Patents

Literature

35results about How to "Grinding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

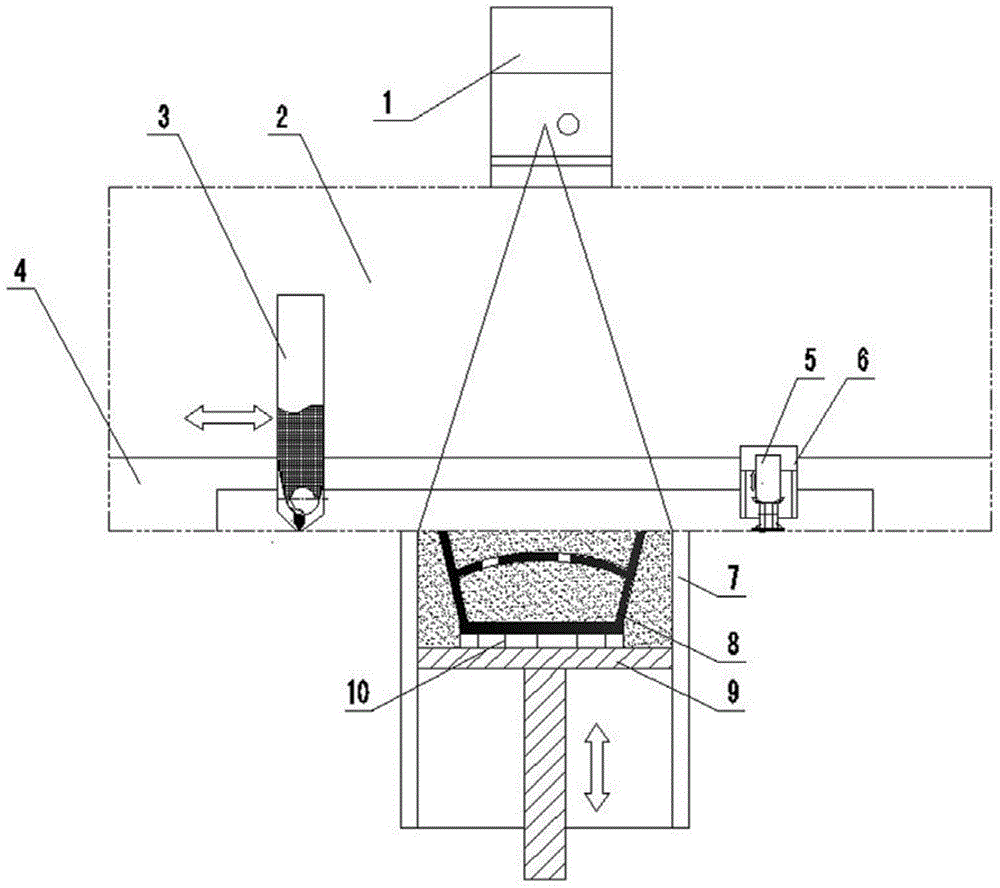

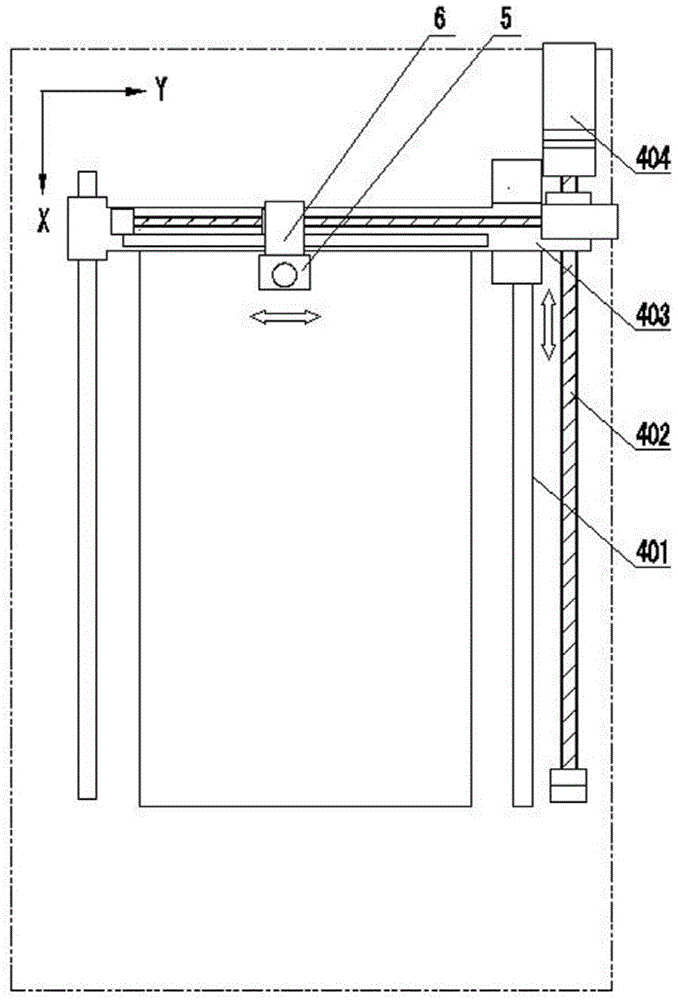

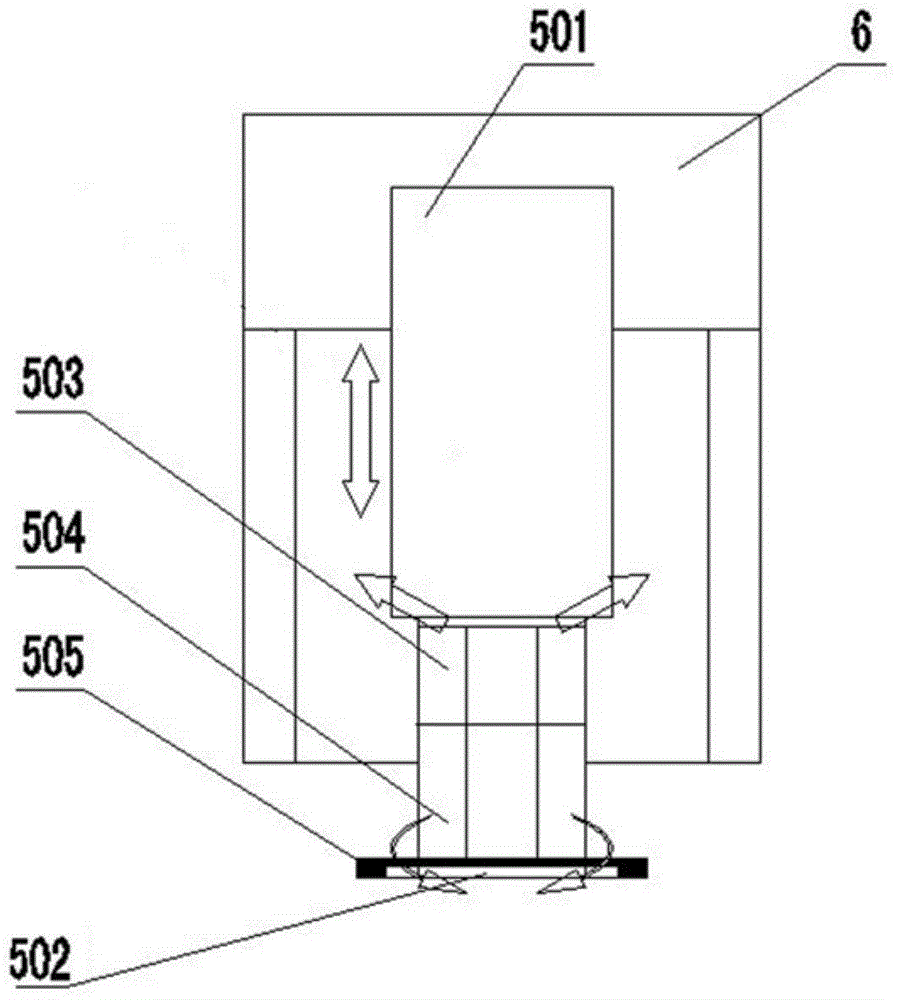

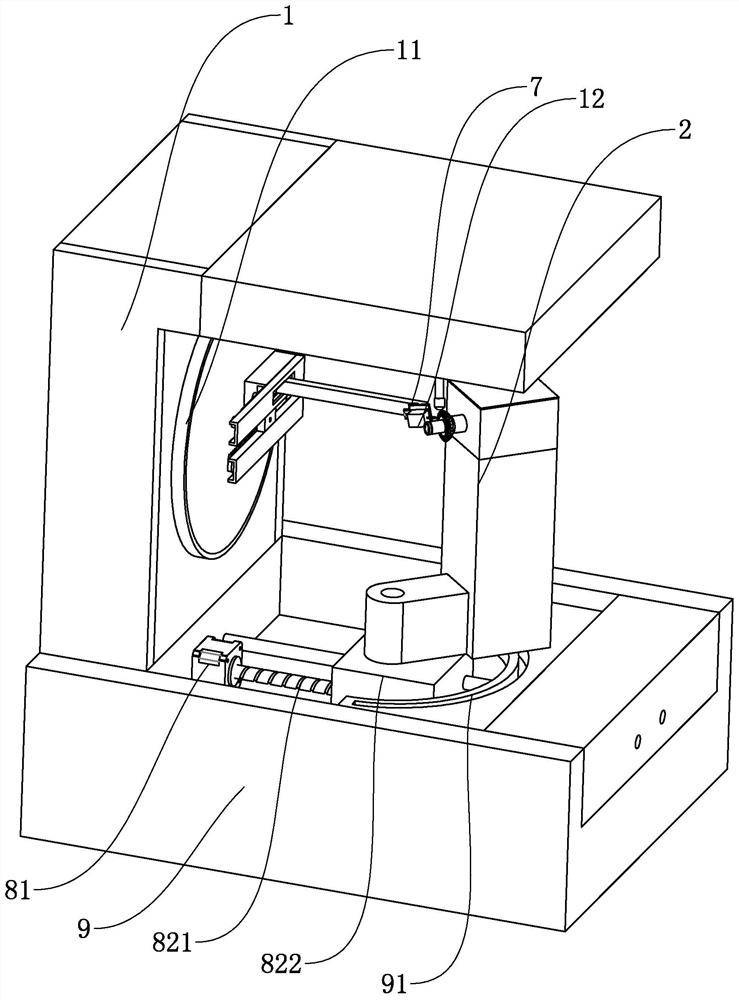

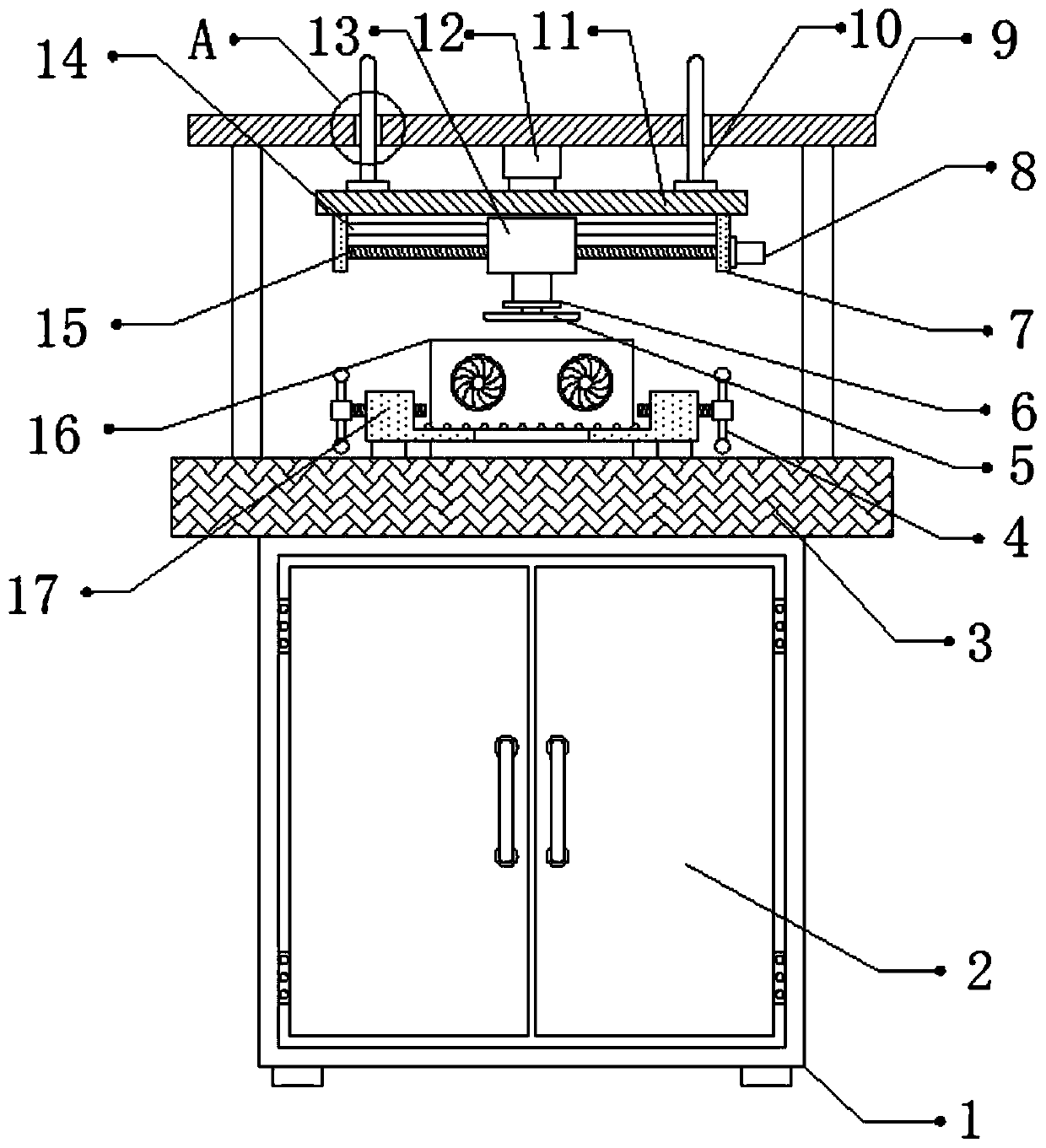

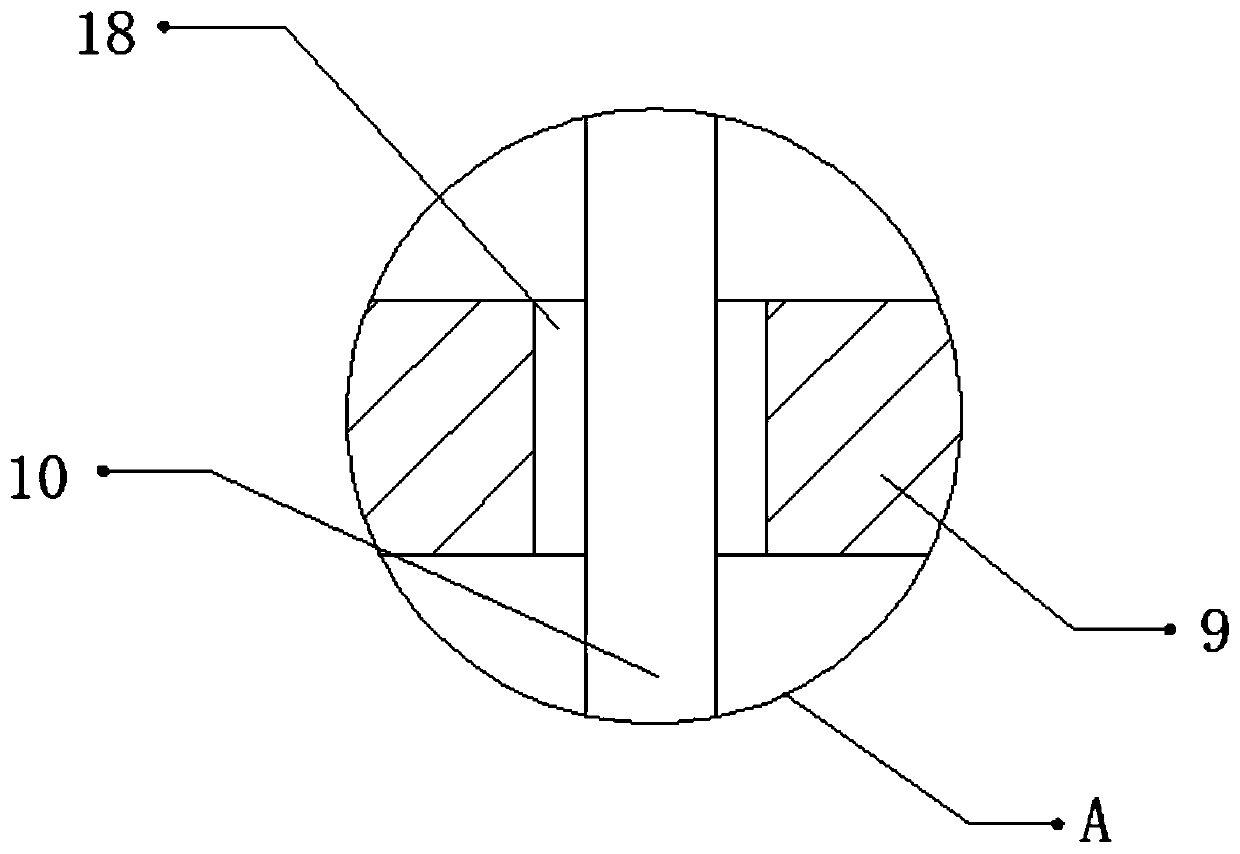

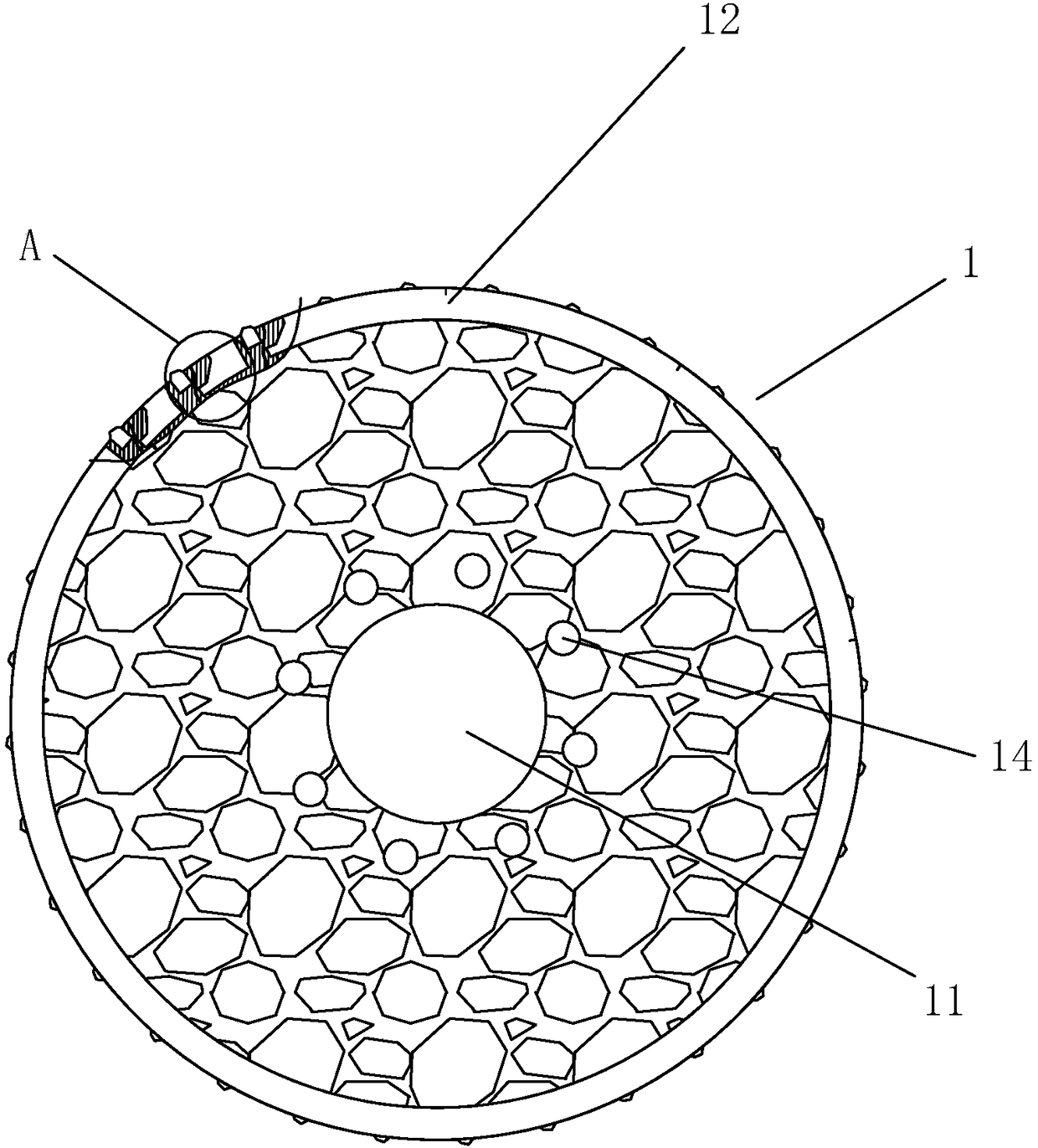

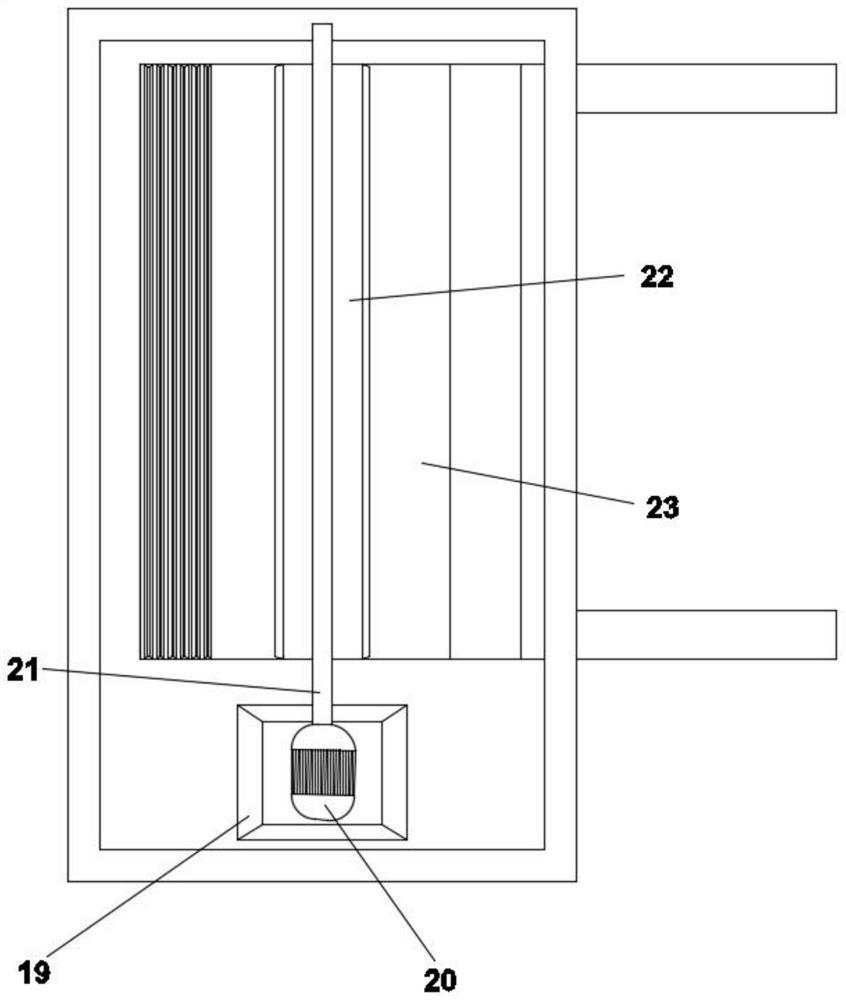

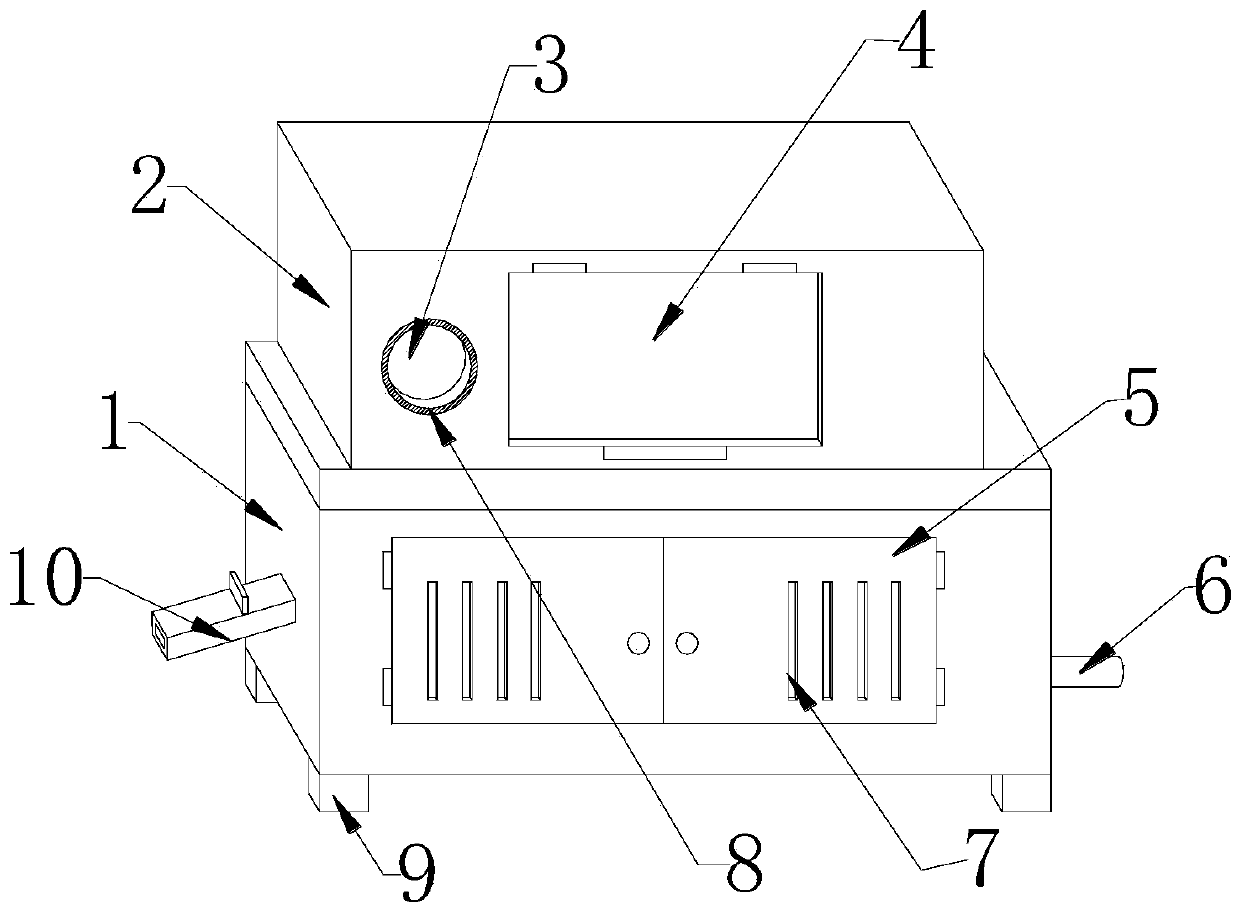

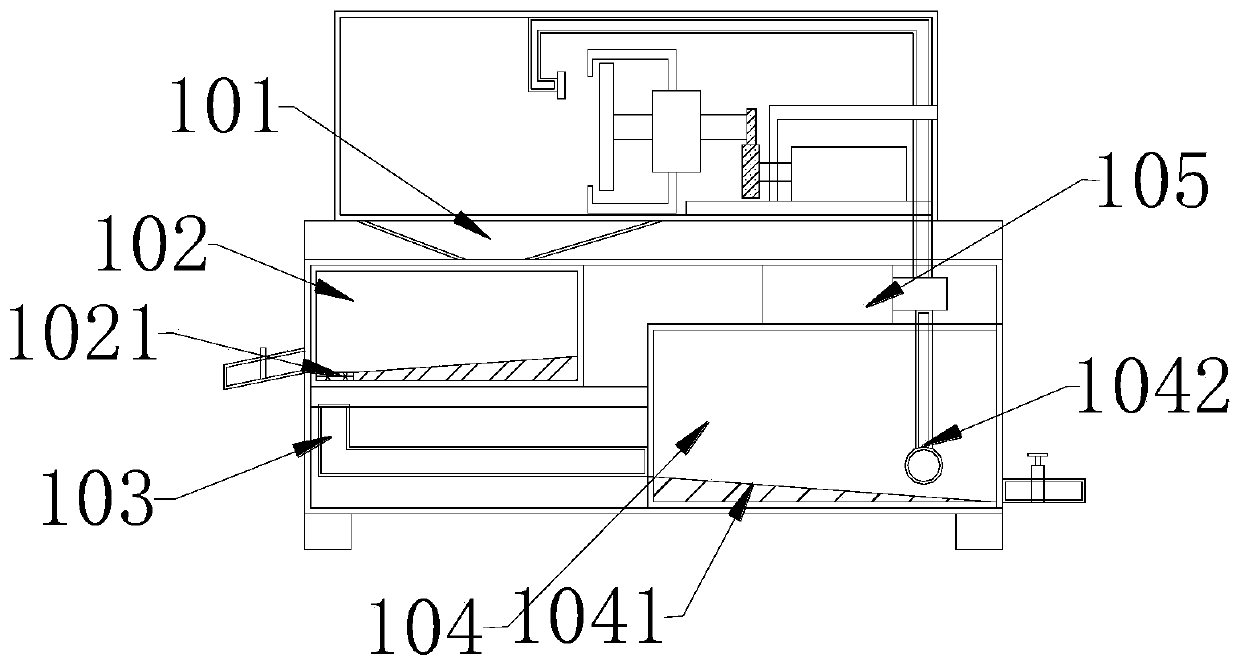

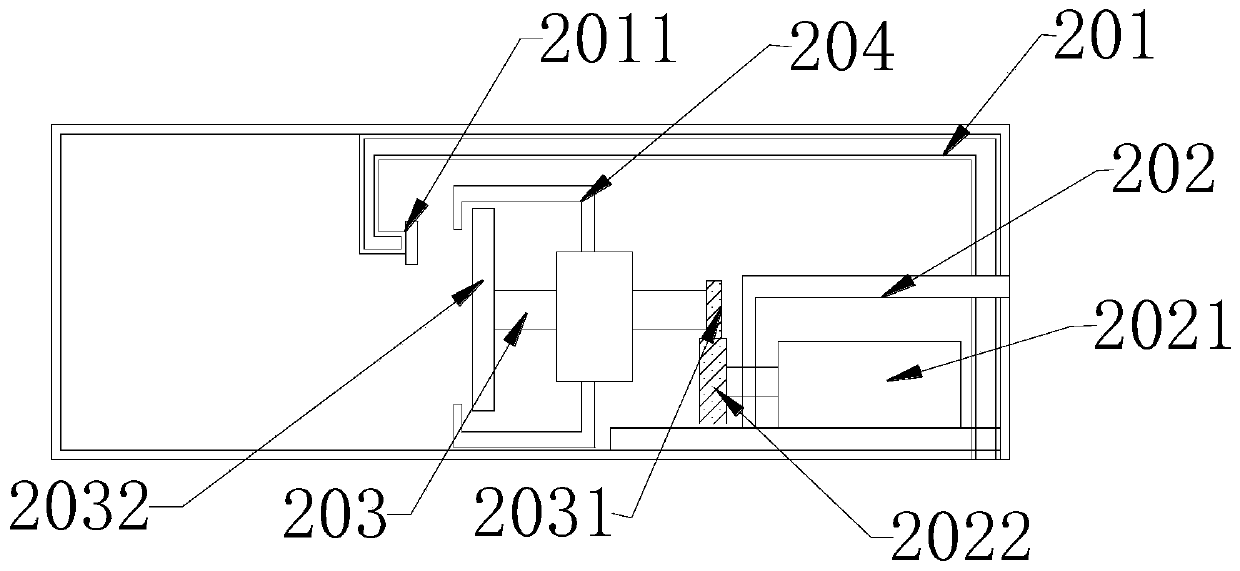

System suitable for metal powder melting material increasing manufacturing

InactiveCN104959603AEliminate bumpsEliminate warpingAdditive manufacturing apparatusIncreasing energy efficiencyHigh-speed grindingGalvanometer

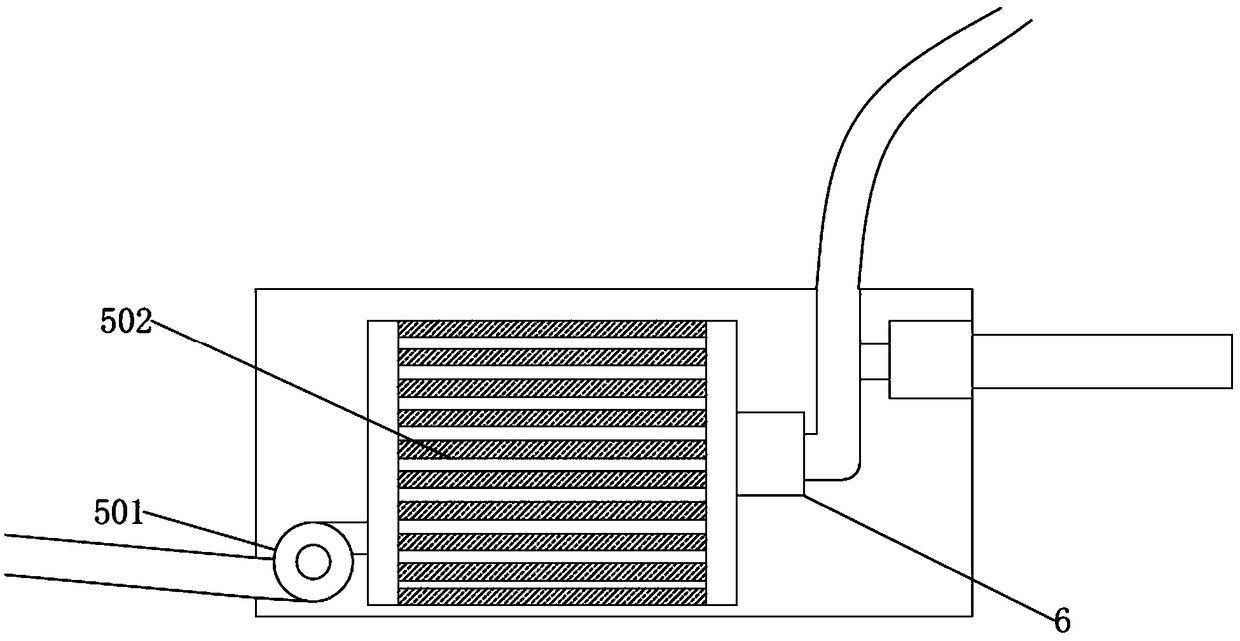

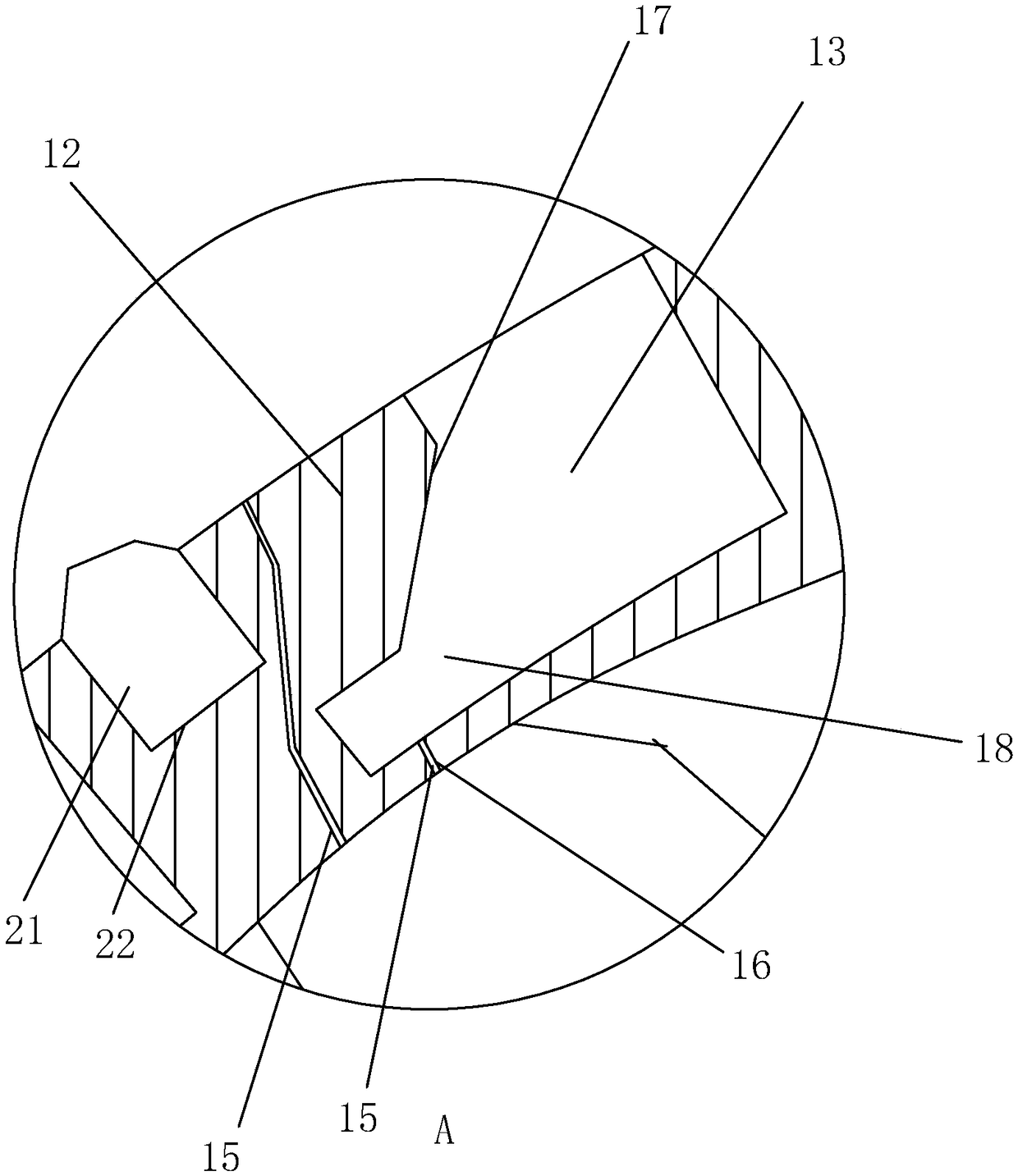

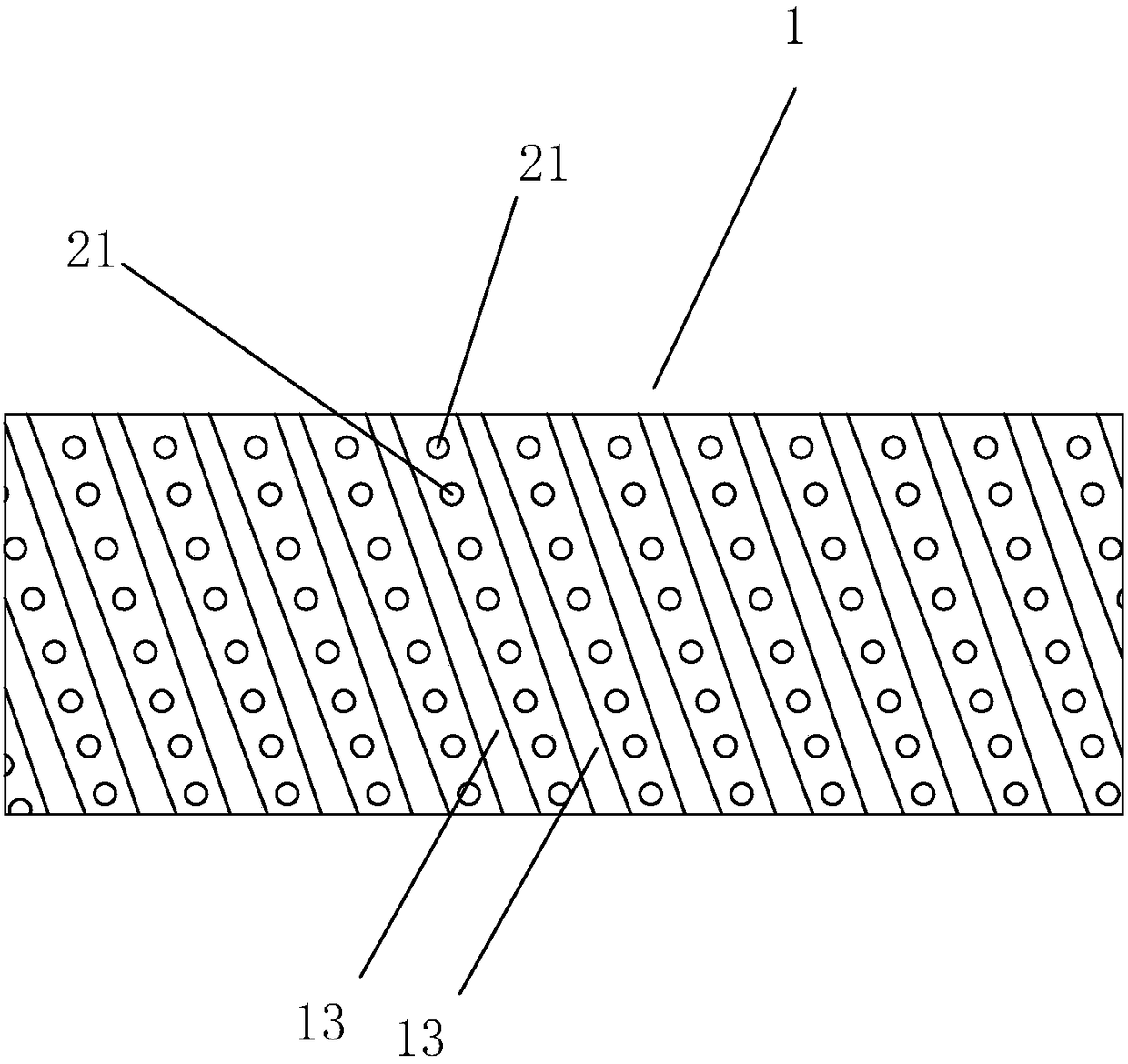

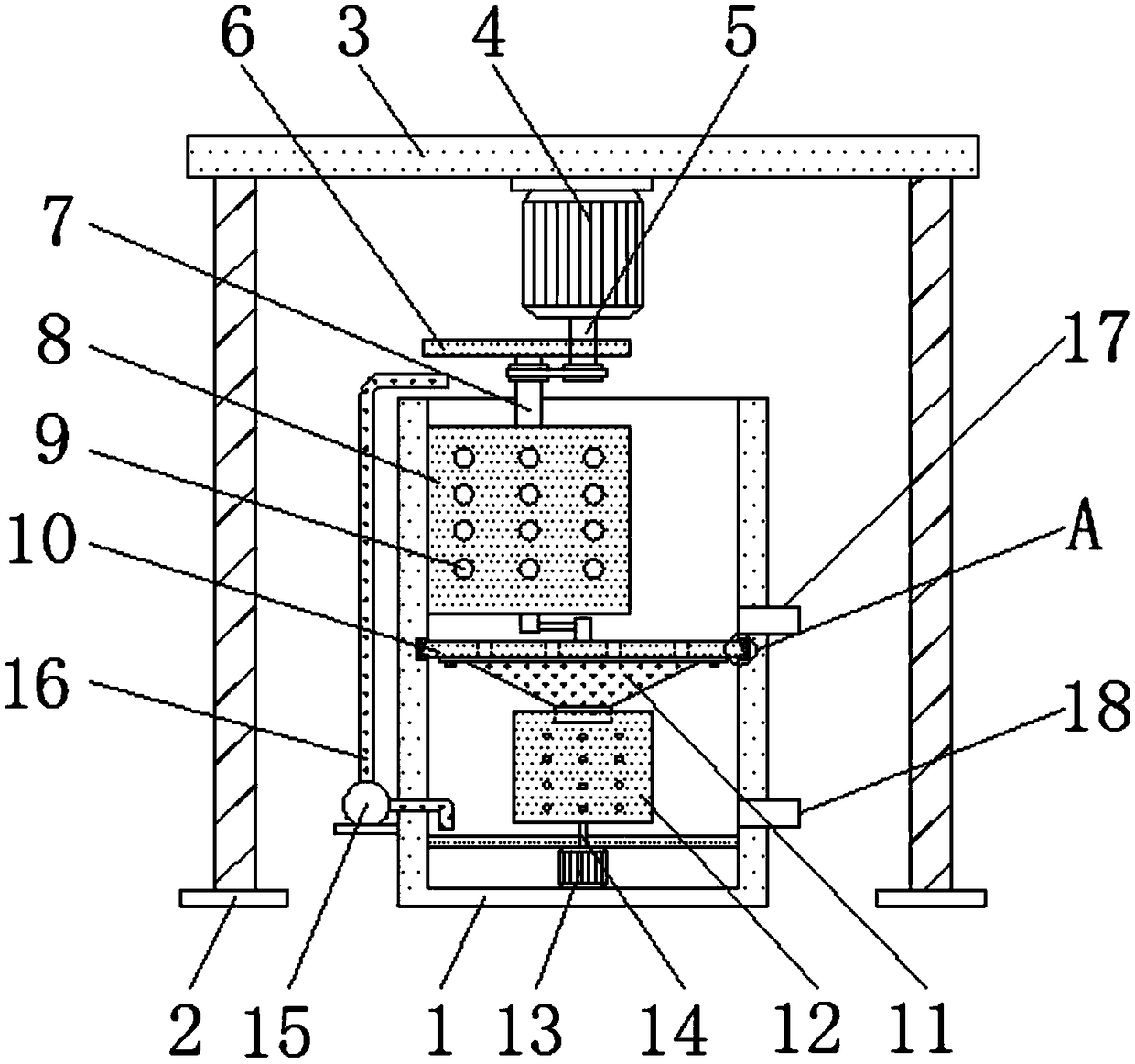

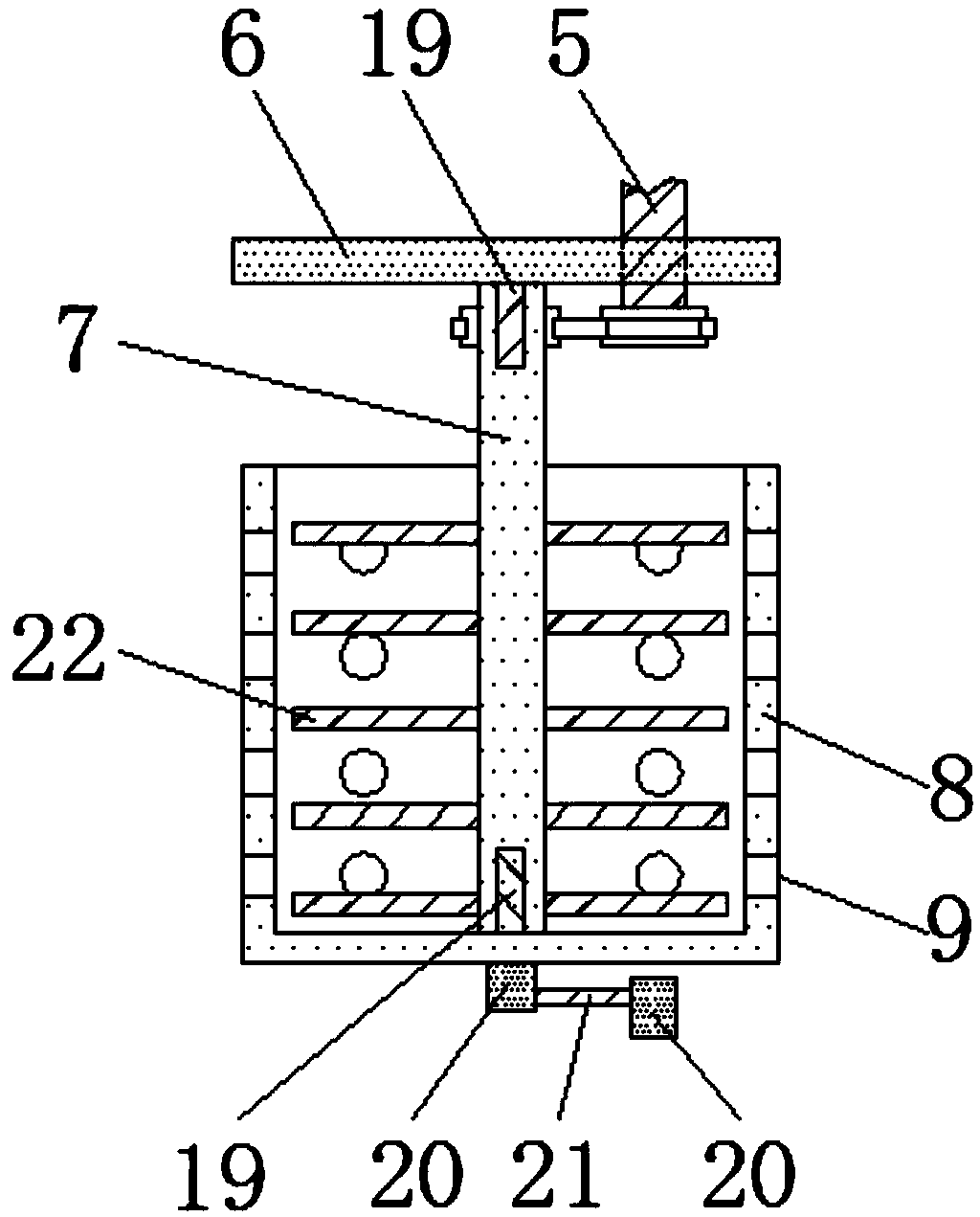

The invention discloses a system suitable for metal powder melting material increasing manufacturing. The system is formed by compositing of a fiber laser galvanometer scanning mechanism and a high-speed grinding head. The fiber laser galvanometer scanning mechanism is provided with an XY workbench. The high-speed grinding head is arranged on a Y axis of the XY workbench through a Y axial sliding block. After multiple layers are manufactured on a workpiece, the high-speed grinding head slides along the Y axis of the XY workbench and carries out the feeding motion in the X axial direction at the same time, and high-speed grinding is carried out on the workpiece. The system suitable for the metal powder melting material increasing manufacturing has the advantages that after the high-speed grinding head is composited with the fiber laser galvanometer scanning mechanism, in the material increasing manufacturing process, scanning is carried out on a powder bed through the fiber laser galvanometer scanning mechanism, metal in a selected area is melted, a protrusion and a warpage in the partial workpiece can be removed by the high-speed grinding head, the upper surface of the workpiece can be maintained in smooth, the residual protruding peak on the surface of the workpiece and the plastic deformation degree can be effectively lowered, and the roughness on the surface of the workpiece is favorable to be lowered.

