MHz photonic crystal fiber ultra-short pulse laser based on multichannel pulse compressor

A photonic crystal fiber, pulse compression technology, applied in the laser, laser parts, optical resonator structure/shape and other directions, can solve the problems of increasing the number and complexity of components, difficult to adjust easily, energy loss, etc., to reduce the pulse The effect of repetition rate, extended heat dissipation time, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

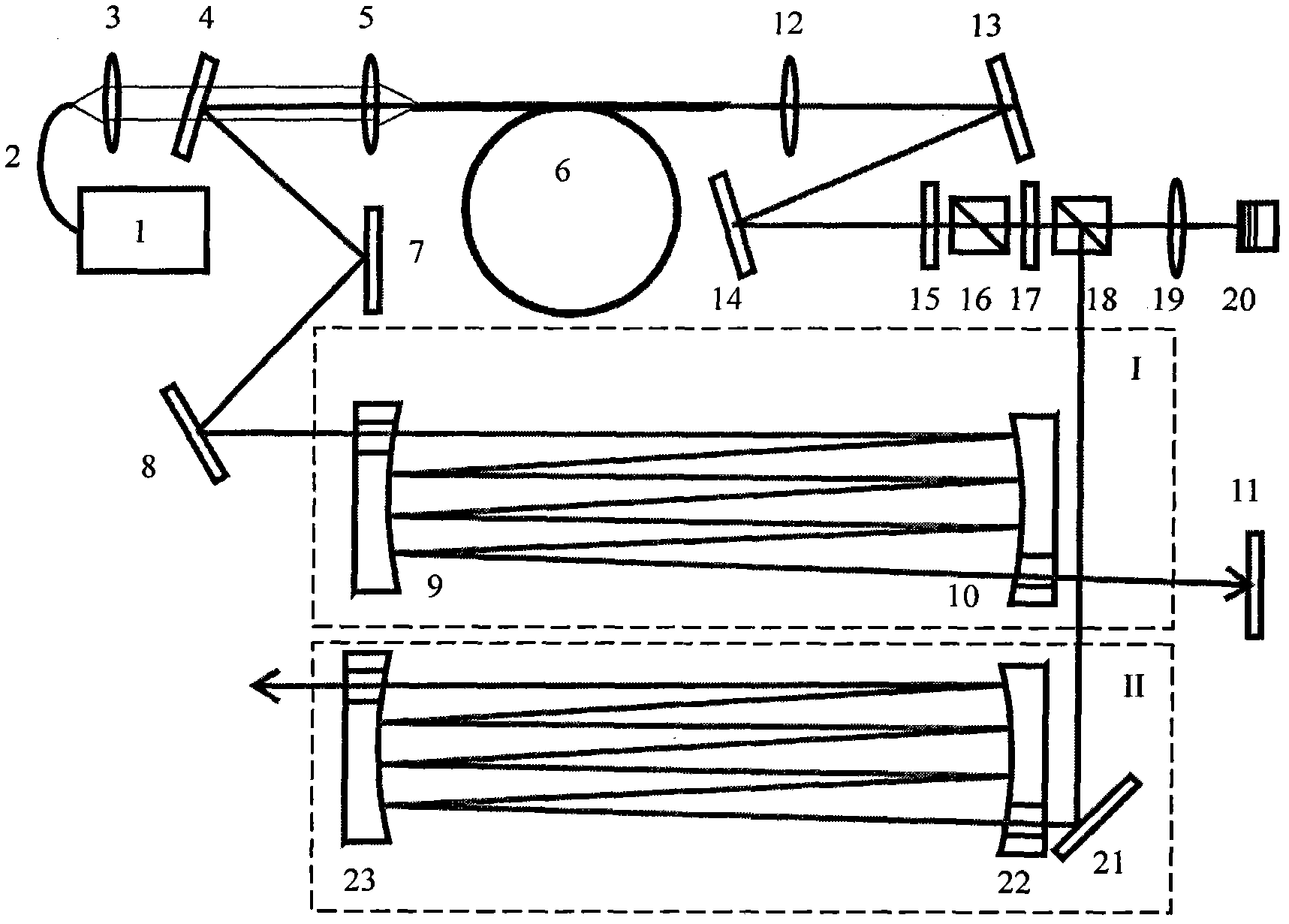

