Patents

Literature

201 results about "Lead phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

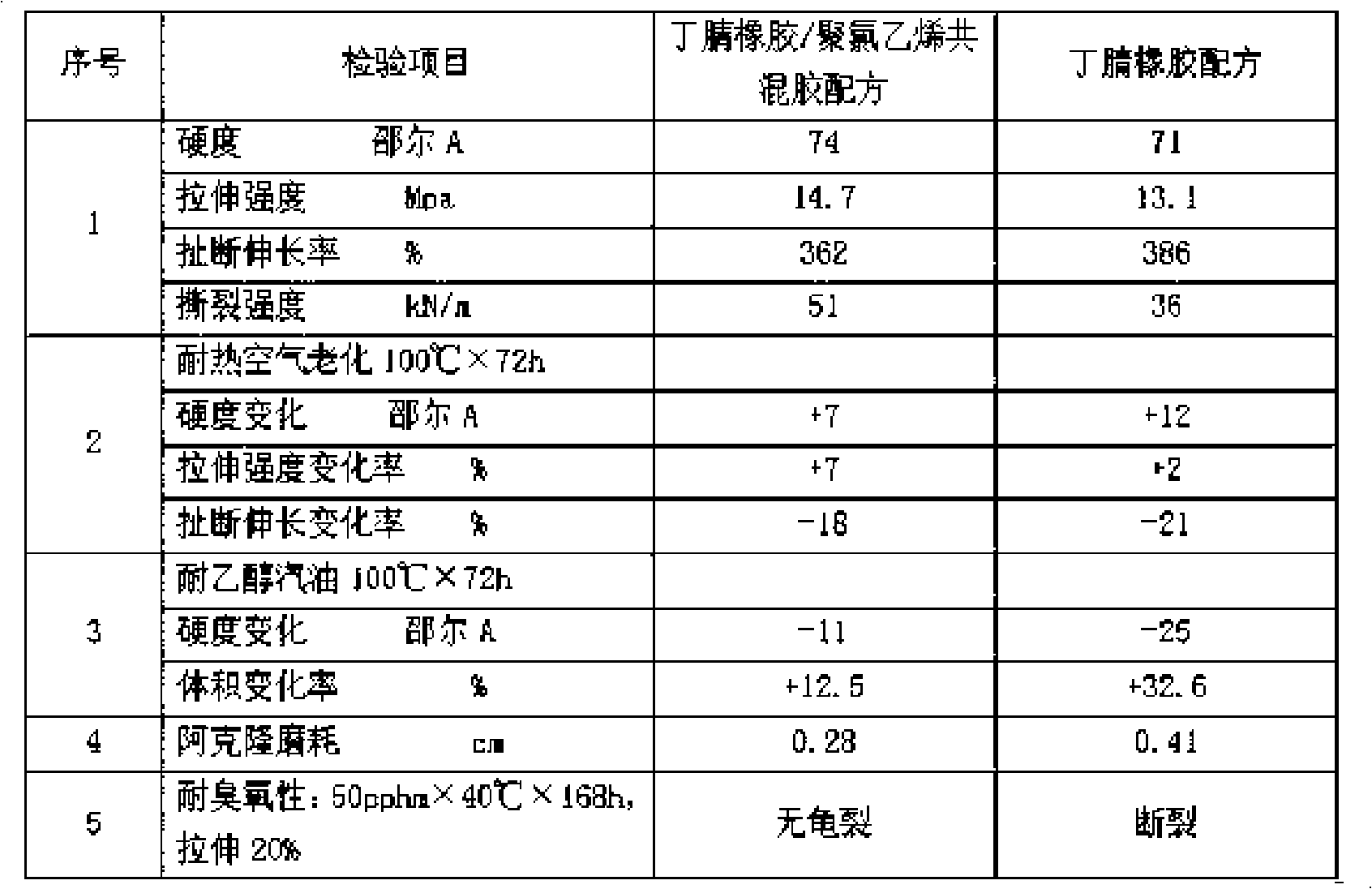

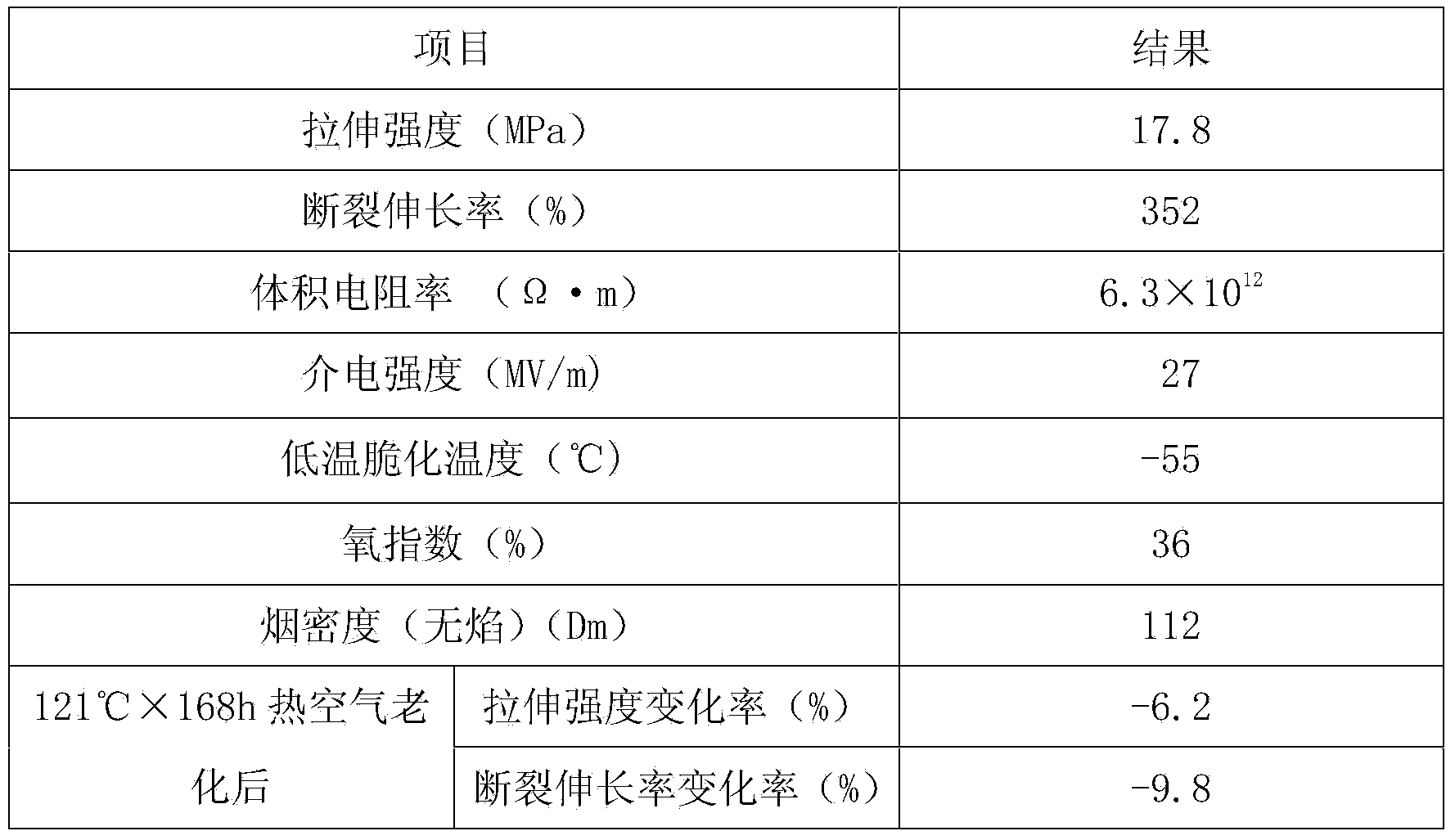

Polyvinyl chloride elastomer formula for flame-retarded mining flexible cable and its processing method

InactiveCN1676546AOvercome stickiness and blackeningOvercomes defects that can cause electrical crackingInsulated cablesInsulated conductorsElastomerRubber material

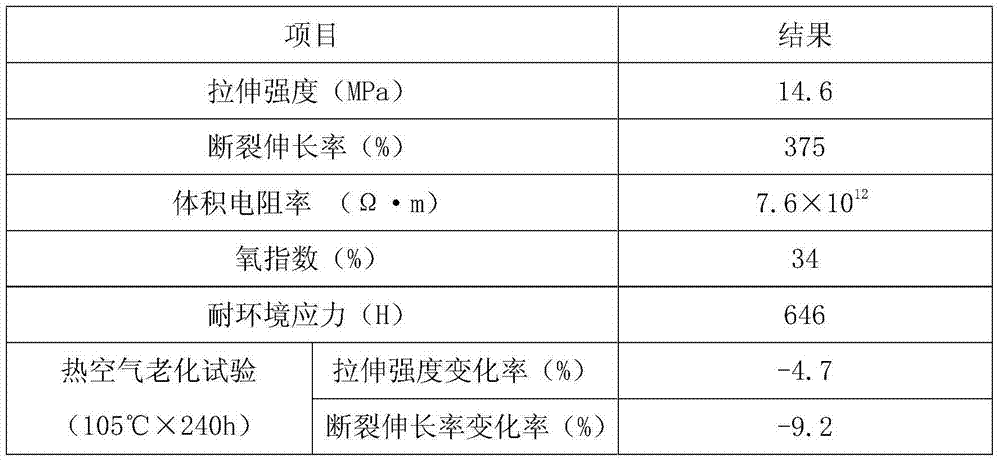

This invention relates to PVC elastomer formula for flame retarding mine use sofe cable and its processing technique. The formula includes the following contents(weight share): high polymerized PVC 100, low polymerized PVC 10-50, the plasticizer 60-120, tri-salt lead sulfate 2-5, disalt lead phosphate 2-5, disalt lead stearate 0.5-1.5 barium stearate 0.5-1.0, inflaming retarding agent 10-20, assistant retarding agent 2-7, antioxidant 0.1-1.0, bulking agent 10-30. The processing technique is as follows: match every group according to weight ratio and then past them; knead the pasting and powder under 90-110deg.C for 4-10 minutes, plasticize the kneaded mixture and particlize the processed rubber material and storage them. The elasticity of PVC of this invention can arrive the elasticity of rubber, and its electrical performance, hot endurance, inflaming retarding performance and tensile and breaking elongation are up to the standards.

