j or of the at least one group of pixels (154) and to generate at least one nonlinearsum signal S′=Σijs′ij; and —at least one evaluation device (126), the evaluation device (126) being configured to determine at least one longitudinal coordinate z of the object (118) by evaluating the nonlinear sum signal S′.

Owner:TRINAMIX GMBH

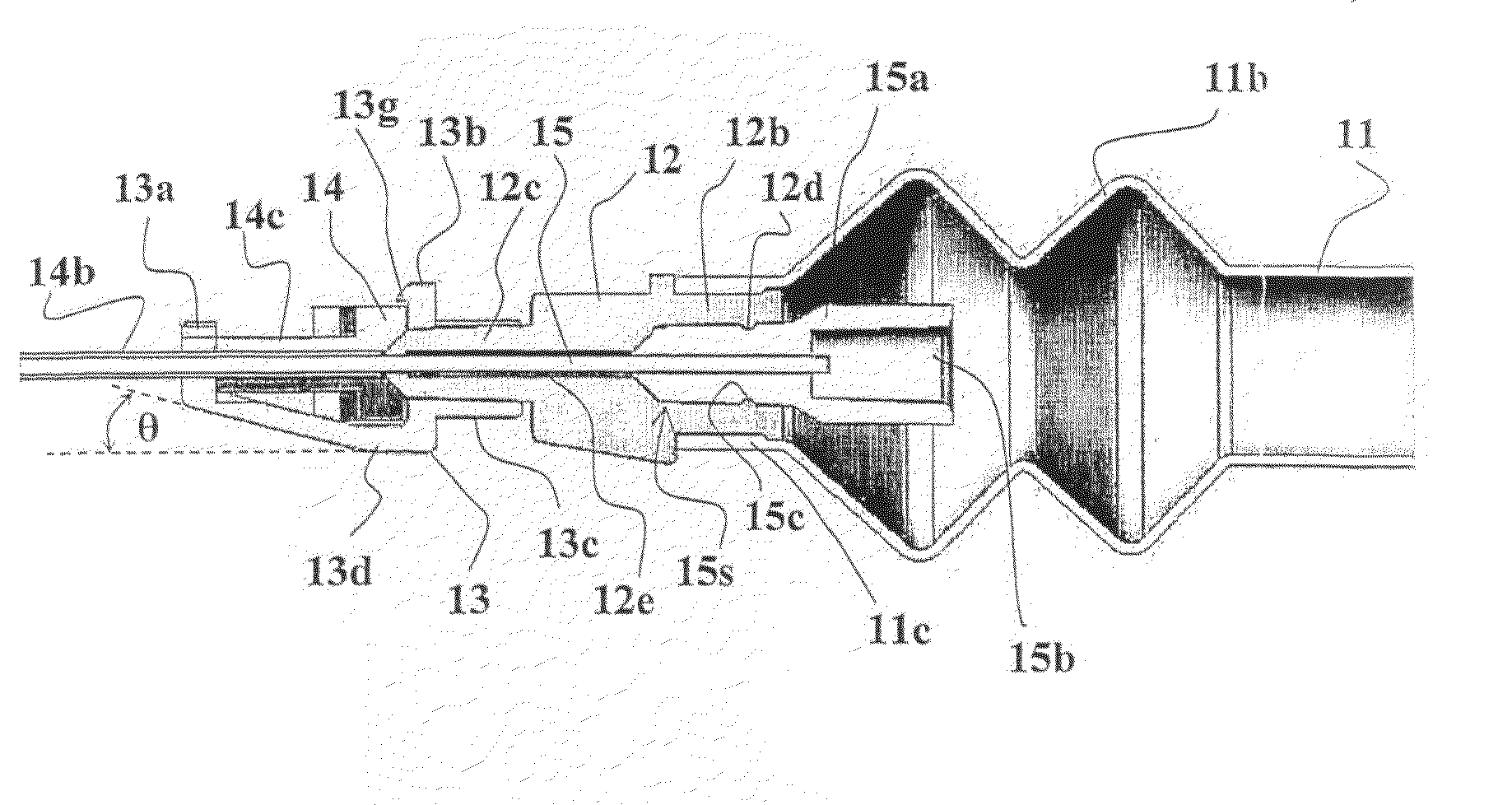

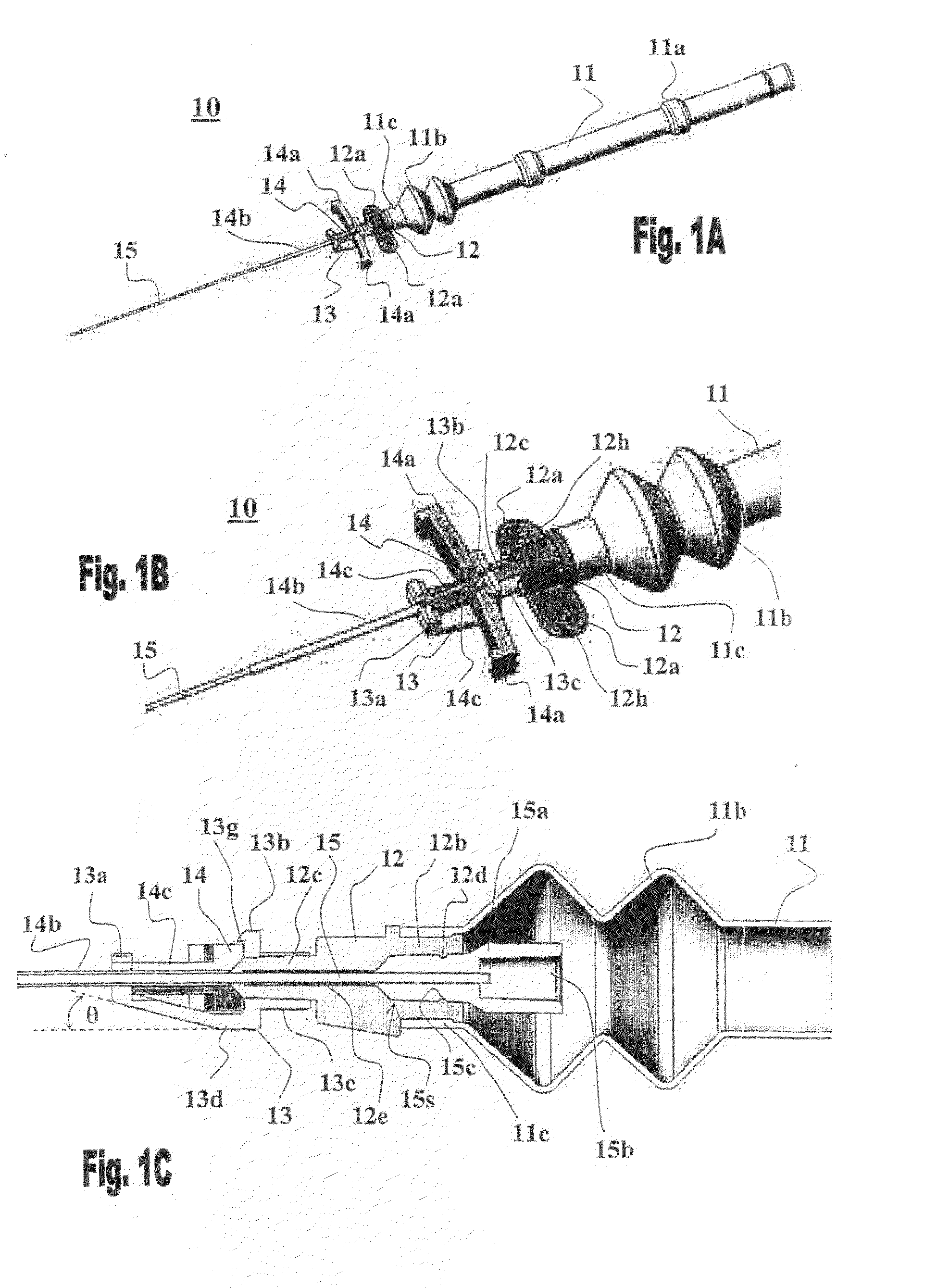

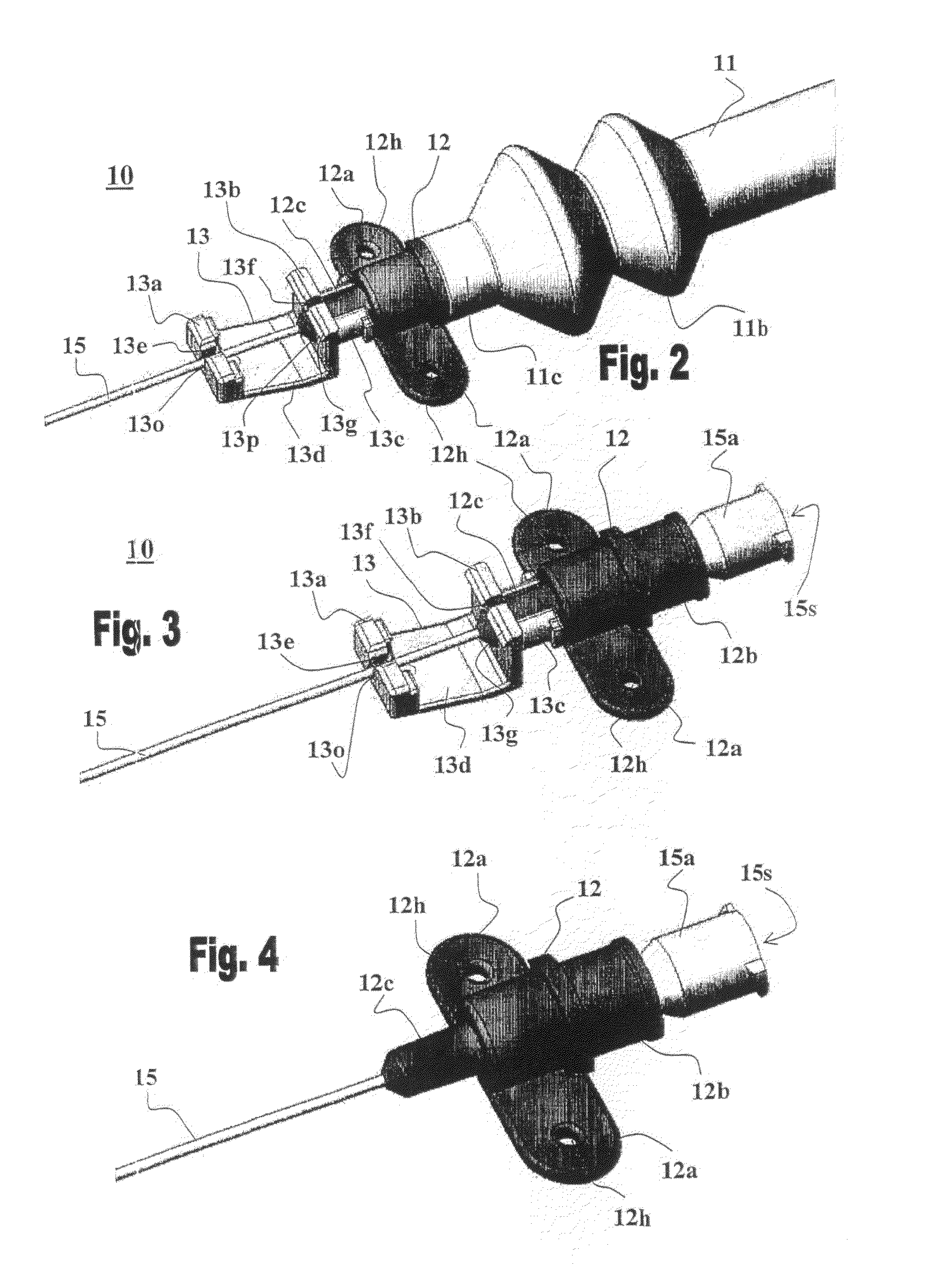

Catheter insertion apparatus and method of use thereof

InactiveUS20090306591A1Avoid unnecessaryEasy to disassembleGuide needlesGuide wiresCatheter hubCatheter introducer

The invention relates to a catheter insertion system utilizing a catheter introducer device having an introducer sheath, the catheter insertion system comprise a catheter containment unit in which a catheter tube having a catheter hub is held, said catheter containment unit comprises an opening adapted to sealably and reversibly connect to an inserter head, said inserter head is adapted to sealably and reversibly connect, and provide said catheter tube passage, to said catheter introducer device, wherein said catheter containment unit comprises at least one flexible portion and an elastic / resilient portion located near its opening for advancing portions of said catheter tube through said passage, and wherein said inserter head is adapted to sealably receive a portion of said catheter hub in a socket provided therein.

Owner:FLEXICATH

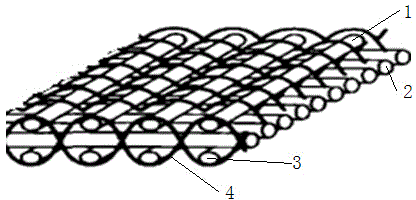

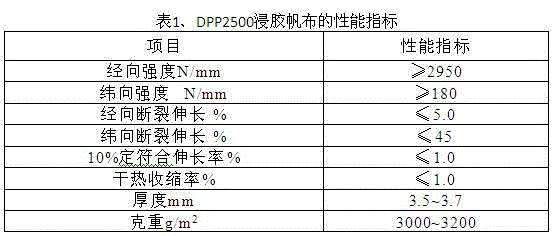

Aramid rubber canvas fabric structure for high-strength conveyor belts and production process of aramid rubber canvas fabric structure

InactiveCN104611819AEasy to weaveGood physical and mechanical propertiesConveyorsMulti-ply fabricsYarnEngineering

The invention discloses an aramid rubber canvas fabric structure for high-strength conveyor belts and a production process of the aramid rubber canvas fabric structure. The aramid rubber canvas fabric structure comprises warps and wefts, aramid materials are adopted in the warps, at least four warps are paved in the belt length direction, nylon industrial yarns are adopted in the wefts which are crisscrossly paved on upper end faces and lower end faces of the warps, the wefts on upper and lower layers are tightly crisscrossly bonded to the warps by adopting bundling yarns, and a canvas fabric structure is obtained after secondary bath gum dipping; the production process includes single-layer canvas knitting, secondary bath gum dipping and reeling. Single-layer structures of the warps adopting the aramid materials and the weft adopting the nylon materials are knitted through bundling yarns, the high-strength conveyor belts with the strength higher than 2500N / mm are produced after secondary bath gum dipping, mechanical physical properties of the conveyor belts are improved, layer reduction and weight reduction of the conveyor belts are realized during the production process, the conveyor belts are adaptively high strengthened, less layered and lightweight, energy consumption is reduced, the production process is further simplified, and production efficiency is higher.

Owner:浙江尤夫科技工业有限公司

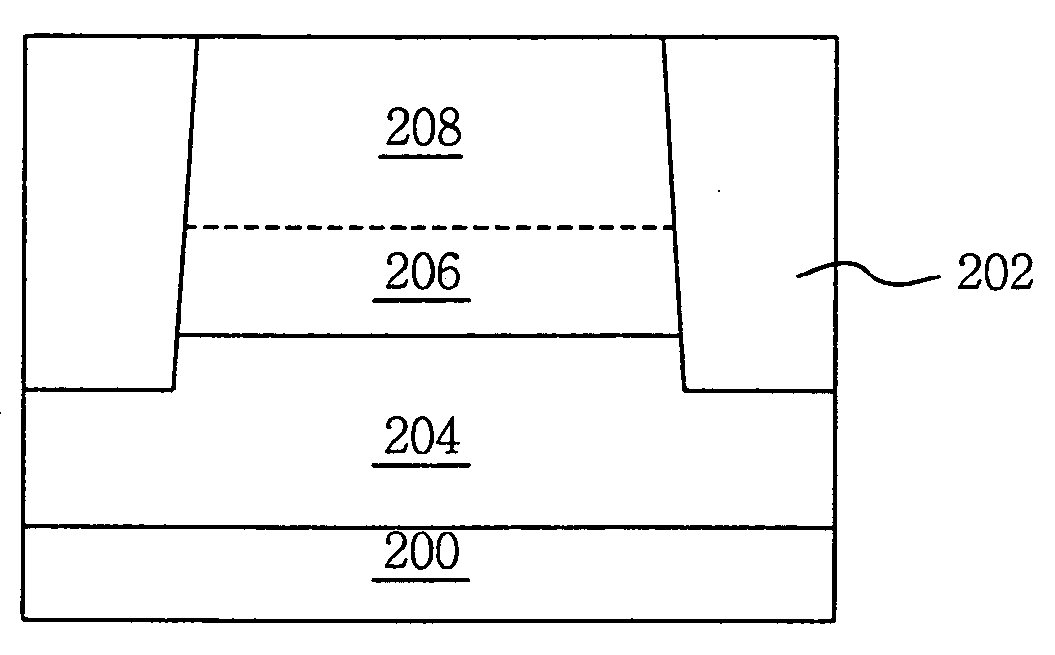

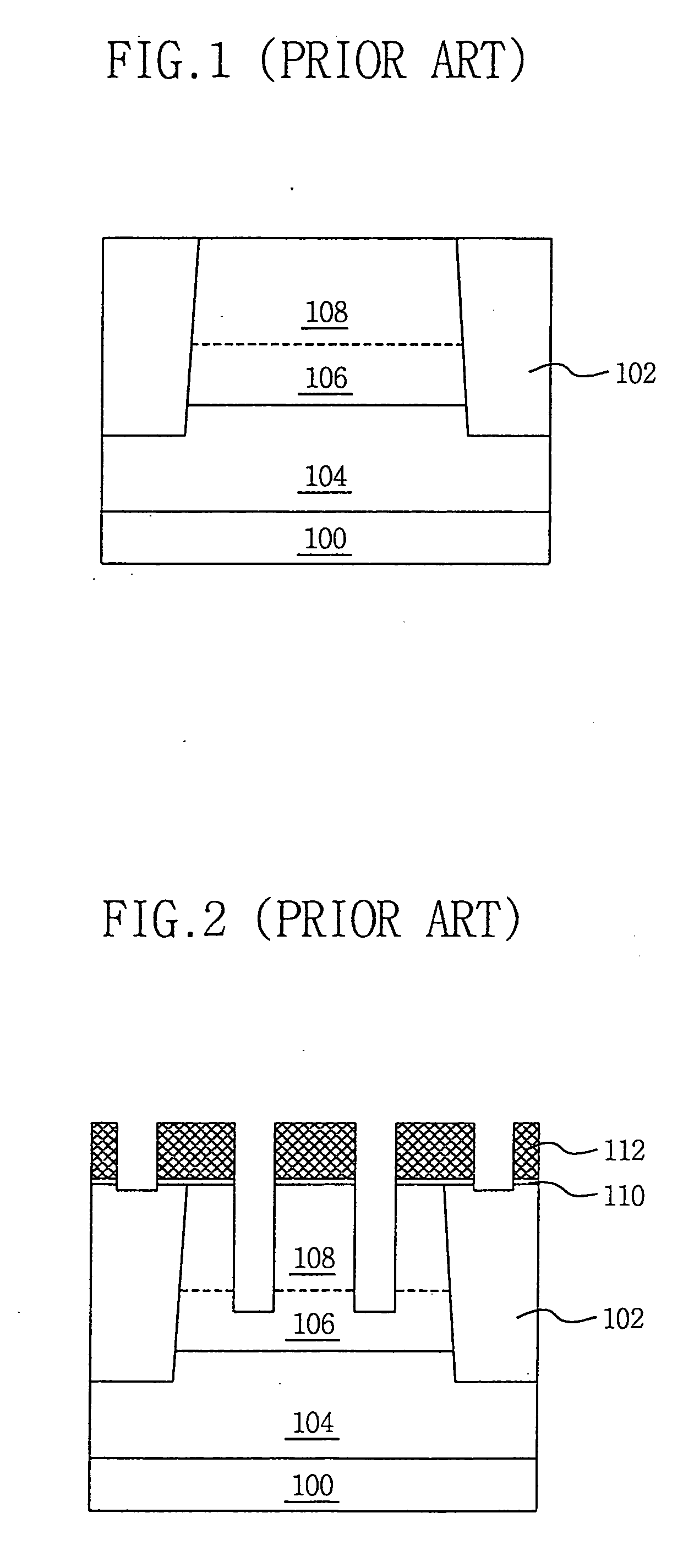

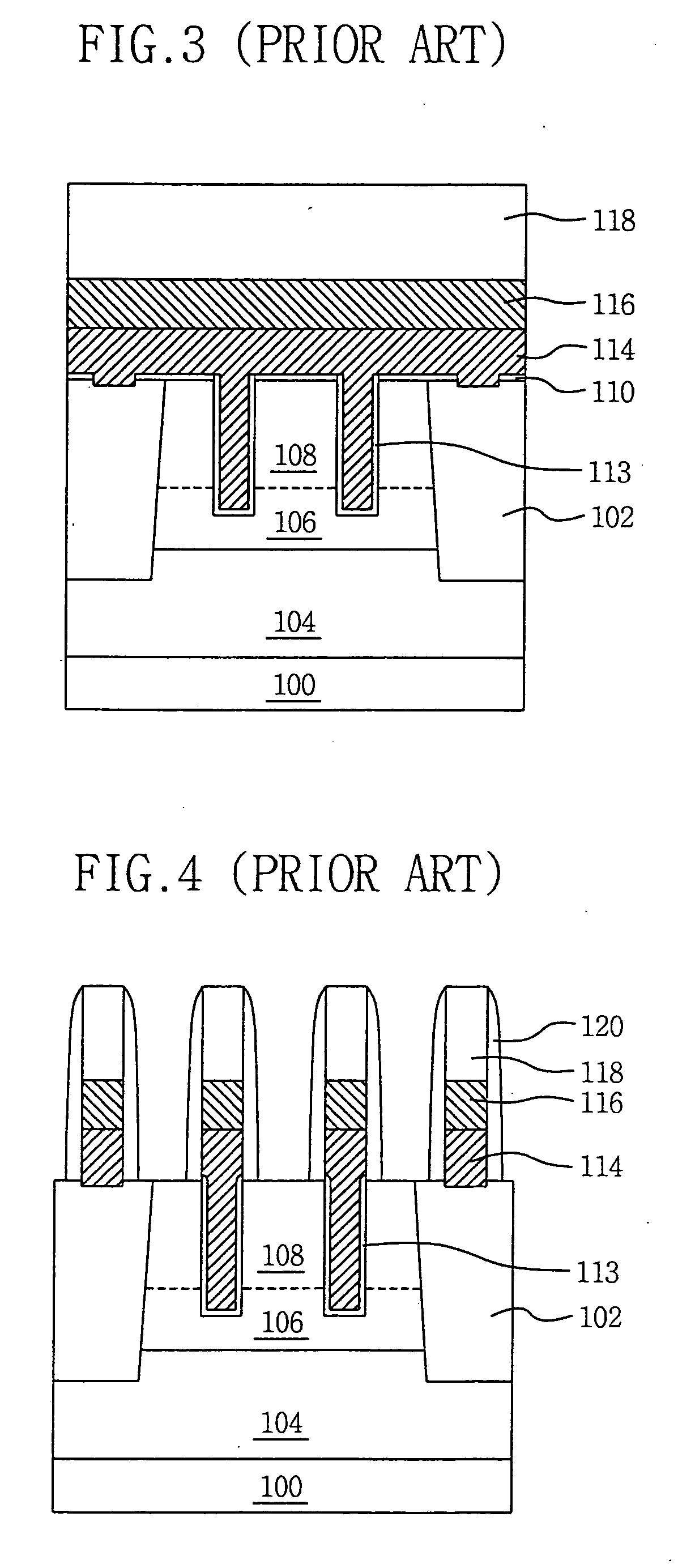

Recess gate transistor structure for use in semiconductor device and method thereof

InactiveUS20050087776A1Reduce load capacityReduction of gate lengthTransistorSemiconductor/solid-state device manufacturingInsulation layerDevice material

An inner spacer is formed in a sidewall of a gate in contact with a first active region that is electrically connected to an upper capacitor, thereby reducing a gate induced drain leakage (GIDL). A structure of a recess gate transistor includes a gate insulation layer, a gate electrode, a first gate spacer, a second gate spacer and source / drain regions. The gate insulation layer is formed within a recess. The gate electrode is surrounded by the gate insulation layer and is extended from within the recess. The first gate spacer is spaced with a predetermined distance horizontally with a portion of the gate insulation layer, being formed in a sidewall of the gate electrode. The second gate spacer is formed in another part of the sidewall of the gate electrode. The source / drain regions are formed mutually oppositely on first and second active regions with the gate electrode therebetween.

