Patents

Literature

437 results about "Dimethyl sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethyl sulfide (DMS) or methylthiomethane is an organosulfur compound with the formula (CH₃)₂S. Dimethyl sulfide is a flammable liquid that boils at 37 °C (99 °F) and has a characteristic disagreeable odor. It is a component of the smell produced from cooking of certain vegetables, notably maize, cabbage, beetroot and seafoods. It is also an indication of bacterial contamination in malt production and brewing. It is a breakdown product of dimethylsulfoniopropionate (DMSP), and is also produced by the bacterial metabolism of methanethiol.

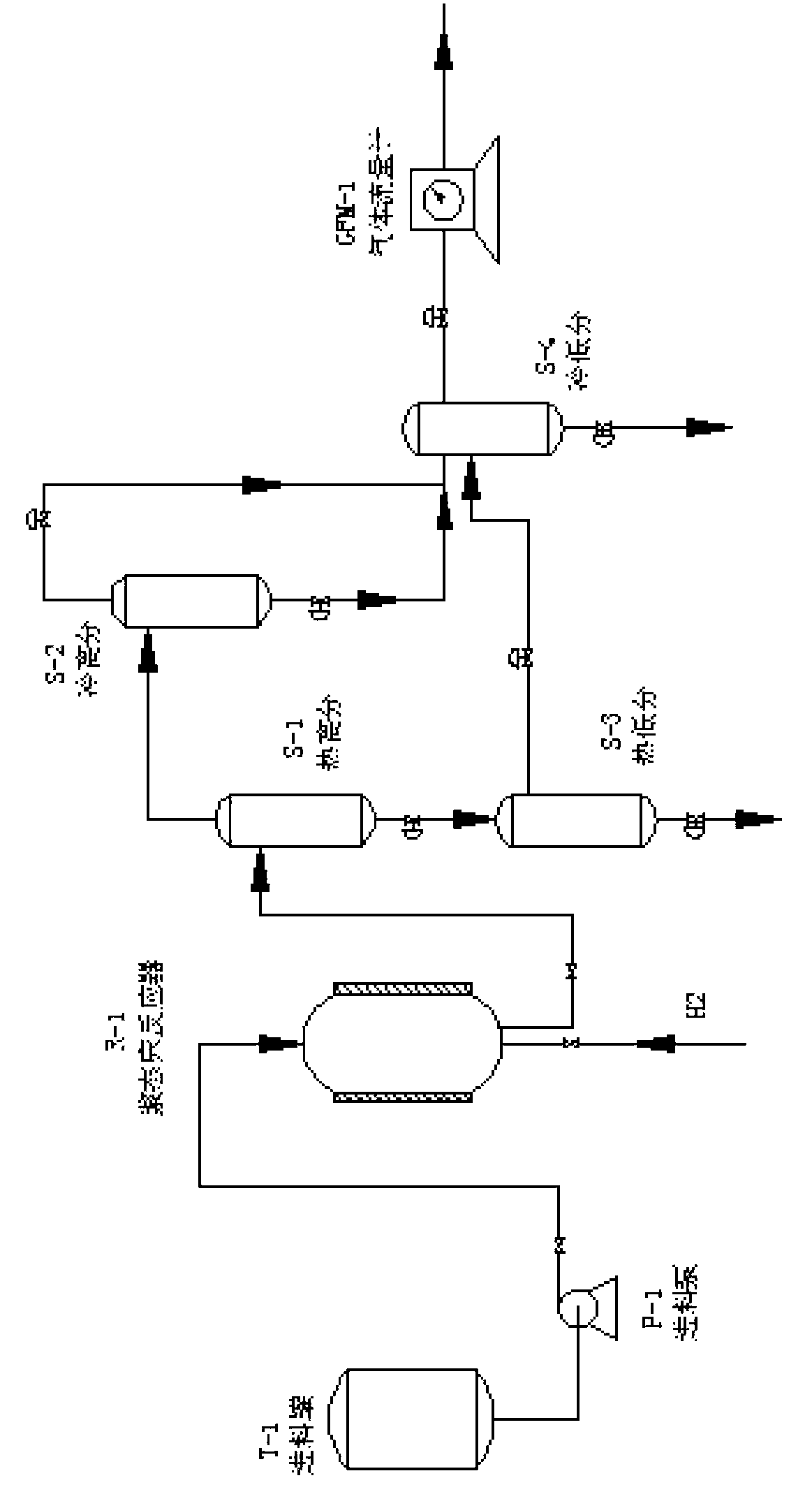

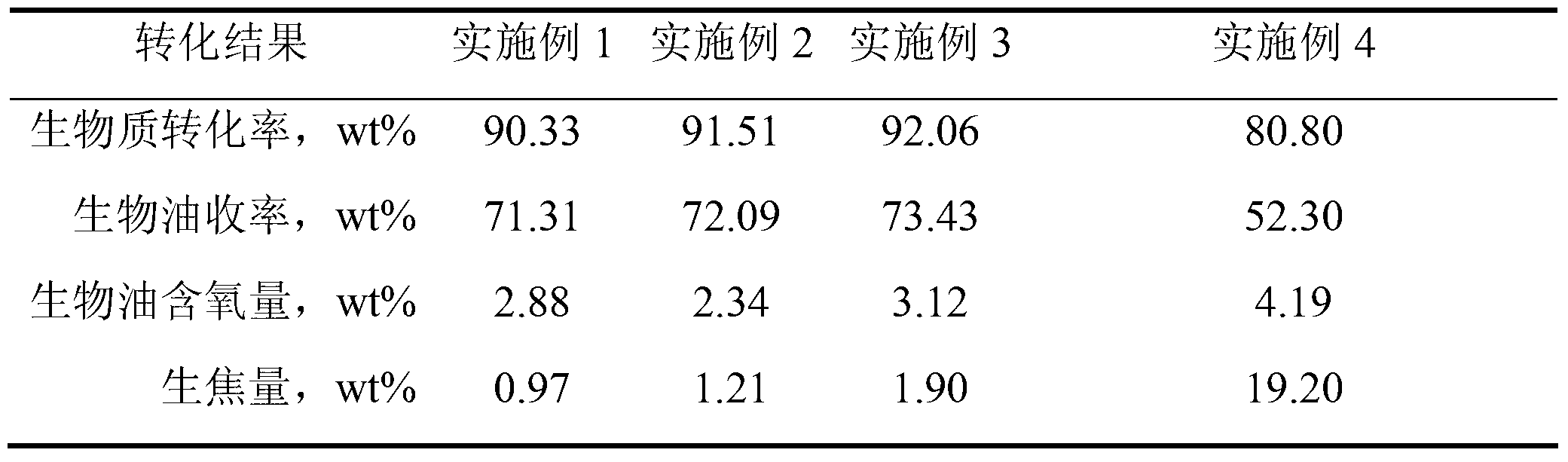

Heavy oil and biomass hydrogenation coliquefaction treatment process

ActiveCN103242871AGood deoxidation effectUniform reaction temperatureBiofuelsHydrocarbon oil crackingDistillationHydrogen pressure

The invention relates to a heavy oil and biomass hydrogenation coliquefaction treatment process in which one or two of heavy oil and biomasses are used as raw materials in vacuum gas oil with the distillation range of 360-540 DEG C and FCC (Fluid Catalytic Cracking) oil slurry. In the process, an oil-soluble transition metal organic compound with hydrogenation activity is used as a catalyst, dimethyl sulfide is used as a vulcanizing agent, a full-back-mixing type empty barrel reactor is used as a slurry column hydrogenation reactor, the reaction temperature is uniform, and the structure is simple. By using the process, the conversion rate of the biomasses can be up to over 90wt% at lower hydrogen pressure of 4-8MPa and the temperature of 370-430 DEGC, and the yield of oil phases is up to over 70wt%. A dispersive hydrogenation catalyst adopted in the process can be used for greatly reducing the quantity of green cokes and taking a better deoxidization effect on the biomasses.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

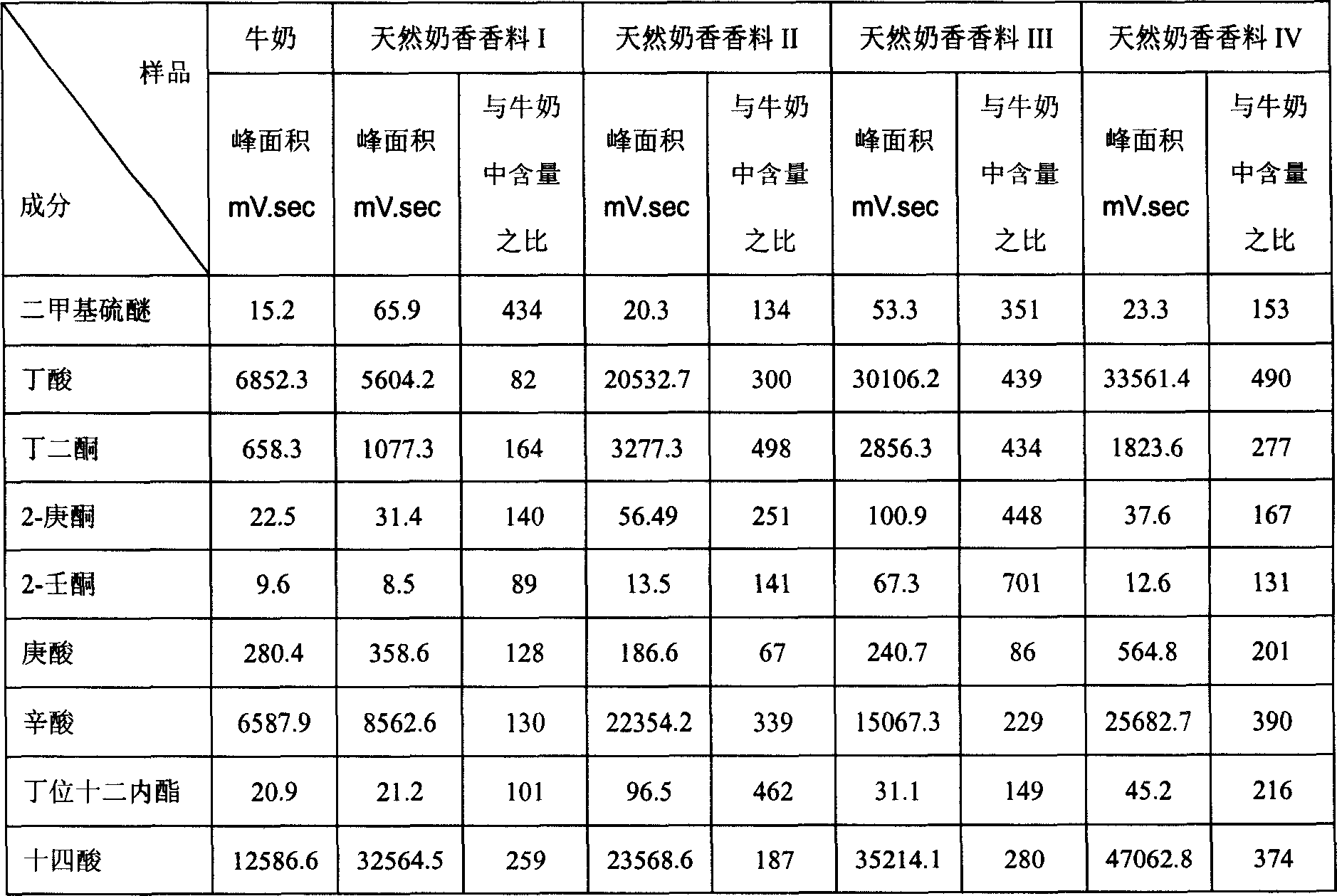

Method for preparing natural milk taste condiment and natural milk taste condiment made thereof

The invention relates to a method for producing natural cream-vanilla condiment, which comprises that using lactic acid bacteria to ferment the fresh milk or milk powder, adding cream into the fermented product, using biological enzyme as protein enzyme and / or lipase to process enzymolysis, heating, concentrating, and emulsifying. The invention can improve 100-500 times of the contents of butanedione, dimethylsulfide or the like. And the inventive condiment can be directly added into food.

Owner:SHENZHEN BOTON FLAVORS & FRAGRANCES

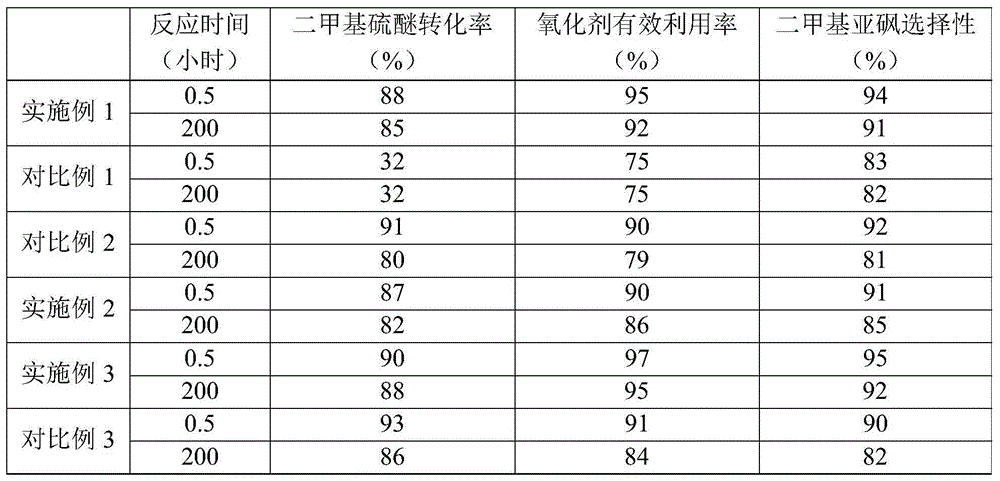

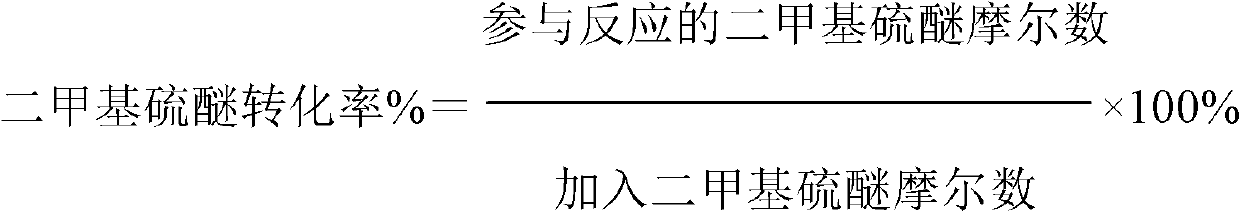

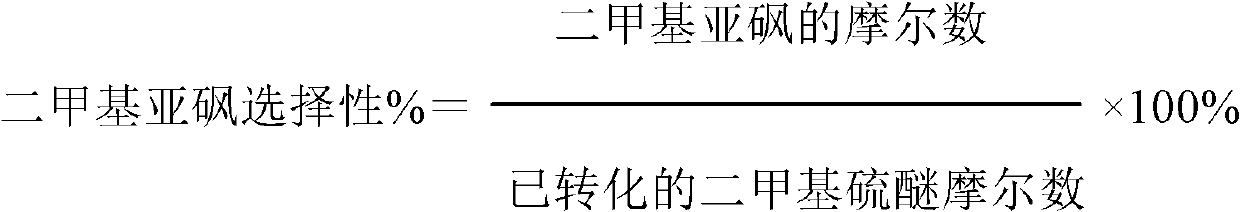

Preparation method of dimethyl sulfoxide

ActiveCN103787932AImprove conversion rateImprove effective utilizationOrganic chemistryOrganic compound preparationMolecular sieveTitanium

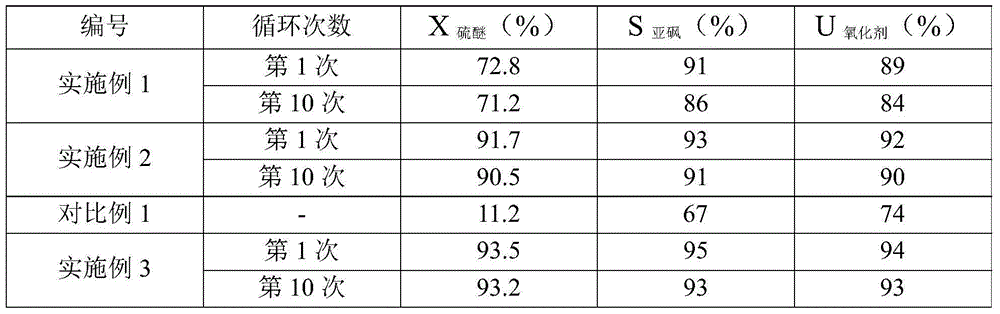

The invention provides a preparation method of dimethyl sulfoxide, the method is as follows: in oxidation reaction conditions, dimethyl sulfide is contacted with at least one oxidant, and the catalyst contains at least one titanium silicon molecular sieve. According to the preparation method of the dimethyl sulfoxide, the dimethyl sulfide conversion rate is high, the effective utilization rate of the oxidant is high, the dimethyl sulfoxide selectivity is good, the usage amount of the dimethyl sulfide and the oxidant can be effectively reduced, and the production cost of the dimethyl sulfoxide can be reduced. According to the method of the invention, the activity stability of the catalyst is good, even by long-time continuous operation and multiple-times of cycle use of the catalyst, a high dimethyl sulfide conversion rate, a high effective utilization rate of the oxidant and high dimethyl sulfoxide selectivity also can be achieved. In addition, the method of the invention is mild in reaction condition, easy to control, and suitable for mass production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flavor oils with reduced sulfur content and use in oral care compositions

ActiveUS20080008729A1Reduce contentSimple and inexpensive and easy to implementCosmetic preparationsToilet preparationsFiltrationDistillation

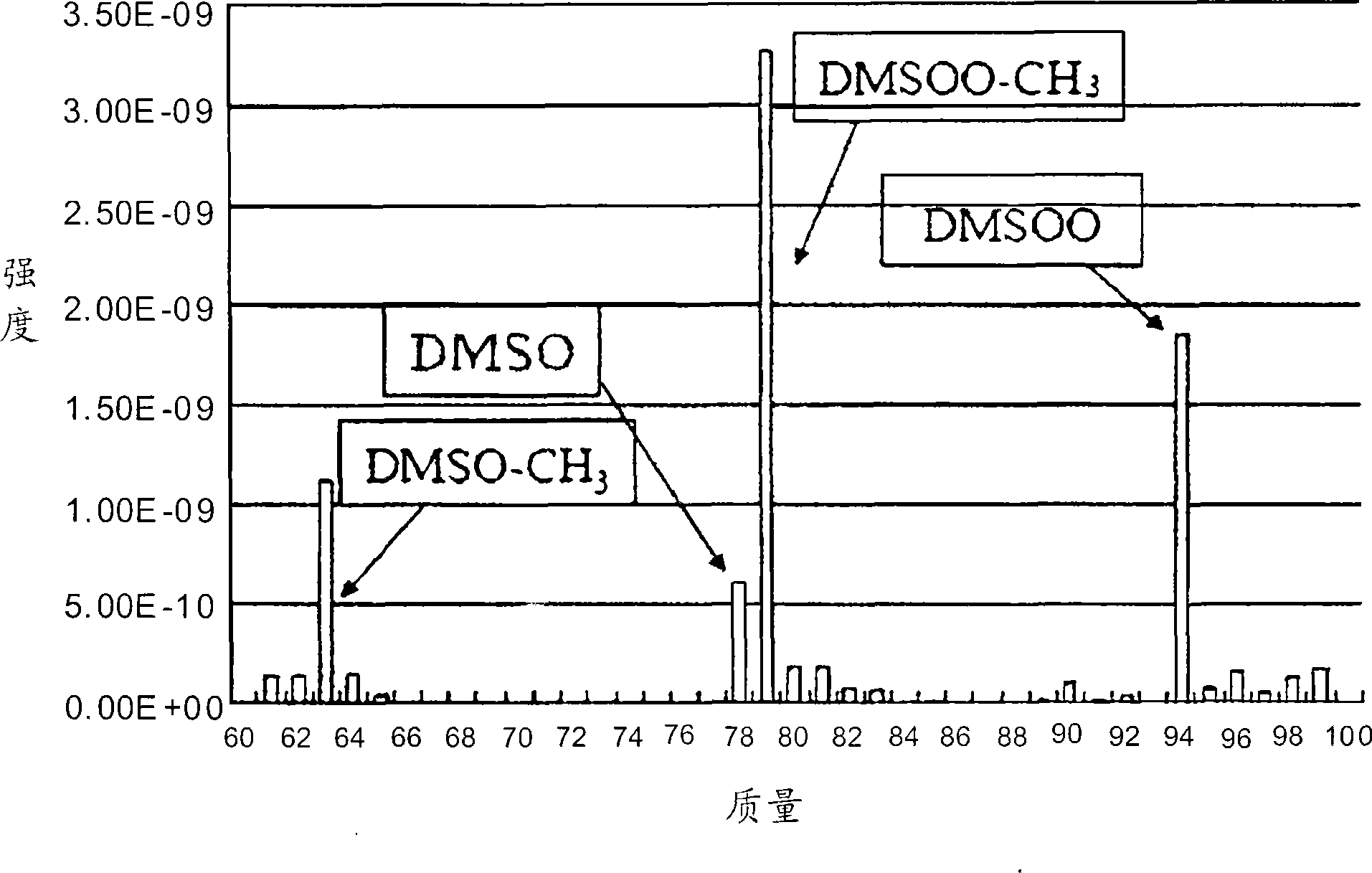

The present invention relates to flavor oils including mint-, fruit- and spice-type flavors that are specially processed to substantially eliminate low-molecular weight sulfur compounds, in particular dimethyl sulfoxide (DMSO), which has been found to be the main precursor of malodorous species such as dimethyl sulfide and methyl mercaptan. These malodorous species are produced via oxidation-reduction reactions involving such sulfur-containing compounds present in flavor oils. A preferred processing method is an aqueous-washing process, which has advantages of being simple, inexpensive and easy to implement while importantly avoiding the problems of typical processes including non-selective removal of desirable components and subjecting the flavor oils to extreme conditions that may destroy other components and result in undesirable changes in flavor or odor character. Other processing methods to selectively remove non-desired components include (1) distillation to remove polar low boiling point components, (2) filtration through adsorbents selective for sulfur compounds, (3) countercurrent extraction and (4) column chromatography. The processing methods may optionally be followed by reengineering to add back desired components that may have been removed or altered during the processing. The specially processed flavor oils are particularly useful in oral care compositions comprising components with chemical reducing capability such as stannous ions, which react with the sulfur-containing compounds to produce malodorous products.

