Method for solidifying and stabilizing fly ash through synergy of ardealite and red mud

A phosphogypsum and fly ash technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problem of high cost and achieve the effect of reducing leaching rate, reducing curing time and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

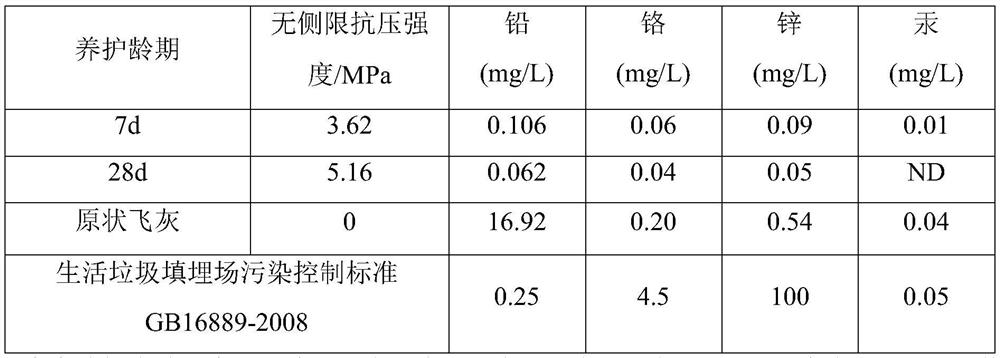

Embodiment 1

[0032] A method for solidifying and stabilizing fly ash with phosphogypsum in conjunction with red mud, comprising the following steps: adding water accounting for 45% of the mass percent of phosphogypsum to the original phosphogypsum, fully mechanically stirring and mixing the phosphogypsum and water, separating solid and liquid, and extracting phosphorus Soluble impurities in gypsum, collect solids and liquids respectively to obtain washed phosphogypsum and washing solution, dry the purified washed phosphogypsum at 120°C for 1-3 hours, add quicklime accounting for 5% by mass to the dried phosphogypsum Mix and grind to prepare phosphogypsum powder. After drying the original red mud, add quicklime accounting for 2% of the mass of the red mud for mixing and grinding to obtain red mud powder; according to the mass percentage, it is phosphogypsum powder 65%, fly ash 5%, 15% red mud powder, and 15% mineral powder are mixed together, and then the admixture whose mass percentage is 8...

Embodiment 2

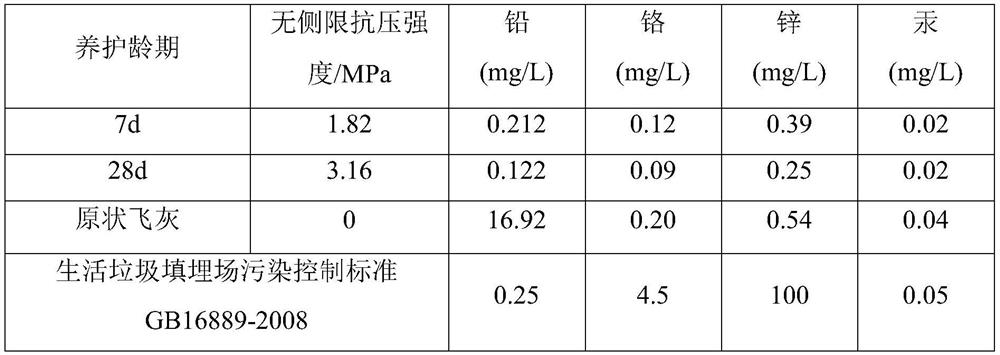

[0038] A method for solidifying and stabilizing fly ash with phosphogypsum in conjunction with red mud, comprising the following steps of adding water accounting for 38% by mass of phosphogypsum to the original phosphogypsum, fully mechanically stirring and mixing the phosphogypsum and water, separating solid and liquid, and extracting the phosphogypsum soluble impurities in medium, collect solids and liquids respectively to obtain washed phosphogypsum and water washing solution, dry the purified phosphogypsum at 180°C for 1h to 3h, add 2% quicklime to the dried phosphogypsum and mix, Carry out grinding treatment to prepare phosphogypsum powder, dry the original red mud and add quicklime accounting for 1% of the mass of the red mud for mixing and grinding to obtain red mud powder; according to the mass percentage, the phosphogypsum powder is 25%, and the original fly ash is 10% %, 50% red mud, and 15% mineral powder, and then add the above-mentioned admixture with a mass percen...

Embodiment 3

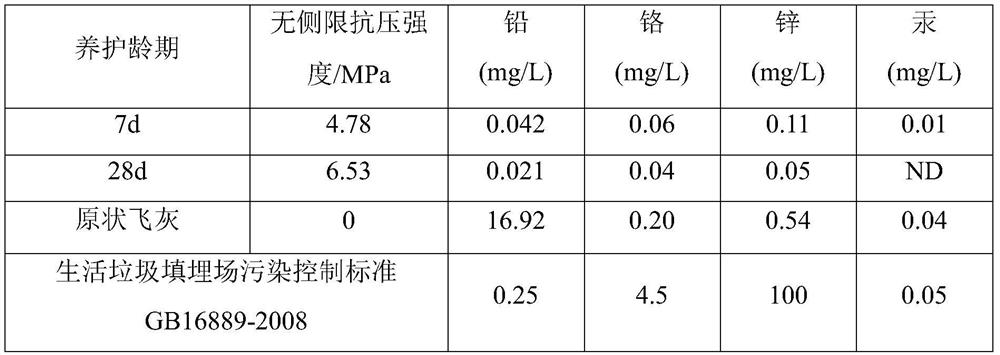

[0044] A method for solidifying and stabilizing fly ash with phosphogypsum in conjunction with red mud, comprising the following steps of adding water accounting for 35% of the mass percent of phosphogypsum to the original phosphogypsum, fully mechanically stirring and mixing the phosphogypsum and water, separating solid and liquid, and extracting the phosphogypsum soluble impurities in medium, collect solids and liquids respectively to obtain washed phosphogypsum and water washing solution, dry the purified phosphogypsum at 180°C for 1h to 3h, add quicklime accounting for 1% by mass to the dried phosphogypsum and mix, and carry out Grinding process is used to prepare phosphogypsum powder. After drying the undisturbed red mud, adding 0.2% of the mass of the red mud with quicklime for mixing and grinding to obtain the red mud powder. According to the mass percentage, 20% of phosphogypsum powder, 20% of undisturbed fly ash, 25% of red mud powder, and 35% of mineral powder are mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com