Heat insulating coating as well as coating method, paint and preparing method thereof

A technology of thermal insulation and primer coating, applied in the direction of coating, polyester coating, epoxy resin coating, etc., can solve the problems of polluting the environment, increasing the cross-sectional area of aluminum alloy door and window profiles, and increasing the production cost of doors and windows.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

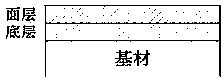

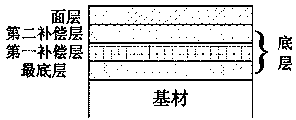

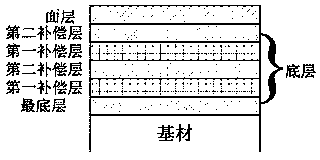

Image

Examples

preparation example Construction

[0077] The present invention simultaneously provides the preparation method of the coating of above-mentioned primer coating, comprises the steps: a, after film-forming agent is crushed, carry out with solidifying agent, nanometer material, powdery filler, leveling agent, pigment or dyestuff and other auxiliary agent Mixing; b. After mixing the mixed raw materials with an extruder, discharge, cool to room temperature, and tablet; c. Send the compressed raw materials to the crushing and screening unit for crushing, grading and sieving, and crushing particle size 170-190 mesh, to obtain the powder of the paint for coating the surface layer; d, adding the hollow microspheres to the powder of the paint for coating the surface layer, and mixing thoroughly to obtain the paint for coating the bottom layer.

[0078] Wherein, the step a breaks the film-forming agent, and the crushing speed is 1440r / min-1450r / min, the purpose is to break the film-forming agent into a particle size of 40-...

Embodiment 1

[0095] Embodiment 1: Common (non-broken bridge) aluminum alloy profiles / doors and windows coated with heat insulation coating of the present invention

[0096] (1) Preparation of coatings, including:

[0097] 1. Prepare the coating for the surface layer according to the following components and parts by weight: epoxy resin 100; curing agent 4.70; leveling agent 1.52; nano-titanium dioxide 0.64; zirconia 5.12; mica powder 12; Carbon black 0.70; other additives 0.50.

[0098] In this example, the film-forming agent epoxy resin was crushed to 40 mesh at a crushing speed of 1440r / min, and then mixed with other components in a high-speed mixer at a speed of 60r / min. After mixing for 10 minutes, enter the twin-screw extruder for mixing. The temperature of the feed section of the extruder is 80°C, and the temperature of the discharge section is 115°C. Discharging, cooling to room temperature, and tableting. Then enter the crushing and screening unit, crush, classify and sieve, an...

Embodiment 2

[0116] Embodiment 2: Aluminum alloy profiles / doors and windows coated with heat insulation coating (non-broken bridge) of the present invention

[0117] (1) Preparation of coatings, including:

[0118] 1. Prepare the coating for the surface layer according to the following components and parts by weight: acrylic resin 100; curing agent 4.50; leveling agent 3.96; benzoin 0.52; nano barium sulfate 3.68; mica powder 13;

[0119] In this embodiment, the film-forming agent acrylate resin is first crushed to 60 mesh, and the crushing speed is 1450r / min, and then it is added into a high-speed mixer with other components, and the mixer speed is 65r / min. Enter the twin-screw extruder for mixing. The temperature of the feed section of the extruder is 110°C, and the temperature of the discharge section is 125°C. The material is discharged, cooled to room temperature, and pressed into tablets. Then enter the crushing and screening unit, crush, classify and sieve, and pass through 100% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com