Owner:THE PROCTER & GAMBLE COMPANY

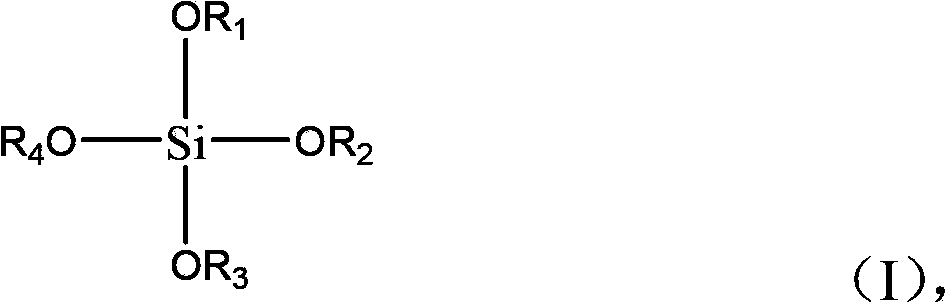

Method for molding tin-silicon molecular sieve, molded tin-silicon molecular sieve prepared by method and method for preparing dimethyl sulfoxide

ActiveCN104549549AHigh catalytic activityIncreased crush strengthOrganic chemistryMolecular sieve catalystsMolecular sieveSlurry

The invention provides a method for molding a tin-silicon molecular sieve and the molded tin-silicon molecular sieve. The method comprises the following steps: carrying out hydro-thermal treatment on a tin-silicon molecular sieve in an aqueous mixture in a closed container; molding slurry obtained in hydro-thermal treatment to obtain a molded body, and roasting, wherein the aqueous mixture is from a crystallized mother liquor containing silicon molecular sieve, and the crystallized mother liquor contains at least one alkaline template agent. The molded tin-silicon molecular sieve prepared by the molding method has a relatively high catalytic activity and high crushing strength. The invention further provides a method for preparing dimethyl sulfoxide. In the method, the molded tin-silicon molecular sieve is used as a catalyst to obtain high conversion rate of dimethyl sulfide, high effective utilization of an oxidant and high selectivity of dimethyl sulfoxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

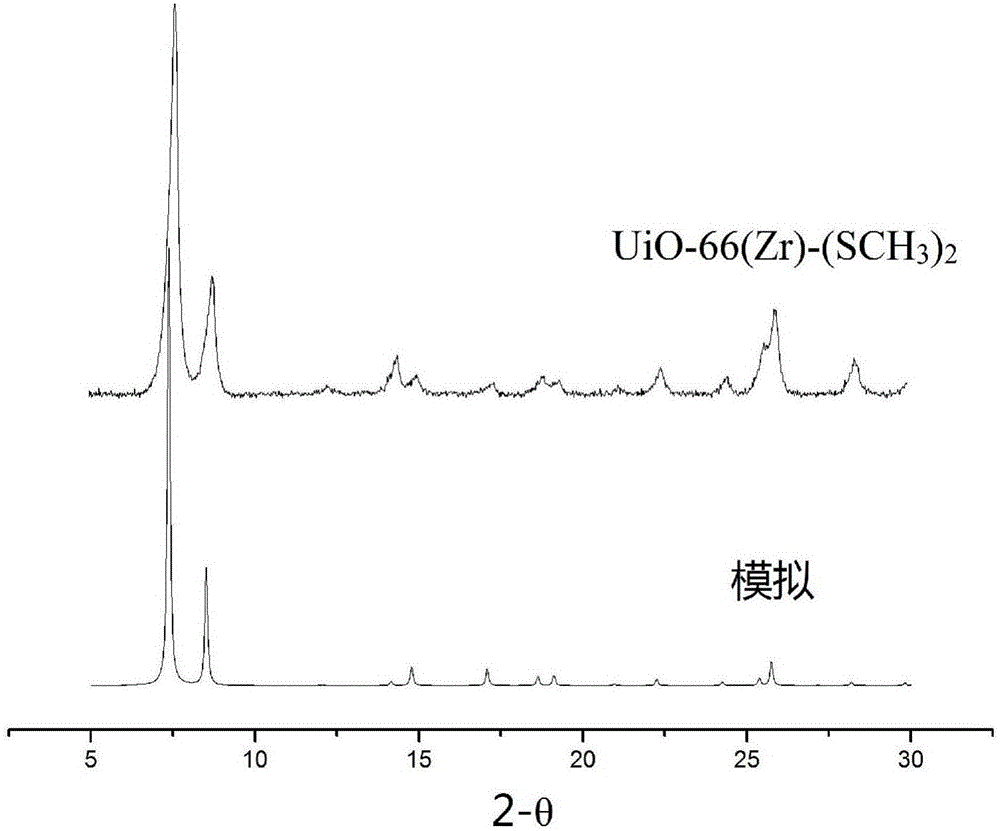

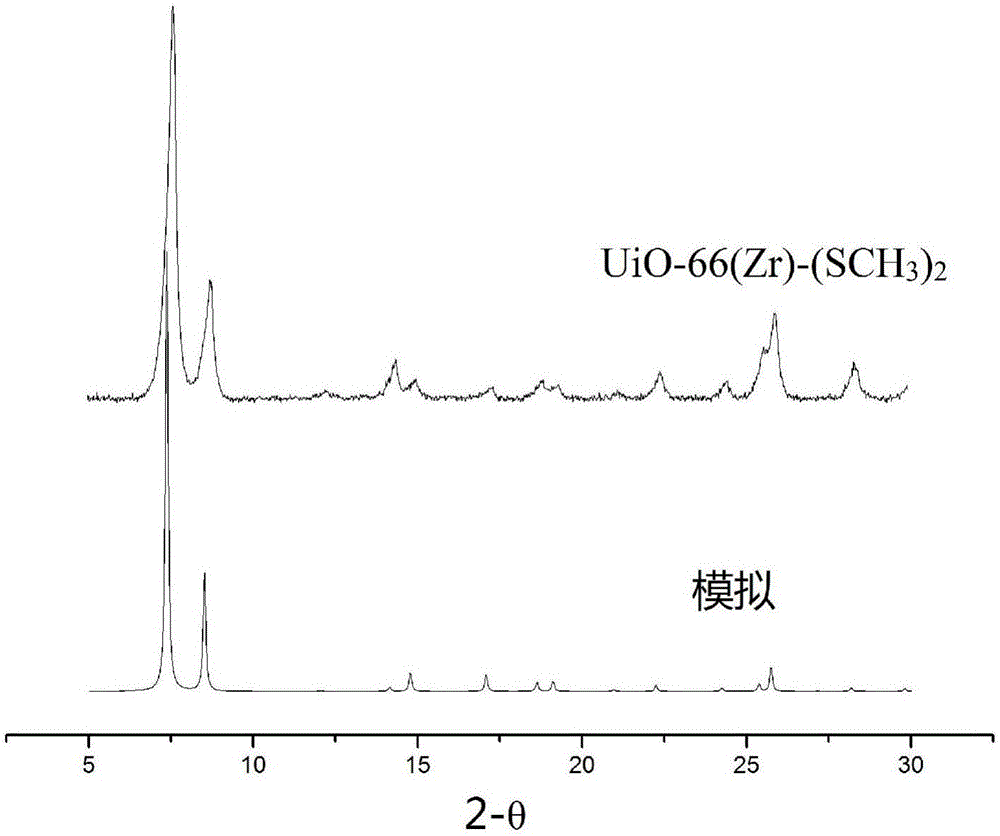

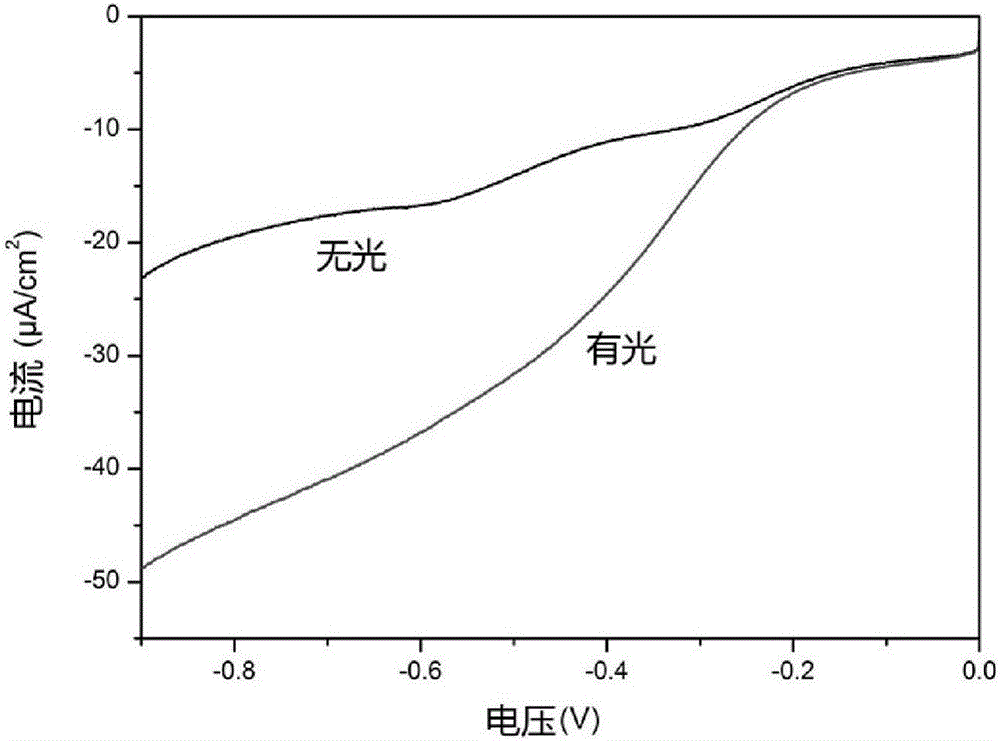

Zirconium organic frame material and preparation method and application thereof

InactiveCN106589398AStable structureImprove performanceHydrogen productionHydrogen/synthetic gas productionClean energyTerephthalic acid

The invention discloses a novel functionalized UiO-66 system zirconium organic frame catalyst material, a preparation method thereof and application of the catalyst material in the aspect of hydrogen generation through visible light catalytic water splitting. The preparation method of the zirconium organic frame catalyst material comprises the steps of 1 preparing a ligand 2,5-dimethyl sulfide terephthalic acid and 2 preparing a zirconium organic frame catalyst material (UiO-66(Zr)-(SCH3)2). The preparation method is simple and stable; the obtained zirconium organic frame catalyst material is stable in structure, can be used for the photoelectrode material for hydrogen generation through photoelectrochemical water splitting, and the performance is better than that of reported metal organic frame materials for hydrogen generation through photoelectrochemical water splitting. The material can be used for visible light catalytic hydrogen production, is excellent in performance and promotes application in clean energy and environment sustainable development.

Owner:CAPITAL NORMAL UNIVERSITY

Method for preparing dimethyl sulfoxide

ActiveCN104557629AReduce usageImprove conversion rateOrganic chemistryMolecular sieve catalystsMolecular sieveMethyl sulfide

The invention provides a method for preparing dimethyl sulfoxide. The method comprises the following step of contacting dimethyl sulfide and at least one oxidant with at least one tin silicate molecular sieve under an oxidation condition. According to the method, especially when peroxide is used as an oxidant, the conversion rate of dimethyl sulfide and the effective utilization rate of the oxidant are high, the selectivity of dimethyl sulfoxide is good, the using amount of dimethyl sulfide and the oxidant can be effectively reduced, and the production cost of dimethyl sulfoxide can be reduced. Furthermore, by adopting the method, the catalyst has good activity stability, and high dimethyl sulfide conversion rate, oxidant effective utilization rate and dimethyl sulfoxide selectivity can stilled be obtained even the catalyst runs continuously for a long time or is recycled for multiple times. Furthermore, the method is mild in reacting condition and easy to control, and is suitable for large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas purification method of low concentration organic compound

InactiveCN101391177ACatalyst carriersDispersed particle separationPurification methodsOrganic compound

The invention discloses a gas purification method for treating low-concentration organic compounds, in particular to a gas purification method aiming at the following malodorous compounds such as sulfides of dimethyl sulfide (DMS), dimethyl disulfide (DMDS), sulfurated hydrogen (H2S) and the like as well as formaldehyde, acetic acid, isopropyl alcohol, acetone and the like. The method comprises: at least one catalyst adsorption unit in parallel connection and / or in series connection; and / or an ozone generating unit which can provide ozone to the catalyst adsorption unit to serve as a component that can strengthen the adsorption function of catalyst and is easy to be treated or is harmless after low temperature oxidation reduction or decomposition reaction, so as to greatly improve the treatment efficiency and extend the service life of the catalyst adsorption material.

