Patents

Literature

68results about How to "Reduce manganese content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting high-valence manganese from manganese carbonate ore

This invention has provided one kind of method to leach high price manganese from manganese carbonateore, which belongs to the hydrometallurgy domain. It takes the glucose or the plant biomass and sulfuric acid as reducing agent of high pricemanganese in manganese carbonate ore, adopting microwave radiation glucose to promote high price manganese to revert, the concrete step includes: Takes 1 copy 100-200 sieve manganese carbonateore, add 10 -20 copy water to modulate the pulp; Again add 60% density sulfuric acid to pulp, the load ratio of mineral powder and sulfuric acid is 1: 6 -9; Simultaneously, add glucose or plant biomass, the load ratio of mineral powder and glucose or plant biomass is 10 -15: 1, stir evenly; radiate under 500 -1000W microwave, stir and respond for 4-10min, leach temperature is controlled at 50degree C-60 degree C, then get lixivium by filtering. This invention has the merits of lower reaction temperature, reducing acid consume and reduce leaching time of the manganese ore, high thermal using and respond rapidly.

Owner:CHONGQING UNIV

Method for reducing manganese content in graphene oxide

ActiveCN103395780AReduce manganese contentUniform particle size distributionGraphiteO-Phosphoric AcidIce water

The invention relates to a method for reducing manganese content in graphene oxide. The method is characterized by comprising: dissolving graphite in a concentrated sulfuric acid and concentrated phosphoric acid mixed solution, adding potassium permanganate to the obtained solution, carrying out a reaction for 9-15 h at a temperature of 40-60 DEG C, adding ice water having a volume of 1-4 times the volume of the mixed acid, uniformly stirring the solution, cooling to achieve a room temperature, adding a hydrogen peroxide solution having a mass of 3-5 times the mass of the graphite to reduce, washing the obtained solution by using distilled water until the pH value is 4-6, and filtering to obtain the graphite oxide wet material. The method has the following beneficial effects that: the method has advantages of simple operation, low water consumption, uniform particle size distribution, no high equipment requirements, and the like, and the graphene oxide with characteristics of uniform particle size distribution and manganese content of less than 20 mug / g can be obtained.

Owner:山东金利特新材料有限责任公司

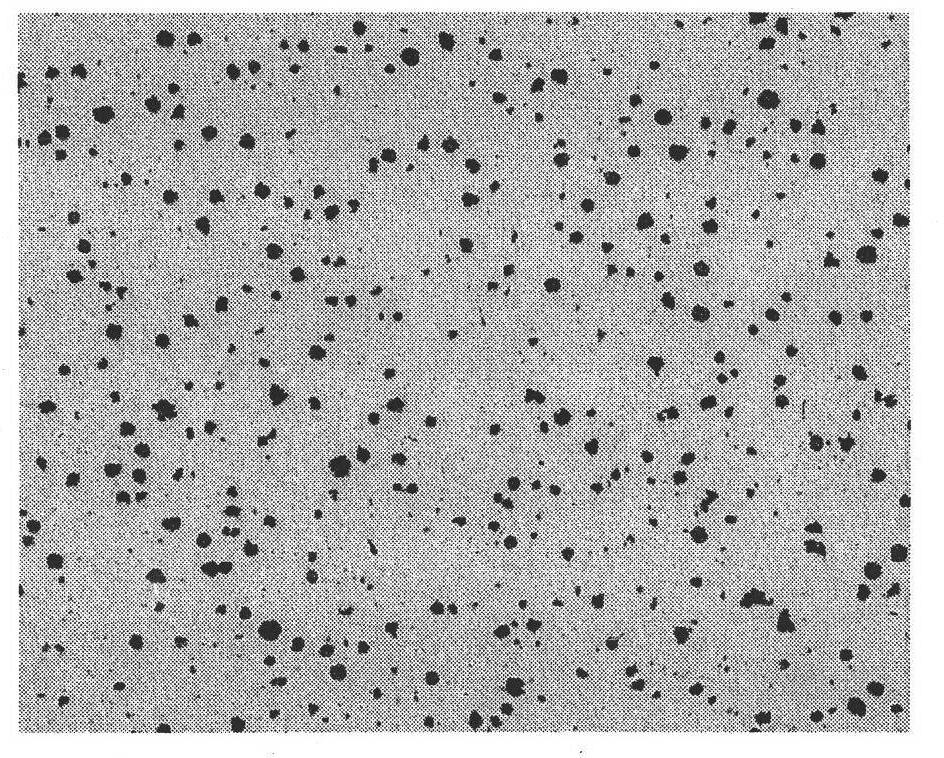

Ausferrite ductile cast iron grinding ball

ActiveCN104152792AHighlight substantive featuresImprove absorption rateGrain treatmentsAlloyDuctile iron

The invention discloses an Ausferrite ductile cast iron grinding ball, and relates to a spherulitic graphite-contained cast iron alloy. The Ausferrite ductile cast iron grinding ball comprises the following chemical elements in percentage by mass: 3.3-3.7% of C, 2.0-3.0% of Si, 1.0-2.5% of Mn, 0.7-3.0% of Cr, 0.1-1.0% of Mo, 0.1-1.0% of Cu, 0.04-0.08% of P, 0.01-0.020% of S, 0.03-0.05% of Mg, 0.02-0.04% of Ce, 0.03-0.07% of B, 0.06-0.12% of Ti, 0.03-0.2% of V, and the balance of Fe. The Ausferrite ductile cast iron grinding ball is prepared by the steps of preparation and smelting of raw materials, spheroidizing treatment, inoculation treatment and microalloying treatment, and isothermal quenching heat treatment. The Ausferrite ductile cast iron grinding ball overcomes the defects of low production efficiency and high consumption of electric energy of a ball mill due to easy surface stripping and crushing and shorter fatigue life of an existing grinding ball product in the service process.

Owner:HEBEI UNIV OF TECH

Flotation method of low ore grade manganous carbonate ore

The invention relates to a process that raw mine is ground into powder which is added with water to be prepared into pulp. Under certain pH value, inhibitor of carboxymethylcellulose nano solution, industrial water glass and tannin solution are added proportionally for absorbing calcium, magnesium and silicate. Then, sodium oleate is added as a collector for closed circuit circulation floating. Foam products after the floatation are flushed by water and then enter a sedimentation tank for the sedimentation or the pressure filtration. Thus, manganese concentrate fines above 20 percent are obtained. In the process, floatation is implemented on low grade poor manganese mine containing 10-14 percent of manganese, carbonaceous rock with the manganese content of 4-9 percent and electrolytic manganese leached slags with the manganese content of 1-3 percent to obtain manganese ore fines, the manganese content of which reaches above 20 percent. The recovery of manganese is more than 85 percent. And non-manganese emission for tailings can be realized. The manganese resources are lead to have extremely high utilization rate. Produced products can also lower acid consumption and ammonia consumption for electrolytic manganese production of downstream industry of manganese mines.

Owner:HUAYUAN QIANGHUA MINING

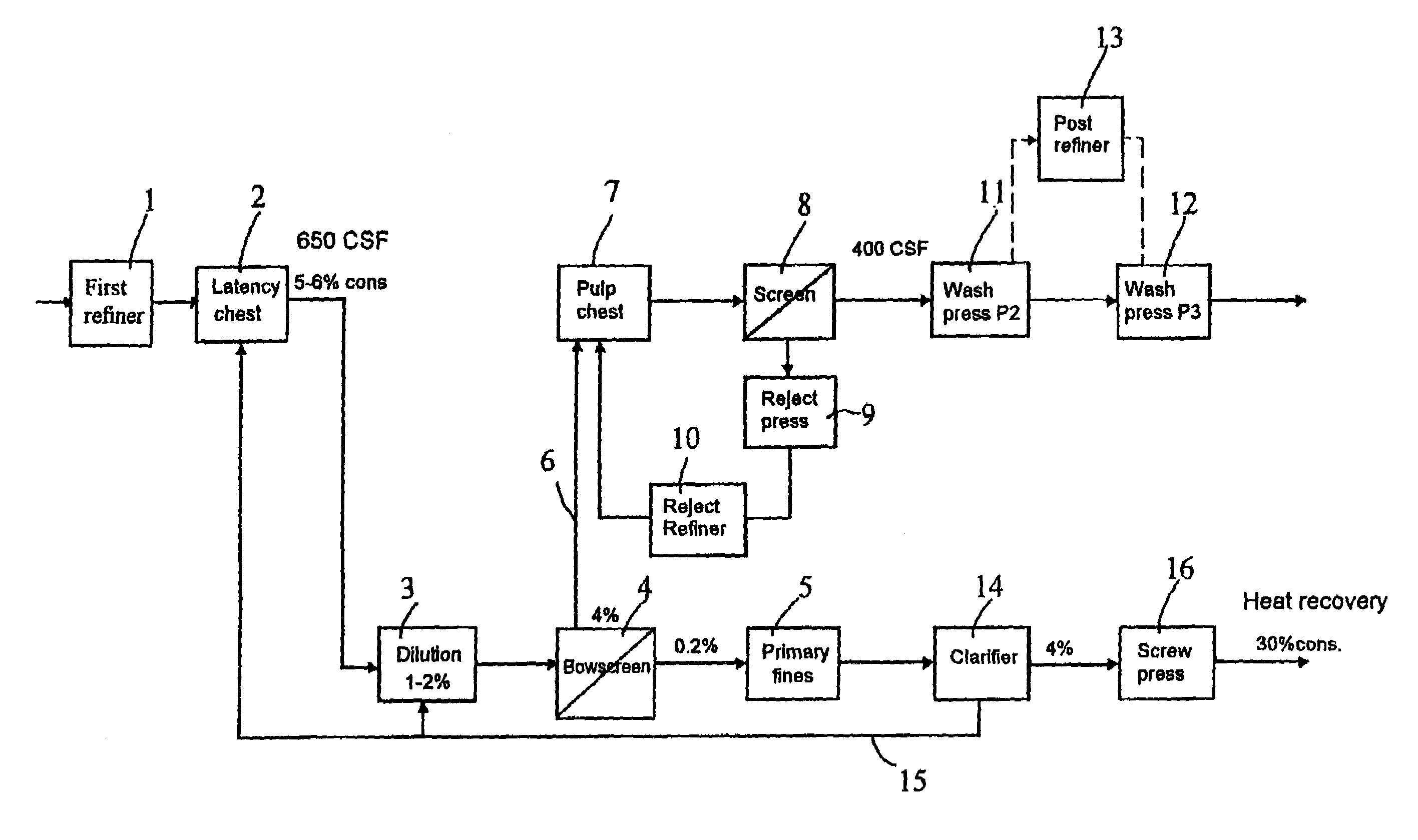

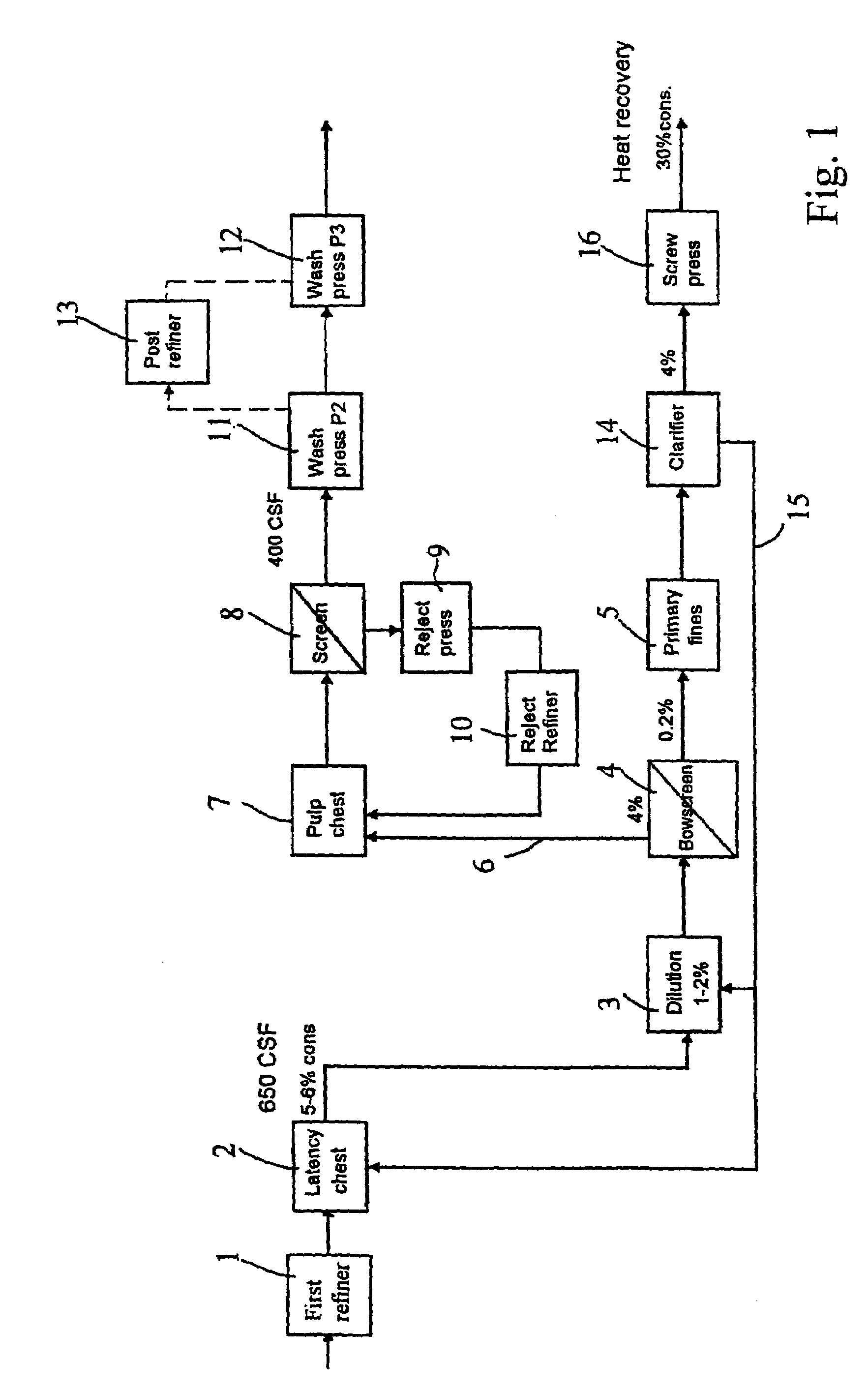

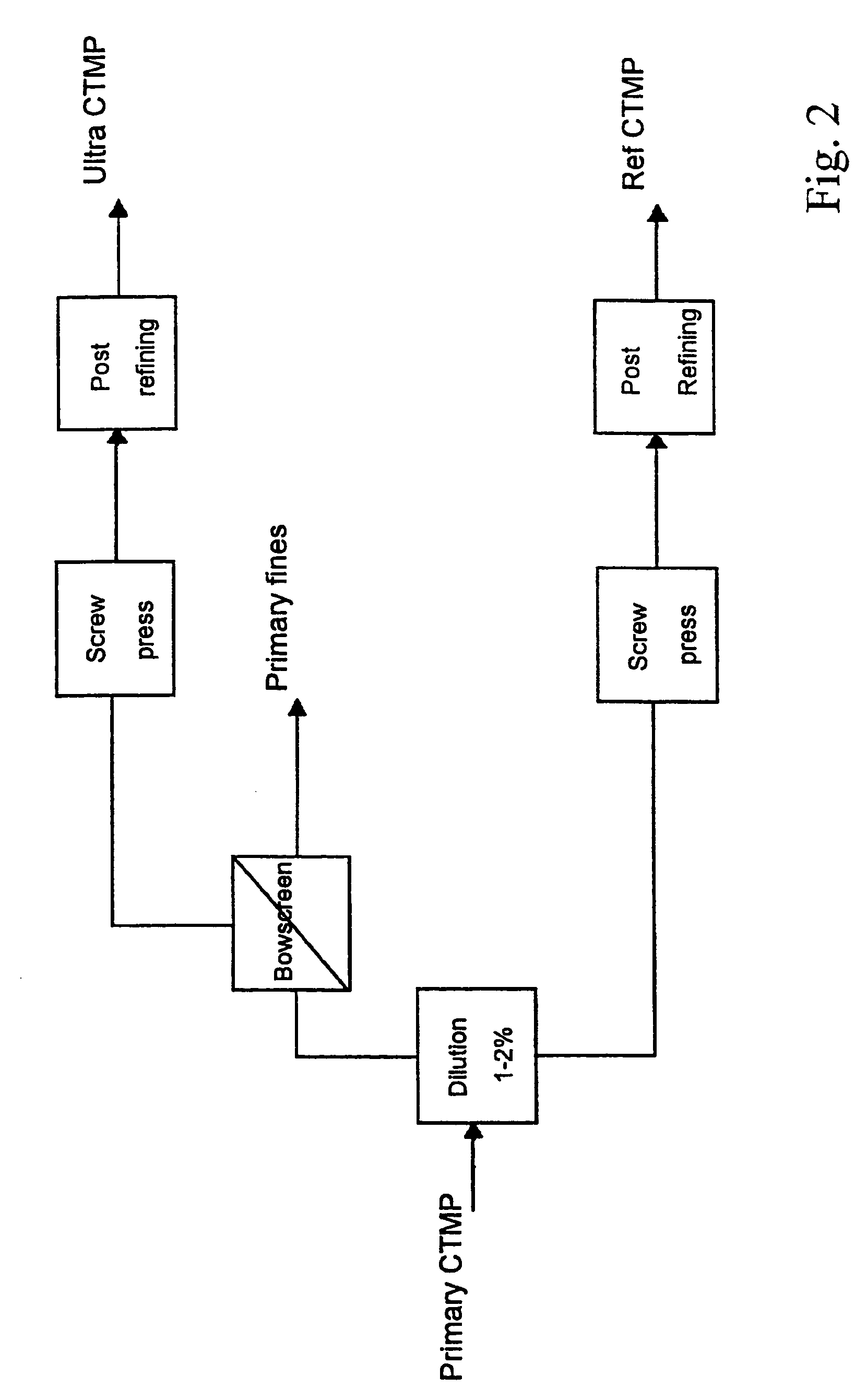

Method in connection with the production of mechanical pulp

InactiveUS7005034B1Reduce consumptionGood removal effectFats/resins/pitch/waxes removal in pulpDigestersCellulosePaperboard

A method in connection with the production of mechanical pulp from a cellulose containing material wherein the material is processed in at least one refining step to produce pulp. According to the invention, the pulp is fractionated (4), after a first refining step (1), in order to separate primary fines (5) from the pulp. The invention also relates to a mechanical pulp, produced by the method, and to a paperboard, which at least partly consists of such mechanical pulp.

