Heavy oil and biomass hydrogenation coliquefaction treatment process

A biomass and co-liquefaction technology, applied in the petroleum industry, biofuels, hydrocarbon oil cracking, etc., can solve the problems of large coke production, bio-oil yield and quality that need to be further improved, and achieve strong coke capacity and promote The effect of high conversion rate and bio-oil yield, biomass conversion rate and bio-oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

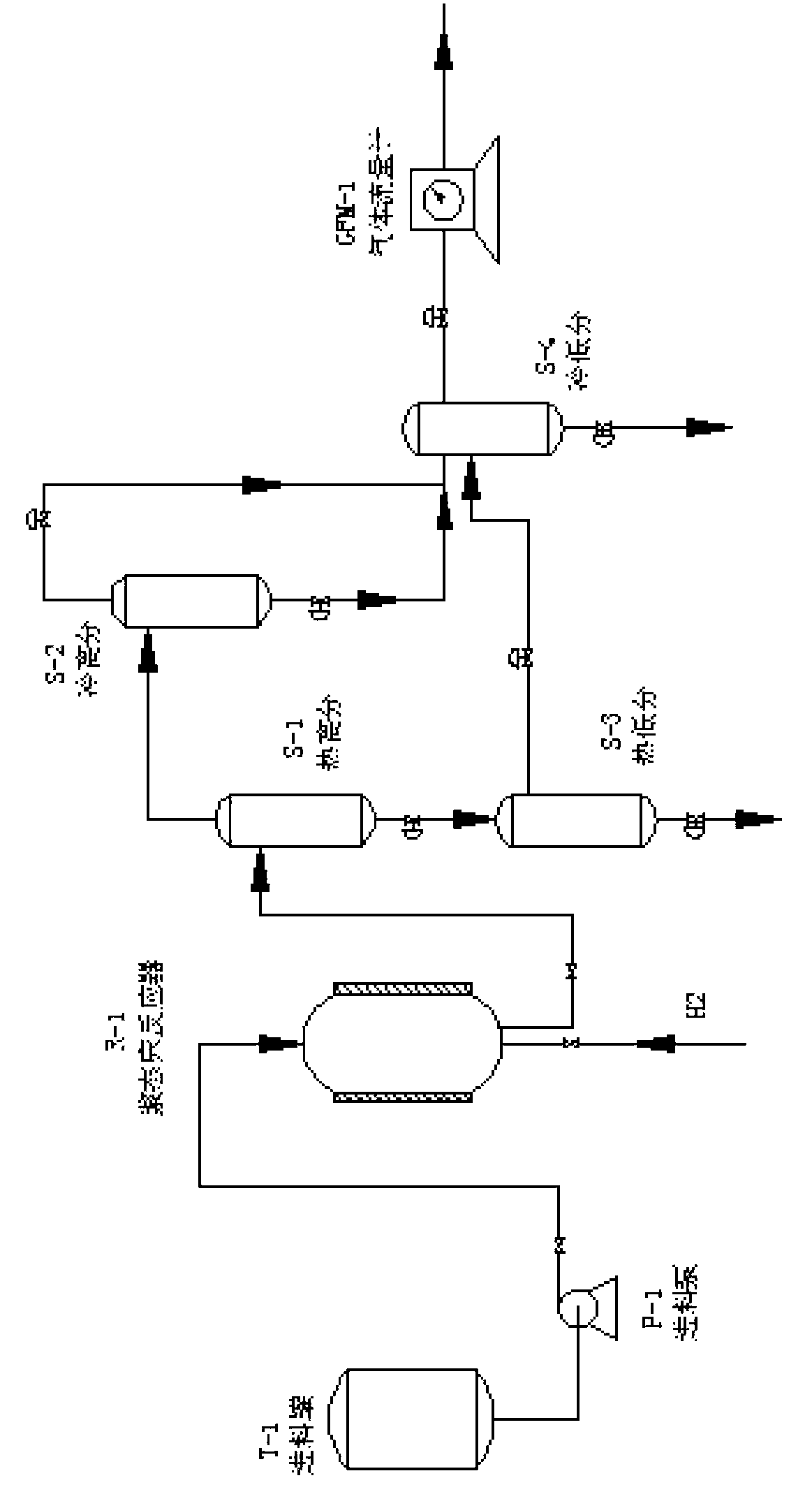

Method used

Image

Examples

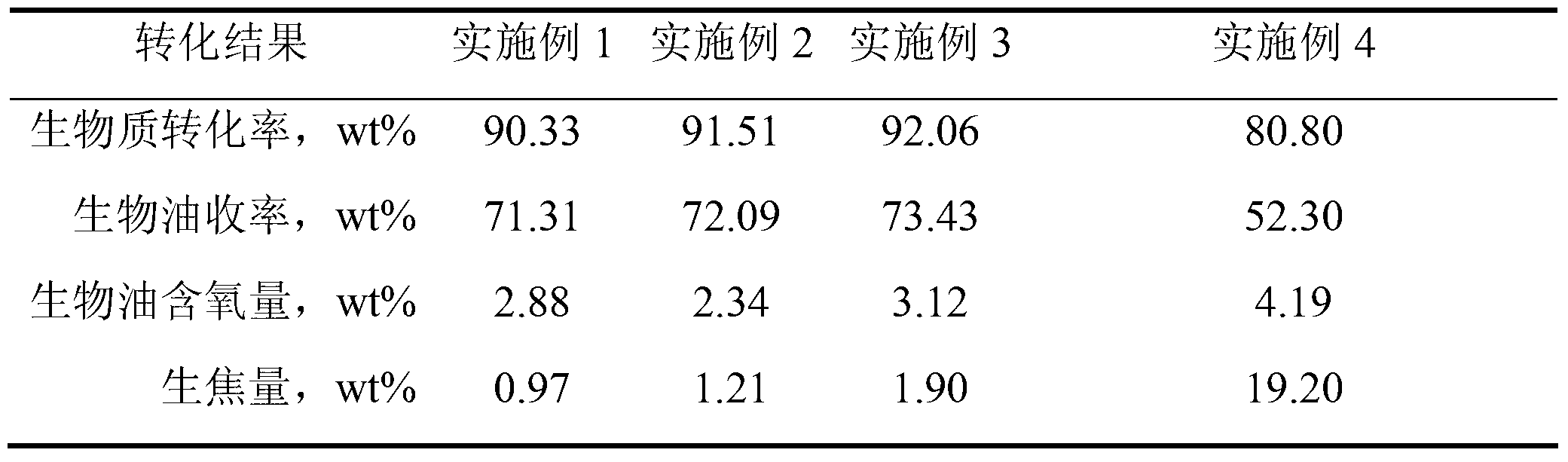

Embodiment 1

[0021] Example 1: Mix pine wood chips with a particle size of 40 to 100 meshes and Karamay vacuum distillate oil with a distillation range of 360 to 540°C in a mass ratio of 10% of pine wood chips as feed, control the reaction temperature to 410°C, and react hydrogen Pressure 5MPa, reaction volume space velocity 1.0h -1 , the ratio of hydrogen to oil is 400, the amount of catalyst added is 300ppm, and the amount of vulcanizing agent added is 0.1%. The slurry bed hydrogenation co-liquefaction experiment is carried out on the reaction materials, and the reaction products are fractionated to obtain liquid bio-oil and coke.

Embodiment 2

[0022] Example 2: Mix straw with a particle size of 40-100 mesh and Karamay vacuum distillate oil with a distillation range of 360-540°C at a mass ratio of 10% of pine wood chips as a feed, control the reaction temperature to 430°C, and the reaction hydrogen partial pressure 5MPa, the reaction volume space velocity is 1.0h -1 , the ratio of hydrogen to oil is 400, the amount of catalyst added is 300ppm, and the amount of vulcanizing agent added is 0.1%. The slurry bed hydrogenation co-liquefaction experiment is carried out on the reaction materials, and the reaction products are fractionated to obtain liquid bio-oil and coke.

Embodiment 3

[0023] Example 3: Mix pine wood chips with a particle size of 40 to 100 meshes and FCC oil slurry at a mass ratio of 15% of pine wood chips as a feed, control the reaction temperature to 430°C, the reaction hydrogen partial pressure to 8MPa, and the reaction volume space velocity to 1.0h -1 , the ratio of hydrogen to oil is 400, the amount of catalyst added is 300ppm, and the amount of vulcanizing agent added is 0.1%. The slurry bed hydrogenation co-liquefaction experiment is carried out on the reaction materials, and the reaction products are fractionated to obtain liquid bio-oil and coke.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com