Patents

Literature

201results about How to "Prevent crusting" patented technology

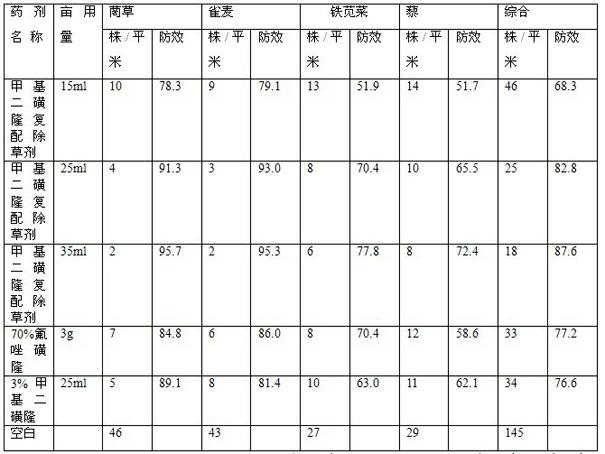

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

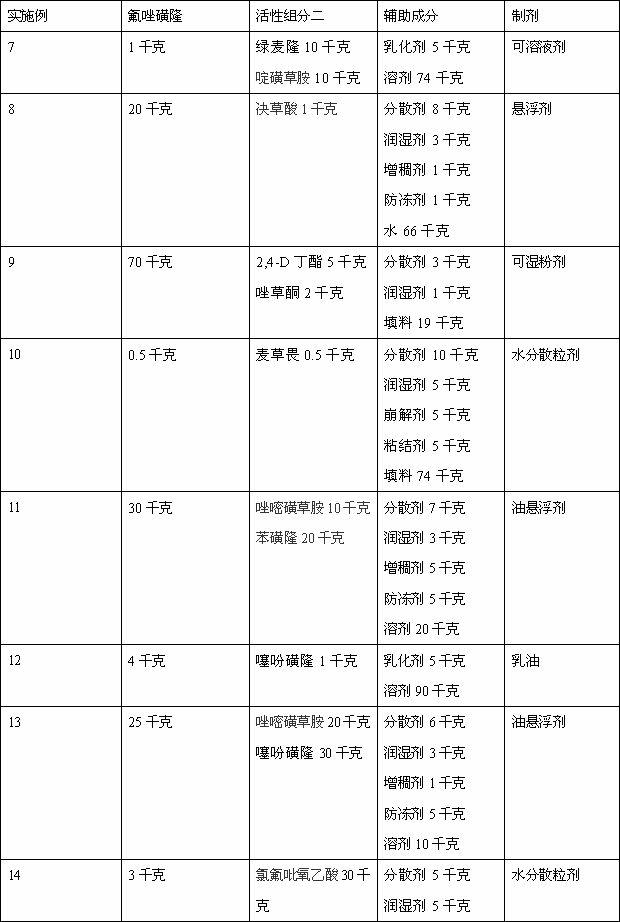

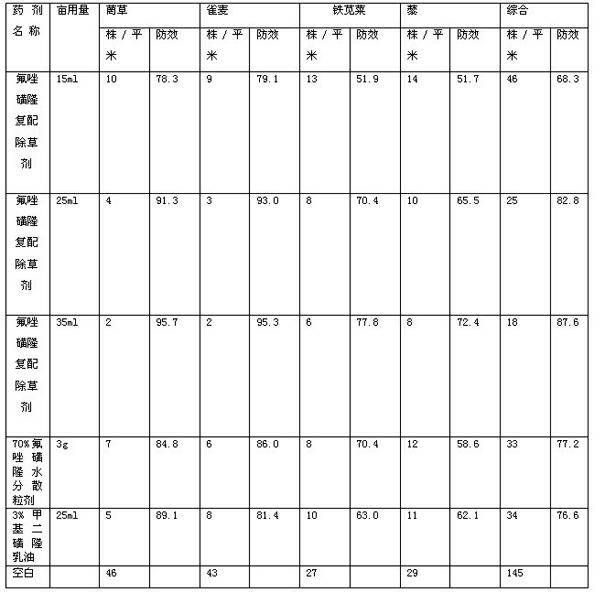

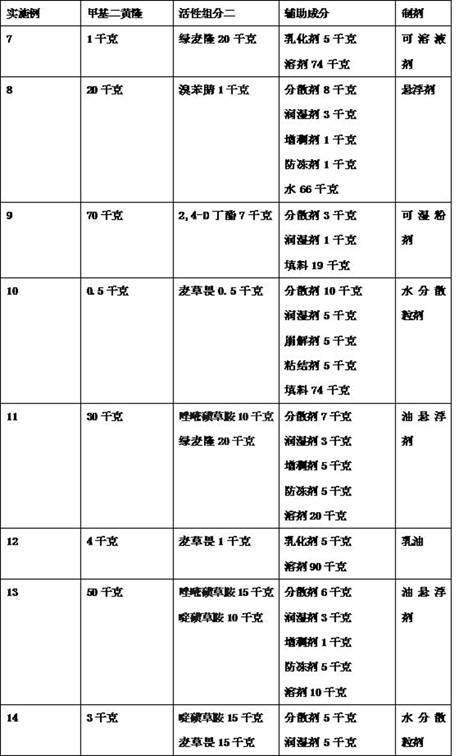

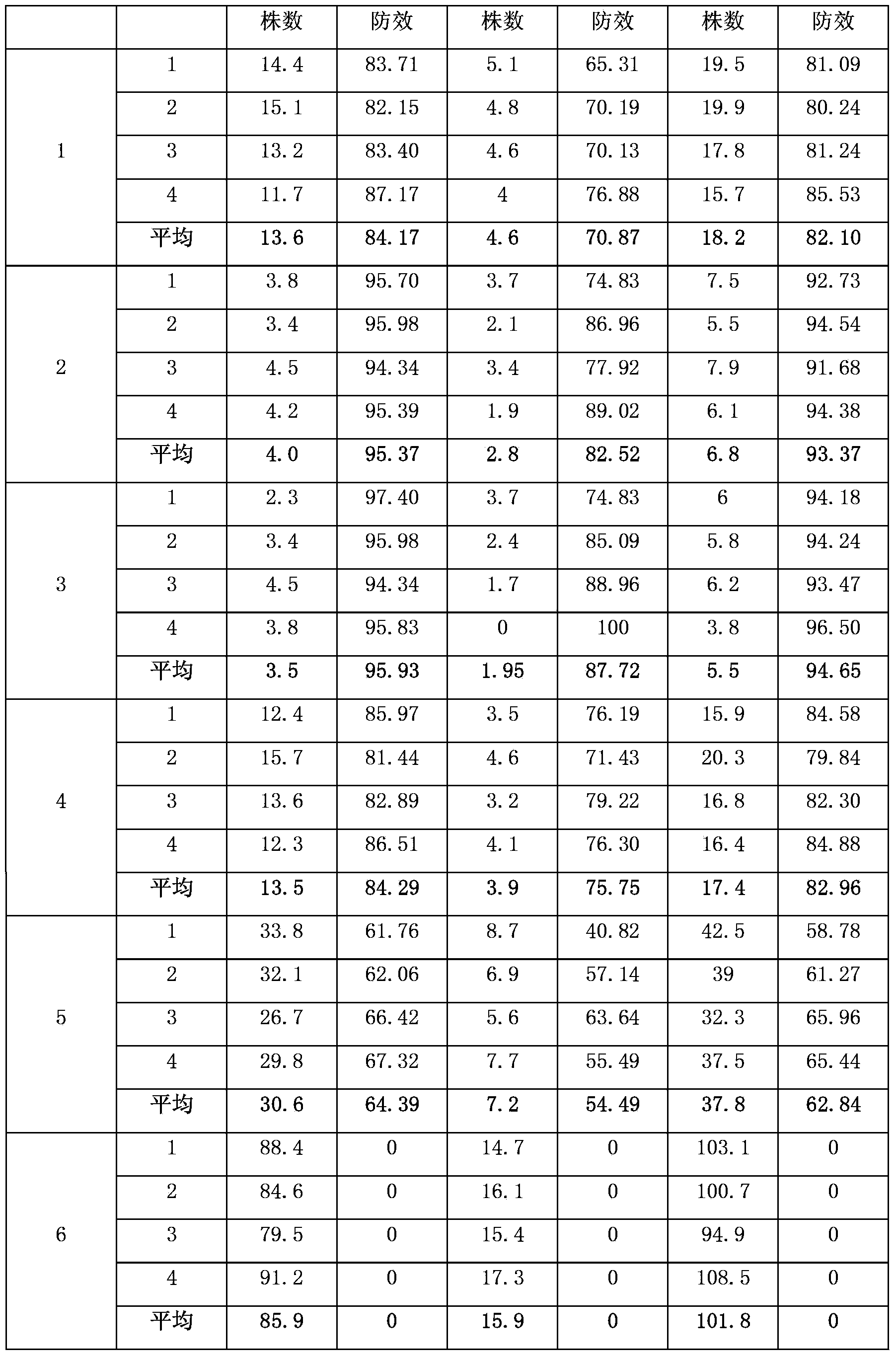

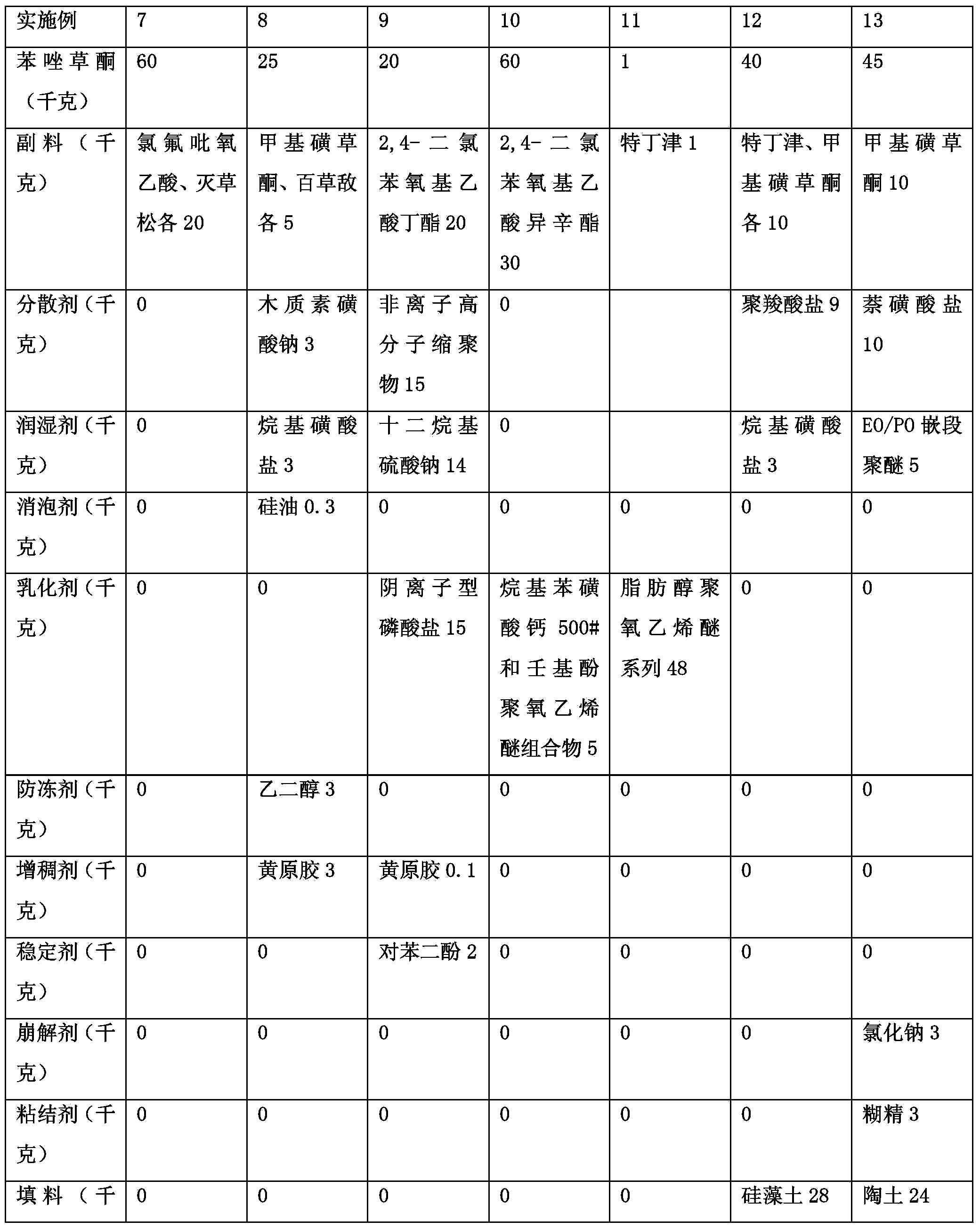

Flucarbazone-Na compounded herbicide

InactiveCN102428945APrevent flocculationAvoid layeringBiocideAnimal repellantsFluroxypyrFluoroglycofen-ethyl

The invention discloses a flucarbazone-Na compounded herbicide which comprises an active component I (flucarbazone-Na), an active component II and auxiliary components, wherein the active component II is one or a combination of several of mesosulfuron methyl, isoproturon, chlortoluron, pyroxsulam, Clodinafop-propargyl, carfentrazone-ethyl, tribenuron-methyl, fluroxypyr, methoxone, 2,4-D-butyl ester, dicamba, bromoxynil, thifensulfuron methyl, amidosulfuron, bensulfuron-methyl, flumetsulam, fluoroglycofen-ethyl and florasulam; the auxiliary components comprise an auxiliary agent and also comprise one of a filler and a solvent; the auxiliary agent is one or a combination of two of an emulsifying agent, a dispersant, a wetting agent, a disintegrant, an agglomerant, an antifreezing agent and a thickening agent; the mass sum of the active component I (flucarbazone-Na) and the active component II is 1%-85% of the total mass of the flucarbazone-Na compounded herbicide; and the mass ratio of the active component I to the active component II is (1:20)-(20:1). The flucarbazone-Na compounded herbicide disclosed by the invention is a novel herbicide for preventing and removing weeds in a wheatland.

