Production device capable of achieving continuous automatic production of semi-tempered plate vacuum glass

A technology for production equipment and vacuum glass, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of high energy consumption, low vacuum degree, inconsistent vacuum degree, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

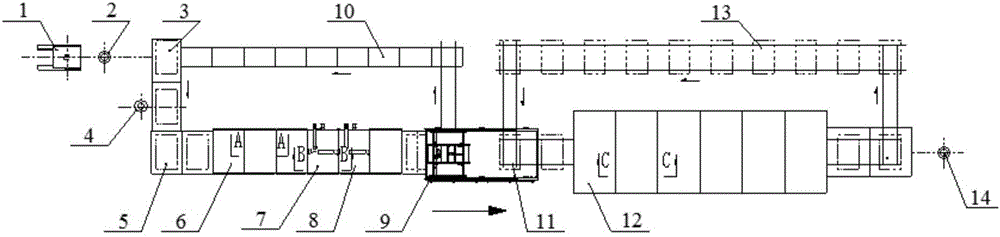

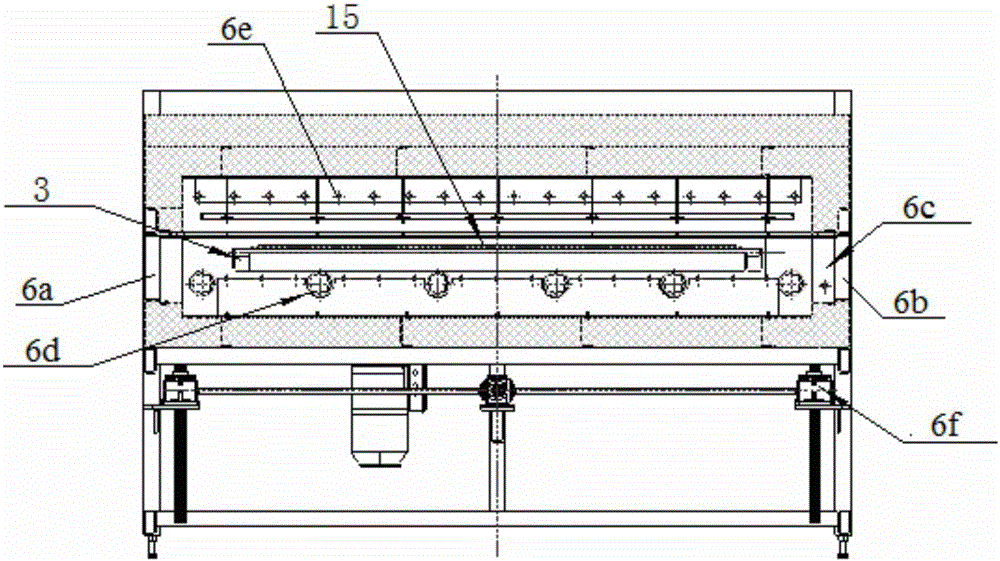

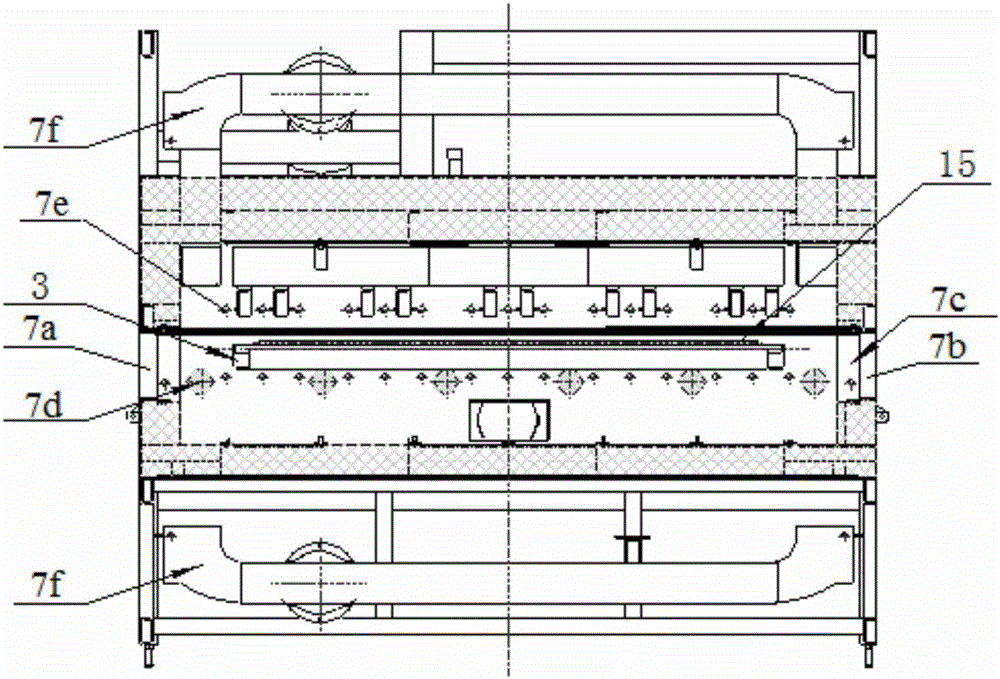

[0026] Such as Figure 1-4 As shown, the production equipment that can realize the continuous automatic production of semi-tempered flat vacuum glass includes: stepping film loading device 1, film loading robot 2, first transmission system, tray 3, point distribution and gluing mechanism 4, corner mechanism 5, Heating edge banding device 6, semi-tempering device 7, cooling device 8, edge banding glass translation mechanism 9, tray rotation mechanism 10, second transmission system, vacuum sealing car 11, vacuum sealing heating device 12, vacuum sealing car rotation Mechanism 13, unloading robot 14; several trays 3 are arranged on the first transmission system, and several vacuum sealing vehicles 11 are arranged on the second transmission system.

[0027] In the production process, it is divided into two stages: the first stage involves point distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com