Patents

Literature

281 results about "Return current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Estimated current return is the return that an investor can expect for a unit investment trust over a short period of time, for instance annually. It is actually an estimate of the interest that the unit holder can expect to receive.

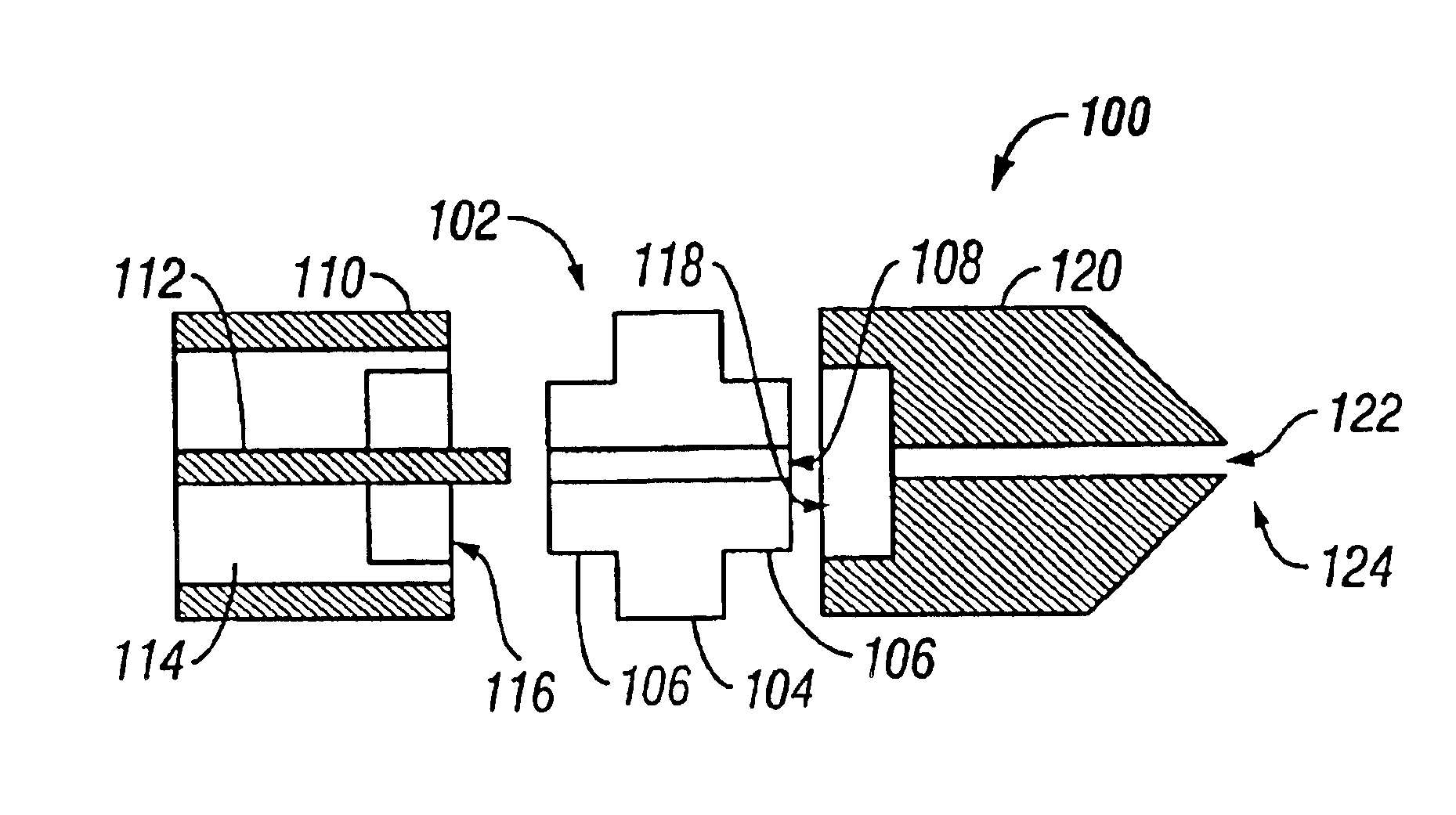

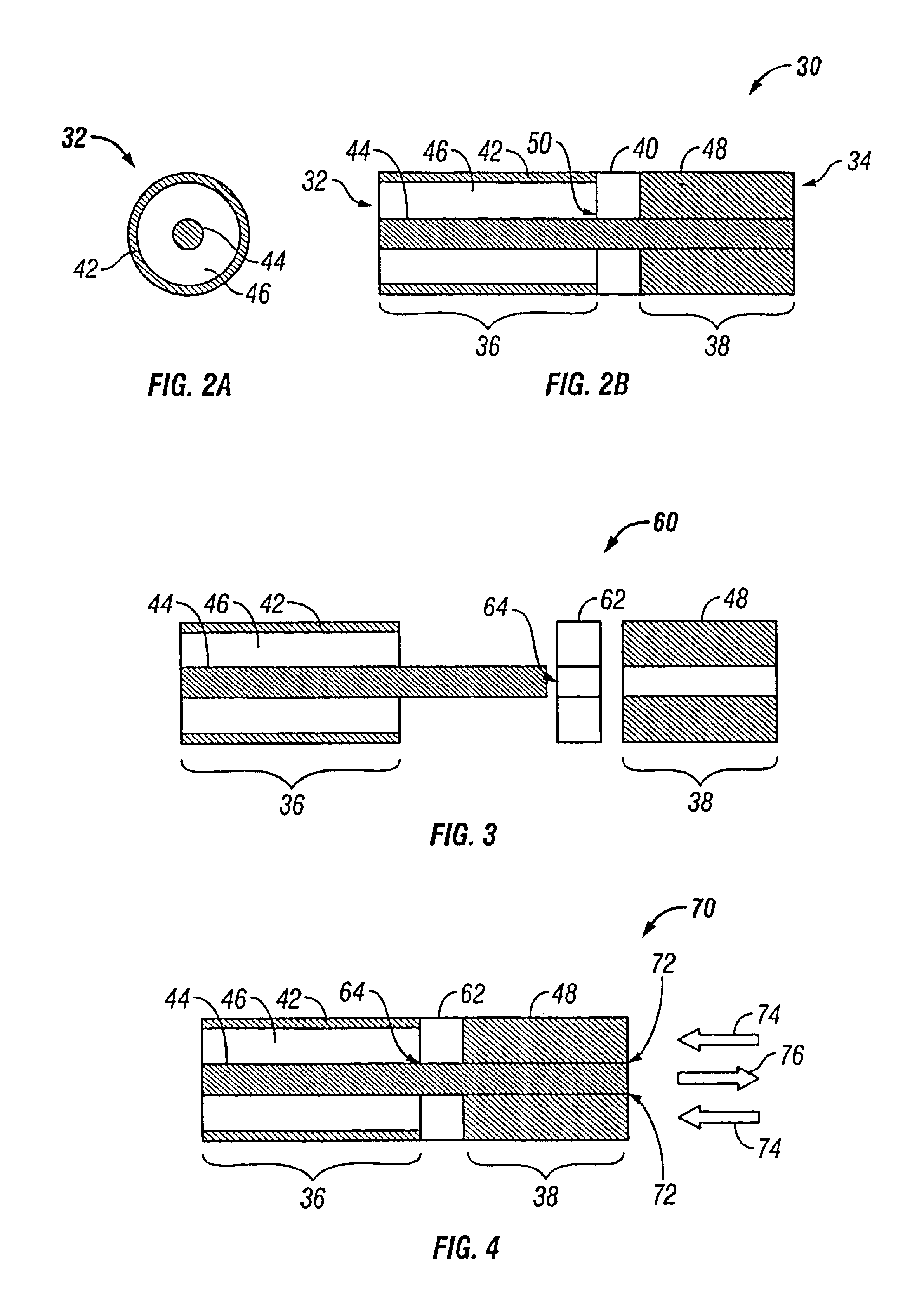

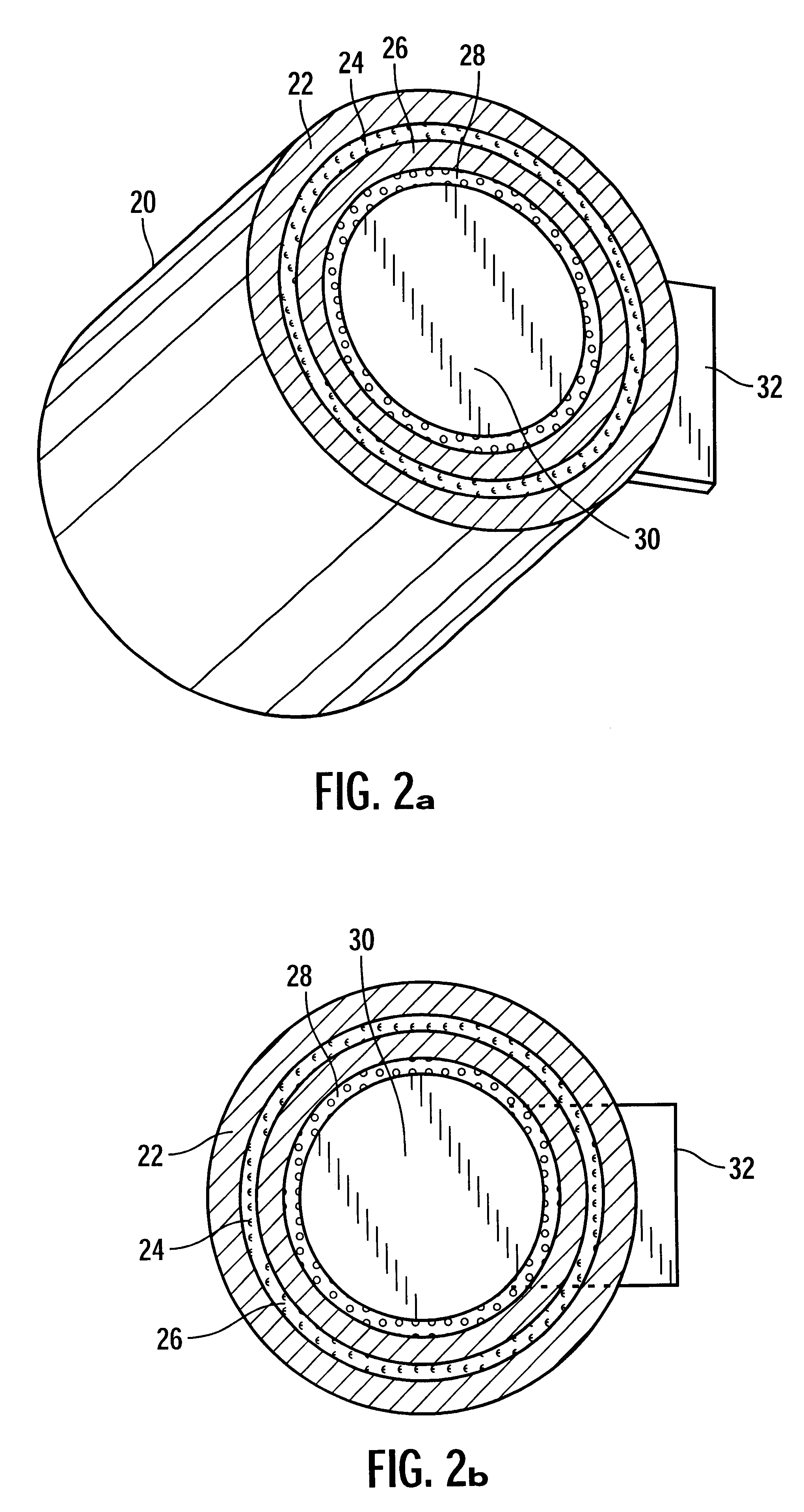

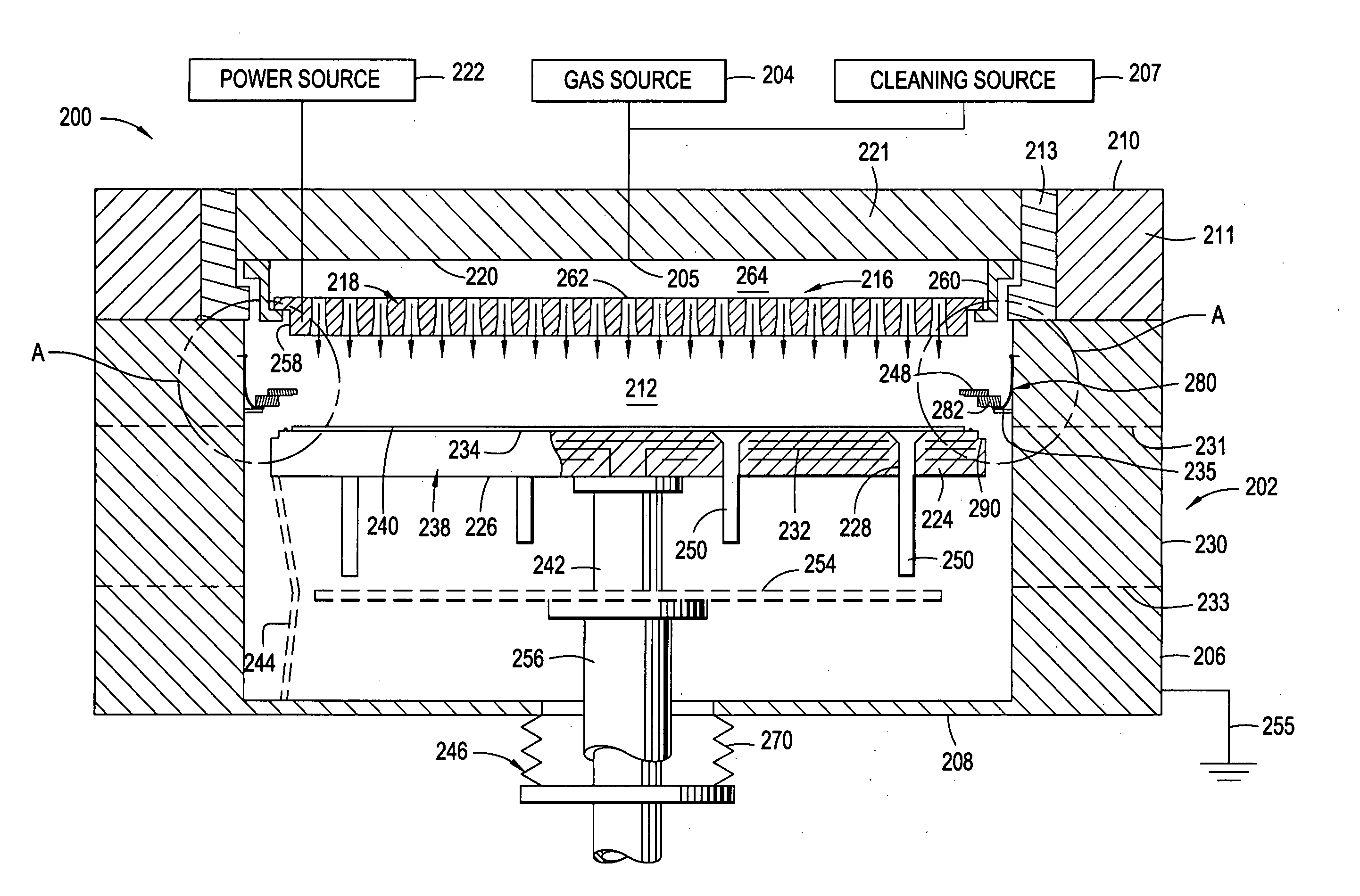

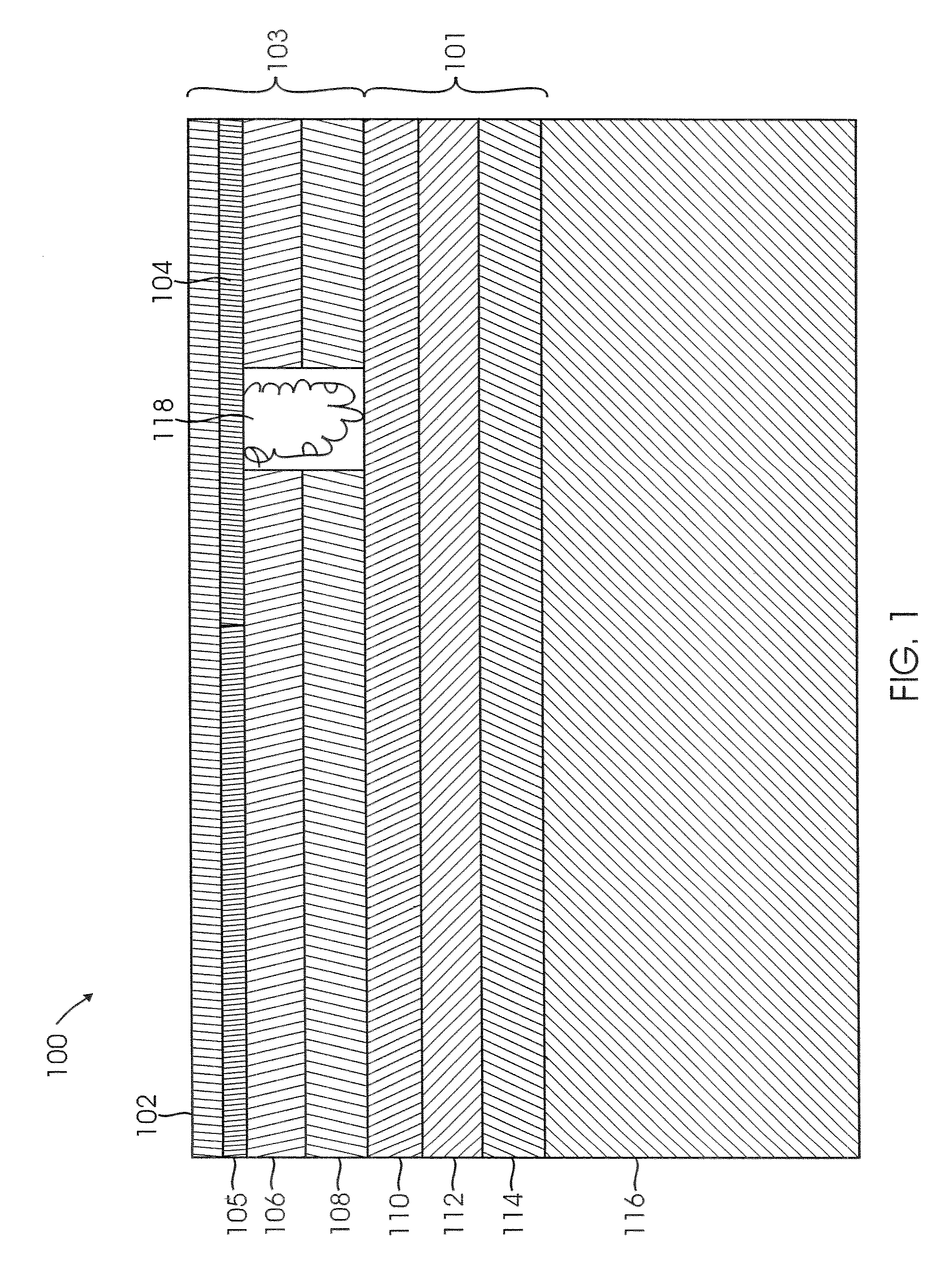

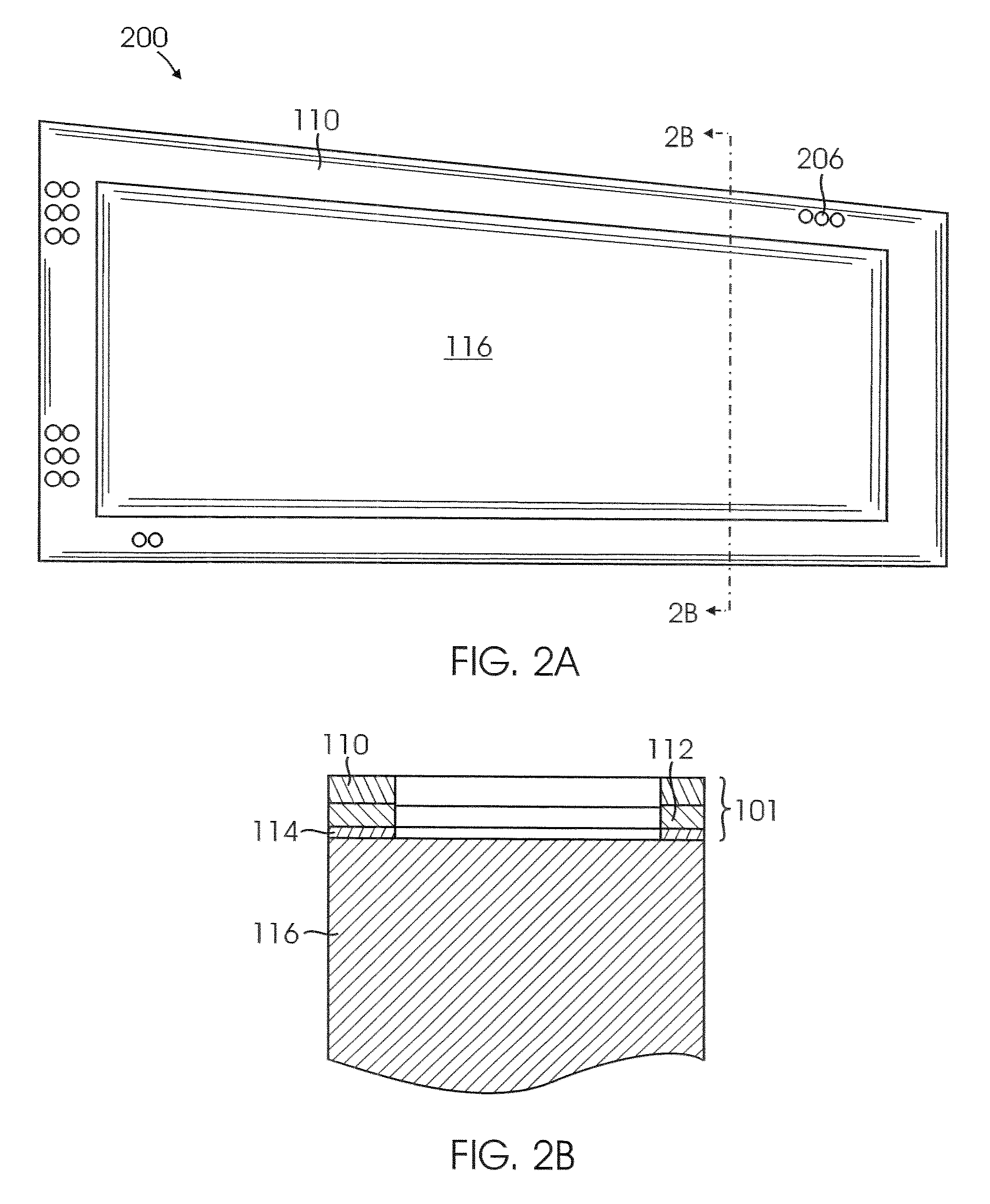

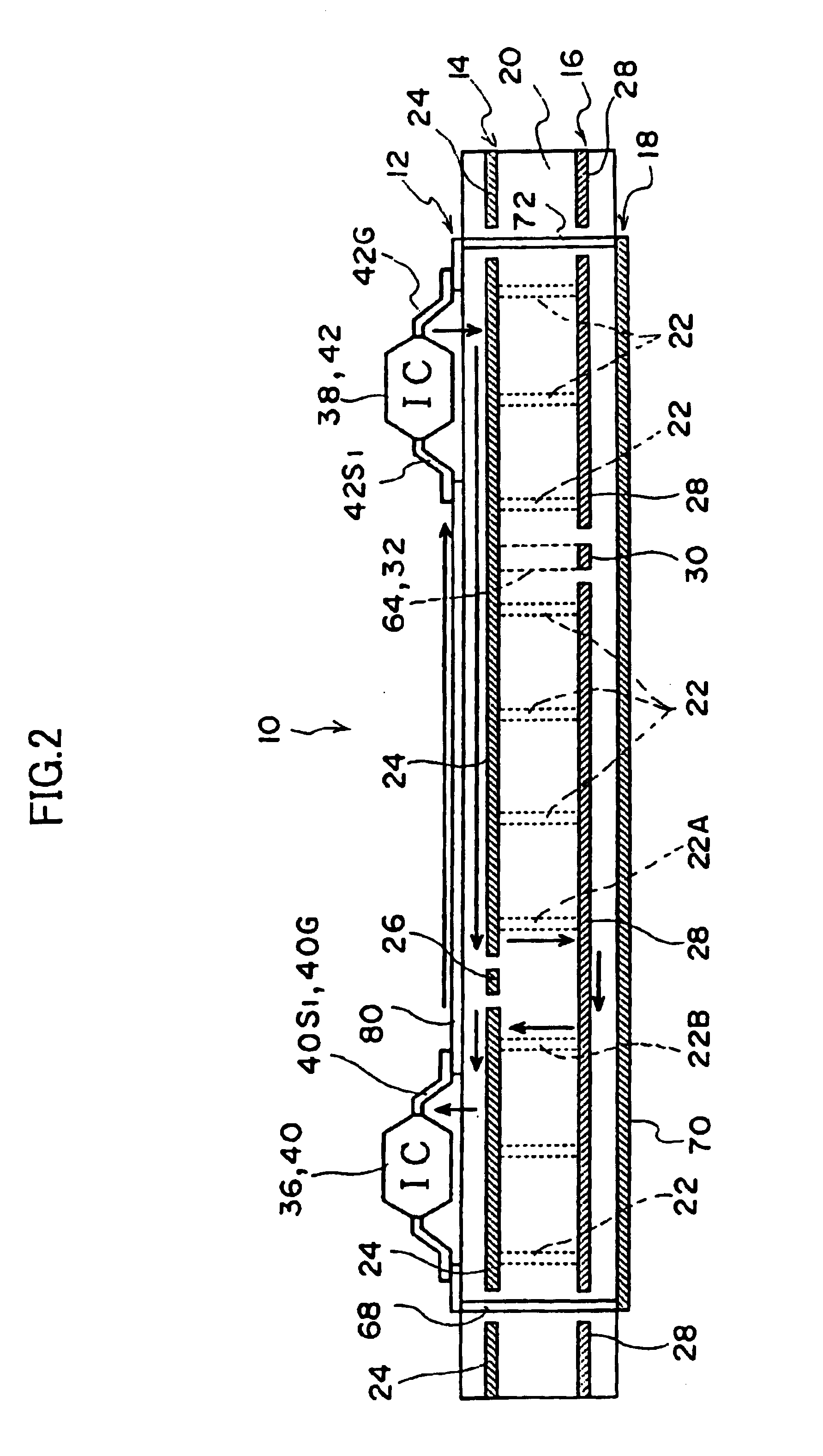

High-strength microwave antenna assemblies

InactiveUS6878147B2Avoid mechanical failureSurgical needlesSurgical instruments for heatingAntenna designElectrical conductor

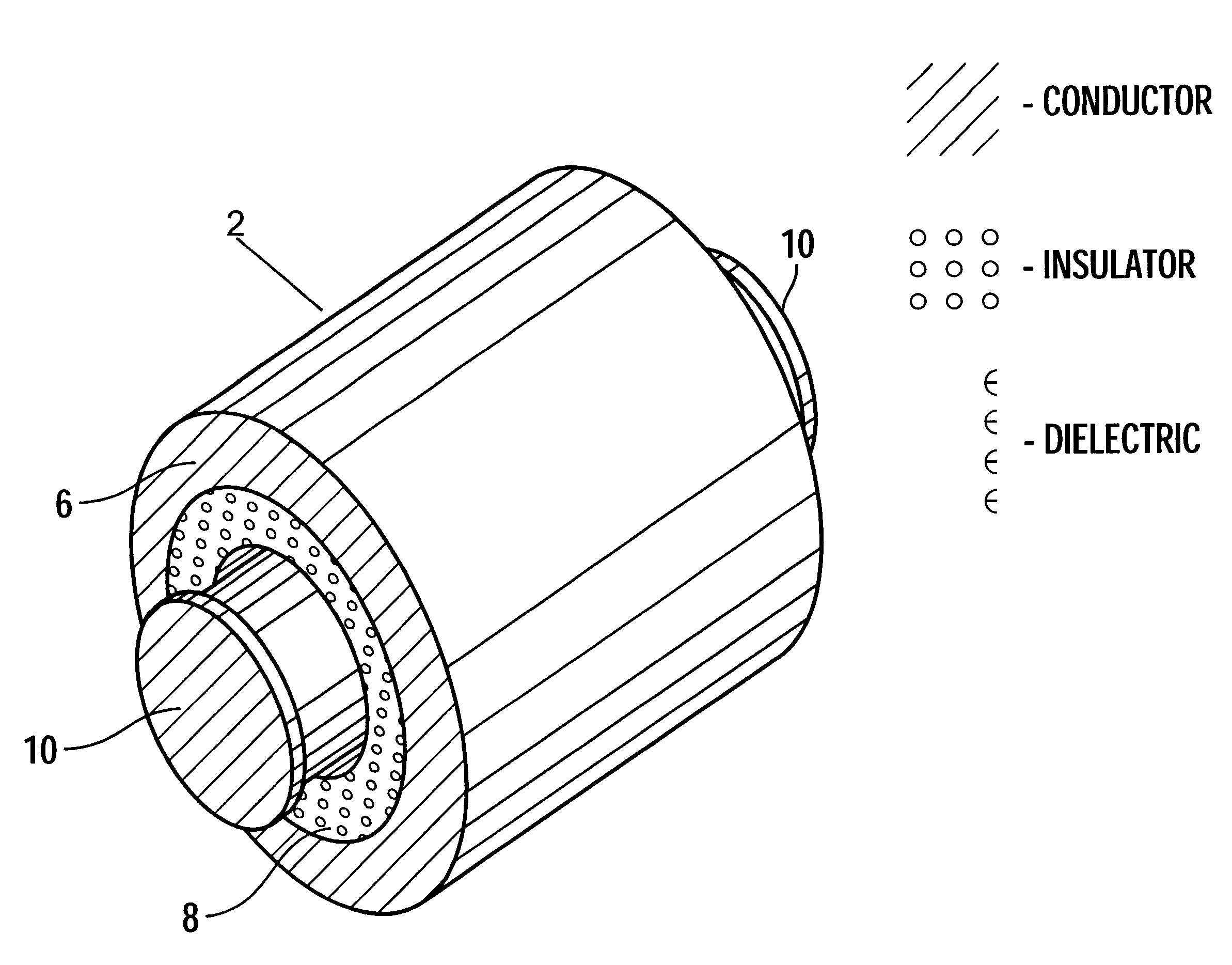

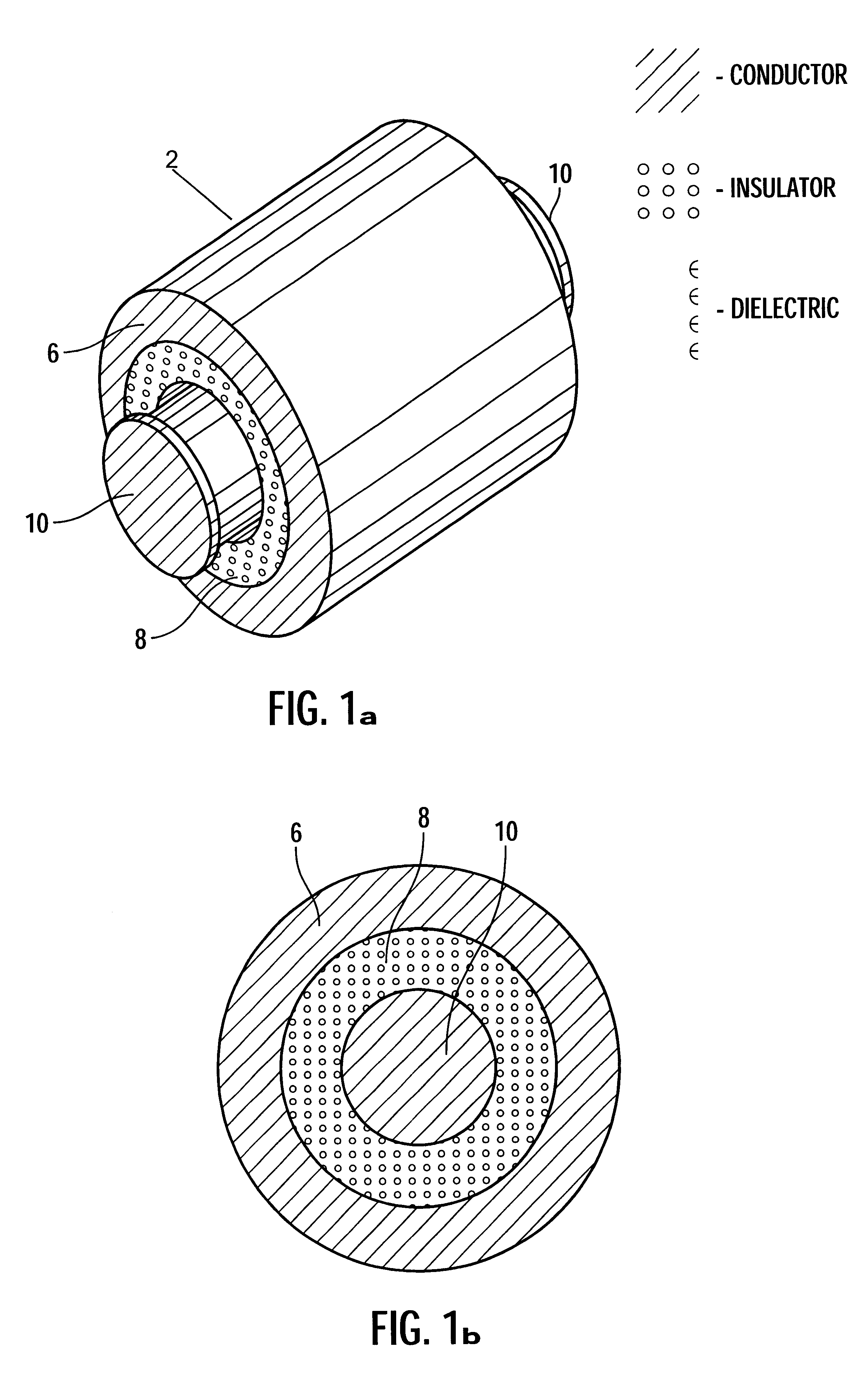

Various high-strength microwave antenna assemblies are described herein. The microwave antenna has a radiating portion connected by a feedline to a power generating source, e.g., a generator. The antenna is a dipole antenna with the distal end of the radiating portion being tapered and terminating at a tip to allow for direct insertion into tissue. Antenna rigidity comes from placing distal and proximal radiating portions in a pre-stressed state, assembling them via threaded or overlapping joints, or fixedly attaching an inner conductor to the distal portion. The inner conductor is affixed to the distal portion by, e.g., welding, brazing, soldering, or by adhesives. A junction member made from a hard dielectric material, e.g., ceramic, can be placed between the two portions and can have uniform or non-uniform shapes to accommodate varying antenna designs. Electrical chokes may also be used to contain returning currents to the distal end of the antenna.