Owner:河北博嘉农业有限公司

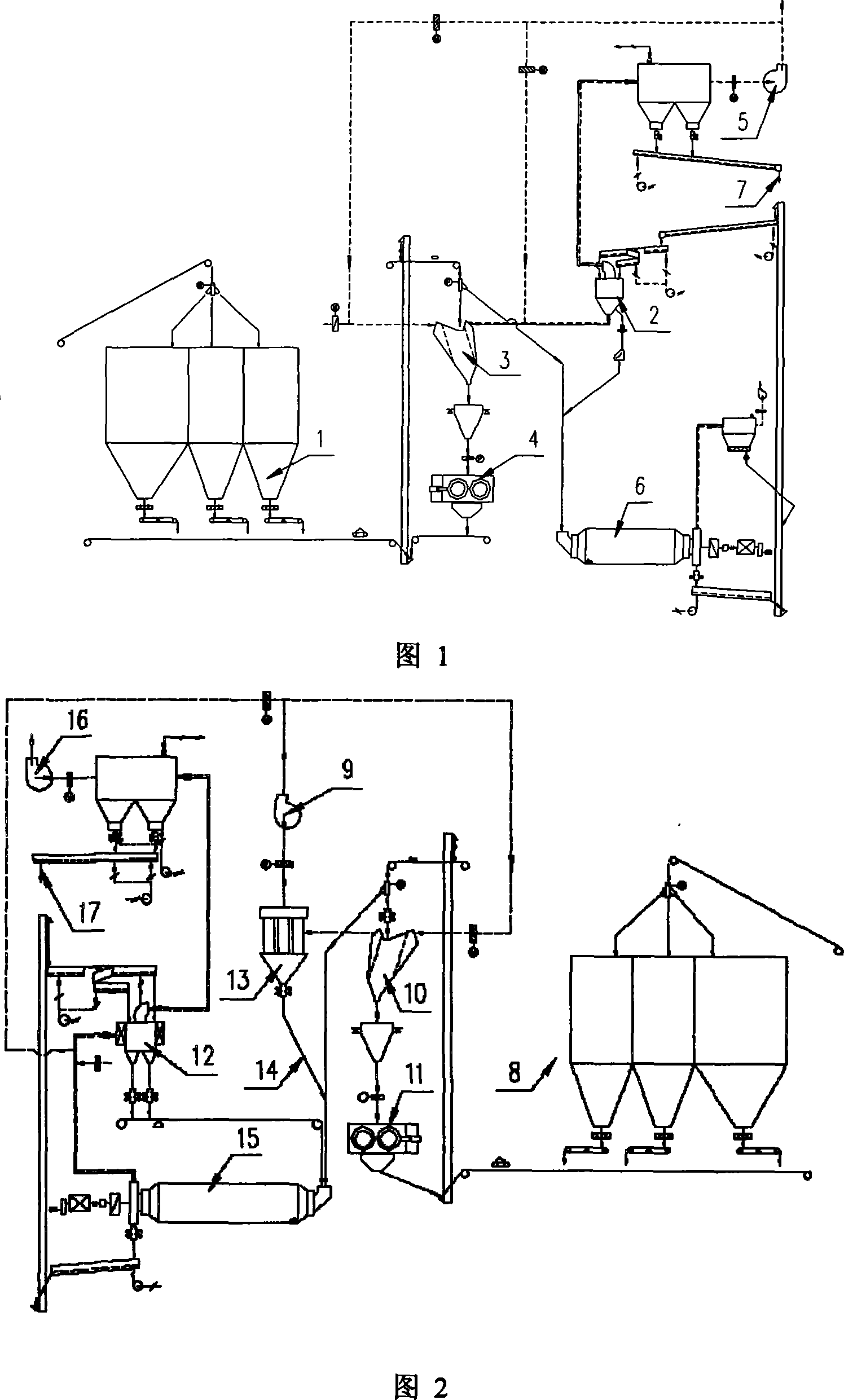

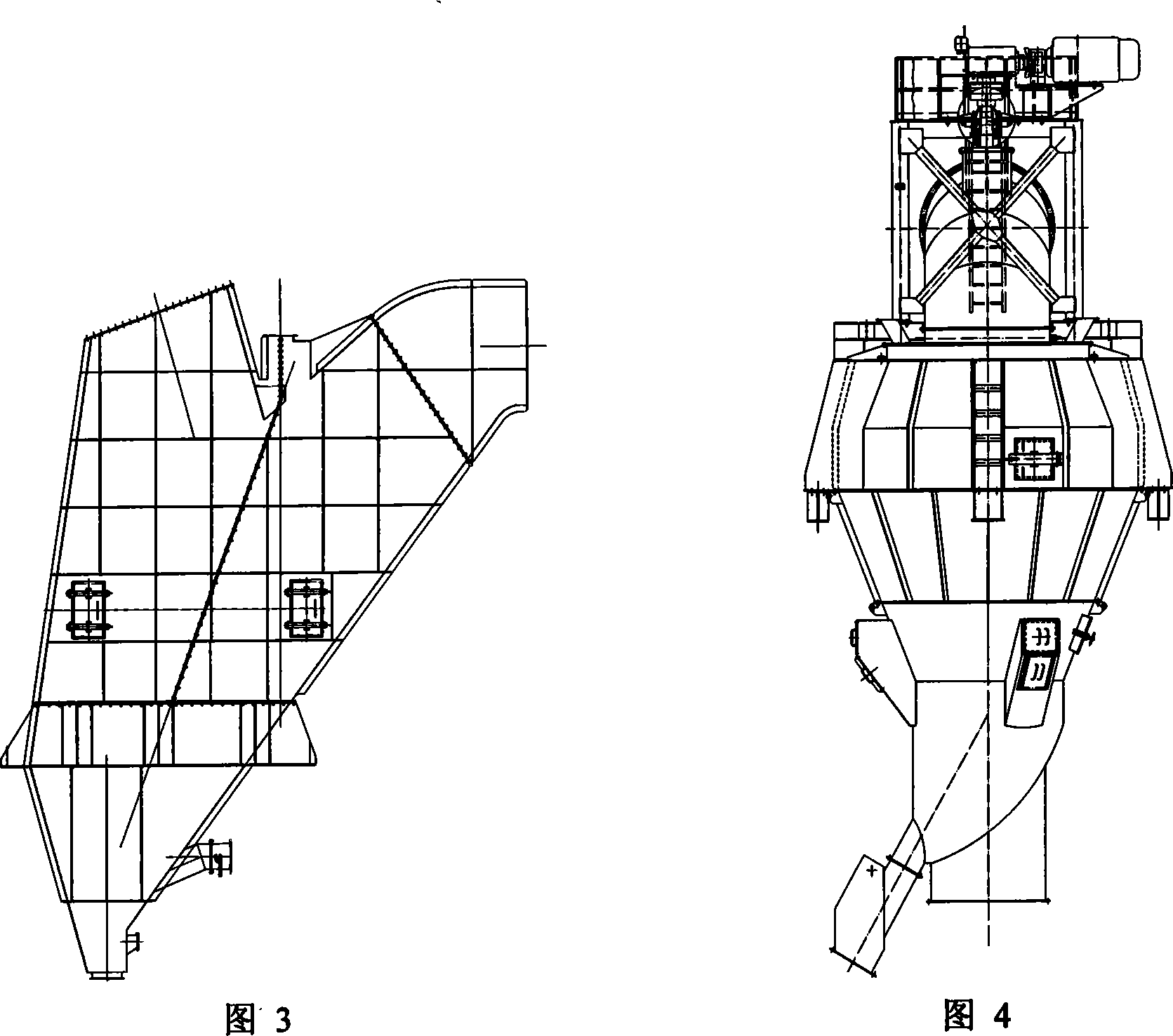

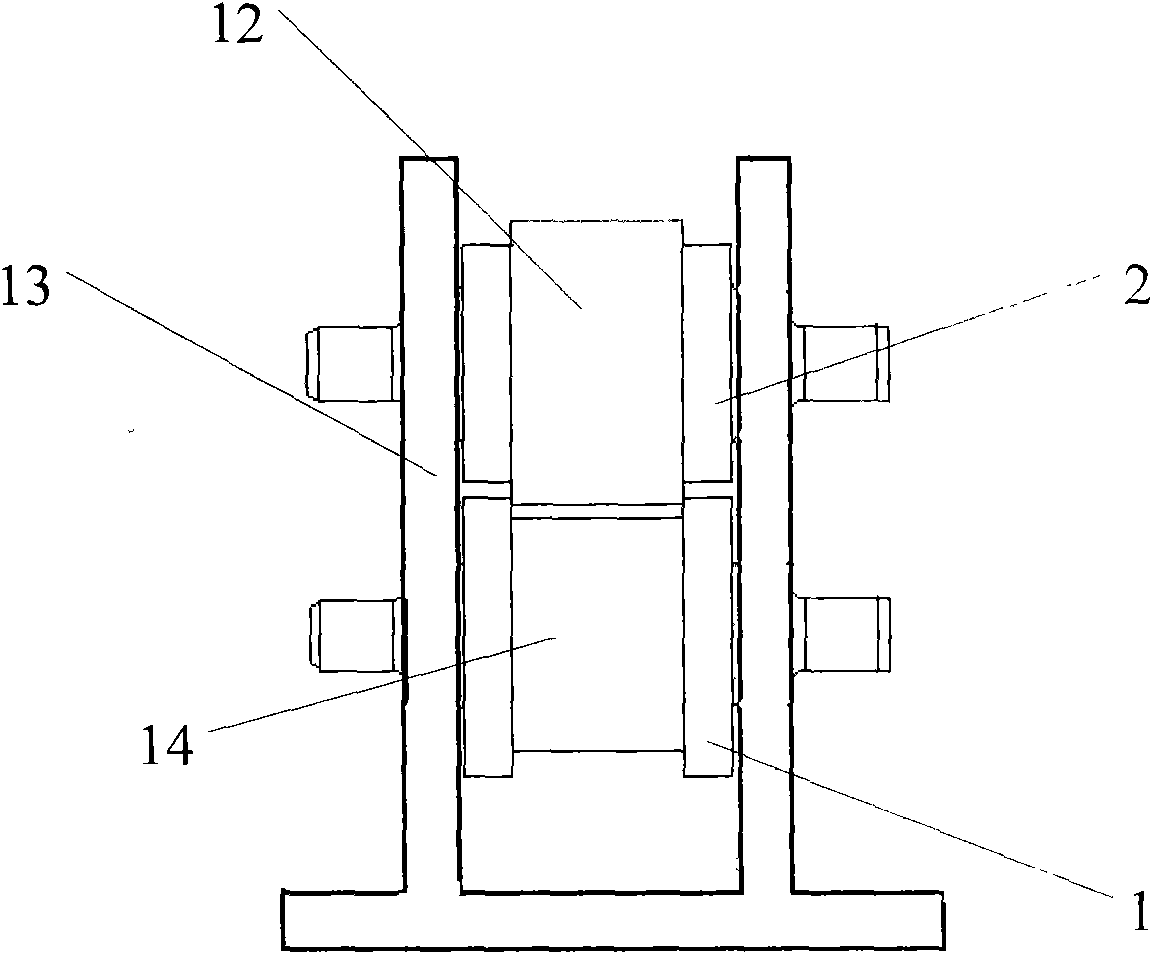

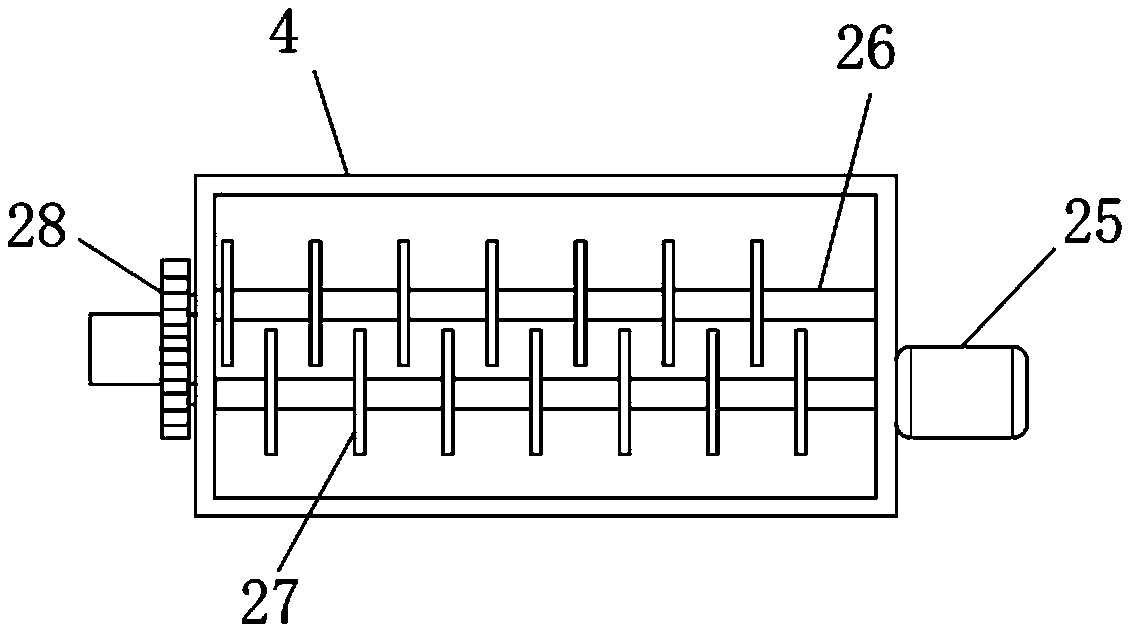

Roller press combination grinding device

ActiveCN101134175AEliminate wear and tearAdapt to the requirements of different statesGrain treatmentsMetallic materialsOperation mode

The present invention relates to one kind of combined rolling press grinding apparatus, and belongs to the field of inorganic non-metal material grinding technology. The combined rolling press grinding apparatus includes one dispensing mechanism, one lifting and conveying mechanism, one rolling press, one ball mill, one powder concentrator, one dust collector and one fan. The present invention has the advantages of low milling loss, simple structure, several operation mode, high grinding efficiency, low power consumption, etc.

Owner:天津椿本输送机械有限公司 +1

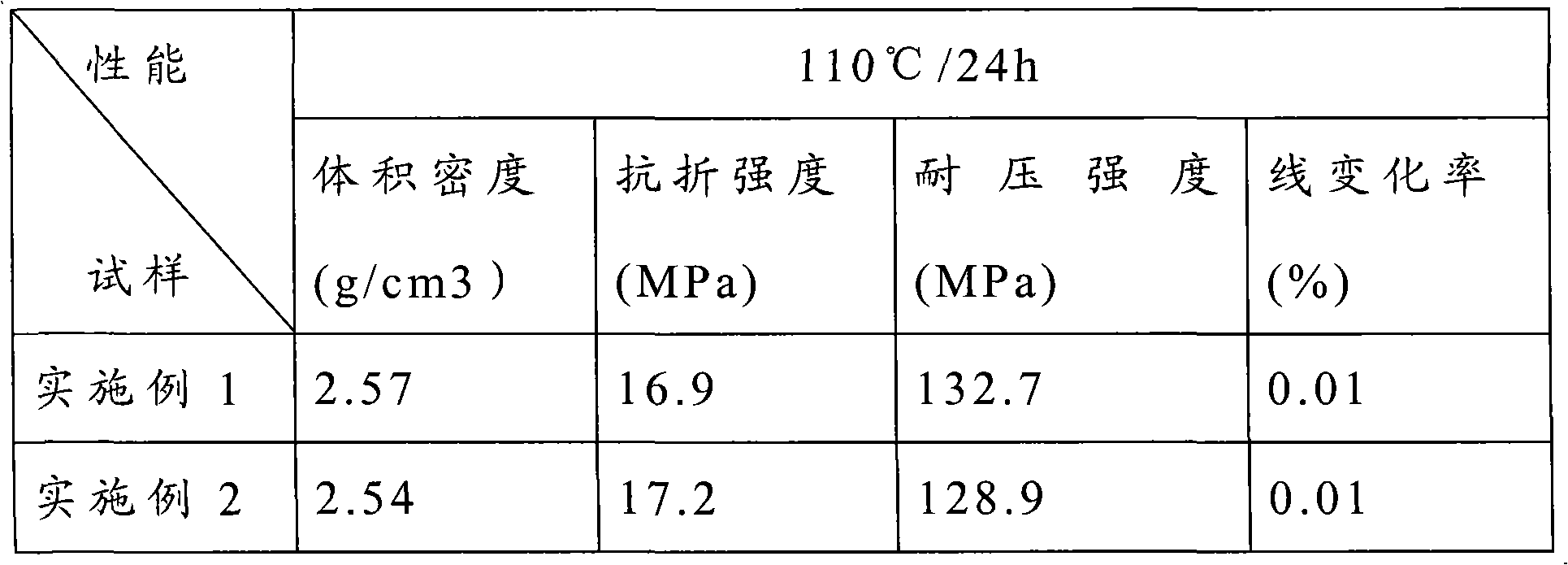

Anti-skinning pouring material for cement kiln

The invention discloses an anti-skinning pouring material for a cement kiln, which is prepared by using a siliceous refractory material as a skeletal material and additionally adding electrically fused magnesia-alumina spinel or silicon carbide powder, silicon nitride, alpha aluminum oxide micropowder, siliceous dust and aluminous refractory cement and a water reducing agent or explosion-proof fiber. The anti-skinning pouring material can effectively reduce the phenomena of skinning and blocking in the cement kiln so as to further reduce the faults of the cement kiln and increase the operating rate of the same, the safety of the cement kiln is effectively enhanced, and the production cost is saved.

Owner:ANHUI RUITAI NEW MATERIALS TECH

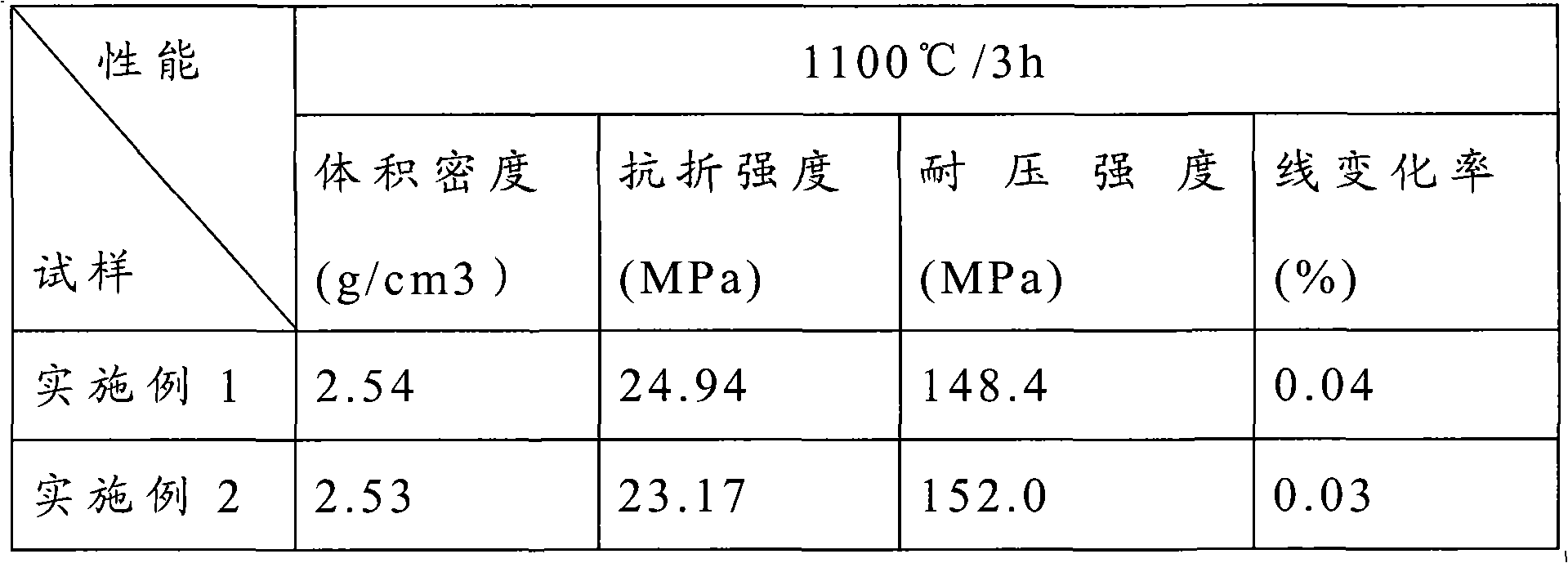

Mesosulfuron-methyl compound herbicide

InactiveCN102550585APrevent flocculationAvoid layeringBiocideAnimal repellantsAdjuvantAdditive ingredient

The invention discloses a mesosulfuron-methyl compound herbicide which consists of mesosulfuron-methyl as active ingredient I, active ingredient II and auxiliary ingredients; the active ingredient II is the combination of one or more of flucarbazone-Na, isoproturon, chlortoluron, pyroxsulam, 2-methyl-4-chlorophenoxy acetic acid, 2,4-D butyl ester, dicamba, bromoxynil, amidosulfuron, bensulfuron-methyl, flumetsulam, fluoroglycofen-ethyl and florasulam; the auxiliary ingredients consists of adjuvant and one of filler and solvent, and the adjuvant is the combination of one or more of emulsifying agent, dispersing agent, wetting agent, disintegrant, binding agent, antifreezing agent and thickening agent; the sum of the weight of the mesosulfuron-methyl as the active ingredient I and the weight of the active ingredient II is 1 to 85 percent of the total weight of the mesosulfuron-methyl compound herbicide; and the weight ratio of the active ingredient I to the active ingredient II is 1:20 to 20:1. The mesosulfuron-methyl mixed herbicide is novel herbicide for wheatlands.

Owner:河北博嘉农业有限公司

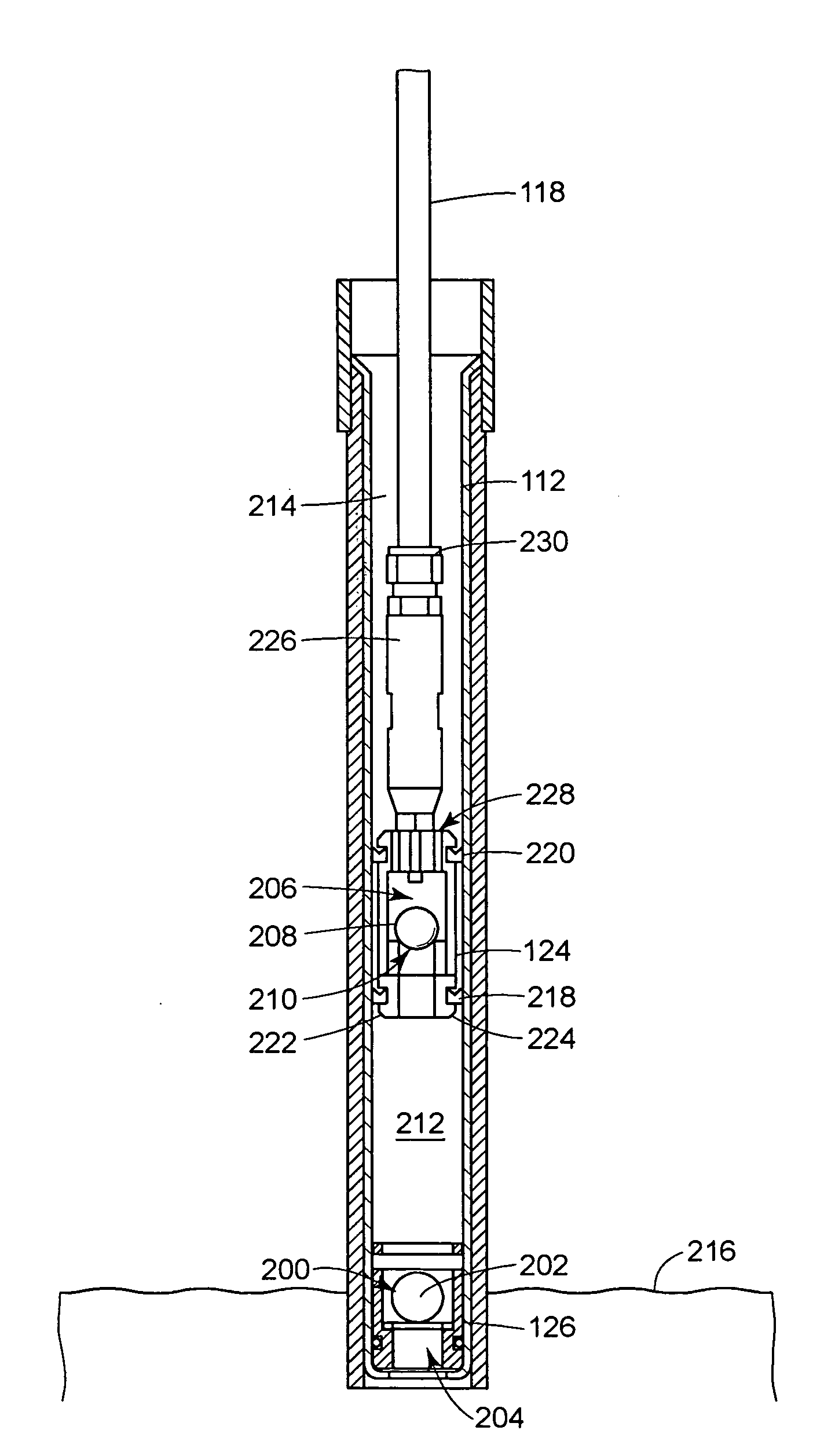

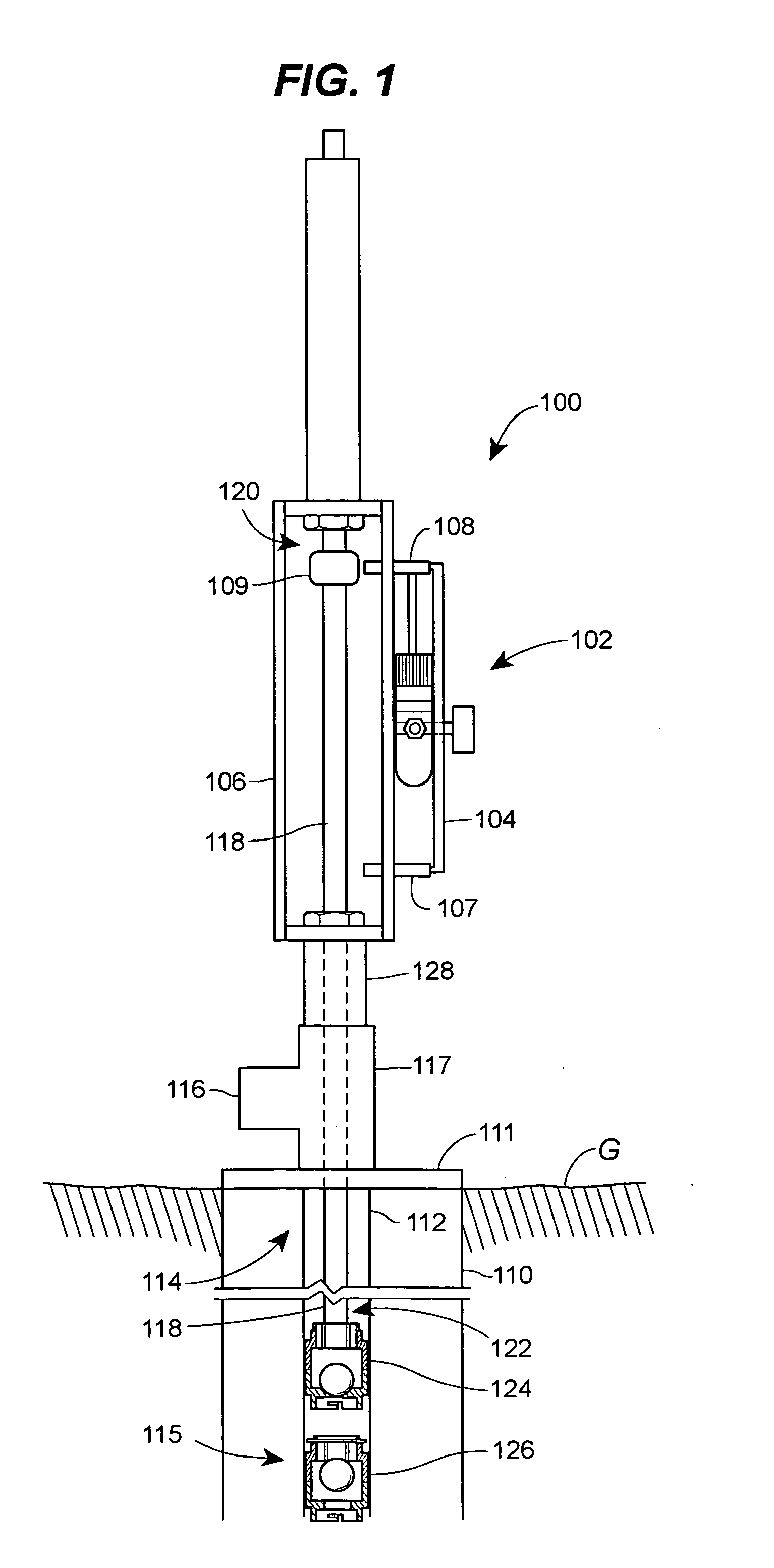

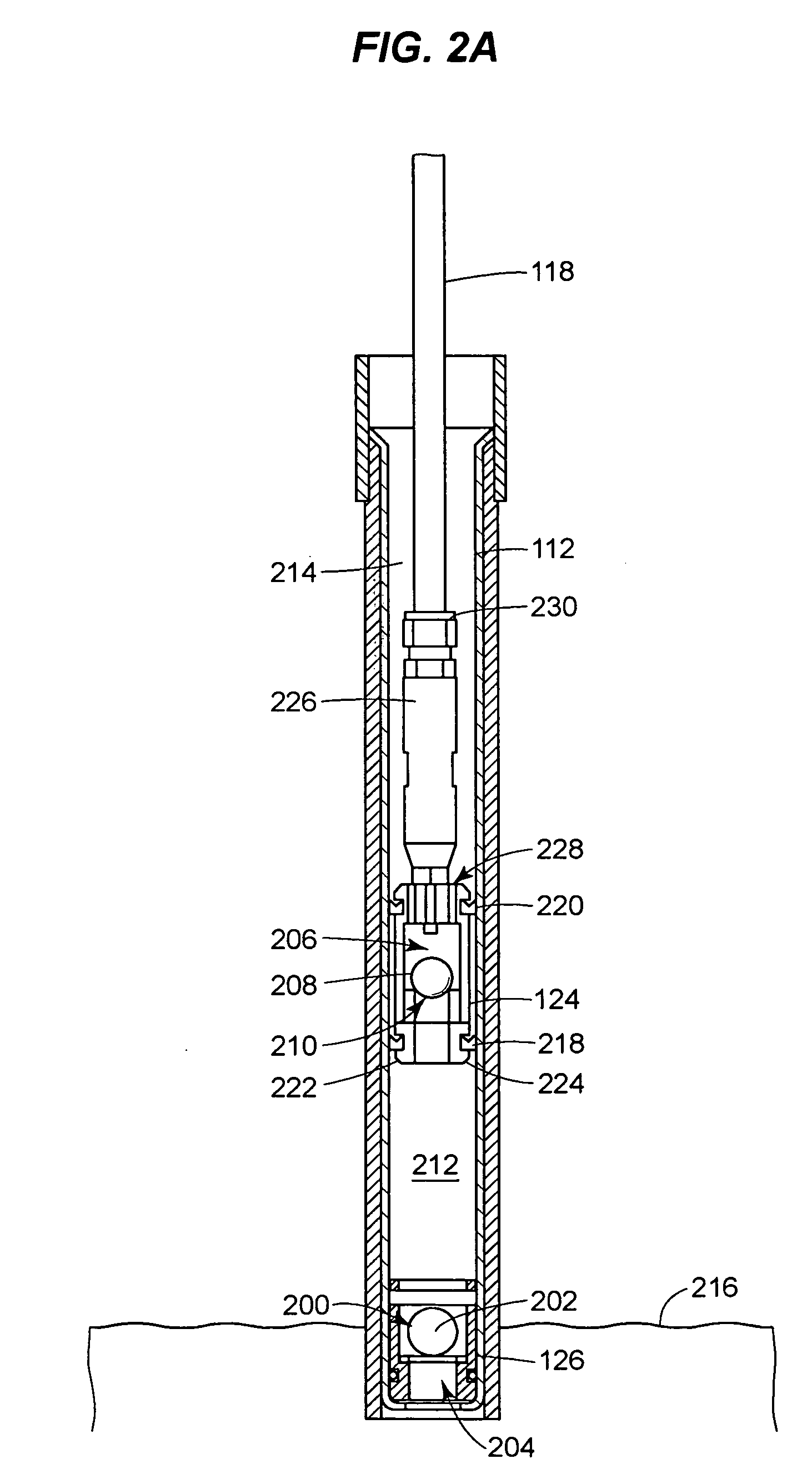

Drive piston and foot valve seat

InactiveUS20080011487A1Wear problemReduce wearConstructionsPositive displacement pump componentsCheck valvePiston

A drive piston valve and a foot valve may each have a valve seat in the form of a non-compressible (e.g., metal or ceramic) sealing plate having a compressible, resilient mating element that retains the ring at an inlet portion of a check valve having a housing formed of another material, such as a low-wear resin material. In some examples, the sealing plate may have a truncated corner for engaging a check ball in its closed positioned while avoiding damage to the check ball or plate resulting from a chemical encrustation build-up or other containment at the sealing edge.

