Patents

Literature

183 results about "Pounds per square inch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The pound per square inch or, more accurately, pound-force per square inch (symbol: lbf/in²; abbreviation: psi) is a unit of pressure or of stress based on avoirdupois units. It is the pressure resulting from a force of one pound-force applied to an area of one square inch. In SI units, 1 psi is approximately equal to 6895 N/m².

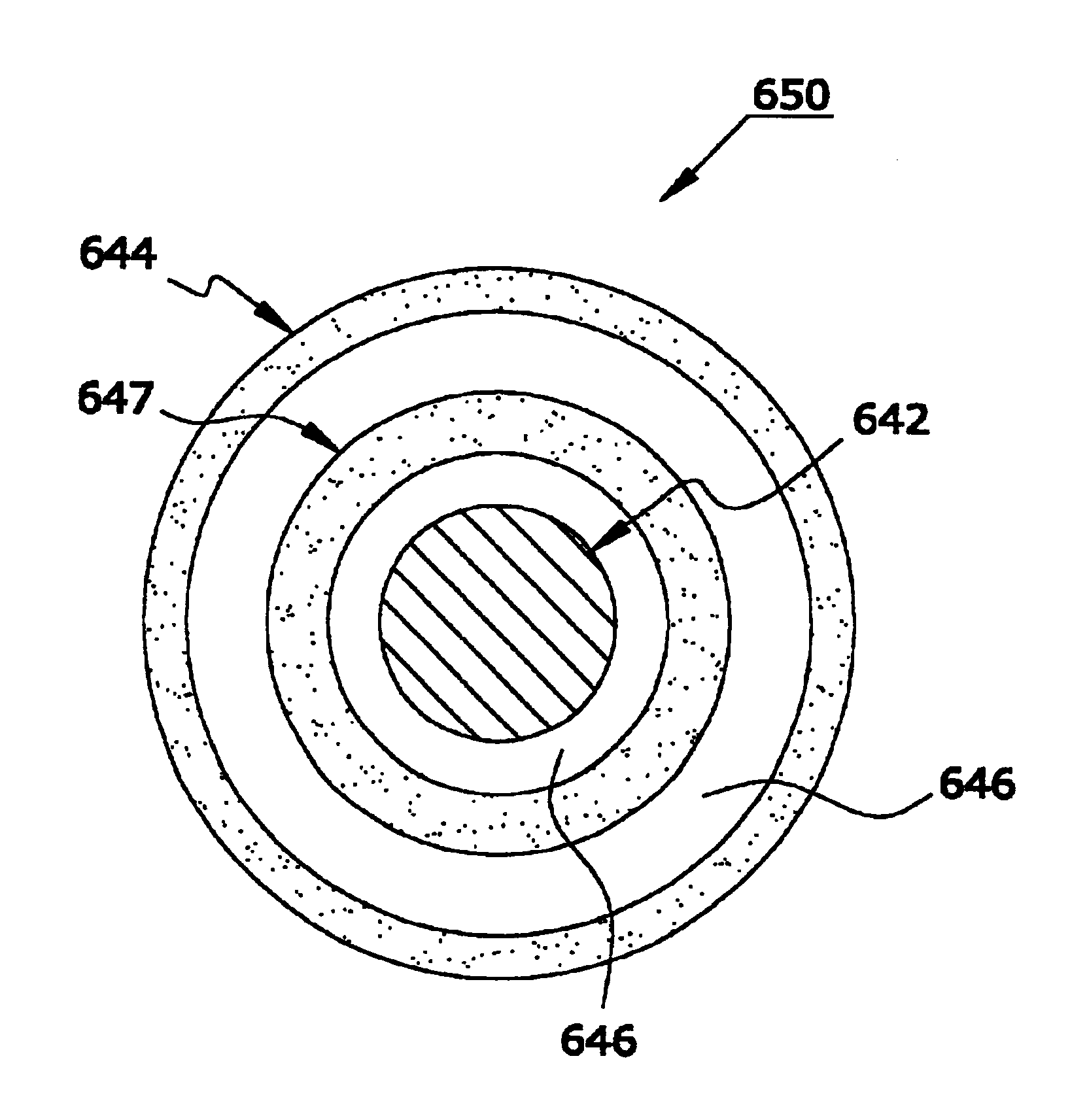

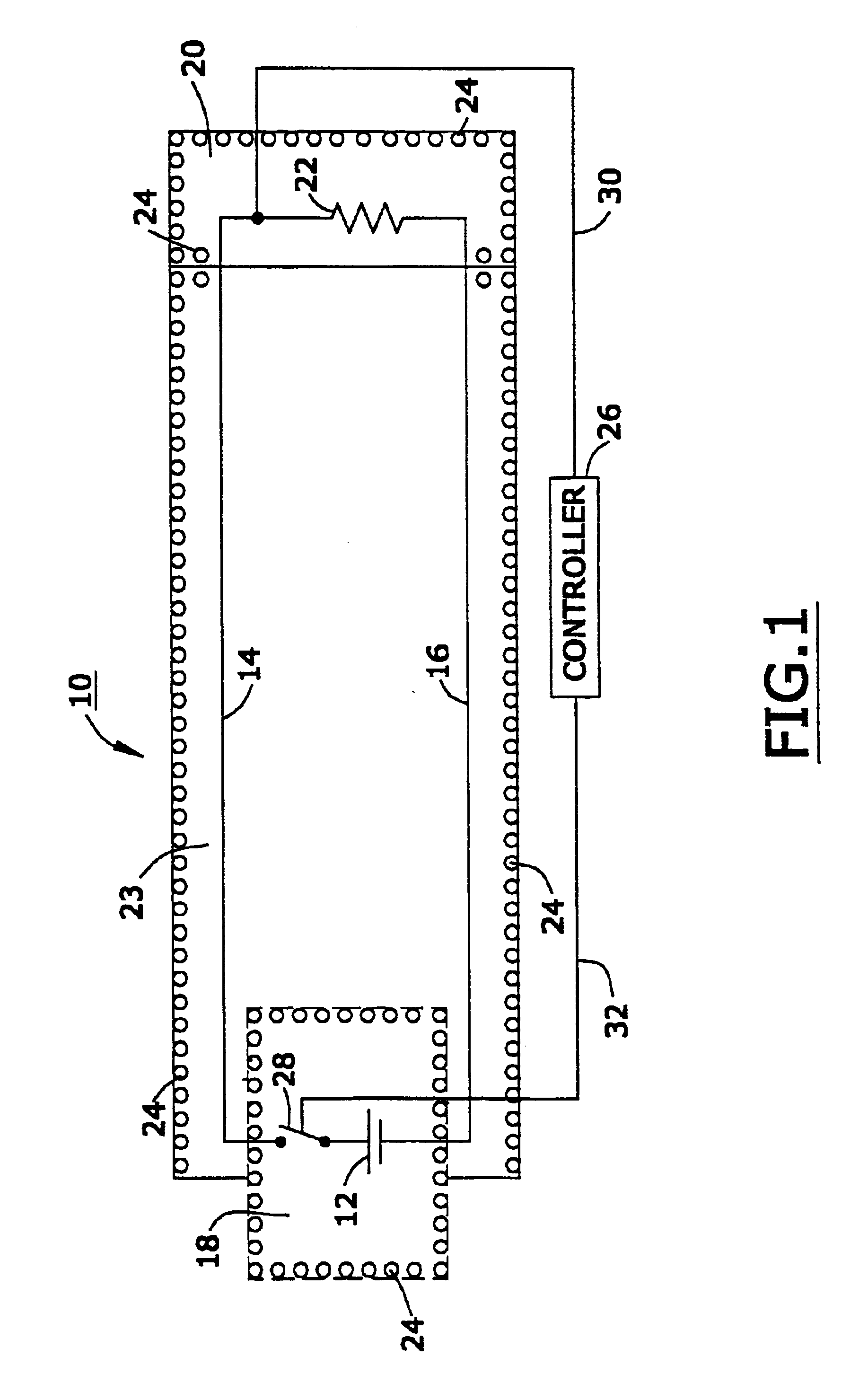

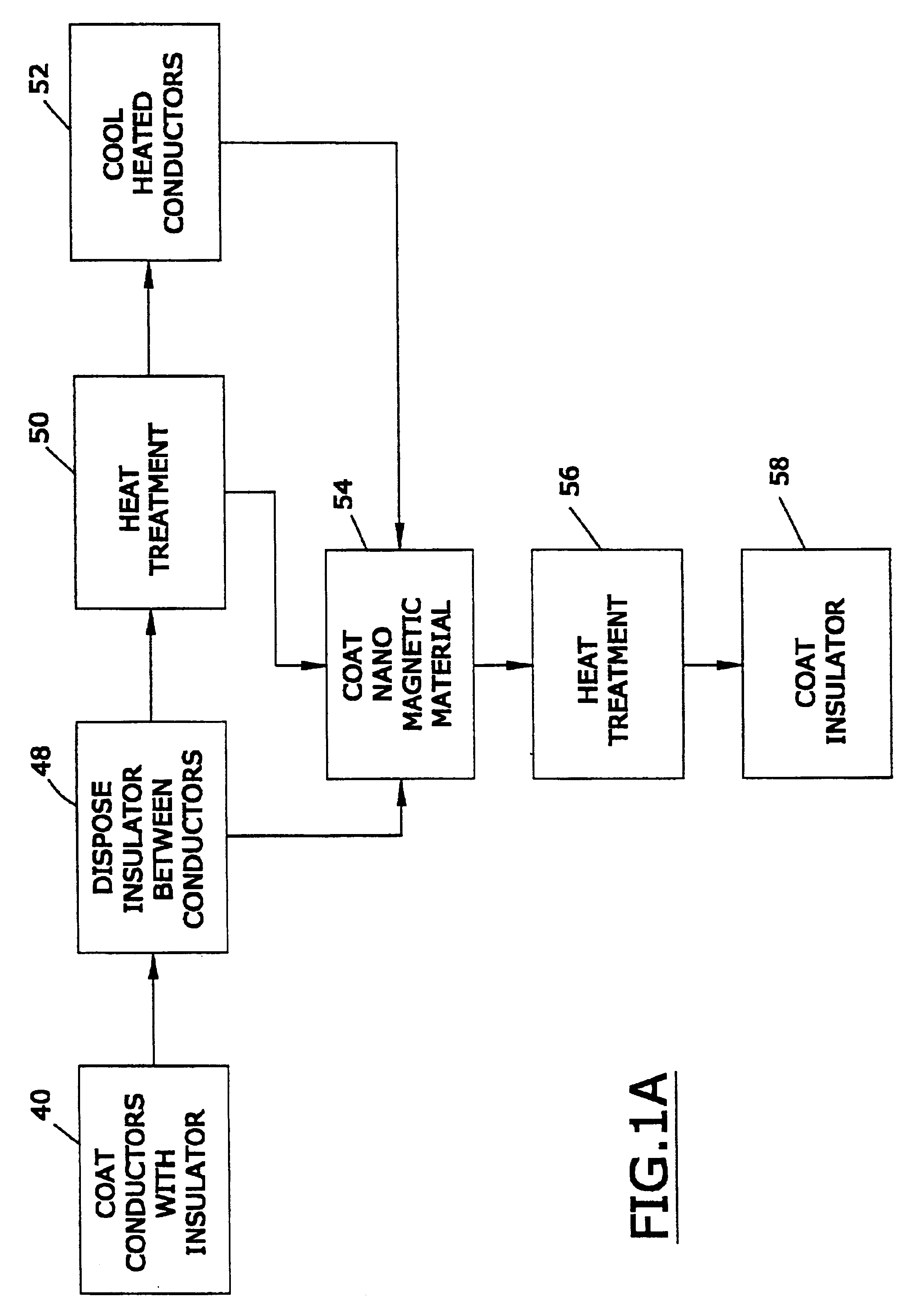

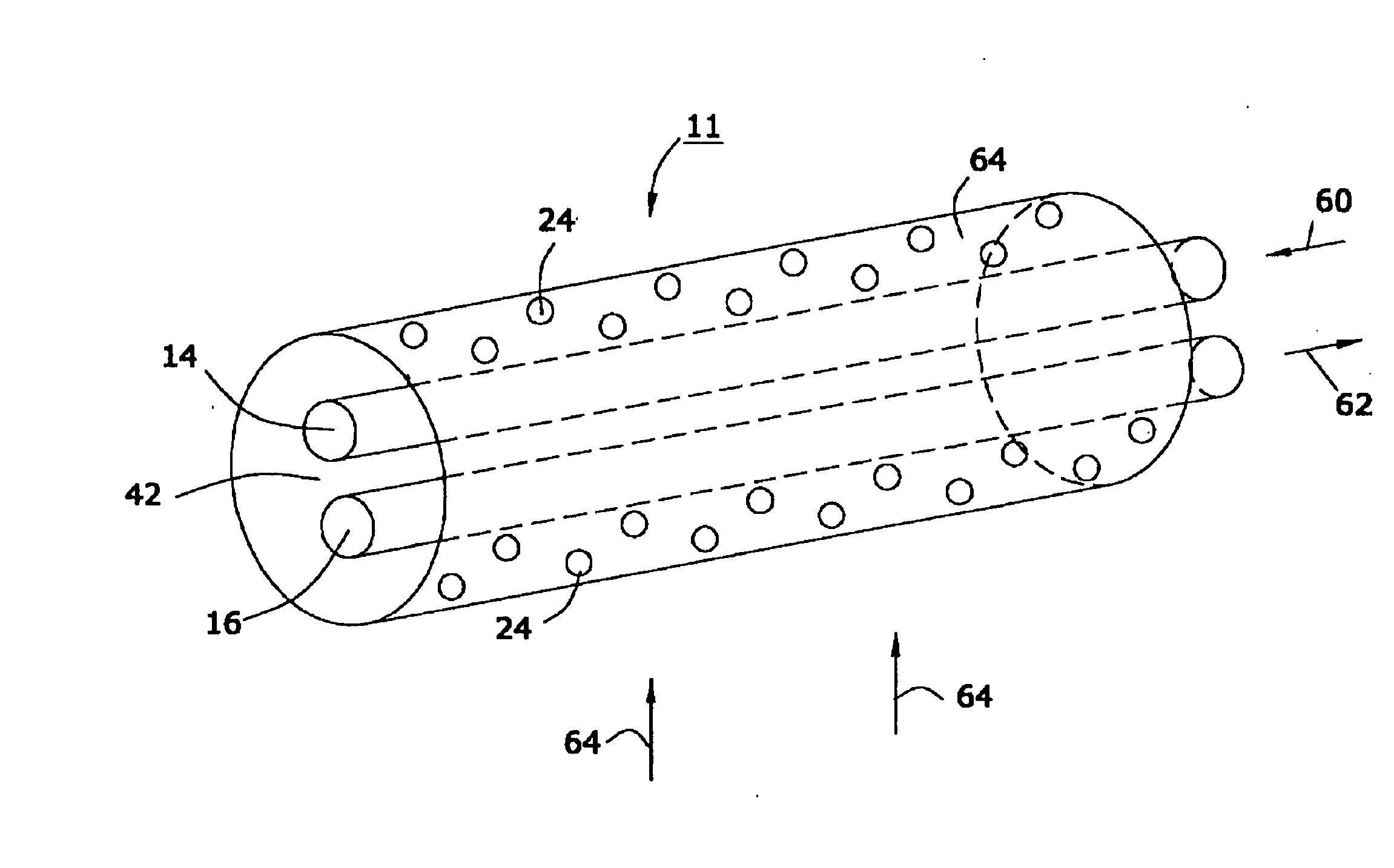

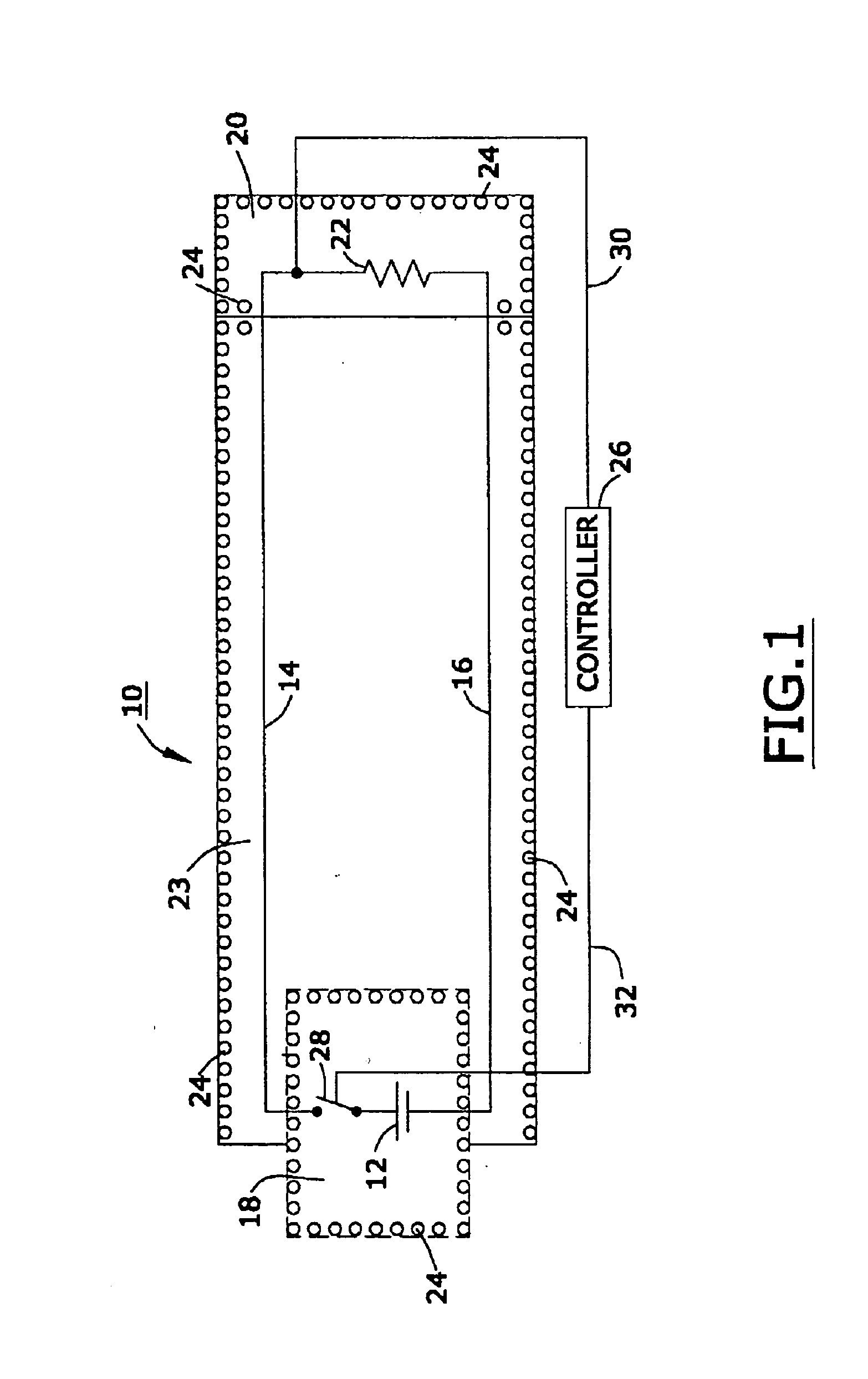

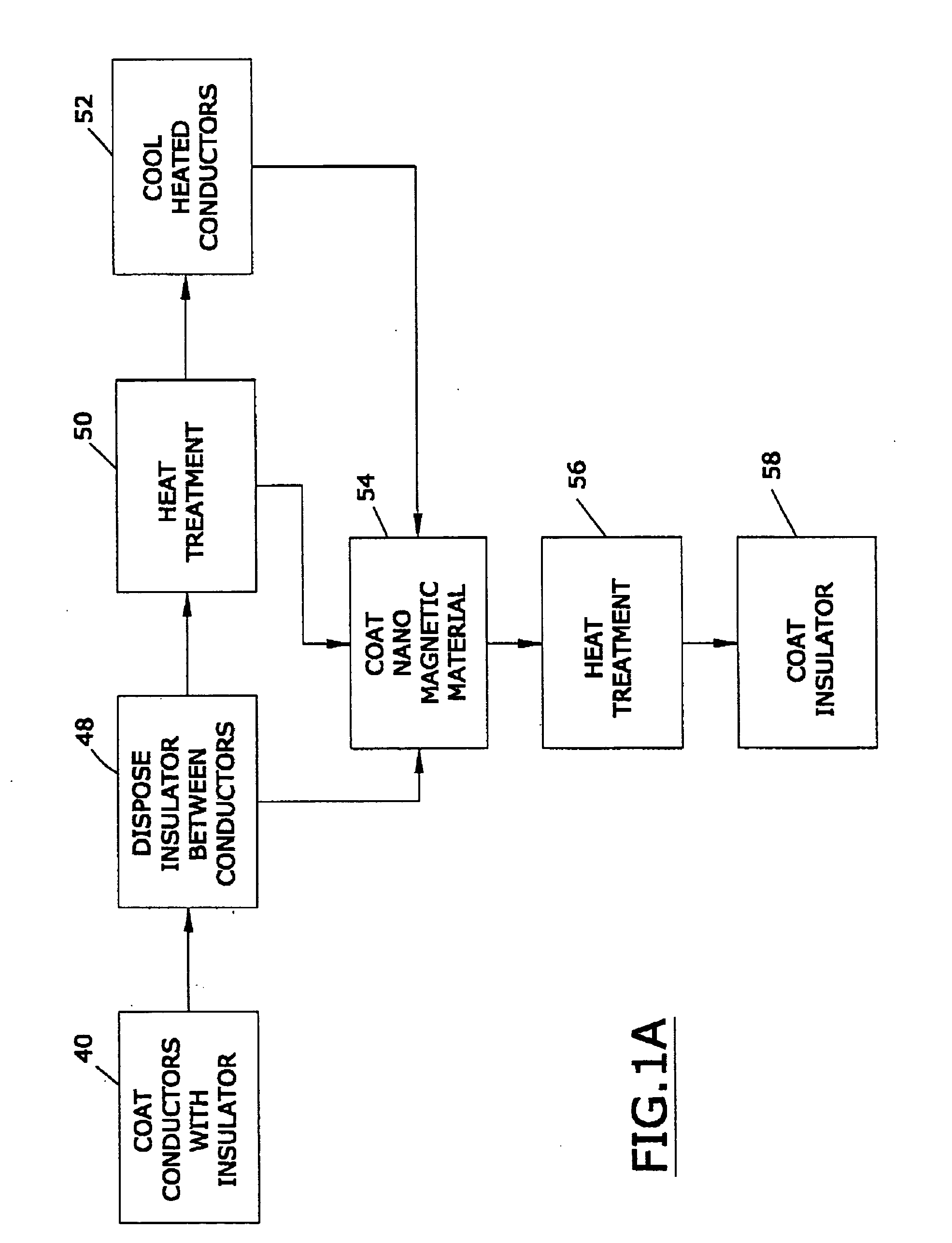

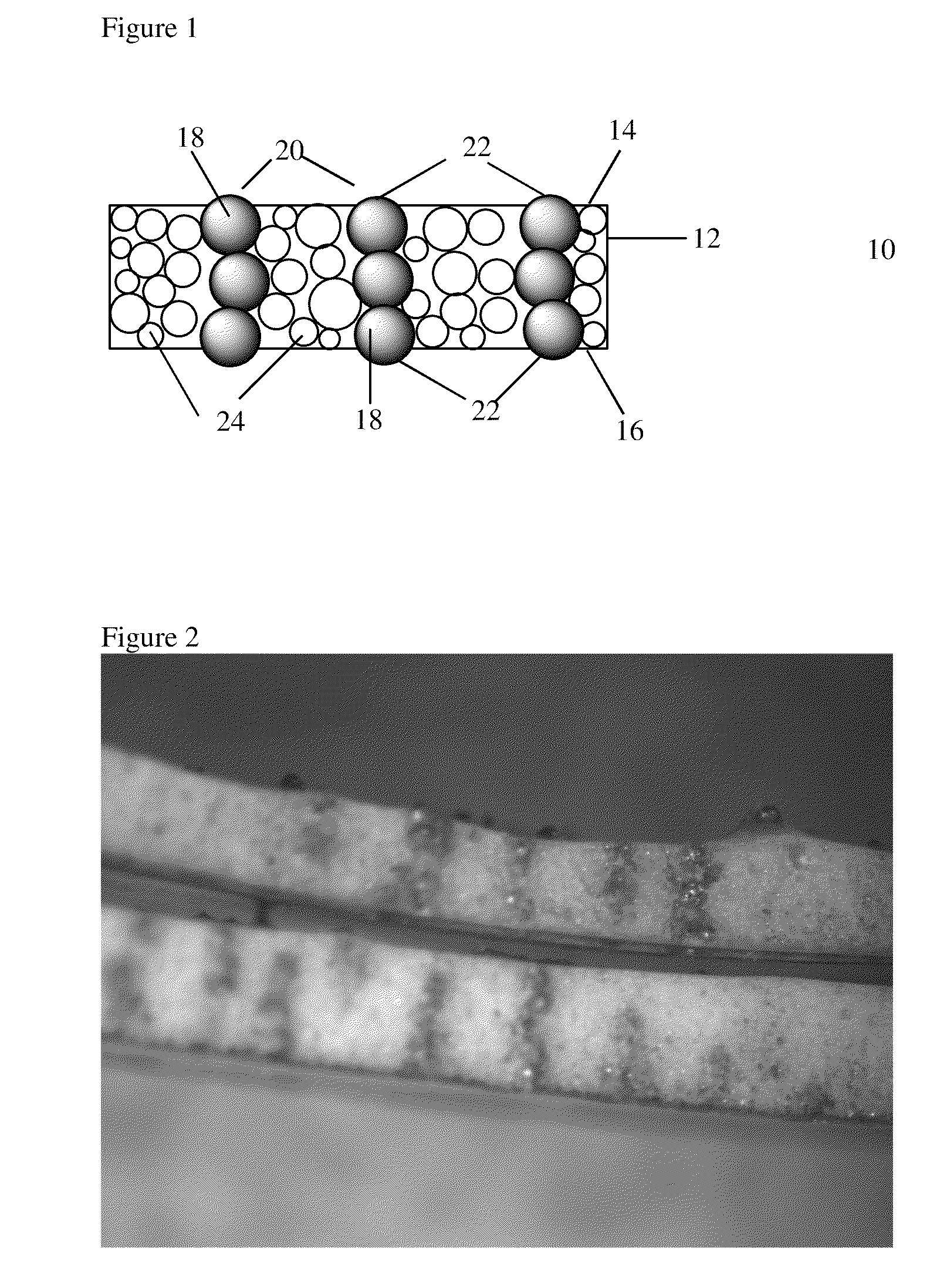

Magnetically shielded conductor

A conductor assembly that contains a flexible conductor and a layer of nanomagnetic material coated onto the conductor. The layer of nanomagnetic material has a tensile modulus of elasticity of at least about 15×106 pounds per square inch, an average particle size of less than 100 nanometers, a saturation magnetization of from about 200 to about 26,000 Gauss, and a thickness of less than about 2 microns.

Owner:BIOPHAN TECH

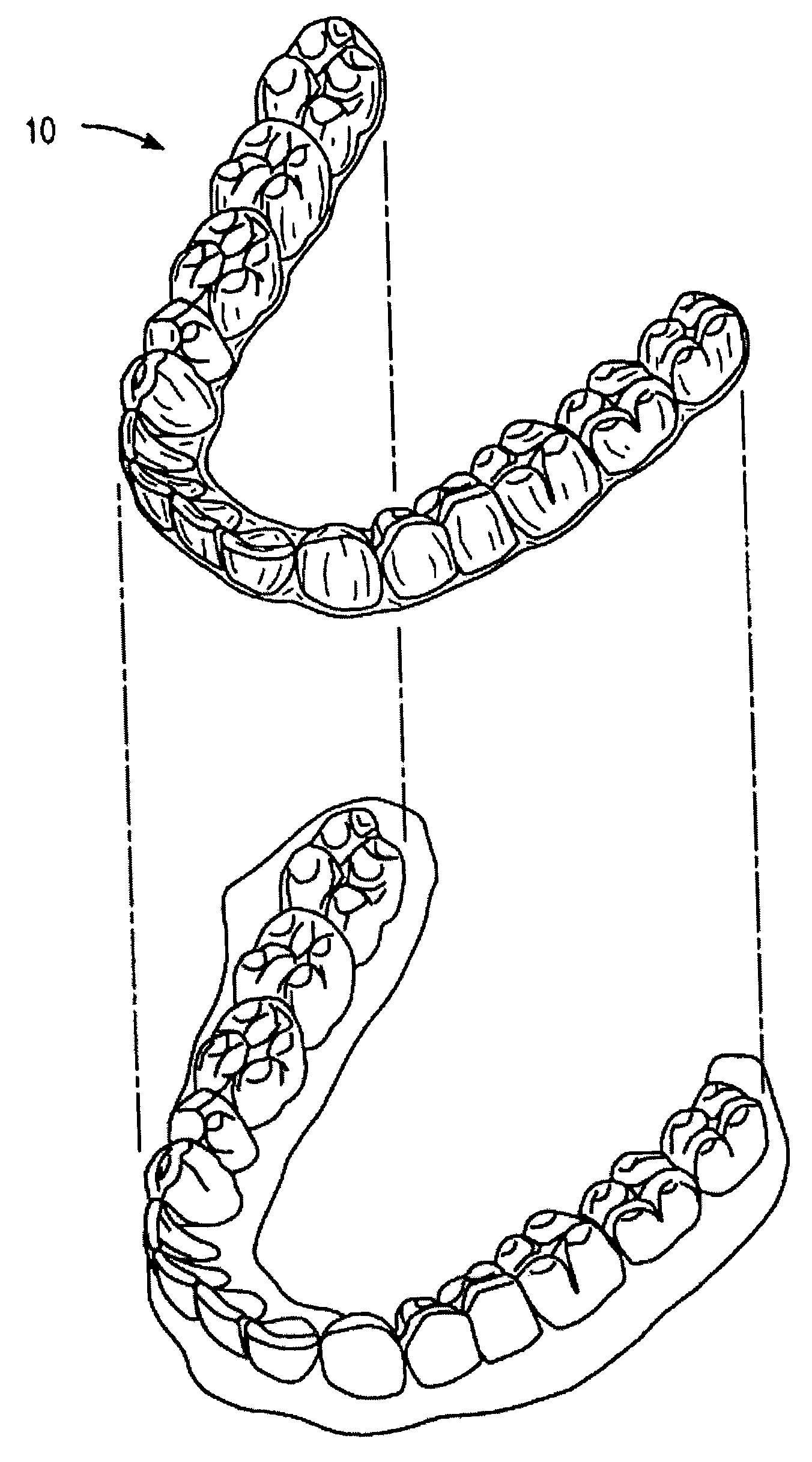

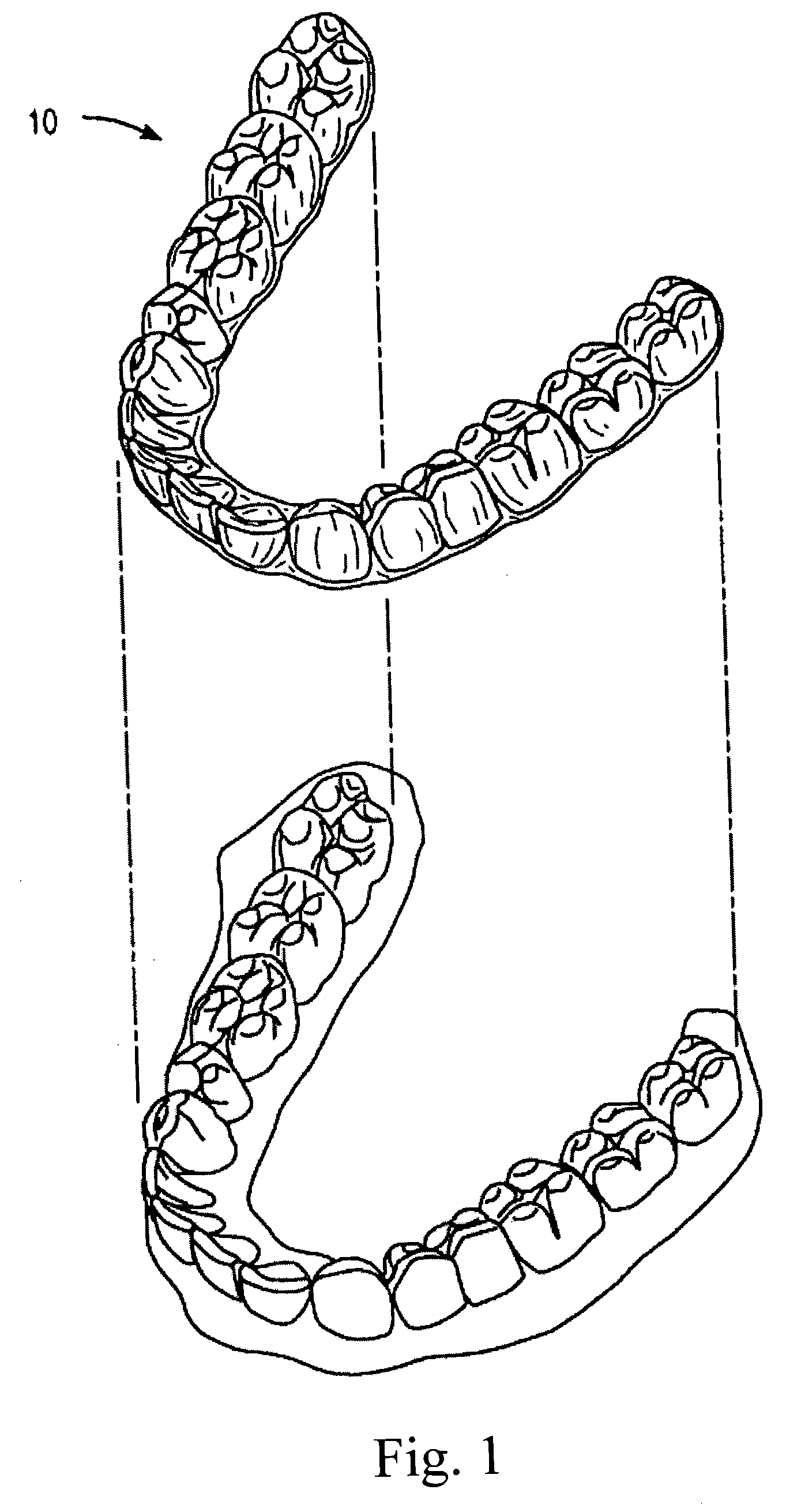

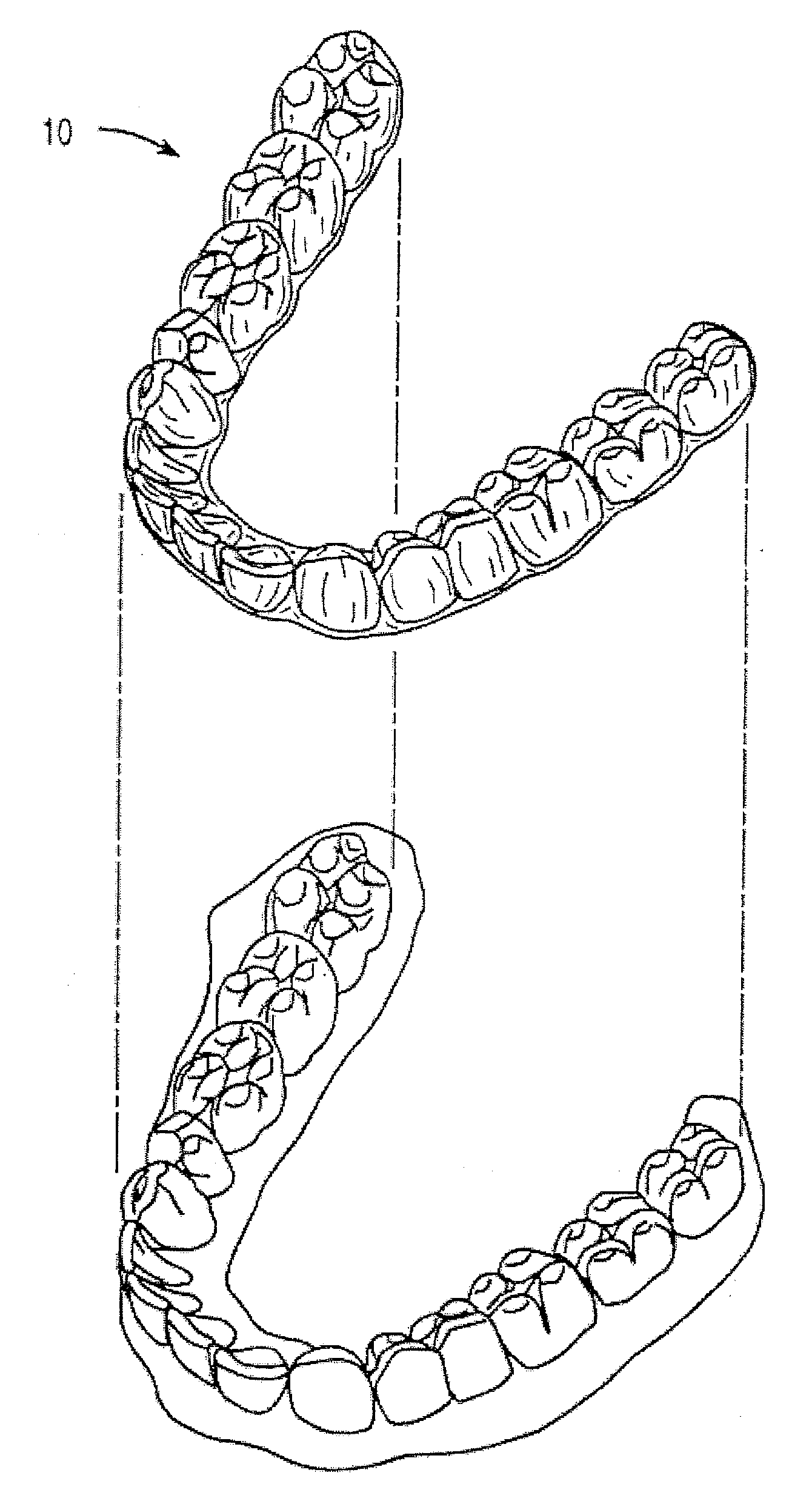

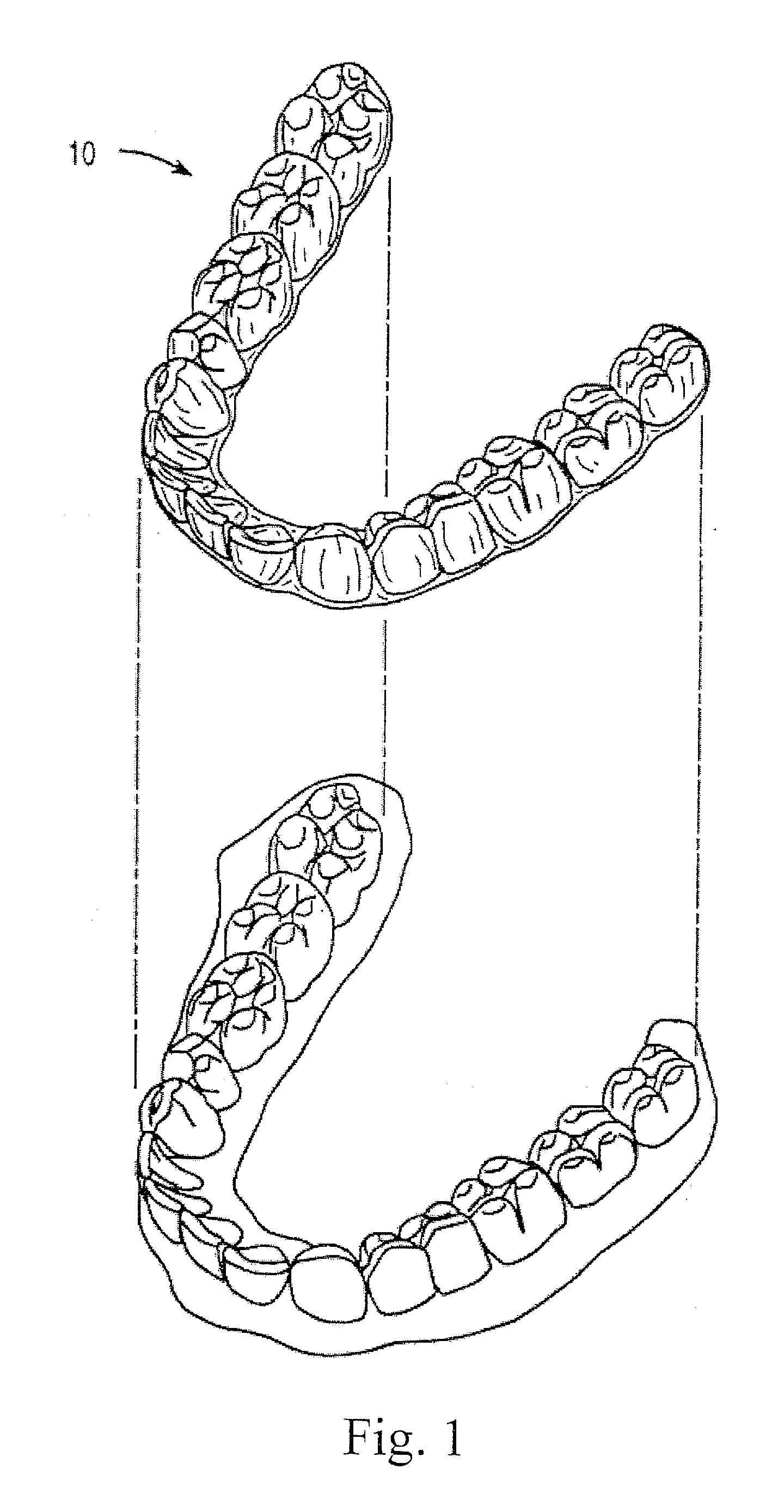

Orthodontic appliances and materials for making same

InactiveUS20060078841A1High glass transition temperatureOthrodonticsDental toolsFlexural modulusStress relaxation

The polymeric shell of a removable dental positioning appliance is formed from transparent polymeric materials having a tensile strength at yield of greater than 6,000 pounds per square inch (psi), an elongation at yield of greater than 4%, an elongation at break of greater than 80%, a tensile modulus greater than 200,000 psi, a flexural modulus greater than 200,000 psi, stress relaxation over time of not more than 50%, and a transmissivity of light between 400 nm and 800 nm greater than 75%.

