Patents

Literature

32results about How to "To achieve the purpose of comprehensive utilization of resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting high-valence manganese from manganese carbonate ore

This invention has provided one kind of method to leach high price manganese from manganese carbonateore, which belongs to the hydrometallurgy domain. It takes the glucose or the plant biomass and sulfuric acid as reducing agent of high pricemanganese in manganese carbonate ore, adopting microwave radiation glucose to promote high price manganese to revert, the concrete step includes: Takes 1 copy 100-200 sieve manganese carbonateore, add 10 -20 copy water to modulate the pulp; Again add 60% density sulfuric acid to pulp, the load ratio of mineral powder and sulfuric acid is 1: 6 -9; Simultaneously, add glucose or plant biomass, the load ratio of mineral powder and glucose or plant biomass is 10 -15: 1, stir evenly; radiate under 500 -1000W microwave, stir and respond for 4-10min, leach temperature is controlled at 50degree C-60 degree C, then get lixivium by filtering. This invention has the merits of lower reaction temperature, reducing acid consume and reduce leaching time of the manganese ore, high thermal using and respond rapidly.

Owner:CHONGQING UNIV

Preparation method of lawn seed carpet containing water absorbent, sustained-release fertilizer and protector

InactiveCN1994038AFacilitated releaseControl release speedSynthetic resin layered productsPaper/cardboard layered productsWater dischargeWastewater

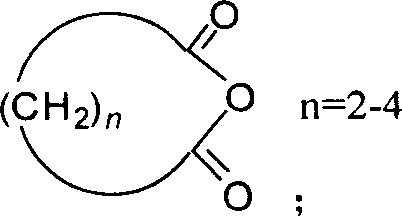

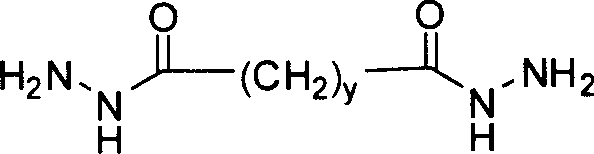

The invention relates to a method for preparing green seed curtain with water absorber, slow-release fertilizer and protector, wherein the method comprises that: the prector comprises 5-20% pesticide, 5-20% herbicide, 3-10% antimold, 1-5% diacid, 1-5% hydrazides, 0.01-0.1% crosslinker, and 40-84% porous adsorption material. The invention coats one adhesive layer on the degradable plastic film; compresses the fiber layer on it and holes; coats adhesive layer on it; sprays needed plant seed, protector, absorber, and slow-release fertilizer on it; compresses the fiber layer. The invention can reduce waste water discharge, high yield, etc.

Owner:李兵 +2

Method for extracting pleurotus eryngii polysaccharide from pleurotus eryngii leftover by using subcritical water

InactiveCN103130911ATo achieve the purpose of comprehensive utilization of resourcesRich sourcesOrganic solventPolymeric adsorbent

The invention provides a method for extracting pleurotus eryngii polysaccharide from pleurotus eryngii leftovers by using subcritical water. The method comprises the following steps of: feeding the pleurotus eryngii leftovers into an extraction kettle; feeding deoxidized deionized water according to a material-liquid mass volume ratio of 1:(5-30); controlling the extraction pressure to be 3-10MPa, the temperature to be 100-250 DEG C and the extraction time to be 10-60min; filtering, cooling and centrifuging; carrying out ultrafiltration by using an ultrafiltration film of which the molecular weight cut-off is 100-300kD; cutting off the filtrate by using an ultrafiltration film of which the molecular weight cut-off is 3-10kD; feeding the crude polysaccharide cut-off liquid into an anion exchange resin column; and eluting by using deionized water; and concentrating under reduced pressure and drying the collected polysaccharide eluate so as to obtain a pleurotus eryngii polysaccharide product. According to the method, a subcritical water extraction technique is combined with the separation means of ultrafiltration edulcoration and resin absorption decoloration, no organic solvents are used in the whole process, the extraction process is green and environment-friendly, and the pleurotus eryngii polysaccharide is high in purity and is applicable to industrial production.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

