Patents

Literature

34results about How to "Reduce magnesium oxide content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

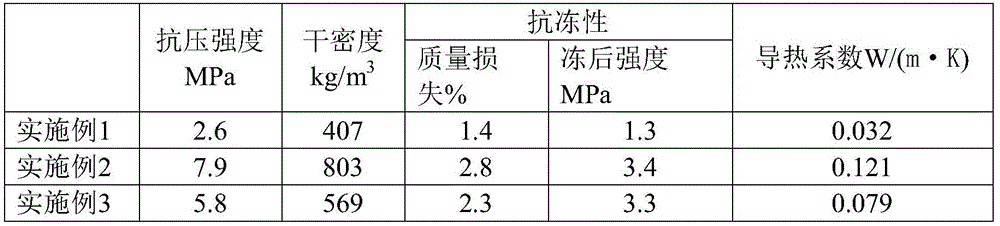

Non-autoclaved aerated concrete prepared by utilizing lithium slag and nickel slag and preparation method of non-autoclaved aerated concrete

The invention relates to non-autoclaved aerated concrete prepared by utilizing lithium slag and nickel slag and a preparation method of the non-autoclaved aerated concrete. The aerated concrete is prepared from the following components in parts by weight: 40 to 80 parts of lithium slag powder, 20 to 60 parts of nickel slag powder, 6 to 20 parts of sodium hydroxide solution, 12 to 30 parts of sodium silicate solution, 0.005 to 0.05 part of aluminum powder, and 0.005 to 0.02 part of foam stabilizer. The preparation method comprises the steps of adding aluminum powder for foaming after uniformly stirring the lithium slag powder, nickel slag powder, sodium hydroxide solution, and sodium silicate solution in accordance with a certain proportion, cutting after curing for 4-6 hours at a temperature of 60 to 80 DEG C, stacking and curing for 7 days. The process is simple, industrial byproducts lithium slag and nickel slag are fully utilized, the high-temperature autoclave curing regime is not used in the whole process, the energy consumption is reduced, and the economic, environmental and social benefits are good.

Owner:SOUTHEAST UNIV

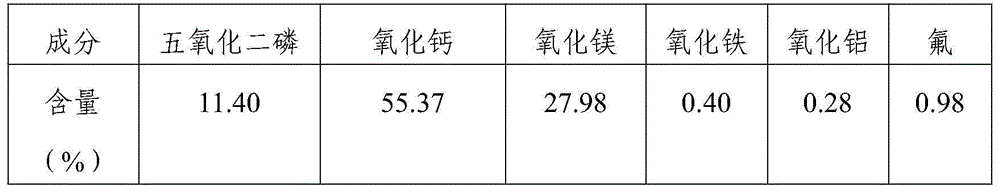

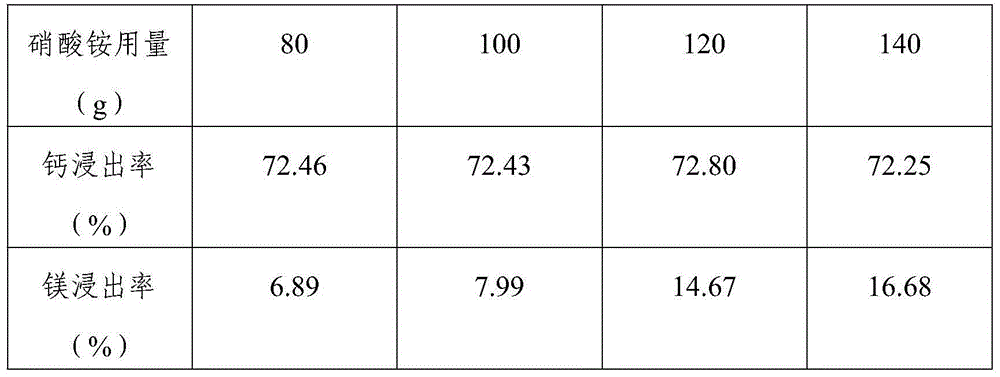

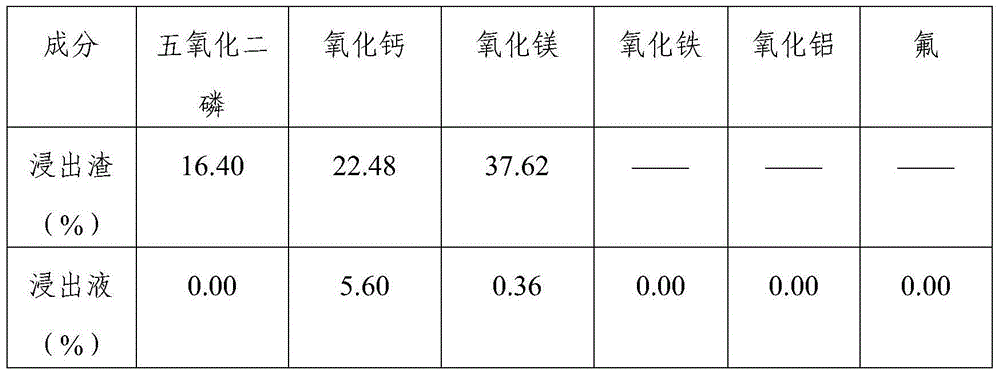

Method for extracting phosphate concentrate from phosphate tailings and cooperatively producing calcium carbonate and magnesium oxide

InactiveCN104860278AHigh economic valueEfficient recyclingCalcium/strontium/barium carbonatesRaw phosphate material treatmentDigestion TreatmentPhosphate

The invention discloses a method for extracting phosphate concentrate from phosphate tailings and cooperatively producing calcium carbonate and magnesium oxide. First, phosphate tailings are calcined under high temperature, hot water is added into the calcined material for digestion treatment, an ammonium nitrate solution is added to the calcined material, the mixture is stirred, calcium is extracted under a certain temperature, calcium-containing leaching liquid and leaching residues are obtained, phosphate concentrate and magnesium-containing leaching liquid are obtained after magnesium is extracted from the leaching residues with an ammonium sulfate solution, calcium carbonate is obtained after the calcium-containing leaching liquid is precipitated by an ammonium carbonate solution, magnesium carbonate is obtained after the magnesium-containing leaching liquid is precipitated by an ammonium carbonate solution, and magnesium oxide is obtained after the magnesium carbonate is calcined. According to the method, phosphate concentrate, calcium carbonate and magnesium oxide are prepared with phosphate tailings as the main raw materials, large-scale treatment can be carried out on the phosphate tailings, the problem that because phosphate tailings pile up in quantity, the phosphate tailings occupy a lot of land and pollute the environment is solved, and the products of phosphate concentrate, calcium carbonate and magnesium oxide are obtained.

Owner:GUIZHOU RES INST OF CHEM IND

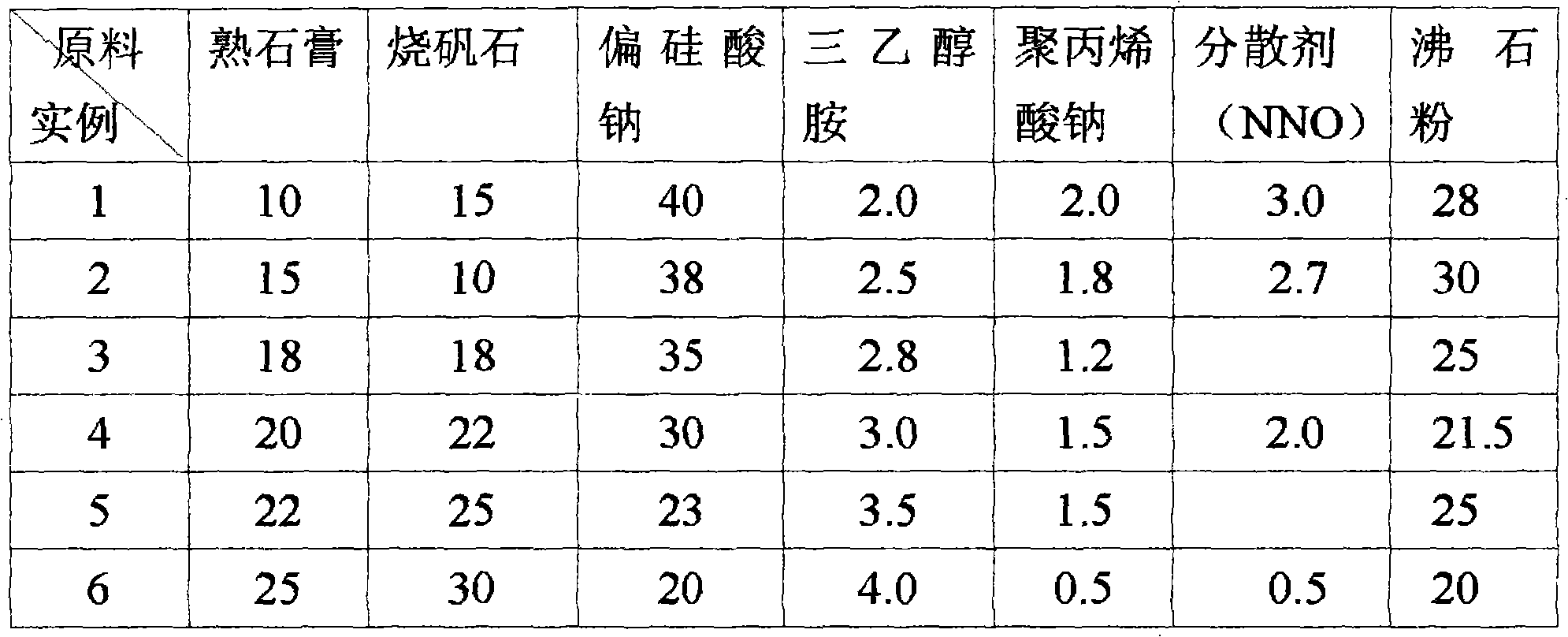

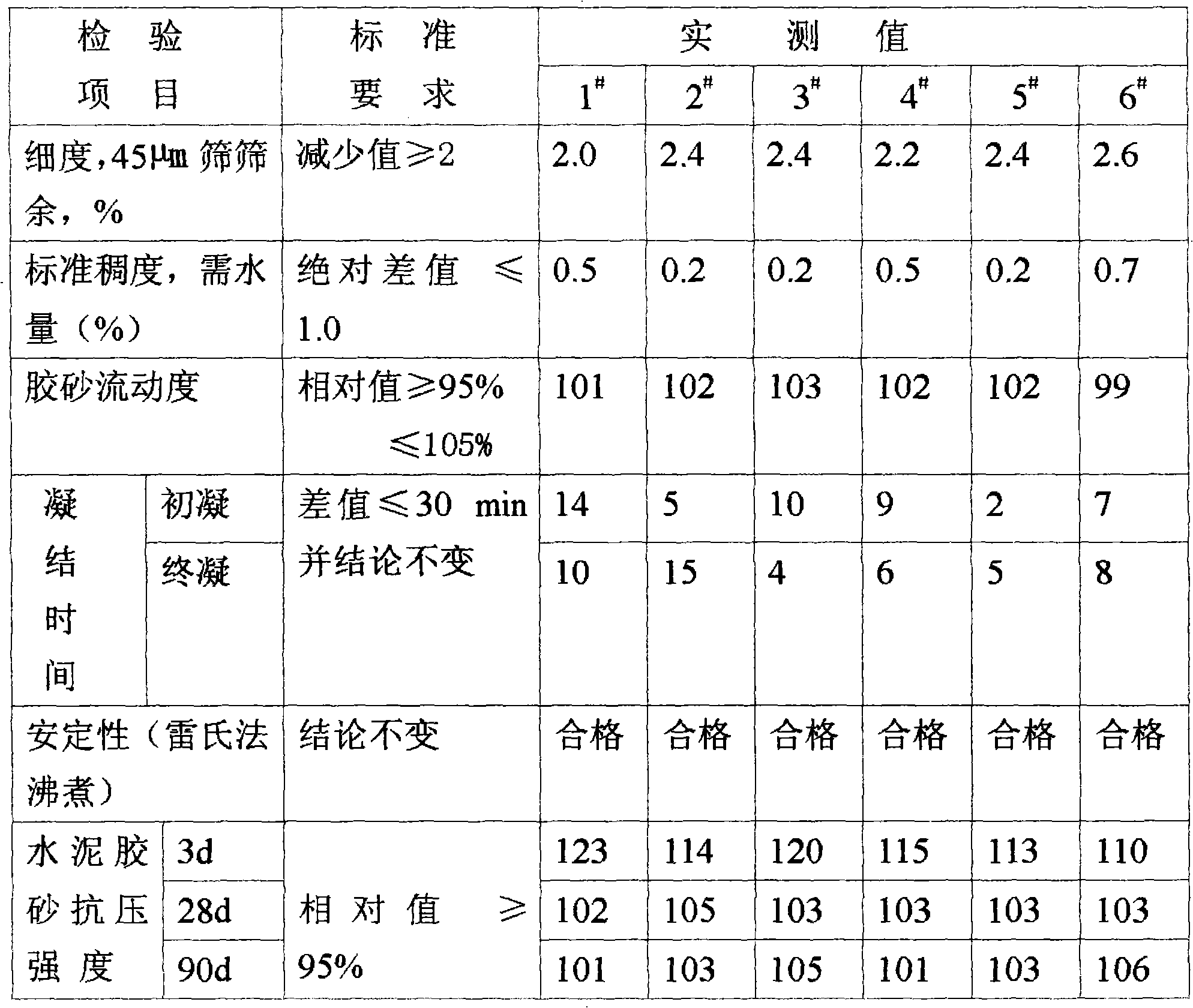

High efficiency cement composite grinding additive and preparation method thereof

InactiveCN101618955AIncrease incorporationIncrease productionSolid waste managementAluminiteSodium metasilicate

The invention discloses a high efficiency cement composite grinding additive, comprising the following raw materials by weight percent: 10-25% of calcined gypsum, 10-30% of calcined aluminite, 20-40% of sodium metasilicate, 2-4% of triethanolamine, 0.5-2% of polyacrylate, 0.5-3% of dispersant and 20-30% of zeolite powder. The preparation method of the high efficiency cement composite grinding additive comprises the following steps: first selecting raw materials, then dripping liquid raw materials-triethanolamine and polyacrylate TH-1100 with a liquid pump in zeolite powder, then preparing reinforced grinding component with a dry powder mixer, finally adding the reinforced grinding component, calcined gypsum, calcined aluminite, sodium metasilicate and dispersant in a kneader to mix for 20-30min and obtaining the product. The product has prominent grinding aid, and can increase the hourly output of mills by 10-15%, reduce the consumption of electricity, and increase the cement 3-day compression strength and the cement 7-day compression strength by more than 20% and the cement 28-day compression strength by 10-15%.

