Patents

Literature

143 results about "Cubic foot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The cubic foot (symbol ft³) is an imperial and US customary (non-metric) unit of volume, used in the United States, and partially in Canada, and the United Kingdom. It is defined as the volume of a cube with sides of one foot (0.3048 m) in length. Its volume is 28.3168 liters or about ¹⁄₃₅ of a cubic meter.

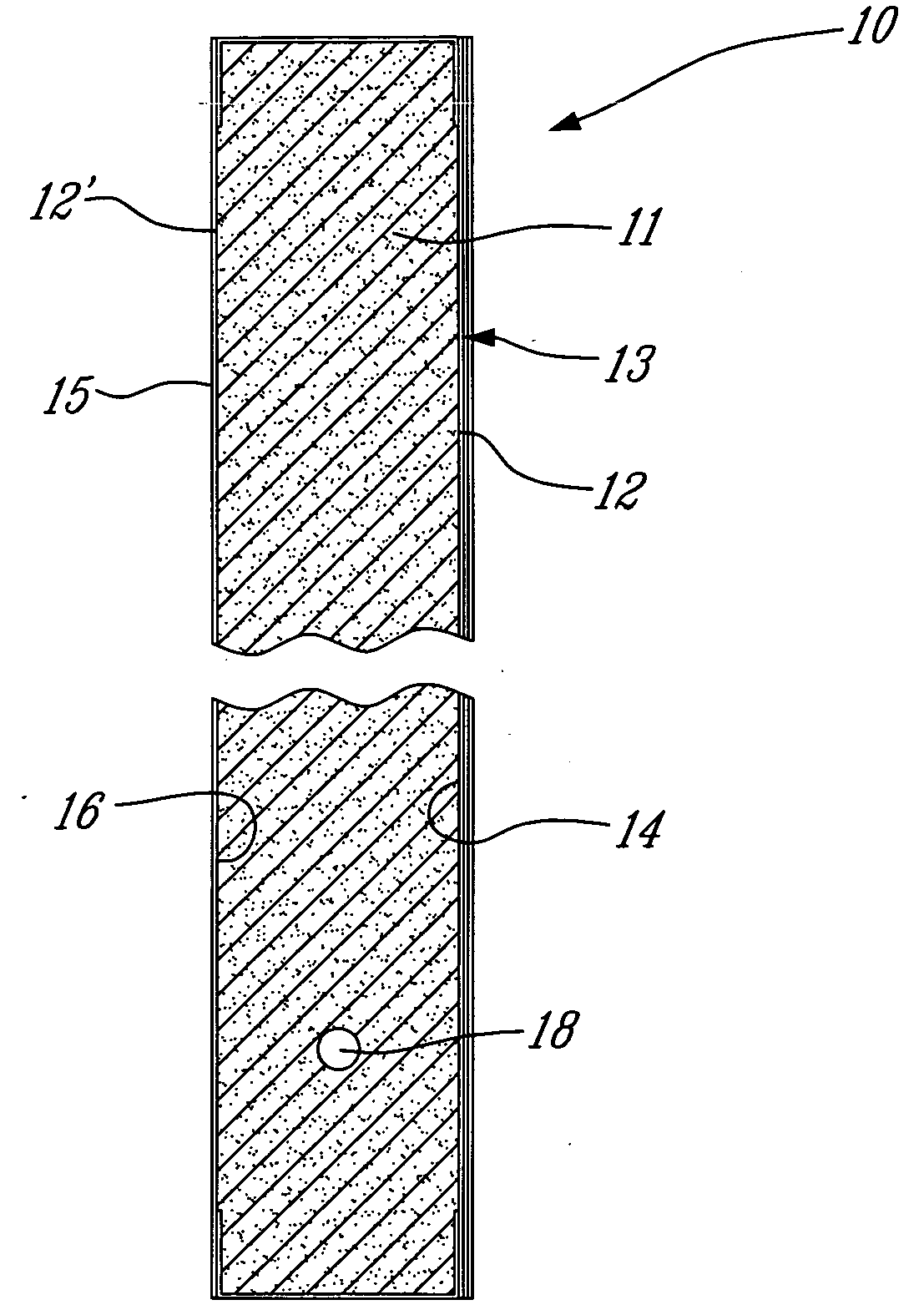

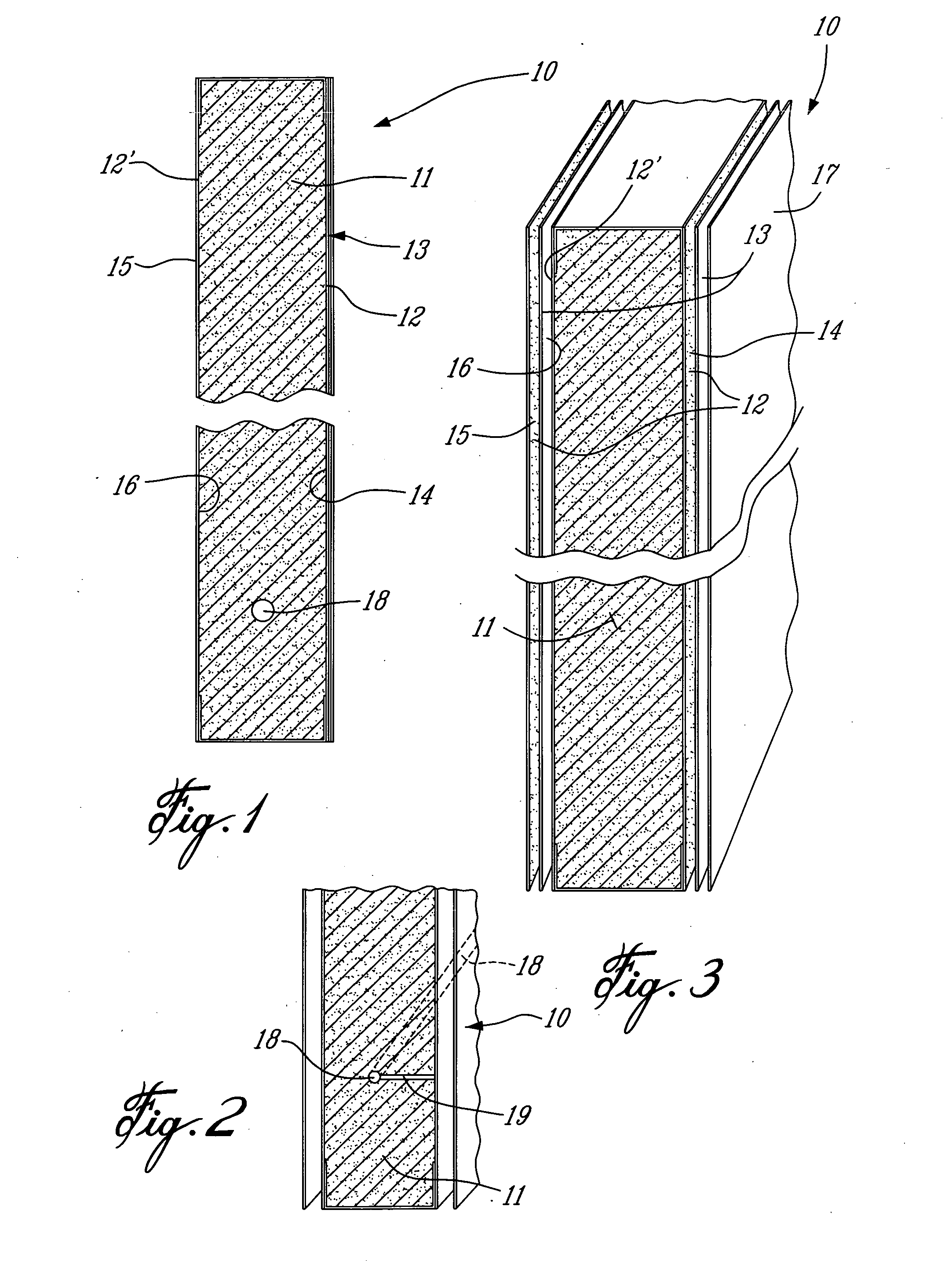

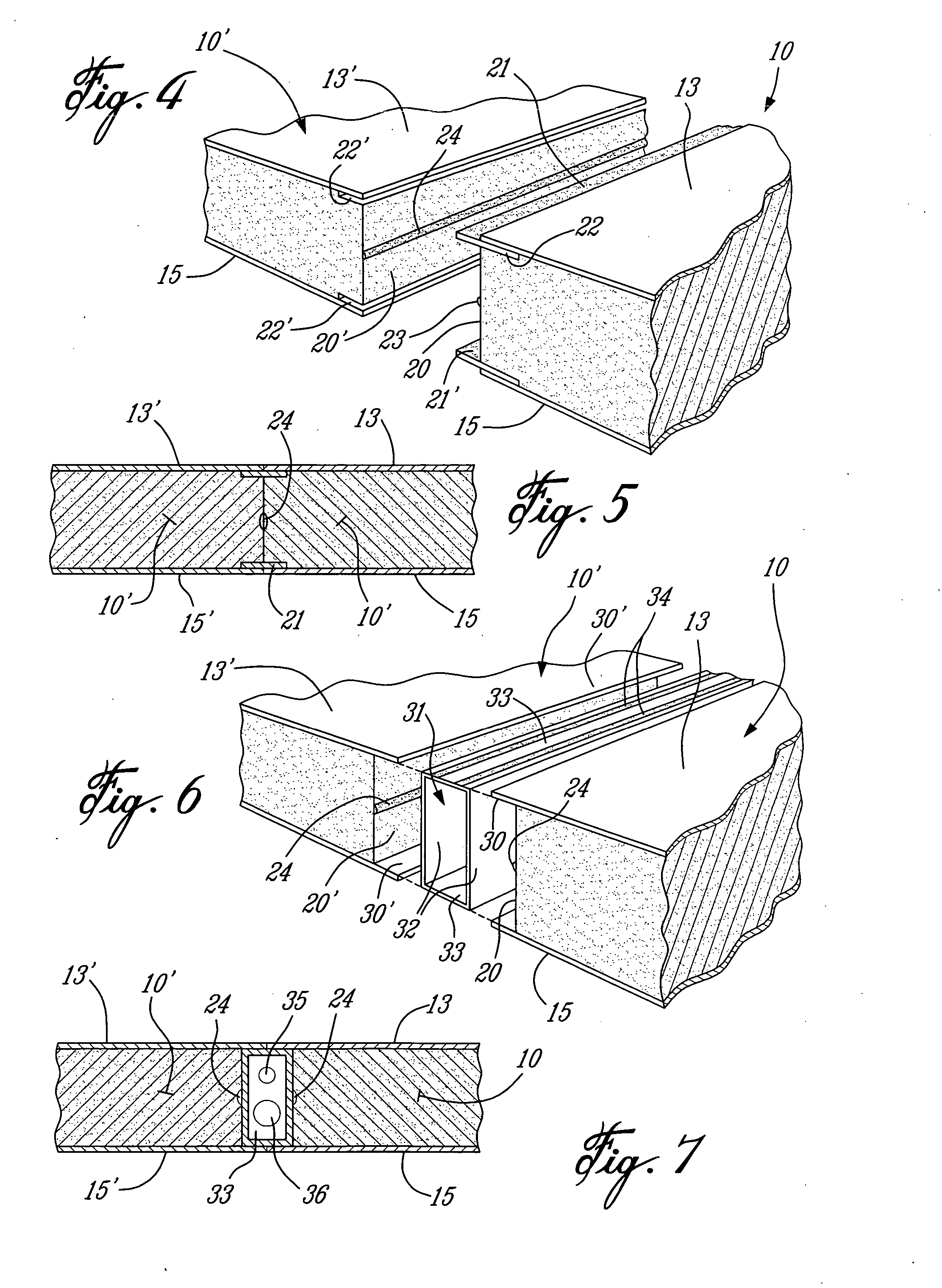

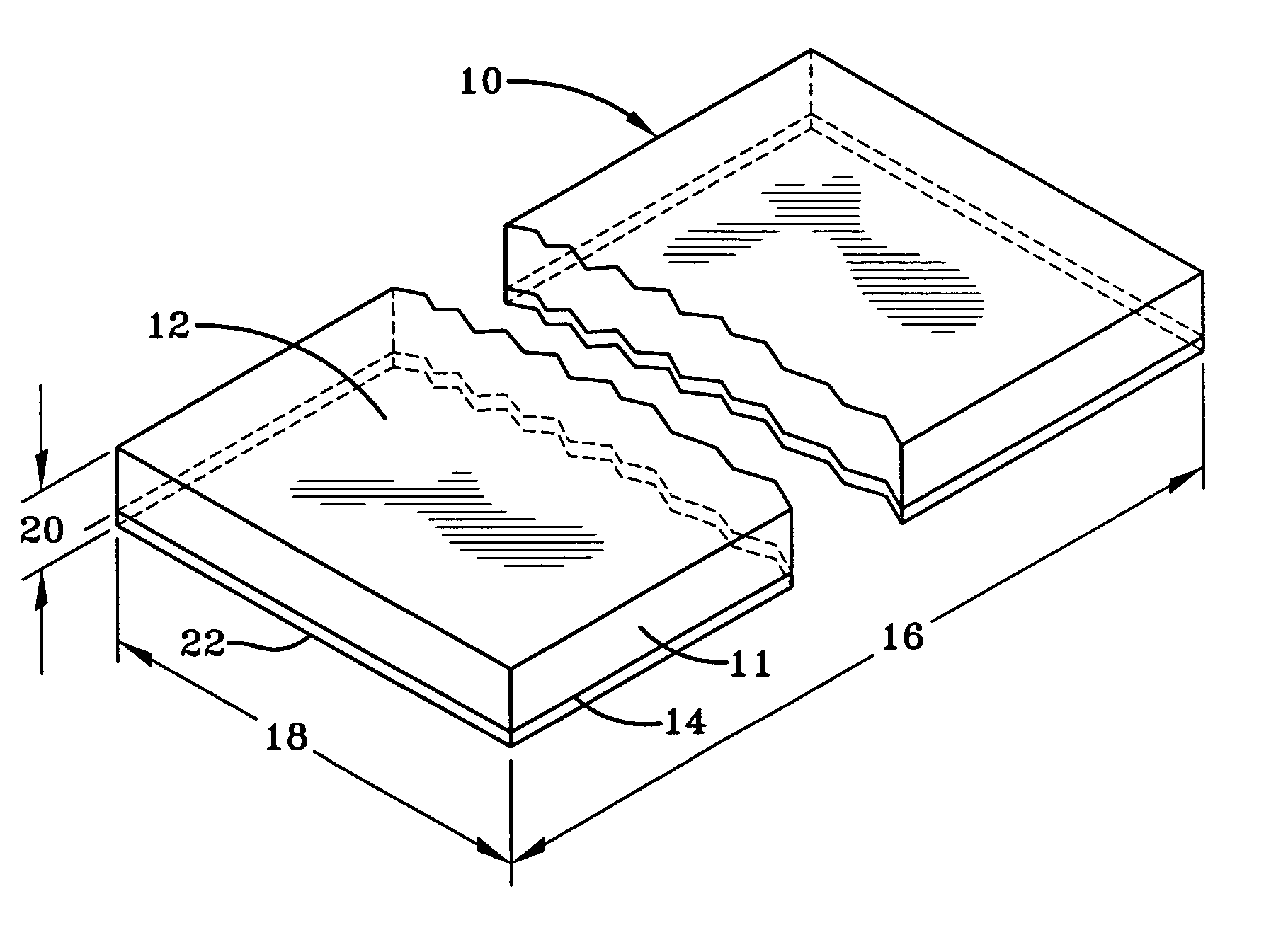

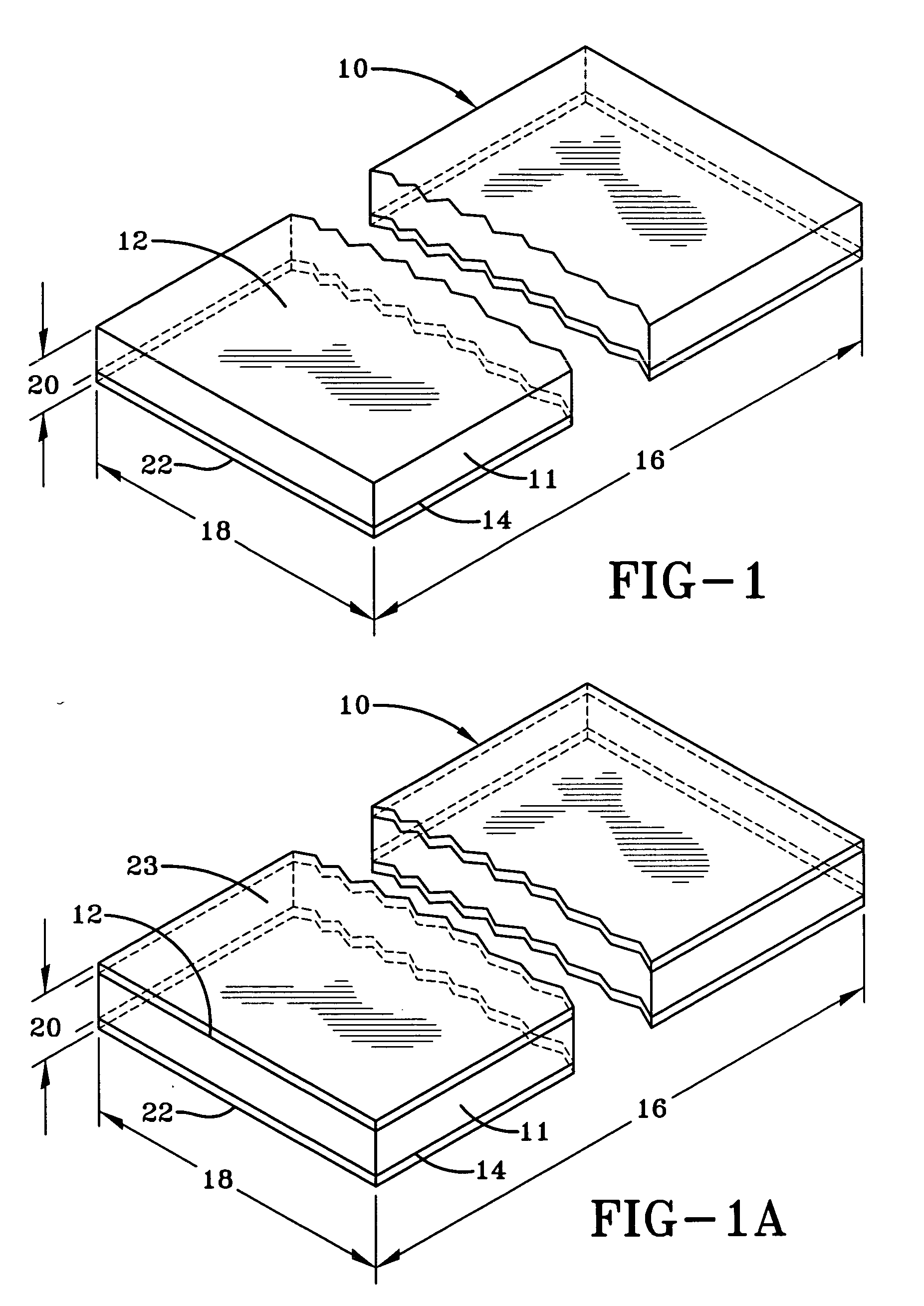

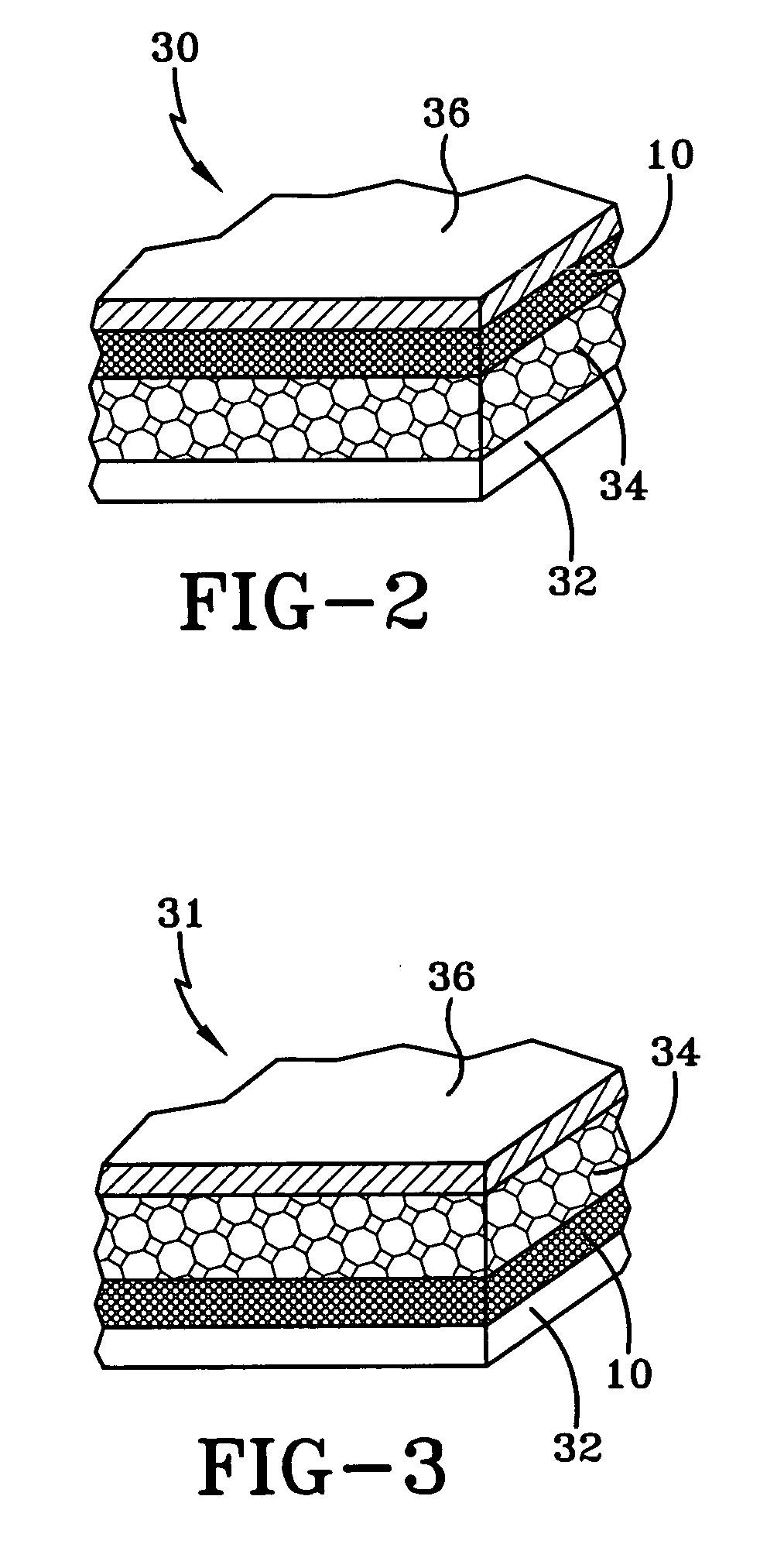

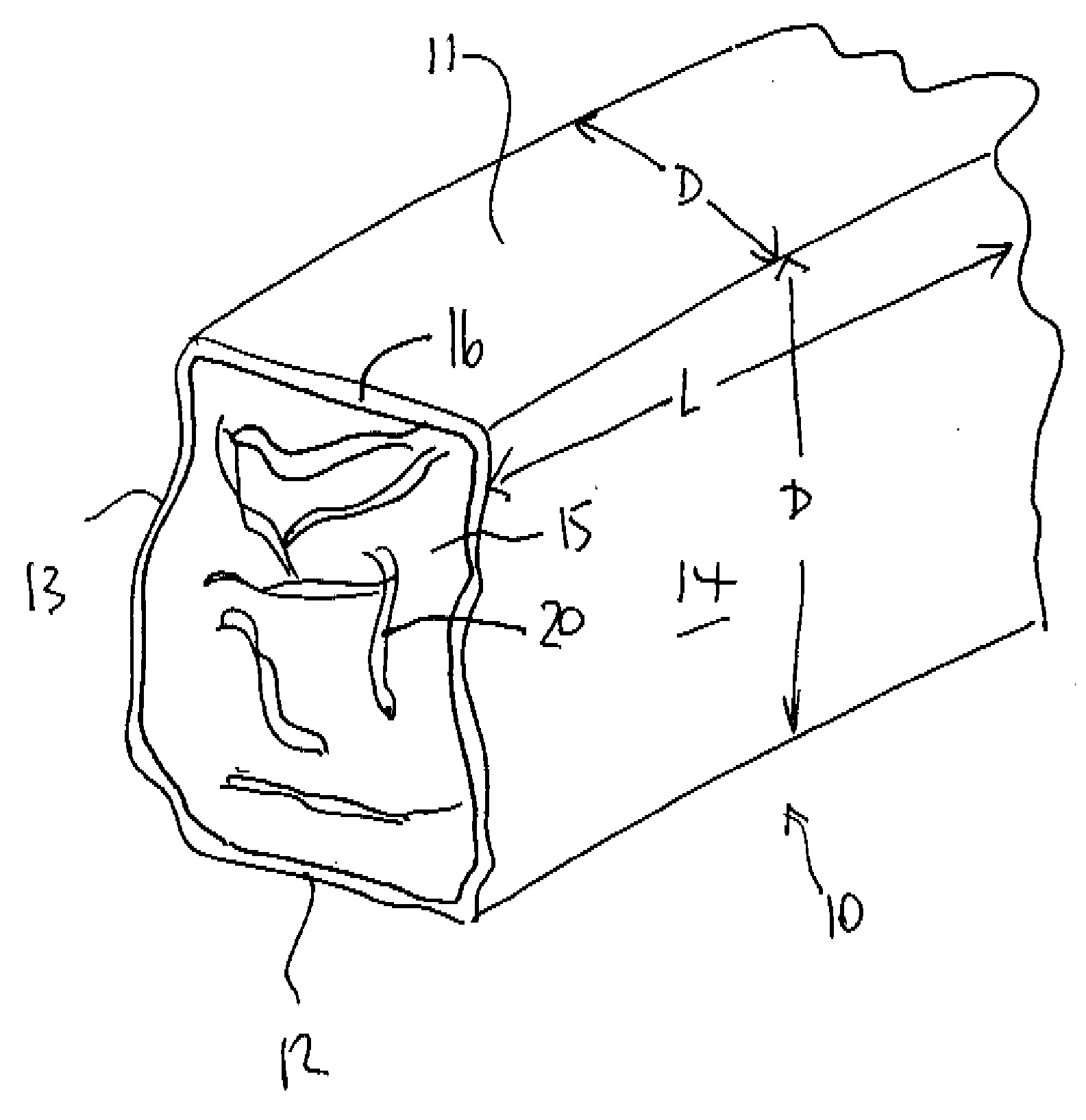

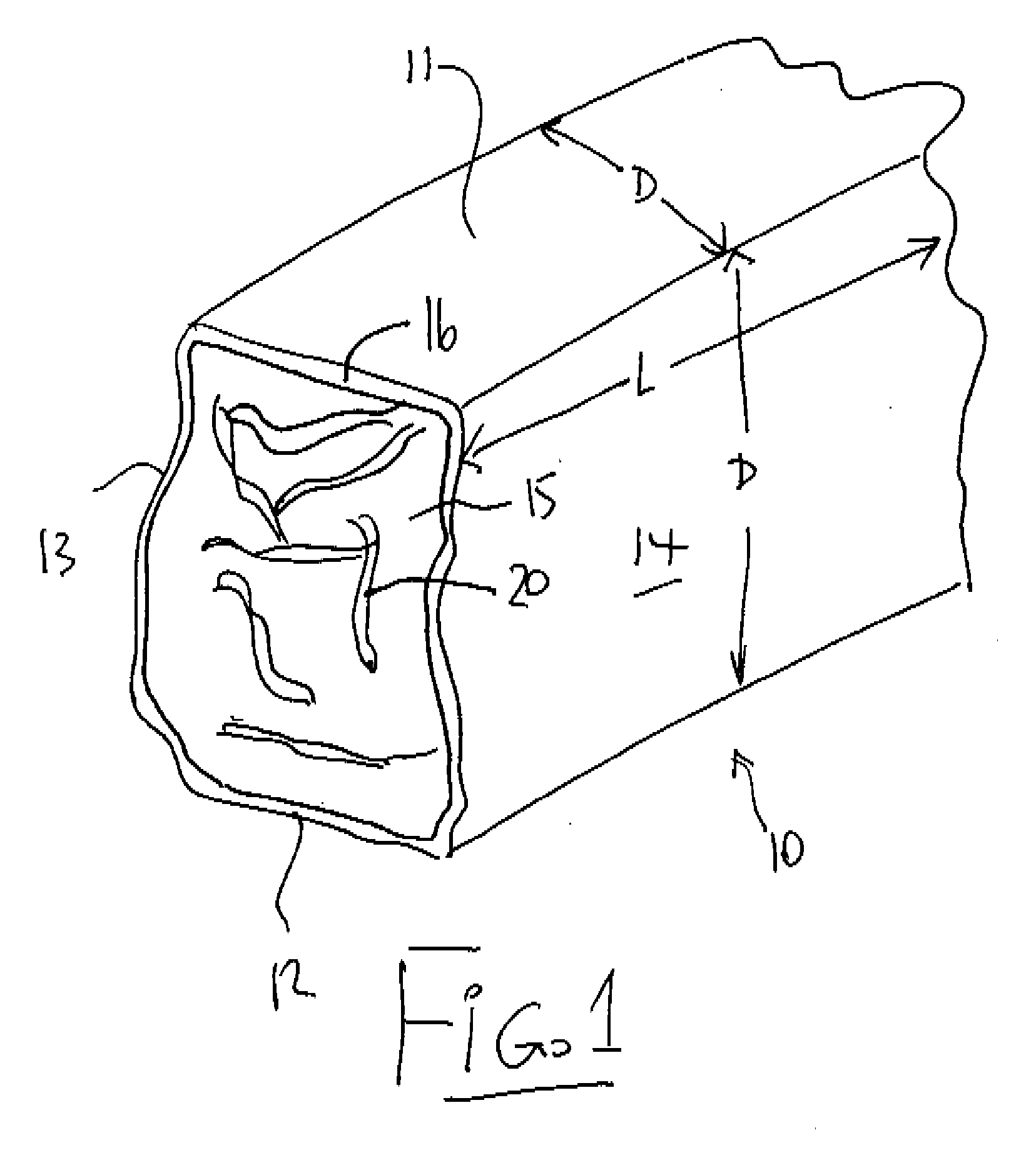

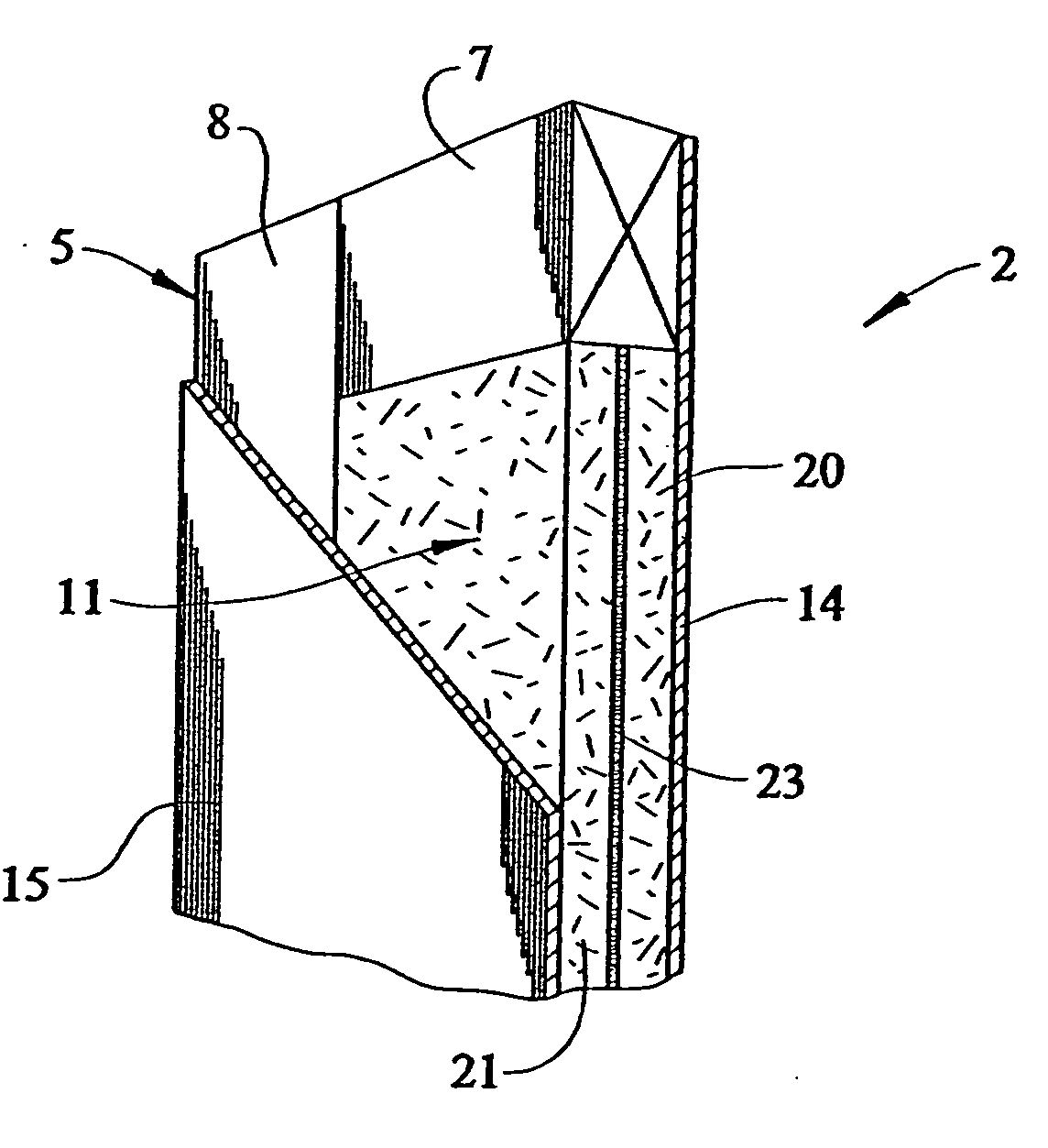

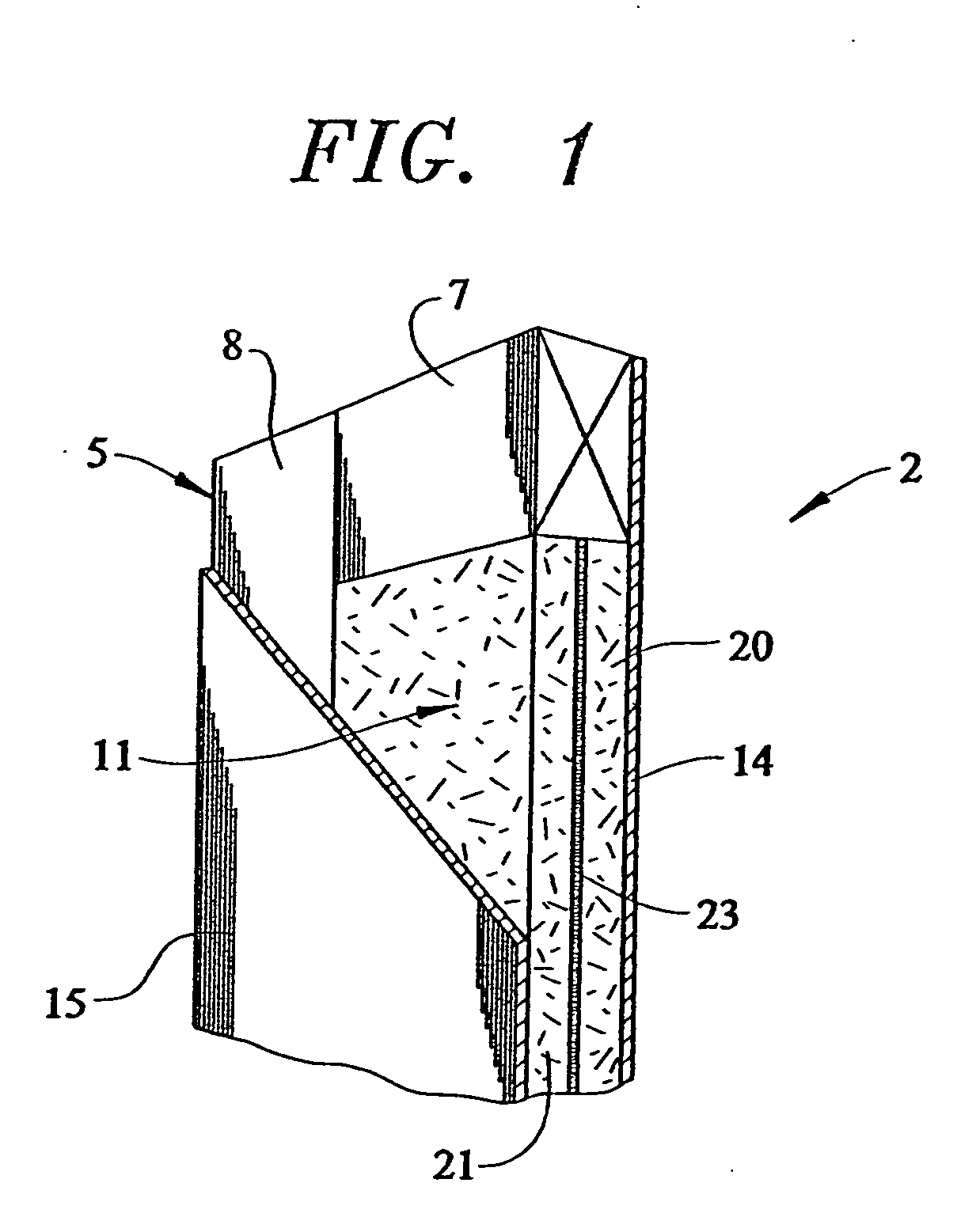

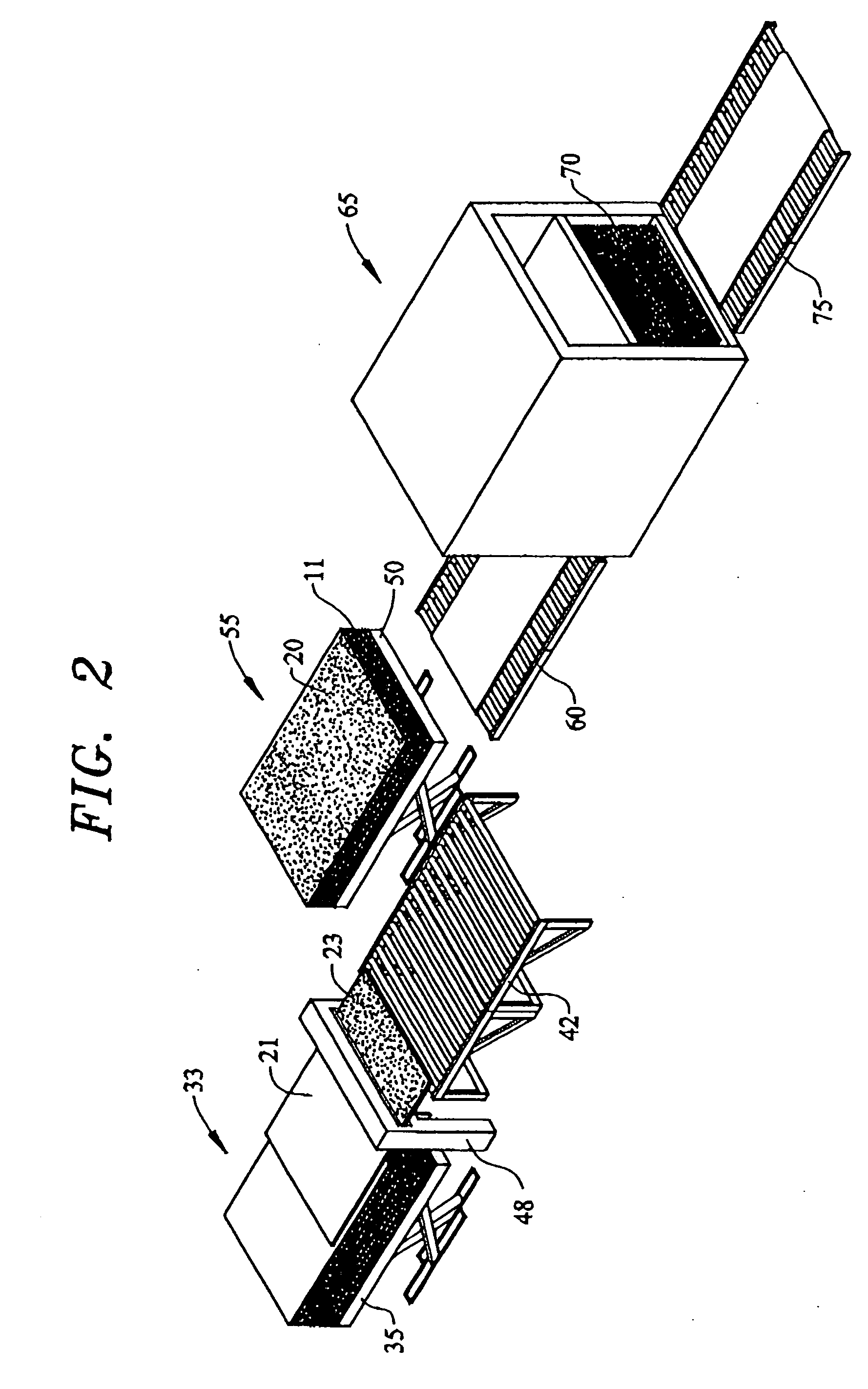

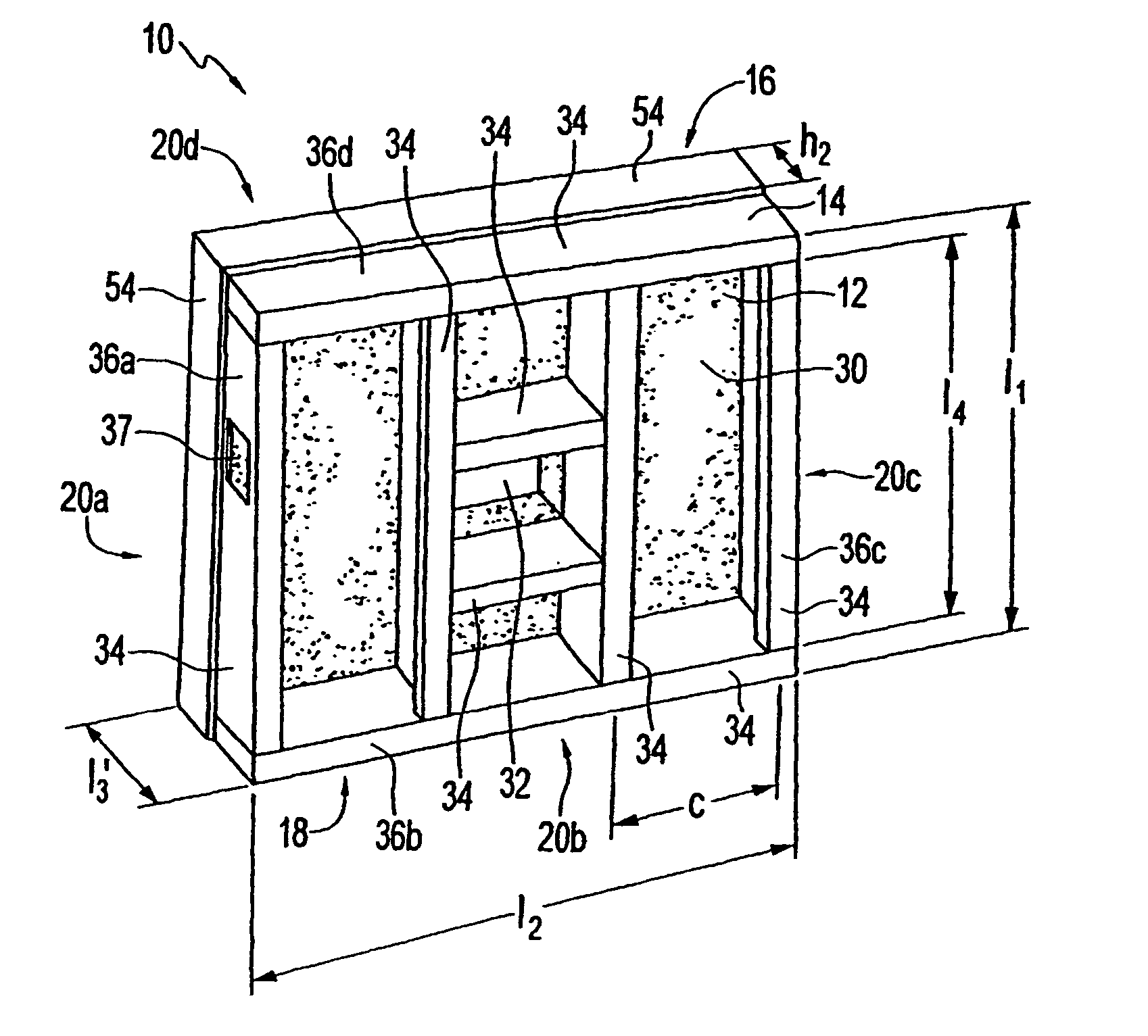

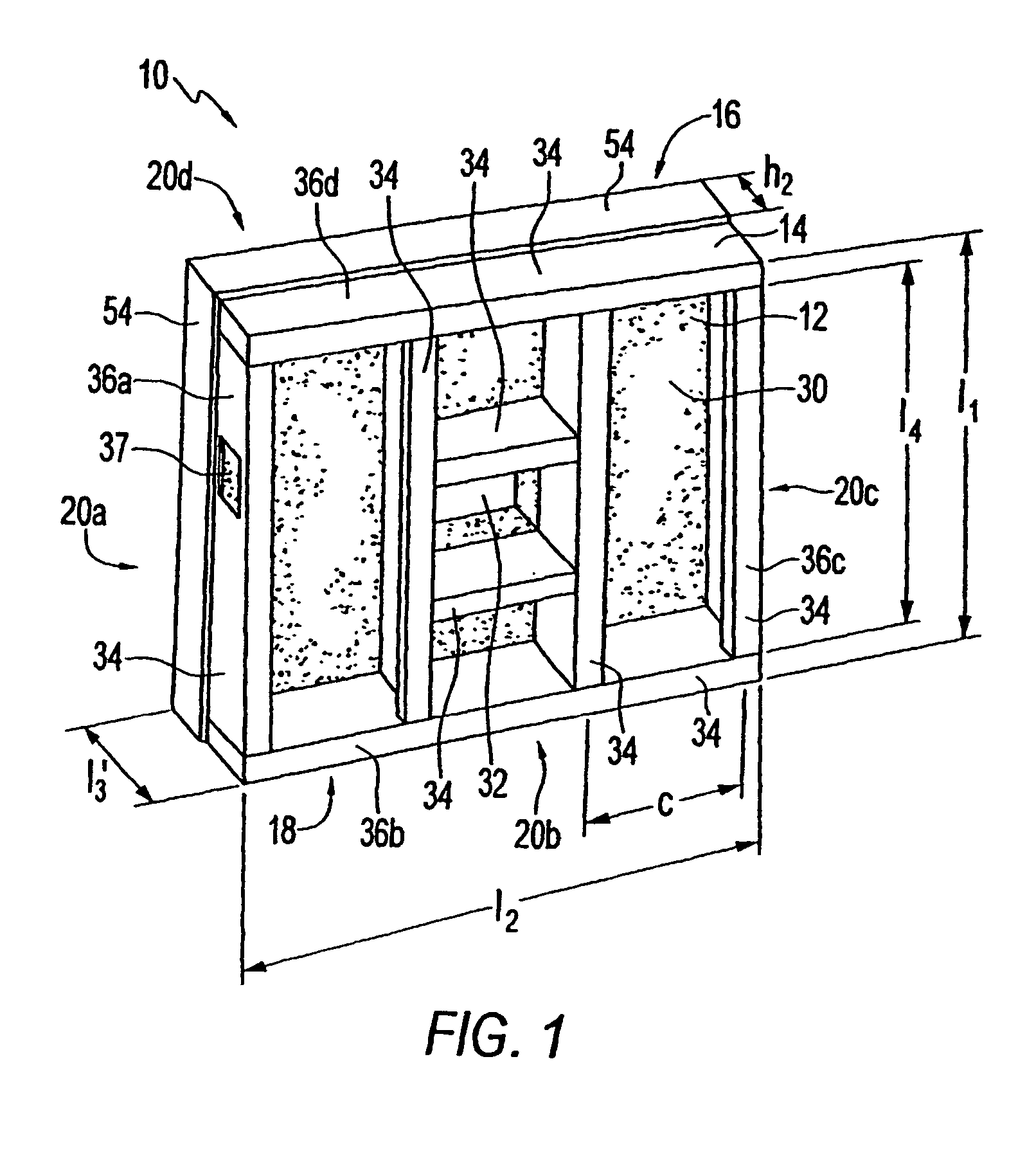

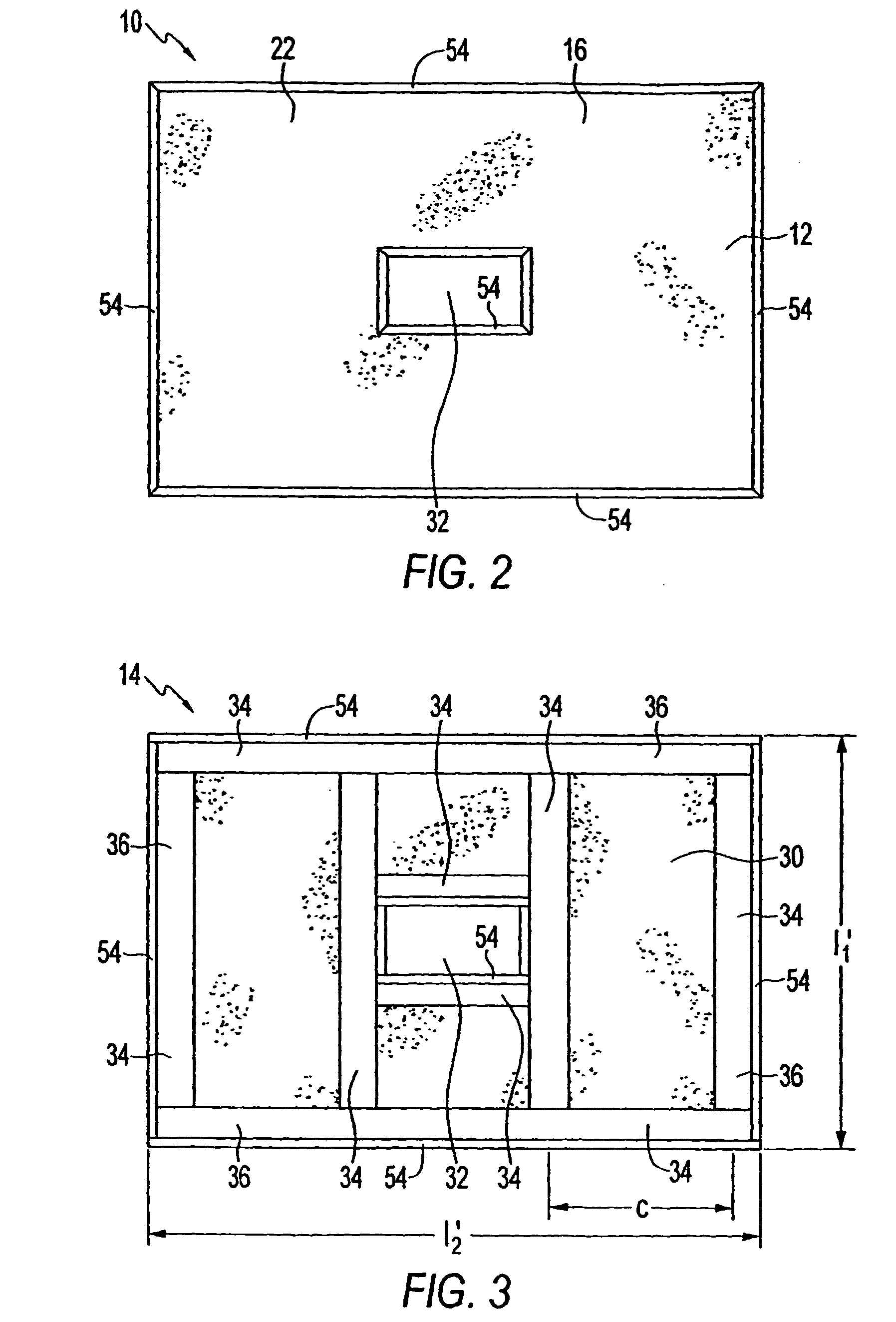

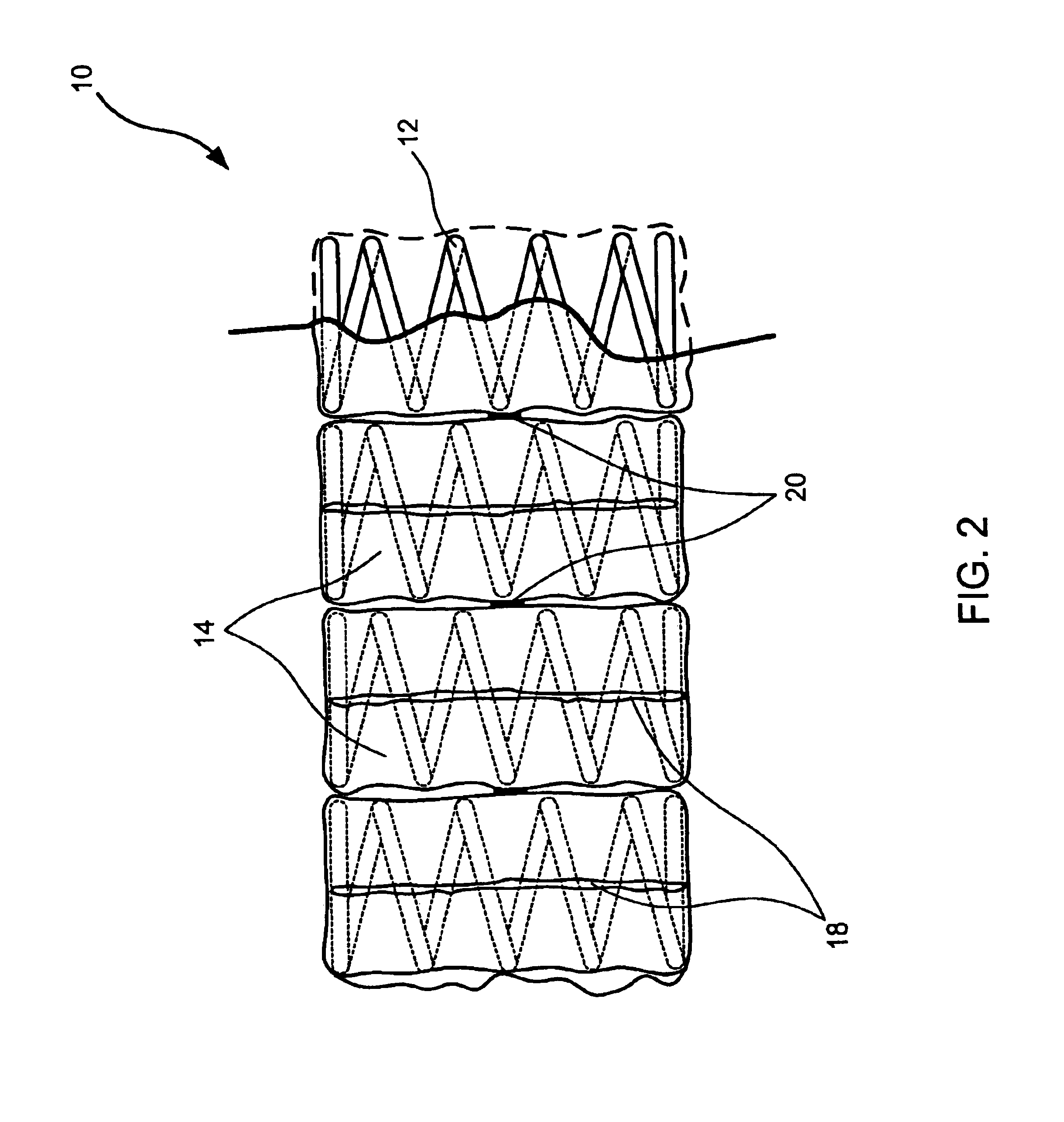

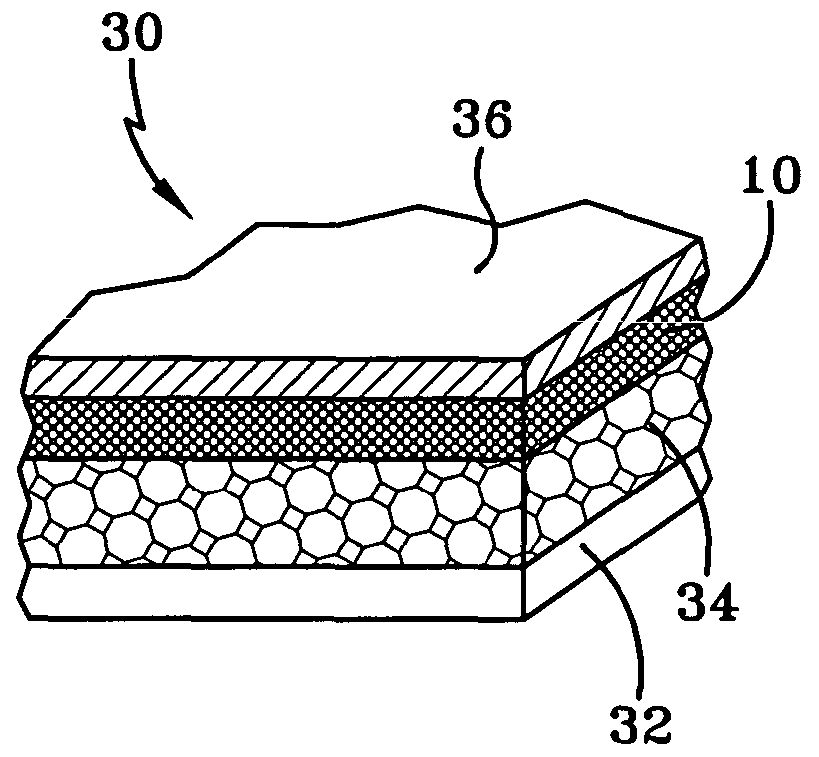

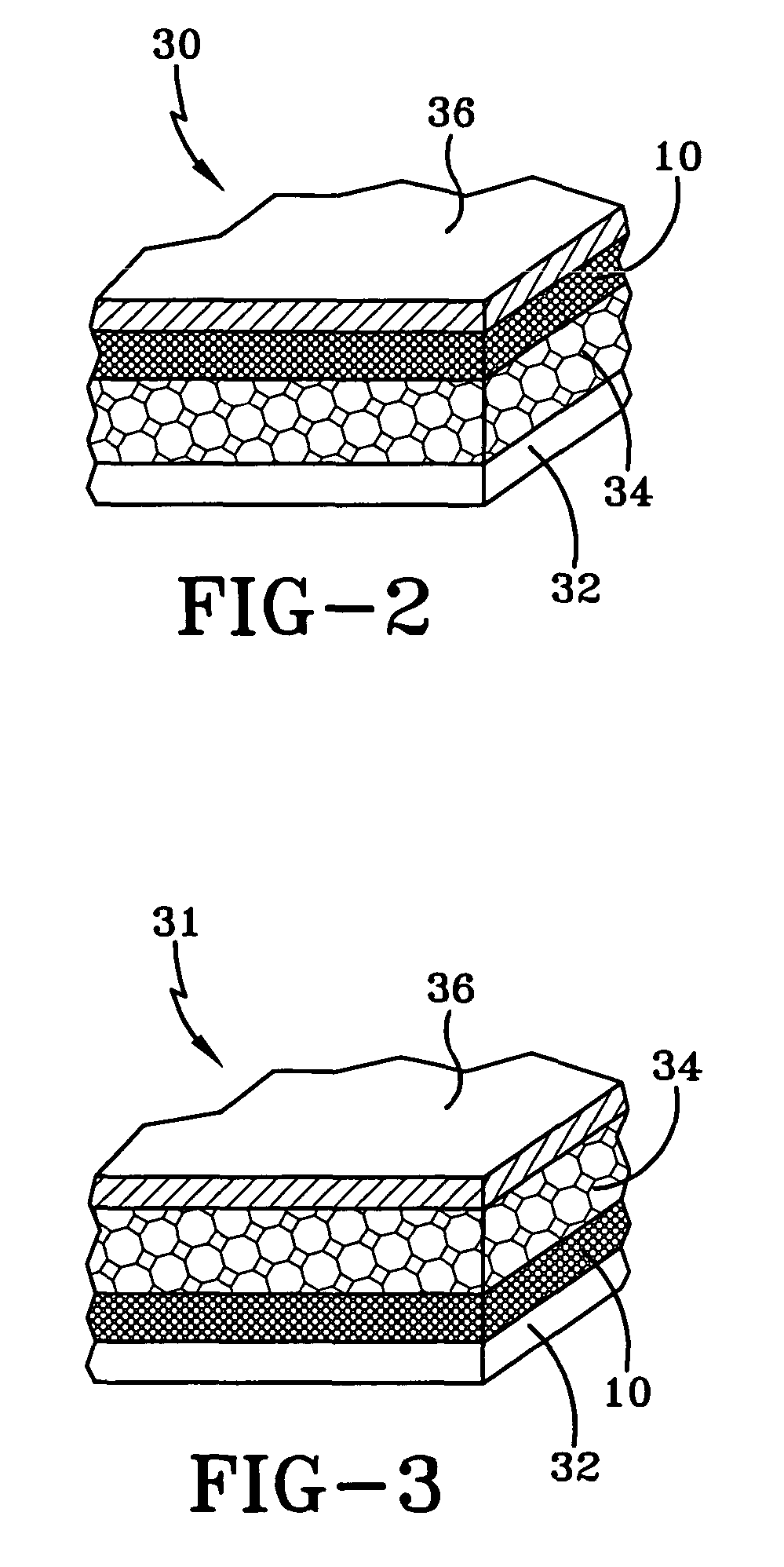

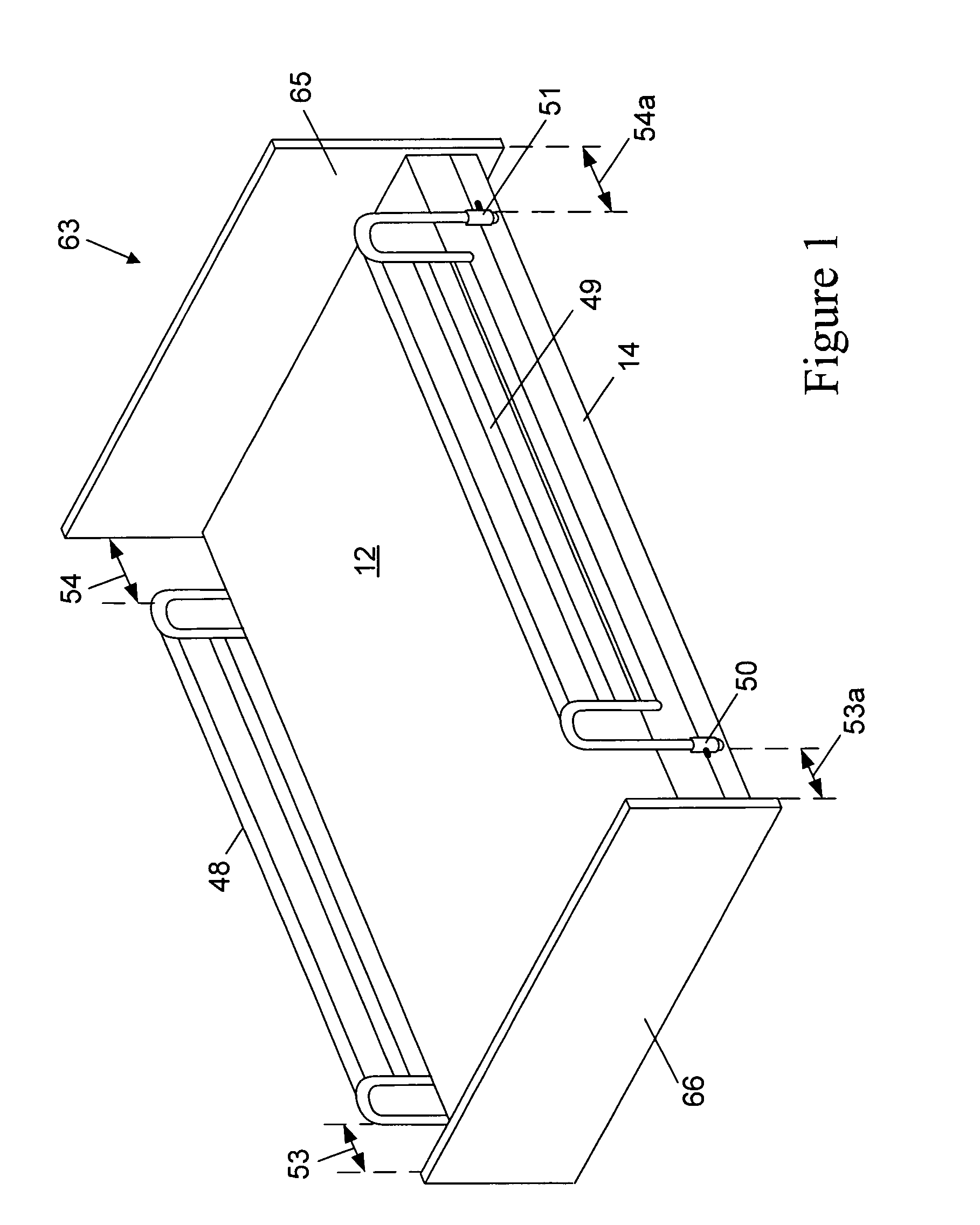

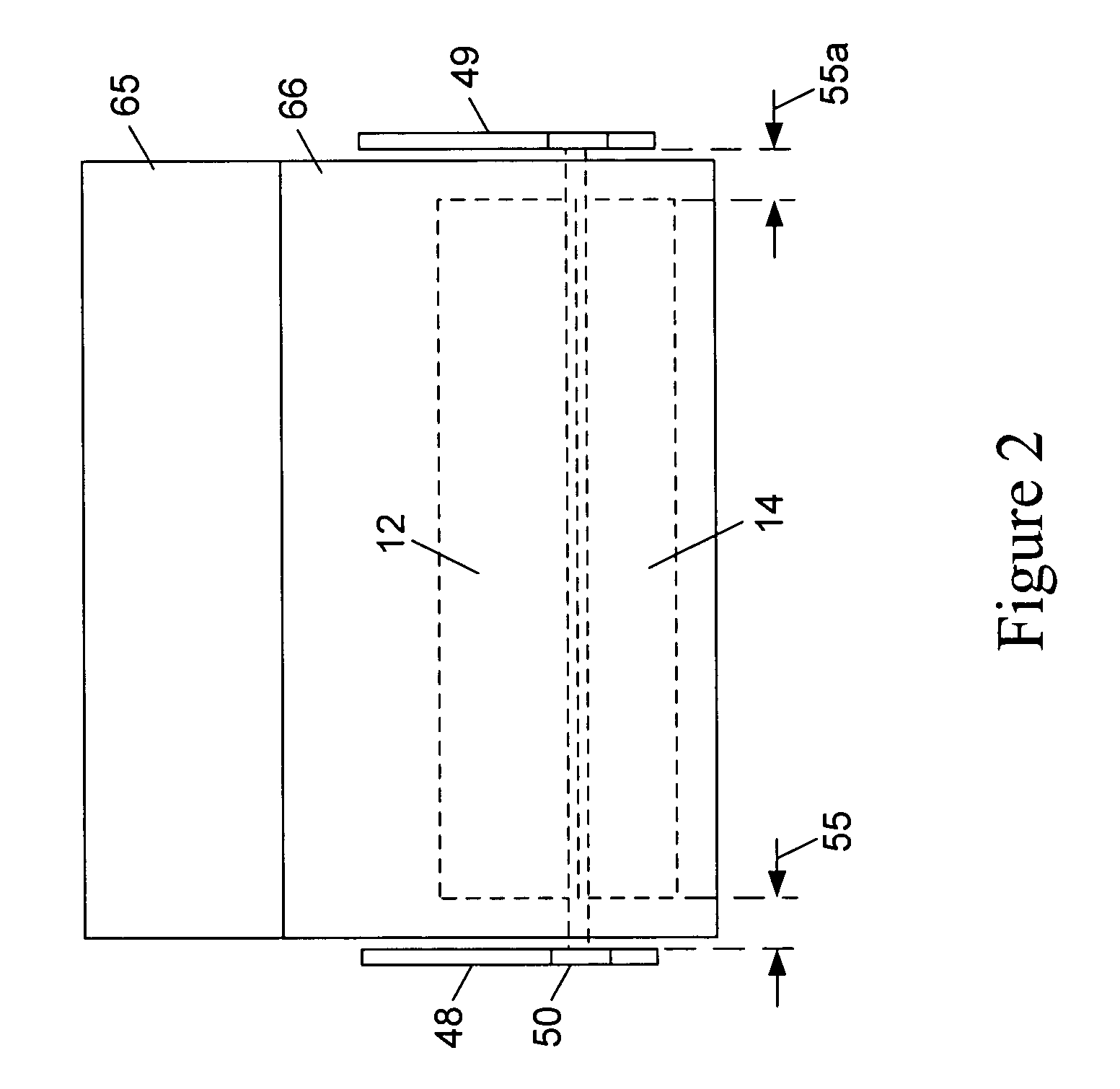

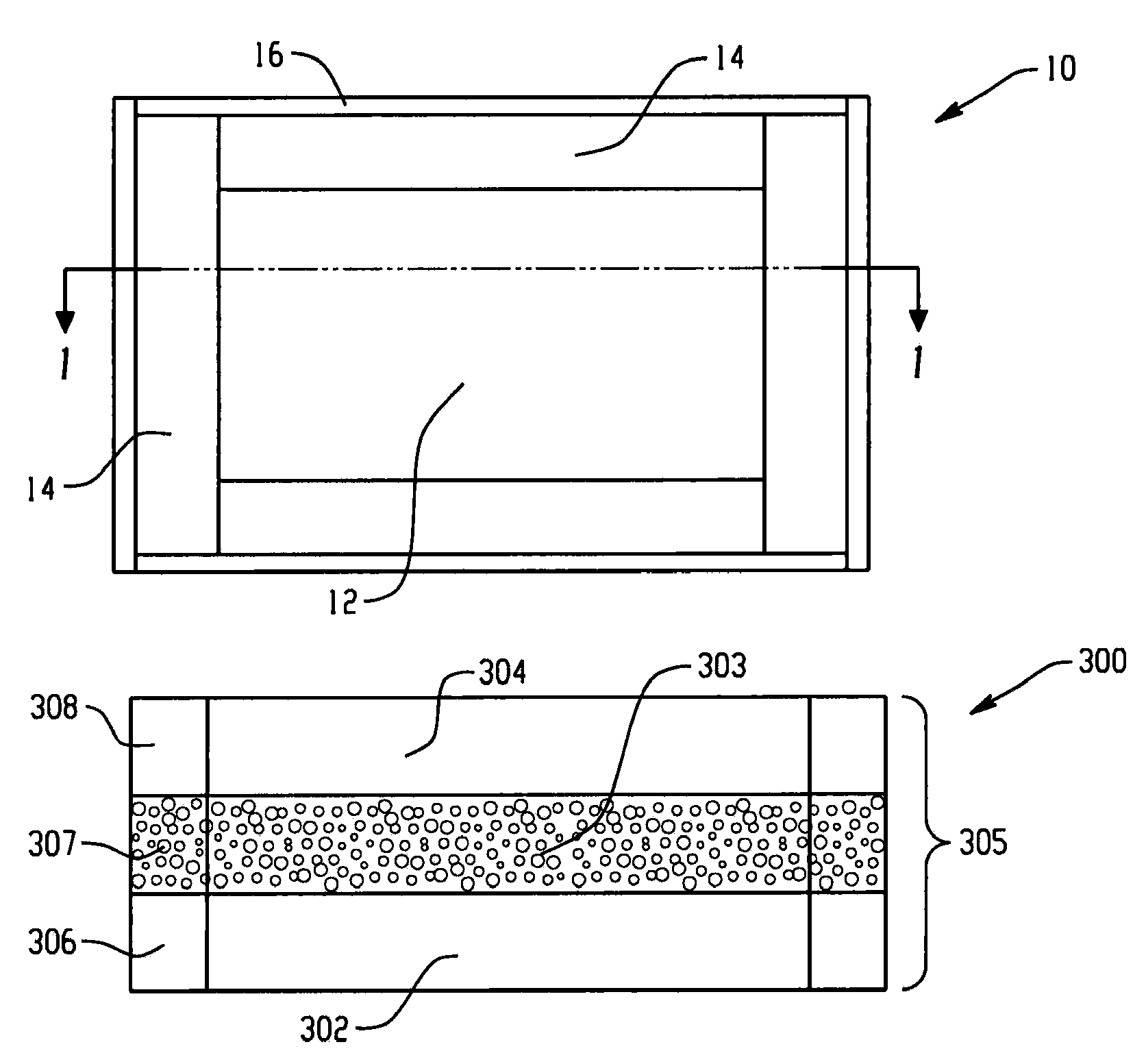

Structural insulated panel construction for building structures

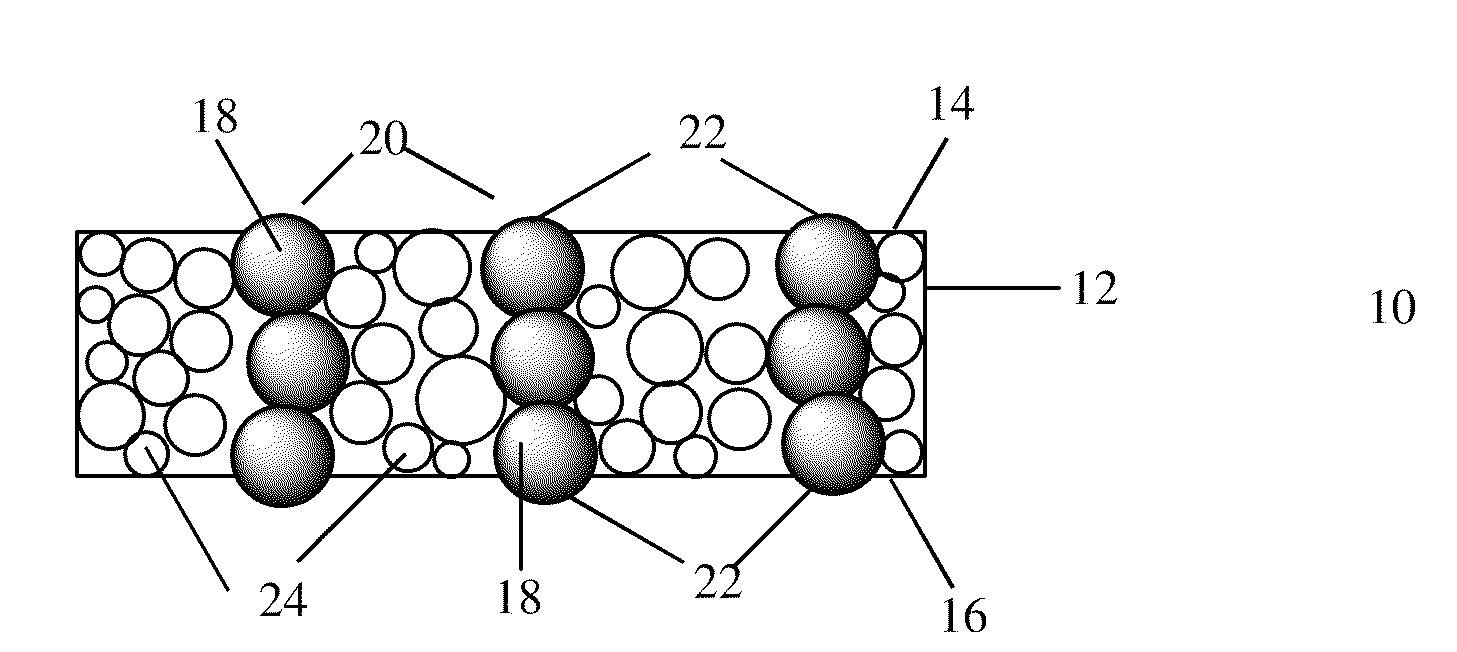

InactiveUS20070125042A1High strengthEasy to assembleSynthetic resin layered productsBuilding componentsRigid coreExpanded polystyrene