Owner:BLACKHAWK TECH

Double-layered alkali grain covering agent for middle ladle

The present invention relates to a double-layered alkali grain heat-insulting covering agent for middle ladle. The heat-insulting covering agent consists of top slag in 10-50 wt% and bottom slag in 50-90 wt%. The bottom slag consists of SiO2 8-15 wt%, CaO 50-60 wt%, MgO 10-20 wt%, Al2O3 1-5 wt%, Fe2O3 1-3 wt%, and fixed carbon 0.01-1 wt%. The top slag consists of SiO2 85-93 wt%, CaO 0.001-3 wt%, MgO 0.001-3 wt%, Al2O3 0.001-3 wt%, Fe2O3 0.003-0.5 wt%, and fixed carbon 0.01-1 wt%. The heat-insulting covering agent forms two layers of slag, the bottom layer covers molten steel to prevent secondary oxidation, reduce carbon content in molten steel and adsorb alumina floating to the surface of molten steel, and the top layer in porous and loose structure covers molten steel to prevent incrusting and carburization.

Owner:上海宝谊保温材料有限公司

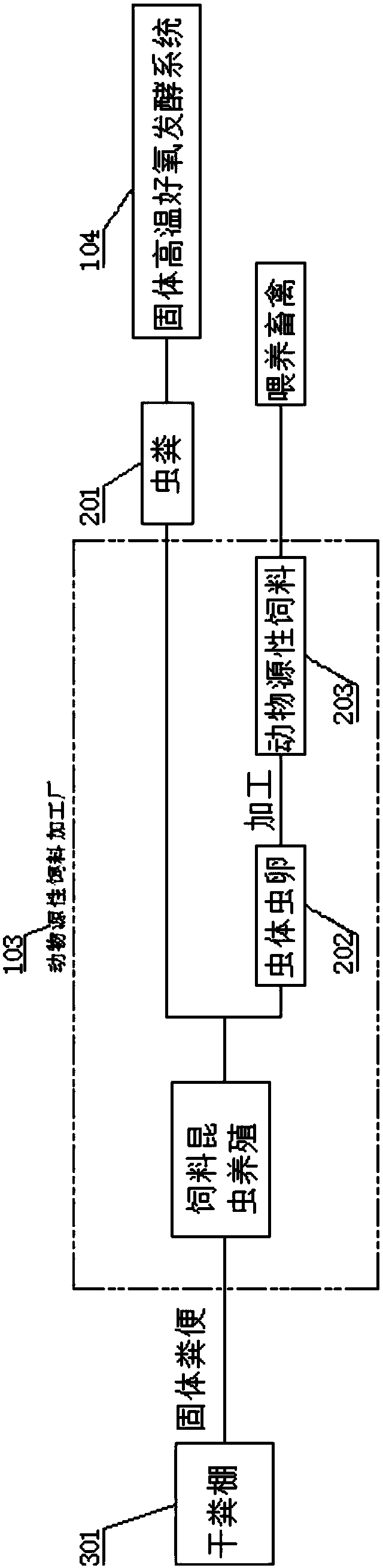

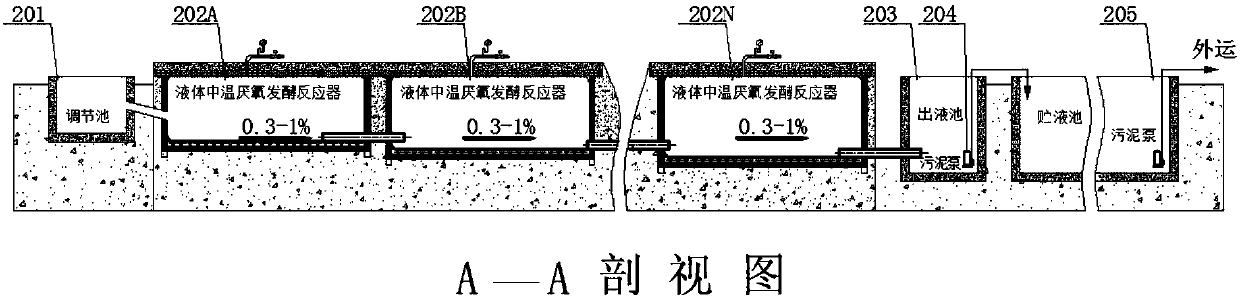

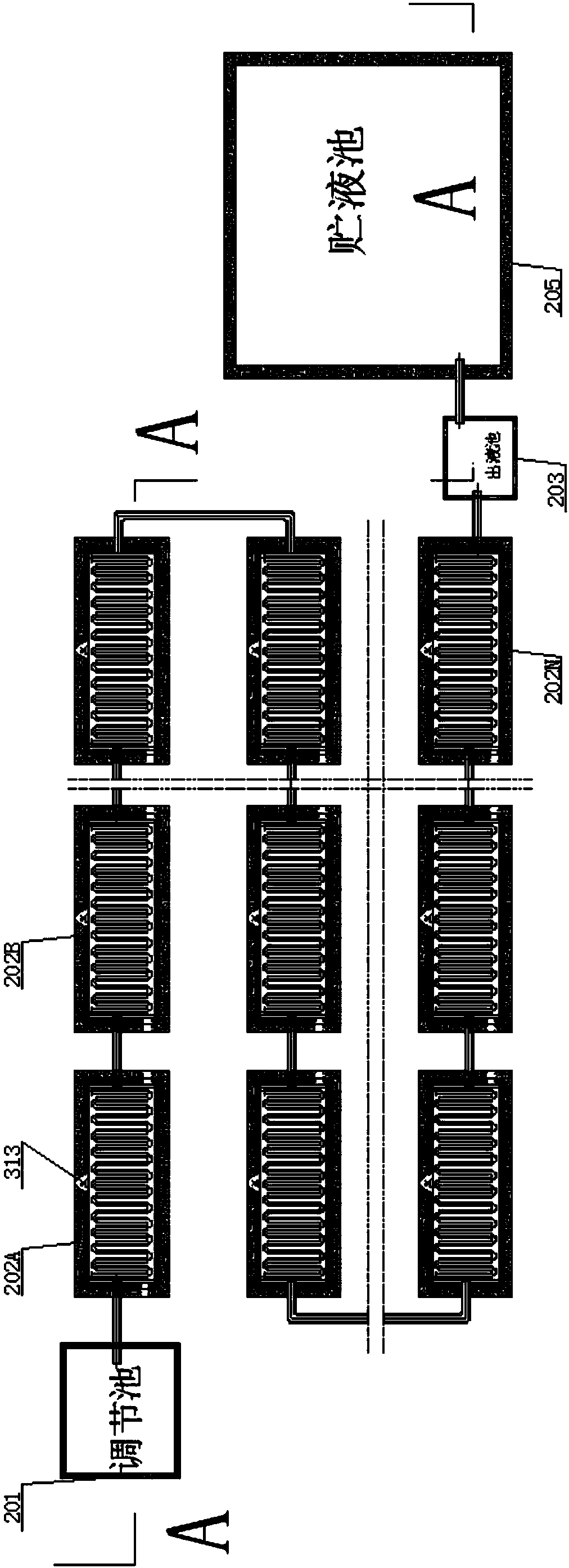

Ecological treatment system and method for pollution of livestock and poultry farm based on combination of planting and breeding

ActiveCN107759254AReduce distractionsHighly consistent qualityBio-organic fraction processingFabaceae cultivationPig farmsFeces

Owner:汪深

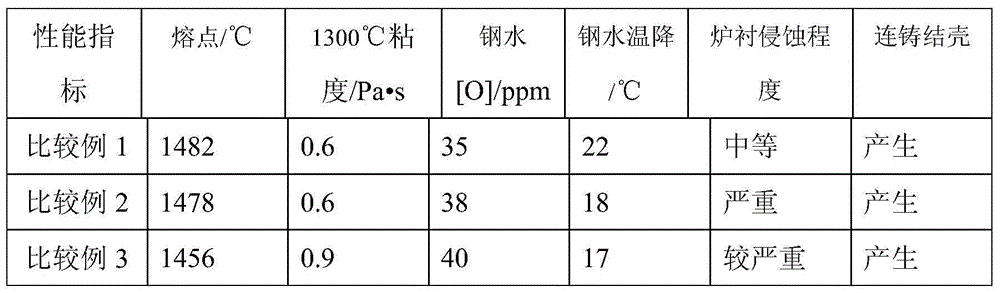

Tundish covering agent and application thereof

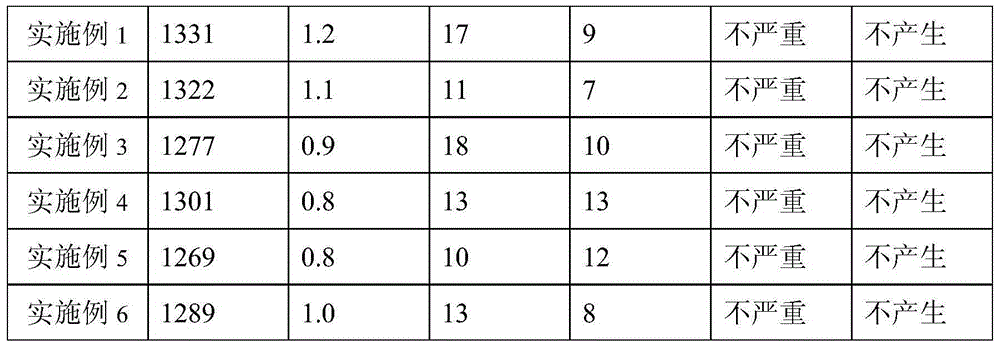

The invention relates to a tundish covering agent and application thereof and belongs to the technical field of tundishes in the continuous casting process. The tundish covering agent is mainly prepared from, by percentage content, 35-45% of CaO, 8-15% of SiO2, 25-30% of Al2O3, 5-15% of MgO, 5-12% of (Na2O+Li2O), 1-5% of B2O3 and 0.5-1% of TiO2. The tundish covering agent has the advantages that the melting point is low and is 1250-1350 DEG C, the viscosity is high and is 0.8-1.2 Pa*s at the temperature of 1300 DEG C, and the basicity is high and is 3-6. The tundish covering agent is applicable to the continuous casting production process, for producing the tundishes, of titanium-added steel. When the tundish covering agent is applied to the continuous casting production process of the titanium-added steel, produced TiO2, produced TiN and other produced inclusion can be effectively dissolved. The inclusion is prevented from entering a crystallizer, the cleanness degree of molten steel is improved, and therefore the quality of cast blanks is improved.

