Structural insulated panel construction for building structures

a technology of structural insulation and construction panels, applied in the direction of synthetic resin layered products, chemistry apparatuses and processes, other domestic articles, etc., can solve the problems of insufficient insulation, heavy machinery is required for manipulation and installation, and is difficult to manipulate, etc., to achieve high wind resistance, easy assembly, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

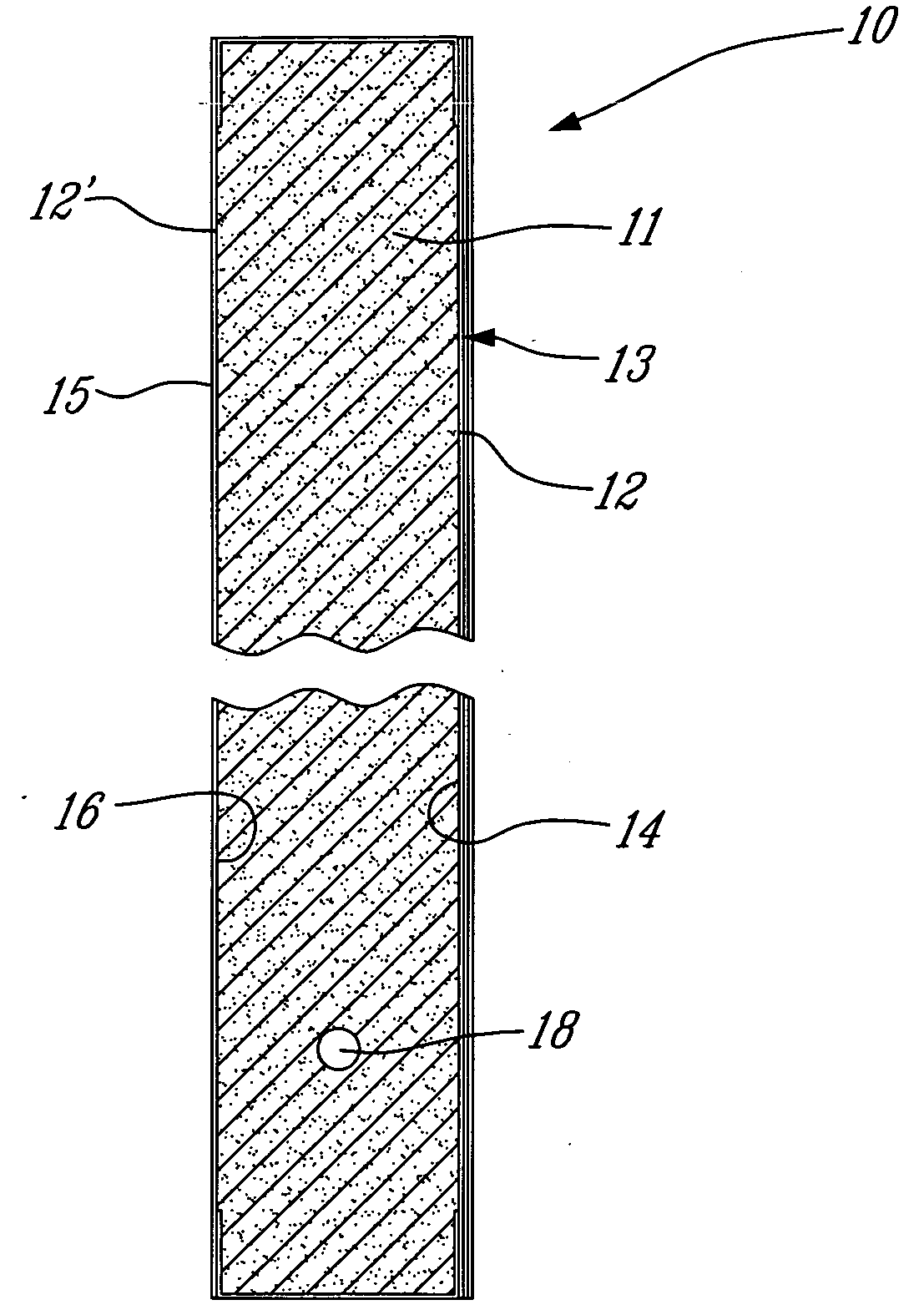