Owner:COVIDIEN LP

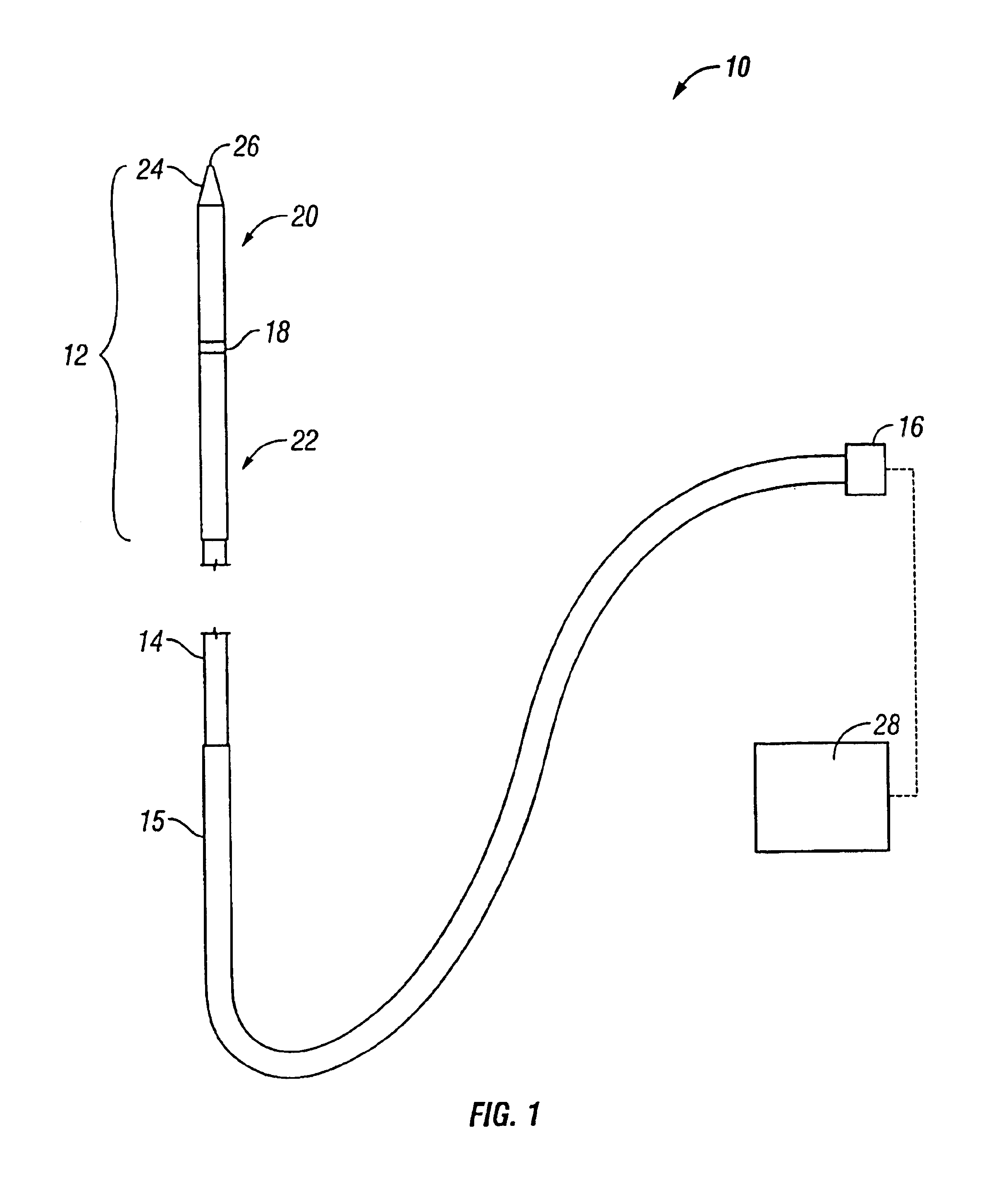

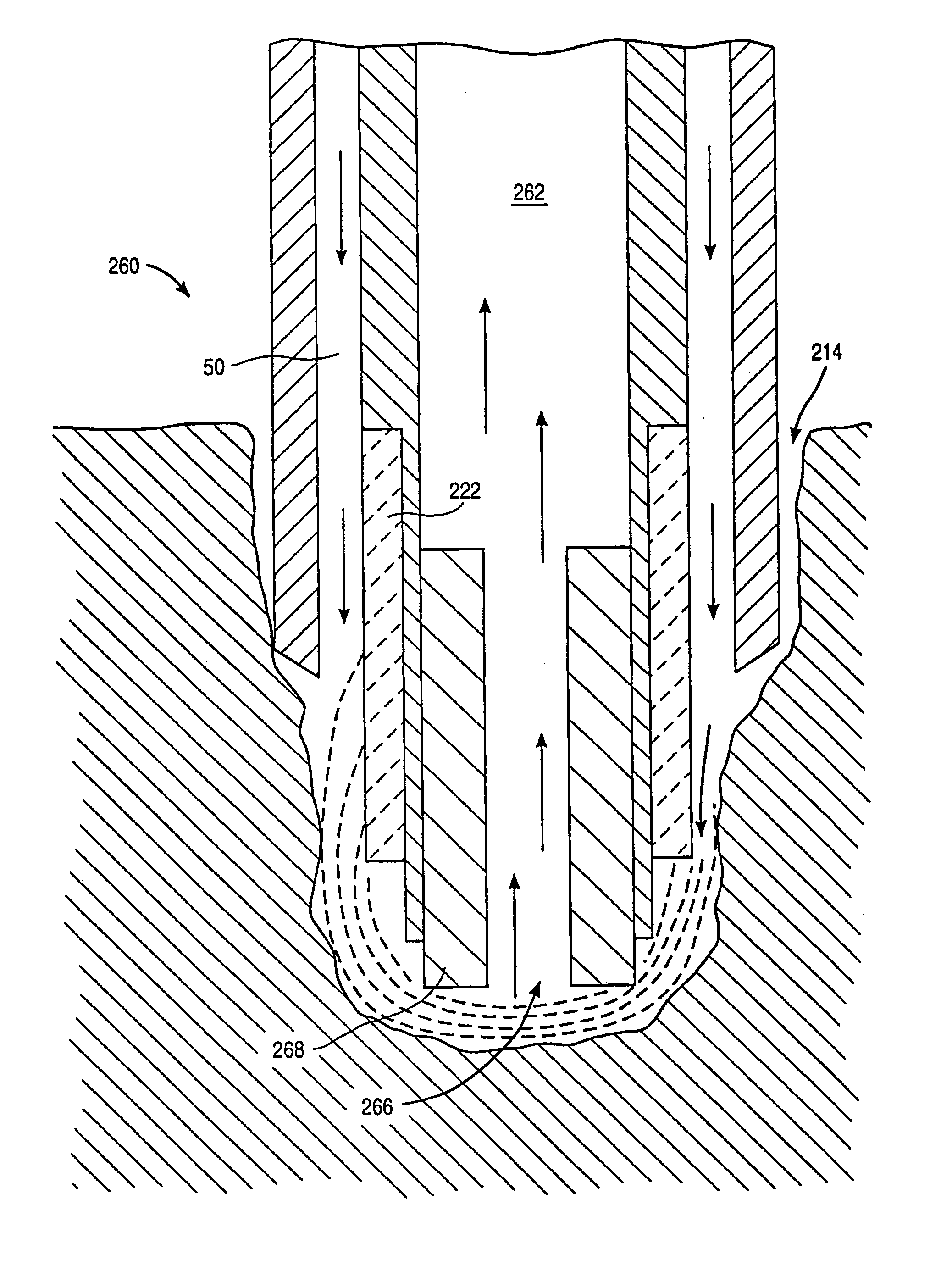

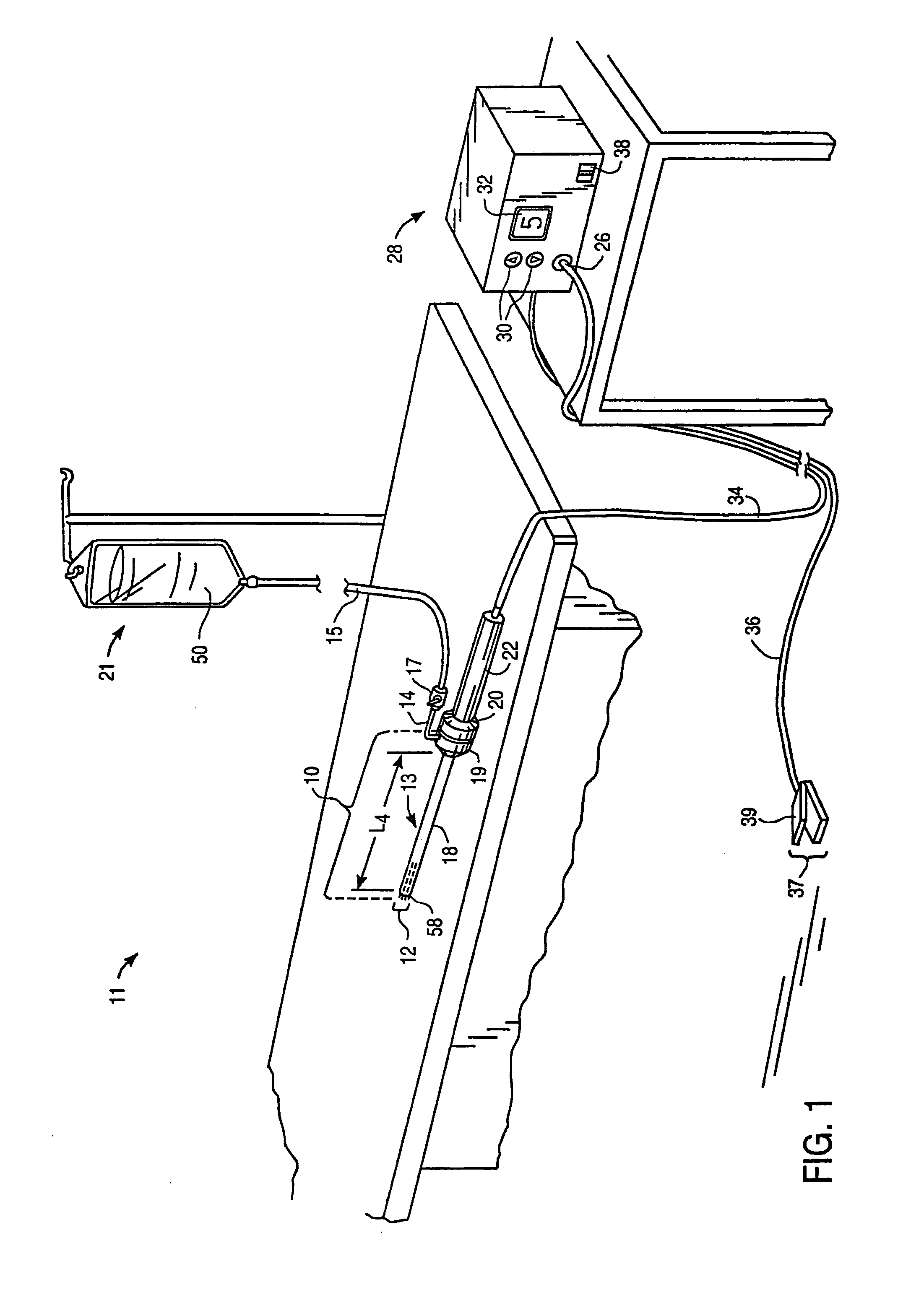

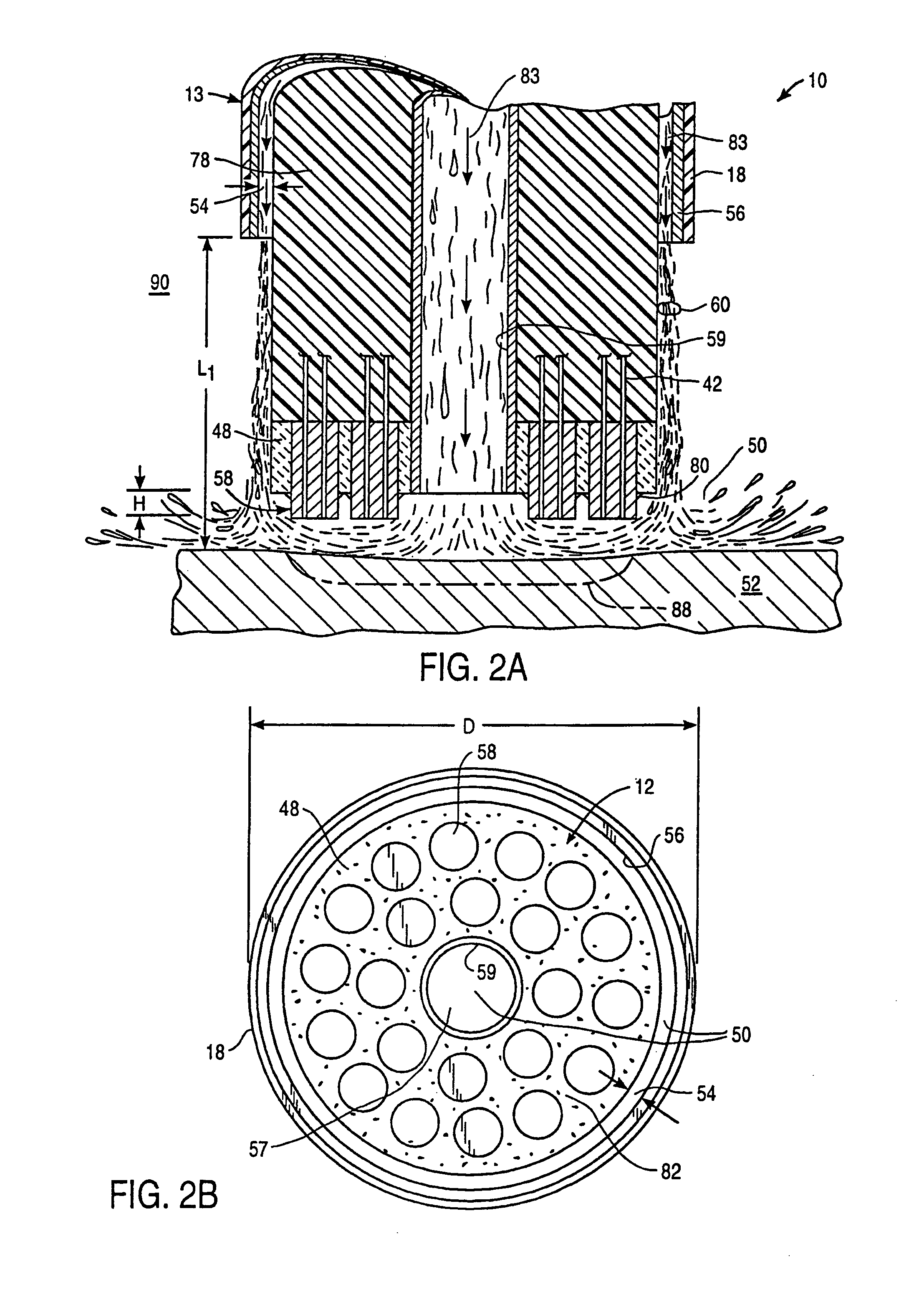

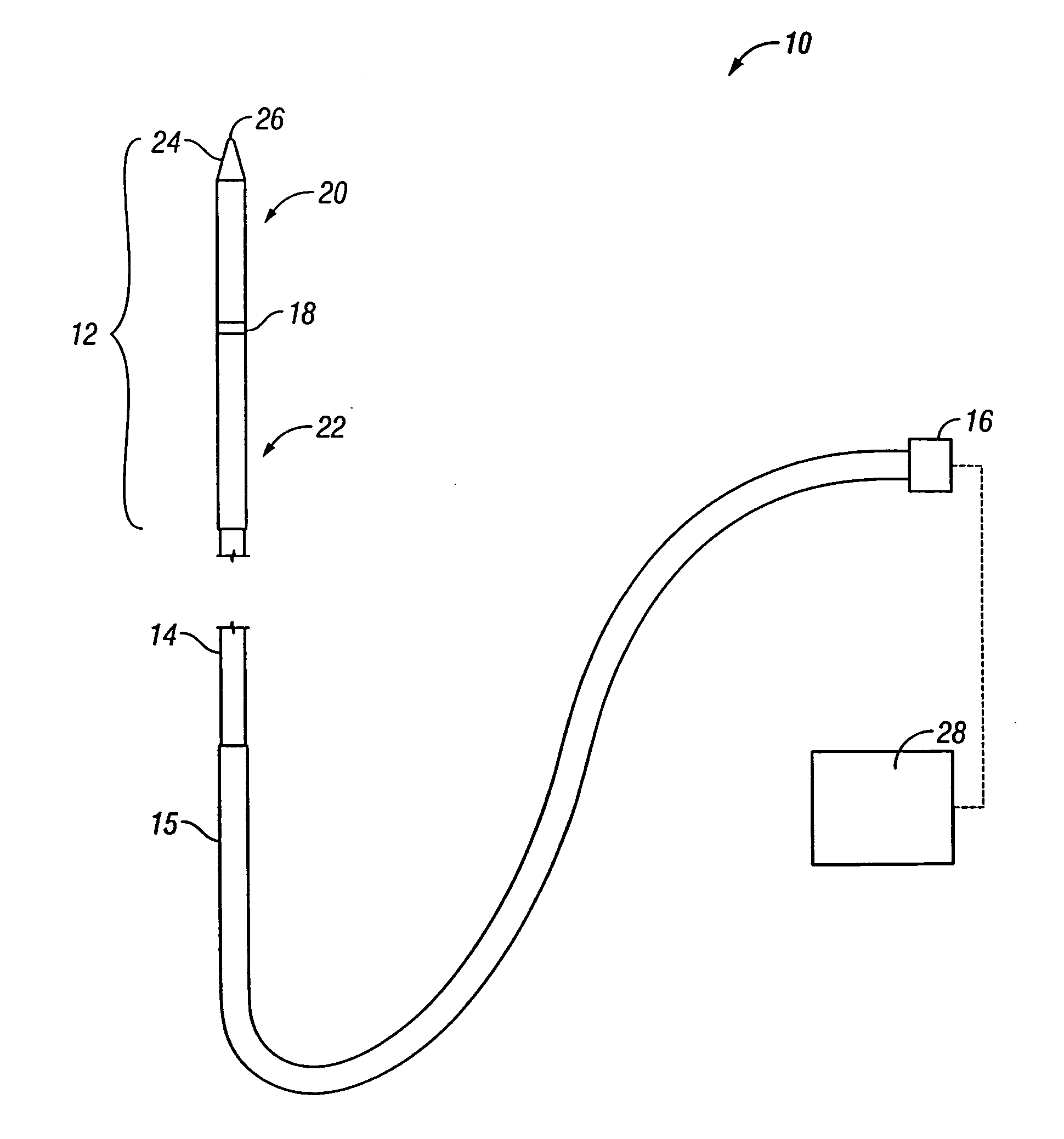

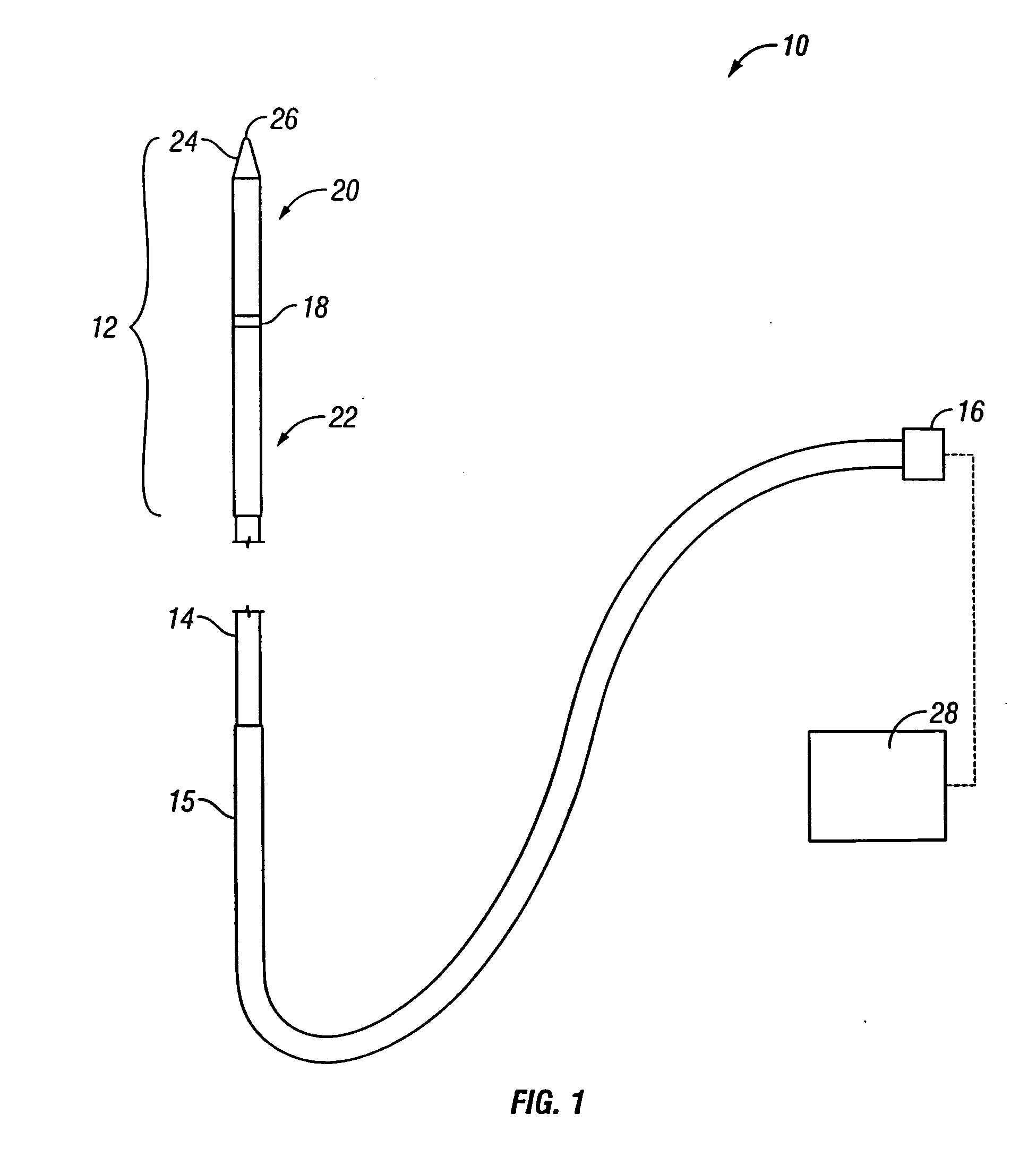

Method for electrosurgical tissue treatment near a patient's heart

InactiveUS7217268B2Control depthControl damageEnemata/irrigatorsHeart valvesElectricityHigh frequency power

An electrosurgical probe (10) comprises a shaft (13) having an electrode array (58) at its distal end and a connector (19) at its proximal end for coupling the electrode array to a high frequency power supply (28). The shaft includes a return electrode (56) recessed from its distal end and enclosed within an insulating jacket (18). The return electrode defines an inner passage (83) electrically connected to both the return electrode and the electrode array for passage of an electrically conducting liquid (50). By applying high frequency voltage to the electrode array and the return electrode, the electrically conducting liquid generates a current flow path between the return electrode and the electrode array so that target tissue may be cut or ablated. The probe is particularly useful in dry environments, such as the mouth or abdominal cavity, because the electrically conducting liquid provides the necessary return current path between the active and return electrodes.