Owner:JIANGWAN SPECIAL CABLE SHANGHAI

Silver-loaded zirconium phosphate/nano-titanium dioxide composite antibacterial agent and preparation method thereof

ActiveCN101720787AGood compatibilitySimple production methodBiocideDisinfectantsLead phosphatePhosphoric acid

The invention discloses a silver-loaded zirconium phosphate / nano-titanium dioxide composite antibacterial agent and a preparation method thereof, and the composite antibacterial agent consists of 70-95 parts of silver-loaded zirconium phosphate with the silver content of 0.5-3.5% and 5-30 parts of SiO2 modified nano-TiO2 with the silver content of 0.5-3.5%. The preparation method comprises the steps of firstly leading phosphate or phosphoric acid to be reacted with soluble zirconium salt for generating zirconium phosphate, washing the zirconium phosphate, then preparing 10-60% suspension, then adding silver nitrate into a system, aging for 2-36 hours, then adding titanium salt, further adding silicate ester or silica sol after completing the addition of the titanium salt, finally adding the silver nitrate, aging for 1-24 hours, then filtering, and carrying out high-temperature calcination for preparation. The composite antibacterial agent has excellent antibacterial performance, the compatibility between the antibacterial agent and a parent material is better, and the production method is simple and easy to control.

Owner:WENGFU (GRP) CO LTD

Attapulgite-modified polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102995446AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsLaminationEpoxySurface layer

The invention discloses attapulgite-modified polyvinyl chloride (PVC) synthetic leather. The attapulgite-modified PVC synthetic leather comprises a surface layer, a foamed layer, a bonding layer and a brushing fabric, and is characterized in that the surface layer is prepared by mixing the following raw materials in parts by weight to form slurry: 70 to 80 parts of SG-2 type PVC resin, 30 to 40 parts of SG-5 type PVC resin, 10 to 15 parts of triethyl citrate, 30 to 35 parts of epoxy butyl oleate, 20 to 25 parts of n-butyl methacrylate, 5 to 6 parts of PVC color paste, 1 to 2 parts of dibasic lead phosphate, 1 to 2 parts of tribasic lead sulfate and 5 to 10 parts of modified diatomite. Through the improvements of the formula and the process, the flexibility of the synthetic leather is improved, and the synthetic leather has a natural comfortable hand feeling similar to that of natural leather and is difficult to damage or tear after being used for 3 to 5 years.

Owner:HEFEI ANSHAN COATING FABRICS

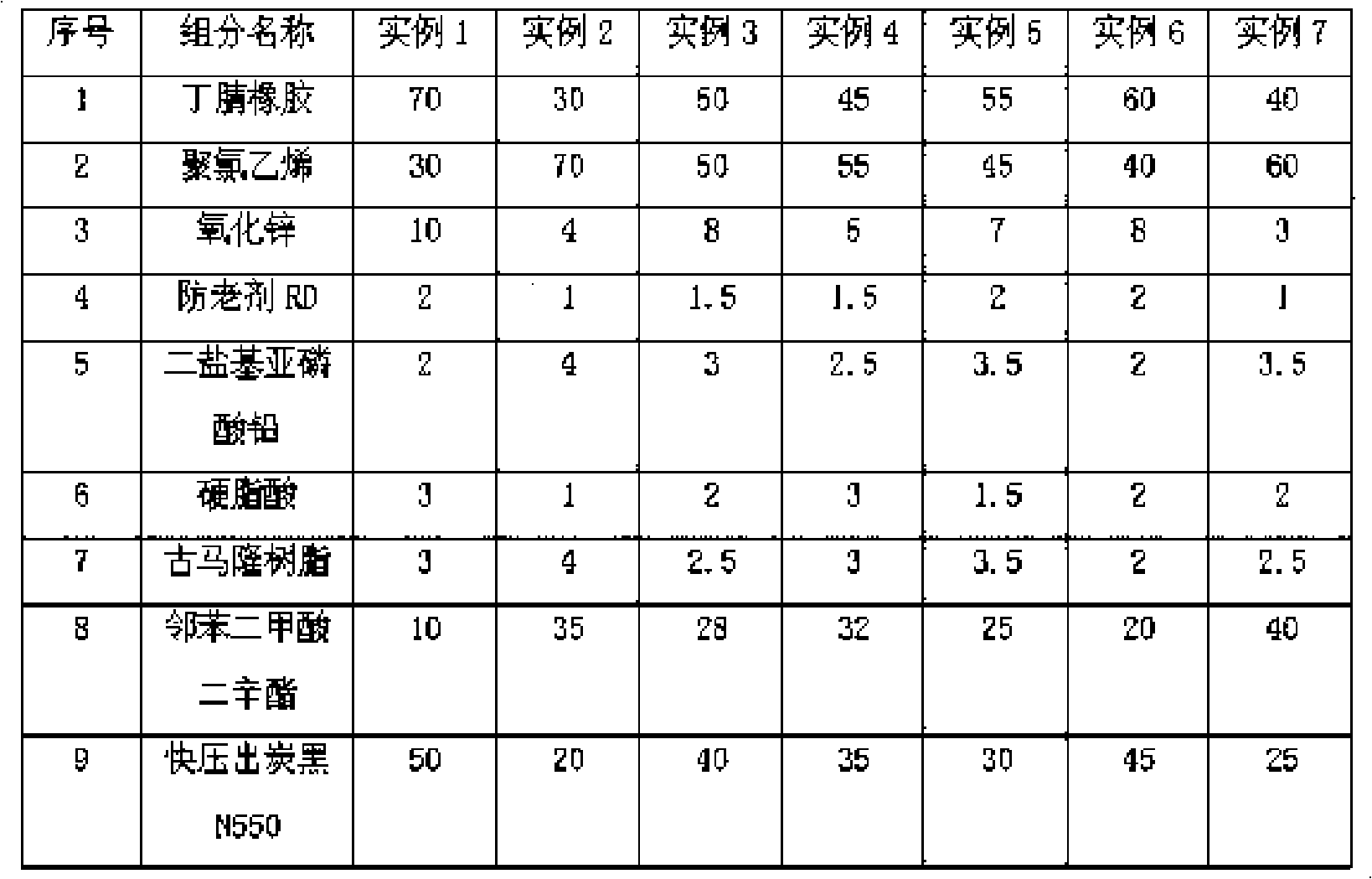

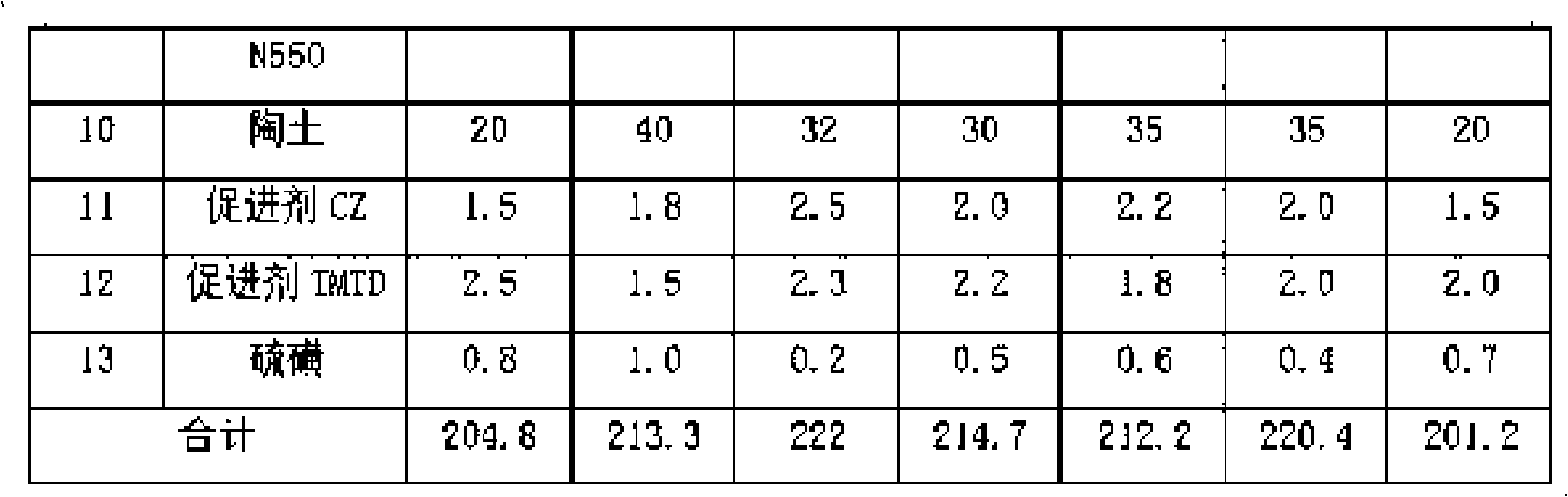

Formula of butyronitrile rubber/polyvinyl chloride co-mixed rubber ethanol resistance gasoline rubber pipe

