Chromium-alloyed cord steel wire rod and production process

A production process, chrome alloy technology, applied in the direction of manufacturing converters, etc., can solve the problems affecting wire rod plasticity, drawing performance and plying performance, high wire breakage rate, etc., to reduce wire breakage rate, reduce manganese content, The effect of reducing carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

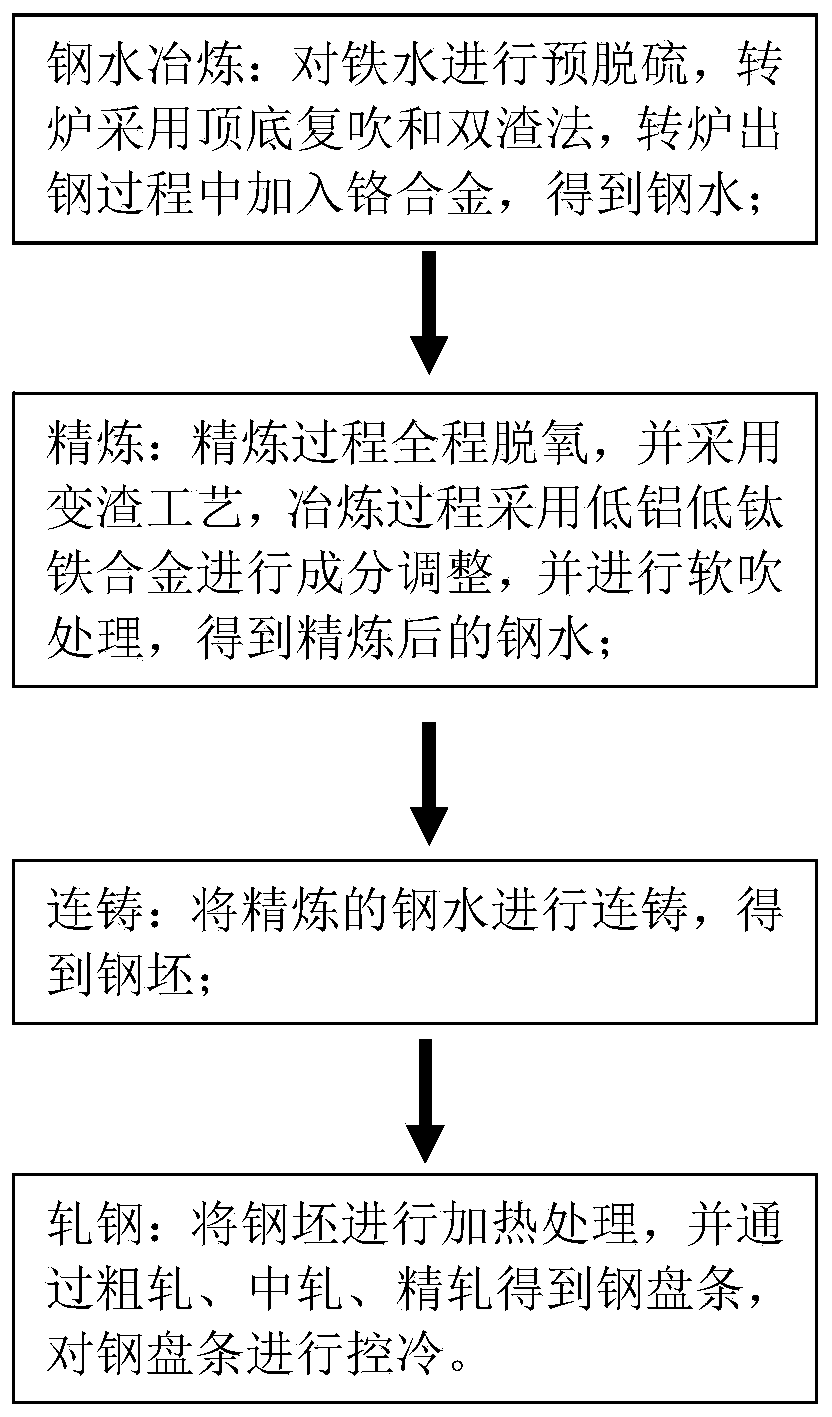

Method used

Image

Examples

Embodiment 1

[0045] A chromium-alloyed cord steel wire rod YLX70ACr, wherein YLX represents Yonggang cord, and A represents the quality grade of the steel.

[0046] The chemical composition and weight percentage content of the chromium alloyed cord steel wire rod YLX70ACr are:

[0047] C: 0.70%, Mn: 0.30%, Si: 0.20%, Cr: 0.35%, P: 0.007%, S: 0.002%, Ni: 0.01%, Cu: 0.01%, Mo: 0.01%, Al: 0.0009%, Ti: 0.0004%, [O]: 0.0013%, [N]: 0.0022%, and the balance is Fe and unavoidable impurities.

[0048] The production process of the chromium alloyed cord steel wire rod comprises the following steps:

[0049] Step S1, molten steel smelting: pre-desulfurize the raw material molten iron by KR (Kambara Reactor) method, the sulfur content of the molten iron can be stably controlled within 0.005% after desulfurization, the converter adopts top-bottom double blowing, and adopts the double slag method to effectively reduce the phosphorus content To less than 0.010%, adopt sliding plate to stop slag in conv...

Embodiment 2

[0055] A chromium-alloyed cord steel wire rod YLX70ACr, where YLX represents Yonggang cord, and A represents the quality grade of the steel.

[0056] The chemical composition and weight percentage content of the chromium alloyed cord steel wire rod YLX70ACr are:

[0057] C: 0.68%, Mn: 0.40%, Si: 0.30%, Cr: 0.40%, P: 0.008%, S: 0.002%, Ni: 0.01%, Cu: 0.01%, Mo: 0.01%, Al: 0.0008%, Ti: 0.0005%, [O]: 0.0012%, [N]: 0.0020%, and the balance is Fe and unavoidable impurities.

[0058] The production process of the chromium alloyed cord steel wire rod comprises the following steps:

[0059] Step S1, molten steel smelting: pre-desulfurize the raw material molten iron by KR (Kambara Reactor) method, the sulfur content of the molten iron can be stably controlled within 0.005% after desulfurization, the converter adopts top-bottom double blowing, and adopts the double slag method to effectively reduce the phosphorus content To less than 0.010%, adopt sliding plate to stop slag in conver...

Embodiment 3

[0065] A chromium-alloyed cord steel wire rod YLX70ACr, where YLX represents Yonggang cord, and A represents the quality grade of the steel.

[0066]The chemical composition and weight percentage content of the chromium alloyed cord steel wire rod YLX70ACr are:

[0067] C: 0.72%, Mn: 0.20%, Si: 0.15%, Cr: 0.30%, P: 0.007%, S: 0.002%, Ni: 0.01%, Cu: 0.01%, Mo: 0.01%, Al: 0.0007%, Ti: 0.0004%, [O]: 0.0013%, [N]: 0.0022%, and the balance is Fe and unavoidable impurities.

[0068] The production process of the chromium alloyed cord steel wire rod comprises the following steps:

[0069] Step S1, molten steel smelting: pre-desulfurize the raw material molten iron by KR (Kambara Reactor) method, the sulfur content of the molten iron can be stably controlled within 0.005% after desulfurization, the converter adopts top-bottom double blowing, and adopts the double slag method to effectively reduce the phosphorus content To less than 0.010%, adopt sliding plate to stop slag in convert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Breaking force | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com