Patents

Literature

105results about How to "Realize automatic receiving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for real-time online game, method and device for game watching, and system

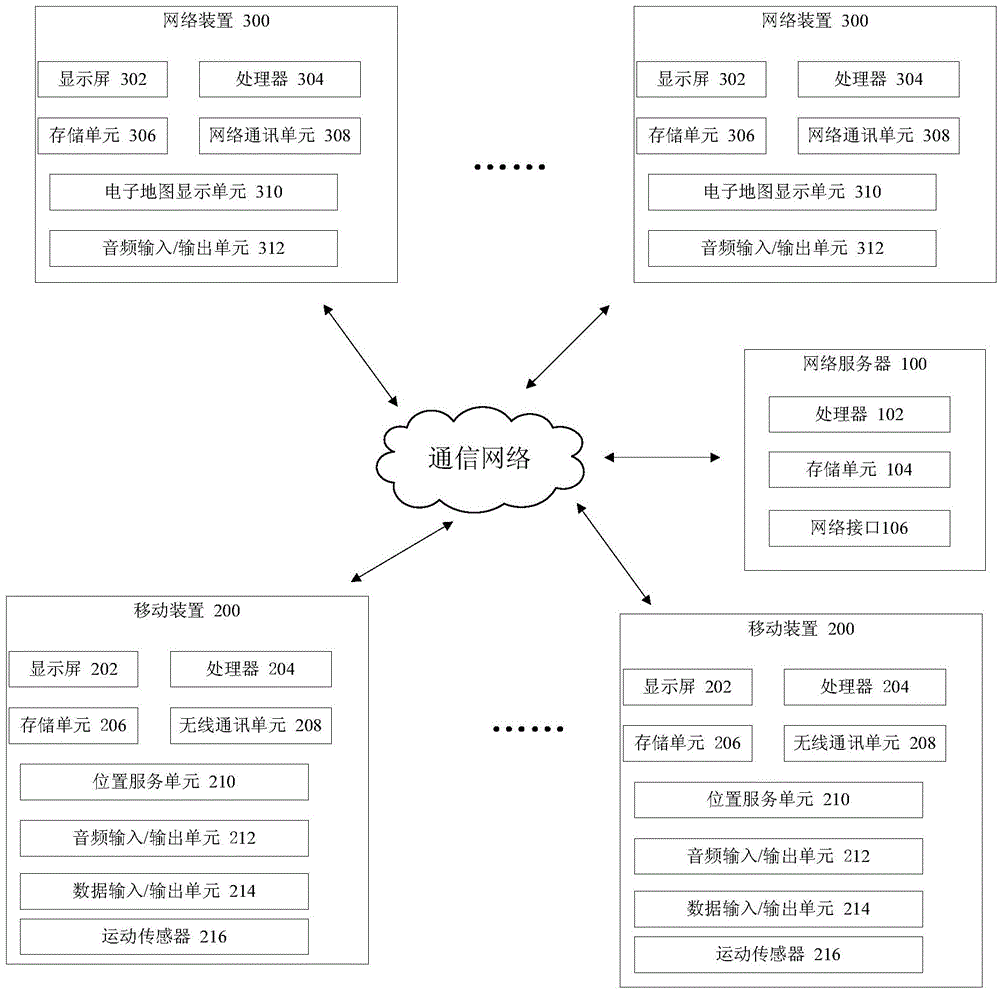

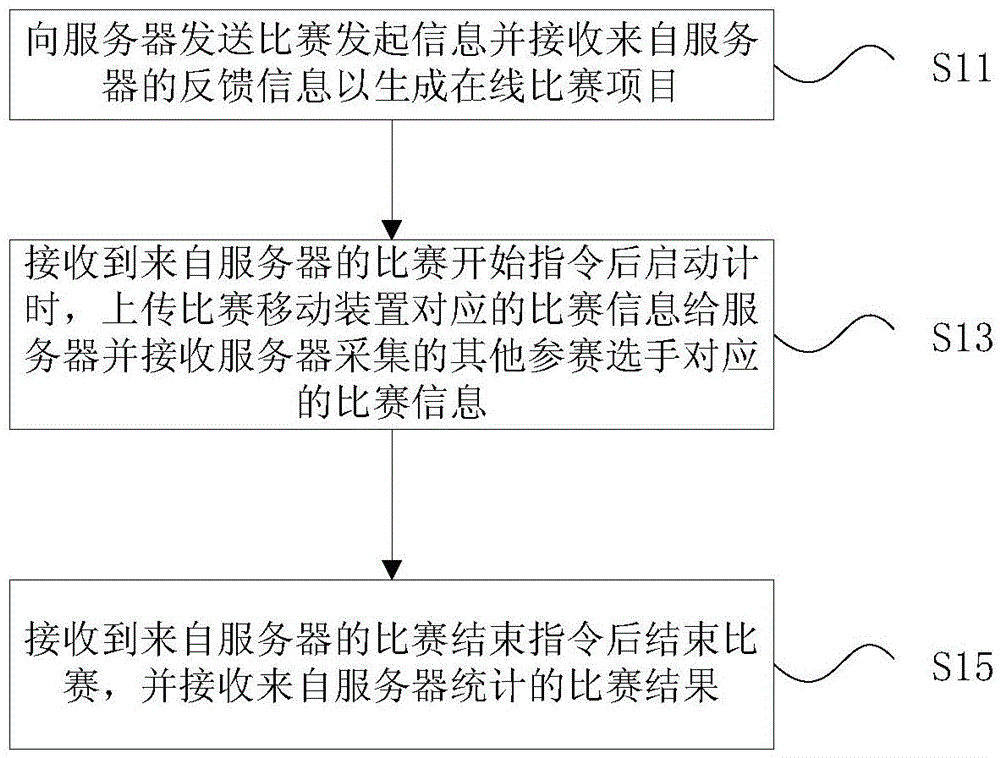

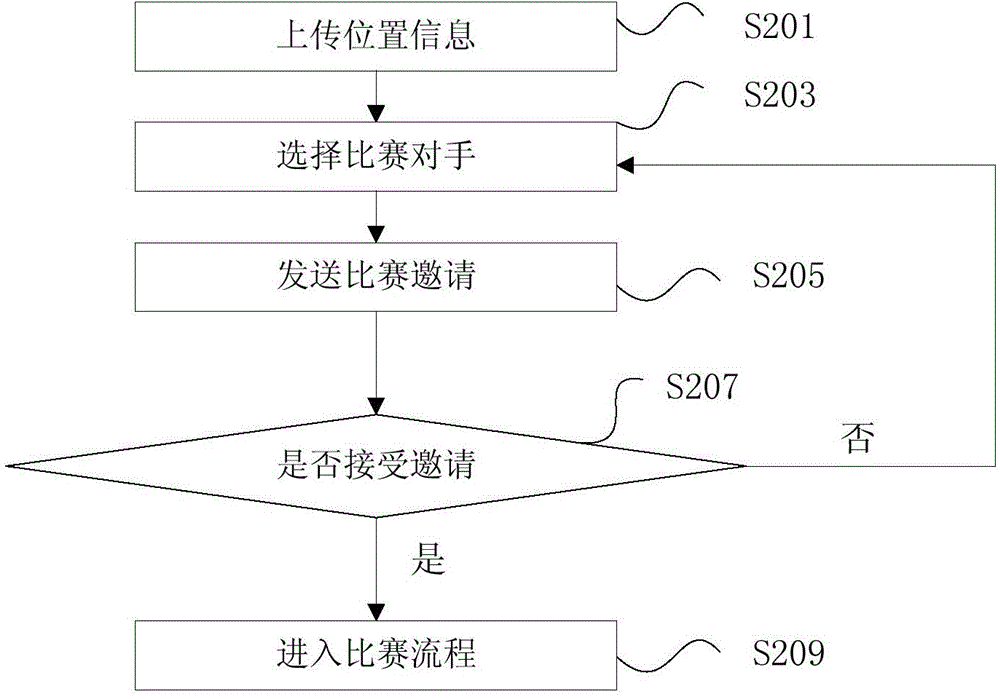

ActiveCN104640072ARealize remote matching competitionRealize real-time trackingData processing applicationsServices signallingMobile deviceComputer science

The invention discloses a method and a device for real-time online game, a method and a device for game watching, and a system. The method and the device for the real-time online game, the method and the device for the game watching, and the system have the advantages that by sending game sponsoring information to a server, the range of game participators of an online game project is widened, and the limitation of contact persons on a self directory of a mobile device is broken, so the different-place matching game of a plurality of users on a network is realized; the starting and finishing of the game are controlled by the server, and the real-time game information corresponding to each game participator is received by the server, so the real-time tracking of the competitive state of each game participator in the game process is realized, and the game result is automatically received the first time after the game is finished; by utilizing a network device, the game information is found in real time, and the encouraging information is sent to the corresponding game participator; the different-place real-time game is realized, the real-time property of the game result is high, and the interesting and activity of all people participating in the sports are favorably improved.