ActiveCN101805467ASolve the shortcomings of poor resistance to ethanol gasolineMeet the use requirementsFlexible pipesPolymer scienceLead phosphate

The invention relates to a formula of butyronitrile rubber / polyvinyl chloride co-mixed rubber ethanol resistant gasoline rubber pipe, comprising the following components in parts by weight: 30-70 parts of butyronitrile rubber, 70-30 parts of polyvinyl chloride, 3-10 parts of zinc oxide, 1-2 parts of anti-aging agent RD, 2-4 parts of dibasic lead phosphate, 1-3 parts of stearic acid, 2-4 parts of coumarone-indene resin, 10-40 parts of dioctyl phthalate, 20-50 parts of fast extruding furnace black (N550), 20-40 parts of figuline and 1.5-2.5 parts of an accelerating agent CZ. Through the performance contrastive analysis of the formula of butyronitrile rubber / polyvinyl chloride co-mixed rubber and the formula of the butyronitrile rubber, the comprehensive performance of the formula of butyronitrile rubber / polyvinyl chloride co-mixed rubber is better with low cost, which can satisfy the requirements of the traditional ethanol resistant gasoline.

Owner:TIANJIN PENGYI GRP CO LTD

Stretch-proof cable sheath insulation material and preparation method thereof

InactiveCN102993518AGood physical propertiesDimensionally stableRubber insulatorsPlastic/resin/waxes insulatorsLead phosphateEthylene thiourea

The invention discloses a stretch-proof cable sheath insulation material and a preparation method thereof. The stretch-proof cable sheath insulation material comprises the following raw materials in parts by weight: 90-100 parts of neoprene CR121, 18-20 parts of chlorinated polyethylene, 15-25 parts of semi-reinforcing carbon black N774, 2-3 parts of magnesium oxide, 1-2 parts of ferrocene, 30-35 parts of mica powder, MB1-2 of antiager MB, 1-2 parts of 2-thiol group benzimidazole, 5-8 parts of dioctyl maleate, 1-2 parts of promoter DM1, 0.8-1 part of dibasic lead phosphate, 12 to 18 parts of nanometer silicon dioxide, 1-3 parts of 4, 4'- oxylbisbenzenesulfonyl hydrazide, 2-4 parts of antioxidant DSTP, 4-6 parts of glass powder, 0.8-1 part of zinc oxide, 2-3 parts of modified calcium carbonate, 5-6 parts of antimony oxide and 4-6 parts of ethylene thiourea. The stretch-proof cable sheath insulation material prepared by the method has the advantages of excellent physical properties, stable size, low percentage of contraction and greatly increased tensile strength, tearing strength resistance and resilience force performance.

Owner:安徽文峰电子科技集团有限公司

Heat-resistant flame-retardant polyvinyl chloride cable material and manufacturing method thereof

ActiveCN101885881AHigh technical contentImprove the lubrication effectPlastic/resin/waxes insulatorsPolymer scienceLead phosphate

The invention relates to a heat-resistant flame-retardant polyvinyl chloride cable material and a manufacturing method thereof. According to a formula, the material comprises the following components: polyvinyl chloride resin, a flame-retardant filler, a dispersing agent, a plasticizer, lead sulfate tribasic, dibasic lead phosphate, lead stearate, isopropyl triphenyl phosphate, chlorinated paraffin, calcium carbonate, zinc stannate, water and zinc borate, an antioxidant and stearic acid. The material has the advantages that: a large amount of graphite serving as a flame-retardant and high-temperature-resistant filler is added; and the graphite and a proper amount of chlorinated paraffin and zinc stannate together assist in enhancing the flame retardant property of a cable. The filler has high compatibility with other materials and high dispersion and is matched with other stabilizers; and the product has high heat-resistant stability and flame retardant property. Meanwhile, the lubricating performance of the product is improved to a great extent; the PVC mixed material has high uniform plasticity and high-speed melt fluidity; and the product has a smooth surface, soft handfeel and superior performance.

Owner:ANHUI LIANJIAXIANG SPECIAL CABLE

Diatomite modified polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102995445AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsLaminationPolyesterPolyvinyl chloride

The invention discloses diatomite modified polyvinyl chloride synthetic leather. The diatomite modified polyvinyl chloride synthetic leather comprises a surface layer, a foaming layer, a bonding layer and a brushing fabric and is characterized in that the surface layer is manufactured by blending the following raw materials in parts by weight into slurry: 40-50 parts of SG-1 type PVC (Polyvinyl Chloride) resin, 70-80 parts of SG-6 type PVC resin, 15-20 parts of sebacic acid propylene glycol polyester, 10-15 parts of acetyl triethyl citrate, 20-25 parts of di-n-butyl maleate, 5-6 parts of PVC color paste, 1-2 parts of imarcaptoacetate dioctyltin, 1-2 parts of dibasic lead phosphate, 1-2 parts of zinc stearate, 5-10 parts of nanometer calcium carbonate and 15-20 parts of modified attapulgite. Through an improvement of a formula and a technology, the flexibility of the synthetic leather is increased, and the diatomite modified polyvinyl chloride synthetic leather has the natural comfortable hand feel similar to that of natural leather and is not easily damaged or torn.

Owner:HEFEI ANSHAN COATING FABRICS

Wood-like bamboo fiber mould composite material

The invention relates to a wood-like bamboo fiber mould composite material. The composition comprises 55 to 70 percent of bamboo fiber, 15 to 55 percent of wood meal, 22 percent of low-density polyethylene (PE), 2 percent of solubilizer, 2.5 percent of lubricant, 1.5 to 2.5 percent of thermoplastic plastic, 3 percent of ultrafine talcpowder of 700 meshes, 1 percent of styrene and methyl acrylate mixed monomer, 2.5 percent of any plastic of polyvinyl chloride (PVC), polypropylene (PP) and PE, 0.2 percent of dibasic lead phosphate, 0.1 percent of dibasic lead stearate, 0.1 percent of lead stearate, 1.0 percent of calcium palmitate, 1 percent of calcium carbonate, 0.1 percent of polymer wax and 3 percent of melamine resin. The invention provides a modified composite material which is environment-friendly, soundproof and heat-insulated, has good sealing performance, and is high in strength and tolerance.

Owner:CHANGSHU FANGTA COATING CHEM

Cold-resistant PVC cable material and preparation method thereof

ActiveCN103275428AImprove cold resistanceImprove wear resistancePlastic/resin/waxes insulatorsPolyesterPolymer science

The invention discloses cold-resistant PVC (polyvinyl chloride) cable material. The cold-resistant PVC cable material comprises the following components in parts by weight: 100 parts of PV, 1 to 35 parts of DOS, 0.1 to 10 parts of adipic acid polyester, 1 to 12 parts of tribasic lead sulfate, 0.1 to 5 parts of dibasic lead phosphate, 0.1 to 5 parts of barium stearate, 0.1 to 5 parts of lead stearate, 0.1 to 5 parts of carbon black, 0.1 to 5 parts of antioxidant, and 0.1 to 10 parts of vulcanizing agent; the cold-resistant temperature of the cold resistant PVC cable material is minus 40 to 50 DEG C; in the prior art, the cold resistance is minus 20 DEG C, which is greatly improved; the abrasive resistance is 800 to 1000 circles; the tensile strength is 10 to 30 MPa; the elongation at break is 300 to 450 percent; the heat-resistance temperature is 105 DEG C; and the shore hardness is 85 to 95. The cold resistant PVC cable material has excellent low temperature resistance, ageing resistance, abrasive resistance, heat resistance and insulativity, and can be widely produced to continuously replace existing materials.

Owner:SUZHOU JUHUIBANG NEW MATERIAL TECH CO LTD

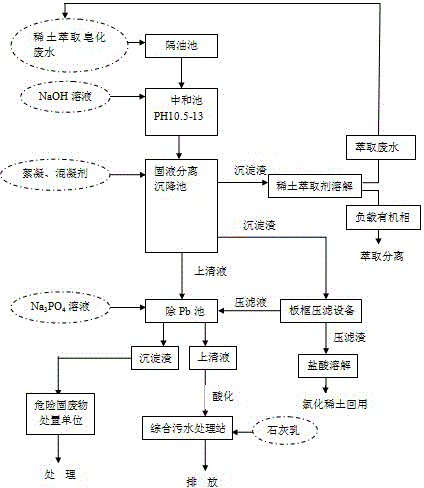

Technology of removing lead and recycling rare earth from saponified wastewater generated during process of rare earth extraction

ActiveCN105087964AEfficient removalAchieve recyclingProcess efficiency improvementFiltrationLead phosphate

The invention discloses a technology of removing lead and recycling rare earth from saponified wastewater generated during the process of rare earth extraction. The technology comprises the following steps: (a) making saponified wastewater which is generated during the process of rare earth extraction go through an oil separation tank to remove the oil; (b) adding a NaOH solution, adjusting the pH to 10.5-13, and separating the solid and the liquid to obtain a supernate containing lead and rare earth precipitate; (c) subjecting the precipitate to plate-frame pressure filtration to obtain press filtrate and pressure-filtered residues; or dissolving the rare earth precipitate by hydrochloric acid or an acidic extractant to obtain a chlorinated rare earth solution, and the extracting rare earth from the chlorinated rare earth solution; (d) adding a Na3PO4 solution into the supernate and / or the press filtrate to obtain lead phosphate precipitate and supernate, wherein the content of total Pb in the supernate is not more than 0.2 mg / L; (e) press-filtering the precipitate, stacking the precipitate together, handing over the precipitate to factories, which has the qualification to process the dangerous solid wastes; acidifying the supernate, adding lime milk to remove the excess PO4<3->, then discharging the wastewater, wherein the content of total Pb in saponified wastewater is not more than 0.2 mg / L, the discharged wastewater can meet the requirements of Pollutant Discharge Standards Of Rare Earth Industry, and at the same time, the rare earth in the wastewater is effectively recycled.