Owner:ALIGN TECH

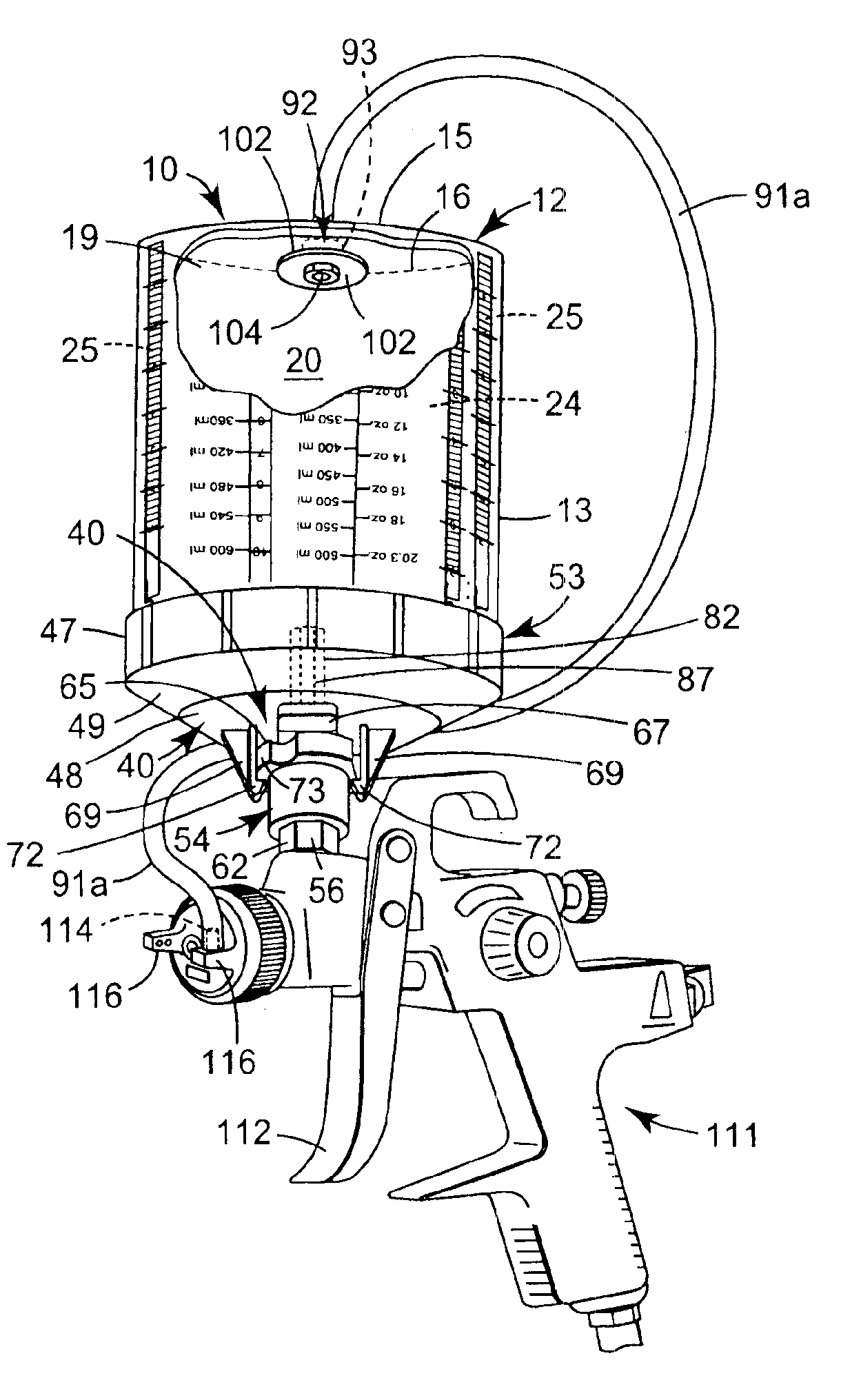

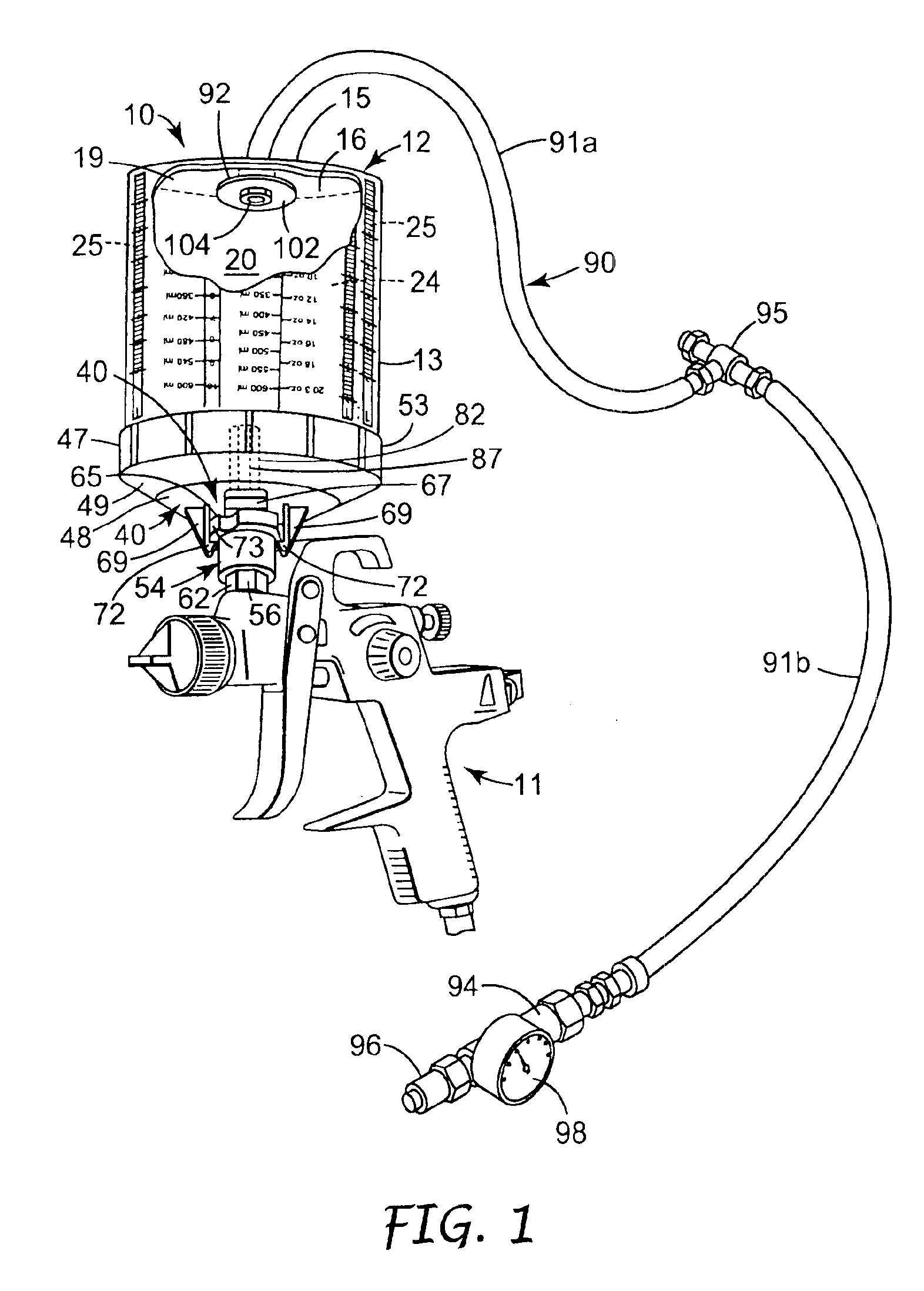

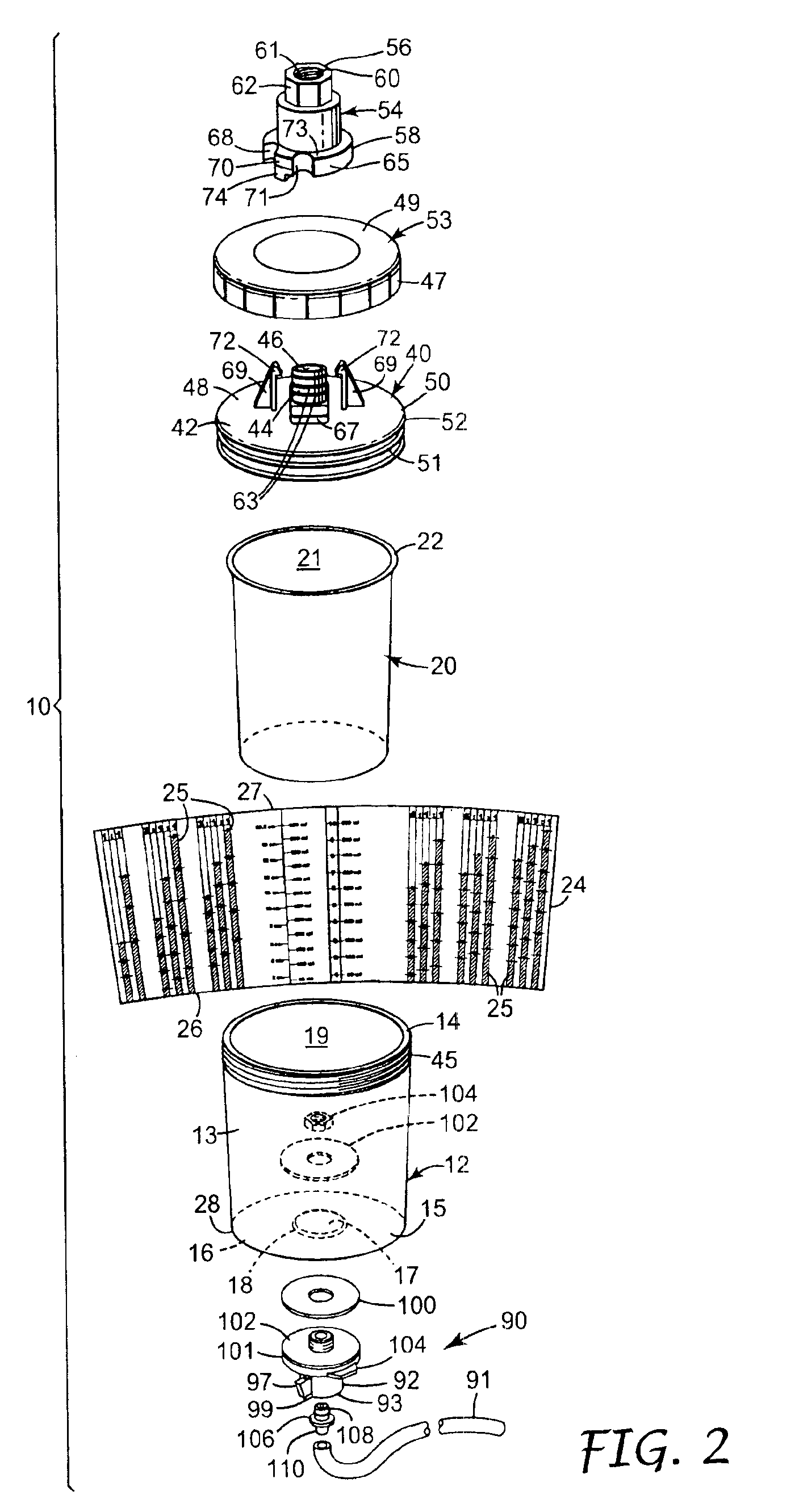

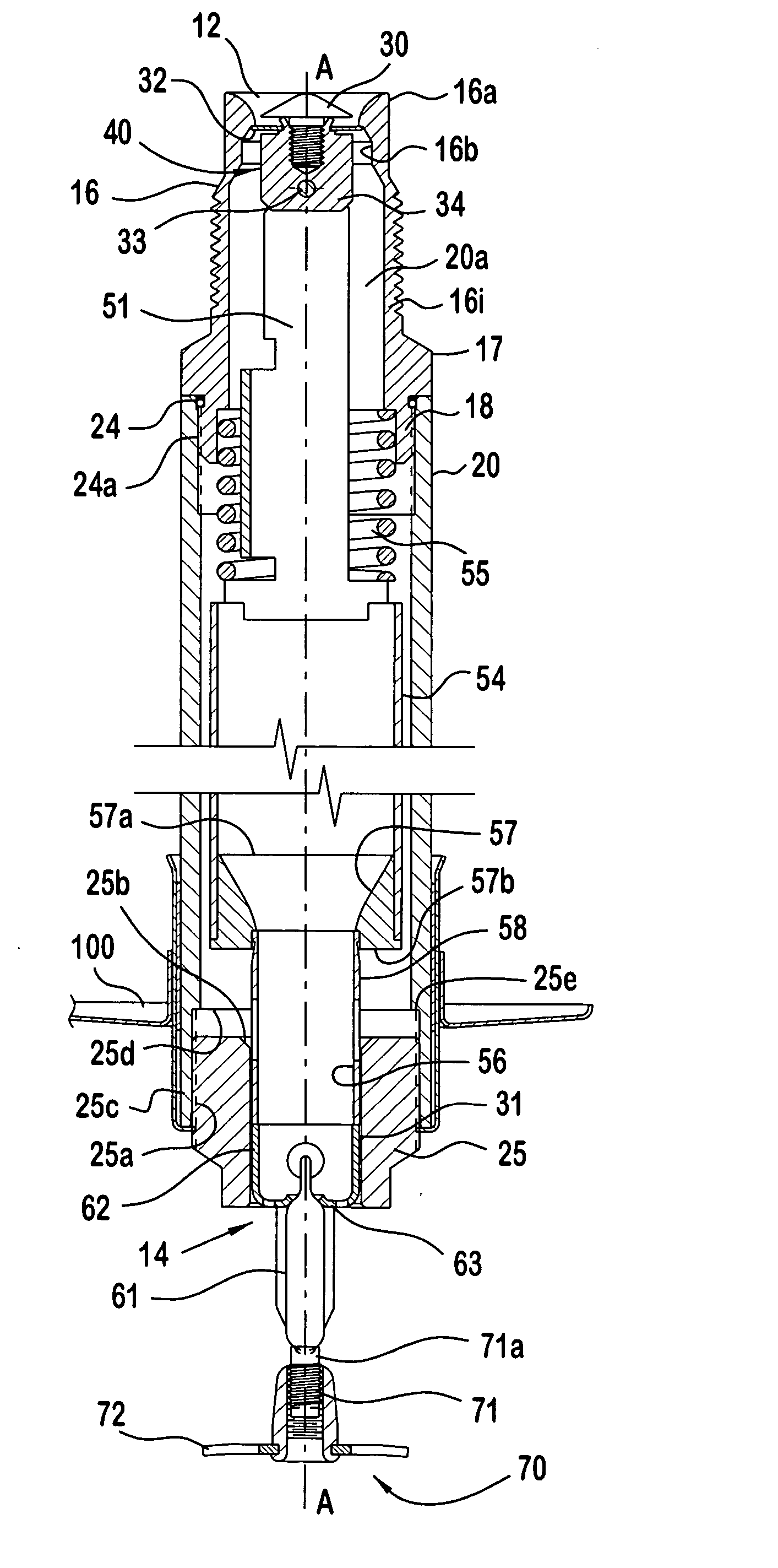

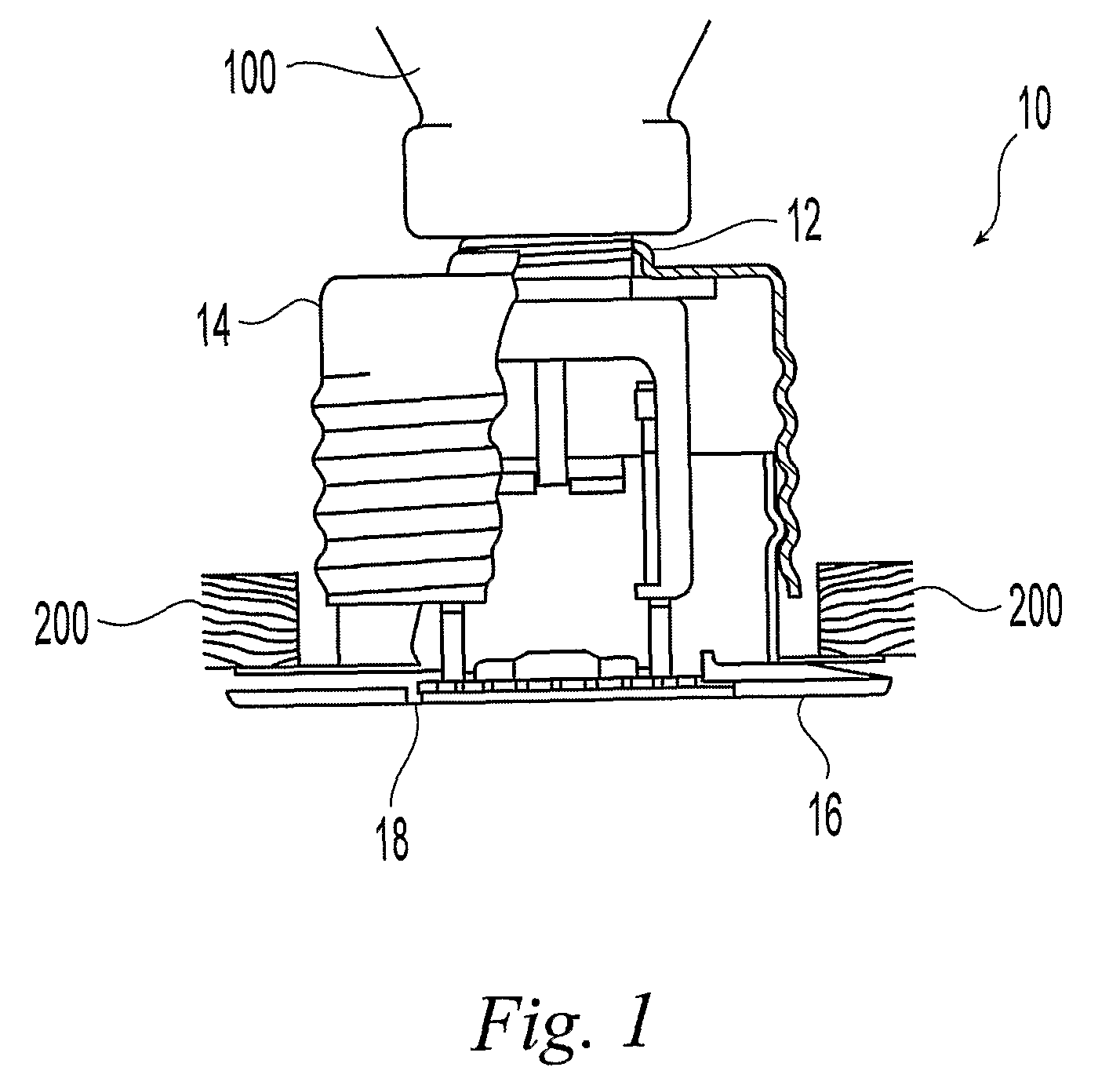

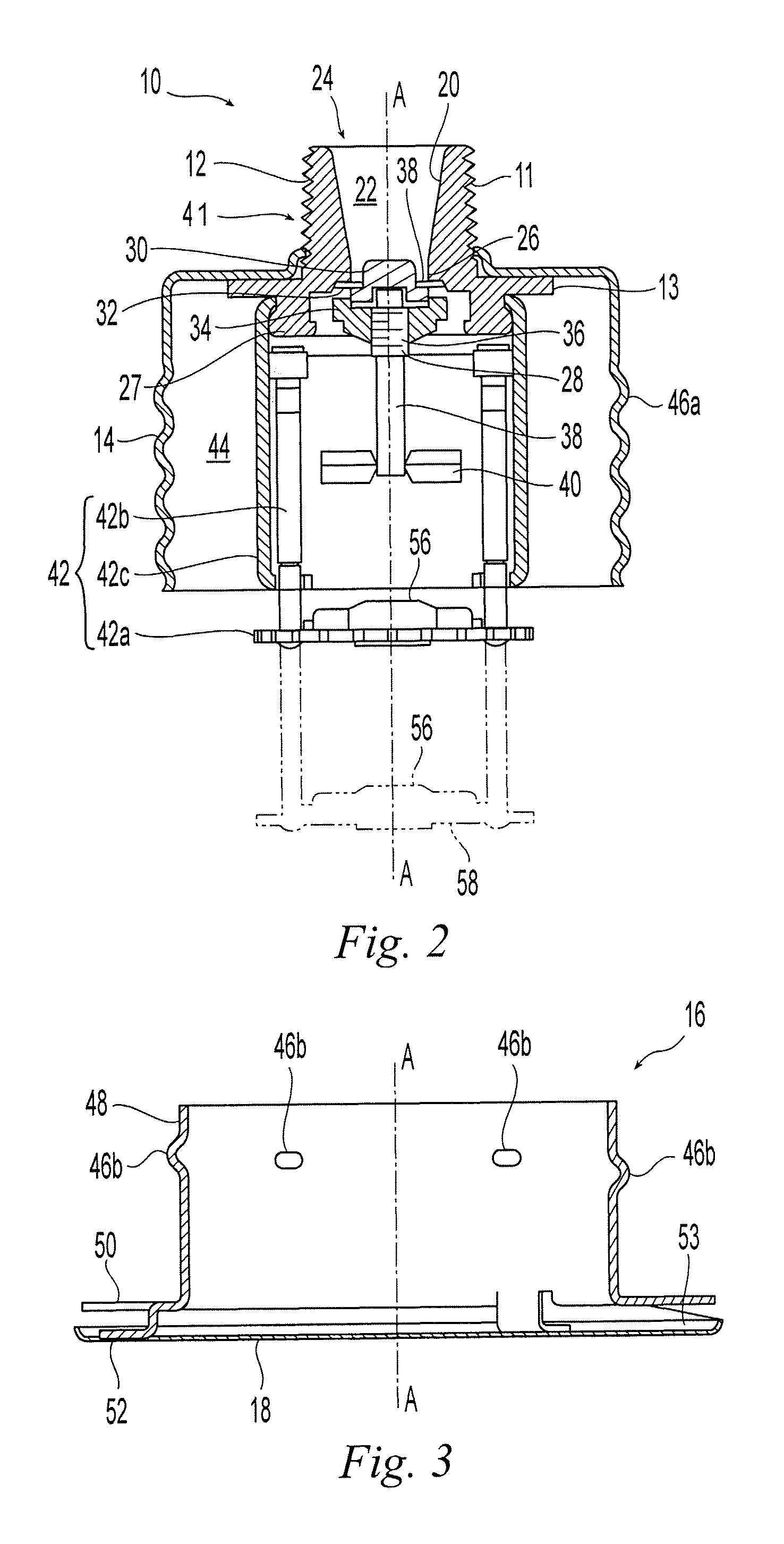

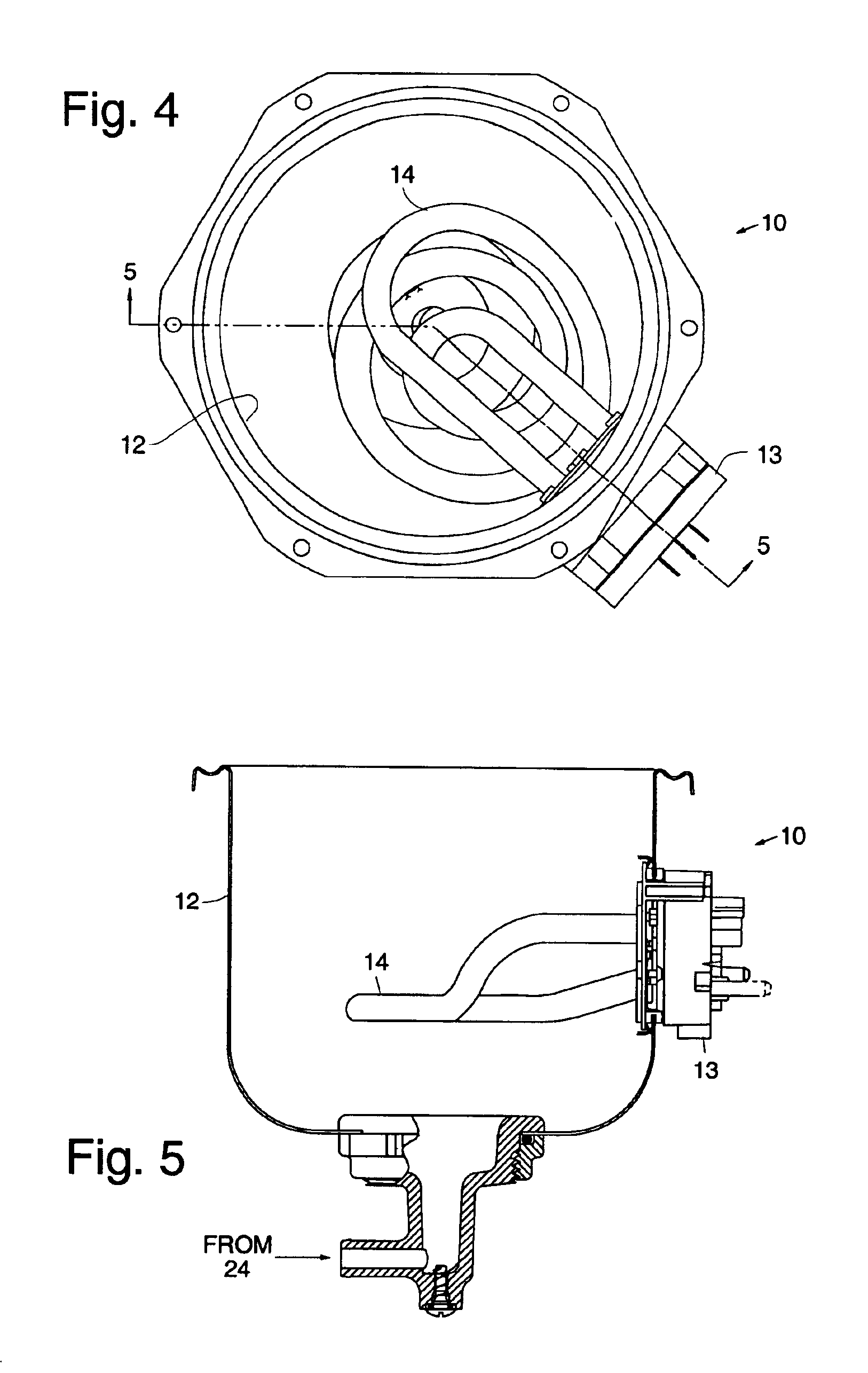

Pressure assisted liquid supply assembly

InactiveUS6953155B2Improve operationImprove versatilityWatering devicesLiquid transferring devicesMechanical engineeringPounds per square inch

An assembly for feeding liquid to the inlet port of a liquid spraying device or spray gun. The assembly includes a stiff container that defines an opening into a cavity in the container, and a flexible liner positioned within the cavity in the container has an outer surface generally corresponding in shape to the inner surface of the container, an inner surface defining a cavity in the liner, and an annular lip along the top end of the side wall defining an opening into the cavity in the liner. An included adapter assembly has a central portion with a through opening that is adapted to engage the inlet port of a liquid spraying device, a transverse portion including a peripheral part adapted for engagement within the flexible liner adjacent said top end of the container, and means for sealing the flexible liner around the peripheral part of the adapter assembly. An air supply assembly connected to the container supplies air at a relatively low pressure (e.g., in the range of about 0.5 to 8 pounds per square inch or 3.5 to 55 kilopascals) between the outer surface of the flexible liner and the inner surface of the container which improves the flow of liquids through the liquid spraying device or spray gun to which the assembly is attached, and allows that spraying device or spray gun to be used in any orientation.

