Patents

Literature

1439 results about "Structural rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In discrete geometry and mechanics, structural rigidity is a combinatorial theory for predicting the flexibility of ensembles formed by rigid bodies connected by flexible linkages or hinges.

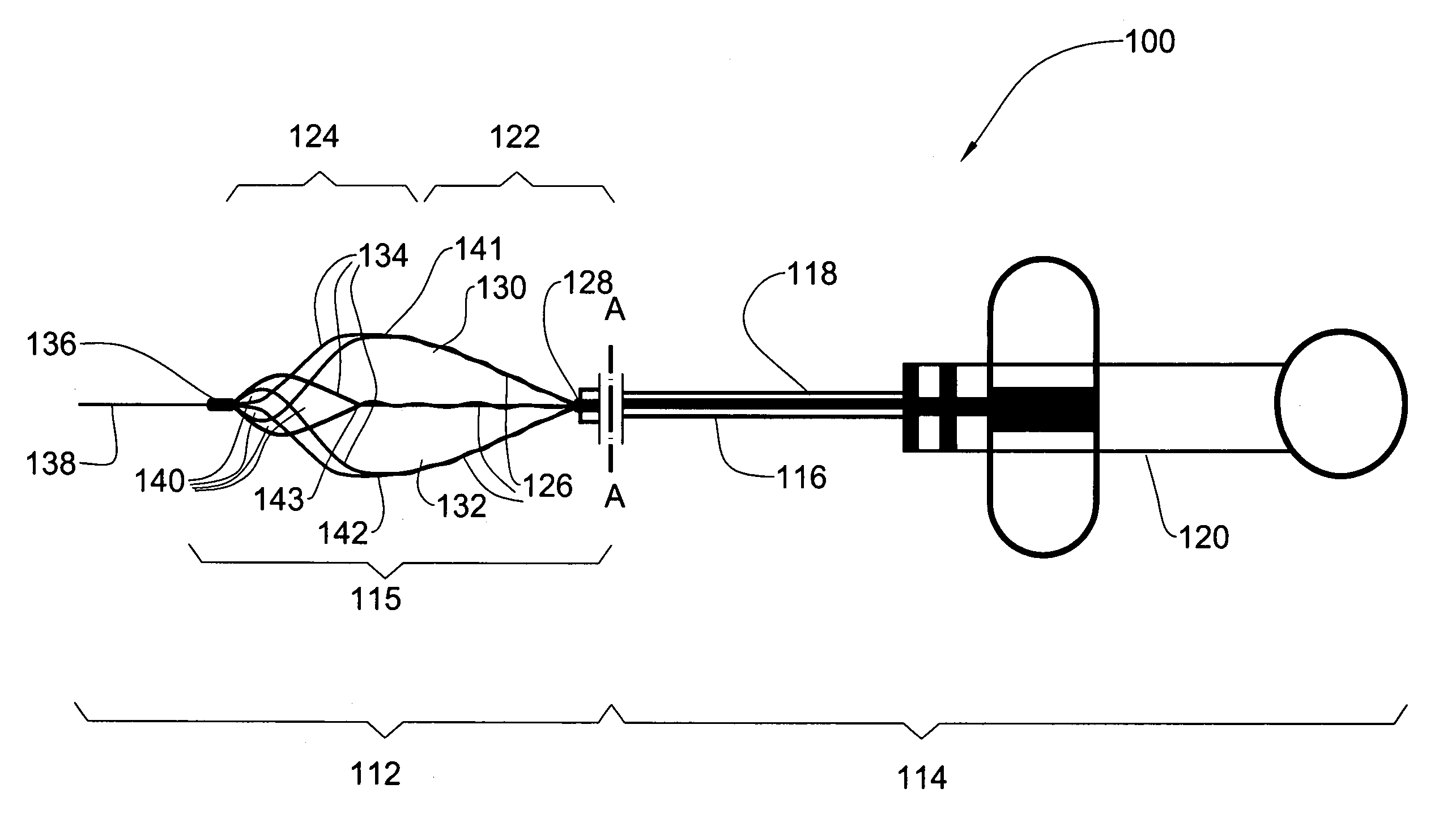

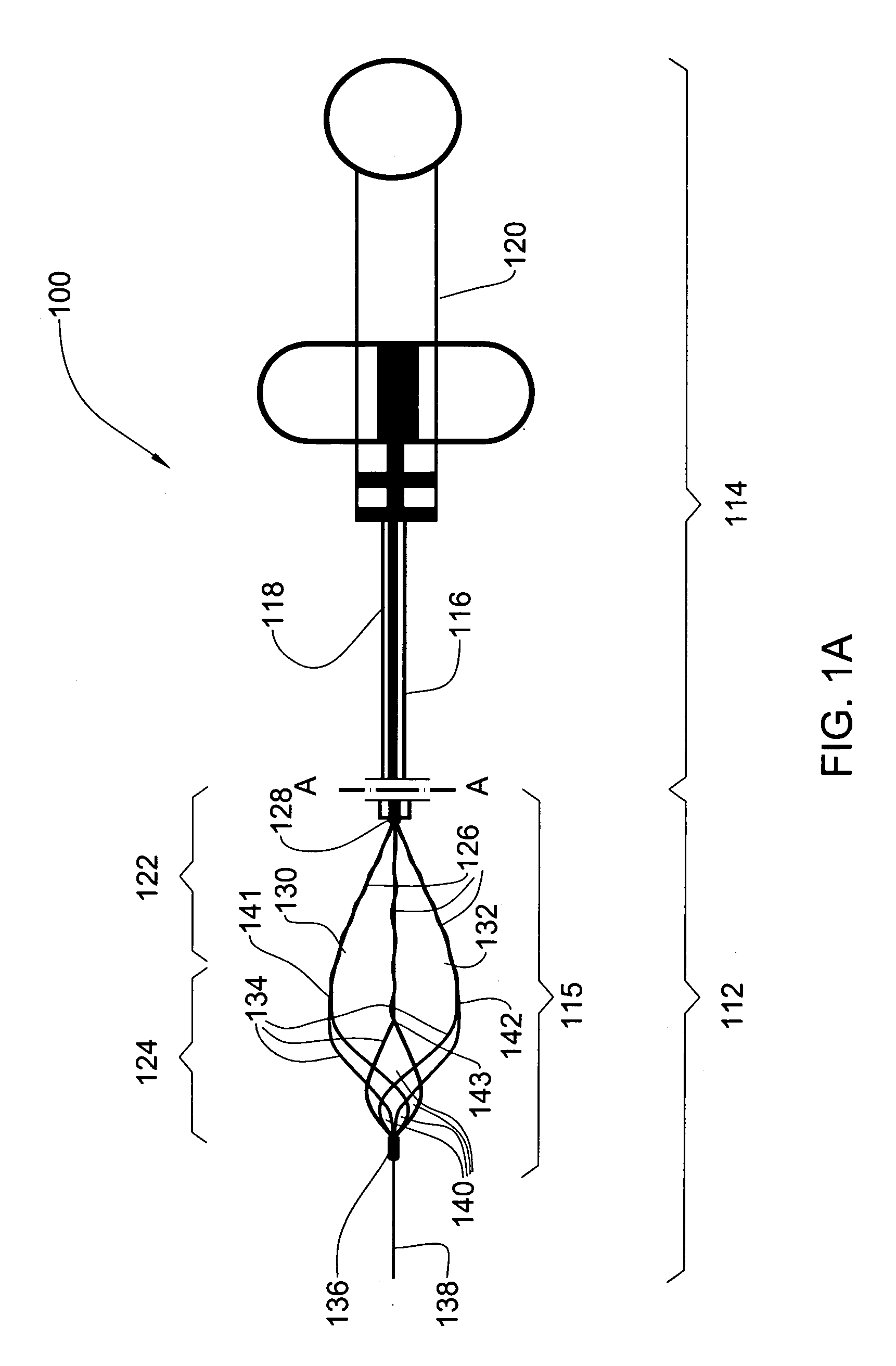

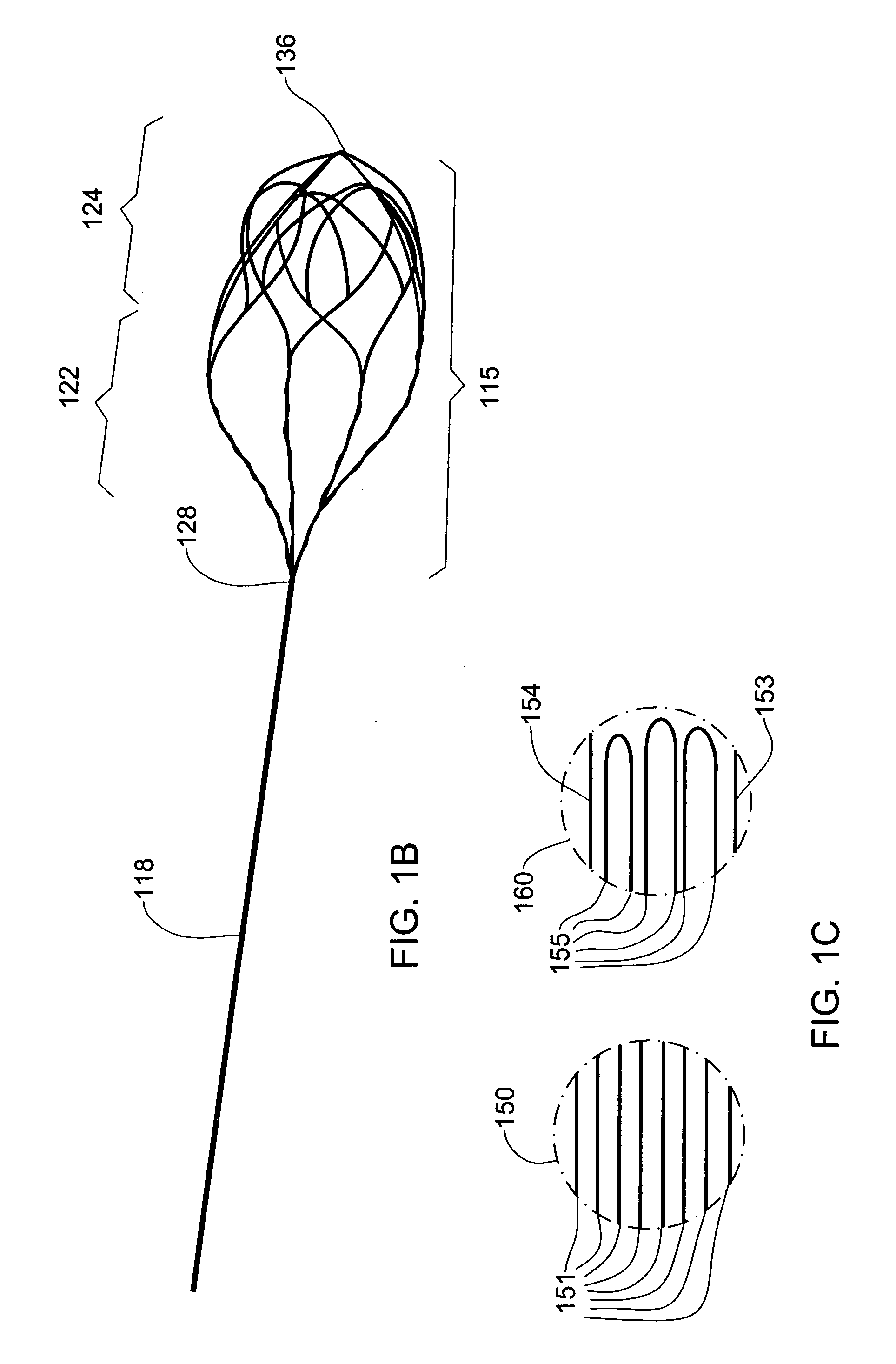

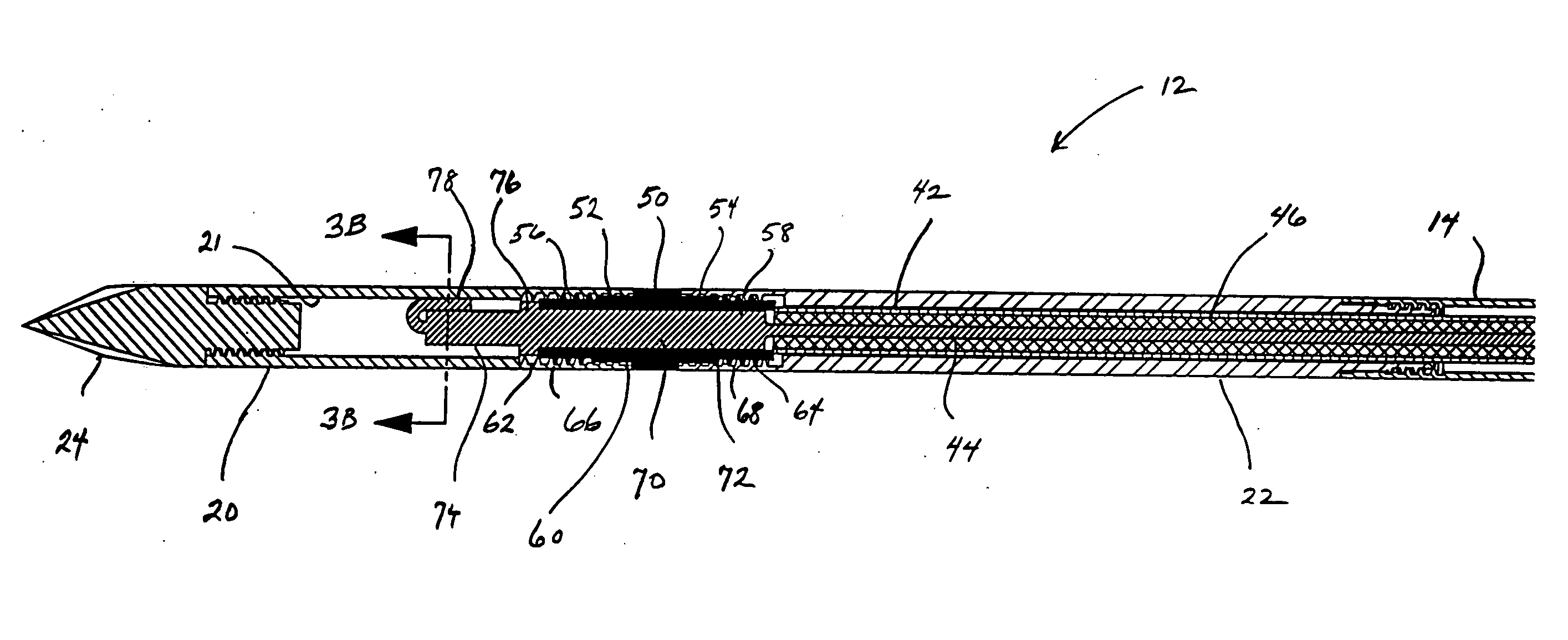

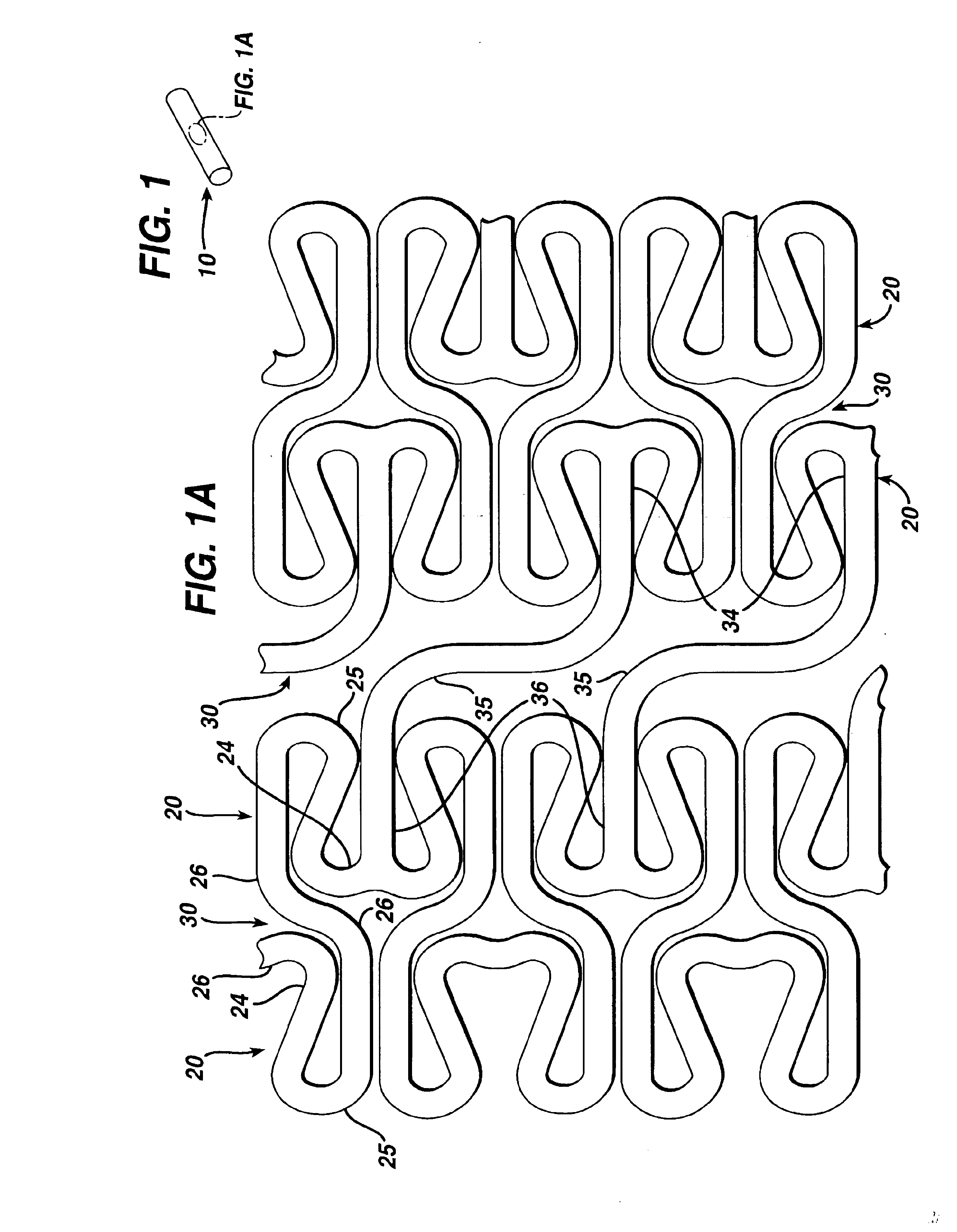

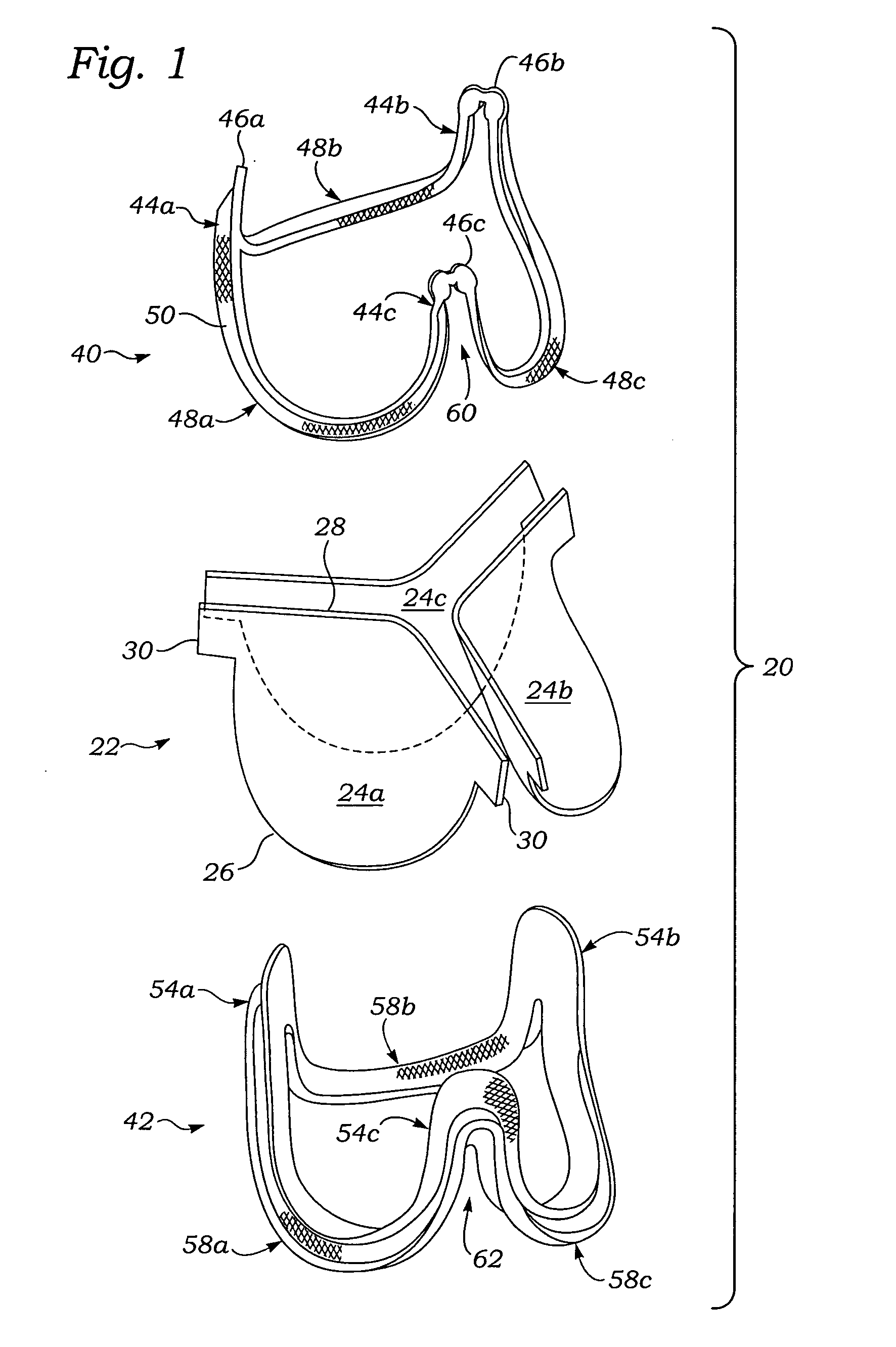

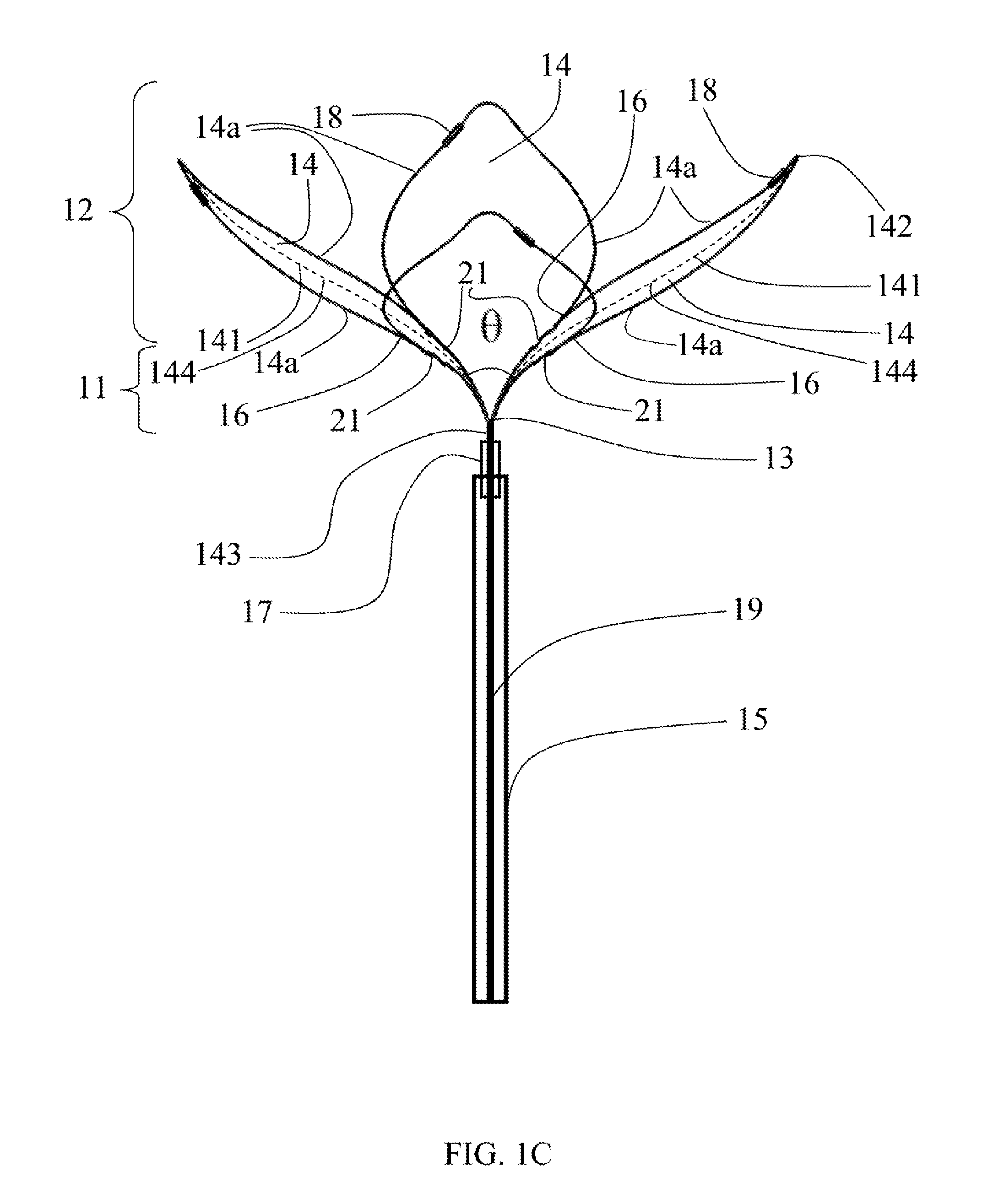

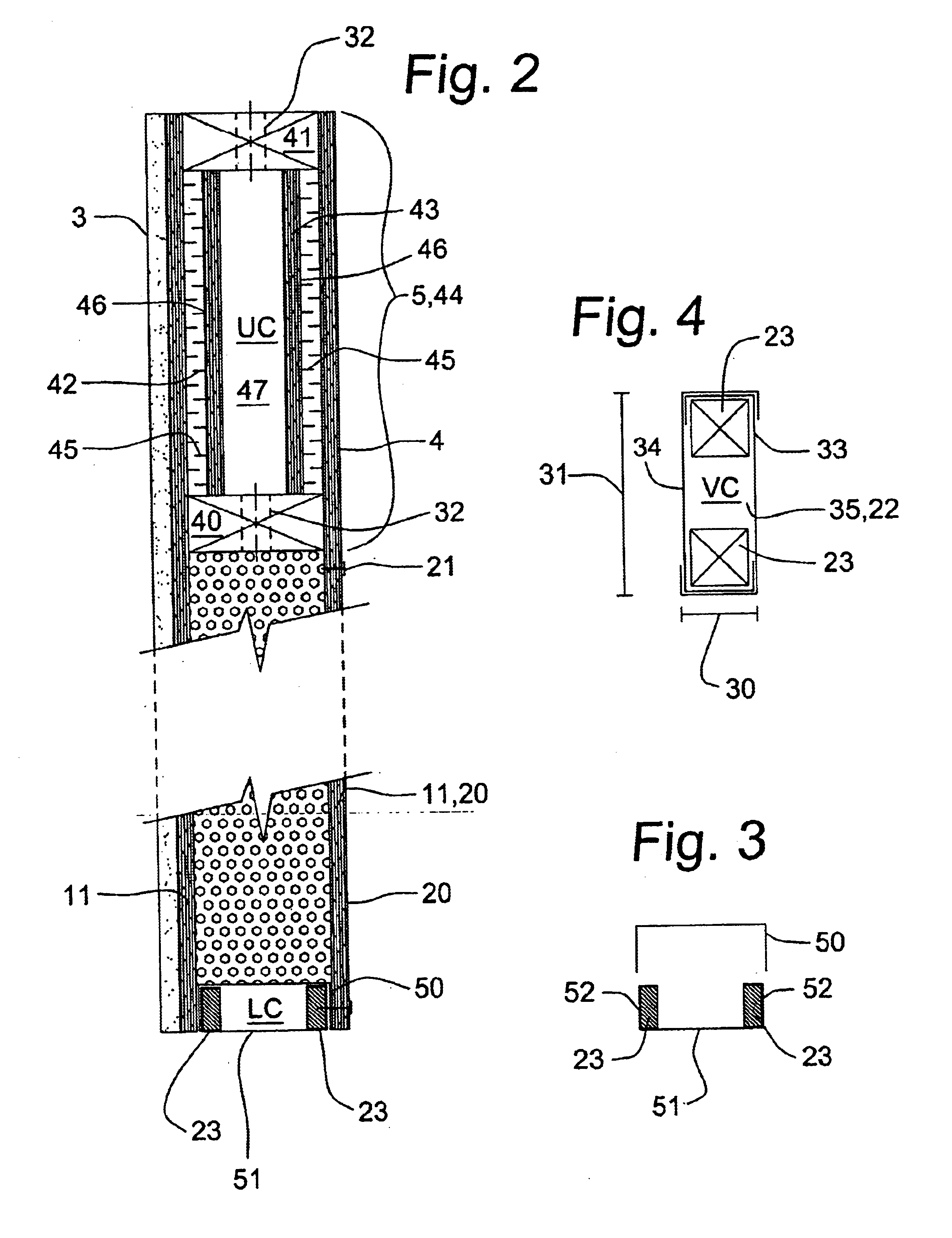

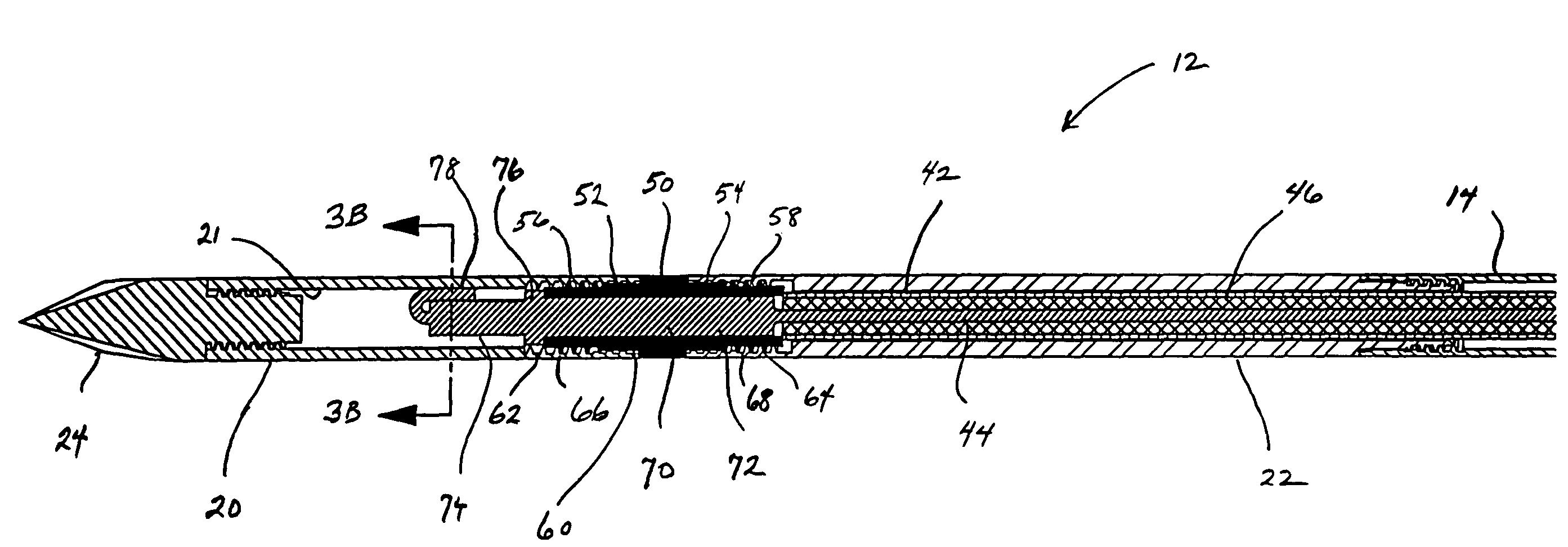

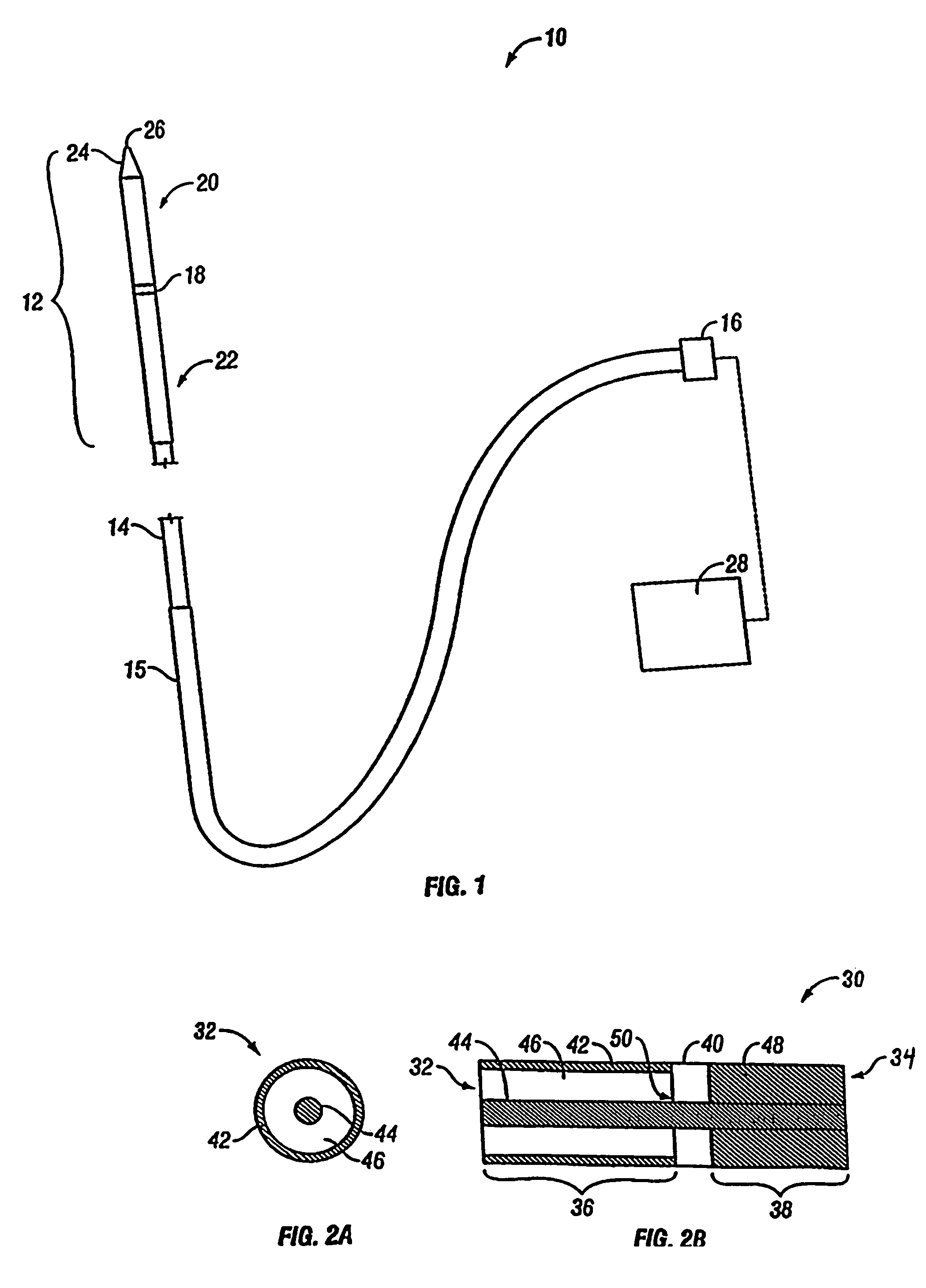

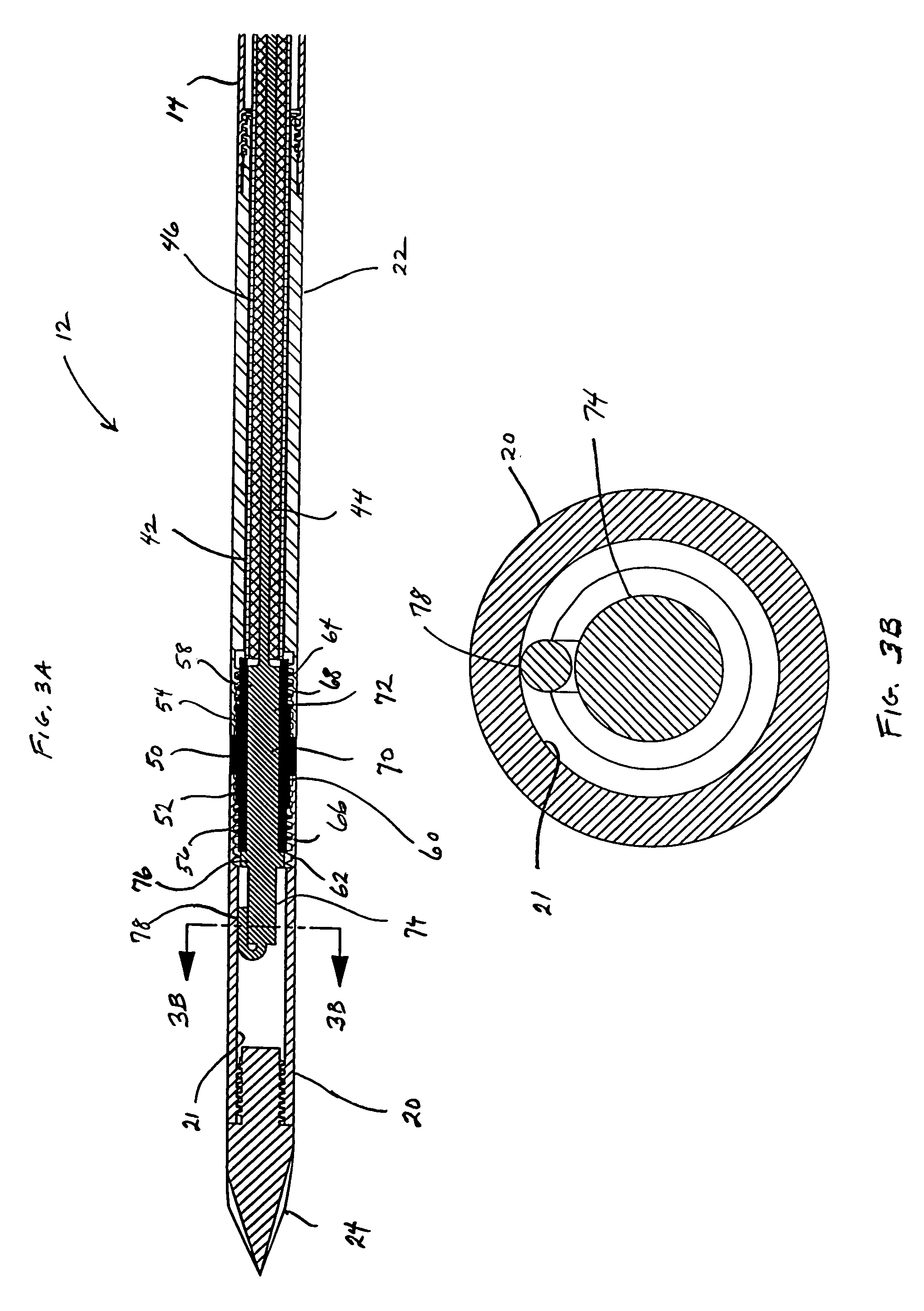

Surgical device for retrieval of foreign objects from a body

A surgical device for removing a foreign object from a body is described. The device includes a retrieval basket for entrapping and retaining the object located in the body, a basket control assembly comprising a tubular sheath adapted to penetrate into the body for reaching the object, and a manipulator for manipulating the basket for extraction the object from the body. The basket comprises a structure having a proximal end and a distal end. The structure is formed by a plurality of filaments fabricated from a single or several wires. The filaments extend from the proximal end towards the distal end. At least a part of the filaments are configured in the form of loops. At least a part of the loops are interlaced so as to define a net at the distal end, and thereby impart structural rigidity and dilatation ability to the basket when opened.