Owner:JG ENVIRONMENTAL TECH +1

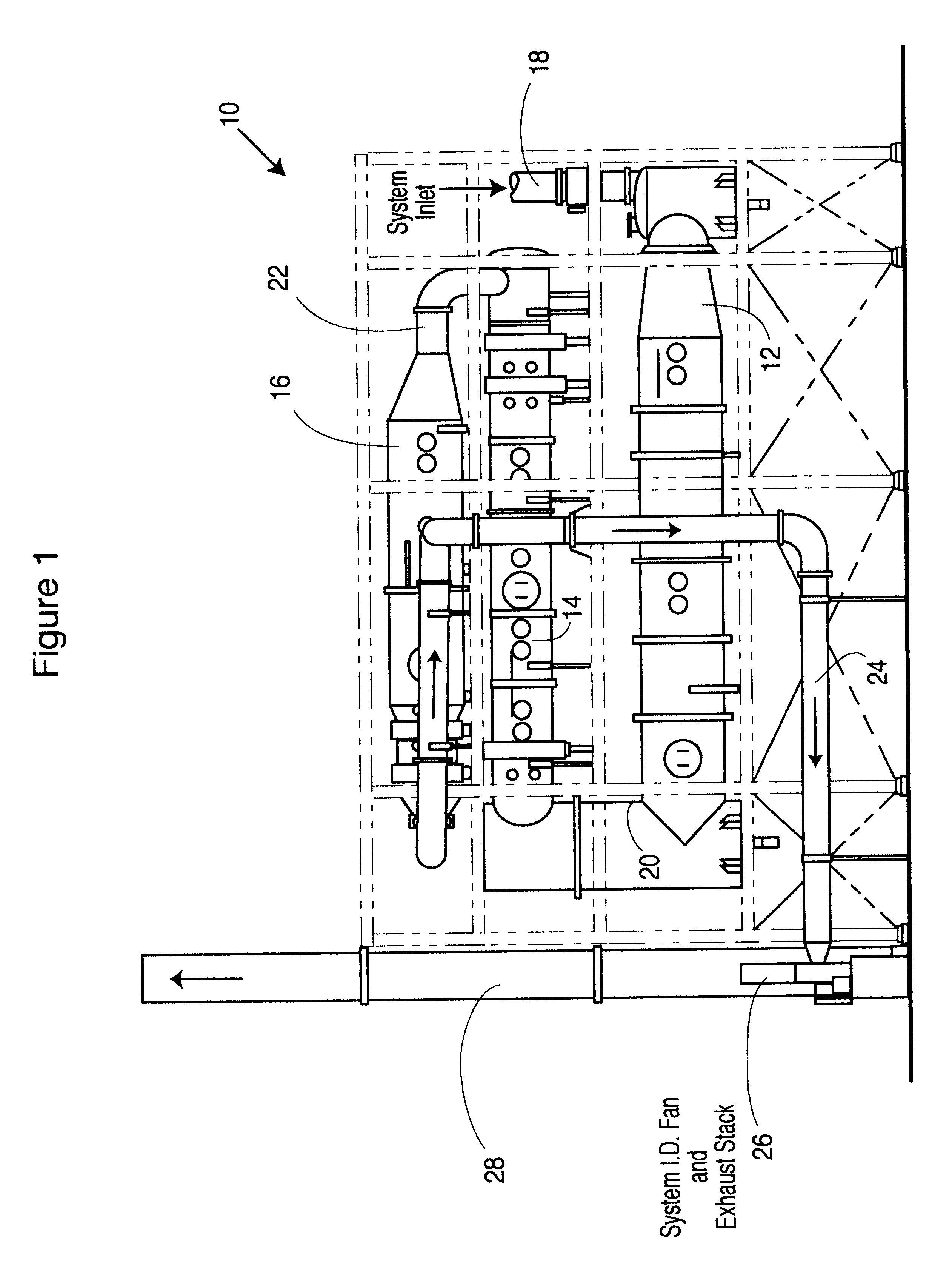

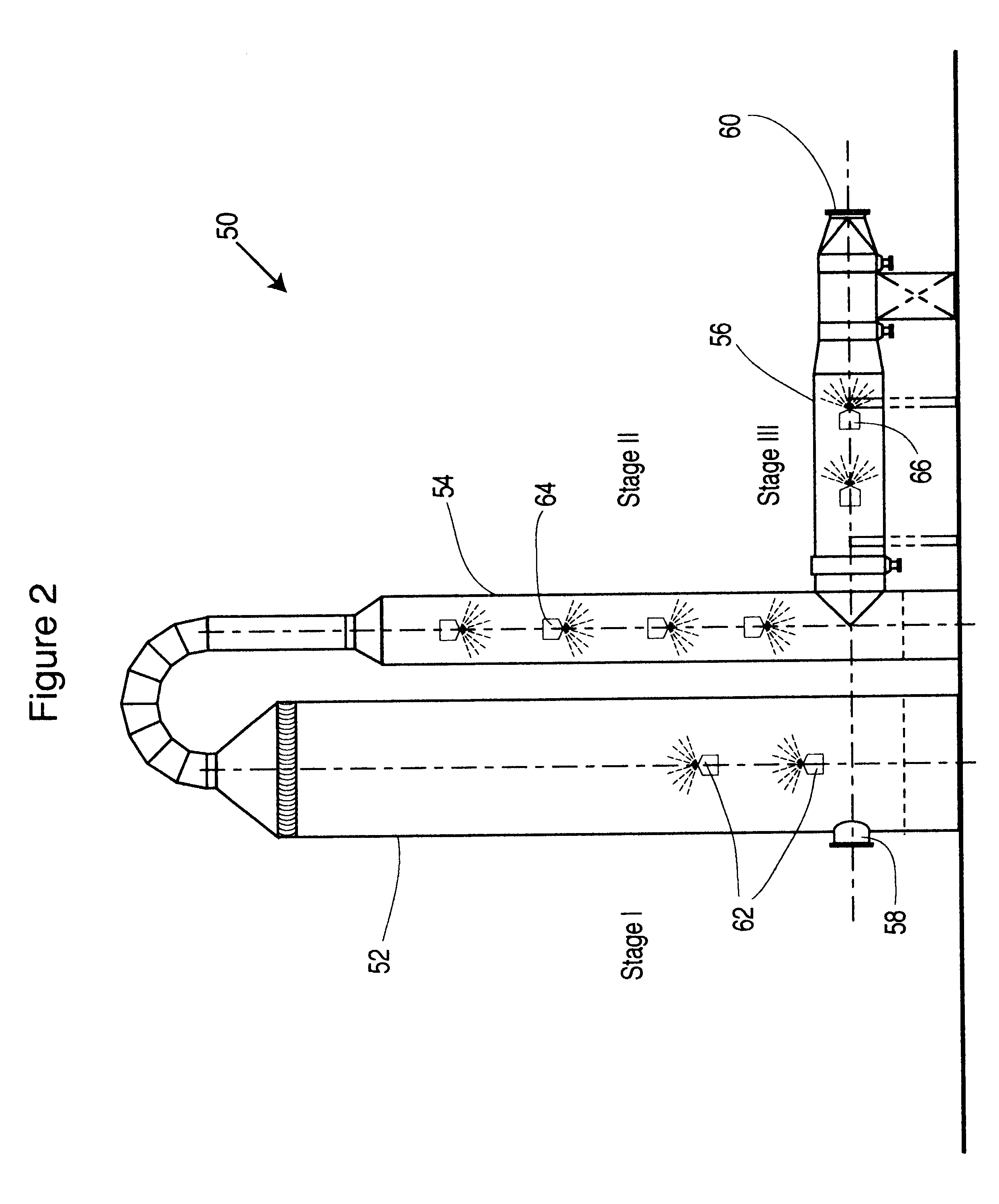

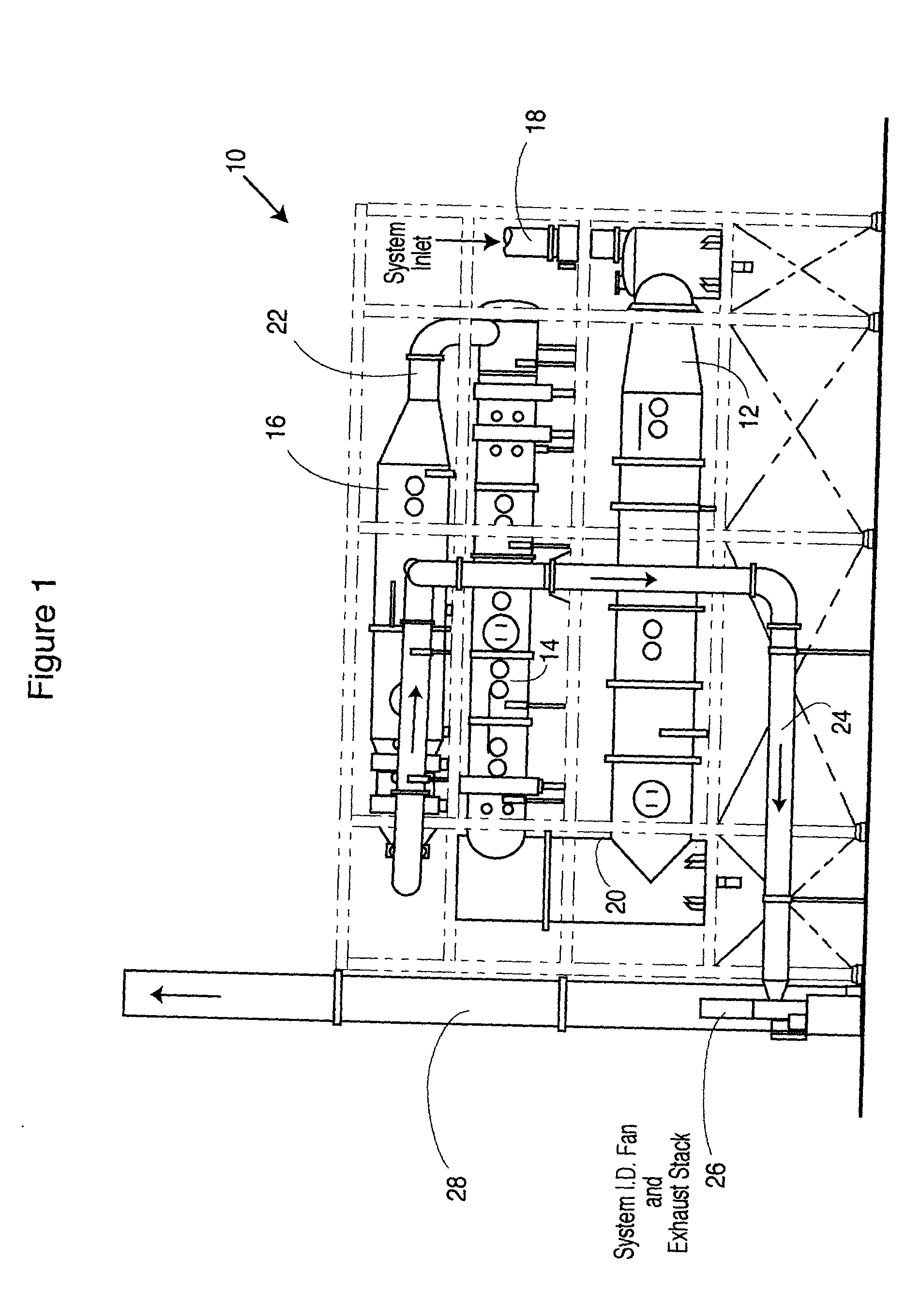

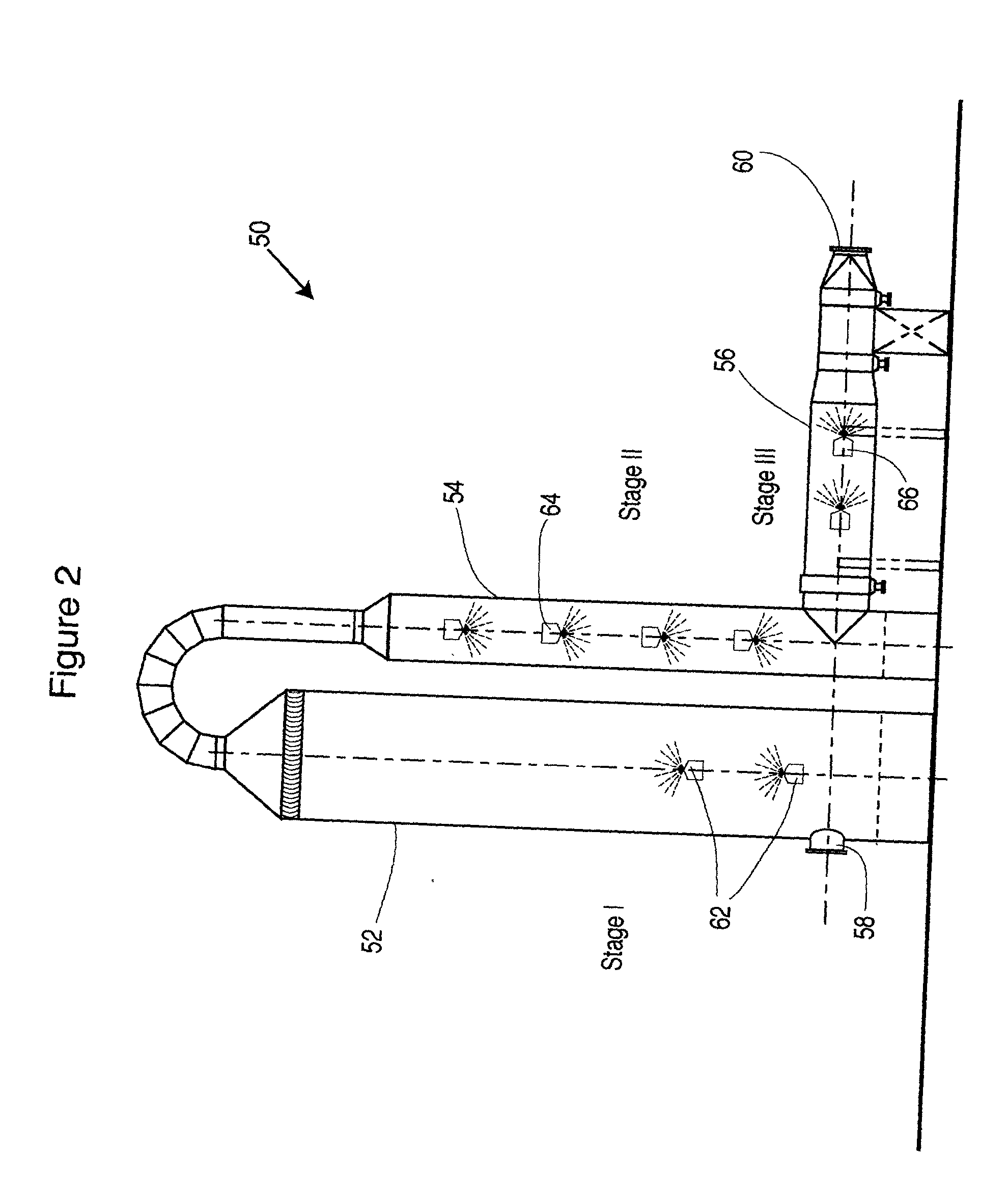

Treatment of gas streams containing reduced sulfur compounds

InactiveUS6579506B2Efficient removalReduce solubilityDispersed particle filtrationElectrostatic separationParticulatesChlorine dioxide

Gas streams containing non-condensible gases (NCG's) including reduced sulfur compounds, such as hydrogen sulfide, dimethyl sulfide, dimethyl disulfide and mercaptans, are treated to remove the NCG's from the gas stream. Following an optional initial gas-liquid contact to cool the gas stream to its adiabatic dewpoint and to remove particulates, the gas stream is subjected to an intimate gas-liquid contact with aqueous chlorine dioxide, in one or more contact stages, to oxidize the reduced sulfur compounds and other oxidizable compounds present in the gas stream, and then the gas stream is passed through an entrainment separator to remove entrained liquid droplets. Acidic gases produced in the oxidization stage and residual chlorine dioxide generally are removed from the gas steam by intimate gas-liquid contact of the gas stream with an aqueous neutralizing and reducing solution, in one or more contact stages, and ten the gas stream is passed through an entrainment separator to remove entrained liquid droplets.

Owner:MEGTEC TURBOSONIC

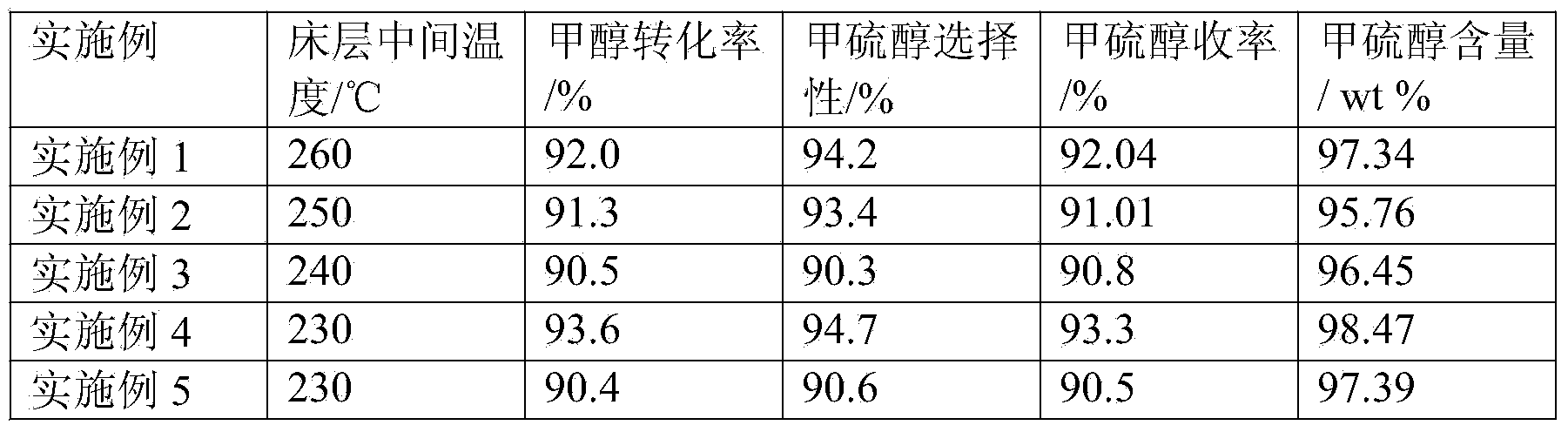

Catalyst for synthesizing methyl mercaptan and preparation method of catalyst

ActiveCN103506130AGood choiceLow activation temperatureThiol preparationMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideReaction temperature

The invention discloses a catalyst for synthesizing methyl mercaptan and a preparation method of the catalyst. The catalyst comprises a carrier, an active component and an assistant, wherein the carrier is gamma-Al2O3, the active component is one or more of Fe2O3, MoO3, ZnO and NiO, and the assistant is alkali metal oxide or alkaline earth metal oxide. The catalyst is prepared as follows: impregnating a precursor of the assistant on the carrier by using a secondary equivalent-volume impregnation method, loading the precursor containing the active component by using the impregnation method again after roasting for one time, and obtaining a target product namely the catalyst for synthesizing the methyl mercaptan after the secondary roasting. According to the catalyst provided by the invention, methyl alcohol and sulfuretted hydrogen are used as raw materials to synthesize the methyl mercaptan, the selectivity of the catalyst is good, the active temperature of the catalyst is lower than that of the prior art, the reaction temperature is between 230-260 DEG C, the yield of the methyl mercaptan is more than 90%, in addition, no dimethyl sulfide is produced in the target product, so that subsequent separation is not needed.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Flavor oils with reduced sulfur content and use in oral care compositions

ActiveUS20080008667A1Reduce contentSimple and inexpensive and easy to implementCosmetic preparationsBiocideSorbentAdditive ingredient

The present invention relates to flavor oils including mint-, fruit- and spice-type flavors that are specially processed to substantially eliminate low-molecular weight sulfur compounds, in particular dimethyl sulfoxide (DMSO), which has been found to be the main precursor of malodorous species such as dimethyl sulfide and methyl mercaptan. These malodorous species are produced via oxidation-reduction reactions involving such sulfur-containing compounds present in flavor oils. A preferred processing method is an aqueous-washing process, which has advantages of being simple, inexpensive and easy to implement while importantly avoiding the problems of typical processes including non-selective removal of desirable components and subjecting the flavor oils to extreme conditions that may destroy other components and result in undesirable changes in flavor or odor character. Other processing methods to selectively remove non-desired components include (1) distillation to remove polar low boiling point components, (2) filtration through adsorbents selective for sulfur compounds, (3) countercurrent extraction and (4) column chromatography. The processing methods may optionally be followed by reengineering to add back desired components that may have been removed or altered during the processing. The specially processed flavor oils are particularly useful in oral care compositions comprising components with chemical reducing capability such as stannous ions, which react with the sulfur-containing compounds to produce malodorous products.

Owner:THE PROCTER & GAMBLE COMPANY

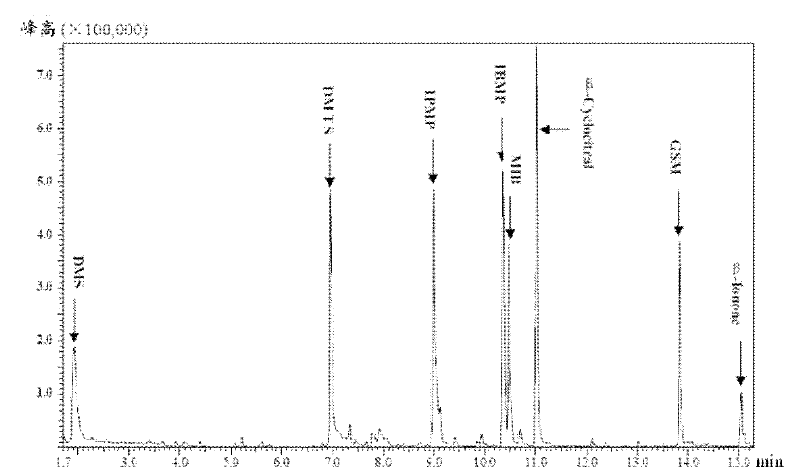

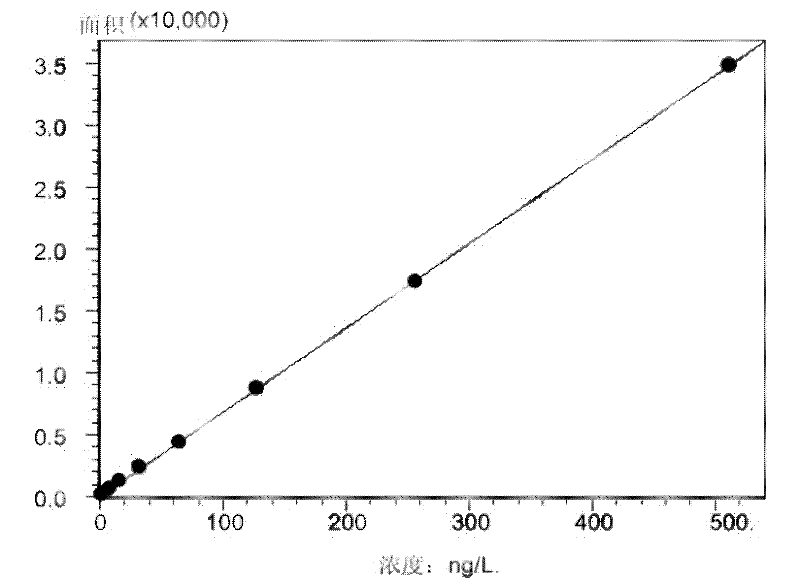

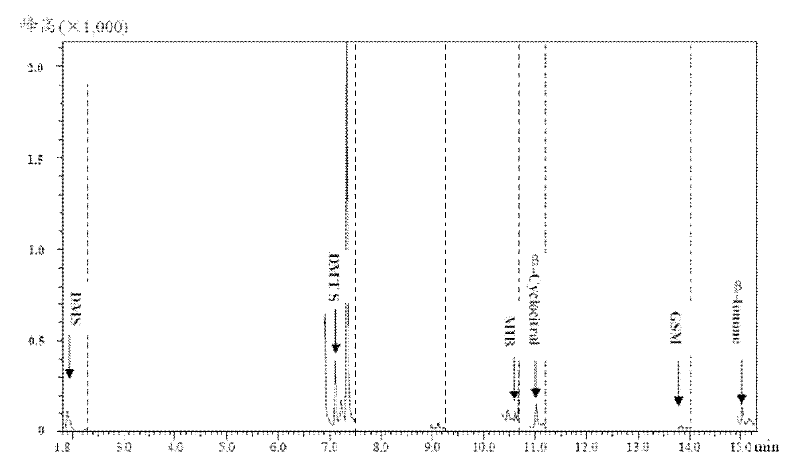

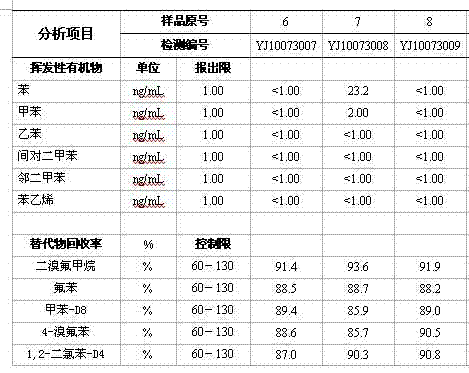

Method for determining eight kinds of odorous substances in water simultaneously

InactiveCN102253156AHigh degree of automationReduce detection efficiencyComponent separationPyrazineWater quality

The invention belongs to the technical field of natural environment water quality monitoring and discloses a method for determining eight kinds of common odorous substances in water simultaneously through use of a method of combining purge-and-trap and gas chromatography / mass spectrometry. The method can be adopted to determine eight kinds of common odorous substances such as dimethyl sulfide (DMS), dimethyl trisulfide (DMTS), 2-isopropyl-3-methoxy pyrazine (IPMP), 2-isobutyl-3-methoxy pyrazine (IBMP), 2-methyl isobornyl (MIB), beta-cyclocitral, geosmin (GSM) and beta-ionone in water simultaneously. Any report on the method for determining the eight kinds of substances in one step is not present yet. The method disclosed by the invention fills the gap and can be used for quantitatively analyzing the eight kinds of odorous substances in water in one step, so that the detection efficiency is greatly increased.