Owner:ARTHROCARE

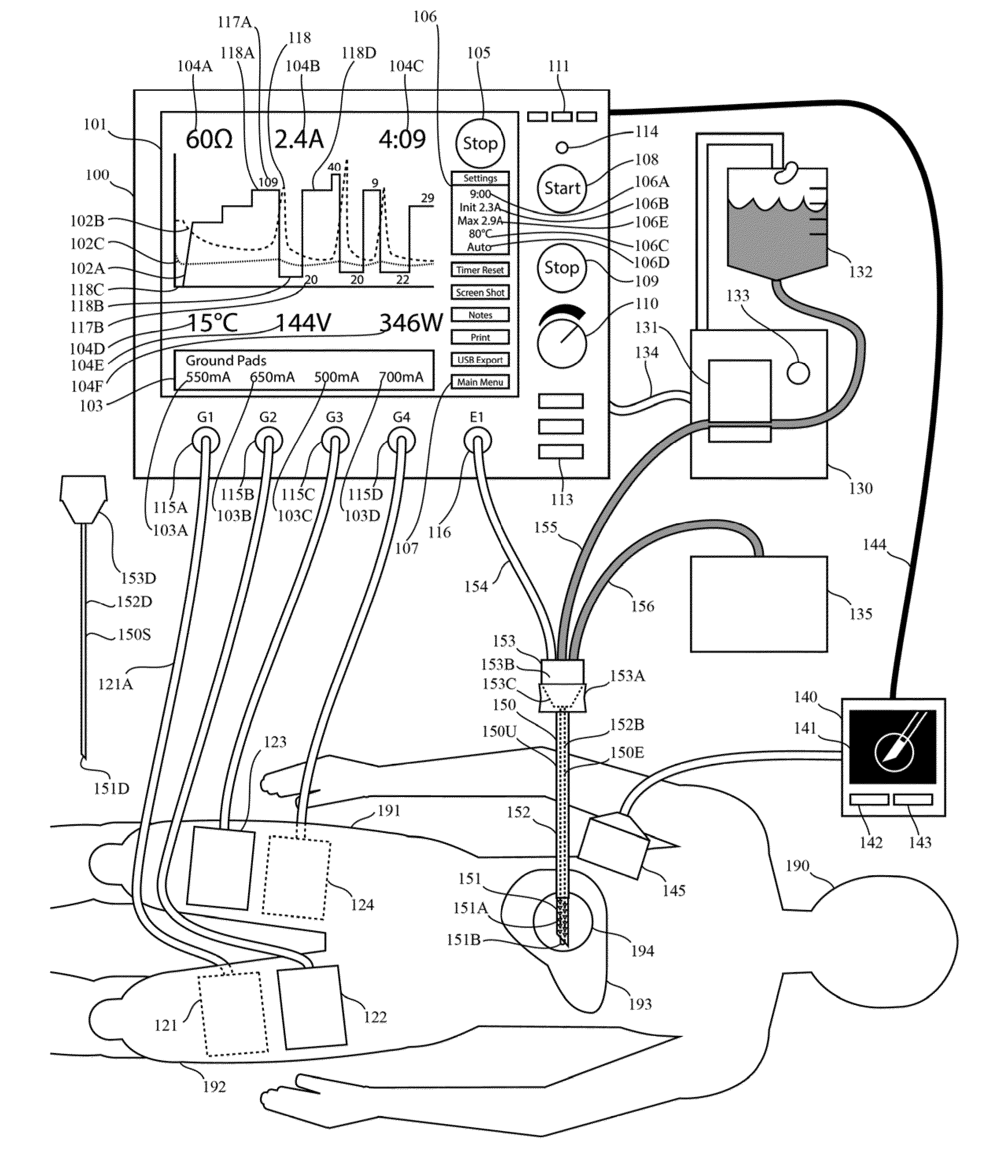

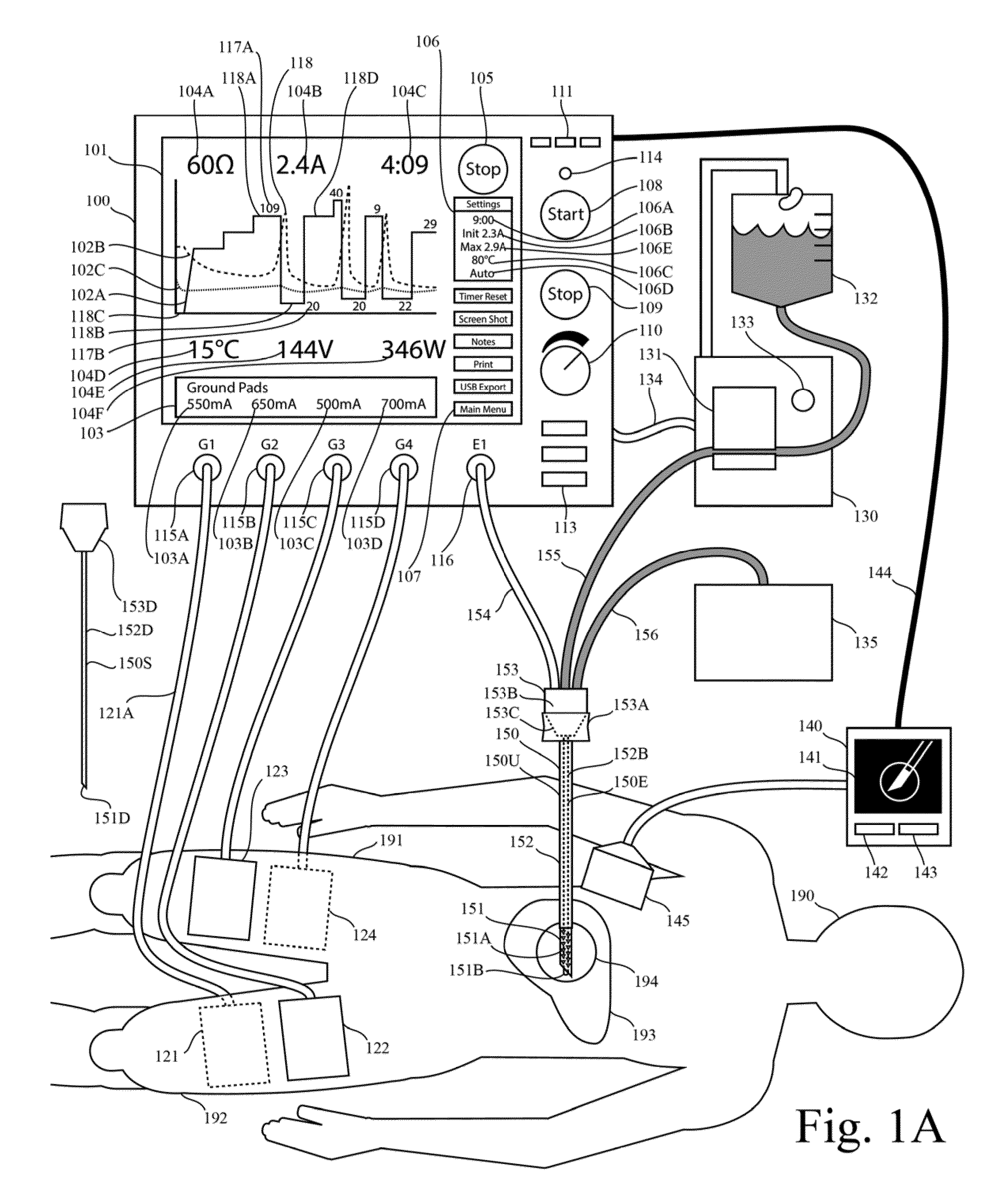

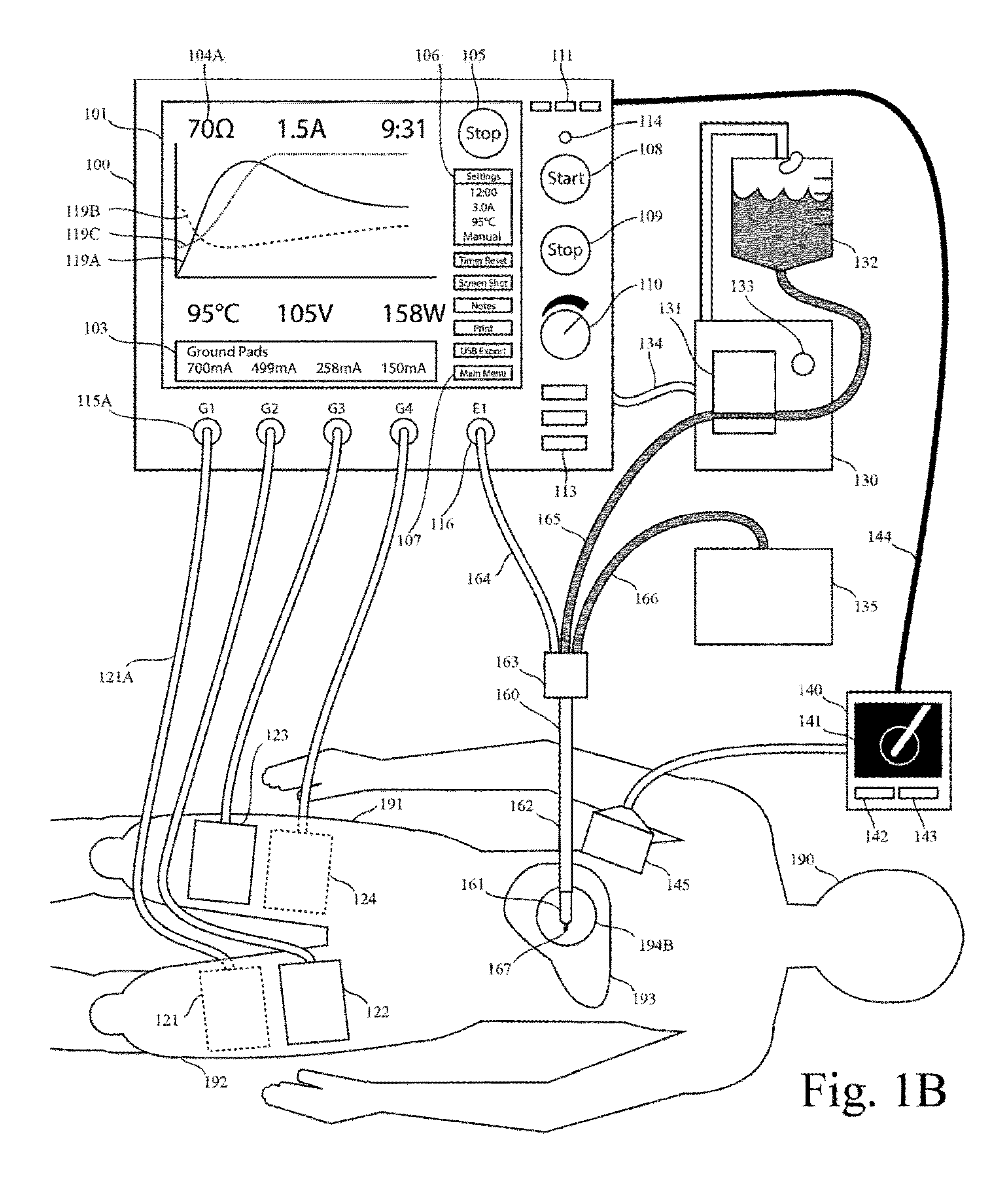

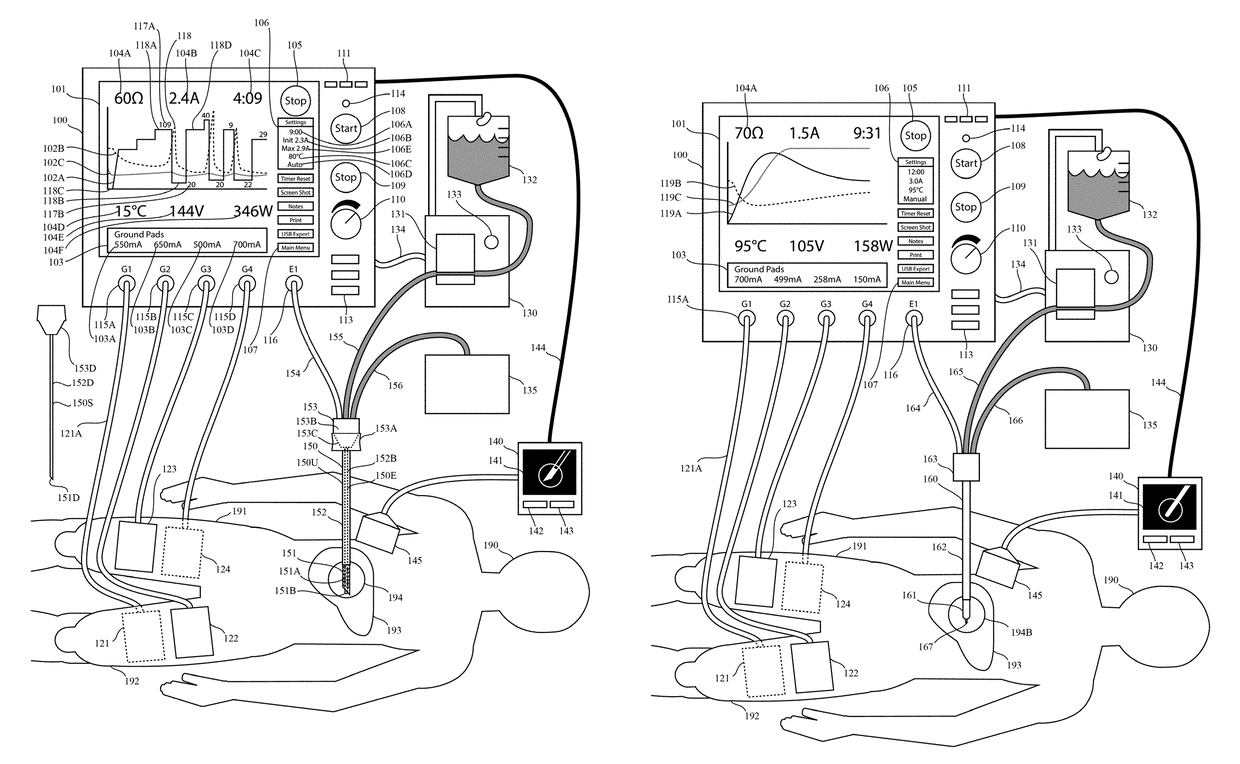

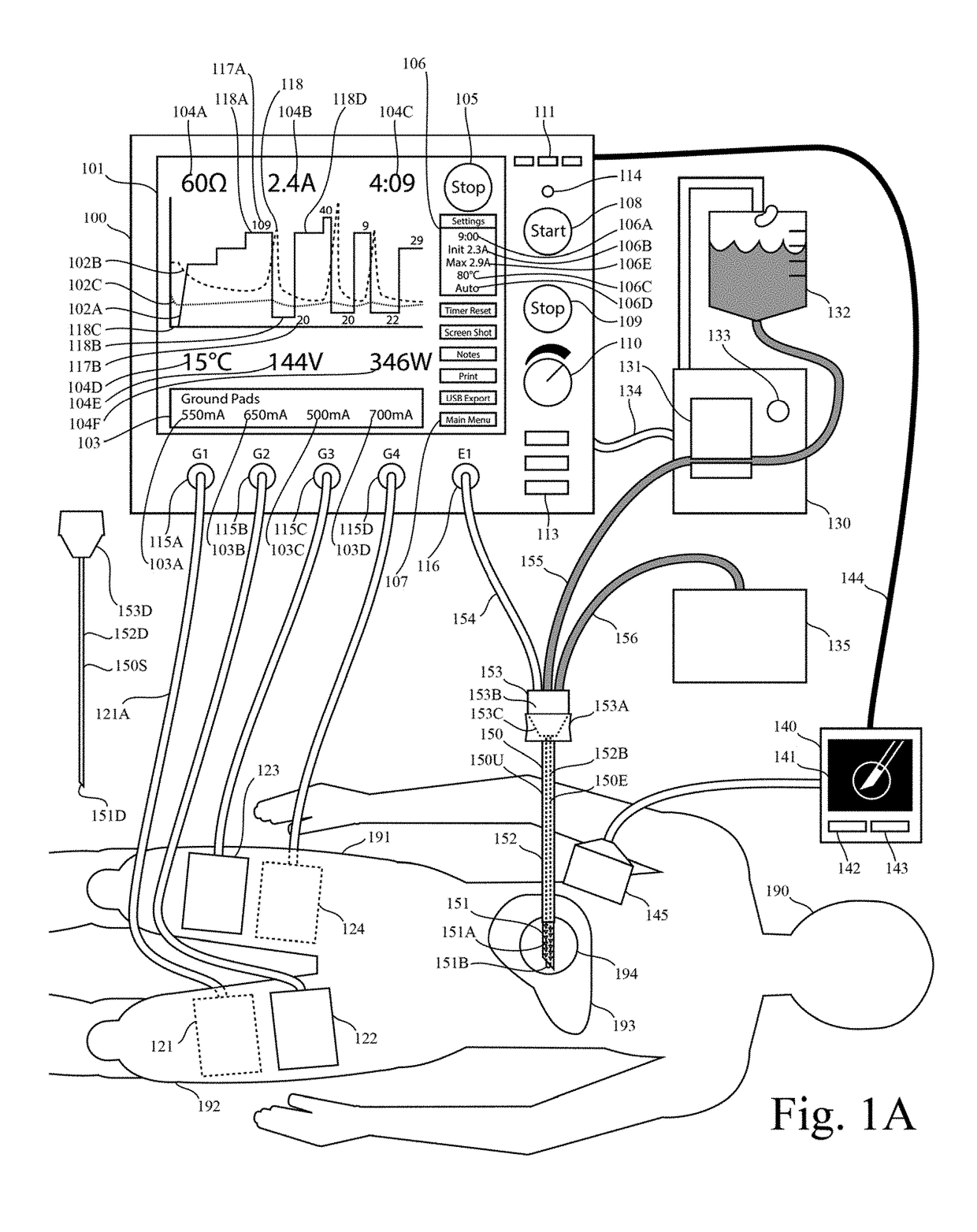

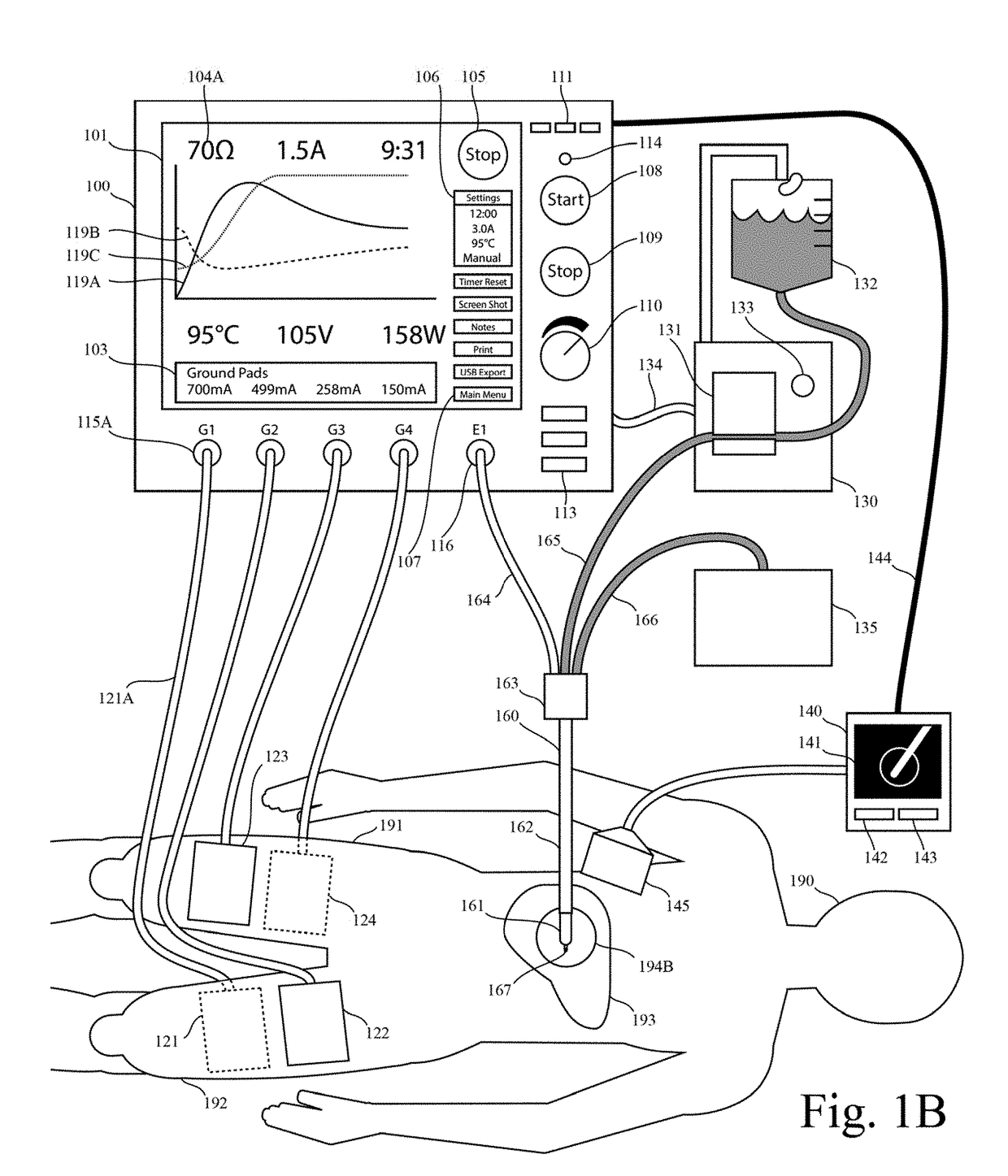

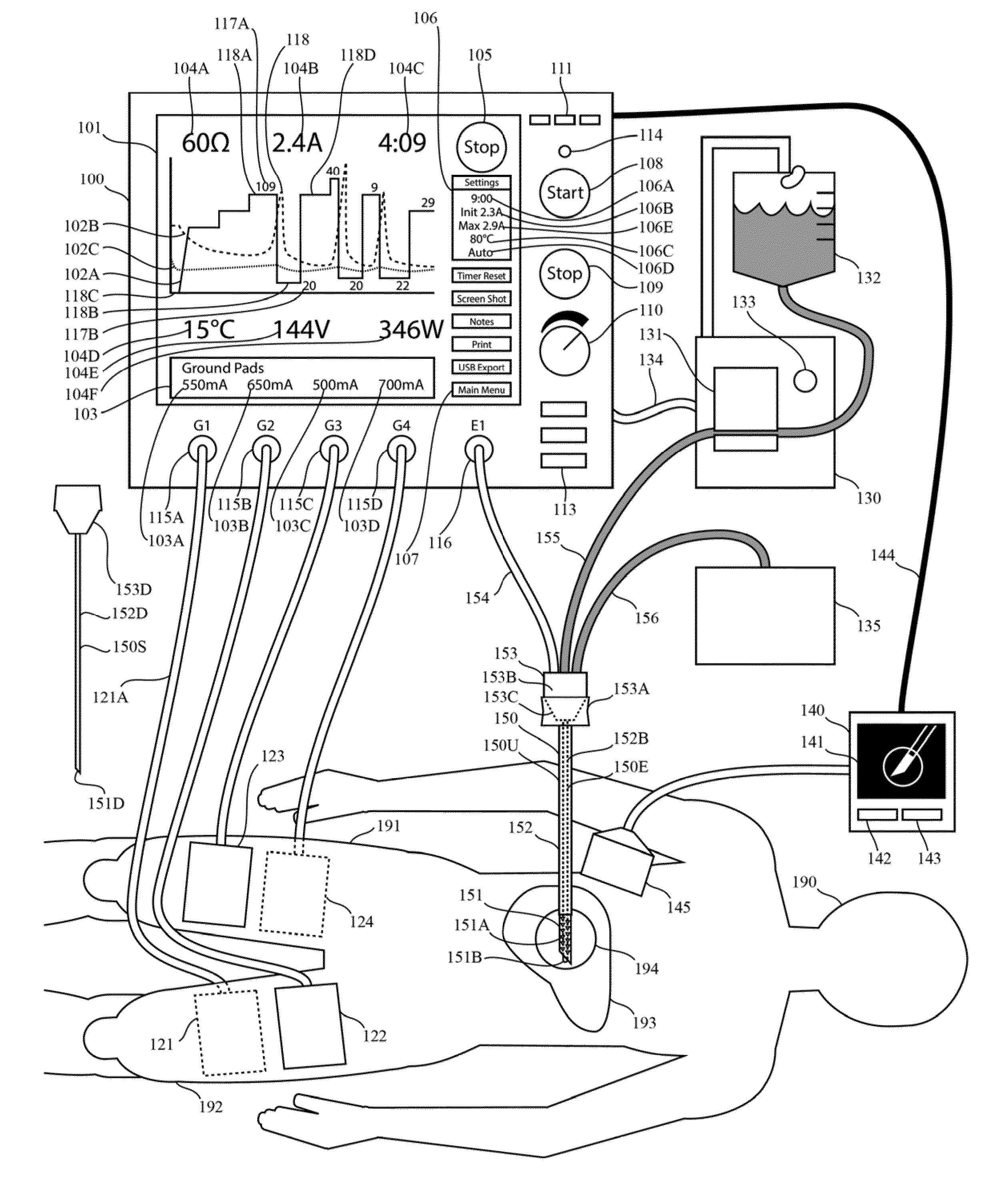

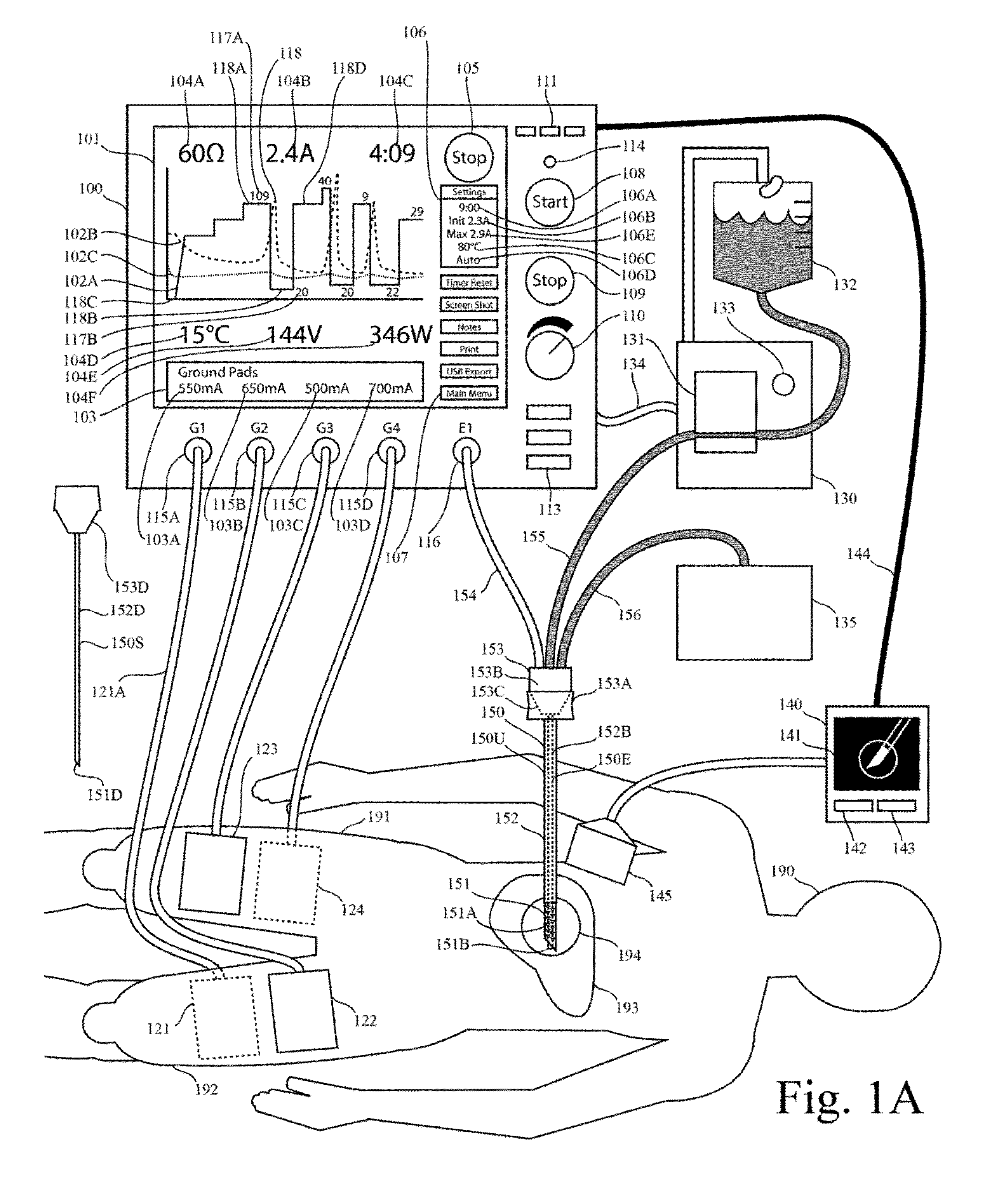

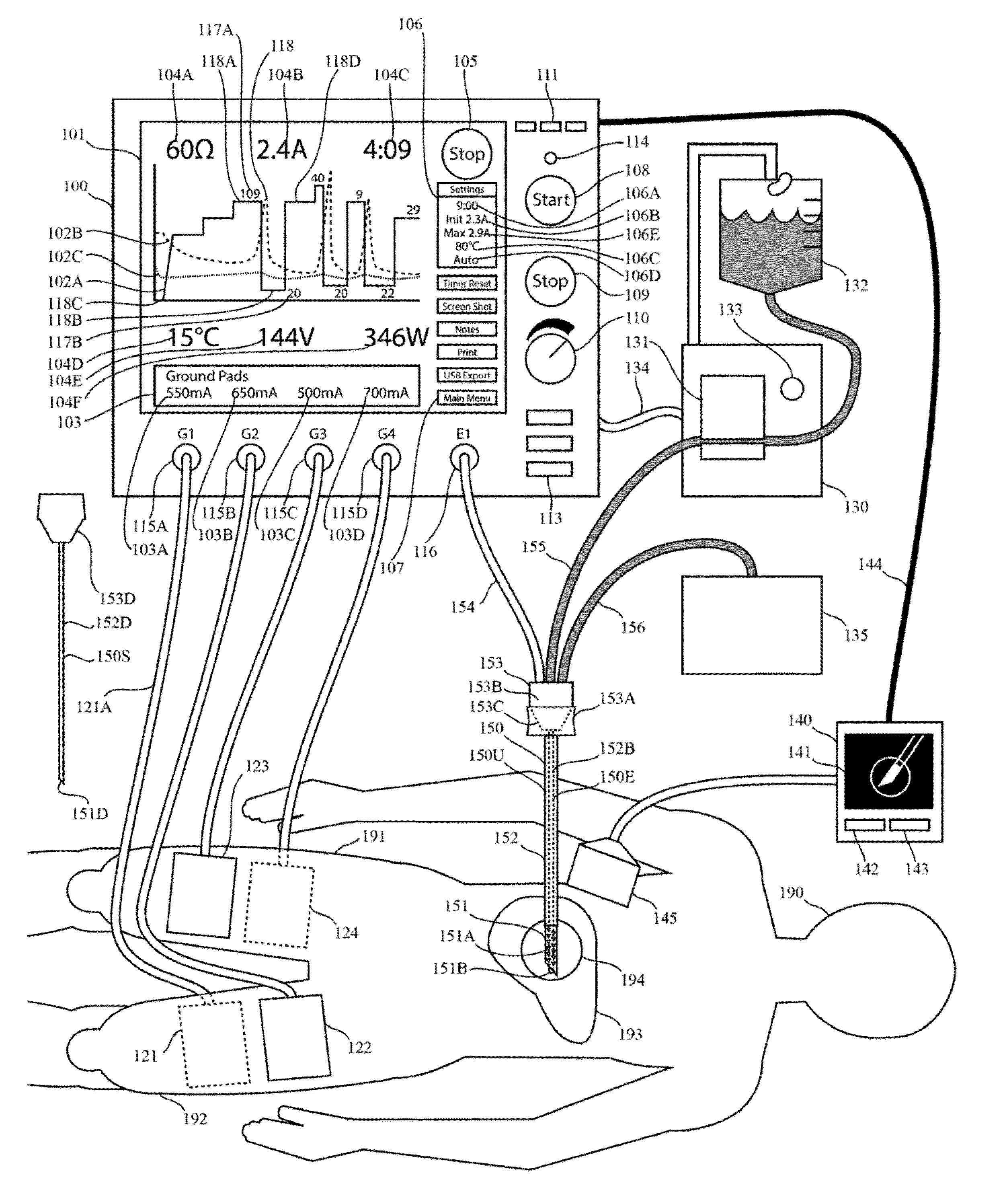

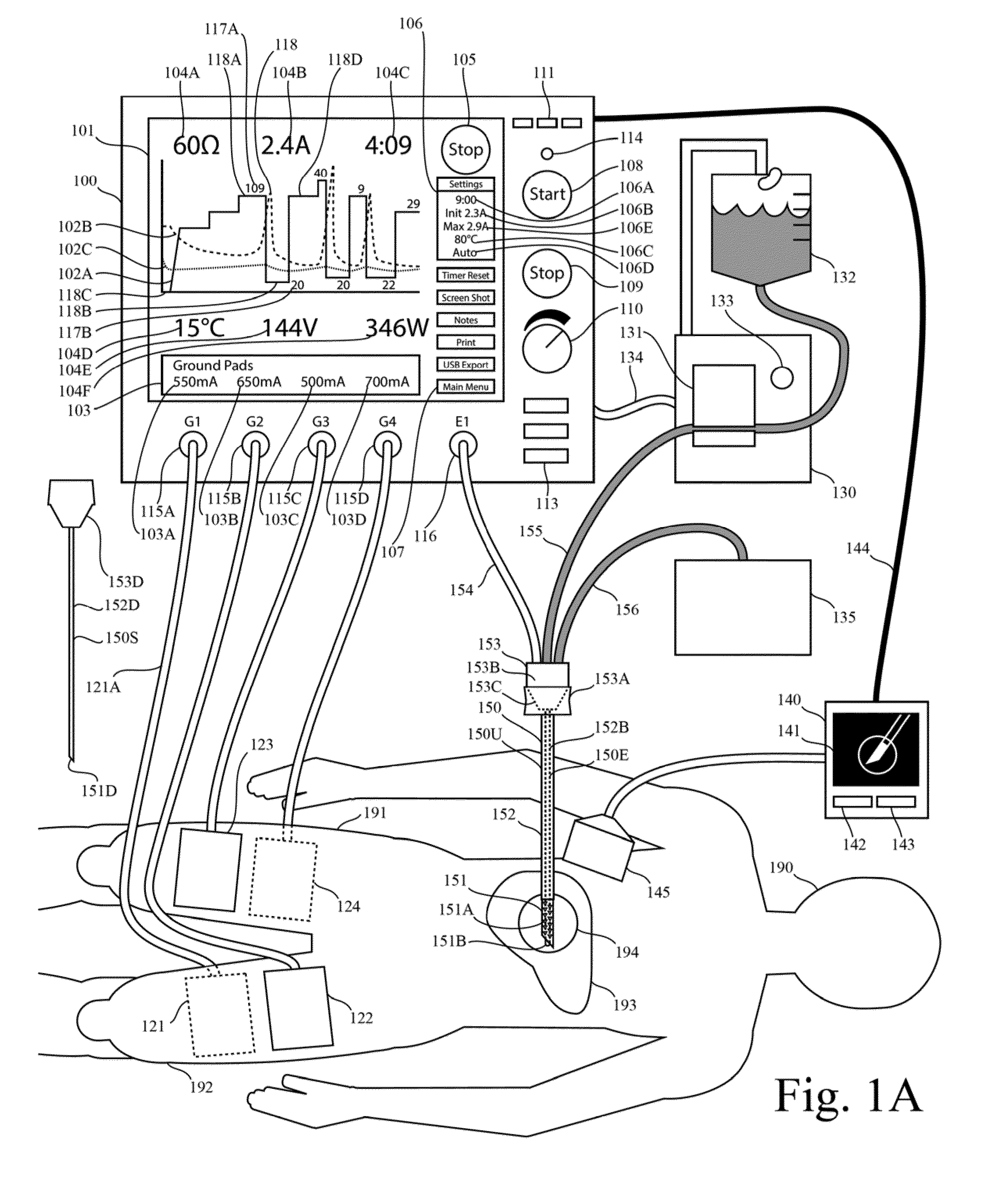

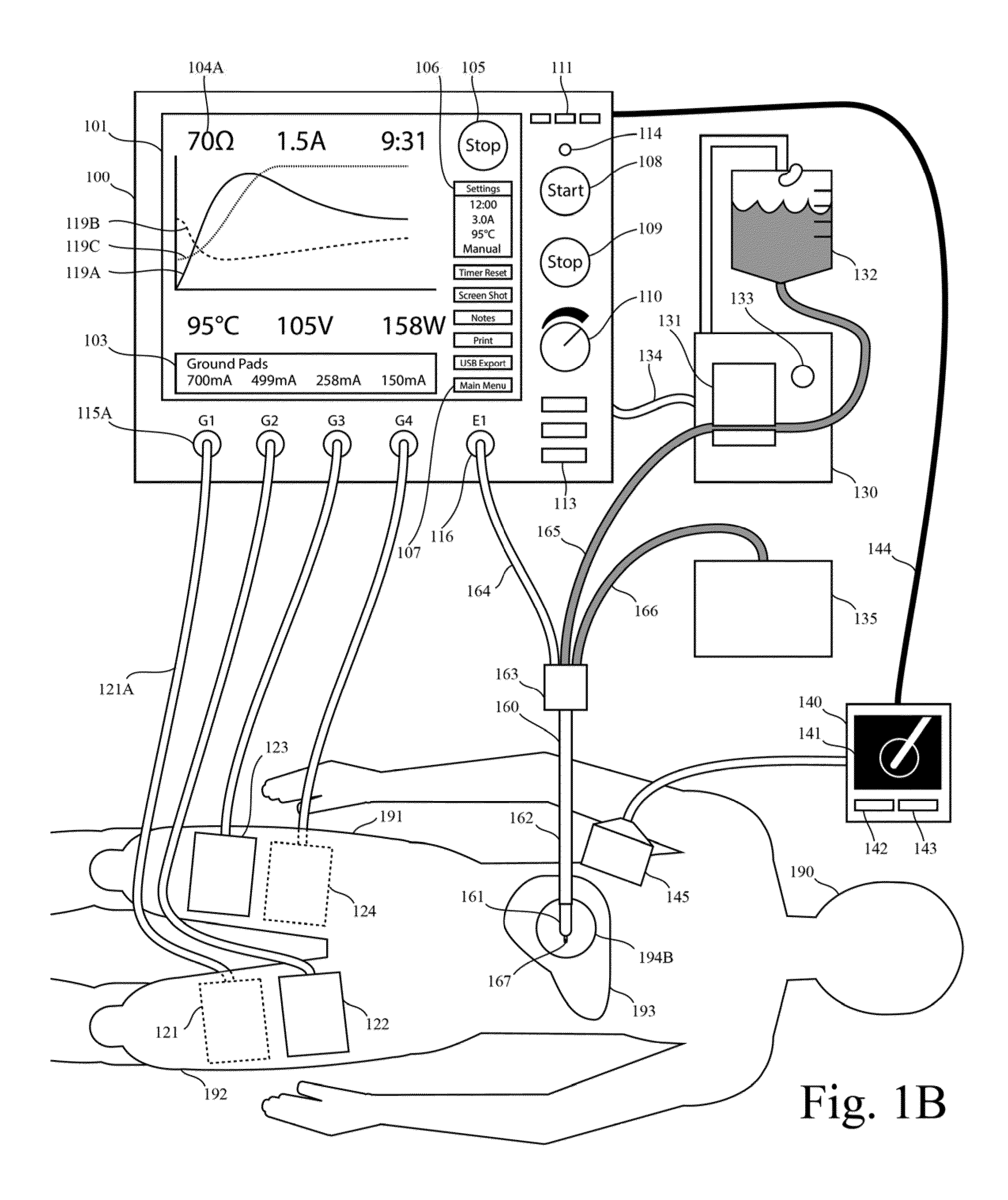

Electrosurgical generator

ActiveUS20150320481A1Increase productionRelieve painElectrotherapyDiagnosticsSonificationReturn current

This invention relates to high-frequency ablation of tissue in the body using a cooled high-frequency electrode connected to a high frequency generator including a computer graphic control system and an automatic controller for control the signal output from the generator, and adapted to display on a real time graphic display a measured parameter related to the ablation process and visually monitor the variation of the parameter of the signal output that is controlled by the controller during the ablation process. In one example, one or more measured parameters are displayed simultaneously to visually interpret the relation of their variation and values. In one example, the displayed one or more parameters can be taken from the list of measured voltage, current, power, impedance, electrode temperature, and tissue temperature related to the ablation process. The graphic display gives the clinician an instantaneous and intuitive feeling for the dynamics and stability of the ablation process for safety and control. This invention relates to monitoring and controlling multiple ground pads to optimally carry return currents during high-frequency tissue ablation, and to prevent of ground-pad skin burns. This invention relates to the use of ultrasound imaging intraoperatively during a tissue ablation procedure. This invention relates to the use of nerve stimulation and blocking during a tissue ablation procedure.

Owner:COSMAN INTRUMENTS LLC

Electrosurgical generator

This invention relates to high-frequency ablation of tissue in the body using a cooled high-frequency electrode connected to a high frequency generator including a computer graphic control system and an automatic controller for control the signal output from the generator, and adapted to display on a real time graphic display a measured parameter related to the ablation process and visually monitor the variation of the parameter of the signal output that is controlled by the controller during the ablation process. In one example, one or more measured parameters are displayed simultaneously to visually interpret the relation of their variation and values. In one example, the displayed one or more parameters can be taken from the list of measured voltage, current, power, impedance, electrode temperature, and tissue temperature related to the ablation process. The graphic display gives the clinician an instantaneous and intuitive feeling for the dynamics and stability of the ablation process for safety and control. This invention relates to monitoring and controlling multiple ground pads to optimally carry return currents during high-frequency tissue ablation, and to prevent of ground-pad skin burns. This invention relates to the use of ultrasound imaging intraoperatively during a tissue ablation procedure. This invention relates to the use of nerve stimulation and blocking during a tissue ablation procedure.

Owner:COSMAN INTRUMENTS LLC

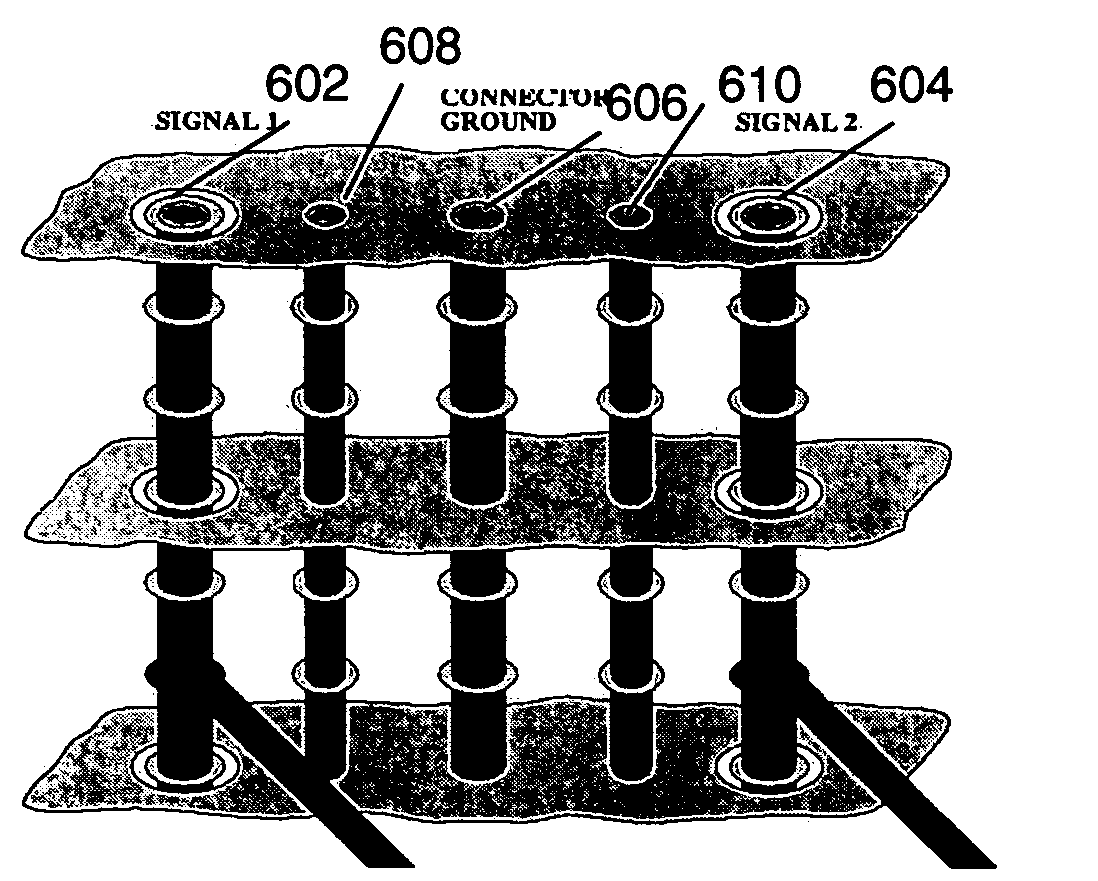

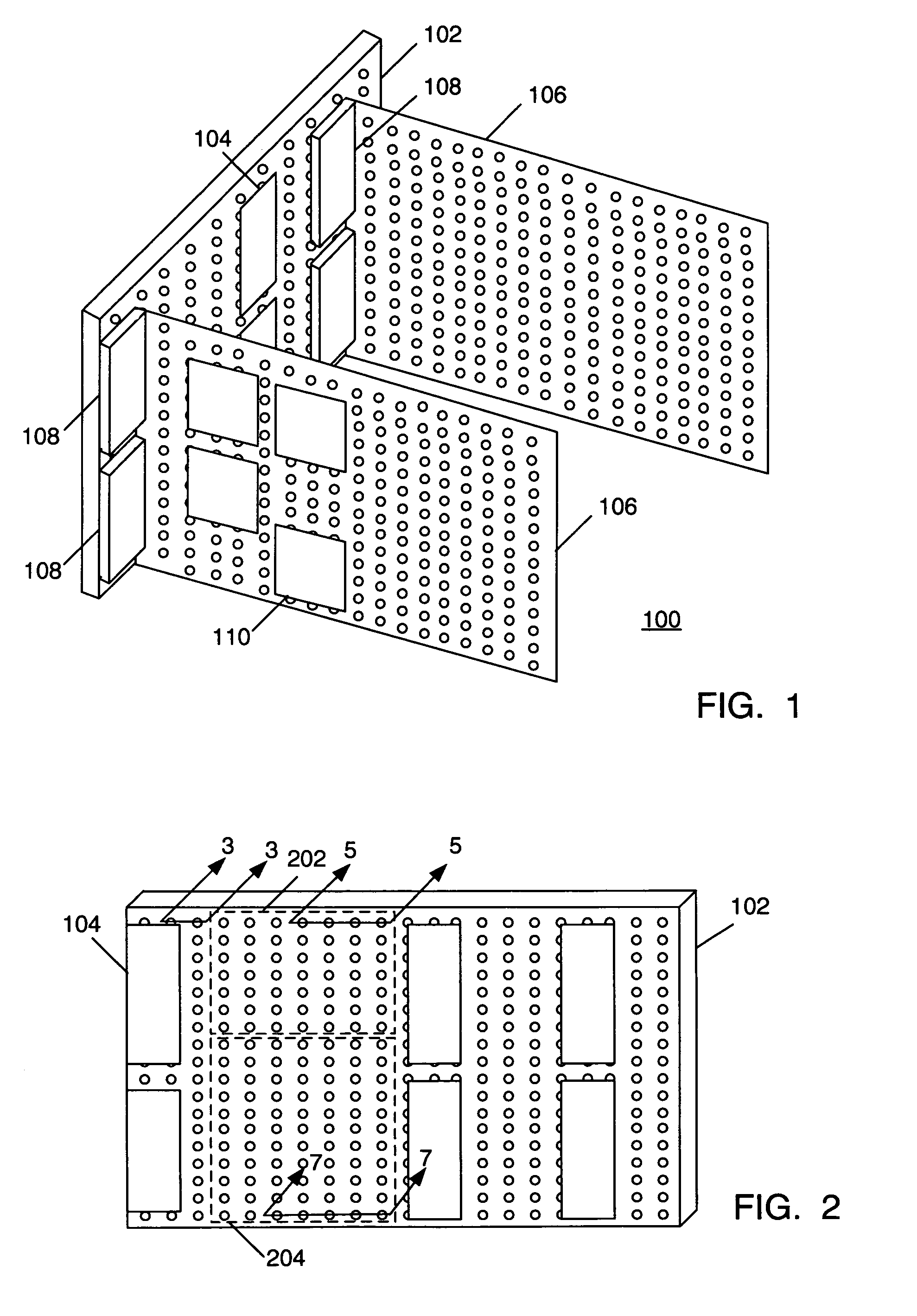

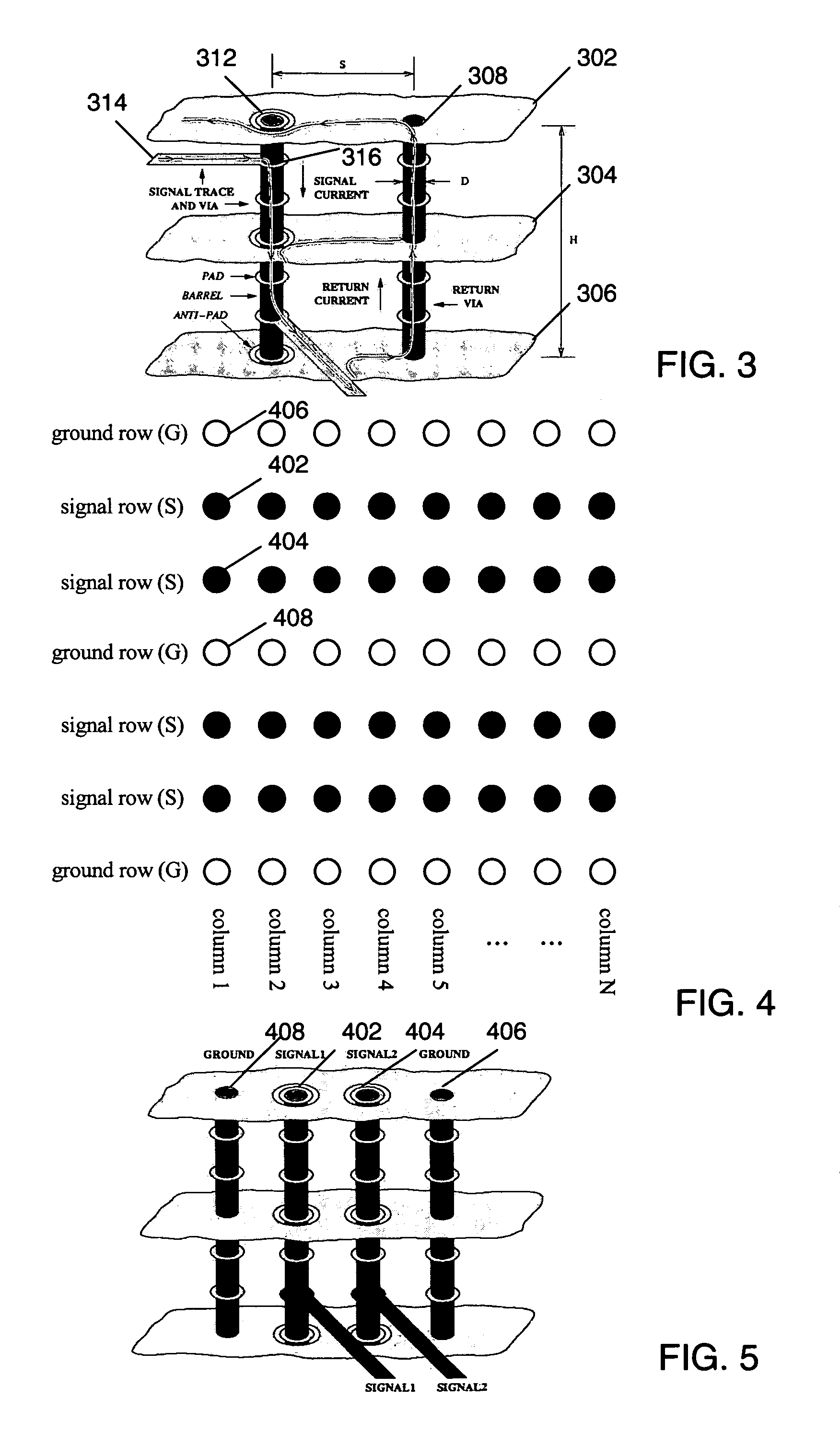

Printed circuit board and method of reducing crosstalk in a printed circuit board

ActiveUS7239526B1Reduce crosstalkCross-talk/noise/interference reductionCoupling device detailsReturn currentGround plane

The embodiments of the present invention relate to an improved printed circuit board having additional rows of ground vias to reduce crosstalk in the board. A printed circuit board according to one embodiment of the present invention comprises a first row of vias and a second row of vias, each having a plurality of signal vias. The circuit board also comprises a plurality of rows of vias being coupled to a ground plane between the first row of signal vias and the second row of signal vias. According to one embodiment, the plurality of rows of vias being coupled to a ground plane comprise rows of vias having different sizes. Some of the vias are designed to receive a component, while others are generally smaller and designed to provide a return current path for the signal vias.