Owner:NORDSON CORP

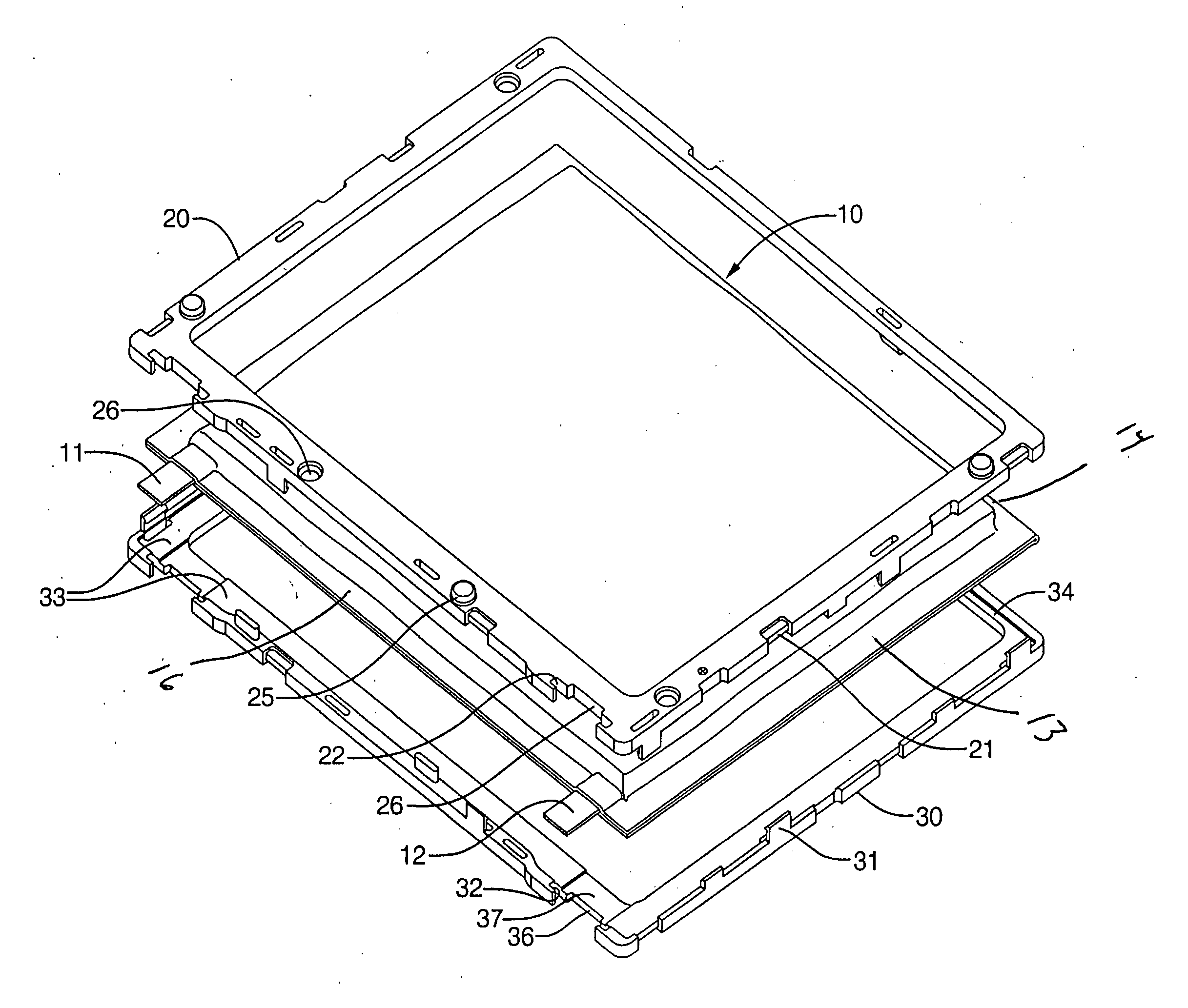

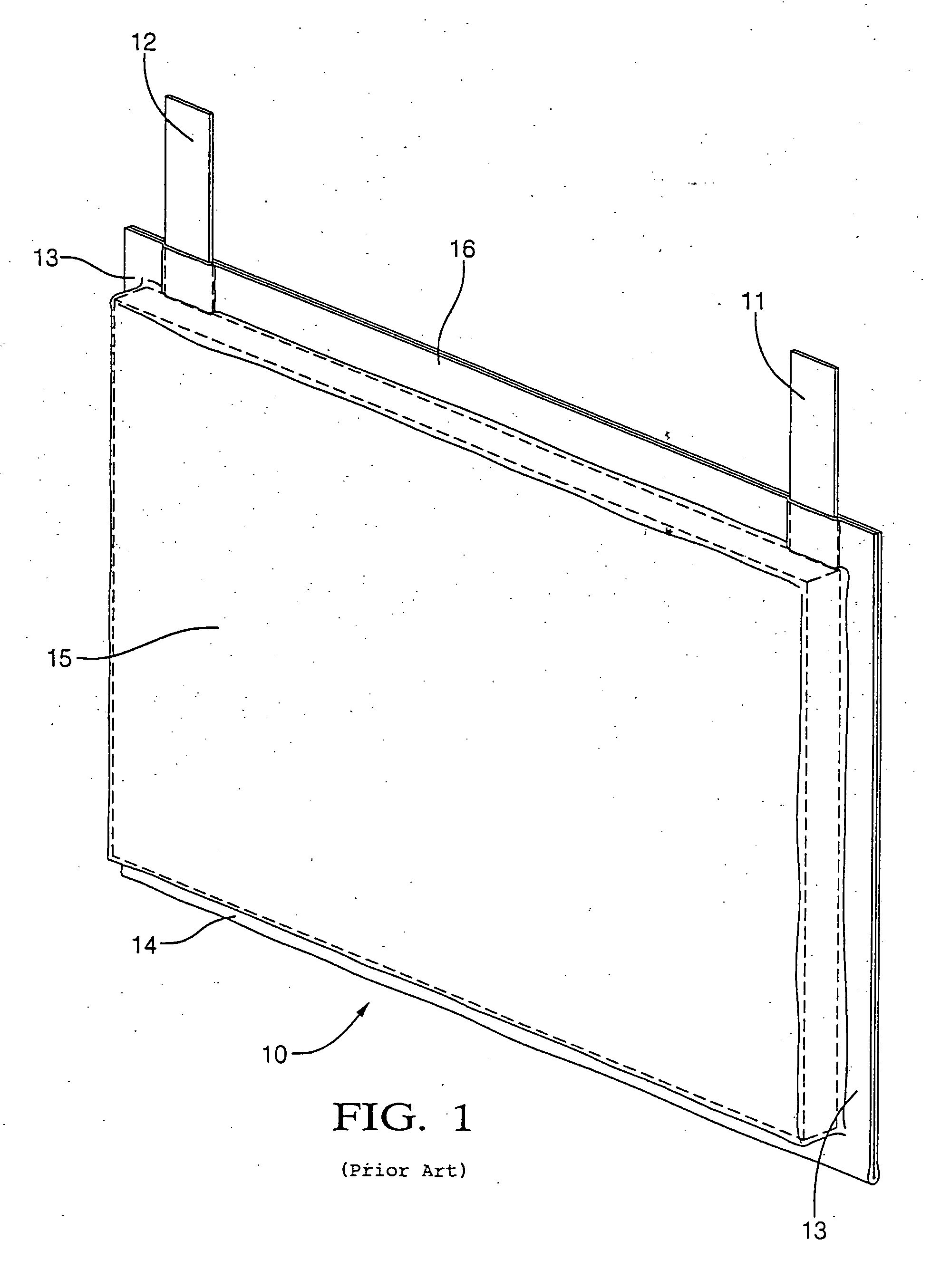

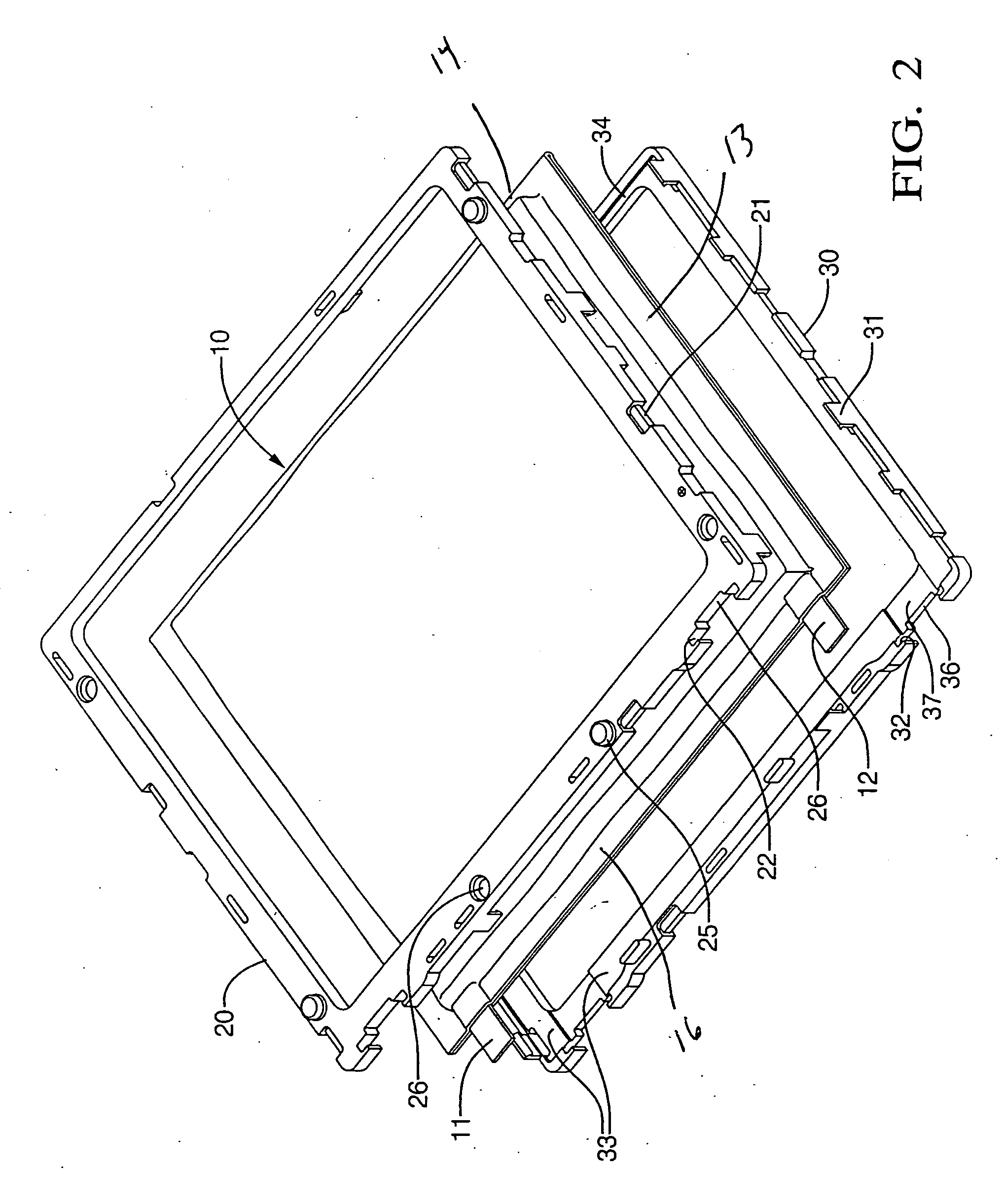

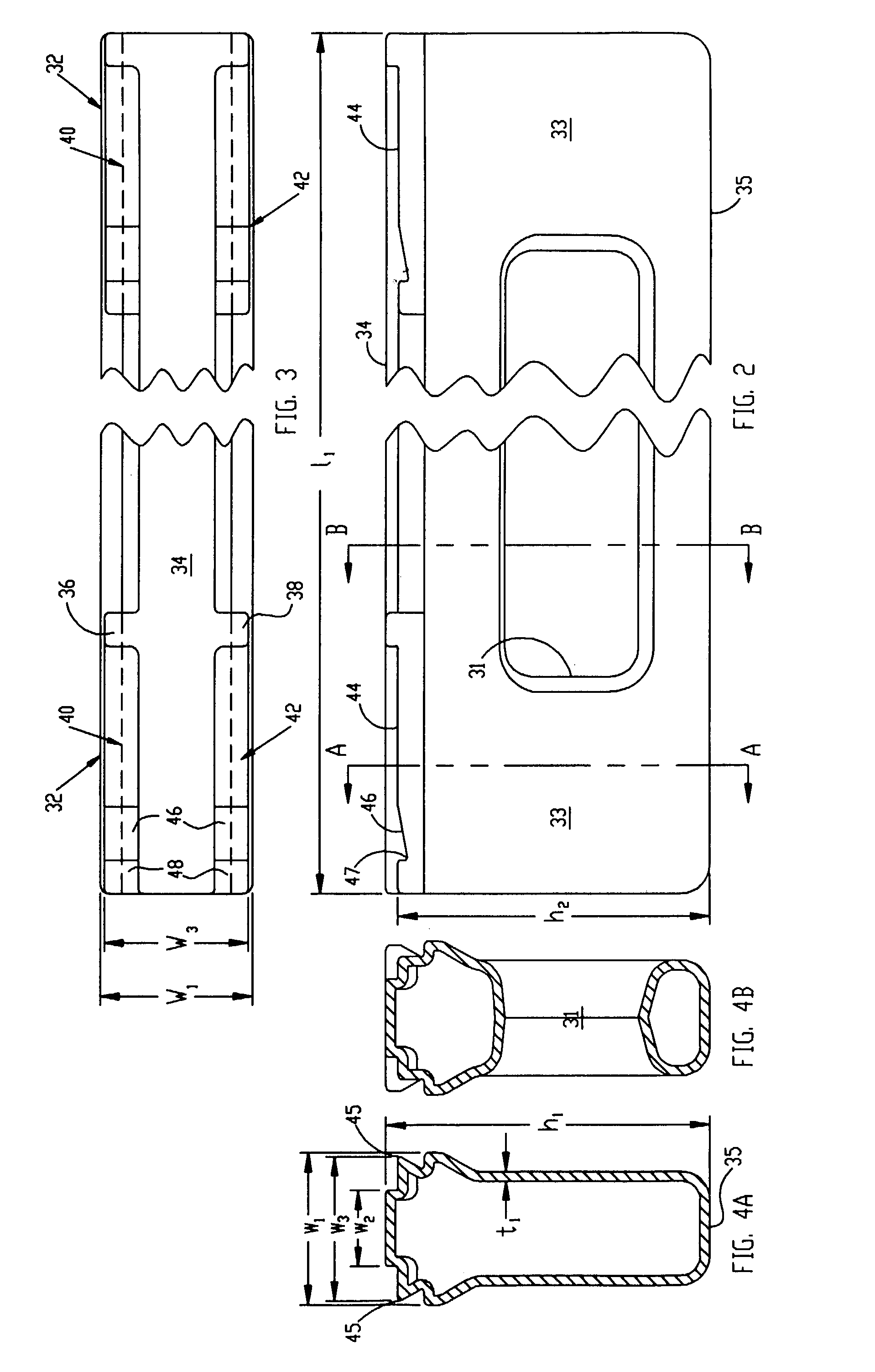

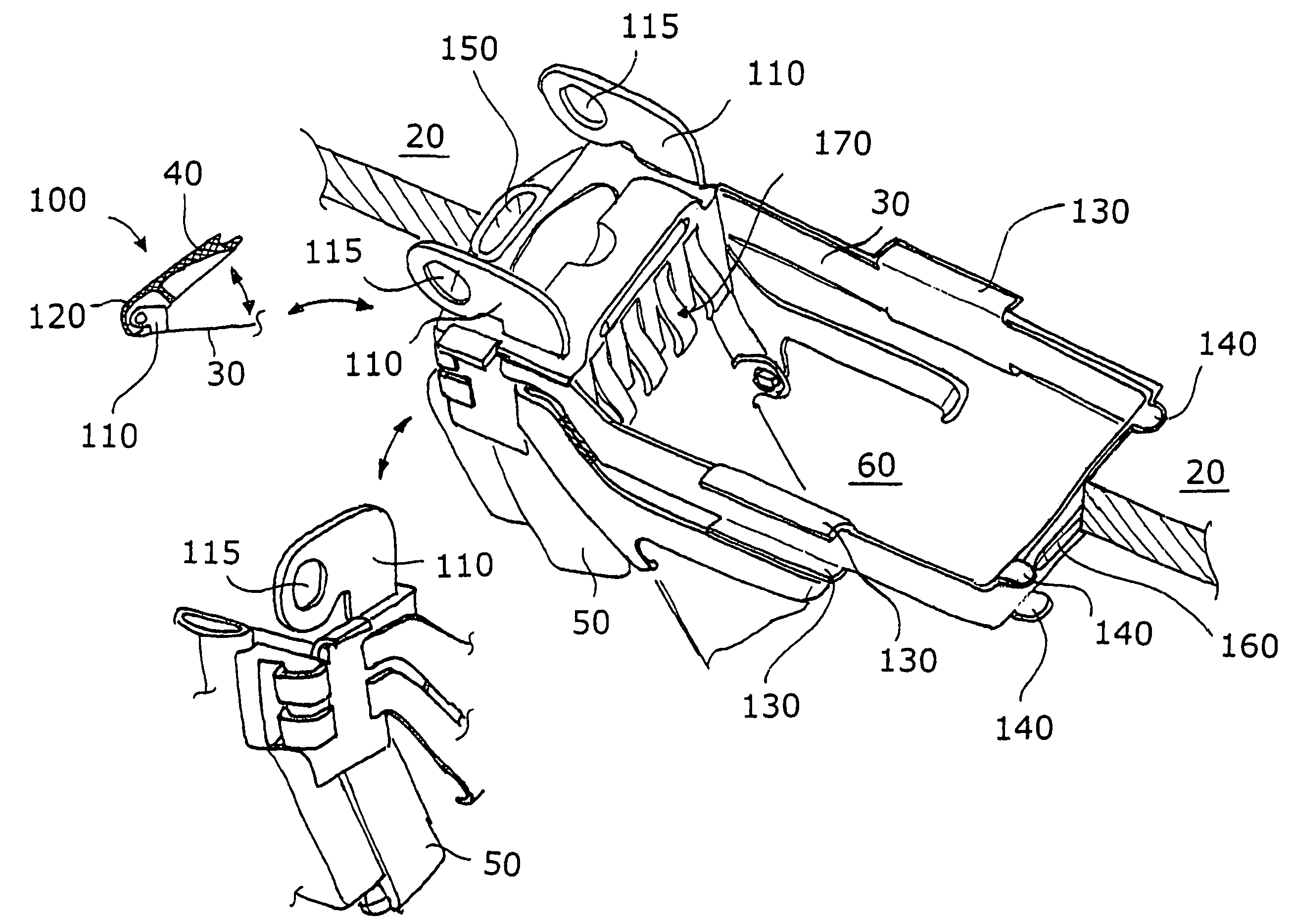

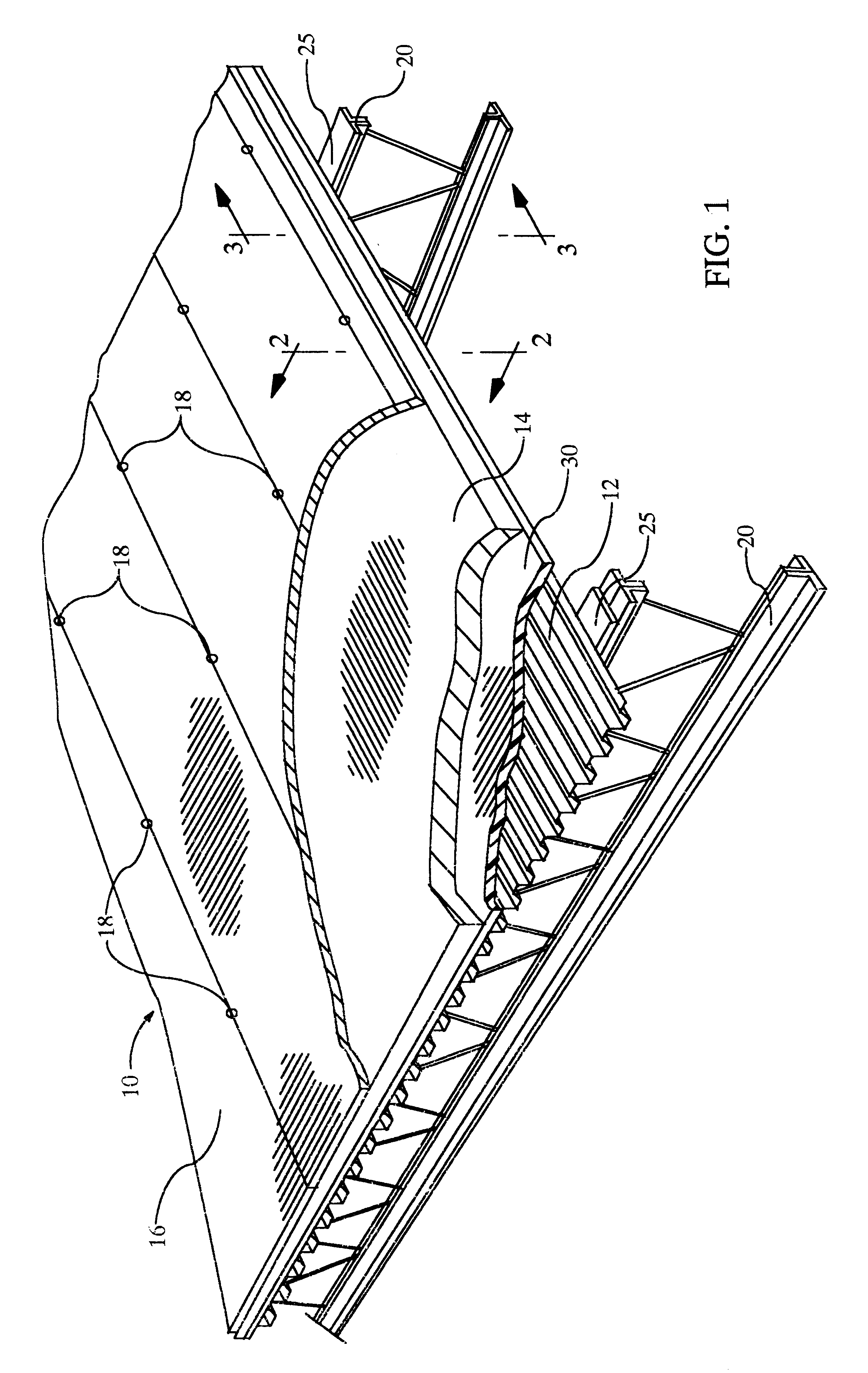

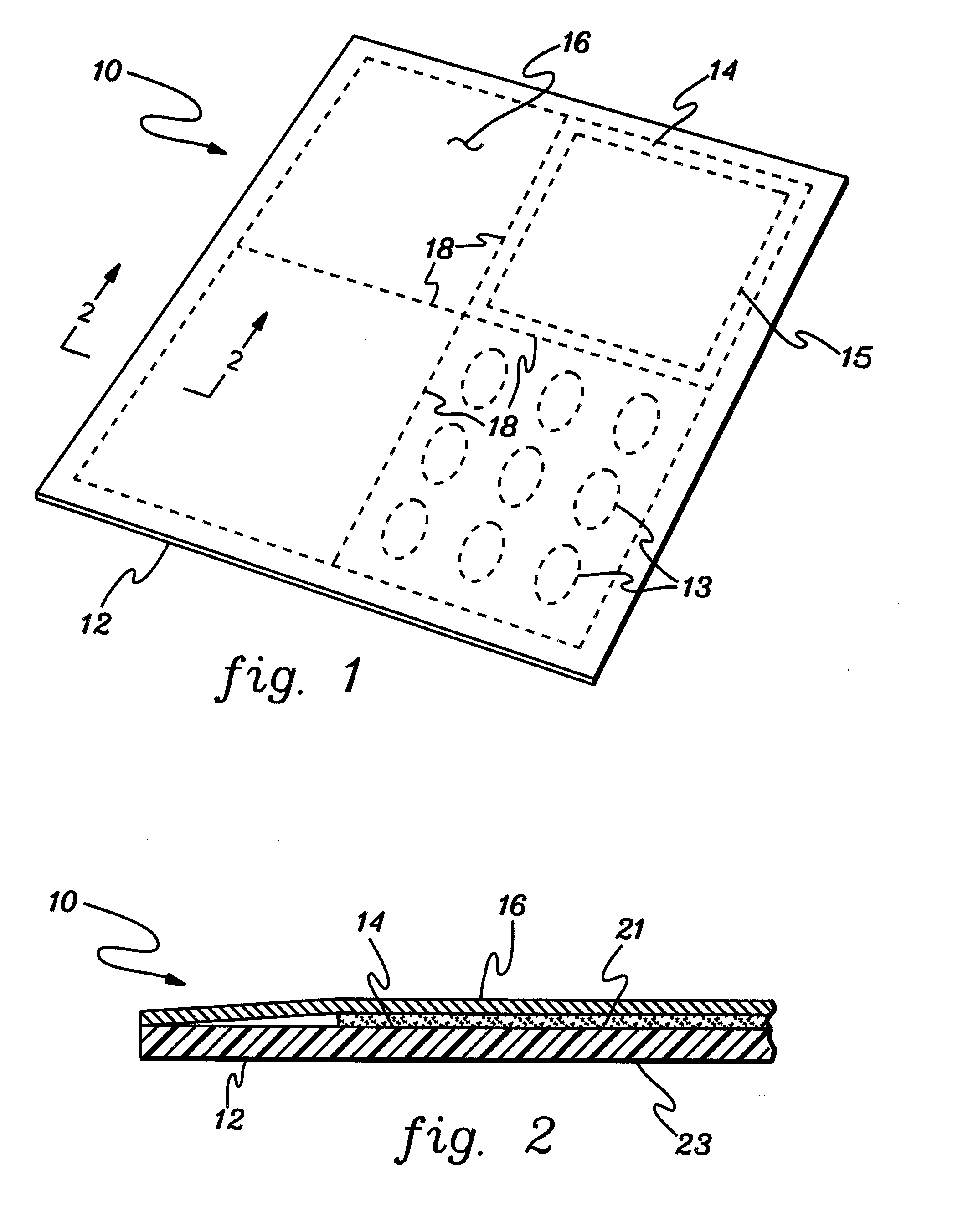

Apparatus and method for securing battery cell packs

ActiveUS20060234119A1Facilitate electrically connectingFacilitate mechanically connectingFinal product manufactureSmall-sized cells cases/jacketsEdge surfaceBattery cell

A framed lithium battery cell group includes a first frame member (20) and a second frame member (30). The frame members are locked together, clamping the lithium battery cell pack (10) on the seal edge surfaces (13, 16), thereby providing structural rigidity and protection from damage due to handling and vibration. Each of the frame members (20, 30) has multiple pins (25) and sockets (26) on the side opposite the clamping surface (33) to facilitate aligning and stacking multiple lithium battery cell pack and frame assemblies to form a lithium battery cell group (50). Each of the frame members (20, 30) include a buss bar capture feature (22, 32) having a bus bar (40) inserted therein for electrically connecting all of the terminals for a given lithium battery pack group to the buss bar (40).

Owner:ENERDEL

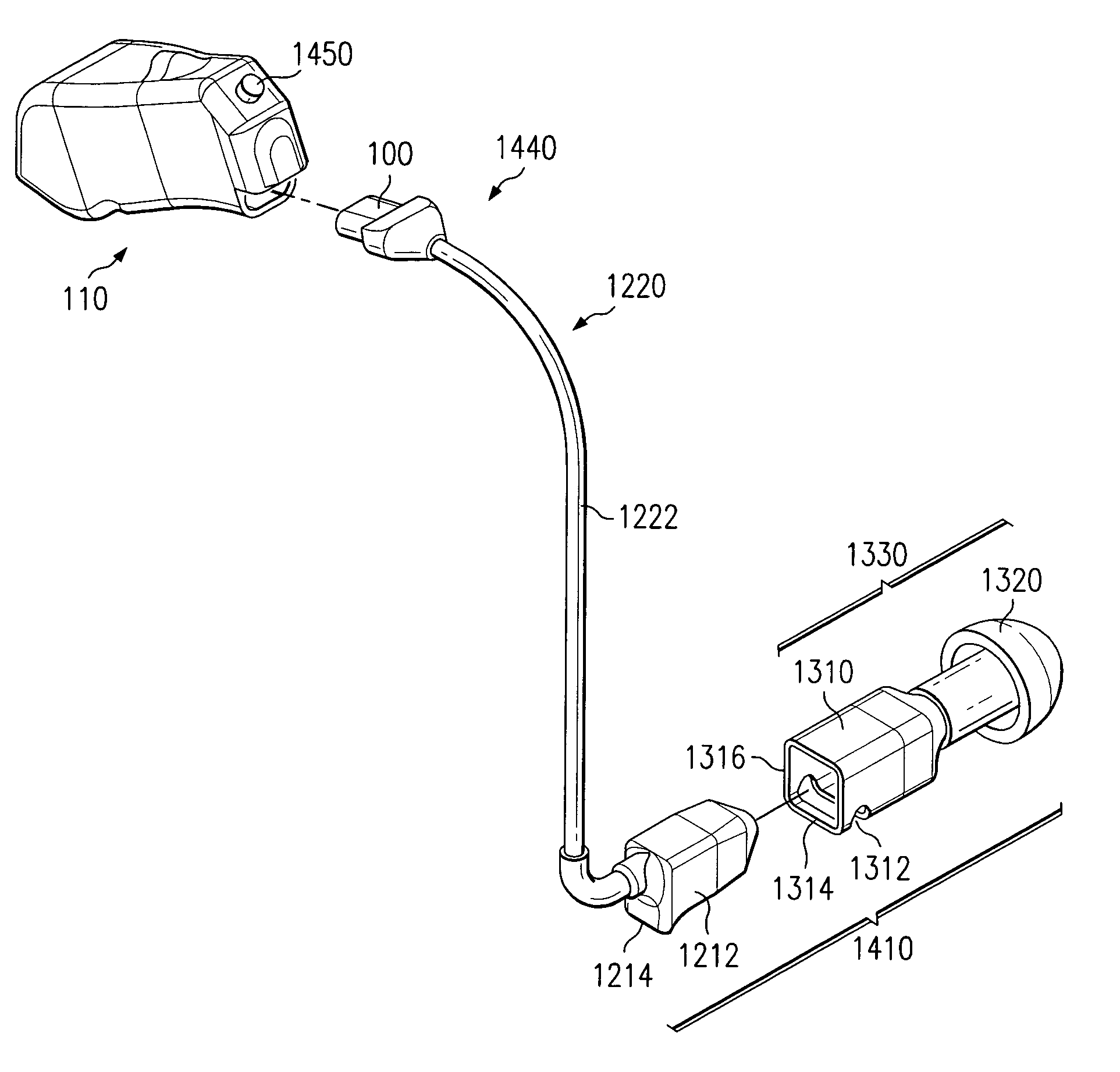

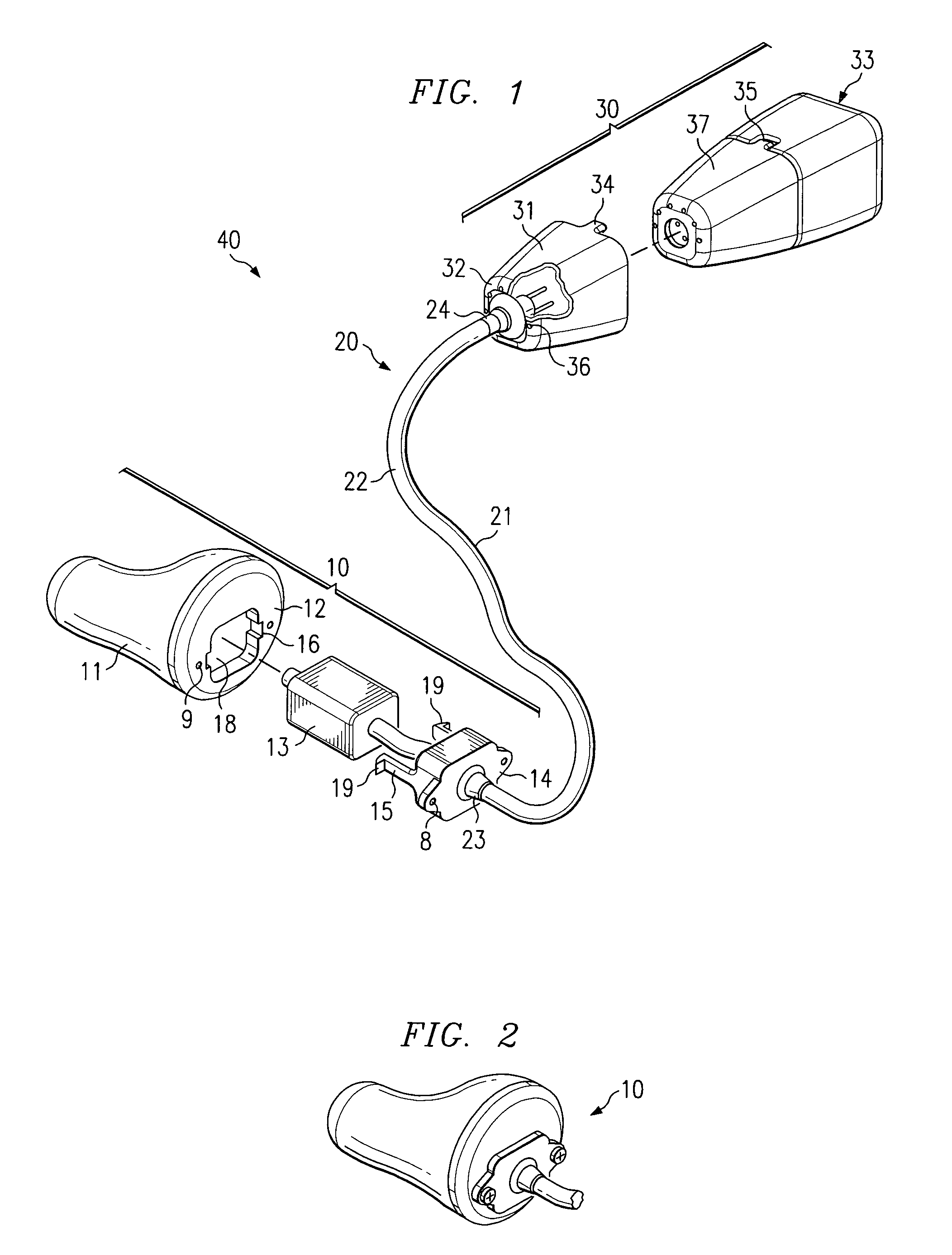

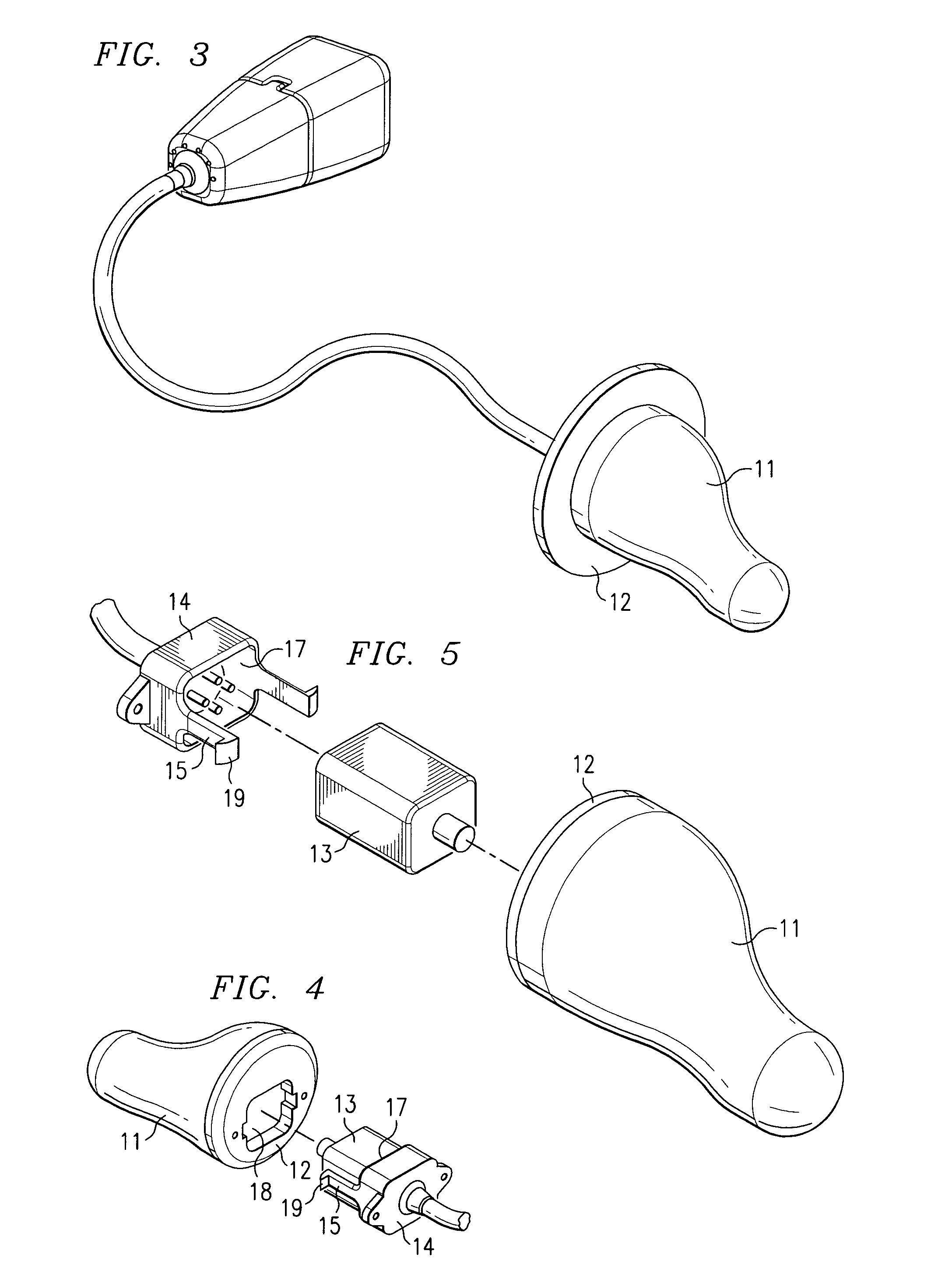

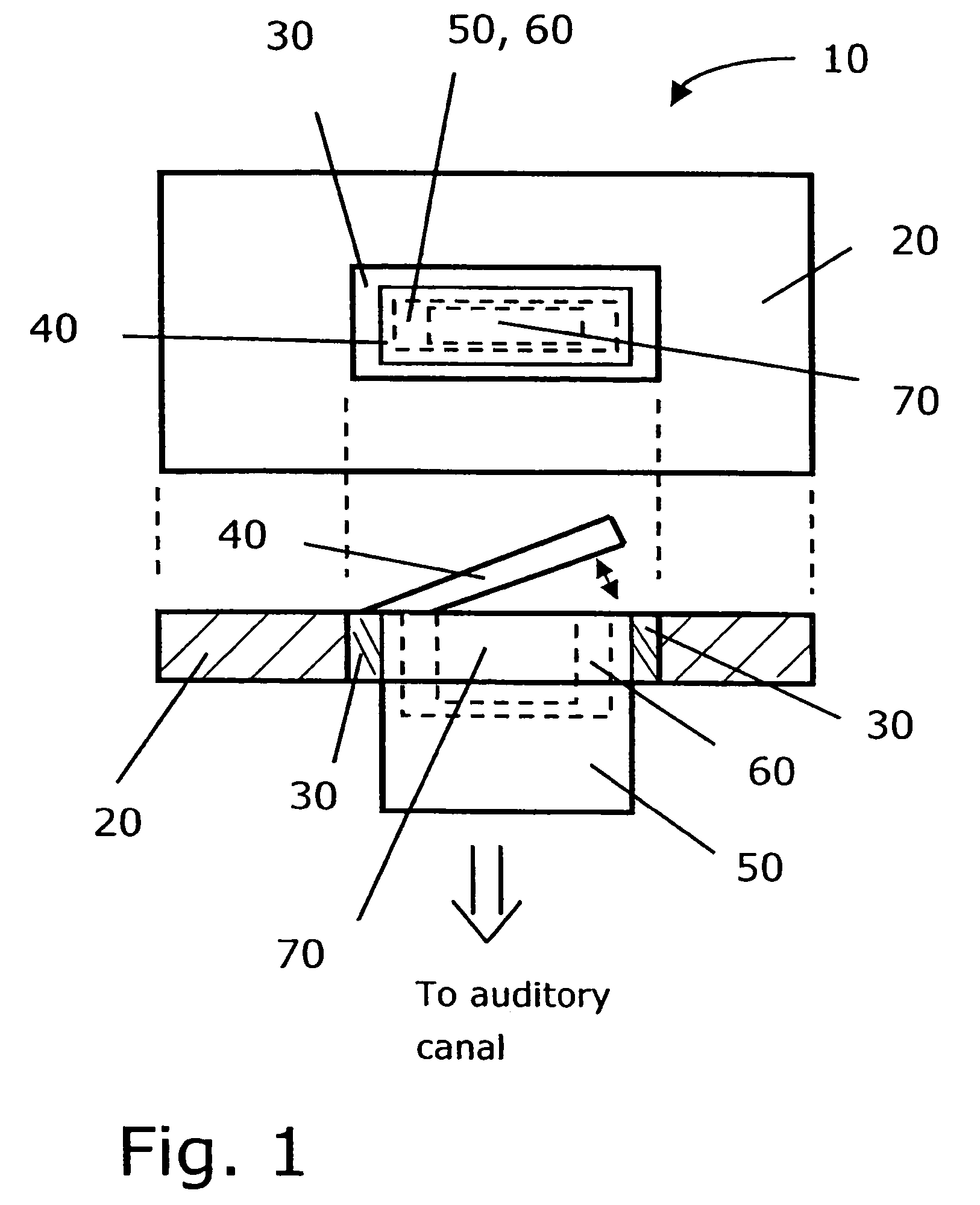

BTE/CIC auditory device and modular connector system therefor

InactiveUS7016512B1Sufficient structural rigidityPrevent removalMicrophonesAdditive manufacturing apparatusEngineeringLoudspeaker

In representative embodiments, the present invention is directed to an at least partially in-the-canal module. The module may include a speaker module that generates audio signals from an electrical driving signal. The speaker module has a tubular body with a diameter that is smaller than the ear canal of the user. The speaker module also includes an arcuate raised ridge. A cushion tip of deformable material may be used to enclose the speaker module within a tubular portion that applies an elastic force to the arcuate raised ridge to prevent removal of the speaker from the cushion tip. Also, the tubular portion is longer than the speaker module to cause the cushion tip to deflect during navigation through the canal. Further, the tip portion of the cushion tip possesses sufficient structural rigidity to prevent the speaker from being pushed through the cushion tip during navigation through the canal.

