Patents

Literature

2435results about How to "Reduce noise pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

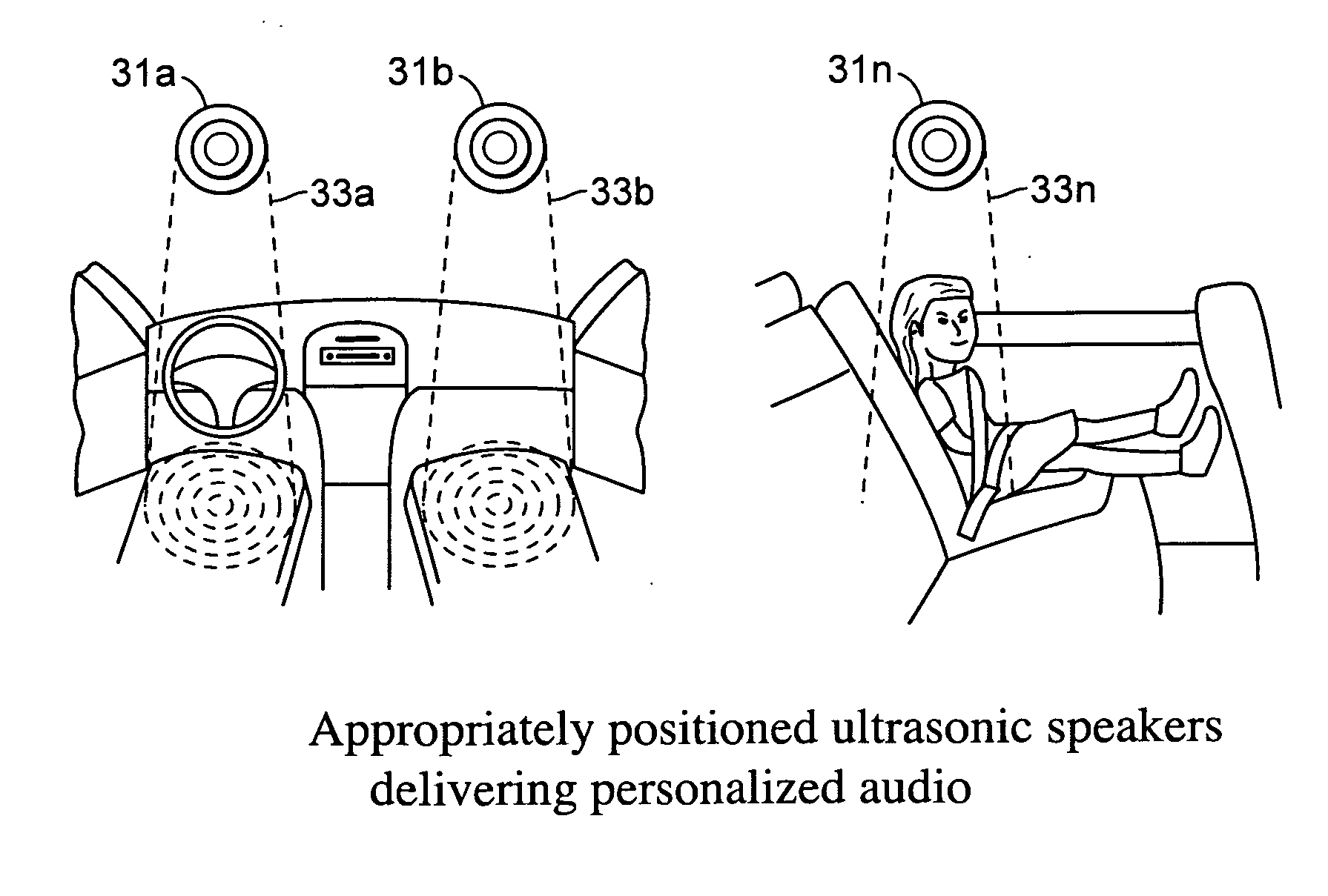

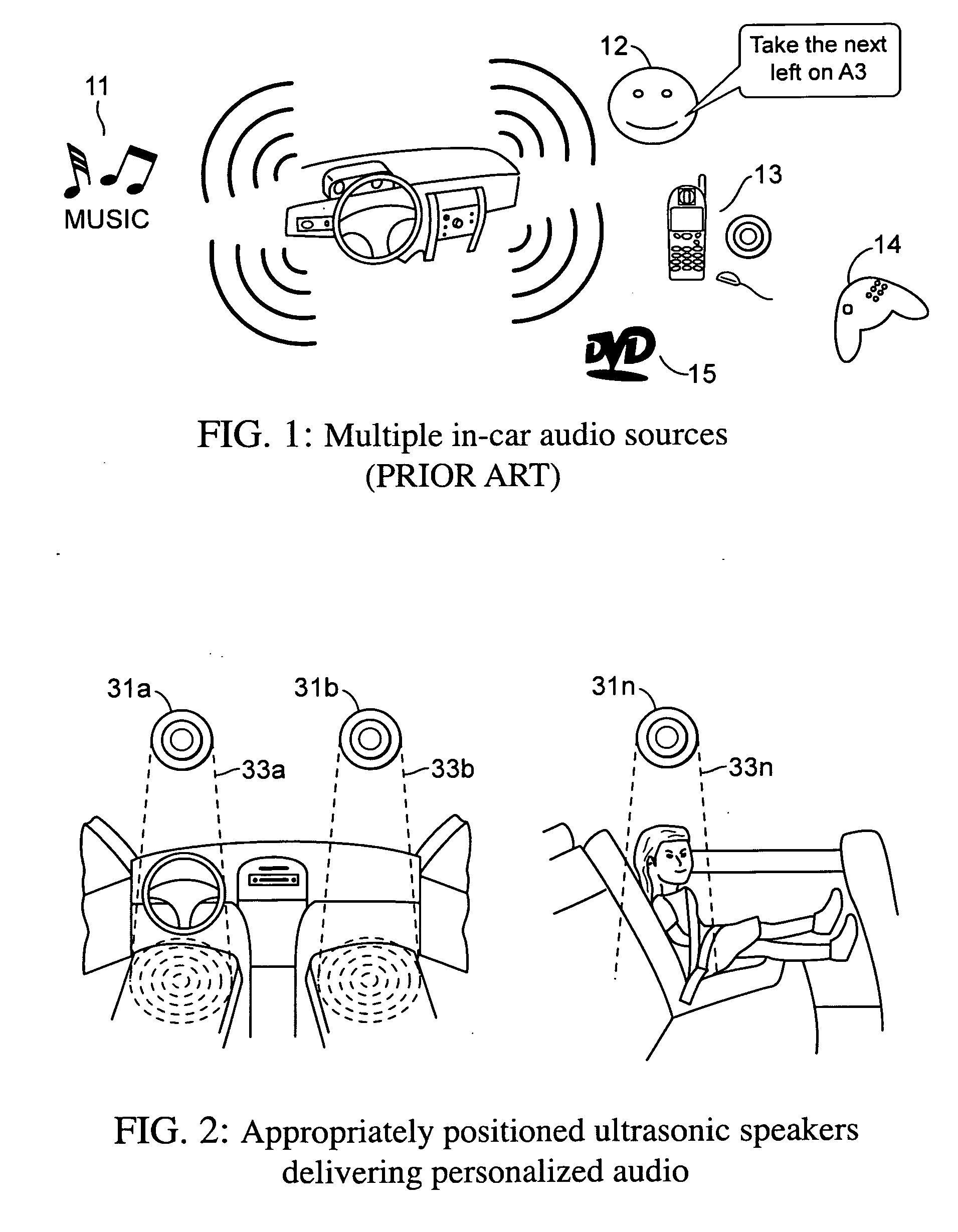

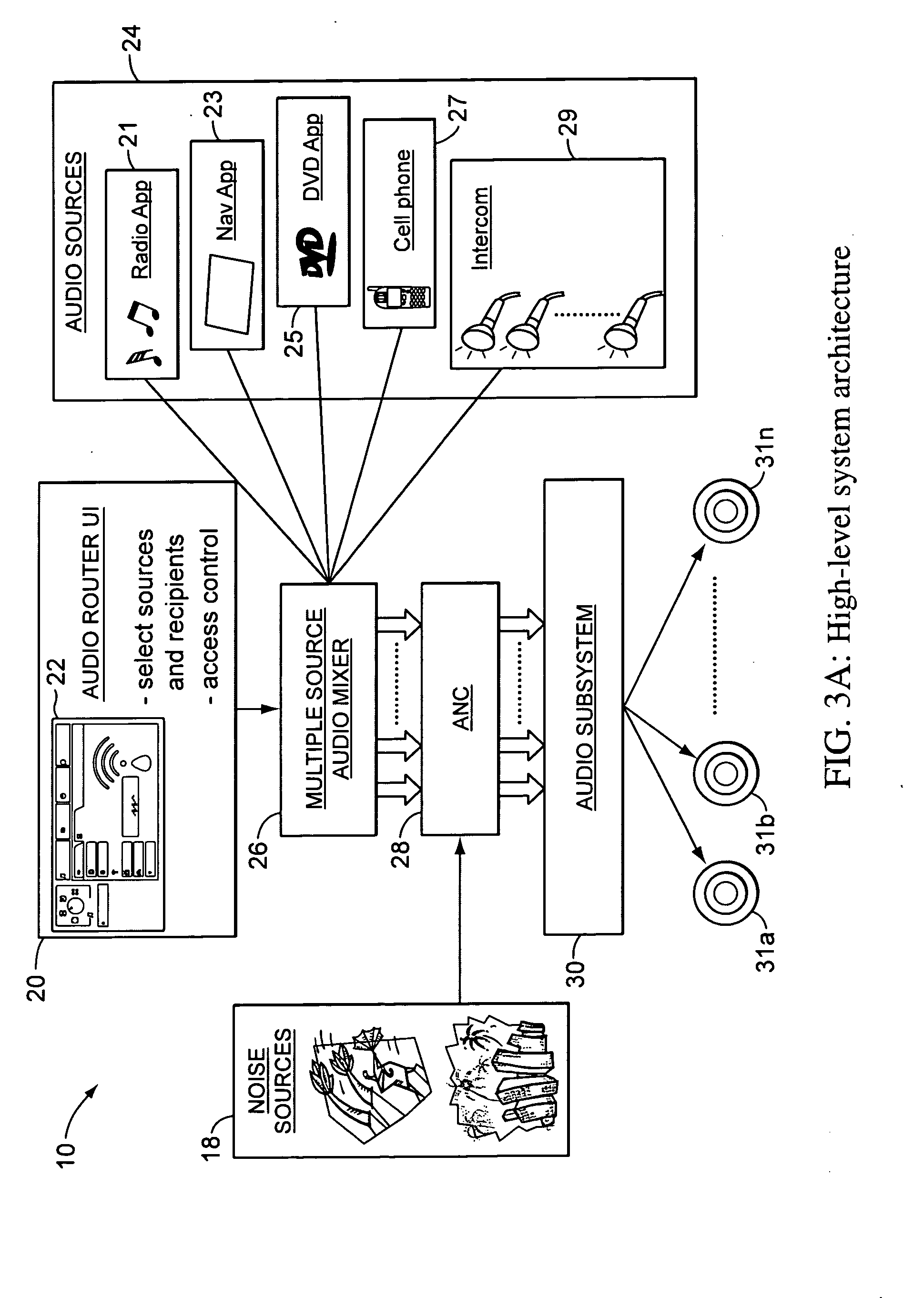

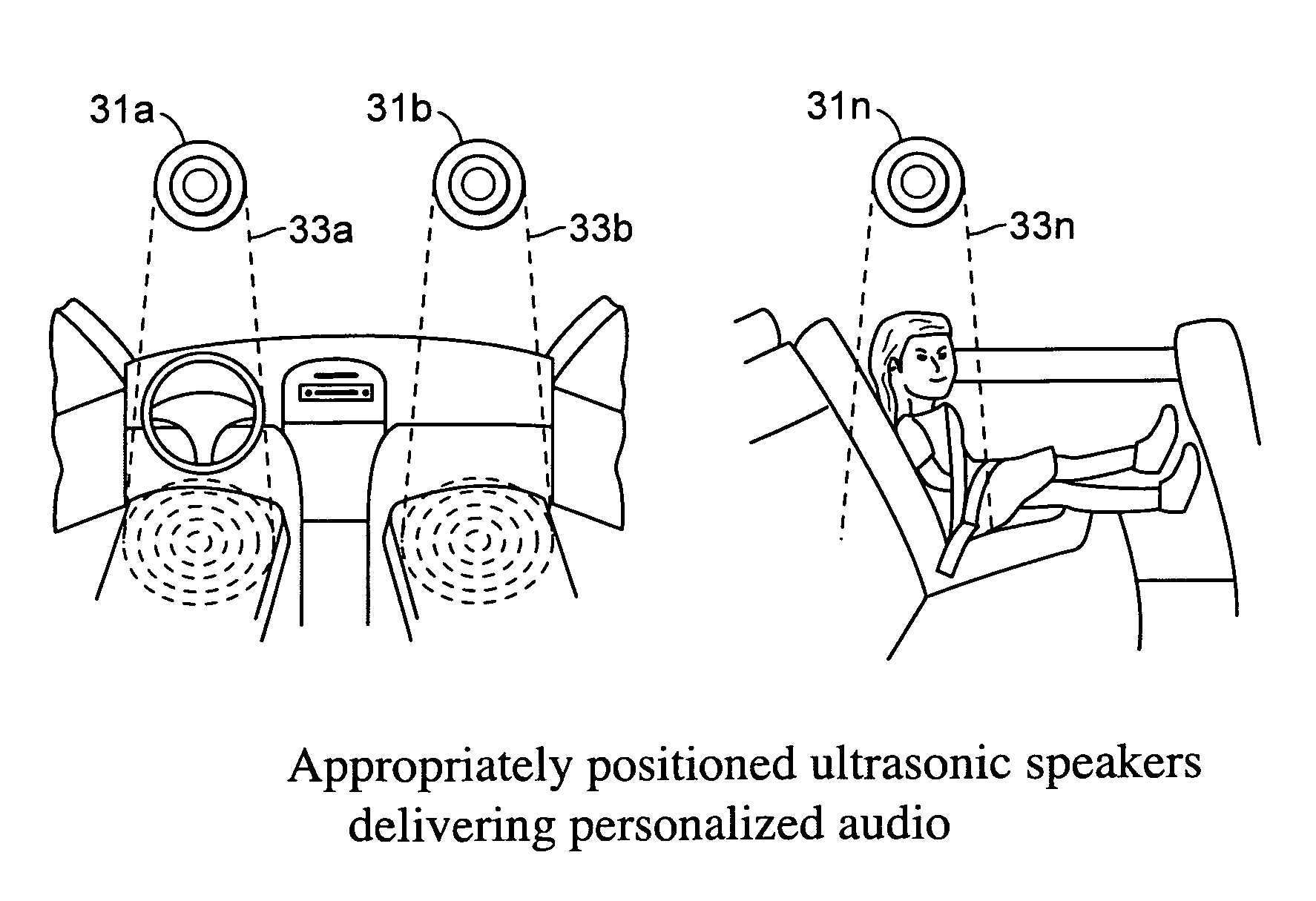

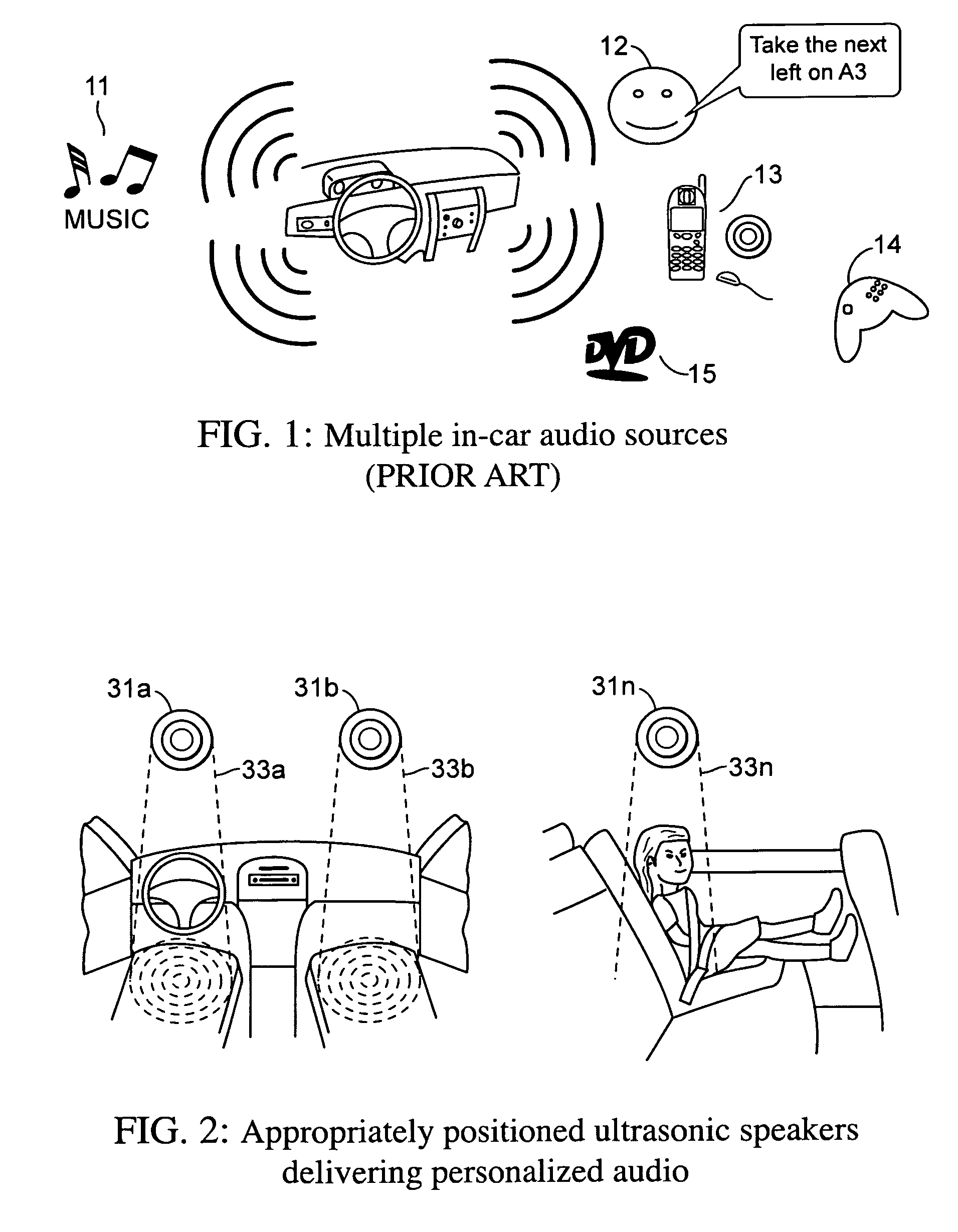

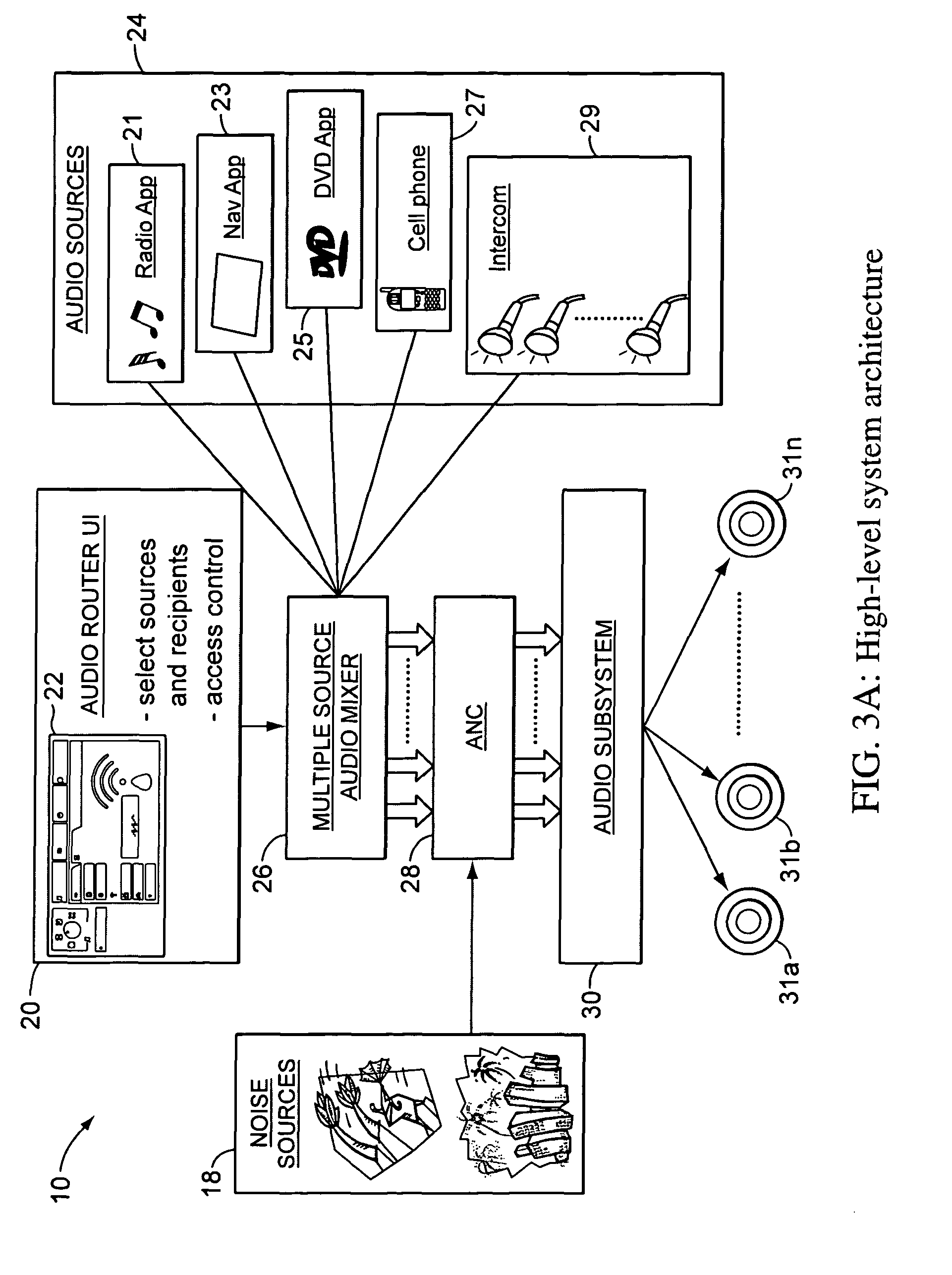

System and method for creating personalized sound zones

Speakers deployed in a space and divided into groups associated with different zones produce a mix of sounds that create internal noise pollution and, combined with external noise, an unpleasant environment for occupants. The present invention contemplates sound systems and methods for creating personalized sound zones to address these and related problems.

Owner:CONTINENTAL AUTOMOTIVE GMBH

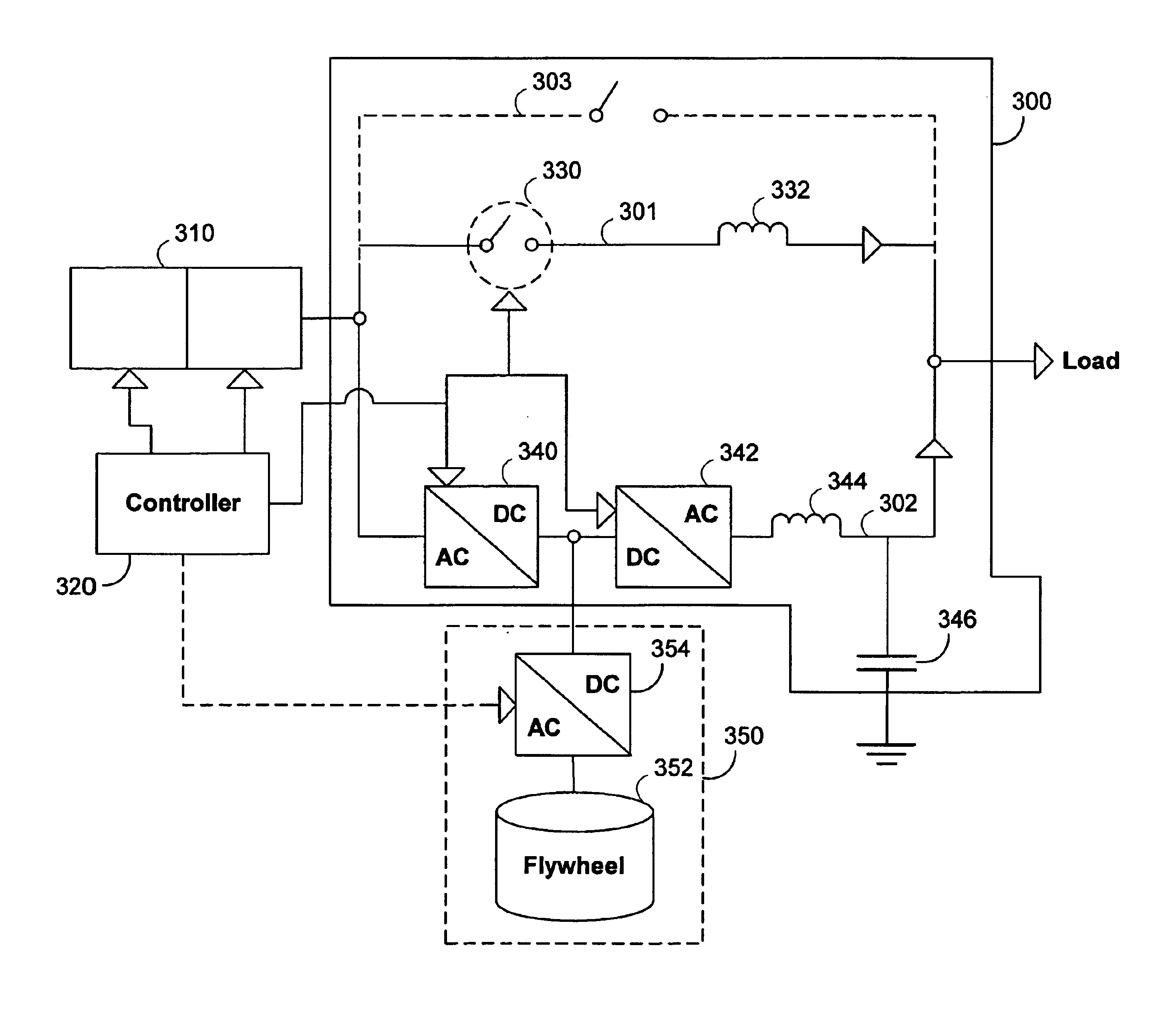

Multiple path variable speed constant frequency device having automatic power path selection capability

InactiveUS6844706B2Maximize engine efficiencySave fuelBatteries circuit arrangementsEmergency protective circuit arrangementsConstant frequencyInductor

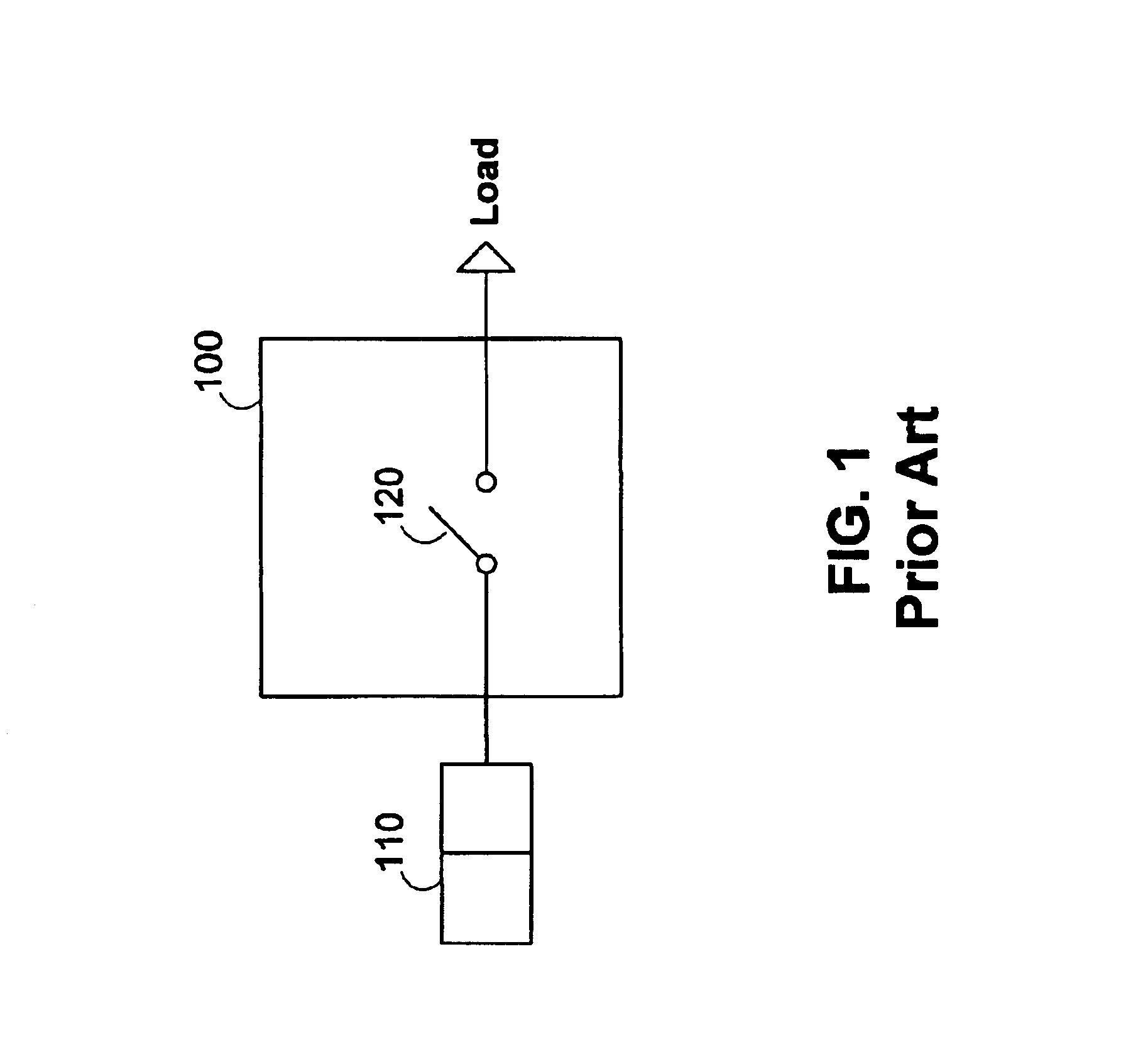

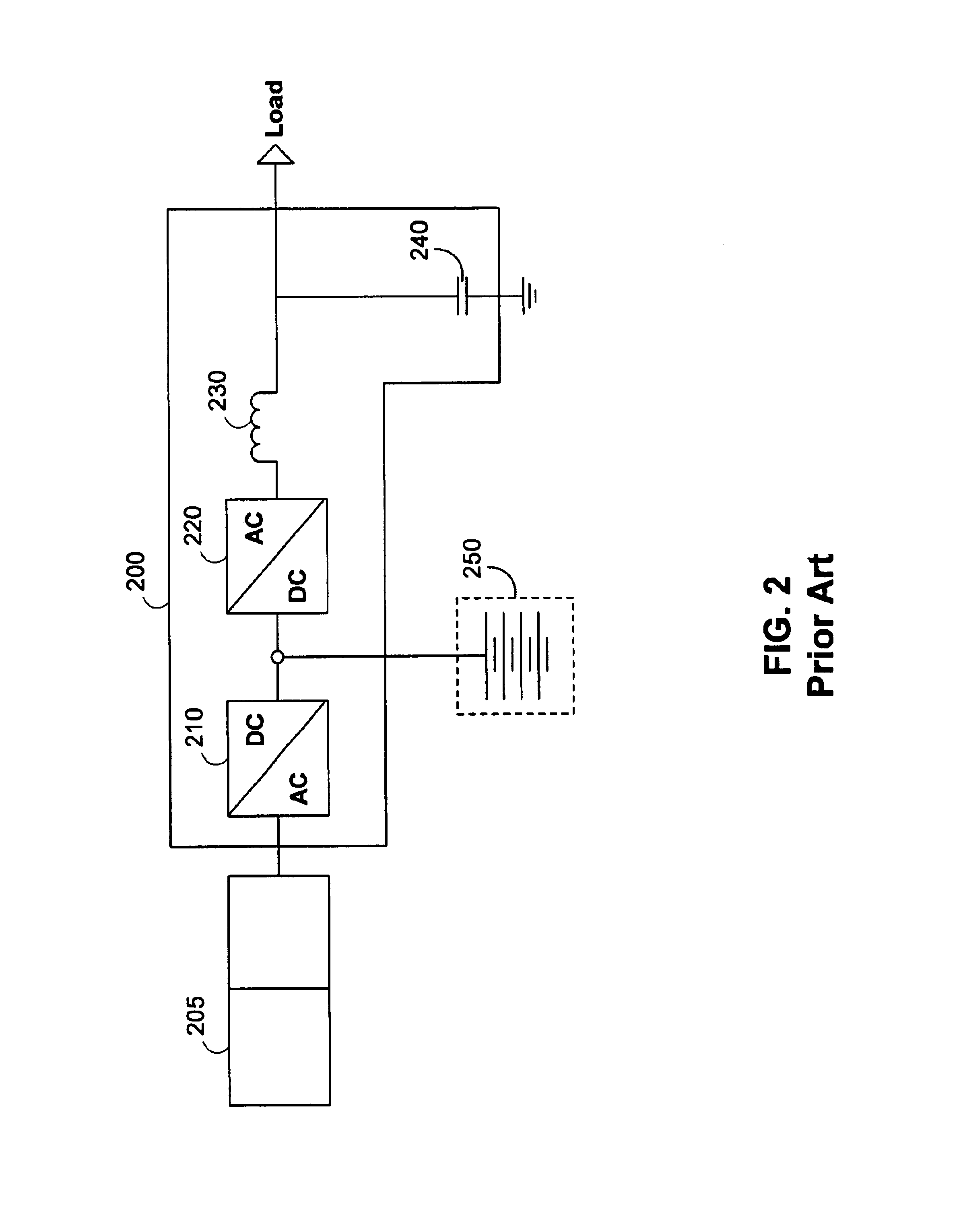

The present invention relates to variable speed constant frequency (VSCF) devices and methods for maximizing engine generator efficiency. In one embodiment, a VSCF device may include at least two paths for conducting power to the load. One path, a line inductor path, may advantageously incur minimal power loss when the engine generator is supplying rated power to a load. A second path, a VSCF path, may be used to ensure that the frequency of the power is maintained at a substantially constant frequency under various load conditions. Another embodiment of the invention describes a process for determining optimal engine generator speed for a particular load. Because engine speed can be varied using any VSCF device, this process determines a speed that minimizes fuel consumption, emissions, and noise pollution for a given load.