Owner:葫芦岛市辽西混凝土外加剂有限公司

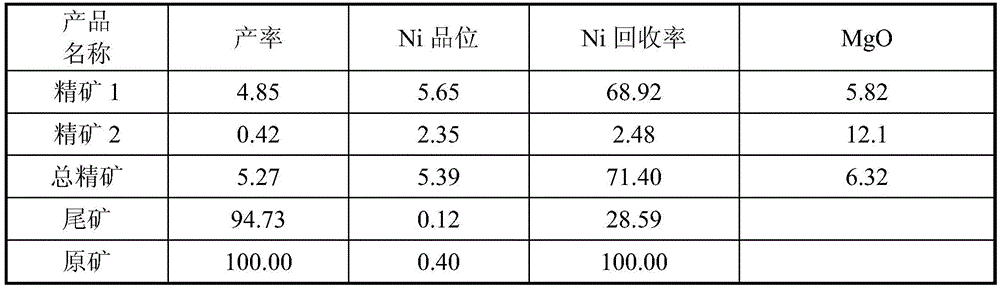

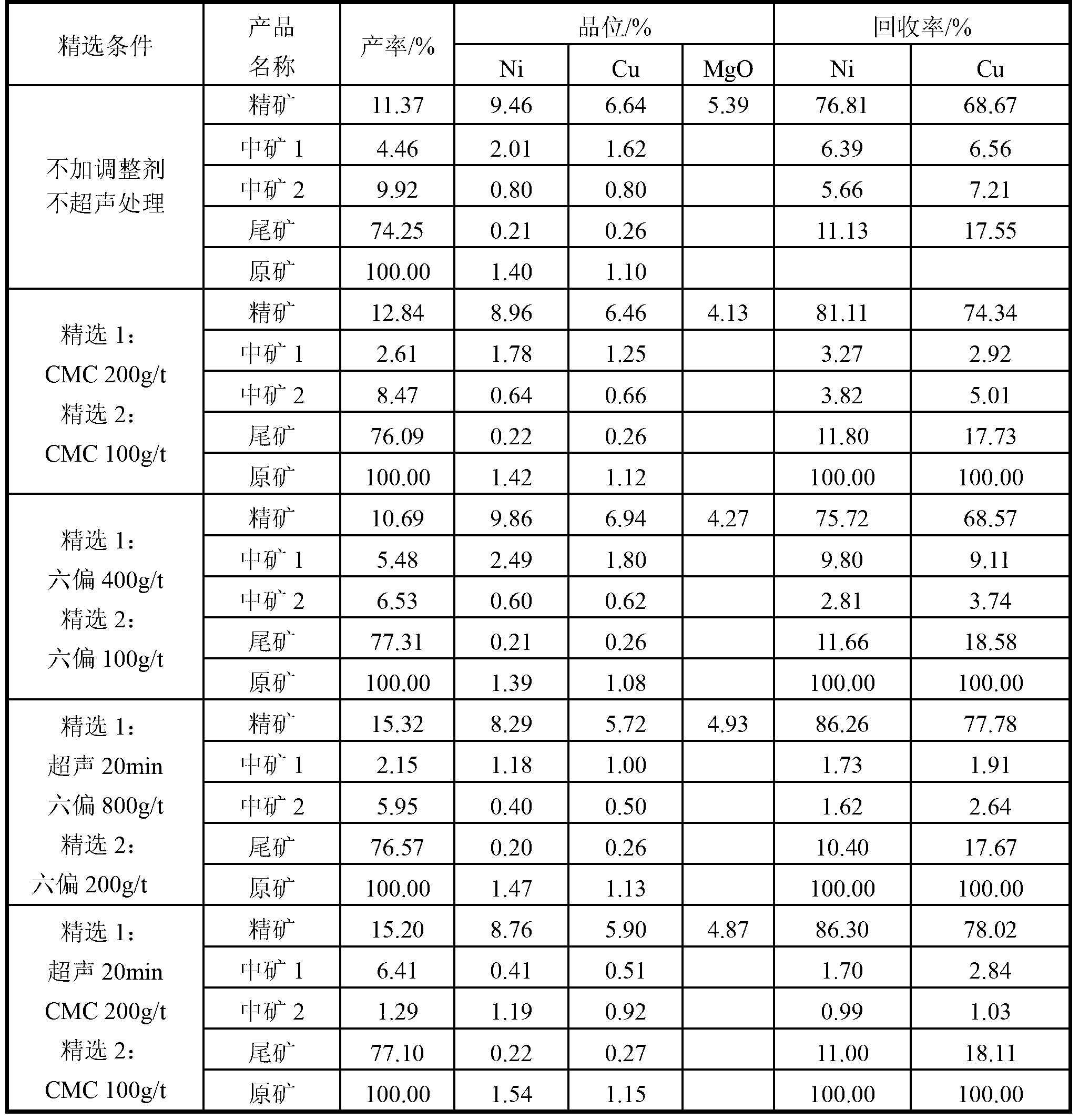

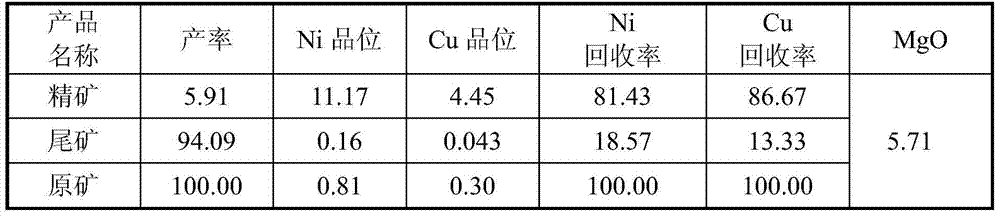

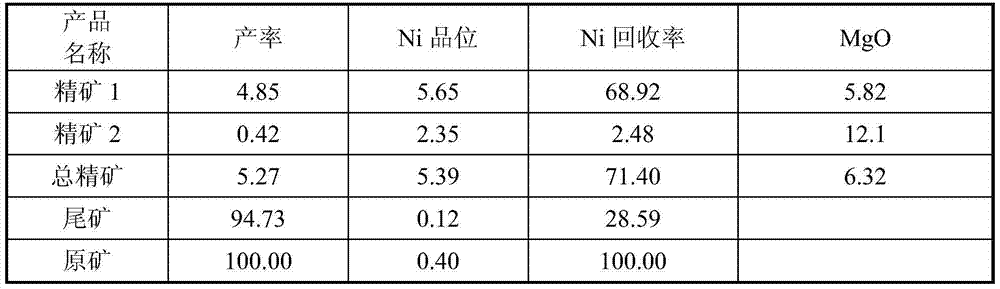

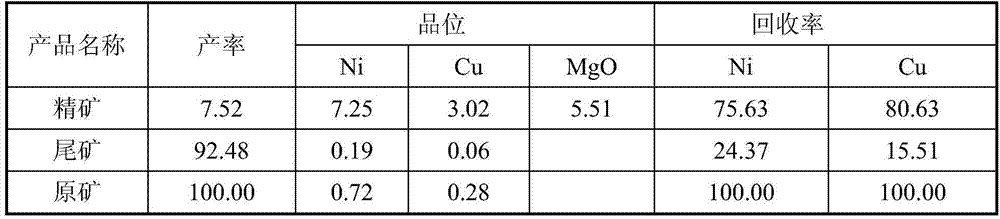

Beneficiation method for separating copper-nickel sulfide ore from serpentine gangue

ActiveCN105413877AIncrease buoyancyWeaken heterogeneous condensationFlotationPyrophosphateSulfide minerals

The invention relates to a beneficiation method for separating copper-nickel sulfide ore from serpentine gangue. The beneficiation method comprises the following steps: when the copper-nickel sulfide ore is roughly concentrated, a polymer reagent poloxamer which can be adsorbed onto the surface of sulfide mineral through hydrophobic interaction but cannot be adsorbed onto the surface of the serpentine gangue is added; ore pulp is dispersed through the steric hindrance of the polymer reagent, the heterocoagulation of serpentine and sulfide minerals is eliminated, the inhibiting effect of serpentine on the sulfide minerals is reduced, and the recovery rate of rough concentration of the copper-nickel sulfide ore containing serpentine is increased; for rough copper-nickel sulfide concentrate obtained through rough concentration, regulators sodium pyrophosphate and carboxymethyl cellulose are added to further disperse and inhibit gangue minerals; meanwhile a collector is added before the regulators are added, so that the collector is adsorbed onto the surfaces of sulfide minerals to protect the sulfide minerals; the selective inhibition to the gangue minerals is realized, and therefore the concentrate grade is increased. The beneficiation method solves the problems that the reagent dosage is large, valuable minerals are inhibited and tailings hardly sedimentate in the traditional method.

Owner:JIANGXI UNIV OF SCI & TECH

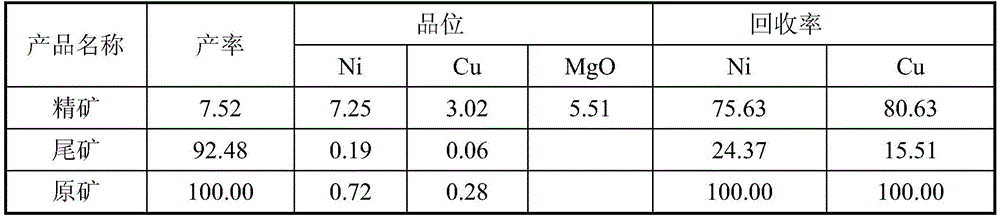

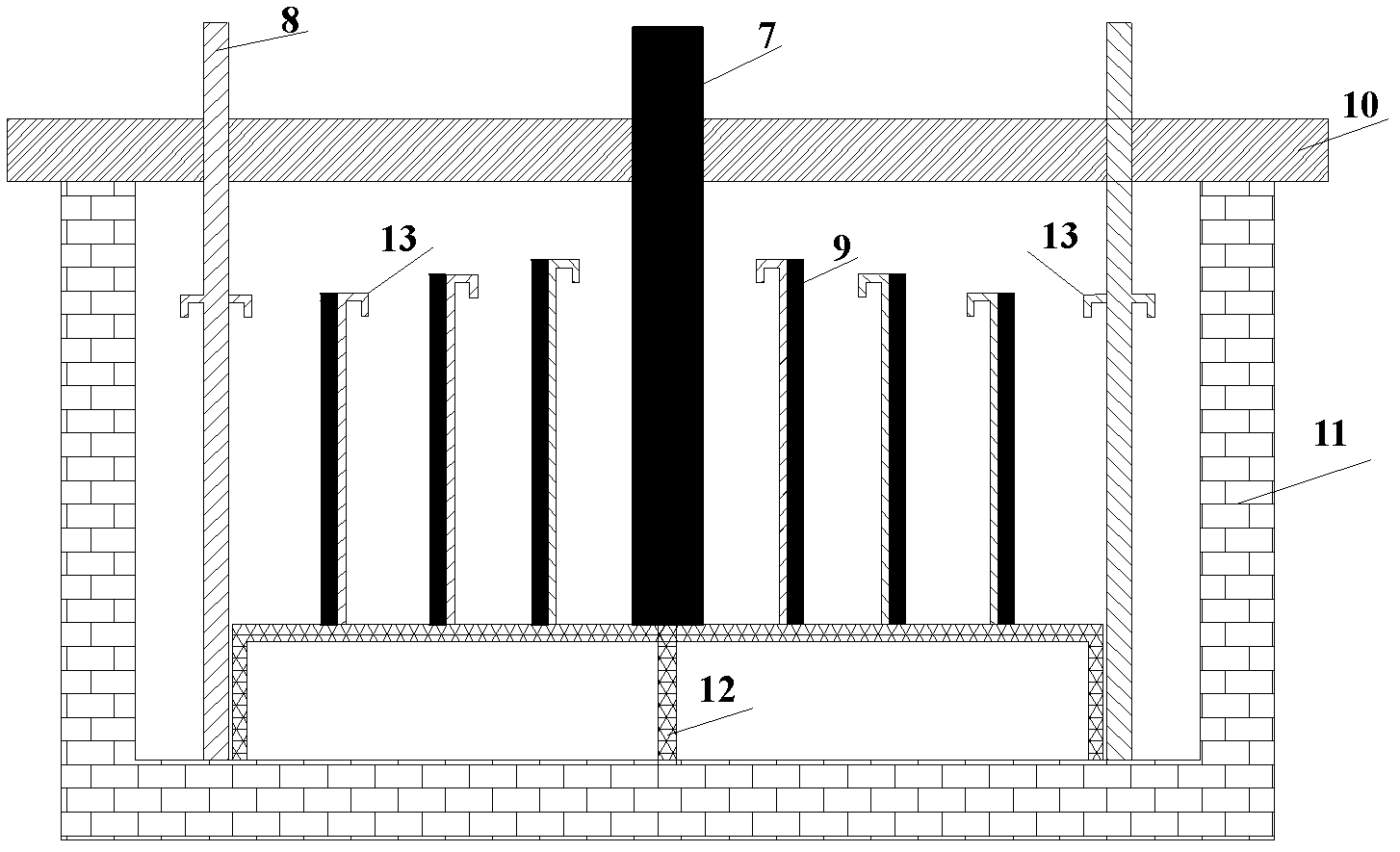

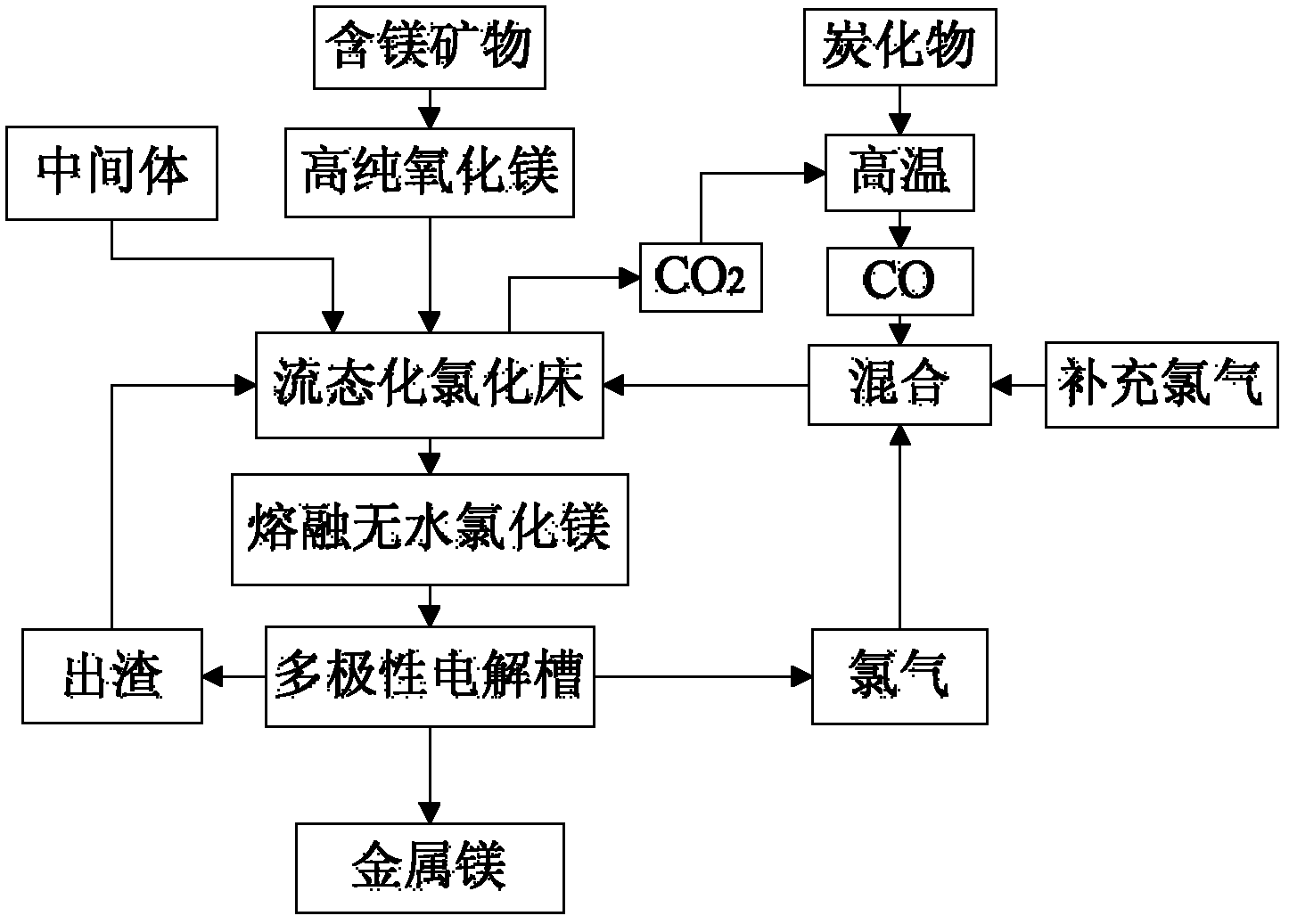

Preparation method of metal magnesium by magnesium-containing mineral and equipment adopted by preparation method