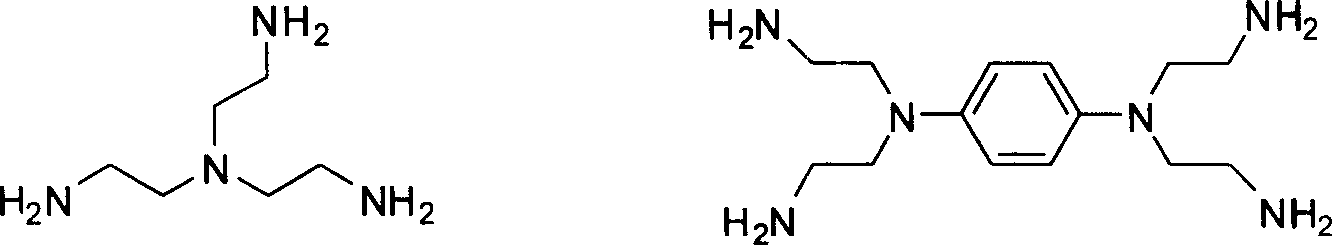

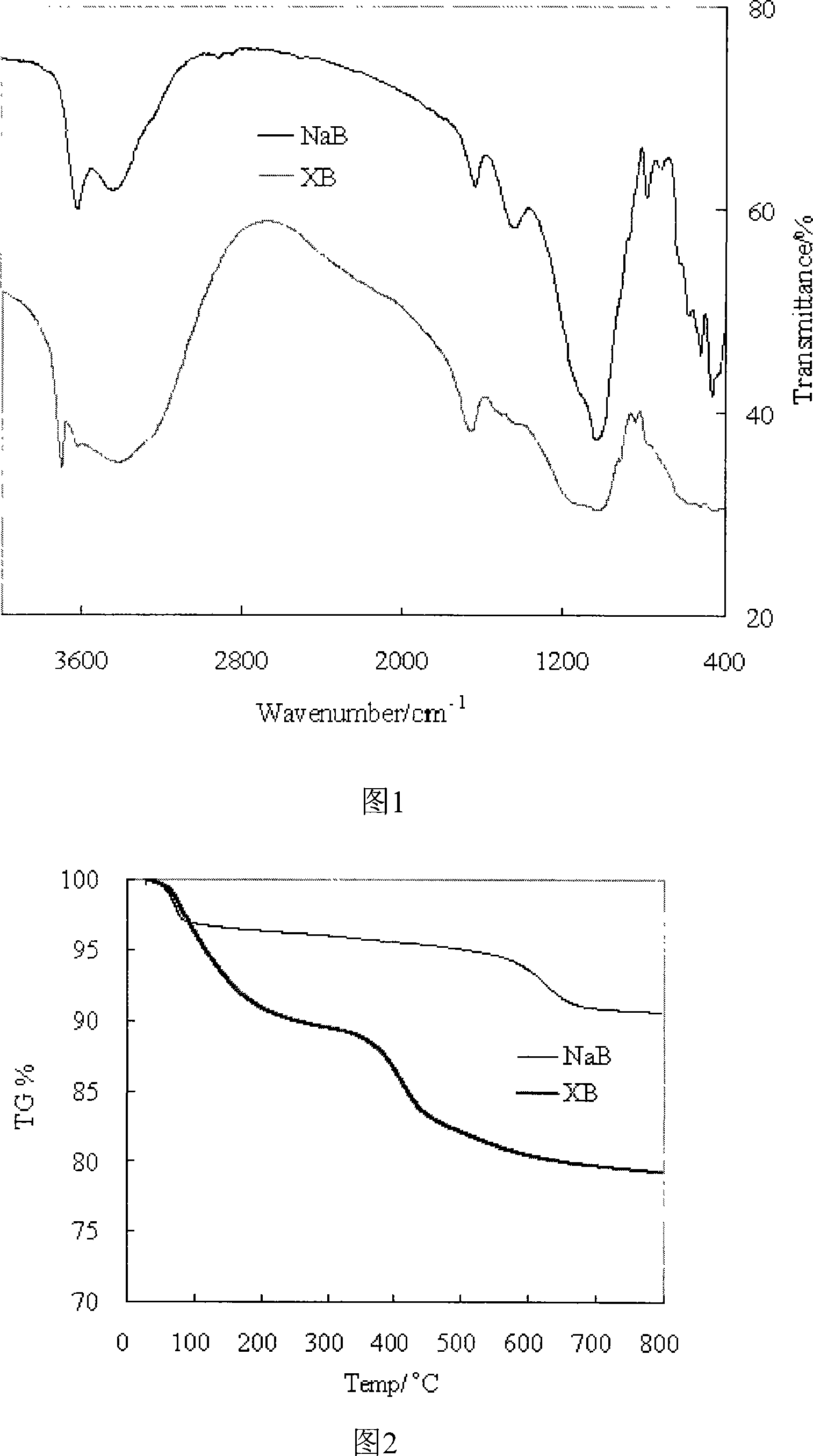

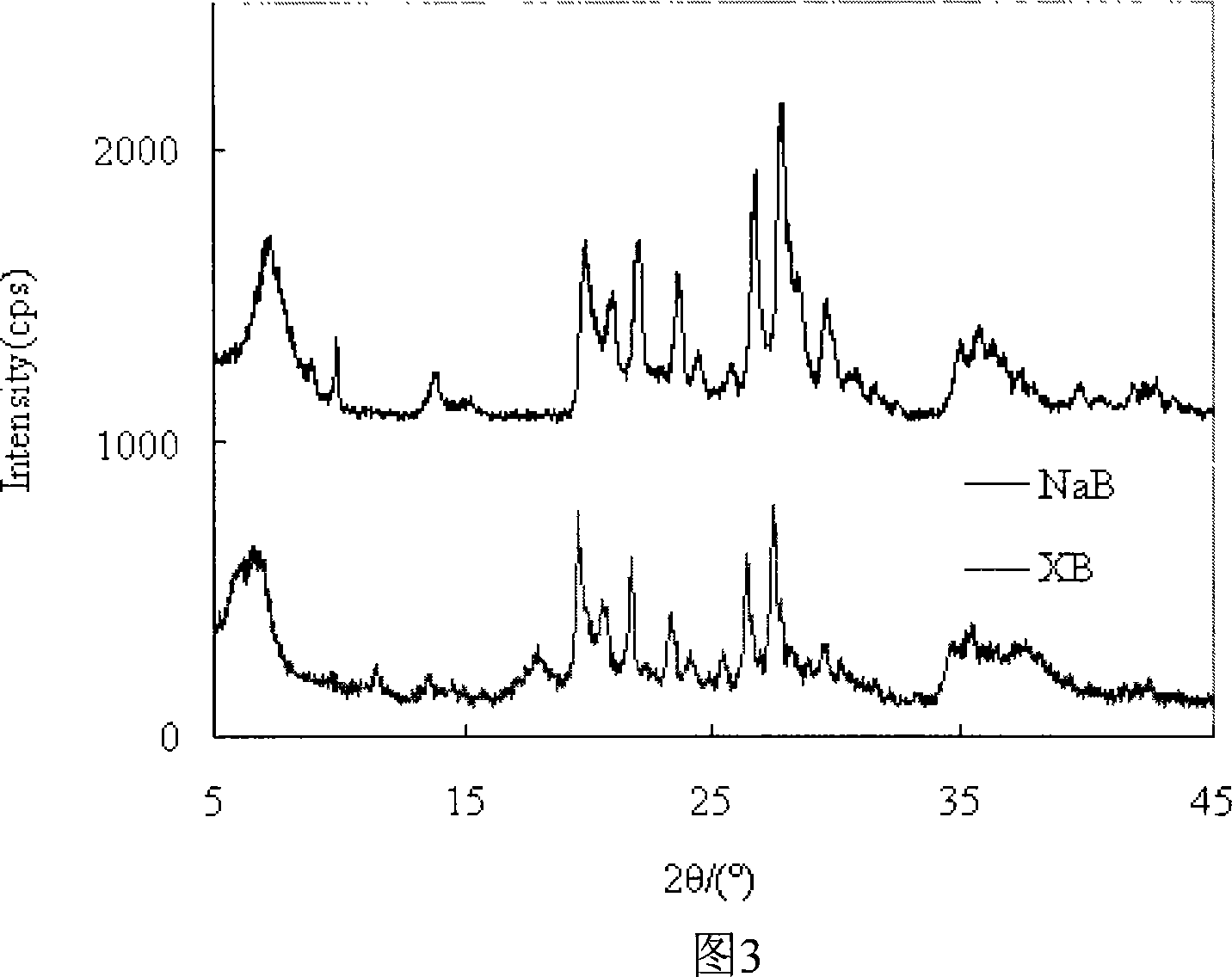

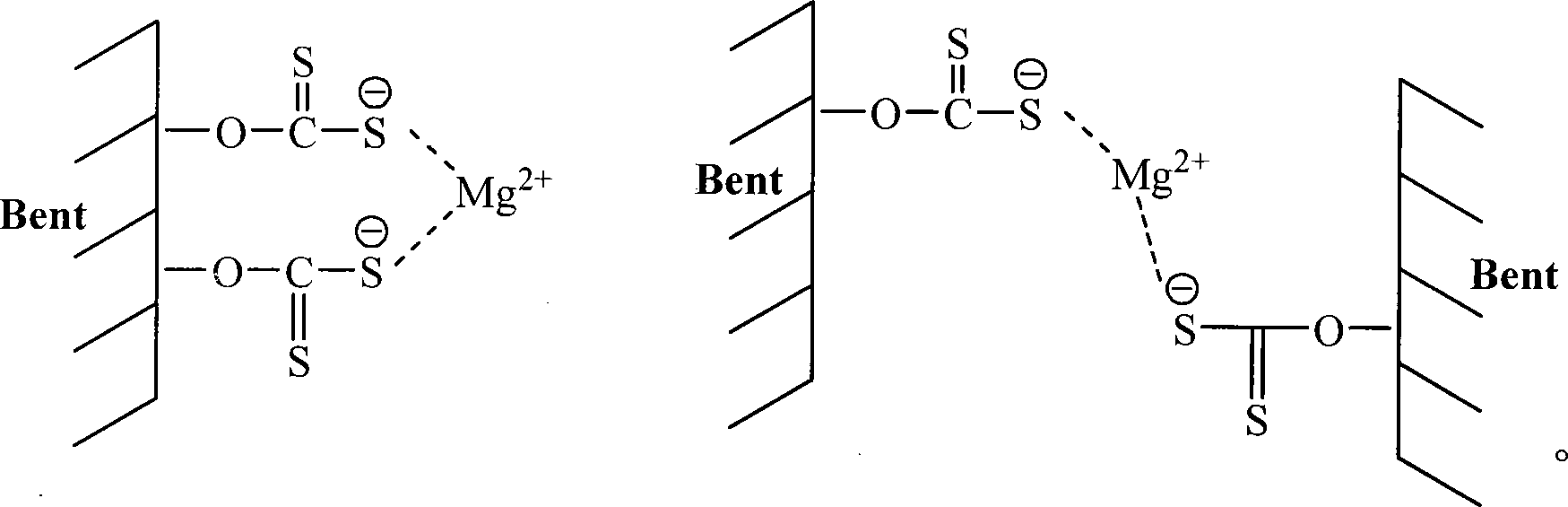

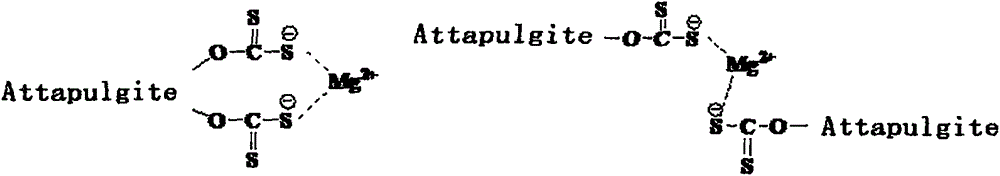

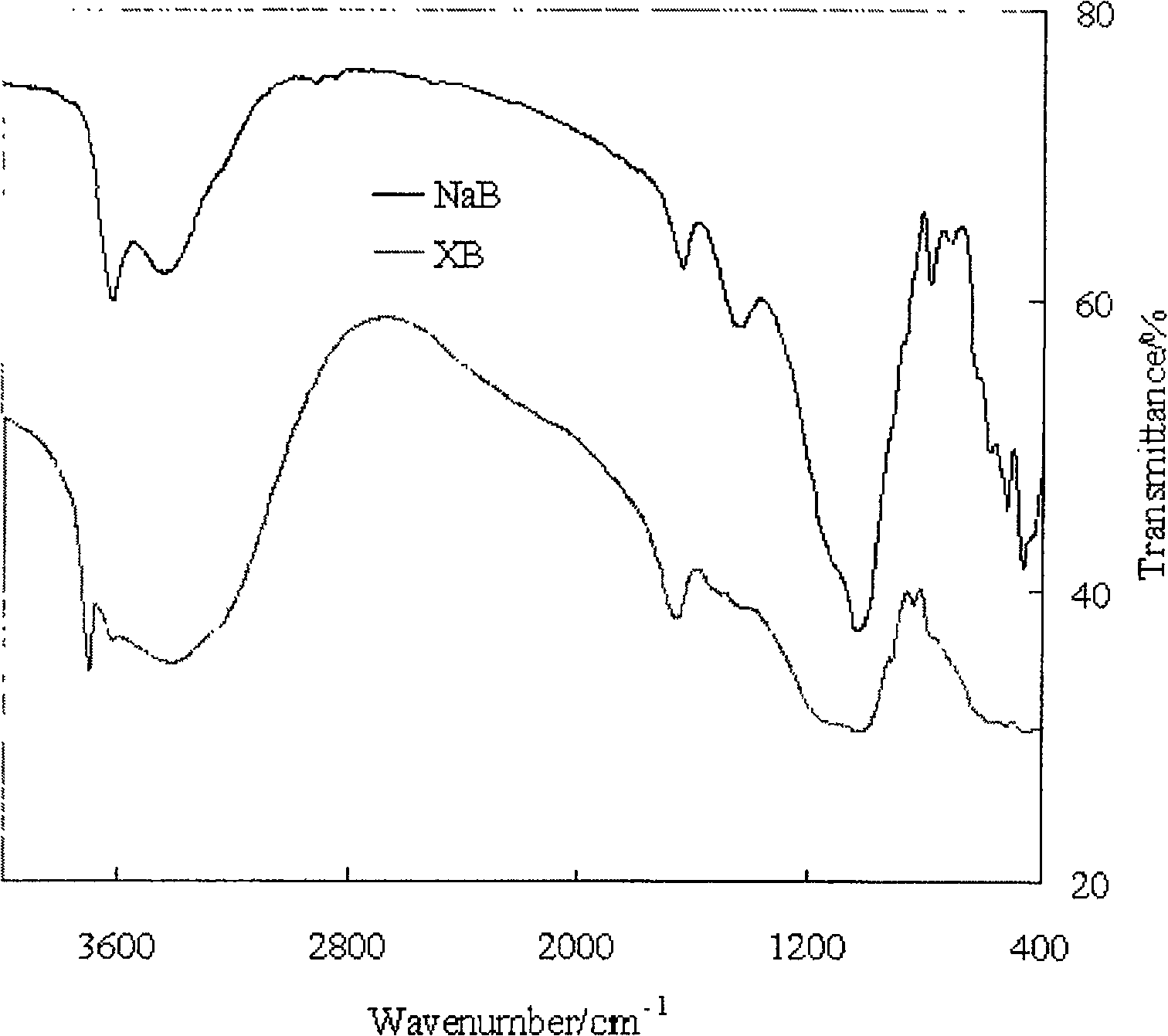

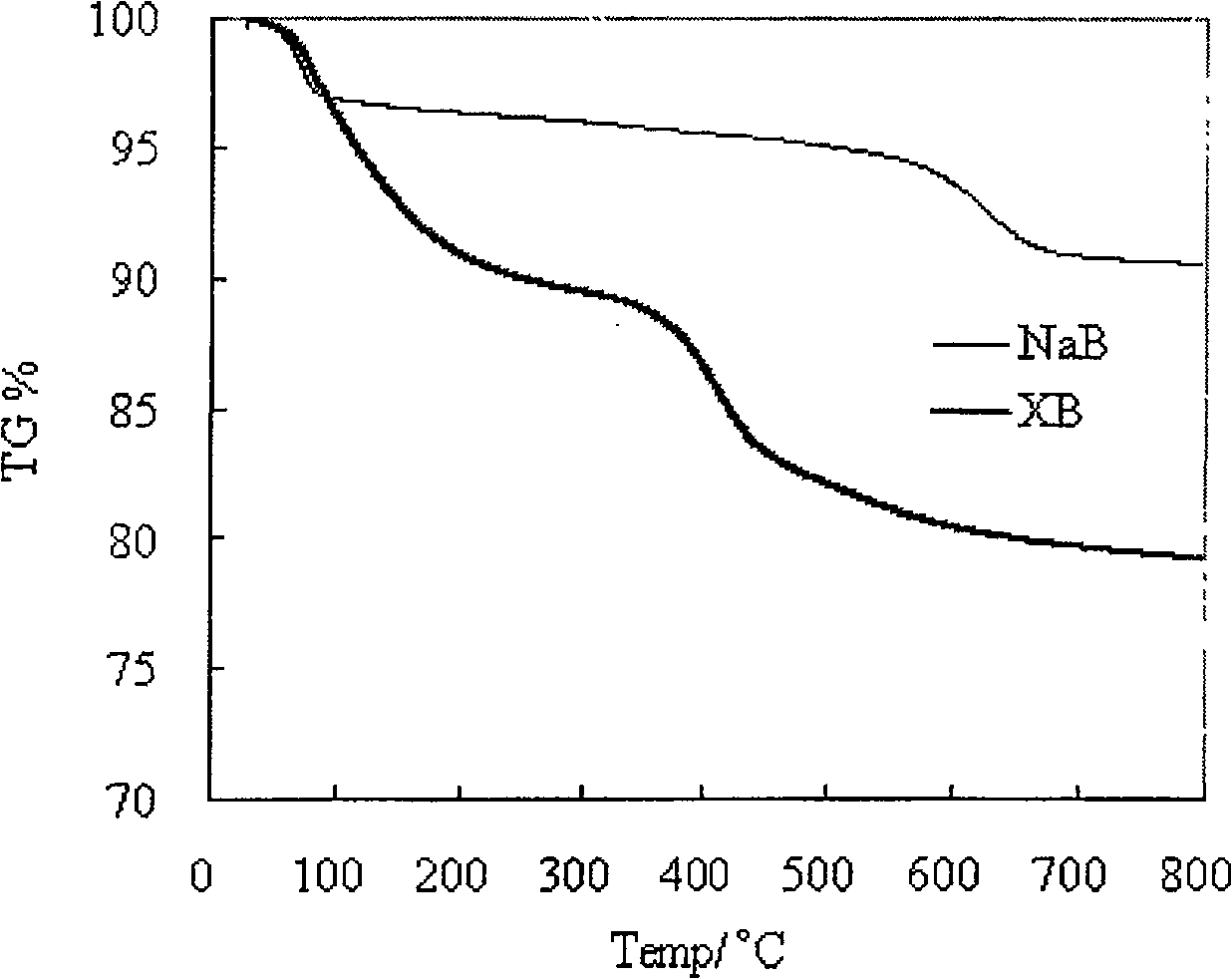

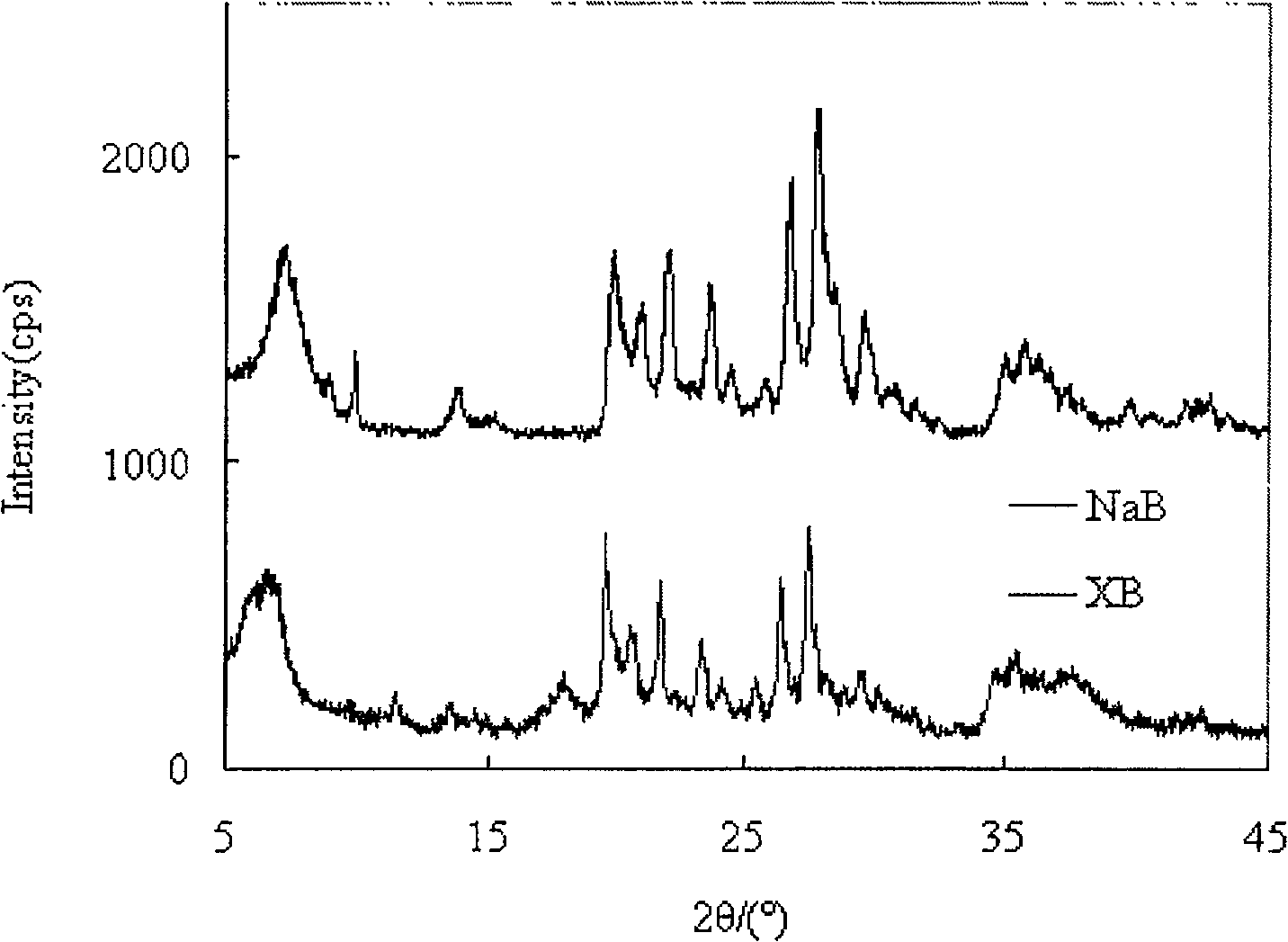

Xanthation bentonite absorbingsubstance and method for preparing the same

InactiveCN101081359AImprove stabilityHigh ion exchange capacityOther chemical processesWater/sewage treatmentSodium BentoniteSorbent

The present invention is xanthated bentonite as one kind of metal ion adsorbent with high adsorption capacity and its preparation process. The metal ion adsorbent with high adsorption capacity is prepared with bentonite sodium as material, and through dispersing, alkalization, reacting with SO2, and treating with magnesium salt to form stable magnesium salt of xanthated bentonite. The xanthated bentonite has powerful adsorption on heavy metal ion, and may be used in treating waste water containing heavy metal ion. Treating waste water containing heavy metal ion with the xanthated bentonite has the features of simple operation, high speed, high metal ion eliminating rate, easy solid-liquid separation, etc.

Owner:NORTHWEST NORMAL UNIVERSITY

Method for producing flavonoids by using pectin-extracted orange peel

The invention discloses a method for extracting, separating and purifying flavonoids from orange peel. In the method, the method for extracting an organic solvent is adopted and extraction is performed under the most optimal process conditions of extraction temperature of 90 DEG C, extraction time of 5 hours, 3 extraction times, 95 percent of alcohol concentration and a ratio of liquid to material of 1:30. The separation and purification adopt macroporous absorbent resin distributed elution to finally obtain orange flavonoids having purity of 90 percent. The method has the advantages of obtaining relatively higher yield and purity, utilizing industrial wastes, reducing environmental pollution and fulfilling the aim of resource comprehensive utilization.