Owner:PILLER USA INC

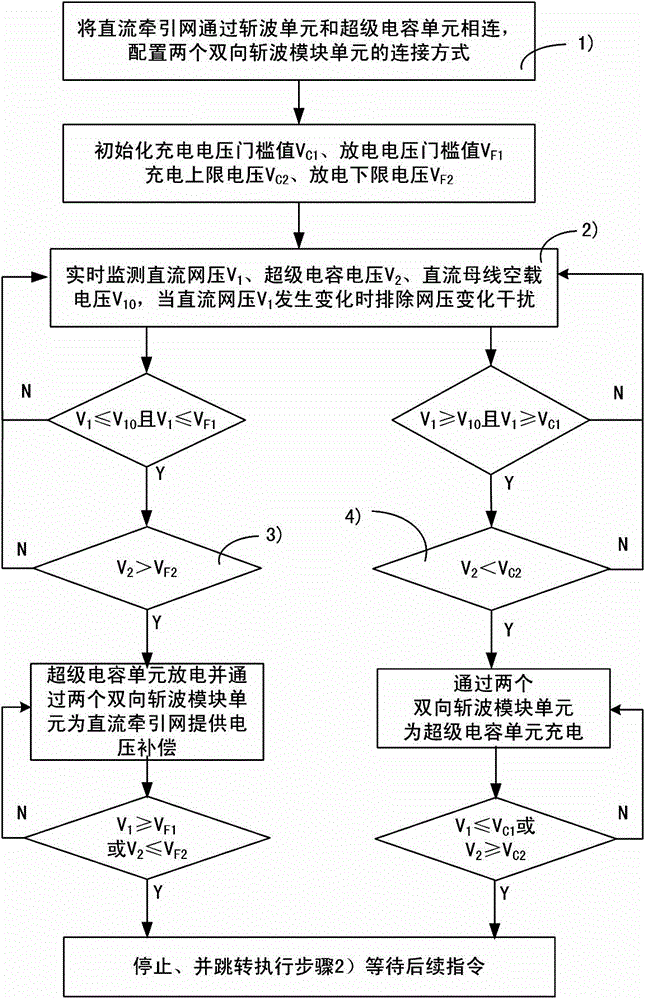

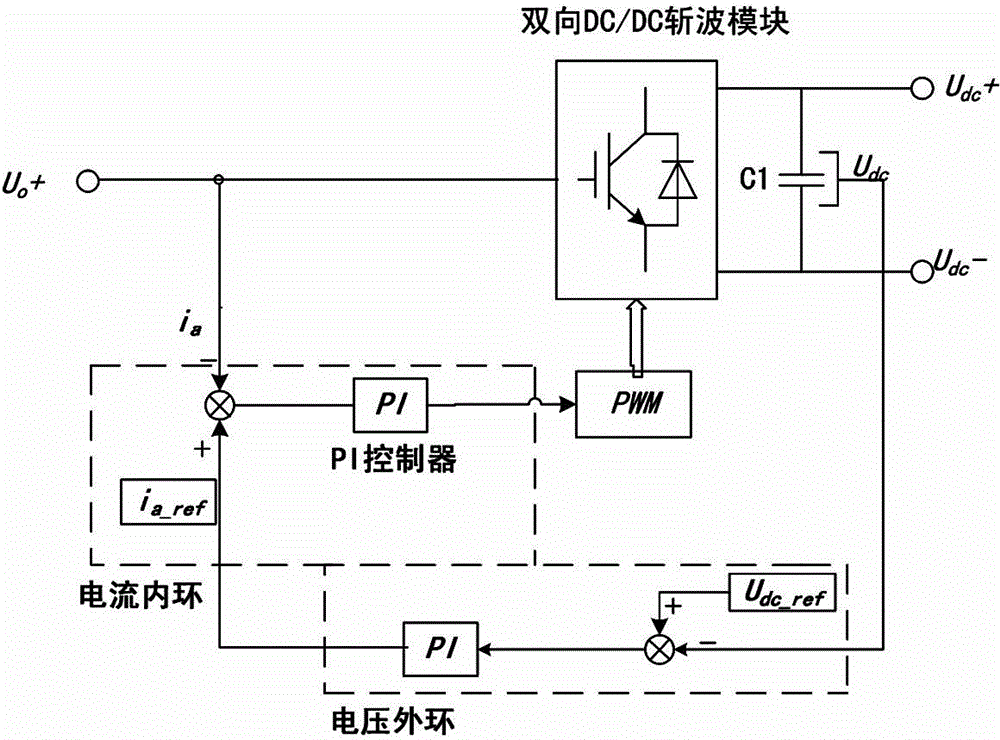

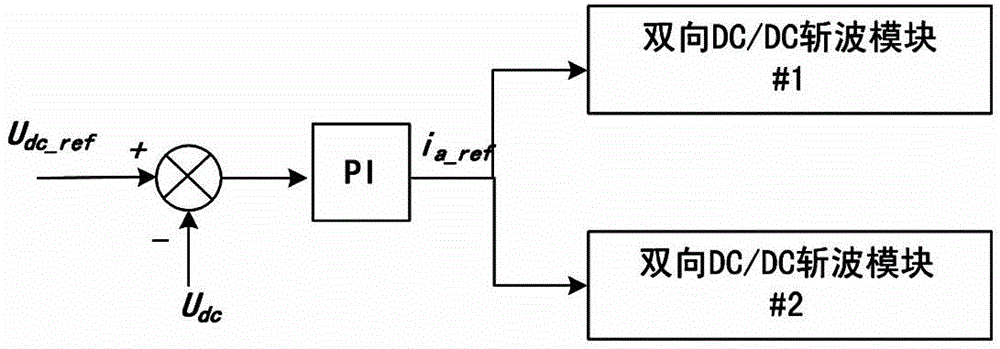

Method and system for recovering regenerative brake energy of energy storage type urban rail based on supercapacitor

ActiveCN104802646AQuick switchImprove versatilityElectrodynamic brake systemsElectric powerCapacitanceRegenerative brake

The invention discloses a method and a system for recovering regenerative brake energy of an energy storage type urban rail based on a supercapacitor. The method comprises the following steps of connecting a direct current traction network of the urban rail through a chopping unit and a supercapacitor unit, wherein the chopping unit comprises two bidirectional chopping module units; according to the connecting type of the two bidirectional chopping module units of the direct current traction network, and the voltages of the direct current network and the supercapacitor, controlling the charging and discharging of the supercapacitor unit. The system comprises the chopping unit, the supercapacitor unit, a chopping control module and a direct current isolation switch unit, wherein the chopping unit comprises the two bidirectional chopping module units which are connected in series or parallel, and each bidirectional chopping module unit comprise one or more than one bidirectional DC / DC (direct current / direct current) chopping module which is connected in parallel. The method and the system have the advantages that the regenerative brake energy of the urban rail can be recovered and fed back, and the method and the system can be applied to the common DC1500V / DC750V direct current traction networks; the universality is strong, the reliability is high, the stability is good, the production cost is low, and the flexibility is high.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD +1

System and method for creating personalized sound zones

Speakers deployed in a space and divided into groups associated with different zones produce a mix of sounds that create internal noise pollution and, combined with external noise, an unpleasant environment for occupants. The present invention contemplates sound systems and methods for creating personalized sound zones to address these and related problems.

Owner:CONTINENTAL AUTOMOTIVE GMBH

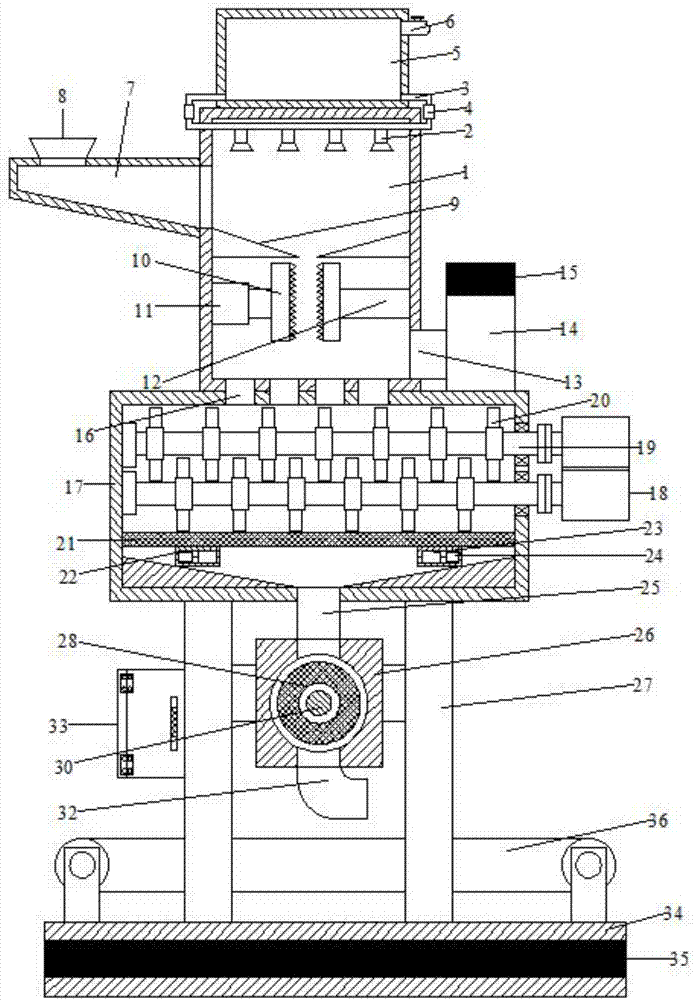

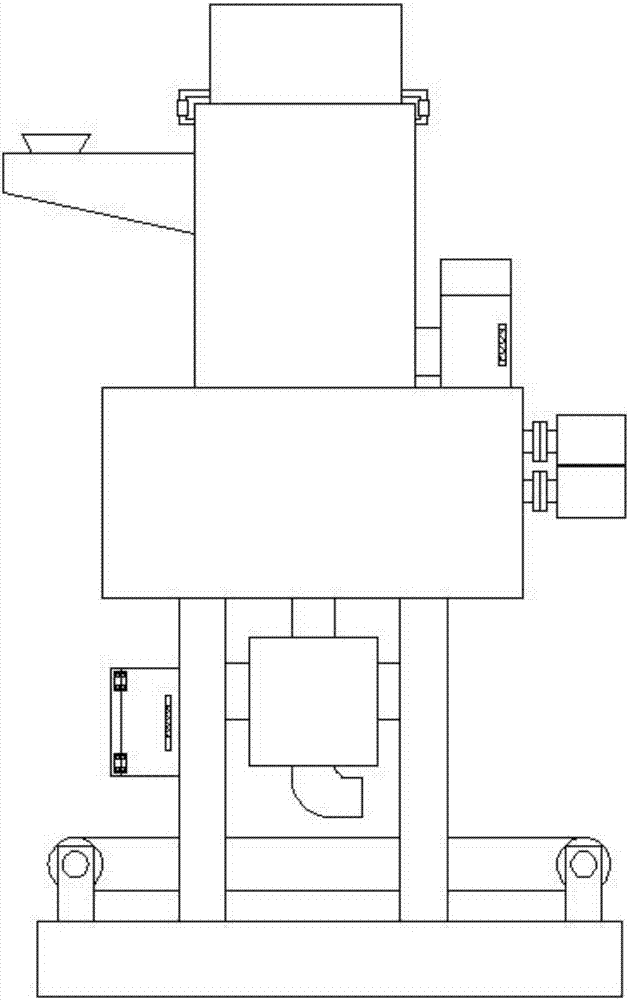

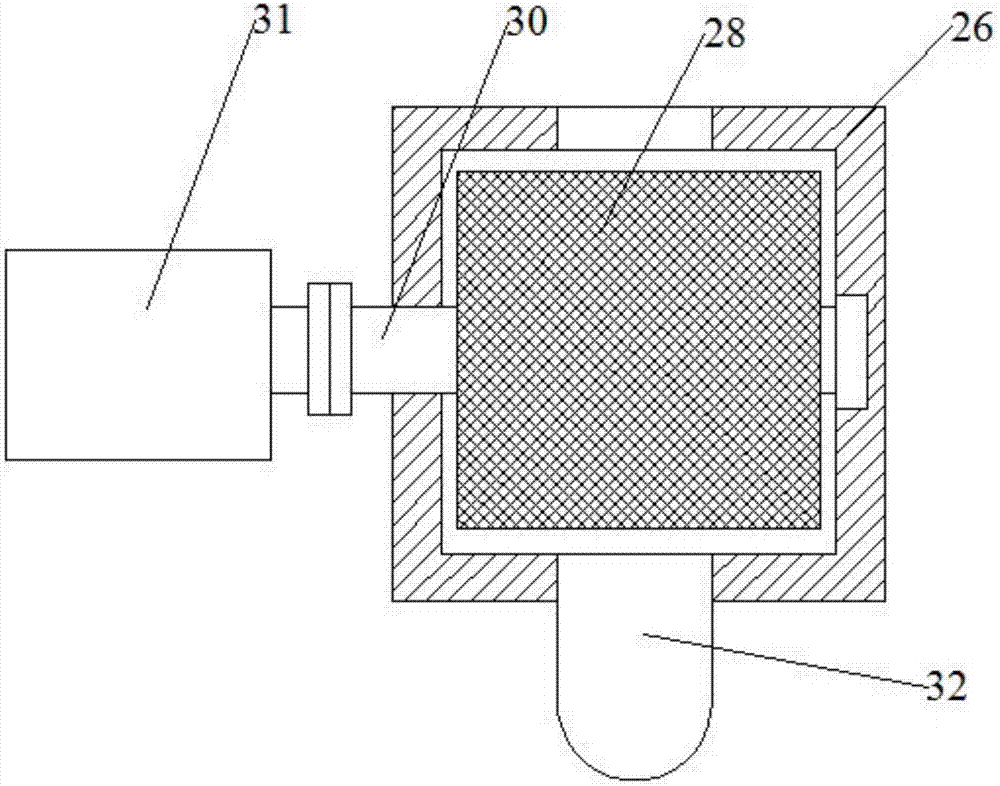

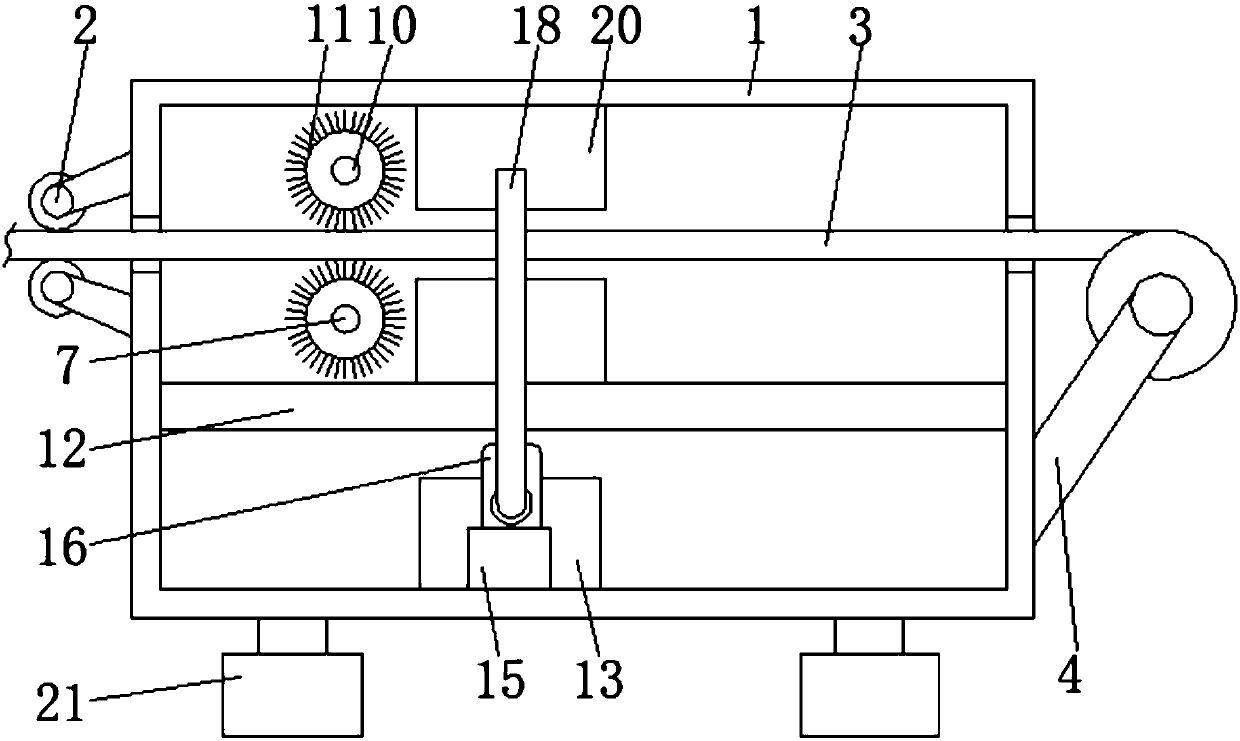

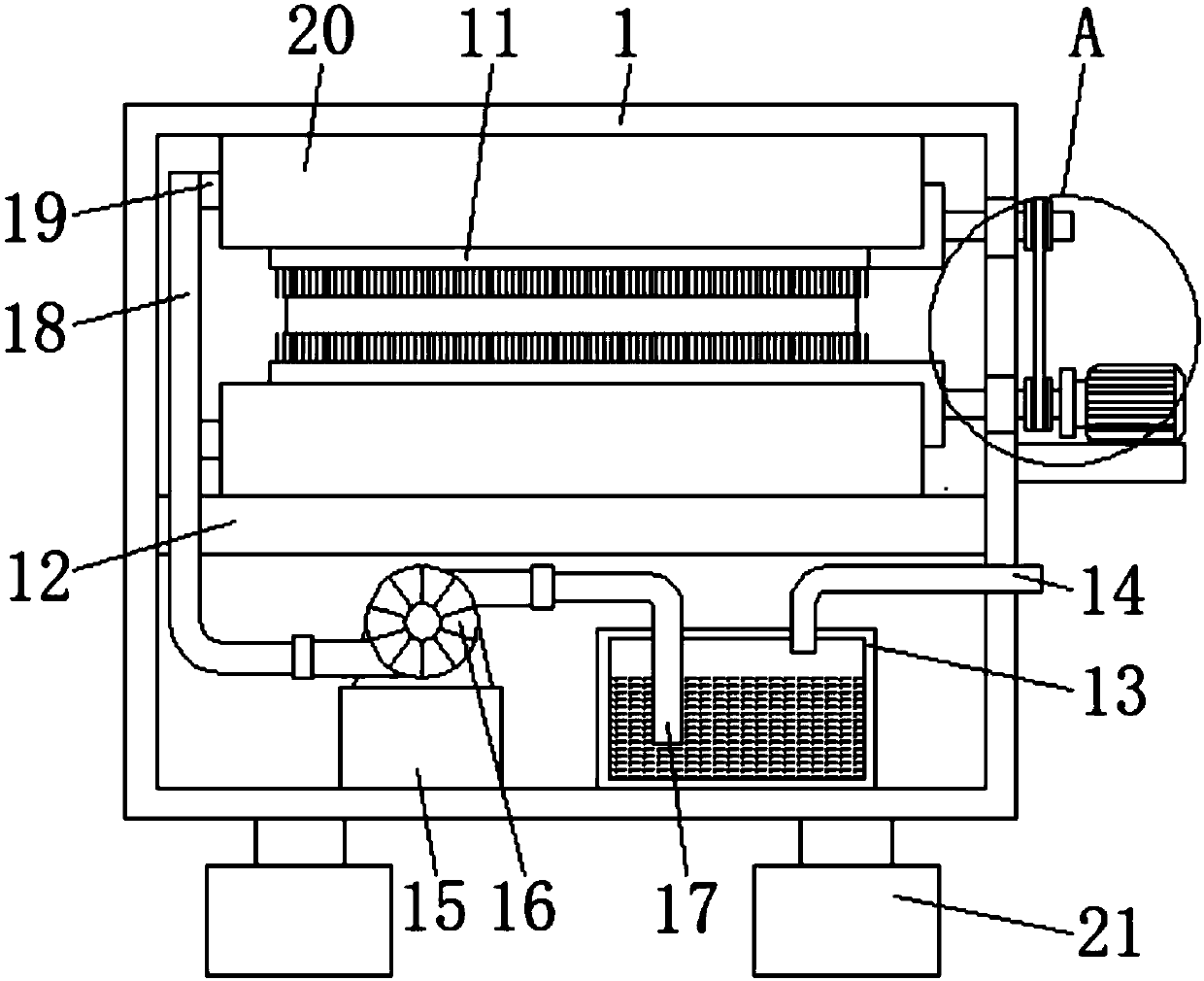

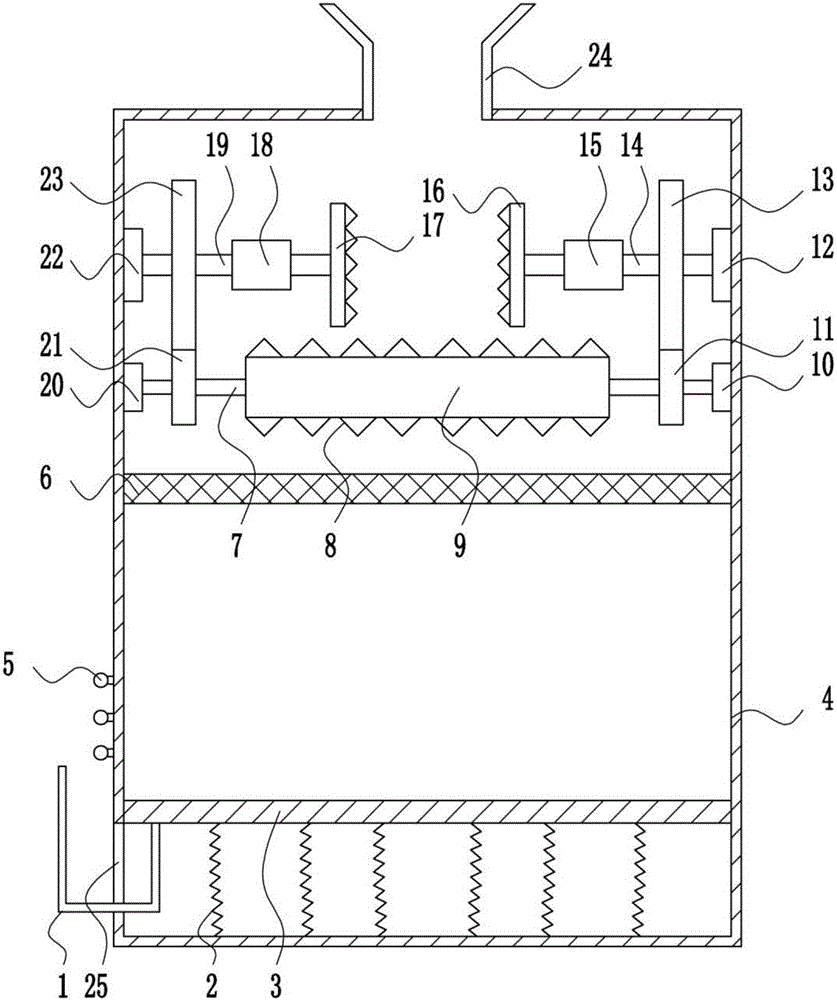

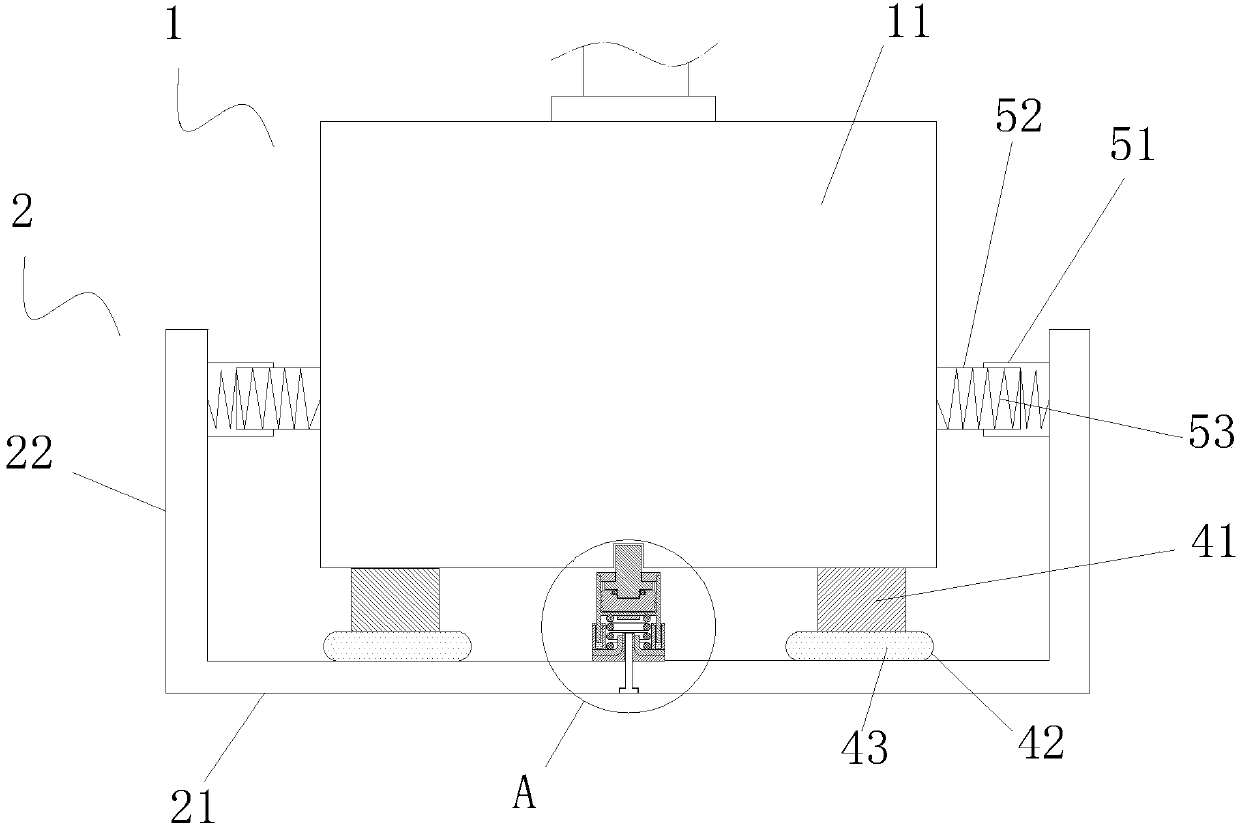

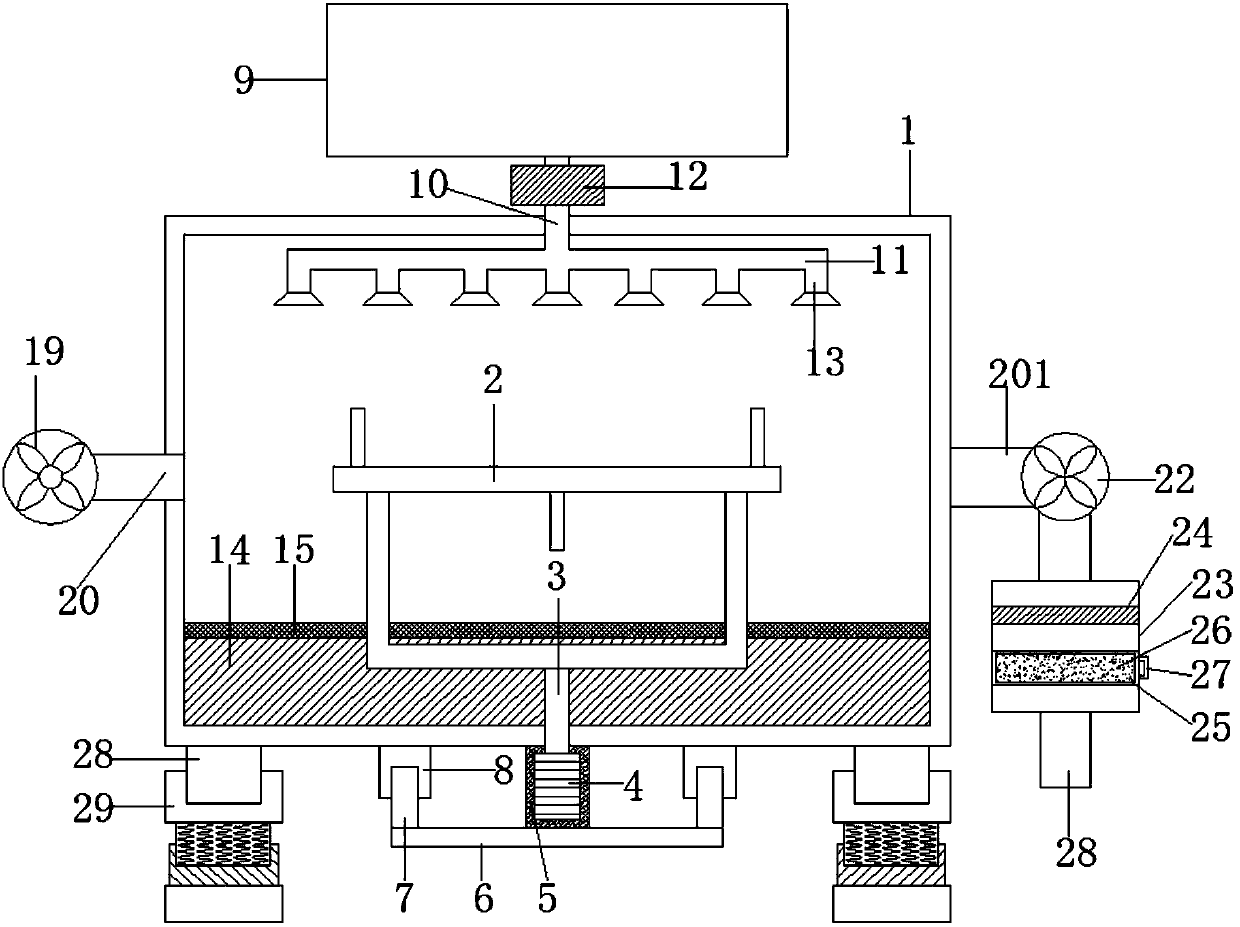

Construction waste treatment device

InactiveCN107214179AEfficient crushingPromote fragmentationConstruction waste recoverySolid waste disposalWater storageArchitectural engineering

The invention discloses a construction waste treatment device, which comprises a crushing chamber, an atomizing nozzle is arranged on the upper side of the crushing chamber, a water suction pipe is arranged on the upper side of the atomizing nozzle, a water storage chamber is arranged inside the upper end of the suction pipe, and a water storage chamber is arranged on the left upper side of the crushing chamber. There is a feeding pipe, the lower end of the right side of the feeding pipe is provided with a drainage plate, the lower side of the drainage plate is provided with a crushing plate, the lower left end of the crushing chamber is provided with a connecting pipe, the right side of the connecting pipe is provided with a rebar storage chamber, and the upper end of the rebar storage chamber is provided with a There is an electromagnet, there is a discharge port on the lower side of the crushing chamber, a crushing chamber is provided on the lower side of the discharge port, a screen is provided at the lower end of the crushing chamber, a discharge pipe is provided in the middle of the lower side of the crushing chamber, and a discharge pipe is provided on the lower side of the discharge pipe. There is a grinding chamber, the four corners of the lower side of the crushing chamber are provided with support columns, the lower side of the grinding chamber is provided with a discharge pipe, the lower side of the support column is provided with a base, the inside of the base is provided with a vibration-damping pad, and the upper middle of the base is provided with a pulley. The construction waste is crushed, separated, crushed, screened, ground and transported, which can effectively protect the environment and save resources.

