Method for extracting phosphate concentrate from phosphate tailings and cooperatively producing calcium carbonate and magnesium oxide

A technology for phosphate tailings and phosphate concentrates, which can be used in the treatment of magnesium oxide, calcium carbonate/strontium/barium, and phosphate materials, and can solve problems such as vegetation destruction, environmental pollution, and land degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

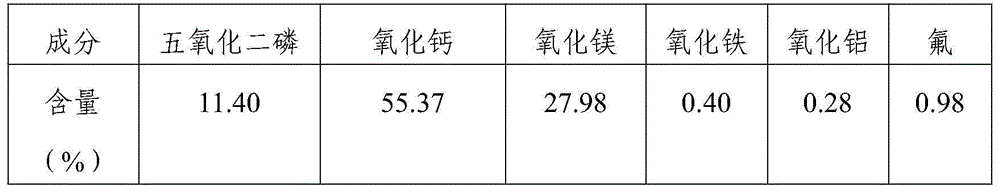

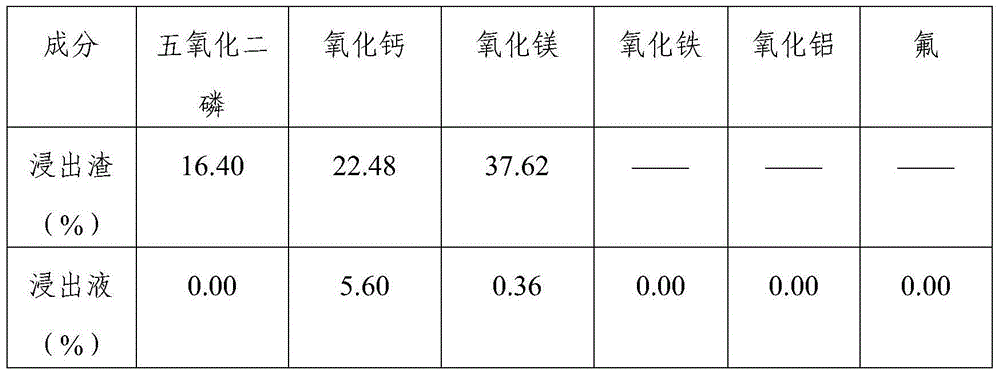

[0074] A method for extracting phosphorus concentrate from phosphorus tailings and co-producing calcium carbonate and magnesium oxide, comprising the following steps:

[0075] (1) calcining: the phosphorus tailings are sent to a calciner and calcined at a temperature of 900 ° C for 50min to obtain a calcined material and carbon dioxide gas, the carbon dioxide gas is passed into the absorption tower, and ammonia water is used to absorb it to obtain an ammonium carbonate solution;

[0076] (2) Digestion: the calcined material and the hot water with a temperature of 60°C are sent into the digestion tank to be mixed, the weight ratio of the calcined material to the hot water is 5:10, and the digestion treatment time is 30 min to obtain a digestion slurry;

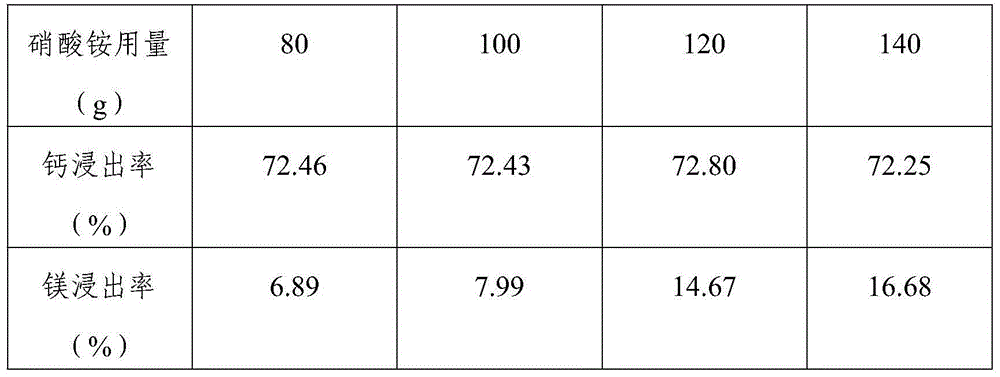

[0077] (3) leaching calcium: after the digestion slurry and ammonium nitrate solution are sent into the leaching tank at a weight ratio of 15:10 and mixed, they are stirred at 5°C for 50 minutes, and the ammonia gas generated by...

Embodiment 2

[0084] A method for extracting phosphorus concentrate from phosphorus tailings and co-producing calcium carbonate and magnesium oxide, comprising the following steps:

[0085] (1) calcination: send the phosphorus tailings into a calciner and calcinate at a temperature of 1000 ° C for 70min to obtain calcined material and carbon dioxide gas, pass the carbon dioxide gas into the absorption tower, and use ammonia water to absorb to obtain an ammonium carbonate solution;

[0086] (2) Digestion: the calcined material and the hot water with a temperature of 100°C are sent into the digestion tank to be mixed, the weight ratio of the calcined material to the hot water is 7:10, and the digestion treatment time is 50 min to obtain a digestion slurry;

[0087] (3) leaching calcium: after the digestion slurry and ammonium nitrate solution are sent into the leaching tank at a weight ratio of 17:12 and mixed, they are stirred at 40° C. for 70 minutes, and the ammonia gas generated by the rea...

Embodiment 3

[0094] A method for extracting phosphorus concentrate from phosphorus tailings and co-producing calcium carbonate and magnesium oxide, comprising the following steps:

[0095] (1) calcination: send the phosphorus tailings into a calciner and calcinate at a temperature of 930 ° C for 55min to obtain calcined material and carbon dioxide gas, pass the carbon dioxide gas into the absorption tower, and use ammonia water to absorb to obtain an ammonium carbonate solution;

[0096] (2) Digestion: the calcined material and the hot water with a temperature of 70°C are sent into the digestion tank to be mixed, the weight ratio of the calcined material to the hot water is 6:10, and the digestion treatment time is 45min to obtain a digestion slurry;

[0097] (3) leaching calcium: after the digestion slurry and ammonium nitrate solution are sent into the leaching tank at a weight ratio of 16:10 and mixed, they are stirred at 20 ° C for 55 min, and the ammonia gas generated by the reaction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com