Owner:HEAR WEAR TECH

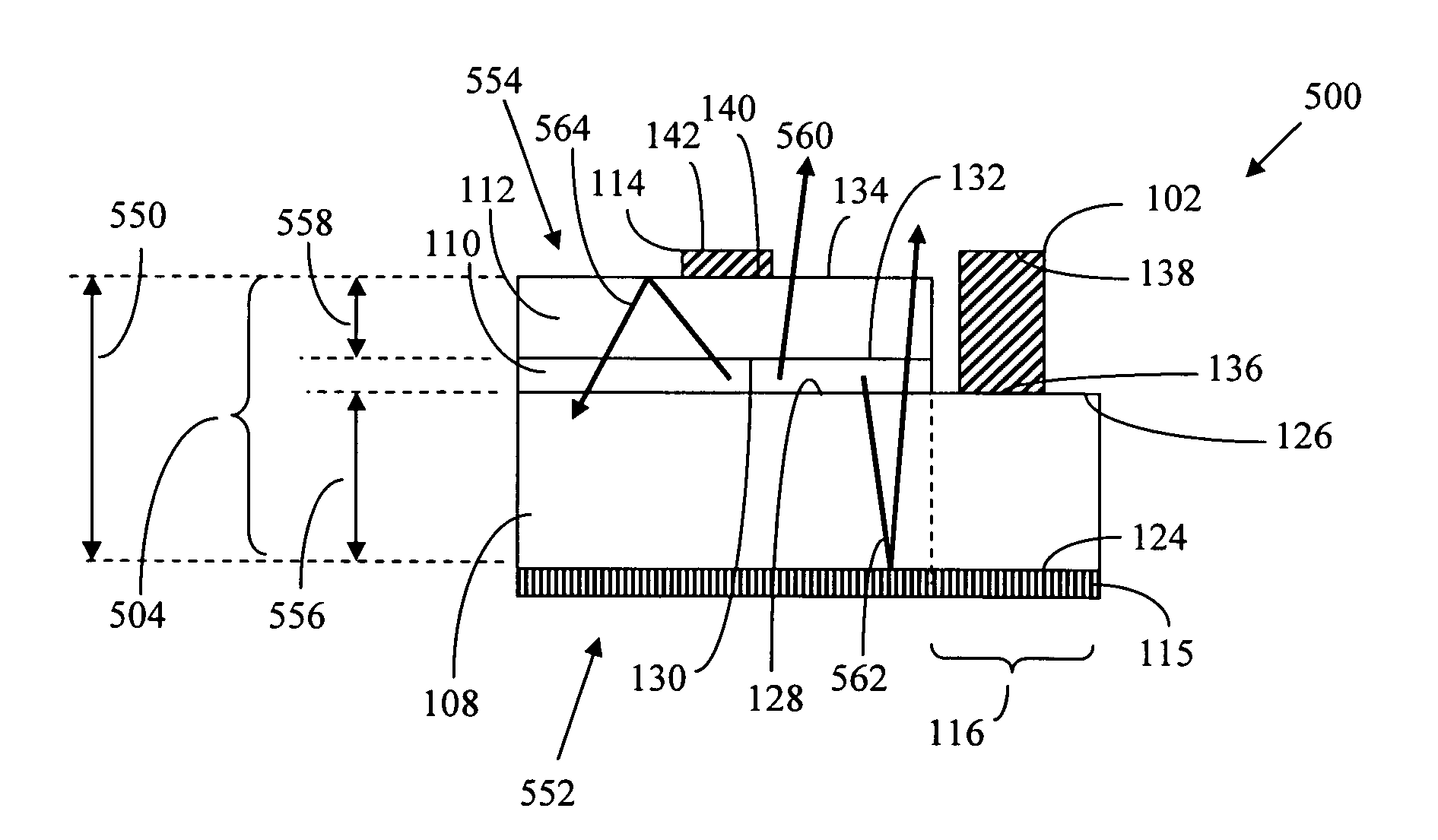

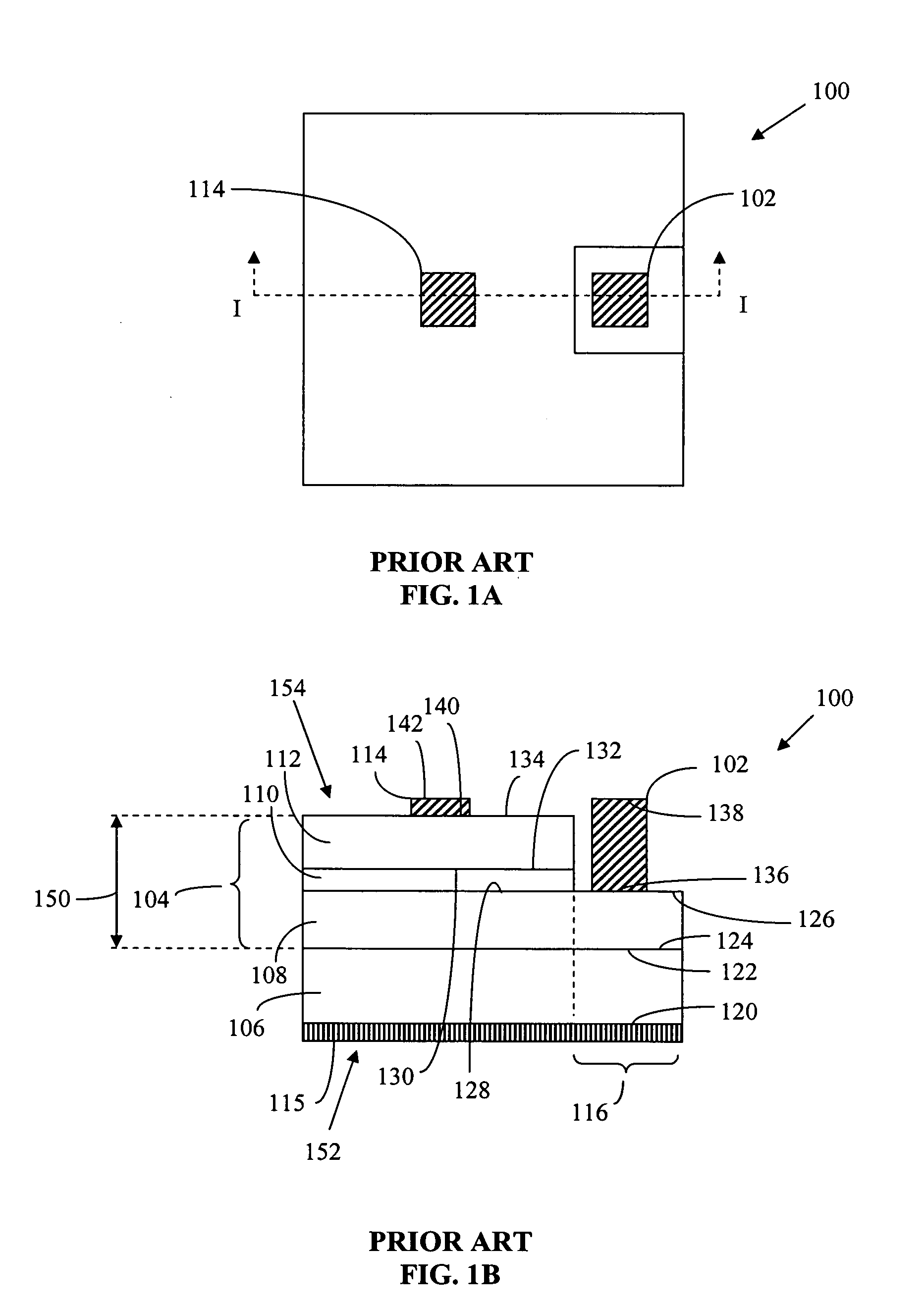

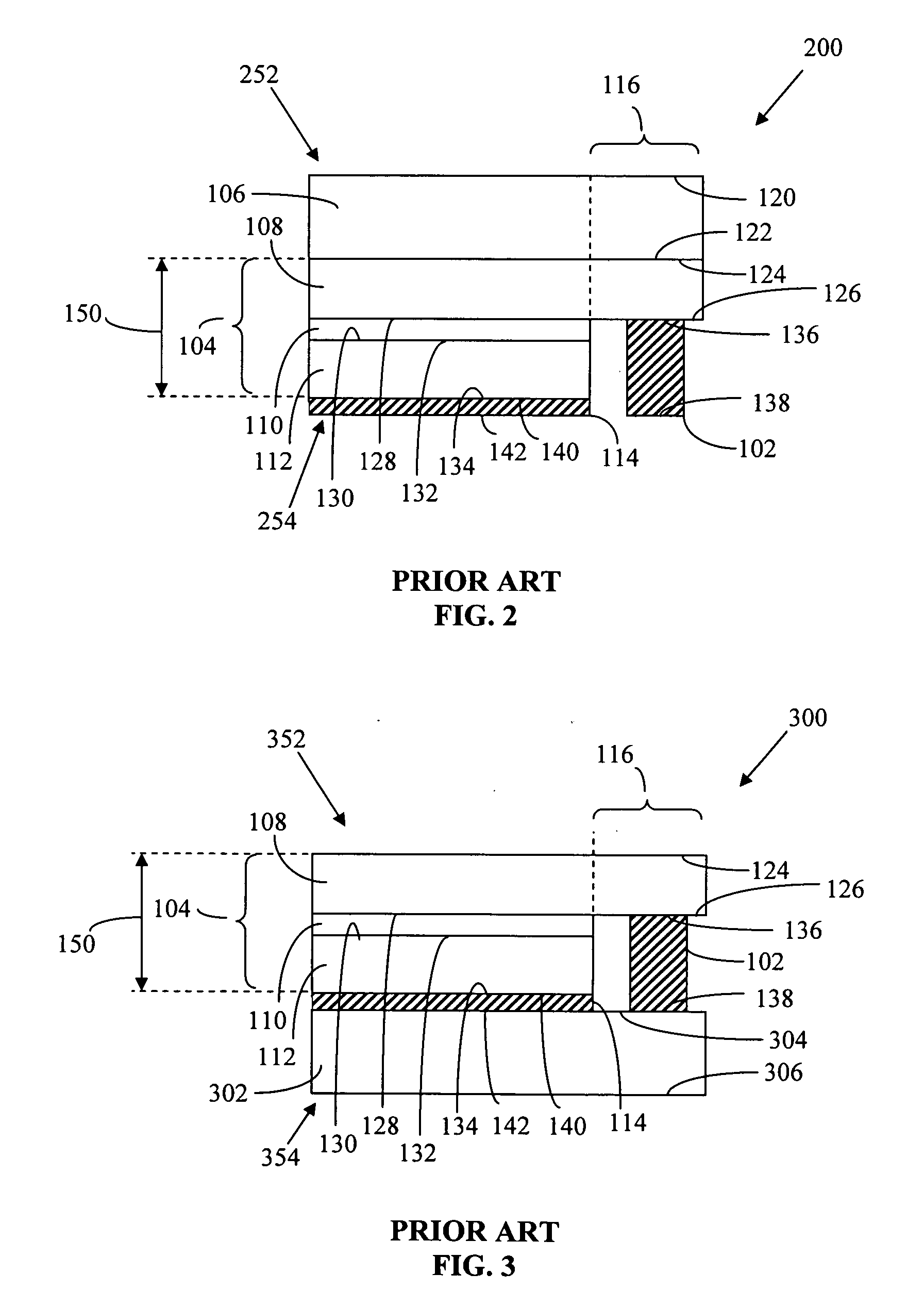

Substrate-free light emitting diode chip

InactiveUS20090140279A1Improve structural strengthIncreasing the thicknessSolid-state devicesSemiconductor devicesStructural rigidityVapor phase

A light emitting diode (LED) chip has a multilayer semiconductor structure that is at least 10 microns thick and does not require an attached growth substrate or transfer substrate for structural rigidity or support. The multilayer semiconductor structure includes a first doped layer, a second doped layer and an active region interposed between the first doped layer and the second doped layer. Optionally, the multilayer semiconductor structure includes an undoped layer. At least one of the layers of the multilayer semiconductor structure is at least 5 microns thick and is preferably deposited by hydride vapor phase epitaxy.

Owner:GOLDENEYE

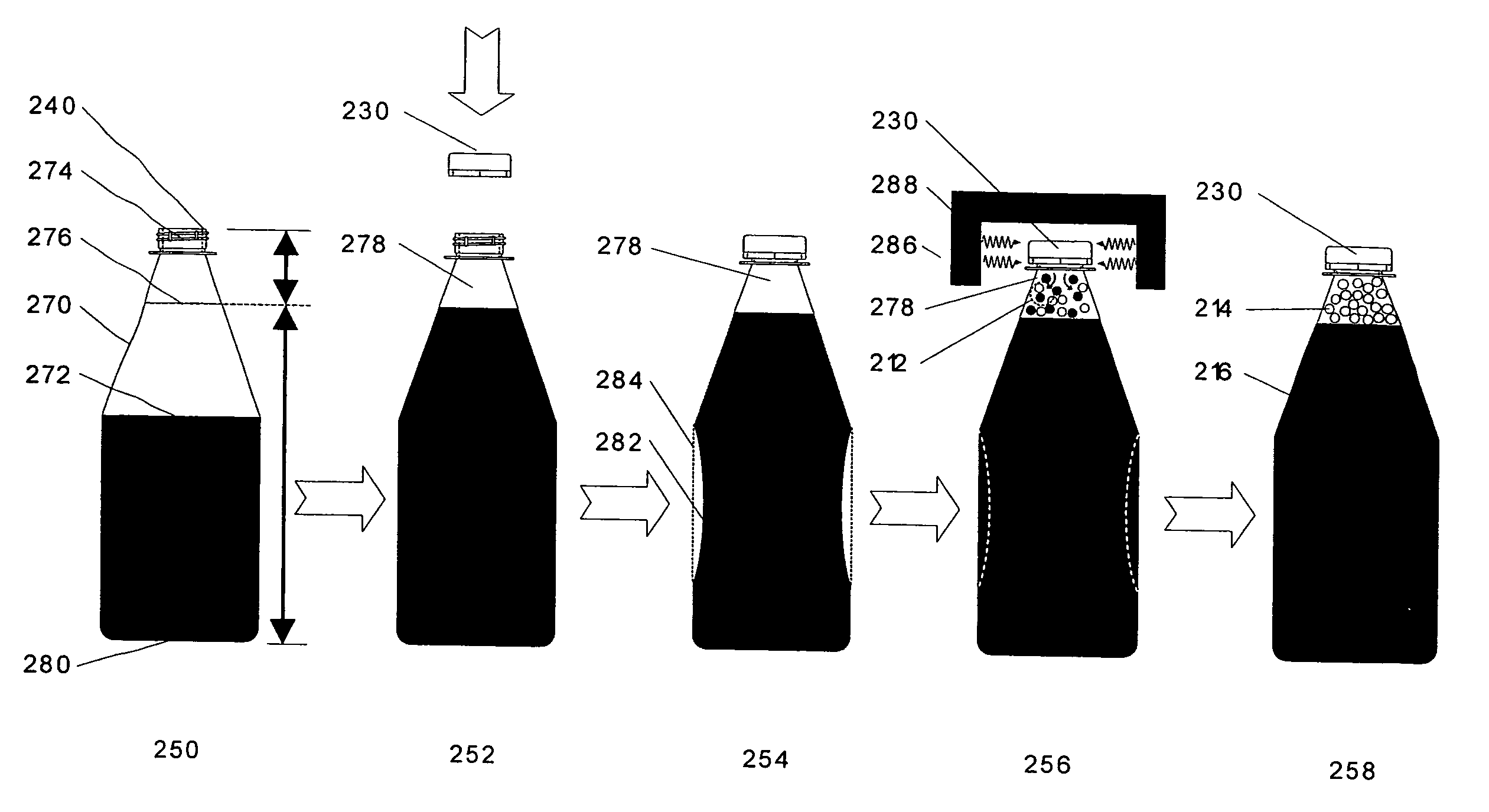

Method and device for pressurizing containers

Owner:INOFLATE

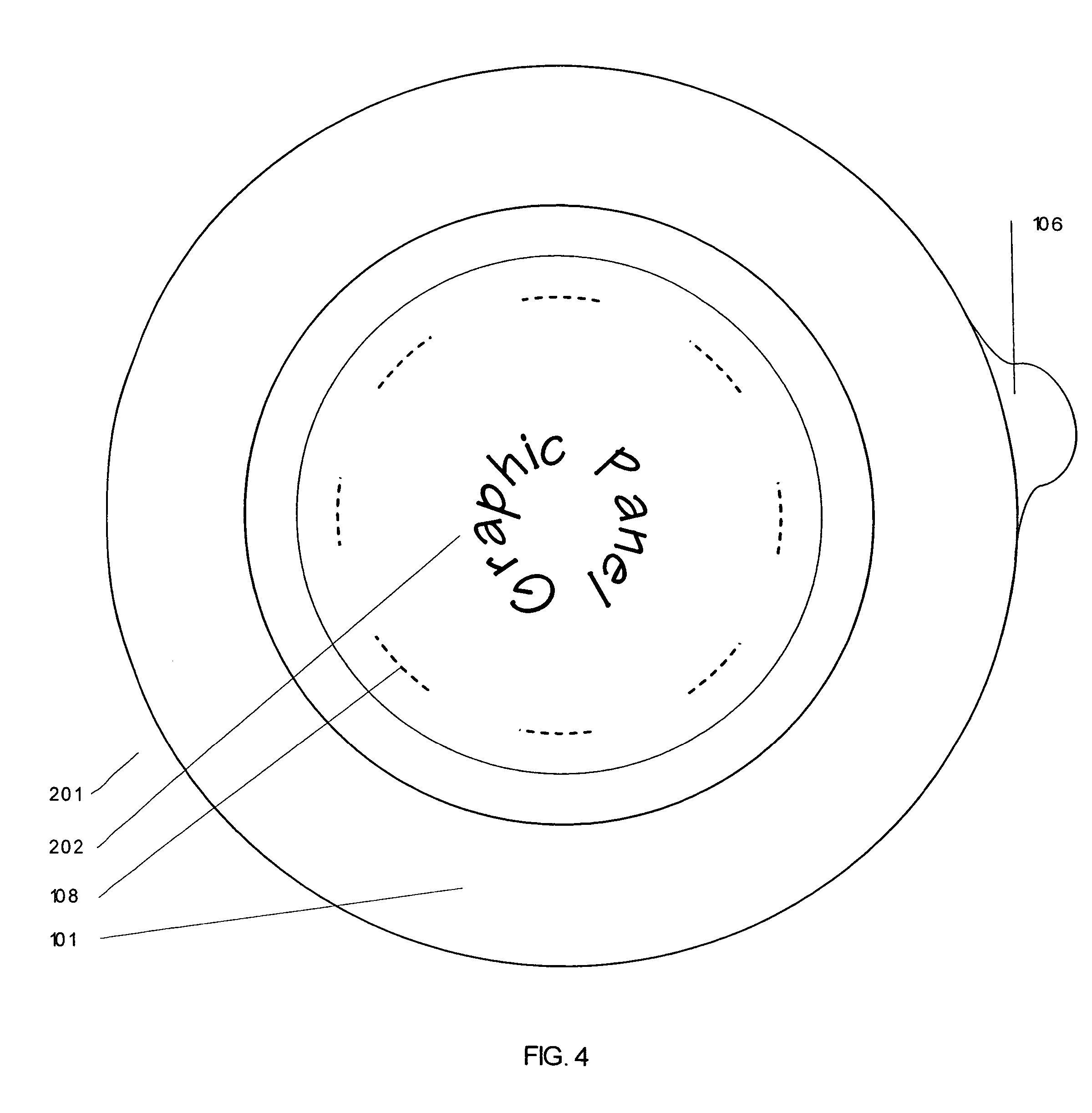

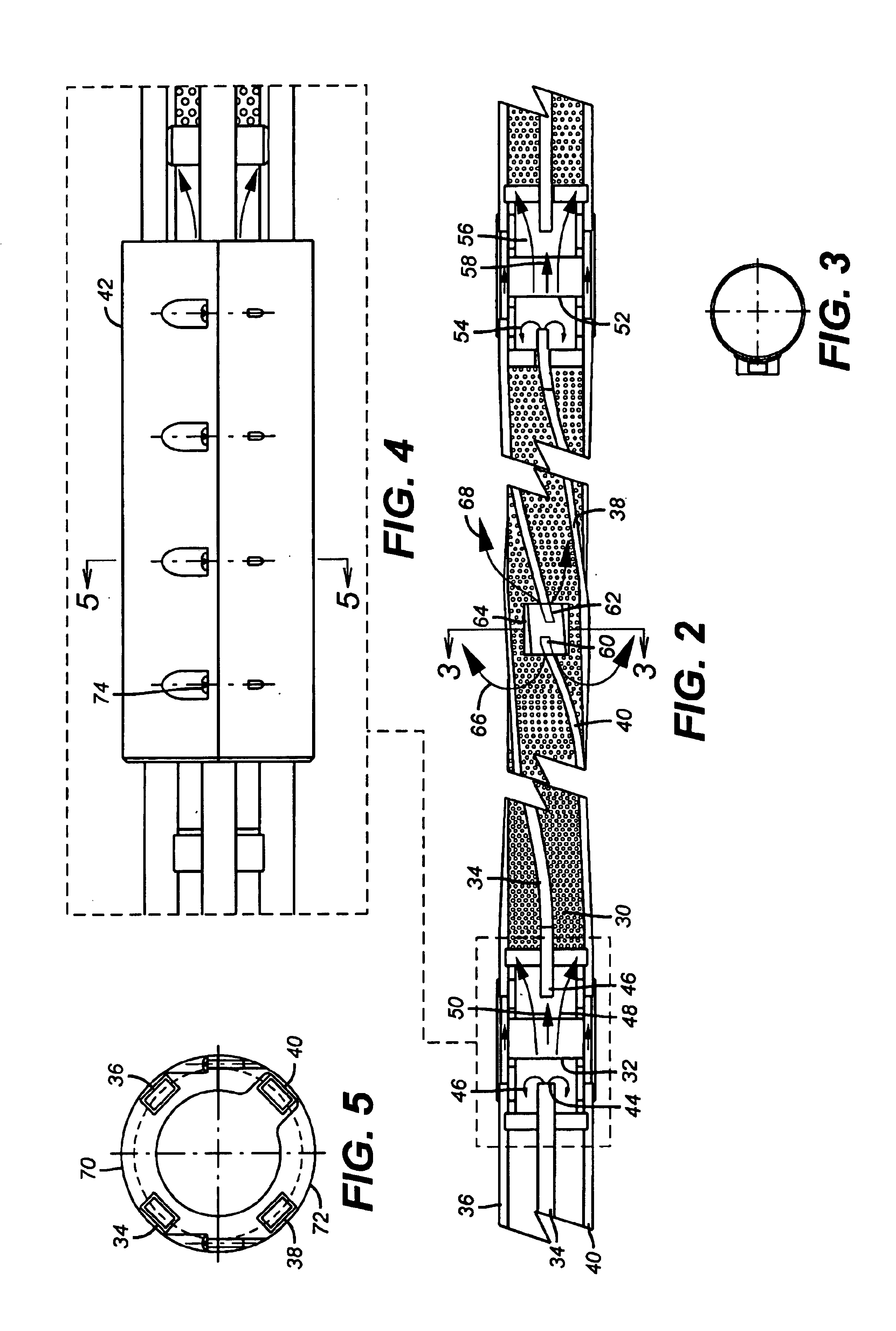

Reinforced high strength microwave antenna

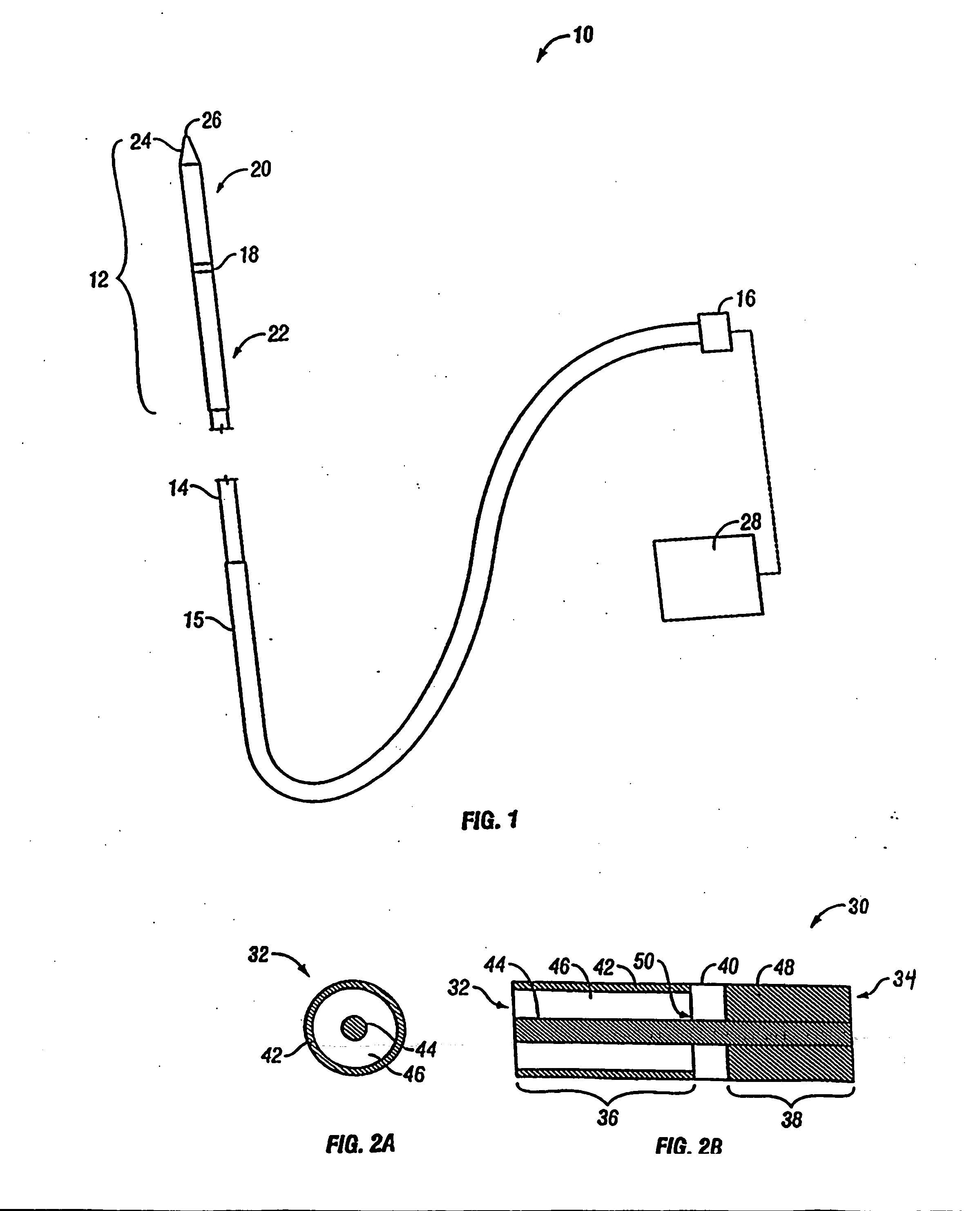

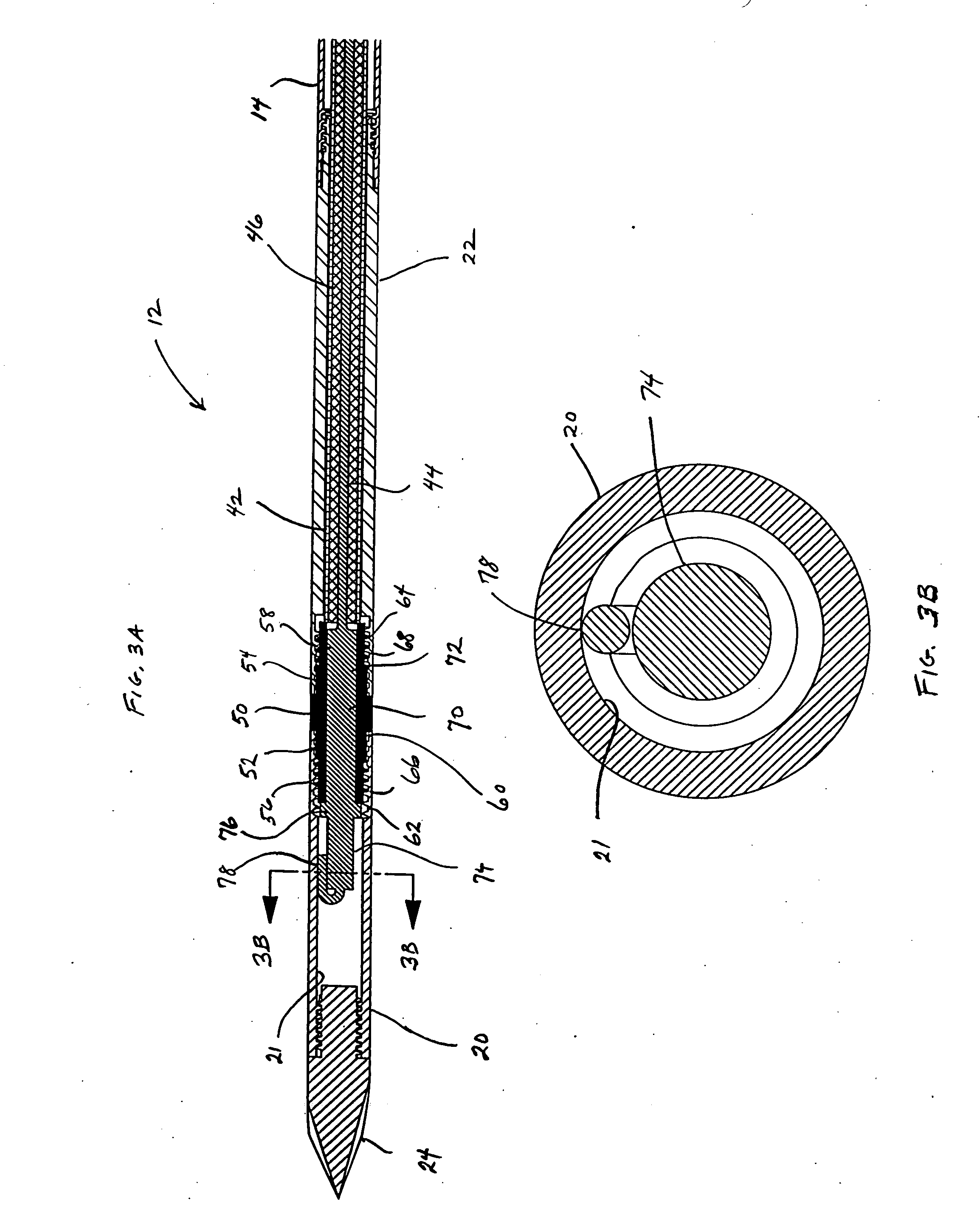

InactiveUS20060259024A1High energy concentrationHigh strengthElectrotherapySurgical instruments for heatingMicrowaveHigh intensity

High-strength microwave antenna assemblies and methods of use are described herein. The microwave antenna has a radiating portion connected by a feedline to a power generating source, e.g., a generator. Proximal and distal radiating portions of the antenna assembly are separated by a junction member. A reinforcing member is disposed within the junction member to increase structural rigidity.

Owner:TYCO HEALTHCARE GRP LP

Flexible stent

InactiveUS6955686B2Increase flexibilityImproved scaffoldingStentsBlood vesselsInsertion stentStructural rigidity

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

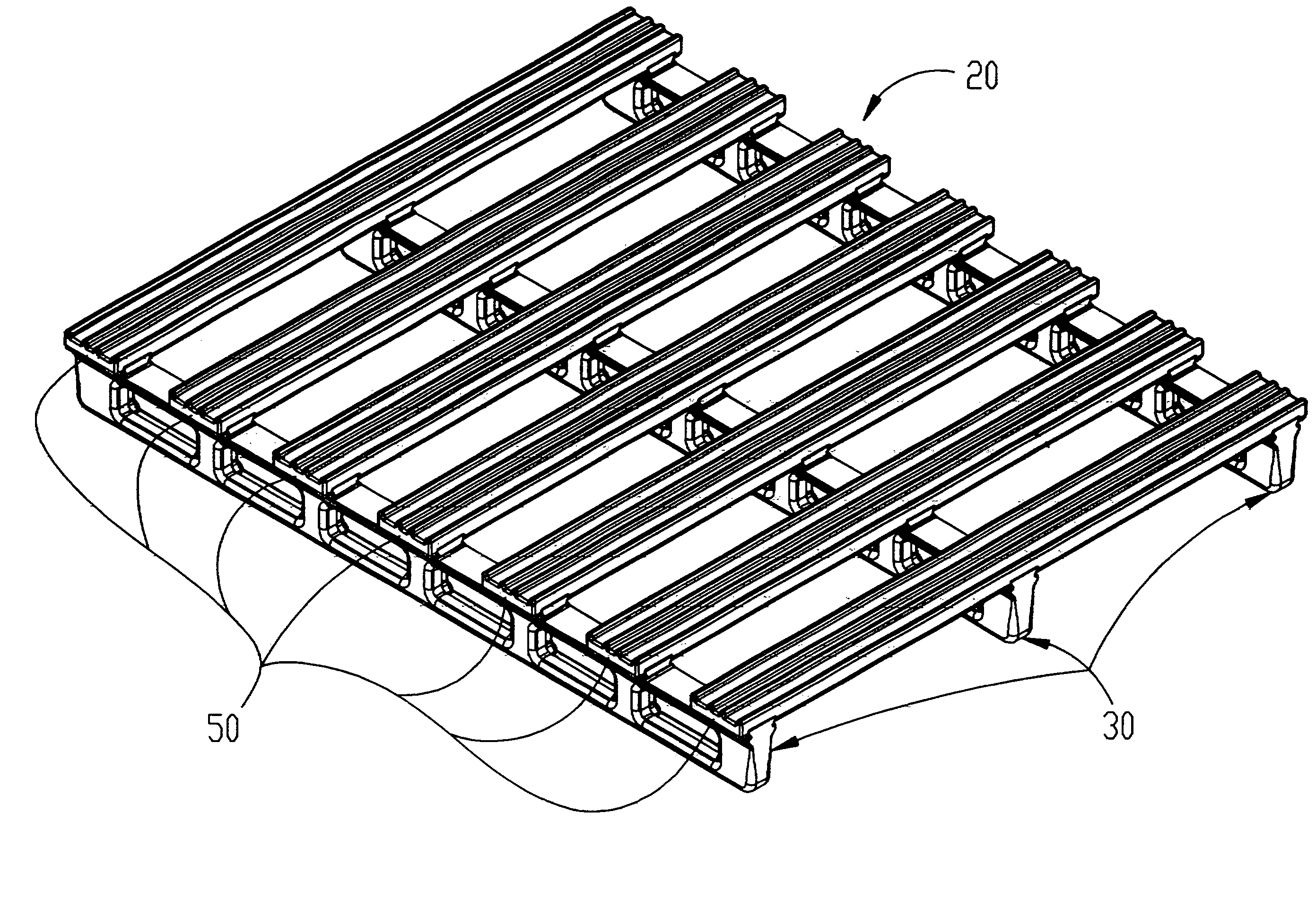

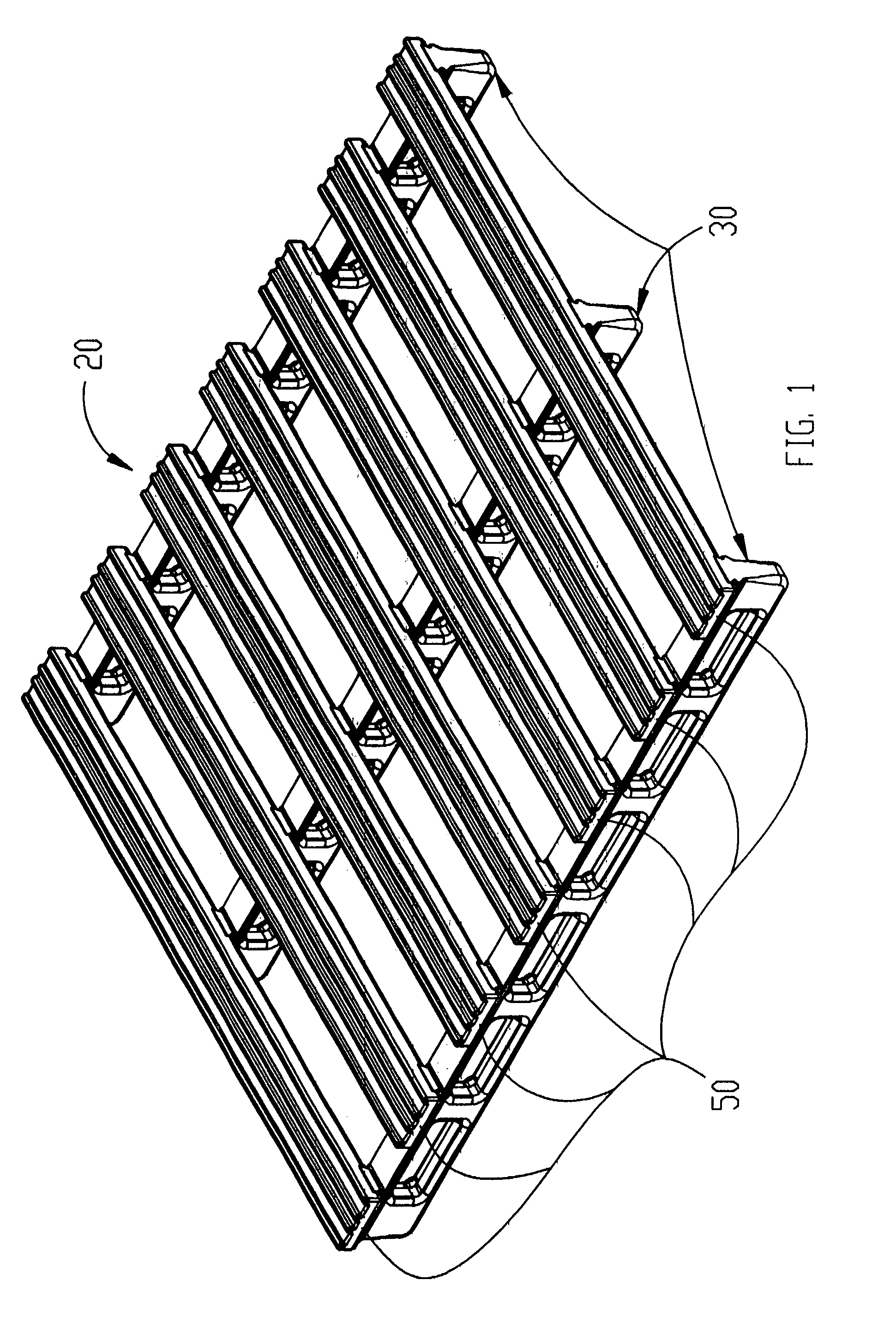

Plastic pallet

InactiveUS6938558B1Provide strengthThe process is convenient and fastOther manufacturing equipments/toolsRigid containersEngineeringLoad distribution

A two-part, blow-molded plastic pallet includes slats which lock onto support stringers by sliding, dovetail engagement. The upper and lower surfaces of the stringer are flat to enhance load distribution. A vertical staking through the slat at a plurality of locations affords structural rigidity.