Owner:GUANGZHOU OGGI3D ELECTROMECHANICAL

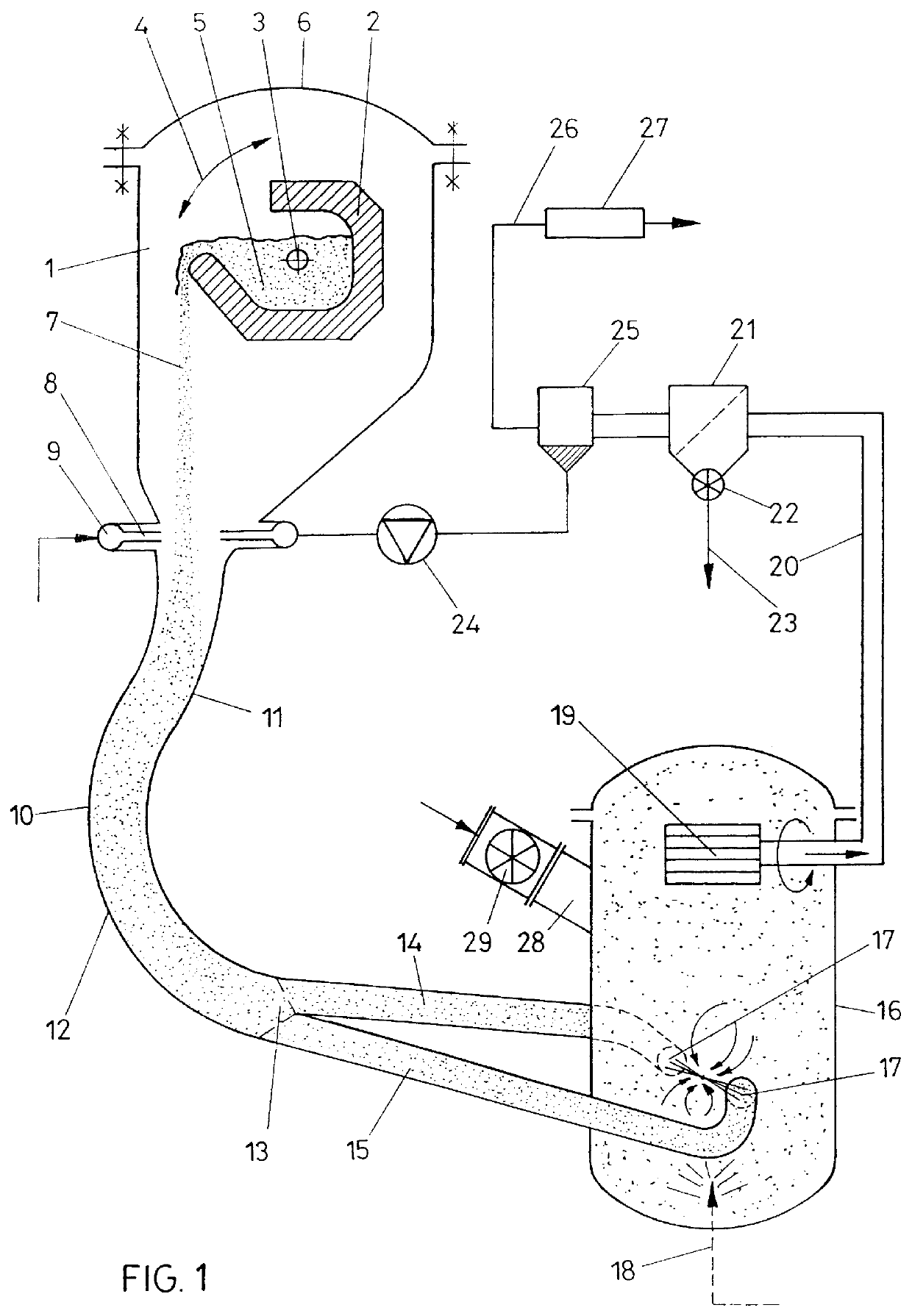

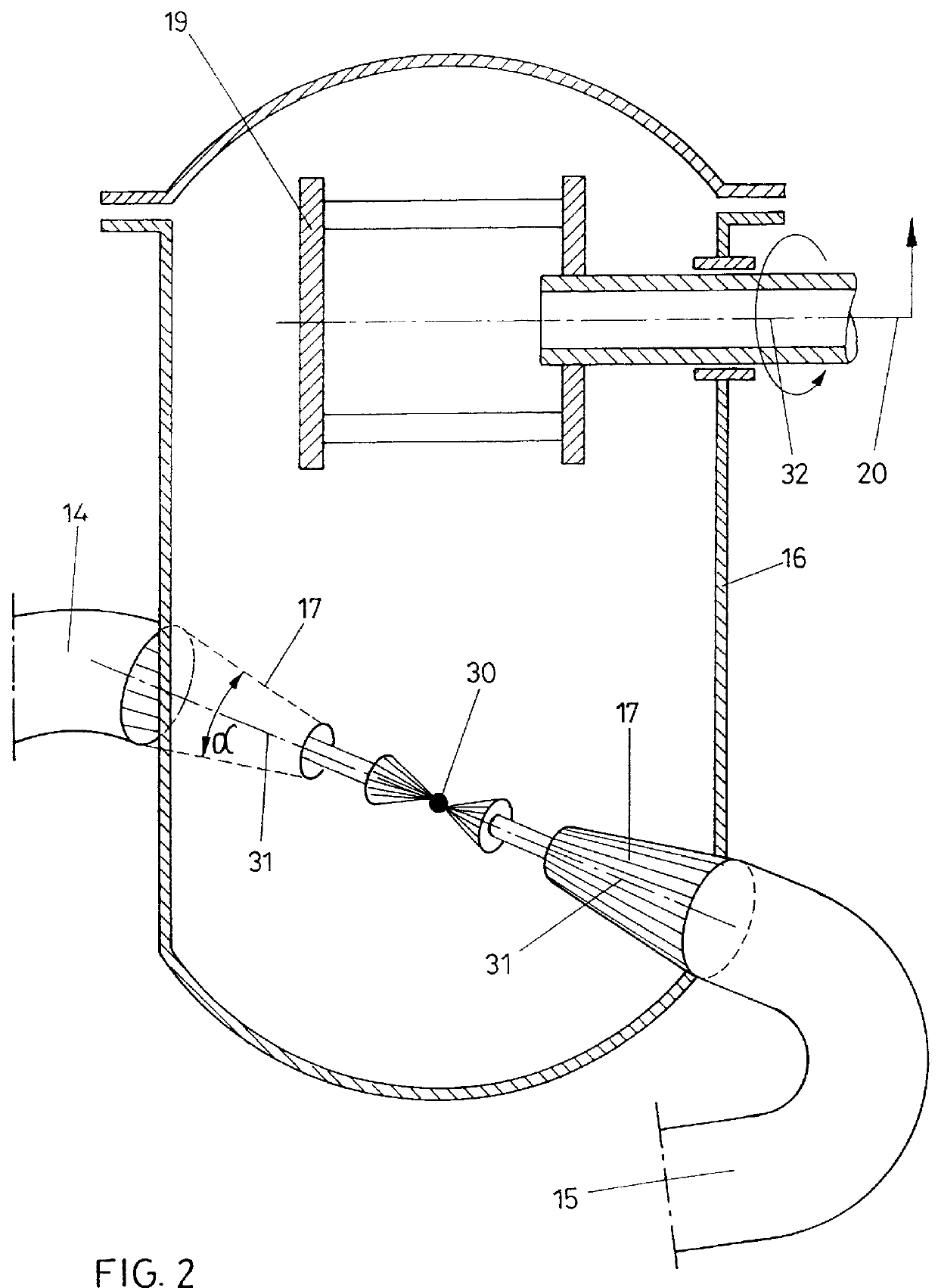

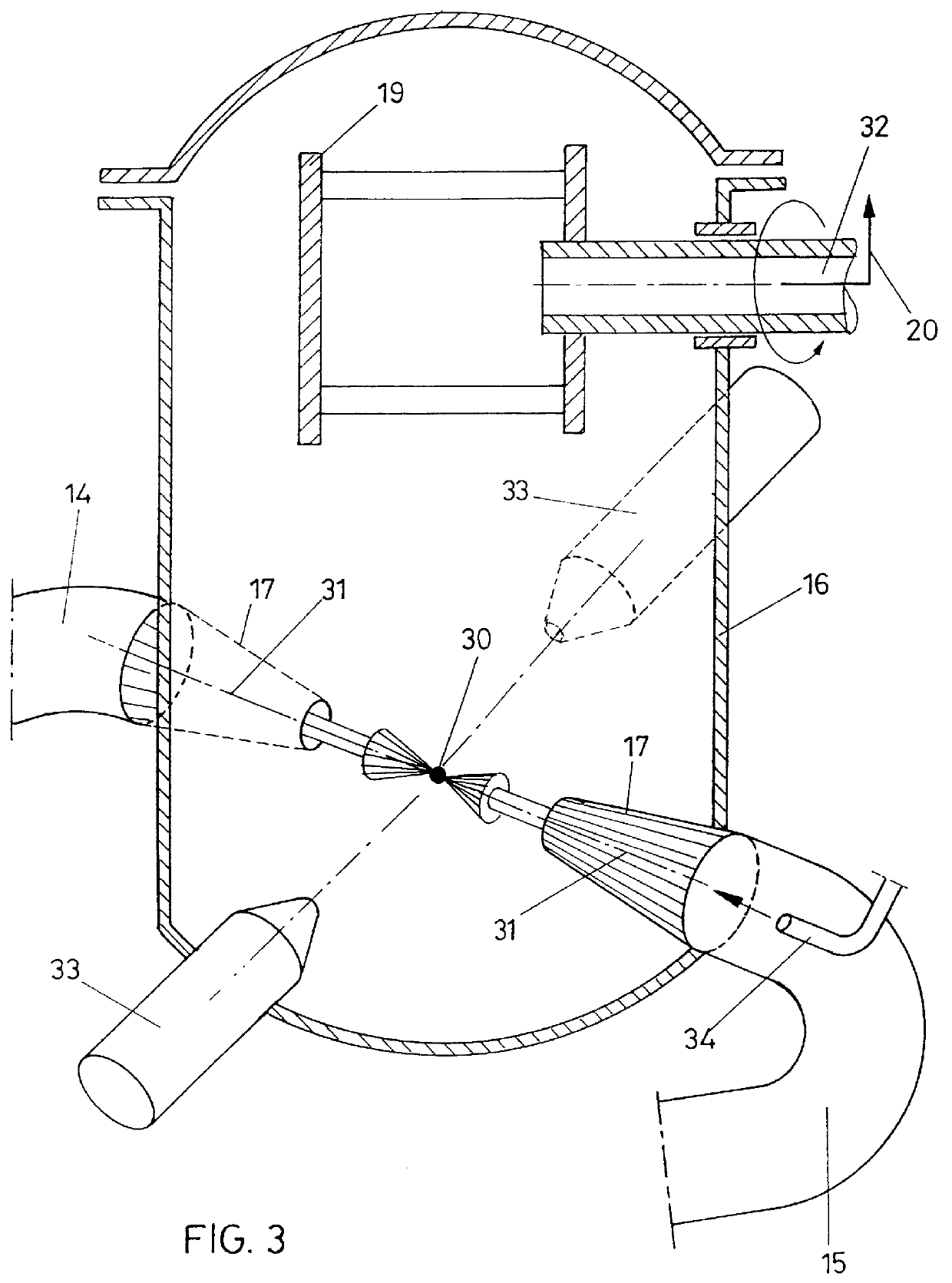

Method for granulating and grinding molten material and device for carrying out said method

InactiveUS6082640AReduce expenditureEfficient introductionGas current separationIncreasing energy efficiencyWater jetMolten material

PCT No. PCT / AT98 / 00243 Sec. 371 Date Jun. 29, 1999 Sec. 102(e) Date Jun. 29, 1999 PCT Filed Oct. 14, 1998 PCT Pub. No. WO99 / 22031 PCT Pub. Date May 6, 1999In a process for granulating and comminuting molten material, the slag melt is acted upon by compressed water and discharged together with the vapour formed. The liquid slag is introduced into a granulation chamber in a free flowing jet while directing compressed water jets against the slag jet, whereupon the solidified and granulated slag is conducted through a pneumatic conveyor duct and a distributor along with the vapour formed. The partial streams leaving the distributor, via conically tapering nozzles are transferred into a grinding space exhibiting a lower pressure than the granulation space and from which the comminuted and solidified material is drawn off.

Owner:HOLCIM

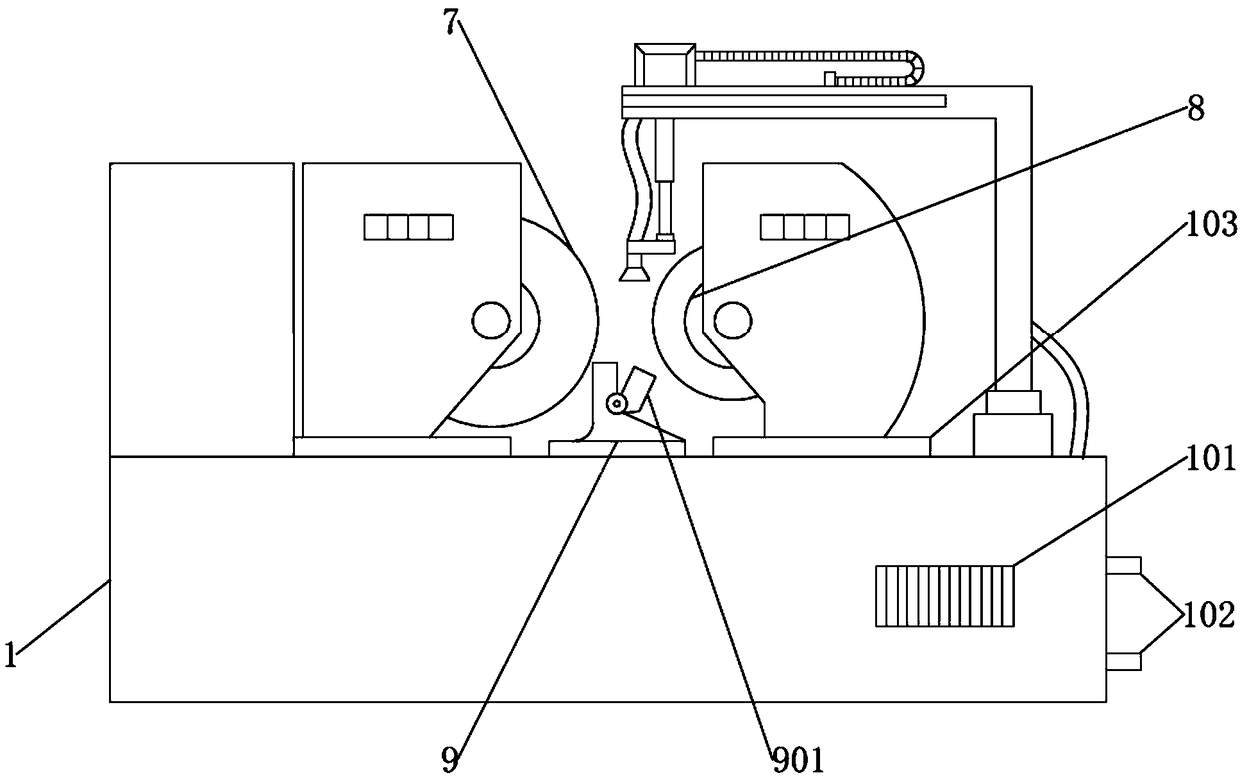

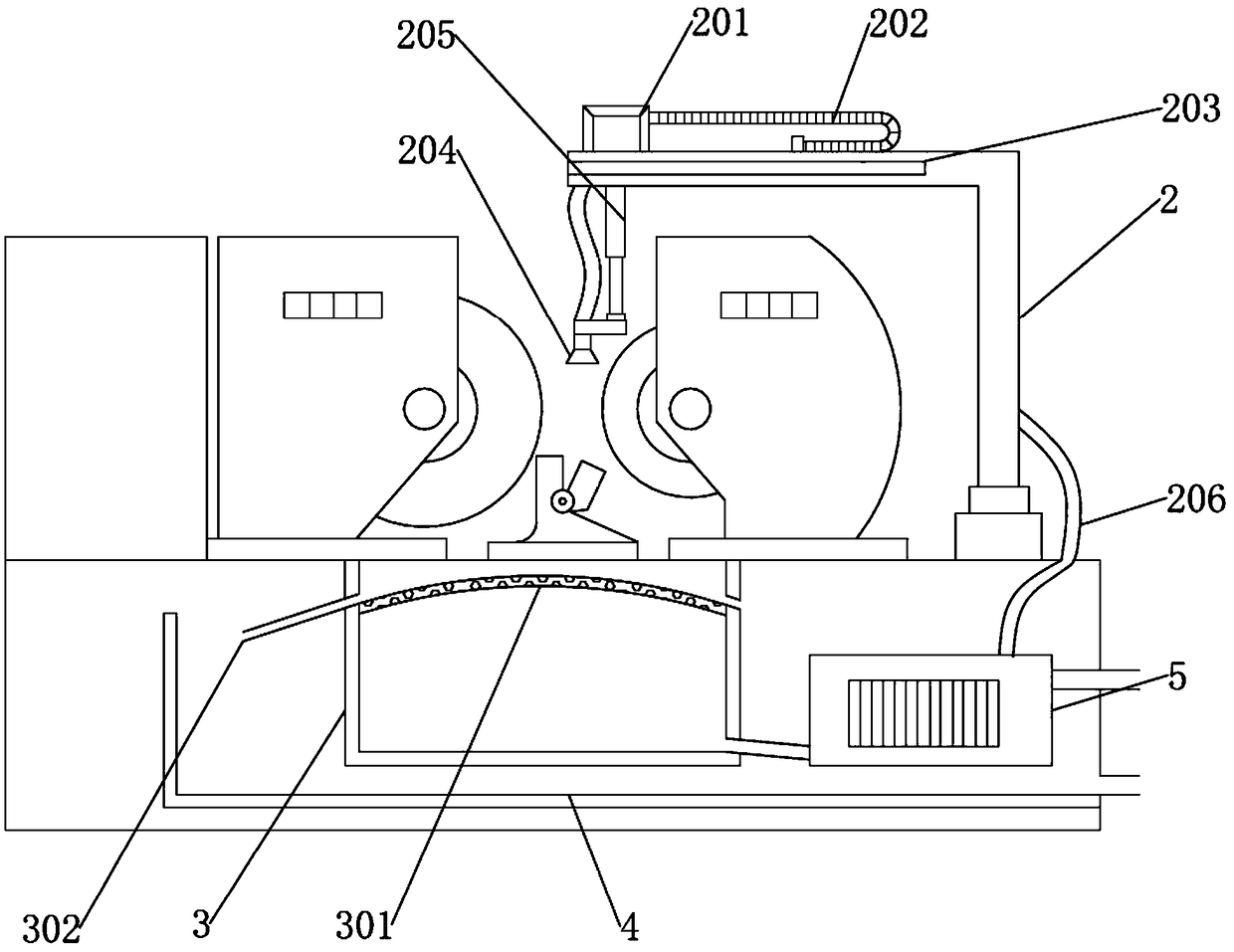

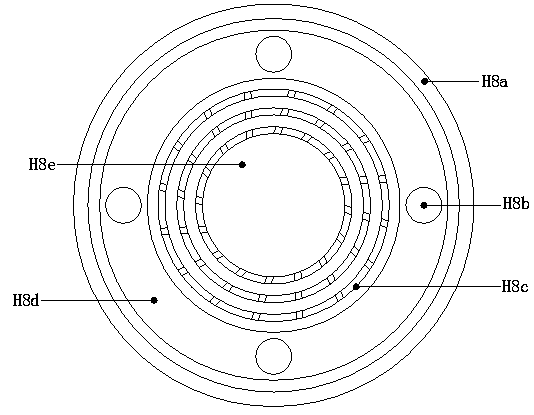

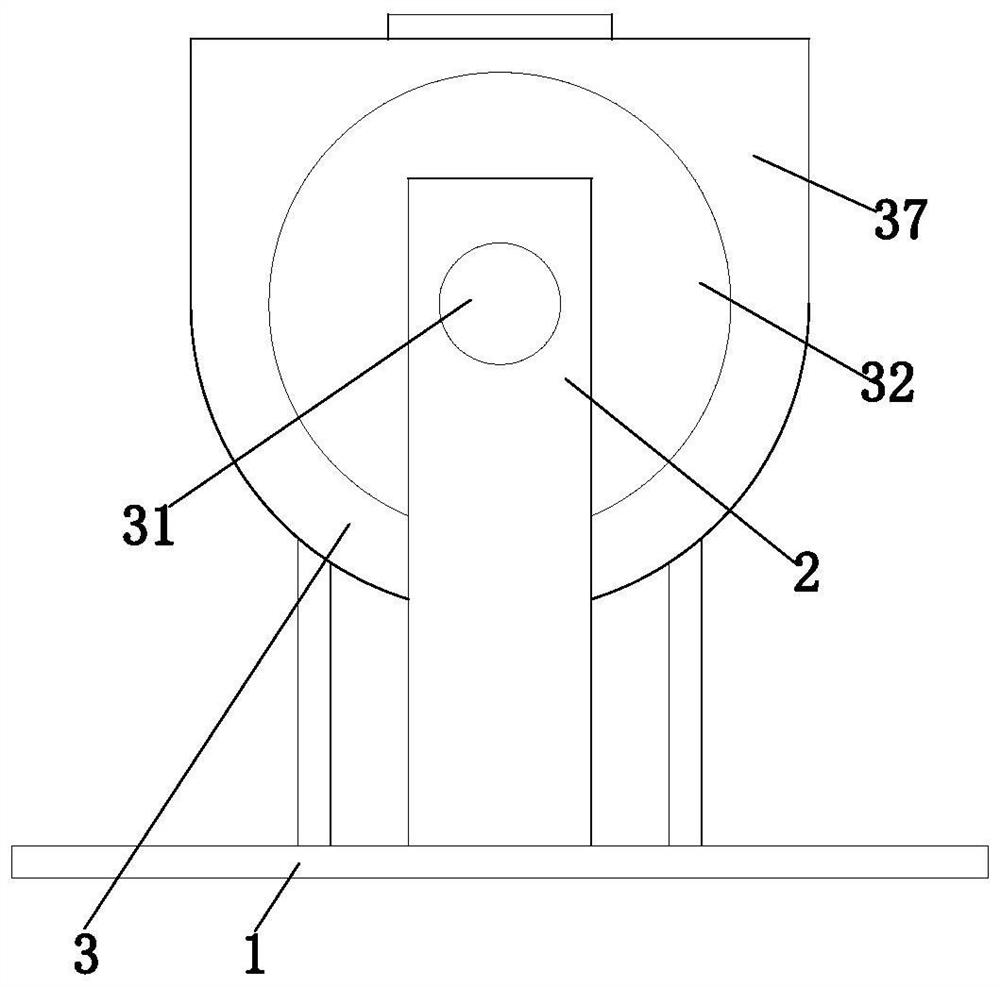

Centerless grinding machine

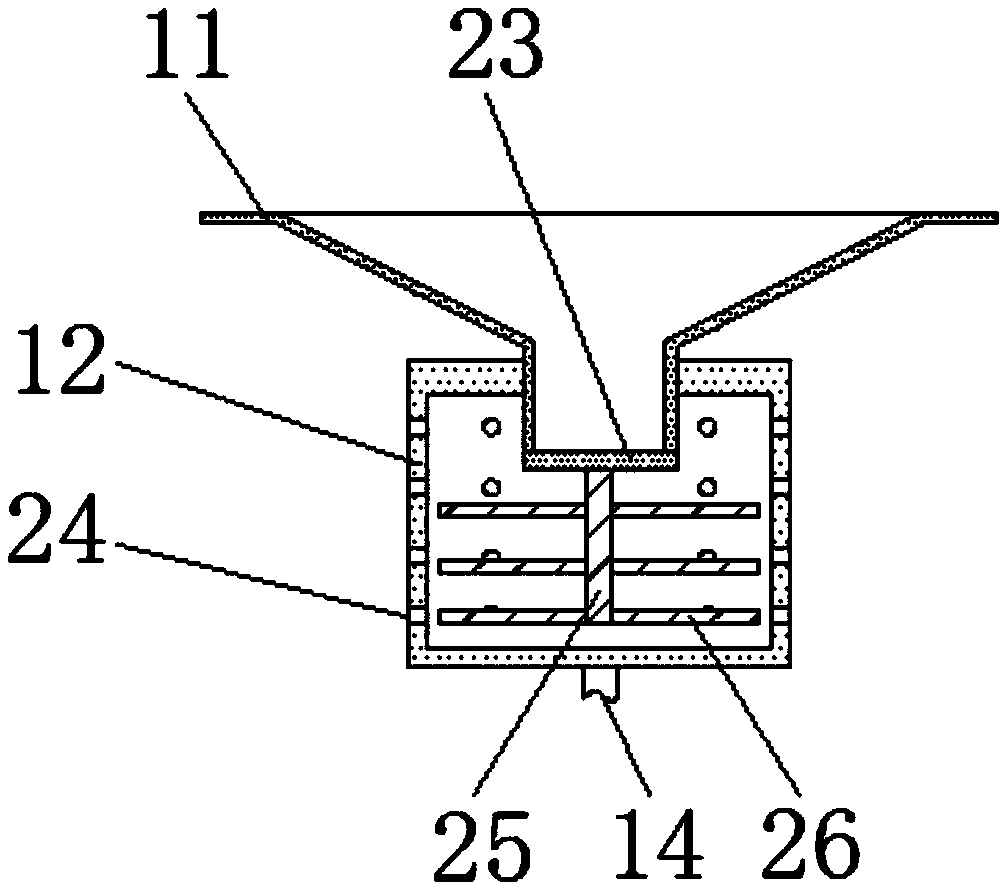

InactiveCN108788961AAchieve the effect of reuseGrinding effectRevolution surface grinding machinesGrinding/polishing safety devicesEngineeringWater level