Owner:INST OF AQUATIC LIFE ACAD SINICA

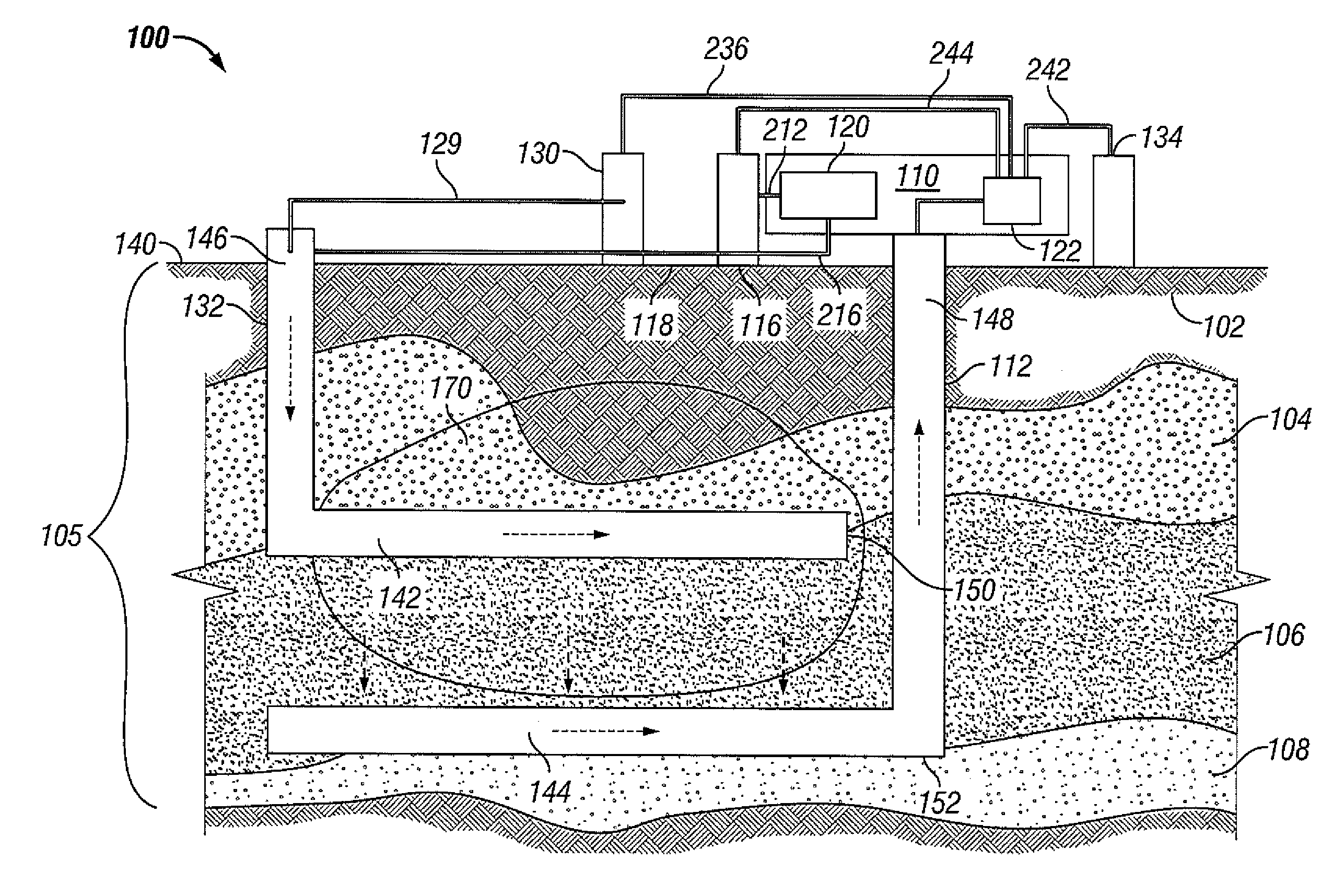

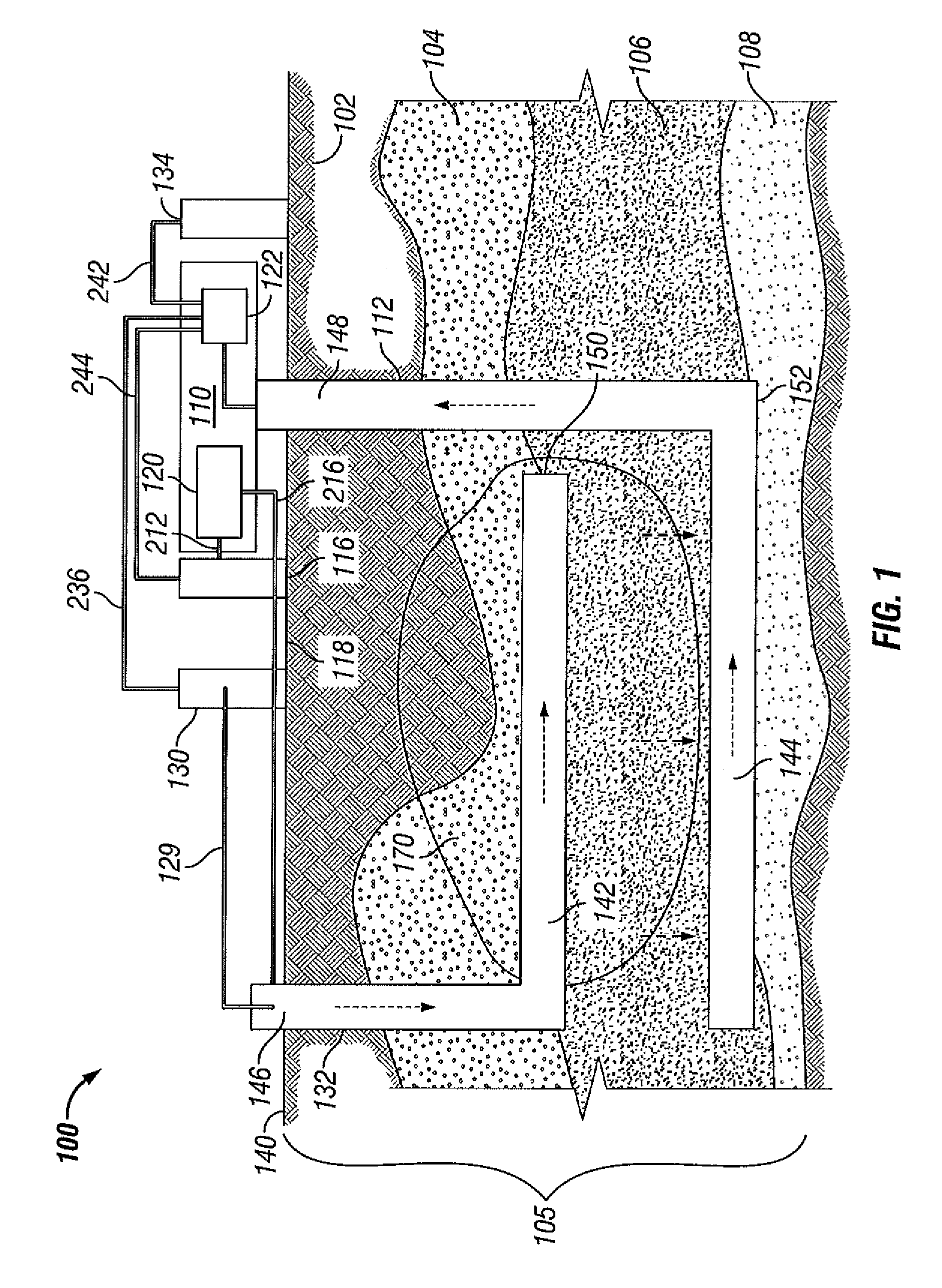

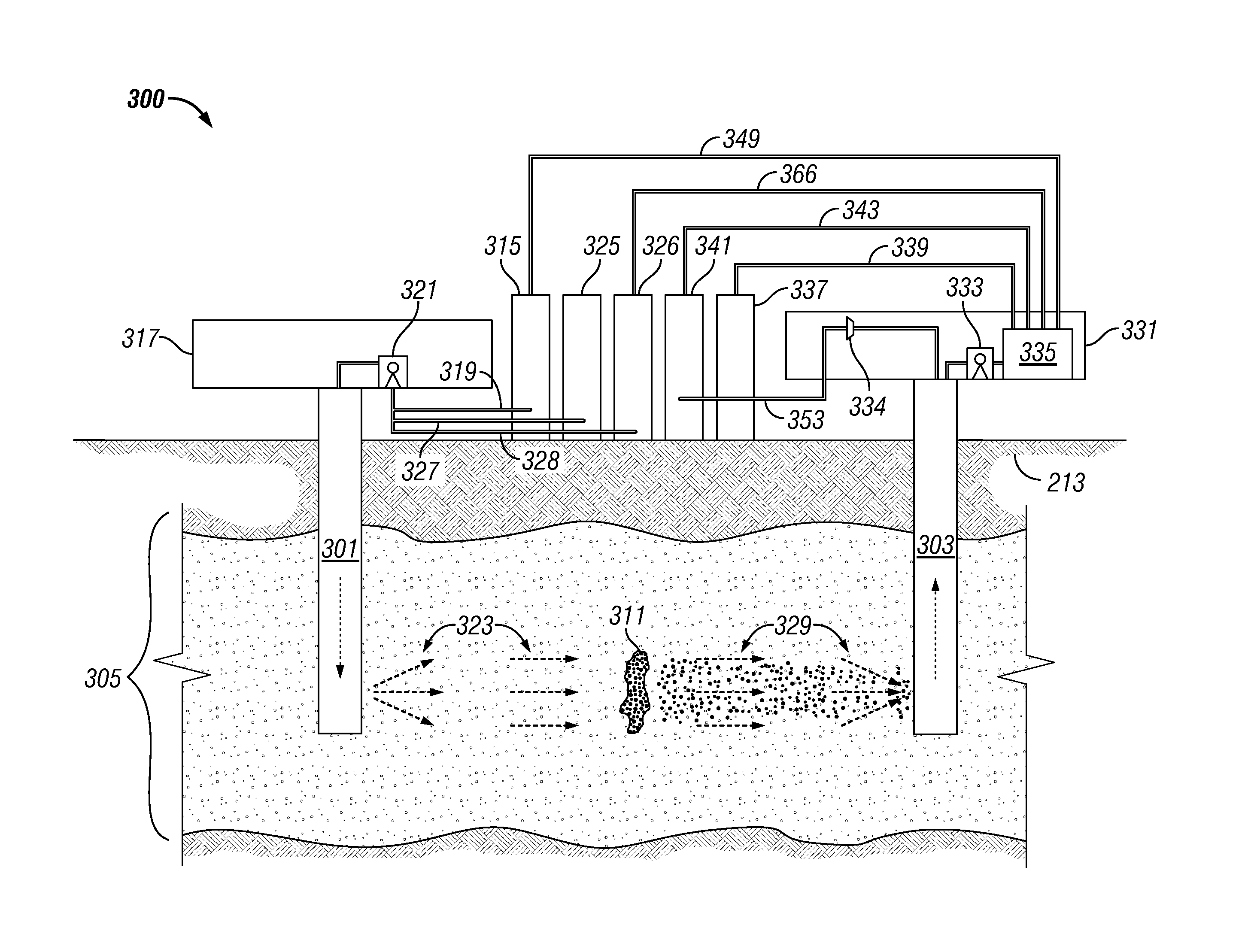

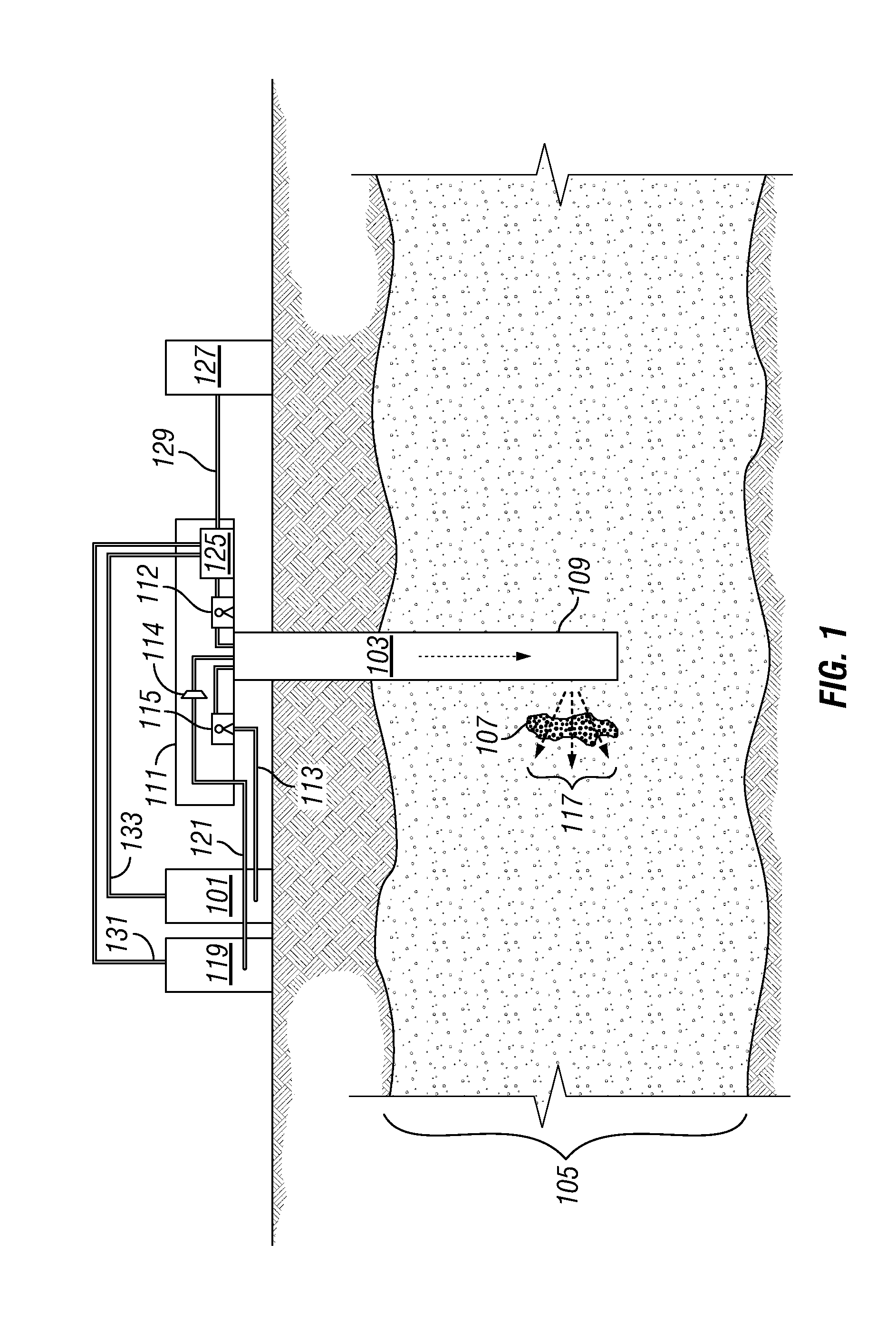

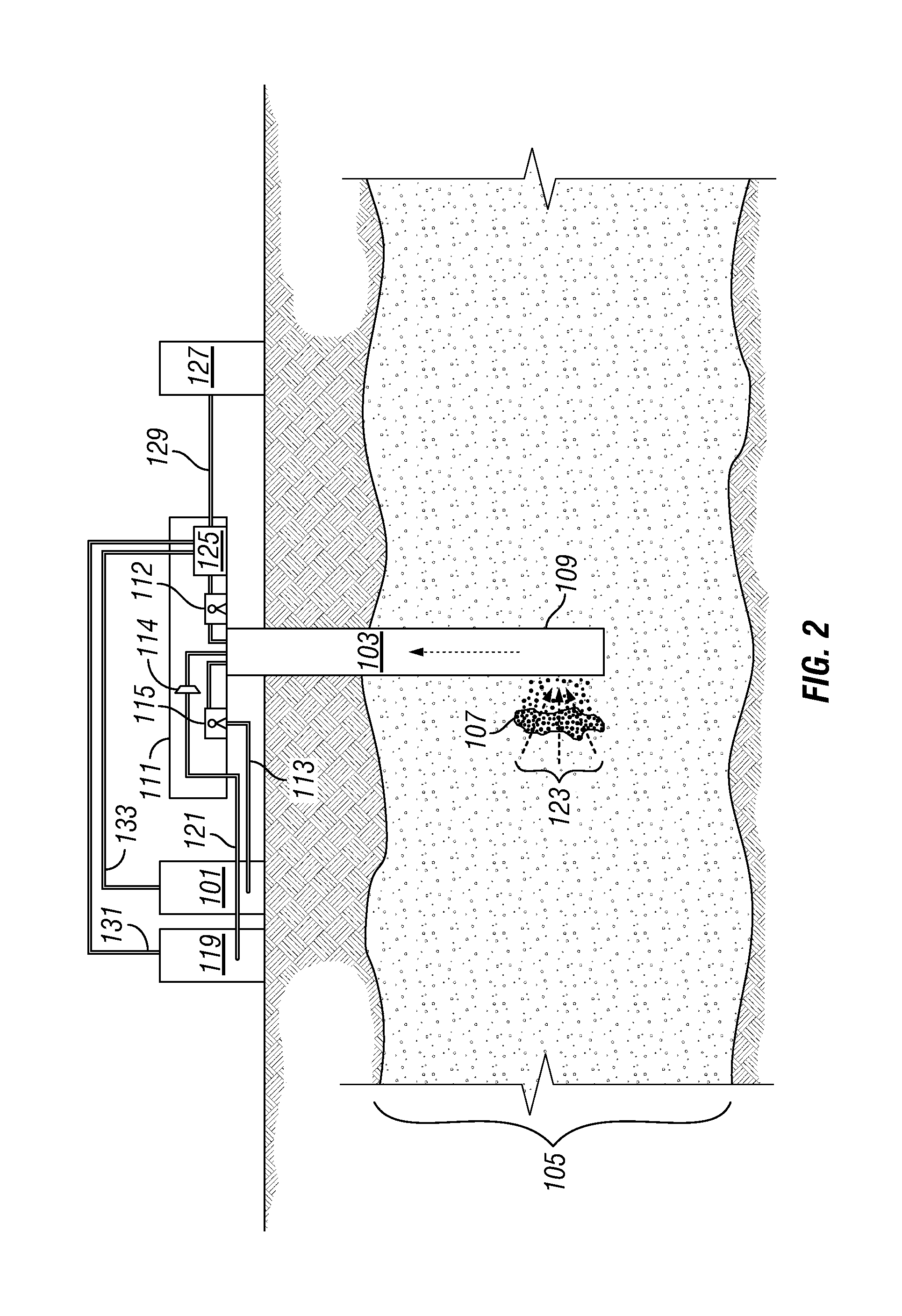

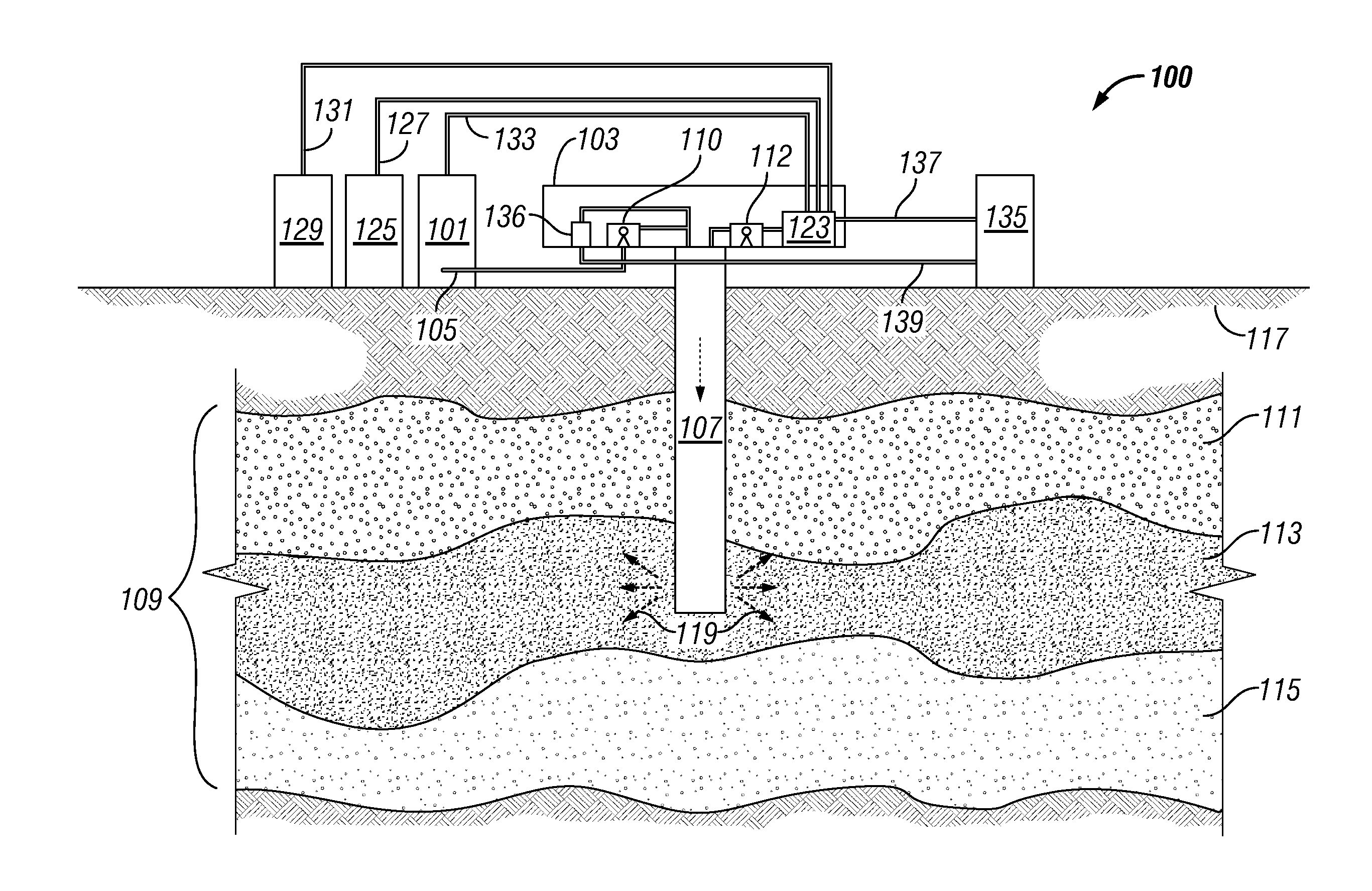

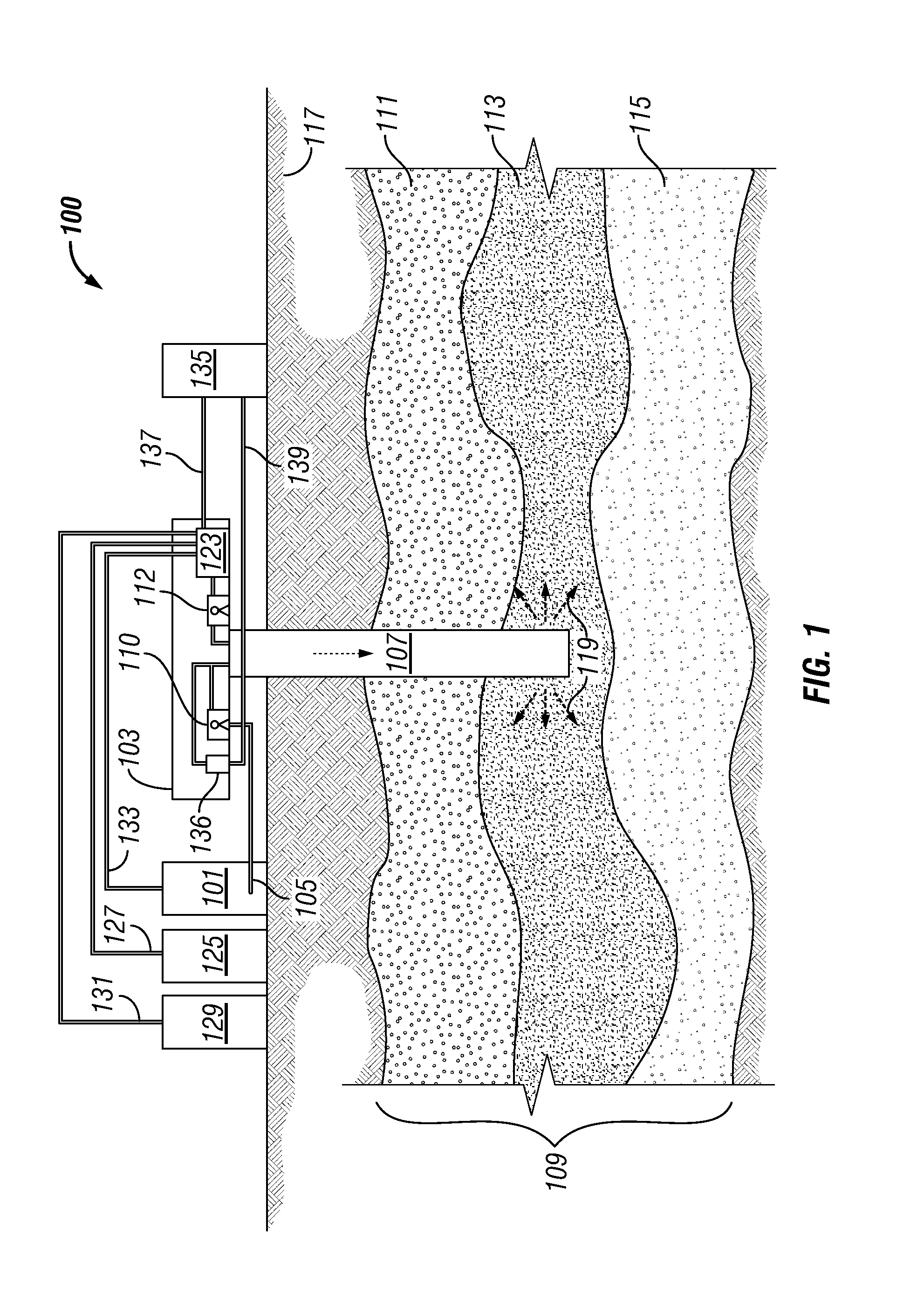

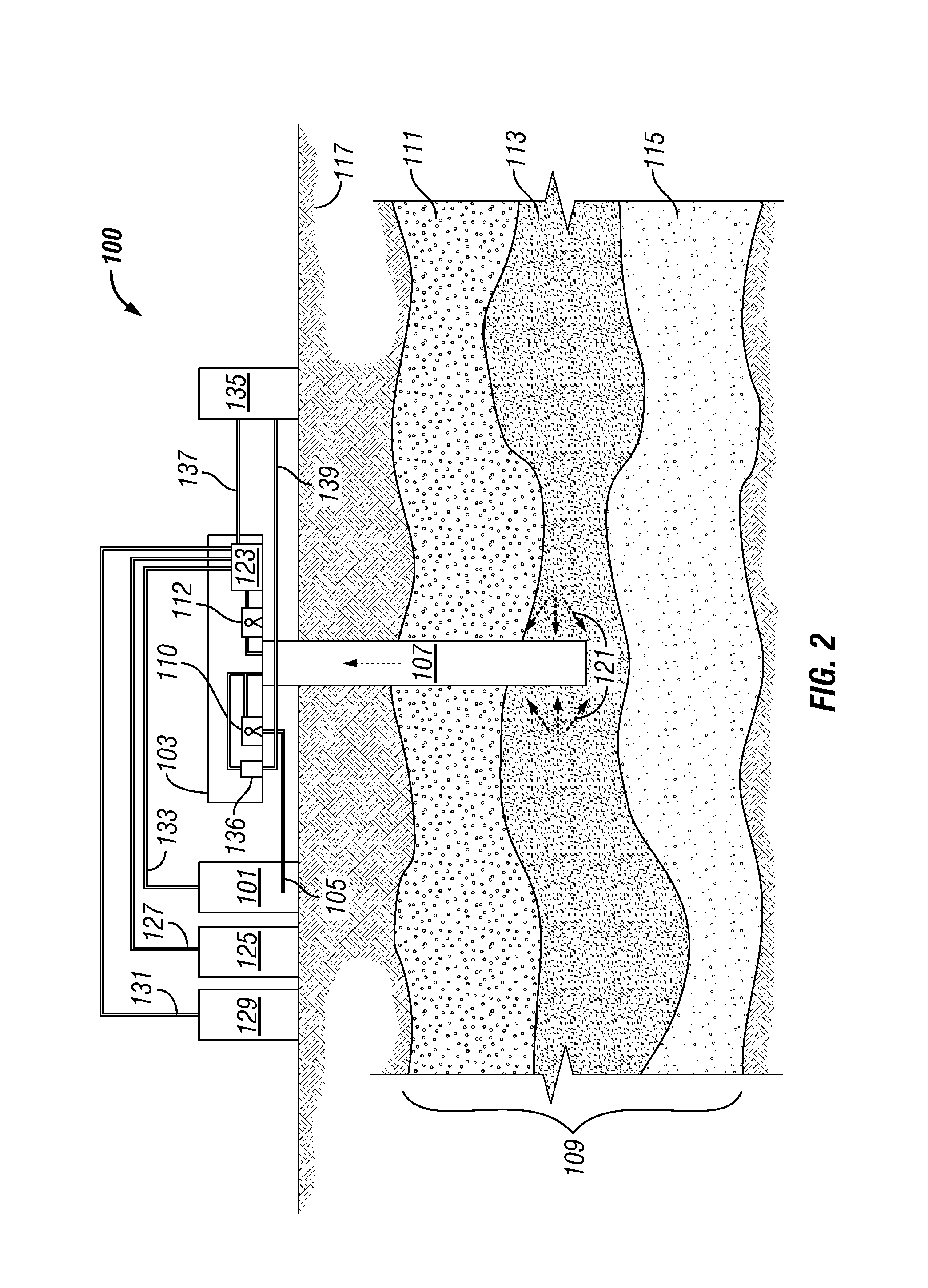

Oil recovery system and method

A system and process are provided for recovering oil from an oil-bearing formation. An oil recovery formulation that is first contact miscible with a liquid petroleum composition that is comprised of at least 15 mol % dimethyl sulfide is introduced together with steam or hot water into a subterranean oil-bearing formation comprising heavy oil, extra heavy oil, or bitumen, and oil is produced from the formation.

Owner:SHELL OIL CO

Active carbon ceramic with selectivity and preparation method thereof

InactiveCN102452845AAchieve purificationAchieve filterabilityOther chemical processesSustainable biological treatmentPhosphate ionPapermaking

The invention discloses active carbon ceramic with selectivity. The active carbon ceramic is mainly prepared from the following raw materials in parts by weight: 30-70 parts of sludge, 2-15 parts of kaolin and 1-5 parts of a metal M or an oxide of the metal M. The active carbon ceramic with selectivity has an amorphous Si-C-M structure, and the specific surface area is 400-500 m<2> / g. In the invention, a formula for adding crop hull waste and the like into waste water of the papermaking industry and residual sludge and kaolin of the food industry and a sewage treatment plant is adopted, oxygen-free heating and burning are performed, and porous ceramic carbon particles or powder is activated with microwaves, so that active carbon ceramic with biological selectivity is formed. An obtained ceramic material has the functions of selectively adsorbing benzene, phenol, hydrocarbons, dimethyl sulfide and thioether malodorous substances, and is used for filtering air; ceramic carbon contains a biological medium filter material for providing effective carbon sources and minerals for air filtering and waste water treatment for microorganisms; and the material has the functions of adsorbing phosphate radical ions in water and removing oxygen-enriched components from water.

Owner:漯河微陶净化材料有限公司

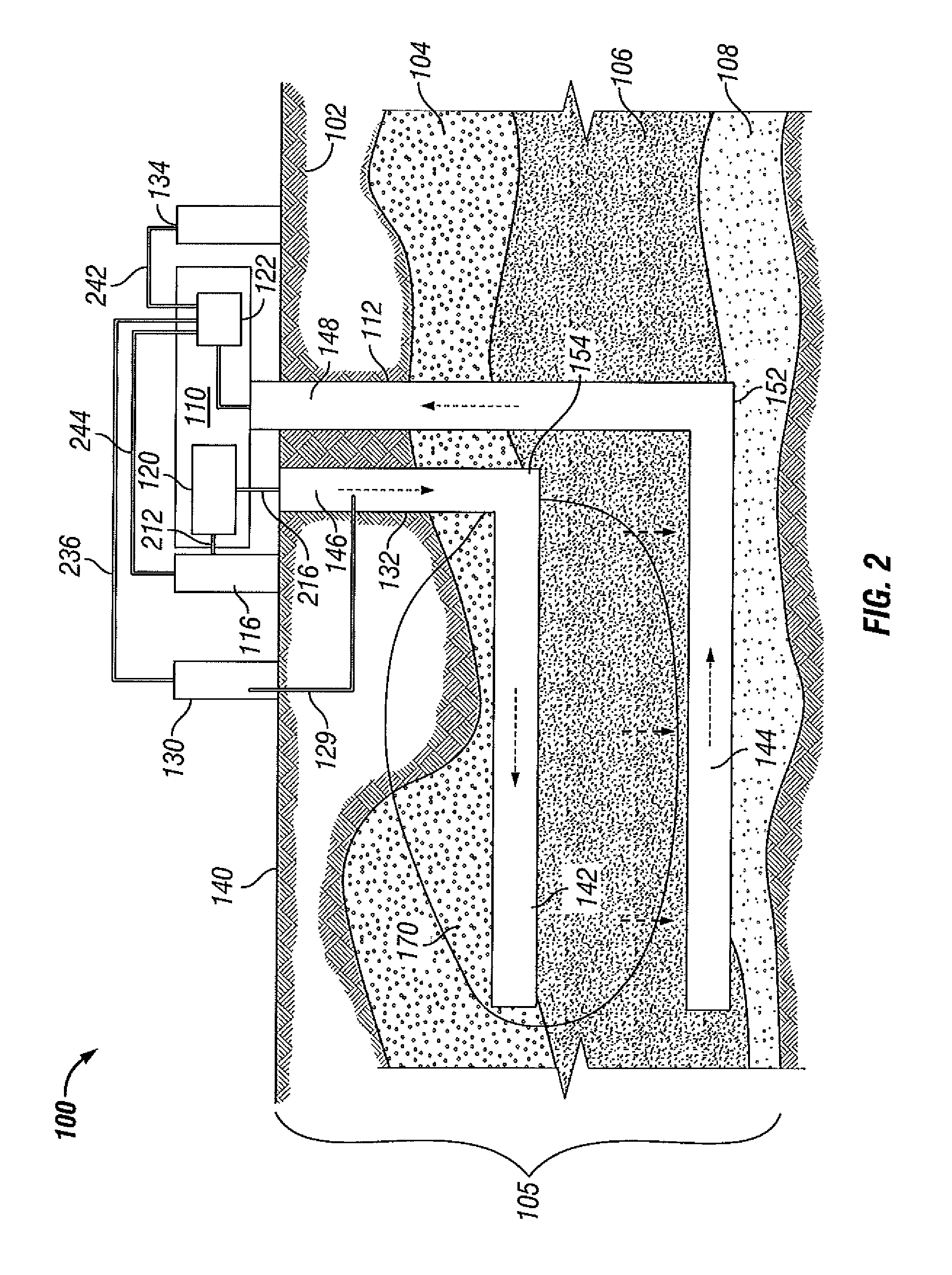

Remediation of asphaltene-induced plugging of an oil-bearing formation

A system and method for remediation of asphaltene-induced fouling of an oil-bearing formation is provided wherein an asphaltene solvent comprising at least 75 mol % dimethyl sulfide is introduced into an oil-bearing formation containing asphaltene deposits and the dimethyl sulfide is contacted with the asphaltene deposits.

