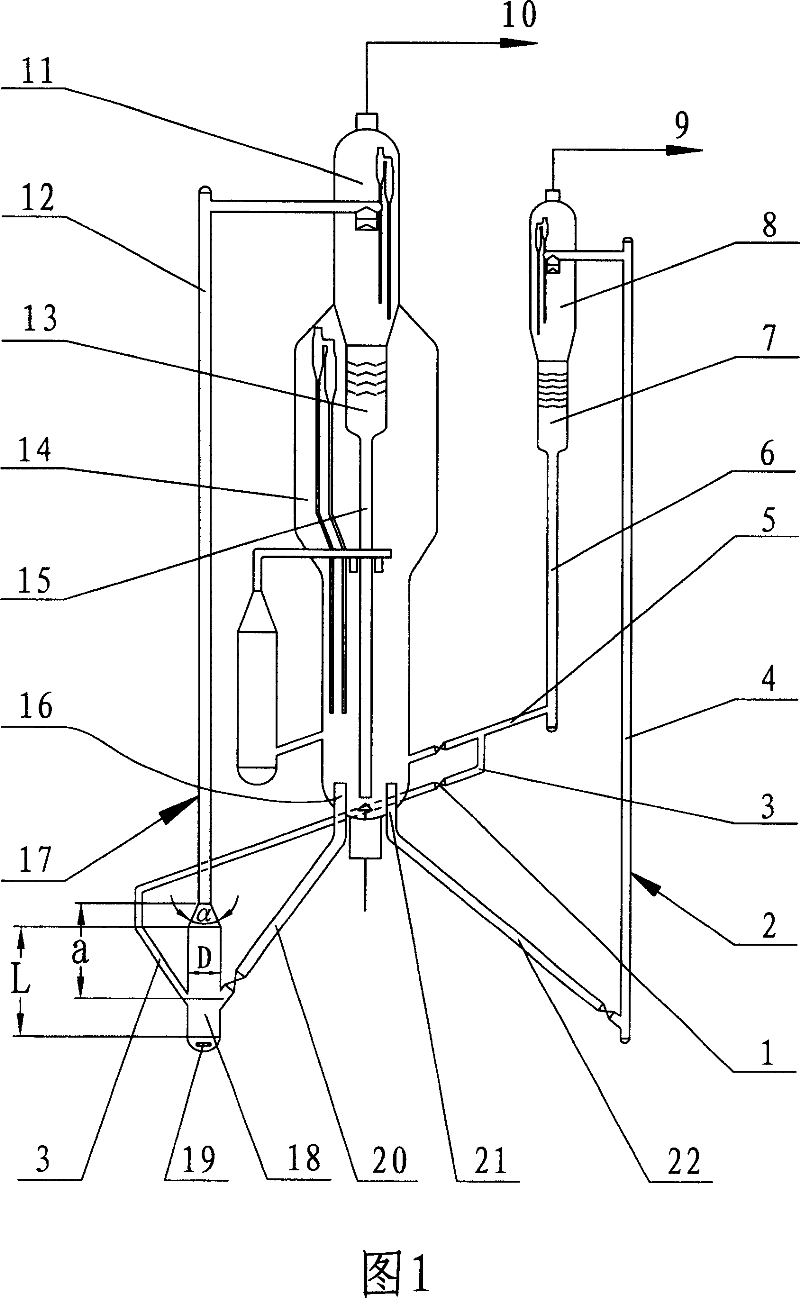

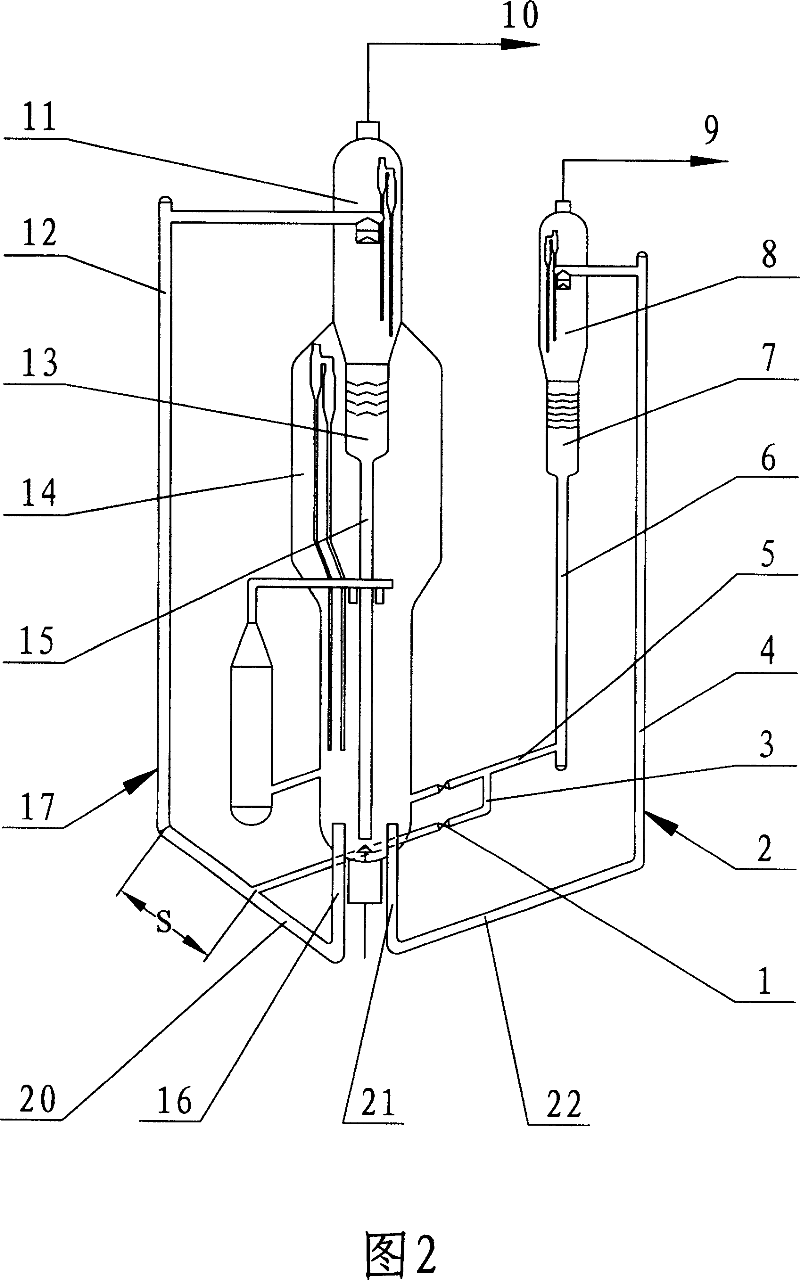

Catalytic cracking method and apparatus

A catalytic cracking and catalyst technology, applied in the direction of catalytic cracking, cracking, petroleum industry, etc., can solve the problems of overall activity reduction, lack of flexibility in adjustment, etc., and achieve the goal of reducing local temperature, improving product distribution and product properties, and great flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to the comparative example, the difference is the weight mixing ratio of the stripped spent catalyst from the light hydrocarbon riser reactor and the regenerated catalyst from the regenerator in the catalyst mixing tank, the temperature of the mixed catalyst in the catalyst mixing tank, and the lift of heavy oil The agent-to-oil ratio, refining ratio and reaction time of the tube reactor. Table 4 shows the operating conditions, product distribution and partial properties of the gasoline produced in the heavy oil riser reactor of this example.

Embodiment 2

[0031] According to the comparative example, the difference is the weight mixing ratio of the stripped spent catalyst from the light hydrocarbon riser reactor and the regenerated catalyst from the regenerator in the catalyst mixing tank, the temperature of the mixed catalyst in the catalyst mixing tank, and the lift of heavy oil The agent-to-oil ratio, refining ratio and reaction time of the tube reactor. The operating conditions, product distribution and some properties of the gasoline produced in the heavy oil riser reactor of this example are shown in Table 5.

Embodiment 3

[0033] According to the comparative example, the difference is the weight mixing ratio of the stripped spent catalyst from the light hydrocarbon riser reactor and the regenerated catalyst from the regenerator in the catalyst mixing tank, the temperature of the mixed catalyst in the catalyst mixing tank, and the lift of heavy oil The agent-to-oil ratio, refining ratio and reaction time of the tube reactor. The operating conditions, product distribution and partial properties of the gasoline produced in the heavy oil riser reactor of this example are shown in Table 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com