The invention discloses a centerless grinding machine. The centerless grinding machine comprises a grinding machine base, a water collecting water tank, a grinding wheel and a metal chip filtering plate, two grinding wheel adjusting sliding rails are fixedly installed on the upper surface of the grinding machine base, a water cooling system is connected to the upper surface of the grinding machinebase in an inserted mode, a horizontal rod is welded to the top of the water cooling system, and a water level adjusting sliding block is connected to the upper surface of the horizontal rod in a sliding mode; and one side of the water cooling system is connected with a water supply pipe in an inserted mode, and the water collecting water tank is fixedly installed inside the grinding machine base. According to the centerless grinding machine, the metal chip filtering plate is fixedly connected to the center of the inner part of the water collecting water tank, cooling liquid flowing down after grinding through the centerless grinding machine can be filtered through the metal chip filtering plate, scrap iron left by grinding through grinding wheel inside the cooling liquid is filtered, sothat the situation that the scrap iron is sprayed onto the grinding wheel again after passing through the water cooling system, then scratches are left on the surface of a ground workpiece is avoided,and the problem that the interior of the cooling liquid cannot be secondarily utilized due to the residual scrap iron is solved.

Owner:MAANSHAN YASHIDA INTELLIGENT TECH CO LTD

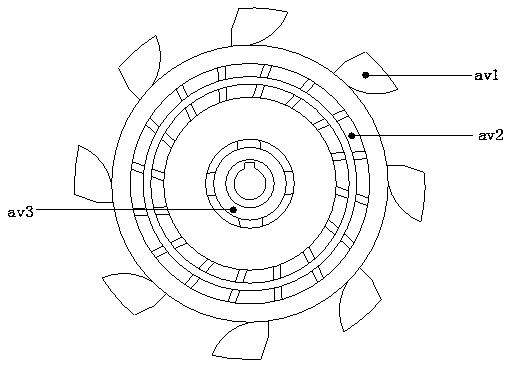

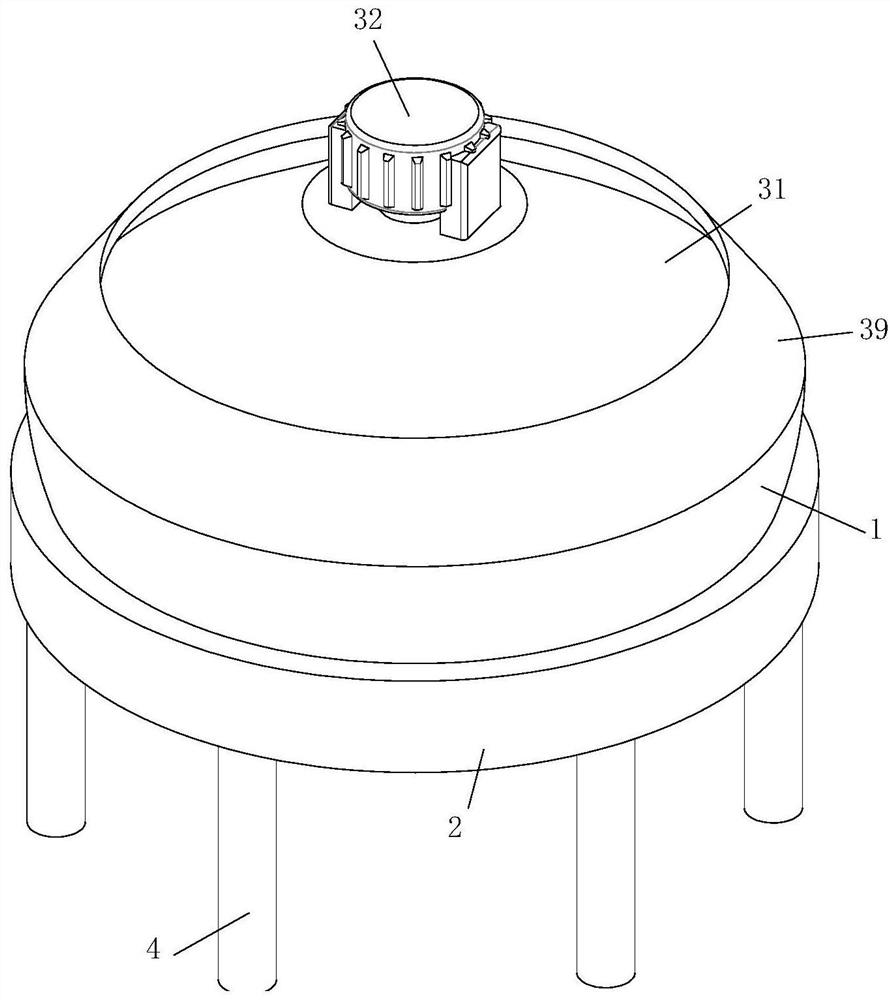

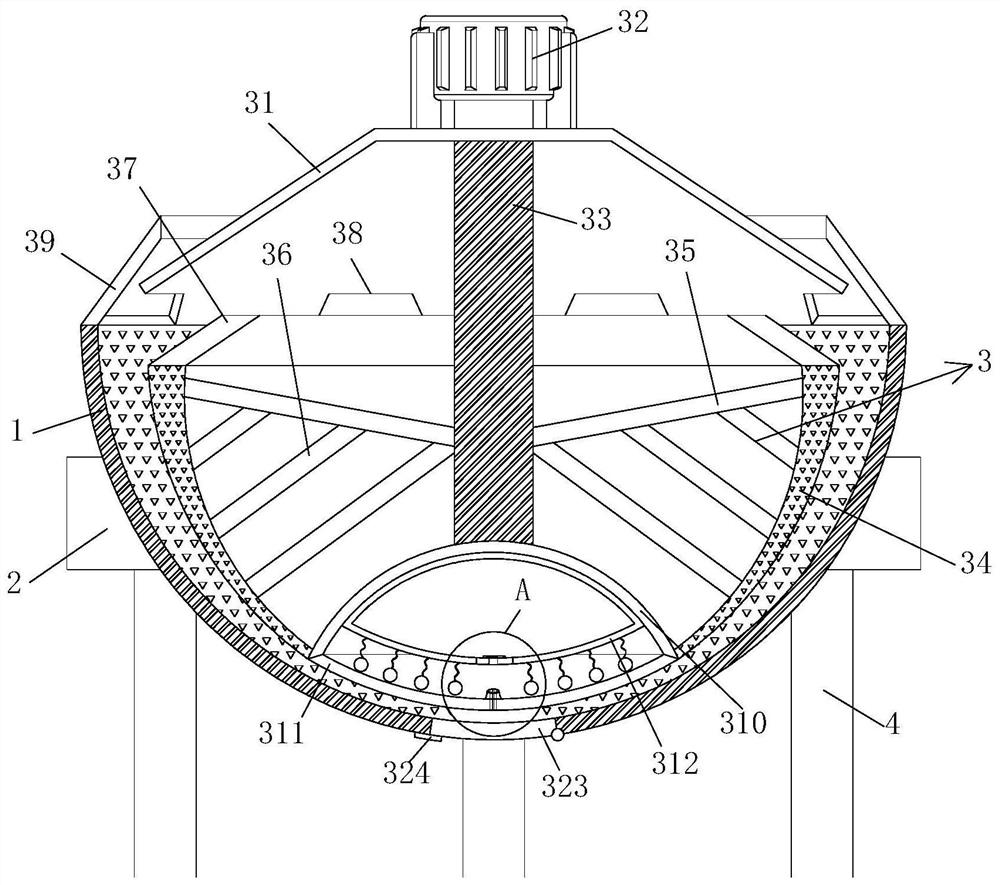

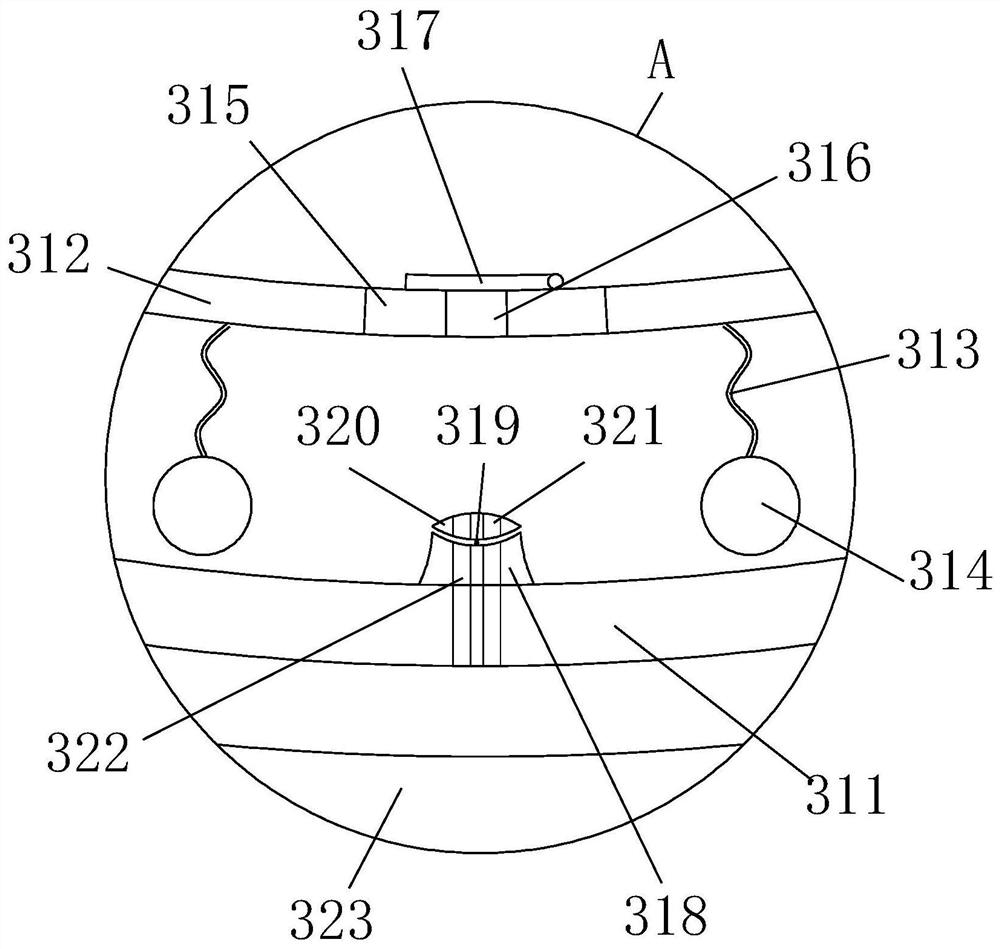

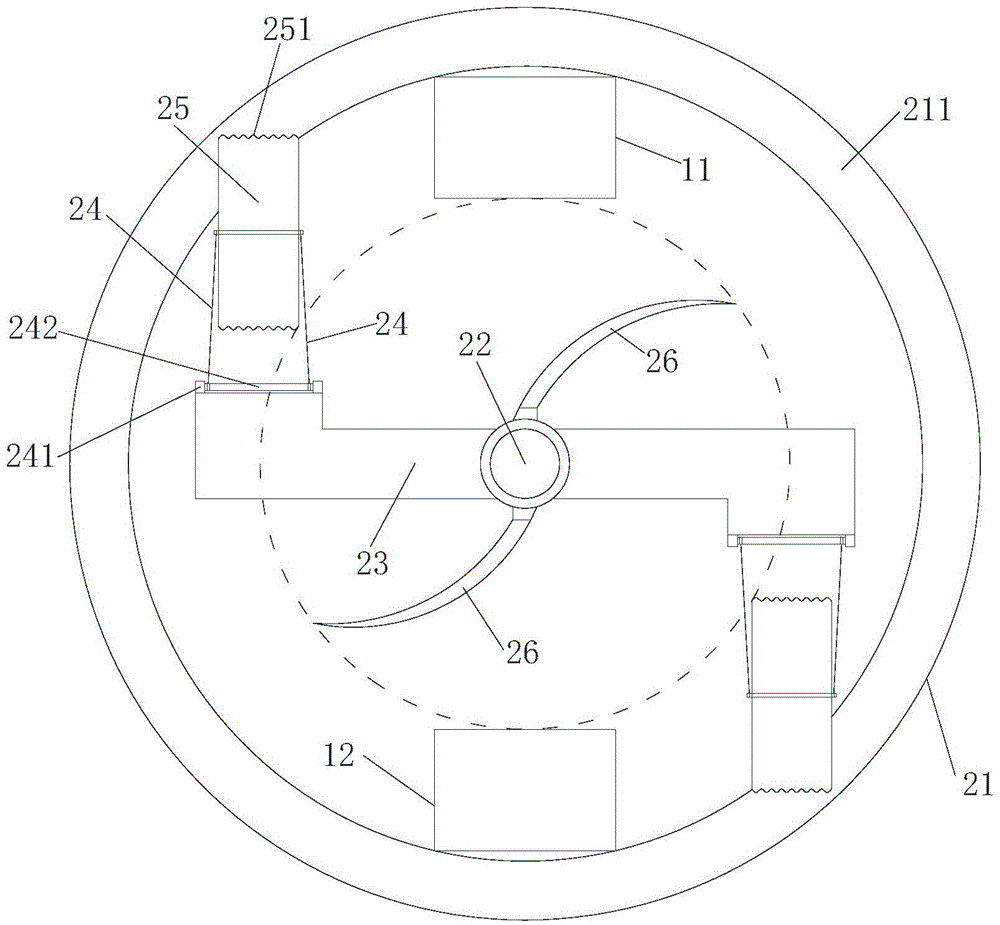

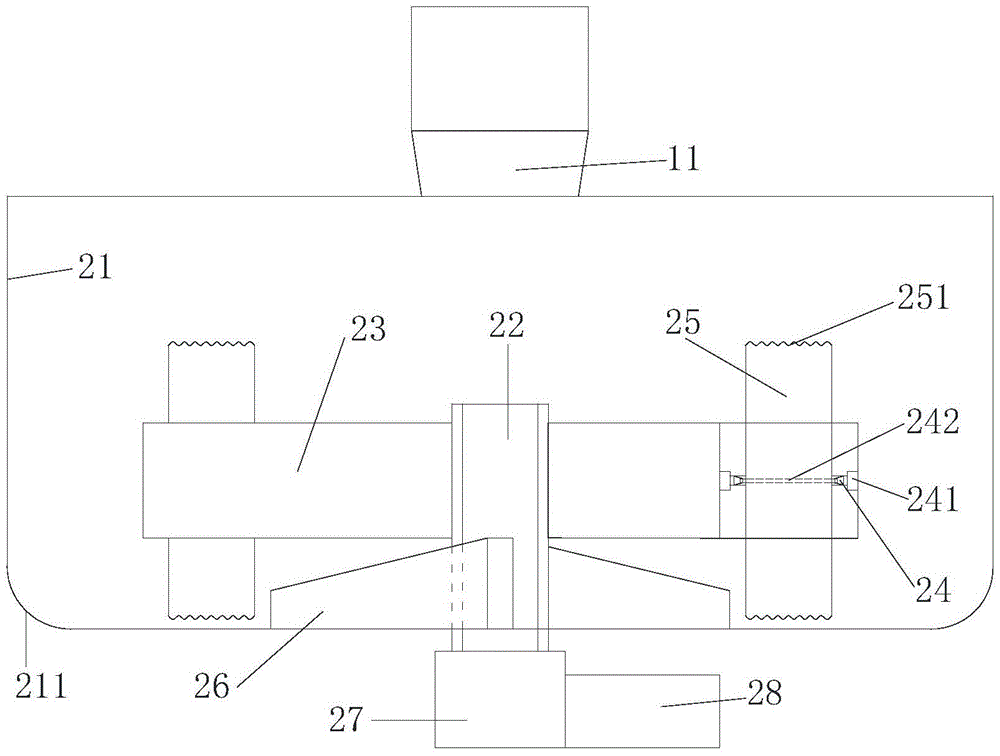

Grinding device for food processing

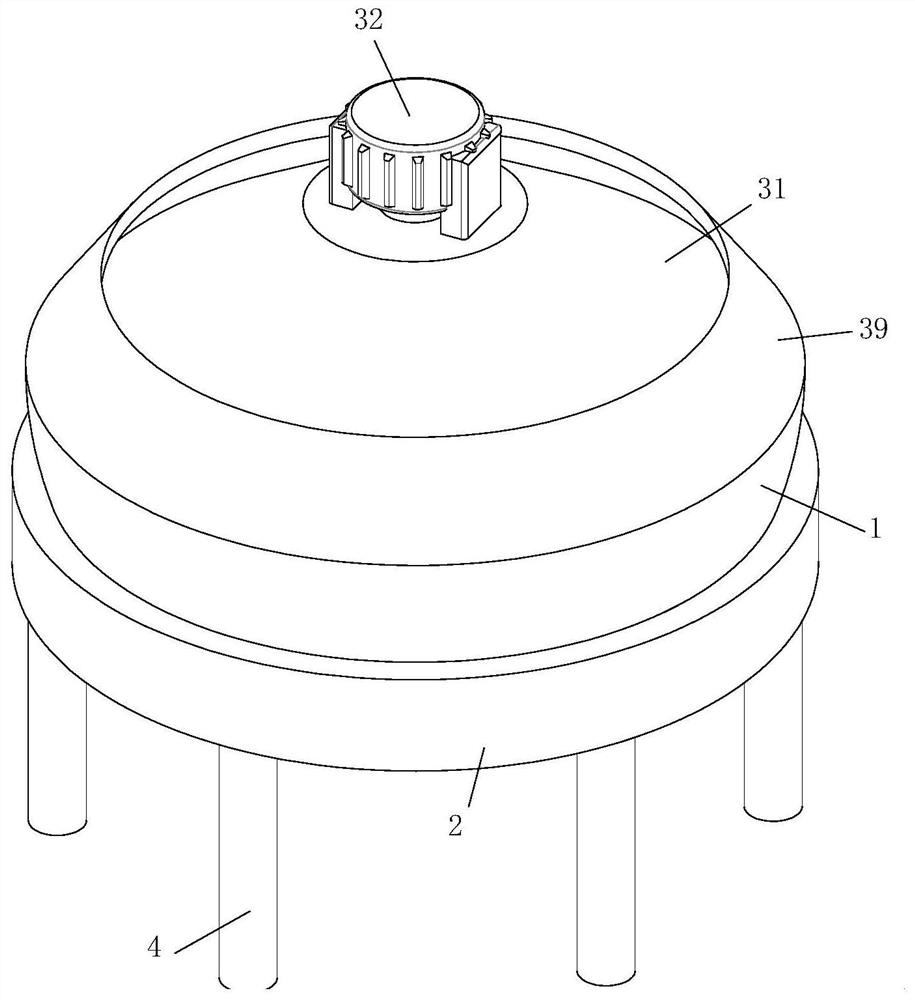

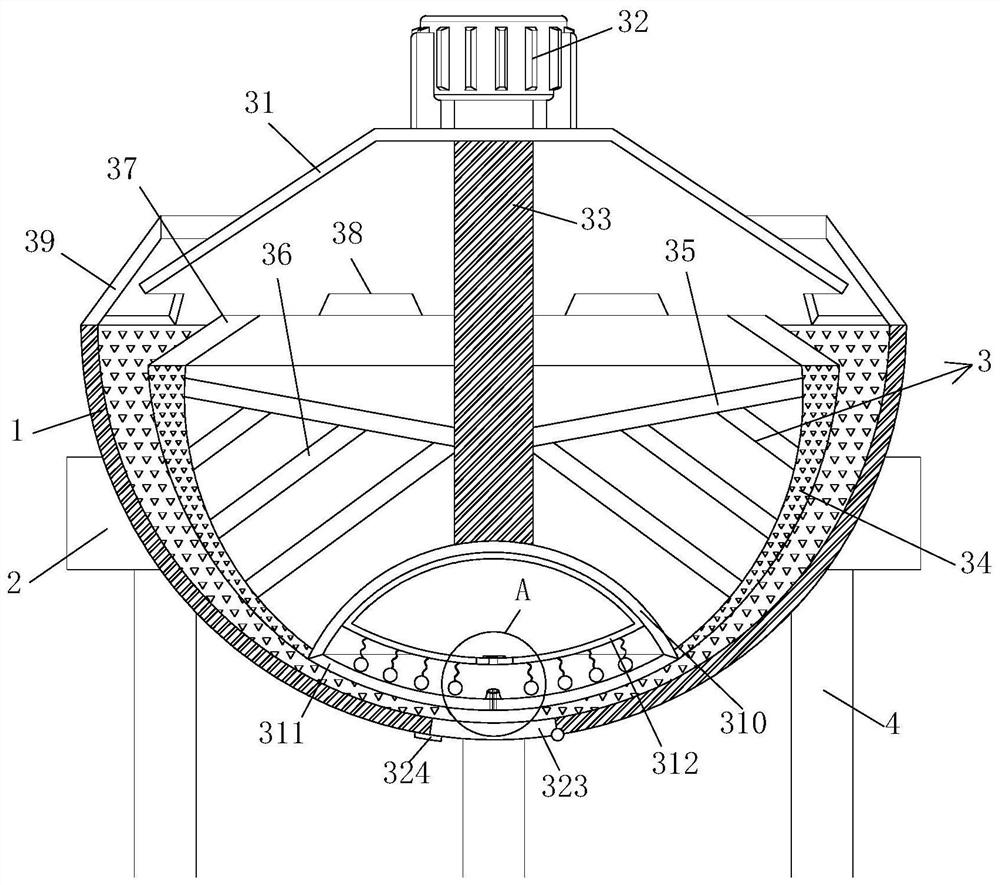

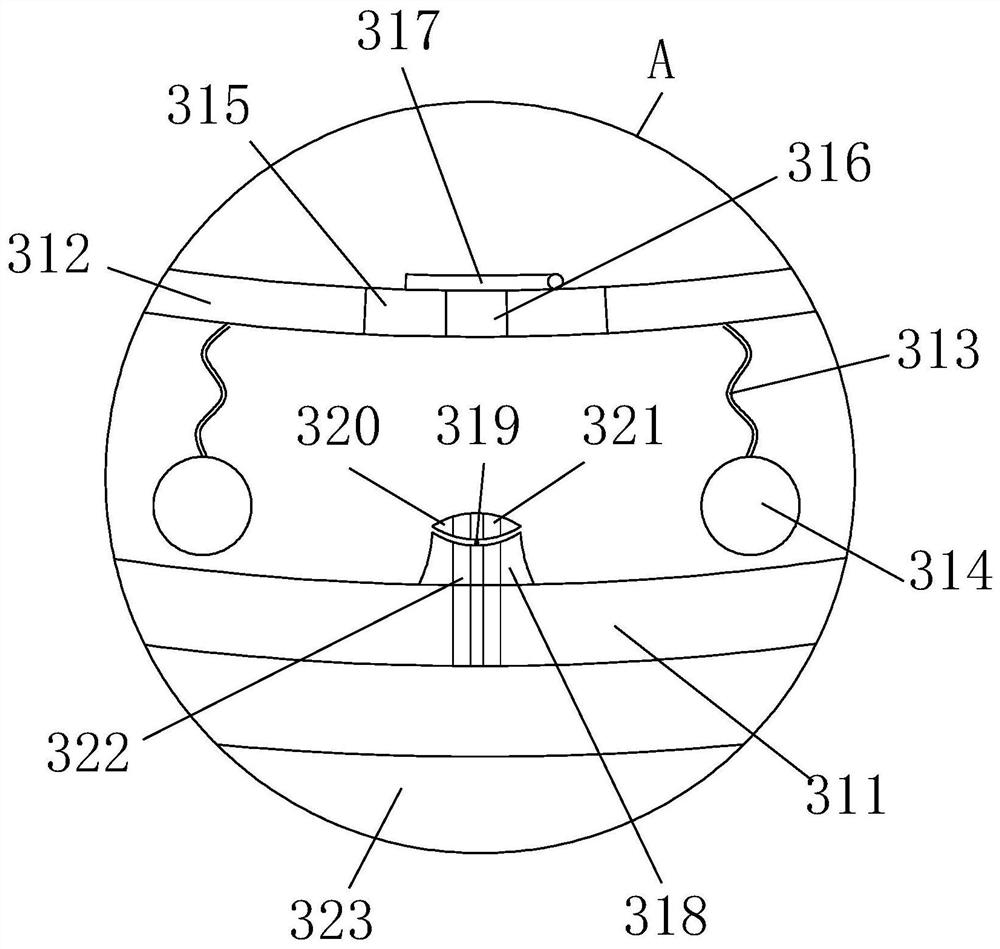

ActiveCN112742510AAvoid adsorptionImprove grinding effectCleaning using gasesGrain treatmentsThermal dilatationFood processing

The invention provides a grinding device for food processing, and relates to the field of food processing. The grinding device comprises an arc-shaped grinding box for grinding Chinese prickly ash, a supporting ring for supporting the arc-shaped grinding box and a variable-cavity grinding mechanism for grinding the Chinese prickly ash in the arc-shaped grinding box, and the surface of the arc-shaped grinding box is fixedly connected with the supporting ring. According to the grinding device for food processing, a special structure capable of changing the grinding space is designed according to the problem that in the conventional grinding process of Chinese prickly ash, powder is easily adsorbed on the grinding device to occupy the grinding space, and a thermal expansion structure is adopted to control mixing and falling of the powder at the grinding structure in real time so that the problems that fine Chinese prickly ash powder is difficult to separate in the grinding process by a conventional grinding device, the fine and smooth Chinese prickly ash powder is easy to adhere to the grinding device to influence the grinding effect, a lot of grinding space is occupied, and the food processing efficiency is influenced to a certain extent are effectively solved.