Owner:SHELL OIL CO

Preparation process of chlorinated phenol

ActiveCN105777499AHas a positioning effectReduce consumptionOrganic chemistryOrganic compound preparationChlorinated phenolsEthyl Chloride

The invention discloses a preparation process of chlorinated phenol; phenol is used as a raw material, a mixture of arbitrary one of diphenyl sulfide and dimethyl sulfide, arbitrary one of acetic acid and toluene sulfonic acid and arbitrary one of aluminum trichloride and ferric trichloride is used as a catalyst, a chlorinated phenol crude product is generated through sulfuryl chloride chlorination, and a target product is obtained by melt crystallization. The mixed catalyst used in the reaction has a positioning function, the content of p-chlorophenol in the monochlorophenol mixture generated from the reaction is greater than 83%, the content of 2,4-dichlorophenol in dichlorinated phenol generated from the reaction is greater than 98%, the amount of trichlorinated phenol impurities generated from the reaction is reduced, and 2,4,6-dichlorophenol with the content greater than 99% and the total yield more than or equal to 98% is obtained without purification treatment; moreover, energy consumption is greatly reduced, and high-content p-chlorophenol and high-quality 2,4-dichlorophenol can be produced at the same time.

Owner:兰州诚胜化工科技有限公司

Treatment of gas streams containing reduced sulfur compounds

InactiveUS20020034468A1Efficient removalReduce solubilityDispersed particle filtrationElectrostatic separationParticulatesChlorine dioxide

Gas streams containing non-condensible gases (NCG's) including reduced sulfur compounds, such as hydrogen sulfide, dimethyl sulfide, dimethyl disulfide and mercaptans, are treated to remove the NCG's from the gas stream. Following an optional initial gas-liquid contact to cool the gas stream to its adiabatic dewpoint and to remove particulates, the gas stream is subjected to an intimate gas-liquid contact with aqueous chlorine dioxide, in one or more contact stages, to oxidize the reduced sulfur compounds and other oxidizable compounds present in The gas stream and then the gas stream is passed through an entrainment separator to remove entrained liquid droplets. Acidic gases produced in the oxidization stage and residual chlorine dioxide generally are removed from the gas steam by intimate gas-liquid contact of the gas stream with an aqueous neutralizing and reducing solution, in one or more contact stages, and ten the gas stream is passed through an entrainment separator to remove entrained liquid droplets.

