Patents

Literature

313results about How to "Low leaching rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resource utilization method of plant bamboo reed after restoring heavy metal contaminated soil

ActiveCN103464101APrevent proliferationRealize deep purificationOther chemical processesDispersed particle separationResource utilizationBiochar

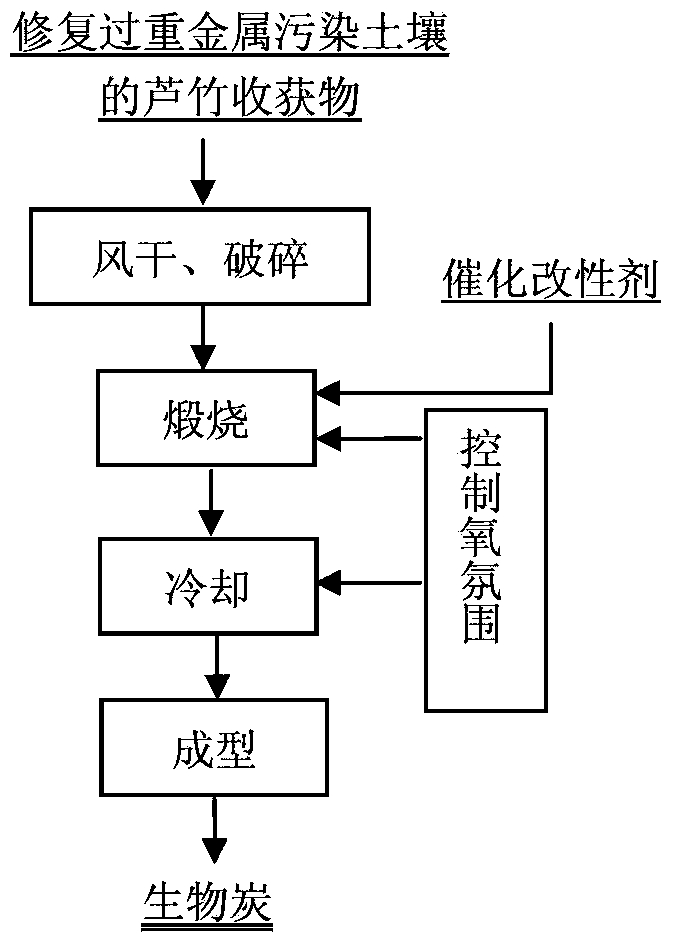

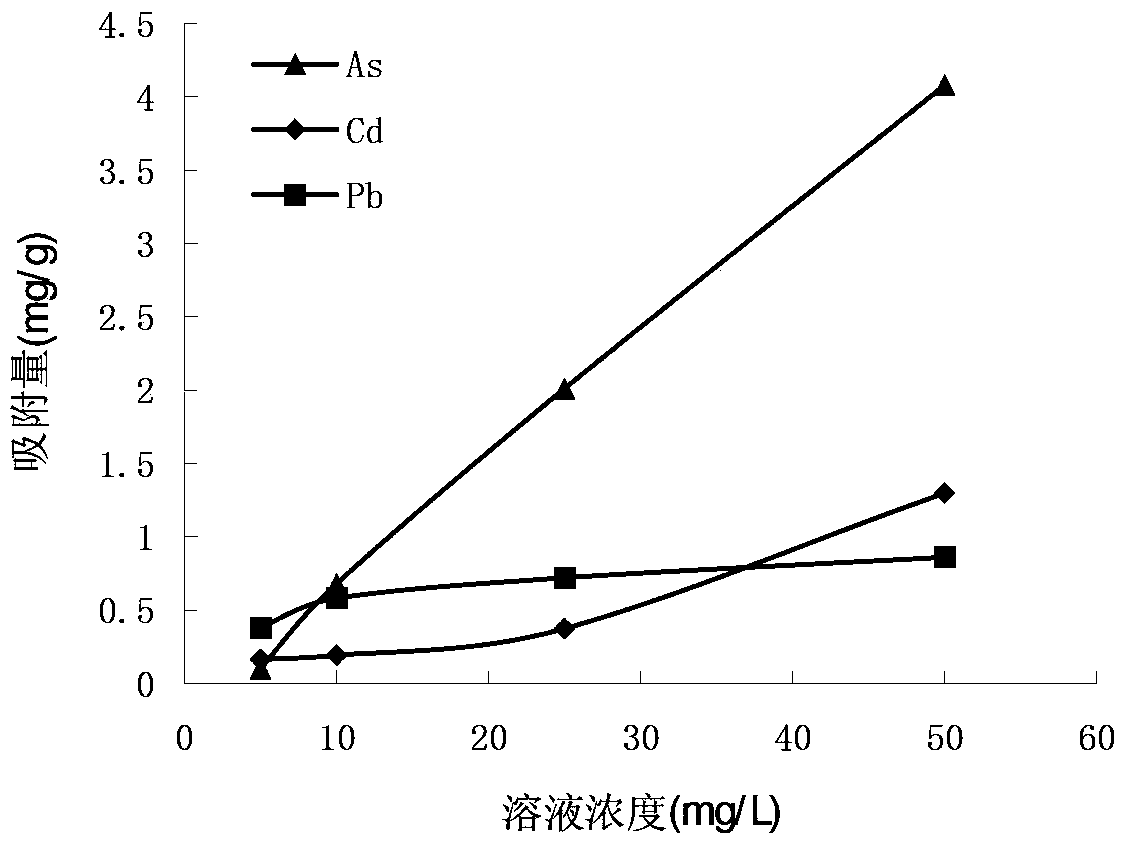

The invention discloses a resource utilization method of plant bamboo reed after restoring heavy metal contaminated soil. The method comprises the following steps: air-drying and crushing the harvested plant bamboo reed used for restoring heavy metal contaminated soil, adding a catalytic modifier under a condition of controlling oxygen atmosphere, calcining the plant bamboo reed at 200-800 DEG C for 0.5-4 h, and cooling the plant bamboo reed to obtain charcoal, wherein the yield of the bamboo reed charcoal is 25-75%. When the bamboo reed charcoal is used for adsorbing heavy metals and compounds thereof in contaminated soil, wastewater or waste gases, the adsorption capacity reaches 0.4-6.0 mg / g; meanwhile, the bamboo reed charcoal can be used as an energy source raw material or a reducing agent to be comprehensively utilized by metallurgy enterprises. The invention provides an engineering approach for biomass resource utilization of contaminated soil restoring plants and solving the problem of potential secondary pollution.

Owner:CENT SOUTH UNIV

Heavy metal-contaminated soil remediation agent and preparation method thereof

InactiveCN105567247AHigh porosityHigh adsorption valueOther chemical processesOrganic fertilisersSodium BentoniteActivated Aluminum Oxide

The invention provides a heavy metal-contaminated soil remediation agent. The remediation agent is prepared from, by weight, 30%-45% of quick lime, 10%-25% of biomass charcoal, 10%-15% of kieselguhr, 10%-15% of sodium bentonite, 10%-15% of activated aluminum oxide, 5%-10% of nitrilotriacetic acid, 1%-5% of sodium lignin sulfonate and 1%-5% of sodium dodecyl sulfate. A preparation method comprises the steps that the quick lime, the biomass charcoal, the kieselguhr, the sodium bentonite, activated aluminum oxide, nitrilotriacetic acid, sodium lignin sulfonate and sodium dodecyl sulfate are stirred and mixed to be uniform according to the weight ratio, and then the soil remediation agent is prepared. The prepared soil remediation agent has the good effect when cadmium-lead-zinc-mercury compound contaminated soil is remedied.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Method for decomposing stone coal vanadium ore by aging with sulfuric acid

InactiveCN102912123AReduce energy consumptionPure leachateProcess efficiency improvementWater contentLeaching rate

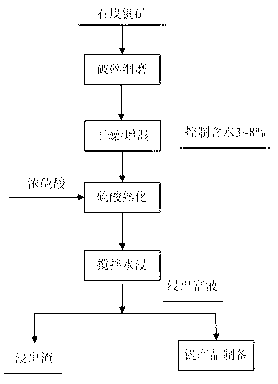

The invention discloses a method for decomposing stone coal vanadium ore by aging with sulfuric acid, which comprises the following steps: crushing the stone coal vanadium ore, carrying out fine grinding until the 65% of the stone coal vanadium ore is smaller than 0.074mm, controlling the water content at 3-8 wt%, adding sodium sulfate which accounts for 3-8 wt% into the material, adding concentrated sulfuric acid which accounts for 15-30 wt% into the material, aging for 12-48 hours, and leaching the aging material with water, wherein the liquid-to-solid ratio ml / g for leaching is 1.5:1-3:1, the leaching reaction is carried out at 85-100 DEG C for 2-6 hours, the vanadium leaching rate in the stone coal vanadium ore is higher than 80%, and the iron leaching rate is lower than 5%. The technique can implement controlled leaching of iron, and has the advantages of short process, high vanadium leaching rate, low iron leaching rate and the like.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

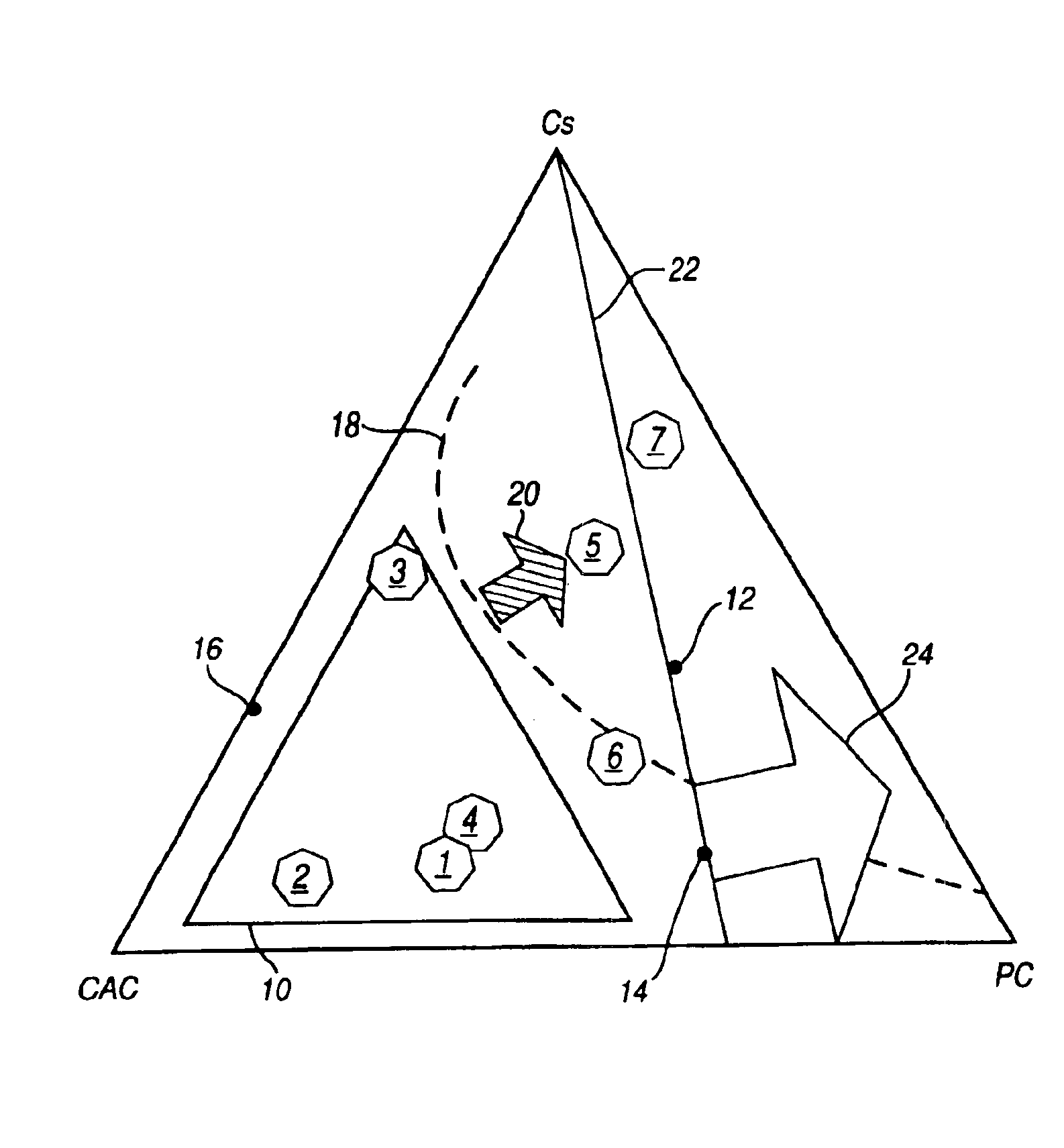

Non-efflorescing cementitious bodies

InactiveUS6923857B2Satisfactory physical propertyReduce weatheringSolid waste managementPretreated surfacesCalcium silicateHydrated alumina

A non-efflorescing cementitious body is formed from sources of calcium aluminate, calcium silicate, calcium sulphate and reactive silica, these ingredients being present in such relative proportions that, upon hydration, both monosulphate (C3A.CŜ.12H) and hydrated alumina (AH3) are formed. Also disclosed is a hydraulic binder and a paste from which such bodies can be formed and a method for forming such bodies. In addition to exhibiting low efflorescence, these bodies retain satisfactory physical properties, especially good durability to natural weathering conditions.