A structural insulated laminated construction panel for building structures is described. The panel comprises a rigid core material layer of expanded polymeric material having opposed flat parallel surfaces. An outer skin is adhesively secured to one of the flat surfaces and an inner skin is adhesively secured to the other of the flat surfaces. The core material layer has a density of about 2 lbs / cubic foot. The core material is preferably an expanded polystyrene material. A building structure is constructed from such panels used as exterior and interior wall panels, floor panels and roof panels.

Owner:HUGHES JOHN +3

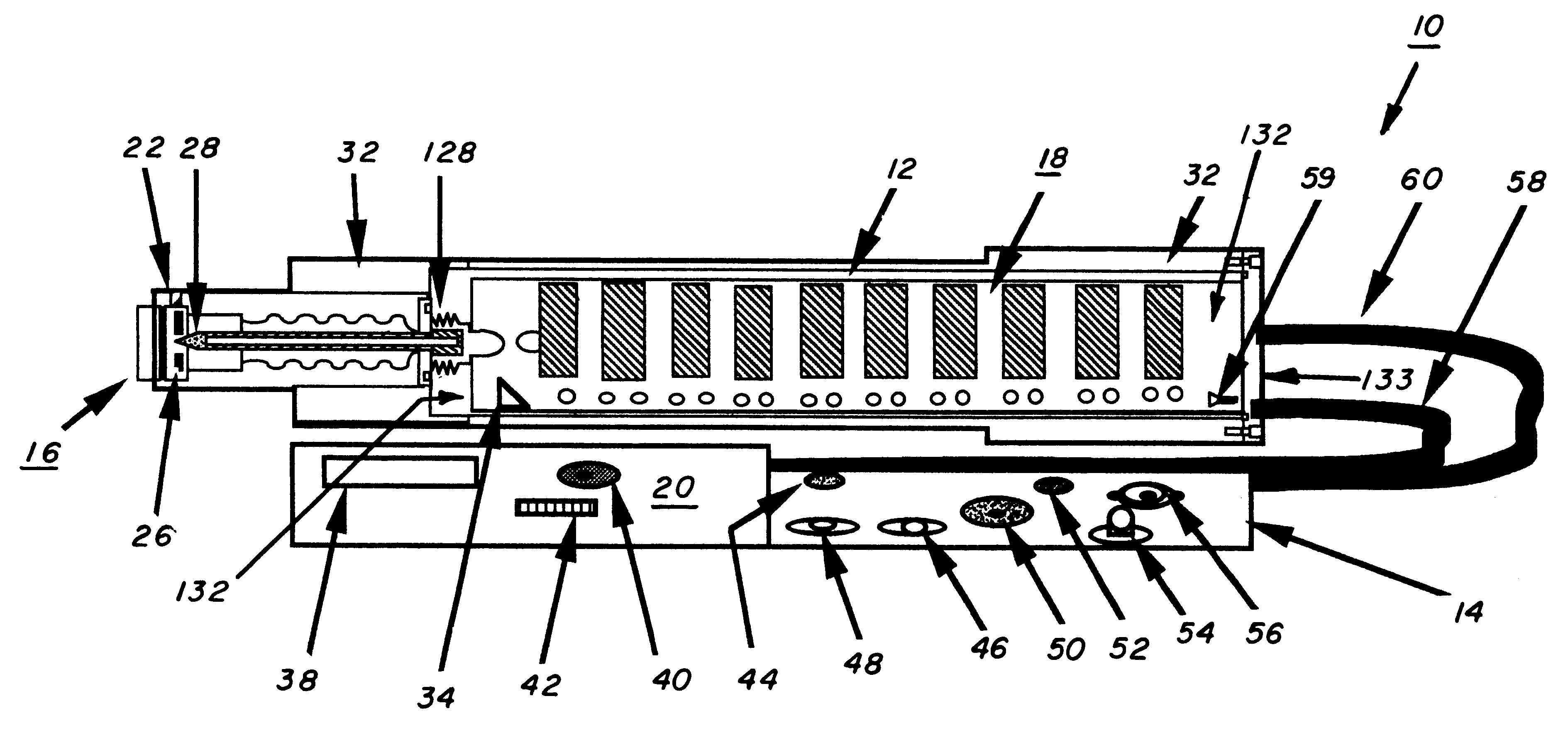

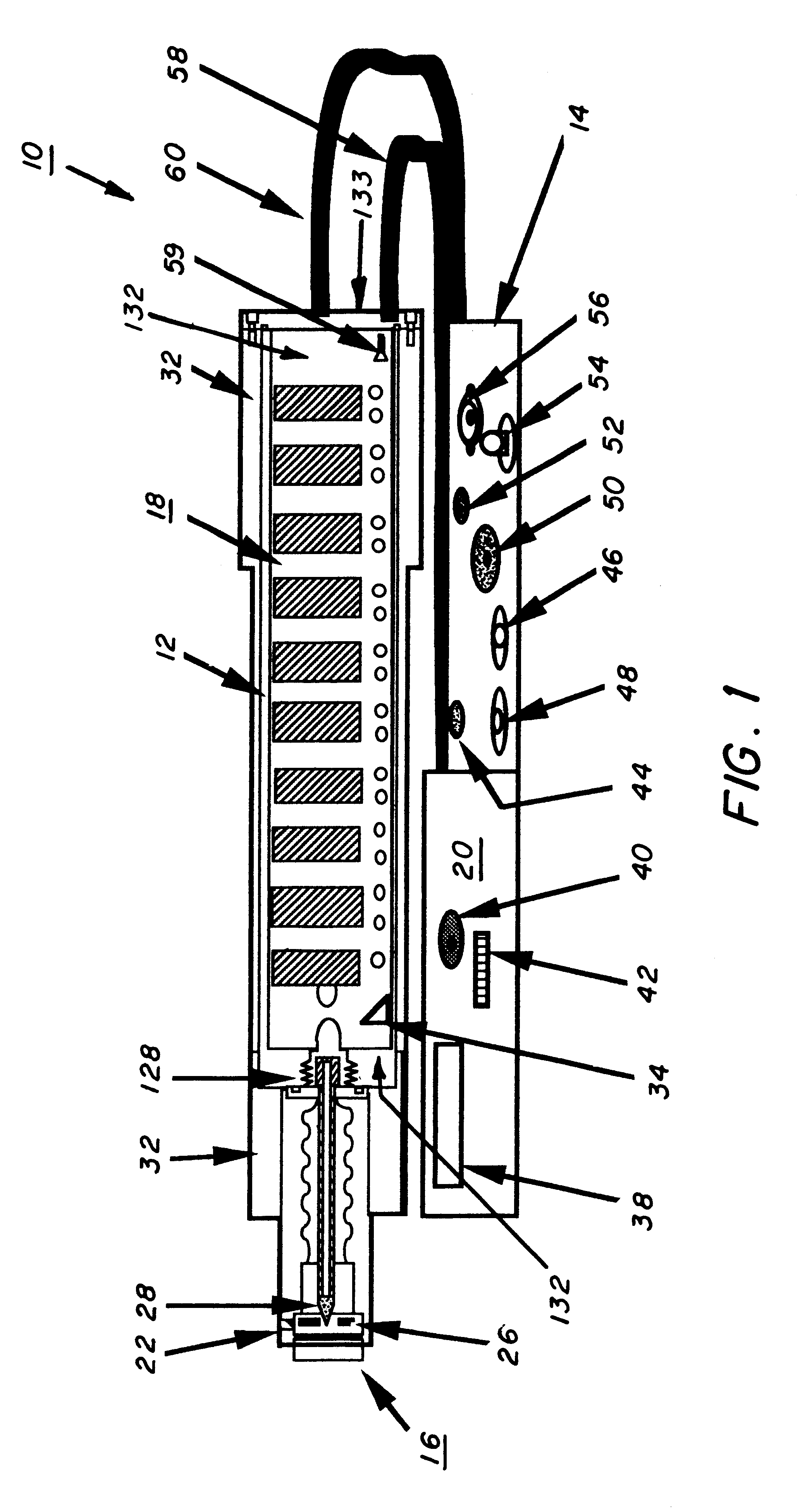

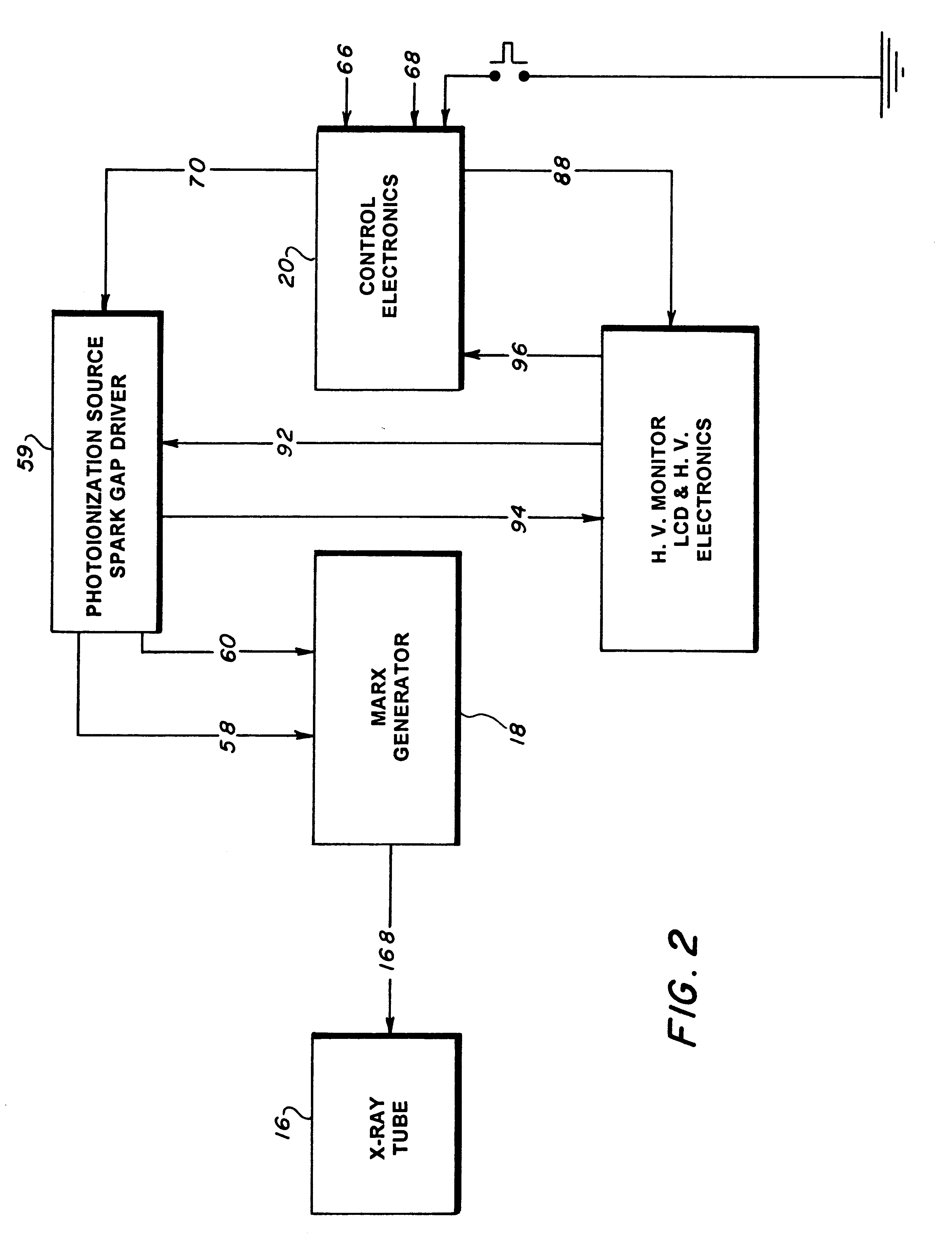

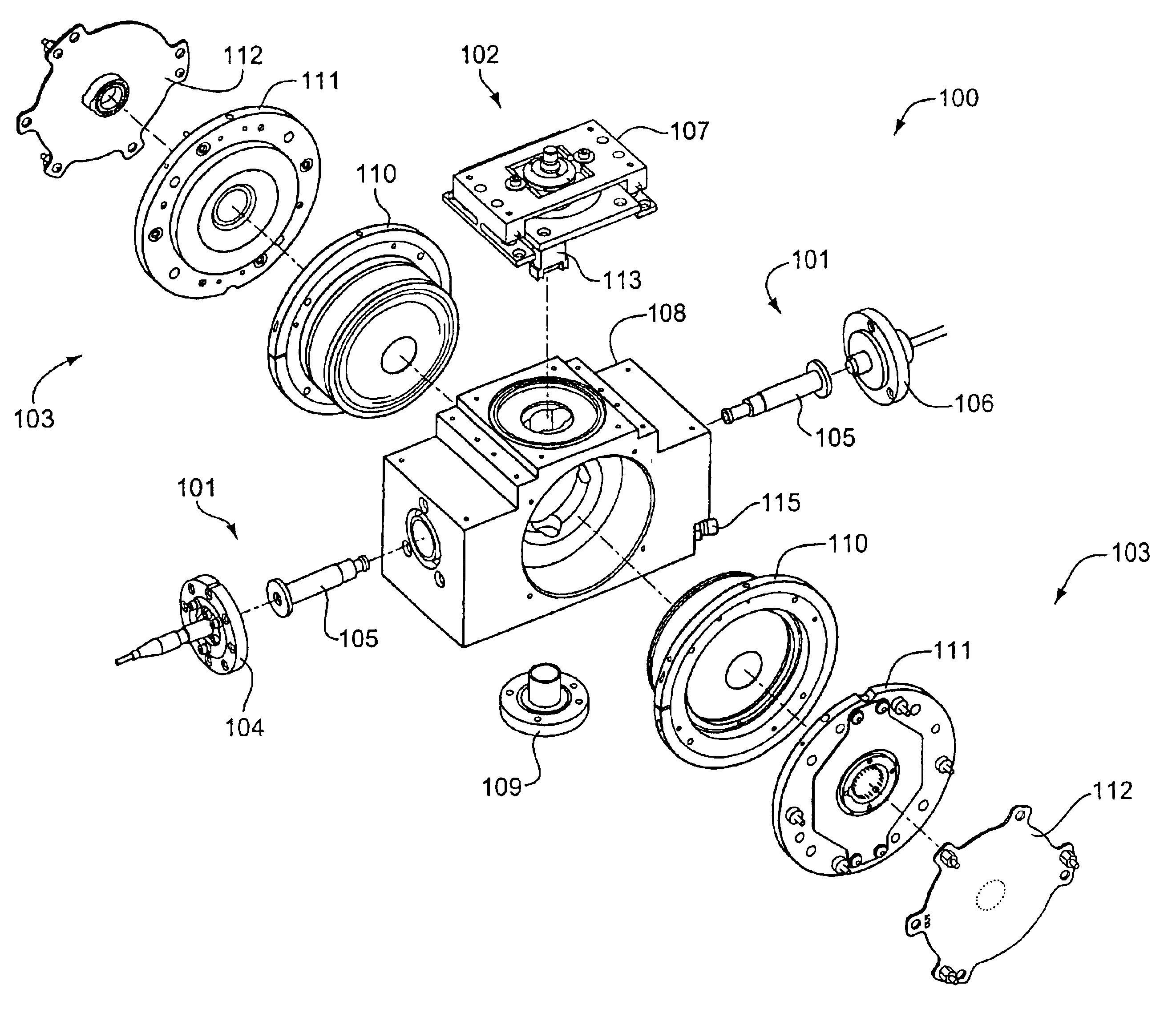

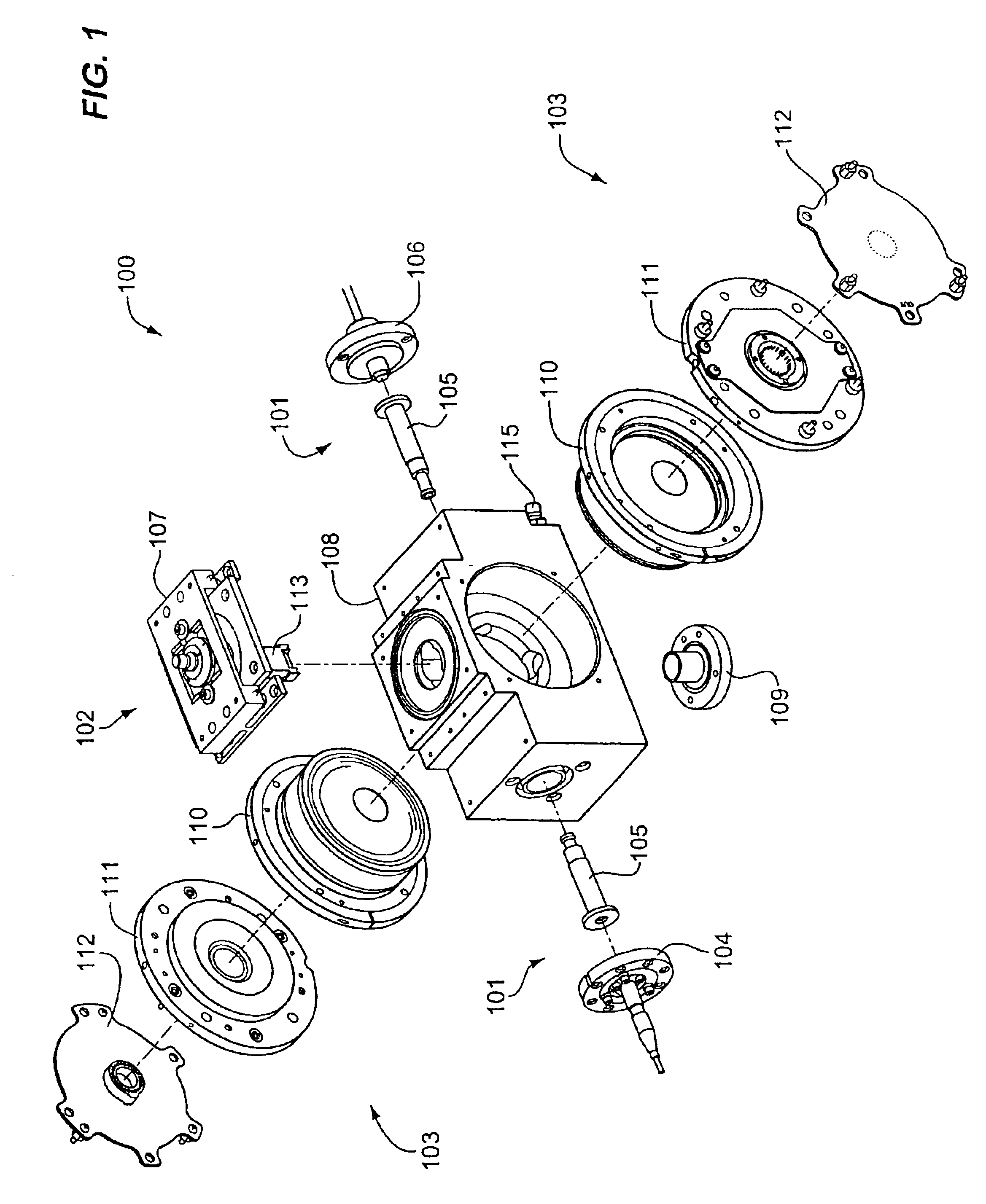

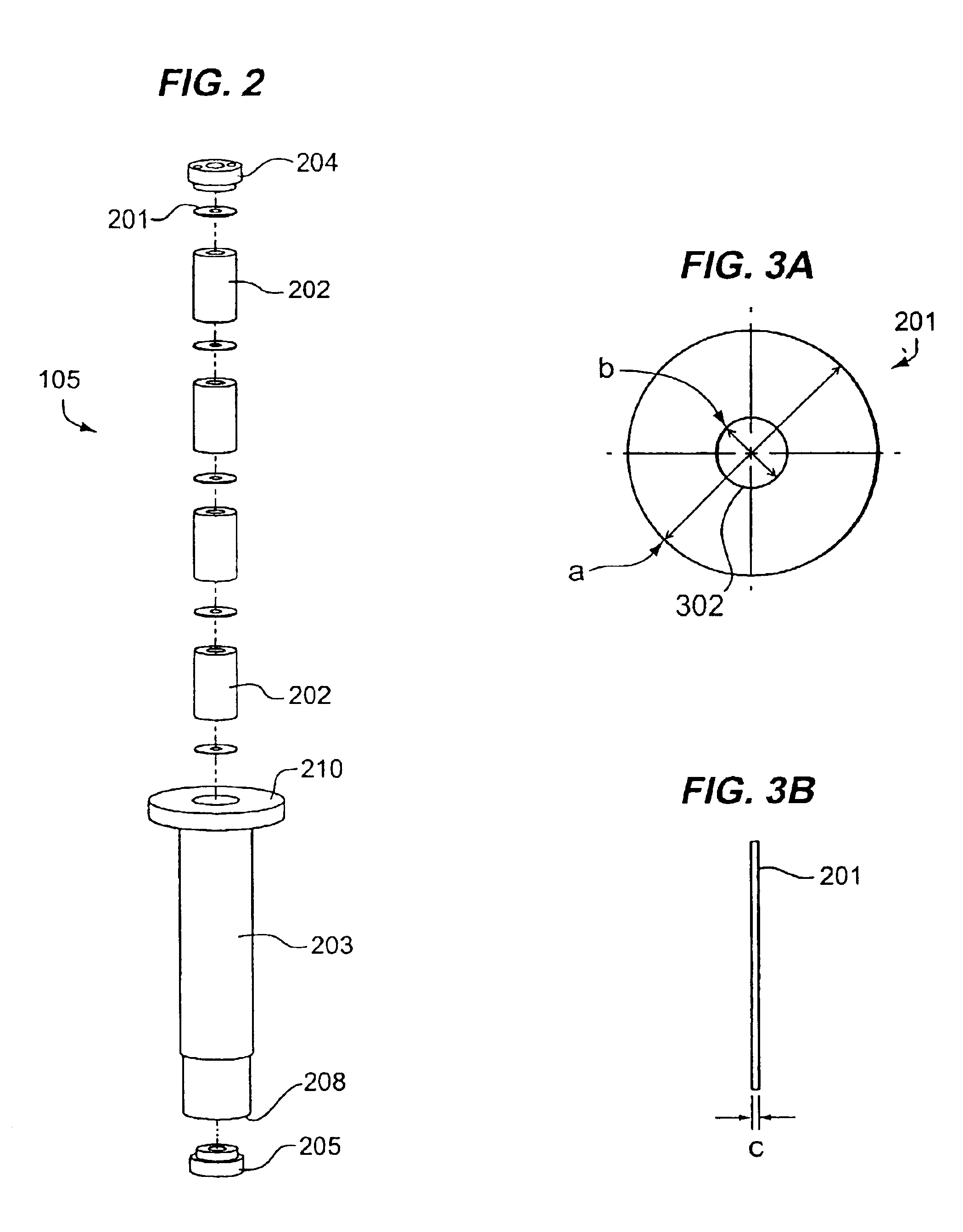

Mobile X-ray unit

A portable X-ray unit, of a relatively light-weight, occoping a volume of less then one-half a cubic foot containing an x-ray head assembly, a unique Marx generator, a plurality of spark-gap switches and control electronics is disclosed. The Marx generator allows for the development of a relatively high voltage in excess of 100 kV, yet allows for the discharge thereof within the nanosecond range. The Marx generator is enclosed by an acrylic insulator that cooperates with an aluminum enclosure, which functions as a return current path for the capacitors in the Marx generator and also as a shield against the escape of electromagnetic radiation from the pulsed x-ray unit. The Marx generator and spark-gap switches are confined within the pressurized chamber that may contain nitrogen gas to reduce the separation of the gap in the spark-gap switches.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

