Drum fermentation reactor-based bacterial cellulose production technology

A bacterial cellulose and production process technology, applied in the direction of microorganism-based methods, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the limitations of wide application, low productivity, low output, etc. problems, to achieve the effect of wide application range, strong production capacity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

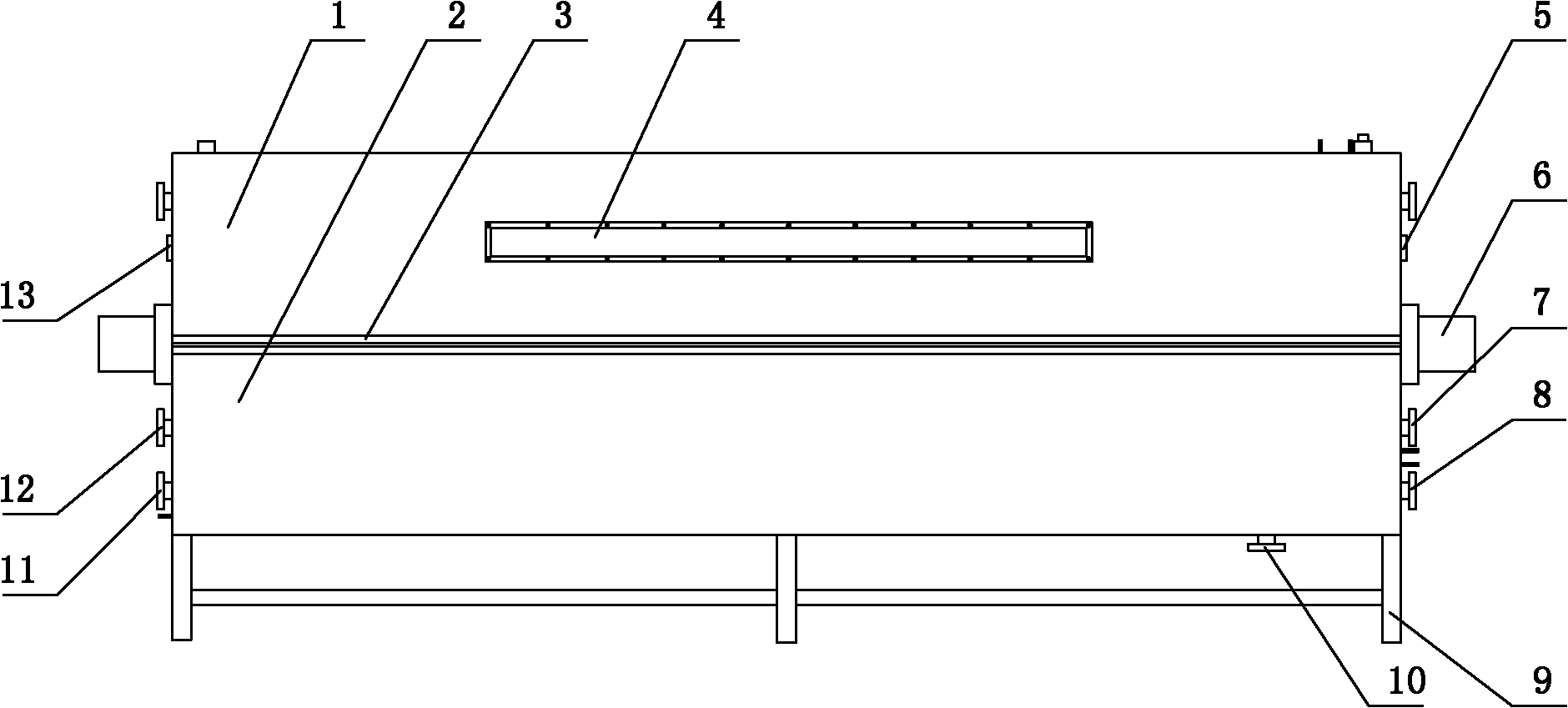

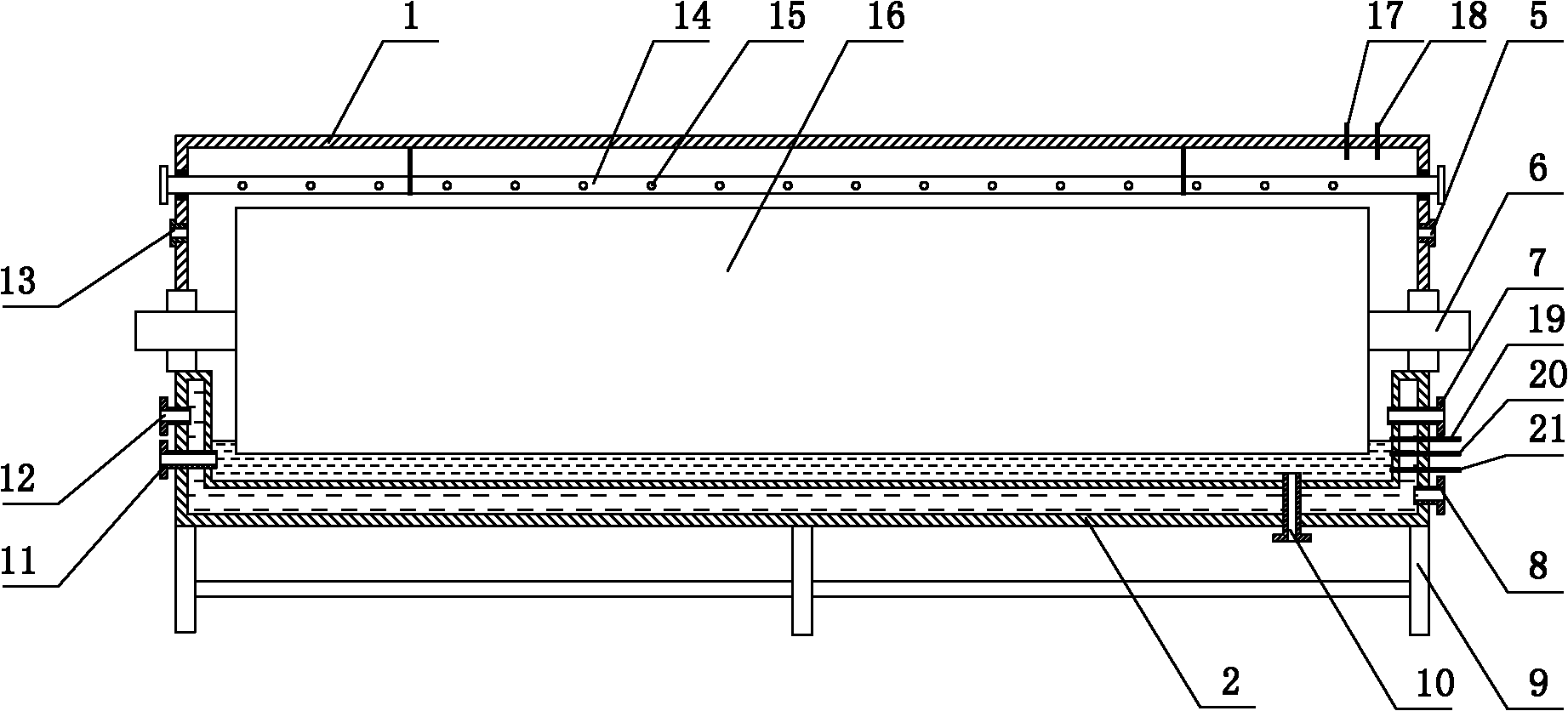

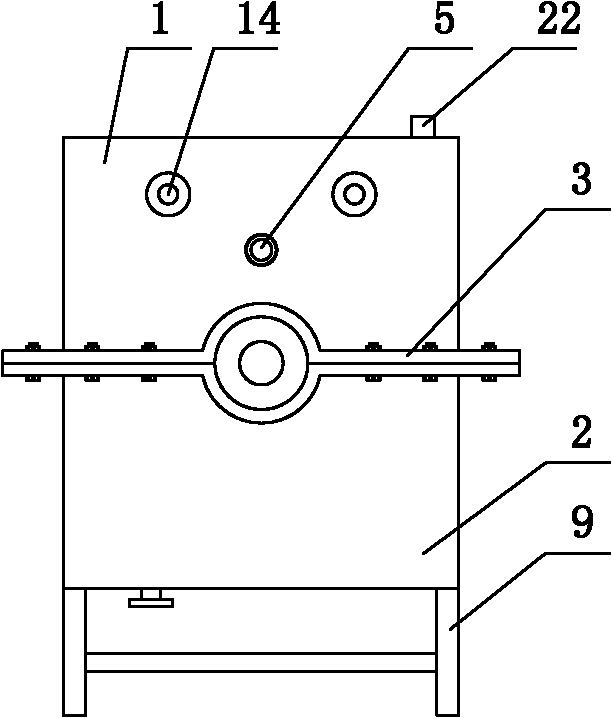

[0036] In order to better illustrate the production process of the bacterial cellulose of the present invention, the structure of the rotary drum fermentation reactor used in the present invention is firstly described.

[0037] The structure of the drum-type bacterial cellulose fermentation reactor adopted in the bacterial cellulose production process is: mainly by the support 9, the horizontal housing, the drum 16 horizontally installed in the horizontal housing, and the drive motor (in the figure) not shown) and a scraper. The horizontal shell is composed of the upper air dust isolation shell 1 and the bottom jacket type feed liquid tank 2, which are assembled and installed through the flange connection edges 3 around them. The drum is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com