Owner:LAFARGE ALUMINATES

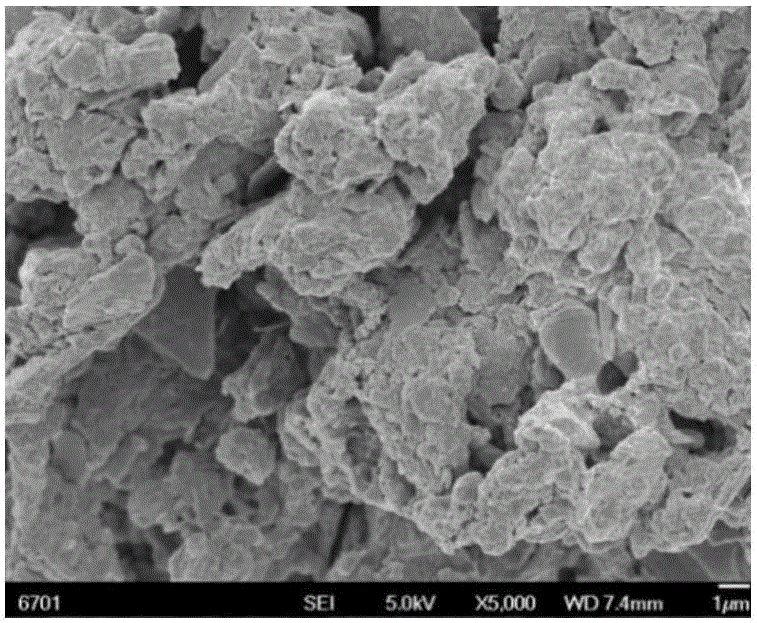

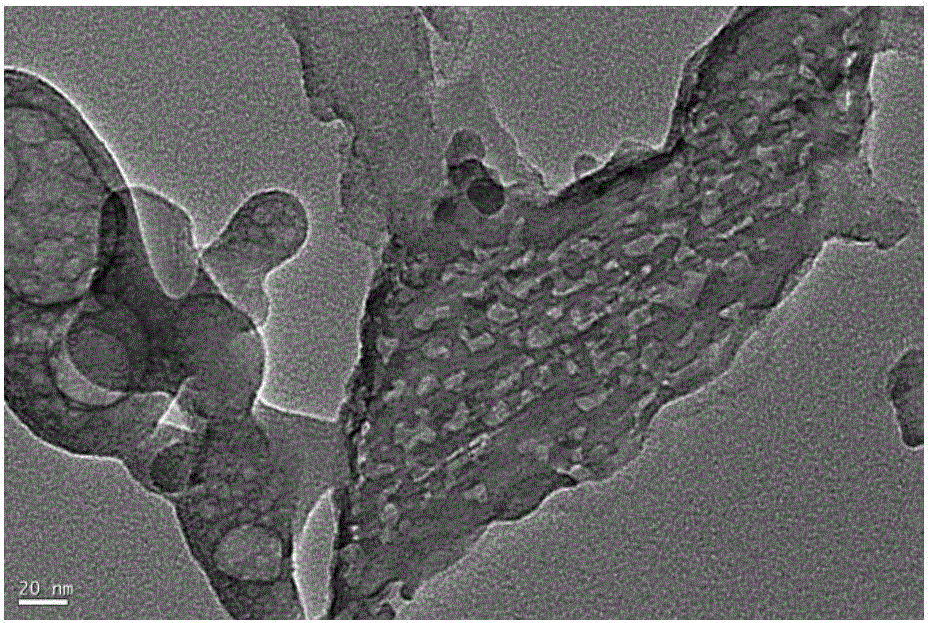

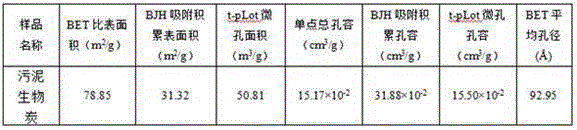

Sludge charcoal for repairing heavy metal contaminated soil and preparation method of sludge charcoal

InactiveCN106010542ASolve secondary pollutionSolve disposal problemsBiofuelsSpecial form destructive distillationSludgeSoil heavy metals

The invention belongs to the technical field of in-situ repair of heavy metal contaminated soil. Municipal sludge is used for preparing sludge-based charcoal through thermophilic thermolysis. The charcoal can be used as a repairing agent for the heavy metal contaminated soil. The sludge charcoal repairing agent comprises thickened sludge and palygorskite. A final black product namely the sludge-based charcoal is produced through the steps of performing biological and physical anhydration on sludge, then mixing the sludge after the biological and physical anhydration with the palygorskite, performing feeding into an atmosphere furnace, and then performing thermophilic thermolysis. The sludge charcoal is produced from the following components of 5-10% of the palygorskite and the balance of thethickened sludge. According to the sludge charcoal disclosed by the invention, the municipal sludge is subjected to decrement and harmless treatment, so that the municipal sludge can enter cycle of material and energy in natural environment again, and the difficult problem of treating and disposing the sludge is solved. The sludge charcoal is added to the heavy metal contaminated soil, so that heavy metal contaminated substances can be effectively solidified, the purposes of being durable and stable in repairing effect and being free from secondary pollution are realized, and the sludge charcoal is an ideal soil heavy metal contamination repairing agent with low cost.

Owner:LANZHOU JIAOTONG UNIV

Method for preparing radioactive waste solidified body

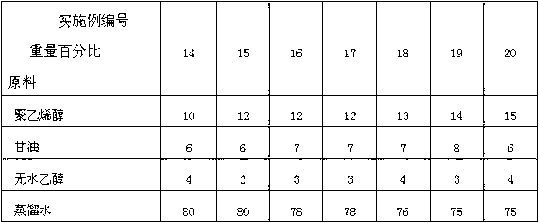

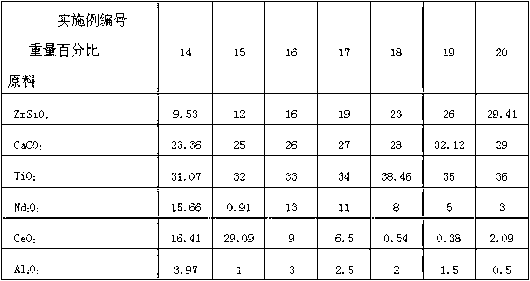

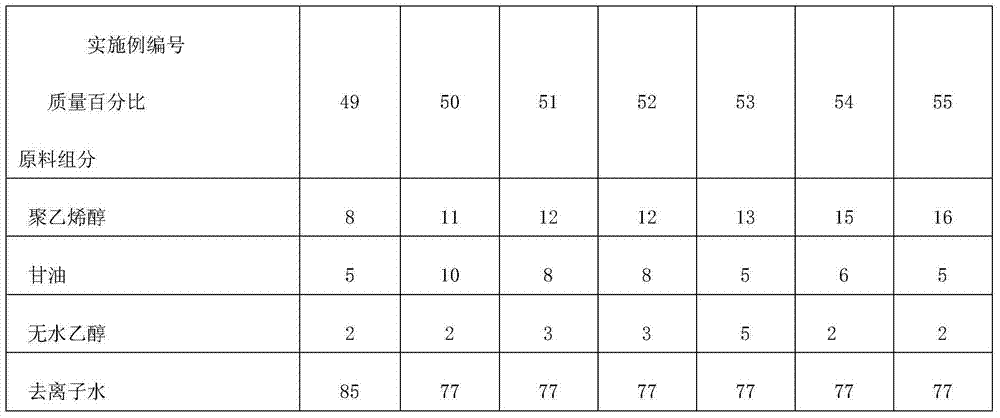

InactiveCN102930915AImprove performanceEasy to excludeRadioactive decontaminationHigh densityPolyvinyl alcohol

The invention discloses a method for preparing a radioactive waste solidified body. The method is characterized by comprising the following steps of: finely grinding a raw material which comprises 9.53 to 29.41 weight percent of ZrSiO4, 23.36 to 32.12 weight percent of CaCO3, 31.07 to 38.46 weight percent of TiO2, 0 to 15.66 weight percent of Nd2O3, 0 to 29.09 weight percent of CeO2 and 0 to 3.97 weight percent of Al2O3; drying the raw material; and adding polyvinyl alcohol sol, granulating, screening, molding, discharging the sol, performing vacuum hot-pressing sintering, and thus obtaining the radioactive waste solidified body. By adoption of the method, the raw material is low in cost, a high-purity and high-density perovskite acorite and titanite combined mineral solidified body is prepared at low temperature by using a simple and practical hot-pressing sintering technology, and foundation is laid for engineering application to artificial rock solidification treatment of high-level waste.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Heavy metal contaminated soil restorative agent as well as preparation method thereof and application thereof

InactiveCN105754611AEasy to prepareGood governanceContaminated soil reclamationOrganic fertilisersContaminated soilsBiomass

The invention provides a heavy metal contaminated soil restorative agent. The restorative agent is prepared from the following components in weight ratio: 20-30 percent of biomass charcoal, 30-50 percent of quick lime, 10-20 percent of molecular sieve, 10-20 percent of sodium bentonite, 1-10 percent of polyepoxysuccinic acid and 1-10 percent of sodium lignin sulfonate. A preparation method for the heavy metal contaminated soil restorative agent comprises the following steps: firstly, mixing the biomass charcoal, quick lime, molecular sieve, sodium lignin sulfonate and sodium bentonite in mass ratio to obtain a mixture; and then, adding the polyepoxysuccinic acid into the mixture in mass ratio to stir and uniformly mix, thereby obtaining the prepared soil restorative agent. The prepared soil restorative agent has good effect in restoring the cadmium, lead and zinc compound contaminated soil.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Heavy metal cadmium, lead and arsenic compound contaminated soil restorative agent and preparation method thereof

InactiveCN105754610AHigh porosityHigh adsorption valueContaminated soil reclamationOrganic fertilisersSodium BentoniteActivated Aluminum Oxide

The invention provides a heavy metal cadmium, lead and arsenic compound contaminated soil restorative agent. The heavy metal cadmium, lead and arsenic compound contaminated soil restorative agent is prepared from the following components in percentage by weight: 30-50 percent of biomass charcoal, 5-10 percent of diatomite, 5-10 percent of sodium bentonite, 5-10 percent of activated aluminum oxide, 10-20 percent of dithiocar-bamate, 5-10 percent of ethylenediaminetetraacetic acid, 5-10 percent of tartaric acid, 5-10 percent of polyacrylamide and 5-10 percent of sodium dodecyl sulfate. A preparation method for the heavy metal cadmium, lead and arsenic compound contaminated soil restorative agent comprises the following steps: mixing the biomass charcoal, diatomite, sodium bentonite, activated aluminum oxide, ethylenediaminetetraacetic acid, tartaric acid, polyacrylamide and sodium dodecyl sulfate in mass proportion to obtain a mixture; and adding the dithiocar-bamate into the mixture in corresponding mass proportion to sufficiently mix uniformly, thereby obtaining the prepared soil restorative agent. The prepared soil restorative agent has good effect in restoring the cadmium, lead and arsenic compound contaminated soil.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Remediation agent and application for combined contaminated soil

ActiveCN105583223AEasy to prepareGood governanceAgriculture tools and machinesOther chemical processesCalcium biphosphateSoil remediation

The invention provides a remediation agent and application for combined contaminated soil. The remediation agent is composed of, by weight, 30%-50% of biomass charcoal, 10%-20% of hydroxy calcium phosphate, 10%-20% of potassium humate, 10%-20% of alpha-cyclodextrin, 5%-10% of kieselguhr and 5%-10% of plant ash. The components give full play to the synergistic effect, through the effects of chelating, depositing, adsorbing, improving, PH value adjusting and the like, the content of available heavy metal in the soil is made to be decreased greatly, and the prepared soil remediation agent has a good effect during cadmium-lead-arsenic combined contaminated soil remedying. The remediation agent for the combined contaminated soil has the advantages that the preparation method is simple and practicable, and the remediation effect is good.

Owner:深圳润康生态环境股份有限公司

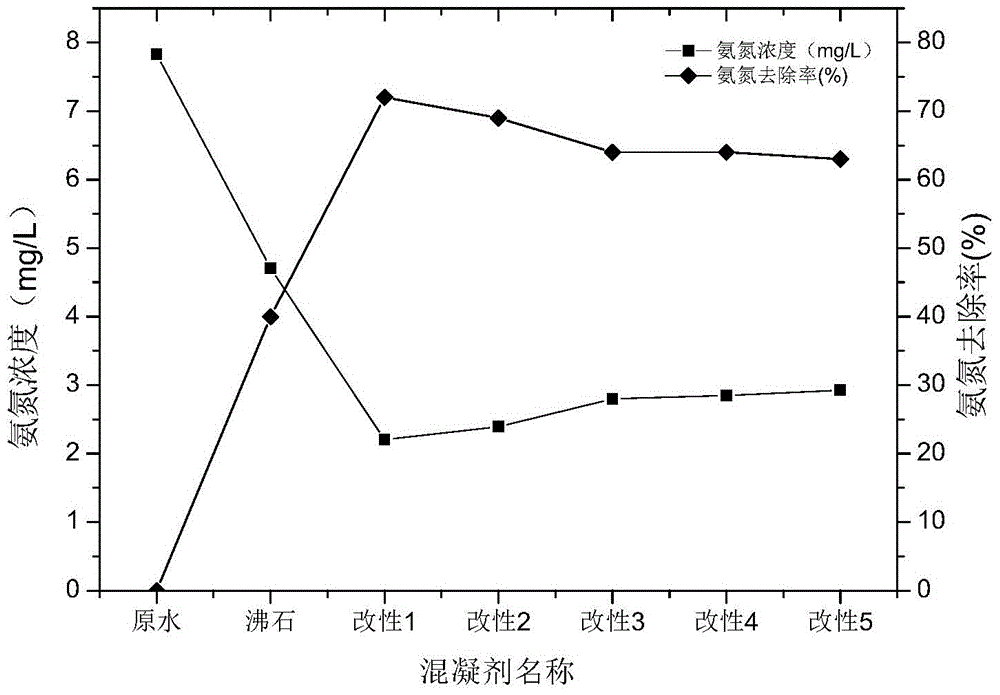

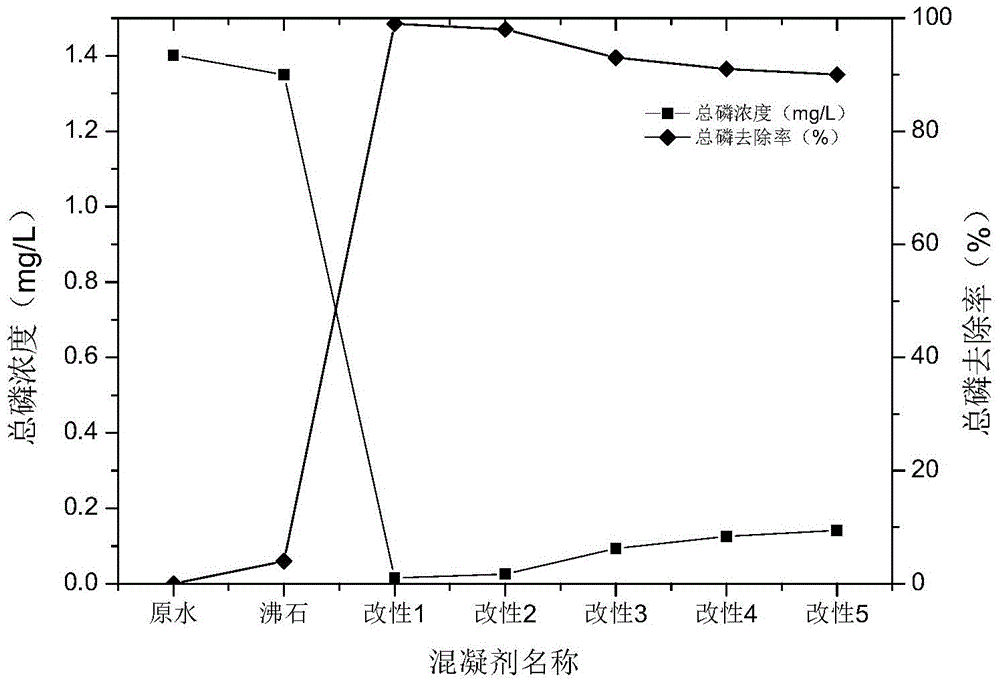

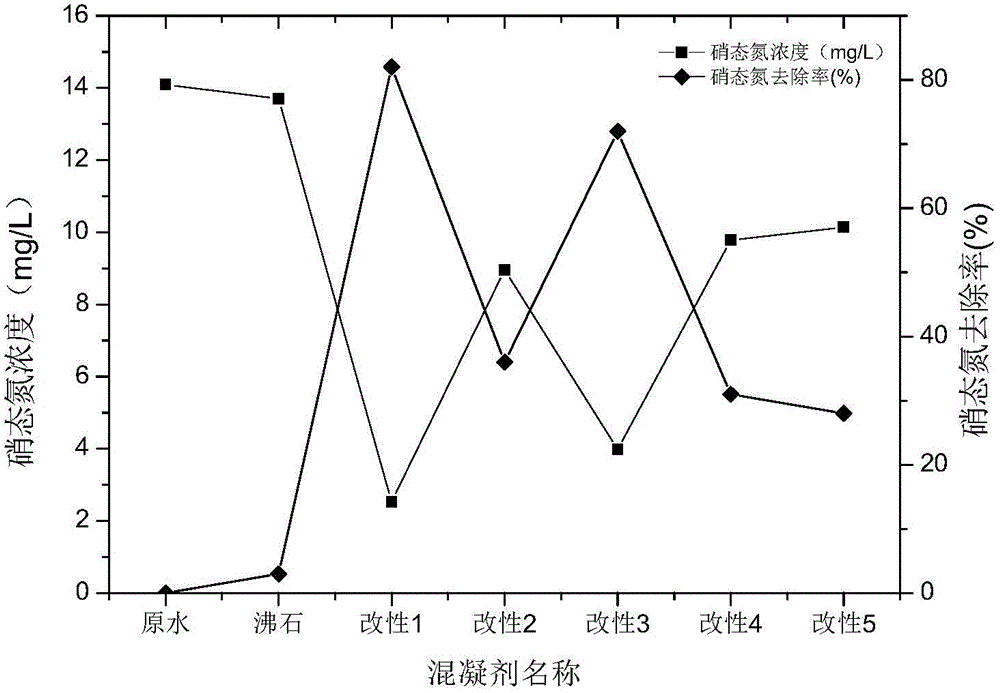

Modified zeolite organic matter composite agent for synchronous nitrogen and phosphorus removal of sewage, and preparation method, application and application method of modified zeolite organic matter composite agent

ActiveCN104971699AReduce dosageLow costOther chemical processesWater/sewage treatment by flocculation/precipitationTherapeutic effectLanthanum

The invention discloses a modified zeolite organic matter composite agent for synchronous nitrogen and phosphorus removal of sewage, and a preparation method, application and an application method of the modified zeolite organic matter composite agent, belonging to the field of waste water treatment. According to the invention, a mixed solution of hexadecyltrimethylammonium bromide and lanthanum chloride is used as a modifying solution to be used for modifying zeolite, and then the modified zeolite is mixed with polyaluminum ferric chloride (PAFC) in different ratios to prepare the modified zeolite organic matter composite agent. The modified zeolite organic matter composite agent is applied to biochemistry tail water in a sewage treatment plant, the ammonia nitrogen treatment effect is relatively good, and nitrate nitrogen and total phosphorus treatment effects are improved greatly. The composite agent has the advantages of being easy to operate, better than a coagulant in settling property, good in treatment effect, wide in application range and capable of removing nitrate nitrogen and ammonia nitrogen simultaneously; in the practical engineering operation, the use amount of the composite agent can be changed flexibly to realize an ideal treatment effect, nitrogen and phosphorus contaminants in water can be removed synchronously, and particularly a very good purifying effect on low-concentration nitrogen and phosphorus in the biochemistry tail water is realized.

