Patents

Literature

70results about How to "Reduce crust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based colorful real stone-type stone-like coating and production process thereof

ActiveCN104293056ANot easy to sinkAddressing Fragile ConsequencesMulticolor effect coatingsWater basedEmulsion

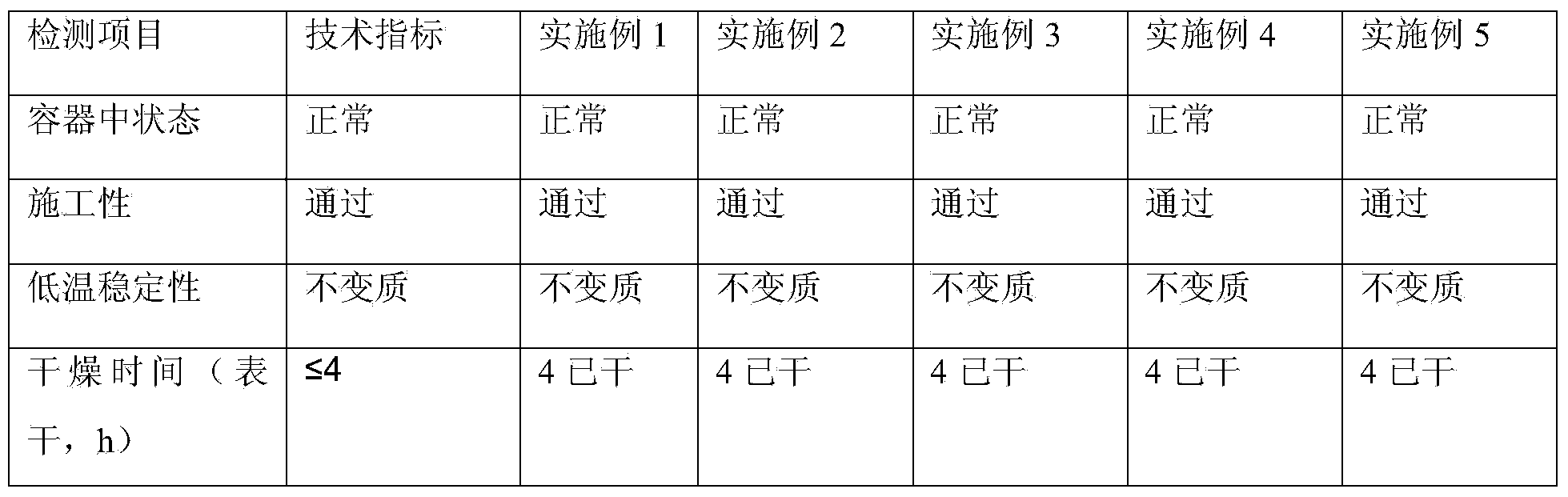

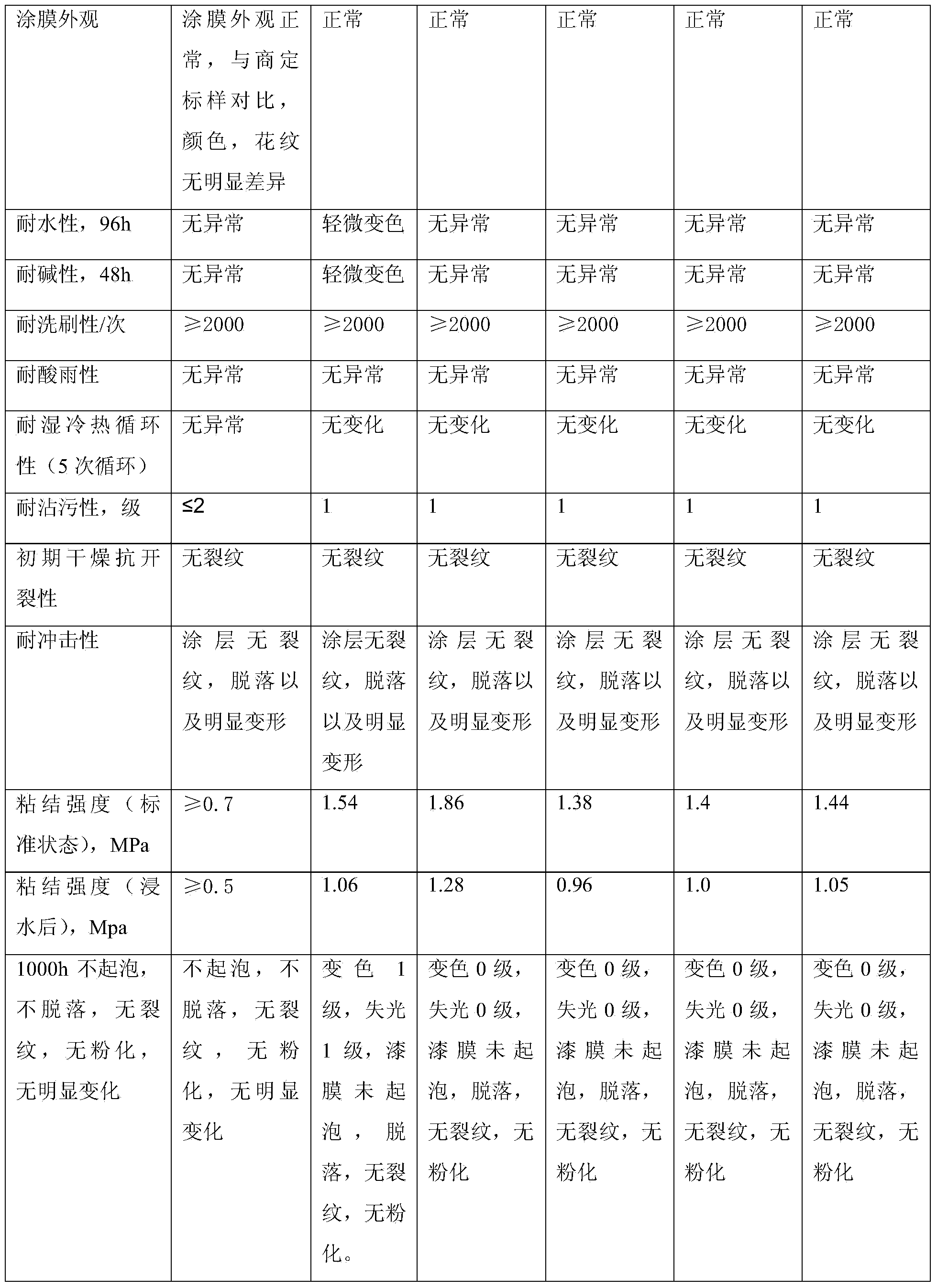

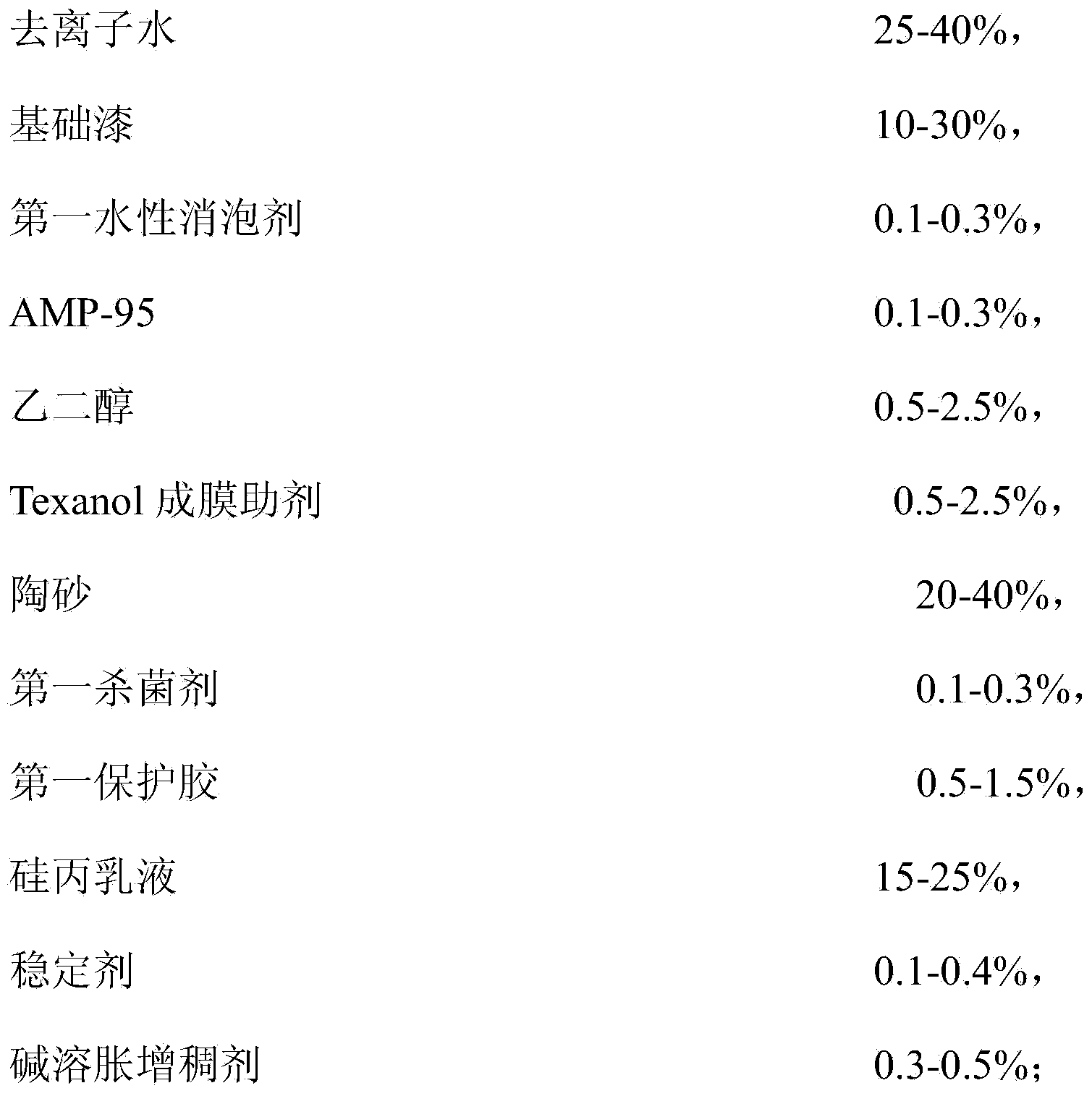

The invention discloses a water-based colorful real stone-type stone-like coating and a production process thereof. A few of colorful real stone-type stone-like coatings at present are good in crack resistance, high in fidelity and good in weather fastness, but are complicated in production process, and high in demands on production personnel; particles are easily broken; and the storage stability is poor. The water-based colorful real stone-type stone-like coating disclosed by the invention comprises the following raw materials in percentage by mass: 25%-40% of deionized water, 10%-30% of a base paint, 0.1%-0.3% of a first water-based defoaming agent, 0.1%-0.3% of AMP-95, 0.5%-2.5% of ethylene glycol, 0.5%-2.5% of a Texanol coalescing agent, 20%-40% of ceramsite sand, 0.1%-0.3% of a first sterilizing agent, 0.5%-1.5% of first protective glue, 15%-25% of a silicone acrylic emulsion, 0.1%-0.4% of a stabilizer and 0.3%-0.5% of an alkali swelling thickening agent. The coating disclosed by the invention is good in storage stability; and particles are not easily broken.

Owner:杭州潮头建材有限公司

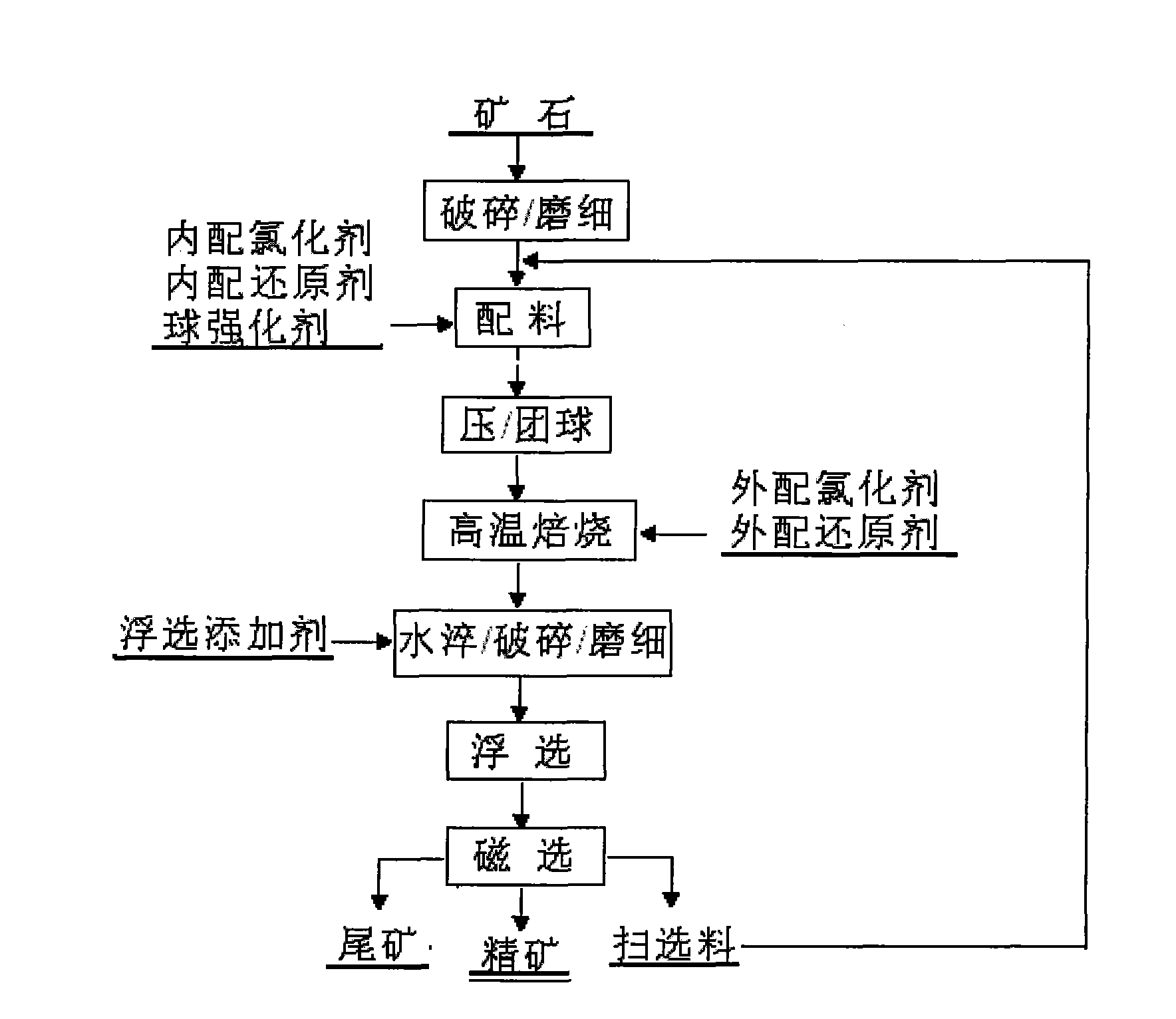

Method for efficiently concentrating cobalt and nickel from low-grade nickeliferous laterite ore

InactiveCN101514401ASimple processPractical processMagnetic separationWet separationLower gradeAlloy

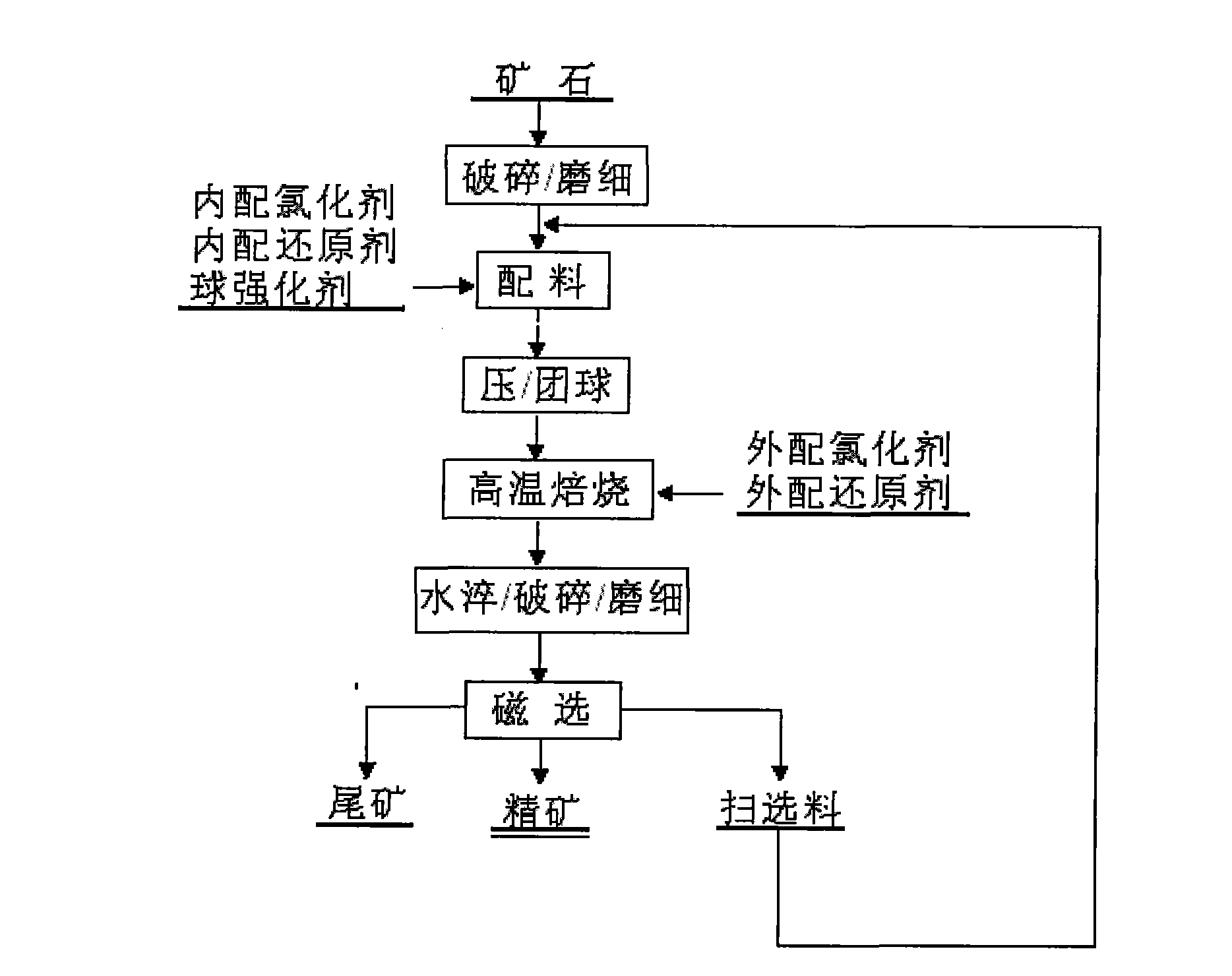

The invention provides a method for efficiently concentrating cobalt and nickel from a low-grade nickeliferous laterite ore. The method is based on mine-phase reconstruction, and the ore is subject to physical treatment, high temperature chlorination and reduction roasting to convert the nickel and the cobalt in the ore from oxide or composite oxide (silicate and ferrite) mineral into magnetic metal or alloy, magnetic separation method or combined floatation-magnetic separation method is used for separation to concentrate the cobalt and the nickel. The method is used for treating the low-grade nickeliferous laterite ore (Ni is 0.2-2.0%), contents of the nickel ore concentrate is more than ten times of that of the crude nickel ore; and the nickel recovery is more than 80%.

