Process for preparing alkyd resin coating

A technology of alkyd resin and preparation process, which is applied in the field of preparation technology of ionic liquid application, can solve the problems of mixing and inputting together, affecting the drying performance of paint film, performance failure, etc., achieving less environmental pollution, and facilitating the control and production of process conditions Manage and simplify the effect of operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

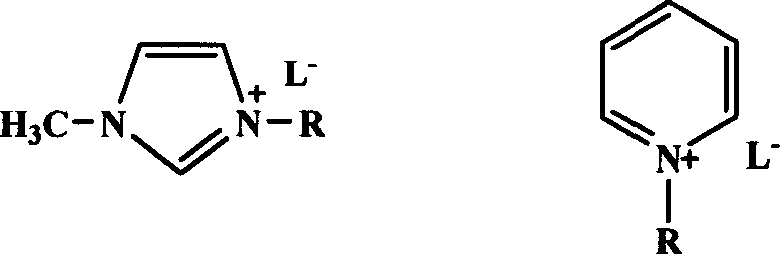

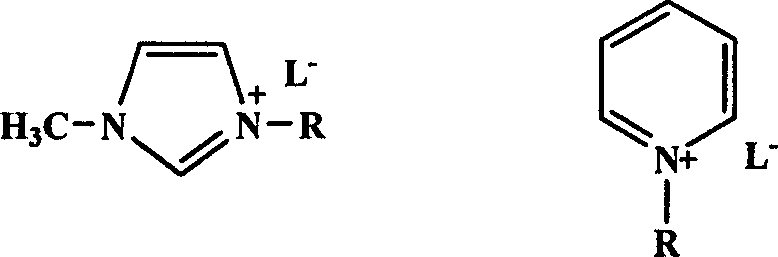

[0024] Embodiment 1 uses 1-butyl-3-methylimidazolium acetate ionic liquid

[0025] Add 34.3 parts of soybean oil, 26.3 parts of glycerin, and 2 parts of ionic liquid into the reactor, raise the temperature to 100°C, stir for 3 hours, add 39.4 parts of phthalic anhydride, 3 parts of toluene, heat up and reflux until the reaction temperature reaches 220°C, react for 3 hours, and take a sample After measuring the acid value ≤ 20mg KOH / g, lower the temperature, dilute with xylene according to the requirements of the resin coating, and discharge the material with a viscosity ≤ 18s.

Embodiment 2

[0026] Embodiment 2 uses ethylpyridine acetate ionic liquid

[0027] Add 34.3 parts of soybean oil, 26.3 parts of glycerin, and 1 part of ionic liquid into the reactor, raise the temperature to 80°C, stir for 3 hours, add 39.4 parts of phthalic anhydride, 5 parts of xylene, heat up and reflux until the reaction temperature reaches 220°C, and react for 3 hours. After taking a sample to determine the acid value ≤ 20mg KOH / g, cool down, dilute with xylene according to the requirements of the resin coating, and discharge the material with a viscosity ≤ 18s.

Embodiment 3

[0028] Embodiment 3 uses ethylpyridine hexafluorophosphate ionic liquid

[0029] Add 34.3 parts of linseed oil, 26.3 parts of glycerin, and 5 parts of ionic liquid into the reactor, raise the temperature to 100°C, stir for 3 hours, add 39.4 parts of phthalic anhydride, 6 parts of toluene, heat up and reflux until the reaction temperature reaches 220°C, and react for 3 hours. After taking a sample to determine the acid value ≤ 20mg KOH / g, cool down, dilute with xylene according to the requirements of the resin coating, and discharge the material with a viscosity ≤ 18s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com