Owner:CENT SOUTH UNIV

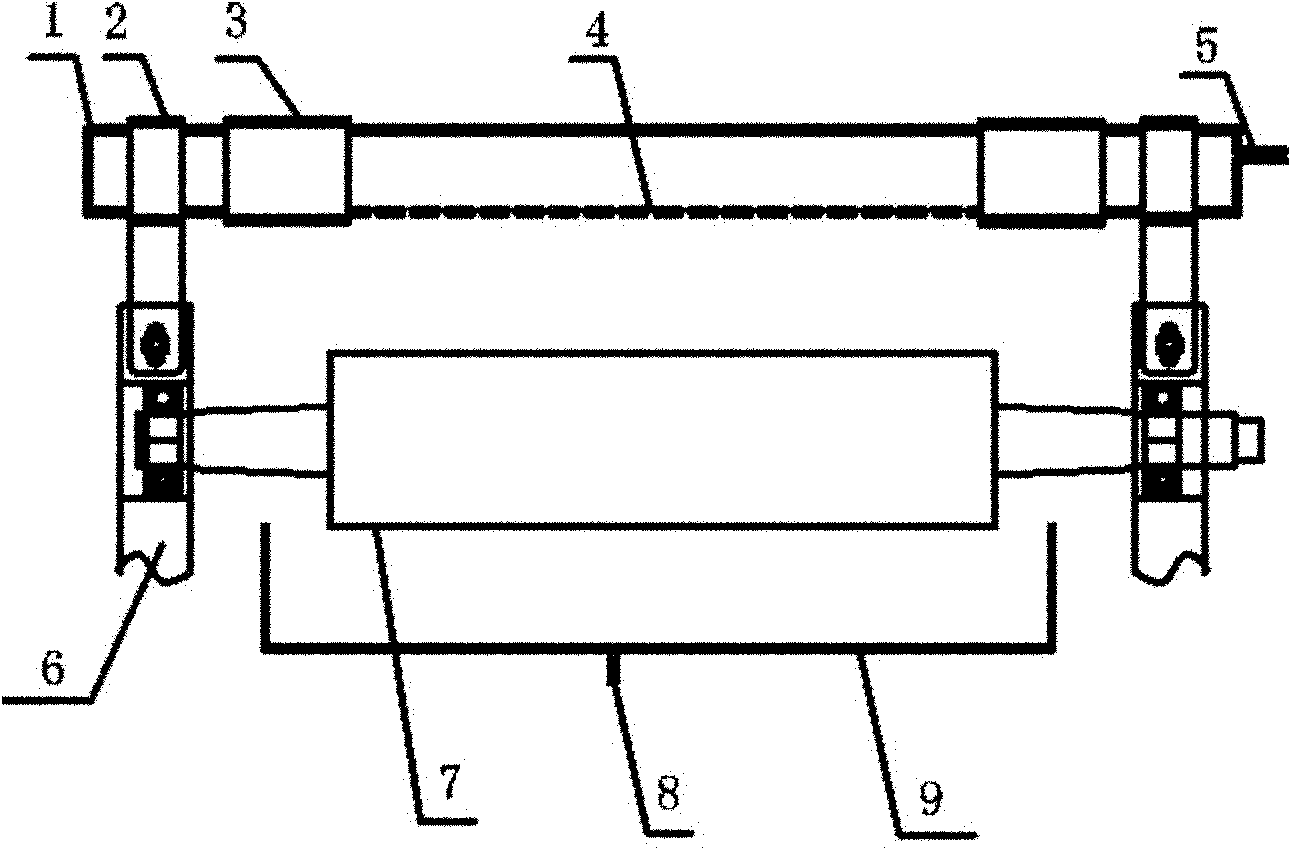

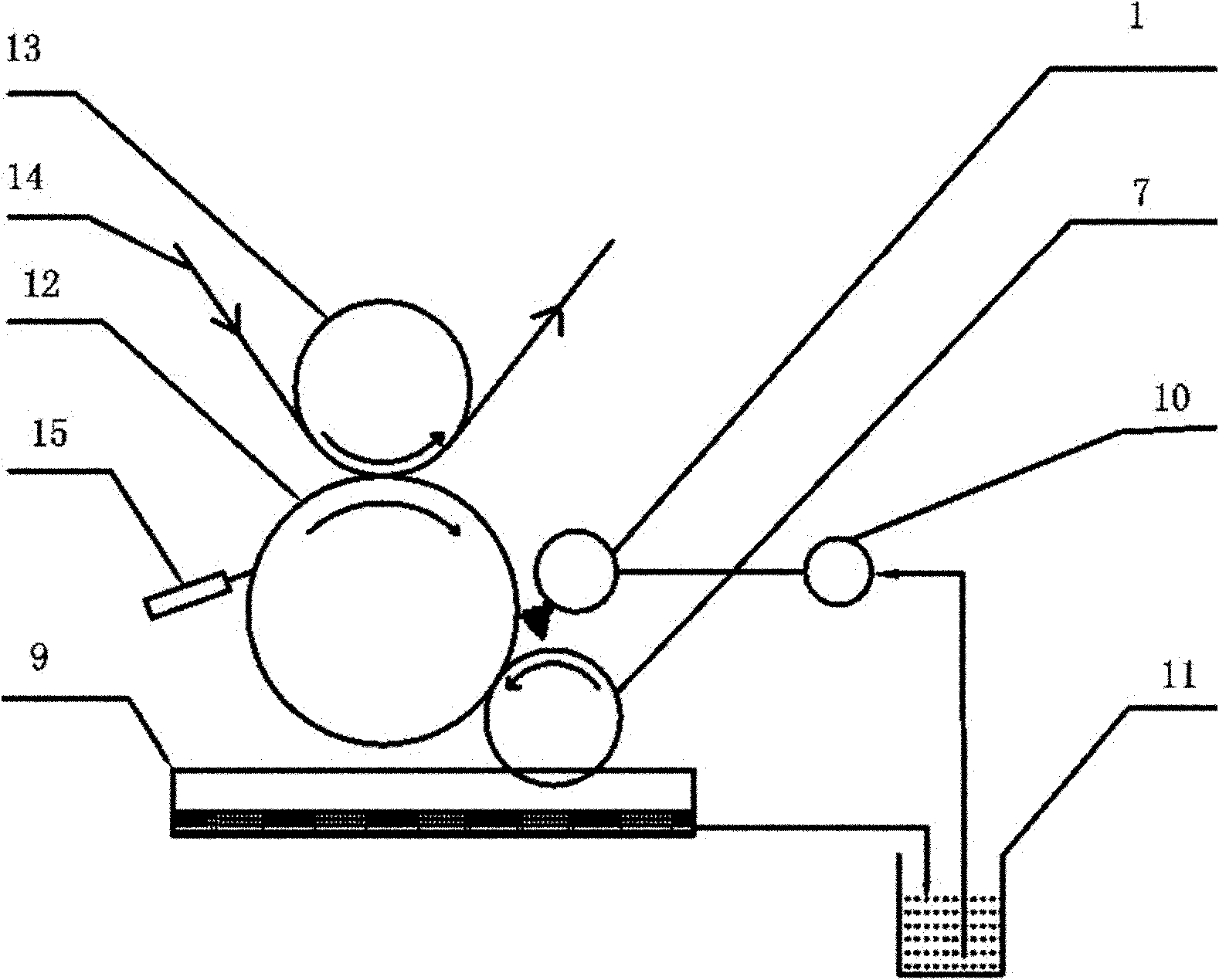

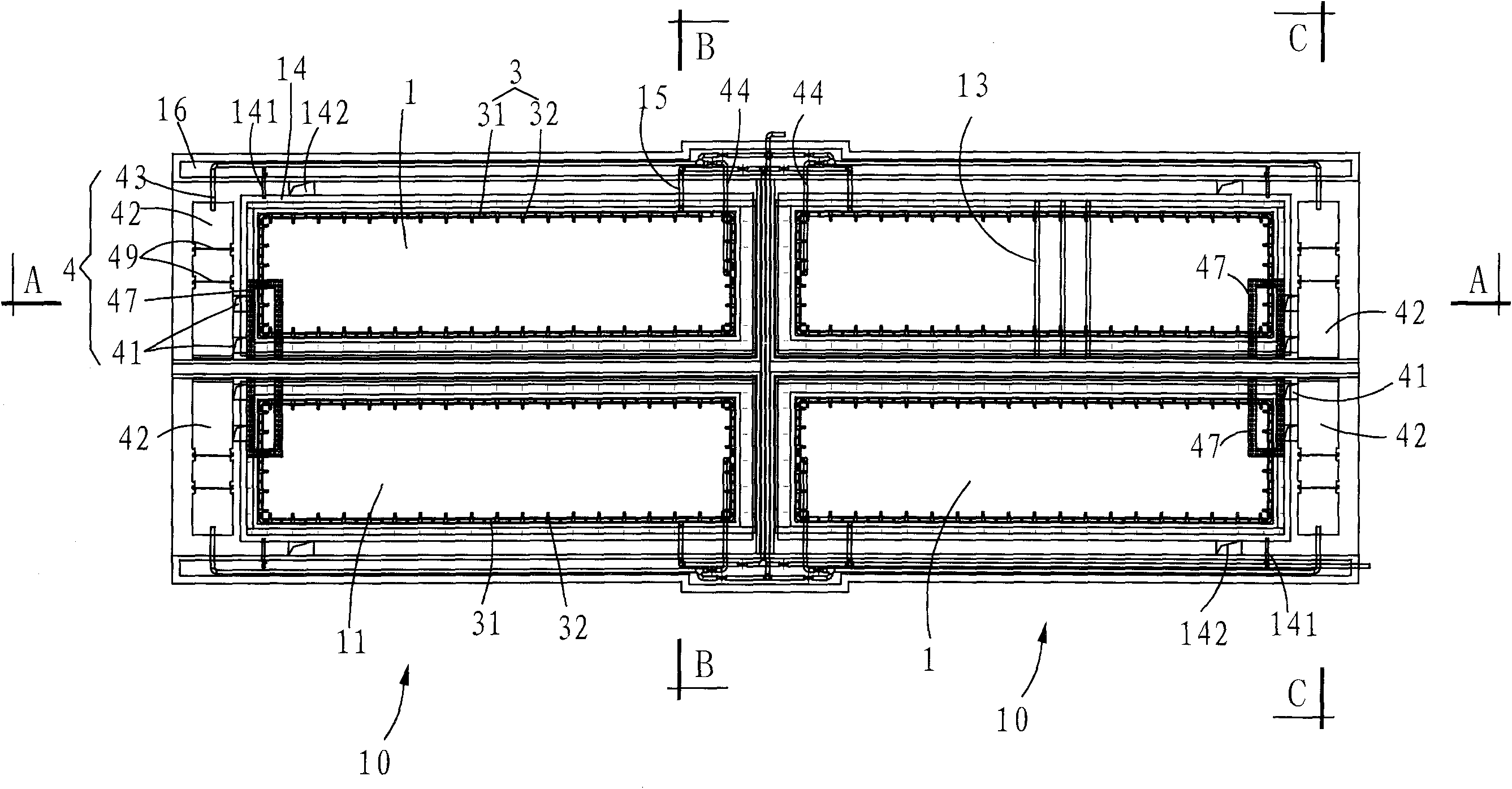

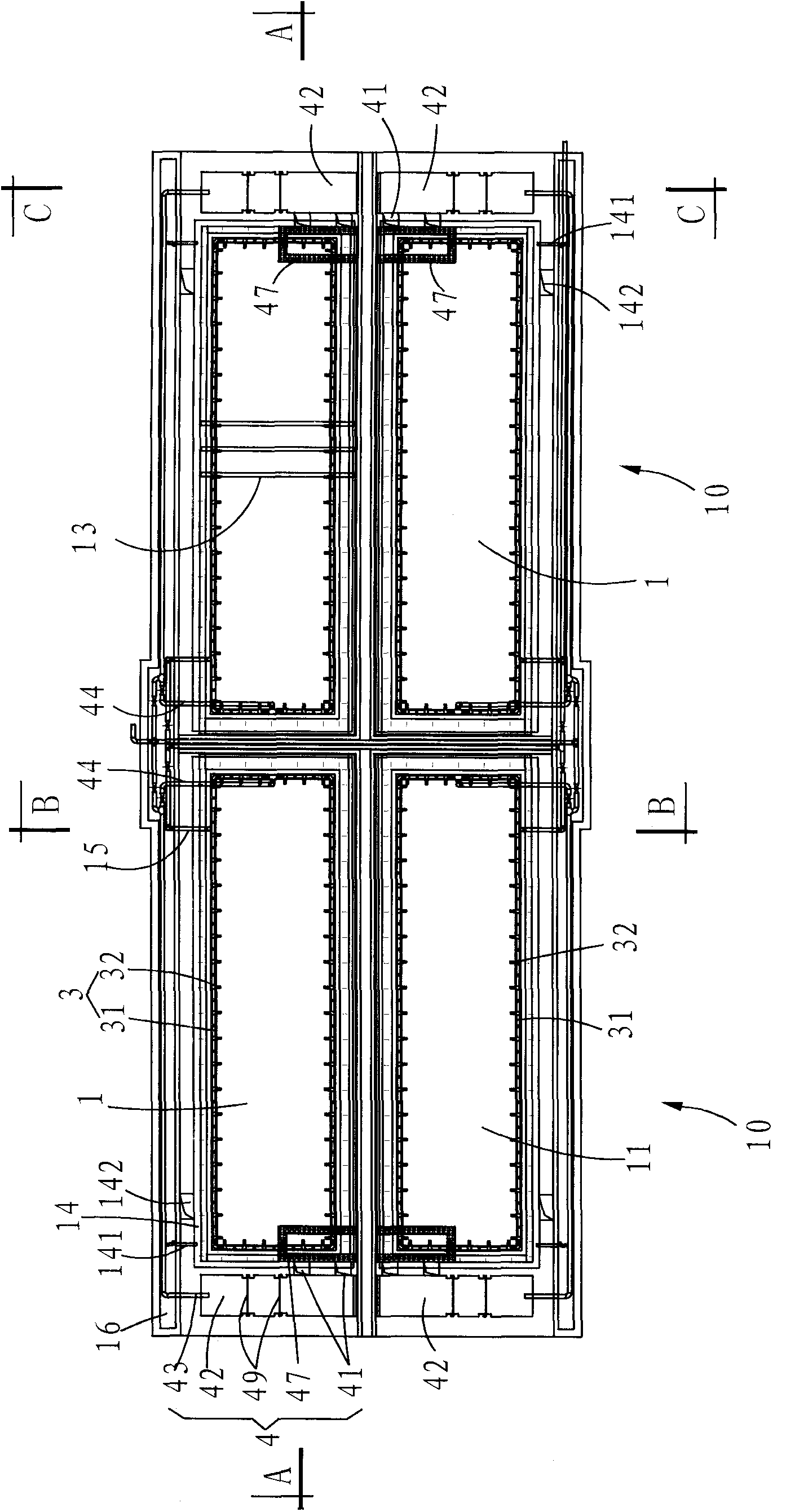

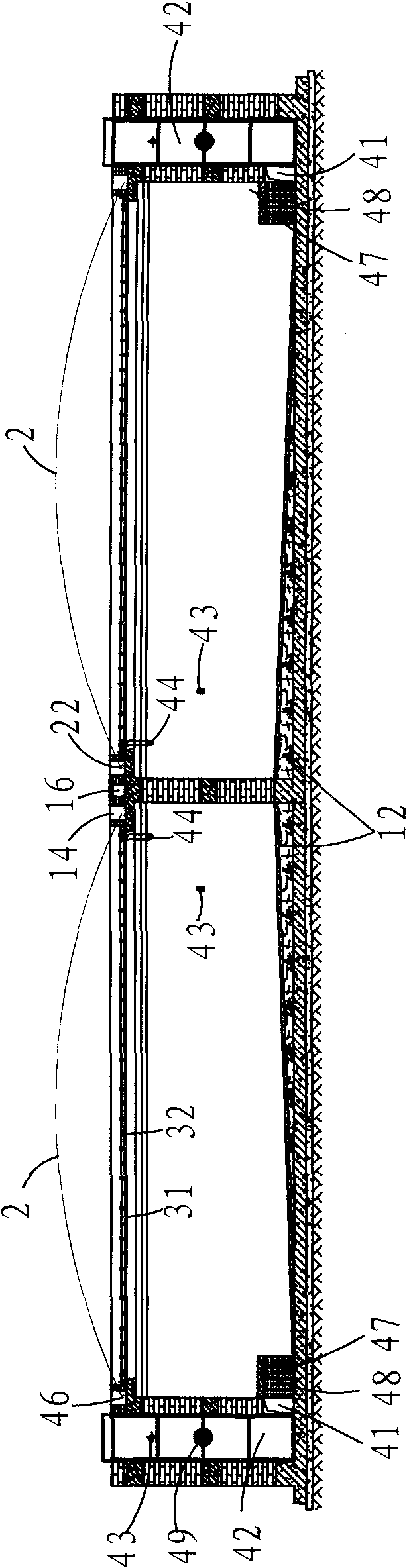

Ink jetting and supplying device of unit type intaglio press

ActiveCN101973162AReduce fatigue ratePrevent crustingPrinting press partsEvaporationPulp and paper industry

The invention relates to an ink jetting and supplying device of a unit type intaglio press. The device comprises an ink jetting tube assembly, a circulating pump, an ink fountain and an ink delivery roller assembly, wherein the ink jetting tube assembly comprises an ink jetting tube, a fixed support and an adjusting ring; the ink jetting tube is fixed on an ink delivery roller swing arm above an ink delivery roller by the fixed support; the adjusting ring is arranged on the ink jetting tube on the inner side of the fixed support; one side of the ink jetting tube is provided with an ink inlet hole; ink jetting holes are formed on the ink jetting tube and are opposite to a tangent position of a printing plate roller and the ink delivery roller; the ink delivery roller assembly comprises the ink delivery roller and the ink delivery roller swing arm; and the ink delivery roller is fixed on the ink delivery roller swing arm by a bearing and is arranged below the printing plate roller. By the structure, ink is directly jetted on the printing plate roller, and the ink delivery roller rolls the ink to fulfill the aim of fully defoaming, so that the evaporation of solvents is reduced, the fatigue rate of the ink is reduced, the ink is prevented from crusting, the disadvantages, such as ink lines, color difference and the like, are overcome, and the ink is not spattered even if the printing plate roller rotates at a high speed.

Owner:湖北宏裕新型包材股份有限公司

Biogas production method

InactiveCN101812481APrevent crustingContinuous productionWaste based fuelFermentationTotal solid contentBiogas production

The invention provides a biogas production method. The method comprises the following steps of: feeding materials, and pre-treating the materials; adding water or biogas slurry into an anaerobic pond where the materials are piled, sealing the anaerobic pond for fermentation, refluxing the biogas slurry or adding water every other 1 to 10 days, periodically stirring the material so as to prevent large-scaled incrustation of the materials, and simultaneously collecting biogas; and after the reaction of the materials in the anaerobic pond is ended, discharging the materials. In the method, the organic materials, of which the total solid content and the suspended matter content are high, can be used as raw materials, the incrustation of the materials is prevented in a process of producing the biogas, and the yield of the biogas produced by degradation and conversion of the materials is high.

Owner:张华 +1

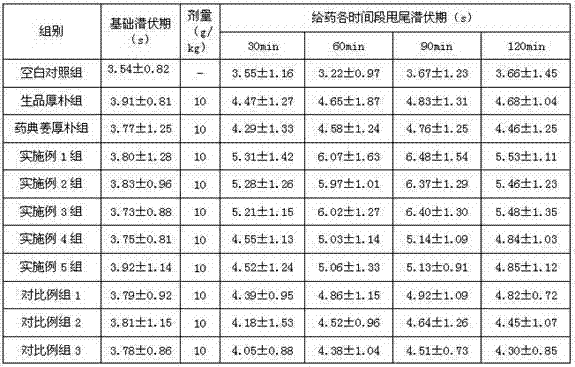

Novel processing method of gingered Mangnolia officinalis

The invention relates to a novel processing method of gingered Mangnolia officinalis. The novel processing method comprises the following steps of: pretreating materials, carrying out closed accumulation for sweating, carrying out uniform stirring and covered moistening with ginger extract liquid after sweating, frying with slow fire, carrying out covered moistening, and then placing in a manner of layer-by-layer to carry out demisting. The Mangnolia officinalis treated by adopting the Chinese herbal medicine processing method is high in effective ingredient content, Mangnolia officinalis mist occurs on the surface, and the Mangnolia officinalis with mist is superior to the gingered Mangnolia officinalis and raw Mangnolia officinalis in the pharmacopeia on the anti-inflammatory and analgesic effects.

Owner:江西樟邦精细中药饮片有限责任公司

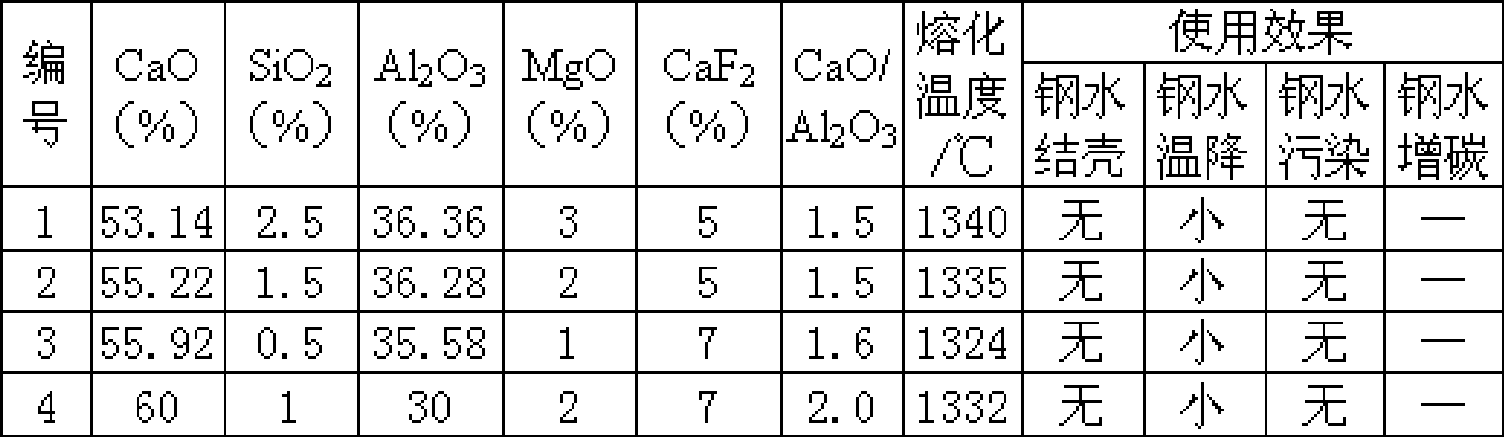

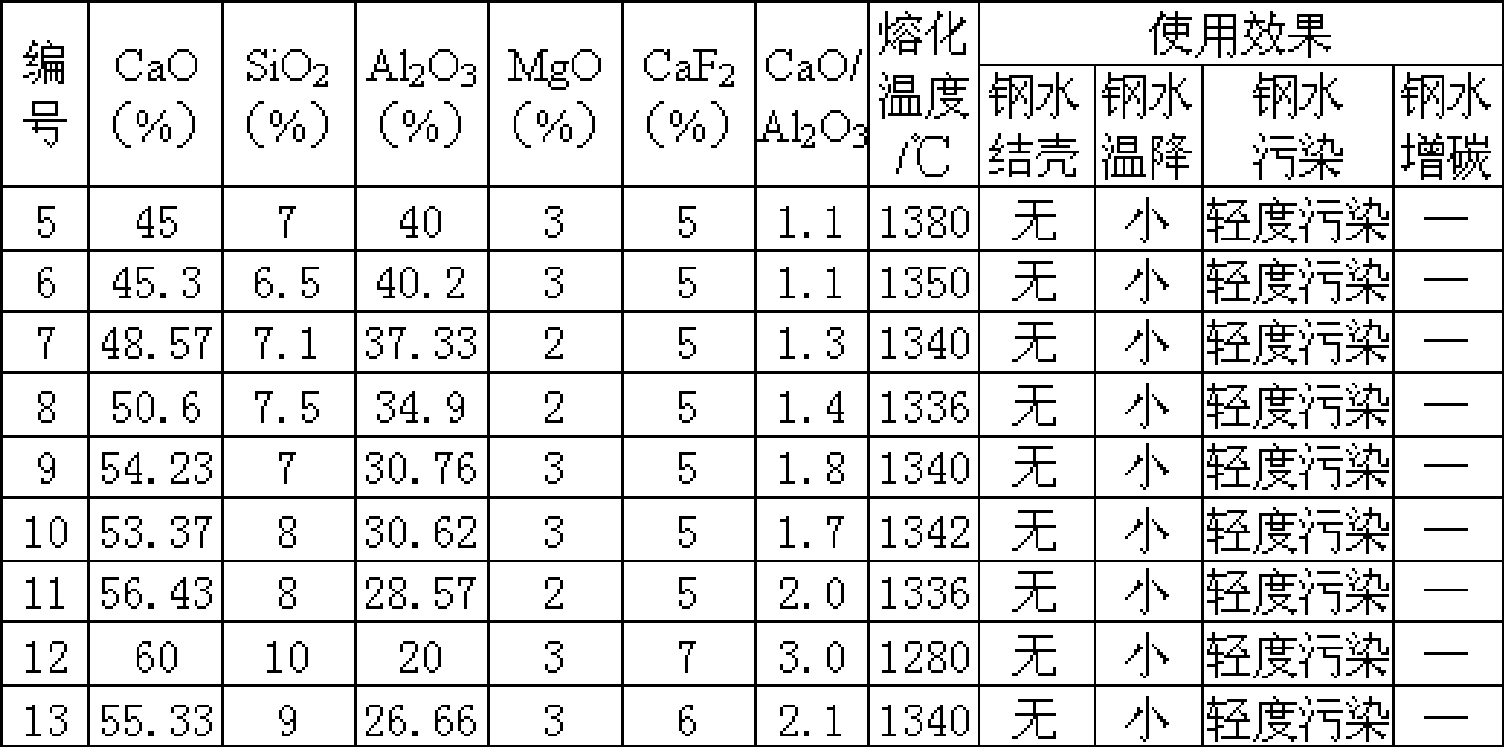

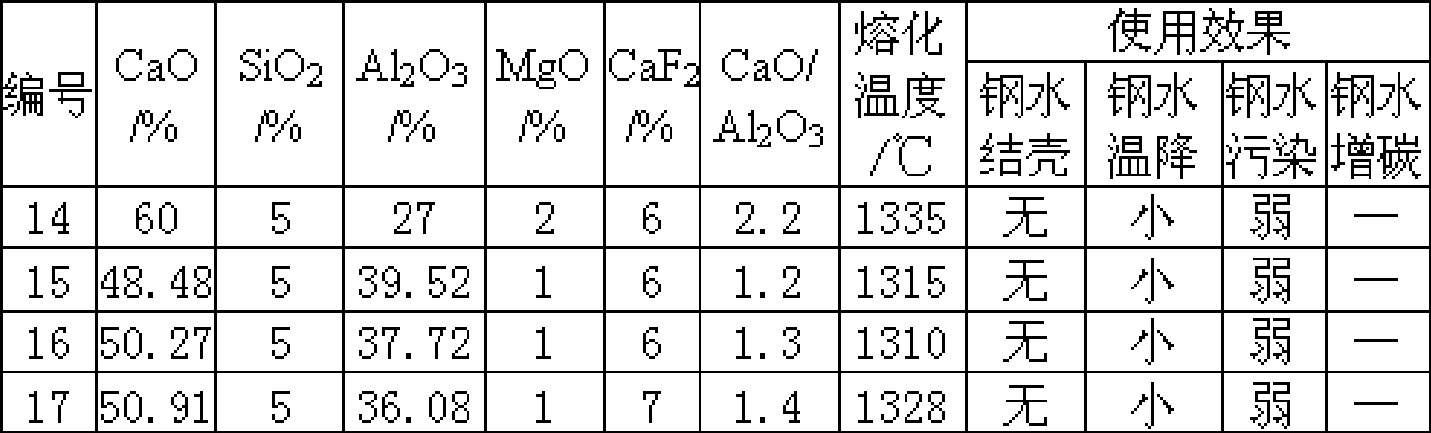

Double-layer tundish covering agent

The invention relates to a double-layer middle coating agent which belongs to the field of metallurgy. The invention solves the technical problem of providing a double-layer middle coating agent capable of preventing crusting on a slag surface. The double-layer middle coating agent comprises an upper layer of slag materials and a lower layer of slag materials; wherein, the components of the lower layer of slag materials thereof comprise 40 to 60 weight portions of CaO, 20 to 40 weight portions of Al2O3, as well as 5 to 7 weight portions of CaF2; moreover, the weight ratio between CaO and Al2O3 is 1 to 3. The double-layer middle coating agent not only can prevent crusting on the slag surface, but also has stronger capacity for absorbing impurities and excellent heat preservation function; moreover, the double-layer middle coating agent can reduce the secondary pollution to molten steel and has broad application prospect.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