Owner:CENT SOUTH UNIV

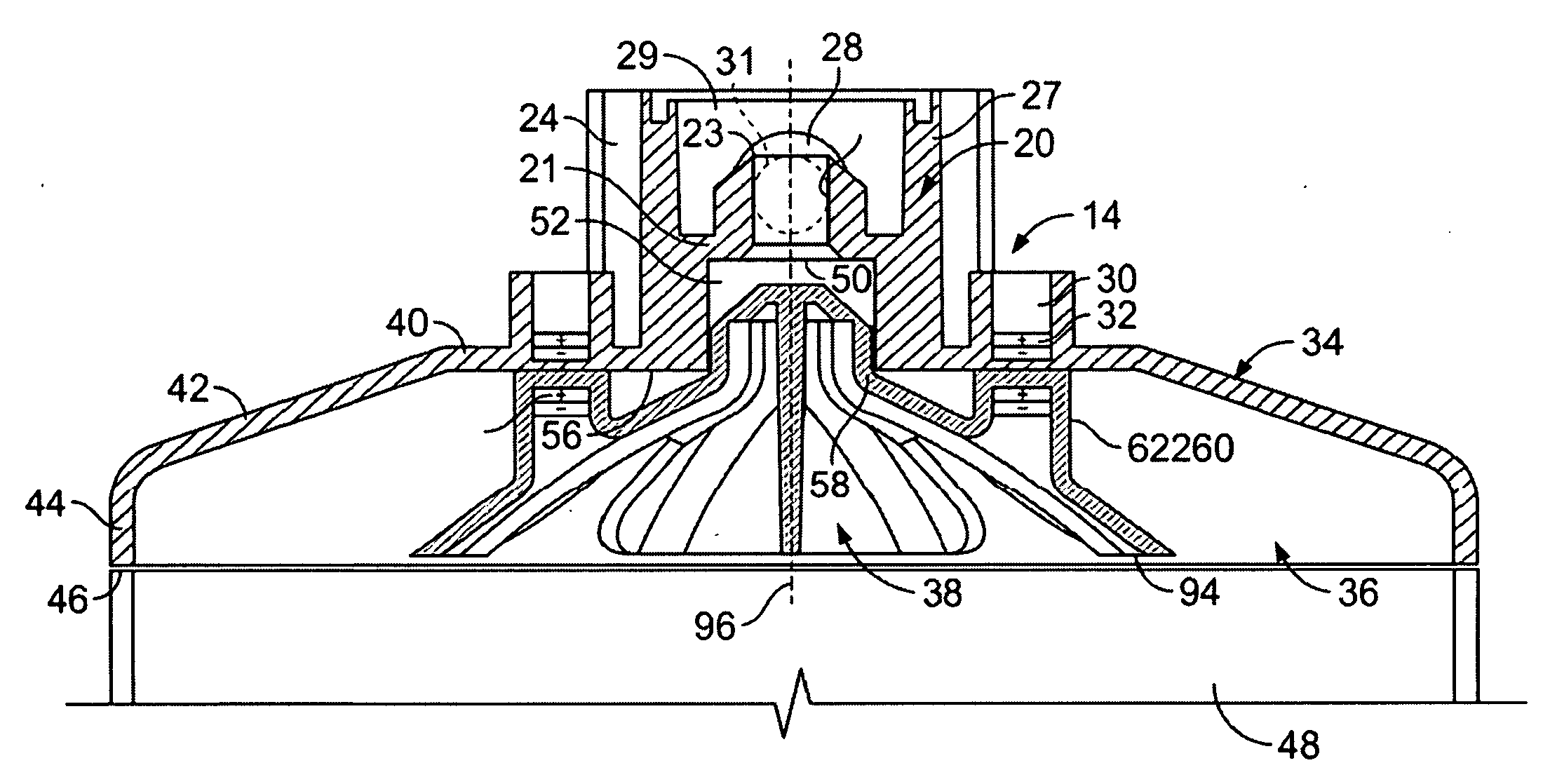

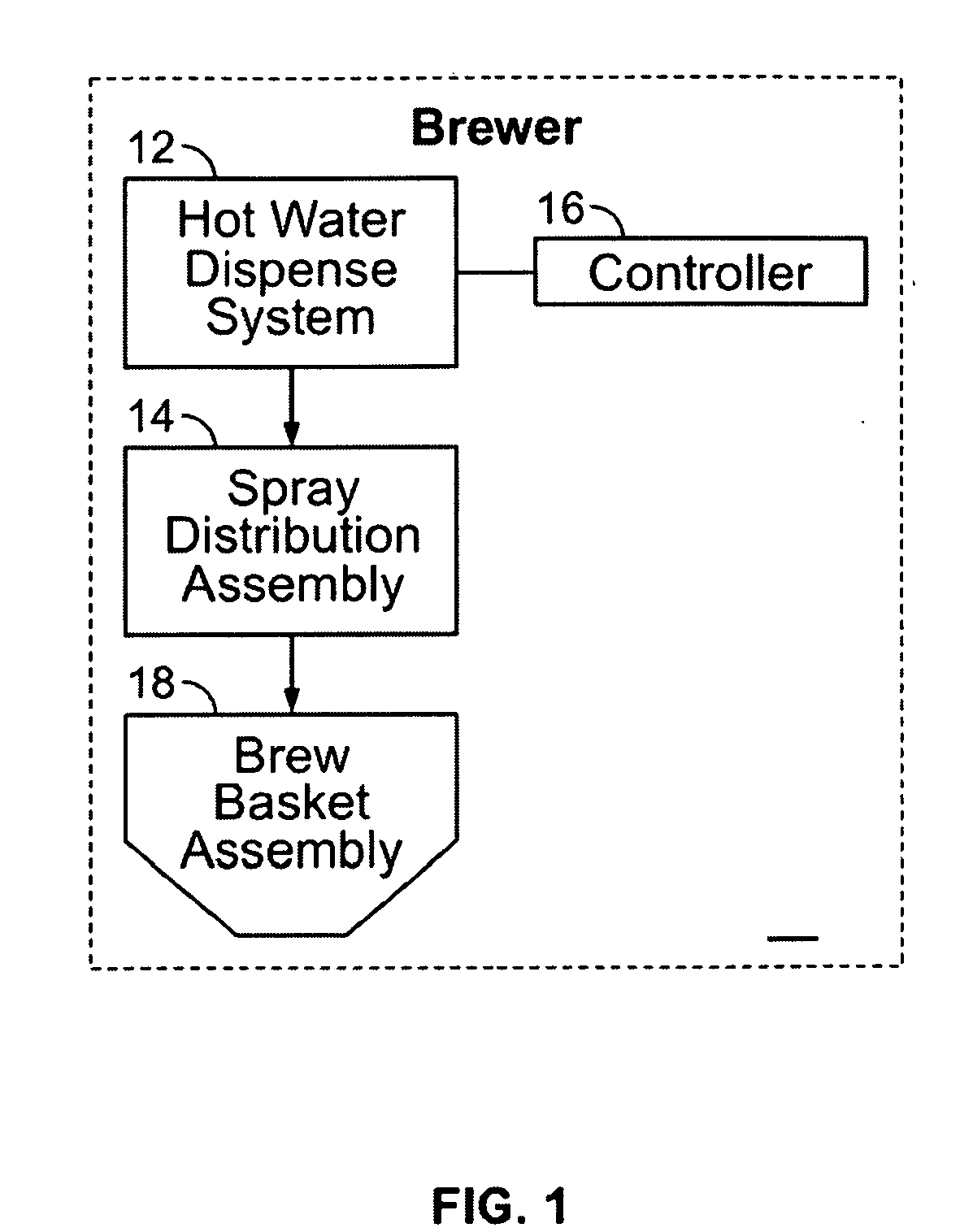

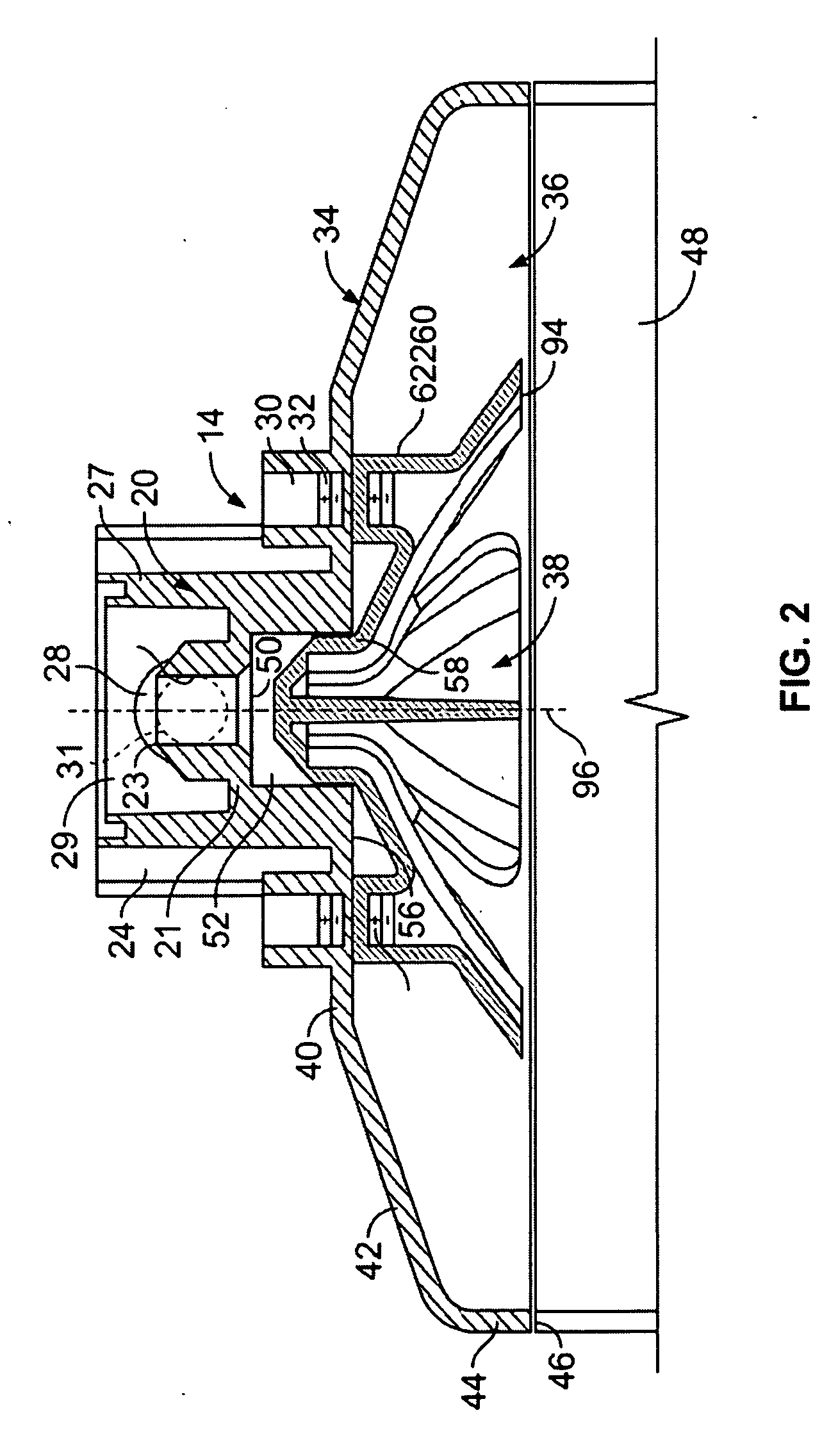

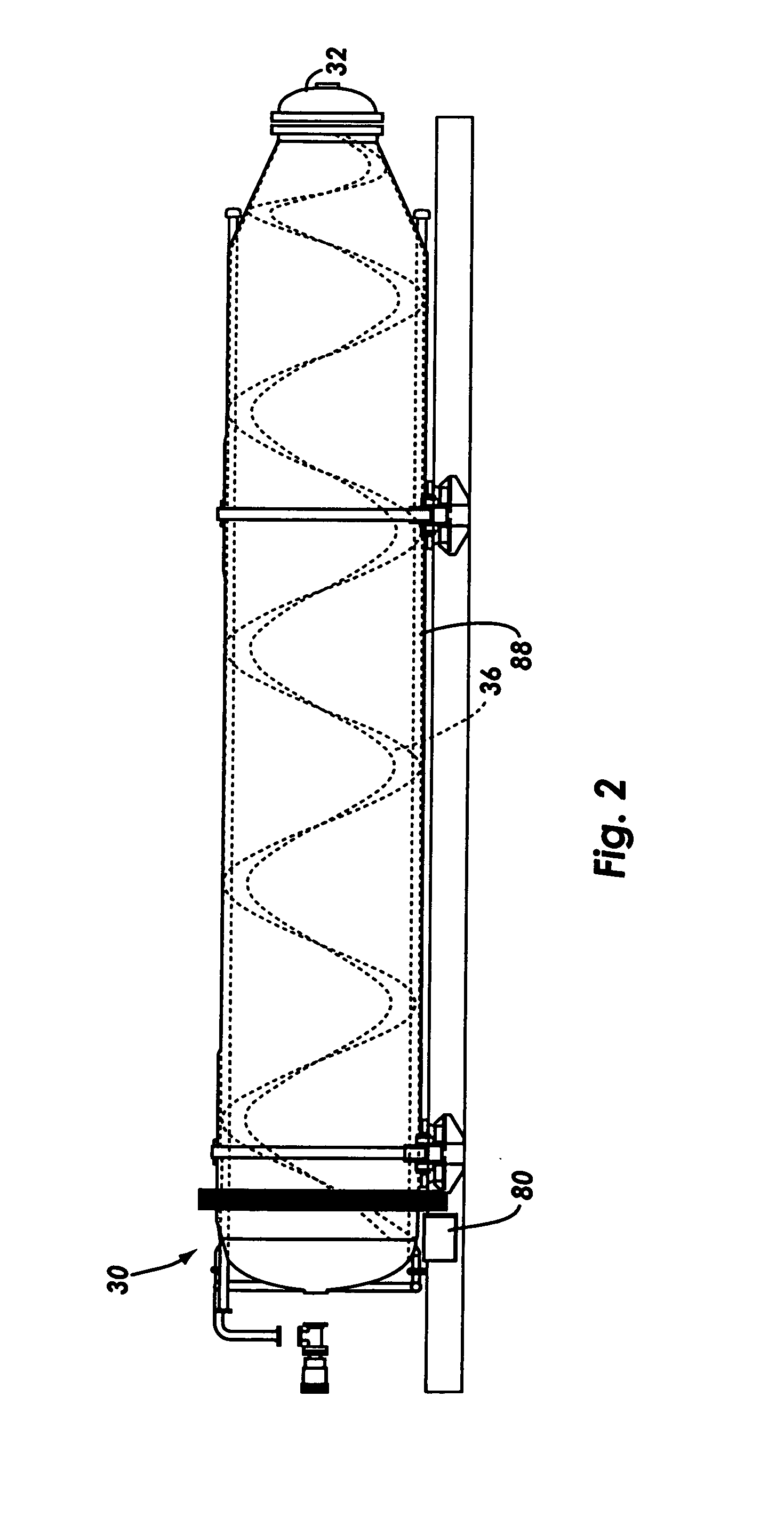

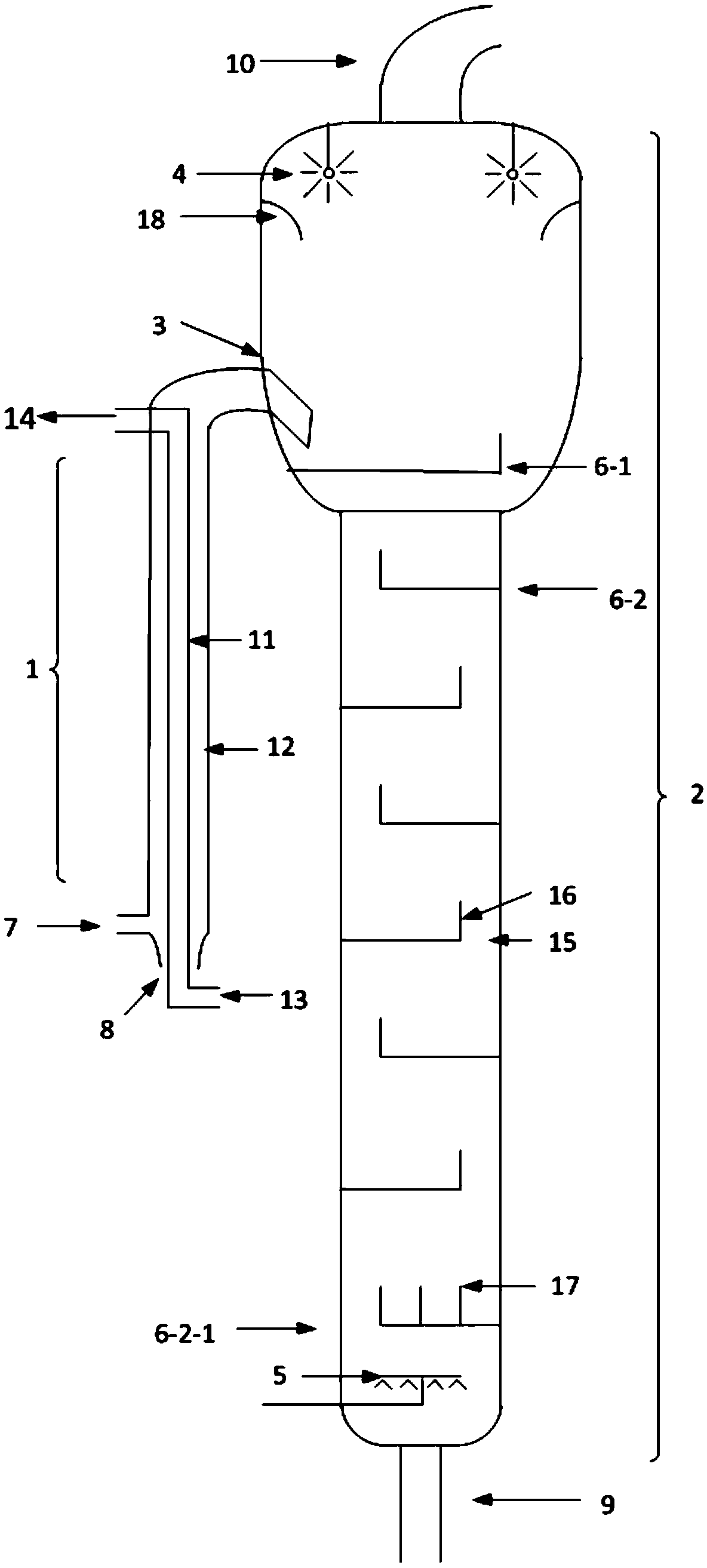

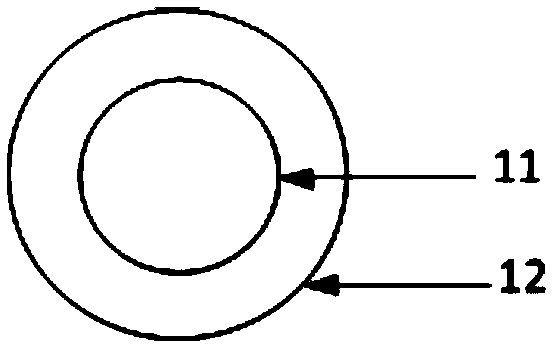

Spray distribution assembly, beverage brewer with spray distribution assembly and methods

ActiveUS20090226585A1Reduce evaporationResidue reductionTea substituesTea alkaloid content reductionEngineeringThermal water

A hot beverage brewer (10) having a hot water dispense system (12), a brew basket assembly (18) for holding ingredient to be mixed with the hot water to make a freshly brewed hot beverage and a controller (16) for controlling the delivery of hot water from the hot water dispenser system to the brew basket (18) with a spray distribution assembly (14) having a spray head (20) having a generally vertical passageway (22) for receipt of hot water and an umbrella-like member (34). A spray plate (38) mounted beneath the umbrella-like member (34) has a downwardly, outwardly tapered top surface with radiating, downwardly directed, upwardly facing grooves and an upwardly standing central core (58) snuggly received within the passageway (22) joined to the underside of the top of the umbrella-like member (34) with a plurality of vertical radially, outwardly facing grooves (68) extending from the top to the bottom to form a plurality of peripheral closed channels for passing hot water to upwardly facing grooves (74) of the umbrella-like body. Mineral encrustation is reduces by making the spray plate (38) of a material, such a polypropylene, that is hydrophobic and has a heat transfer coefficient that is substantially less than that of metal to reduce evaporation of residual water from the surface of the spray plate. Alternatively, the spray plate (38) is coated with PTFE or the like. The spray plate (38) has a surrounding outer edge that varies in radial distance from the core around a periphery of the umbrella-like body to form a plurality of radially extending pedals (80) separated by a plurality of slots (82). Tooless securing means (32, 60) permits relative rotation of the core within the passageway (22) scrape clean the core and passageway of residue. A method provides for retrofitting flat plate spray plate type distribution systems with the spray plate (38) though the use of an adapter (158)

Owner:FOOD EQUIPMEENT TECH COMPANY

Electrolytic cathode containing titanium boride-carbon coating, and preparation method thereof

The invention discloses an electrolytic cathode containing a titanium boride-carbon coating, and a preparation method thereof. The electrolytic cathode is characterized in that: a coating is coated on the surface of the electrolytic cathode, wherein the coating comprises components of, by mass: 20 to 22% of TiB2, 15 to 20% of epoxy resin, 24 to 27% of diethylene triamine, 0.3 to 0.8% of carbon fiber, and balance of graphite powder. The preparation method of the aluminum electrolytic cathode comprises steps that: the materials are sufficiently mixed and uniformly coated on the surface of the electrolytic cathode; the coating