The invention belongs to the field of metal material, and relates to a preparation method of metal magnesium by magnesium-containing mineral and equipment adopted by the preparation method. The method comprises the following steps of: converting useful components in magnesium-containing mineral into high-activity magnesium oxide, and under the effects of high temperature and a catalytic midbody, enabling the high-activity magnesium oxide to have chlorination reaction with chlorine and carbon monoxide, so that molten magnesium chloride anhydrous is generated; and mixing the molten magnesium chloride anhydrous with the other molten inorganic salt according to a certain proportion to be taken as electrolyte, and leading the electrolyte into a multi-polarity electrolytic cell to electrolyze, so that the metal magnesium is prepared. The technology adopts the fluidzed chlorination bed and the multi-polarity electrolytic cell of the novel equipment, and adds the midbody of catalytic reaction in the process of chlorination, so that the preparation method is more high-efficiency and energy-saving compared with the conventional method. The waste gas and the waste residue generated in the whole process are treated to be reused, so that the preparation method and the equipment are environment-friendly.

Owner:UNIV OF SCI & TECH BEIJING

Method for extracting phosphate concentrate from phosphate tailings and cooperatively producing calcium ammonium nitrate and magnesium ammonium sulphate

InactiveCN104860279AEfficient recyclingAlleviate the status quo of depletionMagnesium compoundsCalcium/strontium/barium nitratesPhosphateDigestion Treatment

The invention discloses a method for extracting phosphate concentrate from phosphate tailings and cooperatively producing calcium ammonium nitrate and magnesium ammonium sulphate. Phosphate tailings are calcined under high temperature, hot water is added into the calcined material for digestion treatment, an ammonium nitrate solution is added to the calcined material, the mixture is stirred, calcium is extracted under a certain temperature, calcium-containing leaching liquid and leaching residues are obtained, phosphate concentrate and magnesium-containing leaching liquid are obtained after magnesium is extracted from the leaching residues with an ammonium sulfate solution, and calcium ammonium nitrate and magnesium ammonium sulphate are obtained after the calcium-containing leaching liquid and the magnesium-containing leaching liquid are concentrated and dried. According to the method, phosphate concentrate, calcium ammonium nitrate and magnesium ammonium sulphate are prepared with phosphate tailings as the main raw materials, large-scale treatment can be carried out on the phosphate tailings, the problem that because phosphate tailings pile up in quantity, the phosphate tailings occupy a lot of land and pollute the environment is solved, and the obtained phosphate concentrate, calcium ammonium nitrate and magnesium ammonium sulphate can bring certain economic interests.

Owner:GUIZHOU RES INST OF CHEM IND

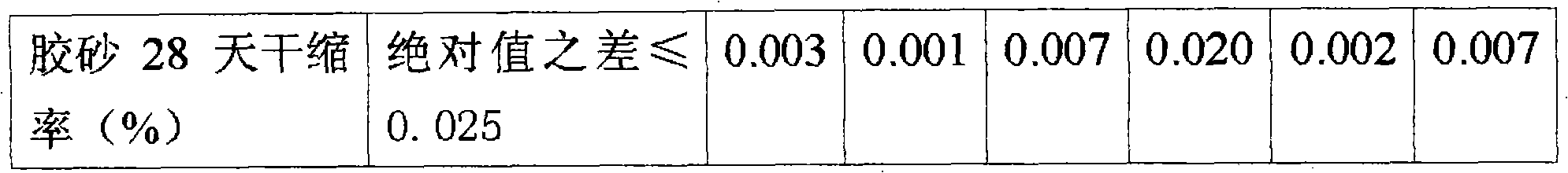

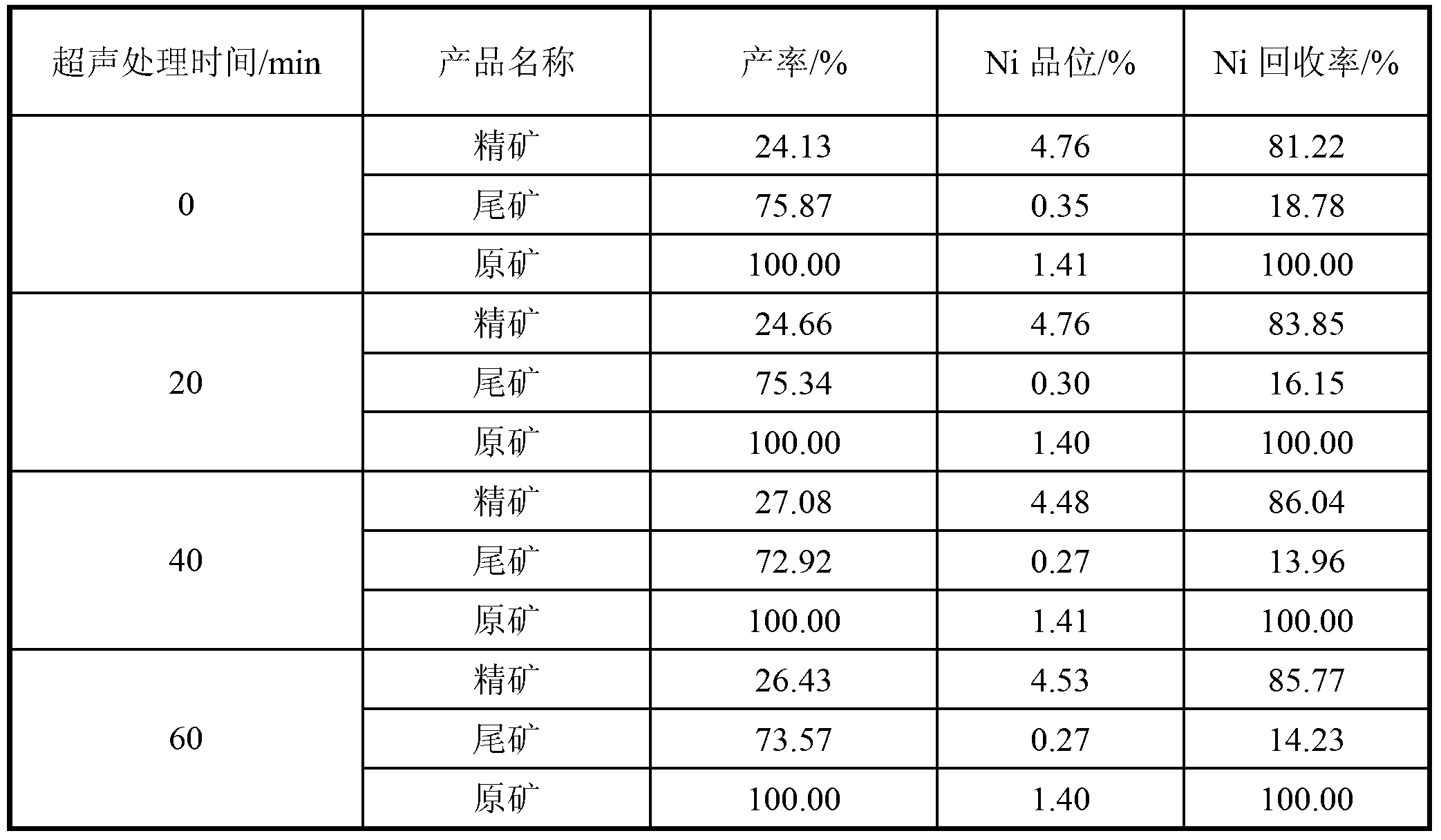

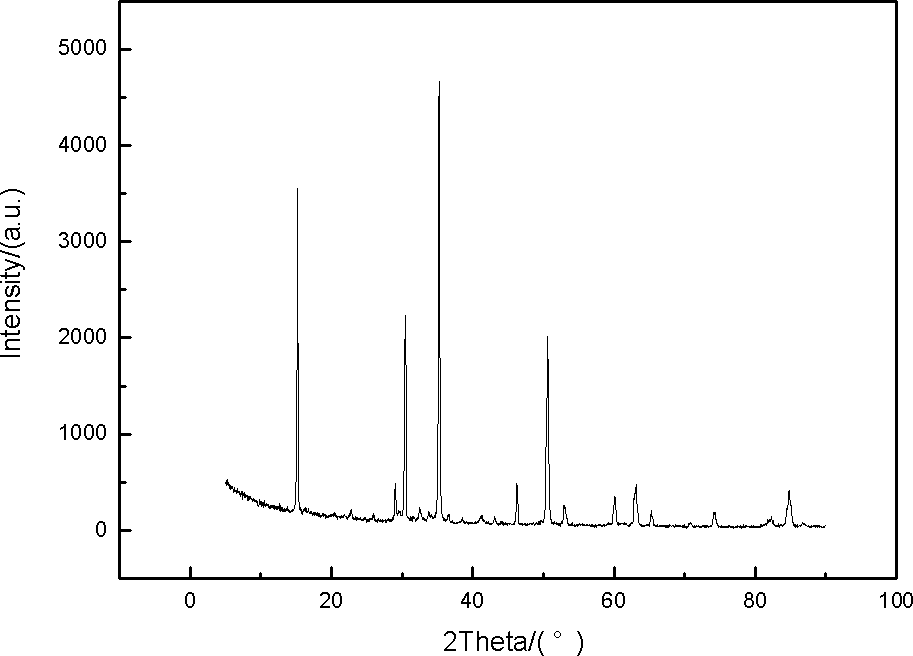

Method for improving flotation recovery rate of copper and nickel and reducing content of magnesium oxide in concentrates of copper-nickel sulfide ores

InactiveCN103301948AImprove adsorption capacityElimination of heterogeneous condensationFlotationUltrasound - actionNickel sulfide

The invention relates to a method for improving the flotation recovery rate of copper and nickel and reducing content of magnesium oxide in concentrates of copper-nickel sulfide ores. According to the method, before the copper-nickel sulfide ores are subjected to flotation, ultrasonic waves are used for carrying out dispersion treatment on ore pulp. The ore pulp can be crude ore pulp added with a collecting agent, or ore pulp which comprises the collecting agent and enters a random flotation operation; the ultrasonication can be carried out before flotation and also can be simultaneously carried out with flotation. According to the invention, supersonic jet generated in the ultrasonic treatment and cavatition are utilized to desorb serpentine pulp covering the surface of sulphide mineral, the flotation recovery rate of the sulphide mineral is improved, the quantity of the serpentine pulp entering the concentrates is reduced and the content of magnesium oxide in the concentrates of the copper-nickel sulfide ores is reduced, so that a sorting index is improved.

Owner:CENT SOUTH UNIV

Method for preparing anhydrous magnesium chloride by utilizing magnesium oxide

ActiveCN102491383AReduce dosageReduce manufacturing costMagnesium chloridesAnhydrous magnesium chlorideAmmonium chloride mixture

The invention relates to a method for preparing anhydrous magnesium chloride by utilizing magnesium oxide. The method comprises the following steps of: (1) mixing magnesium oxide and ammonium chloride uniformly to obtain a mixture of the magnesium oxide and the ammonium chloride; and (2) placing a covering above the mixture, heating and reacting to obtain the anhydrous magnesium chloride. In the anhydrous magnesium chloride prepared by the method, the content of the magnesium oxide is within 0.5 weight percent, so the anhydrous magnesium chloride can be used for producing magnesium by an electrolytic process directly. By the method for preparing the anhydrous magnesium chloride, the production process of the anhydrous magnesium chloride can be shortened, the production efficiency can be improved, the production cost can be reduced, and the environment-friendly investment cost can be reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

