Patents

Literature

3777results about "Fireproof doors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

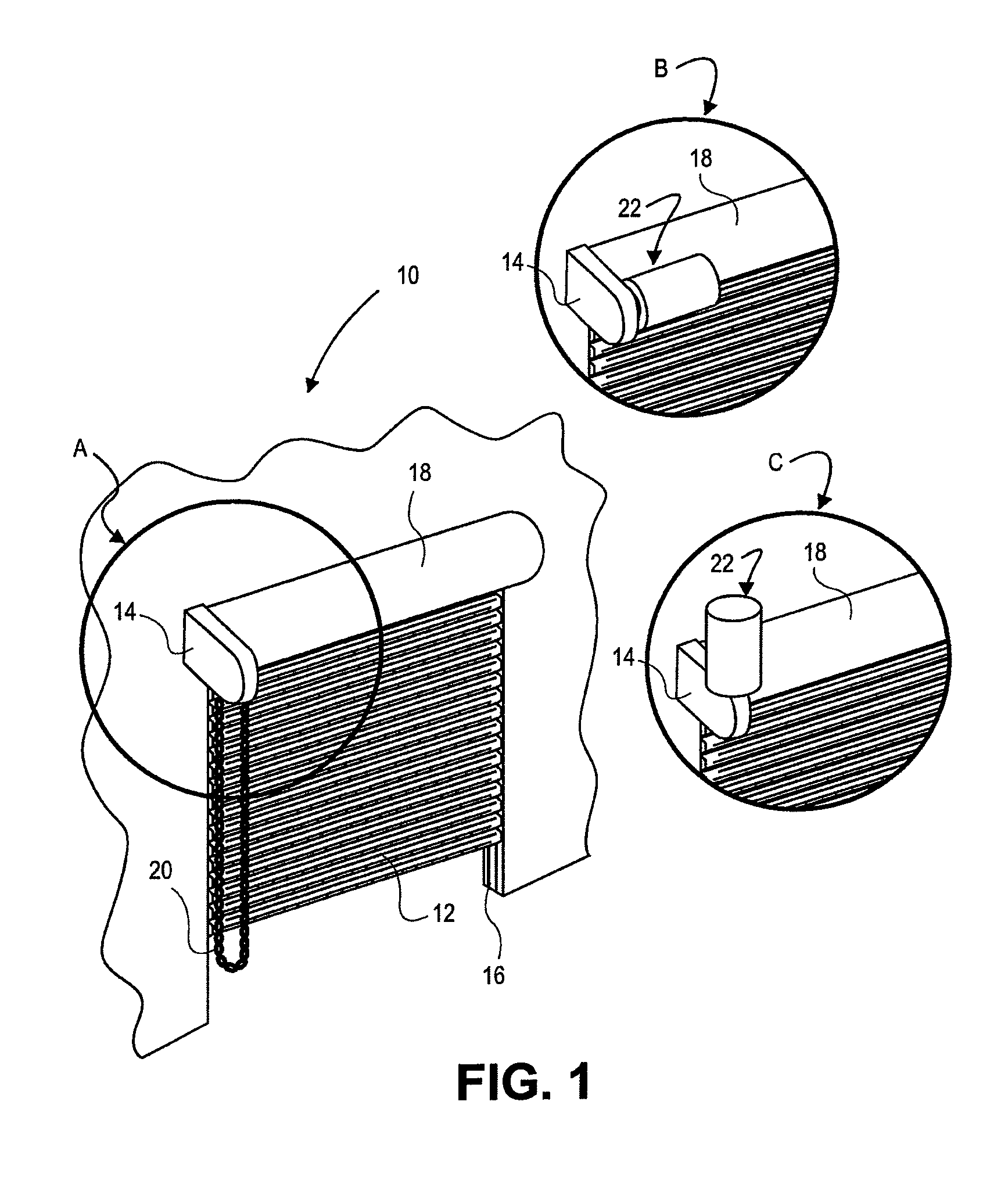

Fire retardant wooden door with intumescent materials

InactiveUS6745526B1Prevent the spread of fireEasy to installFireproof doorsDoor leavesTongue and grooveEngineering

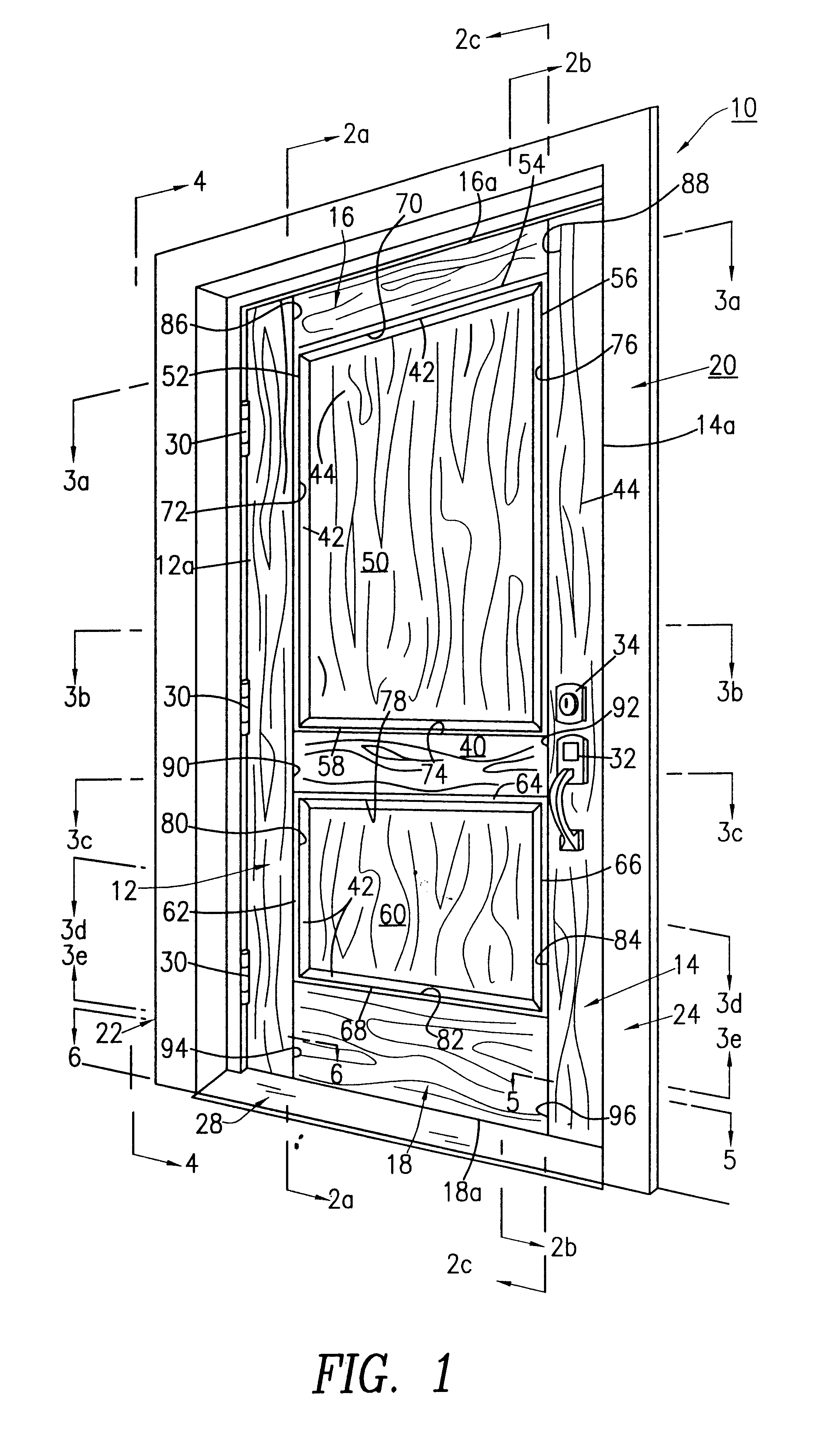

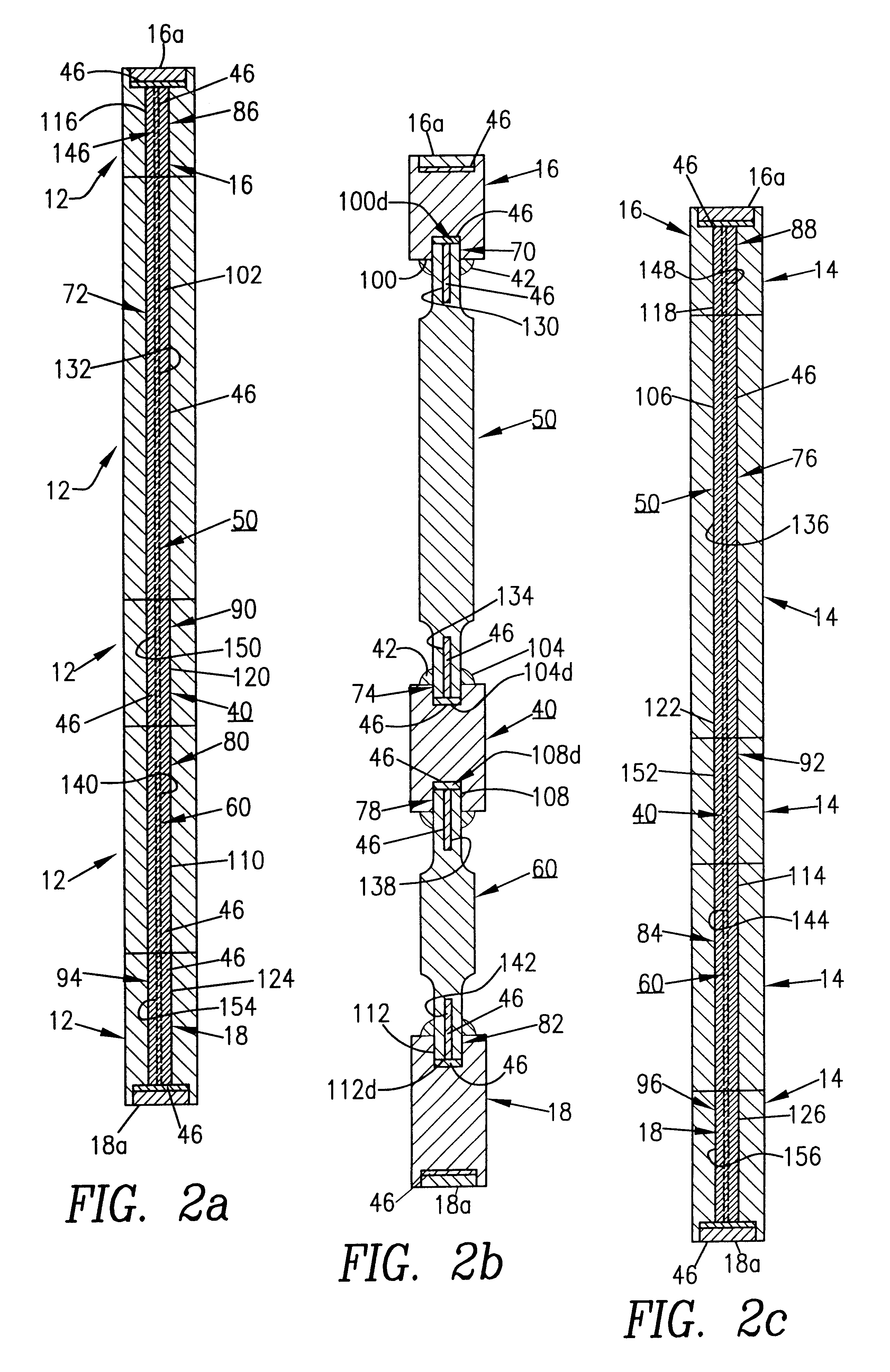

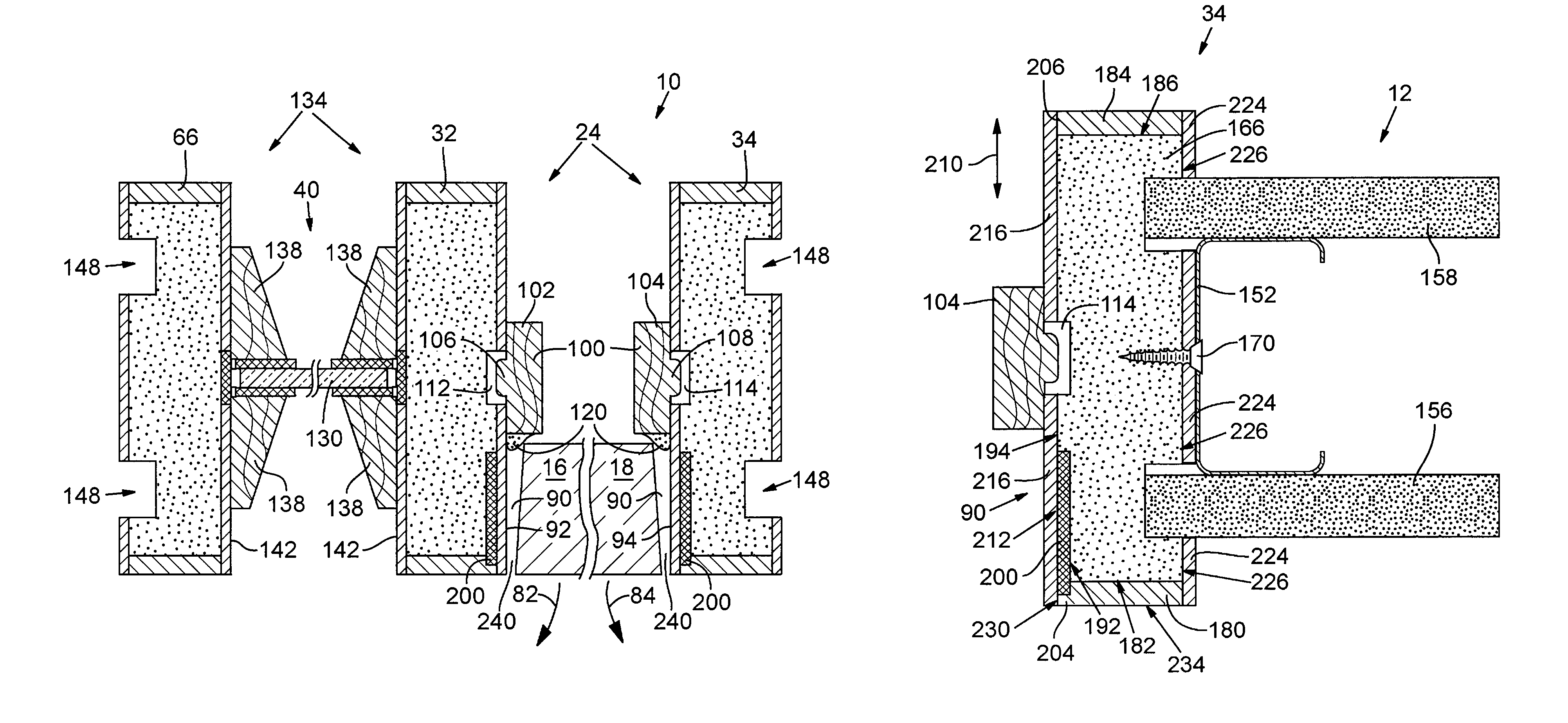

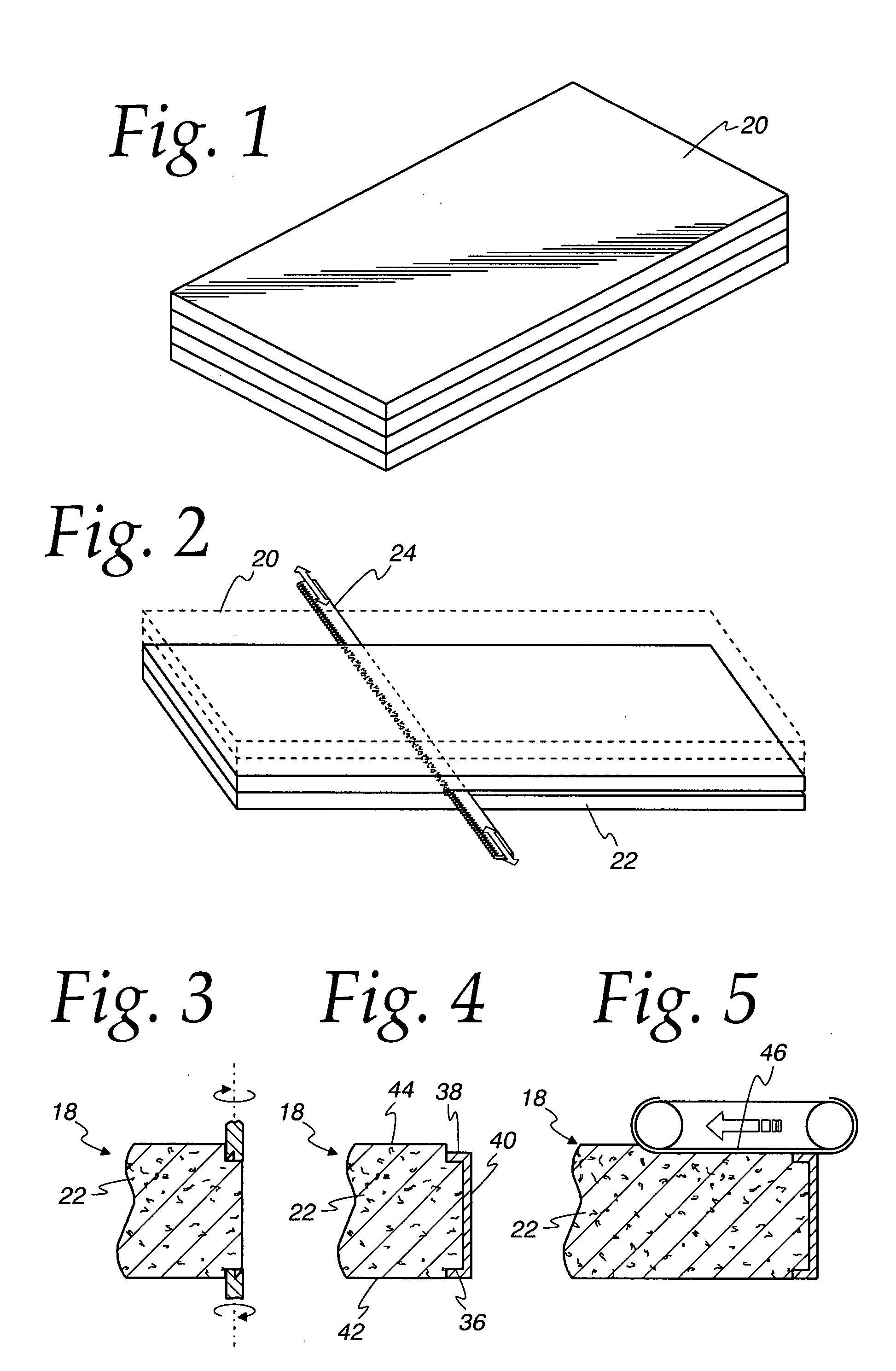

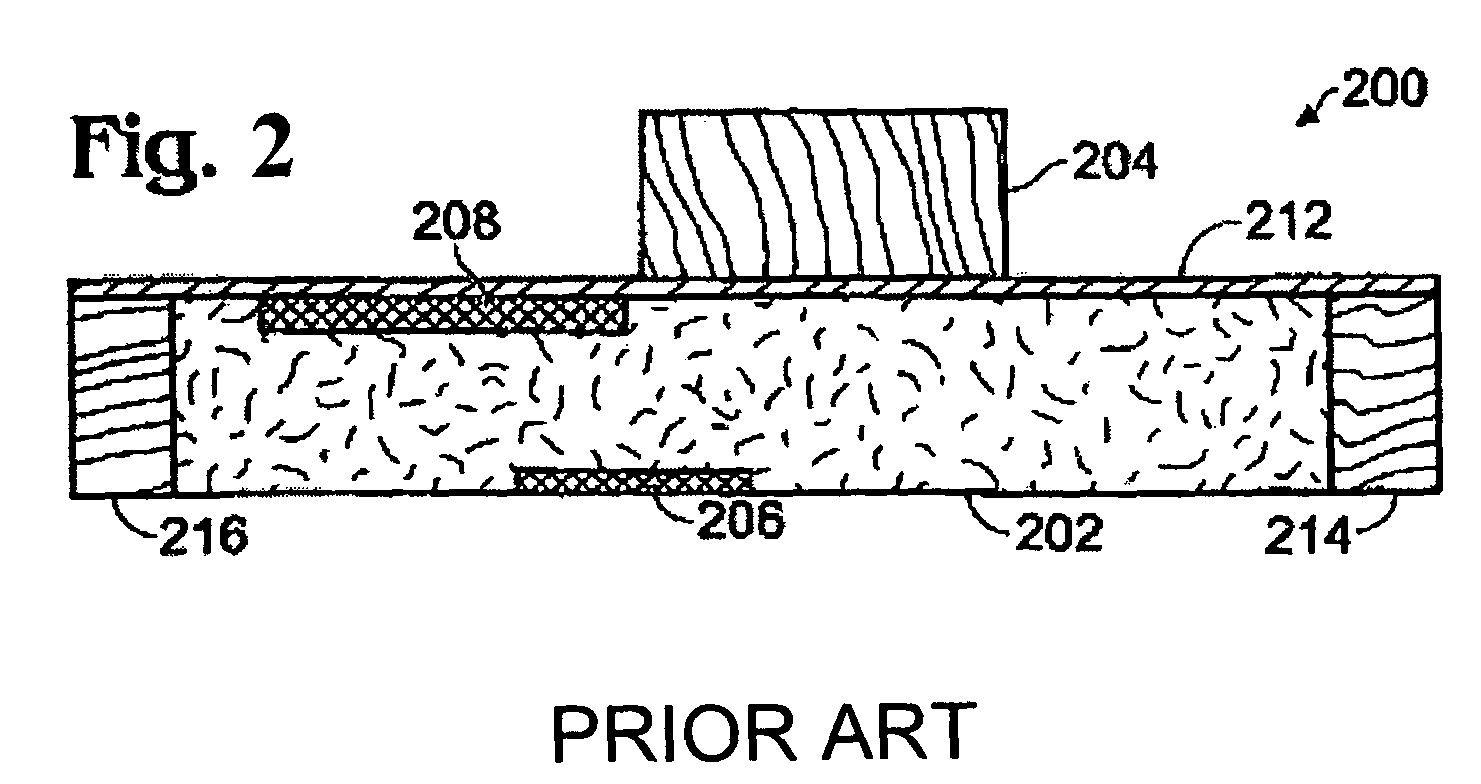

A fire retardant wooden door that prevents the spread of fire through the door during a fire. The fire retardant wooden door has at least one door panel connected to stiles and rails by tongue and groove joints, and the tongue and groove joints have intumescent material therein. Each of the tongue and groove joints includes a tongue section having the intumescent material along a distal edge of the tongue section which expands upon exposure to heat or fire to seal the tongue and groove joints in order to prevent the heat or fire from passing through the door during a fire. Each of the tongue sections includes an interior channel extending along the axis of the tongue section, and the interior channel extends into the door panel. The interior channel has the intumescent material embedded therein which expands upon exposure to heat or fire to further seal the tongue and groove joints in order to prevent the heat or fire from passing through the door during a fire.

Owner:AUTOVINO ENRICO

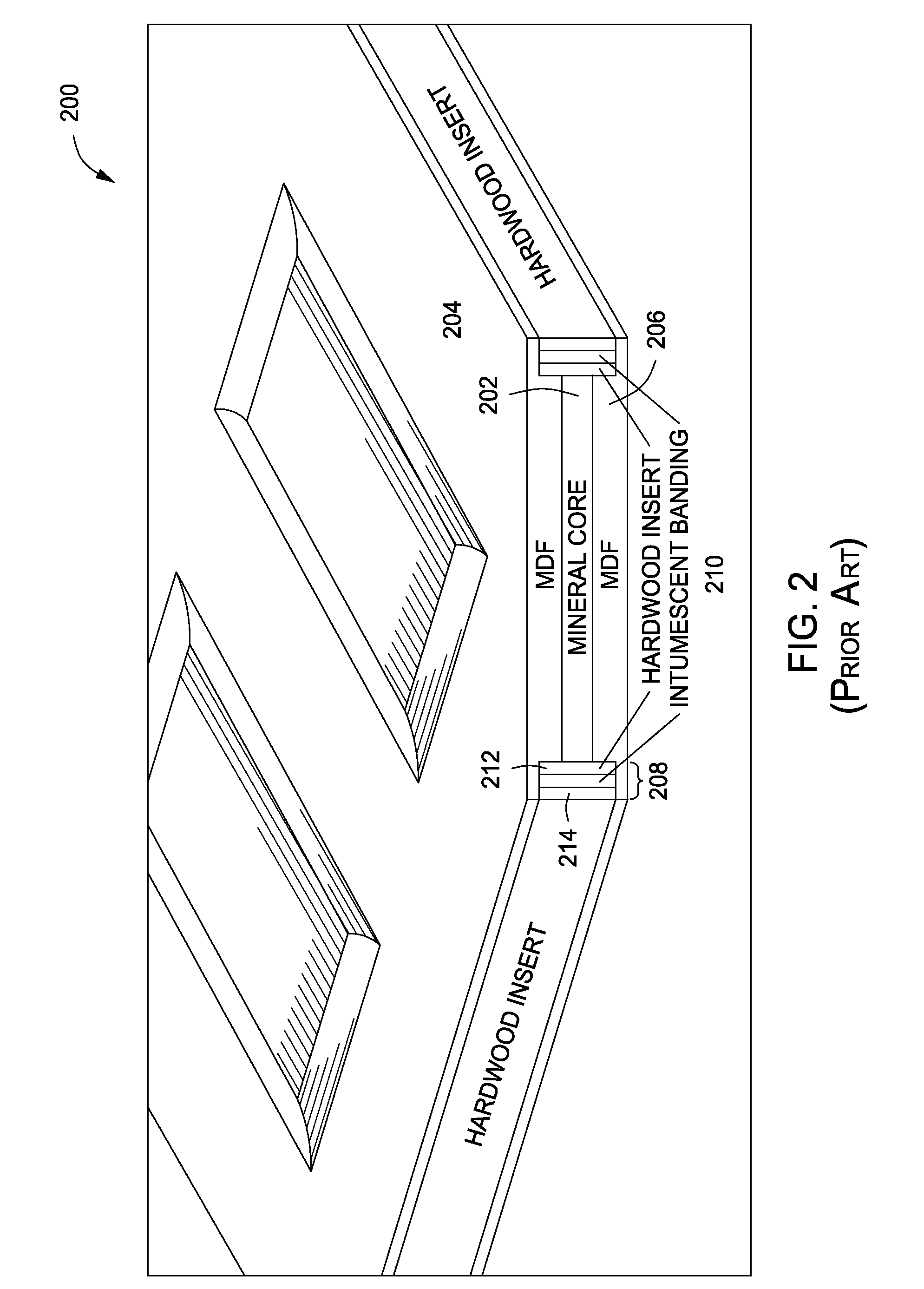

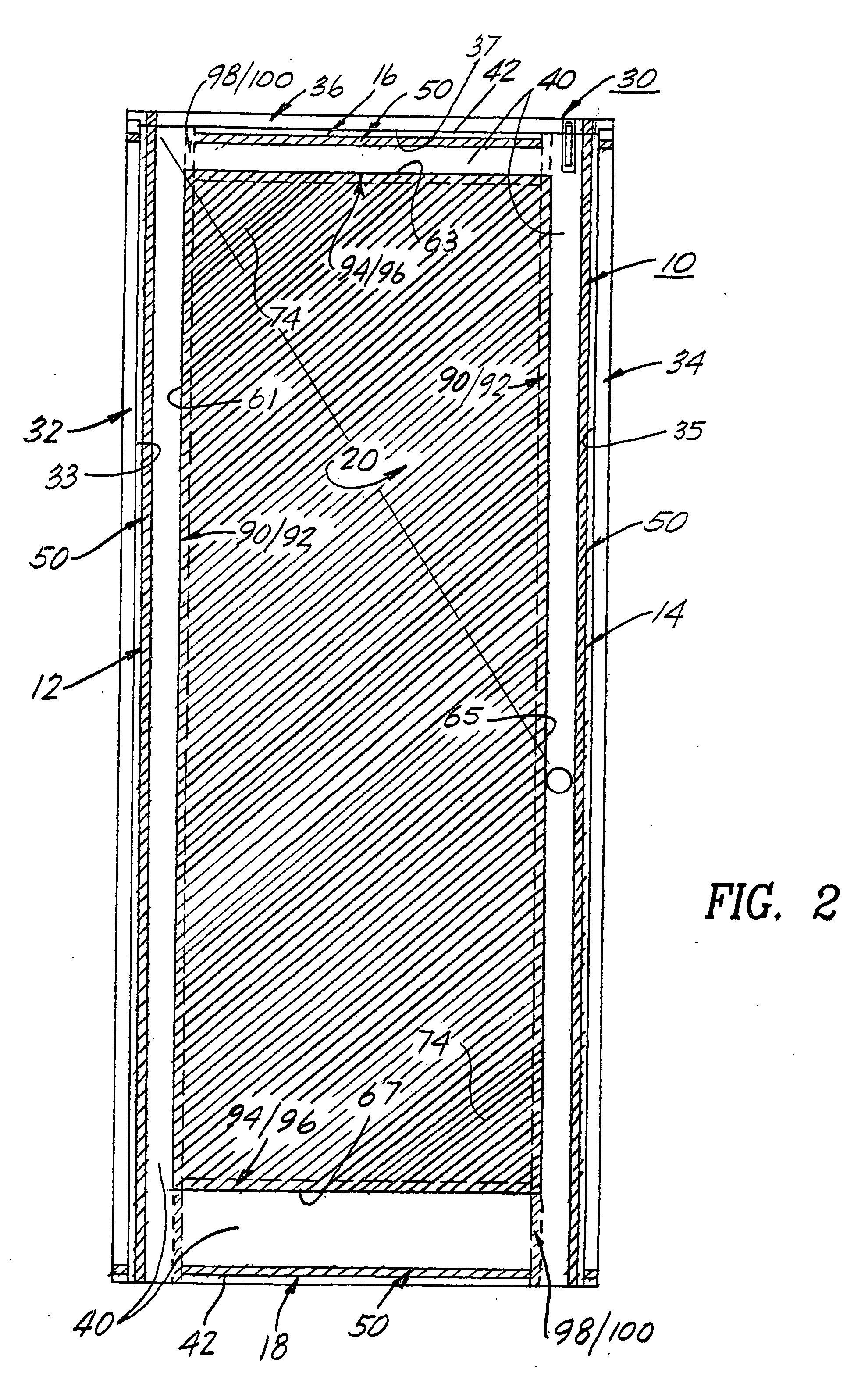

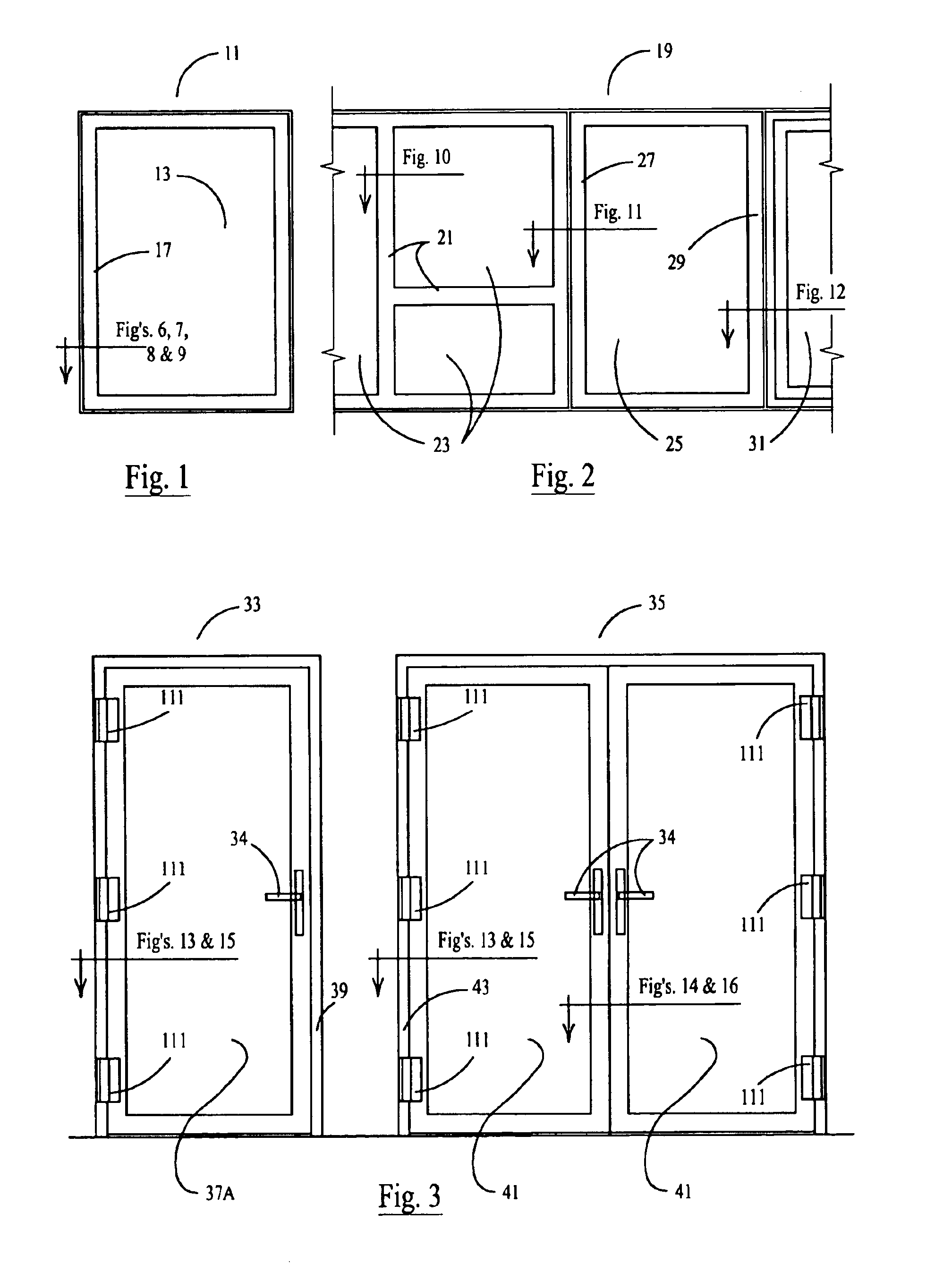

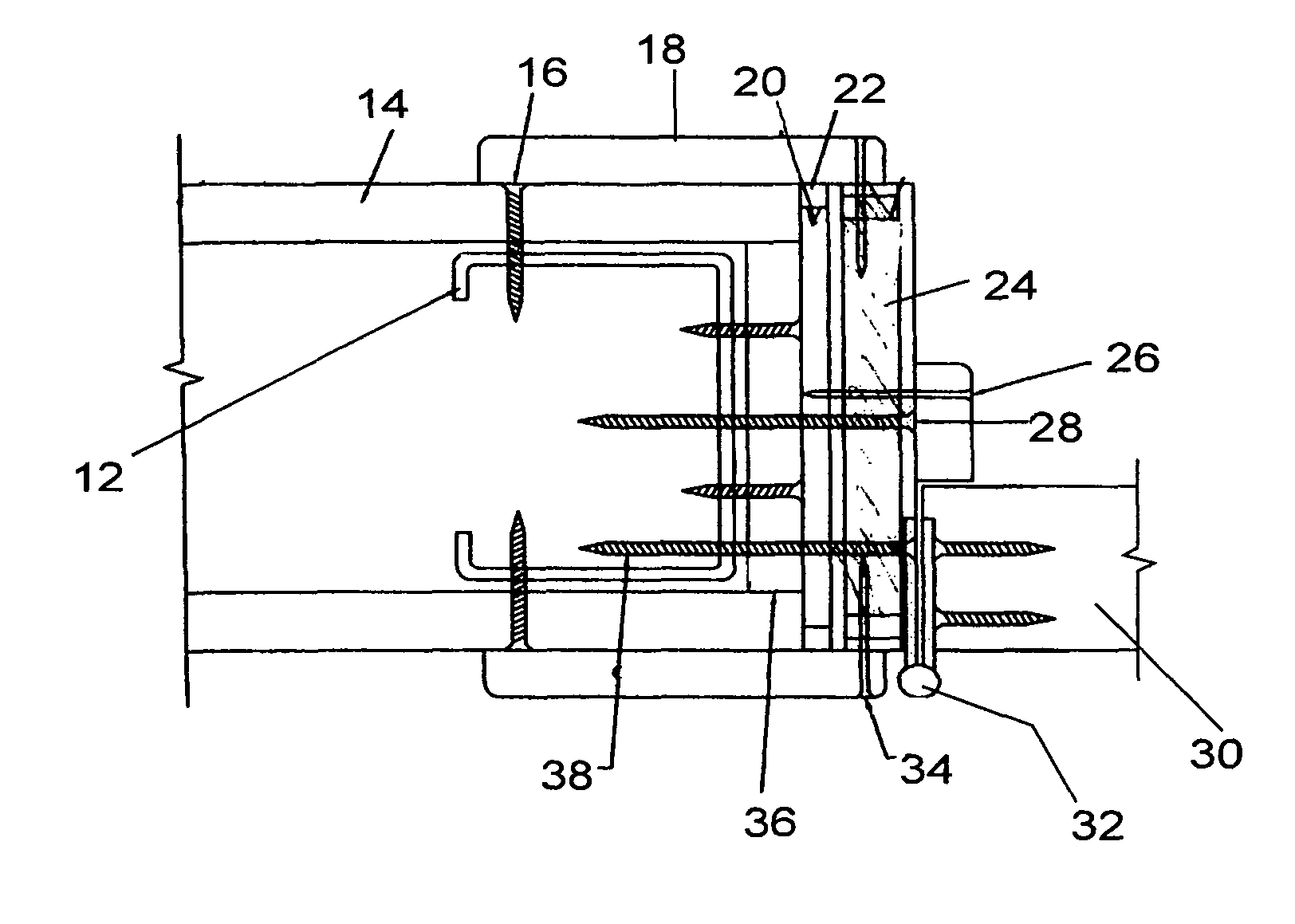

Fire-resistant wood assemblies for building

InactiveUS7059092B2Good lookingPrevent tamperingFireproof doorsWindow/door framesEngineeringWood plank

Door and glazing frames include intumescent material positioned in a dado that is formed in a jamb side surface. Trim materials are positioned over the intumescent material to improve the appearance of the frame and to prevent tampering with and damage to the intumescent material. The jamb trim is preferably made of a cut hardwood panel having a thickness that allows heat to be transmitted to the intumescent material in the event of a fire so that the intumescent material will expand and fill a clearance space between the frame and the door or glazing. The expanded intumescent material inhibits the transmission of smoke and heat between the door and door frame. After expanding, the intumescent material will char and solidify, which may provide an added benefit of structural support for the door and or glazing.