is heated from normal temperature to 150 DEG C, such that the coating is cured, and the electrolytic cathode containing the titanium boride-carbon coating is obtained.According to the invention, good wettability of aluminum liquid and the electrolytic cathode is utilized, such that aluminum oxide deposition is not easy to be left on the surface of the electrolyticcathode. Therefore, deposition or crusting is not easy to occur, current is uniformly distributed, disturbance of magnetic fields to the aluminum liquid is reduced, current efficiency is improved, energy consumption is reduced, the service life of an electrolyte tank is prolonged, and aluminum liquid level and polar pitch can be appropriately reduced. With the electrolytic cathode provided by theinvention, an average working voltage and a secondary reaction probability of the aluminum electrolyte tank are reduced, aluminum electrolytic production is improved, and the quality of aluminum products is improved.

Owner:YUNNAN RUNXIN ALUMINUM

Sealant formula

The invention provides a sealant formula which is low in cost and capable effectively saving production cost under the premises of guaranteeing binding strength of products, effectively reducing ratio of tangential to radial shrinkage and improving construction performance. The sealant formula is prepared from, by weight, 55%-60% of heavy calcium powder, 5%-8% of ash calcium powder, 30%-35% of plaster, 1.0%-1.7% of bentonite, 1%-1.5% of latex powder, 2%.-3%. Of hydroxypropyl methyl cellulose, 1%.-3%. of a retarder and 2%.-3.5%. of wood fiber.

Owner:浙江杰林新材料科技股份有限公司

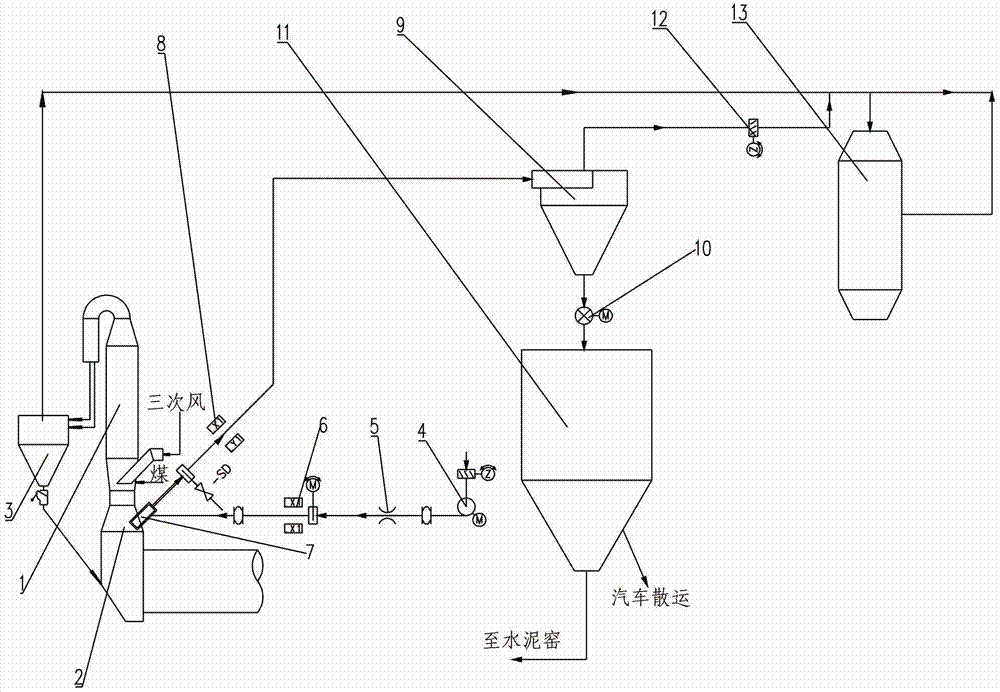

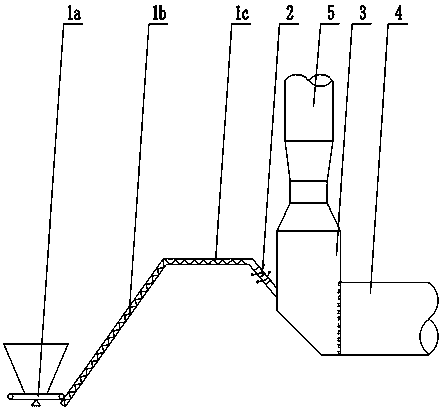

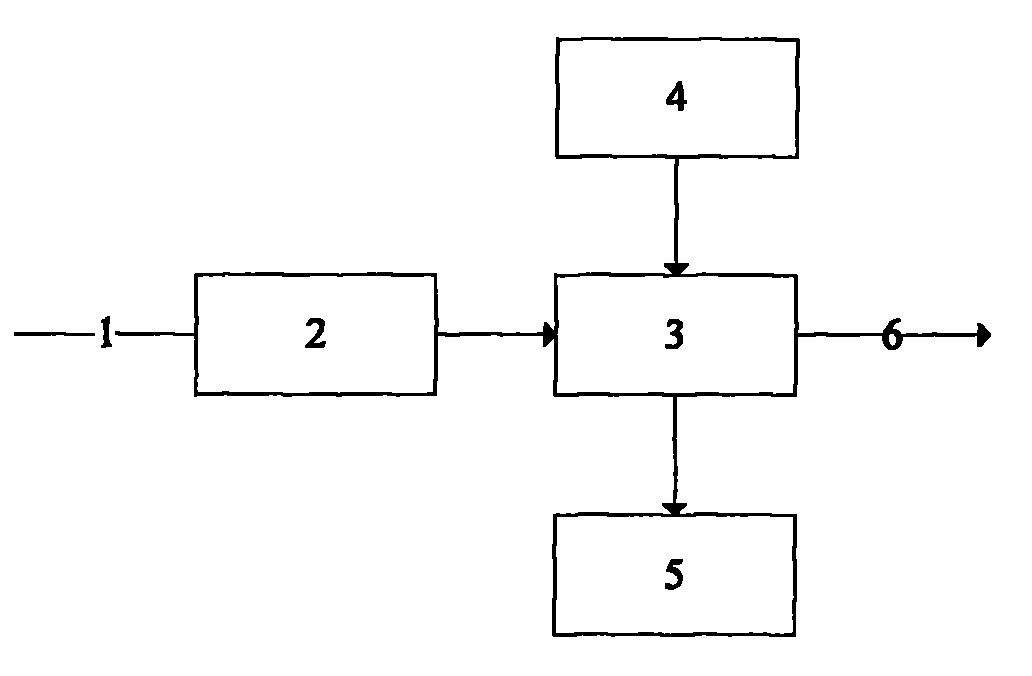

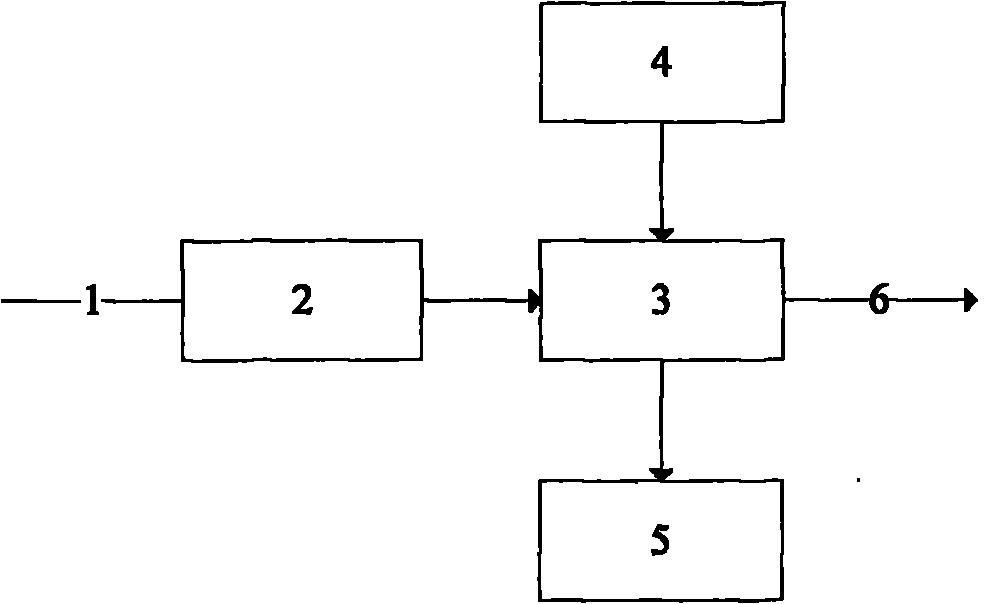

Bypass process and system for cement kiln

InactiveCN103486867AReduce CL contentReduce generationIncreasing energy efficiencyWaste heat treatmentRefuse-derived fuelCyclonic separation

The invention relates to a bypass process and a bypass system for a cement kiln. After bypass flue gas discharged from a feed-end chamber of the cement kiln passes through a mixing chamber to be subjected to heat exchange cooling, the flue gas passes through a cyclone separation device and over 80 percent of dust enters a bypass ash bin; after gas discharged from the cyclone separation device is mixed with the flue gas separated from the top of the kiln tail of the cement kiln, the mixed gas enters a kiln tail waste heat boiler to carry out waste heat power generation; and the dust which is separated from the cyclone separation device and enters the bypass ash bin is conveyed to a cement grinding mill to carry out cement batching or is loaded in bulk and transported out of a factory by a vehicle to be processed. The quantities of chlorine in ash and chlorine in RDF (Refuse Derived Fuel), which are taken into the cement kiln, can be reduced; the feed-end chamber is prevented from being crusted and blocked; and a bypass is sufficiently utilized to extract flue gas waste heat; and meanwhile, the bypass system is more flexible for model selection and has strong adaptability and cost is greatly reduced.

