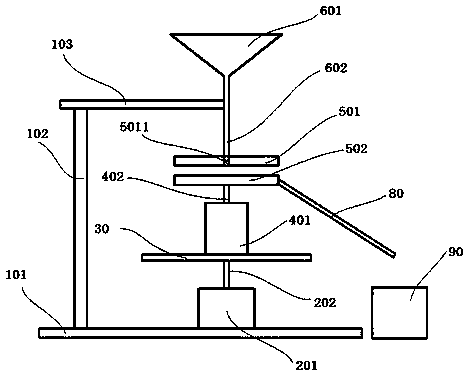

Beans crushing and collecting device

A collection device and bean technology, which is applied in grain processing, etc., can solve the problems of low grinding efficiency, inability to automatically collect bean powder, and long time consumption, and achieve the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

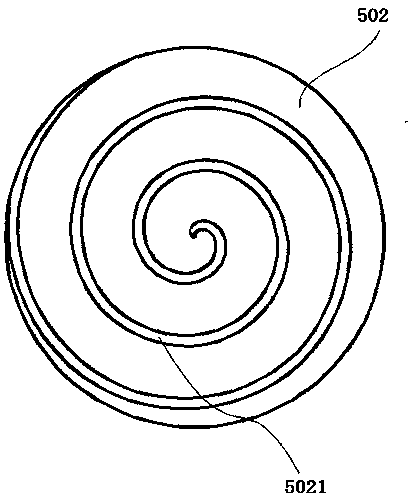

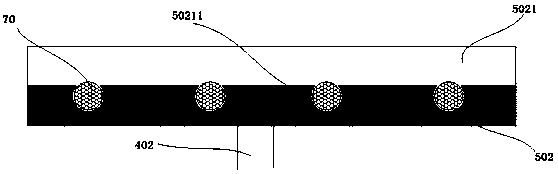

[0025] The upper surface of the lower grinding disc 502 is provided with a plane spiral groove 5021. The starting point of the spiral of the groove 5021 is the feed inlet, and the end of the spiral is the outlet. The feeding port of the disc 502; the rotation direction of the body 401 of the motor is consistent with the spiral direction of the groove 5021, and the beans are ground between the upper grinding disc 501 and the groove 5021. When the motor rotates, the beans are driven to move along the spiral direction , prolong the grinding time of beans, make the grinding of beans more fully, thus improve the grinding efficiency.

[0026] The groove depth of the groove 5021 gradually decreases from the inlet to the outlet.

[0027] The groove depth of the groove 5021 gradually decreases from the feed inlet to the discharge outlet, and the distance between the lower surface of the upper grinding disc 501 and the bottom of the groove 5021 gradually decreases, and the beans roll ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com