Owner:YANTAI ANDRE PECTIN

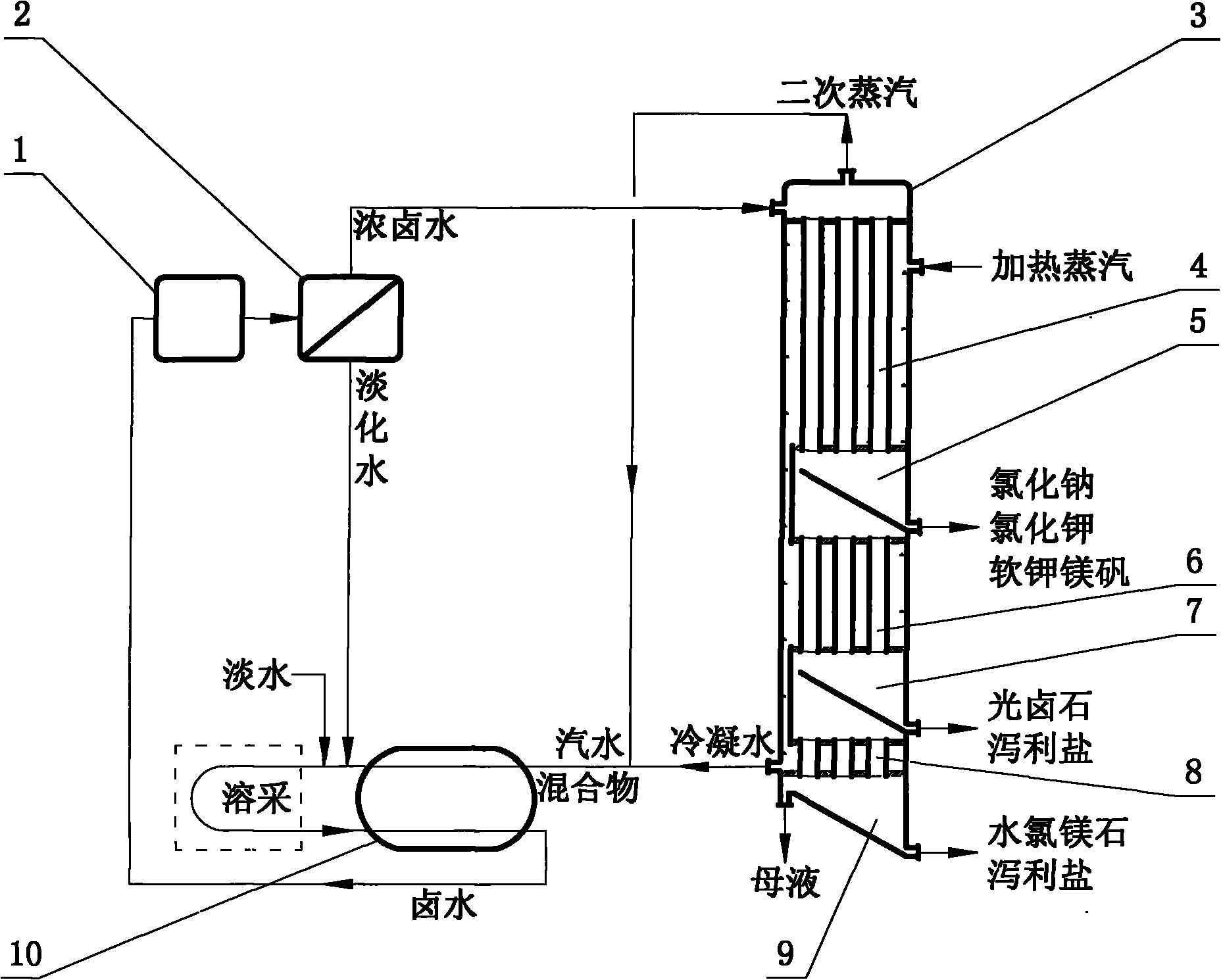

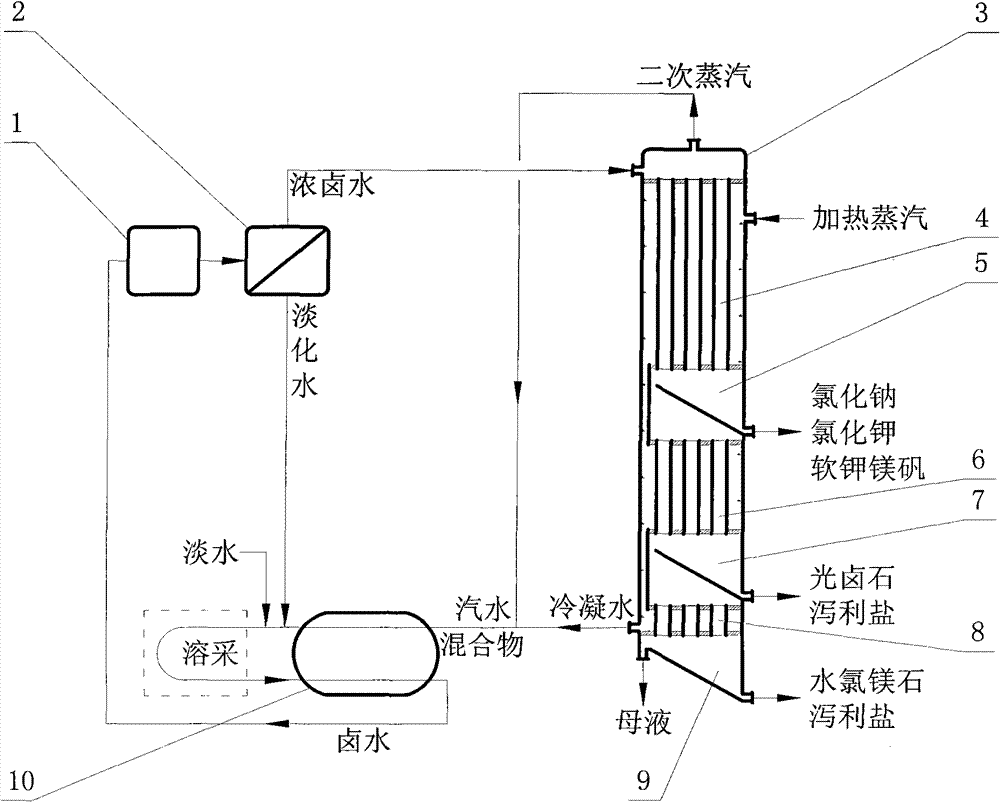

Method for rapidly manufacturing industrial salt by utilizing sylvine mine and device

ActiveCN102139891AReduce dependenceEvaporation process is fastMagnesium chloridesEnergy inputDesalinationMineralogy

The invention provides a method for rapidly manufacturing industrial salt by utilizing sylvine mine and a device, belonging to the technical field of comprehensive utilization of mineral salt and brine. The method for manufacturing the industrial slat is as follows: the solution mining is carried out on the sylvine mine and brine is extracted, the brine is initially concentrated by low grade heatenergy and then is evaporated step by step to obtain products including carnallite, bischofite and the like; desalination water and condensate water are circulated and used for solution mining; and waste heat is simultaneously recycled. The device for manufacturing industrial salt comprises a heater, a desalination apparatus and a heat exchanger. The invention has simple process route, high efficiency of production process, is convenient to use the low grade heat energy, has the energy saving advantage, can extract various inorganic salt products by classification and realizes the comprehensive utilization of energy sources and resources.

Owner:SHANXI UNIV

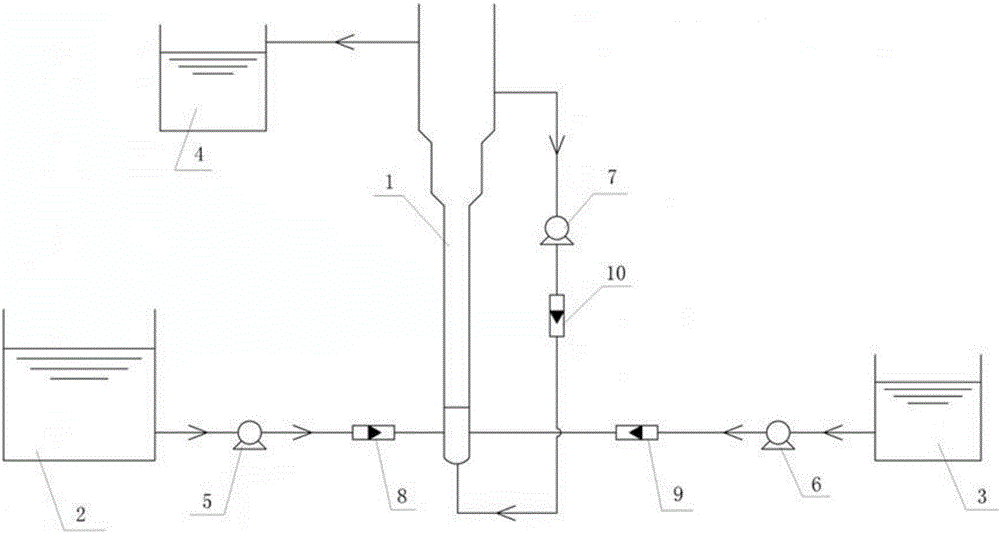

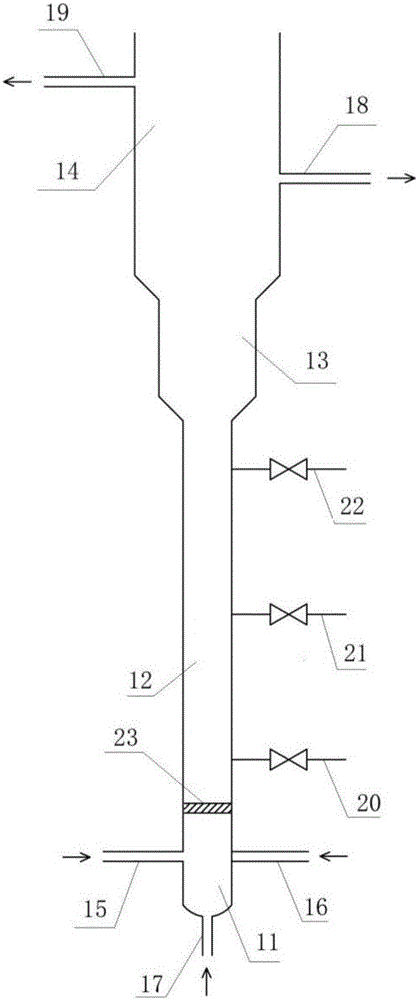

Method and device for preparing sandy cryolite from fluoride waste water

PendingCN106830034AAvoid environmental pollutionWide range of applicationsAluminium fluoridesFluidized bedWater tanks

The invention discloses a device for preparing sandy cryolite from fluoride waste water. The device comprises a fluidized bed reactor, a waste water tank, a chemical box and a water collecting box, wherein a water inlet of the fluidized bed reactor is connected with the waste water groove through a water inlet pump; a chemical inlet of the fluidized bed reactor is connected with the chemical box through a chemical feeding pump; a water outlet of the fluidized bed reactor is connected with the water collecting groove; a backflow outlet of the fluidized bed reactor is connected with a backflow inlet of the fluidized bed reactor through a backflow pump; cryolite crystal seeds are arranged in the fluidized bed reactor; a sampling opening is formed in the fluidized bed reactor. The invention also provides a method for preparing the sandy cryolite from the fluoride waste water. The fluorine can be recovered from the waste water for preparing the sandy cryolite.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

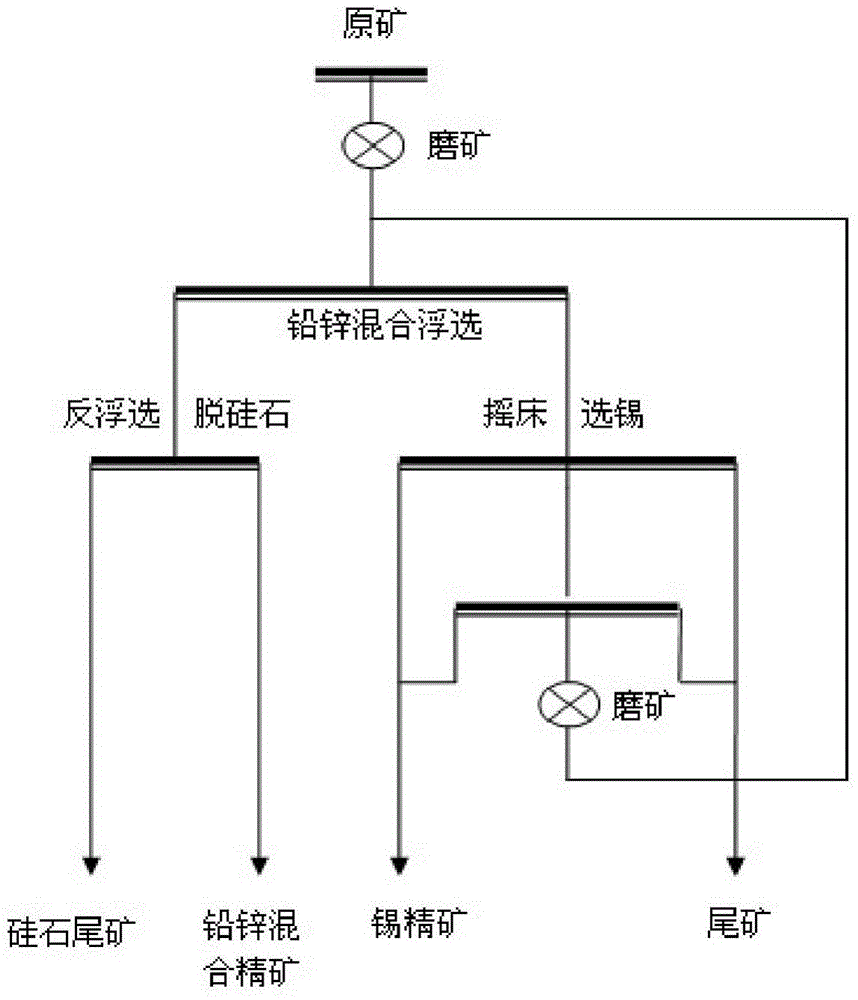

Ore selection method for treating tin, lead and zinc polymetallic oxidized ore

The invention discloses an ore selection method for treating tin, lead and zinc polymetallic oxidized ore. The ore selection method includes: firstly, crushing and ball-milling raw ore; then directly subjecting the raw ore subjected to ball-milling to lead and zinc oxide ore mixed floatation and feeding floating ore into foam products; feeding products in a floatation tank to a primary table concentrator for gravity concentration to obtain tin concentrate, first-section middlings and tailings; feeding the first-section middliings to a secondary table concentrator for gravity concentration to obtain tin concentrate, second-section middlings and tailings; subjecting the second-section middlings to grinding and then combining the same into the ore subjected to lead and zinc oxide mixed floatation. The foam products which are silica tailings are subjected to reverse floatation to get rid of silica, so that the products in the flotation tank are final lead and zinc mixed concentration. By the adoption of lead and zinc mixed floatation and reverse flotation of the lead and zinc mixed concentrate to get rid of the silicon, recovery rate of useful metals is increased in the mixed floatation, types and dosage of medicament are reduced, environmental pollution is low, and purposes of conforming to the state policy of cleaner production and circular economy and achieving energy conservation, emission reduction, consumption reduction and comprehensive utilization of resources are achieved.