Owner:HUNAN JIANCHENG INFORMATION TECH

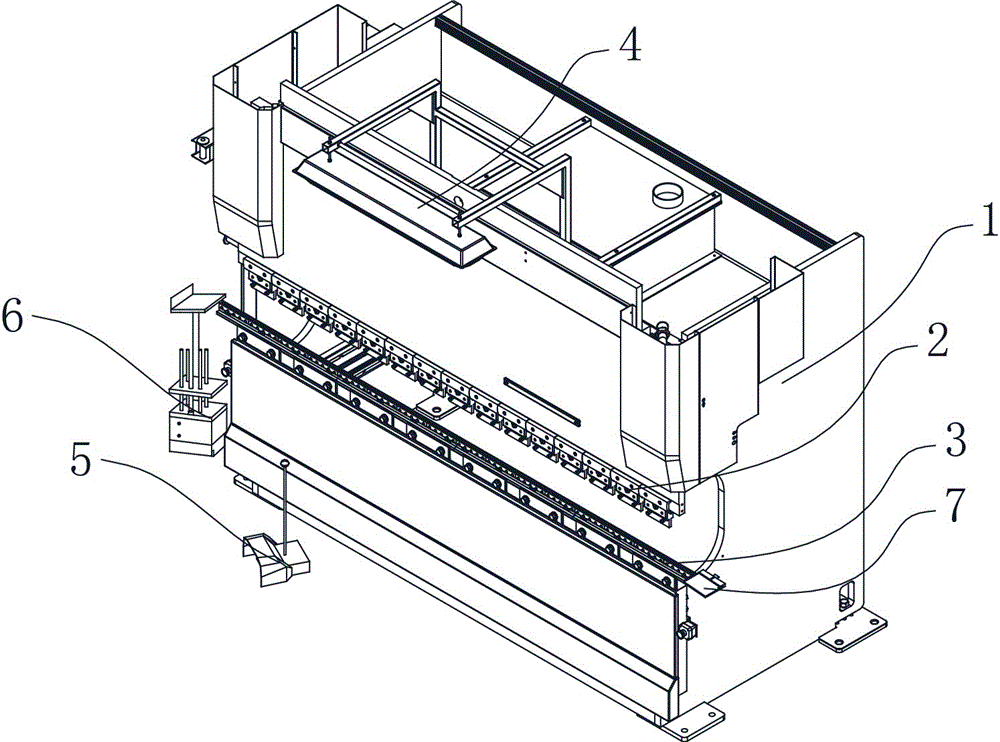

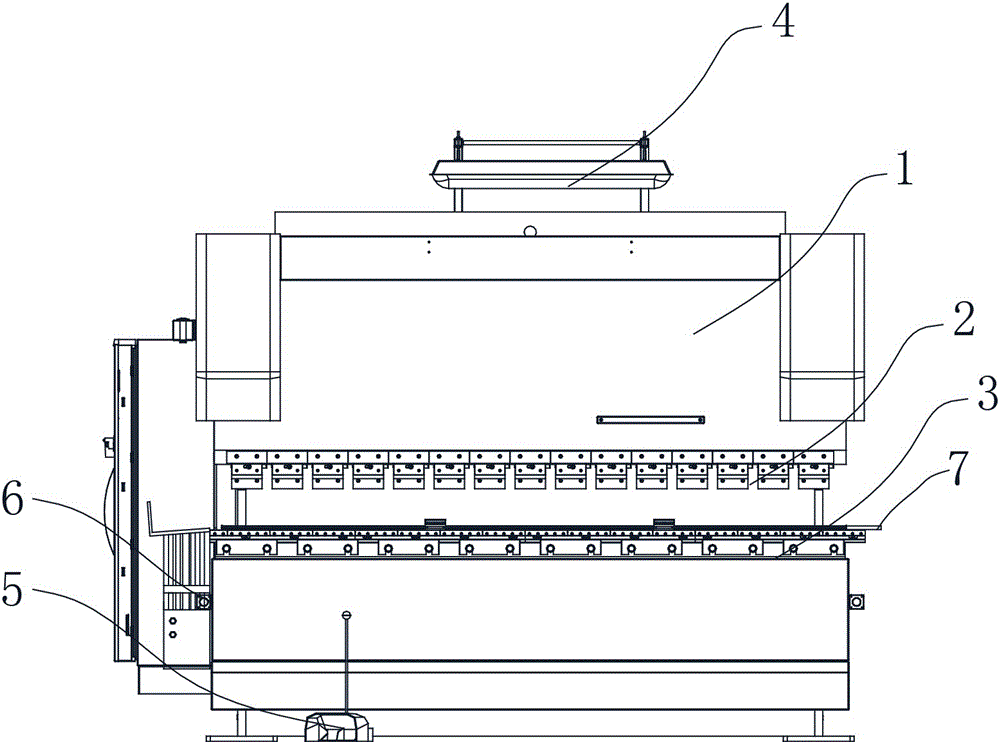

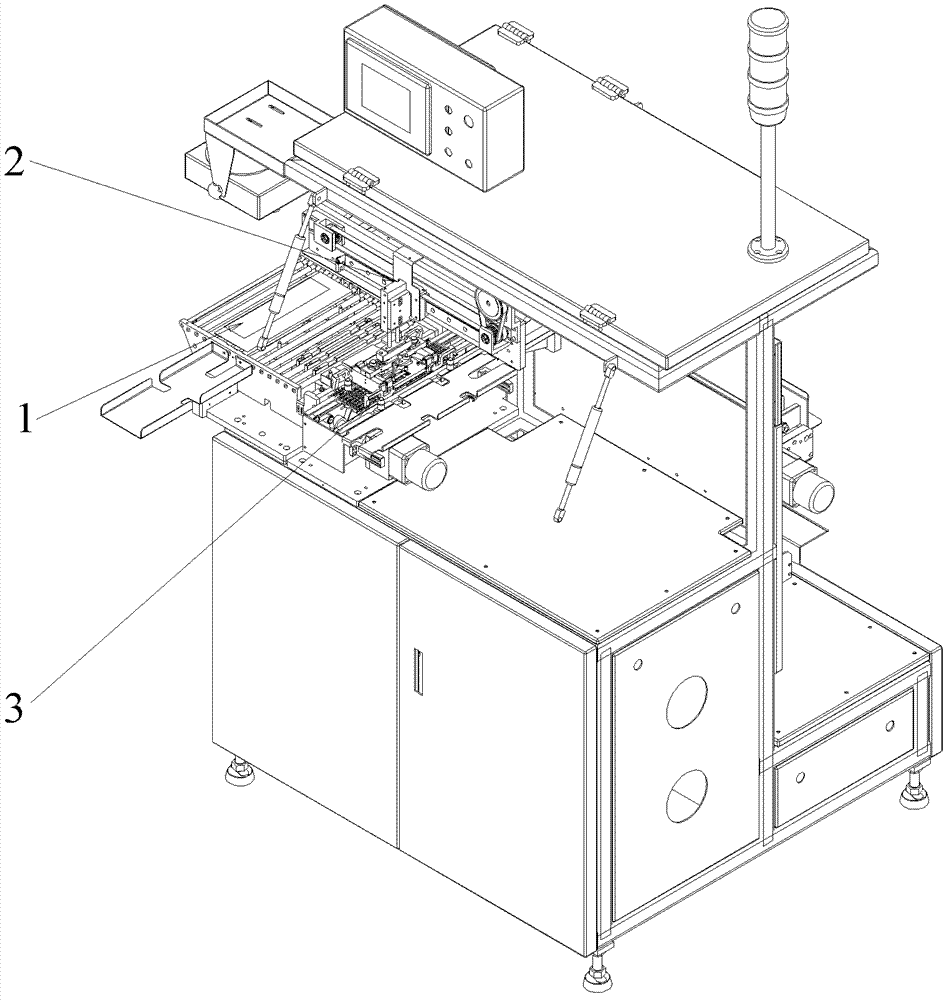

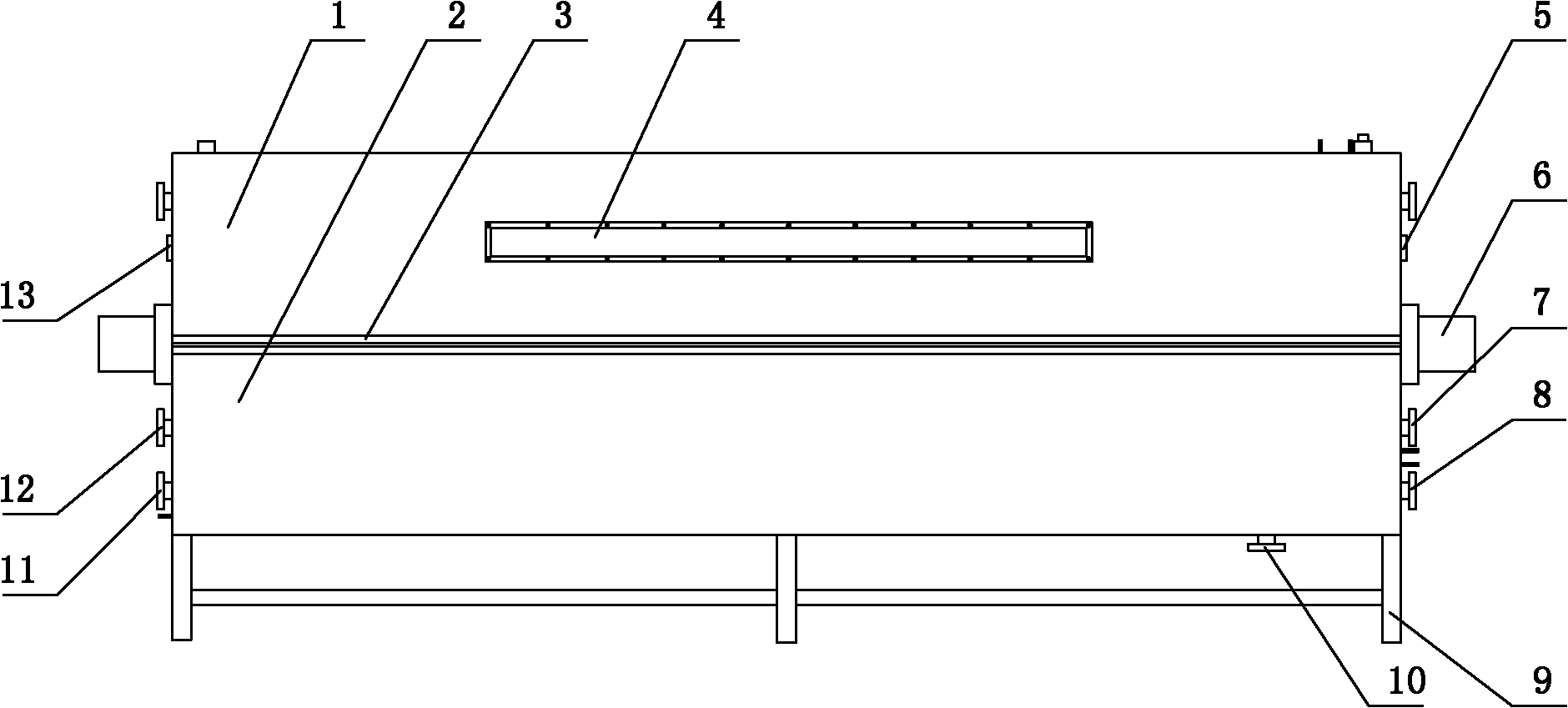

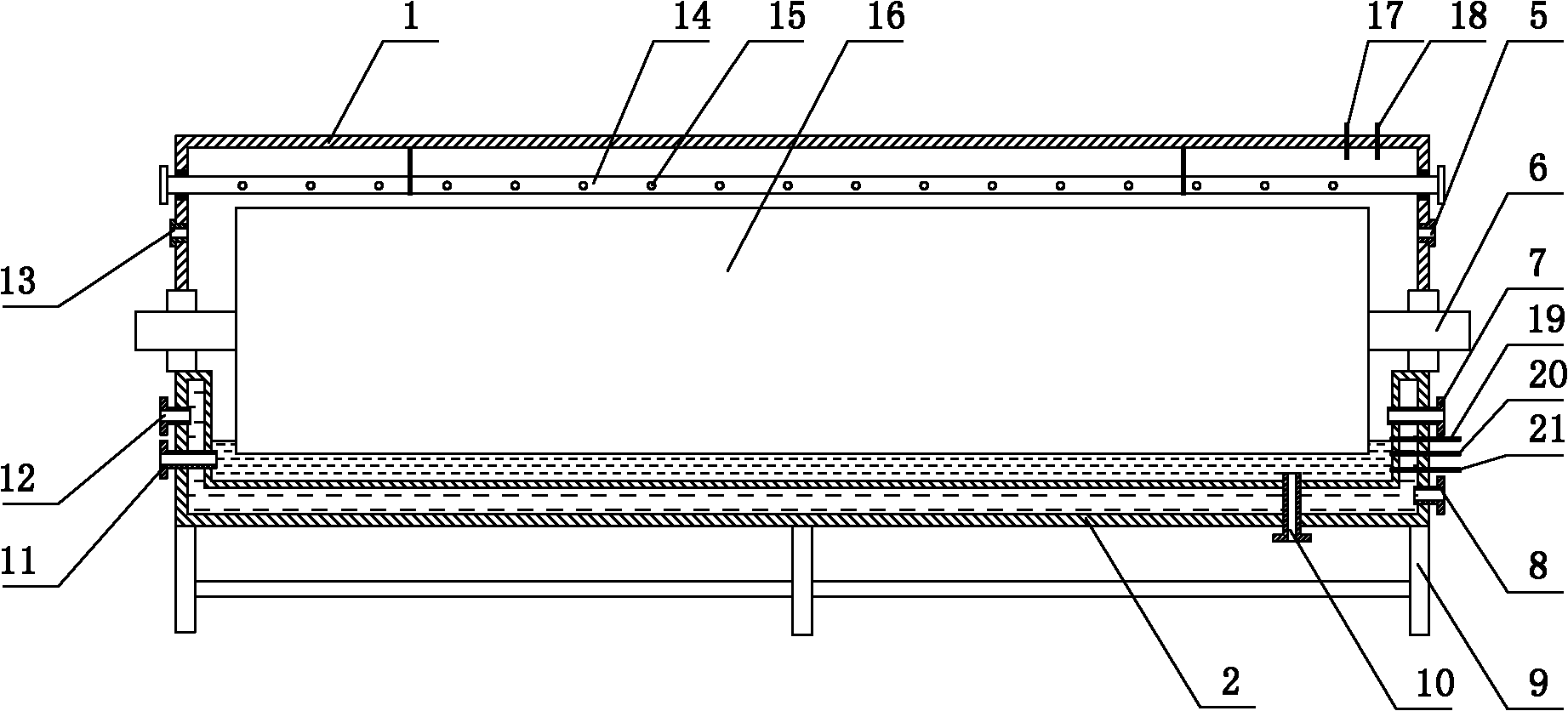

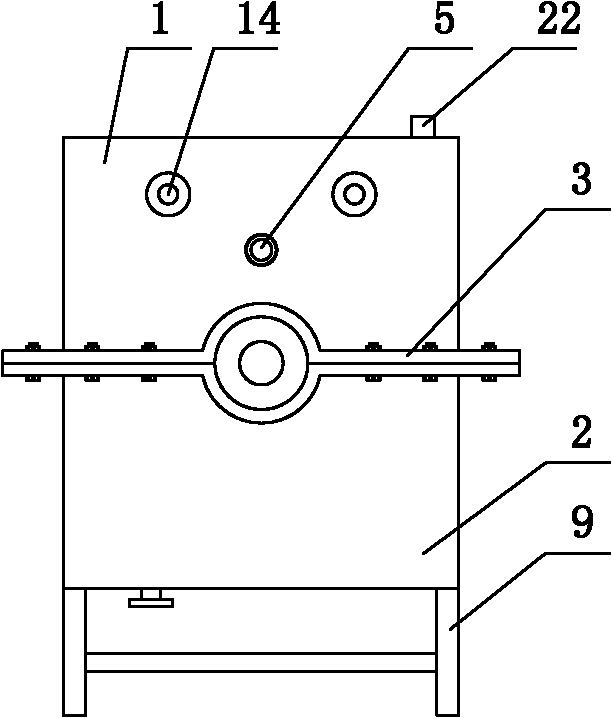

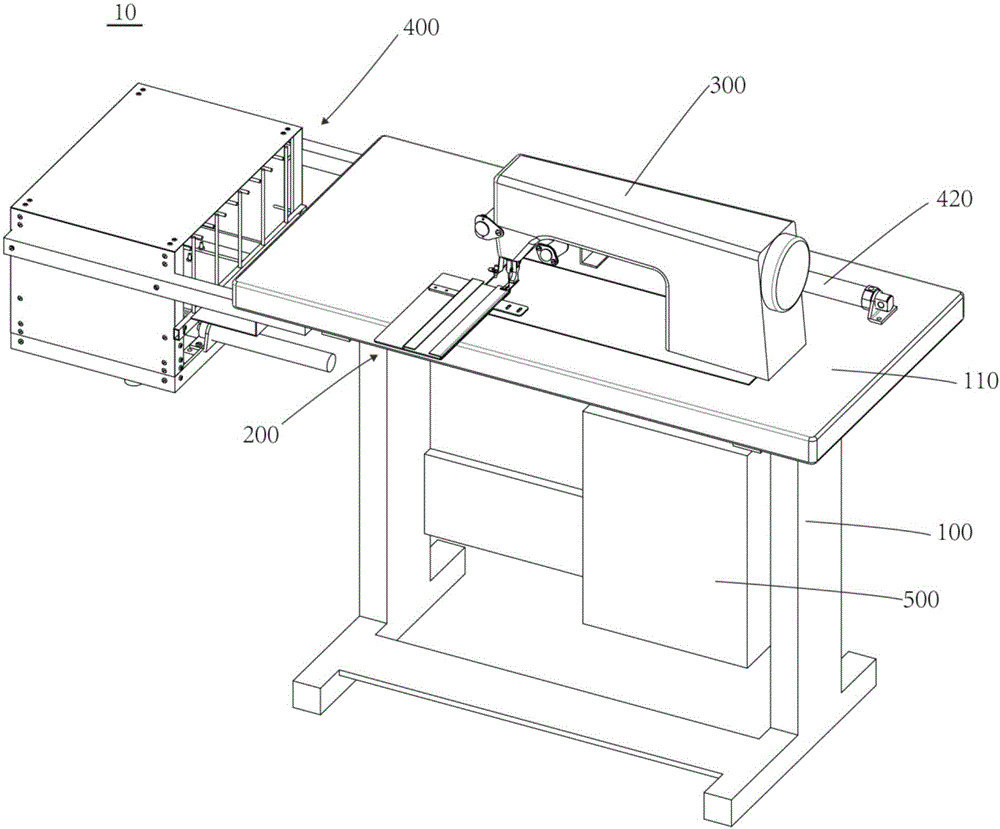

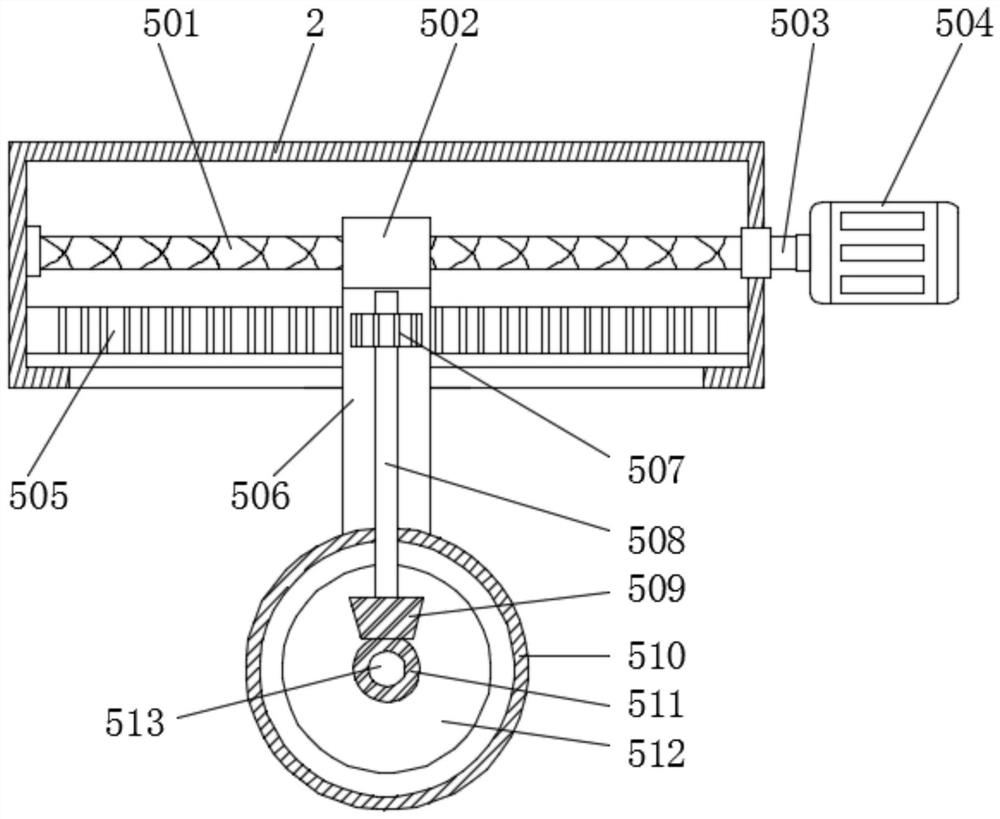

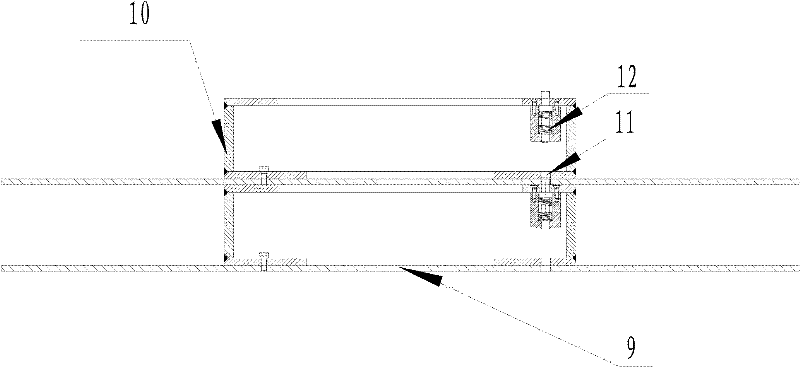

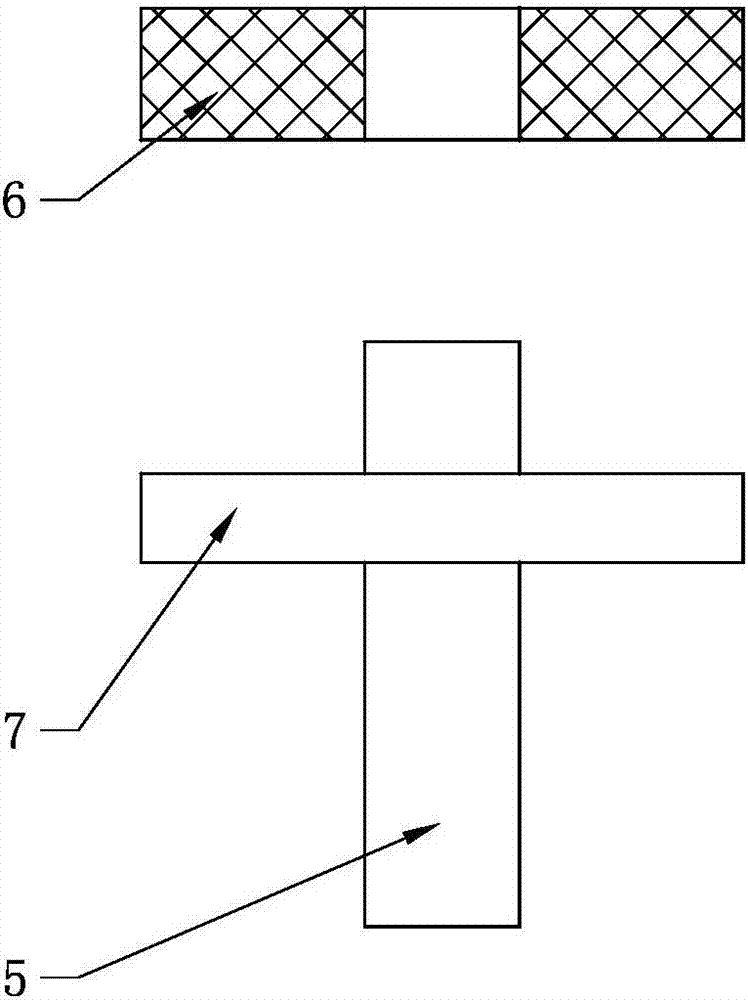

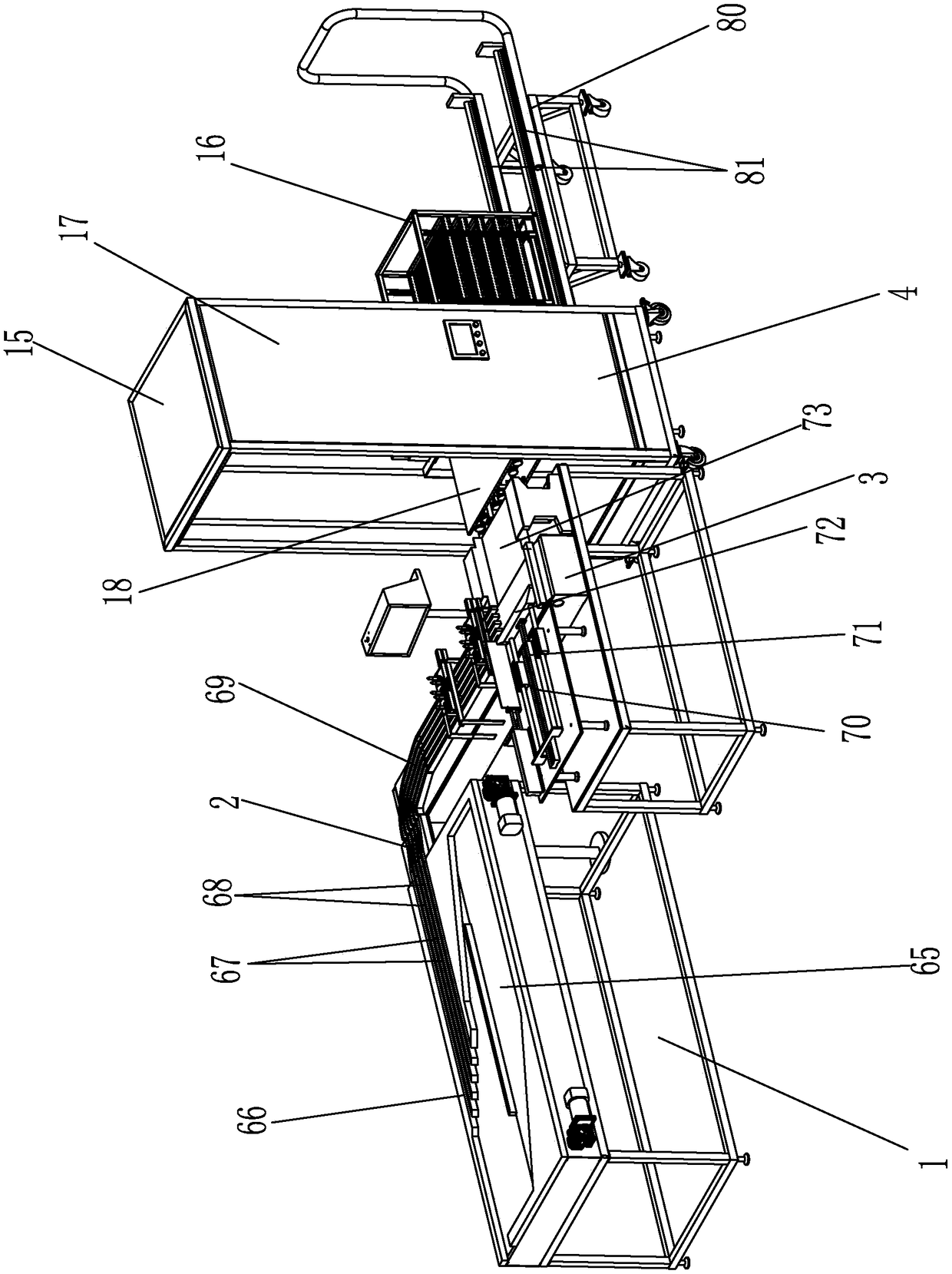

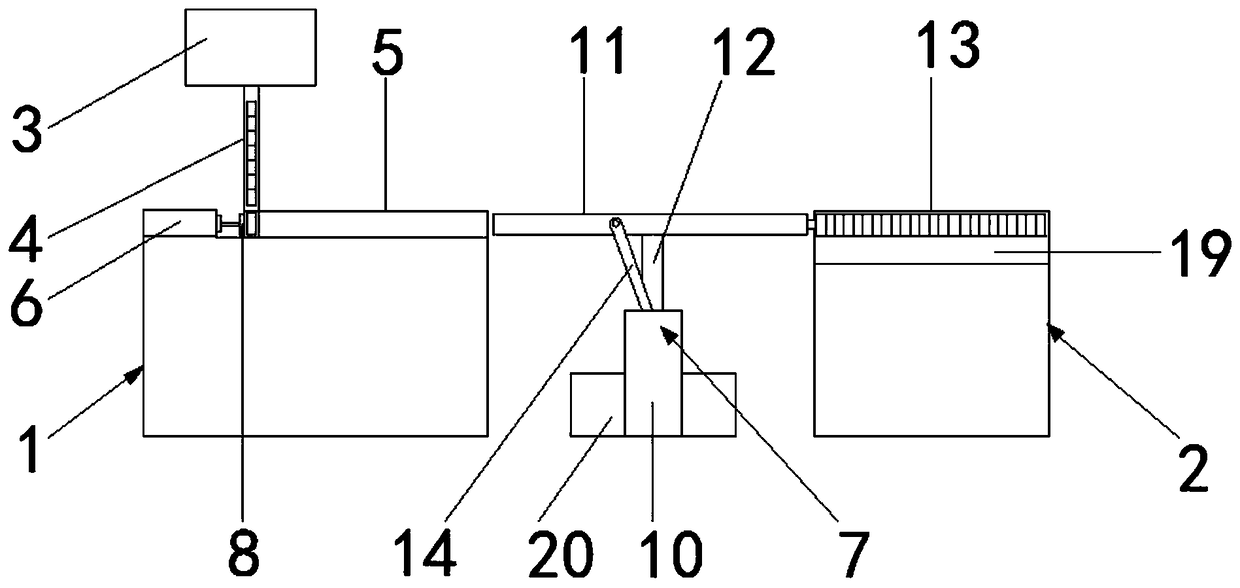

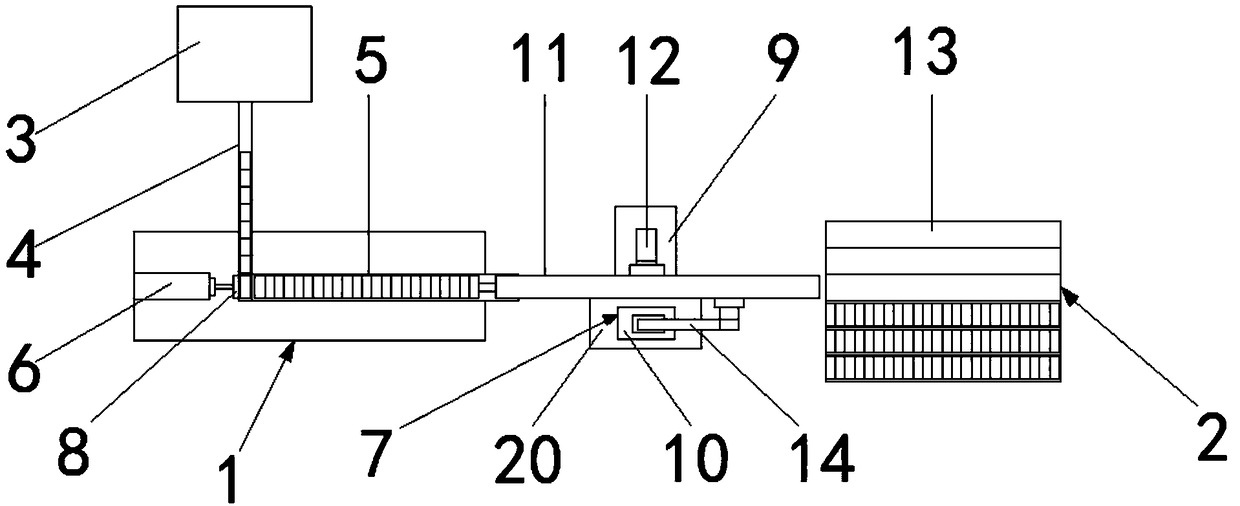

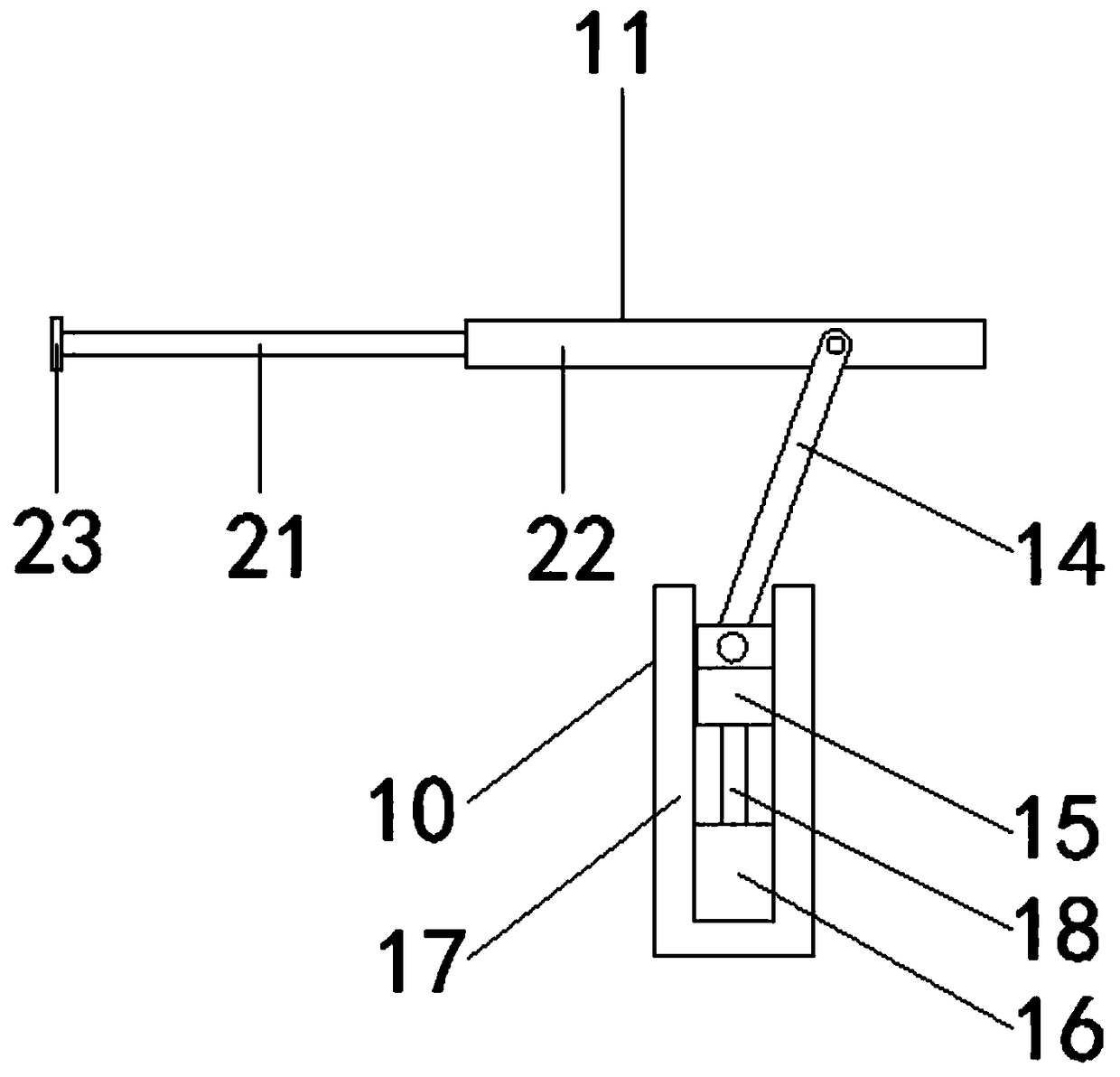

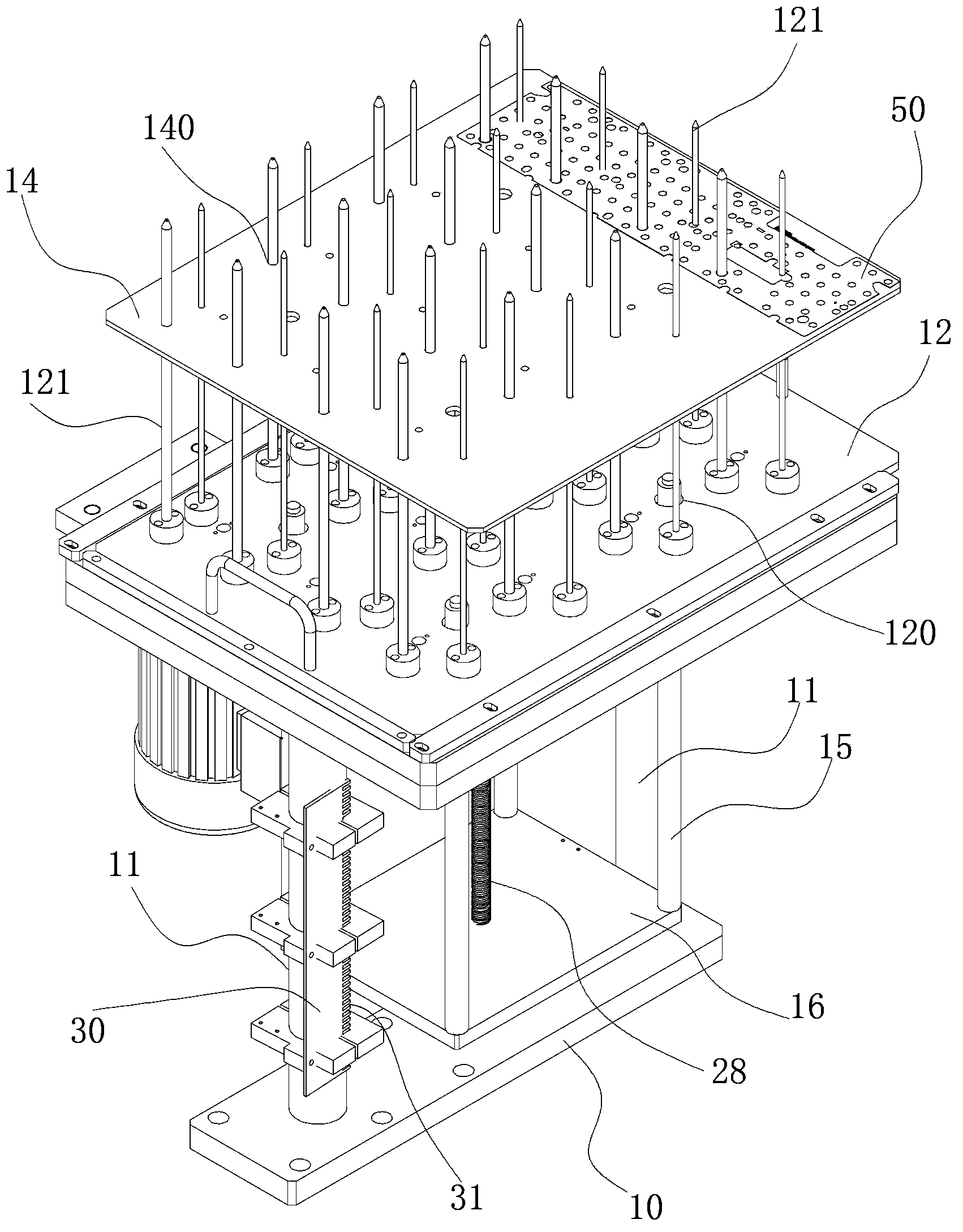

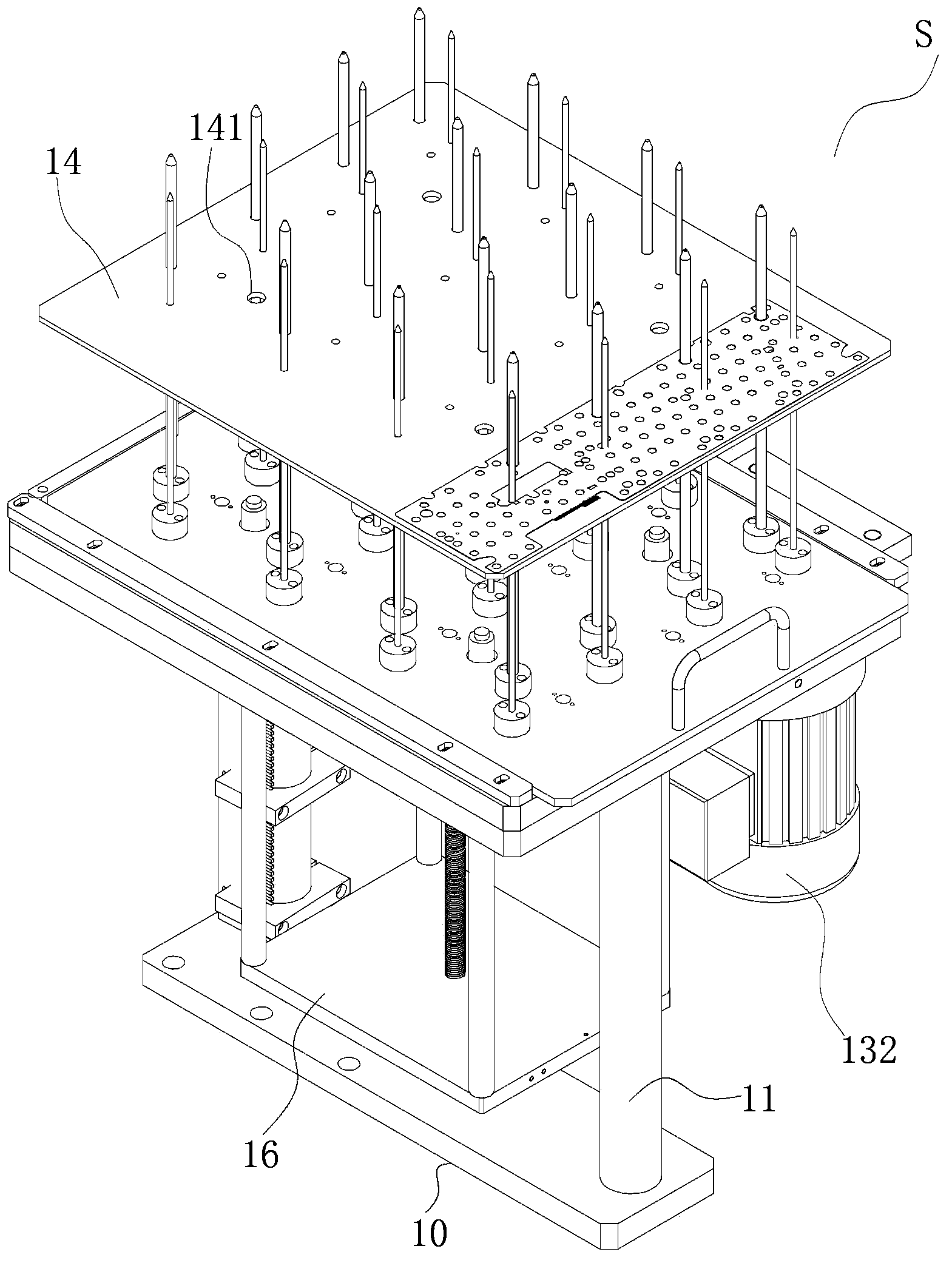

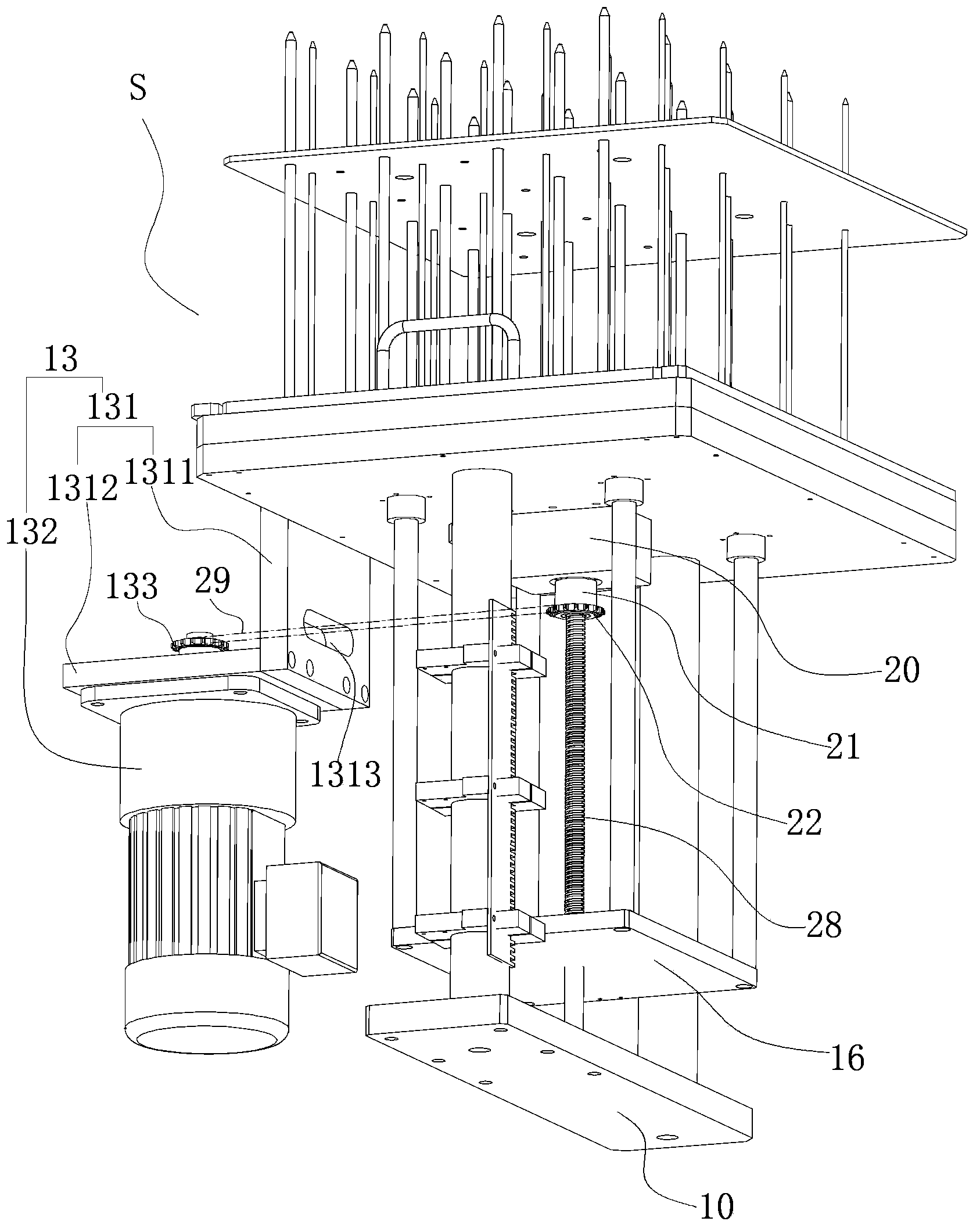

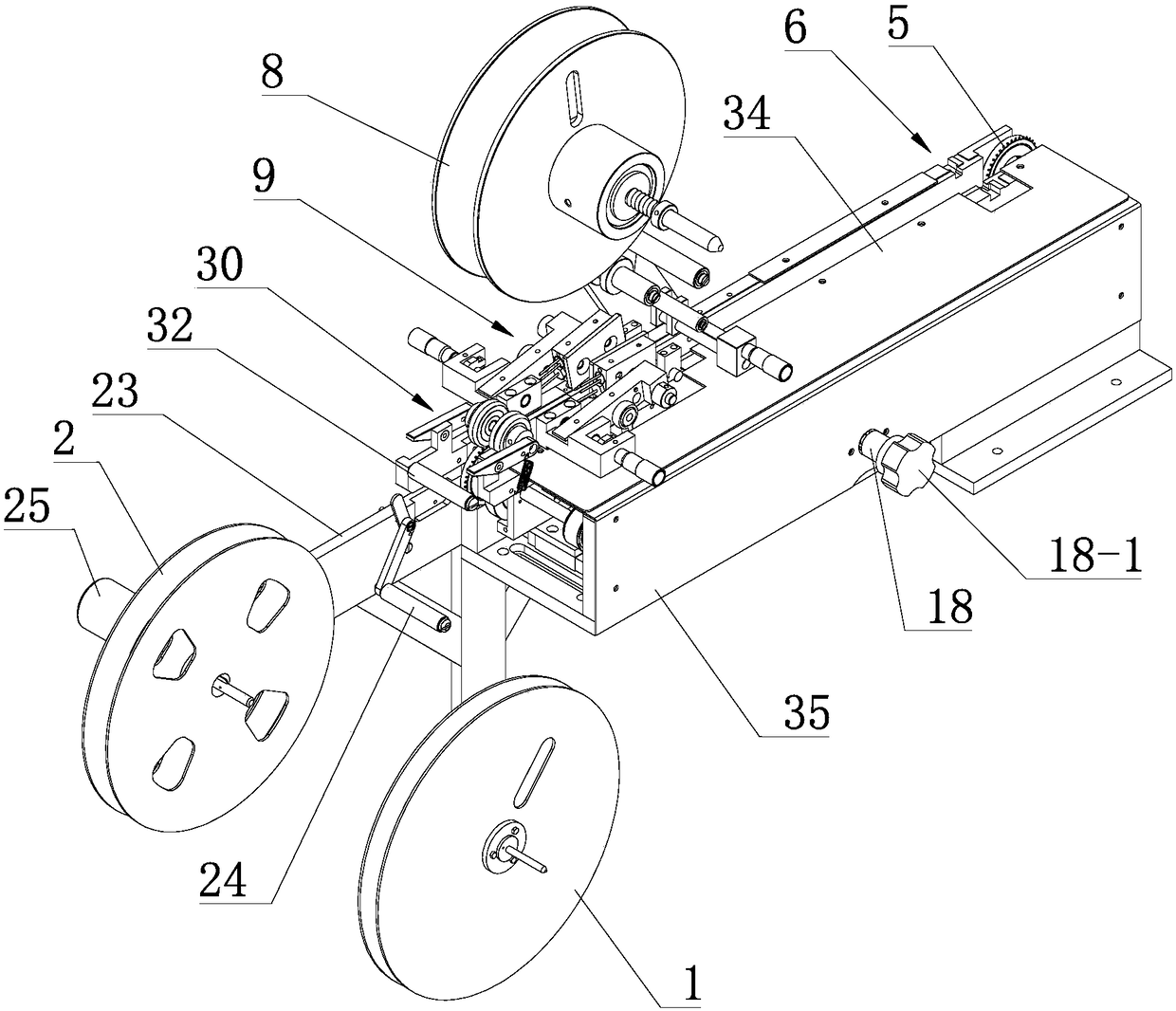

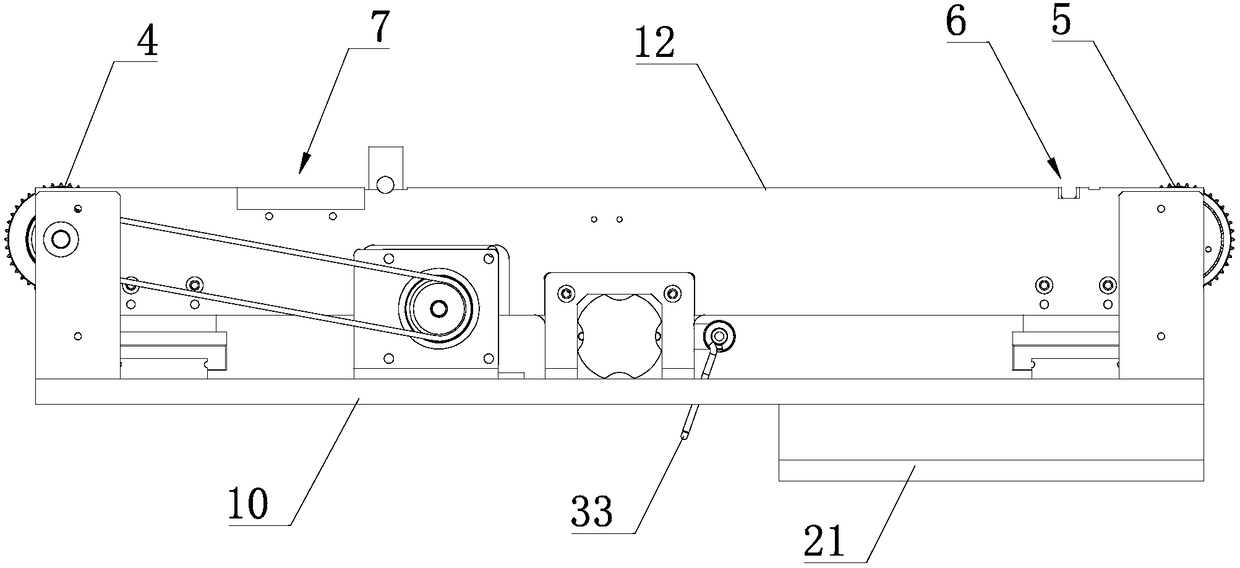

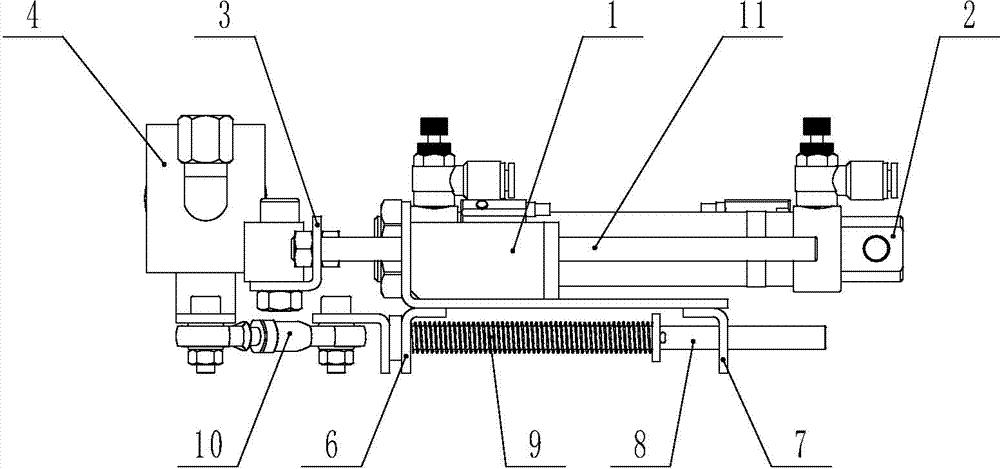

Full-automatic material delivery system

InactiveCN105903836ARealize automatic receivingImprove efficiencyMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a full-automatic material delivery system which comprises a box body, wherein an upper die and a lower die matched with the upper die are arranged on the box body; a groove is formed in the middle of the lower die; a material inlet and a material outlet are formed in two sides of the box body; a positioning plate for controlling the position of a material plate is arranged at the material inlet; an automatic material collection mechanism is arranged at the material outlet; a plurality of rollers are arranged on two sides of the groove and are uniformly arranged on a gear belt in a spacing manner; a plurality of conveying gears are arranged in the gear belt; a cross frame is arranged below the conveying gears. The full-automatic material delivery system has the following beneficial effects that the material feeding position of the original bending machine is changed, so that materials are fed from an opening in the side surface of the bending machine, realizing synchronous material feeding and discharging and greatly improving the efficiency; meanwhile, the material feeding position is not required to be gathered, so that positioning is precise; a packing device can realize automatic material collection, and the whole device is integrated.