Owner:PERES VICTOR L

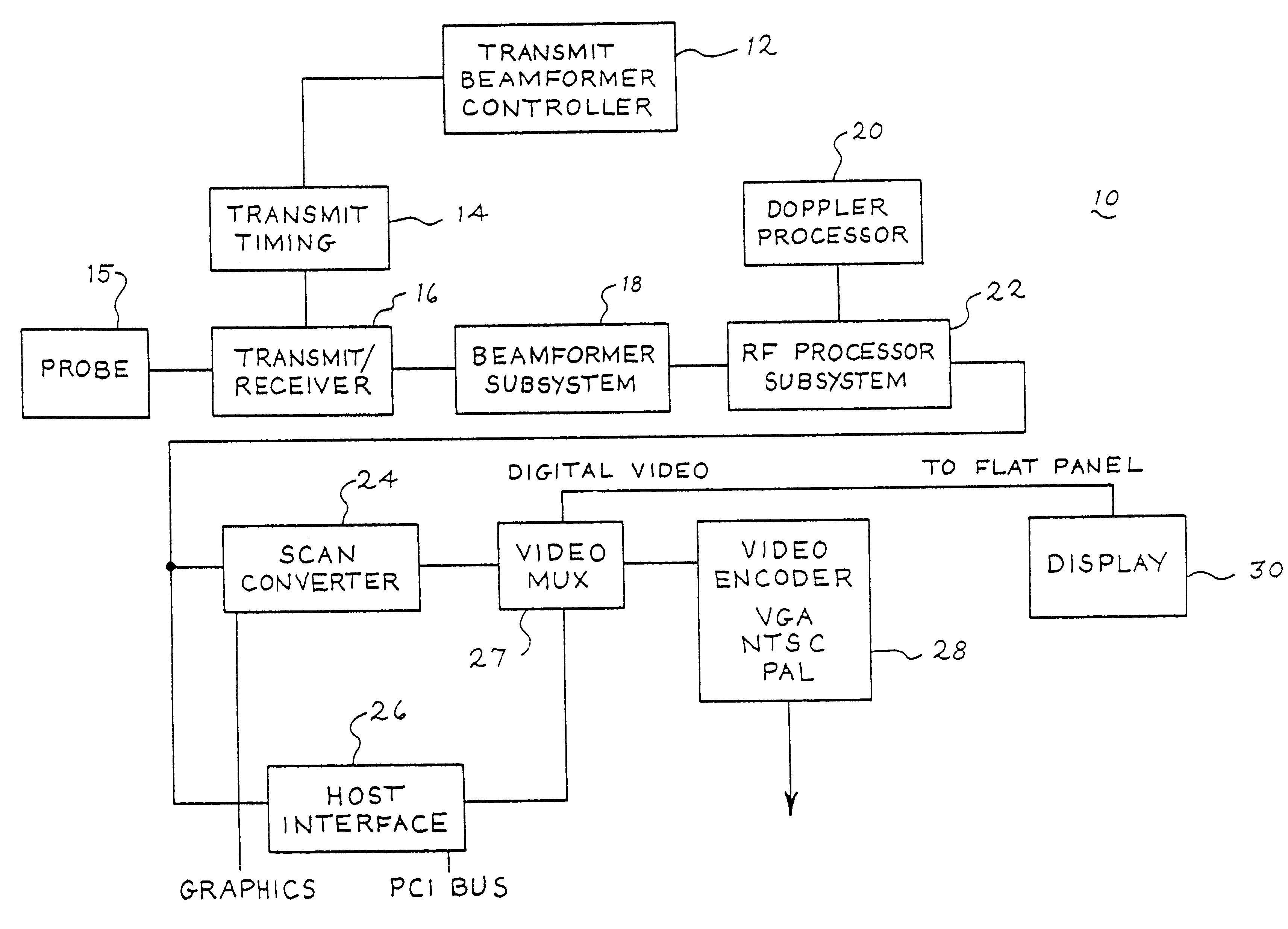

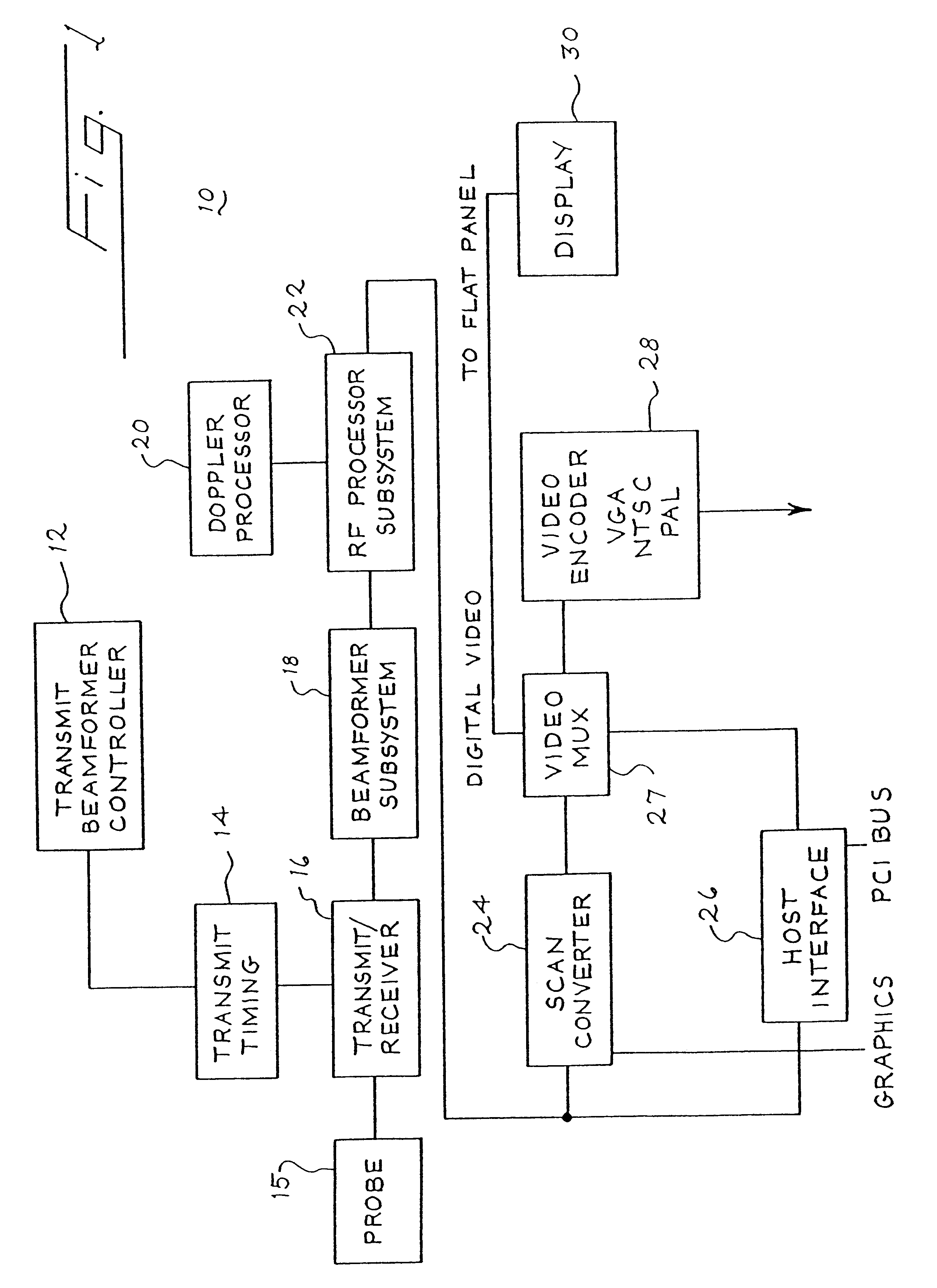

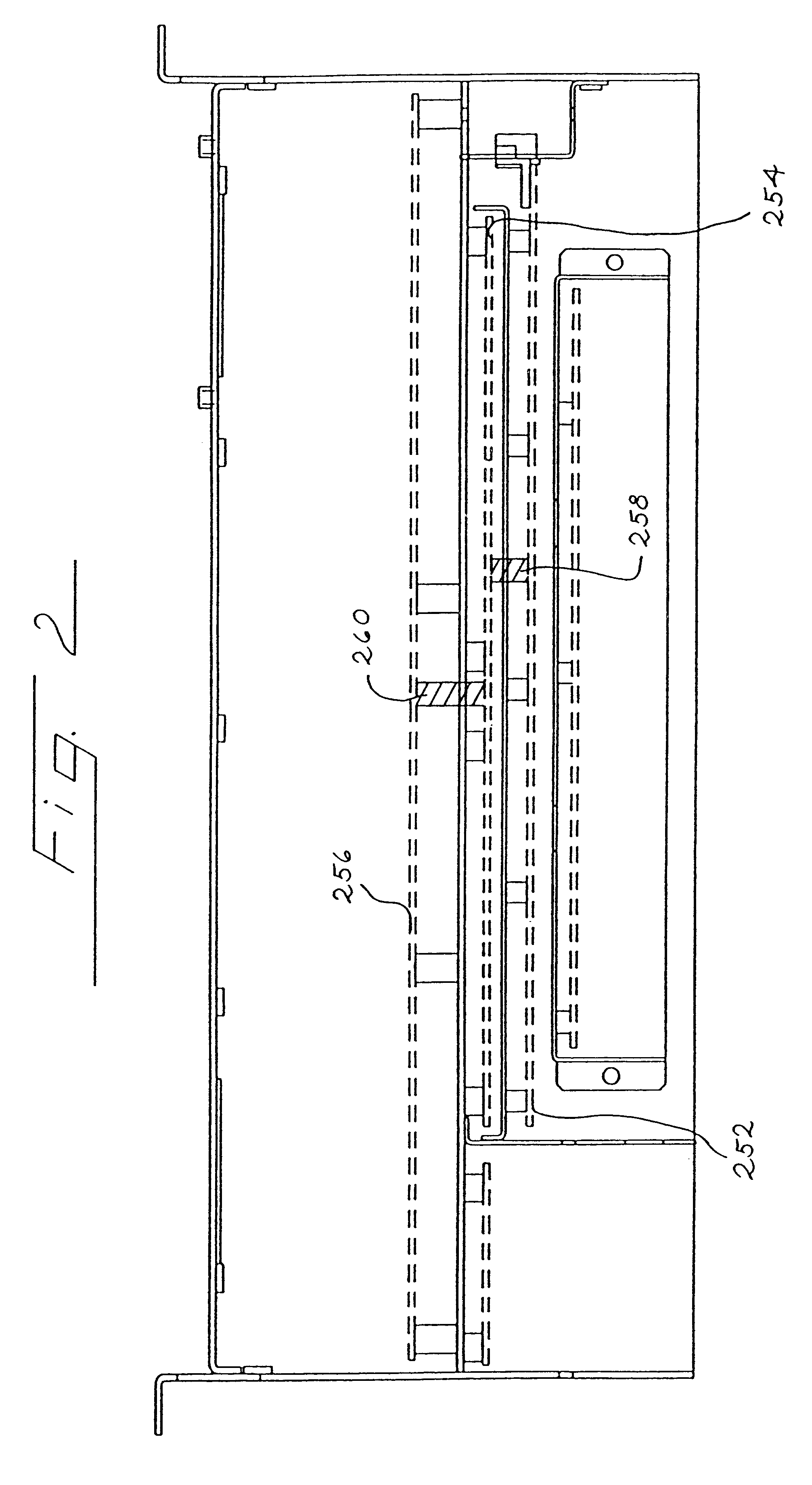

Medical diagnostic ultrasound system and method

InactiveUS6561979B1Heat dissipation capabilityWave based measurement systemsElectrocardiographySonificationHigh density

A portable medical diagnostic ultrasound system is provided which includes shielding for electromagnetic interference by forming shielded enclosed compartments around the individual components of the ultrasound system. This compartmentalization of components isolates EMI between the components themselves as well as the outside world. Further, the EMI shielding provides structural rigidity and support for the entire ultrasound system. In another aspect, the EMI shielding provides heat dissipation capability for the internal components of the ultrasound system. The portable medical diagnostic ultrasound system further provides a transducer connector which provides high density interconnects between the transducer and the ultrasound system while providing an ergonomically easy to handle connector. Further, the connector is rugged, providing a high number of connection and disconnection cycles.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

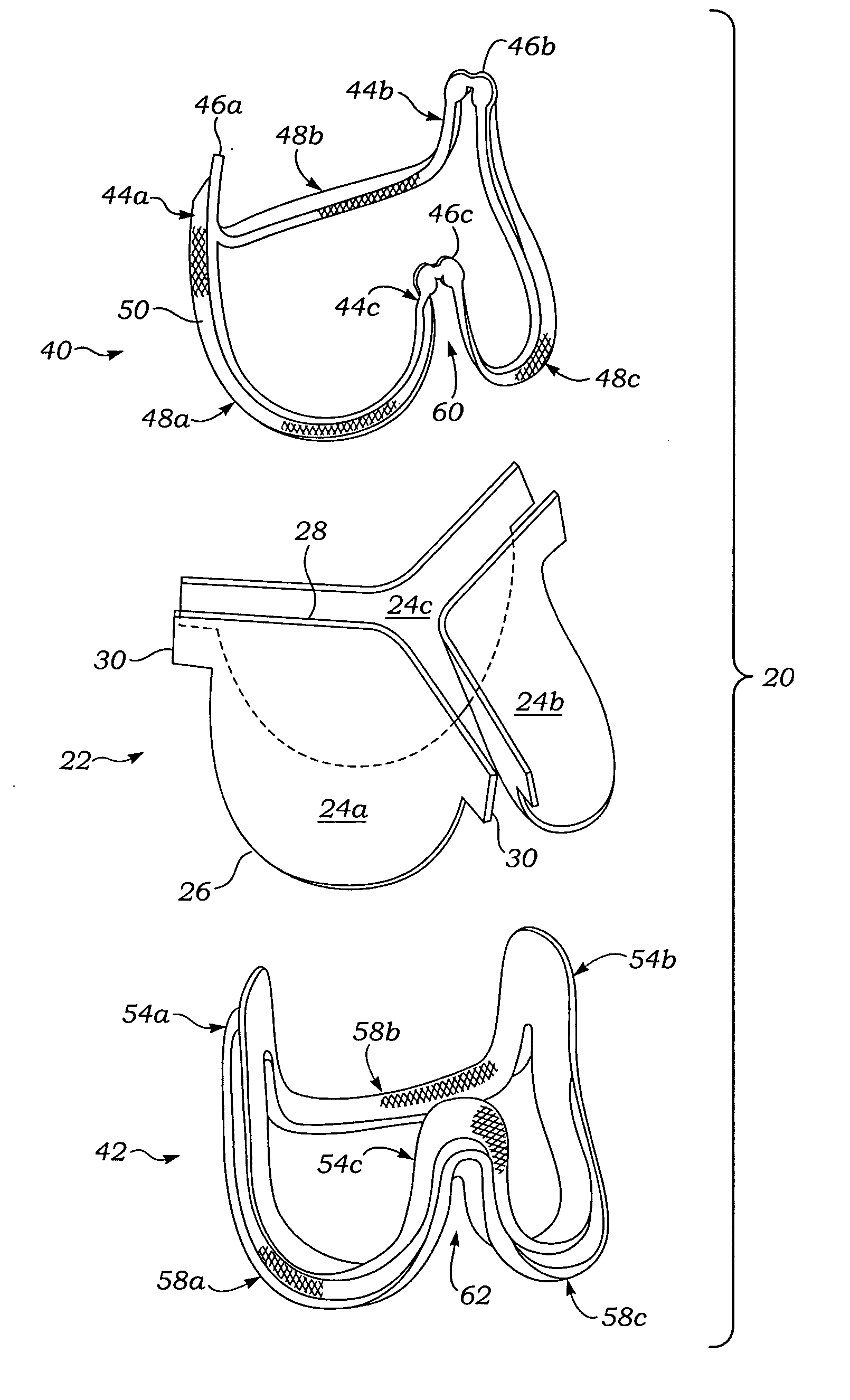

Controlled separation heart valve frame

InactiveUS20050228494A1Same material stiffnessReduce the possibilityHeart valvesEngineeringProsthetic heart

A highly flexible prosthetic heart valve having an internal leaflet support frame that is designed to separate into individual cusps after implantation. The leaflet support frame (or “stent” or “wireform”) has a plurality of alternating cusps on an inflow end and commissures on an outflow end. The cusps of flexible leaflets attach around the support frame cusps. The support frame provides structural rigidity during implantation, but each support frame commissure has a point of weakness that is designed to fracture upon repeated relative movement of the cusps after implantation such that the support frame cusps separate. Because of the flexible nature of the heart valve, after the cusps separate the implanted heart valve does not significantly impede the natural motions of the annulus or adjacent vessel walls. The support frame may be a homogeneous material such as Nitinol with the point of weakness being a narrowing at the commissure tips. The commissure tips can include enlarged regions adjacent the point of weakness that help prevent the separated ends from poking through surrounding fabric.

Owner:EDWARDS LIFESCIENCES CORP

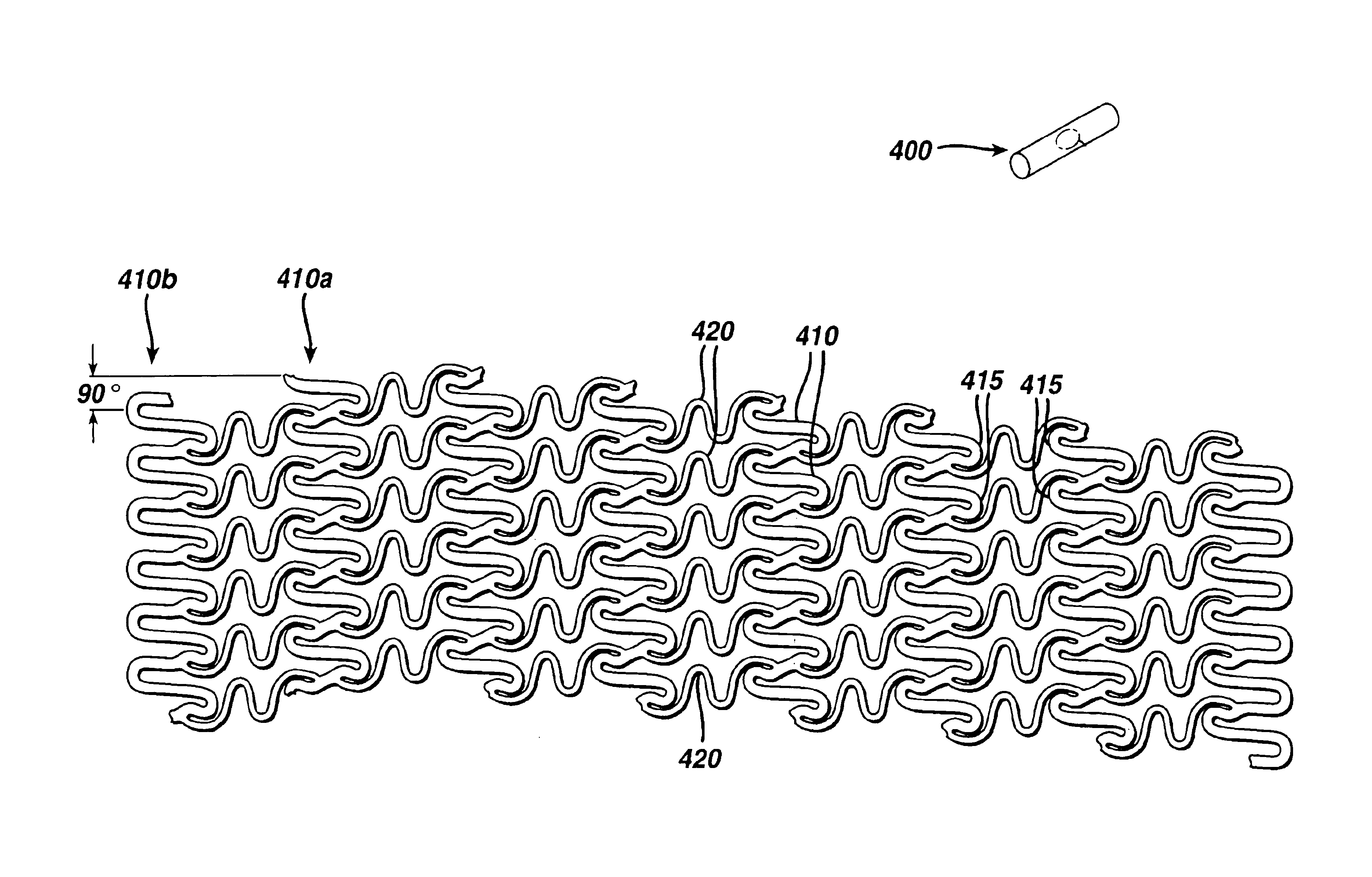

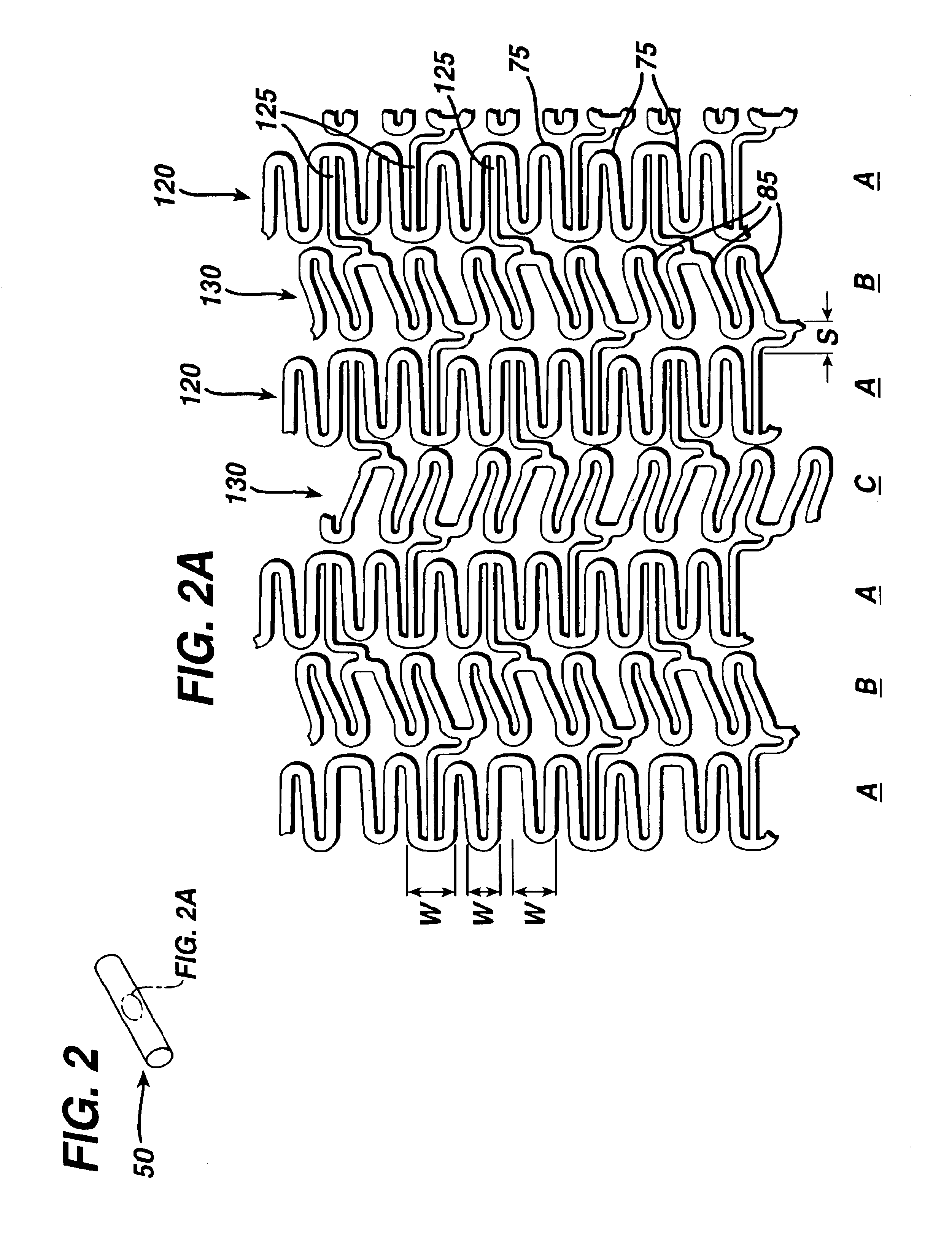

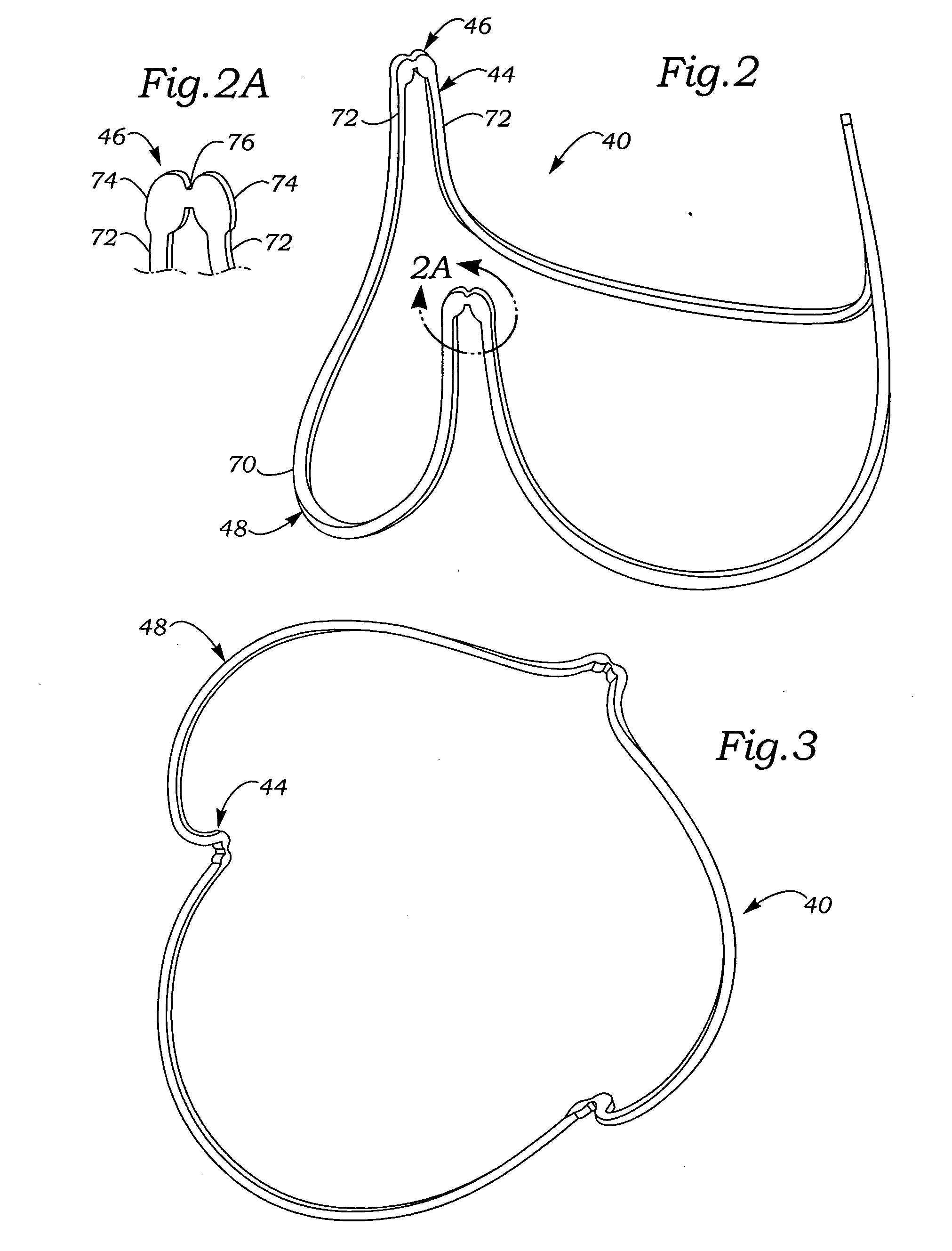

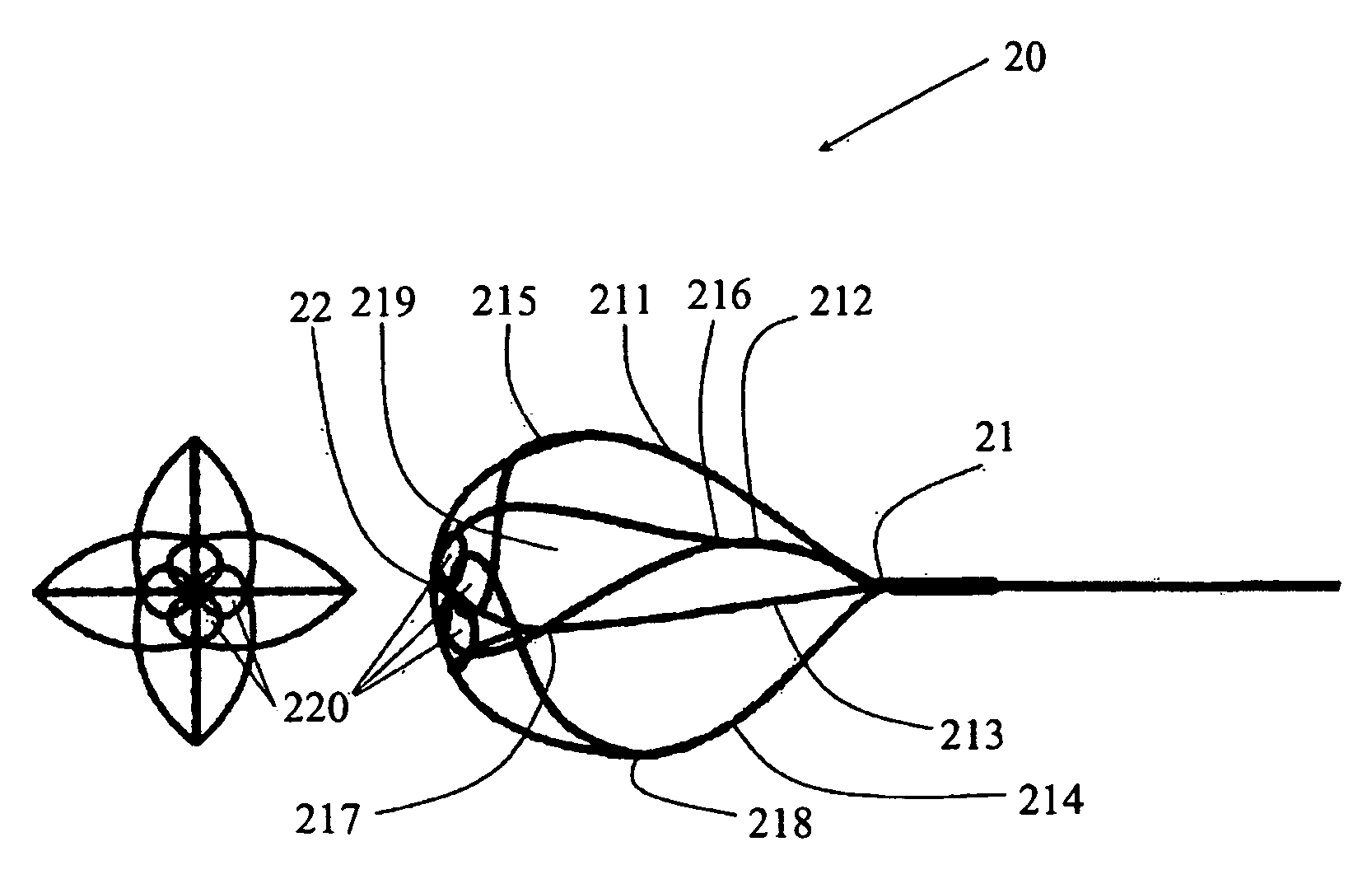

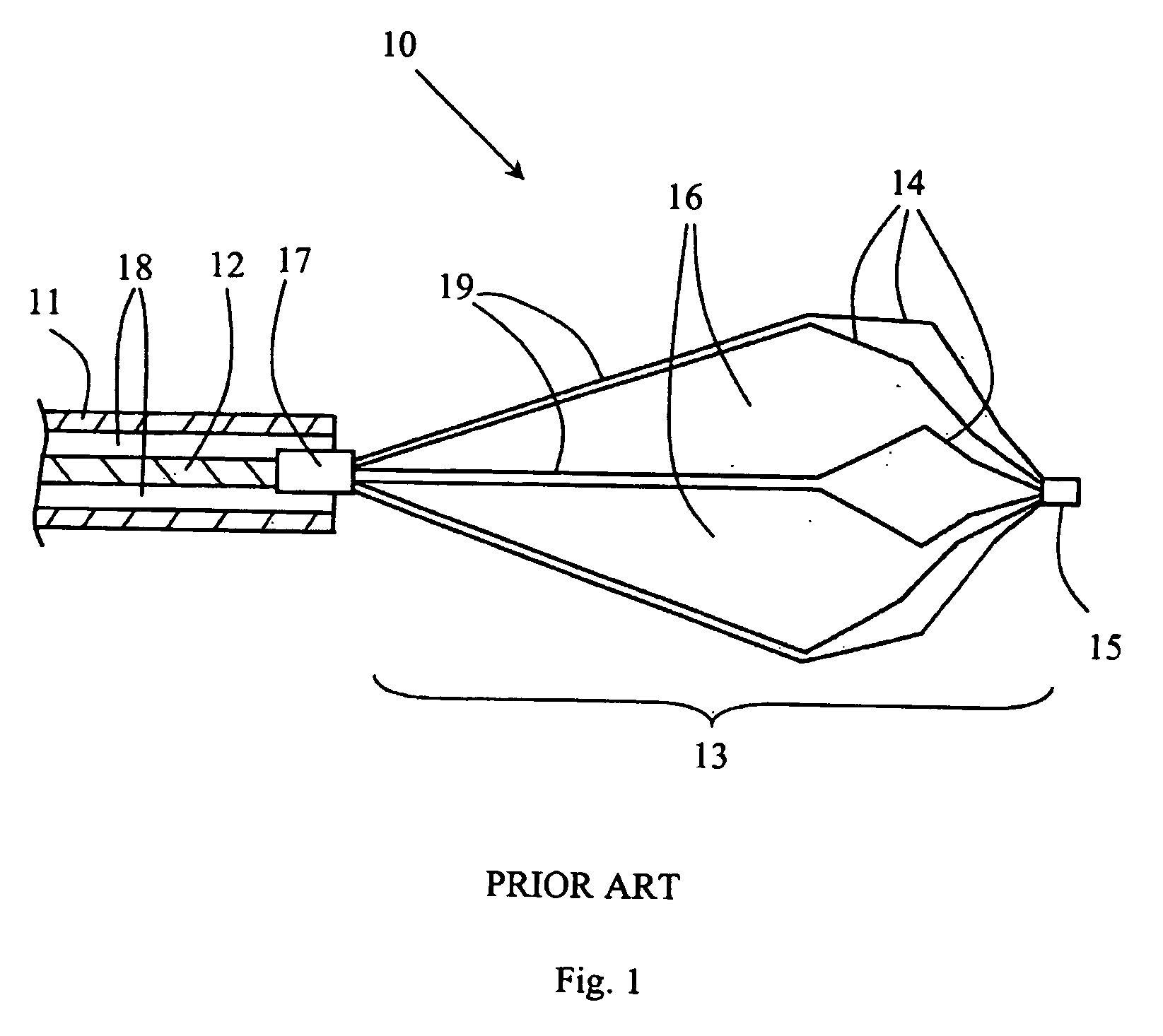

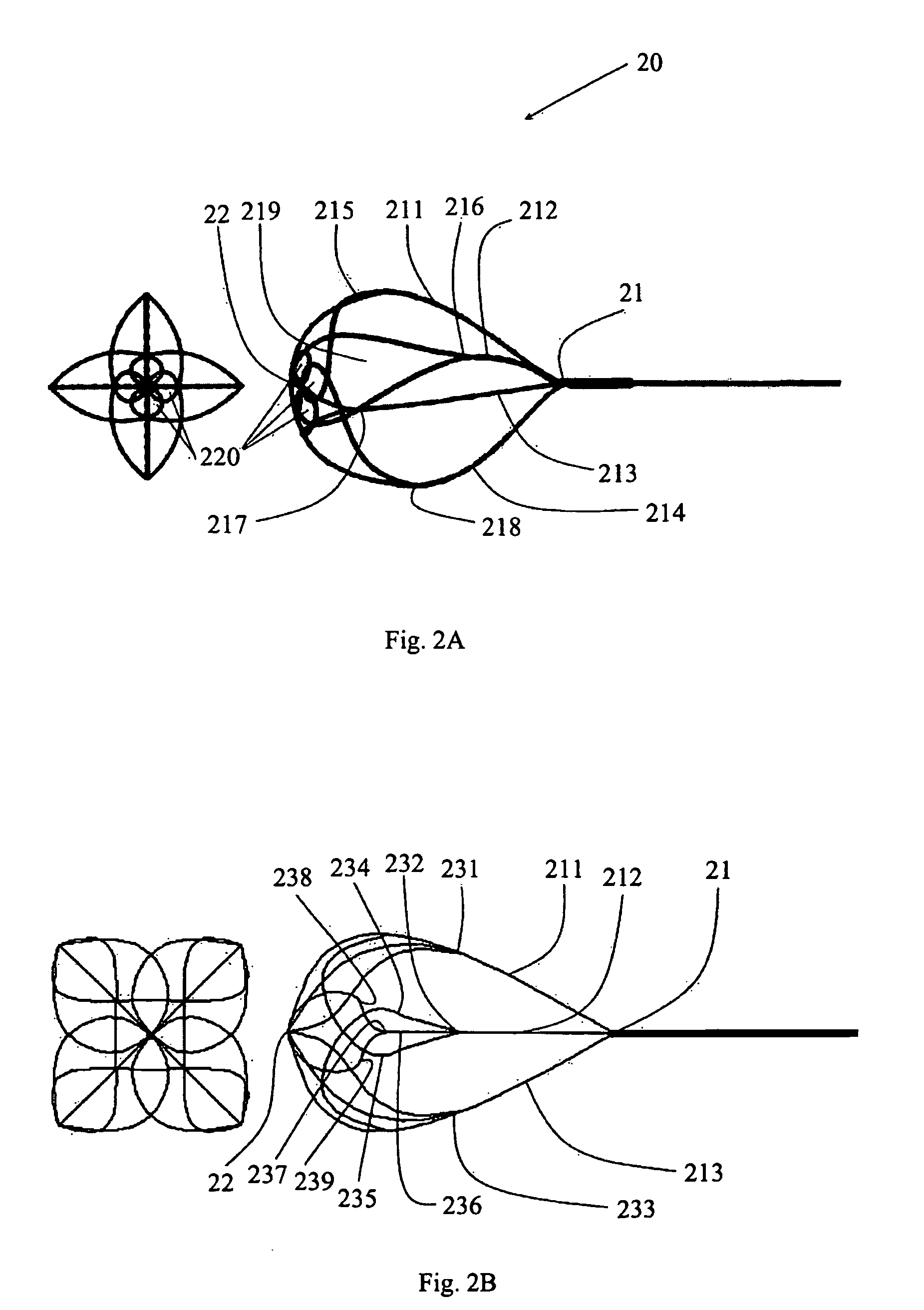

Retrieval snare for extracting foreign objects from body cavities and method for manufacturing thereof

ActiveUS20080086149A1Provide structural rigidityProvide dilatation abilityWire articlesSurgeryDistal portionForeign object

A retrieval snare for entrapping and retaining a foreign object located in a body and a method for manufacturing of the snare are provided. The snare comprises a structure having a proximal portion and a distal portion and includes a plurality of filaments. The filaments extend from an end of the proximal portion towards the distal portion and return to the end of the proximal portion to form a plurality of loops. The loops are not interconnected at the distal portion, but each side of each loop are connected to a side of an adjacent loop in the proximal portion at more than one point, thereby providing structural rigidity and dilatation ability to the snare.