Owner:GUANGDONG ZHUJIANG RARE EARTHS

PET (polyethylene glycol terephthalate) fiber/mulberry bark composite sound absorbing cotton and preparation method of PET fiber/mulberry bark composite sound absorbing cotton

InactiveCN102965841AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsNon-woven fabricsFiberPolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / mulberry bark composite sound absorbing cotton, which comprises the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of mulberry bark fibers, 10 to 15 parts of emulsifying agents OP-9, 5 to 10 parts of peregal O-25, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of EVA (ethylene vinyl acetate), 15 to 20 parts of nanometer barite powder, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of dioctyl phthalate, 4 to 6 parts of decabromodiphenyl ether, 2 to 3 parts of tristearin, 1 to 2 parts of vinyltriethoxysilane, 2 to 3 parts of calcium stearate, 1 to 2 parts of dibasic lead phosphate, 0.5 to 1.5 parts of anti-ageing agents OD (octyl decyl) and 1 to 2 parts of antioxidants DLTP (dilauryl thiodipropionate). The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

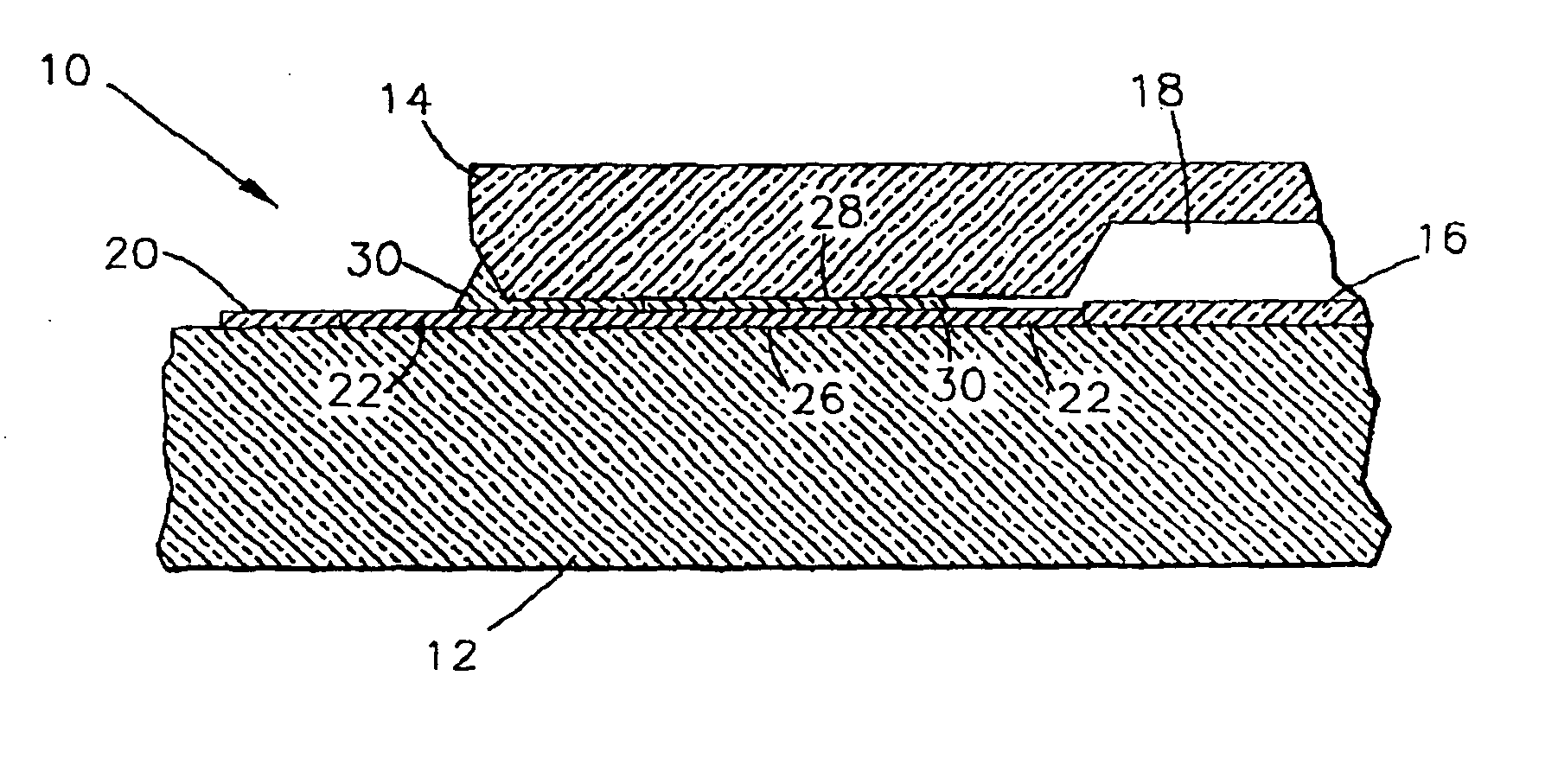

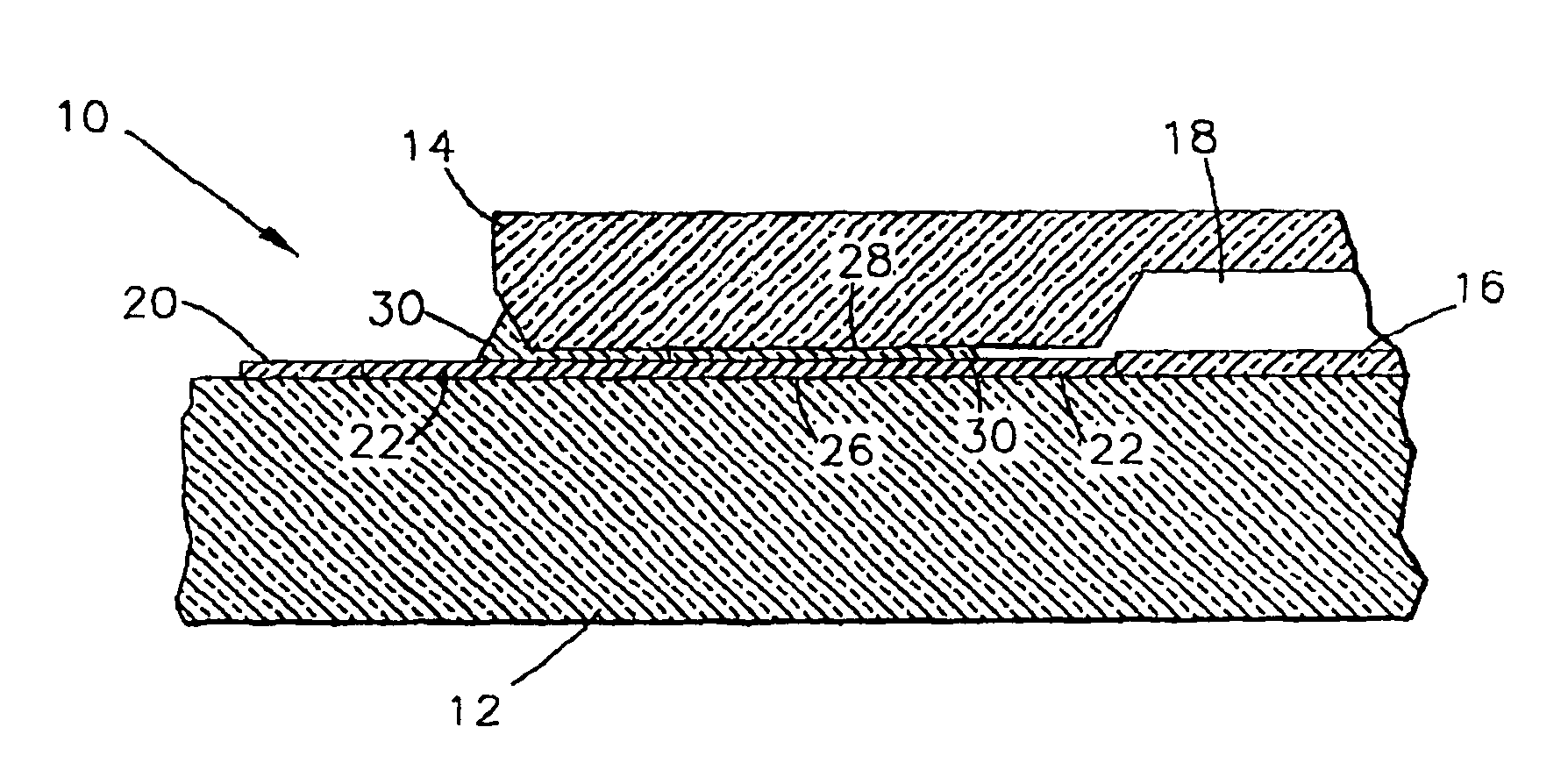

Glass frit bond and process therefor

InactiveUS20050058841A1Inhibitory contentSemiconductor/solid-state device detailsSolid-state devicesPhosphate ionFrit

A lead-containing glass material of the type suitable for use in a wafer bonding process, wherein the moisture resistance of the glass material is increased by the presence of a lead phosphate coating on an outer exposed surface of the material, thereby acting as a barrier to reaction of moisture with the lead of the glass material. A source of reactive phosphate ions is applied to the glass material so as to spontaneously form the desired lead phosphate coating.