High density polyurethane and polyisocyanurate construction boards and composite boards

A covered low-slope or flat roof comprising (a) a roof deck, (b) an optional insulation board including a polyurethane or polyisocyanurate cellular structure having a density that is less than 2.5 pounds per cubic foot, (c) a coverboard including a polyurethane or polyisocyanurate cellular structure having a density greater than about 2.5 pounds per cubic foot, and (d) a membrane.

Owner:HOLCIM

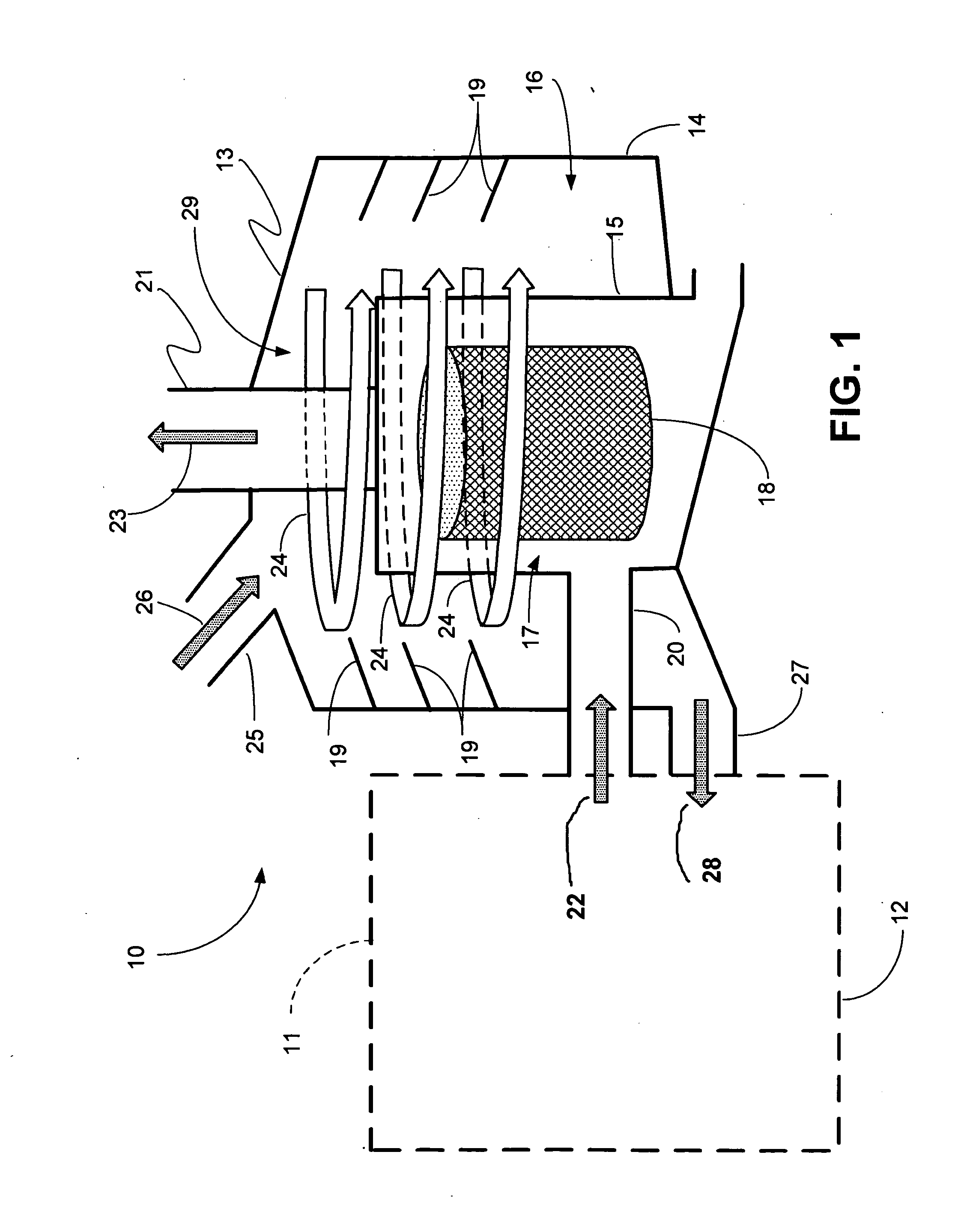

Low noise intracavity laser particle counter

ActiveUS6903818B2High power operationEffective noise reductionRadiation pyrometryScattering properties measurementsLow noiseEddy current

An optical particle counter has a gain-apertured laser cavity producing laser light, an inlet jet providing fluid flow into a particle detecting region within the laser cavity, the inlet jet having an inlet jet orifice; a detection optics assembly located to collect light scattered from particles with the detecting region for producing an output signal indicative of the particles; and an optical barrier complex located to reduce noise as compared to the gain-apertured system without the optical barrier complex for fluid flow rates greater than or equal to about 0.1 cubic feet per minute. The optical barrier complex inhibits laser light from illuminating turbulent eddy currents originating on the interior walls of the inlet jet. The optical barrier complex includes one or more physical apertures, one or more optical stops, or both which are located to prevent laser light from illuminating the eddy currents.