Owner:彭利辉

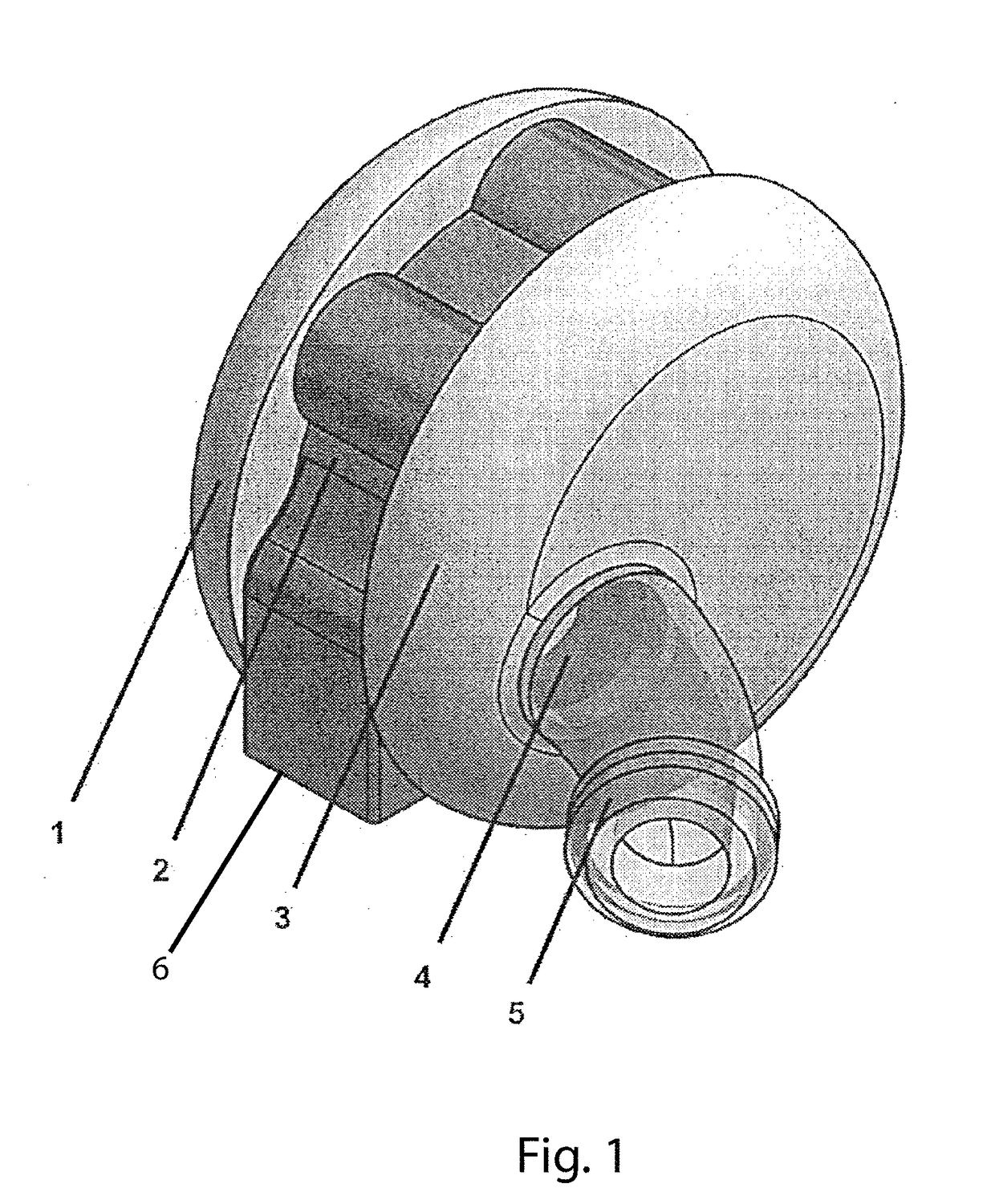

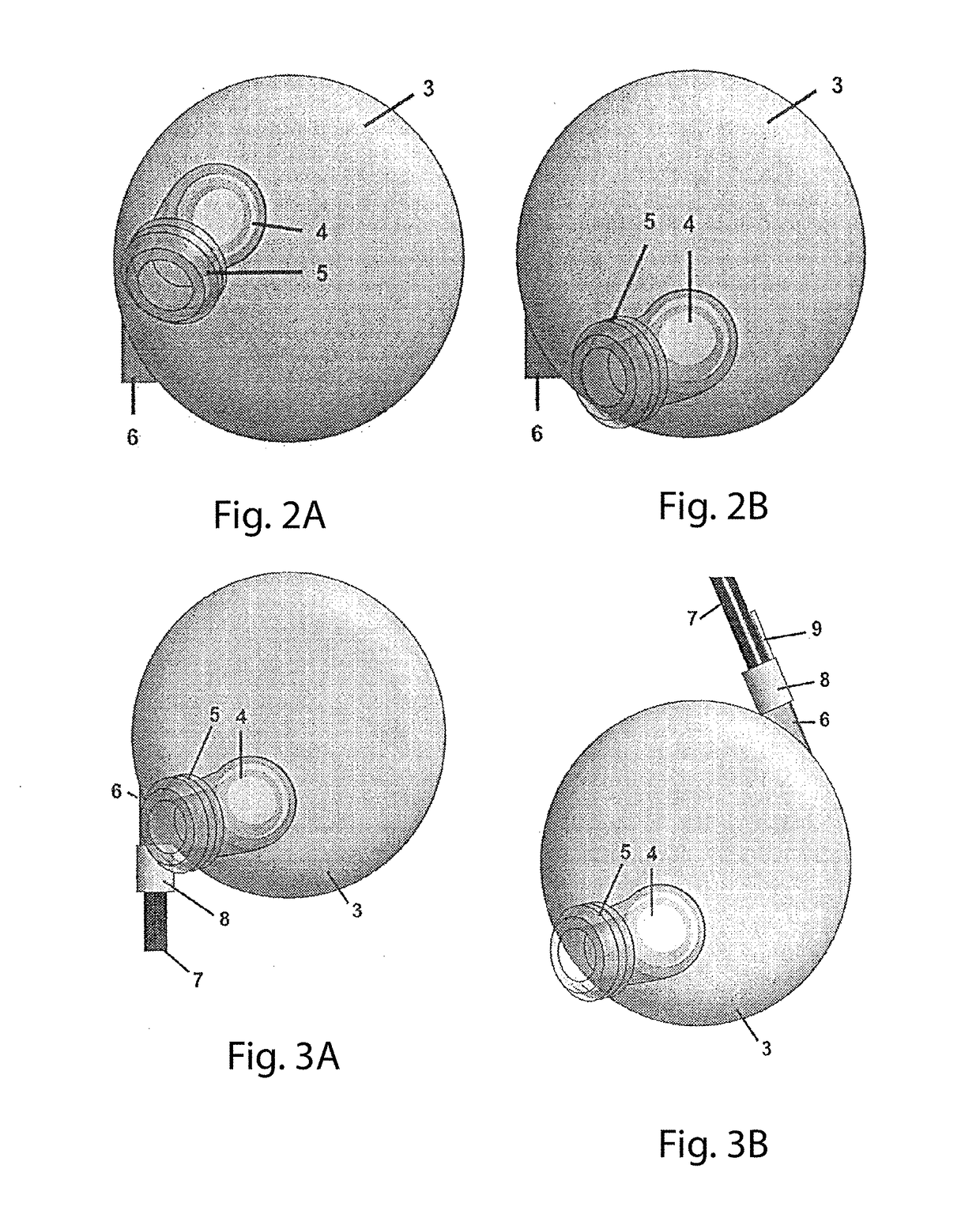

In-ear hearing device and broadcast streaming system

ActiveUS9848257B2Improve isolationQuality improvementHearing aid ventsIntra aural earpiecesLive voiceFrequency spectrum

An improved earbud design providing for full modularity; improved and variable hearing protection, sound quality, comfort, fit, aesthetics, and signal connectivity; and the ability to maintain environmental sound directionality comprised of a multitude of new features with variable vents and membranes which dilute the harmful pneumatic effects of sound while improving its acoustic quality. A location-based transmission system provides event attendees to mix live sound with streamed sound through Ambrose Earbuds for reduced hearing risk and no quality detriments due to timing gaps, occlusion or ear tip spectral broadening, and enables noise pollution-free musical performances. A displacement-based digital compression algorithm caps maximum output air displacement as well as sound pressure level. Thus, an earbud is provided that through adjustments and modularity can act as a personal listening device, a hearing protection device and as a personal aesthetic statement with customized fit and comfort.

Owner:ASIUS TECH

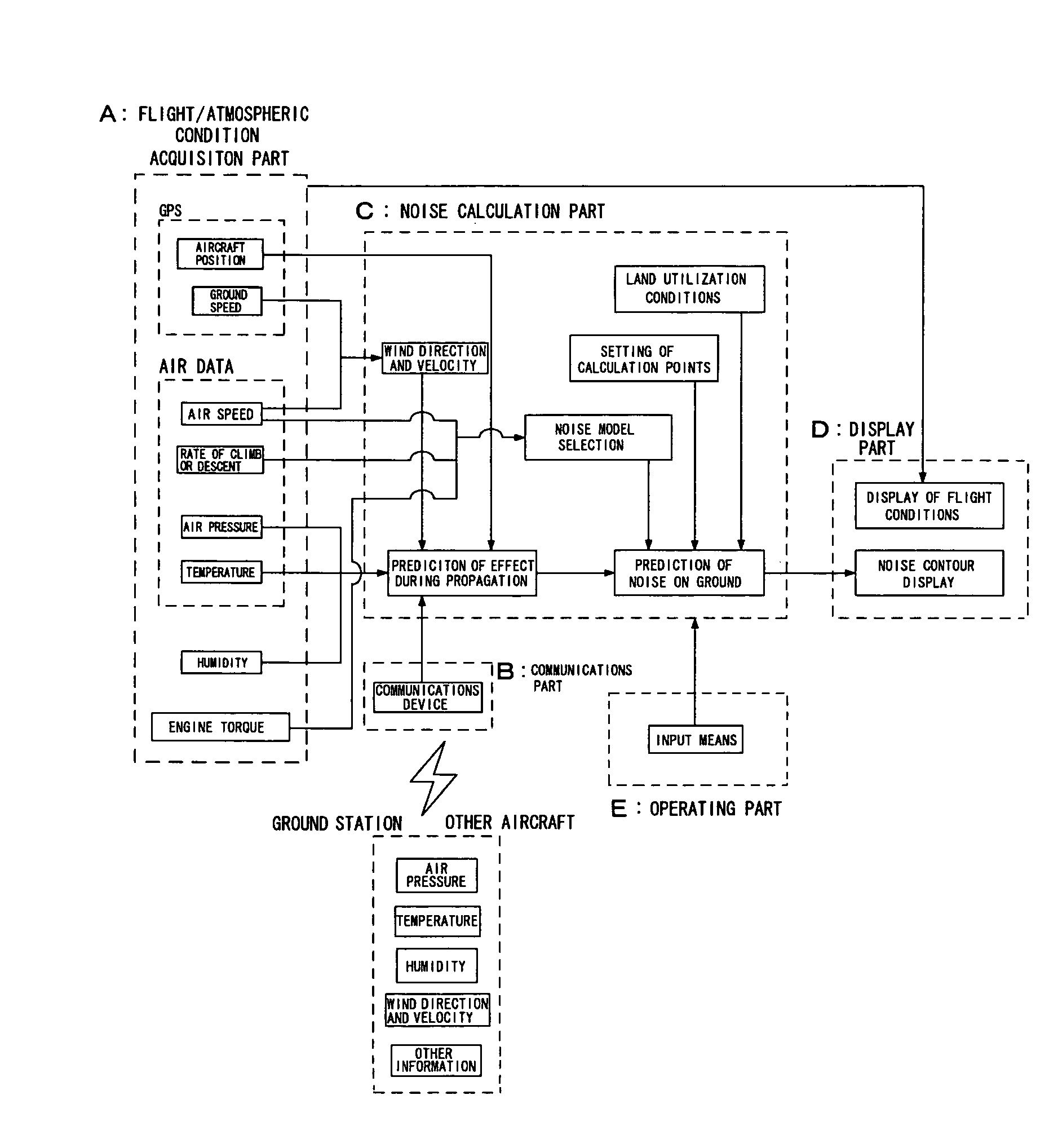

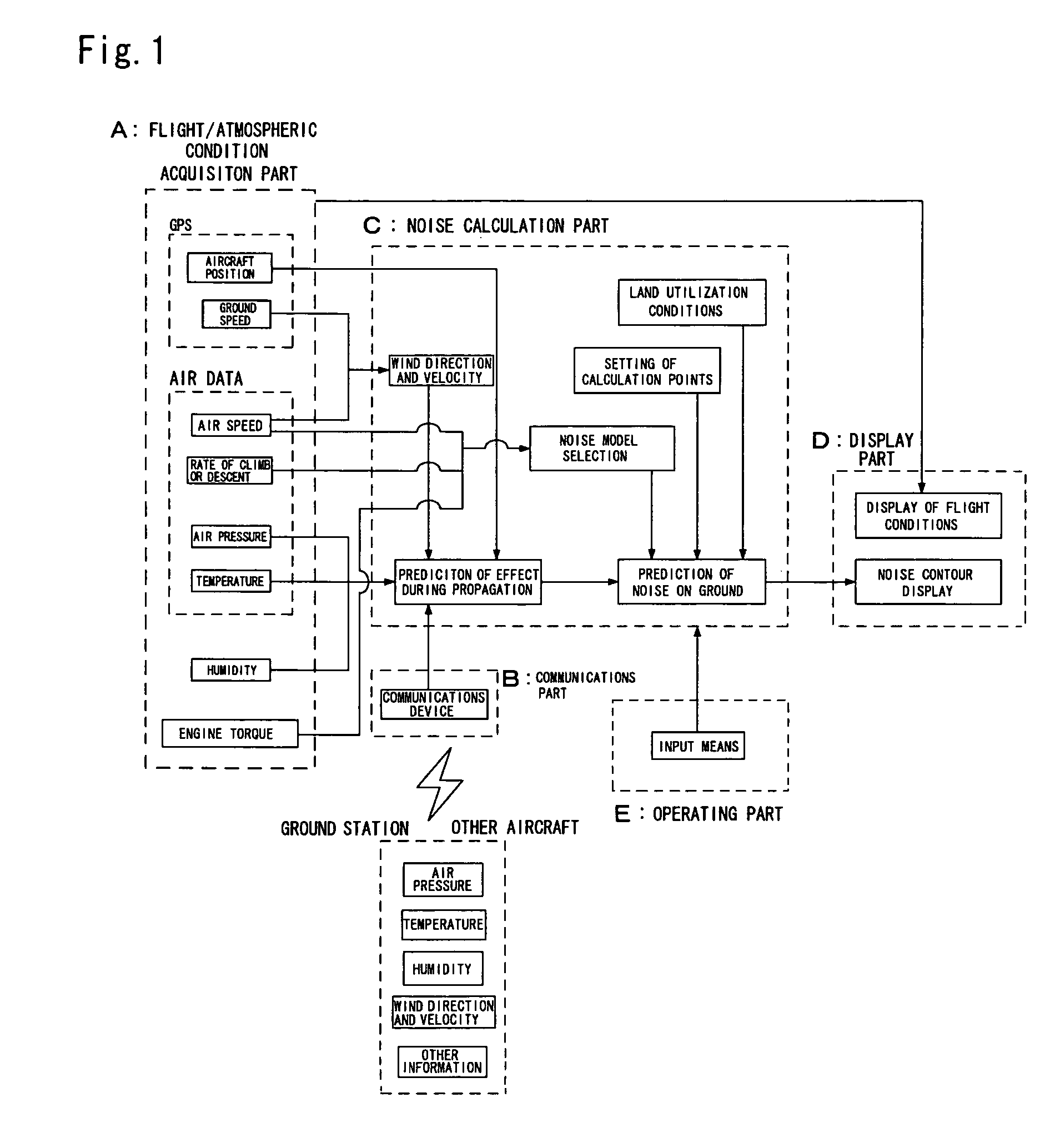

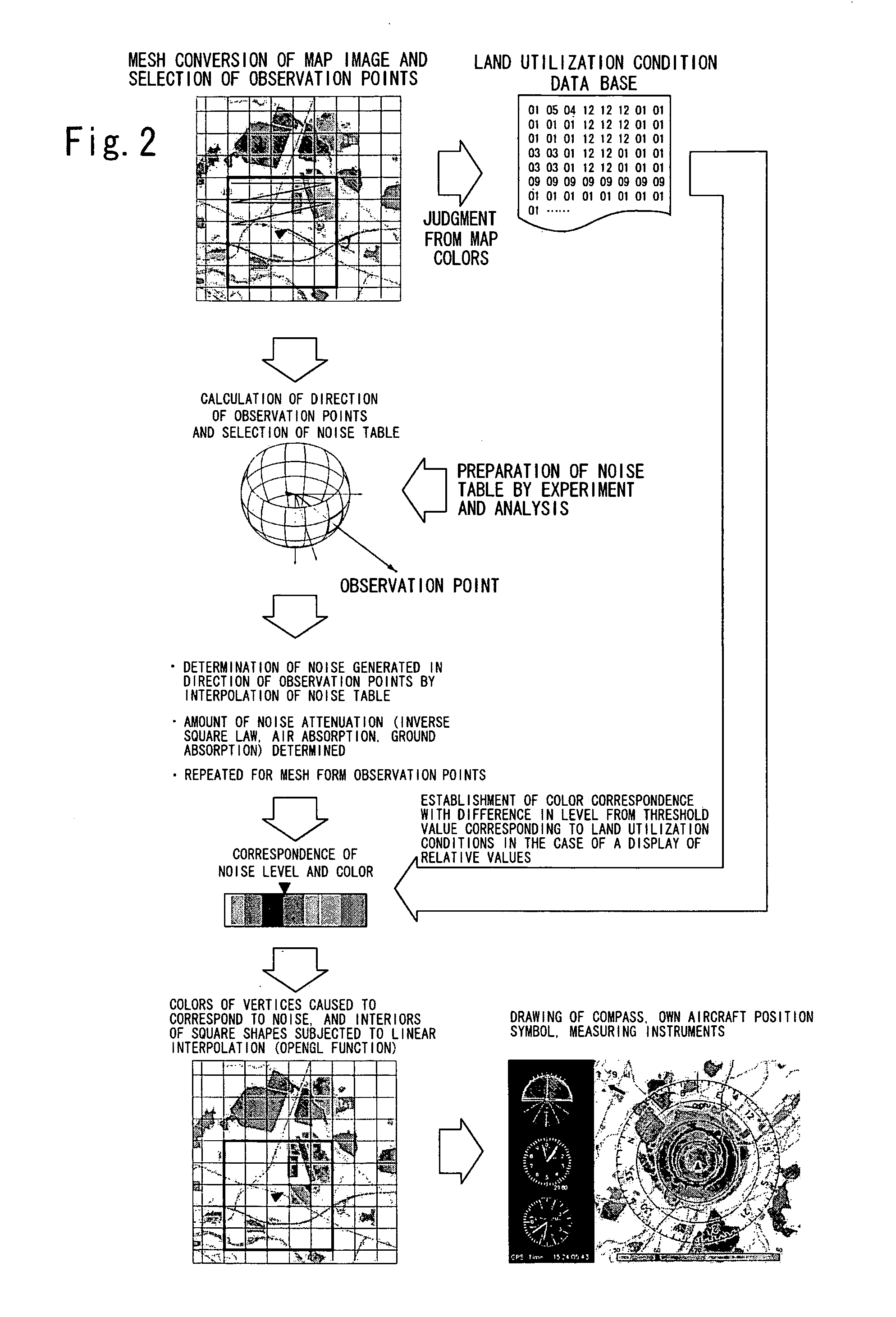

Low-noise flight support system

InactiveUS7383104B2Reduce noise pollutionInstruments for road network navigationDigital data processing detailsNoise generationLow noise

It is an object of the present invention to provide a system that is used to provide support so that a pilot can perform flight operations that reduce noise pollution, by devising this system so that noise conditions on the ground are calculated and displayed on the basis of map information for the flight area in which facilities and the like are described, environmental conditions in the flight area such as the wind direction and wind velocity, or the temperature and density of the atmosphere, and noise generation data for the aircraft itself. The apparatus for supporting low-noise flight according to the present invention comprises means for estimating the noise generated by an aircraft using flight data such as the flight speed, the climb and descent rates, the engine power and the like of the aircraft, means for calculating the level at which the noise generated by the aircraft is propagated in the respective regions on the ground, and means for displaying the calculation results on a map in quantitative terms.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

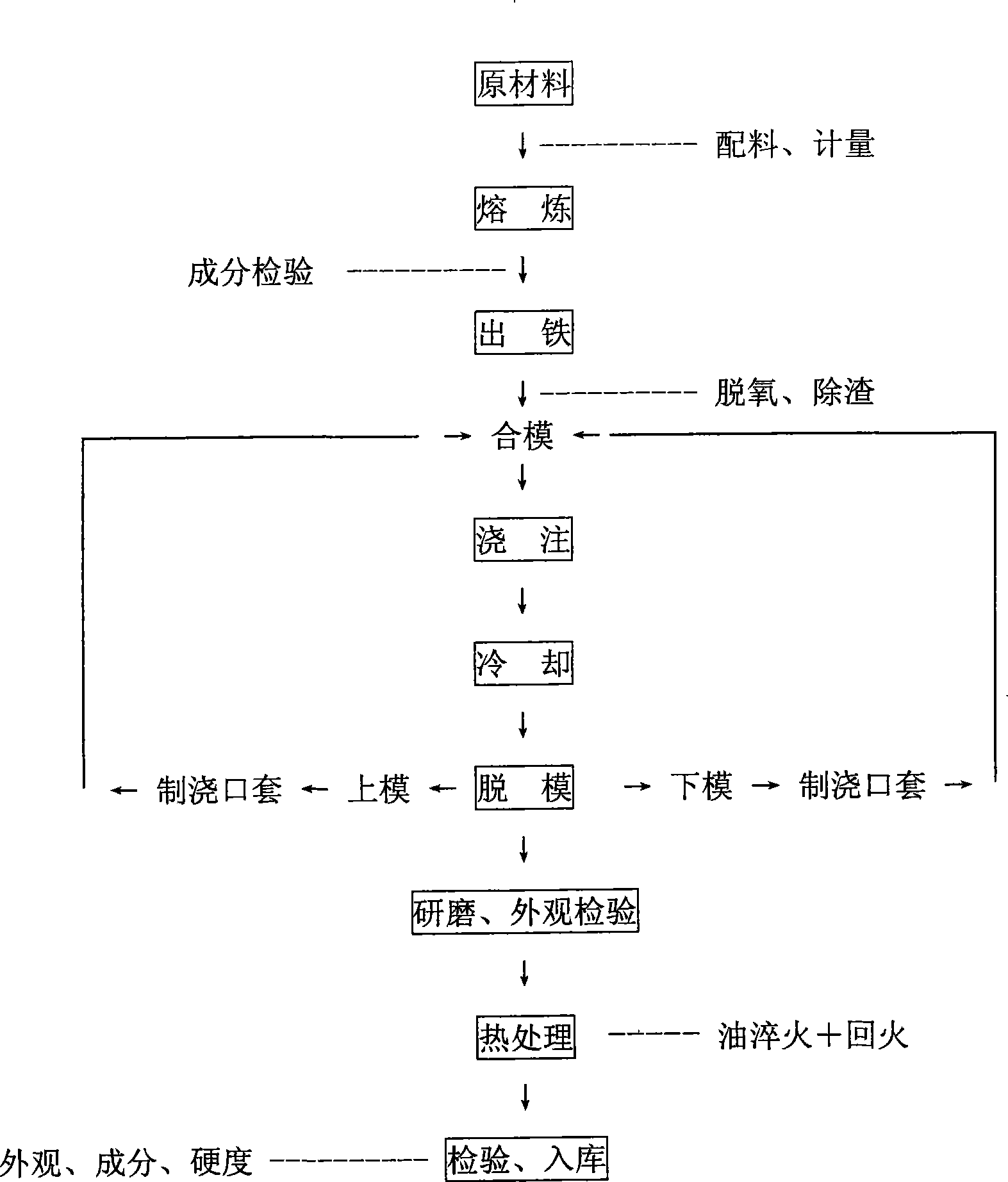

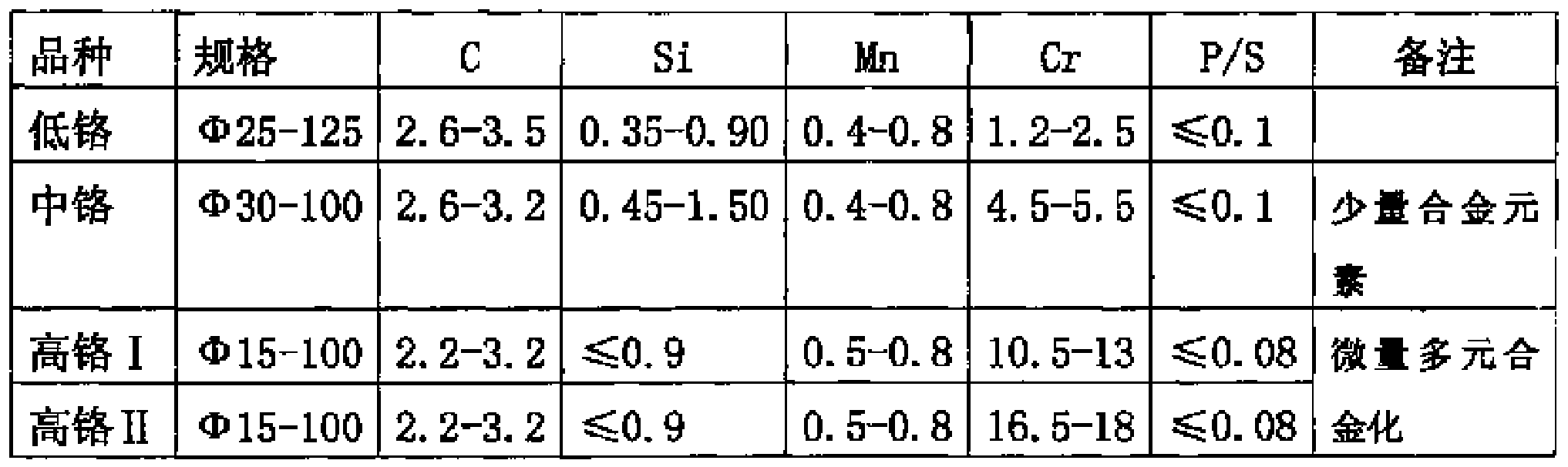

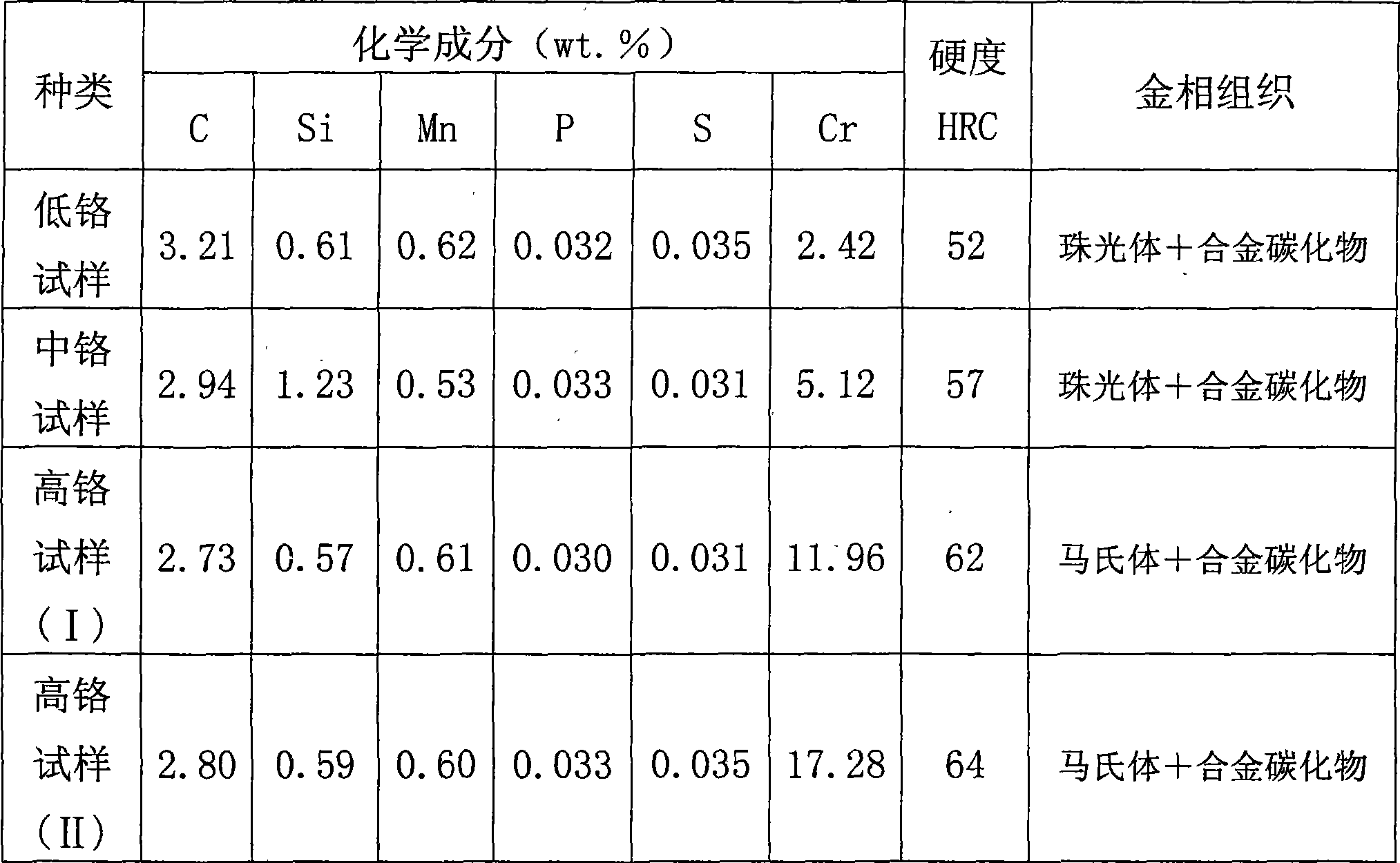

High abrasion proof re-synthesizing cast iron grinding ball and production method thereof

InactiveCN101445889AHigh hardnessImprove toughnessEdge grinding machinesPolishing machinesIntermediate frequencyCarbide

The invention relates to a high abrasion proof resynthesizing cast iron grinding ball for a ball grinding mill and a preparation method thereof. The method reduces the content of carbon in material on the premise that carbide is formed in materials, thereby reducing the contents of chrome and molybdenum in the material and simultaneously controlling the content of other elements, so that the obtained material of the grinding ball has good overall mechanical property and service performance. Compared with a No. 45 steel forging ball, the abrasion proof property of the grinding ball is improved by 3 to 10 times, so that both the consumption of steel products and the recourses are saved. In the method, cast iron is melted and synthesized by using an intermediate frequency electric furnace and a large amount of scrap steel, steel scraps and other renewable resources are utilized, so that not only the quality of synthetic cast iron products is improved and the performance is stabler, but also the pollution to environment is reduced.

Owner:MAANSHAN YIFENG INDAL GROUP

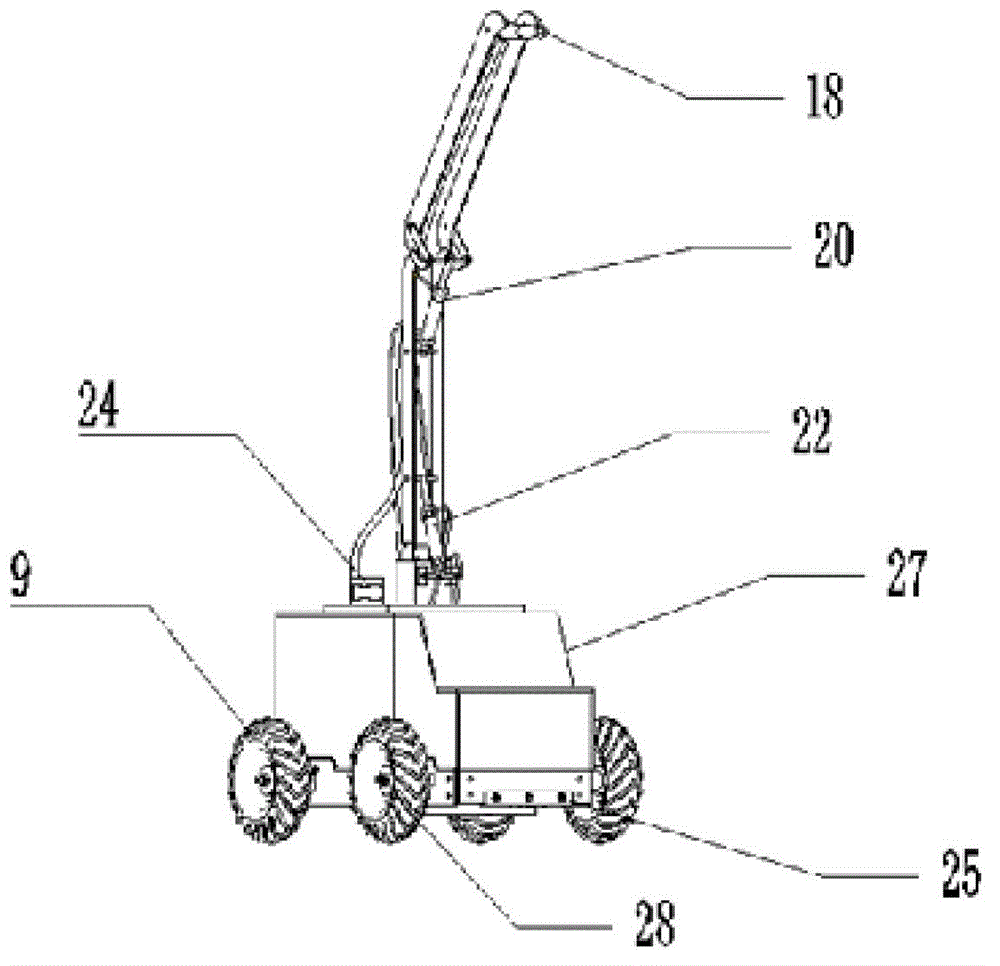

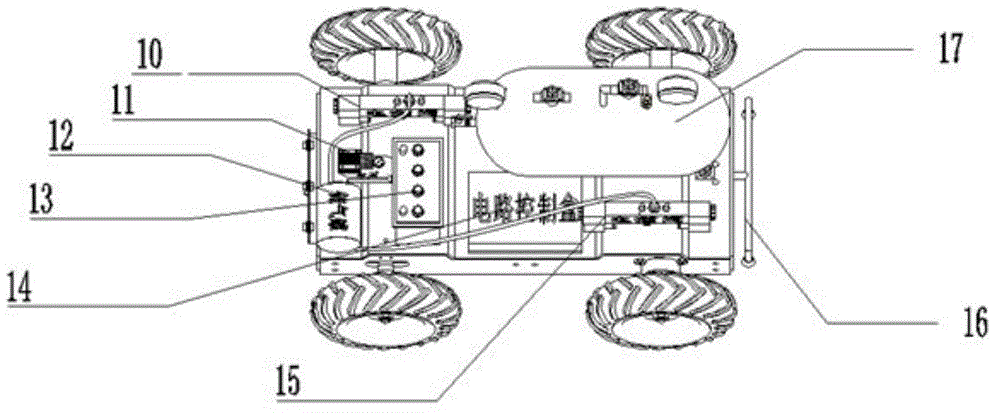

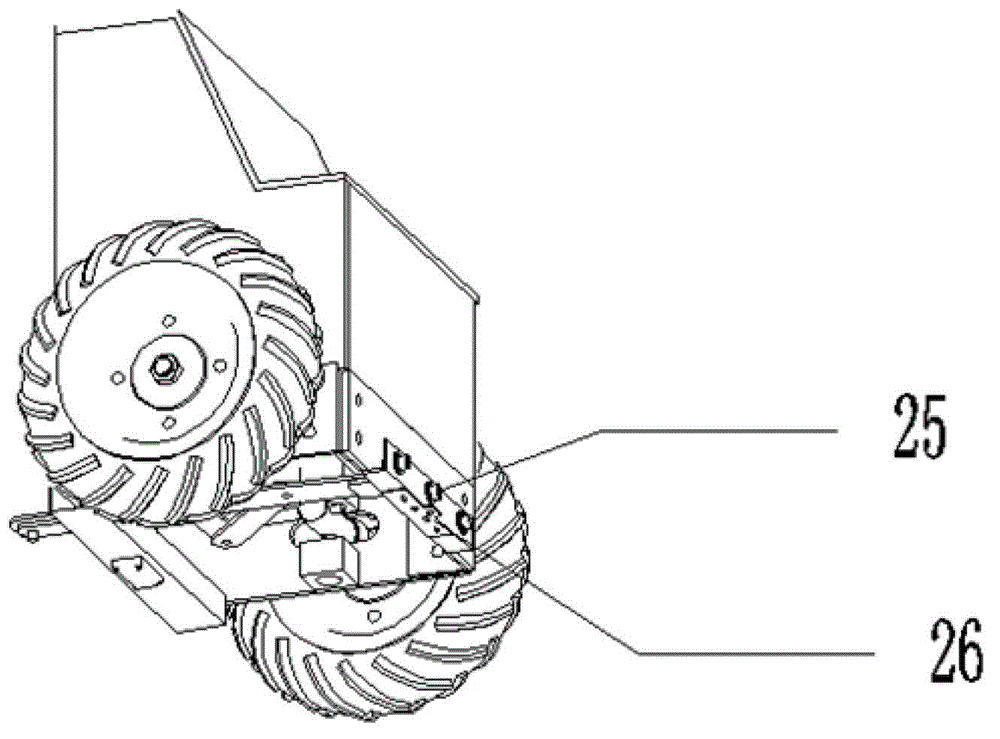

Small-sized intelligent spraying vehicle

InactiveCN103147416ASimple structureLow costWatering devicesRoad cleaningSolenoid valveControl system

The invention provides a small-sized intelligent spraying vehicle. The spraying vehicle comprises a vehicle body (27), a power supply (13), a travel mechanism, a pressurizing spraying system and a control system, wherein the travel mechanism comprises front wheels (28) and rear wheels (9), which are arranged on a framework chassis; the front wheels (28) are driven by an independent suspension structure; the rear wheel (9) are respectively driven by a motor (8); the pressurizing spraying system consists of an air way and a waterway, and the on-off of the air way and the waterway are controlled by a solenoid valve; the control system comprises a master controller (14) and a pavement monitoring sensor for monitoring a pavement state and transmitting monitored information to the master controller; and the master controller receives signals from the pavement monitoring sensor, and analyzes and calculates the signals to control the corresponding actions of the front wheels, the rear wheels and the pressurizing spraying system to realize intelligent spraying without depending on manpower.