Owner:HUAXIN CEMENT +2

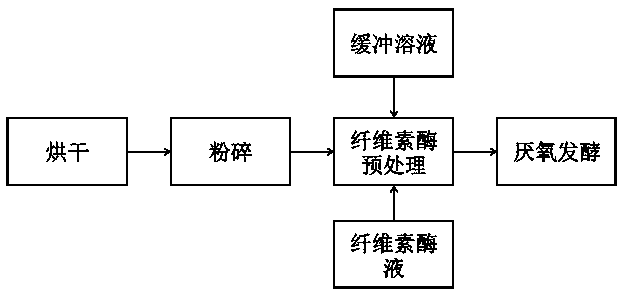

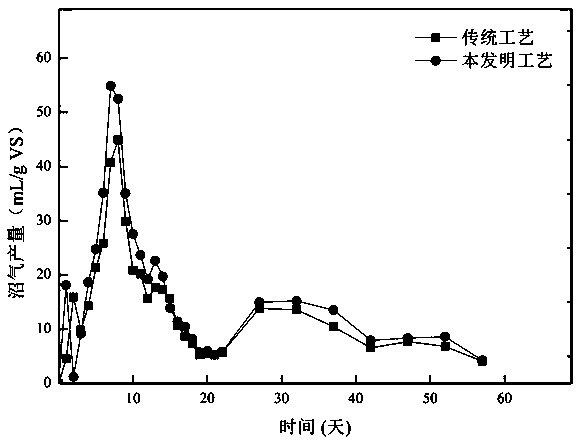

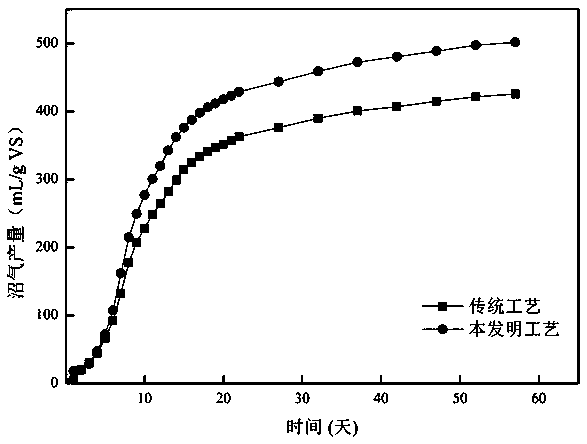

Lignocellulose anaerobic methane-producing pretreatment and fermentation technology

InactiveCN105506030AEffective hydrolysisIncrease concentrationWaste based fuelFermentationEngineeringMicrobiology

The invention relates to a lignocellulose anaerobic methane-producing pretreatment and fermentation technology. Pretreatment is conducted on lignocellulose through cellulase, and hydrolysis of the lignocellulose in the anaerobic fermentation process is facilitated. The technology comprises the steps that the moisture content of the raw materials is adjusted to below 10%; physical crushing is conducted on the lignocellulose through a crushing machine; the cellulase is added into the crushed lignocellulose; a buffer solution is added into lignocellulose and cellulase mixed liquor, and the solid content is controlled to blow 10%; a reaction is conducted for 72 h at 50 DEG C, and full stirring is conducted; an anaerobic fermentation inoculum is directly added into the lignocellulose and cellulase mixed liquor to be fermented, and the additive amount of dry matter of the inoculum is 50%-300% of that of the dry matter of the lignocellulose. According to the lignocellulose anaerobic methane-producing pretreatment and fermentation technology, the content of the cellulase inside a reactor can be increased, the content of the cellulase in the anaerobic fermentation process is increased, the efficiency of anaerobic fermentation is promoted, and the daily gas yield, the accumulated gas yield and the unit raw material gas yield are increased.

Owner:TONGJI UNIV

Soil remediation method

InactiveCN104492805AGood stabilizing and curing effectGood adsorption and ion exchange propertiesContaminated soil reclamationBase exchangeIon exchange

The invention relates to a soil remediation method. The method comprises the following steps: (1) preparing biological molecular sieves by mixing molecular sieves and microorganisms; (2) uniformly mixing the biological molecular sieves and soil according to the mass ration of (1-3) to 100 to obtain primarily treated soil, and 50-70 days later, uniformly mixing the biological molecular sieves and the primarily treated soil according to the mass ratio of (1-3) to 100. The biological molecular sieves obtained according to the method disclosed by the invention have good adsorption and ion exchange properties, meet the requirements of soil remediation and improvement, and enhance microorganism groups of the soil; the biological molecular sieves can be directly used as a soil amendment to improve the supply condition of beneficial trace elements required by crops, reduce the soil sourness and improve the base exchange capacity of soil, the content of heavy metal ions can be reduced by 40 percent in about 20 days, and the chemical residues can be reduced by 50 percent; and the biological molecular sieves can be used for improving the soil structure, regulating the PH value and chemical and physical properties, and degrading deposited chemicals and organic substances.

Owner:YUNNAN SHENGQING ENVIRONMENTAL PROTECTION TECH CO LTD

Novel soil conditioner and preparation method thereof

InactiveCN106544035AImprove the soil environmentControl soil compactionAgriculture tools and machinesOrganic fertilisersNutrientFertilizer

The invention relates to the field of agriculture, particularly a novel soil conditioner and a preparation method thereof. The novel soil conditioner comprises the following components in parts by weight: 20-50 parts of water retention agent, 15-40 parts of natural peat, 10-20 parts of additive, 5-10 parts of diatomite, 2-5 parts of alginic acid, 8-10 parts of lignin material, 8-10 parts of lime, 8-10 parts of high-molecular compound and 0.5-2 parts of fertilizer synergist. The soil conditioner can obviously improve the soil environment, so that the soil is more beneficial to crop growth; the soil conditioner can be well fused with the soil, thereby helping the soil release various nutrient elements which are beneficial to plant absorption; and the soil conditioner is capable of treating the phenomena of soil hardening, desertification and salinization, enhancing the soil permeability, improving the soil structure, improving the soil viscosity, reducing the soil erosion and soil crust, and reducing the loss of nutrients.

Owner:广东盆地一号生物产业有限公司 +1

Molten iron thermal insulating agent taking fly ash deducted from dry quenching as raw material and manufacturing and using method of molten iron thermal insulating agent

The invention provides a molten iron thermal insulating agent taking fly ash deducted from dry quenching as a raw material and a manufacturing and using method of the molten iron thermal insulating agent. The molten iron thermal insulating agent comprises the following components in percentage by weight: 50%-100% of fly ash deducted from dry quenching, 0-50% of water-granulated blast furnace slag,and 0-10% of expanded perlite. Compared with the prior art, the molten iron thermal insulating agent and the manufacturing and using method have the beneficial effects that 1) 90%-100% of the raw material of the molten iron thermal insulating agent comprises metallurgical waste in a metallurgical enterprise, machining or grinding is not required, the cost is remarkably lower to that of the similar molten iron thermal insulating agent, the cost is continuously reduced according to a formula, and the cost reducing requirements of enterprises at different levels are met; 2) the molten iron thermal insulating agent can be tightly combined with high blast slag on the surface of molten iron, slagging is easy, the heat conductivity coefficient is small, the thermal insulating effect is stable and reliable, resulfurization is not needed, and the steelmaking cost is not increased; 3) the slag gathering effect is good, the crusting phenomenon of an opening of a molten iron jar is reduced, and the workload and the working difficulty of manual slag removal are reduced; and 4) the economic benefits and the environmental benefits are remarkable, and the molten iron thermal insulating agent hasremarkable economic benefits and popularization and application values within the industry.

Owner:ANGANG STEEL CO LTD

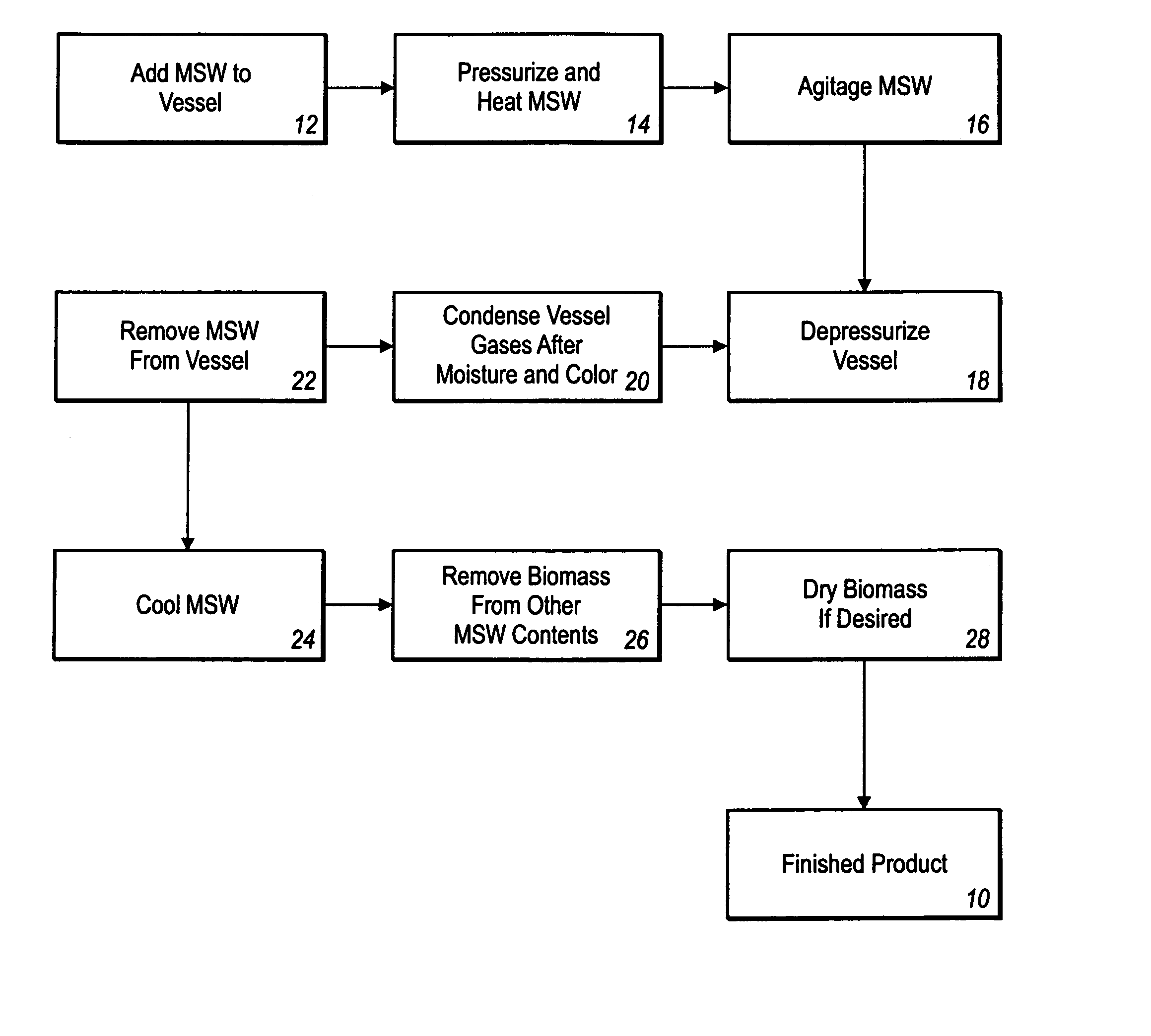

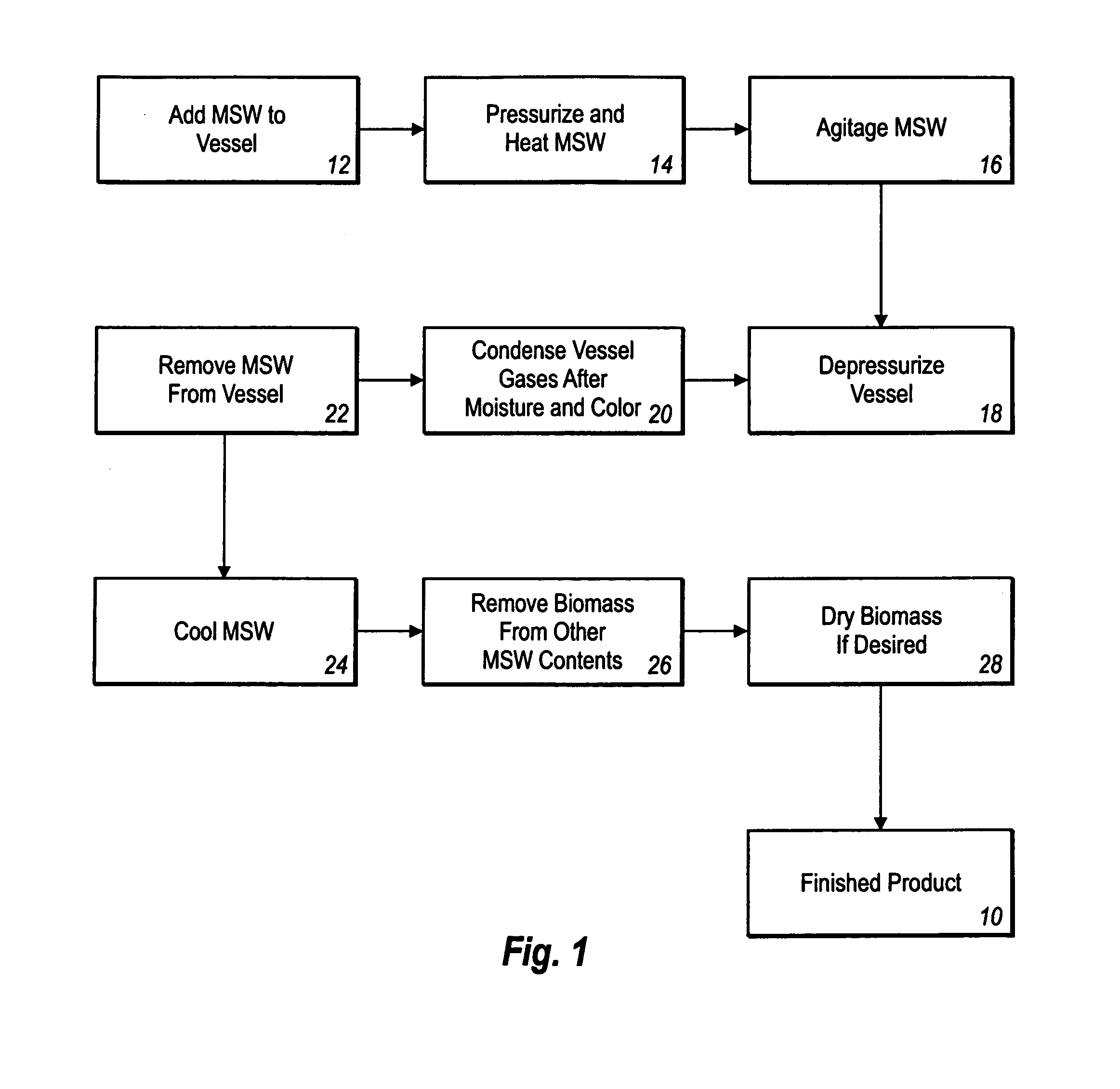

Soil amendment product and method of processing

InactiveUS20060112749A1Increase oxygenationImprove breathabilityExcrement fertilisersCremation furnacesSoil conditionerBiomass

A soil amendment product made from biomass, and a method of making a soil amendment product from biomass. The soil amendment is made by processing biomass in a pressurizable reaction vessel with heat, pressure and agitation.

Owner:BRAND NEW CO 393

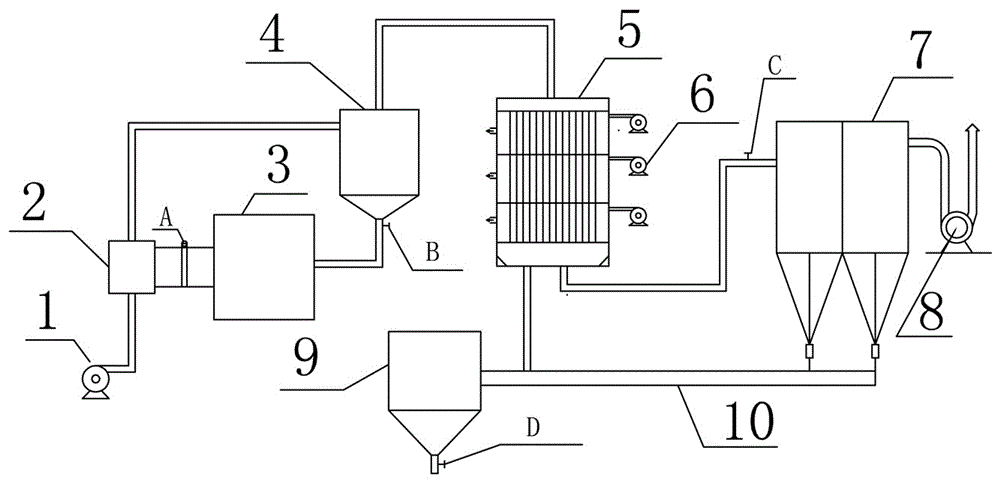

Device and method for removing VOC (voltaic organic compound) in emulsion

ActiveCN108654124AEfficient removalIncrease vaporization rateLiquid degasification with auxillary substancesEvaporationBenzeneEmulsion

The invention discloses a device and a method for removing VOC (voltaic organic compound) in an emulsion. The device body comprises a steam and liquid mixer and a VOC removal tower, wherein the steamand liquid mixer is of a multi-layer sleeve tube type structure or a tube type structure with a perforated plate; a tower body of the VOC removal tower is separated into an upper part and a lower part, the inner diameter of the upper part is greater than the inner diameter of the lower part, the upper part is provided with a rotary spraying device at the top part of the VOC removal tower, and thelower part is provided with a gas distributor at the bottom part of the VOC removal tower; a screen plate is arranged between the rotary spraying device and the gas distributor. The method using the device to remove the VOC in multiple emulsions has the advantages that the foaming and crusting are avoided in the treatment process; especially for hydrophobic VOC of BA, St, benzene series and the like, the continuous and high-efficiency effects are realized, and the like; the method has great application and popularization prospect in the fields of ultralow VOC, clean-odor emulsions.

