700MPa low-alloy high-strength welding wire for heavy machinery and use method thereof

A low-alloy high-strength, heavy-duty machinery technology, used in welding media, welding equipment, welding equipment and other directions, can solve the problems of large splash, high price, scarcity of nickel and molybdenum elements, etc., to prevent performance degradation, high price, improve low temperature The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The relevant technical contents not mentioned below can adopt or learn from the prior art.

[0031] In order to enable those skilled in the art to better understand the technical solutions in the application, the technical solutions in the embodiments of the application are clearly and completely described. Obviously, the described embodiments are only part of the embodiments of the application, rather than Full examples. Based on the embodiments in this application, all other embodiments obtained by persons of ordinary skill in the art without creative efforts shall fall within the scope of protection of this application.

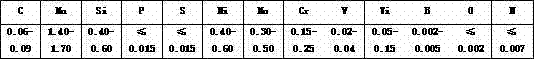

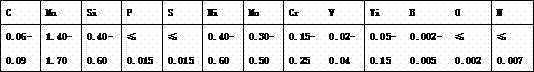

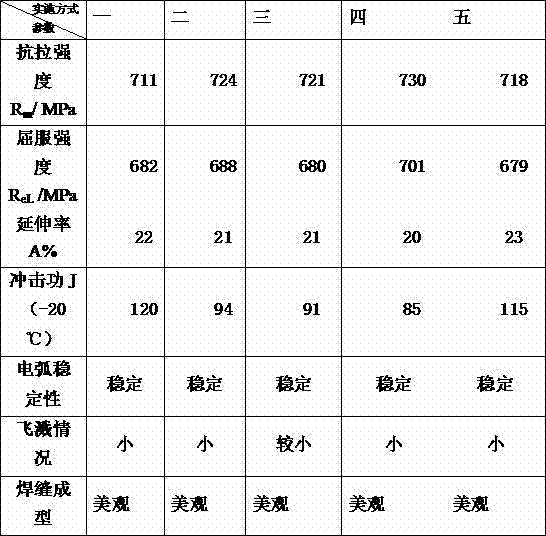

[0032] According to the chemical composition range of the welding wire of the present invention and the mass percentages used in the following examples, a multi-furnace welding wire steel was smelted in a vacuum induction furnace, and processed into a diameter of 1.2 mm through forging, rolling, wire drawing, copper plating and shaft winding. The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com