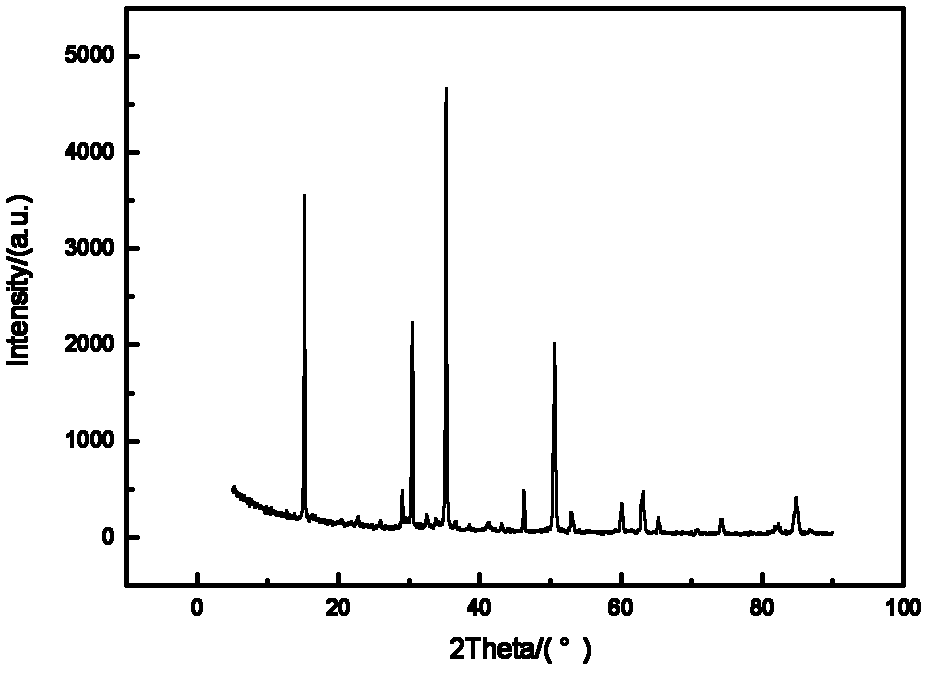

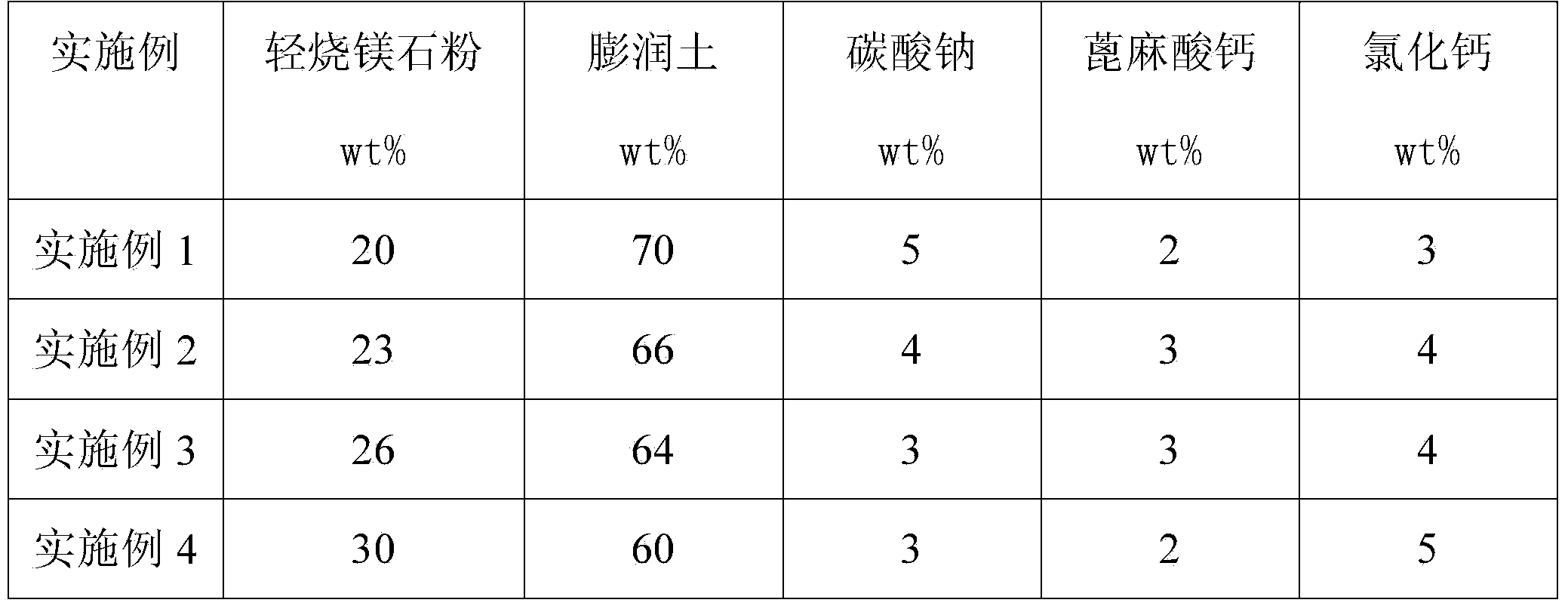

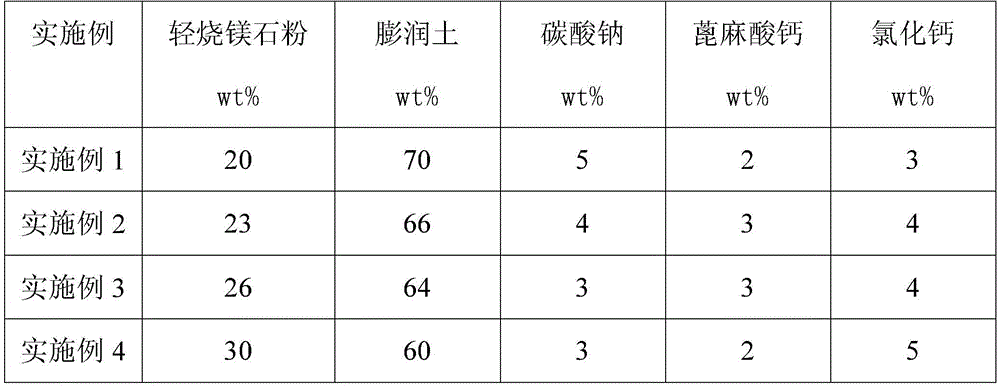

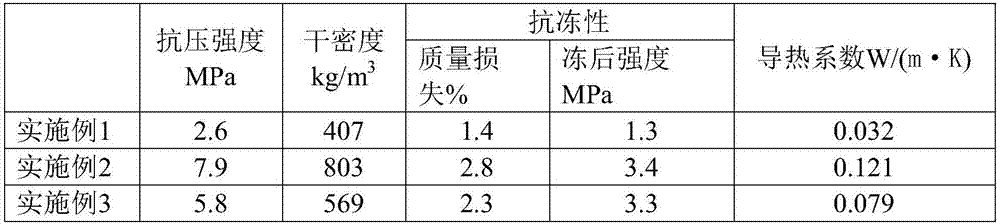

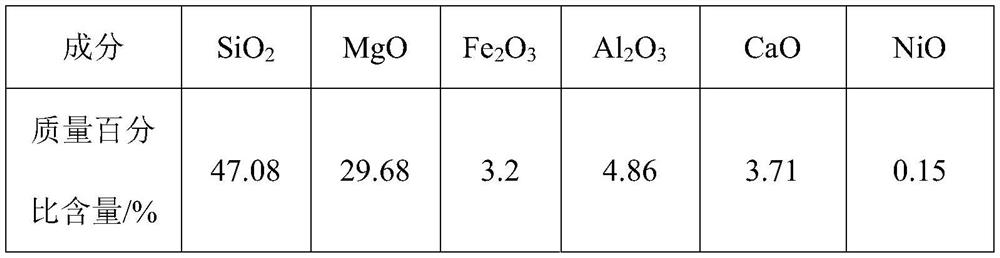

Magnesium composite bentonite for pelletizing

The invention provides magnesium composite bentonite for pelletizing. The bentonite comprises the following components in percentage by weight: 20-30% of light-burned magnesite powder, 60-70% of bentonite, 3-5% of sodium carbonate, 2-3% of calcium ricinoleate and 3-5% of calcium chloride; the magnesium composite bentonite comprises the following main chemical components in percentage by weight: 25-30% of MgO, 45-55% of SiO2, and less than 15% of water. By adopting the magnesium composite bentonite disclosed by the invention, the MgO content of a pellet ore can be increased to 1.5%, the mechanical strength of the pellet ore can be increased by 1.5-2%, the initial softening temperature of the pellet ore can be increased by 150-200 DEG C, the MgO content of a sintering ore can be reduced relatively, the quality of the sintering ore can be improved, and the consumption of a sintering fuel can be reduced.

Owner:王志

Solid heat storage material, and preparation method and application thereof

The invention belongs to the field of high temperature materials, and in particular, relates to a solid heat storage material, and a preparation method and an application thereof. The solid heat storage material comprises the following raw materials in parts by weight: 5-95 parts of iron ore, 5-50 parts of magnesium iron bricks, 5-20 parts of iron scales, 5-20 parts of a silicon carbide dedusting powder, 1-20 parts of aluminum nitride, 1-5 parts of beryllium nitride, 0.5-5 parts of boron mud, 1-2.5 parts of sodium hexametaphosphate, 1-2 parts of a magnesium aluminum high temperature cementing agent and 1-4 parts of water. The material is low in cost and high in specific heat; and the value of the thermal conductivity coefficient is adjusted according to different ingredient ratios, so as to meet the requirements of different heat storage devices.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

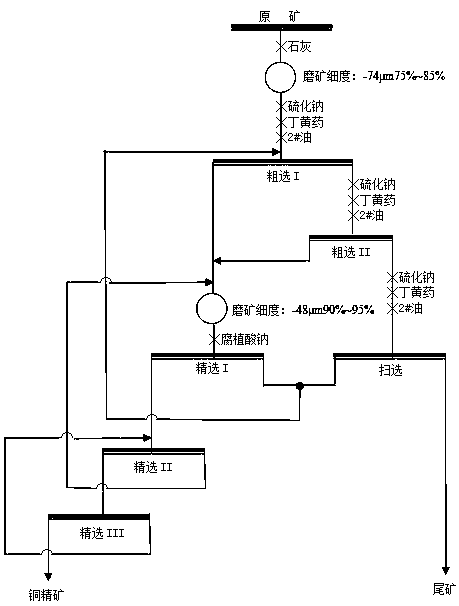

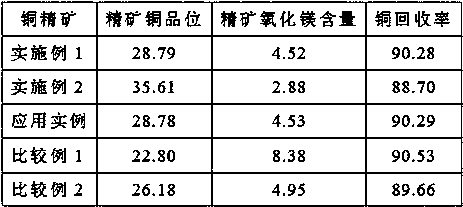

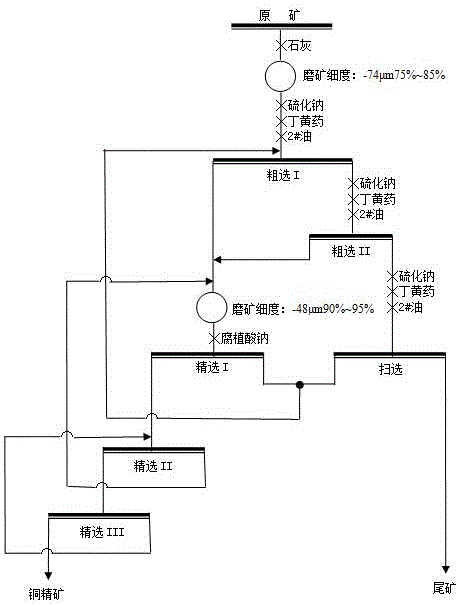

A beneficiation process for reducing magnesium oxide content in copper sulfide ore flotation concentrate

The invention relates to a mineral processing technology capable of reducing the content of magnesium oxide in flotation concentrates of sulphide copper ores, and belongs to the technical field of mineral processing. The method comprises the following four steps: ore grinding, flotation, regrinding and concentration. Compared with the prior art, the mineral processing technology has the characteristics that sodium humate is used as an inhibitor of dolomite, the use amount of the sodium humate is small, but the inhibition effect is high; and a chemicals adding mode of regrinding copper rough concentrates and then adding the sodium humate in concentration is adopted, selectivity of the inhibition effect can be improved, and influence to recycling of copper minerals is small. The flotation agent used in the mineral processing technology is non-toxic or has low toxicity, is environmentally friendly, and is easy to popularize and use.