Owner:XILINX INC

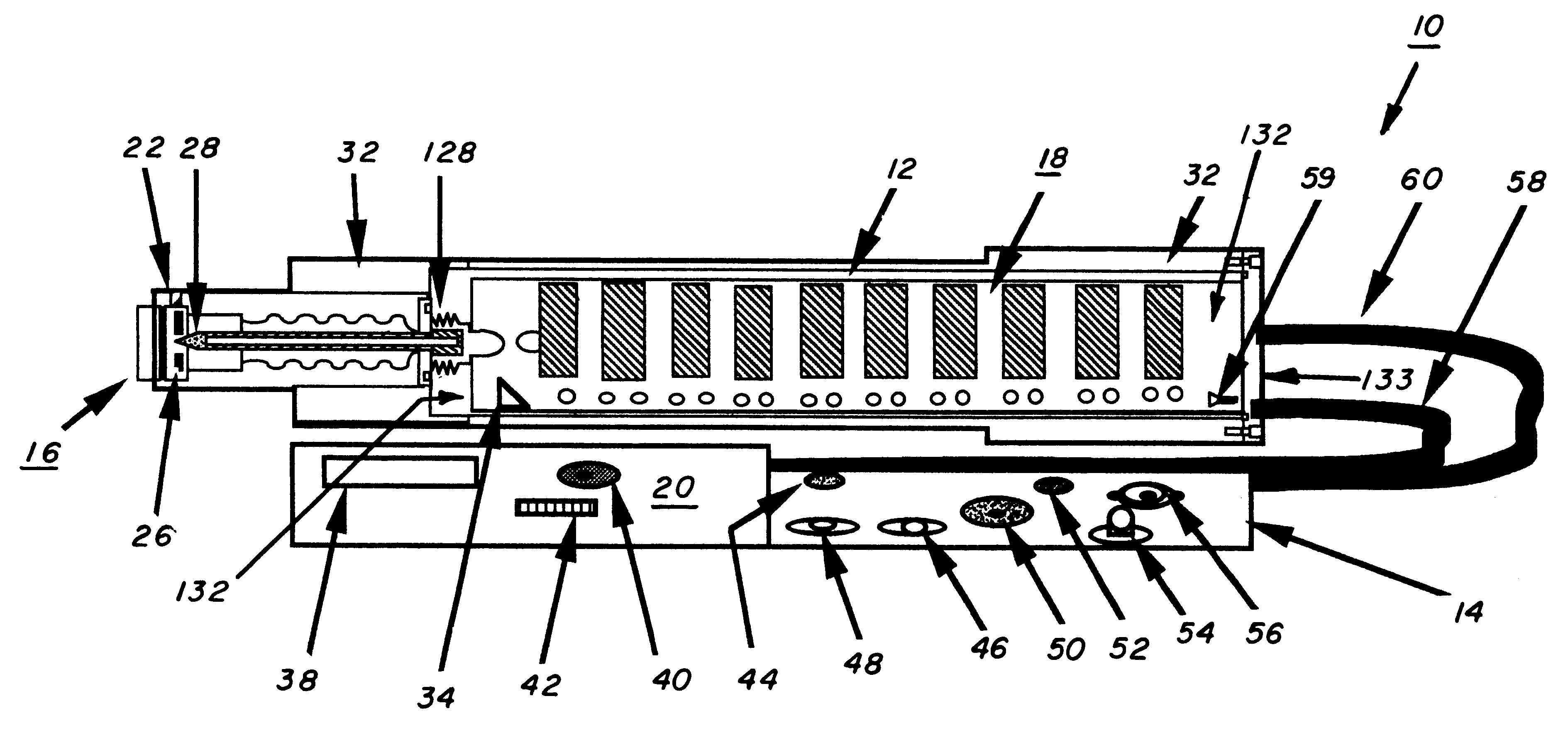

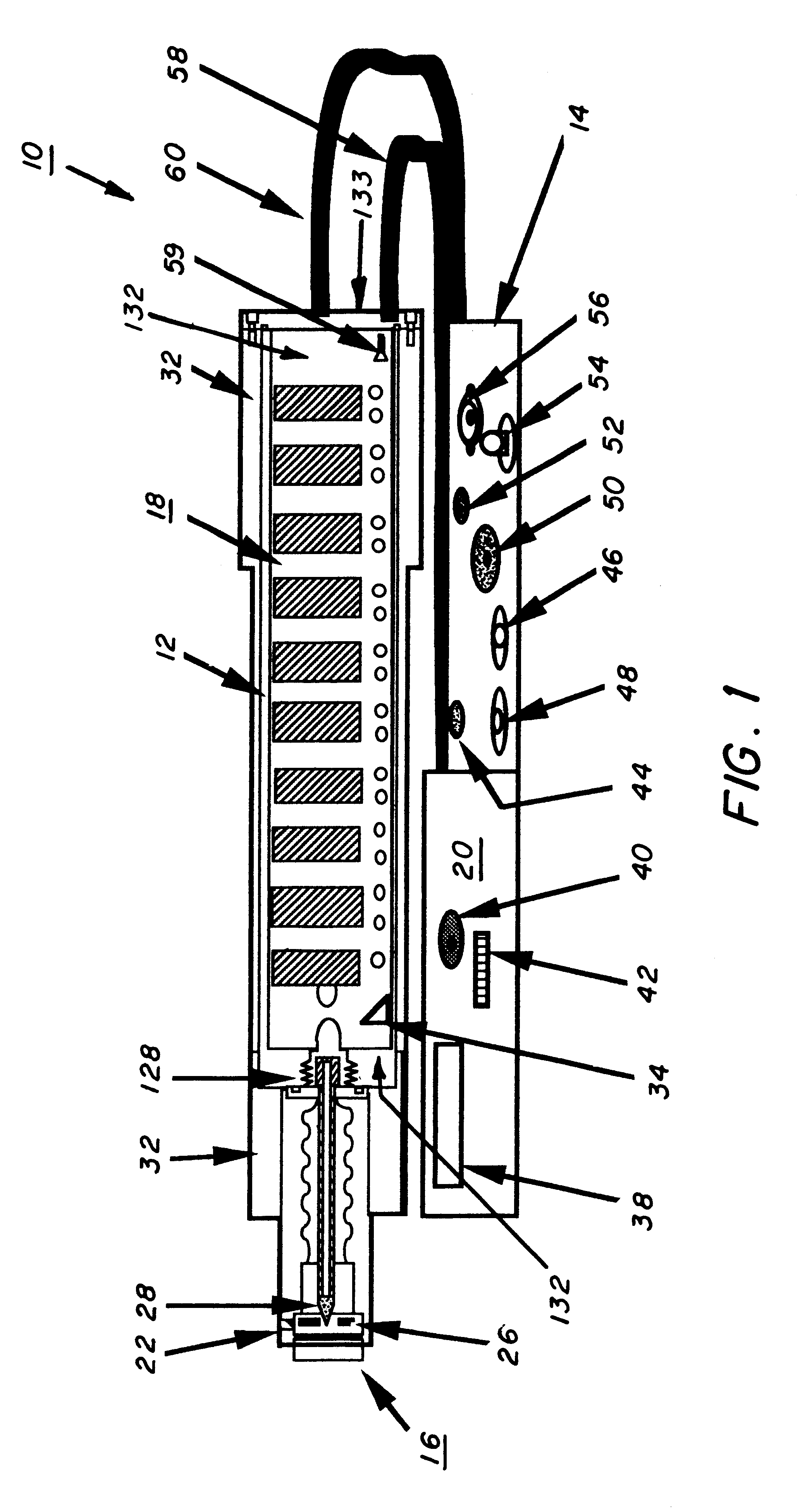

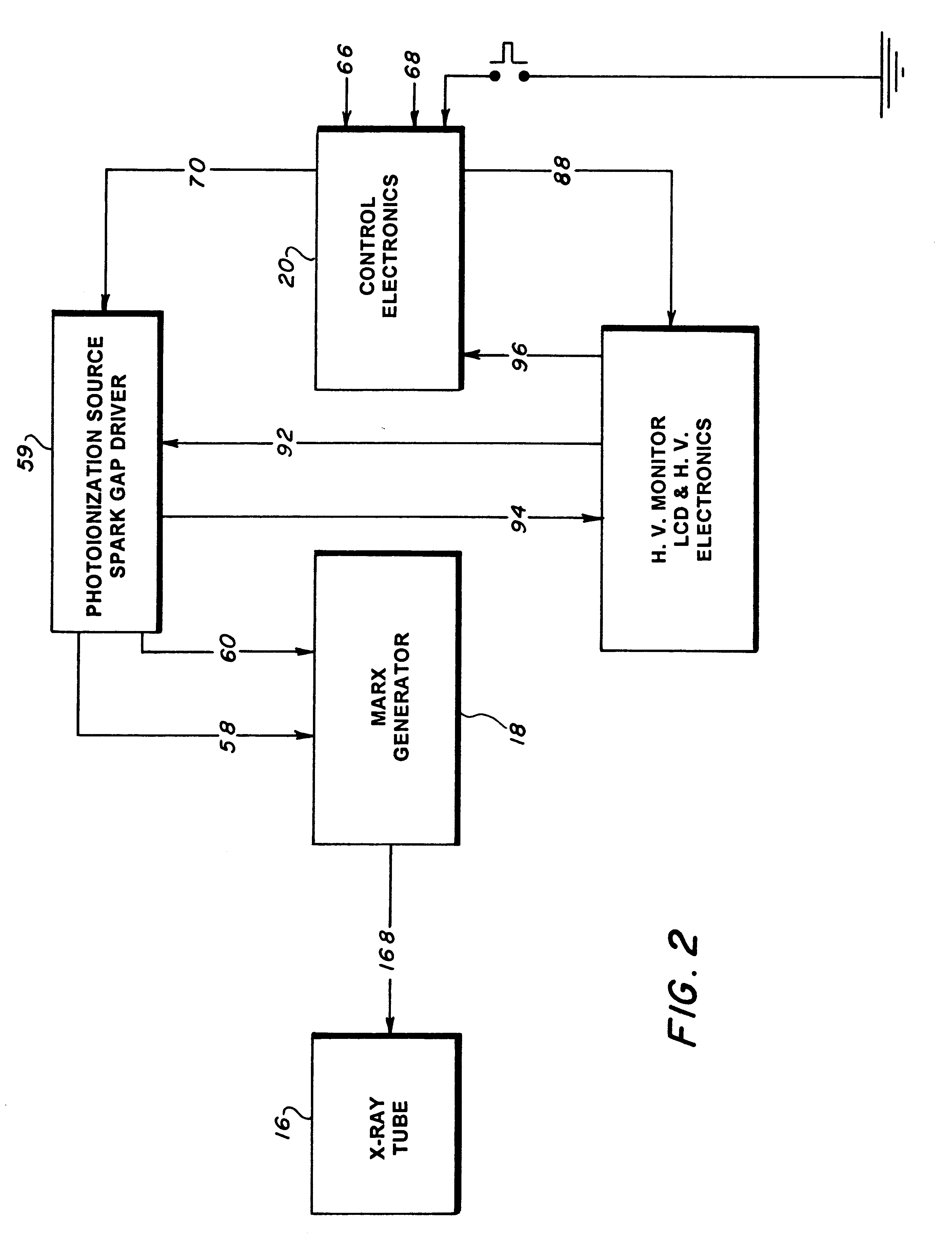

Mobile X-ray unit

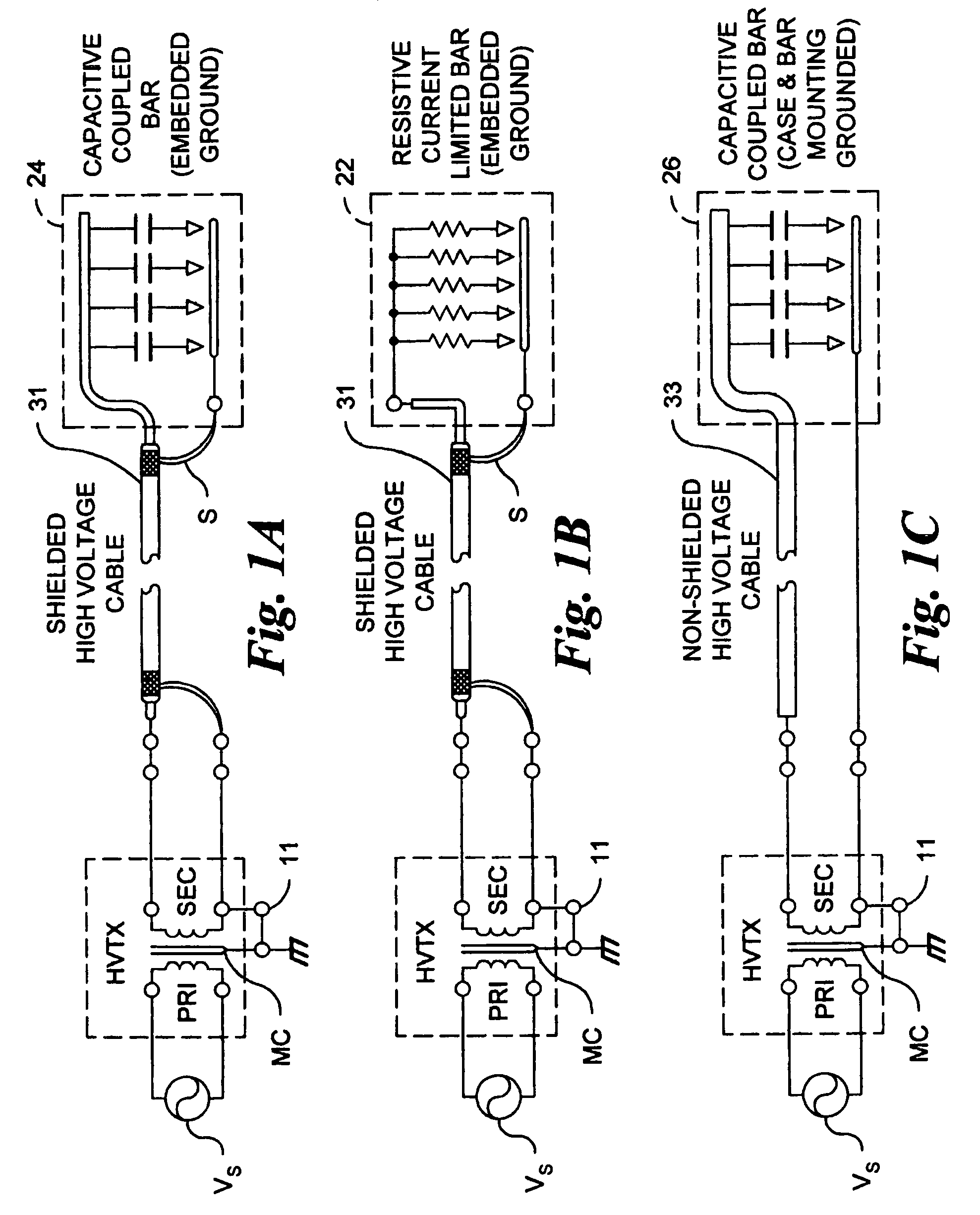

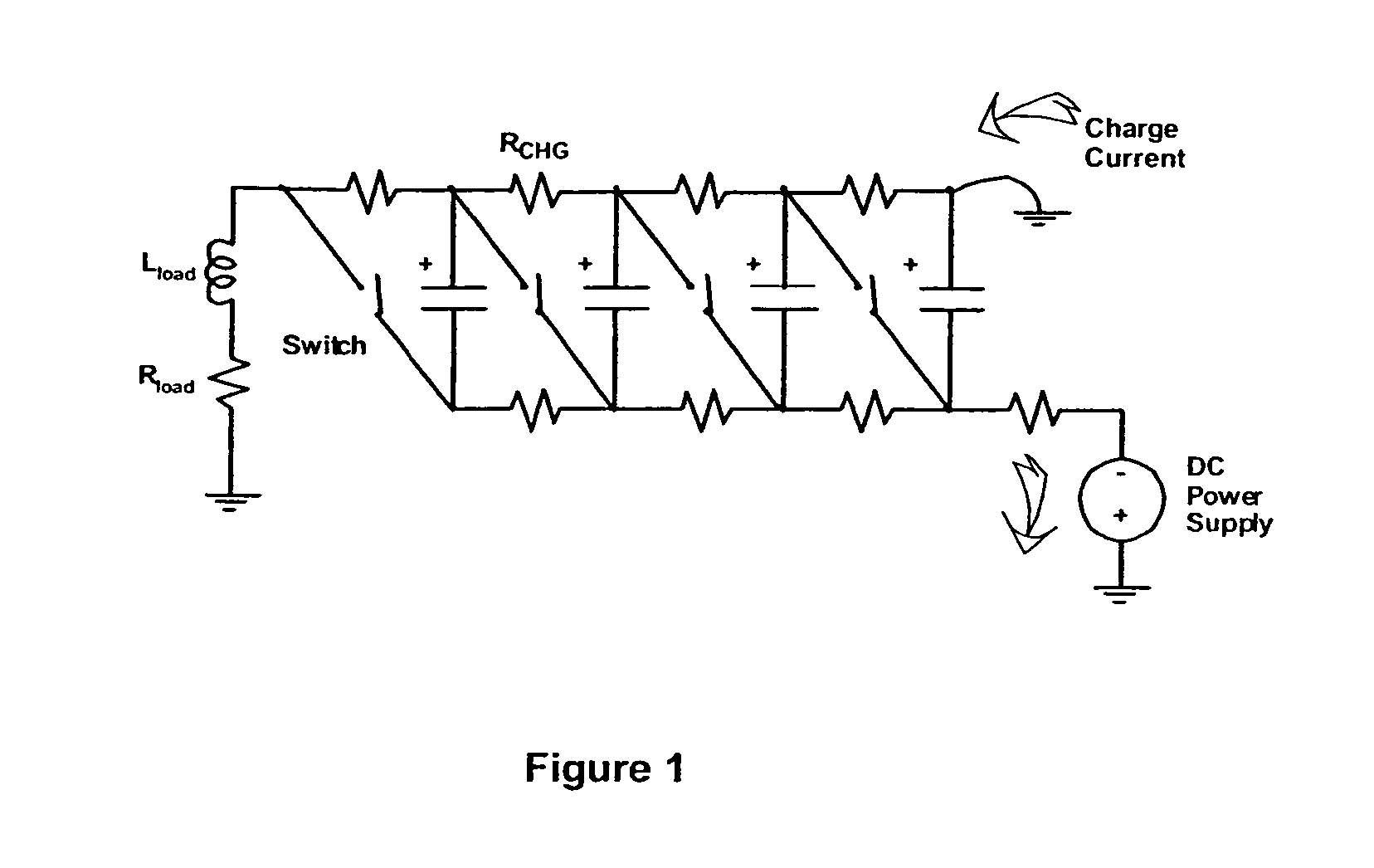

A portable X-ray unit, of a relatively light-weight, occoping a volume of less then one-half a cubic foot containing an x-ray head assembly, a unique Marx generator, a plurality of spark-gap switches and control electronics is disclosed. The Marx generator allows for the development of a relatively high voltage in excess of 100 kV, yet allows for the discharge thereof within the nanosecond range. The Marx generator is enclosed by an acrylic insulator that cooperates with an aluminum enclosure, which functions as a return current path for the capacitors in the Marx generator and also as a shield against the escape of electromagnetic radiation from the pulsed x-ray unit. The Marx generator and spark-gap switches are confined within the pressurized chamber that may contain nitrogen gas to reduce the separation of the gap in the spark-gap switches.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Via structure with dual current path

InactiveUS6479764B1Area minimizationReduce inductancePrinted circuit aspectsElectrical connection printed elementsReturn currentPrinted circuit board

Provided is a via for use in a printed circuit board or integrated circuit having first, second, third, and fourth layers. The via includes a first path capable of transmitting a forward current from the first to the second layer and a second path capable of transmitting a return current resulting from the forward current from the third to the fourth layer to return to a source of the forward current.

Owner:IBM CORP

High-strength microwave antenna assemblies

InactiveUS20050062666A1High strengthAvoid mechanical failureSurgical needlesSurgical instruments for heatingAntenna designElectrical conductor

Various high-strength microwave antenna assemblies are described herein. The microwave antenna has a radiating portion connected by a feedline to a power generating source, e.g., a generator. The antenna is a dipole antenna with the distal end of the radiating portion being tapered and terminating at a tip to allow for direct insertion into tissue. Antenna rigidity comes from placing distal and proximal radiating portions in a pre-stressed state, assembling them via threaded or overlapping joints, or fixedly attaching an inner conductor to the distal portion. The inner conductor is affixed to the distal portion by, e.g., welding, brazing, soldering, or by adhesives. A junction member made from a hard dielectric material, e.g., ceramic, can be placed between the two portions and can have uniform or non-uniform shapes to accommodate varying antenna designs. Electrical chokes may also be used to contain returning currents to the distal end of the antenna.

Owner:TYCO HEALTHCARE GRP LP

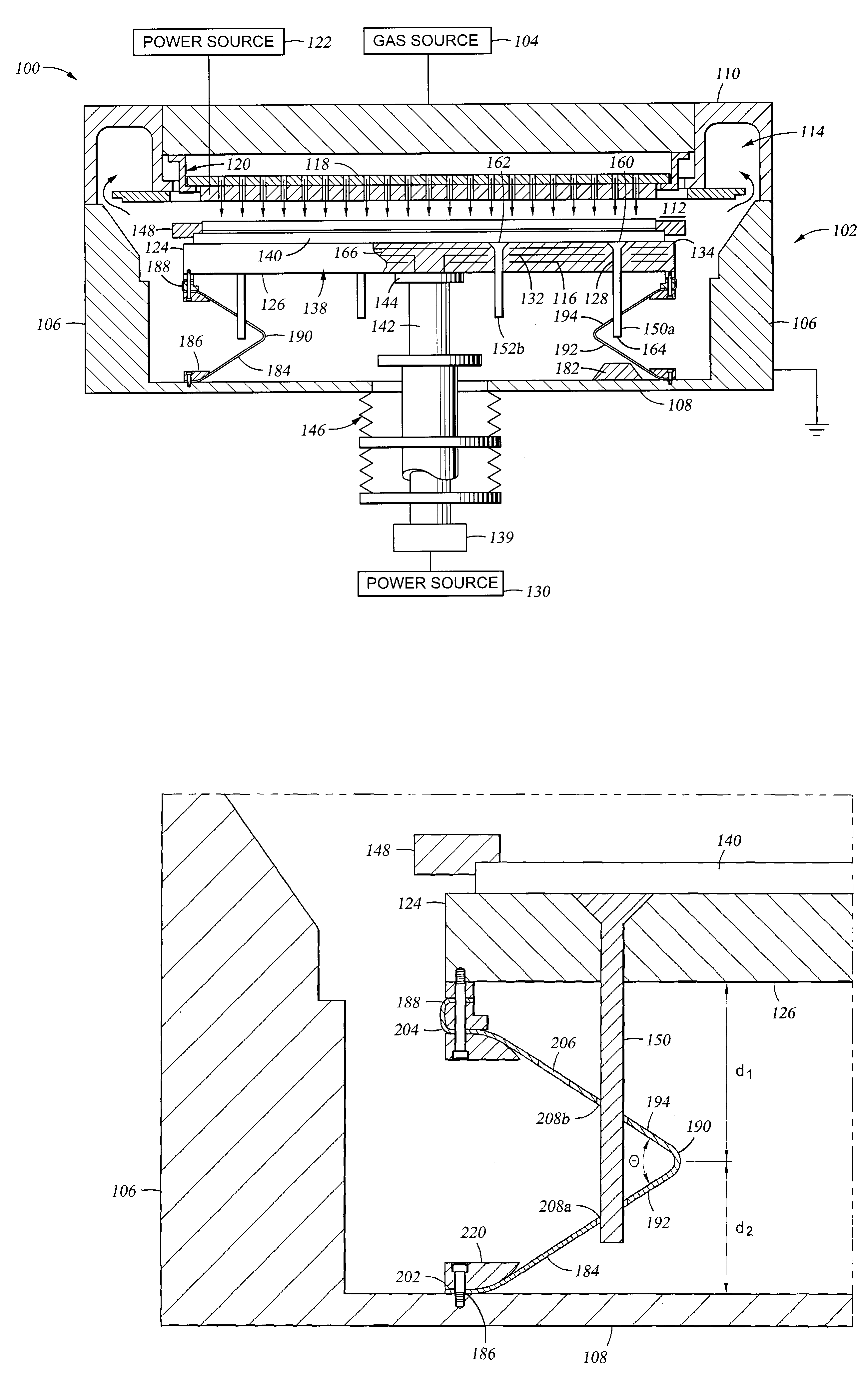

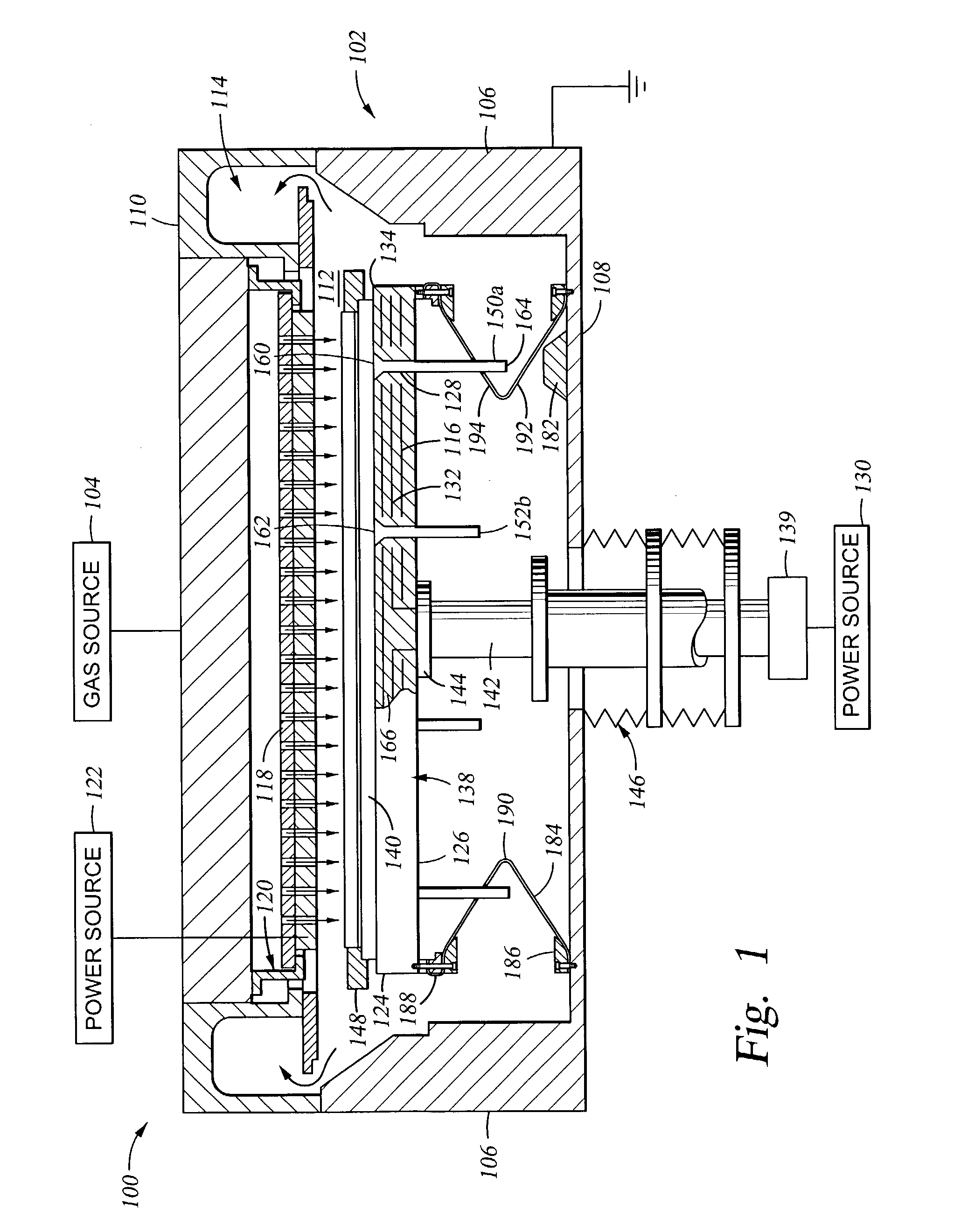

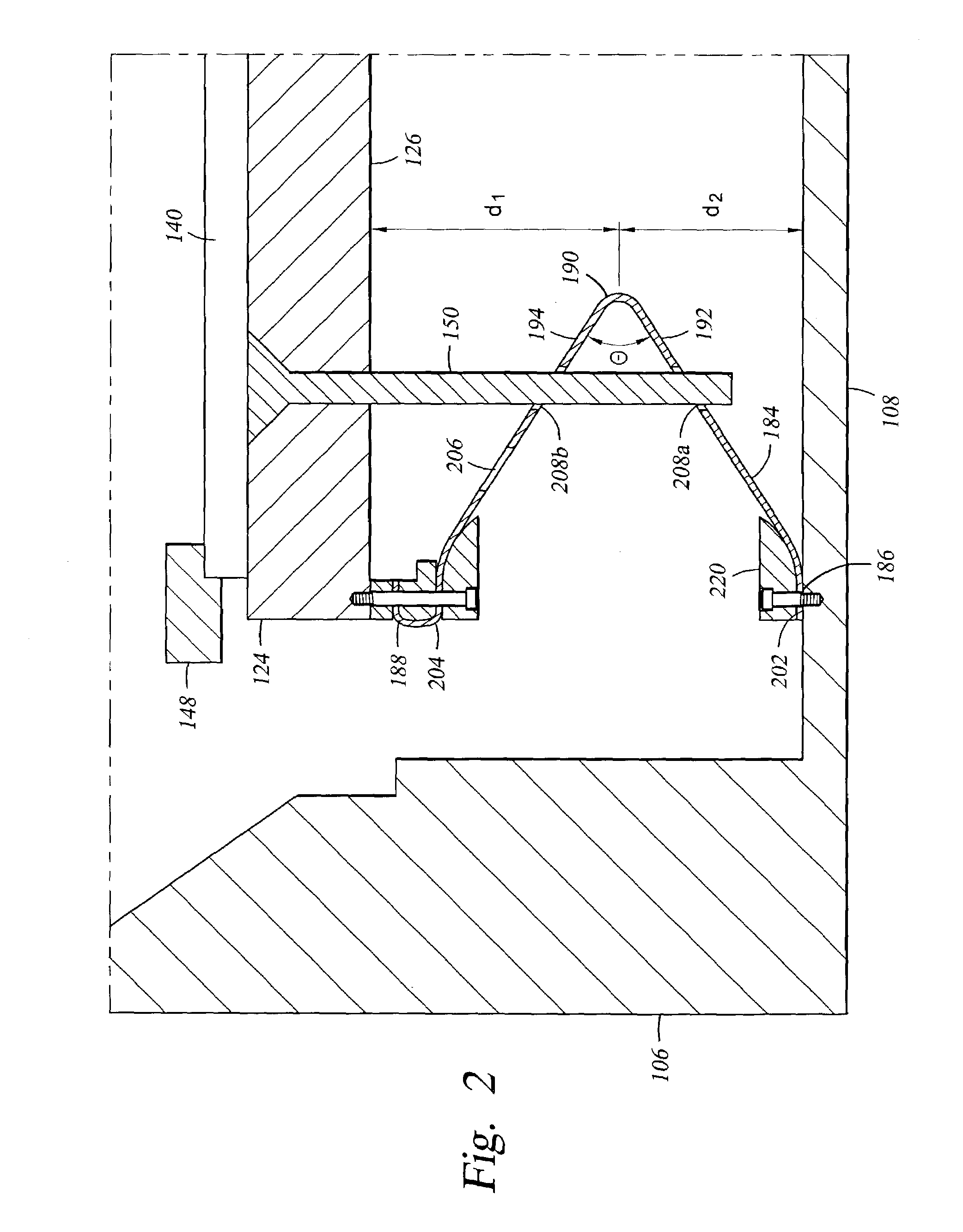

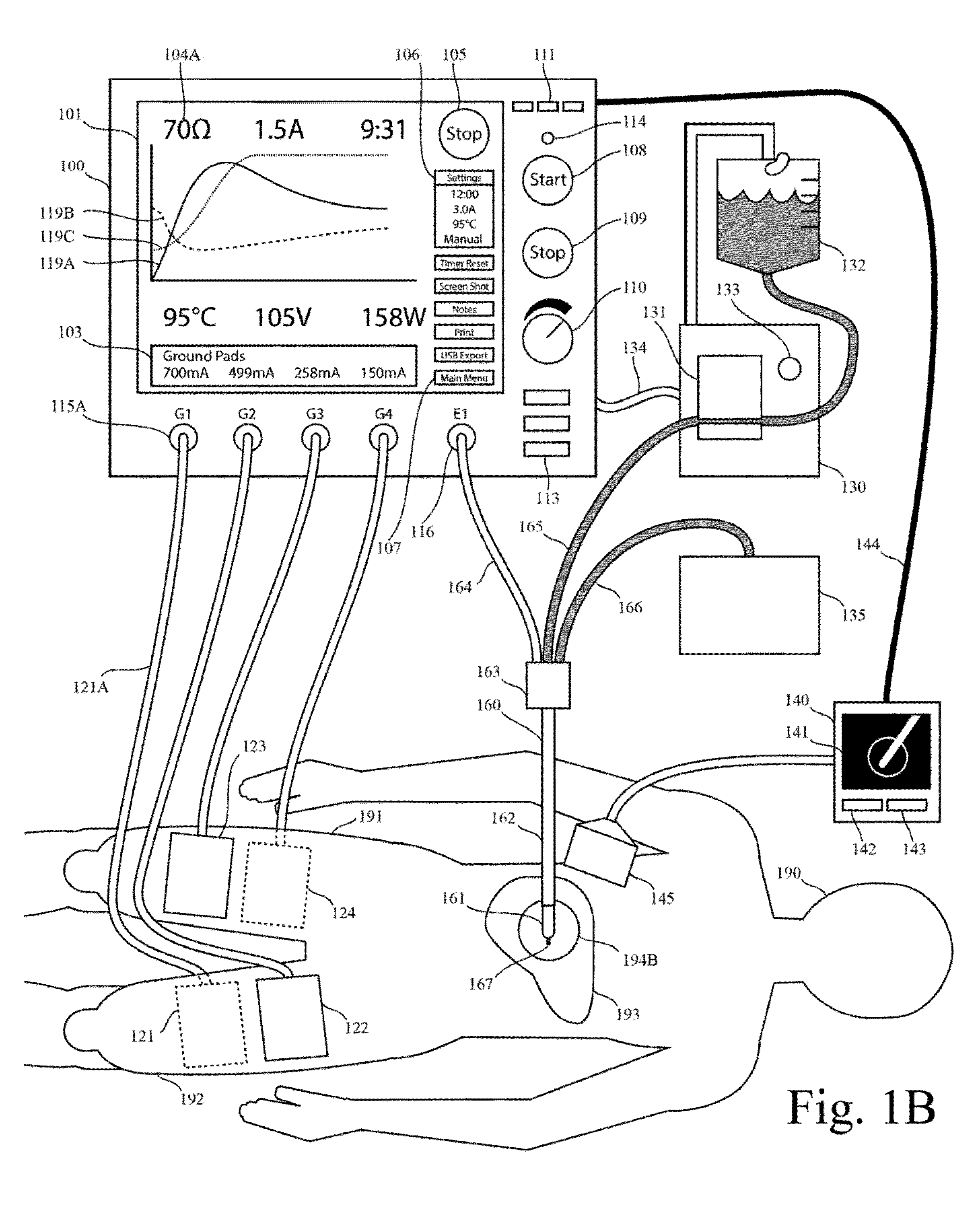

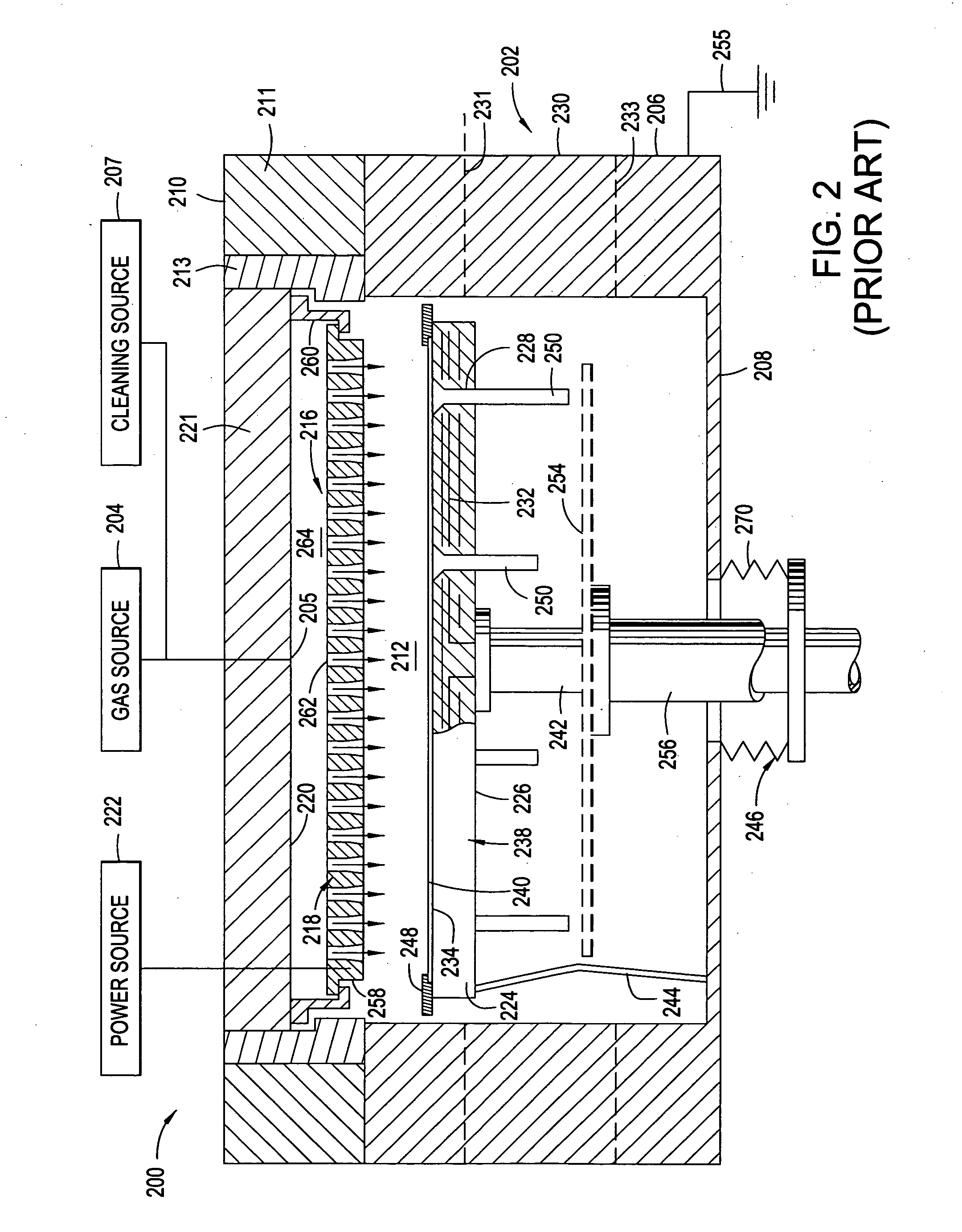

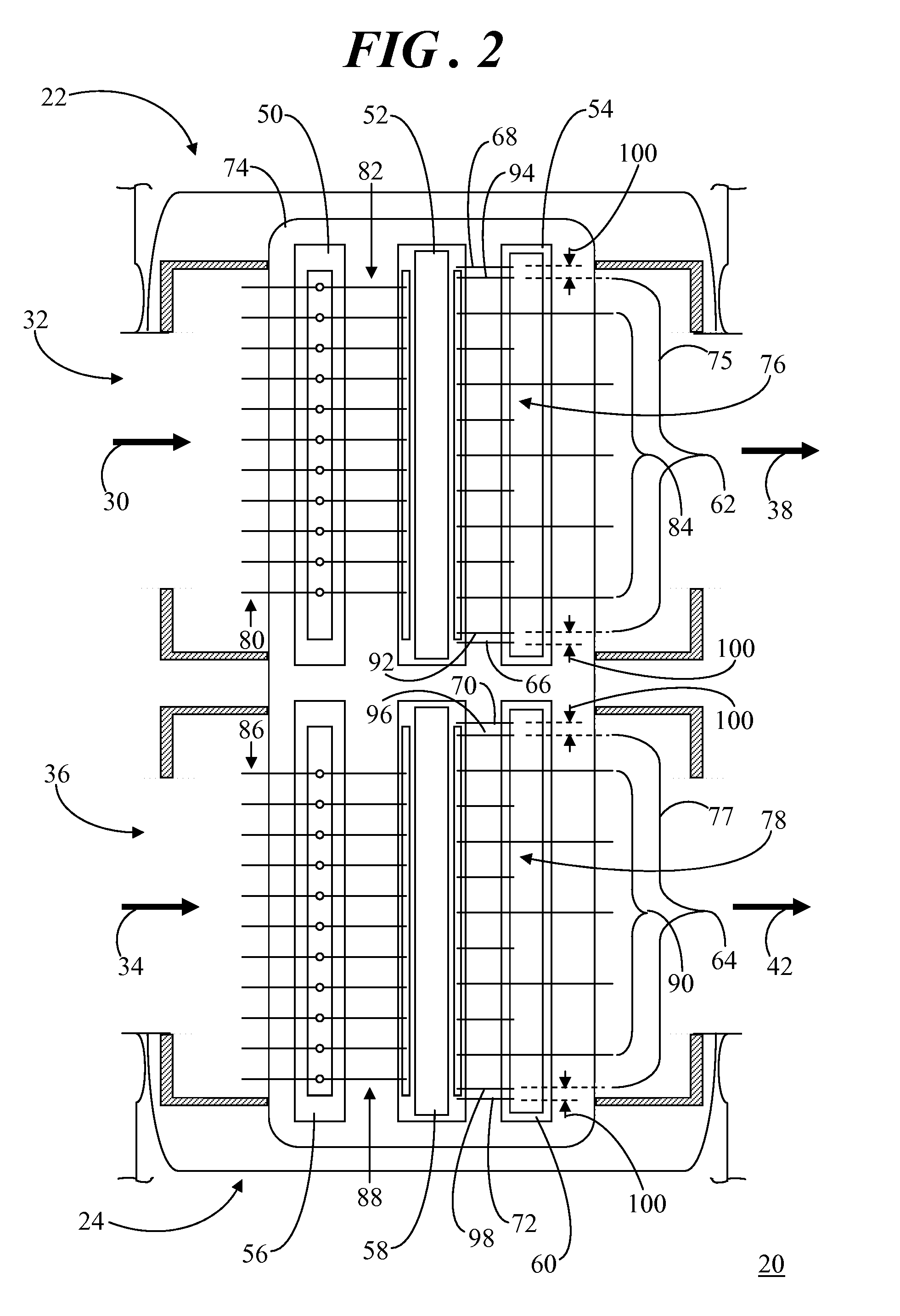

RF current return path for a large area substrate plasma reactor

InactiveUS7083702B2Electric discharge tubesSemiconductor/solid-state device manufacturingReturn currentEngineering

An apparatus for providing a return current path for RF current between a chamber wall and a substrate support is provided comprising a low impedance flexible curtain having a first end and a second end, the first end adapted to be electrically connected to the chamber wall and the second end adapted to be connected to the substrate support, wherein the curtain further comprises at least one fold in the curtain material, located an axial distance between the first end and the second end, and at least one perforation cut into the curtain proximate the second end.

Owner:APPLIED MATERIALS INC

Electrosurgical generator

ActiveUS20150320478A1Increase productionRelieve painElectrotherapyDiagnosticsSonificationReturn current

This invention relates to high-frequency ablation of tissue in the body using a cooled high-frequency electrode connected to a high frequency generator including a computer graphic control system and an automatic controller for control the signal output from the generator, and adapted to display on a real time graphic display a measured parameter related to the ablation process and visually monitor the variation of the parameter of the signal output that is controlled by the controller during the ablation process. In one example, one or more measured parameters are displayed simultaneously to visually interpret the relation of their variation and values. In one example, the displayed one or more parameters can be taken from the list of measured voltage, current, power, impedance, electrode temperature, and tissue temperature related to the ablation process. The graphic display gives the clinician an instantaneous and intuitive feeling for the dynamics and stability of the ablation process for safety and control. This invention relates to monitoring and controlling multiple ground pads to optimally carry return currents during high-frequency tissue ablation, and to prevent of ground-pad skin burns. This invention relates to the use of ultrasound imaging intraoperatively during a tissue ablation procedure. This invention relates to the use of nerve stimulation and blocking during a tissue ablation procedure.

Owner:COSMAN INTRUMENTS LLC

RF grounding of cathode in process chamber

ActiveUS20060060302A1Control movementElectric discharge tubesSemiconductor/solid-state device manufacturingElectricityPower flow

An apparatus for providing a short return current path for RF current between a process chamber wall and a substrate support is provided. The RF grounding apparatus, which is RF grounded and is place above the substrate transfer port, establishes electrical contact with the substrate support only during substrate processing, such as deposition, to provide return current path for the RF current. One embodiment of the RF grounding apparatus comprises one or more low impedance flexible curtains, which are electrically connected to the grounded chamber wall, and to one or more low impedance blocks, which make contacts with the substrate support during substrate processing. Another embodiment of the RF grounding apparatus comprises a plurality of low impedance flexible straps, which are electrically connected to the grounded chamber wall, and to one or more low impedance blocks, which make contacts with the substrate support during substrate processing. Yet another embodiment of the RF grounding apparatus comprises a plurality of probes, which either are electrically connected to the grounded chamber wall or are grounded by other means, and actuators accompanying the probes. The actuators move the probes to make electrical contact with the substrate support during substrate processing.

Owner:APPLIED MATERIALS INC

Electrosurgical generator

ActiveUS20150320480A1Increase productionRelieve painElectrotherapyDiagnosticsSonificationReturn current

This invention relates to high-frequency ablation of tissue in the body using a cooled high-frequency electrode connected to a high frequency generator including a computer graphic control system and an automatic controller for control the signal output from the generator, and adapted to display on a real time graphic display a measured parameter related to the ablation process and visually monitor the variation of the parameter of the signal output that is controlled by the controller during the ablation process. In one example, one or more measured parameters are displayed simultaneously to visually interpret the relation of their variation and values. In one example, the displayed one or more parameters can be taken from the list of measured voltage, current, power, impedance, electrode temperature, and tissue temperature related to the ablation process. The graphic display gives the clinician an instantaneous and intuitive feeling for the dynamics and stability of the ablation process for safety and control. This invention relates to monitoring and controlling multiple ground pads to optimally carry return currents during high-frequency tissue ablation, and to prevent of ground-pad skin burns. This invention relates to the use of ultrasound imaging intraoperatively during a tissue ablation procedure. This invention relates to the use of nerve stimulation and blocking during a tissue ablation procedure.