Owner:MEGTEC TURBOSONIC

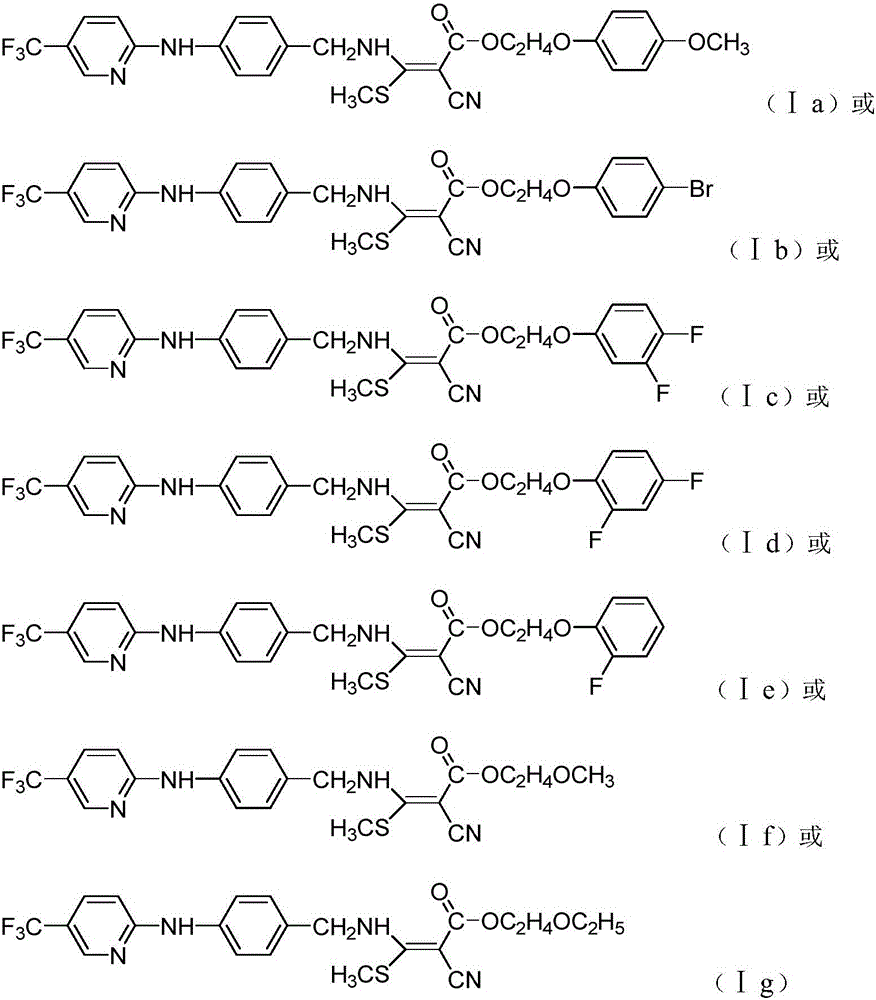

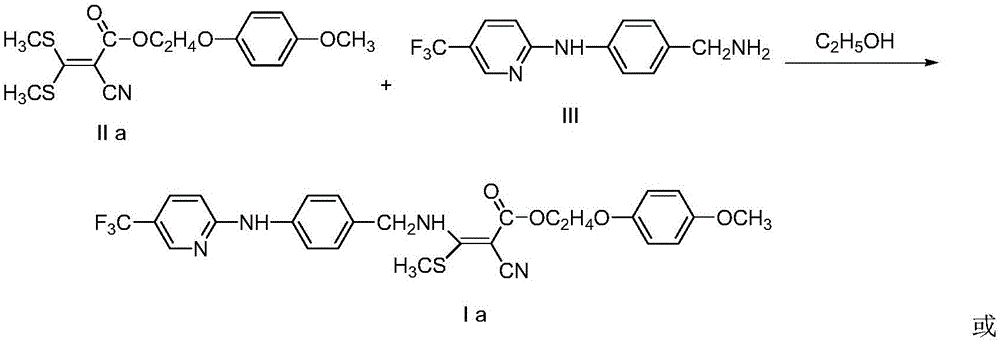

Preparation and application of cyanoacrylate compound with pyridine diarylamine structures

The invention relates to a cyanoacrylate compound (I) with pyridine diarylamine structures, a method for preparing the cyanoacrylate compound and application thereof.The method includes carrying out reaction on 3, 3-dimethyl sulfide-2-cyanoacrylate and diarylamine benzyl ammonia with pyridyl to obtain the cyanoacrylate compound.The cyanoacrylate compound with the pyridyl diarylamine structures, the method and the application have the advantages that excellent effects of preventing and controlling broadleaf weeds can be realized by the cyanoacrylate compound with the pyridyl diarylamine structures, and the cyanoacrylate compound can be used for preparing herbicides in the field of agriculture, horticulture and the like.

Owner:NANTONG NTEC MONOFILAMENT TECH CO LTD

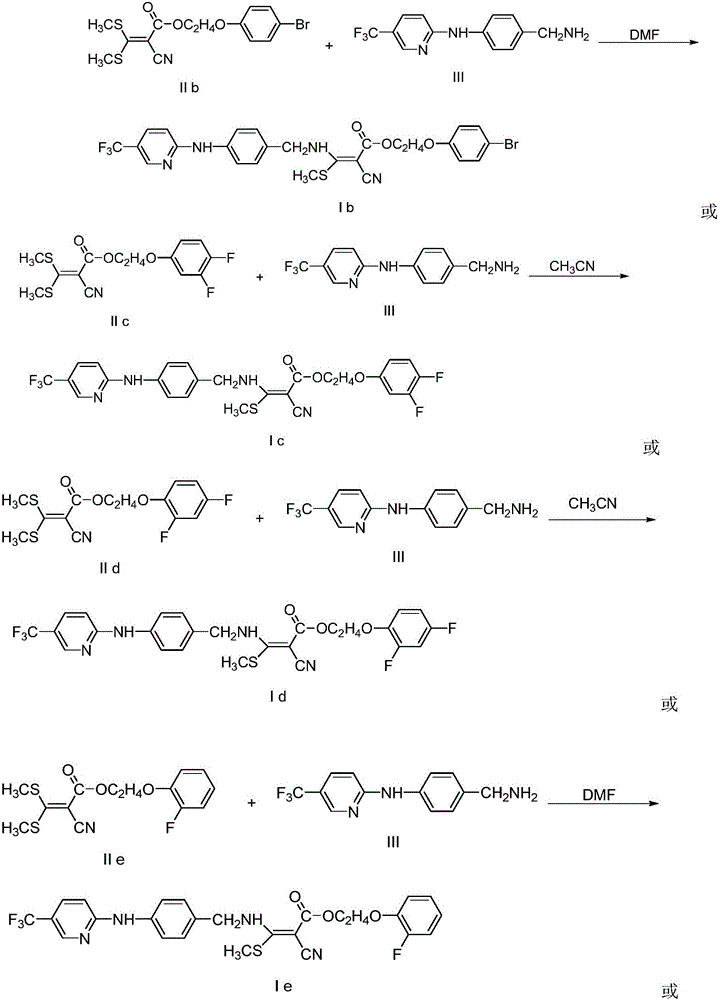

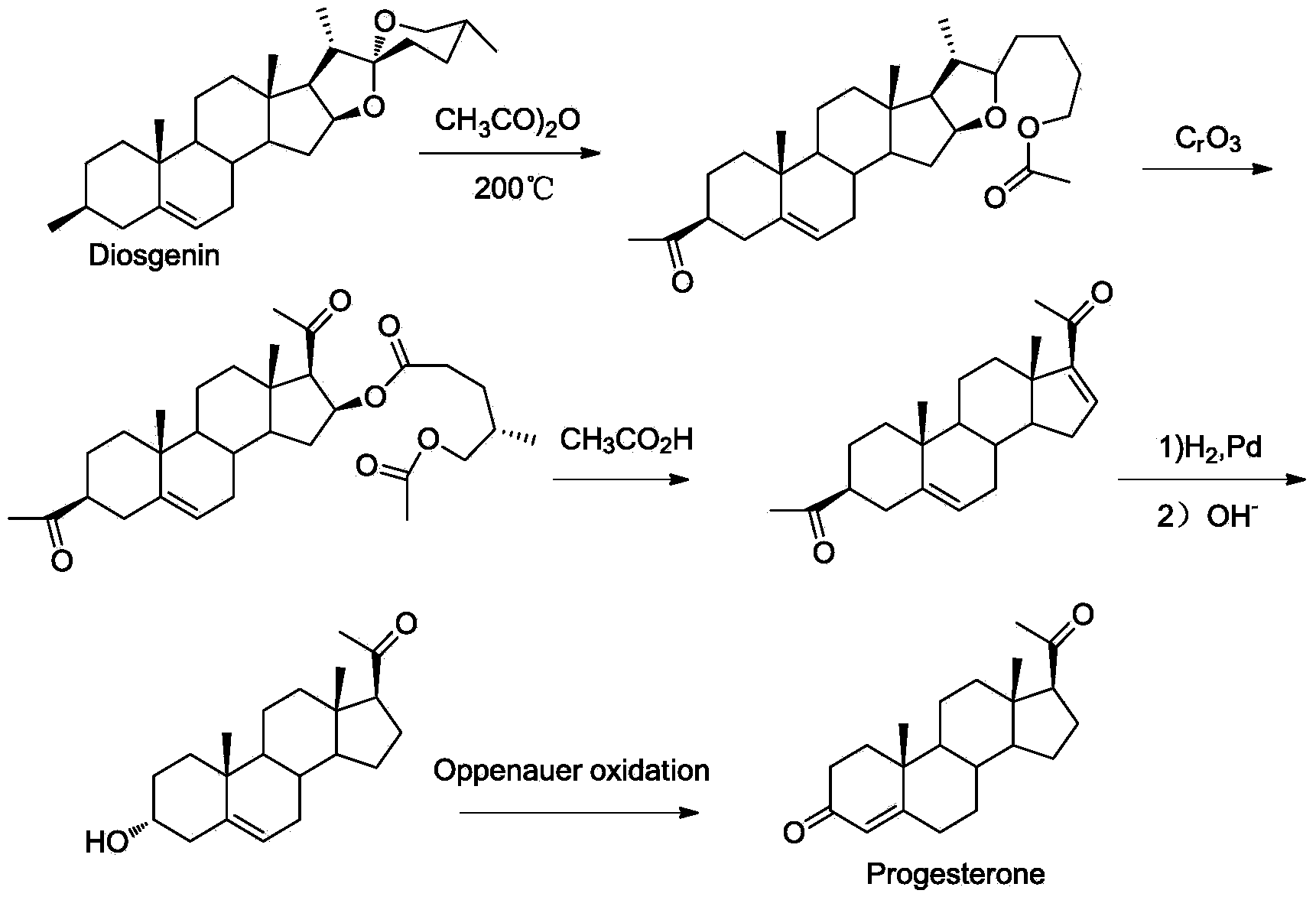

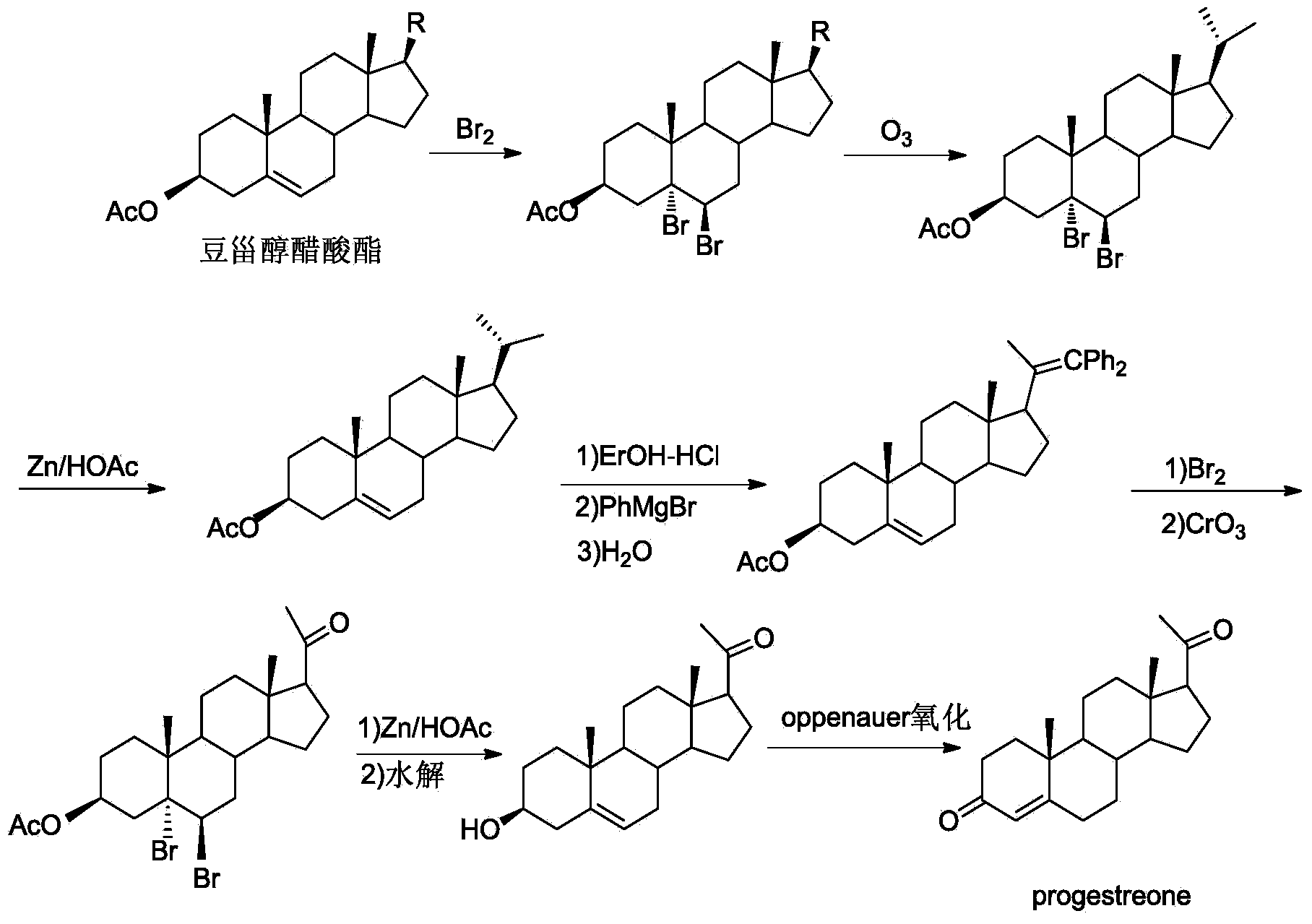

New technique for synthesizing progesterone

InactiveCN104109183ARaw materials are easy to getEasy to operateSteroidsN dimethylformamideN-Chlorosuccinimide

The invention discloses a new technique for synthesizing progesterone, which comprises the following steps: by using a phytosterin fermentation product (20S)-20-hydroxymethylpregna-4-ene-3-one as an initial raw material, oxidizing with a dimethyl sulfide / N-chlorosuccinimide mixture, and carrying out oxidative decarboxylation reaction in a DMF (N,N-dimethylformamide) solution of DBU (1,8-diazabicyclo(5.4.0)undec-7-ene), Cu(OAc)2.H2O and 2,2'-dipyridine to obtain the progesterone. The technique has the advantages of simple process, high yield (up to 80%), favorable product quality, accessible raw materials and low preparation cost.

Owner:HUBEI GEDIAN HUMANWELL PHARMACEUTICAL CO LTD

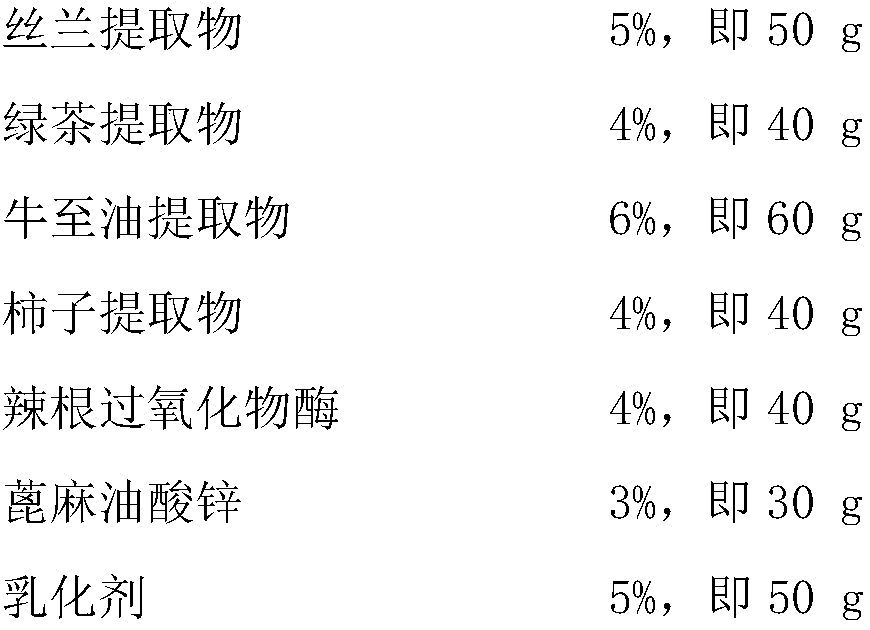

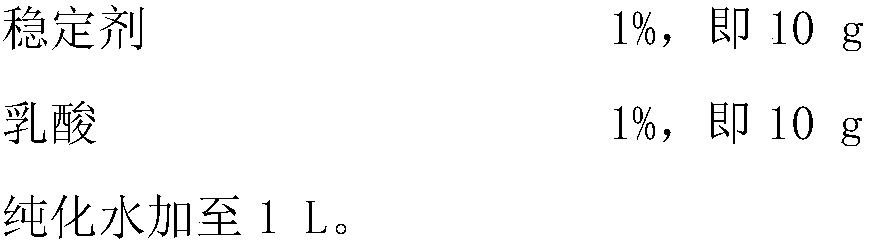

Composite biological deodorization spray for pets and preparation method thereof

ActiveCN109646361AGood deodorizing propertiesEfficient removalCosmetic preparationsToilet preparationsORIGANUM OILFeces odor

The invention relates to composite biological deodorization spray for pets and a preparation method thereof. The spray is suitable for solving the problems of halitosis, body odor, feces odor and thelike of dogs and cats. The deodorization spray comprises, by mass, 5-8% of a Spanish bayonet extract, 4-5% of a green tea extract, 6-8% of an origanum oil extract, 4-5% of a persimmon extract, 4-5% ofa horseradish extract, 3-4% of zinc diricinoleate, 5-6% of an emulsifier, 1-2% of a stabilizing agent, 1-2% of a pH value regulator and the balance purified water. It is proved through deodorizationeffect identification that the deodorization performance of the spray is good, and the spray can quickly eliminate ammonia gas, hydrogen sulfide, methyl mercaptan, dimethyl sulfide, dimethyl disulfideand various common odor molecules of the pets within 5 minutes. Meanwhile, pathogenic microorganisms can be effectively inhibited and killed, and generation of odor can be inhibited from the source.

Owner:SHANDONG SINDER TECH +2

Synthesis method of taxane drug 7, 10-methoxy-docetaxel

The invention discloses a synthesis method of taxane drug 7, 10-methoxy-docetaxel. The synthesis method includes using 7, 10-trichloro-ethoxycarbonyl-10-deacetylbaccatin III (compound 1, CAS (chemical abstracts service) number 95603-44-4) as starting material, using triethyl silicon substrate for protection, and performing reactions of removal of protecting group of trichloro-ethoxycarbonyl, dimethyl sulfide etherification, hydrogenation reduction, removal of protecting group of the triethyl silicon substrate, side chain condensation and side chain deprotection to obtain the 7, 10-methoxy-docetaxelf with more than 99% purity. Reaction conditions are simple and mild. The synthesis method has the advantages that the required equipment is simple and is easy to operate, and methylate reagents such as highly toxic methyl iodide or dimethyl sulfate is not needed. The synthesis method is applicable to industrial production.