Owner:荣成鲁洋水产食品有限公司

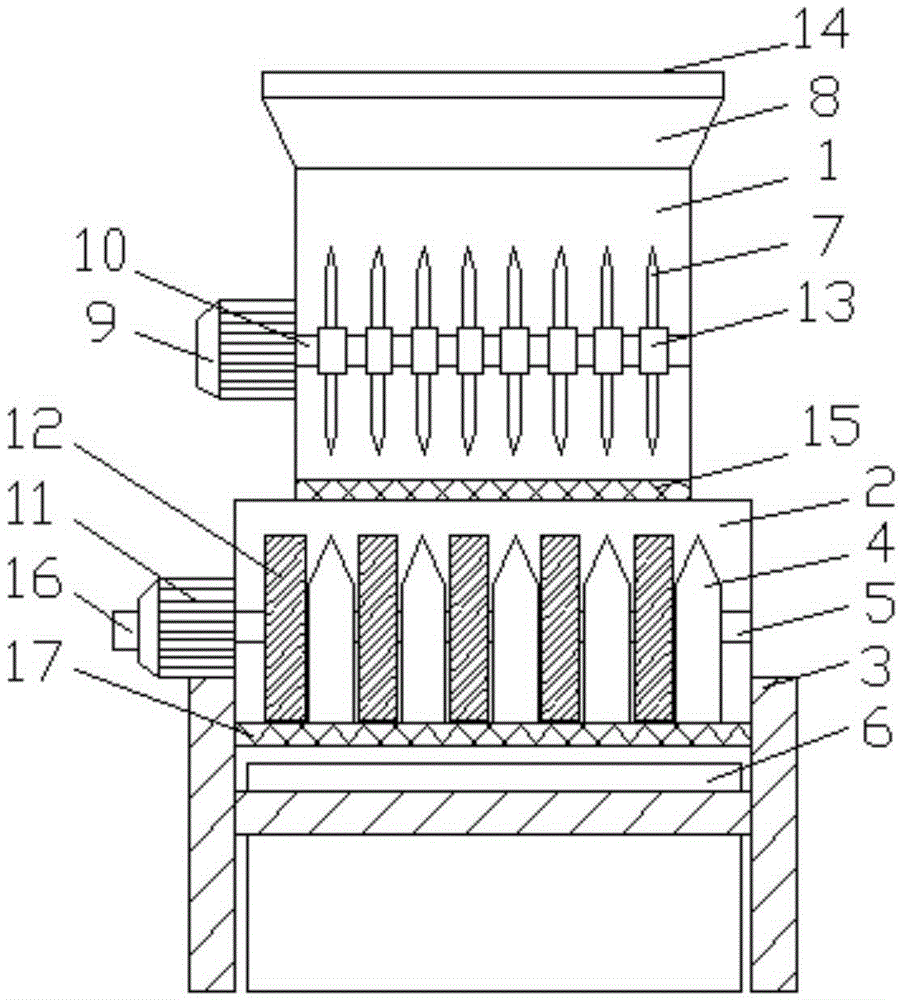

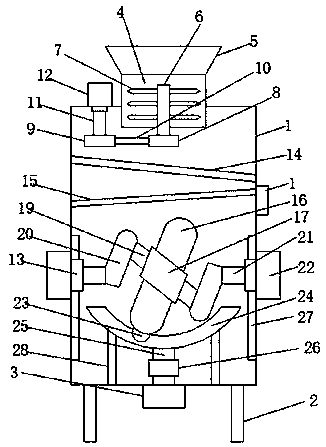

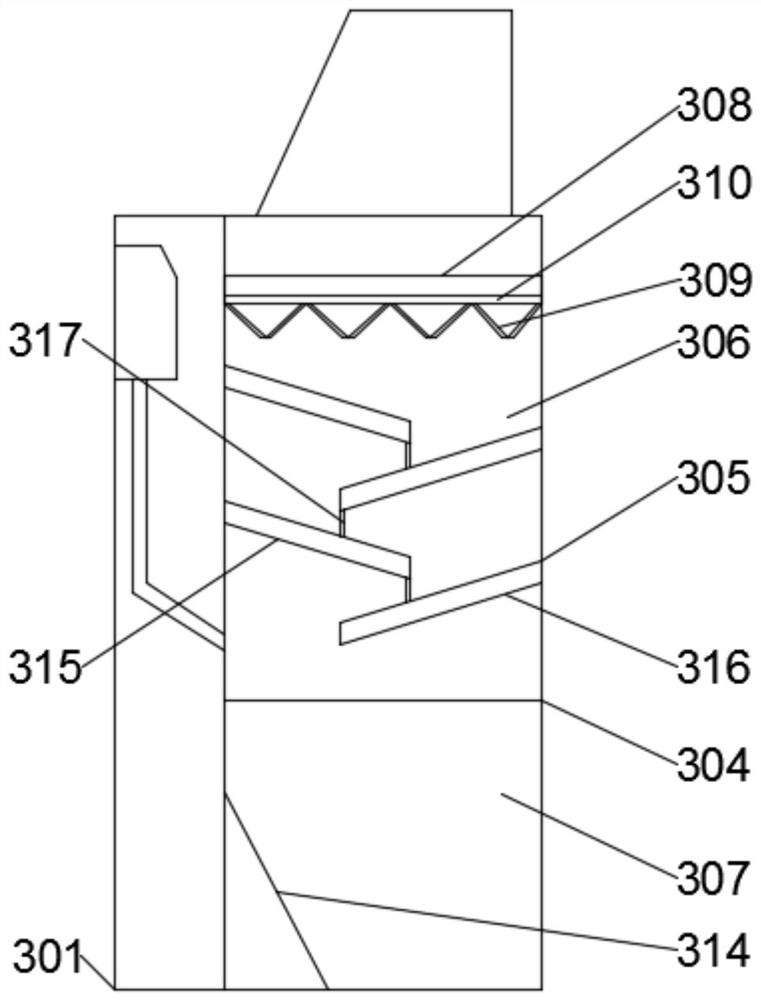

Grinding machine capable of smashing medicine materials in advance

The invention belongs to the technical field of grinding machinery and discloses a grinding machine capable of crushing medicinal materials in advance, comprising a grinding chamber, a grinding chamber, a support leg, a storage bin, a feeding hopper, a grinding motor, a grinding shaft, a grinding motor, a grinding wheel, and a feeding Cover, first vibrating screen and governor, one side of the crushing chamber is fixed with a crushing motor, one end of the crushing motor is provided with a crushing shaft, and the crushing shaft axially runs through the crushing chamber, and the lower side of the crushing chamber is set There is a grinding chamber, and support legs are fixed on both sides of the grinding chamber, a grinding motor is fixed on one side of the grinding chamber, a grinding shaft is fixed on one side of the grinding motor, and several grinding wheels are arranged on the grinding shaft , the lower side of the grinding chamber is provided with a storage bin. The invention fully pulverizes and grinds the Chinese herbal medicine through the pulverizing chamber and the grinding chamber, while improving the working efficiency, the quality of the Chinese herbal medicine powder is guaranteed, and the invention has a simple structure, small volume, and is convenient for transportation and installation.

Owner:CHONGQING FULING DISTRICT FUJI TRADING CO LTD

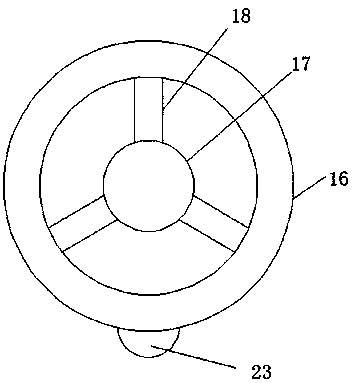

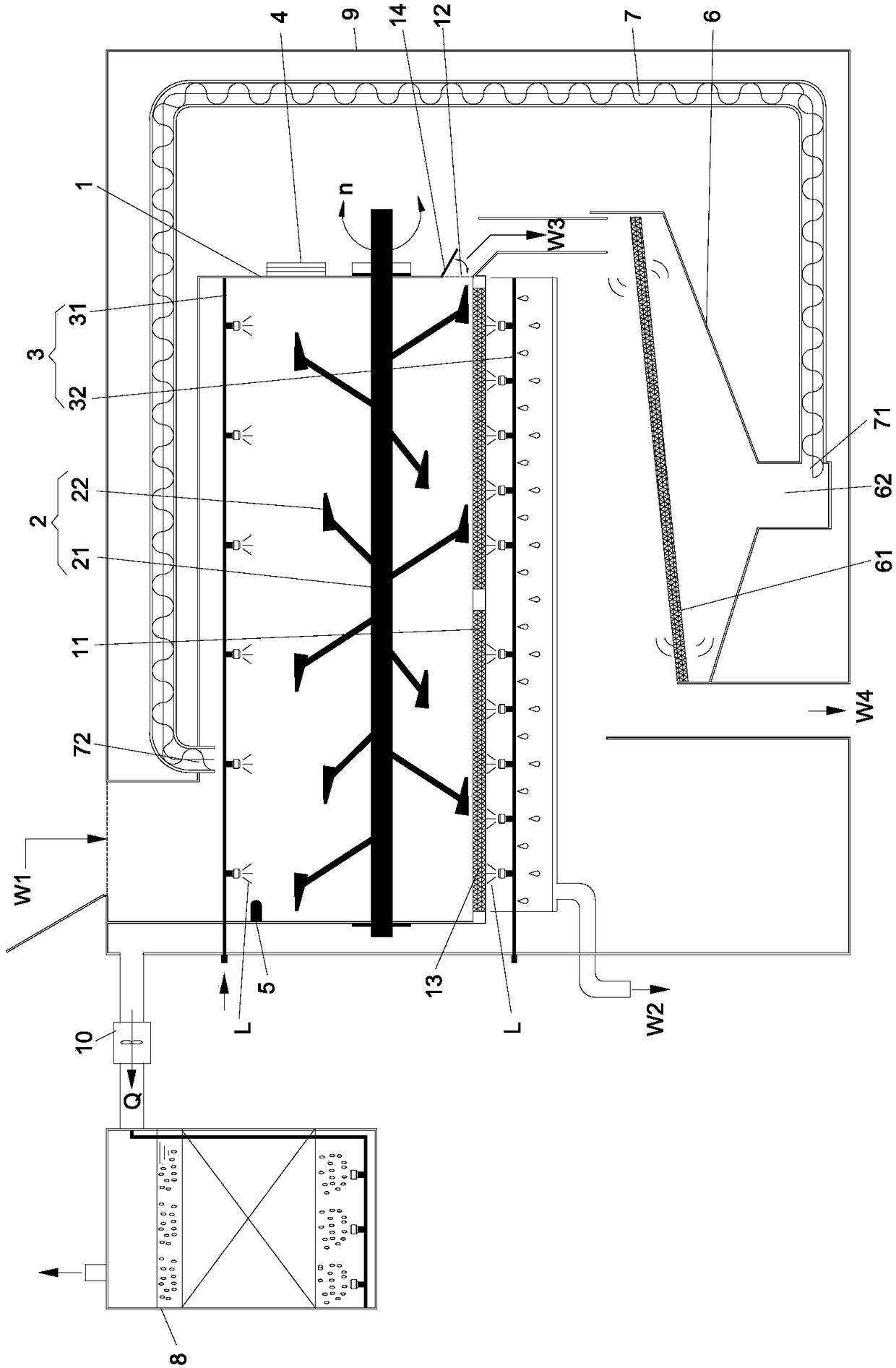

Organic garbage treatment system with automatic classification function

ActiveCN105903754AAchieve separationPromote resource utilizationSolid waste disposalResource utilizationEnvironmental engineering

The invention provides an organic garbage treatment system with an automatic classification function. The organic garbage treatment system with the automatic classification function is used for carrying out classification treatment on kitchen garbage, and comprises a grinding-separating device, wherein the grinding-separating device comprises a cylinder block, a stirring device rotationally arranged in the cylinder block, and a spray device facing the interior of the cylinder block; a charge port is arranged in the upper part of the cylinder block; a discharge hole and an unloading port are arranged in the lower part of the cylinder block; the stirring device is used for grinding organic garbage into organic matter particles; a liquid sprayed by the spray device carries the organic matter particles and is rushed out from the discharge hole, and is subjected to resource utilization in the subsequent process; and massive garbage which is difficult to decompose or incapable of being decomposed is automatically discharged from the unloading port. The organic garbage treatment system with the automatic classification function, which is provided by the invention, has the advantages that the occupied space is less, the garbage treatment energy consumption is low, the system is simple to operate, the running cost is low, the generated odour is less, useful parts in the garbage can be effectively recycled, environment cannot be polluted, and the like. The organic garbage treatment system with the automatic classification function can be used as a front-end pre-treatment classification system in a process for treating garbage rich in organic matters, such as kitchen garbage, and can also be used for carrying out automatic garbage classification treatment in a municipal domestic garbage transfer station.