Owner:WASHINGTON HARDWOODS & ARCHITECTURAL PROD

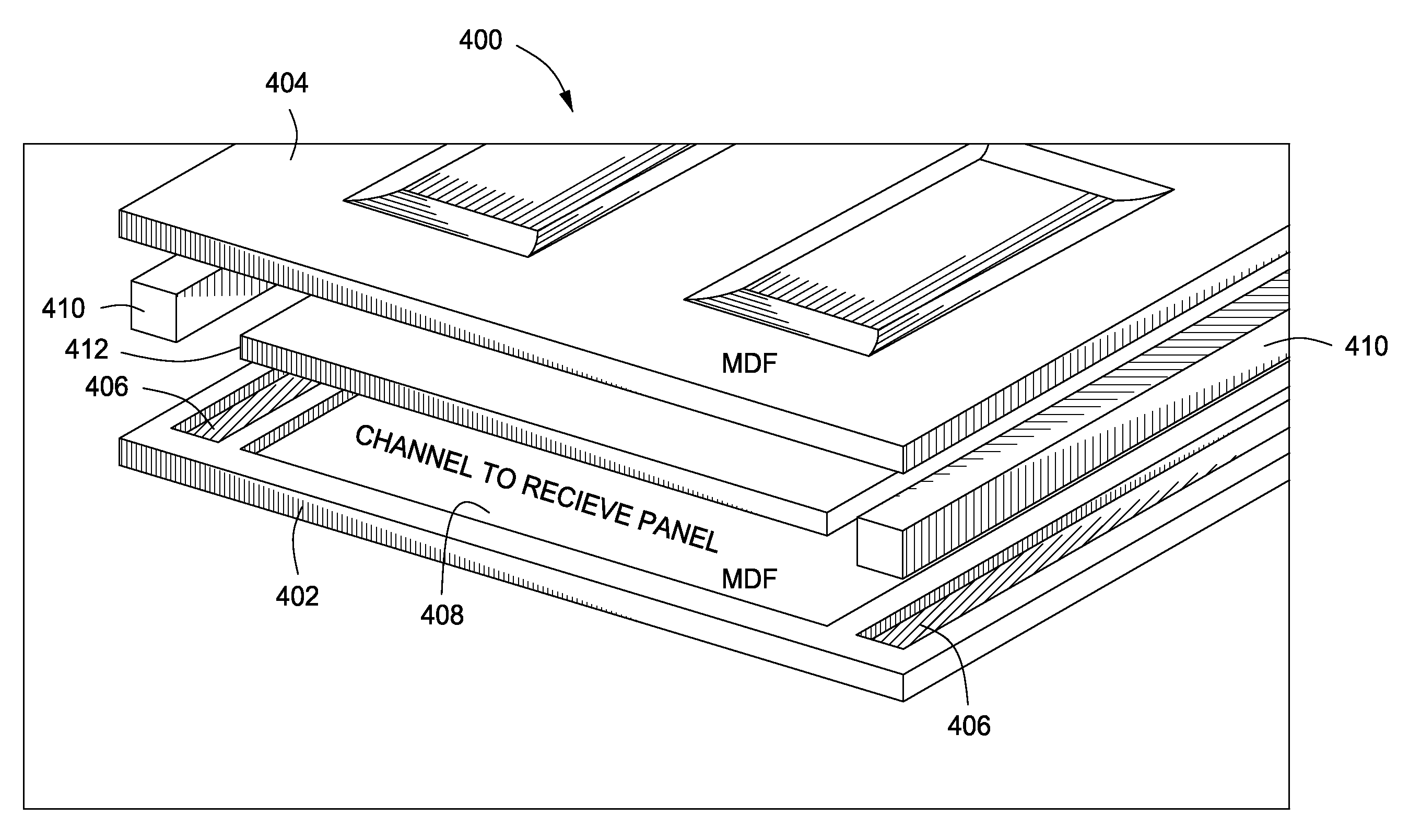

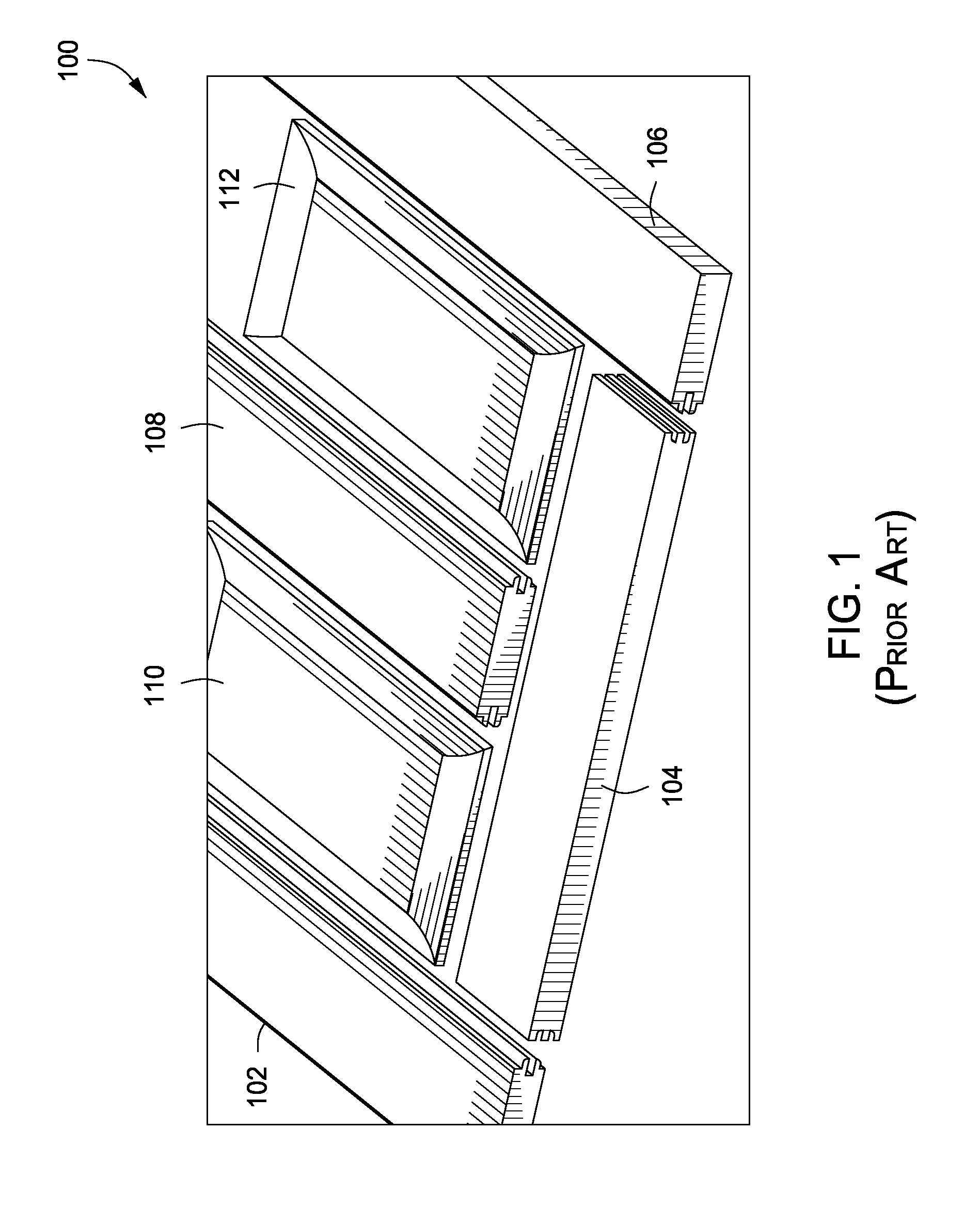

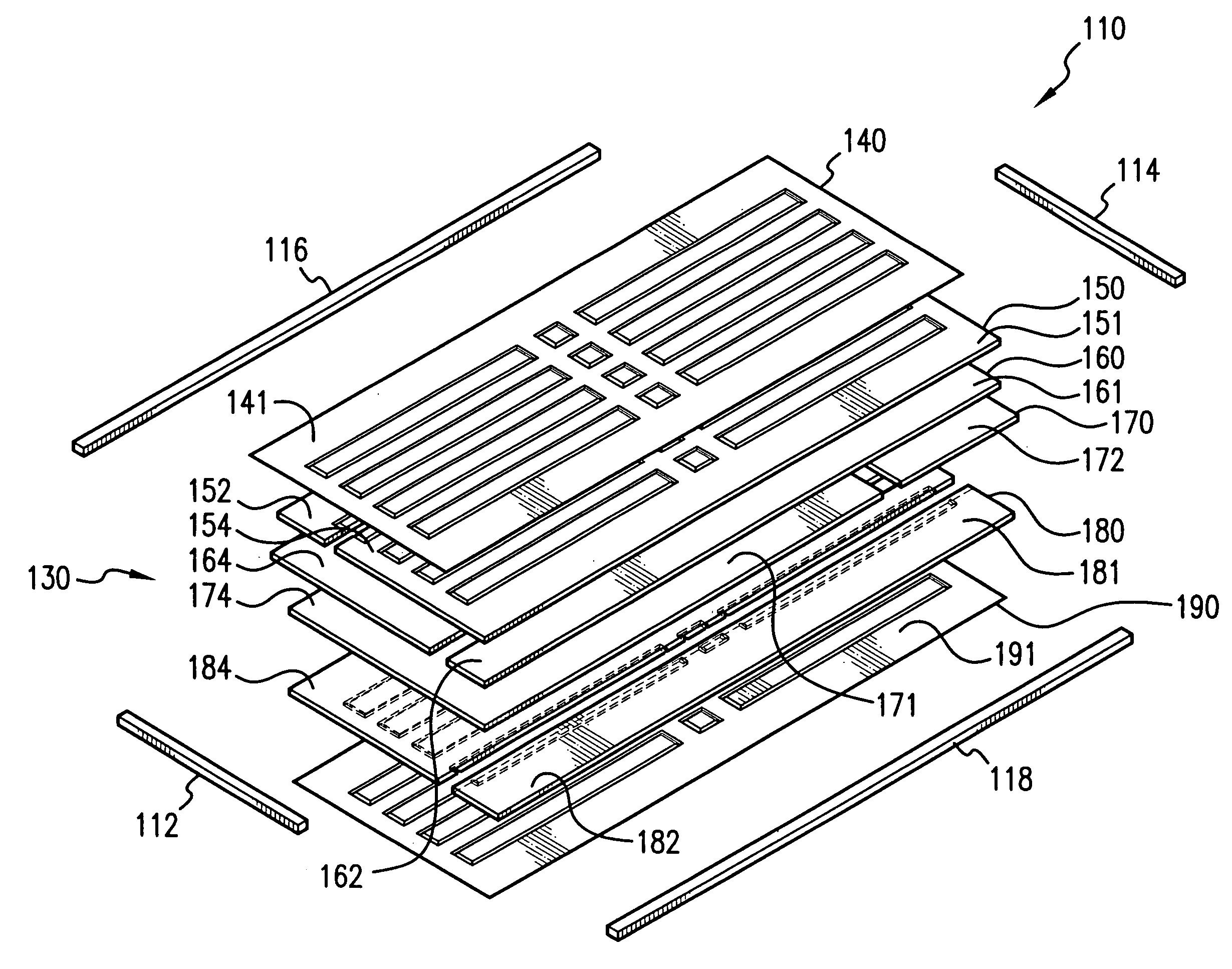

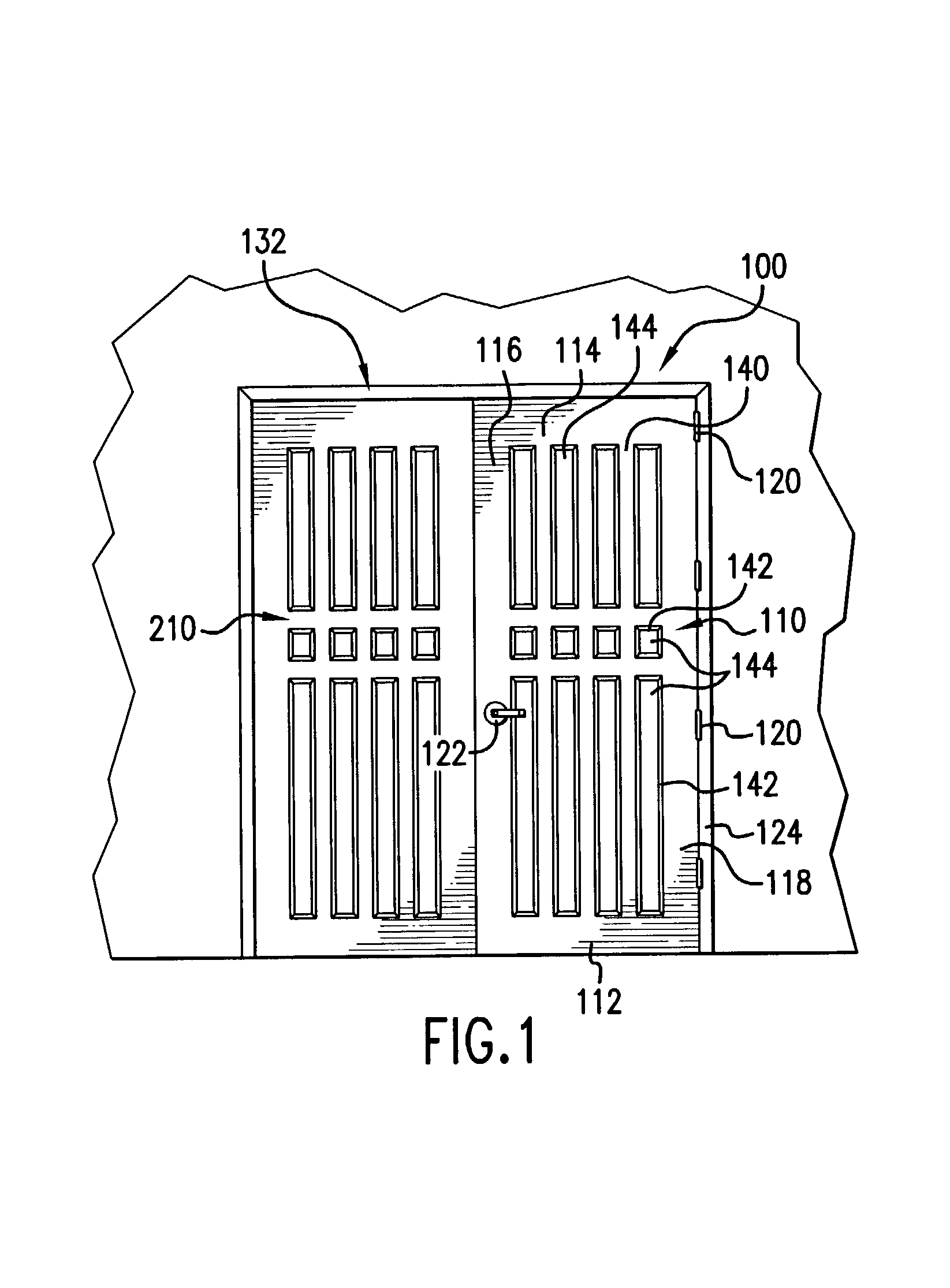

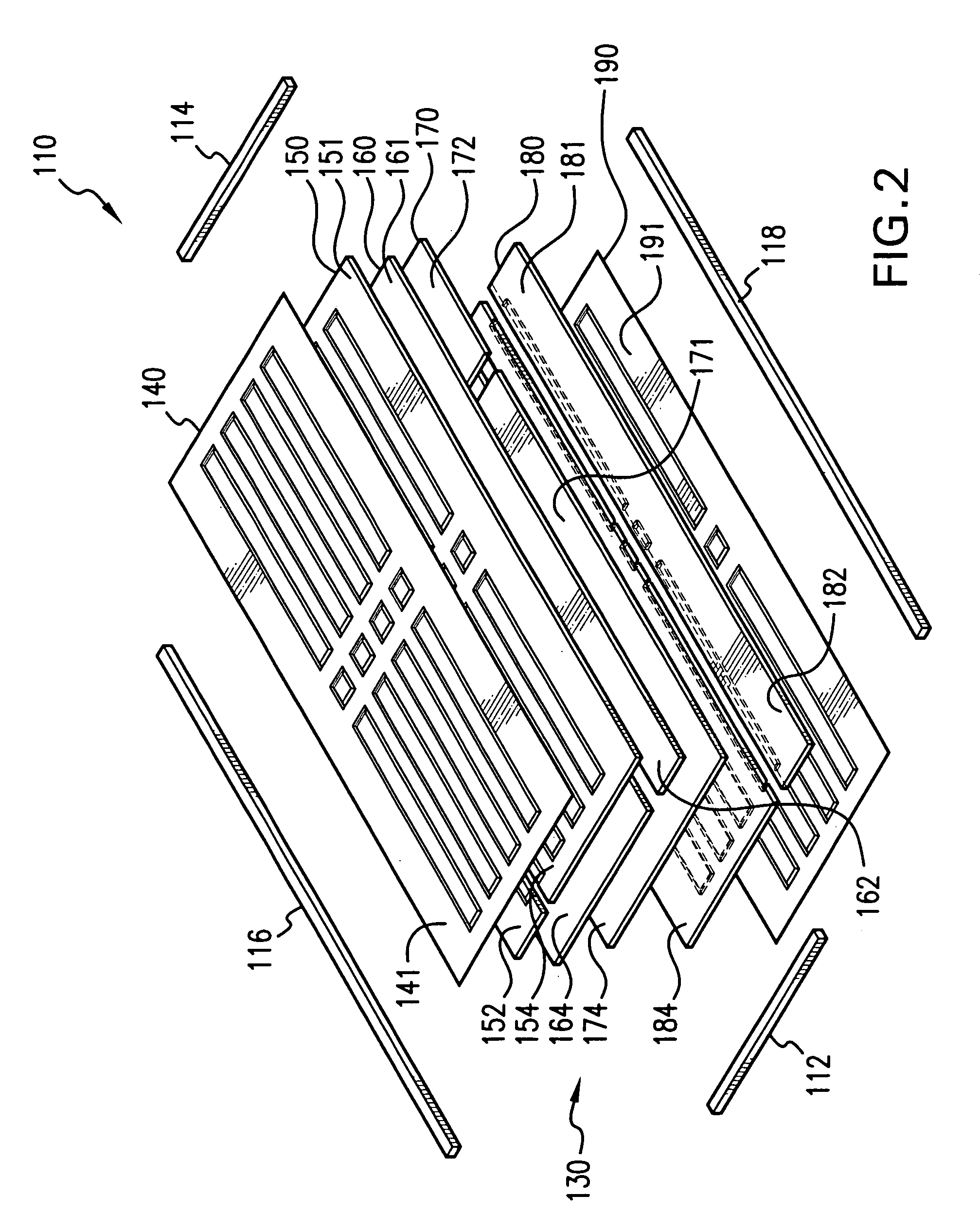

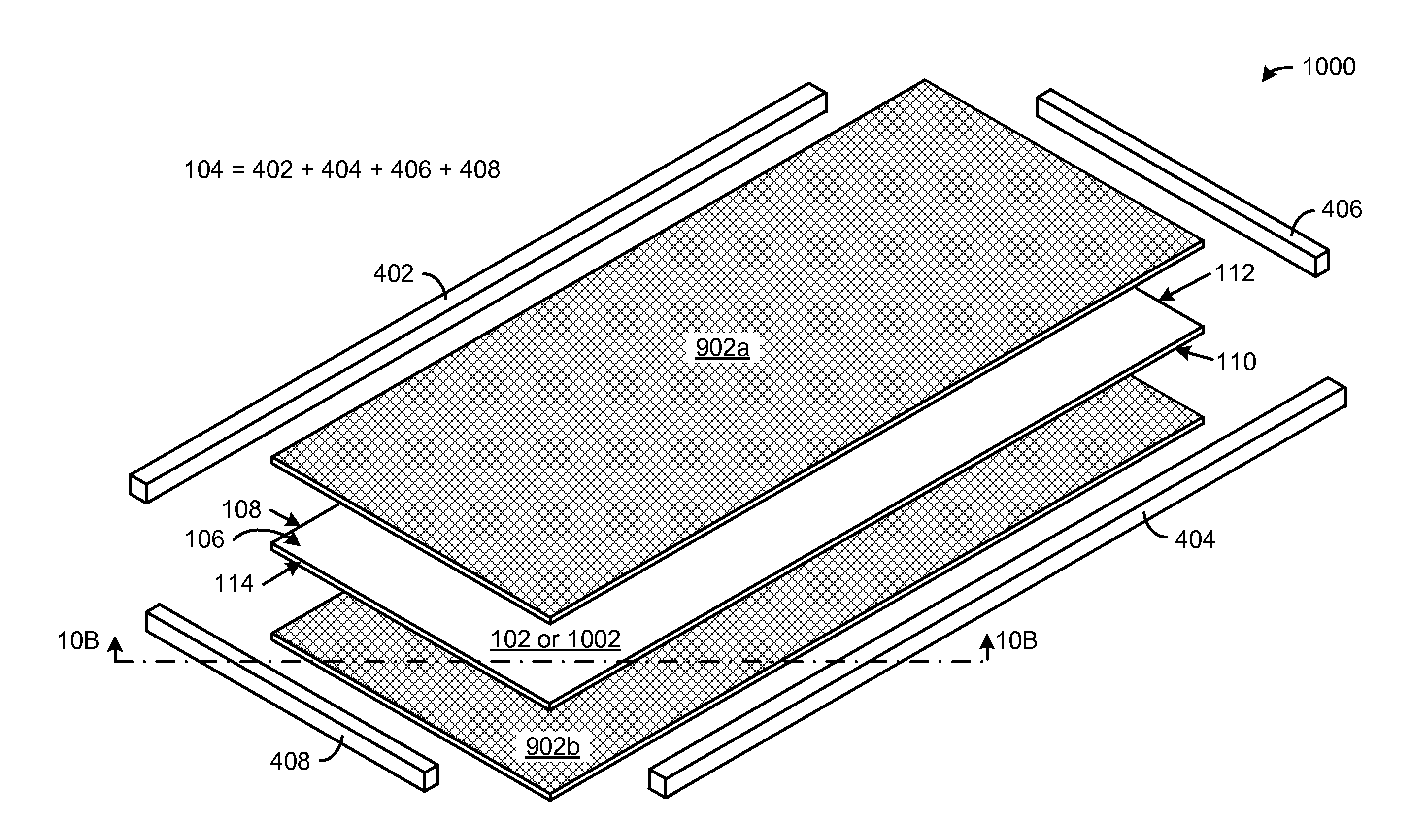

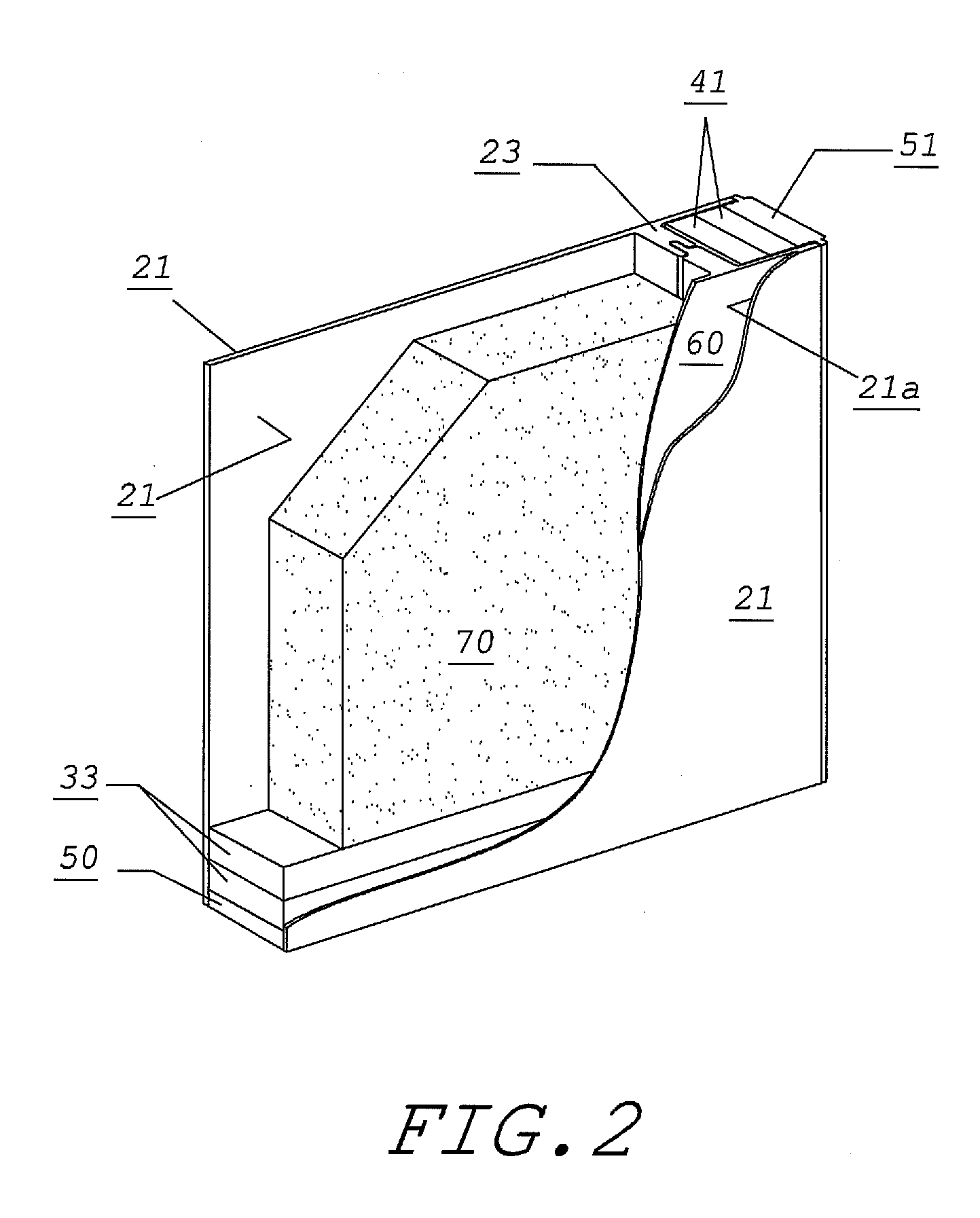

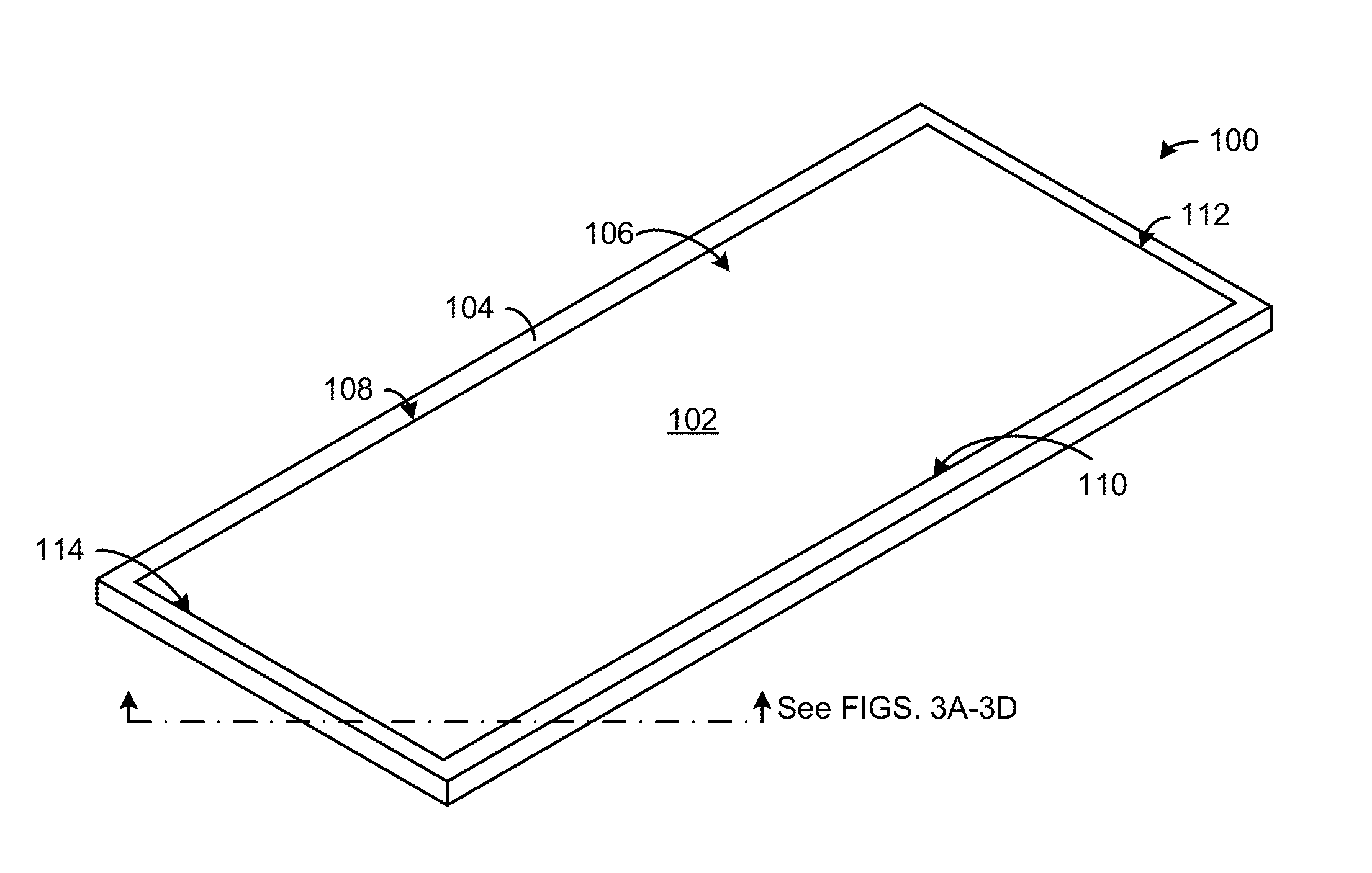

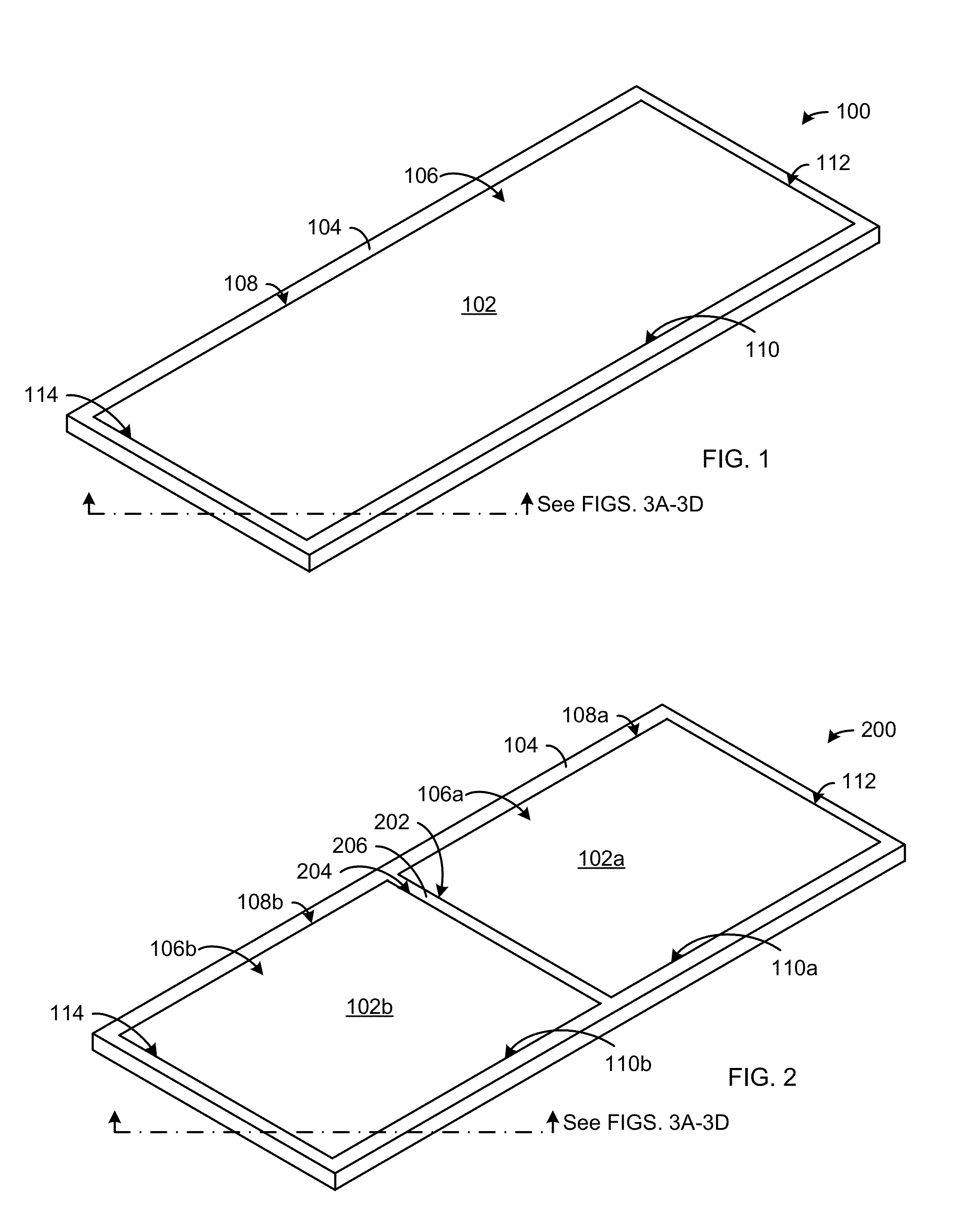

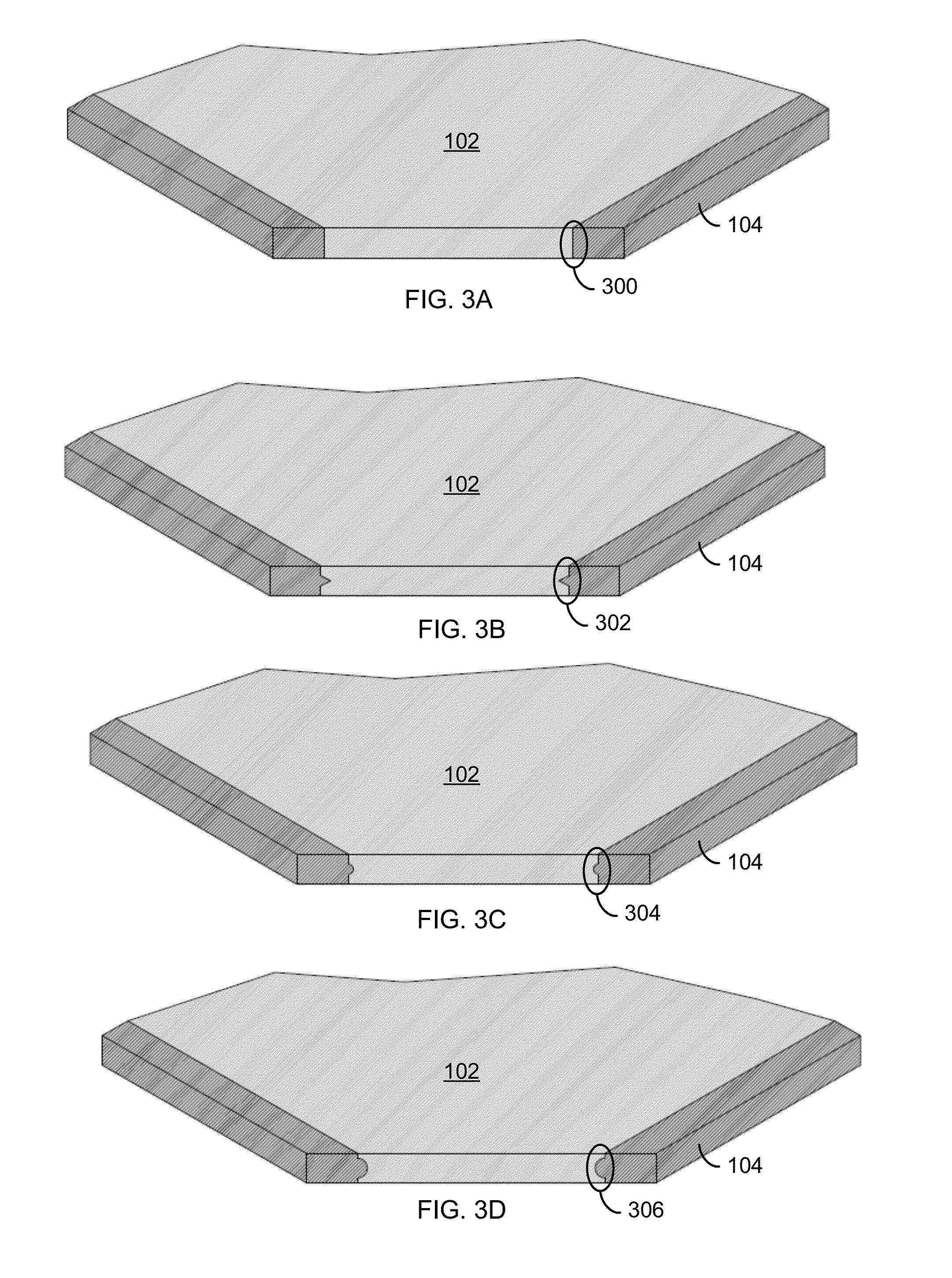

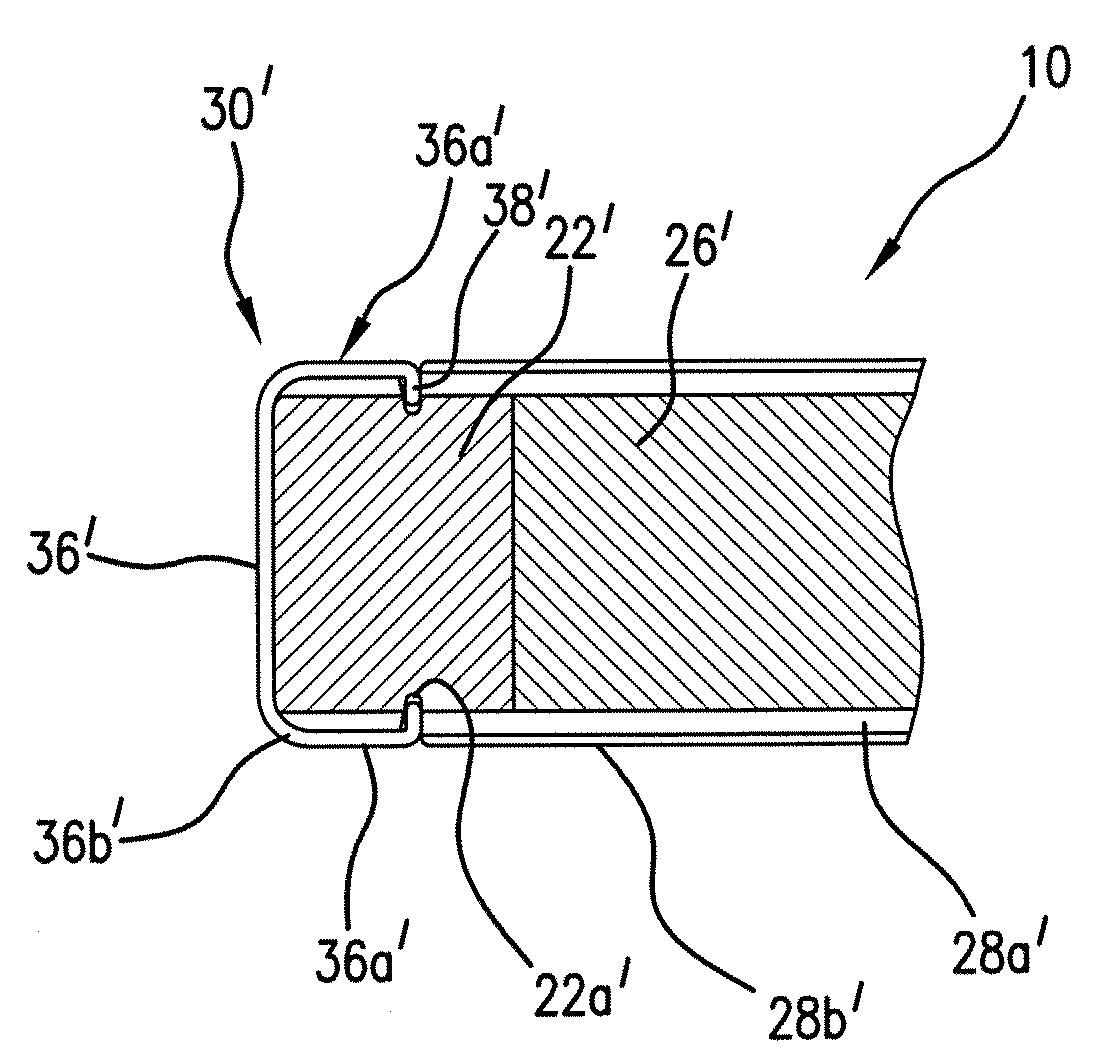

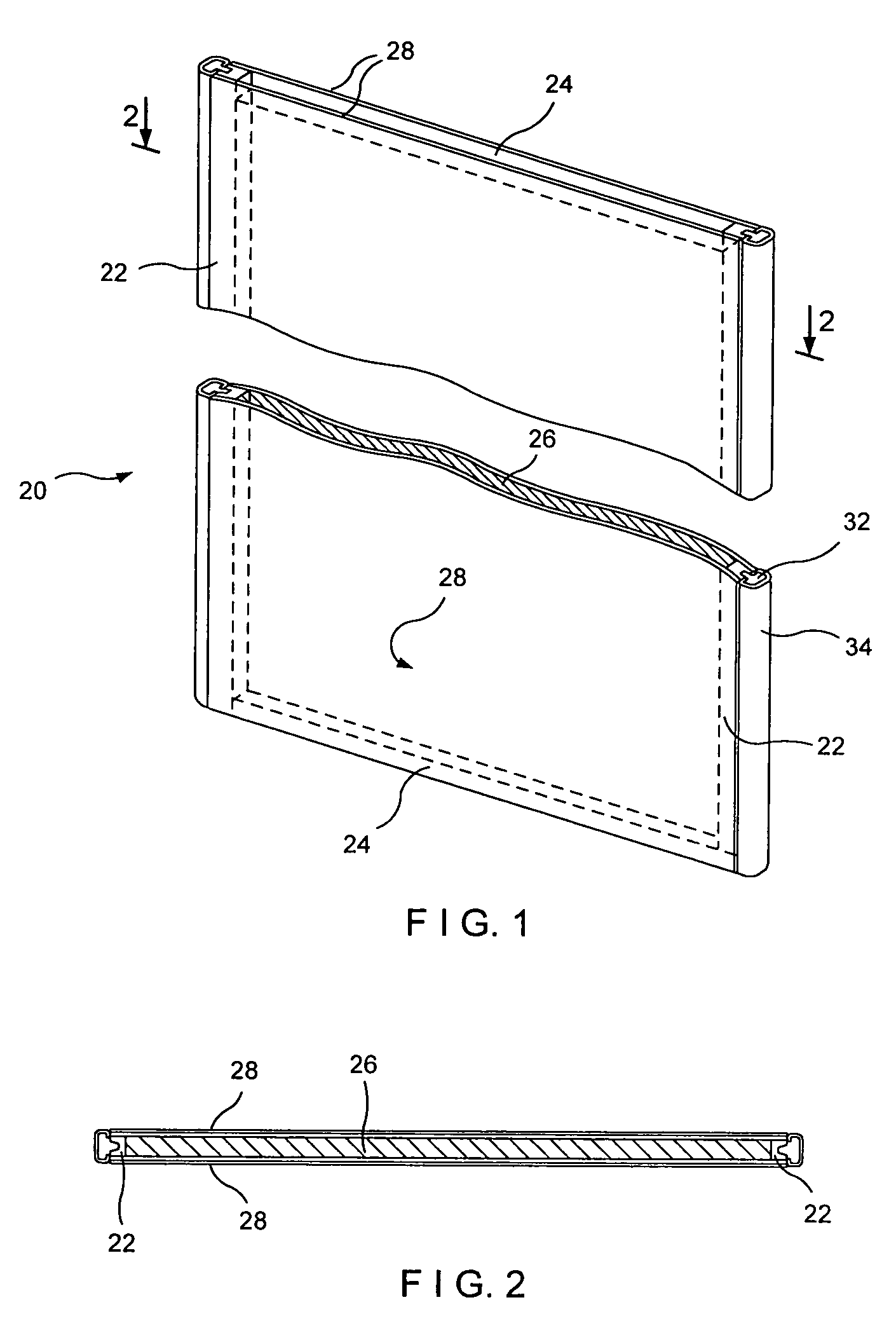

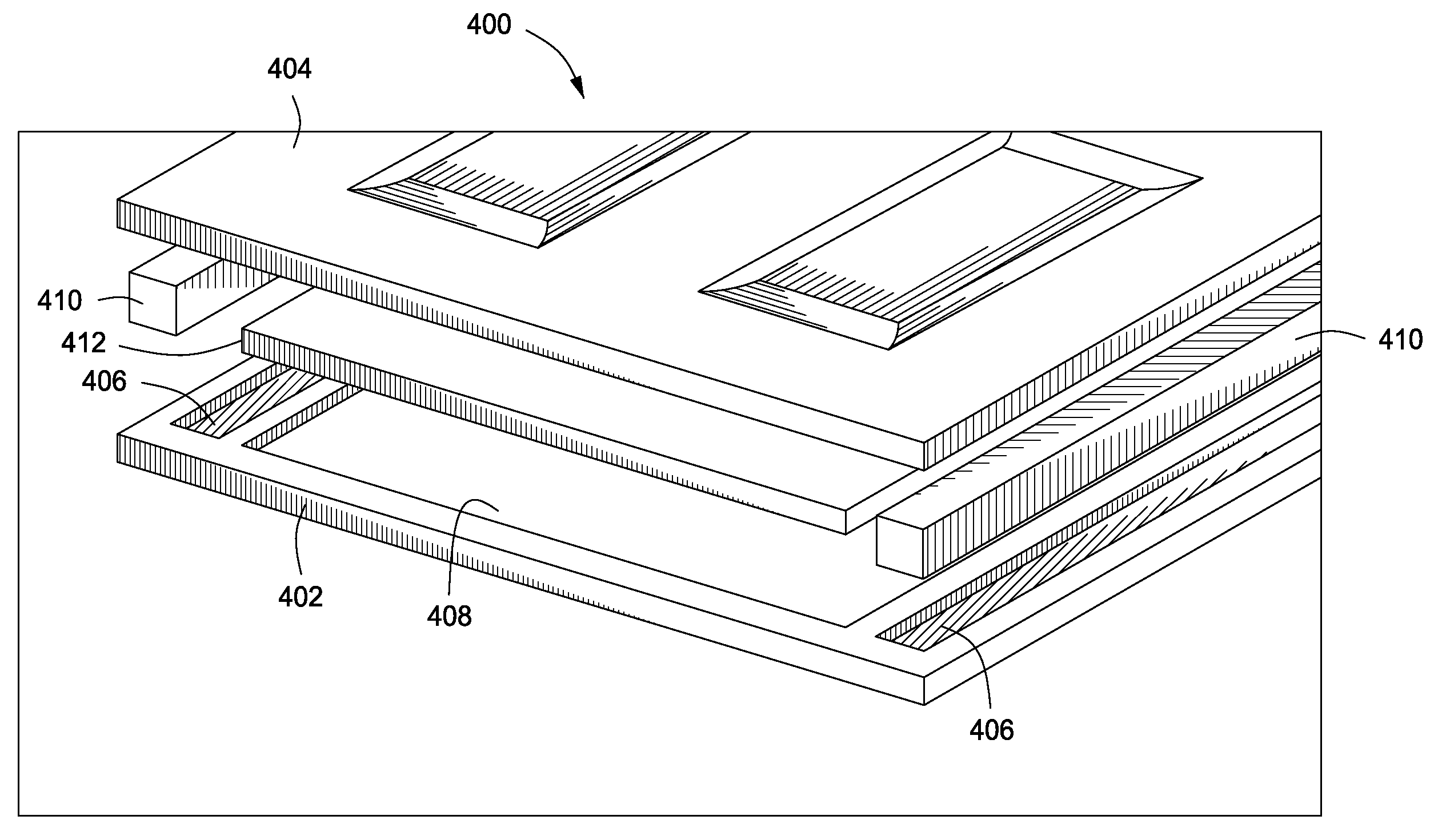

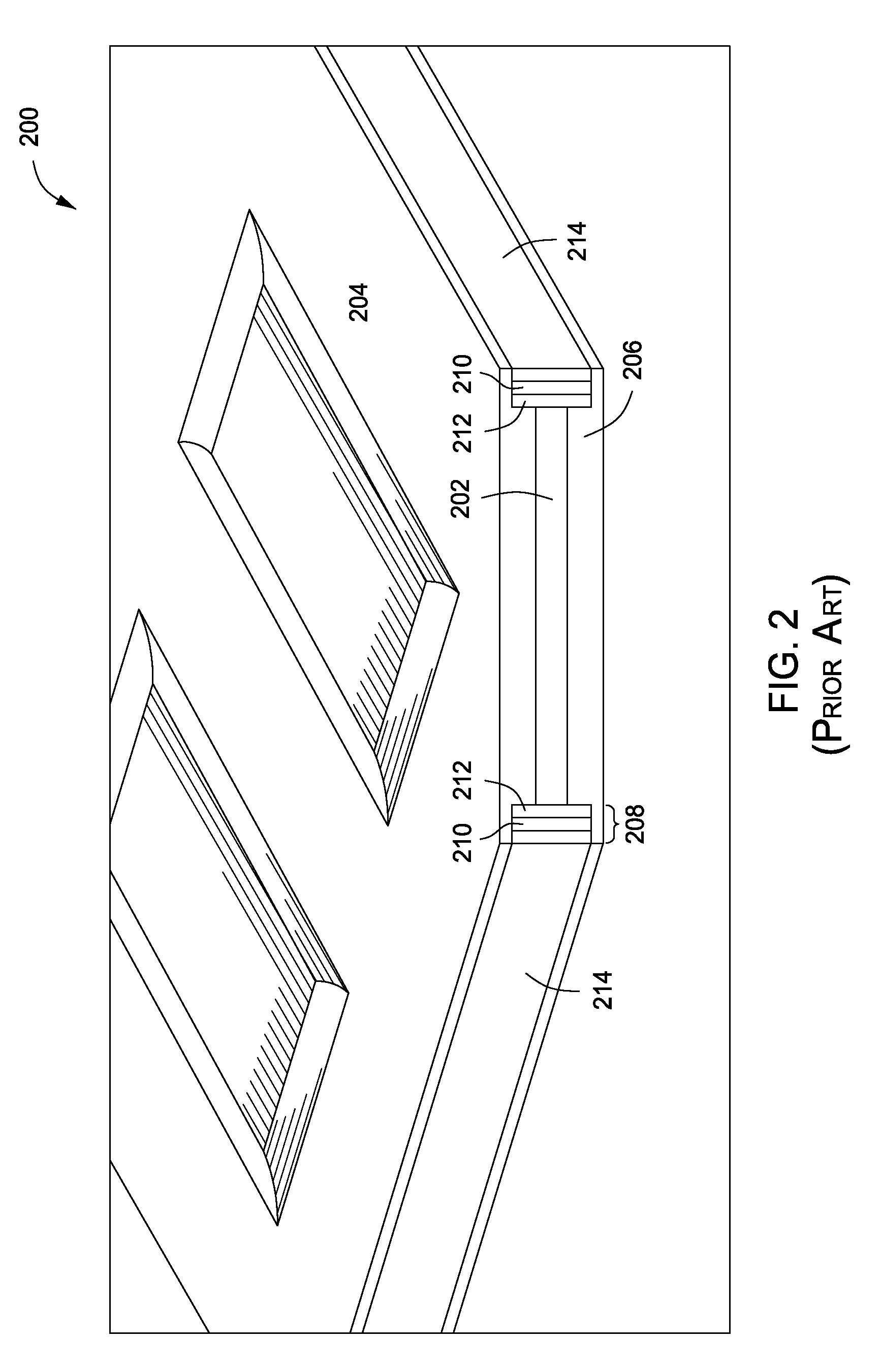

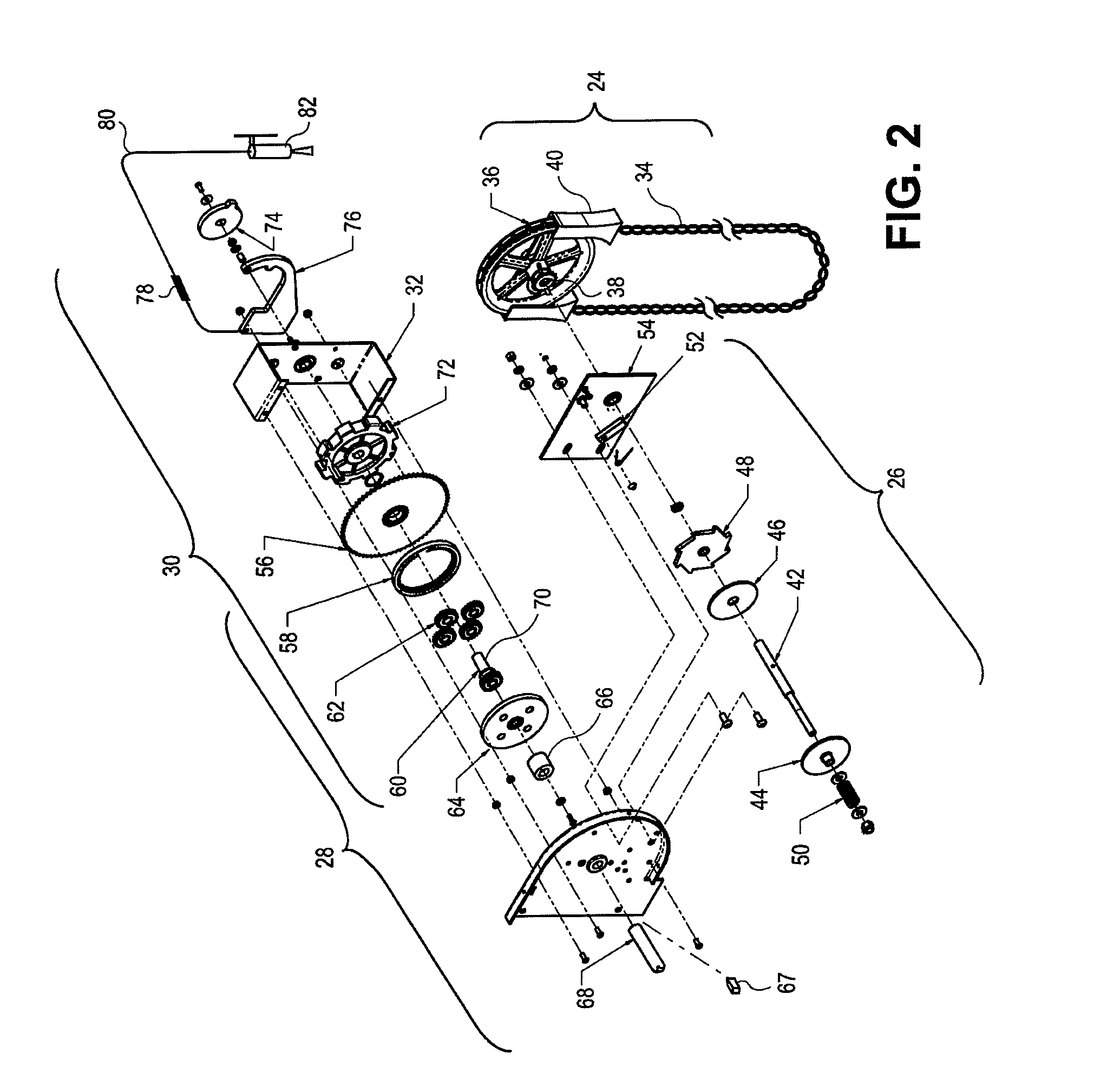

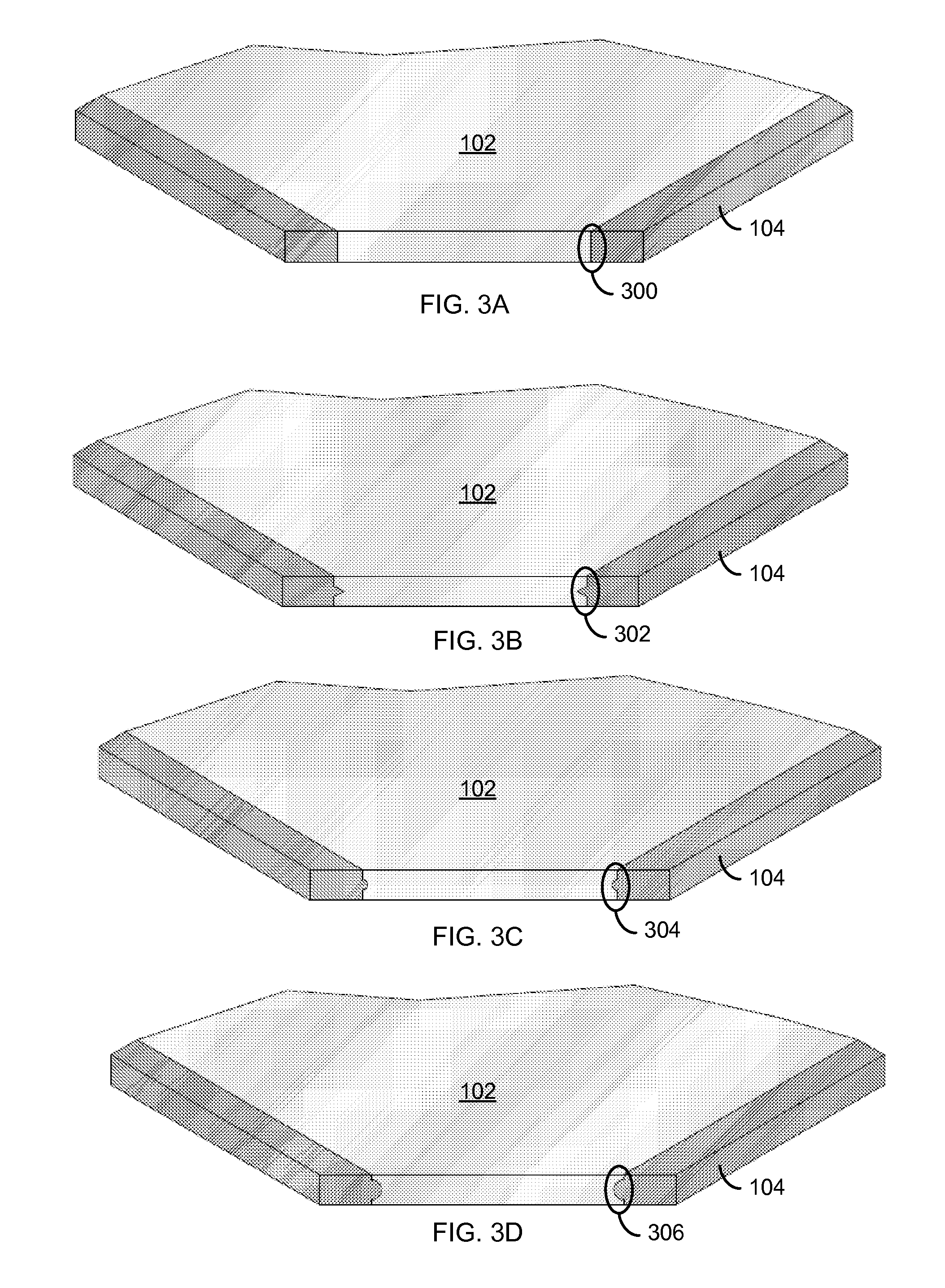

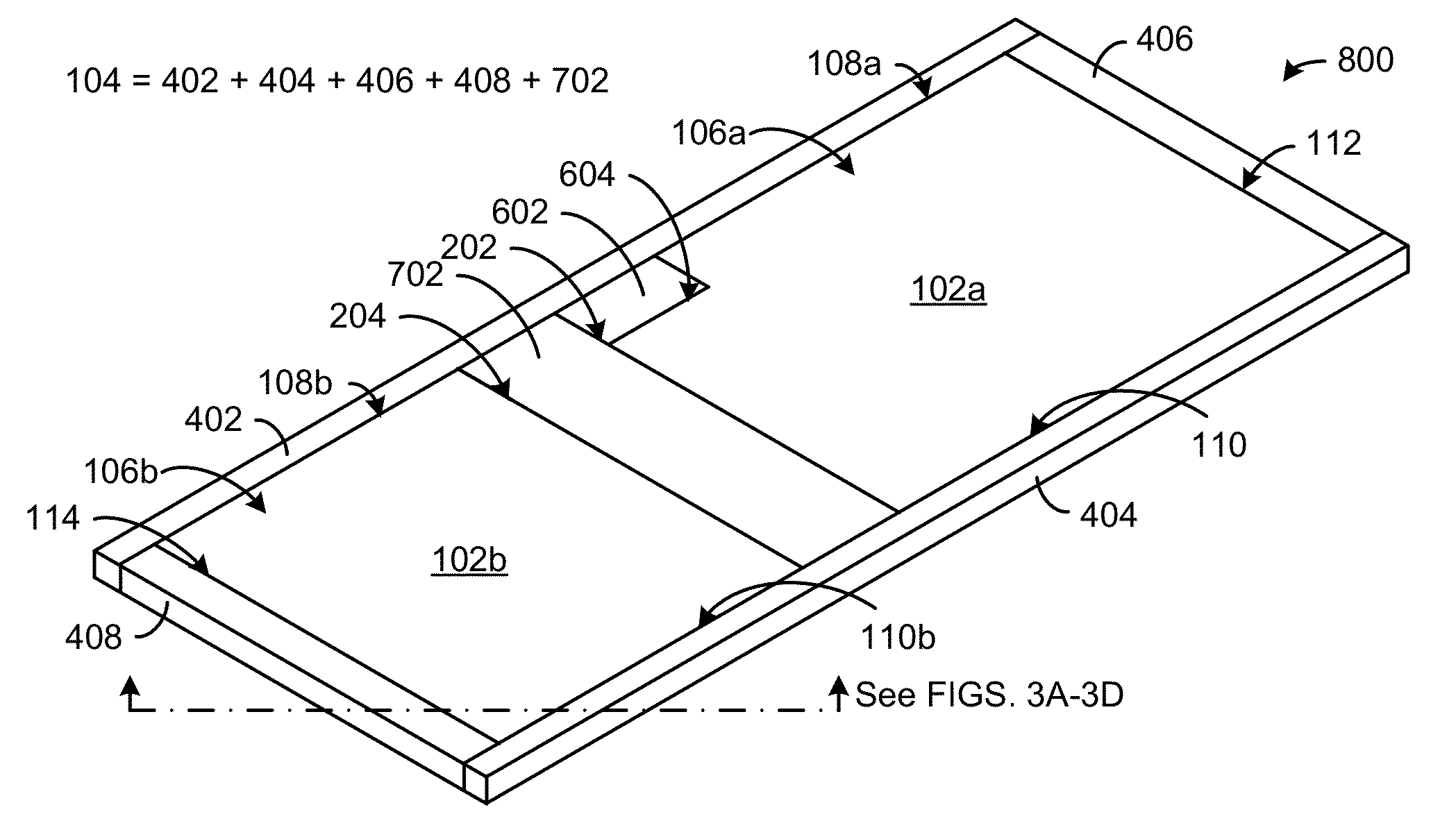

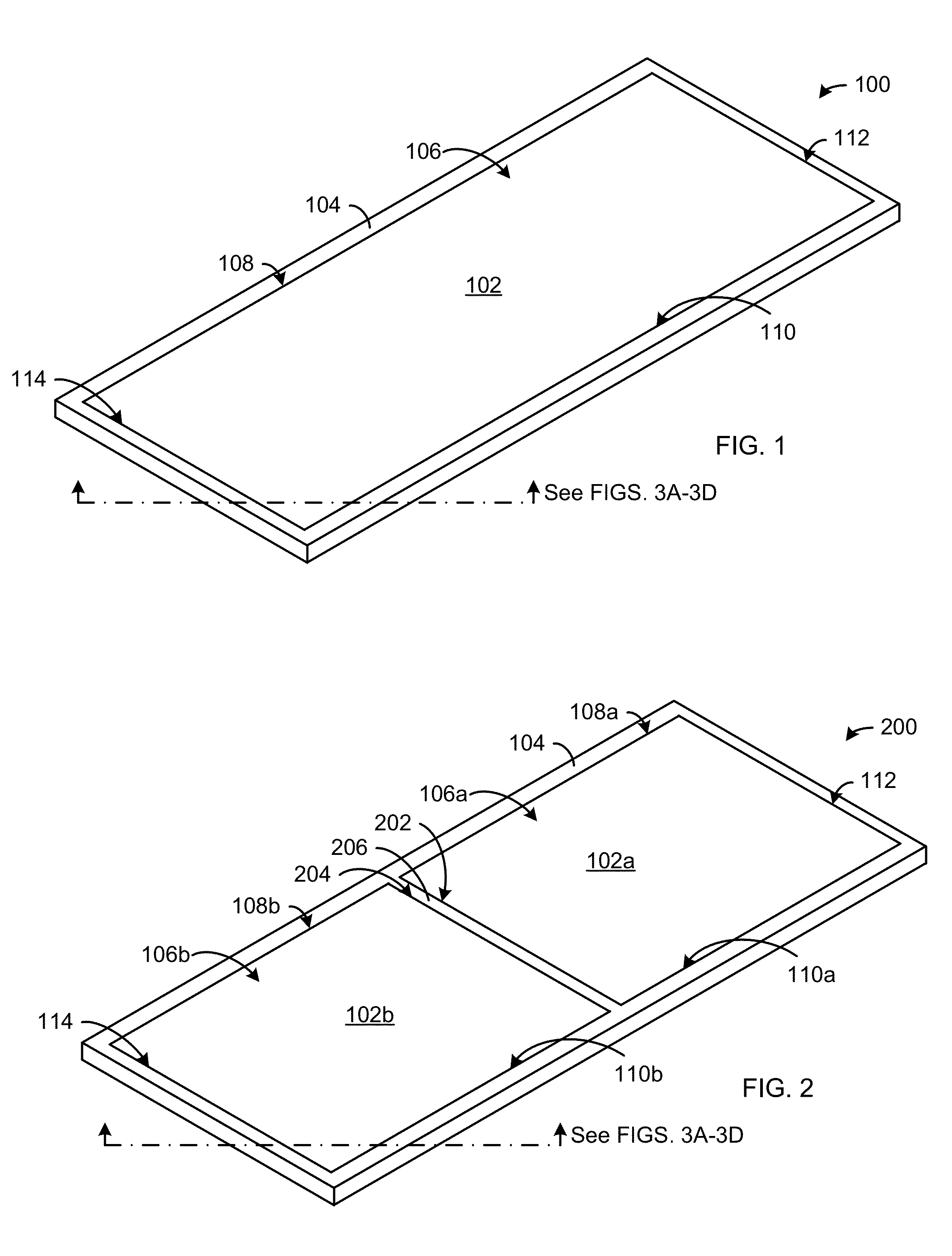

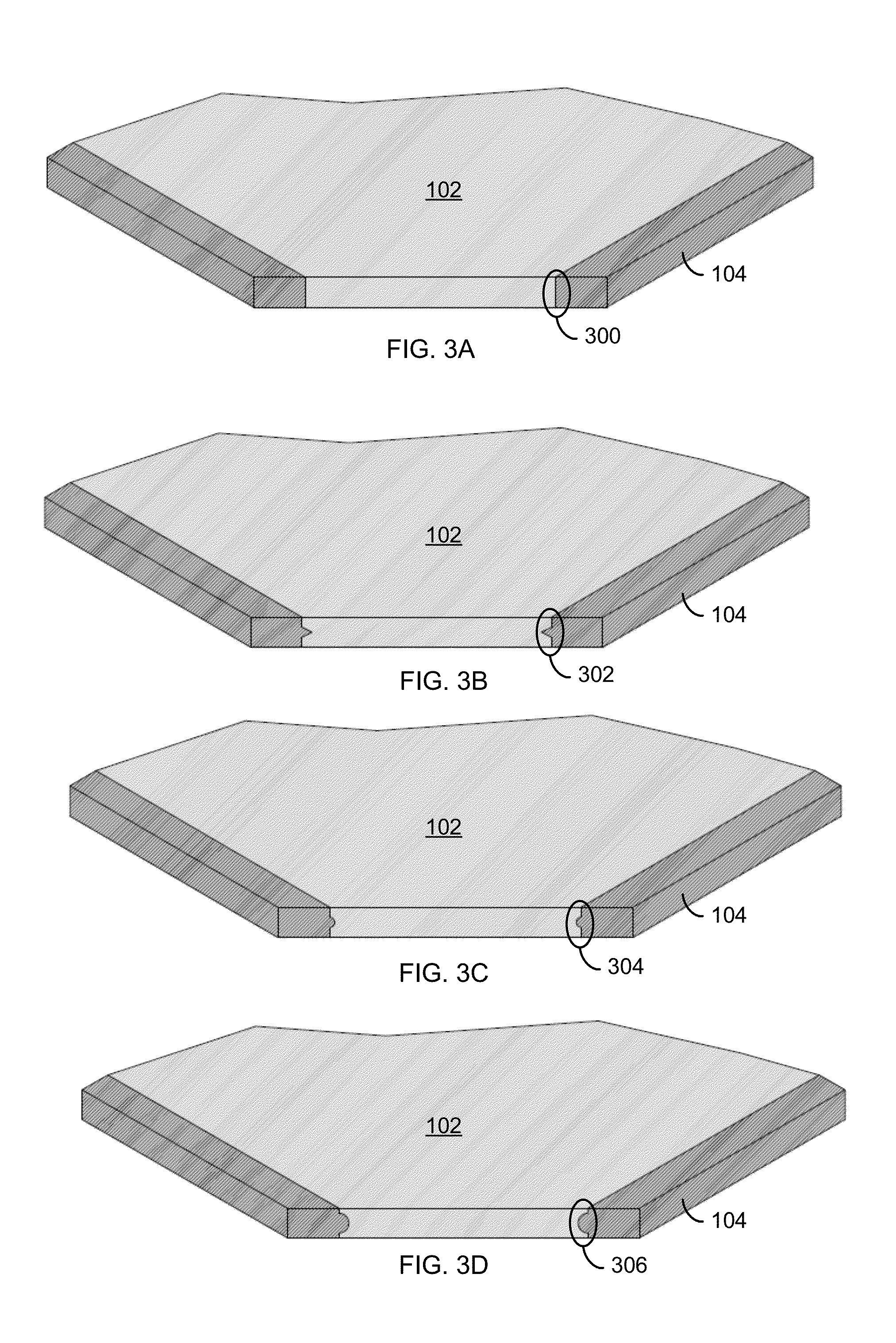

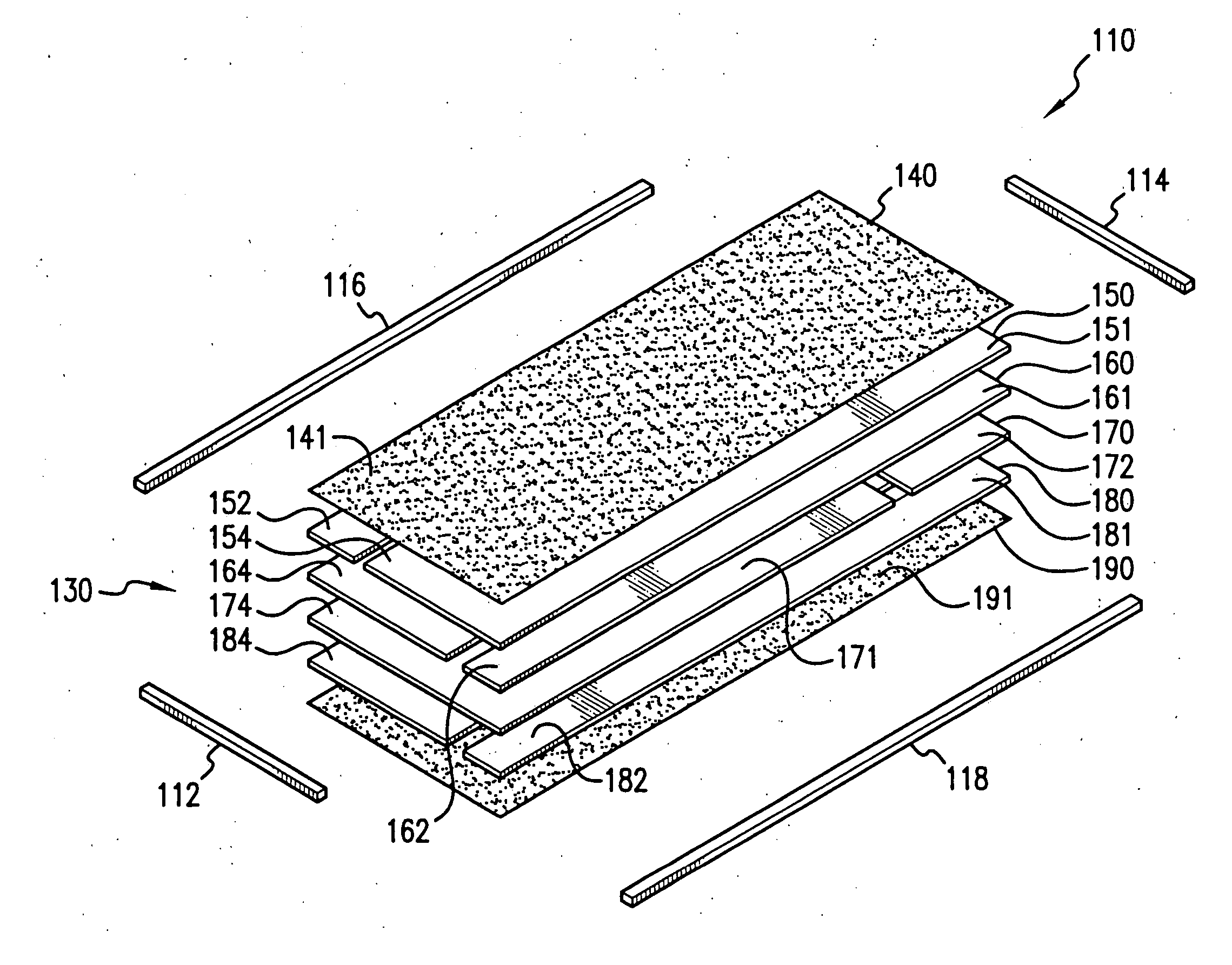

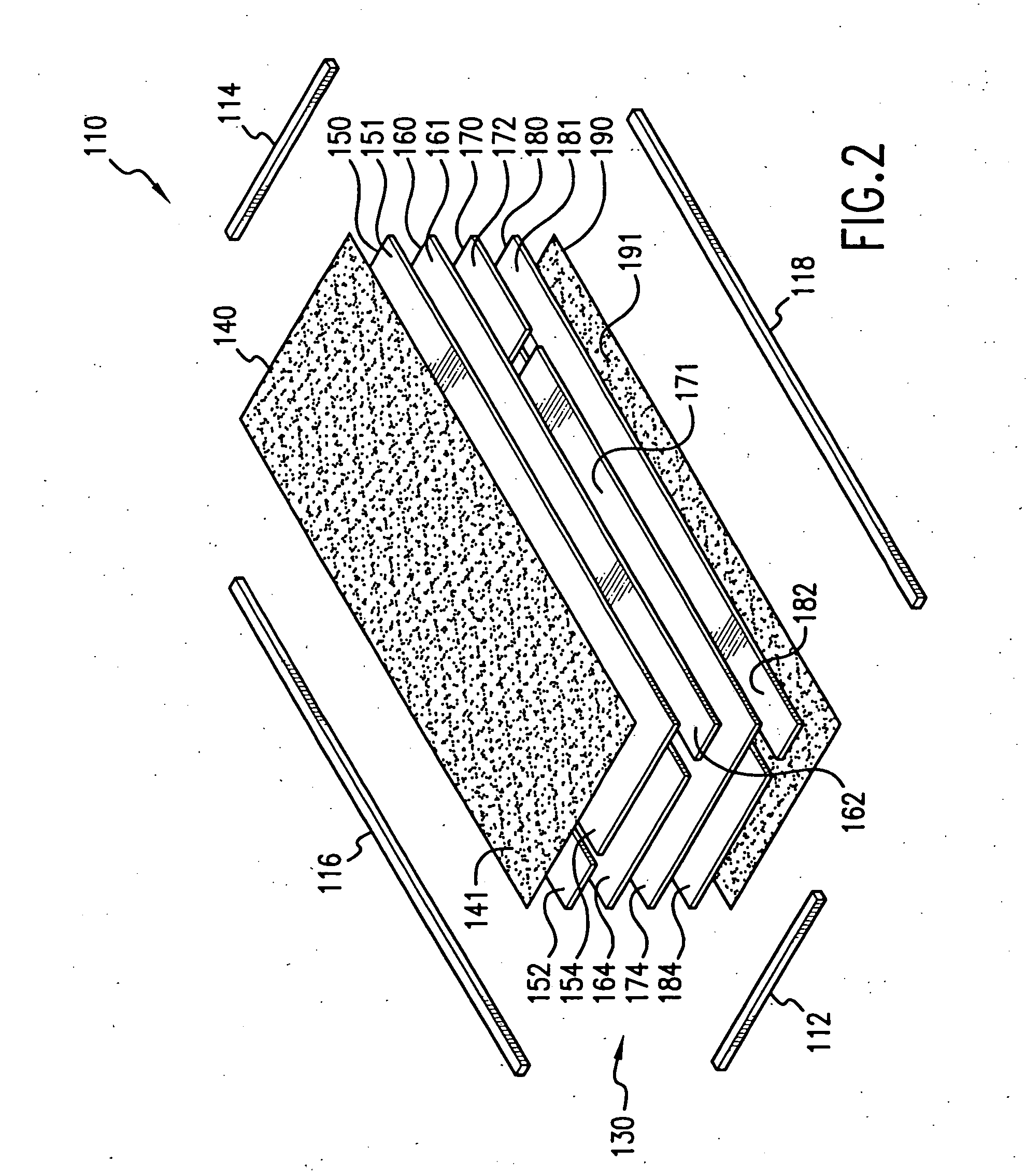

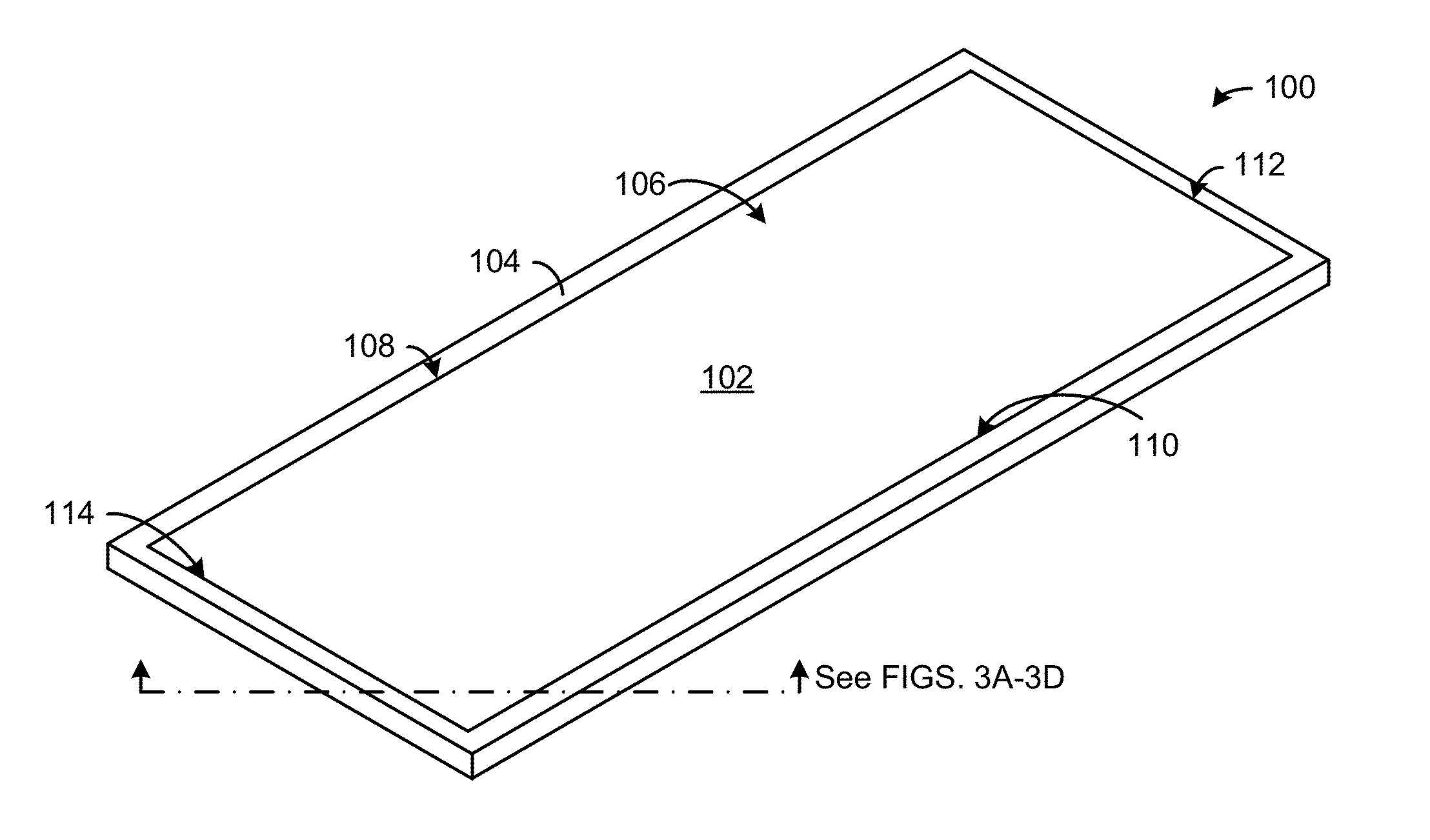