Owner:WANHUA CHEM GRP CO LTD +1

Dry process rotary kiln cement production line based facility and method for cooperatively processing electrolytic manganese residues

PendingCN110981231AReduce crustReduce dosageFurnace typesCement productionProcess engineeringCo-processing

The invention discloses a dry process rotary kiln cement production line based facility and method for cooperatively processing electrolytic manganese residues. The facility mainly comprises a rotarykiln, a kiln tail smoke chamber, a decomposition furnace, a manganese residue metering-delivering device, and a wind locking feeder. The discharge head end of the manganese residue metering-deliveringdevice is communicated with the feed inlet of the wind locking feeder. The discharge outlet of the wind locking feeder is communicated with the kiln tail smoke chamber. The kiln tail smoke chamber iscommunicated with a rotary chamber and the decomposition furnace. The invention also provides a method that utilizes the facility to process electrolytic manganese residues. The facility has a simplestructure, the technical process is short, the automatic control is easy, the investment is low, the processing amount is large, and the method is safe and environmentally friendly.

Owner:湖南省小尹无忌环境能源科技开发有限公司

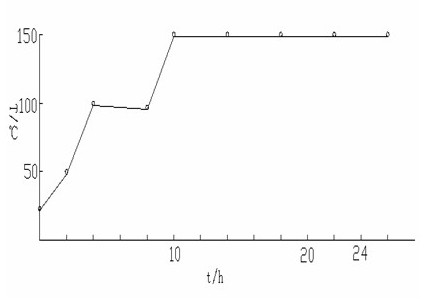

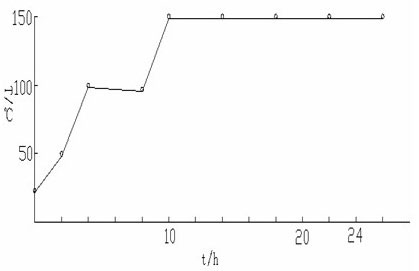

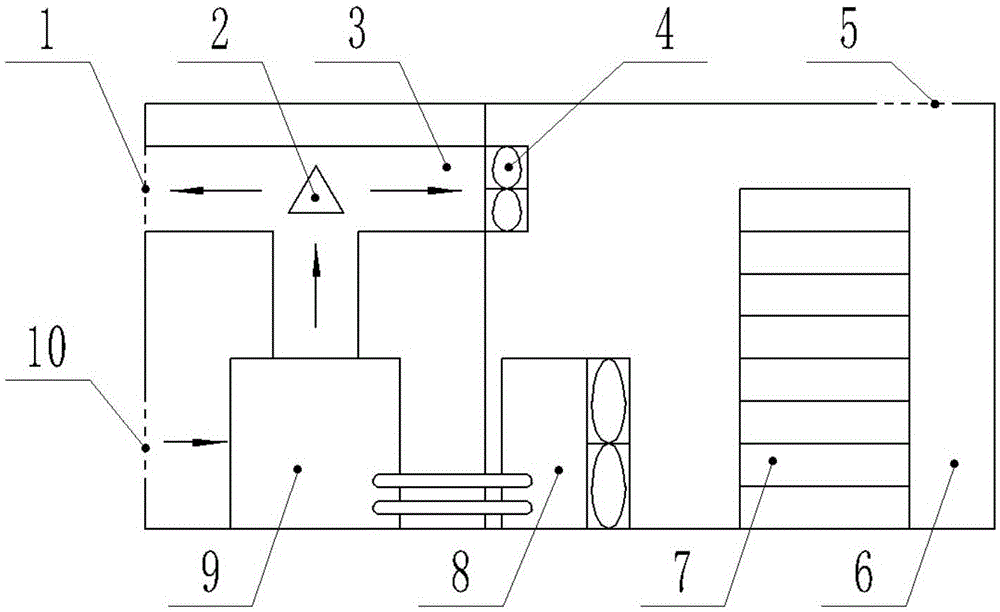

Intermittent cooling heat pump drying device and method

ActiveCN105004149AReduce surface crustingReduce crackingDrying solid materials with heatDrying gas arrangementsEngineeringMechanical engineering

The invention discloses an intermittent cooling heat pump drying device and method which are particularly suitable for drying fruits and vegetables, and belongs to the field of agricultural products. According to the method, during drying operation, drying temperature continuously rises and drops, and intermittent cooling drying is formed during corresponding lasting time. Cold capacity generated when the heat pump drying device runs is introduced into a dying chamber and is used for cooling materials, and serves as an achievement means of the intermittent cooling drying method. By means of the intermittent cooling heat pump drying device and method, the outward-diffusion rate of water in the materials can be effectively increased; the drying speed can be effectively increased; the drying quality is improved; and meanwhile the using efficiency of the heat pump drying device is improved.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI +1

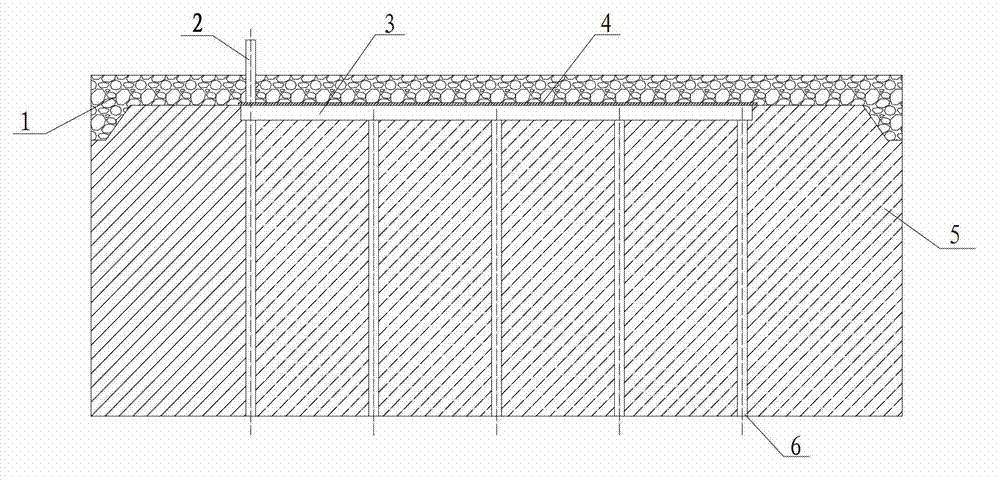

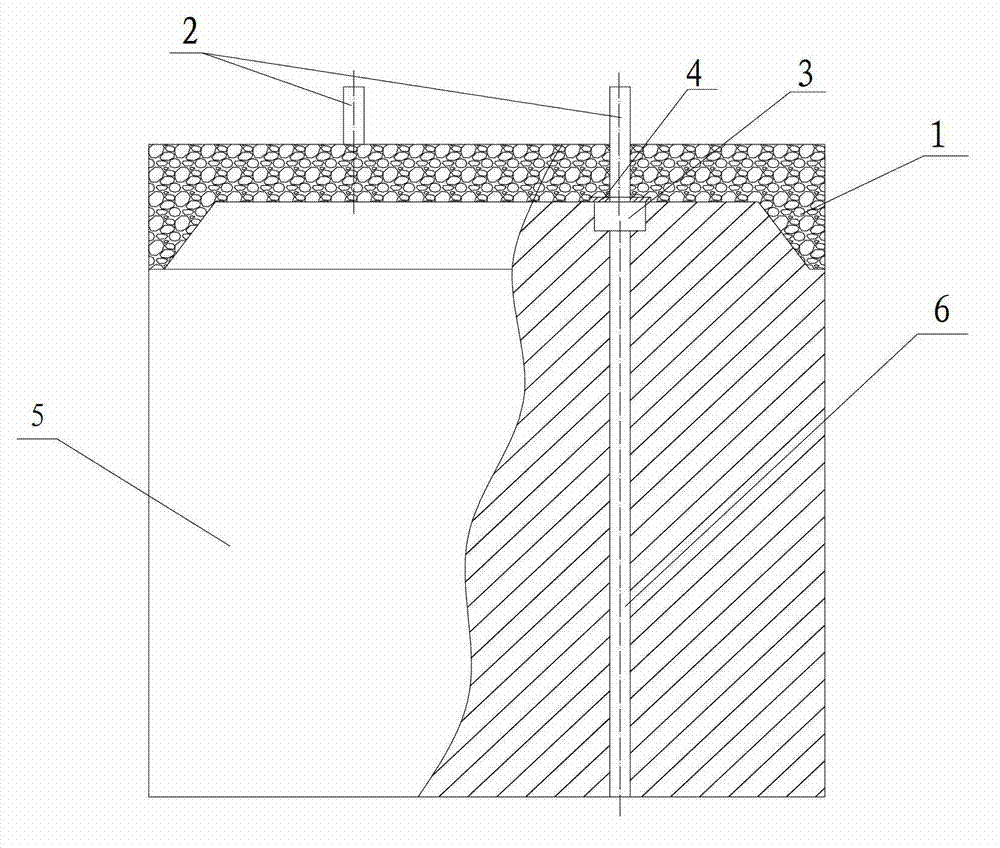

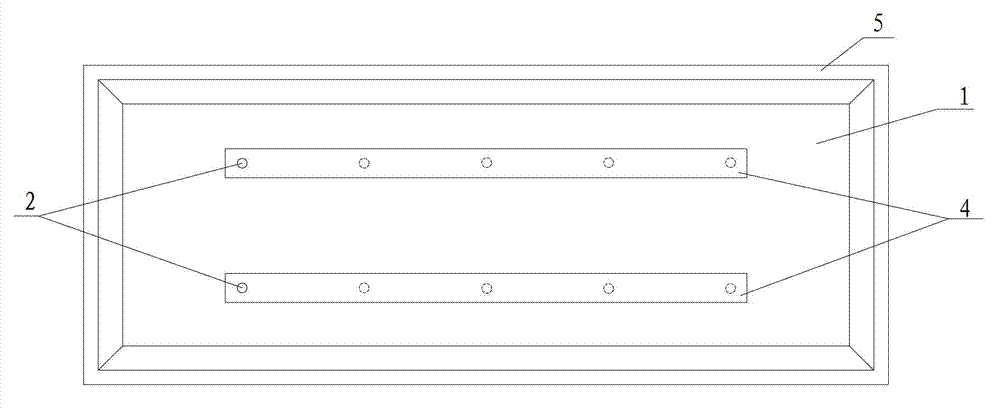

Film pressure thermal dehydration method and equipment for high-moisture sludge

InactiveCN102108001ADecrease the concentration gradientMoisture migration path is shortSludge treatment by de-watering/drying/thickeningSludge dewateringMoisture

The invention discloses a film pressure thermal dehydration method and equipment for high-moisture sludge, and belongs to the technical field of sludge dehydration. The method is characterized by comprising the following steps of: spreading the sludge subjected to conventional mechanical dehydration into a film of 1 to 10mm, regulating hot extrusion temperature and pressure for partition wall hot extrusion dehydration, separating out moisture in a liquid form, and further applying the sludge after the moisture is separated out. The invention has the advantages that: the energy consumption is low, and the energy utilization rate is high; in the dehydration process, seamless compression is adopted, and a wall-sticking phenomenon of conventional equipment is avoided, so that the whole dehydration process is smooth and feasible; and the process flow is simple and high in feasibility, other substances are not introduced, and the further treatment and recycle of the sludge are not influenced.

Owner:DALIAN UNIV OF TECH

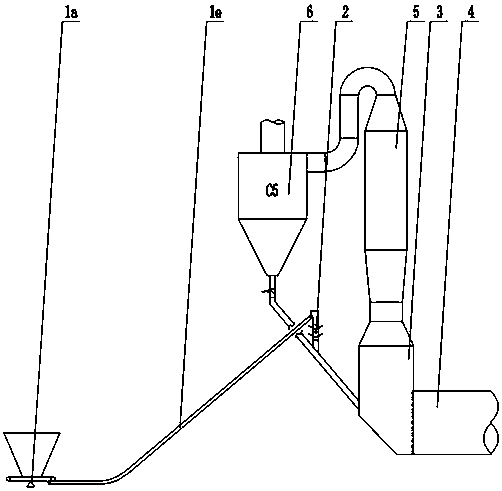

Bypass exhaust device and treatment method for cooperative household refuse treatment of cement kiln

InactiveCN106369622AReduce crustImprove ventilationEmission preventionRotary drum furnacesExhaust fumesChain conveyor

The invention provides a bypass exhaust device and a treatment method for cooperative household refuse treatment of a cement kiln. A high pressure fan is connected with a collecting box through a pipeline, and the collecting box is connected with a cyclone dust collector connected with a multitubular air cooled box. The bottom of the multitubular air cooled box is connected with the upper portion of a dust remover through a pipeline; and the bottom of the dust remover is connected with a dust collecting bin through a chain conveyor. The treatment method comprises the steps that high-temperature smoke discharged out of a smoke chamber enters the collecting box; the cooled smoke enters the cyclone dust collector through the pipeline; collected dust is recovered by the smoke chamber, and discharged waste gas enters the multitubular air cooled box; and dust collected by the multitubular air cooled box is fed into the dust collecting bin through the chain conveyor, and the dust in the dust collecting bin can be transported away through a bulk vehicle to serve as cement mixtures or cement raw materials. The content of alkali in the kiln exhaust smoke drops to 0.43% from 0.62%, the content of sulphur drops to 0.2% from 0.36%, and the content of chlorine drops to 0.31% from 0.76%.

Owner:GEZHOUBA SONGZI CEMENT

Soil stabilizer capable of improving drying shrinkage performance of compacted soil and preparation method thereof

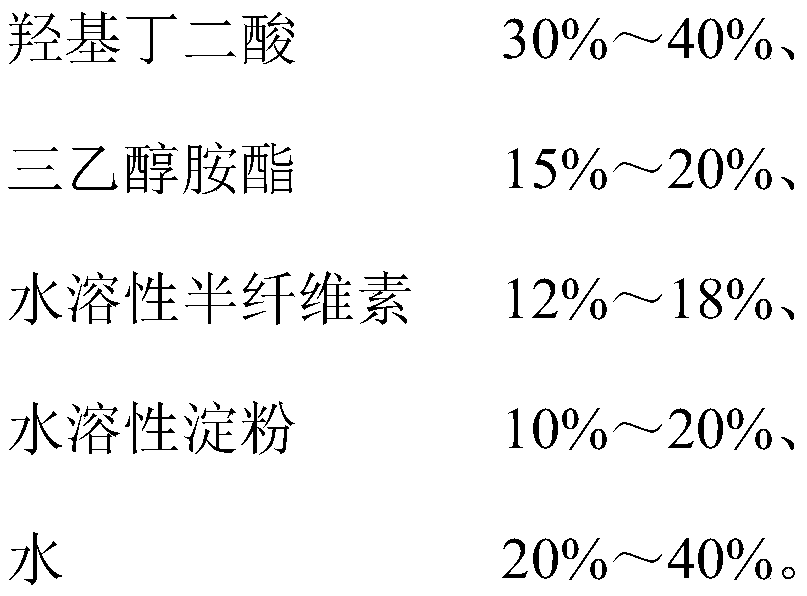

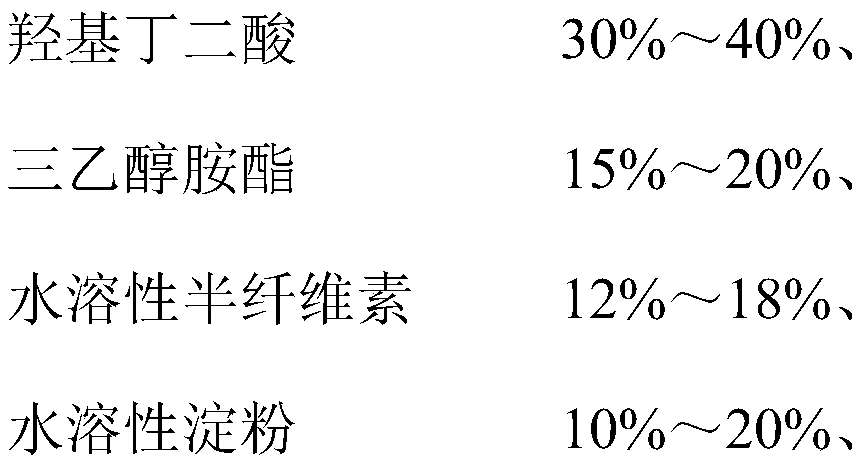

InactiveCN111575010AEffective consolidationHigh strengthRoadwaysBuilding constructionsButanedioic acidSoil science

The invention discloses a soil stabilizer capable of improving the drying shrinkage performance of compacted soil and a preparation method of the soil stabilizer. The soil stabilizer is prepared fromthe following raw materials (in percentage by mass): 30%-40% of hydroxysuccinic acid, 15%-20% of triethanolamine ester, 12%-18% of water-soluble hemicellulose, 10%-20% of water-soluble starch and 20%-40% of water. The soil stabilizer of the invention have the following beneficial effects that: (1) the formula of the soil stabilizer is reasonable and scientific in collocation, the properties of soil can be changed, so the effects of solidifying and hardening the soil and reducing the shrinkage of the soil in the hardening process are achieved, dry shrinkage resistance is excellent, and the soilstabilizer is an ideal soil stabilizer for projects such as highway subgrades or subbases; and (2) the soil stabilizer provided by the invention is mainly applied to reinforcement soil of highway subgrades or subbases and other projects, can also be used for soil reinforcement of water conservancy projects, airport projects and the like, and has a wide application range.