Owner:YUYAO POWER EQUIP BUILD & REPAIR FACTORY +1

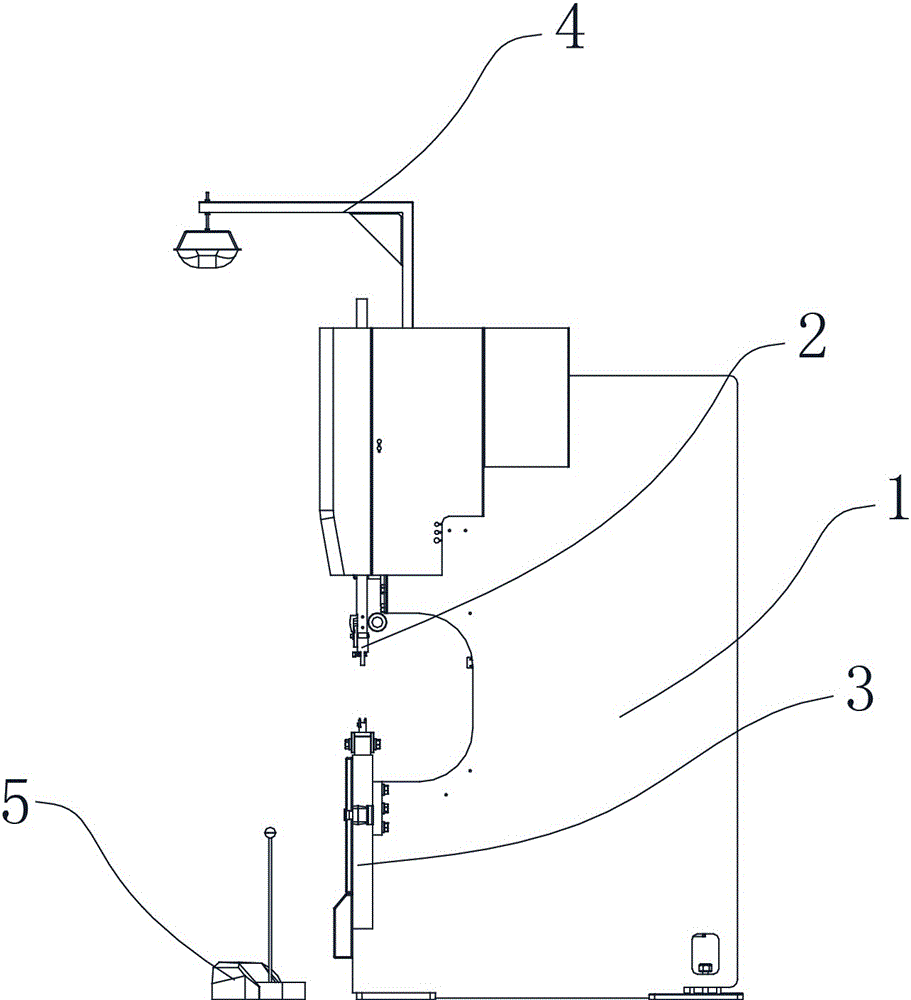

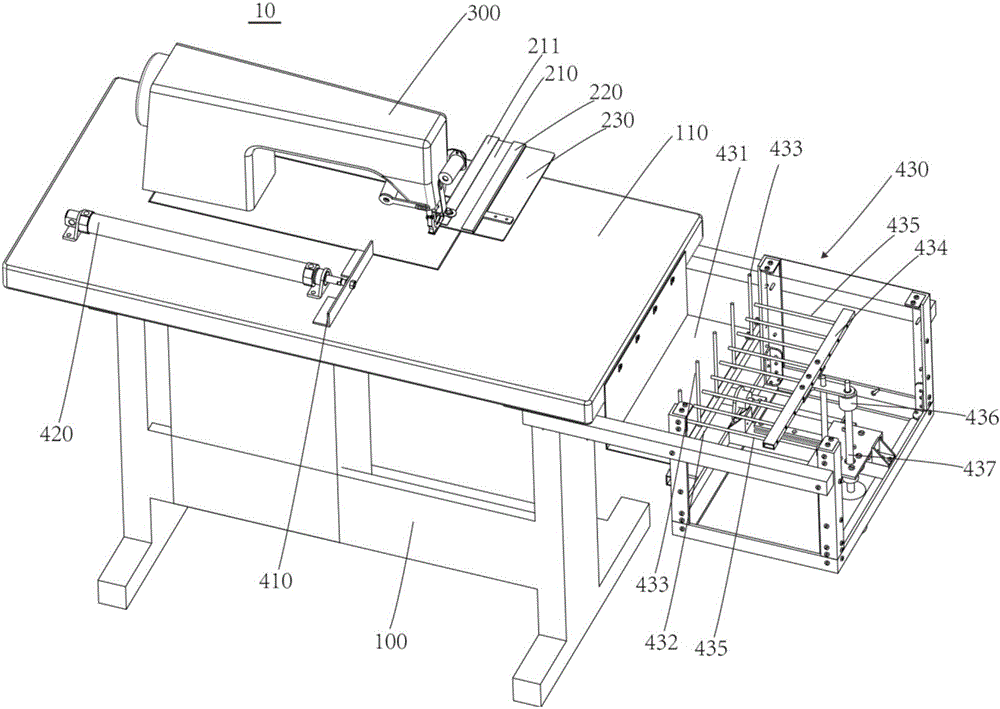

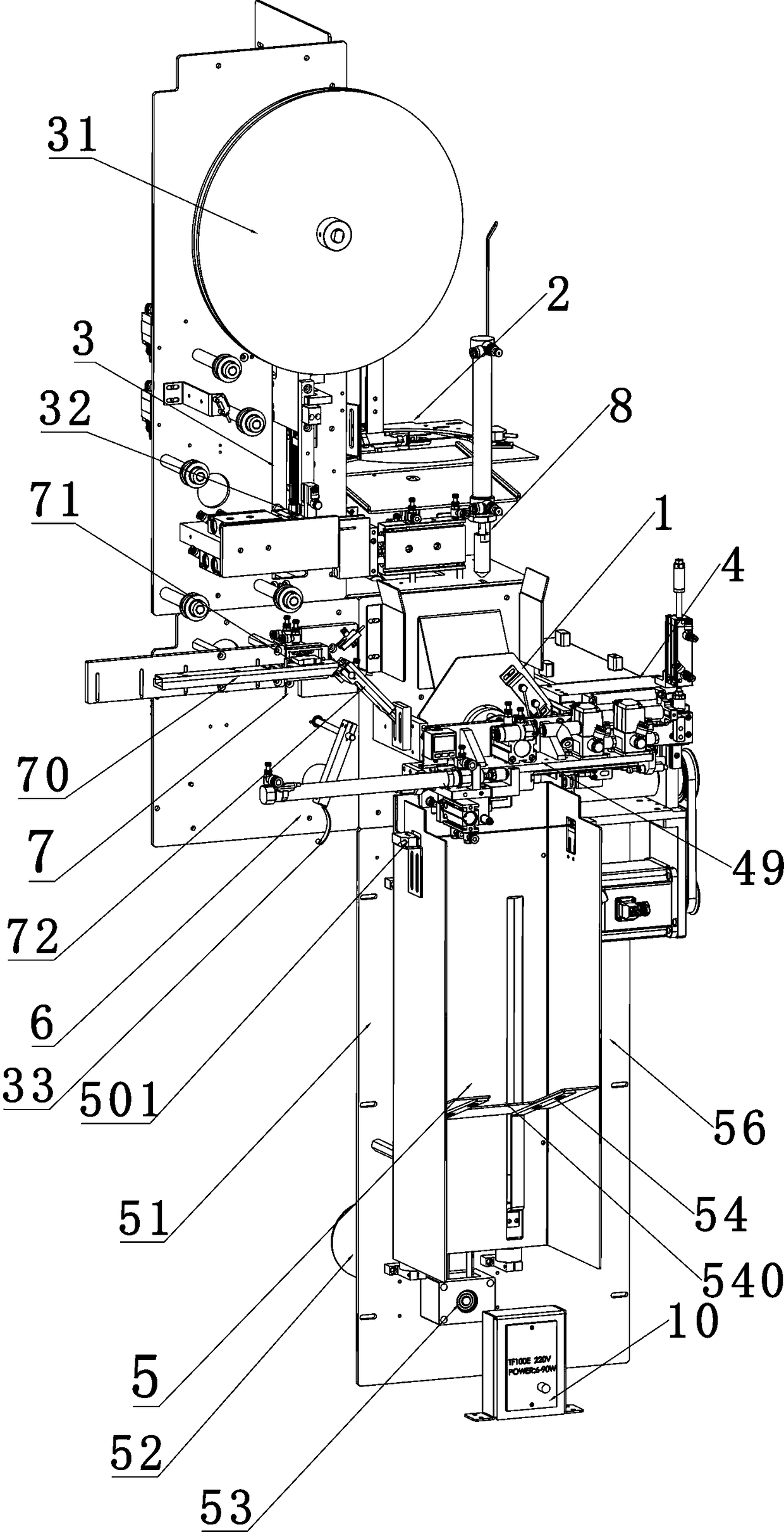

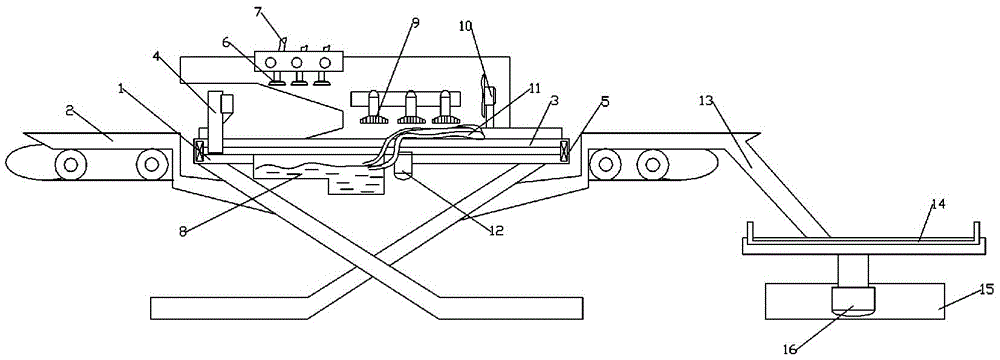

Automatic cutting machine of latticed cut-offs

ActiveCN107313237AShorten the timeSave human effortSevering textilesLaser beam welding apparatusEngineeringBiomedical engineering

The invention discloses an automatic cutting machine of latticed cut-offs, which comprises a controlling device, a material-conveying device, an image acquisition and processing device and a galvanometer cutting device. The material-convening device is electrically connected with the controlling device to convey the latticed cut-offs. The image acquisition and processing device is electrically connected with the controlling device to attain the sub-image of the grid clothing which is conveyed by the material-conveying device, and the image acquisition and processing device aims to attain a plurality of grid clothing, then implements the matching to form an integrated grid image. According to the grid image, the controlling device defines the latticed off-cut position of the grid clothing, and according to the latticed off-cut position, defines the position of the cutting line. The galvanometer cutting device is on the top of the material-conveying device, and the galvanometer cutting device is electrically connected with the controlling device. According to the position of the cutting line, the galvanometer cutting device is used for cutting the grid clothing into a plurality of latticed cut-offs. The automatic cutting machine of latticed cut-offs has a high efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

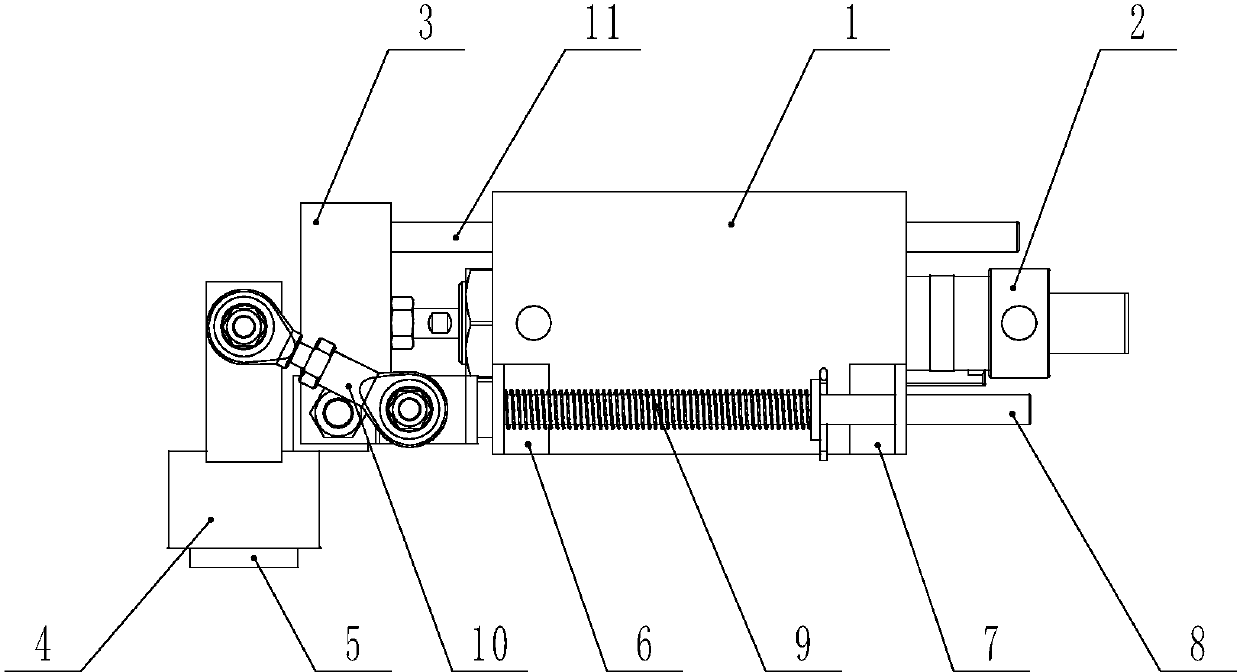

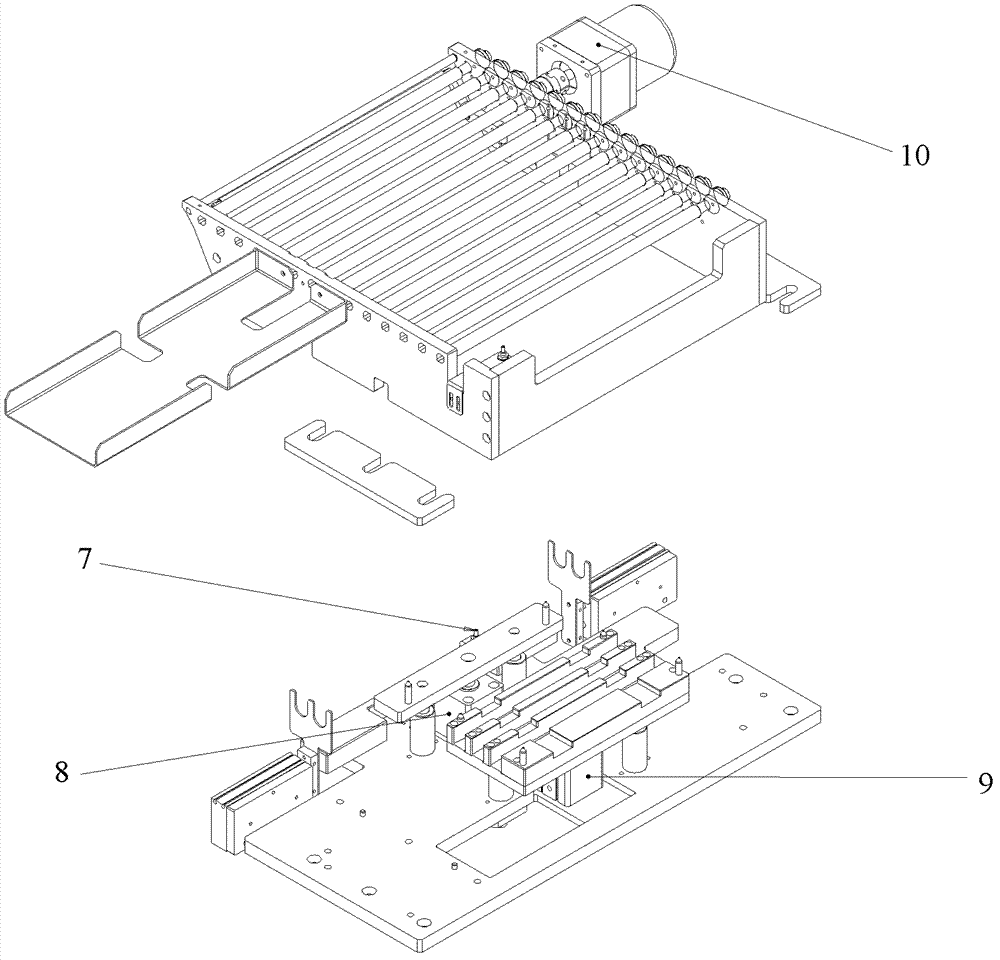

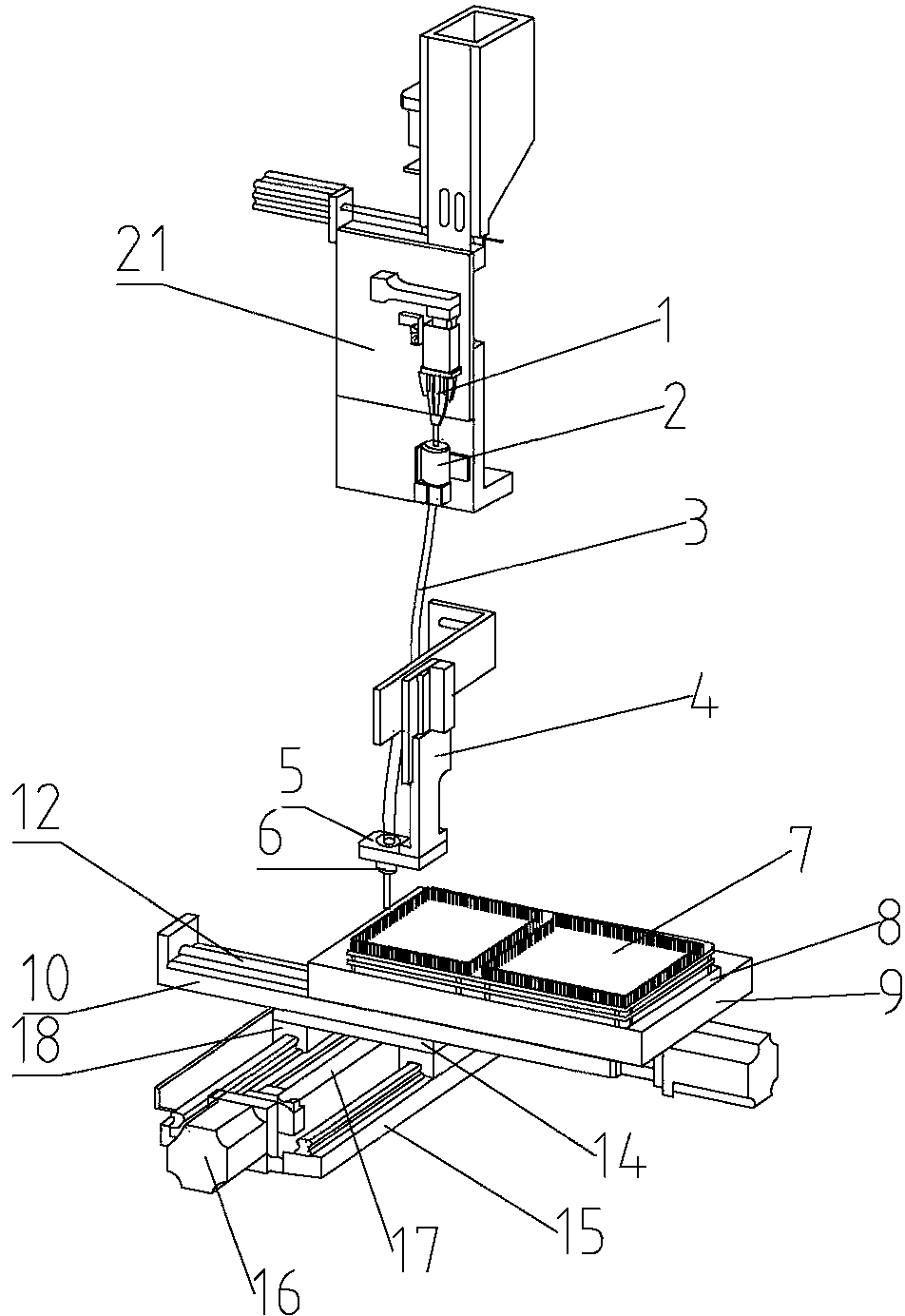

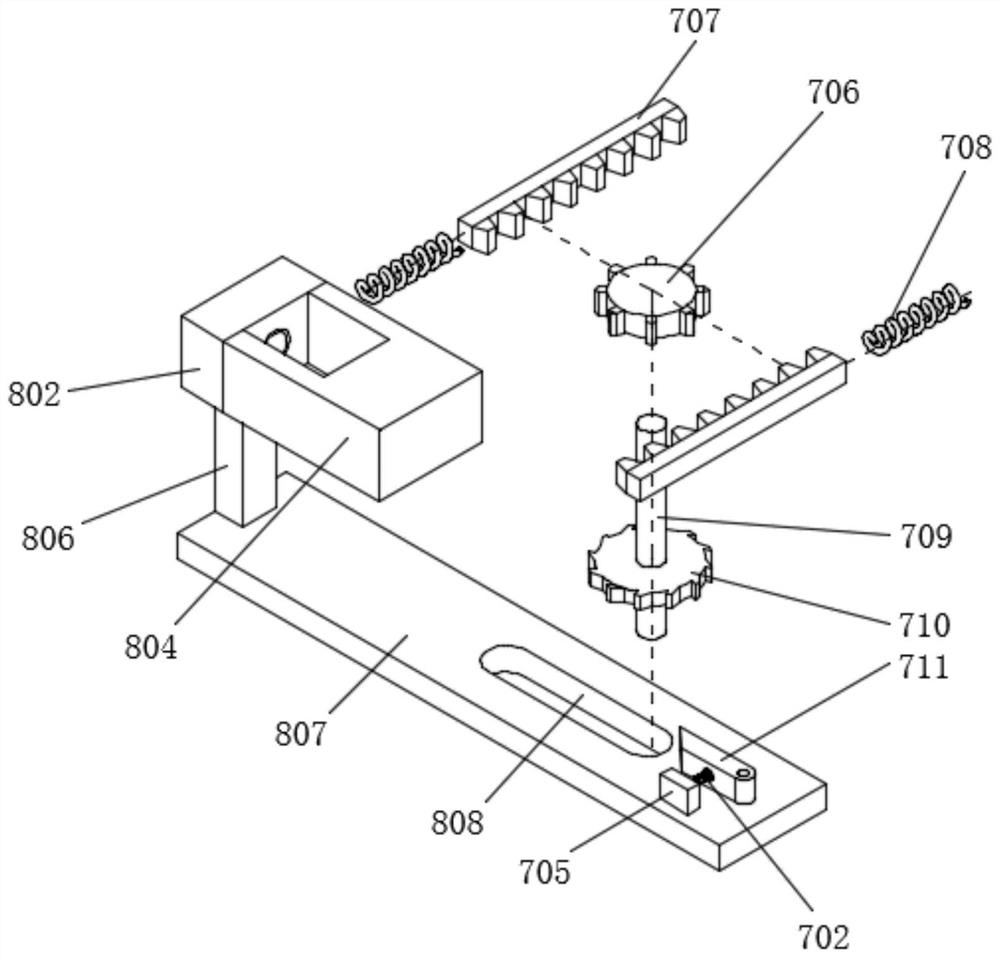

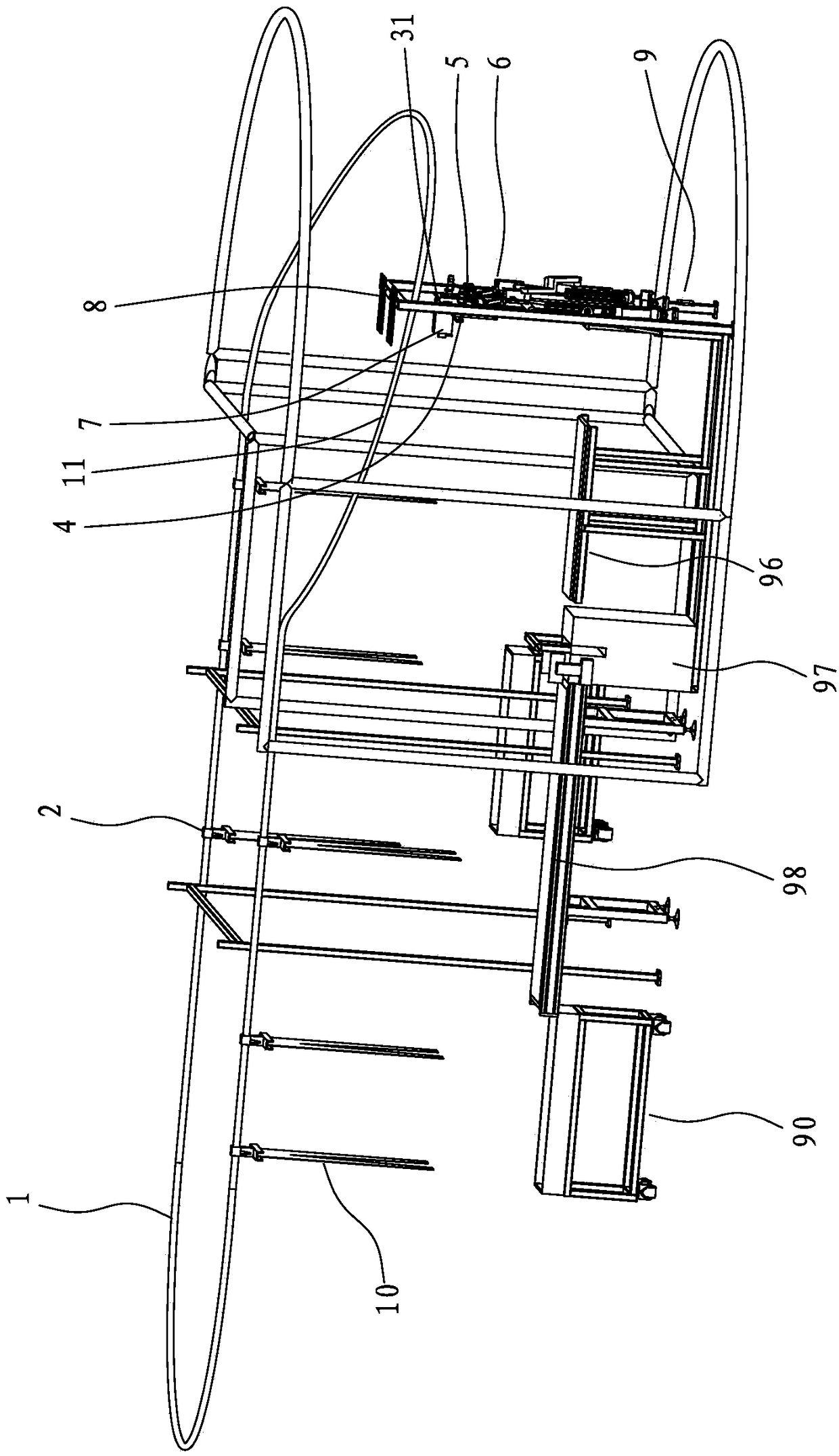

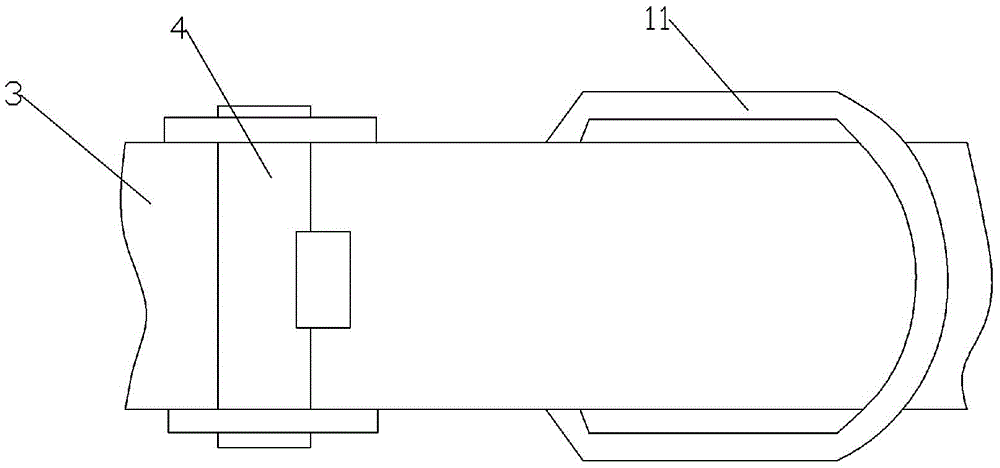

Electrode plate wrapping method

ActiveCN102856527BMobile stable and reliableAchieve overlayElectrode manufacturing processesFinal product manufactureEngineeringElectrode