Owner:PARTICLE MEASURING SYST

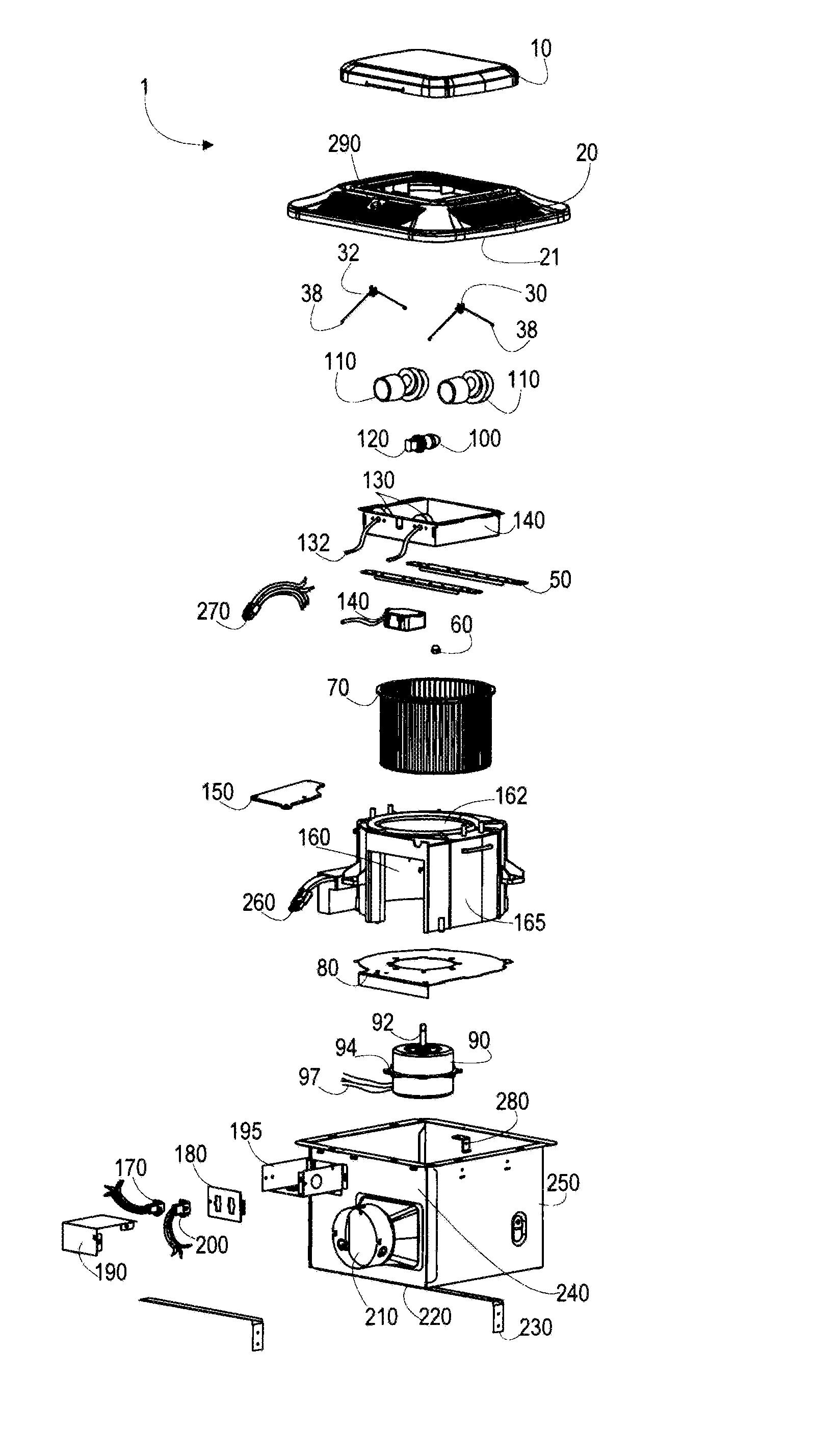

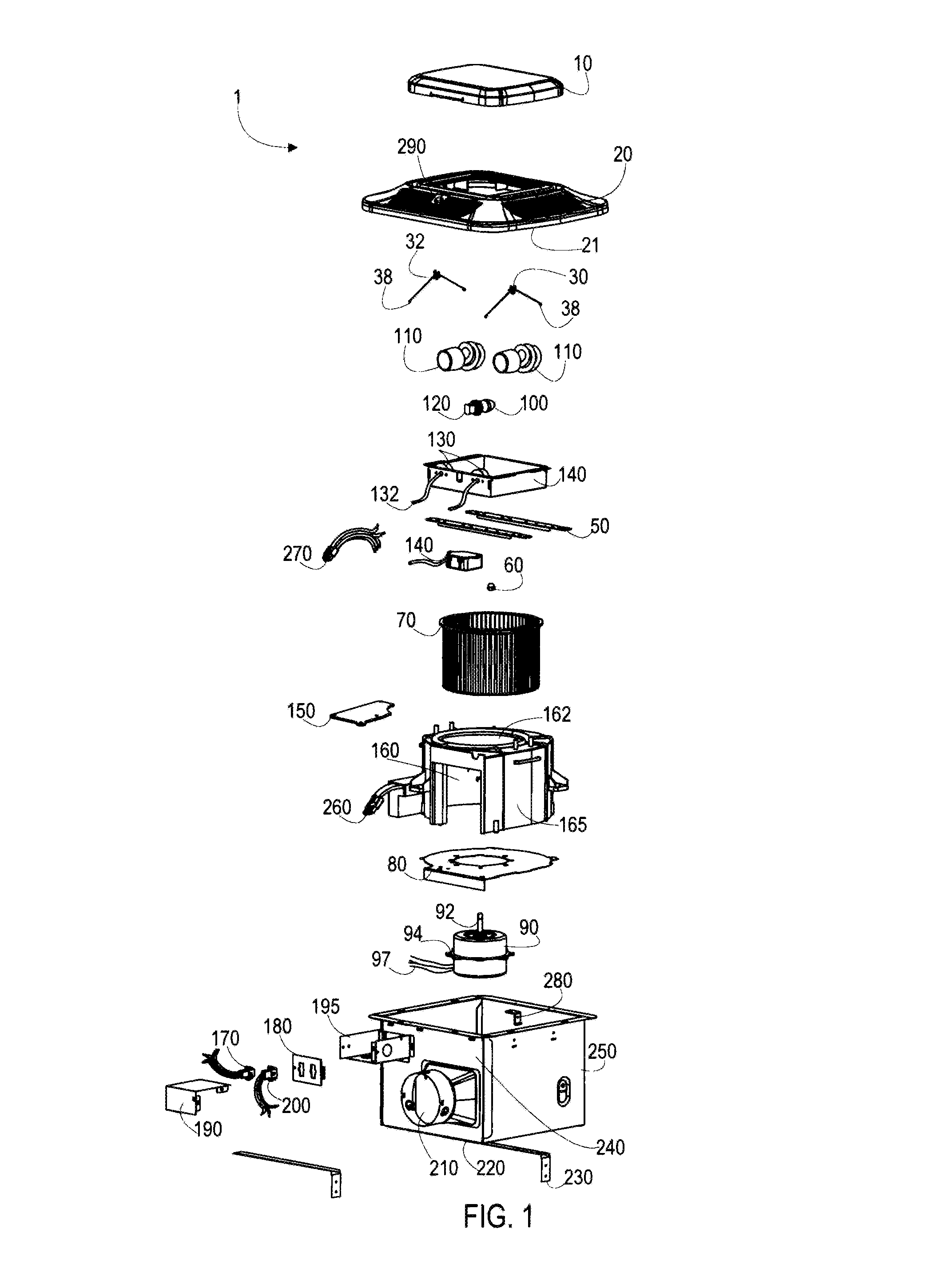

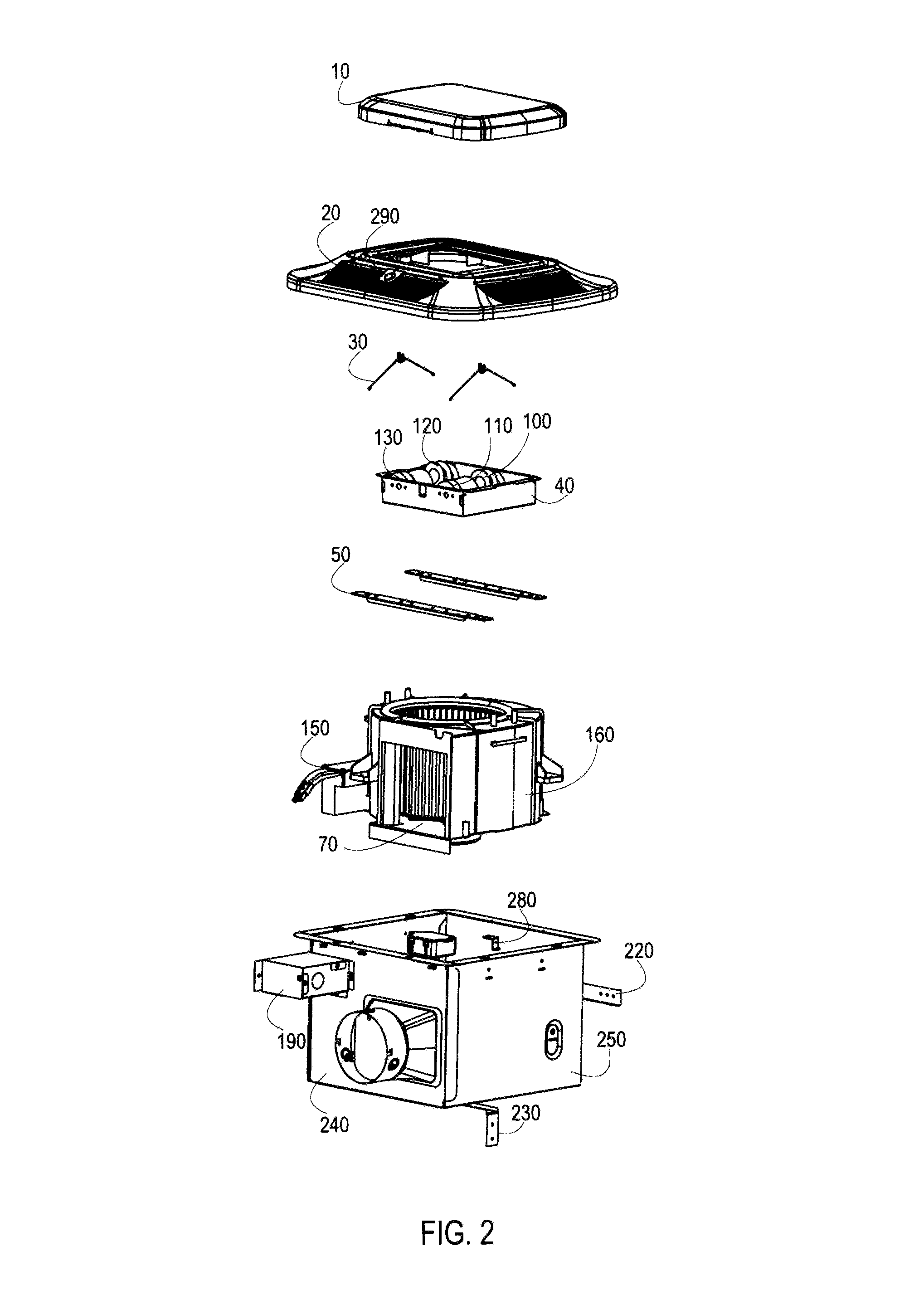

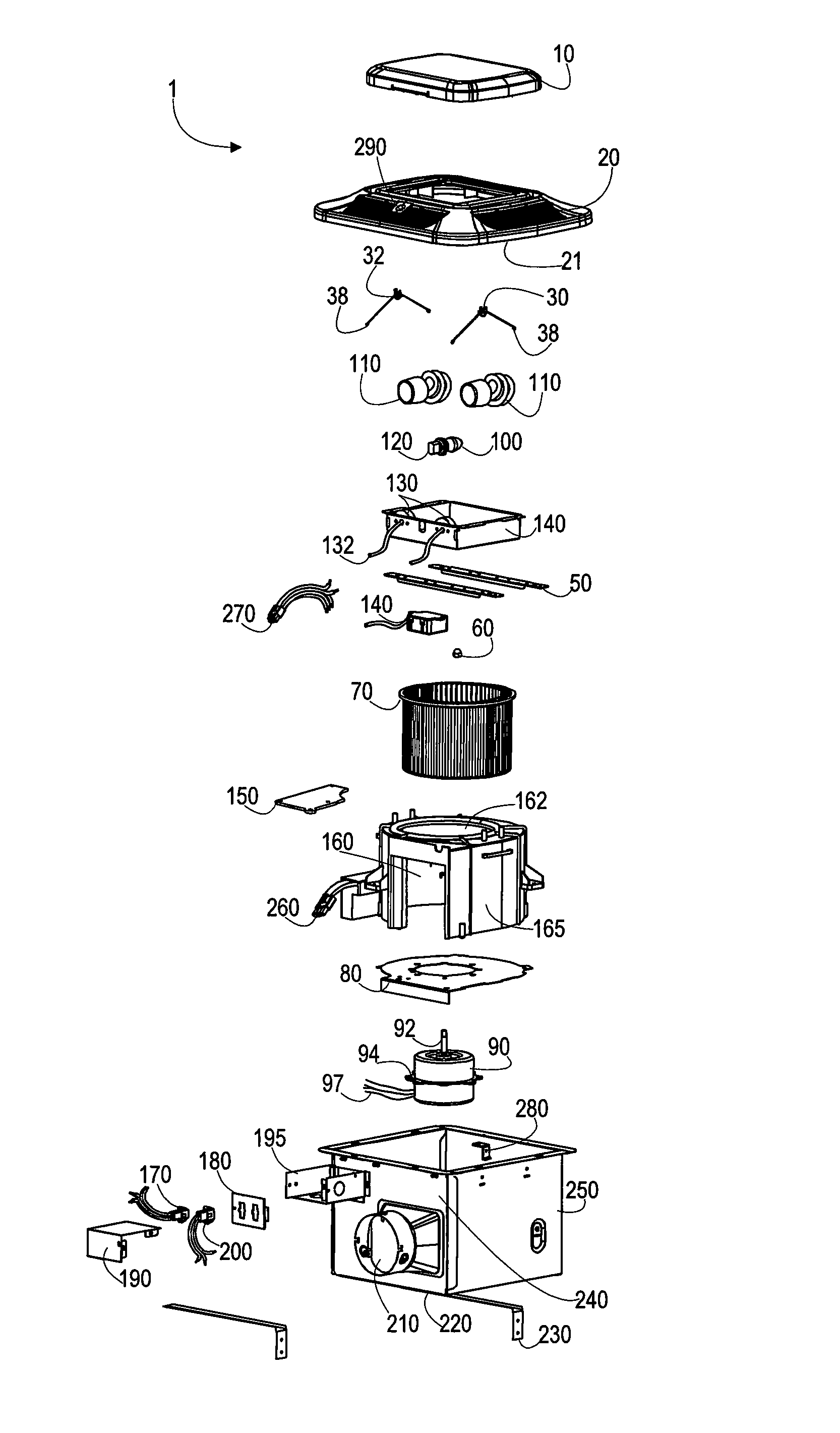

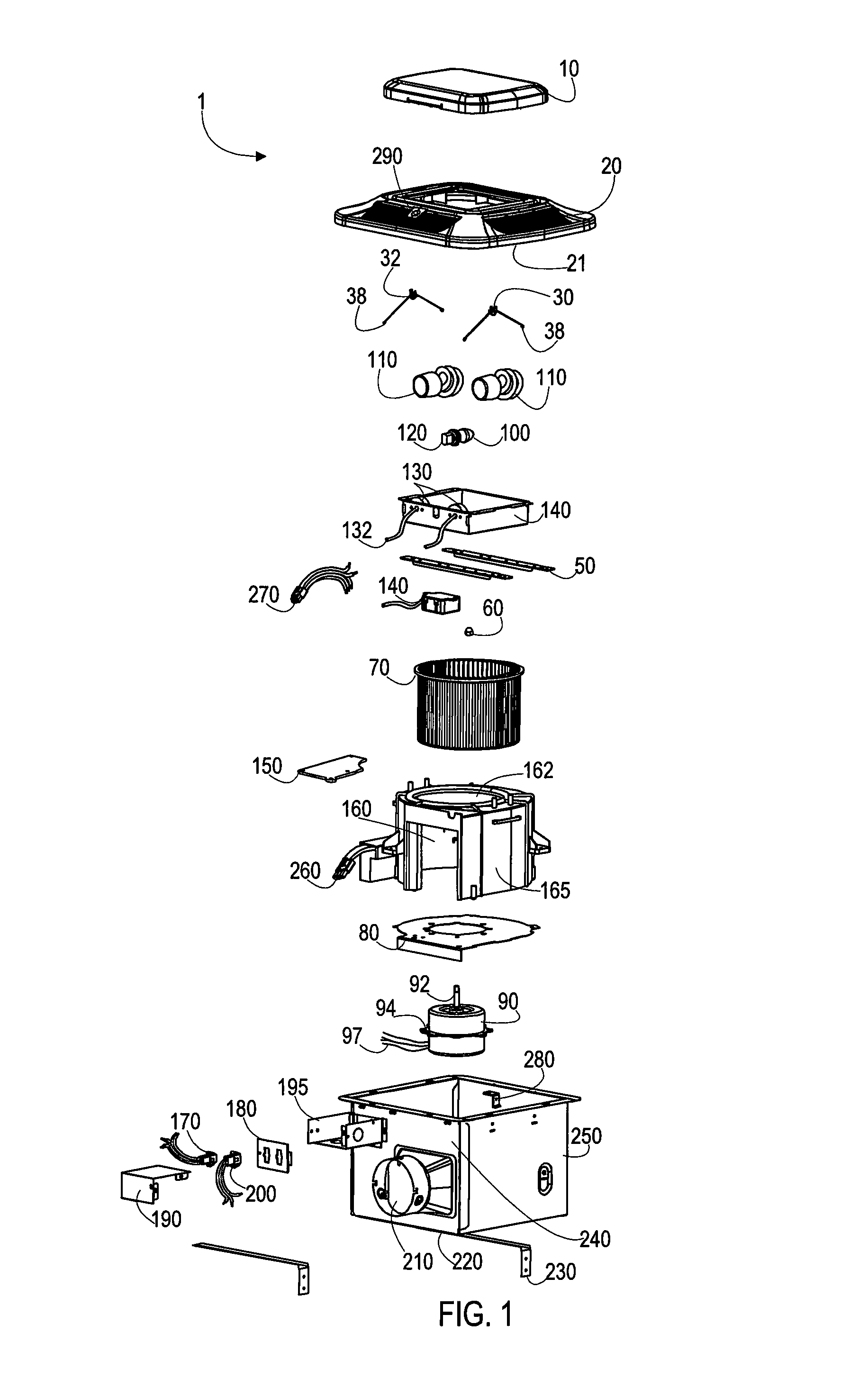

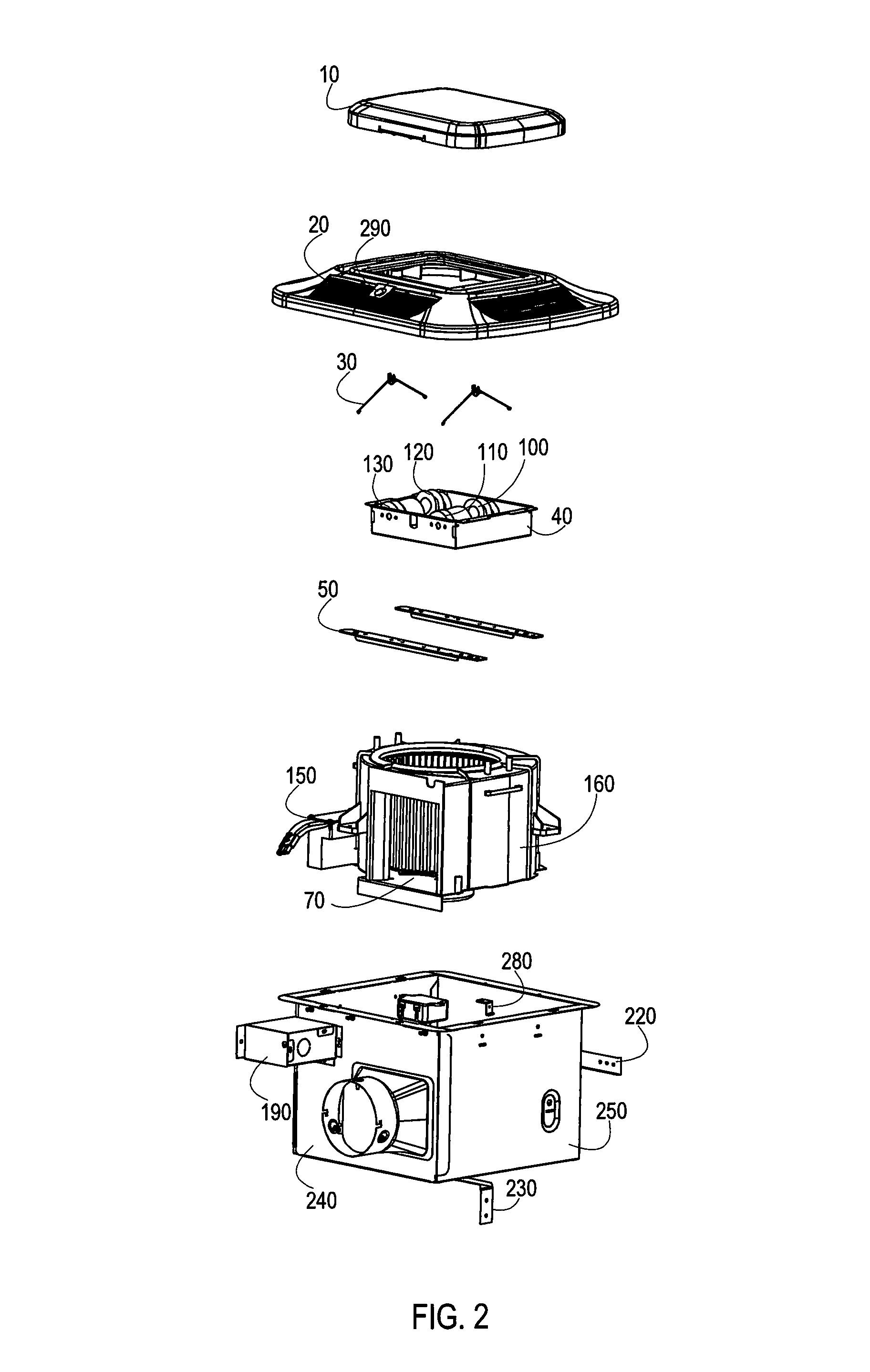

110 CFM bath fan with and without light

Owner:CHIEN LUEN INDS

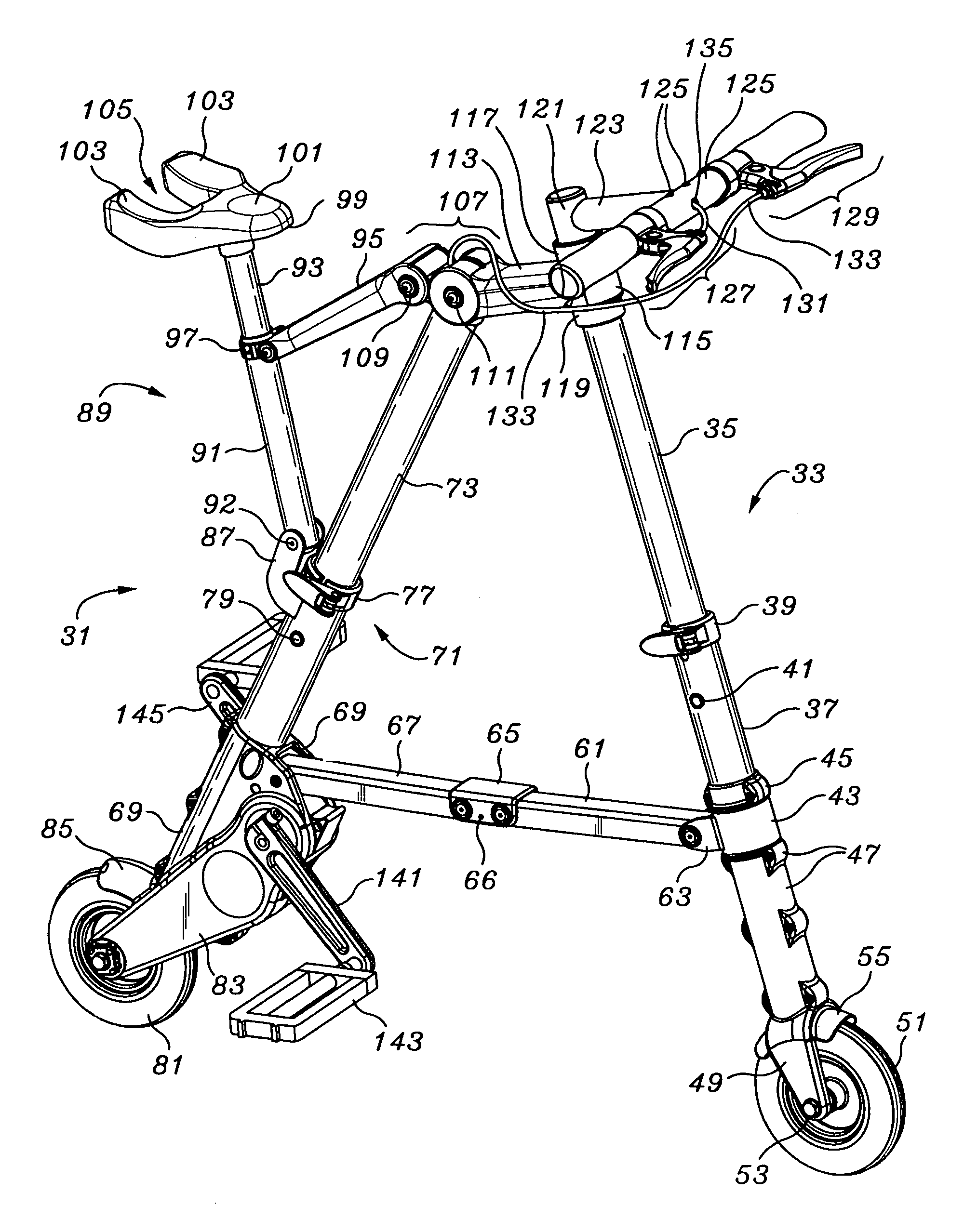

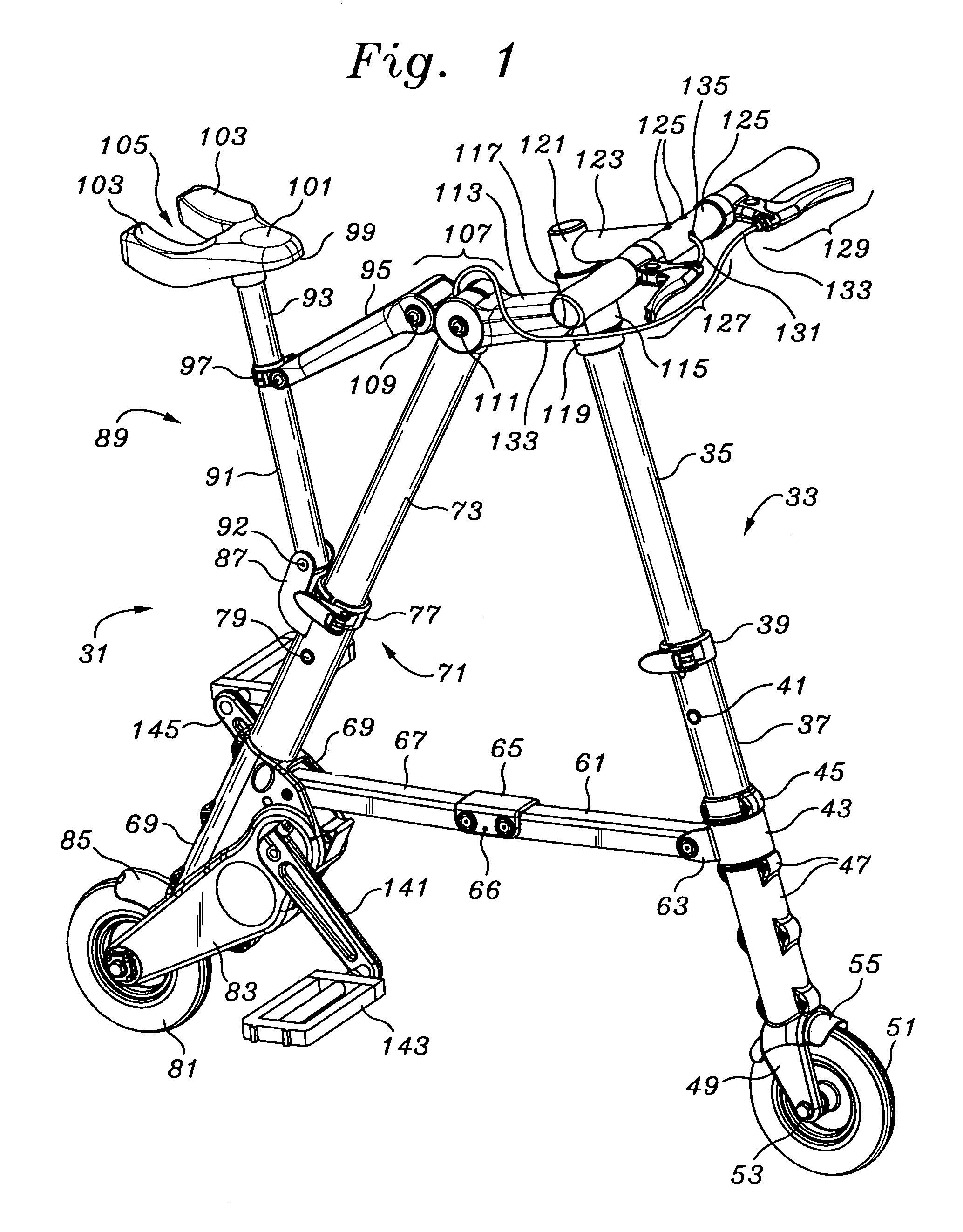

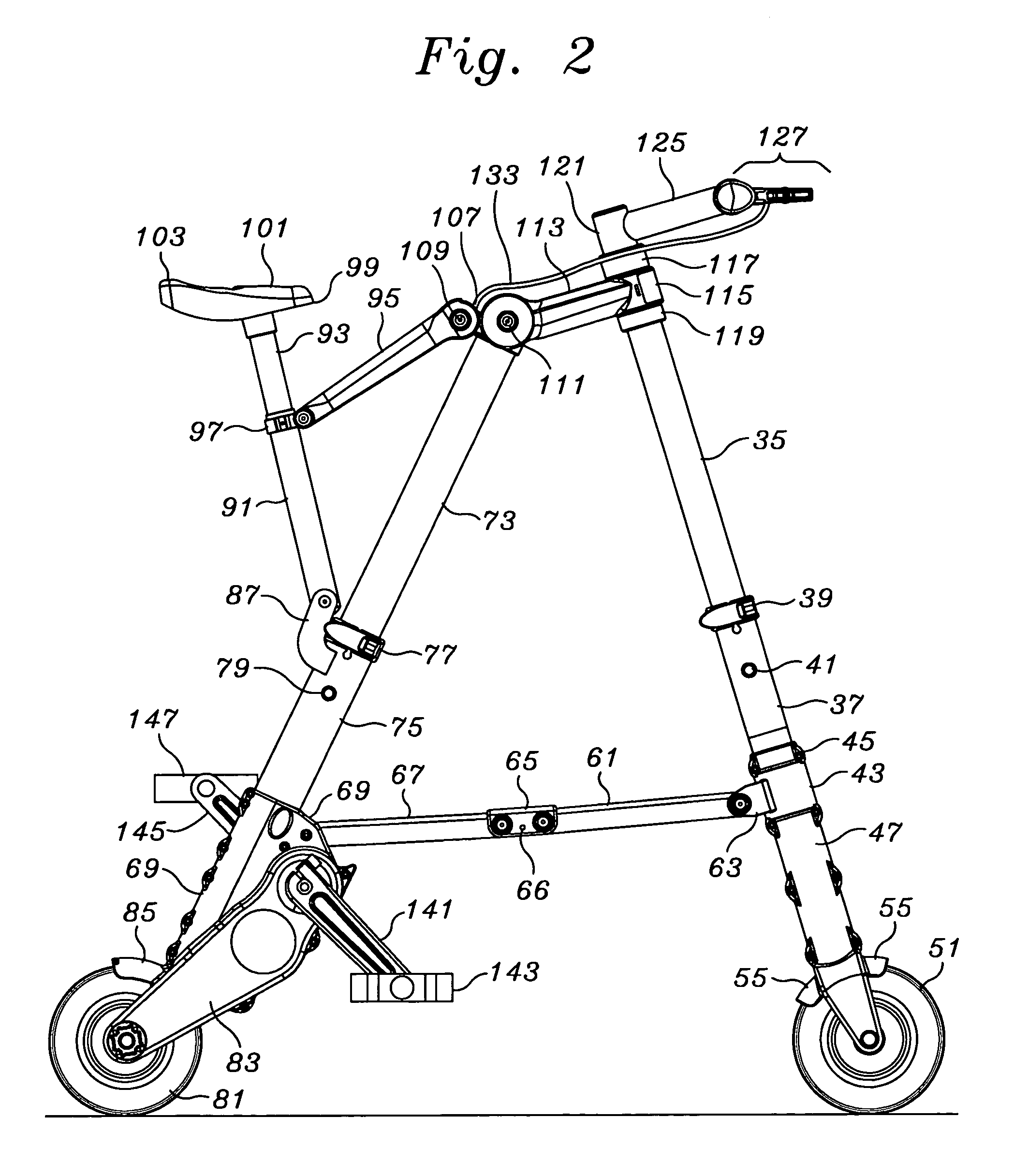

Portable folding bicycle

InactiveUS6986522B2Eliminate riskReadily be taken awayPassenger cyclesWheel based transmissionDeployment timeEngineering

Owner:SINCLAIR REFINING

Plant biomass solid fuel

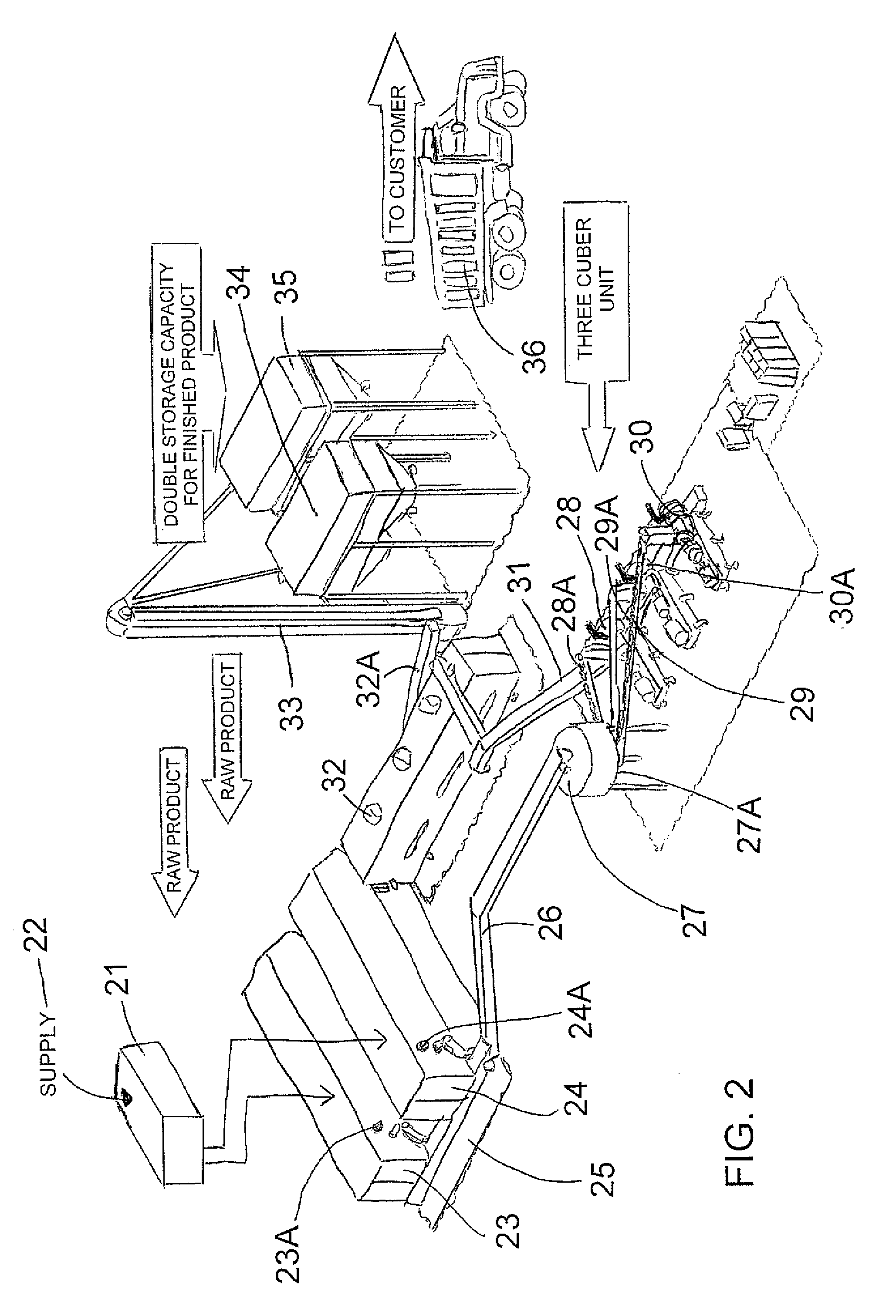

A solid fuel is formed in a cuber to form body pieces formed of materials extruded through a die with a density greater than 35 lbs / cu ft; an energy content greater than 6500 BTU / lb; transverse dimensions less than 1.5 inches; and a length less than 4 inches; from plant biomass material which contains components when extended of greater than 1.0 inch. Primarily the materials are paper or other cellulose product and crop residue such as wheat straw. The cellulose and lignin from these materials act without additional binders as binders and encasing materials. The moisture content is maintained at a target value by mixing selected quantities of the materials without drying. The cubing machine has a feeding system where the space between the inner rotor and outer casing is smaller than 4 inches and the height of the outer flight is less than 1 inch.