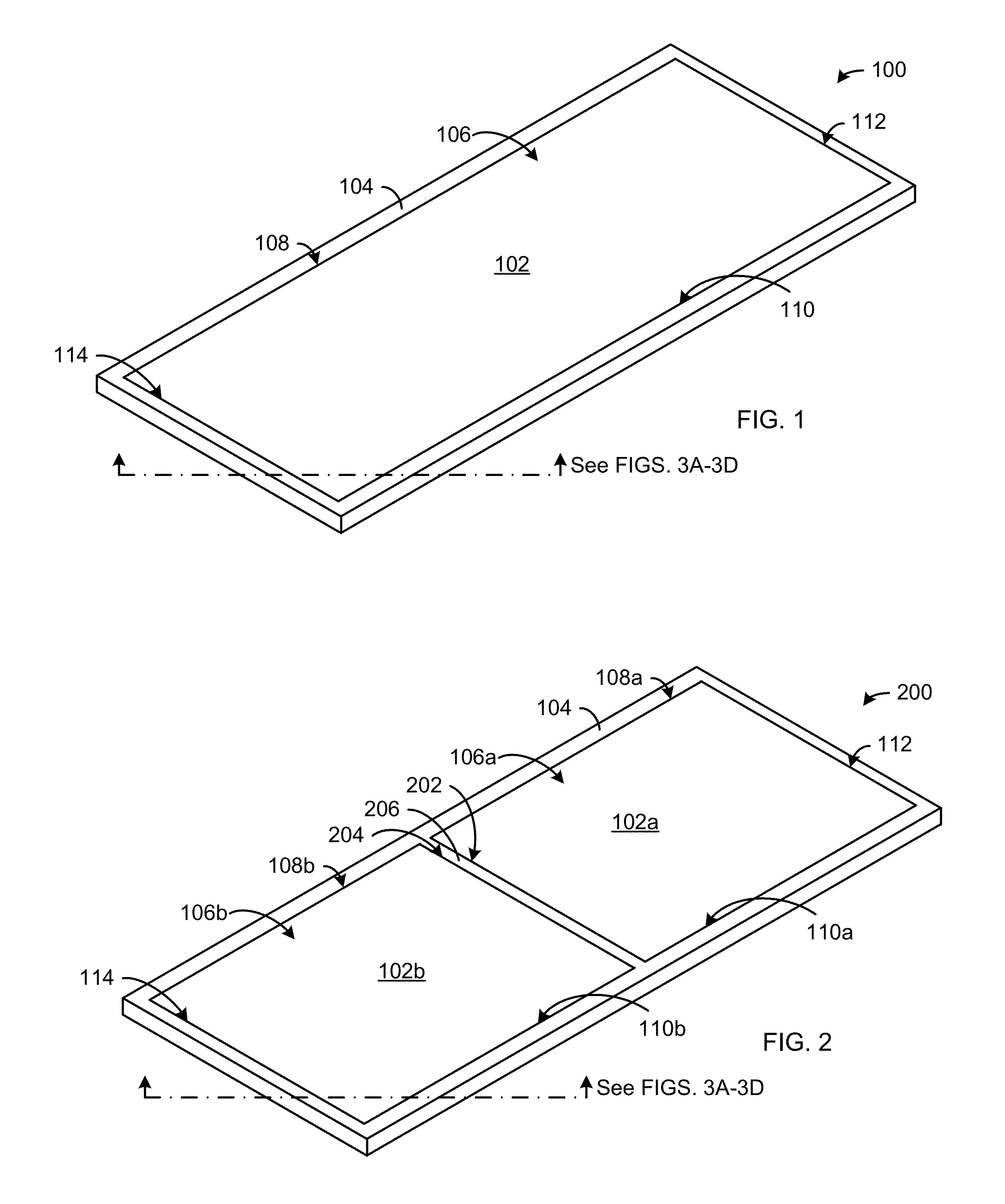

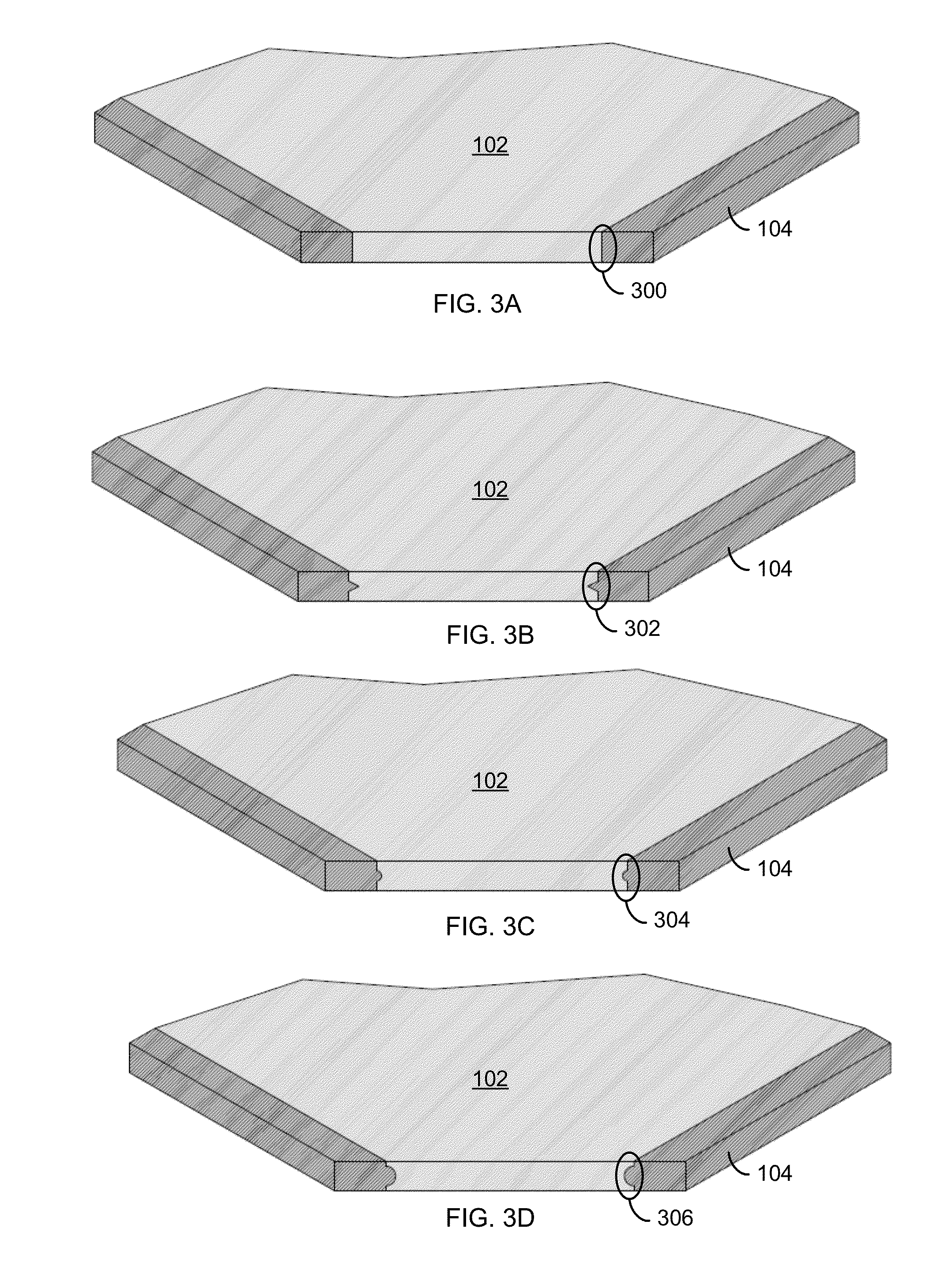

System, Method and Apparatus for Producing Fire Rated Doors

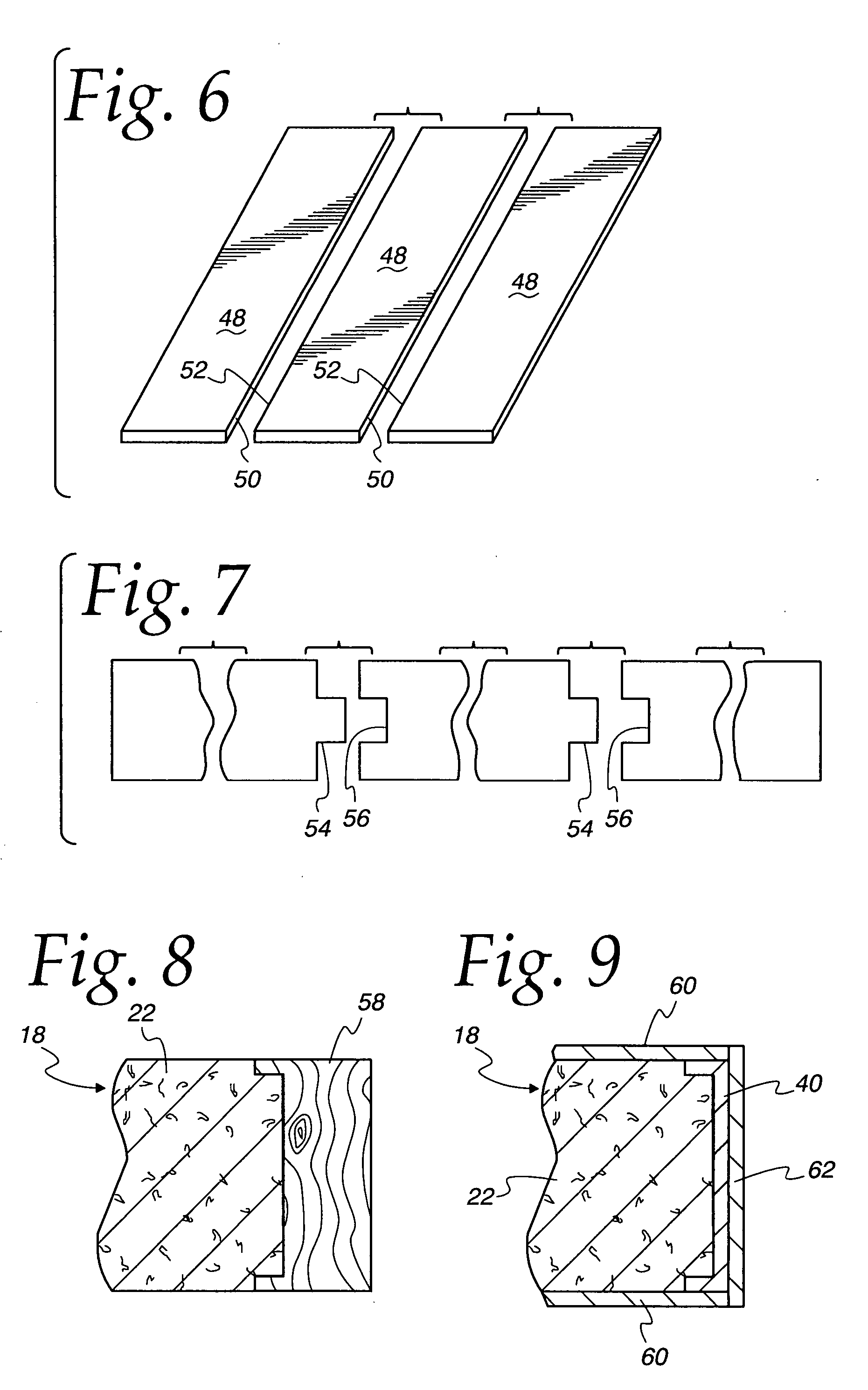

ActiveUS20070193220A1High strengthRaise the gradeFireproof doorsDoor leavesEngineeringUltimate tensile strength

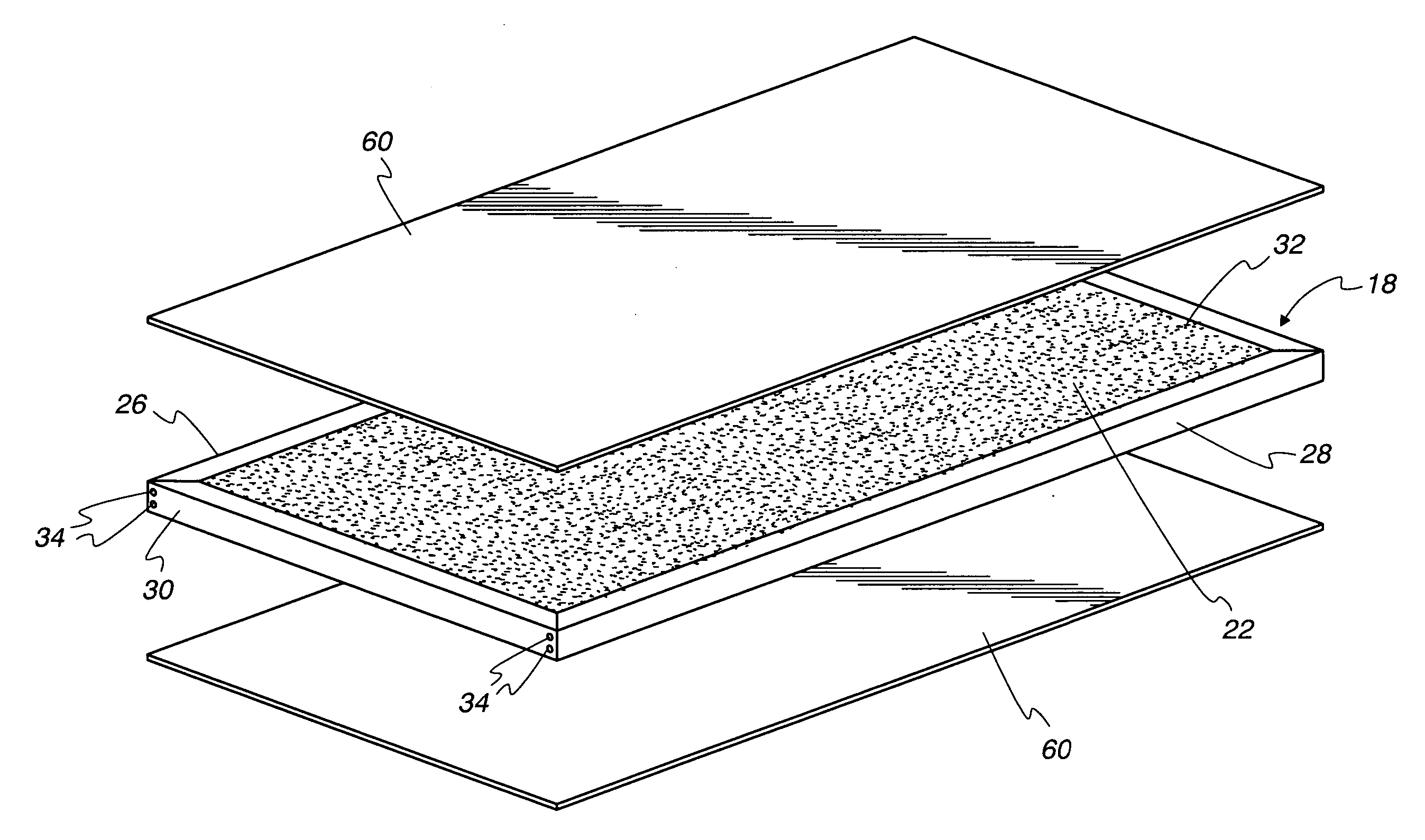

The present invention provides a system, method and apparatus for producing fire rated doors having added strength, better finishing and low cost manufacturing flexibility. The fire rated doors are made from two panels “sandwiched” together. An optional interior layer (e.g., fire resistant material, lead sheeting, steel or Kevlar) can be added between the door panels for various purposes. Splines, stiles or sticks are inserted in longitudinal channels in the door panels to provide assistance in aligning the door panels and greater hardware holding strength. An intumescent banding material