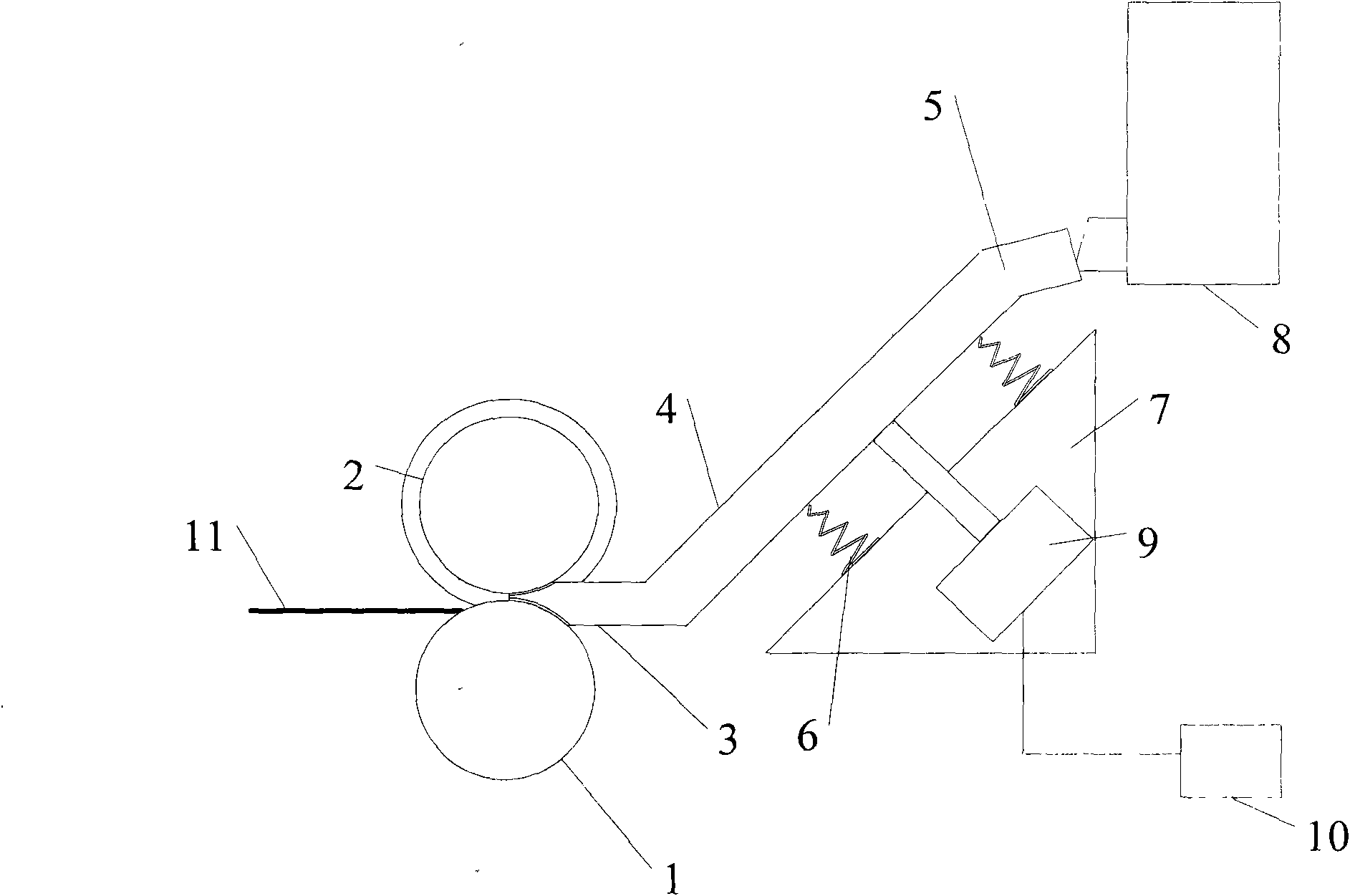

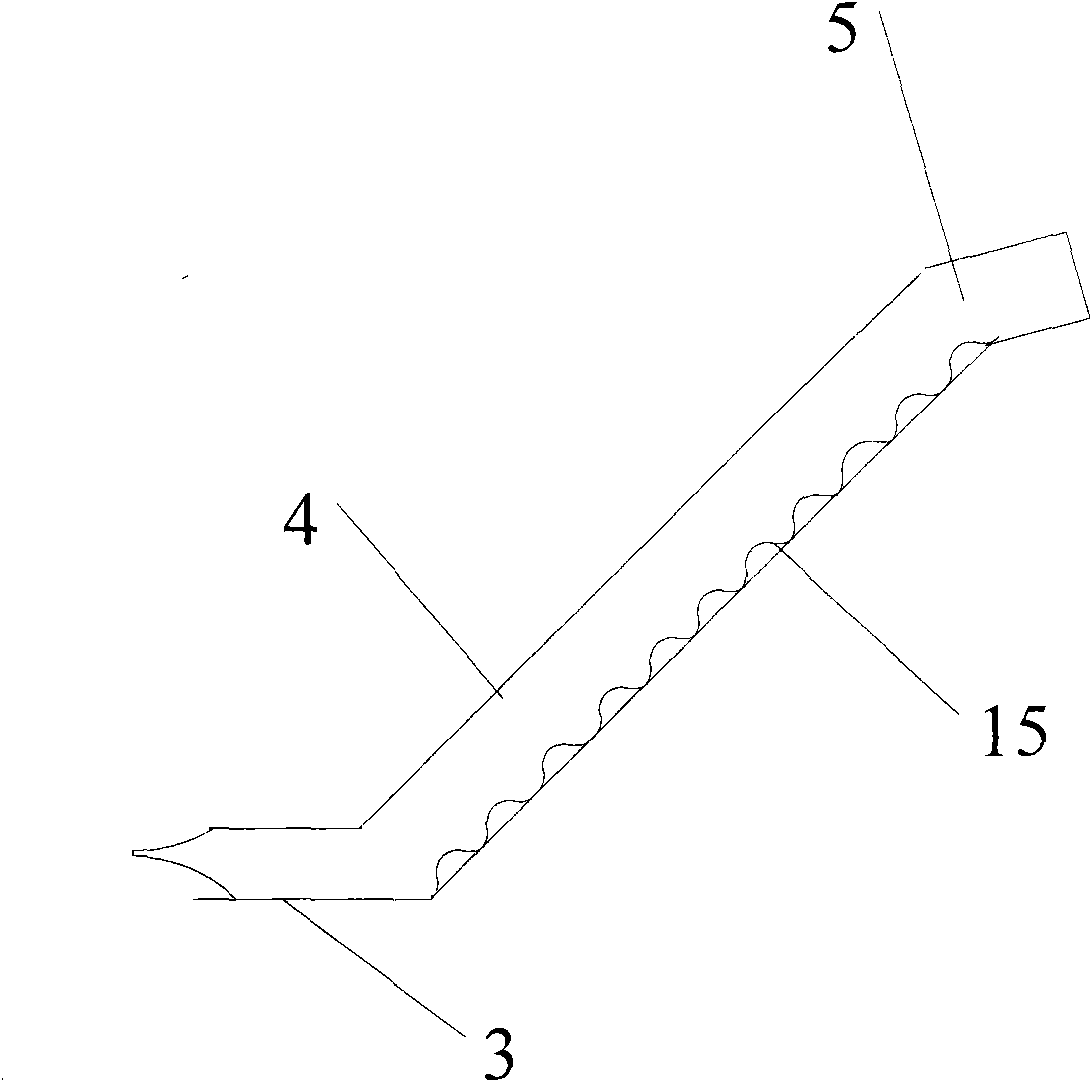

Continuous rheomolding device for manufacturing metal plate strips

InactiveCN101890431AIncreased speed of continuous rheological formingGood formabilityMetal rolling arrangementsEngineeringAlloy

The invention provides a continuous rheomolding device for manufacturing metal plate strips. The device comprises an inclined plate, a base, an electromagnetic vibration exciter and a double-roller rolling mill and is characterized by also comprising the double-roller rolling mill, wherein the inclined plate is formed by connecting a feeding section, a pulping section and a discharging section in turn; the lower side of a bottom plate of the pulping section is connected with the upper end of a spring; the lower end of the spring is fixed on the base; one end of the electromagnetic vibration exciter is fixed on the base, and the other end of the electromagnetic vibration exciter is connected with the lower side of the bottom plate of the pulping section; and gaps are formed between the bottom plate and two side plates of the discharging section and the roll surfaces of upper and lower rollers of the double-roller rolling mill. The range of vibration frequency which can be provided by the electromagnetic vibration exciter adopted by the device is expanded greatly and the vibration frequency is adjusted so that an alloy structure can be improved more effectively and molten metal is prevented from crusting on the surface of the inclined plate.

Owner:NORTHEASTERN UNIV

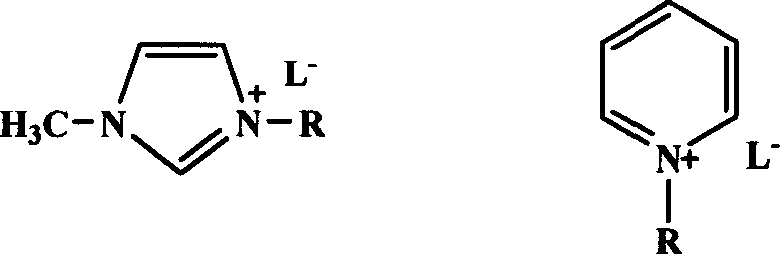

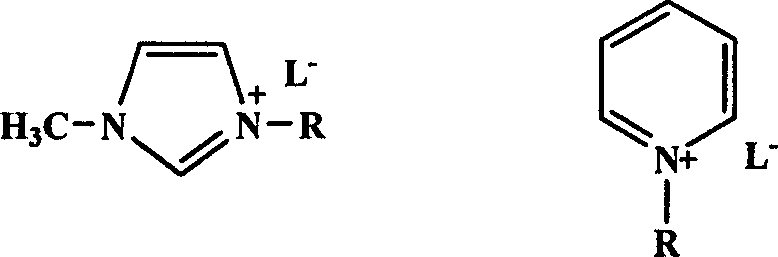

Process for preparing alkyd resin coating

InactiveCN1935918AAvoid disadvantagesSimplify operating proceduresPolyester coatingsMethyl benzeneResin coating

The invention relates to alkyd resin coating preparing technology. It includes the following steps: according to mass shares fatty acid 30-40, glycerol 20-30, ion liquid 1-10 are stirring at 50-100 degree centigrade for 1-5h; adding into benzene anhydride 35-45, toluene or methyl benzene 3-6 to do back flow reaction at 220-240 degree centigrade for 3-5h; cooling, diluting, filtering to gain the alkyd resin coating. The invention is a green clear technological line which can increase esterifying reaction, reduce oxygen absorbed for coating oxidation drying, simplify operational program, reduce cost, fit for industrialization production in certain scale etc.

Owner:ZHEJIANG UNIV OF TECH

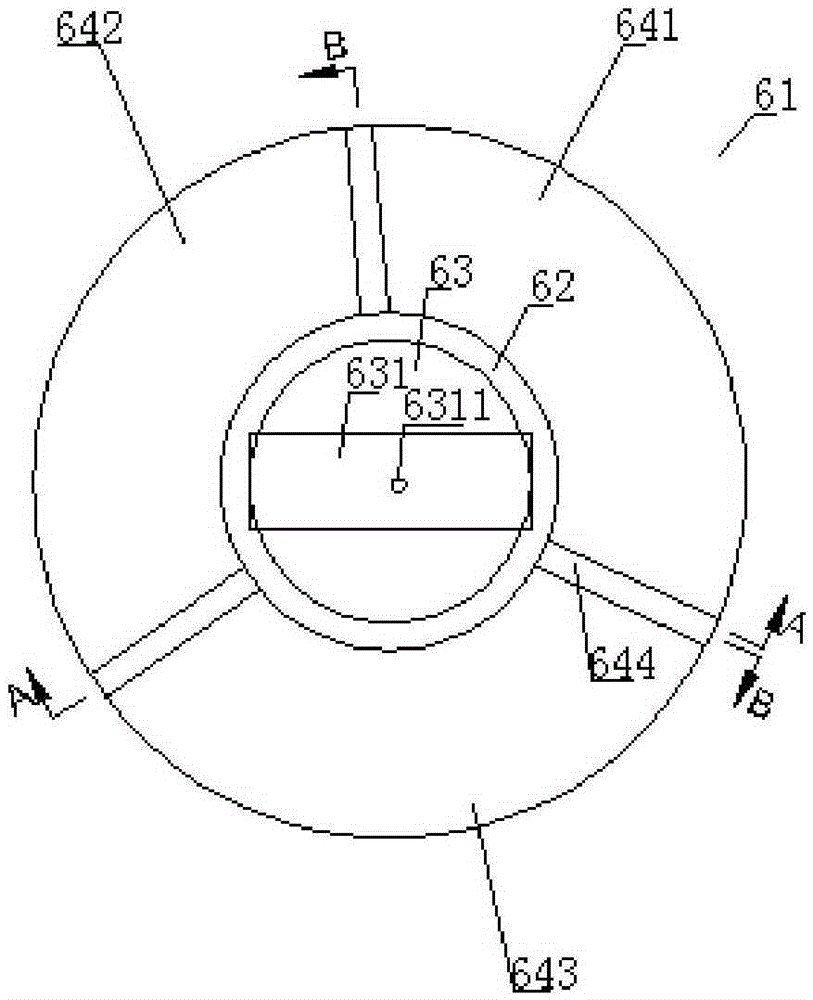

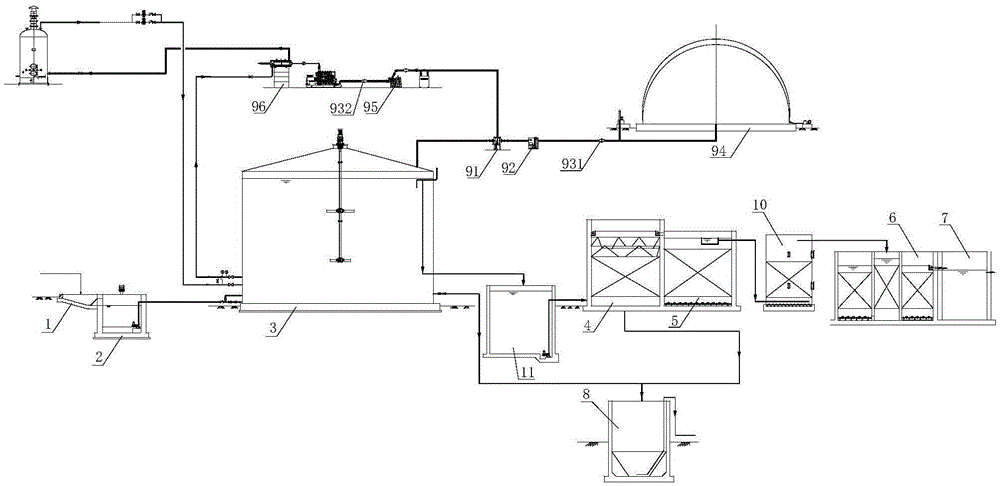

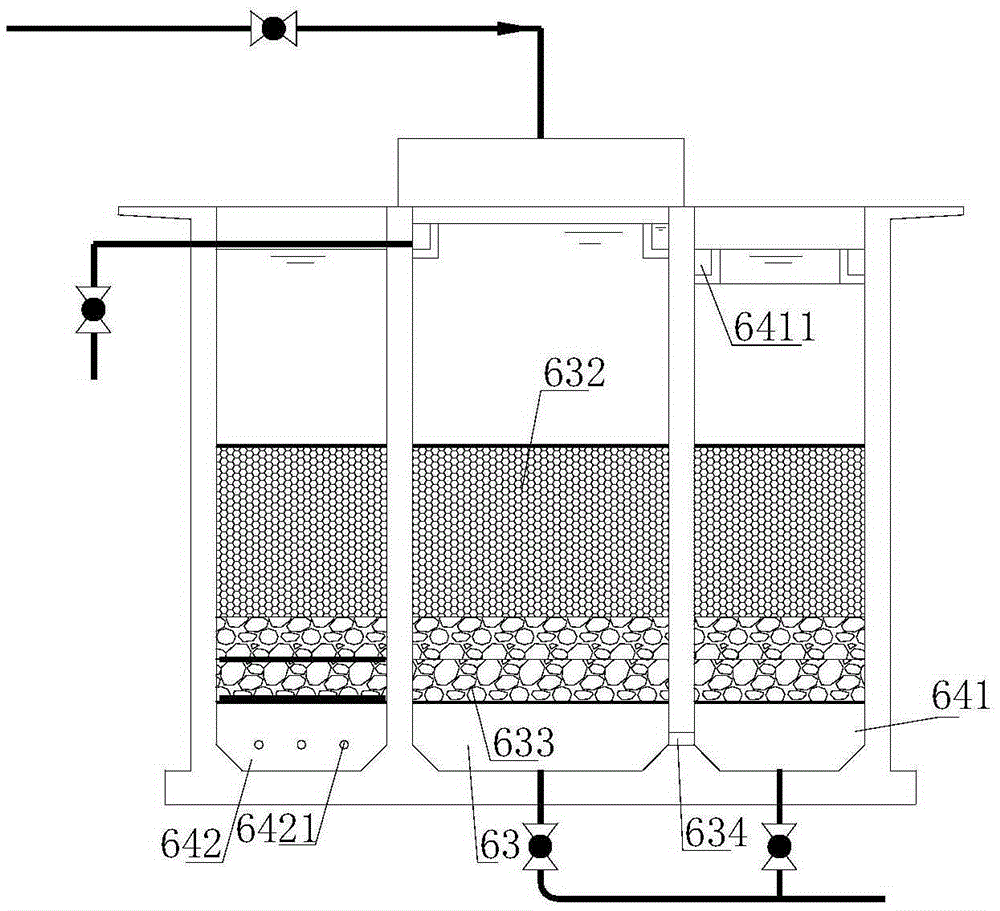

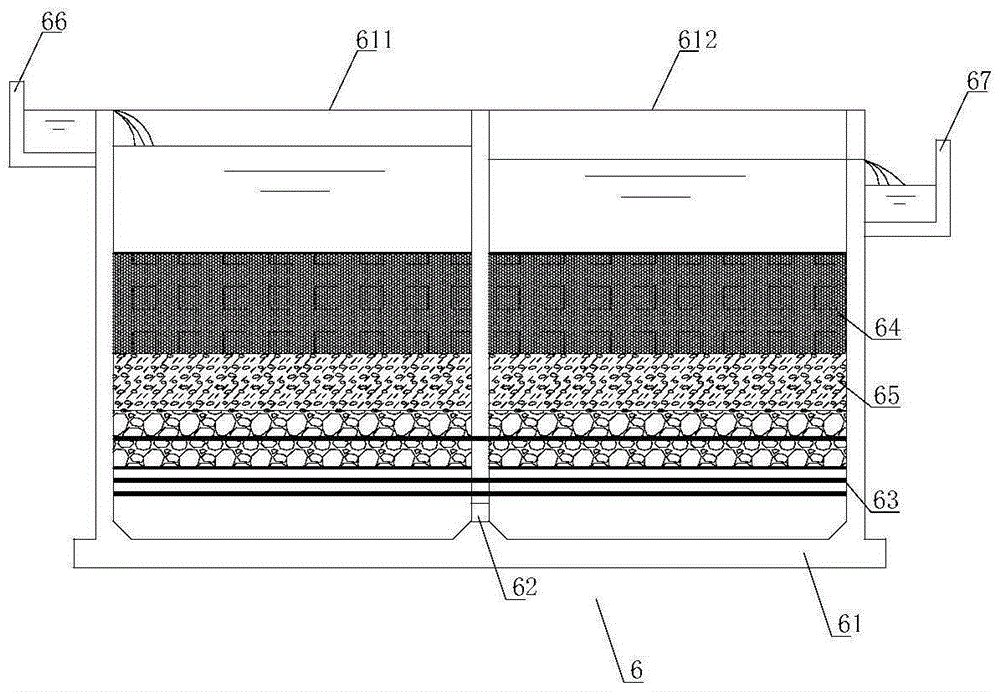

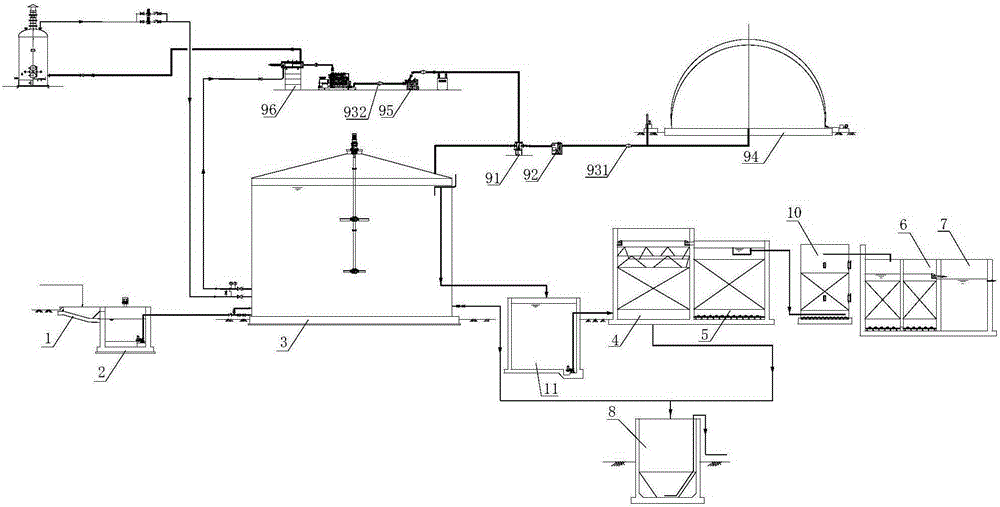

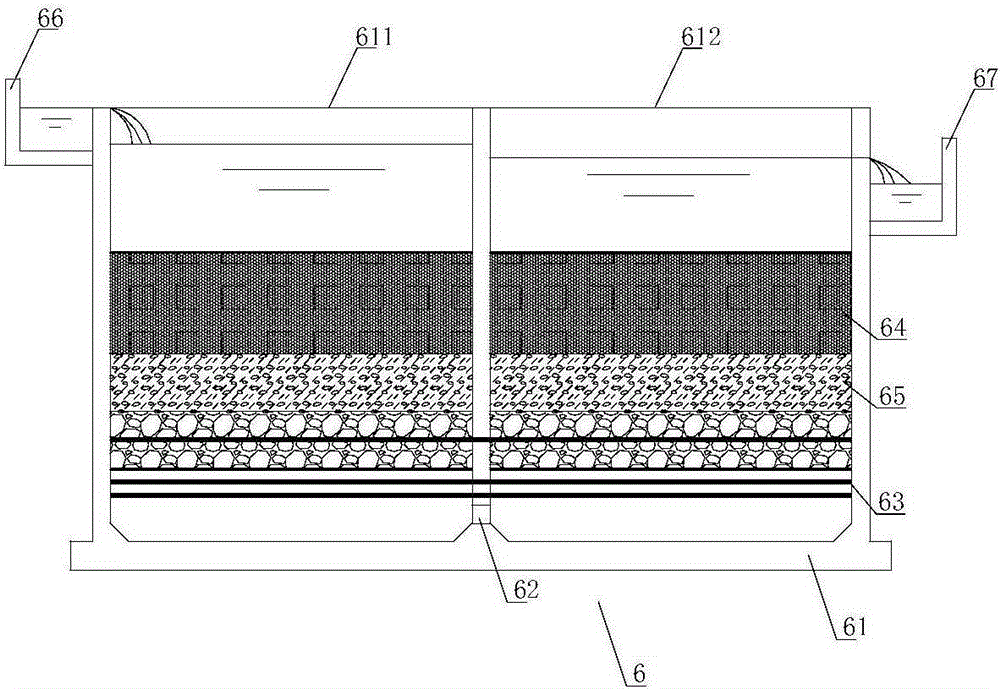

Aquaculture wastewater processing system and method thereof

InactiveCN105384302AEfficient killingImprove purification intensityMultistage water/sewage treatmentElectrolysisConcentration gradient

The present invention relates to the technical field of wastewater processing, and discloses an aquaculture wastewater processing system. The system comprises a feed hopper (1), a homogenate pool (2), a biogas pool (3), an upstream anaerobic sludge bed reactor (4), an activated sludge reaction tank (5), a micro-electrolysis reactor (10), an annular aerated biofilter (6) and an ozone disinfection pool (7) that are sequentially connected, wherein the biogas pool is connected with a sludge concentration pool (8). The present invention also discloses an aquaculture wastewater processing method. The method comprises the following steps: anaerobic digestion processing, activated sludge processing, micro-electrolysis reaction, annular aerated biofilter biochemical processing and ozone disinfection. According to the aquaculture wastewater processing system and method thereof, the technology is simple, the concentration gradient in the reaction process is large, and sludge expansion is unlikely to occur; the anti-load shock capability is strong, and the processing effect is good; and by adjusting the operation cycle and controlling the length of time of each working procedure, the effect of removing nitrogen and phosphorus is obvious.