Owner:GAUTHIER STEPHANE +4

110 CFM bath fan with and without light

Owner:CHIEN LUEN INDS

Conductive polymer foams, method of manufacture, and articles thereof

A method of manufacturing a polymer foam composite is described, the method comprising forming an article having a first surface and an opposite second surface from a precursor composition, the precursor composition comprising a polymer foam precursor composition, and a filler composition comprising a plurality of magnetic, electrically conductive particles; foaming the precursor composition to form a plurality of cells in precursor composition; applying a magnetic field to the foamed precursor composition, wherein the magnetic field is of a strength and applied for a time effective to align the electrically conductive, magnetic particles into mutually isolated chains between the first surface and the opposite second surface of the article; and solidifying the polymer foam precursor composition to provide a polymer foam composite having a density of about 1 to about 125 pounds per cubic foot and a volume resistivity of about 10−3 ohm-cm to about 103 ohm-cm at a pressure of 60 pounds per square inch. Polymer foam composites made by this method are also described, as well as articles formed therefrom.

Owner:WORLD PROPERTIES

Formulated resin component for use in spray-in-place foam system to produce a low density polyurethane foam

The subject invention provides an open-celled polyurethane foam formed from a polyurethane spray foam system that mixes a formulated resin component with an isocyanate component. The resultant open-celled polyurethane spray foam has a density of about ½ pound per cubic foot. The resin component includes water as a blowing agent, a first aliphatic, amine-initiated polyol having a number-average molecular weight of from 150 to 500 and having tetra-functionality, and a second polyol having terminal hydroxyl groups and having a number-average molecular weight of from 3500 to 8000. A curing component having at least one primary amine group and having a number-average molecular weight of from 150 to 5000 is also included in the resin component. The spray foam system reacts a) the resin component and b) the isocyanate component in a volumetric ratio of a) to b) of from 1:1.2 to 1:5 and having an isocyanate index of from 15 to 70.

Owner:BASF CORP

Biosolid storage and dispersal

ActiveUS20130123103A1Improve soil qualityEasy to handleBiocideExcrement fertilisersCombustionWaste stream

A particle is provided that includes 5 wt % to 90 wt % of agricultural biomass, combustion residues, biosolids, or a combination thereof. A binder intermixed with the agricultural biomass, combustion residues, biosolids, or a combination thereof retains the mixture in the form of a particle. The resultant particle creates a use for existing waste streams while also improving soil quality. A process of stabilizing agricultural biomass, combustion residues, biosolids, or a combination thereof particles is also provided that includes combining agricultural biomass, combustion residues, biosolids, or a combination thereof with mineral and / or synthetic chemical fragments having a bulk density of greater than about 40 pounds per cubic foot and a sizing of about 100% passing through a 30 mesh screen and about 50% or more passing through a 200 mesh screen. By adding binder, a particle is formed that is deodorized and / or stabilized. Through the choice of binder, the particle can be rendered dispersible to rapidly disintegrate into soil.

Owner:THE ANDERSONS

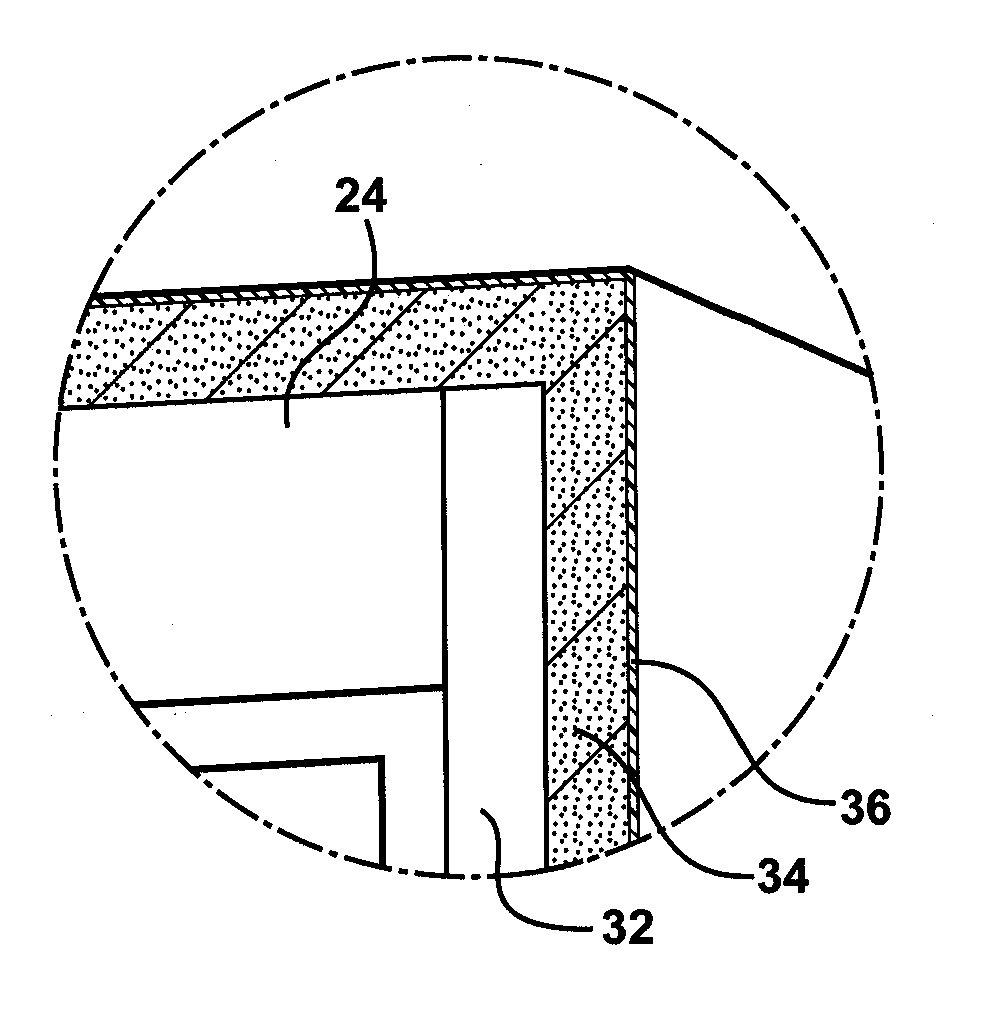

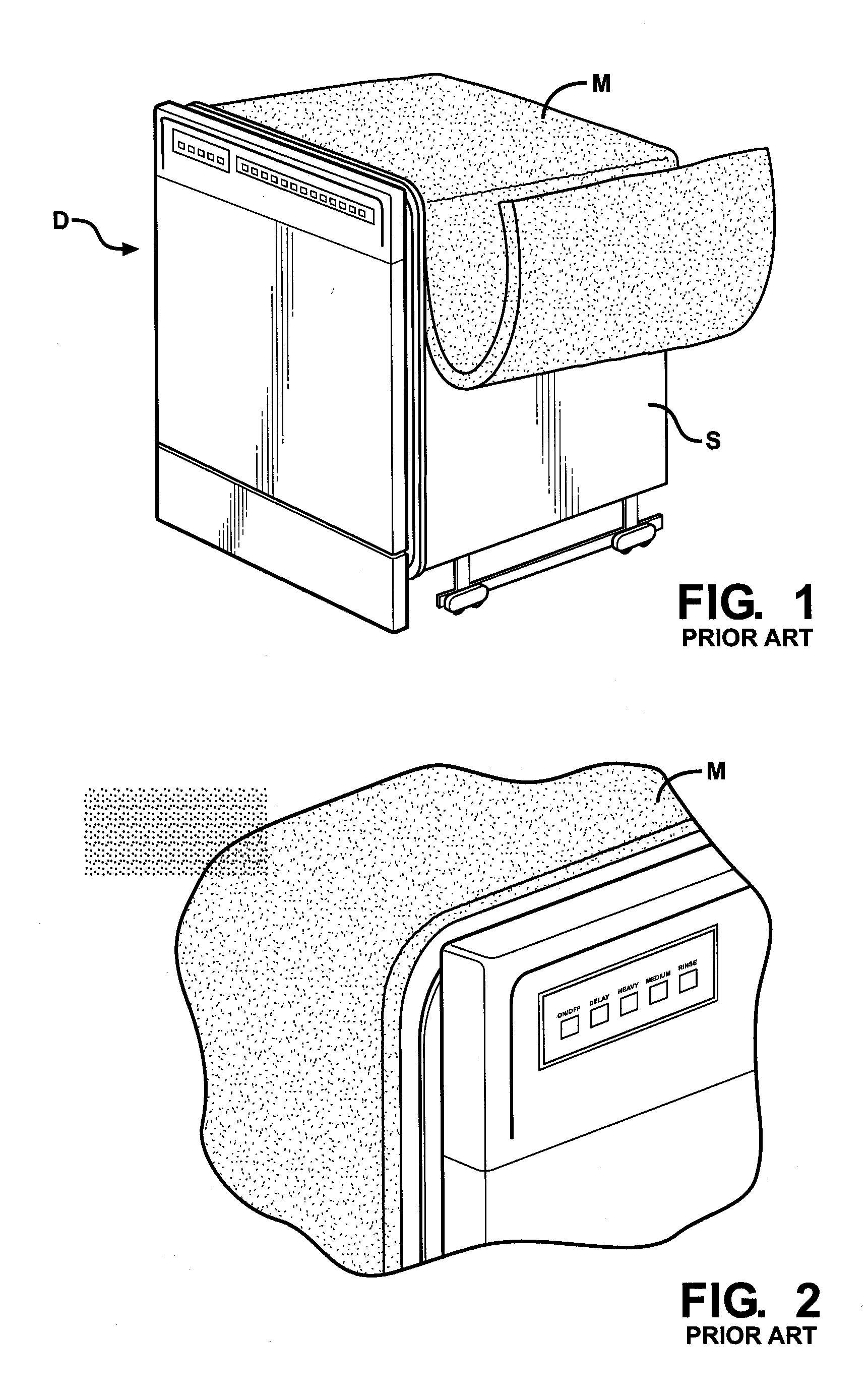

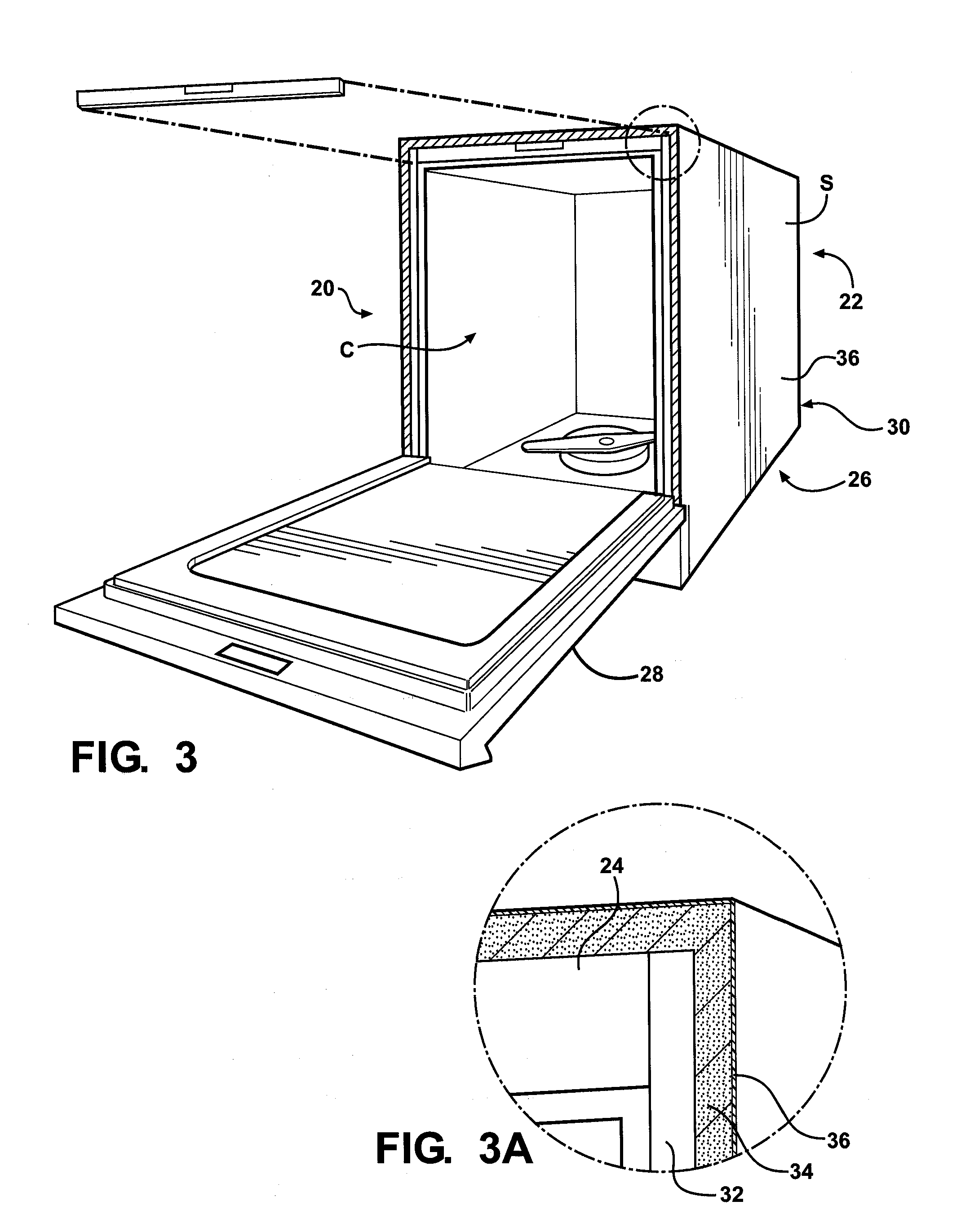

Appliance comprising polyurethane foam

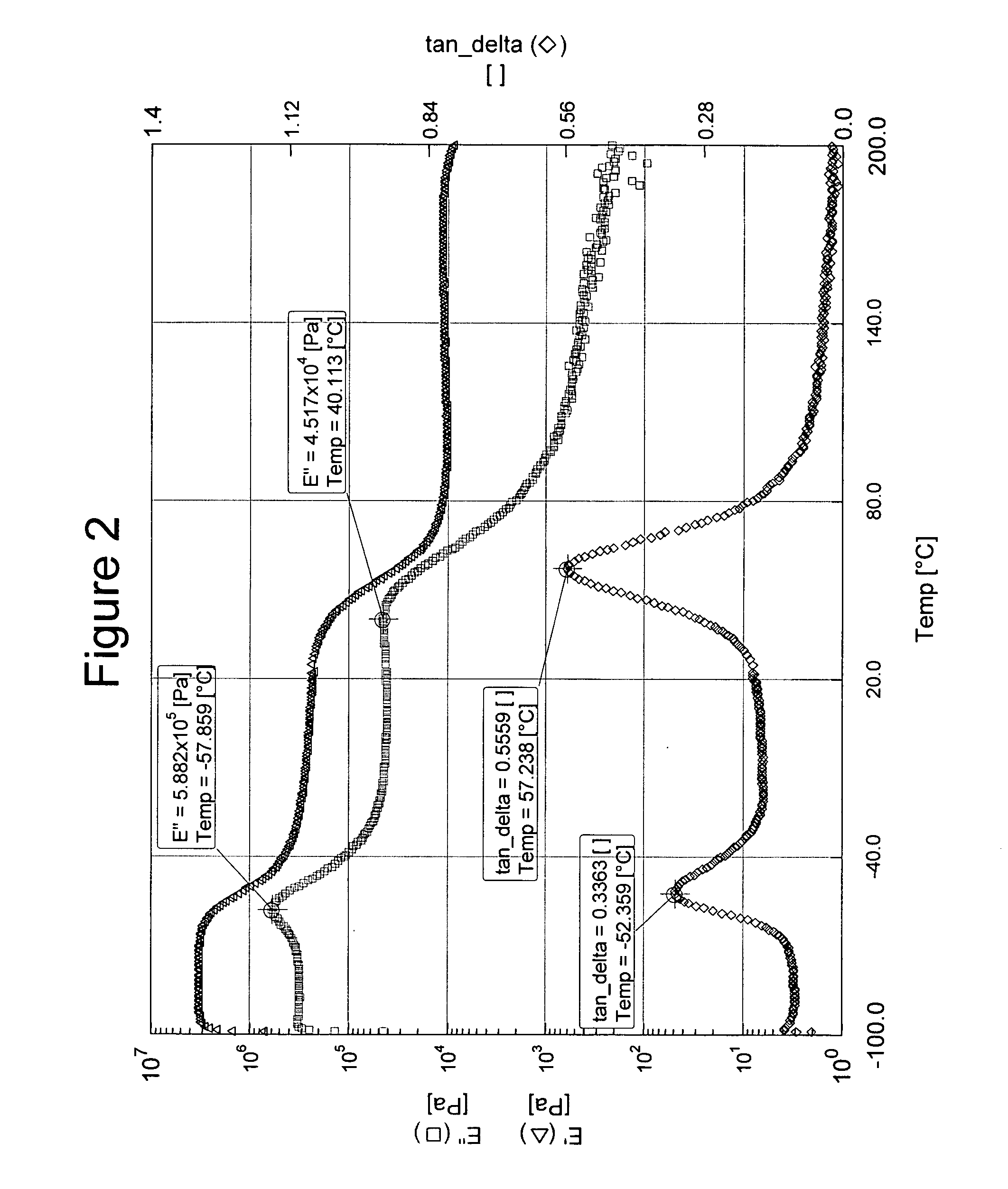

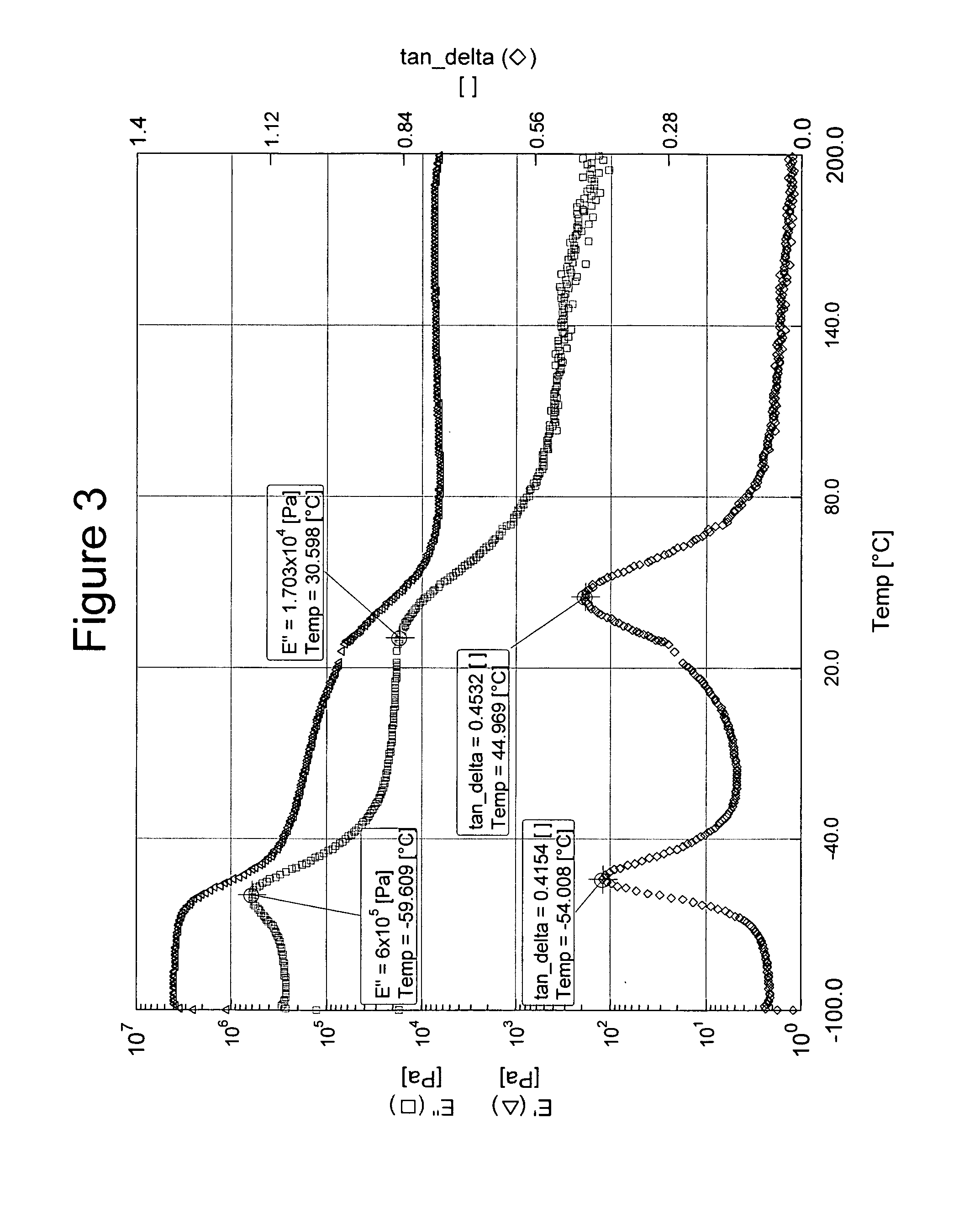

InactiveUS20110168217A1Reduce noiseReduce vibrationTableware washing/rinsing machine detailsLayered productsDamping factorEngineering

An appliance includes a housing having top and bottom panels disposed opposite each other and a plurality of walls connected to the top and bottom panels. The top and bottom panels and the plurality of walls define a cavity of the appliance. The housing also has an outermost surface about which a polyurethane foam is disposed. The polyurethane foam reduces noise and vibrations emitted from the appliance during use and has a density of from 20 to 50 pounds per cubic foot (pcf). The polyurethane foam also has a damping factor of at least 0.2 measured at a temperature of from 40° C. to 60° C. Furthermore, the polyurethane foam has a k-factor of less than 2.0 btu-in / hr-ft2-° F. which reduces an amount of energy required to operate the appliance. The appliance is formed by applying the polyurethane foam to at least one of the top panel, bottom panel, and plurality of walls.

Owner:BASF AG

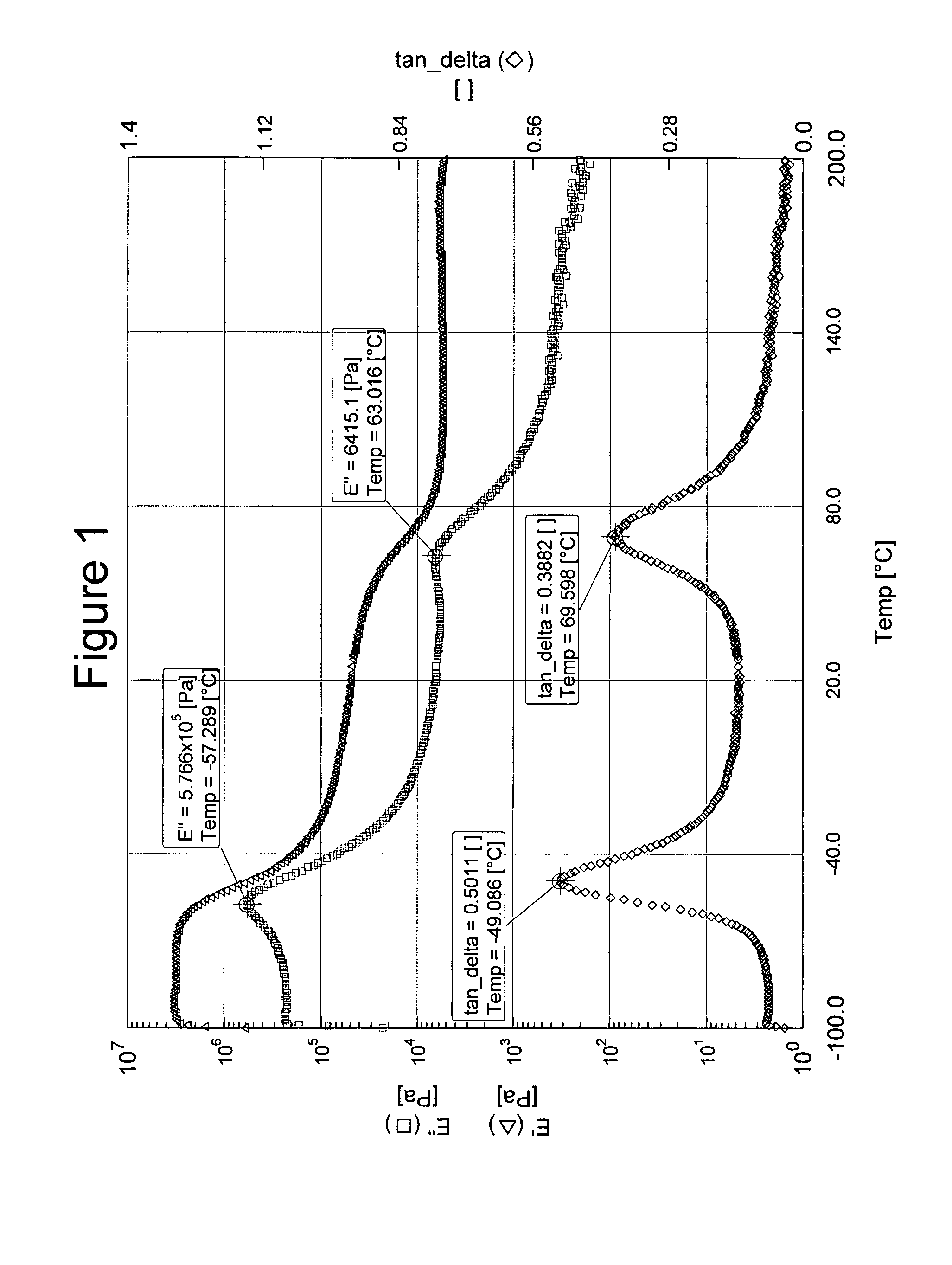

Viscoelastic polyurethane foam

The subject invention provides a viscoelastic polyurethane foam having a density of from one to twenty pounds per cubic foot. The foam is formed from a composition that is a reaction product of an isocyanate component (A), a first polyether polyol (B), a second polyether polyol (C), and a chain extender (D). The chain extender (D) has a backbone chain with from two to eight carbon atoms and has a weight-average molecular weight of less than 1,000 and is present in an amount of from 5 to 50 parts by weight based on 100 parts by weight of the composition. The viscoelastic polyurethane foam a first glass transition temperature greater than zero and a second glass transition temperature less than zero and having a tan delta peak ratio of the first glass transition temperature to the second glass transition temperature less than 2.2.

Owner:BASF CORP

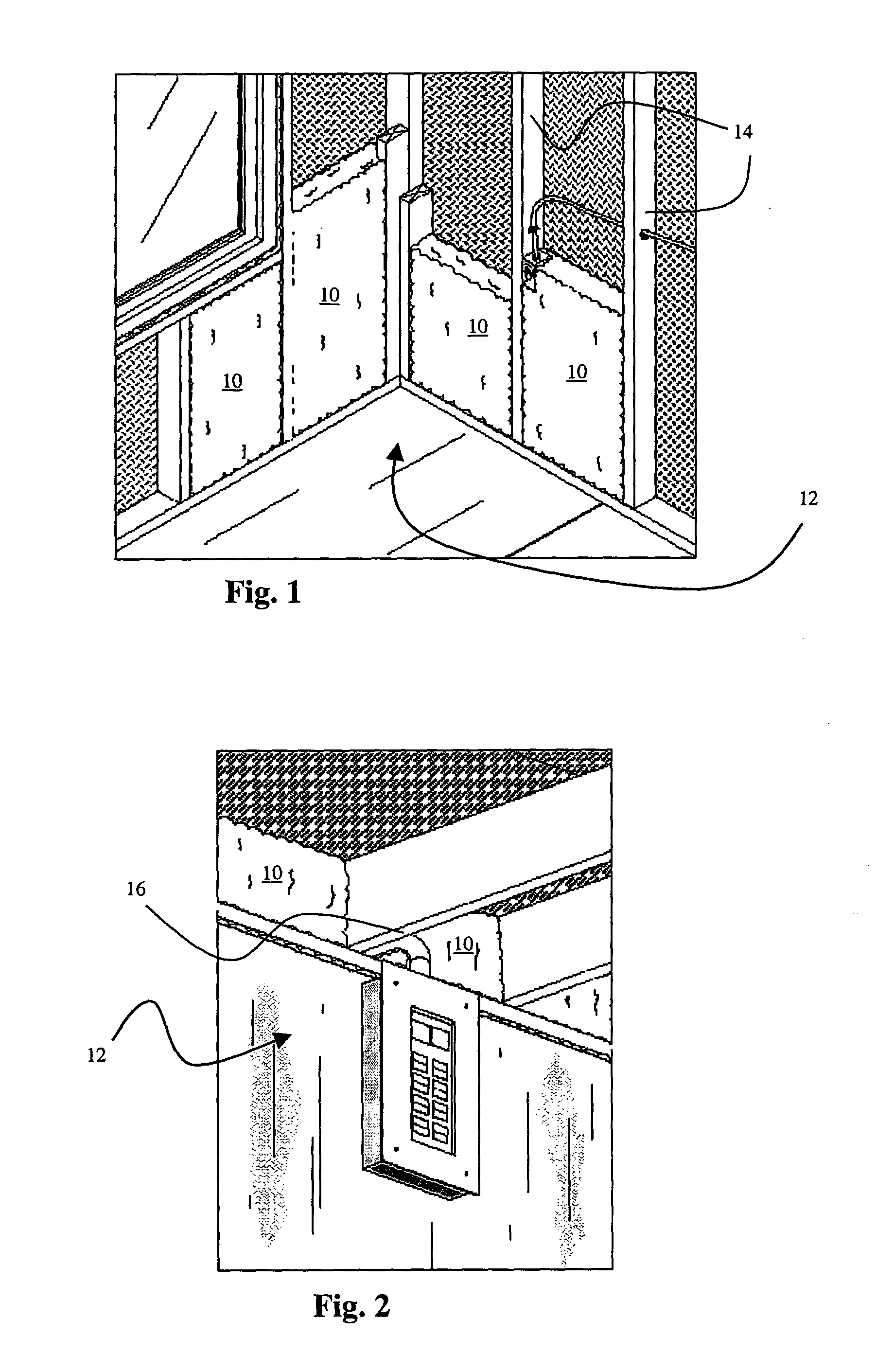

Fire door core assembly

A laminated fire door including a core, containing panels or boards made from an organic material including flax, and a fibrous binder constituting a sodium silicate adhesive, is used to make a door exhibits at least a 45 minute fire rating. In accordance with a preferred form of the invention, the fire door core is formed by using a silicate adhesive, preferably sodium silicate, in the order of 25 mils (0.6 mm) to laminate together two flax boards, each having a thickness in the range of 0.625-0.875 inches (approximately 16-22 mm), with each of the laminated flax boards having a density of between 20 and 45 pounds per cubic foot (320-700 kgs / m3).