Owner:YUXI MINING +1

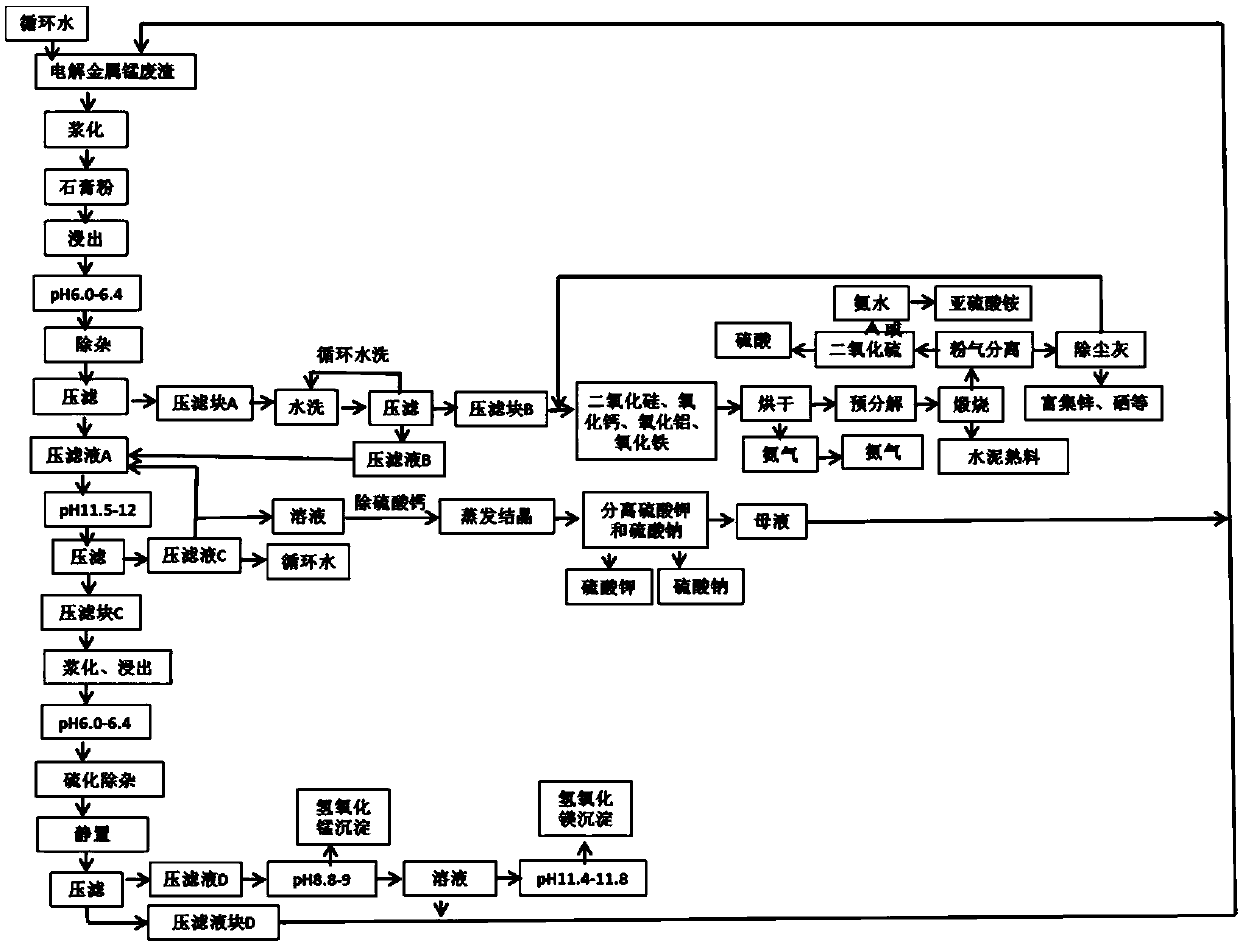

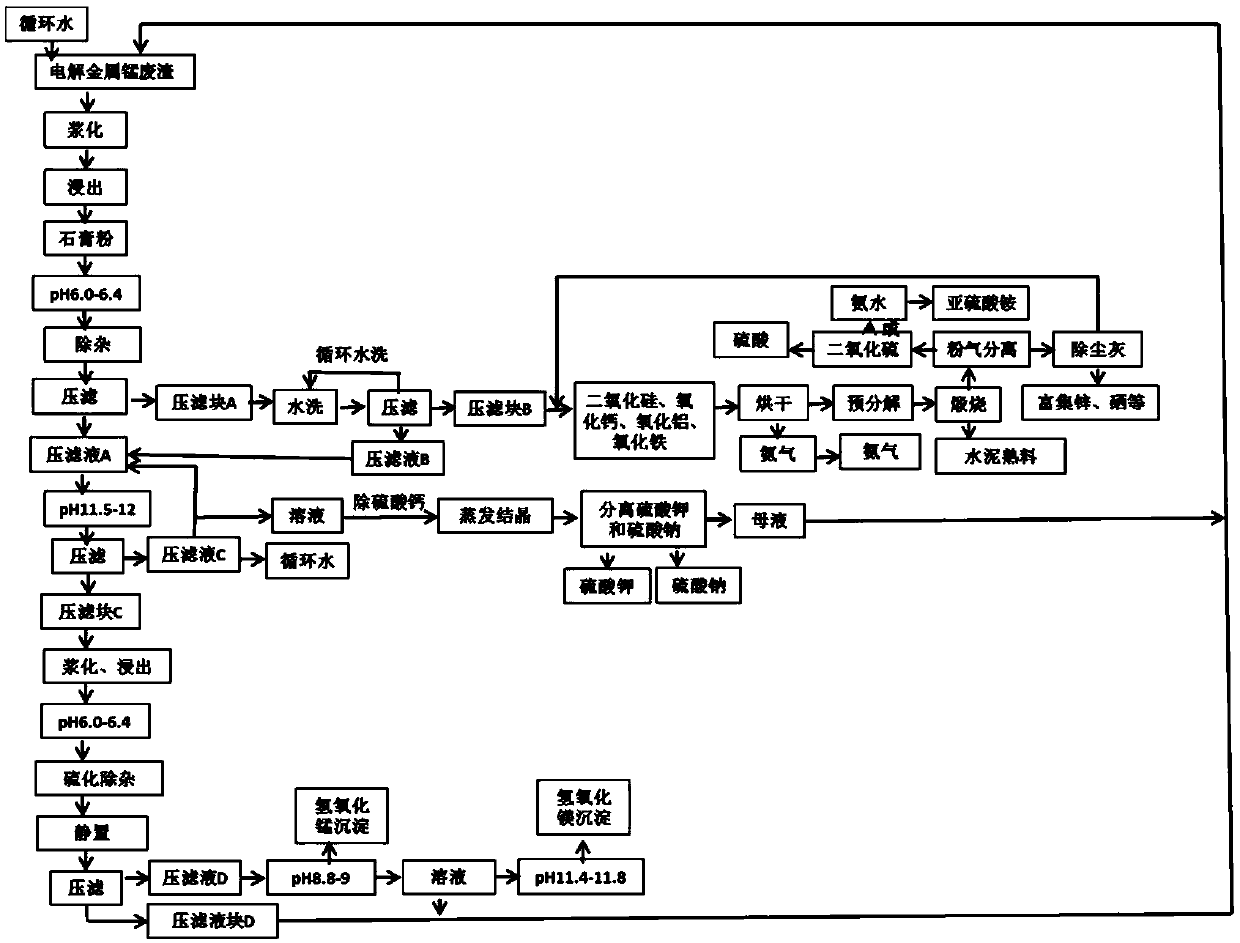

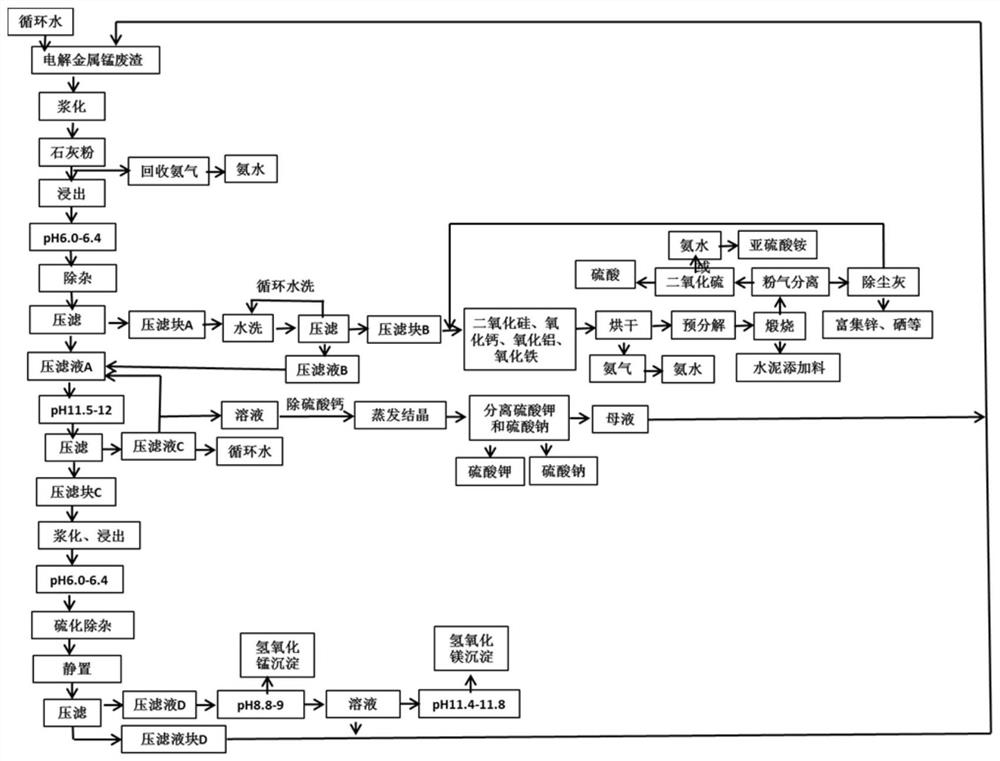

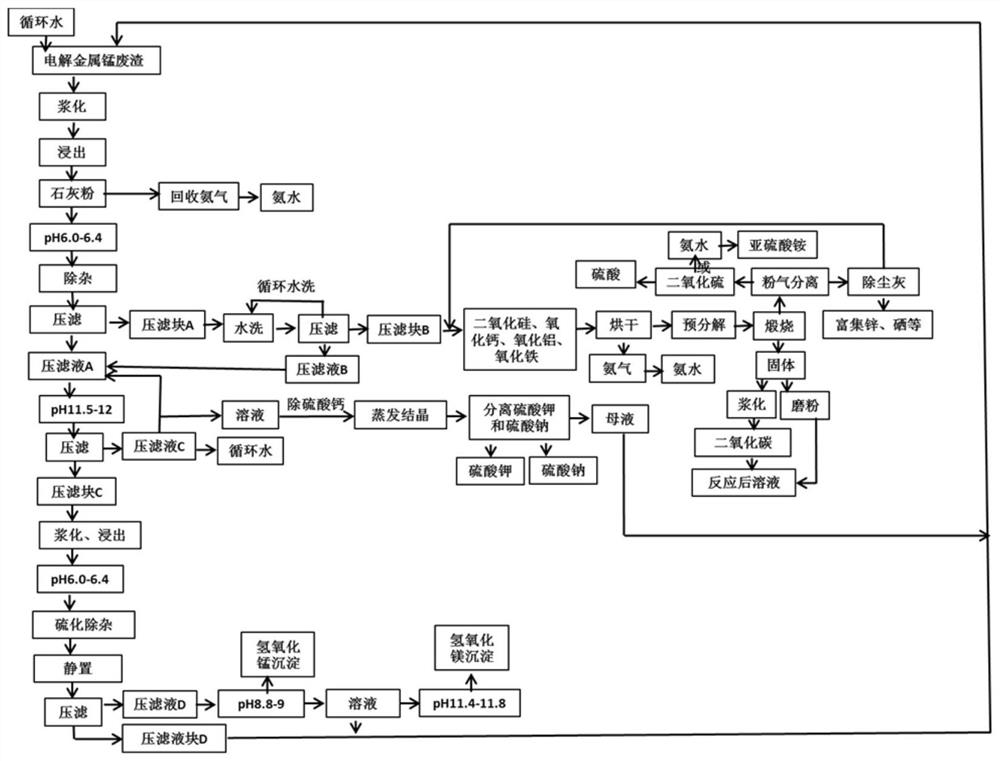

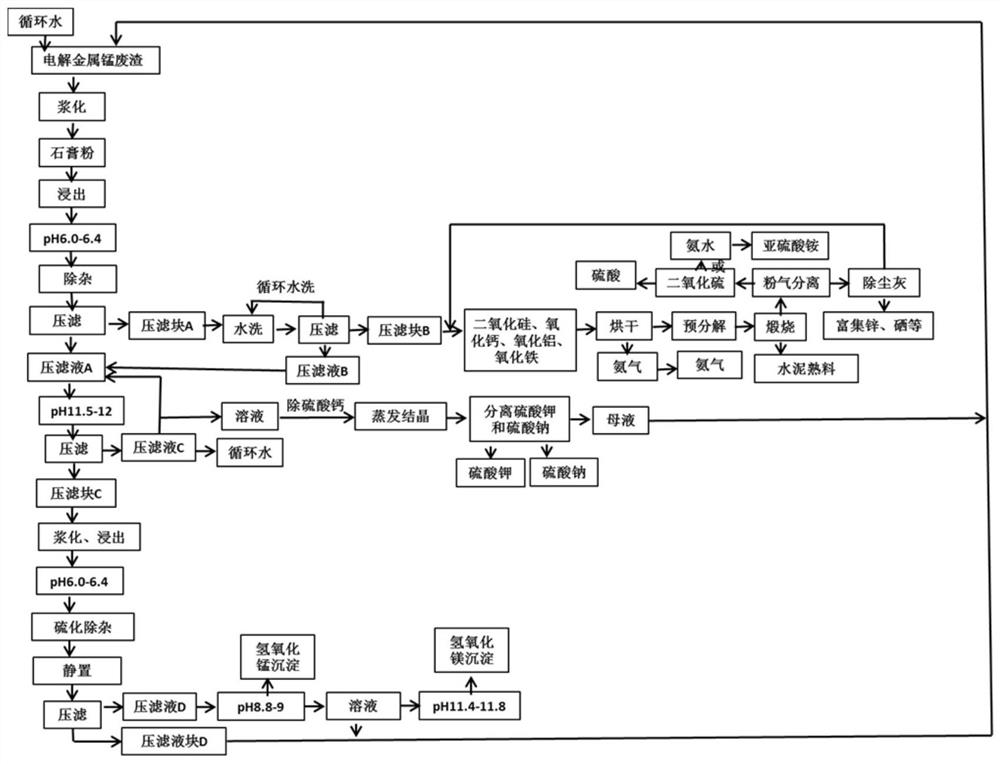

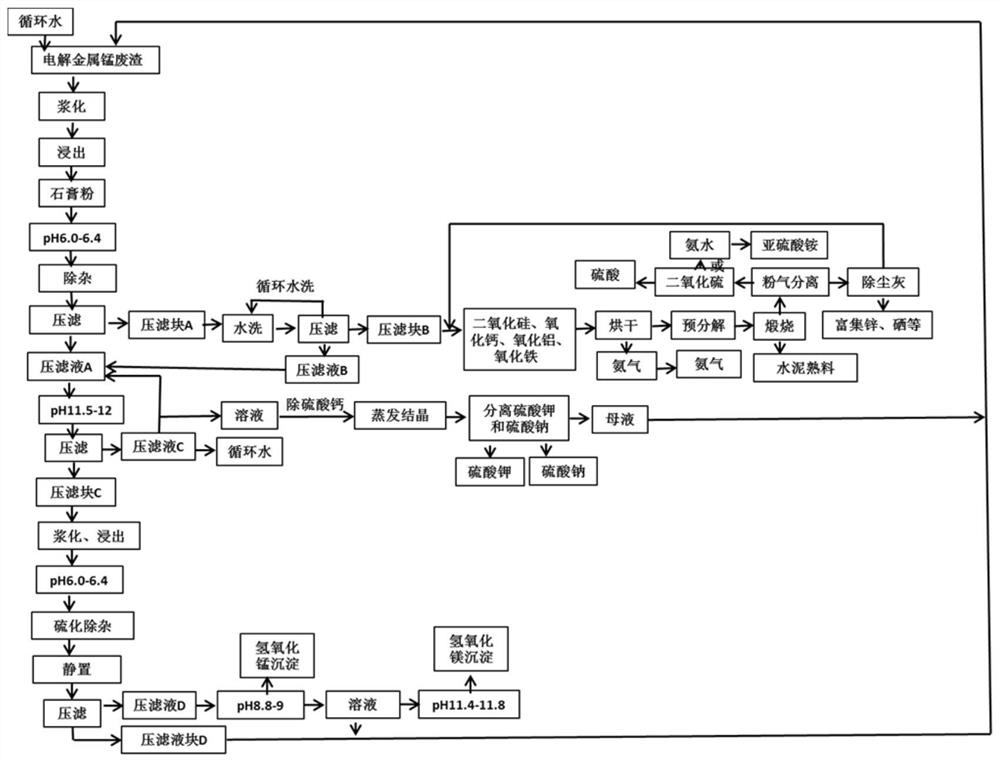

Method for combining electrolytic manganese metal waste residues and gypsum to produce cement clinker and ammonium hydroxide

ActiveCN110732543AImprove recycling ratesEnable recyclingSolid waste disposalElectrolysisClinker (waste)

The invention relates to a treatment method of electrolytic manganese metal waste residues. The treatment method comprises the following steps: A, grinding gypsum or drying calcined gypsum and then grinding to obtain gypsum powder; B, slurrying the electrolytic manganese metal waste residues, leaching, and adding the gypsum powder; adjusting the pH of a solution to 6.0-6.4, removing iron, carryingout filter pressing to obtain a filter pressing block A and a filter pressing solution A, washing the filter pressing block A with water, and then carrying out filter pressing to obtain a filter pressing block B and a filter pressing solution B; adjusting the pH of the filter pressing solution A to 11.5-12, and carrying out filter pressing to obtain a filter pressing block C and a filter pressingsolution C; C, adding silicon dioxide, calcium oxide, aluminum oxide and iron oxide into the filter pressing block B, drying, pre-decomposing, and calcining to obtain cement clinker; D, slurrying thefilter pressing block C, leaching, adjusting the pH to 6.0-6.4, removing impurities, standing, and carrying out filter pressing to obtain a filter pressing block D and a filter pressing solution D, adding ammonia water into the filter pressing solution D to adjust the pH to 8.8-9, and continuously adding an ammonia water solution to adjust the pH to 11.4-11.8. The method realizes recycling of resources.