Owner:徐雪祥

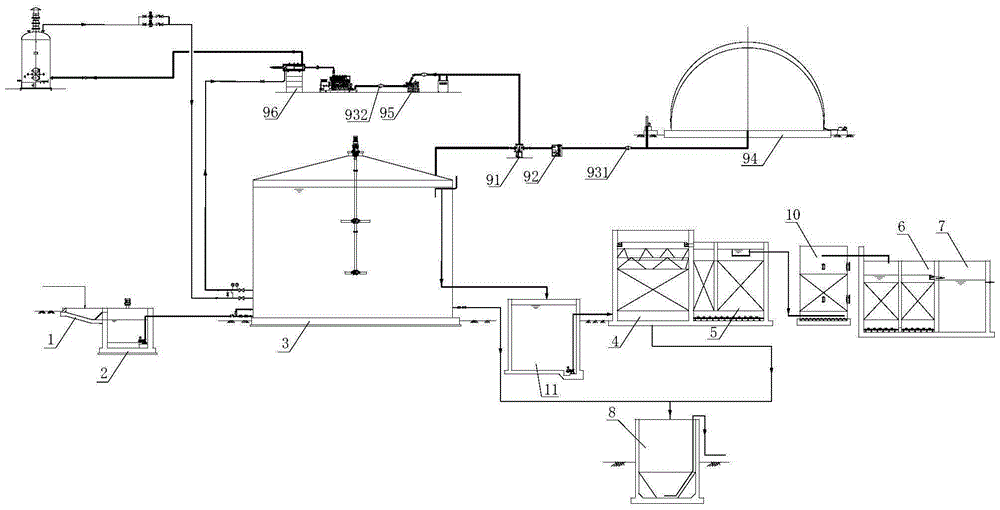

System and method suitable for treating high concentration organic wastewater

InactiveCN105174622AEfficient killingImprove purification intensityMultistage water/sewage treatmentHigh concentrationFlame arrester

The invention relates to the technical field of sewage treatment and discloses a system suitable for treating high concentration organic wastewater. The system comprises a feed hopper (1), a homogenizing tank (2), a biogas tank (3), an up-flow anaerobic sludge bed (4), a cyclic activated sludge bioreactor (5), a microelectrolysis reactor (10), a baffled biological aerated filter (BBAF) (6) and an ozone disinfection tank (7), which are connected in sequence, wherein the biogas tank is connected with a sludge thickening tank (8); a biogas purification and storage gas supply system comprises a gas-water separator (91), a biogas desulfurizer (92), a first flame arrester (931) and a gas storage tank (94) in sequence; and the gas-water separator (91) is also connected with a gas supercharging device (95), a second flame arrester (932) and a waste heat recovery device (96). The system and the method have the beneficial effects that the process is simple; the concentration gradient in the reaction process is large, so that sludge bulking is not easy to happen; the system has strong load impact resistance and good treatment effects; and the simultaneous denitrification and dephosphorization effects of the BBAF are obvious by adjusting the cycle of operation and controlling the working procedure time length.

Owner:HANGZHOU DINGLONG ENVIRONMENTAL PROTECTION SCI & TECH

Binder for installation of thermal insulation decorative plate

The invention provides a binder for installation of a thermal insulation decorative plate. The binder comprises, by weight, 25 to 40% of cement, 25 to 45% of silica sand of 20 to 40 meshes, 8 to 15% of silica sand of 40 to 70 meshes, 3 to 8% of silica sand of 70 to 140 meshes, 0 to 5% of talcum powder, 0 to 5% of ground calcium carbonate powder, 2 to 8% of dispersible latex powder, 0 to 1% of cellulose ether, 0 to 0.6% of plant fibers and 0 to 0.5% of a thixotropic agent. The binder for installation of the thermal insulation decorative plate has the characteristics of high adhesion, strong anti-sliding capability, strong initial adhesion, long construction operation time and difficult skinning, effectively solves the problems produced in thermal insulation decorative plate pasting installation, guarantees enough adhesion between a thermal insulation decorative plate and a wall surface, and improves safety of the thermal insulation decorative plate in engineering application.

Owner:ASIA CUANON TECH SHANGHAI

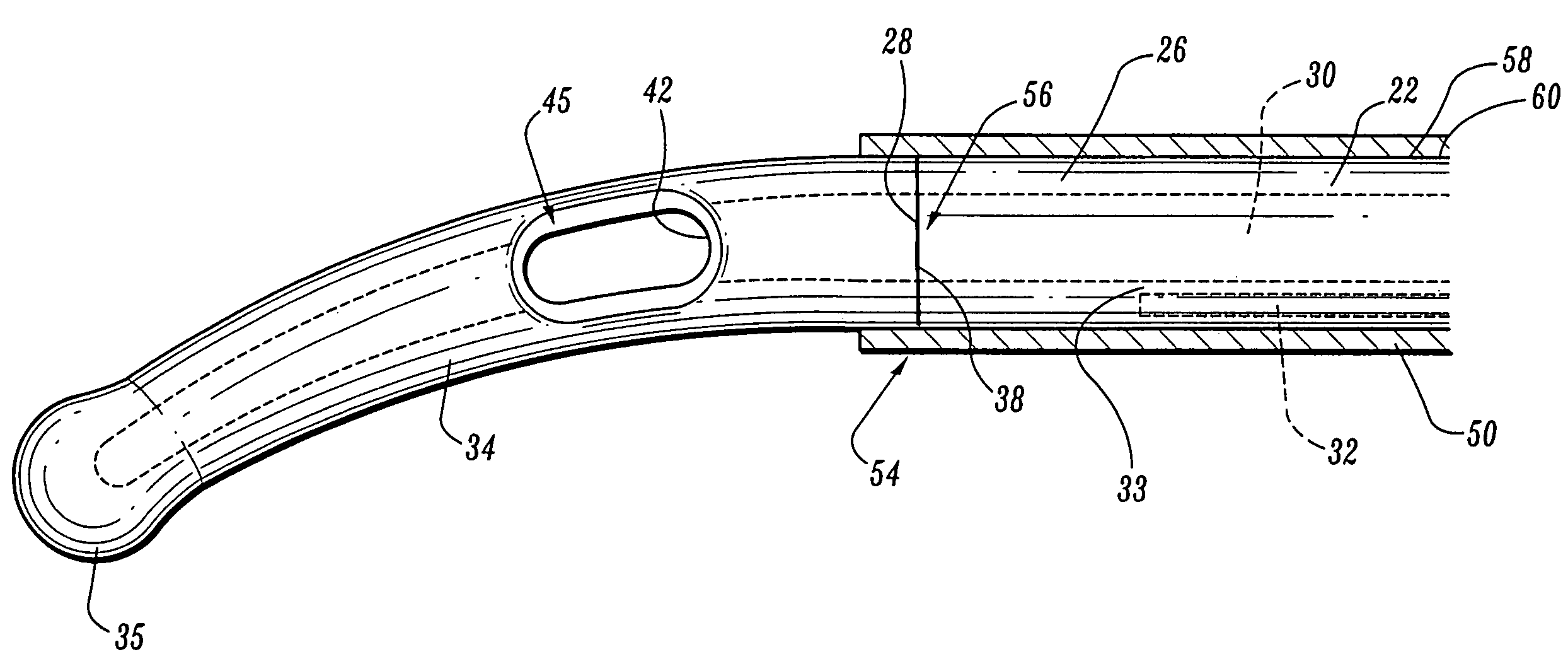

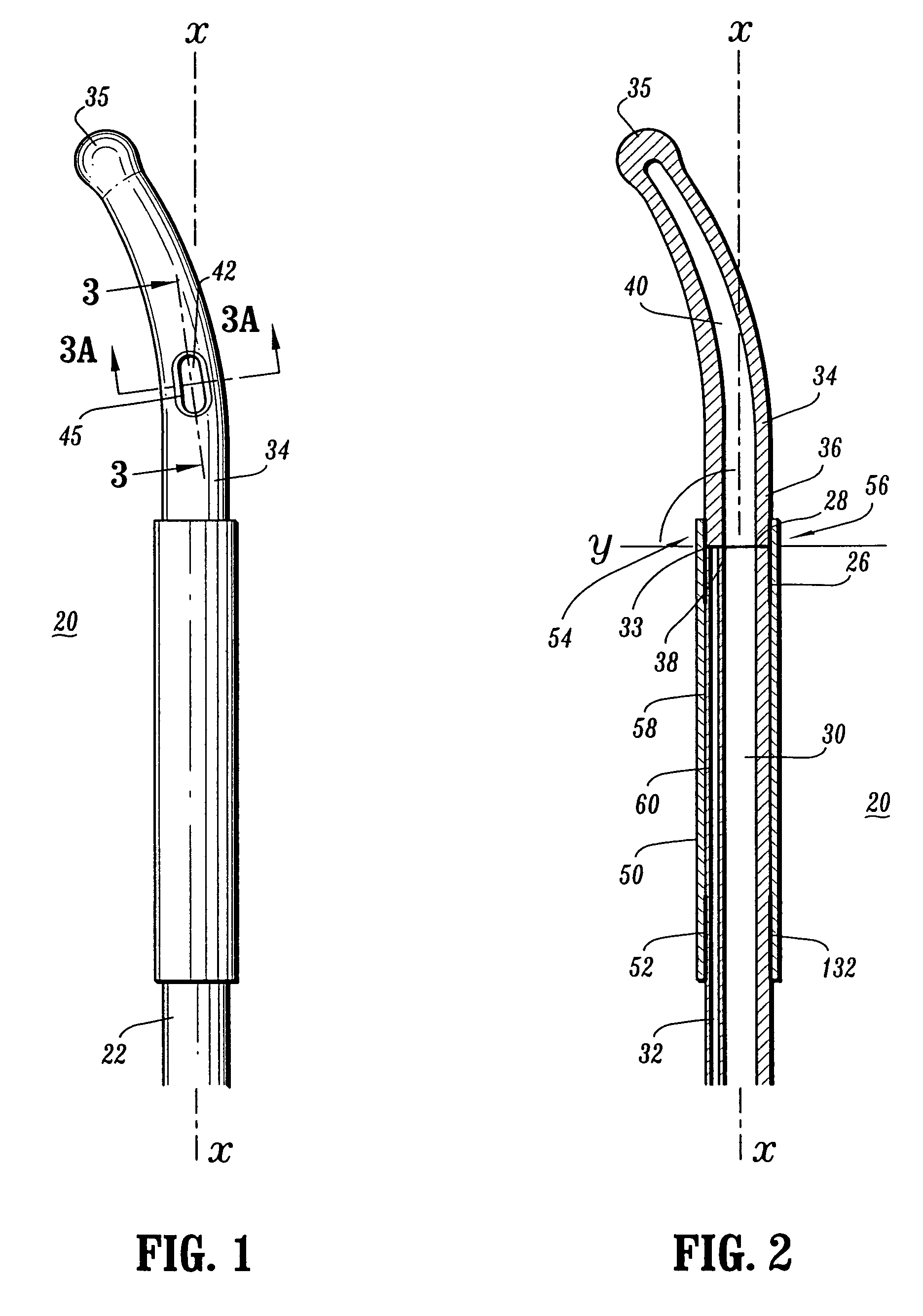

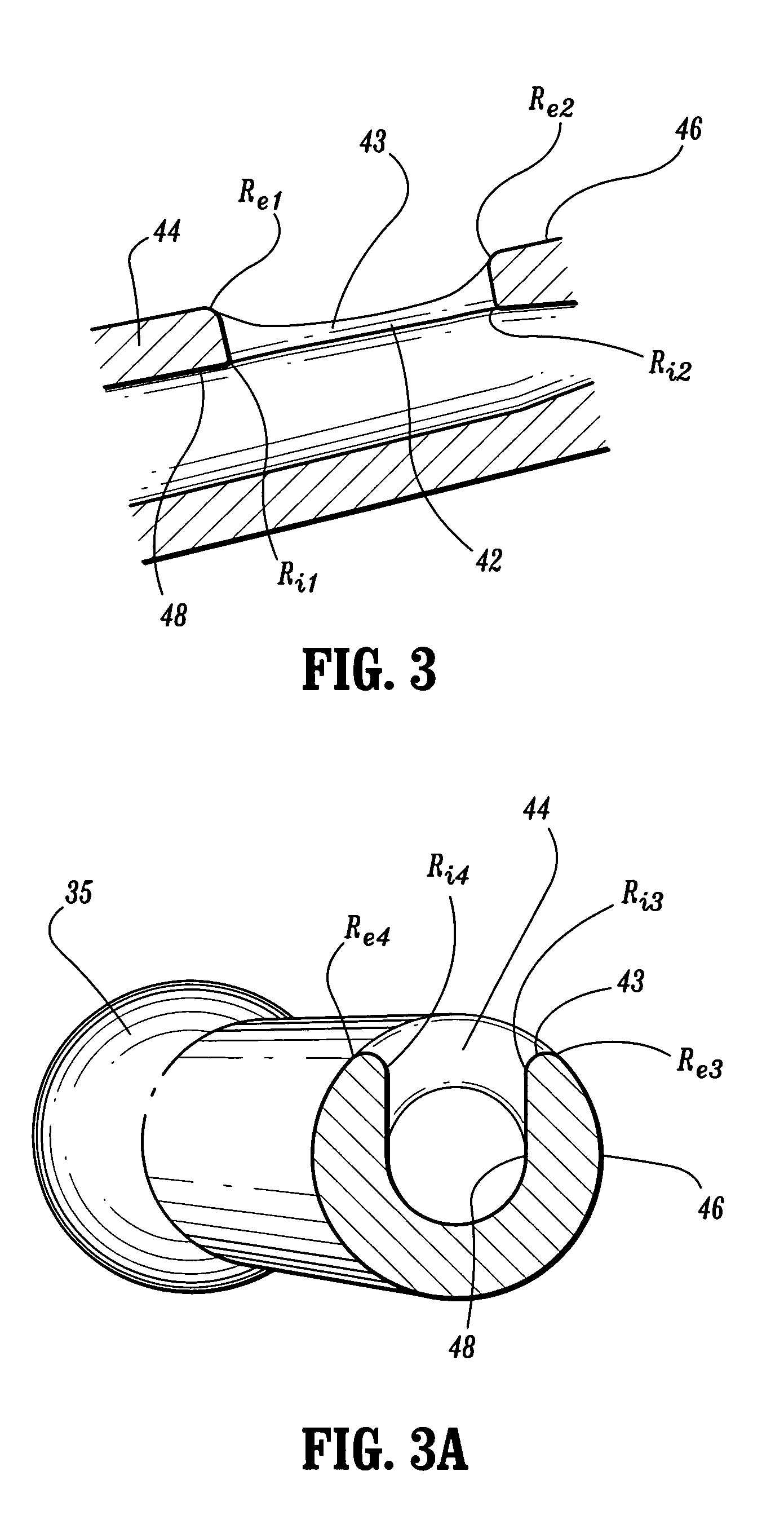

Urology catheter

ActiveUS7655000B2Facilitate tip insertionEasy and efficient assemblyStentsWound drainsUrologic surgeryDistal portion

Owner:KPR U S LLC

System and method for treating wastewater by applying activated sludge

InactiveCN105174621AImprove purification intensitySimple processWaste based fuelTreatment with anaerobic digestion processesBiogasAnaerobic digestion

The invention relates to the technical field of sewage treatment and discloses a system for treating wastewater by applying activated sludge. The system comprises a feed hopper (1), a homogenizing tank (2), a biogas tank (3), an up-flow anaerobic sludge bed (4), an activated sludge reaction tank (5), a microelectrolysis reactor (10), a baffled biological aerated filter (BBAF) (6) and an ozone disinfection tank (7), which are connected in sequence, wherein the biogas tank is connected with a sludge thickening tank (8). The invention also discloses a method for treating wastewater by applying activated sludge. The method comprises anaerobic digestion treatment, treatment by adopting an activated sludge method, microelectrolysis reaction, biochemical treatment with the BBAF and ozone disinfection. The system and the method have the beneficial effects that the process is simple; the concentration gradient in the reaction process is large, so that sludge bulking is not easy to happen; the system has strong load impact resistance and good treatment effects; and the simultaneous denitrification and dephosphorization effects of the BBAF are obvious by adjusting the cycle of operation and controlling the working procedure time length.

Owner:HANGZHOU DINGLONG ENVIRONMENTAL PROTECTION SCI & TECH

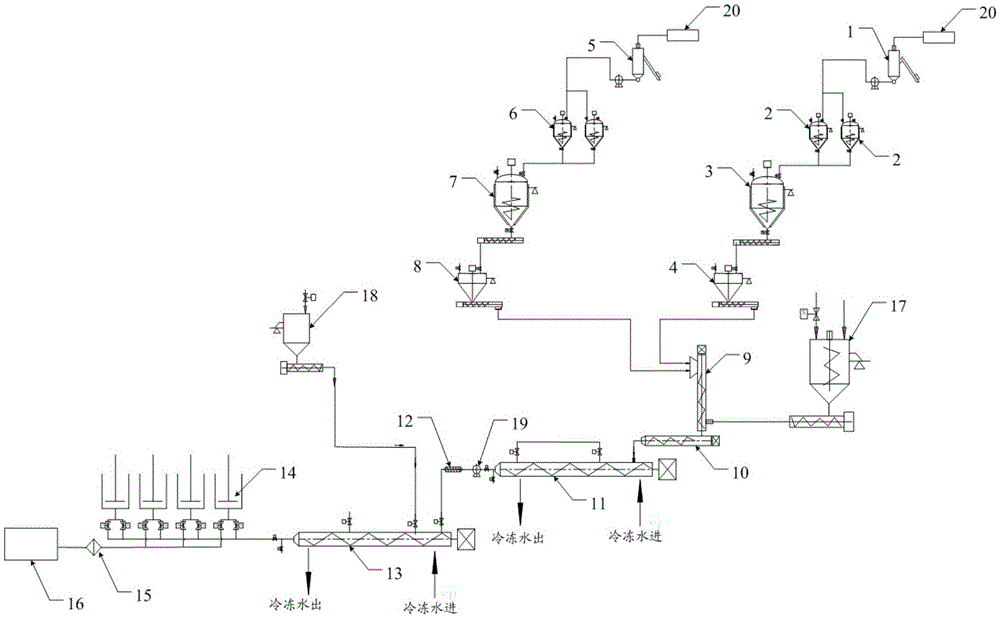

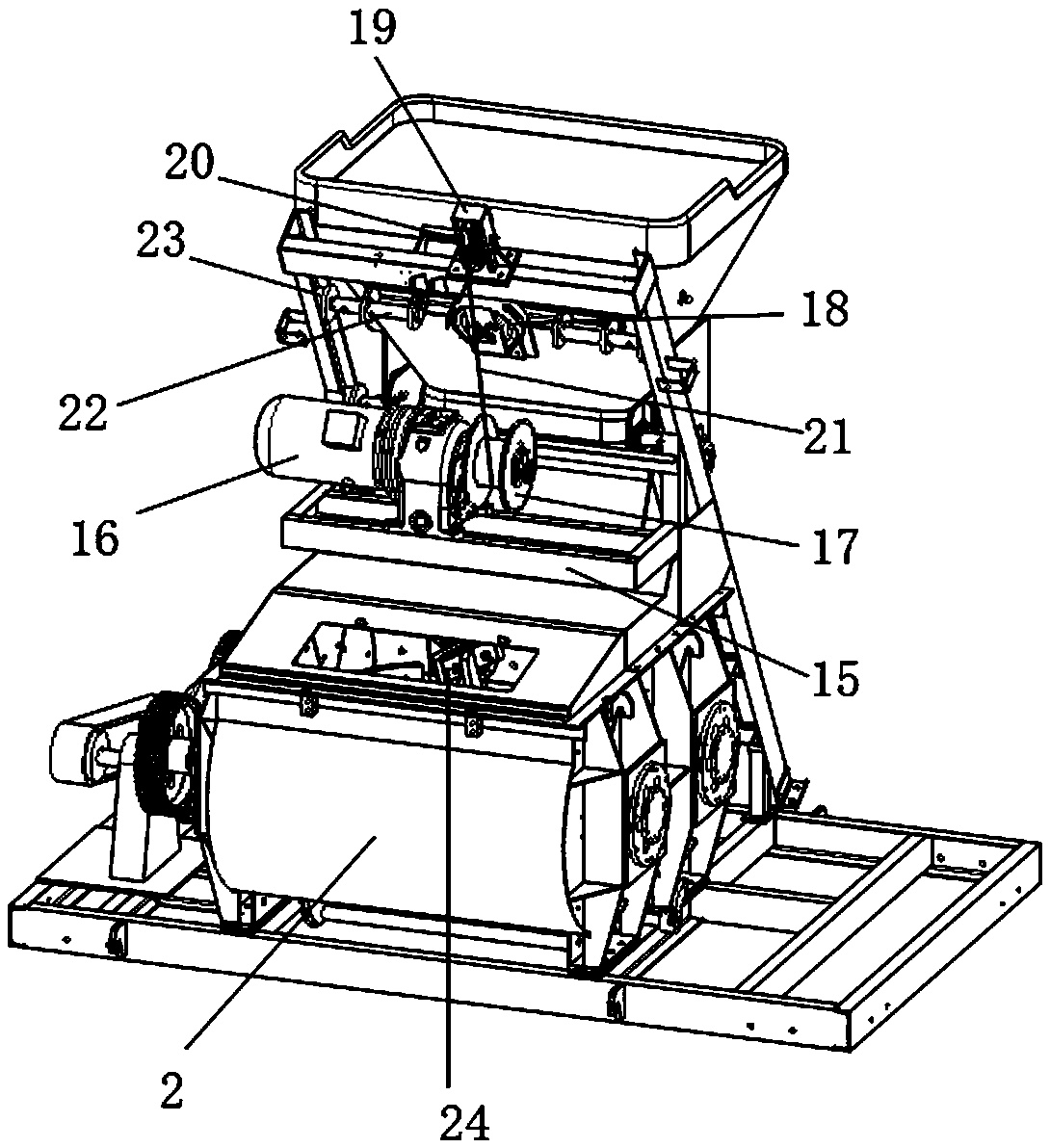

Continuous and automatic production line of polyurethane adhesive and production method thereof

ActiveCN105647455ARealize continuous automatic productionPrevent crustingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesProduction linePolyurethane adhesive

The embodiment of the invention discloses a continuous and automatic production line of a polyurethane adhesive and aims to solve the problem that since the materials are in contact with air, crust is generated and influence is caused on the product quality in the intermittent production process of the existing polyurethane adhesive. The continuous and automatic production line of the polyurethane adhesive comprises a calcium powder bale breaker, a calcium powder drying tank, a calcium powder cooling storehouse and a calcium powder measuring tank which are successively connected with one another via a pipeline; a carbon black powder bale breaker, a carbon black powder drying tank, a carbon black powder cooling storehouse and a carbon black powder measuring tank are successively connected with one another via the pipeline; a side feeder, a pre-mixing screw machine, a first-stage screw machine, a high-viscosity material cooler, a second-stage screw machine, a material pressing machine, a filter and a split charging device are connected with one another via the pipeline; the outlets of a prepolymer measuring tank, the calcium powder measuring tank and the carbon black powder measuring tank are communicated with the inlet of the side feeder via the pipeline; the outlet of a catalyst measuring tank is communicated with the inlet of the second-stage screw machine via the pipeline.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

Topramezone and terbuthylazine compounded herbicide

InactiveCN103430947APrevent flocculationAvoid layeringBiocideAnimal repellantsSuspending AgentsToxicology

The invention discloses a topramezone and terbuthylazine compounded herbicide which comprises an oil suspended agent mainly prepared from topramezone, terbuthylazine, an assistant and a solvent, wherein the mass percent of the topramezone is 1-60%, the mass percent of terbuthylazine is 1-40%, and the mass sum of the topramezone and terbuthylazine takes 2-90% of the total mass of theherbicide. The topramezone and terbuthylazine compounded herbicide provided by the invention is a novel herbicide composition with a good weeding effect.