Owner:2843 5816 QUEBEC

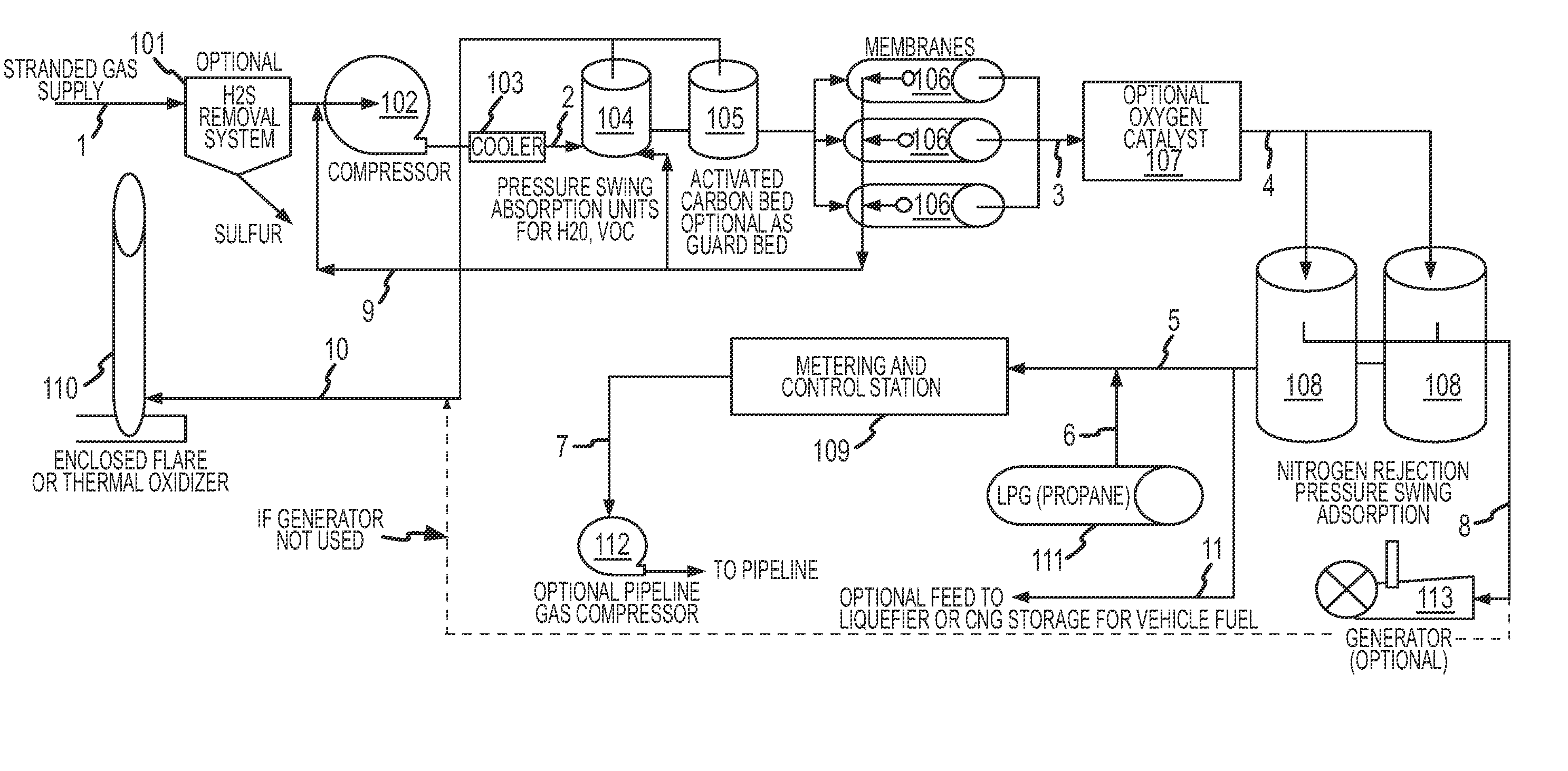

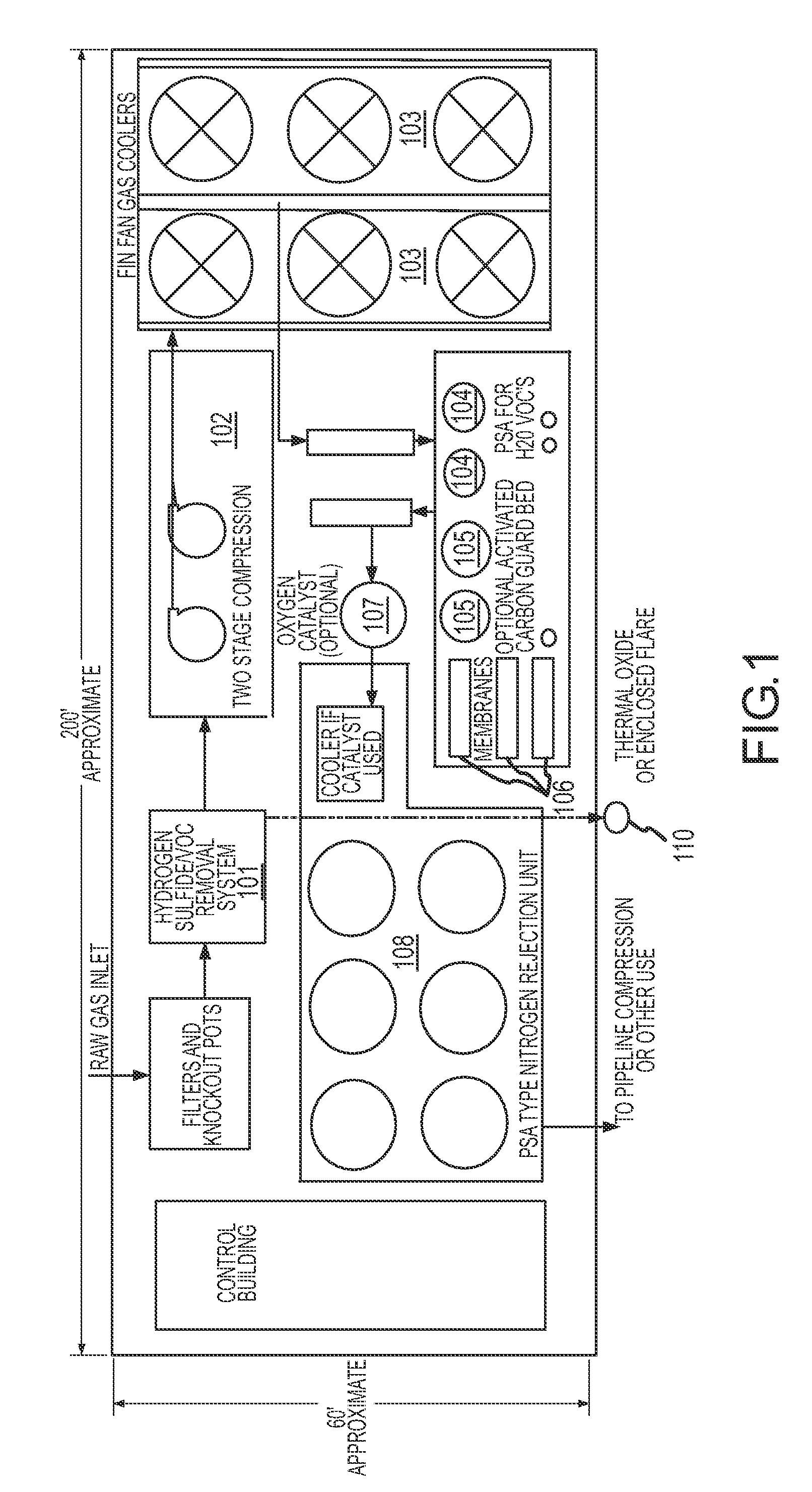

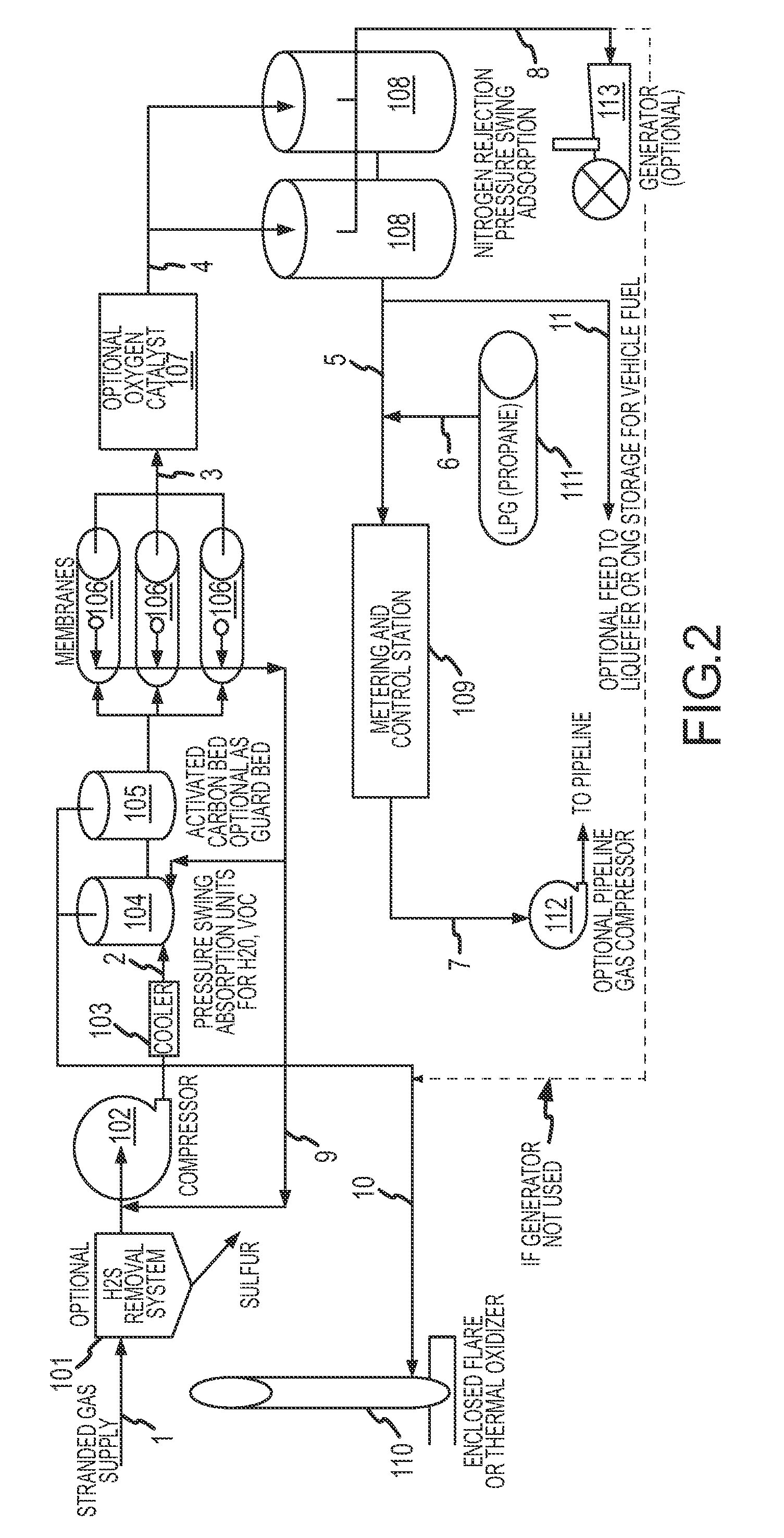

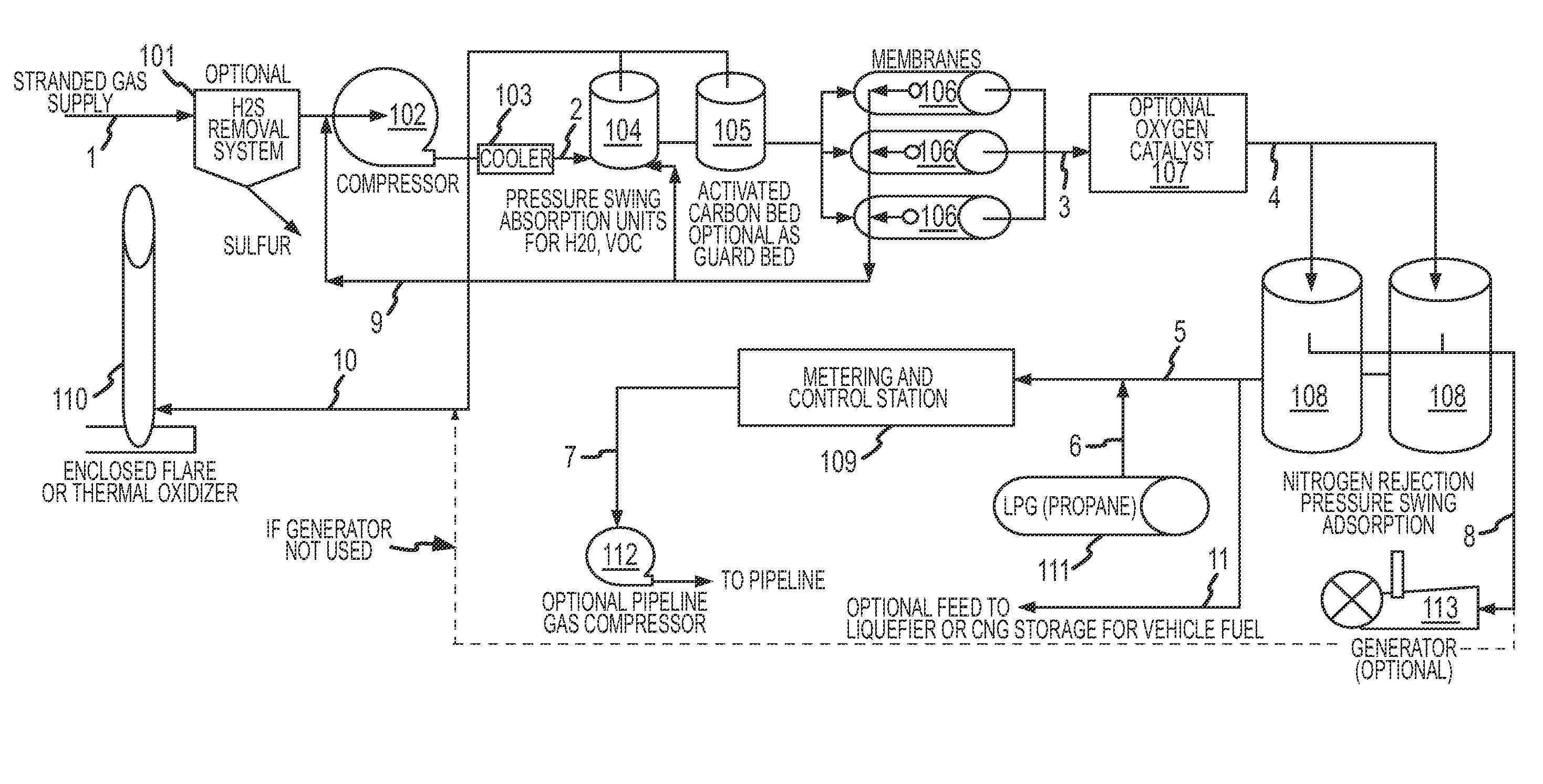

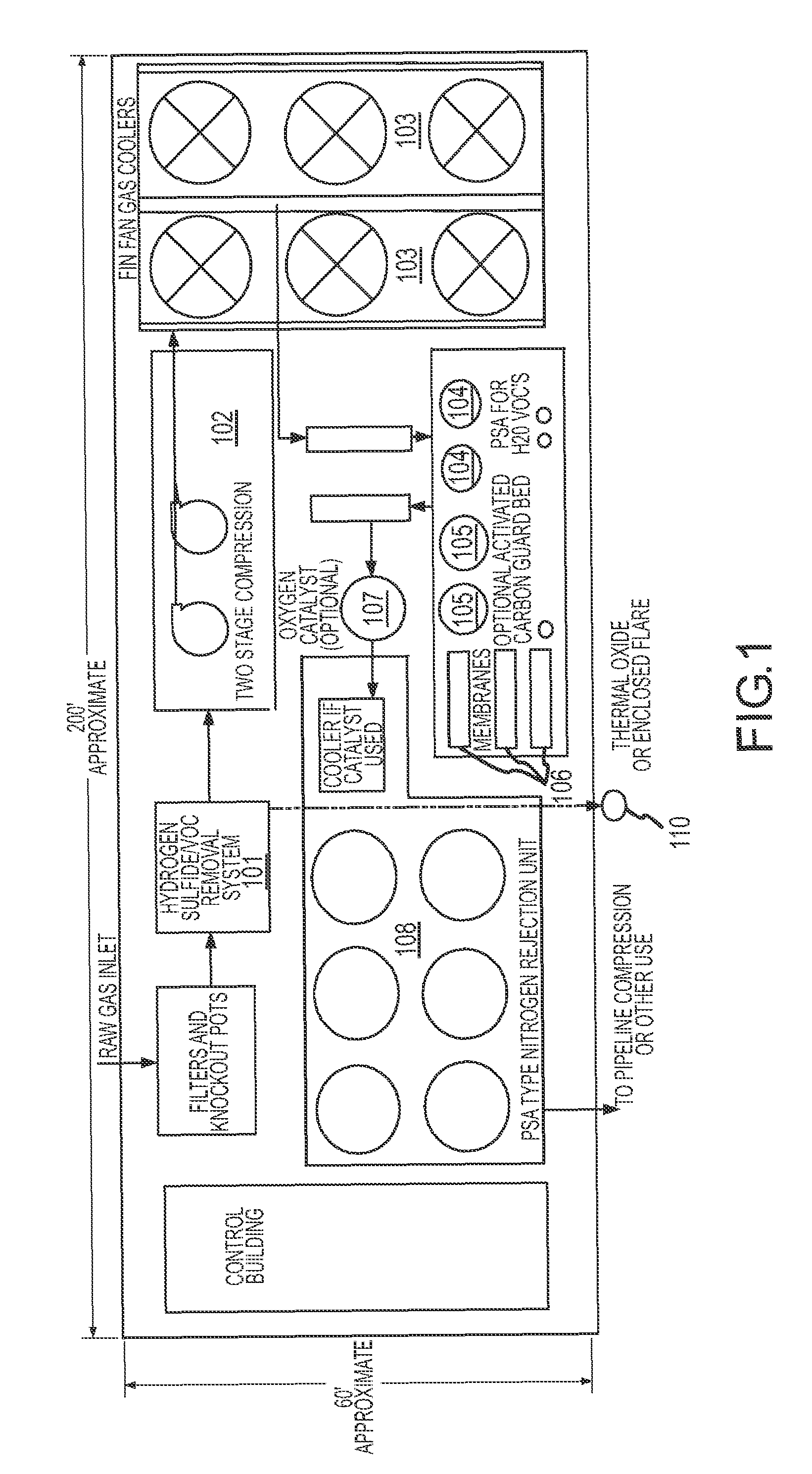

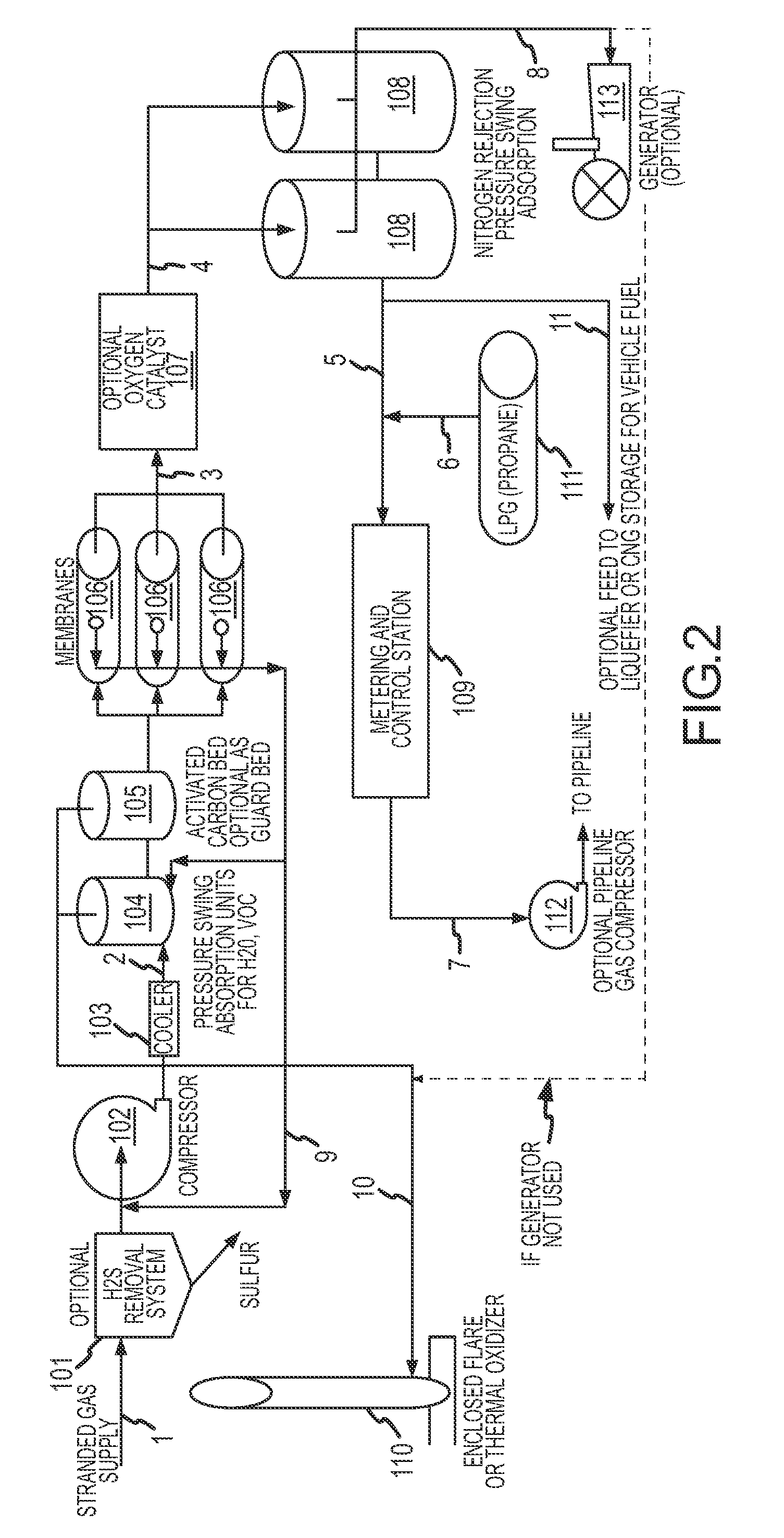

Method for processing landfill and other stranded gas containing commercial quantities of methane and contaminated by carbon dioxide, nitrogen and oxygen into a pipeline or vehicle quality natural gas product

Stranded natural gas, when contaminated by difficult to remove constituents such as Nitrogen and Oxygen, has long been considered uneconomical to process into pipeline quality gas and is abandoned or utilized in other energy applications where economically viable. Landfill Gas (LFG) is often considered a stranded gas although in many instances it is available at reasonable distances to natural gas pipelines, and has only rarely been processed for injection into natural gas pipelines. Other stranded contaminated gases, such as gases vented from remote oil wells or coal beds where access to transportation pipelines is not feasible are also candidates for collection. In many instances, billions of cubic feet of methane rich LFG has been vented or flared into the atmosphere. The present invention utilizes a variety of components and provides a product gas that will meet all known pipeline requirements and / or vehicle fuel specifications without the need for blending with pipeline gas and without using cryogenic separation techniques or partial cryogenic processes. The invention also provides a product gas suitable for further processing into Liquefied Natural Gas.

Owner:INGENCO HLDG LLC

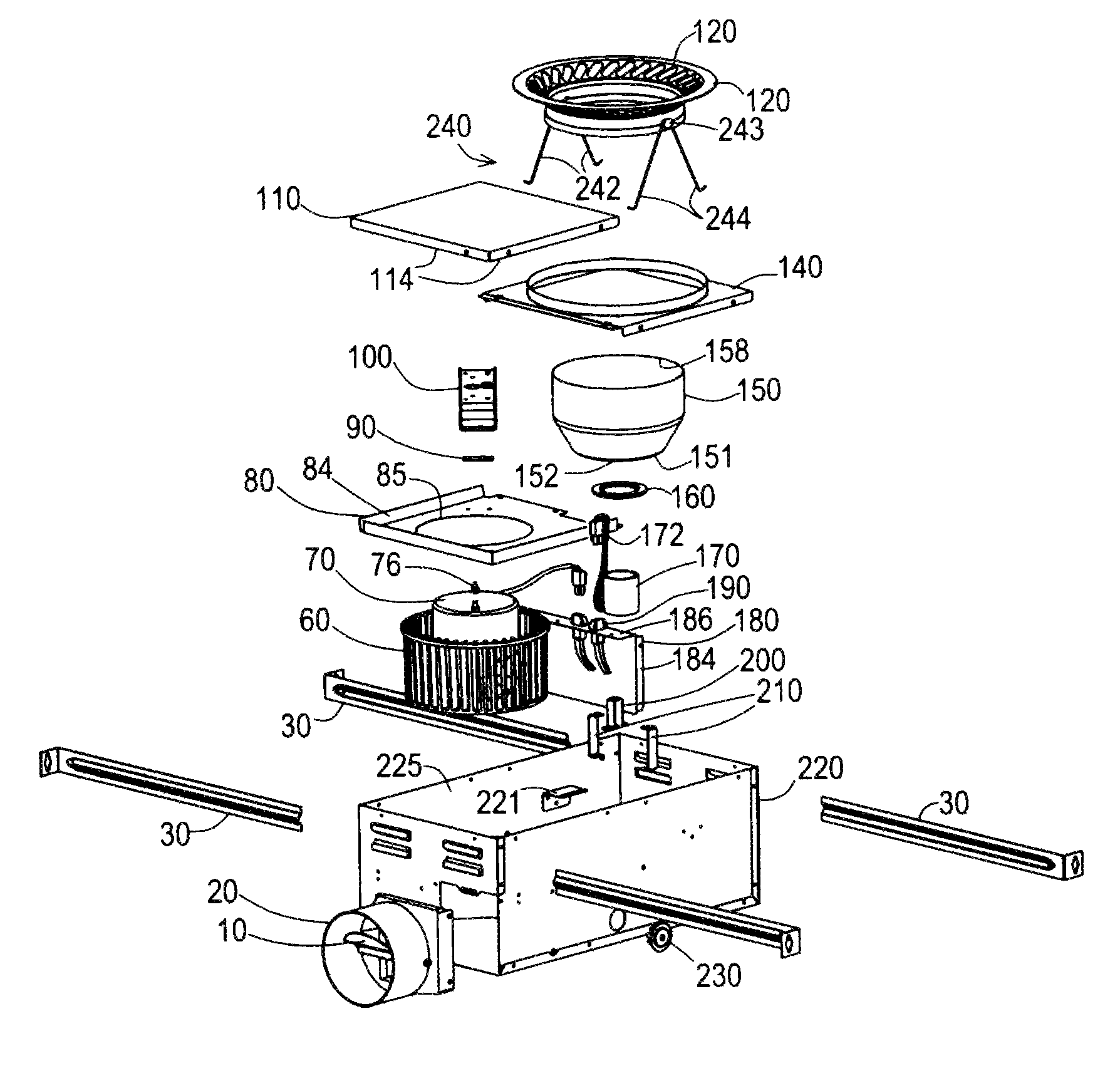

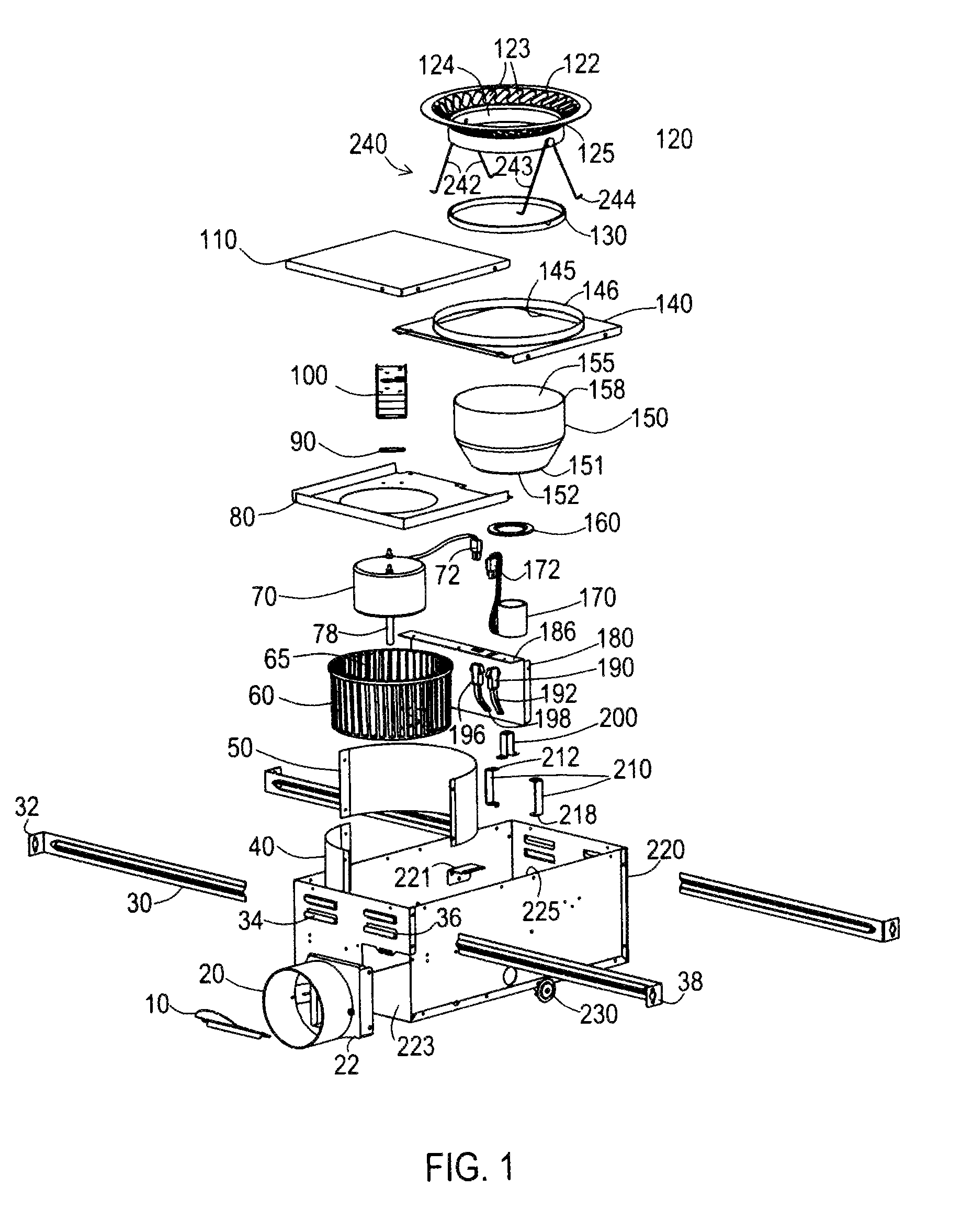

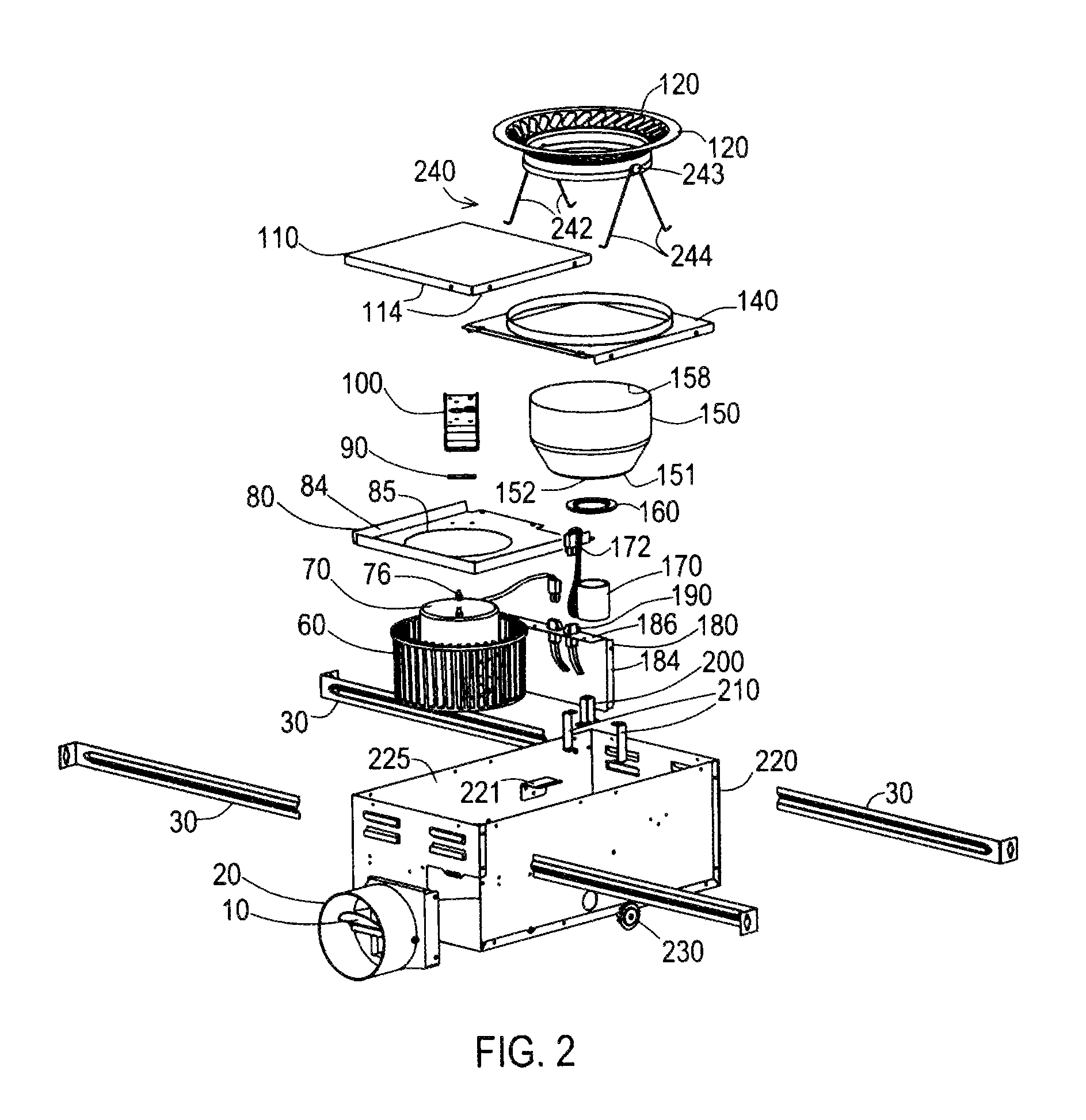

70 CFM bath fan with recessed can and telescoping side suspension brackets

ActiveUS8961126B1Avoid lightLighter componentPump componentsVehicle interior lightingJoistEngineering

