Production system and production method for reducing magnesium content in nickel concentrate

A technology of production system and magnesium content, applied in the field of metallurgy, can solve the problems of low economy, decline of concentrate grade, large amount of waste water, etc., achieve significant economic benefits, reduce treatment costs, and reduce treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

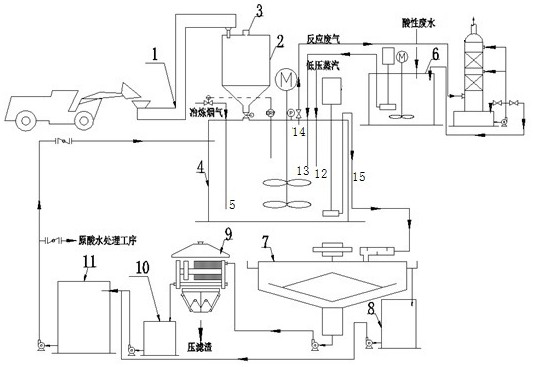

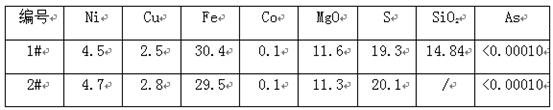

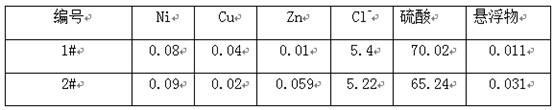

[0038] The high-magnesium-nickel concentrate is sent to the concentrate elevator 1 by a forklift, and the concentrate elevator 1 sends the concentrate to the concentrate quantitative silo 2 (the concentrate quantitative silo 2 is designed according to the acid-ore ratio of 4:1) ), stop feeding when the feed reaches the design height, and concentrate the ore for use; send the acid waste water to the design liquid level of the acid waste water tank 6, and measure the acidity 67g / L; open the agitator 4 of the magnesium reduction reactor for stirring, and open the flue gas exhaust Control valve, open acid waste water tank 6 acid waste water pump and concentrate quantitative silo 2 feeding valve, add high-magnesium nickel concentrate and acid waste water synchronously according to the acid-solid ratio 3.5-4:1, after the feeding is completed, close the flue gas exhaust Air control valve, concentrate quantitative silo 2 feeding valves, acid waste water tank 6 acid waste water pump, st...

Embodiment 2

[0043] The high-magnesium-nickel concentrate is sent to the concentrate elevator 1 by a forklift, and the concentrate elevator 1 sends the concentrate to the concentrate quantitative silo 2 (the concentrate quantitative silo 2 is designed according to the acid-ore ratio of 4:1) ), stop feeding when the feed reaches the design height, and concentrate the ore for use; send the acid waste water to the design liquid level of the acid waste water tank 6, measure the acidity 70g / L, and add the magnesium-reducing liquid appropriately when the acidity is too high; open the magnesium-reducing reactor 4 Stir with the agitator, open the flue gas exhaust control valve, open the acid waste water tank 6 acid waste water pump and the concentrate quantitative silo 2 feed valve, and simultaneously add high-magnesium-nickel concentrate and For acid waste water, after the feeding is completed, close the flue gas exhaust control valve, concentrate quantitative hopper 2 discharge valve, acid waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com