Owner:SAMSUNG ELECTRONICS CO LTD

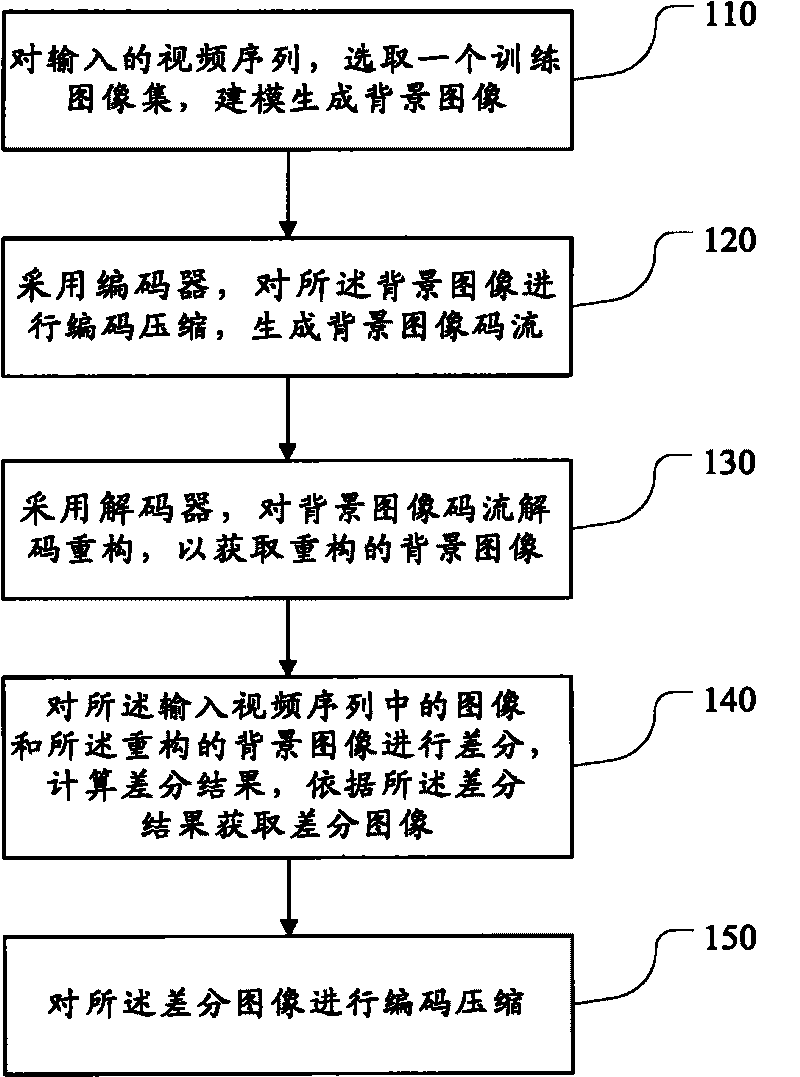

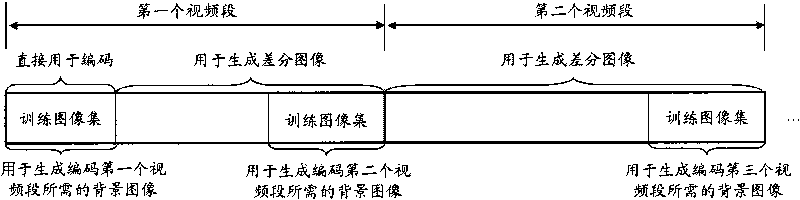

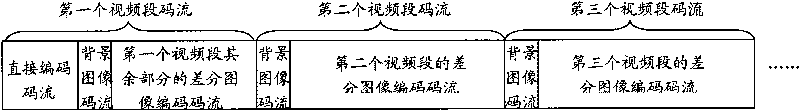

Background modeling-based static camera video compression method and background modeling-based static camera video compression system

ActiveCN101742319AAvoid splittingImprove compression efficiencyTelevision systemsDigital video signal modificationVideo sequenceCompression method

The invention discloses a background modeling-based static camera video compression method and a background modeling-based static camera video compression system. The method comprises the following steps: for an input video sequence, selecting a training image set and modeling the selected training image set to generate a background image; adopting a coder to encode and compress the background image to generate a background image code stream; adopting a decoder to decode and reconstruct the background image code stream to acquire a reconstructed background image; differentiating images in the input video sequence and the reconstructed background image, calculating a differentiation result and acquiring a differential image according to the differentiation result; and encoding and compressing the differential image. In the method and the system, a fixed scene part and other parts of video are compressed respectively by utilizing the characteristic that a scene of the video sequence is fixed and establishing and updating a model describing the relatively fixed scene in the video so as to eliminate redundancy in the video sequence to a greater extent to obtain better compression performance.

Owner:PEKING UNIV

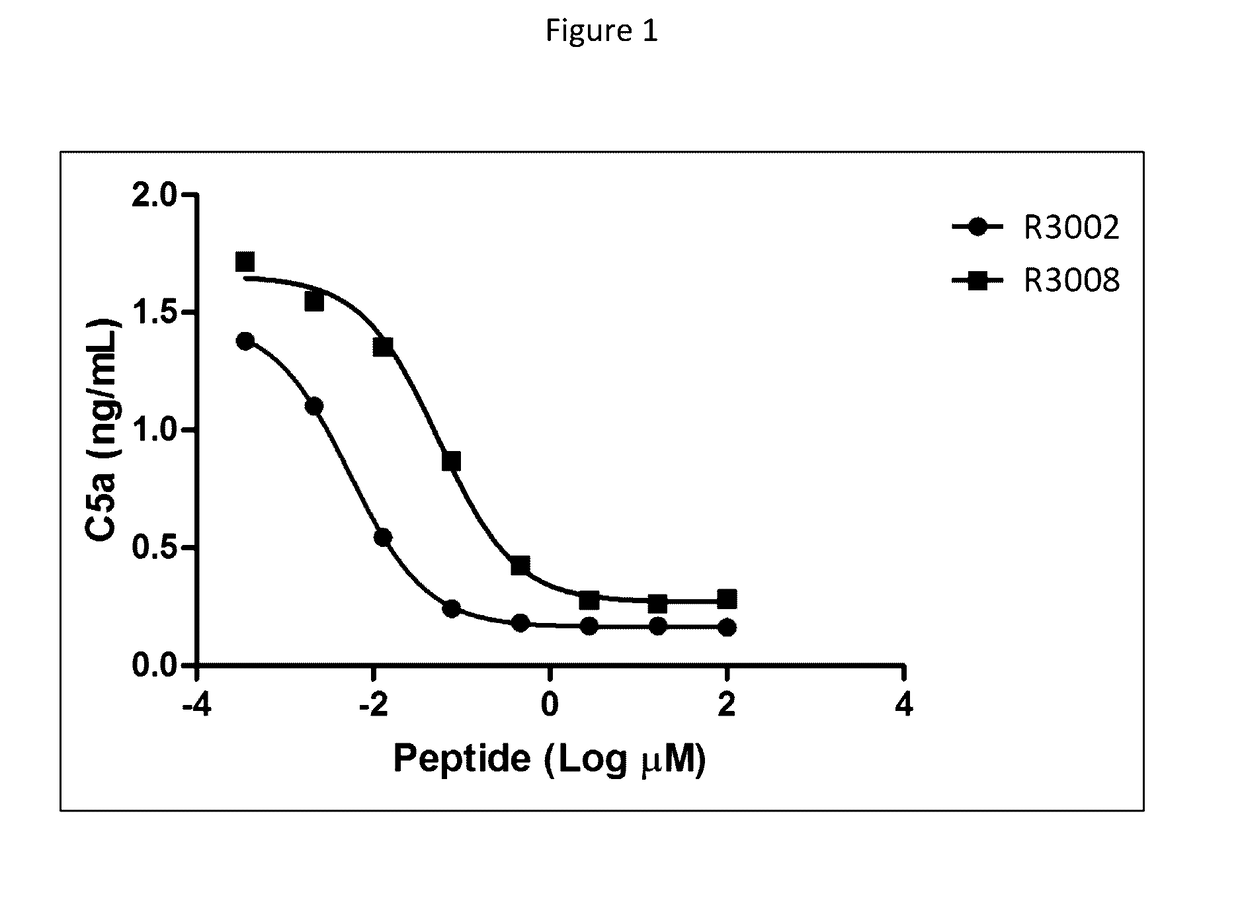

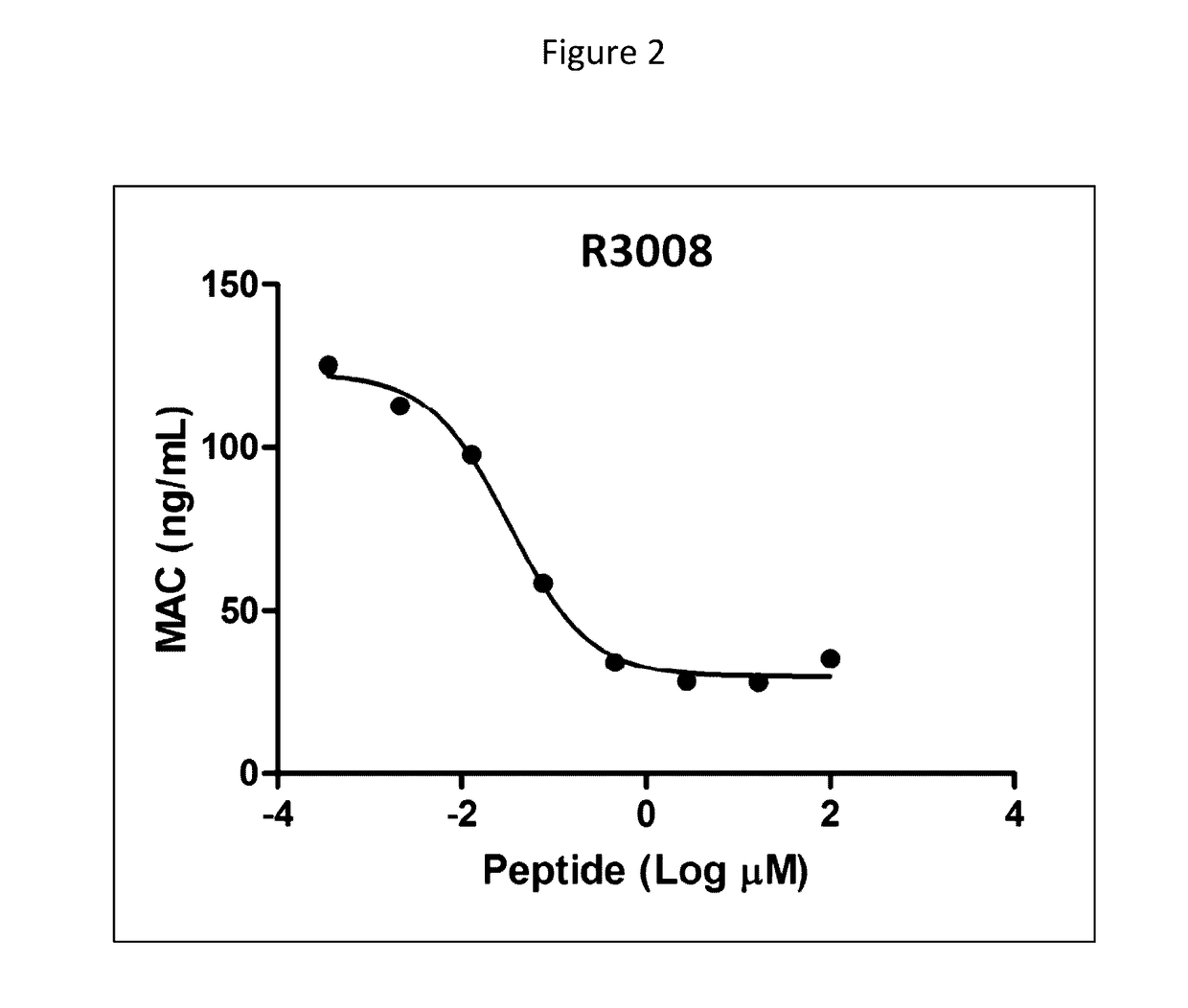

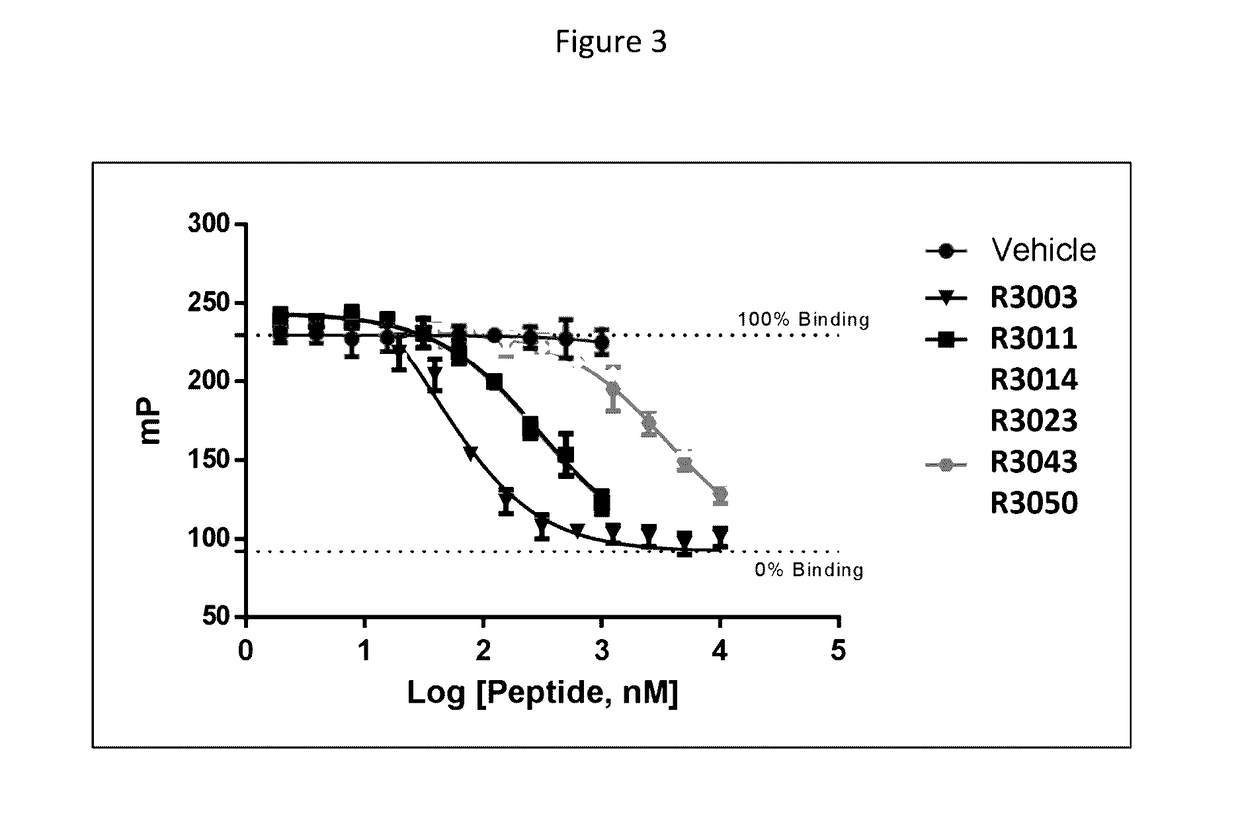

Modulation of complement activity

ActiveUS20170137468A1Reduce C5a levelReduce attackSenses disorderNervous disorderComplement activityCell biology

The present invention provides modulators of complement activity. Also provided are methods of utilizing such modulators as therapeutics.