Owner:NANJING UNIV

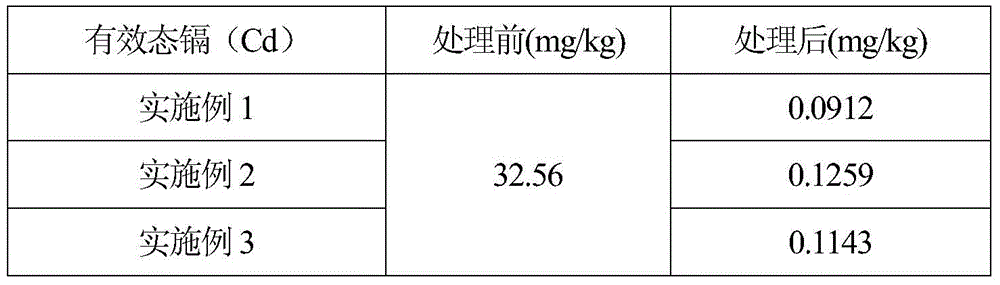

Cadmium contaminated soil restoring agent and using method and application thereof

InactiveCN105713616AHigh porosityHigh adsorption valueAgriculture tools and machinesOther chemical processesIron powderTherapeutic effect

The invention provides a cadmium-contaminated soil remediation agent, which consists of the following components by weight ratio: 30-50% of biomass charcoal, 10-20% of iron powder, 10-20% of plant ash, 10-20% of sodium sulfide, Zeolite 10‑20%; the above components fully exert synergistic effects, and through reduction, precipitation, adsorption, improvement, and adjustment of PH value, the effective cadmium in the soil is greatly reduced, and the prepared soil remediation agent can be used to repair cadmium-contaminated soil. With good effect, the restoration agent of the present invention has the advantages of simple preparation method, feasibility and good treatment effect.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

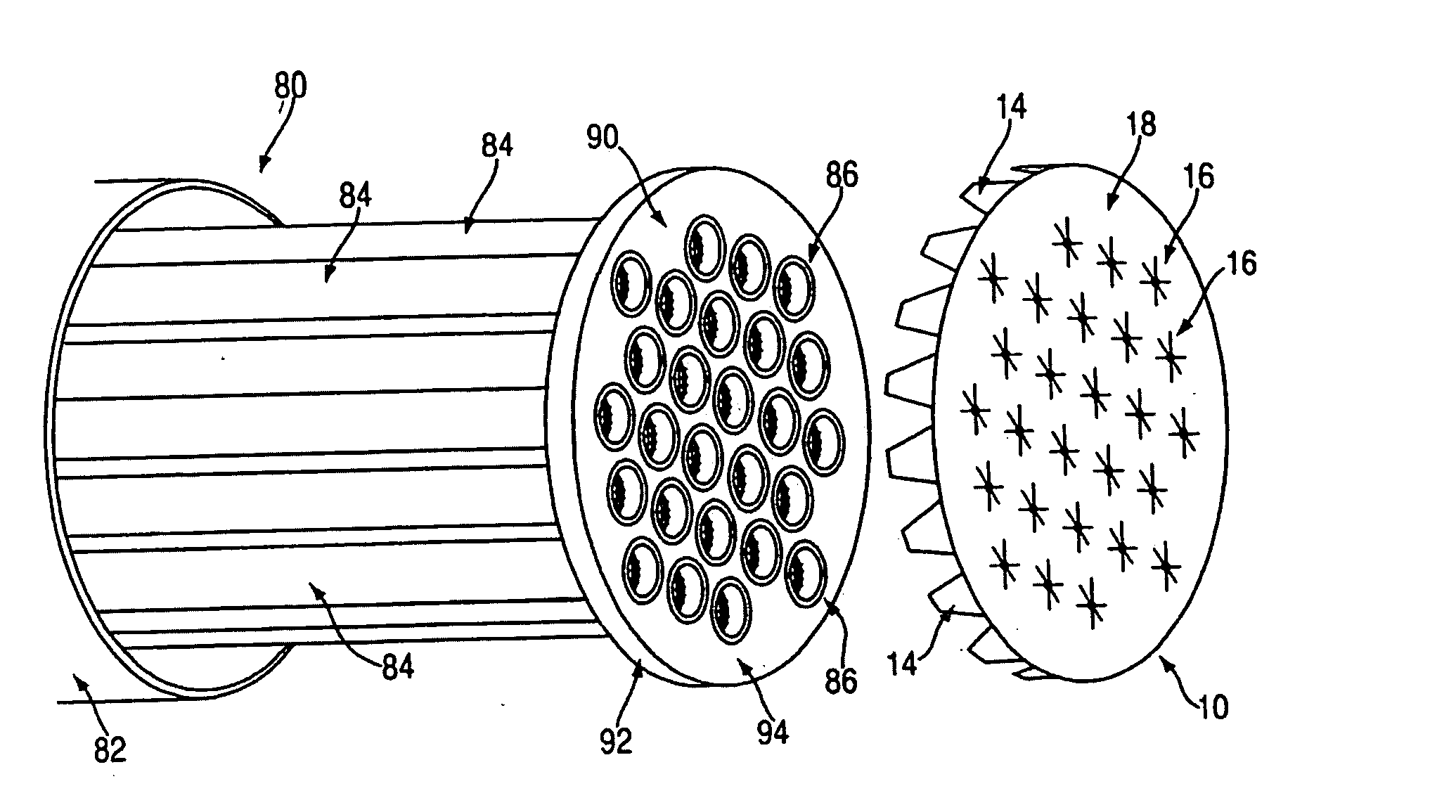

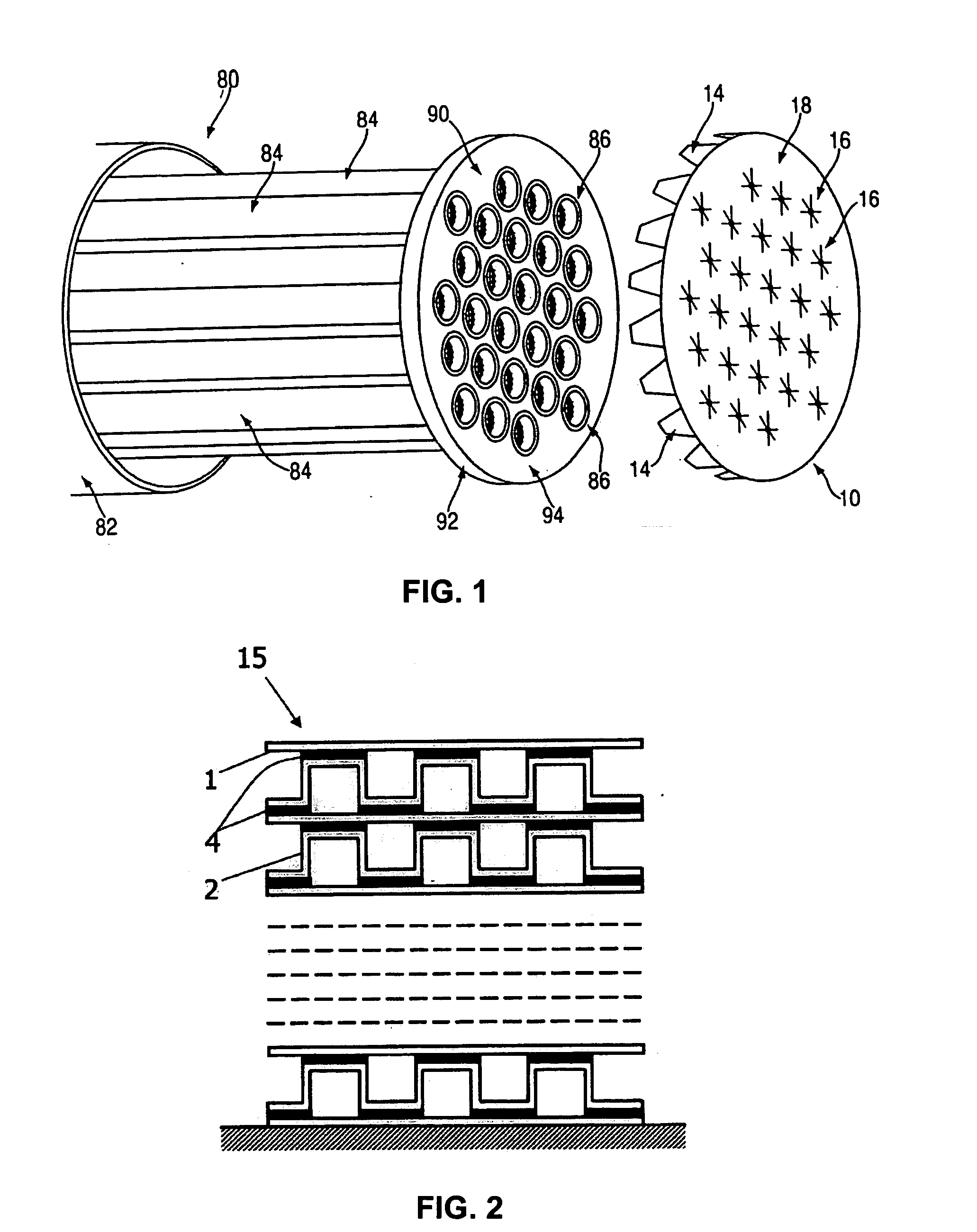

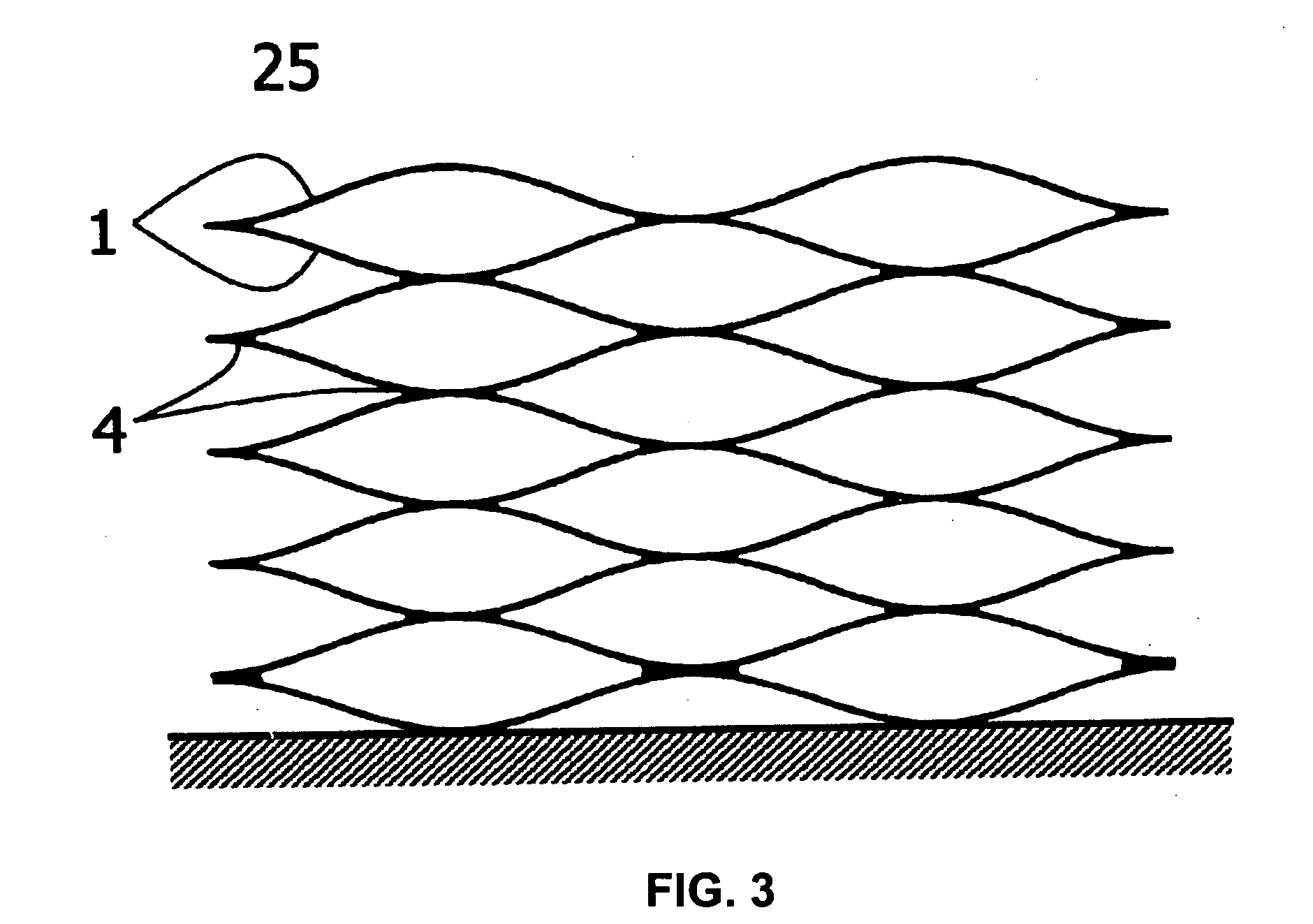

Iron-based brazing filler metals

InactiveUS20060090820A1Low leaching rateCorrosion resistanceHeat exchanger casingsStationary tubular conduit assembliesFiller metalMaterials science

A plurality of parts is brazed using an iron-based brazing filler metal. The parts generally include stainless steel, and the brazed assembly forms a heat exchanger characterized by effective corrosion resistance and low rates of leaching of nickel into fluids passing therethrough. The heat exchanger is especially suited for use in processing items intended to be ingested by humans or animals.