Owner:河北博嘉农业有限公司

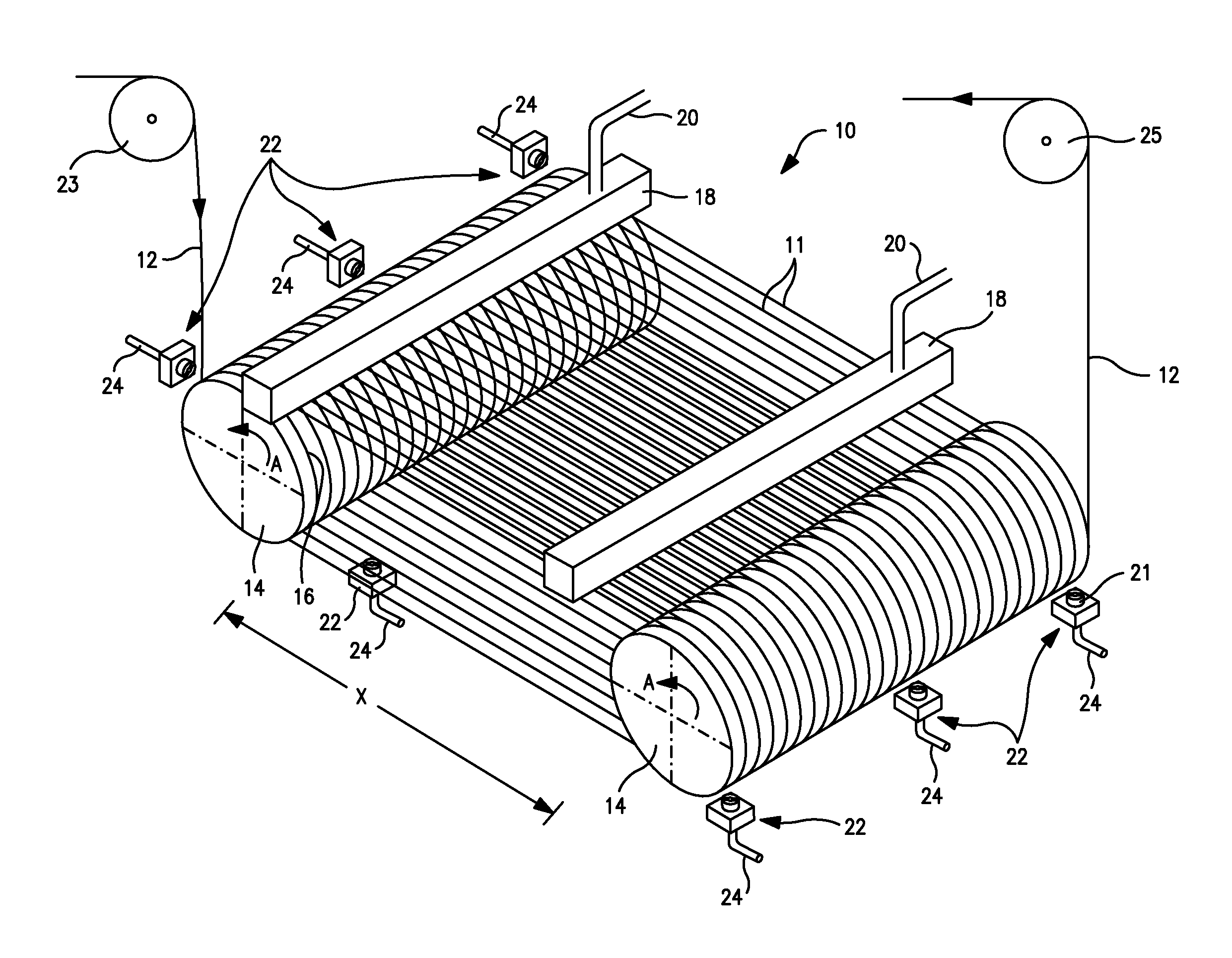

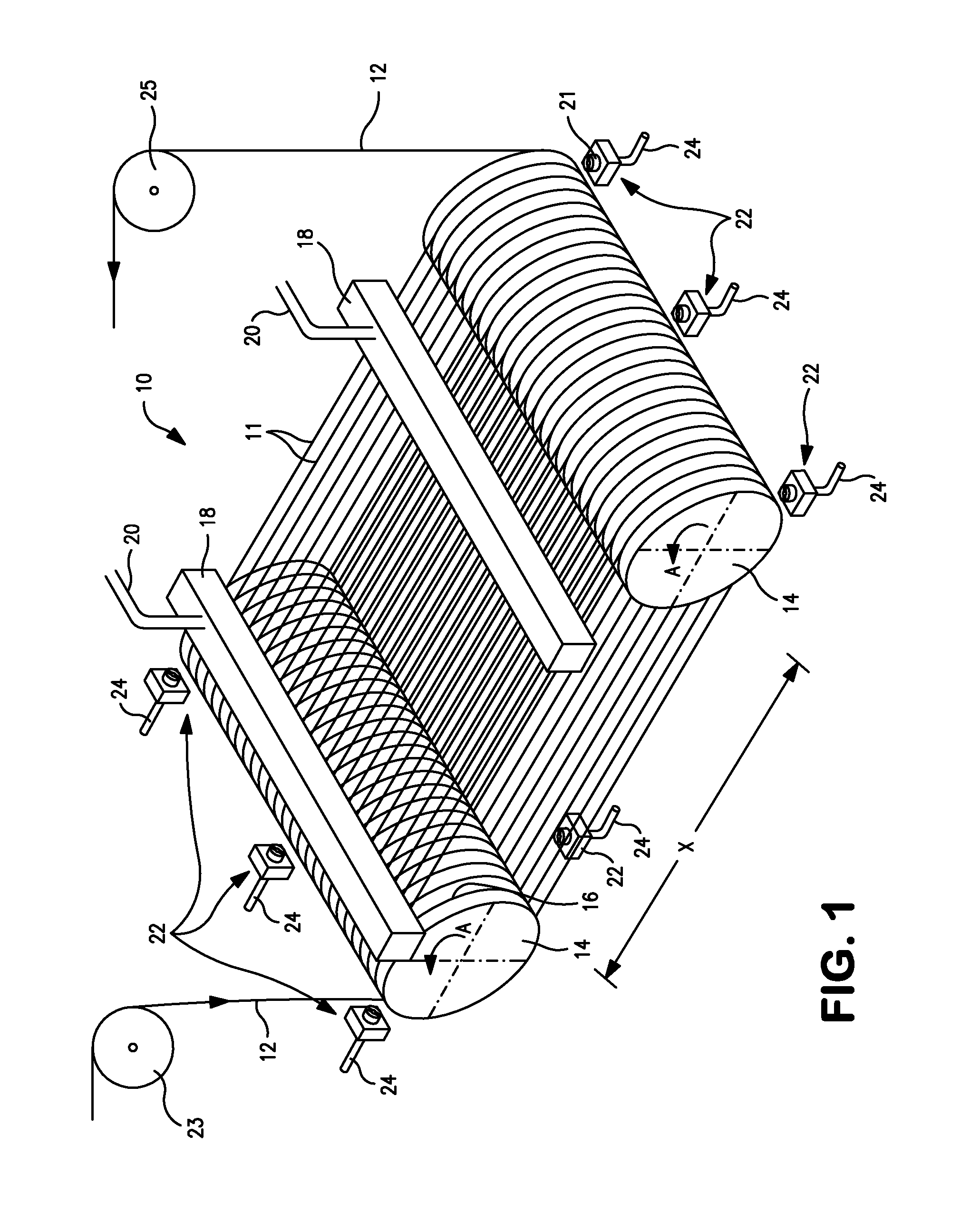

Self-cleaning wiresaw apparatus and method

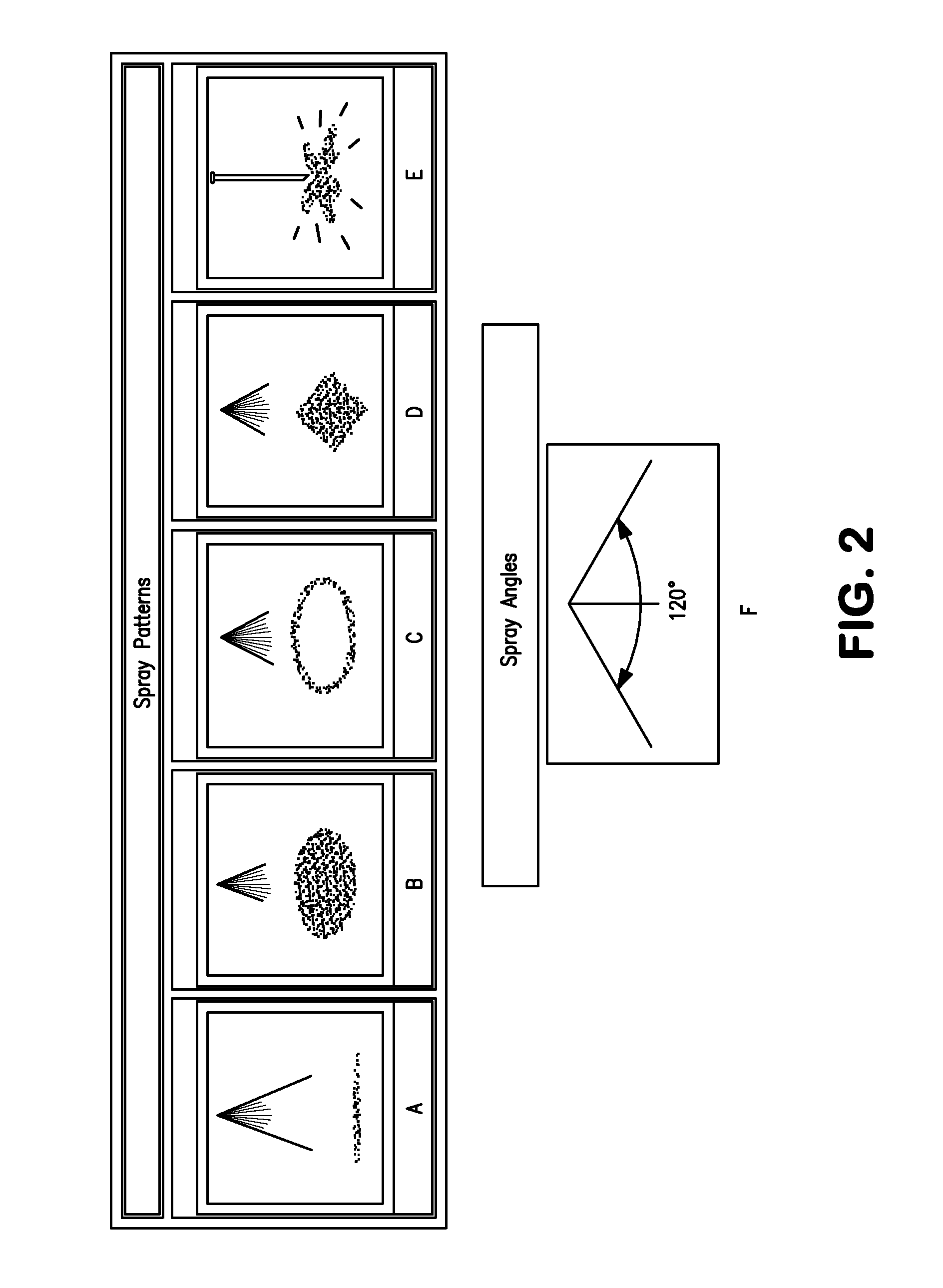

InactiveUS20120006312A1Suitable humidityPrevent crustingWorking accessoriesFine working devicesEngineeringWire saw

The present invention provides a self-cleaning wiresaw cutting apparatus including a cleaning mechanism adapted to clean the components of the wiresaw before, during, or after a cutting process or to humidify the cutting region of the apparatus. The apparatus contains at least one dispenser adapted to dispense an aqueous fluid onto various components of the wiresaw.

Owner:CABOT MICROELECTRONICS CORP

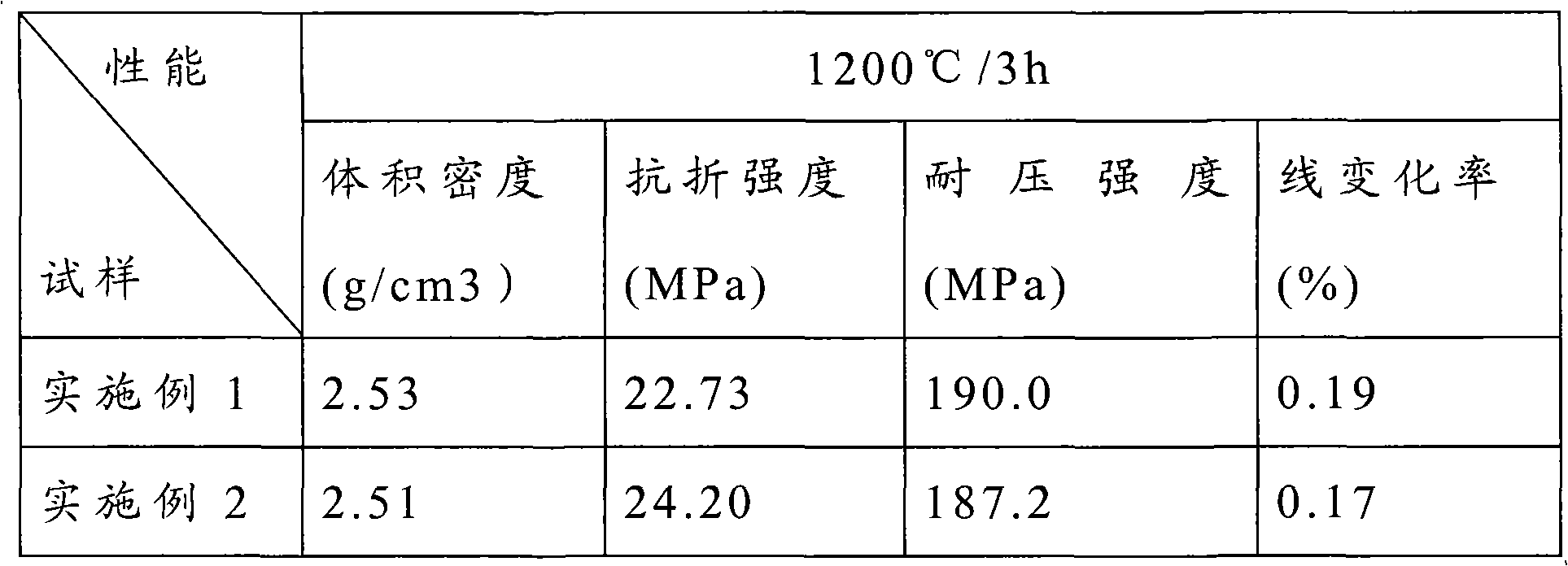

Silicon carbide anti-skinning castable and preparation method thereof

InactiveCN109987949AImproves Strength and ToughnessEnhanced expansion and contraction performanceSilica fumeMagnesium Aluminate

The invention discloses a silicon carbide anti-skinning castable and a preparation method thereof. The castable is prepared from the following raw materials in parts by weight: 20-25 parts of flint clay brick waste material, 18-23 parts of corundum brick waste material, 16-22 parts of magnesium aluminate spinel brick waste material, 7-12 parts of silicon carbide powder, 6-10 parts of silica fume,8-13 parts of aluminum oxide powder, 9-11 parts of calcium aluminate cement, 6-8 parts of silicon nitride powder, 0.1-0.25 part of explosion-proof fiber, 1-2 part of high-temperature binder, 0.5-1 part of water reducing agent and 6-9 parts of water. The preparation method of the castable comprises the following steps: crushing raw materials; preparing an initial mixture; and preparoffing the castable. The castable disclosed by the invention is good in anti-cracking performance; the silica fume reacts with oxygen at a high temperature to generate silicon oxide, so that large gaps between explosion-proof fibers and other substances are blocked, invasion and corrosion of other substances are avoided, the skinning resistance is good, and aluminum oxide can form an aluminum oxide protection layer on the outer side of the smooth surface of silicon nitride, so that the silicon nitride is prevented from reacting at a high temperature.

Owner:宜兴市泰科耐火材料有限公司

Highlight printing ink

The invention relates to highlight printing ink. The highlight printing ink includes, by mass, fluorine-modified polyurethane resin, a levelling agent, an oxidant, aluminum powder, an adhesion promoter, pigment, a defoamer, a dispersing agent, polyacrylate resin, modified nanometer titanium dioxide and a solvent. The highlight printing ink is good in adhesion force to polycarbonate automotive meter panel substrates, high in light reflection rate, waterproof, antifouling, and capable of effectively preventing crusting and granulation phenomena. The automotive meter panel substrates are provided with highlight and matt printing ink layers through screen printing, and the highlight printing ink and the matt printing ink are different in light reflection intensity, thus forming a visual sense difference and achieving a metal wire drawing effect.

Owner:绍兴百嘉汽车电子仪表有限公司

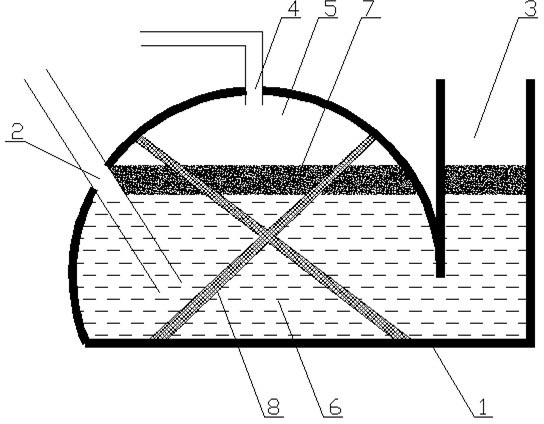

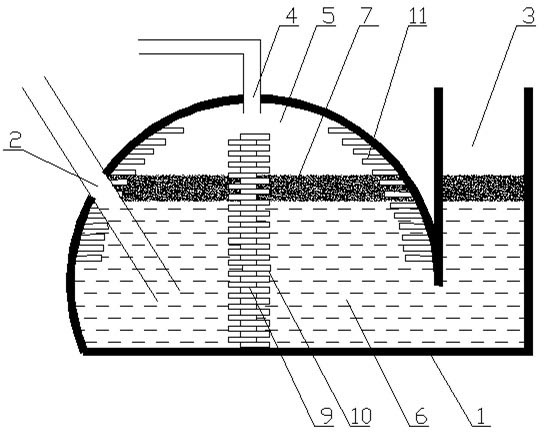

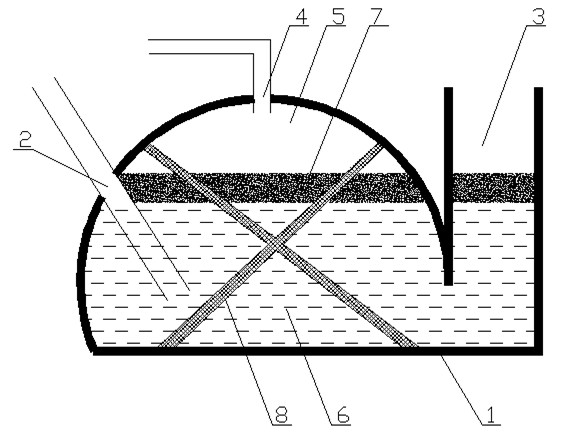

Anti-crusting biogas pool

InactiveCN102191172AImprove gas production efficiencyImprove securityBiochemistry cleaning apparatusGas production bioreactorsEnvironmental engineeringBiogas production

The invention discloses an anti-crusting biogas pool, which comprises a biogas pool body, wherein the biogas pool body has a feeding opening, a discharging opening and a biogas outlet; a gas chamber and a fermentation chamber are arranged up and down in the biogas pool body; the discharging opening is a hydraulic chamber; and a protruding object which protrudes from an inner wall surface and is used for scraping scum is arranged in the biogas pool body. In the invention, a hydraulic biogas pool is adopted, the protruding object is arranged in the biogas pool body, the protruding object scraps the scum on the surface of feed liquid in the fermentation chamber by using the rise and fall of the liquid surface in the fermentation chamber when the biogas is produced and used, and thus, the crusting of the scum is prevented and the biogas production efficiency and safety of the biogas pool are improved.

Owner:金海

Slag covering agent

The invention provides a slag covering agent which is composed of an introduction material of C and an introduction material of SiO2. The slag covering agent comprises, by weight, 40-95% of C, 5-20% of SiO2, 0-10% of Al2O3, 0-10% of CaO, 0-10% of MgO, 0-1.0% of water and 0-15% of impurities. The introduction material of C is one or two of blast furnace gas dust with the content of C being above 5%, gangue, carbonized rice hulls, pulverized coal and coke powder. The introduction material of SiO2 is one or two of pulverized coal with the content of SiO2 being above 10%, heating furnace waste sand, cast waste sand and carbonized rice hulls. The volume density of the slag covering agent is 0.55-2.90 g / cm<3>. The slag covering agent can effectively prevent the slag surface from crusting, direct outward heat dissipation of the slag surface is reduced, the slag outflow rate and the productivity are increased, the stability of slag surface components is guaranteed, and interference to target slag components and the subsequent product performance is avoided. Meanwhile, the operation time for subsequent temperature increase can be shortened, energy consumption can be lowered, and use cost can be reduced.