Owner:庞炼红

Method for utilizing carbonate type middle-low-grade phosphorite to manufacture phosphate concentrate

ActiveCN102745658ASimple processEasy to operateRaw phosphate material treatmentLower gradePhosphorite

The invention discloses a method for utilizing carbonate type middle-low-grade phosphorite to manufacture phosphate concentrate, and the method comprises the following steps of: taking the carbonate type middle-low-grade phosphorite as a raw material; and crushing, roasting, digesting, carbonizing and separating to obtain the phosphate concentrate. The method disclosed by the invention can utilize the carbonate type middle-low-grade phosphorite to manufacture the phosphate concentrate and has the characteristics of simple process flow, easiness for operation of reaction, high phosphorus recycling rate and low content of magnesium oxide in the phosphate concentrate; and the invention provides an effective manner to utilize the carbonate-type middle-low-grade phosphorite.

Owner:WENGFU (GRP) CO LTD

A kind of solid heat storage material and its preparation method and application

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Method for utilizing carbonate type middle-low-grade phosphorite to manufacture phosphate concentrate

ActiveCN102745658BSimple processEasy to operateRaw phosphate material treatmentLower gradePhosphorite

The invention discloses a method for utilizing carbonate type middle-low-grade phosphorite to manufacture phosphate concentrate, and the method comprises the following steps of: taking the carbonate type middle-low-grade phosphorite as a raw material; and crushing, roasting, digesting, carbonizing and separating to obtain the phosphate concentrate. The method disclosed by the invention can utilize the carbonate type middle-low-grade phosphorite to manufacture the phosphate concentrate and has the characteristics of simple process flow, easiness for operation of reaction, high phosphorus recycling rate and low content of magnesium oxide in the phosphate concentrate; and the invention provides an effective manner to utilize the carbonate-type middle-low-grade phosphorite.

Owner:WENGFU (GRP) CO LTD

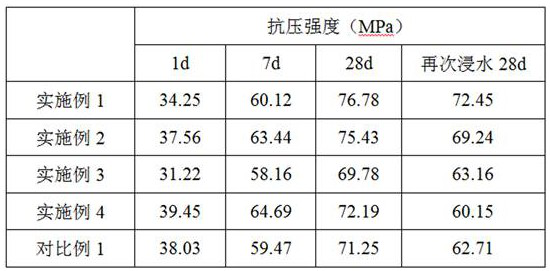

Magnesium phosphate cement containing C4AF solid solution and preparation method

ActiveCN113880476AReduce magnesium oxide contentReduce contentMagnesium phosphateMagnesium orthophosphate

The invention discloses magnesium phosphate cement containing a C4AF solid solution and a preparation method thereof. The magnesium phosphate cement is prepared from the following raw materials in parts by weight: 30-40 parts of the C4AF solid solution, 40-50 parts of MgO, 15-20 parts of phosphate, 0-5 parts of boric oxide or 5-10 parts of borax. The composition range of the final mineral phase of the cement is determined, corresponding minerals can be directly combined for preparation, the C4AF solid solution and the intermediate component of MgO can be prepared by adopting a high-temperature mode, and finally, the intermediate component is prepared with a proper amount of phosphate and a boron-containing substance. The cement composition can endow the magnesium phosphate cement with excellent hydration hardening performance, and the water resistance can be greatly improved. Meanwhile, the source of raw materials needed for preparing the C4AF solid solution is wide, the requirement of magnesium phosphate cement for dead-burned MgO is reduced, and carbon peak reaching / carbon neutralization can be achieved easily.

Owner:FUZHOU UNIV

Mineral processing technology capable of reducing content of magnesium oxide in flotation concentrates of sulphide copper ores

The invention relates to a mineral processing technology capable of reducing the content of magnesium oxide in flotation concentrates of sulphide copper ores, and belongs to the technical field of mineral processing. The method comprises the following four steps: ore grinding, flotation, regrinding and concentration. Compared with the prior art, the mineral processing technology has the characteristics that sodium humate is used as an inhibitor of dolomite, the use amount of the sodium humate is small, but the inhibition effect is high; and a chemicals adding mode of regrinding copper rough concentrates and then adding the sodium humate in concentration is adopted, selectivity of the inhibition effect can be improved, and influence to recycling of copper minerals is small. The flotation agent used in the mineral processing technology is non-toxic or has low toxicity, is environmentally friendly, and is easy to popularize and use.

Owner:YUXI MINING +1

Method for co-producing manganese hydroxide and sulfuric acid or ammonium sulfite by electrolytic manganese waste slag

ActiveCN110734093BReduce contentQuality improvementSulfur compoundsAmmonium sulfitesFiltrationSulfate

The invention relates to a method for co-producing manganese hydroxide and sulfuric acid or ammonium sulfite with electrolytic manganese waste slag, comprising the following steps: A. slurrying electrolytic manganese metal waste slag, leaching, adjusting pH to 6.0-6.4, removing iron, and pressing filtration to obtain Press filter block A and press filter liquid A, press filter press block A after water washing, obtain press filter block B and press filter liquid B; Regulate the pH of press filter liquid A to 11.5-12, press filter, obtain press filter block C and press filter liquid C, press filtrate C circulation treatment, after potassium and sodium enrichment, remove calcium sulfate, evaporate and crystallize, separate potassium sulfate and sodium sulfate; B. calculate according to production needs and add the required substances to the press block B, dry Drying, pre-decomposition, and calcination to obtain cement additives or solids. The sulfur dioxide produced by calcination is separated from the dedusting ash for powder gas separation. The sulfur dioxide gas is used to make sulfuric acid. The dedusting ash and filter press block B are calcined together to enrich selenium and zinc; C. Slurry the filter block C, leaching, adjust the pH to 6.0-6.4, remove impurities, stand still, and press filter to obtain the filter block D and the filter liquid D, adjust the pH of the filter liquid D to 8.8-9, and continue to adjust the solution pH to 11.4‑11.8. This method realizes the joint output of multiple products.

Owner:庞炼红

A kind of beneficiation method for separating copper-nickel sulfide ore and serpentine gangue

ActiveCN105413877BIncrease buoyancyWeaken heterogeneous condensationFlotationPyrophosphateSulfide minerals

The invention relates to a beneficiation method for separating copper-nickel sulfide ore from serpentine gangue. The beneficiation method comprises the following steps: when the copper-nickel sulfide ore is roughly concentrated, a polymer reagent poloxamer which can be adsorbed onto the surface of sulfide mineral through hydrophobic interaction but cannot be adsorbed onto the surface of the serpentine gangue is added; ore pulp is dispersed through the steric hindrance of the polymer reagent, the heterocoagulation of serpentine and sulfide minerals is eliminated, the inhibiting effect of serpentine on the sulfide minerals is reduced, and the recovery rate of rough concentration of the copper-nickel sulfide ore containing serpentine is increased; for rough copper-nickel sulfide concentrate obtained through rough concentration, regulators sodium pyrophosphate and carboxymethyl cellulose are added to further disperse and inhibit gangue minerals; meanwhile a collector is added before the regulators are added, so that the collector is adsorbed onto the surfaces of sulfide minerals to protect the sulfide minerals; the selective inhibition to the gangue minerals is realized, and therefore the concentrate grade is increased. The beneficiation method solves the problems that the reagent dosage is large, valuable minerals are inhibited and tailings hardly sedimentate in the traditional method.

Owner:JIANGXI UNIV OF SCI & TECH

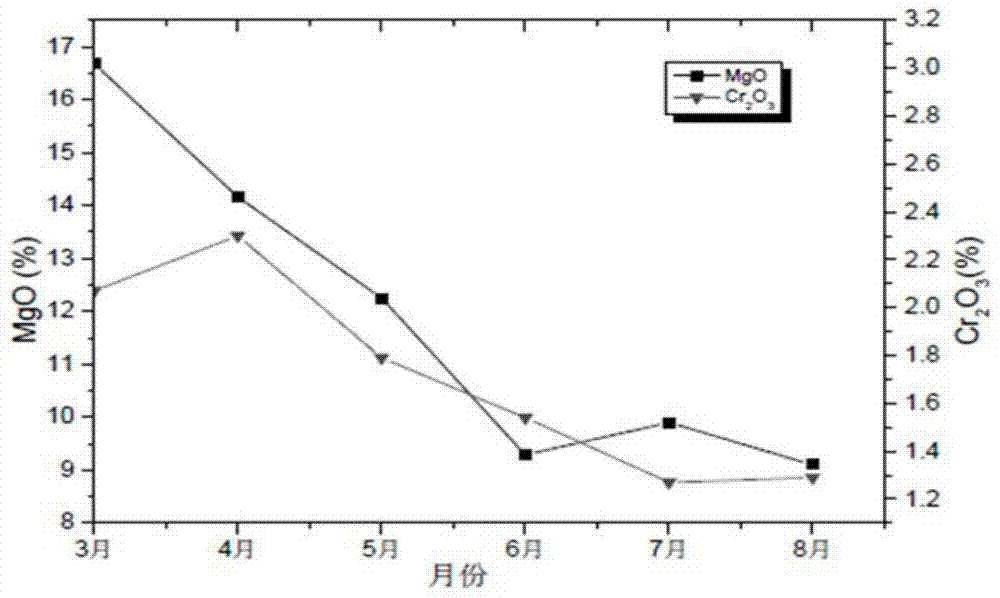

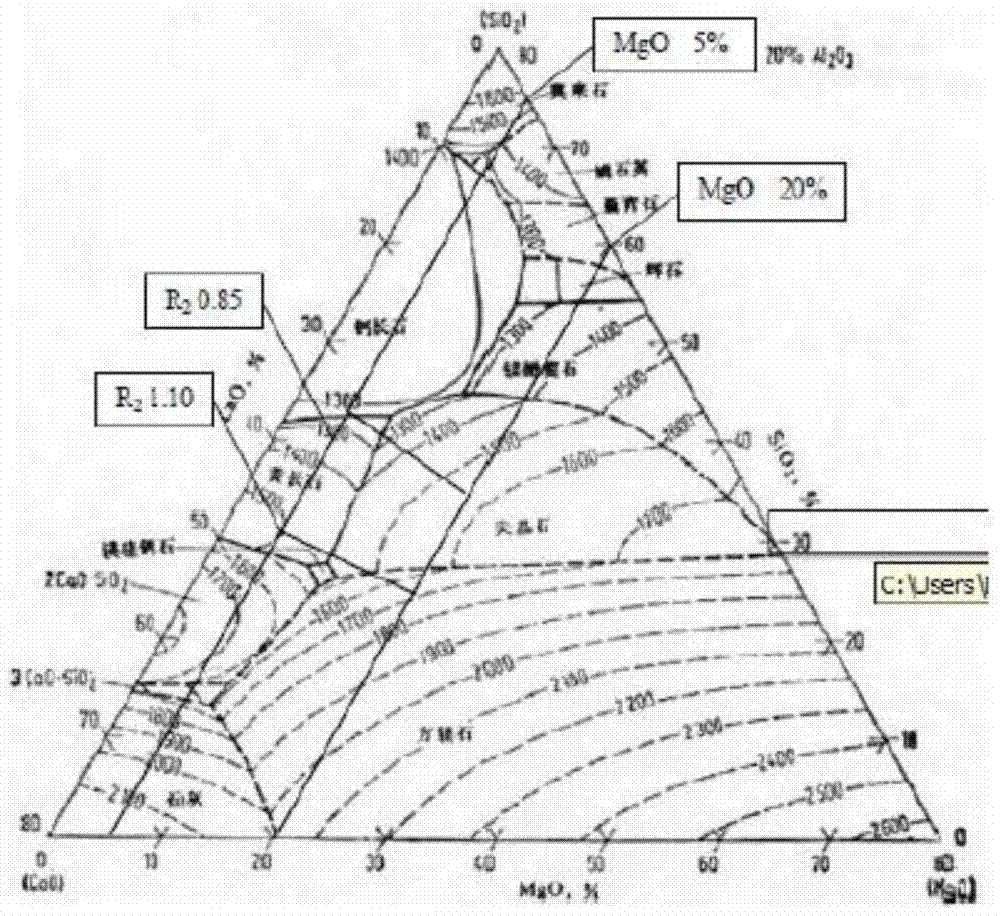

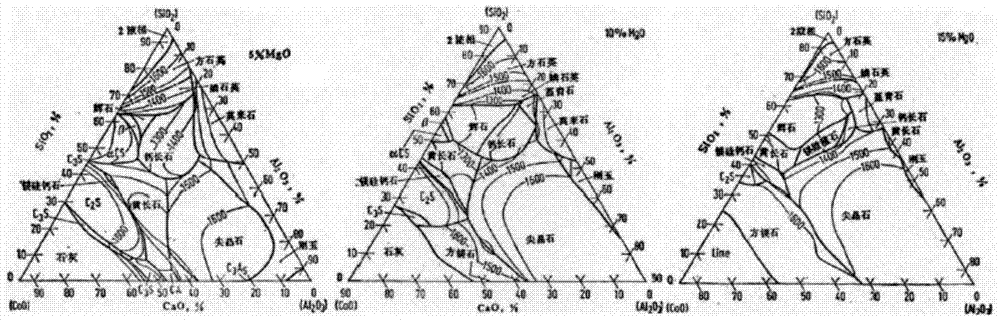

Method for Smelting Laterite Nickel Ore in Blast Furnace for Reducing Magnesium Oxide Content in Slag

The invention discloses a method for smelting laterite nickel ore in a blast furnace which can reduce the content of magnesia in slag. The method is to sieve the raw laterite nickel ore with a 25mm sieve first, and then crush and sieve the oversize material with a 25mm sieve. The sintered ore is sent to the blast furnace for smelting; in the blast furnace slag removal process, the steelmaking converter refining reduced slag is sprayed into the blast furnace slag for secondary slagging, and the injection amount of the steelmaking converter refining reducing slag is less than 1% of the mass of the blast furnace slag / 12. The invention effectively reduces the MgO content of the blast furnace slag from the original 16-20% to below 10%, can reduce the content of Cr2O3 and FeO, improves the desulfurization effect of the blast furnace, saves lime for steelmaking production, and reduces the production cost of the metallurgical process , to ensure the quality of molten steel, and at the same time, the blast furnace slag can be used in a large amount in the cement industry, with remarkable economic and social benefits.