Owner:METGLAS INC

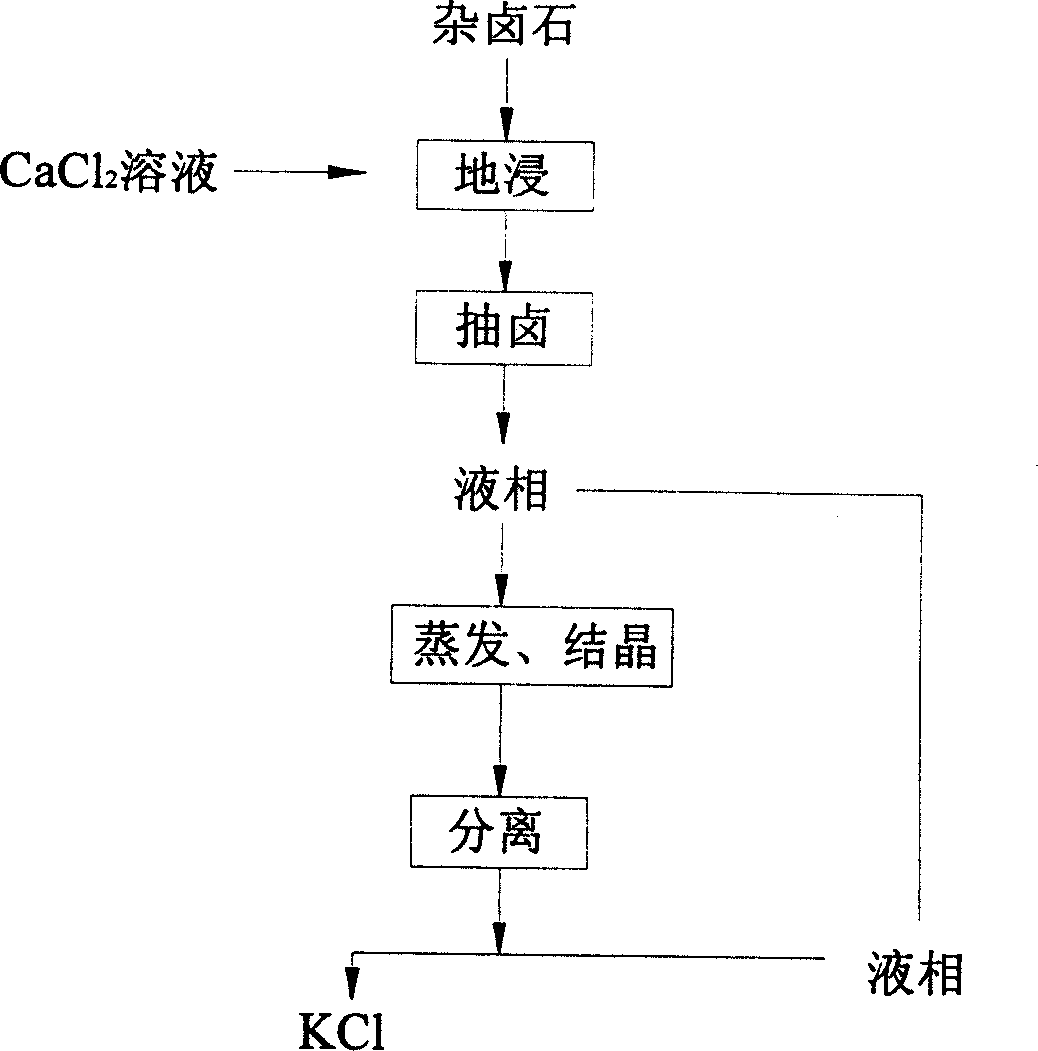

Potassium leach-out exploitation method from mamanite ore

InactiveCN1766138AThe solution mining method is simpleReduce the impactProcess efficiency improvementEarth surfaceAqueous solution

The leach mining method for kalium in polyhalite comprises: after leaching treatment to broken ore, recovering leaching liquid contained Ca2+ and / or Ba2+, and / or at least one from CO32-, HCO3-, PO43-, HPO42-, and SiO32-, while preferring CaCl2 liquid. This method fits to deep buried ore and ground or superficial layer ore with extraction rate more than 80%.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

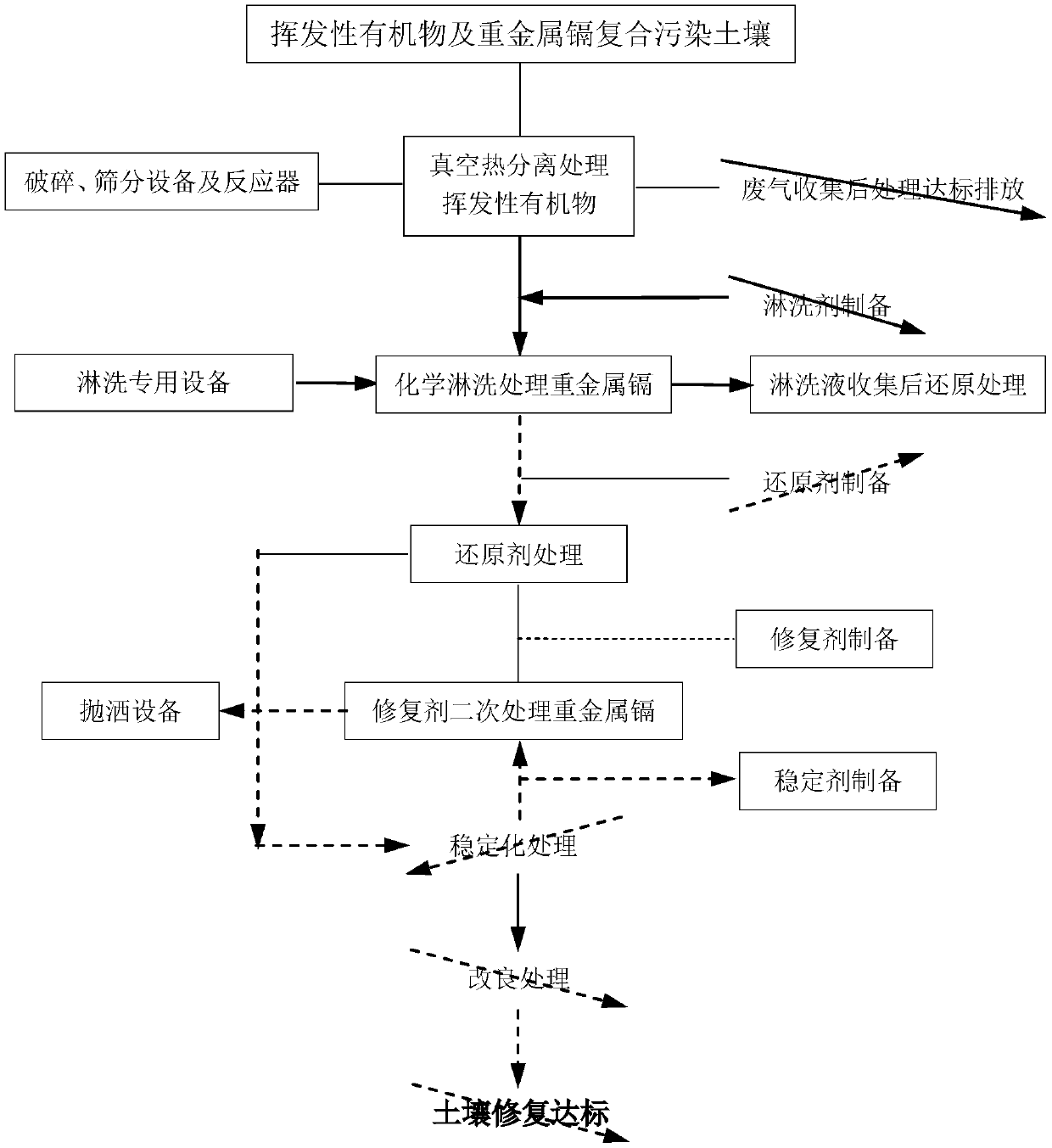

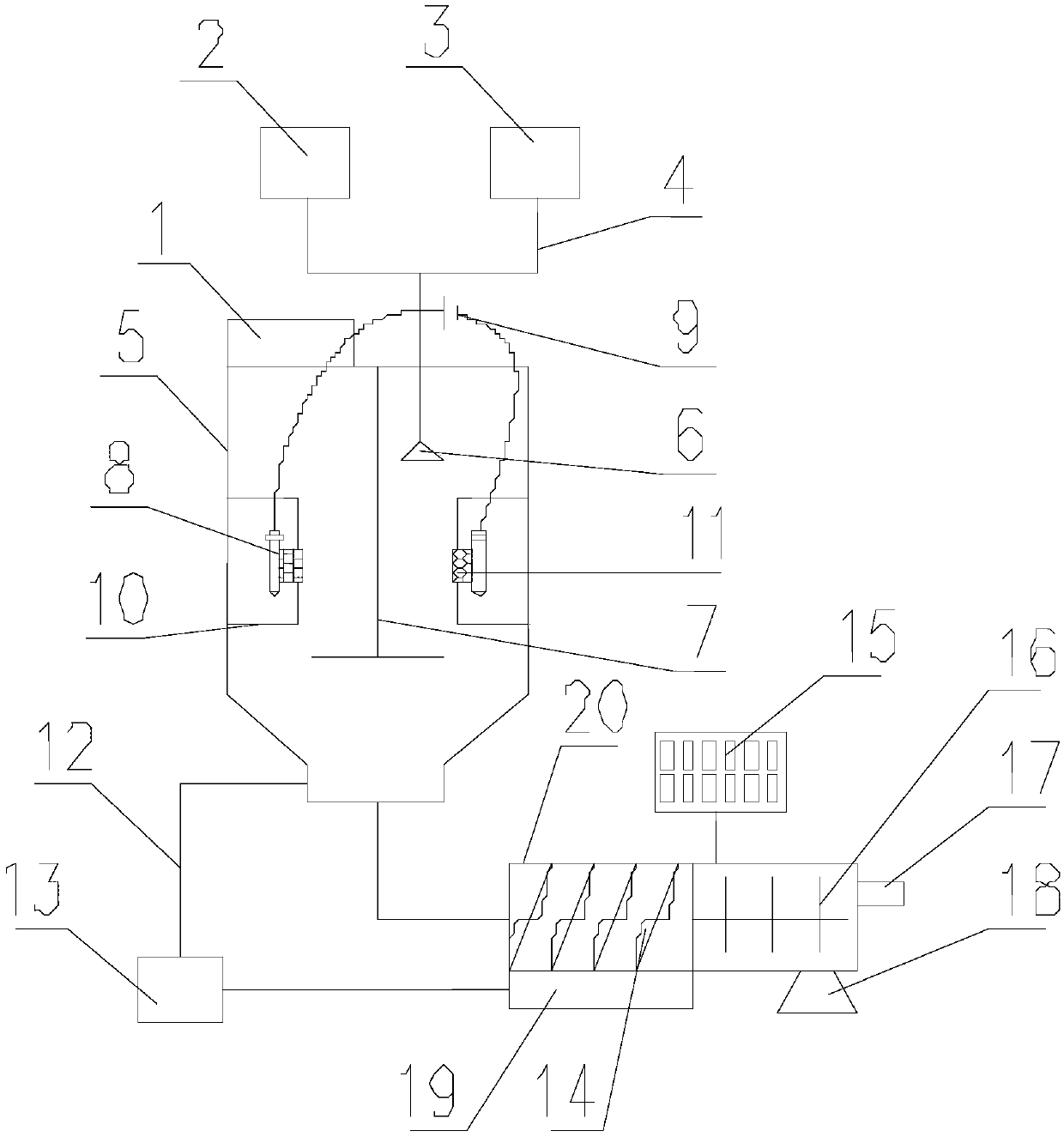

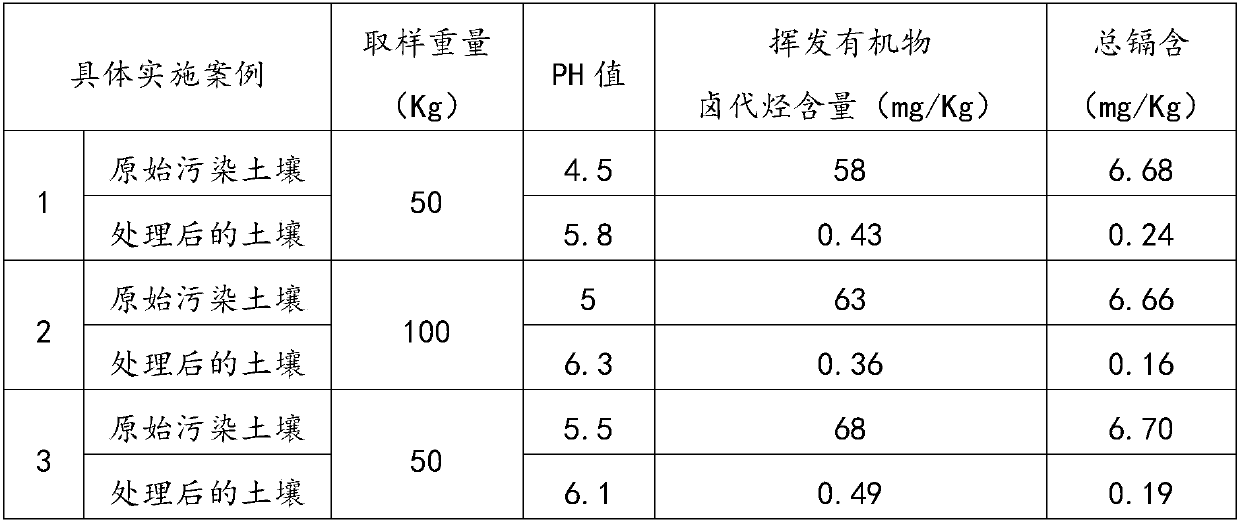

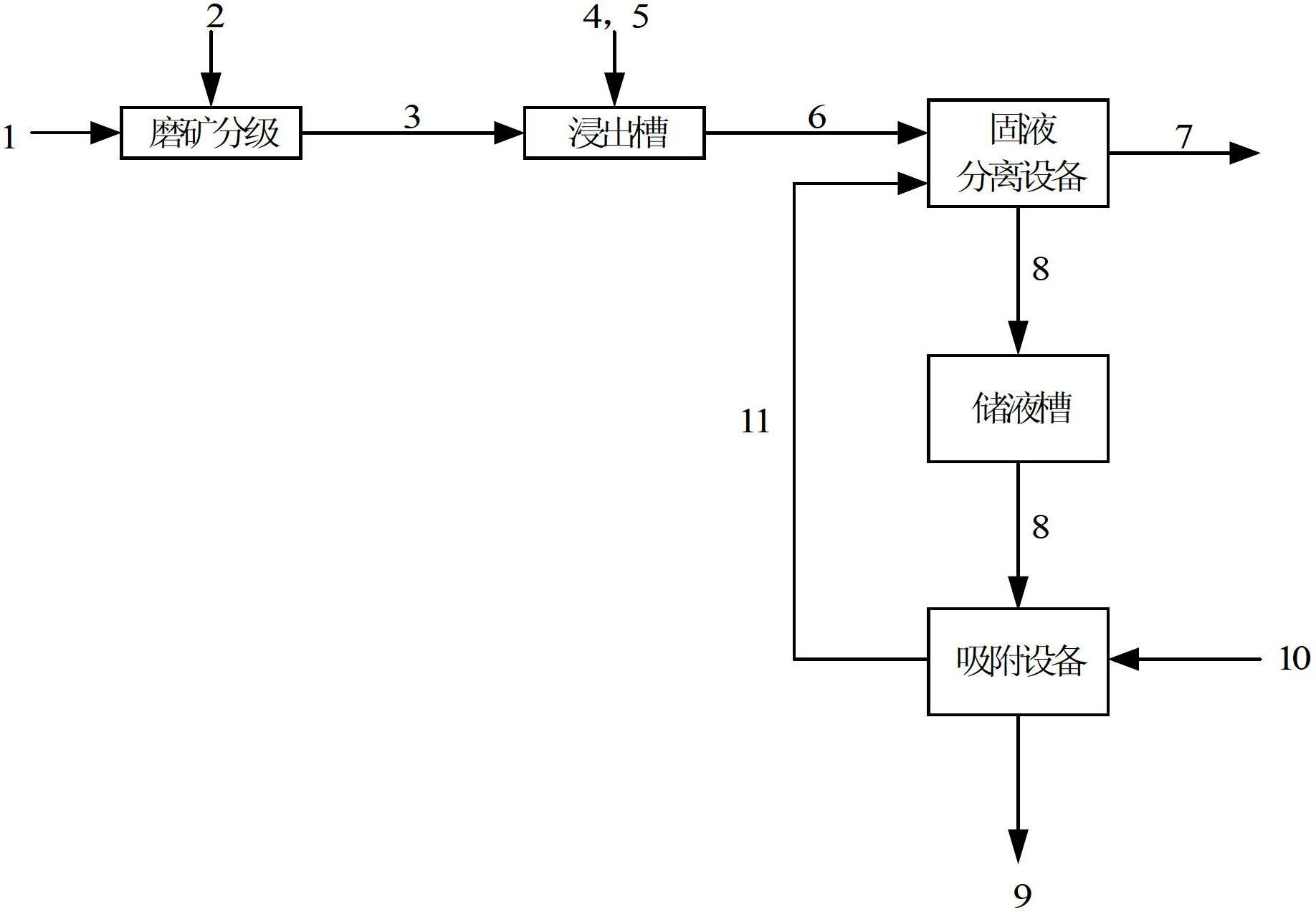

Contaminated soil repair method and repair device

PendingCN109513736ALow costAchieve the purpose of removalContaminated soil reclamationMicrobial agentContaminated soils