Owner:3M INNOVATIVE PROPERTIES CO

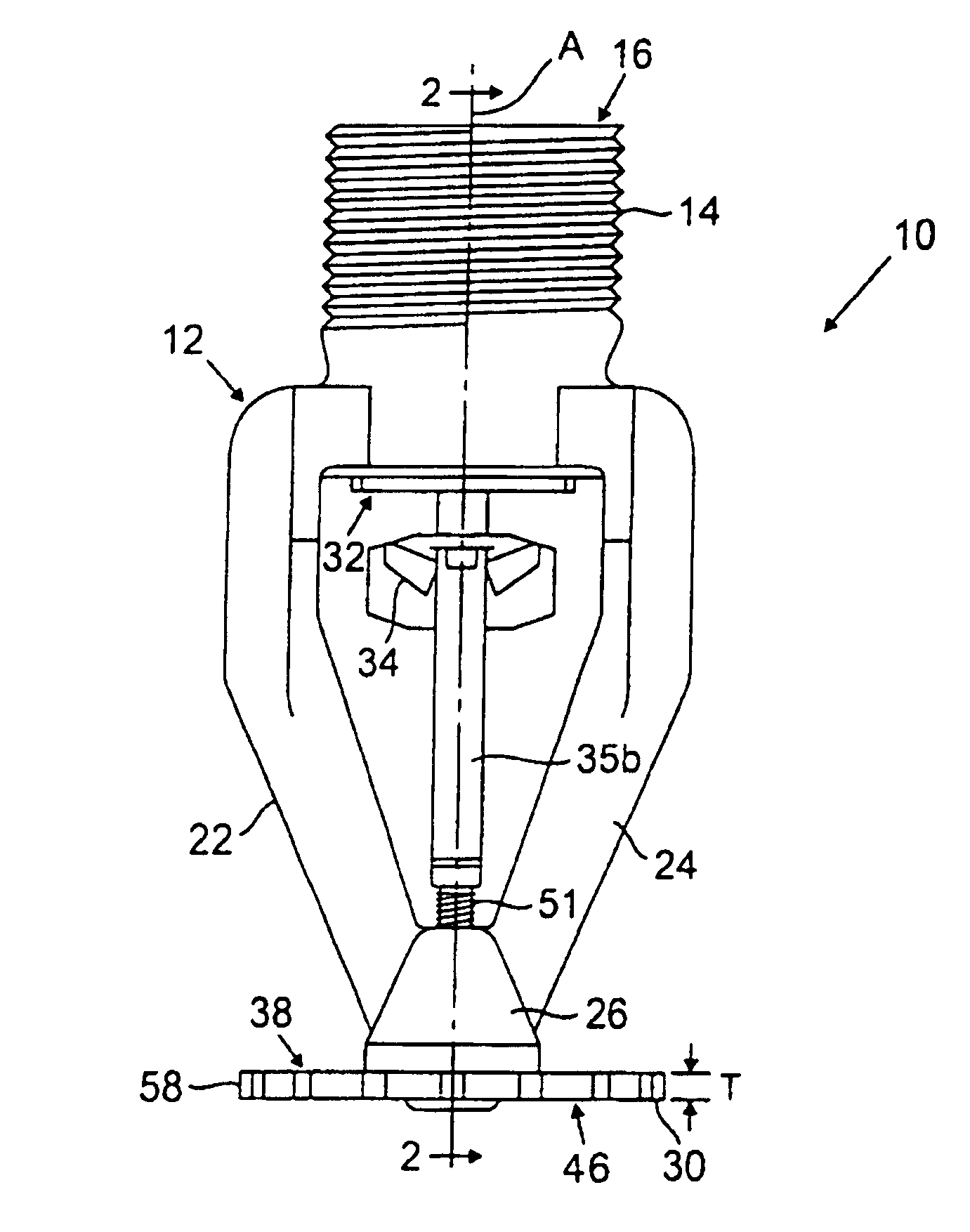

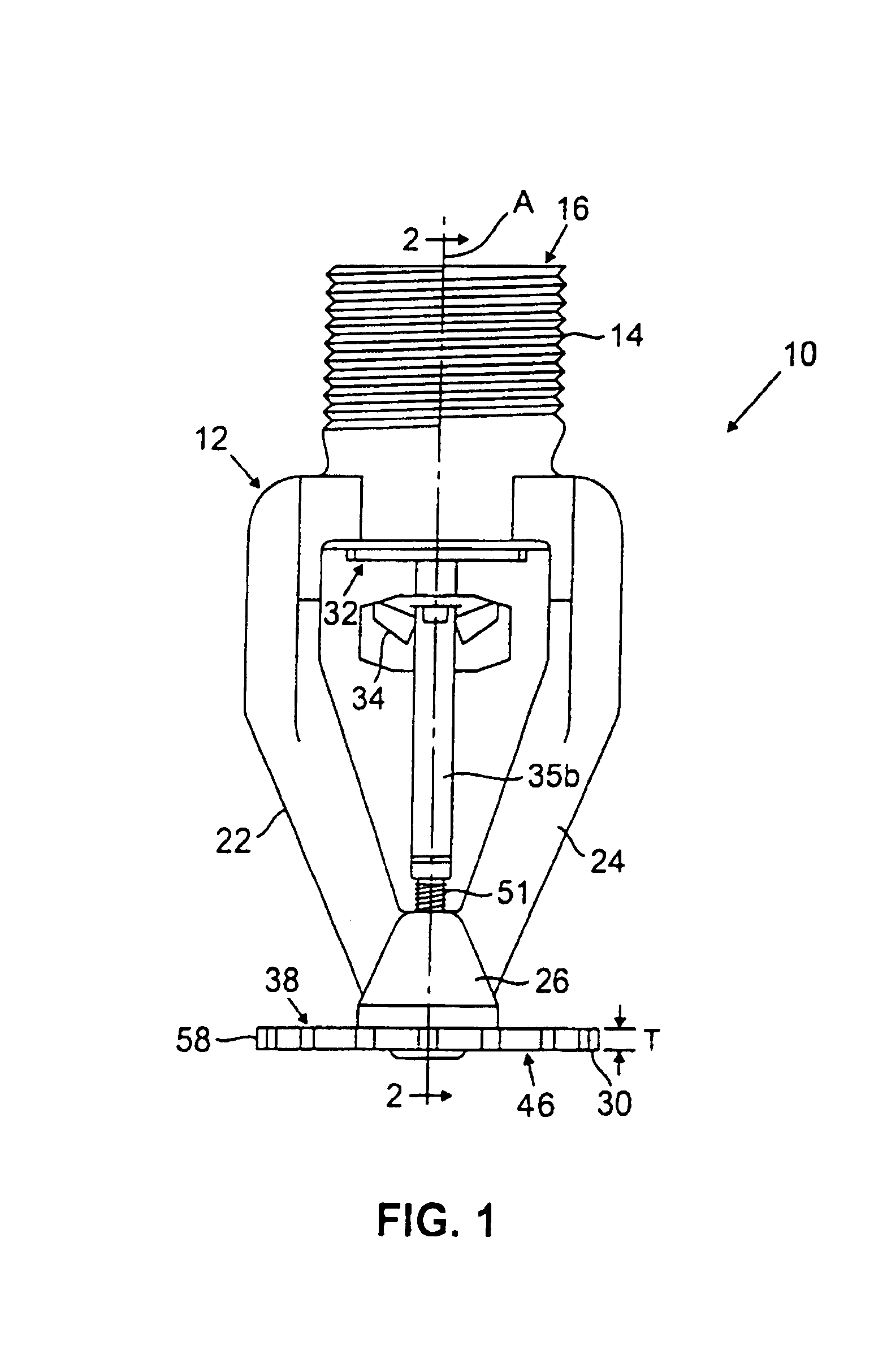

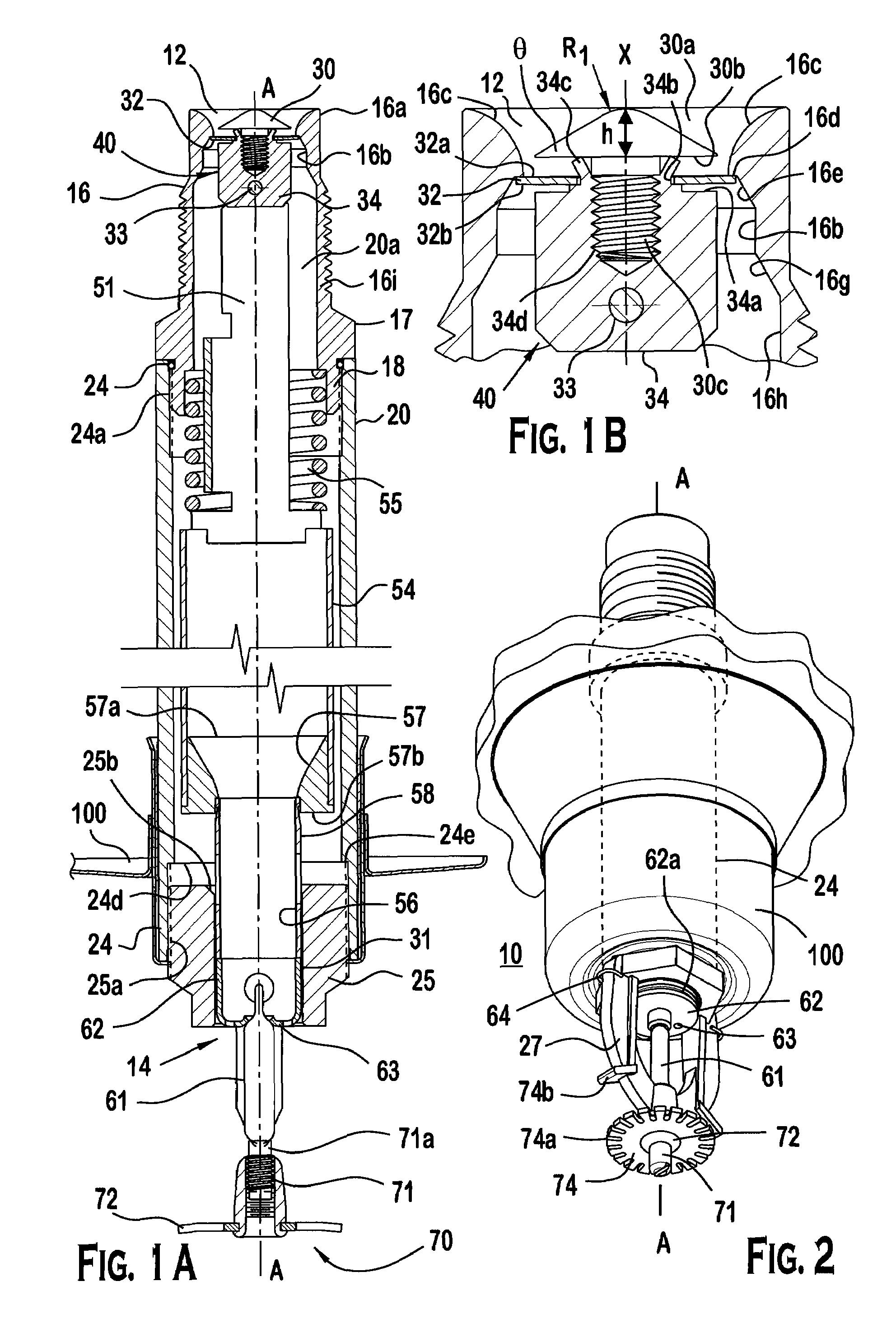

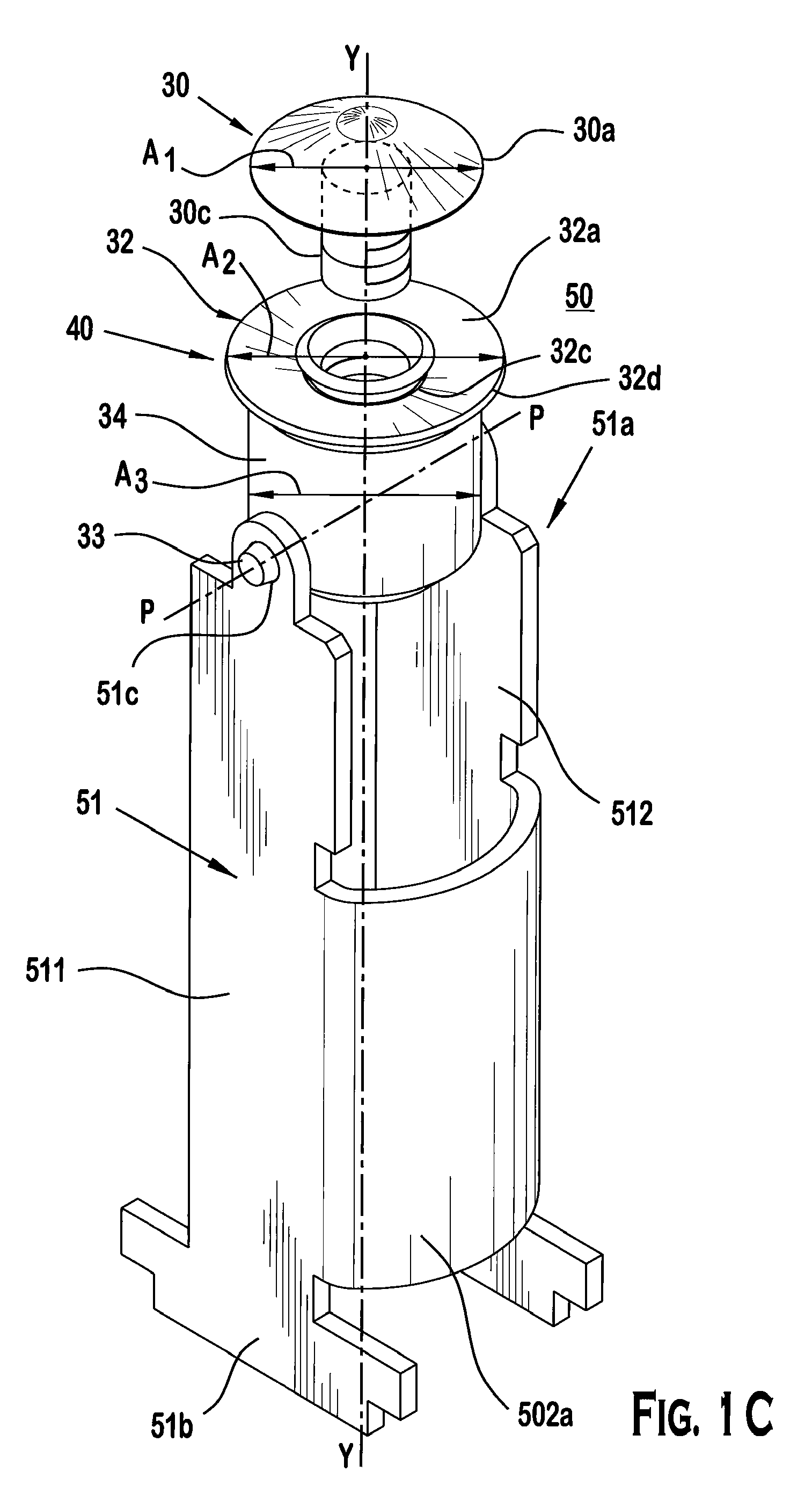

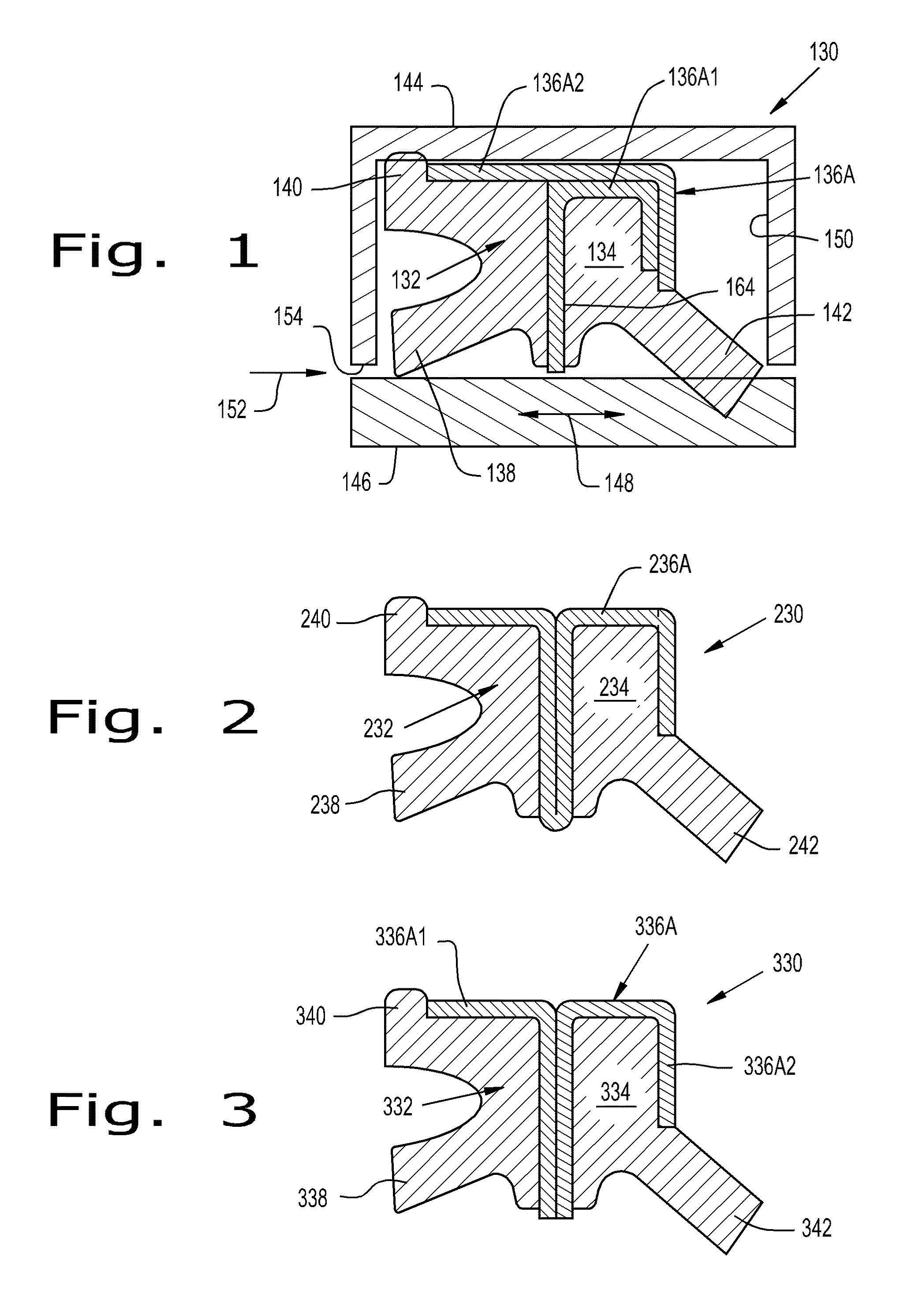

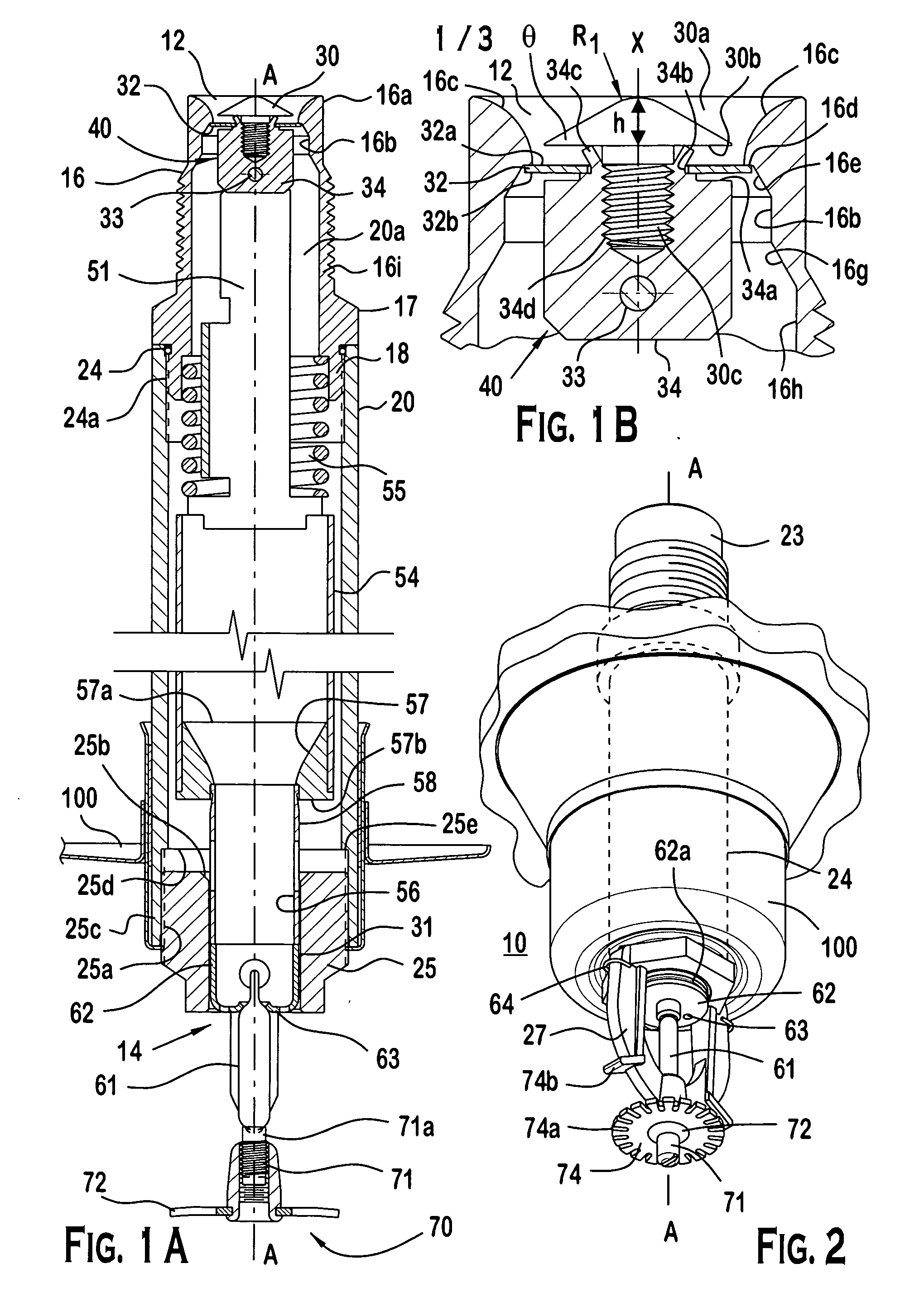

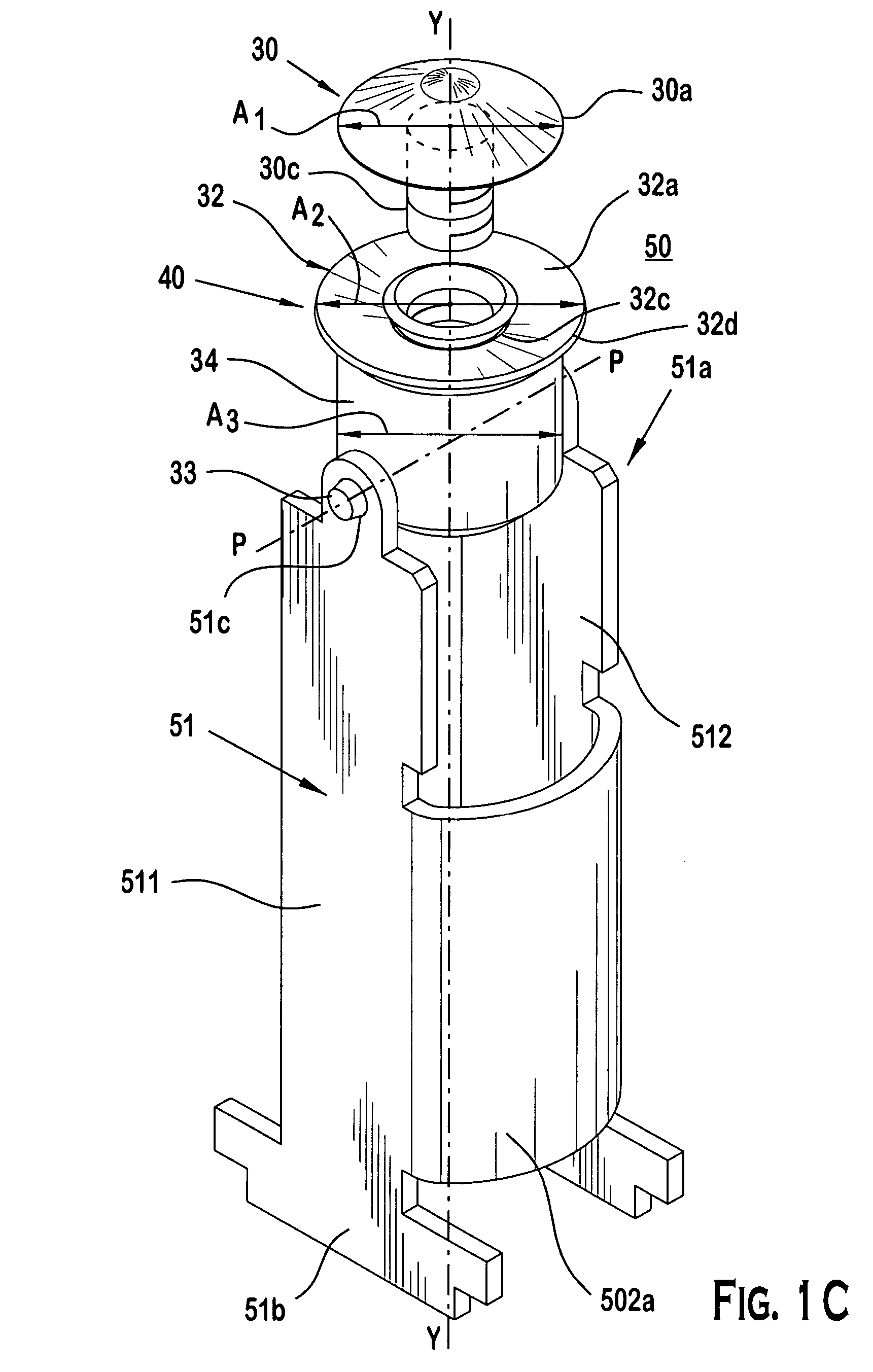

Early suppression fast response fire protection sprinkler

An early suppression fast response pendent-type fire protection sprinkler is suitable for use in accordance with one or more of NFPA 13, NFPA 231 and NFPA 231C to protect single row rack storage, double row rack storage and multiple row rack storage, the sprinkler having a K-factor of about 25 and flowing pressure of about 15 pounds per square inch. Preferably, the sprinkler has a body defining an orifice and an outlet for delivering a flow of fluid from a source, and a deflector mounted with a first surface opposed to flow of fluid from the outlet. The deflector defines at least one pair of generally opposed reentrant slots extending from the first surface through the deflector, the reentrant slots extending from slot openings at an outer peripheral edge of the deflector inwardly from the peripheral edge toward a deflector axis.

Owner:TYCO FIRE PRODS LP

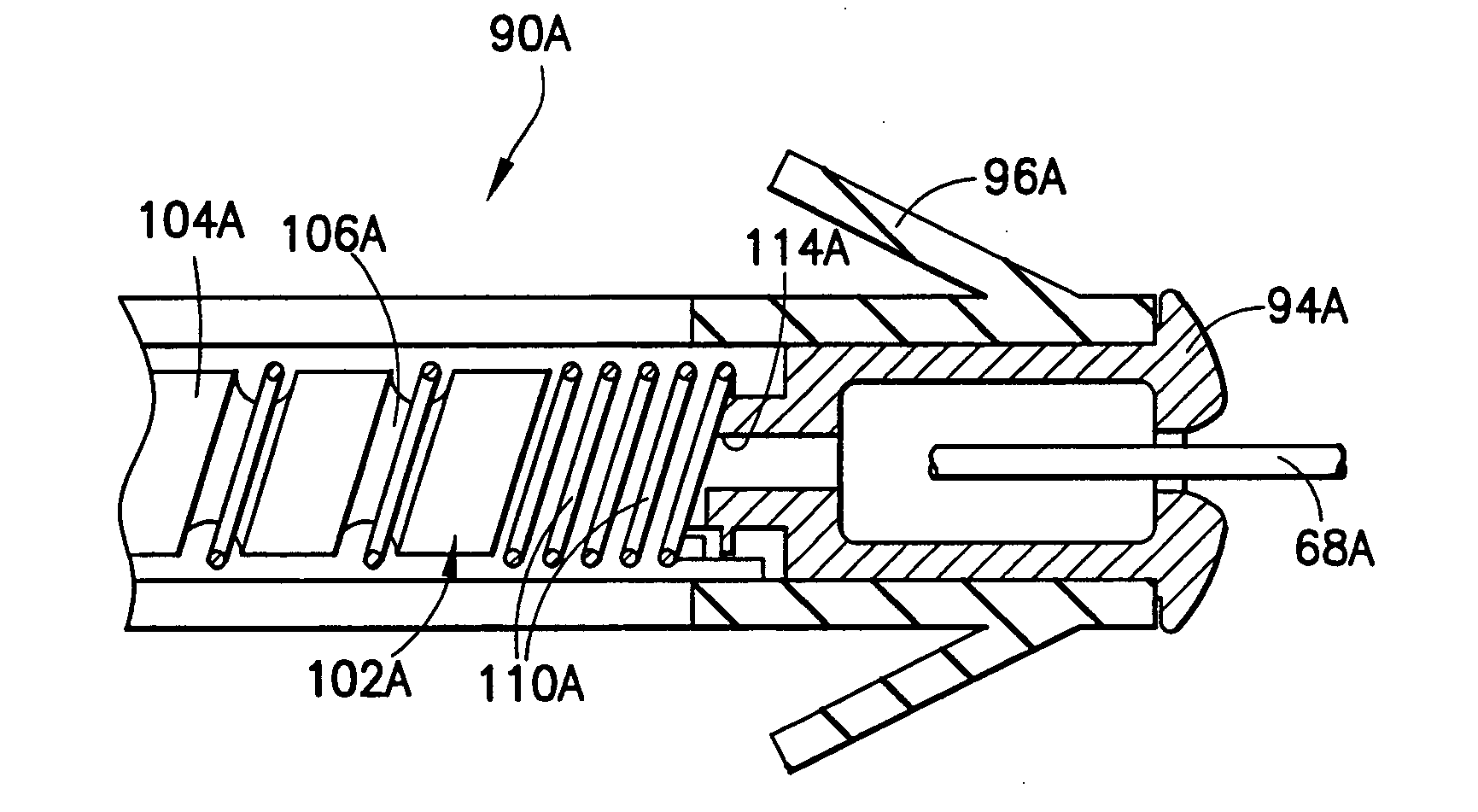

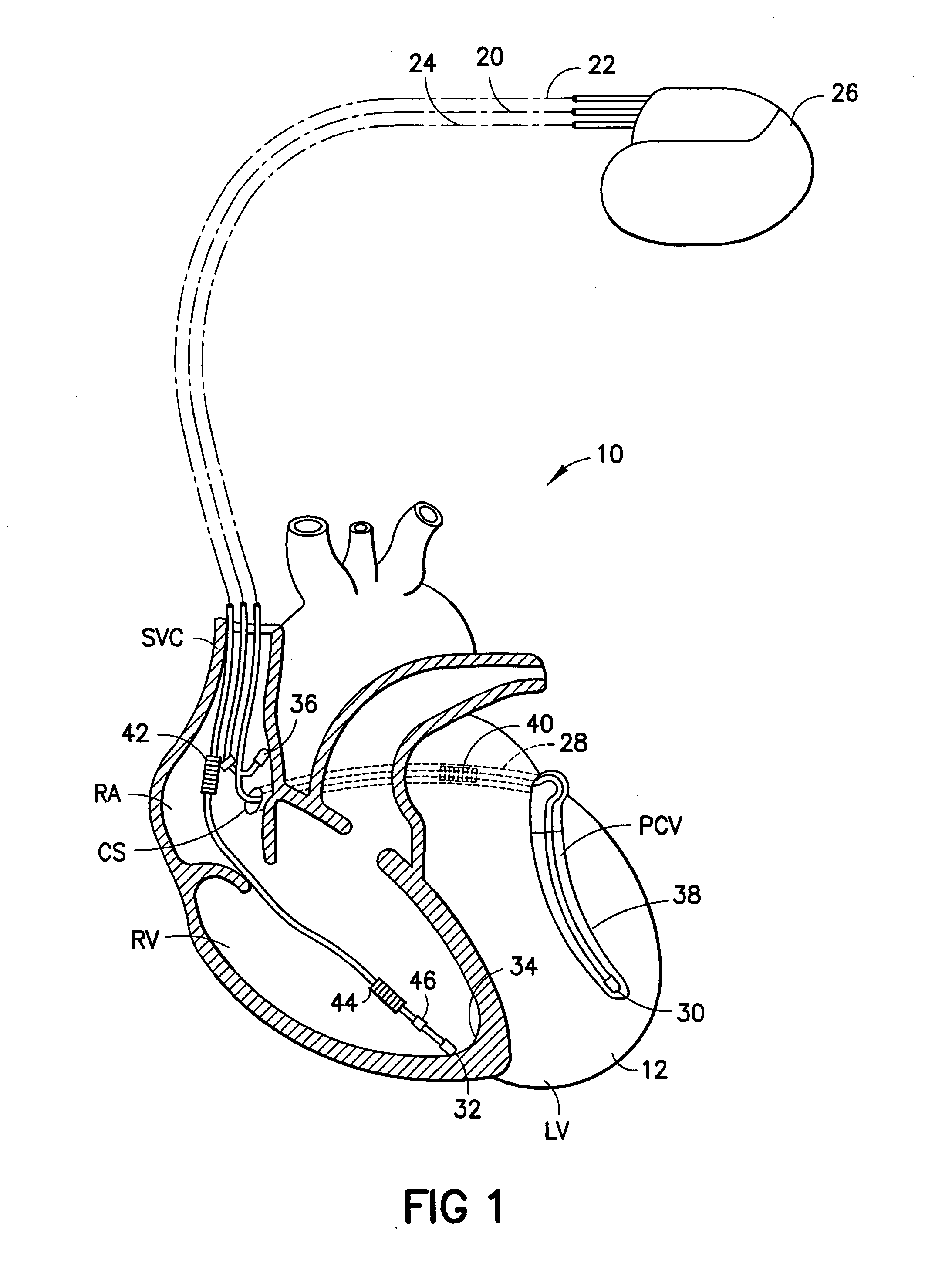

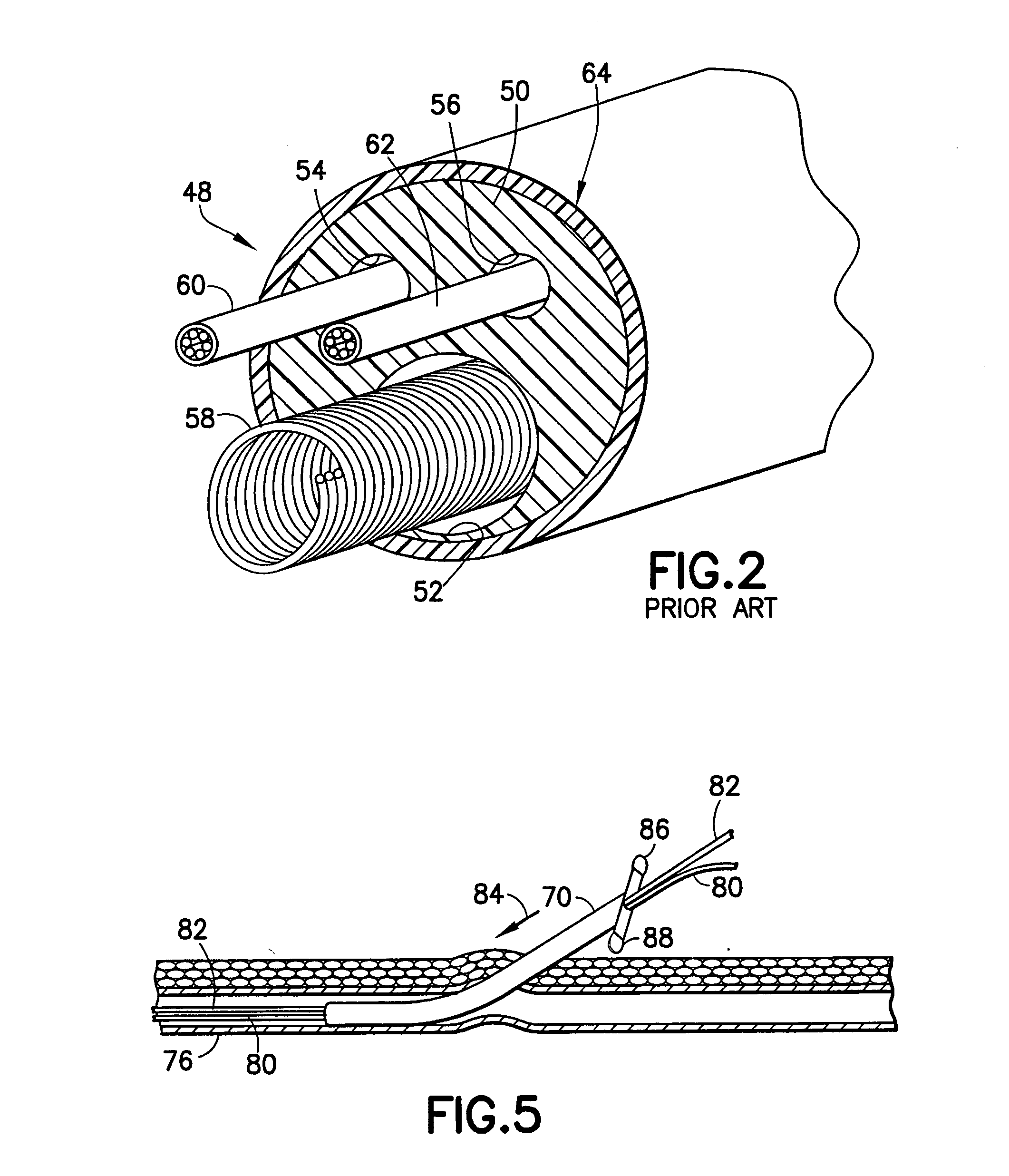

Lead body construction

InactiveUS20050080471A1Alleviate “ whip-like ” actionStiffnessTransvascular endocardial electrodesExternal electrodesElectrical conductorYoung's modulus

An implantable cardiac stimulation lead system for use with a stimulation device includes a lead body preferably having an outer diameter of less than 4 French and formed of a biocompatible material having a Young's modulus of at least 20,000 pounds per square inch. In the lead body, an inner insulator is composed of a suitable polymer such as PTFE or ETFE with an outer peripheral surface formed with a helical groove containing a conductor extending between a proximal connector and a distal tip electrode, and an outer insulator composed of polyurethane or silicone rubber or a combination thereof is positioned around the inner insulator. The lead system may be formed with a lumen for receiving a guidewire longitudinally through the lead body. A pair of insulated conductors may be received in the helical groove, one extending to the distal tip electrode, the other extending to a ring electrode proximally spaced from the distal tip electrode.