concealed by a banding material around the perimeter of the door seals the door within its frame during a fire. The door design and the automated manufacturing process provide greater design choice, reduced cost and faster fabrication.

Owner:POLYMER WOOD TECH

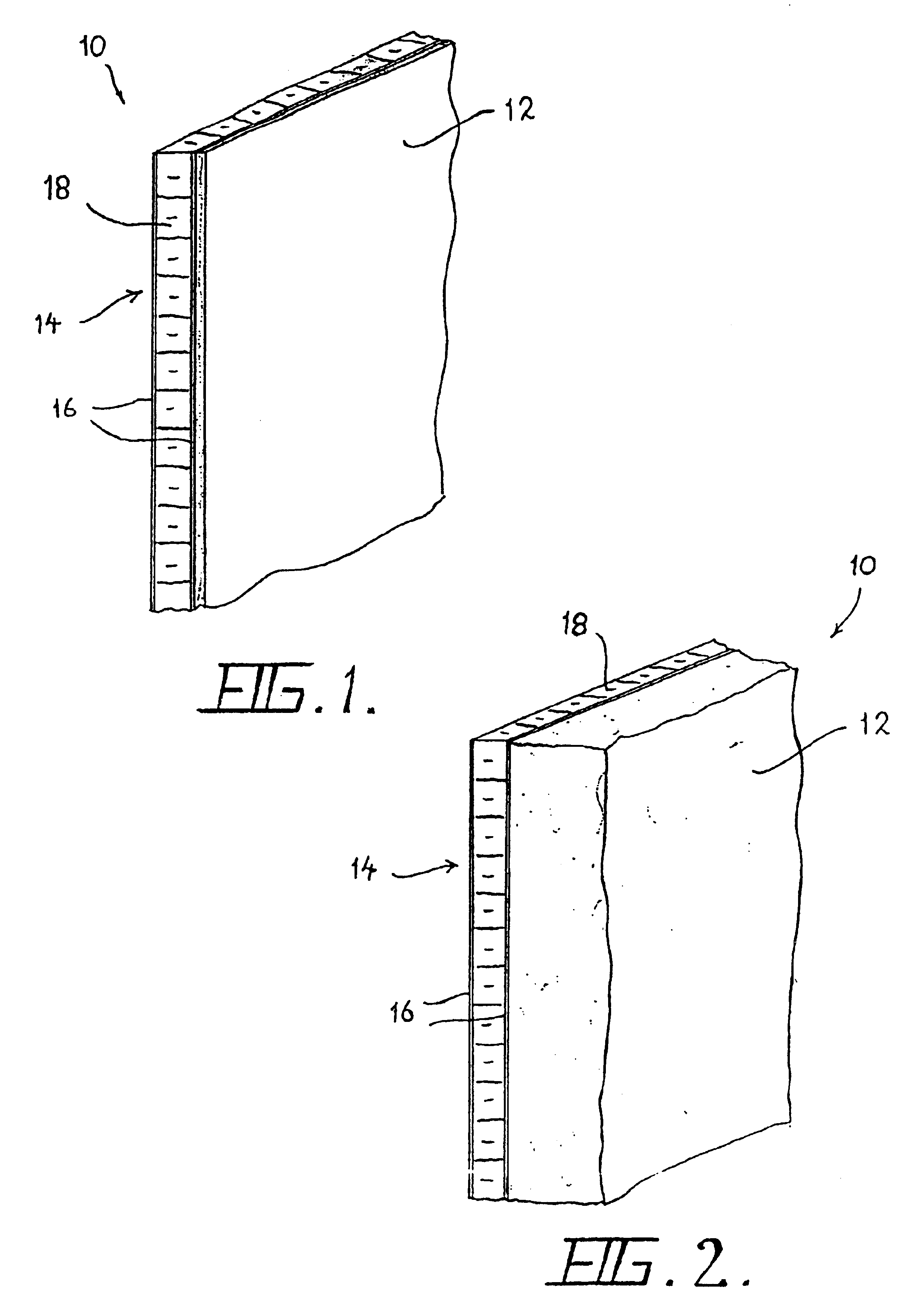

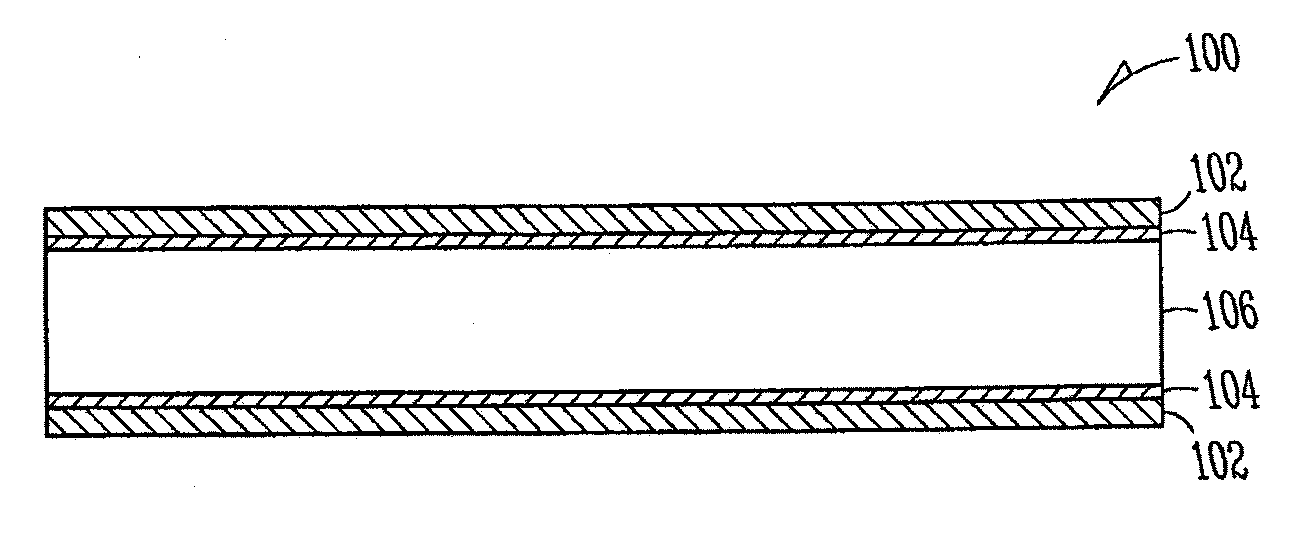

Multi-layered fire door and method for making the same

InactiveUS7185468B2Reduce complexityLow costFireproof doorsSynthetic resin layered productsPorous layerEngineering

A door has a core that includes a porous layer having a thickness and two opposing major surfaces. In one construction, the core also includes three fire-retardant layers, and two of the fire-retardant layers are separated by the porous layer. The porous layer and the fire-retardant layers are coupled together. Other constructions include one or more fire-retardant layers in balanced or unbalanced placement around the porous layer.

