Self-balancing external prestressing strengthening method for bridge structure

A technology of external prestressing and bridge structure, which is applied in the field of bridge and structural engineering in civil engineering, can solve the problems of insignificant improvement of rigidity of FRP reinforced structure, insufficient stability of fatigue resistance and insufficient connection reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

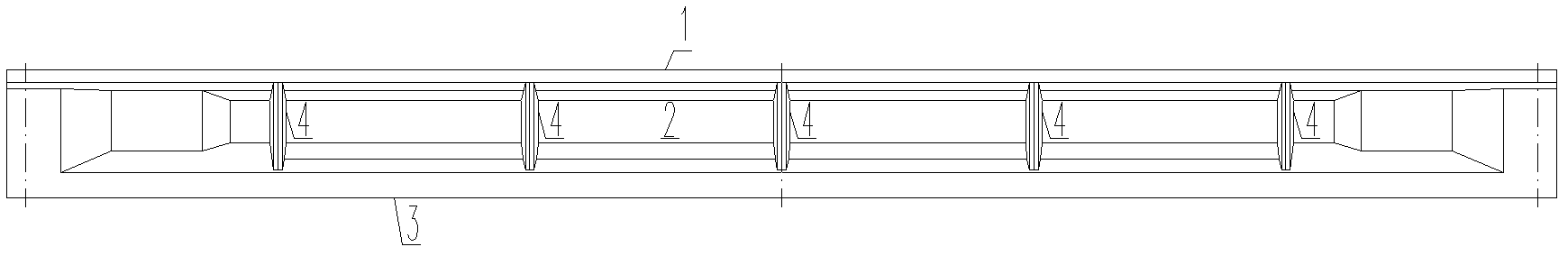

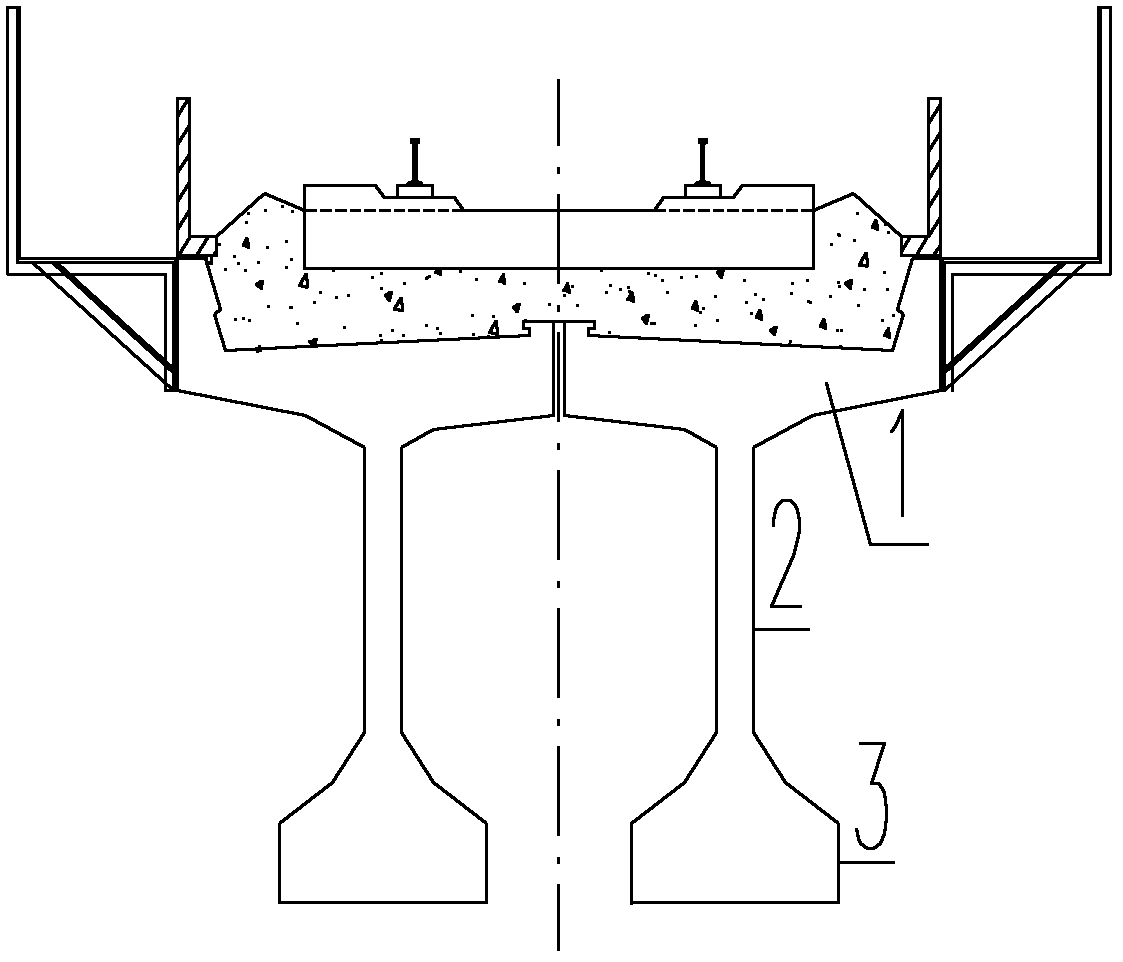

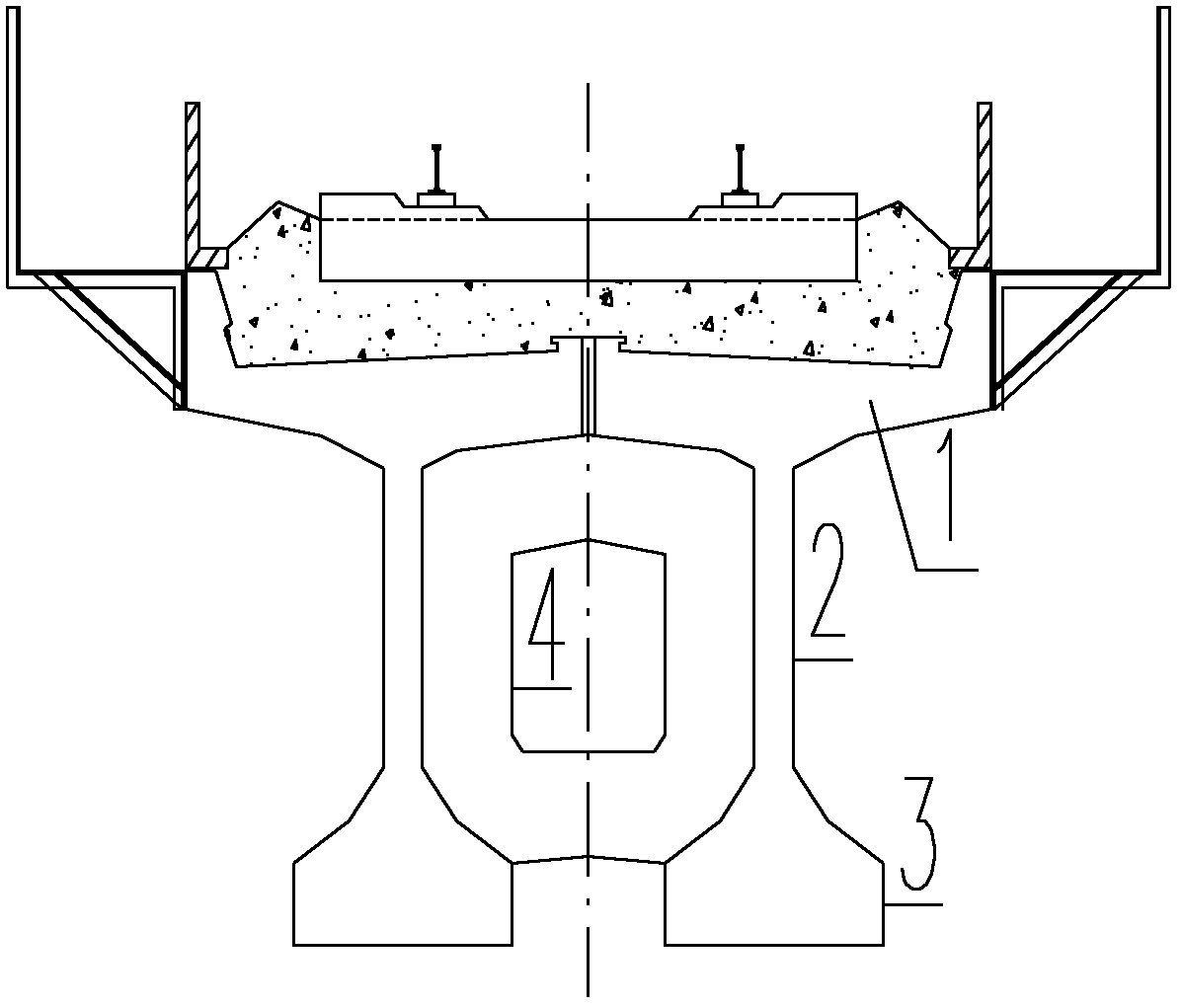

[0105] Preferred embodiments of the present invention are described below in conjunction with accompanying drawings, wherein reference numerals in the figure represent: 1-concrete T-beam top plate; 2-concrete T-beam web; 3-concrete T-beam bottom plate; 4-diaphragm; 5-The joint of the upper flange; 6-Steering block; 7-External cable; 8-New diaphragm; 9-External cable diverter; 10-External cable anchor; 11-HDPE inner pipe; ; 13-reinforced concrete on the upper flange; 14-I-beam, 15-horizontal connection system, 16-transverse connection system, 17-U-shaped hoop; 18-web stiffener; 19-three-sided surrounding welding.

[0106] The solution of the present invention is to provide a bridge structure self-balancing external prestressing reinforcement method on the basis of the prior art. The concrete T beam top plate of the two concrete T beams forms the upper flange of the main beam, and the concrete T of the two concrete T beams The lower flange is formed on the beam bottom plate, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com