Owner:CHIEN LUEN INDS

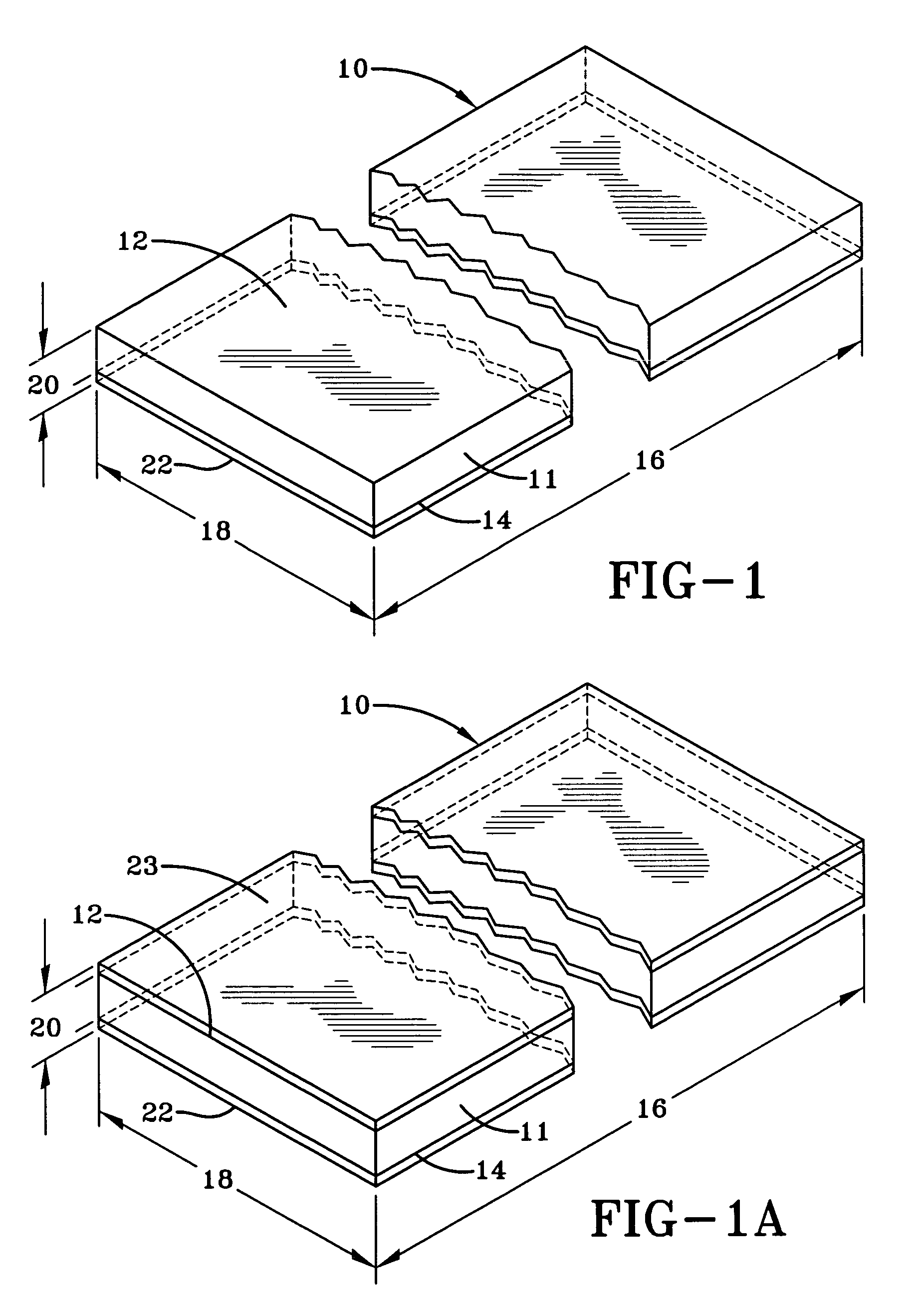

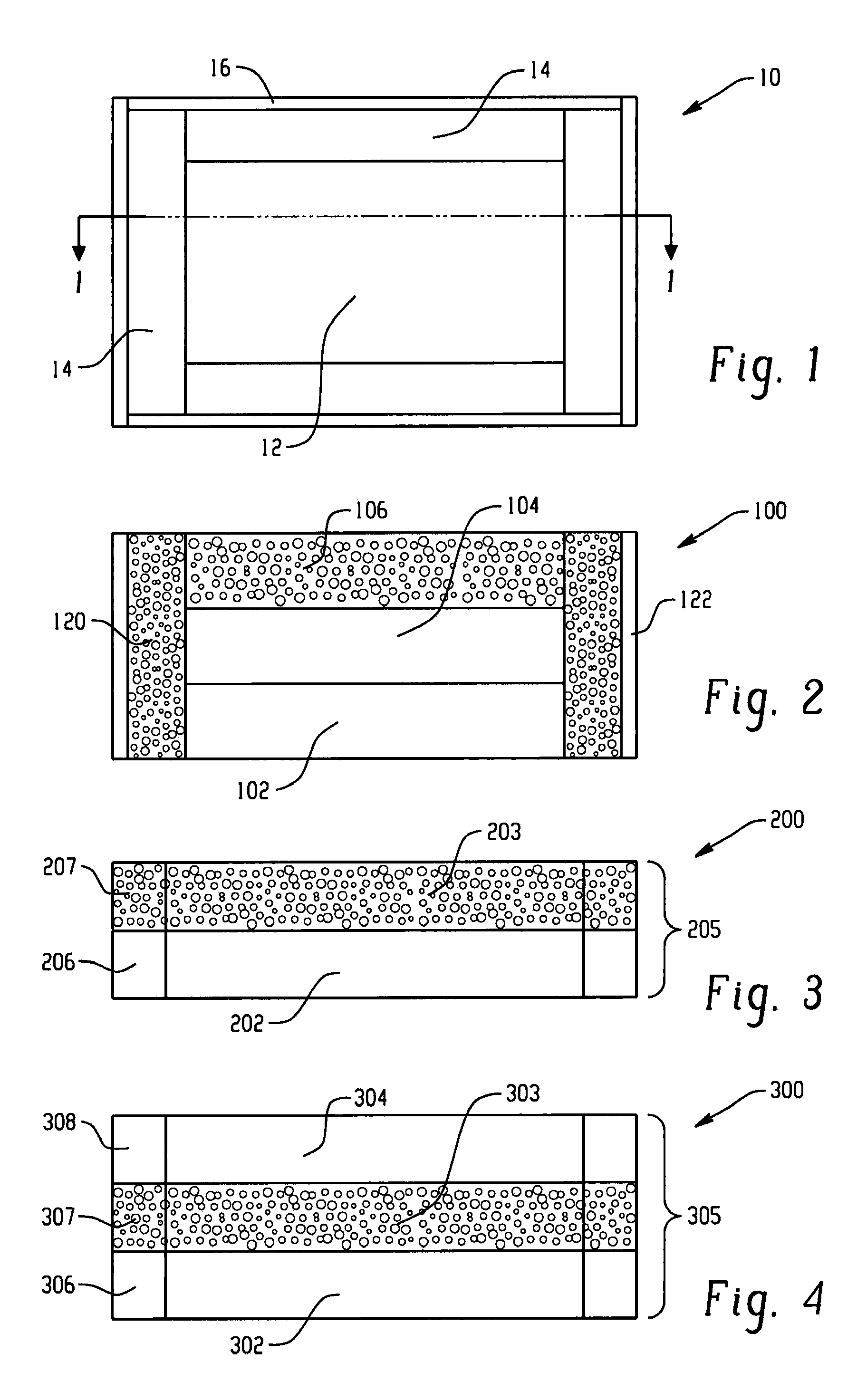

Composite building panel and method of making composite building panel

InactiveUS20070062151A1Need be addressConstruction materialNatural patternsVolumetric Mass DensityEuhedral and anhedral

A composite panel and method of fabricating is provided which includes a frame having a plurality of spaced apart frame members, and a concrete slab made of aerated concrete having a density of 400 to 1760 kg / m3 (25 to 110 pcf) pounds per cubic foot. Fastened to the frame members is a reinforcing layer. The concrete slab, having a front face and a rear face, embeds the reinforcing layer and a portion of the frame such that the frame protrudes from the rear face of the slab. At least one tab and one tab opening is disposed on an embedded portion of the frame, and the concrete slab extends through the tab opening.

Owner:ECOLITE INT

Viscoelastic polyurethane foam

The subject invention provides a viscoelastic polyurethane foam being flame retardant and having a density of greater than two and a half pounds per cubic foot that comprises a reaction product of an isocyanate component, an isocyanate-reactive blend, and a chain extender. The isocyanate-reactive blend includes a first isocyanate-reactive component and a second isocyanate-reactive component. The first isocyanate-reactive component includes at least 60 parts by weight of ethylene oxide (EO) based on 100 parts by weight of the first isocyanate-reactive component and the second isocyanate-reactive component includes at most 30 parts by weight of EO based on 100 parts by weight of the second isocyanate-reactive component. The chain extender is reactive with the isocyanate component and has a backbone chain with from two to eight carbon atoms and is present in an amount of from 5 to 50 parts by weight based on 100 parts by weight of the foam. A composition useful in making the viscoelastic polyurethane foam is also disclosed.

Owner:BASF CORP

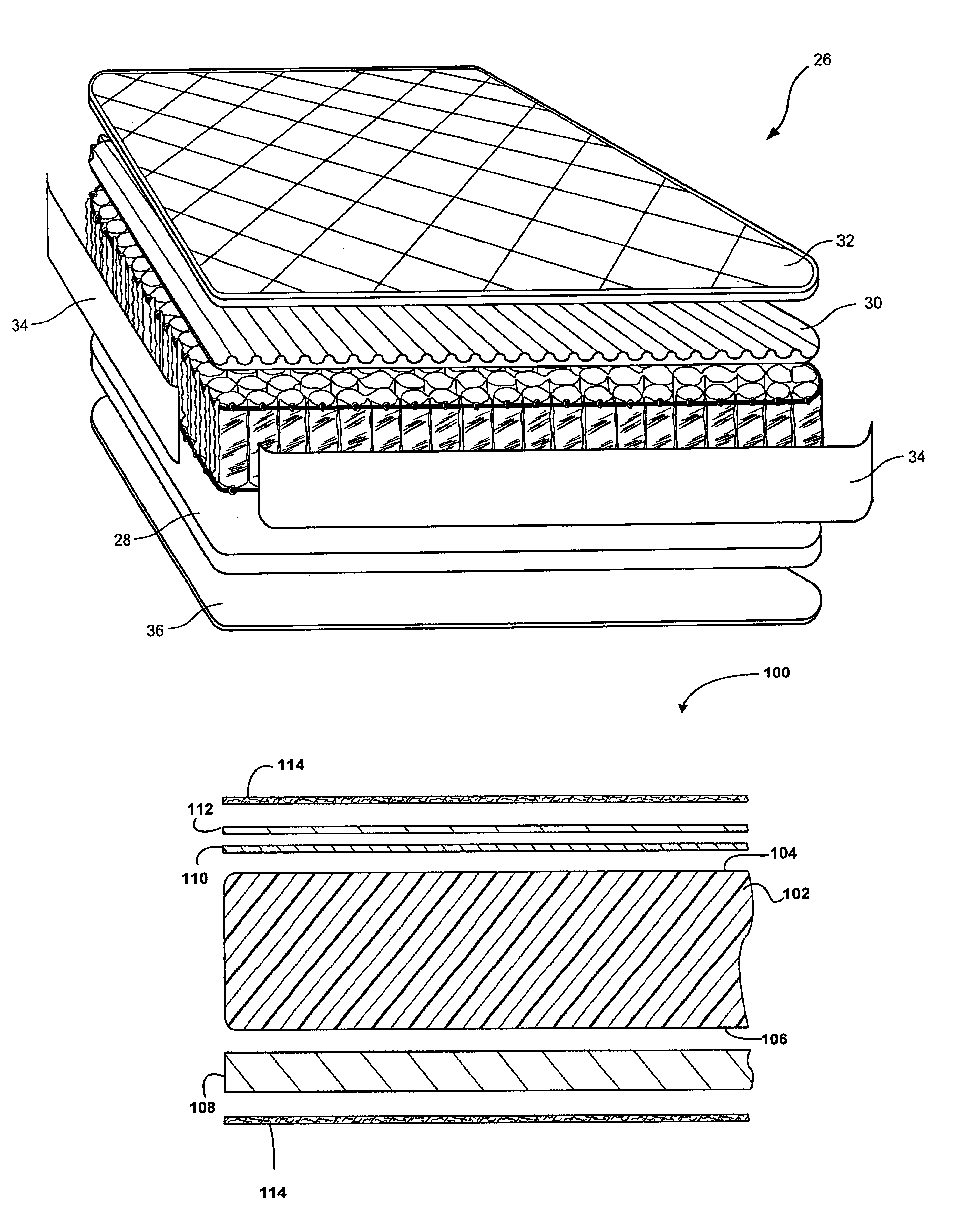

No-flip mattress systems and methods

A no-fip mattress is constructed of a mattress core, a first padding layer positioned on top of the core, wherein the first padding layer has a density in the range from about 0.5 pounds per cubic foot to about 3 pounds per cubic foot and a firmness in the range from about 8 IFD to about 45 IFD. A second padding layer is adjacent to the first padding layer, wherein the second padding layer has a density in the range from about 0.5 pounds to about 1.9 pounds, and an IFD in the range from about 5 to about 23. A bottom support layer is beneath the core, and comprises a relatively dense and firm material.

Owner:DENVER MATTRESS

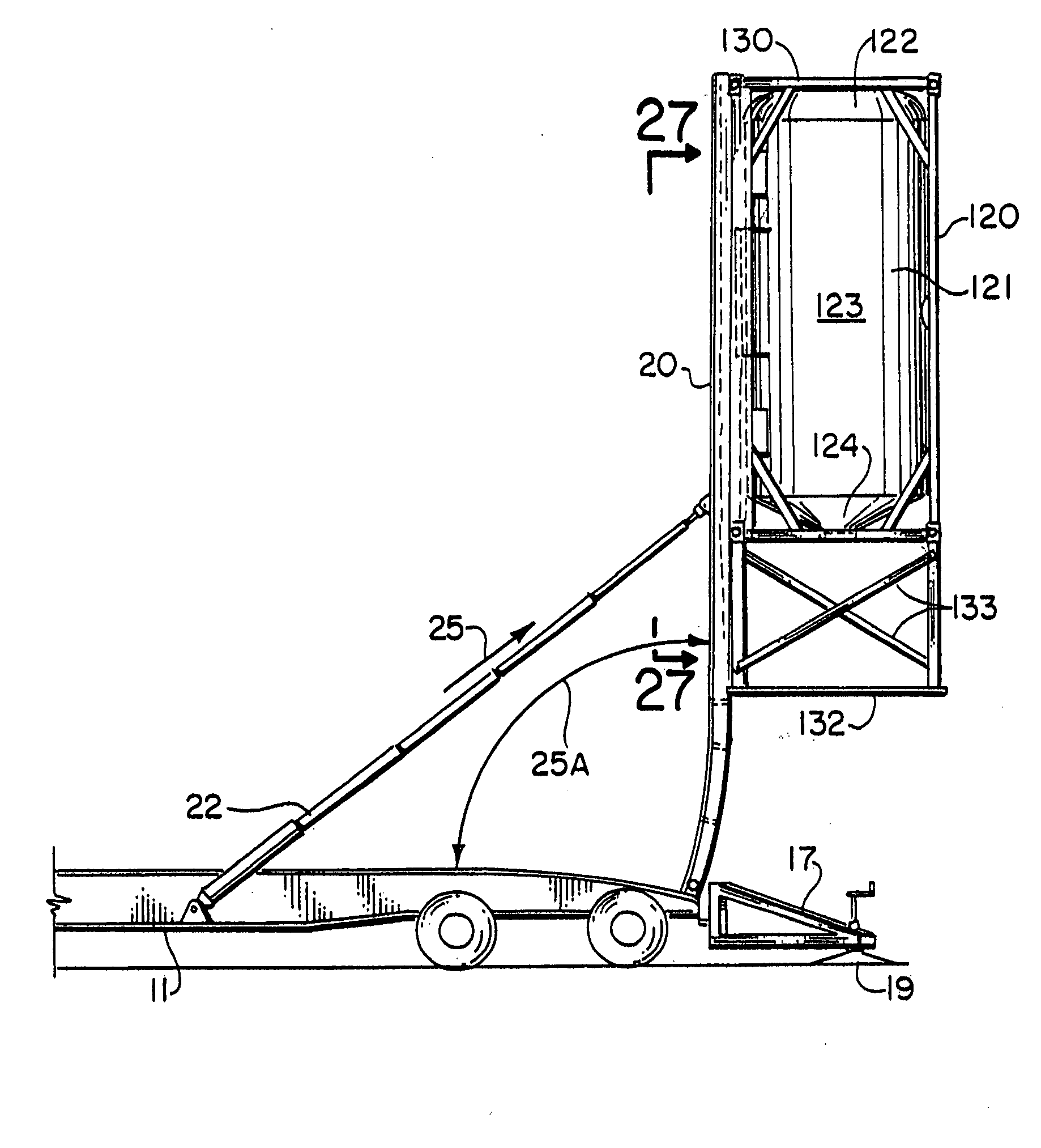

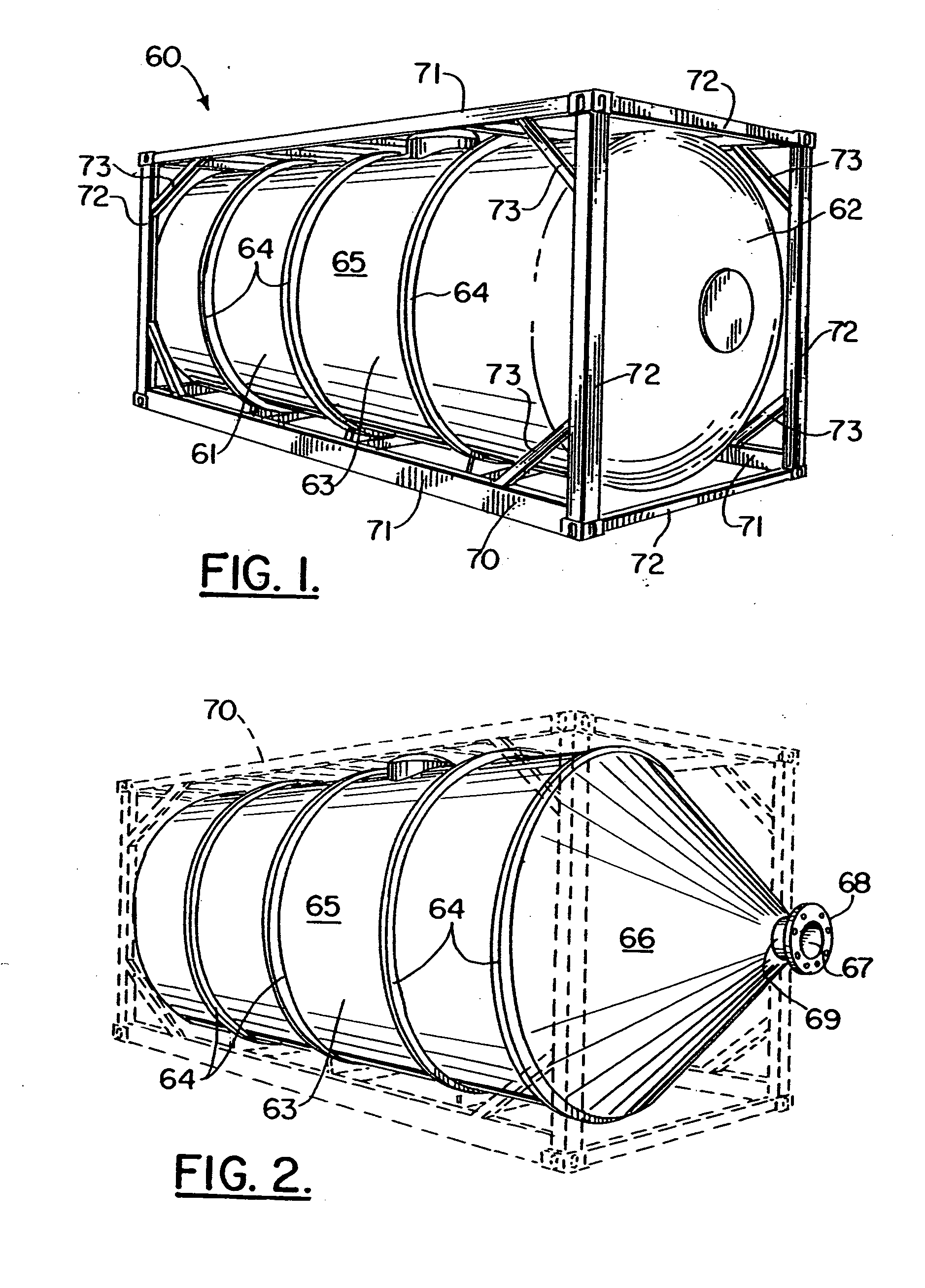

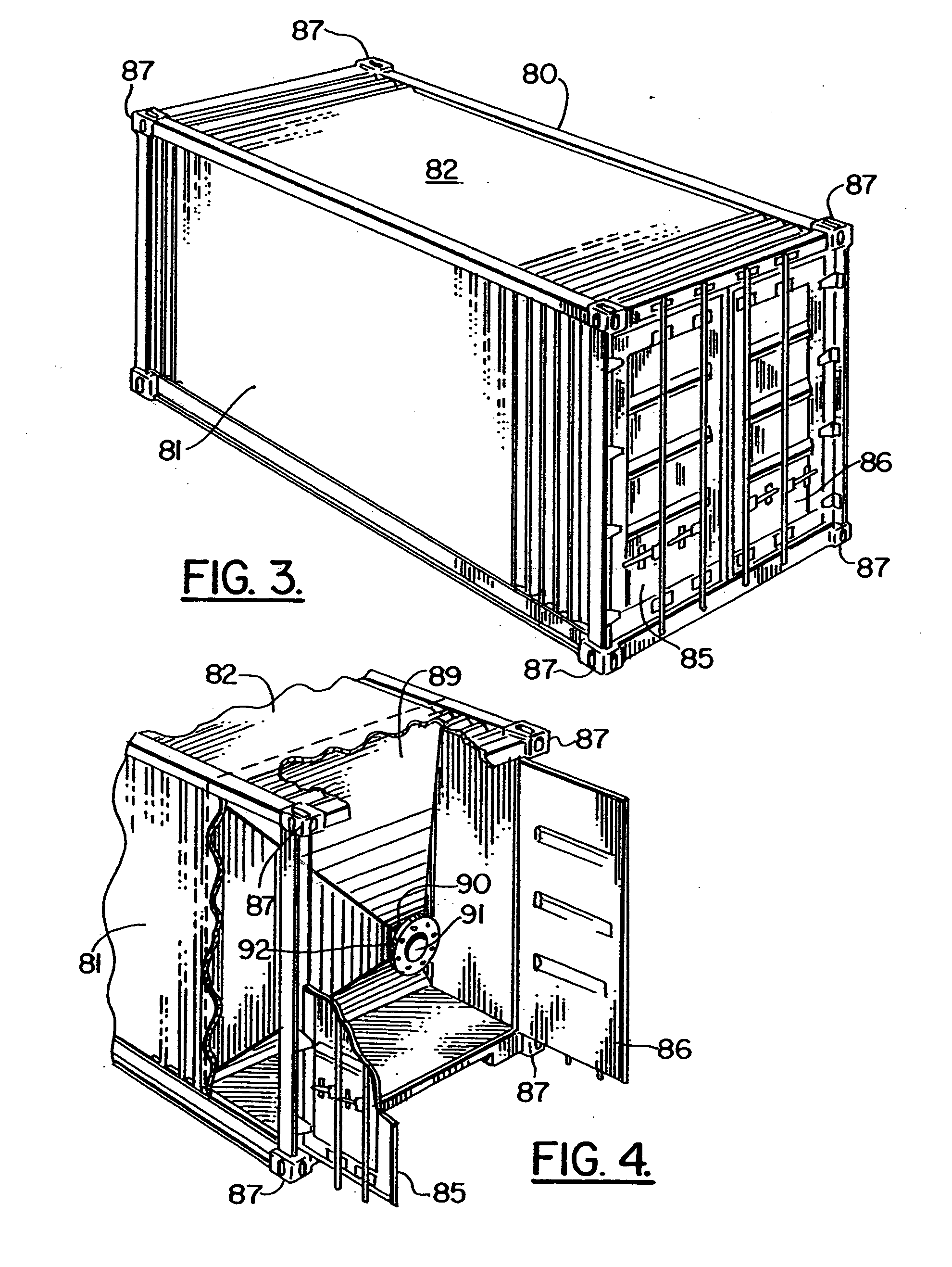

Method and apparatus for supplying bulk product to an end user

InactiveUS20050260062A1Eliminate environmental exposureEliminate product degradationTank vehiclesMixing operation control apparatusMarine engineeringEnd user

A method and apparatus for supplying bulk material to an end user includes the step of providing a bulk material source that is at a location distant from the end user and a specially configured vessel and trailer apparatus for transporting the bulk material to the end user. The vessel is filled with bulk material at the bulk material source and then transported with a specially configured trailer. Alternatively, at source or destination, the vessel can remain as a temporary storage device, free-standing from the trailer. Other similar container configurations are provided as alternate containers for use with the method of the present invention. During transport between the bulk material source and the end user, the vessel is filled or partially filled with a selected bulk material. During transport, the vessel is in a generally horizontal position, supported by the trailer and a specially configured elevator. The vessel is unloaded from the trailer by moving the vessel longitudinally along the trailer and by transferring the vessel from a generally horizontal position upon the trailer to an elevated upright position. The vessel is then lowered from the elevated position to a lowered, final installed position that is behind the trailer. The vessel is preferably loaded with between about 1 and 50,000 pounds of bulk material. The vessel preferably has a volume of between about 500 and 2,000 cubic feet. The same trailer can be used to load an empty vessel. Specially configured outriggers help align the elevator with the vessel during loading of a vessel to the trailer. Different connecting frames can be used as an interface between the elevator and the vessel for differently configured vessels. In an alternate embodiment a trailer—rail—trailer system is disclosed wherein a trailer to transport a vessel to a first terminal, a special rail frame is attached to the vessel enabling a rail car to transport the vessel from a first to a second terminal and a trailer can transport the vessel from the second terminal to a worksite.

Owner:TILT TANK L L C

Method for processing landfill and other stranded gas containing commercial quantities of methane and contaminated by carbon dioxide, nitrogen and oxygen into a pipeline or vehicle quality natural gas product

Stranded natural gas, when contaminated by difficult to remove constituents such as Nitrogen and Oxygen, has long been considered uneconomical to process into pipeline quality gas and is abandoned or utilized in other energy applications where economically viable. Landfill Gas (LFG) is often considered a stranded gas although in many instances it is available at reasonable distances to natural gas pipelines, and has only rarely been processed for injection into natural gas pipelines. Other stranded contaminated gases, such as gases vented from remote oil wells or coal beds where access to transportation pipelines is not feasible are also candidates for collection. In many instances, billions of cubic feet of methane rich LFG has been vented or flared into the atmosphere. The present invention utilizes a variety of components and provides a product gas that will meet all known pipeline requirements and / or vehicle fuel specifications without the need for blending with pipeline gas and without using cryogenic separation techniques or partial cryogenic processes. The invention also provides a product gas suitable for further processing into Liquefied Natural Gas.

Owner:INGENCO HLDG LLC

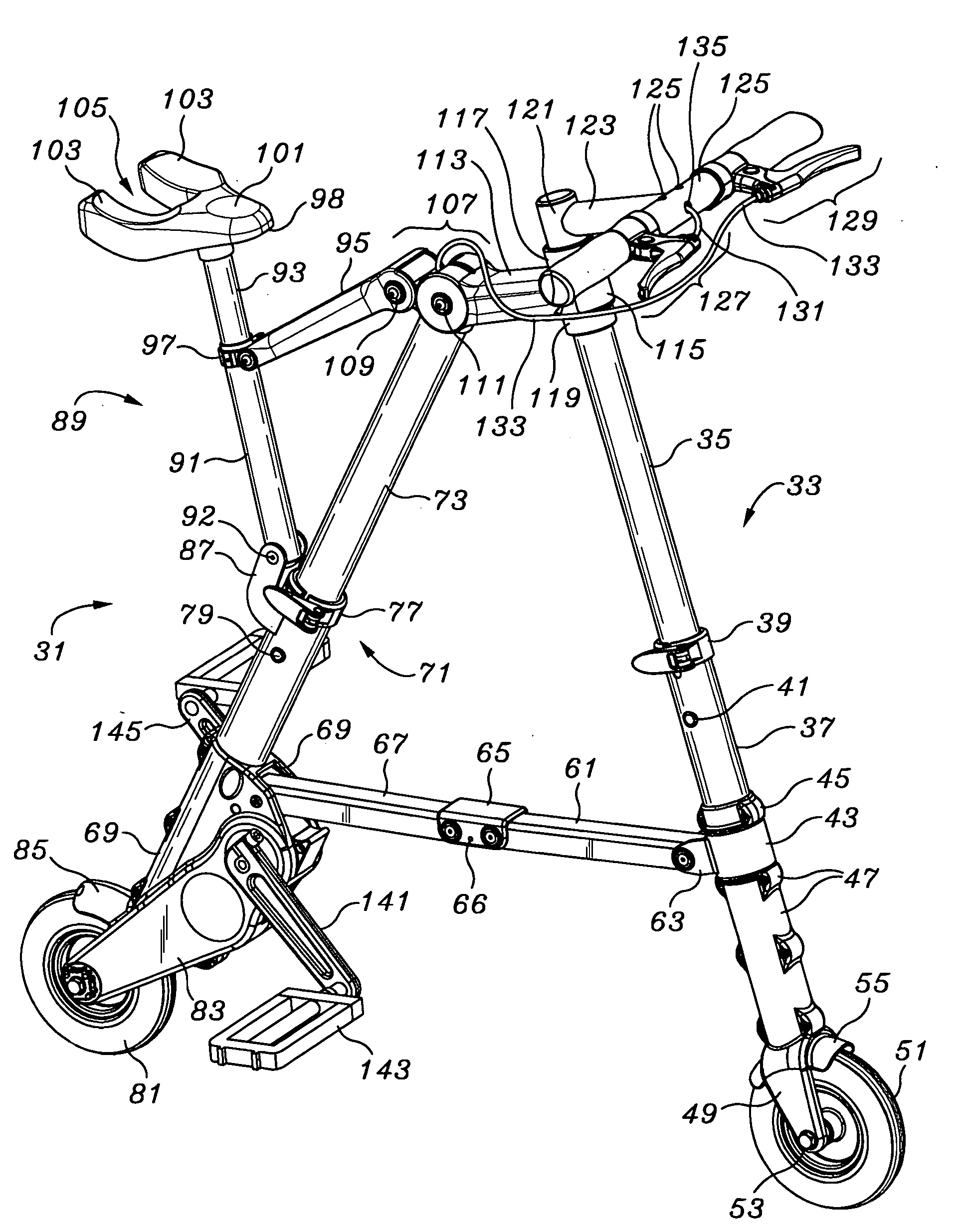

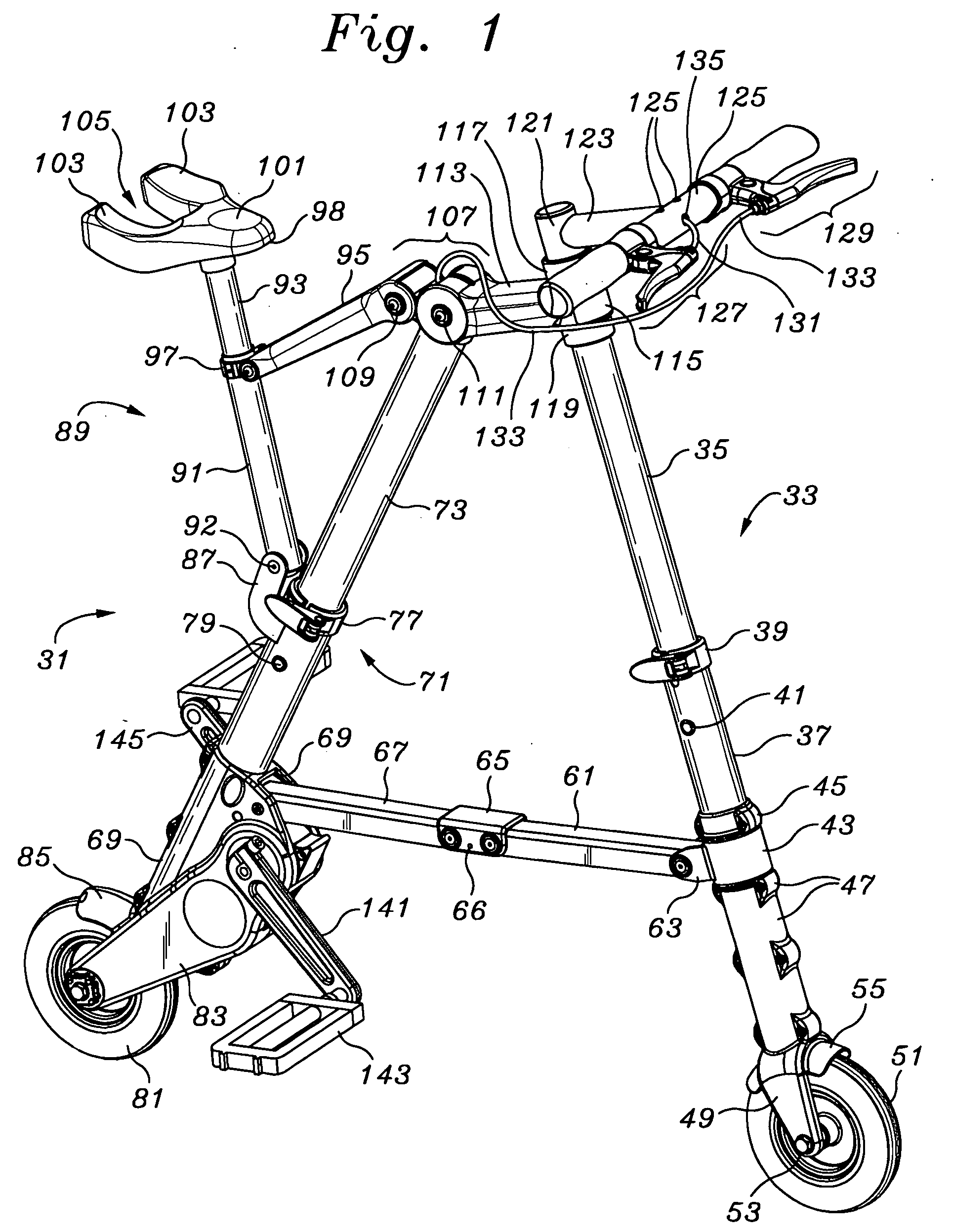

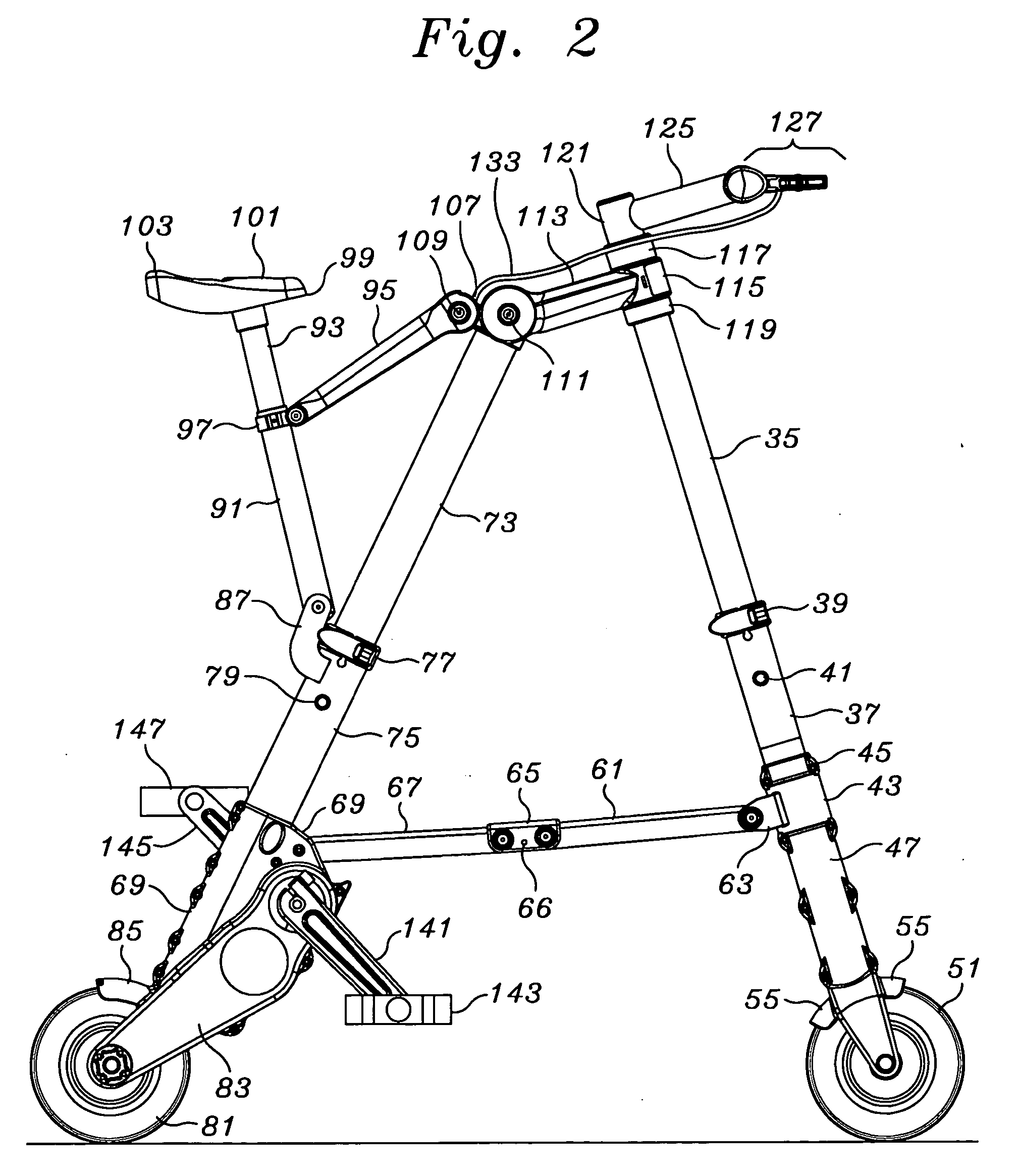

Portable folding bicycle

InactiveUS20050263979A1Readily be taken awayReduced consciousnessPassenger cyclesWheel based transmissionDeployment timeEngineering

A folding bicycle presents a number of advantages over both conventional and other foldable bicycles. The folded size of 12×25×6 inches (305×635×153 millimeters) compares favorably to other folding bicycles, and its 11 lb (eleven pound, or 5 kilogram mass) weight is significantly superior to even the closest lightweight model at eighteen pounds, and about half of the average portable bike weight of twenty-two pounds. The folded volume of the bike at 1800 square inches is slightly over one cubic foot. The portable bicycle has a folding stowage time of about 10 seconds, and a deployment time of about 6 seconds. A folding pedal and handle bar design contributes significantly to a folded lateral profile.