Owner:无锡紫杉药业股份有限公司

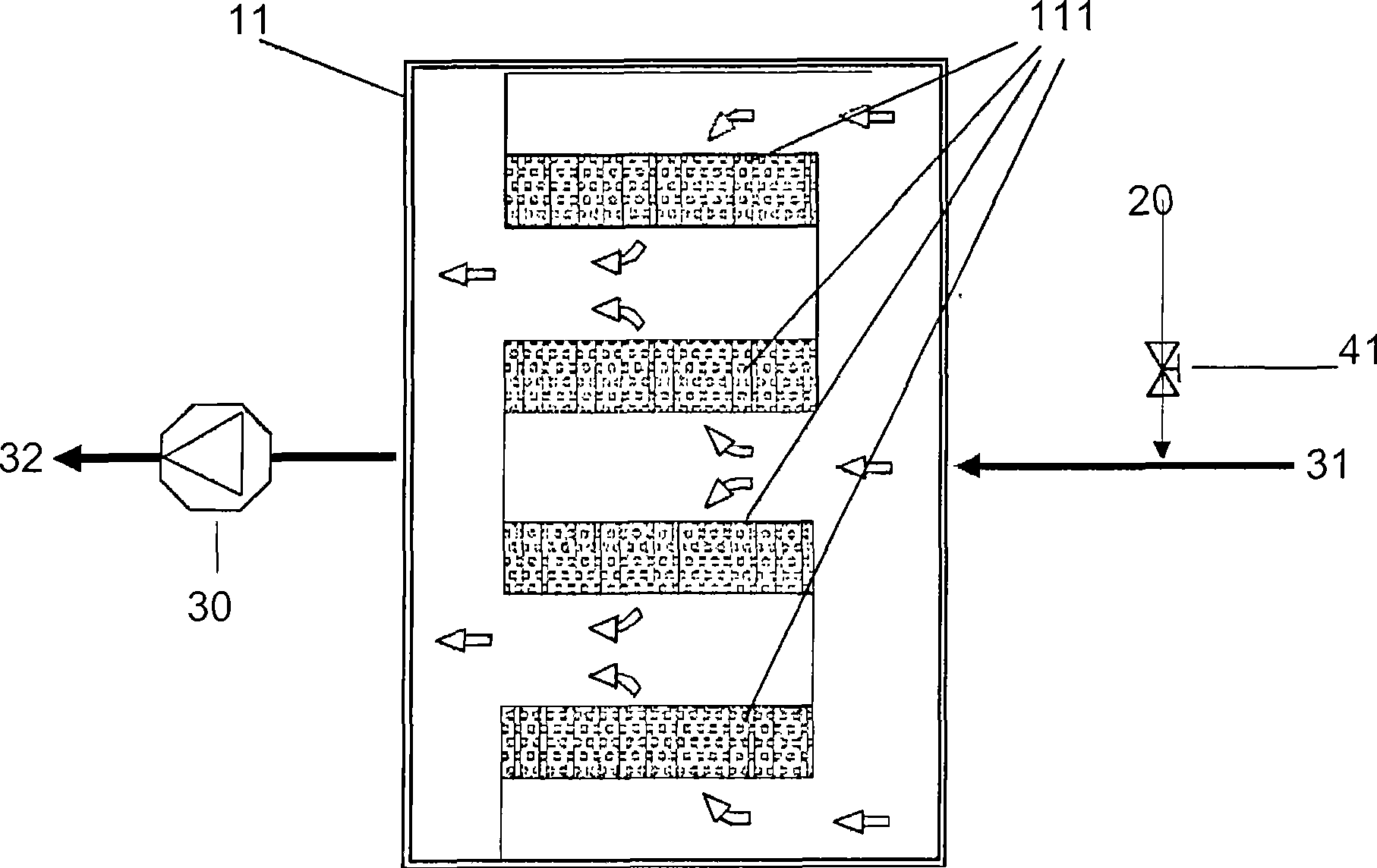

Method for preparing dimethyl sulfoxide

ActiveCN104557630AImprove effective utilizationImprove conversion rateOrganic chemistryMolecular sieve catalystsMolecular sieveFixed bed

Owner:CHINA PETROLEUM & CHEM CORP +1

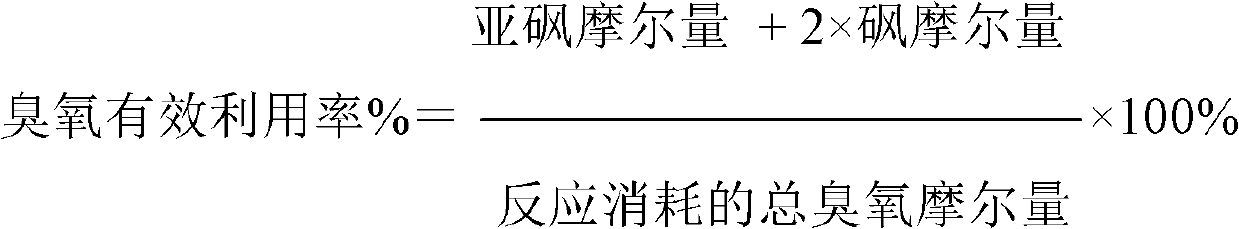

Method for oxidizing dimethyl sulfide

ActiveCN103288691AImprove effective utilizationHigh selectivityOrganic chemistryOrganic compound preparationOxidizing agentHigh selectivity

The invention discloses a method for oxidizing dimethyl sulfide, which comprises the step of contacting dimethyl sulfide with an oxidizing agent under oxidation reaction conditions and is characterized in that the oxidizing agent is gas containing ozone. The method disclosed by the invention is free from any inhibitor or initiator in feed gas and has high selectivity and higher effective ozone utilization rate; particularly, the effective ozone utilization rate is greatly increased in the presence of a titanium-containing catalyst; furthermore, the method disclosed by the invention is simple in process and easy for control and is beneficial to industrial production and application; in addition, compared with the traditional method, the problems of being complex in traditional production process, corrosive in equipment, harmful for discharging and the like are overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

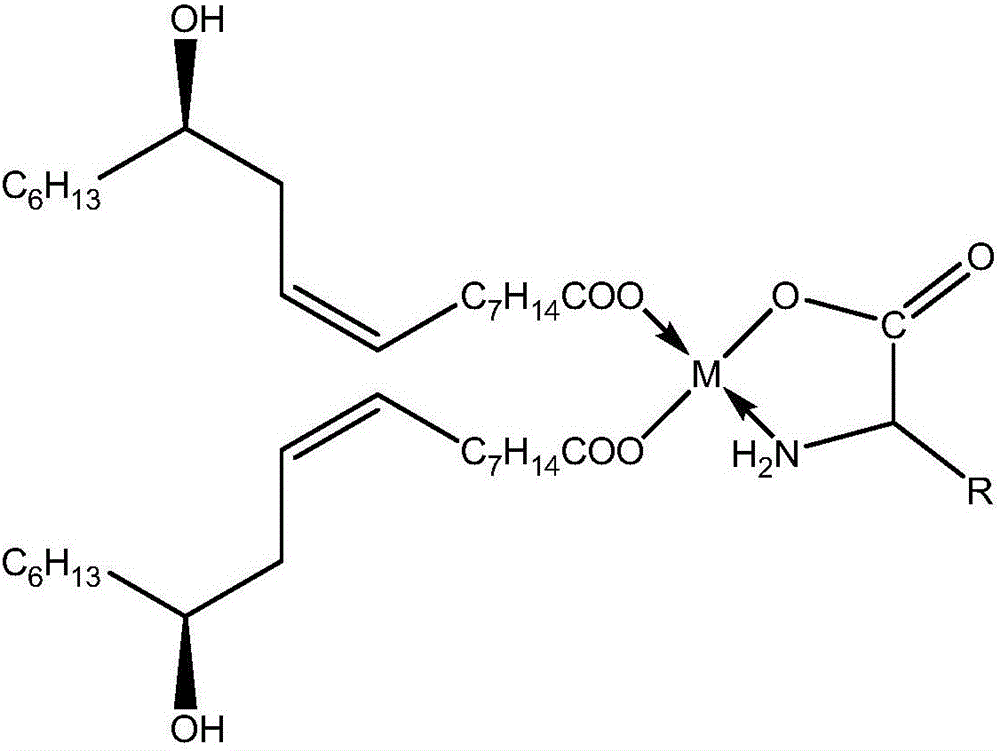

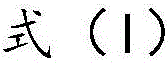

Deodorization composition and application thereof

ActiveCN106620780AChemically stableMeet the requirements of green environmental protectionCosmetic preparationsToilet preparationsAntibacterial agentParaformaldehyde

The invention discloses a deodorization composition and application thereof. The deodorization composition contains an amino acid complex of (9Z,12R)-12-hydroxy-octadecanoic acid zinc salt and / or copper salt, paraformaldehyde and / or 3-methoxy-4-hydroxybenzaldehyde, a stabilizer, a penetrant, an antibacterial agent and an antistatic agent, wherein the weight ratio of the components is 1:(0.1-4.0):(0.05-0.5):(0.05-0.5):(0.001-0.2):(0.001-0.2). A method for removing foul odor, provided by the invention, comprises contacting an aqueous solution containing the deodorization composition with the foul odor. The deodorization composition disclosed by the invention can meet green and environment-friendly requirements, and can be applicable to elimination of off-odors of ammonium, hydrogen sulfide, methyl mercaptan, dimethyl sulfide and the like. The deodorization composition disclosed by the invention can effectively relieve the problem of pollution of the off-odors to the environment, has an excellent deodorization performance, is small in dosage, is simple in treatment process and obvious in effect, and is easy to promote and apply.

Owner:深圳市爱康泉水处理服务有限公司

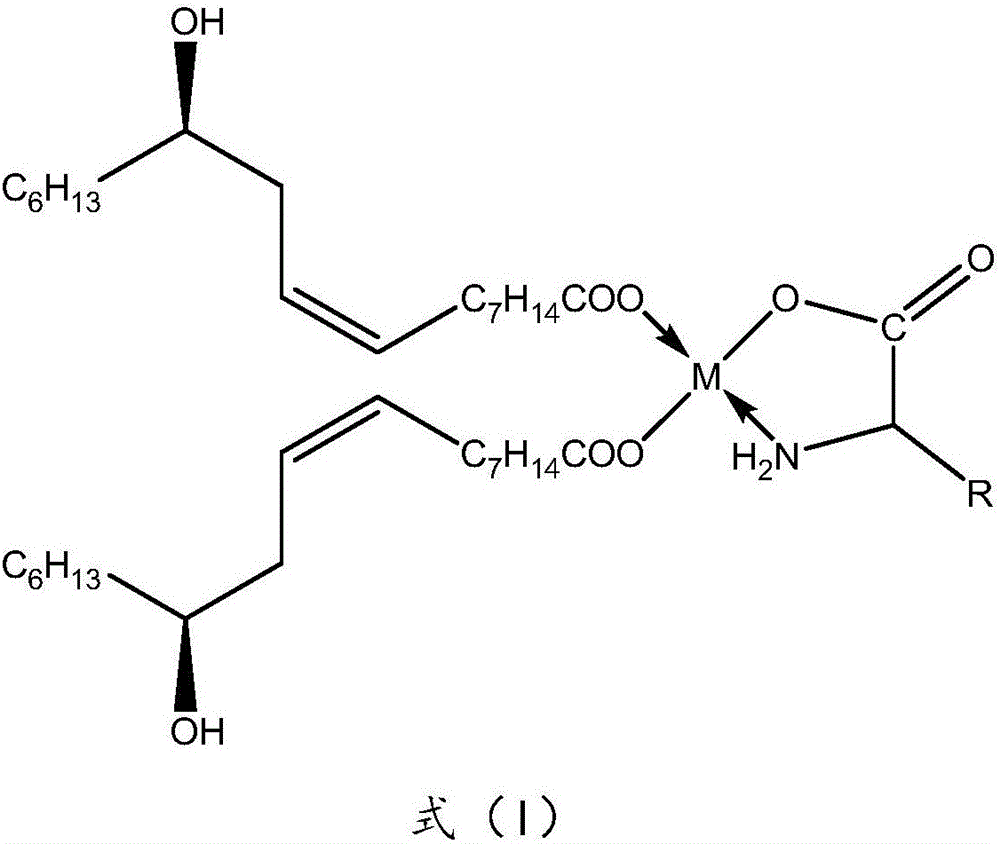

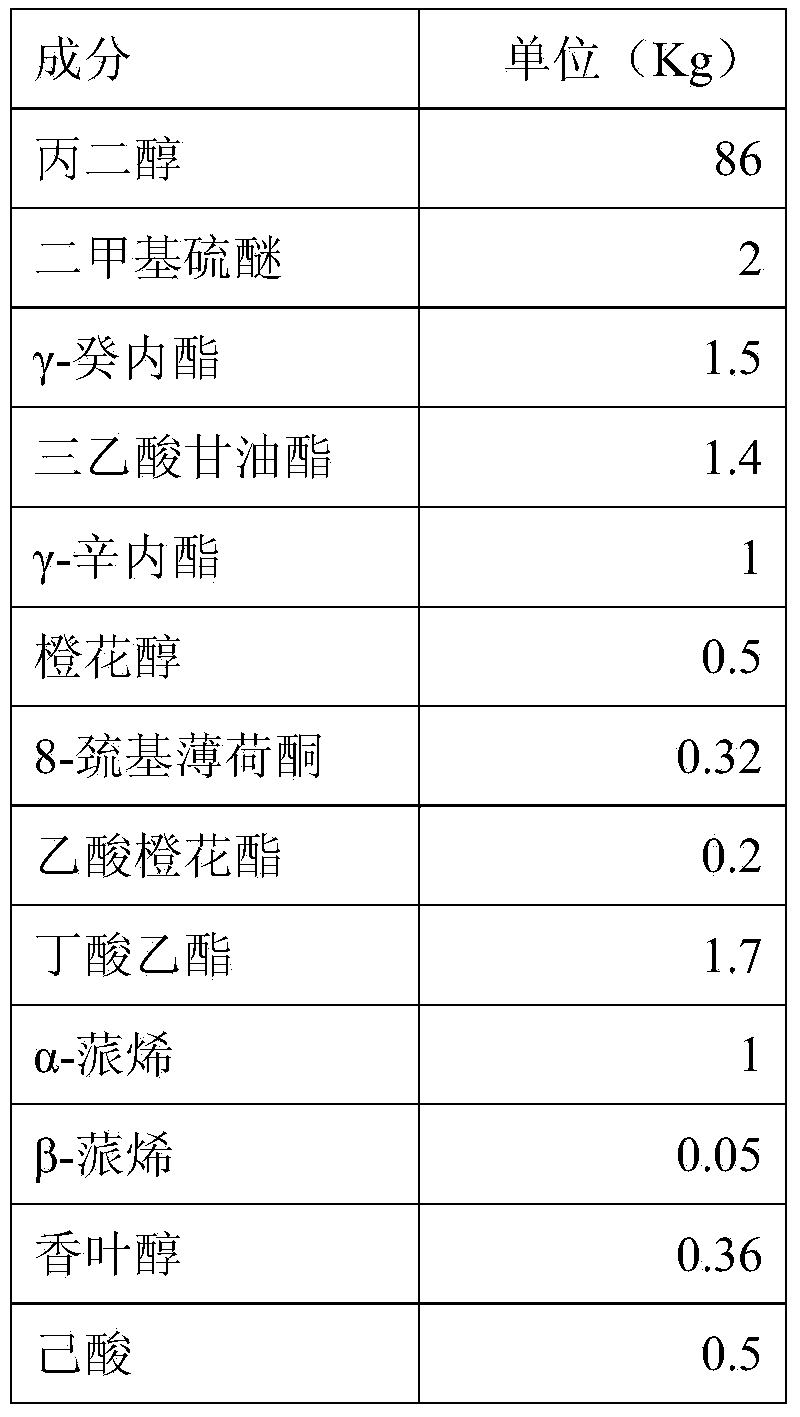

Mango essence

ActiveCN104194937AReduce manufacturing costHuge sales marketEssential-oils/perfumesFood preparationFruit juiceDimethyl sulfide

The invention discloses mango essence, which is mainly composed of such components as propylene glycol, cis-3-hexenyl acetate, dimethyl sulfide, gamma-decalactone, leaf alcohol, alpha-pinene, beta-pinene, 8-thiol menthone and leaf aldehyde. According to the mango essence disclosed by the invention, a formula is proposed according to an original aromatic compound in natural mango juice, therefore the mango essence having aroma of natural mango is prepared. By adding the mango essence to food, drink and the like as a food additive, a finished product has aroma and taste of the natural mango.

Owner:ZHEJIANG GREEN CRYSTAL FLAVOR

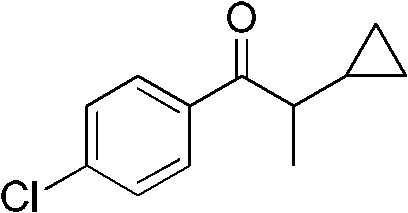

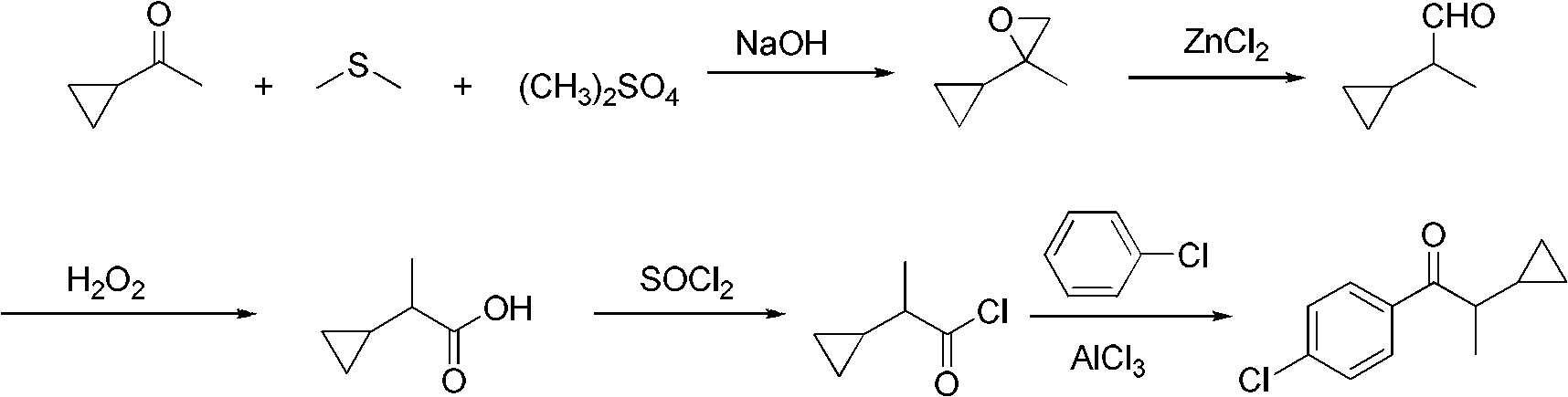

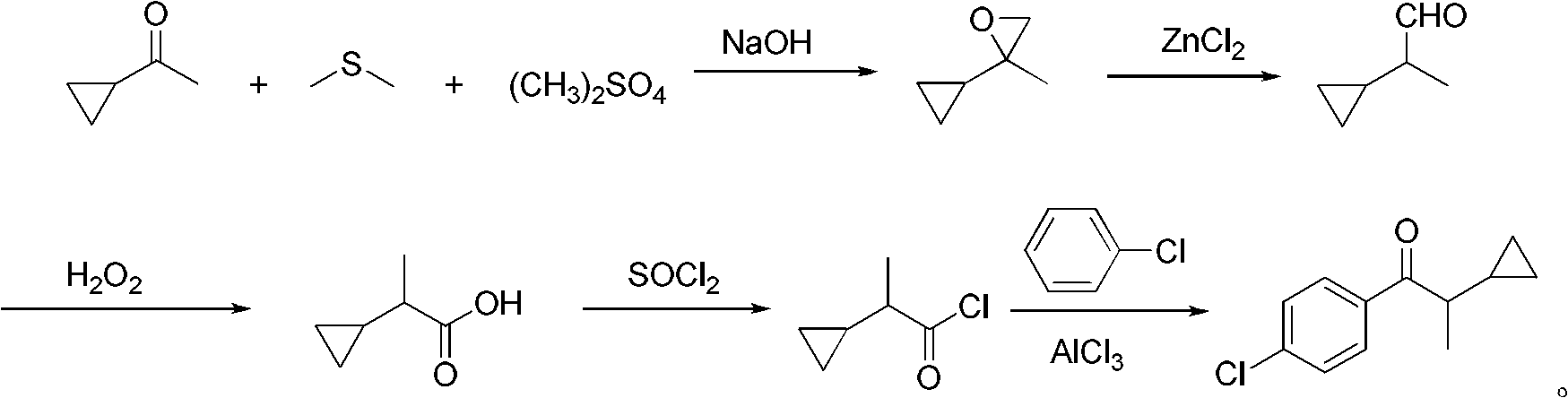

Preparation method of 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone

ActiveCN102584558AHigh product contentHigh yieldCarbonyl compound preparation by condensationPhenyl groupSodium hydroxide

The invention discloses a preparation method of 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone. The preparation method comprises the steps that: (1) cyclopropyl methyl ketone, dimethyl sulfate, dimethyl sulfide and sodium hydroxide take epoxidation reaction to obtain 2-cyclopropyl-2-methyl propylene oxide; (2) the 2-cyclopropyl-2-methyl propylene oxide is catalyzed and re-ranged by anhydrous zinc chloride at the room temperature to obtain 2-cyclopropyl propionaldehyde; (3) the 2-cyclopropyl propionaldehyde is oxidized by 40 percent oxydol at the room temperature to obtain 2-cyclopropyl monoprop; (4) the 2-cyclopropyl monoprop and thionyl chloride take reaction to obtain 2-cyclopropyl propionyl chloride; (5) the 2-cyclopropyl propionyl chloride takes reaction with chlorobenzene and anhydrous aluminum trichloride to obtain the 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone with the content being 98.0 percent to 98.7 percent, and the total yield is 80.0 percent to 83.1 percent. The preparation method has the advantages that the steps are simple, raw materials are cheap and are easy to obtain, easy-self-ignition compounds are not used, organic solvents are not used in the steps (2) and (3), three wastes are few, and the preparation method is suitable for industrialization.