Owner:COSMAN INTRUMENTS LLC

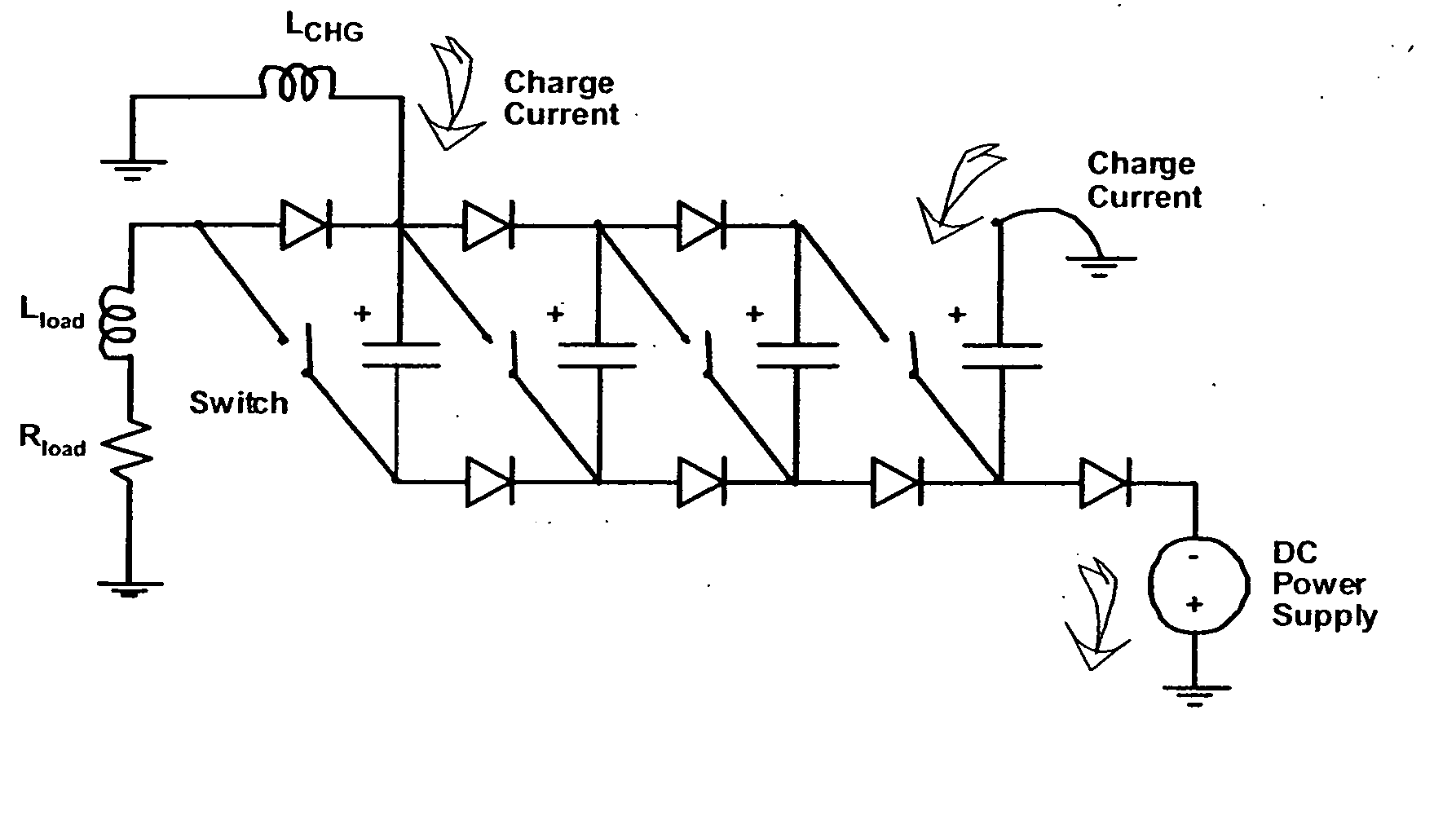

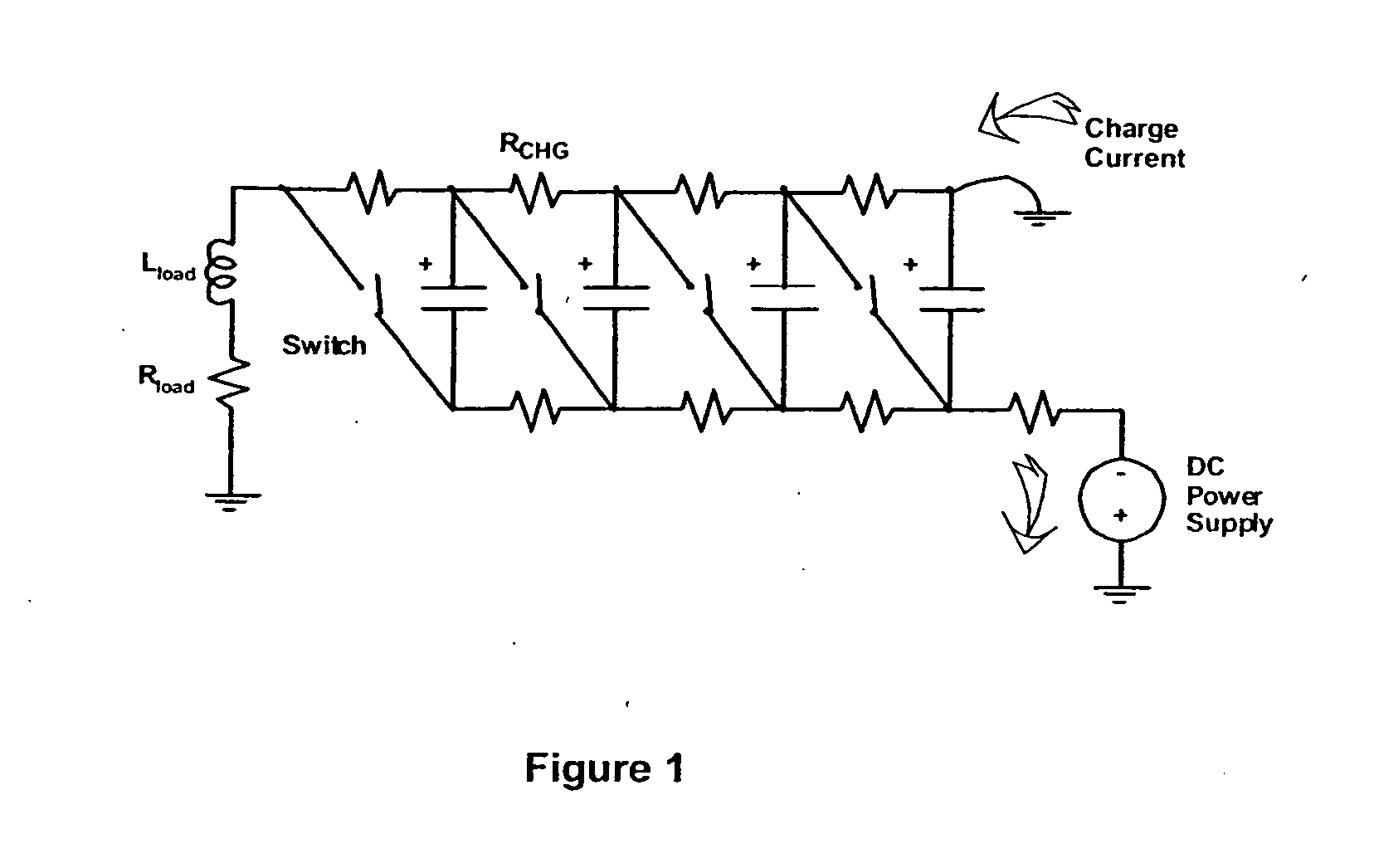

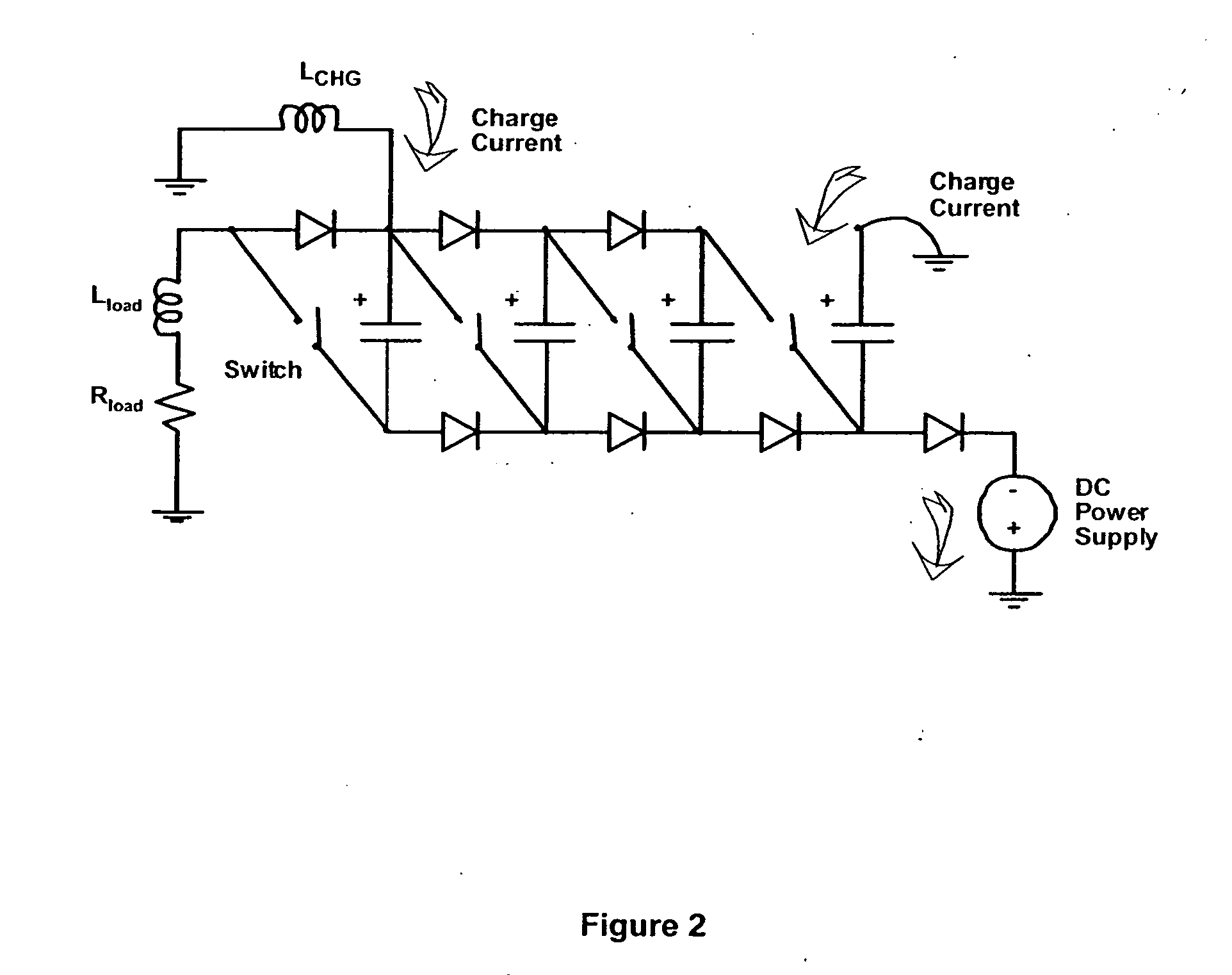

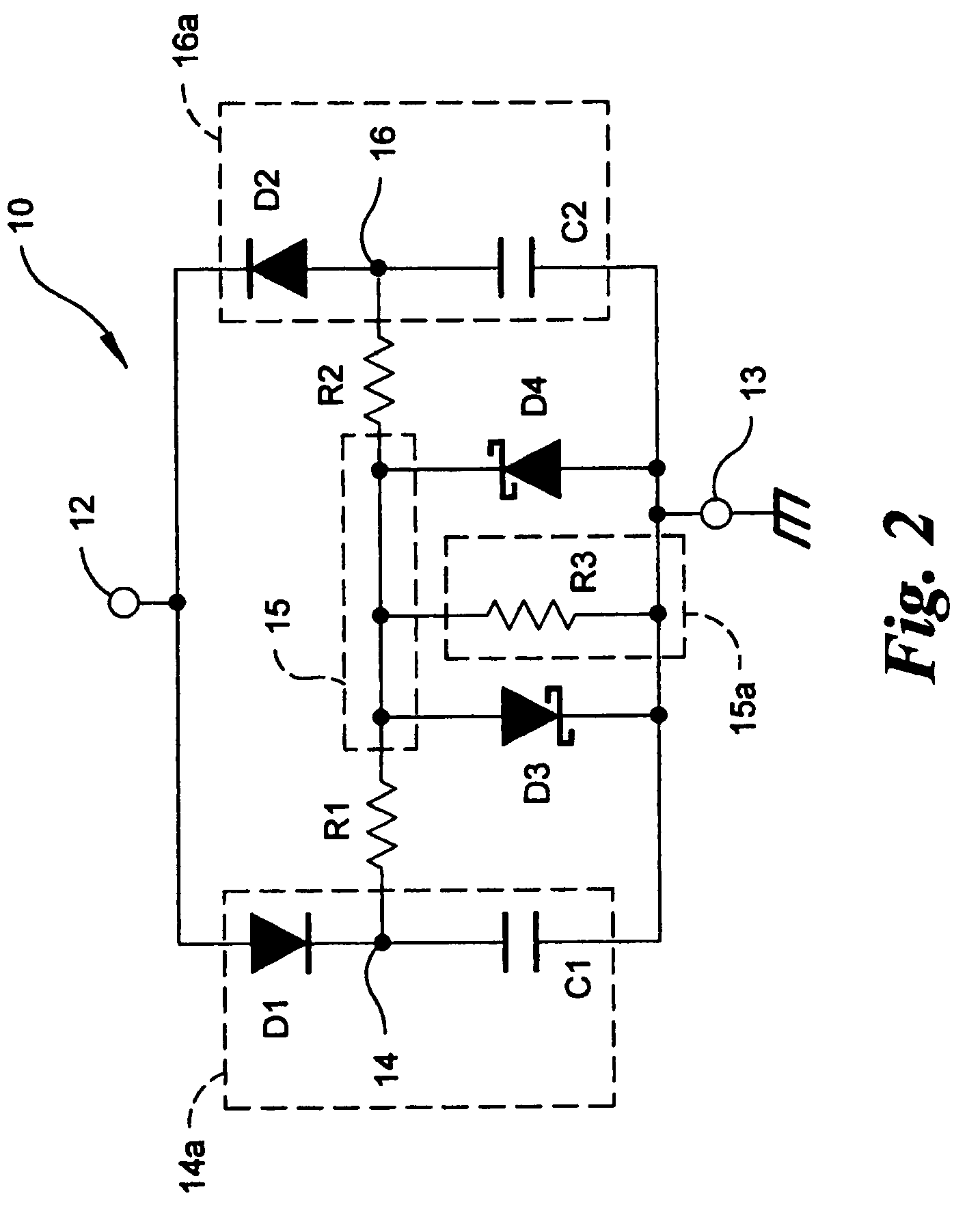

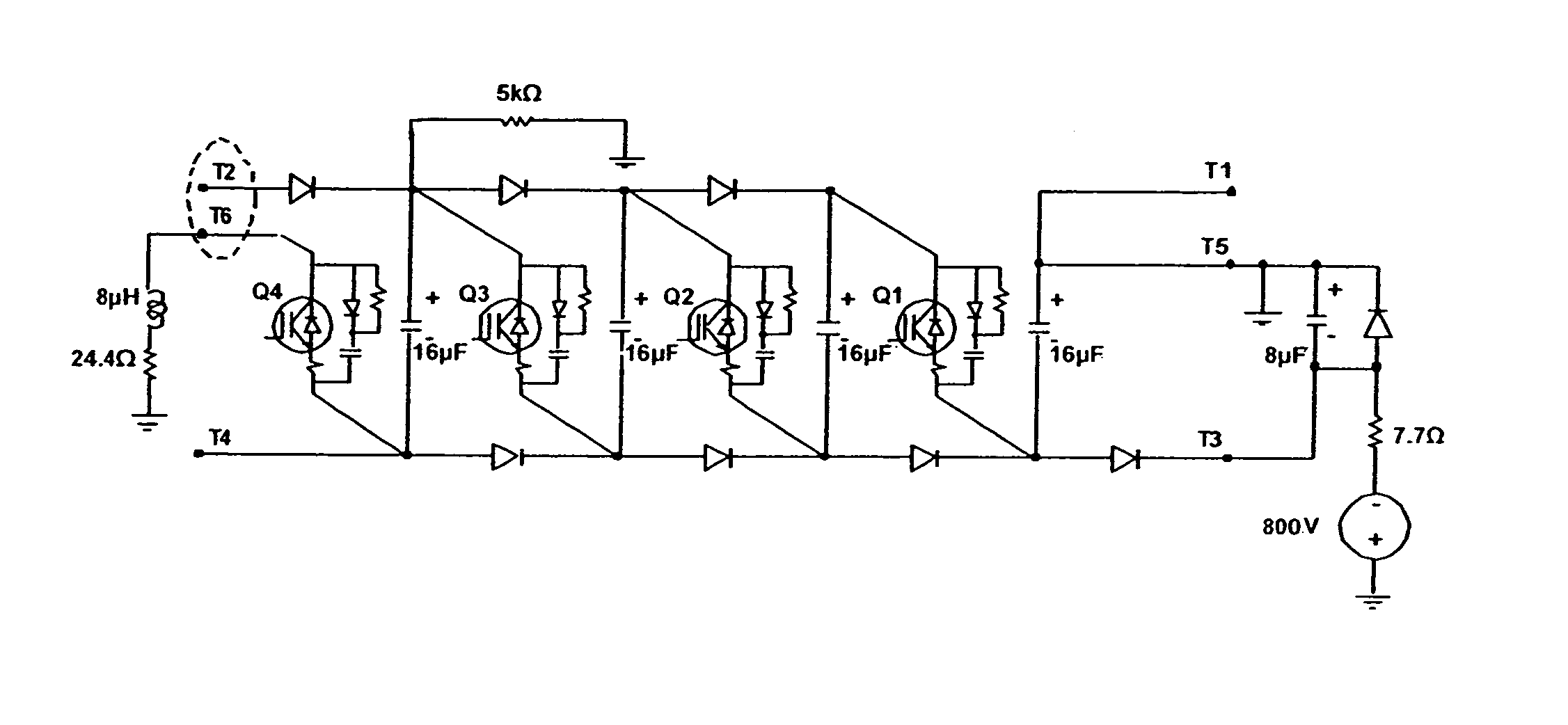

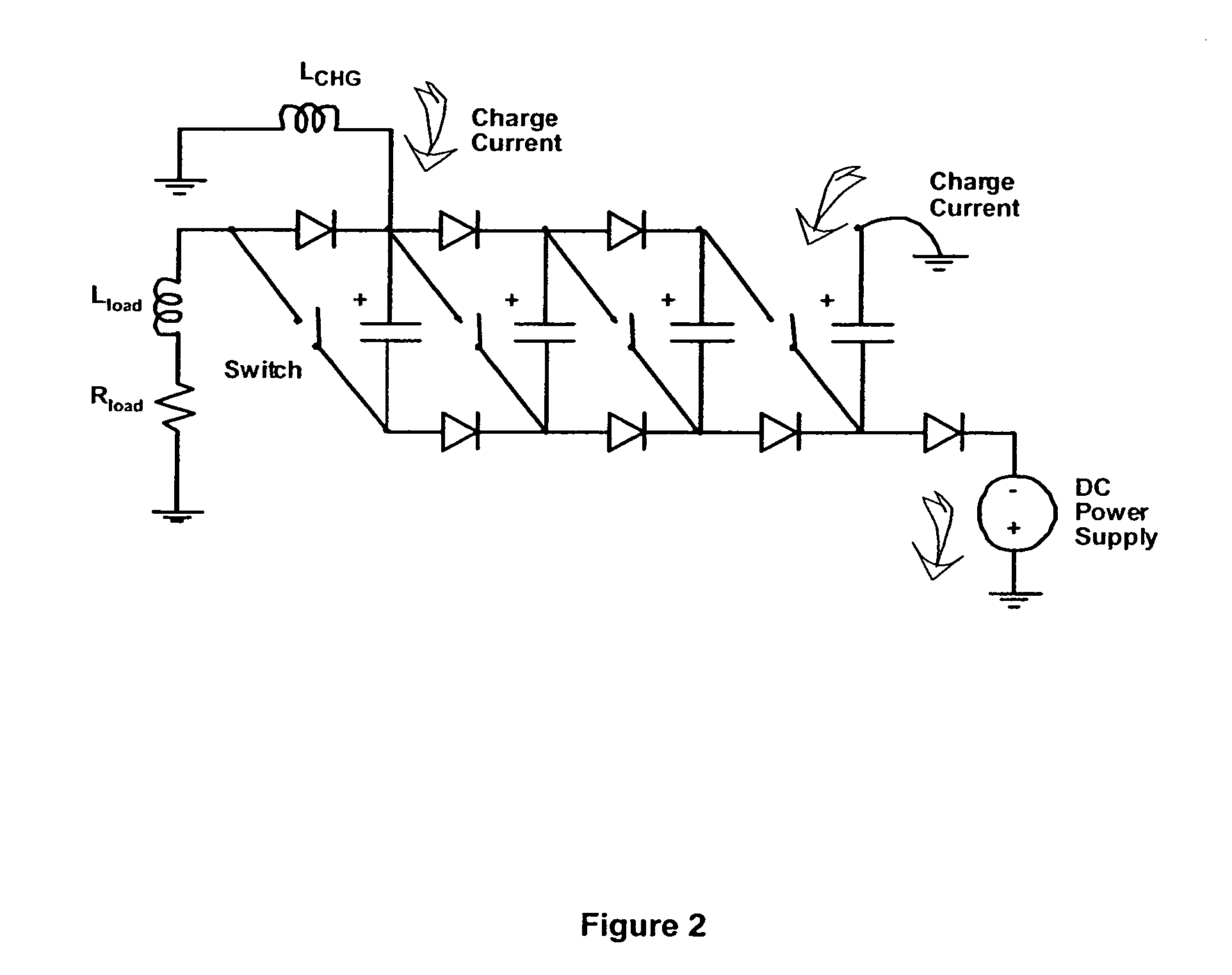

Diode-directed solid-state marx generator

An apparatus having one or more modular stages for producing voltage and current pulses. Each module includes a diode charging means to charge a capacitive means that stores energy. One or more charging impedance means are connected to the diode charging means to provide a return current pathway. A solid-state switch discharge means, with current interruption capability, is connected to the capacitive means to discharge stored energy. Finally, a control means is provided to command the switching action of the solid-state switch discharge means.

Owner:LOS ALAMOS NATIONAL SECURITY

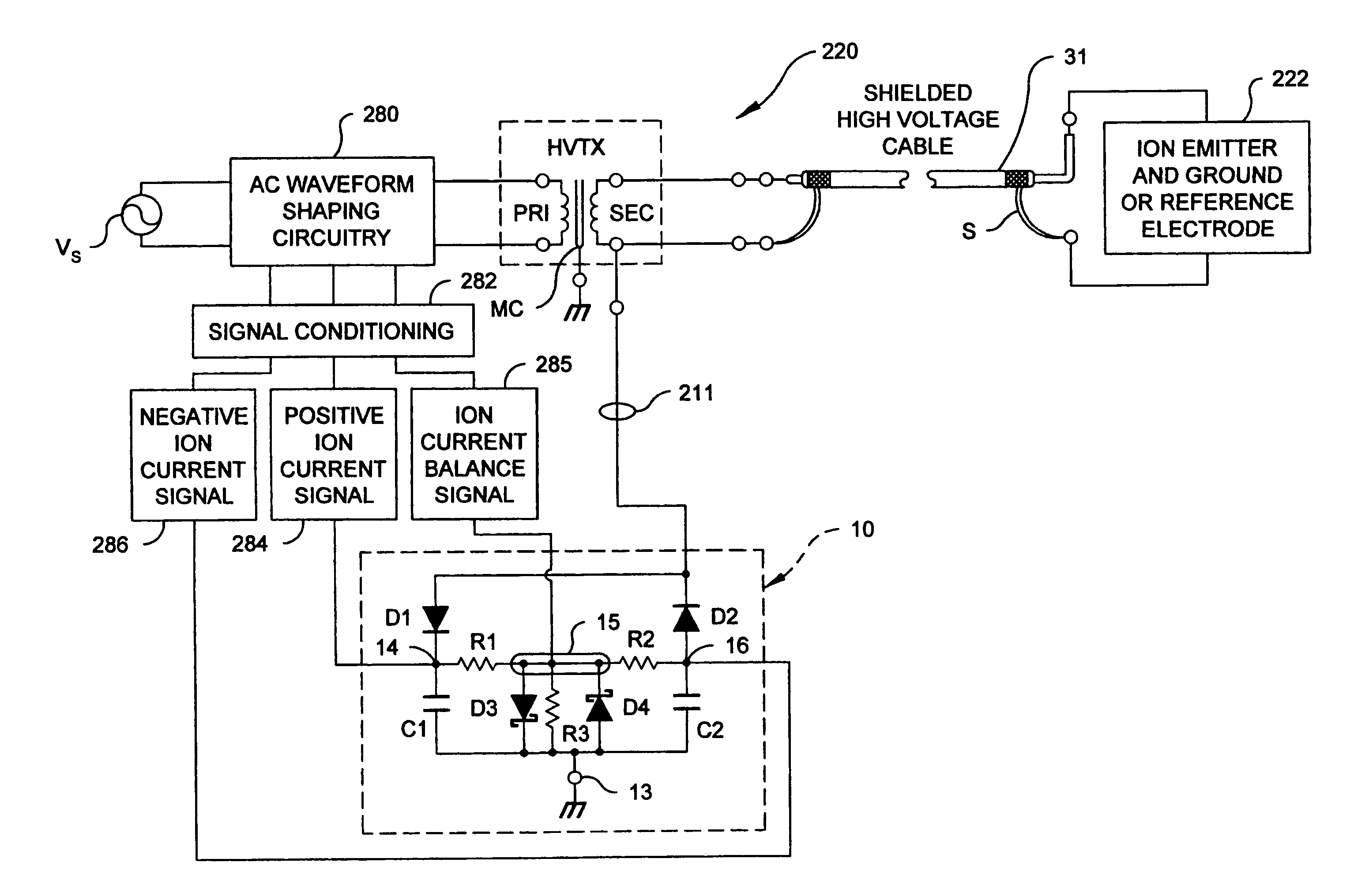

Alternating current monitor for an ionizer power supply

Owner:ILLINOIS TOOL WORKS INC

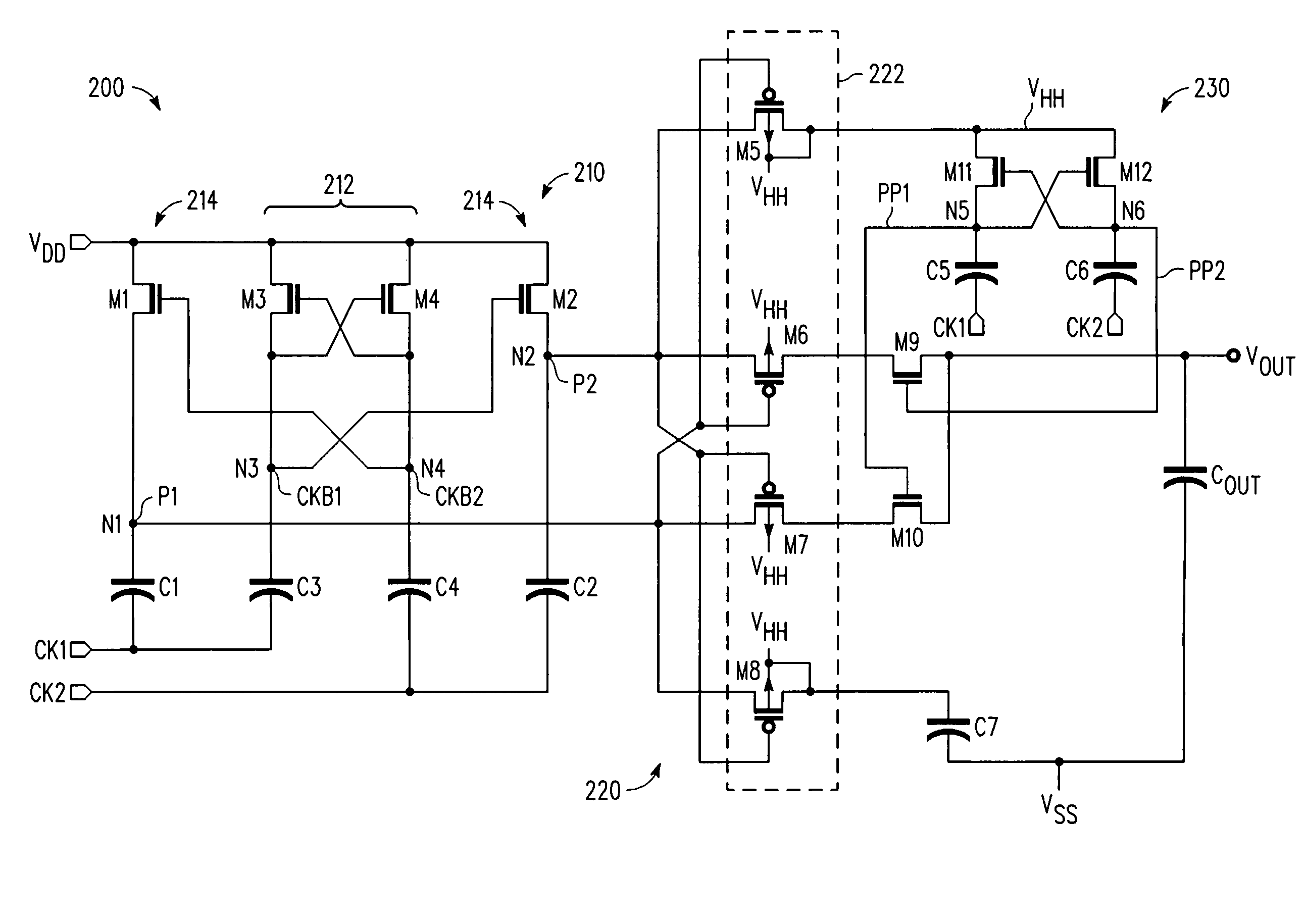

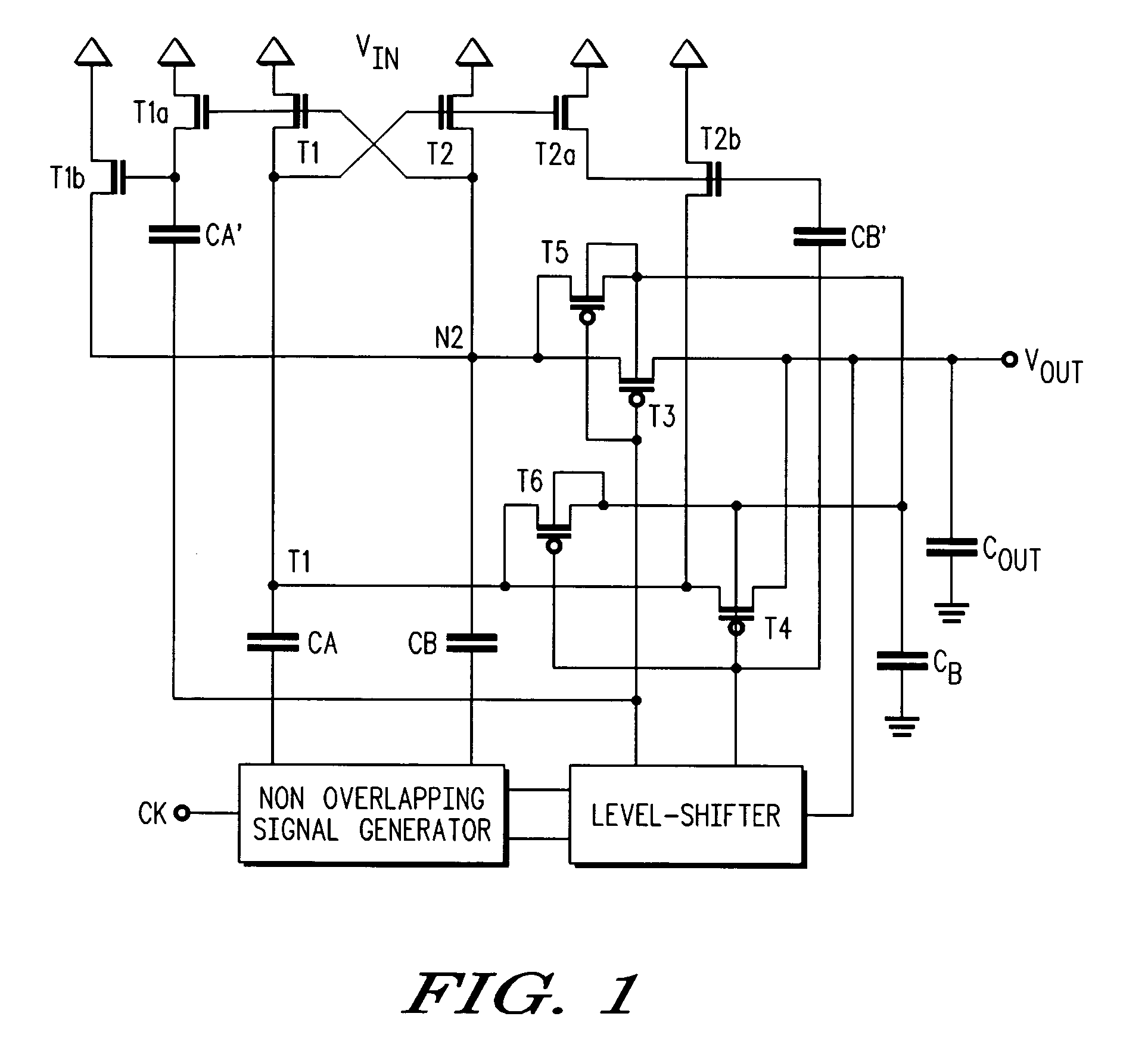

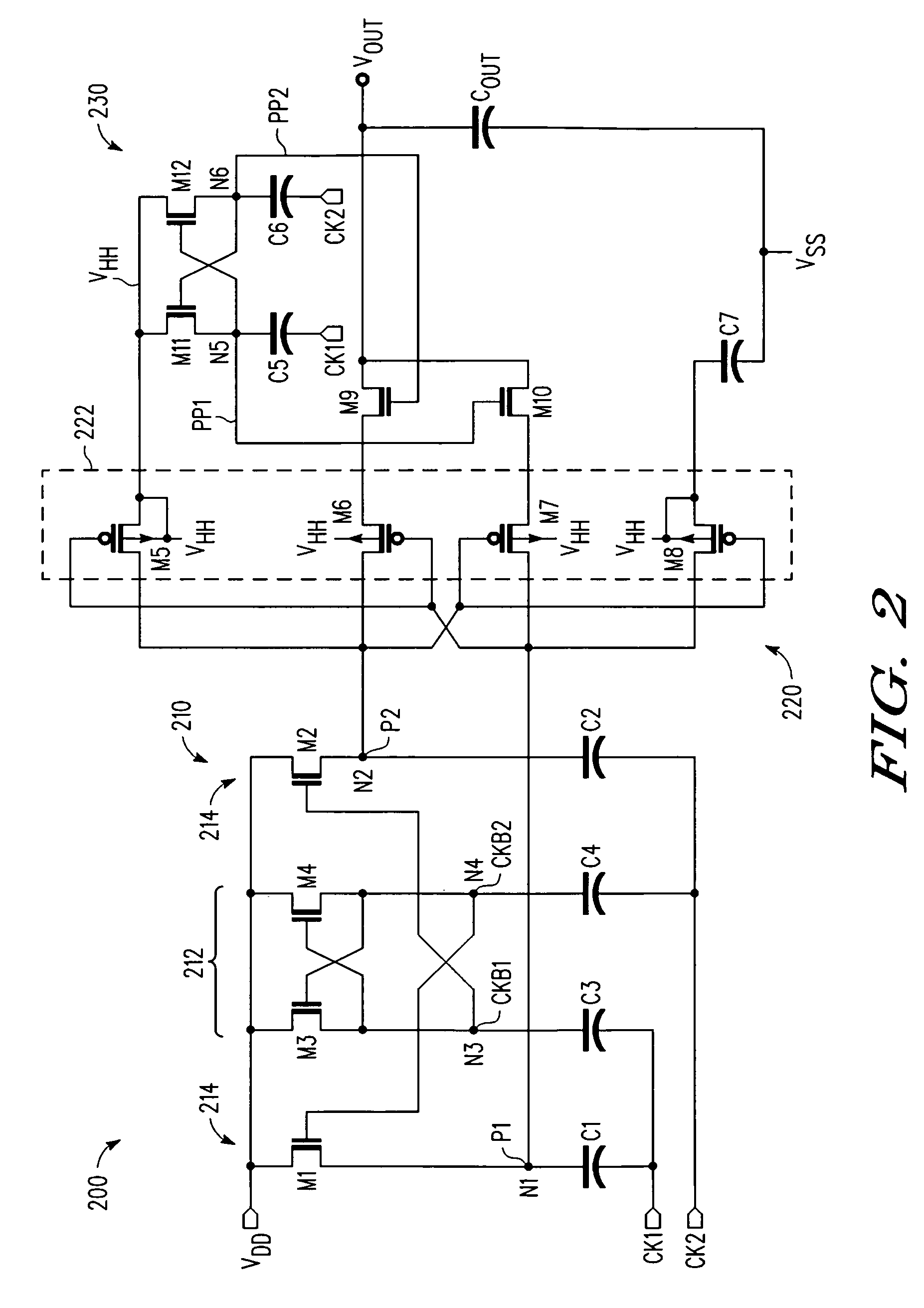

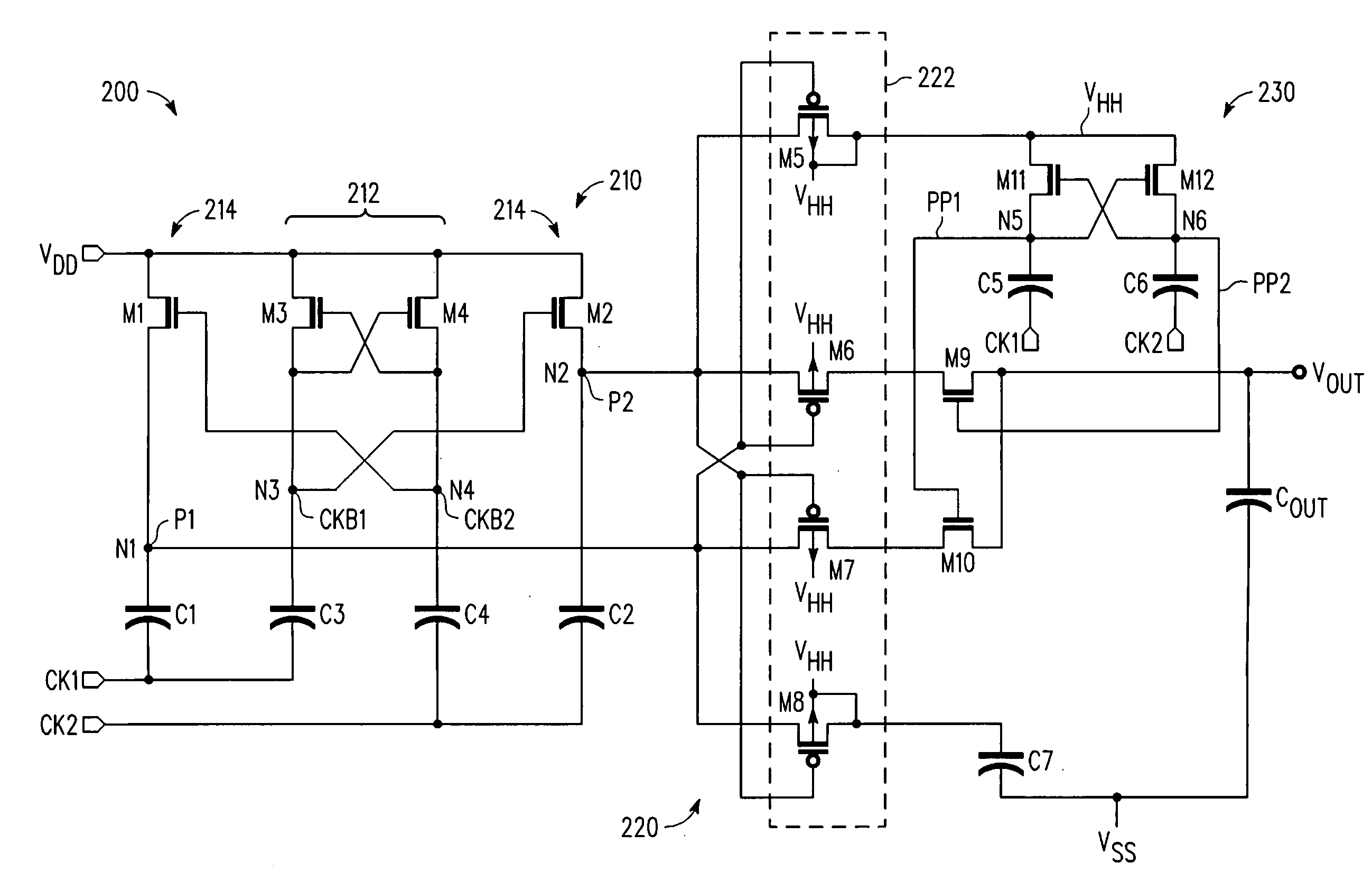

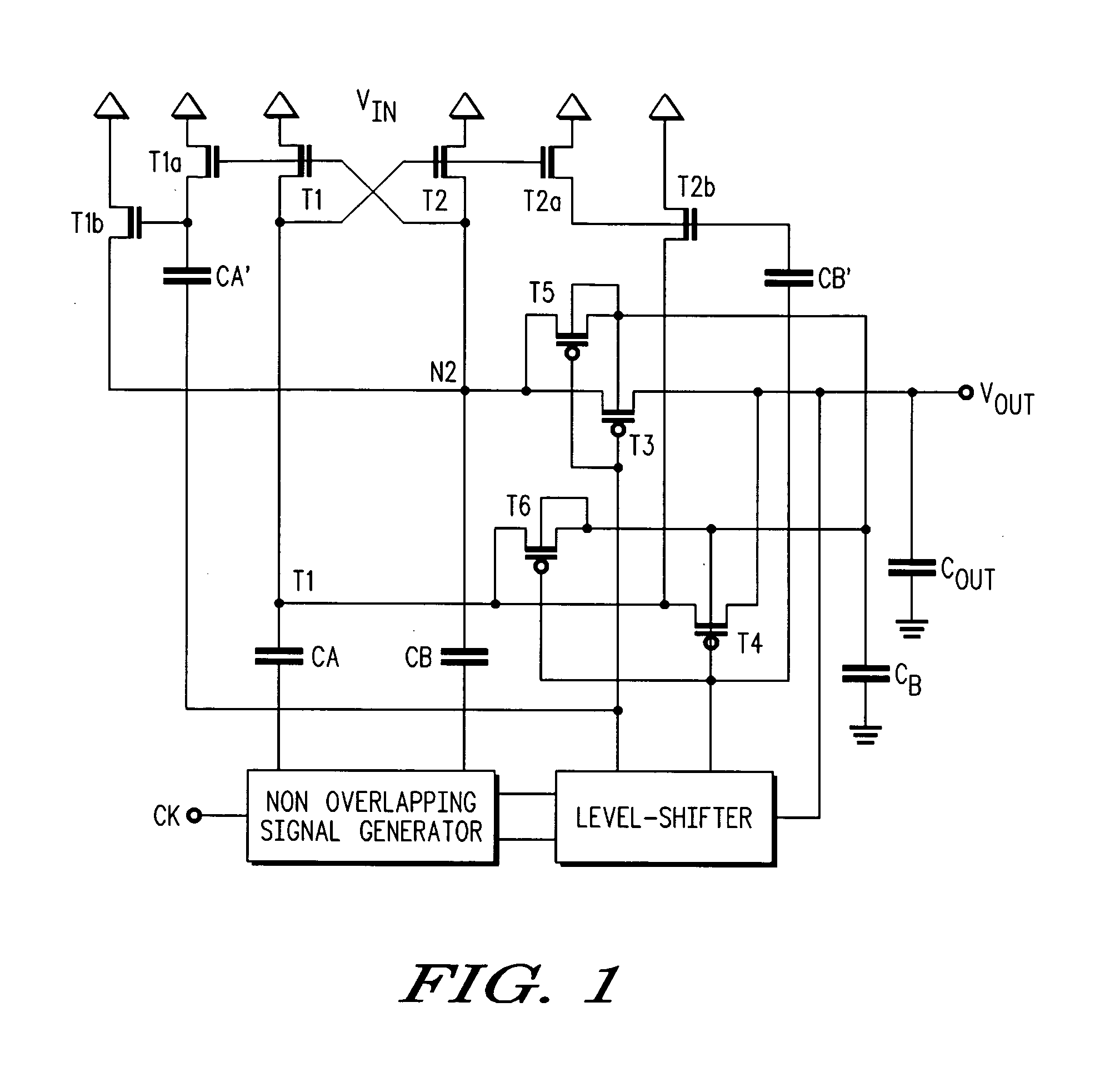

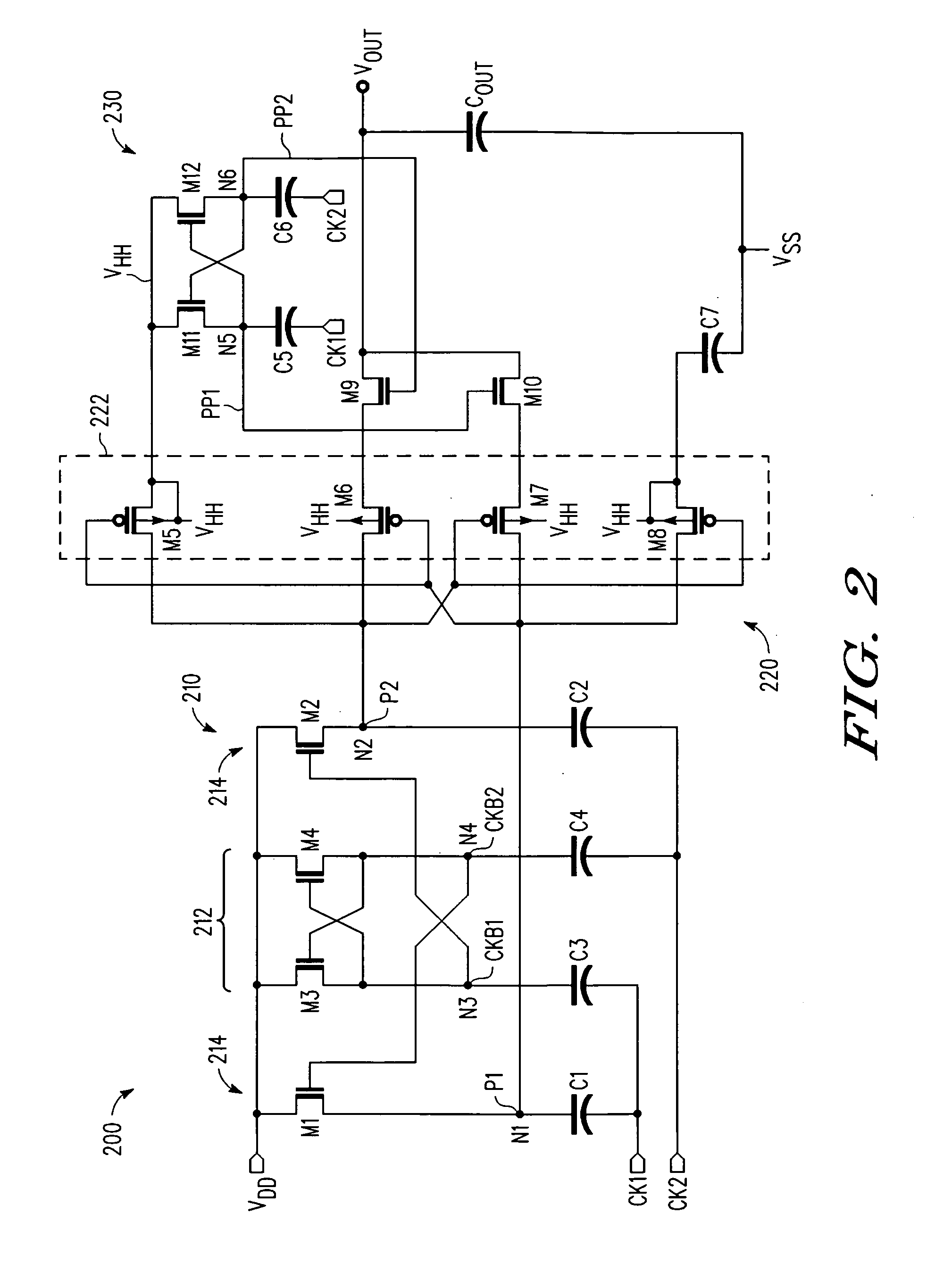

Voltage multiplier with improved efficiency

InactiveUS7602233B2Ac-dc conversionApparatus without intermediate ac conversionVoltage multiplierReturn current

A multi-stage voltage multiplication circuit and methodology are provided which use a multi-stage charge pump boosting circuit (210) and two-stage pass gate circuit (220) having complementary power switches (M6, M9, M7, M10) to efficiently develop an output voltage (VOUT) that is higher than the input supply voltage (VDD). By using a two-stage complementary switch to connect boosted clock signals (P1, P2) from a charge pump (210) to the multiplier output (VOUT), return current from the storage capacitor (COUT) to the pumping capacitor (C1, C2) is blocked, thereby increasing power transfer efficiency, even at high clock frequencies. In addition, a boosted auxiliary voltage is generated by an additional boosting stage (230) and applied to the PMOS wells of the pass gate circuit (220), thereby preventing latch-up and backflow.