Owner:COOK MEDICAL TECH LLC +1

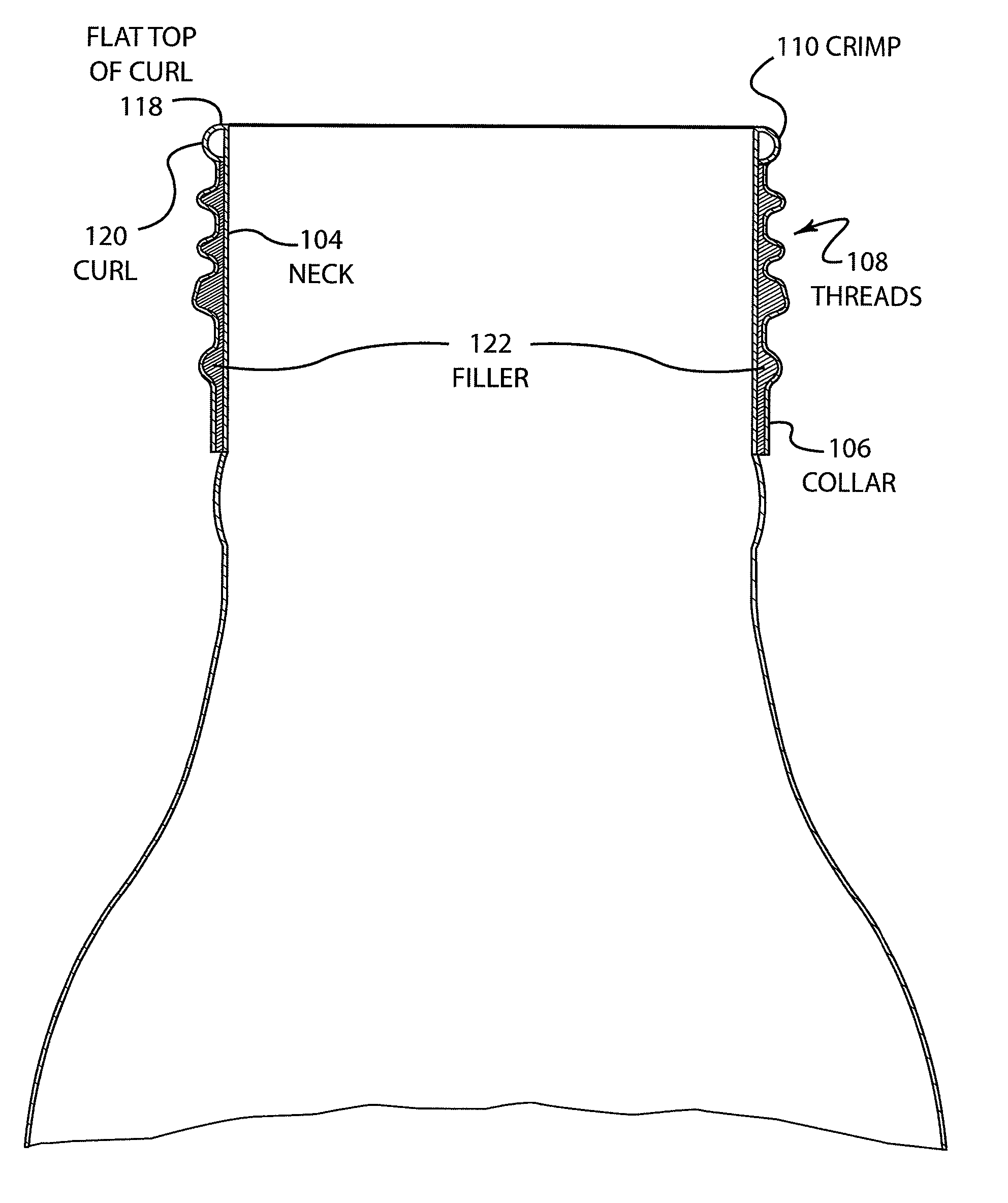

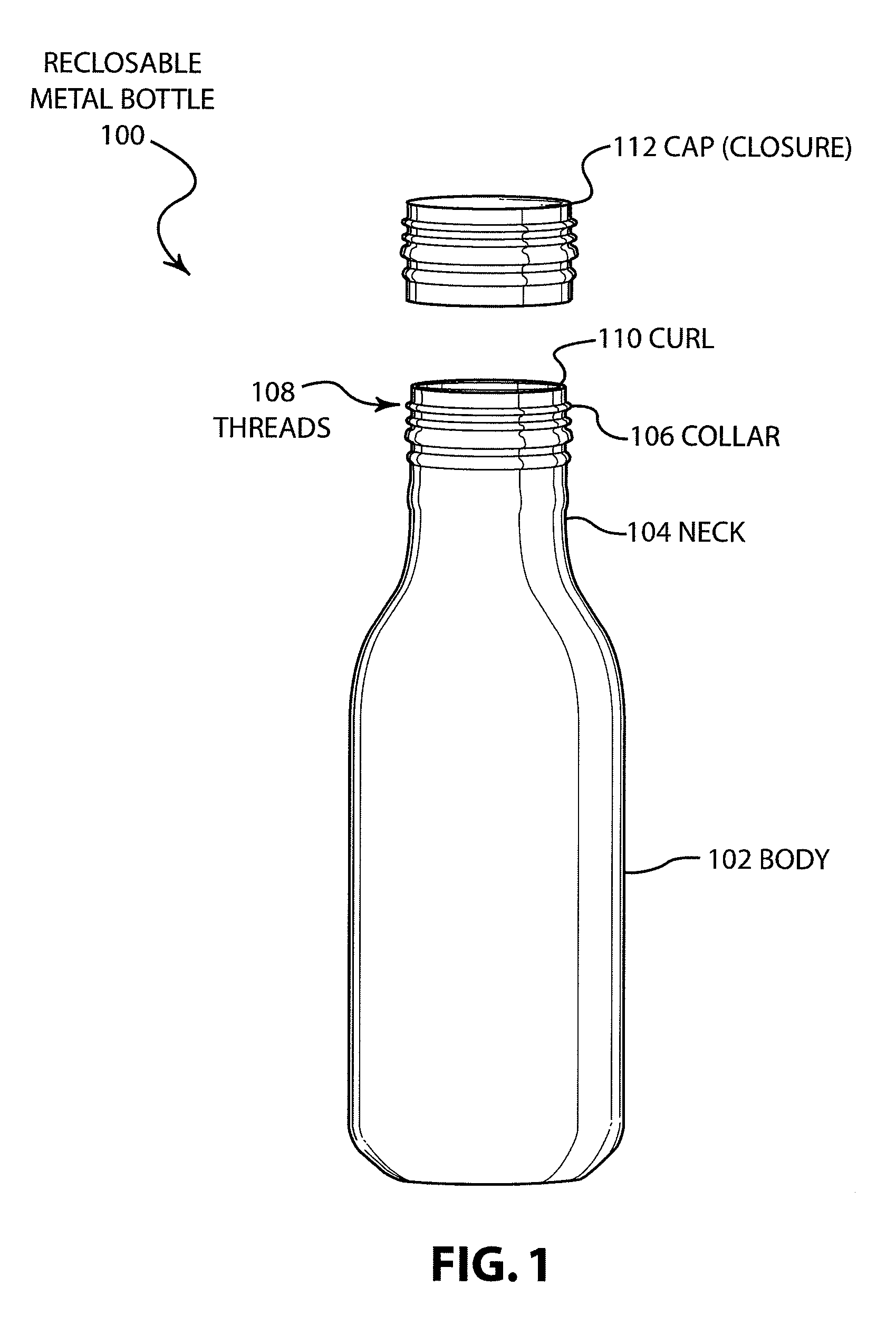

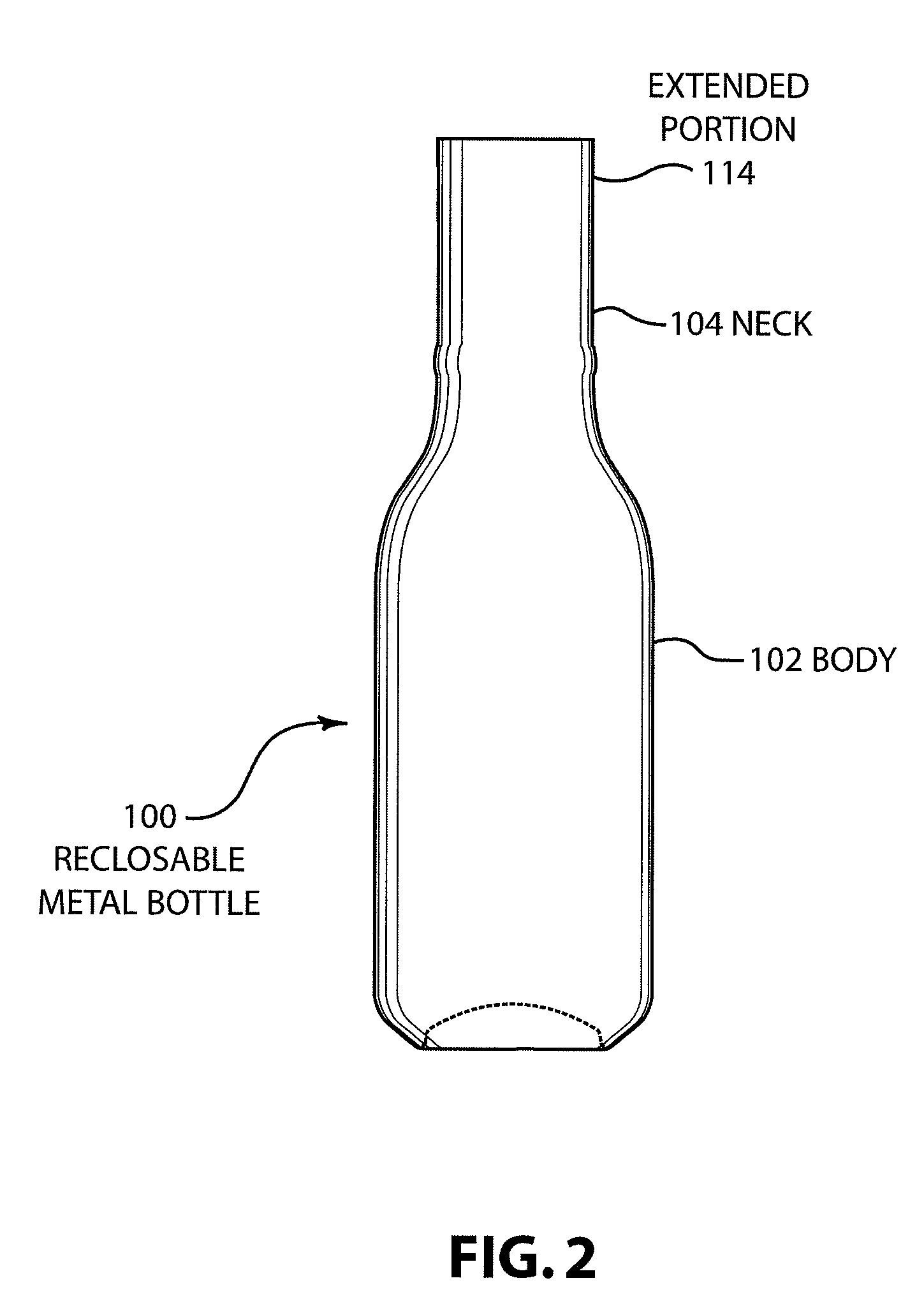

Reclosable metal bottle

InactiveUS20070051687A1Provide rigidityProvide strengthClosure capsRigid containersEngineeringBottle

Disclosed is an unique reclosable metal bottle in which a trim portion of the neck can be reused and mounted on the neck as a collar, or a separate collar provided, that has the structural rigidity necessary to form threads or lugs for recloseability. Thin wall metal bottles, having thicknesses on the order of thin wall metal cans currently in use, can be made using this process with minimal material waste since the trim neck portion is reused as a threaded collar. Structural rigidity and strength can be added by using fillers to backfill the indentations of the threads in the collar. Threads or lugs can be used, including pressure release lugs, that add both safety and convenience. Since the reclosable metal bottle is an all-metal container, the bottle can be recycled without introducing contaminants.

Owner:OMNITECH INT +1

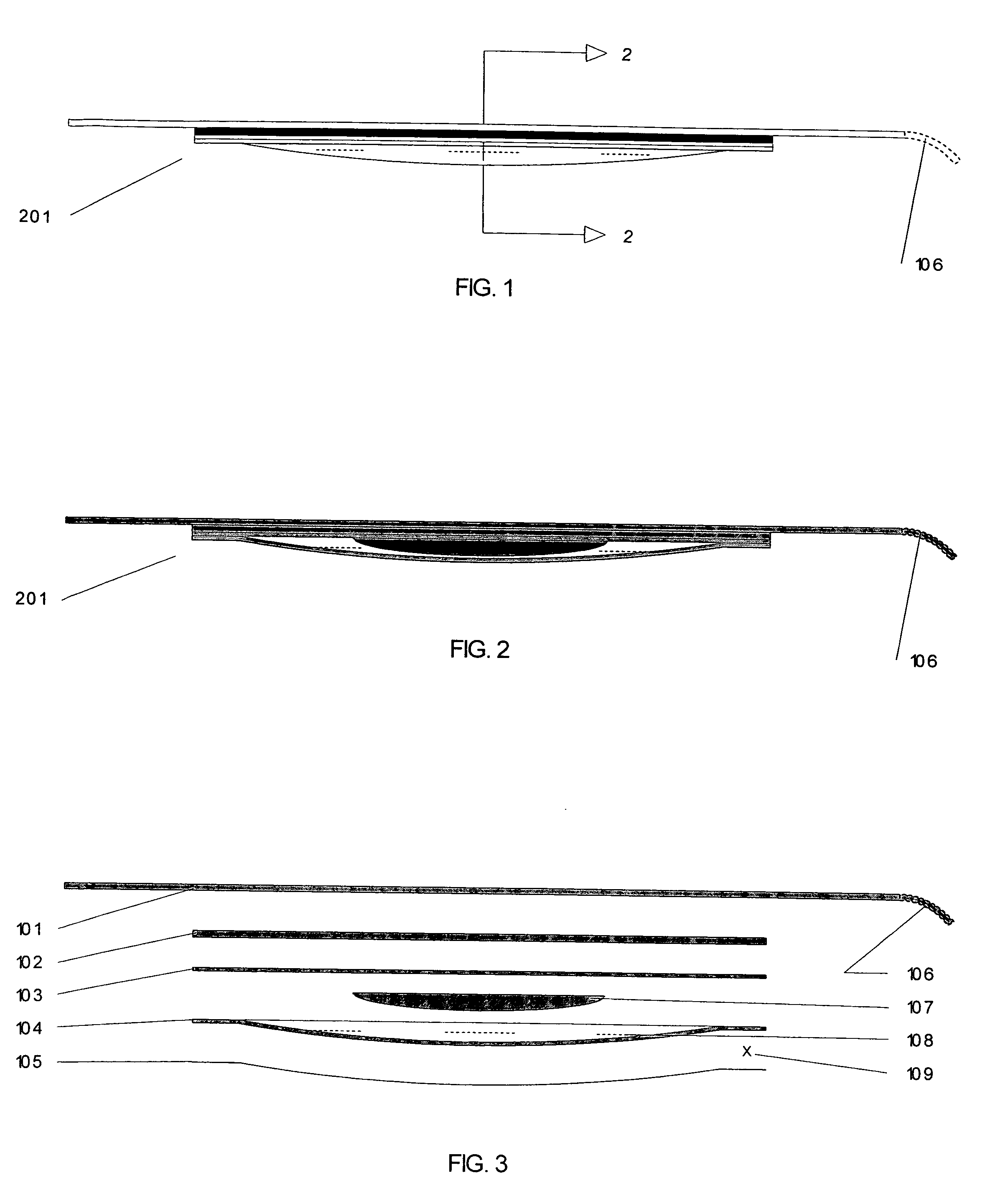

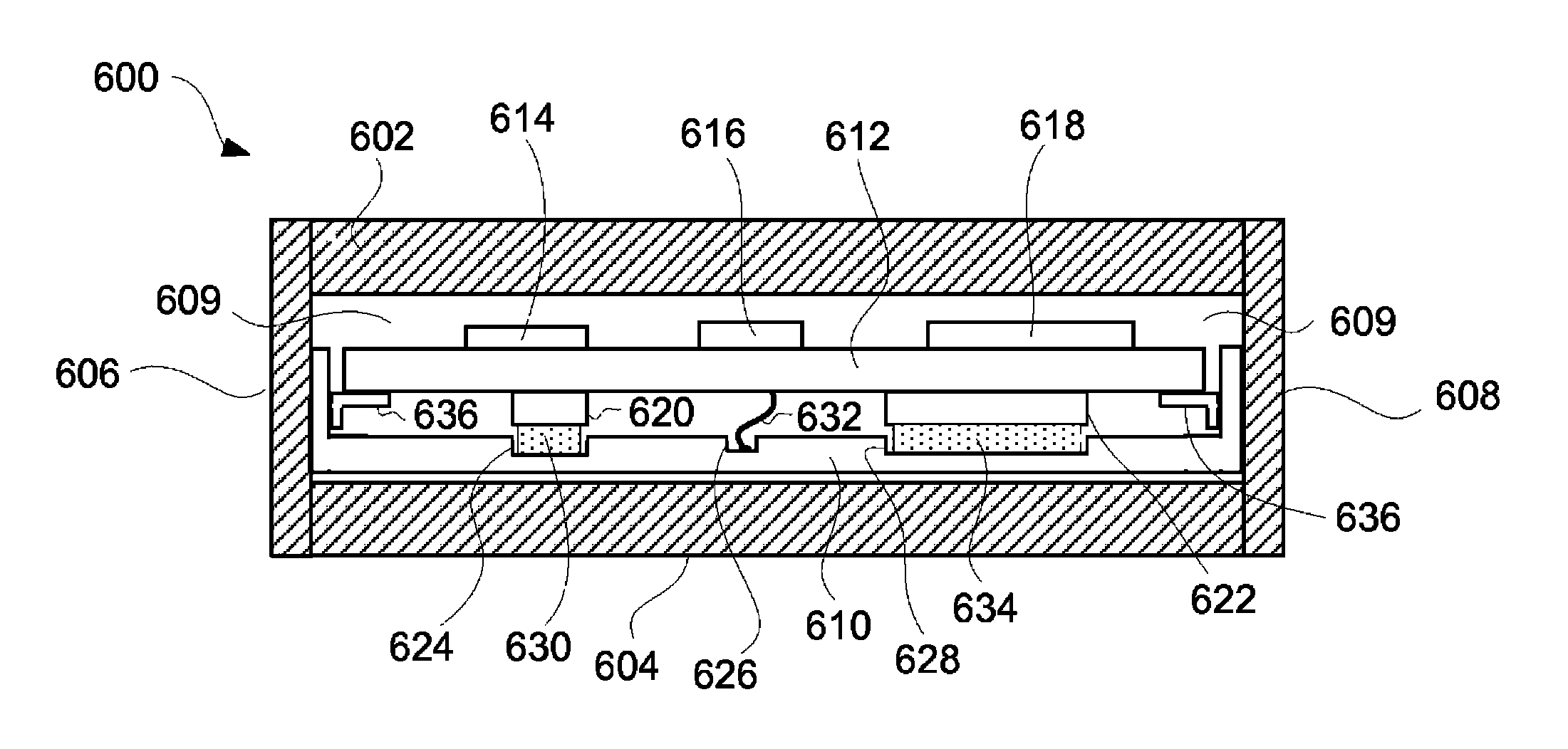

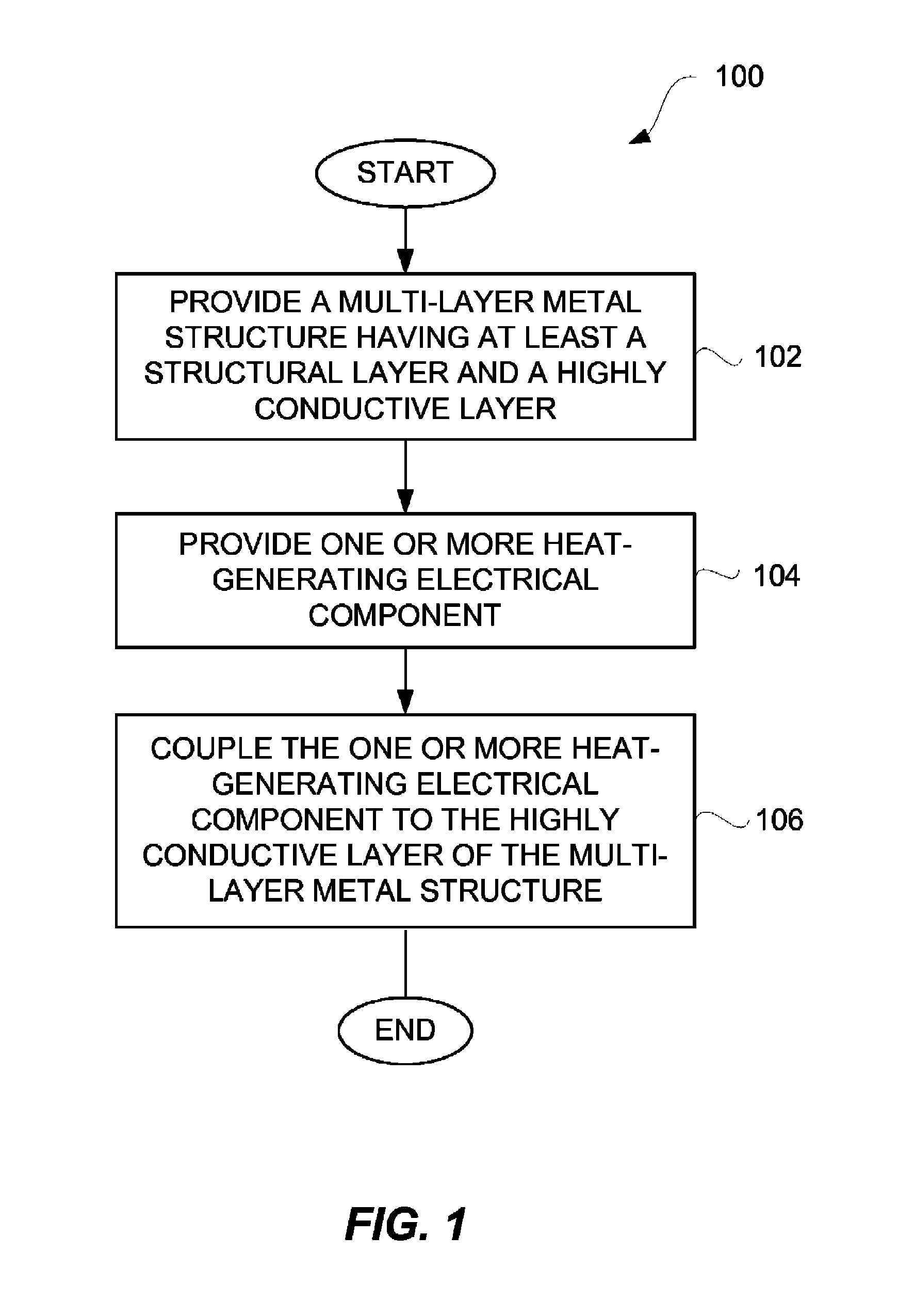

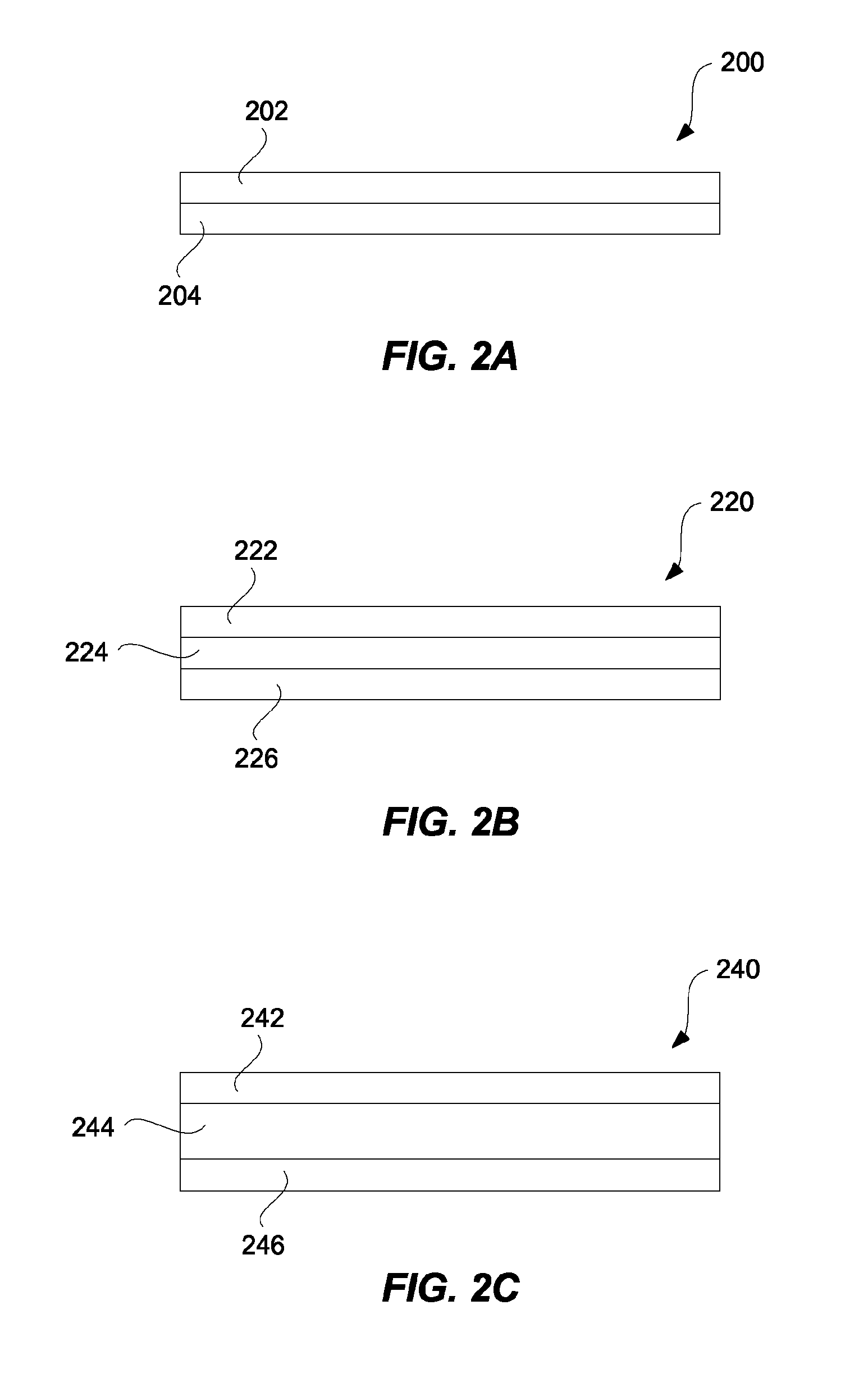

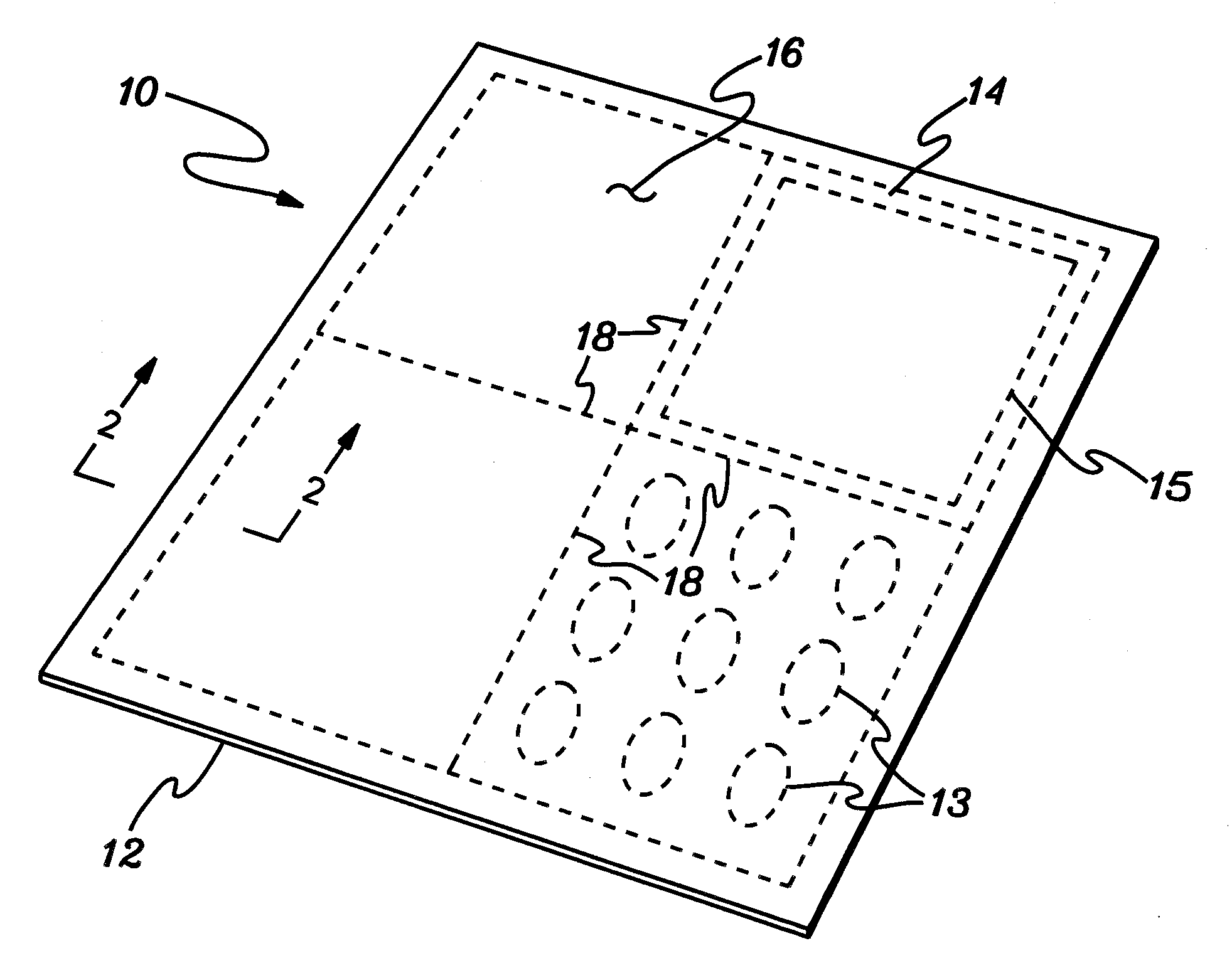

Thin multi-layered structures providing rigidity and conductivity

ActiveUS8879266B2Improve conductivityIncreasing the thicknessPrinted circuit assemblingDigital data processing detailsEngineeringGround plane

Electronic devices having a multi-layer structure that provides enhanced conductivity (thermal and / or electrical conductivity) are disclosed. The multi-layer structure can have a plurality of adjacent layers. At least one layer can primarily provide structural rigidity, and at least another layer can primarily provide enhanced conductivity. The layer of high conductivity can serve to provide the electronic device with greater ability to disperse generated heat and / or to provide an accessible voltage potential (e.g., ground plane). Advantageously, the multi-layer structure can provide enhanced conductivity using an otherwise required structural component and without necessitating an increase in thickness.

Owner:APPLE INC

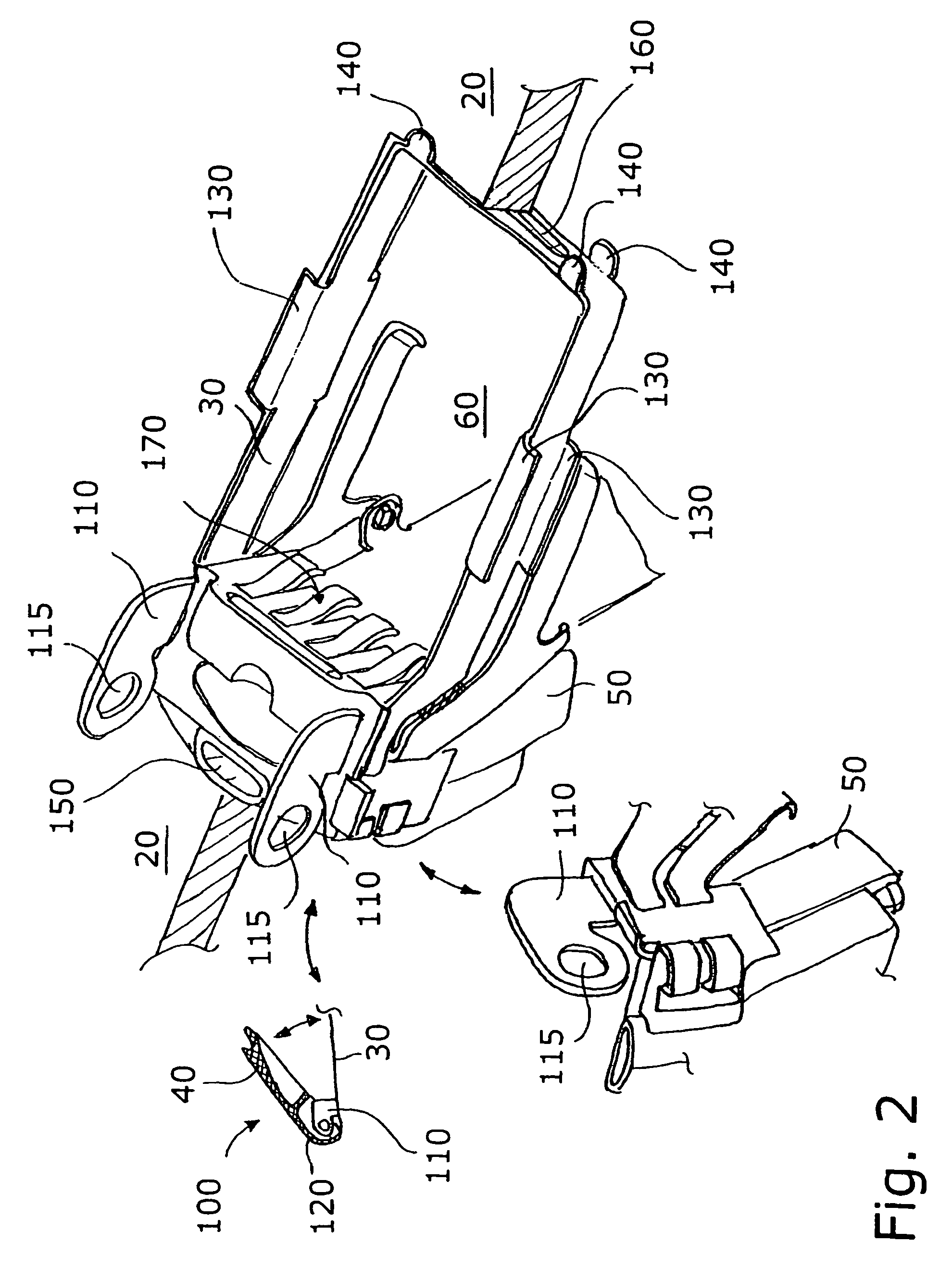

Miniature hearing aid insert module

InactiveUS7403630B2Easy to manufacture and to user-customize and to repairEasy to manufactureCompletely in canal hearing aidsAdditive manufacturing apparatusCouplingClosed loop

According to the present invention, there is provided a hearing aid insert module comprising a socket module, and a substantially closed-loop frame comprising electrically conductive portions, the closed-loop frame further comprising engaging means adapted to releasably couple the hearing aid insert module to a faceplate of a hearing aid. The invention is of advantage in that releasable coupling of the faceplate to the socket module via the frame is capable of rendering the insert module easier to manufacture, to user-customize and to repair. The frame is arranged to impart a majority of structural rigidity to the faceplate when inserted therein. Such rigidity is of benefit in that the faceplate is capable in use of applying a flexural component to the frame which could damage the frame if not of sufficiently substantial rigidity.

Owner:SONION ROSKILDE

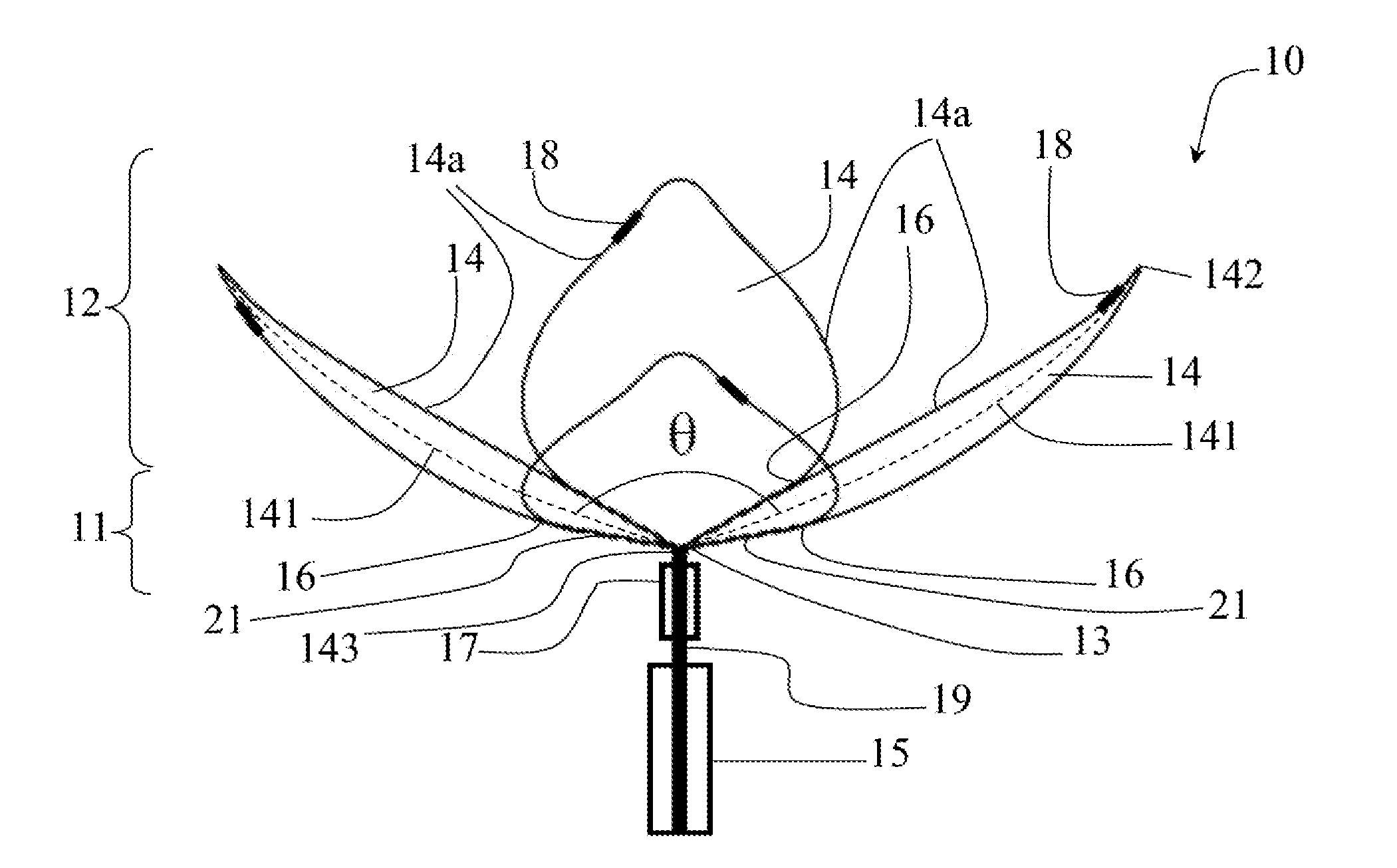

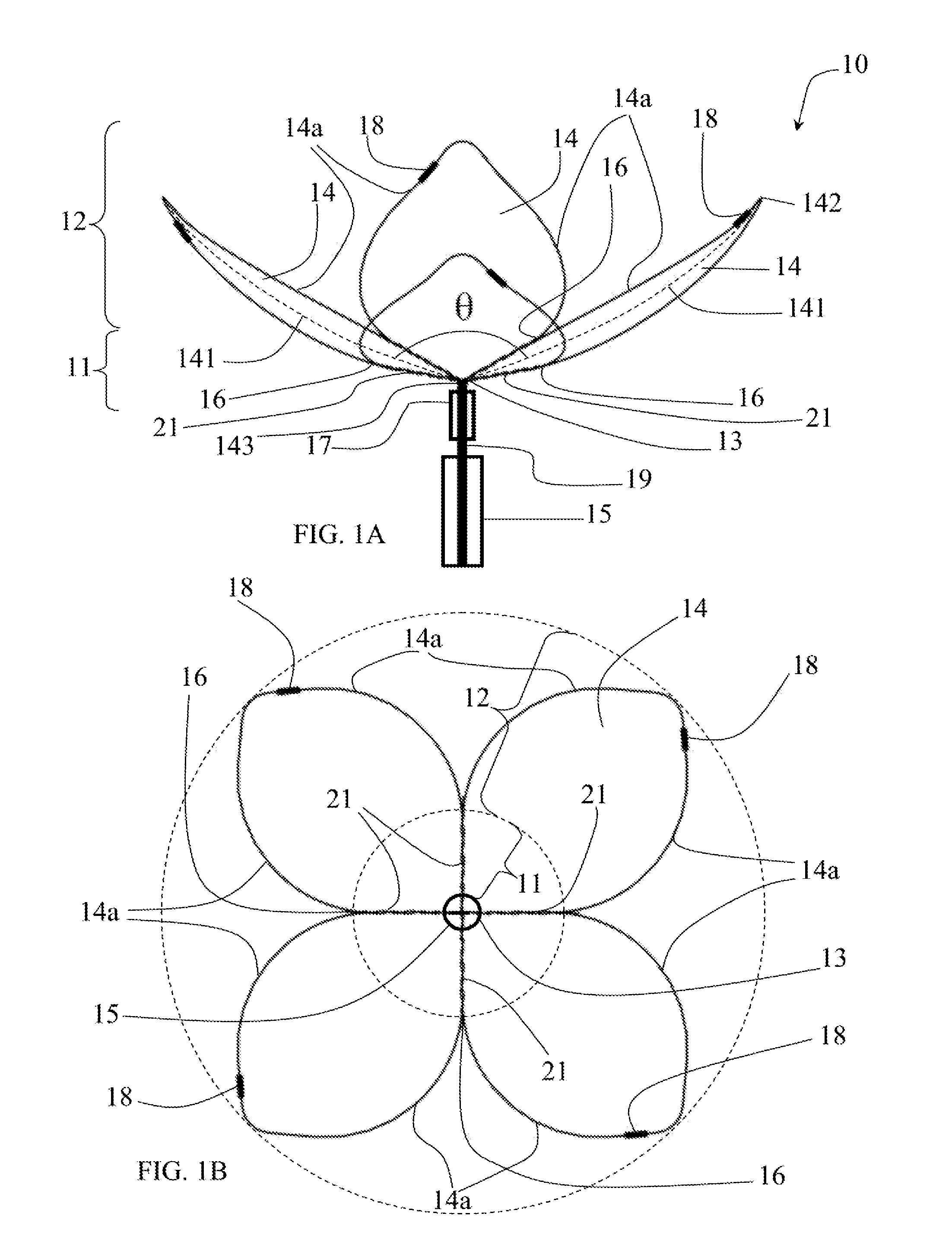

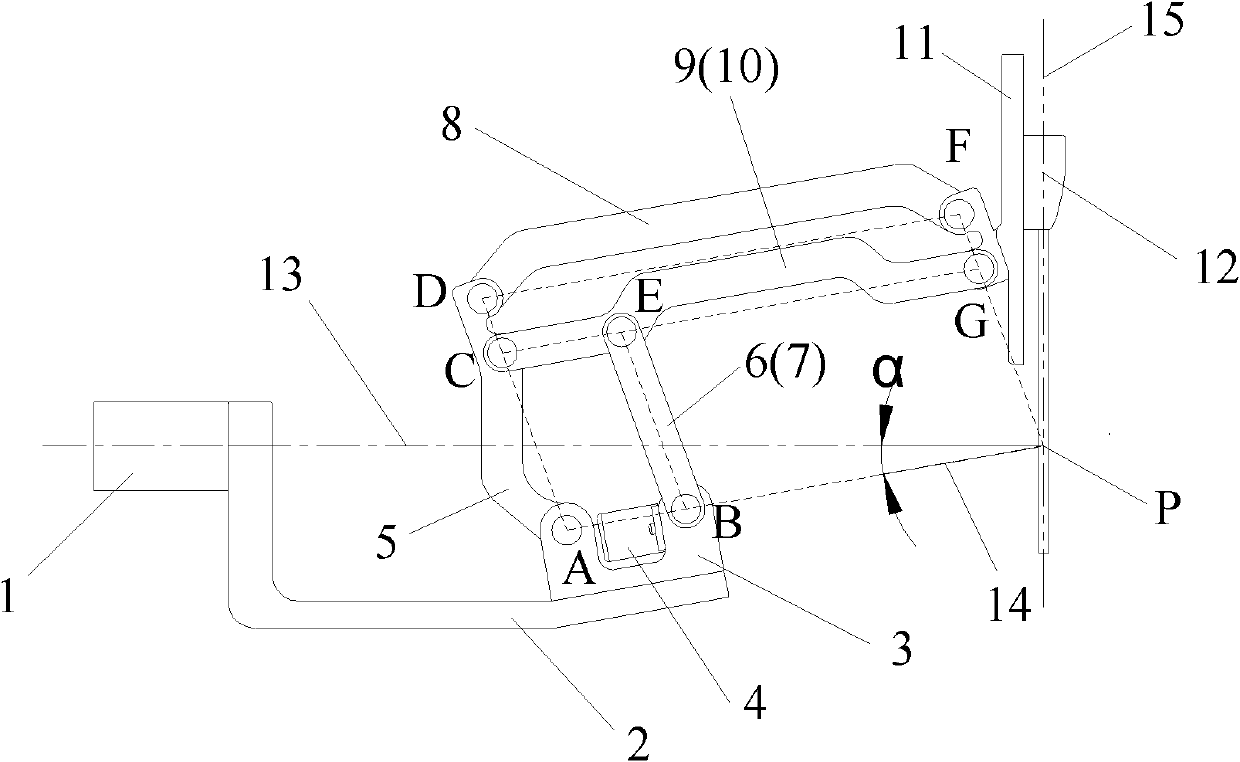

Minimally invasive robot mechanical arm having large movement space and high structural rigidity

ActiveCN101919739ALarge space for exerciseImprove rigidityDiagnosticsSurgical robotsEngineeringTarsal Joint

The invention discloses a minimally invasive robot mechanical arm having a large movement space and a high structural rigidity, which comprises a telescopic seat provided with a surgical tool, wherein one end of a connecting rod IV is connected with the telescopic seat, a connecting rod V and a connecting rod VI are arranged at both sides below the connecting rod IV, one end of the connecting rod V and one end of the connecting rod VI are connected with the telescopic seat, the other end of the connecting rod IV is connected with the top end of a connecting rod I, the other end of the connecting rod V and the other end of the connecting rod VI are connected to outer walls at both sides of the top part of the connecting rod I, the bottom end of the connecting rod I is connected with the front end of a joint II seat, the bottom end of a connecting rod II and the bottom end of a connecting rod III are installed on outer walls at both sides of the back end of the joint II seat by rotating shafts, and the top end of the connecting rod II and the top end of the connecting rod III are respectively connected to the connecting rod V and the connecting rod VI; and the rotating shafts are connected with a second rotation driving device, and a connecting frame is connected with a first rotation driving device. By using the structure, the movement space of the mechanism is greatly enlarged, and the rigidity of the mechanism is increased, thereby lowering the requirements for the initial pose of the robot.