Owner:DELPHI TECH IP LTD

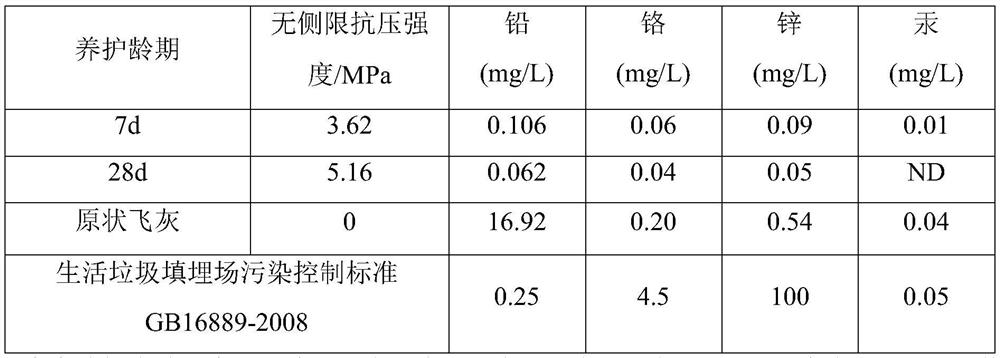

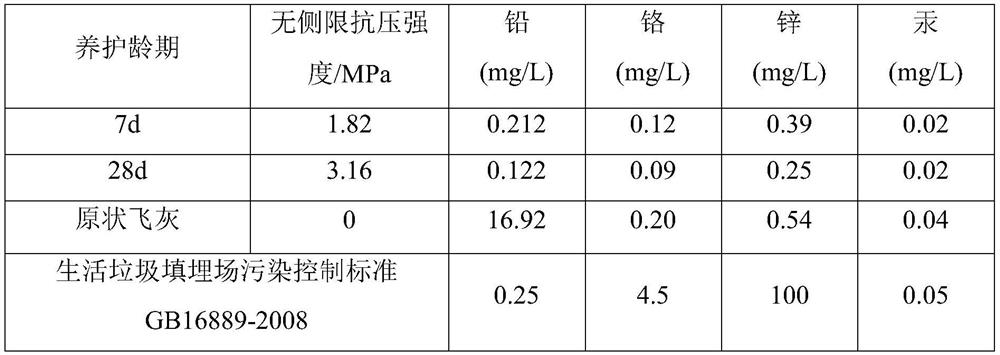

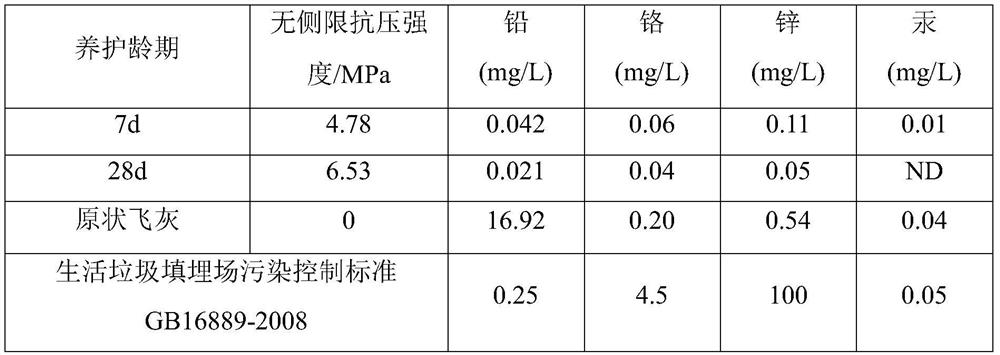

Method for solidifying and stabilizing fly ash through synergy of ardealite and red mud

ActiveCN113024214ALower pHLow leaching rateSolid waste managementO-Phosphoric AcidHydrogen phosphate

The invention relates to the technical field of resource utilization of bulk industrial solid wastes, in particular to a method for solidifying and stabilizing fly ash by synergy of ardealite and red mud, which comprises the following steps: uniformly mixing washing liquid and fly ash to obtain fly ash slurry; mixing and stirring fly ash, mineral powder, an additive ardealite powder and red mud powder to prepare a curing agent; and naturally curing the fly ash slurry for 2-24 hours, and adding a curing agent into the fly ash slurry to further cure and stabilize the heavy metals in the fly ash. According to the method disclosed by the invention, in the fly ash curing process, the alkalinity of the fly ash is neutralized by utilizing purified ardealite water washing liquid, soluble phosphoric acid, hydrogen phosphate radicals, dihydrogen phosphate radicals and fluorine ions react with Pb<2+> to generate stable mineral precipitates such as lead phosphate, lead fluorophosphate and lead chlorophosphate, so that the effect of curing and stabilizing the fly ash is achieved, and the leaching rate of lead in the fly ash is reduced. The curing agent is added into the fly ash slurry, and is excited to react to generate a hydration product to secondarily cure / stabilize heavy metals in the fly ash.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Nano attapulgite modified composite sound absorbing material and preparation method thereof

The invention discloses a nano attapulgite modified composite sound absorbing material. The material is prepared from the following raw materials in parts by weight: 100-120 parts of barite powder, 50-60 parts of ceramsite, 40-50 parts of nano attapulgite, 80-90 parts of styrene-acrylic emulsion, 55-65 parts of modified tree ashes, 15-20 parts of zinc borate, 20-30 parts of mineral wool fibers, 10-20 parts of nanocarbon, 20-30 parts of EVA (ethylene-vinyl acetate copolymer), 15-20 parts of POE (polyolefin elastomer), 5-10 parts of EMDP, 5-8 parts of trioctyl trimellitate, 4-6 parts of triphenyl phosphate, 2-3 parts of zinc stearate and 1-2 parts of dibasic lead phosphite. The material has the beneficial effects that the problem of developing and researching the sound absorbing material urgently is solved and the novel sound absorbing material which meets the requirements, can stand the tests of harsh environments and has the advantages of high tensile strength, high elongation, high breaking strength, good sound absorbing effect and the like is prepared.