Owner:JELD-WEN

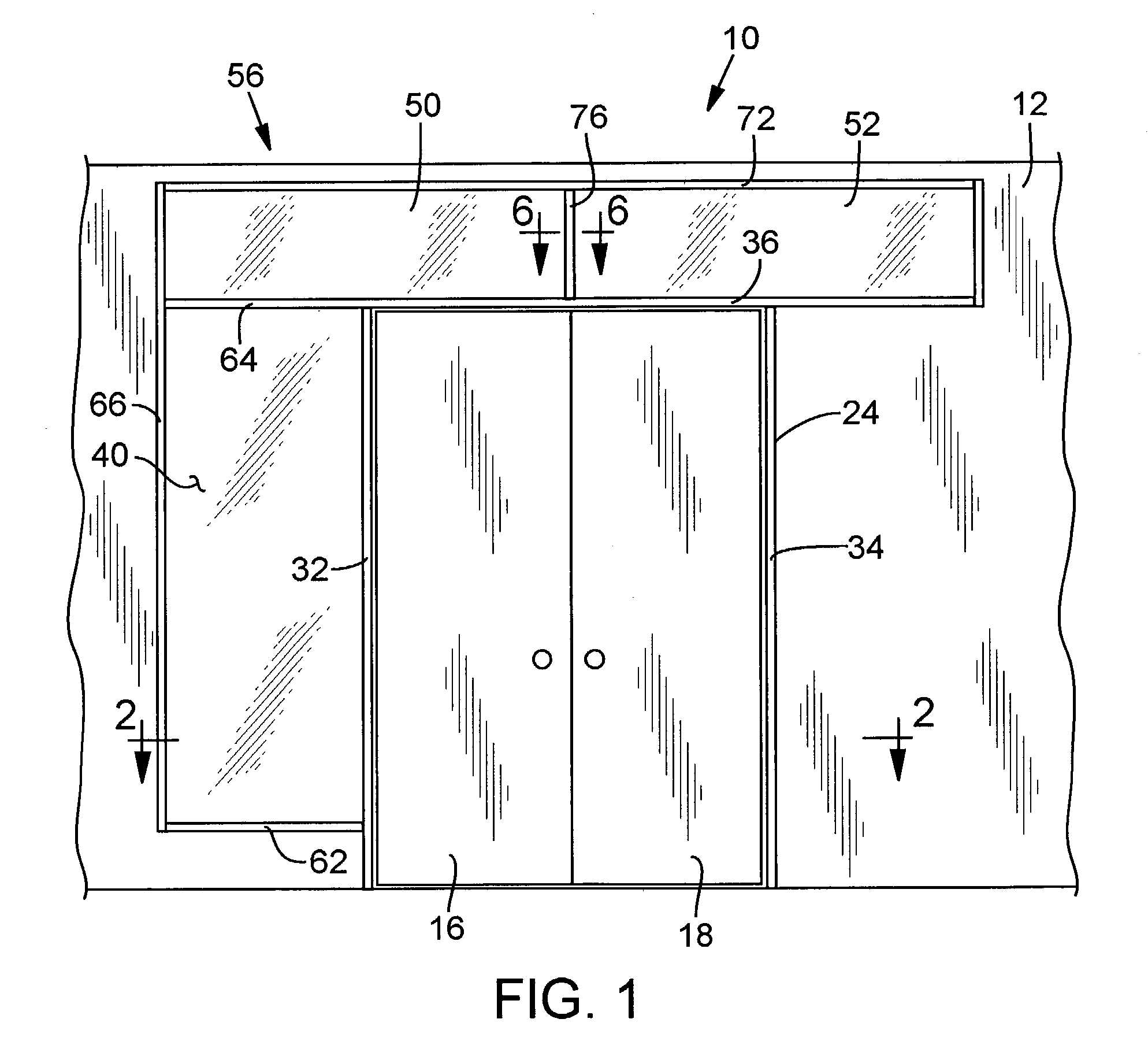

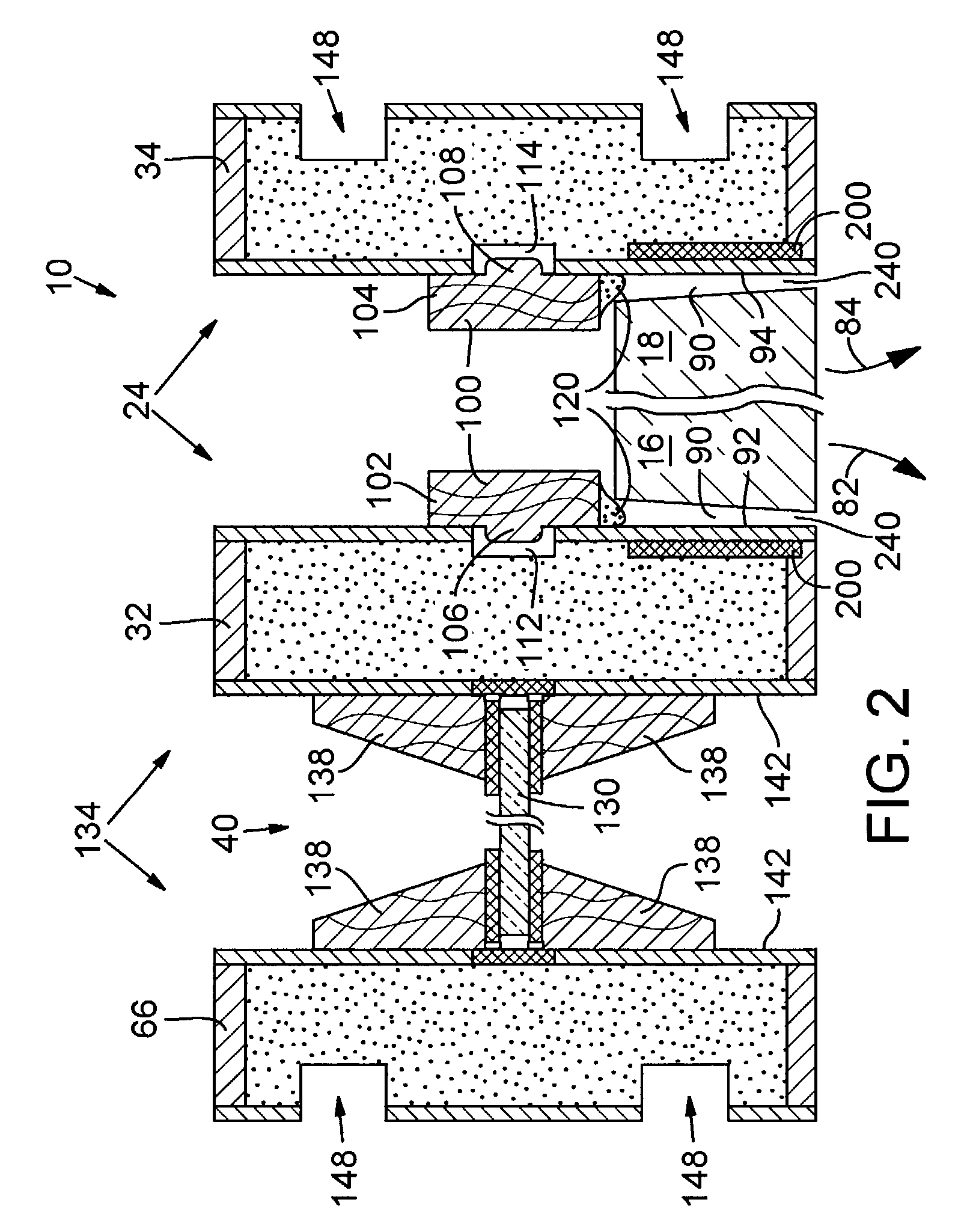

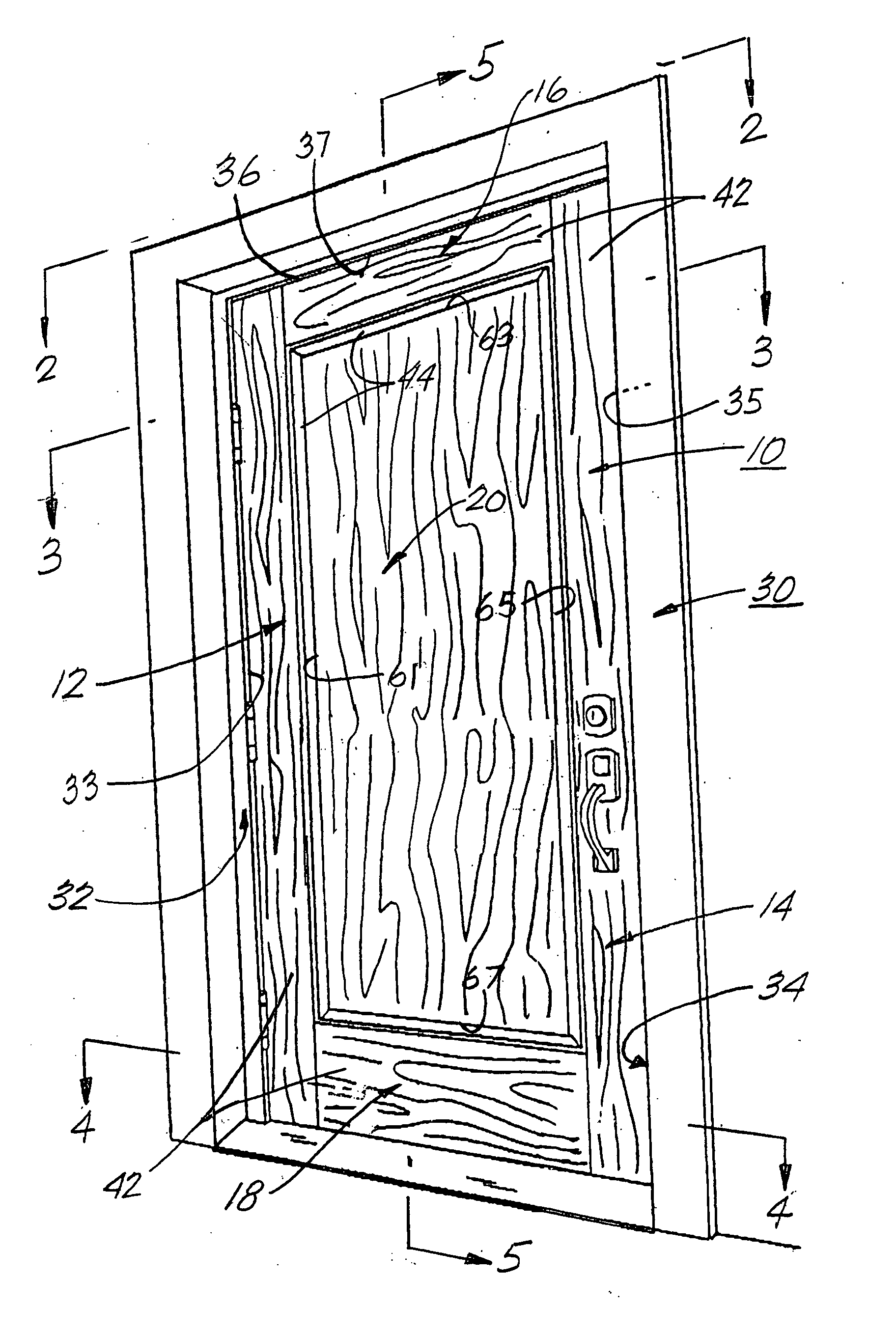

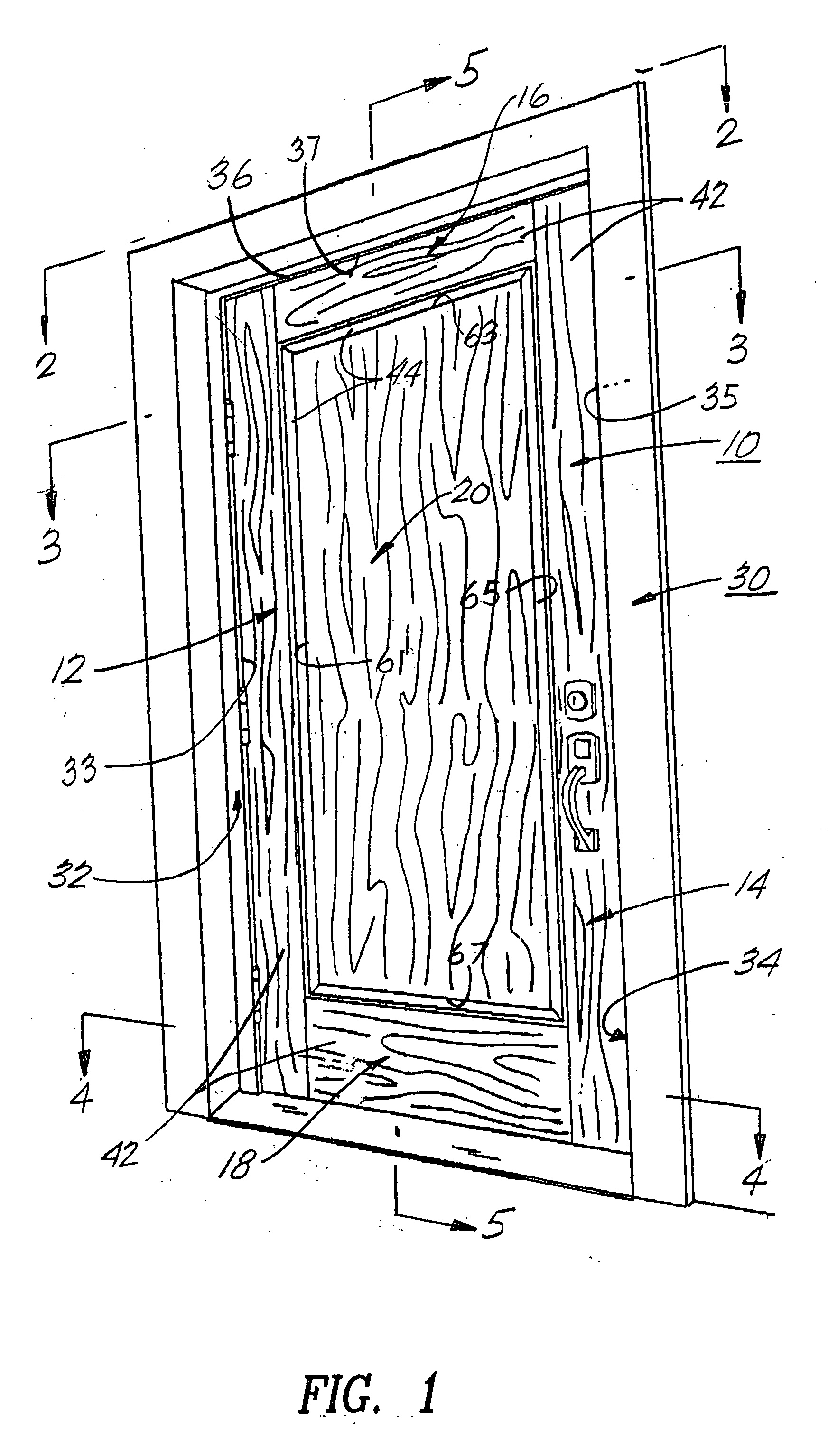

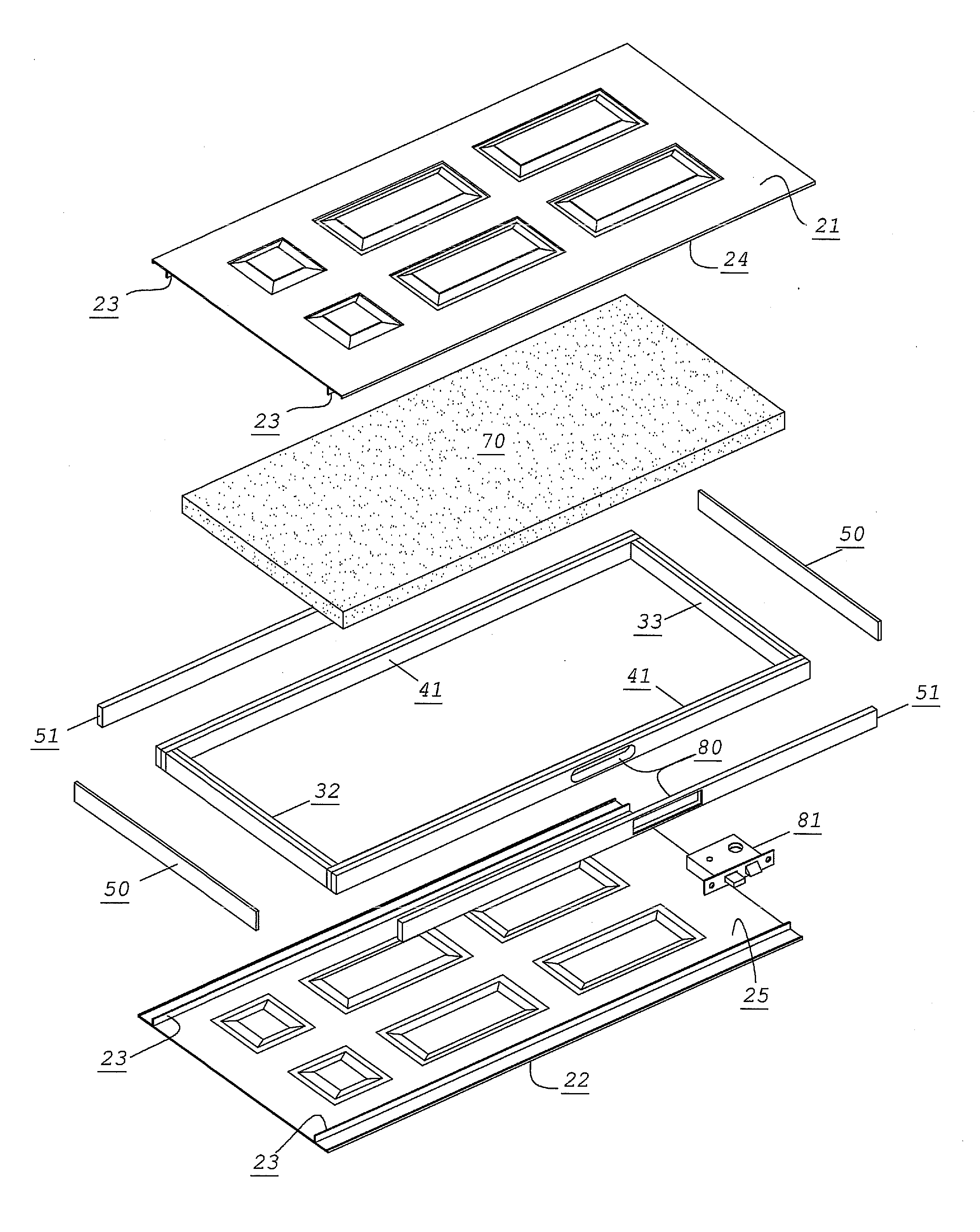

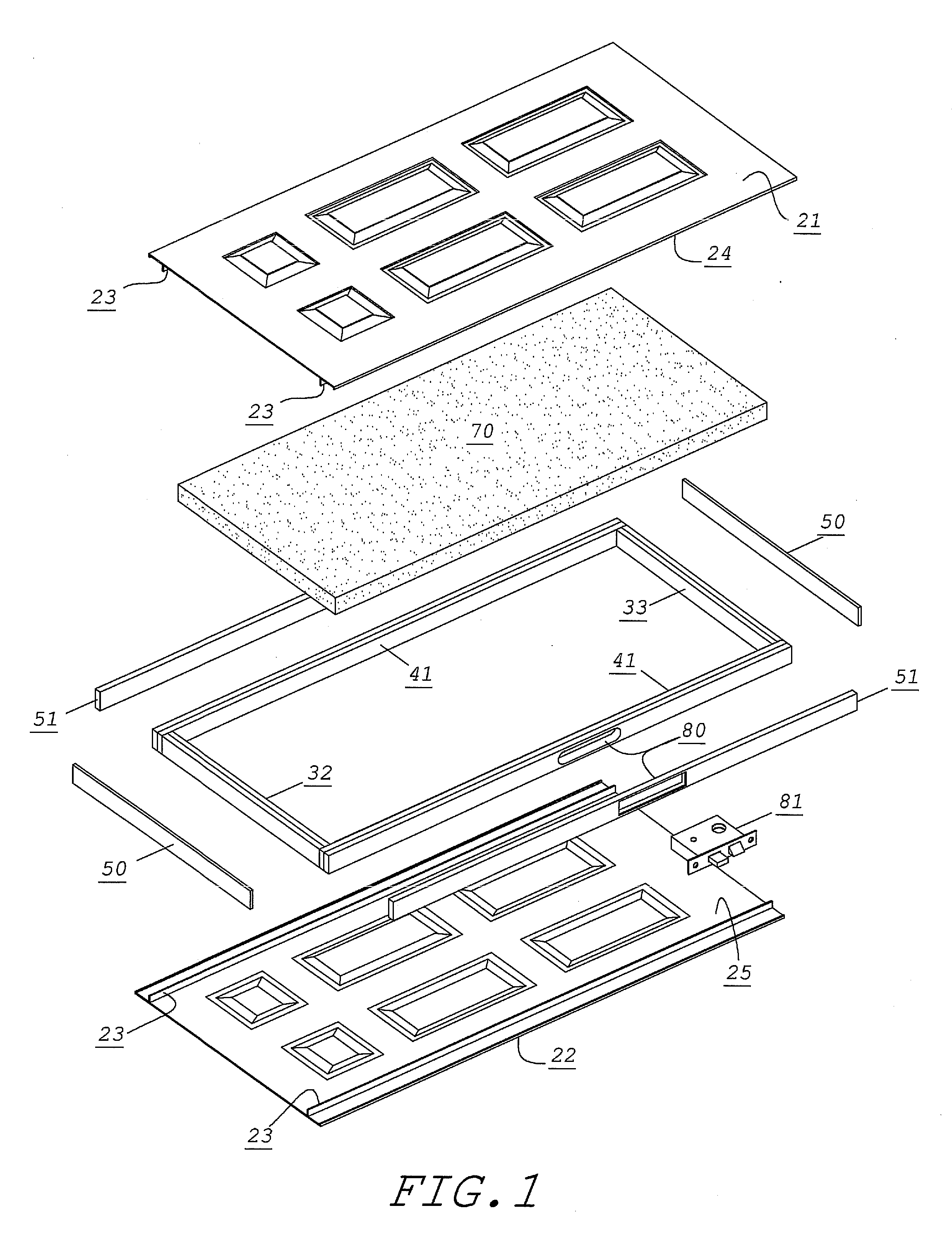

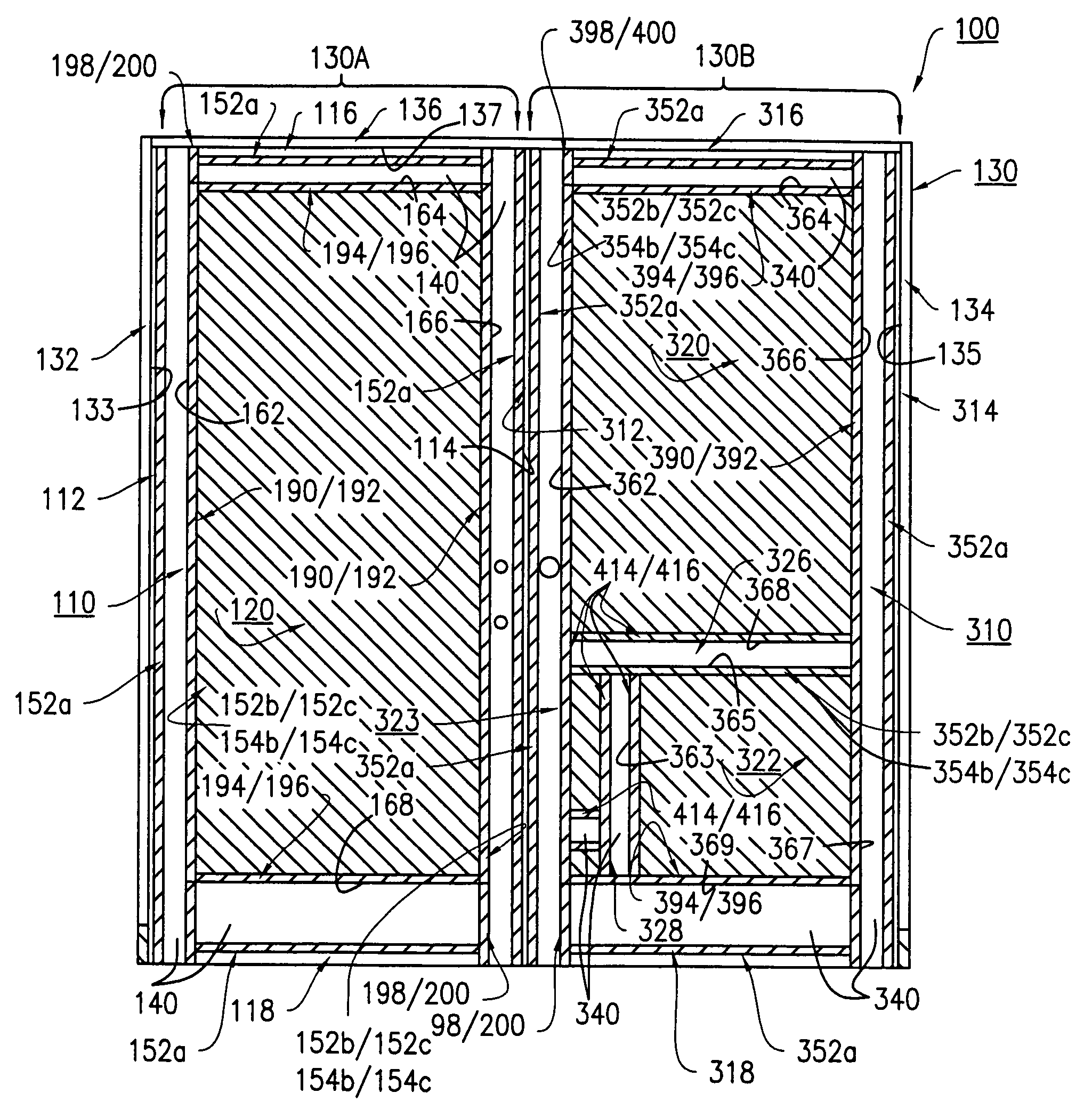

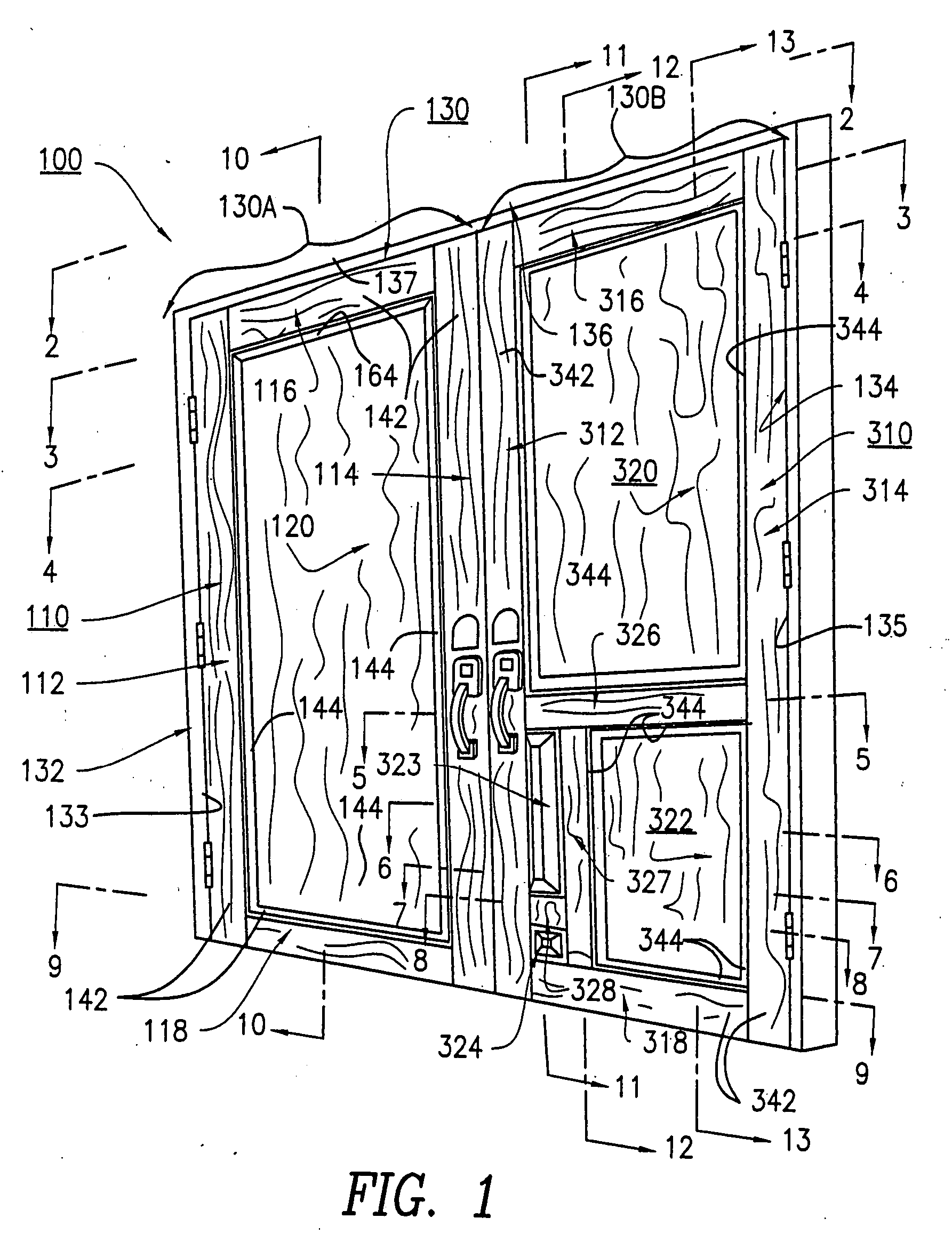

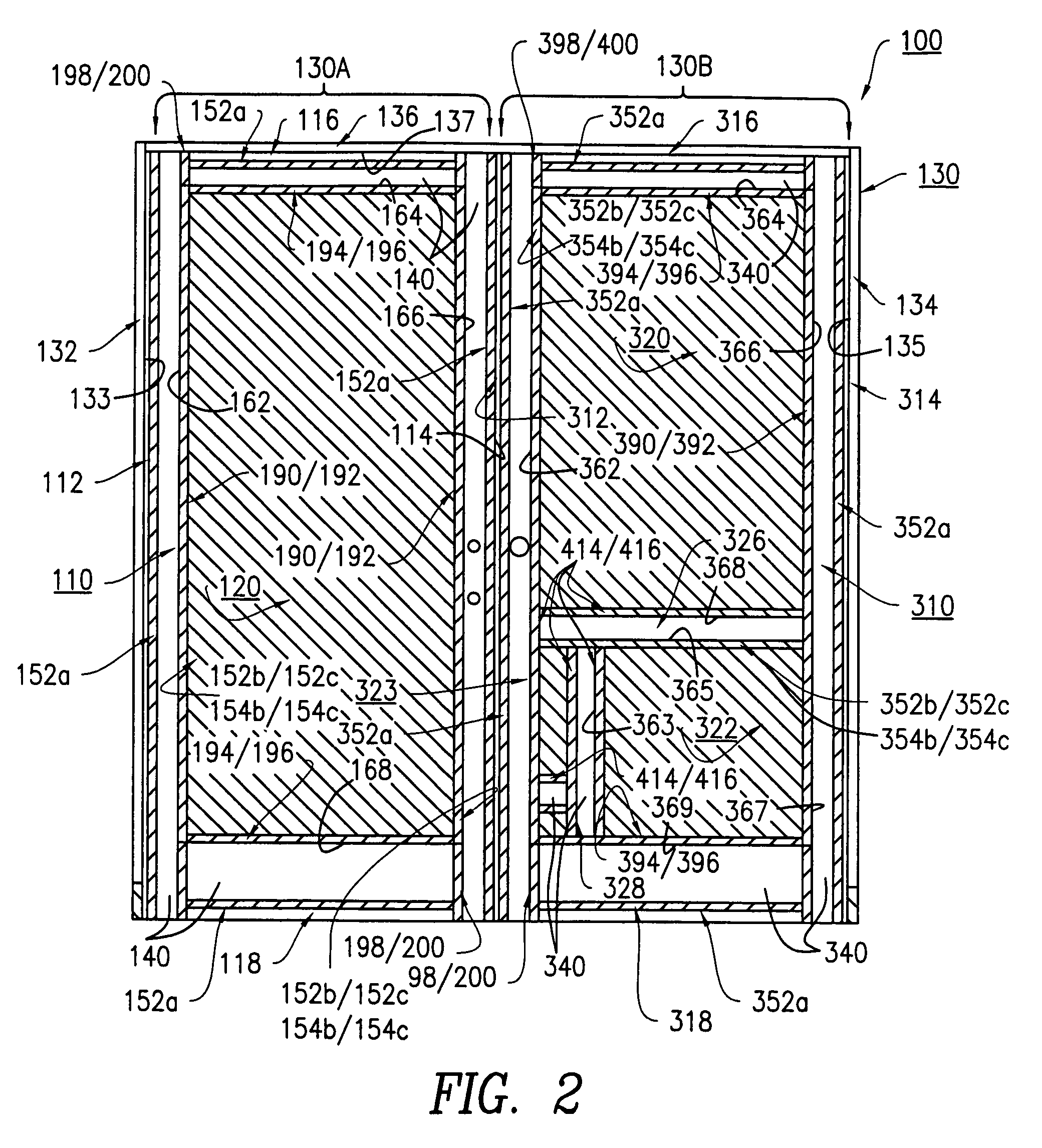

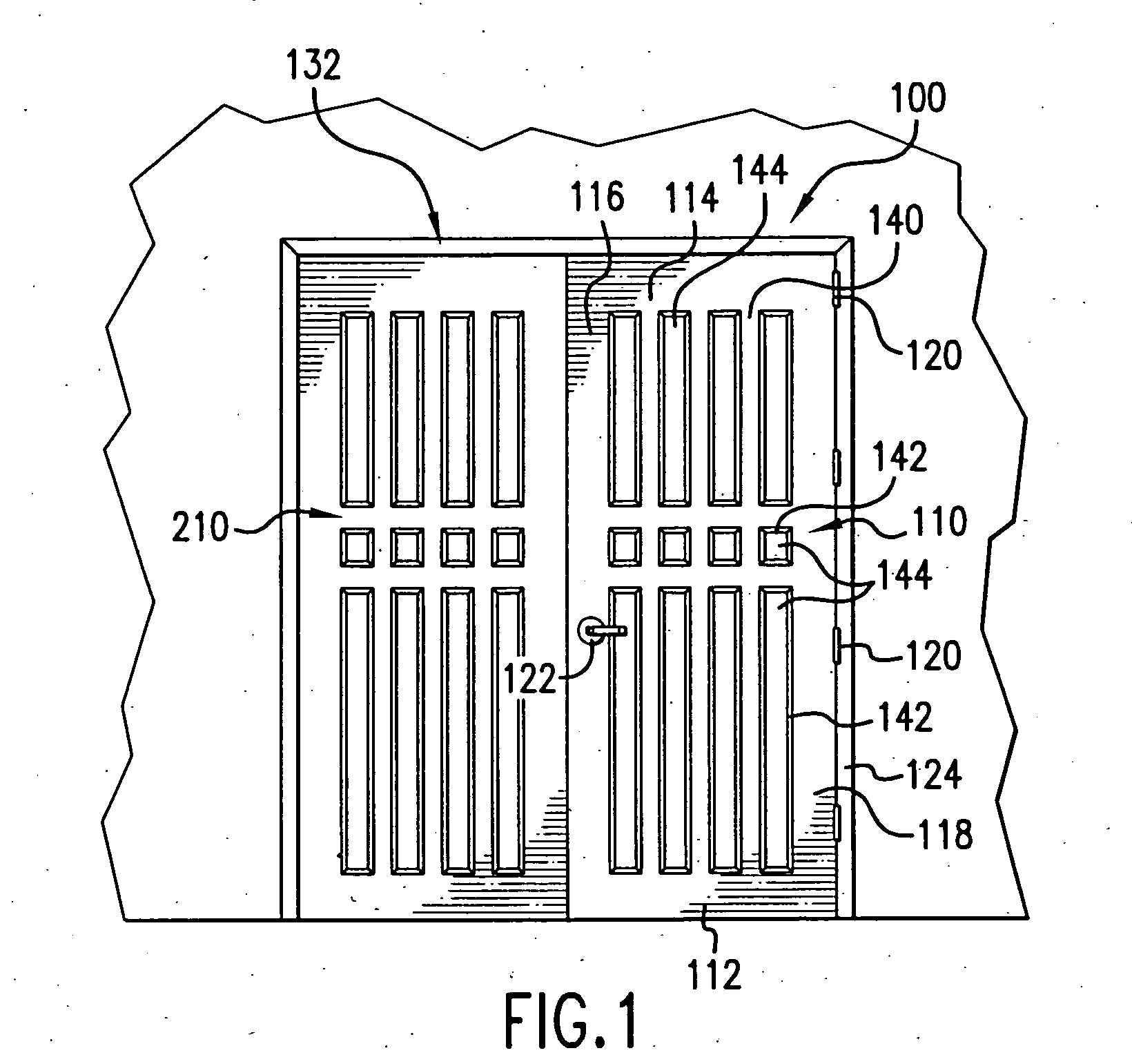

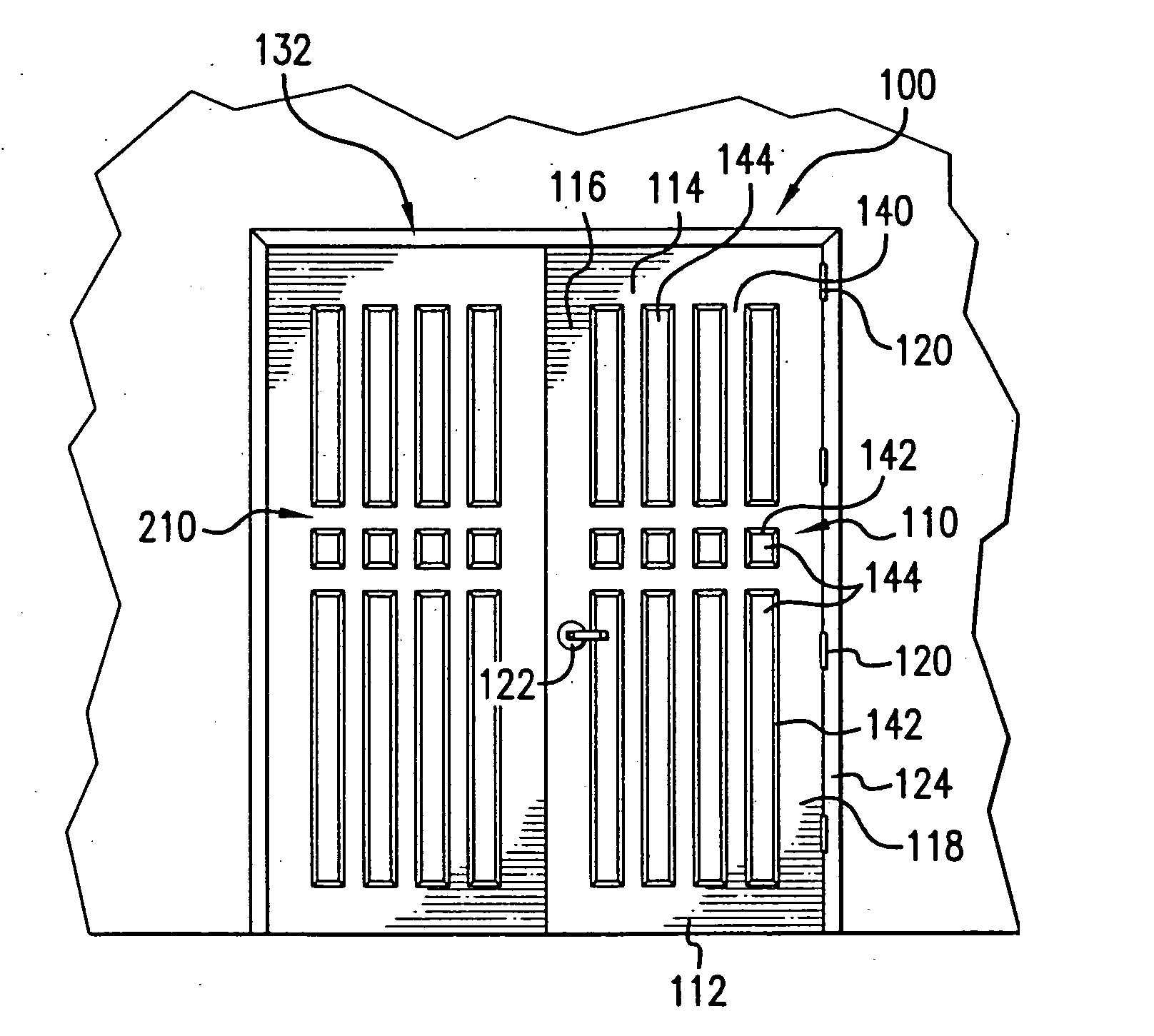

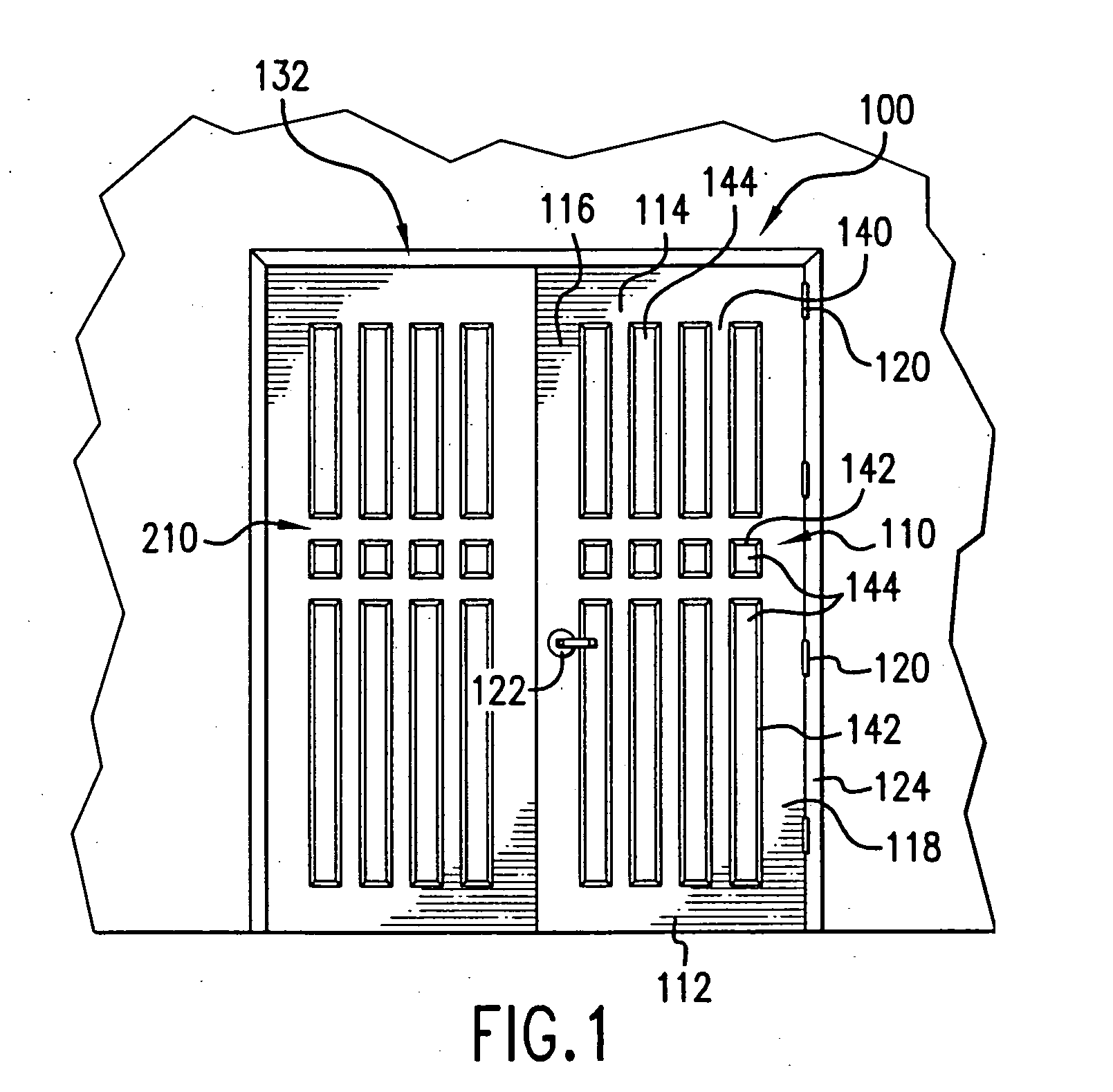

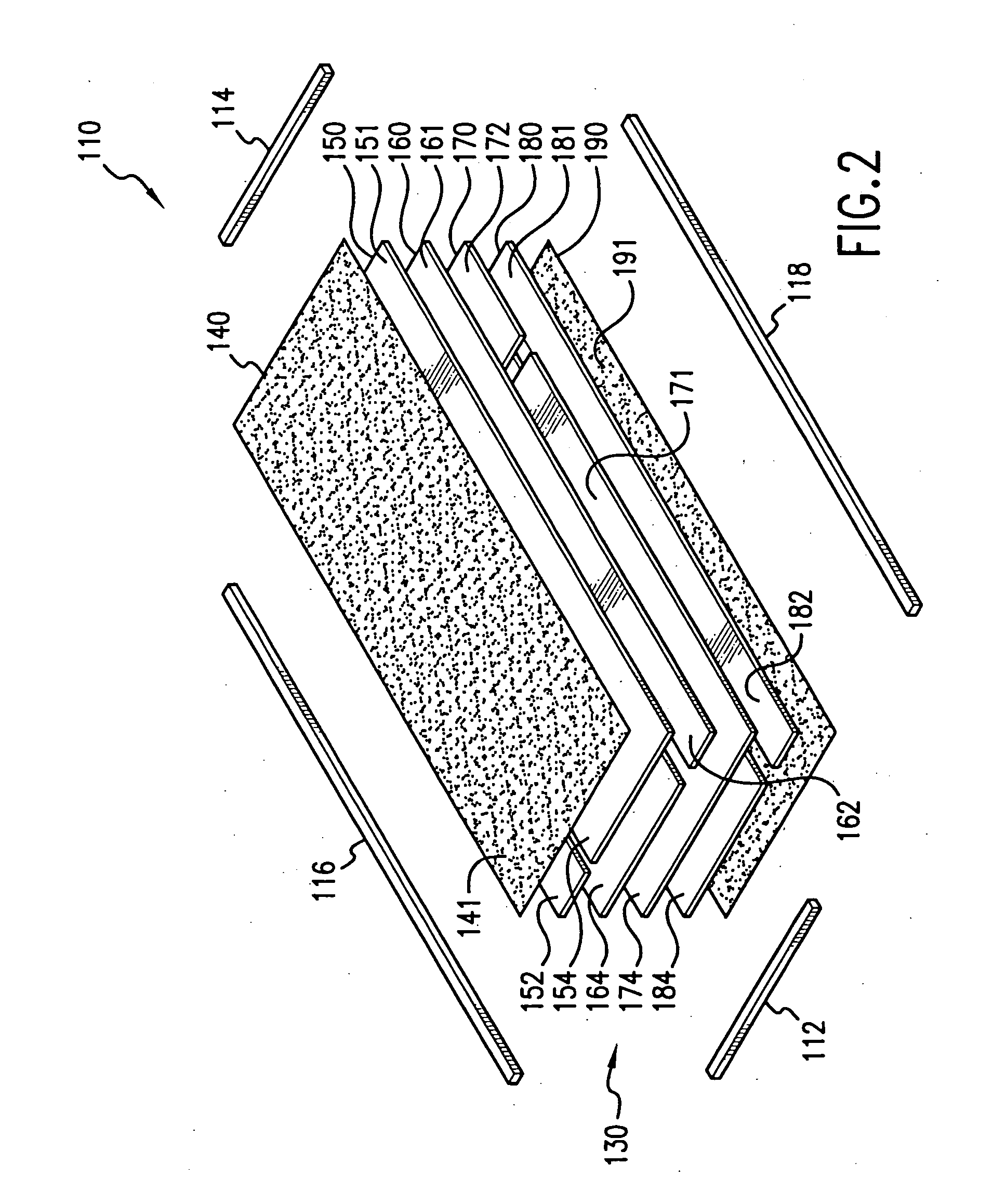

Fire retardant panel door and door frame having intumescent materials therein

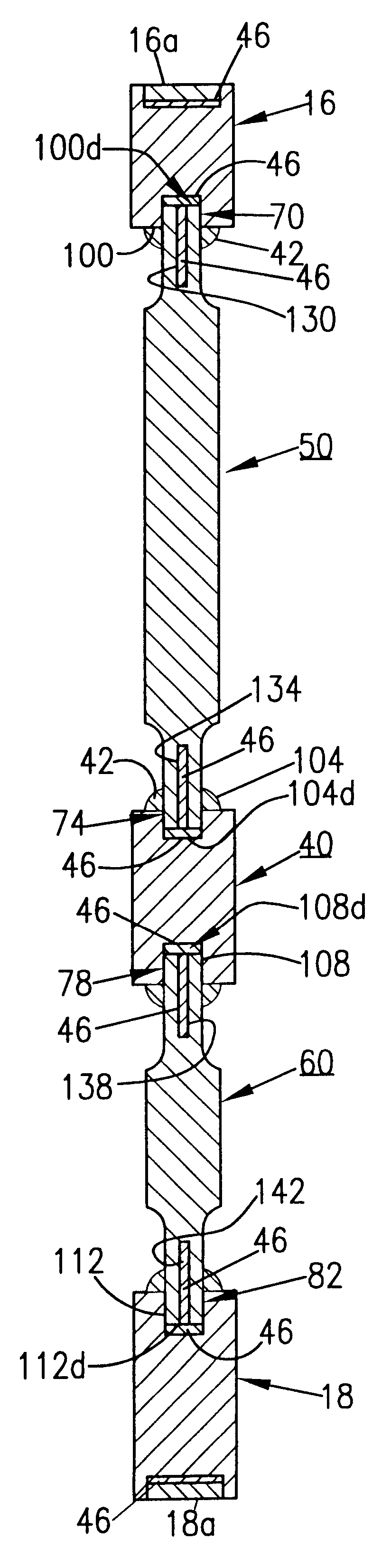

InactiveUS20050284030A1Prevent the spread of fireFireproof doorsBuilding locksComposite laminatesRefractory

A fire retardant panel door and door frame that prevents the spread of fire through the door during a fire. The fire retardant panel door has at least one door panel and stiles and rails. The door panel includes an interior center composite section formed by a first plurality of layers of intumescent materials and a first plurality of layers of fire resistant materials disposed between and laminated to a pair of outer sections formed of wood for enclosing the interior center composite section to form a composite laminated door panel. Each of the stiles includes a first center core formed of wood enclosed by a second plurality of layers of intumescent materials and a second plurality of layers of fire resistant materials; and the second layers of intumescent and fire resistant materials are enclosed by a first applique layer formed of wood to form a composite laminated stile. Each of the rails includes a second center core formed of wood enclosed by a third plurality of layers of intumescent materials and a third plurality of layers of fire resistant materials; and the third layers of intumescent and fire resistant materials are enclosed by a second applique layer formed of wood to form a composite laminated rail. The first, second, and third plurality of layers of intumescent materials are activated to expand upon exposure to heat and / or fire to prevent the heat and / or fire from passing through at least one door panel, the stiles and the rails of the panel door during a fire for at least 90 minutes. At least one door panel is connected to the panel door by tongue and groove joints; and the tongue and groove joints have a fourth plurality of layers of intumescent materials and a fourth plurality of layers of fire resistant materials in the tongue and groove joints; and wherein the fourth plurality of layers of fire resistant materials in the tongue and groove joints are activated to expand upon exposure to heat and / or fire to seal the joints in order to prevent the heat and / or fire from passing through the panel door during a fire for at least 90 minutes.