The invention discloses a contaminated soil repair method and a repair device. The repair method comprises the steps of (S1) vacuum thermal separation: performing thermal separation on soil in a vacuum environment so as to separate hazardous substances, and purifying the hazardous substances; (S2) chemical washing: chemically washing the soil on which the vacuum thermal separation is performed; (S3) reduction treatment: adding a reducing agent to the soil on which the chemical washing is performed; (S4) repair: applying a soil repair agent to the soil on which the reduction treatment is performed; (S5) stabilizing treatment: applying a heavy metal cadmium stabilizer and a microbial agent to the repaired soil; and (S6) improvement and maintenance: improving and maintaining the stabilized soil. According to the contaminated soil repair method, the contaminated soil can be thoroughly repaired once with low cost and high efficiency.

Owner:SHANGHAI ONEDEAR ENVIRONMENT TECH

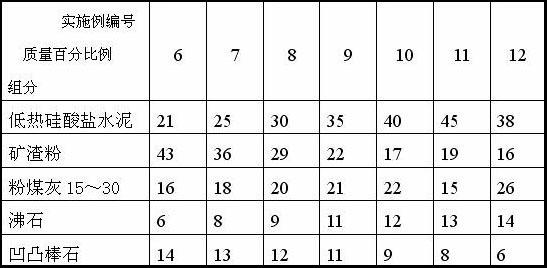

High-salt high-alkali Medium-low-level radioactive liquid waste cement solidified body and preparation method thereof

InactiveCN102169737AStrong adsorption capacityIncrease retention capacityRadioactive decontaminationSlagCoal

The invention discloses a high-salt high-alkali medium-low-level radioactive liquid waste cement solidified body which is composed by mixing the following components: high-salt high-alkali medium-low-level radioactive liquid waste and, solidification material, water glass and cellulose ether, wherein the high-salt high-alkali medium-low-level radioactive liquid waste to the solidification material is 0.55-0.75: 1 in mass proportion; the modulus of the water glass is 2.5-3.5 based on Na2O in the water glass and the mass of the solidification material is 1-3% of the mass of the water glass ; the mass of the solidification material is 0.05-0.5% of the mass of the cellulose ether; the component mass percent of the solidification material is as follows: 20-40% of low-heat Portland cement, 15-50% of slag powder, 15-30% of coal ash, 5-15% of zeolite and 5-15% of attapulgite; and the cement solidification body with various properties meeting the requirements is obtained by carrying out normal-temperature maintenance on the mixed slurry which obtained by mixing and stirring. The high-salt high-alkali medium-low-level radioactive liquid waste cement solidified body is suitable for the solidification of the medium-low-level radioactive liquid waste, which has the total salt concentration being 100-400g / L, the pH value being larger than 13 and the nuclide being 90Sr or / and 137 Cs.

Owner:SOUTHWEAT UNIV OF SCI & TECH

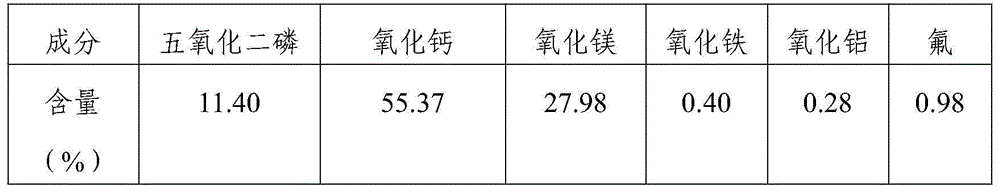

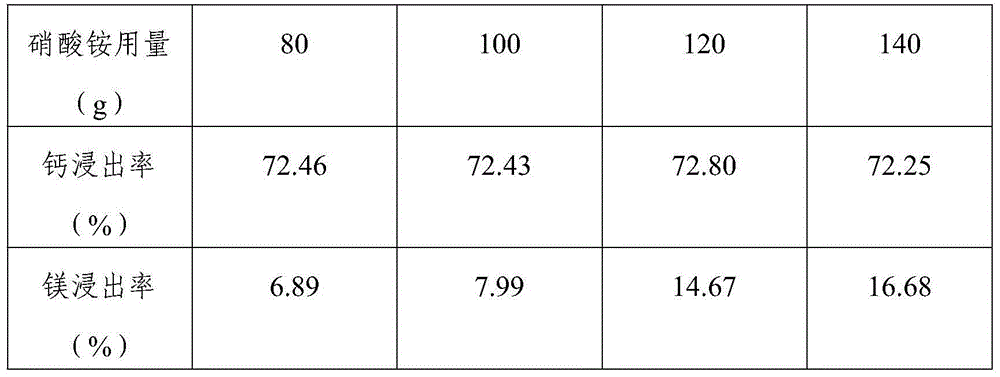

Method for extracting phosphate concentrate from phosphate tailings and cooperatively producing calcium carbonate and magnesium oxide

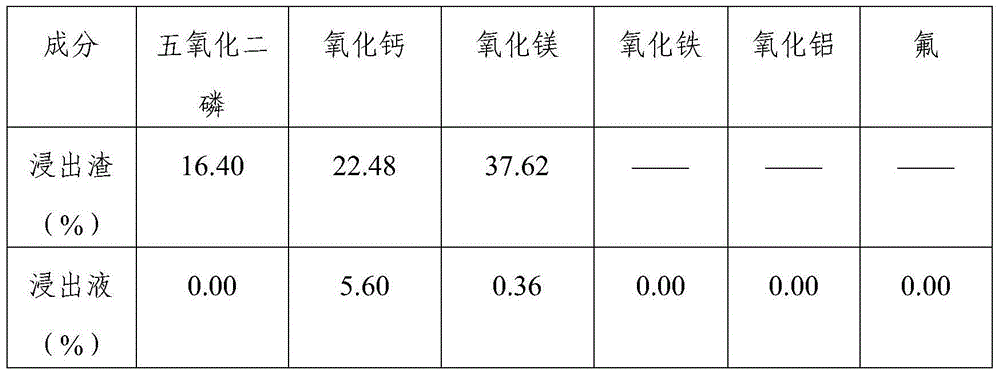

InactiveCN104860278AHigh economic valueEfficient recyclingCalcium/strontium/barium carbonatesRaw phosphate material treatmentDigestion TreatmentPhosphate

The invention discloses a method for extracting phosphate concentrate from phosphate tailings and cooperatively producing calcium carbonate and magnesium oxide. First, phosphate tailings are calcined under high temperature, hot water is added into the calcined material for digestion treatment, an ammonium nitrate solution is added to the calcined material, the mixture is stirred, calcium is extracted under a certain temperature, calcium-containing leaching liquid and leaching residues are obtained, phosphate concentrate and magnesium-containing leaching liquid are obtained after magnesium is extracted from the leaching residues with an ammonium sulfate solution, calcium carbonate is obtained after the calcium-containing leaching liquid is precipitated by an ammonium carbonate solution, magnesium carbonate is obtained after the magnesium-containing leaching liquid is precipitated by an ammonium carbonate solution, and magnesium oxide is obtained after the magnesium carbonate is calcined. According to the method, phosphate concentrate, calcium carbonate and magnesium oxide are prepared with phosphate tailings as the main raw materials, large-scale treatment can be carried out on the phosphate tailings, the problem that because phosphate tailings pile up in quantity, the phosphate tailings occupy a lot of land and pollute the environment is solved, and the products of phosphate concentrate, calcium carbonate and magnesium oxide are obtained.

Owner:GUIZHOU RES INST OF CHEM IND

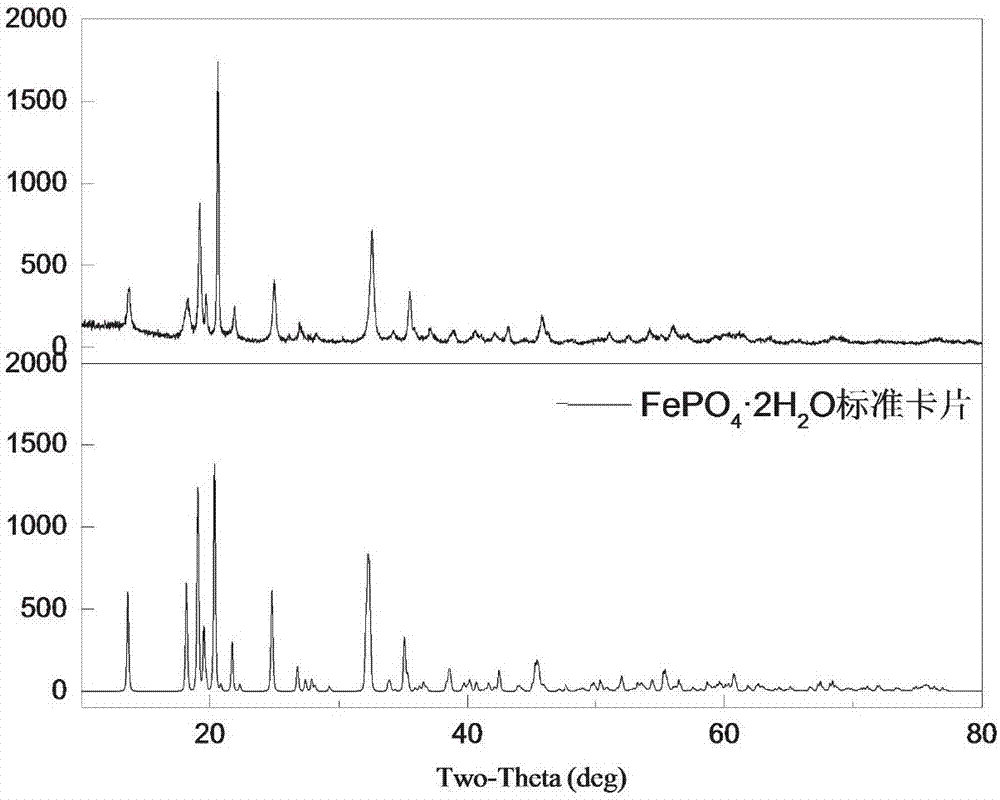

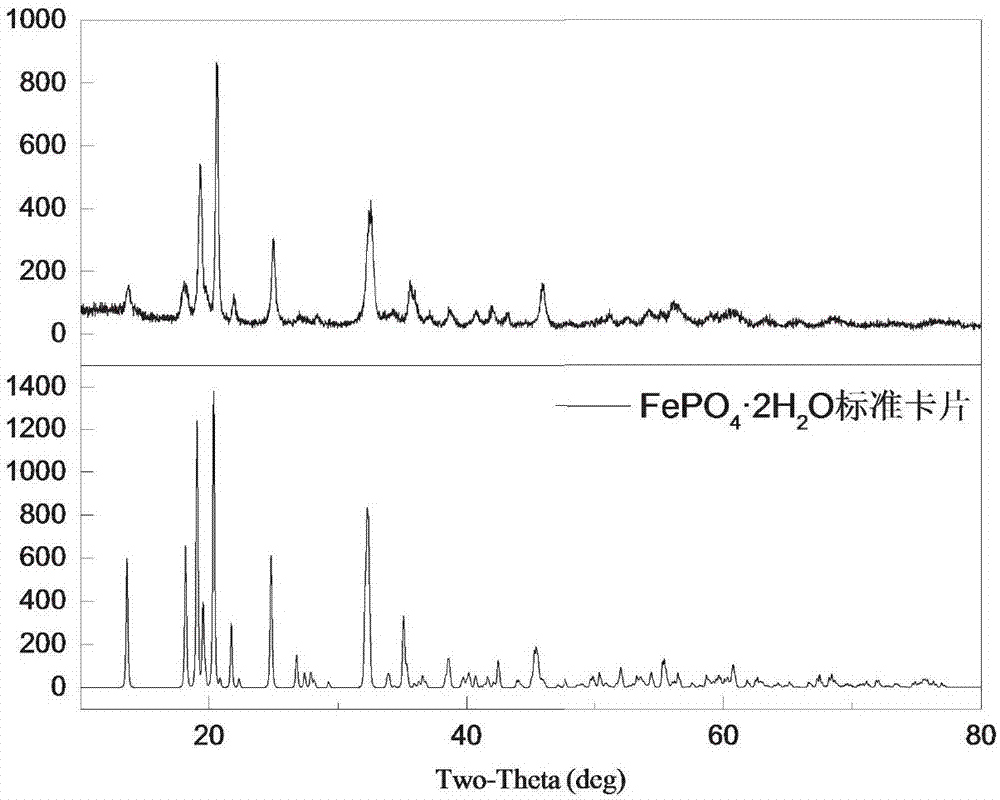

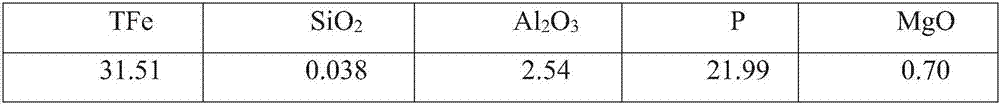

Method for normal-pressure phosphoric-acid leaching of nickel-cobalt and synchronous preparation of iron phosphate

ActiveCN106987728AImprove leaching rateEfficient separationProcess efficiency improvementPhosphorus compoundsPhosphoric acidLaterite

The invention discloses a method for the normal-pressure phosphoric-acid leaching of nickel-cobalt and the synchronous preparation of iron phosphate. The method comprises the following steps: subjecting laterite nickel ore to normal-pressure acid leading treatment, and then carrying out solid-liquid separation to obtain a leaching residue of iron phosphate and a leaching solution of enriched nickel-cobalt, wherein in the leaching process, phosphoric acid with a concentration of 1-3 mol / L is adopted; the adding amount of phosphoric acid is 1-3 times as much as the theoretical molar mass of metal elements in the leached transformed laterite nickel ore; and the laterite nickel ore is subjected to transformation at 300-400 DEG in advance before the acid leading treatment. The method is particularly suitable for the treatment of low-grade limonite-type laterite nickel ore; the nickel-cobalt recovery rate is high; the nickel-iron separation effect is good; and the leaching residue of iron phosphate is not only applicable to the preparation of iron phosphate lithium batteries but also utilized as a raw material for the manufacturing of catalysts and ceramics.

