Fire retardant wooden door with intumescent materials

a technology of intumescent materials and fire-retardant wooden doors, which is applied in the field of fire-retardant wooden doors and fire-retardant doors, can solve the problems of not teaching or disclosing the prior art patents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 10

Preferred Embodiment 10

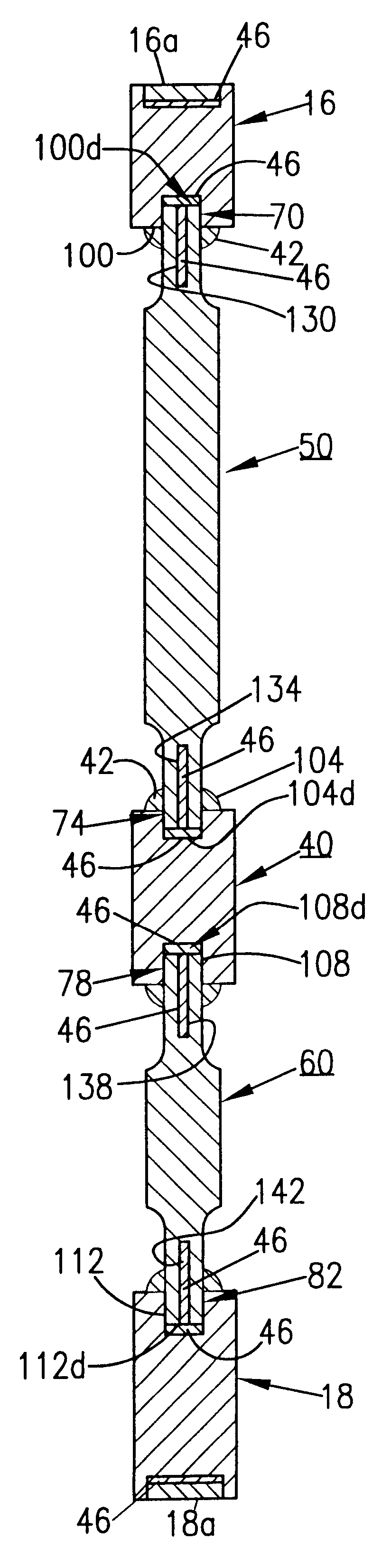

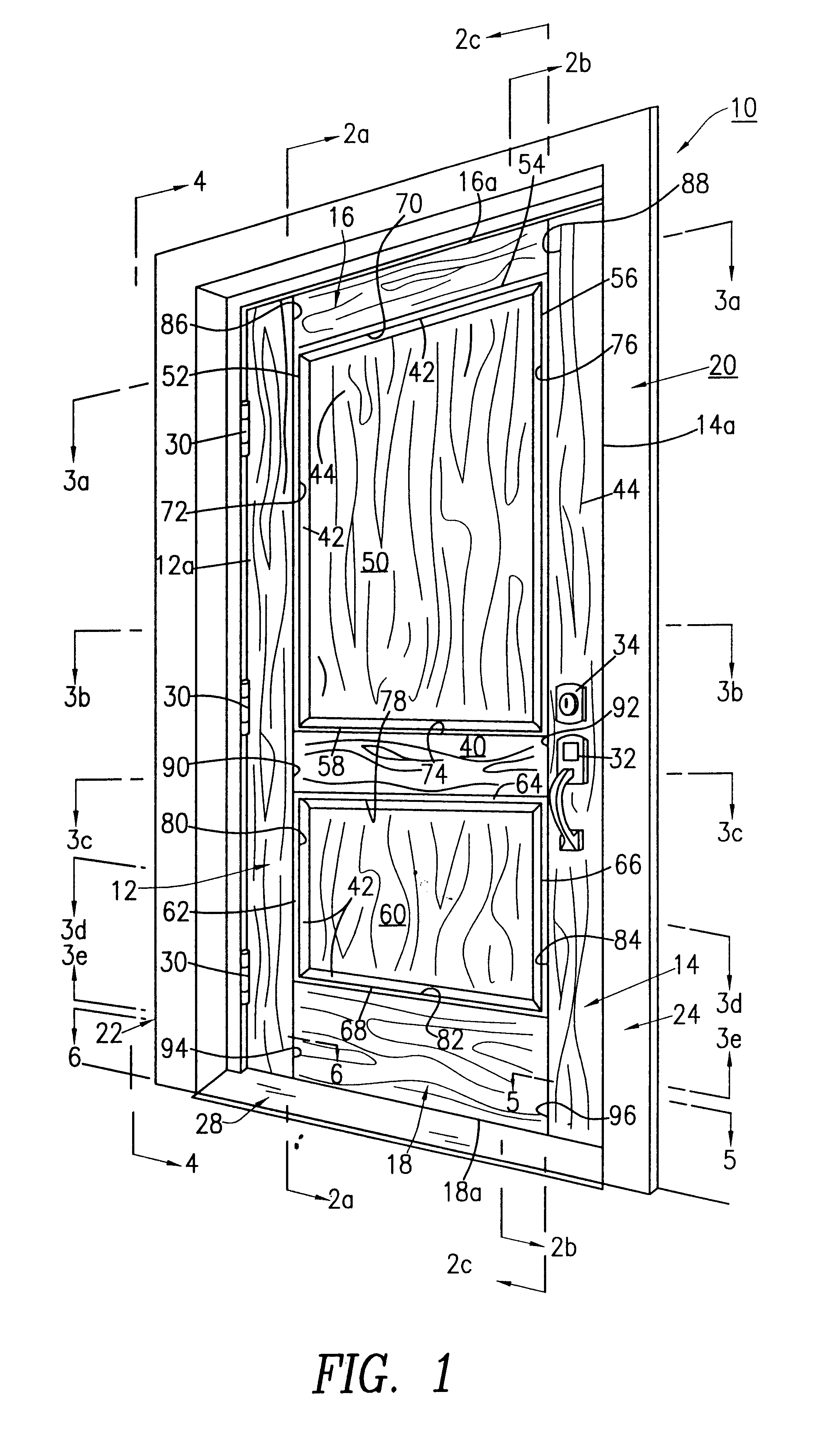

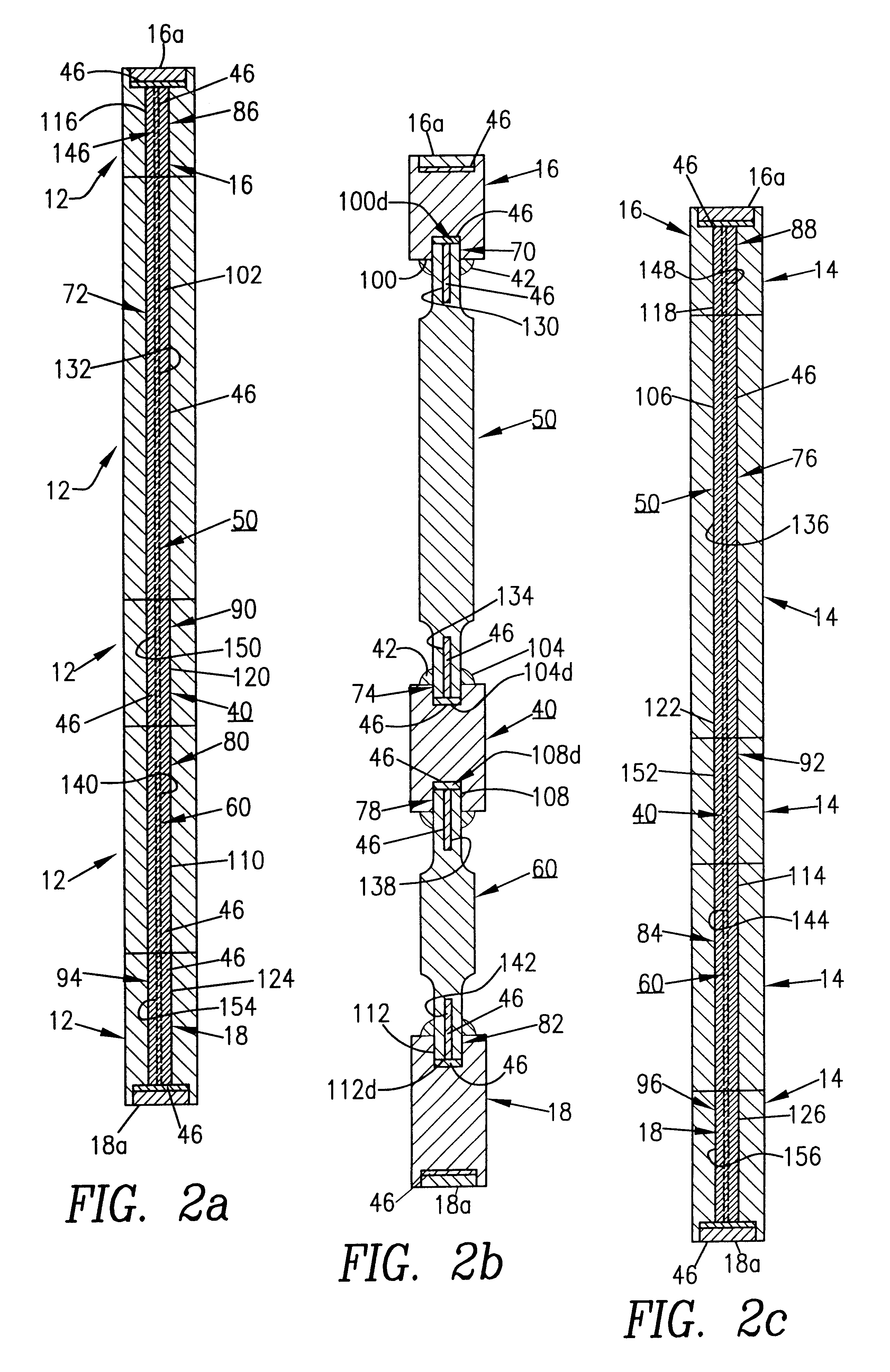

The fire retardant wooden door 10 of the preferred embodiment of the present invention is represented in detail by FIGS. 1 through 6 of the patent drawings. The fire retardant door 10 is used to fireproof an area and to prevent fire from spreading to other areas within a home dwelling, commercial building or industrial plant.