Owner:PACESETTER INC

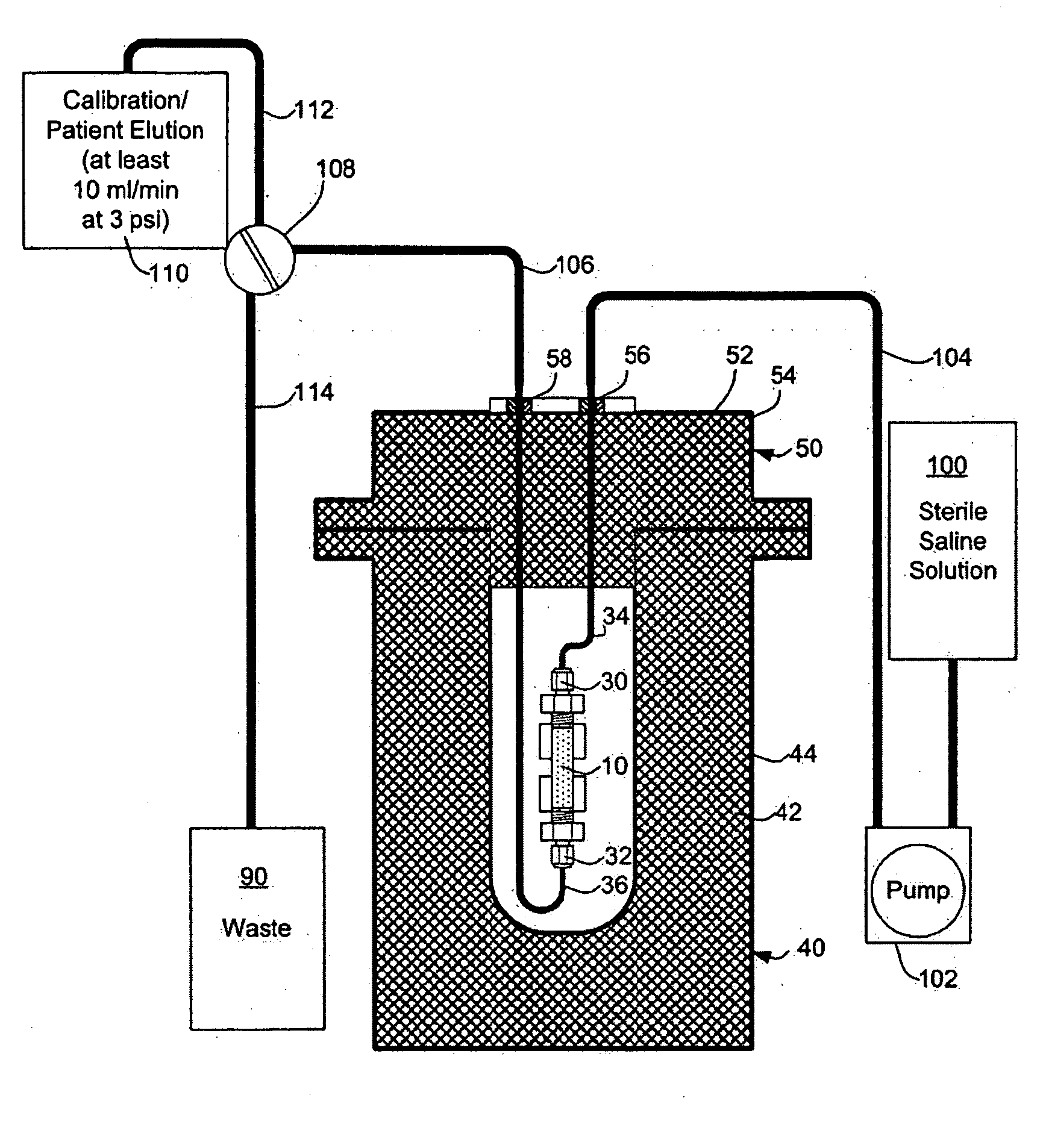

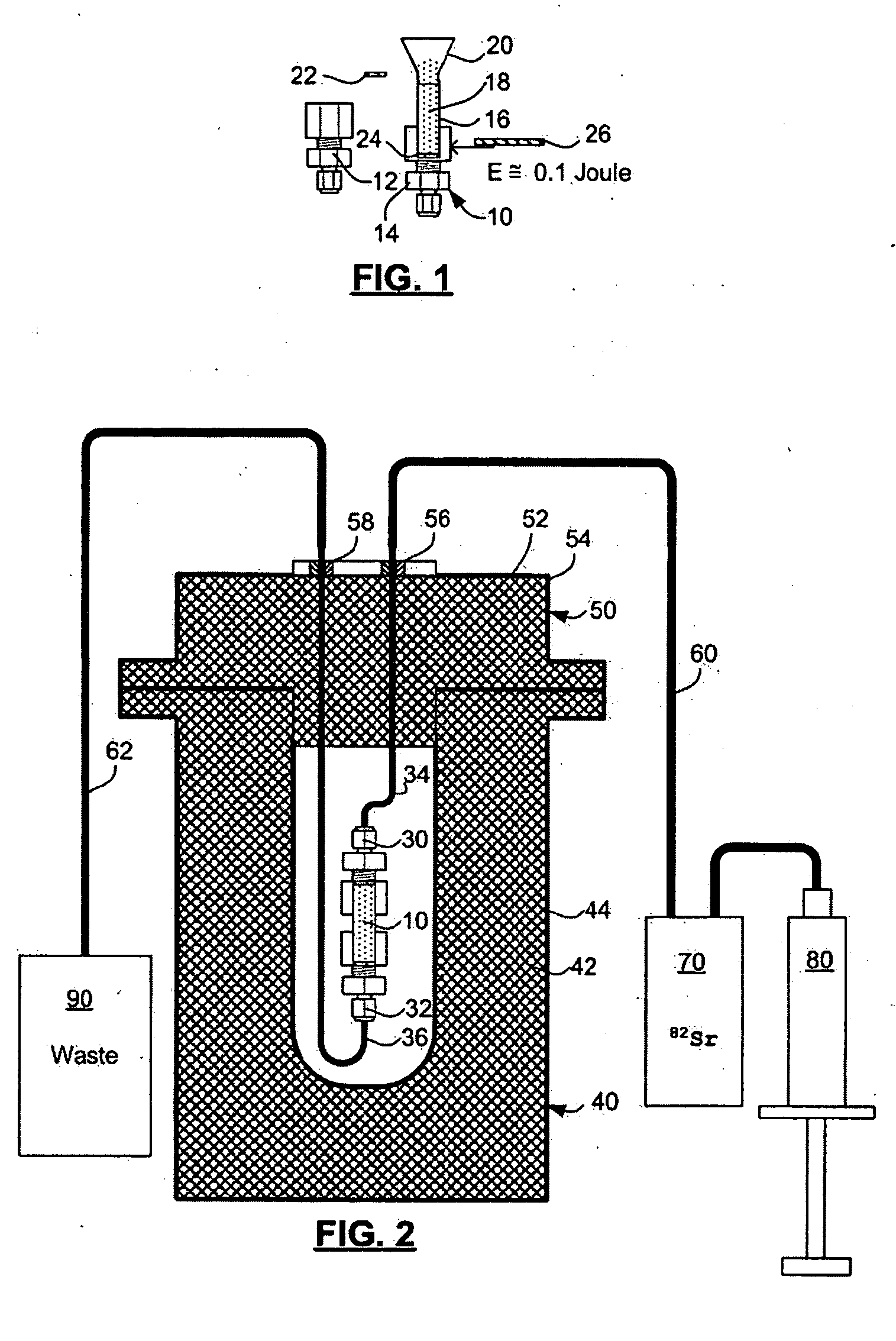

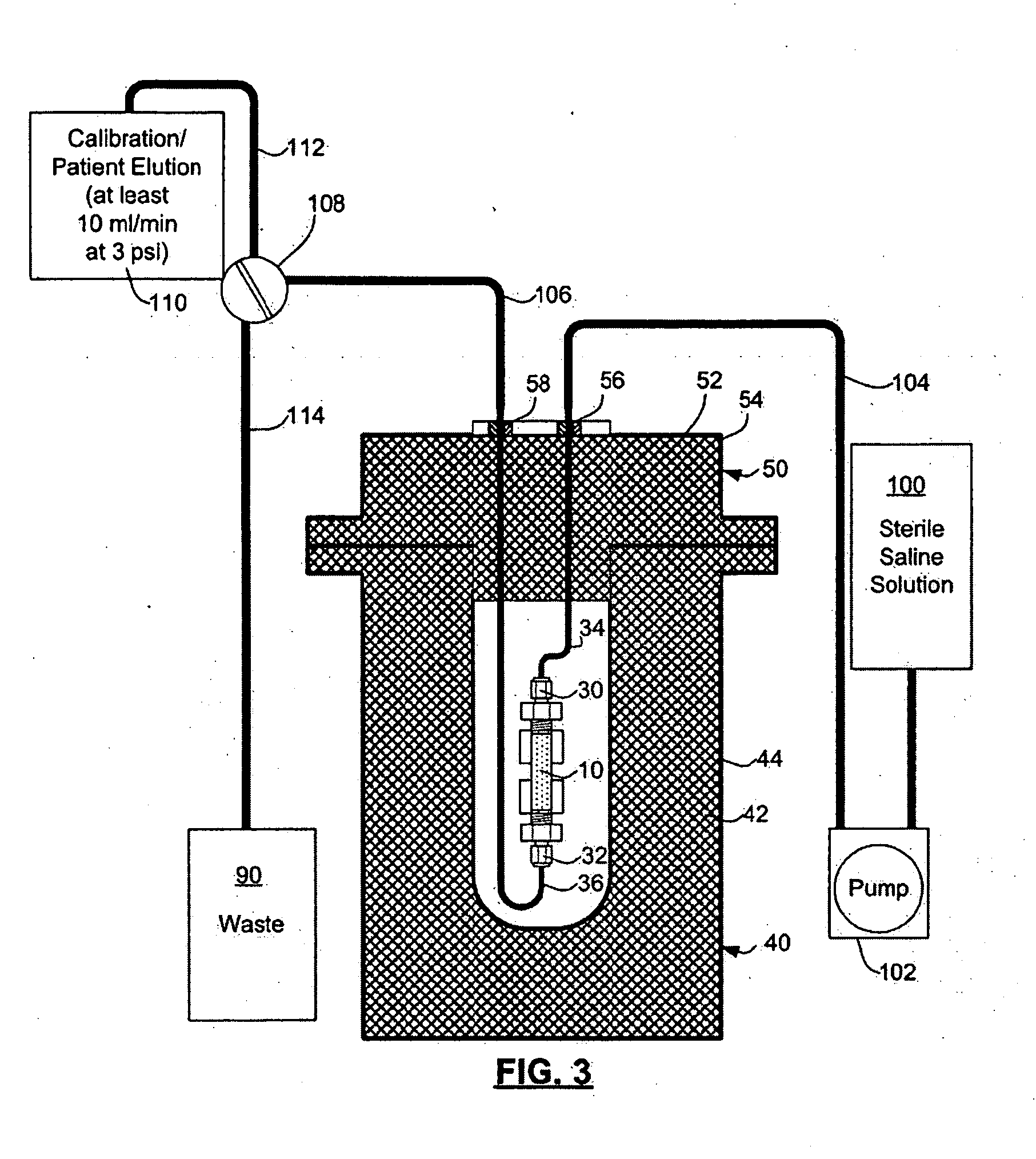

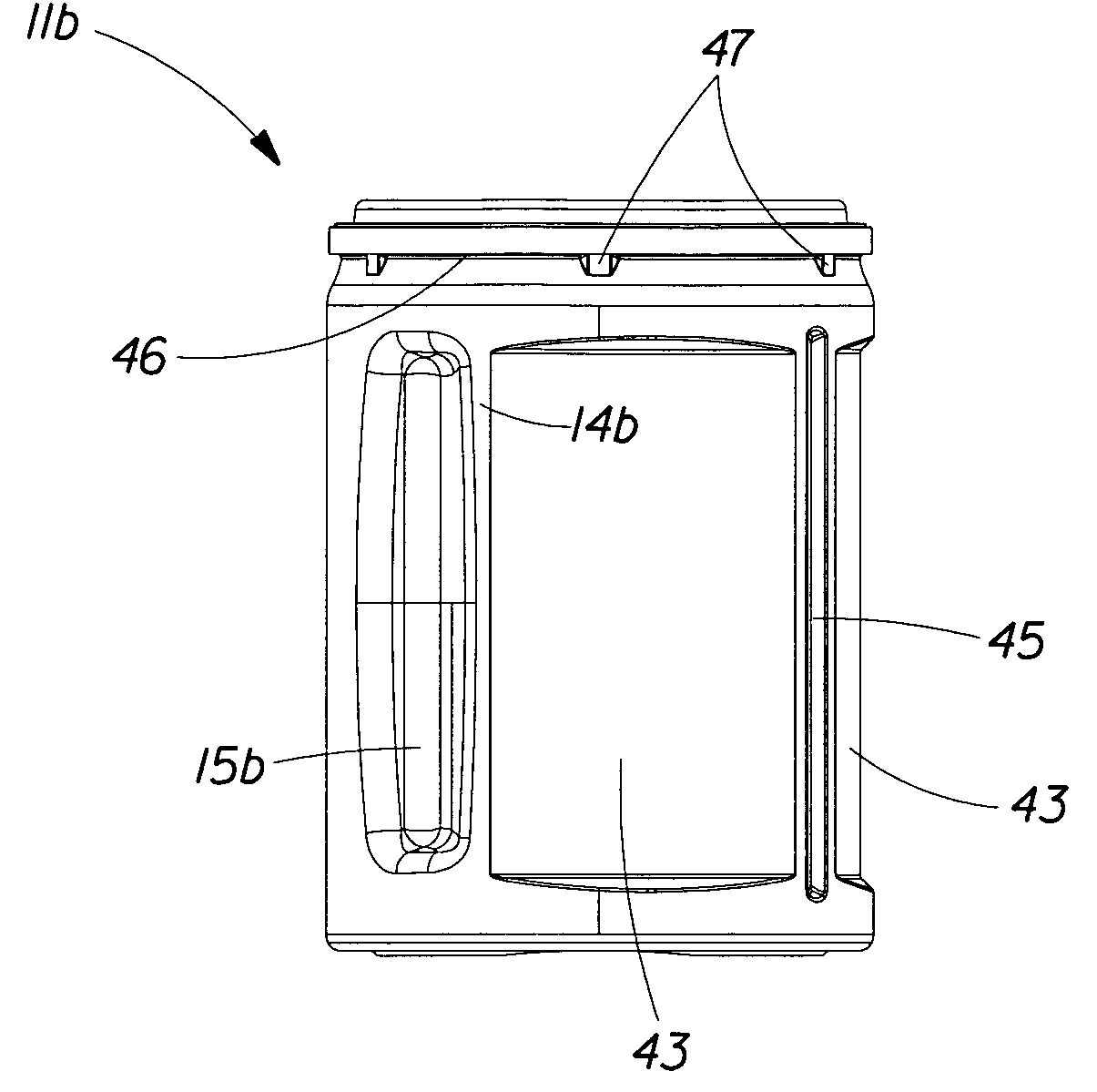

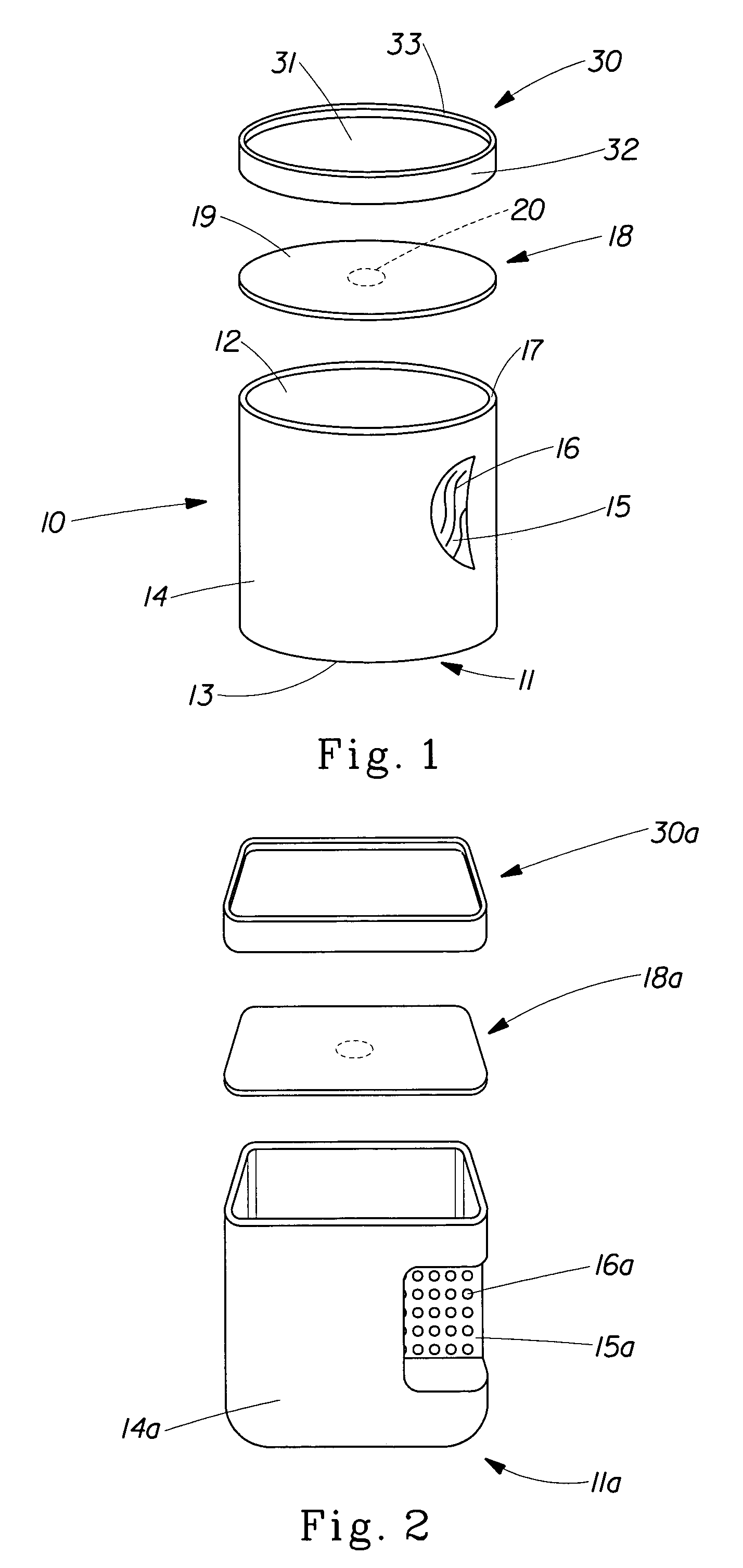

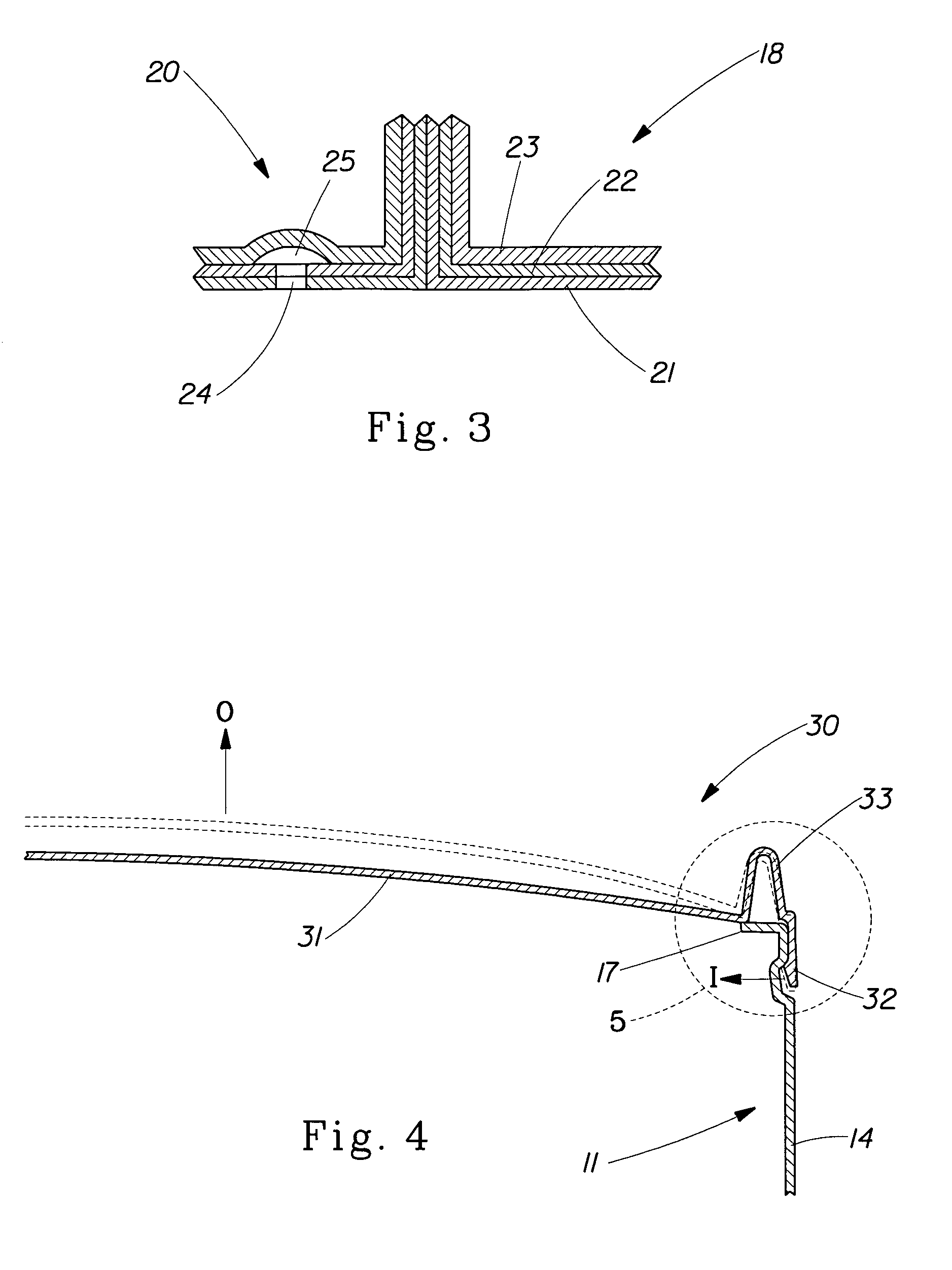

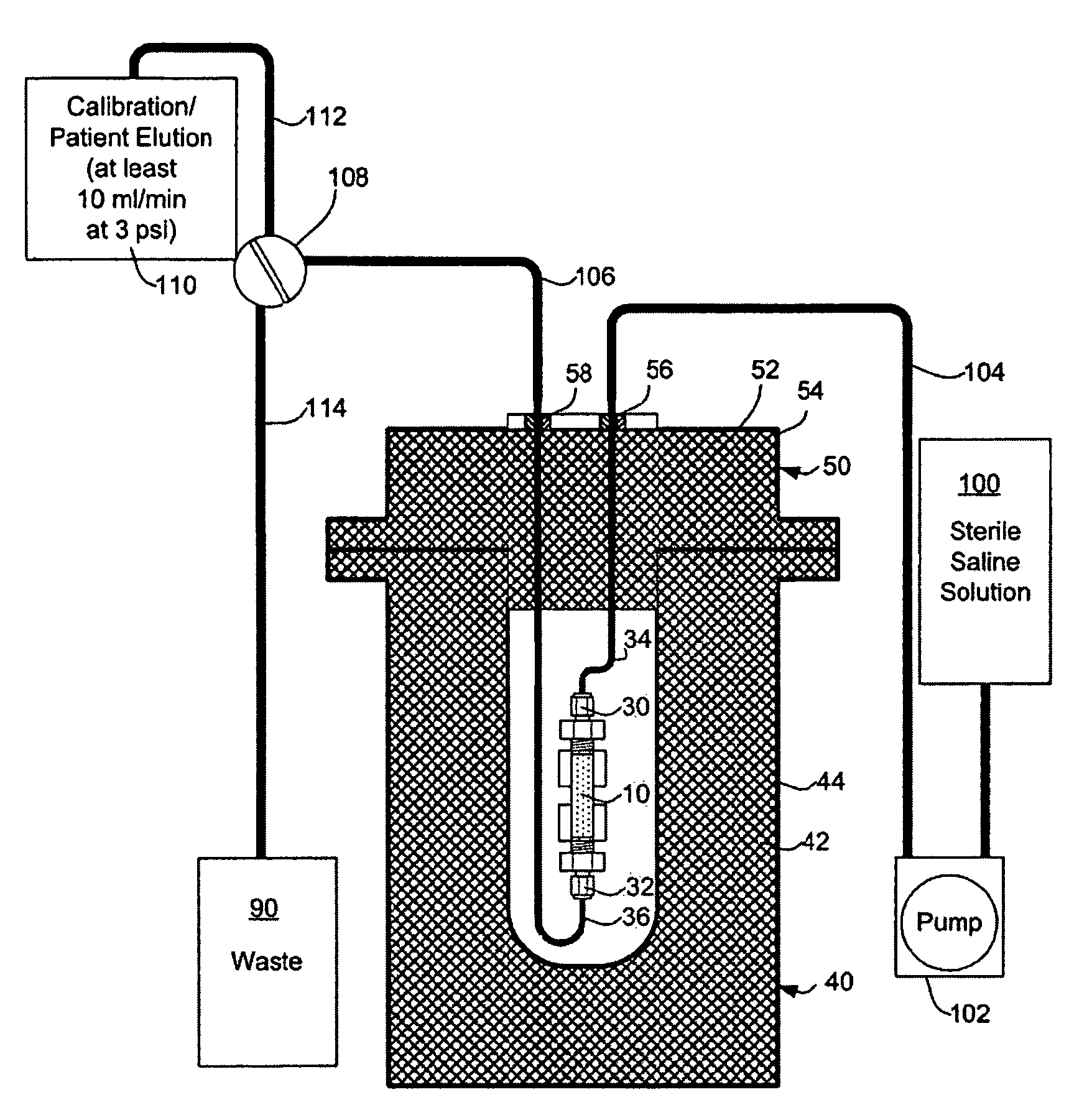

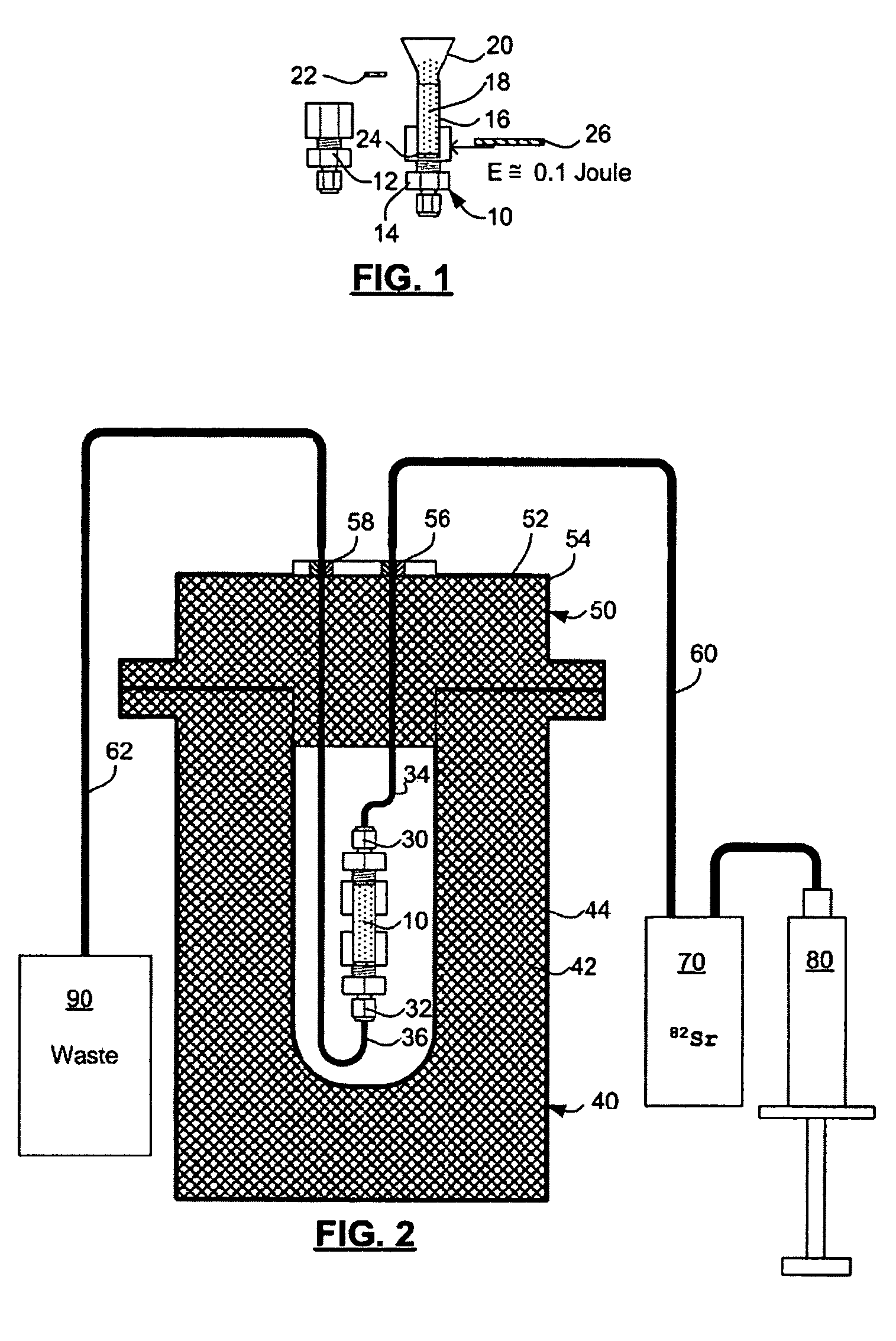

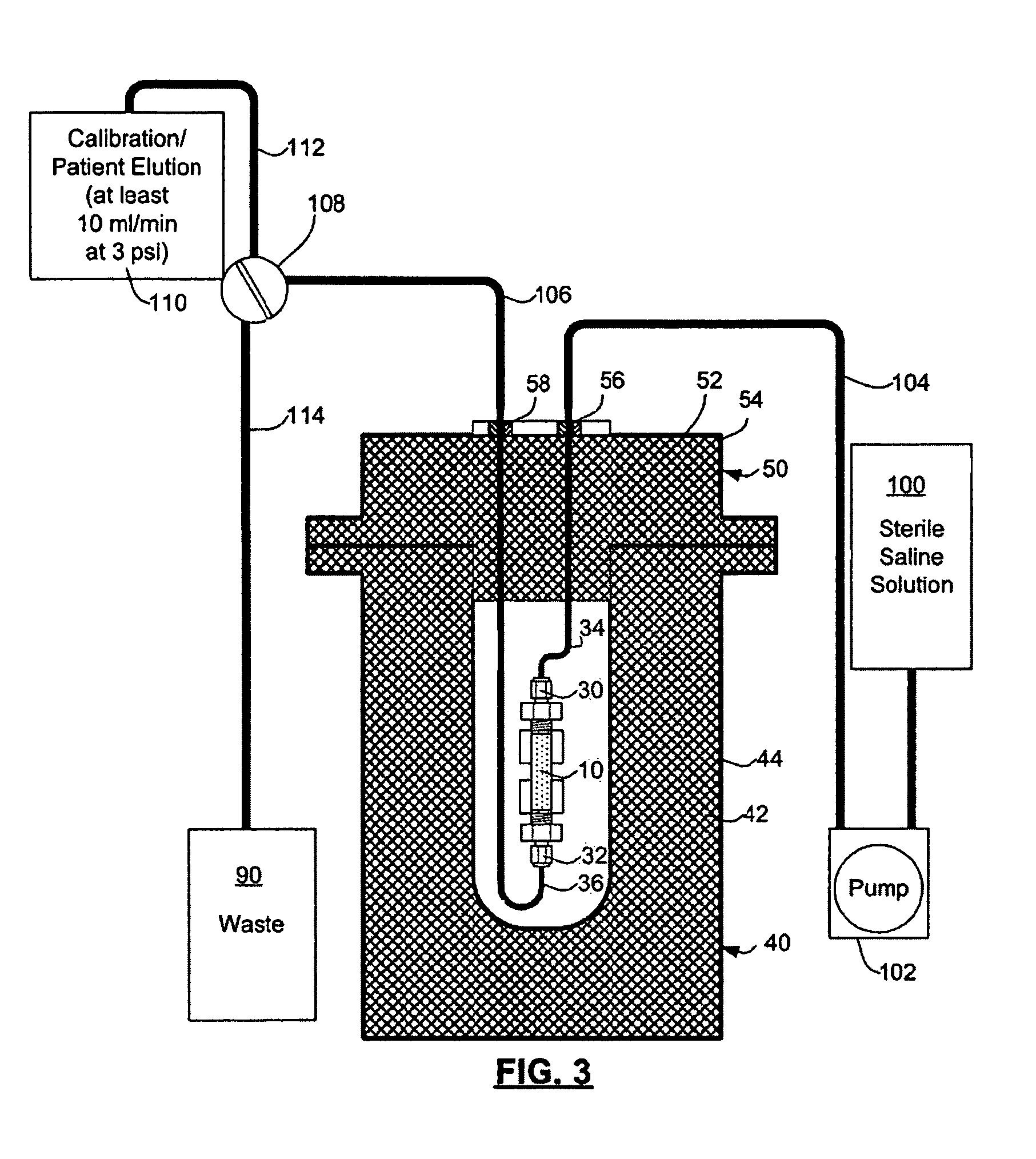

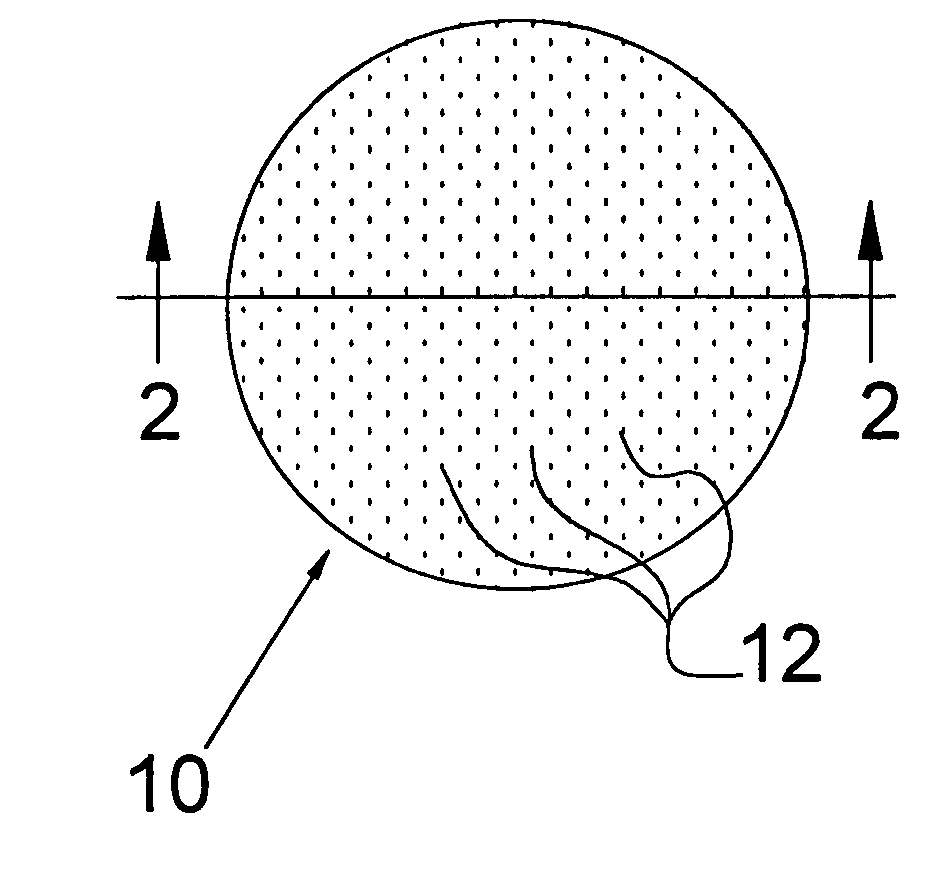

Rubidium generator for cardiac perfusion imaging and method of making and maintaining same

ActiveUS20070140958A1Low pressure elutionFacilitates precision flow controlIn-vivo radioactive preparationsConversion outside reactor/acceleratorsFractographyRubidium

An 82Sr / 82Rb generator column is made using a fluid impervious cylindrical container having a cover for closing the container in a fluid tight seal, and further having an inlet for connection of a conduit for delivering a fluid into the container and an outlet for connection of a conduit for conducting the fluid from the container. An ion exchange material fills the container, the ion exchange material being compacted within the container to a density that permits, the ion exchange material to be eluted at a rate of at least 5 ml / min at a fluid pressure of 1.5 pounds per square inch (10 kPa). The generator column can be repeatedly recharged with 82Sr. The generator column is compatible with either three-dimensional or two-dimensional positron emission tomography systems.

Owner:OTTAWA HEART INST RES

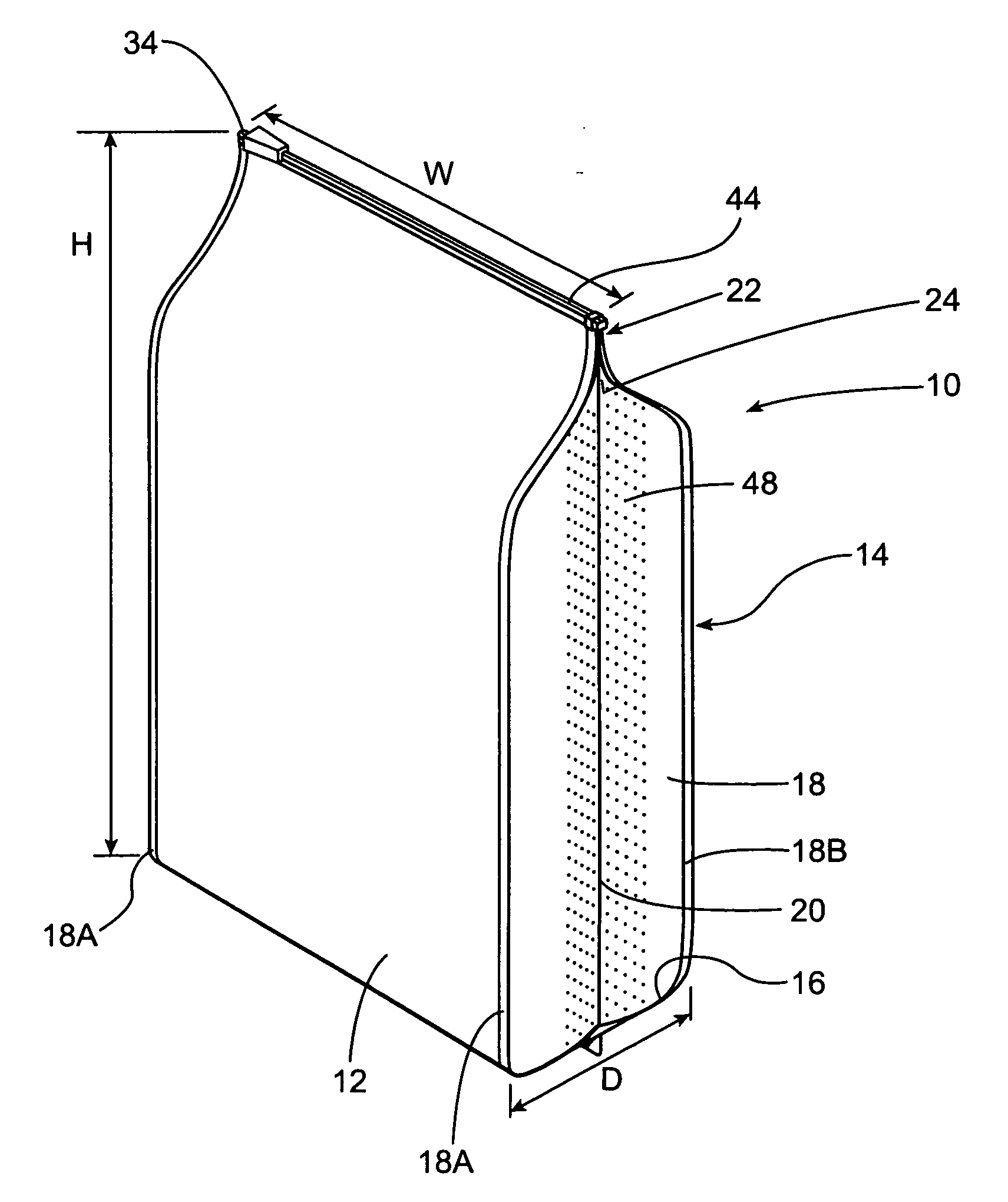

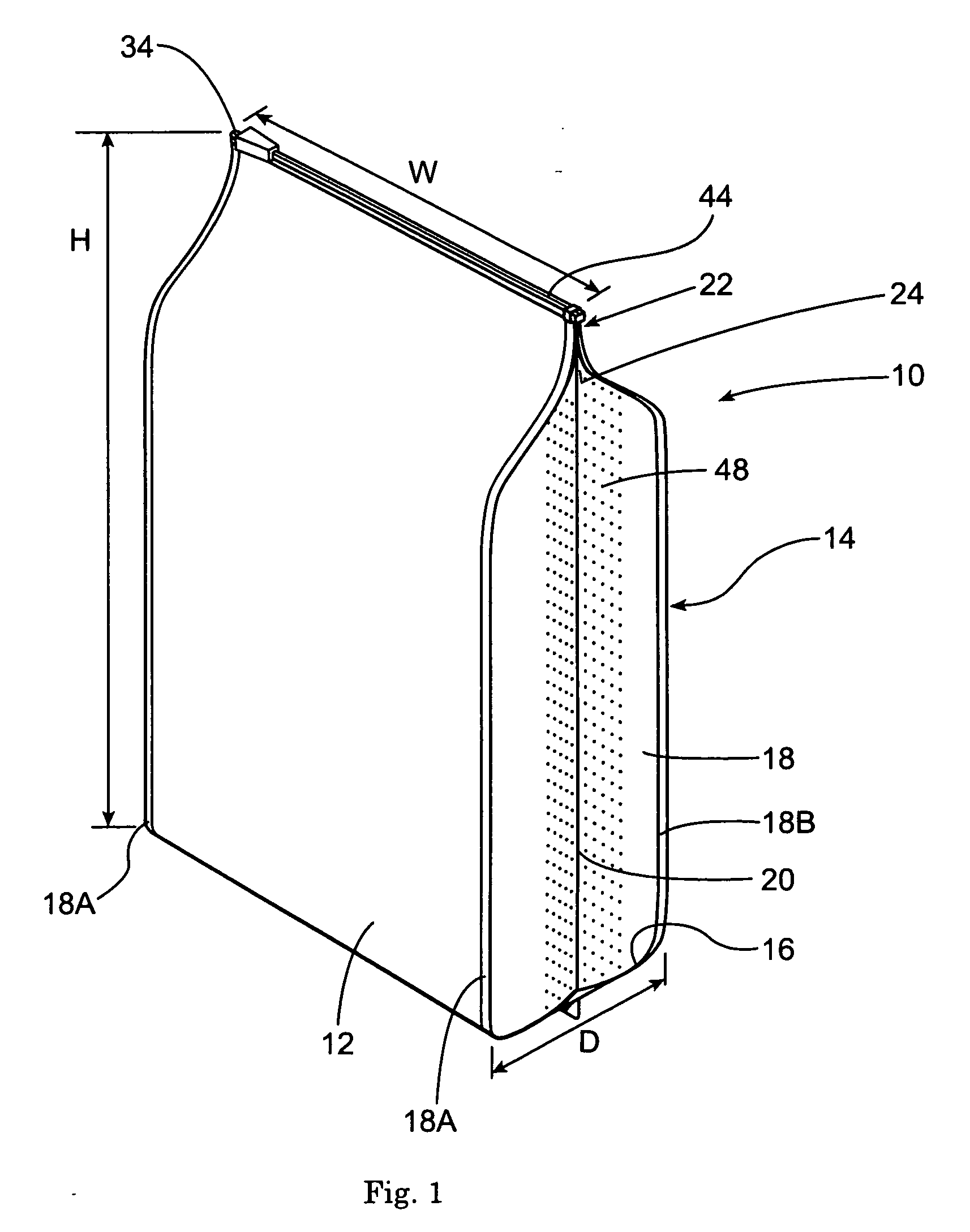

Packaging system to provide fresh packed coffee

A fresh packaging system for roast and ground coffee having a top load capacity of at least about 16 pounds (7.3 Kg) comprising a container with a closed bottom, an open top, and a body enclosing a perimeter between the bottom and the top. A protuberance is continuously disposed around the perimeter of the body proximate to the top and forms a ridge external to the body. A flexible closure is removeably attached and sealed to the protuberance so that the closure seals the interior volume of the container. The container bottom and container body are constructed from a material having a tensile modulus number ranging from at least about 35,000 to at least about 650,000 pounds per square inch (at least about 2,381 to at least about 44,230 atm).

Owner:THE PROCTER & GAMBLE COMPANY +3

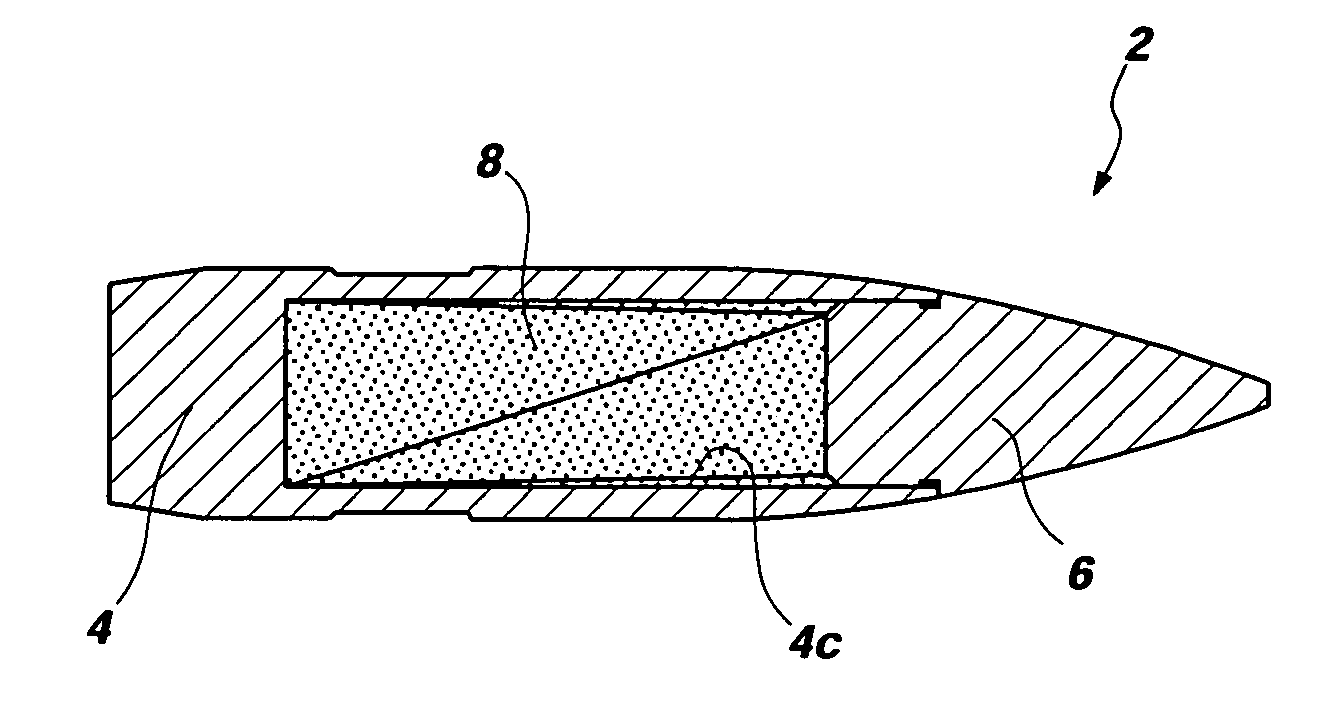

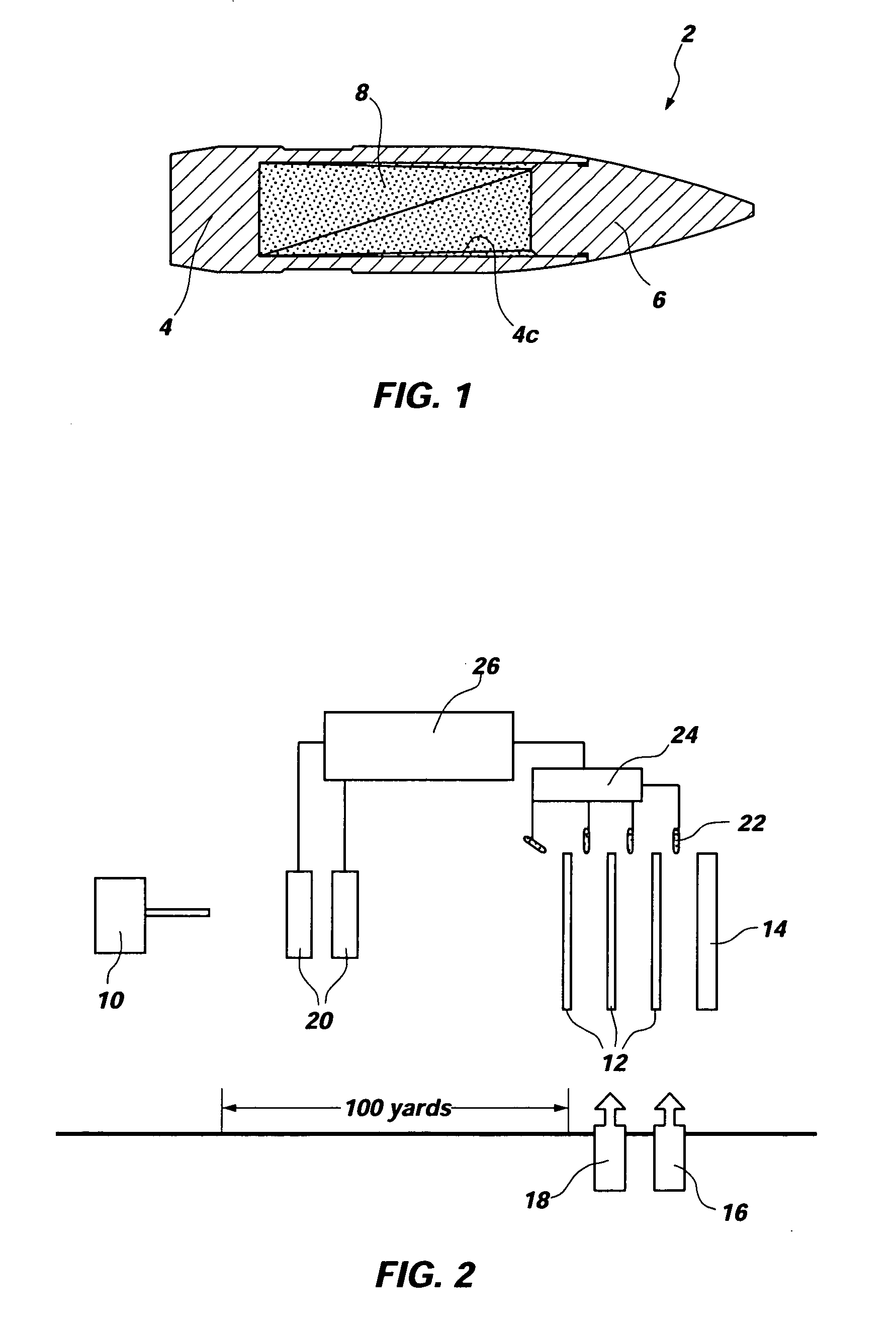

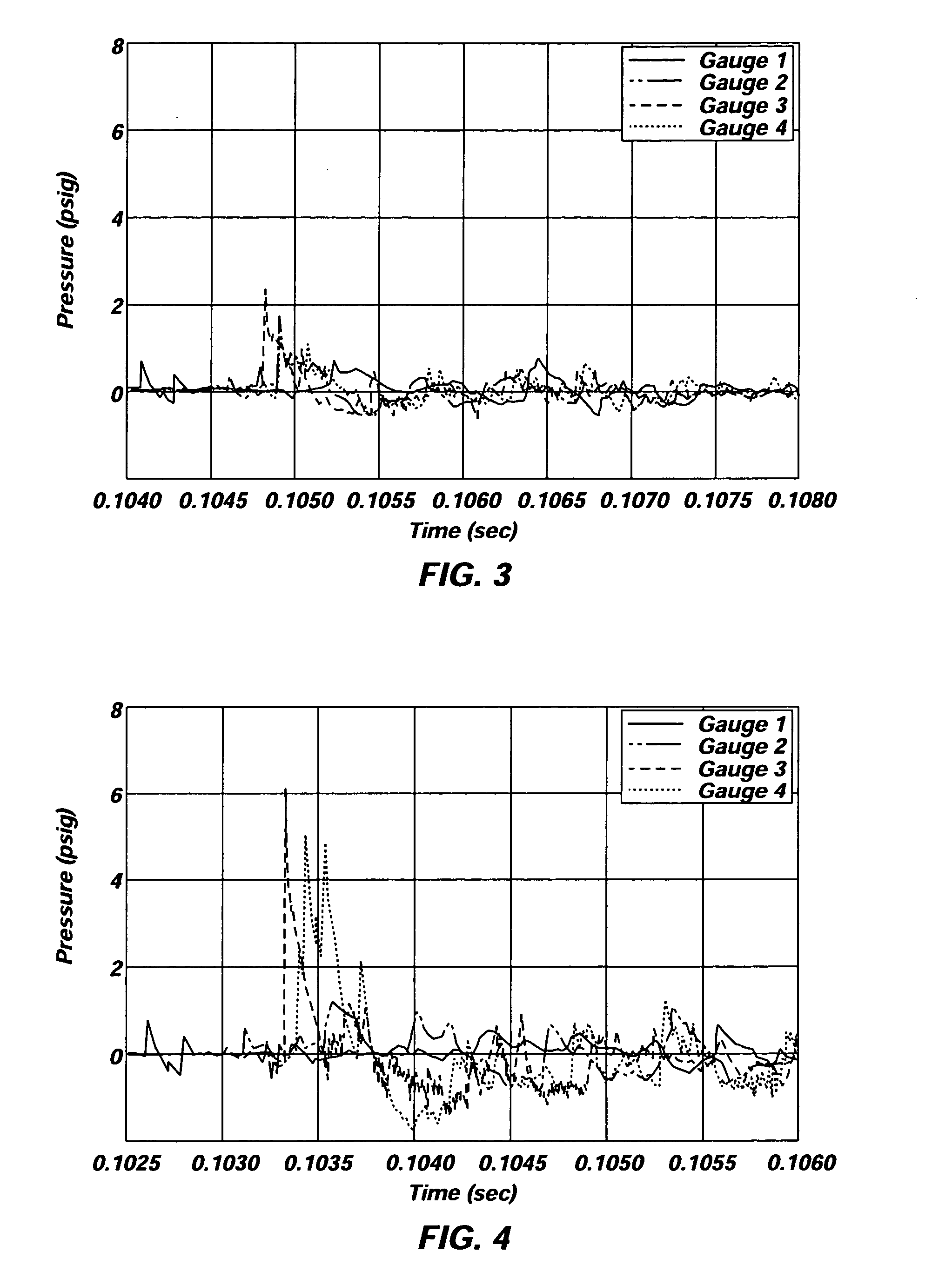

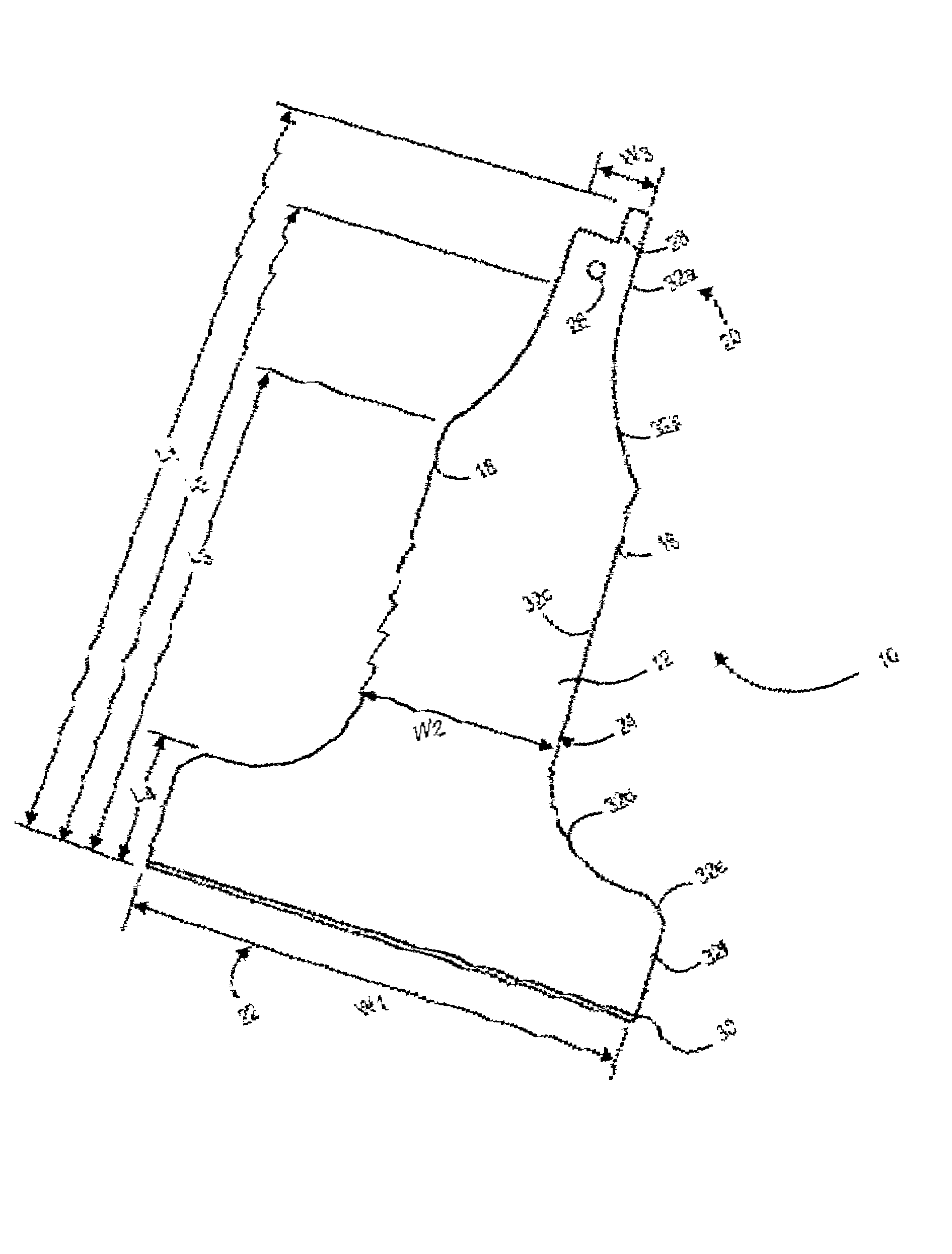

Reactive material enhanced munition compositions and projectiles containing same

A reactive material that includes at least one of a fuel, an oxidizer, and a class 1.1 explosive and is formulated for use in a reactive material projectile. The reactive material is formulated to provide at least one of an overpressure of greater than approximately 9 pounds per square inch at a radial measurement of 12 inches from a point of impact on a target, a hole greater than approximately 2 square inches at an optimum penetration level in a target, and pressure, damage, and a flame when the reactive material bullet impacts a target. The fuel may be a metal, a fusible metal alloy, an organic fuel, or mixtures thereof. The oxidizer may be an inorganic oxidizer, sulfur, a fluoropolymer, or mixtures thereof. A reactive material projectile having the reactive material disposed therein is also disclosed.