Owner:RA PHARMA

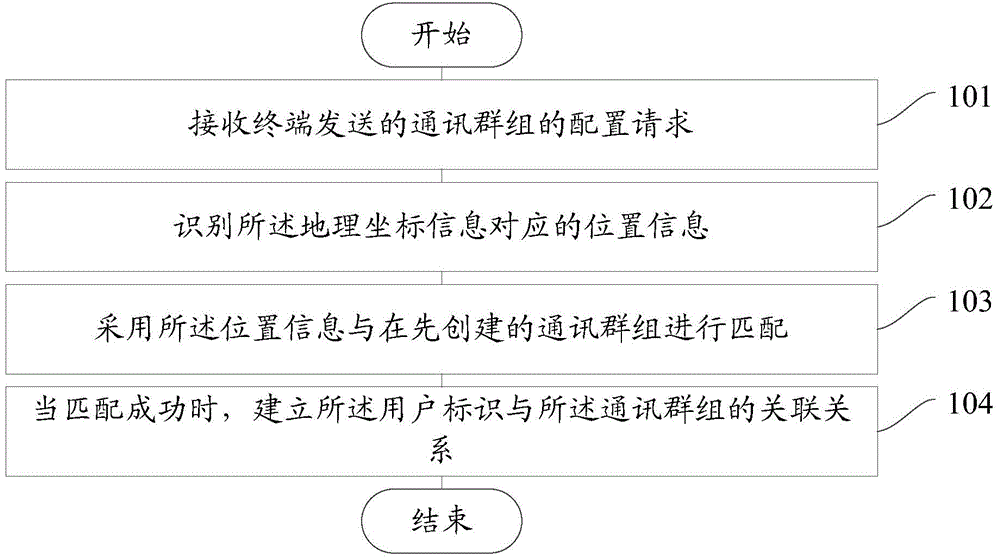

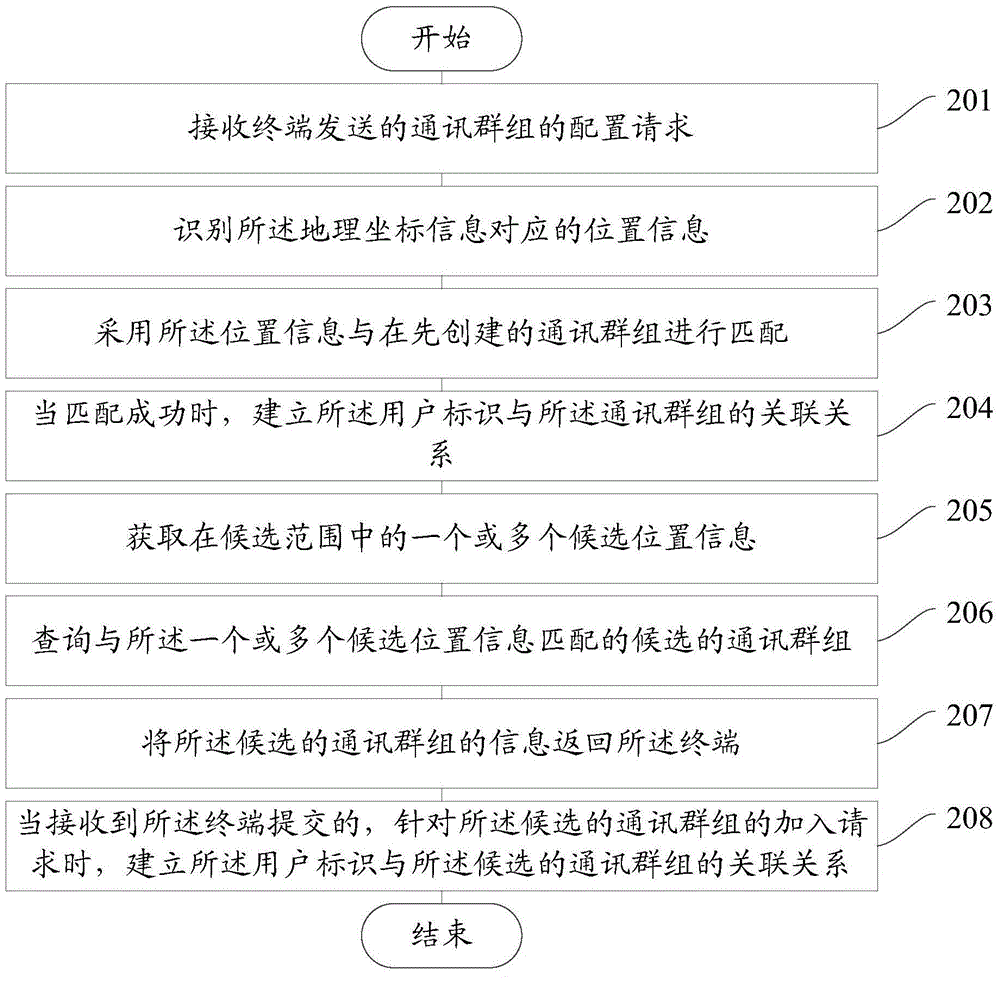

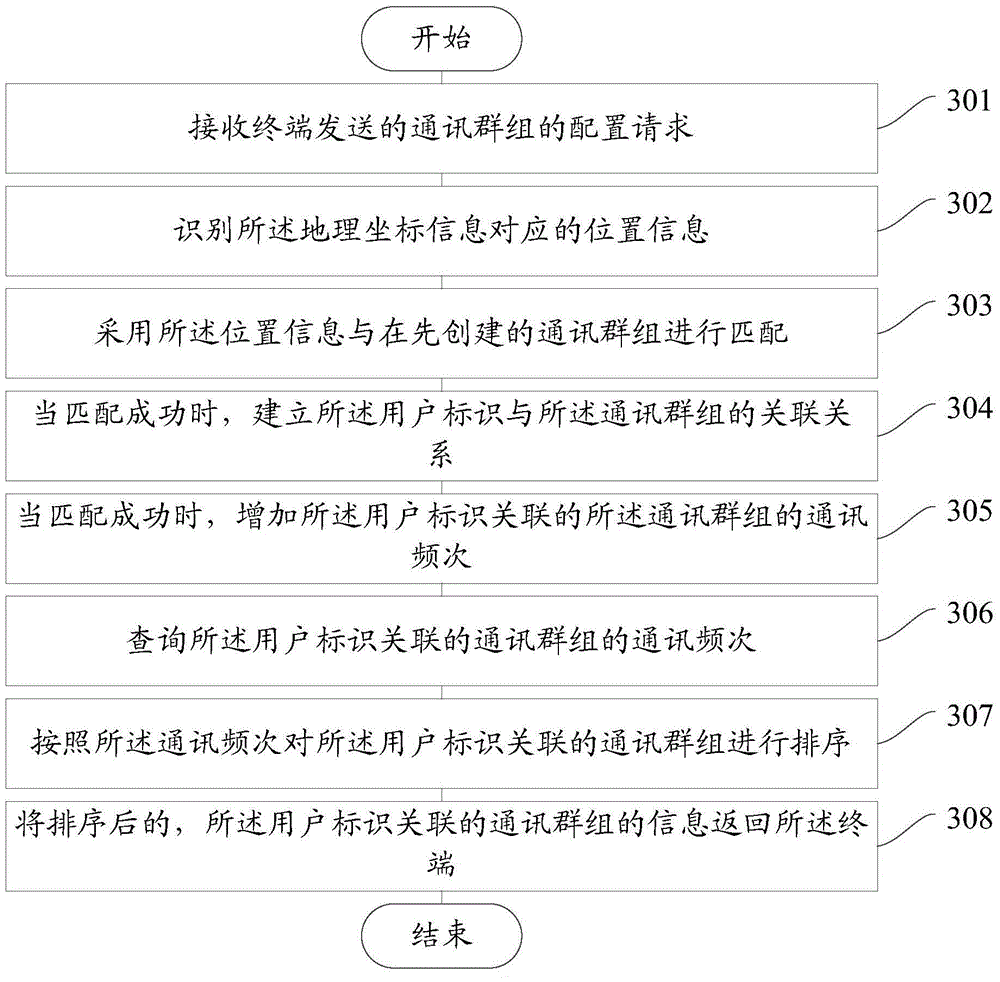

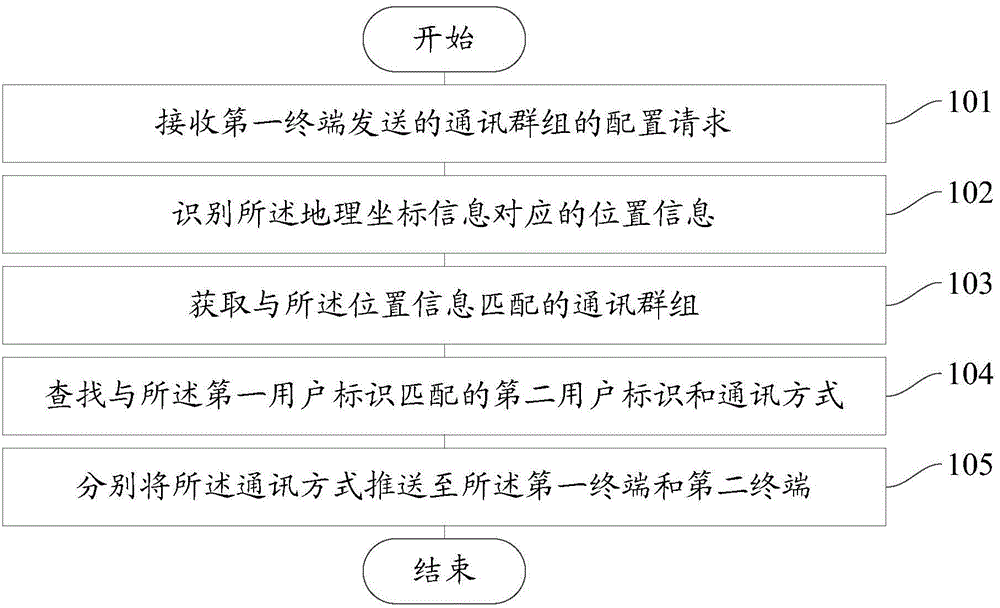

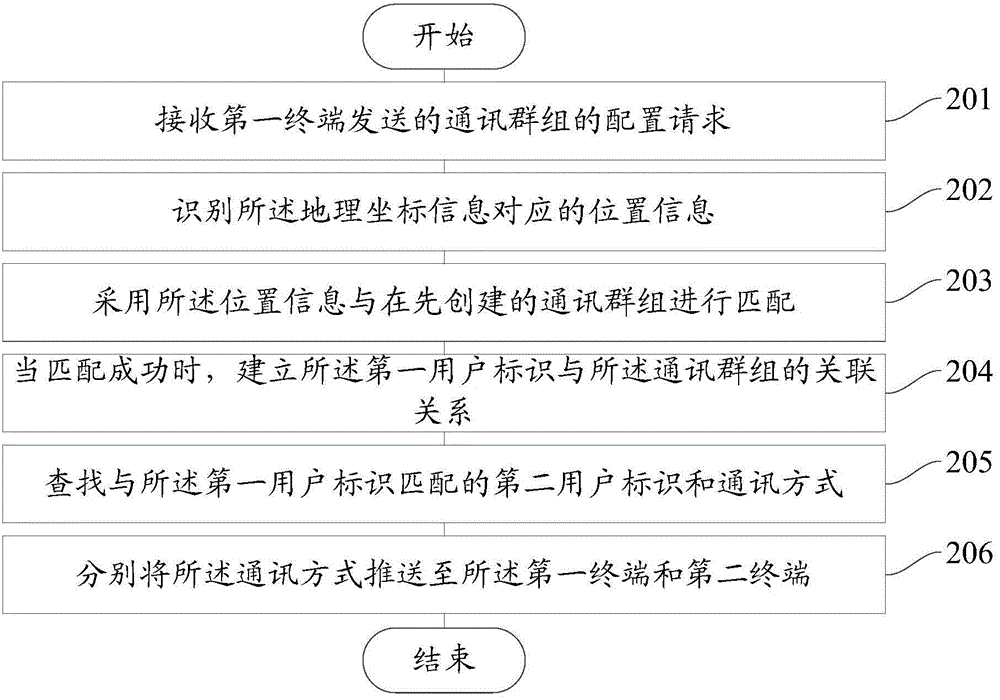

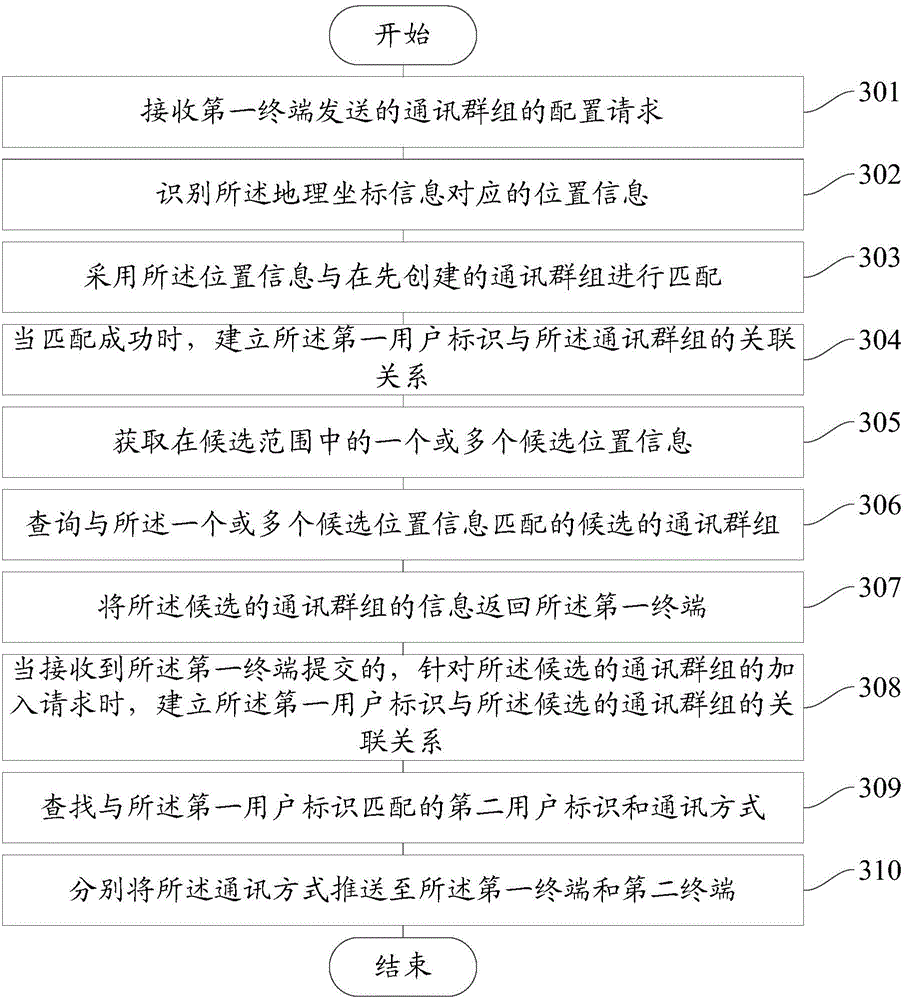

Communication group configuration method and device

InactiveCN104580431AImplement auto-joinReduce communication frequencyData switching networksUser identifierComputer science

The embodiment of the invention provides a communication group configuration method and device. The method comprises the following steps: receiving a communication group configuration request sent by a terminal, wherein the configuration request comprises geographic coordinate information and a user identifier; identifying location information corresponding to the geographic coordinate information; matching the location information with a communication group created in advance; when matching is successful, establishing the relationship between the user identifier and the communication group. Through the method and device provided by the embodiment of the invention, automatic joining of the communication group is realized, so that users do not need to search the communication group according to keywords, and the users can join the communication group without invitation or application because members in the communication group have the same authority, thereby reducing the communication frequency among terminals of invited users or application users, terminals of a manager and a server in the process of invitation or application, greatly improving the operation simplicity, shortening the consumed time, and reducing the system resources and network bandwidth consumed by the terminals and the server.

Owner:BEIJING QIHOO TECH CO LTD +1

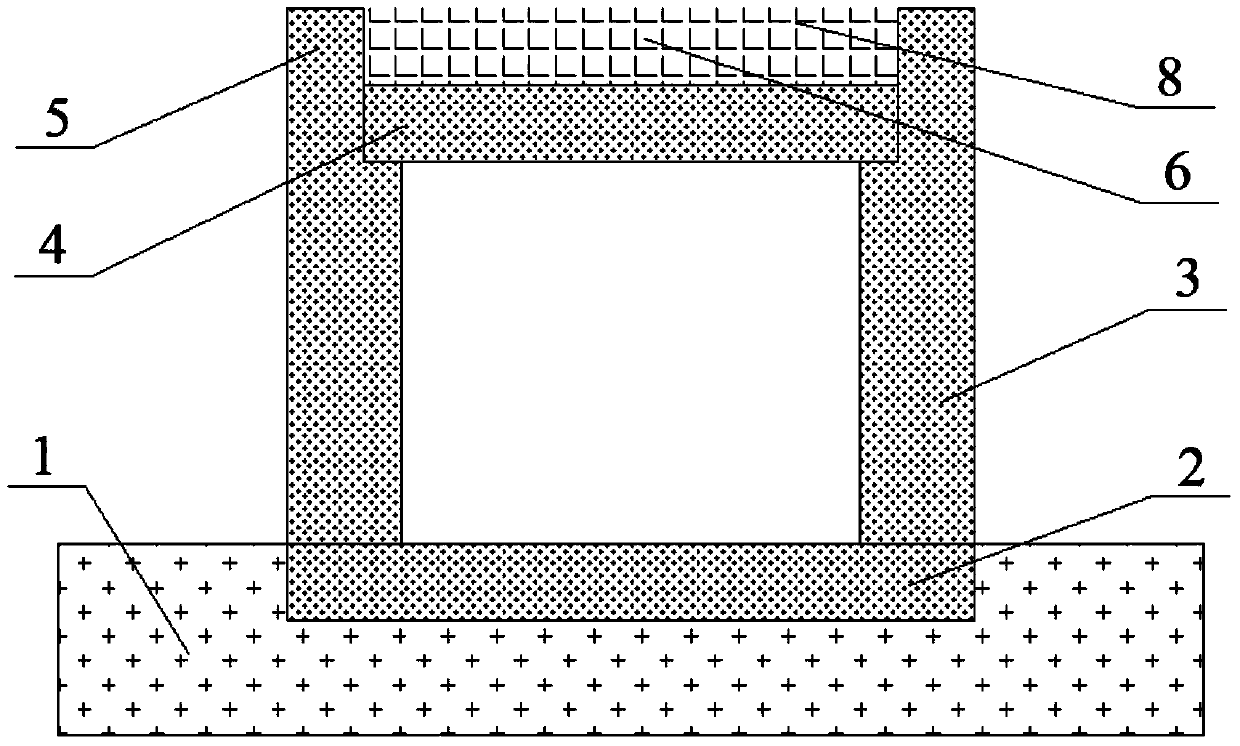

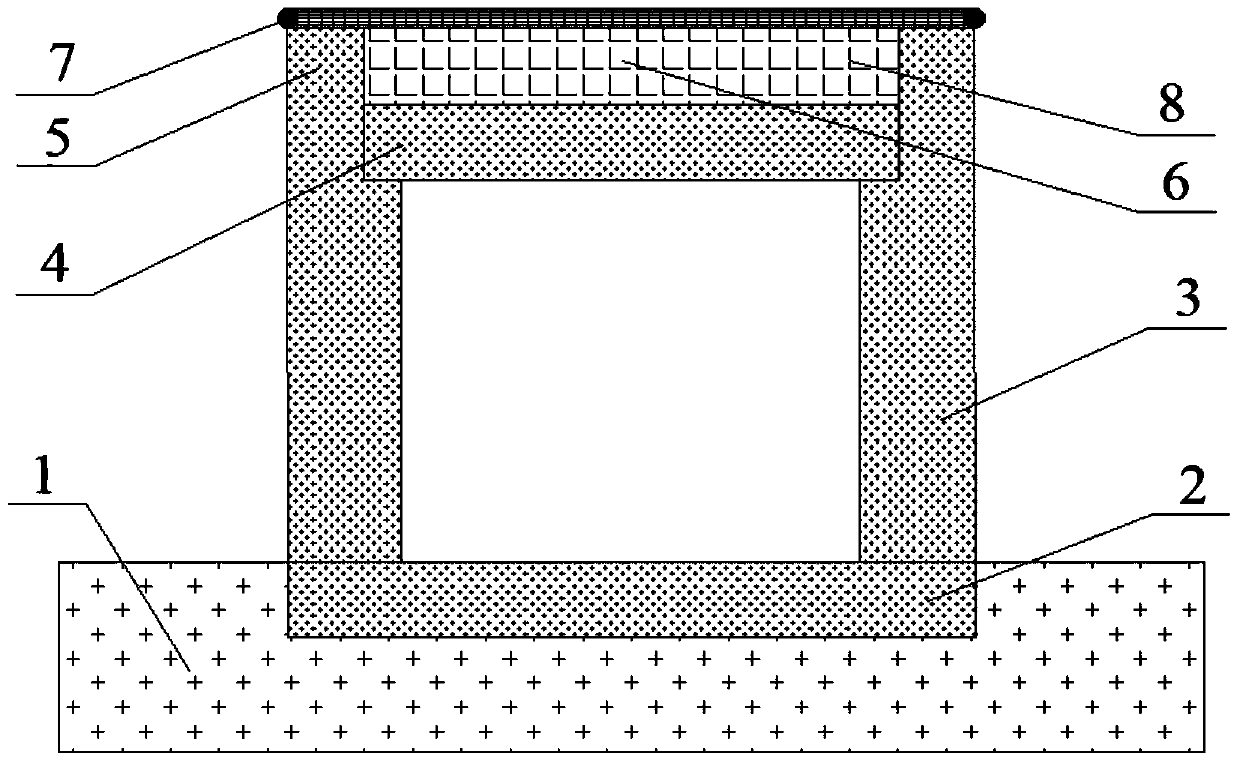

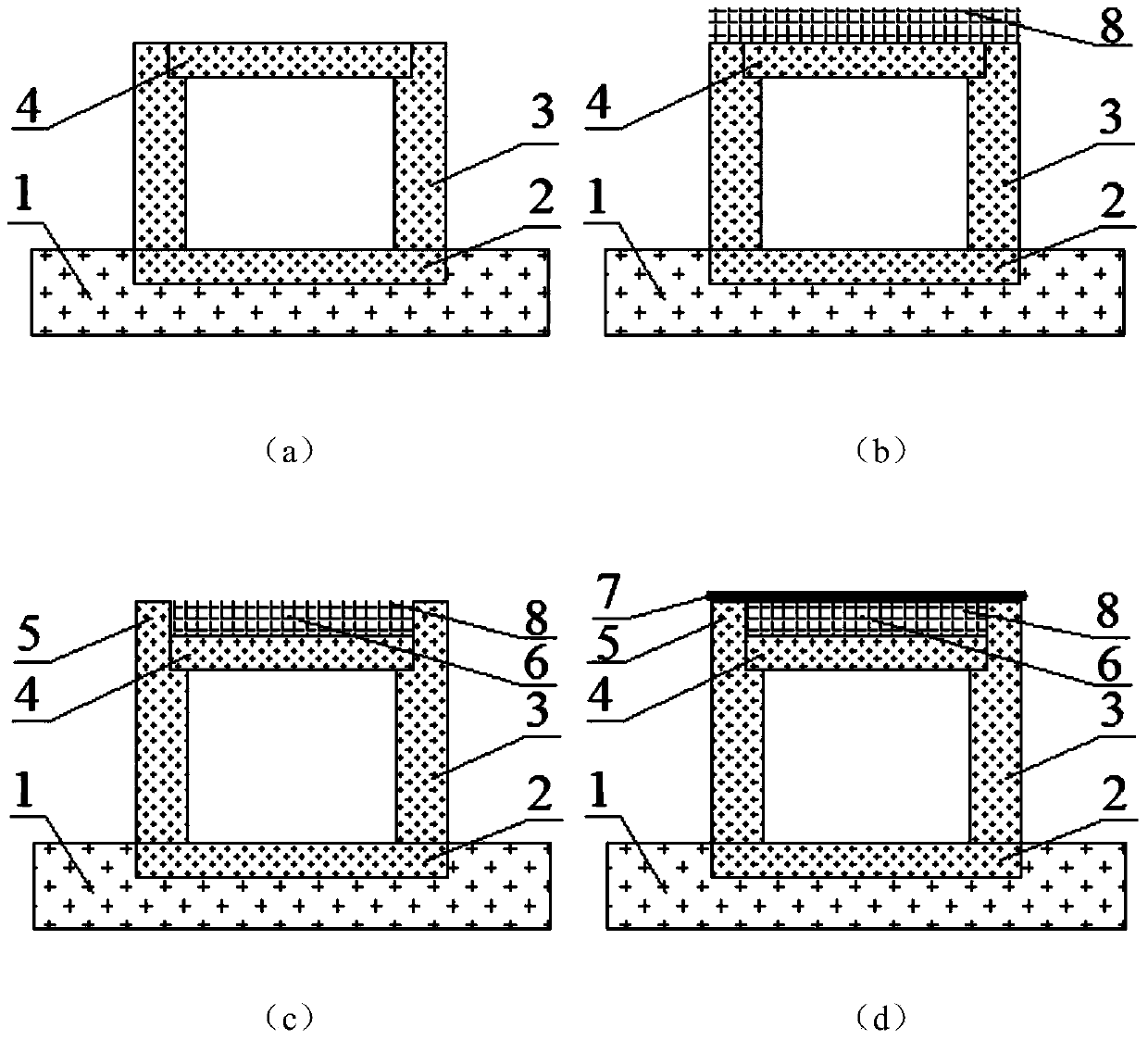

Load-shedding type rigid culvert structure

InactiveCN103952986AReduce the maximum bending momentRelieve pressureGround-workLoad SheddingStress distribution