Owner:LUOYANG INST OF SCI & TECH

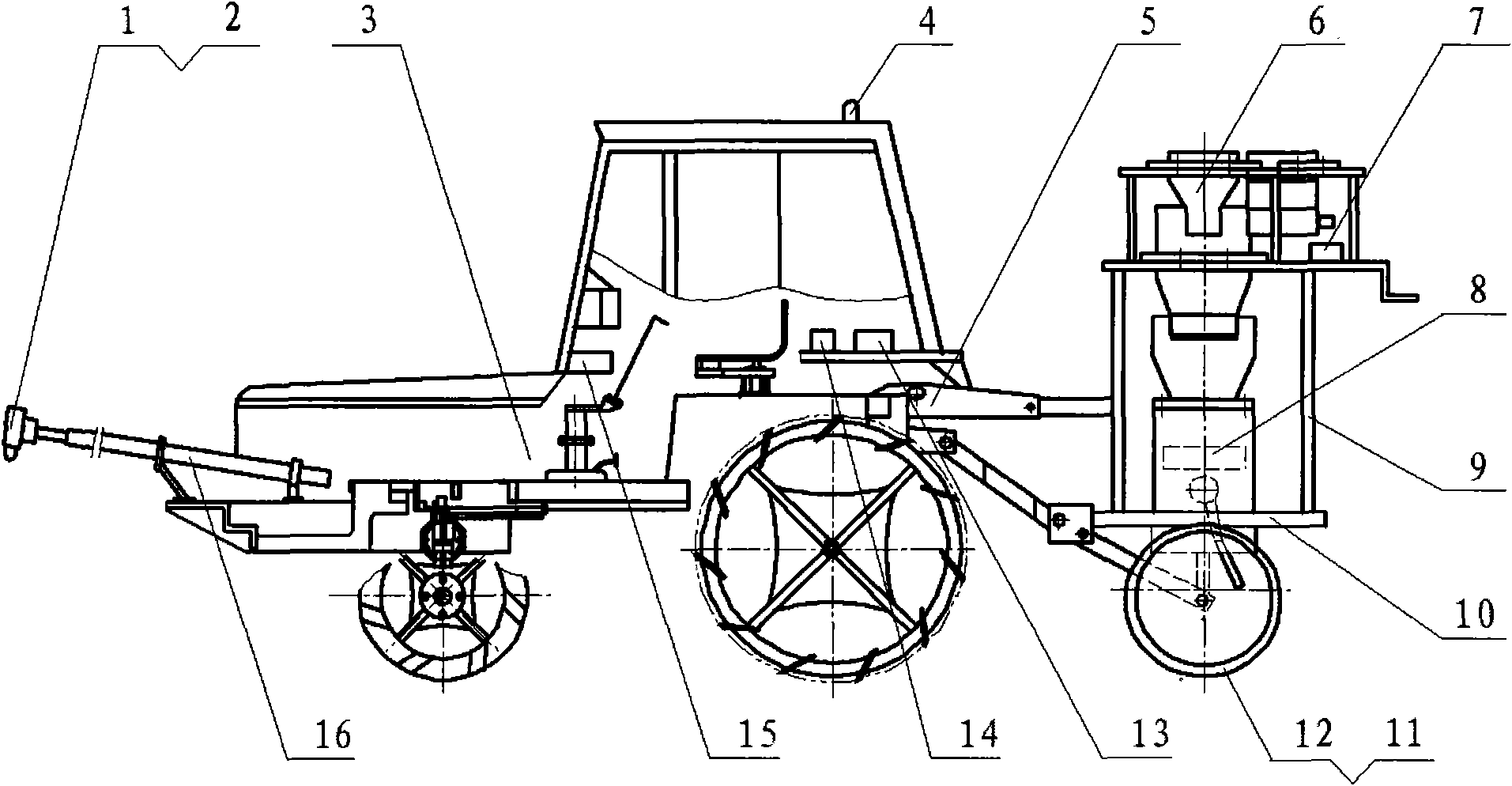

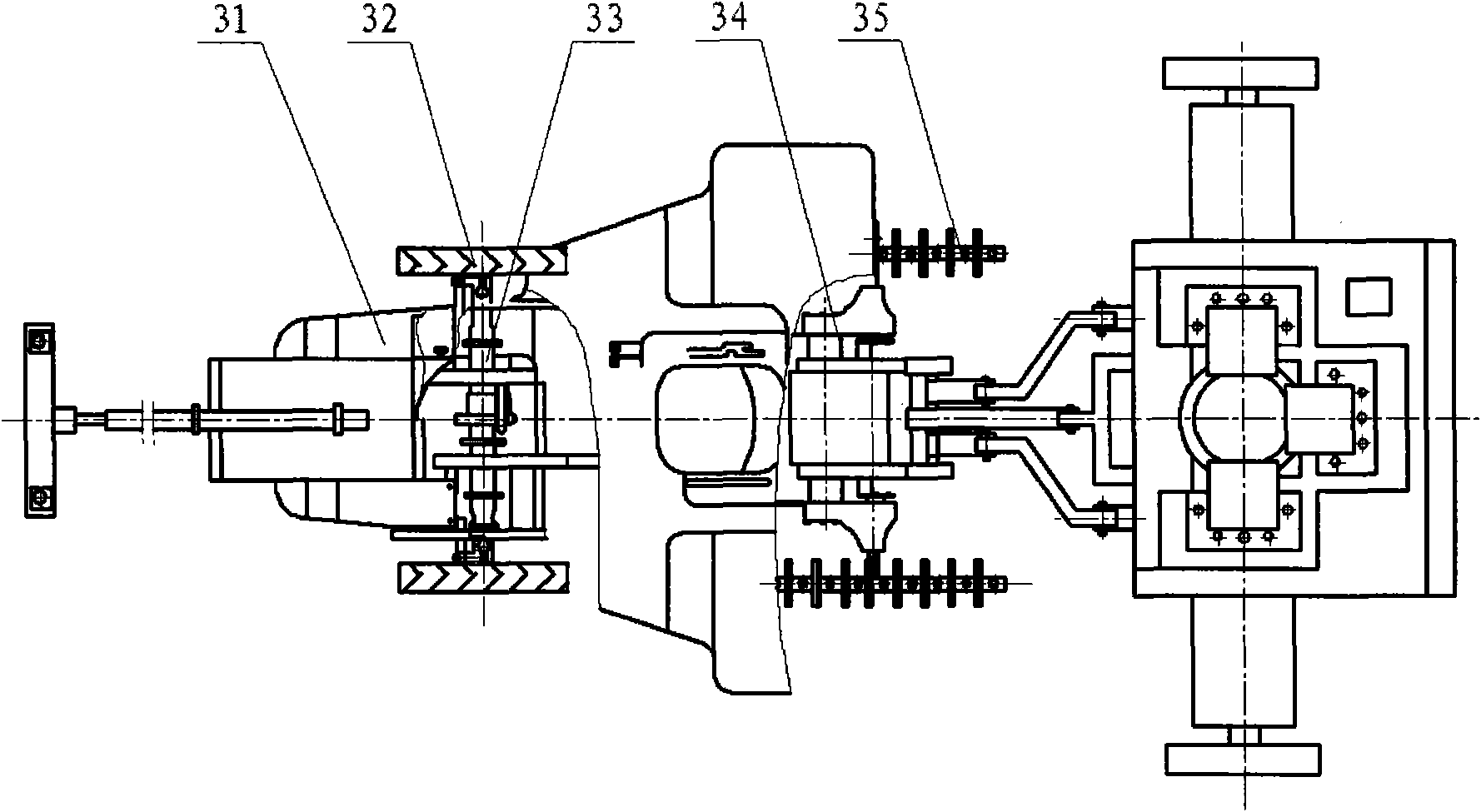

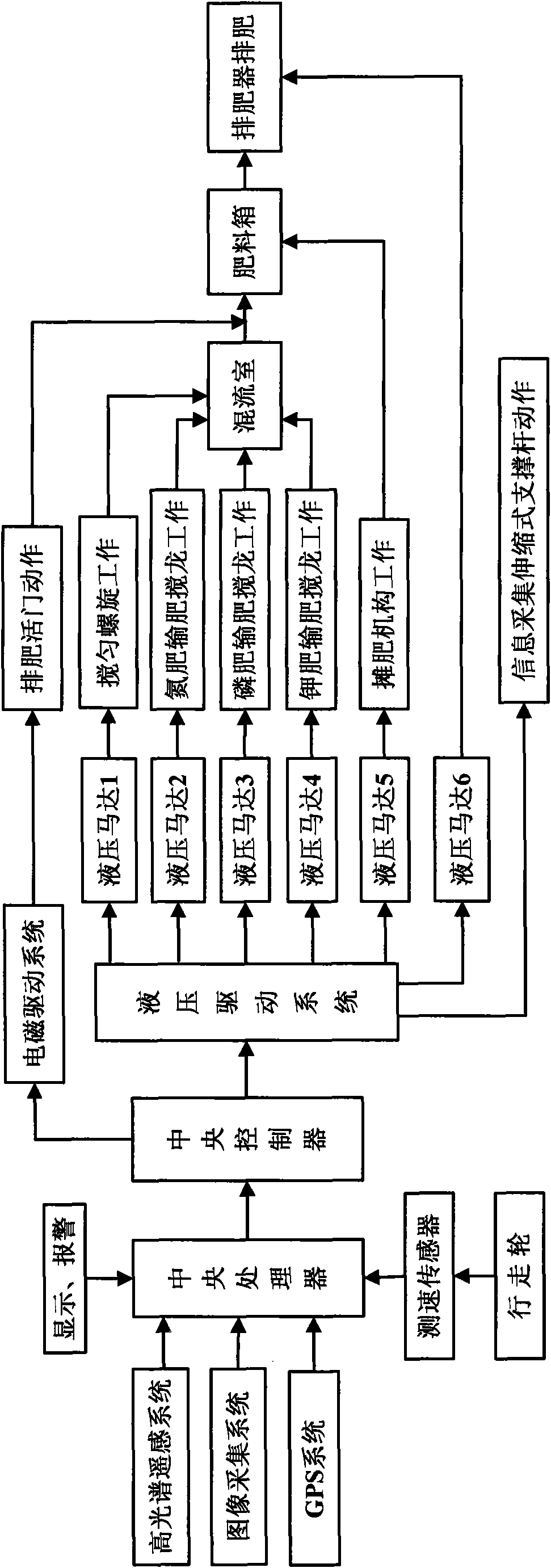

Intelligent variable rate fertilizer for rice and variable rate fertilization method thereof

ActiveCN101773016AEnough dynamic reaction timeSuitable for fertilization during growth periodFertiliser distributersMaterial analysis by optical meansControl systemAgricultural engineering

The invention discloses an intelligent variable rate fertilizer for rice and a variable rate fertilization method thereof. In the technical scheme of the variable rate fertilizer, a hyperspectral remote sensing system and an image acquisition system are arranged on the front end of a traction engine body; a variable rate fertilization unit is arranged on the upper part of a support rack; a fertilizer spreading mechanism is connected with the variable rate fertilization unit and is arranged on the lower part of the support rack; a speed measuring sensor is arranged on a ground wheel; the variable rate fertilization unit and the fertilizer spreading mechanism are both connected with a hydraulic drive system; a GPS antenna and a GPS mobile station which can communicate with the hyperspectral remote sensing system and the image acquisition system are arranged in the traction engine body; and a control system is used for processing data and controlling the actuation of the variable rate fertilization unit and the fertilizer spreading mechanism. The variable rate fertilization method realizes real-time detection of the contents of N, P and K in rice through information fusion of the hyperspectral remote sensing system and the image acquisition system, and can achieve the rice fertilization according to needs based on nutritional profits and losses. The invention has the advantages of accurate fertilization and good controllability, and is suitable for fertilization in the rice growing period.

Owner:江苏洋口港建设发展集团有限公司

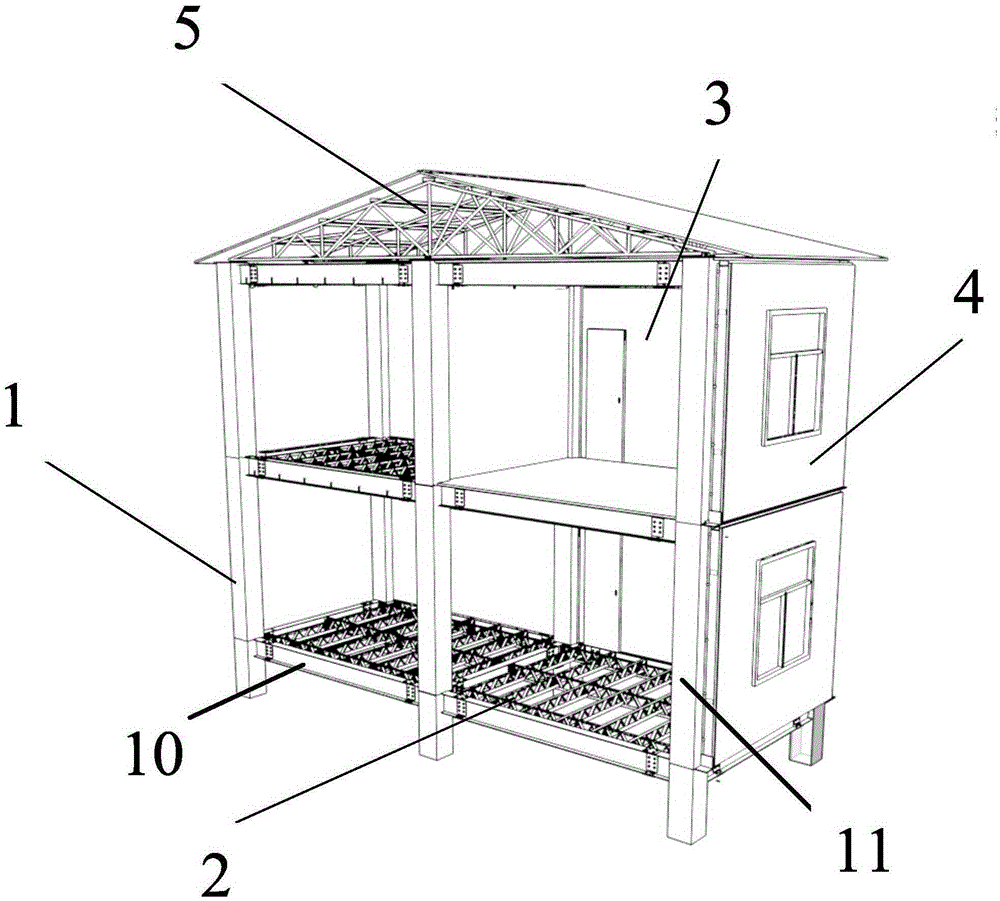

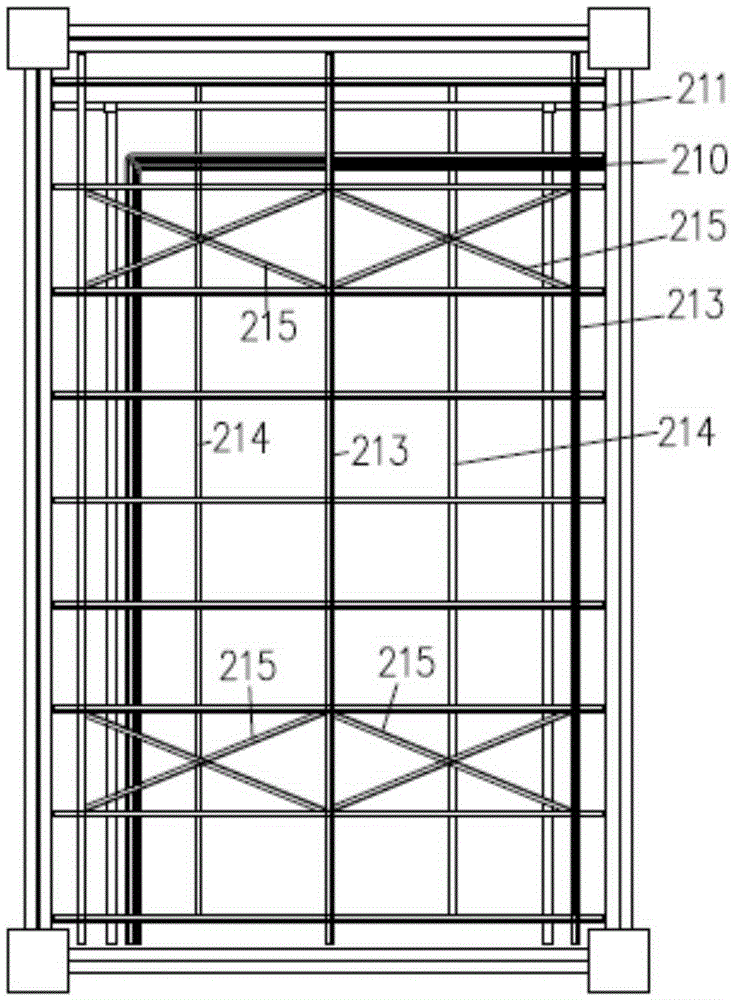

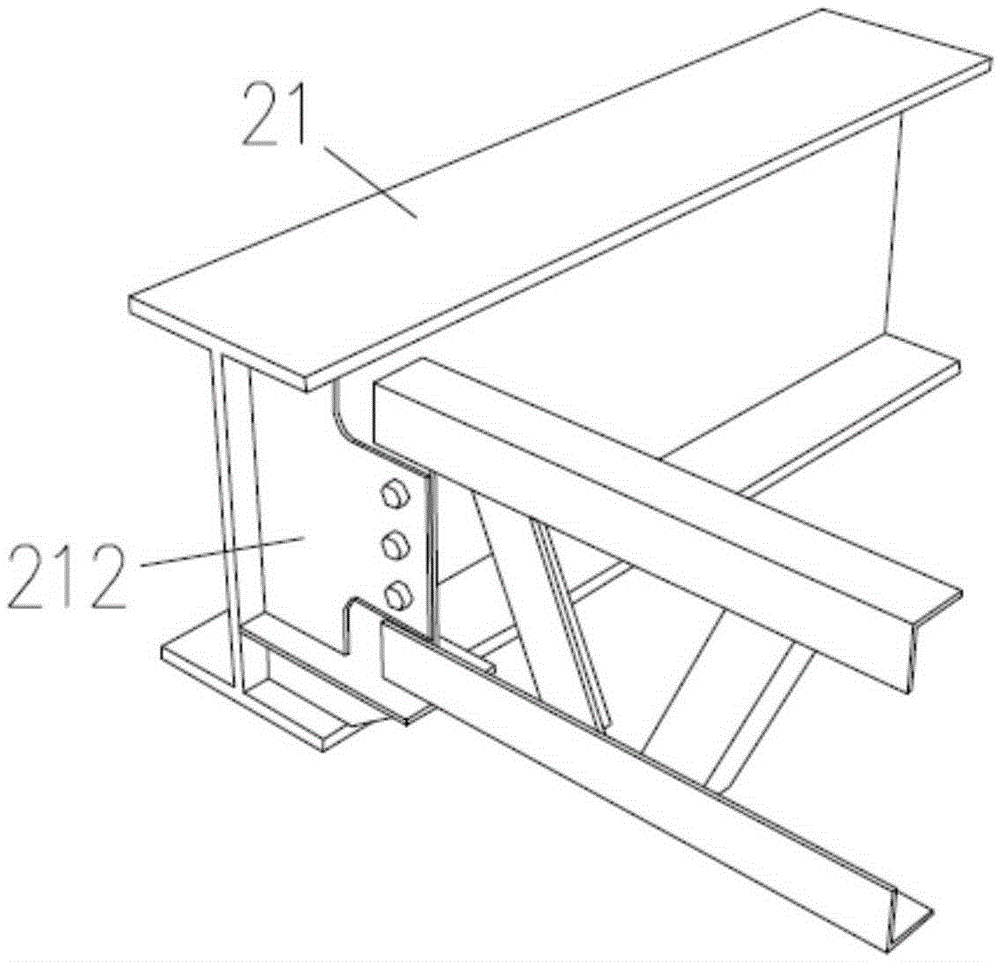

Integrated assembly type steel structure building

InactiveCN105317110AReduce noise pollutionImprove construction efficiencyRoof covering using slabs/sheetsConstruction materialPipingUtilization rate

The invention provides an integrated assembly type steel structure building. The integrated assembly type steel structure building comprises a main body framework, floor bearing plates, internal wall bearing plates, external wall bearing plates and a roof; the floor bearing plates, the internal wall bearing plates, the external wall bearing plates and the roof are connected with the main body framework through connecting parts, the internal wall bearing plates are arranged to be adjacent to the external wall bearing plates, the roof is arranged at the upper end of the main body framework, and the outer surfaces of the internal wall bearing plates, the outer surfaces of the external wall bearing plates and the outer surface of the roof are each provided with decoration and fitment plates in an integrated mode, and the interiors of the decoration and fitment plates are correspondingly provided with cable conduits and water pipes in an integrated mode. In this way, the integrated assembly type steel structure building has the advantages of being stronger in integrity, convenient to construct, high in repeating utilization rate, capable of reducing production cost and wide in application range, and integral installation and disassembly of prefabricated part and the connecting parts in a factory can be achieved; meanwhile, large-scale production at a construction site is easy to achieve, and construction waste is greatly reduced.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