Owner:ORBITAL ATK INC

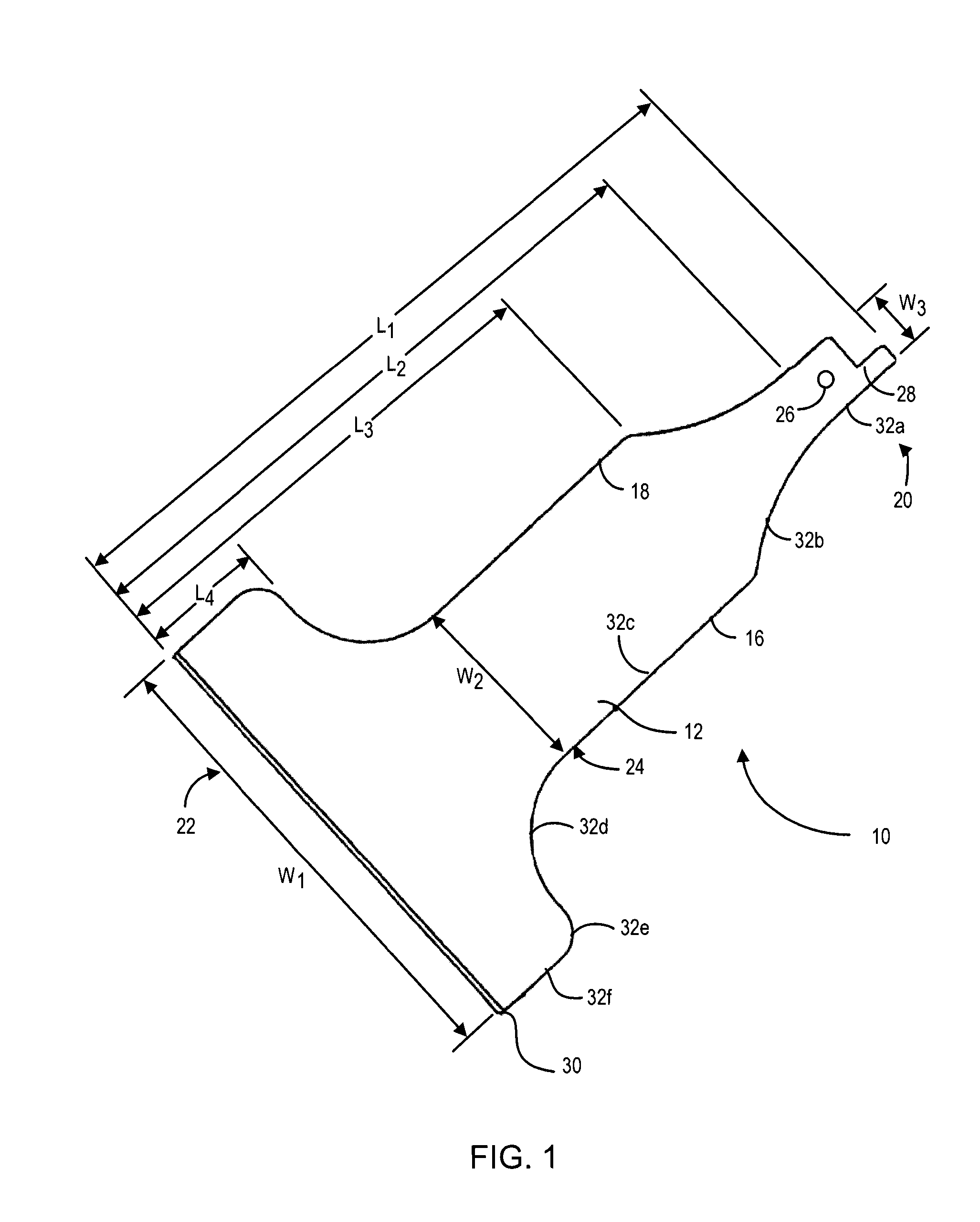

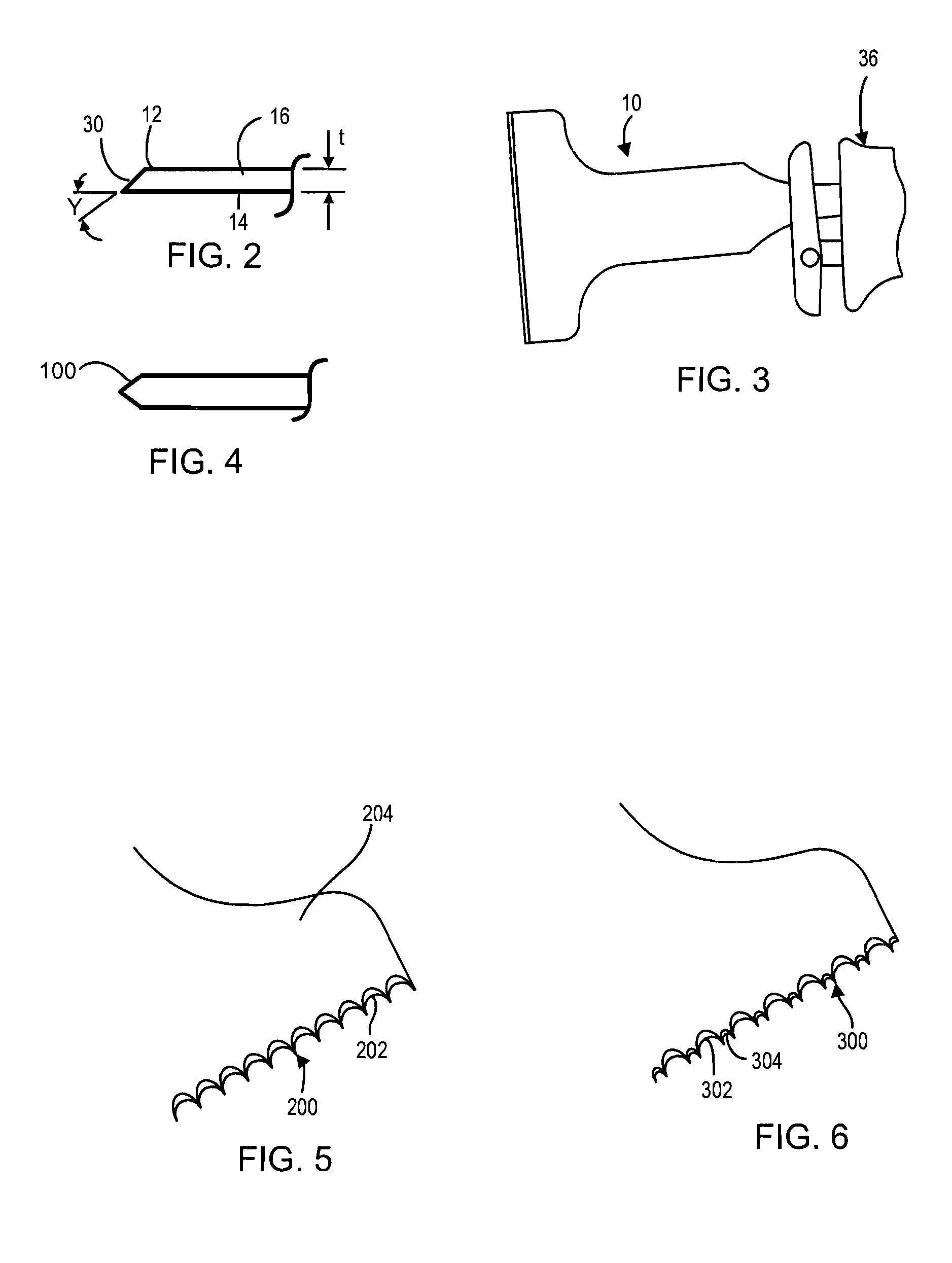

Scraper Blade

InactiveUS20090320299A1Easy to convertLow costCleaning using toolsOther artistic work equipmentsManganeseHardness

A scraper blade preferably configured for use with a reciprocating saw. The blade has a first end comprising a mounting structure, and a second end with a cutting edge. The second end is coupled with and spaced apart from the first end. Preferably, the first end is configured to be mounted in a reciprocating saw chuck and the first and second ends are integral. Further, the first and second ends are preferably manufactured from heat treated steel comprising between approximately 0.45 to 1.05% carbon and between approximately 0.3 to 1.0% manganese. Preferably, the steel has a yield tensile strength of between approximately 150,000 to 250,000 pounds per square inch, a modulus of elasticity of between approximately 20,000 to 40,000 kilopounds per square inch, and a hardness on the Rockwell C scale of between approximately 30 to 60.

Owner:SM PRODS

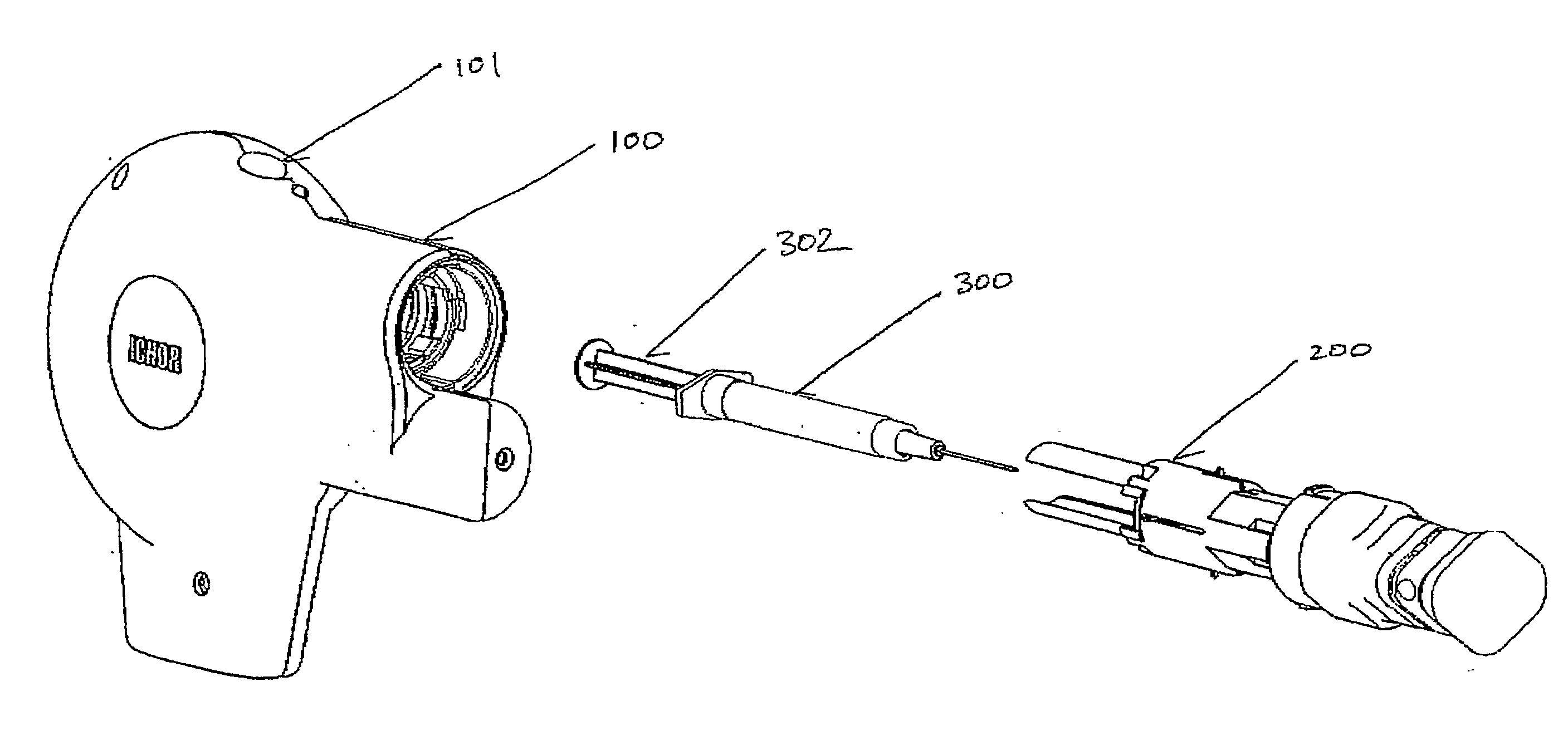

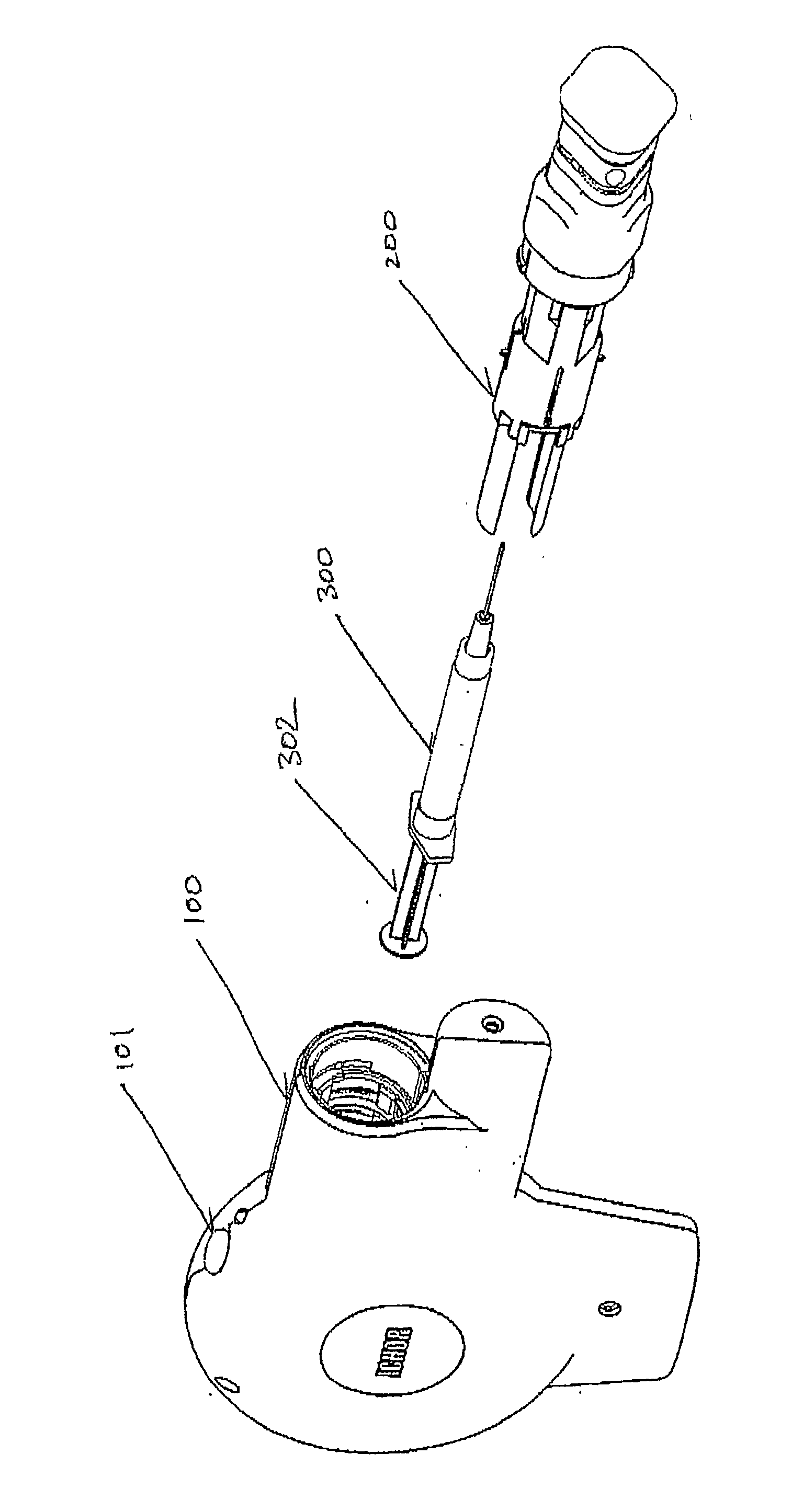

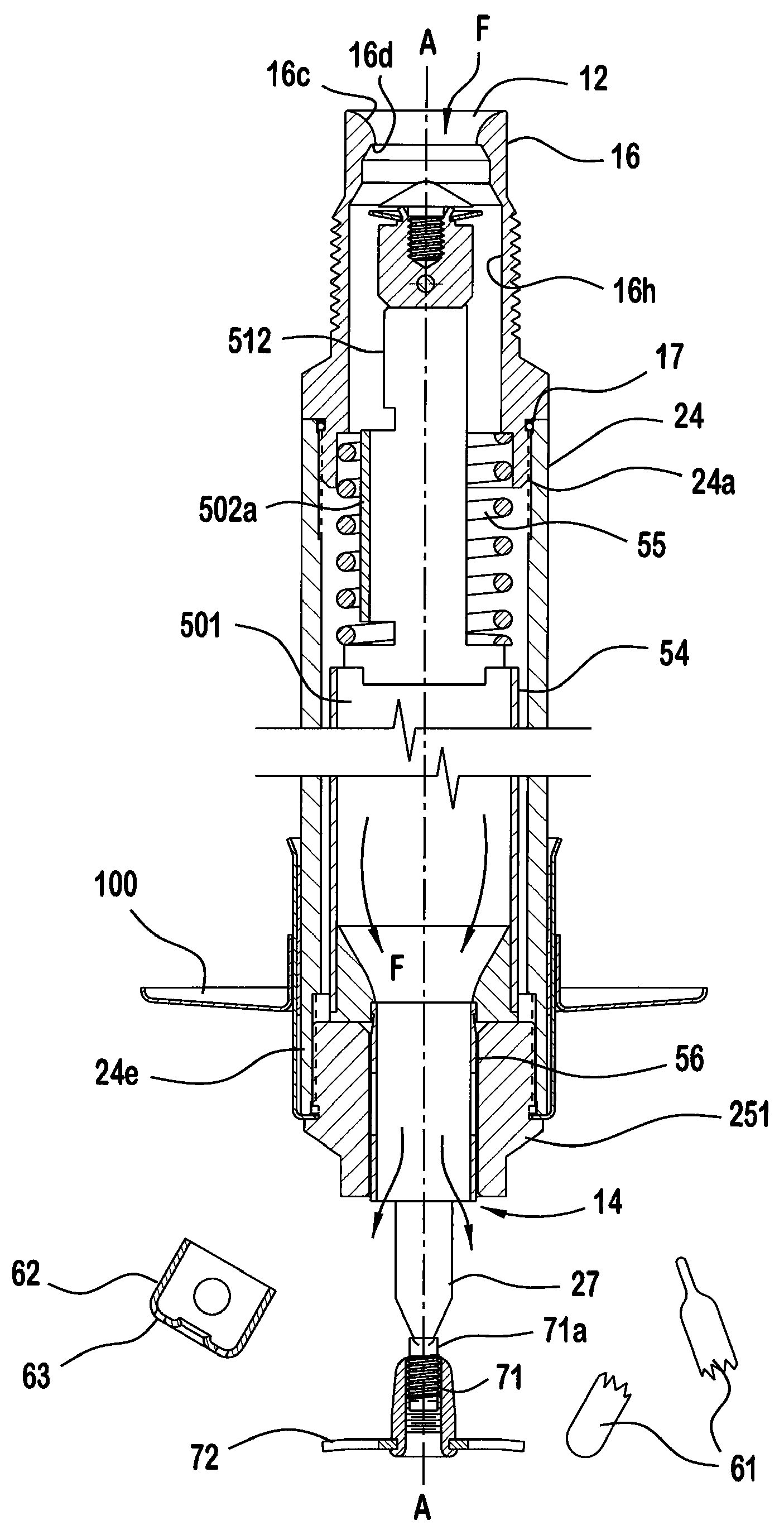

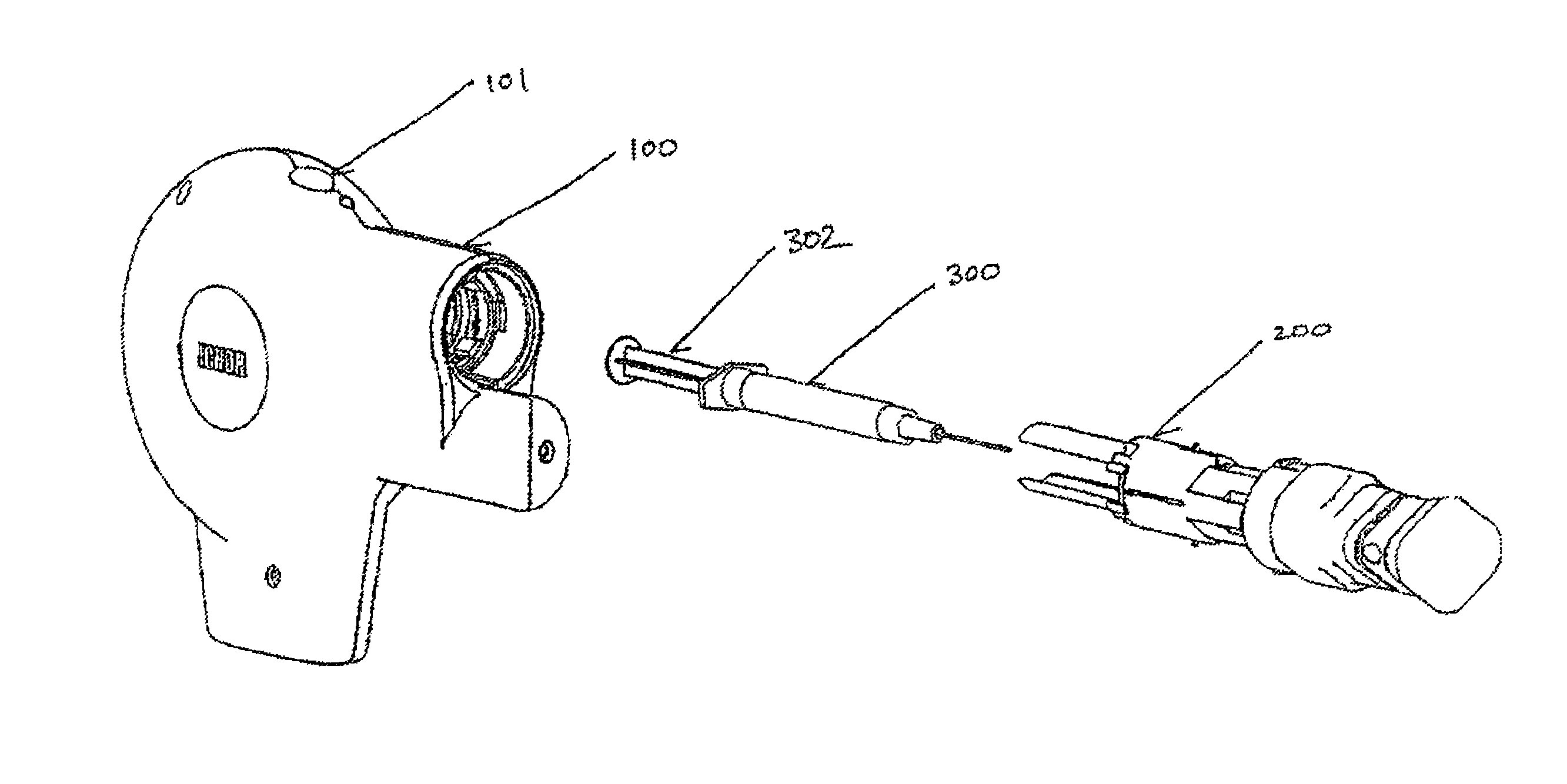

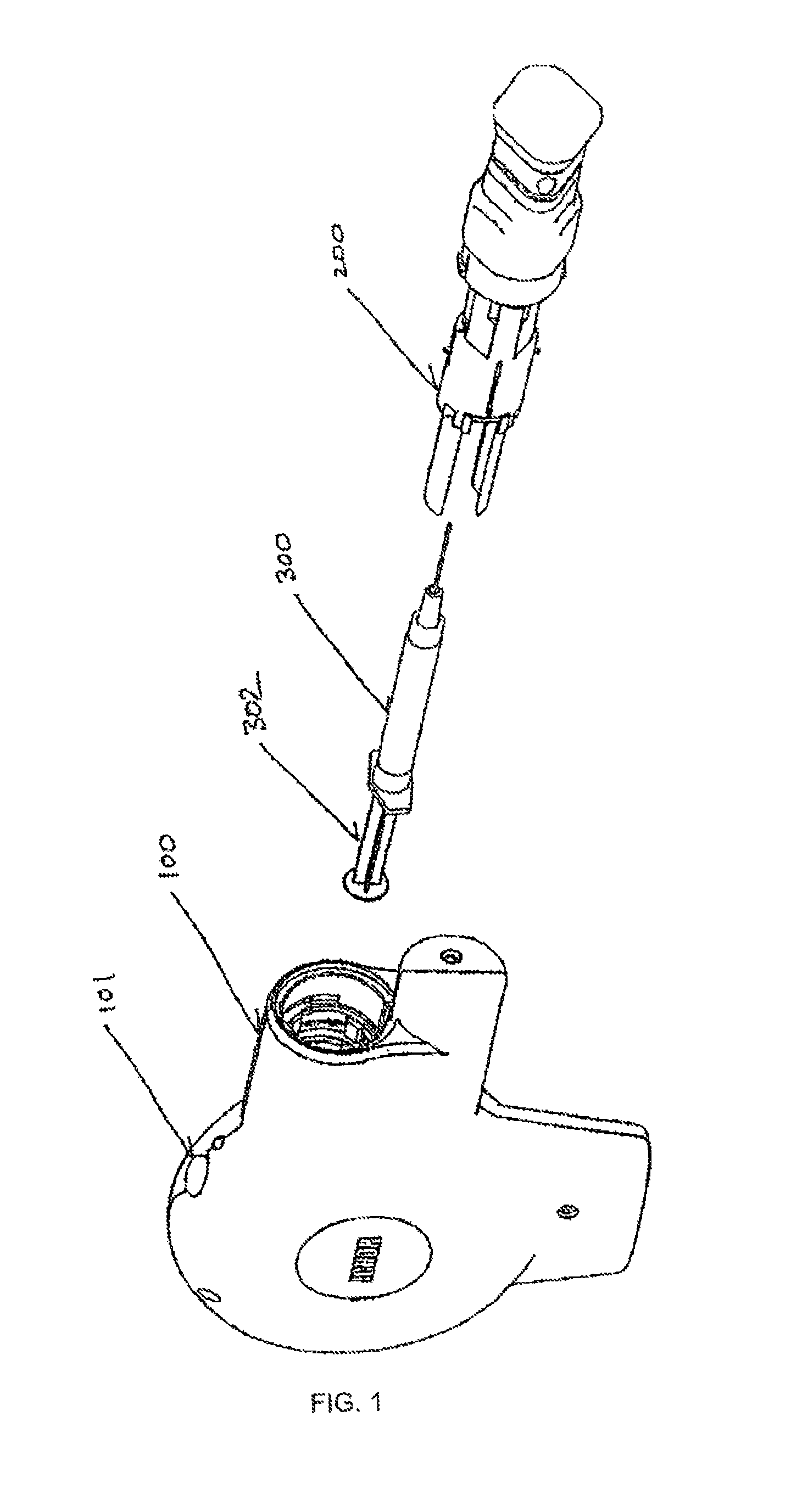

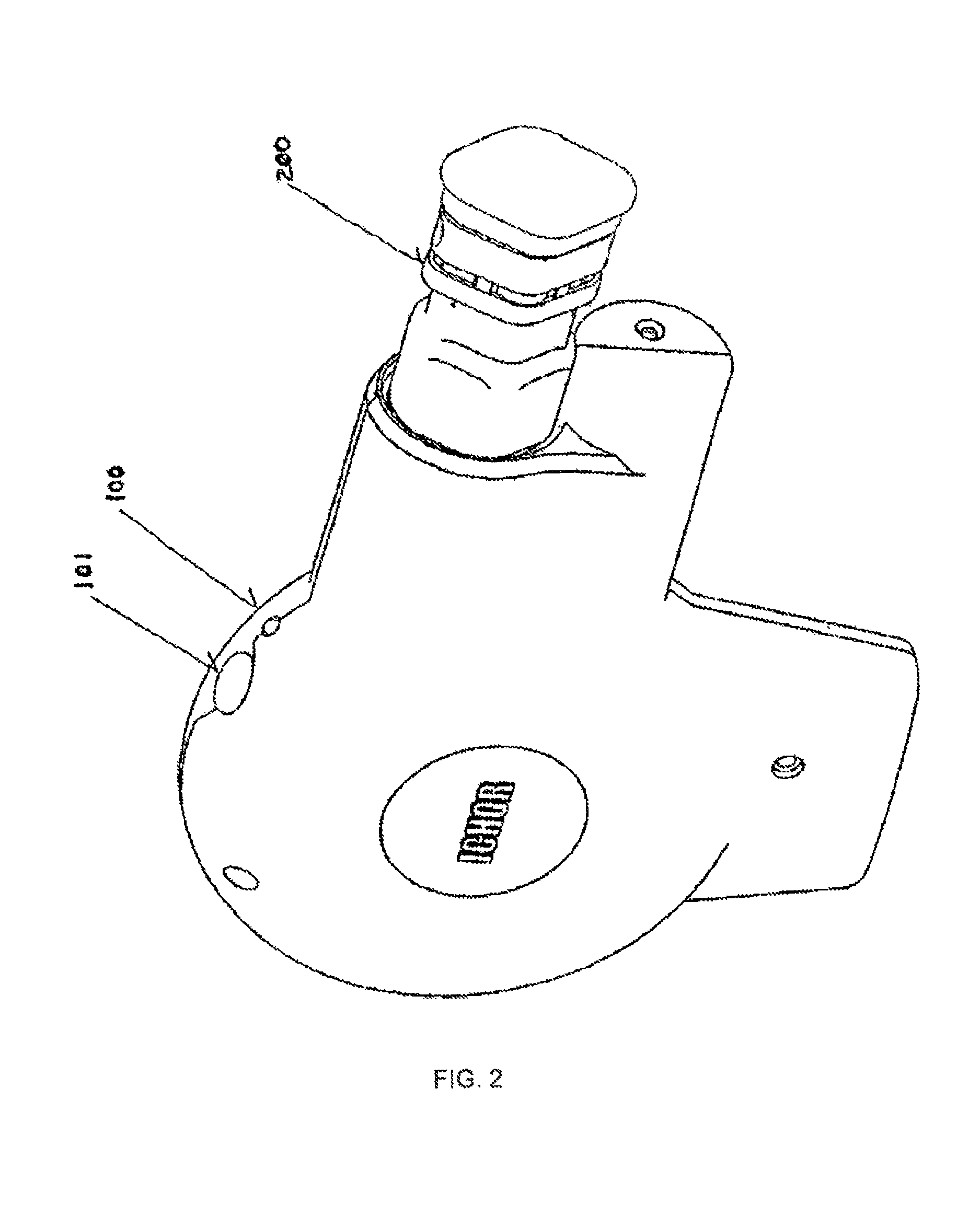

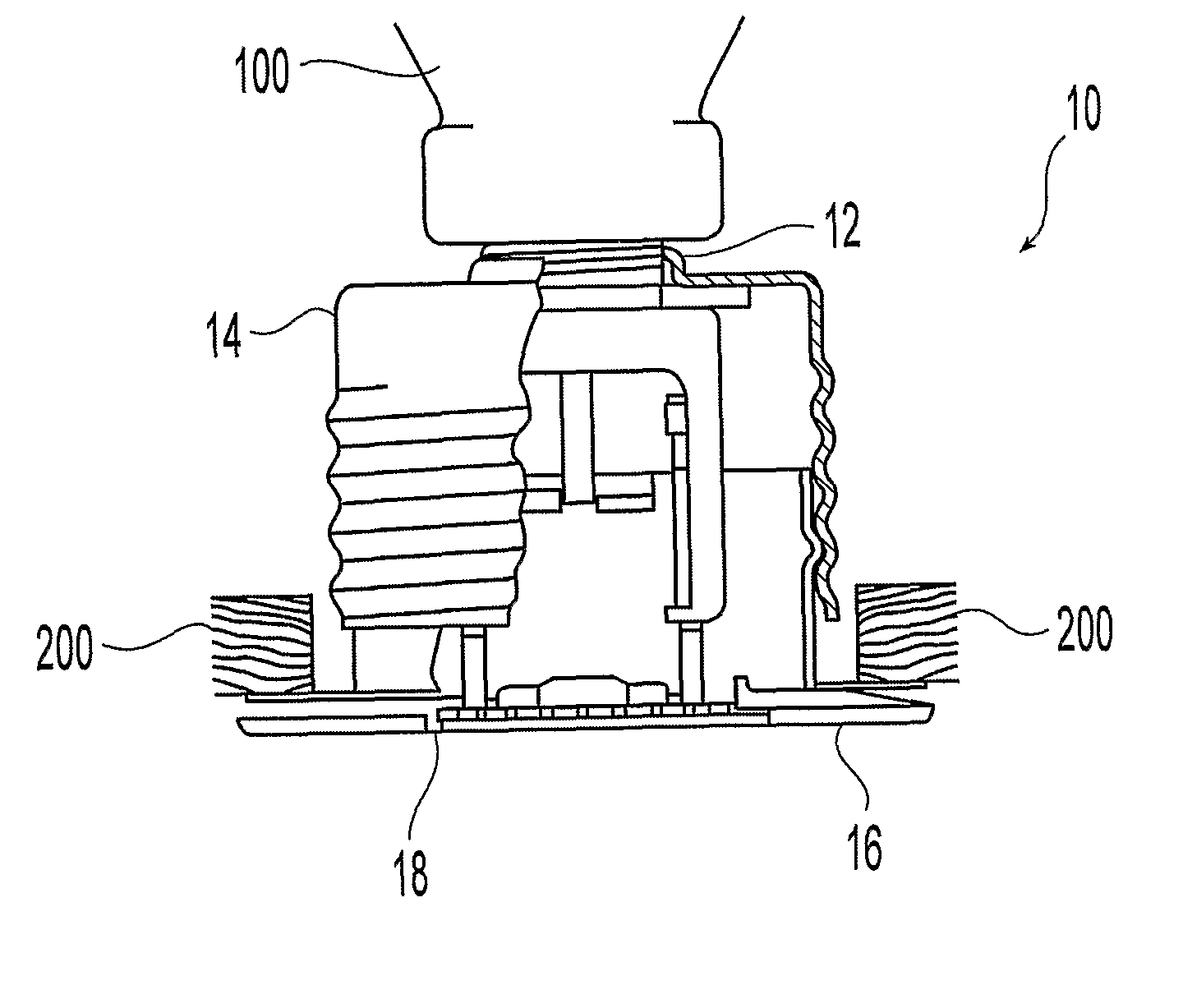

Apparatus for electrically mediated delivery of therapeutic agents

ActiveUS20120078161A1Easy to adaptFunction increaseSkin piercing electrodesElectricitySquare Millimeter

Apparatus for the delivery of an electrical field which facilitates the intracellular delivery of a therapeutic agent to a predetermined site within the tissue of a patient. The apparatus will comprise a plurality of penetrating electrodes arranged in a predetermined spatial relationship, each electrode with a cross sectional area contributing to the total cross sectional area of all electrodes, and structural means incorporating an inanimate source of energy operatively connected to the plurality of electrodes for deploying the electrodes, wherein the source of energy is sufficient to impart a force of at least 1000 pounds per square inch (0.7 kilogram per square millimeter) of total cross sectional area of all electrodes at the initiation of the deployment of the electrodes. The apparatus will also comprise means for generating an electrical field which facilitates the intracellular delivery of a therapeutic agent, which means is operatively connected to said electrodes at least in their deployed state.