Owner:STORA ENSO AB

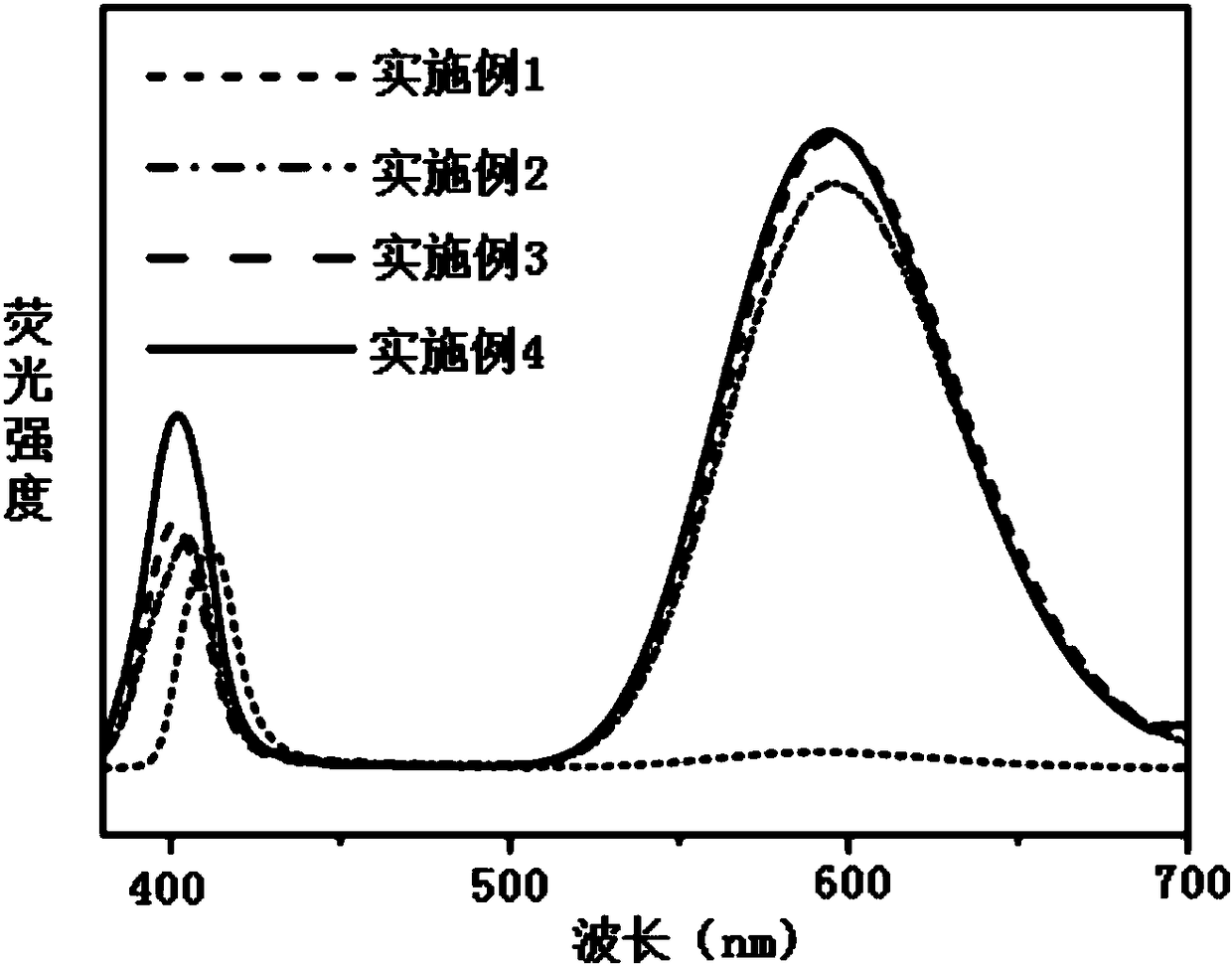

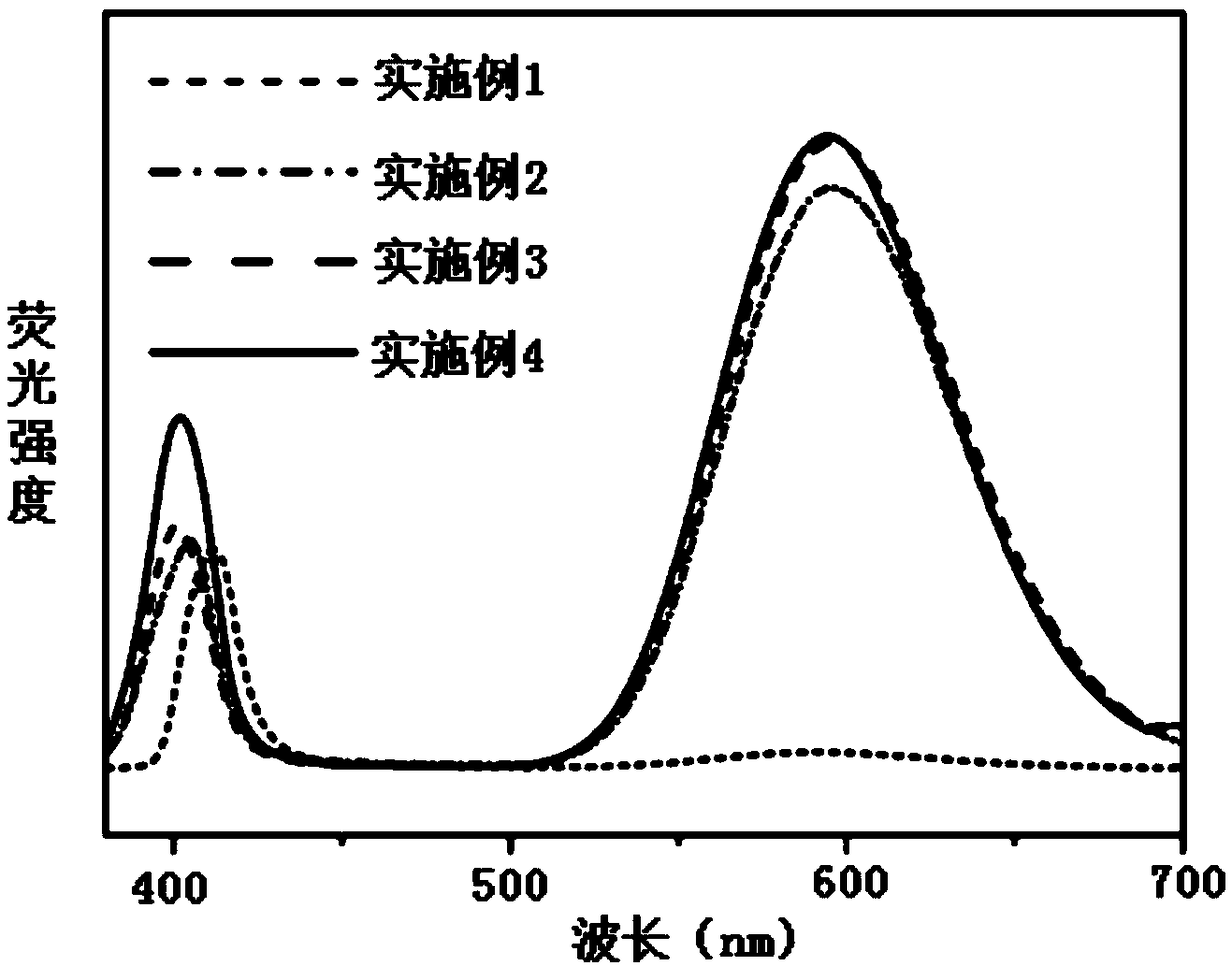

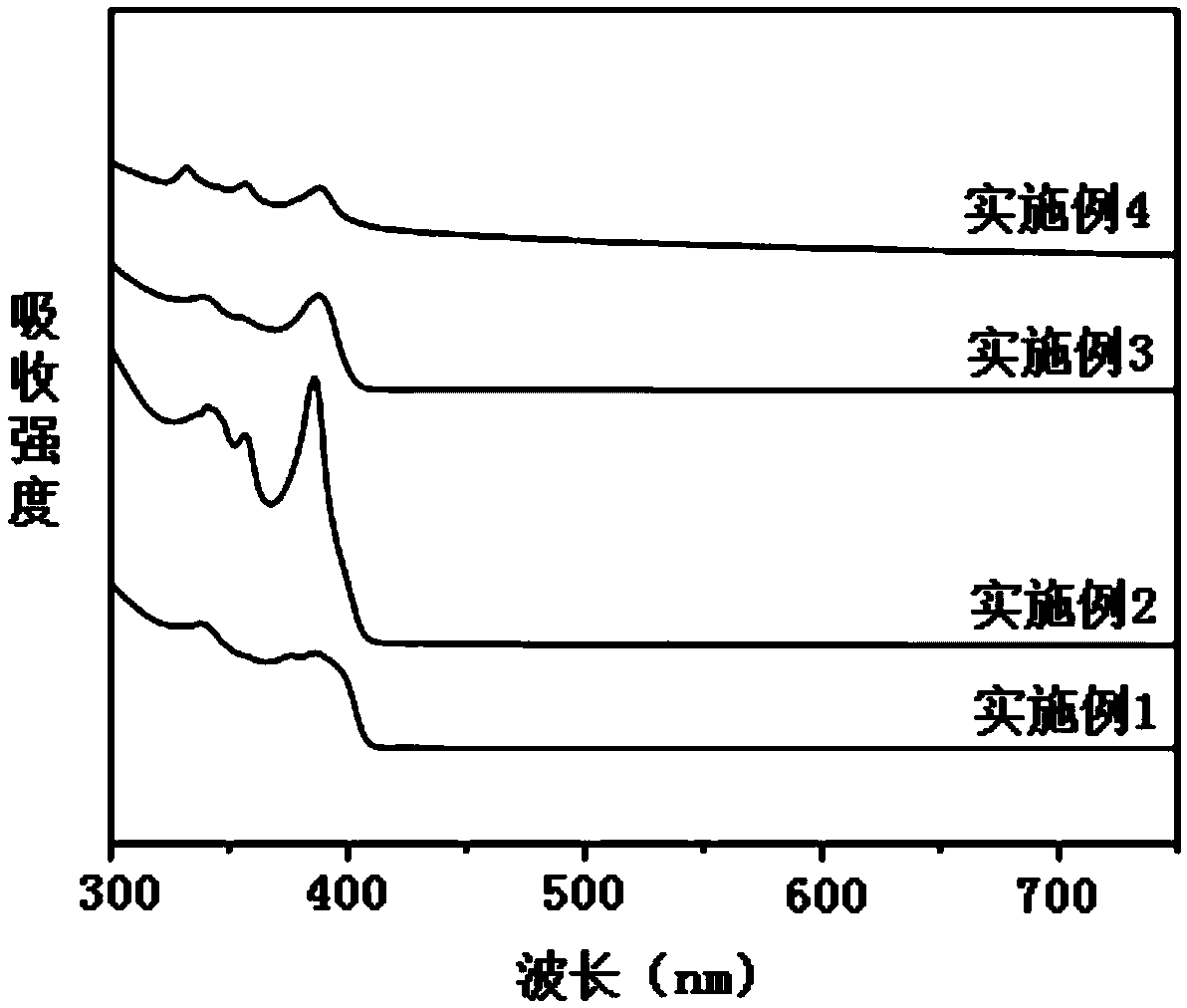

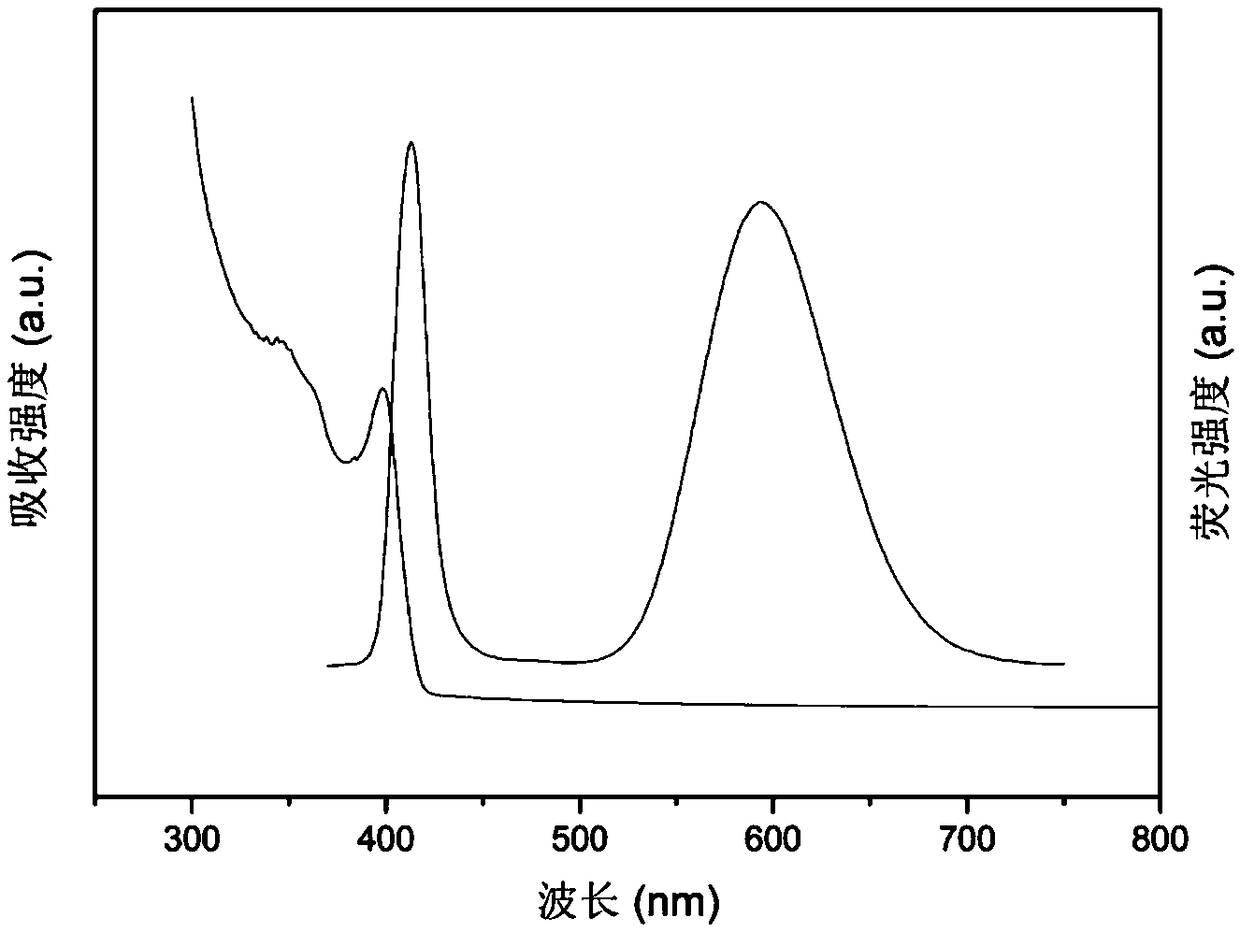

Manganese-doped inorganic halogen perovskite quantum dot, and preparation method and application thereof

ActiveCN108504356AReduce manufacturing costImprove production efficiencyInksNanotechnologyHalogenPhysical chemistry

The invention discloses a manganese-doped inorganic halogen perovskite quantum dot, and a preparation method and an application thereof. The preparation method comprises the following steps: dissolving lead salt and manganese chloride, and carrying out heating at 80 DEG C to 110 DEG C so as to obtain a halogen precursor; dissolving caesium salt so as to obtain a caesium precursor; adding the caesium precursor into the halogen precursor, and carrying out heating at 80 DEG C to 110 DEG C so as to obtain a quantum dot solution; and purifying the quantum dot solution so as to obtain the manganese-doped inorganic halogen perovskite quantum dot. The invention provides a method for high-yield preparation of the manganese-doped inorganic halogen perovskite quantum dot without the need of protection of inert gas at a low temperature. The method provided by the invention reduces preparation cost, improves preparation efficiency, and can be used for large-scale production. The quantum dot is applied to invisible ink which has good effect, is convenient to write and has stable invisible effect; meanwhile, after manganese is doped, the quantum dot has greatly-improved thermal stability and greatly-reduced toxicity.

