Method for co-producing manganese hydroxide and sulfuric acid or ammonium sulfite by electrolytic manganese waste slag

A technology for electrolytic manganese metal and ammonium sulfite, applied in the direction of manganese oxide/manganese hydroxide, alkali metal sulfite/sulfite, chemical instruments and methods, etc., can solve resource waste, affect water balance, and exceed the standard of magnesium content and other issues, to achieve stable production, reduce unit power consumption, and improve recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

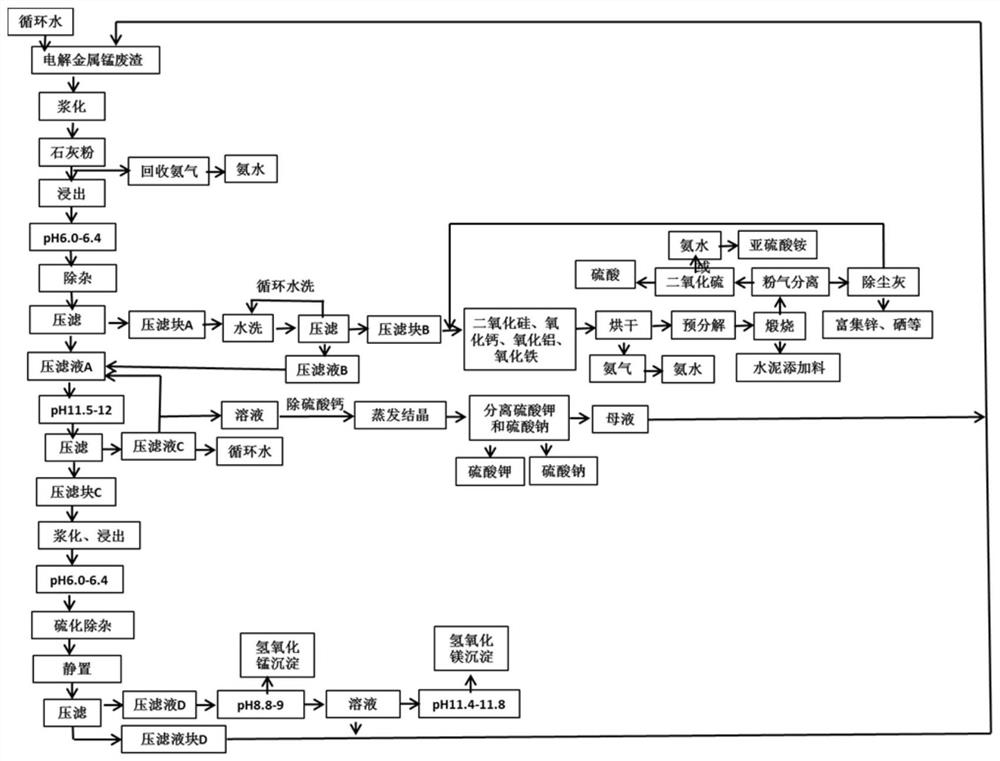

[0046] according to figure 1 The process flow shown is for treating electrolytic manganese metal waste slag, and the specific steps are:

[0047] A. Detect the content of manganese in the electrolytic manganese metal waste residue (according to "GB / T 8654.7-1988 Metal Manganese Chemical Analysis Method Potentiometric Titration Determination of Manganese Content", the manganese content is 6.6%; according to "GB / T 176-2017 "Cement Chemical Analysis Method" in the determination of calcium oxide in the potassium permanganate titration method to detect the content of calcium oxide in the waste residue, the measured calcium oxide content is 11.8%; according to "GB / T176-2008 Cement Chemical Analysis Method" The EDTA titration difference subtraction method (substitution method) in the method detects the content of magnesium oxide in the waste residue, and the content of magnesium oxide is measured to be 3.1%) and water is mixed according to the mass ratio of 1:5.7, and lime powder is ...