Owner:NORTH STAR INNOVATIONS

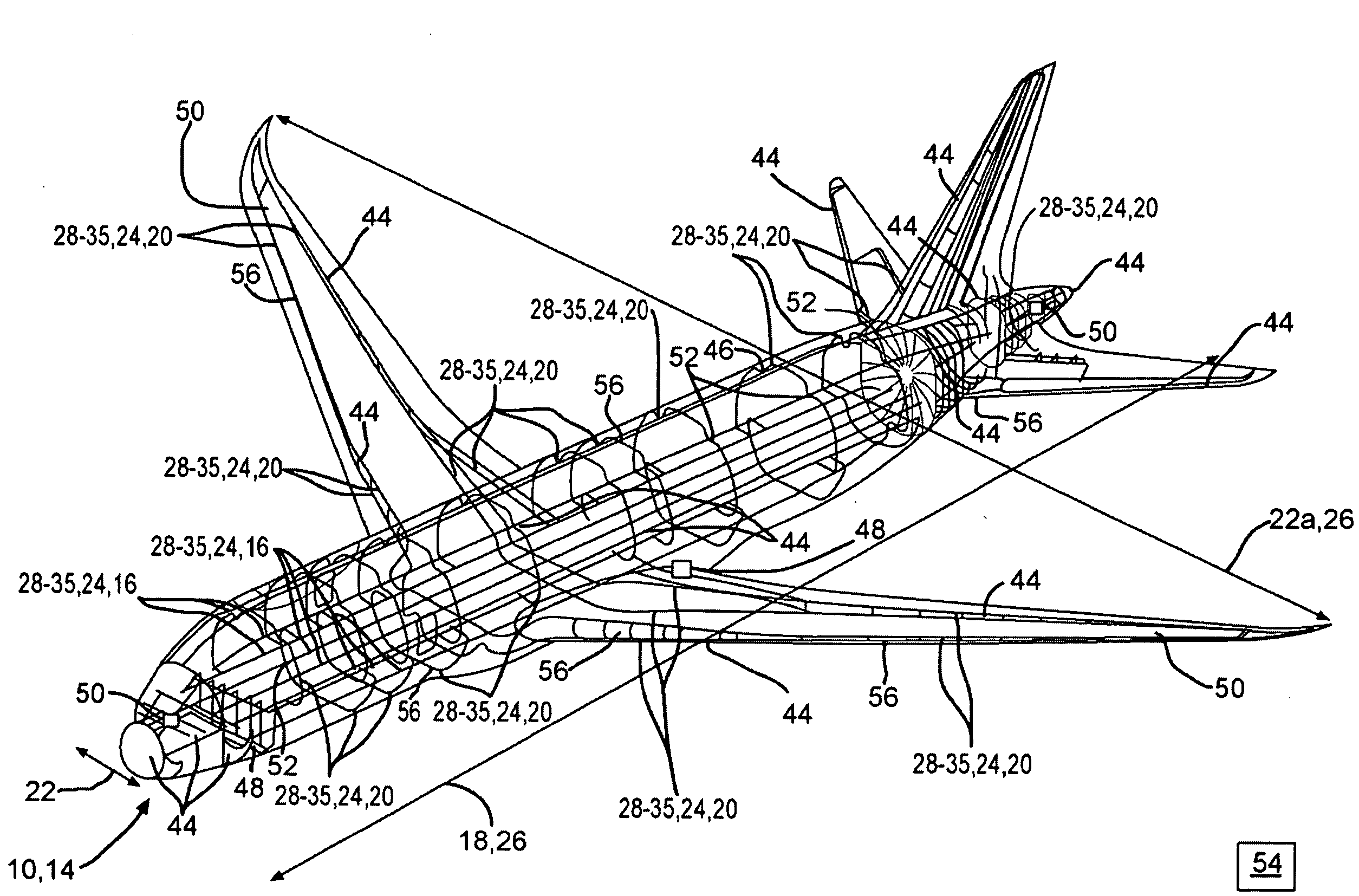

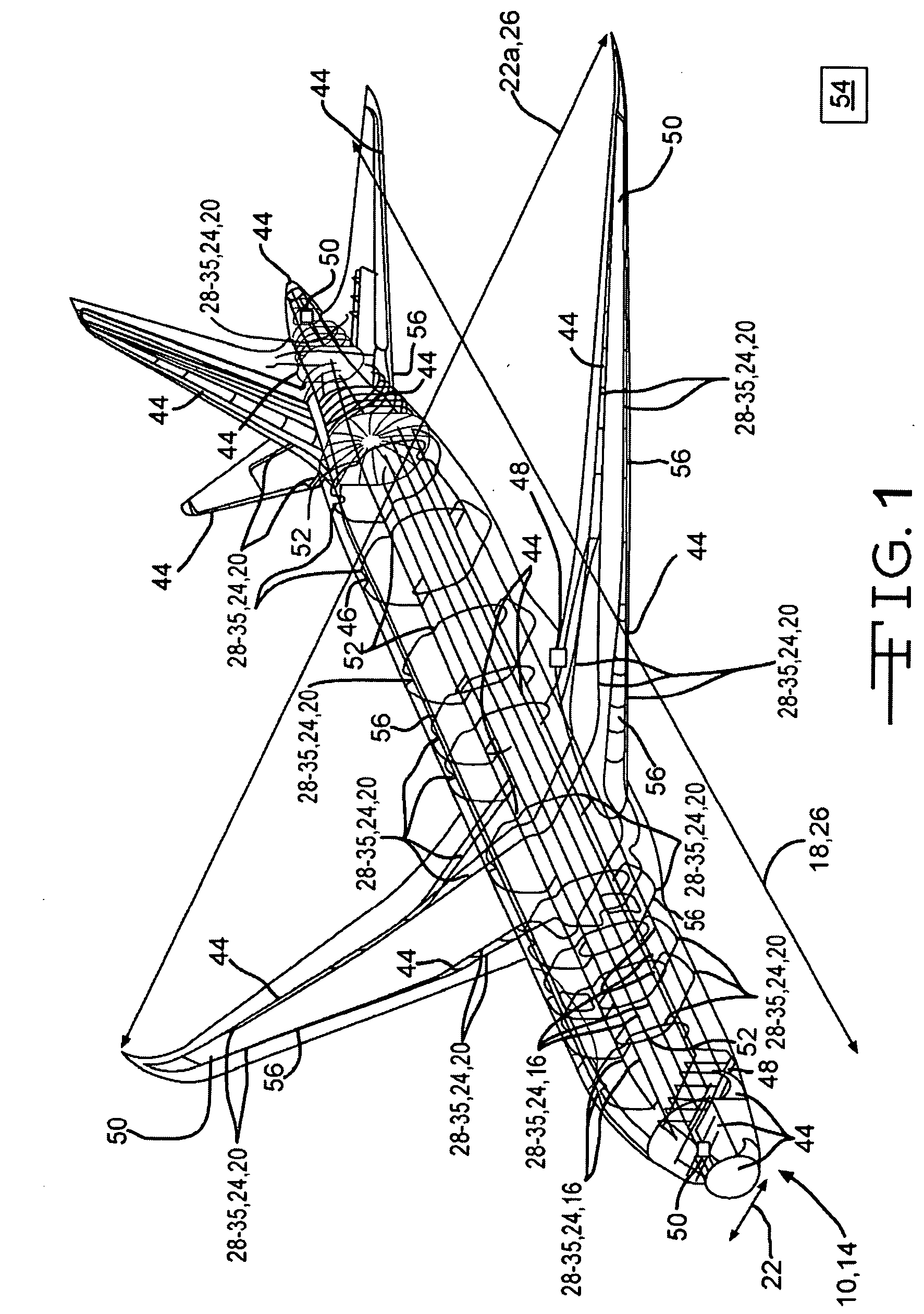

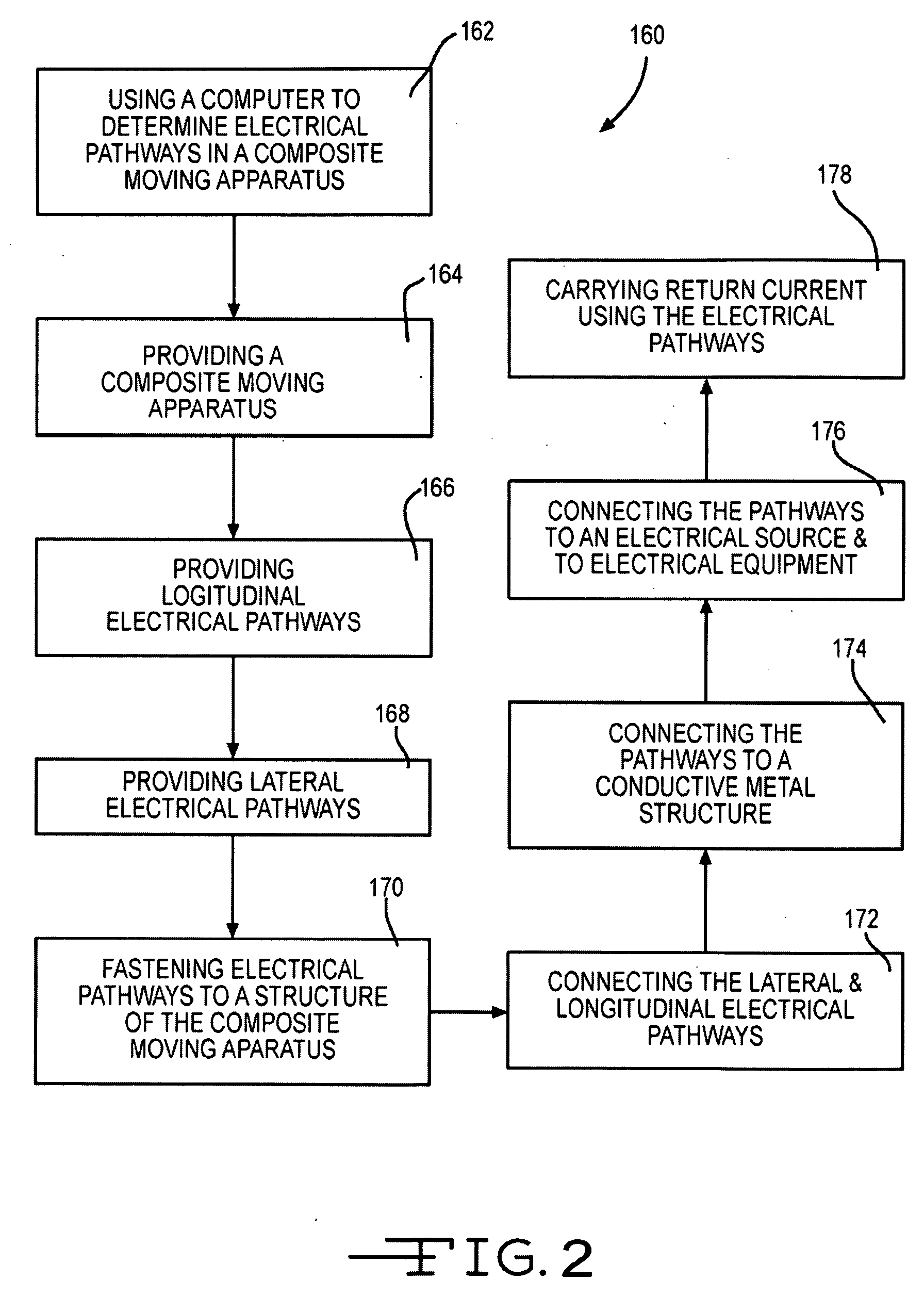

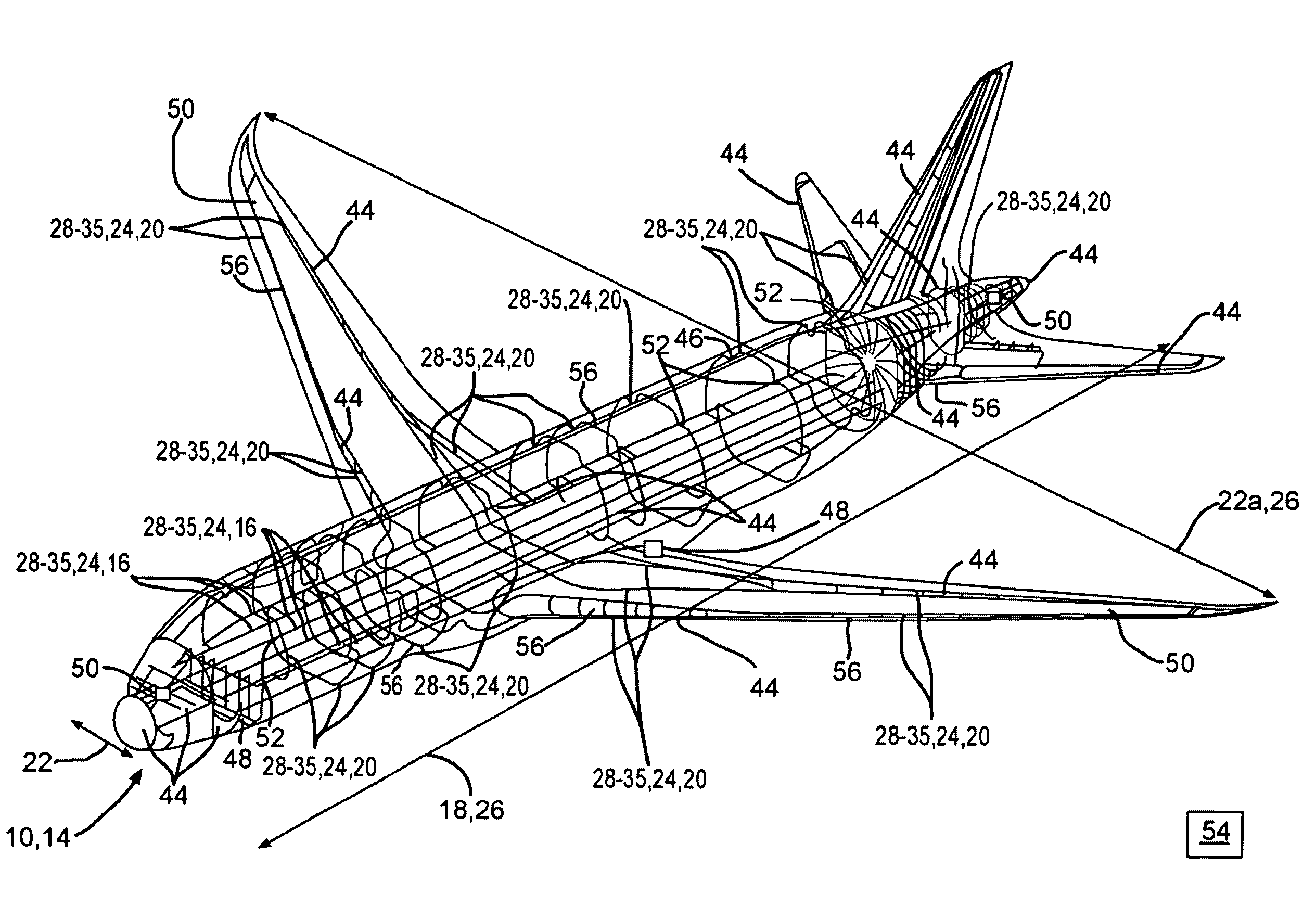

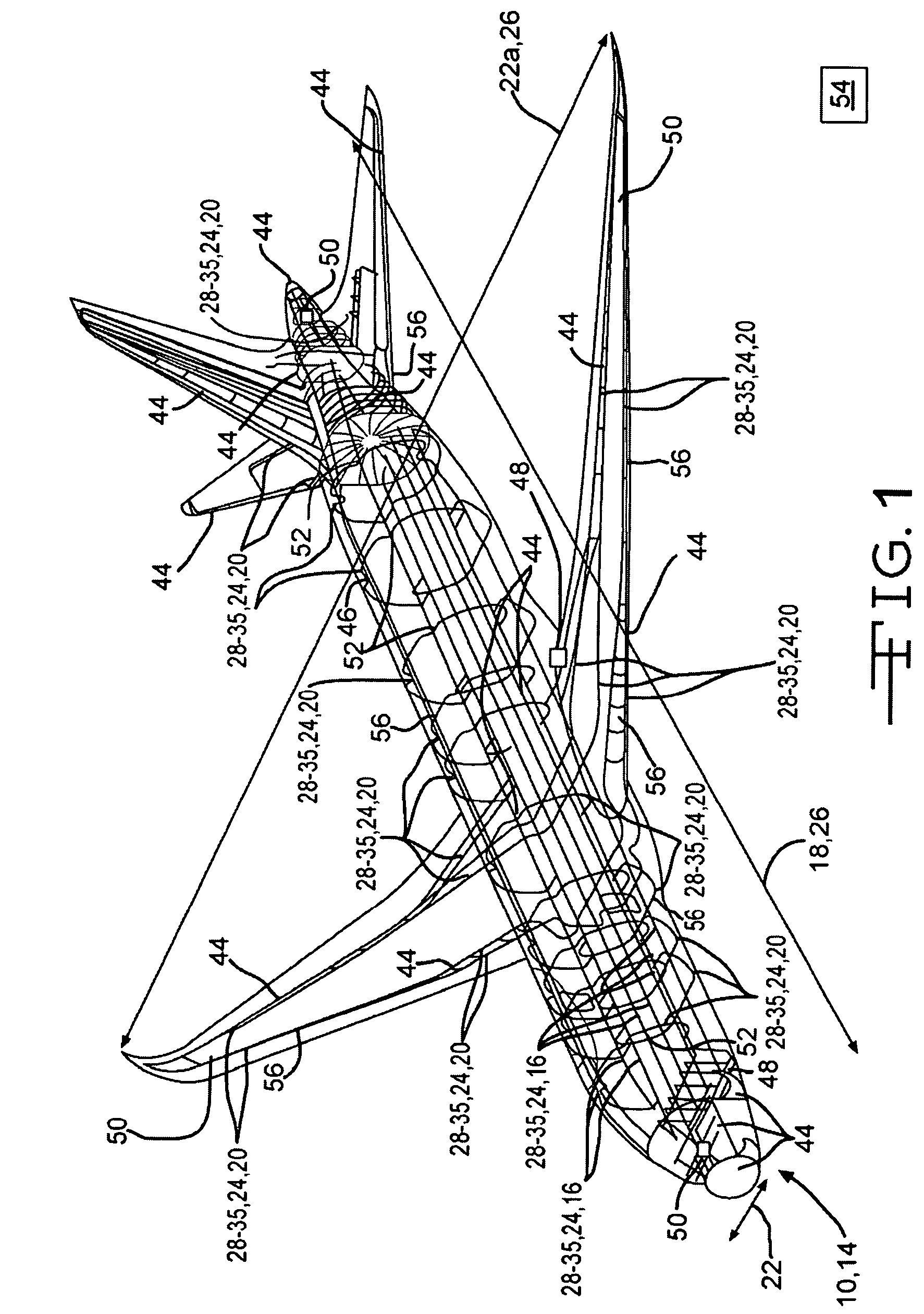

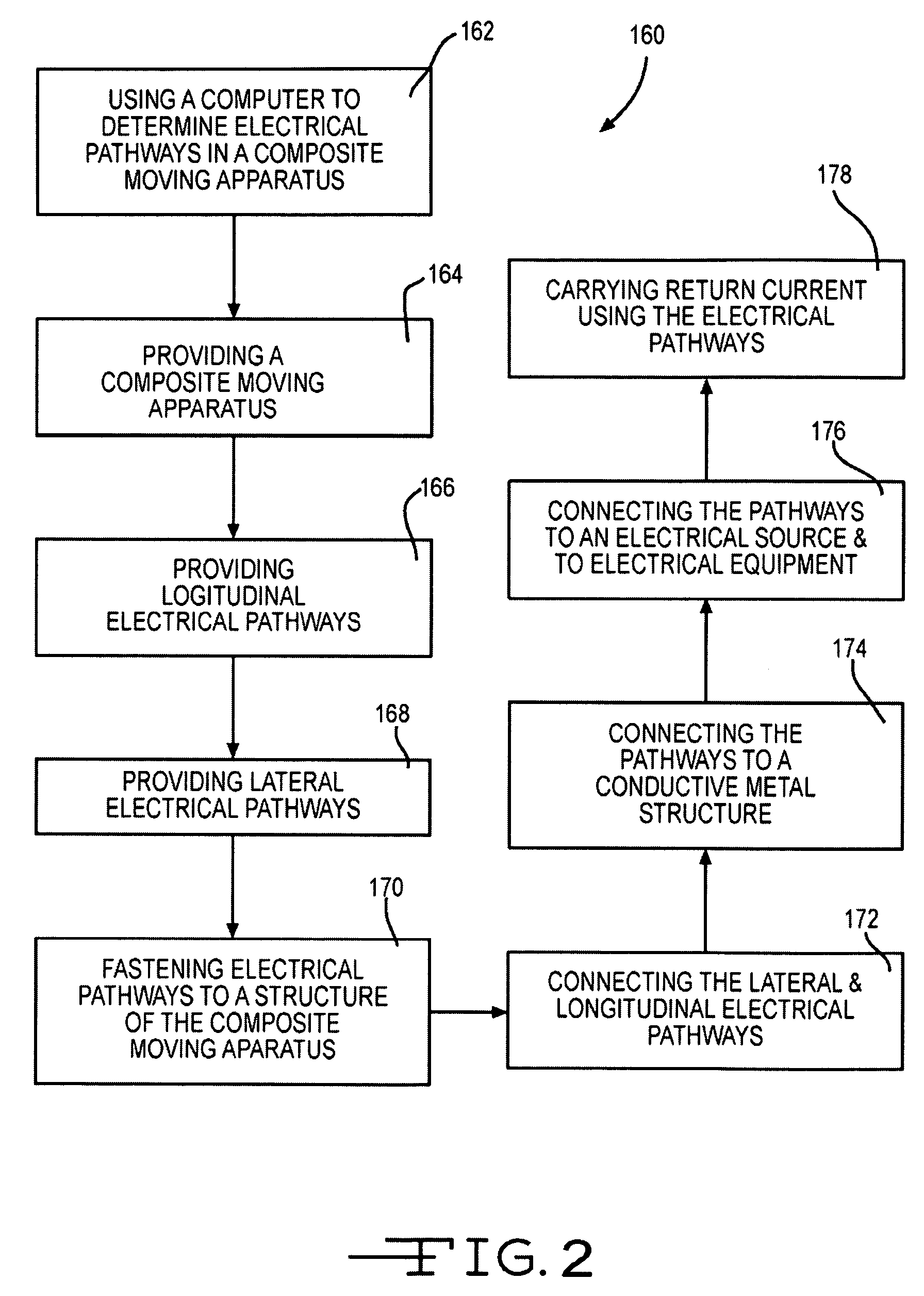

Current return network

ActiveUS20100127564A1Minimizing resistanceMinimizing voltage differentialInstallation of lighting conductorsElectric devicesElectricityElectrical resistance and conductance

A composite moving apparatus made substantially of composites may include a plurality of longitudinal conductive electrical pathways extending along a substantial length of the composite moving apparatus, and a plurality of lateral conductive electrical pathways extending along a substantial lateral width of the composite moving apparatus. The longitudinal and lateral conductive electrical pathways may be connected in order to provide redundant electrical pathways extending along a substantial portion of the composite moving apparatus. The redundant electrical pathways may carry return current, carry fault current, provide grounding, carry lightning current, provide electromagnetic shielding, minimize resistance and voltage differential, and / or provide a bleed path for electrostatic charge.

Owner:THE BOEING CO

Voltage multiplier with improved efficiency

InactiveUS20090219077A1Ac-dc conversionApparatus without intermediate ac conversionVoltage multiplierReturn current

A multi-stage voltage multiplication circuit and methodology are provided which use a multi-stage charge pump boosting circuit (210) and two-stage pass gate circuit (220) having complementary power switches (M6, M9, M7, M10) to efficiently develop an output voltage (VOUT) that is higher than the input supply voltage (VDD). By using a two-stage complementary switch to connect boosted clock signals (P1, P2) from a charge pump (210) to the multiplier output (VOUT), return current from the storage capacitor (COUT) to the pumping capacitor (C1, C2) is blocked, thereby increasing power transfer efficiency, even at high clock frequencies. In addition, a boosted auxiliary voltage is generated by an additional boosting stage (230) and applied to the PMOS wells of the pass gate circuit (220), thereby preventing latch-up and backflow.

Owner:NORTH STAR INNOVATIONS

Current return network

ActiveUS8031458B2Minimizing resistanceMinimizing voltageInstallation of lighting conductorsElectric devicesElectricityElectrical resistance and conductance

A composite moving apparatus made substantially of composites may include a plurality of longitudinal conductive electrical pathways extending along a substantial length of the composite moving apparatus, and a plurality of lateral conductive electrical pathways extending along a substantial lateral width of the composite moving apparatus. The longitudinal and lateral conductive electrical pathways may be connected in order to provide redundant electrical pathways extending along a substantial portion of the composite moving apparatus. The redundant electrical pathways may carry return current, carry fault current, provide grounding, carry lightning current, provide electromagnetic shielding, minimize resistance and voltage differential, and / or provide a bleed path for electrostatic charge.

Owner:THE BOEING CO

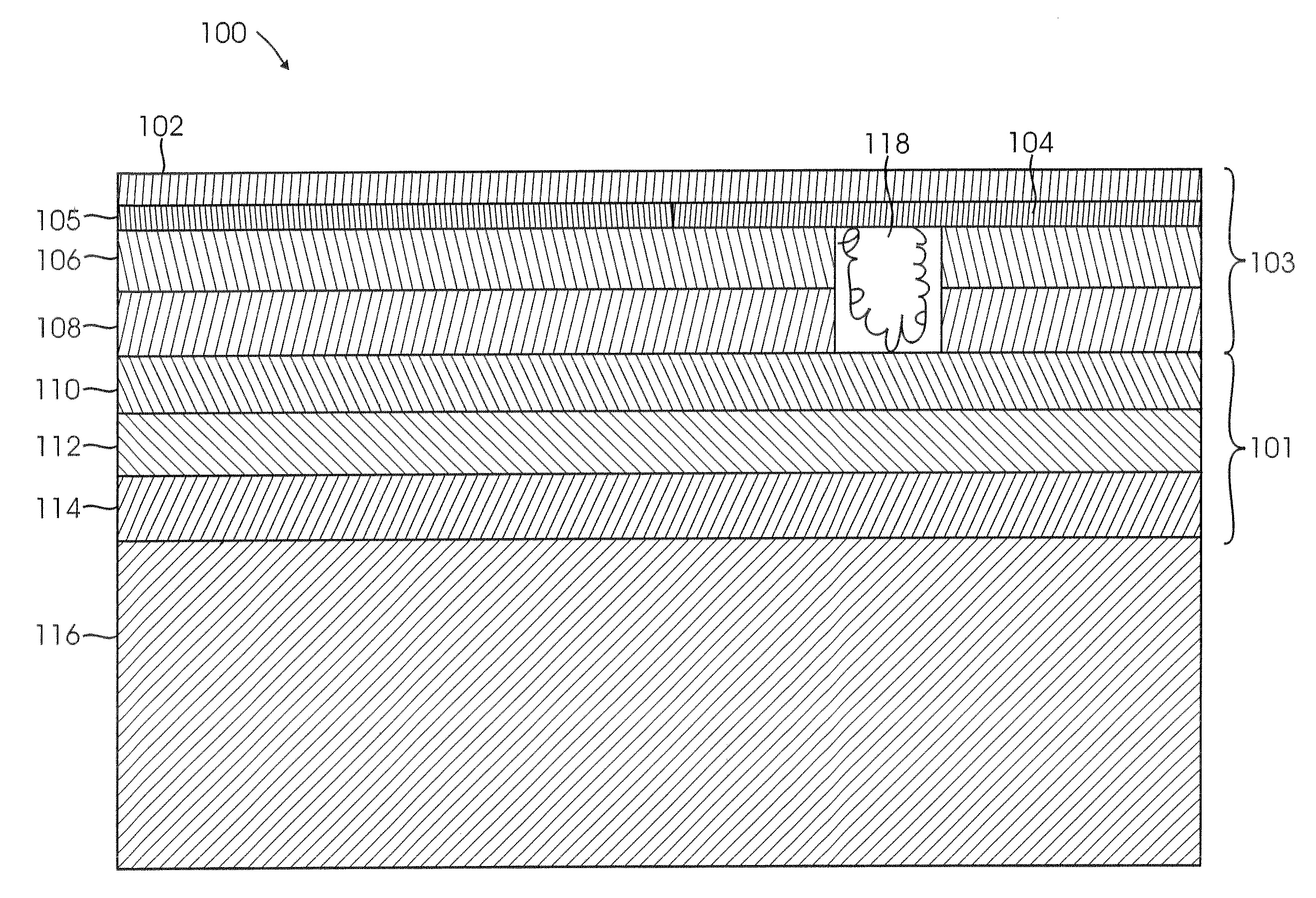

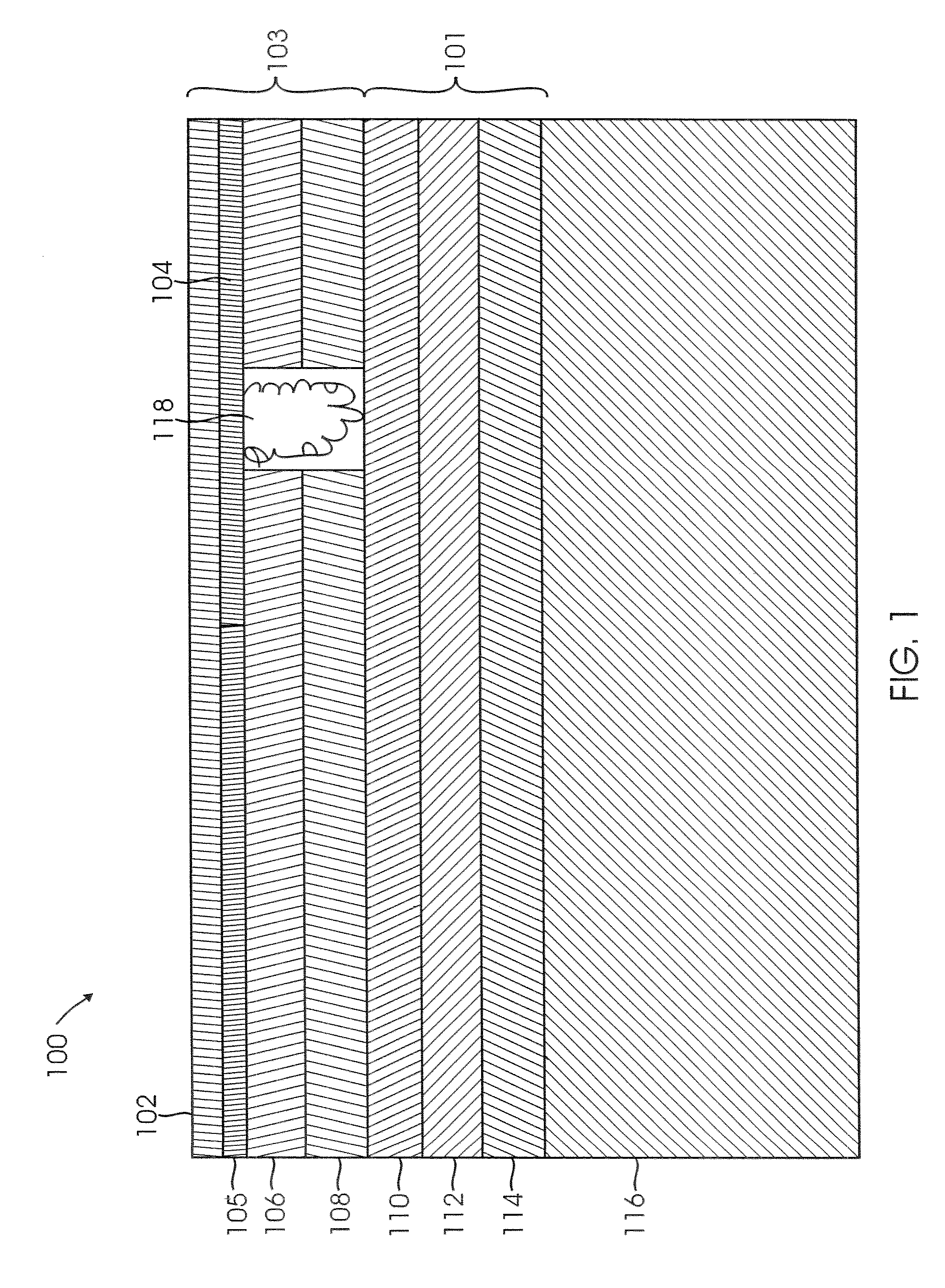

Lightning strike protection method and apparatus

ActiveUS20080144249A1Effective controlImproved and simplified lightning protectionAircraft lighting protectorsEmergency protective arrangement detailsLightning strikeMetal foil

A method and apparatus for implementing a return current network that is external to a composite structure, which directs a current along a known path to the aircraft grounding system using appliqués. The appliqués have a dielectric polymer to isolate the return current from the structure, and a metal foil for conducting the current

Owner:THE BOEING CO

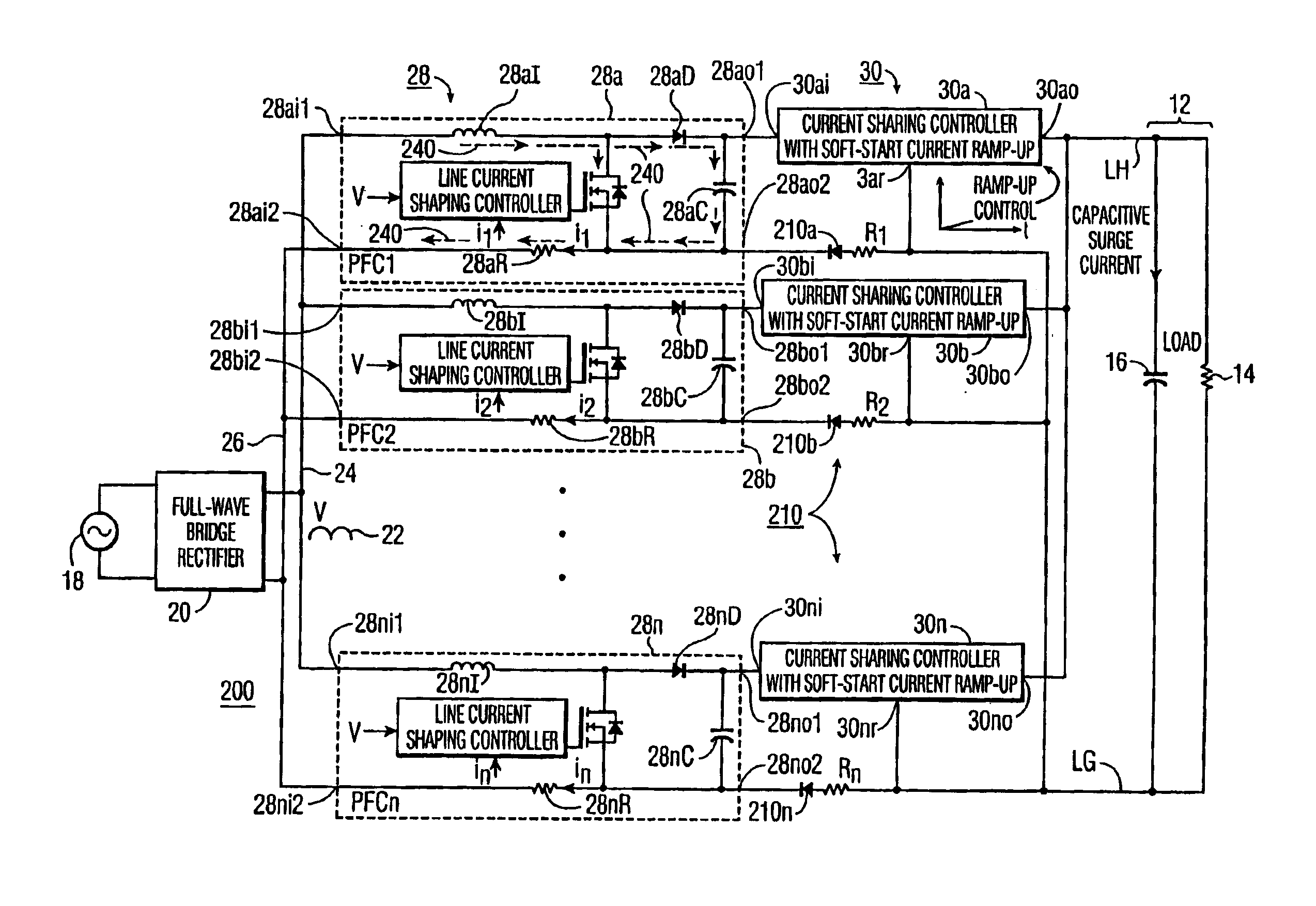

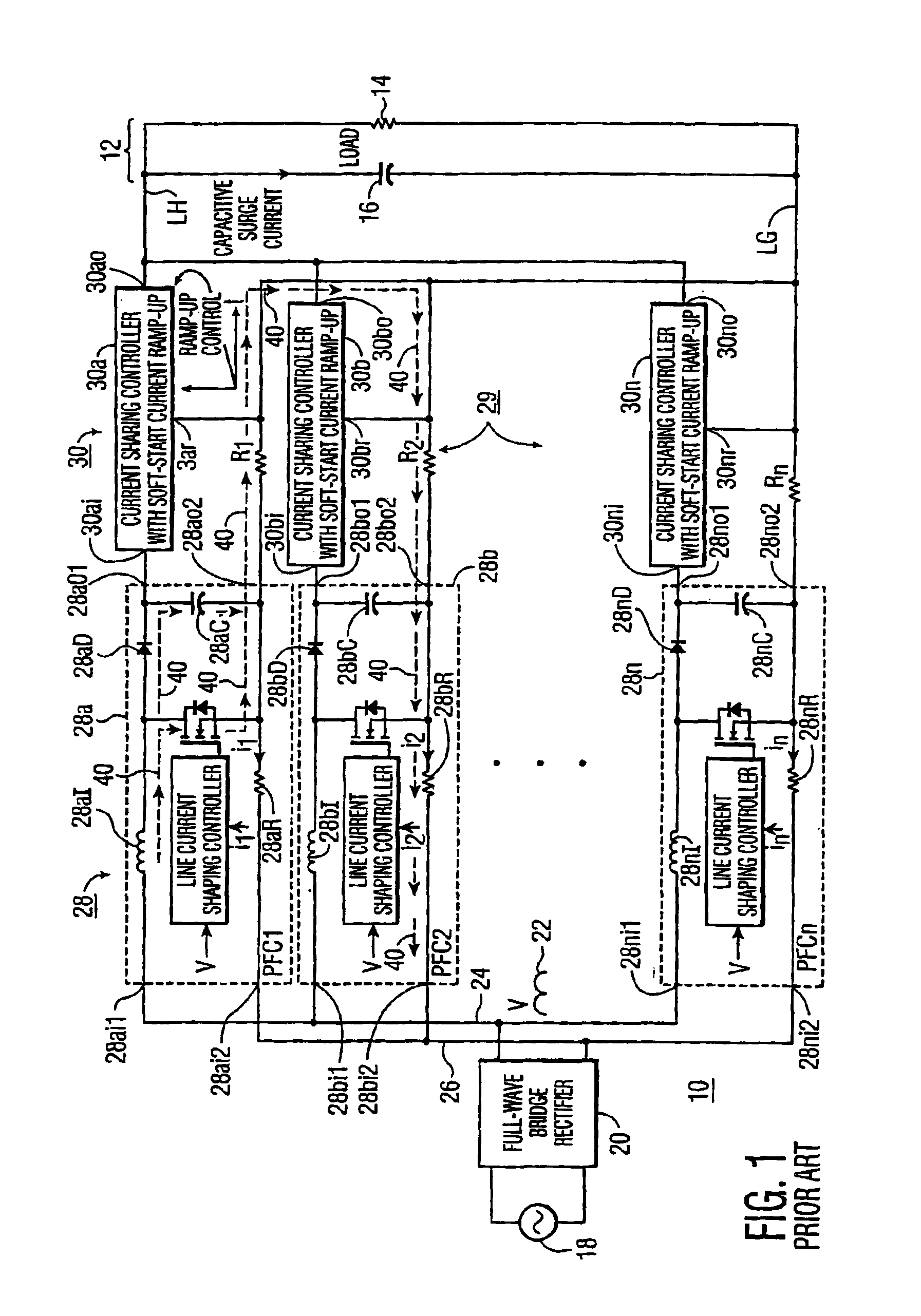

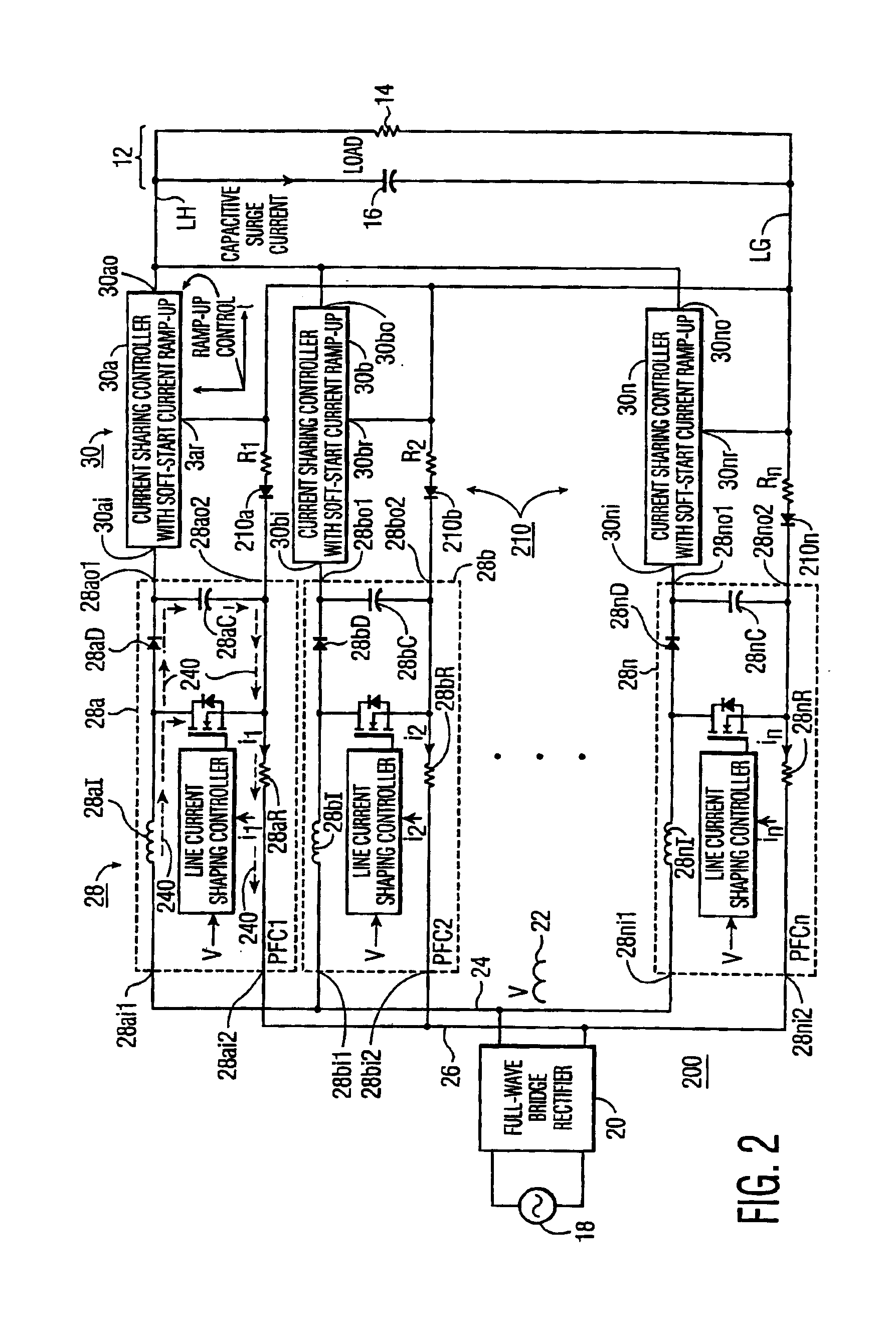

Paralleled power factor correcting AC-to-DC converters with improved current balance

InactiveUS6903946B1Ac-dc conversion without reversalEfficient power electronics conversionCapacitancePhase correction

A power supply for a capacitive-resistive load includes plural paralleled phase correcting modules together with current sharing controllers for tending to equalize their currents. Each module is provided with a diode, poled to prevent forward current from flowing in the return current path, for aiding in equalizing module currents. Surge currents are reduced by a single saturable reactor coupled to the combined outputs of current sharing controllers, thereby avoiding the need for soft-start in each controller. A precharging path extends from a source of pulsating direct voltage to the load, for precharging the load capacitance at turn-on.