Owner:HUAZHONG UNIV OF SCI & TECH

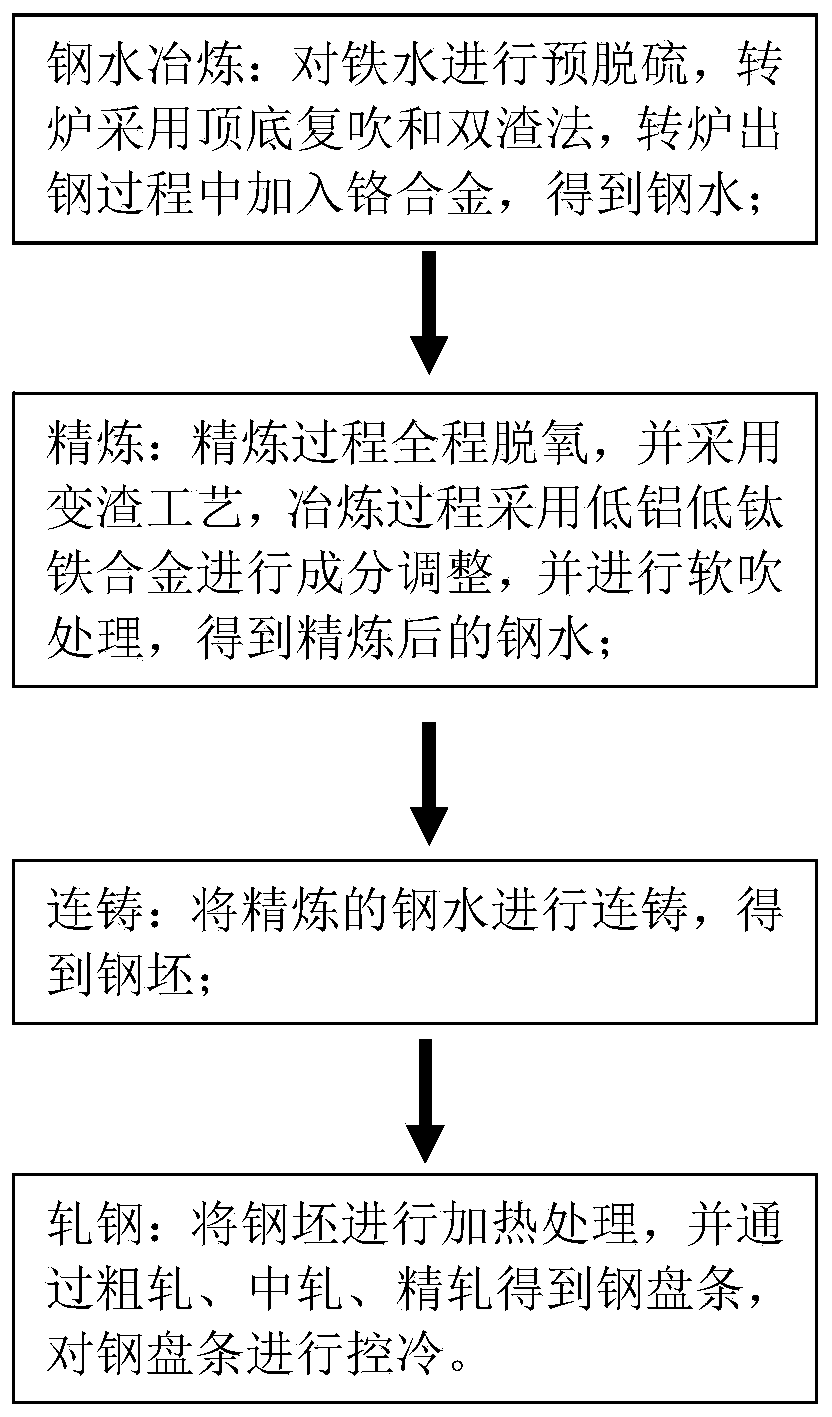

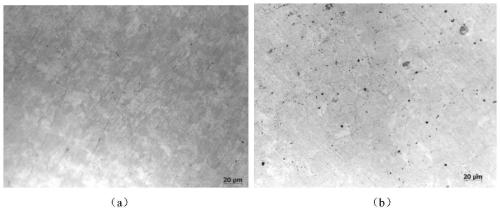

Chromium-alloyed cord steel wire rod and production process

ActiveCN111534753AReduce carbon contentReduce manganese contentManufacturing convertersMachining processThermal treatment

The invention provides a chromium-alloyed cord steel wire rod and a production process. The chromium-alloyed cord steel wire rod comprises the following chemical components of, in percentage by weight, 0.68%-0.82% of C, 0.20%-0.40% of Mn, 0.15%-0.30% of Si, 0.30%-0.40% of Cr, less than or equal to 0.012% P, less than or equal to 0.008% of S, less than or equal to 0.05% of Ni, less than or equal to0.05% of Cu, less than or equal to 0.03% of Mo, less than or equal to 0.003% of Al, less than or equal to 0.002% of Ti, less than or equal to 0.002% of [O], less than or equal to 0.005% of [N], and the balance Fe and unavoidable impurities. The production technology comprises the following steps of smelting molten steel, and adding chromium alloy in the converter tapping process; refining to obtain molten steel; carrying out continuous casting on the molten steel obtained after refining to obtain a steel billet; and heating the steel billet to obtain a chromium-alloyed cord steel wire rod, and carrying out controlled cooling on the chromium-alloyed cord steel wire rod. According to the chromium-alloyed cord steel wire rod and the production process, microalloying is adopted, the chromiumcontent is increased, the carbon content and the manganese content are reduced to compensate for the performance of the steel wire rod and the finished steel wire, carbon segregation of the steel wirerod is improved, the net carbon forming probability is reduced, the plasticity and the machining performance of the steel wire rod can be improved at the same time, and the strand combining and wirebreaking rate in the steel wire rod cord machining process is reduced.

Owner:JIANGSU YONGGANG GROUP CO LTD

Method for producing low-manganese steel

The invention discloses a method for producing low-manganese steel. Desulphurized molten iron is added into a first converter, 1 / 2-3 / 4 of total lime is added within 3 min after smelting starts, the left lime is added within 5 min, the lance position is 2.2-2.4 m within the first 4 min, the oxygen flow amount is 198-202 m<3> / h.t steel, and the oxygen pressure is 0.75-0.85 MPa. The tapping temperature of the first half steel is 1420-1440 DEG C, and half steel carbon is 2.8-3.2%. Slag tapping is controlled after tapping of the first half steel, and the slag thickness is smaller than 80 mm. The last half steel is subjected to blowing normally according to the internal control requirements of the converter, boiling steel tapping is conducted in a slag pushing-off mode, the slag thickness is smaller than 80 mm, and 2.5-3.5 kg / t steel of jarred lime is added during steel tapping. The last half steel is moved to an LF workstation after being hung on a jar to be subjected to heating and slagging, bottom blowing is conducted in the whole process, the bottom blowing argon flow amount is 80-100 m<3> / h, slagging lime is added in two or three times, and the total amount is 8-10 kg / t steel. The stirring time is not shorter than 25 min, and then slagging-off treatment is conducted. 1-3 kg / t steel of lime is added after slagging-off. According to the method, the final manganese content in the steel can be stably controlled to be smaller than 0.025%. The process is easy to operate, convenient and feasible.

Owner:ANGANG STEEL CO LTD

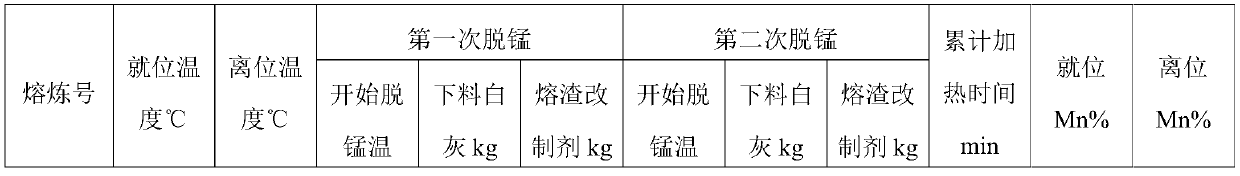

Method for utilizing high-manganese molten iron to smelt ultra-low-manganese steel

ActiveCN110453032ACapable of deep demanganizationReduce manganese contentManufacturing convertersProcess efficiency improvementSlagManganese

The invention discloses a method for utilizing high-manganese molten iron to smelt ultra-low-manganese steel and belongs to the field of steel and iron metallurgy. The method for utilizing the high-manganese molten iron to smelt the ultra-low-manganese steel comprises the steps that in the converter process, the double-slag smelting technology is adopted for removing elements like manganese in most molten iron, the technology of converter low-temperature tapping and LF refining furnace deep manganese removing is adopted for further removing the manganese, on the condition that the molten ironentering the furnace is high-manganese molten iron with the manganese content higher than 0.40%, the manganese content in the molten iron is stably controlled below 0.02%, and the smelting requirementof the ultra-low manganese steel is met.

Owner:BAOTOU IRON & STEEL GRP

Substrate for strapping band

The invention belongs to the field of ferrous metallurgy materials, in particular relates to a substrate for a strapping band and a production method thereof. The substrate comprises the following chemical components in percentage by weight: 0.14-0.20 percent of C, 0.17-0.37 percent of Si, 0.55-0.75 percent of Mn, less than or equal to not more than 0.035 percent of P,0.01-0.04 percent of AL and the balance of Fe and inevitable impurities, wherein the tensile strength is not less than 7850Mpa, the elongation percentage is not less than 8 percent and the repeated bending times is not less than 8. In the production method, the smelting steps comprises the specific steps of molten iron pretreatment sulfur removal station, top and bottom combined blown converter, LF (Low Frequency) steel ladle refining and slab continuous casting,; the hot rolling steps comprises the specific steps of heating, rough rolling, hot rolling, finish rolling, laminar cooling and reeling; and the cold rolling steps comprises the specific steps of acid pickling, cold rolling and heat treatment. The steel grade has reasonable mixture ratio of chemical components and higher product strength, elongation percentage and repeated bending times compared with national standard. The production method of the substrate can ensure the chemical organization and physical performance of the steel grade.

Owner:TANGSHAN GUOFENG IRON & STEEL

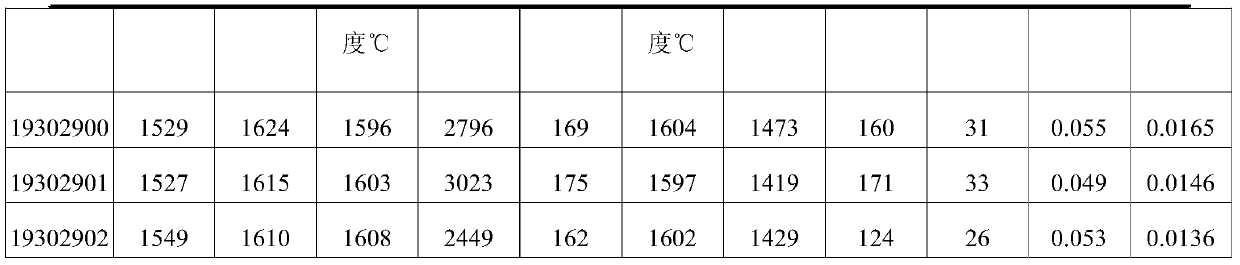

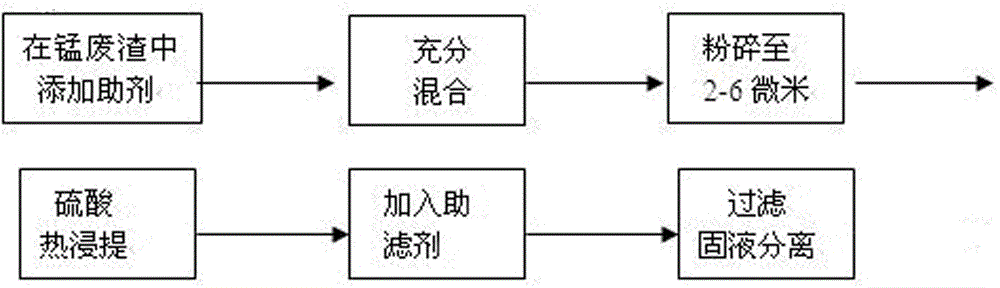

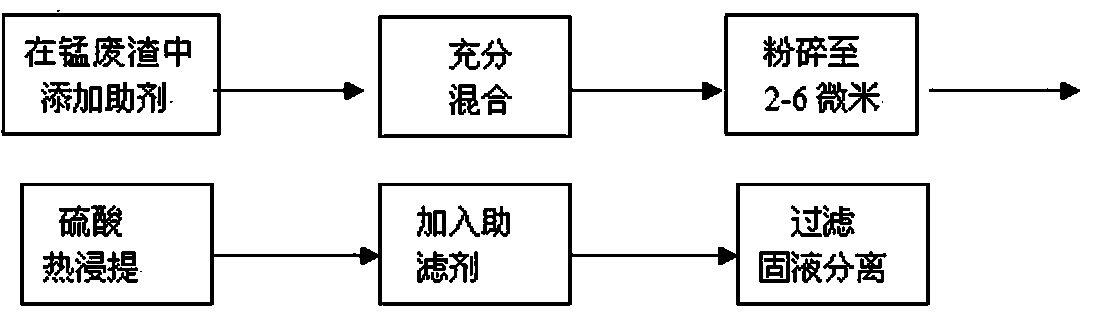

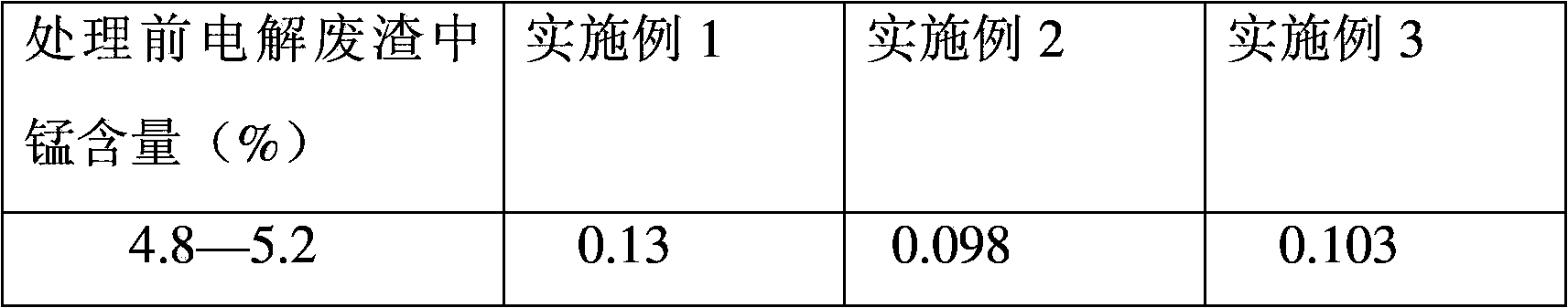

Method for extracting manganese from electrolytic manganese waste residues or low-quality manganese ore by utilizing mechanochemical method and auxiliary agent thereof

ActiveCN102719667AReduce manganese contentIncrease profitProcess efficiency improvementElectrolysisManganese

The invention relates to a production process for extracting the manganese element by utilizing electrolytic manganese waste residues and a production process for extracting the manganese element by utilizing low-quality manganese ore, in particular to a method for extracting manganese from the electrolytic manganese waste residues or the low-quality manganese ore by utilizing a mechanochemical method and an auxiliary agent thereof. The method comprises the following steps of: adding the auxiliary agent with the weight percentage being 2.0-11.0% in the claim 1 or 2 in the electrolytic manganese waste residues or the low-quality manganese ore, fully and uniformly mixing, crushing till the diameter D 50 is 2-6mum, then carrying out heat extraction by using sulfuric acid with the weight 5-10 times that of the auxiliary agent for 2-4 times, and filtering to separate leaching liquor for producing the electrolytic manganese. The method has the advantages that the auxiliary agent is added in the treatment process of the electrolytic manganese waste residues or the low-quality manganese ore, and is crushed together with the electrolytic manganese waste residues or the low-quality manganese ore so as to generate certain-level action, then the heat extraction is carried out by using the sulfuric acid, and after solid-liquid separation, the content of the manganese in the waste residues is reduced to about 0.1%, or even lower.