Owner:CENT SOUTH UNIV

Method for strongly leaching laterite-nickel ore at normal pressure by using sulphuric acid

InactiveCN103146919AImprove leaching rateHighly corrosiveProcess efficiency improvementThermal insulationEmission standard

The invention relates to a method for strongly leaching laterite-nickel ore at normal pressure by using sulphuric acid, which comprises the following steps of: adding laterite-nickel ore into leacheate, mixing and ball-milling to be less than or equal to 100 mesh, adding concentrated sulphuric acid according to the liquid-solid ratio of (4-9):1, increasing the temperature to 150-160 DEG C, maintaining reaction for 20-60 minutes, decreasing the temperature to 80-100 DEG C, filter pressing, and pressing filtrate in a thermal insulation storage tank; adding leacheate, the volume of which is the same to that of a filter cake, to carry out pressure washing and filter pressing, obtaining filtrate and the filter cake again, also pressing the filtrate in the thermal insulation storage tank, discharging the filter cake, mixing and washing by using hot water so that crystal substances are thoroughly dissolved, and filtering to obtain the filtrate and the filter cake; and purifying the filtrate and removing impurities from the filtrate, continuously carrying out pressure washing by using clean water through the filter cake in a counter-current manner, and continuously detecting the pH value of pressure washing liquid until leached residues achieve emission standard. According to the invention, the leaching efficiency of nickel-cobalt can be increased by above 99wt%; most of all metallic elements which can be dissolved by sulphuric acid can be leached; silica gel does not exist in the leaching process; and the filtering performance of the leached residues is good.

Owner:广西冶金研究院有限公司

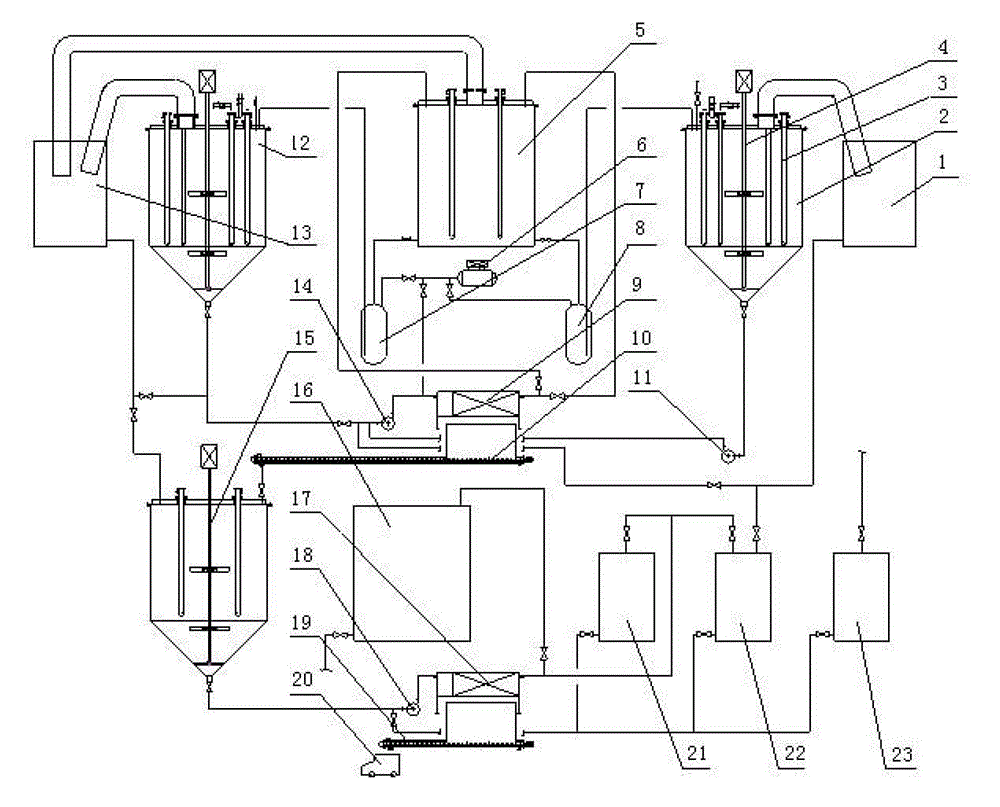

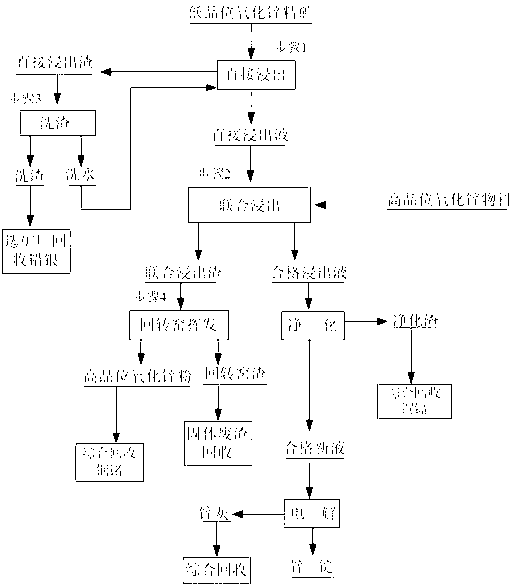

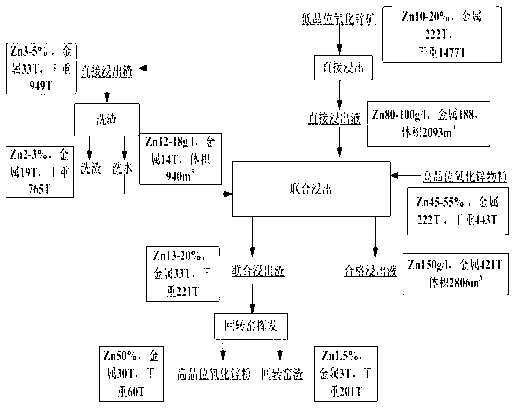

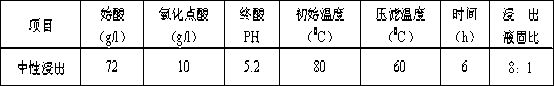

Method for treating low-grade zinc oxide ores by wet method

InactiveCN102703694ATake advantage ofLow leaching ratePhotography auxillary processesProcess efficiency improvementElectrolysisIndium

The invention discloses a method for treating low-grade zinc oxide ores with high iron content and large argillization degree by a wet method. The method comprises the following steps of: 1, leaching directly, namely crushing the zinc oxide ores, performing ball-milling, and putting the zinc oxide ores and zinc electrolytic effluent into a reaction tank for reacting, wherein a leachate obtained after reaction is used for joint leaching, and leaching slag is conveyed to be washed in the next step; 2, performing joint leaching, performing leaching reaction of high-grade zinc oxide ores and a solution obtained after direct leaching is performed, wherein a neutral solution is used for purification, and the leaching slag is conveyed to a rotary kiln; 3, washing the slag, namely putting the slag leached directly and a weak acid solution into a reaction tank, stirring, reacting, allowing the solution to return for leaching directly, conveying the washed leaching slag to a dressing plant and separating to recover valuable metals such as lead and silver; and 4, reducing and volatilizing in the rotary kiln, namely mixing the leaching slag and coat uniformly, putting the mixture into the kiln for reacting to obtain zinc oxide smoke for recovering indium germanium and kiln slag for recovering iron and residual coal. By the method, metal ore resources can be utilized effectively, so the method has the advantages of low production cost, high leaching rate of zinc, high comprehensive utilization of the valuable metals and the like, the original production equipment and production flow can be utilized, and industrialization is easy to realize.

Owner:GUANGXI JINSHAN INDIUM & GERMANIUM METALLURGICAL CHEM

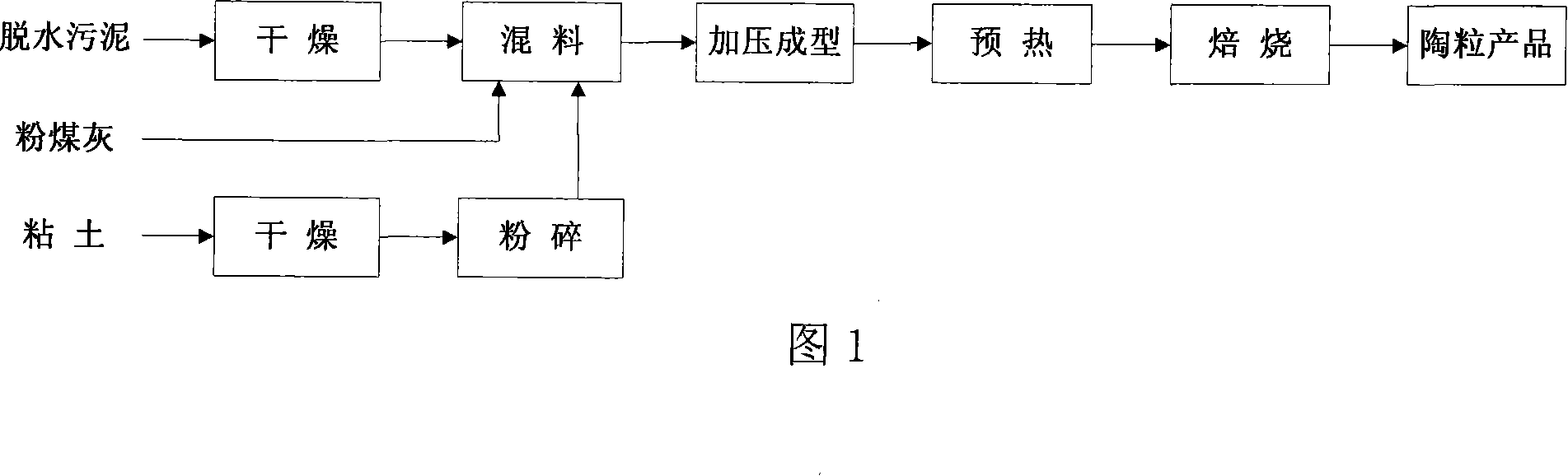

Method for preparing haydite by sintering urban domestic sewage sludge

InactiveCN101148348ACause secondary pollutionImprove performanceCeramic materials productionClaywaresSludgeSewage

The present invention relates to solid waste treating technology, and discloses sewage sludge treating and utilizing process. Sewage sludge in over 70 %, fly ash and clay as the material are treated through drying, crushing, mixing, press forming, preheating and roasting to obtain haydite product. The roasted haydite has one compact glaze layer in the surface and great amount of inside pores, and possesses compressive strength, water absorption, environment safety, etc reaching relevant standard. Using sewage sludge in making building material is significant.