Owner:SHAANXI COMM CONSTR GRP CO LTD

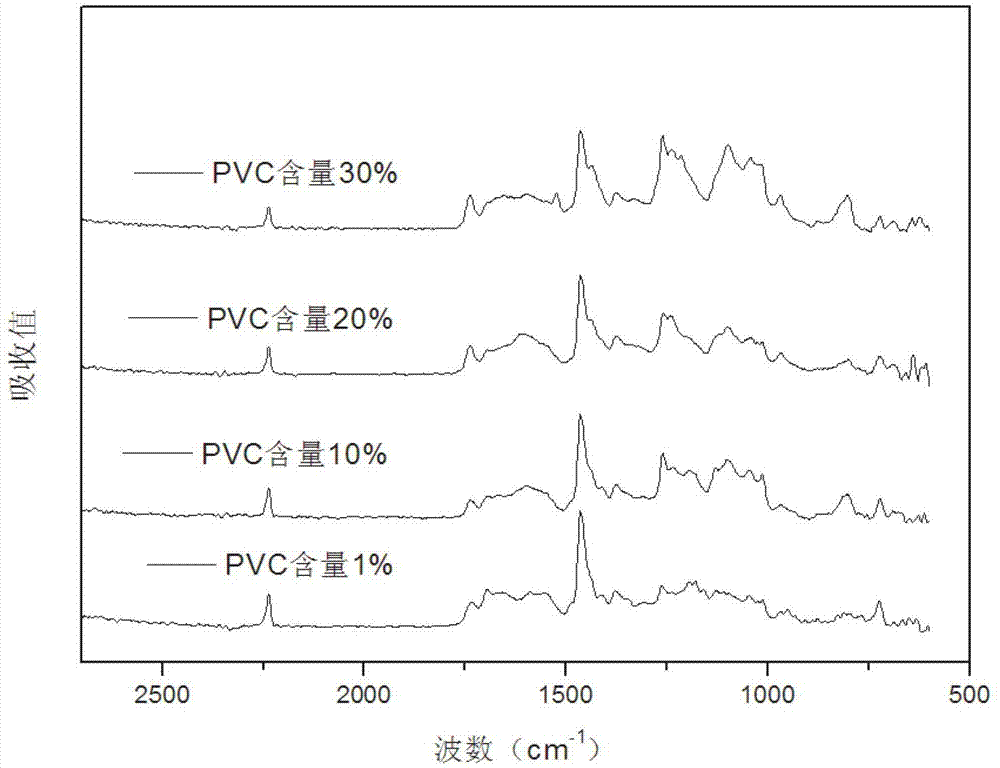

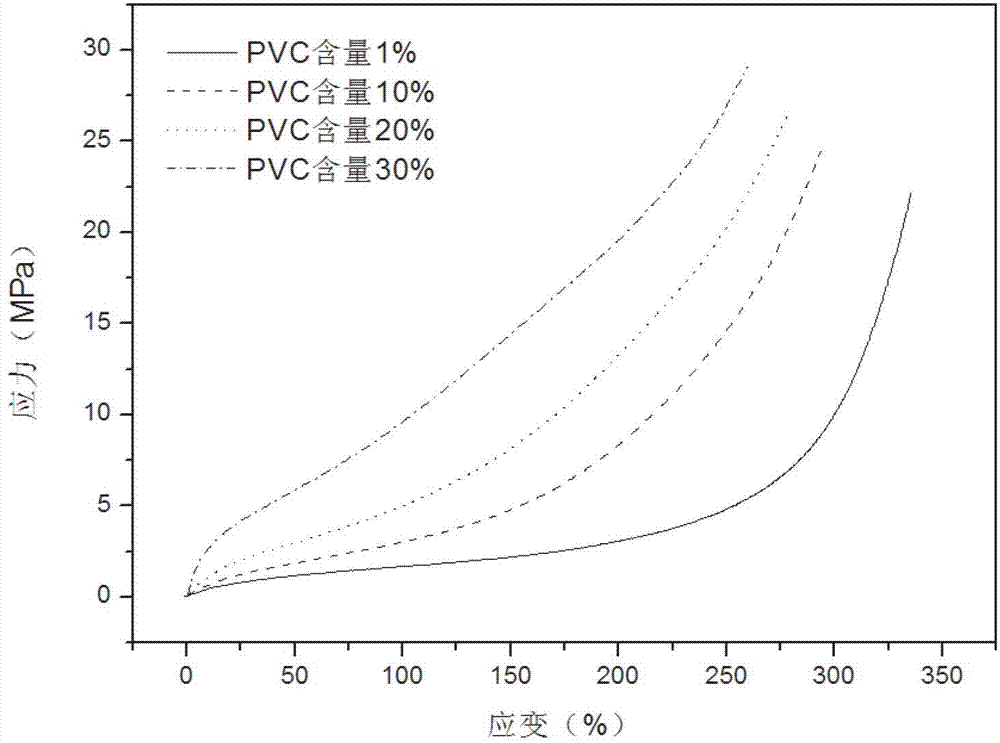

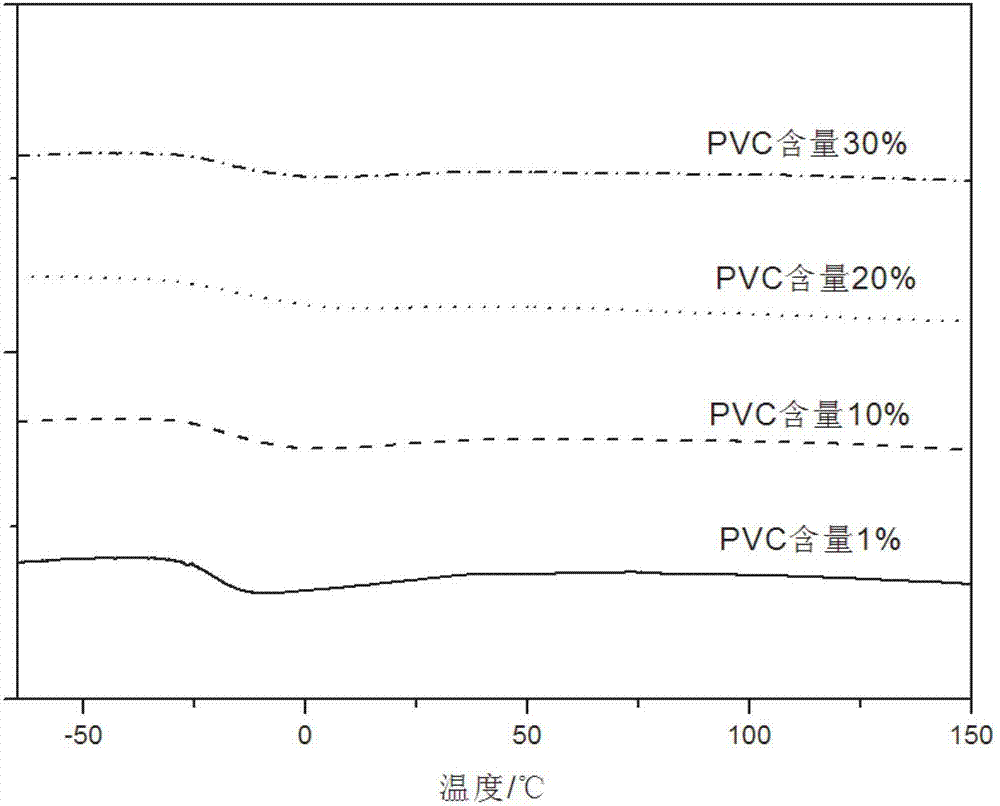

Non-vulcanized glue film of hydrogenated butyronitrile-polyvinyl chloride blended emulsion and preparation and application thereof

The invention discloses a non-vulcanized glue film of a hydrogenated butyronitrile-polyvinyl chloride blended emulsion and a preparation method and an application thereof, which belong to a chemical product and a preparation method thereof. The method is characterized in that: a non-vulcanized self-crosslinking HNBR (Hydrogenated Nitrile Butadiene Rubber) / PVC (Polyvinyl Chloride) latex film is prepared from HNBR or a HXNBR (Hydrogenated Carboxyl Nitrile Butadiene Rubber)-PVC blend emulsion by means of the self-crosslinking capability in the absence of a vulcanizing agent by using the self-crosslinking capability of HNBR or HXNBR latex with a latex steeping method. The method comprises the following steps of: uniformly mixing HNBR or HXNBR latex with a PVC emulsion to prepare a mixed latex emulsion; and steeping, leaching and drying the mixed emulsion to obtain a glue film product. A process of the non-vulcanized glue film has the advantages of simple and practicable process, low energy consumption, capability of self-crosslinking without adding any crosslinking agent and high performance.

Owner:BEIJING UNIV OF CHEM TECH

Molten iron heat insulation agent with metallurgical waste as raw material, and manufacturing and application method thereof

InactiveCN107574284AGood material coverageImprove efficiencyProcess efficiency improvementQuenchingPerlite

The invention provides a molten iron heat insulation agent with metallurgical waste as a raw material, and a manufacturing and application method thereof. The molten iron heat insulation agent comprises, by weight, 40%-70% of dry quenching fly ash, 20%-42% of water quenching blast furnace slag, 4%-10% of expanded perlite and 3%-8% of bentonite. The molten iron heat insulation agent has the beneficial effects that the molten iron heat insulation agent is totally composed of light spheres and is free of scattering during field use and good in material coverage, and the field operation environment and the use efficiency of the heat insulation agent are obviously improved; 60% or more of the raw material of the molten iron heat insulation agent is composed of metallurgy waste which does not need to be mechanically processed or ground, and the cost of the raw material is low; the molten iron heat insulation agent can be closely bonded to the blast furnace slag on the surface of molten iron,can make slag to be formed easily, and is small in heat conductivity coefficient, stable and reliable in heat insulation effect and free of resulfurization, and the steelmaking cost is not increased;the slag accretion effect is good, the phenomenon of crusting of a molten iron bottle mouth is reduced, and the workload of manual slag removal is reduced; and the molten iron heat insulation agent has obvious economic benefits and environmental benefits.

Owner:ANGANG STEEL CO LTD

Method for growing zinc-rich selenium organic moss tea

InactiveCN107836265AMeet planting standardsSimple structureCalcareous fertilisersSuperphosphatesOrganic fertilizerMoss

The invention discloses a method for planting a zinc-rich selenium organic mossy tea. The method includes the following steps of (1) seed selection: selecting tea plant varieties; selecting seedlings;(2) soil preparation and application of base fertilizer: fully reclaiming land, regulating soil pH, digging planting ditches, placing 10-15cm grass ash and crushed straw mixture in the planting ditches, backfilling with 5-10cm soil, adding 5-10cm of special organic fertilizer; then backfilling the planting ditches fully with soft soil; (3) field planting: planting tea seedlings in the above-mentioned planting ditches, compacting, and watering, wherein the planting density is 2000-3000 plants per mu; and (4) daily management of tea plantations. The planting technology of the method achieves good technical effects, the yield and quality of the tea are greatly improved, the quality of the tea is also significantly improved, the chemical pesticide content is significantly reduced, and the quality standards of organic tea are met.

Owner:石阡裕和原生态农牧发展有限公司

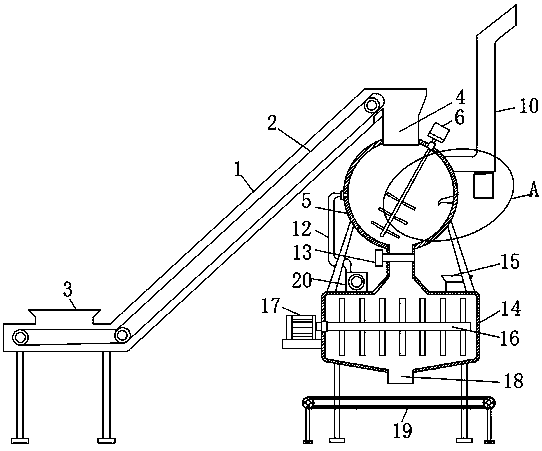

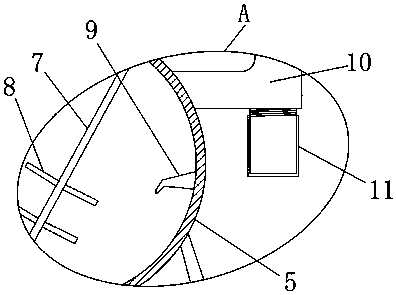

Straw carbonization returning soil improvement method

InactiveCN111534312AImprove physicsGood chemistryDirect heating destructive distillationBiofuelsSoil scienceBiological property

The invention relates to the technical field of soil improvement methods, and discloses a straw carbonization returning soil improvement method. The method involves a straw carbonization device, whichmainly comprises a mounting shell, a combustion bin and a mixing bin; the combustion bin is arranged above the mixing bin; an ignition mechanism is mounted on the inner cavity wall of the combustionbin; a hole is formed in the inner wall of the combustion bin and is provided with a flue; and inner cavities of the combustion bin and the mixing bin are communicated with each other. According to the method, the effect of straws is maximized, the excellent effect of the straws on the soil is brought into full play, the physical, chemical and biological properties of the soil can be improved through the mixture of a soil conditioner in the carbonization process, the soil conditioner is more suitable for plant growth, and the method is one of effective methods for restoring the comprehensive production capacity of the soil. The preparation method disclosed by the invention integrates transportation, mixing and carbonization, is continuous in production and high in yield, and is suitable for large-scale production, and the mixing quality of the soil conditioner is stable.

Owner:ANHUI SCI & TECH UNIV

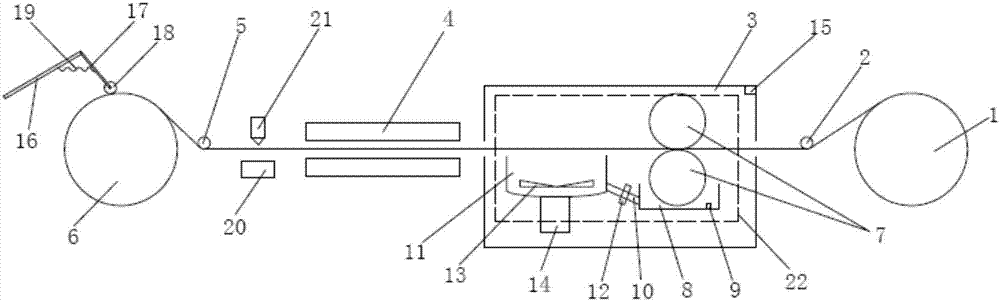

Improved two-side offset paper coating machine

InactiveCN107983585AStable temperatureReduce crustLiquid surface applicatorsCoatingsElectricityEconomic benefits

The invention provides an improved two-side offset paper coating machine and relates to the field of paper making technical equipment. The machine comprises an uncoiling device, a first guide roller,a coating device, a drying device, a second guide roller and a coiling device. The coating device is an enclosed box, the two sides of the enclosed box are provided with an inlet and an outlet. A coating roller set is arranged in the enclosed box, an ink groove is formed below the coating roller set, the bottom of the ink groove is provided with a pressure sensor, the ink groove is connected witha container through a connection pipe, the connection pipe is provided with a switching valve, the switching valve is electrically connected with the pressure sensor, a stirring disc is arranged at the bottom of the container and connected with a motor below the container, and a temperature controller is arranged in the enclosed box. The improved two-side offset paper coating machine has the beneficial effects that the coating quality is good, the automation degree is high, the skinning rate of glue, coating, ink and other media which are placed in the coating mechanism is low, and economic benefits are increased.

