Upper gas guide and gas collecting type anode structure for aluminum electrolysis

A technology of anode structure and aluminum electrolysis, which is applied in the field of upper gas-guiding and gas-collecting anode structure for aluminum electrolysis, which can solve the problems of clogging vent holes and achieve the effects of preventing crusting, improving exhaust effect, and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

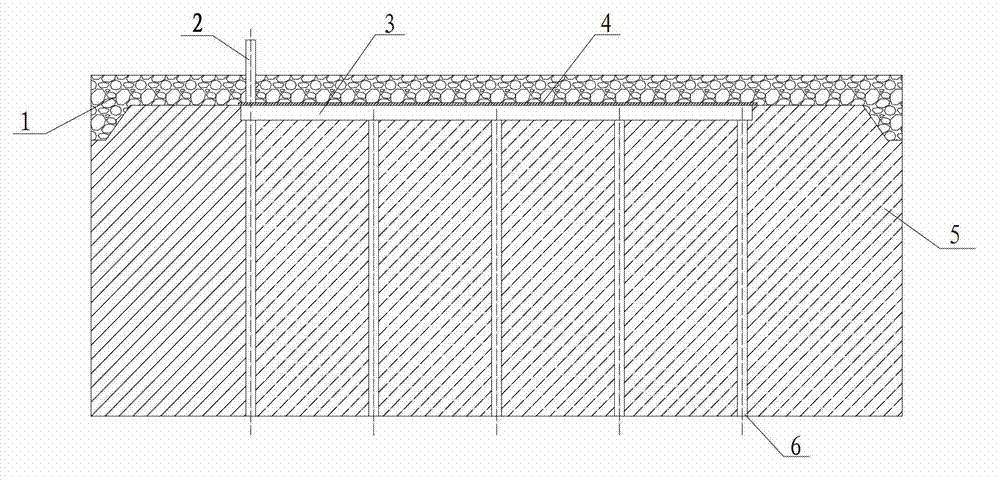

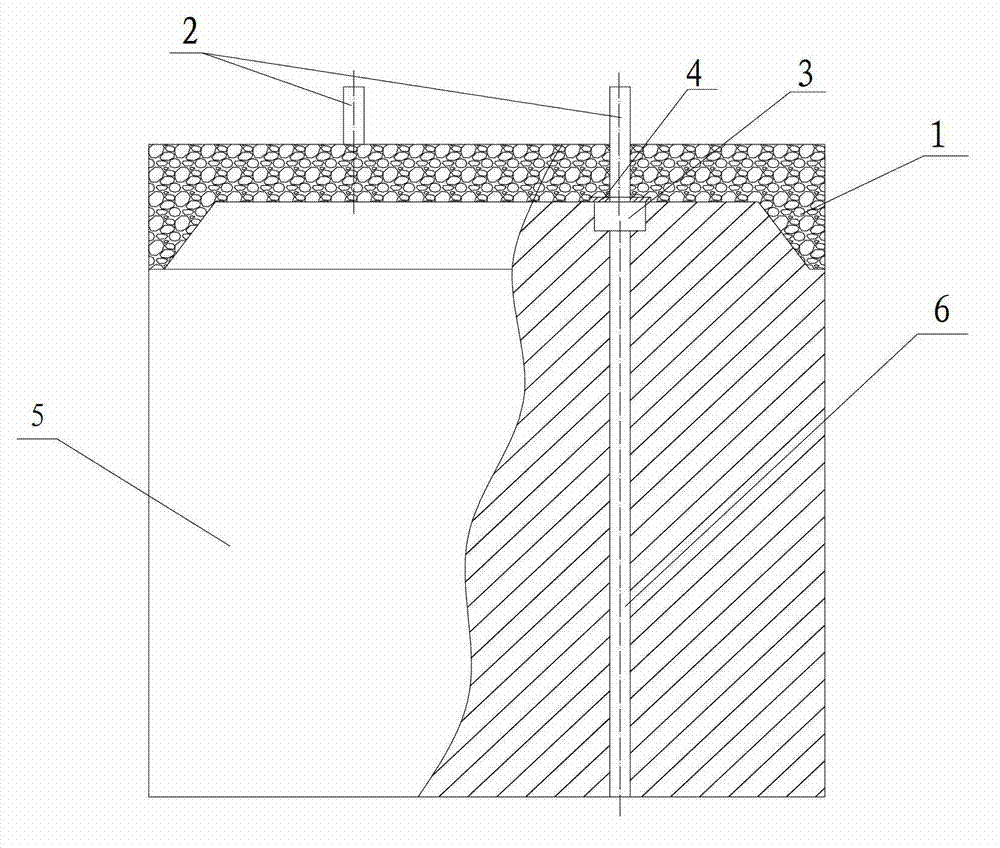

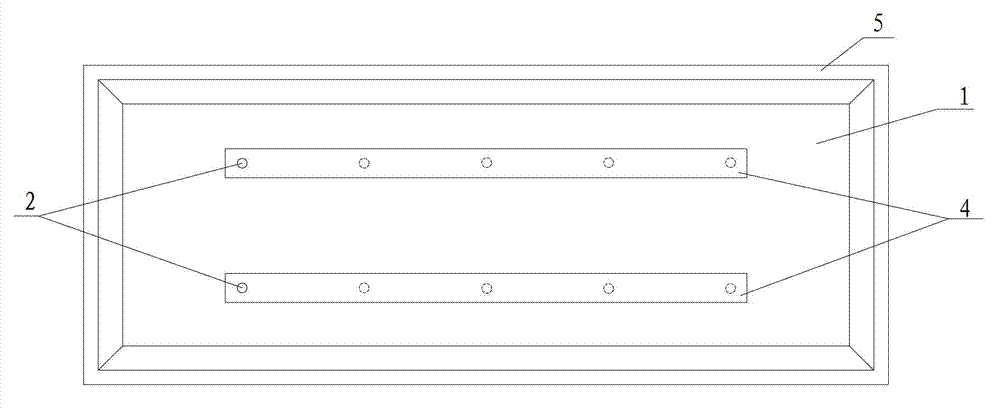

[0031] see figure 1 , figure 2 with image 3 , the upper part of the anode carbon block 5 is provided with two air-guiding grooves 3 and the air-guiding groove cover plate 4 covering the air-guiding grooves 3, the length, width and depth of the air-guiding grooves 3 are respectively 1065-1070 mm, 40-45mm and 30-40mm, five anode perforations 6 communicate with the air guide groove 3, the diameter of the anode perforation 6 is 20-30mm, the exhaust pipe 2 is placed on the air guide groove cover plate 4 and connected with the air guide groove 3 connected, the upper part of the anode carbon block 5 is provided with a crust insulation layer 1 covering the air guide groove cover plate 4 and the air guide groove 3.

[0032] see figure 1 , figure 2 with image 3 , during the process of electrolytic cell anode roasting and molding, two air-guiding grooves 3 are made on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com