A kind of magnesia composite bentonite for pelletizing

A technology of bentonite and magnesia, which is applied in the field of magnesia composite bentonite, can solve the problems of reducing calcium ferrite content in sinter, reducing the mechanical strength of sinter, and high melting point of MgO, so as to strengthen blast furnace smelting, improve sinter quality, and reduce thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the following, the present invention will be further described in conjunction with the embodiments.

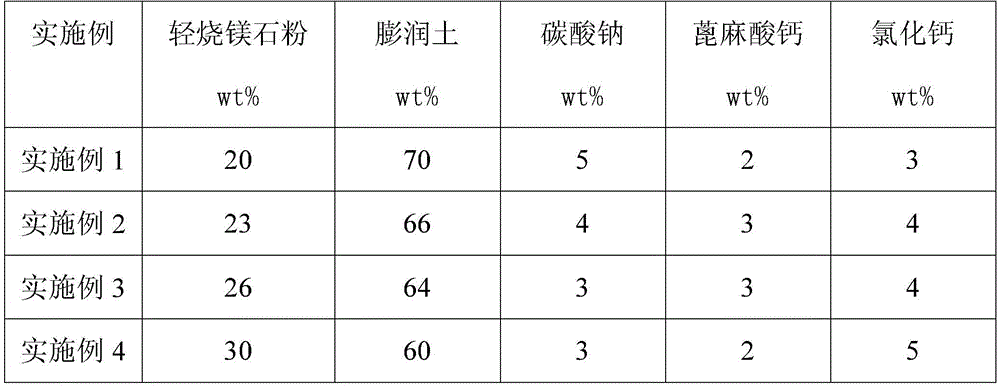

[0014] The components and wt% content of magnesia composite bentonite in the examples are shown in Table 1.

[0015] Example 1~4 Magnesium composite bentonite component wt% content table

[0016]

[0017] At the same time, the MgO and SiO in the magnesium composite bentonite should be controlled 2 And moisture to ensure that the content of the main chemical components is controlled within: 25-30% of MgO, SiO 2 45~55%, and moisture content <15%.

[0018] The specific compounding method of the magnesia composite bentonite of the present invention is:

[0019] According to the requirements of the blast furnace for the MgO content in the pellets, during the pellet batching process, the batching ratio is converted into weight kilograms, controlled by the electronic belt scale, and added to the pellets according to the ratio of 3.5 to 4.0% of the magnesium composite bentonite It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com