As shown in FIG. 1, the fire retardant wooden door 10 includes stiles 12 and 14, rails 16 and 18 and is hingedly connected within a door frame 20. The door frame 20 includes a left side doorjamb 22, a right side doorjamb 24, an upper header 26 and a lower sill 28. Suitable hinges 30 are used to mount the door 10 to the hinge jamb 22 in a manner which allows the door 10 to be opened or closed. A handle 32 is provided to operate a latch 34 which retains the door in the closed position.

The fire retardant wooden door 10 further includes a center panel 40, an upper panel 50 and a lower panel 60. Panel 50 has edges 52, 54, 56 and 58, and panel 6...

embodiment 200

Alternate Embodiment 200

The fire retardant wooden door 200 and its component parts of the alternate embodiment of the present invention is represented in detail by FIGS. 7 and 8 of the patent drawings. The fire retardant door 200 is also used to fire proof an area and to prevent fire from spreading to other areas within a home dwelling, commercial building or industrial plant. All aspects of the second embodiment of the fire retardant wood door 200 are exactly the same except for the use of fire-tempered glass panels 250 and 260 within an alternate door frame 220 which replace the wood panels 50 and 60 of the fire retardant wooden door 10 of the preferred embodiment.

In all other aspects, all of the component parts are exactly the same as the preferred embodiment of the fire retardant wood door 10 except for using of the fire tempered glass panels 250 and 260 within the door frame 220, as shown in FIGS. 7 and 8.

Operation of the Present Invention

In operation, when fire or excessive he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com