Owner:LOCKHEED MARTIN CORP

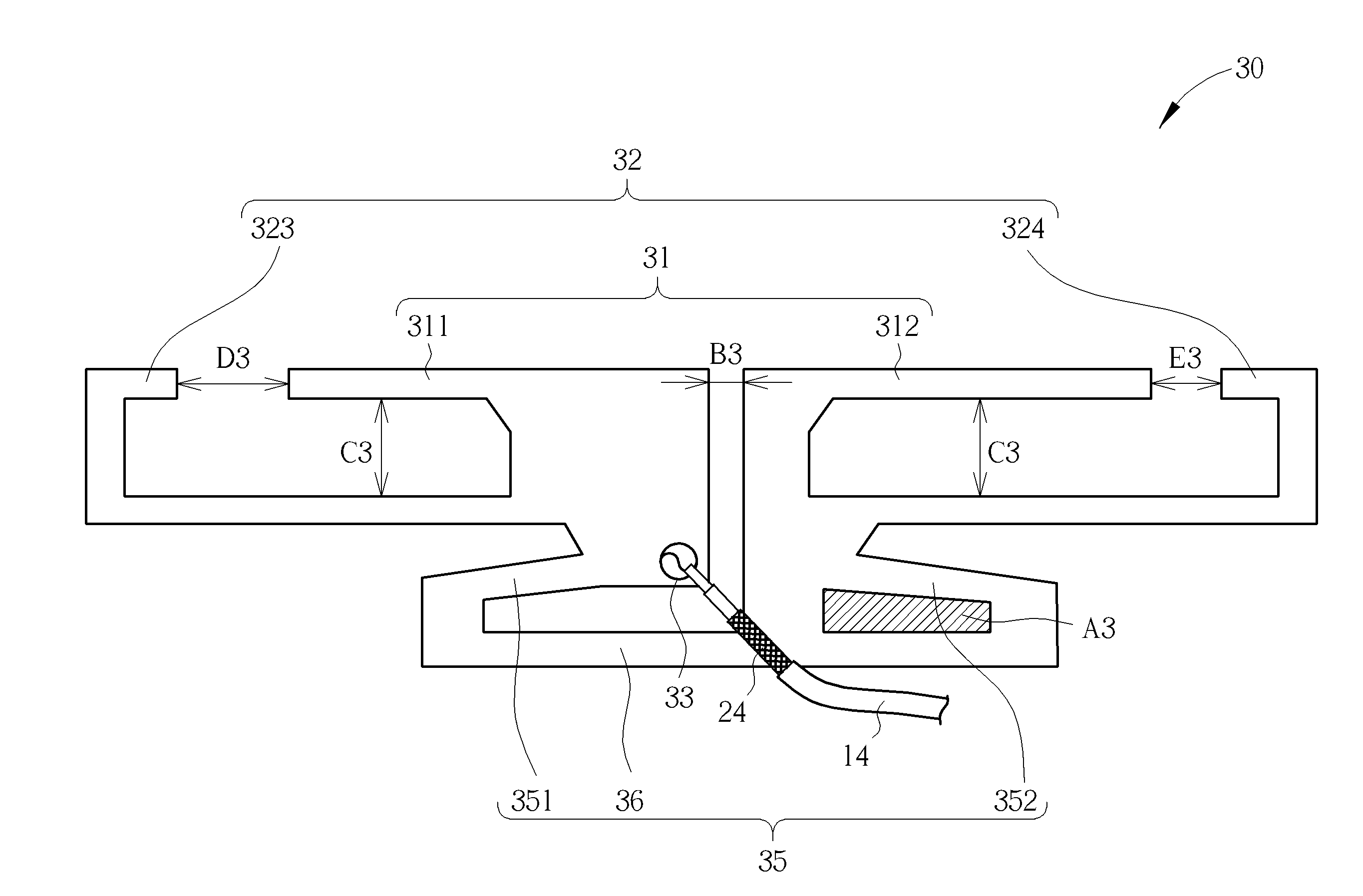

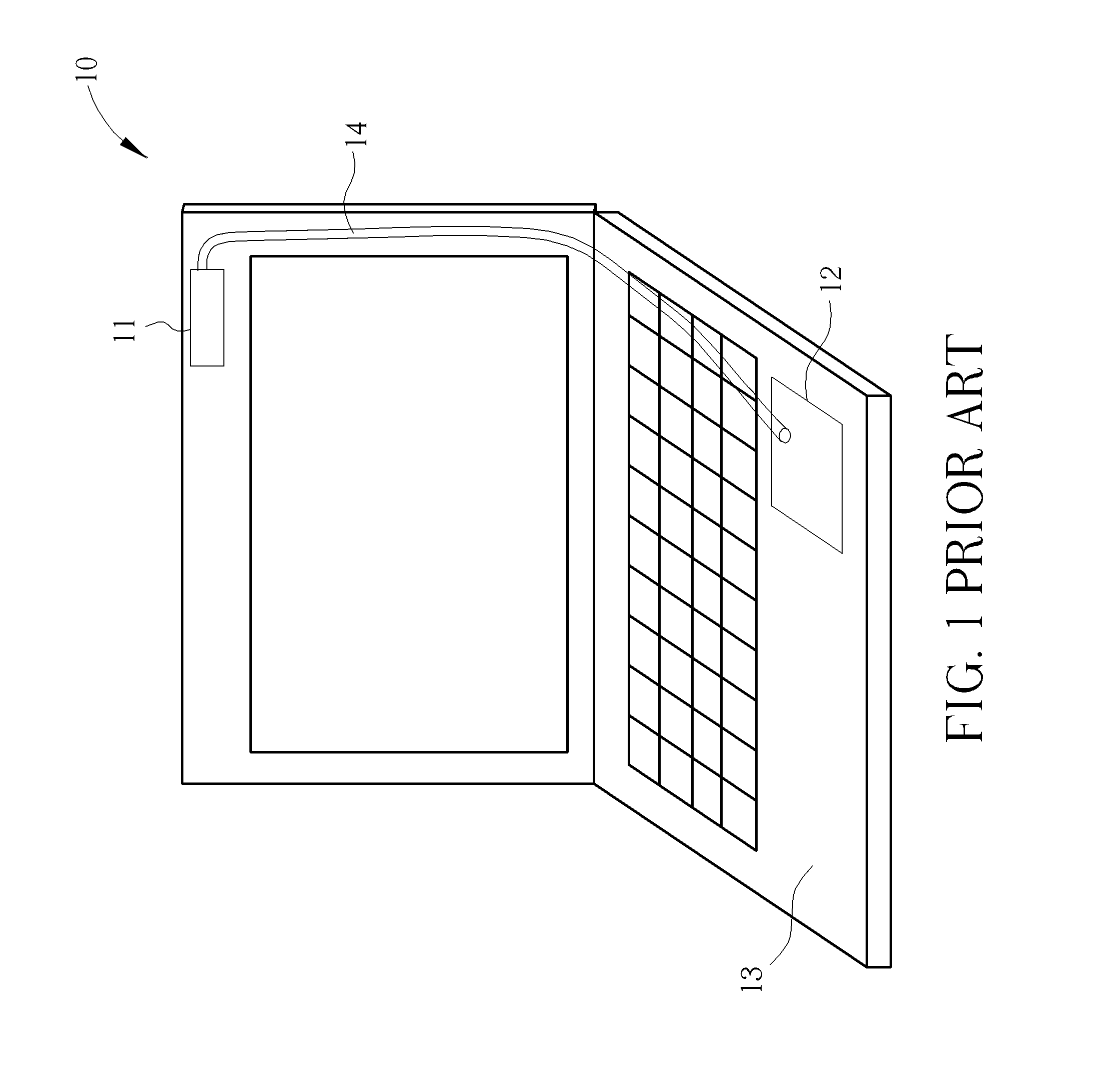

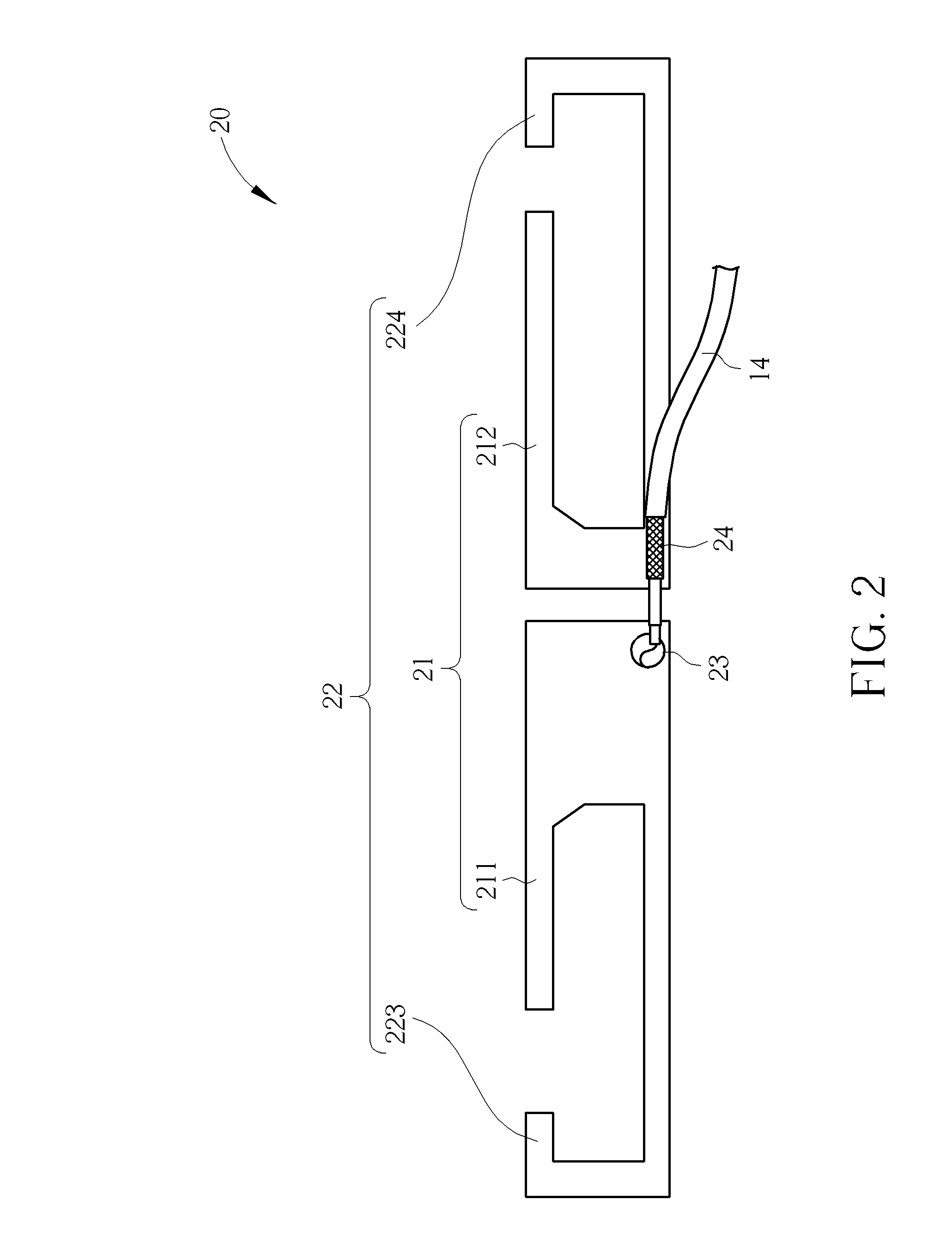

Dipole Antenna and Radio-Frequency Device

ActiveUS20140132469A1Improve antenna performanceBalance feed-in impedanceSimultaneous aerial operationsAntenna feed intermediatesReturn currentRadio frequency signal

A dipole antenna is disclosed. The dipole antenna includes a feed-in terminal, a balun, a first radiator and a second radiator. The feed-in terminal is used for feeding in a radio-frequency signal. The balun is electrically connected to the feed-in terminal for driving out a return current of the dipole antenna to balance a feed-in impedance of the dipole antenna. The first radiator is electrically connected to the feed-in terminal and the balun for radiating the radio-frequency signal in a first frequency band. The second radiator is electrically connected to the first radiator, the feed-in terminal and the balun for radiating the radio-frequency signal in a second frequency band.

Owner:WISTRON NEWEB

Lightning strike protection method and apparatus

ActiveUS7525785B2Effective controlReduce weightAircraft lighting protectorsEmergency protective arrangement detailsLightning strikeMetal foil

A method and apparatus for implementing a return current network that is external to a composite structure, which directs a current along a known path to the aircraft grounding system using appliqués. The appliqués have a dielectric polymer to isolate the return current from the structure, and a metal foil for conducting the current

Owner:THE BOEING CO

Printed wiring board

InactiveUS6937480B2Radiation suppressionHigh densityMagnetic/electric field screeningCross-talk/noise/interference reductionReturn currentEngineering

A printed wiring board is provided which can be applied even to circuit boards operating at high speed, and which can suppress electromagnetic wave radiation, and which can suppress a deterioration in density of mounting. At the printed wiring board, a first signal wire layer, a first ground layer having a first power source wire, a second ground layer having a second power source wire, and a second signal wire layer, are laminated. The first ground layer and the second ground layer are interlayer connected by many via holes. Return current, of signal current flowing through a signal wire, flows in the first ground layer, and a path of the return current is cut midway therealong at a position of the first power source wire. However, the return current is detoured by the via hole to the second ground layer, and flows thereat.

Owner:FUJIFILM BUSINESS INNOVATION CORP

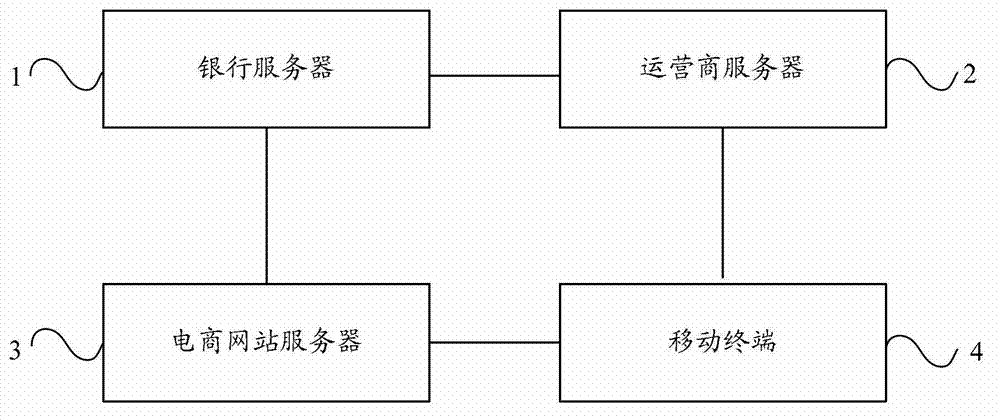

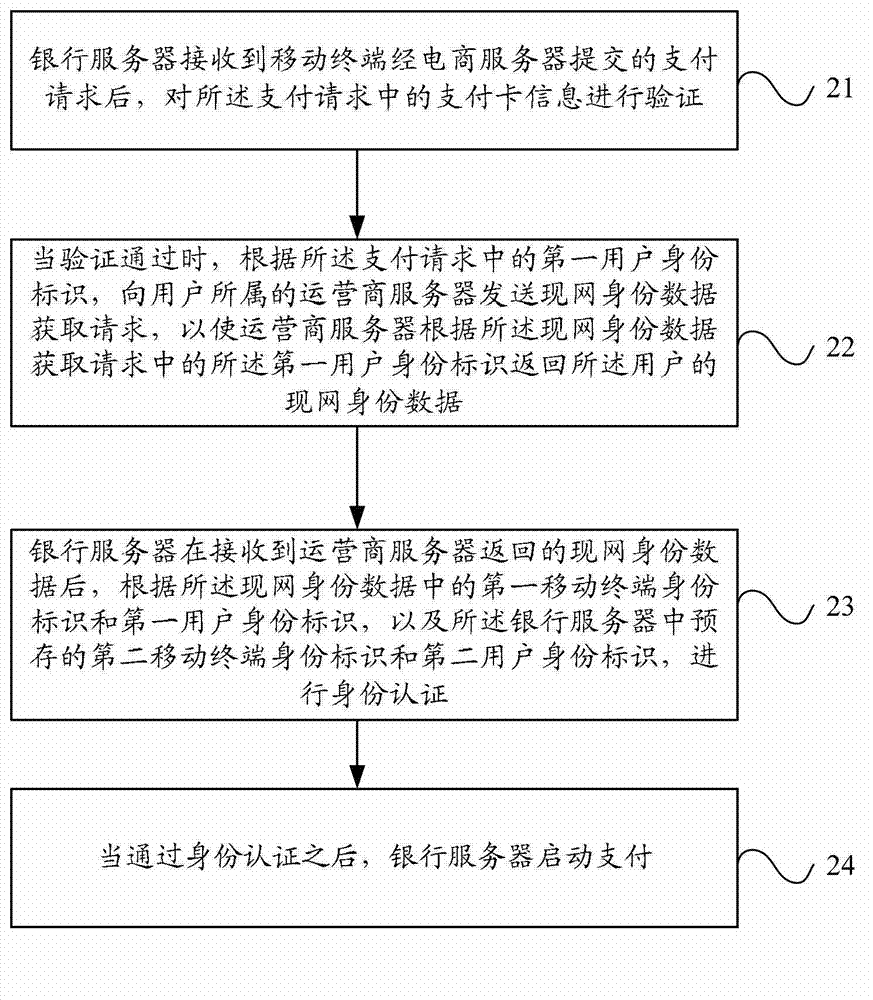

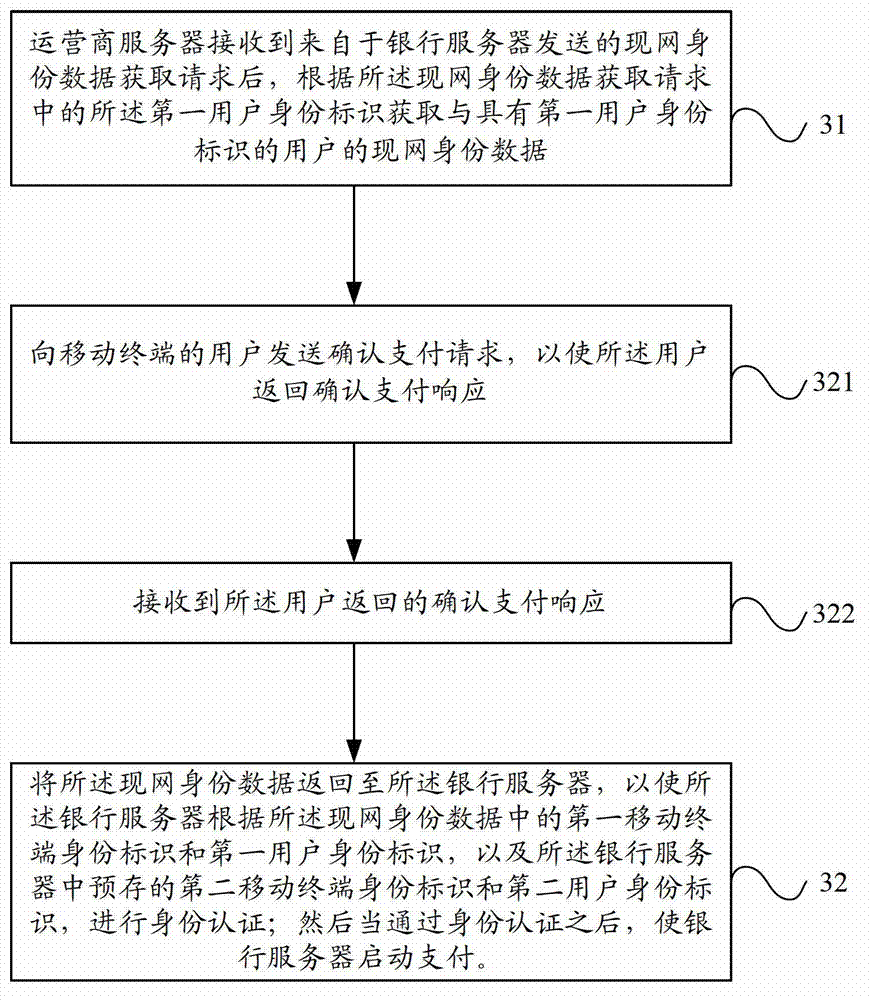

Authentication method and system for mobile payment

InactiveCN102930435AEnsure safetyUser identity/authority verificationProtocol authorisationReturn currentData acquisition

The invention provides an authentication method and an authentication system for mobile payment. The method comprises the following steps of: after a payment request submitted by an E-commerce server to a mobile terminal is received, checking payment card information in the payment request; after passing the checking, sending a current network identification data acquisition request to an operator server to which a user belongs according to a first user identification label in the payment request to ensure that the operator server can return current network identification data according to the first user identification label in the current network identification data acquisition request; after the current network identification data returned by the operator server is received, authenticating the identification according to a first mobile terminal identification label and a first user identification label in the current network identification data and a second mobile terminal identification label and a second user identification label which are prestored in a bank server; and after passing the identification authentication, starting paying. According to the method, identification is checked based on the current network identification data, so that the safety of mobile payment is guaranteed.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

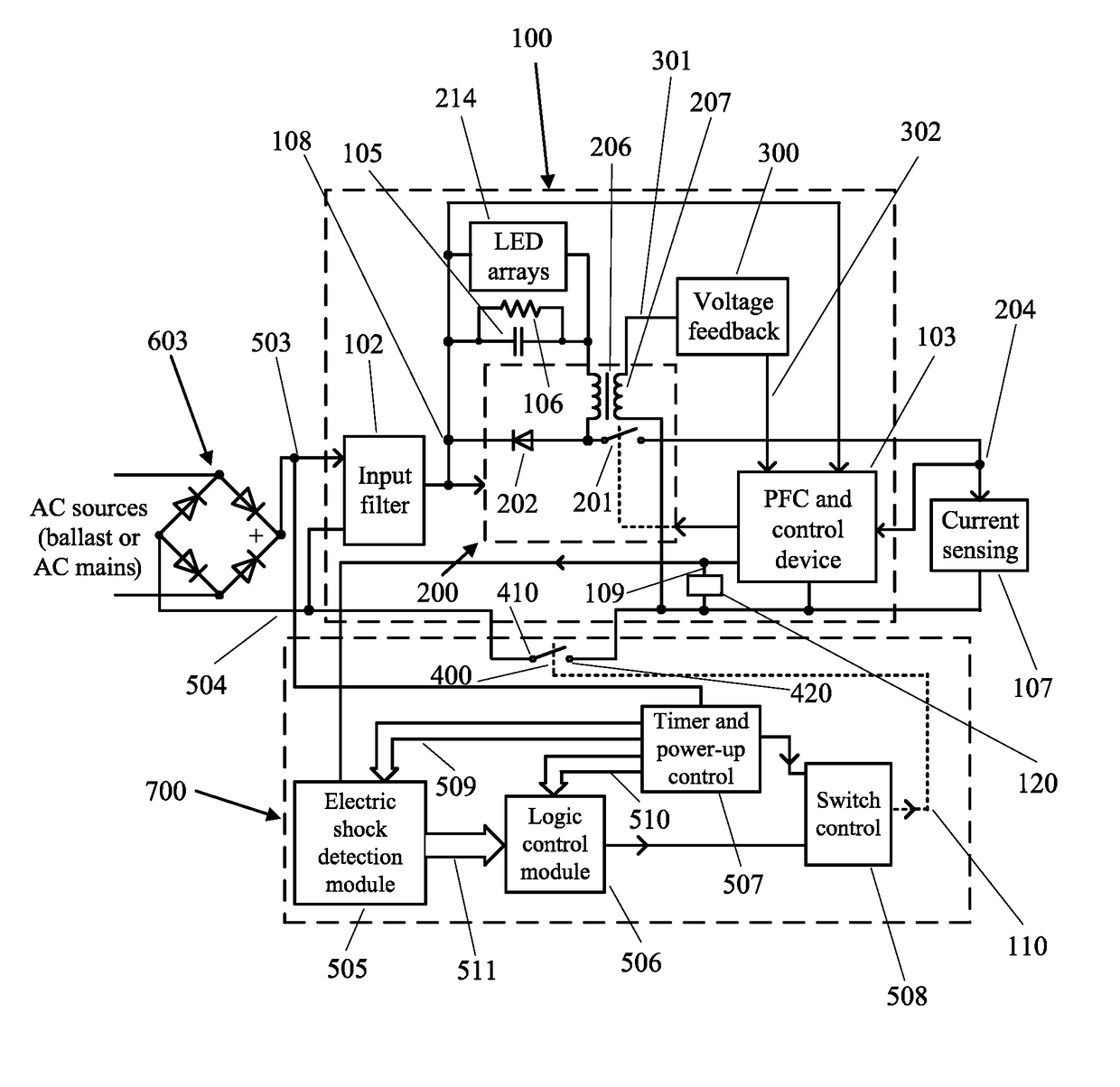

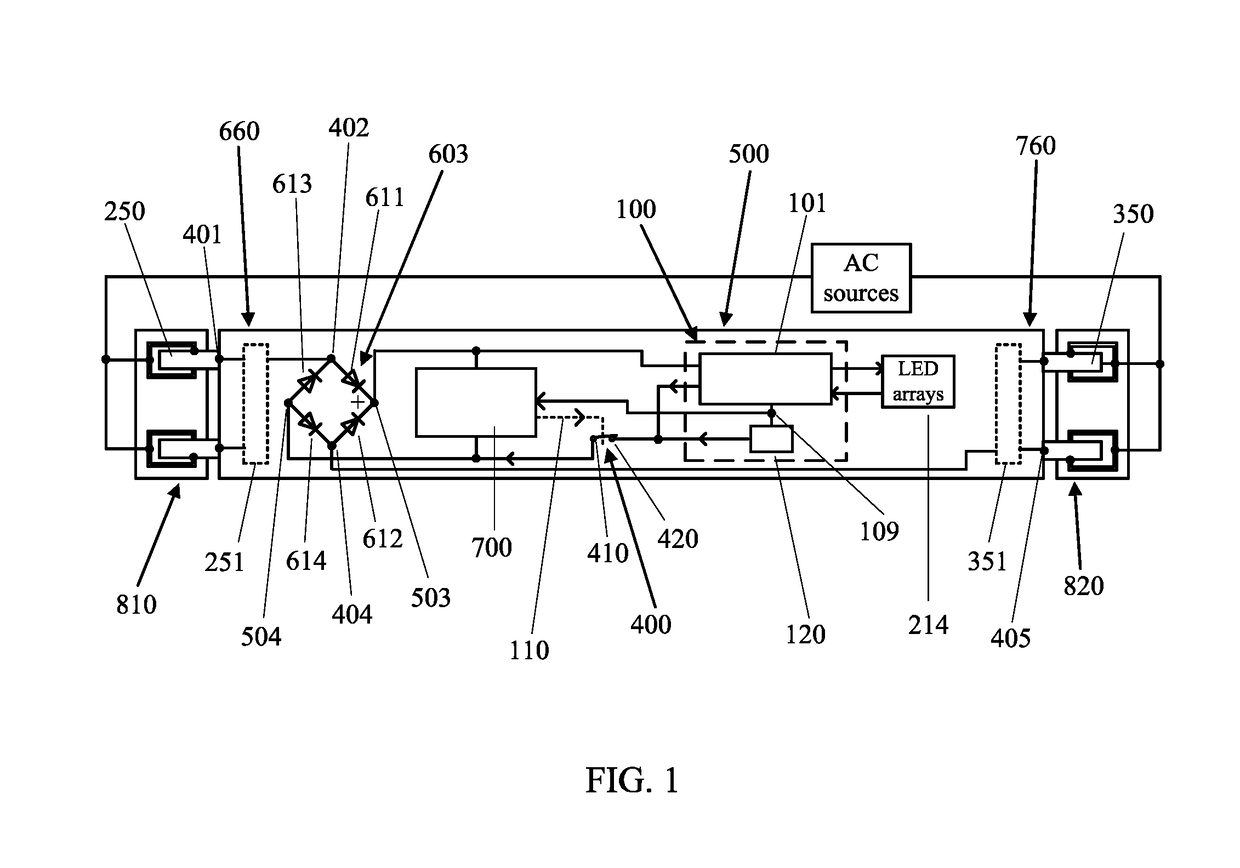

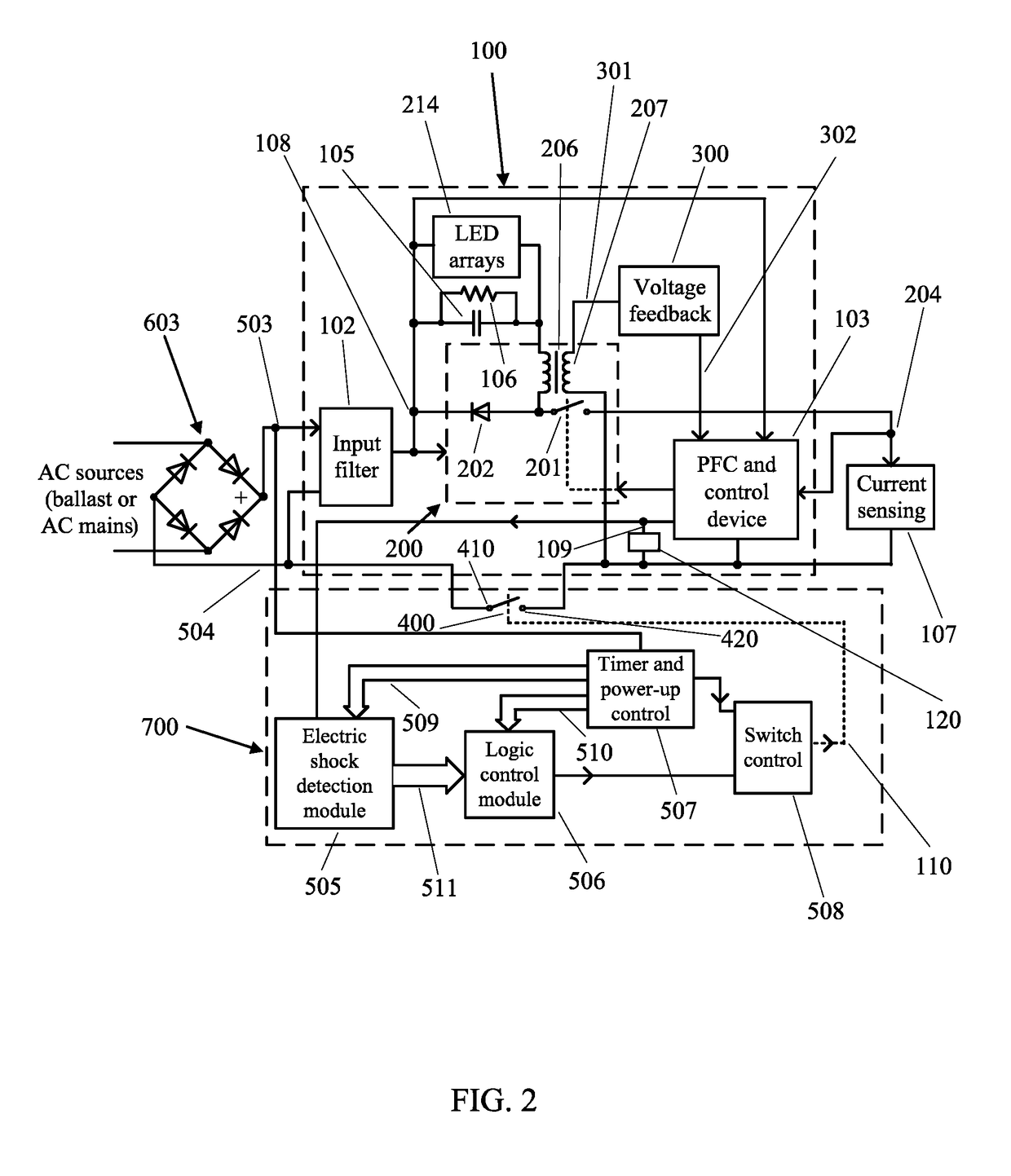

Linear Solid-State Lighting With Electric Shock Prevention

ActiveUS20170311397A1Efficiently provideEasy to controlEfficient power electronics conversionElectroluminescent light sourcesReturn currentLed array

A linear light-emitting diode (LED)-based solid-state lamp comprises an LED driving circuit, LED arrays, at least one rectifier, and an electric current flow control module. The LED driving circuit comprises a control loop compensation device with a control loop correction signal to precisely control an electric current to flow into the LED arrays. The electric current flow control module uses the control loop correction signal in a way that it detects and determines if the linear LED-based solid-state lamp is operated in a normal mode or in an electric shock hazard mode. When an electric shock hazard is identified, the electric current flow control module shuts off a return current flow from the LED arrays to reach the at least one rectifier, thus eliminating an overall through-lamp electric shock current. The scheme can effectively prevent a through-lamp electric shock from occurring during relamping or maintenance.