Owner:BEIFANG UNIV OF NATITIES

Drier for printing ink and printing ink containing drier

InactiveUS6899756B2Reduce manganese contentLess to environmentSiccativesInksPrinting inkPolymer chemistry

A drier for oxidative polymerization-drying printing ink is provided, which does not contain cobalt capable of exerting an adverse influence on the environment and health and which is environmentally friendly. A printing ink containing the drier is also provided. The drier for oxidative polymerization-drying printing ink contains a cerium salt of a fatty acid and a manganese salt of a fatty acid.

Owner:DAINIPPON INK & CHEM INC

Method for improving production efficiency of Q345B hot rolled narrow strip steel

ActiveCN109487165ALow costIncrease productivityTemperature control deviceManufacturing convertersAlloyDeoxygenation

The invention relates to the technical field of steel rolling in the steel metallurgy technology and relates to a method for improving the production efficiency of Q345B hot rolled narrow strip steel.The method includes the following steps that firstly, molten iron pretreatment is conducted; secondly, converter smelting is conducted, wherein the converter steel putting time is not shorter than 2min, when molten steel is discharged by one fifth, calcium silicon, silicon carbide, silicomanganese, vanadium nitrogen and ferroniobium are added in a batched manner for deoxygenation alloying, a carburant is added for increasing carbon, and adding is completed when molten iron is discharged by three fourths; the temperature of a steel ladle is larger than or equal to 700 DEG C, 3 kg / t to 6 kg / tof modification agents are added to the steel ladle bottom before tapping, and then online baking of the steel ladle is conducted; thirdly, bottom argon blowing stirring is conducted in the whole process, argon blowing is conducted for 13 min to 15 min totally, the argon flow is controlled to be 200 L / min to 300 L / min in 10 min before argon blowing, and the argon flow is controlled to be 50 L / minto 80 L / min before departing; fourthly, continuous casting is conducted, protective casting is conducted in the whole process, the superheat degree of tundish molten steel is controlled to range from20 DEG C to 30 DEG C; and fifthly, hot rolling is conducted. By means of the method, an alloy replacing method is used for reducing the adding amount of alloy materials, the converter tapping temperature can be reduced, and therefore the purpose of improving the production efficiency and capacity is achieved.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Manufacturing method of high manganese high nitrogen low nickel non-magnetic stainless steel and product thereof

ActiveCN106868423AHigh symmetrical stabilityIncreased symmetrical stabilityFoundry mouldsElectric furnaceNiobiumNon magnetic

The invention provides a manufacturing method of a high manganese high nitrogen low nickel non-magnetic stainless steel and a product thereof. The stainless steel is single phase austenite stainless steel which comprises the following chemical components in percentages by mass: greater than 0 but less than or equal to 0.1% of C, less than or equal to 0.01% of S, less than or equal to 0.015% of P, greater than 0 but less than or equal to 1.0% of Si, greater than or equal to 16% but less than or equal to 18% of Mn, greater than 0 but less than or equal to 2% of Ni, greater than or equal to 10% but less than or equal to 14% of Cr, greater than or equal to 1% but less than or equal to 2% of N, greater than or equal to 0.3% but less than or equal to 1% of Cu, greater than or equal to 0.3% but less than or equal to 5% of Mo, greater than or equal to 0.3% but less than or equal to 1% of Nb and the balance of Fe. The manufacturing method comprises the following steps: heating and smelting raw materials, and performing decarbonization, desulfuration and deoxygenation; raising the temperature to 1600 DEG C and adding nickel; adjusting the temperature of a bath to 1550 DEG C, and adding ferromolybdenum, ferrocolumbium and a metal copper; adding a desoxidant for secondary deoxidization, introducing nitrogen, adjusting the temperature of the bath to 1610-1620 DEG C, and adding nitrogen containing ferrochromium; adjusting the temperature of the bath to 1150-1250 DEG C, introducing nitrogen, adding nitrided ferromanganese, pouring, quenching and air cooling, and machining to form a panel, heating the panel to 650-700 DEG C, keeping the temperature for 30min, and performing furnace cooling to room temperature. The stainless steel through deep punching is still non-magnetic, and needs not to be annealed and demagnetized. The manufacturing method is high in nitrogen-increasing efficiency and low in loss of equipment.

Owner:宁波市博祥新材料科技有限公司

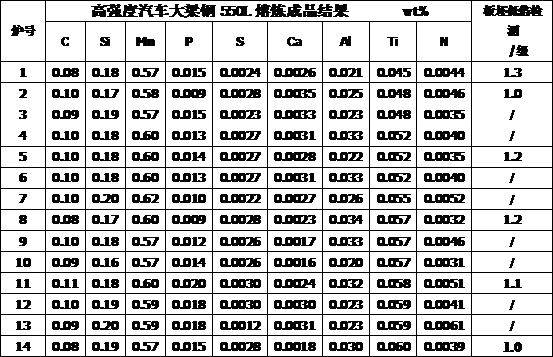

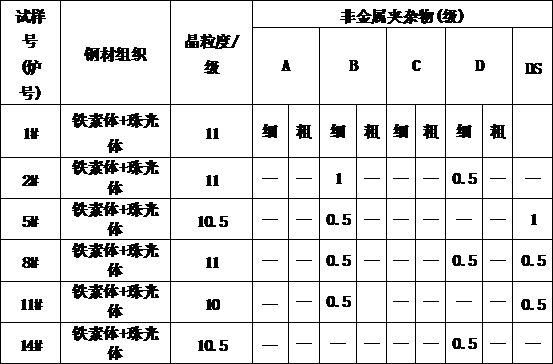

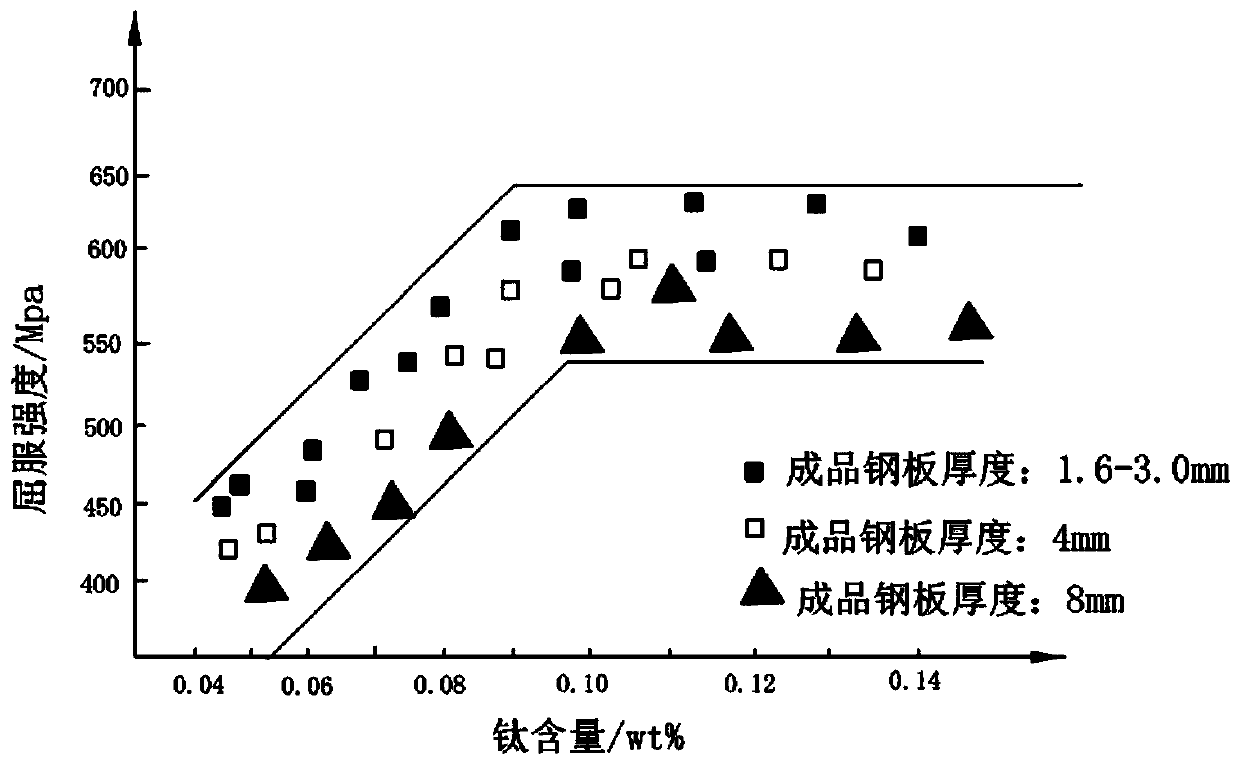

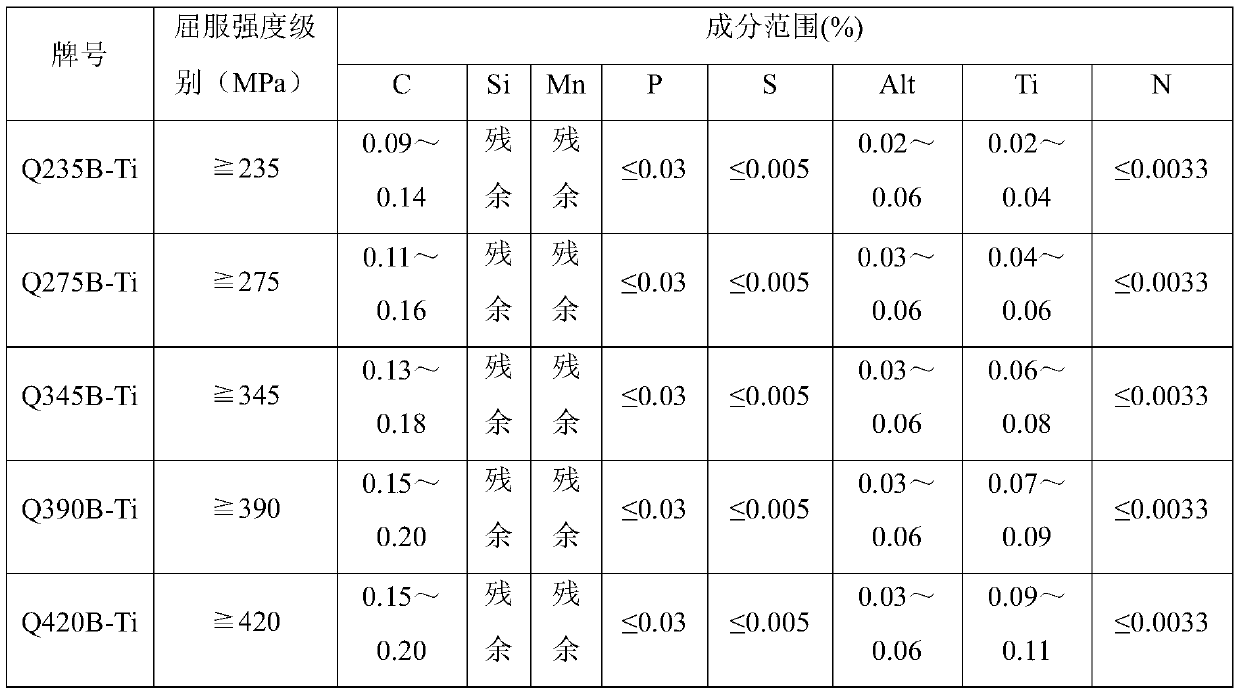

Preparation method of high-strength 550L automobile beam steel

ActiveCN113265502AImprove performance and stabilityReduce manganese contentManufacturing convertersMolten steelContinuous rolling

The invention discloses a preparation method of high-strength 550L automobile beam steel, which comprises the steps of enabling beam steel to comprise the following components: 0.080-0.11 wt% of C, less than or equal to 0.20 wt% of Si, 0.55-0.65 wt% of Mn, less than or equal to 0.018 wt% of P, less than or equal to 0.004 wt% of S, 0.045-0.060 wt% of Ti, 0.020-0.035 wt% of Al, 0.0030-0.0045 wt% of N and less than or equal to 0.0020 wt% of steel TO; performing converter smelting tapping control, wherein [C] is 0.06-0.08%, [P] is less than or equal to 0.015%, [S] is less than or equal to 0.008% and [O] is less than or equal to 400PPm, during converter tapping, fluorite, calcium carbide and active lime are mixed according to a mass ratio of 1:1:3, and are added in three times according to the interval of 1 minute, 2 minutes and 3 minutes in the converter tapping process, and the adding target value is 600 kg per converter; performing oxygen determination before LF refining treatment; and performing continuous casting, wherein continuous casting molten steel is cast under the protection of argon, the heating temperature of a plate blank is 1210-1230 DEG C, a hot-rolled coil with the thickness of 3.0-10 mm is obtained by adopting a hot continuous rolling mill through rolling, and the finish rolling temperature is 854-858 DEG C.