Owner:GUANGXI JINSHAN INDIUM & GERMANIUM METALLURGICAL CHEM

Method for eliminating calcium sulphate with bittern

InactiveCN101172686AIncreased sodium chloride contentLess quantityWater/sewage treatmentCommon-ion effectSalting out

The invention provides seawater processing technology, in particular to a method of removing calcium sulphate by use of brine. 5 to 13 degrees Be brine is added with industrial crude salt to make the brine concentration to 17 to 25 degrees Be and dissolve the calcium sulphate. According to the rule of brine dissolving salt and the salting-out theory as well as the common ion effect theory, the composition of the(5 to 13 degrees Be) brine is changed by adding the industrial crude salt to increase the sodium chloride content in the brine so as to increase the brine concentration up to 17 to 25 degrees Be, thereby reducing the solubility of the calcium sulphate and dissolving most of the calcium sulphate; besides, the dissolved brine can be directly used for producing the vacuum refined salt.

Owner:ENG TECH INST CO LTD OF CNSIC

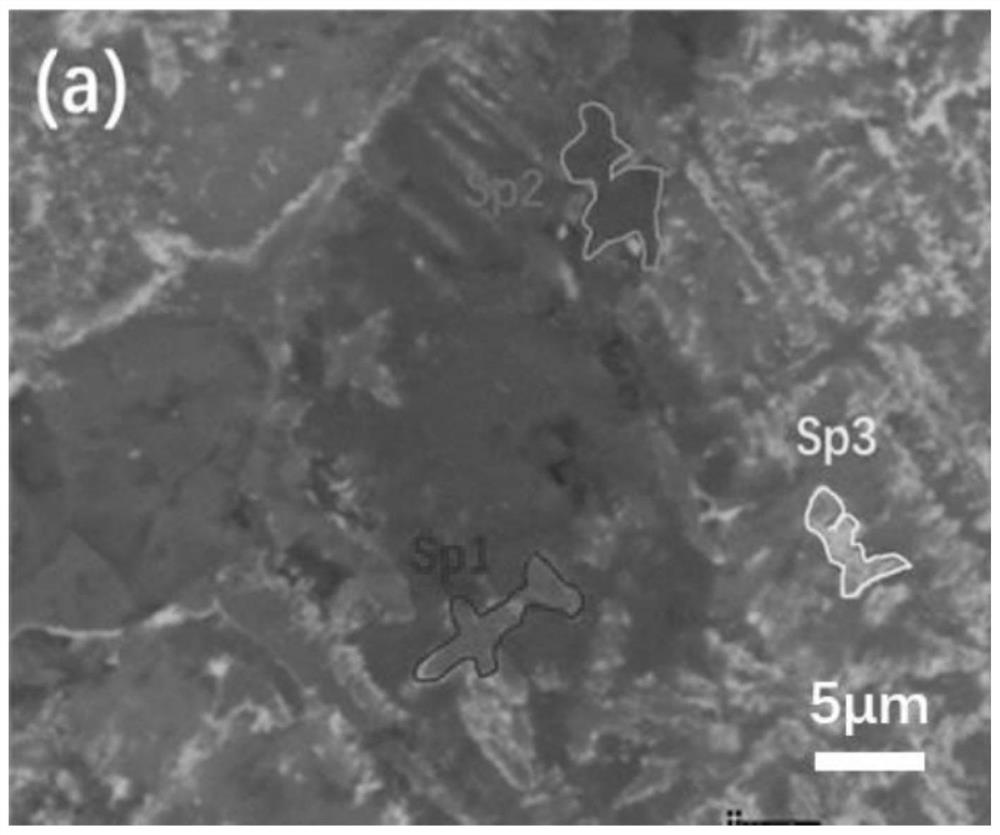

Method for preparing gelling composite material with piezoelectric property, gelling composite material and application of gelling composite material

ActiveCN113135754APromote generationGood piezoelectric coefficientSolid waste managementSlagRoad traffic

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

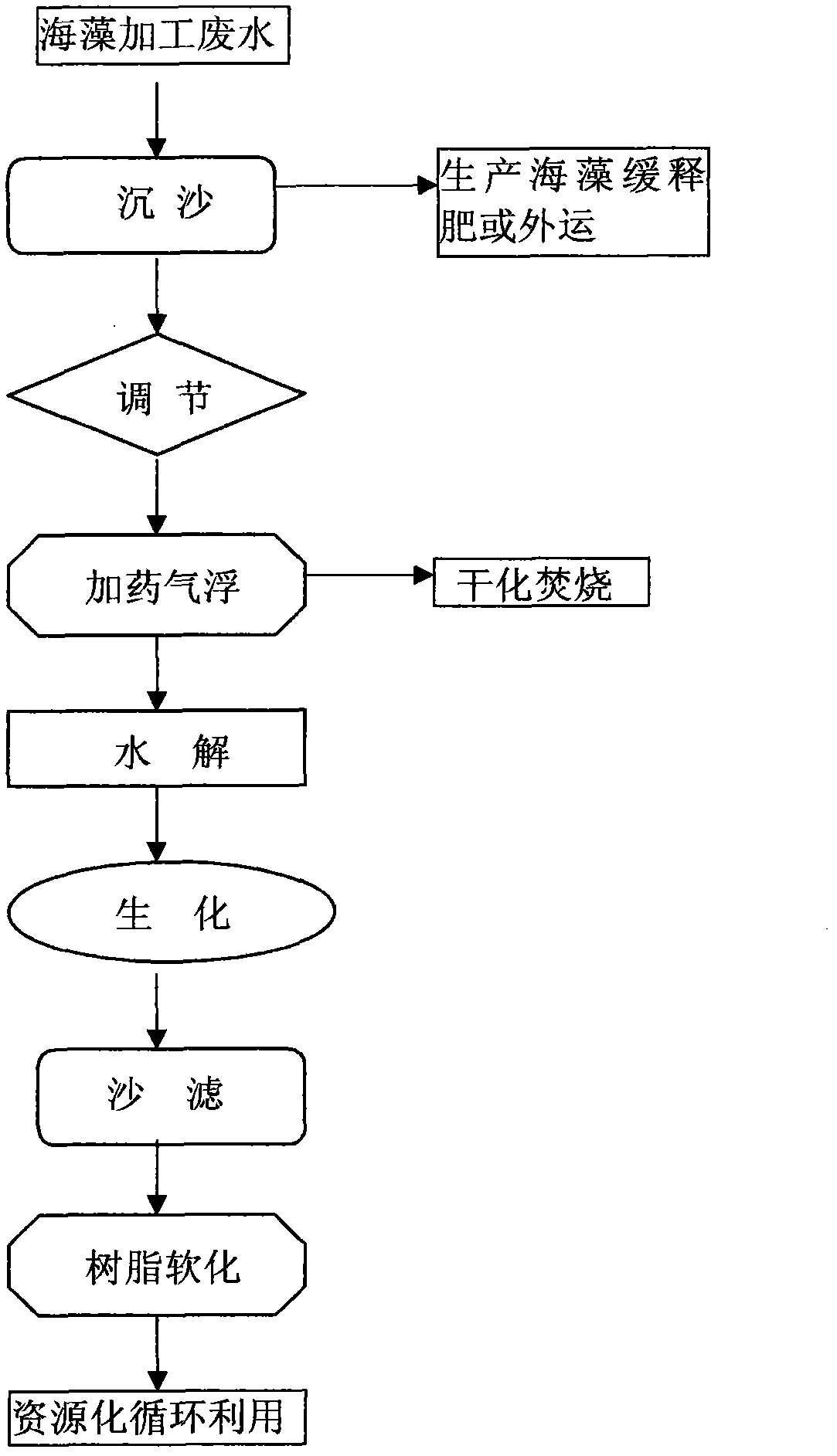

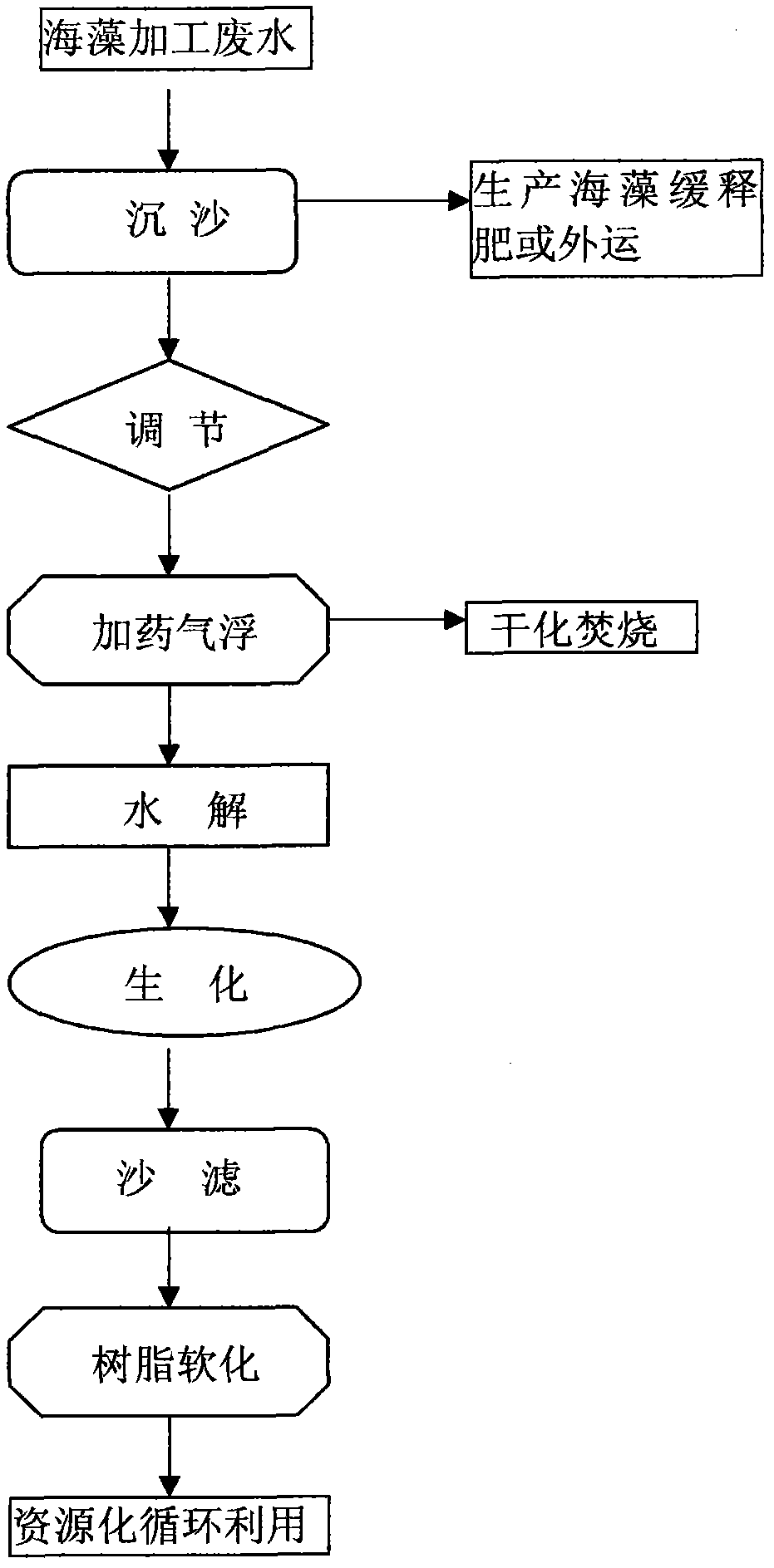

New process for wastewater recycling comprehensive treatment in alga processing

ActiveCN102701513AExpand the scope of processingEasy to handleMultistage water/sewage treatmentEnvironmental resistanceAluminium chlorohydrate

The invention relates to a new process for wastewater recycling comprehensive treatment in alga processing industry. The process comprises the following steps of: desilting, regulating, adding chemicals, performing air floating, hydrolyzing, performing biochemical treatment, performing sand filtration, softening resin and recycling. The process has the advantages that (1) wastewater generated by processing brown algae can be treated, and alga wastewater which is generated by the processing of red algae, green algae and blue algae, alga leisure foods and convenience foods can also be treated, so that the range of the wastewater treatment of alga processing is enlarged; (2) according to the steps of adding the chemicals and performing the air floating, one of the chemicals is a calcium chloride solution, and the process is economic and environment-friendly, and has a good treatment effect compared with other wastewater treatment processes of using a polyaluminium chloride solution; and (3) the wastewater treated by a resin softening technology can be recycled completely, so that water resources can be saved to fulfill the aim of the recycling comprehensive utilization of the alga wastewater.