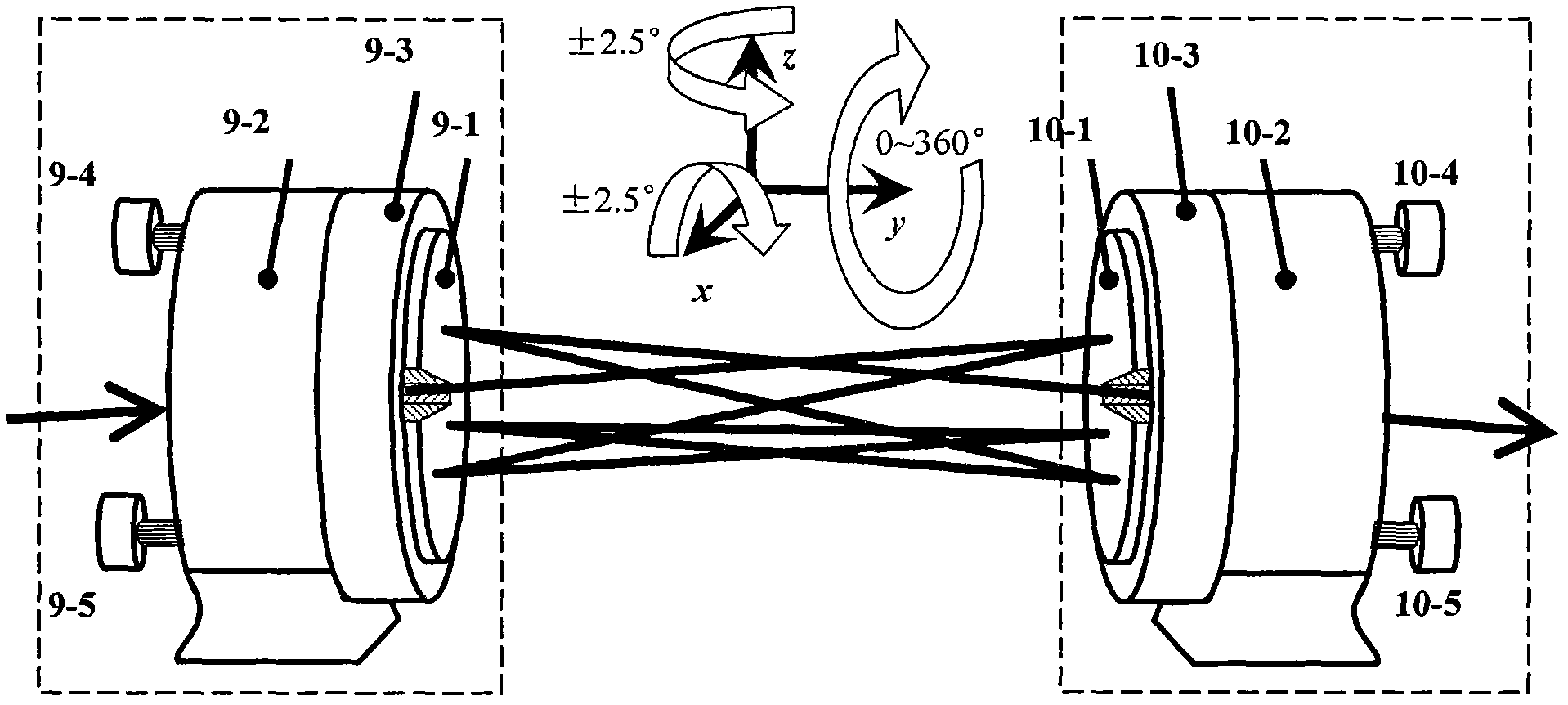

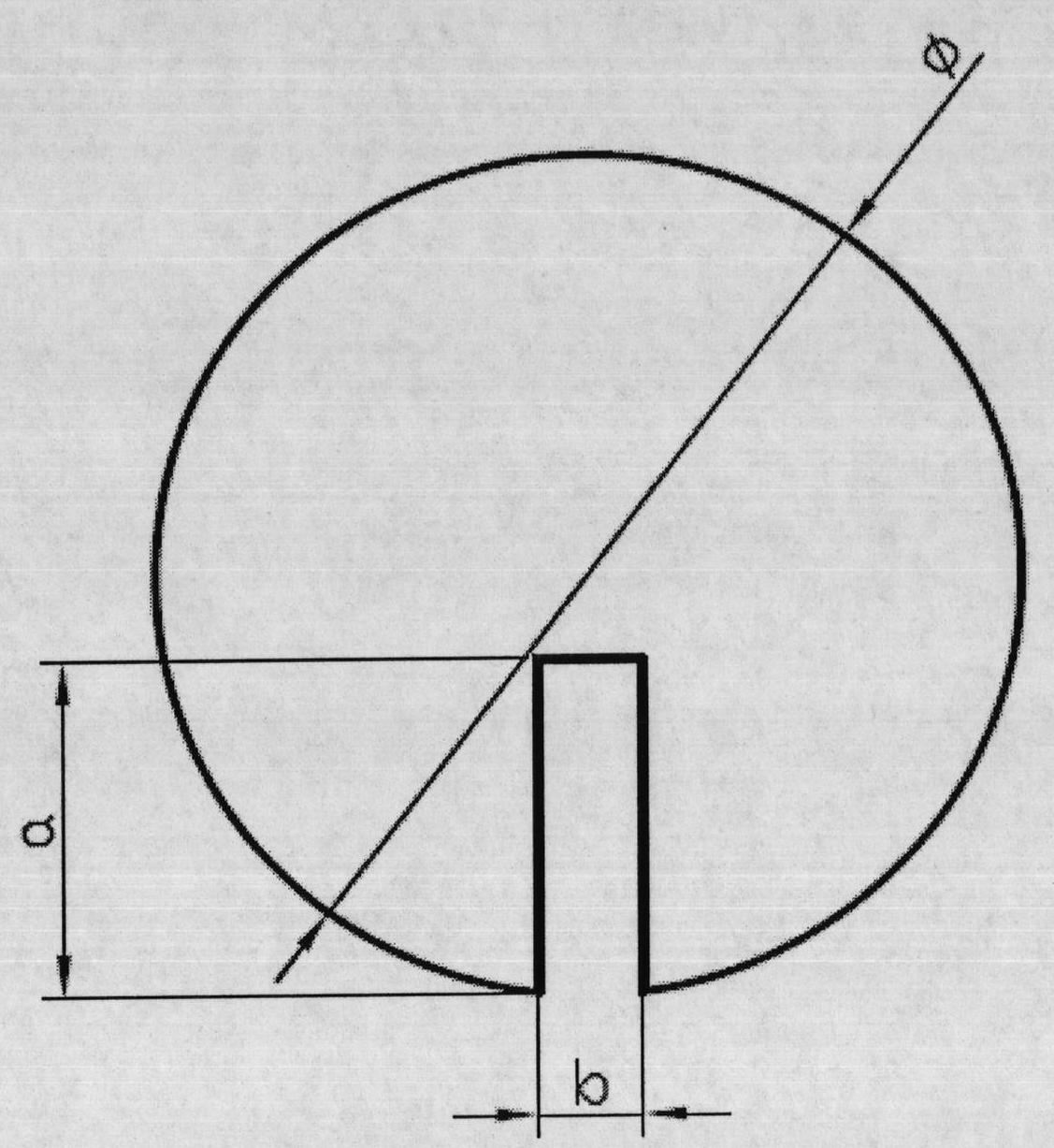

[0032] The specific implementation plan for obtaining a megahertz photonic crystal fiber ultrashort pulse laser based on a multi-pass pulse compressor is as follows: use a precise five-dimensional adjustment frame to fix the output multimode fiber 2 of the diode pump source 1, and precisely adjust the up and down of the multimode fiber 2 , left and right, forward and backward translation, and tilt and pitch angles, so that the end face is located at the focal point of the pump light collimating aspheric lens 3, and the collimated pump light is output. The core diameter of the multimode optical fiber 2 is 100-400 μm, the numerical aperture NA is 0.2-0.4, the output wavelength is 976-980 nm, and the output power is 5-30 W. Aspherical lenses 3, 5, 12 and focusing lens 19 are all coated with broadband anti-reflection coatings with a transmittance higher than 99.5% for the 976-1100nm band, and are assembled on a precision five-dimensional adjustment frame to precisely adjust up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com