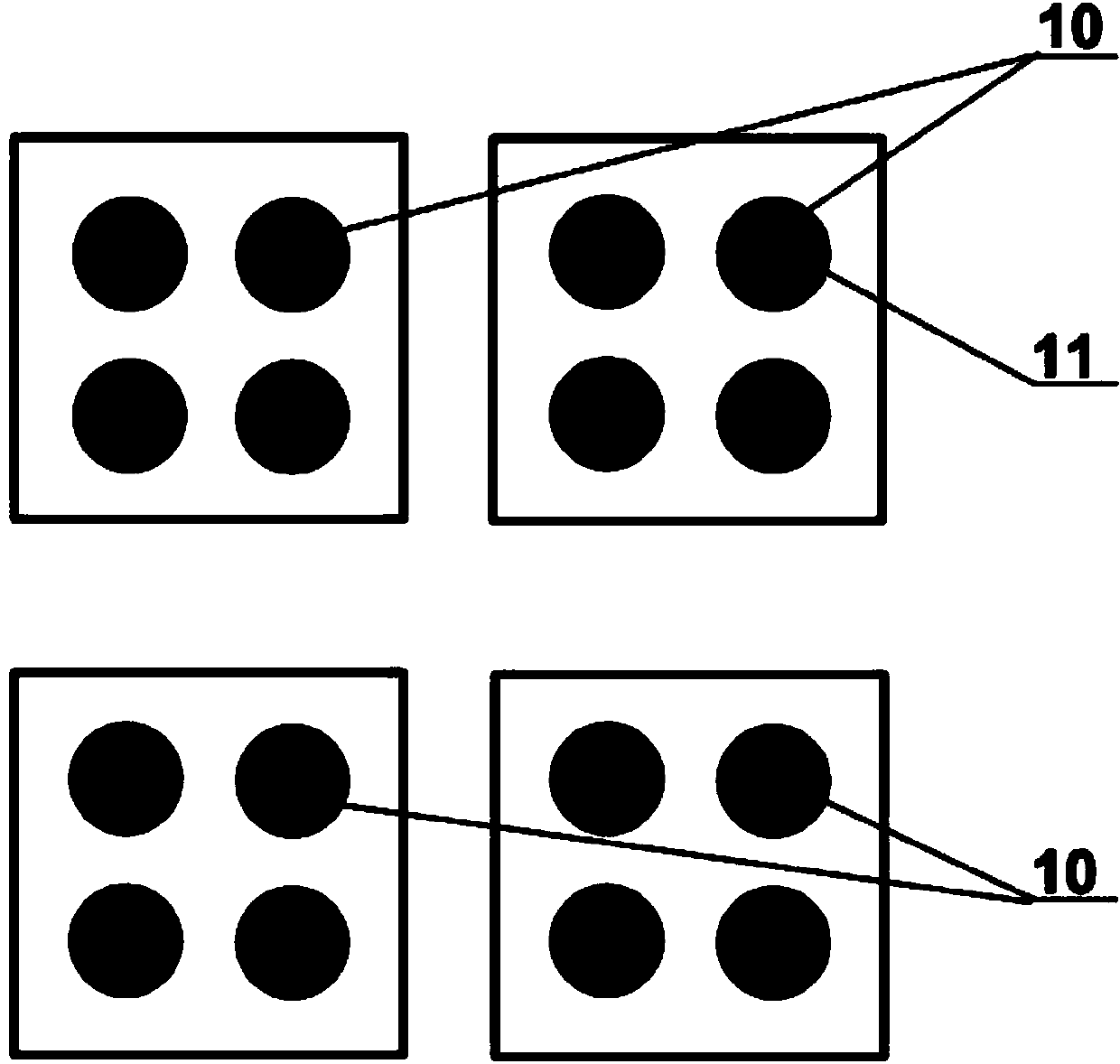

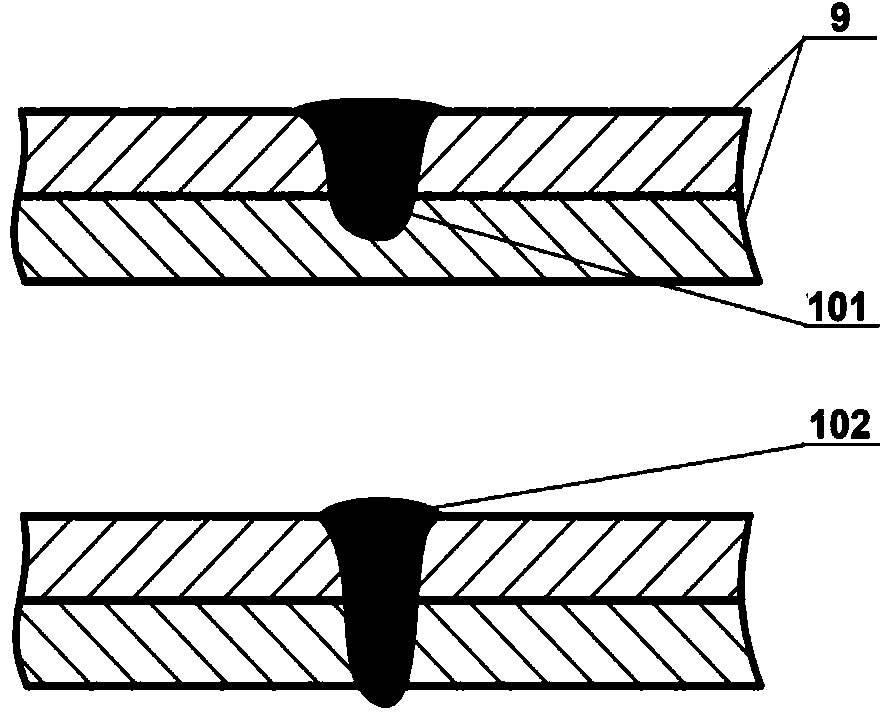

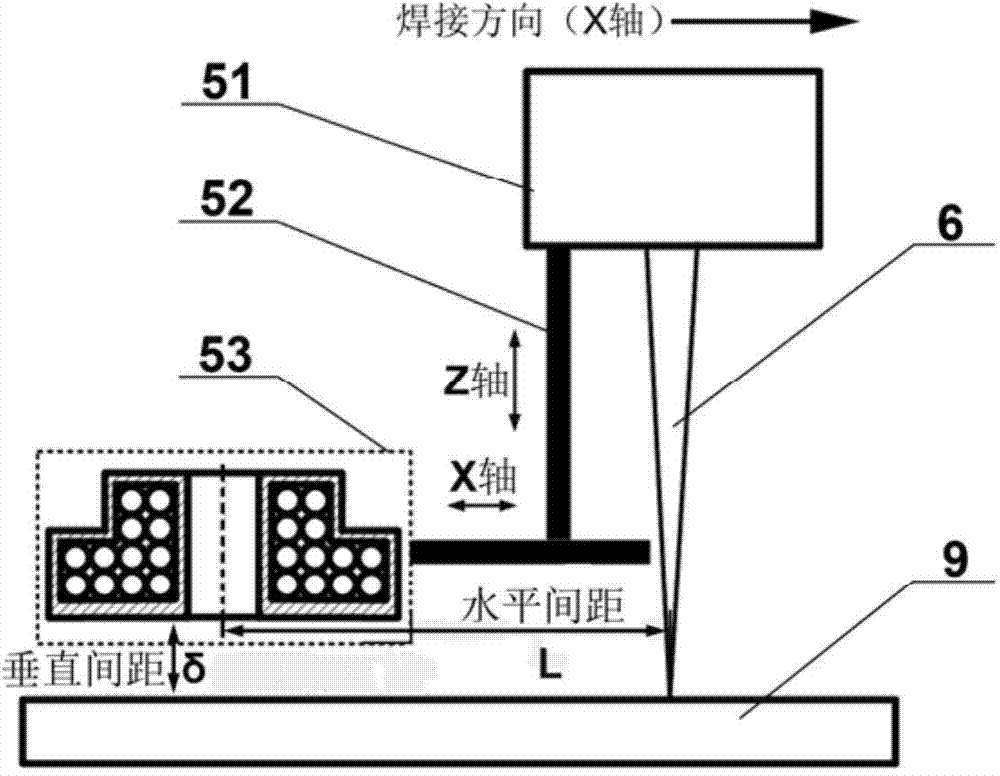

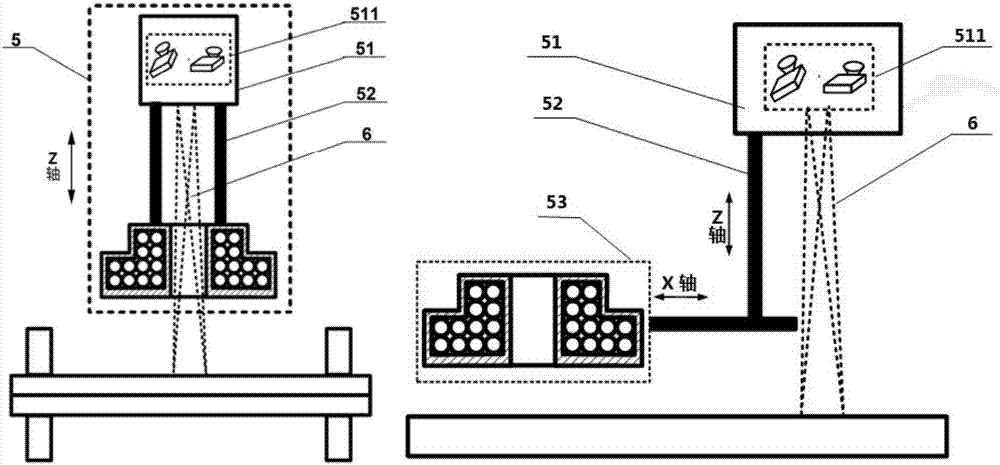

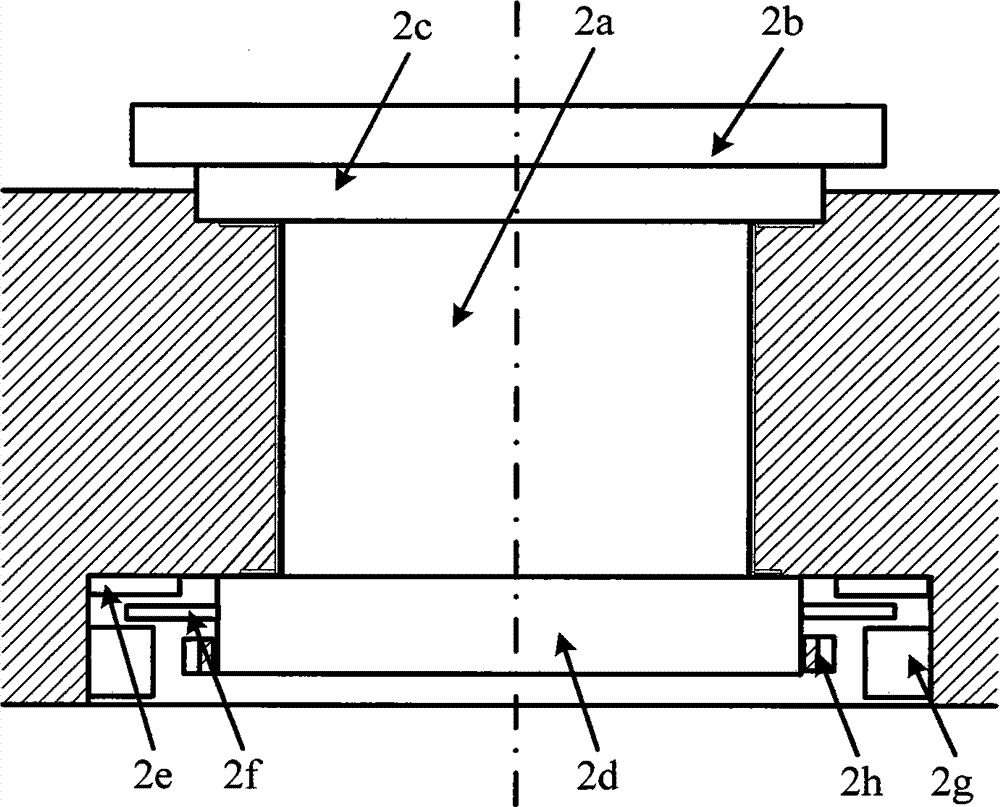

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

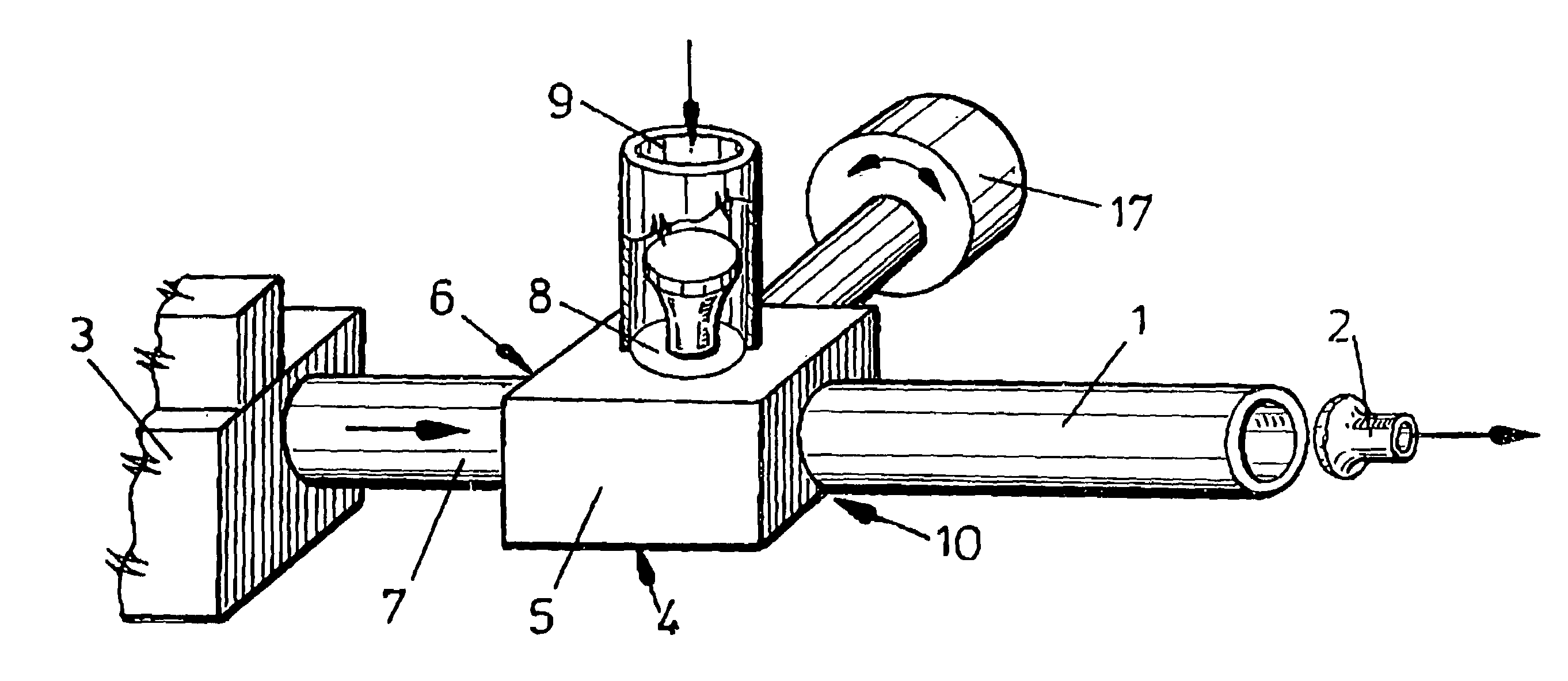

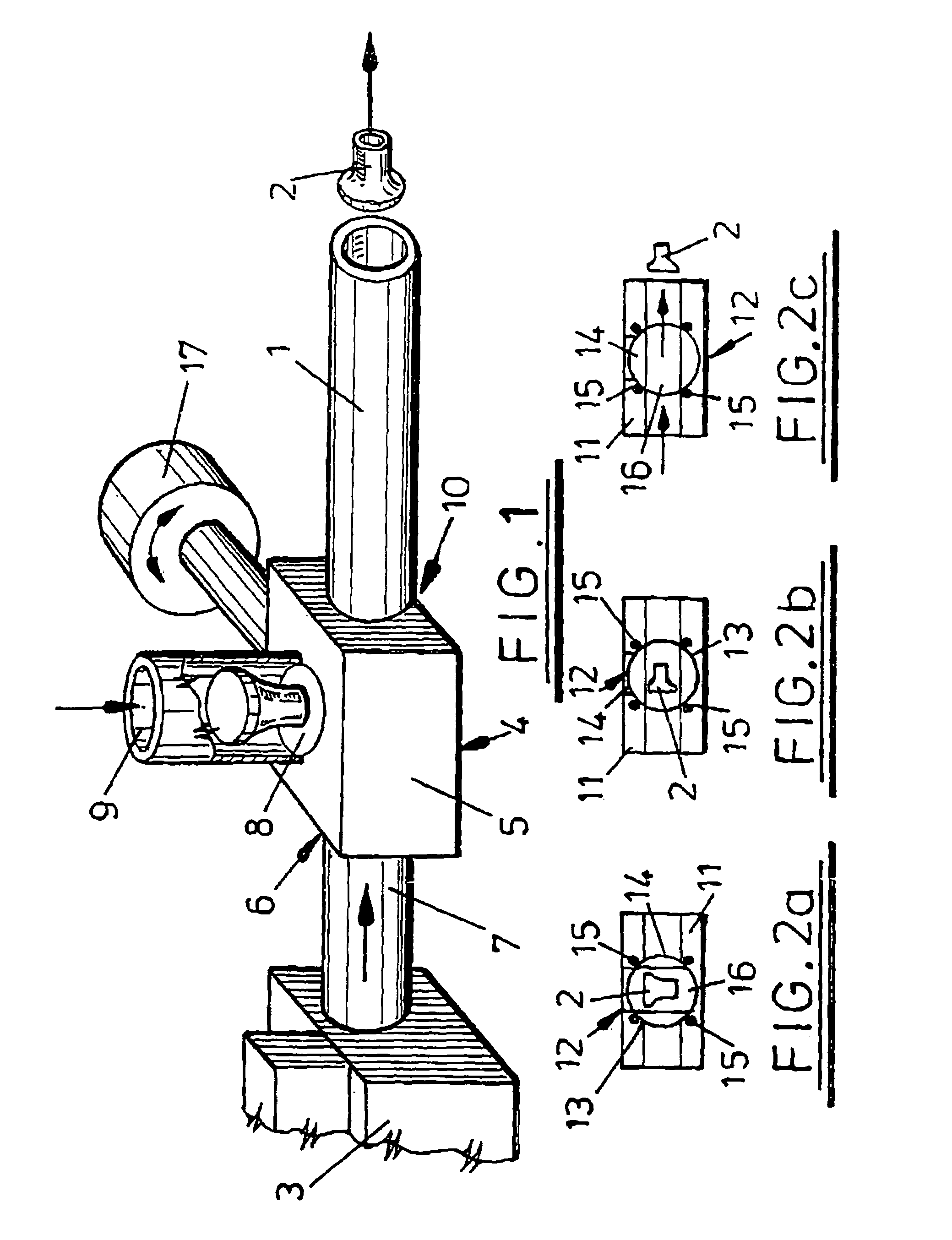

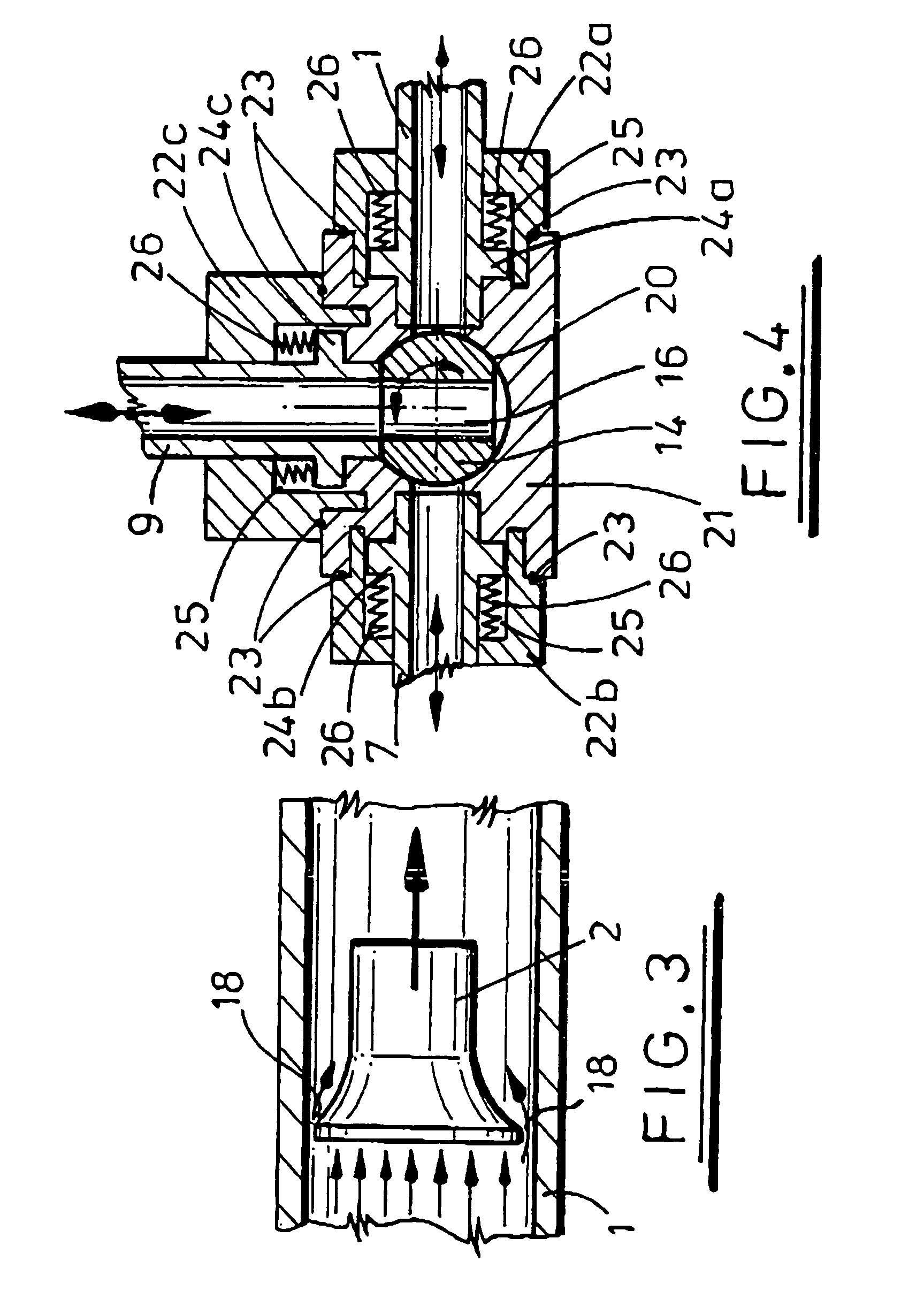

Fastener delivery apparatus

InactiveUS6951298B1Reduce frictionReduce the power requiredStapling toolsMetal working apparatusEngineeringRivet

A fastener delivery tube (1) is connected between a supply of fasteners, such as rivets (2), and the nose of a fastener setting machine. The delivery tube (1) is connected to an outlet tube (7) of a source of compressed air (3), the outlet tube (7) having an internal bore substantially equal in size to the internal bore of the delivery tube (1). The supply of fasteners is connected to the delivery tube via a feeder tube (9) and transfer gate (4). The transfer gate (4) is sealed so as to prevent leakage of air from the delivery tube (1). The arrangement reduces turbulence in the delivery tube (1) ensures that friction between the fastener (2) and the tube (1) is reduced and permits compressed air to be supplied at significantly lower pressure than has heretofore been possible.

Owner:ATLAS COPCO IAS UK LIMITED +1

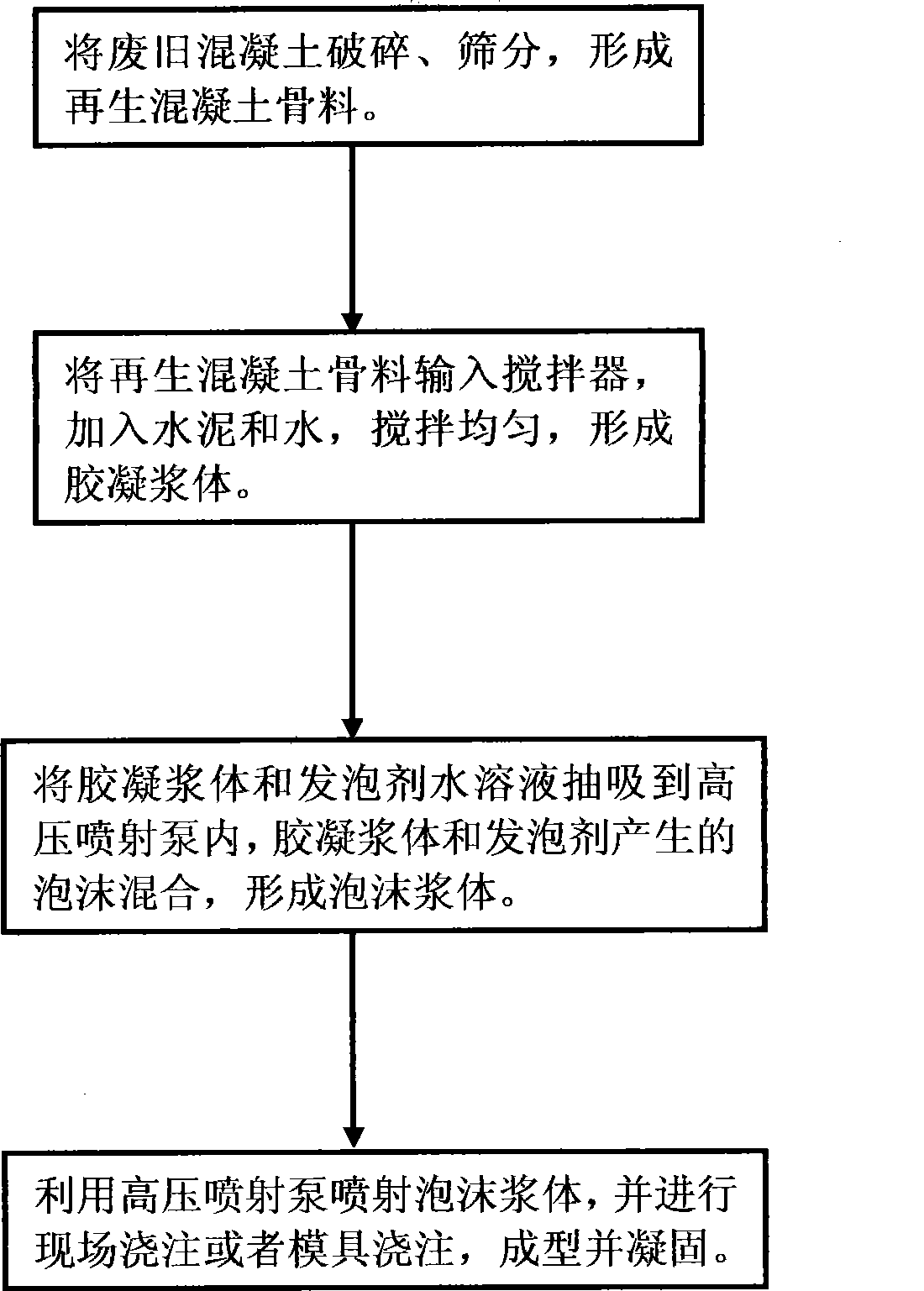

Foaming concrete made by waste and old concrete and production method thereof and use

InactiveCN101391902ASpeed up the solidificationGuaranteed continuitySolid waste managementCeramicwareUnderground pipelineSubgrade

The invention discloses light foaming concrete made by waste concrete, and the production method and application of the foaming concrete. The foaming concrete is formed by the mixing of regenerated foaming concrete aggregate formed after the smashing and screening of the waste concrete, jellous slurry formed by adding concrete, fly ash and water, and foam generated by a foaming agent. After on-spot injection, pouring or mould pouring, the foaming concrete can be used in a plurality of aspects in municipal infrastructure construction such as weak subgrade processing, high filling subgrade, road-widening subgrade, temporary subgrade, various underground pipeline foundation, narrow slot and small clearance space filling, road landslide emergency backfilling, building heat preservation, sound insulation walls and the like. The adoption of the waste concrete for making the foaming concrete has the advantages of utilizing the waste, being environment-friendly, saving energy and having low cost, and the like, and the produced foaming concrete has a plurality of good performances such as light weight, no lateral confinement compression resistance, self-compaction and vibro-free property, and the like.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

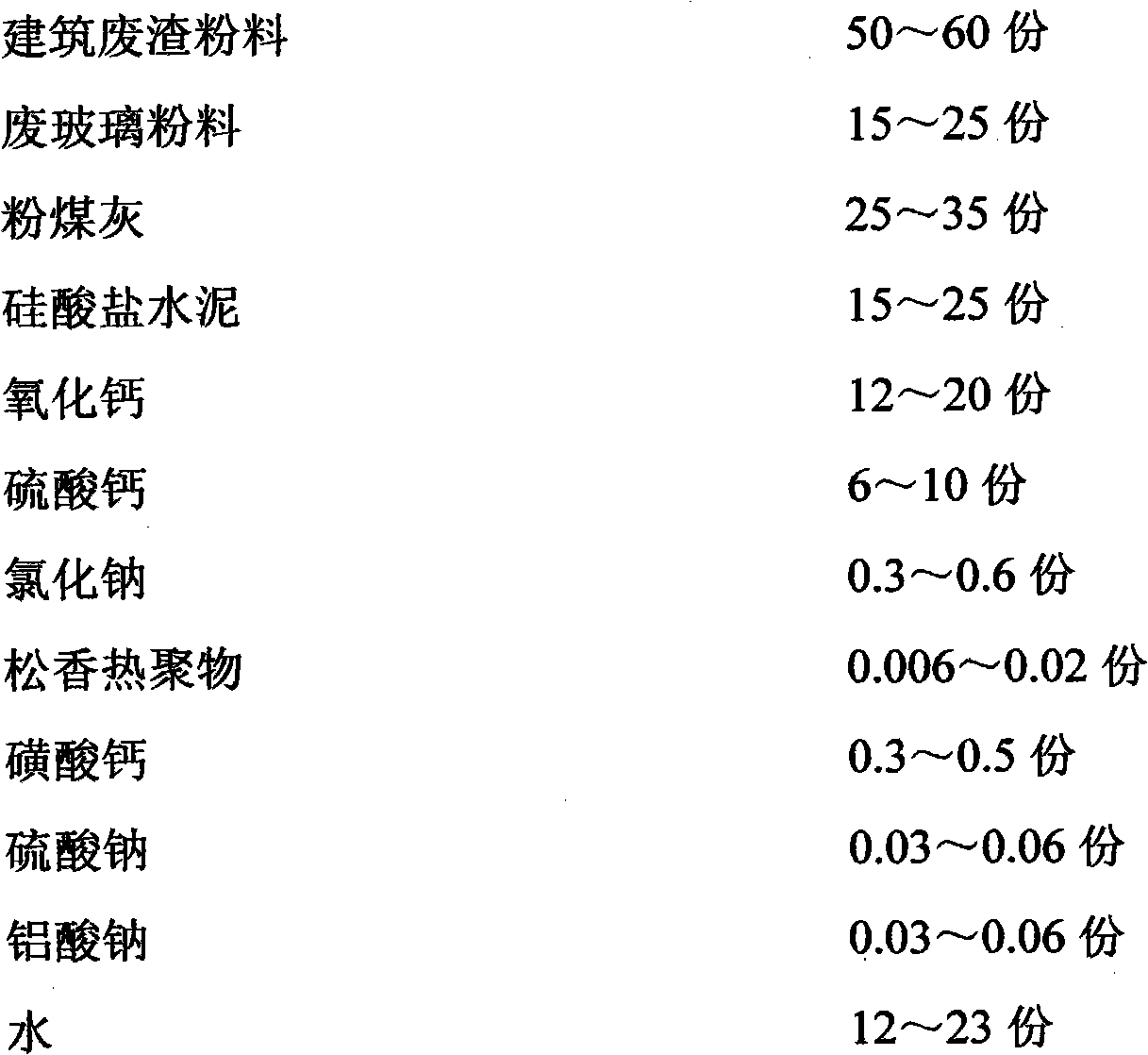

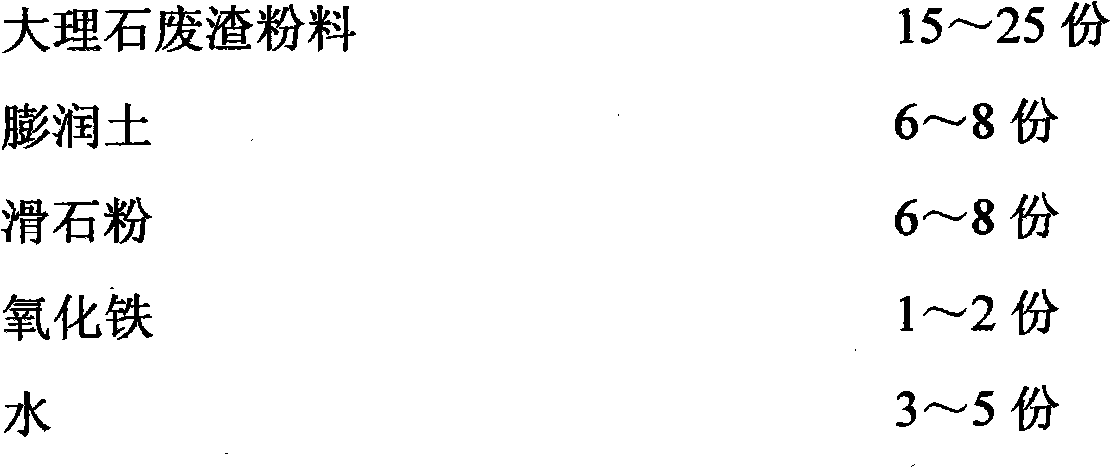

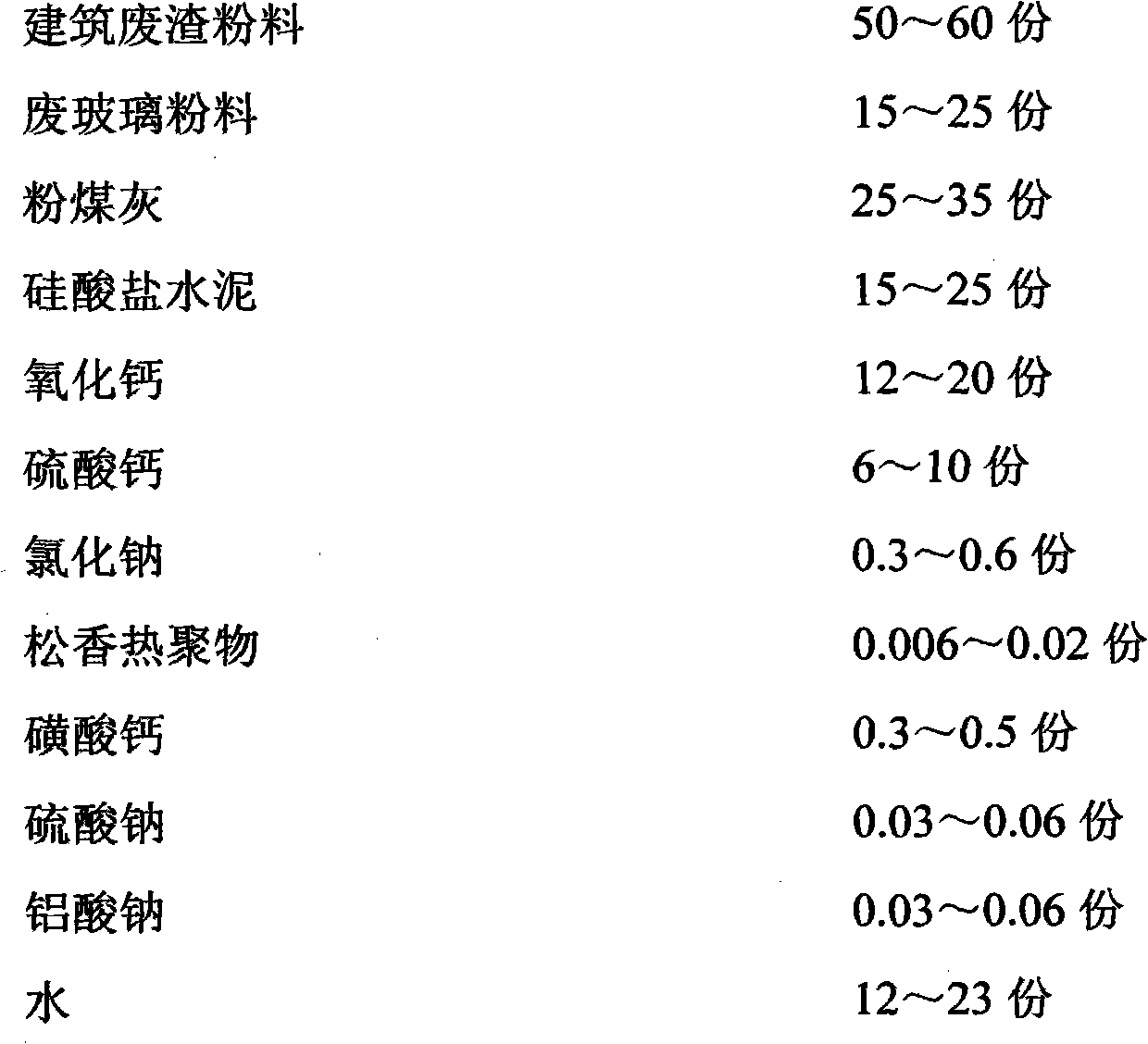

Water permeable bricks produced by using building waste residue and manufacturing method thereof

InactiveCN102418308APrevent subsidenceEasy constructionSolid waste managementSingle unit pavingsSodium BentoniteBrick

The invention relates to water permeable bricks produced by using building waste residue and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps: mechanically stirring a lower-layer brick material, which is formed by uniformly mixing building waste residue powder, waste glass powder, fly ash, portland cement, calcium oxide, calcium sulfate, sodium chloride, rosin pyrolytic polymer, calcium sulfonate, sodium sulfate, sodium aluminate and water, to be in a moist state, then performing mechanical vibration extrusion to form lower-layer bricks, further uniformly distributing an upper-layer brick material, which is formed by uniformly mixing marble waste residue powder, bentonite, talcum powder, iron oxide and water, on the upper parts of the lower-layer bricks through a secondary material distributing machine for forming a layer of surface material, then preparing water permeable adobe under the pressure of 25-30MPa, further performing steam curing, heating, keeping temperature constant and naturally cooling down to prepare water permeable brick products by using the building waste residue. The products have multiple functions of having water permeability, gas permeability and water retention property, reducing the temperature, reducing the noise, regulating the climate, eliminating the heat island effect of an urban, improving the air quality, keeping the circulation of surface water and the like, and have the advantages and effects of no pollution, low cost and good benefits.

Owner:河源市固体废物集中处置中心有限公司

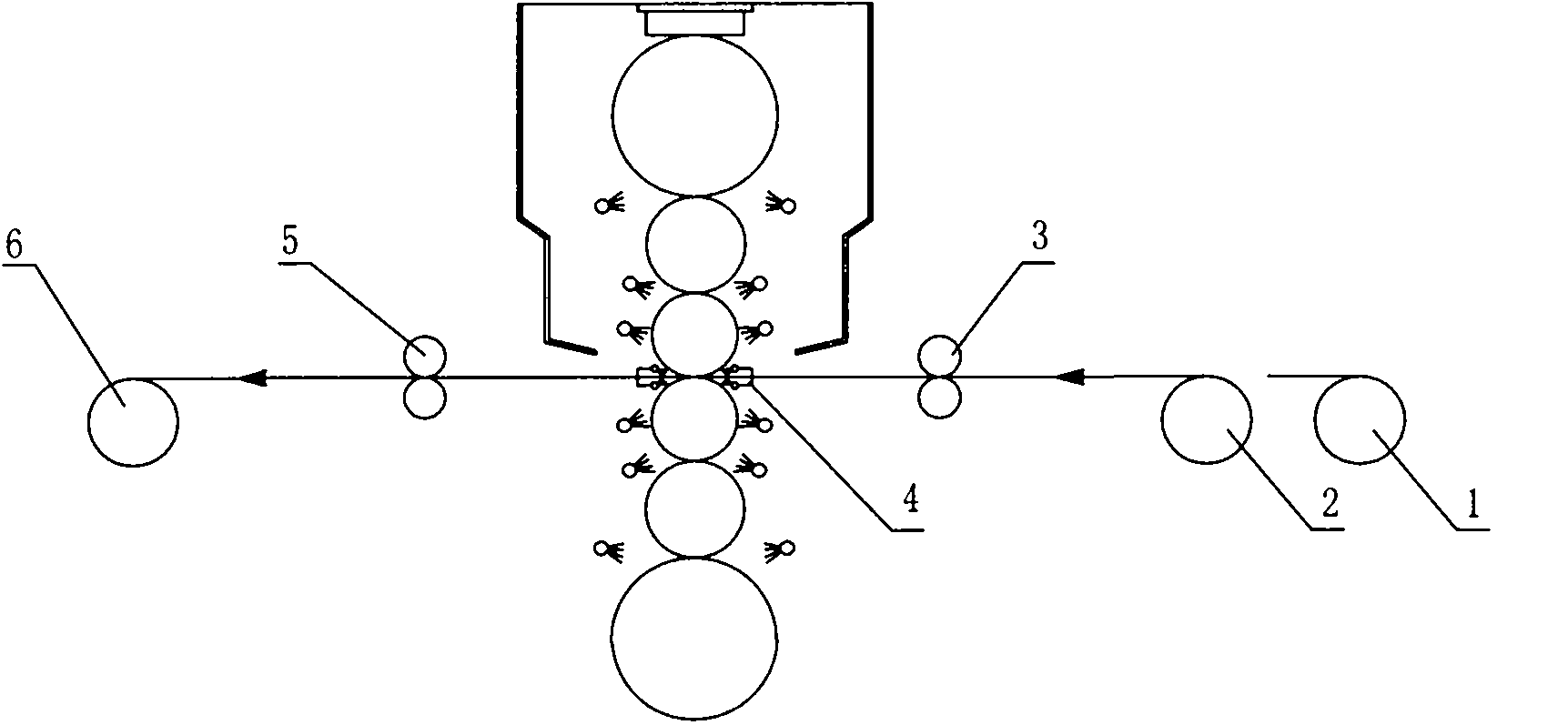

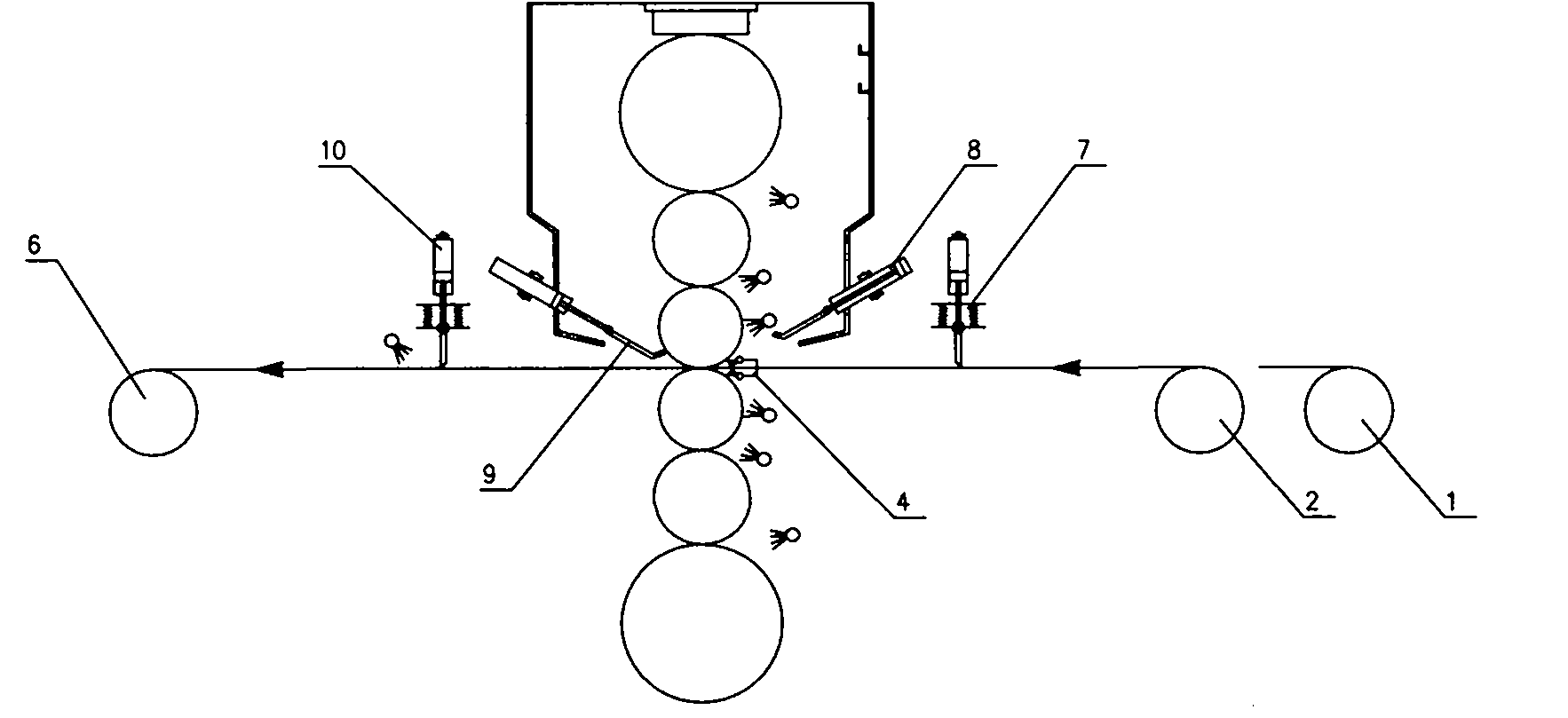

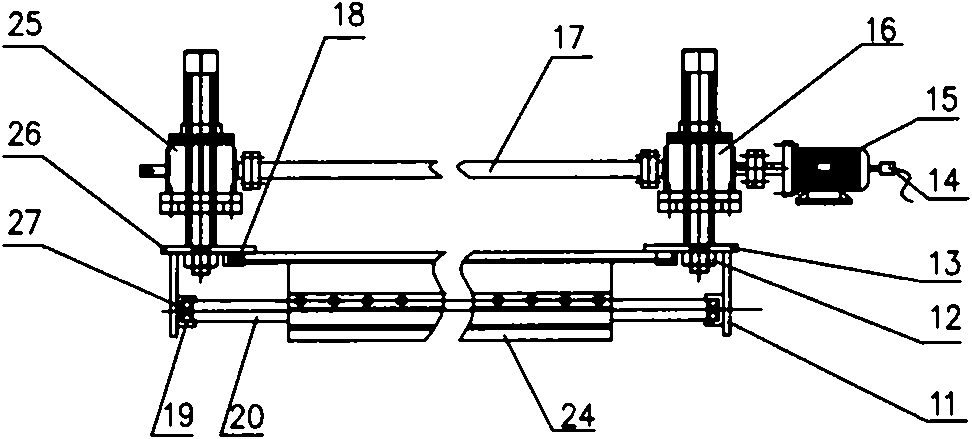

Textile fabric dust removal device

InactiveCN107805931AEfficient removalTo achieve a comprehensive cleaning effectMechanical cleaningPressure cleaningBody rollEngineering

The invention discloses a textile cloth dedusting device, which comprises a device body, openings are opened on both sides of the device body, and two symmetrical rollers are fixedly installed on the left end of the device body, between the two rollers room set with textile fabrics. The textile fabric dedusting equipment can drive the first rotating shaft and the second rotating shaft to rotate through the provided first pulley and the second pulley under the action of the motor, so that the two rolling brushes can simultaneously clean the upper surface and the second rotating shaft of the textile fabric. The lower surface is cleaned to effectively remove the cotton dust, cotton wool and other dust adhering to the textile fabric, achieving a comprehensive cleaning effect. Through the suction pipe set, under the action of the fan, the dust cover can The cotton dust, cotton wool and other dust cleaned by the rolling brush can be effectively absorbed, which prevents the cotton dust, cotton wool and other dust cleaned by the rolling brush from being scattered inside the equipment body, causing re-contamination of the textile fabric, and ensuring the cleaning efficiency.