The invention relates to an electrode plate wrapping method, which comprises the steps of: first, arranging a positive electrode plate and a negative electrode plate in an electrode plate material box vertically respectively, above all using a sucking disc to suck the positive electrode plate laterally, then turning the positive electrode plate downward by 90 degrees and placing it in a material trough, moving the positive electrode plate placed in the material trough forward by one working position, at the same time moving separator paper from top to bottom, cutting the separator paper off and disposing it on the material trough vertically, further moving the positive electrode plate forward by one working position, and making the front end of the positive electrode plate contact the central part of the separator paper in the moving process, along with the forward moving of the positive electrode plate, wrapping the positive electrode plate with the separator paper, then further moving the positive electrode plate forward by one working position, simultaneously employing the sucking disc to suck a negative electrode plate laterally, and placing the negative electrode plate right over the wrapping completed positive electrode plate, then keeping moving the negative electrode plate, the separator paper, and the positive electrode plate forward into a material receiving device, and when the number of a plate pack is collected, sending the plate pack out.

Owner:江苏金帆电源科技有限公司

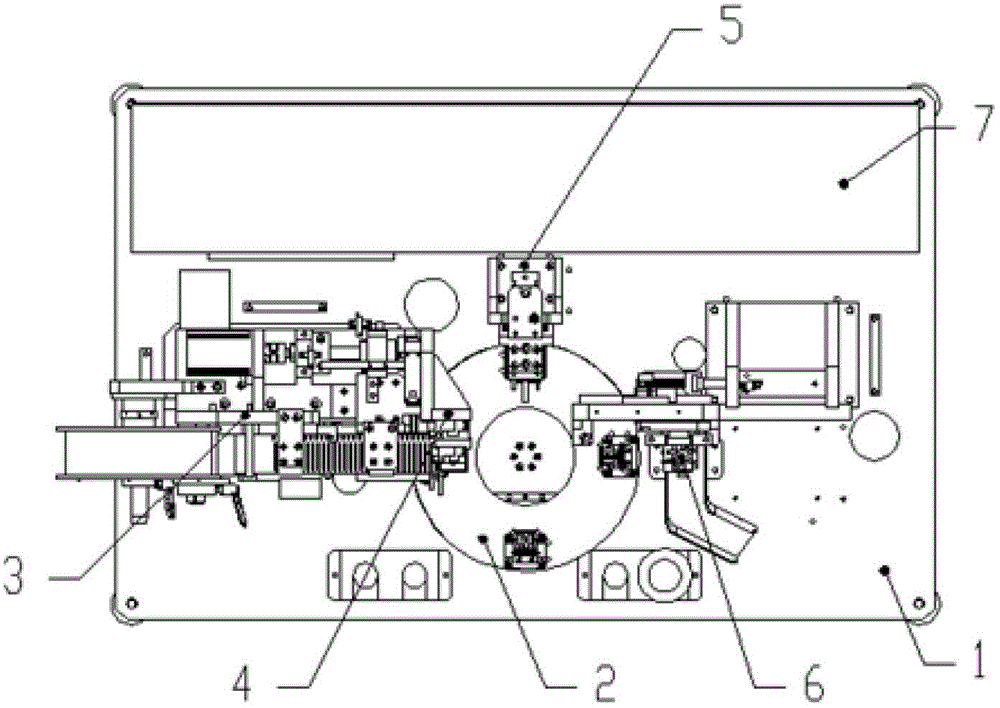

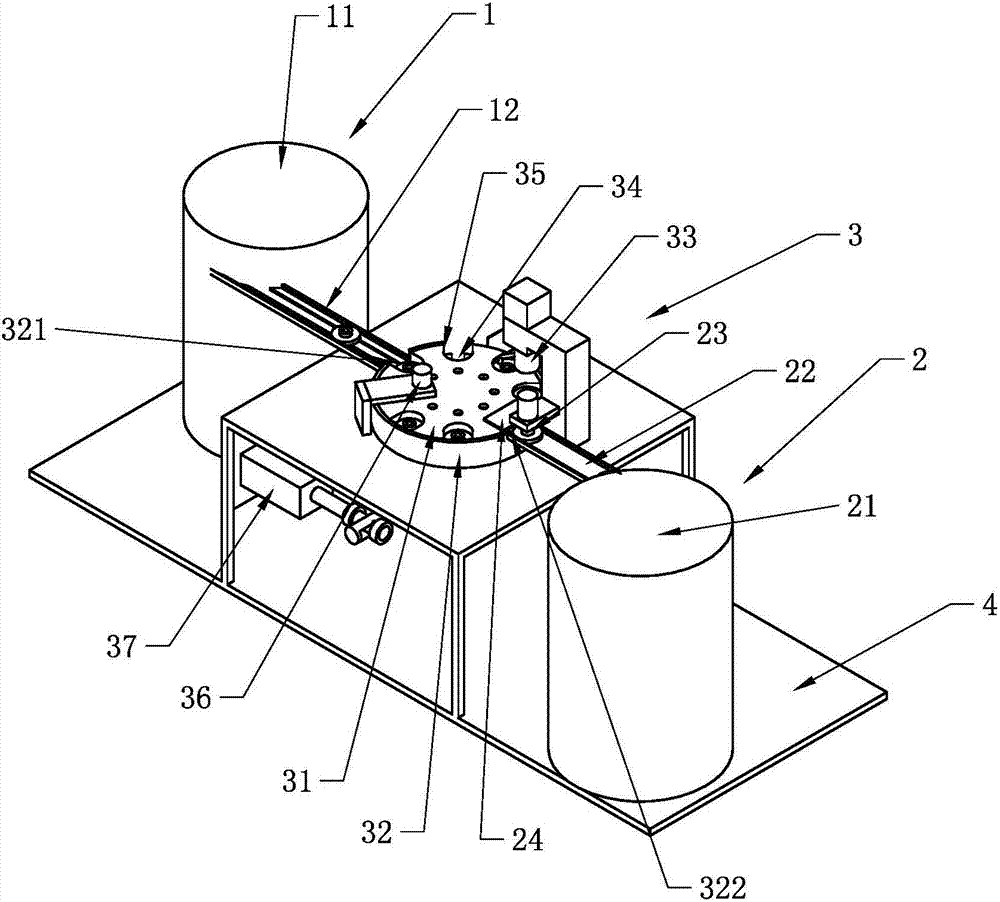

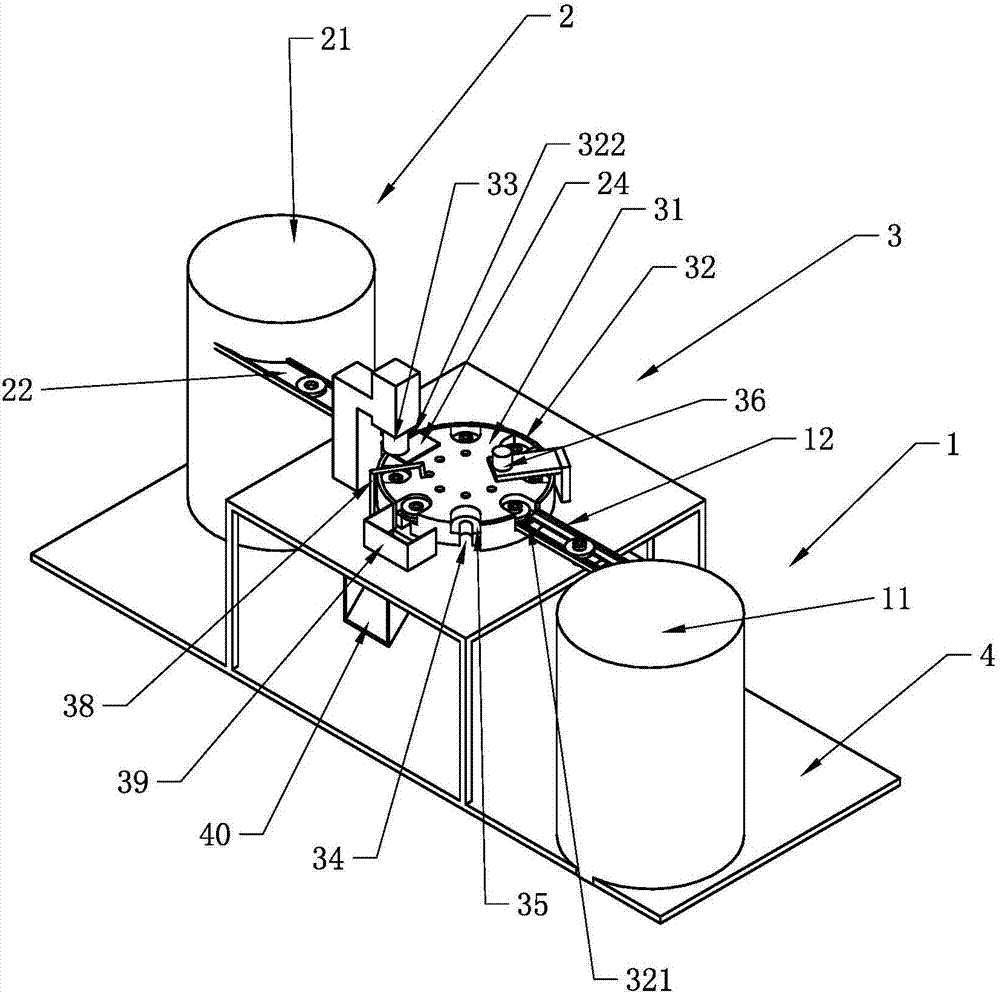

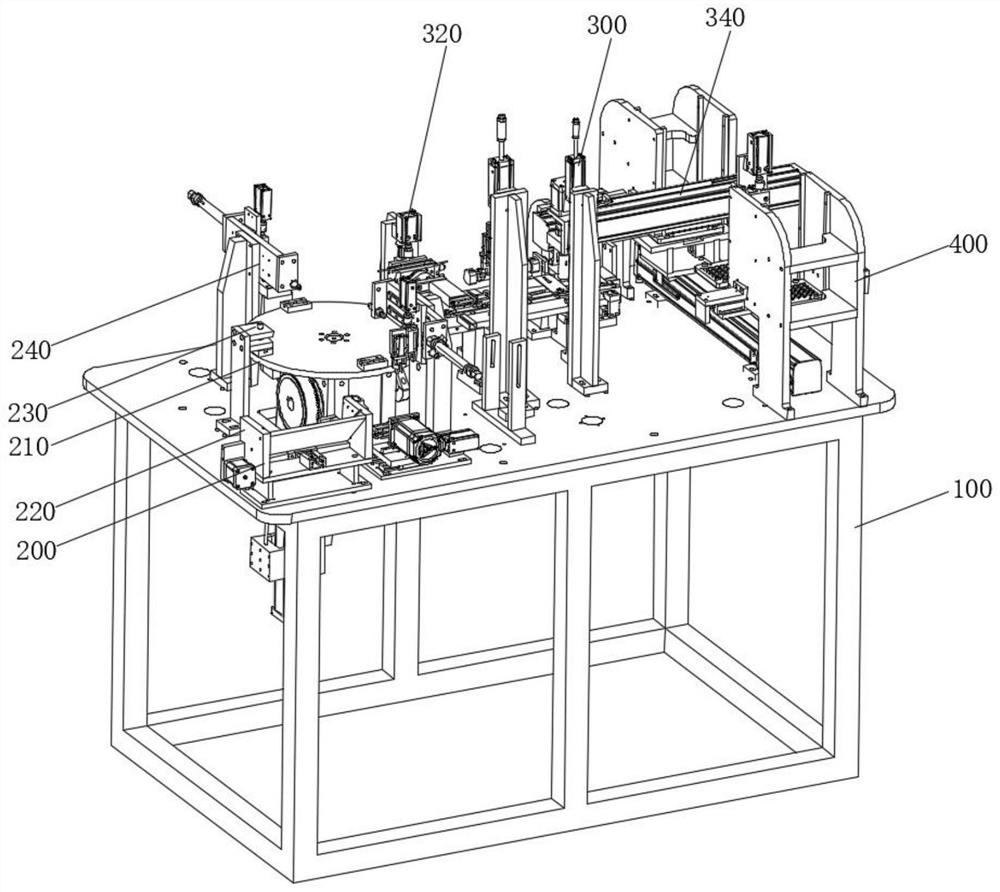

Adhesive tape sticking device

The invention discloses an adhesive tape sticking device, which comprises a rack, a carrier turntable instrument, an adhesive tape feeder, an adhesive tape sticking instrument, a component discharge instrument and a controller. Specifically, the adhesive tape feeder is used for adhesive tape feeding, the adhesive tape sticking instrument is disposed at the adhesive tape discharge end of the adhesive tape feeder, and a suction nozzle on the adhesive tape sticking instrument can suck an adhesive tape. The carrier turntable instrument is located on the rack, and can convey the carrier thereon to the place right below the suction nozzle so as to stick the adhesive tape by the suction nozzle. The component discharge instrument can send the carrier of an adhesive tape sticked product into a discharge flow channel for discharge. And the controller controls the work of each component. The adhesive tape sticking device provided by the invention realizes automatic peeling and sticking of adhesive tapes and automatic receiving of sticked products, achieves full automatic work, and has no need for manual operation. The adhesive tape sticking speed is fast, and the sticked adhesive tapes are accurate in positions and are firm. Manpower and space are saved, the production efficiency is improved, and production cost is reduced.

Owner:KUNSHAN FULIRUI ELECTRONICS TECH

Automatic material collecting machine

InactiveCN102765595AFree from accidental damageNot affectedConveyor partsEngineeringMechanical engineering

The invention discloses an automatic material collecting machine which comprises a material sorting mechanism, a material strip picking and placing mechanism, a material strip conveying mechanism, a first material box conveying mechanism, a material box grabbing mechanism and a second material box conveying mechanism. The material sorting mechanism is positioned below the material strip picking and placing mechanism, the material strip conveying mechanism is positioned on one side of the material sorting mechanism, the first material box conveying mechanism is positioned below the material box grabbing mechanism and is opposite to the material strip conveying mechanism, and the second material box conveying mechanism is positioned below the first material box conveying mechanism. By the aid of the automatic material collecting machine, operators do not need to directly contact with chips by hands, so that the chips are guaranteed against being accidentally damaged or affected.

Owner:上海功源电子科技有限公司

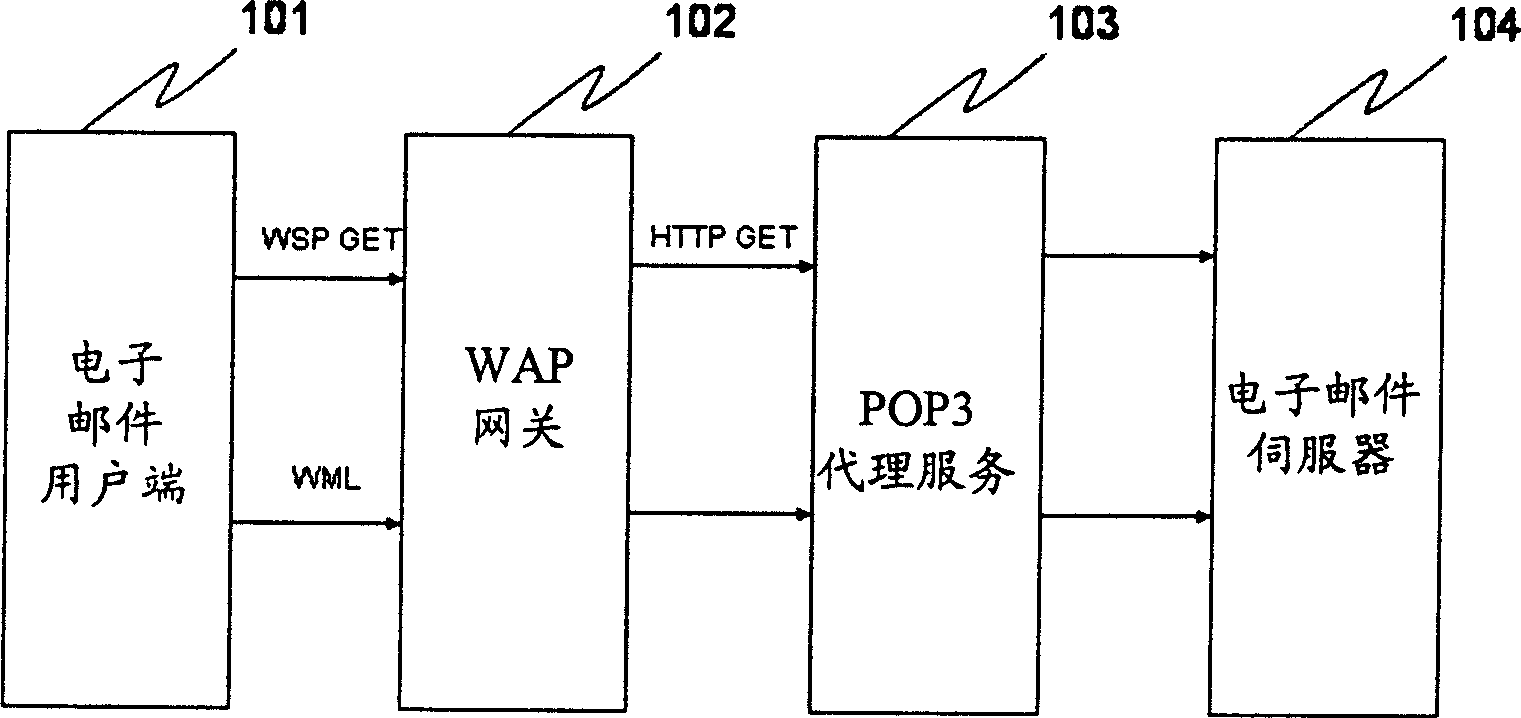

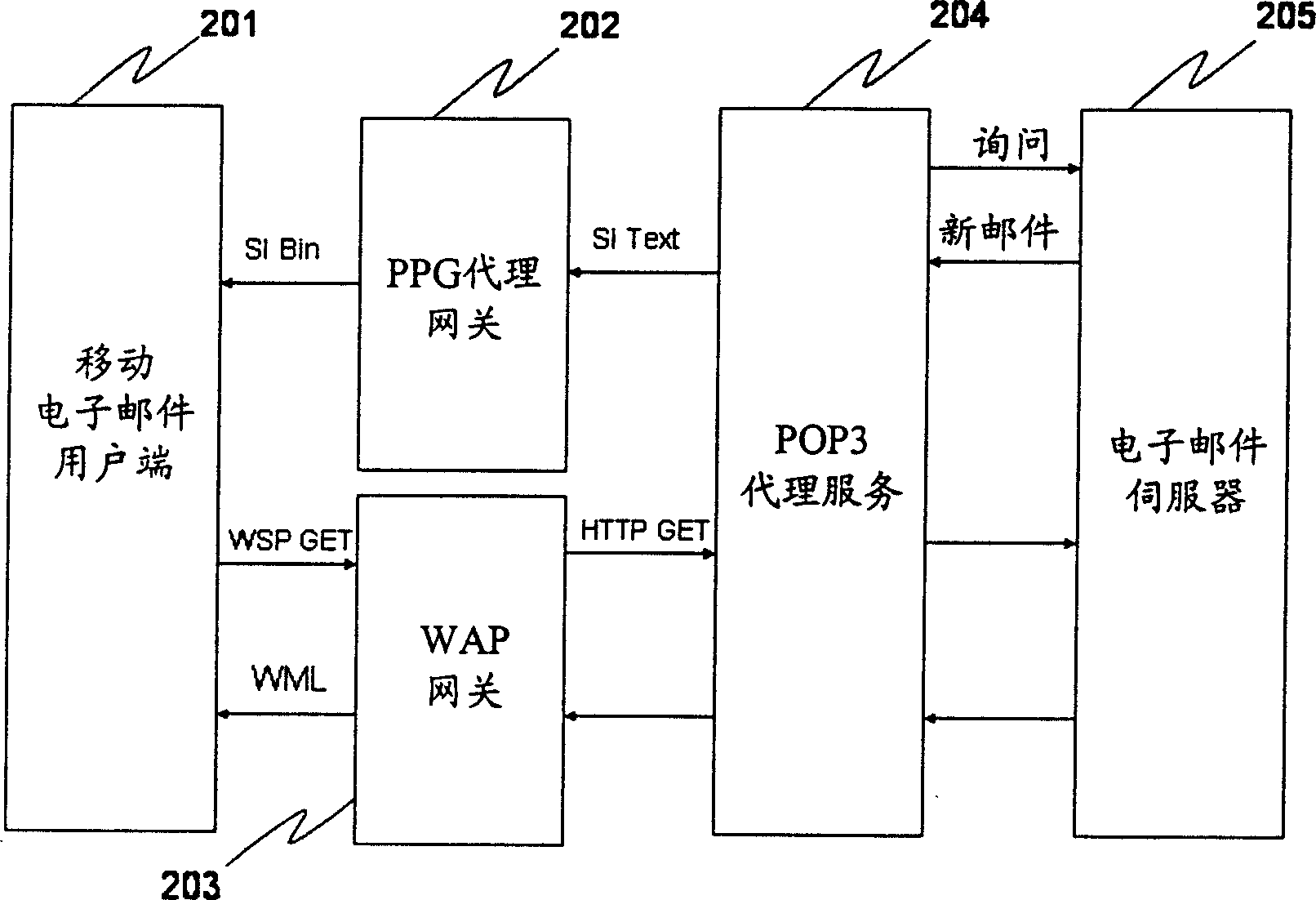

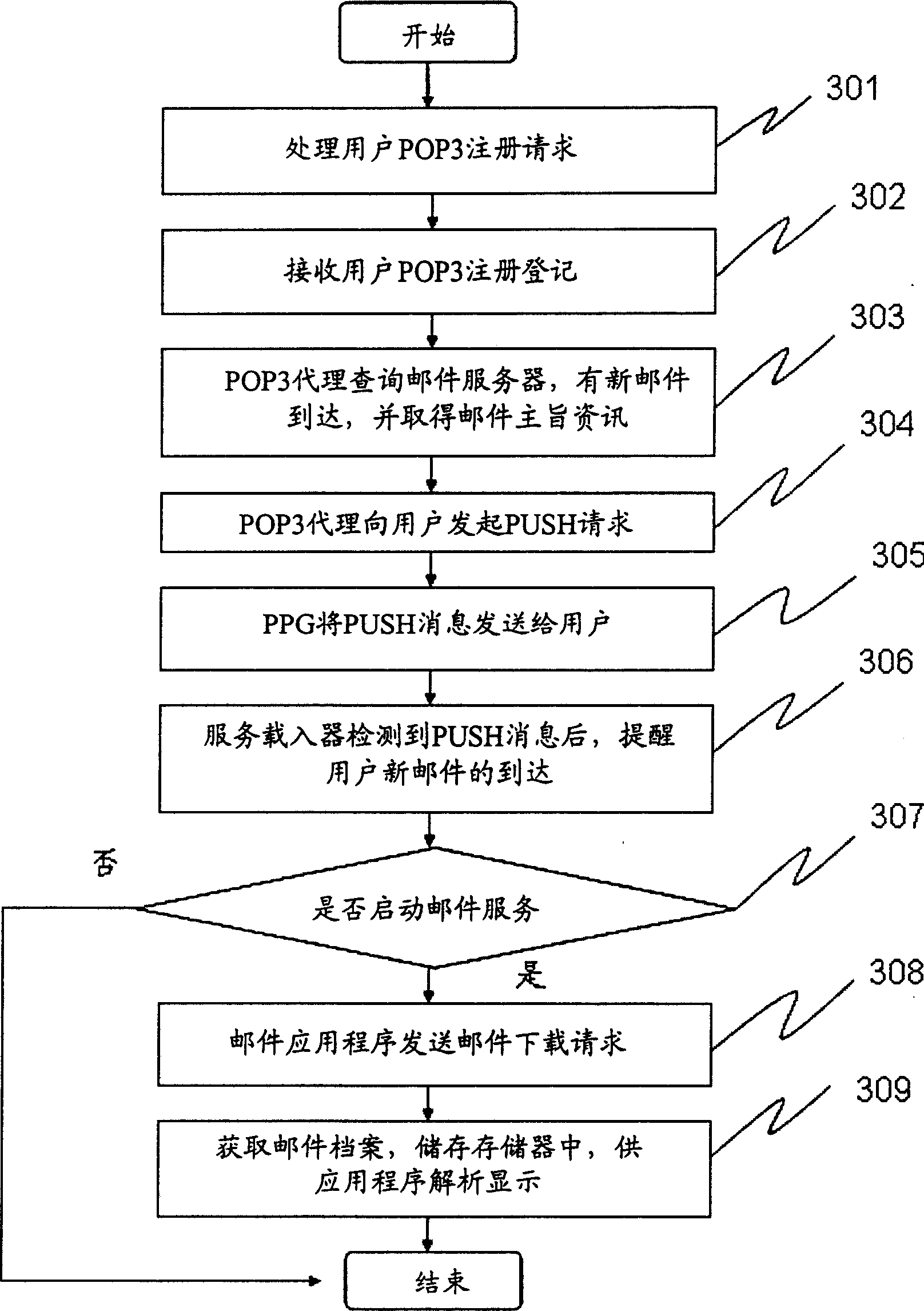

Realizing method for automatic receiving mobile phone mail

InactiveCN1741506ARealize automatic receivingUnderstand in timeData switching networksComputer networkMobile phone

A method for automatically receiving mobile phone mail includes using mobile phone built - in WAP browser to carry out POP3 service register , checking whether there is new mail or not periodically by POP3 proxy , taking key data of mail back if there is , using POP3 proxy as push initiator to initiate push request to user according key data and databank data , utilizing push proxy gateway to provide delivery information to user in brief information mode , prompting user that new mail is arrived when delivery information is detected by server at user end , starting service according to user selection for realizing automatic - receiving purpose .