Embodiment 2

[0053] according to figure 1 The process flow shown is for treating electrolytic manganese metal waste slag, and the specific steps are:

[0054] A. Detect the content of manganese in the electrolytic manganese metal waste slag (according to "GB / T 8654.7-1988 Metal Manganese Chemical Analysis Method Potentiometric Titration Determination of Manganese Content", and the manganese content is 6.7%; according to "GB / T 176-2017 "Cement Chemical Analysis Methods" in the determination of calcium oxide in the potassium permanganate titration method to detect the content of calcium oxide in the waste residue, the measured calcium oxide content is 14.9%; according to "GB / T176-2008 Cement Chemical Analysis Method" The EDTA titration difference subtraction method (substitution method) in the method detects the content of magnesia in the waste residue, and the content of magnesia measured is 2.3%) and water is mixed according to the mass ratio of 1:4.5, and lime powder is added (the consump...

Embodiment 3

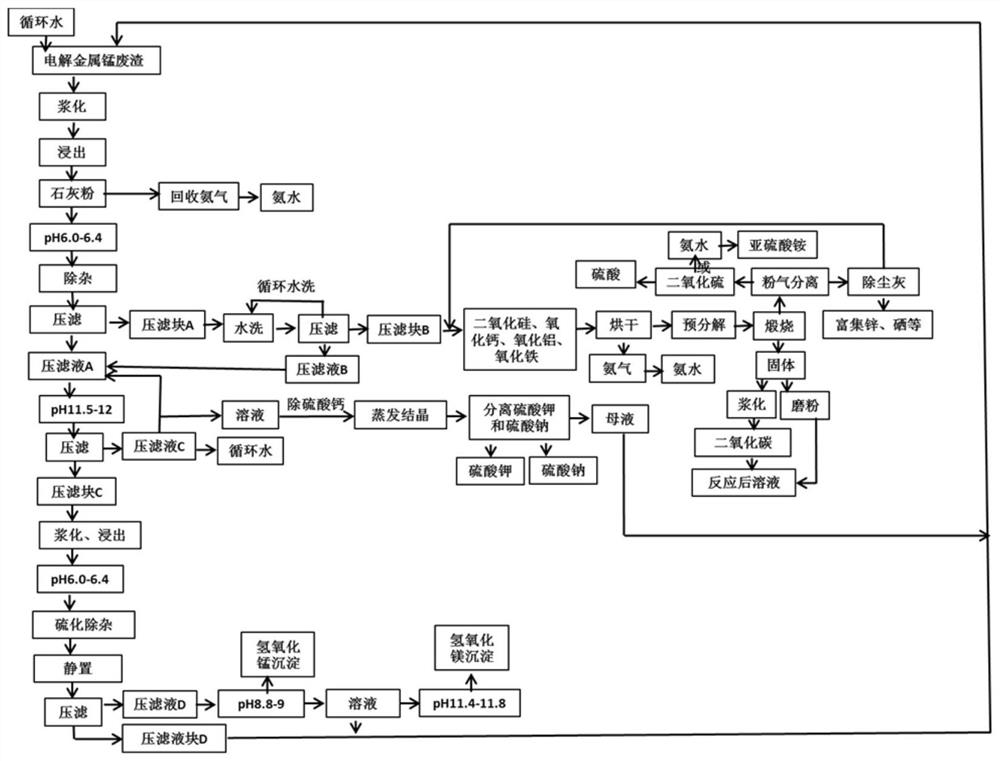

[0060] according to figure 2 The process flow shown is for treating electrolytic manganese metal waste slag, and the specific steps are:

[0061] A. Detect the content of manganese in the electrolytic manganese metal waste slag (according to "GB / T 8654.7-1988 Metal Manganese Chemical Analysis Method Potentiometric Titration Determination of Manganese Content", and the manganese content is 5.8%; according to "GB / T 176-2017 "Cement Chemical Analysis Methods" in the determination of calcium oxide in the potassium permanganate titration method to detect the content of calcium oxide in the waste residue, the measured calcium oxide content is 13.5%; according to "GB / T176-2008 Cement Chemical Analysis Method" The EDTA titration difference subtraction method (substitution method) in the waste residue is used to detect the content of magnesium oxide in the waste residue, and the measured content of magnesium oxide is 2.2%) mixed with water according to the mass ratio of 1:5.7, and sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com