Owner:XINJIANG BAYI IRON & STEEL

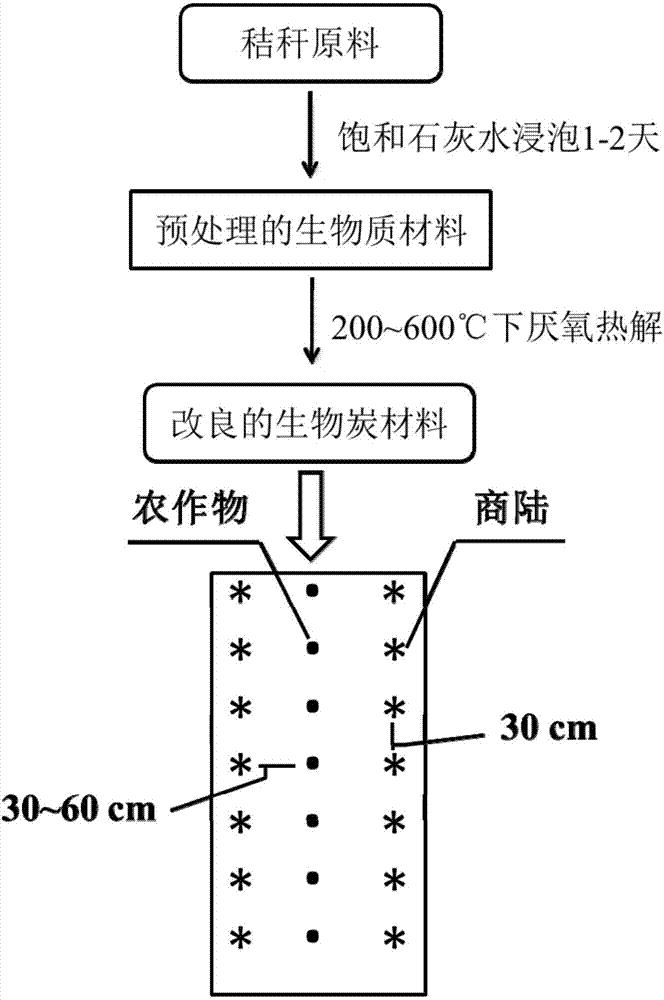

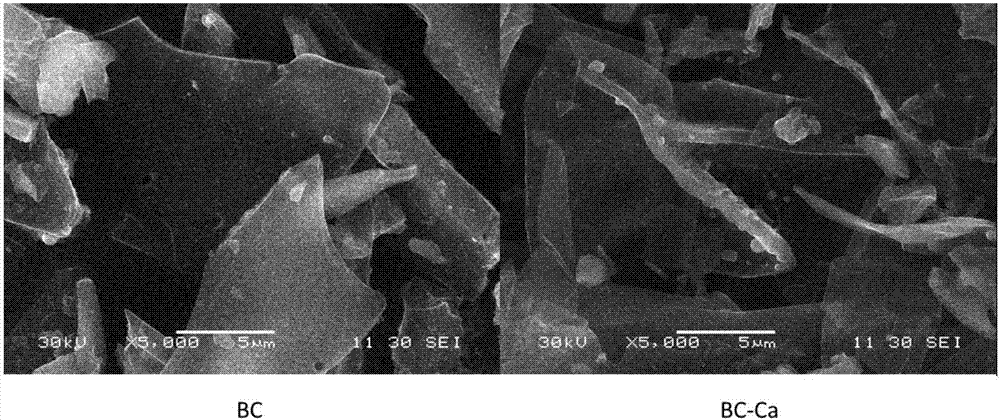

Method for safely planting crops on manganese contaminated soil

InactiveCN107081334AReduced bioavailabilityIncrease productionContaminated soil reclamationHorticultureHyperaccumulatorManganese

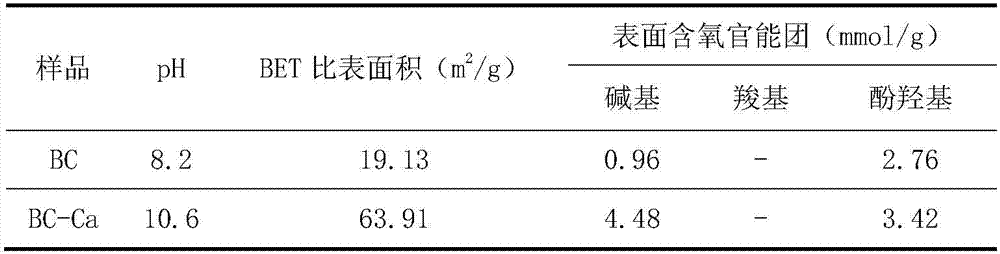

The invention discloses a method for safely planting crops on manganese contaminated soil. The method comprises the following steps that straw is soaked in an alkaline solution for 1-2 days and subjected to pyrolysis for 1-2 hours at the temperature of 200-600 DEG C under the low-oxygen or anoxic condition after being taken out of the alkaline solution, pyrolysis cooling and smashing are conducted in sequence, and improved straw charcoal is obtained. The improved straw charcoal is applied to the manganese contaminated soil, and radix phytolaccae is planted dispersedly. The next year the radix phytolaccae grows, the crops are interplanted between the plants of the radix phytolaccae. The method for safely planting the crops on the manganese contaminated soil is provided by adopting the mode of applying the improved straw charcoal, planting the manganese hyperaccumulator radix phytolaccae and then interplanting other crops, so that safety production is achieved while the manganese contaminated soil is remedied, and the high soil utility value is obtained.

Owner:HUNAN UNIV OF SCI & TECH

Non-quenched and tempered steel containing Ti and N and applied to automobile engine crankshaft and preparation method

The invention belongs to the field of metal materials, and relates to non-quenched and tempered steel containing Ti and N and applied to an automobile engine crankshaft. The non-quenched and temperedsteel comprises chemical components in percentage by mass as follows: 0.44%-0.48% of C, 0.25%-0.45% of Si, 0.82%-0.92% of Mn, 0.12%-0.21% of Cr, 0.07%-0.10% of V, 0.02%-0.03% of Ti, 0.010%-0.020% of N, smaller than or equal to 0.025% of P, 0.040%-0.060% of S and the balance of Fe and normal impurities. The microscopic structure of a large rolled bar (with diameter being 110 mm) containing the components is pearlite+ferrite, and the structure of the large rolled bar is thinner and has good uniformity; austenite grain size in the position of 1 / 2 radius of the large rolled bar can reach level 8.0, and core-surface grain size range can be as low as level 0.5. The crankshaft is made of the large rolled bar as a raw material through die forging, and the microscopic structure of the crankshaft ispearlite+grain boundary ferrite+intragranular ferrite; yield strength in the position of 1 / 2 radius of a main journal of the crankshaft can reach 500 MPa or higher, tensile strength can reach 800 MPaor higher, and room-temperature impact energy KU2 can reach 20 J or higher; hardness of a cross section of an output end of the crankshaft is 240-260 HB, which is suitable for drilling operation, andmachining cost can be reduced. Therefore, requirements for structure uniformity of the large rolled bar and comprehensive mechanical properties of the crankshaft can be met.

Owner:UNIV OF SCI & TECH BEIJING

Manganese doped inorganic halogen perovskite quantum dots and preparation method thereof

ActiveCN108728089AReduce manufacturing costImprove production efficiencyMaterial nanotechnologyNanoopticsQuantum yieldHalogen

The invention discloses manganese doped inorganic halogen perovskite quantum dots and a preparation method thereof. The preparation method comprises the following steps: lead salt and manganese chloride are dissolved and heated at 80-110 DEG C, and a halogen precursor is obtained; cesium salt is dissolved, and a cesium precursor is obtained; the cesium precursor is added to the halogen precursor,the mixture is heated at 80-110 DEG C, and the manganese doped inorganic halogen perovskite quantum dots are obtained. The method for preparing the manganese doped inorganic halogen perovskite quantumdots with high yield at lower temperature needs no inert gas protection, preparation cost is reduced, preparation efficiency is improved, quantum yield is as high as 62.41% which is 12.41% higher than the current highest quantum yield of 54% with a hot injection method, and the method can be applied to mass production.

Owner:HUAZHONG UNIV OF SCI & TECH

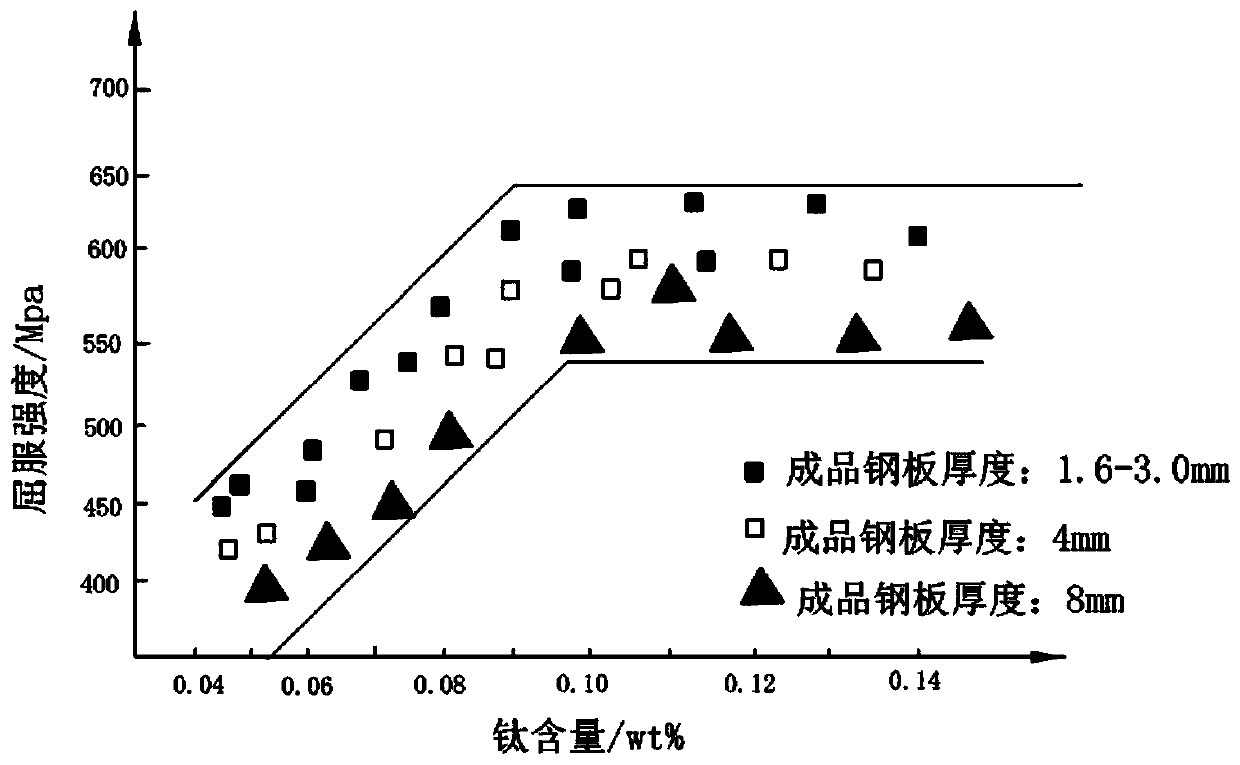

Titaniferous carbon steel and production method thereof

ActiveCN109706404APrecise control of effective [Ti] contentStable control of effective [Ti] contentManufacturing convertersSmelting processTitanium

The invention discloses titaniferous carbon steel and a production method thereof. The titaniferous carbon steel comprises, by weight, 0.09%-0.20% of C, 0.02%-0.11% of Ti, 0.02%-0.06% of Alt and the balance Fe and inevitable impurities, wherein Alt shows total aluminum. According to the produced titaniferous carbon steel, Si and Mn are completely replaced with titanium, and cost is saved under thecondition of enhancing the strength of steel. The invention further provides a smelting process for precisely controlling the contents of O, N and S in molten steel and a rolling and after-rolling cooling process for controlling TiC particle fine dispersion precipitation. The effective Ti content in the molten steel can be stably controlled, precipitated TiC particles are large in number and small in size, and therefore the effect of stably improving the strength of the steel is achieved, and steel strength fluctuation caused by non-precise control of the smelting and rolling processes is avoided.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