Owner:青岛聚大洋藻业集团有限公司

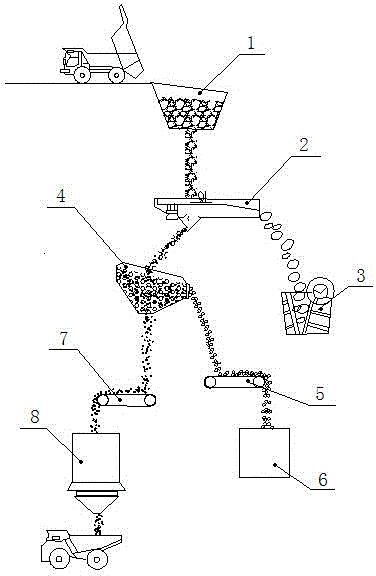

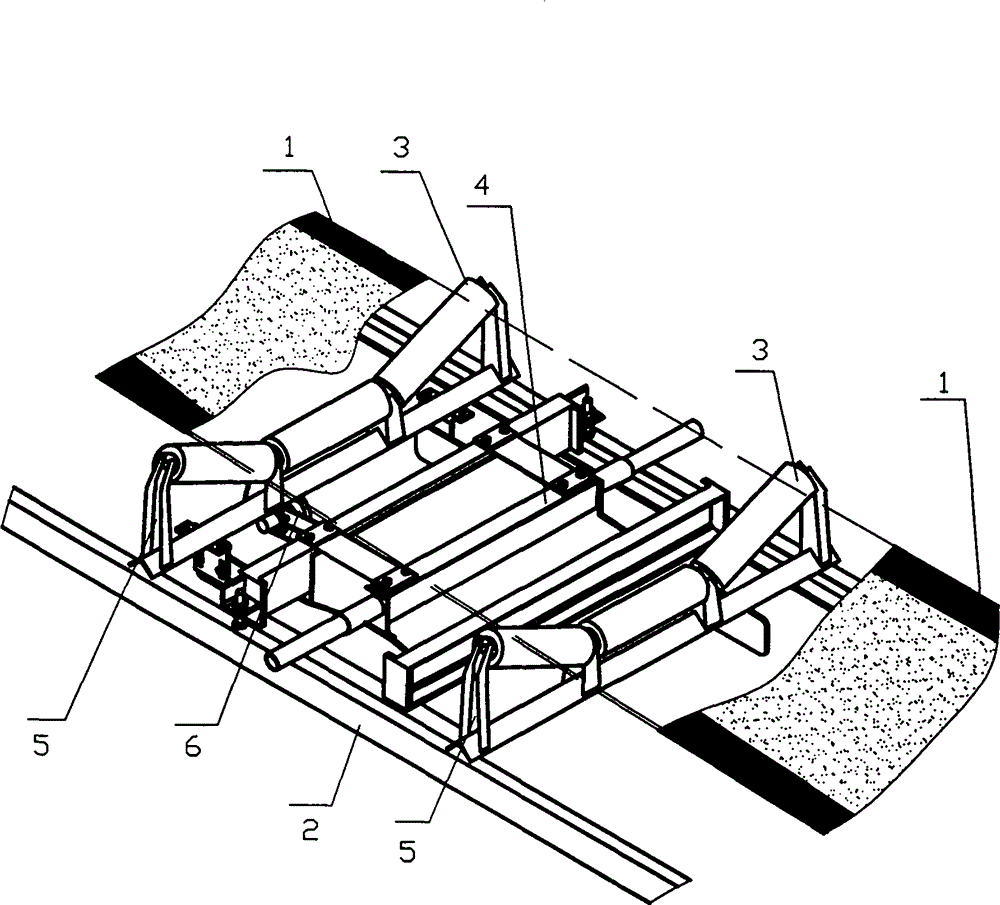

Ore muck separation system

InactiveCN102942321ATo achieve the purpose of comprehensive utilization of resourcesSolve pollutionSolid waste managementPortland cementEngineering

The invention discloses an ore muck separation system which comprises a material tank and a grizzly feeder. A crushing machine is arranged at the position of a material outlet of the grizzly feeder, a sieving device is arranged at the position of a hopper below a grizzly sieving face of the grizzly feeder, a belt conveyor I is arranged at the position of a material outlet of the sieving device, an aggregate storage bin is arranged at a discharging end of the belt conveyor I, a belt conveyor II is arranged at the position of an outlet below the sieving face of the sieving device, and a muck bin is arranged at a discharging end of the belt conveyor II. Compared with ore muck separation systems, the ore muck separation system has the advantages that stripping aggregated rock generated during ore extraction is comprehensively treated by means of a winnowing process, and selected muck contains siliceous corrective additions required for firing clinker, so that the selected muck can be used as a raw material for producing Portland cement clinker, the purpose of comprehensive utilization of resources is achieved, problems that the muck in ores pollutes environment, occupies land and wastes resources are solved, and comprehensive utilization of the ore resources is achieved.

Owner:SHANDONG CEMENT PLANT

Method for synthesizing 2,4-dinitro-6-bromoaniline by using bromamine acid product wastewater

PendingCN112851523ATo achieve the purpose of comprehensive utilization of resourcesSimple processOrganic compound preparationAmino compound preparationDisperse dyeSodium cyanide

The invention relates to the technical field of chemistry and chemical engineering, and discloses a method for synthesizing 2,4-dinitro-6-bromoaniline by using bromamine acid product wastewater. The method comprises the steps of 1, adding sodium cyanide for reaction, synthesizing a disperse dye from byproducts in mother liquor and separated trace main products, filtering, and washing a filter cake with hot water to obtain the disperse dye; 2, adding an oxidizing agent into the filtrate and the washing liquid to oxidize and remove sodium cyanide, then reacting with 2,4-dinitroaniline, pulping in a sulfuric acid medium, dropwise adding sodium chlorate, reacting at the temperature of 35-75 DEG C, filtering the reaction liquid after bromination, washing a filter cake until the pH value is 6-7, and drying to obtain the product 2,4-dinitro-6-bromoaniline; and 3, decolorizing the mother liquor with activated carbon, performing membrane treatment, concentration and separation, recycling low-concentration salt water, and spraying high-concentration salt to be dry to serve as industrial salt (or serving as an active or acid dye assistant for internal digestion of a company). The problems of high COD and high-salt mother liquor wastewater of bromamine acid dye products in the prior art are solved.

Owner:ZHEJIANG YIDE CHEM

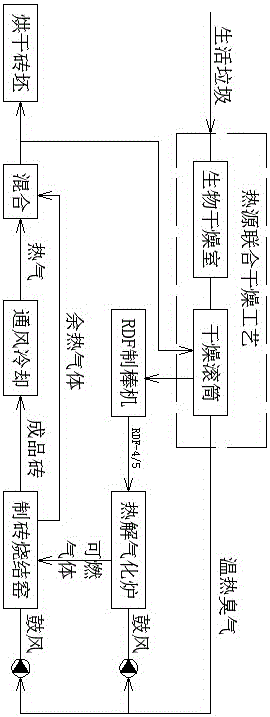

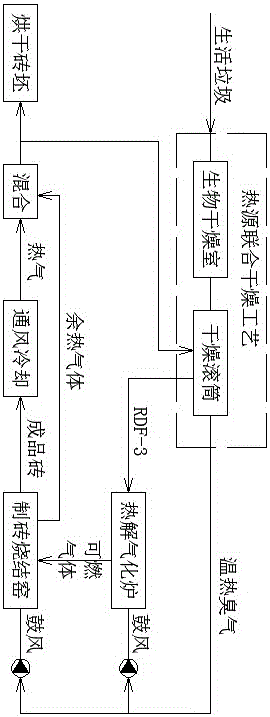

Application of household refuse pyrolytic gasification combustible gas in shale sintered brick process

InactiveCN106147813AReduce pollutionNo emissionsEnergy inputSpecial form destructive distillationThermal energyRefuse-derived fuel

The invention discloses application of household refuse pyrolytic gasification combustible gas in shale sintered brick process, including the steps of treating household refuse with combined heat drying process to produce RDF (refuse derived fuel), and performing pyrolytic gasification to obtain combustible gas; delivering the combustible gas into a brick-producing sintering kiln to sinter finished bricks; exhausting waste heat gas produced by cooling of finished bricks; mixing waste heat gas produced by combustion in the brick-producing sintering kiln and hot gas produced by cooling; introducing part of mixed gas into a brickyard drying kiln to dry green bodies; introducing the other part into a drying cylinder that is used in the drying process to dry refuse; introducing gas that is produced by drying the refuse into a brickyard blower and a pyrolytic gasifier blower. Heat produced by the refuse is utilized to sinter bricks during domestic refuse treatment, so that heat is made full use; stinking gas produced by drying the refuse is introduced into the brickyard blower and the pyrolytic gasifier blower and is combusted, thereby being discharged.

Owner:FUJIAN ZHENGREN ENVIRONMENTAL PROTECTION

Xanthic acid-based attapulgite adsorbent as well as preparation method and application thereof

InactiveCN106111072AImprove stabilityHigh ion exchange capacityOther chemical processesWater contaminantsMagnesium saltWastewater

The invention discloses a xanthic acid-based attapulgite adsorbent. The adsorbent is prepared from attapulgite, sodium hydroxide, carbon disulfide, soluble magnesium salt and deionized water. The invention also discloses a preparation method of the xanthic acid-based attapulgite adsorbent. The preparation method comprises the following steps: dispersing and alkalifying attapulgite, then subjecting attapulgite to reaction with carbon disulfide, then carrying out transformation by utilizing magnesium salt to generate a magnesium salt solution of xanthic acid-based attapulgite and finally carrying out washing and drying, thus obtaining the xanthic acid-based attapulgite adsorbent. The xanthic acid-based attapulgite adsorbent is used for removing dyes in wastewater. The xanthic acid-based attapulgite adsorbent provided by the invention has strong dye adsorption capacity, short adsorption time and high adsorption capacity. The preparation method is simple and practicable to operate and rapid and convenient to operate and has the advantages of high dye decolorization rate and easiness in solid-liquid separation after adsorption.