Owner:HONG KONG PRODUCTIVITY COUNCIL

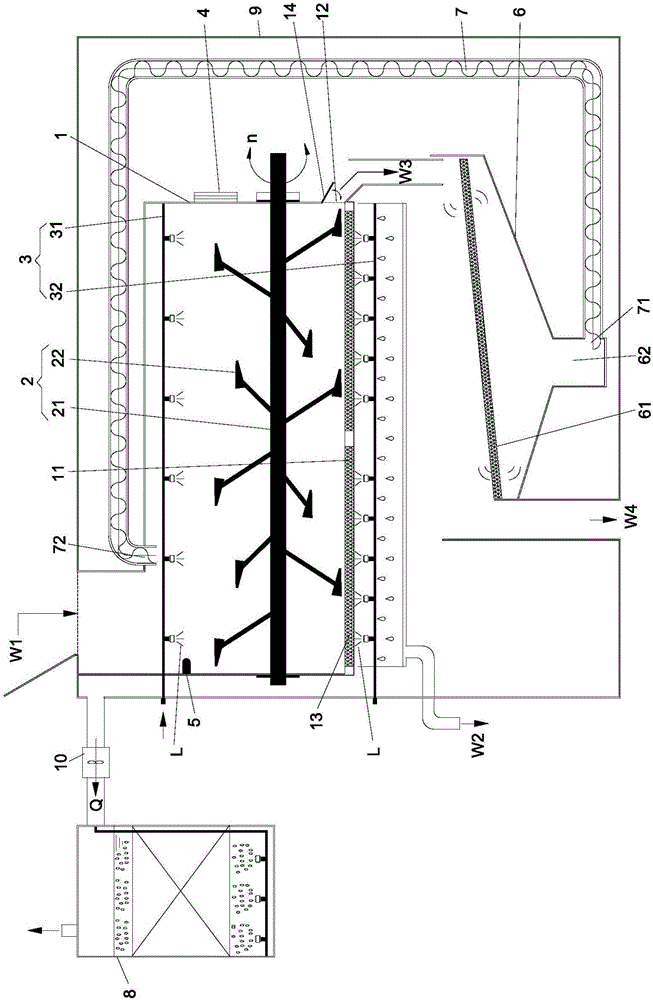

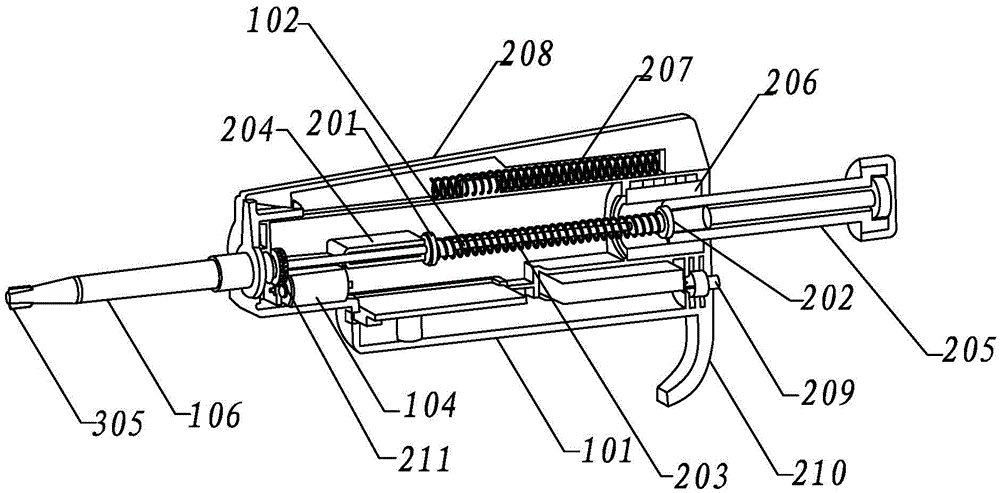

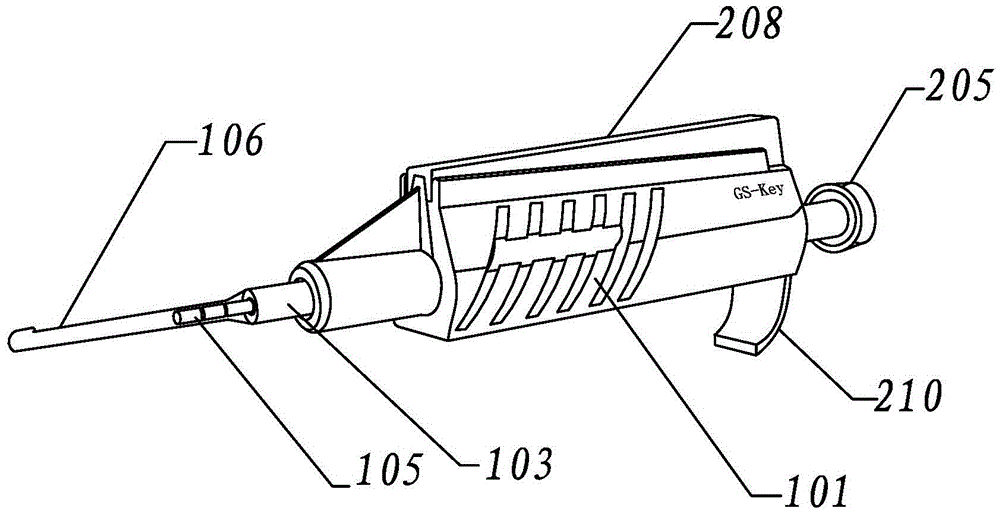

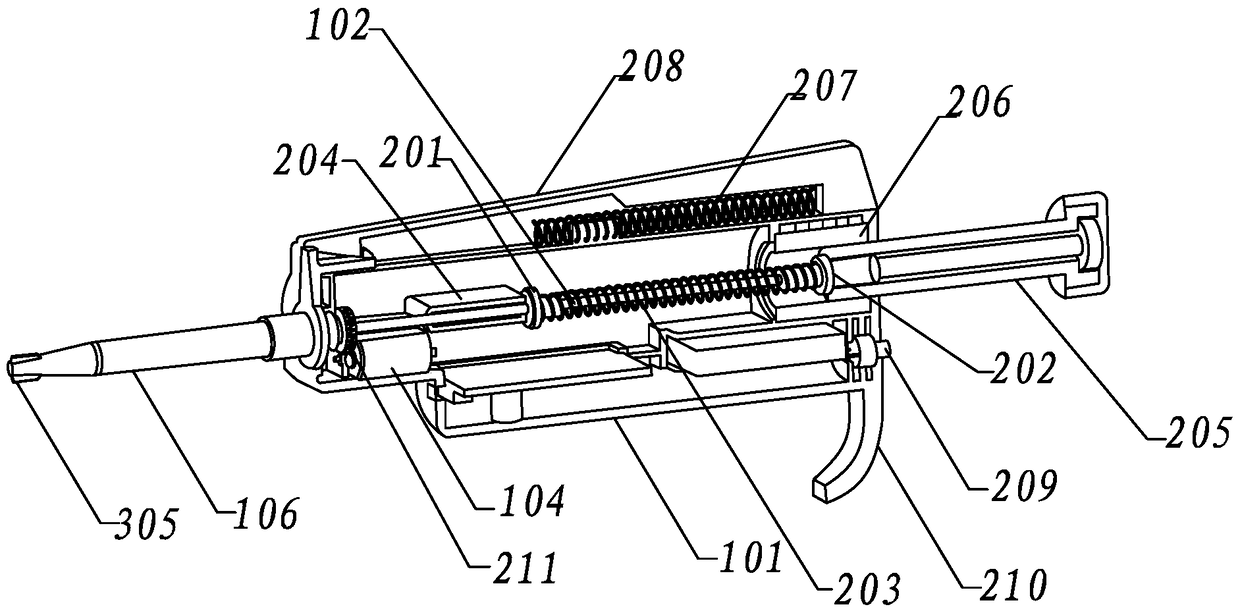

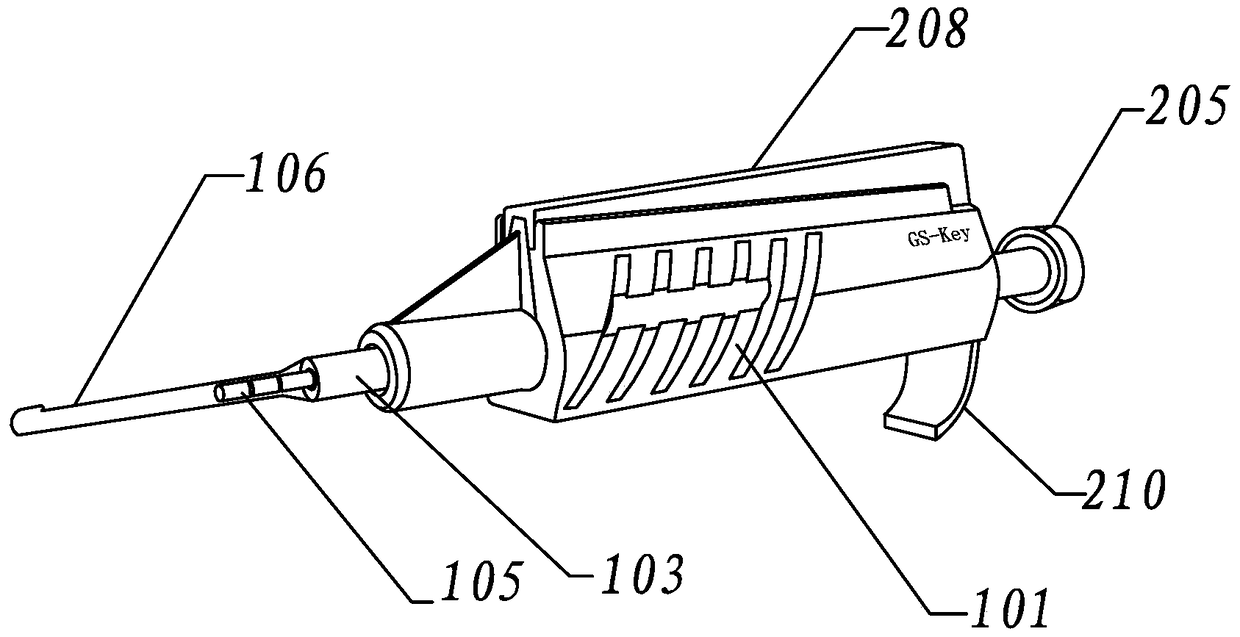

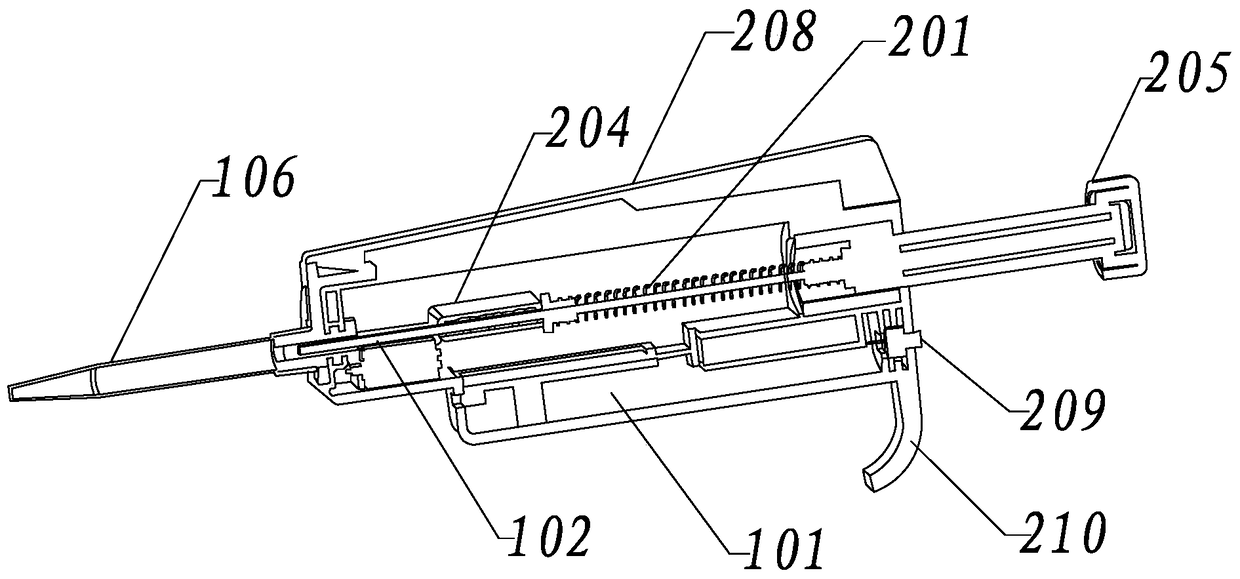

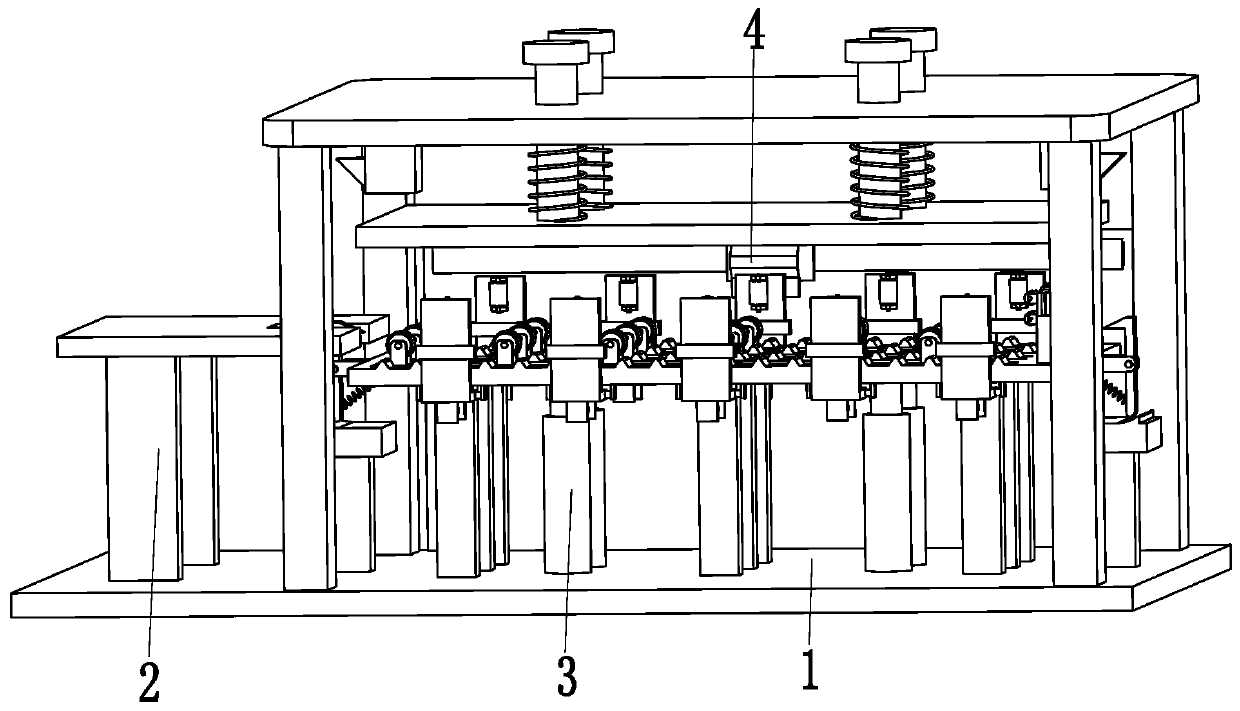

Multifunctional biological substance separating device

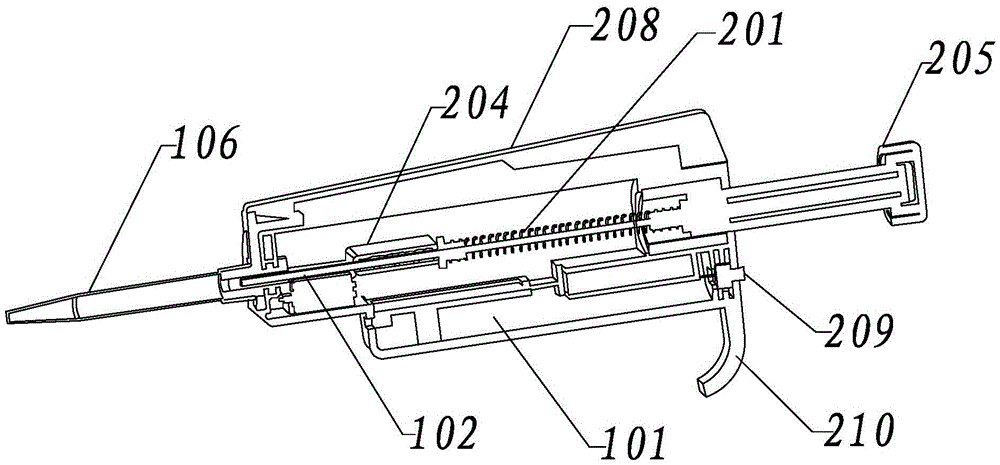

InactiveCN105420074AEasy to separateCompact structureBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic beadBiochemical engineering

The invention provides a multifunctional biological substance separating device, and belongs to the technical field of biology. The multifunctional biological substance separating device comprises a shell, a main shaft pushing rod, a return device, a magnetic sleeve connecting ring and an electric device, wherein the main shaft pushing rod penetrates through the shell; two ends of the main shaft pushing rod both stretch out of the shell; one end of the main shaft pushing rod is provided with a magnetic post; the magnetic sleeve connecting ring is arranged on the main shaft pushing rod in a sleeving way; one end, which is positioned outside the shell, of the magnetic sleeve connecting ring is provided with a magnetic sleeve; the return device is arranged in the shell and is used for enabling the main shaft pushing rod to move towards the direction which is far away from the magnetic sleeve; the electric device is connected with the magnetic sleeve connecting ring and is used for enabling the magnetic sleeve connecting ring (comprising the magnetic sleeve arranged thereon) to do rotary motion. The multifunctional biological substance separating device provided by the invention is particularly suitable for being applied to a process of extracting a nucleic acid through a paramagnetic particle method, has the effect of enabling a magnetic bead to be quickly separated from a system (mostly a lysis solution or an eluent) therein the magnetic bead exists and is compact in structure and convenient in operation.

Owner:SHANXI ZDGSY BIO SCI CO LTD +1

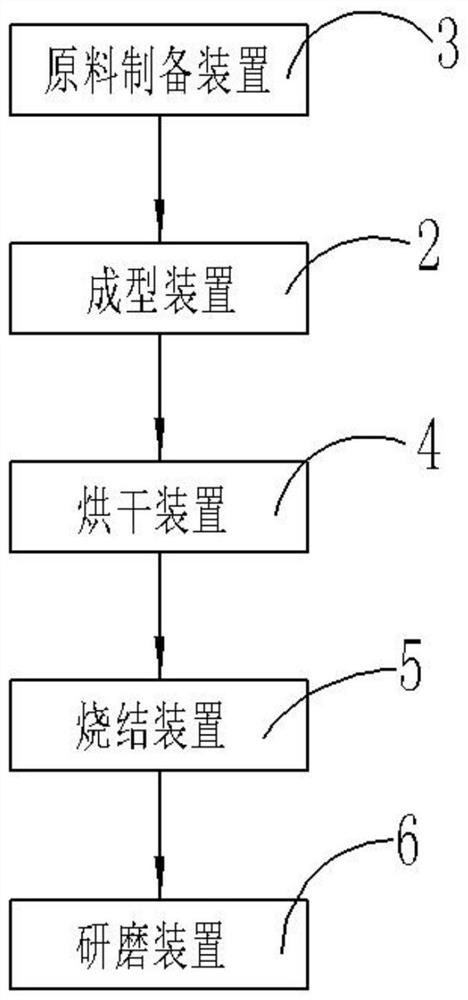

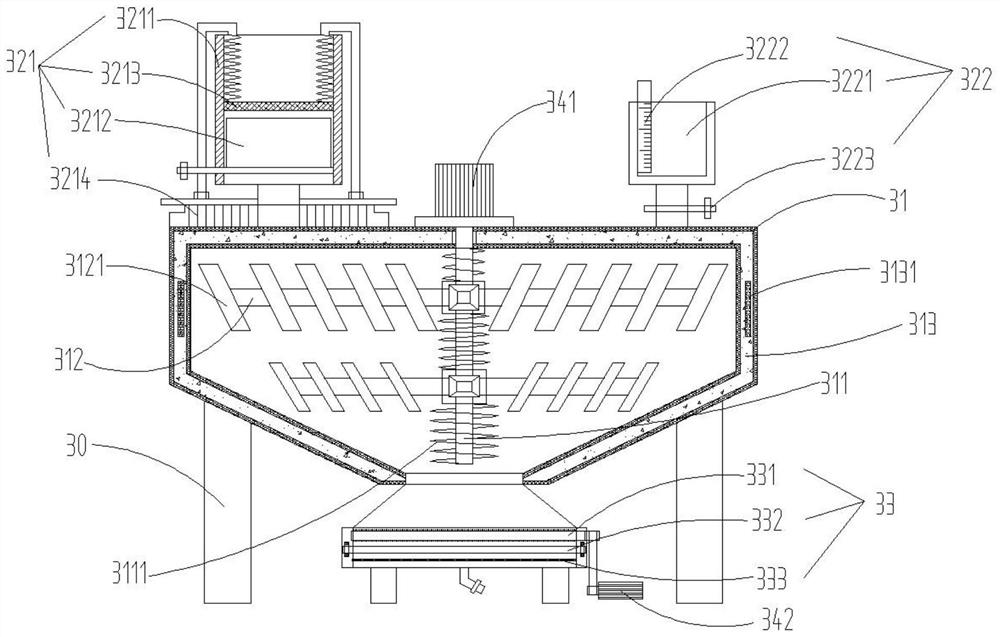

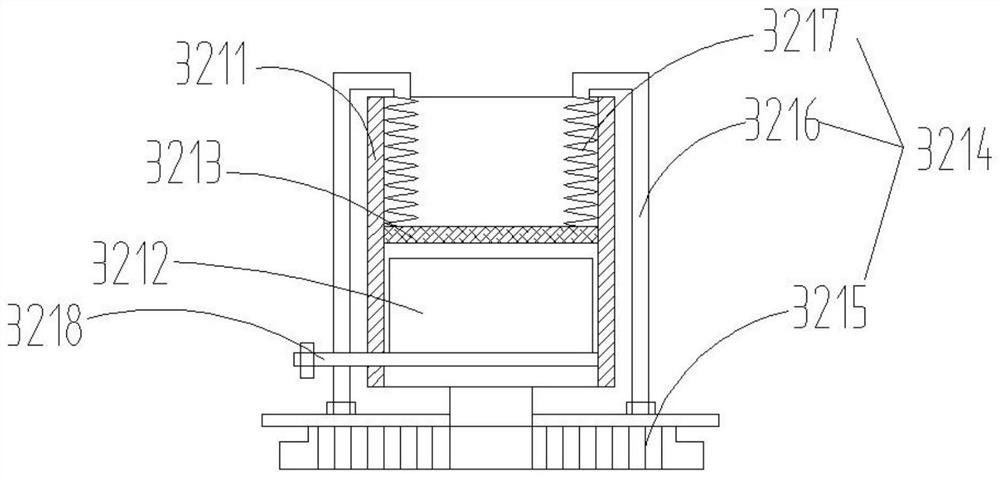

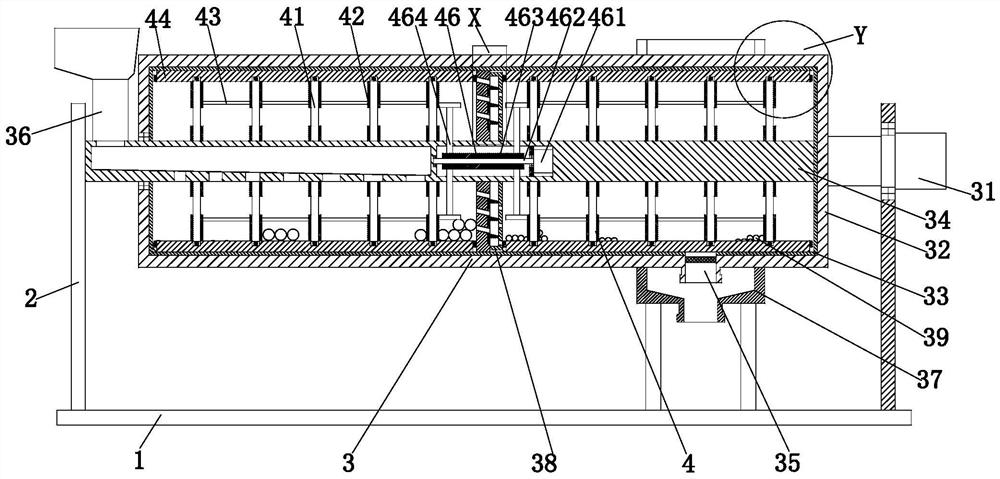

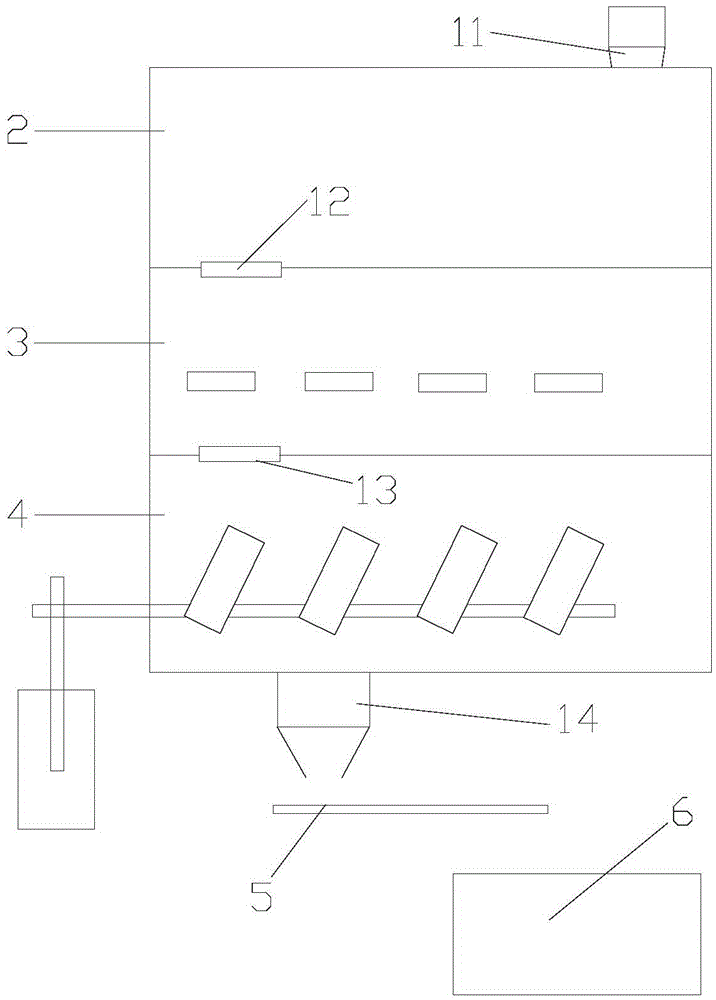

Electronic ceramic production system

ActiveCN111645182AReduce the possibilityGuarantee product qualityGrinding carriagesGrinding drivesMoulding deviceWhole systems

The invention relates to an electronic ceramic production system. According to the electronic ceramic production system, electronic ceramic processing is achieved by combining multiple devices, the whole system is reasonable in processing, firstly, the raw material preparation device is used for preparing high-quality ceramic slurry, then the high-quality ceramic slurry is put into the forming device for automatic forming, a green body is put into the drying device for drying after forming, the green body is preliminarily dried, in order to prevented cracks from being generated in the sintering process, the green body is placed in the sintering device after drying, by designing a feeding and taking structure of the sintering device, a user cannot be scalded in the using process, ceramic production is completed after sintering is completed, surface treatment of a ceramic product is carried out in the next step, the grinding device adopted for surface treatment is good in grinding effect, and meanwhile, dust generated in the grinding process is collected, so that dust pollution in a processing workshop is avoided; and electronic ceramics produced by using the whole system are high inquality, the whole system is used in the workshop, so that cleanliness of the workshop is guaranteed, and the safety production effect is improved.

Owner:新化县正能精细陶瓷有限公司

Beans crushing and collecting device

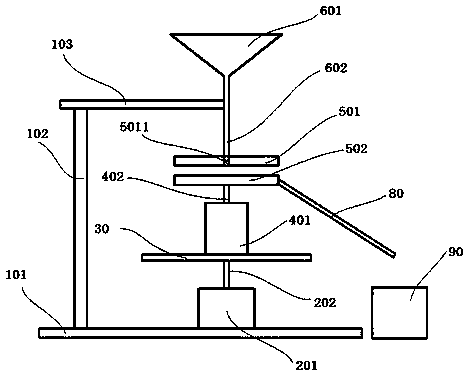

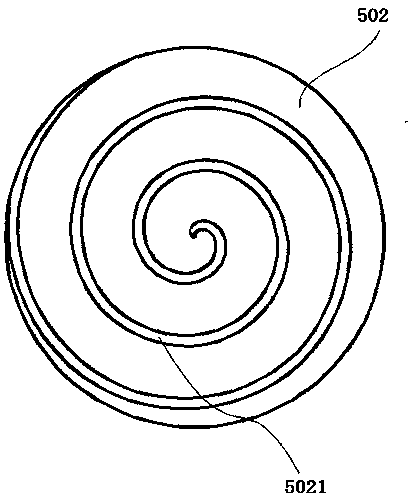

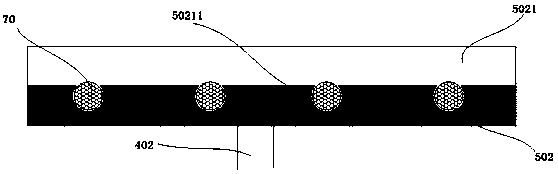

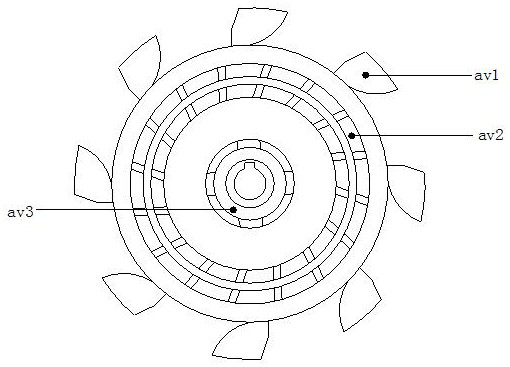

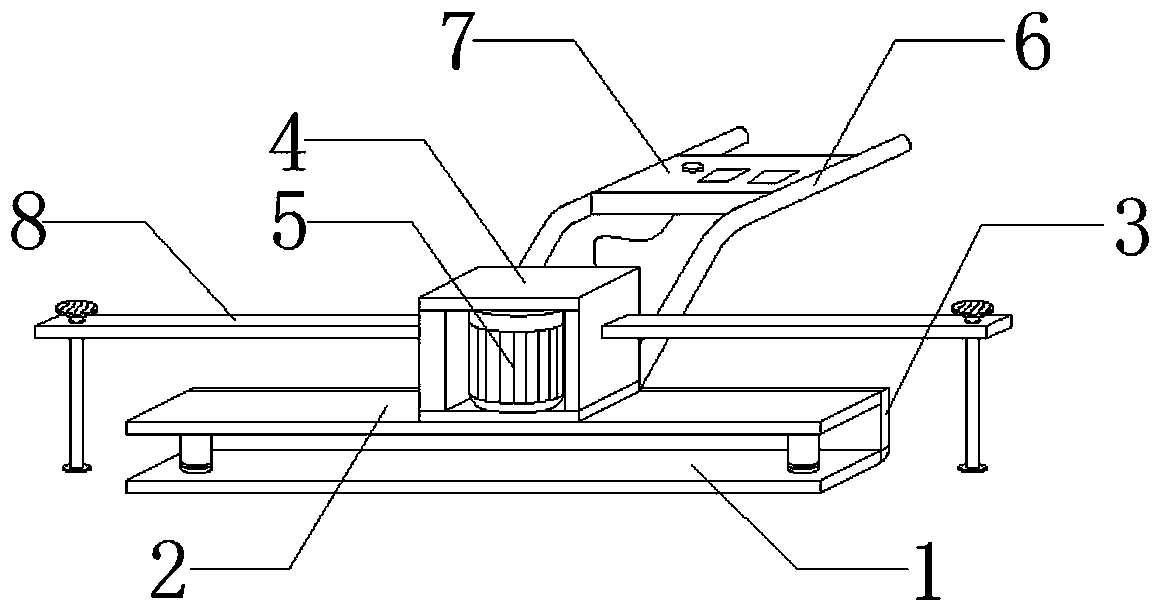

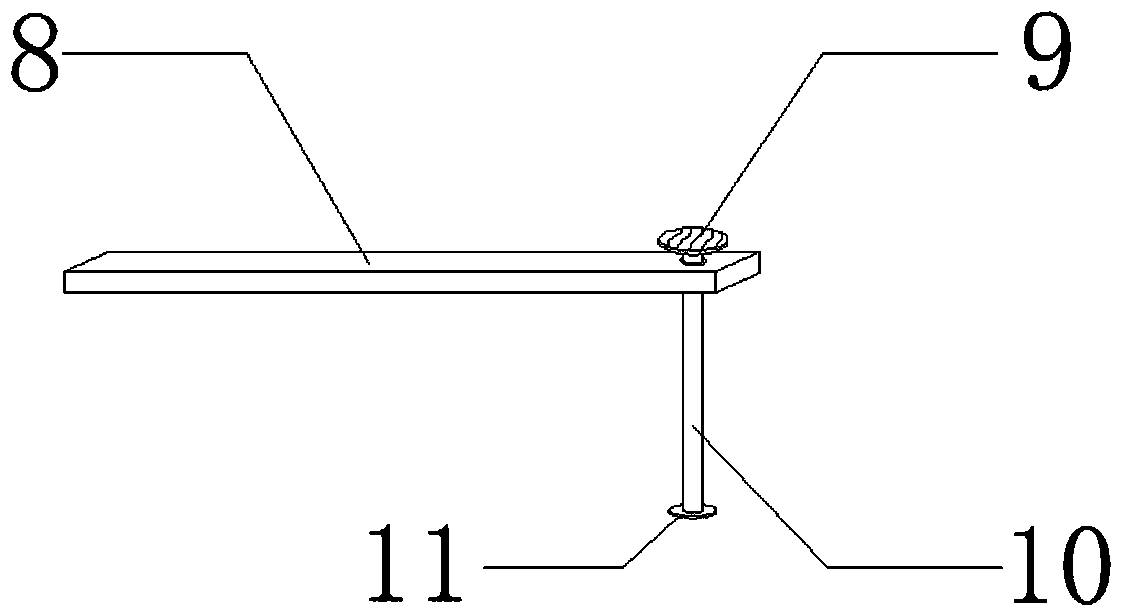

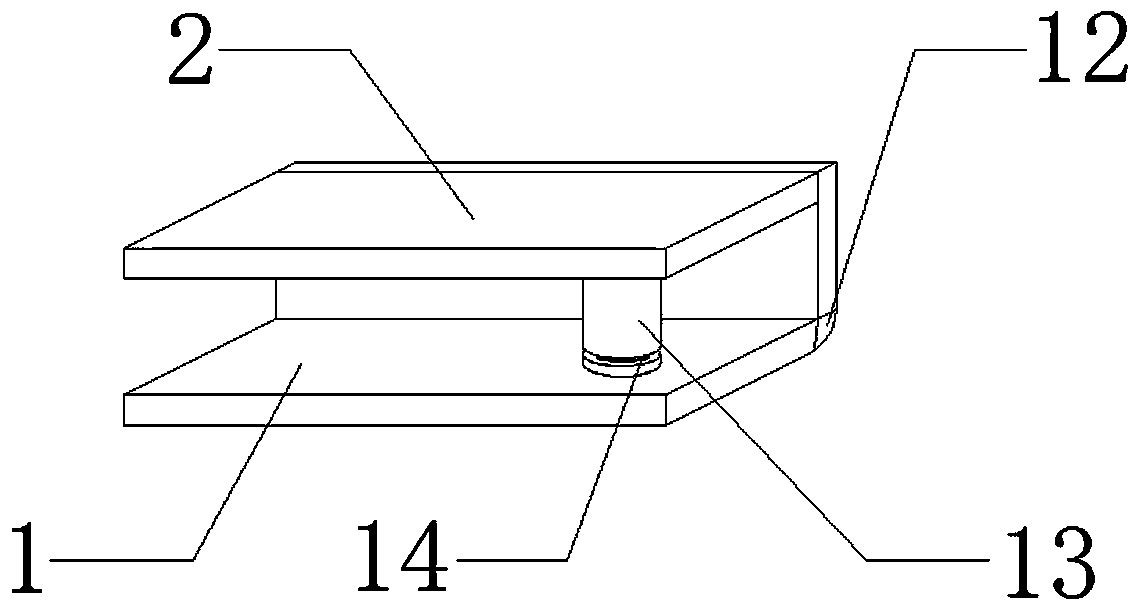

PendingCN107824282AGrind fullyAvoid frictionless rotationGrain treatmentsElectric machineryEngineering