Owner:ATRISTIC DOORS & WINDOWS

Gypsum Composites used in Fire Resistant Building Components

A composite product includes gypsum in an amount of 70 to 90% by weight, fibers in an amount of 1.5 to 26% by weight substantially homogeneously distributed through the composite, and a rheology-modifying agent in an amount of 0.5 to 6% by weight. The composite is caused or allowed to cure to form a cured composite. The cured composite is a fire resistant component used in a fire-rated door core, a fire-rated door or a fire-rated building panel. The fire resistant component may include a building panel, a door panel, a door core, a door rail, a door stile, a door lock block, a door border, or a door insert.

Owner:THE INTELLECTUAL GORILLA

Synthetic door with improved fire resistance

Using integrally formed stiles on skins of sheet molded plastics (thermosetting) employed to form the exterior surfaces of a synthetic door having sheets of reinforcing materials adhered to the inner surface of each of the skins, the skins can be connected through the integral stiles and slats of a fire proof materials can be affixed to these stiles and rails closing the top and bottom opening between the skins to increase the fire resistance of the resulting door when the core is filled with a phenolic foam. The structure described reduces the weight of the resulting door and places the fire resistant materials around the door edges which are the most susceptible to failure during a fire while structurally tying the slats together through the sheets of carbon fiber or fiberglass disposed on the inner surfaces of the skins whereby failure (disintegration) of the skins during a fire will not lead to a collapse of the door as with some prior art door structures. A slat of polyvinyl chloride can be employed to cover the fire proof slats so the door edges can be trimmed so it will fit into the door frame and the edges will be pleasingly attractive.

Owner:CHEN KUEI YUNG WANG

Ceramicized silicon rubber, preparation method and application

ActiveCN102964836AEasy to processReduce manufacturing costRubber insulatorsPlastic/resin/waxes insulatorsCouplingOrganic group

The invention relates to a ceramicized silicon rubber, which comprises 1)60-100 parts of silicon rubber, wherein a general formula is (RnSiO4-n / 2)m, R is an organic group, n is the organic number (1,2,3) connected to silicon atoms, and m is polymerization degree (greater than and equal to 2); 2)20-100 parts of silicon dioxide; 3)1-20 parts of silicone oil, wherein the general formula is (RnSiO4-n / 2)m, R is an organic group, n is the organic number (1,2,3) connected to silicon atoms, and m is polymerization degree (greater than and equal to 2); 4)0.1-10 parts of coupling agent and 5)20-120 parts of ceramicized powder. The above raw materials are mixed in a kneader and then vacuumized, the ceramicized powder and the coupling agent are added in the kneader and then uniformly mixed to form the bulk ceramicized rubber, and the ceramicized rubber is performed roll mixing and filtered to obtain the ceramicized silicon rubber. The ceramicized silicon rubber has the advantages that the processing is easy, the production cost is low, the ceramicized silicon rubber can be performed ablation to a ceramic shell, and can protect the burned objects from damaging.

Owner:常州市沃科科技有限公司

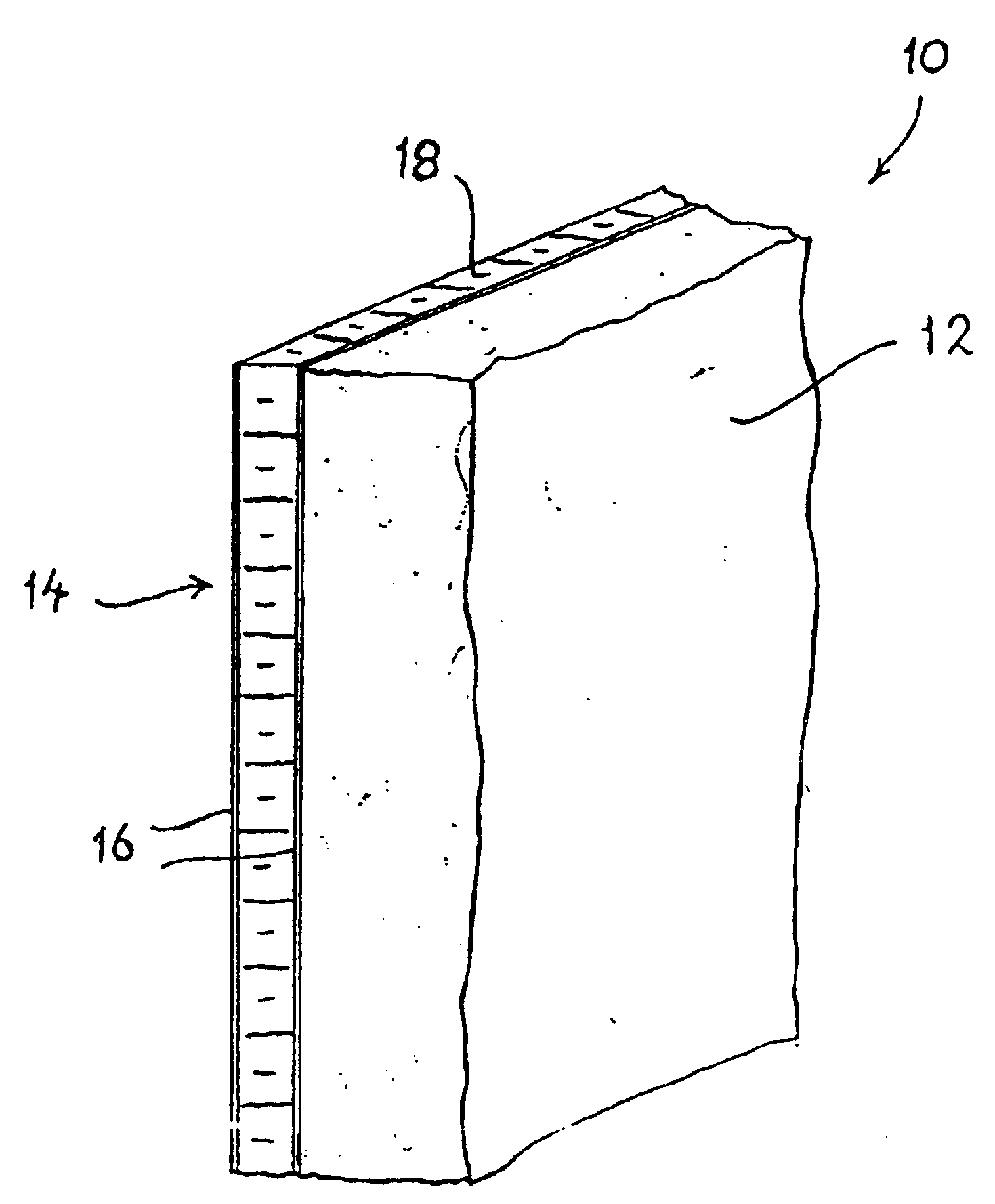

Fire barrier panel

A fire barrier panel of the kind suitable for lining car decks and engine rooms of high speed aluminum ferries is described. The panel (10) includes a relatively thin layer of inorganic insulating material (12) adhered to a lightweight support structure (14). The layer of inorganic insulating material may be an intumescent material made from mineral fibers. The decribed lightweight support structure (14) is a honeycomb panel having a honeycomb core (18) of non-combustible aluminum foil provided with two face skins made of glass reinforced plastics resin material (16). This construction of the honeycomb panel (14) is lightweight and has high stiffness and rigidity suitable for stiffening and supporting the insulating material into a rigid panel. The layer of intumescent material (12) supported on the panel expands when exposed to high temperatures to form a thick fire insulating barrier panel. Because the panels are self-supporting, and therefore support structures, installation costs are much lower than for prior art fire insulation systems.

Owner:ASHMERE HLDG

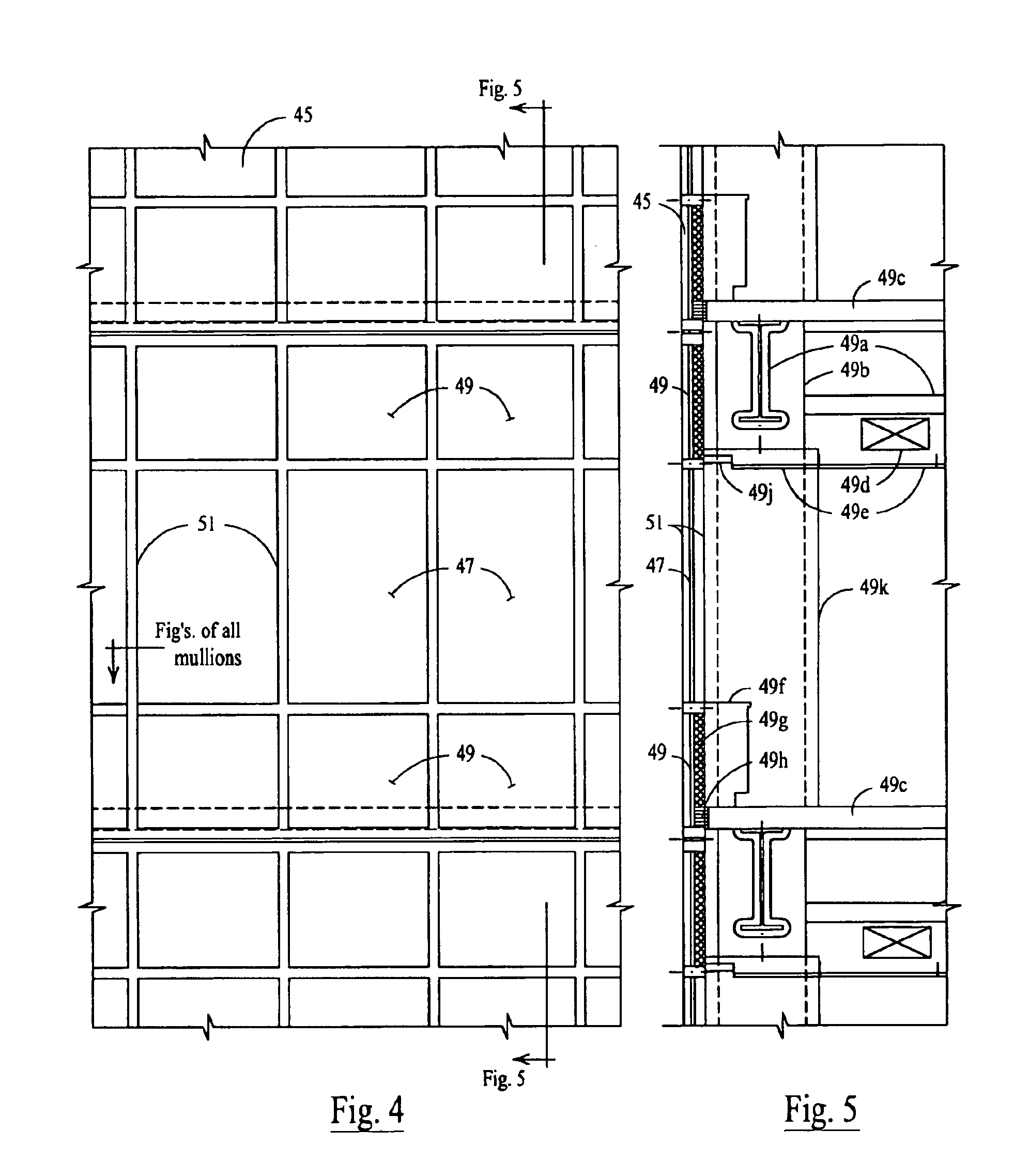

Fire resistant rated fenestration, including curtain wall systems, for multiple story buildings

Apparatus and systems for a fire resistant rated fenestration including curtain wall systems for multiple story buildings capable of withstanding a seismic load. Fire resistant panels are mounted in a fire resistant mullion where the mullion may be one element, or may have an inner structural shell and an outer shell. A barrier of fire resistant material is disposed between the inner and outer shells. A sealer compound or a fire resistant compressible filler seals the space between the mullion and the fire resistant panels. The inner structural shell member is connected to an elastic panel fastener that is connected at its opposite end to fire resistant panels. The fastener allows the fire resistant panels to move in response to a seismic load without damage to the mullion or panels.

Owner:MEDIA CURTAINWALL CORP

Pearlite fiber composite fire-proof heat insulation board

The invention relates to a fire-proof material, in particular to a fire-proof heat insulation material used for filling an interlayer of fire protection equipment such as fireproof door and the like, and fire-proof heat insulation decorating material used for a fire-resistive partition in building and decorating. The invention aims at providing the fire-proof heat insulation material which has the advantages of higher compression strength and impact-resistant strength, wide application scope and longer service life, and the novel fire-proof heat insulation material also has higher fire-proof heat insulation property, does not pollute the environment and harm the human health and is lighter in specific gravity. The invention makes up the defects that the existing expanded perlite heat insulation board is fragile when being collided and short in the service life. In order to achieve the aim, the invention adopts the scheme that the novel fire-proof heat insulation material comprises the components based on parts by weight: 40-90 parts of expanded perlite powder particles, 10-50 parts of bonding agent and 5-60 parts of glass fiber.

Owner:BOND GRP CO LTD

Fire rated door core

InactiveUS20140000193A1High densityFireproof doorsNoise insulation doors/windowsEngineeringHigh density

Owner:THE INTELLECTUAL GORILLA

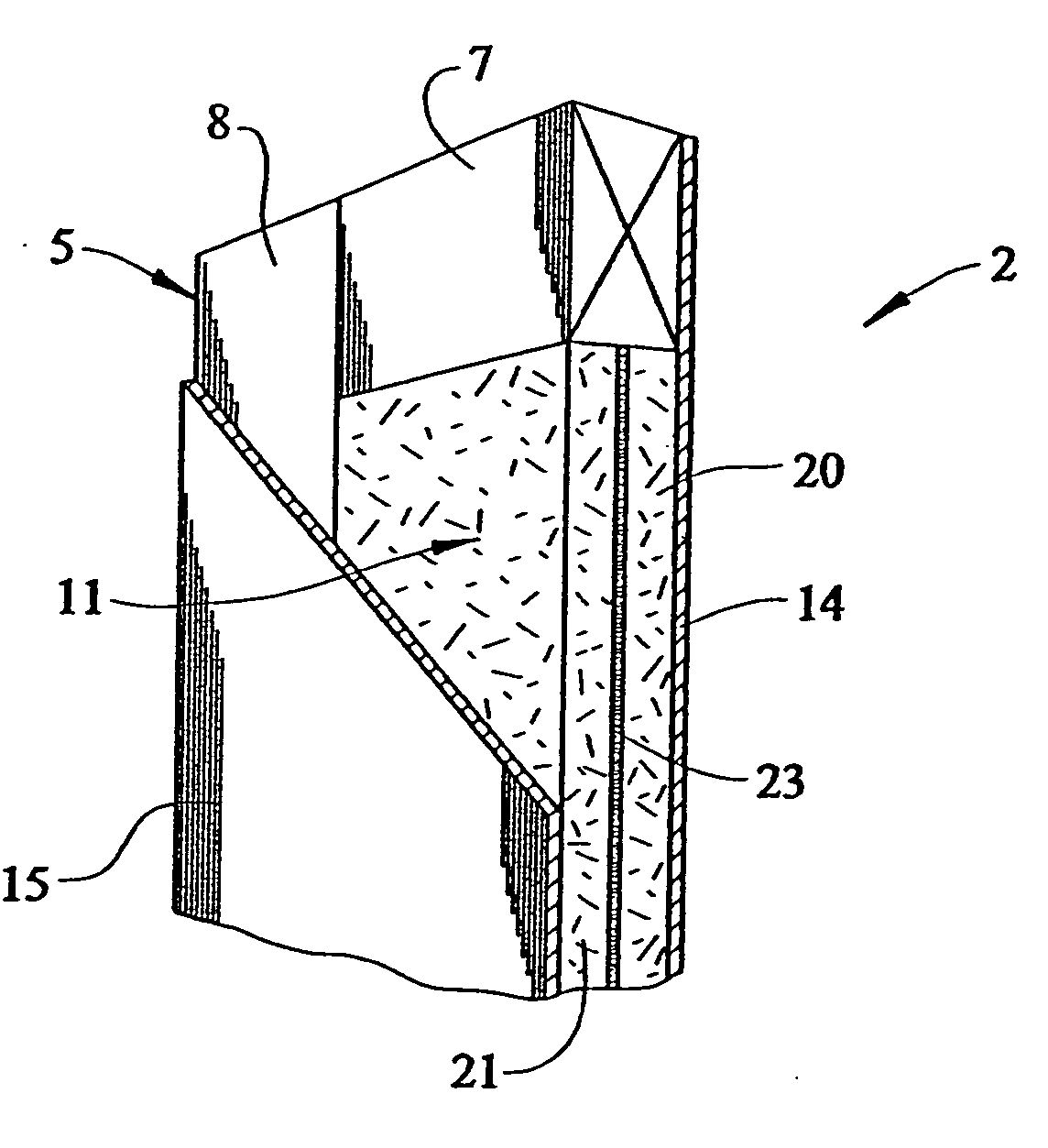

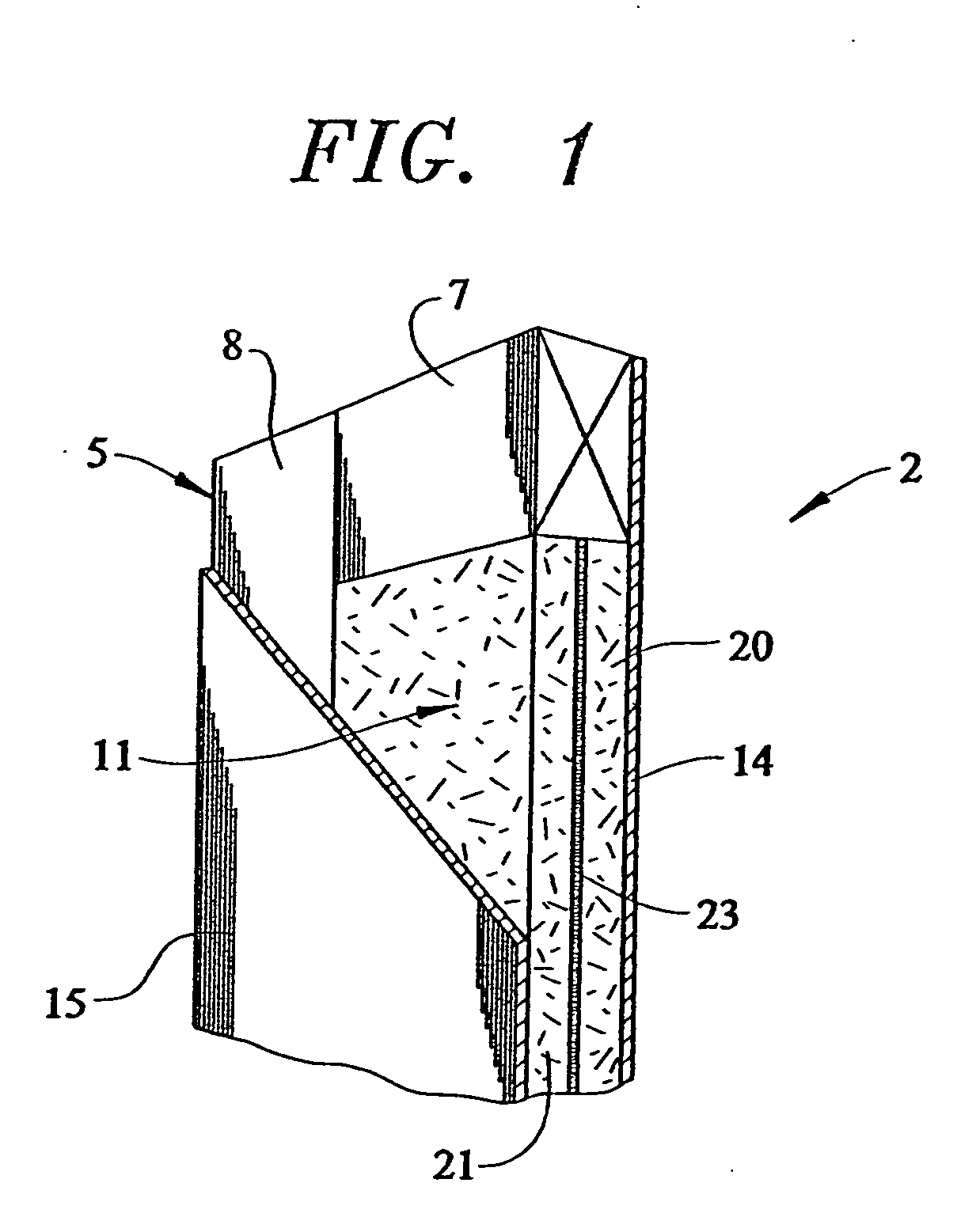

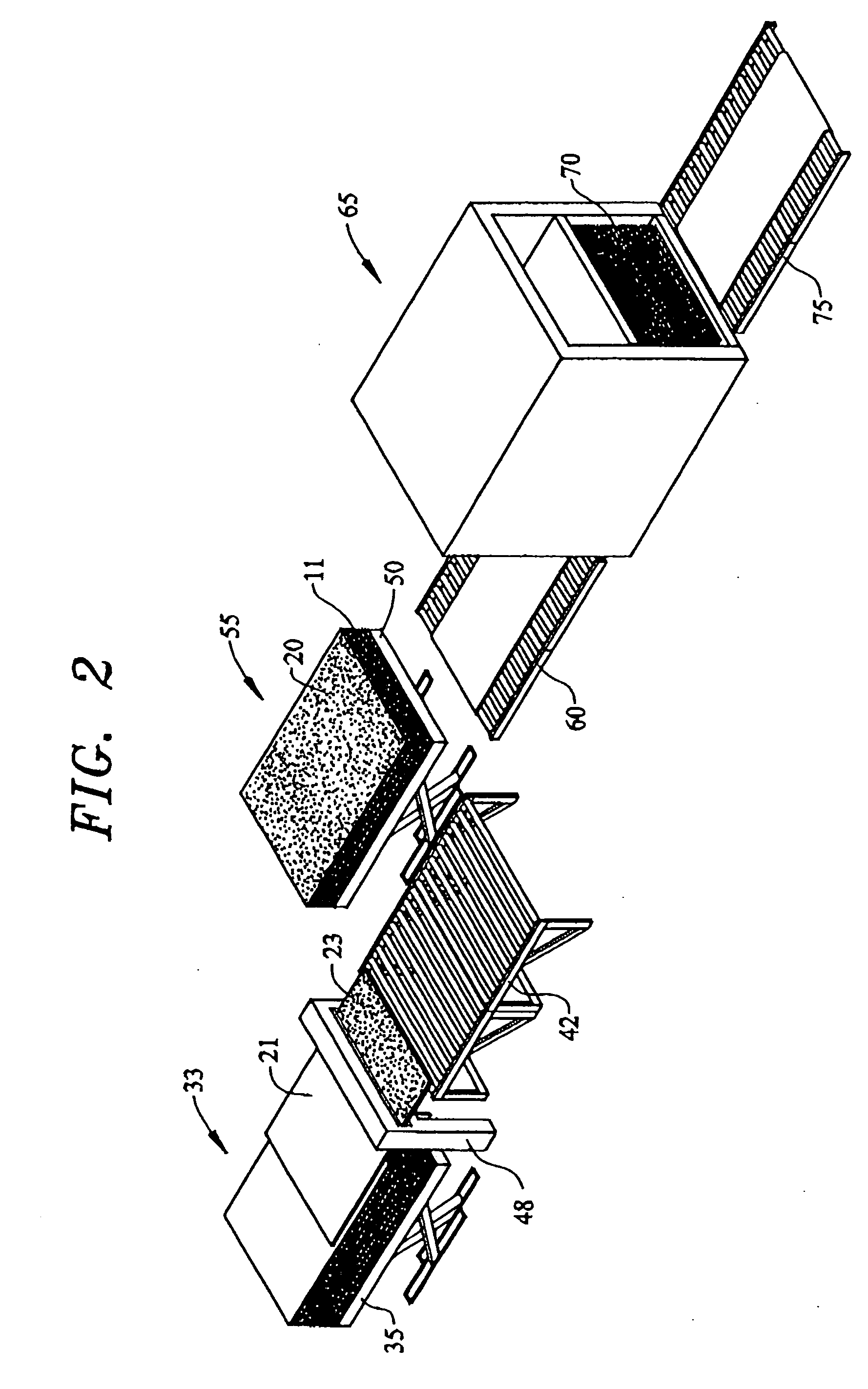

Fire door core assembly

A laminated fire door including a core, containing panels or boards made from an organic material including flax, and a fibrous binder constituting a sodium silicate adhesive, is used to make a door exhibits at least a 45 minute fire rating. In accordance with a preferred form of the invention, the fire door core is formed by using a silicate adhesive, preferably sodium silicate, in the order of 25 mils (0.6 mm) to laminate together two flax boards, each having a thickness in the range of 0.625-0.875 inches (approximately 16-22 mm), with each of the laminated flax boards having a density of between 20 and 45 pounds per cubic foot (320-700 kgs / m3).

Owner:2843 5816 QUEBEC

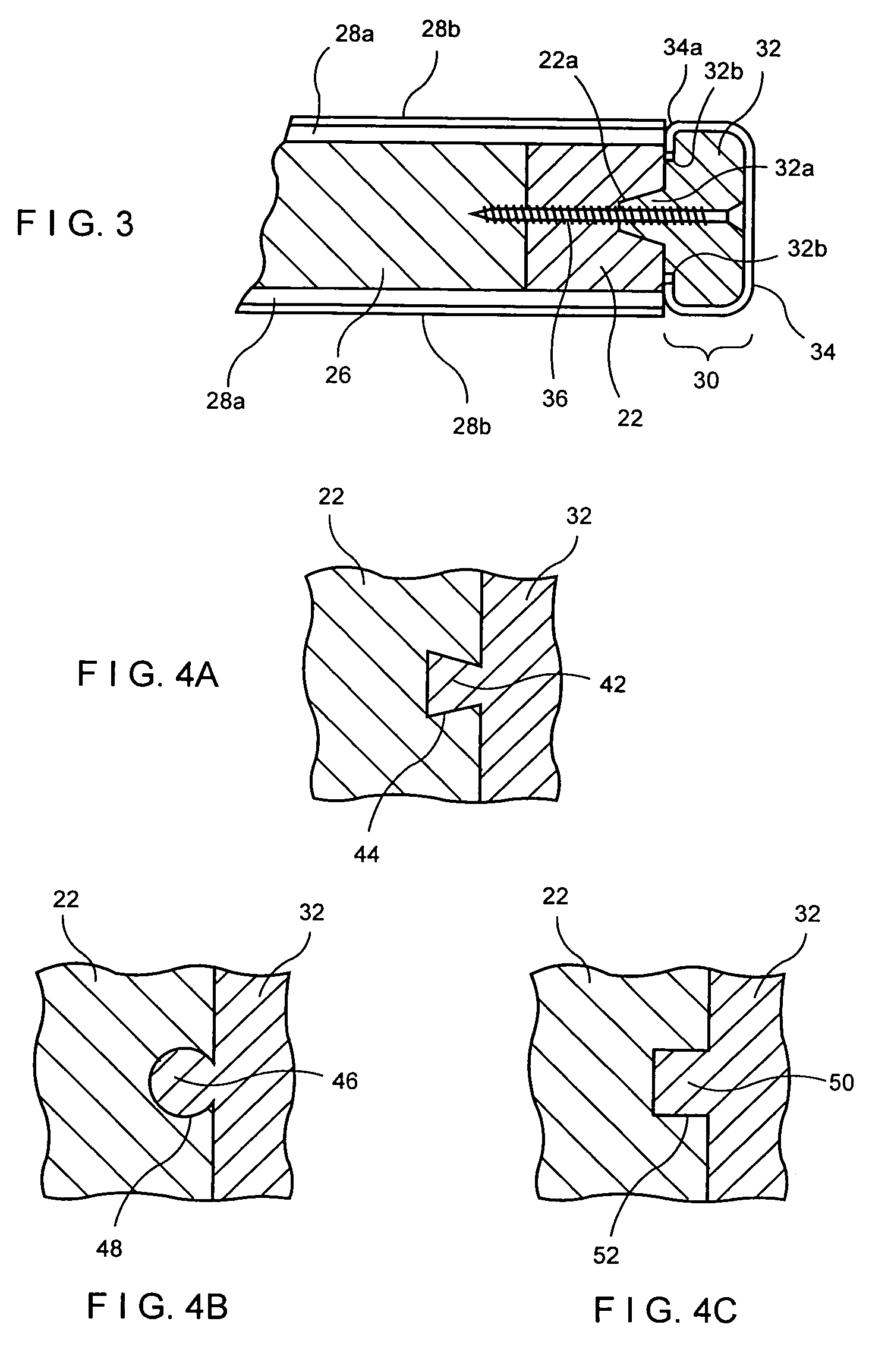

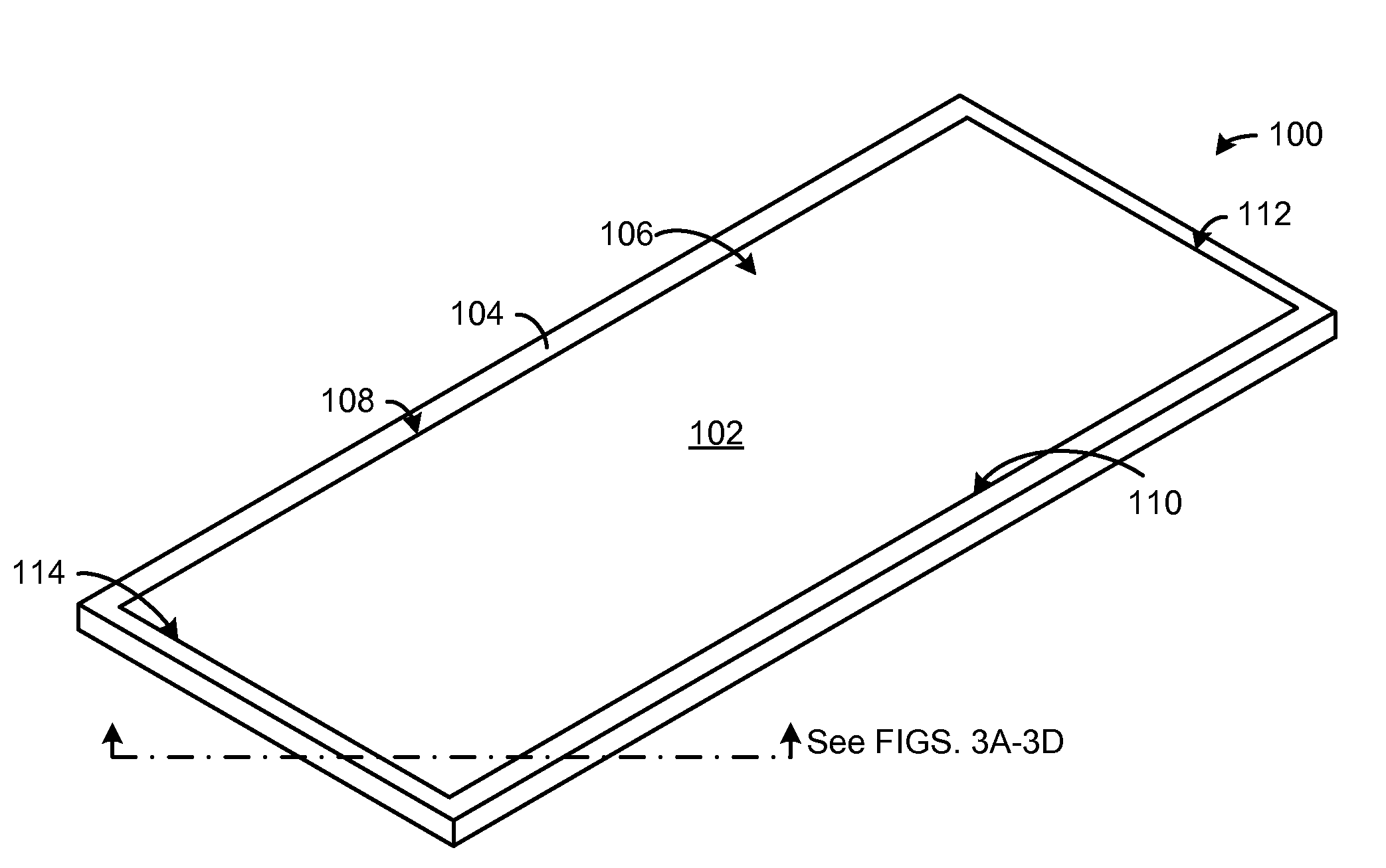

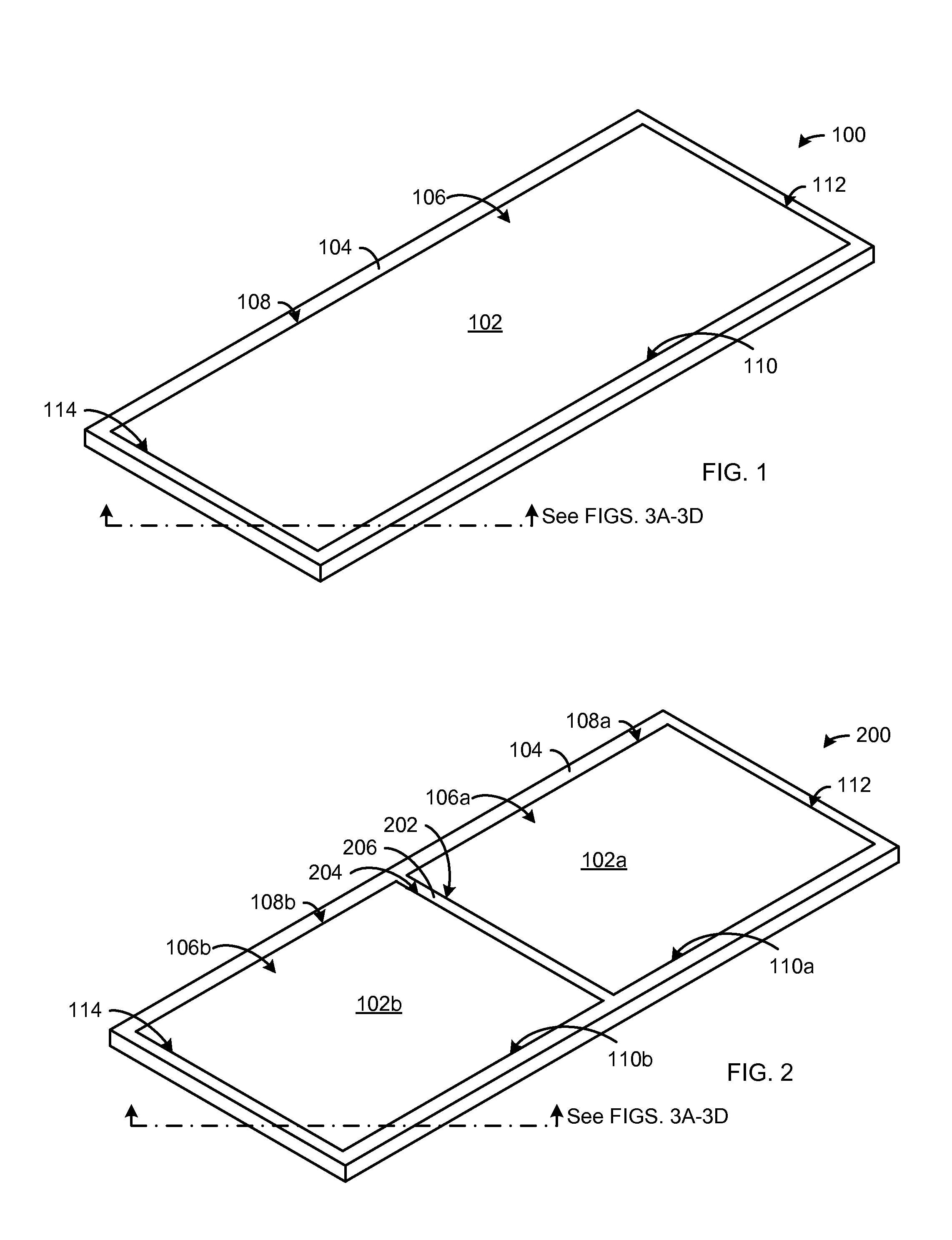

Door edge construction

InactiveUS7886501B2Simply and inexpensively restoredMinimize necessityFireproof doorsDoor leavesCouplingEngineering

A door is constructed with a separate member joined to the door edge by a tongue-and-groove coupling and screws so as to be readily removable and replaceable. The separate member sustains the impacts imparted to the door by carts or wagons pushed past the door and can be readily replaced when damaged, thus avoiding replacement of the entire door. A flexible cover snaps over the outer surface of the separate member to add impact resistance and aesthetic appeal. Intumescent strips may be inserted inside or outside of the cover to enhance sealing between the door, and as adjacent door or door frame, thereby improving the fire resistance rating of the door. Accent strips or reveals of contrasting or complementary colors may be incorporated to add to the aesthetic appeal of the door. The door construction is of particular utility in schools, health care facilities and other institutions.

