Continuous and automatic production line of polyurethane adhesive and production method thereof

An automatic production line and adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as skinning and affect product quality, to avoid skinning, high production efficiency, and ensure cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

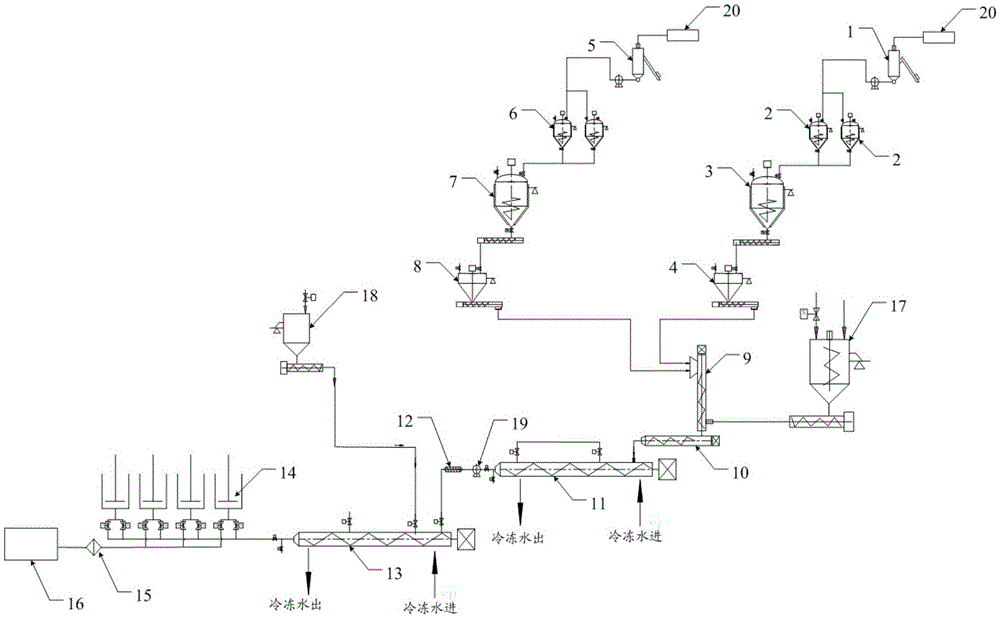

[0033] The embodiment of the invention discloses a continuous automatic production line and a production method of polyurethane adhesive, which can solve the problem of skinning caused by material contacting air in the existing intermittent production process of polyurethane adhesive, which affects product quality.

[0034] see figure 1 , in the embodiment of the present invention, a continuous automatic production line of polyurethane adhesive comprises:

[0035] The calcium powder unpacking machine 1, the calcium powder drying tank 2, the calcium powder cooling powder bin 3 and the calcium powder metering tank 4 are connected through pipelines in turn;

[0036] The carbon black powder unpacking machine 5, the carbon black powder drying tank 6, the carbon black powder cooling powder bin 7 and the carbon black powder measuring tank 8 are sequentially connected by pipelines;

[0037] The side feeder 9, the premix screw machine 10, the first-stage screw machine 11, the high-vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com