The invention provides a beans crushing and collecting device, which comprises a substrate, a connecting rod and a mounting rod. The lower end of the connecting rod is fixedly connected with the substrate, and the connecting rod is positioned on the substrate and parallel to the substrate. A pneumatic cylinder comprises a cylinder body and a piston rod. The cylinder body is fixedly installed on the upper surface of the substrate. A support plate is connected to the cylinder body through the piston rod, and the support plate is parallel to the substrate. A motor comprises a motor body and a rotating shaft. A grinding disc comprises an upper disc-shaped grinding disc and a lower disc-shaped grinding disc. The upper surface of the lower grinding disc is provided with a planar spiral groove. The upper grinding disc and the lower grinding disc are coaxially arranged. The center of the upper grinding disc is provided with a through hole. A hopper comprises a hopper body and a hopper mouth. The hopper body is connected to the hopper mouth through a through hole. The lateral side of the hopper mouth is connected to the connecting rod through the mounting rod. The device also comprises a chute, one end of which is fixedly installed at the lateral side of the lower grinding disc at a discharge opening. A storage tank is arranged below the other end of the chute. Vertical height of one end of the chute is greater than vertical height of the other end of the chute. By integrating grinding and collection, the device of the invention has high grinding efficiency.

Owner:惠州市肆方农业发展有限公司

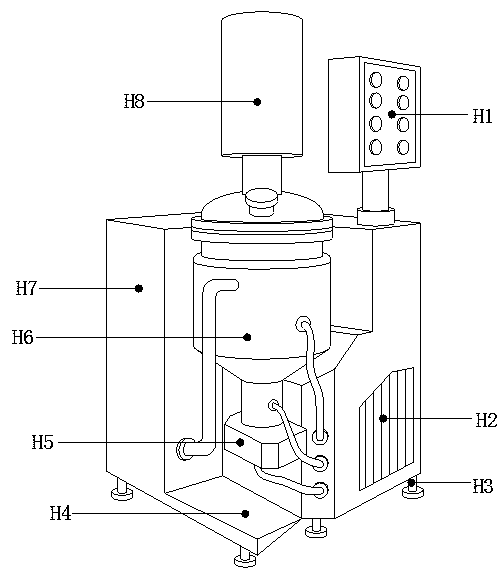

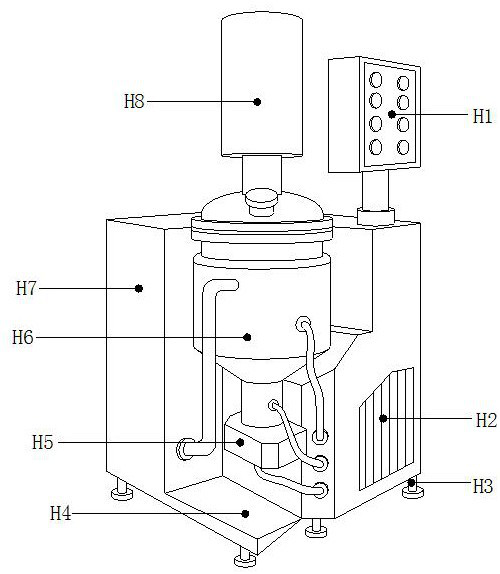

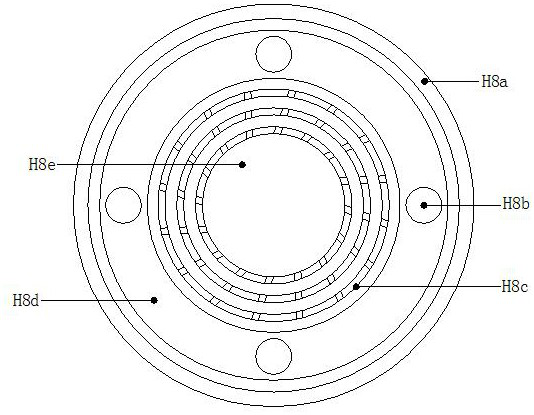

Preparation device for graphene-doped hydrogen storage material

ActiveCN110282601AAvoid Hydrogen Permeability DropsPrevent raw materials from cakingHydrogenGrapheneCvd grapheneProcess engineering

The invention discloses a preparation device for a graphene-doped hydrogen storage material; the structure of the device comprises a controller, a heat dissipation groove, fixed foot margins, a material holding table, a preparation port, a preparation tank, a control main engine, and a doping tank. Graphene raw materials in the doping tank uniformly pass through a material scraping groove when entering; the material scraping groove and a discharge ring are fixedly arranged; the raw materials are guided to an area in which the discharge ring and a grinding embedded ring are matched for pulverization treatment through poking blocks when a grinding mechanism rotates, and then enter a dispersion component for dispersed blanking; the decrease of hydrogen permeability caused by stacked blanking can be avoided; a gas compression mechanism can generate gas to pneumatically control the dispersion component under the driving of a built-in drive shaft; the clogging of the graphene raw materials is avoided; high-precision pulverization can be performed on flake graphite after the whole use; the raw materials are effectively prevented from agglomerating in the blanking process; a state of powdery falling is formed; the permeability of hydrogen doping is greatly improved; the hydrogen storage effect is higher.

Owner:GUIZHOU UNIV OF ENG SCI

Device for extracting and grinding wormwood

InactiveCN108970780AGrinding effectAvoid the impact of normal workGrain treatmentsDrive wheelElectric machinery

The invention discloses a device for extracting and grinding wormwood. The device comprises a shell; a discharging port is formed on a middle position on the bottom of the shell; a feeding port is formed on the top of the shell; a first rotating shaft is arranged in the feeding port; multiple sets of smashing blades are arranged on the two sides of the first rotating shaft; a driven wheel is arranged on the bottom of the first rotating shaft; a driving wheel is arranged on one side of the driven wheel; the driving wheel is connected with the driven wheel through a belt; a second rotating shaftis penetrated through the middle of the driving wheel; the top of the second rotating shaft is penetrated through the shell and is connected with a first driving motor on one side of the top of the shell; a first filter screen is arranged on the inner top of the shell. The device disclosed by the invention has the beneficial effects of reasonable design, simple structure and convenience in use. Compared with the traditional extracting device, the device disclosed by the invention has the advantages that the sufficient grinding property is effectively promoted, so that the purifying rate can be effectively increased and the use ratio can be effectively increased.

Owner:安徽清山艾草制品有限公司

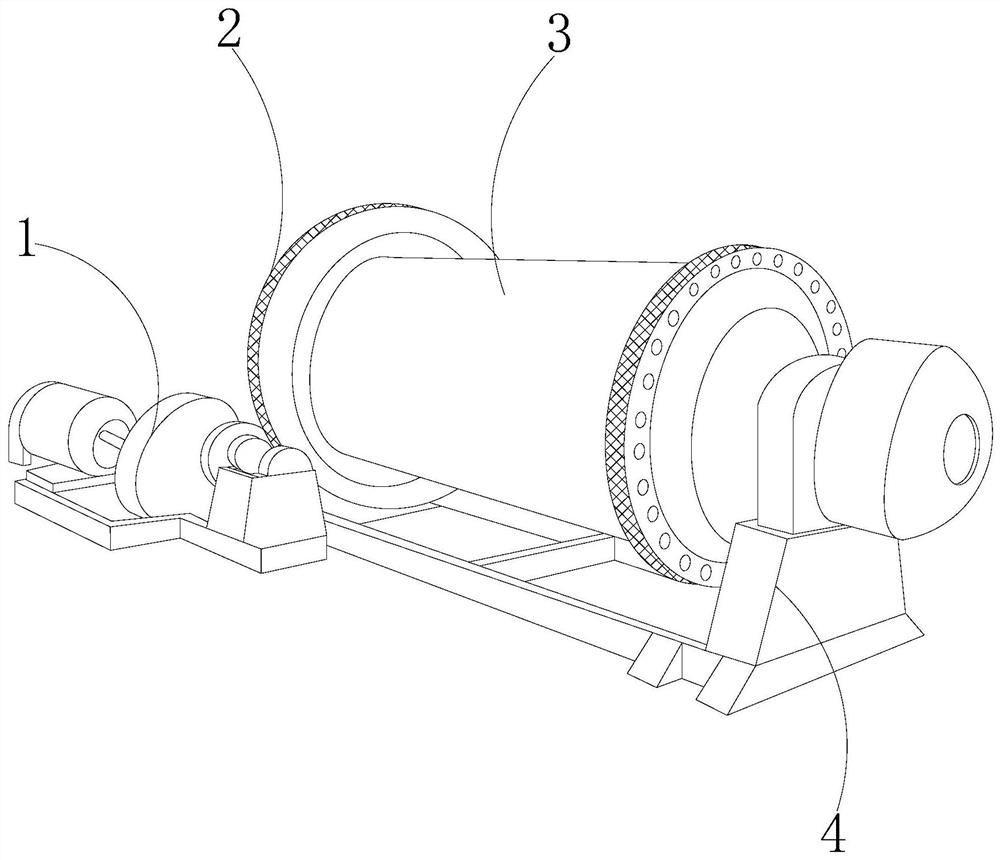

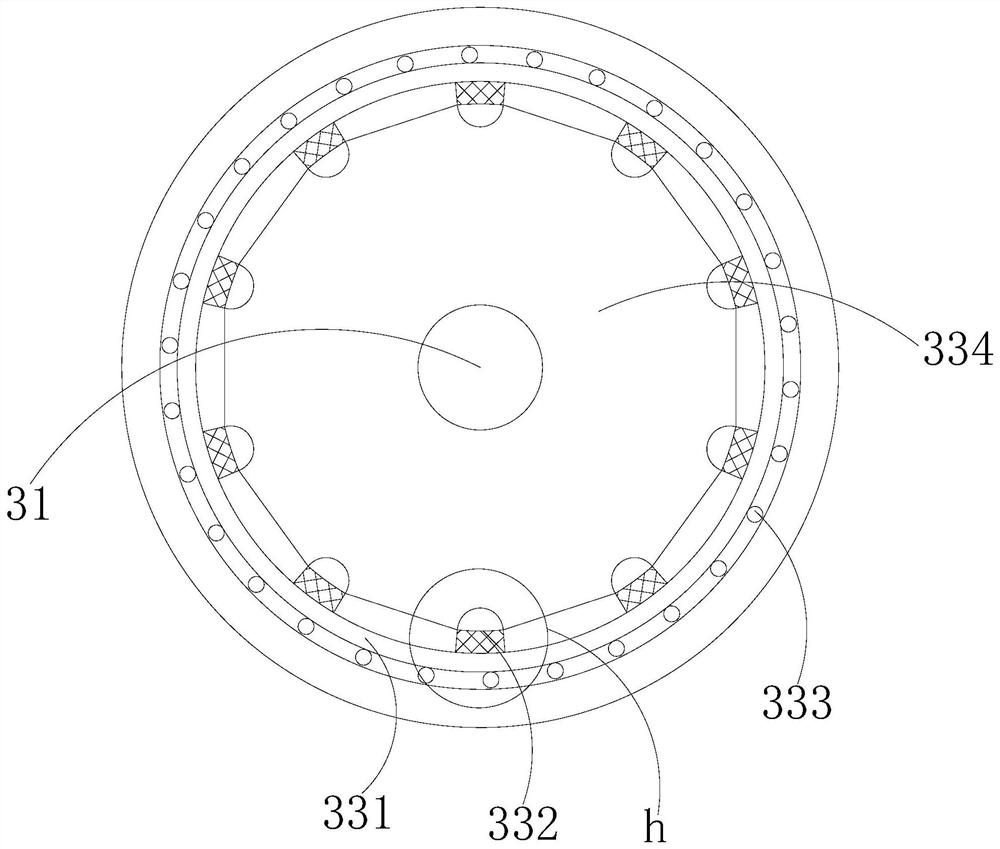

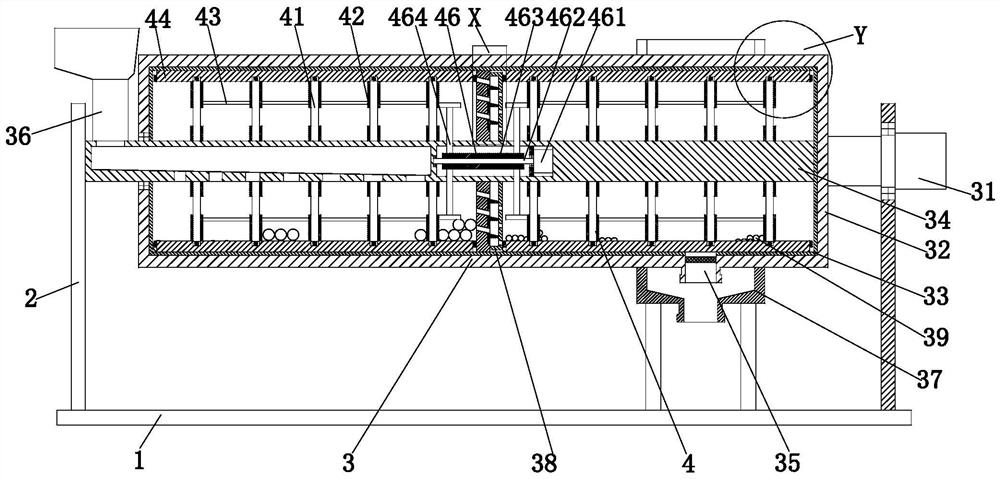

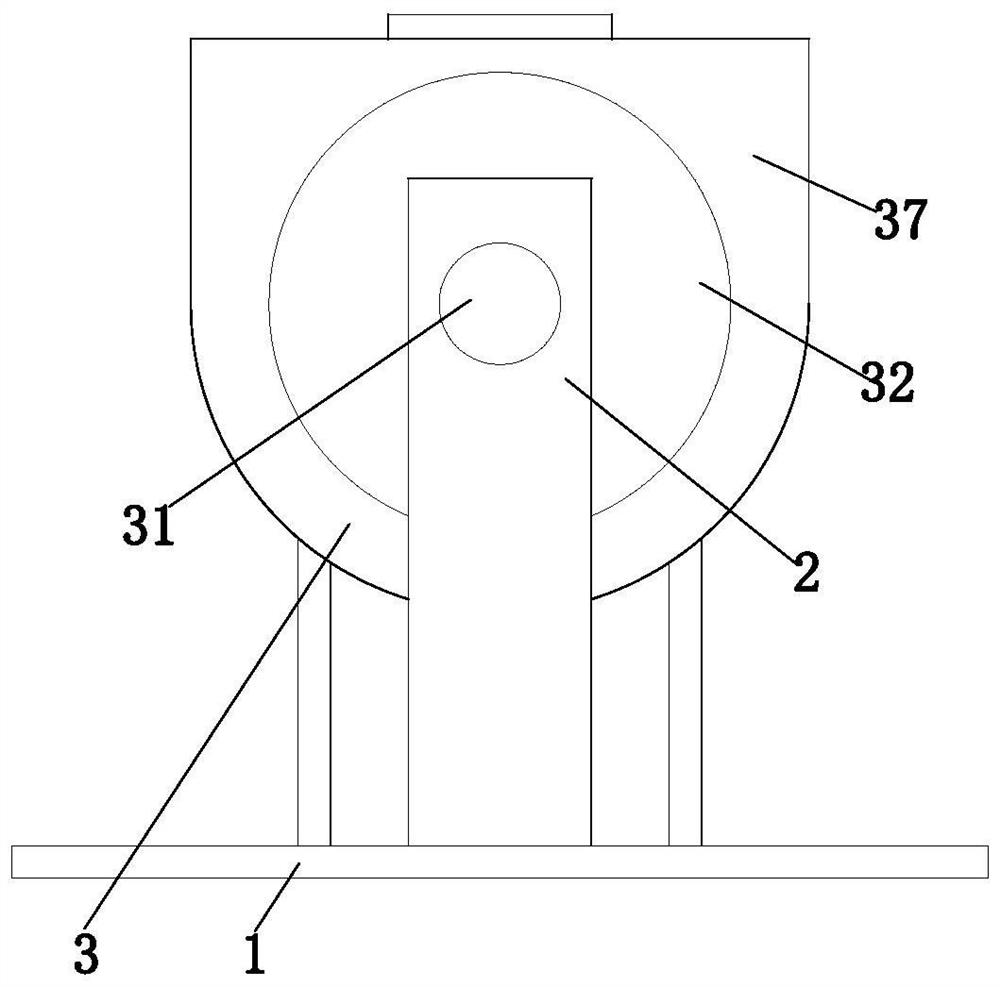

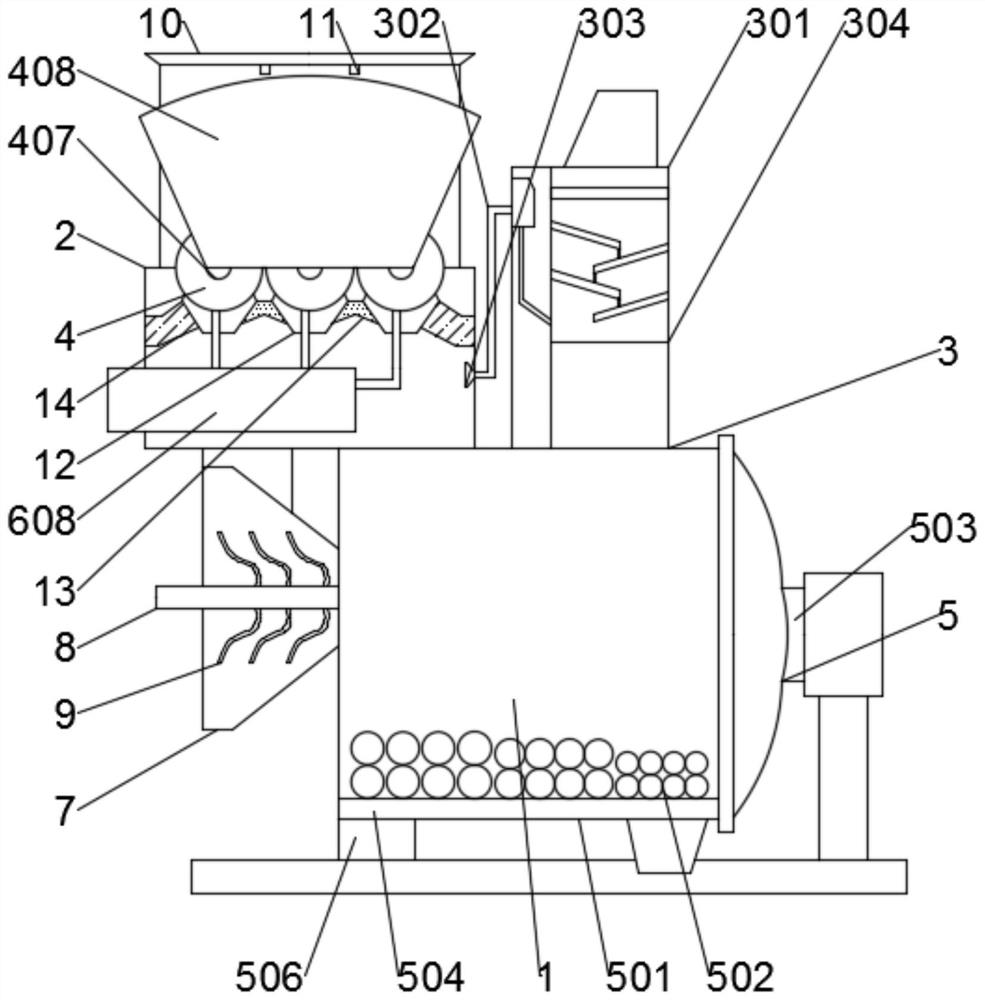

Ball mill for graphene production

The invention discloses a ball mill for graphene production. The ball mill structurally comprises a motor, a gear, a rotary drum mechanism and a supporting frame, wherein the motor is in threaded fitwith the gear, the gear is fixedly embedded in the outer side of the rotary drum mechanism, the supporting frame is located at the lower end of the rotary drum mechanism, and the rotary drum mechanismis provided with a feeding port, a roller, a rotating mechanism and a discharging port. According to the ball mill, a rotating ring and balls are in fitting rotation, iron balls are clamped on the side faces of stress mechanisms, after the iron balls fall off under the action of gravity, elastic blocks are compressed when the sliding plates are subjected to the action of the iron balls, so that material grinding is prevented from being hindered by vibration generated by springback, the impact force borne by the sliding plates is reduced, the sliding plates are prevented from deforming due toexcessive stress, and the material grinding effect is prevented from being affected by unevenness of the sliding plate; and bending plates are compressed by the gravity of the iron balls, the surfacetension of the friction plates to fit is enhanced, fan-shaped plates is extruded by fixing rings, hollow balls in the middle of connecting plates are compressed by ball blocks, and meanwhile, a slightinertia force is generated under the fitting pressure, so that the fitting gripping force of friction mechanisms to the iron balls is enhanced.