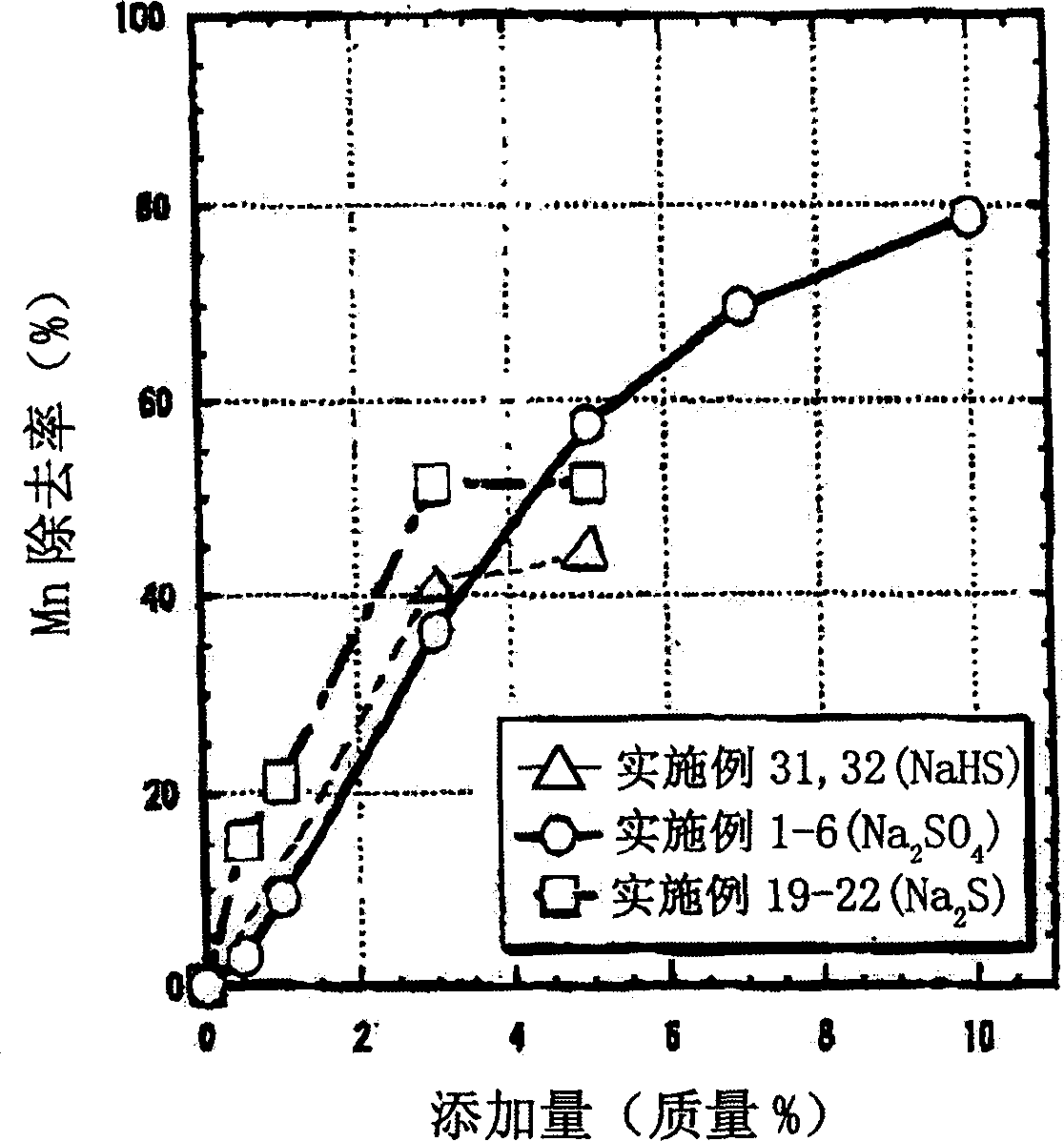

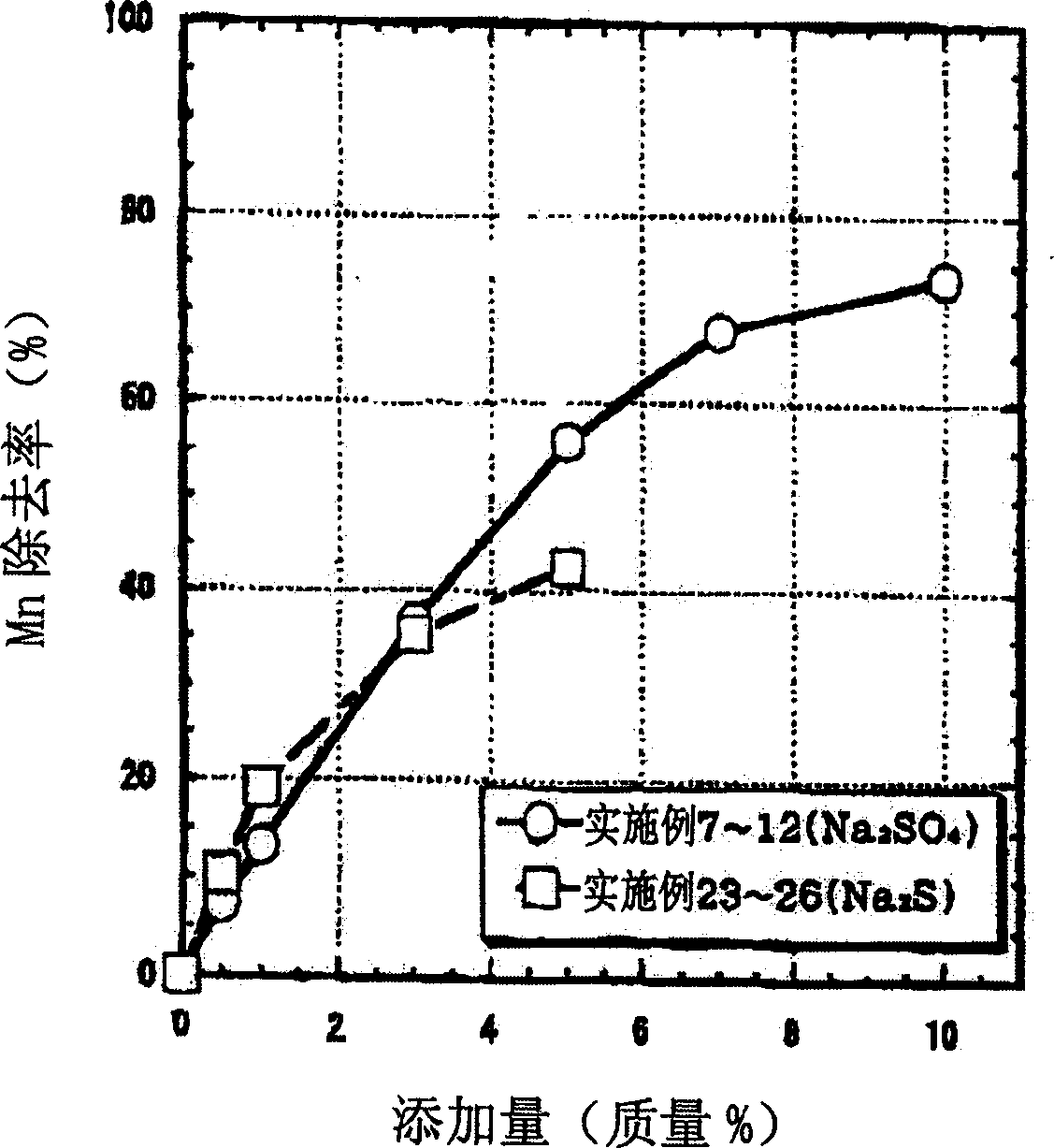

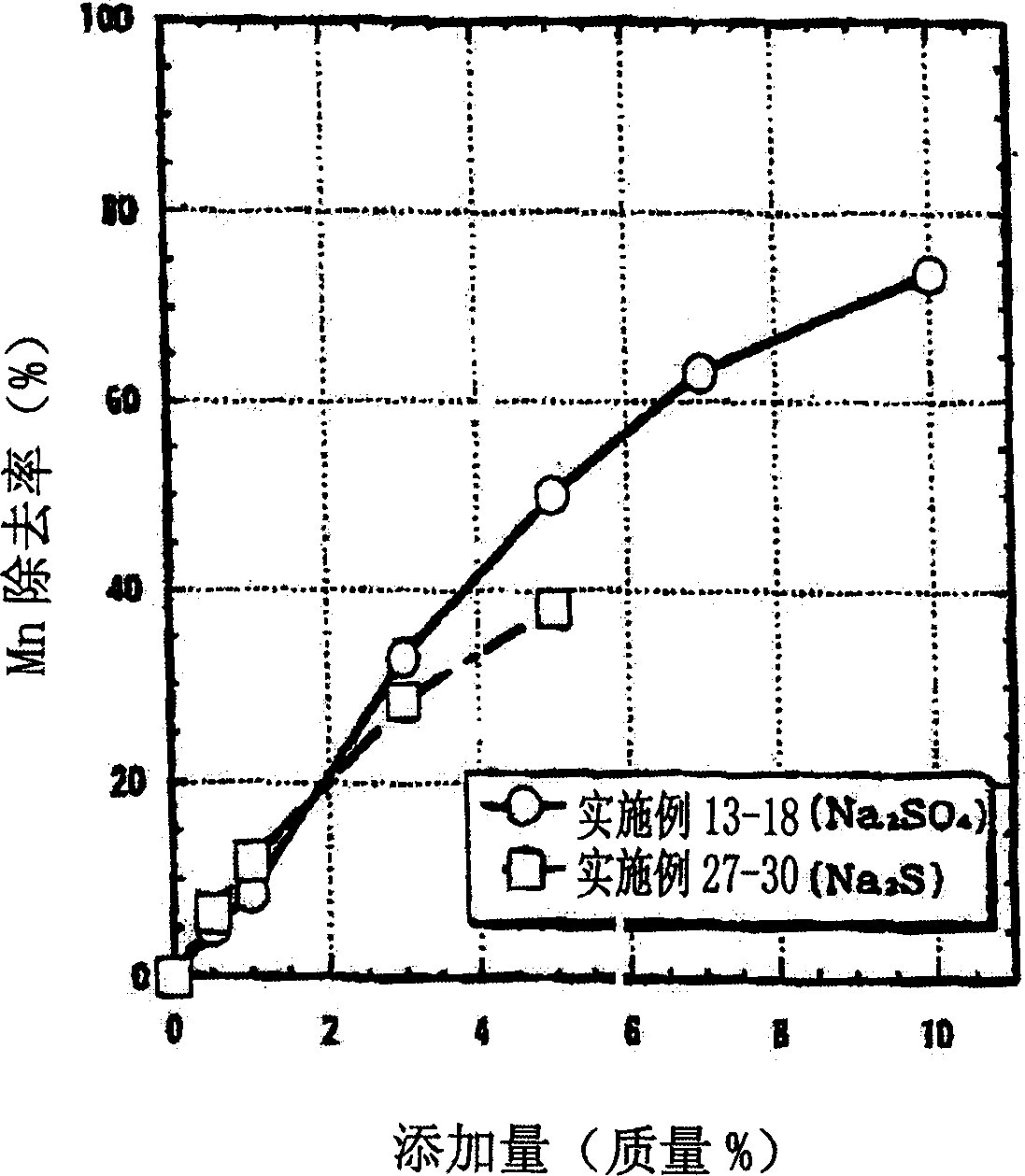

Method for removing manganese in cast iron molten liquid and method for manufacturing nodular graphite cast iron

A method for removing manganese in molten cast iron, characterized in that it comprises adding sodium sulfate while mixing into a molten cast iron as an additive, or adding sodium sulfide while mixing into a molten cast iron as an additive, adding hydrogen sodium sulfide while mixing into a molten cast iron as an additive. The method can be employed in the production of cast iron, and thus allows the production of a cast iron of high ductility which is improved in elongation characteristics without detriment to tensile strength, even when a steel scrap being cheap and having a high Mn content is used as a raw material.

Owner:ASAHI TEC CORP

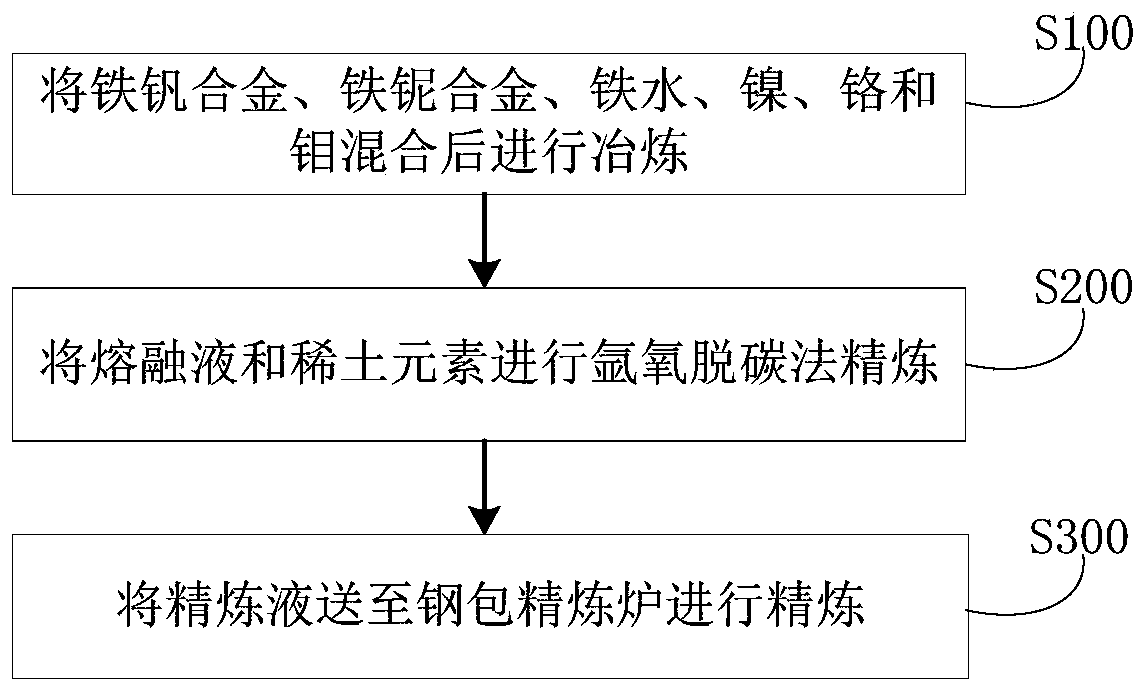

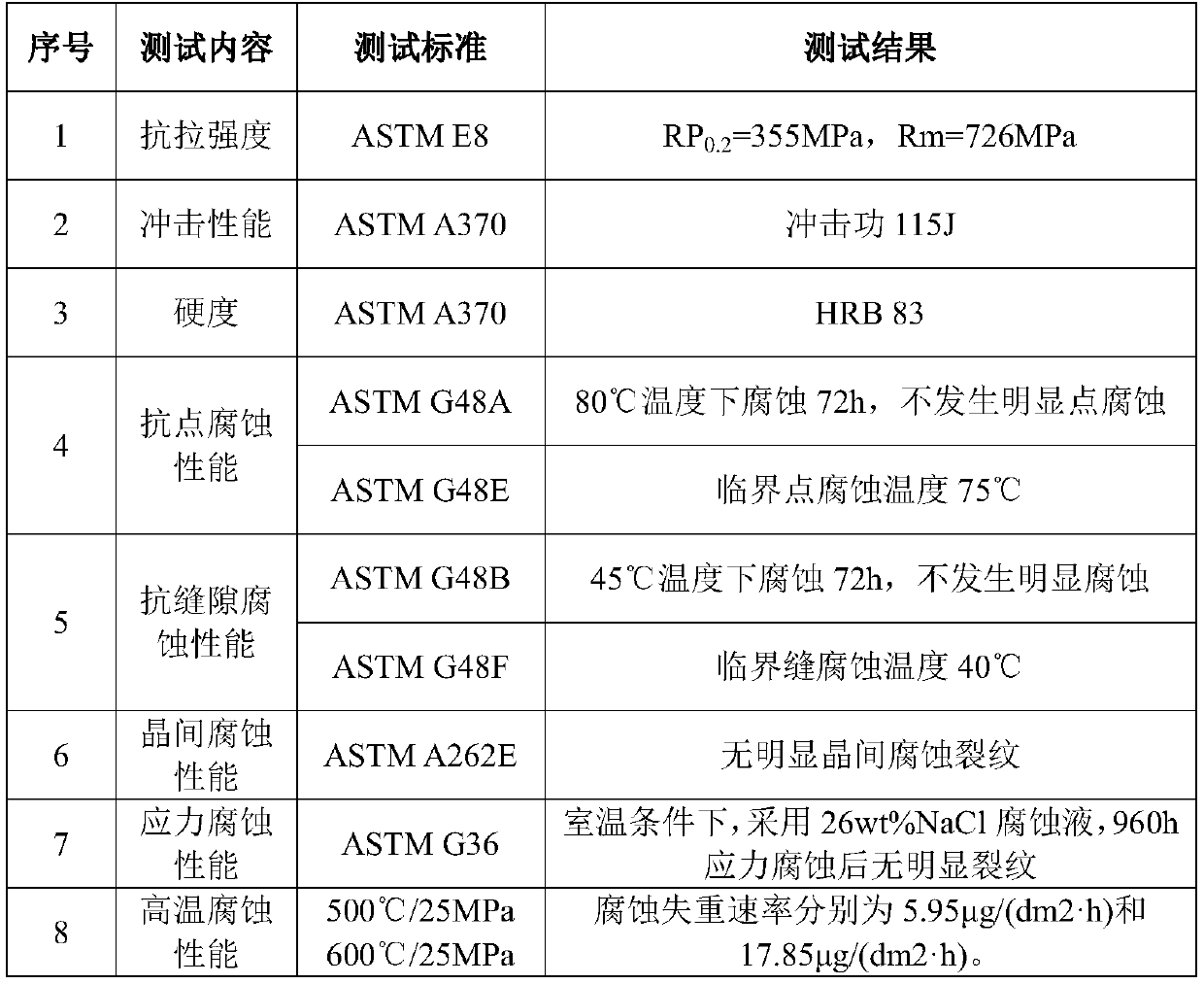

Improved corrosion-resistant superaustenitic stainless steel and preparation method thereof

InactiveCN110066957AMinimizes the effect of corrosion resistanceHigh strengthRare-earth elementNiobium

The invention discloses improved corrosion-resistant superaustenitic stainless steel and a preparation method thereof. The stainless steel comprises the following components of, by weight, 0.01 wt%-0.02 wt% of carbon, 0.4 wt%-0.6 wt% of silicon, 0 wt%-0.2 wt% of manganese, 0 wt%-0.02 wt% of phosphorus, 0 wt% to 0.01 wt% of sulfur, 21 wt%-22 wt% of chromium, 24 wt%-25.5 wt% of nickel, 6.0 wt%-7.0 wt% of molybdenum, 1 wt%-3 wt% of vanadium, 0 wt%-3 wt% of niobium, 0.20 wt%-0.25 wt% of nitrogen, 0 wt%-0.1 wt% of rare earth elements and the balance iron. The improved corrosion-resistant superaustenitic stainless steel does not add manganese or has a low manganese element content, is high in nitrogen content, good in normal-temperature resistance and high-temperature corrosion resistance, highin strength and excellent in comprehensive performance.