Owner:YINGHUADA (SHANGHAI) ELECTRONIC CO LTD

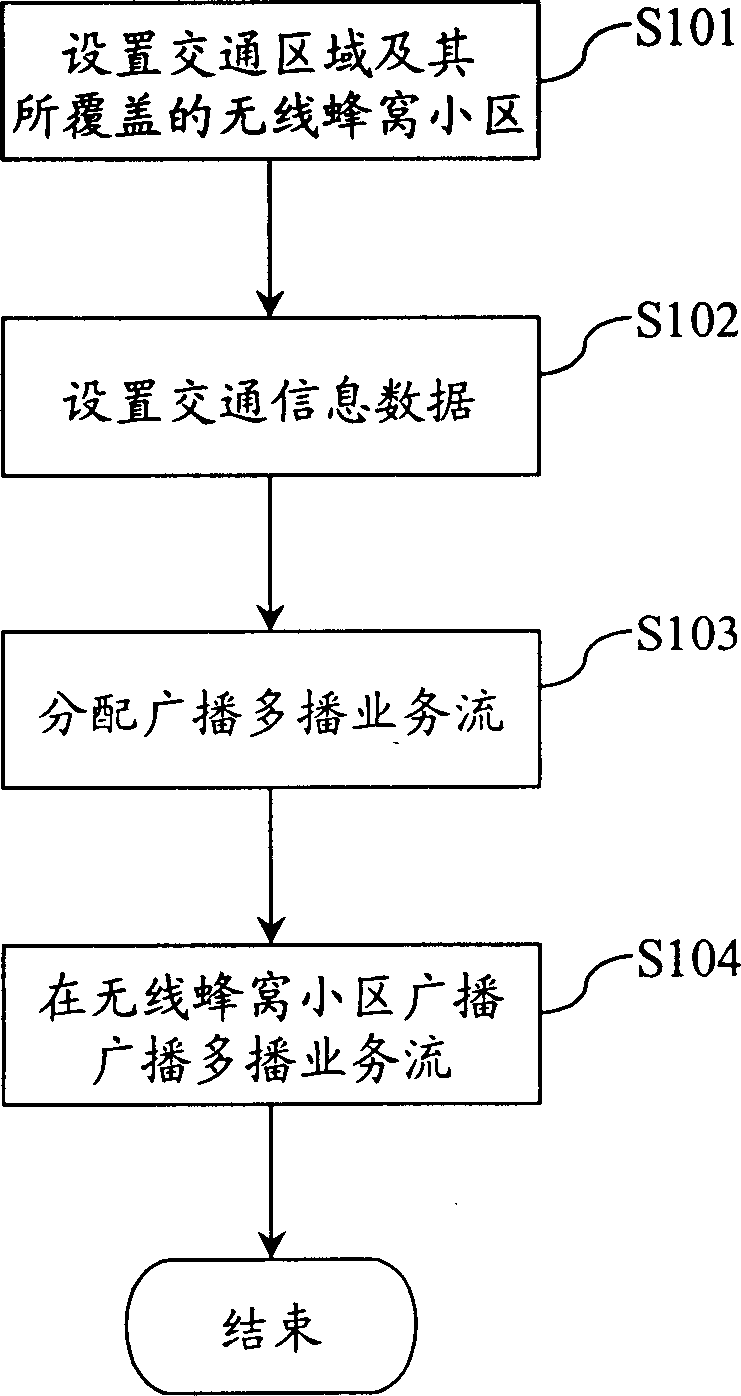

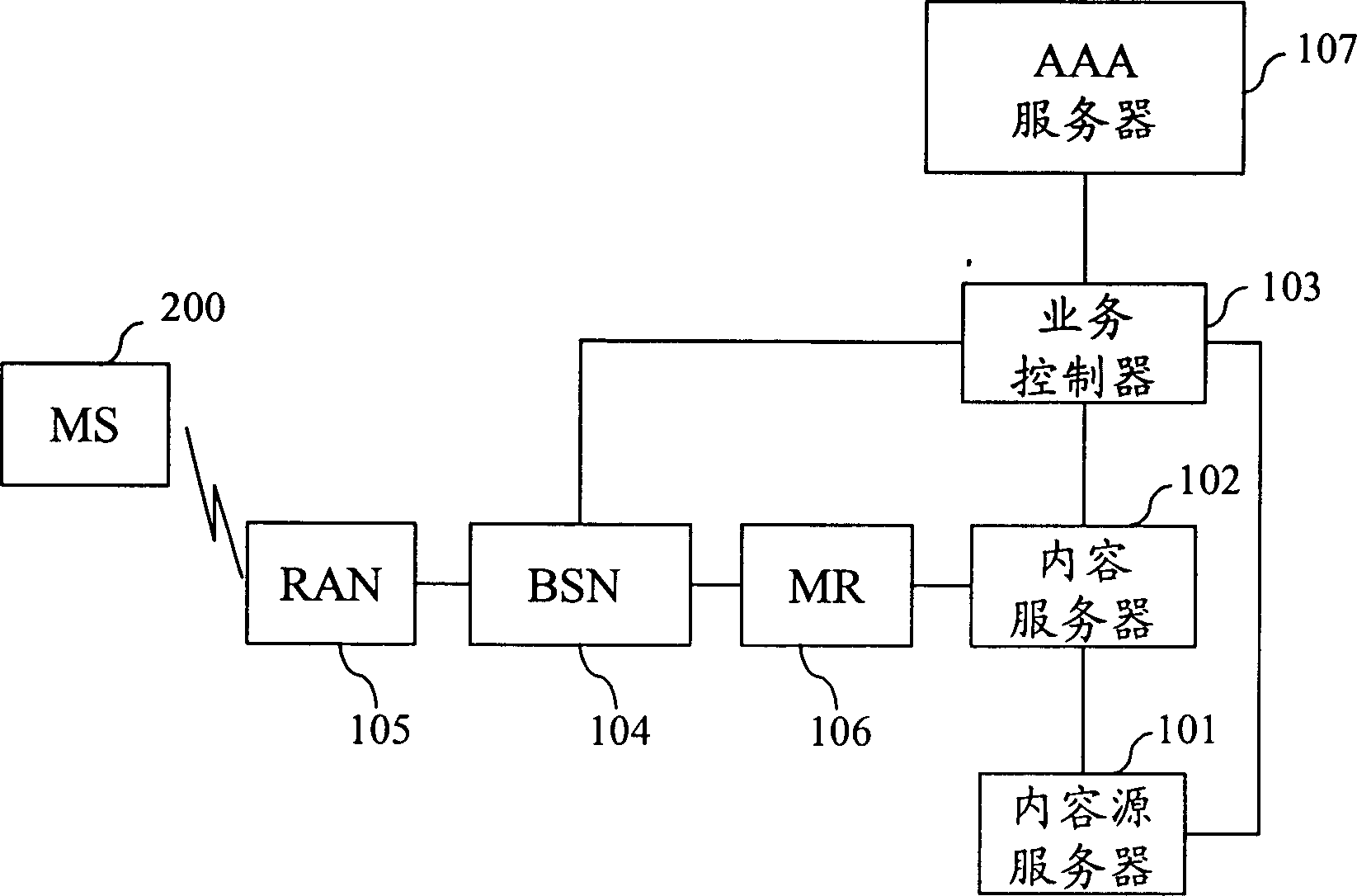

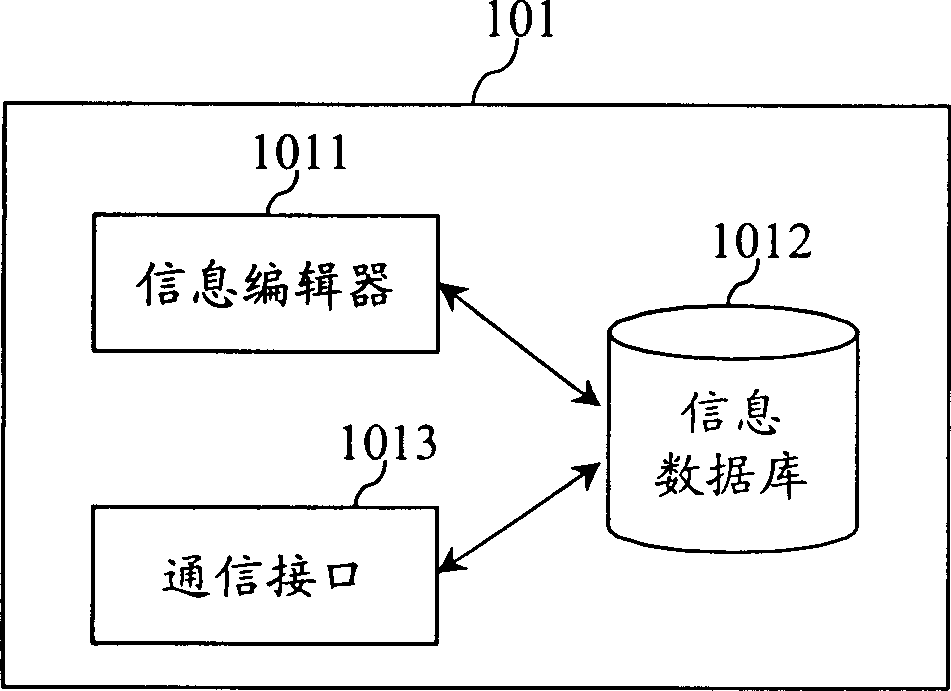

Broadcasting method and system of traffic information data

ActiveCN1845479ARealize automatic receivingEasy to adjustRoad vehicles traffic controlBroadcast specific applicationsTraffic capacityHoneycomb

The disclosed method for traffic information data broadcast comprises: setting traffic region as well as the covered wireless honeycomb subzone; setting corresponding information data; allocating one broadcast / multicast business stream with business stream label opposite to said traffic area; broadcasting the business stream on said subzone. This invention brings benefit to user and can improve city traffic capacity.

Owner:HUAWEI TECH CO LTD

Drum fermentation reactor-based bacterial cellulose production technology

ActiveCN101979635AReduce concentrationLow costBioreactor/fermenter combinationsBiological substance pretreatmentsFermentationCulture mediums

The invention relates to drum fermentation reactor-based bacterial cellulose production technology, which comprises the following steps of: (1) sterilizing hollow equipment; (2) sterilizing culture medium; (3) inoculating; (4) performing rotary fermentation; (5) harvesting bacterial cellulose films; and (6) cleaning equipment. The bacterial cellulose production technology breaks through the limitation that the traditional tray culture method is performed manually and has low production efficiency, realizes continuous and mechanical work of bacterial cellulose fermentation production and film preparation, has the advantages of high treatment capacity, high efficiency, convenience, high degree of automation and the like, and can effectively improve the labor productivity, reduce the production cost and stabilize the product quality.

Owner:天津实发中科百奥工业生物技术有限公司

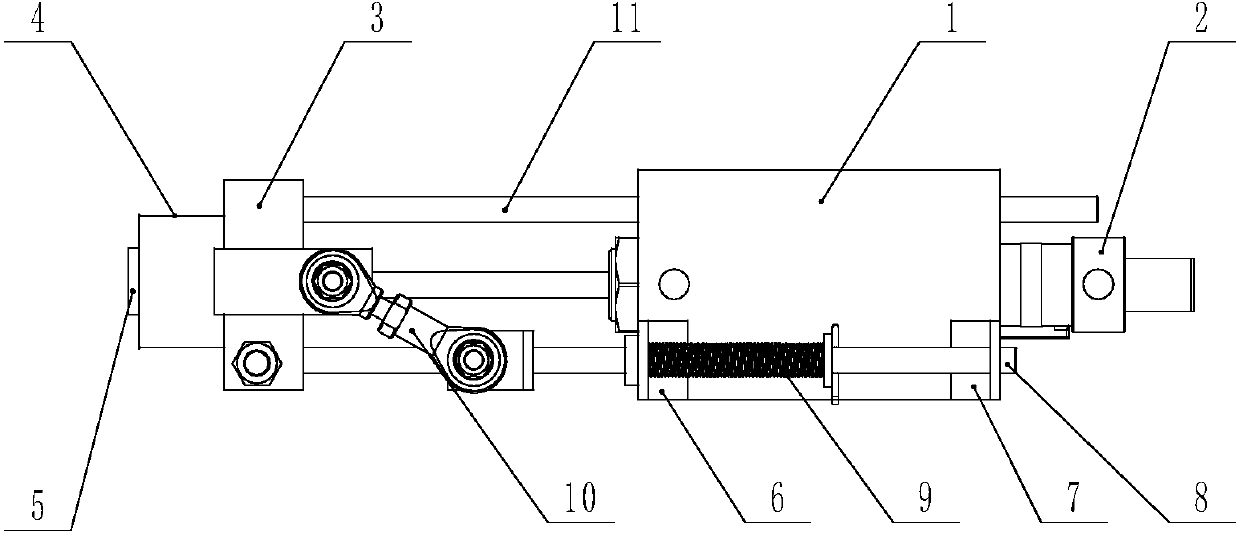

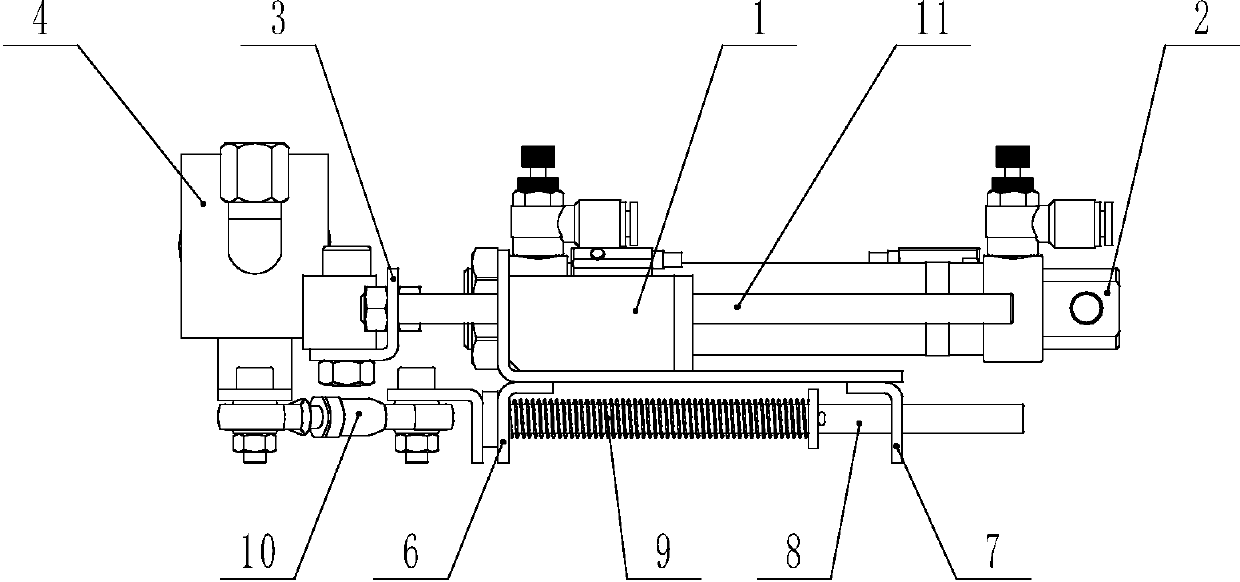

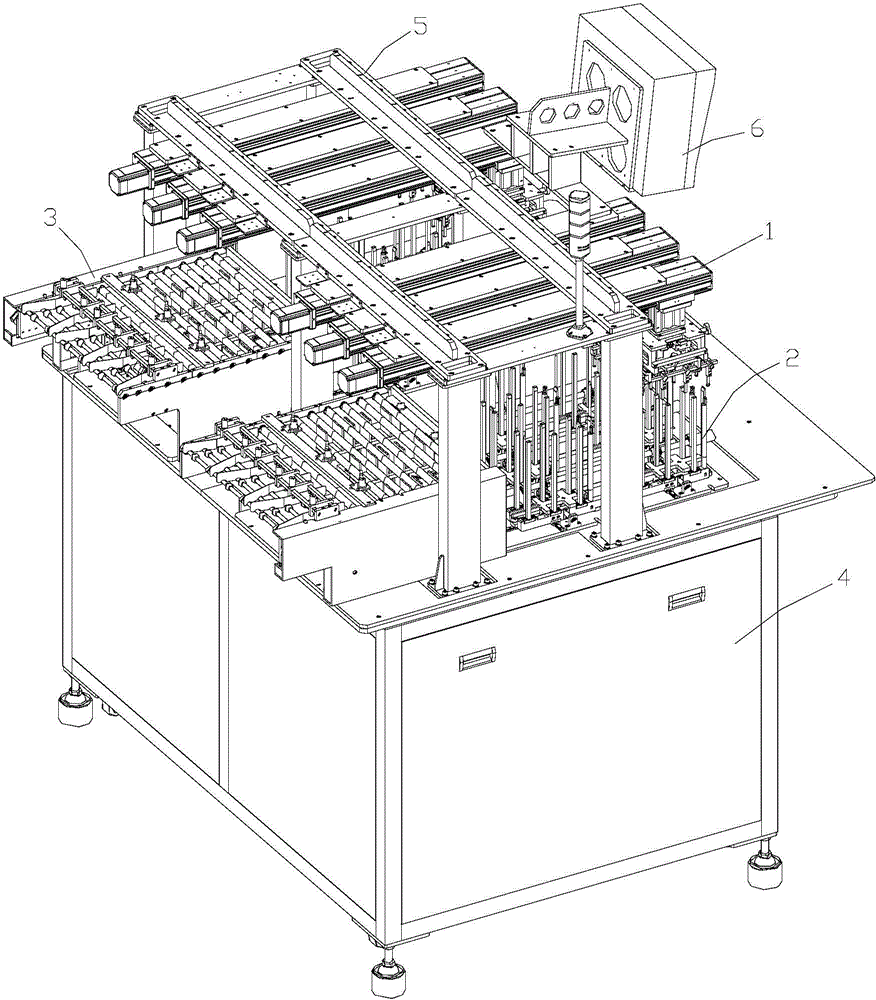

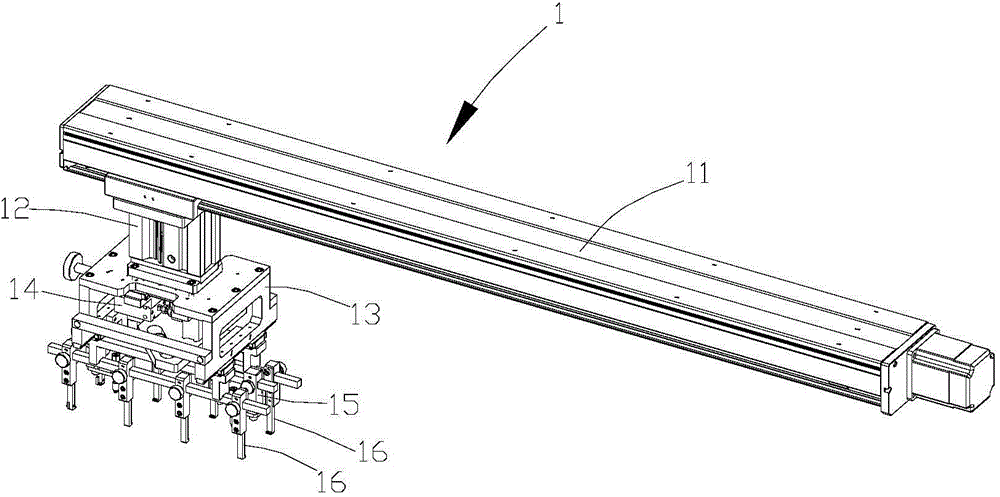

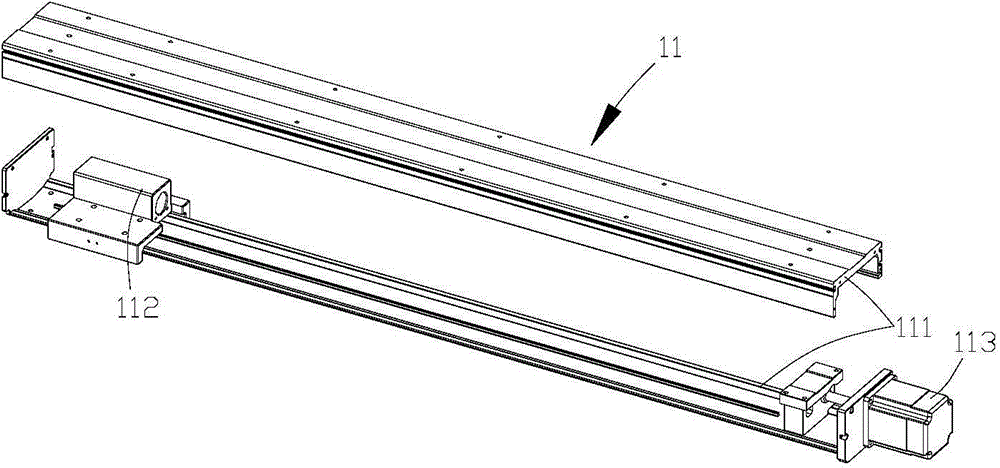

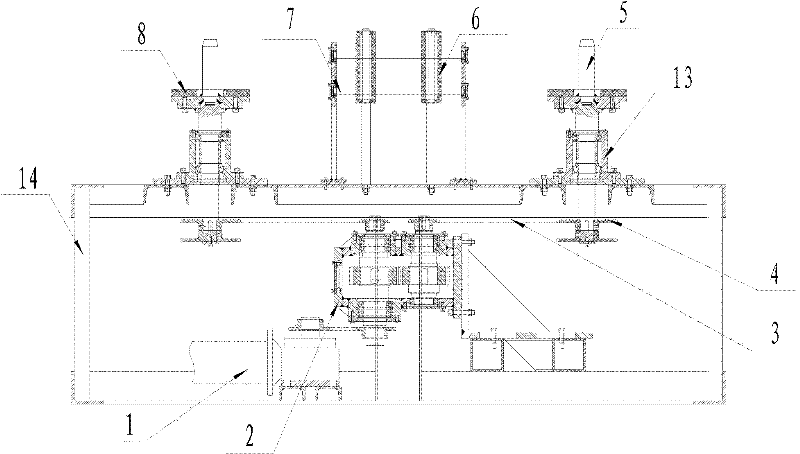

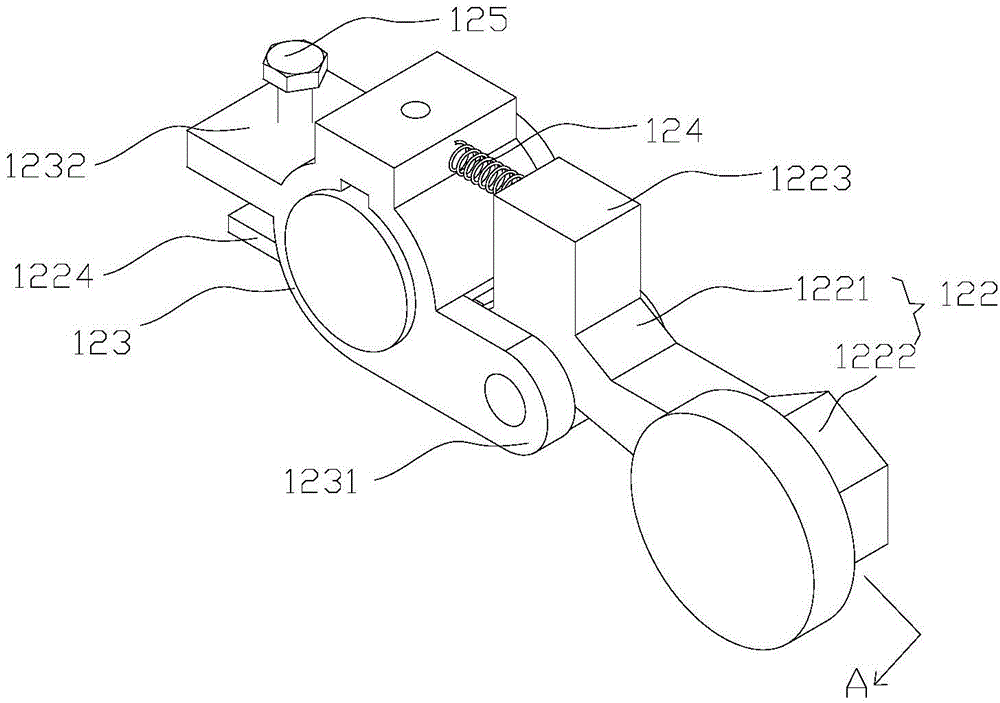

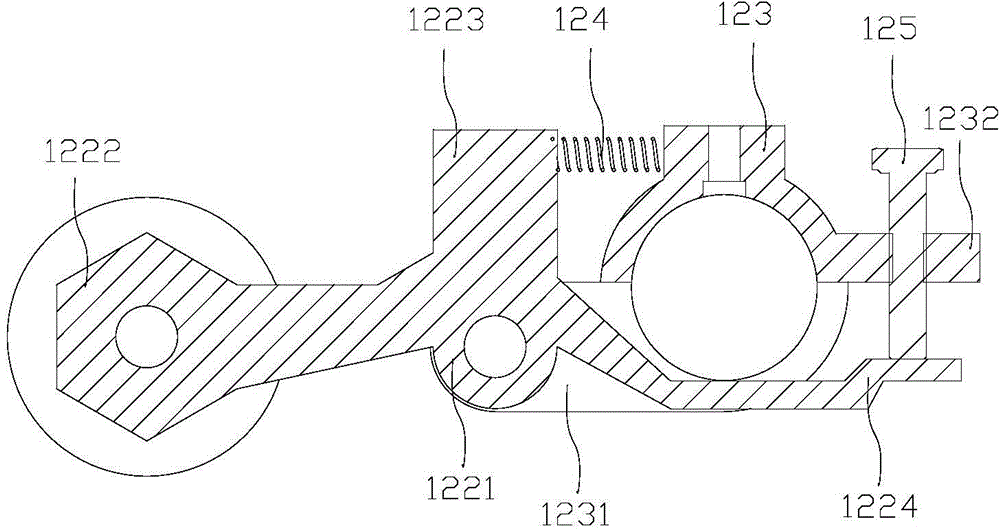

Collecting device for sheet type integrated circuit plating equipment

ActiveCN104562125ARealize automatic receivingImprove plating efficiencyElectrolysis componentsSemiconductor devicesEngineeringFront and back ends

The invention discloses a collecting device for sheet type integrated circuit plating equipment. The collecting device comprises a base and further comprises a sorting frame assembly, a collecting box assembly, a stand and a collecting clamp assembly which are arranged on the base; the collecting clamp assembly is arranged above the collecting box assembly; the front end and the rear end of the sorting frame assembly are respectively provided with a feeding hole and a temporary storage area, wherein the temporary storage area of the sorting frame assembly is arranged near the front end of the collecting box assembly and extends to the position below the collecting box assembly; the collecting clamp assembly comprises a horizontal guide rail mechanism, an adsorbing component and two clamping components, wherein the adsorbing component and the two clamping components can be arranged on the horizontal guide rail mechanism in a horizontal sliding way and a vertical lifting way; and the collecting box assembly comprises a collecting box mounting support, a collecting box and an auxiliary box, wherein the collecting box and the auxiliary box are arranged on the collecting box mounting support. The collecting device for the sheet type integrated circuit plating equipment can be used for collecting sheets automatically in the process of plating the sheets, thus the integral plating efficiency of the sheets can be improved effectively.