The invention relates to the technical field of geotechnical engineering and road engineering, and particularly discloses a load-shedding type rigid culvert structure, which comprises a foundation, culvert side walls, a culvert top plate, load-shedding blocks and load-shedding holes, wherein the load-shedding blocks are positioned just above the culvert side walls, and form an integral structure together with the culvert side walls, the load-shedding holes are positioned between the two load-shedding blocks just above a culvert, and the interior of each load-shedding hole is filled with light-weight flexible material. The culvert structure has the advantages that after the structure is adopted, the construction and operation are easy and convenient, and the implementation is easy; the pressure of soil at the top of the culvert is obviously reduced, and the problem of cracking of the culvert is effectively solved; one part of load at the top of the culvert is transferred into the surrounding soil through the soil arch effect at the top of the culvert, the other part of load is transferred to the foundation through the culvert side walls, and then the vertical compressive capability of the culvert side walls is fully realized; the maximum bending moment of the culvert side walls is effectively reduced, and the stress distribution of the culvert is more reasonable; the stress asymmetry of the culvert is effectively reduced, and the separation and cracking of the connecting part of the top of the culvert and the side wall are avoided; the load-shedding effect is obviously improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

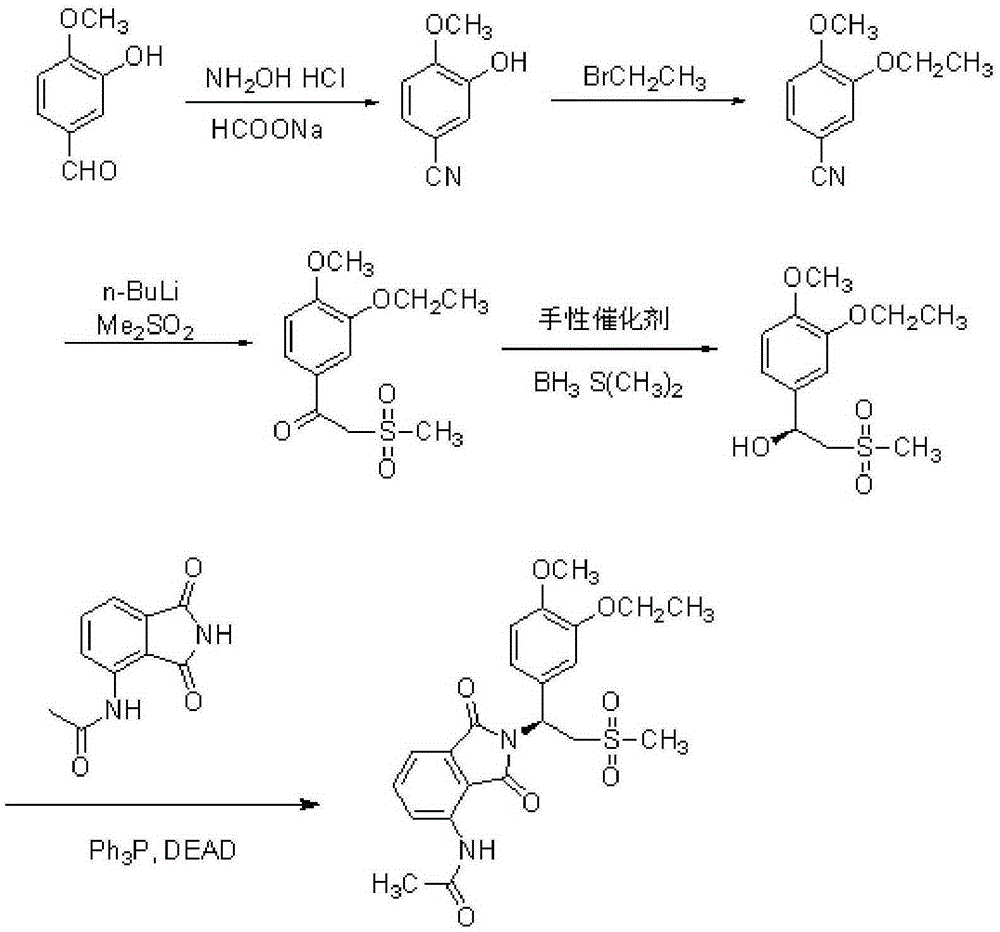

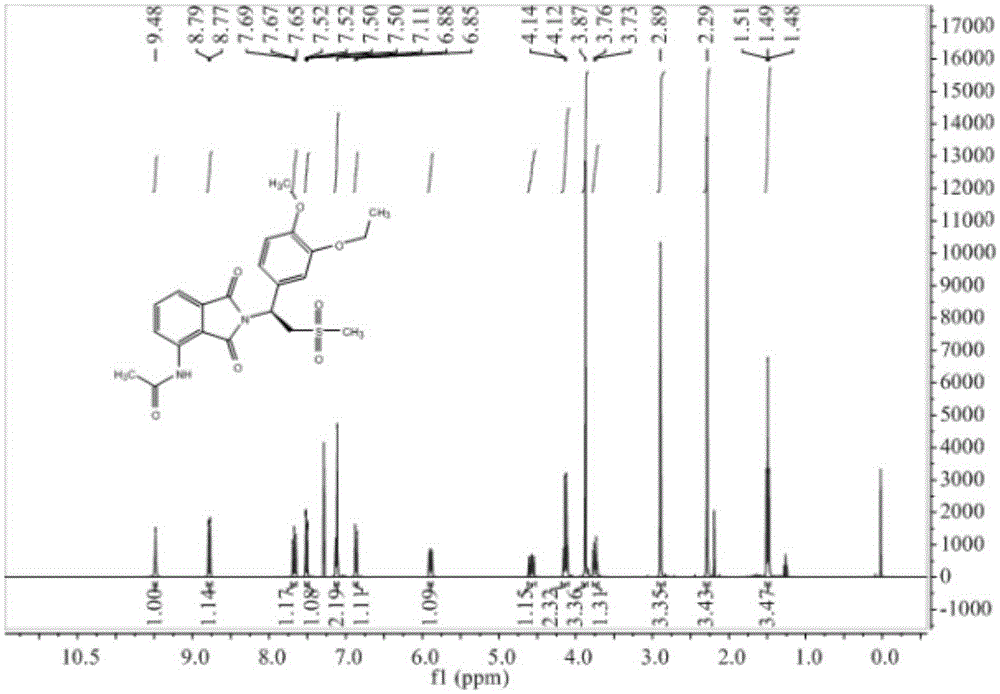

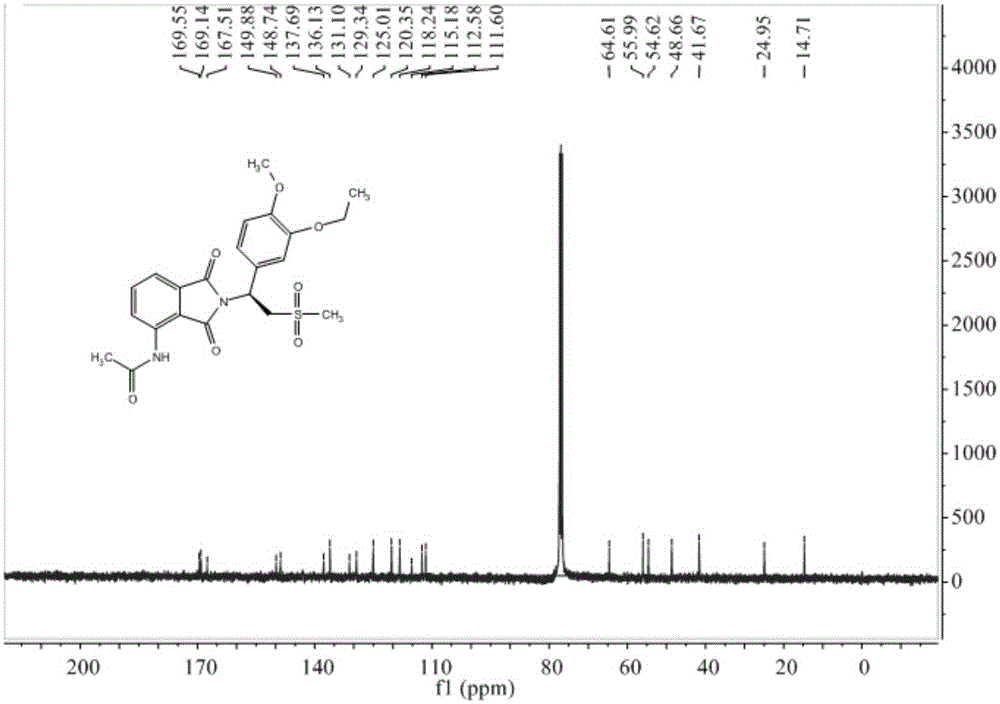

Preparation method of Apremilast

InactiveCN105330586AAvoid splittingReduce waste disposalOrganic chemistryBromineBENZYL ALCOHOL/WATER

The invention relates to a preparation method of Apremilast, comprising the following steps: by taking 3-hydroxy-4-methoxybenzaldehyde as a staring material, reacting with hydroxylamine hydrochloride to obtain 3-hydroxy-4-methoxy cyanobenzene, reacting with bromoethane to obtain 3-ethyoxyl-4-methoxy cyanobenzene, and then reacting with dimethyl sulfone under the action of n-butyllithium, and hydrolyzing in aqueous hydrochloric acid solution to obtain 1-(3-ethyoxyl-4-methoxyphenyl)-2-(mesyl)ketol); finally by taking S-(-)-alpha, alpha-diphenyl-2-pyrrolidine methanol as a chiral catalyst and taking borane dimethyl sulfide complex solution as a reductant, obtaining chirality S-3-ethyoxyl-4-methoxy group-alpha[(mesyl)benzyl alcohol], and then reacting with 3-acetamido-phthalimide under the action of triphenylphosphine and diethyl azodicarboxylate, thus obtaining the Apremilast. According to the preparation method, the process is effectively simplified, the reaction conditions are mild, the product yield and purity are relatively high, and large-scale industrial production is benefited.

Owner:DONGHUA UNIV

Method for machining slotted holes on carbon fiber laminated boards

The invention discloses a method for machining slotted holes on carbon fiber laminated boards, which belongs to a machining method for nonmetallic materials, solves the problem that by the existing milling and drilling methods, carbon fiber laminated boards are easy to laminate, split and burn, and aims at improving the machining precision of carbon fiber composite products and reducing the surface roughness of carbon fiber composite products. The method disclosed by the invention comprises a clamping step, a machining step and a post-processing step, wherein the machining step is one or two of a milling machining step and a drilling machining step. According to the invention, in the machining process, a non-deformed clamping mode is used, and through selecting reasonable cutting tool materials, geometric parameters of cutting tools, and milling and drilling machining parameters, the appearance allowances in machining are reasonably arranged, thereby solving the quality problems of laminating, splitting and burning and the like existing in the process of opening or drilling carbon fiber thin-wall revolution bodies and carbon fiber laminated boards by using the traditional methods, so that the qualified rate of carbon fiber parts is increased from 50% to more than 99%.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Method and device for pushing information based on communication group

ActiveCN104580430AImprove simplicityReduce consumptionBroadcast service distributionLocation information based serviceTime responseResource consumption

The embodiment of the invention provides a method and a device for pushing information based on a communication group. The method comprises the steps of receiving a configuration request which is sent by a first terminal, for the communication group, wherein the configuration request comprises geographical coordinate information and a first user identifier; identifying position information corresponding to the geographical coordinate information; acquiring the communication group matched with the position information, wherein the communication group is provided with one or more associated second user identifiers; searching a second user identifier matched with the first user identifier and a communication mode; respectively pushing the communication mode to the first terminal and a second terminal, wherein the second terminal is a terminal corresponding to the matched second user identifier. According to the method and the device which are provided by the embodiment of the invention, the convenience in operation is greatly improved, and the time cost is reduced; meanwhile, the system resource consumption and the network bandwidth consumption which are caused by multi-time response of checking operation by the first terminal and a server are reduced.

Owner:BEIJING QIHOO TECH CO LTD

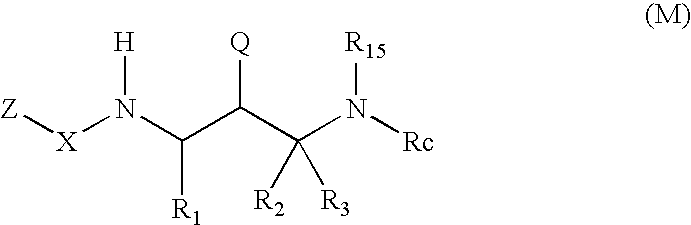

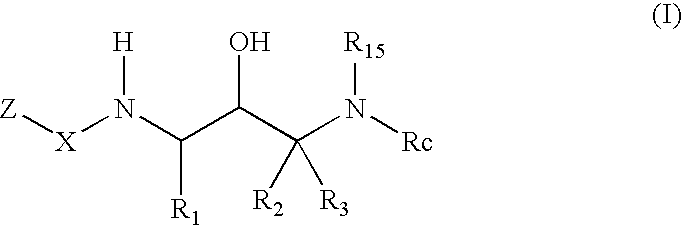

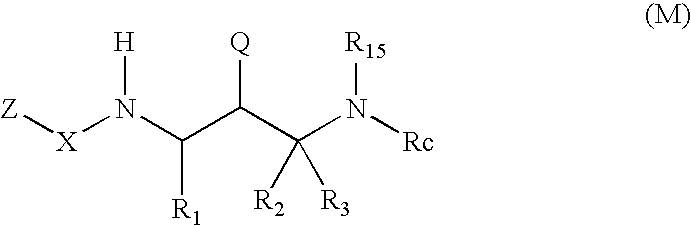

2-Amino- and 2-thio- substituted 1,3-diaminopropanes

InactiveUS20050267199A1Suppression problemInhibit productionBiocideNervous disorderGreek letter betaThio-

Disclosed are compounds of the formula: where variables Q, Z, X, R15, R2, R3, and Rc are defined herein. Compounds disclosed herein are inhibitors of the beta-secretase enzyme and are therefore useful in the treatment of Alzheimer's disease and other diseases characterized by deposition of A beta peptide in a mammal.

