Novel organic semi-conductor solid laser and preparation thereof

An organic semiconductor, solid-state laser technology, applied in the structure of the active region, the structure of the optical resonator, etc., can solve problems such as affecting the efficiency of optical outcoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

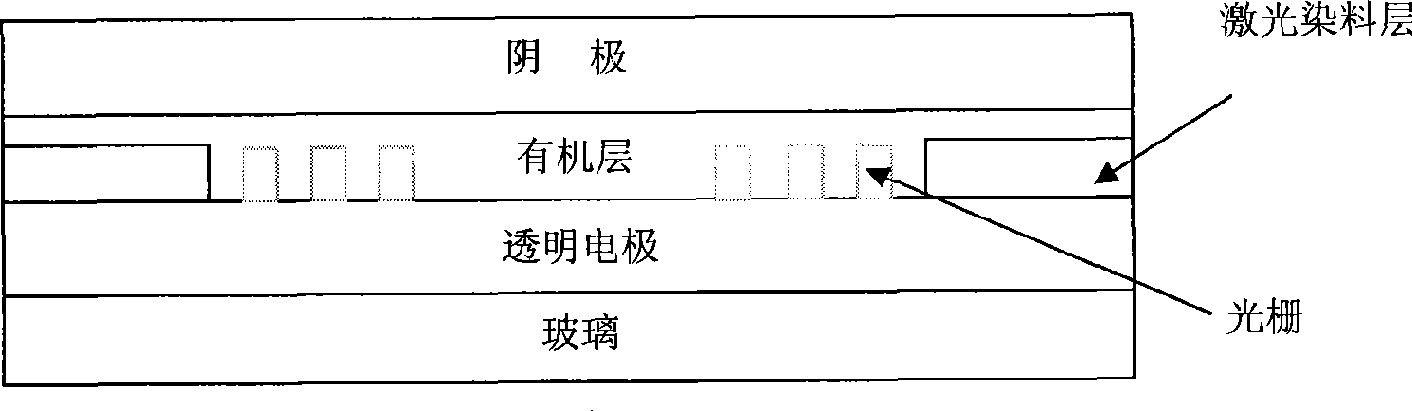

[0044] Embodiment one: see figure 1 . The thickness of the ITO is 150nm, the thickness of the organic layer is 250nm, and the thickness of the metal electrode layer is 200nm. The width of the middle active layer is 5mm. LiF was used as the DBR grating (refractive index 1.30) with a thickness of 150 nm. The grating has a diffraction order of 2.0 and a period of 360 nm. Coumarin6 was used as the material of the light-emitting layer, and DCM:AlQ (1.0% mass ratio) was used as the laser pigment layer (width 2.0 mm, thickness 150 nm). A pulse voltage is applied to the device with a pulse width (duration) of 5 microseconds and a period of 10 Hz. Thus realizing a red laser.