Owner:东莞奥美特科技有限公司

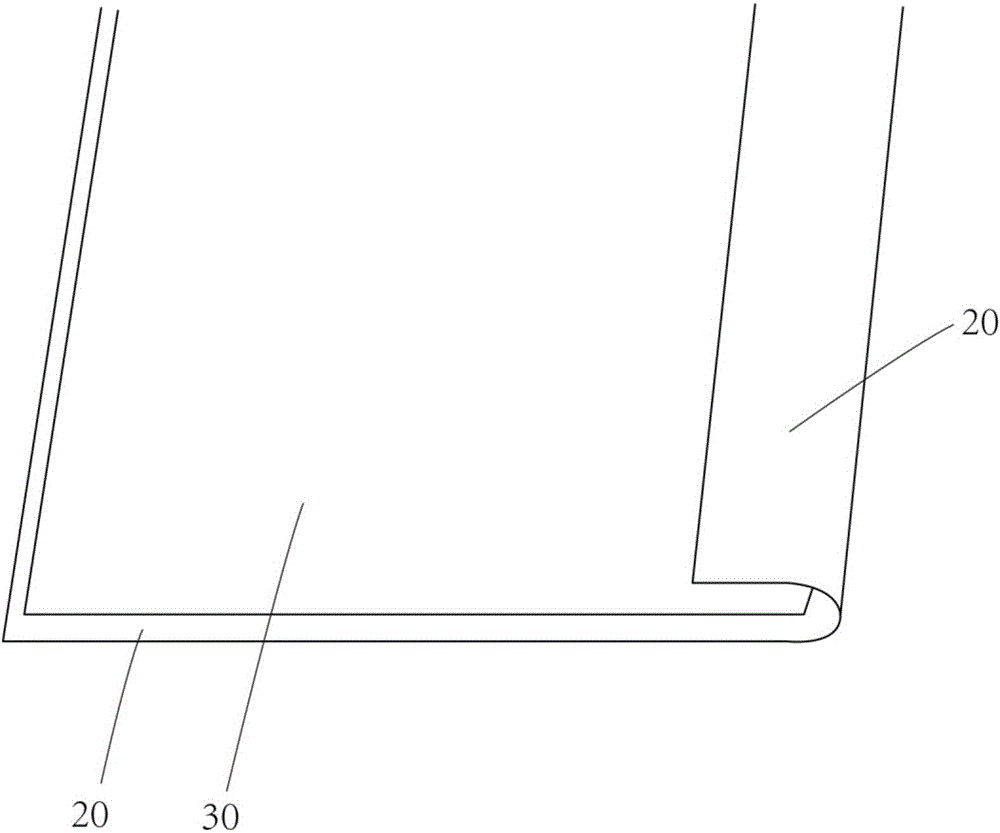

Covering machine

ActiveCN106436035ASave human effortImprove work efficiencyWork-feeding meansSewing-machine control devicesEngineeringMechanical engineering

The invention discloses a covering machine, including a machine body, a margin-wrapping device and a sewing device. The margin-wrapping device is provided with a folding board, which is arranged on the machine body; one side of the folding board curves as an arch from an end to the opposite end to form a folding part. A first off-cut and a second off-cut are placed on a binder in an overlapping way, and a side of the first off-cut can encase the second off-cut in an overlapping way through the folding part. The sewing device is arranged on the machine body; the sewing device is used for sewing the first off-cut and the second off-cut bound by the binder to form a bound off-cut. The covering machine improves work efficiency and the stability of products.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

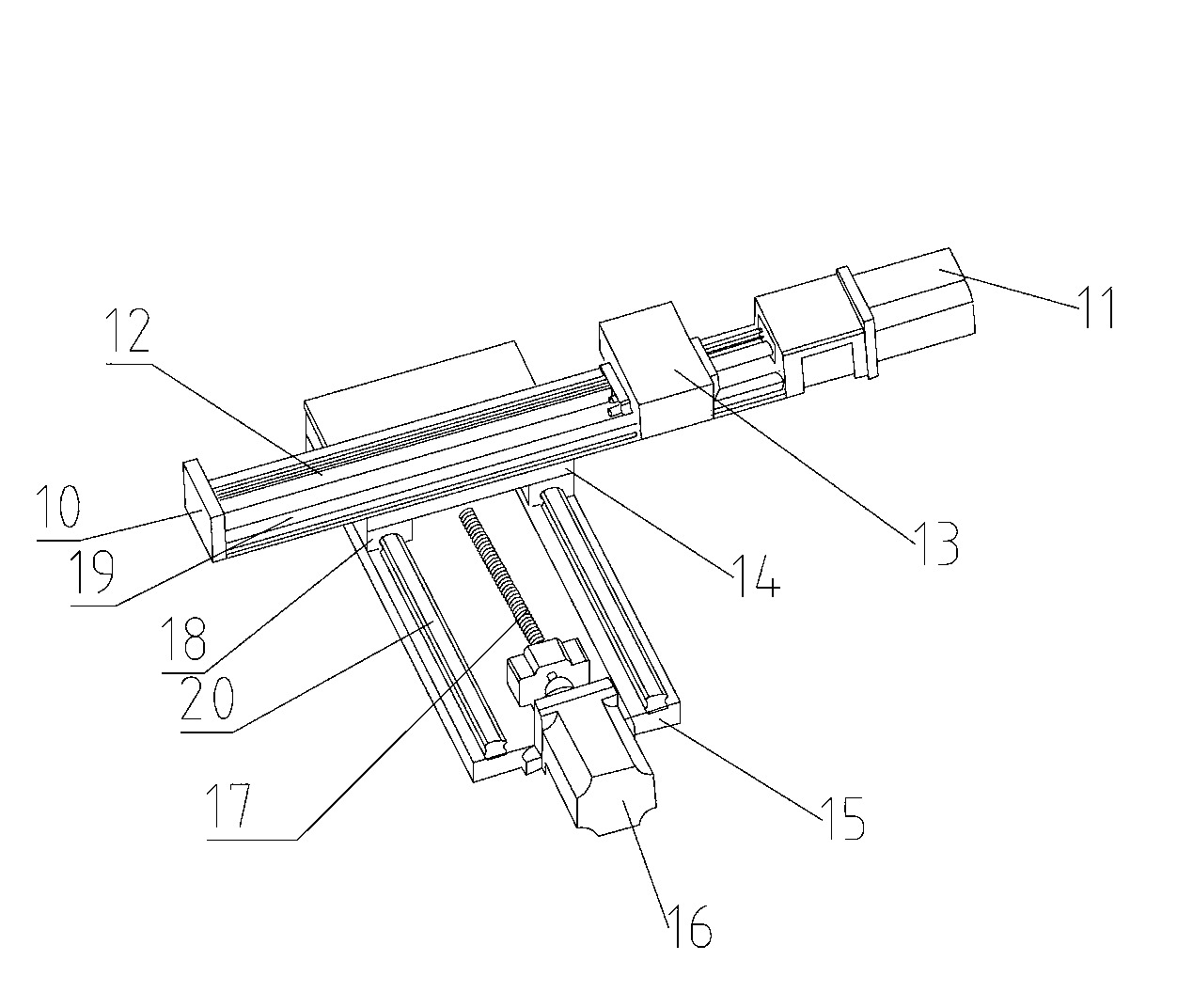

CNC discharging disc inserting device for PCB tiny-drill groove forming

ActiveCN103287845AIncrease the rate of receiptLow costControl devices for conveyorsMachining processDrill

The invention relates to the field of PCB tiny-drill machining, in particular to a CNC discharging disc inserting device for PCB tiny-drill groove forming. The CNC discharging disc inserting device for PCB tiny-drill groove forming comprises a discharging mechanism and a receiving mechanism. The discharging mechanism comprises a discharging machine frame. Discharging pneumatic fingers and a collecting hopper are installed on the discharging machine frame. The collecting hopper is arranged below the pneumatic fingers. A discharging opening is formed in the bottom end of the collecting hopper. A discharging pipe is installed on the discharging opening. The material receiving mechanism comprises a vertically moving receiving air cylinder, an X-Y moving device located below the vertically moving receiving air cylinder and a material disc point location board arranged on the X-Y moving device and used for bearing a material disc. The bottom end of the vertically moving receiving air cylinder is provided with a material guiding groove. The bottom end of the discharging pipe extends into the material guiding groove, so that automation and systematization of the PCB tiny-drill machining are achieved, production efficiency is improved, labor cost is reduced, the quality of a PCB tiny drill is improved, the machining cost of the PCB tiny drill is reduced and the safety of an operator is guaranteed in the process of PCB tiny-drill machining.

Owner:GUANGDONG DTECH TECH CO LTD

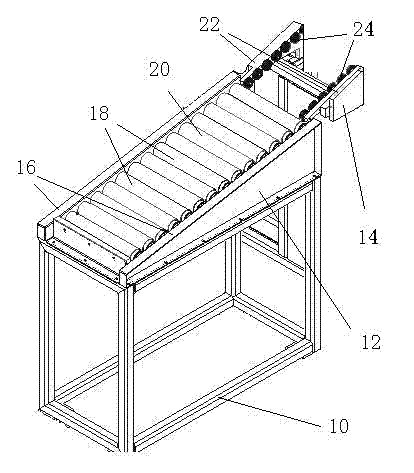

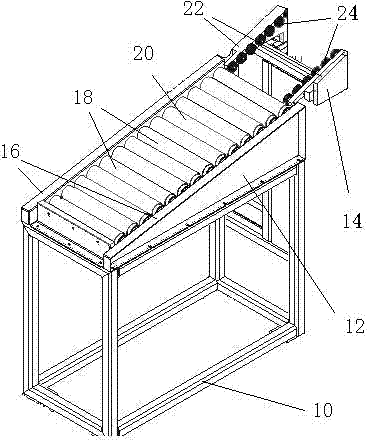

Receiving device for laser marking machine

InactiveCN102555539ASimple structureImprove efficiencyTypewritersOther printing apparatusX-machineMechanical engineering

The invention discloses a receiving device for a laser marking machine. The receiving device comprises a bracket, and is characterized in that: a discharging device is arranged on the bracket; an inclined discharging surface is formed on the discharging device and consists of a plurality of parallel rotating shafts; and a higher end of the discharging surface is connected with the laser marking machine. The receiving device of the laser marking machine is connected with a belt conveying device of the laser marking machine through a roller and the rotating shafts on an inclined surface, a machined workpiece falls naturally along the receiving device under the action of gravity, and the lowest end of the receiving device can be connected with the belt conveying device or a container for storing workpieces, so that an automatic receiving process can be realized. The receiving device for the laser marking machine has the advantages of simple structure, high efficiency and the like.

Owner:SIP GOLDWAY TECH

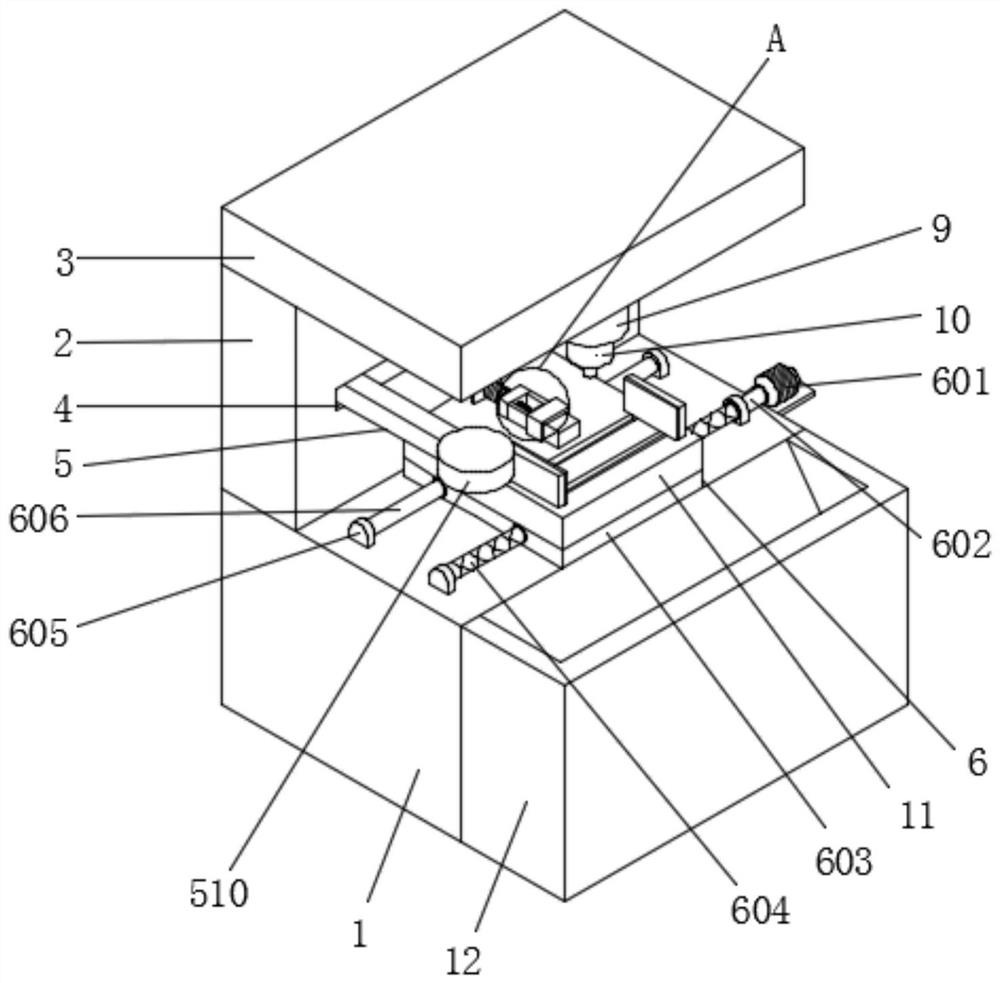

Rapid positioning hardness detection equipment for concrete detection and use method of rapid positioning hardness detection equipment

PendingCN114486445AGuaranteed accuracyImprove the detection effectGrinding drivesPreparing sample for investigationPolishingStructural engineering

The invention discloses rapid positioning hardness detection equipment for concrete detection and a use method thereof, and belongs to the technical field of concrete detection.The rapid positioning hardness detection equipment comprises a working platform, a moving assembly is movably connected to the top of the working platform, a placing platform is fixedly connected to the top of the moving assembly, and a clamping assembly is movably connected to the interior of the placing platform; and one side of the clamping assembly is movably connected with a pushing assembly, one side of the top of the working platform is fixedly connected with a supporting box body, the top of the supporting box body is fixedly connected with a top plate, and an inner cavity of the supporting box body is movably connected with a grinding assembly. According to the concrete sample polishing device, through the polishing assembly, a first gear drives a first bevel gear to rotate through a second rotating shaft, the first bevel gear drives a second bevel gear to rotate, and the second bevel gear drives a polishing disc to polish the outer surface of a concrete sample through a third rotating shaft, so that the flatness of the outer surface of the concrete sample is ensured; the accuracy of the detection effect is ensured.

Owner:寿光市润达新型建材有限公司

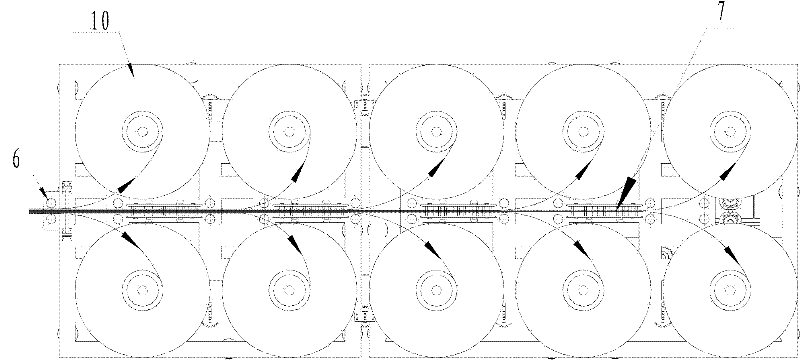

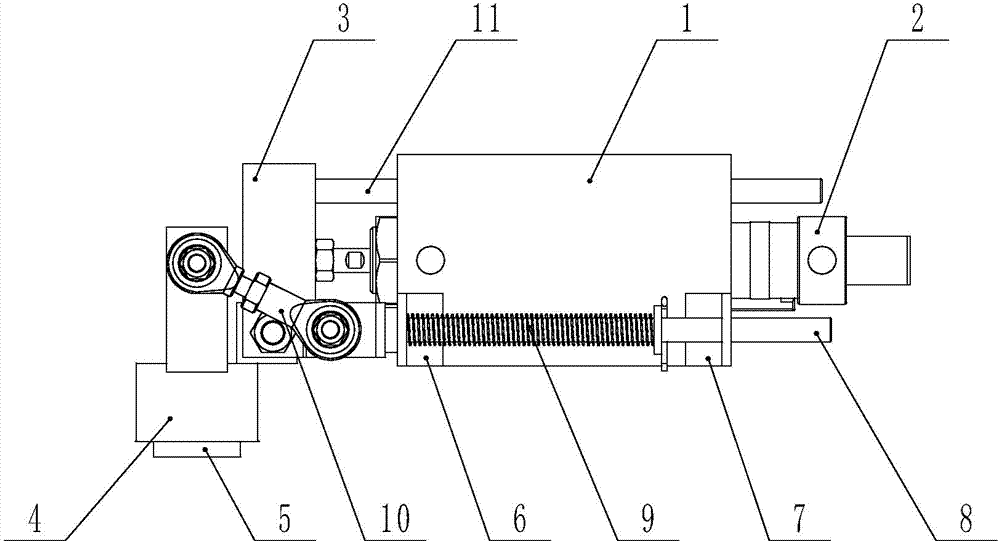

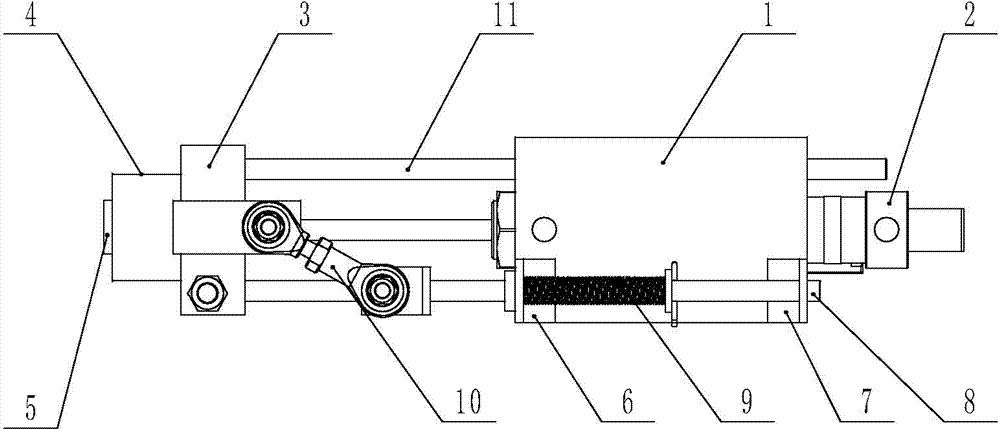

Material-receiving system for band saw gear milling machine

ActiveCN102528167ALess bendingReduce bruisesMetal sawing tool makingMetal working apparatusQuality levelMechanical engineering

The invention relates to a material-receiving system for a band saw gear milling machine. A plurality of material-receiving plates are arrayed on two sides at the top of a base bracket, so as to form two rows of material-receiving plates in parallel; the two rows of material-receiving plates are located at same altitude, thereby forming a layer of material-receiving plates; a material supporting mechanism and a material stopping wheel are arranged between the two rows of material-receiving plates; the material supporting mechanism is used for supporting a band saw; the material stopping wheelis used for limiting a transmission direction of the band saw; one layer or multiple vertical parallel layers of the material-receiving plates are arranged; positioning holes, by which positioning shafts vertically pass through each layer of the material-receiving plates, are formed; the bottom of each of the positioning shafts is connected with a material-receiving slewing mechanism; a constant speed gear box is arranged on the base bracket between the two rows of material-receiving plates; a motor output shaft is connected with an input shaft of the constant speed gear box; and two output shafts of the gear box are respectively connected with the material-receiving slewing mechanisms on two sides of the constant speed gear box through a conveying mechanism. In the material-receiving system for the band saw gear milling machine provided by the invention, saw bands are directly divided into upper and lower two layers which do not interfere and contact each other; the quality accidents, such as bending, bumping, and the like, of the saw bands are avoided while the materials are received; and the quality level during a band saw gear milling process is increased.

Owner:BICHAMP CUTTING TECH (HUNAN) CO LTD

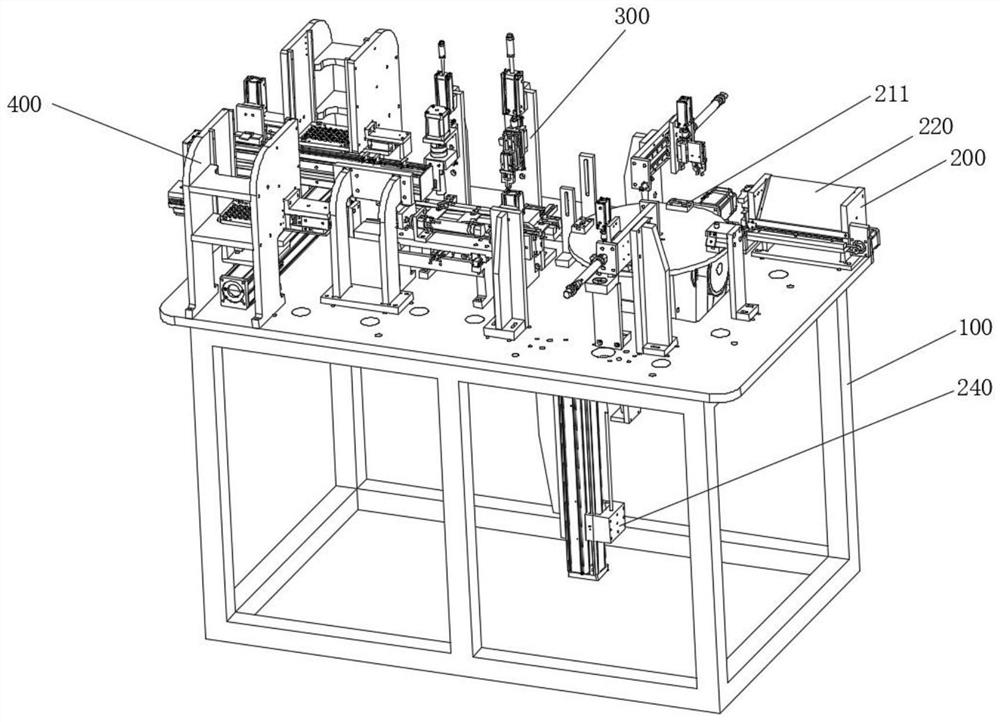

Assembling device for water pipe connector

PendingCN107511663AAvoid increasing labor intensityImprove assembly efficiencyMetal working apparatusWater pipeRotating disc

The invention discloses an assembling device for a water pipe connector. The assembling device comprises a machine frame, and an assembling mechanism, a first conveying mechanism and a second conveying mechanism are arranged on the machine frame; the assembling mechanism comprises a horizontally arranged rotating disc, a limiting plate which is arranged in the circumferential direction of the rotating disc, and a first lifting rod arranged on the top of the rotating disc and used for pressing gaskets on inner cores, and the limiting plate and the first lifting rod are connected with the machine frame; a plurality of first openings used for allowing the inner cores to be arranged vertically are uniformly distributed in the radial edge of the rotating disc, and first grooves used for accommodating circular rings and the gaskets are formed in the tops of the side walls of the first openings; and the limiting plate, the first openings and the first grooves form a limiting cavity used for limiting moving of the inner cores, the circular rings and the gaskets, the limiting plate is provided with a first opening part allowing the inner cores and the circular rings to pass through and a second opening part allowing the gaskets to pass through, the first opening part communicates with the first conveying mechanism, and the second opening part communicates with the second conveying mechanism. According to the assembling device for the water pipe connector, automatic assembling of the water pipe connector is realized, and assembling efficiency is improved.