Owner:ELAN PHARM INC

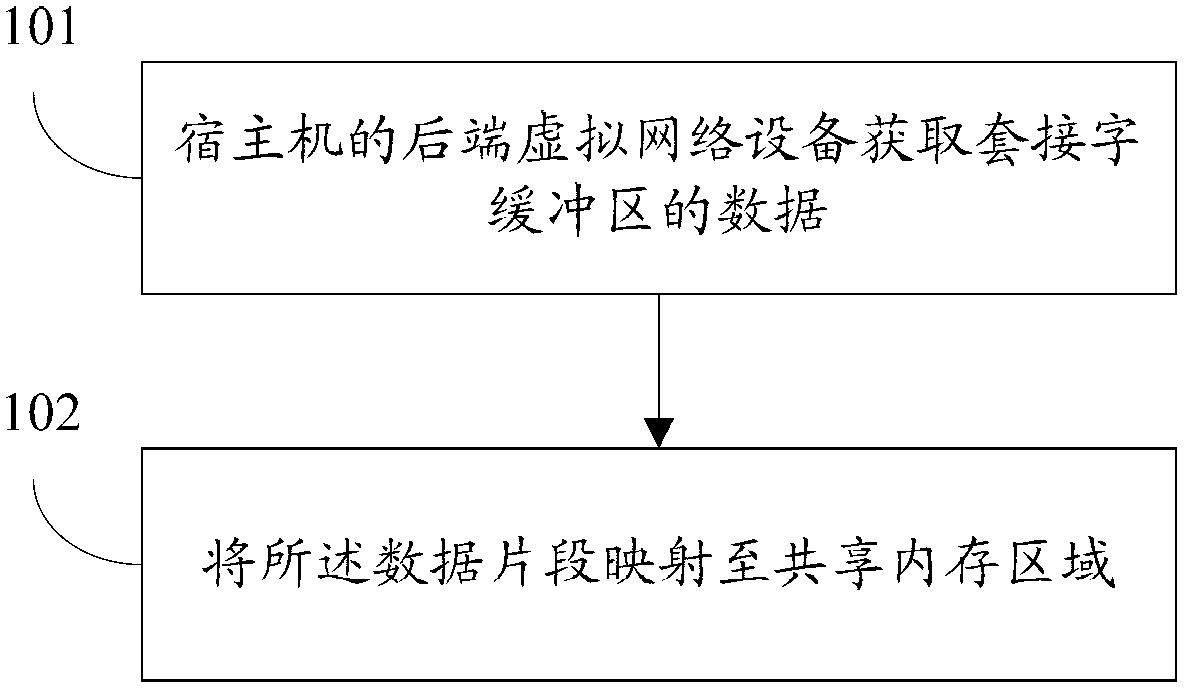

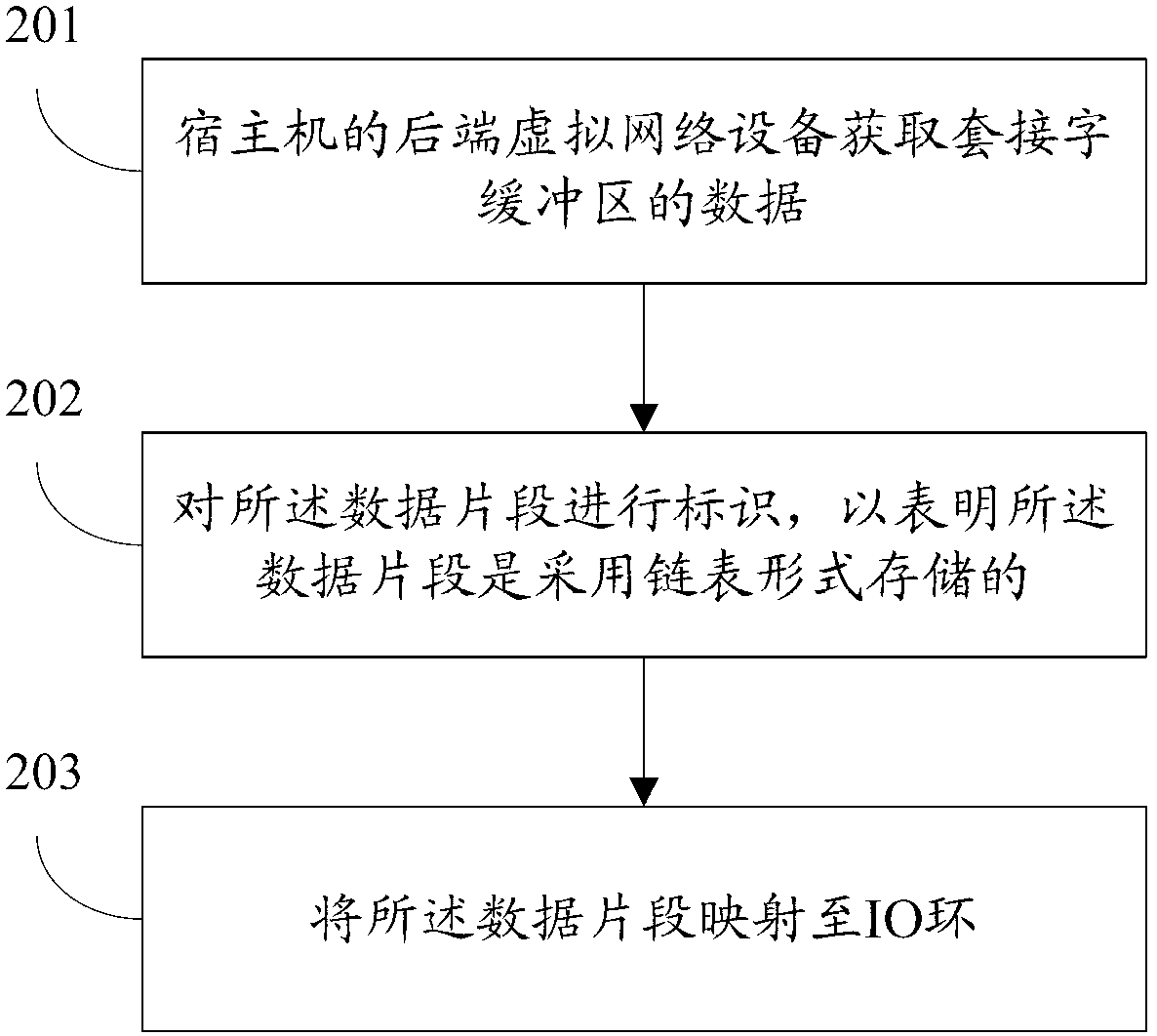

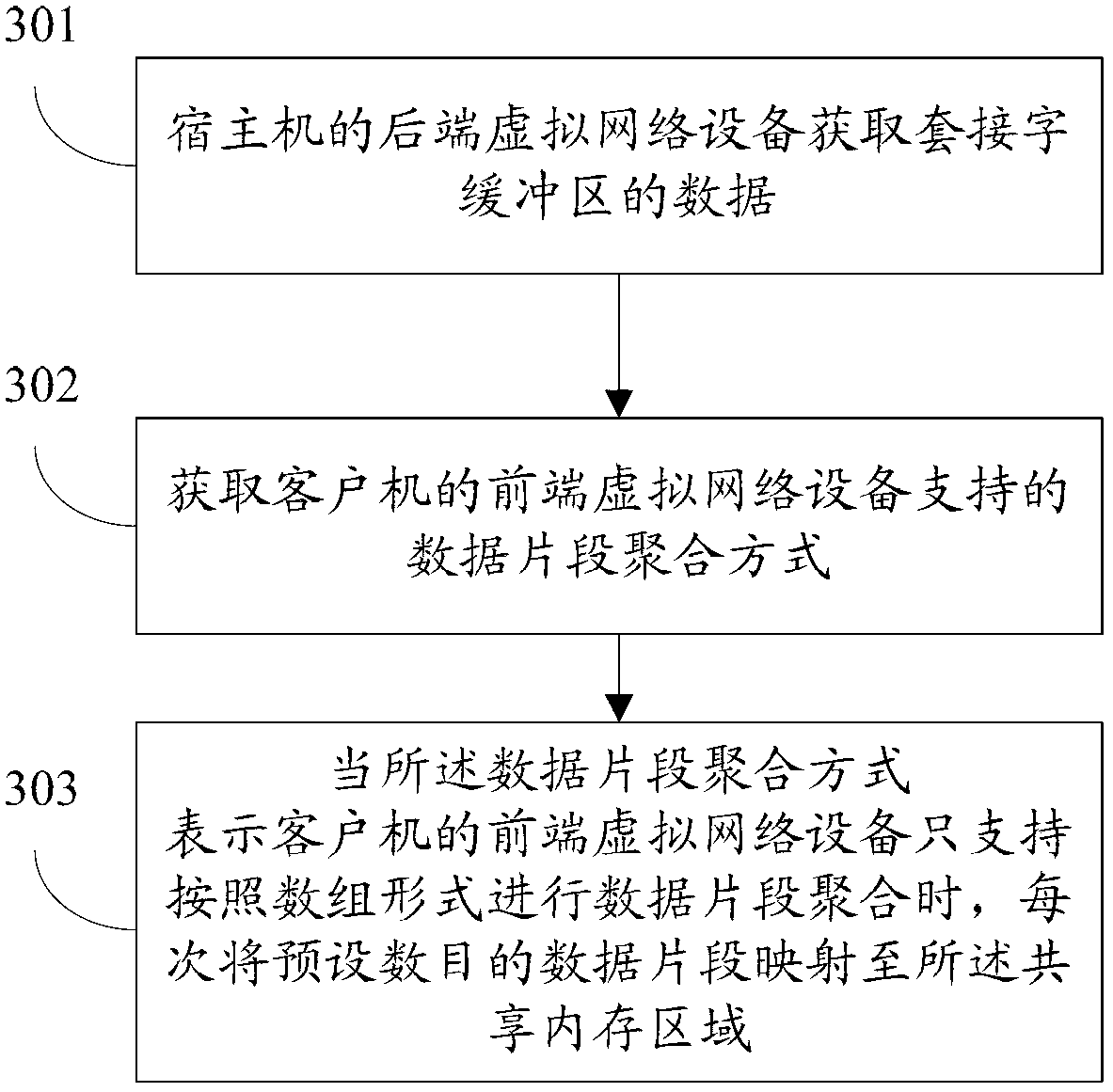

Data transmission method, data receiving method and system based on virtual machine

InactiveCN103176833AAvoid splittingReduce overheadData switching networksSoftware simulation/interpretation/emulationNetwork packetData transmission

The invention discloses a data transmission method, a data receiving method and a system based on a virtual machine. The data transmission method is applied to a virtual machine framework provided with a host and a client. The method includes the steps that a back end virtual network device of the host acquires data of a socket buffer area; data slots of the data of the socket buffer area are stored in the form of a chain table, wherein the size of the data slots is equal to that of a data package sent by a physical network card of the host; and the data slots are mapped to a shared memory area so that the client can read the data slots from the shared memory area conveniently. According to method or the system, separation of big data packages can be avoided, and system overhead of the Host can be reduced.

Owner:HUAWEI TECH CO LTD

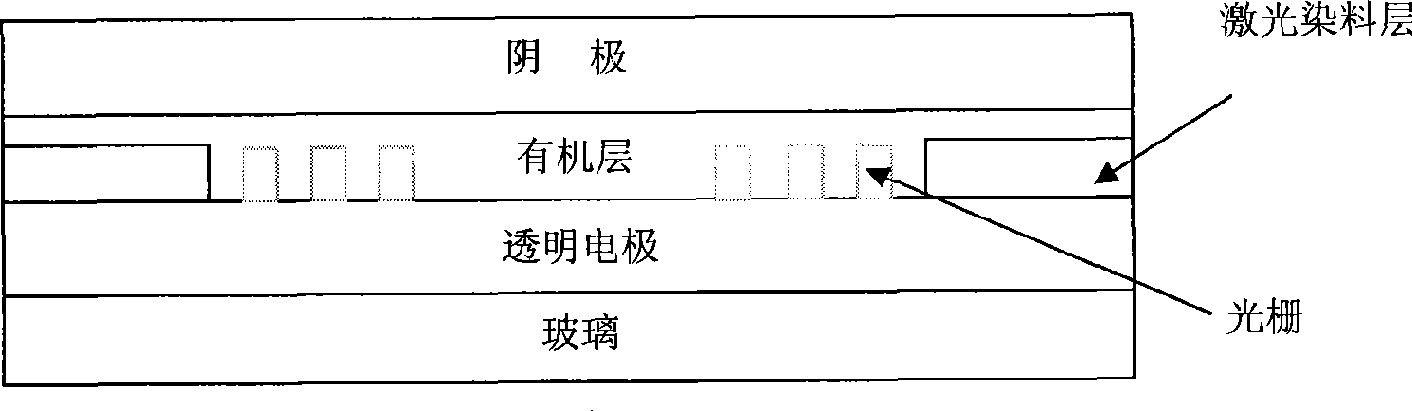

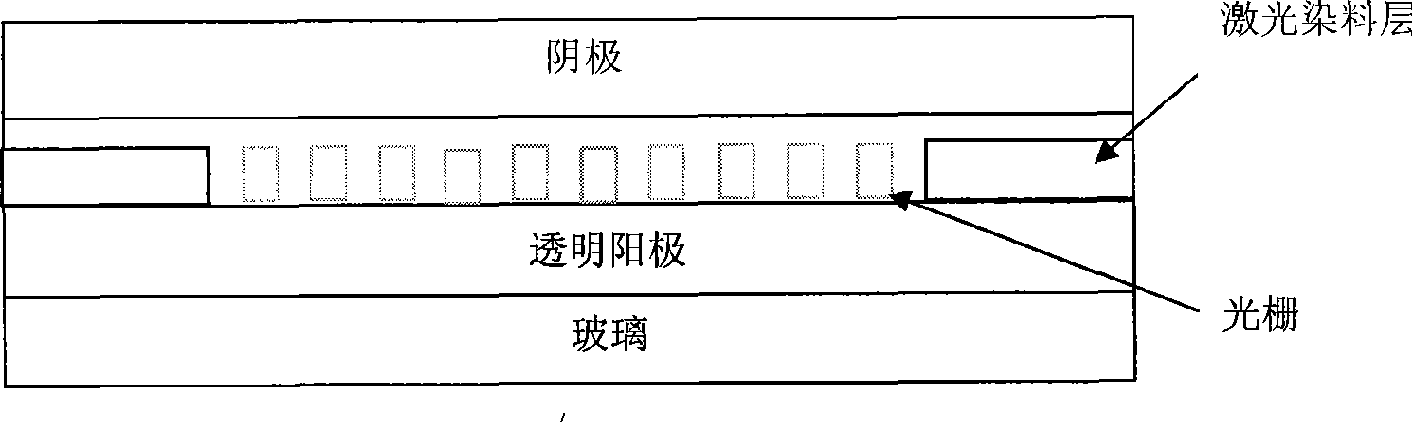

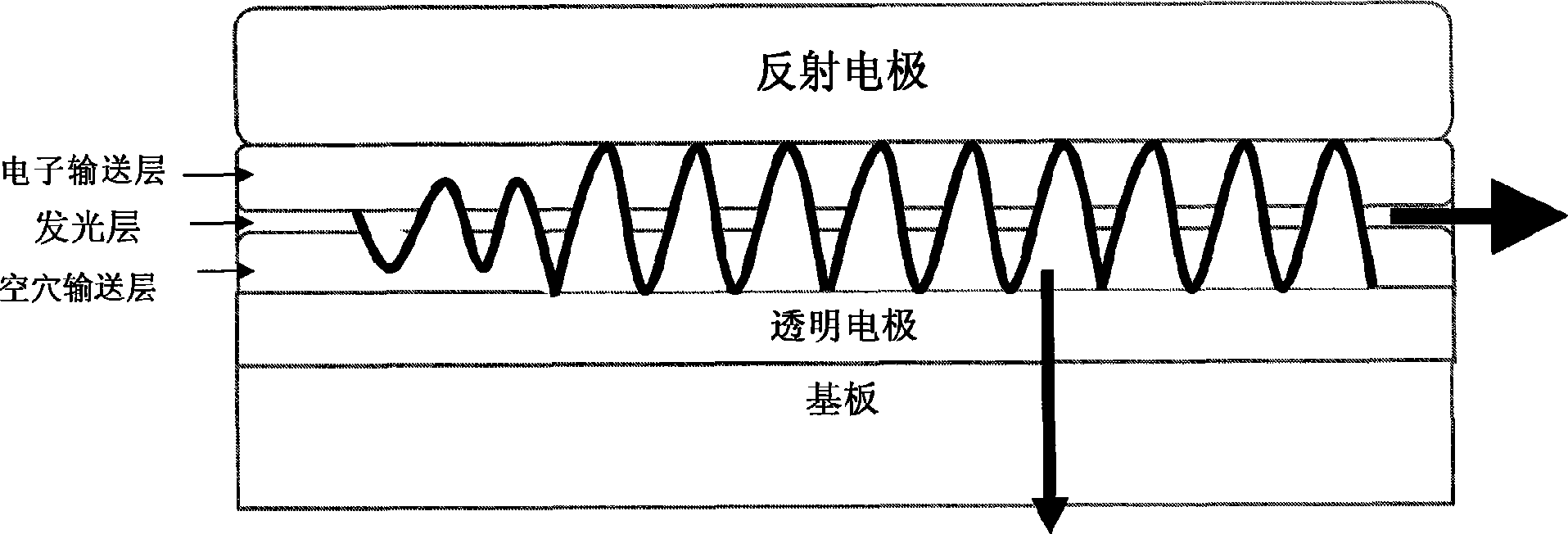

Novel organic semi-conductor solid laser and preparation thereof

InactiveCN101388523AAvoid splittingAvoid absorptionLaser optical resonator constructionLaser active region structureDiffraction orderGrating

The invention relates to a novel organic semiconductor solid laser and a method for manufacturing thereof, wherein a distributing Bragg resonator DBR or a distributing feedback resonator DFB is arranged on the anode of an organic electroluminescent luminescent diode through adopting the photoetching technique, the resonator chooses LiF, SiO2, SiNx or Al2O3 to finish through a vacuum coating or a magnetron sputtering method, the calculation formula of Bragg wavelength lambda Bragg is that lambda Bragg=neff2 lambada / m, wherein neff is effective refractive index constant, m and lambada are respectively the diffraction order and the periodic time of grating. The novel organic semiconductor solid laser combines photoluminescence and electroluminescence, which utilizes EL light of high-intensity OLED and low ASE threshold organic thin film on the same device of a pump to avoid the organic luminescent layer in an OLED period from absorbing light by electric charge and exciton, avoid exciton resolution generated by strong light, and achieves OLED pump laser.

Owner:SHANGHAI UNIV

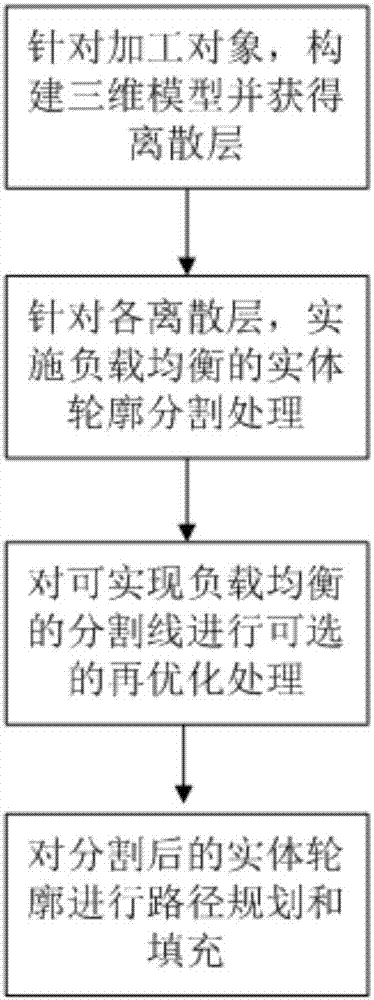

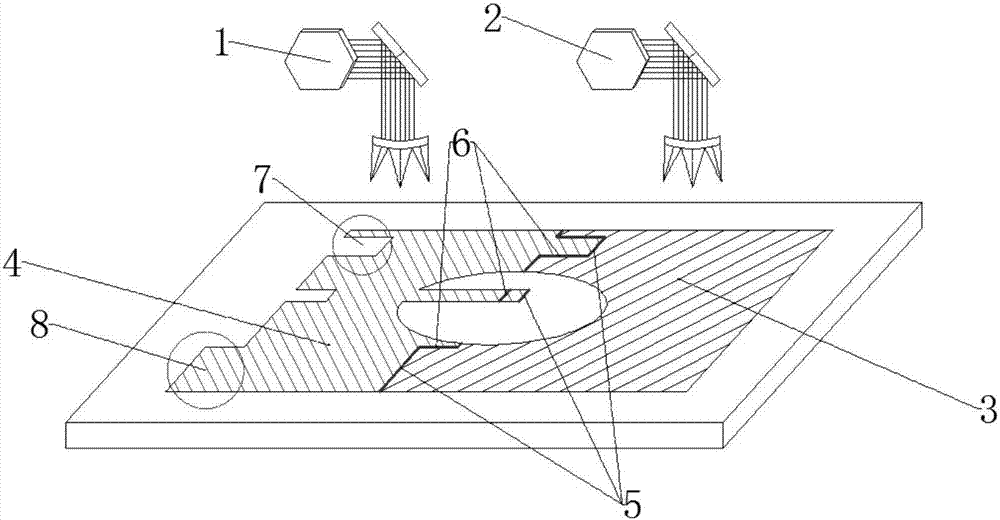

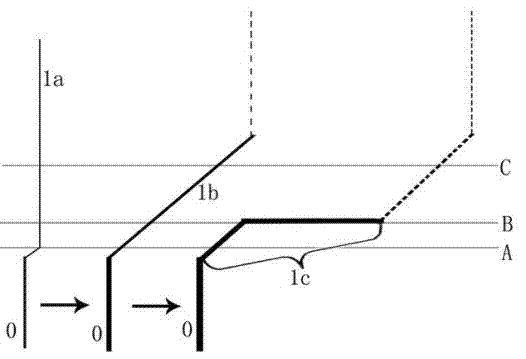

Load balancing scanning forming method used for multilaser selective laser melting (SLM) forming device

ActiveCN107498052AConsistent laser processing timeMaximize processing efficiencyAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSplit lines

The invention belongs to the related technical field of additive manufacturing, and discloses a load balancing scanning forming method used for a multilaser selective laser melting (SLM) forming device. The method comprises the steps that (a) corresponding three-dimensional models are established for to-be-machined components, and the models are subjected to hierarchy slicing and discrete treatment to obtain model profiles of all discrete layers; (b) according to a certain algorithm, an optimized parting line is found out from an intermediate overlapping area between every two adjacent galvanometer scanning areas; and (c) all areas after optimized parting is completed are subjected to path programming and filling, and thus the whole load balancing scanning forming process is completed. Through the load balancing scanning forming method provided by the invention, the problems that currently, during machining of multilaser SLM forming equipment, the galvanometer set working efficiency is low, temperature field distribution is uneven, and the multilaser boundary area performance deteriorates can be effectively solved, and meanwhile, the method has the characteristics of high efficiency, high quality, convenient control and the like, so that the method is particularly suitable for manufacturing and application occasions of large-size workpieces of complex internal structures.