Owner:SHAOXING HOUDAO AUTOMATION EQUIP CO LTD

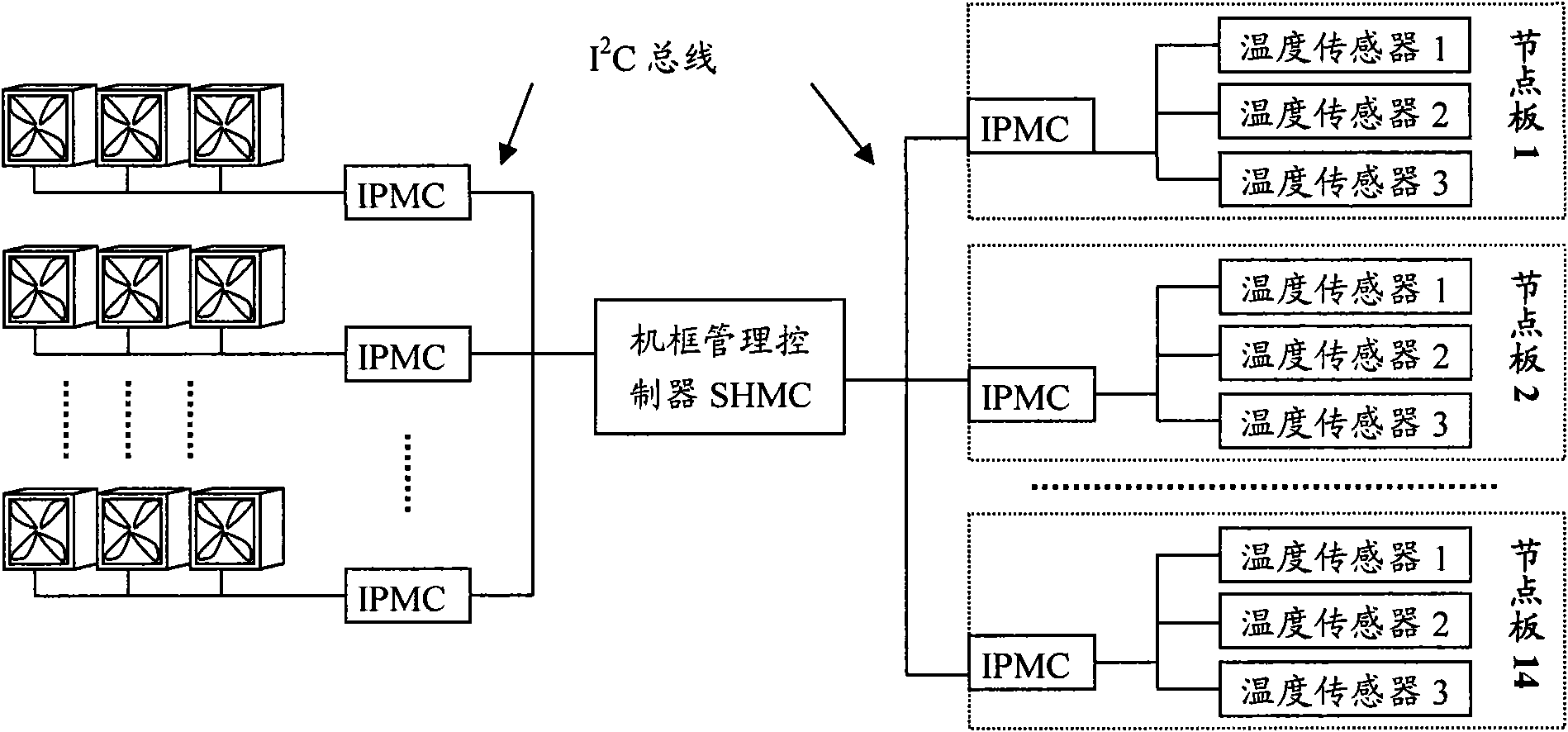

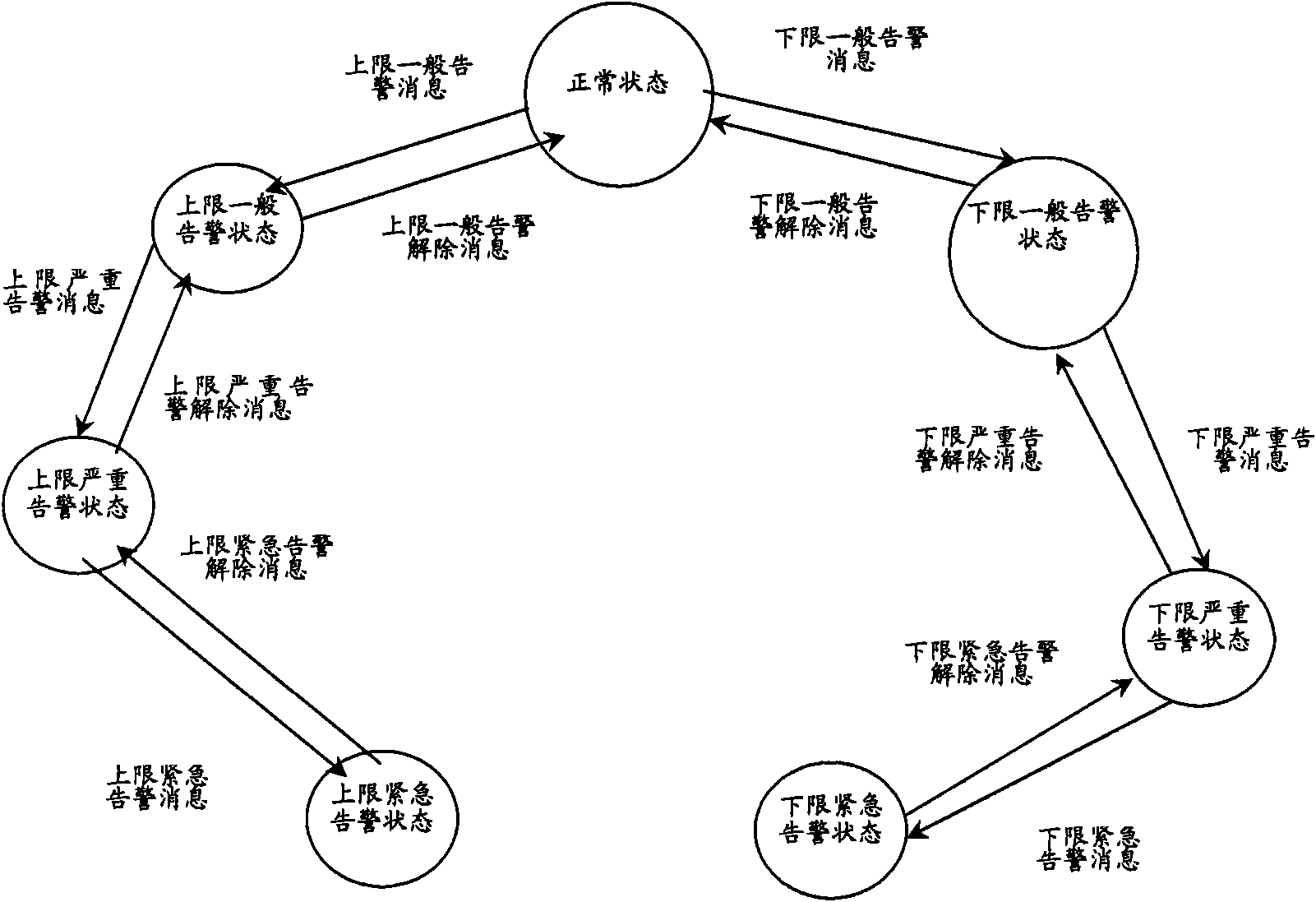

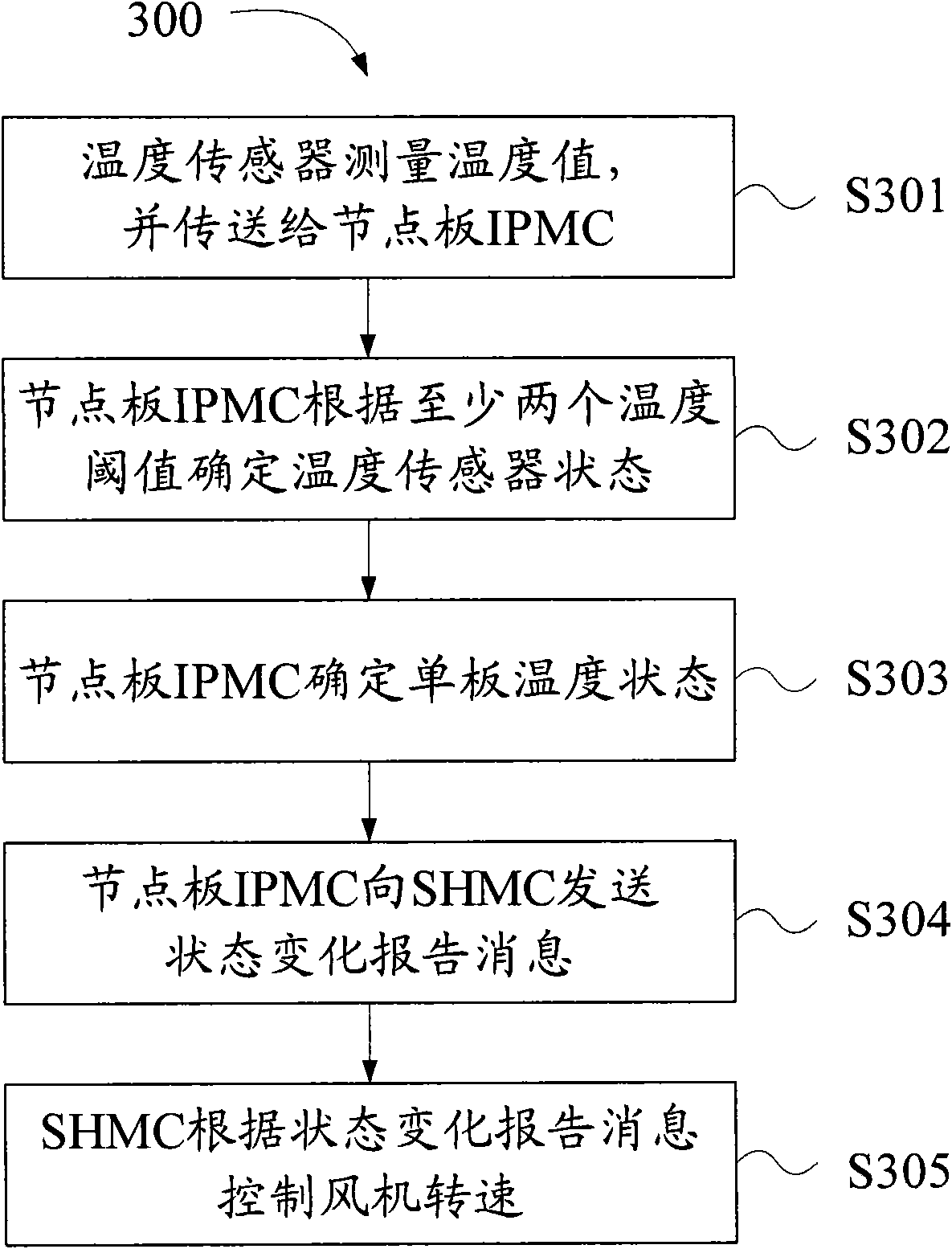

Control device and method of cooling fan of ATCA (Advanced Telecom Computing Architecture) system

ActiveCN101871465AReduce noise pollutionGuaranteed Cooling RequirementsPump controlCooling/ventilation/heating modificationsIonic polymer–metal compositesGusset plate

The invention provides control device and method of a cooling fan of an ATCA (Advanced Telecom Computing Architecture) system. The device comprises temperature sensors, a gusset plate IPMC (Ionic Polymer-Metal Composite) connected with the temperature sensors, and an SHMC (Shelf Management Controller) connected with the gusset plate IPMC, wherein the temperature sensors are used for measuring the temperature values of the areas where the temperature sensors are arranged and transmitting the temperature values to the gusset plate IPMC; the gusset plate IPMC is used for determining the states of the temperature sensors according to the temperature values of the temperature sensors on the gusset plate IPMC and temperature threshold values, determining single-plate temperature states and sending a state change report message to the SHMC according to the changes of the single-plate temperature states, and each temperature sensor at least comprises two temperature threshold values; and the SHMC is used for controlling the speed of the cooling fan according to the state change report message. By adopting the device and the method, the optimal control on the cooling fan can be realized, and energy saving control and noise reduction are realized while the cooling requirement of the system is guaranteed.

Owner:DATANG MOBILE COMM EQUIP CO LTD

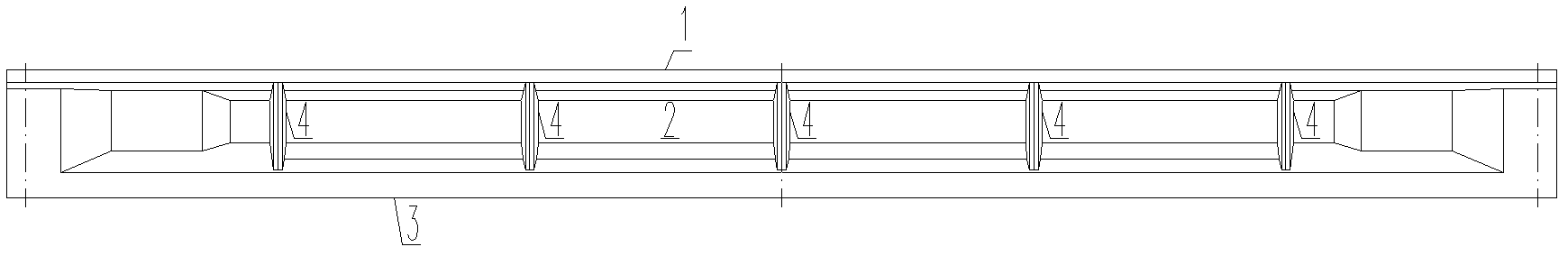

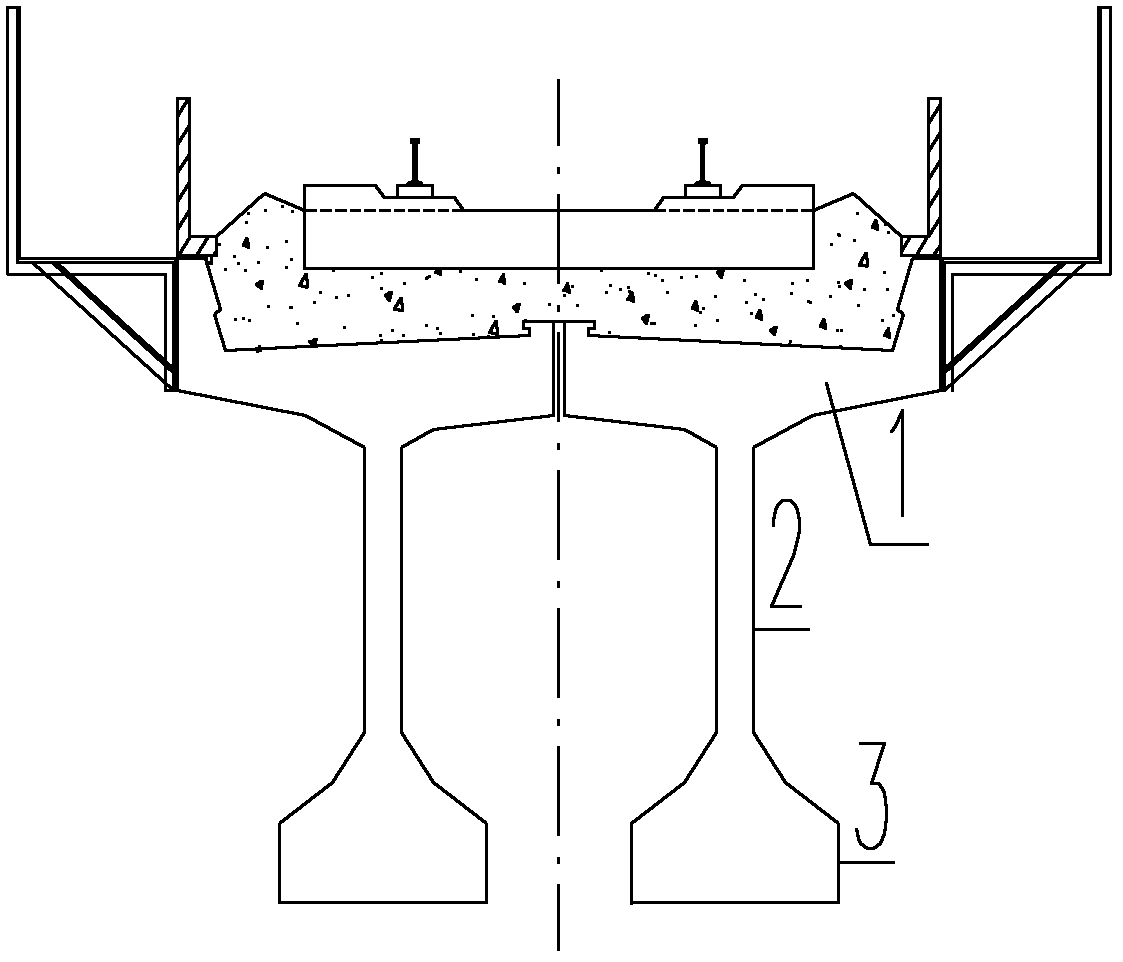

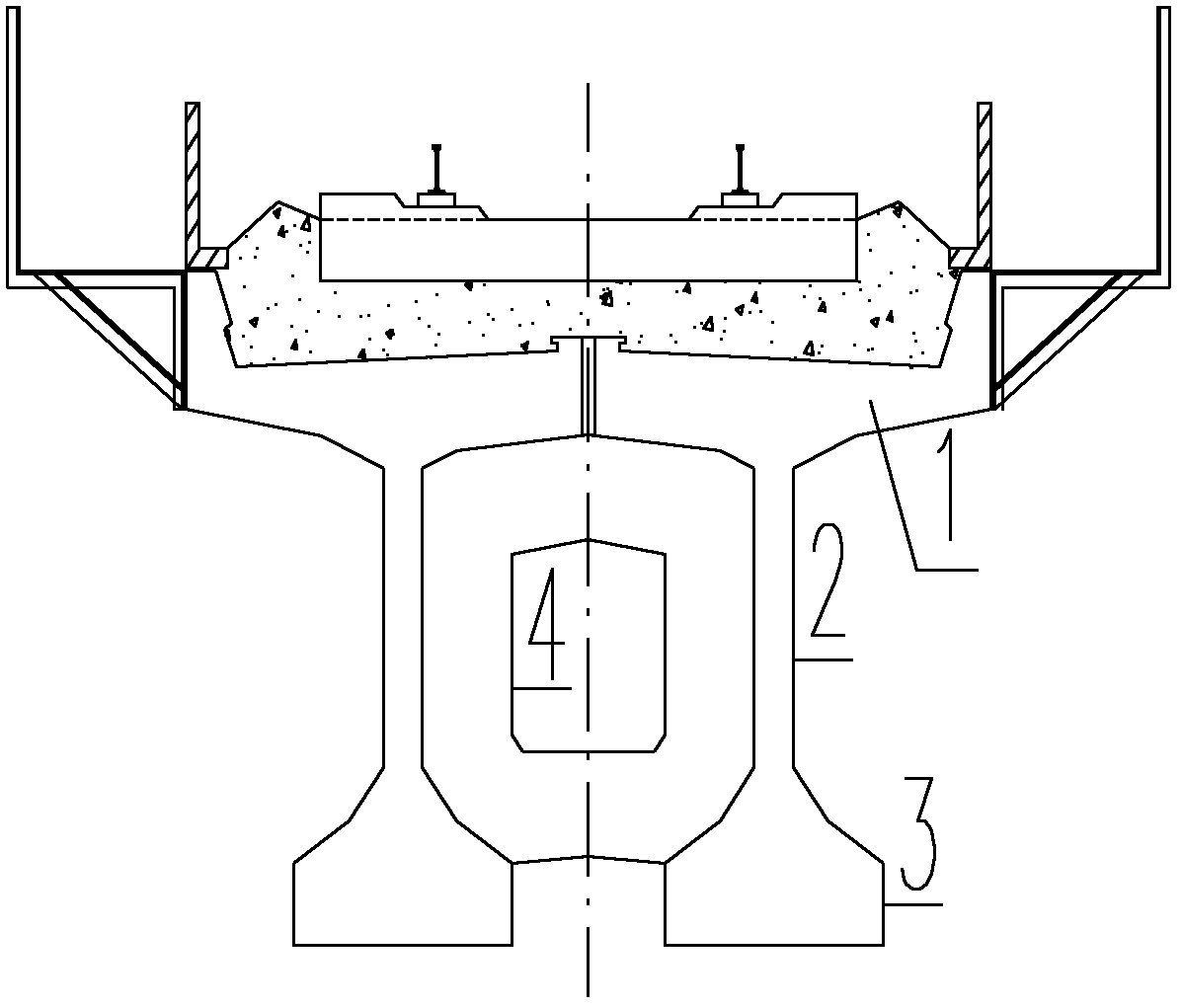

Self-balancing external prestressing strengthening method for bridge structure

ActiveCN102587296AReduce the burden onGive full play to the role of reinforcementBridge erection/assemblyBridge strengtheningConcrete beamsT-beam

The invention relates to a self-balancing external prestressing strengthening method for a bridge structure. The self-balancing external prestressing strengthening method is characterized by comprising the following steps of: carrying out interface processing at a connecting place (5) of a top flange of a concrete beam; (2) inserting reinforced bars at the connecting place (5) of the top flange of the concrete beam; (3) installing the reinforced bars at the connecting place (5) of the top flange of the concrete beam; (4) installing the reinforced bar of a steering block (6) and a diverter (9) at the bottom of the beam; (5) symmetrically adding diaphragm plates at a place far away from the end of the beam by 2-3m, and installing an anchorage device (10); (6) concreting the connecting place (5) of the top flange of the beam, the steering block (6) and the newly added diaphragm plates (8); and (7) installing and tensioning an anchoring external cable, thus obtaining a self-balancing external prestressing strengthening structure. An external prestressing system can be used for detecting and adjusting the stress of the cable at any time, inspecting the corrosion condition of the cable and can also be used for maintaining and replacing the cable when necessary. The self-compacting concrete solves the problems of dense reinforcement assembly, complex structure, narrow space of formworks and traditional structural members, cavities caused by the blocking of aggregates and the like, effectively ensures the dense degree of placing concrete and increases the strengthening effect. The self-balancing external prestressing strengthening method can be used for strengthening heavy railroad brides, concrete box girders and T beams.

Owner:SHUOHUANG RAILWAY DEV +3

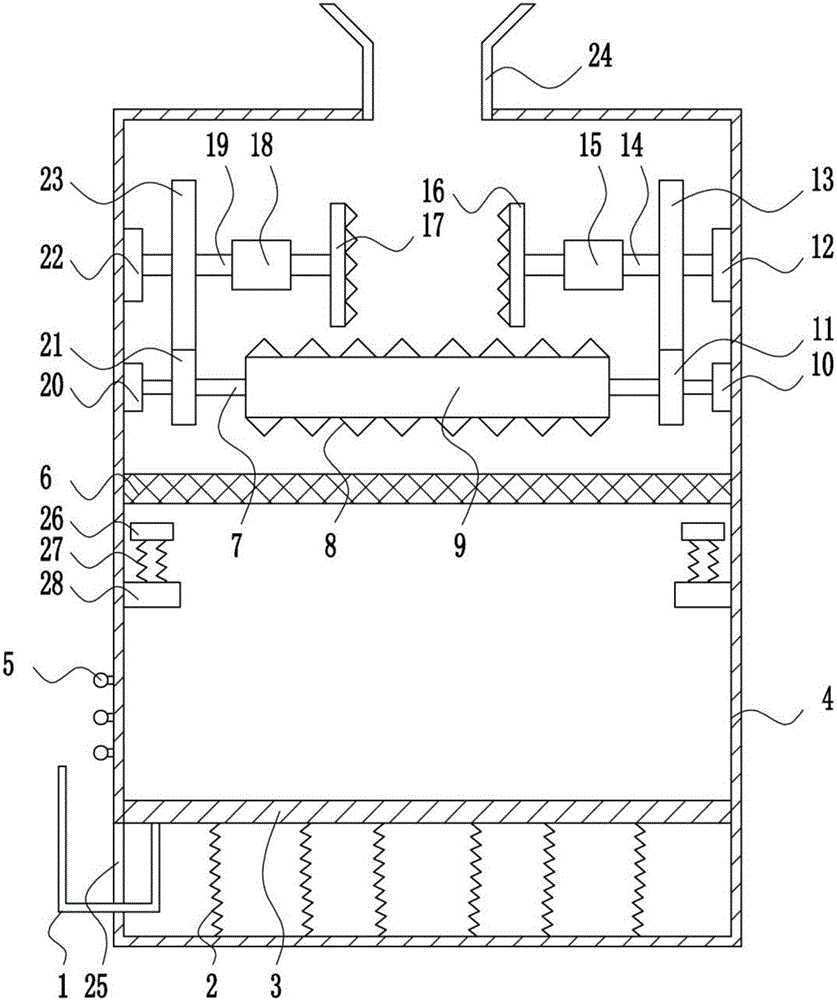

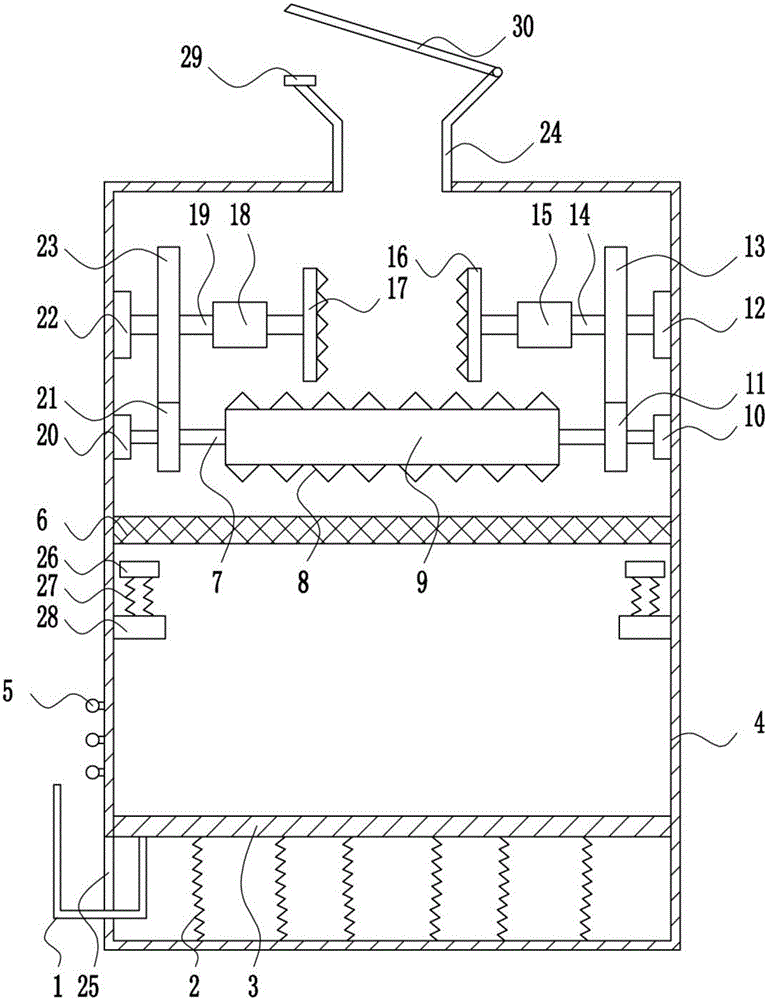

Environment-friendly treatment device for mosaic tiles

InactiveCN106269024AImprove processing efficiencyReduce dust and noiseSievingScreeningNoise pollutionMagnet

The invention relates to a treatment device, in particular to an environment-friendly treatment device for mosaic tiles. The environment-friendly treatment device for the mosaic tiles comprises a moving baffle, a first elastic part, a bearing plate, a treatment box, an indication lamp, an iron wire net, a third rotating shaft, breaking teeth, a breaking cylinder, a third bearing pedestal, a second small gear, a second bearing pedestal, a second large gear, a second rotating shaft, a second electric push rod, a second crushing plate, a first crushing plate, a first electric push rod, a first rotating shaft, a servo motor, a first small gear, a first bearing pedestal and the like. A moving hole is formed in the bottom of the inner left wall of the treatment box. The effects that the dust pollution is reduced, the noise pollution is reduced, the treatment efficiency is high, and the service life of the device is long are achieved, a magnet and an iron cover are arranged, and the treatment box can be closed.

Owner:CHONGQING RYAN PAINT CO LTD

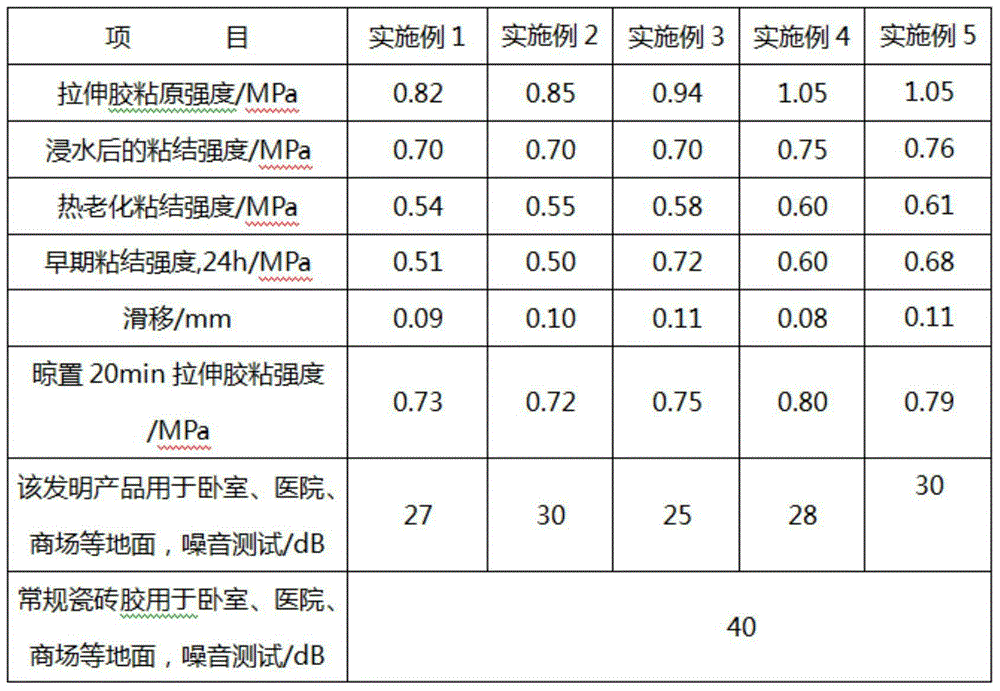

Cement-based adhesive

The invention discloses a cement-based adhesive which consists of an inorganic gel, elasticity modulus filler, sand and a dry-mixed mortar additive, wherein the mass percentages of the various components in the adhesive are as follows: 35-45% of inorganic gel, 15-30% of elasticity modulus filler, 17-47% of sand, 3-8% of dry-mixed mortar additive and the balance of water. The cement-based adhesive disclosed by the invention has the following beneficial effects that by adding the low elasticity modulus filler which has the advantages of good elasticity, shock-proofing, sound insulation and the like, the cement-based adhesive has the characteristics of shock absorbing, noise reduction and the like, so that a problem of noise generated from the collision of ceramic tiles in a public place is relieved; in addition, the cement-based adhesive provided by the invention also solves the problems of low compressive strength, low bonding strength and the like of the adhesive after the low-modulus filler is added; shearing strength on the interfaces of the ceramic tiles caused by heat expansion and cold contraction is reduced and the bonding durability of the ceramic tiles on the basis of shock absorbing and noise reduction is improved; therefore, the cement-based adhesive is quite high in promotional value.