Owner:ICHOR MEDICAL SYST

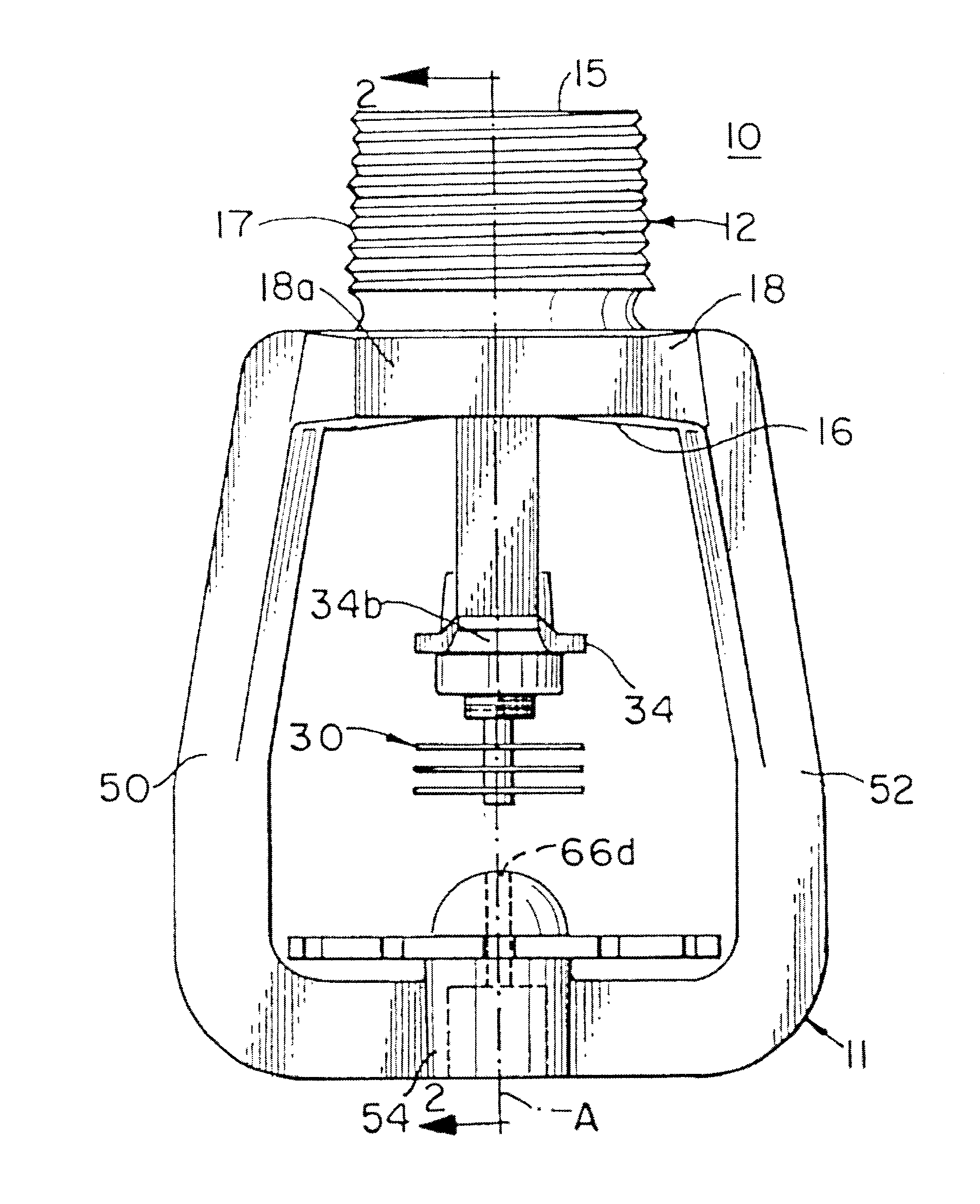

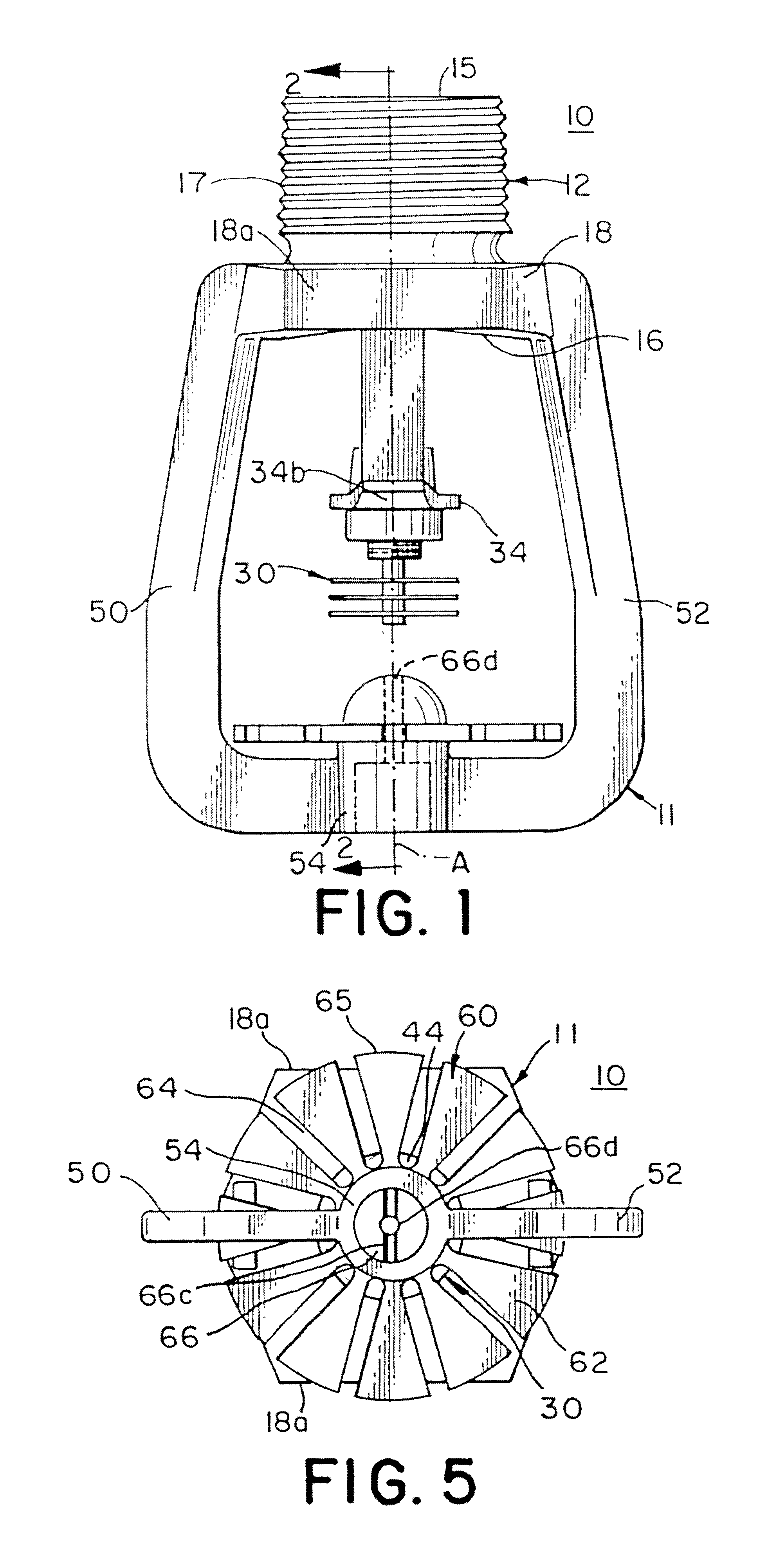

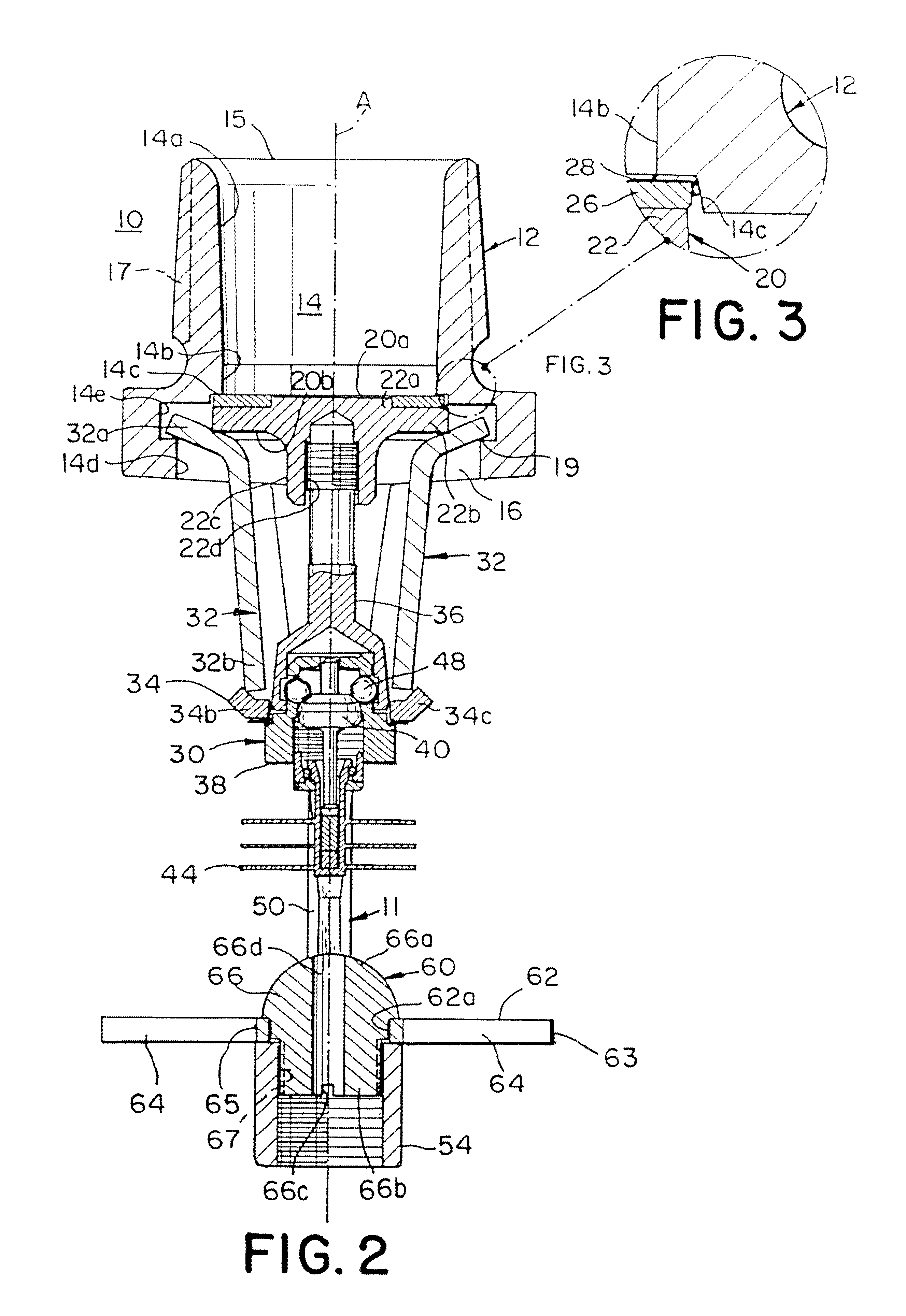

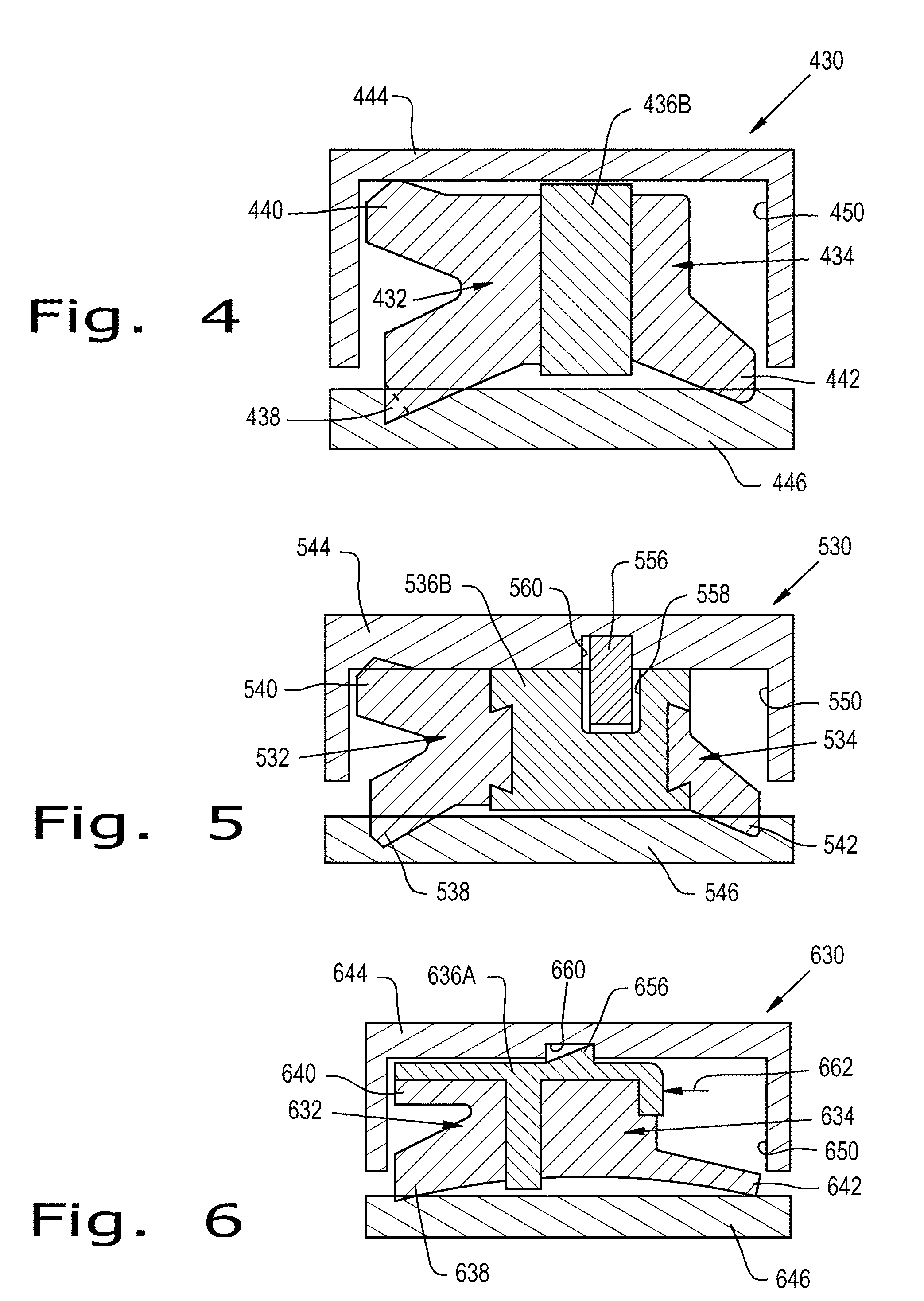

Low pressure, early suppression fast response sprinklers

A low pressure, early suppression fast response sprinkler includes a generally tubular body having an inlet ends, an opposing discharge end and an internal passageway extending between the inlet and discharge ends with a K factor greater than 16 where the K factor equals the flow of water in gallons per minute through the internal passageway divided by the square root of the pressure of water fed into the tubular body in pounds per square inch gauge. A deflector is coupled with the tubular body and spaced from and generally aligned with the discharge end of the internal passageway so as to be impacted by a flow of water issuing in a column from the discharge end upon activation of the sprinkler. The deflector is configured and positioned to deflect the flow of water generally radially outwardly all around the sprinkler. A closure is releasably positioned at the discharge end of the tubular body so as to close the internal passageway by a heat responsive trigger mounted to releasably retain the closure at the discharge end of the tubular body. The trigger has a response time indices (RTI) of less than 100 meter1 / 2 sec1 / 2. A specific pendent sprinkler with a nominal K factor of 25, an RTI of less than 40 m1 / 2 sec1 / 2 and delivering at least 100 gallons per minute at an operating pressure at or below 20 psig is described.

Owner:CENT SPRINKLER

Magnetically shielded conductor

A conductor assembly that contains a flexible conductor and a layer of nanomagnetic material coated onto the conductor. The layer of nanomagnetic material has a tensile modulus of elasticity of at least about 15×106 pounds per square inch, an average particle size of less than 100 nanometers, a saturation magnetization of from about 200 to about 26,000 Gauss, and a thickness of less than about 2 microns.

Owner:BIOPHAN TECH

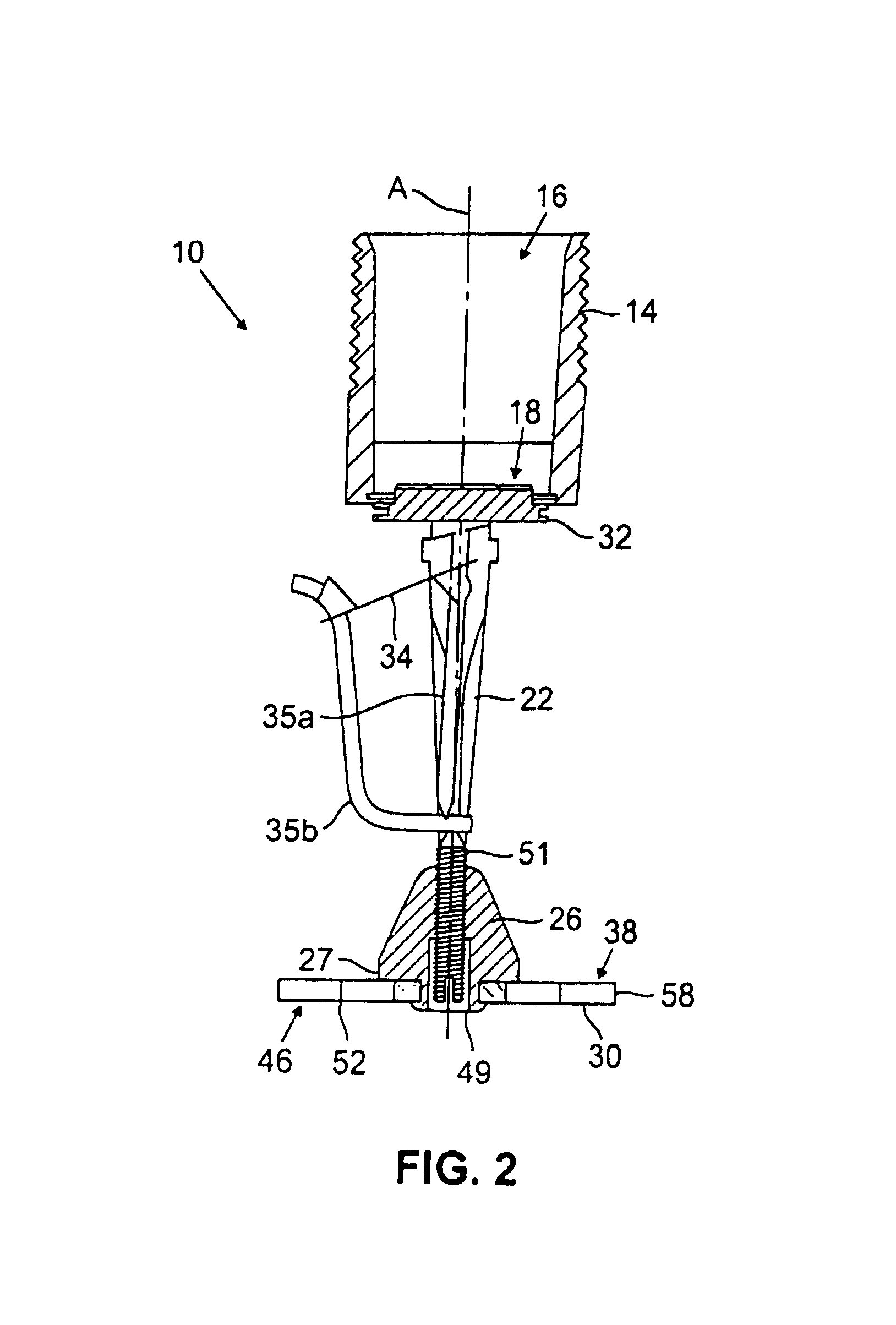

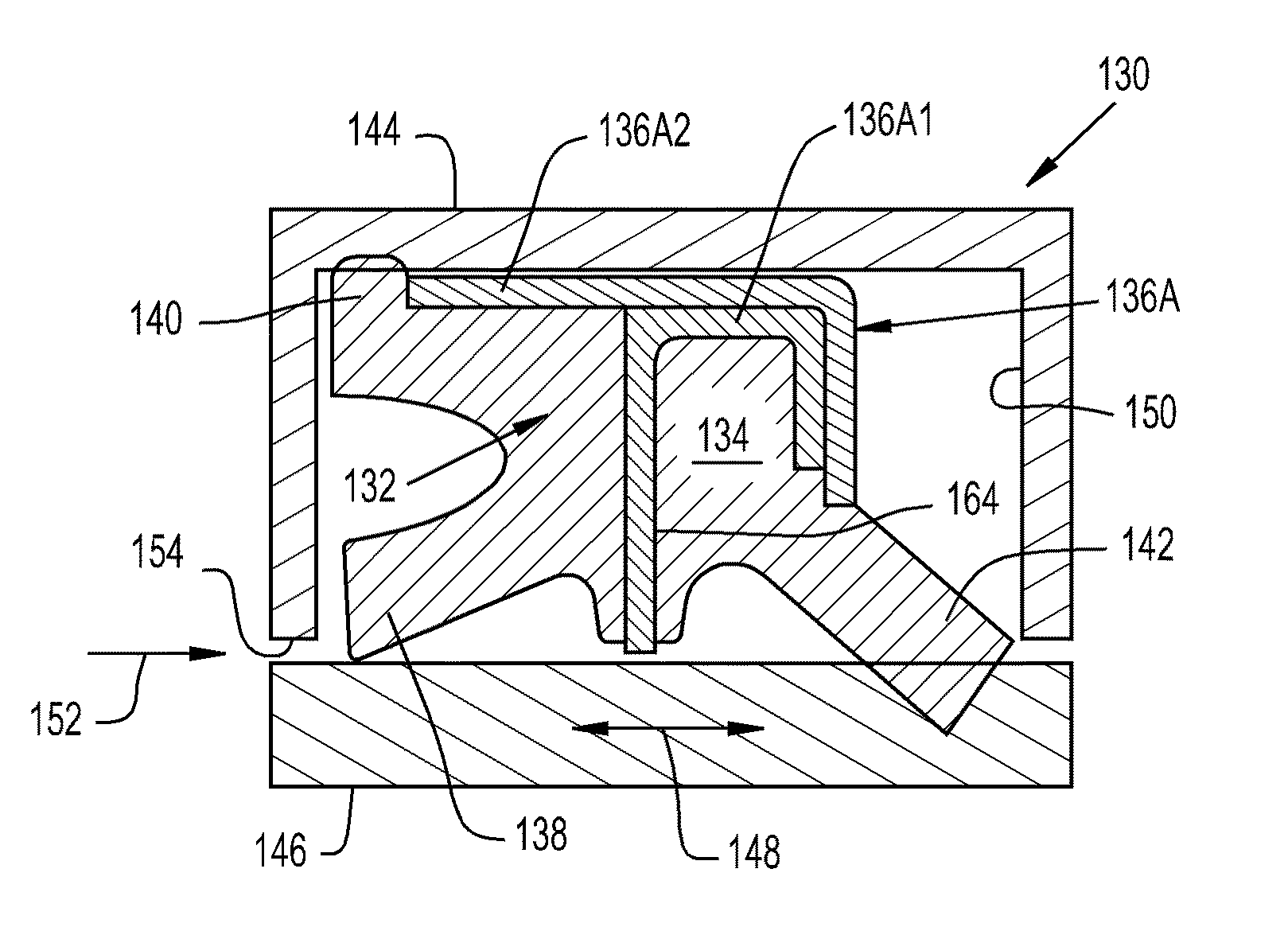

Dry sprinkler with a diverter seal assembly

A dry sprinkler is provided that includes a structure, a fluid deflecting structure, a locator, a metallic annulus and a shield. The structure defines a passageway extending along a longitudinal axis between an inlet and an outlet. The structure has a rated K-factor defining an expected flow of fluid in gallons per minute from the outlet divided by the square root of the pressure of the flow of fluid fed into the inlet of the passageway in pounds per square inch gauge. The fluid deflecting structure is proximate the outlet. The locator is movable along the longitudinal axis between a first position and a second position. The locator supports the metallic annulus. The metallic annulus includes first and second metallic surfaces spaced apart along the longitudinal axis between an inner and outer circumference with respect to the longitudinal axis. The shield has a first face exposed to the inlet and a second face confronting the first metallic surface to define a gap therebetween. Various methods are also described.

Owner:TYCO FIRE PRODS LP

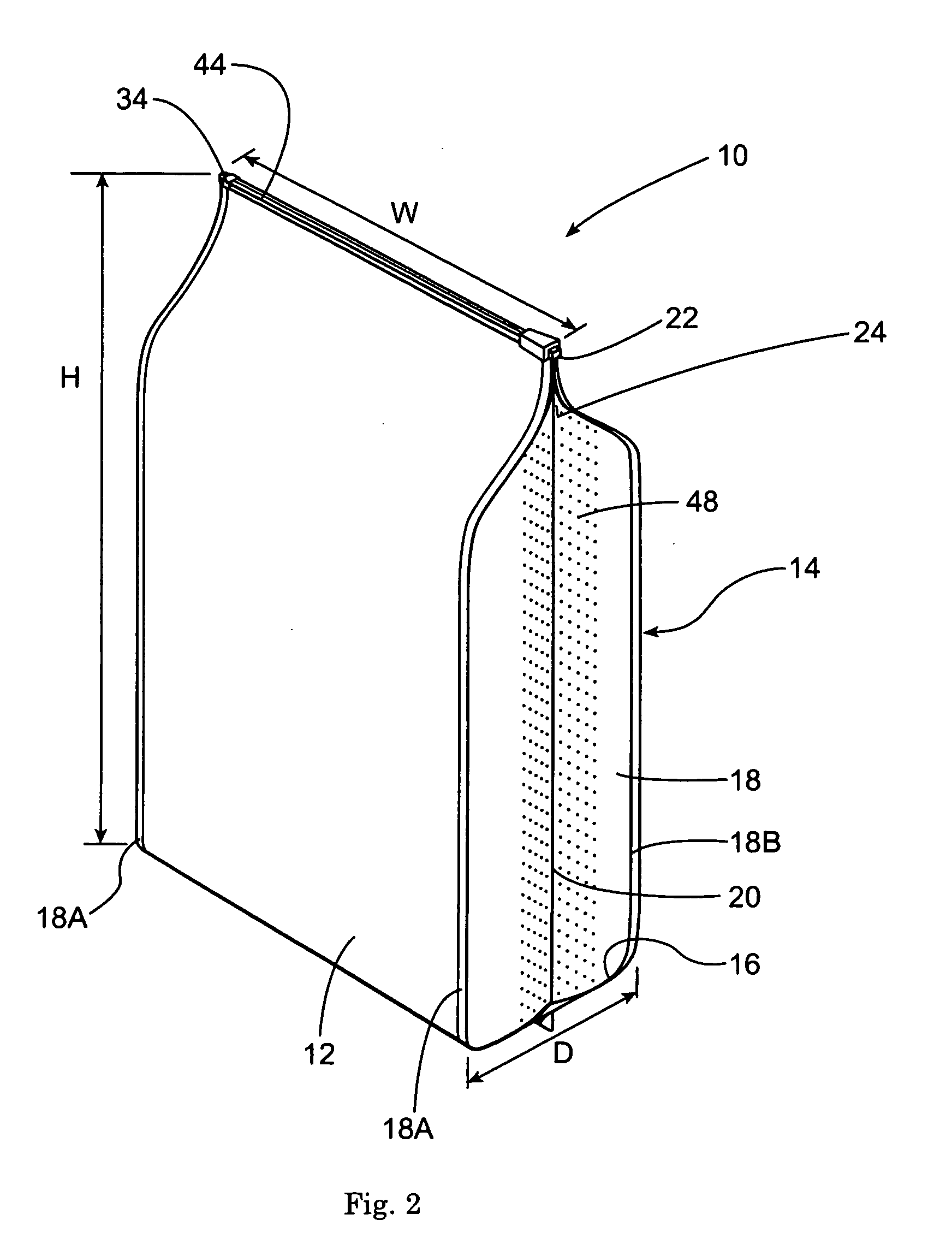

Bag and article of manufacture

InactiveUS20090136163A1Stable and resistant to tippingImprove palatabilityPackage recyclingBagsParticulatesEngineering

Disclosed is an article of manufacture including bag having a front surface; a rear surface; two side surfaces each having a gusset therein and connecting the front and rear surfaces; a flattenable bottom surface formed by connecting the front, rear, and side surfaces; and a top surface formable by connecting the front, rear, and side surfaces. The bag has a height, a width, and a depth, and defines an internal volume. The bag is sealable and has a seal strength of at least about 1,600 pounds per square inch. The bag is formed from a plastic laminate having a thickness of from about 130 to about 200 microns and a tensile strength of at least about 3,400 pounds per square inch. The article of manufacture also includes at least about 15 pounds of a particulate, flowable composition contained therein. The bag can also have a closure system comprising a non-reusable closure and a reusable closure. Also included are methods, using the article of manufacture, of enhancing palatability of an oxidizable, particulate, flowable composition contained therein.

Owner:MARS INC

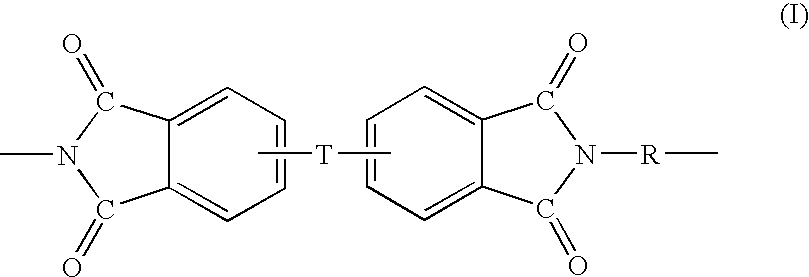

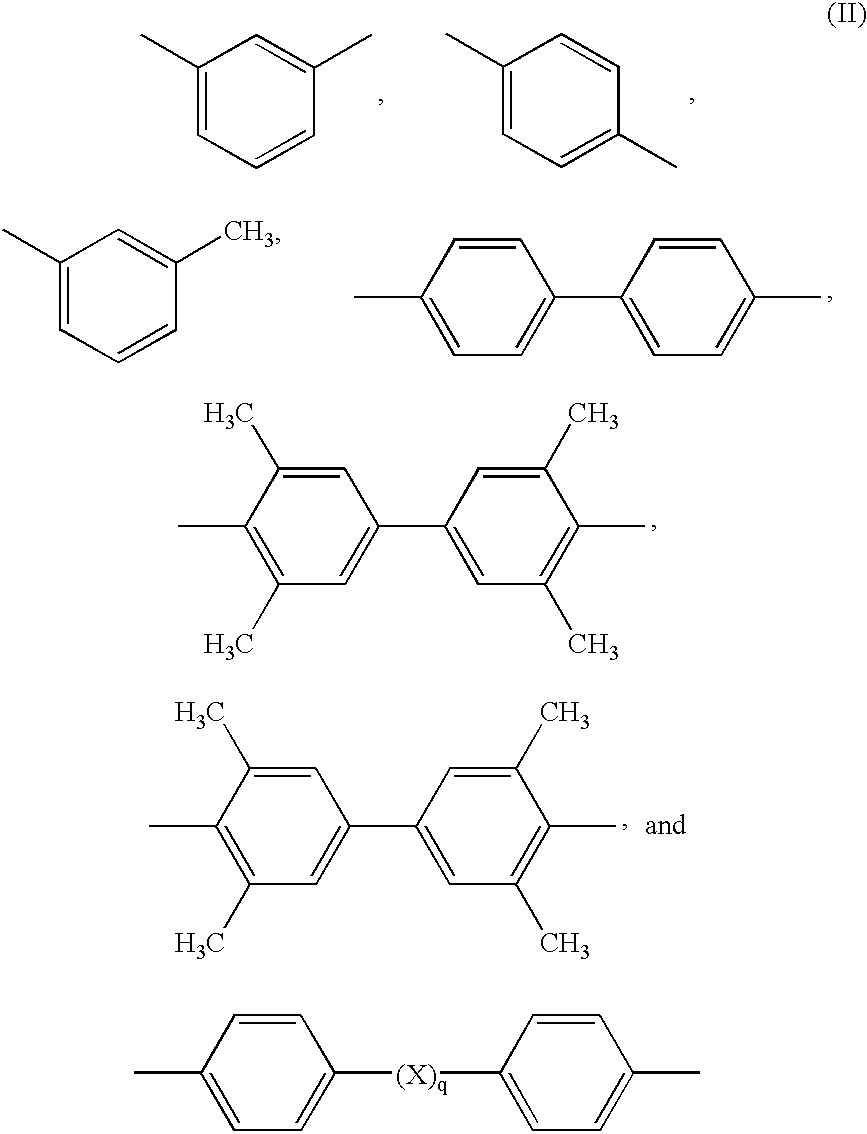

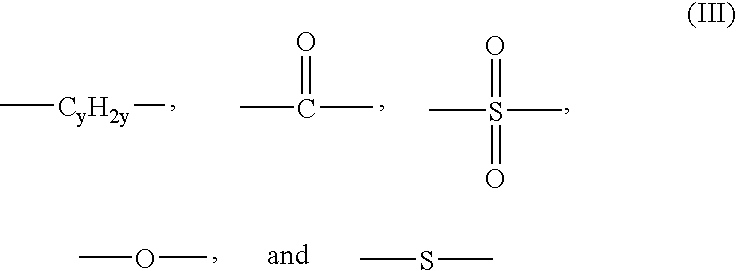

Data storage medium and method for the preparation thereof

ActiveUS20040063031A1Improve melt processingImprove moldingRadiation applicationsLayered productsHeat deflection temperatureVolatiles

A data storage medium includes a substrate, a reflective metal layer, and a haze-prevention layer between the substrate and the reflective metal layer. The substrate includes an amorphous thermoplastic resin having a heat distortion temperature of at least about 140° C., a density less than 1.7 grams per milliliter, and an organic volatiles content less than 1,000 parts per million measured according to ASTM D4526. The haze-prevention layer includes a material having a volume resistivity of at least 1x10<-4 >ohm-centimeters and a tensile modulus of at least about 3x10<5 >pounds per square inch. The data storage medium resists hazing of the reflective layer at elevated temperatures.

Owner:SHPP GLOBAL TECH BV

Apparatus for electrically mediated delivery of therapeutic agents

ActiveUS9364664B2Function increaseShorten the lengthSkin piercing electrodesElectricitySquare Millimeter

Owner:ICHOR MEDICAL SYST

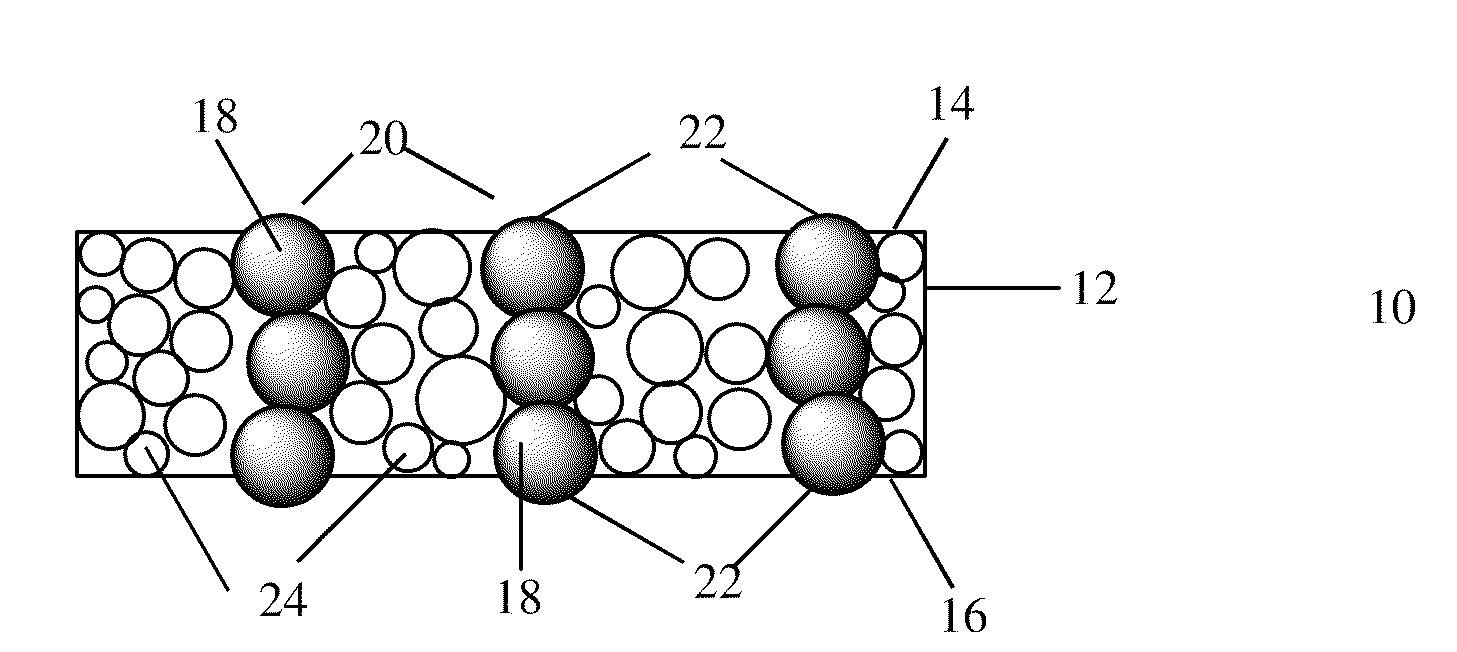

Conductive polymer foams, method of manufacture, and articles thereof

A method of manufacturing a polymer foam composite is described, the method comprising forming an article having a first surface and an opposite second surface from a precursor composition, the precursor composition comprising a polymer foam precursor composition, and a filler composition comprising a plurality of magnetic, electrically conductive particles; foaming the precursor composition to form a plurality of cells in precursor composition; applying a magnetic field to the foamed precursor composition, wherein the magnetic field is of a strength and applied for a time effective to align the electrically conductive, magnetic particles into mutually isolated chains between the first surface and the opposite second surface of the article; and solidifying the polymer foam precursor composition to provide a polymer foam composite having a density of about 1 to about 125 pounds per cubic foot and a volume resistivity of about 10−3 ohm-cm to about 103 ohm-cm at a pressure of 60 pounds per square inch. Polymer foam composites made by this method are also described, as well as articles formed therefrom.