Owner:ANGANG STEEL CO LTD

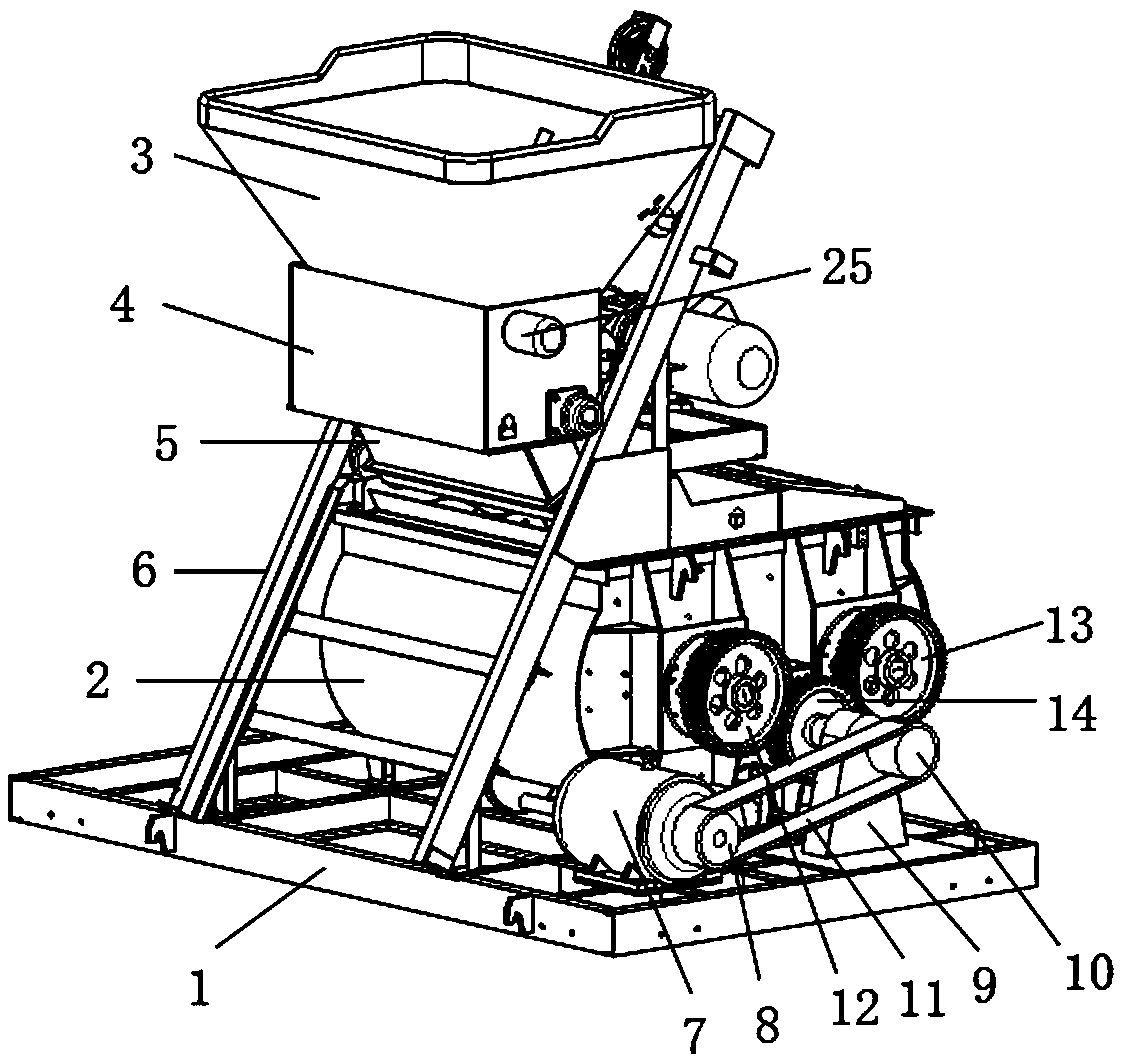

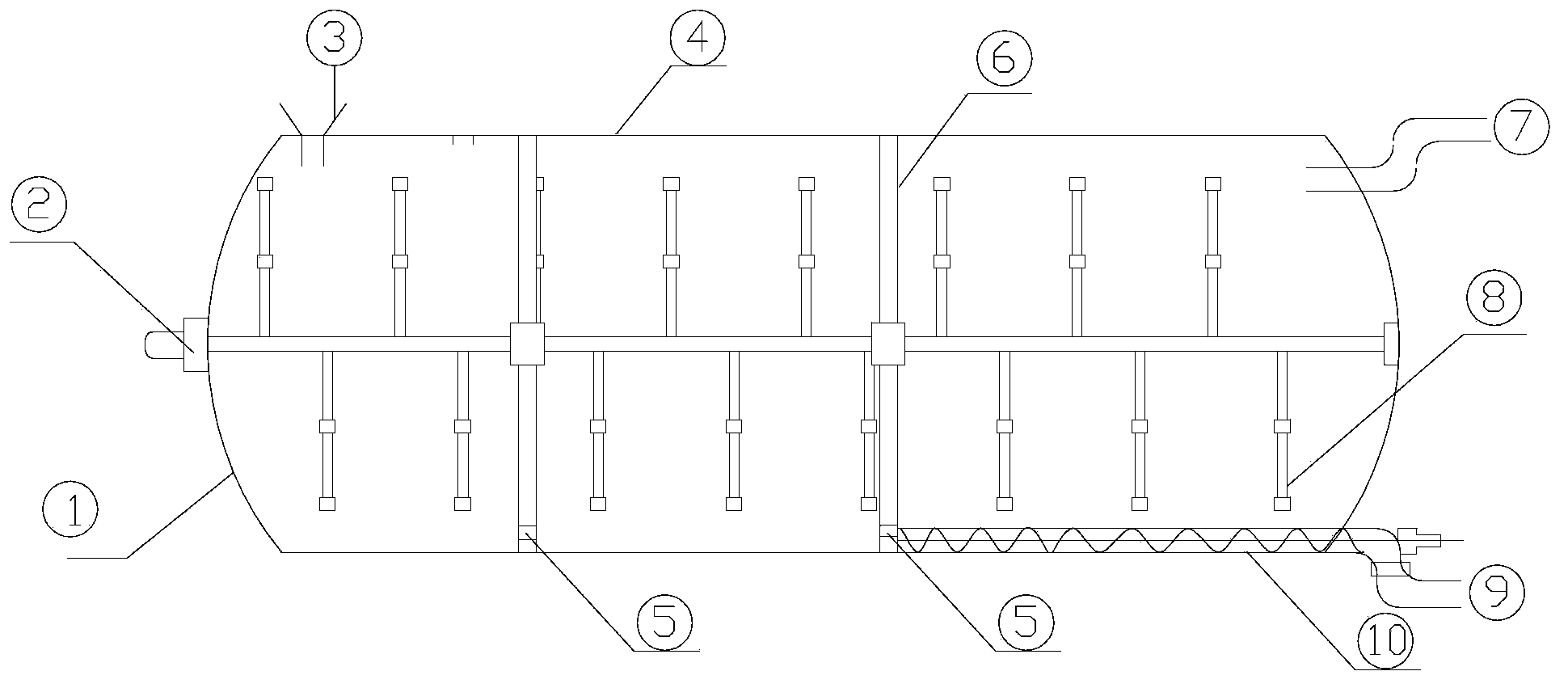

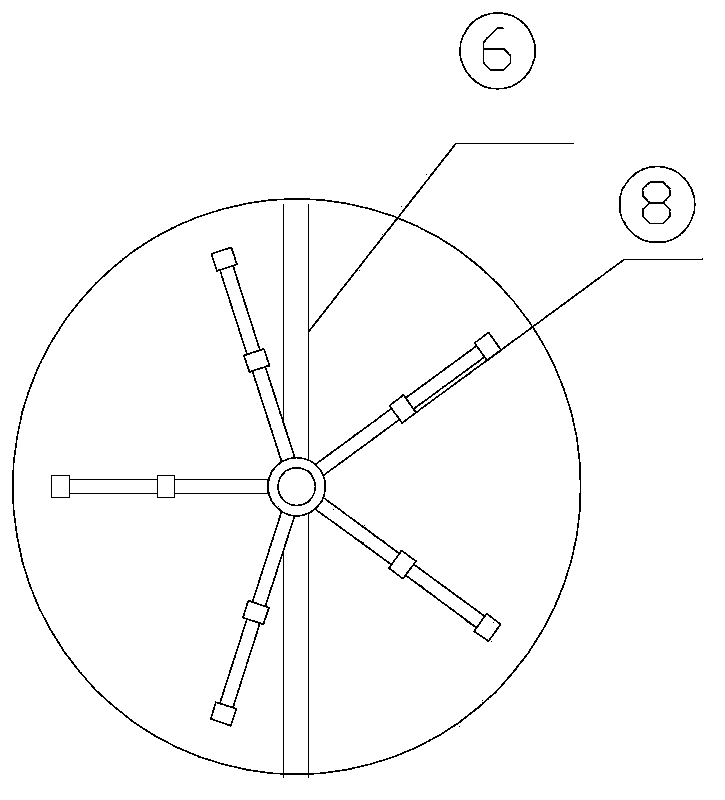

Efficient dry-type anaerobic fermentation equipment for organic solid waste

InactiveCN103881901ALow costCompact structureGas production bioreactorsWaste based fuelSlagSmall footprint

An efficient dry-type anaerobic fermentation equipment for organic solid waste is disclosed. A horizontal main tank is provided with a material inlet, a slag outlet, a gas outlet and a liquid outlet; the main tank is inside divided into multiple fermentation chambers by separation plates, a stirrer is horizontally inserted along the center of the main tank, the bottom of the main tank is provided with a biogas discharging device which is communicated with the slag outlet, and the bottom of each separation plate is provided with a communicating pore. The efficient dry-type anaerobic fermentation equipment is high in organic loading, high in gas production efficiency, small in land occupation area and low in energy consumption, and also helps to avoid problems of biogas residue crusting and secondary pollution existed in wet-type anaerobic fermentation.

Owner:TIANJIN DESHENGYUAN ENVIRONMENT ENG

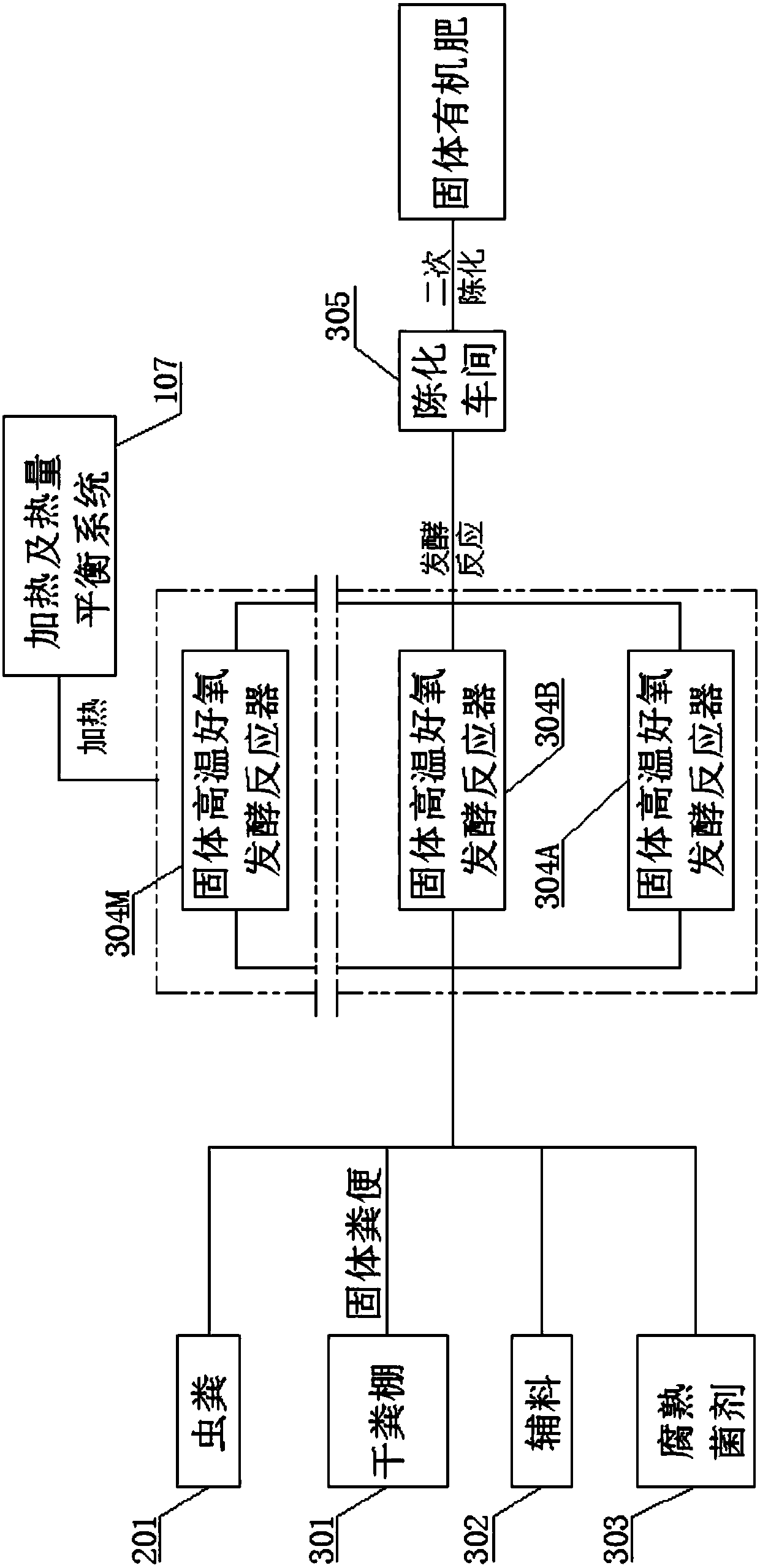

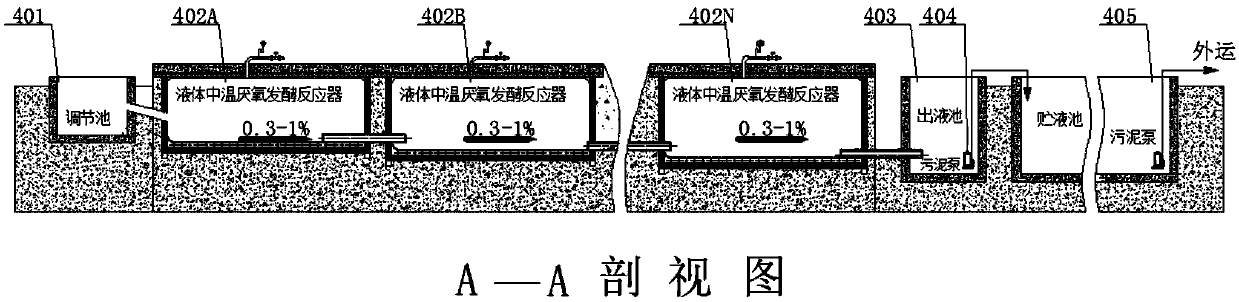

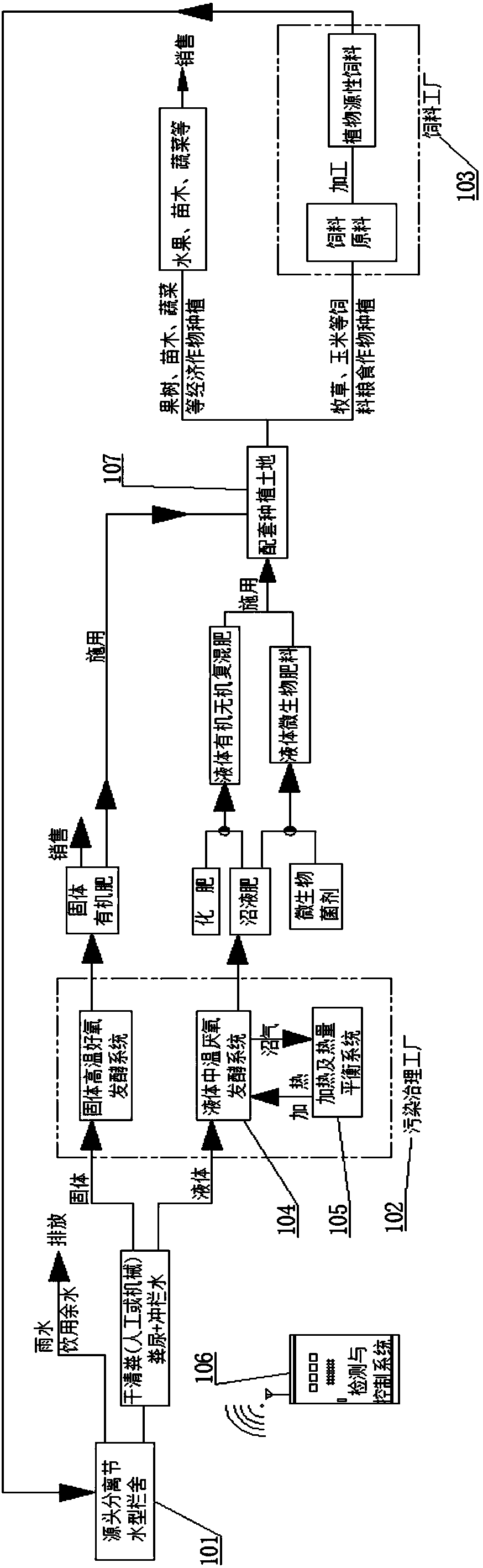

Ecological management system and ecological management method for excrement liquid of livestock and poultry

ActiveCN107651822ASolve pollutionSustainability does not harmExcrement fertilisersGas production bioreactorsEcological environmentInorganic compound

The invention relates to an ecological management system for excrement liquid of livestock and poultry. The ecological management system comprises a source-separation water-saving house, a pollution treatment factory, a fodder factory and an auxiliary planting land. The pollution treatment factory comprises a high-temperature solid aerobiotic-fermentation system, a middle-temperature liquid anaerobic-fermentation system, a heating and heat balance system and a detection control system. A regulation pool is connected with a feed inlet of the middle-temperature liquid anaerobic-fermentation system through a delivery pump, methane generated by the middle-temperature liquid anaerobic-fermentation system is delivered to the heating and heat balance system, and the heating and heat balance system is connected a heating coil of the middle-temperature liquid anaerobic-fermentation system through a pipeline. The ecological management system has the advantages that finished products, namely liquid organic and inorganic compound fertilizer and liquid microbial fertilizer, of the pollution treatment factory are used for irrigation and drop irrigation of plants planted on the auxiliary plantingland, and pastures are taken as fodder raw materials for the fodder factory, so that cultivation cost is reduced, nutrition level of fodder is improved, and harmonious development of the breeding industry and the biological environment is promoted.

Owner:汪深

Water-retaining agent and preparation method thereof

ActiveCN106947494AImprove permeabilityEnhance water storage capacityOrganic fertilisersSoil conditioning compositionsFiberSulfate

The invention relates to a water-retaining agent and a preparation method, specifically to a water-retaining agent containing aloe gel and a preparation method thereof. The water-retaining agent is prepared from the following raw materials (by weight): 3-10 parts of aloe gel, 10-20 parts of humus, 50-70 parts of plant fiber, 10-20 parts of starch, 2-3 parts of ferric sulfate, 25-35 parts of acrylic acid, 7-15 parts of acrylamide, and 80-120 parts of 27-37% aqueous alkali. The water-retaining agent provided by the invention is environment-friendly, has advantages of simple process and strong water retaining capacity, and can provide nutrients essential for growth of plants, and has effects of fixing sand and preserving water and improving soil.

Owner:SICHUAN LYUDA ENVIRONMENTAL PROTECTION SCI & TECH DEV

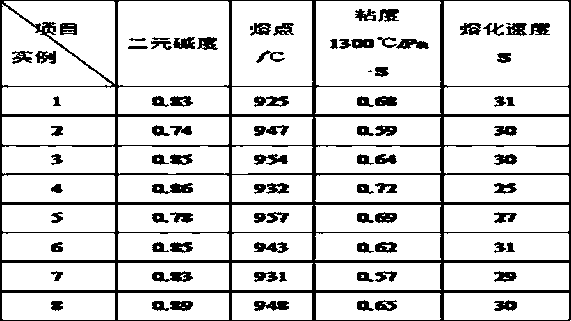

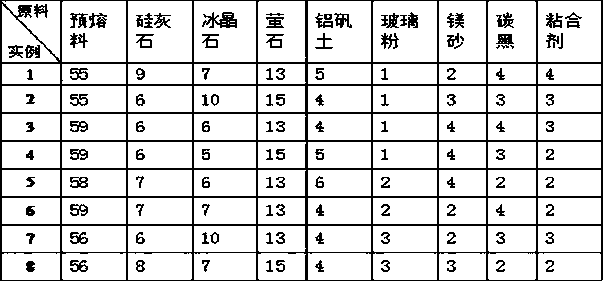

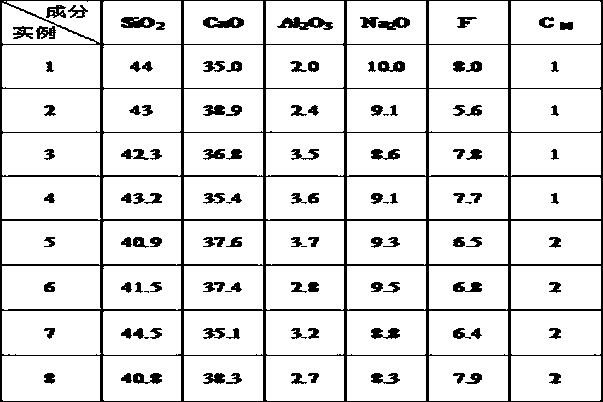

Continuous casting crystallizer casting powder for 400 stainless steel

InactiveCN108160960AEnables lubrication and heat transferAchieve lubricationCarbon steelChemical composition

The invention belongs to the technical field of steel making, and particularly relates to continuous casting crystallizer casting powder for 400 stainless steel. The continuous casting crystallizer casting powder for 400 stainless steel comprises the chemical components of, by weight percentage, 35-40% of CaO, 40-48% of SiO2, 2.0-4.0% of Al2O3, 8-10% of Na2O, 5-8% of F- and 1-2% of solid C. The chemical components of the continuous casting crystallizer casting powder for 400 stainless steel are used cooperatively, a proper smelting speed is kept while the heat preservation function is guaranteed, and an obtained casting blank is smooth in surface, regular in folding mark and free of concaves or other quality problems.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com