Owner:开平市佳思雅卫浴有限公司

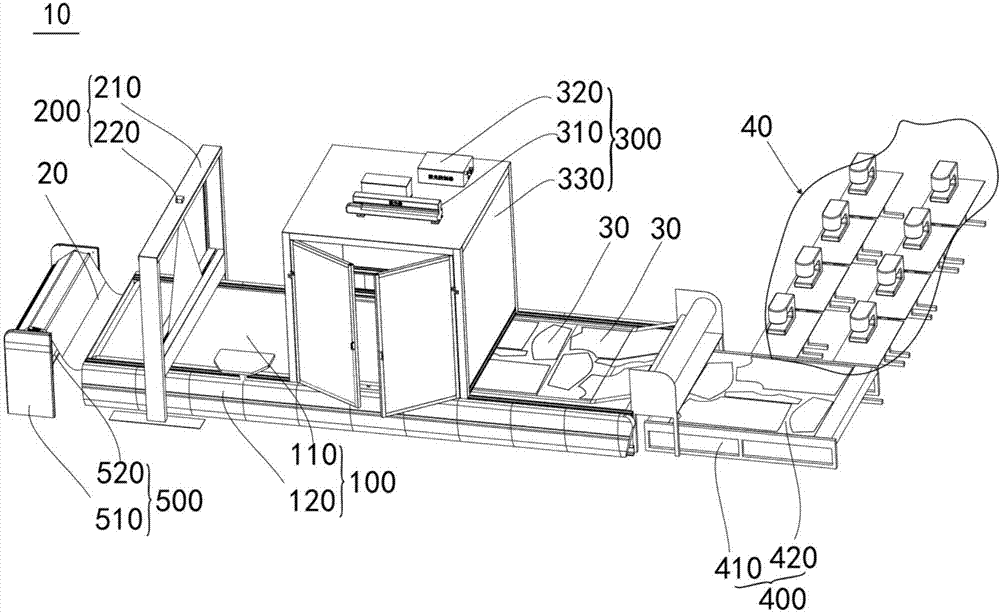

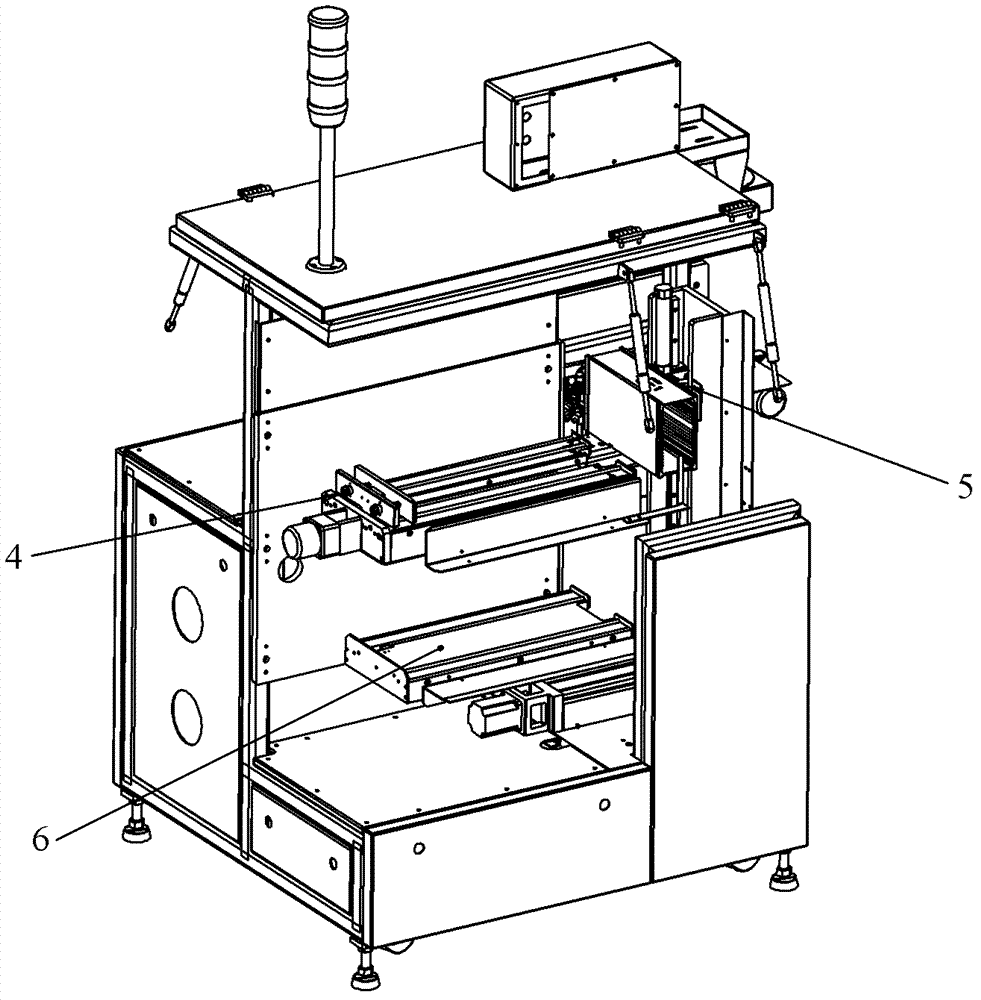

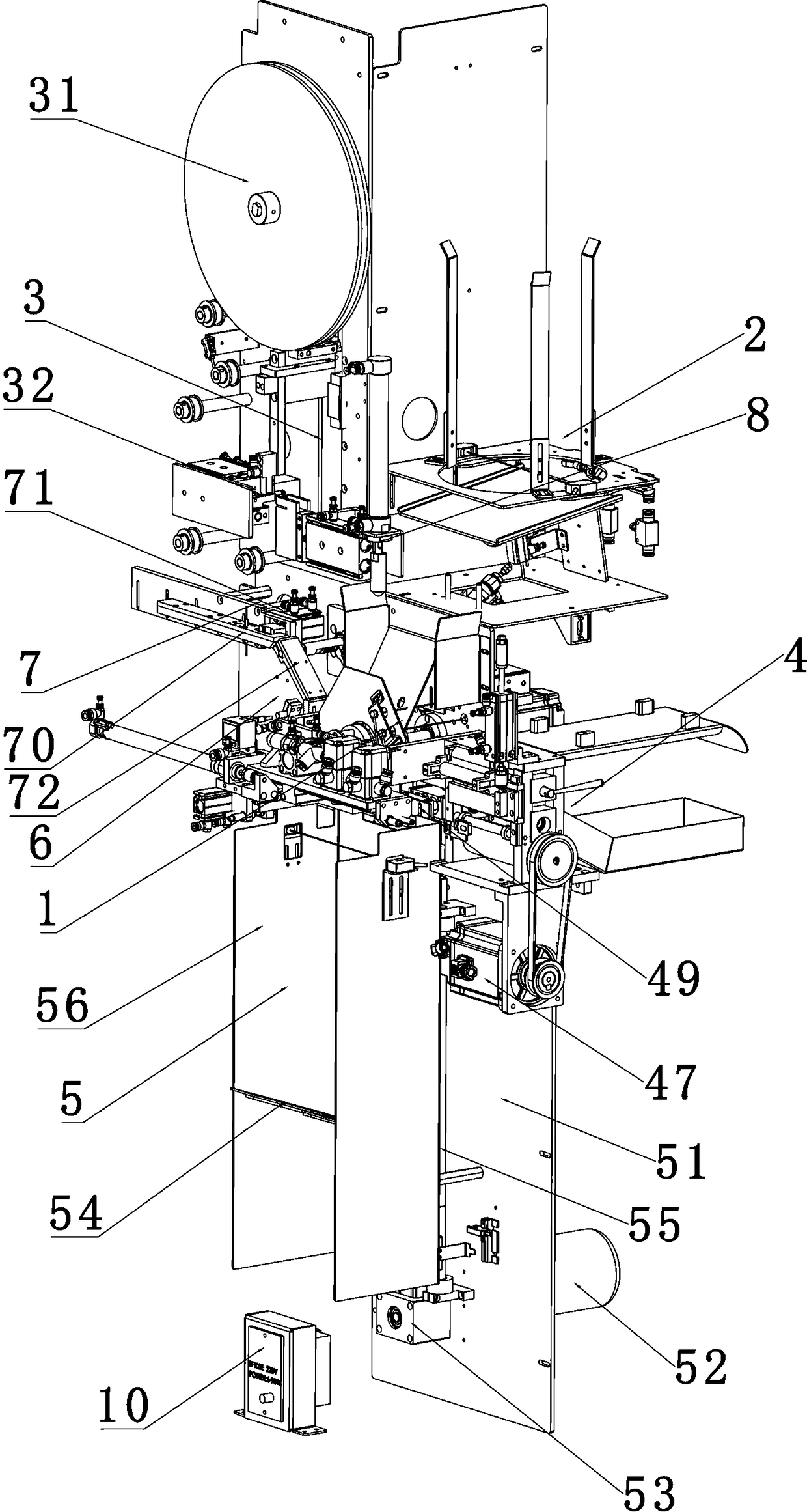

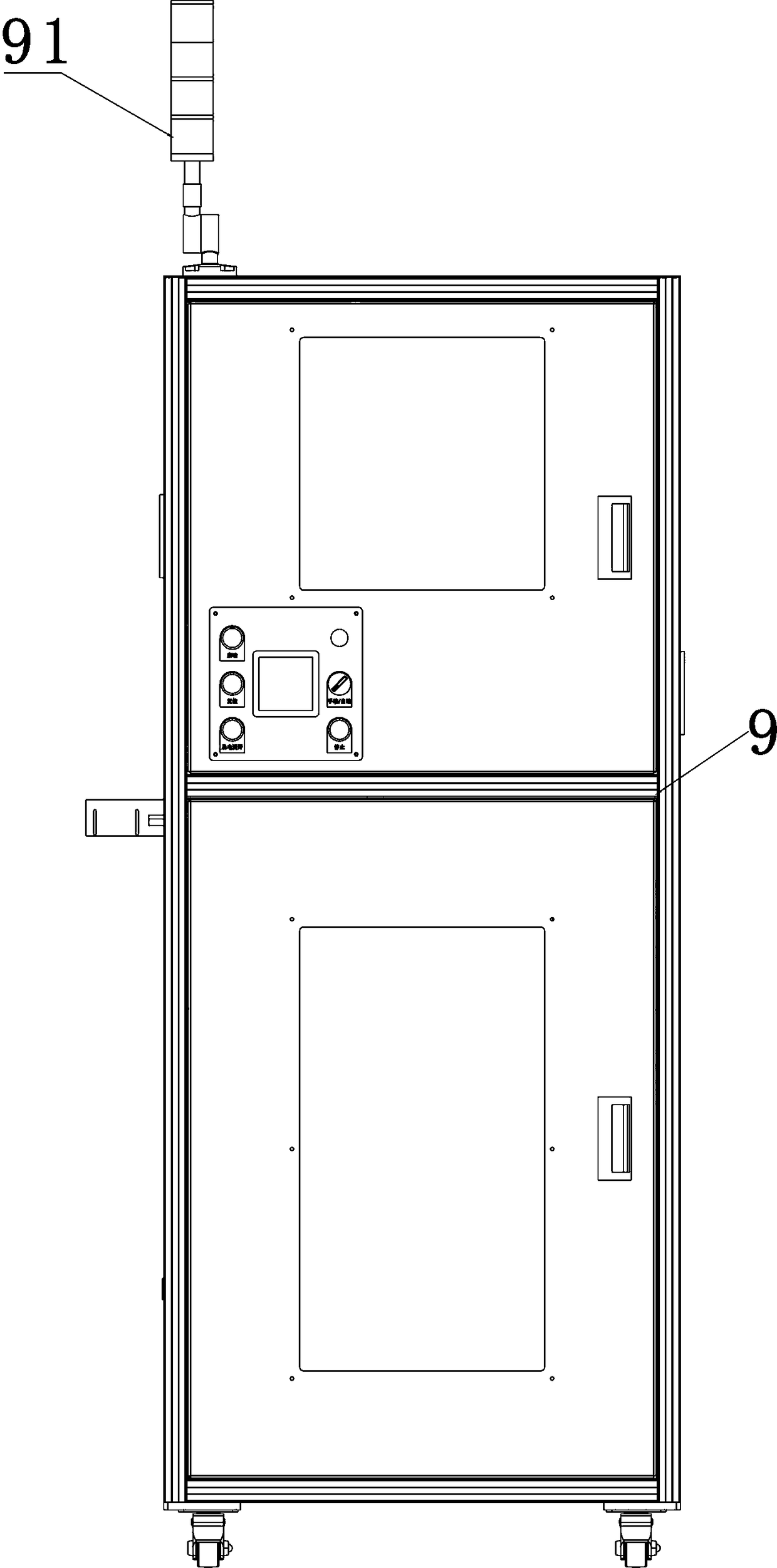

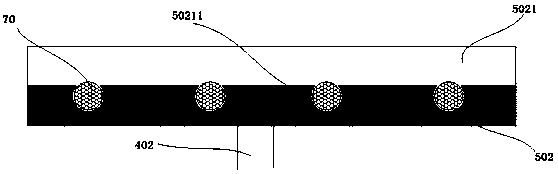

Continuous full-automatic material receiving machine for semiconductor chip tape

PendingCN109368339ARealize automatic receivingAchieve insertionLabelling machinesWebs handlingSemiconductor chipEngineering

The invention discloses a continuous full-automatic material receiving machine for a semiconductor chip tape. The continuous full-automatic material receiving machine comprises a winding mechanism forwinding the semiconductor chip tape, a feeding mechanism for providing material trays, a glue pasting mechanism for pasting ending glue, a labeling mechanism for pasting labels on the material traysand a material tray lifting mechanism for collecting the material trays; the winding mechanism, the feeding mechanism, the glue pasting mechanism, the labeling mechanism and the material tray liftingmechanism are correspondingly mounted on an inner mounting plate; the winding mechanism is mounted in the middle of one side of the inner mounting plate; the material tray lifting mechanism is mountedat the lower end of the inner mounting plate and is positioned directly below the winding mechanism; the winding mechanism is positioned directly above the winding mechanism; the glue pasting mechanism is positioned on the other side of the winding mechanism; and the labeling mechanism is positioned on one side of the winding mechanism. The continuous full-automatic material receiving machine further comprises a material guiding mechanism for conveying a chip carrier tape. The output end of a material guiding rail in the material guiding mechanism extends to the winding mechanism and is butted with the winding mechanism.

Owner:深圳市恒峰锐机电设备有限公司

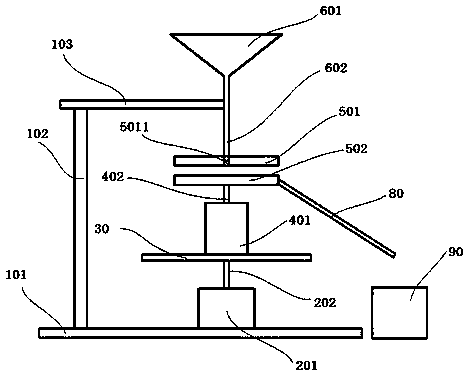

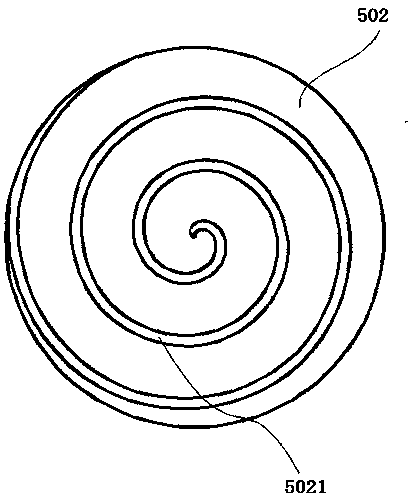

Beans crushing and collecting device

PendingCN107824282AGrind fullyAvoid frictionless rotationGrain treatmentsElectric machineryEngineering

The invention provides a beans crushing and collecting device, which comprises a substrate, a connecting rod and a mounting rod. The lower end of the connecting rod is fixedly connected with the substrate, and the connecting rod is positioned on the substrate and parallel to the substrate. A pneumatic cylinder comprises a cylinder body and a piston rod. The cylinder body is fixedly installed on the upper surface of the substrate. A support plate is connected to the cylinder body through the piston rod, and the support plate is parallel to the substrate. A motor comprises a motor body and a rotating shaft. A grinding disc comprises an upper disc-shaped grinding disc and a lower disc-shaped grinding disc. The upper surface of the lower grinding disc is provided with a planar spiral groove. The upper grinding disc and the lower grinding disc are coaxially arranged. The center of the upper grinding disc is provided with a through hole. A hopper comprises a hopper body and a hopper mouth. The hopper body is connected to the hopper mouth through a through hole. The lateral side of the hopper mouth is connected to the connecting rod through the mounting rod. The device also comprises a chute, one end of which is fixedly installed at the lateral side of the lower grinding disc at a discharge opening. A storage tank is arranged below the other end of the chute. Vertical height of one end of the chute is greater than vertical height of the other end of the chute. By integrating grinding and collection, the device of the invention has high grinding efficiency.

Owner:惠州市肆方农业发展有限公司

Automatic transfer system of adjustable loading tray for final sterilized product

The invention relates to an automatic transfer system of an adjustable loading tray for a final sterilized product, and is characterized in that: the machine comprises a multi-track feeding device, amulti-track bottle picking device, a multi-track sorting machine, a material receiving and transferring device and a material loading and transferring device. The invention has the advantages that: through automatic transfer system of the adjustable loading tray for the final sterilized product, the process realizes automatic material receiving, accurate counting of entire columns and automatic butt transfer to a sterilization cabinet for sterilization through the multi-track feeding device, a multi-track bottle picking device, a multi-track sorting machine, a material receiving and transferring device, and the material loading and transferring device realizes automatic butt transfer to the next process after the sterilization process is completed. In this way, the automation of productionmanagement with accurate and traceable data is realized, and in addition, the adjustable loading tray facilitates efficient and high-quality transfer when replacing products, so that damage of finished products and investment in fixed assets are greatly reduced, and the automation is realized.

Owner:温州精越科技有限公司

Bearing receiving device

ActiveCN108946122AReduce investmentReduce labor intensityConveyor partsReciprocating motionElectro hydraulic

The invention relates to the field of bearing conveying, in particular to a bearing receiving device. The bearing receiving device comprises a pushing mechanism and a stacking mechanism, wherein a transverse first stacking groove is formed in the joint of the pushing mechanism and a discharging channel, and an electro-hydraulic push rod is arranged at one end, close to the discharging channel, ofthe first stacking groove; and a transmission mechanism comprises a base, a rocker driving mechanism and an electric telescopic rod, wherein the base is fixedly connected with a supporting rod, the supporting rod is movably hinged to the electric telescopic rod, the other side of the electric telescopic rod connected with the supporting rod is movably hinged with the rocker driving mechanism, oneend, far away from the pushing mechanism, of a conveying mechanism is provided with the stacking mechanism. The bearing receiving device is simple in structure, safe and reliable; under the driving ofthe rocker driving mechanism, the electric telescopic rod reciprocates between the first stacking groove and a second stacking groove, and meanwhile, the electric telescopic rod movably sleeves witha bearing through stretching and retracting, so that high automation material collecting is achieved, and manual investment is greatly reduced.

Owner:BENGBU FEIYU BEARING

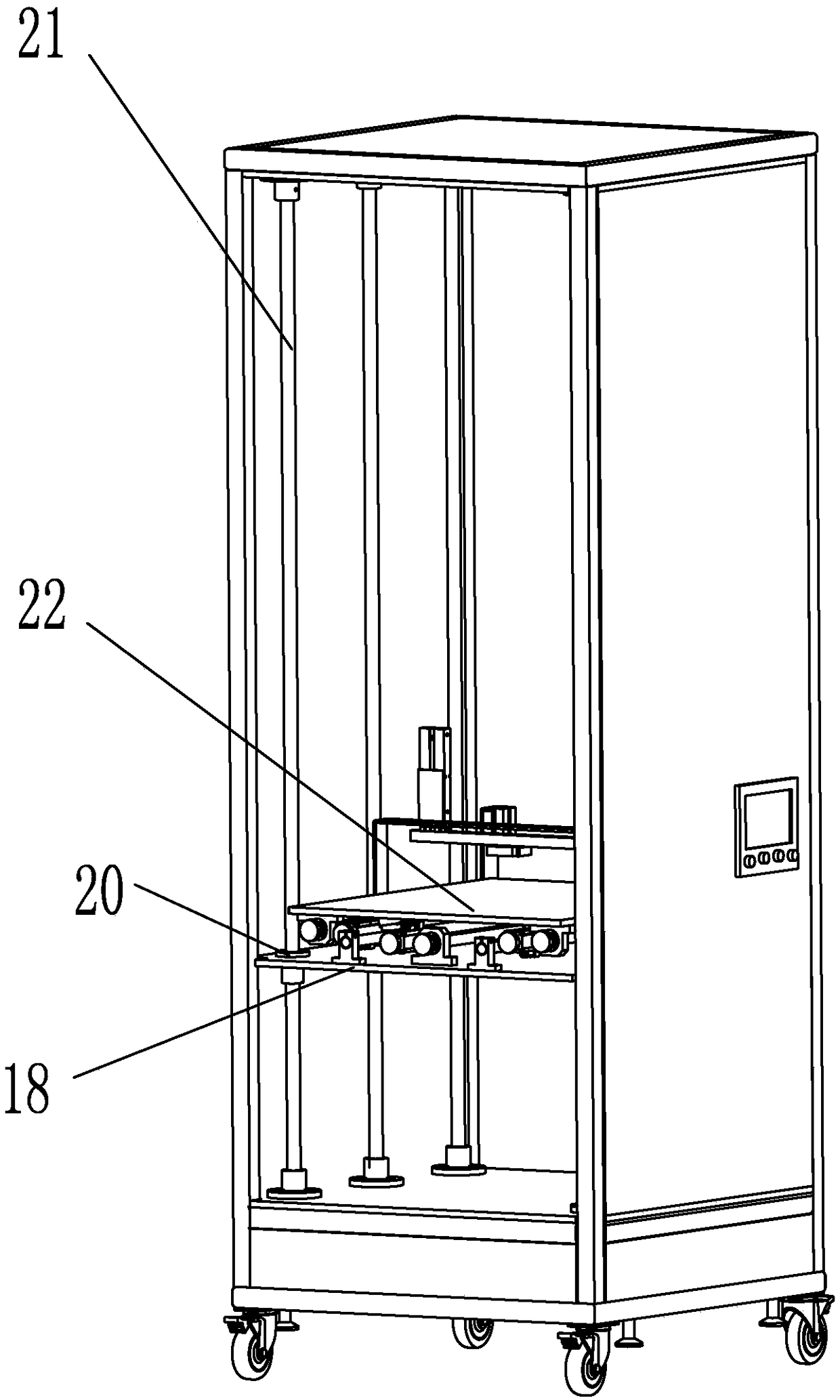

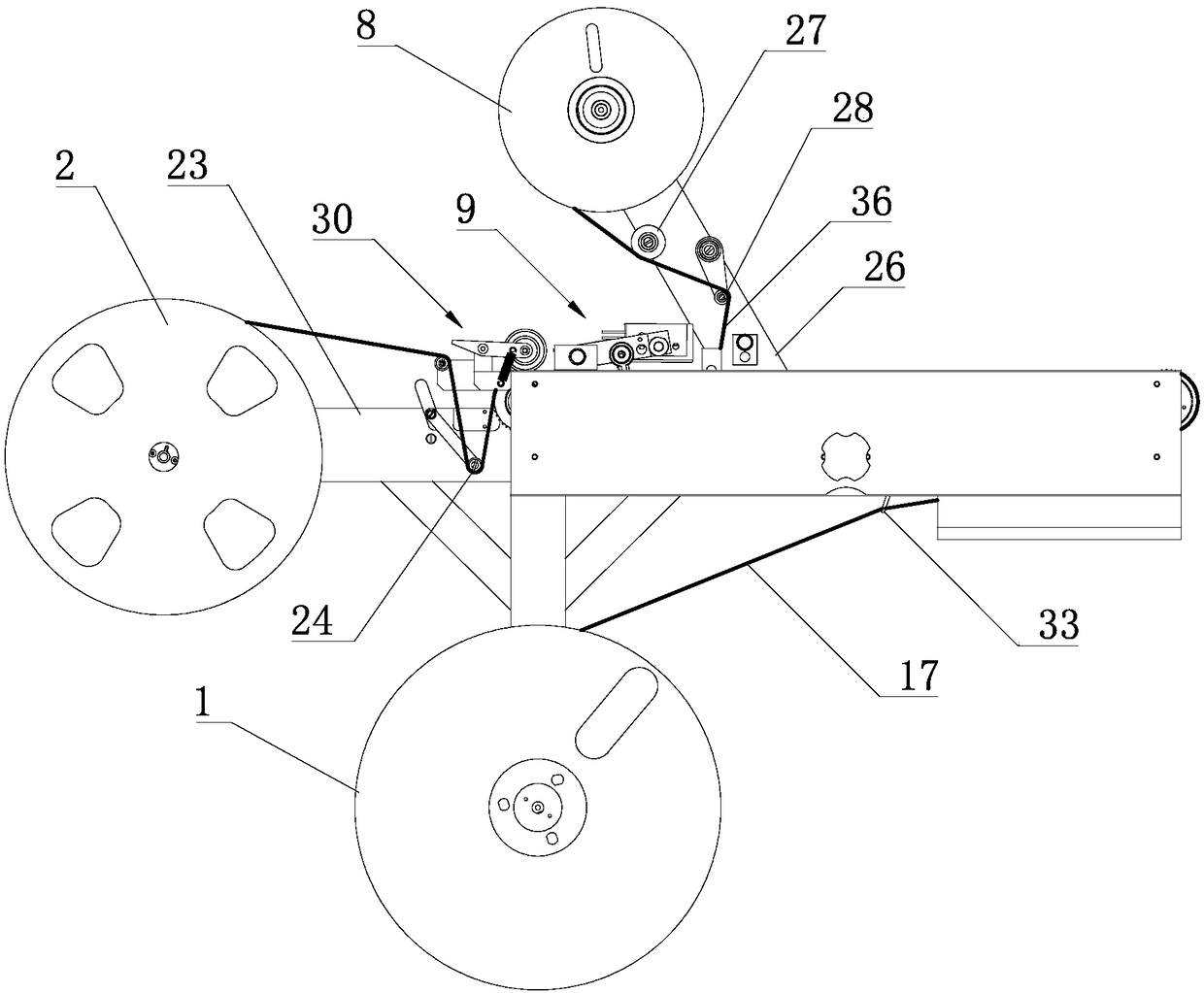

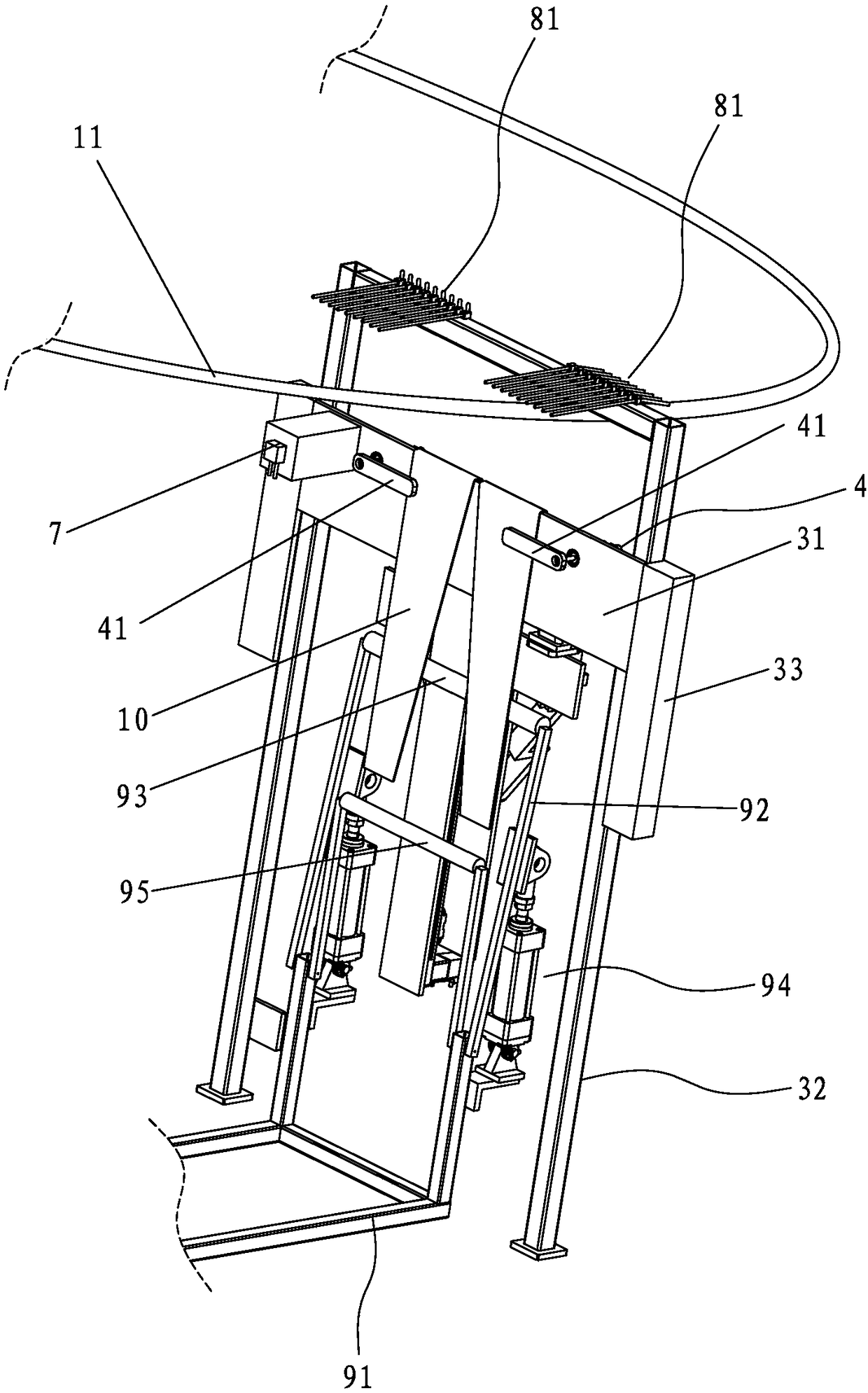

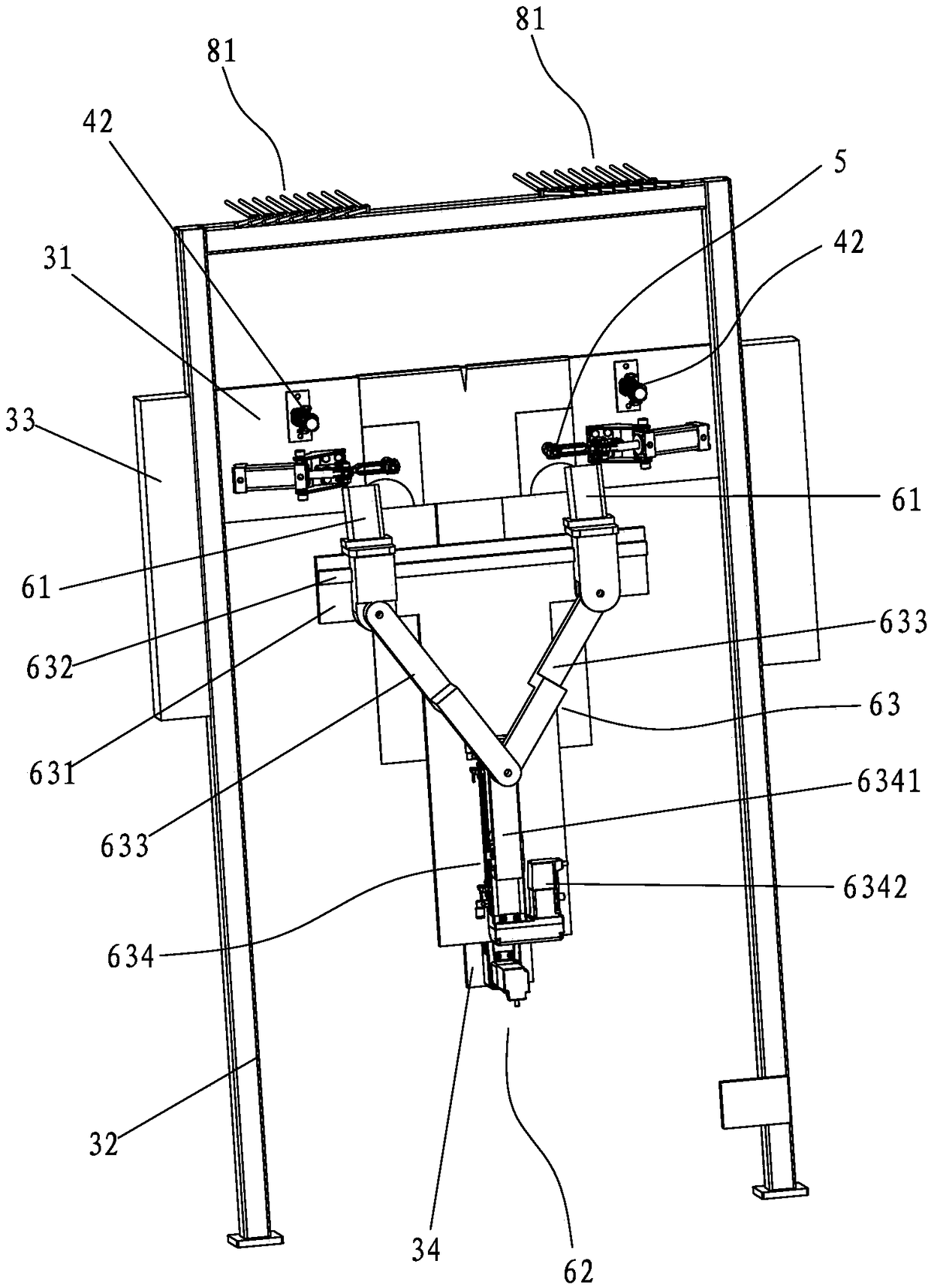

Lifting type material supporting mechanism and material collecting device of conducting film assembly

InactiveCN103407825ANeatly positionedRealize automatic receivingPile receiversArticle deliveryManipulatorRobot

The invention discloses a lifting type material supporting mechanism and a material collecting device of a conducting film assembly. The lifting type material supporting mechanism comprises a base plate, a fixed plate, a motor assembly, a material supporting plate, a plurality of guiding rods, a nut base and a screw rod, wherein two stand columns are arranged above the base plate, the fixed plate is fixed at the upper end of each stand column, the motor assembly is provided with a driving wheel, the material supporting plate is arranged above the fixed plate, the guiding rods penetrate through guiding holes formed in the fixed plate, the upper end of each guiding rod is fixedly connected with the material supporting plate, and the lower end of each guiding rod is fixedly connected with a lower connecting plate, the nut base is provided with a driven wheel which is connected with the driving wheel in a transmission mode, and the screw rod is in threaded connection with a nut hole. In the process of stacking materials, the positions of the materials are neat and cannot be changed easily, the material placement positions do not need to be changed when a mechanical arm or a robot places the materials, the using efficiency of the robot or the mechanical arm is improved easily, and productivity is improved. According to the material collecting device of the conducting film assembly, the automatic material collection of the FPC conducting film assembly is achieved, manual material collecting is not needed, labor cost is reduced, and material collecting efficiency is improved.

Owner:SHENZHEN RAPOO TECH

Reel type take-up device in recording equipment

PendingCN108372946AHigh degree of automationRealize automatic receivingPackagingWebs handlingAutomationElectrical and Electronics engineering

The invention discloses a reel type take-up device in recording equipment, which comprises a payoff reel, a take-up reel, a chip strip conveying mechanism and a laminating mechanism, wherein the chipstrip conveying mechanism comprises two supporting guide plates and a chip strip driving mechanism, the chip strip driving mechanism comprises transmission gears and a chip strip driving part, the transmission gears include a driving gear and a driven gear, and the driving gear and the driven gear are respectively arranged between two ends of the two supporting guide plates; the supporting guide plates are also provided with a chip placement station and a lamination station which are located between the driving gear and the driven gear; the laminating mechanism comprises a film reel for the placement of a film strip, and a combining mechanism for attaching the film strip onto the chip strip, and the combining mechanism comprises a heating block located over the lamination station and a heating driving mechanism fixed on the supporting guide plates to drive the heating block to press the film strip. The automation degree of the reel type take-up device is high, full-automatic take-up can be realized, and thereby the take-up efficiency can be increased.

Owner:GUANGZHOU MINGSEN TECH CO LTD

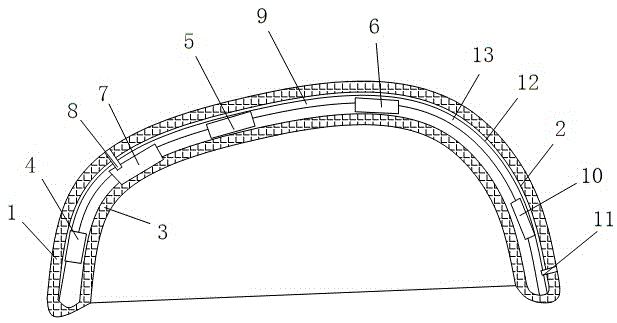

Field individual combat helmet based on Beidou navigation satellite

InactiveCN105411078ARealize automatic receivingImprove protectionSatellite radio beaconingHelmetsNatural satelliteElectronic communication

The invention discloses a field individual combat helmet based on a Beidou navigation satellite. The field individual combat helmet comprises a shell, an inner container and at least one row of interlayer arranged between the shell and the inner container, wherein the shell and the inner container are connected in sequence, each row of interlayer comprises a bag type body and an inner cavity, and a Beidou receiving antenna and storage unit, a miniature positioner, an arithmetic unit and a voice navigation module are sequentially connected in the inner cavity. According to the field individual combat helmet, and the bag type body packages the electronic communication units, is isolated between the shell and the inner container and better protects the electronic communication units. The arranged electronic communication units enable an individual soldier or a logistic system to conveniently find lost protectors and obtain important combat intelligence information through all terminals on the units after or during field combat, facilitate analysis and retention of combat data and achieve finding of necessary intelligence information in cooperation with a command system or the logistic system, and meanwhile the fighting power of the individual soldier is improved.