Owner:HUAZHONG UNIV OF SCI & TECH

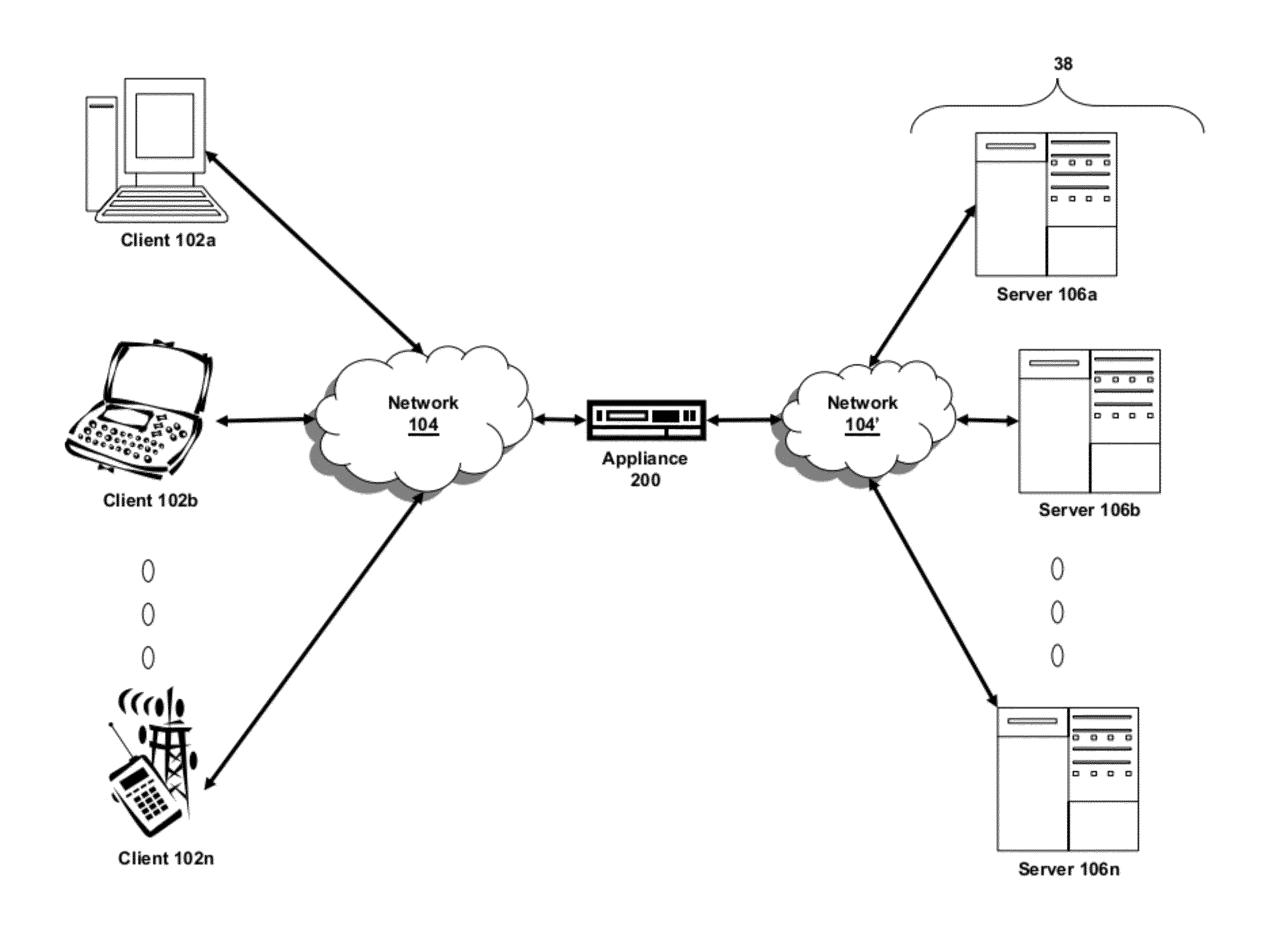

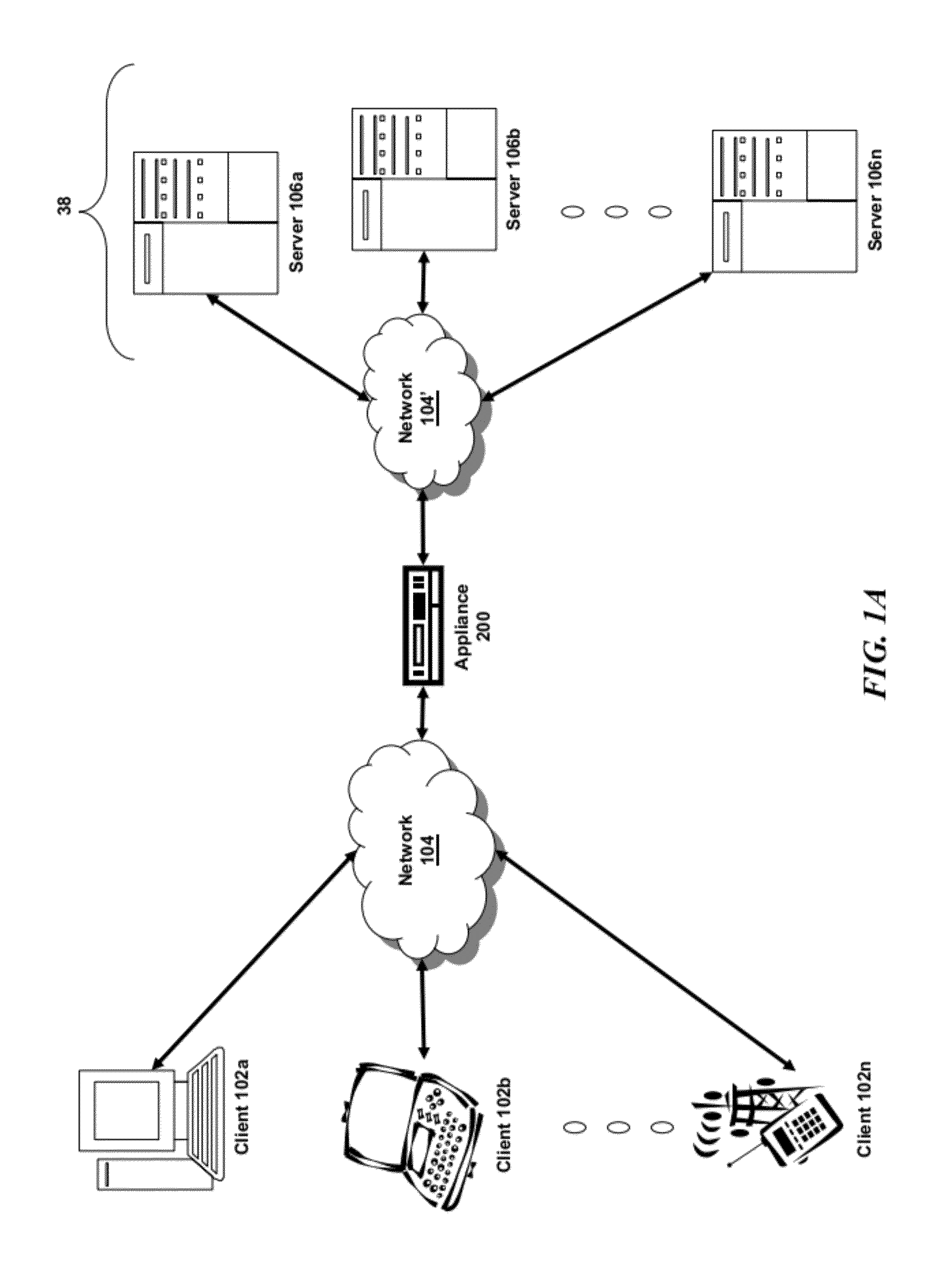

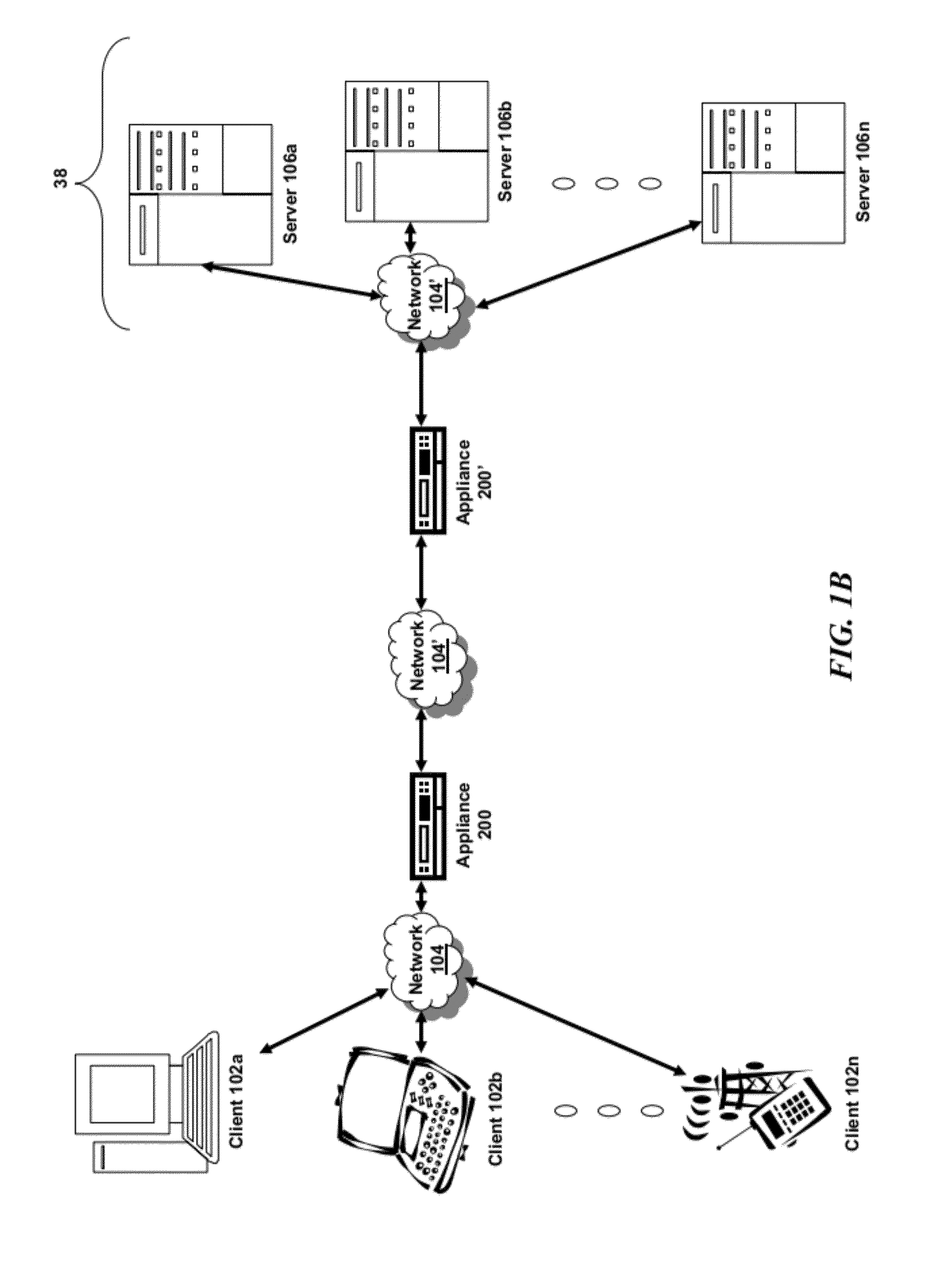

Systems and Methods for Learning MSS of Services

ActiveUS20120250530A1Avoid splittingSplitting packetError preventionFrequency-division multiplex detailsValue setClient-side

The virtual Server (vServer) of an intermediary device deployed between a plurality of clients and services supports parameters for setting maximum segment size (MSS) on a per vServer / service basis and for automatically learning the MSS among the back-end services. In case of vServer / service setting, all vServers will use the MSS value set through the parameter for the MSS value set in TCP SYN+ACK to clients. In the case of learning mode, the backend service MSS will be learnt through monitor probing. The vServer will monitor and learn the MSS that is being frequently used by the services. When the learning is active, the intermediary device may keep statistics of the MSS of backend services picked up during load balancing decisions and once an interval timer expires, the MSS value may be picked by a majority and set on the vServer. If there is no majority, then the highest MSS is picked up to be set on the vServer.

Owner:CITRIX SYST INC

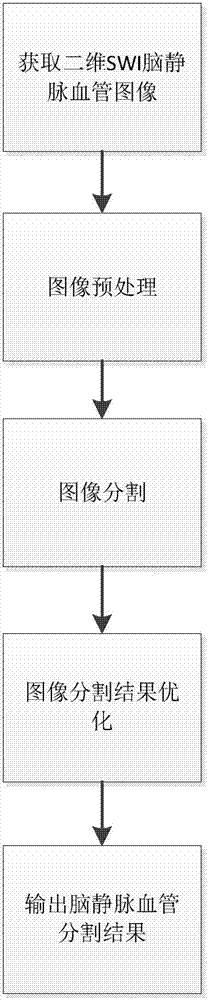

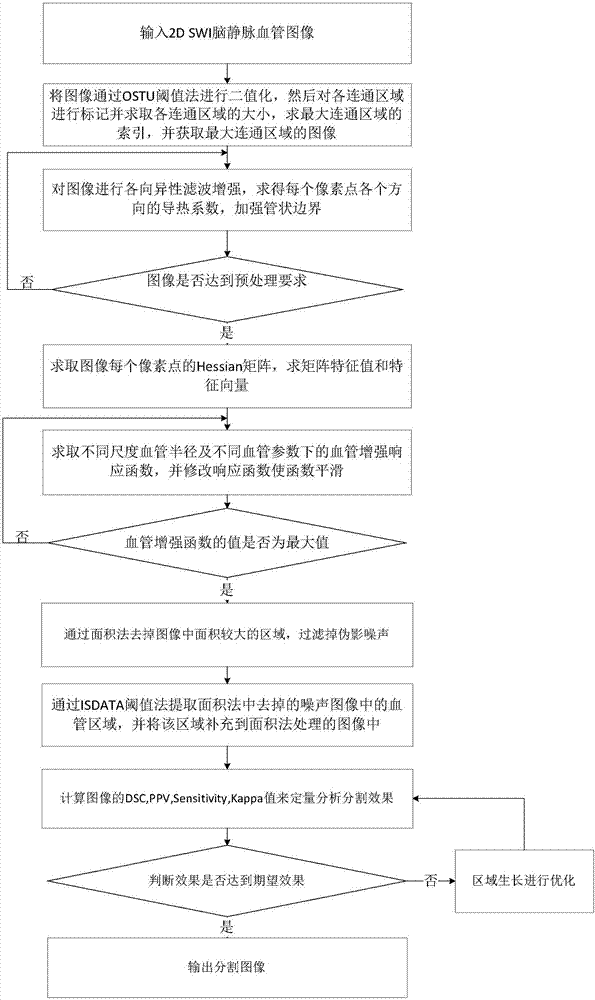

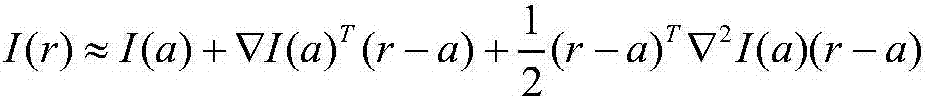

SWI (Susceptibility Weighted Imaging) image based cerebral vein vessel segmentation method

InactiveCN107248155AStrengthen the tubular structureGood removal effectImage enhancementImage analysisBoundary contourSusceptibility weighted imaging

The invention relates to an SWI (Susceptibility Weighted Imaging) image based cerebral vein vessel segmentation method, which comprises the steps of reading each two-dimensional SWI cerebral vein vessel image through magnetic resonance equipment, adjusting the image resolution, and removing the skull and skin covering the periphery of the brain in the images; performing anisotropic filtering enhancement processing on the processed images; then performing improved 2D Hessian matrix filtering enhancement processing; removing a large area of noise caused by artifacts of the brain, segmenting out most small vein vessels, and removing the boundary contour of a brain image; reserving the small vein vessels mistakenly removed; and calculating a DSC value, a PPV, the sensitivity and a Kappa value of each segmented image, and performing optimization on a region with the segmentation effect being poor. The cerebral vein vessel segmentation method can acquire a stable result in different SWI brain images with great difference and under noise and interference conditions, the false positive rate is low, segmentation of a structure which does not belong to the vein is avoided, and requirements of medical images for the safety are met.

Owner:NORTHEASTERN UNIV

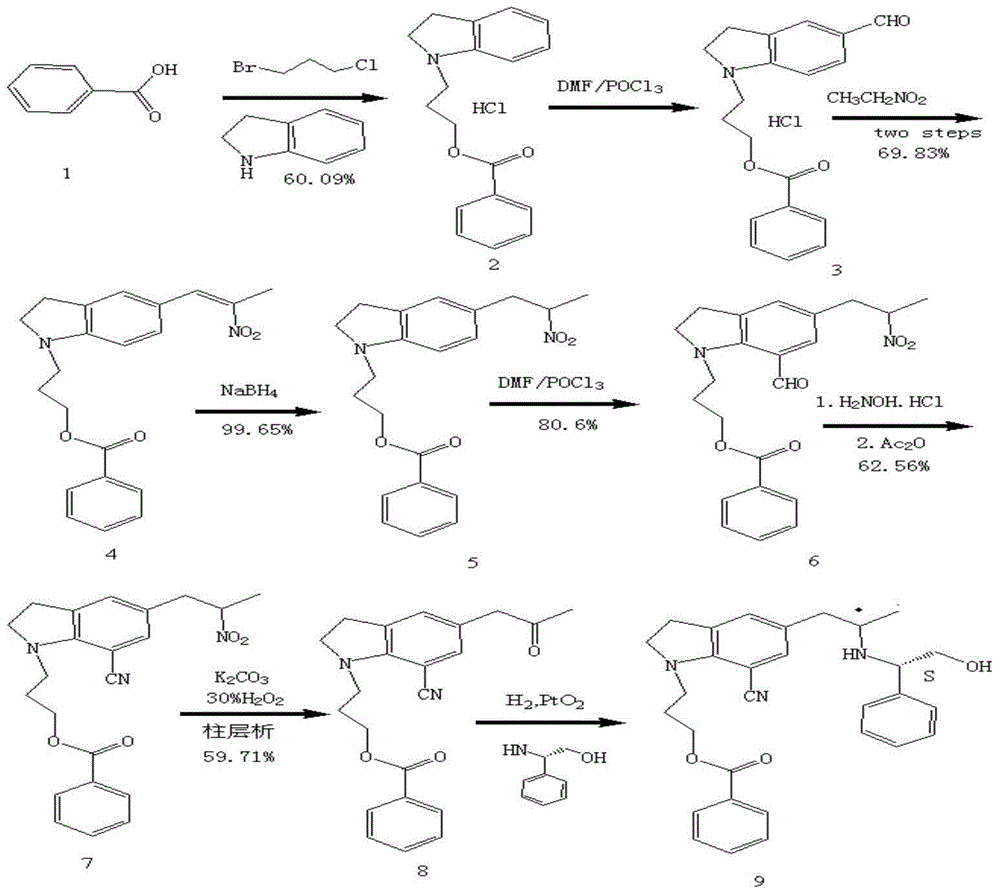

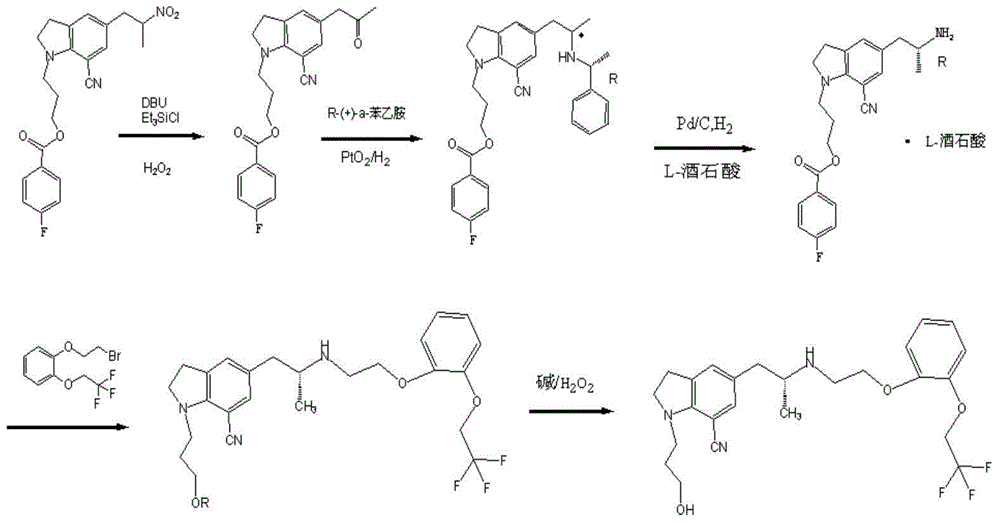

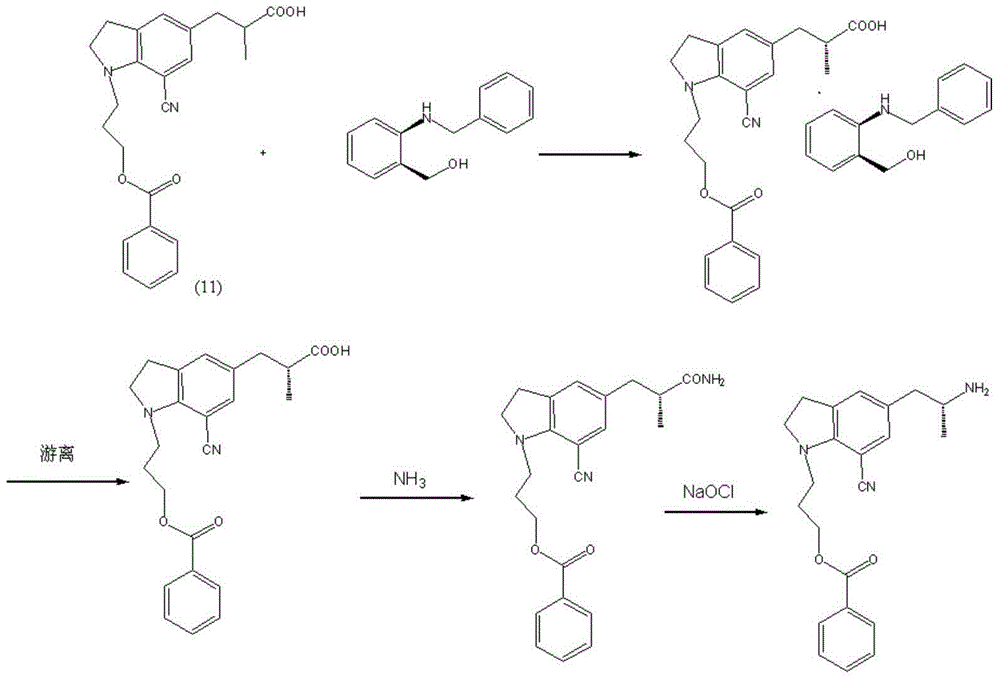

Method for synthesizing silodosin

ActiveCN103554003AAvoid splittingControllable optical purityOrganic chemistryTriethylsilaneSilodosin

The invention discloses a method for synthesizing silodosin. The method comprises the following steps: by taking 7-cyanoindoline as an initial raw material, synthesizing a 1-(benzoyloxypropyl)-7-cyanoindoline compound (I); reacting with a compound (II) to synthesize a key chiral intermediate 5-[(2R)-2-(benzylamino)-1-acetone]-1-{3-(benzoyloxy)propyl]-7-cyanoindoline compound (III), and reducing through triethyl silicane to obtain a compound (IV); performing catalytic hydrogenation to obtain a compound (V), carrying out a condensation reaction with a compound (VI) under alkaline conditions to obtain a compound (VII), and finally, hydrolyzing under alkaline and H2O2 conditions to obtain silodosin. The compound (I) and the compound (II) are subjected to chiral synthesis to obtain the key chiral compound (III), resolution is avoided, and the optical purity is controllable, so that the reaction yield is greatly improved, the reaction conditions are mild, generation of byproducts in a conventional process is avoided, the production cost is reduced, and the purity is high. The labor intensity is alleviated, the method is environment-friendly and easy for industrial production, and the total yield is high and is improved from 20 percent in a literature report to be about 43 percent.