Embodiment 2

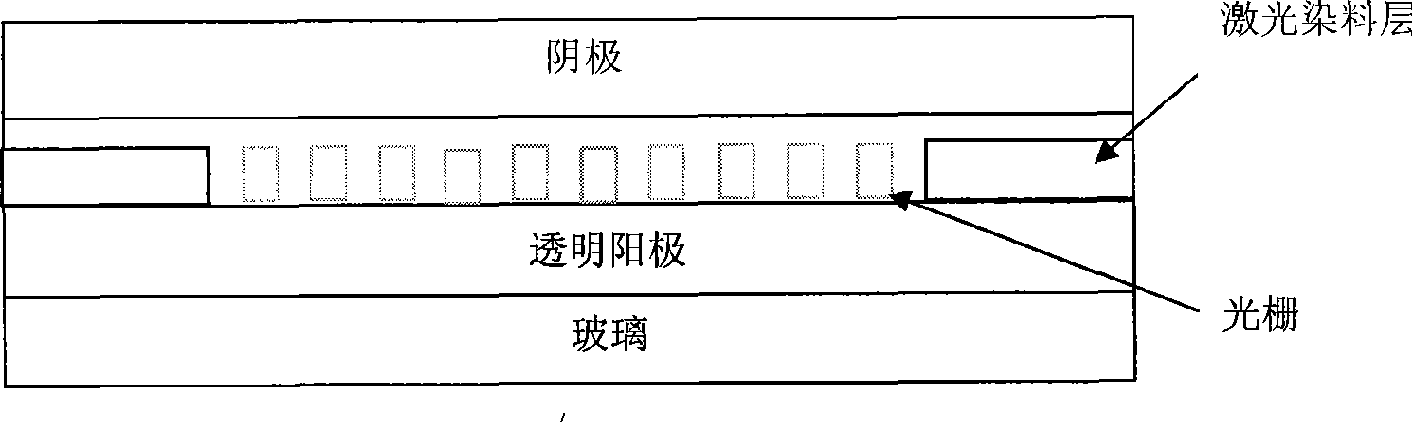

[0045] Embodiment two: see figure 2 . The thickness of the ITO is 150nm, the thickness of the organic layer is 250nm, and the thickness of the metal electrode layer is 200nm. A photoresist is used as the DFB grating with a thickness of 150nm. The grating has a diffraction order of 2.0 and a period of 200 nm. OXD7 was used as the material of the light-emitting layer, and DSB was doped in CBP as the laser pigment layer (width 2.0mm, thickness 150nm). A pulse voltage is applied to the device with a pulse width (duration) of 5 microseconds and a period of 10 Hz. Thus realizing a blue laser. Properties of the invented laser

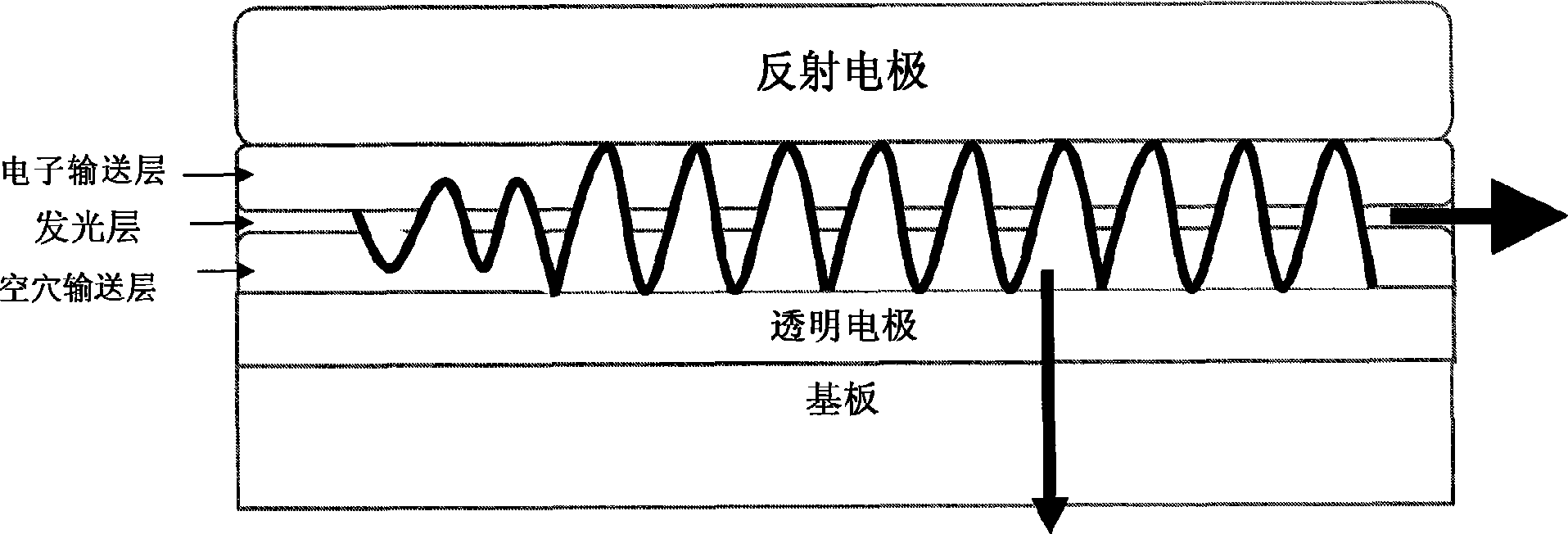

[0046] First, the DCM2 thin film is pumped by laser, when the laser intensity reaches 3.9kw / cm 2 , the spectrum emitted by DCM2 will be narrowed, such as Figure 4 shown. Therefore, the purpose of this invention is to achieve high intensity EL light intensity, making it more than 3.9kw / cm 2 .

[0047] Through this invention, the intensity of cross-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com