Owner:芜湖跃飞新型吸音材料股份有限公司

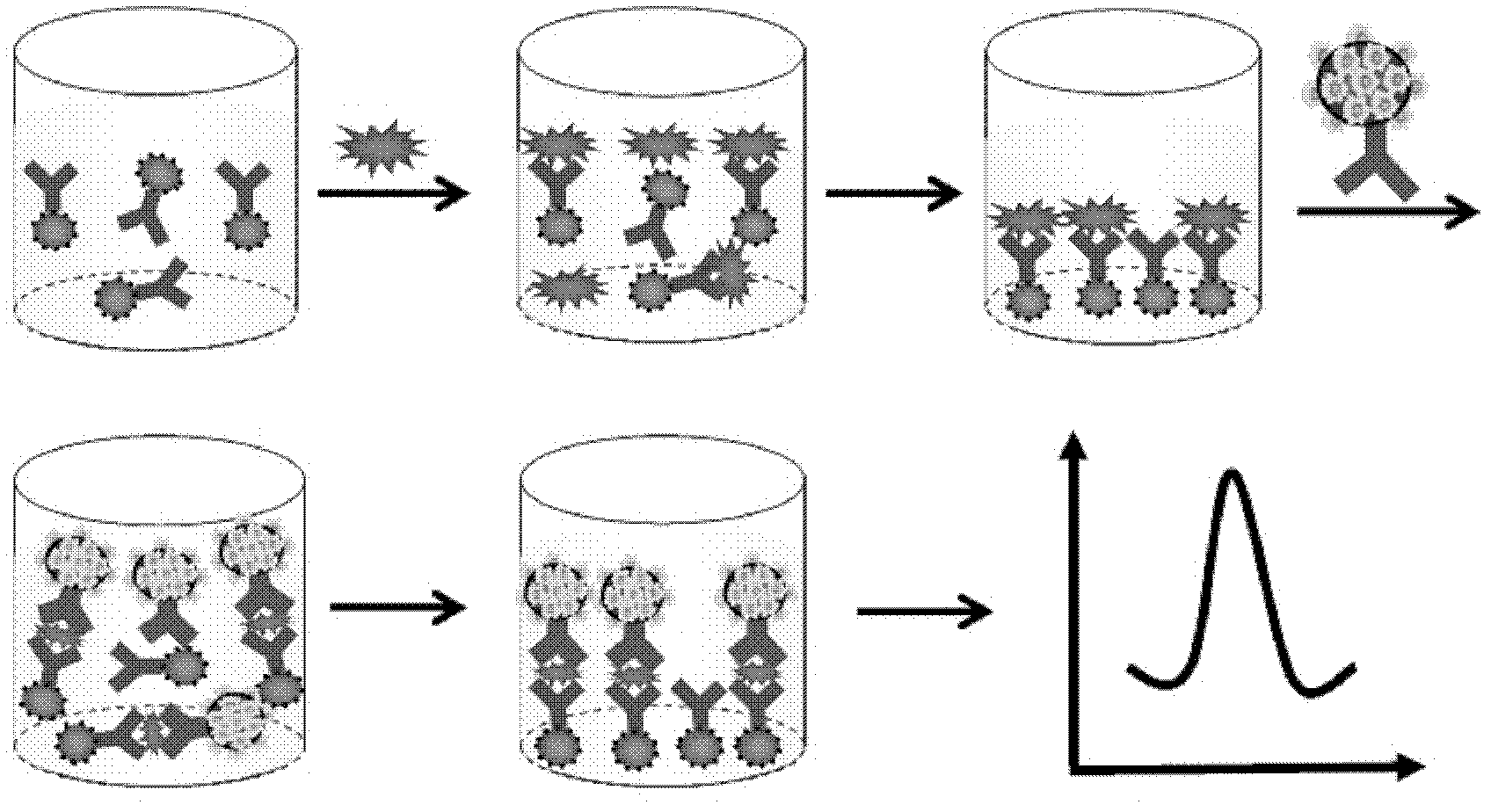

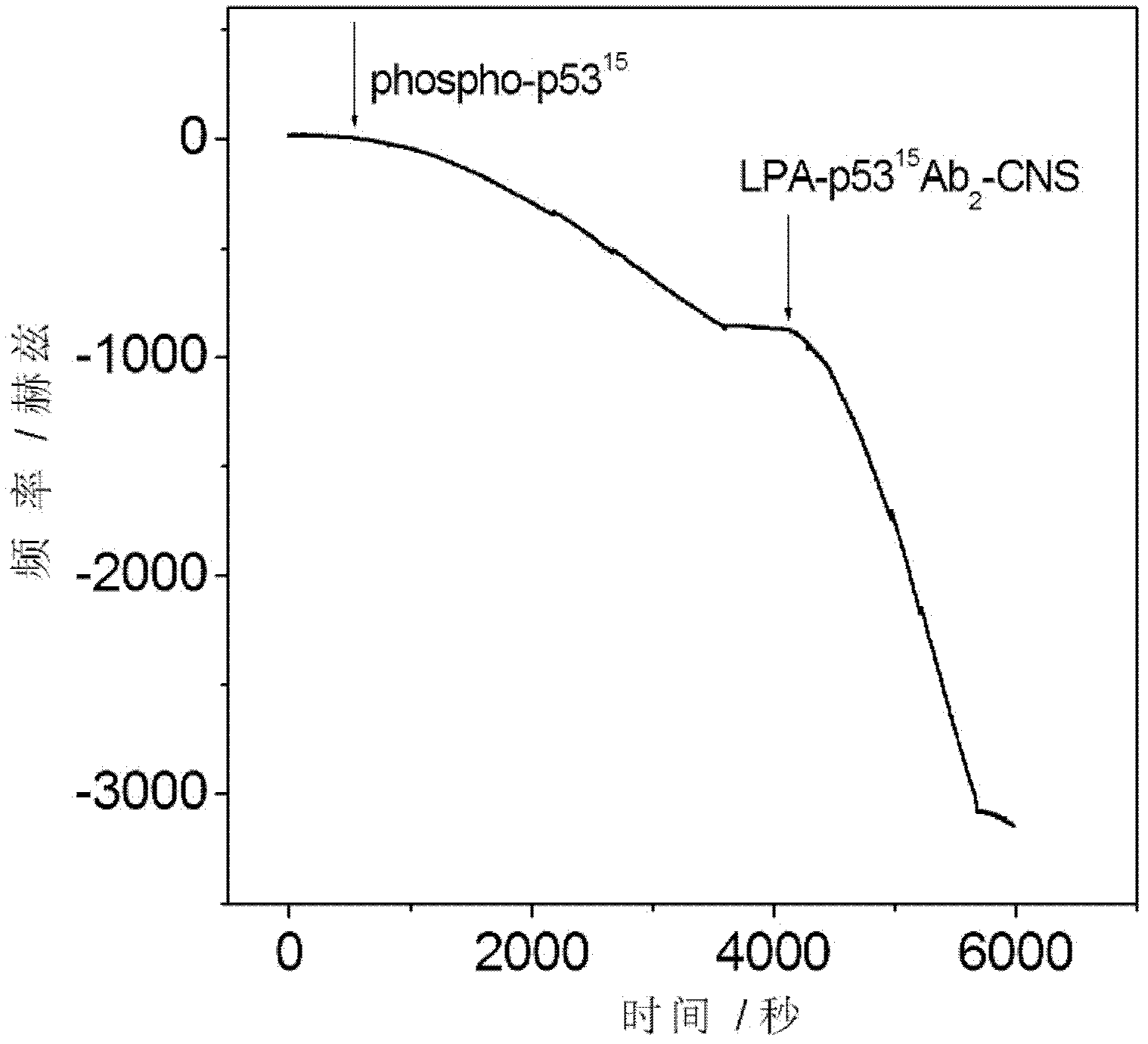

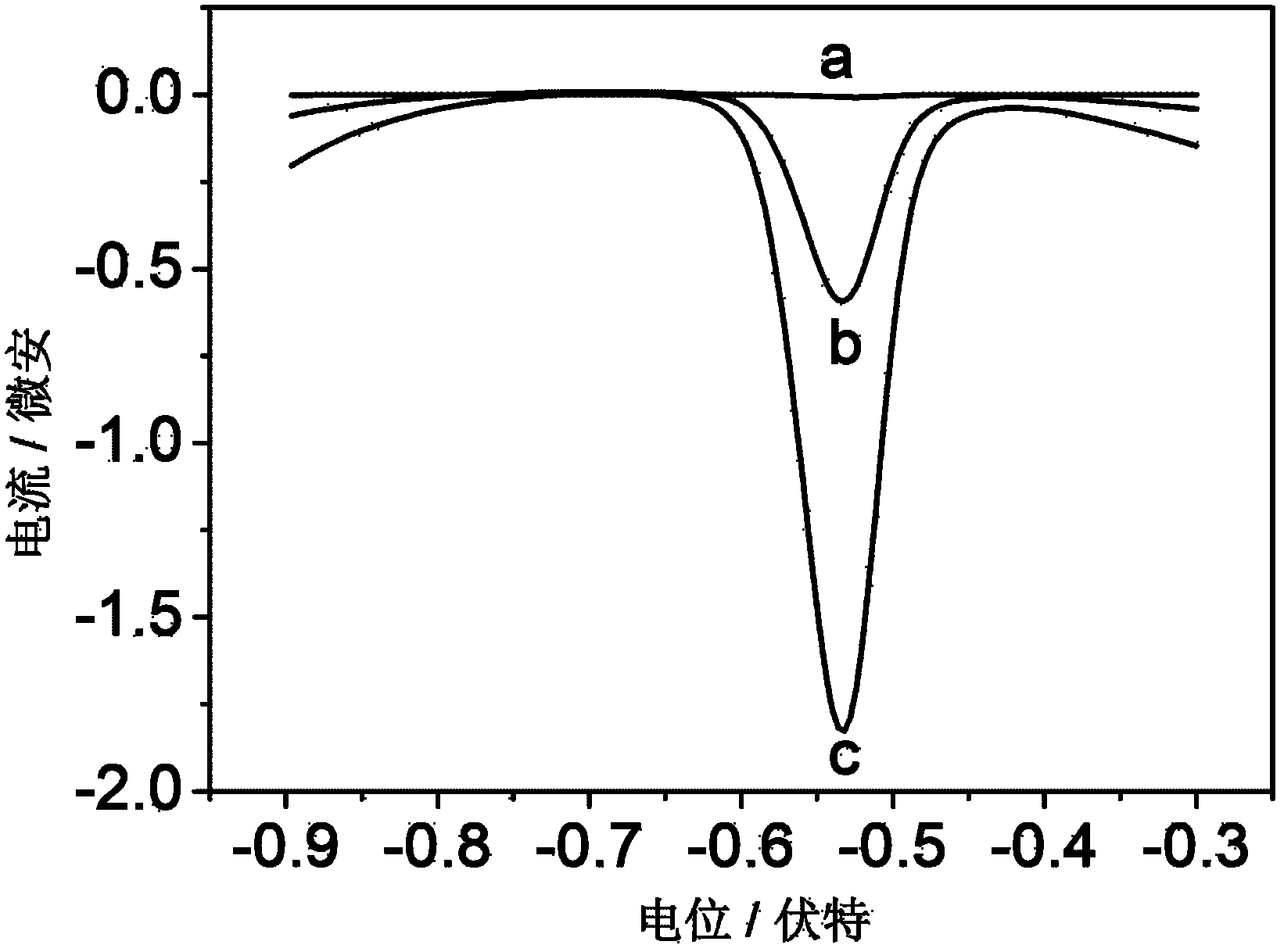

Electrochemical immune sensor for phosphating protein

InactiveCN102253221AIncrease fixed amountGood biocompatibilityBiological testingMaterial electrochemical variablesEpoxySignalling molecules

