Automatic hole forming equipment and hole forming method for composite airfoil components

A composite material and automatic manufacturing technology, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve the problems that cannot meet the needs of composite airfoil parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

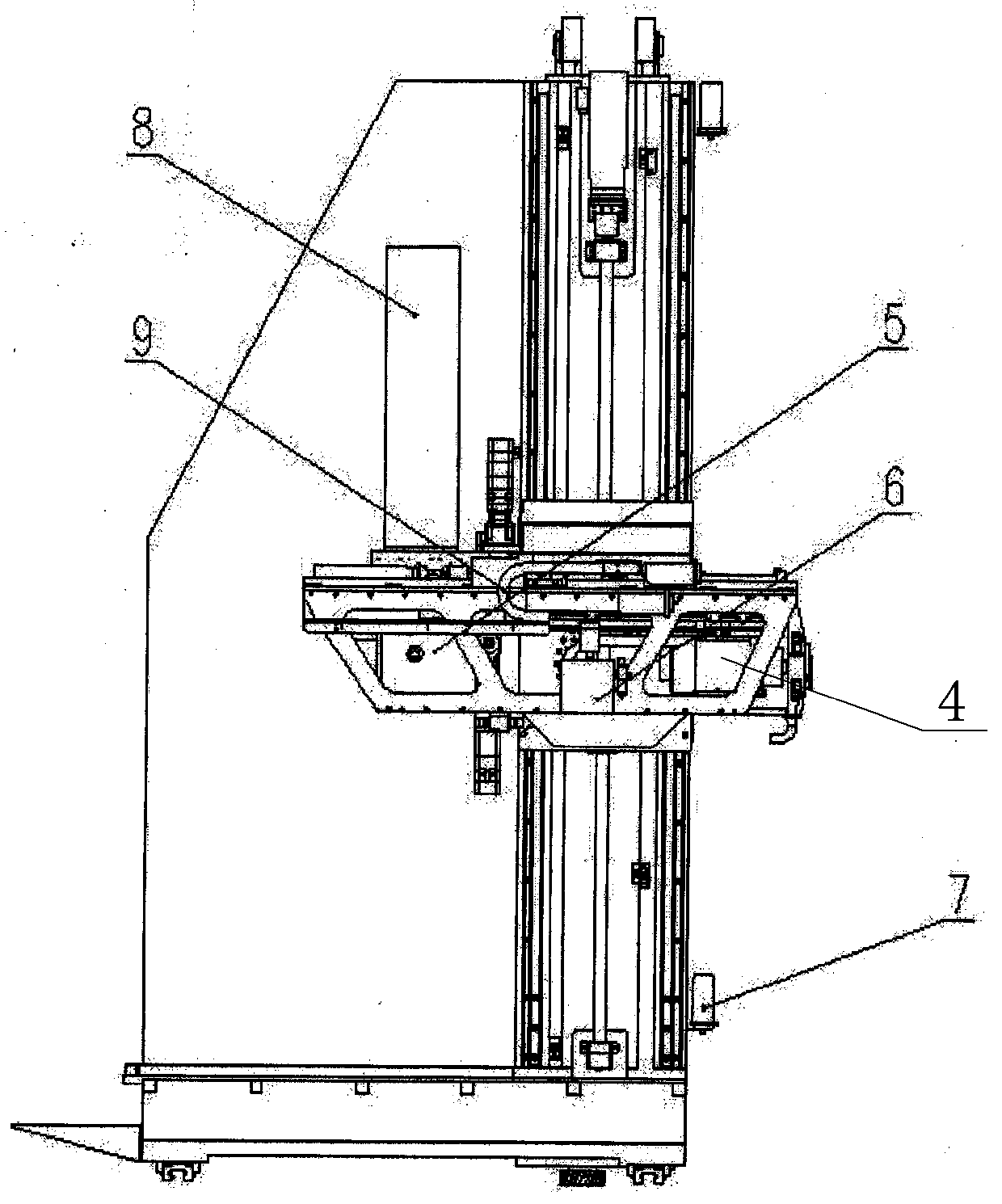

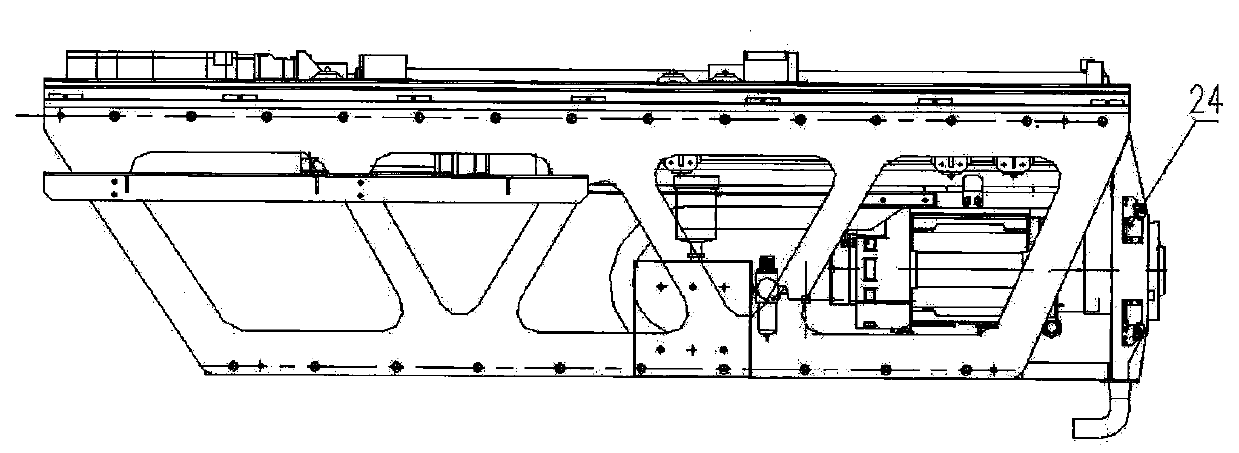

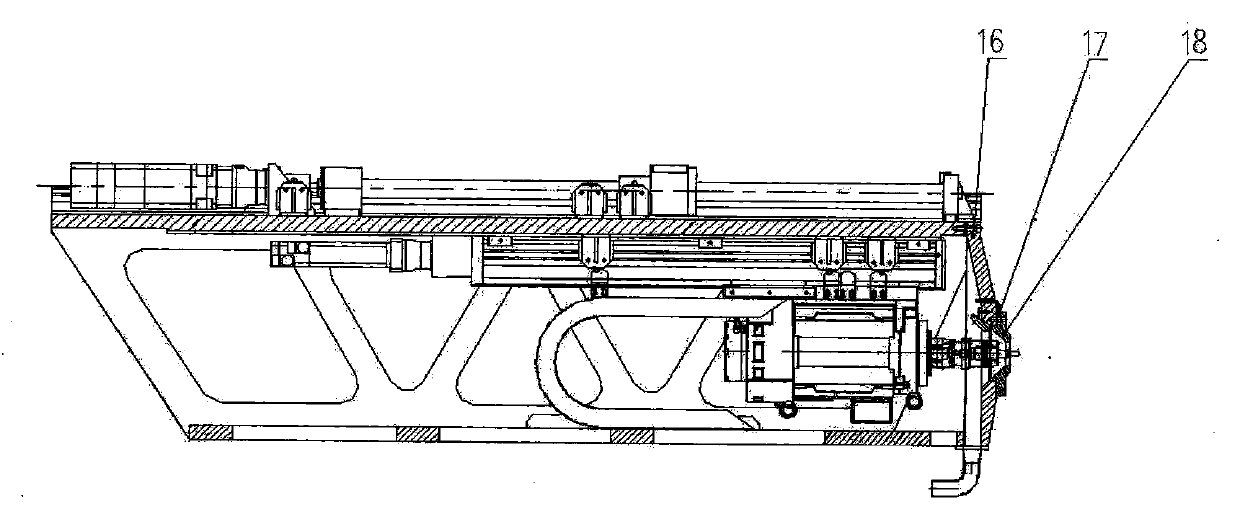

[0047] Such as Figure 1 to Figure 4 As shown, an automatic hole-making equipment for composite airfoil parts is a five-axis linkage numerical control equipment, including main frame 1, B-axis bracket 2, A-axis turntable 3, Z-axis part 4, and Y-axis drag chain 8. Z-axis drag chain 9, chip suction device 5, tool lubrication system 6 and lubricating system oil pump 7, the Z-axis part 4 is equipped with a main shaft, and the main shaft is hydraulically clamped with an integrated structure of drilling, reaming and spot facing The composite cutting tool of the Z-axis part; four laser distance measuring sensors 24 are arranged symmetrically at the end of the Z-axis part 4, and are distributed in four quadrants; A pressure foot 18 is arranged on the circumference of the central hole, and a pressure foot sensor 17 is arranged on the pressure foot 18 .

[0048] The method for making holes by using the above-mentioned automatic hole making equipment for airfoil parts of composite mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com