Owner:佛山市高明区生产力促进中心

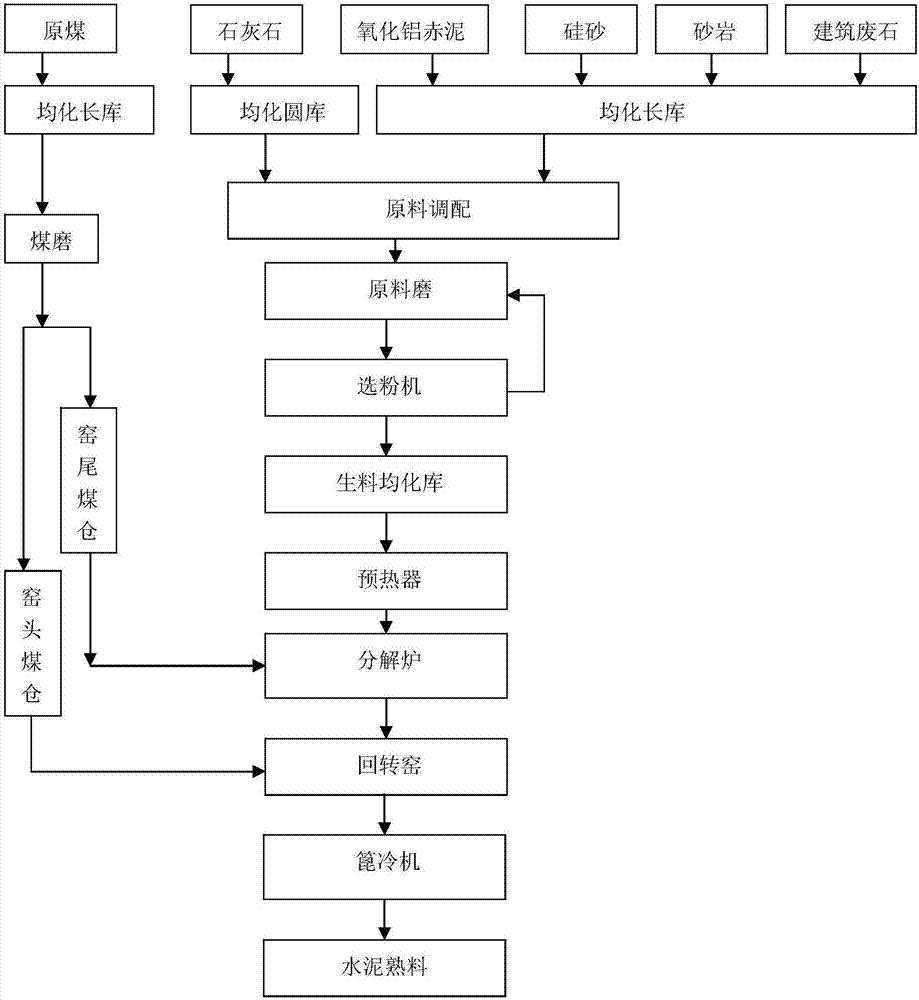

Cement clinker employing silica sand part instead of sandstone and preparation technology of cement clinker

ActiveCN107216055AAchieve control indicatorsImprove sintering qualityClinker productionRed mudToxic industrial waste

The invention relates to a cement clinker employing a silica sand part instead of sandstone. The cement clinker is prepared from the following raw materials in parts by weight: 87-90% of limestone, 2.7-3.0% of alumina red mud and 6-9% of silica sand, sandstone and construction waste rocks, wherein the mass ratio of the silica sand to the sandstone to the construction waste rocks is 1:3:1. A technology specifically comprises the following steps of carrying out burdening, homogenizing, grinding, powder selecting, preheating and decomposing, and finally carrying out high-temperature calcination and then cooling to obtain the cement clinker. By adopting the scheme of replacing the sandstone with the silica sand part to produce the cement clinker, the grindability of raw meal mill is improved; meanwhile, a lot of industrial waste silica sand and construction waste rocks are consumed, so that effective utilization of resources is achieved; the firing quality of the clinker is improved, the firing energy consumption of the clinker is further reduced and the production cost.

Owner:TIANJIN ZHENXING CEMENT

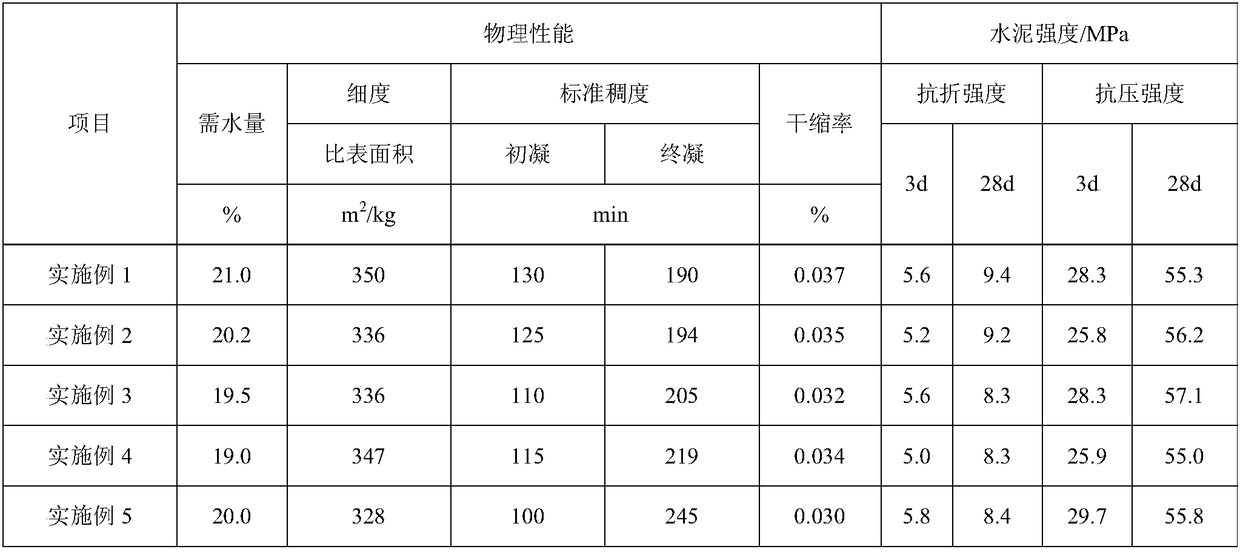

Anti-burst cement and preparation method of same

The invention provides anti-burst cement and belongs to the field of building materials. The anti-burst cement is prepared from, by weight, 40-60% of clinkers, 0.5-5% of phosphogypsum, 1-5% of titanium gypsum, 20-40% of water granulated slag, 2-15% of limestone, 2-10% of black ash, 1-3% of active silicon, 0.1-0.5% of lignin fiber, 0.1-0.5% of polypropylene fibers, 0.3-1% of glass fibers, 0.3-1% ofa water reducing agent, 0.5-2% of sodium polyacrylate, and 0.5-2% of lauryl sodium sulfate. The anti-burst cement is prepared from the water granulated slag, limestone, phosphogypsum, titanium gypsumand black ash as main materials with addition of the active silicon, lignin fiber, polypropylene fibers and glass fibers, so that hydration heat is synergistically reduced, and cracks due to internaltemperature increase in large-size concrete are prevented. In addition, water requirement and shrinking rate are reduced and strength and stability of the cement are improved.

Owner:广西港桥新型建材有限公司

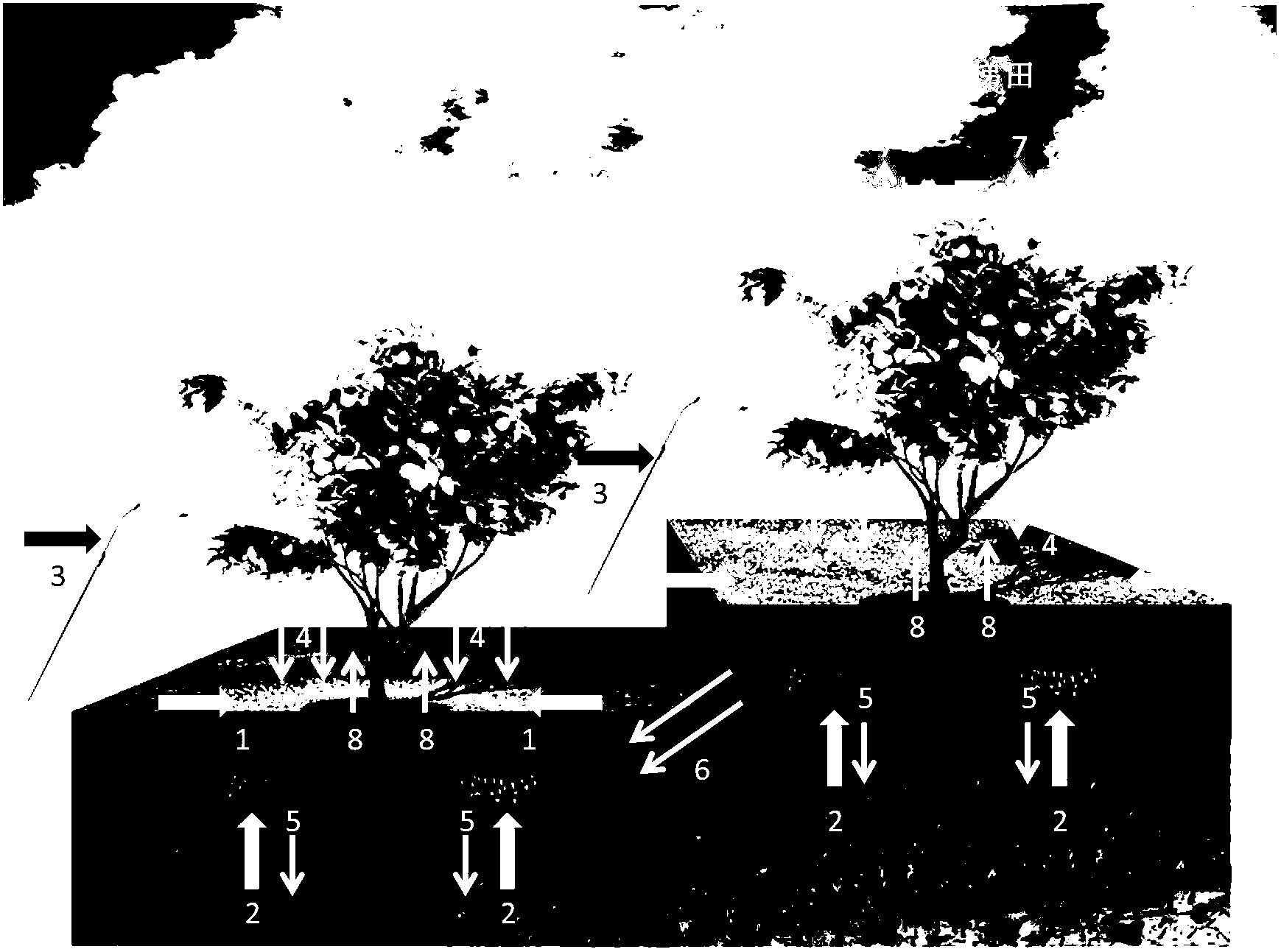

Method for preventing fertilizers of terraces from being polluted

ActiveCN103004499AReduce pollutionReduce deep leakageHorticulture methodsSoil-working methodsVertical projectionFruit tree

The invention provides a method for preventing fertilizers of terraces from being polluted. The method for preventing the fertilizers of the terraces from being polluted is used for applying soil structure conditioners, soil water-holding agents and plant antitranspirants to fruit trees planted in the terraces. On odd number-step terraces (1, 3, 5), the soil structure conditioners are evenly spread within the whole farmland range. On even number-step terraces (2, 4, 6), the soil structure conditioners are evenly spread to a zonal land surface from 1 / 3 to 2 / 3 of the vertical projection radius of the canopy of each fruit tree. According to the method provided by the invention, through comprehensively controlling multiple migration paths, such as infiltration, holding, leaching, uptake and utilization of liquid fertilizers of the terraces with different steps, through functions of reducing leaching leakage and evaporation and the transpiration loss of the liquid fertilizers, holding the liquid fertilizers at root layers of crops and promoting crop physiology functions, the efficient utilization of the liquid fertilizers of terrace orchards is realized. The method provided by the invention is fewer in input, easy in operation and high in applicability and is suitable for being popularized and applied to the terrace orchards. As the utilization rate of the liquid fertilizers and the crop physiology functions are improved, the environmental pollution level is lower.

Owner:CHINA AGRI UNIV

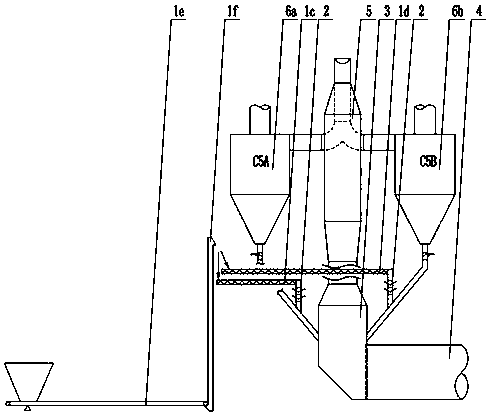

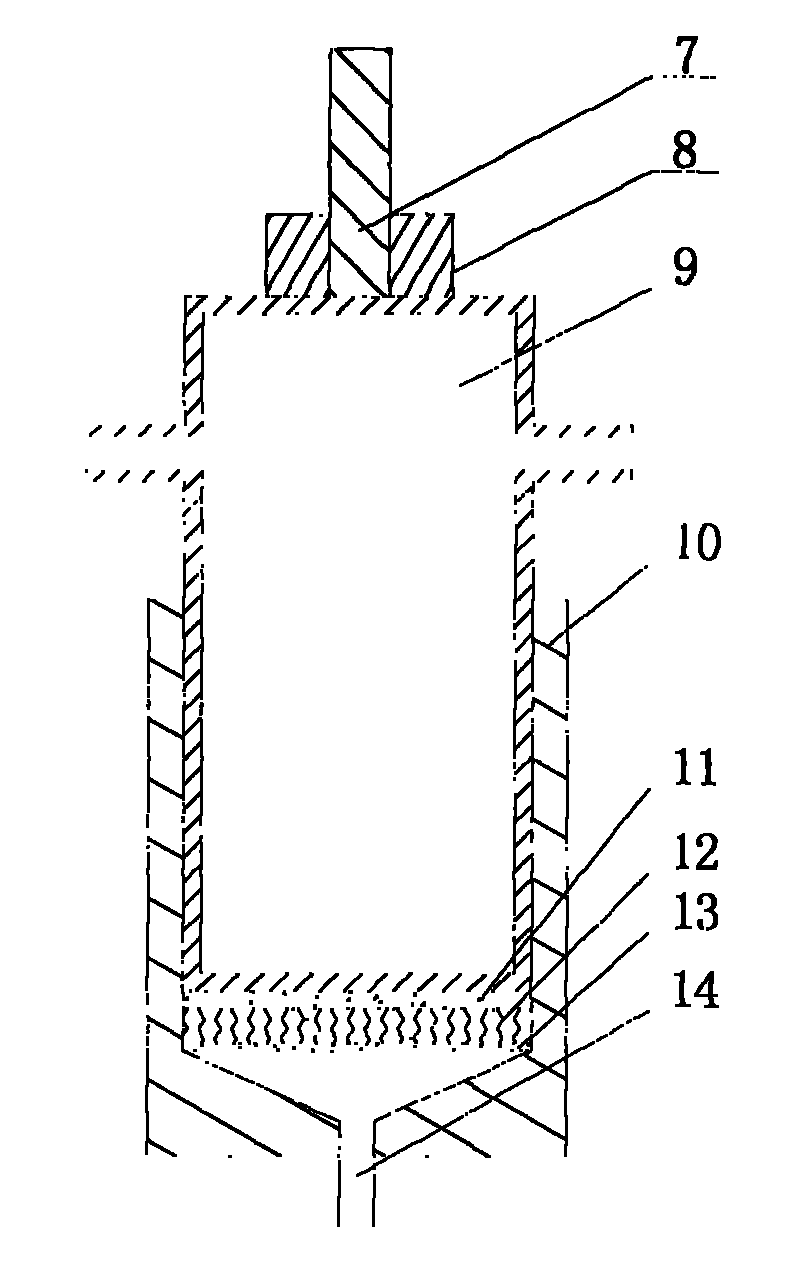

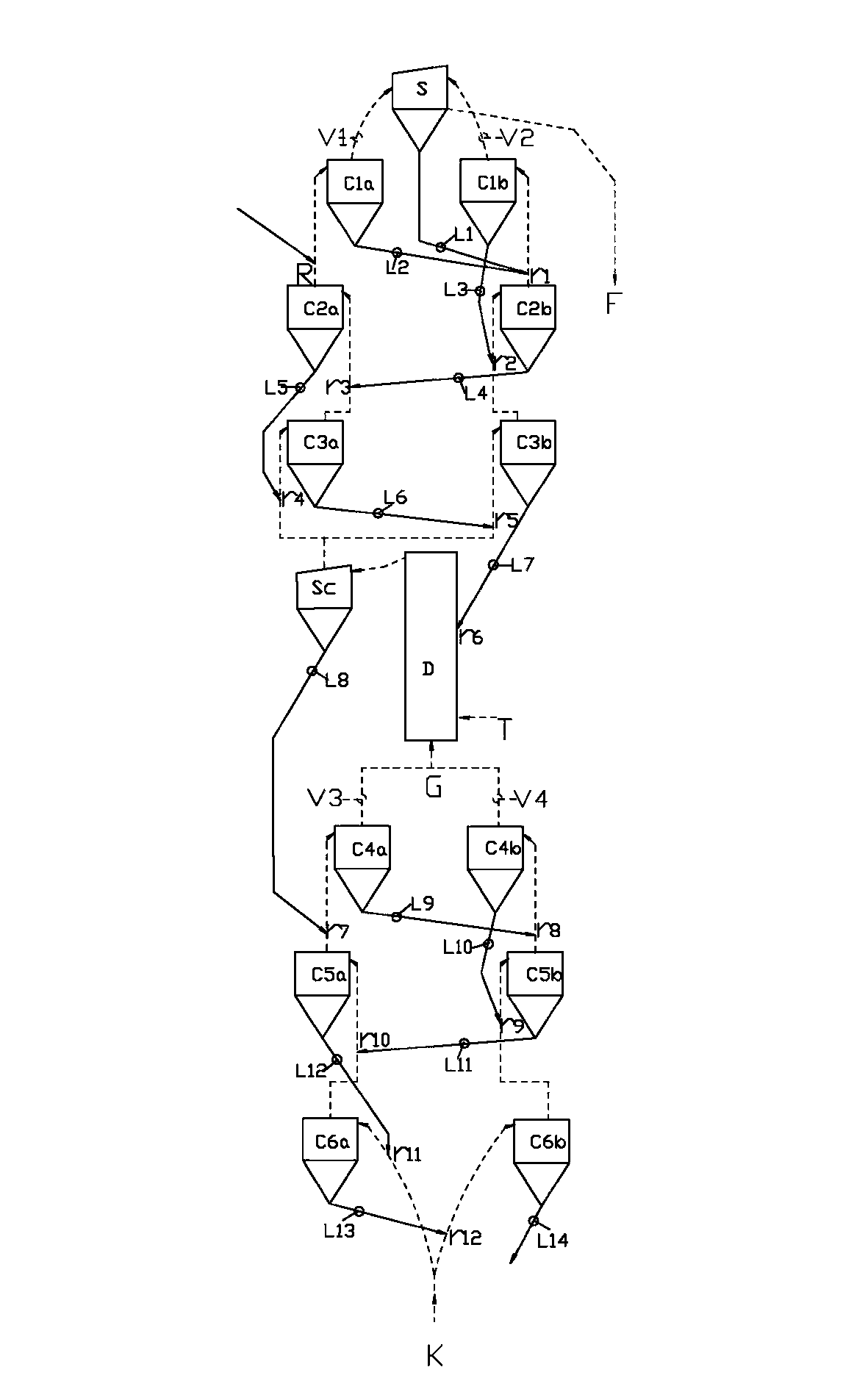

Powdery material suspension type heat exchanger device and powdery material heat exchanger system