Owner:TSINGHUA UNIV

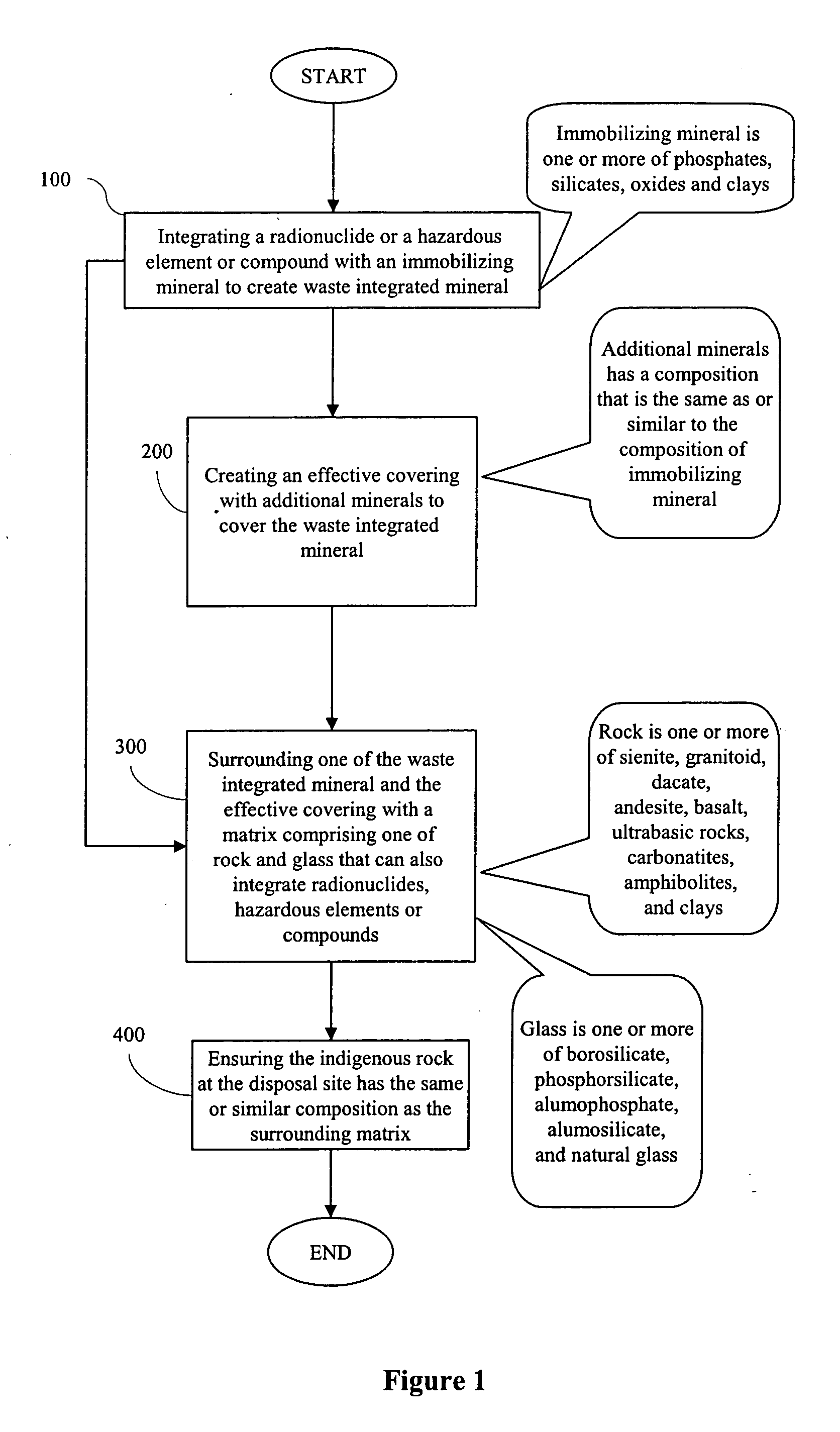

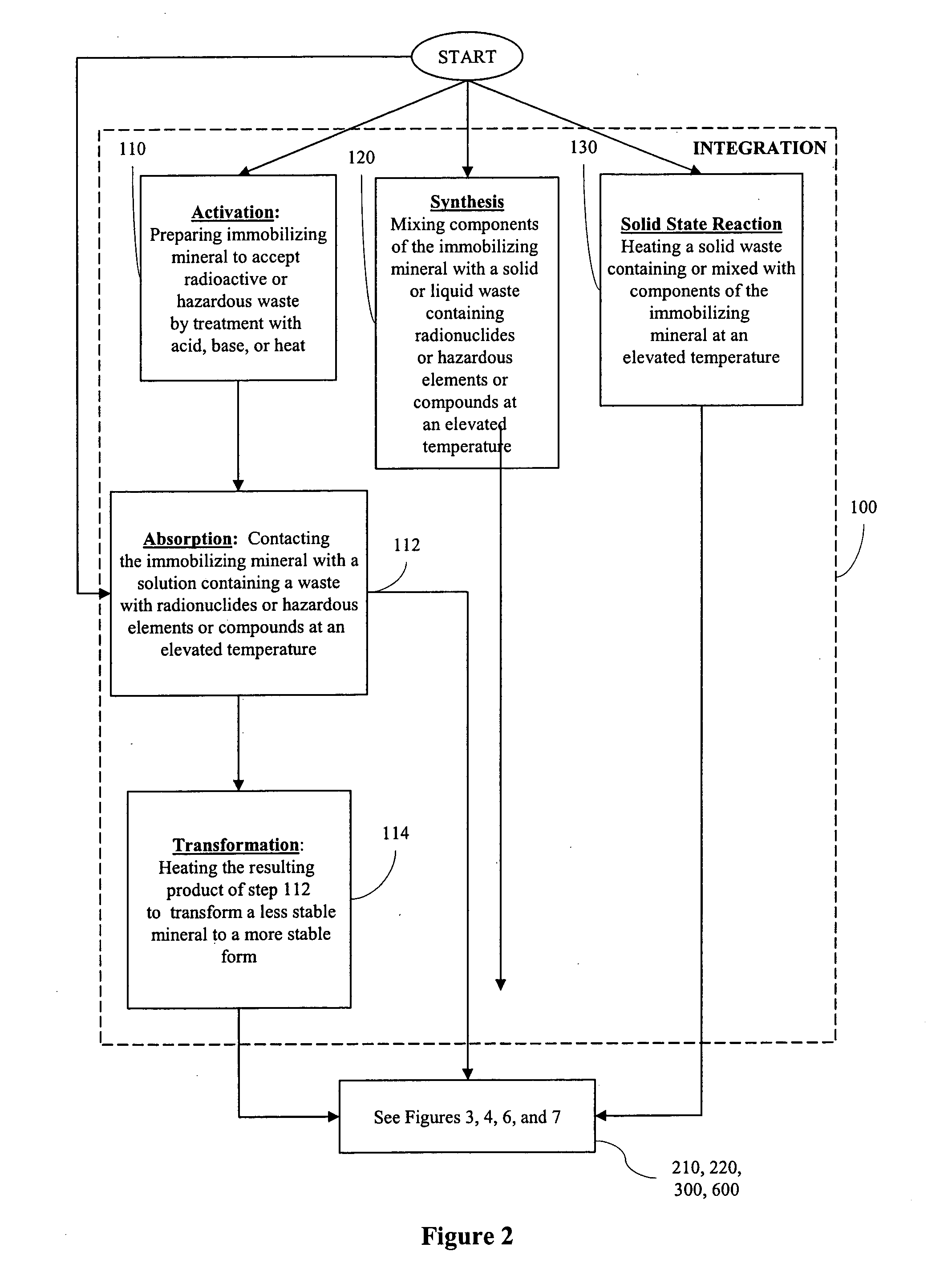

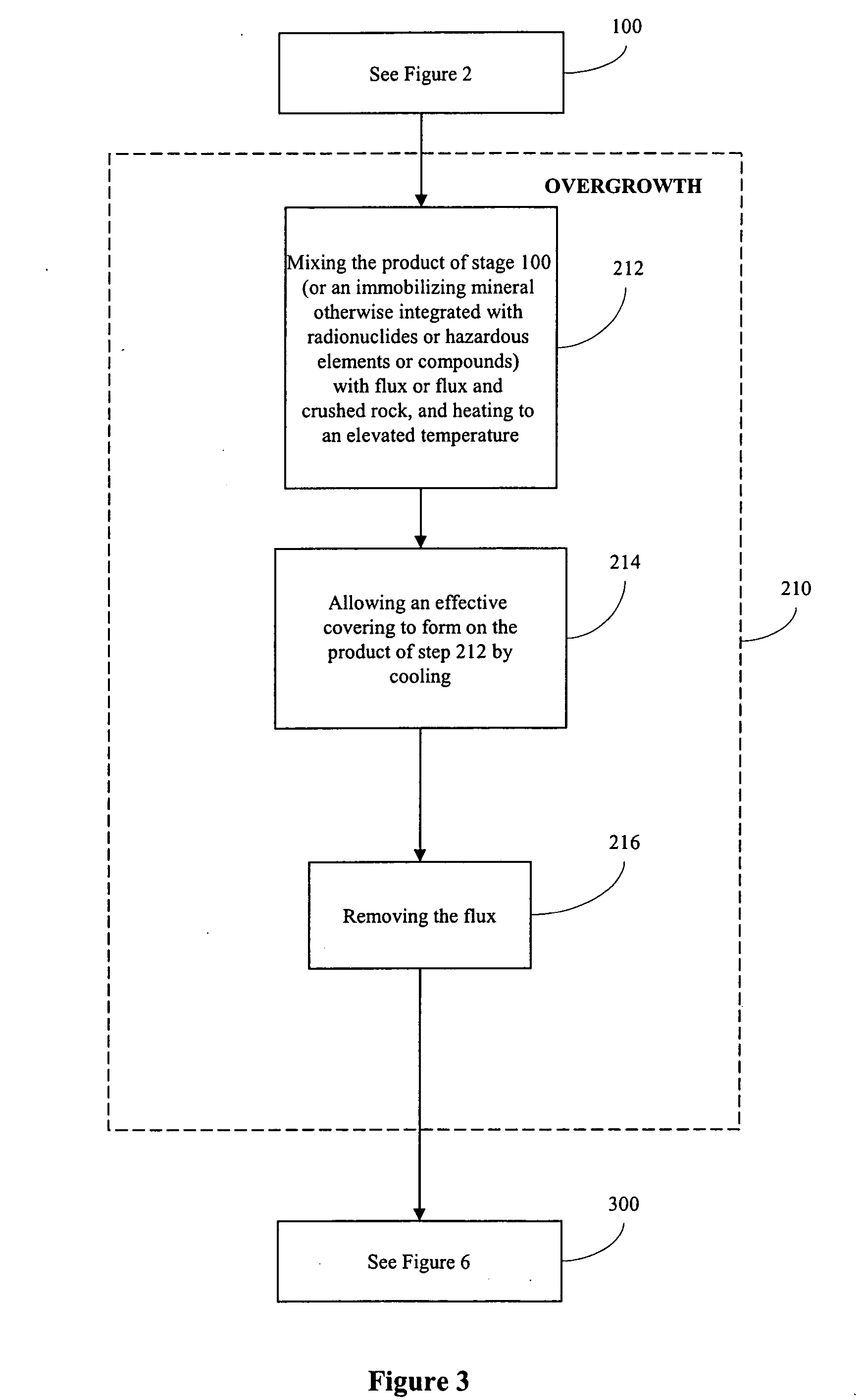

Processes for immobilizing radioactive and hazardous wastes

InactiveUS20060129018A1Excessive wasteHigh waste oxide loadingSludge treatmentSolid waste managementDiffusionEngineering

The present invention utilizes one or more processes to immobilize a waste that contains one or more of radionuclides, hazardous elements, hazardous compounds, and / or other compounds present in the waste. Each of the processes create a barrier against leaching and diffusion of the wastes. The first barrier is created by integrating the waste with an immobilizing mineral. The second barrier is a layer of non-radioactive or non-hazardous material that covers the first barrier. The second barrier may be created using an overgrowth procedure or by sintering. The third barrier is created by a rock or glass matrix that surrounds the first and / or second barriers. The fourth barrier is created by ensuring that the rock or glass has the same or similar composition as the indigenous rock at the disposal site. The resultant rock or glass matrix is in equilibrium with the groundwater or local hydrothermal solutions that are saturated with components of the indigenous rock of the disposal area.

Owner:GEOMATRIX SOLUTIONS INC

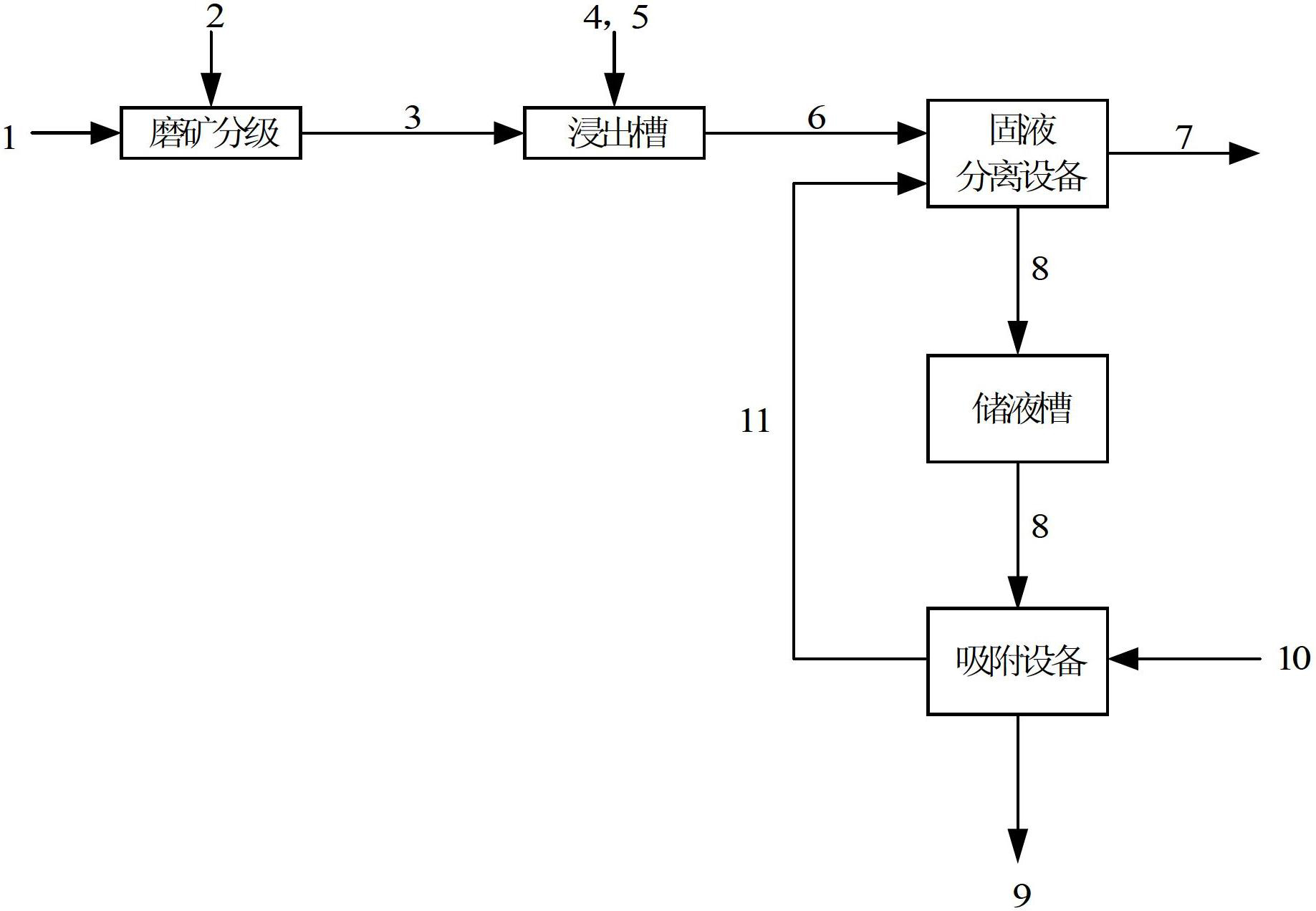

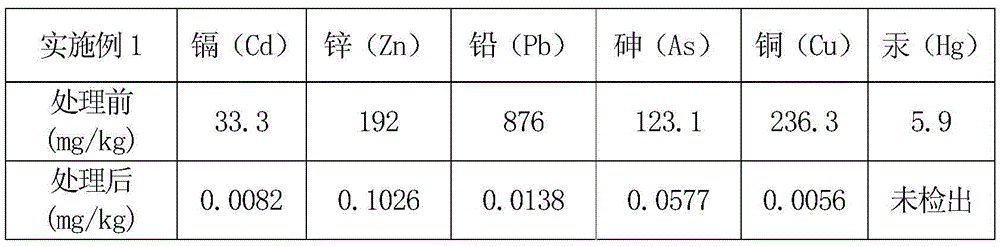

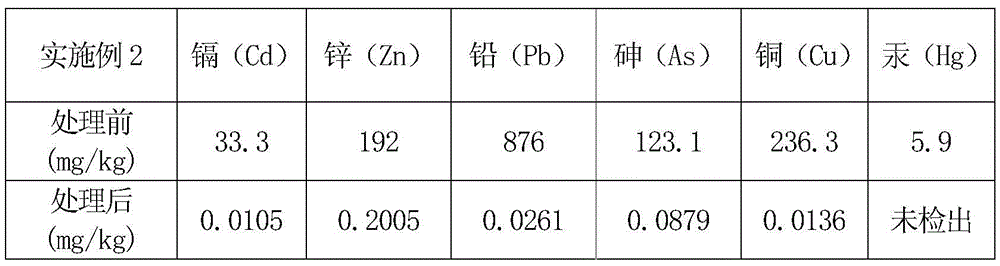

Heavy metal pollution soil restoration agent and application thereof

InactiveCN105542792AHigh porosityHigh adsorption valueAgriculture tools and machinesOther chemical processesThioureaTherapeutic effect

The invention provides a heavy metal pollution soil restoration agent which is composed of the following components in percentage by weight: 30-45% of biomass charcoal, 10-25% of alpha-cyclodextrin, 10-15% of glucose, 10-15% of iron powder, 10-15% of ferrous sulfate, 5-10% of polyacrylamide, 1-5% of sodium sulfide and 1-5% of thiocarbamide. The soil restoration agent has favorable effects on restoring cadmium / lead / zinc / mercury combined pollution soil. The restoration agent has the advantages of simple and feasible preparation and favorable treatment effect.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Remediation method of stabilization/solidification of lead-polluted soil

The invention discloses a remediation method of stabilization / solidification of lead-polluted soil. According to the method, a FeSO4 solution is added to the heavy metal lead-polluted soil, so that H+is generated through oxidization of the Fe2+, thus reducing pH value of soil, and promoting the conversion of instable lead in the soil into an effective state; then biochar and phosphate are added to the heavy metal lead-polluted soil, so that through adsorption, complexness, kation exchange, precipitation and the like between the biochar and phosphate and lead ions, the lead of effective stateis further converted into a lead compound in a stable residue state, thereby reducing the bio-availability of the heavy metal, reducing the content of the heavy metal in effective state in soil, and achieving adsorption and stabilization treatment of lead. The remediation method can reduce the leaching concentration of a leachate from the lead-polluted soil to lower than type III water quality standard (0.01 mg / L) according to the Quality Standard for Ground Water GBT 14848-2017.

Owner:BEIJING GEOENVIRON ENG & TECH

Method for extracting gold from copper-containing gold oxide ore

The invention discloses a method for extracting gold from copper-containing gold oxide ore, belonging to a wet metallurgy technology. The method comprises the steps of: firstly, crushing, grinding and classifying copper-containing gold oxide ore; then carrying out alkali treatment on the copper-containing gold oxide ore; adding a certain proportion of chelant and sodium cyanide for realizing the purposes of inhibiting copper extraction and selective extraction of gold; and finally, extracting gold from the extract solution through adsorption by using conventional active carbon. The method has the advantages of simple process, simple equipment, easy implementation, high gold extraction rate, less chemical consumption, less investment of capital construction, and low cost, easily realizes industrialized production and has better economic benefit.