Owner:WUHU ZHENHUA RONGKE INTELLIGENT TECH

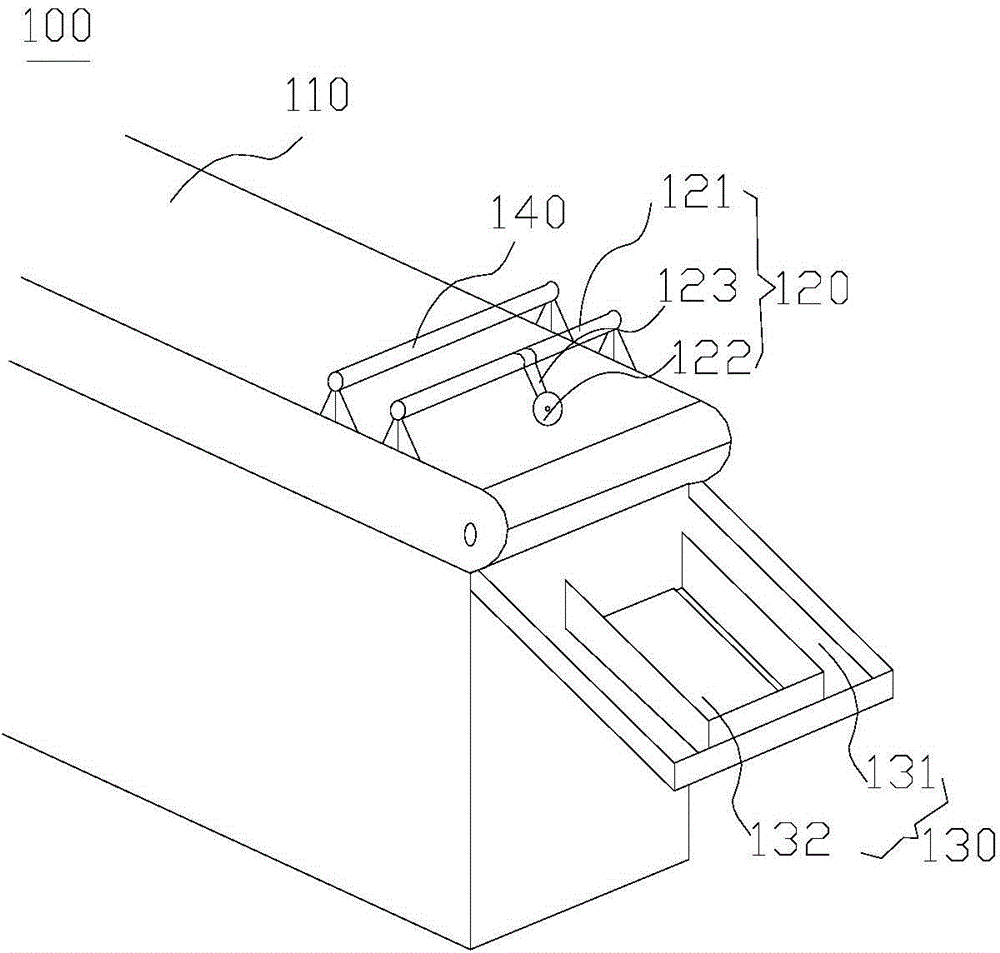

Material receiving device and die-cutting machine comprising material receiving device

ActiveCN104827512ARealize automatic receivingSave human effortMetal working apparatusMechanical propertyMechanical engineering

The invention relates to a material receiving device which comprises a transporting mechanism, a guiding assembly and a material receiving assembly, wherein the material receiving assembly is arranged at one end of the transporting mechanism; the guiding assembly comprises a first support and a guiding element; the first support is arranged on the transporting mechanism; one end of the material receiving assembly is arranged close to the transporting mechanism; the guiding element is arranged on the first support and also arranged towards the transporting mechanism, so that the guiding element holds down products when the products transported by the transporting mechanism are positioned between the guiding element and the transporting mechanism; when the material receiving device works, the products such as paper, are transported to the guiding element by the transporting mechanism, and the guiding element holds down the paper, so that the paper is slightly bent along the direction parallel to the motion direction of the transporting mechanism to form a certain radian, thus has better mechanical property, quickly falls into the material receiving assembly at a certain speed brought by inertial force and falls at the same position, further the paper is automatically arrayed to be orderly, and automatic material receiving is realized, labor force is reduced, and the working efficiency is improved.

Owner:广东康派环创科技有限公司

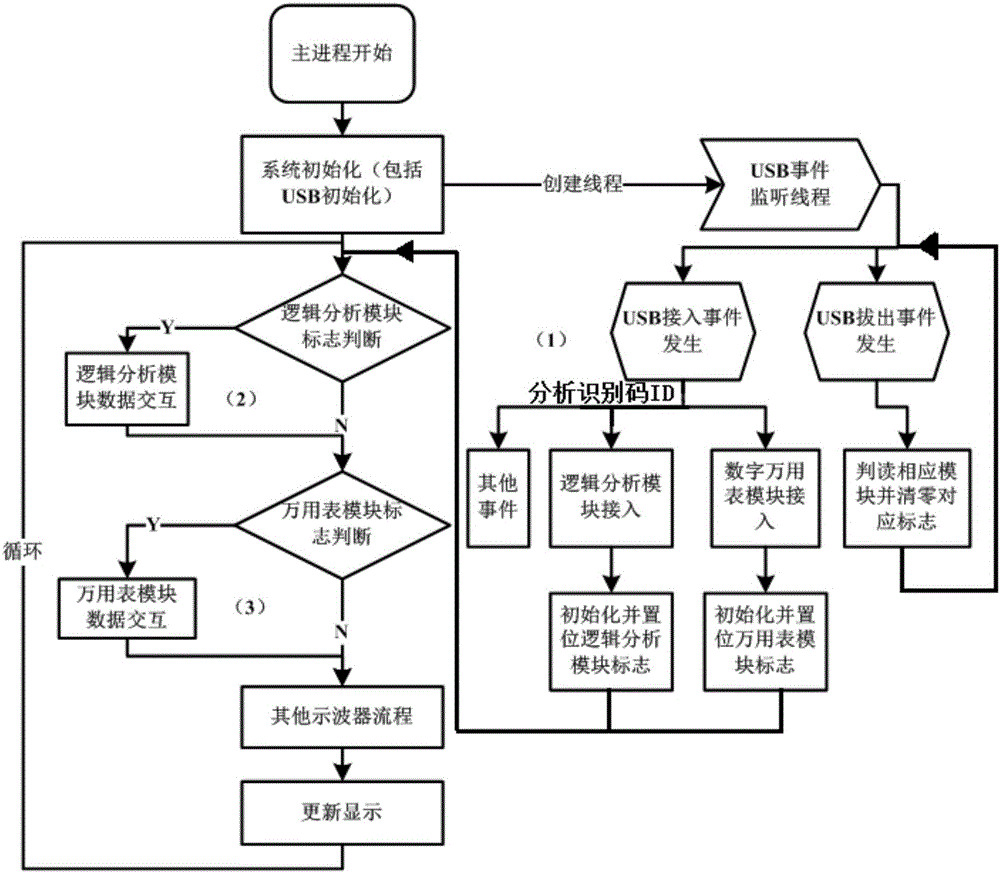

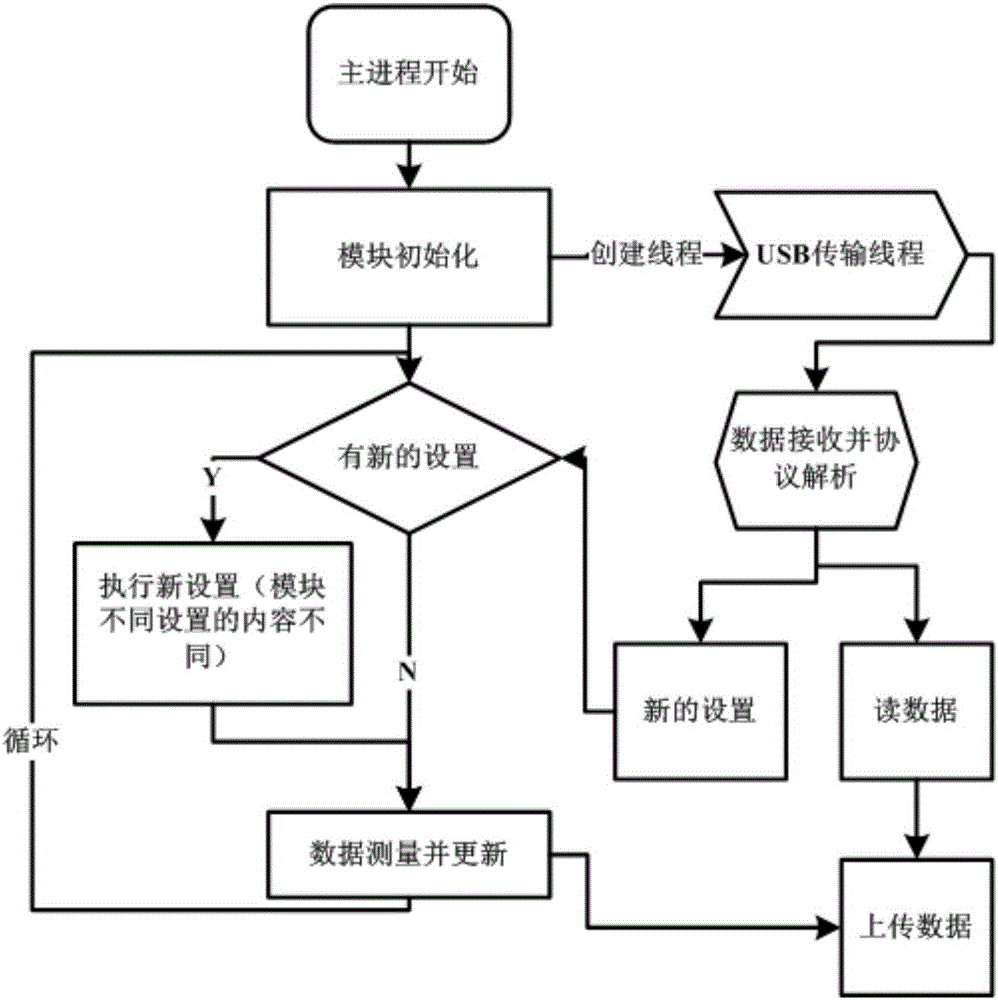

USB communication based modular function expansion method and system for digital oscilloscope

ActiveCN105868132ARealize automatic receivingAchieve interactionElectric digital data processingModularityUSB

The invention discloses a USB communication based modular function expansion method for a digital oscilloscope. The method comprises the following steps: (1) the digital oscilloscope and an external connection device are prearranged; (2) a supporting USB device interface and a USB device drive are arranged, and an identification code of the external connection device is preset; (3) a command and data are packaged; (4) initialization is performed, a USB event monitoring thread is established, and whether a USB accessing event or a USB pulling out event happens is judged; if the USB accessing event happens, the type of the external connection device is judged; if the USB pulling out event happens, the external connection device of which the USB is pulled out is interpreted, and a marker of the device is reset; (5) after the type external connection device is determined, the external connection device is initialized, and the marker of the external connection device is set, a host process judges the marker and jumps to a corresponding operation interface, and data are received and displayed; a USB transmission thread is established for receiving data and analyzing communication protocols, new setting is performed, and data are read; (6) whether new setting is performed is judged; (7) the data are uploaded. The invention further discloses a function expansion system.

Owner:UNI TREND TECH (CHINA) CO LTD

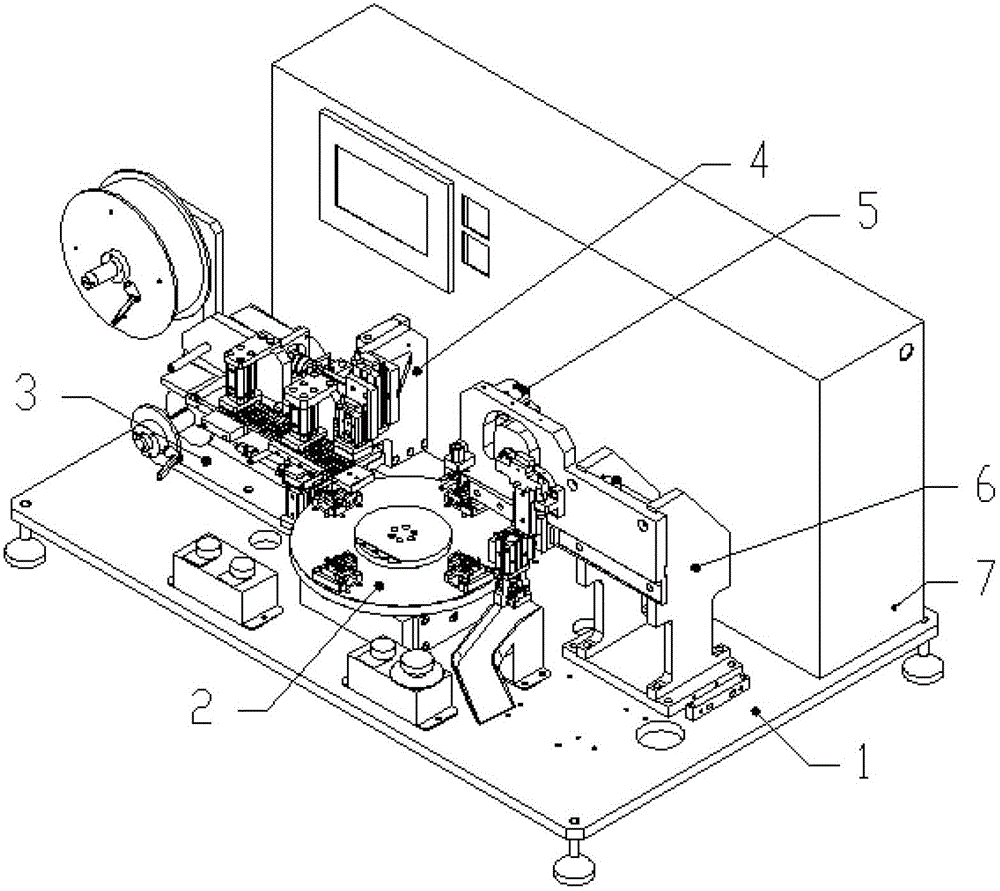

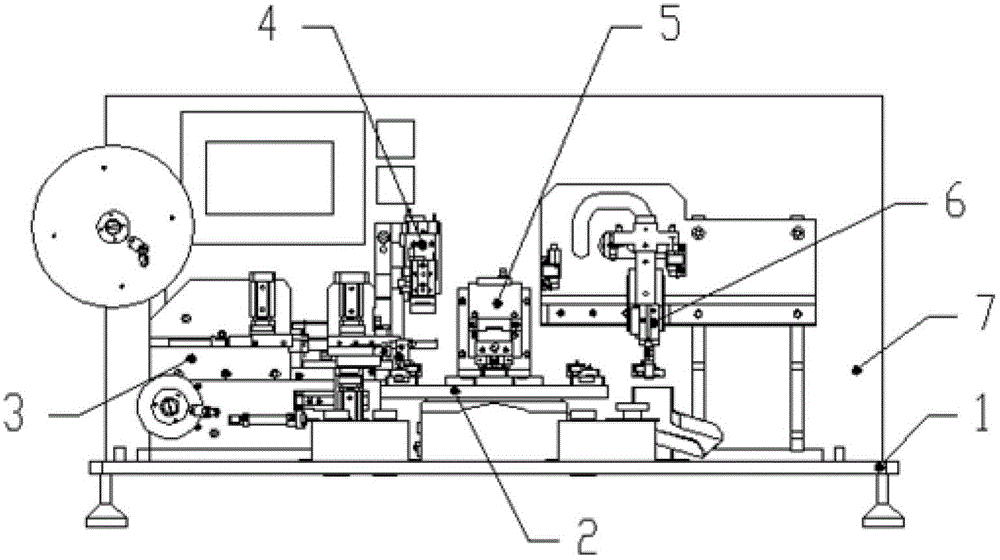

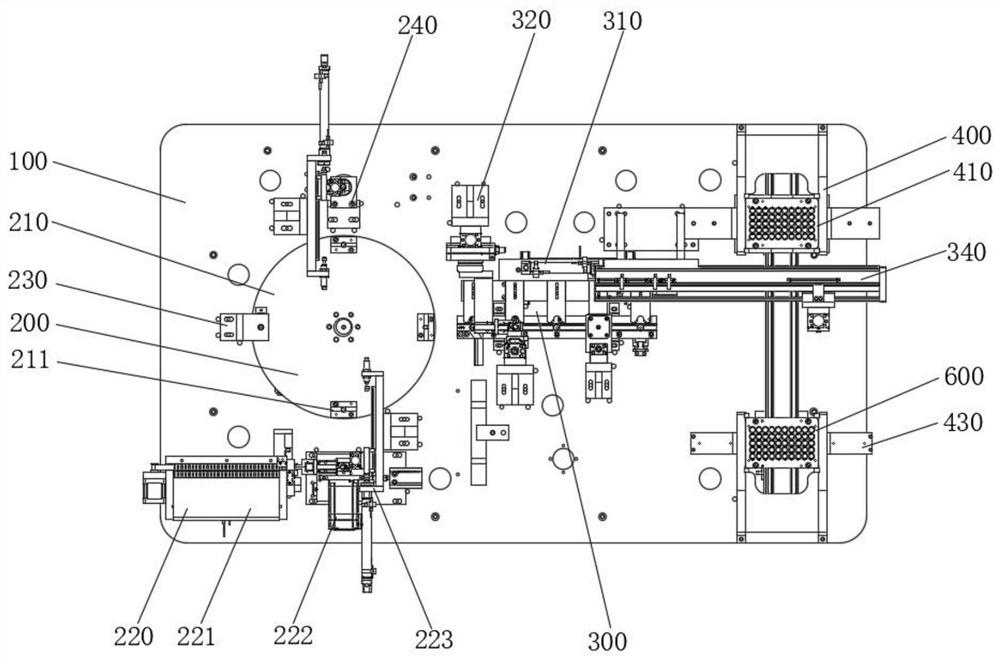

Buzzer automatic assembling machine

ActiveCN113894537ASimple structureRealize pure mechanical processingAssembly machinesPlastic magnetMachining

The invention relates to the field of buzzer automation, in particular to a buzzer automatic assembling machine. The buzzer automatic assembling machine comprises a workbench, and the workbench is provided with a part feeding module, an assembling module and a material receiving module. The buzzer automatic assembling machine is specially used for assembling novel buzzers, magnetic rings are placed and stored in a material bin mode during feeding, the storage quantity is large, during use, a stop block air cylinder drives a stop block to achieve automatic material falling and feeding, the operation is simple, convenient and time-saving, frequent material changing is not needed, synchronous belt material conveying and feeding are achieved, the automation degree is greatly improved, inner supporting type clamping jaws are adopted for taking materials, separation of plastic magnets is achieved through cooperation with magnetic rings with steps, through combining of a plate placing mechanism, a plate conveying mechanism and a plate taking mechanism, the material receiving module achieves automatic material receiving, coils, cover plates and connector lug assembling parts only need to be additionally arranged on the upper portions of buzzer semi-finished products and then pressed so that assembling of the whole buzzers can be achieved, the structure is simple, pure machining can be achieved, existing manual dispensing assembling is replaced, time and labor are saved, and the quality of produced products is higher.

Owner:CHANGZHOU FHD ELECTRONICS CO LTD

Automatic dust blowing method for jeans

ActiveCN109322131AReduce pollutionReduce manufacturing costMechanical cleaningPressure cleaningEngineeringCirculator

The invention discloses an automatic dust blowing method for jeans. The jeans are automatically fed through flow lines and automatically folded upside down and fixed on baffles, pockets are suctionedopen by a suction device, a dust blowing and suction circulator is inserted into the pockets to blow up dusts and inhale to form a blowing and suction cycle system, the dusts are blown up through blowing, and the dusts are suctioned by an outer deduster through suction. Automatic feeding, automatic dust blowing and automatic discharging of the jeans are realized, so workers can stay away from thedust blowing position and stay away from the noise and dust environment, employees are provided with the safe and comfortable production environment, production efficiency is improved, and productioncost is reduced.

Owner:中山益达服装有限公司

Electrode plate wrapping method

ActiveCN102856527AMobile stable and reliableAchieve overlayElectrode manufacturing processesFinal product manufactureEngineeringElectrode

The invention relates to an electrode plate wrapping method, which comprises the steps of: first, arranging a positive electrode plate and a negative electrode plate in an electrode plate material box vertically respectively, above all using a sucking disc to suck the positive electrode plate laterally, then turning the positive electrode plate downward by 90 degrees and placing it in a material trough, moving the positive electrode plate placed in the material trough forward by one working position, at the same time moving separator paper from top to bottom, cutting the separator paper off and disposing it on the material trough vertically, further moving the positive electrode plate forward by one working position, and making the front end of the positive electrode plate contact the central part of the separator paper in the moving process, along with the forward moving of the positive electrode plate, wrapping the positive electrode plate with the separator paper, then further moving the positive electrode plate forward by one working position, simultaneously employing the sucking disc to suck a negative electrode plate laterally, and placing the negative electrode plate right over the wrapping completed positive electrode plate, then keeping moving the negative electrode plate, the separator paper, and the positive electrode plate forward into a material receiving device, and when the number of a plate pack is collected, sending the plate pack out.

Owner:江苏金帆电源科技有限公司

Cooling and collecting device for metallurgical billets

InactiveCN105466225AAchieve recyclingRapid coolingCleaning using toolsHandling discharged materialBraced frameEngineering

The invention discloses a cooling and collecting device for metallurgical billets. The cooling and collecting device comprises a rack and conveyor belts arranged on the left and right sides of the rack. The conveyor belts are dragged by motors to work. The rack is provided with a sliding plate opposite to the conveyor belts on the two sides of the rack in position. A supporting frame used for pushing the billets is arranged on the sliding plate and connected to the side walls of the sliding plate in a sliding mode, and the supporting frame is driven by a servo motor. Spraying heads fixed to the rack are arranged above the sliding plate and connected with a water inlet pipe, a water collecting trough is arranged below the sliding plate, and multiple brushes are mounted above the right side of the sliding plate; brush heads of the brushes can make contact with the billets on the sliding plate, and circulating cooling pipes located on the two sides of the sliding plate are arranged below the brushes; a material sliding plate is connected to the conveyor belt on the right side of the rack and connected with a rotatable material collecting plate. According to the cooling and collecting device for the metallurgical billets, residual accumulated water is avoided, the billets can be quickly cooled, and automatic material collecting can be achieved.

Owner:CHONGQING HAIDE METALLURGY MATERIAL CO LTD

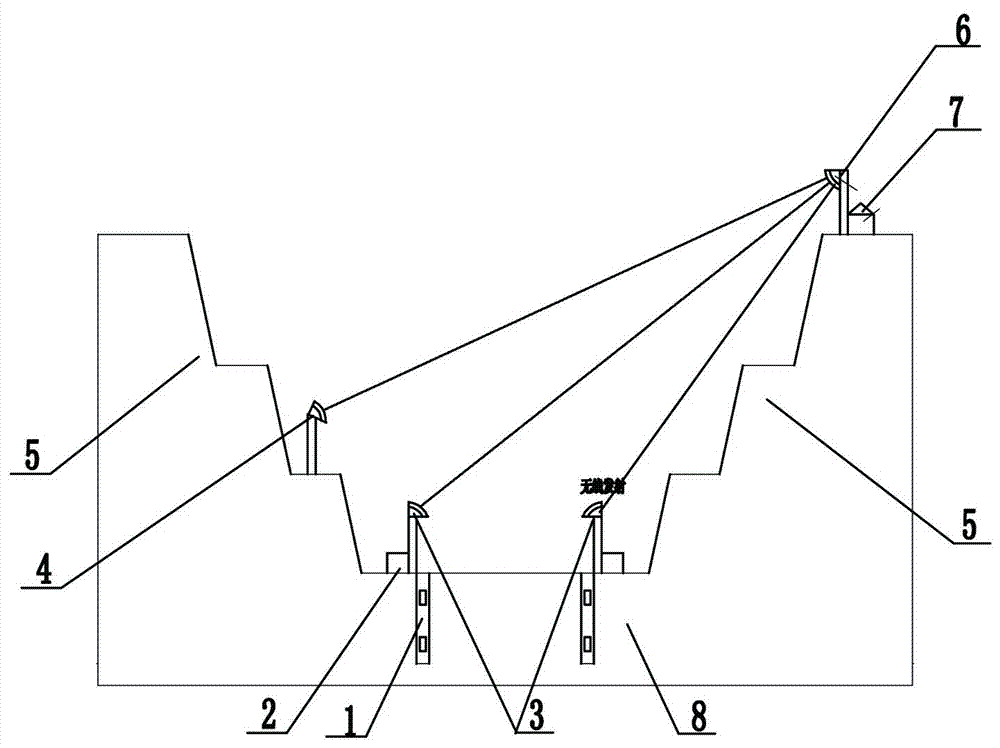

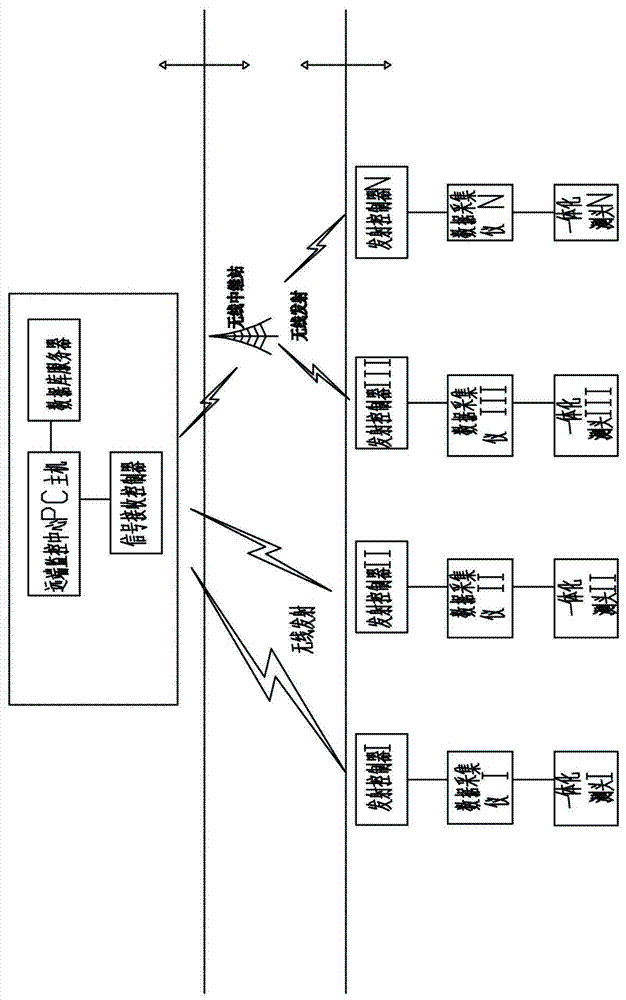

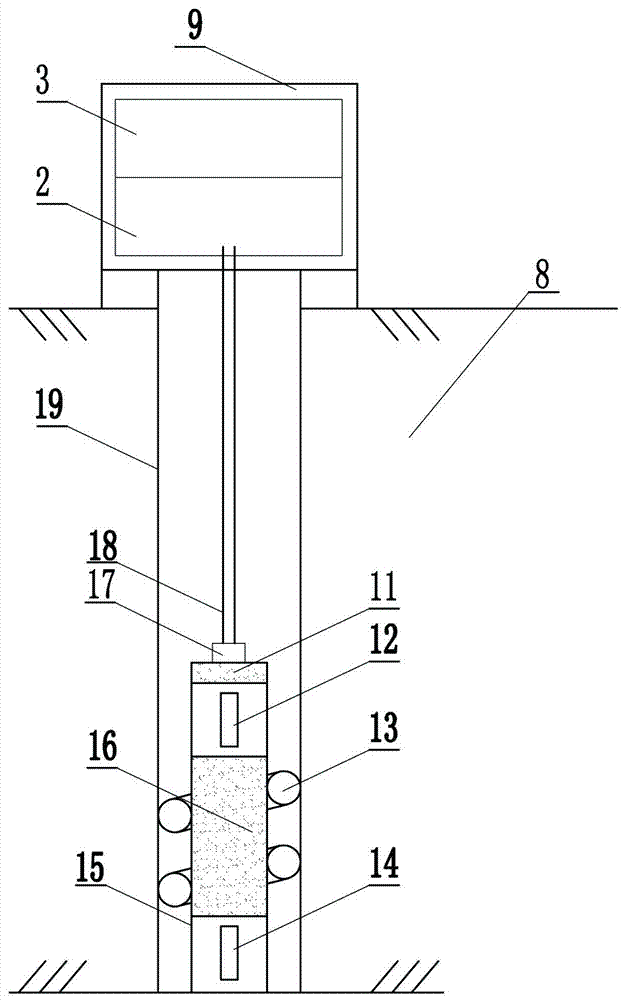

Device for monitoring lower goaf stability in open-pit iron mining

PendingCN107883918AImprove signal receptionEnables continuous monitoringElectric signal transmission systemsPower distribution line transmissionData acquisitionIron mining

The invention relates to a device for monitoring lower goaf stability in open-pit iron mining. The device comprises a signal acquisition system used for acquiring and sending signals as well as a single receiving, analyzing and processing system, and is characterized in that the signal acquisition system is a front-end monitoring unit comprising a plurality of integrated measuring heads with the same structure, a plurality of data acquisition instruments with the same structure, a plurality of wireless signal transmitting units with the same structure and a wireless relay arranged at a commanding point of an open pit, and the data acquisition instruments are connected with the integrated measuring heads through power lines; the single receiving, analyzing and processing system comprises asignal receiving controller, a far-end monitoring center PC host connected with the signal receiving controller as well as a database server. The device has the following advantages: by means of the multiple integrated measuring heads as well as application of signal acquisition, transmission, conversion, emitting and receiving technologies, the signal receiving capacity of the device is improvedeffectively, a multi-channel monitoring system with high sensitivity is formed, and potential safety hazards are eliminated.

Owner:ANSTEEL GRP MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com