Owner:CONSTR SPECIALTIES

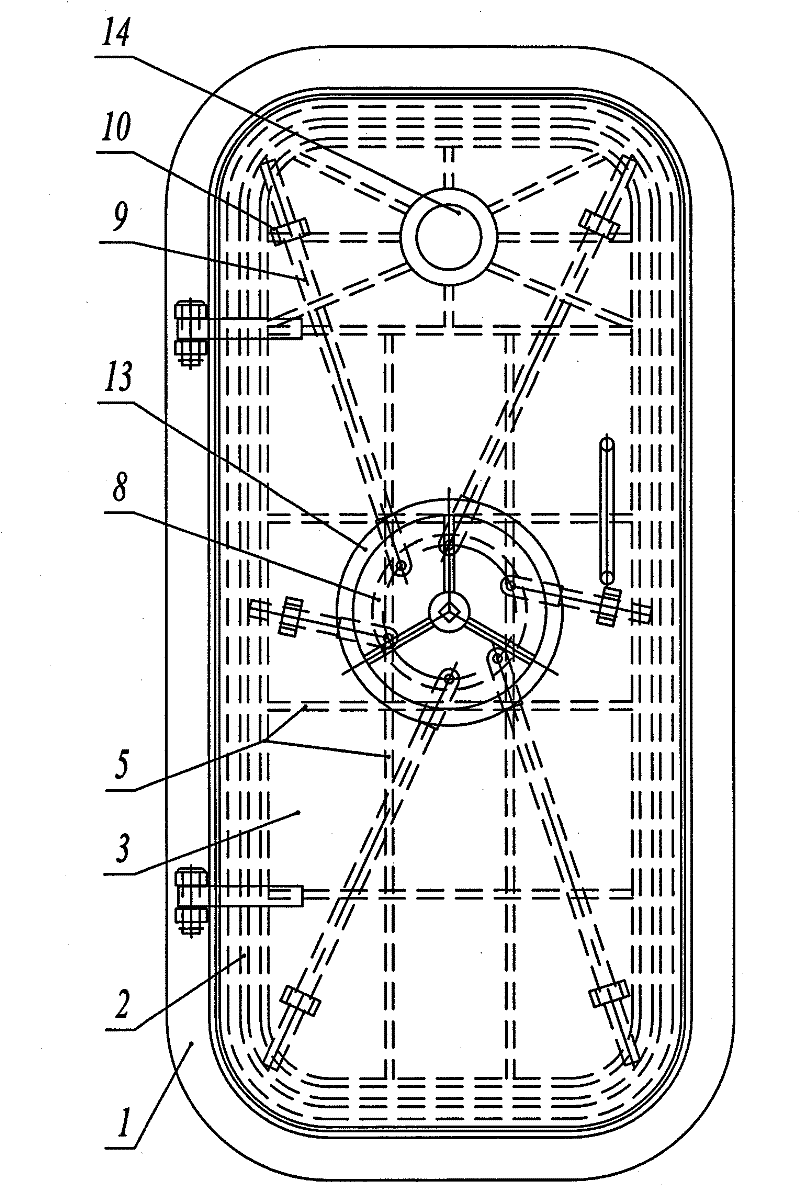

Door

ActiveCN102199977ASimple structureImprove sealingFireproof doorsConstruction fastening devicesInsulation layerLight hole

The invention discloses a door, which comprises a door frame, a door leaf and an opening and closing mechanism, wherein the door leaf is hinged on the door frame, and a secondary sealing structure is adopted between the door leaf and the door frame; the door leaf comprises a basal body and a heat insulation layer; the opening and closing mechanism comprises a rotating shaft, a connecting flange, a connecting rod and a guide sleeve; the rotating shaft passes through a light hole penetrating the door leaf and can rotate in the light hole; on the inner side of the door leaf, the rotating shaft is in threaded connection with the connecting flange; the connecting rod is hinged on the connecting flange; and the connecting rod passes through the guide sleeve arranged on the door leaf. The door is mainly used as a capsule door of a rescue capsule for mine to solve the problems of complex structure and poor sealing and heat insulation effects of the capsule door opening and closing mechanism of the conventional rescue capsule for mine, can also be used as a door of a cabin, a cold store or the like, and has the advantages of simple structure of the opening and closing mechanism and good sealing and heat insulation effects.

Owner:安徽欣万顺安全装备科技有限公司

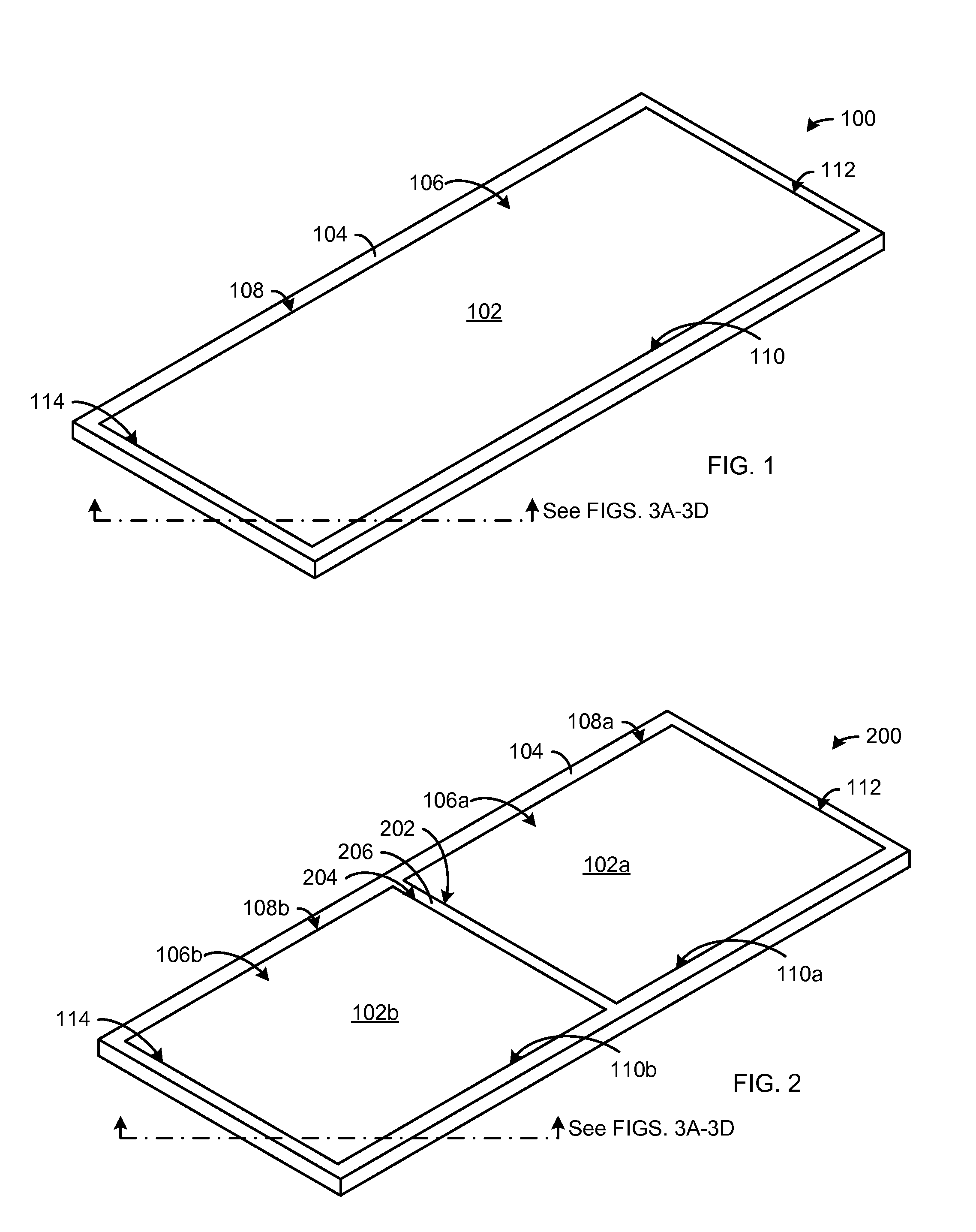

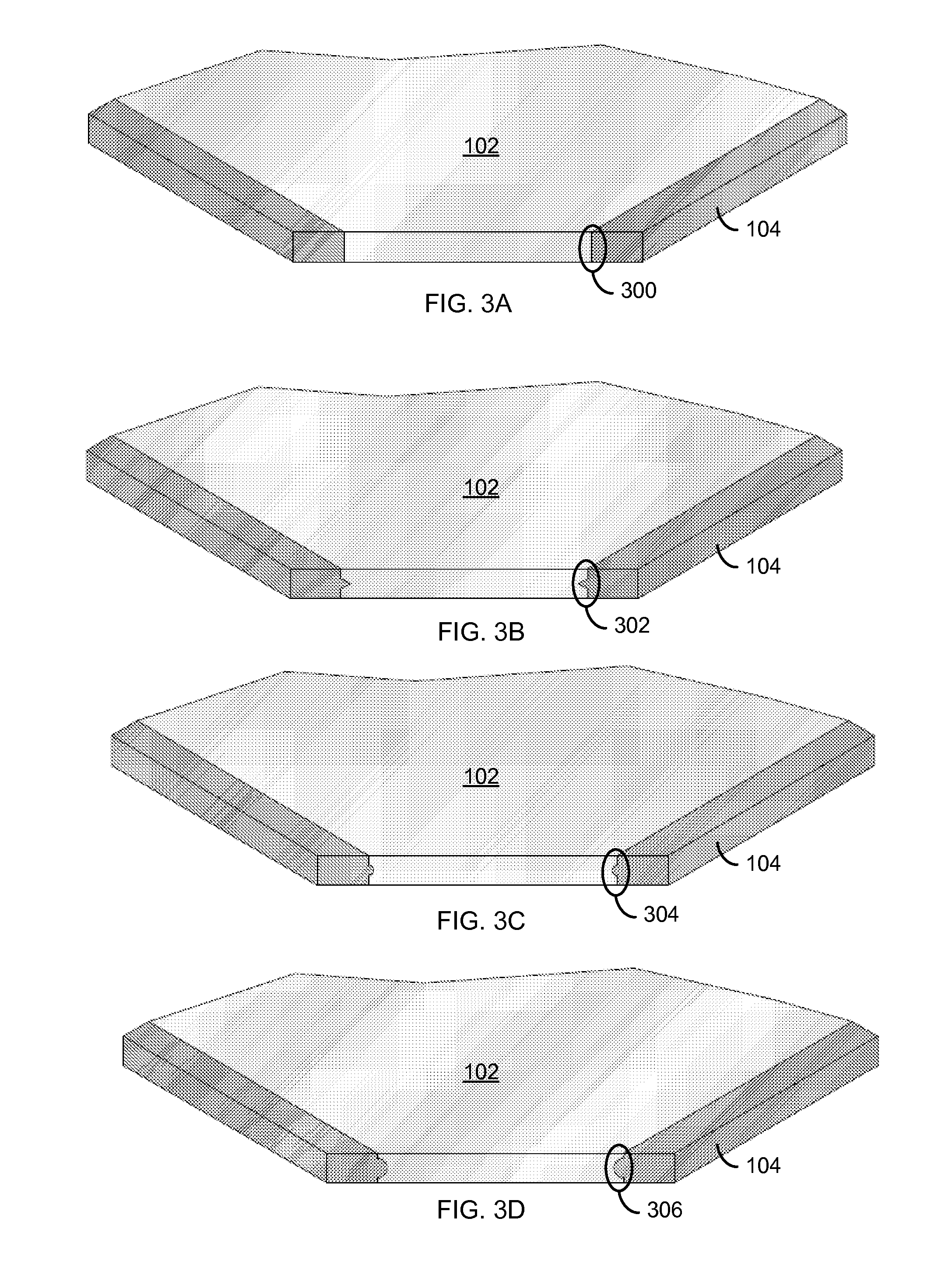

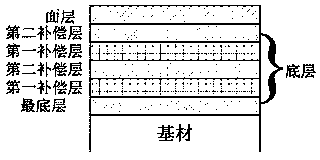

System, method and apparatus for producing fire rated doors

ActiveUS7832166B2High strengthRaise the gradeFireproof doorsDoor leavesEngineeringUltimate tensile strength

The present invention provides a system, method and apparatus for producing fire rated doors having added strength, better finishing and low cost manufacturing flexibility. The fire rated doors are made from two panels “sandwiched” together. An optional interior layer (e.g., fire resistant material, lead sheeting, steel or Kevlar) can be added between the door panels for various purposes. Splines, stiles or sticks are inserted in longitudinal channels in the door panels to provide assistance in aligning the door panels and greater hardware holding strength. An intumescent banding material concealed by a banding material around the perimeter of the door seals the door within its frame during a fire. The door design and the automated manufacturing process provide greater design choice, reduced cost and faster fabrication.

Owner:POLYMER WOOD TECH

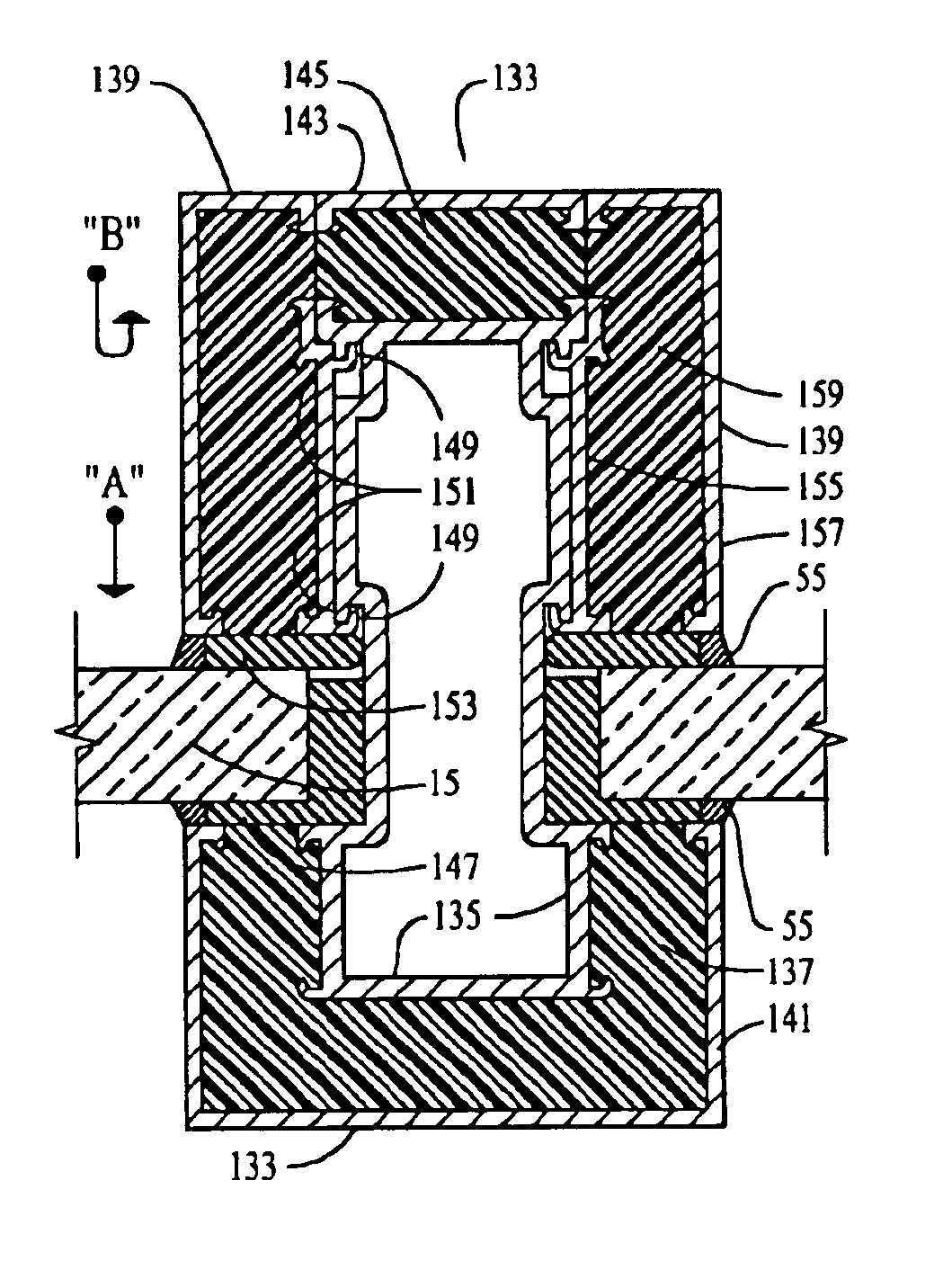

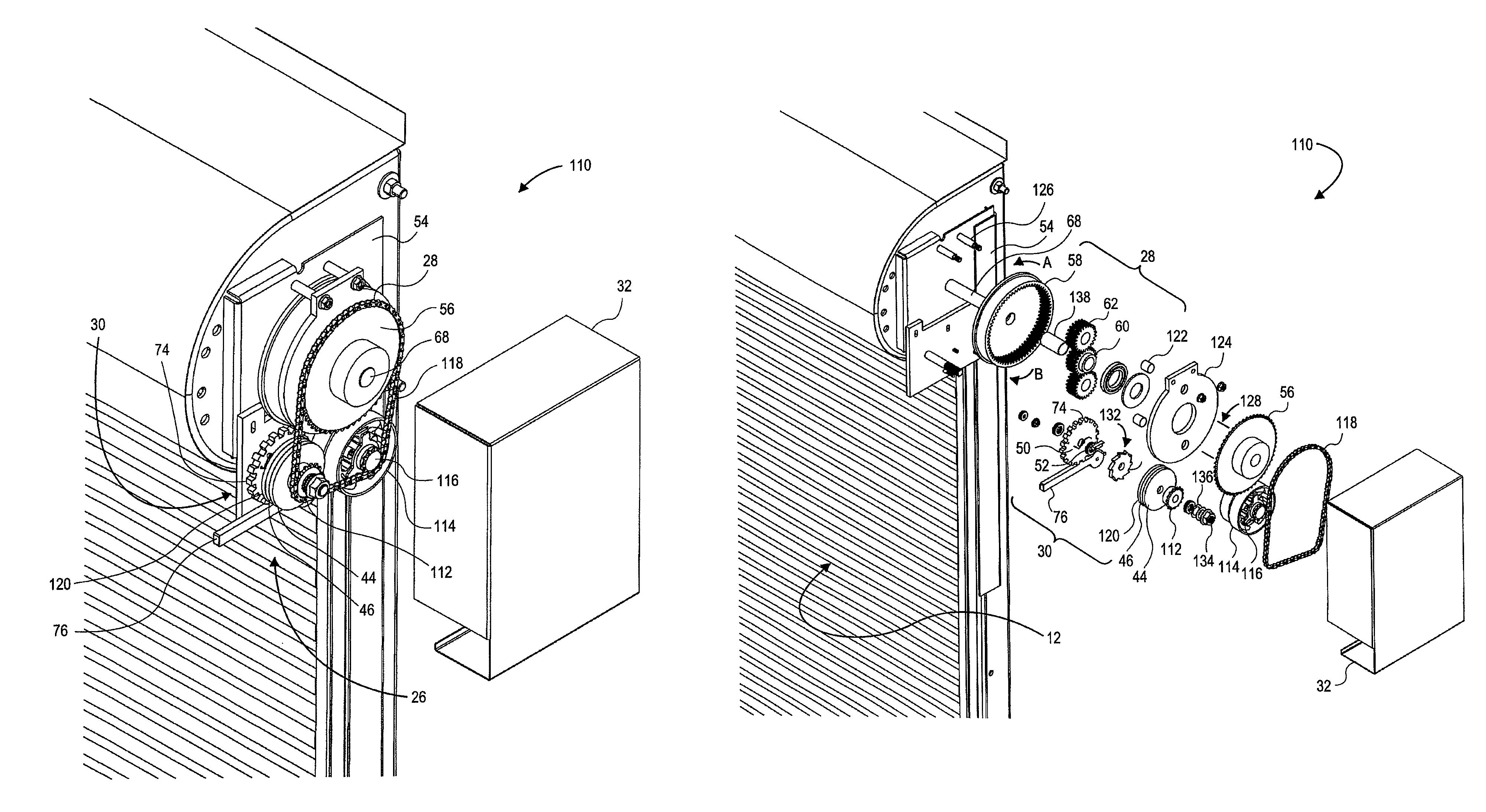

Door release mechanism

A door mechanism includes a bracket and a door shaft, rotationally mounted to the bracket, to operate a door. The door mechanism includes a gear assembly having a ring gear, set of planetary gears, sun gear, and drive sprocket. The ring gear fixed to the door shaft. The door mechanism includes a holding brake to counter the closing bias of the door. The door release has an engaged position in which rotation of the door shaft in the second direction is impeded by a first brake; and a disengaged position in which rotation of the door shaft in the second direction is unimpeded by the first brake. The door mechanism includes a link and a second brake. The link is configured to melt in response to a predetermined temperature. The second brake is configured to provide resistance in response to component rotation exceeding a predetermined speed.

Owner:OVERHEAD DOOR

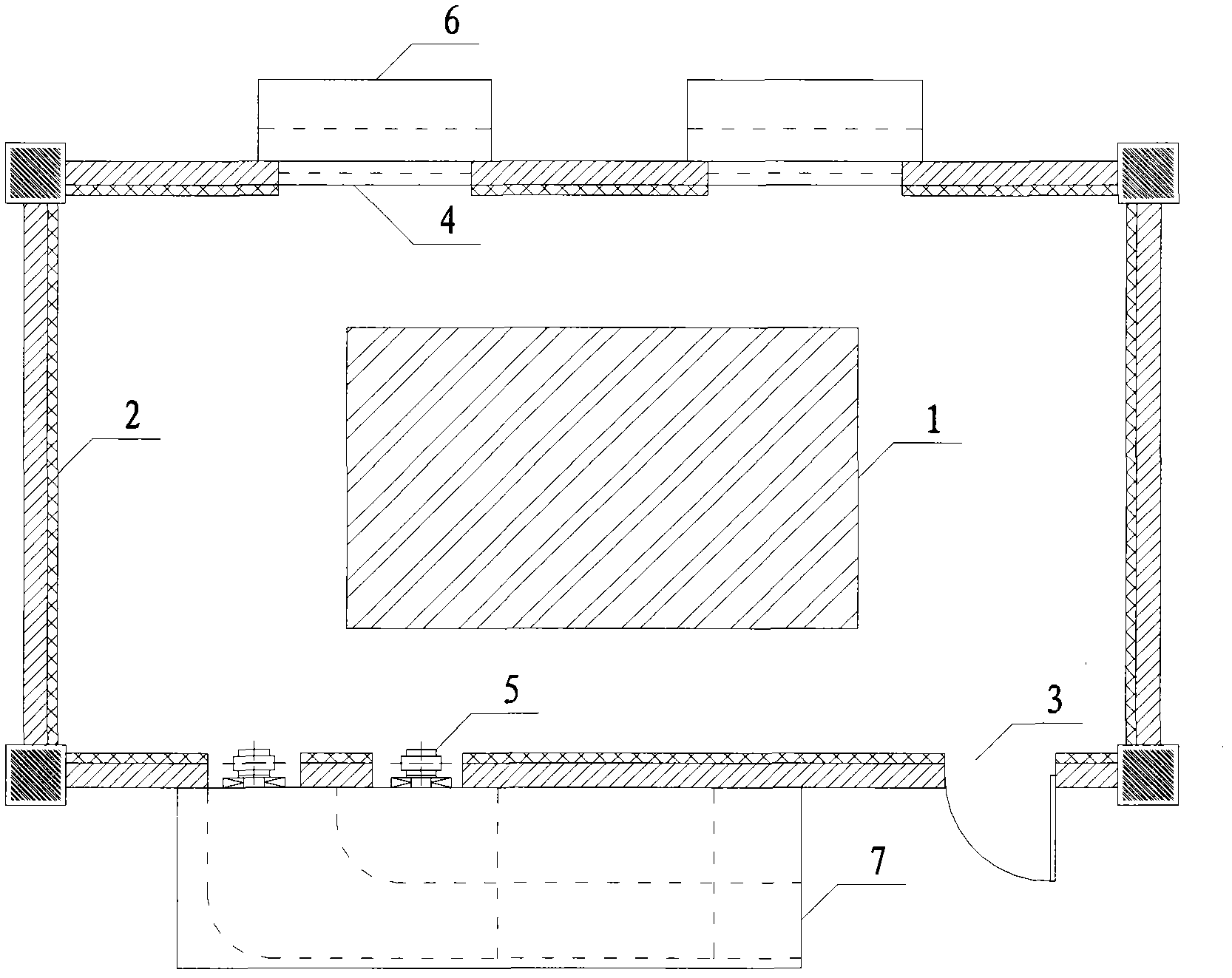

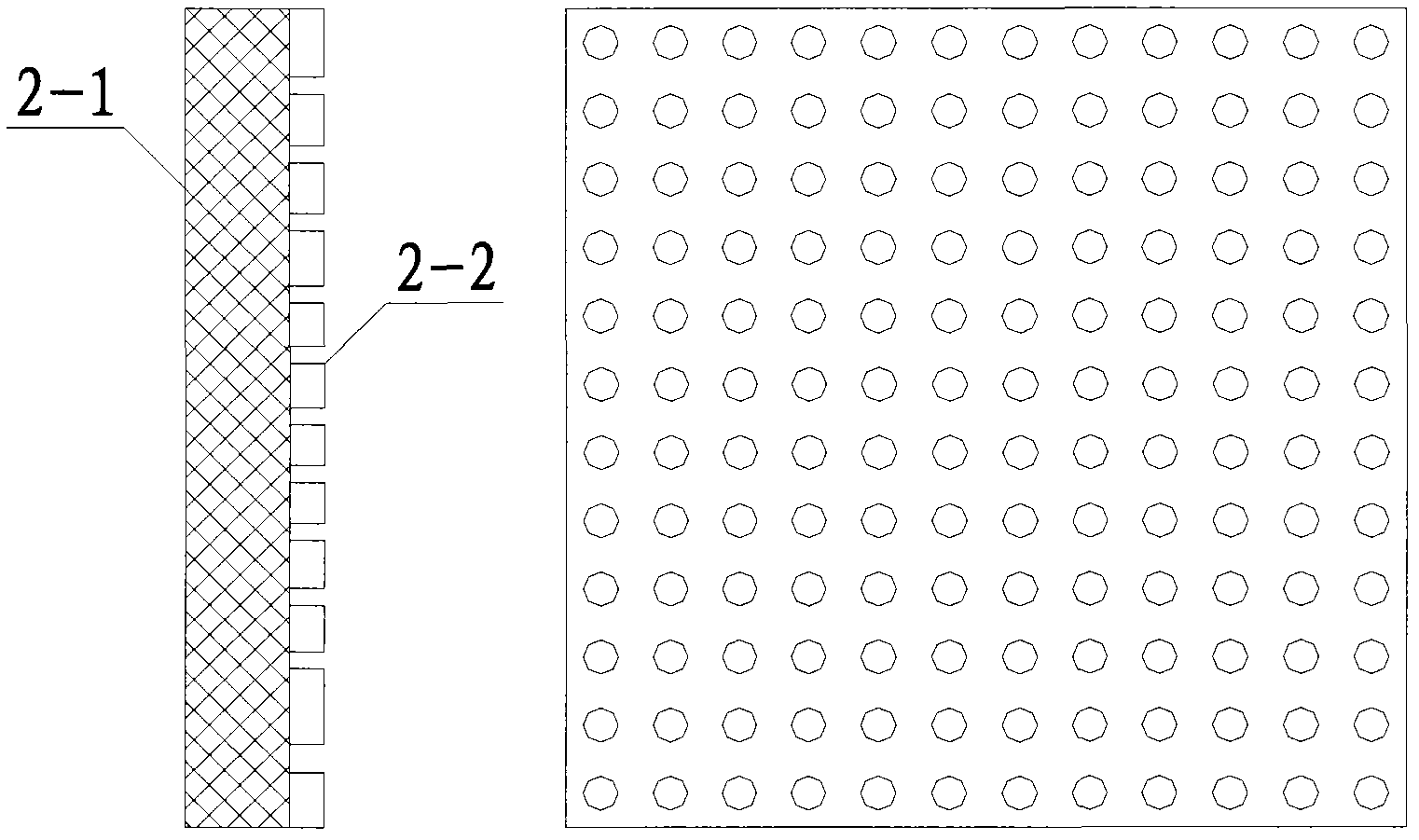

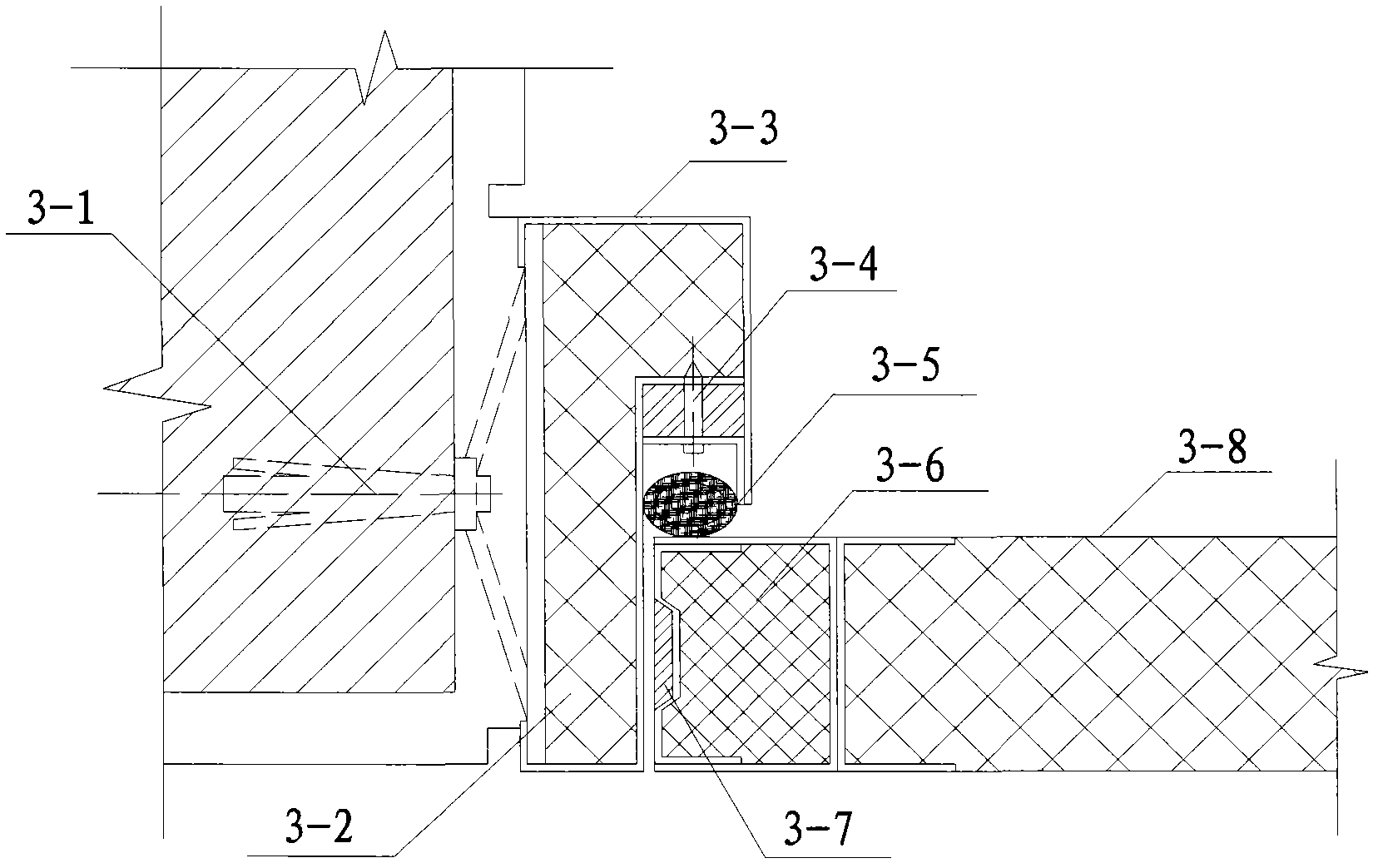

Noise reduction structure of main noise resources of urban indoor substation

The invention relates to a noise reduction structure of main noise resources of an urban indoor substation, belonging to the technical field of noise pollution control in environmental engineering. The noise reduction structure is mainly used for reducing the noise resources of the urban indoor substation, including noise radiated by a main transformer and a reactor 1. The noise reduction structure comprises a wall perforated plate resonance sound absorption structure 2, a sound isolation door 3, a ventilating shutter 4, a low-noise axial flow fan 5, an air intake silencer 6 and an air exhaust silencer 7, wherein the wall perforated plate resonance absorption structure 2 is located inside the wall and comprises a perforated gypsum plate and acrylic cotton; the sound isolation door 3 is filled with glass coated intermediate glass cotton fiber, and the gap of a door frame is filled with sealing strips; the ventilating shutter 4 and the low-noise axial flow fan 5 are used for ventilating and dissipating heat to ensure the safe and stable operation of the main transformer and the reactor; the air intake silencer 6 is installed on the outer part of the ventilating shutter 4, the upper part is a lighting sound-isolating window cover, and the lower part is an air flow channel covering the sound absorption material; and the air exhaust silencer 7 is installed outside a ventilating fan hole, and the interior is an air flow channel covering the sound absorption material.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST +1

Composite door, door core and method of manufacture

InactiveUS20080016820A1Eliminate needLamination ancillary operationsFireproof doorsEngineeringAutoclaved aerated concrete

A method for making the core of a door of autoclaved aerated concrete (AAC). A billet of AAC is provided from which slabs are cut to the approximate dimensions of the door core. A reinforcing band is secured about the perimeter of a slab or a pair of slabs sandwiching a reinforcing panel. The thickness of the slab, or the pair of slabs and reinforcing panel, is then sized for the door core as by sanding. The door is finished by applying skins to the core surfaces and trim to the reinforcing band.

Owner:INNO TECH PLASTICS

Gypsum Composites Used in Fire Resistant Building Components

A composite product includes gypsum in an amount of 60 to 90% by weight, fibers in an amount of 1.5 to 26% by weight substantially homogeneously distributed through the composite, and a rheology-modifying agent in an amount of 0.5 to 6% by weight. The composite is caused or allowed to cure to form a cured composite. The cured composite is a fire resistant component used in a fire-rated door core, a fire-rated door or a fire-rated building panel. The fire resistant component may include a building panel, a door panel, a door core, a door rail, a door stile, a door lock block, a door border, or a door insert.

