Inversing method of inner side clustering hoop of vertical storage tank

A technology of vertical storage tanks and inversion, which is applied in the direction of large-capacity bulk material storage, building types, buildings, etc., and can solve the problems of vertical storage tank group construction difficulties, small application range, slow construction speed, etc., and achieve reduction Damage and repair phenomenon, wide application range, fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

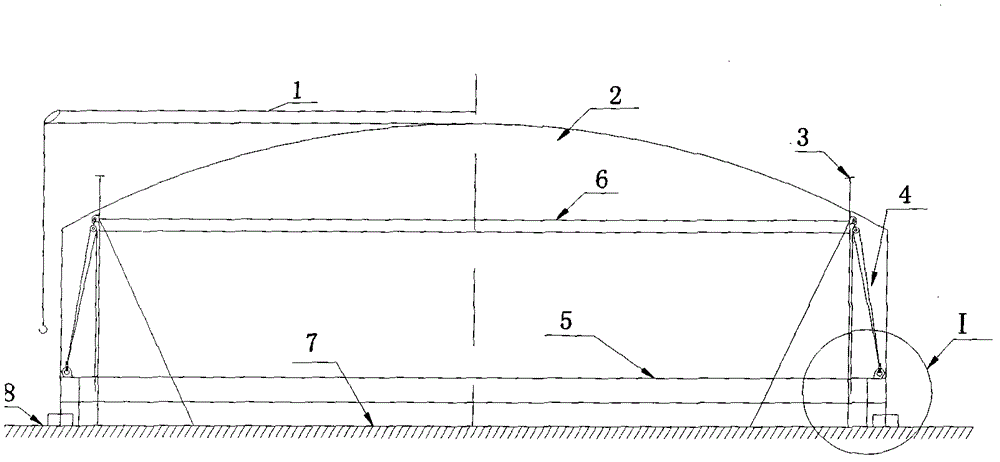

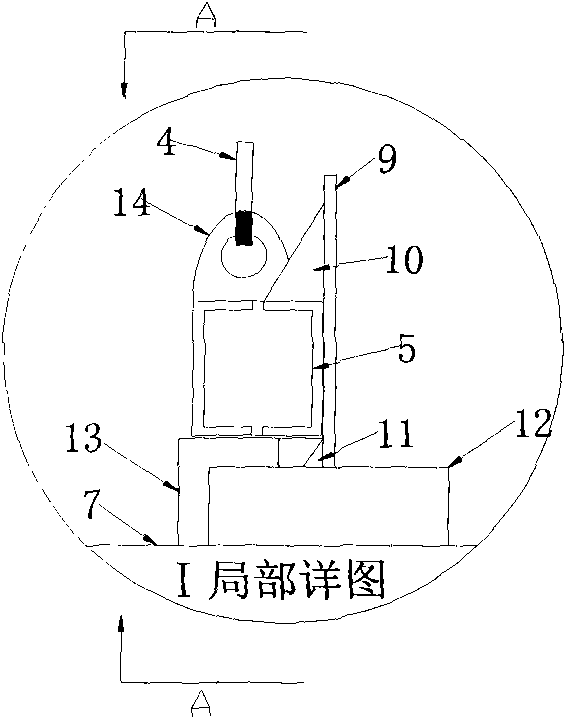

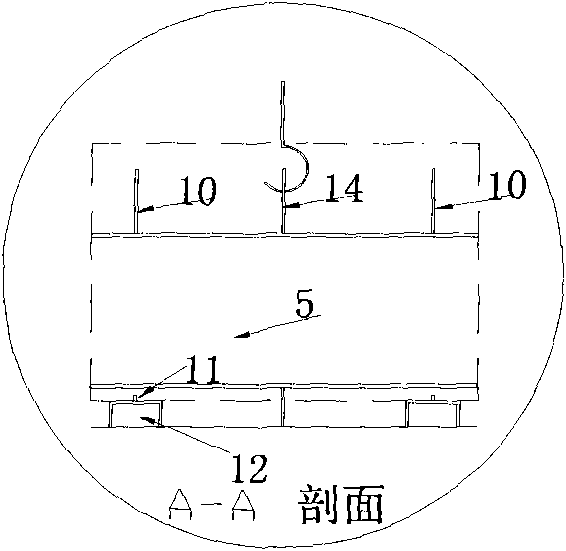

[0027] Such as figure 1 , 2 , 3, 4 as shown in the following steps for construction:

[0028] 1. Set up the pole;

[0029] (1) Determine the number of poles according to the diameter, height and weight of the storage tank. Under normal circumstances, the reasonable distance between the poles is about 4m.

[0030] (2) Determine the length of the holding pole of the group holding 3 on the inner side, the length of the holding pole = the height of the wall panel of the storage tank + the minimum distance between the two hooks of the lifting device (lifting hoist 4) + others = H2+H4+(H1+H3 +H5)

[0031] Among them, H1=300mm, H3=200mm, H5=200mm;

[0032] (3) Determine the specification and model. The maximum bearing capacity of each pole = storage tank weight ÷ the number of poles × safety bearing factor, according to the maximum bearing capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com