Owner:ALEDDRA INC

Apparatus for producing voltage and current pulses

Owner:LOS ALAMOS NATIONAL SECURITY

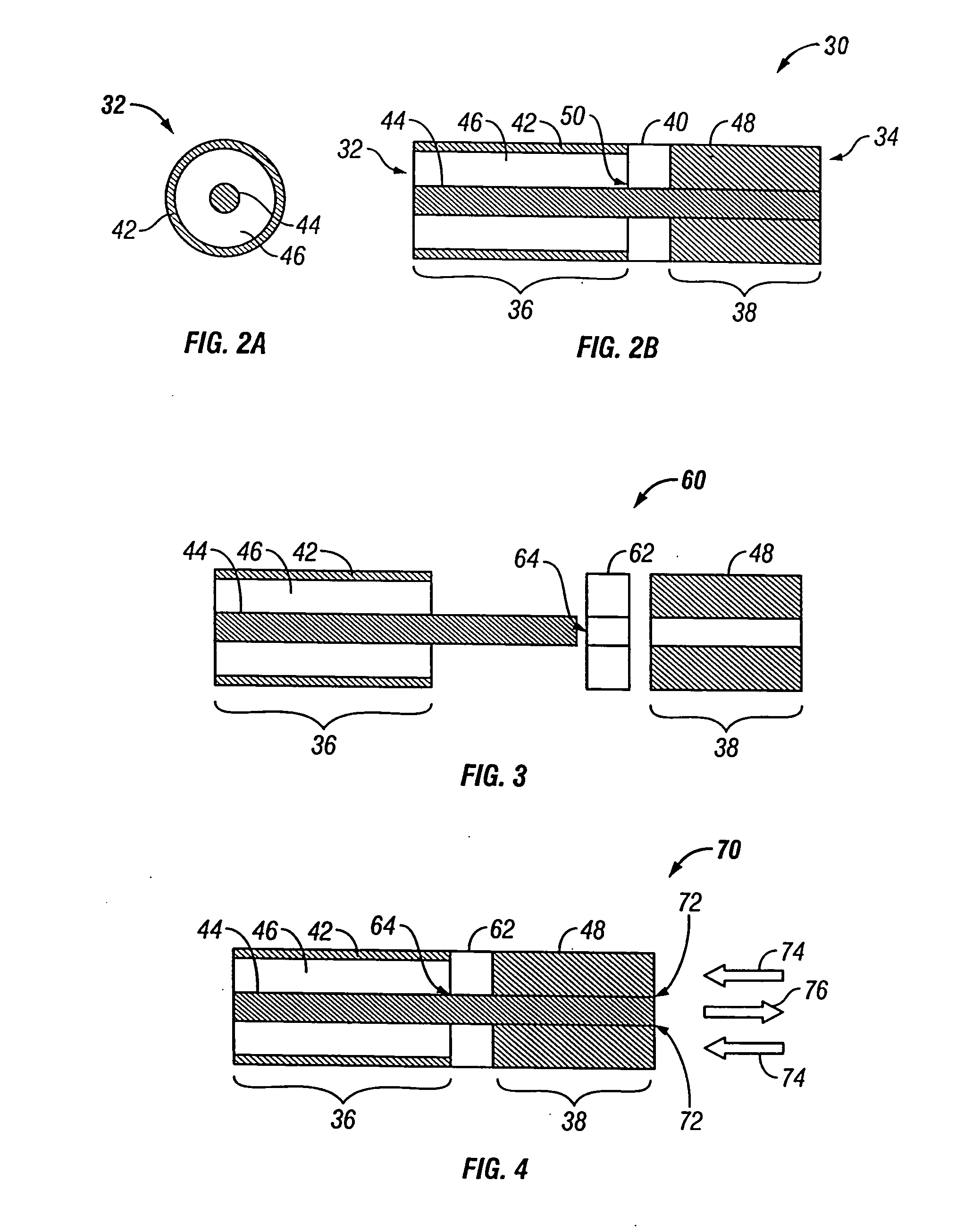

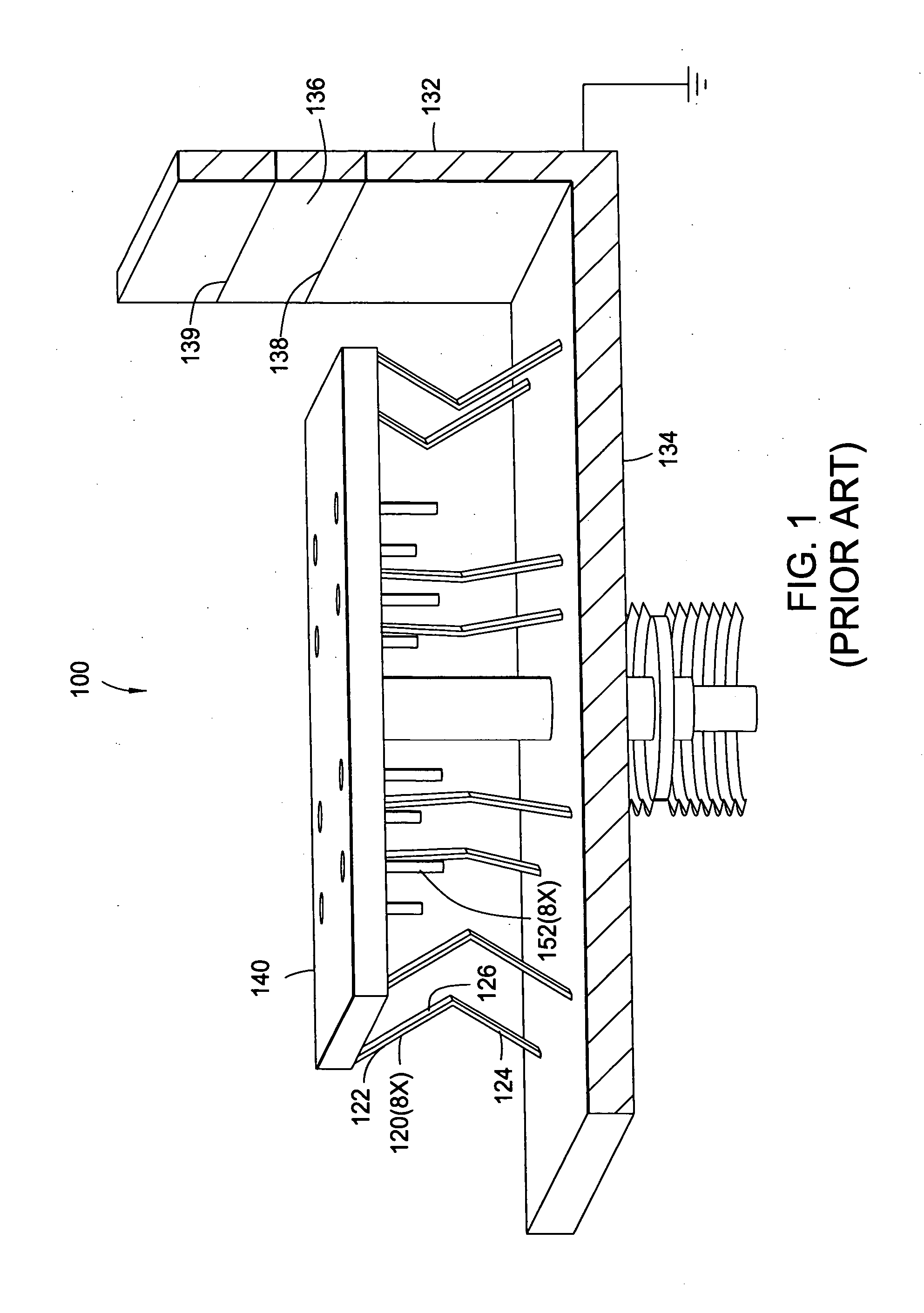

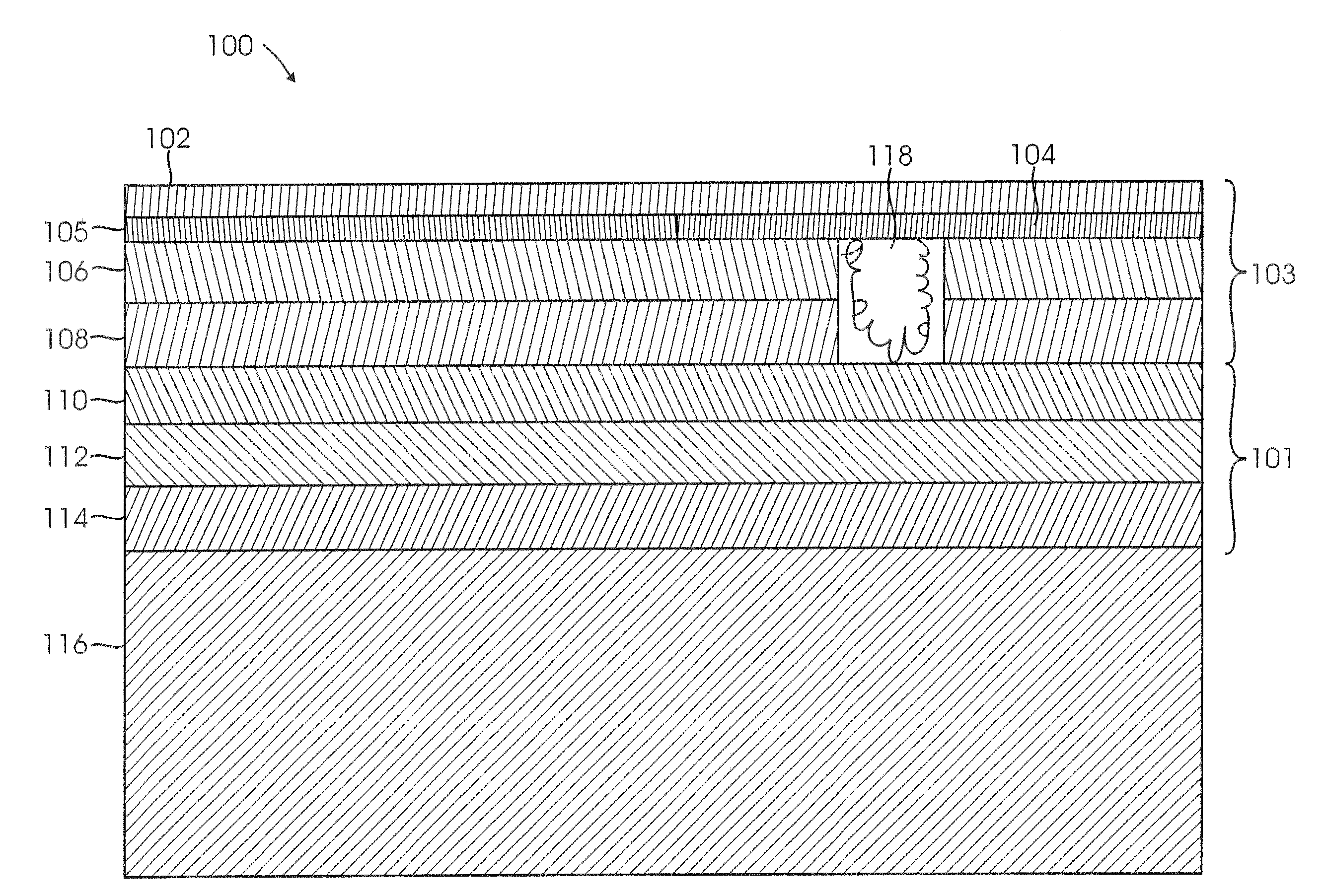

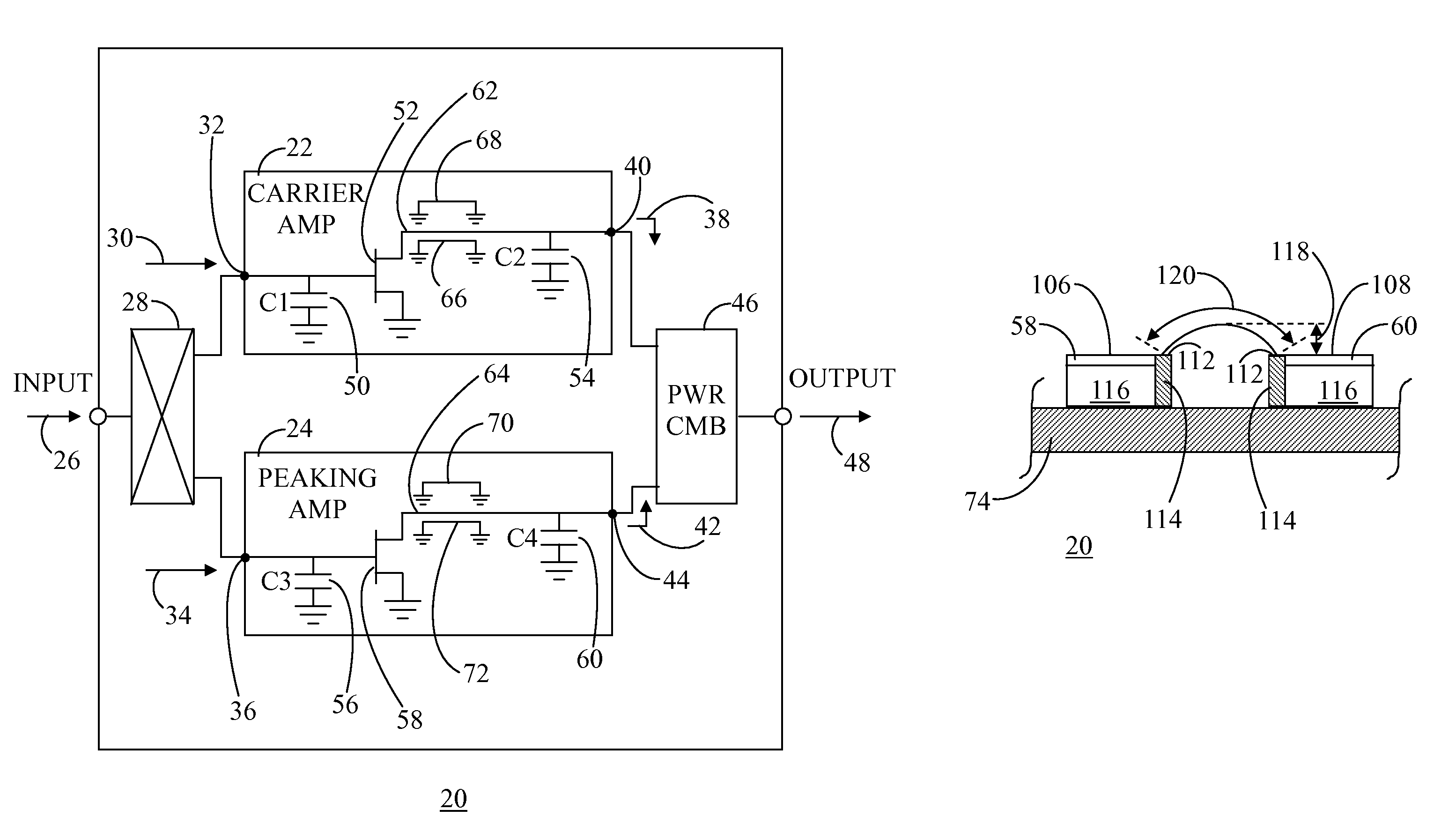

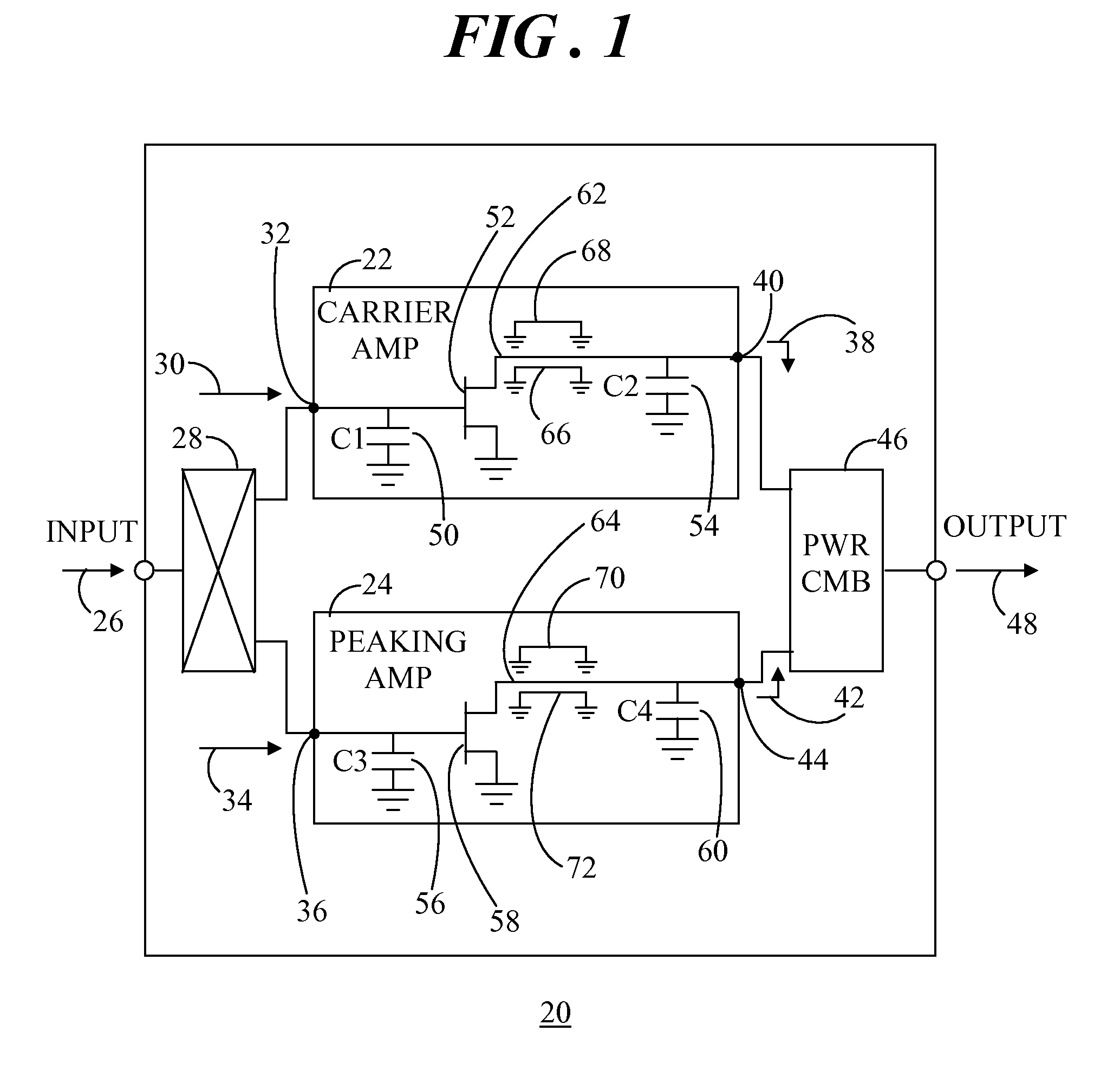

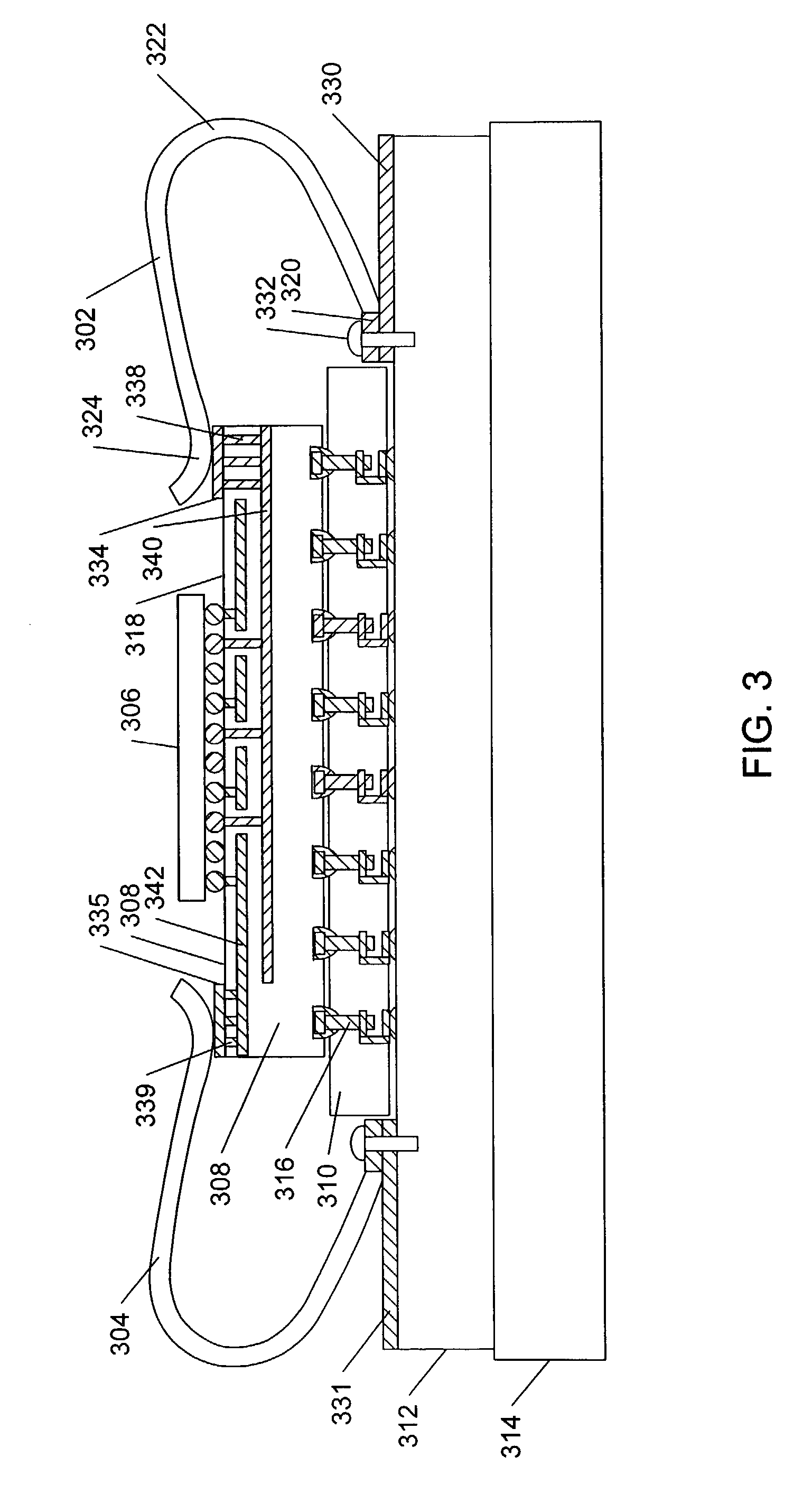

Semiconductor package with reduced inductive coupling between adjacent bondwire arrays

ActiveUS8030763B2Semiconductor/solid-state device detailsSolid-state devicesPower flowReturn current

A semiconductor package (20) includes circuits (22, 24). The circuit (22) includes electrical devices (52, 54) interconnected by a bondwire array (62). Likewise, the circuit (24) includes electrical devices (58, 60) interconnected by a bondwire array (64). Signal wires (76) of the bondwire array (62) are proximate to signal wires (78) of the bondwire array (64). Ground wires (66, 68) are located on either side of, and close to, bondwire array (62). Ground wires (70, 72) are located on either side of, and close to, bondwire array (64). The ground wires (66, 68, 70,72) are electrically coupled to a ground region (74). The ground wires (66, 68, 70, 72) reduce a magnetic flux density (140) via induced return currents (126, 130) on the ground wires of opposite polarity to signal currents (124, 128) on the bondwire arrays (62, 64) to reduce inductive coupling between the adjacent bondwire arrays (62, 64).

Owner:NXP USA INC

Construction method for mine shaft through multilayer goaf

ActiveCN102071940AShorten the construction periodCompletely closedUnderground miningSurface miningSpontaneous combustionBedrock

The invention particularly discloses a construction method for a mine shaft through multilayer goaf, which solves the problem of blankness of the construction method for the conventional mine shaft through goaf. The method comprises the following steps that: 1) the ground and the underground space of the goaf are detected; 2) mechanical analysis is performed on a rock stratum of the goaf; 3) a goaf filling range and filler mechanical property are determined; 4) bedrock is tunneled; 5) a related underground chamber which is integrally connected with a shaft is constructed; and 6) the goaf is filled and reinforced. The construction method fills the blank of the construction method for the shaft through goaf; back filling injection, filling and reinforcing technology is used during the construction of a through goaf of a vertical shaft; the construction method has an advanced, economic and rational technology; the goaf can be completely closed; return current is prevented from entering the goaf, so a coal seam of the goaf has a tendency to spontaneous combustion; thus safe and reliable use of the shaft is guaranteed.

Owner:DATONG COAL MINE GRP

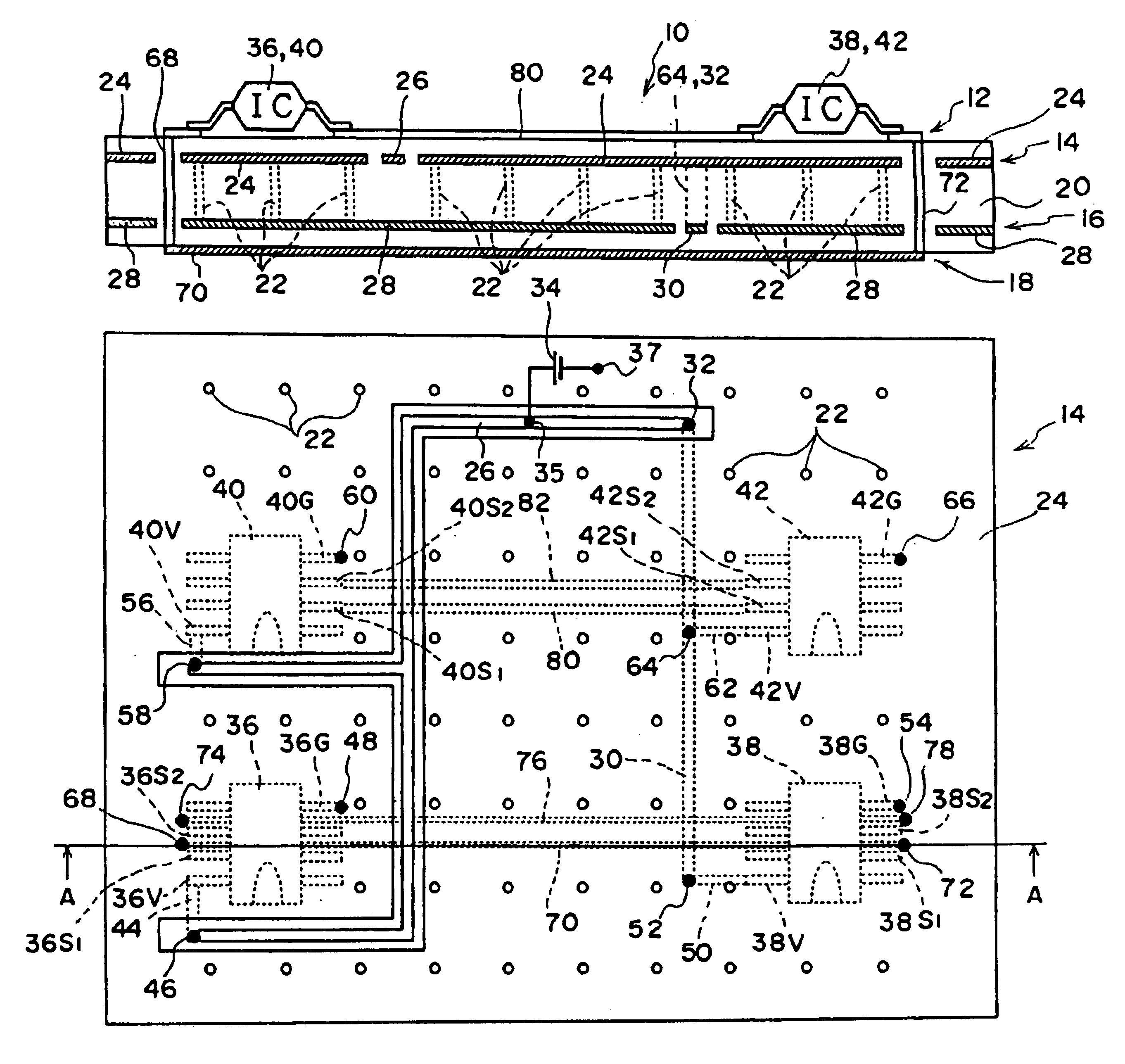

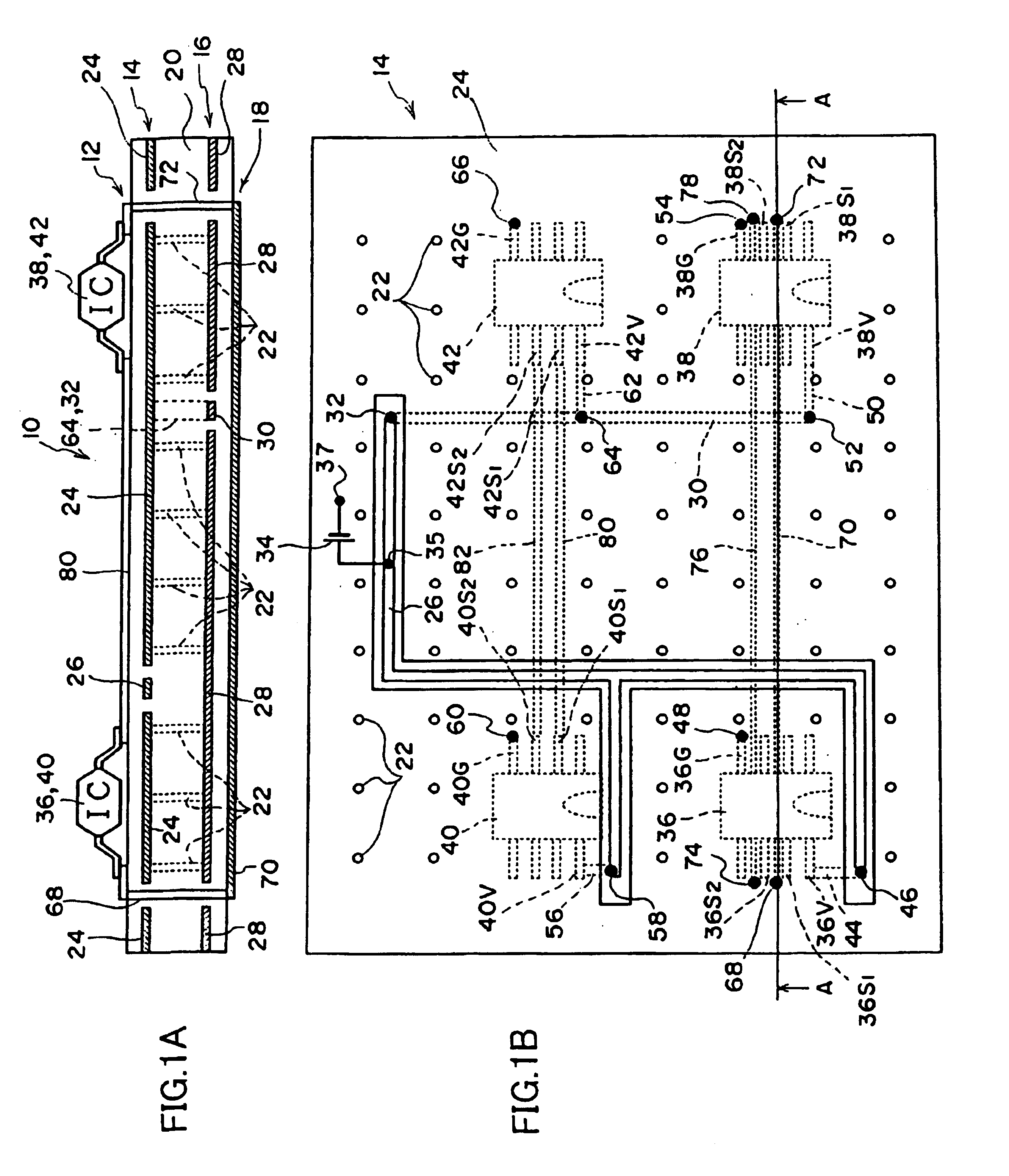

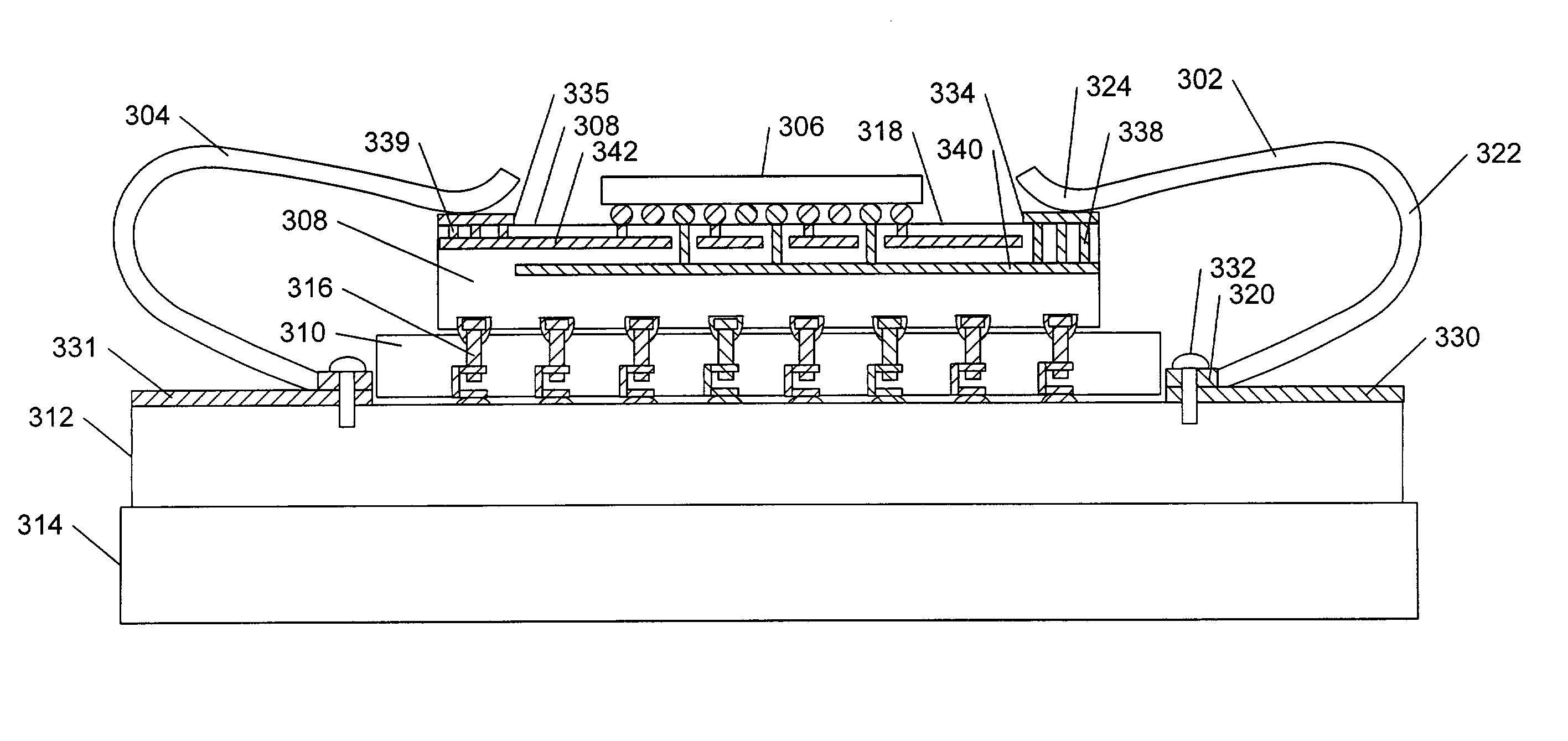

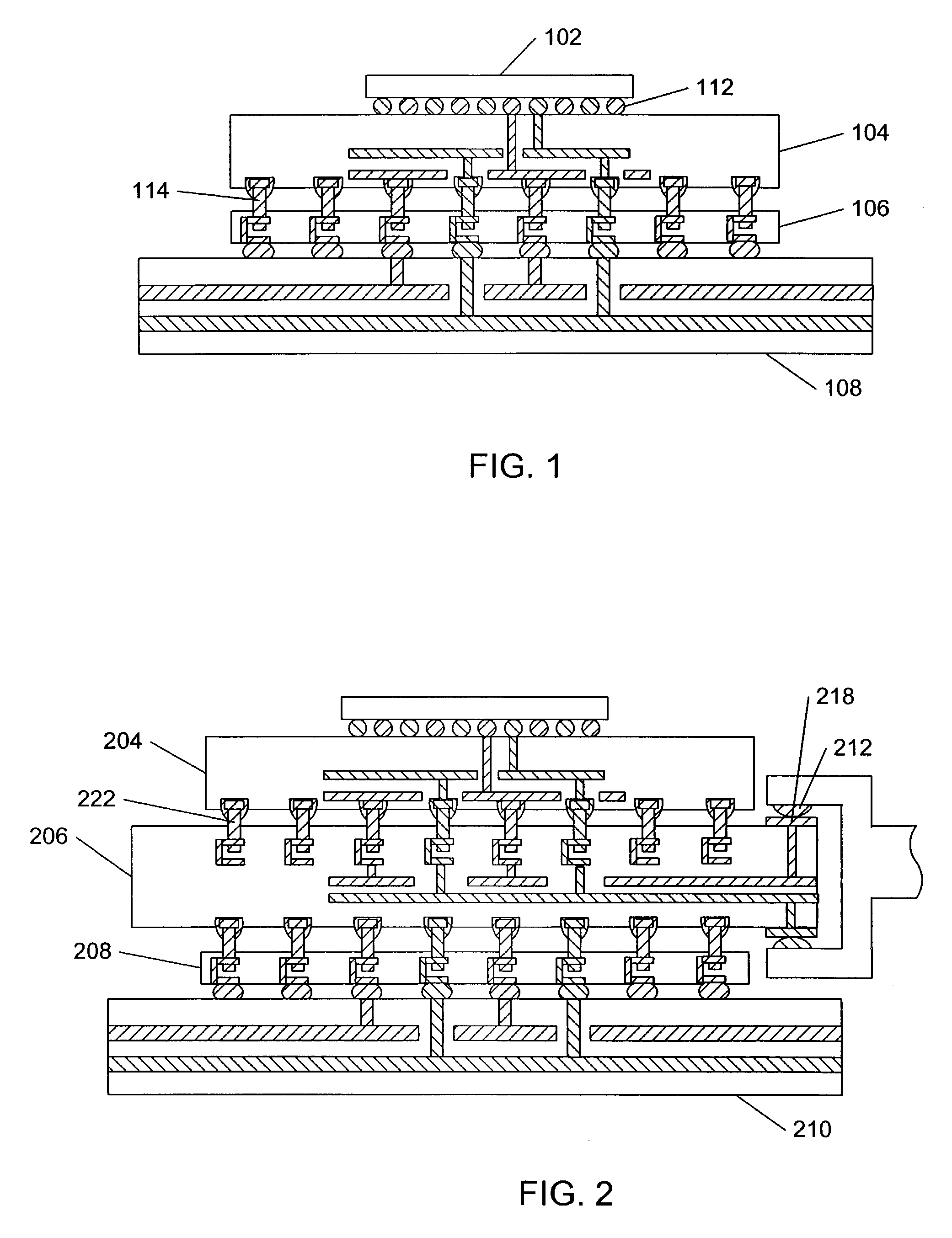

Printed circuit board housing clamp

InactiveUS6975518B2Printed circuit assemblingPrinted electric component incorporationContact padReturn current

An electronic assembly includes one or more conductive clamps (302, 304, FIG. 3), which are used to supply current to an integrated circuit (IC) package (308). The conductive clamps are attached to a printed circuit (PC) board (312), which supplies the current to the IC package over one clamp, and receives returned current from the IC package over another clamp. Each clamp contacts a contact pad (330) on the surface of the PC board, and contacts another contact pad (334) on the top surface of the IC package. Vias (338, 339) and conductive planes (340, 342) within the package then carry current to and from an IC (e.g., IC 306) connected to the package. In another embodiment, the clamp (904, FIG. 9) holds a conductive structure (902) in place between the PC board contact pad (908) and the IC package contact pad (914), and current is carried primarily over the conductive structure, rather than over the clamp.

Owner:INTEL CORP

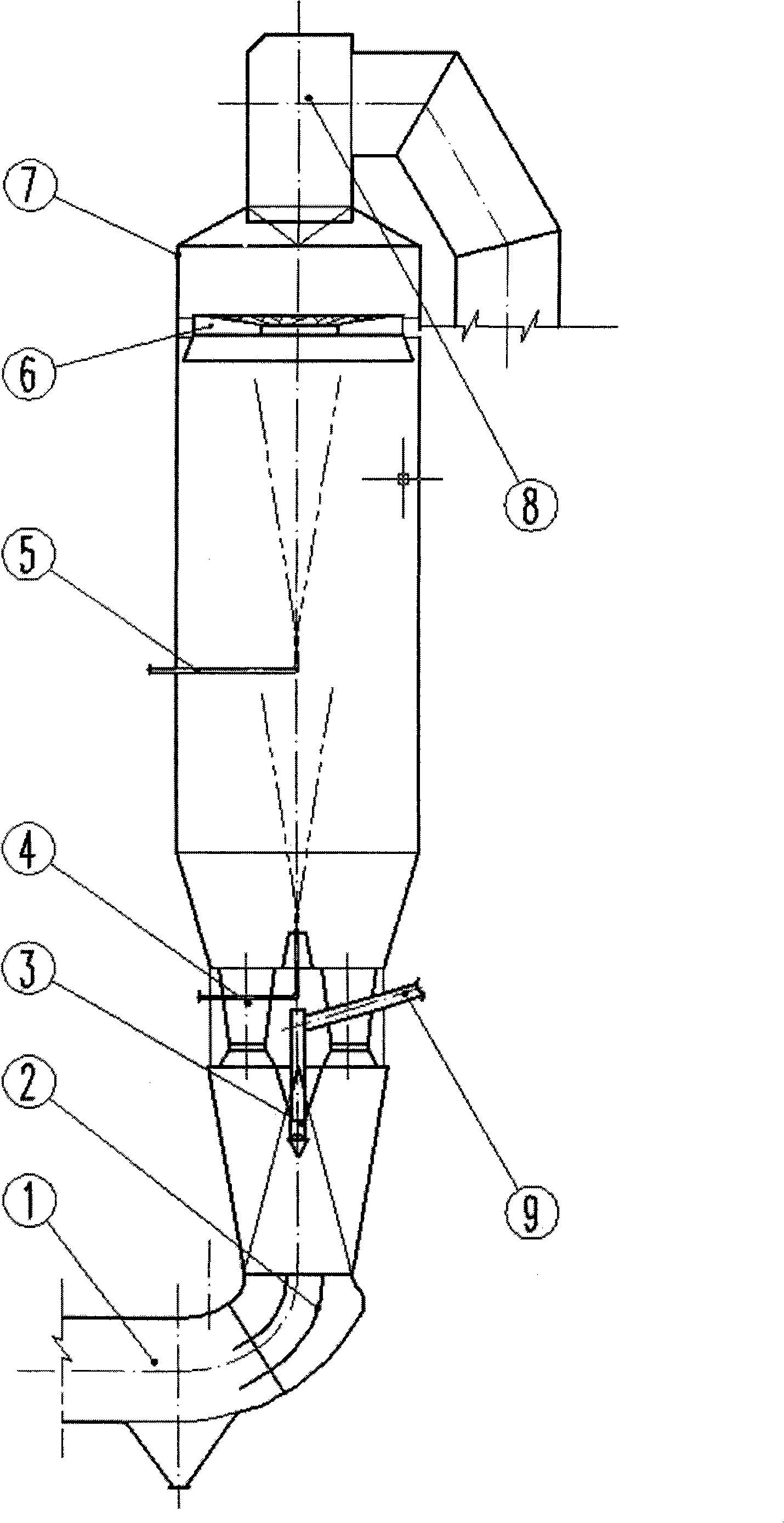

Flue gas desulfurization technique of return current circulating fluidized bed in flow equalizing field

InactiveCN101402019AGood effectIncrease cycle ratioGas treatmentDispersed particle separationRefluxReturn current

The invention relates to a flue gas desulfurization technology for a uniform flow field internal reflux circulating fluidized bed. Core equipment, namely a reactor, of the flue gas desulfurization technology comprises a direct-current streamline bottom air inlet, a guide plate, a central built-in absorbent distributor, a flue gas accelerator, a humidified activated nozzle, a rotating-stream tray gas-solid separator and a central outlet flue on the upper part of a cylinder body of the reactor form the bottom up in turn, wherein the inside of an inlet flue of the reactor is provided with a dual-chip circular uniform flue gas distribution guide plate; and the inside of the reactor is provided with the central built-in absorbent distributor, the 'Laval nozzle' - type flue gas accelerator, thetwo-stage double-fluid humidified activated nozzle and the rotating-stream tray gas-solid separator. The flue gas desulfurization technology is reasonable in configuration; flue gas in the reactor obtains ideal and stable uniform fluid field and temperature field; an absorbent obtains high circulation ratio and high utilization rate; and two-stage humidification can effectively improve the reaction activity of the absorbent, and can also effectively avoid wetted wall, fouling and collapsed bed. Moreover, the flue gas desulfurization technology guarantees the desulfurization efficiency, obviously reduces the dust content of the outlet flue, greatly lightens the load of a rear bag-type duster, and solves the technical problems in a flue gas desulfurization technology for a semi-dry circulating fluidized bed.

Owner:北京联合拓展科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com