Owner:LIANYUNGANG GUIKE PHARMA

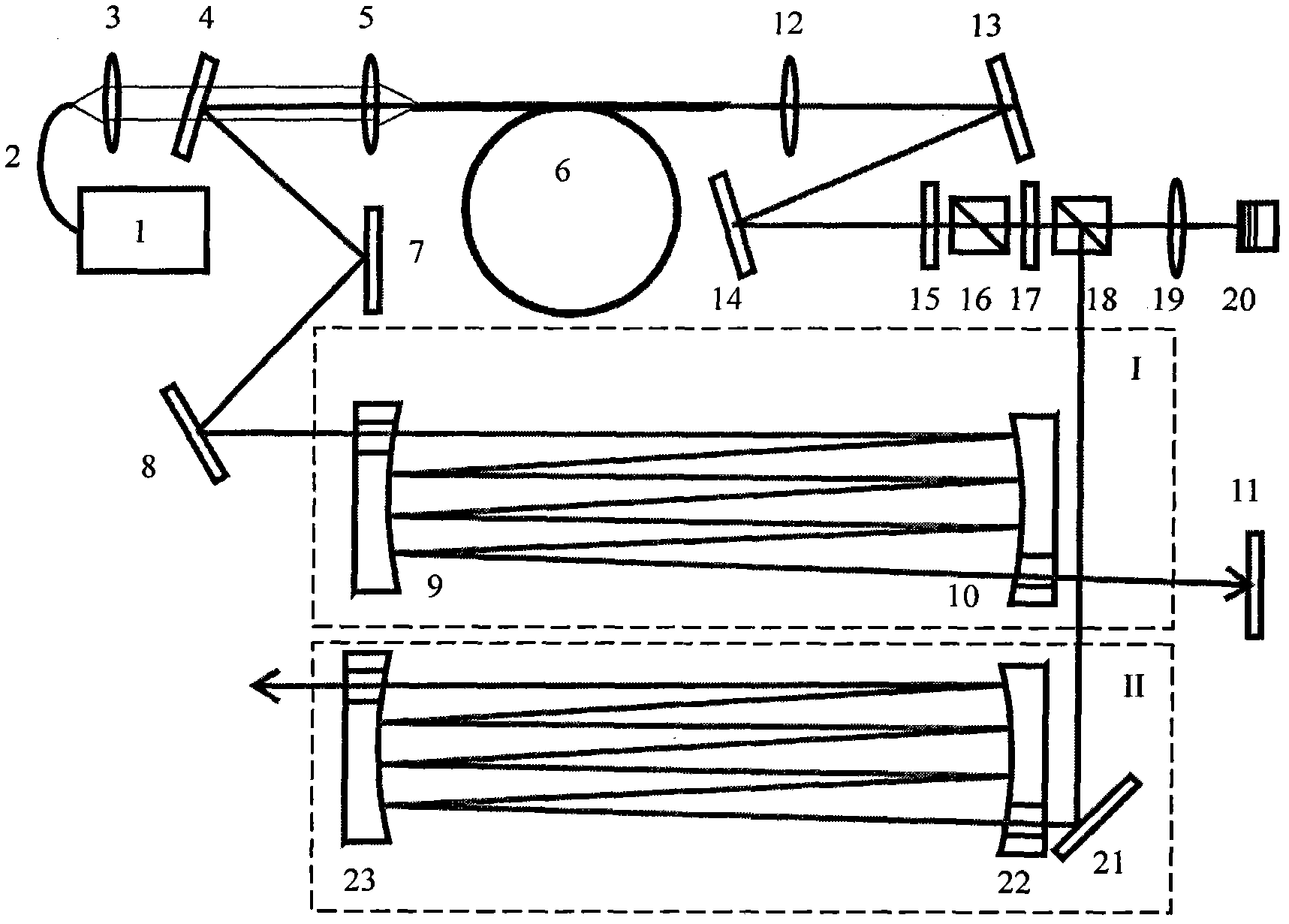

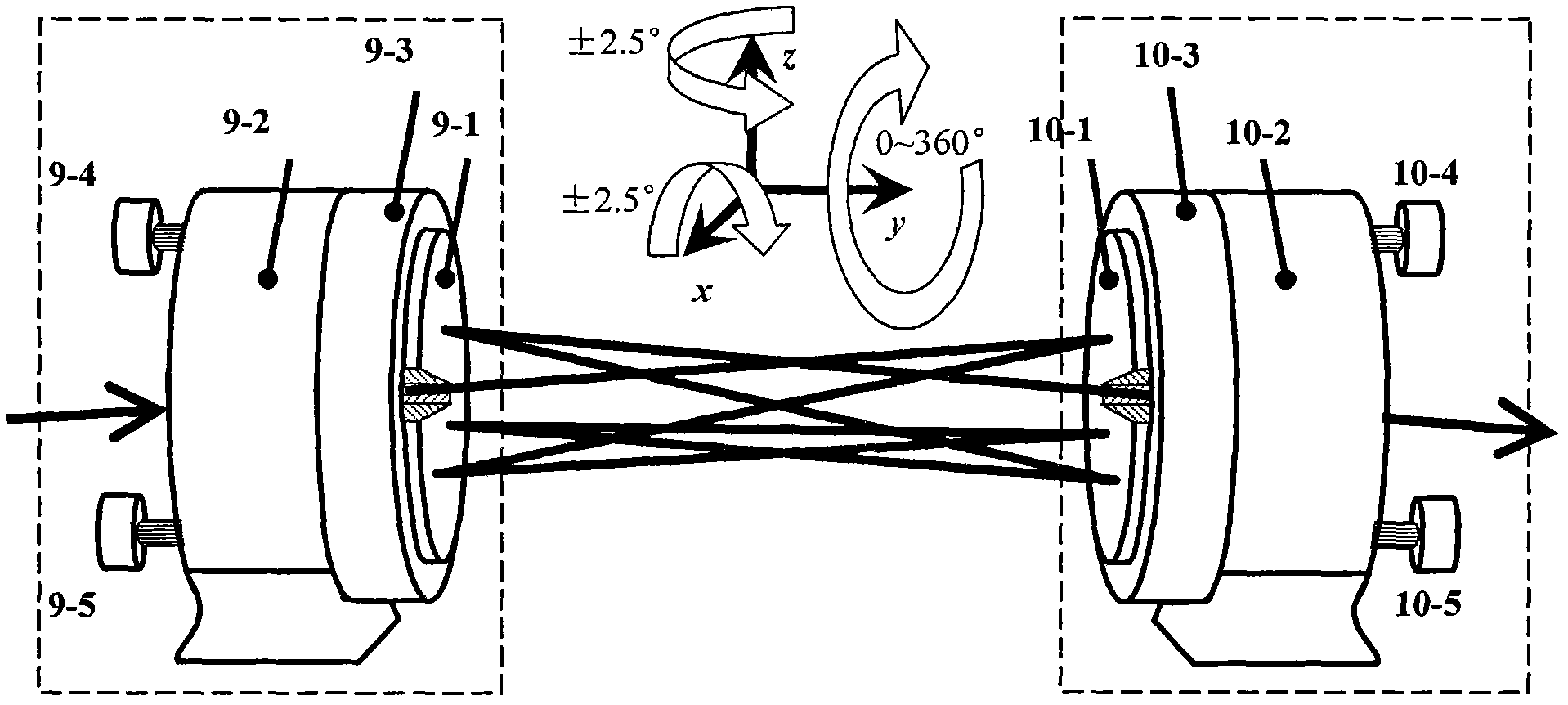

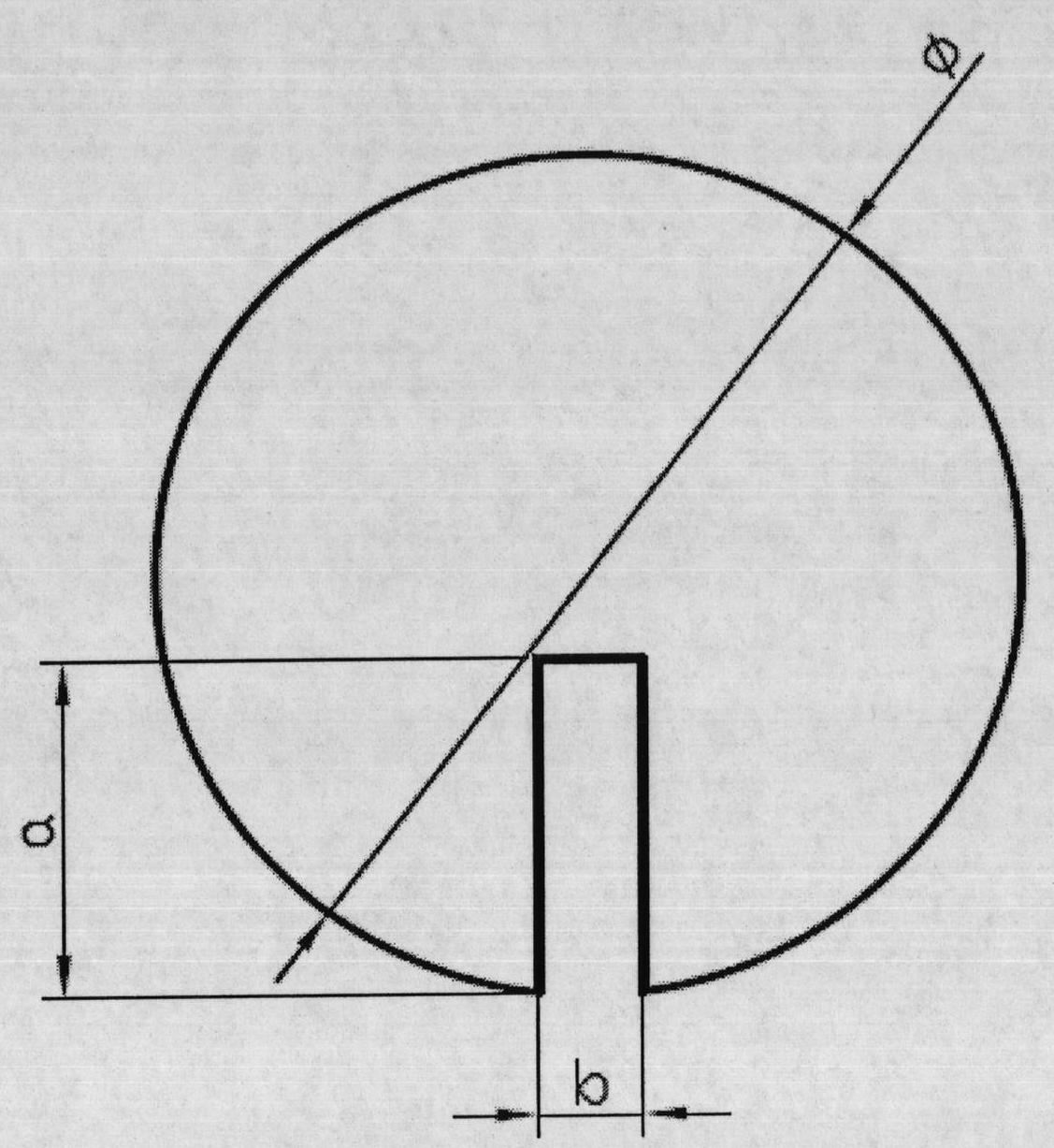

MHz photonic crystal fiber ultra-short pulse laser based on multichannel pulse compressor

InactiveCN101938081AHigh single pulse energyReduce repetition rateOptical resonator shape and constructionActive medium shape and constructionHigh energyDispersion compensation

The invention discloses a MHz photonic crystal fiber ultra-short pulse laser based on a multichannel pulse compressor. The laser comprises a diode pumping source, a photonic crystal fiber, an intra-cavity pulse compressor, a semiconductor saturable absorber mirror and an extra-cavity pulse compressor, wherein the inter-cavity pulse compressor and the extra-cavity pulse compressor respectively are an intra-cavity multichannel pulse compressor and an extra-cavity multichannel pulse compressor. The main bodies of the multichannel pulse compressors are end mirrors in which two concave spherical surfaces are coaxially and oppositely arranged, each end mirror is provided with a rotating ring, and a concave spherical reflector is arranged in the rotating ring. The MHz photonic crystal fiber ultra-short pulse laser has the advantages that the low recurrence frequency of the pulse laser greatly reduces heat accumulation of pulse on components and prolongs the service life of the components, meanwhile, the intra-cavity multichannel compressor and the extra-cavity multichannel compressor with low loss and compact structure overcome the disadvantages of other chromatic dispersion compensation technologies, and the ultra-short pulse laser with low cost, high energy and high peak power output is realized.

Owner:TIANJIN UNIV

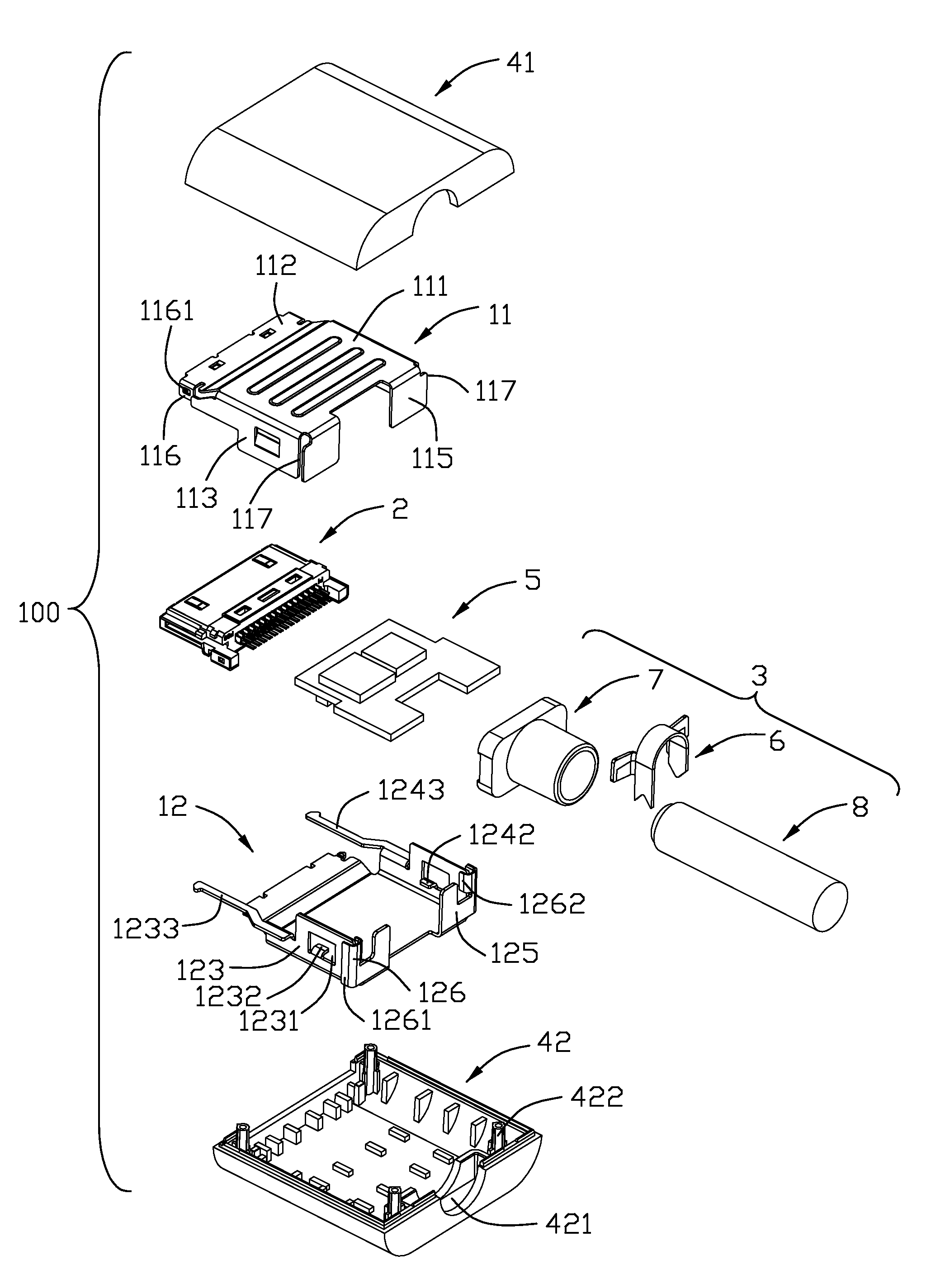

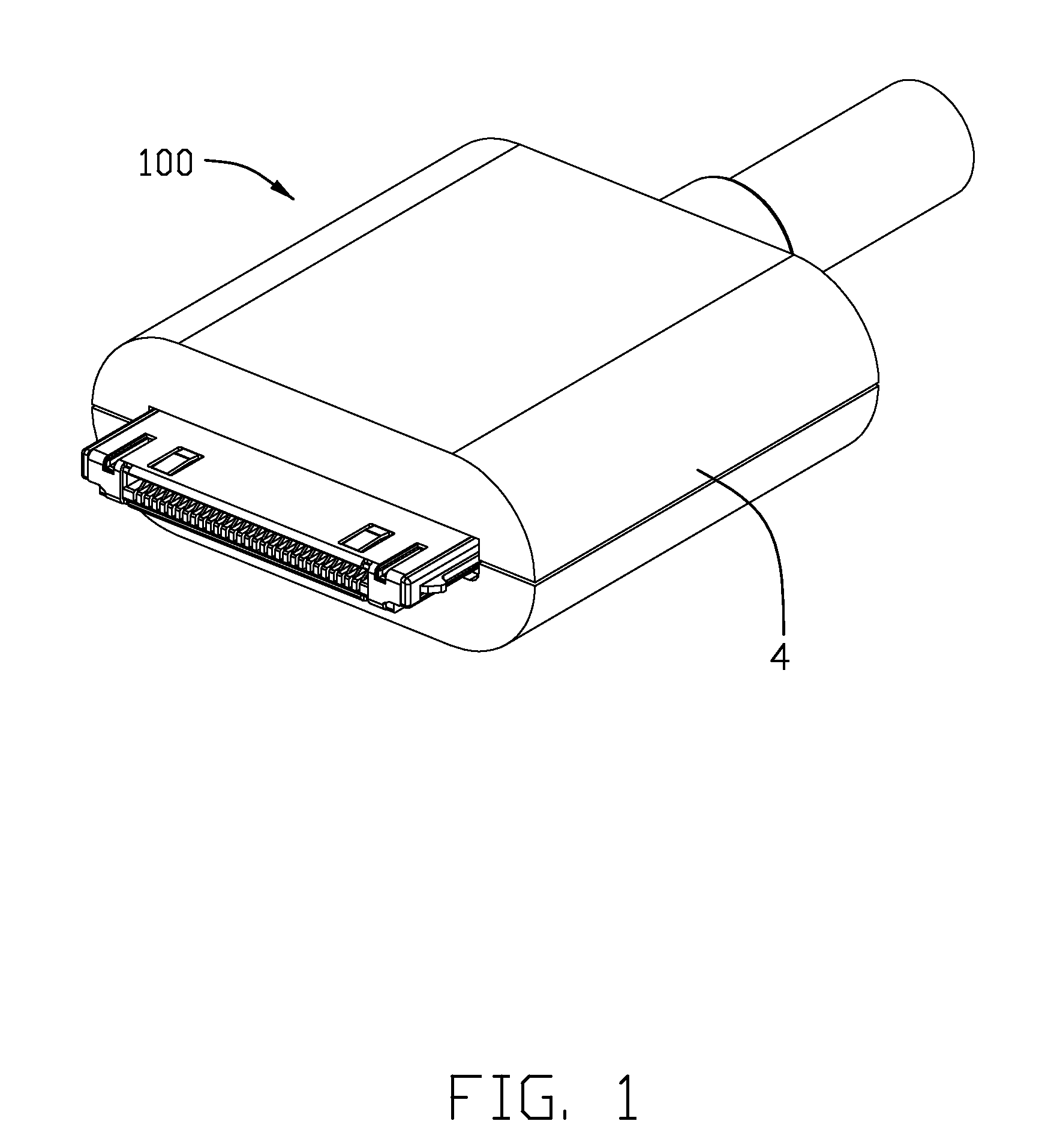

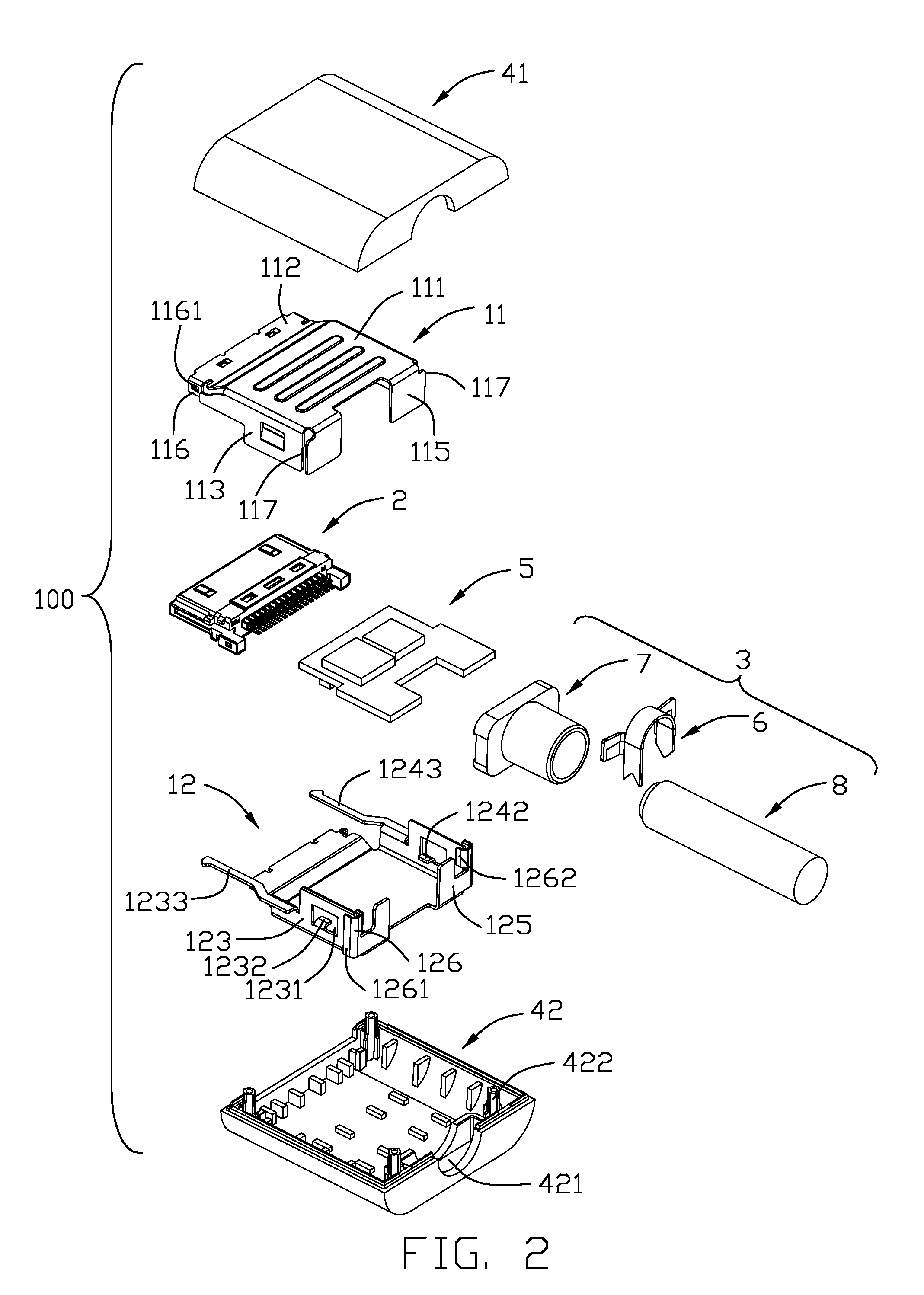

Cable connector assembly with improved shielding member

InactiveUS7922536B2Avoid splittingElectrically conductive connectionsCoupling protective earth/shielding arrangementsPrinted circuit board

Owner:HON HAI PRECISION IND CO LTD

Fast frame-climbing method of shed frame pear tree boughs

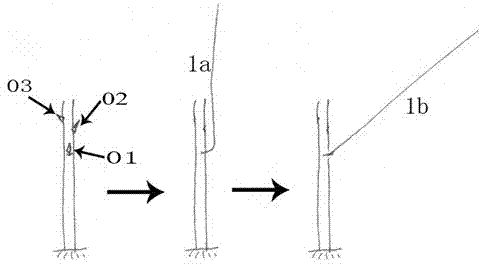

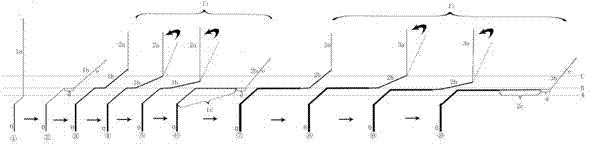

ActiveCN103081676AIncrease pavedIncrease reachCultivating equipmentsHorticulture methodsShootAgricultural engineering

The invention provides a fast frame-climbing method of shed frame pear tree boughs. The frame-climbing method is carried out on a shed frame of a three-line one plane or two-line one plane mode, and frame climbing is carried out by three steps of strengthening, pulling in an inclined mode, and pulling in a level mode. The first step of strengthening is that young shoots are guided onto an elevation guide line in a vertical mode during a growing season so that the young shoots can keep a vertical growing state. The second step of pulling in an inclined mode is that base parts of the shoots growing vertically are pulled in a level mode and fixed behind the shed frame face during autumn of the same year, and then are guided onto the elevation guide line according to a 45-degree angle, namely, the base parts of the shoots are firstly pulled in a level mode and fixed and then pulled in an inclined mode. The third step of pulling in a level mode is that the shoots are pulled in a level mode and fixed on the shed frame face during autumn of the next year. The fast frame-climbing method has the advantages of being fast in frame-climbing, few in water shoots, small in trimming quantity, large in frame face fruit area, high in output and the like.