Owner:ZIJIN MINING GROUP

Soil remediation agent

InactiveCN105623667AHigh porosityHigh adsorption valueOrganic fertilisersSoil conditioning compositionsSodium BentoniteCadmium Cation

The invention provides a soil remediation agent. The soil remediation agent is composed of, by weight, 10-25% of hydroxyl calcium phosphate, 30-45% of biomass charcoal, 10-15% of sodium sulfide, 10-15% of sodium bentonite and 10-15% of ammonium phosphate. The soil remediation agent is effective in remediation of soil contaminated by cadmium, lead, zinc, arsenic, copper and mercury.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Cadmium-lead compound contaminated soil remediation agent and application thereof

InactiveCN105754612AEasy to prepareGood governanceContaminated soil reclamationOrganic fertilisersTreatment effectSoil remediation

The invention provides a cadmium-lead compound contaminated soil remediation agent, prepared from the following components by a weight ratio: 30-50% of biomass charcoal, 10-20% of polyepoxysuccinic acid, 10-20% of polyacrylamide, 10-20% of starch and 10-20% of sodium bentonite; the components give full play to the synergy, and effective state of cadmium and lead in soil are greatly reduced by carrying out chelation, precipitation, absorption, improvement, PH value adjustment and the like on the components; the prepared soil remediation agent has a good effect in remediation of the cadmium-lead compound contaminated soil; the remediation agent provided by the invention has the advantages of being simple and feasible in preparation method as well as good in treatment effect.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Green tea fermented tea beverage and preparation method thereof

The invention discloses a green tea fermented tea beverage and a preparation method thereof. The preparation method comprises the steps that green tea leaves are taken and smashed and are subjected to non-thermal sterilization, distilled water, saccharosephosphorylase, other complex enzymes, a carbon source,plant sourceoligopeptide, saccharomycetes and lactic acid bacteria are respectively added, a multi-process synchronized and integrated technology including low temperature digestion, enzymolysis, fermentation and the like is performed, the multi-process synchronized and integrated technology is finished after being completed, residue removal and filtration are performed to obtain green tea fermented tea juice, low temperature digestion of the tea leaves, glycosylation modification of catechin and brewing of nutrition and flavor of the fermented tea beverage are achieved at a time, the stability of the green tea fermented tea beverage is improved, the bitter taste of the product is decreased, the flavor quality of the beverage is improved, and the bioavailability of the catechin is improved. The method is simple and convenient to operate and obvious in effect and has a good popularization and application value and market prospect.

Owner:浙江圣氏生物科技有限公司

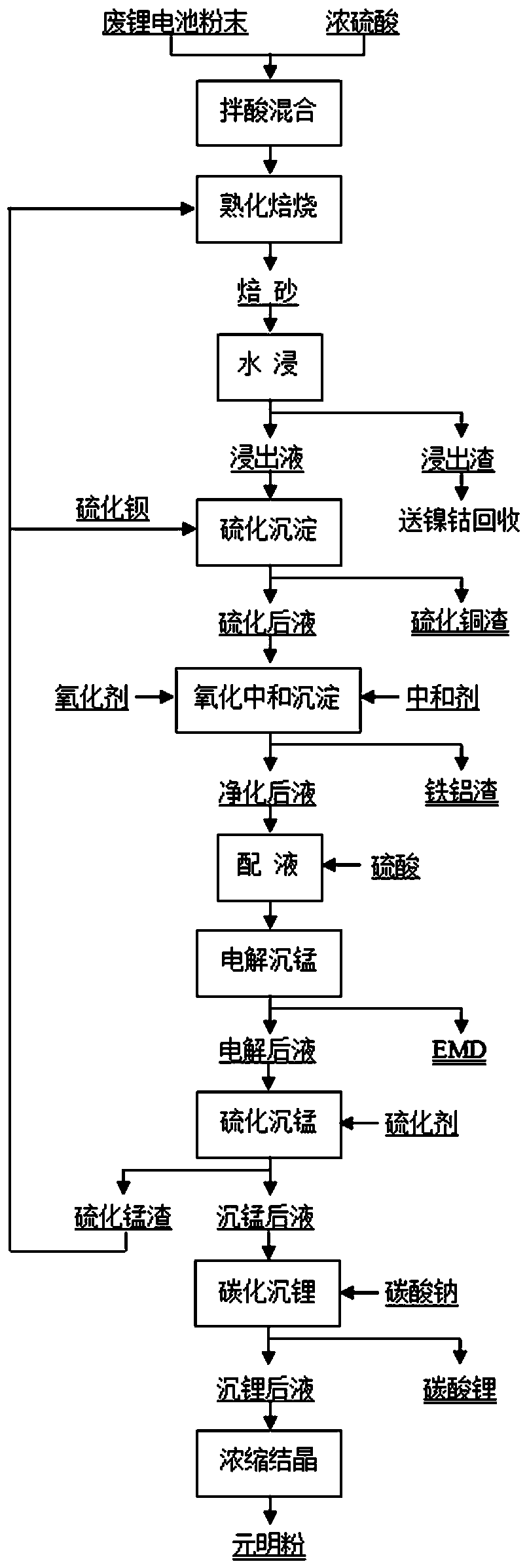

Manganese dioxide recovery method by waste lithium ion battery powder selective lithium-extracting and electrolytic separation

ActiveCN111254294AEfficient separationGood qualityElectrolysis componentsWaste accumulators reclaimingManganese oxideLithium carbonate

The invention discloses a manganese dioxide recovery method by waste lithium ion battery powder selective lithium-extracting and electrolytic separation. The method comprises the steps that a certainamount of waste lithium ion battery powder is weighed, concentrated sulfuric acid is added, and the mixture is fully stirred and mixed; the acid-stirred-and-mixed battery powder is placed in an electric furnace for being roasted at a certain temperature for a predetermined time; the roasted battery powder is mechanically stirred and leached with pure water at a predetermined temperature; slurry issubjected to liquid-solid separation, filter residue is fed to a wet method nickel-cobalt-manganese recovery system, and impurities of a lithium-containing leaching solution are removed by using sulfide precipitation and oxidation neutralization precipitation step by step; a lithium-containing purification solution electrolyzes to produce manganese dioxide powder at a predetermined current density, acidity and temperature; and after residual manganese ions of the lithium-containing solution after electrolytic manganese precipitation are removed, and a saturated sodium carbonate solution is added for carbonization lithium precipitation to produce lithium carbonate powder. The method creates good conditions for the subsequent recovery of nickel and cobalt by sulfuric acid leaching, and canrealize the efficient separation of lithium and manganese in lithium-rich liquid through electrodeposition, and comprehensively recover a electrolytic manganese dioxide product.

Owner:CENT SOUTH UNIV

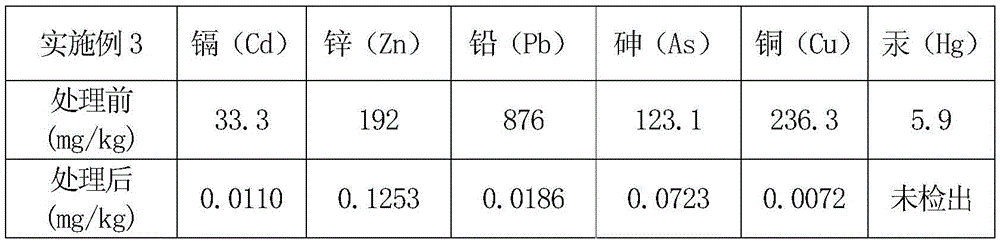

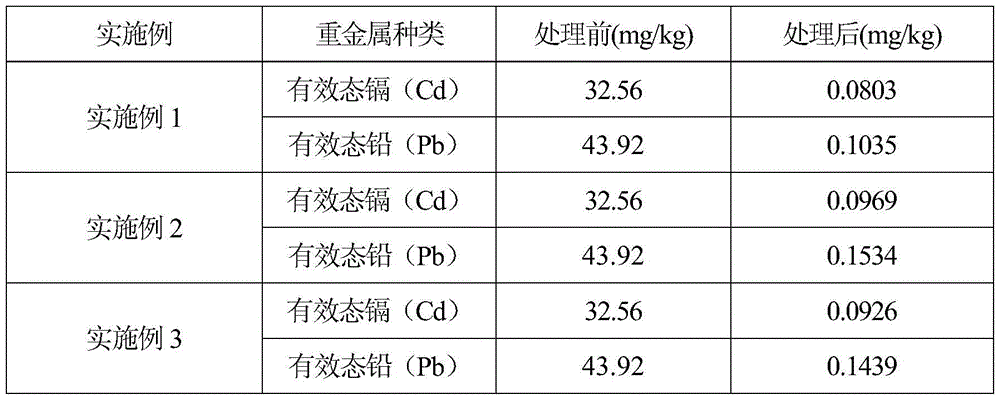

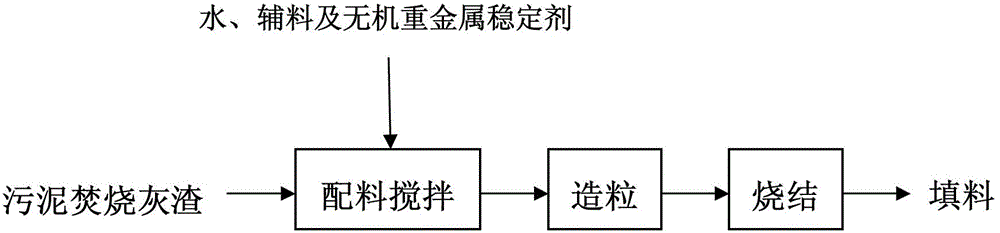

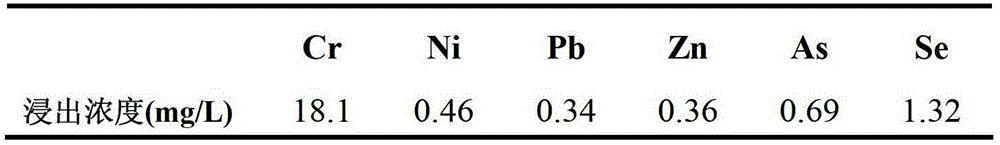

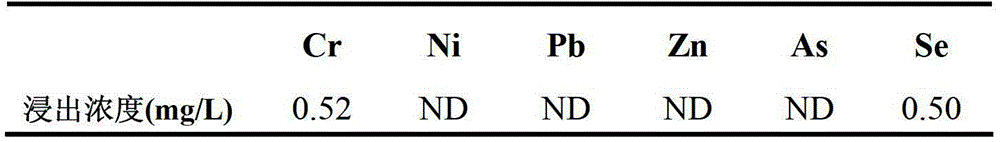

Heavy metal stabilizing method in process of preparing filler by chemical sludge burning ash

ActiveCN103145403AImprove stabilityLow leaching rateCeramic materials productionClaywaresPhosphateSludge

The invention relates to a heavy metal stabilizing method in a process of preparing filler by chemical sludge burning ash. An inorganic heavy metal stabilizer is prepared by using calcium oxide and potassium dihydrogen phosphate to prepare a calcium potassium phosphate cementing material supplemented by bentonite; the chemical sludge burning ash is used as a raw material, clay or shale is used as an auxiliary material, and a small amount of the inorganic heavy metal stabilizer is doped; and the raw material, the auxiliary material and the inorganic heavy metal stabilizer are mixed according to a certain proportion and stirred by adding water, pelletted and sintered to prepare the filler with small heavy metal leaching rate. The invention provides the heavy metal stabilizing method which is in good stabilizing effect and has universality to different heavy metal components and shapes. The process for preparing the filler by using the chemical sludge burning ash doped with the inorganic heavy metal stabilizer has the advantages of low operating cost, short disposal period, small secondary pollution, high degree of resources and the like compared with the conventional chemical sludge treatment and disposal manner.

Owner:NANJING UNIV OF TECH

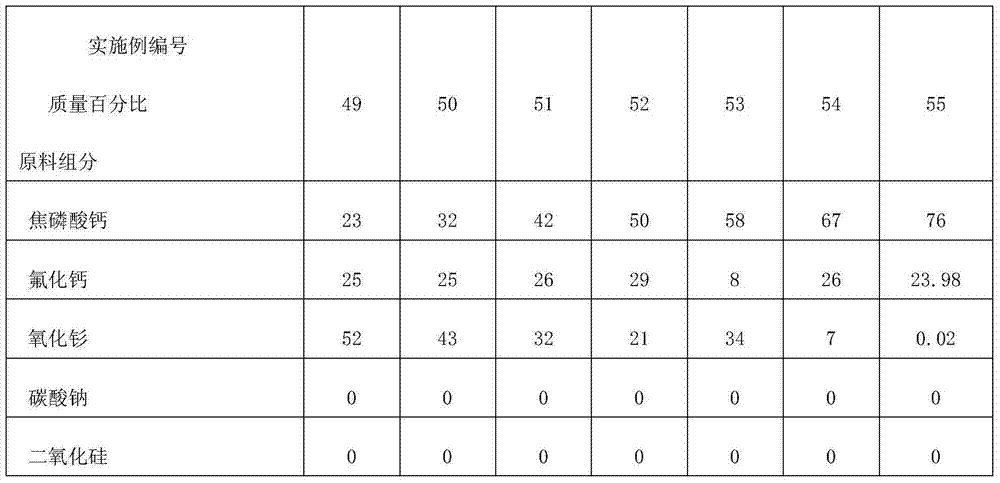

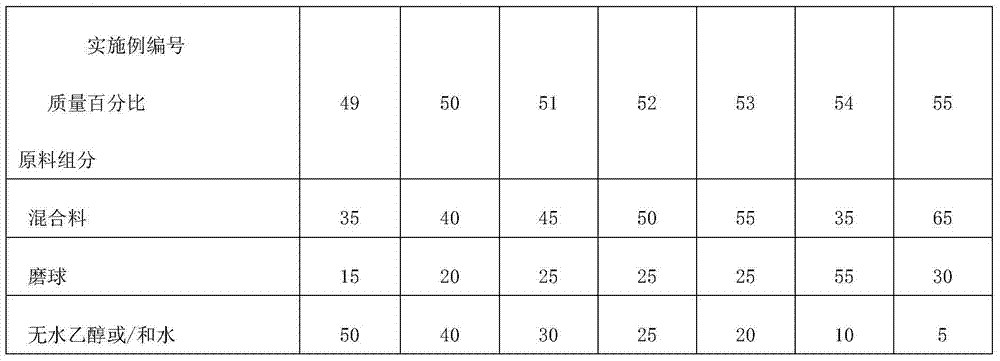

Method for preparing fluorapatite ceramic solidified body

The present invention discloses a method for preparing a fluorapatite ceramic solidified body. The method is characterized by comprising the steps of: taking and mixing 23-76 wt.% of calcium pyrophosphate, 8-26 wt.% of calcium fluoride, 0. 02-52wt.% of samarium oxide (europium oxide, gadolinium oxide), 0-15 wt.% of sodium carbonate, 0-16 wt.% of silica to obtain a mixture; grinding, drying, granulating, molding, discharging rubber and conducting vacuum hot pressing sintering on the mixture to obtain a fluorapatite ceramic solidified body. The method not only utilizes the phosphorus in high-level radioactive waste in a recycling way, but also can address the problem of low solubility of phosphorus and minor actinides nuclide in glass solidified body. The fluorapatite ceramic cured body prepared by the invention has excellent preparation geological stability, irradiation stability, mechanical stability, chemical stability and thermal stability, and can be used as a ceramic solidified body for safe treatment of minor actinides high-level radioactive waste with high toxicity, long half-life period and strong radioactivity.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com