Owner:定西师范高等专科学校

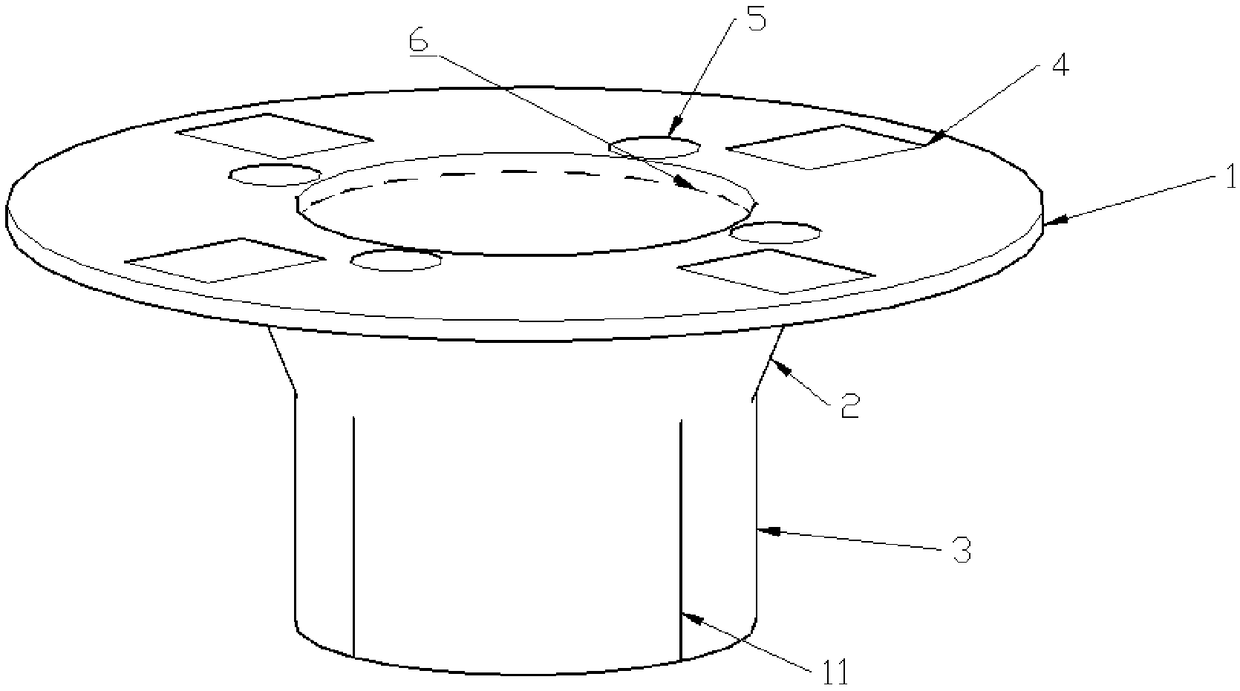

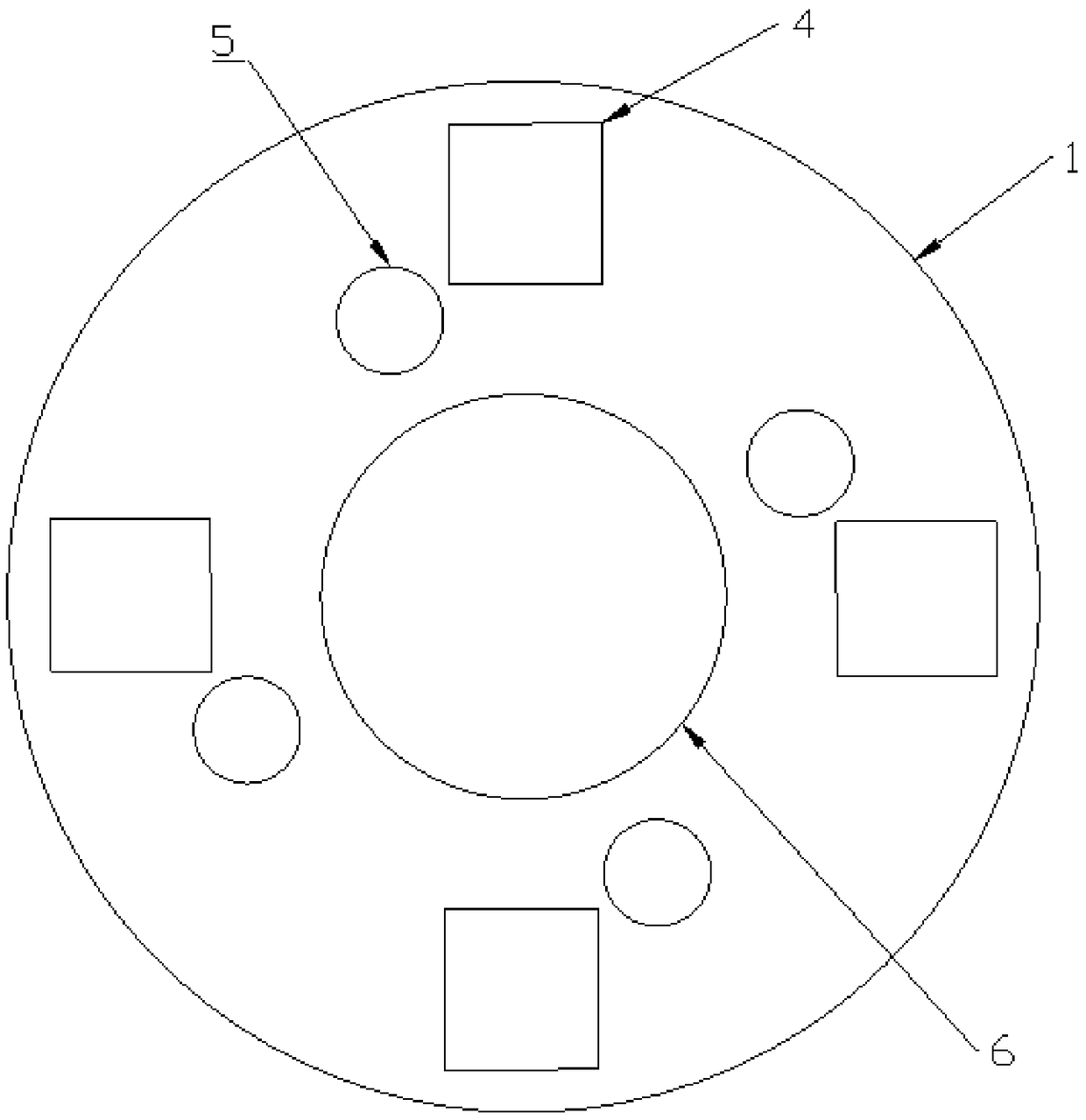

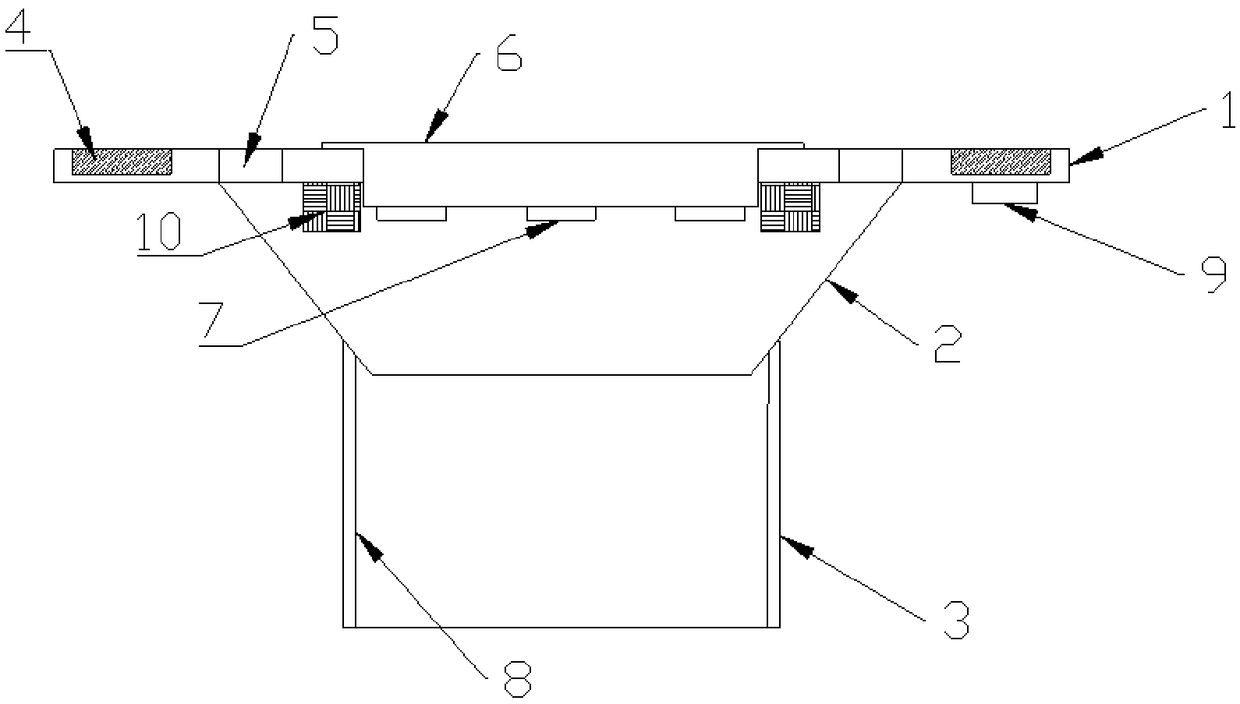

Versatile dining table with garbage collection function

The invention discloses a multifunctional dining table with garbage collection function. The invention belongs to the technical field of food and beverage, comprising a support column of a hollow dining table, a table top arranged above the support column of the dining table, a door for opening and closing is arranged on the support column of the hollow dining table, a heat preservation area is arranged at the center of the table top, a plurality of electromagnetic stoves are uniformly arranged around the table top, and one end of each electromagnetic oven close to the heat preservation area is provided with a garbage inlet. The invention is provided with a garbage inlet and a garbage sliding bin matched with the garbage inlet, A garbage bin is arranged below the garbage sliding bin, so that the rubbish generated on the dining table does not have to be piled on the table, The desktop is clean and tidy while avoiding placing a large number of garbage cans beside the seats, which affectsthe comfort of the diners, and a peculiar smell suction warehouse with carbon residue is arranged, and the peculiar smell is eliminated by using the carbon residue discarded from the kitchen, so thatthe peculiar smell is eliminated, the comfort degree is increased, and the purpose of comprehensive utilization of resources is achieved at the same time.

Owner:XIDIAN UNIV

Deep metamorphic clay type gold ore leaching method with high recycle rate

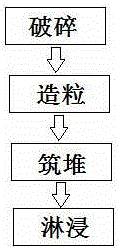

The invention discloses a deep metamorphic clay type gold ore leaching method with high recycle rate, comprising: breaking raw ore, and adding lime to the broken fine-grain ore; adding thin saw dust to the obtained fine-grain ore, and mixing well; adding cement to the fine-grain ore, and granulating with a granulating machine; piling coarse-grain ore at the bottom, and placing fine-grain pellets above the coarse-grain core for heaping; sprinkling and heap leaching with cyanides to leach out elemental gold. In the heap leaching and gold leaching process, gold in the ore is efficiently recycled. By means of adding the saw dust and cement to granulate and pelletize for heaping and leaching, permeability of the heaped ore and chemicals consumption for slurry are optimized, usage of chemicals is reduced, leaching rate and leaching recycle rate are increased, and residual leachate after leaching is simple to treat. The national policies for clean production and cyclic economy are met, and energy conservation, emission reduction and resource comprehensive utilization are achieved.

Owner:KUNMING METALLURGY INST

Method for extracting high-valence manganese from manganese carbonate ore

This invention has provided one kind of method to leach high price manganese from manganese carbonateore, which belongs to the hydrometallurgy domain. It takes the glucose or the plant biomass and sulfuric acid as reducing agent of high pricemanganese in manganese carbonate ore, adopting microwave radiation glucose to promote high price manganese to revert, the concrete step includes: Takes 1 copy 100-200 sieve manganese carbonateore, add 10 -20 copy water to modulate the pulp; Again add 60% density sulfuric acid to pulp, the load ratio of mineral powder and sulfuric acid is 1: 6 -9; Simultaneously, add glucose or plant biomass, the load ratio of mineral powder and glucose or plant biomass is 10 -15: 1, stir evenly; radiate under 500 -1000W microwave, stir and respond for 4-10min, leach temperature is controlled at 50degree C-60 degree C, then get lixivium by filtering. This invention has the merits of lower reaction temperature, reducing acid consume and reduce leaching time of the manganese ore, high thermal using and respond rapidly.

Owner:CHONGQING UNIV

Method for cooperatively treating electrolytic manganese residue by dry method rotary kiln cement plant production line

InactiveCN110986577AReduce the temperatureReduce crustRotary drum furnacesCement productionCement factoryManganese

The invention provides a method for cooperatively treating electrolytic manganese residue by a dry method rotary kiln cement plant production line. The method comprises the steps that in the dry method rotary kiln cement plant production line which operates normally, the electrolytic manganese residue is continuously fed into a kiln tail smoke chamber of dry method rotary kiln production line equipment, meanwhile, oxidizing atmosphere calcinaiton in a rotary kiln and kiln tail draught fan breezing are controlled, and normal calcinaiton of clinkers in the kiln and the stable operation of the rotary kiln cement plant production line are maintained. The method is simple to operate, the investment in technological upgrading is small, the disposal quantity of the manganese residue is greater, no second pollution generates, resource utilization of protogenetic electrolytic manganese residue and stocked or discarded electrolytic manganese residue can be fully achieved, and the protection of asocial ecological environment and a natural environment is facilitated.

Owner:湖南省小尹无忌环境能源科技开发有限公司

Xanthation bentonite absorbingsubstance and method for preparing the same

InactiveCN100558460CImprove stabilityHigh ion exchange capacityOther chemical processesWater/sewage treatmentSodium BentoniteMagnesium salt

The invention provides a metal ion adsorbent with high adsorption capacity—xanthated bentonite and a preparation method thereof. The high adsorption capacity metal ion adsorbent is prepared by taking sodium bentonite as raw material, reacting with carbon disulfide after dispersion and alkalization, and then transforming with magnesium salt to generate stable magnesium salt of xanthate-based bentonite. The xanthate-based bentonite has strong adsorption capacity for heavy metal ions, and can be applied to the treatment of wastewater containing heavy metal ions. The process of the invention is used for the treatment of heavy metal wastewater, and has the characteristics of simple and easy operation, fast and convenient operation, high removal rate of metal ions, easy separation of solid and liquid, and the like.