Owner:WORLD PROPERTIES

Seal assembly

A seal assembly, includes a seal element including at least one seal lip, a wiper element including a wiper lip, and a structural element attached to the seal element and the wiper element, the seal assembly being configured for functioning under pressure in an amount greater than 500 pounds per square inch.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

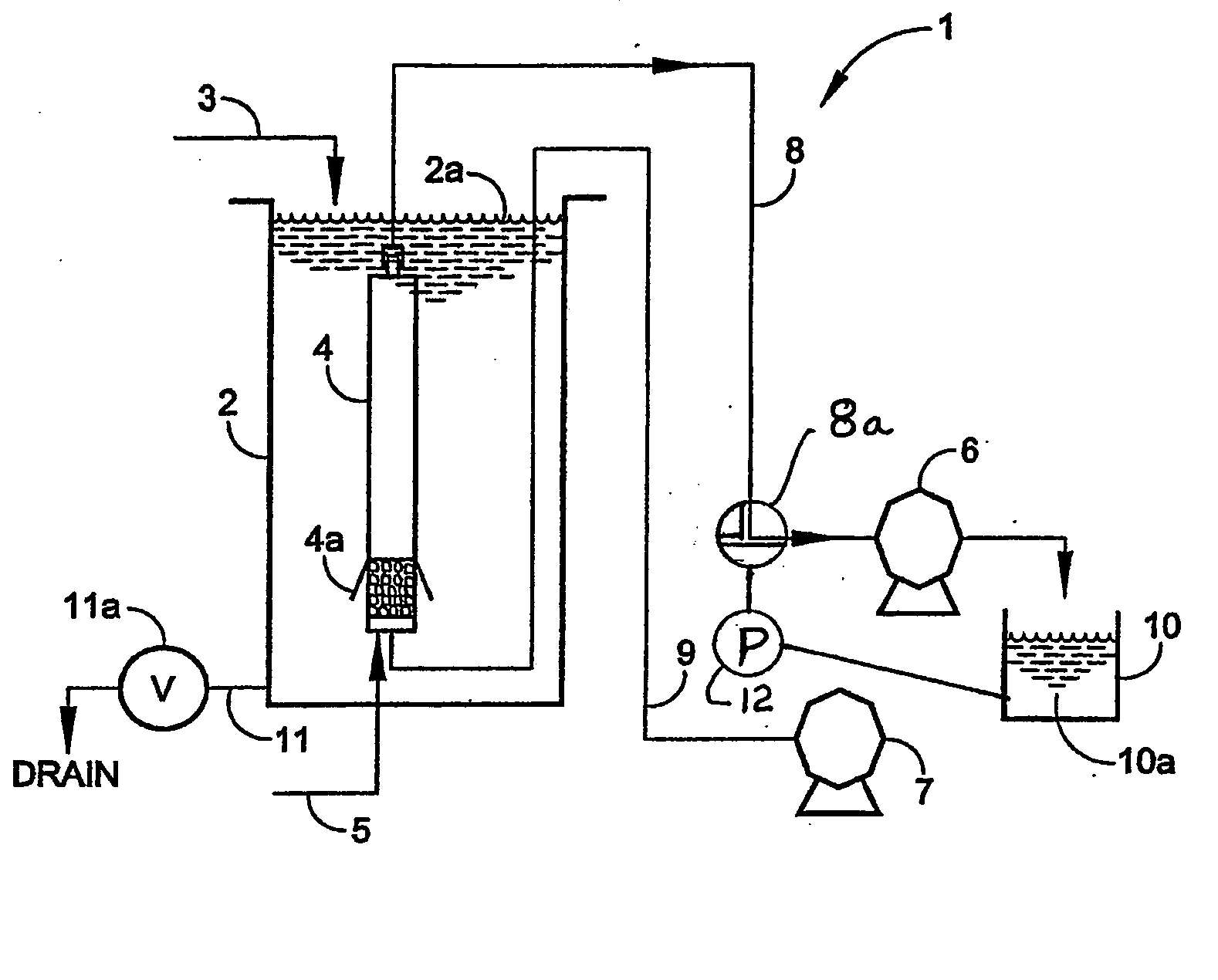

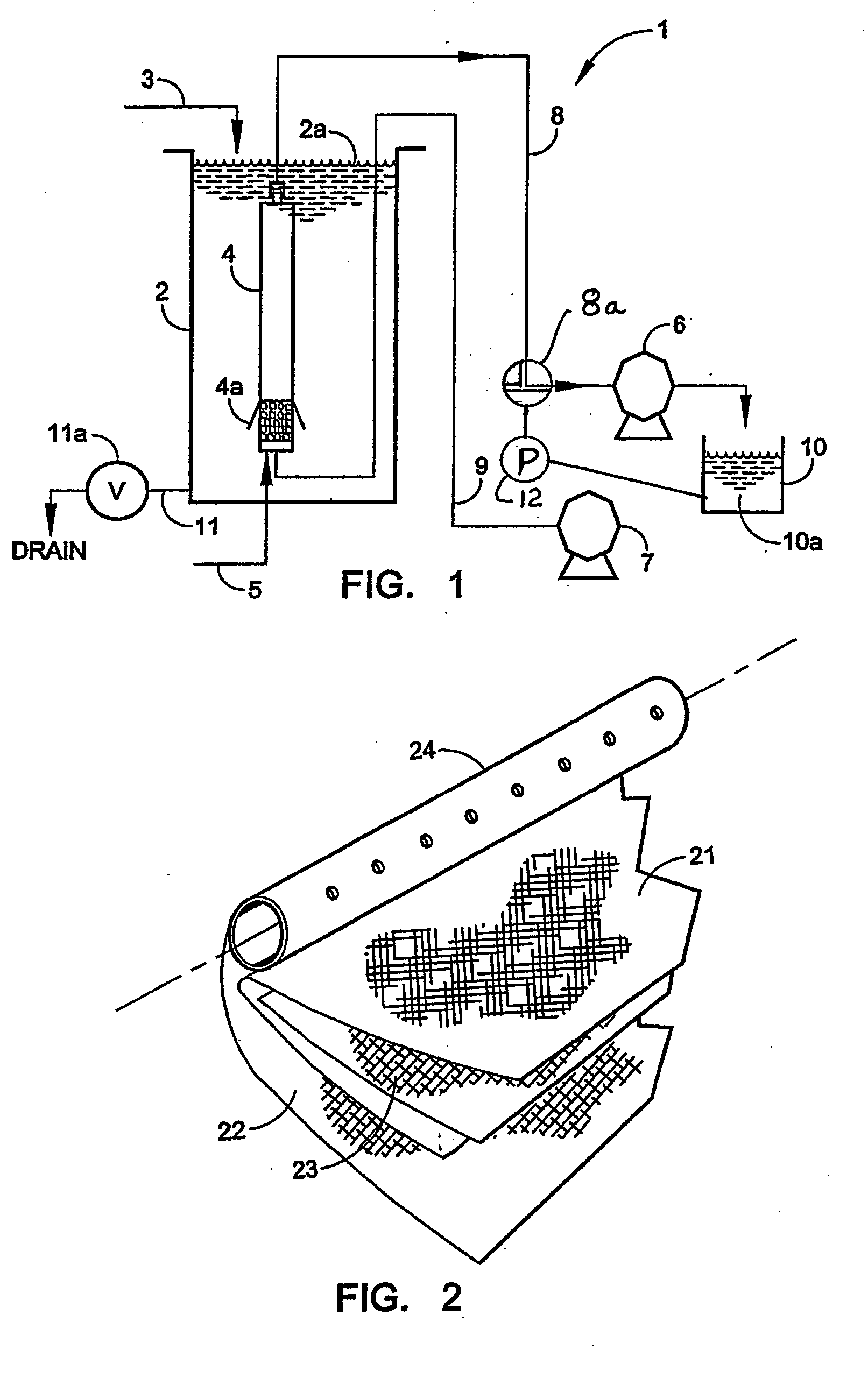

Low pressure filtration

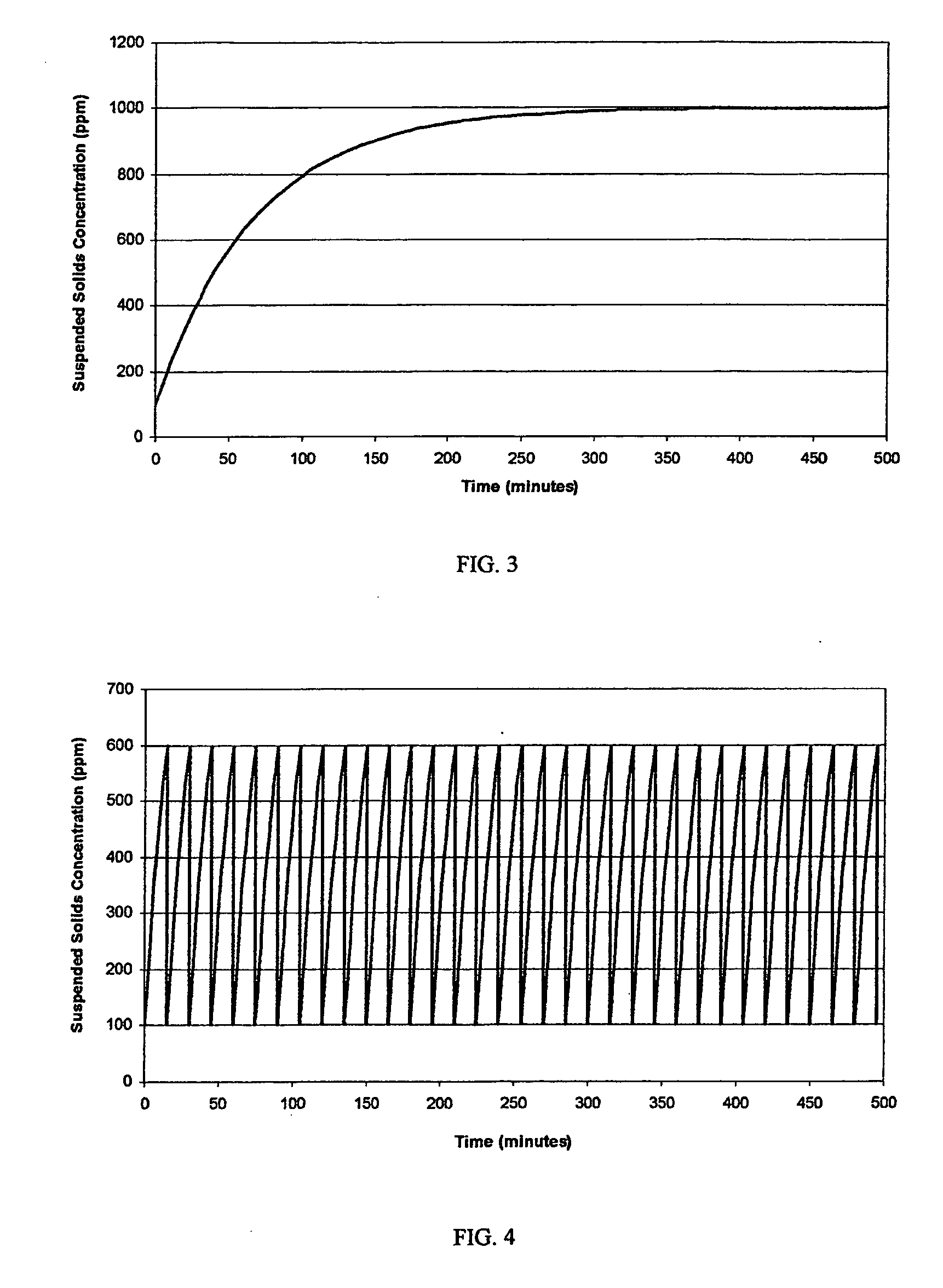

ActiveUS20070131614A1Produced economicallyReduce energy consumptionMembranesUltrafiltrationFiltrationStreamflow

High flow, low-pressure ultrafiltration or microfiltration spiral wound membrane cartridges are used in filtration of liquid feedstocks having high suspended solids. Applications may utilize either vacuum or pumping for transmembrane drive pressure (TMP), and gas may optionally be bubbled up through the cartridges with certain feedstocks. Water permeate flux rates as high as 90 gallons per square foot per day (gfd) can be obtained at TMPs below 5 pounds per square inch. By locating each spiral wound cartridge in its own casing and supplying liquid feedstock to an open lower end of the casing, as opposed to submerging such cartridges in a tank filled with feedstock, overall low pressure performance is greatly improved. High permeate flow can be maintained for long periods of time between shutdowns for intensive cleaning. TMP is gradually increased to maintain a substantially constant rate of permeate discharge until a target is reached, indicative of solids accumulation on the membrane surface to an undesirable extent; then backflushing is effected for a short time. Discarding the hold-up volume of feedstock in the cartridge, the backflushing fluid and dislodged solids, allows production to be promptly resumed with fresh feedstock at performance at near original levels.

Owner:MANNHUMMEL WATER & FLUID SOLUTIONS GMBH

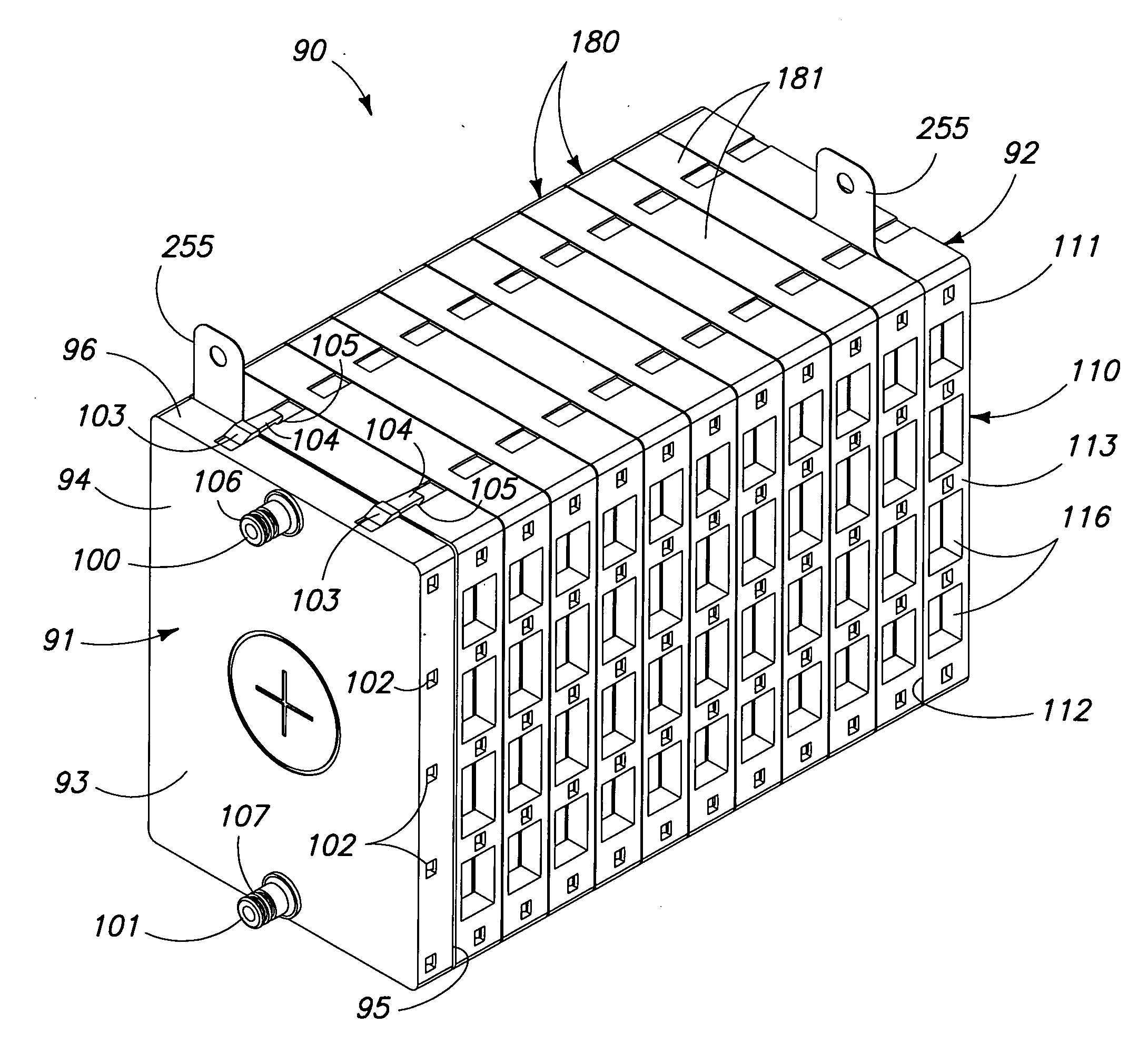

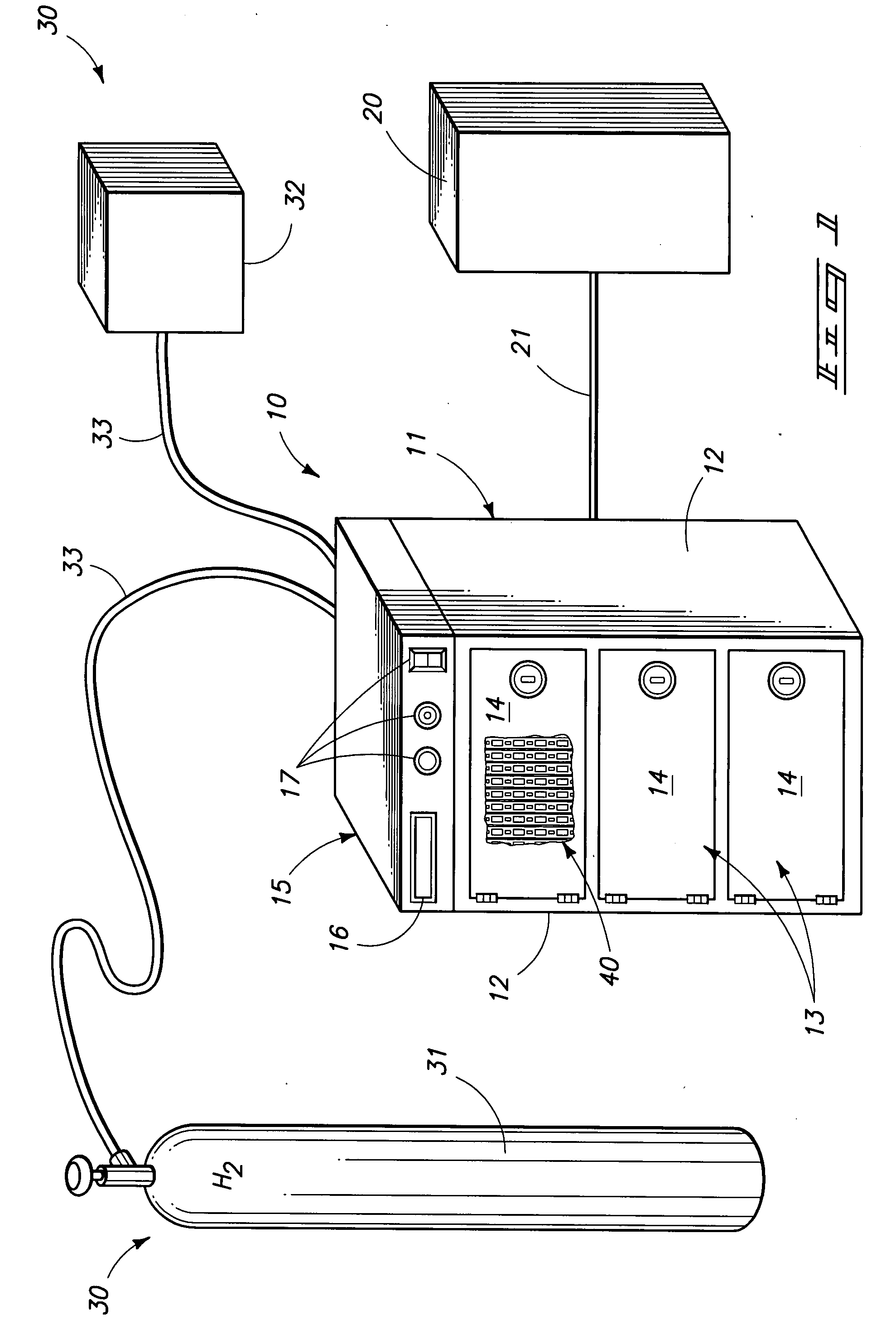

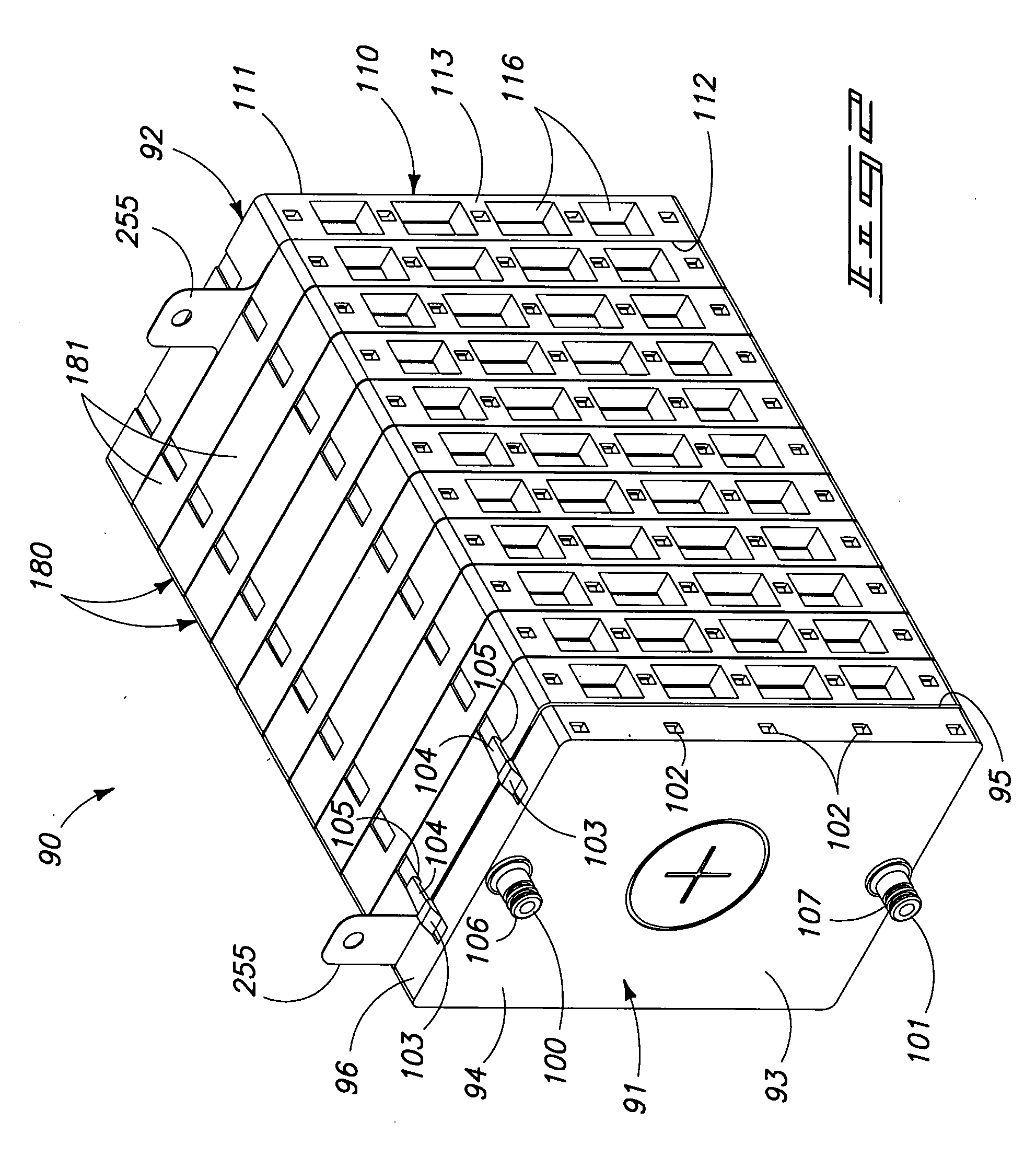

Proton exchange membrane fuel cell stack and fuel cell stack module

ActiveUS20080280178A1Fuel cell heat exchangeCell component detailsEngineeringProton exchange membrane fuel cell

A proton exchange membrane fuel cell stack and novel proton exchange membrane fuel cell module are disclosed and wherein the proton exchange membrane fuel cell stack includes a plurality of repeating, serially electrically coupled fuel cell stack modules, and which are sealably mounted together by a compressive force of less than about 60 pounds per square inch.

Owner:EMERGENT POWER

Orthodontic appliances and materials for making same

The polymeric shell of a removable dental positioning appliance is formed from transparent polymeric materials having a tensile strength at yield of greater than 6,000 pounds per square inch (psi), an elongation at yield of greater than 4%, an elongation at break of greater than 80%, a tensile modulus greater than 200,000 psi, a flexural modulus greater than 200,000 psi, stress relaxation over time of not more than 50%, and a transmissivity of light between 400 nm and 800 nm greater than 75%.

Owner:DESIMONE JOSEPH M +1

Rubidium generator for cardiac perfusion imaging and method of making and maintaining same

ActiveUS8071959B2Low pressure elutionFacilitates precision flow controlIn-vivo radioactive preparationsConversion outside reactor/acceleratorsFractographyRubidium

An 82Sr / 82Rb generator column is made using a fluid impervious cylindrical container having a cover for closing the container in a fluid tight seal, and further having an inlet for connection of a conduit for delivering a fluid into the container and an outlet for connection of a conduit for conducting the fluid from the container. An ion exchange material fills the container, the ion exchange material being compacted within the container to a density that permits the ion exchange material to be eluted at a rate of at least 5 ml / min at a fluid pressure of 1.5 pounds per square inch (10 kPa). The generator column can be repeatedly recharged with 82Sr. The generator column is compatible with either three-dimensional or two-dimensional positron emission tomography systems.

Owner:OTTAWA HEART INST RES CORP

Ceramic impregnated superabrasives

InactiveUS20060042171A1Small surface areaDifferent modulusPigmenting treatmentDrill bitsBoiling pointPolycrystalline diamond

A superabrasive fracture resistant compact is formed by depositing successive layers of ceramic throughout the network of open pores in a thermally stable self-bonded polycrystalline diamond or cubic boron nitride preform. The void volume in the preform is from approximately 2 to 10 percent of the volume of the preform, and the average pore size is below approximately 3000 nanometers. The preform is evacuated and infiltrated under at least about 1500 pounds per square inch pressure with a liquid pre-ceramic polymerizable precursor. The precursor is infiltrated into the preform at or below the boiling point of the precursor. The precursor is polymerized into a solid phase material. The excess is removed from the outside of the preform, and the polymer is pyrolized to form a ceramic. The process is repeated at least once more so as to achieve upwards of 90 percent filling of the original void volume. When the remaining void volume drops below about 1 percent the physical properties of the compact, such as fracture resistance, improve substantially. Multiple infiltration cycles result in the deposition of sufficient ceramic to reduce the void volume to below 0.5 percent. The fracture resistance of the compacts in which the poes are lined with formed in situ ceramic is generally at least one and one-half times that of the starting preforms.