Owner:SHANDONG WEIGAO SURGICAL ROBOT CO LTD

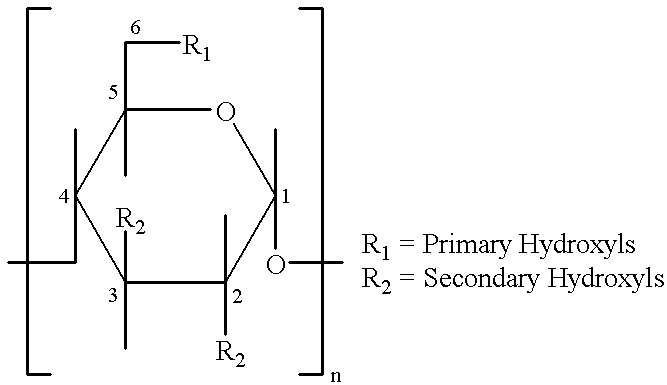

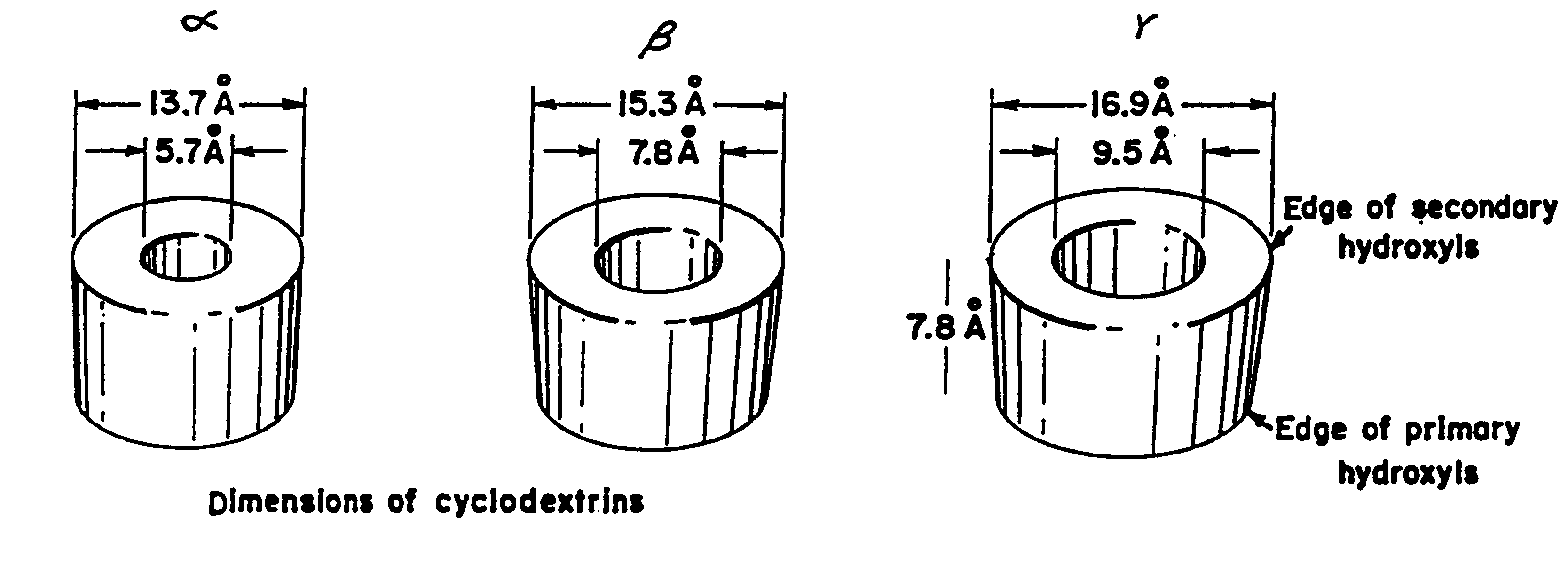

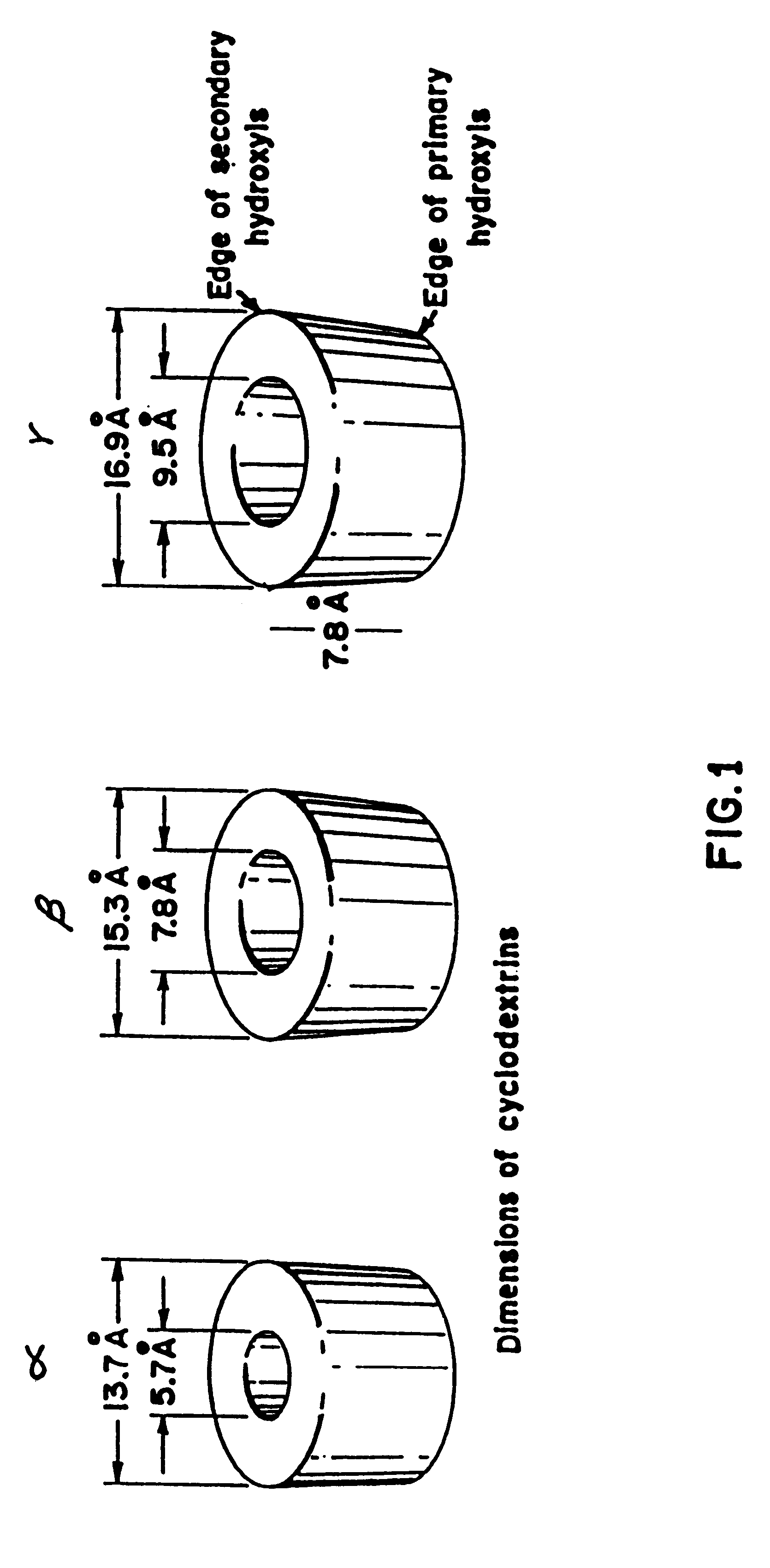

Barrier material comprising a thermoplastic and a compatible cyclodextrin derivative

InactiveUS6218013B1Easy to derivatizeImprove surface propertiesSemi-permeable membranesFlexible coversThermoplasticMoisture

A barrier film composition can comprise a thermoplastic web comprising a thermoplastic polymer and a dispersed cyclodextrin composition having substituents that compatibilize the cyclodextrin in the film. The thermoplastic / cyclodextrin film obtains substantial barrier properties from the interaction between the substituted cyclodextrin in the film material with a permeant. The substituents on the cyclodextrin molecule causes the cyclodextrin to be dispersible and stable in the film material resulting in an extrudable thermoplastic. Such materials can be used as a single layer film material, a multilayer film material which can be coated or uncoated and can be used in structural materials wherein the thermoplastic is of substantial thickness resulting in structural stiffness. The cooperation between the cyclodextrin and the thermoplastic polymer provides barrier properties to a web wherein a permeant can be complexed or entrapped by the cyclodextrin compound and held within the film preventing the permeant from passing through the film into the interior of a film, an enclosure or container. The permeant can comprise a variety of well known materials such as moisture, aliphatic or aromatic hydrocarbons, monomer materials, off flavors, toxic compounds etc.

Owner:CELLRESIN TECH

Method for manufacturing a surgical device for extracting a foreign object

ActiveUS20060004404A1Imparting structural rigidityImparting dilatation abilitySurgeryWire networkEngineeringForeign body

A method for manufacturing the surgical device for removing a foreign object from a body and a retrieval basket of the device are described. The retrieval basket is adapted for entrapping and retaining the object located in the body. The basket comprises a structure having a proximal end and a distal end. The structure is formed by a plurality of filaments fabricated from a single or several wires. The filaments extend from the proximal end towards the distal end, and are bound together to define a plurality of strands. The strands ramify at corresponding branching points into loops having various shapes and sizes. At least a part of the loops are overlapped and / or interlaced so as to define a net, and thereby impart structural rigidity and dilatation ability to the basket when opened. The method of manufacturing the retrieval basket includes selecting at least one wire; weaving the basket from the wire by overlapping and / or interlacing the filaments so that to form a net at least in the vicinity of the distal end; and binding the filaments for forming a shape of the retrieval basket.

Owner:NORDSON CORP

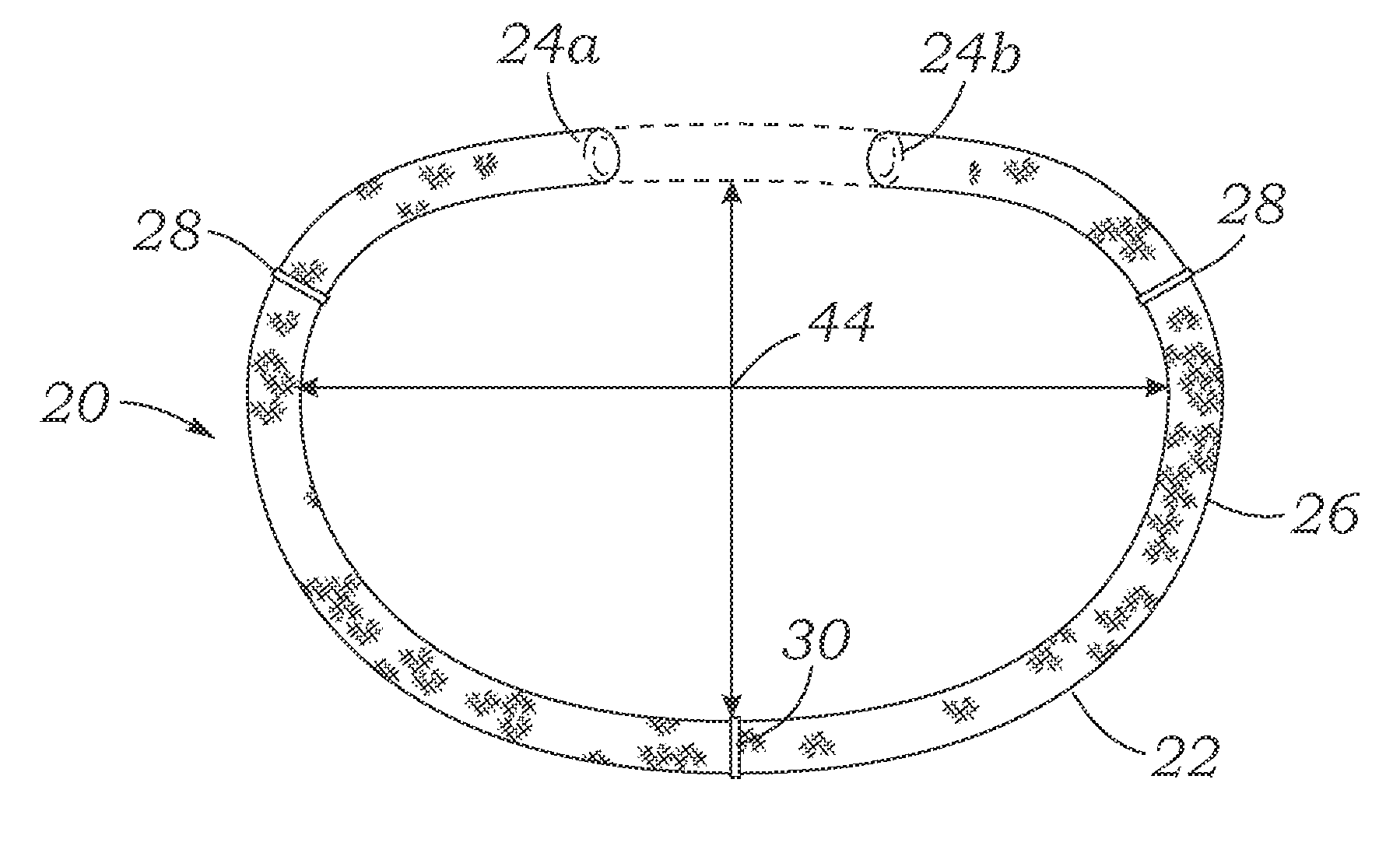

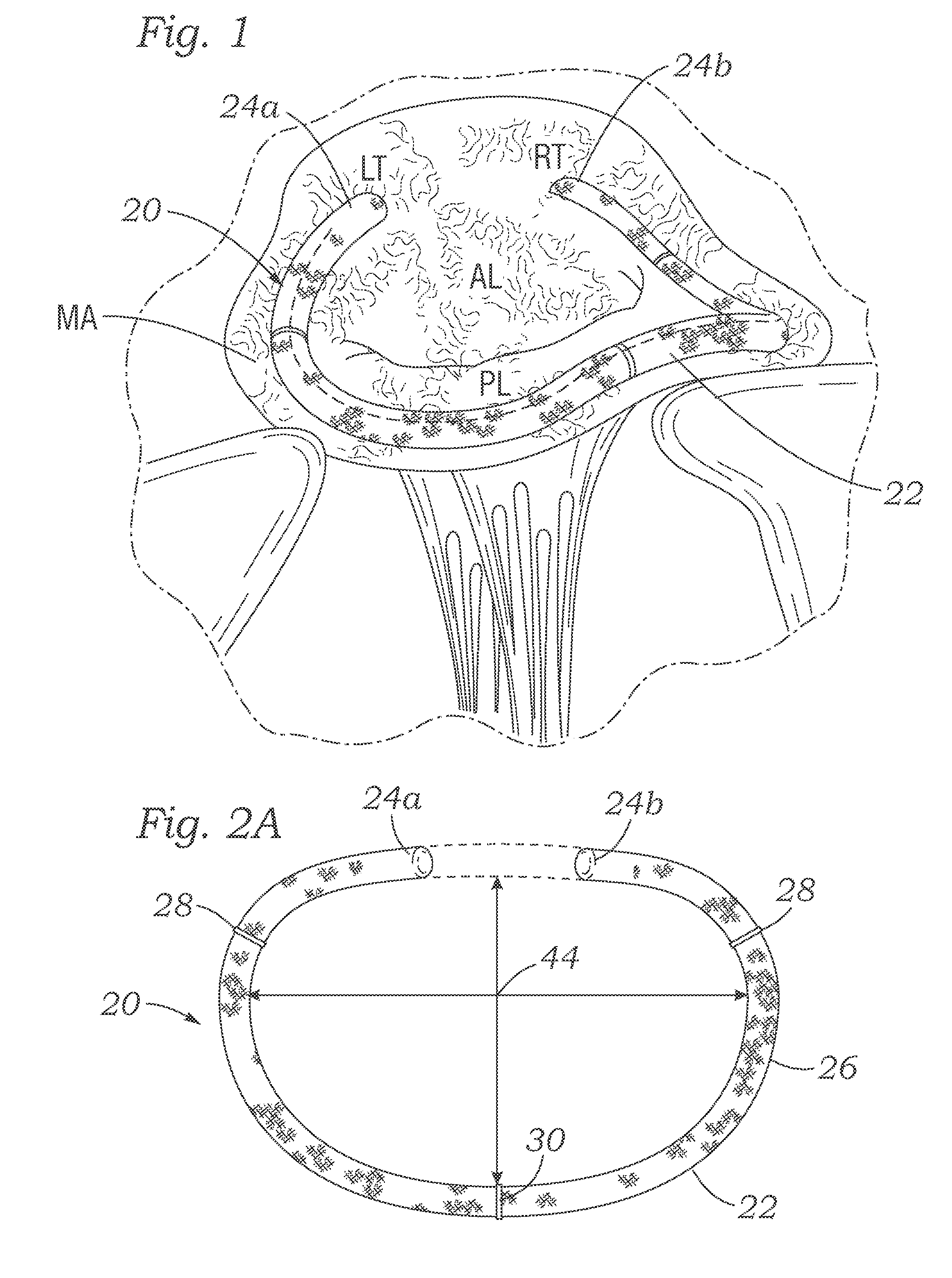

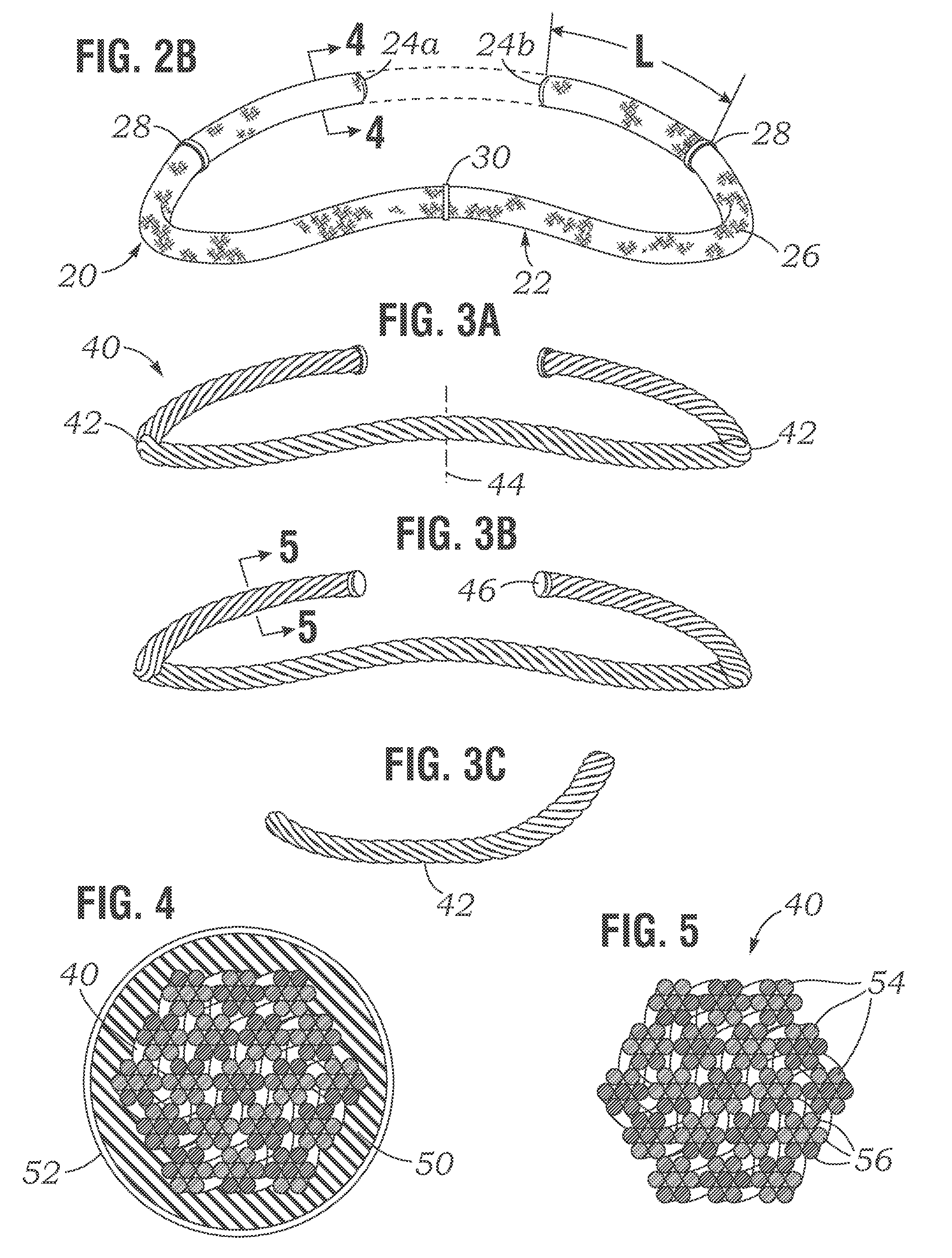

Multi-stranded heat set annuloplasty rings

ActiveUS20140277420A1Improve deployment flexibilitySufficient flexibilityBone implantAnnuloplasty ringsCardiac cycleEngineering

An annuloplasty repair segment for heart valve annulus repair. In one embodiment a multi-stranded cable replaces solid core wire for both the tricuspid and mitral valves. Cable allows for greater deployment flexibility for minimally-invasive surgical (MIS) implant, while still maintaining the required strength and similar tensile properties of solid-core wire. Stranded cable provides a MIS annuloplasty ring with sufficient flexibility in the x-y plane to allow a surgeon to squeeze the ring into a small incision, such as being able to pass through an 18Fr or smaller catheter, while maintaining structural rigidity under forces exerted on the implanted ring by the cardiac cycle. The particular shape of the annuloplasty ring is fixed using a heat setting process.

Owner:EDWARDS LIFESCIENCES CORP

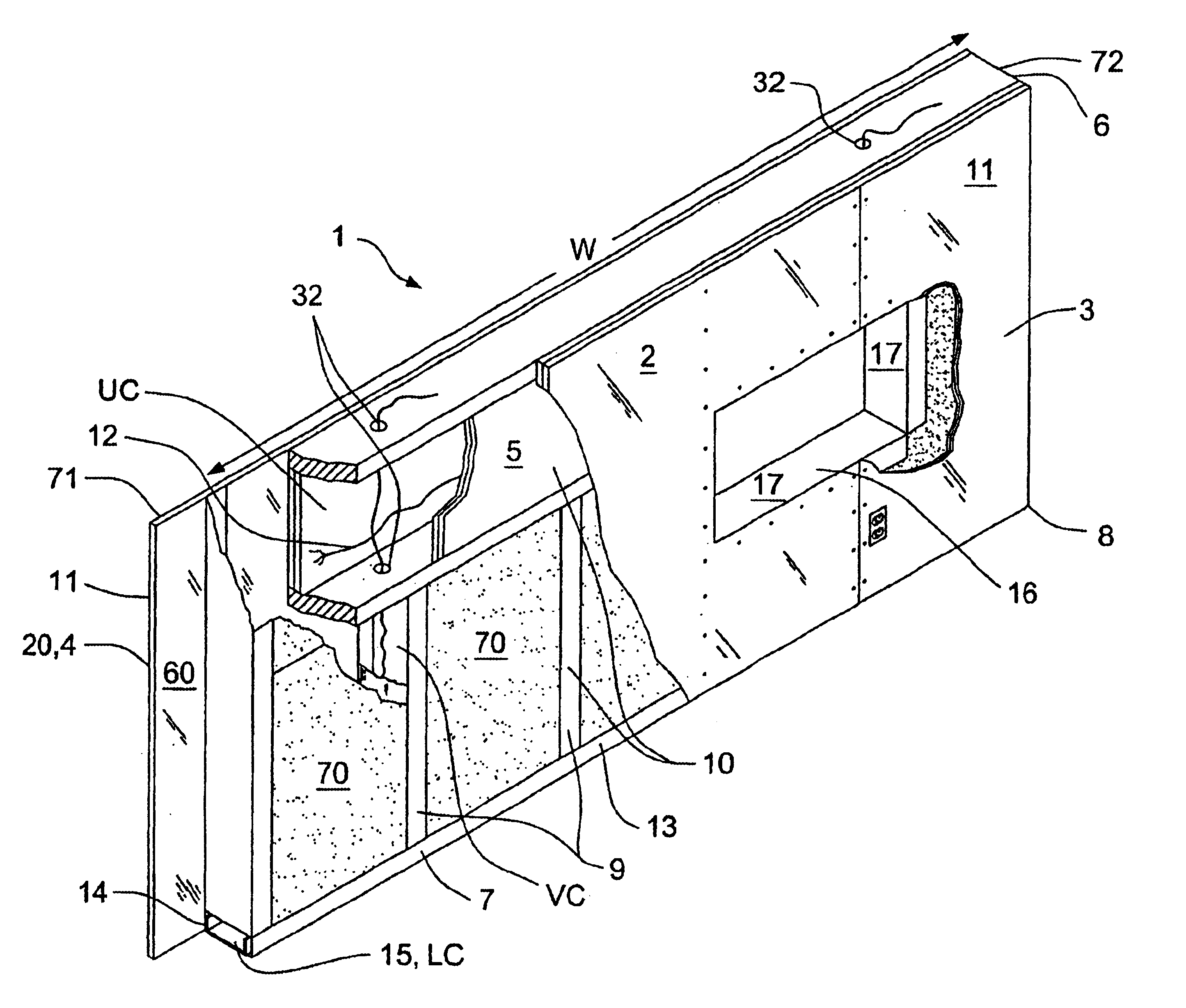

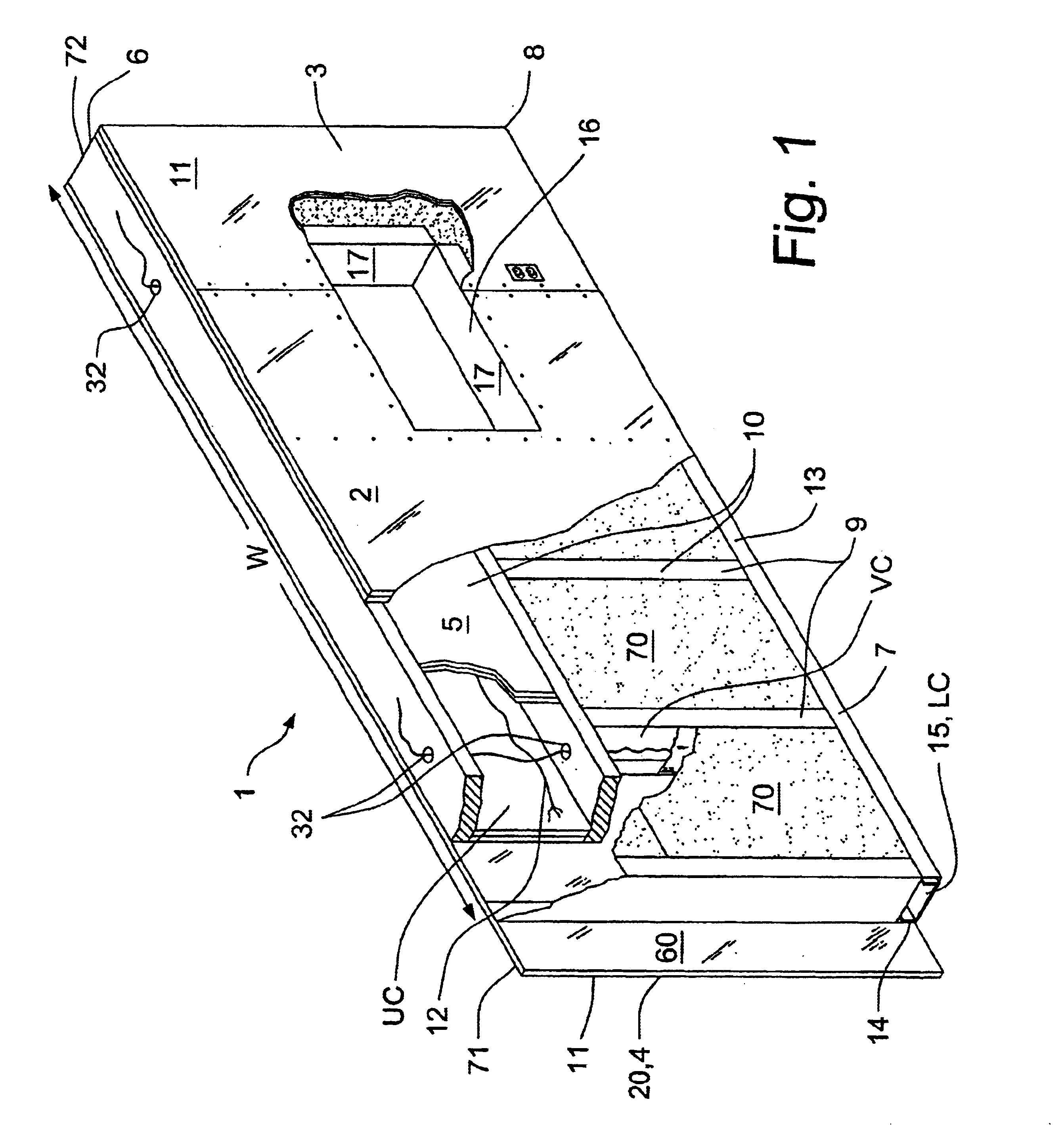

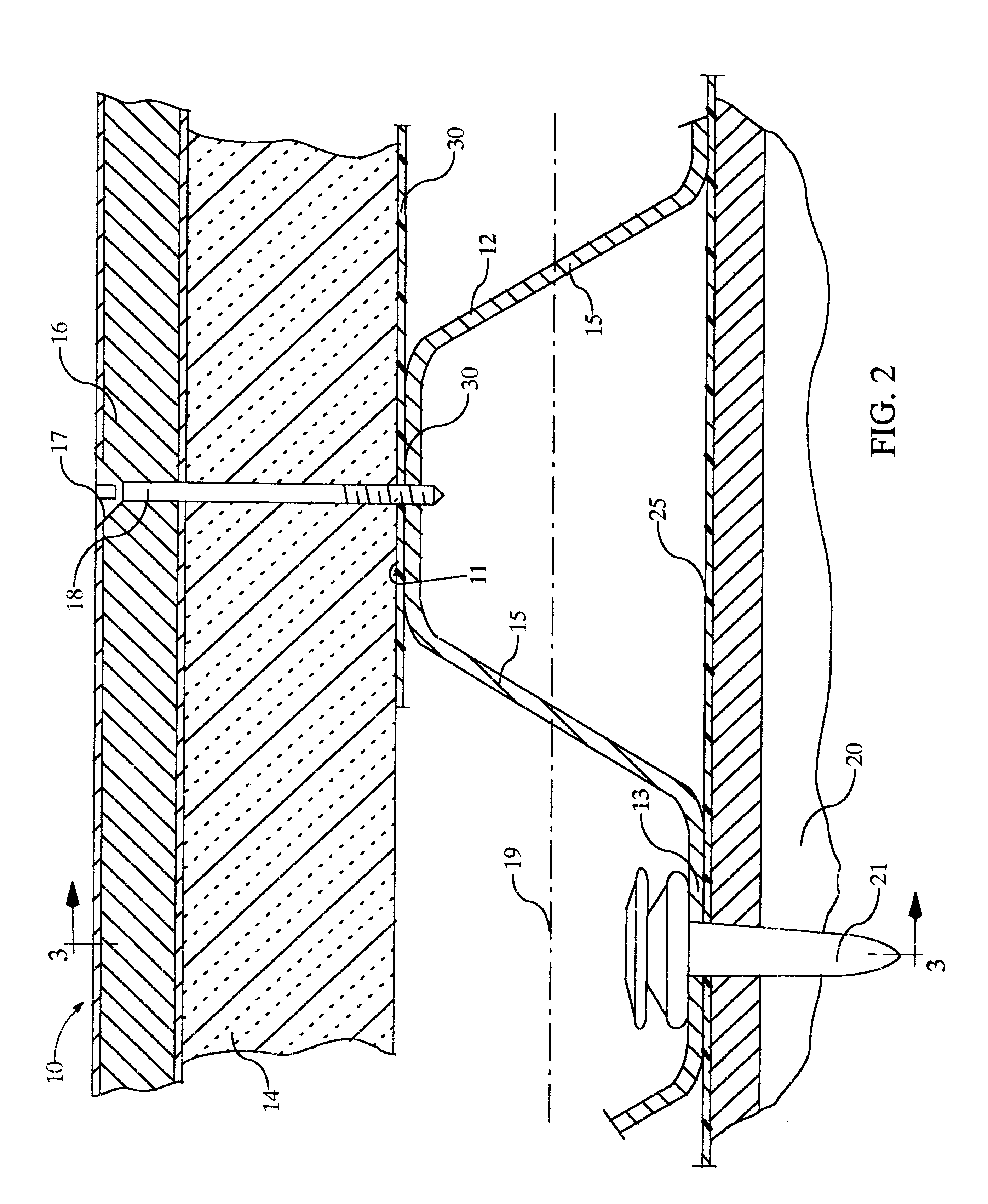

Continuous structural wall system

InactiveUS6854230B2Protection from damageProvide structural rigidityWallsPublic buildingsLoad-bearing wallWall plate

A composite wall panel having continuous upper and lower hollow horizontal chases and spaced hollow vertical chases formed throughout the panel to permit passage of electrical wiring and the like. The chases have protective barriers to protect the wiring from penetration and damage due to mechanical fasteners used to manufacture the panel and to construct load bearing walls using a plurality of manufactured panels. Further, the panel has a continuous header to provide structural rigidity and to permit rapid manufacturing of the panel without the need to frame openings, such as doors and windows, at the time of manufacture. Openings are cut in the panels and finished after the walls are constructed.

Owner:STARKE CHARLES

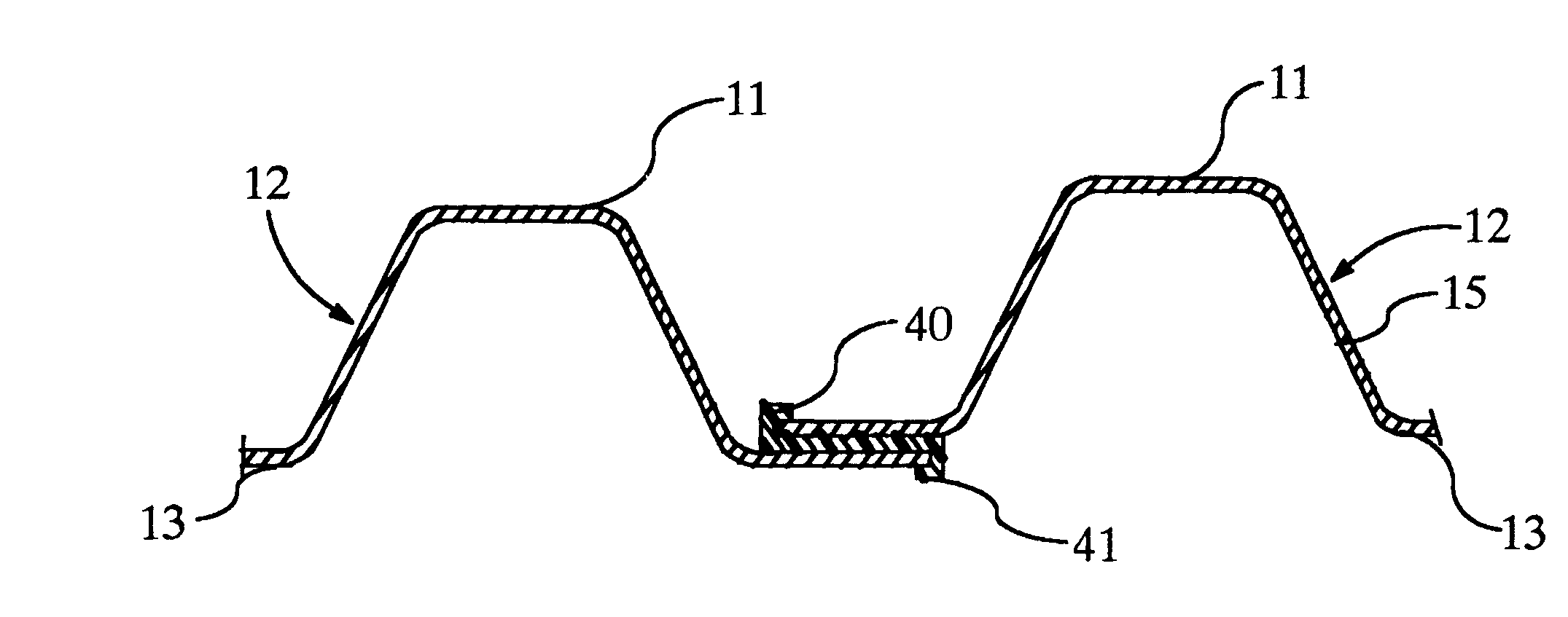

Sound control system for steel roof decks

InactiveUS6250036B1Cancel noiseReduce frictionBuilding roofsRoof covering using slabs/sheetsPurlinControl system

A steel roof deck diaphragm to provide structural rigidity to a building wherein loads of varying intensity can cause movement of structural members, which tends to generate noise when two members rub or work against each other. Corrugated sheets of high tensile steel are supported from below and span the distance between purlins, the corrugated sheets having over-lapping side edges and end edges and upper and lower surfaces. Non-metallic strips of felt form spacers positioned between the over-lapping side edges and end edges to prevent generation of noise resulting from relative movement of the corrugated sheets.