Owner:NORTHWEST NORMAL UNIVERSITY

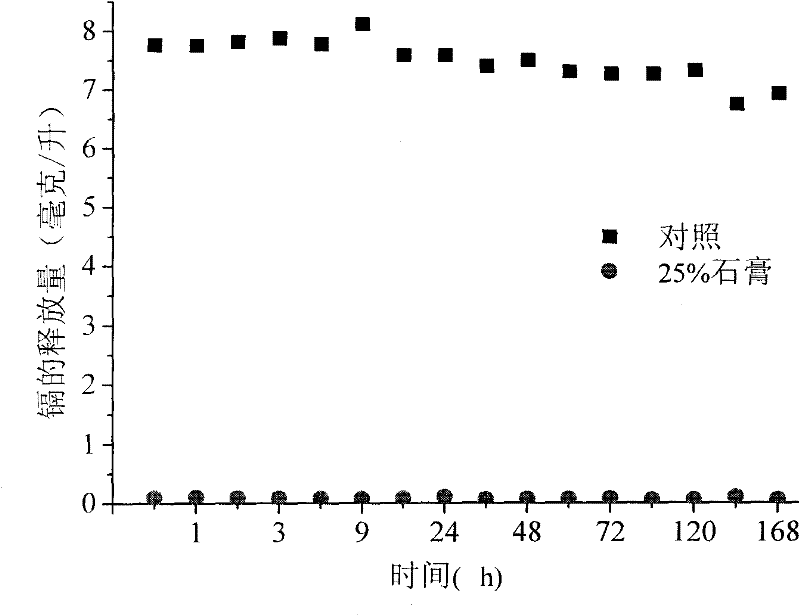

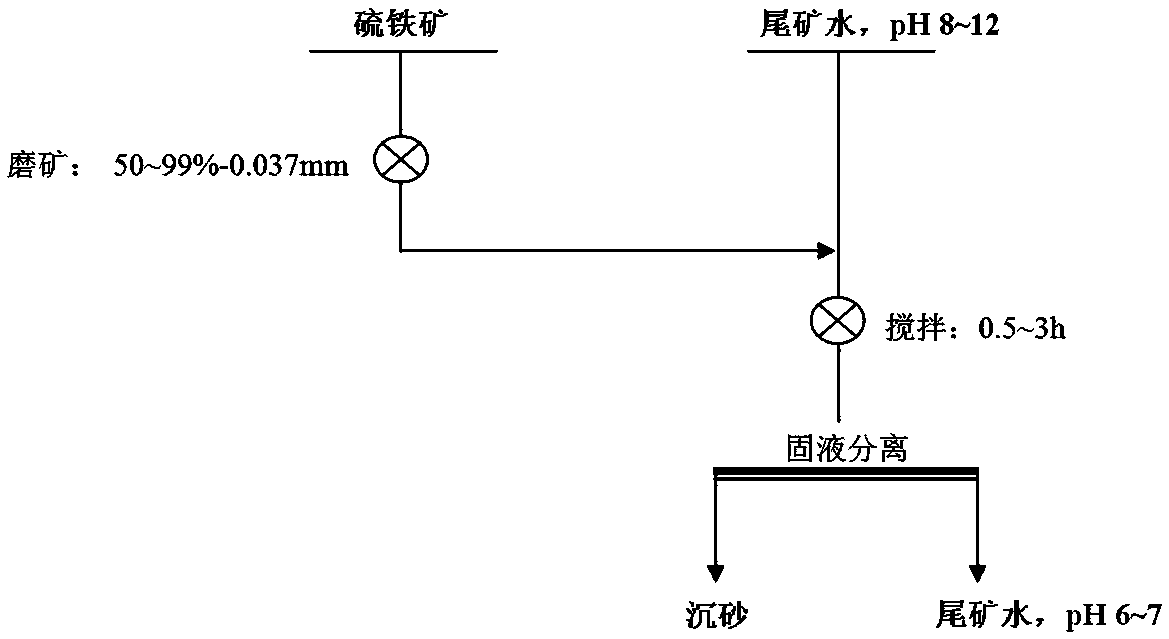

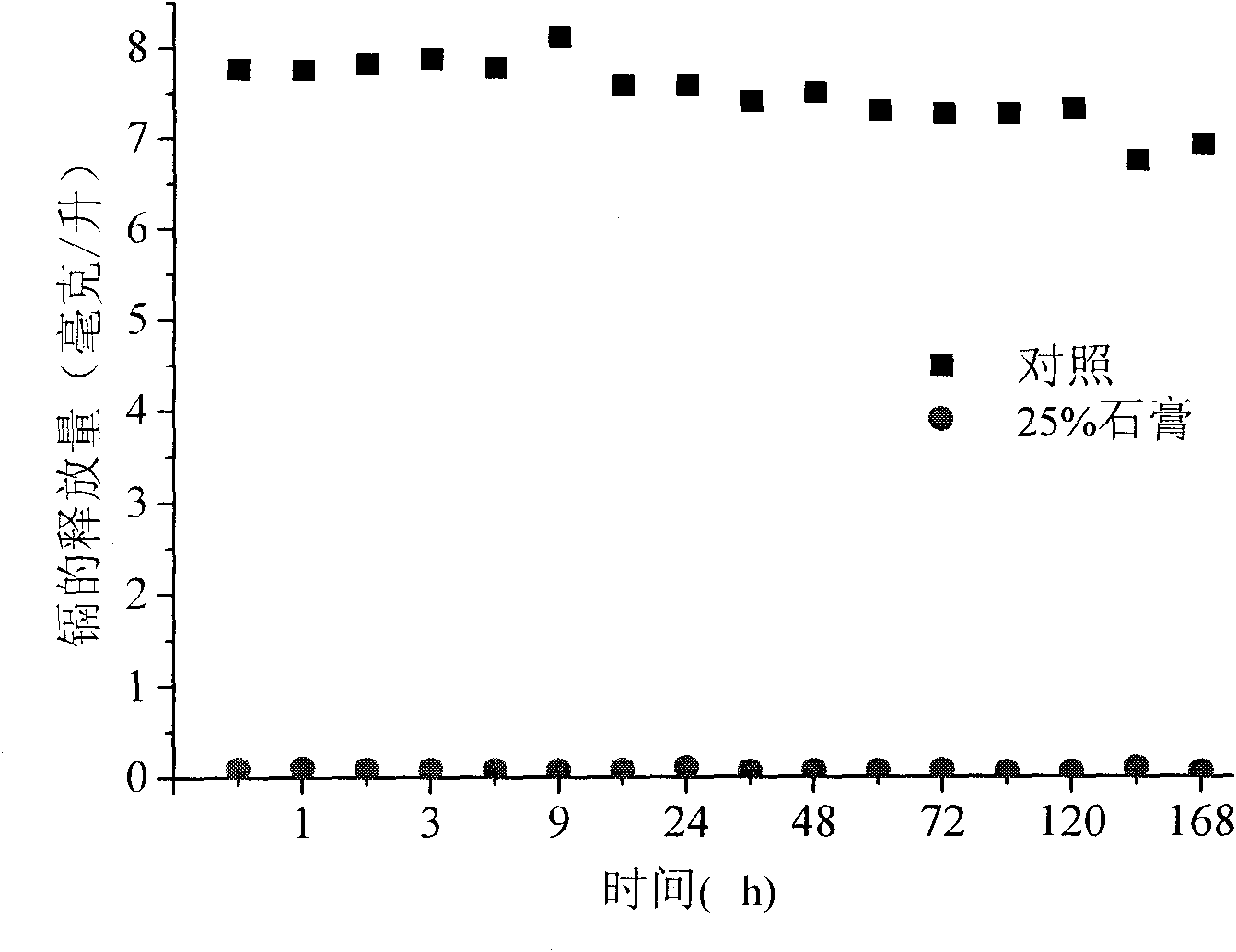

Method for stabilizing and immobilizing cadmium in heavy metal pollution deposition by utilizing flue gas desulfurization gypsum

InactiveCN101746934AReduce releaseInhibition releaseSludge treatmentWater contaminantsRoom temperatureMagnetic stirrer

The invention discloses a method for stabilizing and immobilization cadmium in heavy metal pollution deposition by utilizing flue gas desulfurization gypsum, belonging to the field of environmental-protection technology. 5-25wt percent of desulfurization gypsum is added in the cadmium polluted deposition as stabilization fixing agent, 400ml of water is added according to the proportion of 10ml ofwater in every gram of deposition, under a room temperature condition, the mixture is stirred in a magnetic stirrer at room temperature, so as to carry out cadmium stabilization and immobilization treatment in the heavy metal pollution deposition; the cadmium content in the deposition solution is used as the immobilization effect evaluation parameter of the cadmium in the deposition. In the invention, while solving the problem of the stabilization and immobilization of the cadmium in the deposition, the problem of recycling comprehensive utilization of flue gas desulfurization gypsum in coal-fired power plant is solved, so as to achieve the purposes of controlling waste by waste and recycling comprehensive utilization.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

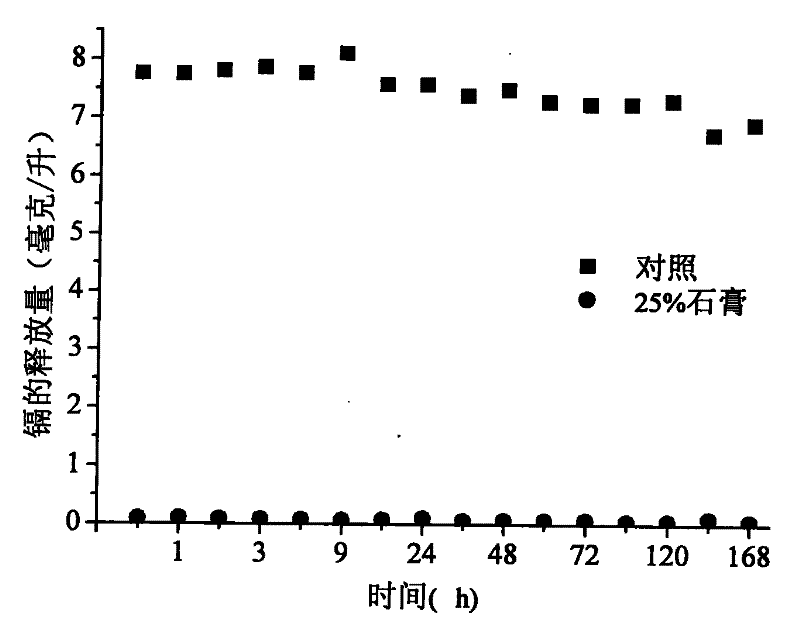

A kind of method preparing nanometer calcium sulfate

ActiveCN106379926BReduced growth rateAvoid resistanceCalcium/strontium/barium sulfatesNanotechnologyChemical industryFlue gas

The invention relates to the field of chemical industry and in particular to a method for preparing nano calcium sulfate. The method comprises the following steps: adding a crystal form control agent into refined lime milk to produce a CaSO4 crystal nucleus, and fully emulsifying the lime milk; atomizing the lime milk to be sprayed into an absorption tower, introducing sintering flue gas and cool-humidified oxidation air into the absorption tower, thereby obtaining gypsum slurry, wherein the sintering flue gas needs to be subjected to dust extraction and purification and cooling humidification before introduction; adding a modifier into the gypsum slurry for performing surface modification treatment, so that the surface of the produced CaSO4 powder is hydrophobic; and preparing nano calcium sulfate through the gypsum slurry subjected to surface modification treatment. The nano calcium sulfate is directly produced by utilizing SO2 in the sintering flue gas, so that the environmental pollution problem is solved, and a comprehensive resource utilization aim is achieved.

Owner:SHAANXI LONGMEN IRON & STEEL

Recycling method of carbide slag

InactiveCN101817651BSolve intractableReduce pollutionCement productionFerric hydroxideClinker (cement)

The invention discloses a recycling method of carbide slag, which comprises the following steps of: (1) reacting the carbide slag with the solution of sodium carbonate and filtering the reaction solution to obtain filtrate B and filter residue A, wherein the filtrate B is the solution of sodium hydroxide; (2) adding the filtrate A into hydrochloric acid, heating the mixture till the mixture boilsto perform a reaction, filtering the reaction solution to obtain a filter residue C and a filtrate D, wherein the filter residue C is used as clinker for cement production; and (3) adding hydrogen peroxide into the filtrate D to perform a reaction for 10 and 20 minutes, adjusting pH value of the reaction solution to 8.5 and 9.0 by using saturated lime water, filtering the reaction solution, drying the filter residue to obtain ferric hydroxide, concentrating the filtrate to precipitate a calcium chloride dehydrate solid, processing the obtained concentrated residual liquid by using the solution of sodium carbonate, filtering the mixed solution to obtain a solid mixture of magnesium carbonate and calcium carbonate, reacting the mixture react with the solution of sulphuric acid and filteringthe reaction solution to obtain calcium sulphate solids and the solution of magnesium sulfate. The resource processing method for the carbide slag has the advantages of various byproducts, high product quality, simple process flow, small equipment investment, easy operation, mild reaction conditions, low production cost, environmental friendliness and wide application prospect.

Owner:开封新巨源环保科技开发有限公司

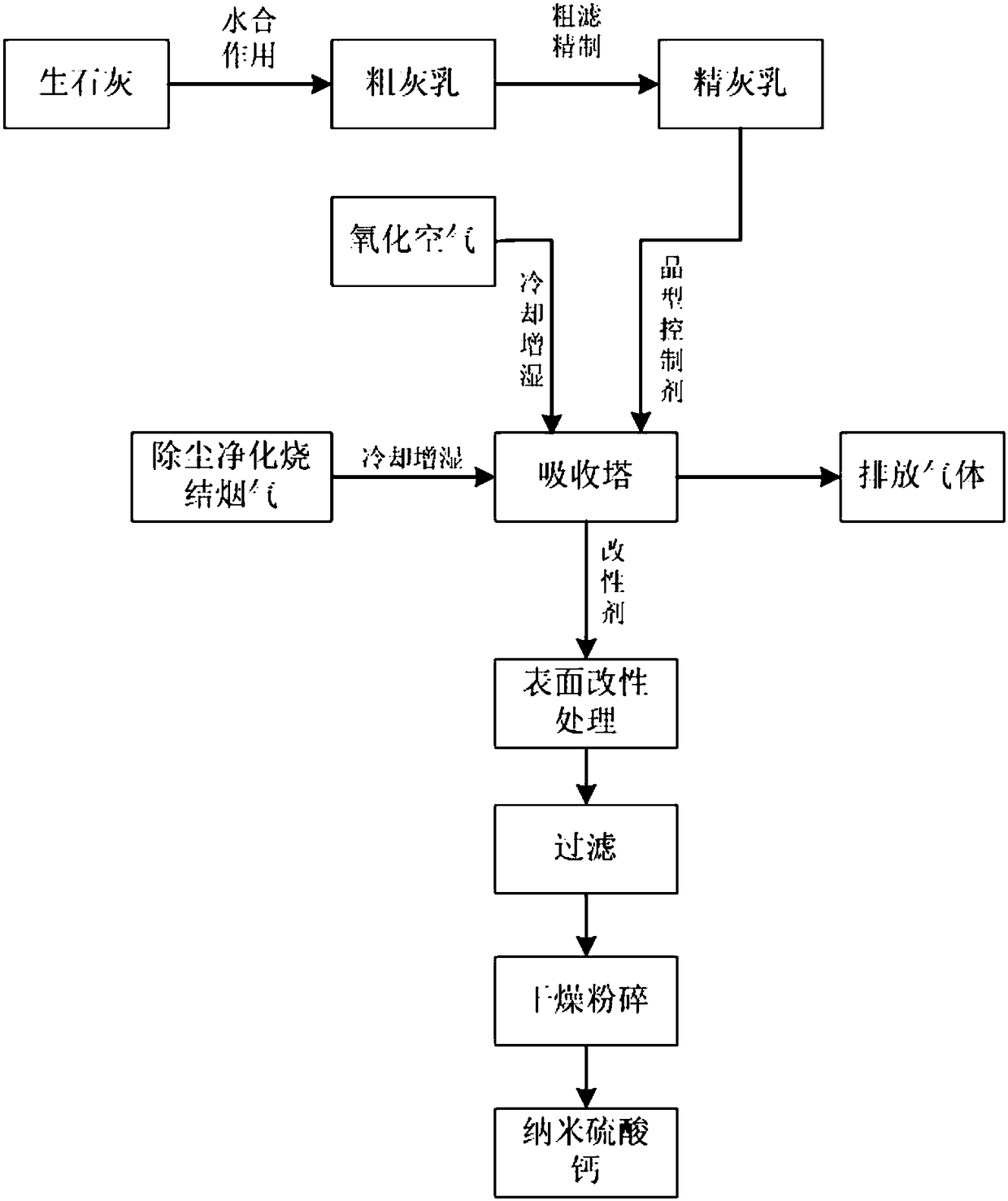

Treatment technology of ore dressing alkaline tail water

InactiveCN109231402ALow process costImprove securityWater/sewage treatment by neutralisationPyriteSulfur

The invention discloses a treatment technology of ore dressing alkaline tail water. The treatment technology of the ore dressing alkaline tail water is used for treating the ore dressing alkaline tailwater by utilizing cheap pyrite and specifically comprises the following steps: carrying out ore grinding on the pyrite until the pyrite with the fineness of -0.037mm accounts for 50 percent or more,so as to obtain a material a; adding the material a into the ore dressing alkaline tail water needing to be treated, stirring at 5 to 50 DEG C and reacting for 0.5 to 3h to obtain a reaction solutionb; carrying out solid-liquid separation on the reaction solution b to obtain settled sand c and reclaimed water capable of being circularly utilized. The treatment technology of the ore dressing alkaline tail water, provided by the invention, has the advantages of low cost, high safety and easiness for operation; the requirements on operational details of technical staff are low and the treatmenttechnology is suitable for large-scale popularization and application, so that the possibility of large-scale implementation is solved radically. Aiming at the alkaline tailing water of a current oredressing factory, the treatment technology adopting the technical scheme has a simple technological flow; the pyrite with the low price is adopted and any medicament does not need to be added; national clean production and circular economy policies are met and the aim of comprehensive utilization of resources is realized.