Owner:INST OF FRUIT & TEA HUBEI ACAD OF AGRI SCI

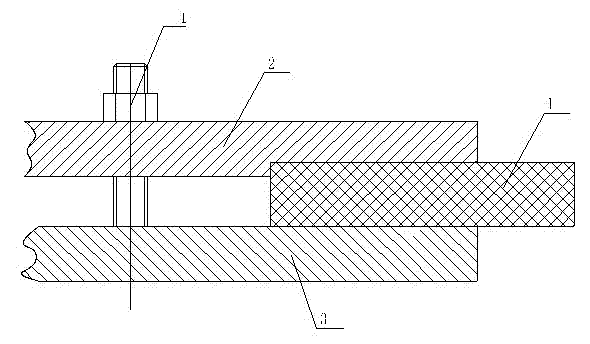

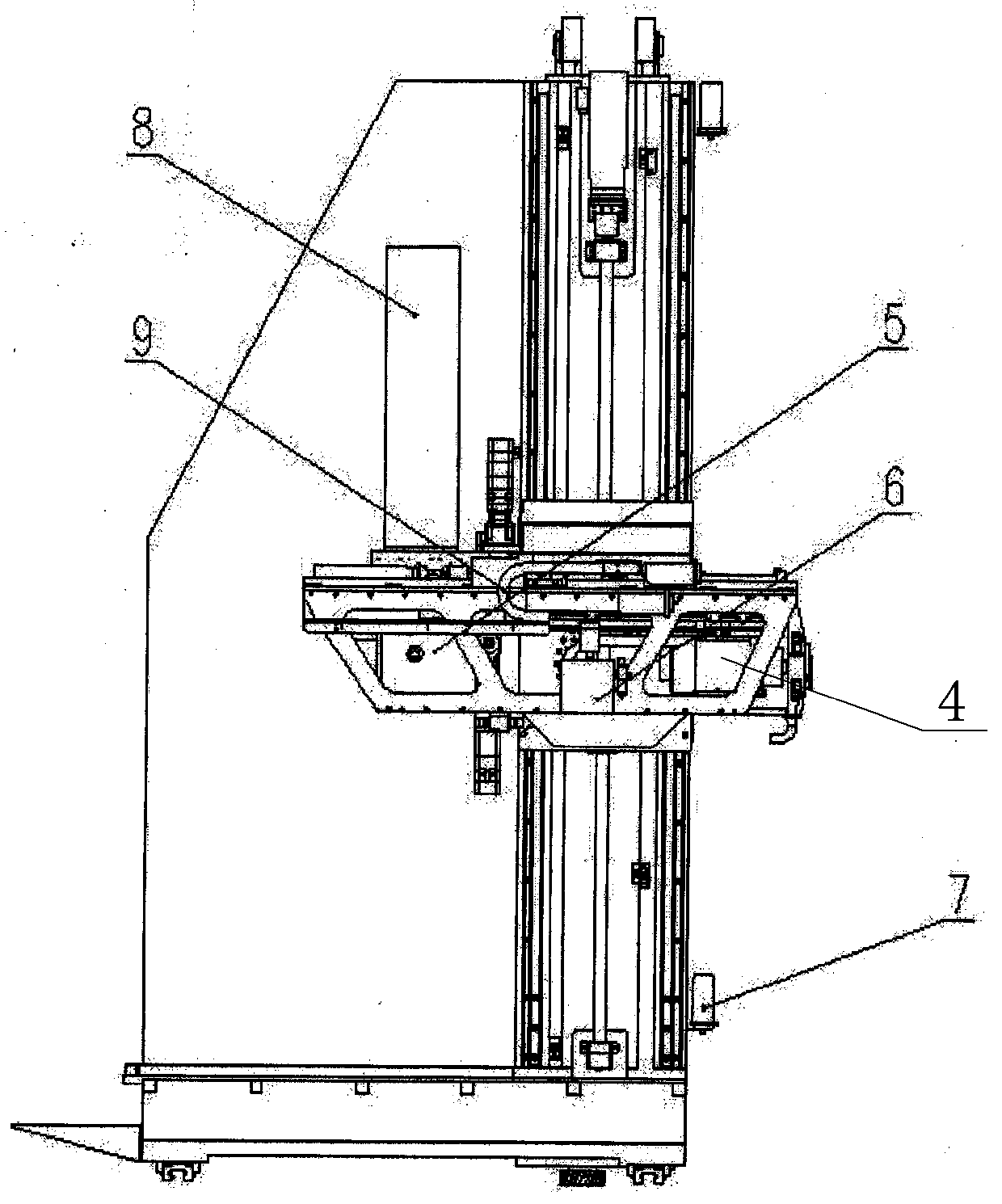

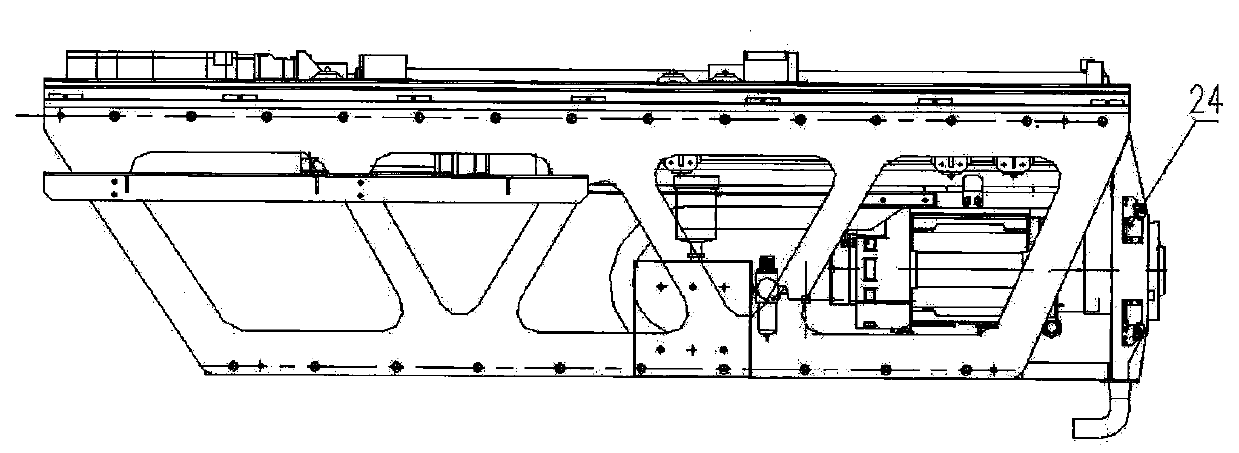

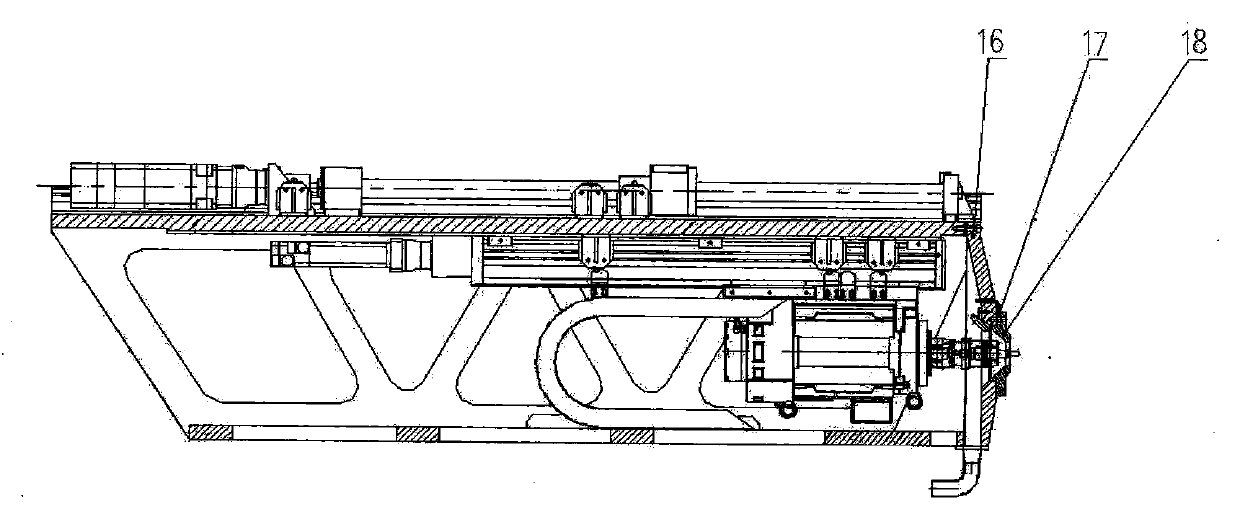

Automatic hole forming equipment and hole forming method for composite airfoil components

ActiveCN103722207AAvoid splittingImprove work efficiencyMetal working apparatusBoring/drilling machinesFour quadrantsLaser ranging

The invention relates to automatic hole forming equipment for composite airfoil components. The automatic hole forming equipment is five-axis linkage numerically controlled equipment, and comprises a main rack, a B-axis support, an A-axis rotary table, a Z-axis subassembly, a Y-axis drag chain, a Z-axis drag chain, a scrap suction device, a knife lubricating system and an oil pump of the lubricating system, wherein a spindle is arranged on the Z-axis subassembly; a component knife which can be used for drilling holes, reaming holes and reaming pits is hydraulically clamped on the spindle; four laser distance measuring sensors are symmetrically arranged at ends of the Z-axis subassembly and are distributed on four quadrants; a pressure foot support is arranged below the Z-axis subassembly; and pressure feet are arranged on the periphery of a center hole of the pressure foot support, and are provided with pressure foot sensors. By using the automatic hole forming equipment and the hole forming method, the clamping and positioning precision is high, the accuracy of formed holes is high, and damage to composites in a hole forming process is reduced, so that the quality of a product is improved while the work efficiency is improved.

Owner:SHENYANG AIRCRAFT CORP

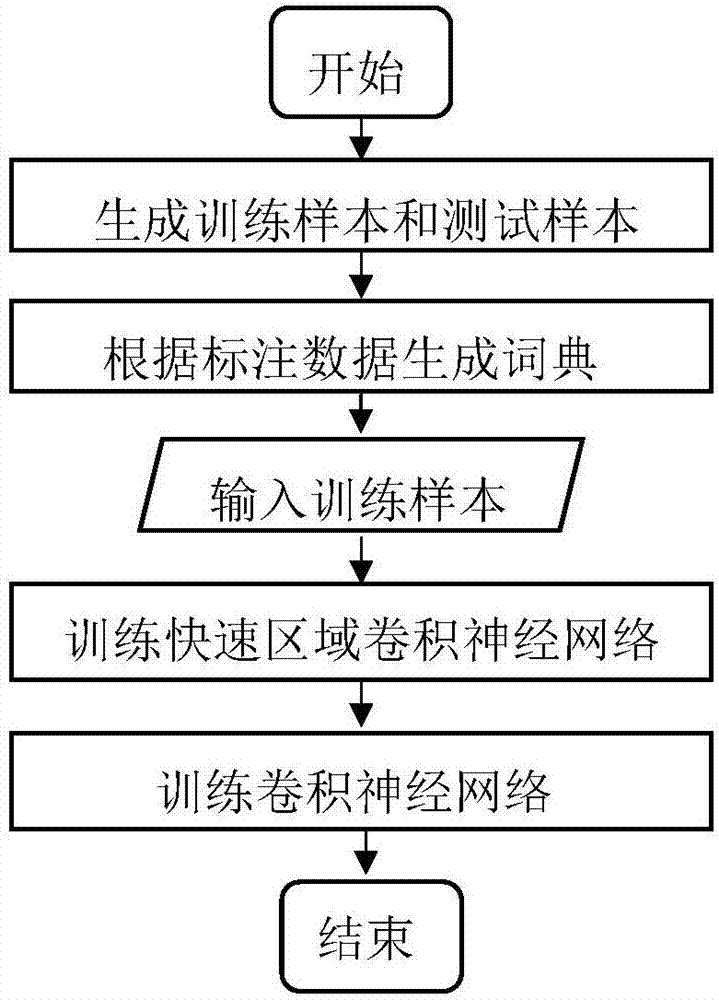

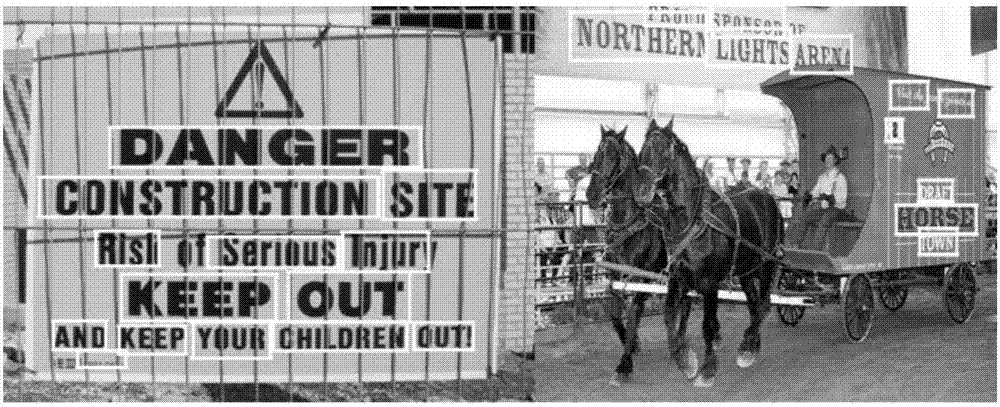

Text detection and recognition method based on convolutional neural network and in natural scene

InactiveCN107203606AAvoid splittingAvoid misidentificationNeural architecturesSpecial data processing applicationsText detectionText recognition

The invention provides a text detection and recognition method based on a convolutional neural network and in a natural scene. The method includes: training a quick area convolutional neural network to acquire a network for text detection in the natural scene to perform text detection in the natural scene; collecting vocabularies to acquire a dictionary; learning features of text vocabularies to train a convolutional neural network classifier, and classifying input areas to realize text recognition. By utilizing the method, good text detection and recognition results can be acquired under the background of different complex degrees and different text fonts and colors.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

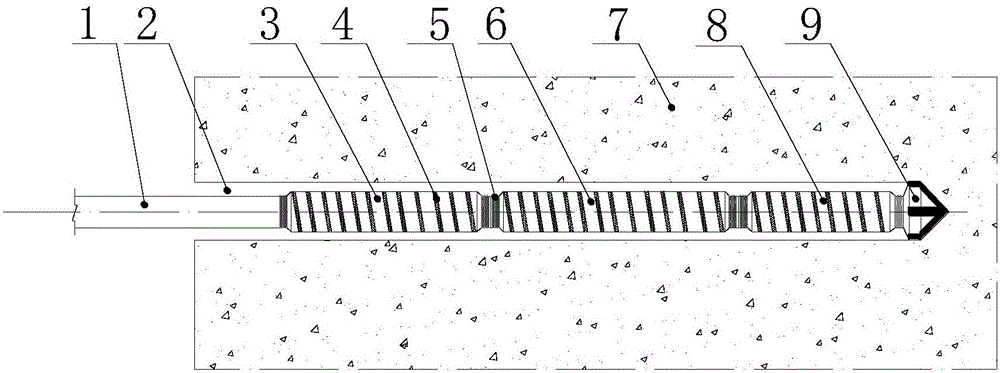

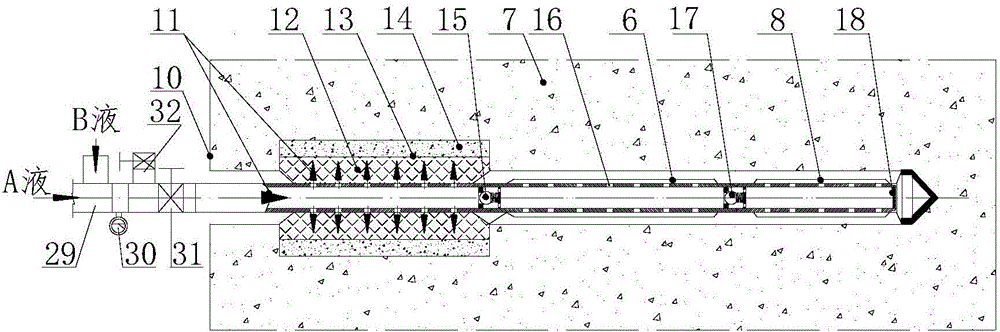

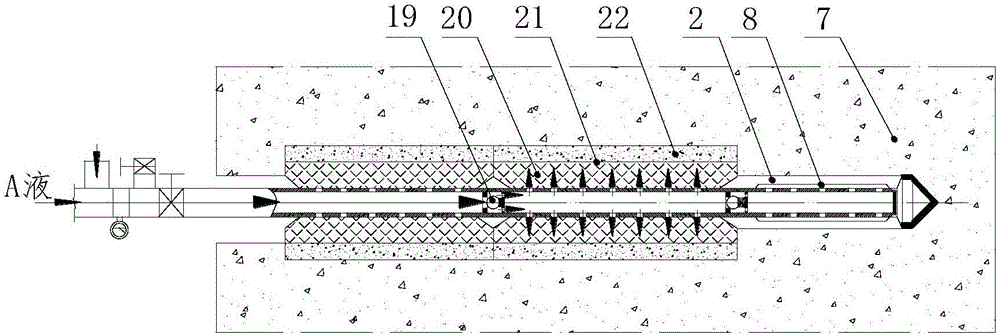

Drilling and grouting combined device for grouting reinforcement of water-rich sand stratum and construction technique

The invention discloses a drilling and grouting combined device for grouting reinforcement of a water-rich sand stratum and a construction technique. The drilling and grouting combined device for grouting reinforcement of the water-rich sand stratum comprises a grouting pipe body. The grouting pipe body is formed by sequentially connecting a plurality of grouting pipes. The outer side of the pipe wall of each grouting pipe is sleeved with an expandable grout container. A plurality of grout outlets are formed in the portions, matched with the grout containers, of the pipe walls of the grouting pipes. Grout enters the grout containers from the grout outlets of the grouting pipes to make the grout containers expand, and thus the grout containers and the sand stratum around the grout containers are compacted. Integrated operation of drilling and grouting reinforcement in the sand stratum can be achieved through the drilling and grouting combined device. According to the drilling and grouting combined device for grouting reinforcement of the water-rich sand stratum and the construction technique, since the grout containers can contain the grout and can expand, the splitting effect of grout on the sand stratum and linear extension of grout veins during grouting in the prior art are eliminated; and the purpose of reserving the grout around drilled holes is achieved, and the effect of compacting the loose sand stratum around the drilled holes is achieved through expansion of the grout containers.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com