Owner:LOADMASTER SYST

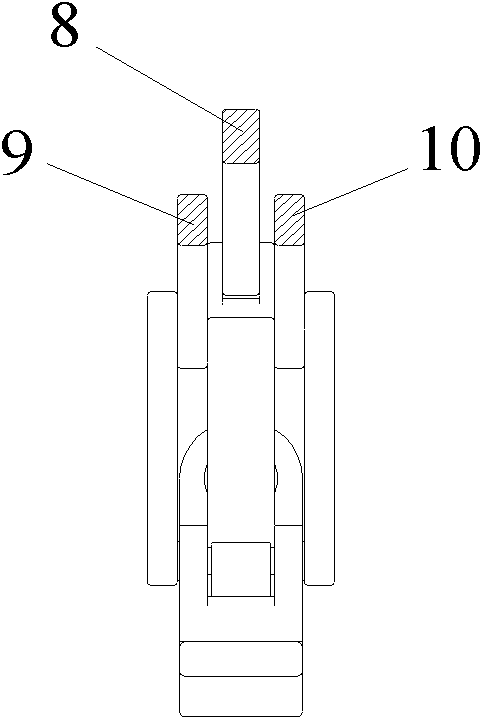

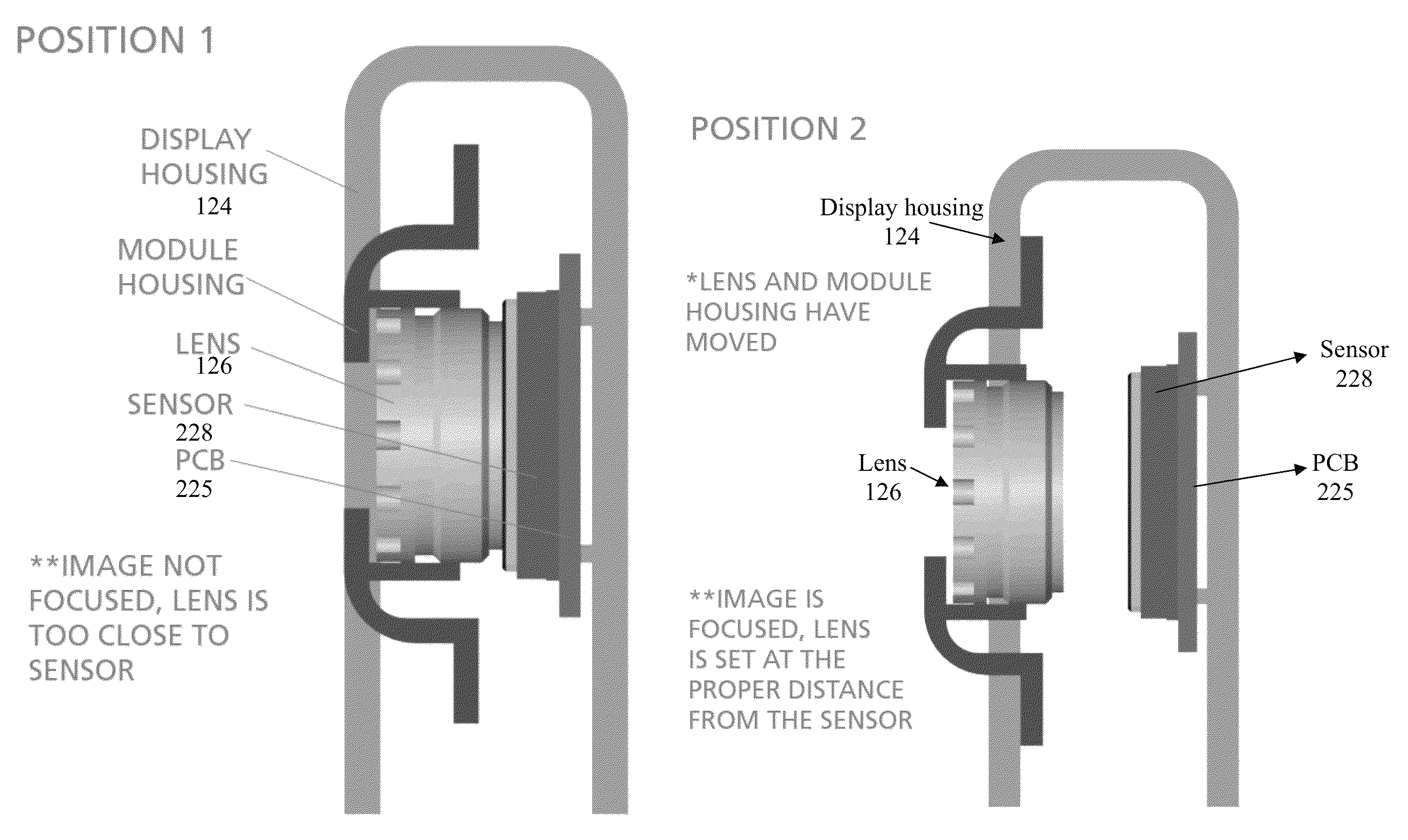

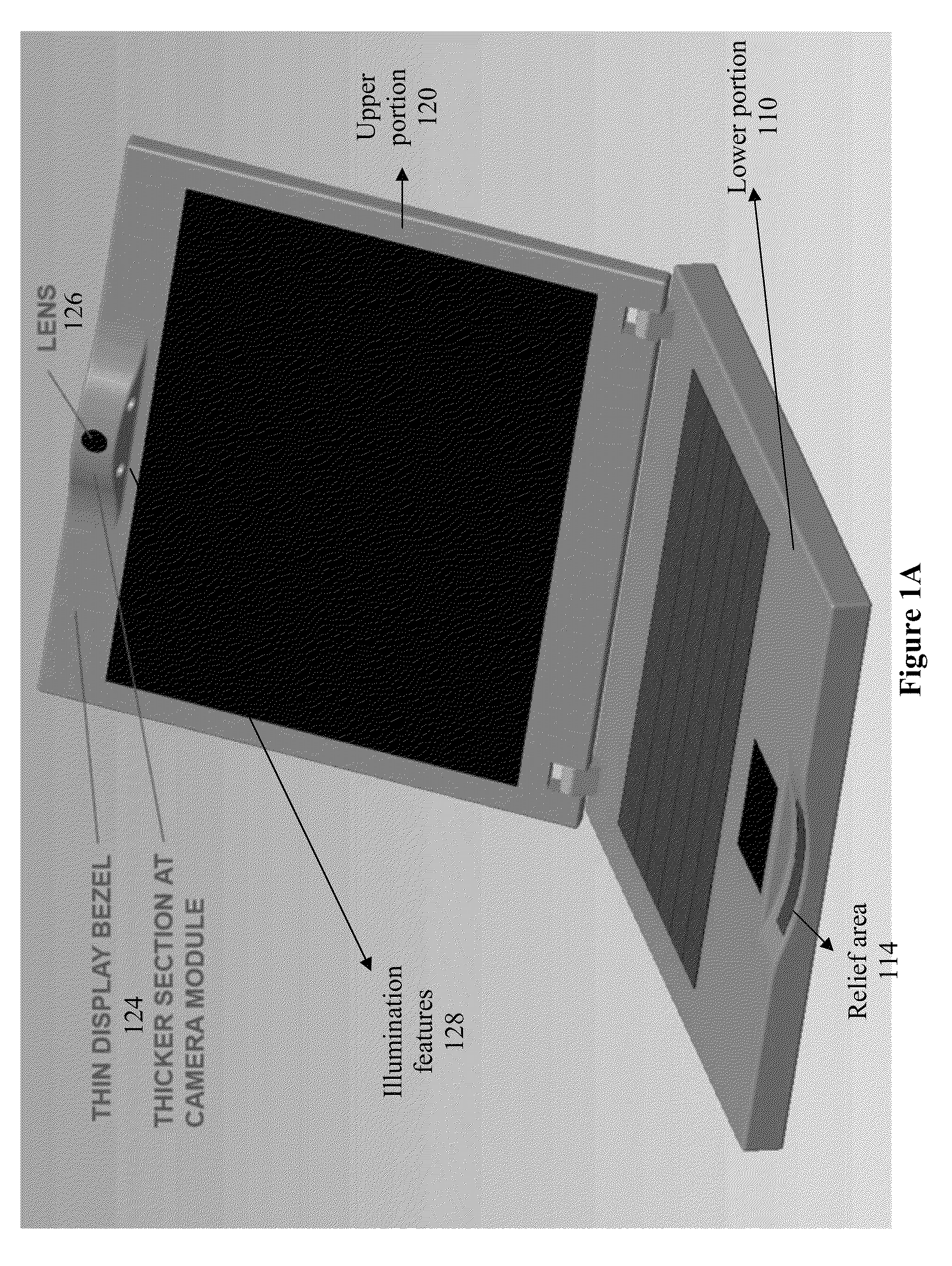

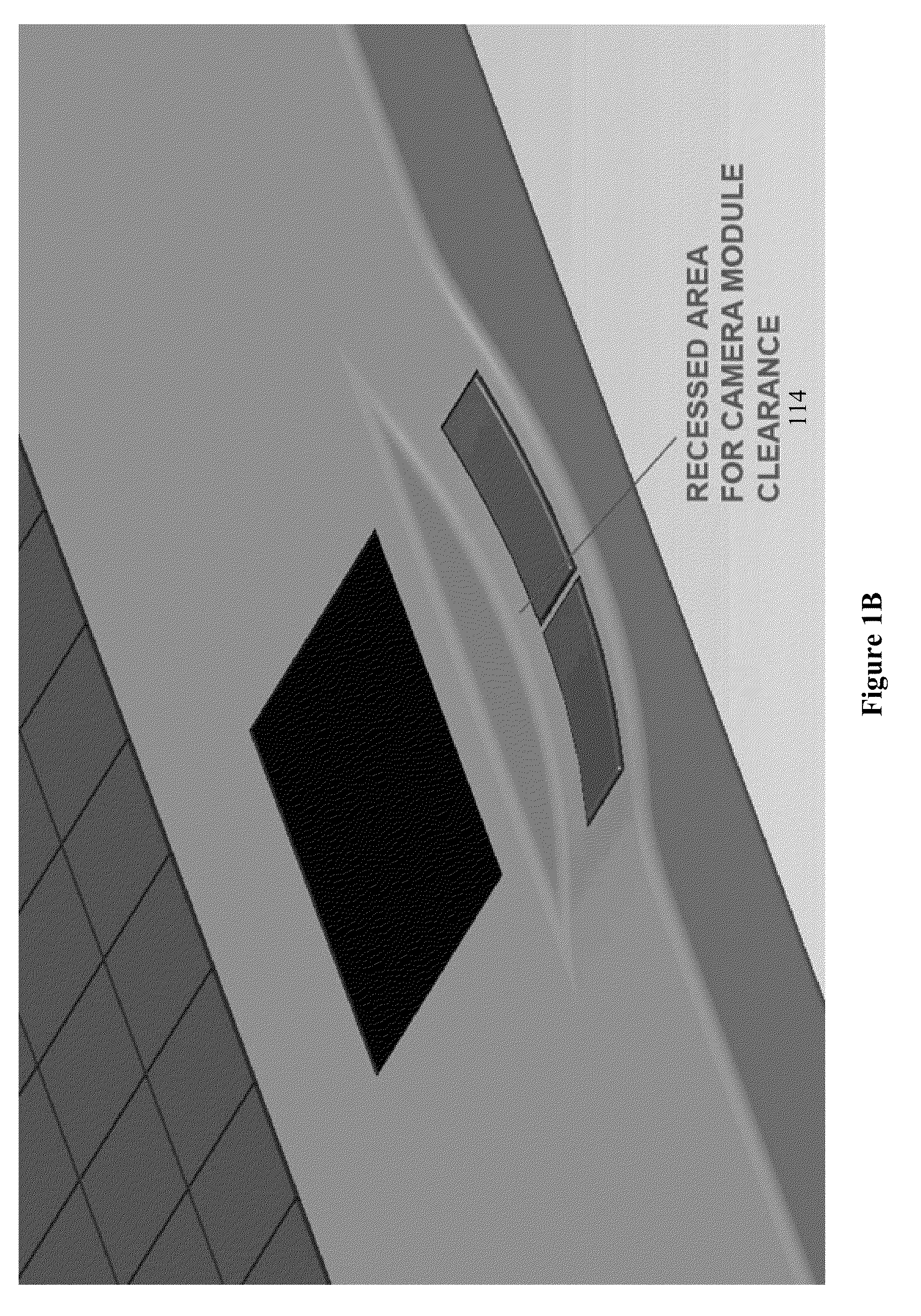

Optimized designs for embedding webcam modules with superior image quality in electronics displays

ActiveUS8432485B1Improve image qualityOptimizationTelevision system detailsColor television detailsImaging qualityDisplay device

The present invention is an apparatus and method of manufacture for providing image capturing modules which can be embedded into thin displays (e.g., in laptop computers) while providing for improved image quality. In accordance with several embodiments, a webcam module embedded in a display has multiple positions. A first position (or a “rest” or “park” position) is the position of the webcam module when it is not in use. In this first position of the webcam module, it is in its most compact configuration, and lends itself to integration into a very thin display. In other positions, the webcam module has a more expanded configuration, thus leading to better image quality. Such an expanded configuration leads, amongst other things, to a larger depth of focus. In one embodiment, a stepped PCB is used to provide good image quality while maintaining a compact form factor as well as structural rigidity.

Owner:LOGITECH EURO SA

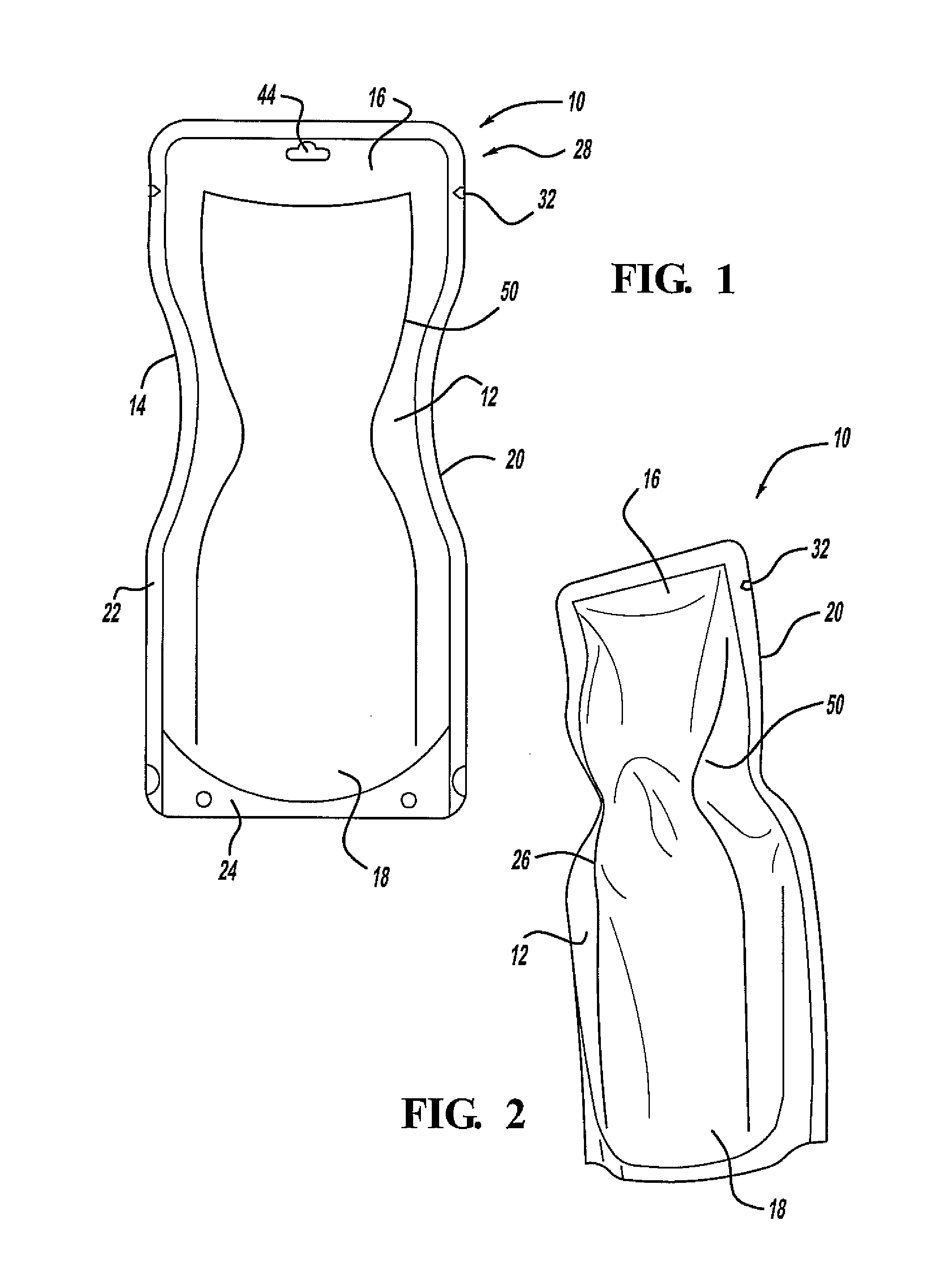

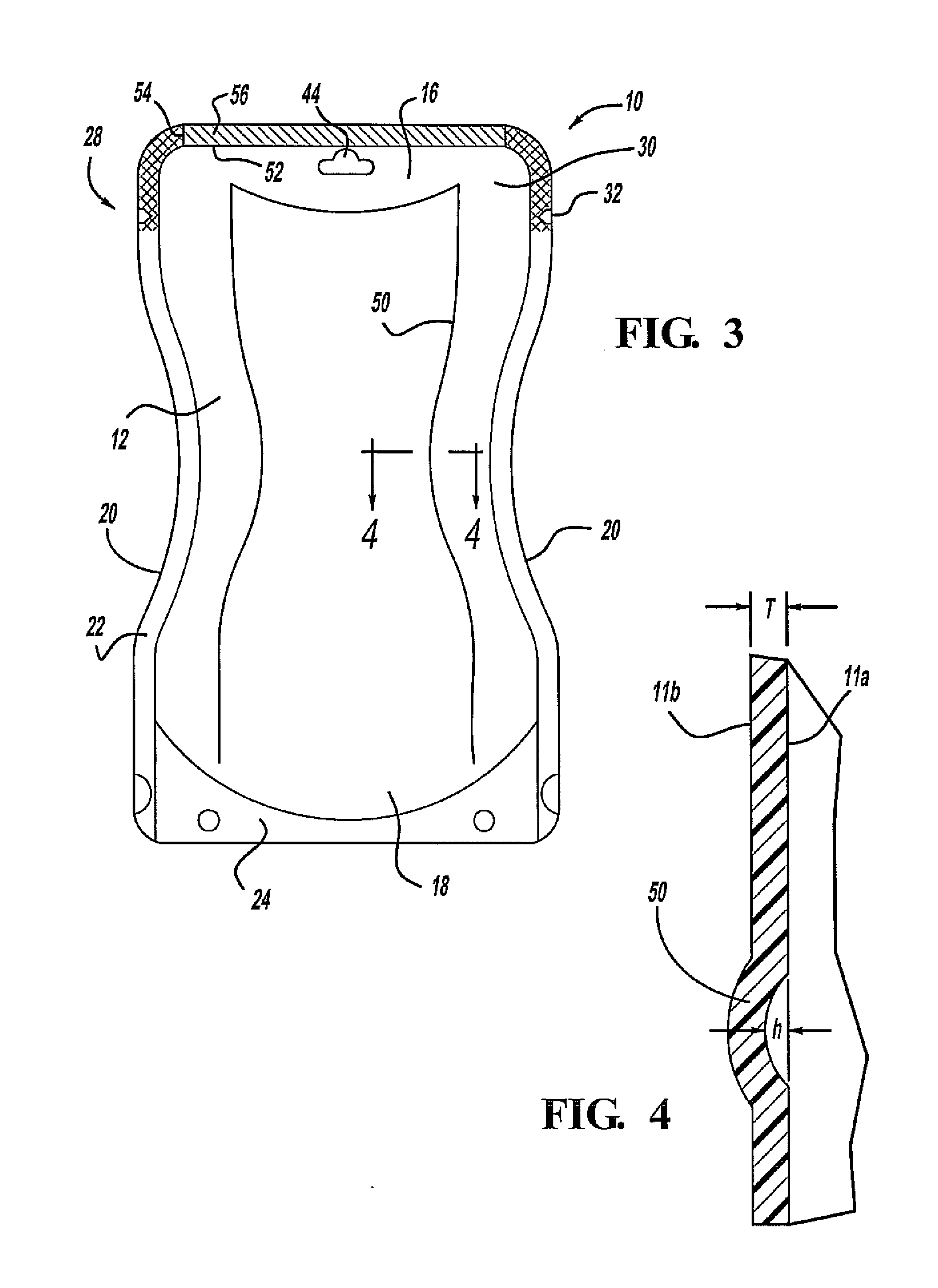

Stand-up flexible pouch and method of forming

InactiveUS20120008884A1Provide rigidityEnvelopes/bags making machineryWrappers shrinkageEngineeringStructural rigidity

A stand-up flexible pouch for packaging a product and a method of forming and filling the pouch is provided. The pouch includes a panel forming a body of the pouch using a flexible material having an inner surface and an outer surface. A rib is integrally formed in the pouch body, and the rib is spaced a predetermined distance from an edge of the pouch body. The ribs provide structural rigidity to the pouch when filled, allowing the pouch to retain the filled shape and stand upright unassisted as the product is removed from the pouch.

Owner:POUCH PAK INNOVATIONS

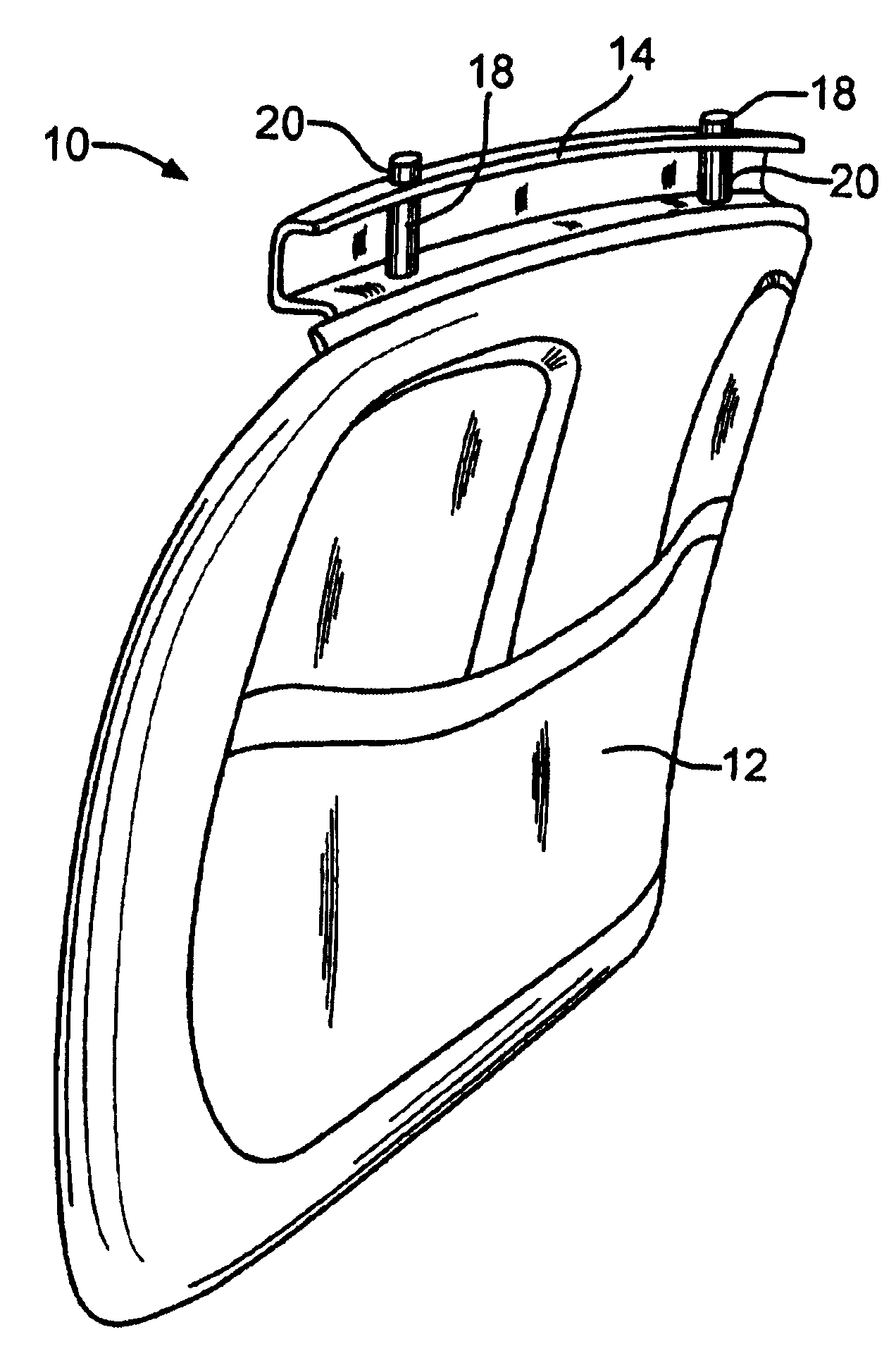

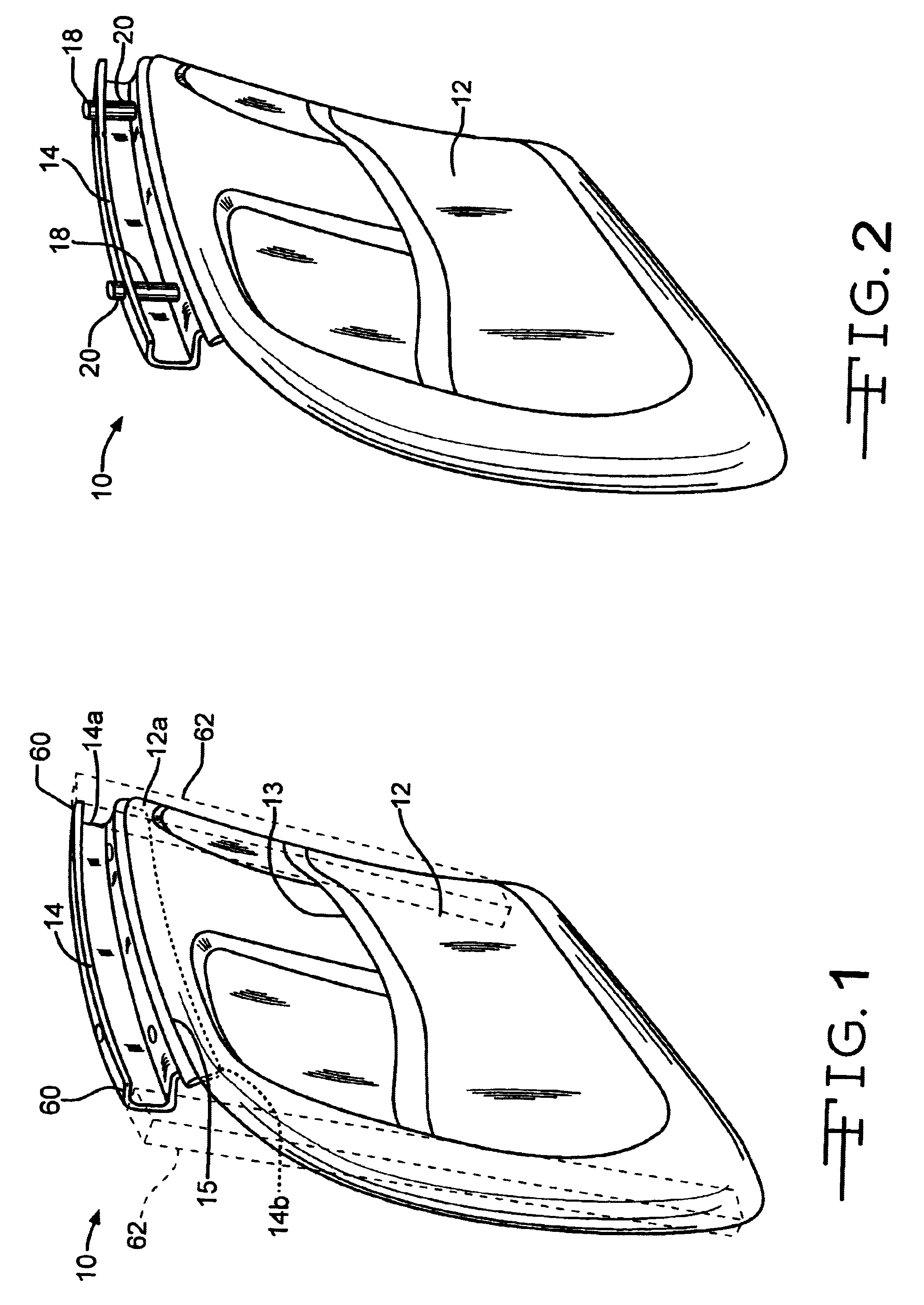

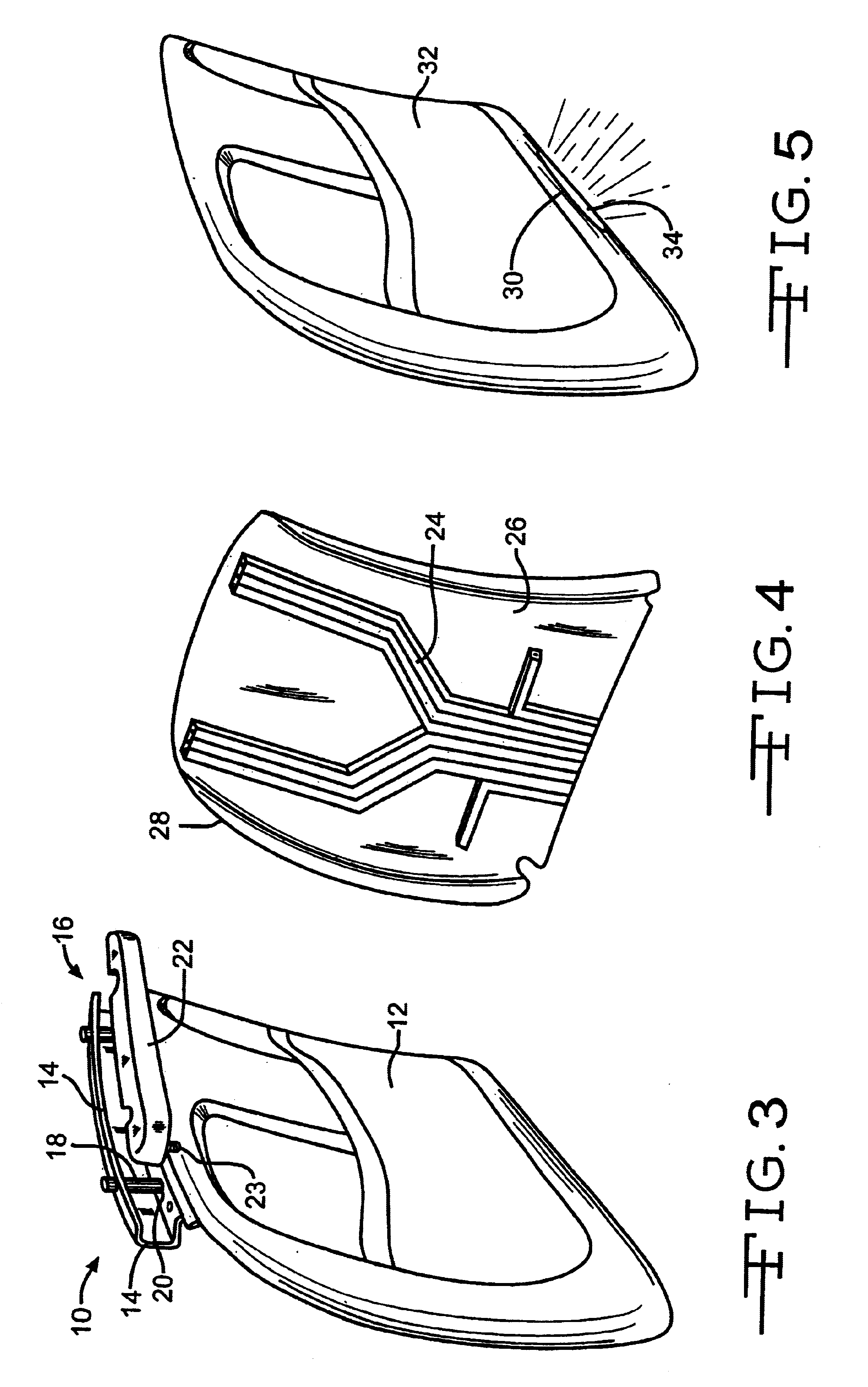

Seat backrest cover module

A seat assembly includes a seat back frame having a pair of spaced apart side rails. A cover is fastened to the frame and extends between the pair of side rails. A rigid cross member is preferably integrally molded in an upper portion of the cover. The cover and the cross member cooperate to provide structural rigidity to the seat back frame.

Owner:LEAR CORP

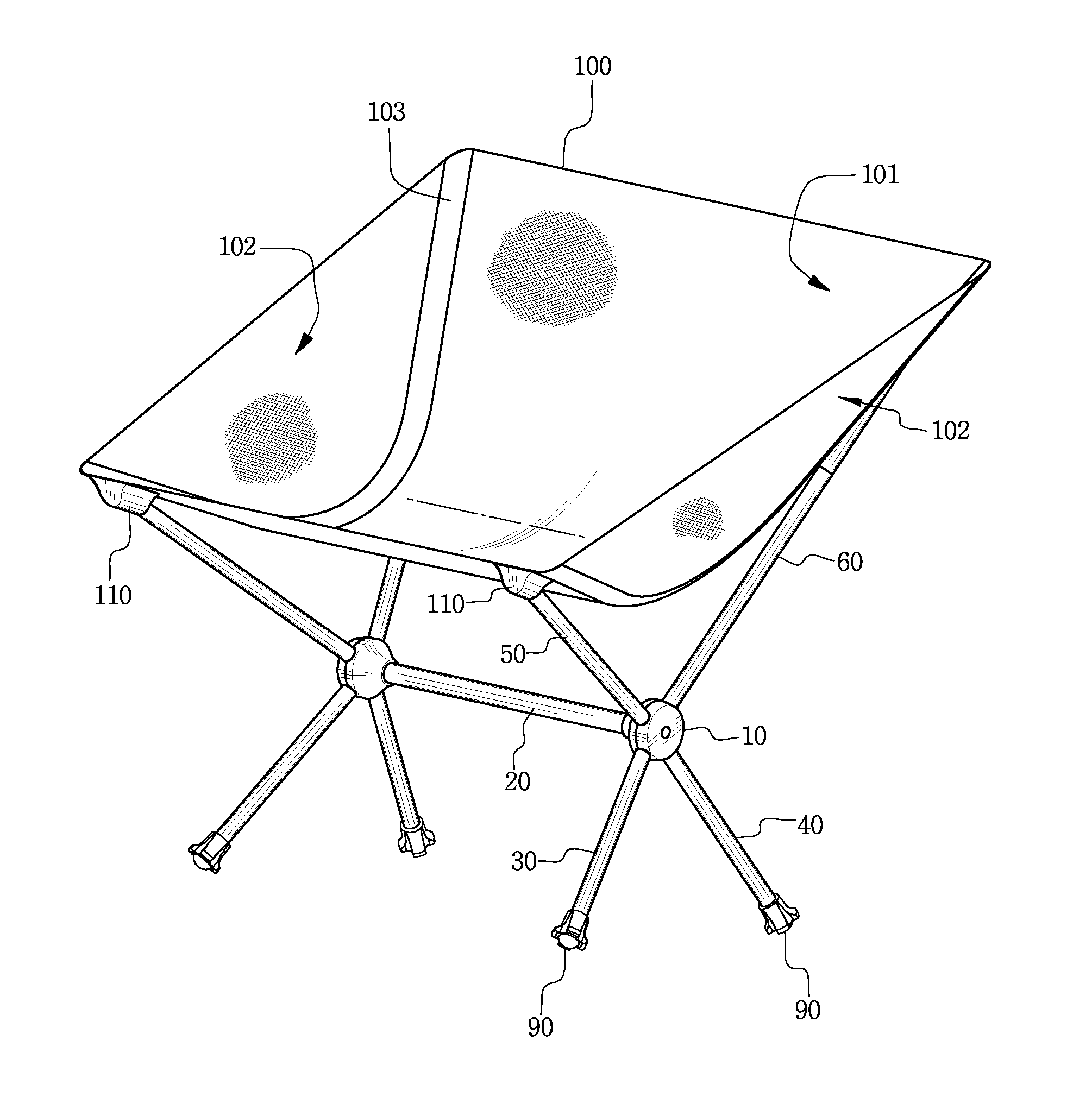

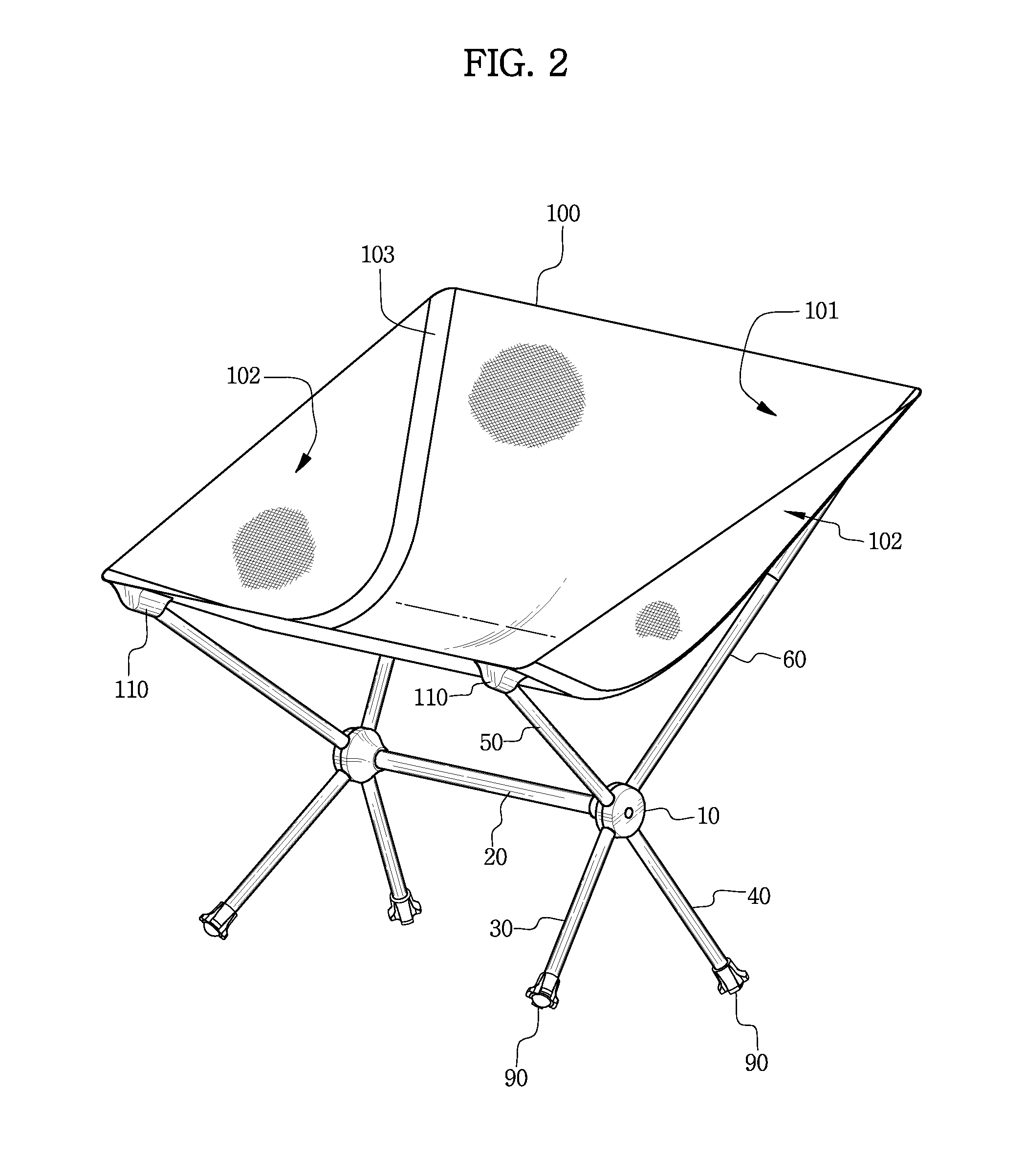

Portable chair

ActiveUS20120104805A1StrengthEasy to unfoldFoldable chairDismountable chairsEngineeringMechanical engineering

The portable chair of the disclosure includes: hubs respectively installed at both left and right sides of the chair; a central support frame connecting both left and right hubs; front and rear leg frames respectively having base ends separably coupled to the lower front and rear outer peripheral surfaces of the respective hubs and respectively having free ends disposed in a manner of radially extending toward the ground surface; front and rear pole frames respectively having base ends separably coupled to the upper front and rear outer peripheral surfaces of the respective hubs and respectively having free ends disposed in a manner of radially extending toward the sky; and a fabric sheet coupled to the free ends of the front and rear pole frames. The structural rigidity is excellent, and the chair may land on the ground surface in a stable posture.