Owner:北京天维宝辰化学产品有限公司

Sintered permeable environmental-friendly brick produced by using ceramic waste residue and manufacturing method thereof

ActiveCN101955349AMitigate the heat island effectGuaranteed water circulationSolid waste managementClimate change adaptationTunnel kilnBrick

The invention relates to a sintered permeable environmental-friendly brick produced by using ceramic waste residue and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: stirring ceramic waste residue powder, waste glass powder, waste porcelain fragment powder, municipal foundation waste sludge powder, calcium oxide, calcium sulfate, bentonite, talcpowder, garbage ash residue powder, waste plant powder and water serving as raw materials to form a wet mixture, and performing mechanical vibration and extrusion molding to obtain the lower-layer brick of the permeable brick; uniformly distributing a layer of fine fabric on the upper part of the lower-layer brick of the permeable brick by using a secondary distributing machine, manufacturing a ceramic waste residue sintered permeable environmental-friendly unburned brick under the pressure of 25 to 30Mpa and naturally drying; and feeding the molded and naturally-dried ceramic waste residue permeable environmental-friendly unburned brick into a tunnel kiln for roasting, controlling the temperature to be between 1,150 and 1,200 DEG C and burning the unburned brick to obtain the ceramic waste residue sintered permeable environmental-friendly brick product. Different specifications of vegetation bricks can also be prepared from the raw materials. The product has the advantages of certain water permeability, air permeability and water retentivity, multiple functions of reducing temperature and noise, regulating climate, eliminating urban heat island effect, improving air quality, maintaining surface water circulation and the like, high strength, no pollution, low cost and good benefit, and meets the requirements of energy conservation, emission reduction, environmental protection, and the development of low carbon economy in China.

Owner:清远绿由环保科技有限公司

Blowing-free emulsion residue removal method

ActiveCN101829693AImprove surface qualityReduce noise pollutionRollsWork cleaning devicesEmulsionRolling mill

The invention belongs to the technical field of cold-rolled emulsion spot treatment, and in particular relates to a blowing-free emulsion residue removal method, which is applied to various cold-rolling mills. The blowing-free emulsion residue removal method is characterized by comprising the following steps of: 1) blocking low inertia force return of the emulsion; 2) blocking side fluid channeling of the emulsion; 3) blocking fluid channeling of intermediate roll shifting empty emulsion; 4) blocking the condensate of the emulsion; 5) rapidly draining the injection beam of the emulsion; and 6) preventing splashing. The blowing-free emulsion residue removal method has the advantages of simpleness and excellent treatment efficiency.

Owner:WISDRI ENG & RES INC LTD

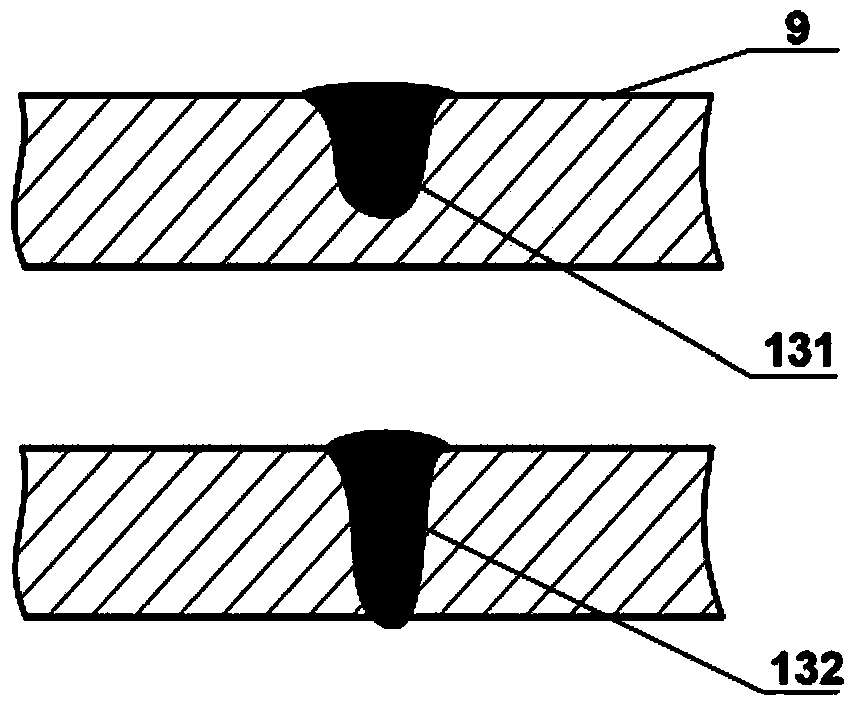

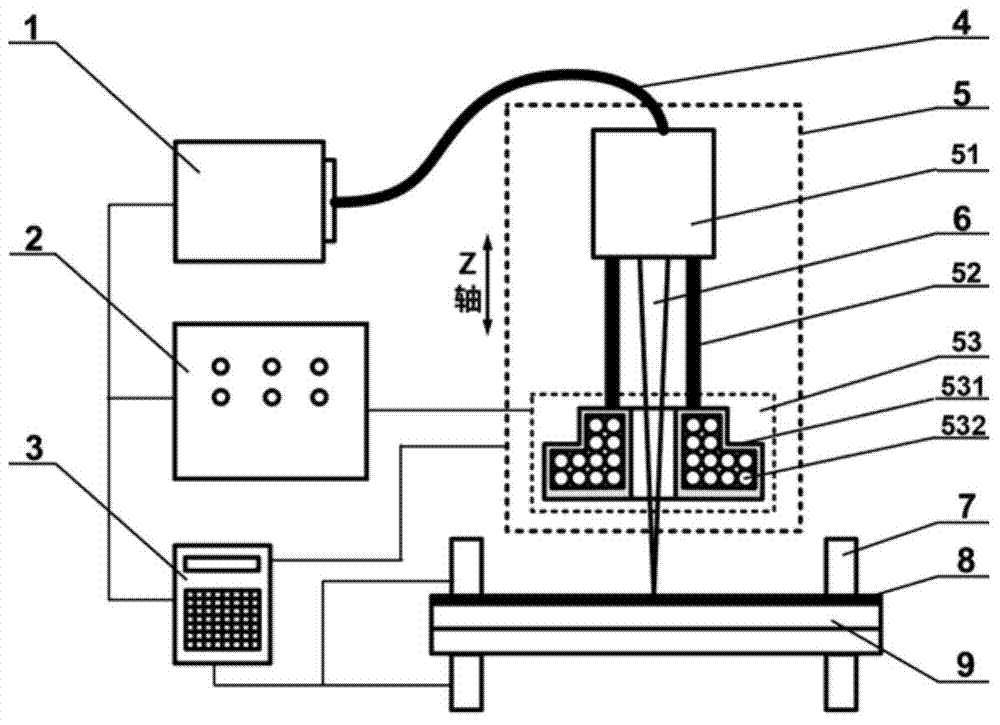

Pulsed high magnetic field auxiliary laser welding method and device

ActiveCN103769746AImprove fatigue strengthSmall structural deformationLaser beam welding apparatusStructural deformationStress concentration

The invention discloses a pulsed high magnetic field auxiliary laser welding method and device. The method and device can be applied to laser spot welding and seam welding. According to the method, in the overall welding process, laser beams are emitted to a workpiece to form a welding connector, a high pulsed magnetic field is exerted to the welding connector which is just solidified and the surrounding area, the pulsed magnetic field generates pressure stress on the surface of the workpiece to enable the connector area to have plastic deformation, residual stress is released to lower the degree of stress concentration and the degree of structural deformation of the welding connector, and the fatigue strength of the welding connector is improved. The device comprises a laser, a pulsed magnetic field generator, a numerical control system, an optical transmission system and a laser pulsed magnetic field composite processing head. The processing head is used for integrating the laser beams and the high pulsed magnetic field, and regulating the perpendicular distance between an electromagnetic conversion device and the surface of the workpiece and the horizontal distance between the electromagnetic conversion device and the laser beams. By means of the pulsed high magnetic field auxiliary laser welding method and device, structural deformation can be lowered, welding quality and processing efficiency are improved, and the processing effect which is superior to that of an existing laser welding process is achieved.

Owner:武汉飞能达激光技术有限公司

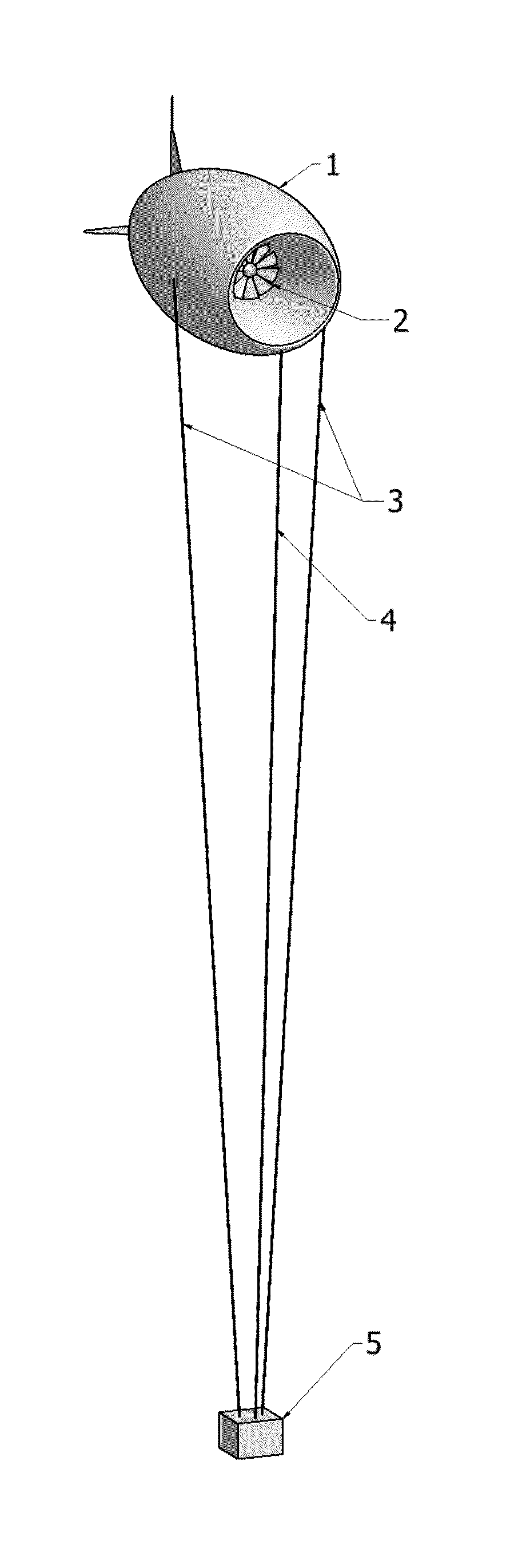

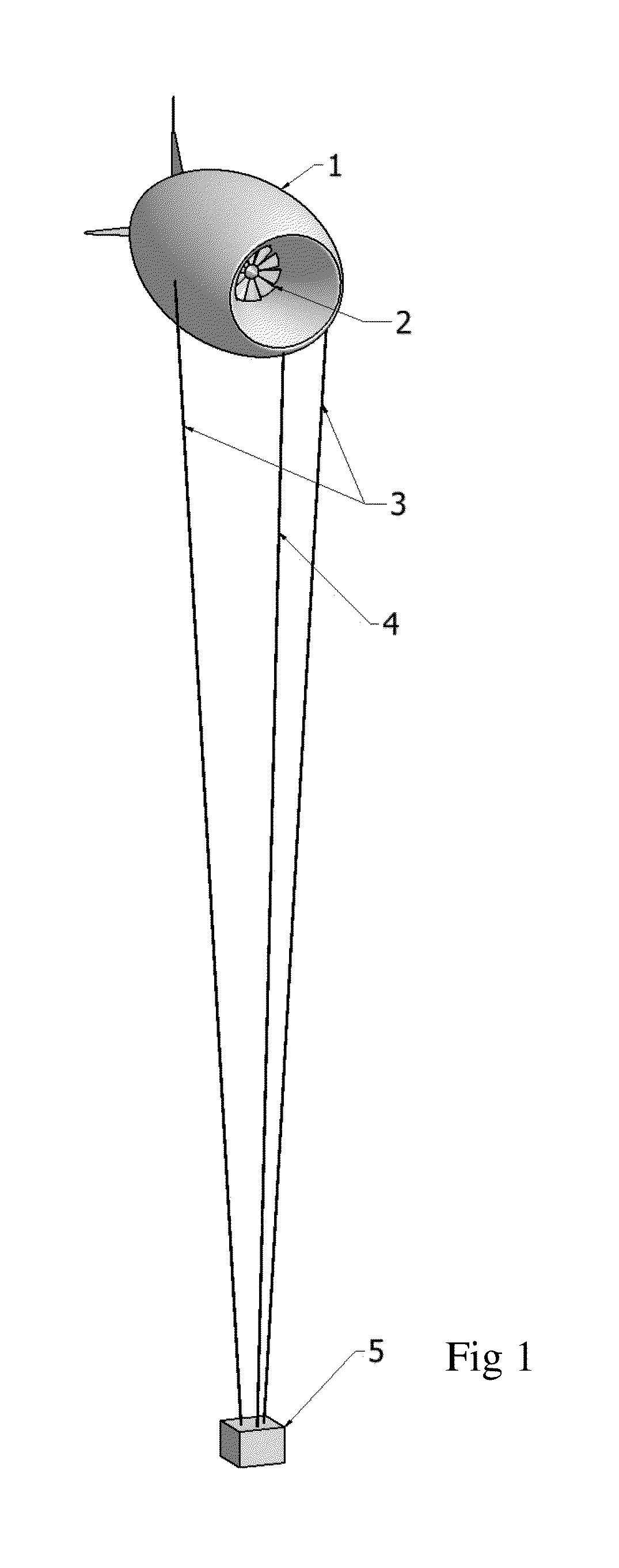

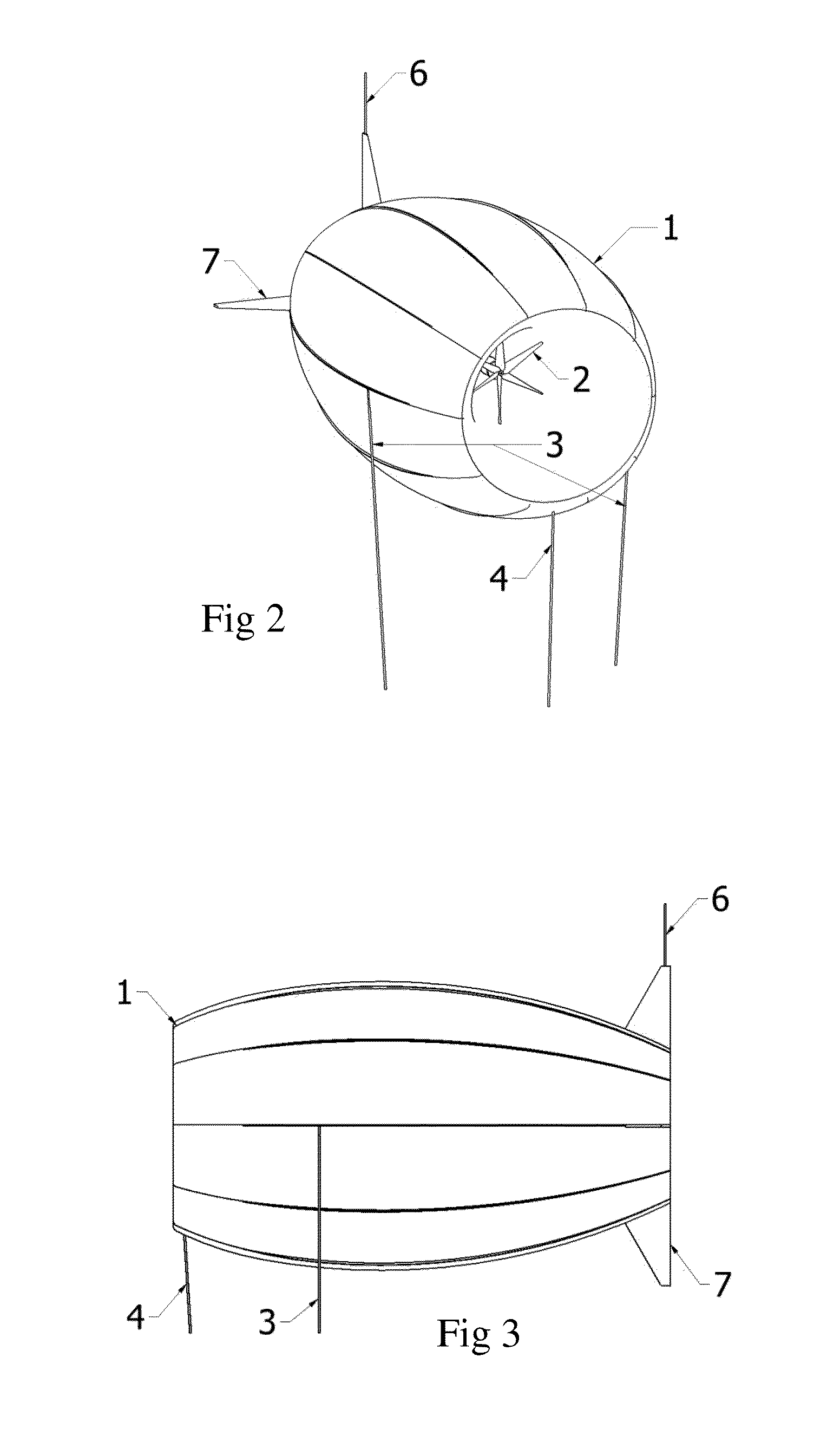

Portable Self-Inflating Airborne Wind Turbine System

InactiveUS20140377066A1Avoids large maintenance costReduce noise pollutionPropellersPump componentsWind forceAutomotive engineering

A portable airborne wind-energy power conversion system, alone or in a modular array, wherein each portable airborne system comprises tethered airship, hydrogen generation system, hydrogen recovery system, and control system, wherein the tethered airship comprises a self-inflating horizontal-axis wind turbine rotor, an electrical generator, a self-inflating aerodynamic shroud surrounding the wind turbine rotor, and stabilizing fins, wherein the aerodynamic shroud has the geometry of a wind concentrator and diffuser in fluid communication with the wind turbine rotor that is located in the narrowest section of the shroud between the concentrator and diffuser sections of said shroud, wherein the airship is additionally self-deflating and the entire system is collapsible into a volume less than one tenth of its original size, so that the portable airborne system can be easily transported, stored, or relocated, wherein the system can continue to produce usable power, even during the process of self-deflation.

Owner:ANDERSON ALEXANDER ANATOLIY

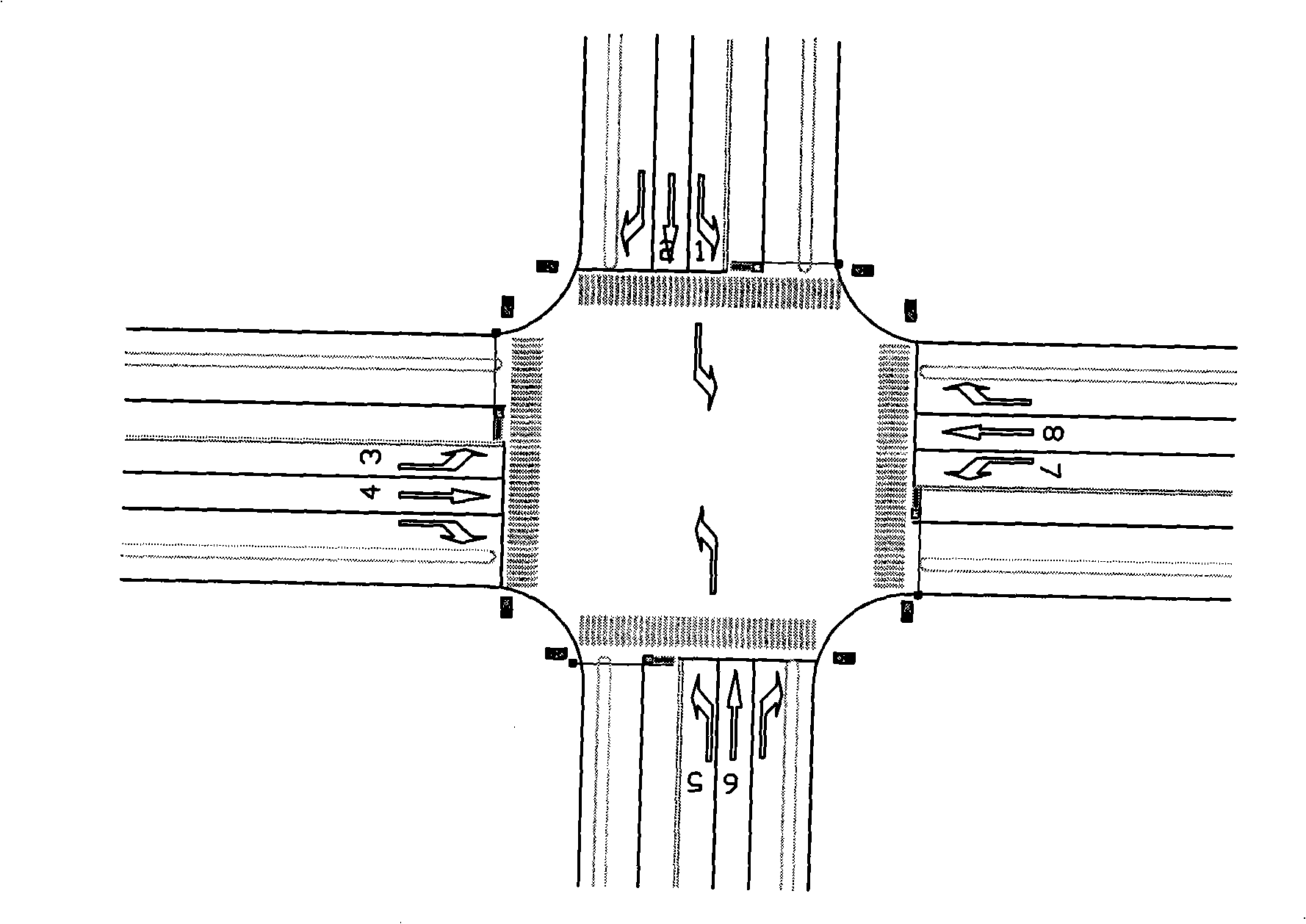

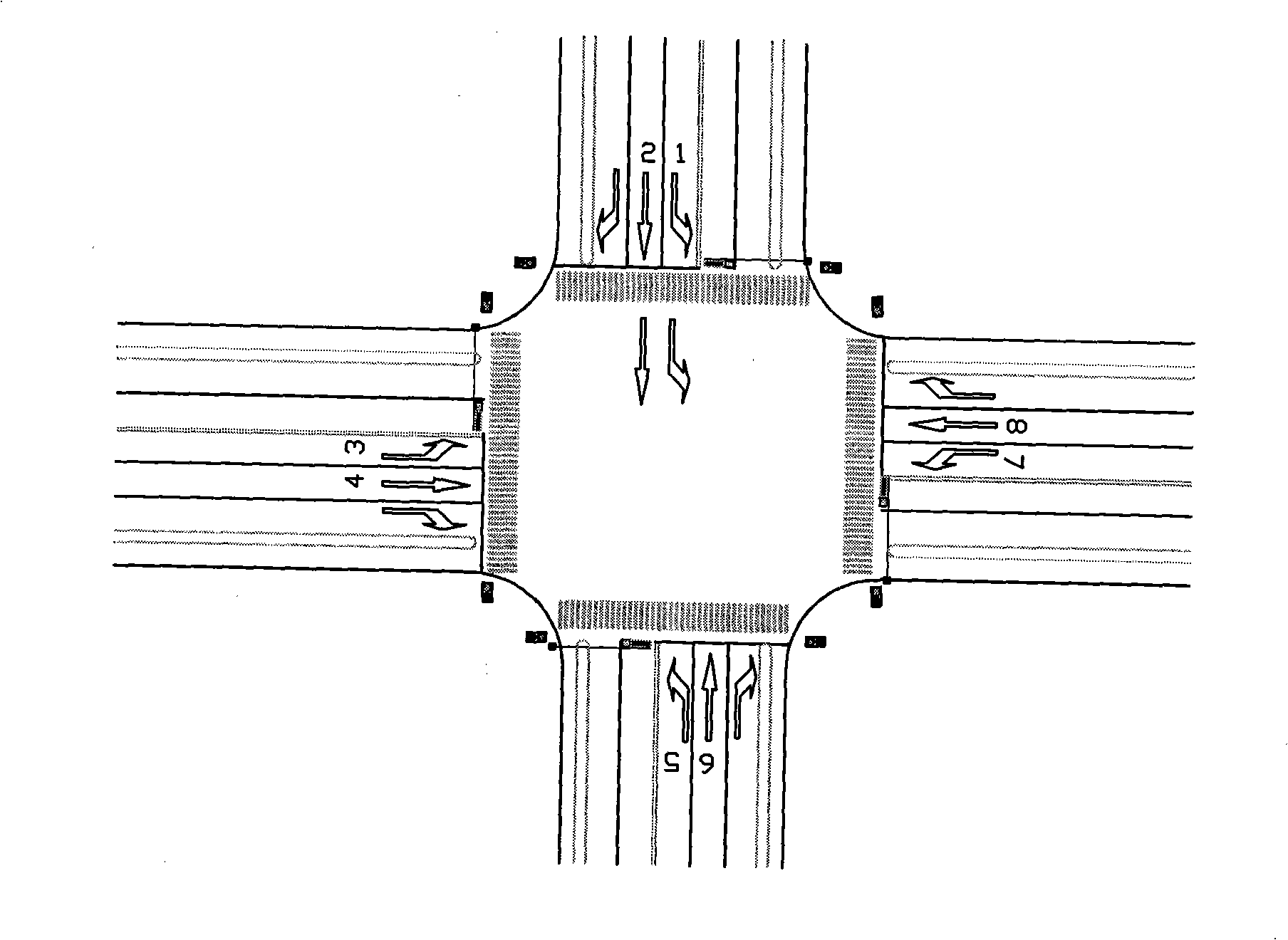

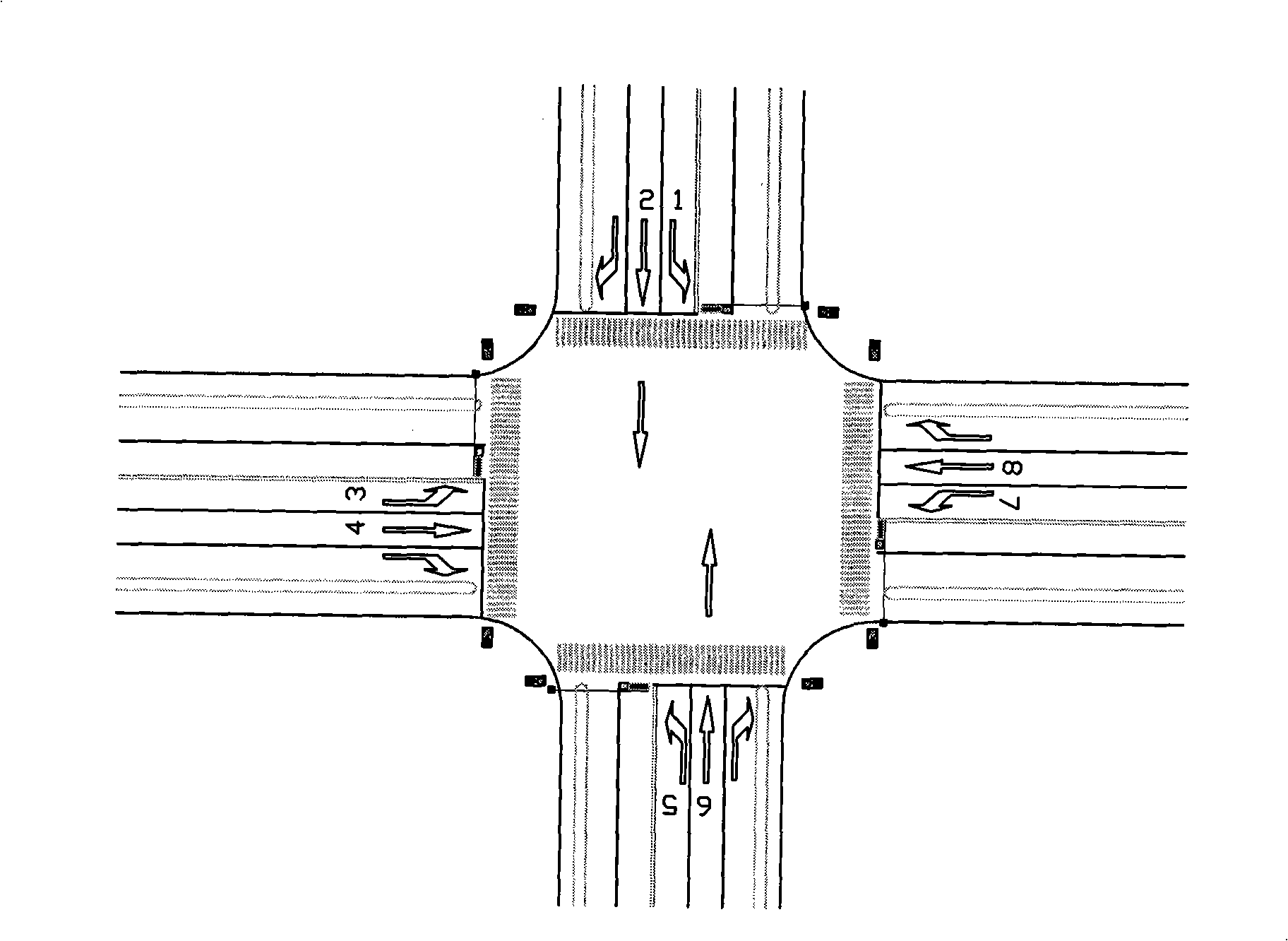

Control method for urban road traffic

InactiveCN101409016AReduce pollutionGet the most out of your utilizationControlling traffic signalsDetection of traffic movementGreen timeSingle vehicle

The invention discloses an urban road traffic control method which comprises the following steps (1) acquiring traffic information of a road junction by an information acquisition device, detecting vehicle information, and computing lane occupancy ratio, an average speed V of a single vehicle and a detection distance L; (2) computing green time S of a single lane; (3) dividing a signal cycle into an east-west release phase and a south-north release phase; wherein, the east-west release phase is divided into an east-west left-turn phase and an east-west straight phase; the south-north release phase is divided into a south-north left-turn phase and a south-north straight phase; if the left-turn lanes and straight lanes in east, south, west and north directions are represented by 1 to 8, and the green time of each lane is S1 to S8 accordingly; the S1 to S8 are respectively computed according to a formula (1) to control the green time of the road junction. The urban road traffic control method acquires and processes car flow information in real time, has high accuracy and effectively utilizes road traffic capacity.