InactiveCN103105067AIncrease temperatureEmission reductionPreheating chargesFurnace coolingCycloneEngineering

The invention relates to a powdery material suspension type heat exchanger device and a powdery material heat exchange system. The device comprises at least two rows of cyclone heat exchangers in parallel, wherein each row of cyclone heat exchangers includes at least two stages of heat exchangers; gas flow flows according to follow paths: the gas flow paths among all the row of cyclone heat exchangers are connected in parallel, and the gas flow paths of each row of cyclone heat exchangers are connected in series; powdery material flow flows according to the following material flow path: the material flow paths of each stage of heat exchangers are connected in series; and the two adjacent stages of cyclone heat exchangers adopt the following material flow connecting ways: a former-stage cyclone heat exchanger located at the terminal end of the material flow series connection path is directly connected with a later-stage cyclone heat exchanger (in the same row of the former-stage cyclone heat exchanger) in a way of former-later stage series connection; and the cyclone heat exchanger in the later-stage in the same row is located at the initial end of the later stage of cyclone heat exchangers. The powdery material heat exchange device and system are flexible in structural arrangement, simple in construction, cost-saving, small in pressure loss, low in power consumption, high in heat exchange efficiency, and good in separating effect, and the harmful exhaust emission amount is small.

Owner:刘红锁 +2

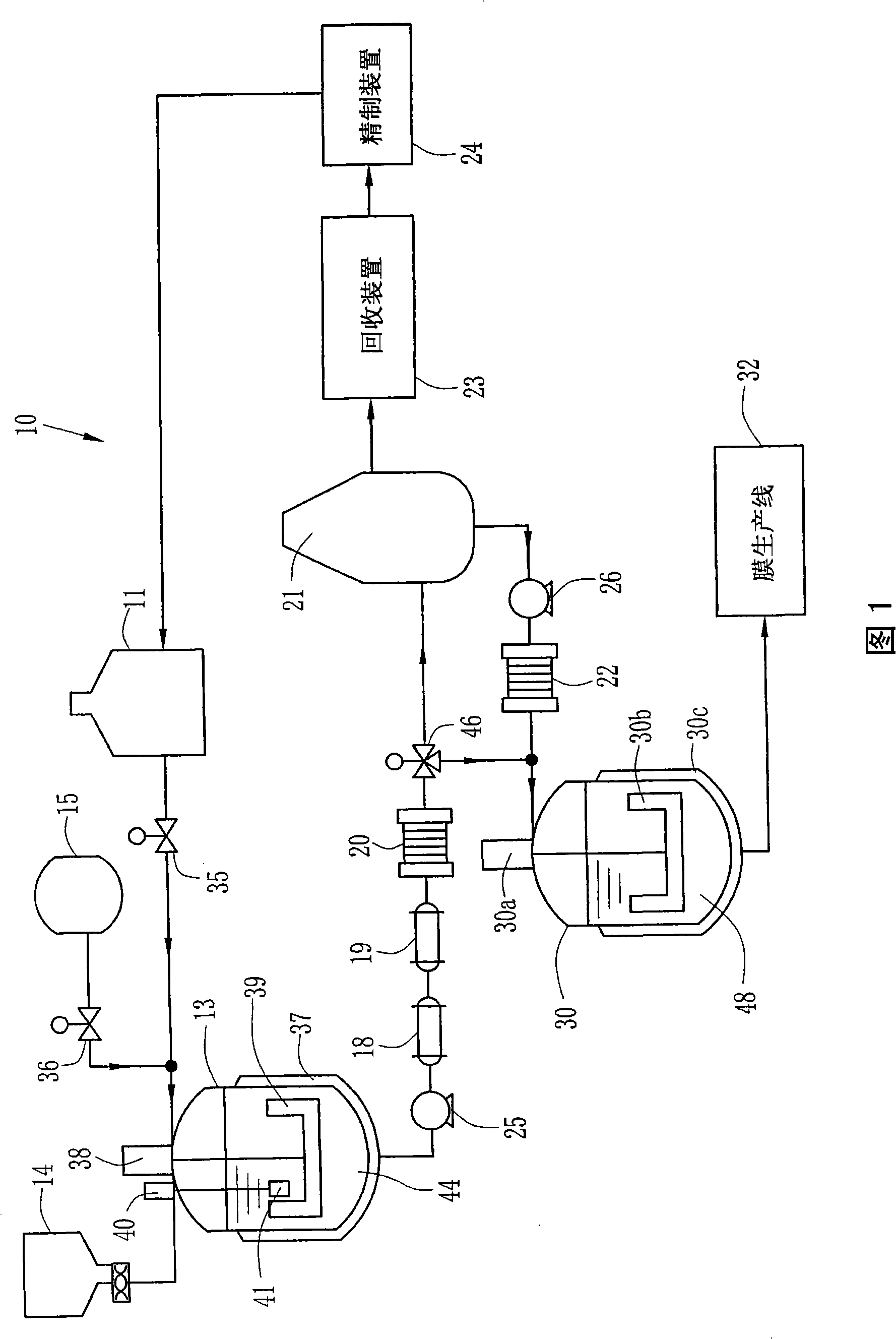

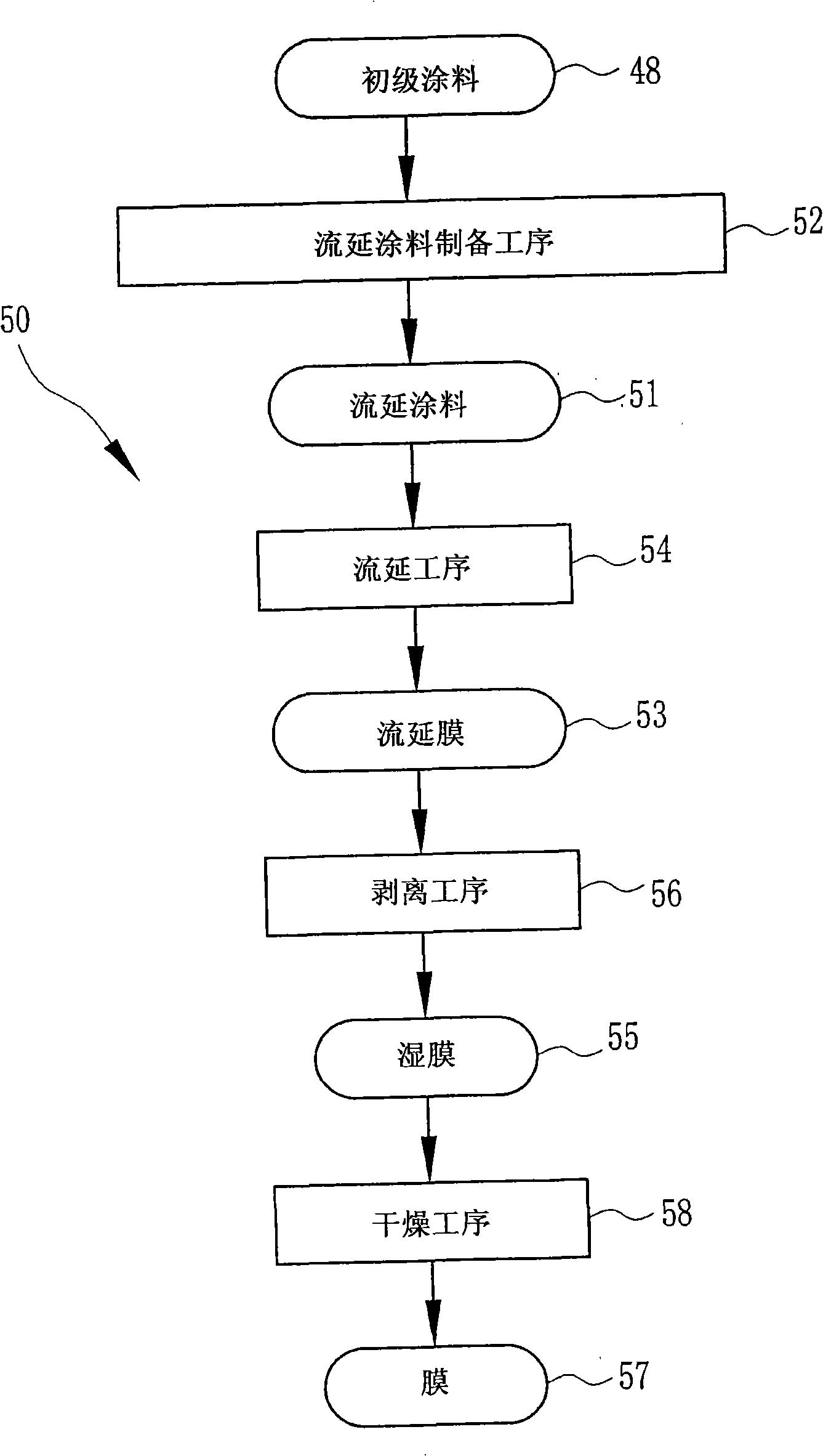

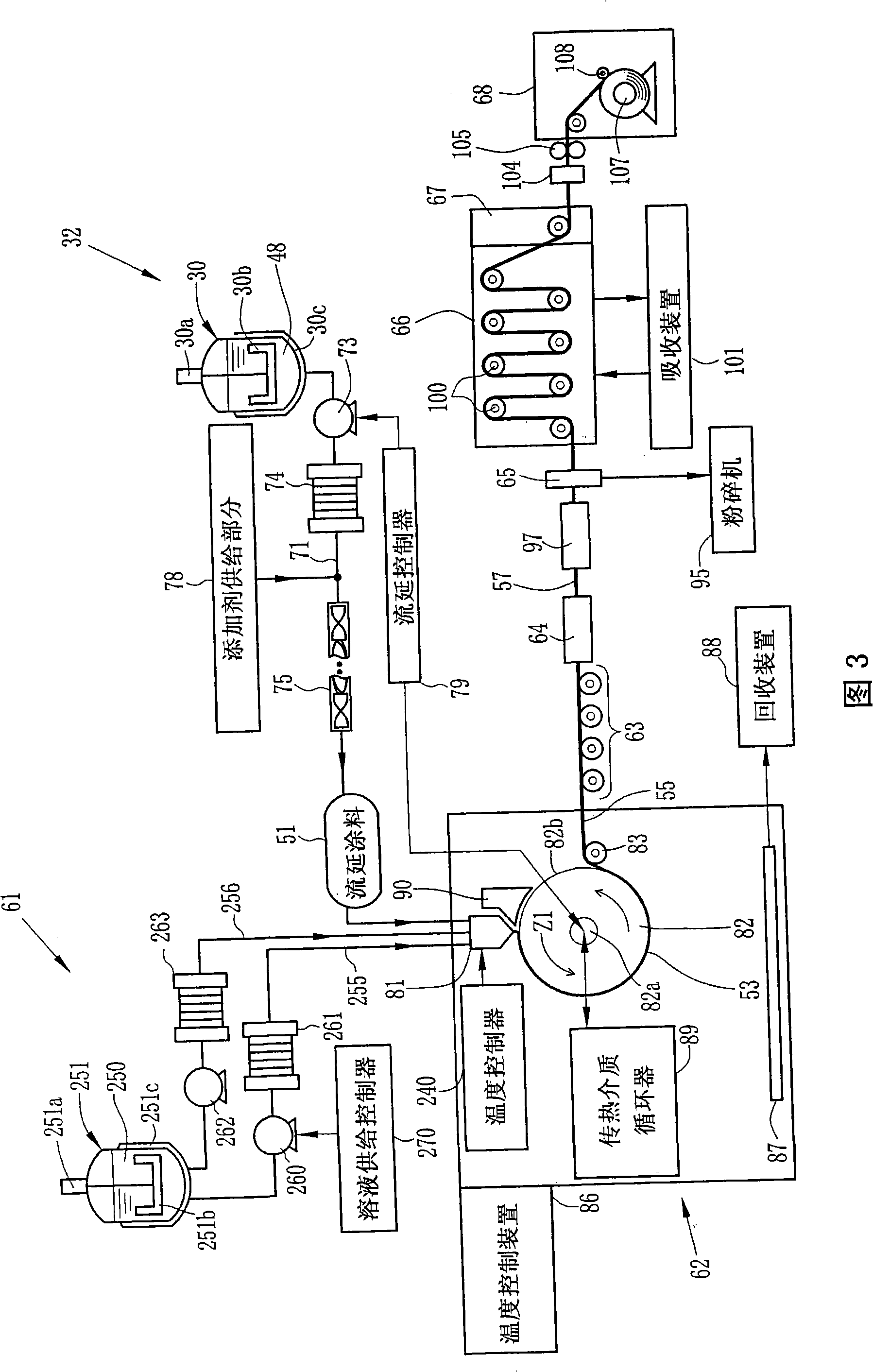

Solvent casting device and solvent casting method

A casting mould comprises a lip plate and an inner frame plate including contact faces respectively. The contact faces form an outlet of the casting mould. Distance between a ridge of the lip plate and a ridge of the inner frame plate is 9 mum at most. In addition, a nozzle is arranged to be close to the outlet. Casting coating is discharged from the outlet to a carrier in order to form a casting channel between the outlet and periphery of the carrier. The nozzle supplies solution to side of the casting channel.

Owner:FUJIFILM CORP

Upper gas guide and gas collecting type anode structure for aluminum electrolysis

The invention discloses an upper gas guide and gas collecting type anode structure for aluminum electrolysis. The upper gas guide and gas collecting type anode structure comprises an anode carbon block (5) and a plurality of anode through holes (6) arranged on the anode carbon block (5), wherein the upper part of the anode carbon block (5) is provided with at least one gas guide groove (3) and a gas guide groove cover plate (4) covering the gas guide groove (3), the anode through holes (6) are communicated with the gas guide groove (3), and the gas guide groove (3) is connected with an exhaust pipe (2). The invention belongs to the upper gas guide and gas collecting type anode structure for aluminum electrolysis, which has the advantages that the gas escaping is favorably realized, and the exhaust effect is improved.

Owner:CENT SOUTH UNIV

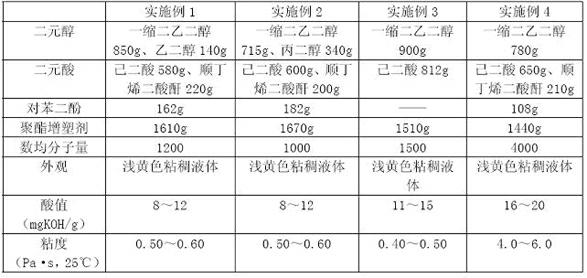

Polyester plasticizer for leading glass fiber to form felt and preparation method of polyester plasticizer

ActiveCN102432854AHigh number average molecular weightGood compatibilityMacromolecular adhesive additivesPolyesterFiber

The invention discloses a polyester plasticizer for leading glass fiber to form a felt and a preparation method of the polyester plasticizer. The polyester plasticizer is prepared from dihydric alcohol and dibasic acid. The preparation method comprises the following steps of: 1) adding the dihydric alcohol and the dibasic acid into a reactor, introducing nitrogen, stirring, rising the temperature to be 200-220 DEG C, and under the temperature, reacting till the acid value of the system is less than or equal to 20mgKOH / g; and 2) reducing the temperature to be 180-190 DEG C, adding hydroquinone, cooling to be 0-40 DEG C, filtering, and obtaining filtrate, i.e. the polyester plasticizer; or directly cooling to be 0-40 DEG C, filtering, and obtaining filtrate, i.e. the polyester plasticizer. In the invention, the compatibility of the polyester plasticizer and a bonding agent for leading the glass fiber to form the felt is good, the softness and the impregnability of a glass-fiber chopped felt can be improved and the use range is wide.

Owner:CHANGZHOU TIANMA GROUP CO LTD

Use of cationic surfactant to improve print quality of dyebased inkjet inks

InactiveUS6986572B2Plain paper text qualityGood ink stabilityMeasurement apparatus componentsDuplicating/marking methodsDiolSURFACTANT BLEND

Owner:HEWLETT PACKARD DEV CO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com