Owner:SICHUAN JINGUANG IND GRP

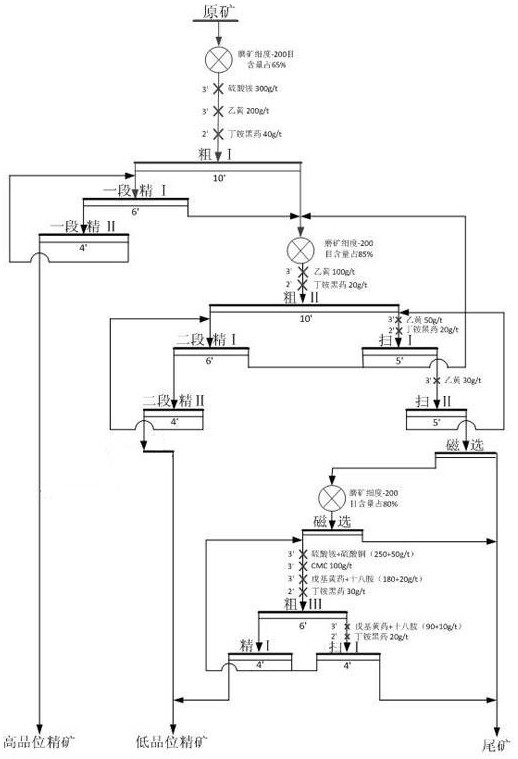

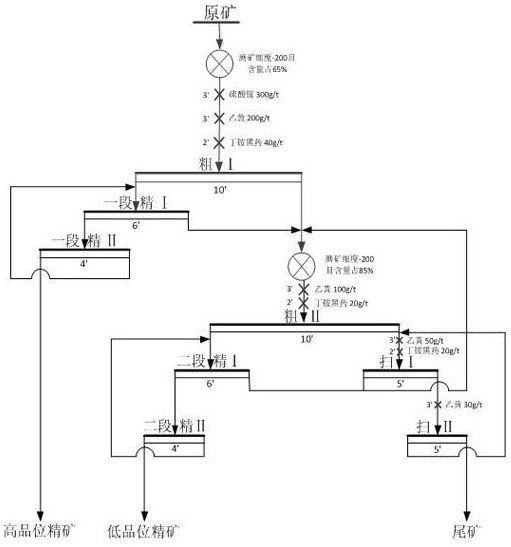

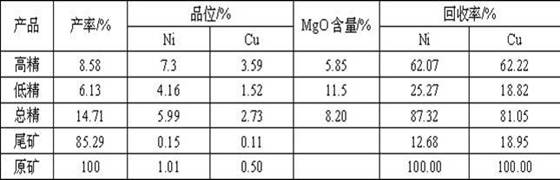

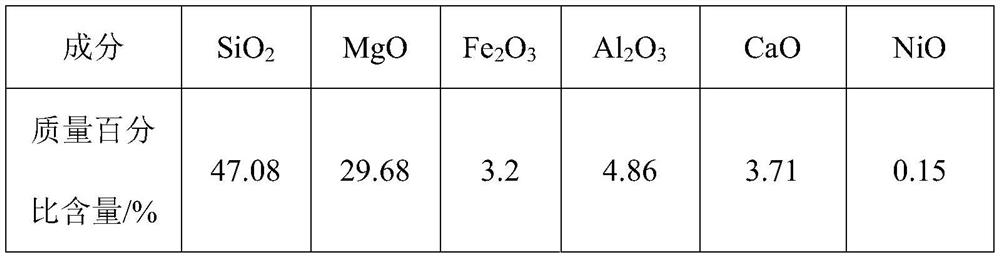

A kind of beneficiation method of copper-nickel sulfide ore

ActiveCN112474030BHigh recovery ratePromote enrichmentFlotationMagnetic separationNickel sulfideCopper sulfide

Owner:JINCHUAN GROUP LIMITED

A kind of method for reducing magnesium oxide in nickel-iron slag and method for preparing slag wool

ActiveCN112322903BReduce magnesium oxide contentImprove reaction efficiencyGlass making apparatusMagnesium chloridesSlagAqueous solution

The invention discloses a method for reducing magnesium oxide in ferronickel slag and a method for preparing slag wool. In the process of making mineral wool from molten ferronickel slag, impregnated carbon is added during the slag discharge process of ferronickel smelting furnace, and the ferronickel slag is treated with impregnated carbon. During the transfer process, the molten nickel iron slag and the impregnated carbon are fully mixed and kept in a holding furnace to reduce the magnesium oxide content in the nickel iron slag; wherein, the preparation process of the impregnated carbon includes: fully mixing the calcium chloride aqueous solution with the carbonaceous material , and then perform solid-liquid separation and drying to obtain impregnated carbon; the amount of impregnated carbon used is determined according to the magnesium oxide content in the nickel-iron slag. The invention can reduce the magnesium oxide content in the ferronickel smelting slag, especially can reduce the magnesium oxide in the free state in the ferronickel smelting slag, is beneficial to improve the quality of slag wool, and is a great reduction in the ferronickel slag containing high magnesium oxide. And high-value utilization has created conditions, and can also realize the recovery of magnesium in nickel-iron slag.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

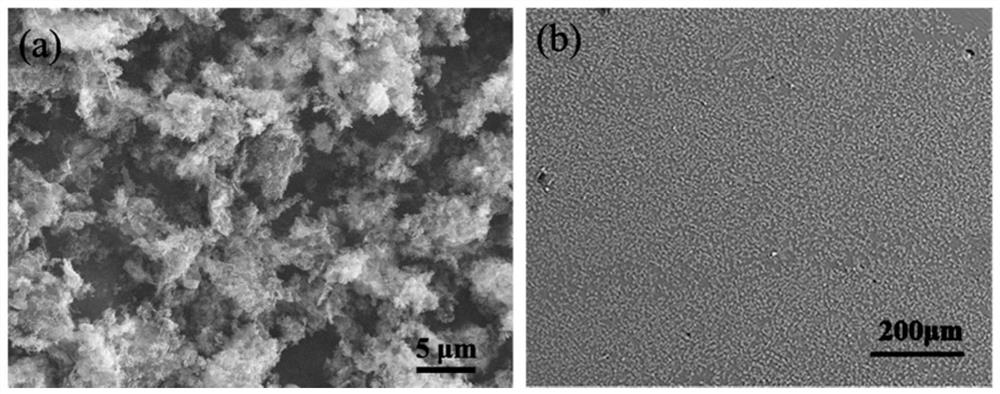

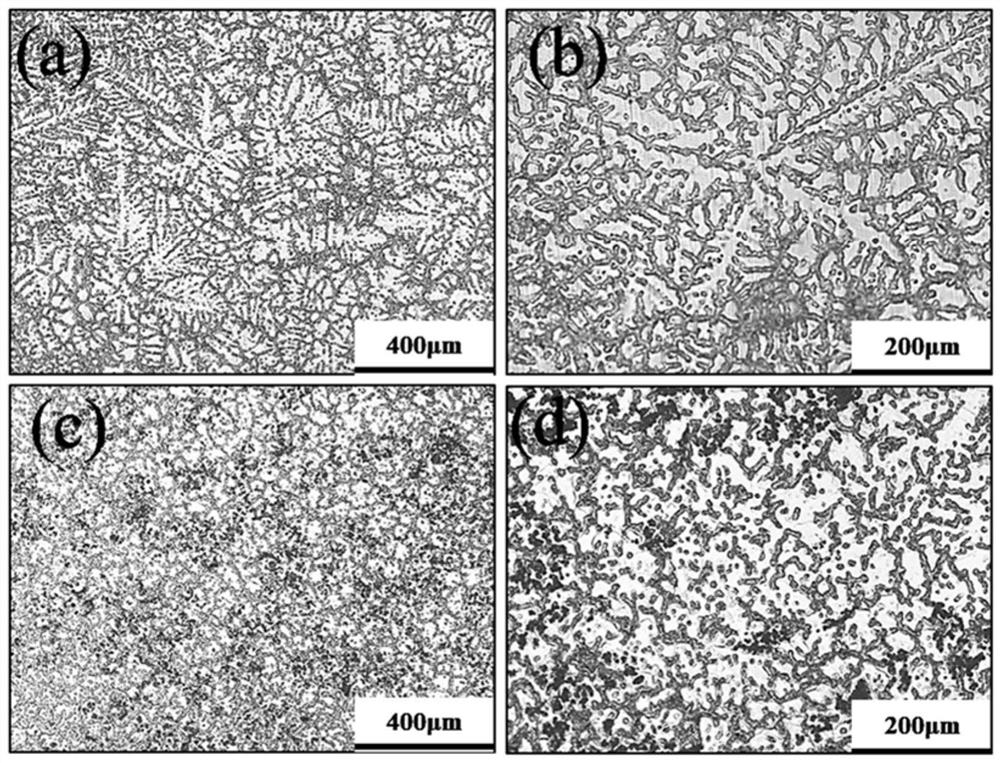

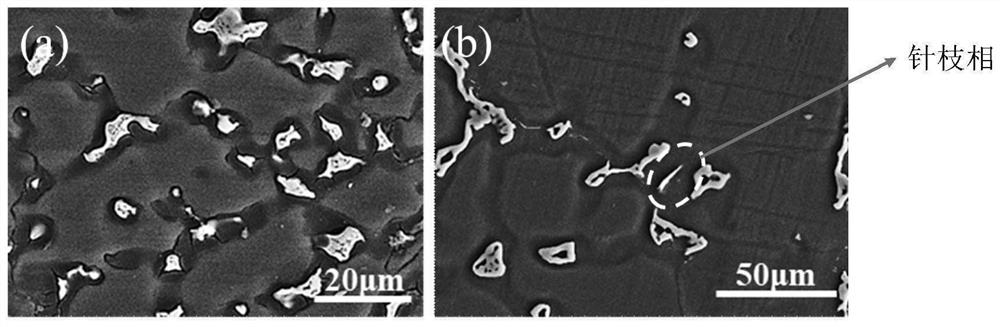

A kind of magnesium alloy graphene modifier and its preparation method and application

The invention relates to a magnesium alloy graphene modifier and a preparation method and application thereof. The method is as follows: heating and melting magnesium in a crucible to obtain a magnesium melt; introducing air or a mixed gas formed by mixing oxygen and rare gas at the top of the crucible, and the volume content of oxygen in the mixed gas is 10-25%; Continuously feed CO into the magnesium melt for magnesia thermal reaction until the mass percentage of graphene generated in the magnesium melt is 0.1-10%, and a composite melt is obtained; a magnesia thermal reaction occurs between CO and the magnesium melt At the same time, make the temperature of the top of the crucible more than 300°C, and ignite the escaped CO that did not participate in the reaction at the top of the crucible; let the composite melt stand still, and then make it solidify to obtain a magnesium alloy graphene modifier. The invention effectively controls the content of magnesium oxide in the reaction product, can not only realize the grain refinement of the matrix magnesium, but also change the morphology of the eutectic structure, so that the casting can obtain ideal mechanical properties.

Owner:HARBIN INST OF TECH

Preparation method of metal magnesium by magnesium-containing mineral and equipment adopted by preparation method

The invention belongs to the field of metal material, and relates to a preparation method of metal magnesium by magnesium-containing mineral and equipment adopted by the preparation method. The method comprises the following steps of: converting useful components in magnesium-containing mineral into high-activity magnesium oxide, and under the effects of high temperature and a catalytic midbody, enabling the high-activity magnesium oxide to have chlorination reaction with chlorine and carbon monoxide, so that molten magnesium chloride anhydrous is generated; and mixing the molten magnesium chloride anhydrous with the other molten inorganic salt according to a certain proportion to be taken as electrolyte, and leading the electrolyte into a multi-polarity electrolytic cell to electrolyze, so that the metal magnesium is prepared. The technology adopts the fluidzed chlorination bed and the multi-polarity electrolytic cell of the novel equipment, and adds the midbody of catalytic reaction in the process of chlorination, so that the preparation method is more high-efficiency and energy-saving compared with the conventional method. The waste gas and the waste residue generated in the whole process are treated to be reused, so that the preparation method and the equipment are environment-friendly.