Owner:KUNMING METALLURGY INST

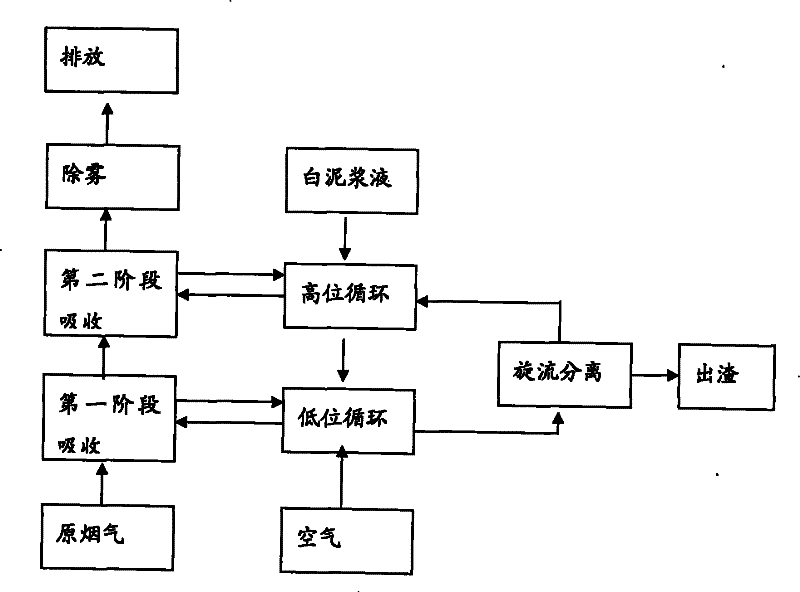

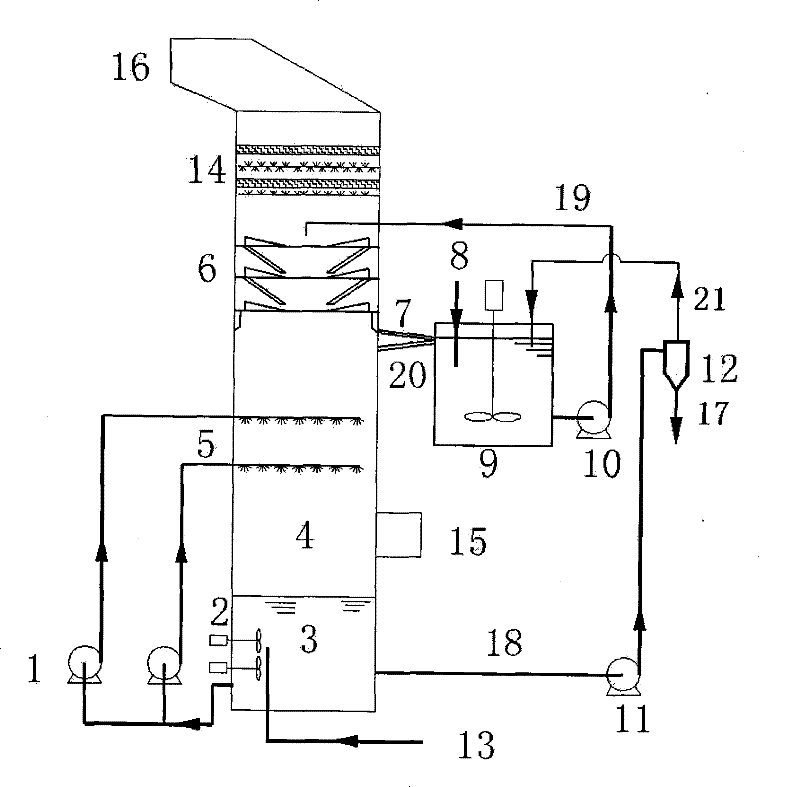

Method for removing sulfur dioxide in flue gas with white slime and device

ActiveCN101301566BGive full play to the valueHigh purityDispersed particle separationFlue gasPhysical chemistry

The invention discloses a method for removing sulfur dioxide in smoke by using white mud, which uses the white mud plasma as desulfurization solution, and implements the two-stage absorption desulfurization to the sulfur dioxide in smoke and then dissipates fog and discharges the smoke. The desulfurization solution absorbed in the first stage is collected at a low position, and is stored for recycling thereby forming a low position cycle, and the desulfurization solution absorbed in the second stage is collected at a high position, and is stored for recycling thereby forming a high position cycle; the desulfurization solution stored in the high position cycle overflows to the low position cycle, and the desulfurization gypsum generated in the low position cycle is pumped out for cyclone separation, top-flowing thin gypsum plasma refluxes to the high position cycle, and the bottom thick gypsum plasma is treated for deslagging. The invention also discloses a device for realizing the method. The inventive method and device has reasonable design and can effectively improve desulfurization efficiency.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH +1

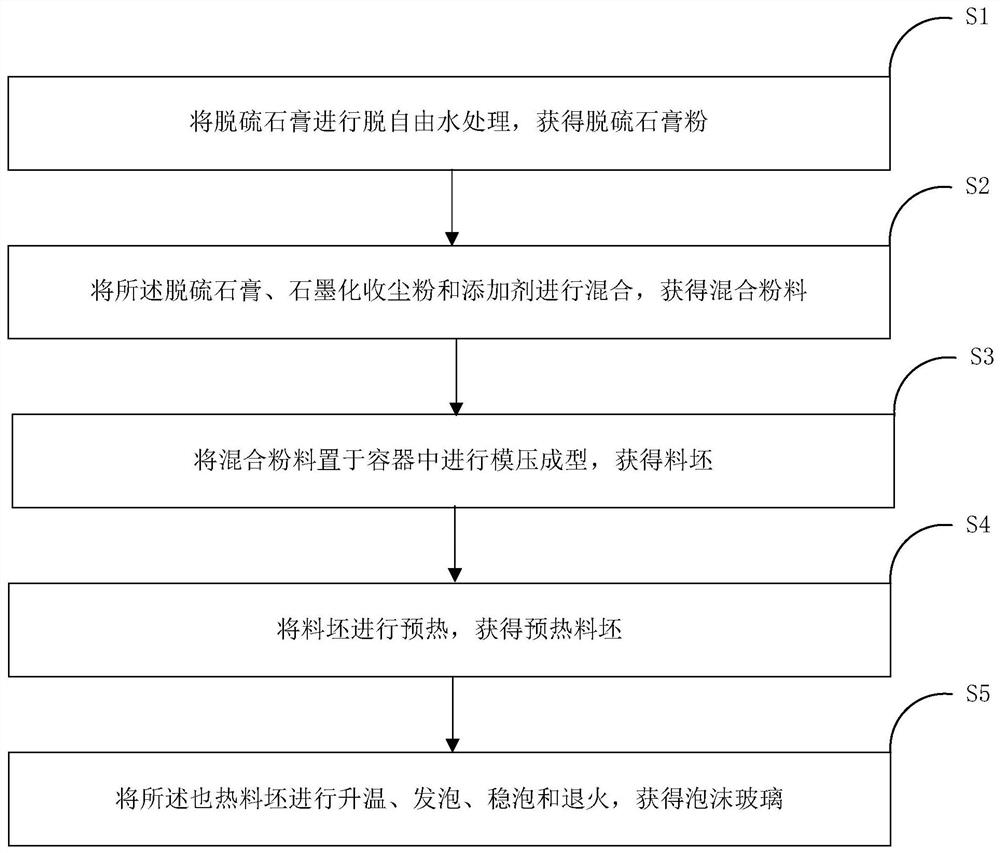

Foam glass and preparation method thereof

ActiveCN113620609ASolve pollutionSolve the difficult problem of stockpilingGlass shaping apparatusCompression moldingGraphite

The invention particularly relates to foam glass and a preparation method thereof, and belongs to the technical field of comprehensive utilization of dust collection powder.The method comprises the following steps: allowing desulfurized gypsum to be subjected to free water removal treating to obtain desulfurized gypsum powder; mixing the desulfurized gypsum, graphitized dust collection powder and an additive to obtain mixed powder; placing the mixed powder in a container to be subjected to compression molding to obtain a material blank ; preheating the material blank to obtain a preheated material blank; and heating, foaming, foam stabilizing and annealing the hot blank to obtain the foam glass. The foam glass is prepared by mixing and utilizing the dust collection powder generated by a graphitization furnace and desulfurized gypsum, a new scheme for preparing the foam glass is provided, meanwhile, the problem that solid waste is difficult to store is solved, the problem of pollution generated by the graphitization furnace is solved, and the purpose of comprehensive utilization of resources is achieved.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for stabilizing and immobilizing cadmium in heavy metal pollution deposition by utilizing flue gas desulfurization gypsum

InactiveCN101746934BReduce releaseInhibition releaseSludge treatmentWater contaminantsRoom temperatureMagnetic stirrer

The invention discloses a method for stabilizing and immobilization cadmium in heavy metal pollution deposition by utilizing flue gas desulfurization gypsum, belonging to the field of environmental-protection technology. 5-25wt percent of desulfurization gypsum is added in the cadmium polluted deposition as stabilization fixing agent, 400ml of water is added according to the proportion of 10ml ofwater in every gram of deposition, under a room temperature condition, the mixture is stirred in a magnetic stirrer at room temperature, so as to carry out cadmium stabilization and immobilization treatment in the heavy metal pollution deposition; the cadmium content in the deposition solution is used as the immobilization effect evaluation parameter of the cadmium in the deposition. In the invention, while solving the problem of the stabilization and immobilization of the cadmium in the deposition, the problem of recycling comprehensive utilization of flue gas desulfurization gypsum in coal-fired power plant is solved, so as to achieve the purposes of controlling waste by waste and recycling comprehensive utilization.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

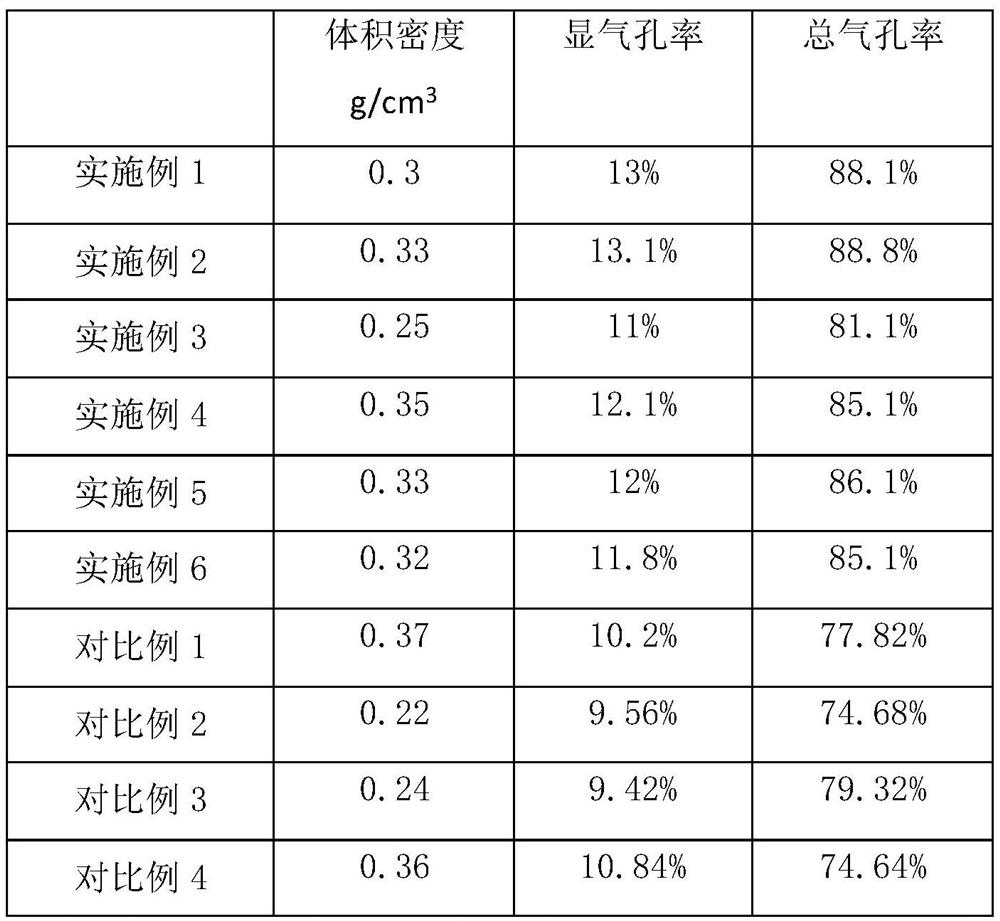

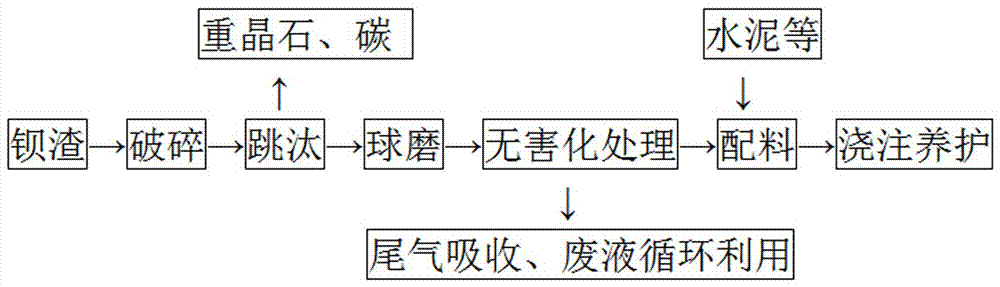

Comprehensive utilization method of barium sulfate waste residue and wall filling material

ActiveCN105236783BEmission reductionReduce manufacturing costSolid waste managementFoam concreteBarium salt

The invention discloses a new process aiming at recycling treatment and comprehensive utilization of barium sulfate waste residues, and is suitable for all barium salt production manufacturing industries. The process has the main innovations that sintered ores and symbionts in the waste residues produced from production of barium sulfate are stripped for the first time, the waste residues are sorted according to the difference of densities of components, and barite and coal which are not reacted completely are recycled and return to a furnace for reuse; the barium sulfate content of the recycled barite component can reach more than or equal to 80%; and the rest of the residues after harmless treatment are used for preparing an energy-saving wall filling material-a foam concrete block having a radiation protection function. The process not only solves barium sulfate waste residue accumulation and land occupation and various pollution problems on the environment but also recycles the barite and coal which are not reacted completely, besides, makes full use of the radiation protection performance of barium, prepares the novel radiation-protection foam concrete block, saves energy, protects the environment, achieves the purpose of comprehensive utilization of resources, and thoroughly solves the solid waste emission problems in the barium salt production industries.

Owner:南风化工(运城)集团有限公司

Device for rapidly manufacturing industrial salt by utilizing sylvine mine

ActiveCN102139891BReduce dependenceEmbody energy-saving featuresMagnesium chloridesEnergy inputInorganic saltsDesalination

The invention provides a method for rapidly manufacturing industrial salt by utilizing sylvine mine and a device, belonging to the technical field of comprehensive utilization of mineral salt and brine. The method for manufacturing the industrial slat is as follows: the solution mining is carried out on the sylvine mine and brine is extracted, the brine is initially concentrated by low grade heatenergy and then is evaporated step by step to obtain products including carnallite, bischofite and the like; desalination water and condensate water are circulated and used for solution mining; and waste heat is simultaneously recycled. The device for manufacturing industrial salt comprises a heater, a desalination apparatus and a heat exchanger. The invention has simple process route, high efficiency of production process, is convenient to use the low grade heat energy, has the energy saving advantage, can extract various inorganic salt products by classification and realizes the comprehensive utilization of energy sources and resources.

Owner:SHANXI UNIV

Homogenization pile metering checking device

InactiveCN104528326ACheck accuracyTake advantage ofConveyorsControl devices for conveyorsEngineeringMaterial resources

A homogenization pile metering checking device consists of a belt, a conveyor beam frame, a supporting roller group, a metering device, a supporting roller group support and a speed measuring device. The homogenization pile metering checking device is installed on each belt conveyor for raw material conveying and can accurately check and meter the weight of a raw material after speed, time and the weight ratio of the raw material in the process are calculated, quantitative management is achieved, manpower and material resources are saved, mine waste residues are fully utilized, and the purpose of comprehensive resource utilization is achieved.

Owner:登封市科技企业孵化服务中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com