Owner:HUNAN HAILI HIGH TECH IND GRP

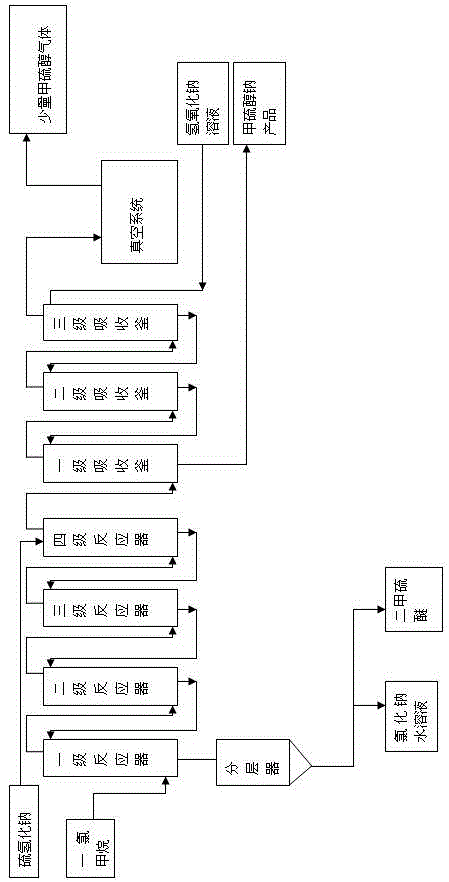

Method for co-producing sodium methyl mercaptide and dimethyl sulfide

ActiveCN102976987AShort reaction timeMild reaction conditionsThiol preparationSulfide preparationSodium hydrosulfideSodium methanethiolate

The invention relates to a method for co-producing sodium methyl mercaptide and dimethyl sulfide, which essentially comprises the following steps of: under a negative pressure condition, filling methane chloride gas into a sodium hydrosulfide solution; implementing a four-stage cascade reaction, absorbing by a sodium hydroxide solution to obtain a sodium methyl mercaptide solution; and making the reaction liquid obtained from the four-stage cascade reaction standing and layering to obtain the dimethyl sulfide. The method for co-producing the sodium methyl mercaptide and the dimethyl sulfide is low in toxicity of the adopted raw materials, short in reaction duration, moderate in required reaction condition, simple in operation, high in product yield and simple in post-treatment; and the method can be massively adopted in the industrial production, and has a great economic value.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Petroleum recovery process and system

A system and process are provided for recovering petroleum from a formation. An oil recovery formulation comprising at least 75 mol % dimethyl sulfide that is first contact miscible with a liquid petroleum composition is introduced into a subterranean petroleum bearing formation comprising heavy oil, extra heavy oil, or bitumen, and petroleum is produced from the formation.

Owner:SHELL OIL CO

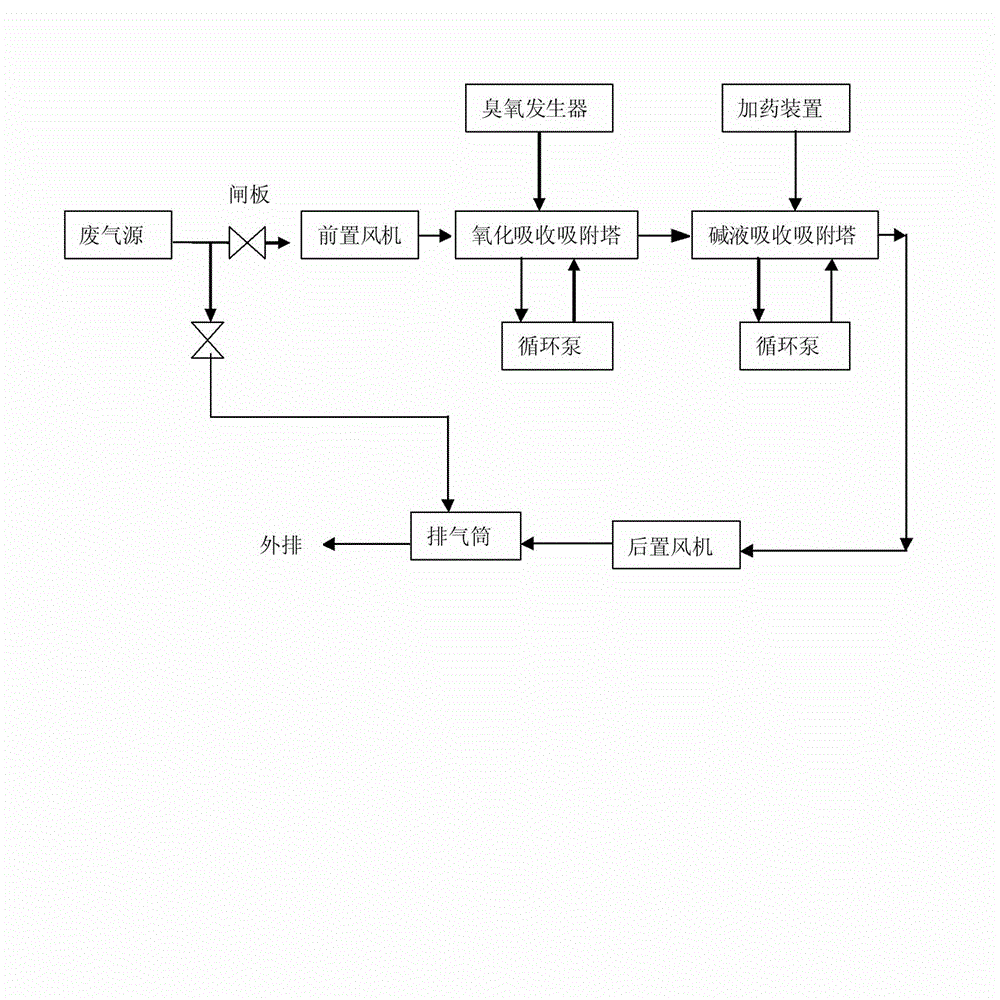

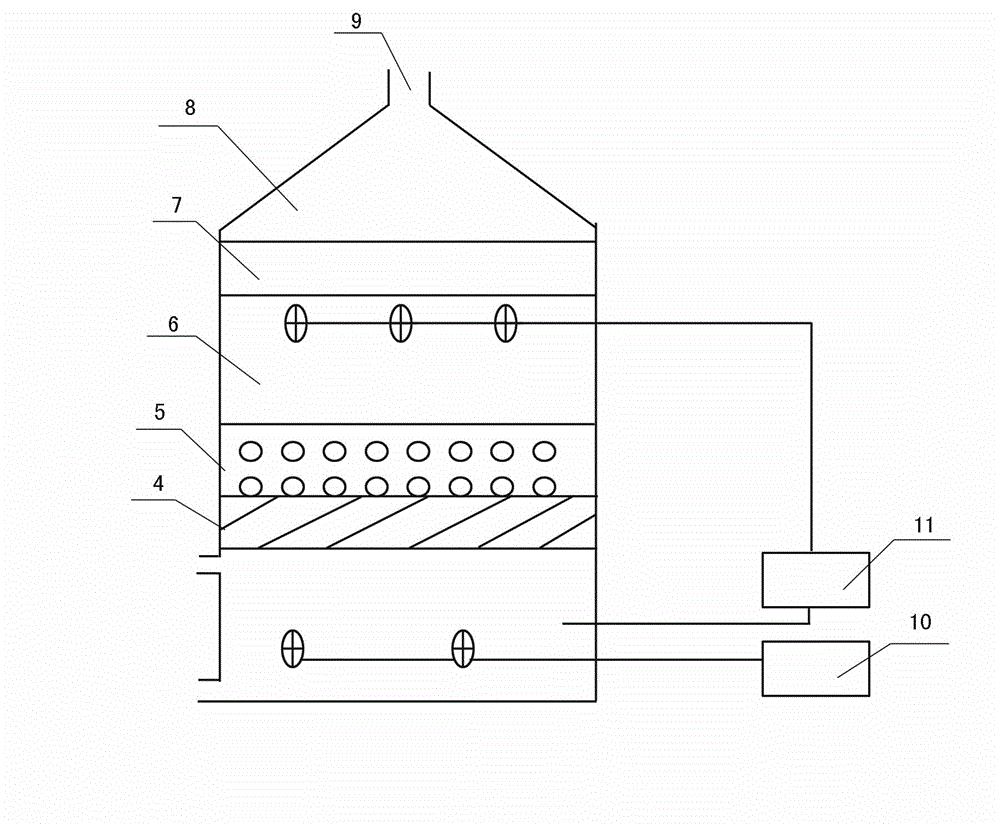

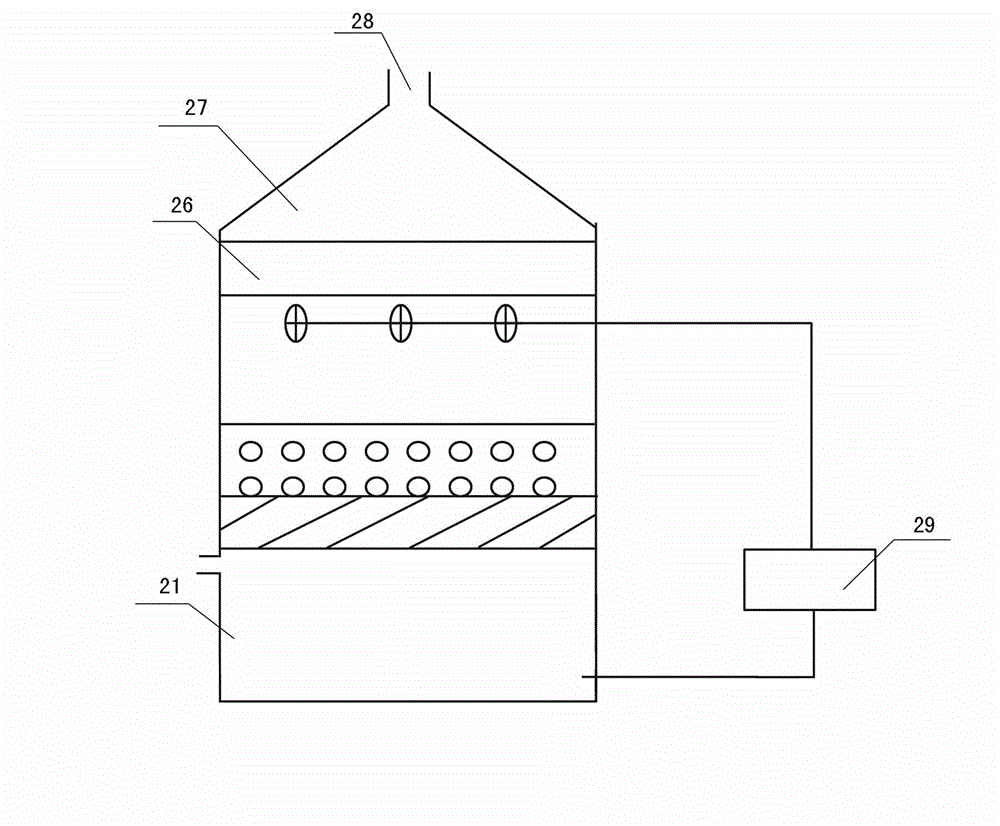

Waste gas integrated treatment device

InactiveCN102743968AEfficient removalAchieve emission standardsDispersed particle separationElectric controlDust particles

The invention discloses a waste gas integrated treatment device which comprises the following five systems: a waste gas collection and discharge system, a waste gas oxidation and absorption-adsorption system, a waste gas alkalization and absorption-adsorption system, an ozone generation system, and an electric control system. Waste gas is absorbed into the oxidation and absorption-adsorption system through a blower fan, is oxidized by ozone and adsorbed by active carbon, then enters the alkalization and absorption-adsorption system, is absorbed by alkali liquor and adsorbed by active carbon, and is discharged through an exhaust funnel. The device can effectively treat organic and inorganic waste gas containing components such as benzene, toluene, butanone, acetic ether, styrene, hydrogen sulfide, ammonia, methyl mercaptan, sulfur dioxide, dimethyl sulfide, acrylic acid, and the like, effectively remove dust particles, solve atmosphere pollution caused by waste gas sources of production workshop, sewage biochemical aeration tank, and the like, realize standard waste gas discharge, and has purification performance technical indexes which reach the domestic advanced level.

Owner:徐旭

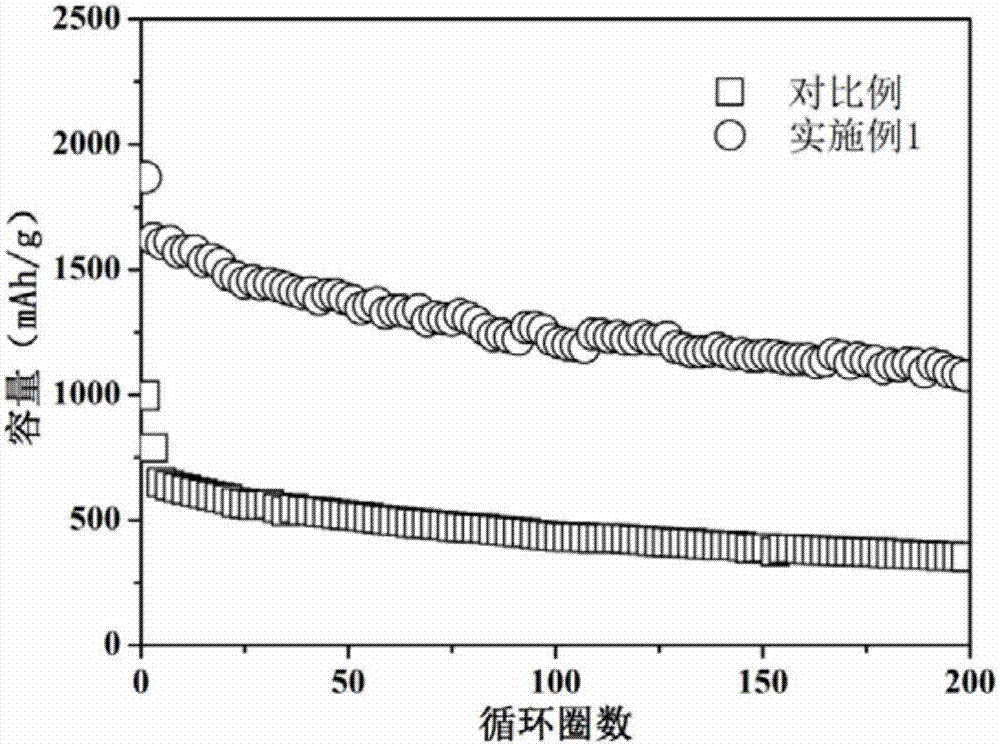

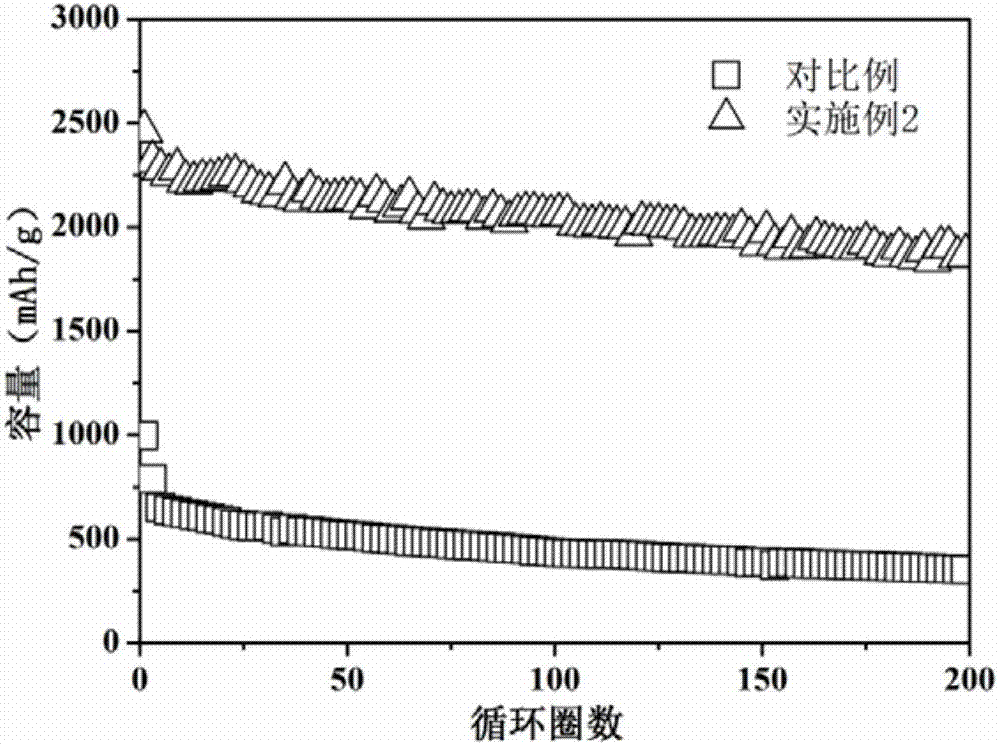

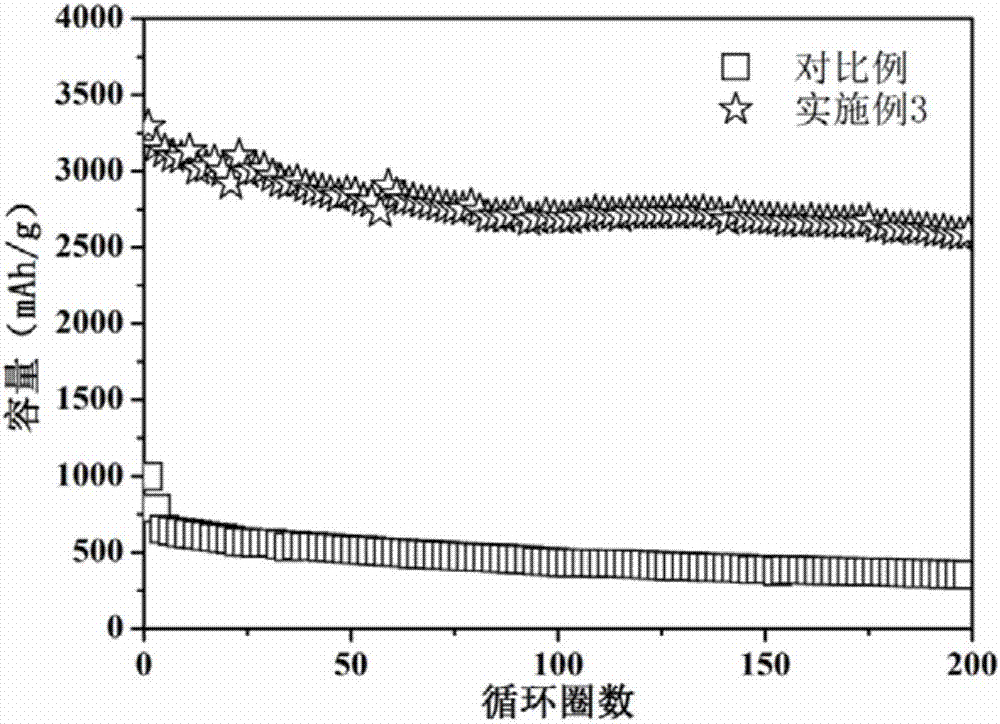

Lithium-sulfur battery electrolyte capable of improving battery capacity and preparation method thereof

ActiveCN106887640AIncrease capacityImprove long-term cycle performanceFinal product manufactureSecondary cellsOrganic solventLithium–sulfur battery

The invention relates to lithium-sulfur battery electrolyte capable of improving battery capacity and a preparation method thereof. The electrolyte is prepared from organic solvents, a lithium salt and an additive and is characterized in that the organic solvents include a first solvent, a second solvent and a third solvent; the first solvent is one or more of 1,3-dioxolane, 1,4-dioxane and 1,1-dimethoxyethane; the second solvent is one or more of glycol dimethyl ether and diglyme; the third solvent is one or more of dimethyl sulfide organics; the volume ratio of the first solvent to the second solvent is (0.5 to 2) : 1, and the volume fraction of the third solvent in the organic solvents is 10 to 40%. Dimethyl ether organics are reduced into methyl lithium sulfur and can contribute capacity except positive active materials. By means of the unique work principle, lithium sulfur batteries prepared from the electrolyte have the characteristics of achieving and even exceeding the theoretical capacity of the lithium sulfur batteries.

Owner:苏州德加能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com