Owner:ZHEJIANG TONGQU TECH

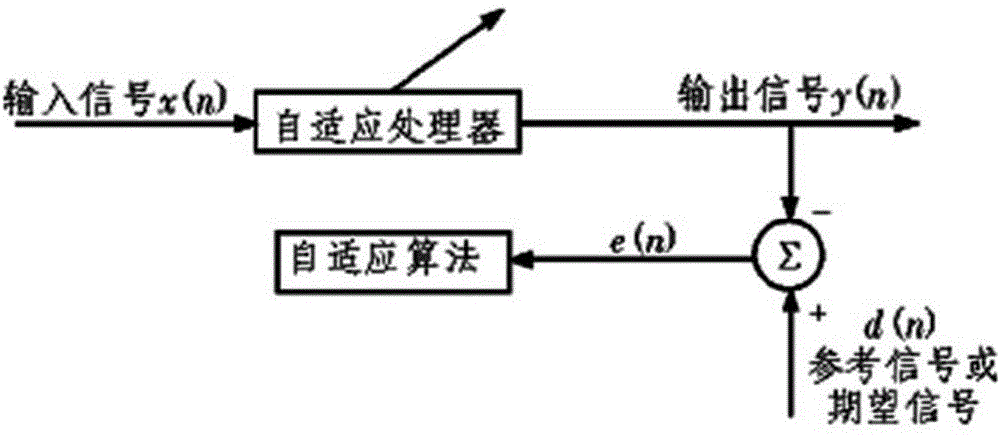

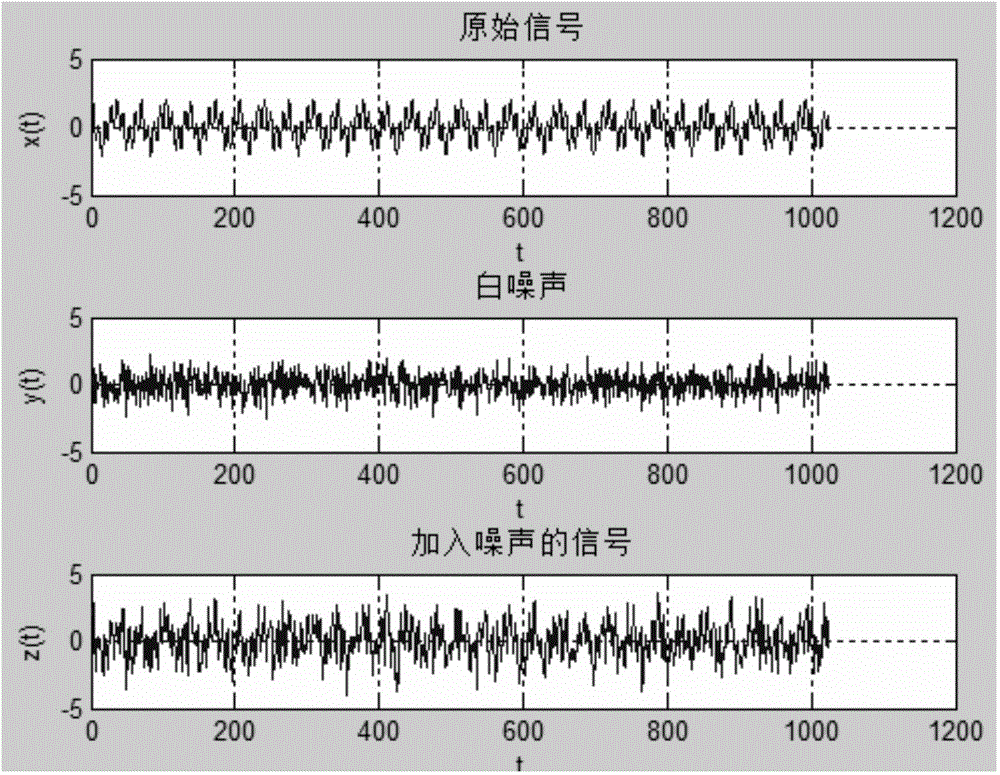

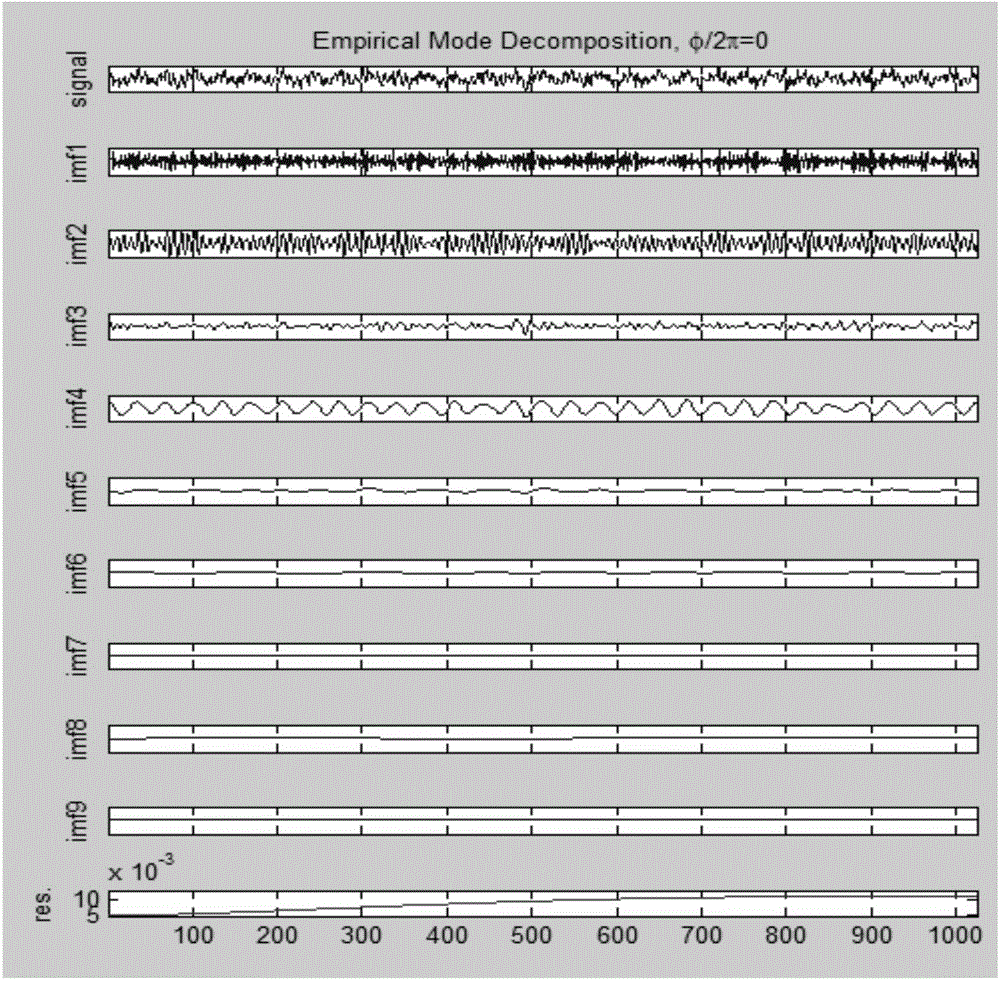

Vibration signal noise reduction method based on variable-step-length LMS-EEMD

InactiveCN104679981AReduce noise pollutionStrong noise pollutionSpecial data processing applicationsLow noiseNoise reduction

The invention discloses a vibration signal noise reduction method based on variable-step-length LMS-EEMD. The method includes: acquiring an initial noise reduction signal according to an original signal; decomposing the initial noise reduction signal, and selecting an IMF component needed in noise reduction; acquiring a final noise reduction signal according to the original signal and the selected IMF component. By the method, the defects of complex operation process, high noise pollution and weak noise reduction capability in the prior art can be overcome, and simple operation process, low noise pollution and strong noise reduction capability are achieved.

Owner:XINJIANG UNIVERSITY

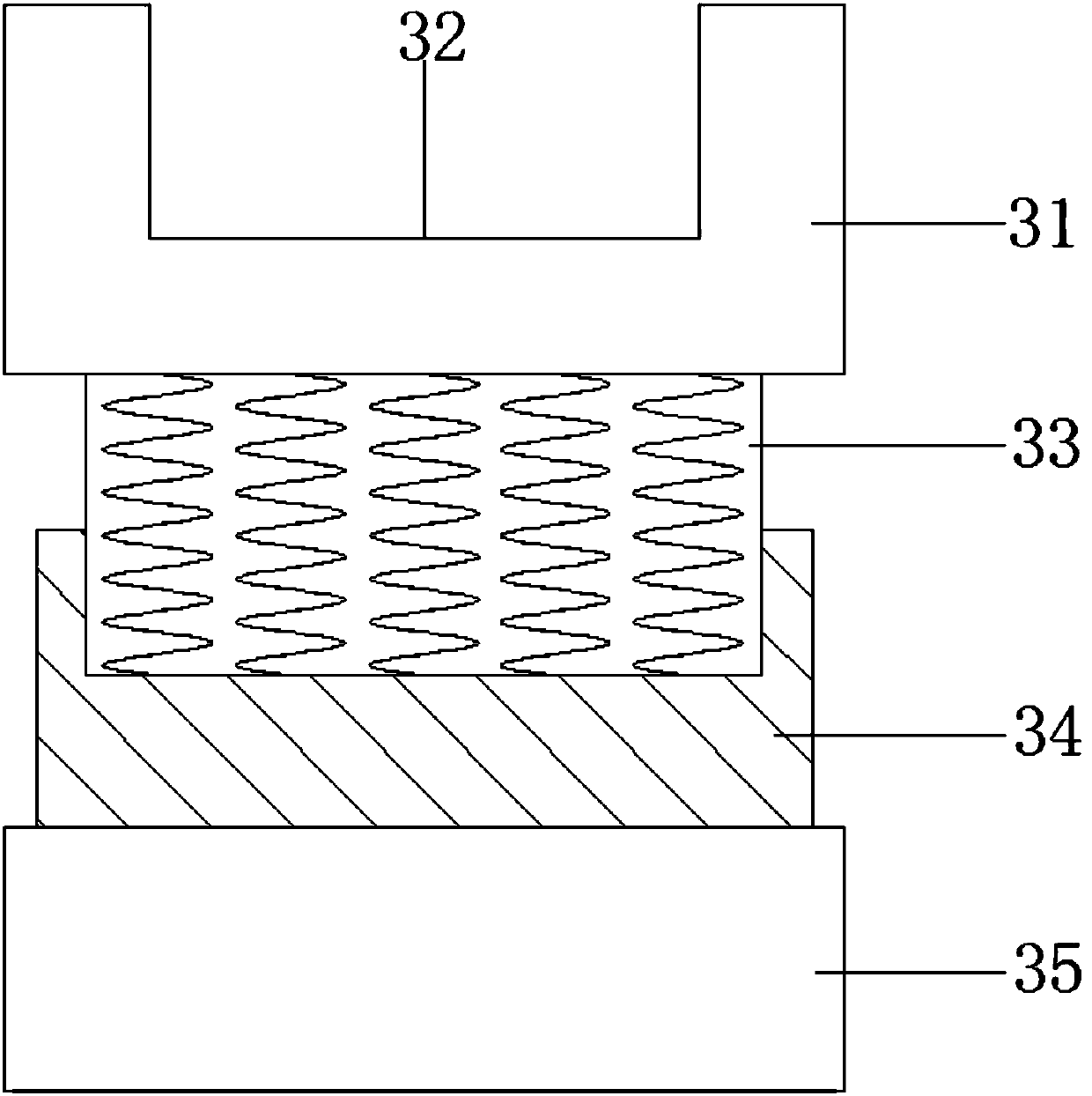

Wind power generation device

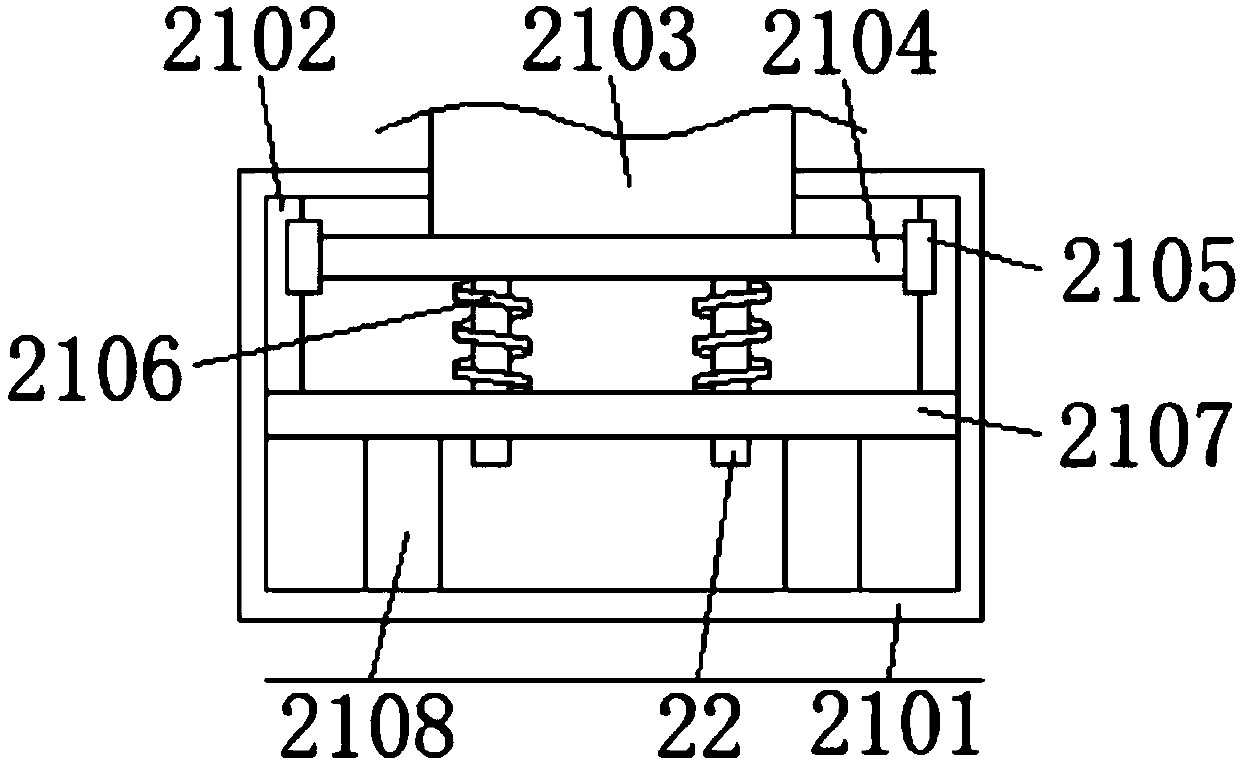

InactiveCN107588151AReduce vibrationHigh mechanical strengthNon-rotating vibration suppressionSupports/enclosures/casingsResonanceEngineering

The invention relates to the field of wind power generation, and particularly discloses a wind power generation device. The device comprises a generator and a square tank, the lower portion of the generator is located in the square tank, a vertical shock absorber is arranged between the bottom plate of the square tank and the bottom surface of the shell of the generator, and transverse shock absorbers are arranged between the four side plates of the square tank and the side surfaces of the shell of the generator; the vertical shock absorber comprises a first shock absorbing mechanism and second shock absorbing mechanisms, wherein the first shock absorbing mechanism comprises an outer sleeve cylinder, a base assembly and a fixing assembly; the second shock absorbing mechanisms comprise twoelastic shock absorbing plates symmetrically fixed to the shell of the generator and pouring bags arranged between the elastic shock absorbing plates and the bottom plate of the square tank, and the transverse shock absorbers comprise outer cylinders fixed to the side plates of the square tank and inner cylinders slidably arranged in the outer cylinders in a sleeved mode. By means of the wind power generation device, shock absorbing and noise reduction can be effectively conducted on the generator, occurrence of resonance between the generator and external environment is prevented, smooth andstable operation of the generation device is ensured, the noise produced by the generator during work is reduced, and the noise pollution is reduced.

Owner:长沙小新新能源科技有限公司

Drilling machine for hardware manufacturing

PendingCN108422014AEasy to adjustEasy to usePositioning apparatusBoring/drilling componentsMotor driveElectric machinery

The invention provides a drilling machine for hardware manufacturing and relates to the technical field of hardware manufacturing equipment. The drilling machine for hardware manufacturing comprises abaseplate, a polishing device is fixedly arranged at the top of the baseplate and comprises a mounting plate, and a rack is fixedly arranged at the top of the mounting plate; a first machine box is fixedly arranged at the left side of the rack, and a first motor is fixedly arranged in the machine box through a motor mounting block. According to the drilling machine for hardware manufacturing, through cooperation of the rack, the first motor, a rotation rod, a first bearing, a sliding ring, a guide rod, a guide ring, a fixing rod, a hydraulic retractable rod and a polishing motor, the slidingring is in threaded connection with the rotation rod, and therefore when the first motor drives the rotation rod to rotate, the sliding ring can drive the polishing motor at the bottom of the slidingring to move left and right; meanwhile, the polishing motor can be moved up and down through the hydraulic retractable rod so that drilling operation on hardware can be conducted, and the drilling machine is convenient to adjust and use during use and helps to improve the efficiency of machining and manufacturing the hardware.

Owner:SUQIAN RONGJIN INFORMATION TECH

Paint spraying device for electrical equipment machining

InactiveCN107661836APrevent leakageImprove working environmentPretreated surfacesLiquid spraying apparatusActivated carbonElectric machinery

The invention discloses a paint spraying device for electrical equipment machining. The paint spraying device comprises a machine body, a paint spraying support is arranged in the center in the machine body, a rotary shaft is connected with the center of the bottom of the paint spraying support, and the bottom of the rotary shaft stretches outside of the machine body and is connected with a rotating motor. A noise-reduction cover is arranged on the outer side of the rotating motor, a horizontal supporting plate is arranged on the lower side of the rotating motor, and lifting rods are connectedwith the left and right ends on the upper side of the supporting plate respectively. According to the paint spraying device for electrical equipment machining, a part is driven by the rotating motorrotate and rise in the paint spraying process, convenience is brought to paint spraying, and the work efficiency is improved. Extra paint in the paint spraying process enters a water tank along with awater curtain and collected by a gauze layer, the paint can be filtered, the paint smell can be adsorbed, and the working environment of operators is improved; activated carbon particles are easily taken out and replaced, and convenience is brought to use; besides, damping can be effectively conducted, the device can more smoothly work, and the safety is improved.

Owner:ZHENJIANG QILONG TECH CO LTD

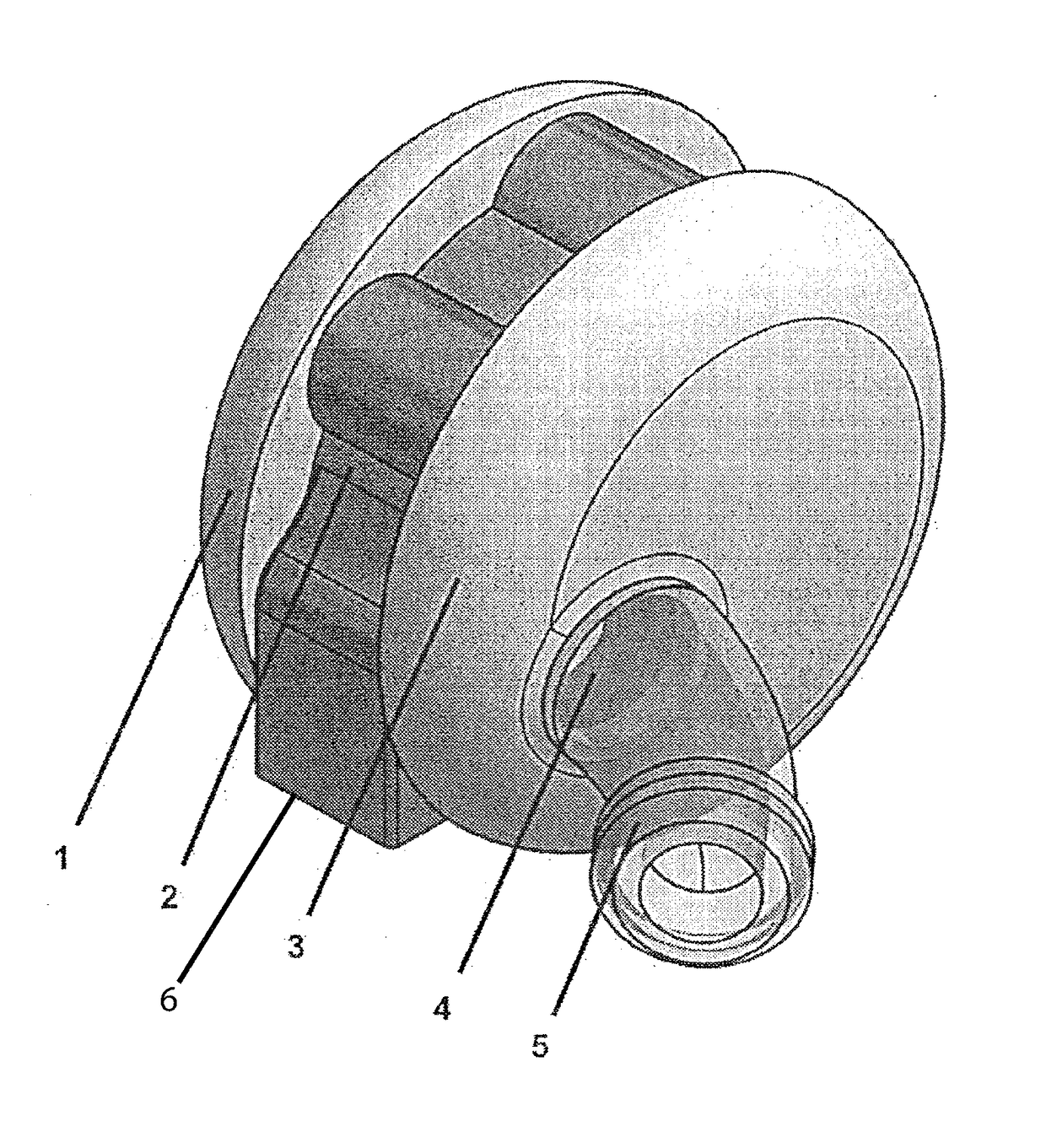

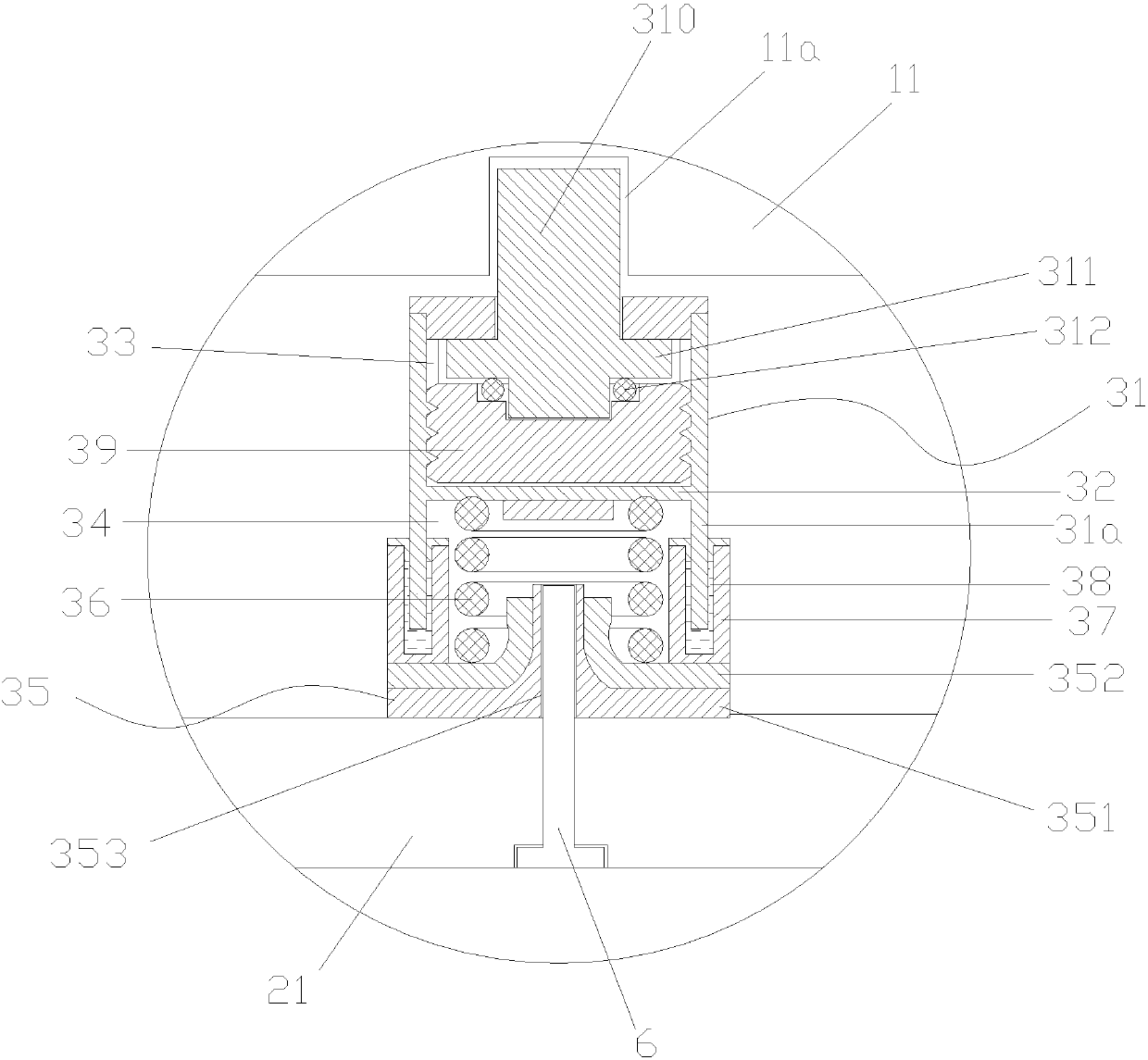

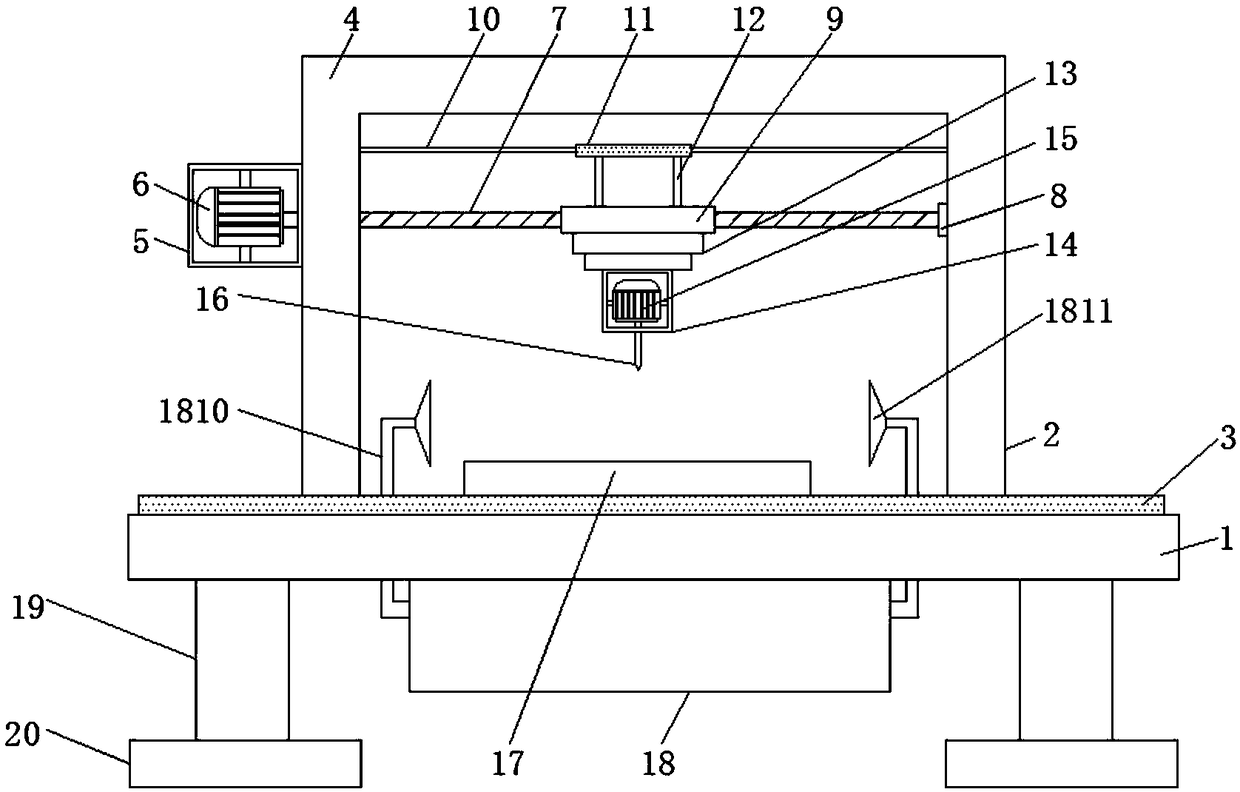

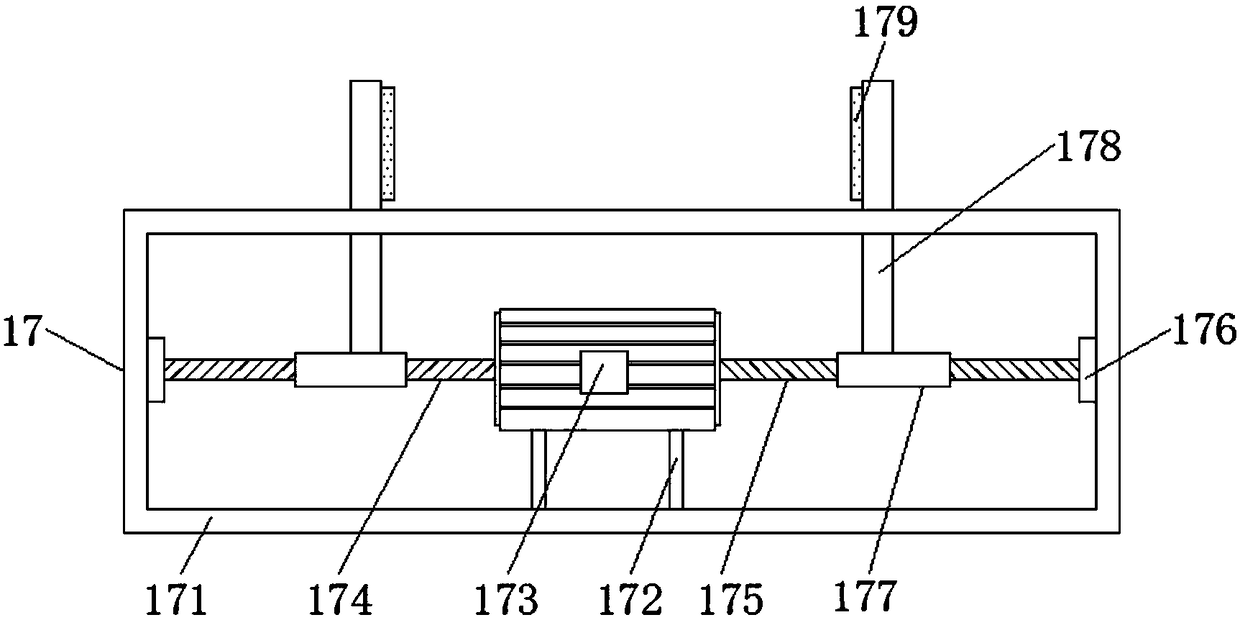

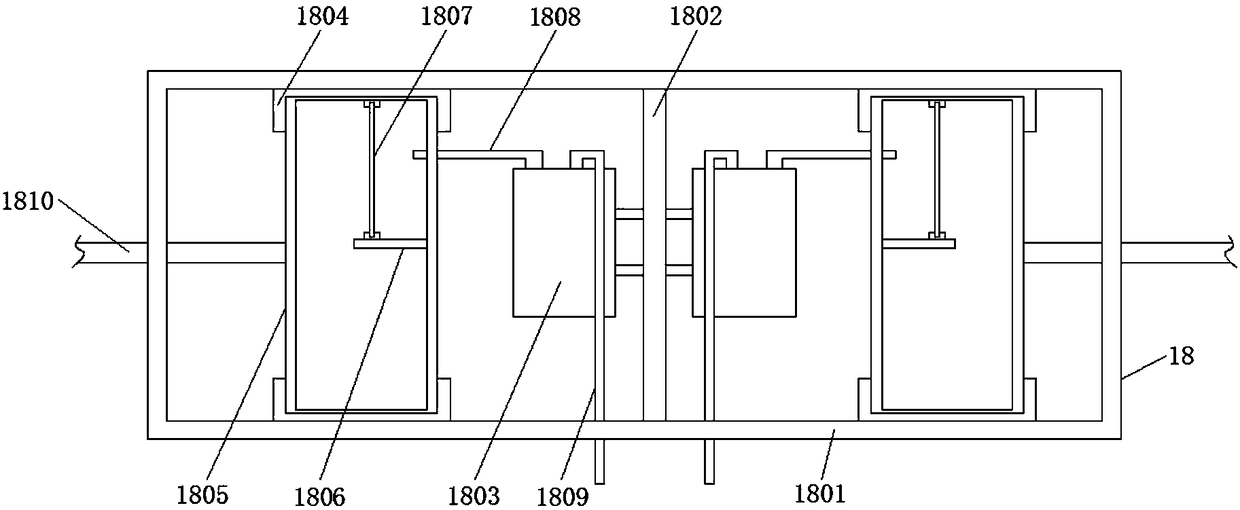

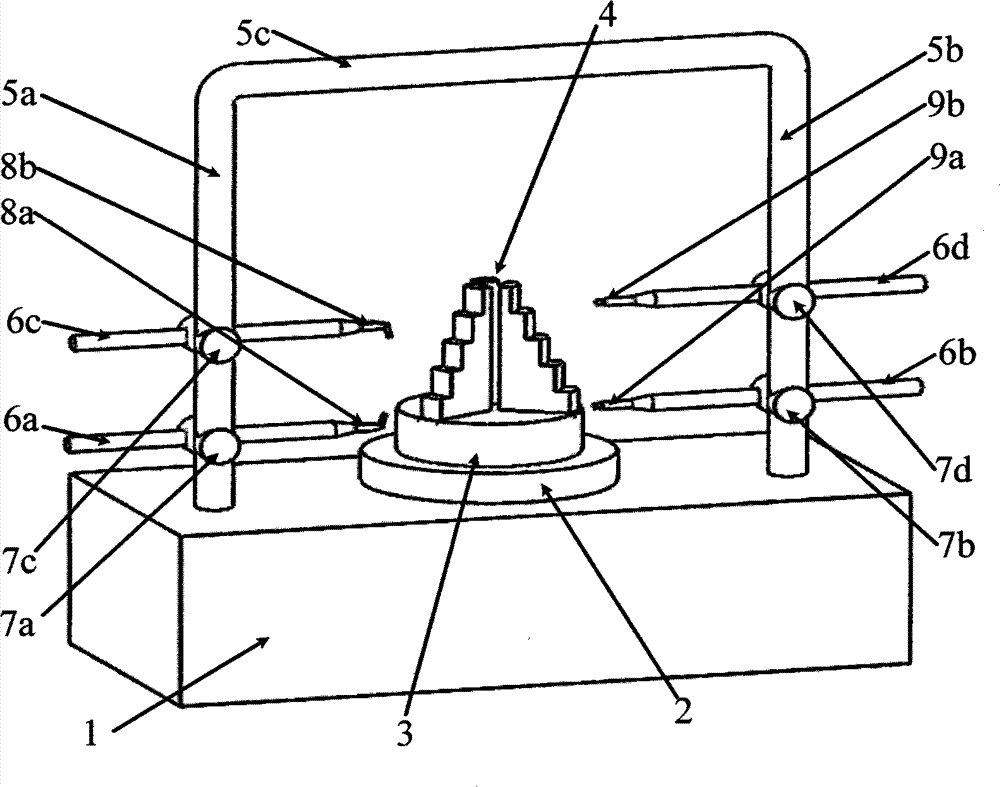

Hydraulic capturing and clamping type aircraft engine rotor assembling method and device based on inductance sensing

InactiveCN103790647AReduce consumptionImprove stabilityMachines/enginesSafety/regulatory devicesAviationRadial error

The invention relates to a hydraulic capturing and clamping type aircraft engine rotor assembling method and device based on inductance sensing, and belongs to the machine assembling technology. According to the hydraulic capturing and clamping type aircraft engine rotor assembling method and device, a rotation standard is determined based on an air floating rotation shaft system; angle location of a rotary table is determined according to an inductive synchronizer; based on a four-measuring-head measuring device, radial errors of a rotor radial assembly face and slant errors of an axial assembly face are extracted, and the influence weights of rotors on the rotor coaxiality after the rotors are assembled are obtained; all the rotors required to be assembled are respectively measured, and the influence weights of the rotors on the rotor coaxiality after the rotors are assembled are obtained; vector optimizing is carried out on the weights of the rotors, and the assembling angles of the rotors are obtained. According to the hydraulic capturing and clamping type aircraft engine rotor assembling method and device, the problem that the coaxiality is low after the aircraft engine rotors are assembled is solved, and after the rotors are assembled, the hydraulic capturing and clamping type aircraft engine rotor assembling method and device have the advantages of being high in coaxiality, reducing vibration, being easy to install and high in flexibility, and improving the engine performance.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com