The invention relates to an electrochemical immune sensor for phosphating protein. In the electrochemical immune sensor, a magnetic nanometer-antibody composition MPs-p53<15>Ab1 is used as an adsorbent to separate the phosphating protein, a carbon nanometer sphere CNS is used as a carrier, lead phosphate-apoferritin (LPA) and a phosphating protein antibody p5315Ab2 are modified on the surface of the CNS, and thus, LPA-p53<15>Ab2-CNS nanometer complexing agent is prepared for detecting signal amplification. According to the sandwich immunoassay principle, the content of the phosphating protein to be detected is in proportion to the captured LPA-p5315Ab2-CNS, and the content of lead ions encapsulated in LPA is detected according to a dissolving volt-ampere method to measure the concentration of the phosphating protein in a sample. The method has the advantages of simplicity and convenience for operation and simple and efficient separation, and the advantage that an integral immunologic reaction is finished in an epoxy (EP) tube; a large number of LPA signal molecules are introduced by taking the CAN as the carrier, and each LPA molecule contains a large number of Pb<2+>, so the sensitivity of detection is improved; and the dissolved Pb<2+> is used as a detection signal without adding an enzyme substrate, so the electrochemical immune sensor is a reagent-free sensor. In the electrochemical immune sensor for the phosphating protein, the linear concentration range of the phosphating protein phosphor-p53<15> is from 0.02 to 20 ng mL<-1>, and the detection limit is 0.01 ng mL<-1>.

Owner:HUAZHONG NORMAL UNIV

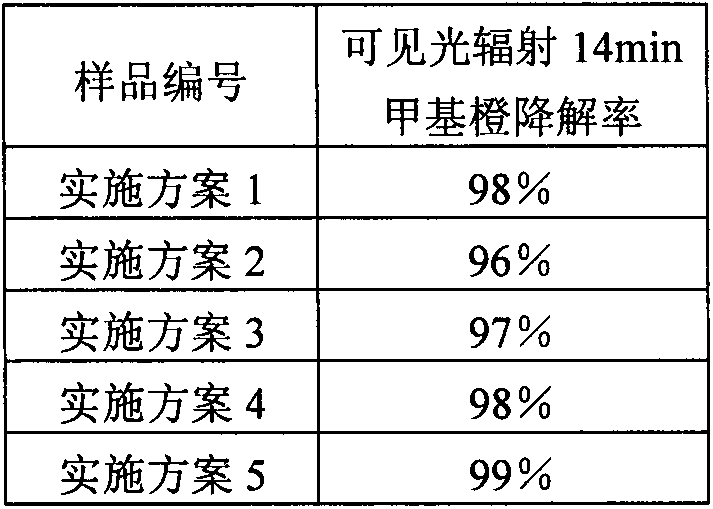

Lead phosphate and silver phosphate composite photocatalyst and preparation method thereof

The invention relates to a lead phosphate and silver phosphate composite photocatalyst and a preparation method thereof, and belongs to the field of inorganic photocatalytic materials. The lead phosphate and silver phosphate composite photocatalyst comprises lead phosphate and silver phosphate. The photocatalyst prepared through the method has photocatalytic activity in the wavelength range from 400 to 800nm, and can catalyze and oxidize organic compounds in radiation of visible light or natural light so that the organic compounds are mineralized into non-toxic and harmless small-molecule matter.

Owner:TIANJIN POLYTECHNIC UNIV

Cold resistant polyvinyl chloride cable material and preparation method thereof

The invention discloses a cold resistant polyvinyl chloride cable material and a preparation method, the cable material comprises the following raw materials by weight: 80-90 parts of SG-3 type PVC resin, 15-20 parts of fluorosilicone rubber, 10-15 parts of polytrifluorochloroethylene, 16-22 parts of dioctyl sebacate, 10-15 parts of dibutyl phthalate, 2-3 parts of lead sulfate tribasic, 1-2 parts of dibasic lead phosphate, 0.5-1 part of bisphenol A, 5-10 parts of nano kaolin, 10-15 parts of gas phase white carbon black, 8-12 parts of nano potash feldspar powder, 1-2 parts of zinc oxide, 0.5-1 part of calcium stearate, 1-2 parts of barium stearate, 2-4 parts of liquid paraffin, 12-16 parts of ammonium polyphosphate, 6-9 parts of barium metaborate and 4-6 parts of composite filling material. The cable material has excellent cold resistance, and can be normally used under low temperature of -50 DEG C--65 DEG C, the shock resistance is good, so that the problems of poor cold resistance and poor shock resistance under low temperature condition of the polyvinyl chloride cable material can be solved.

Owner:ANHUI RONGJIU OPTICAL FIBER COMM

Anti-125 DEG C-level low smoke halogen free-flame retardant single-core cable insulation rubber for railway locomotive

ActiveCN101851368AGuaranteed performanceCost controlPlastic/resin/waxes insulatorsCross-linkPolyolefin

The invention discloses anti-125 DEG C-level low smoke halogen free-flame retardant single-core cable insulation rubber for a railway locomotive. The insulation rubber formulation comprises the following ingredients in parts by weight: 100 parts of cross-linked polyolefin, 2-5 parts of organic peroxide vulcanizer, 1 to 4 parts of sulfur-acid agent and 1 to 4 parts of stabilizer, wherein the cross-linked polyolefin is preferably selected from ethylene-vinyl acetate copolymer EVA-40L-03 produced by DuPont, the organic peroxide vulcanizer is preferably selected from dicumyl peroxide (DCP), the sulfur-acid agent is triallyl isocyanurate (TAIC), and the stabilizer is preferably selected from dibasic lead phosphate. The invention not only has excellent insulation property, but also has excellent weather resistance, ozone resistance, heat-proof aging, acid-base resistance, fuel oil resistance, low smoke zero halogen flame retardant, environment protection, safety and long service life.

Owner:JIANGSU JUYE CABLE

Ageing resistant cable sheath material

ActiveCN103242574AGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesCross-linkDispersity

The invention discloses an ageing resistant cable sheath material which comprises the following raw materials in parts by weight: 95-101 parts of neoprene A-30, 20-30 parts of nano calcium carbonate, 10-16 parts of modified filler, 6-9 parts of ethylene bis stearamide, 4-6 parts of epoxidized soybean oil, 15-20 parts of chlorinated polyethylene, 2-3 parts of diphenylamine, 10-15 parts of potassium feldspar powder, 2-4 parts of dibasic lead phosphate, 2-3 parts of antioxygen DSTP, 3-5 parts of barium stearate, 0.8-1 part of a cross-linking agent ATC, 0.8-1 part of an accelerant TMTD and 1-2 parts of dipentamethylenethiuram. The prepared ageing resistant cable sheath material has excellent performance, size stability, low shrinking percentage, has strong tensile strength, strong tearing strength, strong resilience force performance and also has good oil resistance, heat resistance, sunlight resistance, ozone resistance, acid / alkali resistance and chemical reagent resistance; and the modified filler has good dispersity and surface tension, can further improve the tensile strength and stress at definite elongation of the cable sheath material and reduce heating and compression set of the cable sheath material, is capable of slowing down the aging speed of the cable sheath material, resisting acid and alkali corrosion and reducing production cost.

Owner:ANHUI KANGLIYA CO LTD

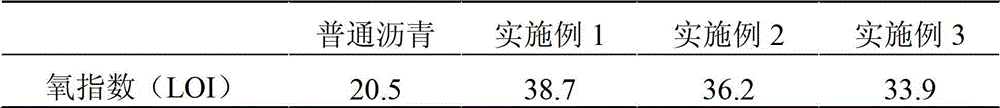

Novel high-performance cooperative system flame retarding asphalt

ActiveCN102942795AImprove temperature sensitivityImprove aging resistanceBuilding insulationsLead phosphateSlurry

The invention discloses novel high-performance cooperative system flame retarding asphalt which is characterized by comprising the following components in parts by weight: 100 parts of asphalt, 1-30 parts of flame retardant, 1-20 parts of synergist, 2-15 parts of compatilizer and 2-4 parts of modifier, wherein the asphalt is one or more of coal tar asphalt, shale asphalt and petroleum asphalt; the flame retardant is an organic silicon flame retardant; the organic silicon flame retardant is reacted with a small amount of zinc borate at a temperature of 90 DEG C for 1.5 hours to obtain a smoke suppression organic silicon flame retardant; the synergist is one or more of stearate, potassium silicate, dibasic lead phosphate, tribasic lead sulfate and calcium carbonate; the compatilizer is one or more of catalytic cracking slurry, de-asphalted oil, solvent refining extract oil, naphthenic oil, white oil and coal tar fraction; and the modifier is powdered butadiene styrene rubber added with anti-aging agent and parting agent. According to the method, the flame retarding effect of the organic silicon flame retardant is improved and the applicability of the organic silicon flame retardant is improved.