Owner:THE INTELLECTUAL GORILLA

Fire retardant panel door and door frame having intumescent materials therein with a 90 minute fire rating

A fire retardant panel door, including a panel door having at least one door panel and stiles and rails. The door panel includes an interior composite section formed by a first plurality of layers of intumescent materials and a first plurality of layers of fire resistant materials disposed between and laminated to a first pair of outer coverings to form a composite laminated door panel. Each of the stiles includes a first core formed of an incombustible material and a second plurality of layers of intumescent materials and a second outer covering to form a composite laminated stile. Each of the rails includes a second core formed of an incombustible material and a third plurality of layers of intumescent materials and a third outer covering to form a composite laminated rail. The first, second, and third plurality of layers of intumescent materials are activated to expand upon exposure to heat and / or fire to prevent the heat and / or fire from passing through the at least one door panel, the stiles and the rails of the panel door during a fire for at least 90 minutes. The at least one door panel is connected to the panel door by joints; and the joints include a fourth plurality of layers each comprising intumescent and fire resistant materials, wherein the fourth plurality of layers of intumescent and fire resistant materials on the joints are activated to expand upon exposure to heat and / or fire to seal the joints in order to prevent the heat and / or fire from passing through the panel door during a fire for at least 90 minutes.

Owner:ENRICO AUTOVINO

Gypsum composites used in fire resistant building components

A composite product includes gypsum in an amount of 60 to 90% by weight, fibers in an amount of 1.5 to 26% by weight substantially homogeneously distributed through the composite, and a rheology-modifying agent in an amount of 0.5 to 6% by weight. The composite is caused or allowed to cure to form a cured composite. The cured composite is a fire resistant component used in a fire-rated door core, a fire-rated door or a fire-rated building panel. The fire resistant component may include a building panel, a door panel, a door core, a door rail, a door stile, a door lock block, a door border, or a door insert.

Owner:THE INTELLECTUAL GORILLA

Heat insulating coating as well as coating method, paint and preparing method thereof

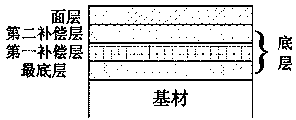

InactiveCN103819998AImprove insulation effectFireproof doorsSynthetic resin layered productsSurface layerMicrosphere

The invention discloses a heat insulating coating as well as a coating method, paint and preparing method thereof and an aluminum alloy sectional material and aluminum alloy doors and windows using the heat insulating coating. The heat insulating coating comprises a bottom layer coating and a surface layer coating, wherein a base material is directly coated with the bottom layer coating, and the surface layer coating is coated with the bottom layer coating; the bottom layer coating comprises the following components in percent by weight: 85-90% of surface layer paint, and 6-15% of hollow microsphere; the surface layer coating comprises the following components in parts by weight: 90-100 parts of a film-forming agent, 1-10 parts of a curing agent, 0.5-10 parts of nanometer material, 20-50 parts of powdery filler, 0.5-2 parts of a flatting agent, 1-1.5 parts of pigment or dye and 0.5-4 parts of other auxiliaries Through the application of the heat insulating coating, common aluminum alloy gates and windows can be enabled to have good heat insulating effects without inserting a non-metallic material (bridge-cutoff aluminum alloy sectional material) between two common aluminum alloy sectional materials. The insulating effects of the bridge-cutoff aluminum alloy sectional material can be further improved when the paint is applied to the bridge-cutoff aluminum alloy sectional material.

Owner:苏州欧亚美华门窗制造有限公司

Rated fire frame and door frame / jamb

The present invention teaches that a tightly woven, and strong layer of fiberglass may be coated or impregnated with sodium silicate in order to produce a strong and fire resistant jamb / frame. The present invention further teaches that a fire doorjamb core may be mass produced from fire resistant layers and the frame core rated for fire safety by a rating agency, thus allowing builders and door manufacturers to produce building structures and doors using that core without individually certifying each model of door or structure. The present invention further teaches a structure / method of mounting for door frames which closely parallels mounting of normal door frames, without special brackets or plates.

Owner:FYREWERKS INC

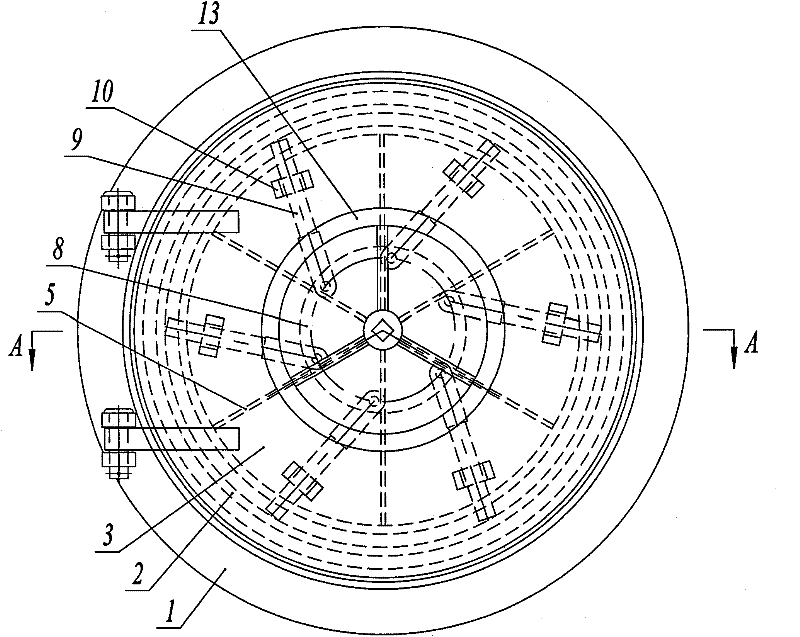

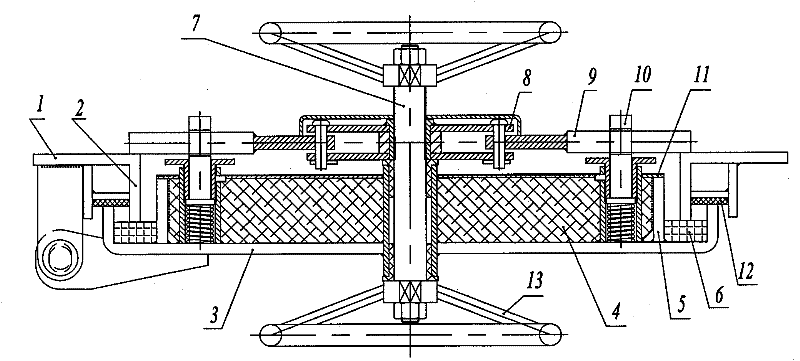

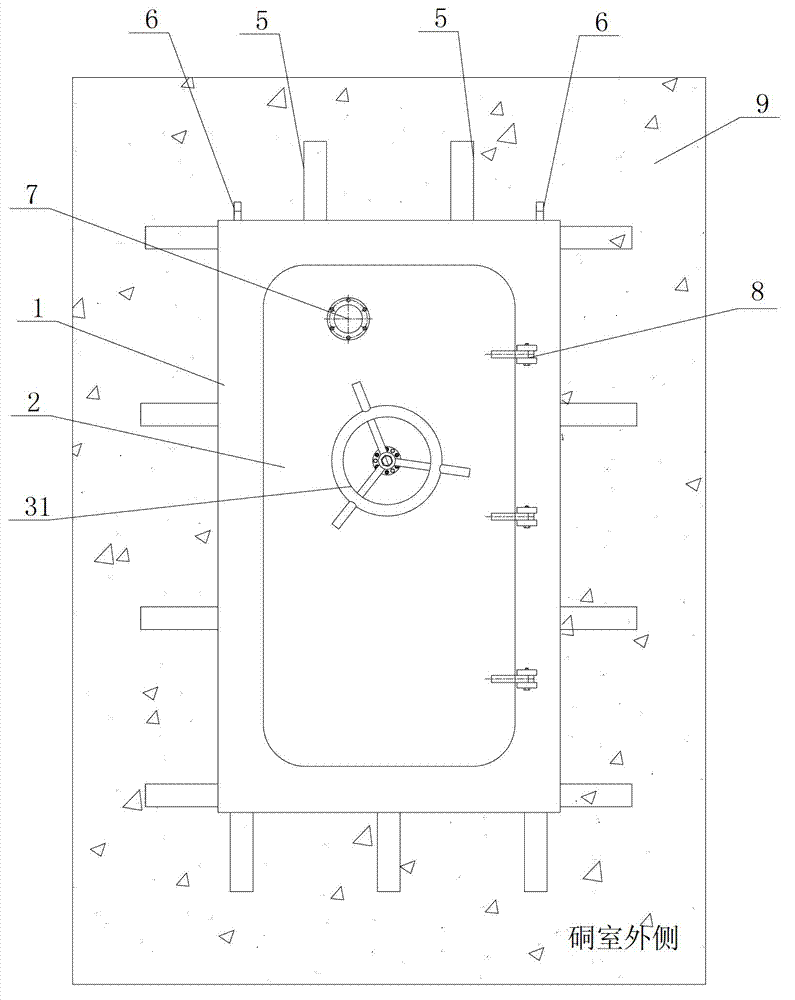

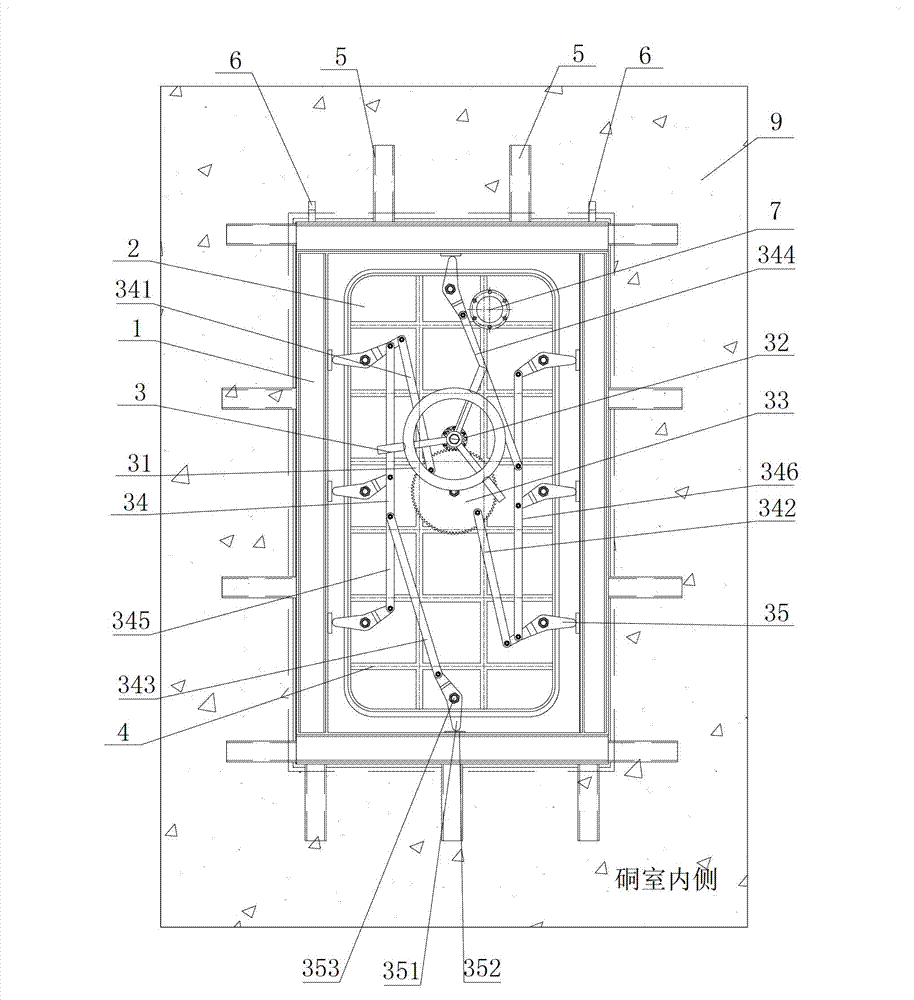

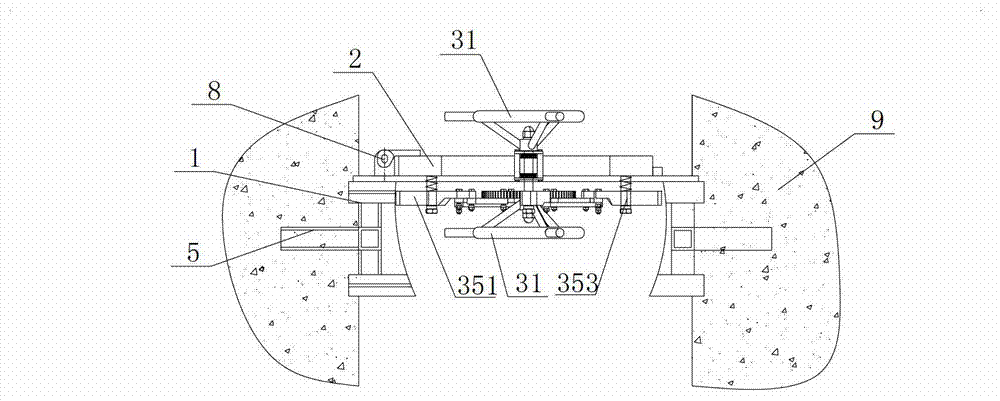

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

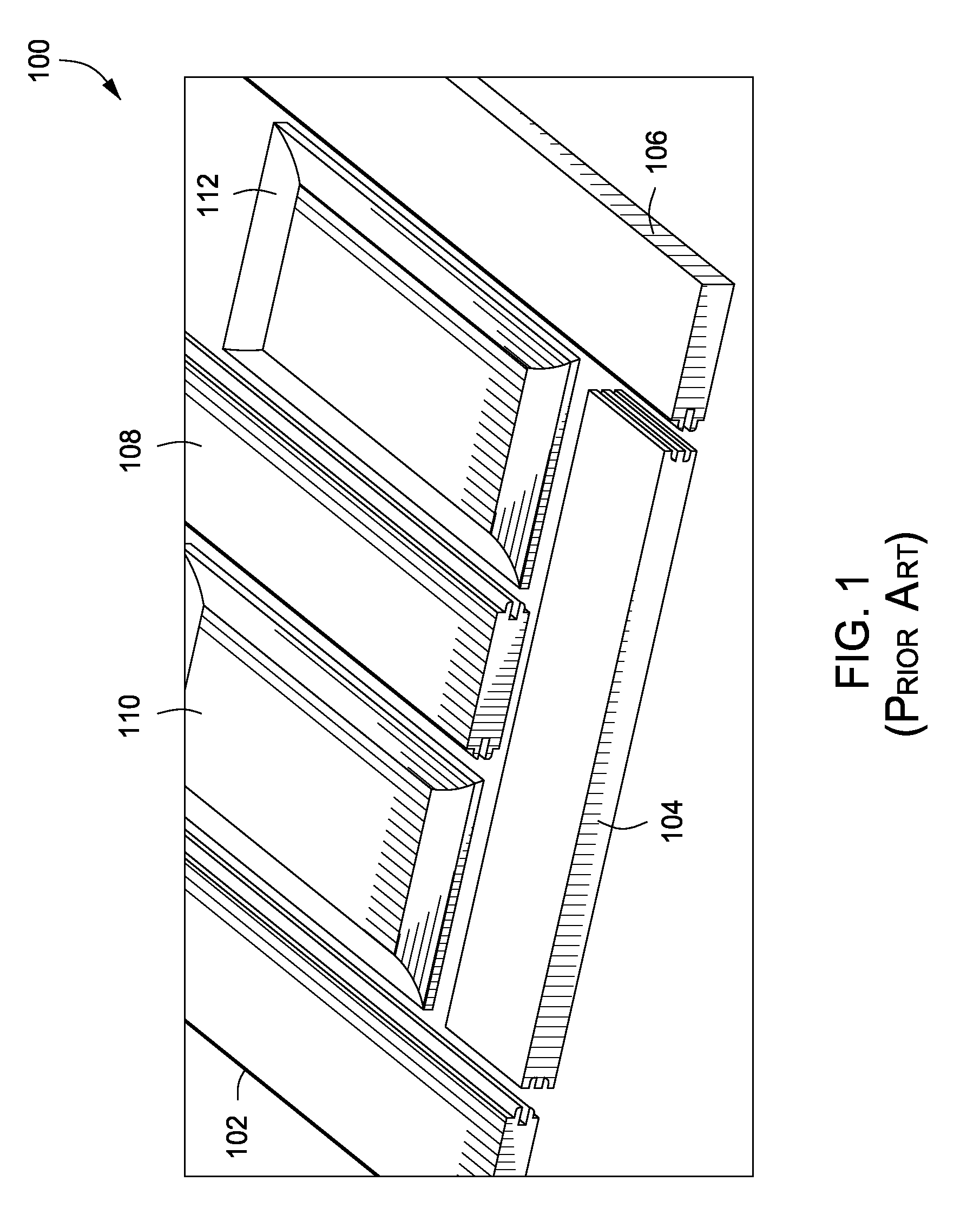

Multi-layered fire door and method for making the same

InactiveUS20070125044A1Reduce complexity and costIncrease flexibilityFireproof doorsSynthetic resin layered productsPorous layerEngineering

A door has a core that includes a porous layer having a thickness and two opposing major surfaces. In one construction, the core also includes three fire-retardant layers, and two of the fire-retardant layers are separated by the porous layer. The porous layer and the fire-retardant layers are coupled together. Other constructions include one or more fire-retardant layers in balanced or unbalanced placement around the porous layer.

Owner:JELD-WEN

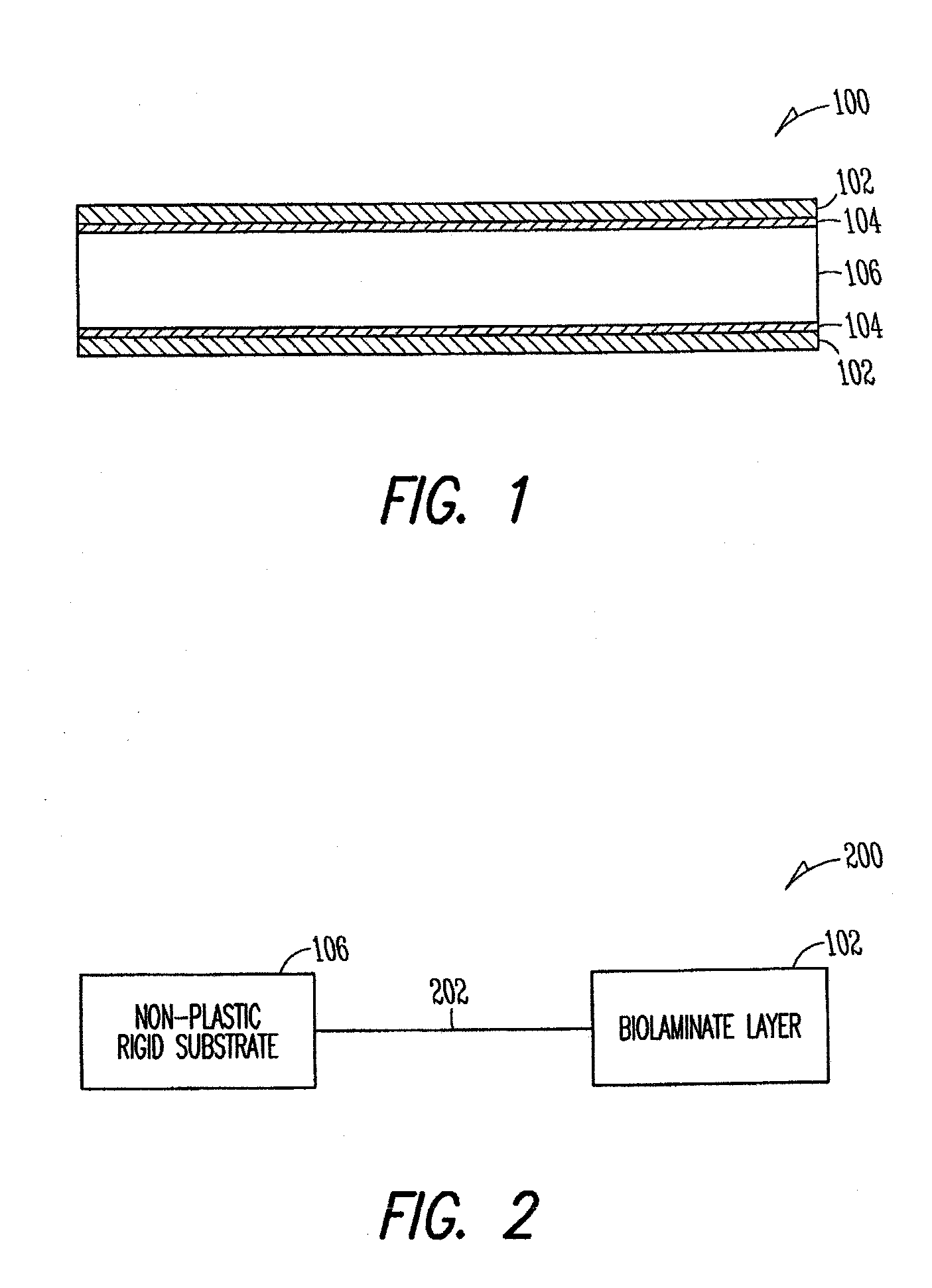

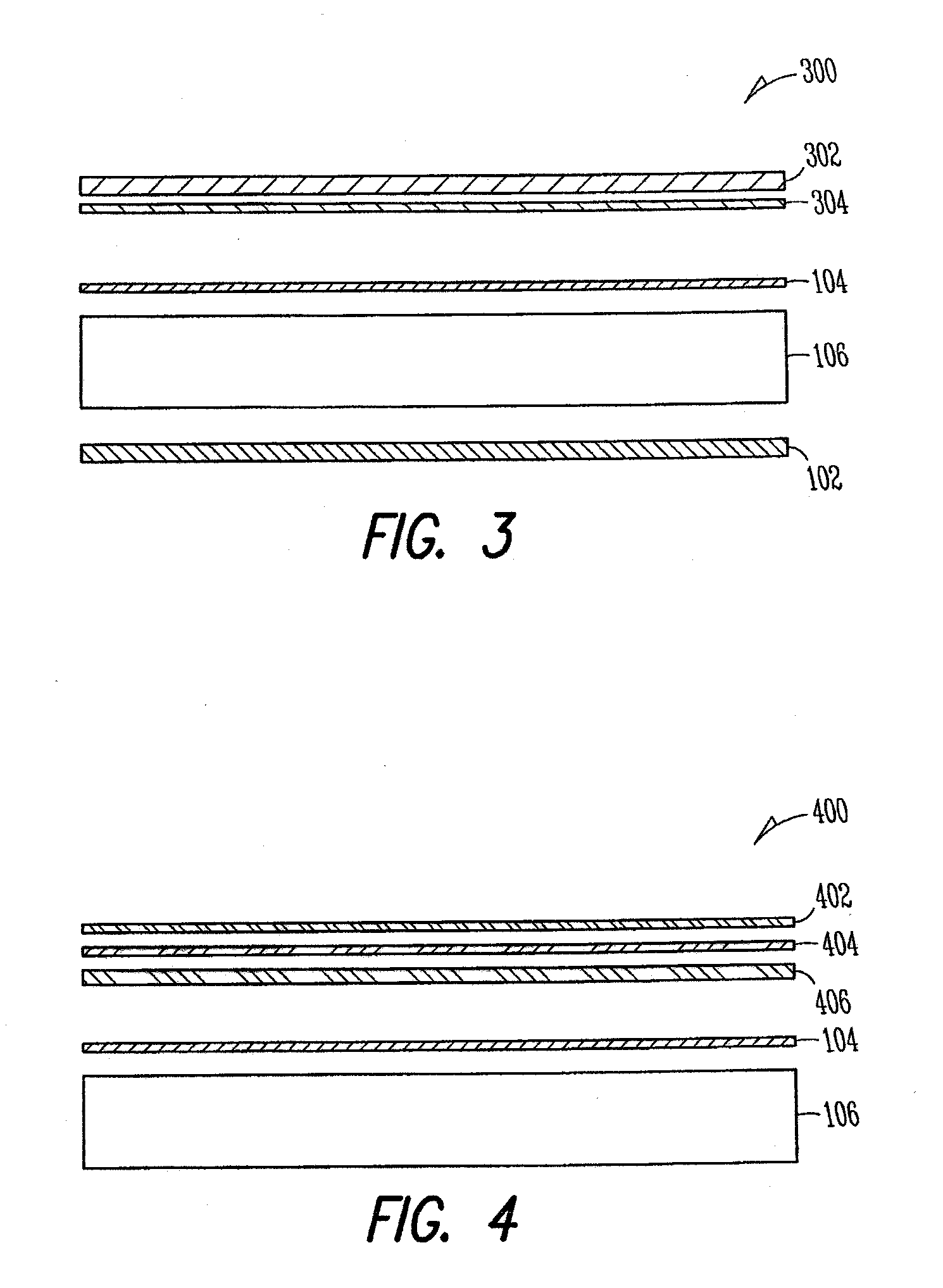

Fire retardant biolaminate composite and related assembly

InactiveUS20120291377A1Good charLow flame spreadFireproof doorsFilm/foil adhesivesFlame spreadEngineering

The present disclosure, in one embodiment, relates to a fire retardant biolaminate composite assembly. The assembly includes a biolaminate layer. The biolaminate layer includes a PLA sub-layer, wherein the biolaminate layer includes a fire retardant. The assembly also includes and an intumescent layer comprising an intumescent material that swells as a result of heat exposure, wherein the biolaminate has good char and low flame spread with minimal smoke generation.

Owner:BIOVATION LLC

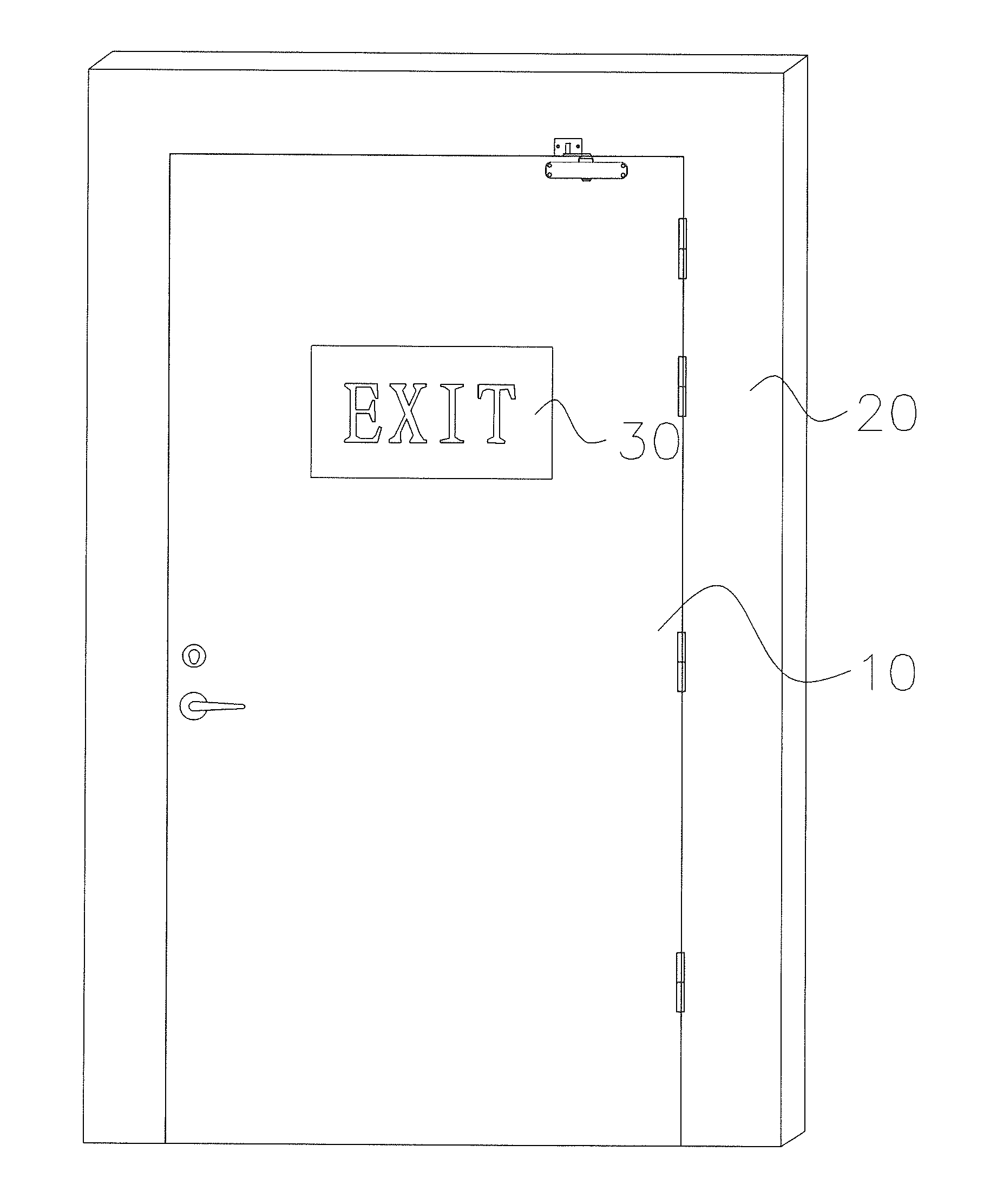

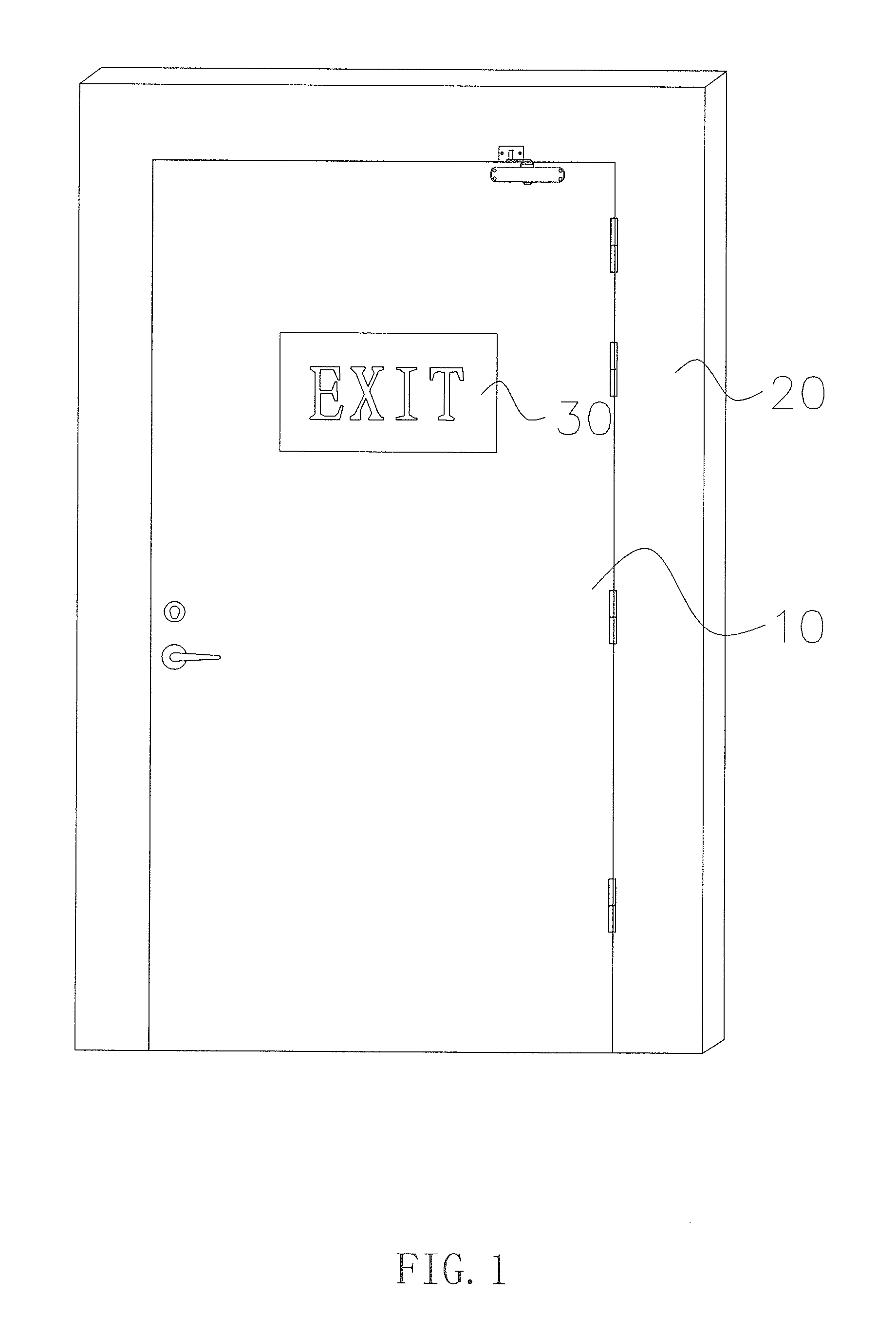

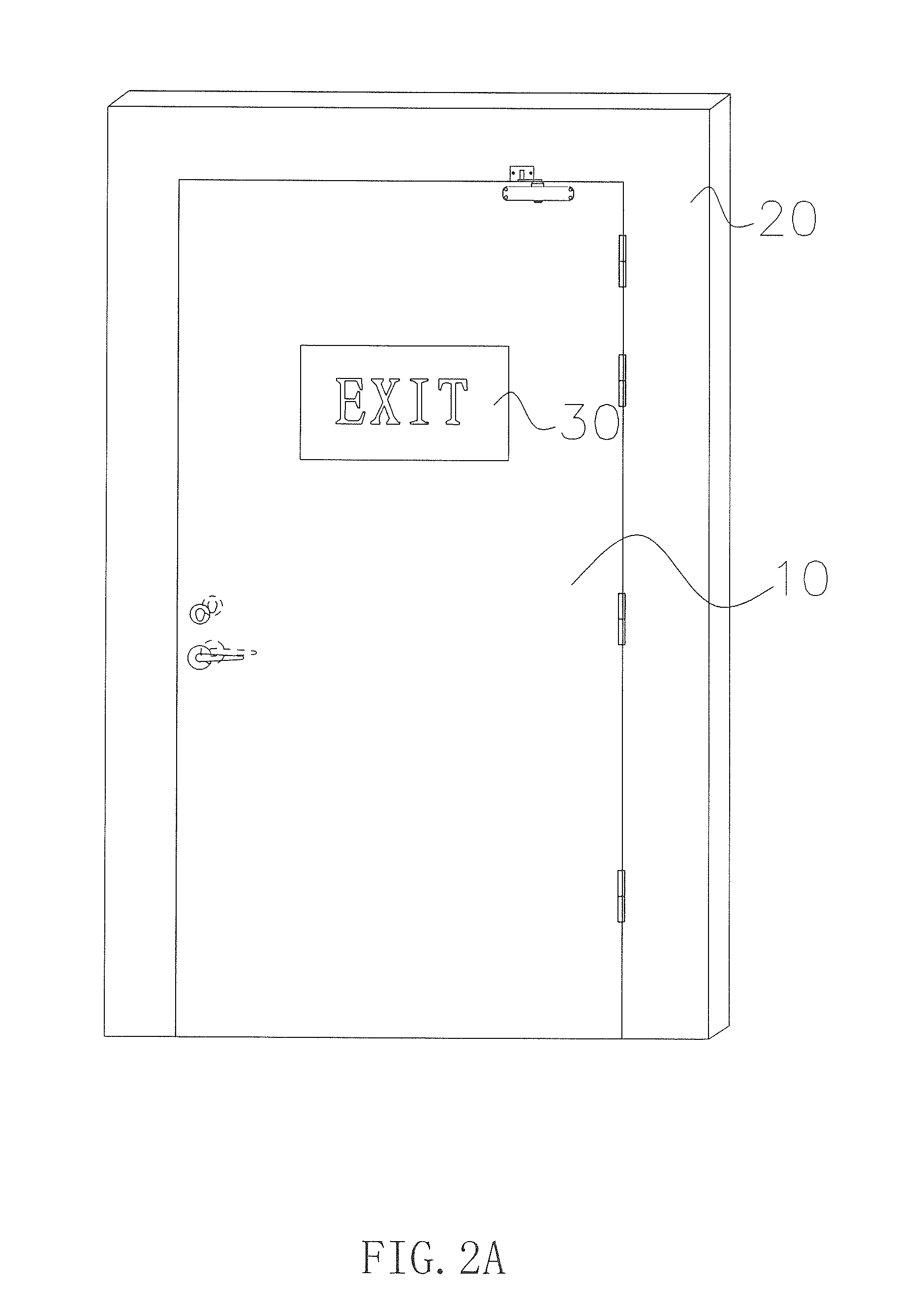

Self-Illuminating Fire Door

InactiveUS20130145693A1Avoid spreadingEasy constructionFireproof doorsIlluminated signsJambMechanical engineering

A self-illuminating fire door includes a door body (10) and a door frame (20), each having a front and a rear sides respectively, includes a self-illuminating member (30) on at least one side of the door body (10) and the door frame (20). The self-illuminating member (30) is made in self-illuminating material and constructed into a block unit, a rod unit or a flat film body unit. The block unit or the rod unit is mounted onto the door body (10) or the door frame (20) at one or both sides. The flat film unit is stick or bonded onto the door body (10) or the door frame (20) at one or both sides. The self-illuminating material is alkaline earth alluminate material, a light-storing type self-illuminating material. The fire door can illuminate under a dark condition or at night, thereby guiding people to exit route to escape from the fire.

Owner:SHENZHEN GUANGAN FIRE FIGHTING & DECORATION ENG

Fire rated door

Owner:THE INTELLECTUAL GORILLA

Multi-layered fire door and method for making the same

InactiveUS20070125043A1Reduce complexity and costIncrease flexibilityFireproof doorsSynthetic resin layered productsPorous layerEngineering

A door has a core that includes a porous layer having a thickness and two opposing major surfaces. In one construction, the core also includes three fire-retardant layers, and two of the fire-retardant layers are separated by the porous layer. The porous layer and the fire-retardant layers are coupled together. Other constructions include one or more fire-retardant layers in balanced or unbalanced placement around the porous layer.

Owner:JELD-WEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com