Owner:UNIV OF SCI & TECH BEIJING

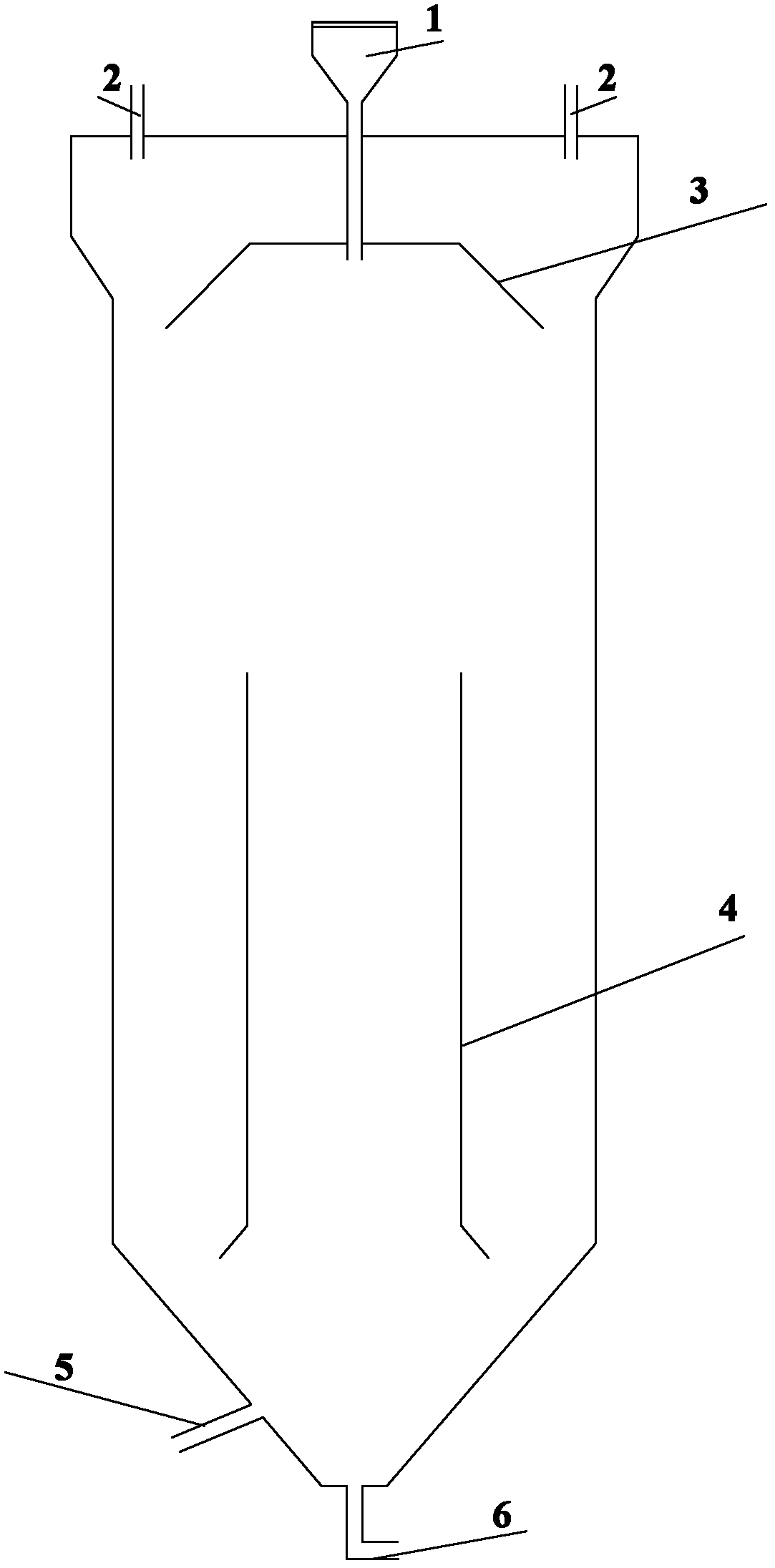

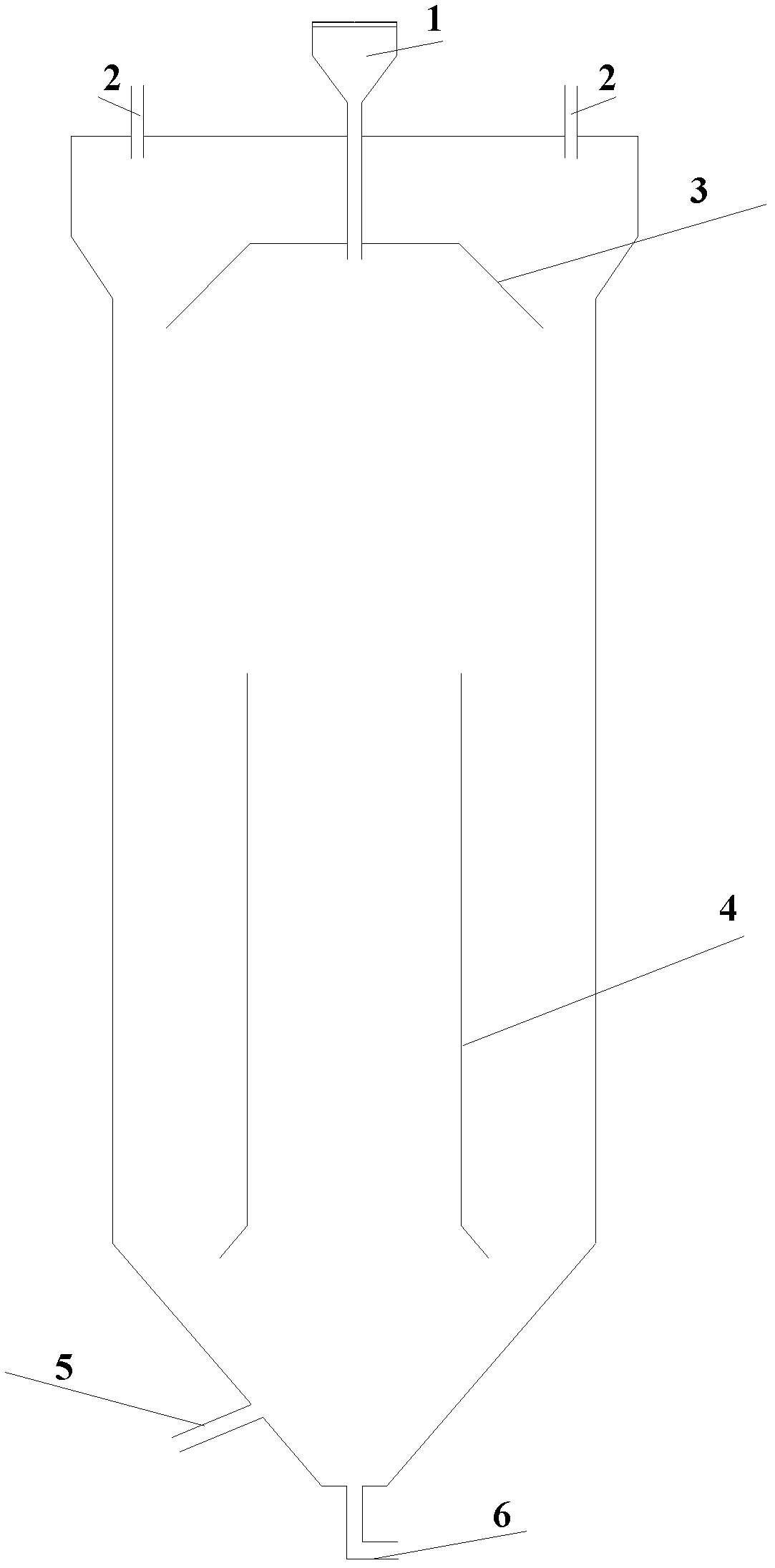

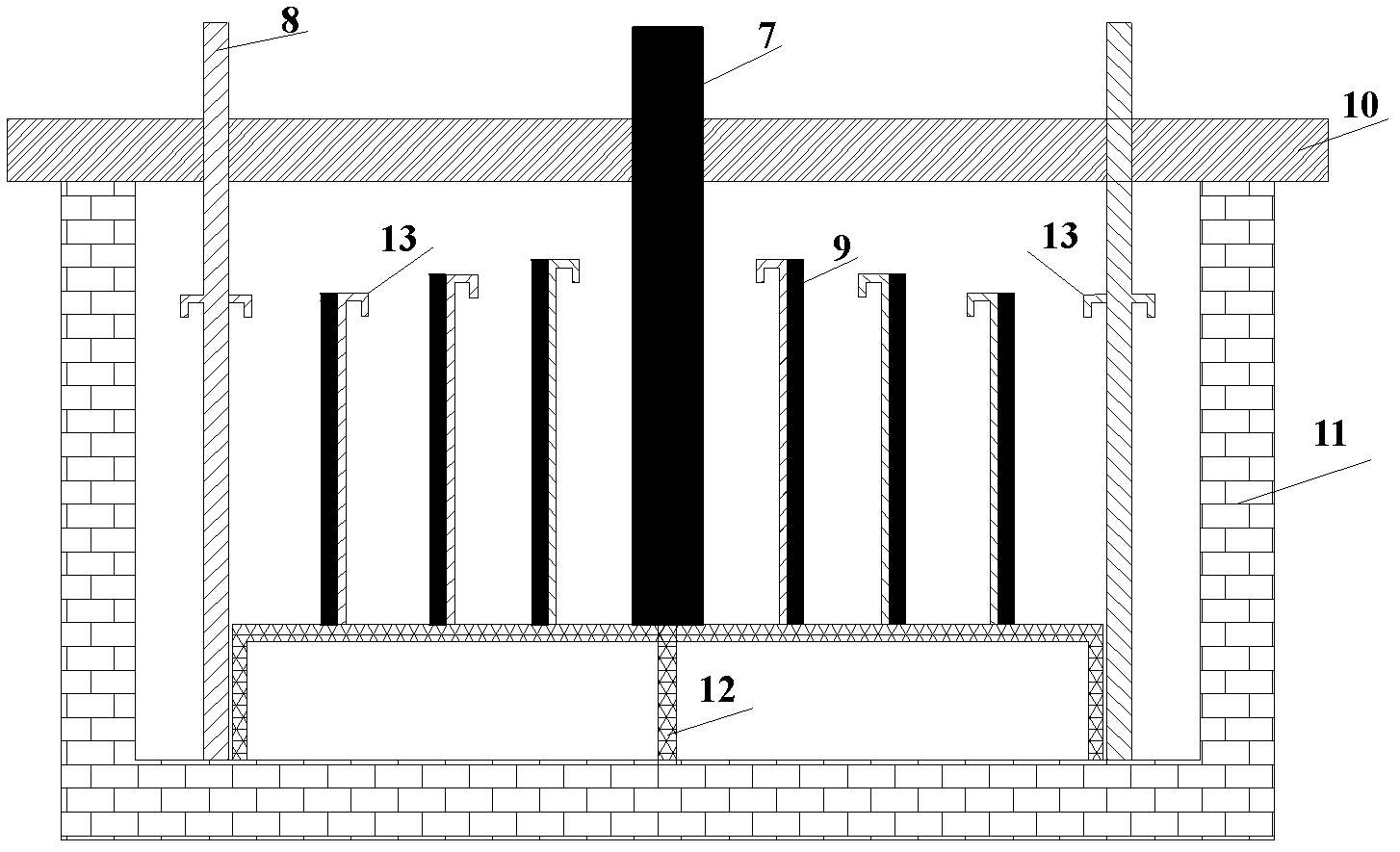

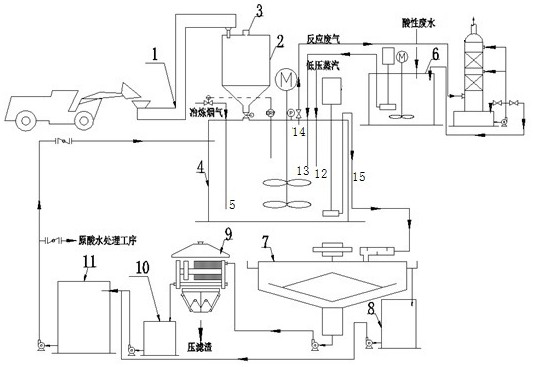

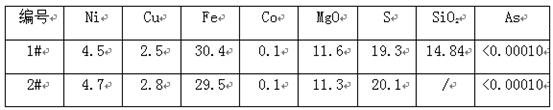

Production system and production method for reducing magnesium content in nickel concentrate

PendingCN113881843AReduce processing costsReduce magnesium oxide contentGas treatmentDispersed particle separationHigh concentrationCobalt

The invention discloses a production system for reducing magnesium content in nickel concentrate. The production system comprises a concentrate elevator, a concentrate quantitative stock bin, a magnesium reduction reactor, a thickener, a supernatant tank, a filter press, a filtrate storage tank, a magnesium-reduced liquid tank and a waste gas absorption tower. A production method comprises the following steps: (1) material adding; (2) material input; (3) steam introduction; (4) material reaction; (5) material discharge; and (6) material reuse. By introducing a high-concentration SO2 reduction environment in smelting flue gas, the reaction potential of acidic wastewater and the concentrate is controlled, the content of magnesium oxide in the concentrate is selectively reduced, and the leaching rate of valuable metals such as nickel, copper and cobalt in the concentrate is reduced to the maximum extent.

Owner:JINCHUAN GROUP LIMITED +1

A kind of graphene-reinforced magnesium-based composite material and preparation method thereof

ActiveCN113278840BIncrease contentHigh strengthExtrusion control devicesMagnesium matrix compositeCrucible

Owner:HARBIN INST OF TECH

A kind of magnesia composite bentonite for pelletizing

The invention provides magnesium composite bentonite for pelletizing. The bentonite comprises the following components in percentage by weight: 20-30% of light-burned magnesite powder, 60-70% of bentonite, 3-5% of sodium carbonate, 2-3% of calcium ricinoleate and 3-5% of calcium chloride; the magnesium composite bentonite comprises the following main chemical components in percentage by weight: 25-30% of MgO, 45-55% of SiO2, and less than 15% of water. By adopting the magnesium composite bentonite disclosed by the invention, the MgO content of a pellet ore can be increased to 1.5%, the mechanical strength of the pellet ore can be increased by 1.5-2%, the initial softening temperature of the pellet ore can be increased by 150-200 DEG C, the MgO content of a sintering ore can be reduced relatively, the quality of the sintering ore can be improved, and the consumption of a sintering fuel can be reduced.

Owner:王志

A kind of non-autoclaved aerated concrete prepared by using lithium slag and nickel slag and its preparation method

The invention relates to non-autoclaved aerated concrete prepared by utilizing lithium slag and nickel slag and a preparation method of the non-autoclaved aerated concrete. The aerated concrete is prepared from the following components in parts by weight: 40 to 80 parts of lithium slag powder, 20 to 60 parts of nickel slag powder, 6 to 20 parts of sodium hydroxide solution, 12 to 30 parts of sodium silicate solution, 0.005 to 0.05 part of aluminum powder, and 0.005 to 0.02 part of foam stabilizer. The preparation method comprises the steps of adding aluminum powder for foaming after uniformly stirring the lithium slag powder, nickel slag powder, sodium hydroxide solution, and sodium silicate solution in accordance with a certain proportion, cutting after curing for 4-6 hours at a temperature of 60 to 80 DEG C, stacking and curing for 7 days. The process is simple, industrial byproducts lithium slag and nickel slag are fully utilized, the high-temperature autoclave curing regime is not used in the whole process, the energy consumption is reduced, and the economic, environmental and social benefits are good.

Owner:SOUTHEAST UNIV

Method for reducing magnesium oxide in ferronickel slag and method for preparing mineral wool

ActiveCN112322903AImprove reaction efficiencyReduce magnesium oxide contentGlass making apparatusMagnesium chloridesSlagMagnesium

The invention discloses a method for reducing magnesium oxide in ferronickel slag and a method for preparing mineral wool. In the process of preparing mineral wool by using molten ferronickel slag, impregnated carbon is added in the slagging process of a ferronickel smelting furnace, the molten ferronickel slag and the impregnated carbon are fully mixed in the transfer process of the ferronickel slag, and heat preservation is carried out in a heat preservation furnace, so that the content of magnesium oxide in the ferronickel slag is reduced; wherein the impregnated carbon preparation processcomprises the following steps: fully mixing a calcium chloride aqueous solution with a carbonaceous material, and then carrying out solid-liquid separation and drying to obtain impregnated carbon; andthe usage amount of the impregnated carbon is determined according to the content of magnesium oxide in the ferronickel slag. According to the method, the content of magnesium oxide in the ferronickel smelting slag can be reduced, particularly, magnesium oxide in a free state in the ferronickel smelting slag can be reduced, the quality of slag wool can be improved, conditions are created for large reduction and high-value utilization of the ferronickel slag containing high magnesium oxide, and recovery of magnesium in the ferronickel slag can also be achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for joint production of cement clinker and ammonia water by electrolytic manganese metal waste slag and gypsum

The invention relates to a treatment method for electrolytic manganese metal waste residue, comprising the following steps: A. Grinding raw gypsum or drying gypsum stone; 6.4, iron removal, press filtration, obtain press filter block A and press filter liquid A, press filter press after the press filter block A washes, obtain press filter block B and press filter liquid B; Adjust the pH of press filter liquid A to 11.5-12, press filter , to obtain press filter block C and press filtrate C; C. add silica, calcium oxide, aluminum oxide, iron oxide to press filter block B, dry, pre-decompose, and calcinate to obtain cement clinker; D. press filter block C slurrying, leaching, adjusting the pH to 6.0-6.4, removing impurities, standing still, and press-filtering to obtain the press-filter block D and press-filtrate D, adding ammonia water to the press-filter D to adjust the pH to 8.8-9, and continuing to add ammonia solution to adjust the pH to 11.4‑11.8. The method realizes the recovery and reuse of resources.

Owner:庞炼红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com