Owner:CHINA ROAD & BRIDGE

Reinforcing and toughening PVC pipe and preparation method thereof

The invention discloses a reinforcing and toughening PVC pipe and a preparation method thereof. The PVC pipe is prepared from the following raw materials in parts by weight: 190-200 parts of PVC resin, 8-10 parts of active light calcium carbonate, 5-7 parts of cubic boron nitride micropowder, 3-4 parts of calcium stearate, 10-14 parts of 2.5-bis(5-tertbutyl-2-benzoxazlyl) phiophen, 1-3 parts of an antioxidant DLTP, 0.7-1 parts of a current-based organic tin stabilizer, 6-8 parts of nitrile rubber, 3-5 parts of oxidized polyethlene wax, 4-6 parts of microcrystalline wax, 2-3 parts of carbon black, 6-9 parts of zinc borate, 2-8 parts of acrylic ester, 2-3 parts of alkylpolyamine ethoxylate, 5-6 parts of dibasic lead phosphate and 8-10 parts of auxiliaries. The PVC pipe disclosed by the invention realizes reinforcing and toughening, and has excellent heat resistance, weather resistance, light resistance, ageing resistance, tensile strength and impact strength, the service life of the PVC pipe is prolonged, and the additional value and the application range of the PVC pipe are increased and expanded.

Owner:泉州泉港华博化工科技有限公司

Heat insulated environmental protection glass

An environment protection type thermal insulating glass contains SiO2, barium phosphate, strontium phosphate, calcium phosphate, magnesium phosphate, beryllium phosphate, lead phosphate and iron phosphate. Its advantages are low water-soluble loss, high resistance to acetic acid, high stability and good effect to adsorb infrared ray and isolate harmful ray and heat.

Owner:CENTURY ZHONGBANG SCI TECH TRADE BEIJING

Glass frit bond and process therefor

A lead-containing glass material of the type suitable for use in a wafer bonding process, wherein the moisture resistance of the glass material is increased by the presence of a lead phosphate coating on an outer exposed surface of the material, thereby acting as a barrier to reaction of moisture with the lead of the glass material. A source of reactive phosphate ions is applied to the glass material so as to spontaneously form the desired lead phosphate coating.

Owner:DELPHI TECH IP LTD

Halogen-free flame-retarded cross-linked polyethylene cable insulating material with low smoke

InactiveCN104479210AReduce migration speedReduce dosagePlastic/resin/waxes insulatorsInsulated cablesAluminium hydroxideLead phosphate

The invention discloses a halogen-free flame-retarded cross-linked polyethylene cable insulating material with low smoke. The insulating material is prepared from the following raw materials in parts by weight: 80-150 parts of cross-linked polyethylene, 10-30 parts of magnesium hydroxide, 5-9 parts of aluminium hydroxide, 1-2 parts of lead sulfate tribasic, 0.5-0.9 part of dibasic lead phosphate, 0.3-0.7 part of paraffin, 20-50 parts of phthalate and 5-15 parts of nano-montmorillonite. The insulating material provided by the invention has the advantages of being light in weight, good in toughness, small in flame and low in burning speed, having no molten drop and less smoke, being anti-migration, good in char forming characteristics, easy in processing and the like.

Owner:GUIZHOU MINGHCOO WIRE & CABLE CO LTD

Bamboo powder-polyvinyl chloride composite materials and process for preparing same

The invention relates to a bamboo powder-polyvinyl chloride composite and its process for preparing, which consists of granulating in the twin-screw extruder after kneading the raw material components comprising bamboo powder, polykoroseal, tribasic lead sulphate, dibasic lead phosphate, calcium stearate, zinc stearate and titanate coupling agent, then obtaining the product by squeezing the master batch in the single screw extractor. The external appearance of the invented bamboo powder-polyvinyl chloride composite is close to the wood, and the invented product has good fire-retardancy. By changing different dies, complex-shaped products can be prepared and is capable of boring, digging and nailing. The product of this invention is of no release of formaldehyde, is of nice appearance, good handle, no warp, excellent resistance to aging, and so it has a prodigious superiority outside, for example, it can be used as marine landscape materials such as corridor, sunshade, baluster and movable dwelling.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Wood-plastic material and preparation method thereof

The invention discloses a wood-plastic material which comprises, by weight, 50.3% to 77% of poly ethylene (PE), propene polymer (PP), poly vinyl chloride (PVC) or acrylonitrile butadiene styrene styrene (ABS) resins; 8.8% to 25.1% of plant fibers; 0.9% to 3.0% of tribasic lead sulfate; 0.1% to 0.5% of zinc stearate; and 0.1% to 0.5% of calcium stearate; and further comprises dibasic lead phosphate, paraffins, stearic acid, acrylate copolymer, chlorinated polyethylene, titanium dioxide, chitin, chitosan and light calcium carbonate. According to the wood-plastic material, the chitin and the chitosan are added to improve the comprehensive performance of the wood-plastic material, the performance of the wood-plastic material achieves the performance of outdoor doors and windows manufactured by common pure polymer materials through a unique formula including mainly fibers, polymer materials, necessary processing agents, chitin and chitosan.

Owner:ANHUI AOBO NEW MATERIAL

Environmental stress crack-resistant polyethylene sheath material for power wire and preparation method thereof

InactiveCN103540008AGood environmental stress cracking resistanceGood high and low temperature resistancePlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethyleneLead phosphate

The invention discloses an environmental stress crack-resistant polyethylene sheath material for a power wire and a preparation method thereof. The environmental stress crack-resistant polyethylene sheath material is prepared from the following substances in parts by weight: 80-100 parts of linear low-density polyethylene, 15-20 parts of polystyrene resin, 10-15 parts of polyphthalamide, 4-8 parts of dimethyl silicon oil, 2-3 parts of dibasic lead phosphate, 1-2 parts of calcium stearate, 1-2 parts of zinc stearate, 0.5-1 part of antioxidant 1010, 1-2 parts of antioxidant 168, 2-4 parts of ethylene distearate amide, 4-6 parts of chlorinated paraffin and 3-5 parts of pine tar. The sheath material has the advantages of excellent environmental stress crack resistance, high-low temperature resistance, acid-base resistance, salt mist resistance, ozone aging resistance, ultraviolet radiation resistance, abrasive resistance and tensile strength, is capable of working normally in a working environment at a temperature ranging from 60 DEG C below zero to 105 DEG C, is non-deformable and non-cracking in long-time use, is safe and reliable and is applicable to internal and external sheathes of overhead power wires in the outdoor.

Owner:天长市富达电子科技股份有限公司

Low-smoke low-halogen flame-retardant PVC cable material and preparation method thereof

InactiveCN104194219AMechanical strength is not affectedDoes not affect heat deflection temperaturePlastic/resin/waxes insulatorsParaffin waxAluminium hydroxide

The invention provides a low-smoke low-halogen flame-retardant PVC cable material and a preparation method thereof. The low-smoke low-halogen flame-retardant PVC cable material comprises the following components in parts by mass: 100 parts of PVC resin, 3-8 parts of nano LDHs complexing agent, 20-40 parts of aluminium hydroxide, 18-25 parts of dioctyl phthalate, 18-25 parts of dioctyl terephthalate, 2-4 parts of lead sulfate tribasic, 2-4 parts of dibasic lead phosphate, 0.5-1.5 parts of stearic acid, 0.5-1.5 parts of paraffin, 20-30 parts of calcium carbonate, 5-8 parts of antimony oxide and 5-8 parts of zinc borate. The PVC cable material provided by the invention is low-smoke, low-halogen and flame-retardant and has good flame retardance and good mechanical and electrical properties.

Owner:ANHUI PACIFIC CABLE CO LTD

Production technology of simulated beautifying plastic module for human face

InactiveCN101579902AElasticResilientCeramic shaping apparatusDomestic articlesFluoresceinRoom temperature

The invention discloses a production technology of a simulated beautifying plastic module for a human face, which comprises the following steps: mixing a certain proportion of toner, fluorescein, resorcinolphthalein, white toner, lipoprotein, dibasic lead phosphate and tribasic lead sulfate; milling the mixture with a small amount of dioctylphthalate to be uniformly mixed and stirred with a proper amount of dioctylphthalate, PVC resin, stabilizer A, heat-resistant oil A, zinc powder and calcium powder in a storage tank of a pulping machine; filtering impurities in a filtering basin, and depositing and despumating serous fluid; then, pouring the filtered serous fluid into a heated mould, and pouring the redundant serous fluid out after the serous fluid stays in the mould for 60-75 seconds; putting the mould in a rubber stove to be heated for 60-120 seconds, taking the mould out, putting the mould in water with room temperature to be cooled for 10-15 seconds, and then, forming a beautifying module; and finally, soaking the beautifying module in a lucent softener for 5-10 minutes to enable the beautifying module to be smoother and softer. The beautifying module produced by the technology of the invention has the advantages of good simulated effect, repeated use, abundant colors and various shapes.

Owner:HENAN REBECCA HAIR PRODS TNC +1

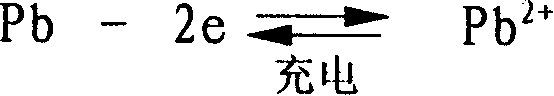

Modification method for cathode activated charcoal of ultracapacitor

InactiveCN1482634AHigh specific capacitanceImprove the modification methodElectrolytic capacitorsCapacitor manufactureCapacitanceLead phosphate

A process for the modification of activated charcoal material for the use of super capacitor negative electrode, wherein a nanometer level lead phosphate or lead sulfate modification layer is first formed in the activated charcoal micropore, then the barium sulfate reactive center is redeposited. After modification, the capacity of the active compound is increased by about 67%, the electrochemical window is expanded by 150 mV, thus improving the weight ratio energy capacity of the assortment type super capacitor. íí

Owner:江苏隆源双登电源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com