Owner:SINCLAIR REFINING

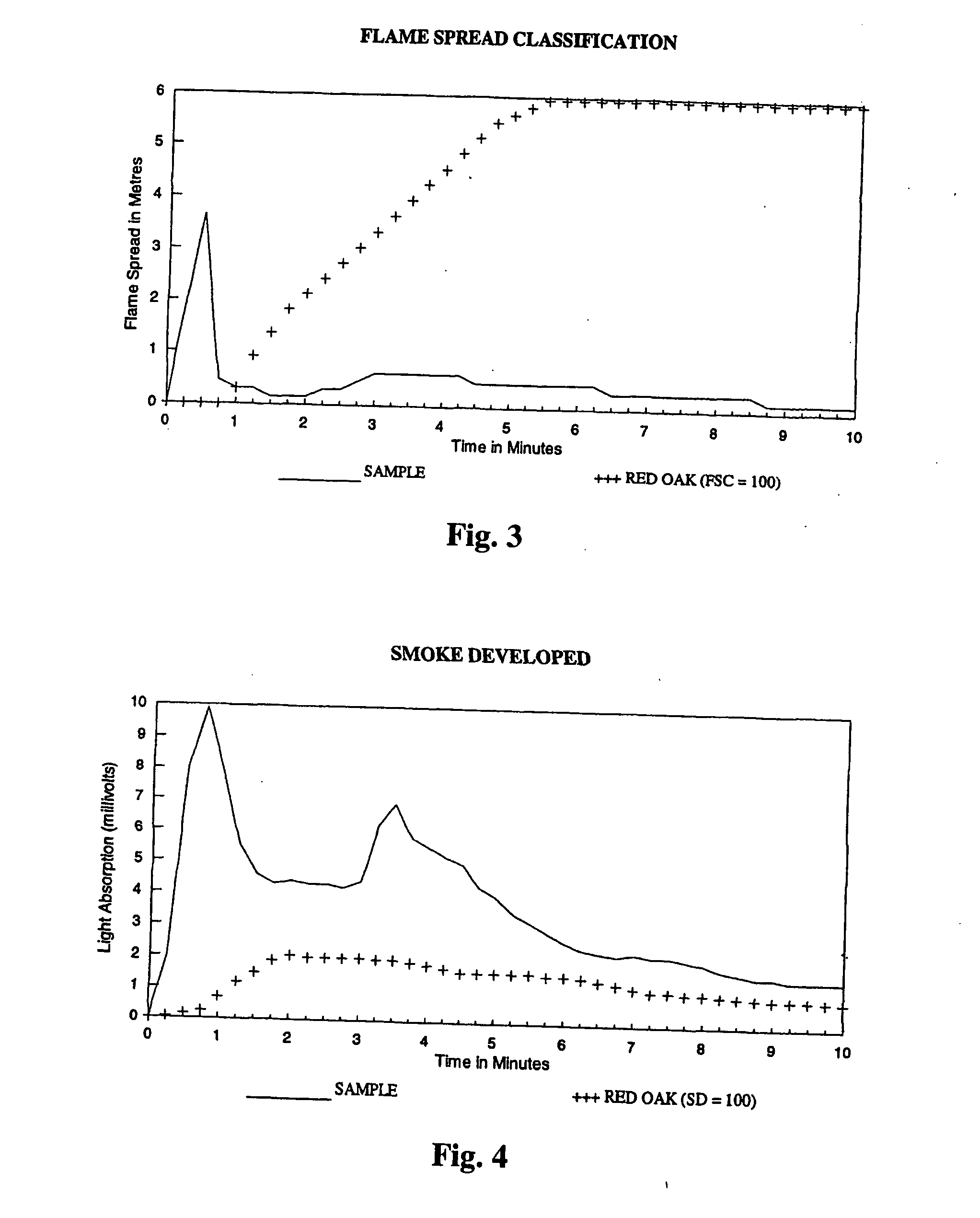

Flame retardant polyurethane products

By providing a polyol-based component and an isocyanate-based component, along with one or more flame retardant and / or smoke suppressant additives, in a reactive, injection molding process, rigid, polyurethane, foam products are achieved which are capable of exceeding all applicable standards for flame retardancy, while also comprising a density ranging between about 2 lbs. per cubic foot and 50 lbs. per cubic foot. In achieving a desired rigid polyurethane products of the present invention, the flame retardant and / or smoke suppressant additives may comprise one or more selected from the group consisting of organic additives, inorganic additives, halogenated additives, and non-halogenated additives. Furthermore, in the preferred embodiment, the three-dimensional rigid, polyurethane, foam products of the present invention comprises a thickness ranging between about 0.1 inches and 6 inches, a width ranging between about 0.1 inches and 96 inches, and an overall length ranging between about 0.1 inches and 288 inches.

Owner:NOMACO

High density polyurethane and polyisocyanurate construction boards and composite boards

A covered low-slope or flat roof comprising (a) a roof deck, (b) an optional insulation board including a polyurethane or polyisocyanurate cellular structure having a density that is less than 2.5 pounds per cubic foot, (c) a coverboard including a polyurethane or polyisocyanurate cellular structure having a density greater than about 2.5 pounds per cubic foot, and (d) a membrane.

Owner:HOLCIM TECHNOLOGY LTD

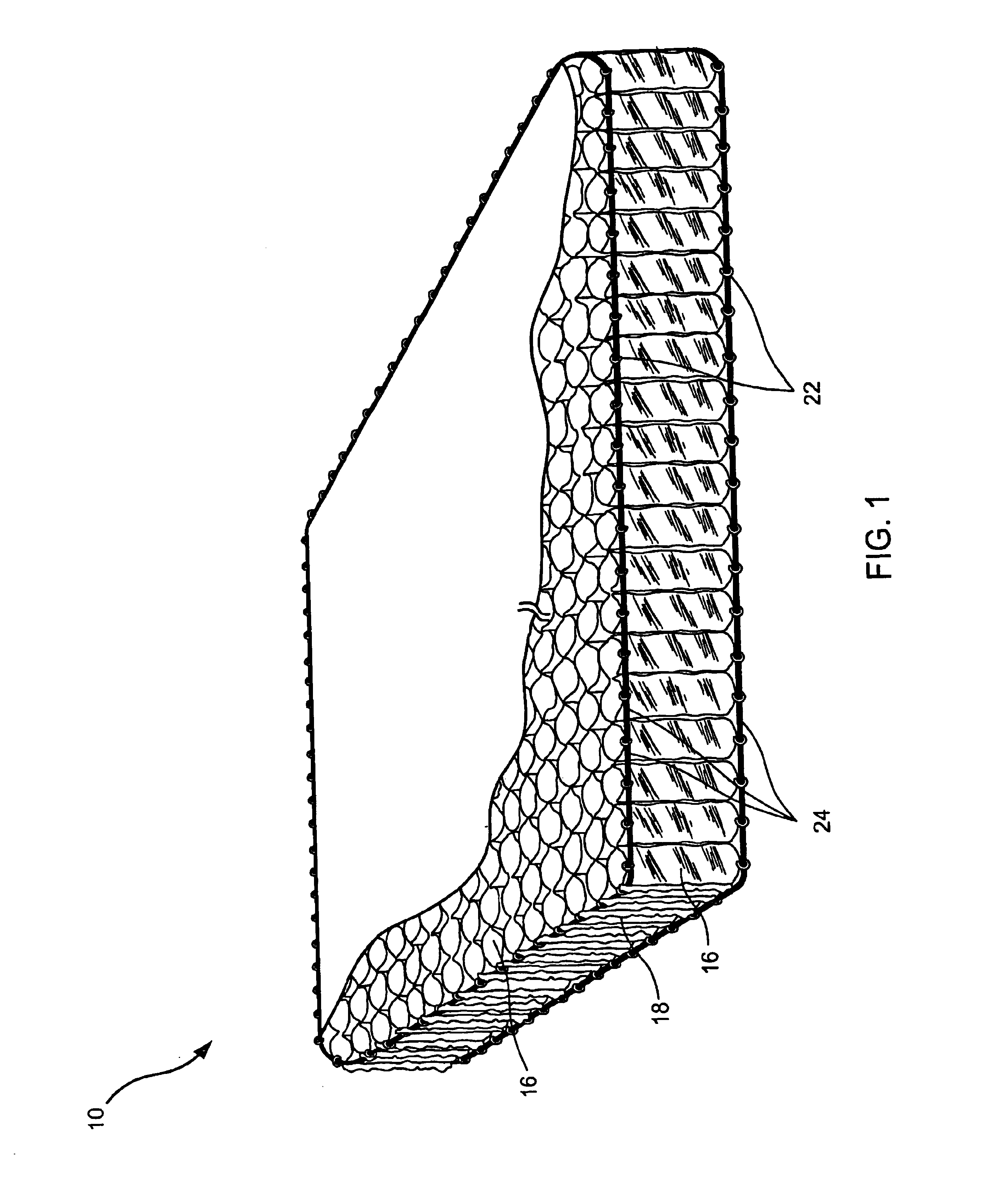

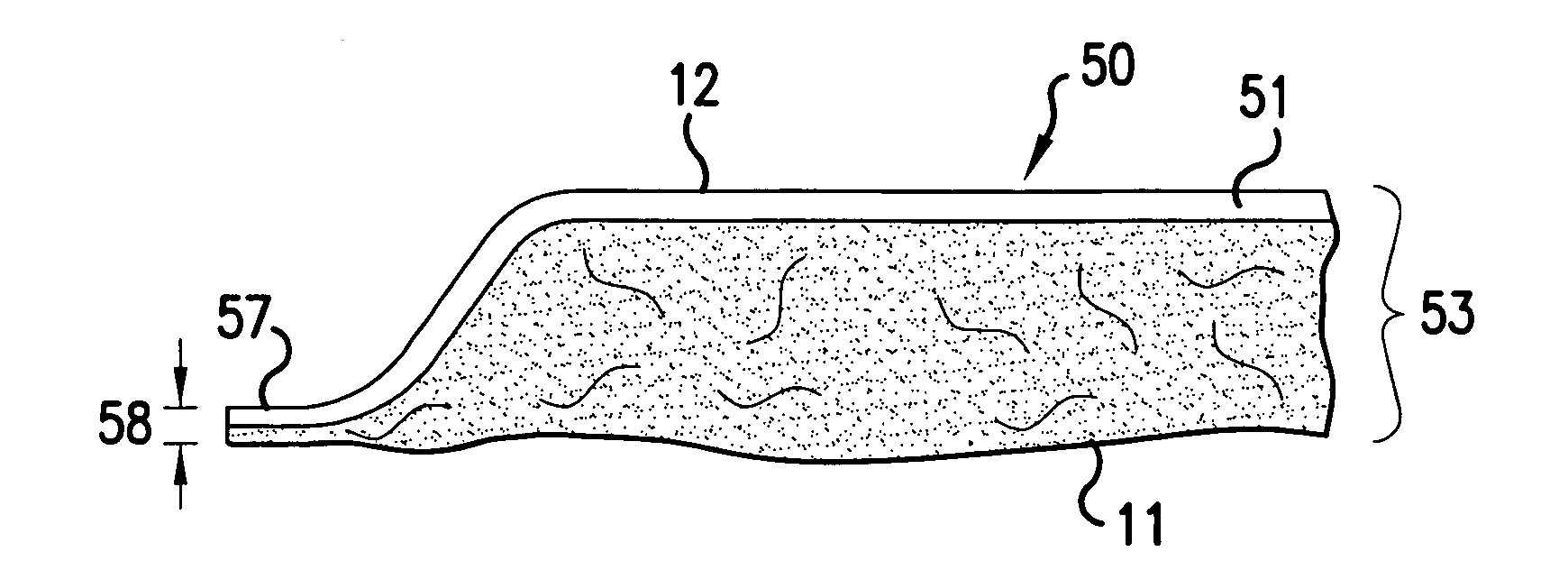

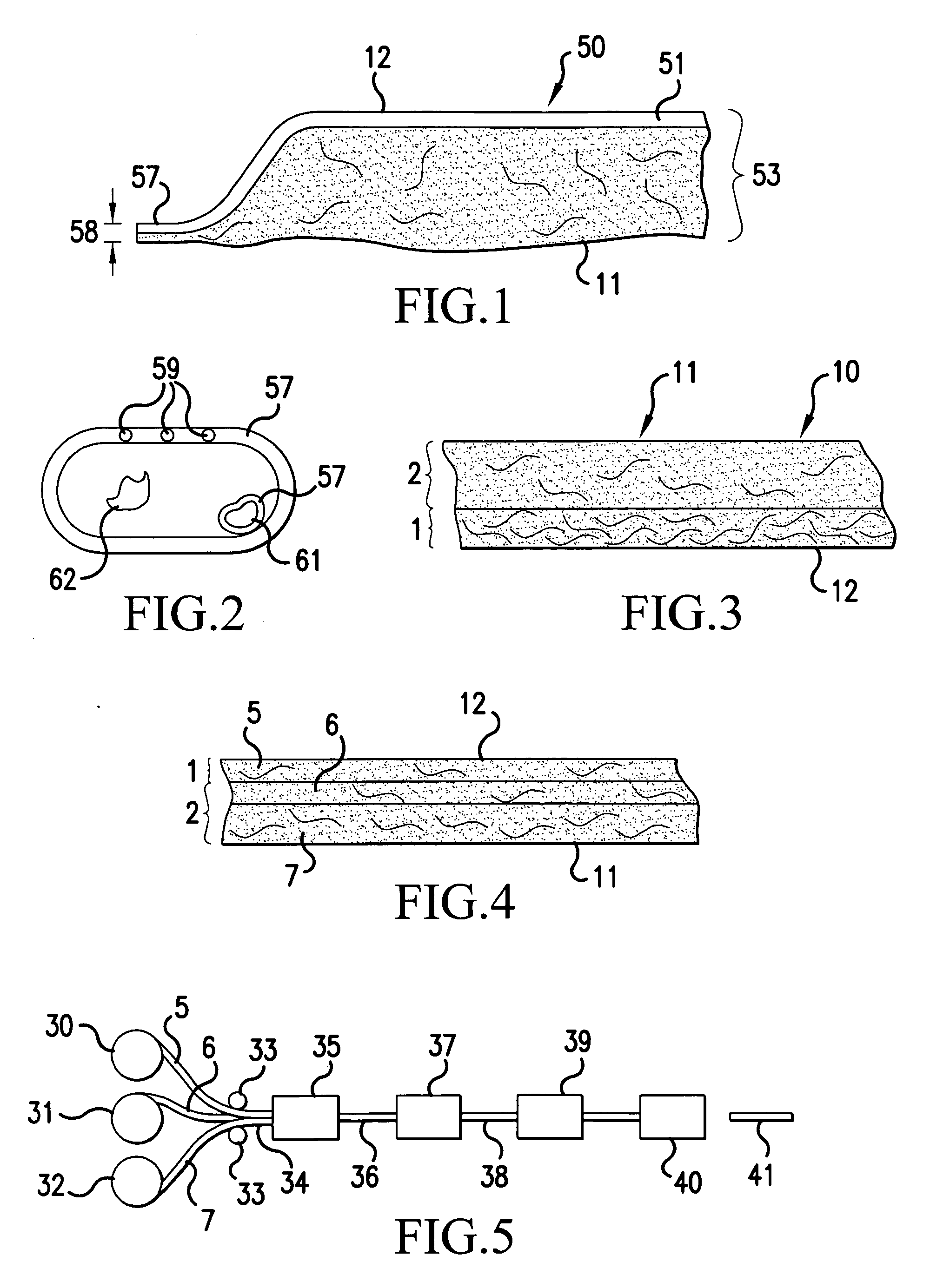

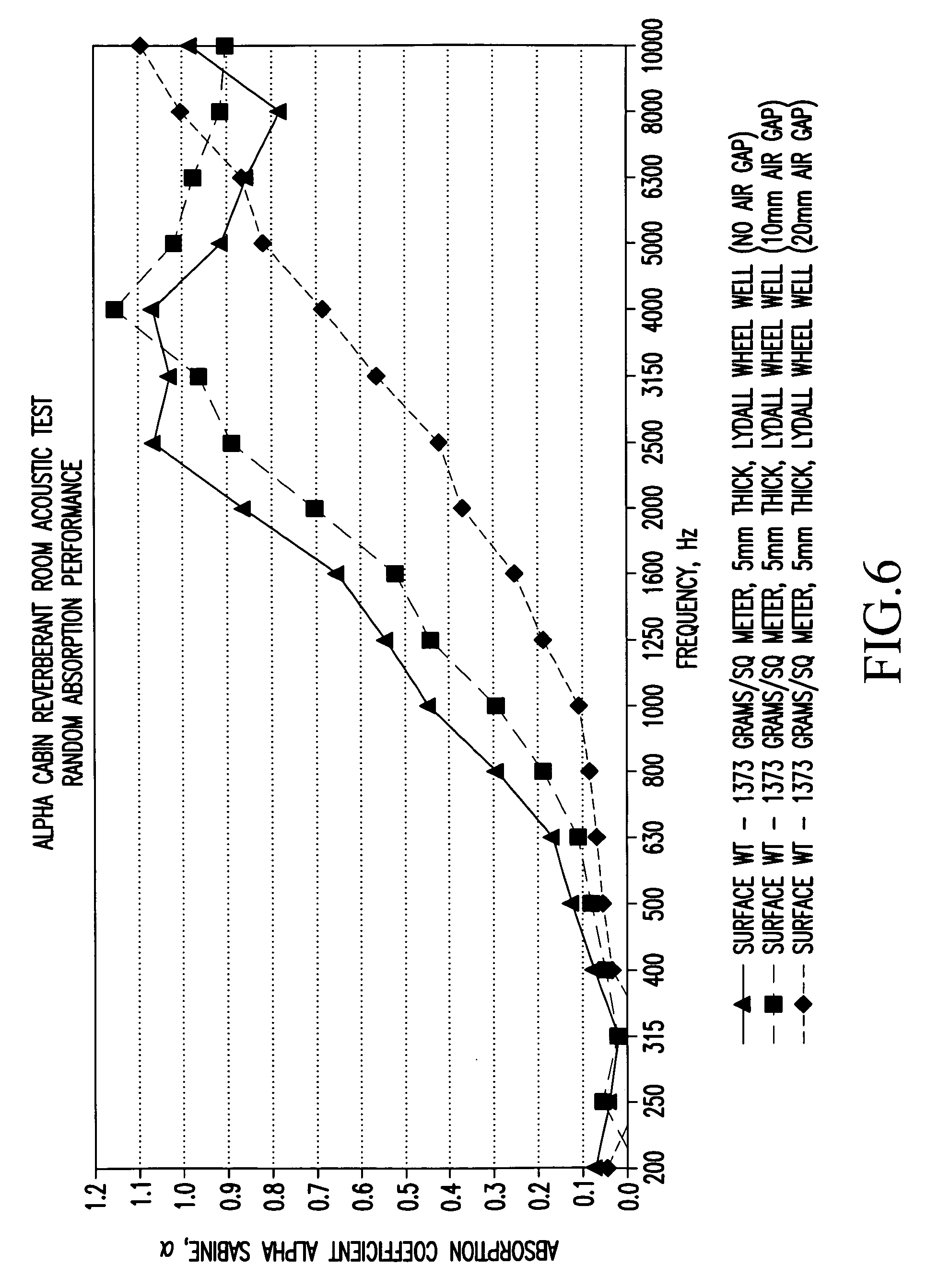

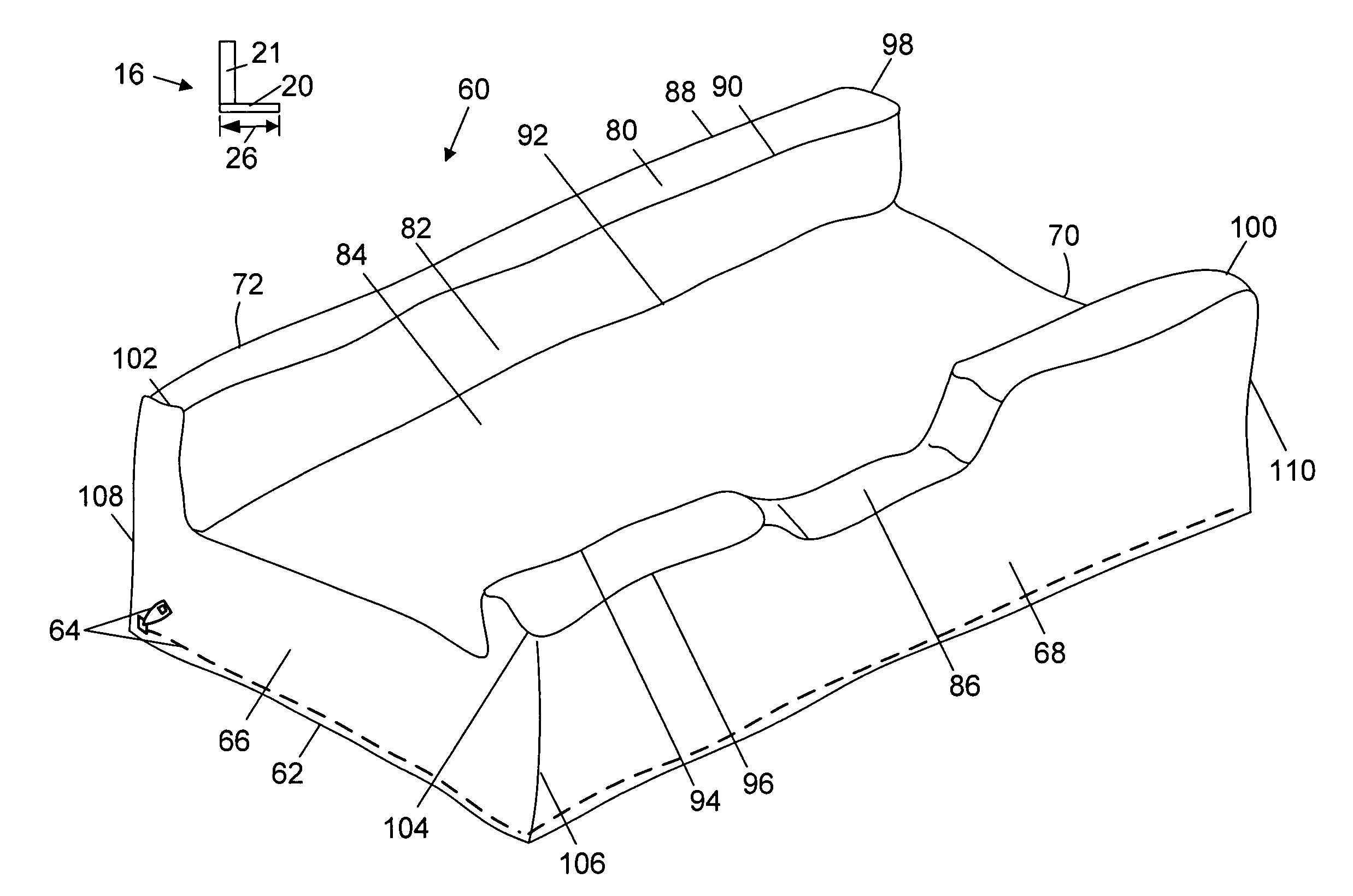

Molded and shaped acoustical insulating vehicle panel and method of making the same

ActiveUS20090085378A1Low costImproved and inexpensiveLayered productsVehicle sub-unit featuresVolumetric Mass DensityFibrous composites

A molded and shaped acoustical insulating vehicle panel having a dry-laid needled fibrous composite composed of a first portion of about 50 to 80 percent meltable binder fibers and about 20 to 50 percent stable fibers and having a second portion of about 20 to 50 percent meltable binder fibers and 50 to 80 percent of staple fibers. The meltable binder fibers are in a molded and resolidified state such that the resolidified binder fibers of the first portion form a substantially continuous, semi-impervious, densified skin integrally associated with and bonded to a surface of the first portion. The molded composite is in such a heat and pressure molded state that the composite has over a predominance of its area a density of from about 12 to 22 lbs. / cubic foot (192 to 352 kg / cubic meter) and the panel is sufficiently rigid as to be self-supporting.

Owner:L INT IP HLDG LLC

Mattress assembly

InactiveUS7246388B2Eliminate greatly reduce riskEliminate needBedsNursing bedsCubic footElectrical and Electronics engineering

Owner:DILIBERTO JR SAMUEL L

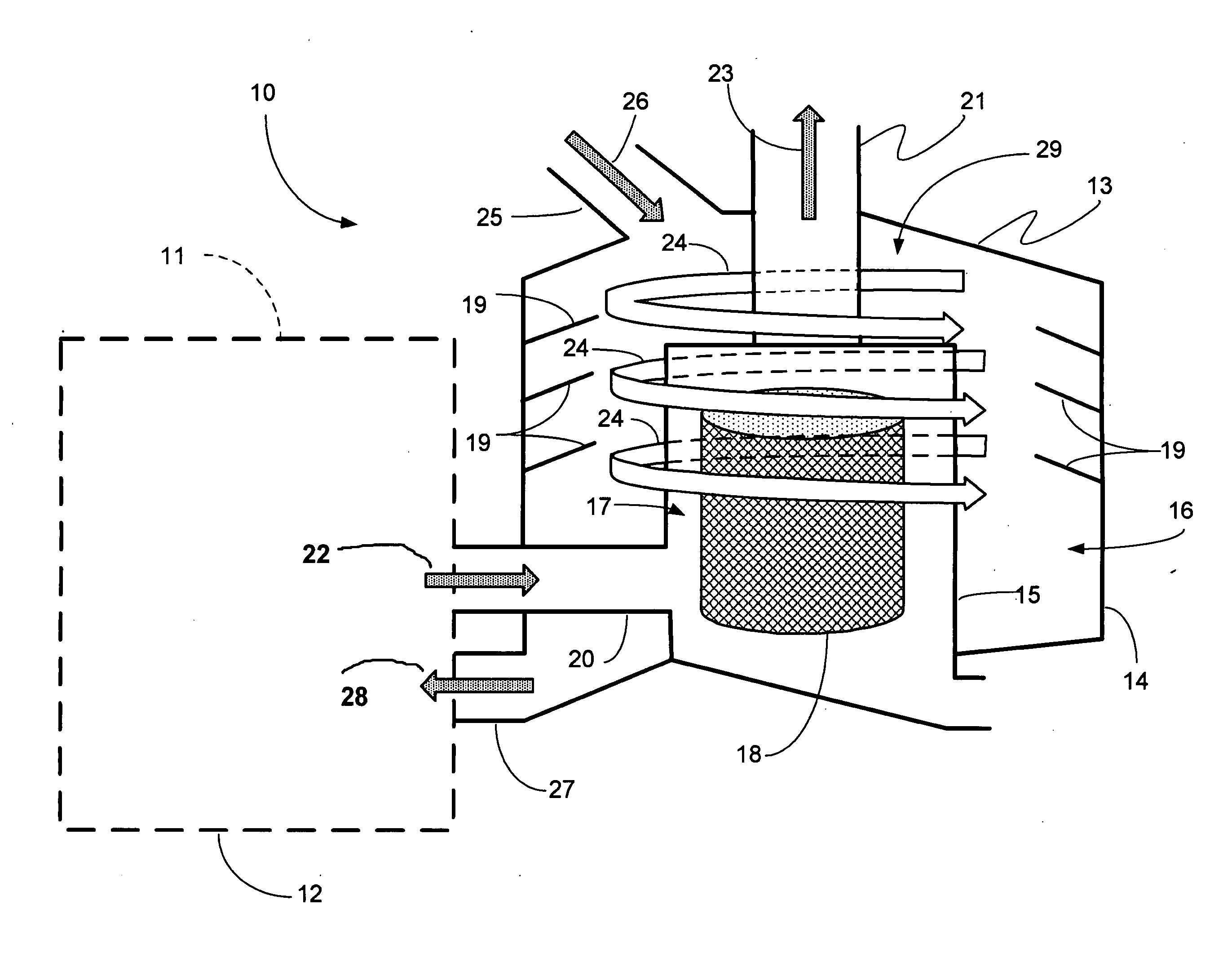

Reduced-emissions combustion utilizing multiple-component metallic combustion catalyst and lightly catalyzed diesel particulate filter

InactiveUS20050164139A1Reduce system costLower requirementLiquid fuel feeder/distributionLiquid fuel pretreatmentCeriumPt element

An improved, robust diesel emission control system employs a lightly diesel particulate filter (DPF), preferably with a platinum containing fuel borne catalyst (FBC) in the fuel. The DPF is preferably of wire mesh construction and at least partially lightly catalyzed with precious metal catalyst, e.g., platinum group metal, having a metal loading of from about 3 to 15 grams per cubic foot to minimize formation of NO2 in the exhaust gas. Preferred fuel borne catalyst levels will be low, e.g., from 0.05 to 0.5 ppm for platinum and 3 to 8 ppm for cerium and / or iron, thereby providing effective engine out emissions reductions without discharging excessive amounts of NO2 to the atmosphere.

Owner:CLEAN DIESEL TECHNOLOGIES

Clothes dryer apparatus with improved lint removal system

InactiveUS20090255145A1Maximize contact timeMaximize energy transferDrying solid materials with heatDrying gas arrangementsFiltrationPulp and paper industry

A method and apparatus for removing lint from air that is discharged from a clothes dryer uses a lint filtration housing mounted on the frame of the clothes dryer, the filtration housing having an interior that contains a filter for removing lint from the dryer exhaust air flow stream. The housing provides an influent fitting for transmitting heating exhaust air from the drying chamber to the housing interior. An ambient air supply enables ambient air to be added to the filtration housing interior. One or more vanes is provided that create an annular vortex within the filtration housing interior. The flow of the annular vortex within the filtration housing interior can be between about 500 and 3,000 cubic feet per second. A flow line transmits pre-heated air from the filtration housing interior to the dryer interior.

Owner:PELLERIN MILNOR

Micronized wood preservative formulations comprising copper and zinc

ActiveUS7632567B1Minimal leachingGood curative effectBiocidePretreated surfacesZinc compoundsPreservative

Use of micronized zinc compounds in wood preservation treatments containing micronized copper compounds significantly increases the efficacy of the treatment with respect to that of the copper compounds alone. Micronized copper compounds used at a retention in the range of from 0.005 to 1 pounds per cubic foot (pcf) expressed as CuO equivalent, and zinc compounds are used at a retention in the range of from 0.005 to 1 pcf expressed as ZnO equivalent, the increase in wood preservation efficacy over similar retentions of copper compounds alone can be seen in as little as 24 months.

Owner:KOPPERS PERFORMANCE CHEM

Mattress and side rail assembly with high airflow

A side rail assembly for supporting an edge of a mattress includes a layer of a polyurethane foam comprising an open cellular structure, wherein the open cellular structure comprises about 10 to about 40 cells per inch, a hardness of about 35 pounds-force to about 100 pounds-force, and a density of about 1.2 pounds per cubic foot to about 2.0 pounds per cubic foot, wherein the layer is configured to be disposed about a perimeter of an inner core of the mattress and is configured to permit the flow of fluid from and to the inner core through the layer.

Owner:DREAMWELL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com