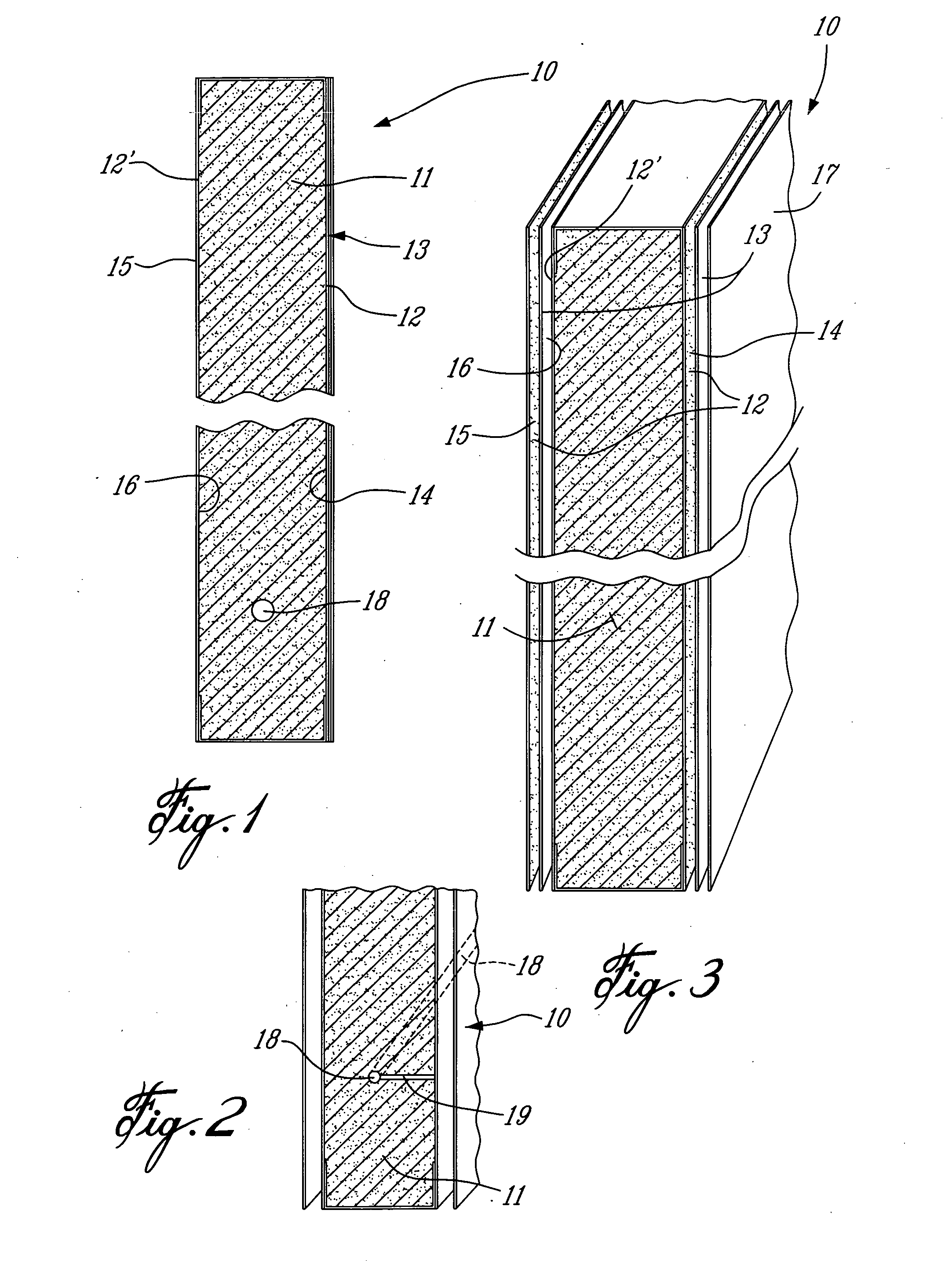

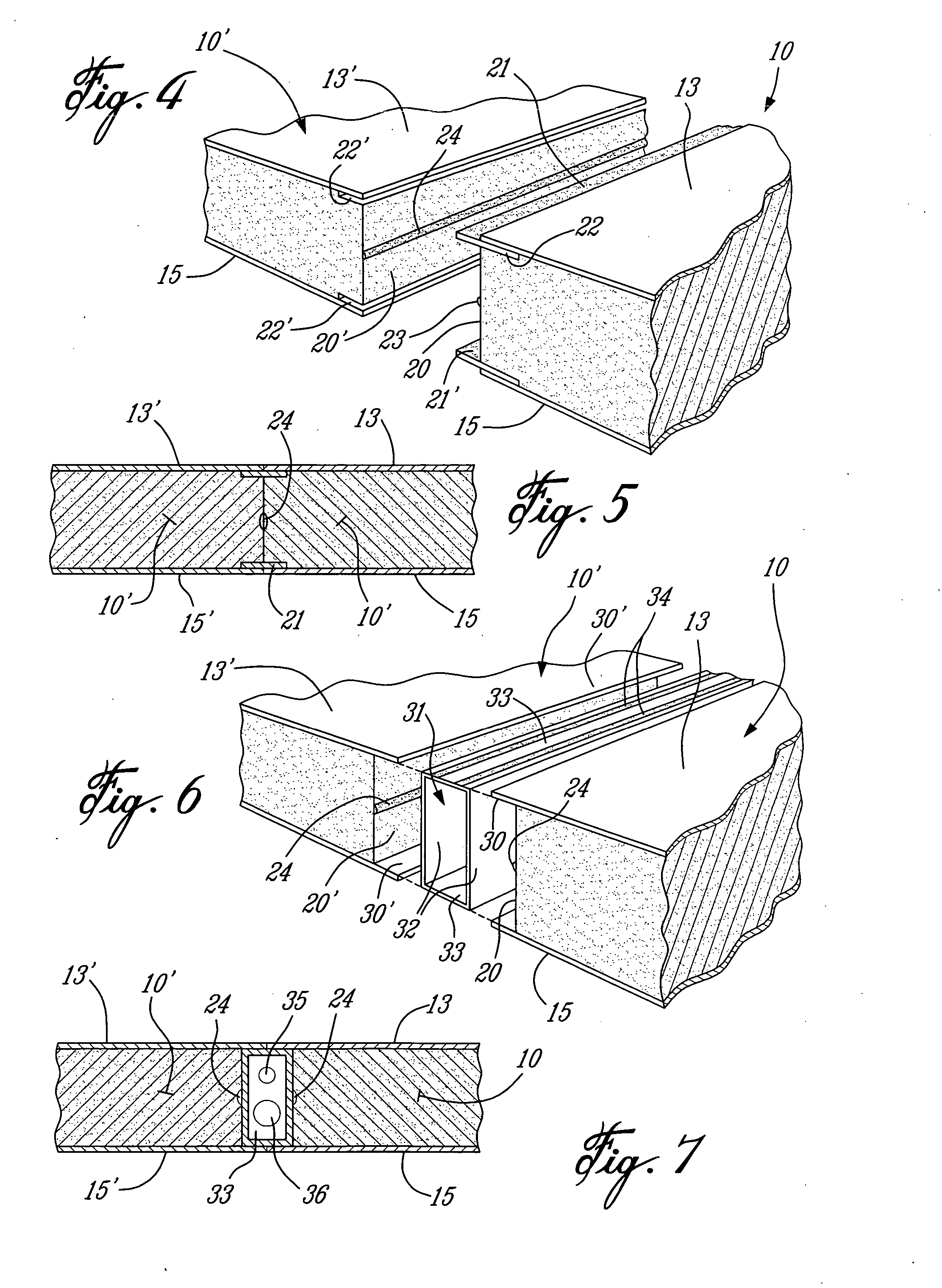

[0039] Referring now to the drawings and more particularly to FIGS. 1 to 3, there is shown generally at 10 a structural laminated construction panel for building structures and constructed in accordance with the present invention. The panel comprises a rigid core 11 of expanded polymeric material, and preferably, but not exclusively, a fire resistant expanded polystyrene and which defines opposed flat parallel surfaces 12 and 12′. A core 11 of one inch thickness has a density of about 2 lbs / cubic foot and excellent insulating properties.

[0040] A continuous outer skin 13 is secured to the outer surface 12 by an adhesive film 14 bonded to the outer surface 12 under controlled heat conditions with the apparatus as disclosed in the aforementioned pending U.S. patent application. The outer skin 13 is a reinforced thermoplastic composite glass fiber sheet and this provides for the attachment of surfacing tiles, concrete polymer, exterior paint and siding by the use of screw fasteners. A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com