Owner:STATE POWER INVESTMENT CORP RES INST

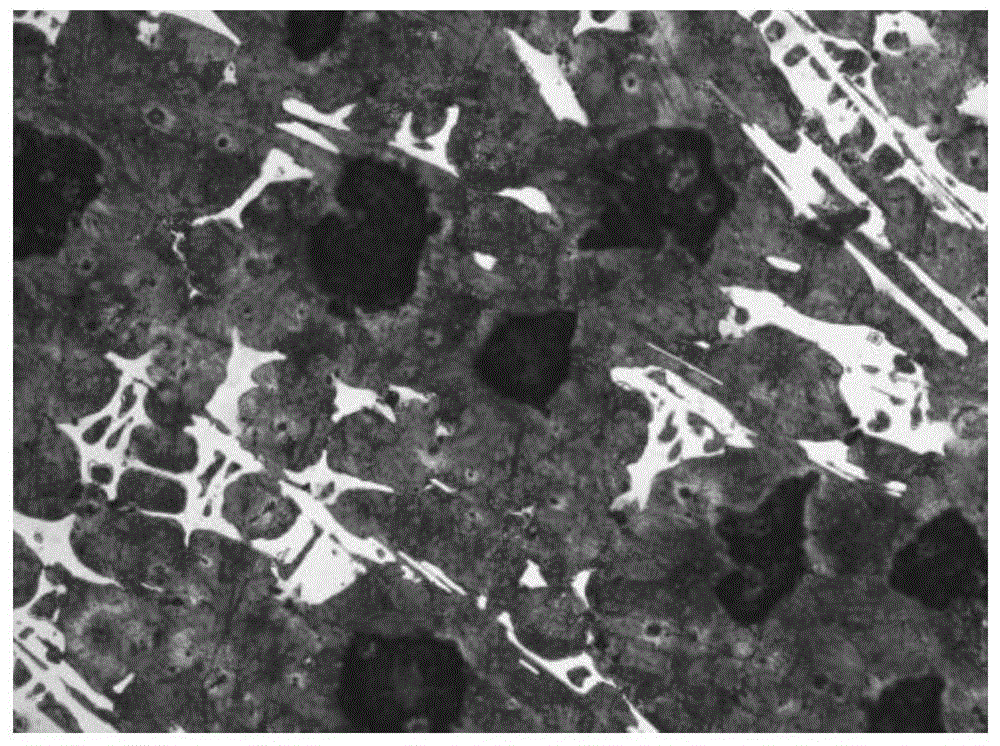

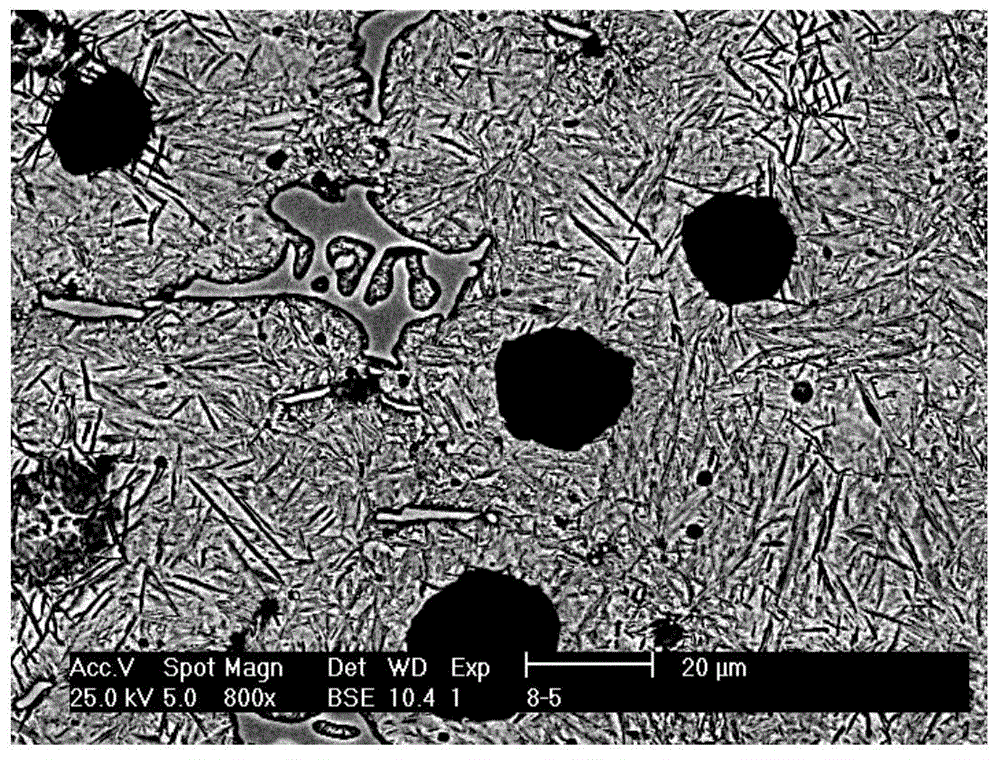

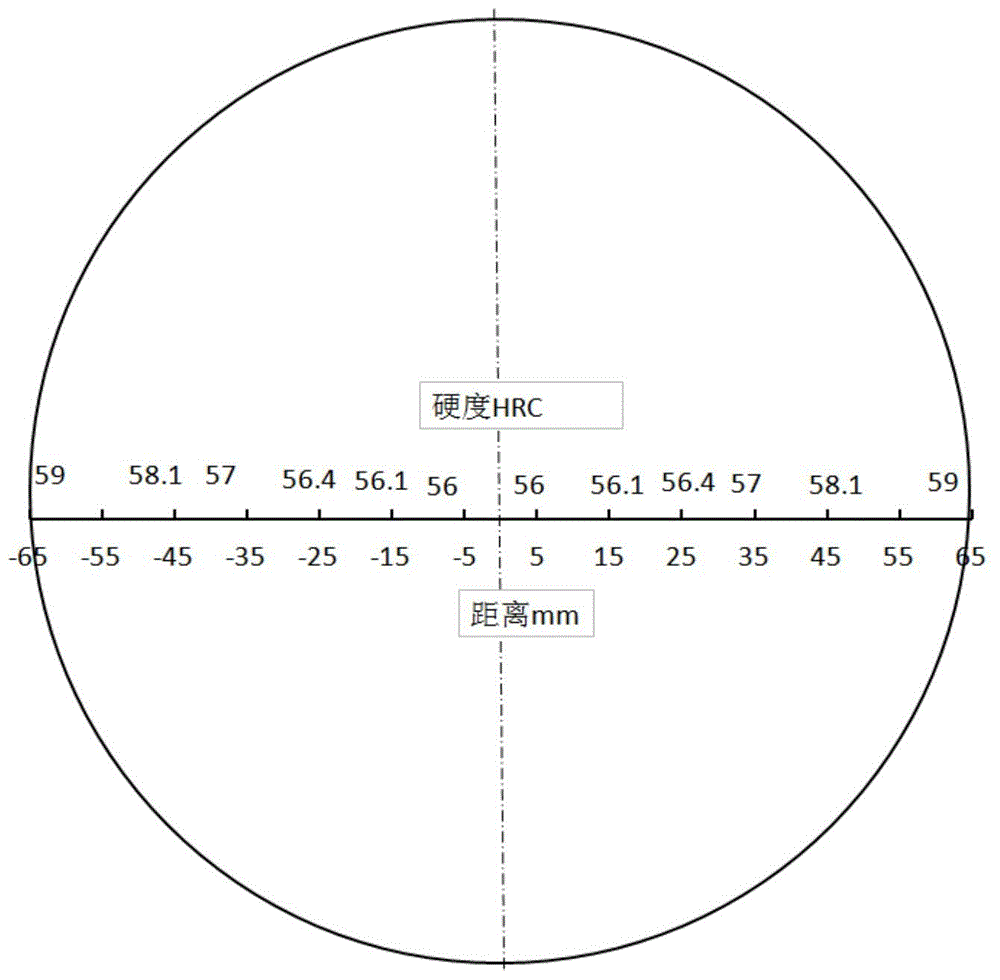

High-hardness alloyed nodular iron die material and preparation method thereof

ActiveCN102168222AReasonable and advancedImprove hardenabilityHigh volume manufacturingIntermediate frequency

Owner:宝武特种冶金有限公司

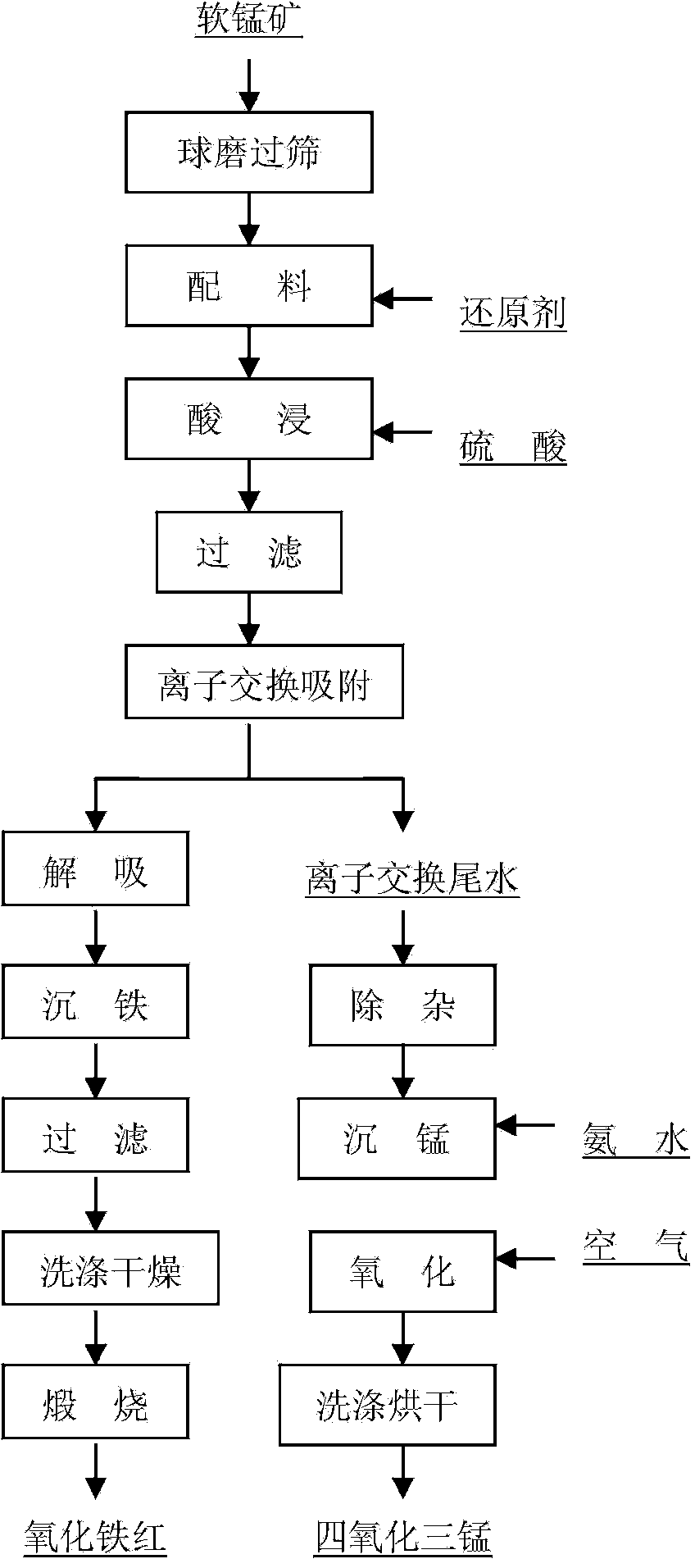

Process for preparing electronic grade manganous-manganic oxide and byproduct nano-iron oxide red from pyrolusite

ActiveCN104016417AHigh purityPotential stabilityMaterial nanotechnologyFerroso-ferric oxidesIonIon exchange

The invention belongs to the technical field of wet metallurgy of manganese, and provides a process for preparing electronic grade manganous-manganic oxide and byproduct nano-iron oxide red from pyrolusite by means of wet reduction. The process is used for preparing an electronic grade manganous-manganic oxide product by steps of ball-mill screening, preparing (adding a reducing agent), acid pickling, ion exchanging by chelate resin, impurity removing, manganese precipitation, oxidizing, washing, baking and the like, wherein an ion exchange eluent is subjected to iron neutralizing precipitation, filtering, washing and drying, calcining and the like to produce a byproduct nano-iron oxide red; the leaching rate of manganese is over 98 percent, the comprehensive recycling rate is more than 90 percent, the content of manganese in the manganous-manganic oxide is 71 percent, the specific surface area is more than 20m<2> / g, the byproduct nano-iron oxide red product can be prepared, the purity of the nano iron red product is more than 95 percent, and the grain diameter of the nano iron red product is less than 100nm. Compared with the prior art, the purity of the manganous-manganic oxide product is increased, the product quality is more stable, and the production cost is reduced.

Owner:JISHOU UNIVERSITY

Method for removing manganese from molten iron in top and bottom combined blown convertor

InactiveCN102559982AHigh efficiency of manganese removalWide variety of sourcesProcess efficiency improvementSlagScrap

The invention discloses a simple, efficient and low-cost method for removing manganese from molten iron in a top and bottom combined blown convertor. The final manganese content of the convertor is controlled to be less than 0.05 weight percent. The method comprises the following specific steps of: adding steel scrap into the convertor, adding the molten iron into the convertor, adding a demanganization agent into the liquid level of the molten iron, supplying oxygen to the liquid level of the molten iron by using an oxygen lance from the top, supplying stirring gas into the molten iron from the bottom, monitoring the CO content of converter gas, and pouring initial slag out when the inhibition of the carbon oxidation is converted into intense carbon oxidation, wherein the amount of poured slag is not less than 60 percent of the total slag amount; and adding the demanganization agent into the liquid level of the molten iron. Compared with the conventional method for removing manganese by a common blowing process or a convertor duplex manganese removal process, the method has the advantages that: special manganese removal equipment is not required, a mature top and bottom combined blown convertor blowing technology is fully utilized, and the dynamical condition for removing manganese from the molten iron is fully met, the common demanganization agent used as the raw material is used, sources are wide, and price is low.

Owner:HEBEI SHOUGANG QIAN AN IRON & STEEL CO LTD +1

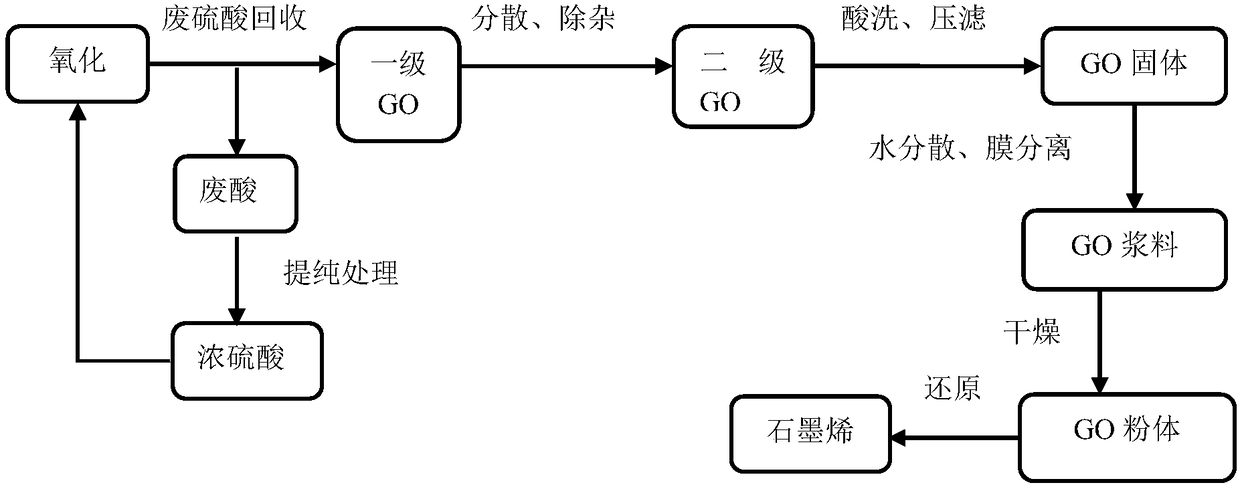

Graphene, production method and use thereof and battery

ActiveCN108545724AReduce manganese contentReduce processingCell electrodesGrapheneSewageLithium-ion battery

The invention provides graphene, a production method and use thereof and a battery, relating to the technical field of graphene. The production method comprises the following steps: (A) after graphitegenerates oxidation reaction with concentrated sulfuric acid and potassium permanganate, carrying out solid-liquid separation, so as to recycle concentrated sulfuric acid and obtain first-grade graphene oxide solids; and (B) removing impurities from first-grade graphene oxide solids by virtue of hydrogen peroxide, carrying out solid-liquid separation so as to obtain second-grade graphene oxide solids, sequentially washing with hydrochloric acid and water so as to obtain refined graphene oxide, and carrying out reduction on refined graphene oxide, so as to obtain graphene. The production method can be used for relieving the technical problems that graphene produced by virtue of an existing graphene production process is high in content and is not applicable to lithium ion battery materials, the amount of sewage produced during the purification is large, and environmental pollution is easily caused, and the purpose of reducing the content of graphene is achieved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

Method for increasing manganese leaching rate in low-grade manganese ore

ActiveCN110684900AImprove leaching rateImprove adsorption capacityPhotography auxillary processesElectrolytic agentActive agent

The invention provides a method for increasing the manganese leaching rate in low-grade manganese ore. In the low-grade manganese ore leaching process, a proper amount of surfactant is added, the surface activity of mineral particles is improved, the adsorption effect of the ore particles on hydrogen ions is improved, oily organic matter is effectively removed, and meanwhile, the manganese leaching rate is improved. In the filter pressing process of a manganese ore leaching solution, the surfactant is continuously filtered away, so that the surface tension of the manganese ore leaching solution is continuously decreased, and the current efficiency of the manganese ore leaching solution tends to be decreased after rising. In the low-grade manganese ore electrolysis process, a proper amountof surfactant is added, so that the surface tension value of the manganese ore leaching solution is optimal, and the current efficiency of electrolytic manganese is remarkably improved. The redox potential of electrolyte is reasonably controlled, so that the current efficiency of the solution is highest. Selenium dioxide with a certain concentration is added into the electrolyte during electrolysis so that occurrence of hydrogen evolution reaction can be inhibited, the current efficiency of the electrolytic manganese process can be remarkably improved, the energy consumption of the electrolytic manganese is low, and the manganese leaching rate is high.

