Method for preparing gelling composite material with piezoelectric property, gelling composite material and application of gelling composite material

A technology of cementitious composite materials, piezoelectric performance, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., to achieve the effect of enhancing piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with specific embodiments.

[0062] Modification and reconstitution process technical parameter in each embodiment and comparative example of table 1

[0063]

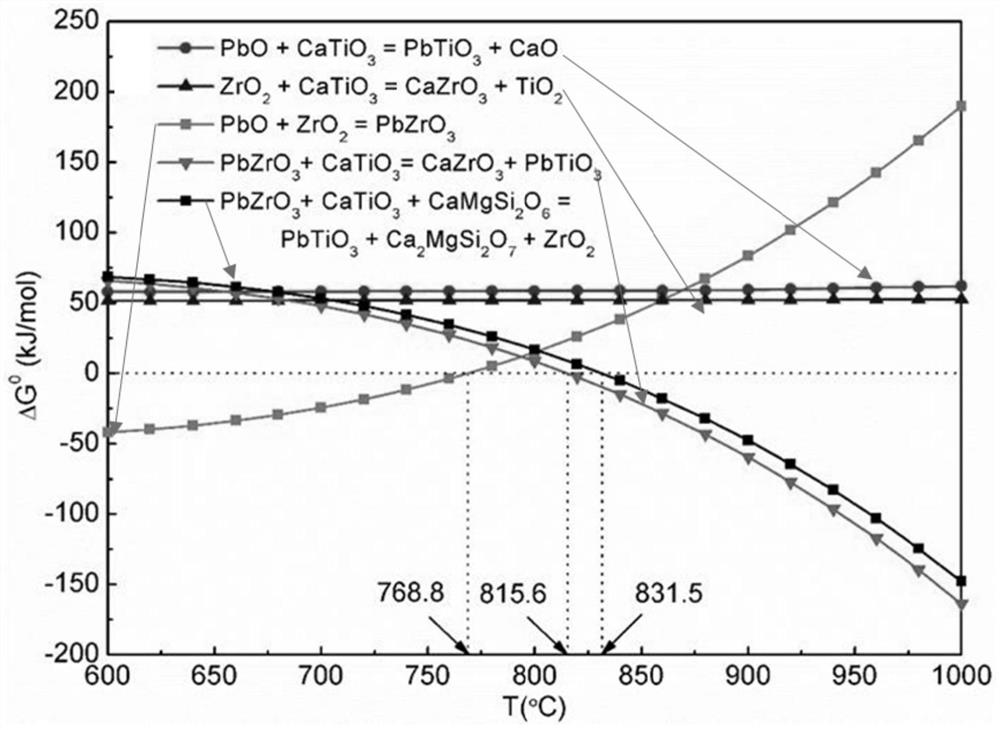

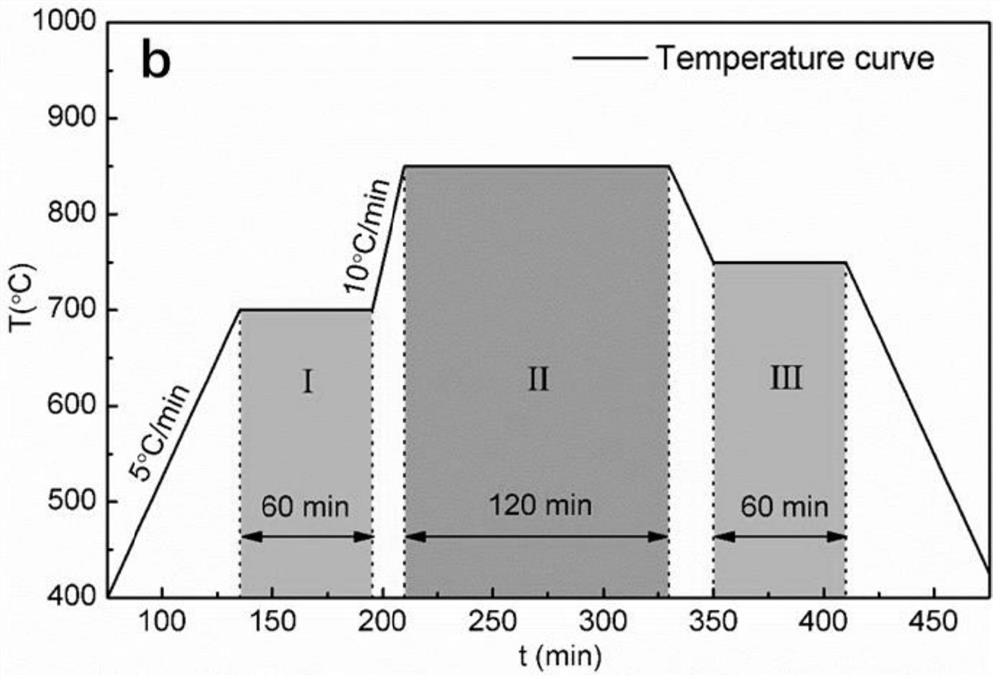

[0064] Crush the massive titanium-containing blast furnace slag and grind it in a grinding tank for 60 seconds. After drying, weigh 16.472g, mix it with 24.844g of analytically pure lead oxide and 6.493g of analytically pure zirconia, and grind for 30min with an agate mortar The above ensures that the components are fully mixed and uniform, and the muffle furnace is used as a heating device. In the first stage (heating stage), the mixed powder is heated to 700°C at a heating rate of 5°C / min and kept for 1h; then heated to 800-910°C at a heating rate of 10°C / min and kept for 2 hours (second stage); the final stage was incubated at 750°C for 1h. After cooling to room temperature with the furnace, a gelled composite sample with piezoelectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com