Reclosable metal bottle

a metal bottle and lid technology, applied in the field of containers, can solve the problems of increasing the overall price of the container, introducing contaminants from the plastic, and high price of the plastic insert, and achieve the effect of ensuring strength and rigidity of the threads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

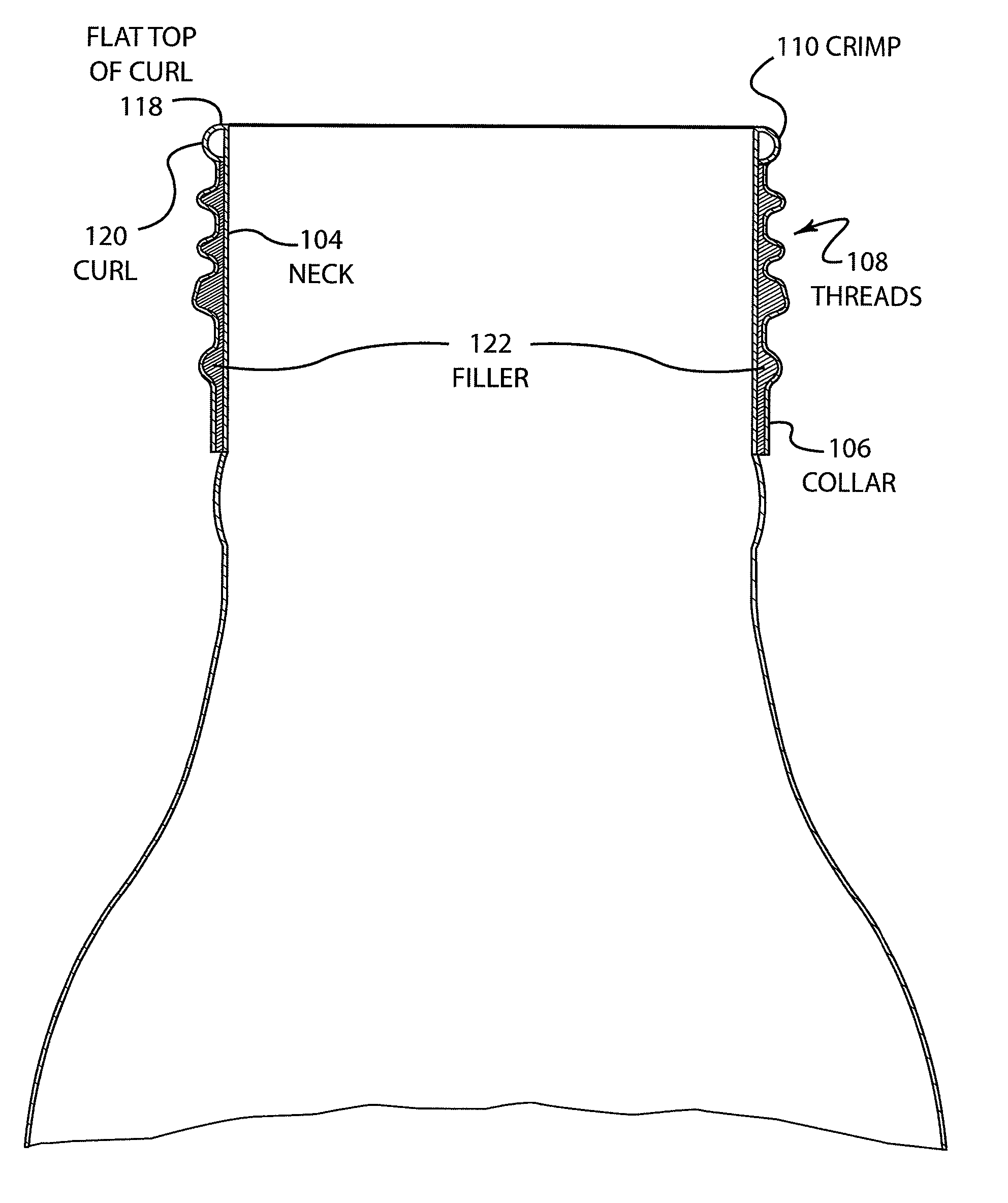

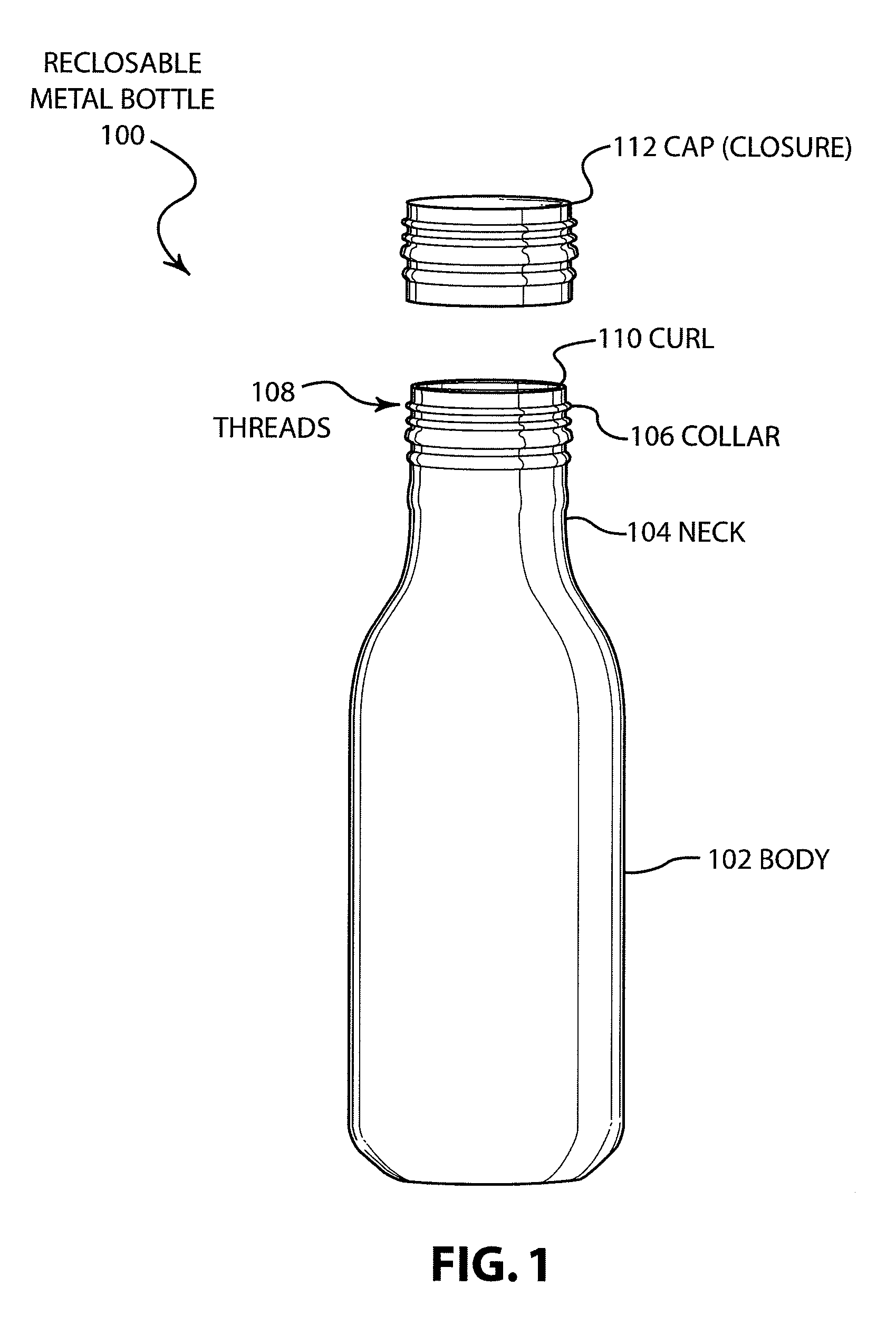

[0025]FIG. 1 is an isometric view of one embodiment of a metal bottle that is made in accordance with the present invention. As shown in FIG. 1, the reclosable metal bottle 100 has a body portion 102 and a neck portion 104. Mounted on the neck portion is a collar 106 that has threads 108. The top of the neck portion 110 is curled and can be crimped to hold the collar 106 in place on the neck portion 104 and retain the collar 106 so that the collar 106 is held on the neck portion 104 and cannot be removed from the end of the neck portion 104. Cap 112 is a standard metal cap with threads that engage threads 108 of the collar 106. The inside top of the cap 112 seals against the smooth curl 110 at the top of neck portion 104.

[0026] The process of forming a typical can body results in the mid portion of the body 102, i.e., the mid-body of a typical aluminum beverage can, to have a thickness of around 4 thousandths of an inch. In some applications, the mid-body may be slightly less thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressures | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com