Owner:LAH JEH KUN

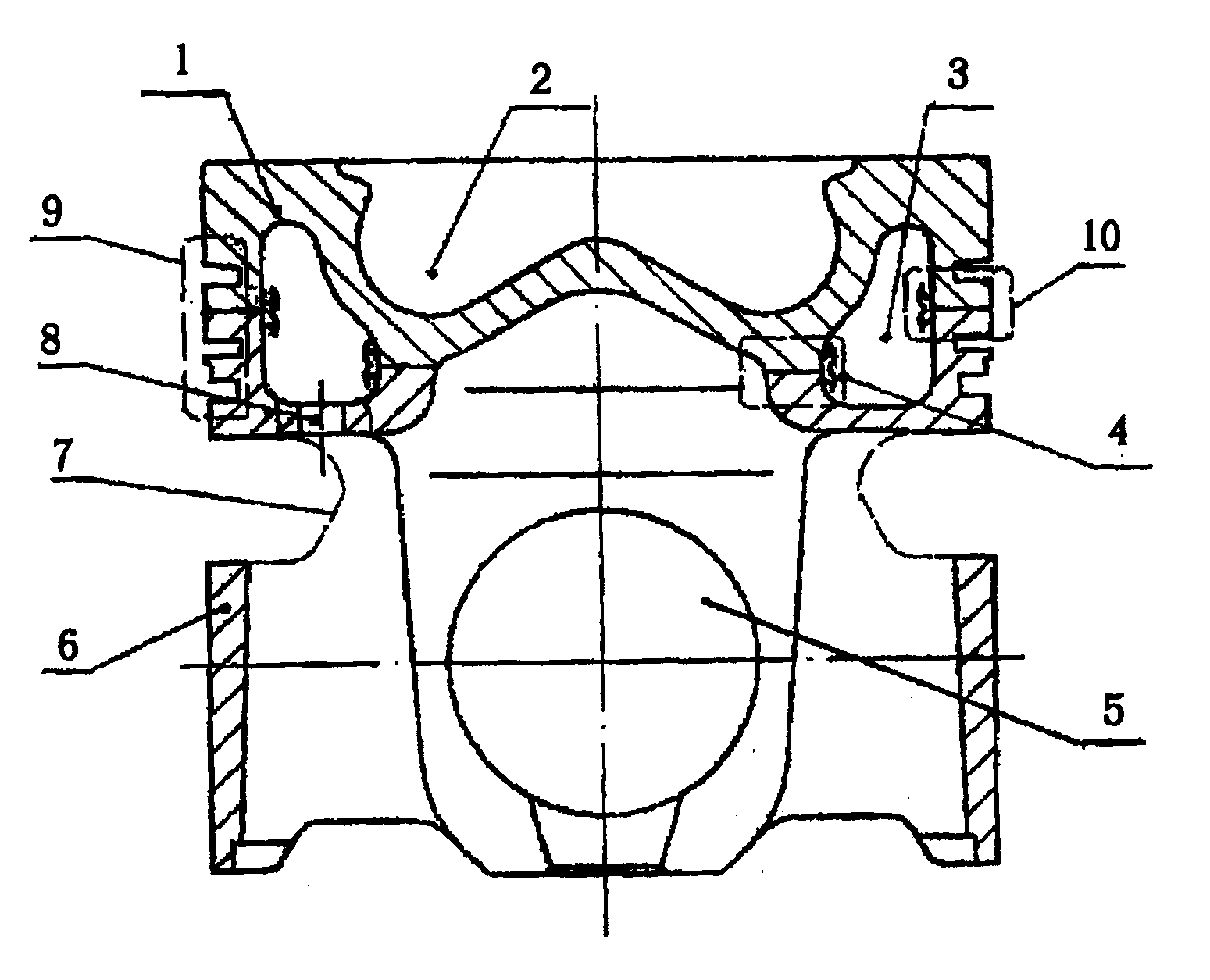

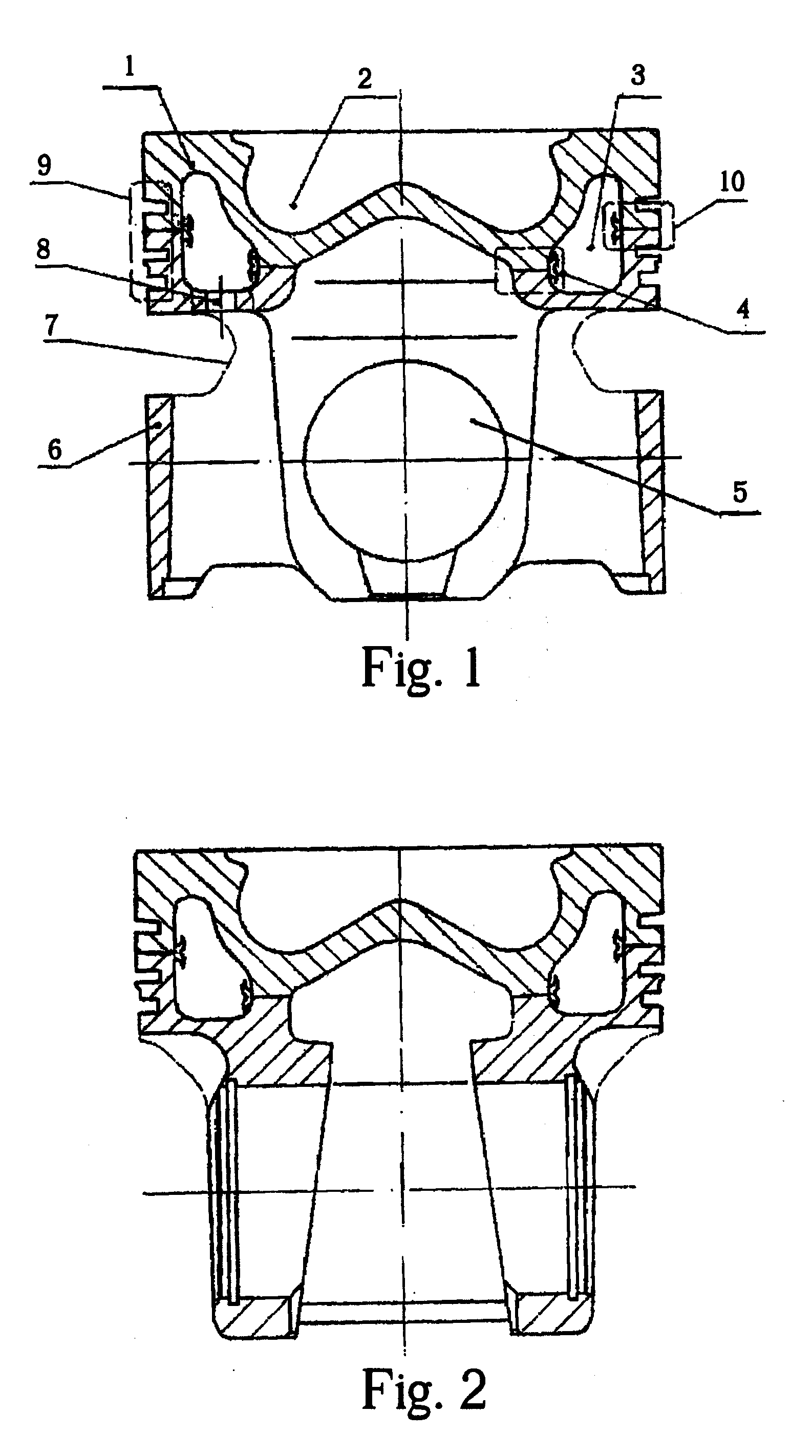

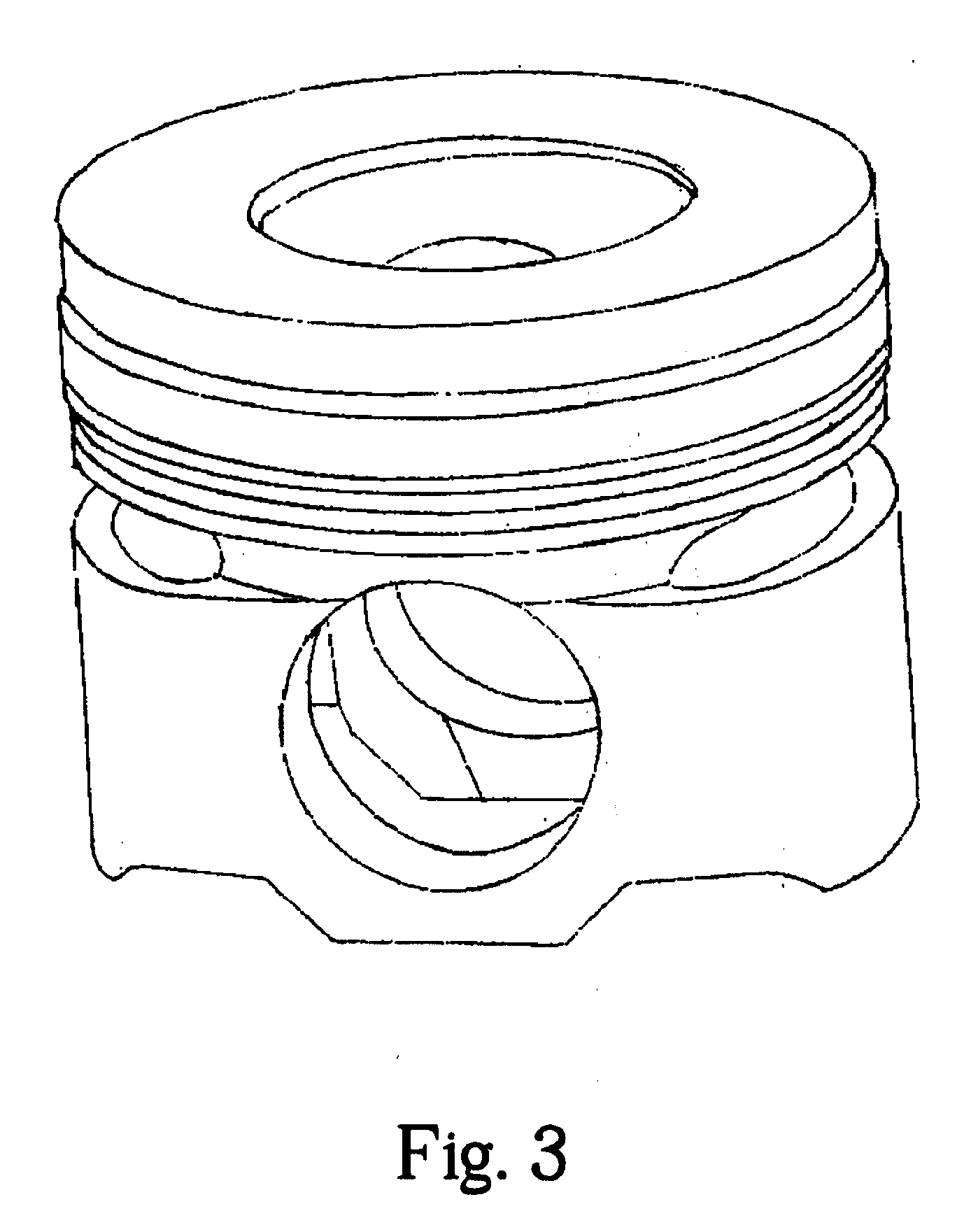

Welding Forged Steel Single Piece Piston and Its Manufacturing Methods

InactiveUS20070079775A1Simple manufacturing processImprove structural strengthAir coolingMachines/enginesFriction weldingCombustion chamber

The present invention has provided a welding forged steel single piece piston and its manufacturing methods. A semi-finished head and a semi-finished skirt are forged respectively; the semi-finished head and semi-finished skirt are heat-treated respectively; rough machining is carried out respectively to the semi-finished head and the semi-finished skirt, and a face of weld between the two adjacent ring grooves is higher than the one under the combustion chamber; the head and the skirt are welded together through friction welding; an annular groove, a combustion chamber, a ring groove, a pinhole, an outer annulus and oil inlet / outlet holes are manufactured respectively; and the surface of the piston is phosphorized and graphitized. Compared with one-piece forged piston, it has better processing technology, because the head and skirt are forged respectively and then welded together. Over-all structural rigidity of the piston has been increased, and distortion of the ring groove in high temperature is slight because the cooling oil recess is sealed through welding. As the annular groove is located on the upper part of skirt, the weight of body of the piston is lowered and this kind of structure can accelerate engine oil returning on, decrease the clearance between the piston and the cylinder and reduce the engine oil consumption.

Owner:SHANDONG BINZHOU BOHAI PISTON

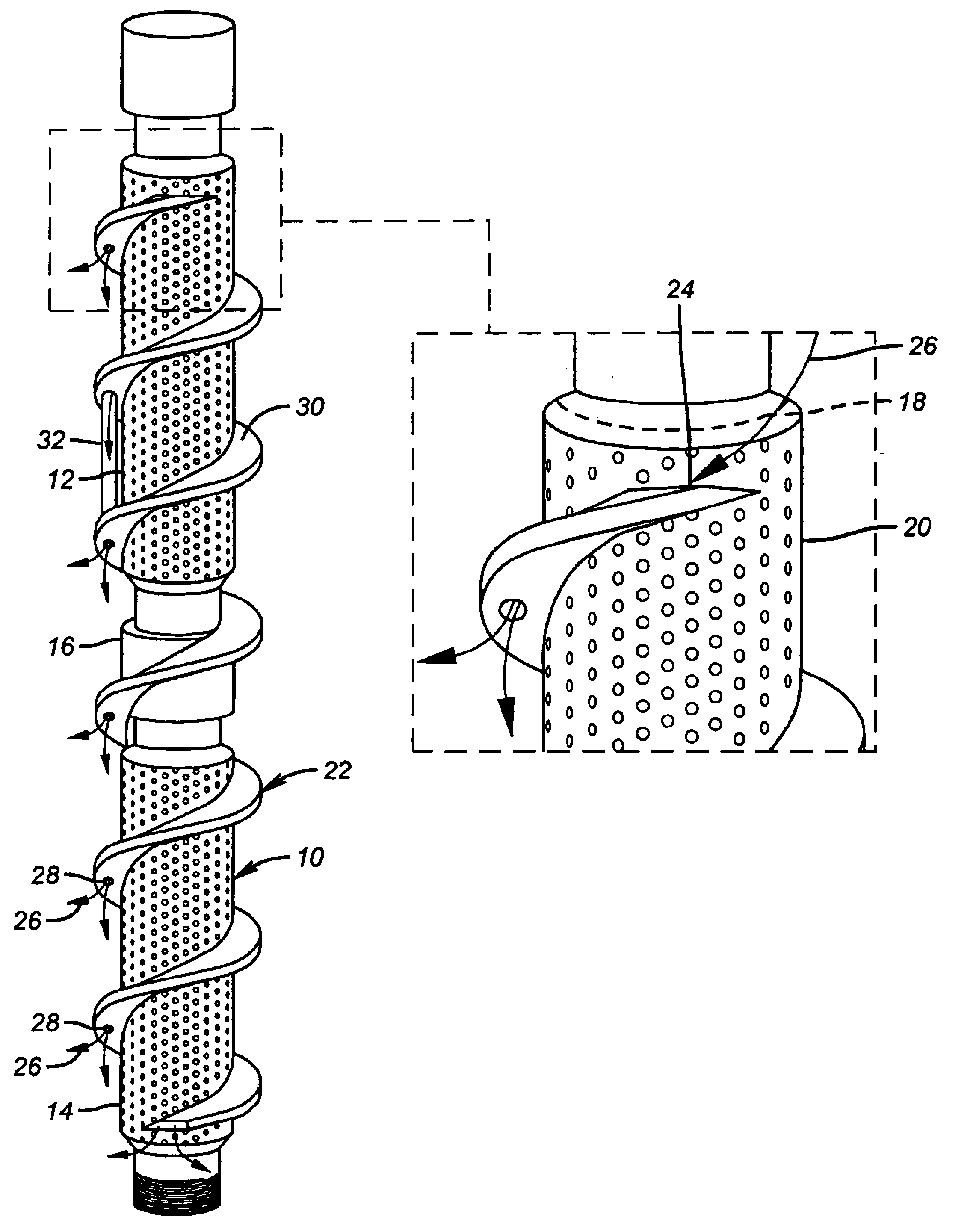

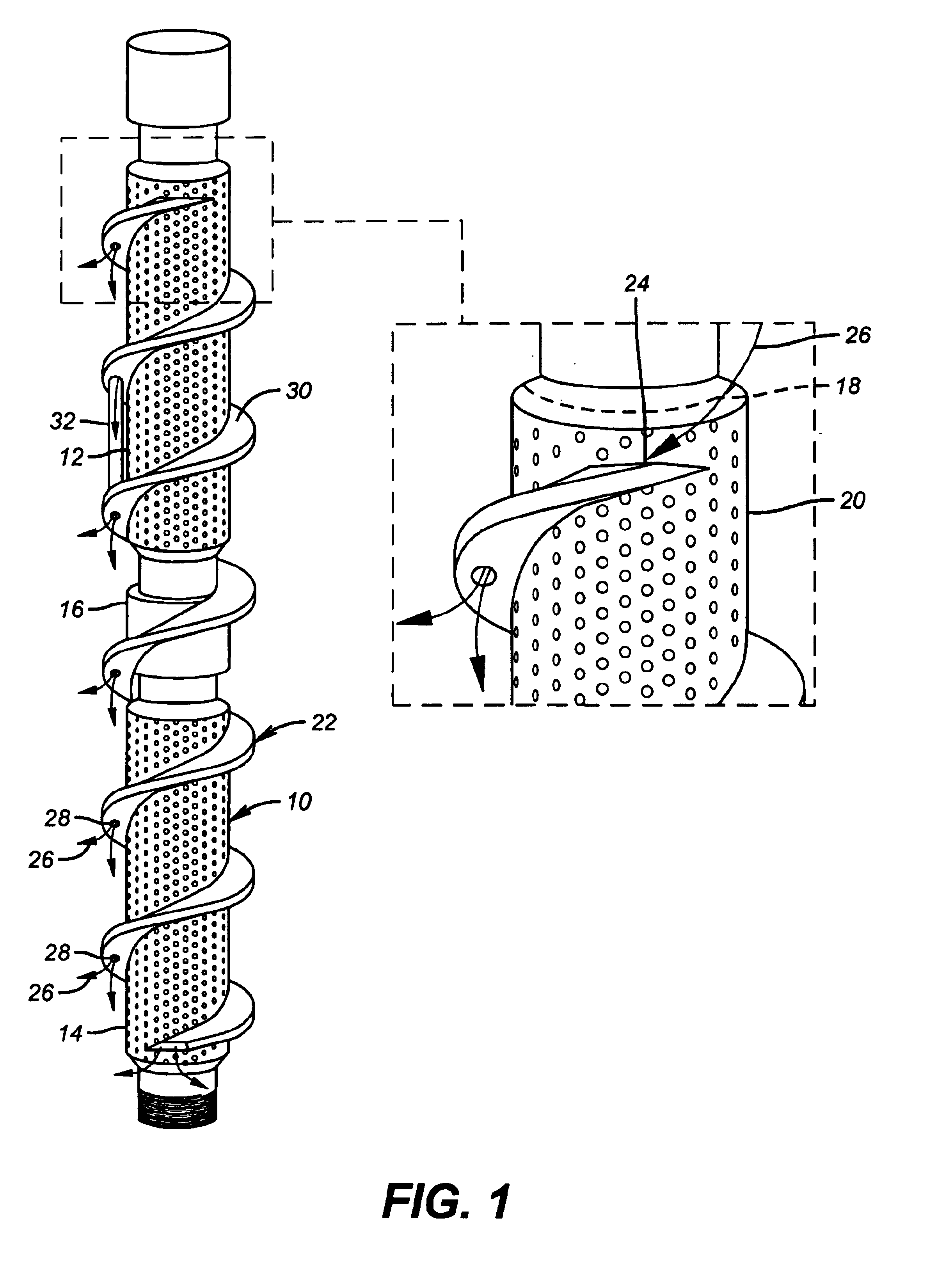

Alternate path auger screen

A gravel pack screen assembly has one or more hollow flight augers that a continuous or segmented with multiple upwardly oriented gravel entrances and multiple downwardly oriented gravel exits. The gravel passes through the auger and around any bridge. The auger helps advance the screen into position as well as to centralize it during gravel deposition. The auger protects the screen during run in as well as the internal passages that pass through it due to its structural rigidity. An alternative embodiment features spirally wound tubes with staggered exit locations for better distribution of the gravel.

Owner:BAKER HUGHES INC

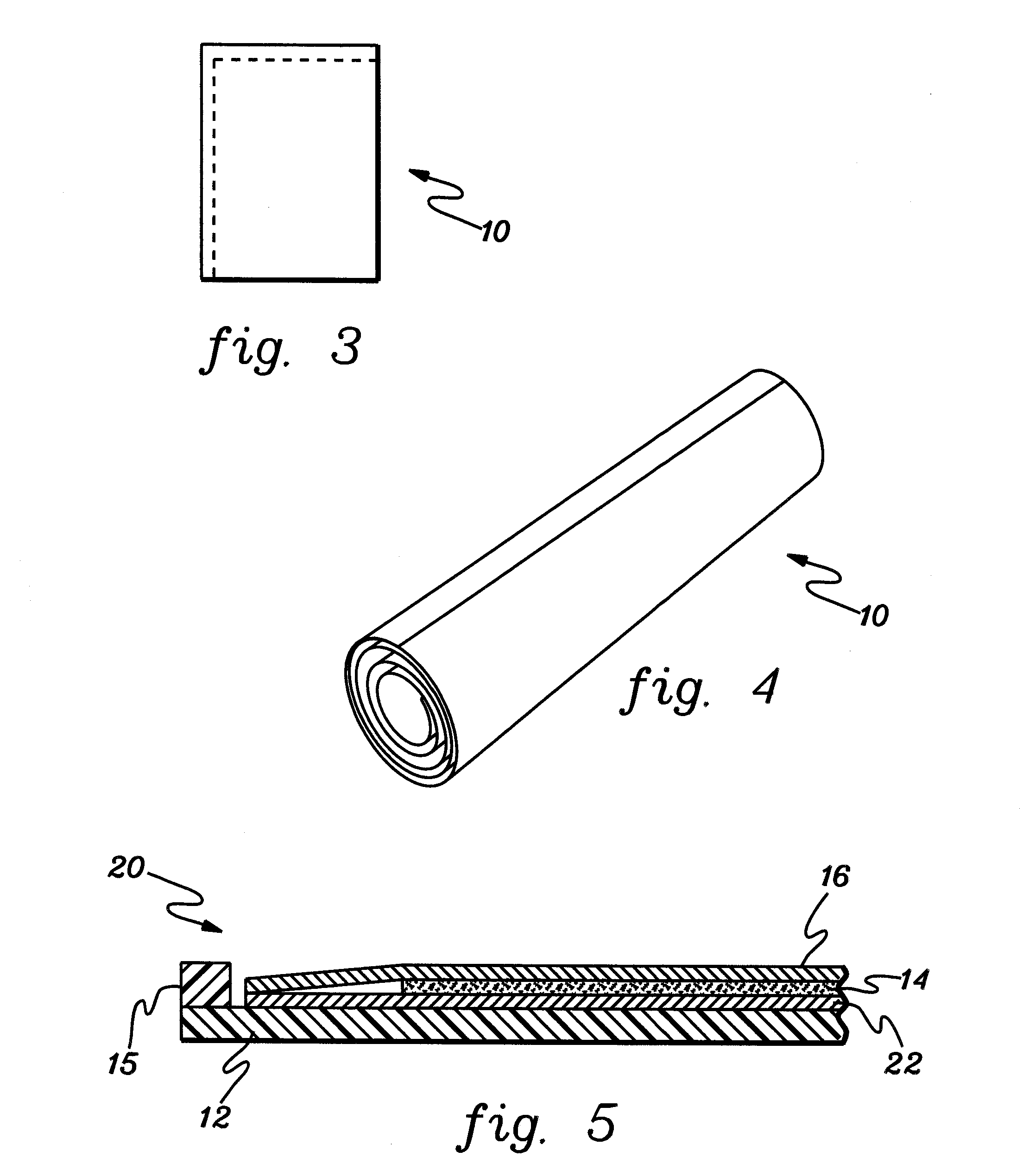

Pet waste collection pad

A waste collection pad for use in training an animal, such as a domestic pet, to urinate or defecate in a predetermined location. The collection pad includes a support frame and a liquid retaining layer mounted above the support frame. The support frame provides structural rigidity to retain the pad in a flattened state. The collection pad is deformable from a first undeformed shape having a first size to a second deformed shape having a second size, smaller than the first size, for example, a more a convenient shape to facilitate handling. The support frame may comprise a perforated sheet having foldable seams allowing the collection pad to be folded. The collection pad may also be rolled into a cylindrical shape to facilitate handling.

Owner:SILVERMAN STEPHEN

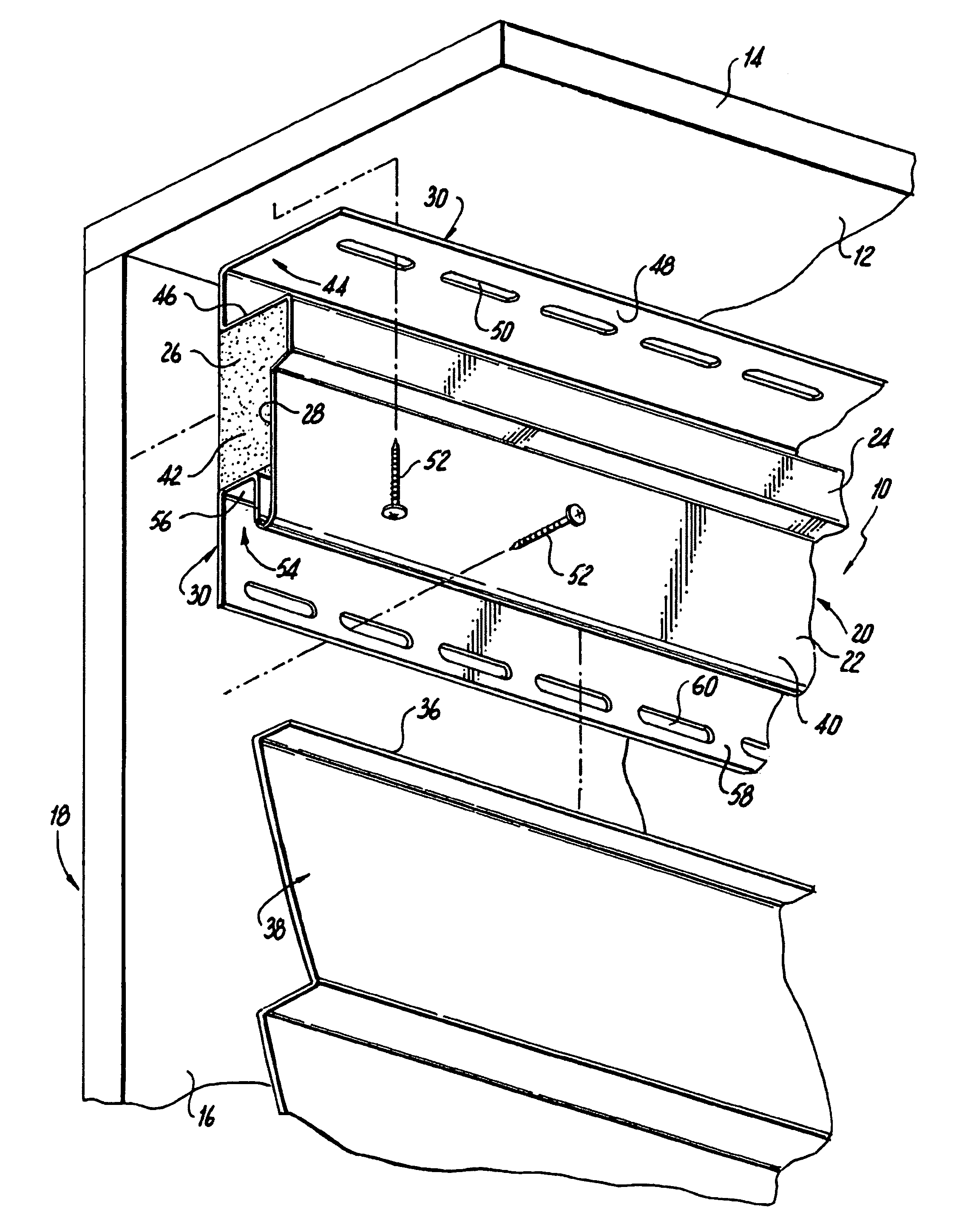

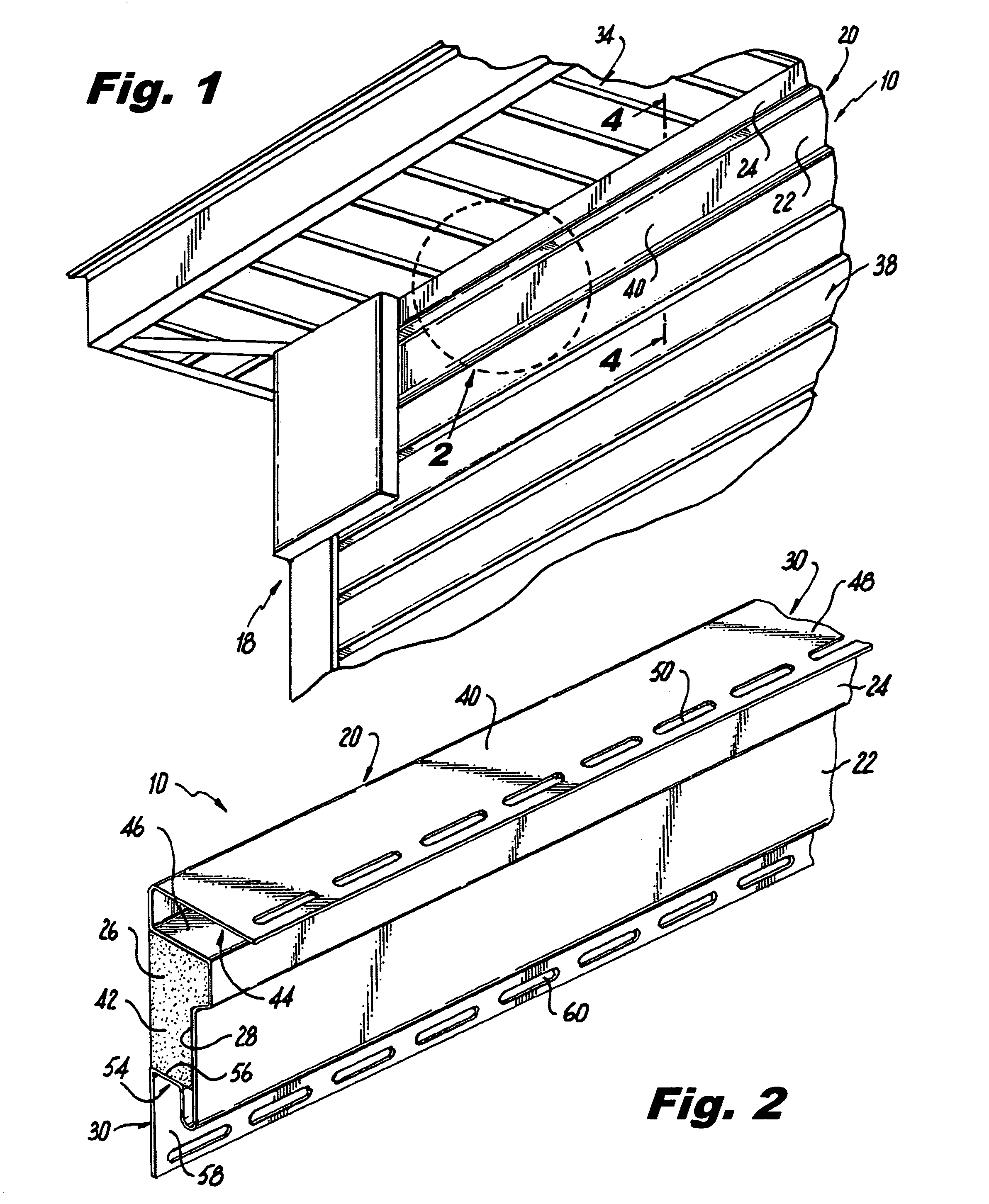

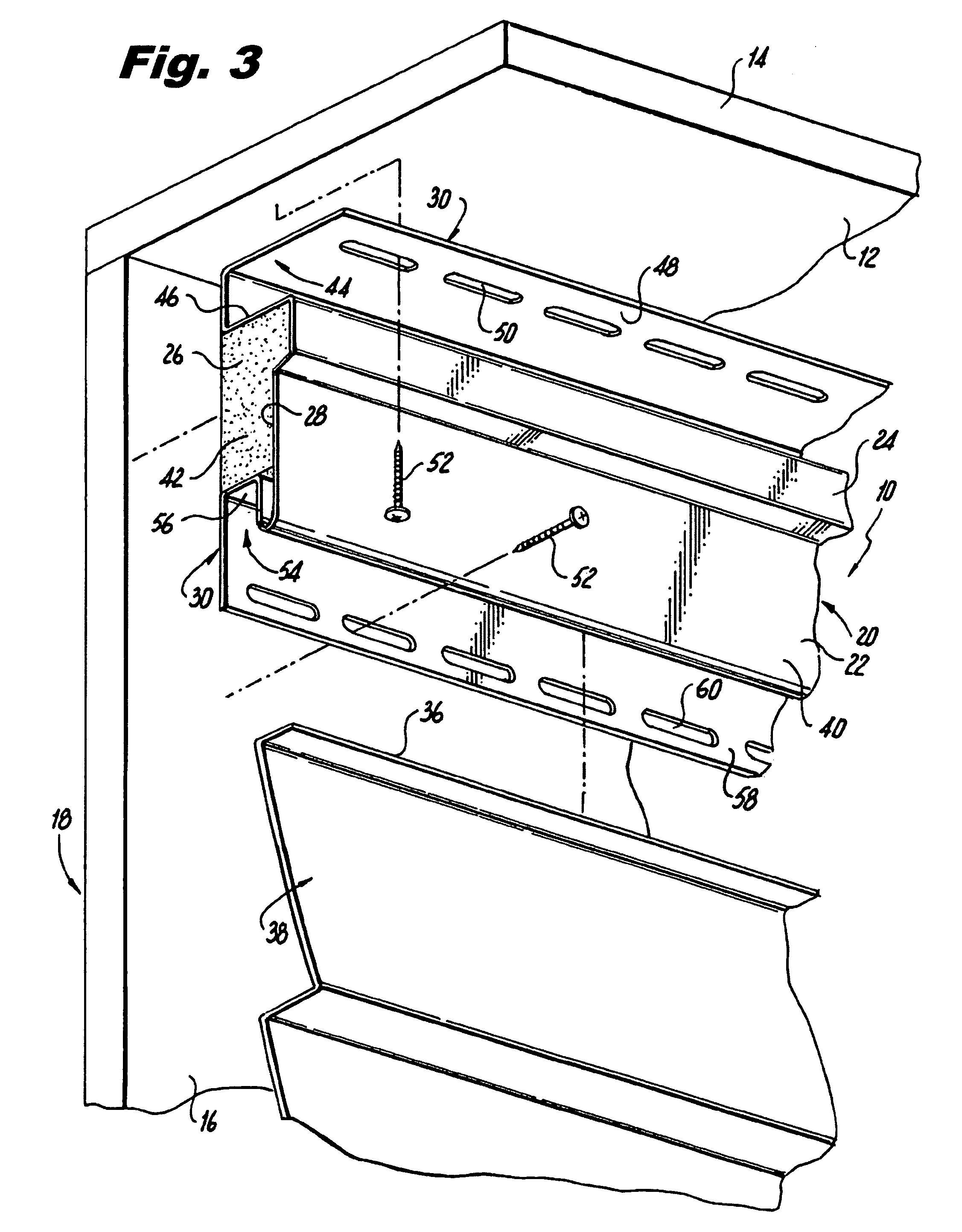

Prefabricated decorative frieze trim

ActiveUS8104234B1Avoid disadvantagesSimple and inexpensive to manufactureRoof covering using slabs/sheetsBuilding roofsEavesLower grade

A prefabricated decorative frieze trim for securement to a lower surface of an eave and an exterior wall surface of a building which comprises a low gauge flexible sheet having a front face with an infinite variety of different ornamental shapes that can be formed thereon. A substrate member is applied to an internal surface of the low grade flexible sheet to provide structural rigidity thereto. A mechanism formed on the low grade flexible sheet is for securing the low grade flexible sheet to the lower surface of the eave and upper portion of the exterior wall surface of the building, whereby a free edge of a soffit component and a free edge of a wall siding can be retained thereto.

Owner:SAWYER STEVEN T

Reinforced high strength microwave antenna

InactiveUS7799019B2High energy concentrationHigh strengthSurgical instruments for heatingSurgical instruments using microwavesMicrowaveHigh intensity

High-strength microwave antenna assemblies and methods of use are described herein. The microwave antenna has a radiating portion connected by a feedline to a power generating source, e.g., a generator. Proximal and distal radiating portions of the antenna assembly are separated by a junction member. A reinforcing member is disposed within the junction member to increase structural rigidity.

Owner:TYCO HEALTHCARE GRP LP

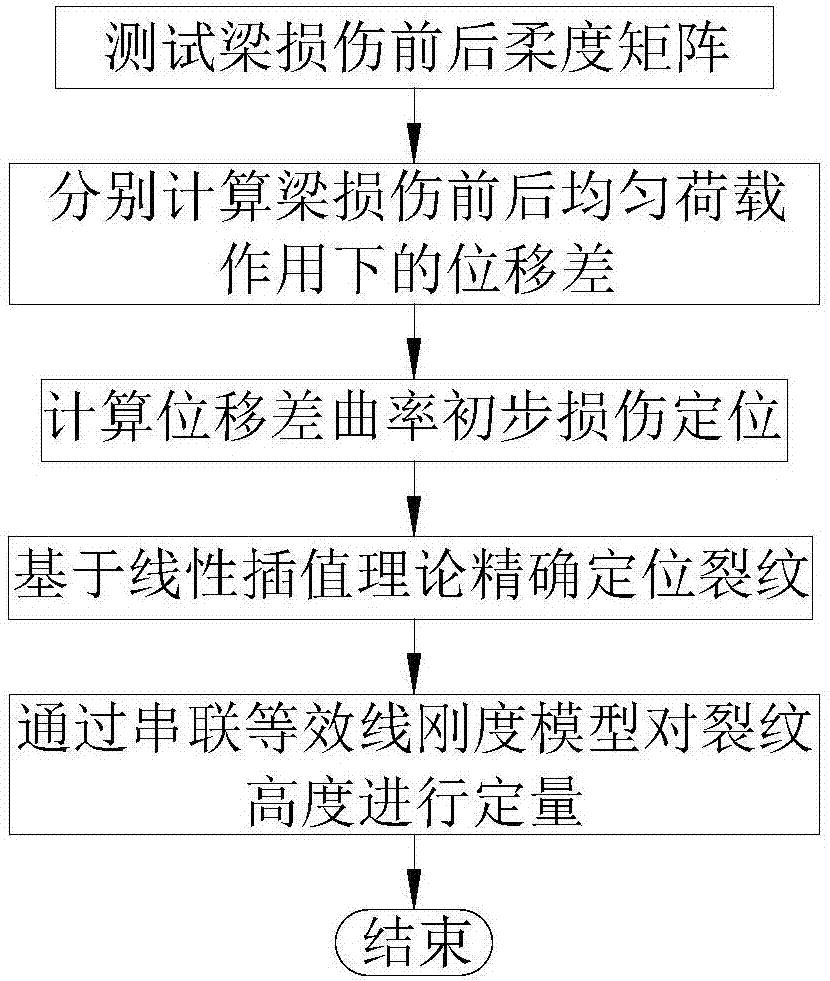

Uniform load surface curvature-based simply supported beam crack damage identification method

ActiveCN107957319AAchieve precise positioningRealize quantitative detectionElasticity measurementMeasurement pointEngineering

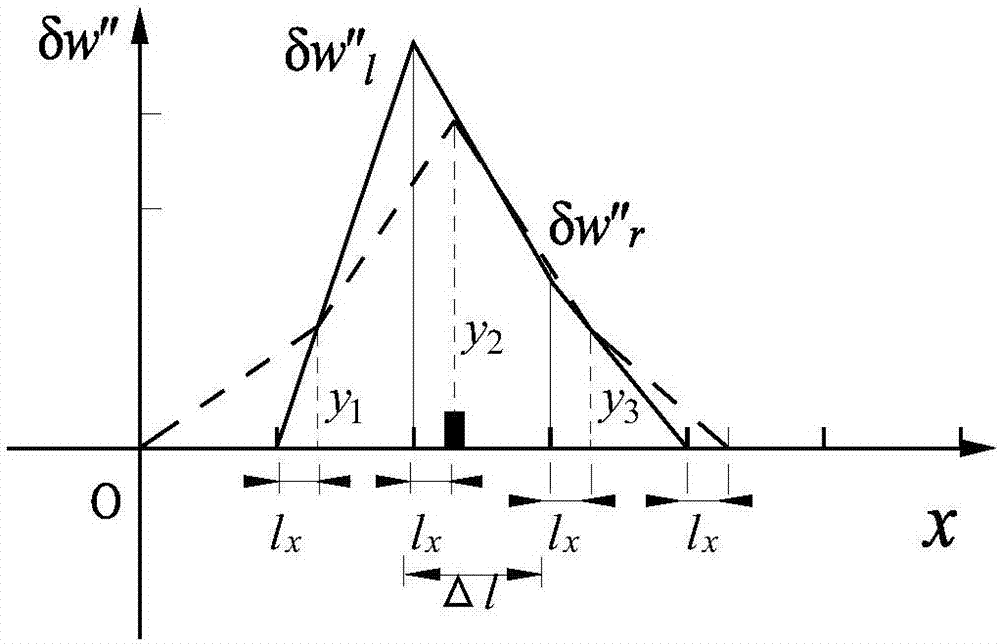

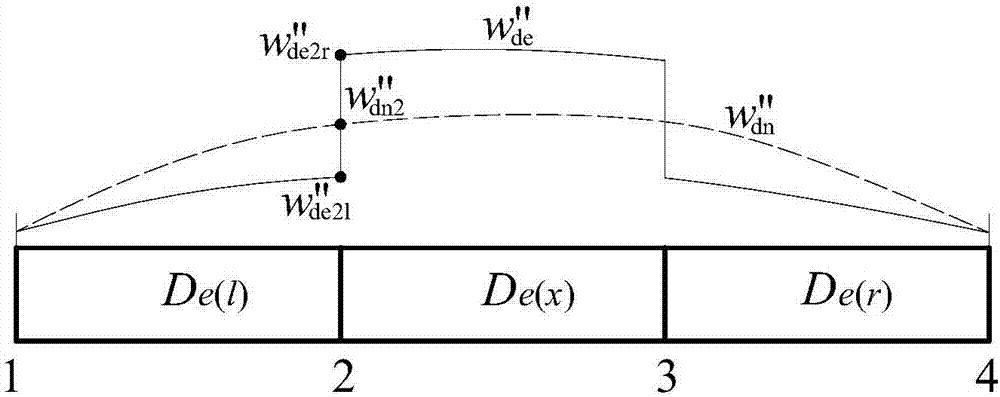

The invention discloses a uniform load surface curvature-based simply supported beam crack damage identification method. The method includes the following steps that: the modal parameters of a simplysupported beam before and after the simply supported beam is damaged are obtained through testing, flexibility matrixes are calculated on the basis of frequencies and vibration modes; a uniform load is applied to the simply supported beam, and the uniform load is multiplied by the difference of the flexibility matrixes which are obtained before and after the simply supported beam is damaged, so that a corresponding displacement difference is obtained; the curvature of the displacement difference is obtained, and a uniform load surface curvature difference is obtained; a relation between the position of a crack and the uniform load surface curvature difference of adjacent measurement points is built based on a linear interpolation theory, so that the accurate positioning of the position ofthe crack can be realized; a uniform load surface curvature-based structural stiffness damage degree identification method is built on the basis of relations between displacement curvatures and structural stiffness and bending moment; and a relation between the height of the crack and a uniform load surface curvature is built through a series equivalent linear stiffness model, so that the quantification of the height of the crack can be realized. With the method of the invention adopted, the position and height of the crack of the simply supported beam can be accurately positioned and quantified. The method is applied to the damage degree evaluation of the structure of a simply supported beam.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com