Owner:RADTKE ROBERT P +1

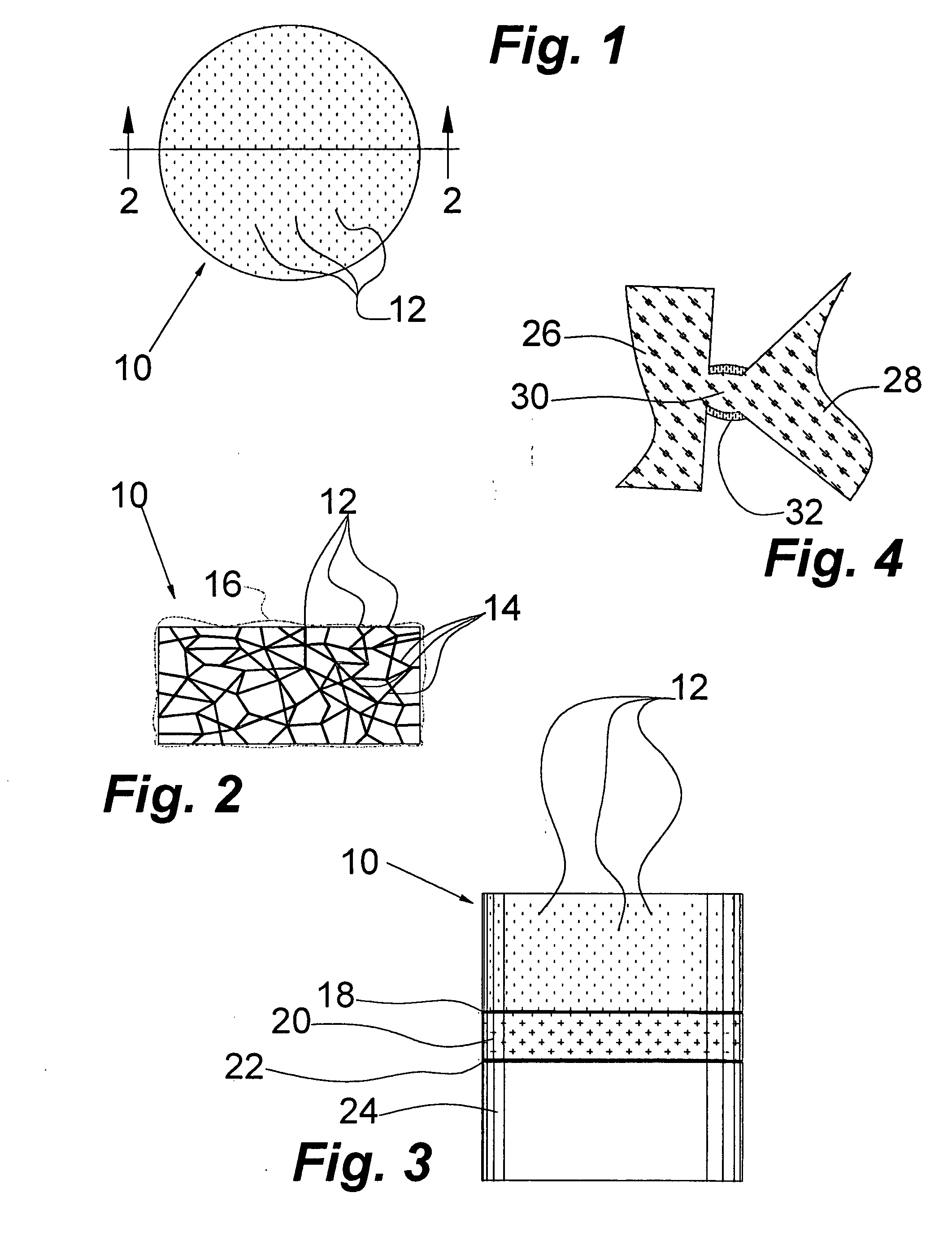

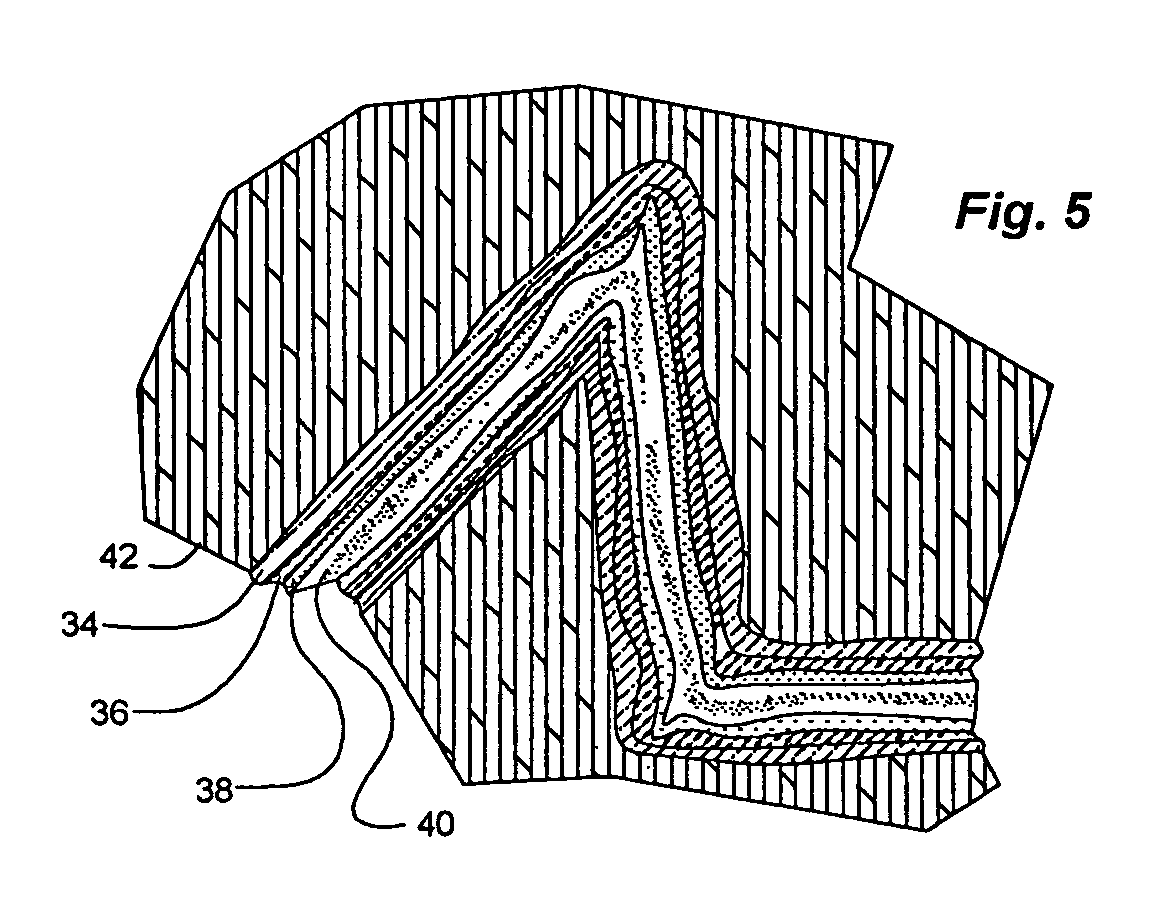

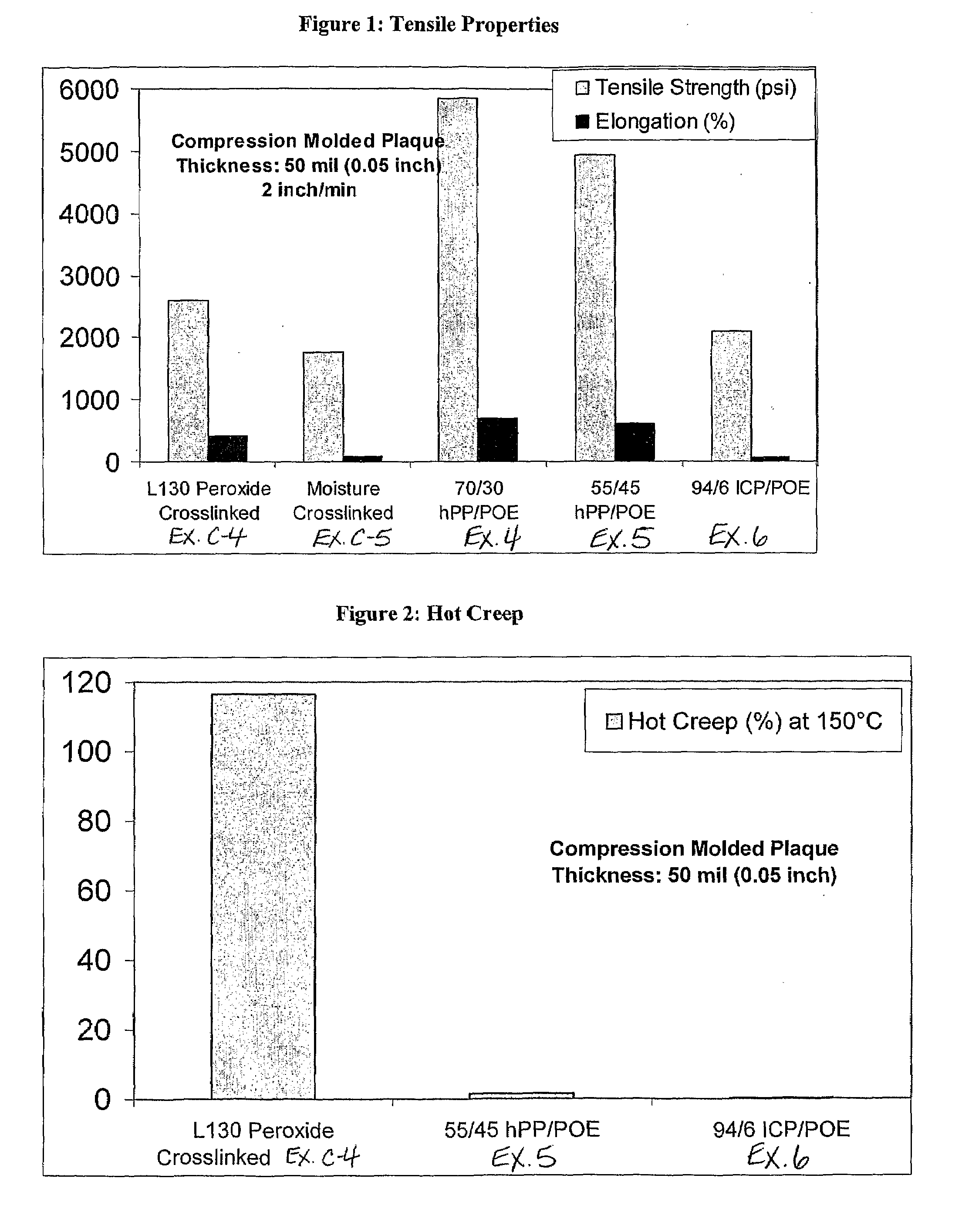

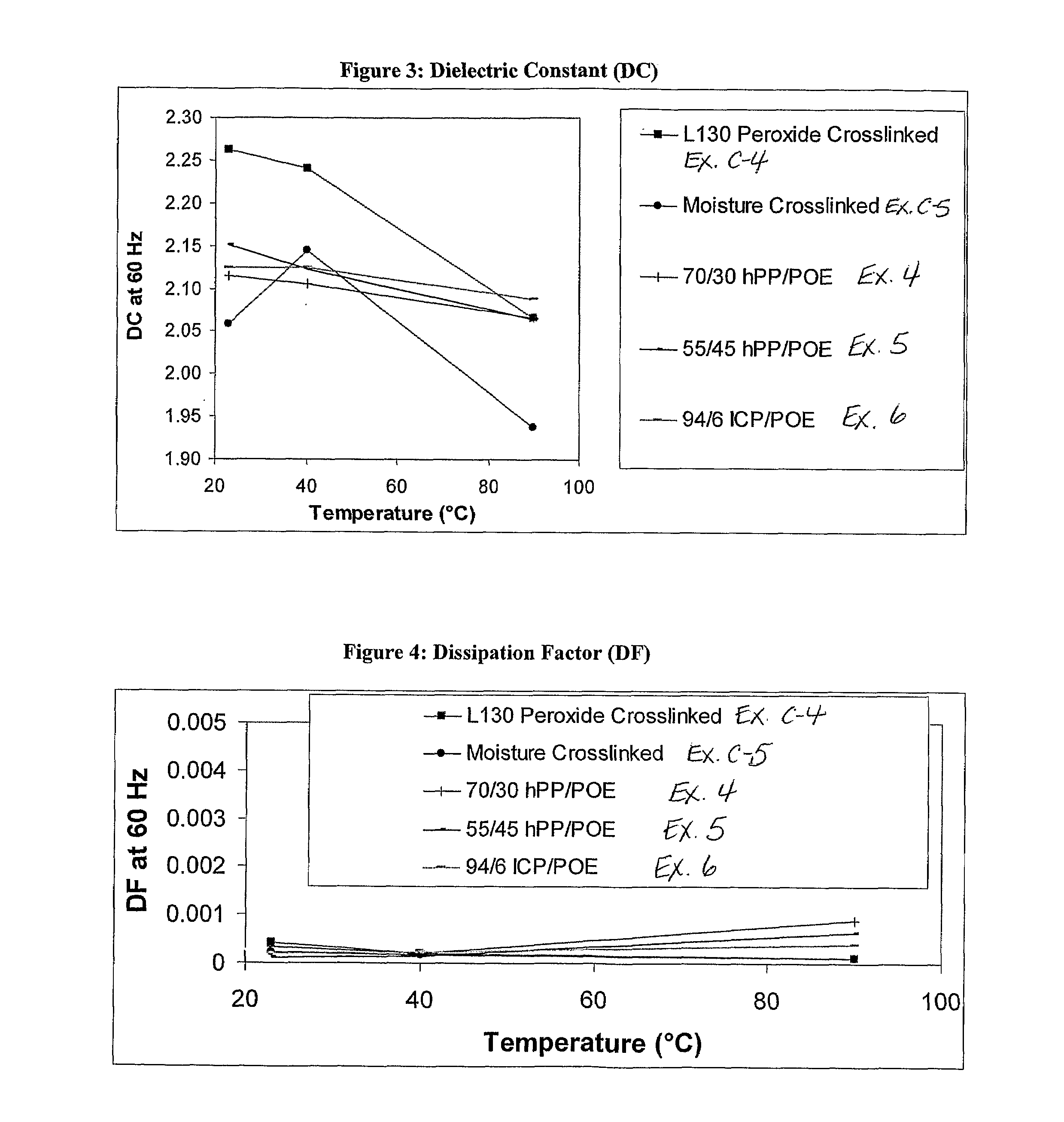

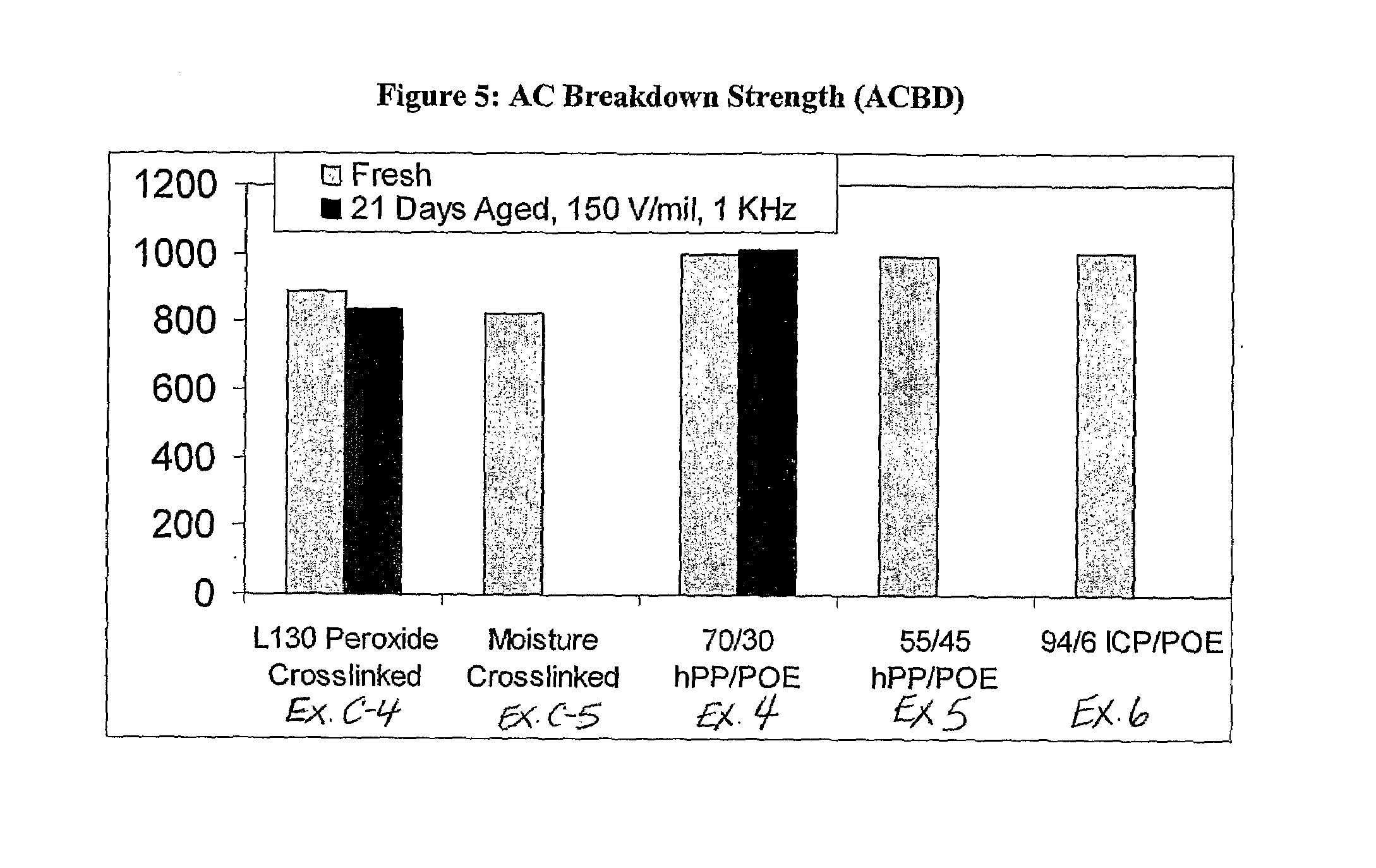

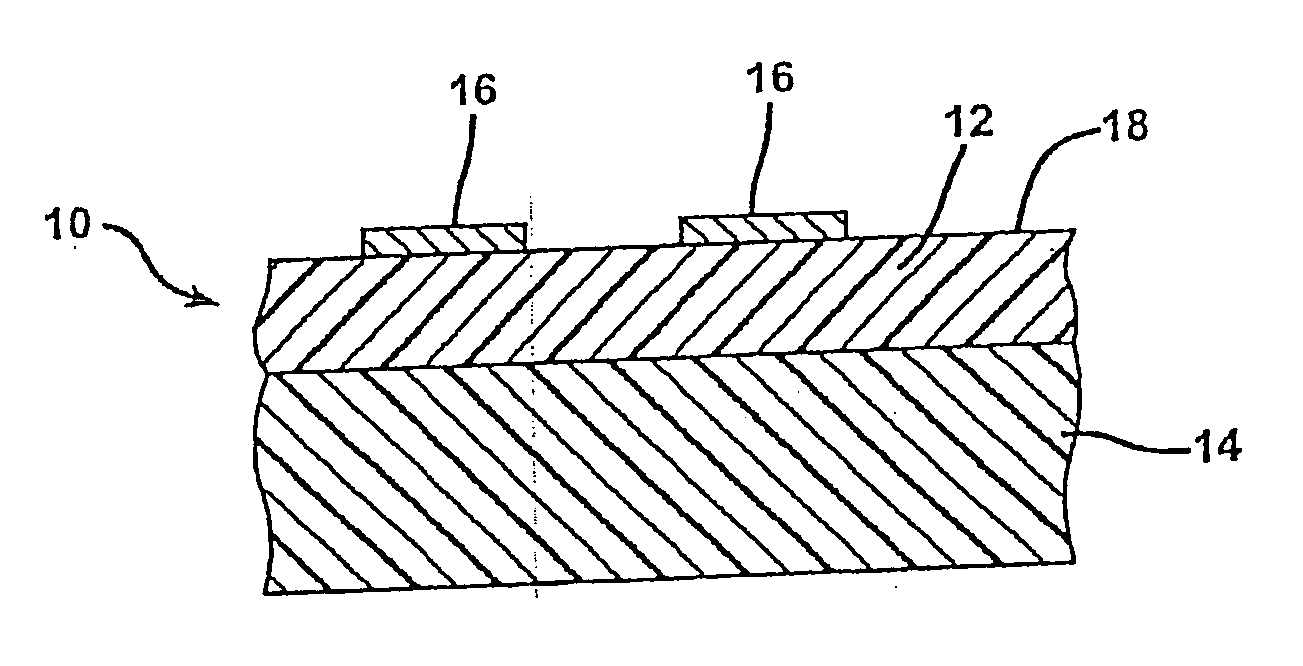

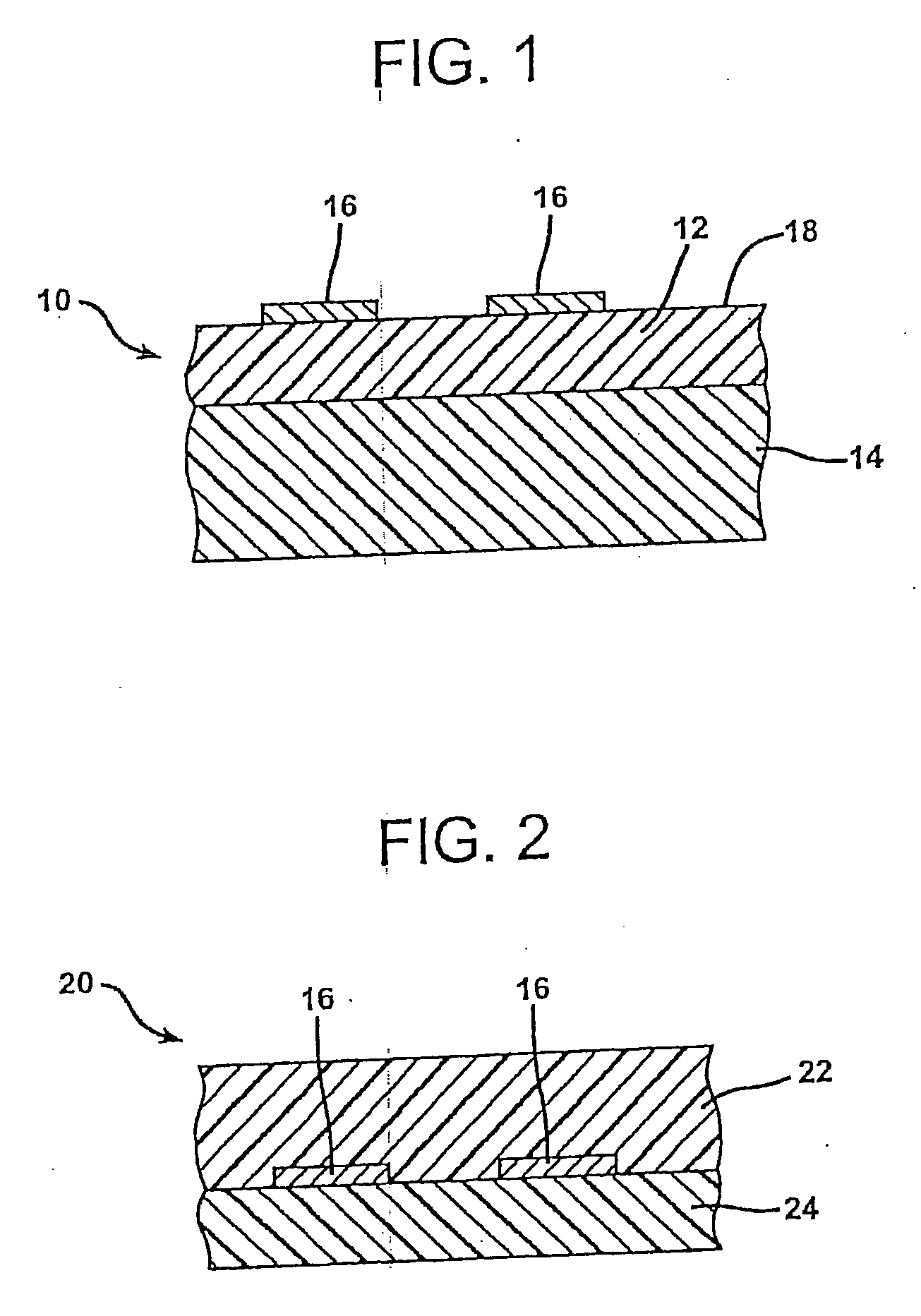

Polypropylene-Based Wire and Cable Insulation or Jacket

The invention is an electrically conductive device, e.g., a wire or cable, having a crush resistance of at least about 18 pounds per square inch (psi), the device comprising: A. An electrically conductive member comprising at least one electrically conductive substrate, e.g., a wire strand or a pair of twisted wire strands; and B. At least one electric-insulating member substantially surrounding the electrically conductive member, e.g., a polymer coating or layer, the electric-insulating member comprising a polymer blend, the polymer blend comprising: 1. At least about 50 weight percent of a polypropylene, and 2. At least about 10 weight percent of an elastomer. In one embodiment, the blend is characterized as having (i) a hot creep of less than 200% at 150 C, (ii) a dielectric constant at 60 Hz and 90 C of less than about 2.5, (iii) a dissipation factor at 60 Hz and 90 C of less than about 0.005, and (iv) an AC breakdown strength of greater than about 600 v / mil.

Owner:KLIER JOHN +2

Method of activating the shrink characteristic of a film

InactiveUS20060275564A1Reduce tensionReduce filmWrappers shrinkageShrinkage connectionsNon-ionizing radiationTwo step

A method of activating the shrink characteristic of a film comprises two steps. First, a film comprising one or more thermoplastic polymers and at least about 0.01 weight % photothermic material is provided. Second, the film is exposed to an amount of non-ionizing radiation effective for the photothermic material to generate heat to cause an effect selected from one or more of: 1) shrinking the film by at least about 5% in at least one direction, and 2) increasing the tension in the film by at least about 50 pounds per square inch in at least one direction.

Owner:CRYOVAC ILLC

Dry sprinkler with a diverter seal assembly

A dry sprinkler is provided that includes a structure, a fluid deflecting structure, a locator, a metallic annulus and a shield. The structure defines a passageway extending along a longitudinal axis between an inlet and an outlet. The structure has a rated K-factor defining an expected flow of fluid in gallons per minute from the outlet divided by the square root of the pressure of the flow of fluid fed into the inlet of the passageway in pounds per square inch gauge. The fluid deflecting structure is proximate the outlet. The locator is movable along the longitudinal axis between a first position and a second position. The locator supports the metallic annulus. The metallic annulus includes first and second metallic surfaces spaced apart along the longitudinal axis between an inner and outer circumference with respect to the longitudinal axis. The shield has a first face exposed to the inlet and a second face confronting the first metallic surface to define a gap therebetween. Various methods are also described.

Owner:TYCO FIRE PRODS LP

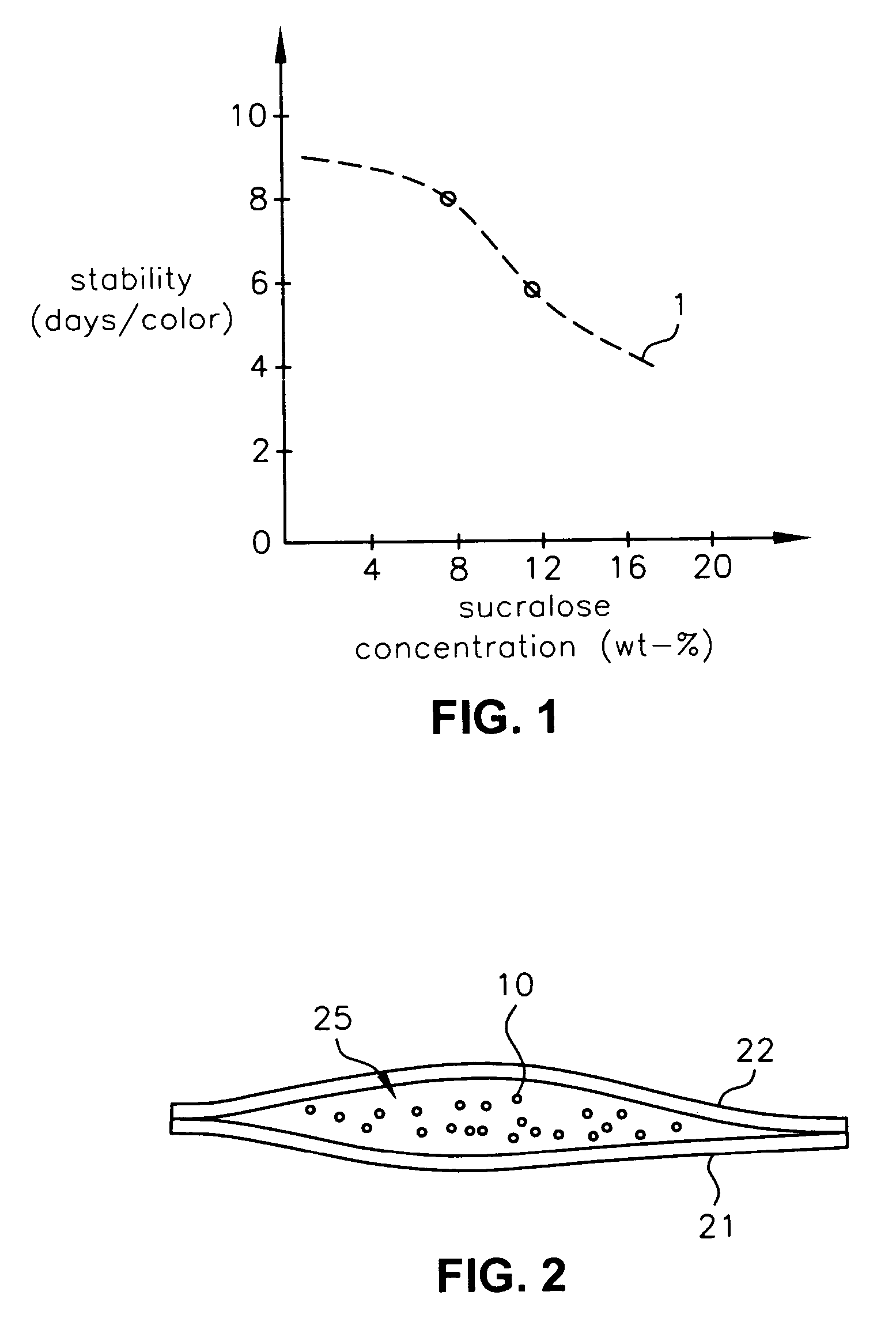

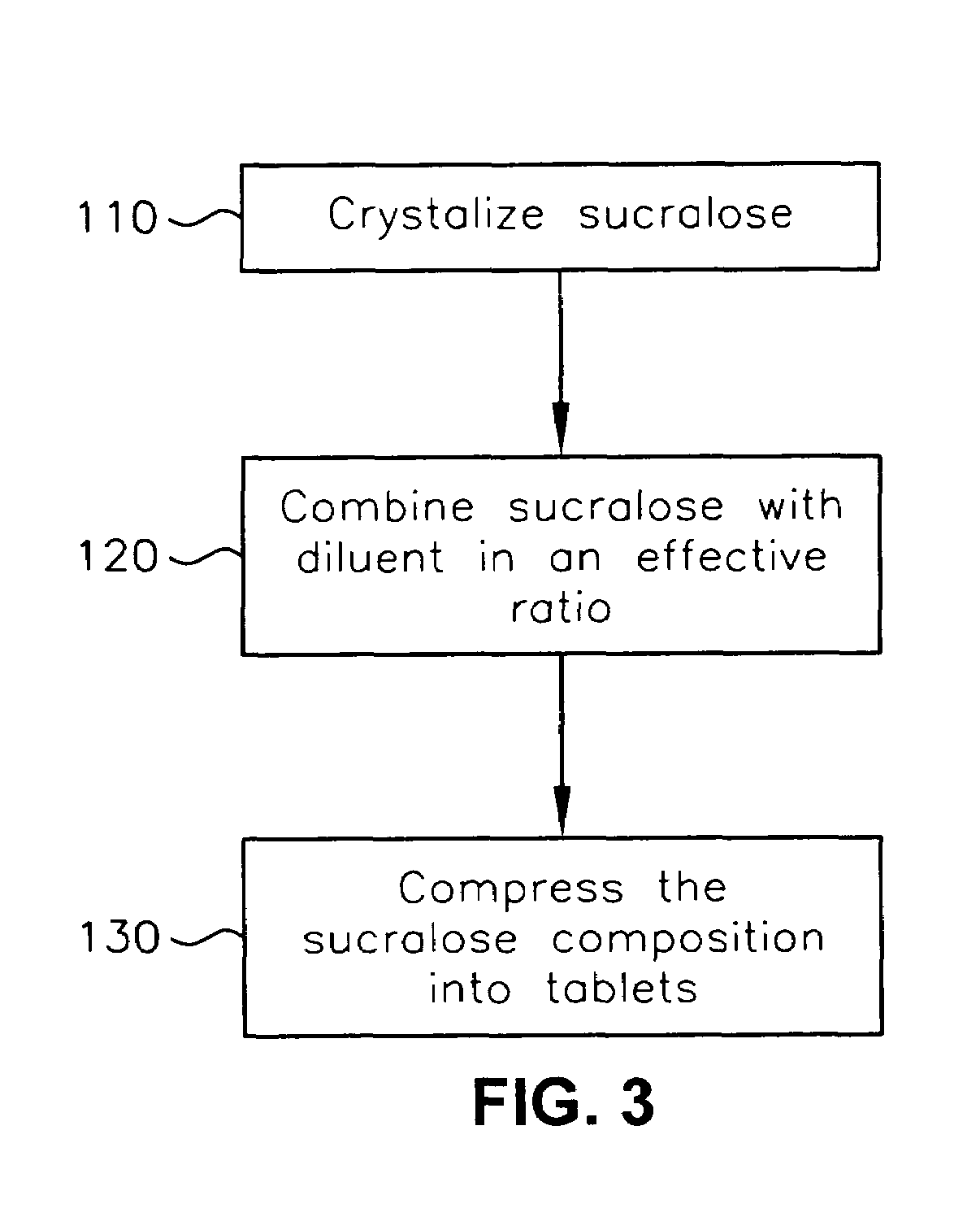

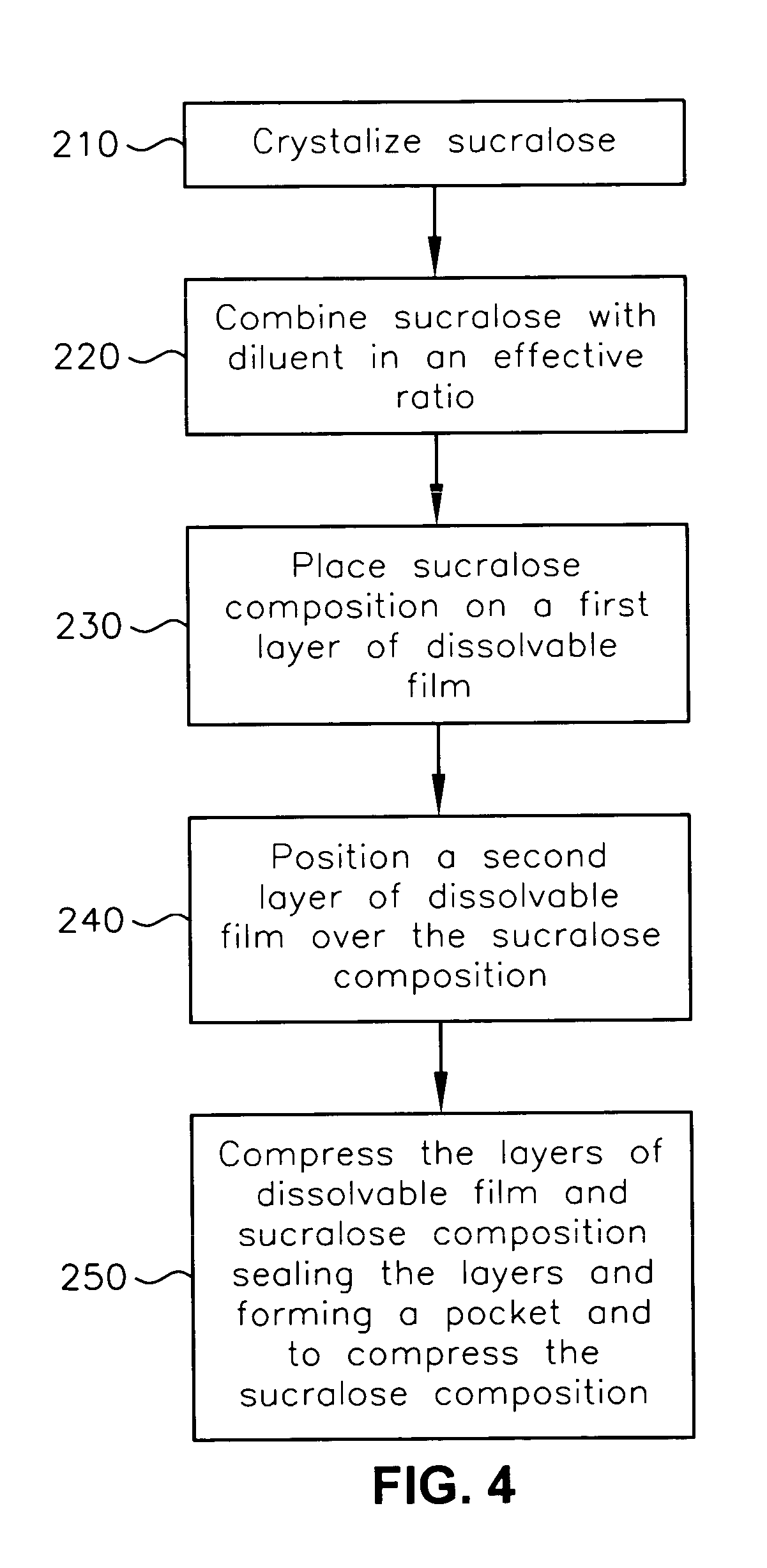

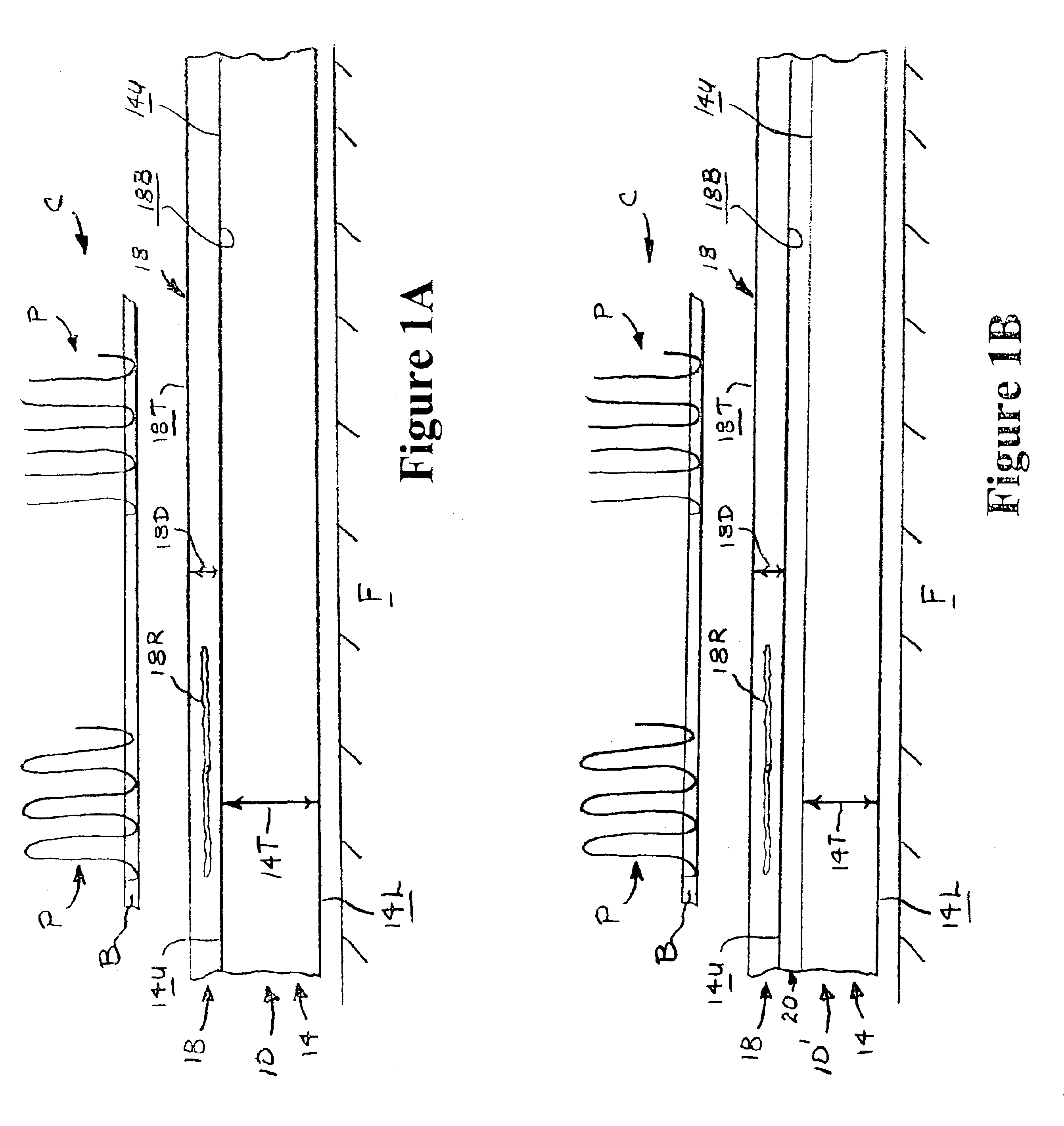

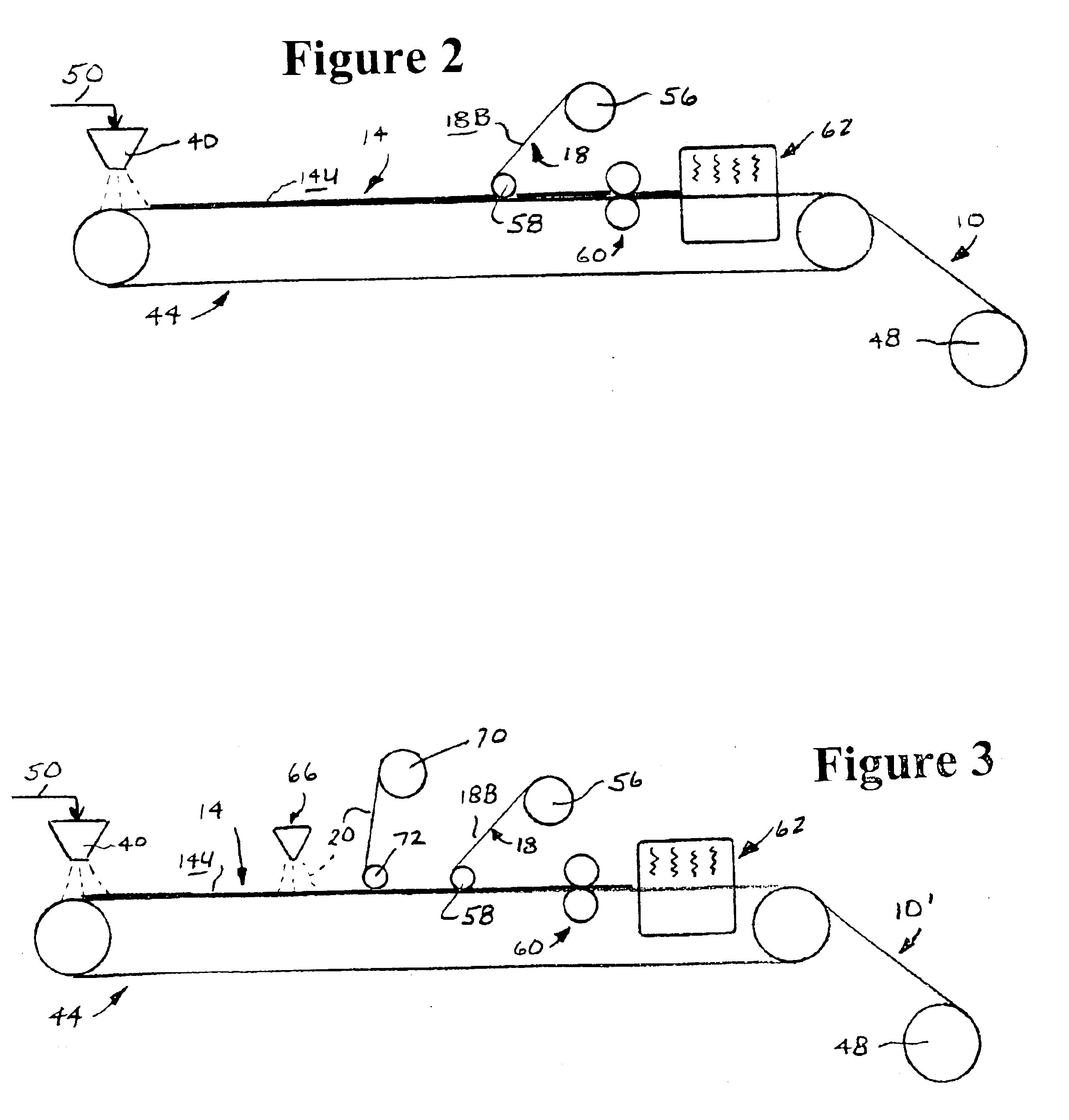

High-intensity sweetener composition and delivery of same

A composition for sweetening ingestable solids or liquids. The composition is compressed and comprises less than about 7.5 weight-% sucralose and one or more diluents. The composition is compressed at a pressure of greater than 2 pounds per square inch. A method of forming the composition and a system for delivering the composition are also provided.

Owner:HEARTLAND CONSUMER PROD

Durable, liquid impermeable and moisture vapor permeable carpet pad

A carpet pad comprises a two-layer structure of a cushion and a barrier film formed of a synthetic polymeric material free of any fibrous substrate laminated thereto. The barrier film may be directly bonded to the cushion or bonded thereto using a layer of adhesive. The carpet pad is simultaneously impermeable to liquid deposited onto the pad from above the barrier film and permeable to moisture vapor at a moisture vapor transmission rate of at least 14.6 grams per square meter per twenty-four hours (14.6 g / m2 / 24 hours). The carpet pad is sufficiently durable to maintain liquid impermeability as measured by a Vetterman Drum Wear Test / Staining / Stain Cleaning Test after at least ten thousand cycles or under a pressure of at least eight pounds per square inch (0.56 kg per square meter) as measured by a Modified Mullen Bursting Strength Test.

Owner:LOWES CO INC

Residential flat plate concealed sprinkler

A pendant sprinkler preferably includes a body having an inner surface defining a passageway. The passageway includes an inlet and an outlet spaced apart along the longitudinal axis and defines a K-factor of about 5. The sprinkler also includes a closure assembly adjacent the outlet to occlude the outlet and a thermally responsive support means for maintaining the closure assembly adjacent the outlet. Also provided are means for distributing a flow of fluid over a protection area ranging from about 144 square feet to about 400 square feet, the fluid distribution having a density of at least 0.05 gallons per minute per square foot (0.05 gpm / ft2) so as to define a range of minimum operating pressures ranging from about seven pounds per square inch to about seventeen pounds per square inch (7-17 psi.) and a range of minimum operating fluid flows ranging from about thirteen gallons per minute to about twenty gallons per minute (13-20 gpm.). The sprinkler preferably includes a thermally responsive plate means for maintaining a minimum spacing between the outlet and the means for distributing.

Owner:TYCO FIRE PRODS LP

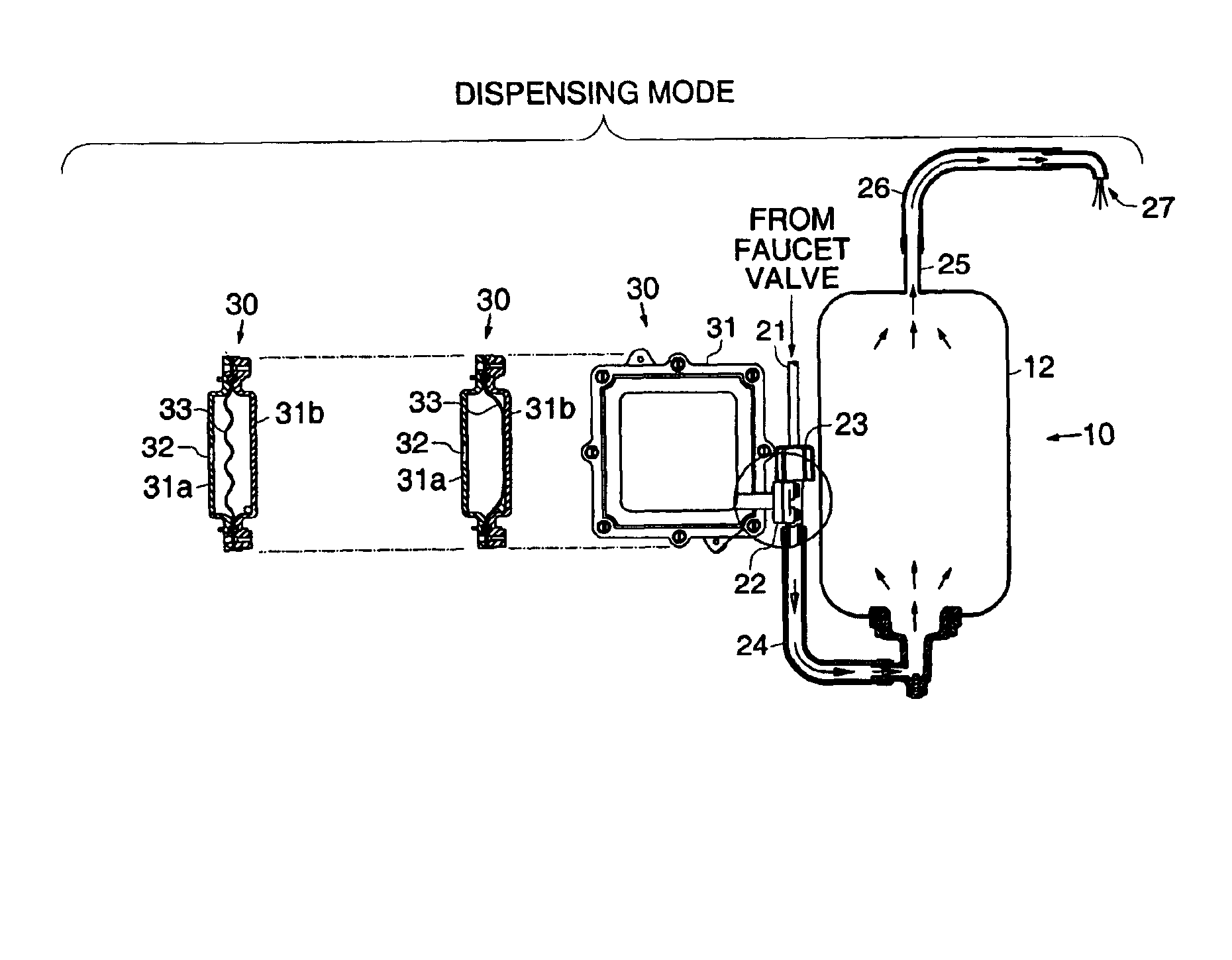

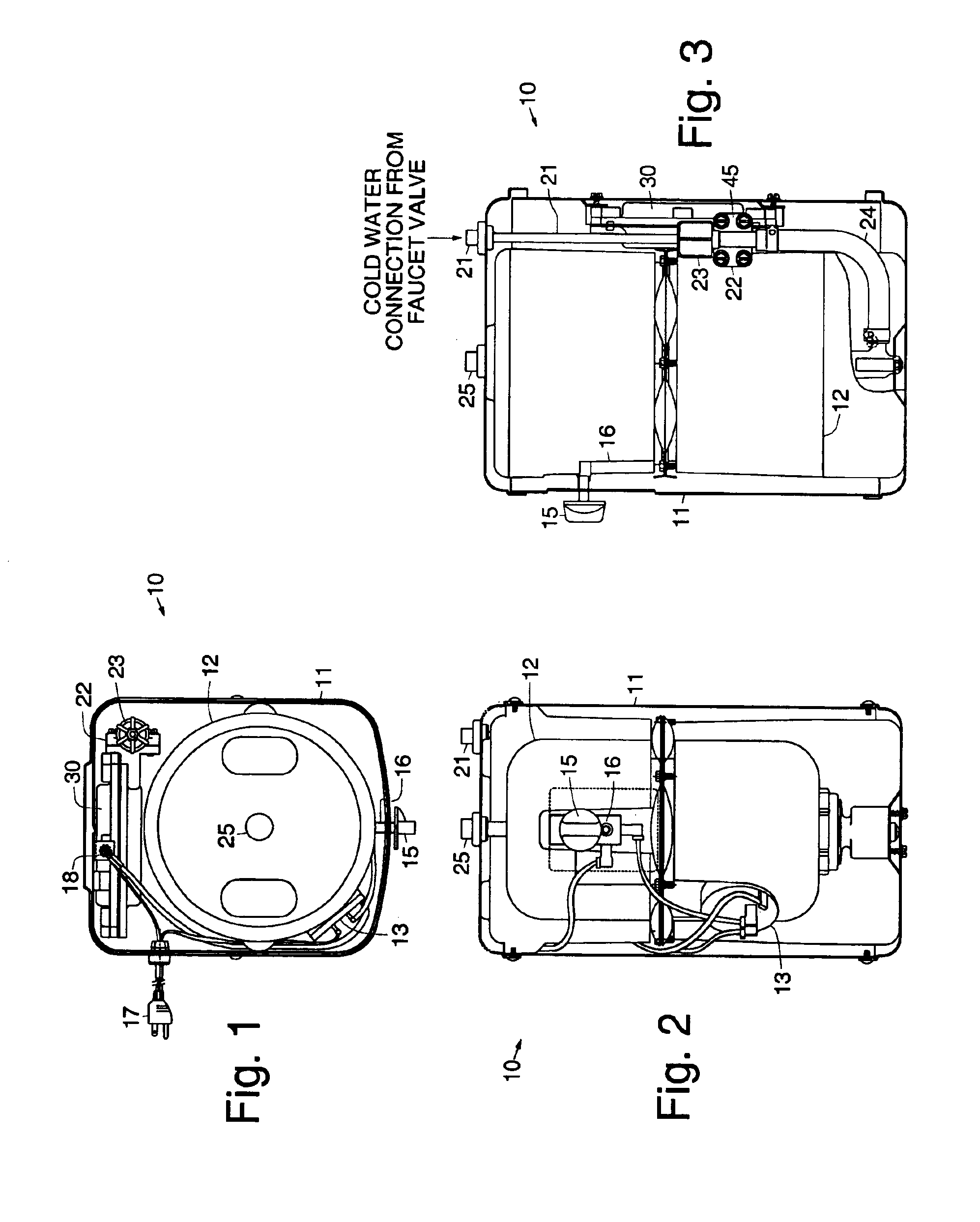

Hot water dispensing system

InactiveUS6847782B1Prevents heating element burn-upImprove abilitiesCooking vesselsImmersion heating arrangementsEngineeringControl switch

Hot water dispersing systems having a self-resetting heater control switch that prevents heater burn-up if the water tank becomes empty, and a variable volume expansion chamber having a flexible bladder that is designed to withstand a pressure of at least 300 pounds per square inch.

Owner:ANAHEIM MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com