Owner:广西大新汇元新能源科技有限责任公司

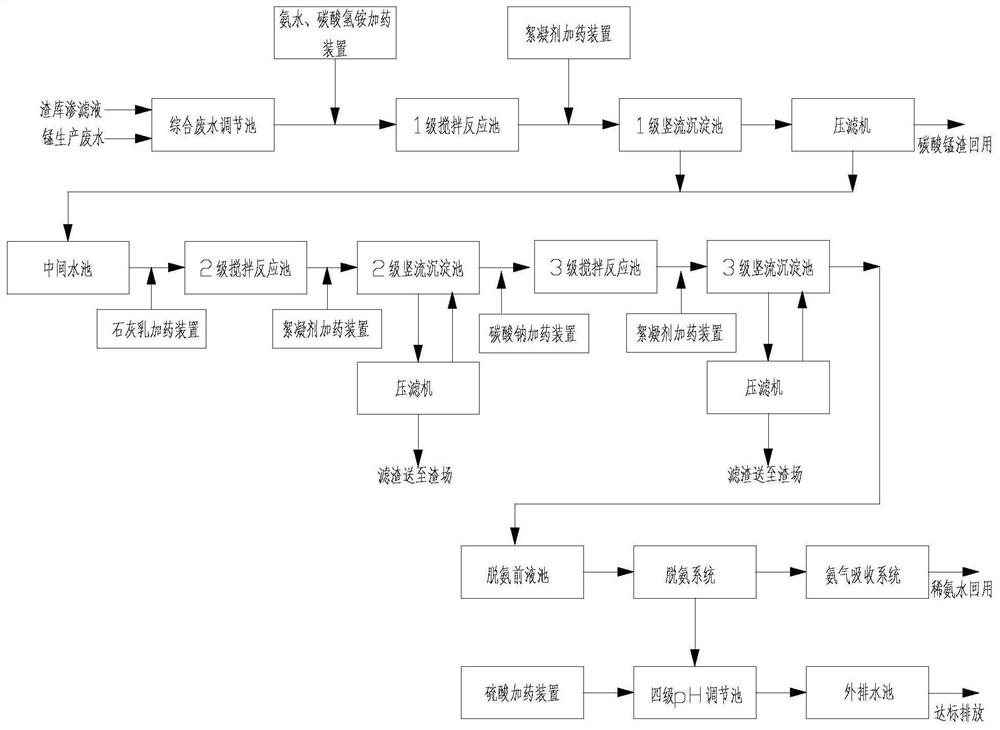

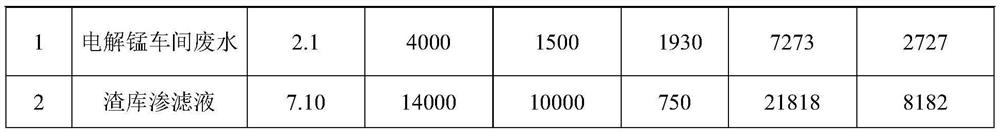

Method for continuously treating electrolytic manganese wastewater to recover manganese and ammonia nitrogen resources

InactiveCN111606487AHigh in manganeseHigh purityWater contaminantsTreatment involving filtrationAmmoniacal nitrogenManganese(II) carbonate

The invention discloses a method for continuously treating electrolytic manganese wastewater to recover manganese and ammonia nitrogen resources, which comprises the following steps: sending electrolytic manganese wastewater into a first-stage stirring reaction tank, regulating the pH value, and adding an ammonium bicarbonate solution at the same time; feeding the reacted wastewater into a first-stage sedimentation tank, adding a flocculating agent for flocculent precipitation, and carrying out filter pressing on underflow sediments to obtain manganese carbonate residues; sending the supernatant overflow and the filter pressing filtrate into a second-stage stirring reaction tank, adjusting the pH value to enable the residual manganese and heavy metal ions to generate hydroxide precipitate,and enabling ammonia nitrogen to generate free ammonia; feeding the reacted wastewater into a second-stage sedimentation tank; feeding the supernatant overflow into a three-stage stirring reaction tank, and adding carbonate to generate calcium carbonate precipitate; feeding the reacted wastewater into a third-stage sedimentation tank; preheating the supernatant overflow, and feeding the preheatedsupernatant overflow into a steam stripping deamination tower for deamination treatment; adjusting the pH value of the effluent of the tower kettle, and discharging the effluent. the purposes of effective treatment of electrolytic manganese comprehensive wastewater and comprehensive recycling of resources are achieved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for extracting manganese in electrolytic manganese waste slag or low-quality manganese ore by mechanochemical method and its additives

ActiveCN102719667BReduce manganese contentIncrease profitProcess efficiency improvementElectrolysisManganese

Owner:BEIFANG UNIV OF NATITIES

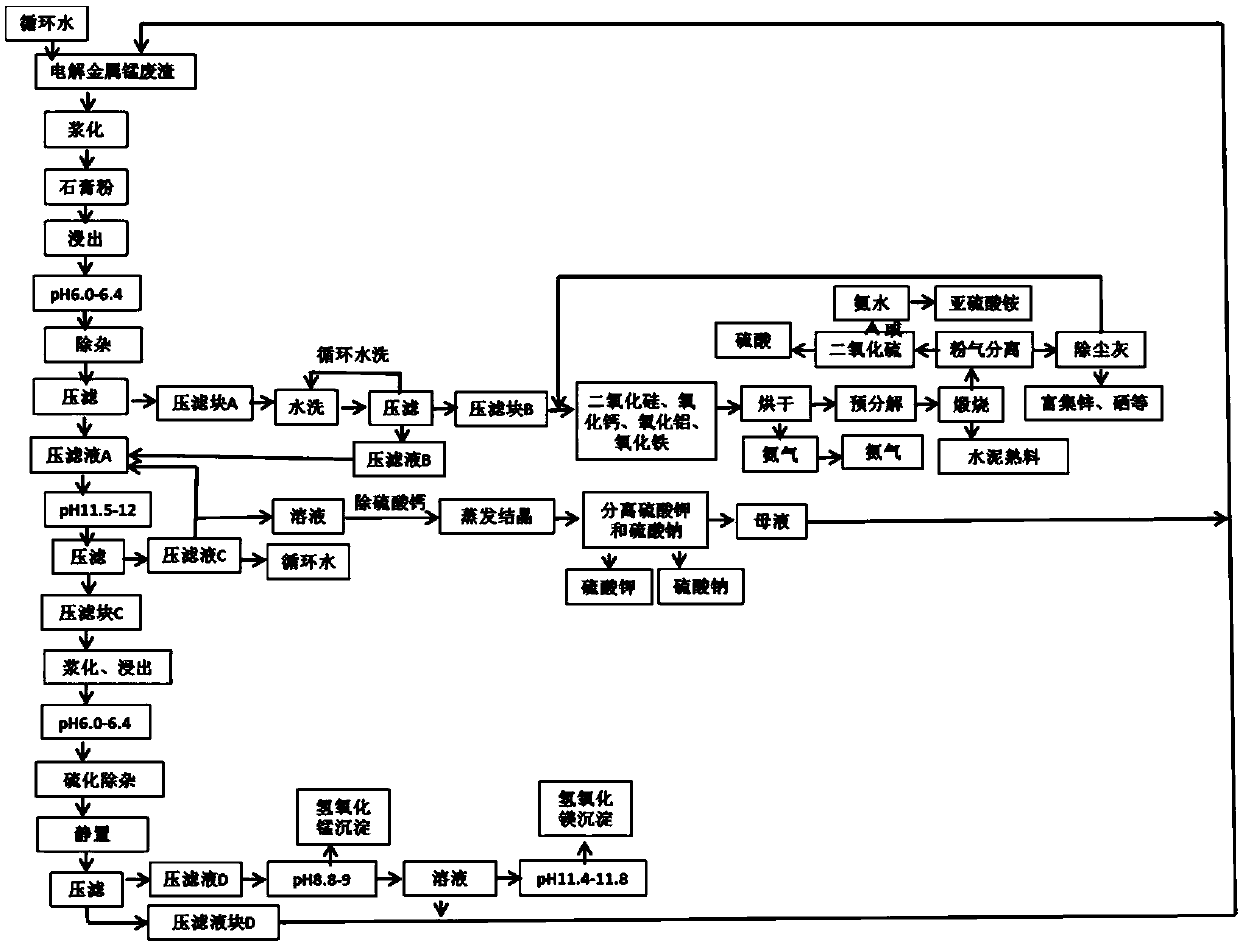

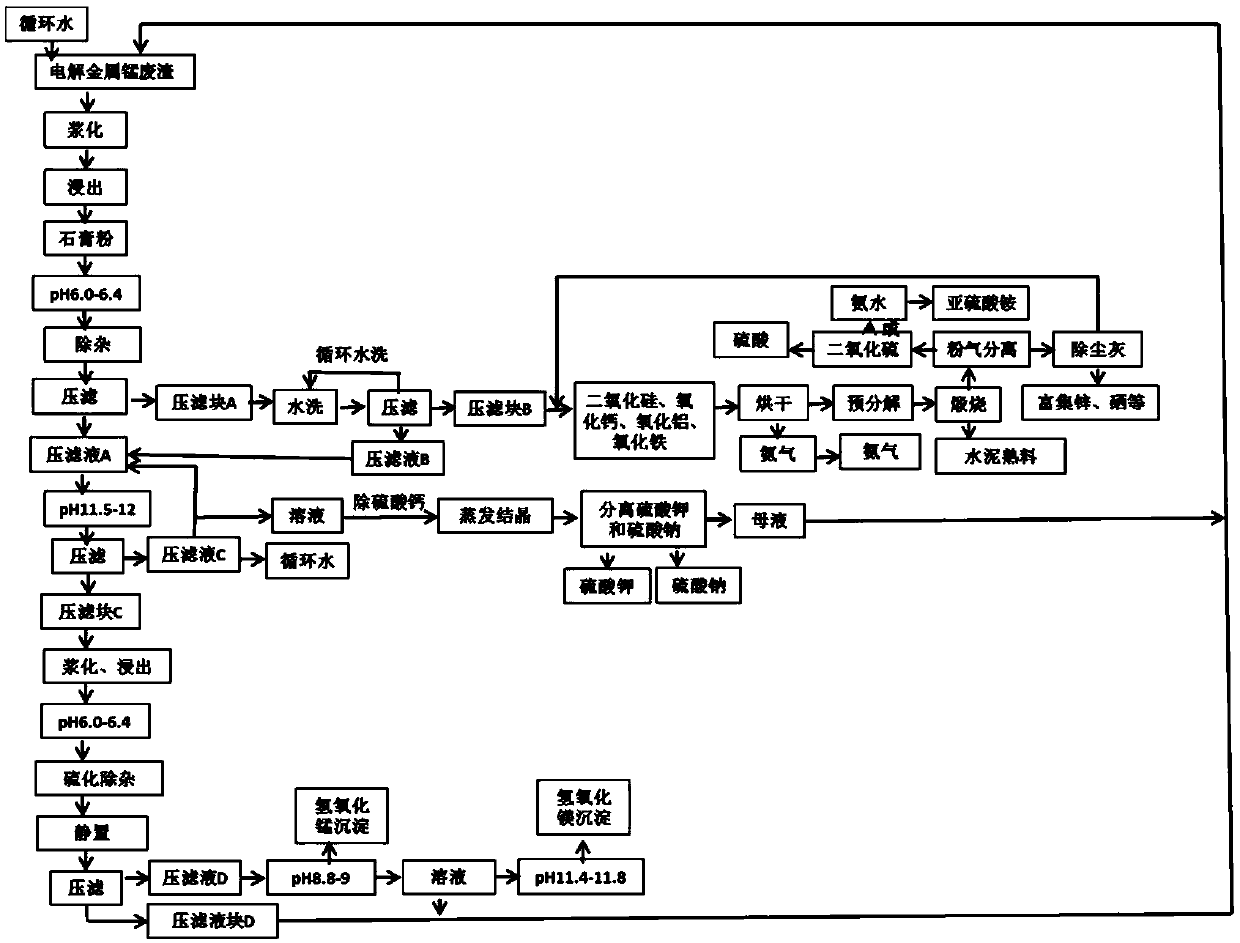

Method for combining electrolytic manganese metal waste residues and gypsum to produce cement clinker and ammonium hydroxide

ActiveCN110732543AImprove recycling ratesEnable recyclingSolid waste disposalElectrolysisClinker (waste)

The invention relates to a treatment method of electrolytic manganese metal waste residues. The treatment method comprises the following steps: A, grinding gypsum or drying calcined gypsum and then grinding to obtain gypsum powder; B, slurrying the electrolytic manganese metal waste residues, leaching, and adding the gypsum powder; adjusting the pH of a solution to 6.0-6.4, removing iron, carryingout filter pressing to obtain a filter pressing block A and a filter pressing solution A, washing the filter pressing block A with water, and then carrying out filter pressing to obtain a filter pressing block B and a filter pressing solution B; adjusting the pH of the filter pressing solution A to 11.5-12, and carrying out filter pressing to obtain a filter pressing block C and a filter pressingsolution C; C, adding silicon dioxide, calcium oxide, aluminum oxide and iron oxide into the filter pressing block B, drying, pre-decomposing, and calcining to obtain cement clinker; D, slurrying thefilter pressing block C, leaching, adjusting the pH to 6.0-6.4, removing impurities, standing, and carrying out filter pressing to obtain a filter pressing block D and a filter pressing solution D, adding ammonia water into the filter pressing solution D to adjust the pH to 8.8-9, and continuously adding an ammonia water solution to adjust the pH to 11.4-11.8. The method realizes recycling of resources.

Owner:庞炼红

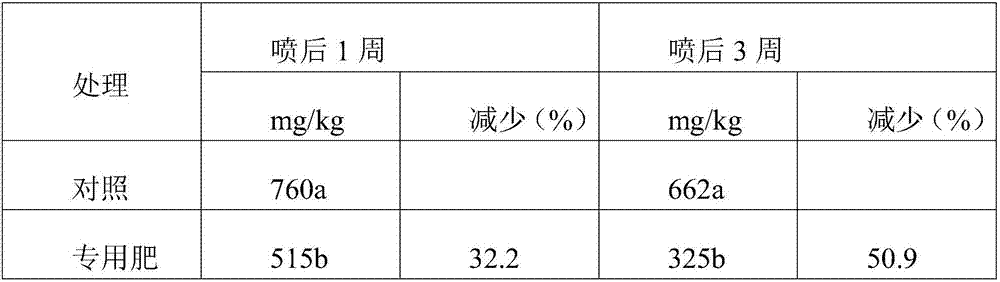

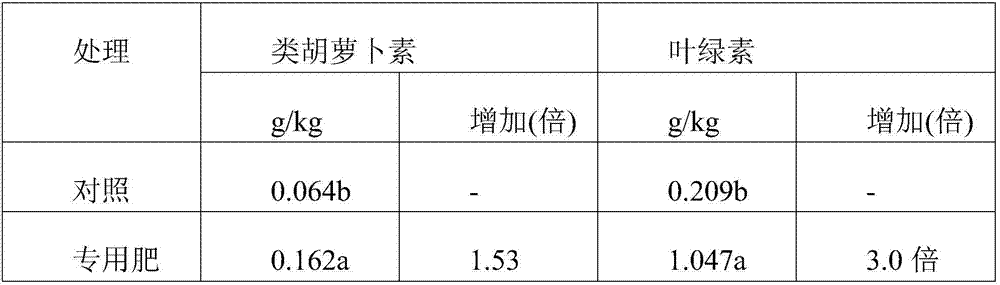

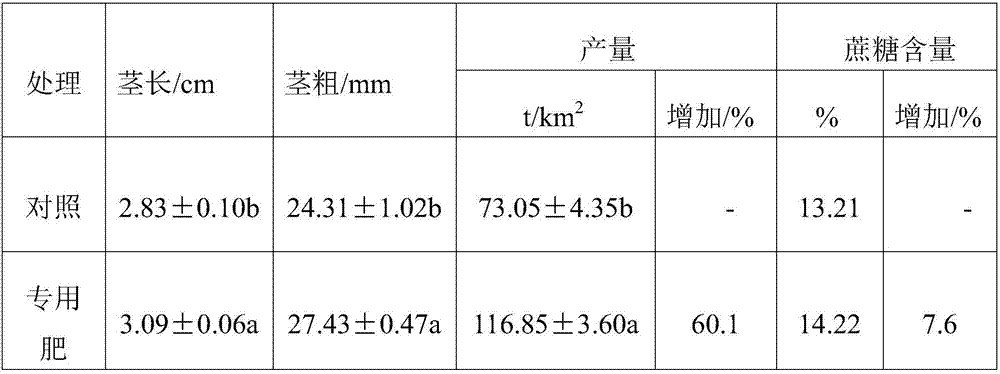

Special fertilizer for preventing and controlling sugarcane manganese toxicity and application method thereof

InactiveCN107473854AElimination of antagonistic effectsEasy to synthesizeMagnesium fertilisersFertilising methodsManganeseNutrient

The invention discloses a special fertilizer for preventing and controlling sugarcane manganese toxicity. The special fertilizer is mainly prepared from an iron fertilizer, a nitrogen fertilizer, boric acid, citric acid and a sulfur fertilizer. By spraying the special fertilizer for preventing and controlling sugarcane manganese toxicity disclosed by the invention, active iron lacking in sugarcane seedlings under stress of manganese toxicity is replenished in a timely manner, and nitrogen, magnesium, boron and sulfur nutrients of the seedlings are regulated, so as to promote chlorophyll synthesis to enable leaves to be green quickly. Through a synergist for inhibiting manganese transport while promoting the absorption and transport of other nutrients in the special fertilizer, the special fertilizer can give full play to nutritional effects thereof, so that the special fertilizer can quickly control the manganese toxicity in ratoon sugarcane, promote growth of seedlings, and increase the yield of cane stalks significantly. After the special fertilizer is applied for 1-3 weeks, the content of manganese in young leaves is decreased by 3.7%-50.9%; after the special fertilizer is applied for 7 days, the content of chlorophyll in young leaves of ratoon sugarcane is increased by more than 3 times, and the proportion of green leaves is increased by more than 5 times; after application, the stalk length during a sugarcane mature period is increased by 4.8% or above, the stalk diameter is increased by 3.9% or above, and the yield is increased by 18.8%-60.1%. The special fertilizer in solid state is convenient for transportation and storage, and easy in application method.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com