Owner:牛虎

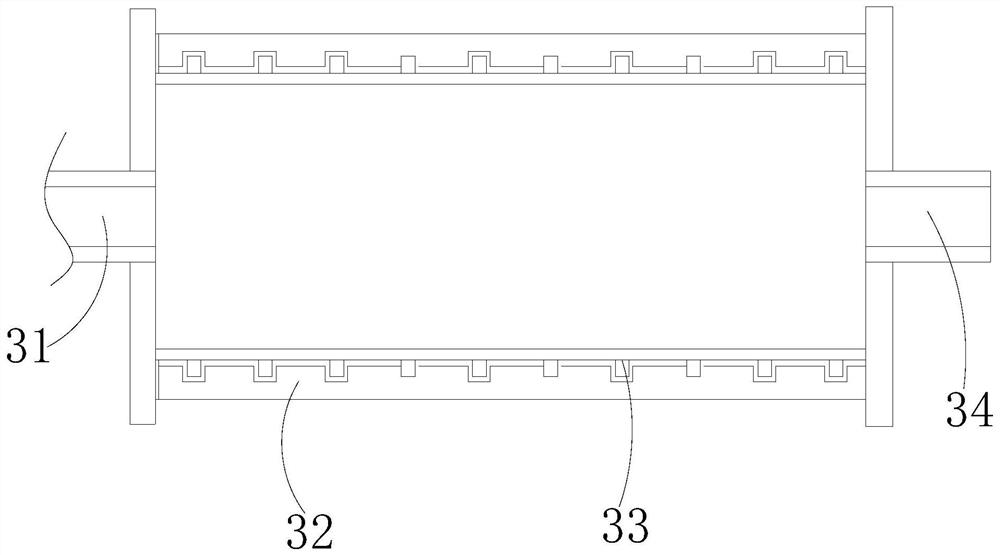

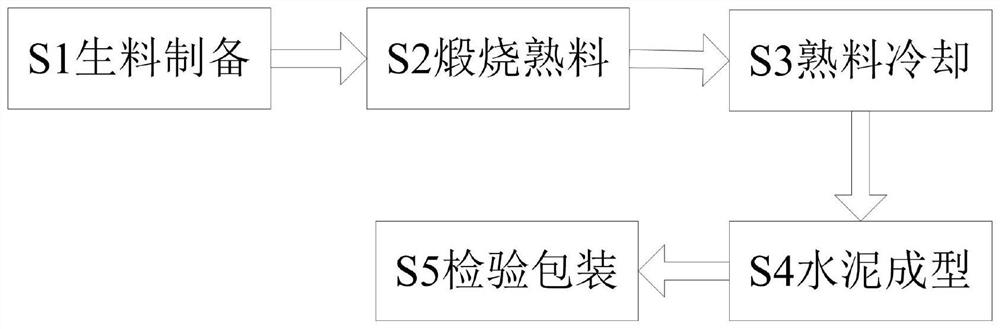

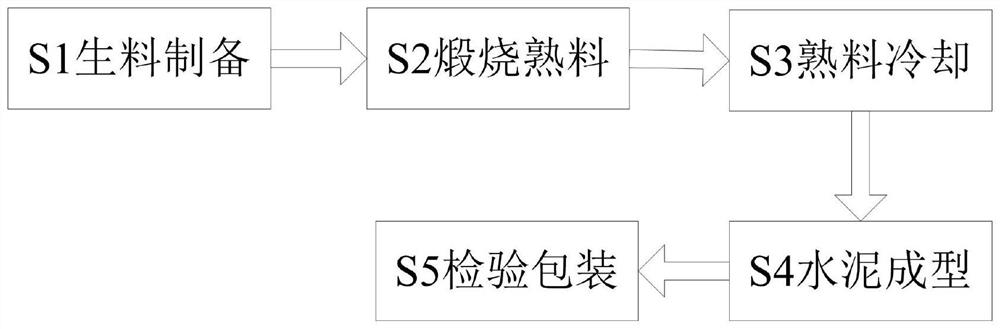

Portland cement preparation method

The invention relates to a Portland cement preparation method. A ball mill is used, the ball mill comprises a bottom plate, a mounting plate, a grinding device and a wall scraping device. The specific method for preparing Portland cement through the ball mill comprises the following steps of raw material preparation, clinker calcination, clinker cooling, cement forming, inspection and packaging. The grinding device comprises a driving motor, a barrel, a lining plate, a feeding pipe, a feeding opening, a discharging opening, a material containing frame, a bin partition plate and a steel ball, and the wall scraping device comprises a supporting rod, a lifting barrel, a connecting rod, a scraping head, a fixing rod and an auxiliary mechanism. When raw materials are ground into powder through the grinding device, the powder attached to the inner wall of the barrel is scraped off in time through the wall scraping device, waste is prevented, meanwhile, the situation that the grinding effect of steel balls is reduced under the influence of the buffering effect of the powder is avoided, and in addition, the wall scraping device can also clean a scraping head regularly, the wall scraping effect is prevented from being influenced by excessive powder adhered to the scraping head.

Owner:黑河关鸟河水泥有限责任公司

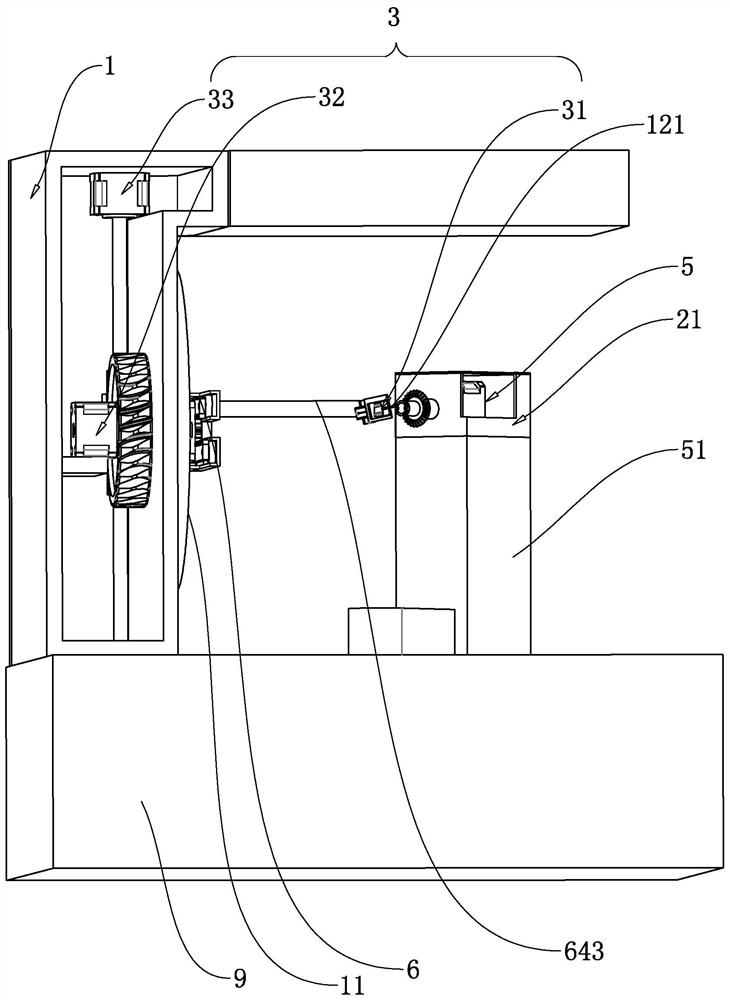

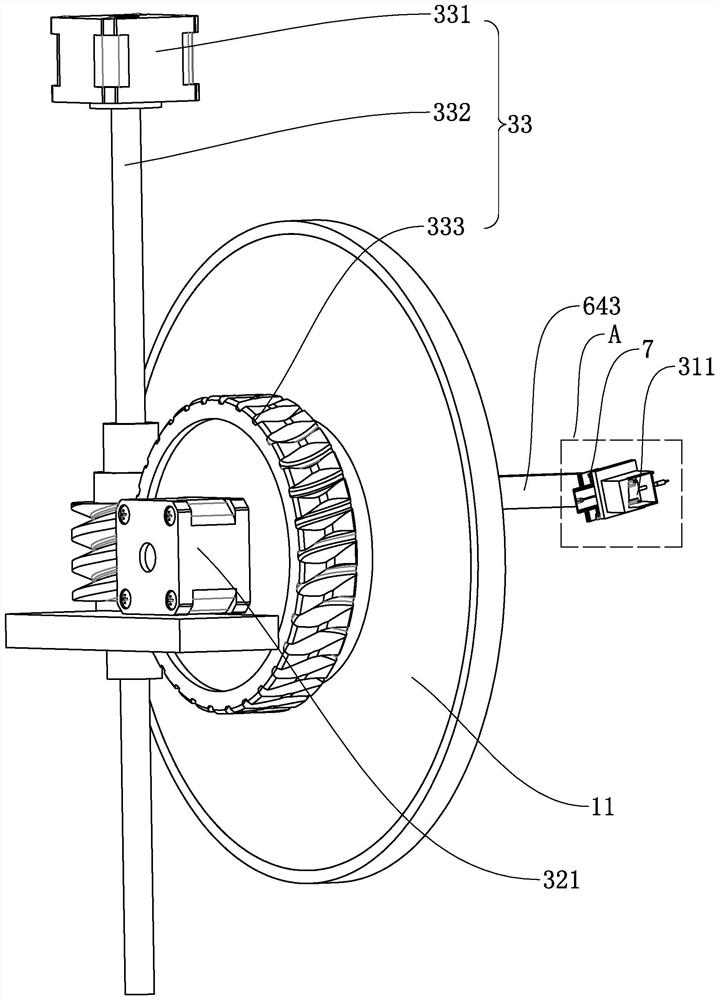

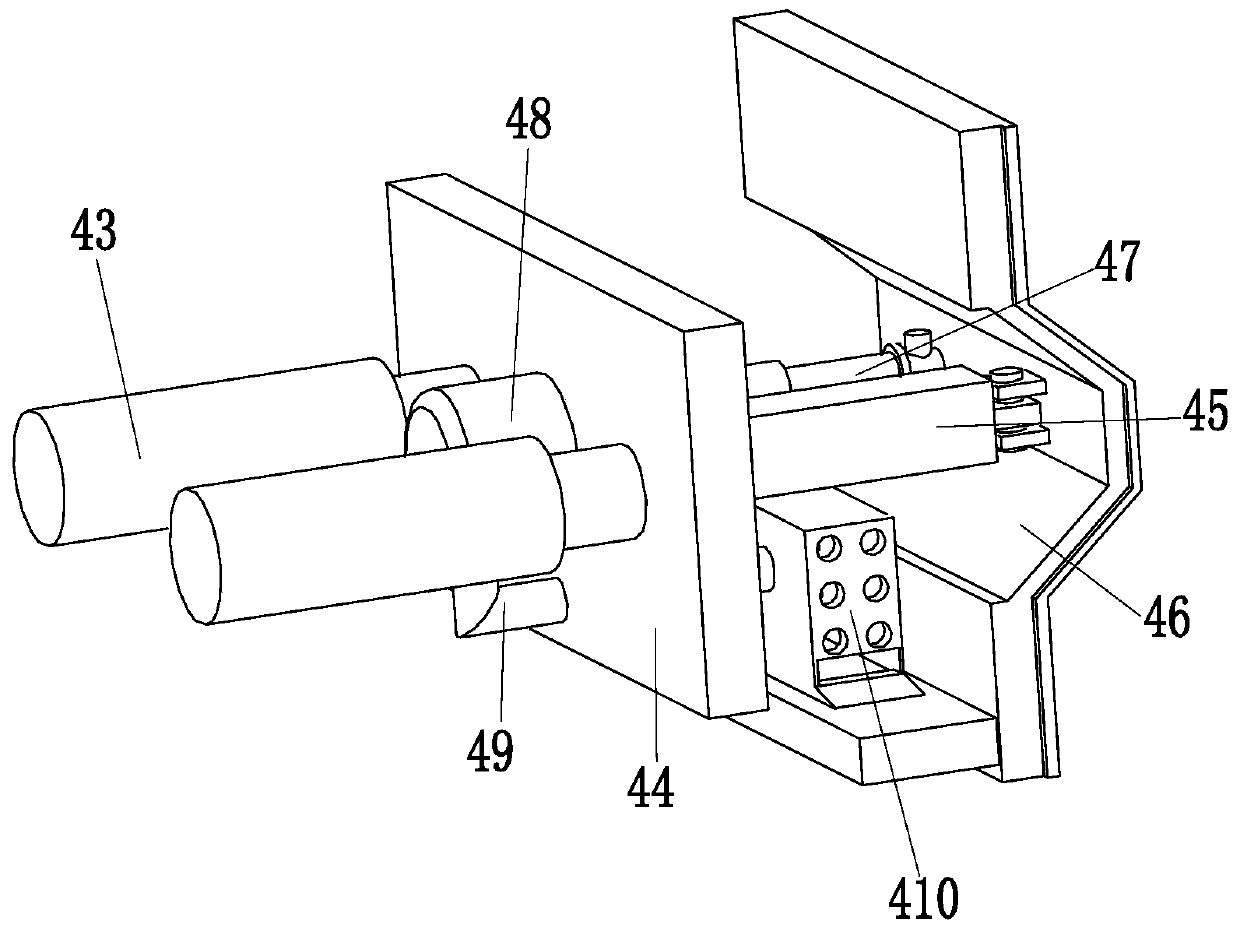

Airplane transmission gear grinding device

PendingCN112372084AEasy to movePlay the effect of reciprocating grindingGear-cutting machinesGear teethAutomotive engineeringAirplane

The invention relates to the technical field of gear grinding machines, in particular to an airplane transmission gear grinding device which comprises a grinding head lathe and a workpiece lathe, wherein a shaking table is mounted on the grinding head lathe and connected to a grinding head base, a grinding head is mounted on the grinding head base, and a drive mechanism for driving the grinding head and the shaking table to work is mounted on the grinding head lathe; the drive mechanism comprises a first drive assembly and a second drive assembly, the first drive assembly being used for driving the grinding head to rotate, the second drive assembly being used for driving the grinding head to move; the driving mechanism further comprises a third drive assembly for driving the shaking tableto rotate; and a workpiece base and a fourth drive assembly are arranged on the workpiece lathe, the four drive assembly being used for driving the workpiece to rotate. the grinding head grinds the tooth surface of the airplane transmission gear under the action of the drive mechanism and the cooperation of the fourth drive assembly, so that the effect of conveniently grinding a special workpiecewith a shaft part is achieved.

Owner:溧阳市腾新机电设备有限公司

Grinding device for food processing

ActiveCN112742510BAvoid adsorptionImprove grinding effectCleaning using gasesGrain treatmentsThermal dilatationFood processing

The invention provides a grinding device for food processing, which includes an arc-shaped grinding box for grinding Chinese prickly ash, a support ring for supporting the arc-shaped grinding box, and a variable cavity for grinding the pepper inside the arc-shaped grinding box A grinding mechanism, wherein a support ring is fixedly connected to the surface of the arc-shaped grinding box, relates to the field of food processing. The grinding device for food processing is based on the problem that powder is easily adsorbed on the grinding device and occupies the grinding space in the existing pepper grinding process. A special structure that can change the grinding space is designed and uses the thermal expansion structure to control the powder mixing and grinding at the grinding structure in real time. Falling, thus effectively solving the problem that the general grinding device is difficult to separate the pepper fine powder during the grinding process. The fine and smooth pepper powder is not only easy to adhere to the grinding device and affect the grinding effect, but also takes up a lot of grinding space. Problems that affect the efficiency of food processing.

Owner:荣成鲁洋水产食品有限公司

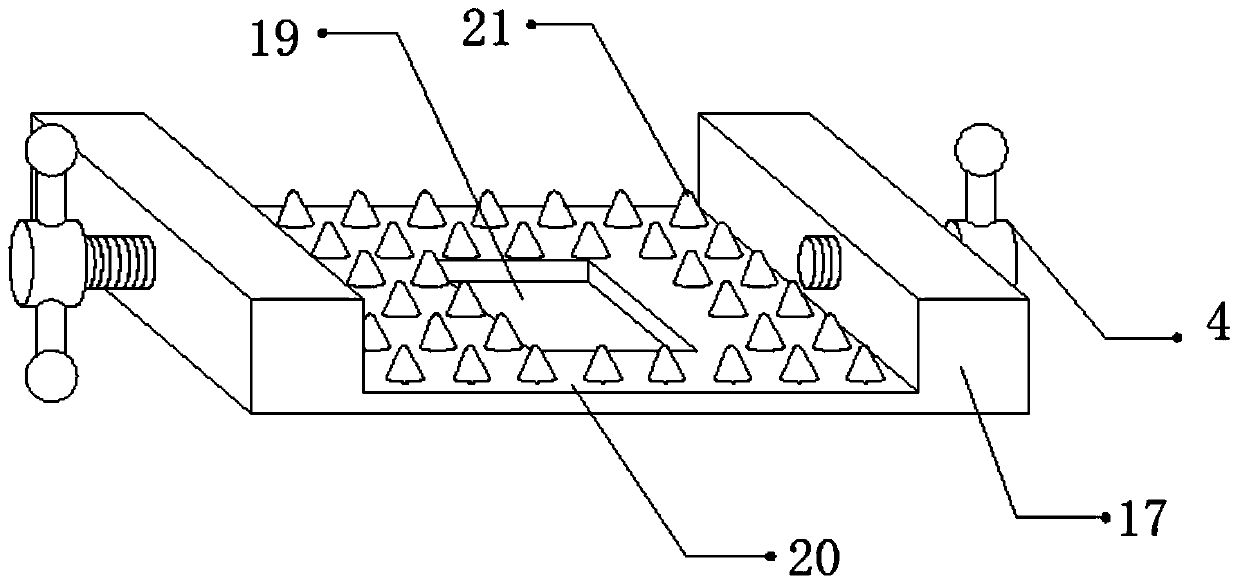

Grinding device good in cooling effect for machining

InactiveCN110977711AEasy to GrindGrinding effectGrinding machinesGrinding/polishing safety devicesCooling effectMachine tool

The invention discloses a grinding device good in cooling effect for machining. The grinding device comprises a fixed base. A fixed plate is fixed to the outer wall of the top of the fixed base. A U-shaped groove is formed in the outer wall of the top of the fixed plate. A plurality of protruding edges distributed at equal intervals are arranged on the inner wall of the bottom of the U-shaped groove. A vent hole is formed in the inner wall of the bottom of the U-shaped groove. A cooling plate is fixed to one side of the outer wall of the top of the fixed base. Cooling holes are formed in the two ends of the outer wall of one side of the cooling plate correspondingly. Cooling fans are fixed to the inner walls of the two cooling holes correspondingly. Fixed rods are fixed to the two sides ofthe outer wall of the top of the fixed base correspondingly. Top plates are fixed to the outer walls of the tops of the two fixed rods correspondingly. The grinding of workpieces can be prevented from being affected by a too high temperature, the shaking of workpieces caused by the shaking of the grinding device in work can be prevented, the machining offset of the workpieces caused by the left-right shaking of a grinding plate can be prevented, and the friction force between a guide column and a through hole can be reduced.

Owner:江苏伯能机床制造有限公司

Wear resistant diamond roller and manufacturing process thereof

ActiveCN108422322AAvoid the problem of not being able to take outGrinding effectGrinding devicesAbrasive surface conditioning devicesWear resistantWater flow

The invention is aimed at providing a wear resistant diamond roller and a manufacturing process thereof. The wear resistant diamond roller includes a roller body. A rotating hole is formed at the circumferential end face center of the roller body in the axial direction of the roller body in a penetrating manner. The wear resistant diamond roller is characterized in that the external surface of theroller body is provided with a diamond layer, the surface of the diamond layer concaves inward to form notches, the notches are obliquely distributed in the surface of the diamond layer, the notchesextend to two opposite end faces of the roller body, water supply channels are arranged in the roller body, capillary paths communicating with the water supply channels are arranged in the roller body, and the capillary paths communicate with the surface of the diamond layer. The rotating hole cooperates with a rotating shaft to control the roller body to rotate in a circumferential direction. A grinding wheel is grinded by the diamond layer arranged on the external surface of the roller body. The water supply channels supply water to the capillary paths. The water flows in the capillary pathsto cool an extremely hot metal layer. Therefore, the usage life of the roller is prolonged.

Owner:JIANGSU XINSHI PRECISION TOOL

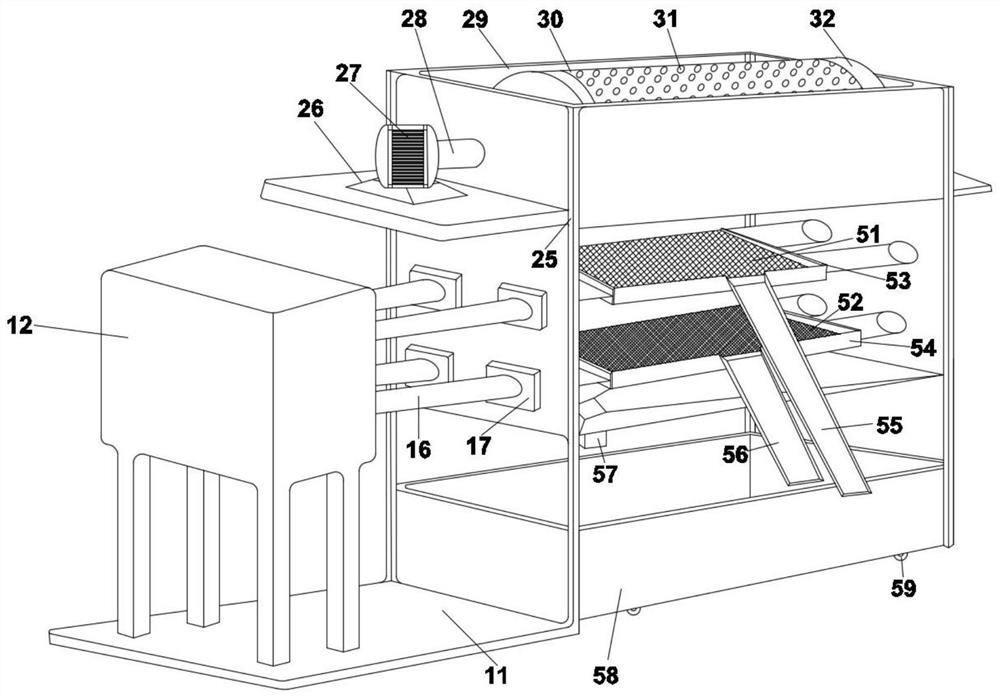

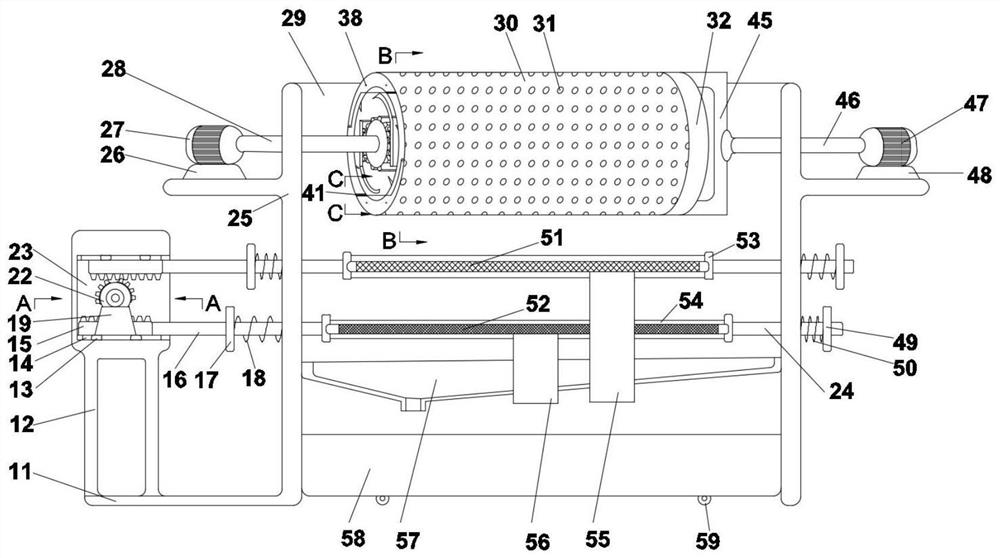

Multistage screening device for particulate matters

InactiveCN108380310AEffective Grading ScreeningEasy extractionCentrifugesGrain treatmentsParticulatesSupport plane

Owner:钱富良

A preparation device for graphene-doped hydrogen storage material

The invention discloses a device for preparing graphene-doped hydrogen storage materials, the structure of which includes a controller, a heat sink, fixed feet, a material holding platform, a preparation port, a preparation tank, a control host, and a doping tank . The graphene raw material in the doping tank of the present invention enters through the scraper groove, and the scraper groove and the discharge ring are fixedly arranged, and the raw material is guided to the discharge ring and the grinding insert by the dial block when the grinding mechanism rotates. The crushing process is carried out in the area matched with the ring, and then it enters the dispersing component for dispersing and blanking, which can avoid the reduction of hydrogen permeability caused by piled material, and the air compressor can generate gas under the drive of the built-in drive shaft to pneumatically control the dispersing component. , to avoid the blockage of graphene raw materials, after the overall use, the graphite flakes can be crushed with high precision, and the raw materials are effectively prevented from agglomerating during the blanking process, forming a powdery falling state, which greatly improves the hydrogen doping Permeability, hydrogen storage effect is higher.

Owner:GUIZHOU UNIV OF ENG SCI

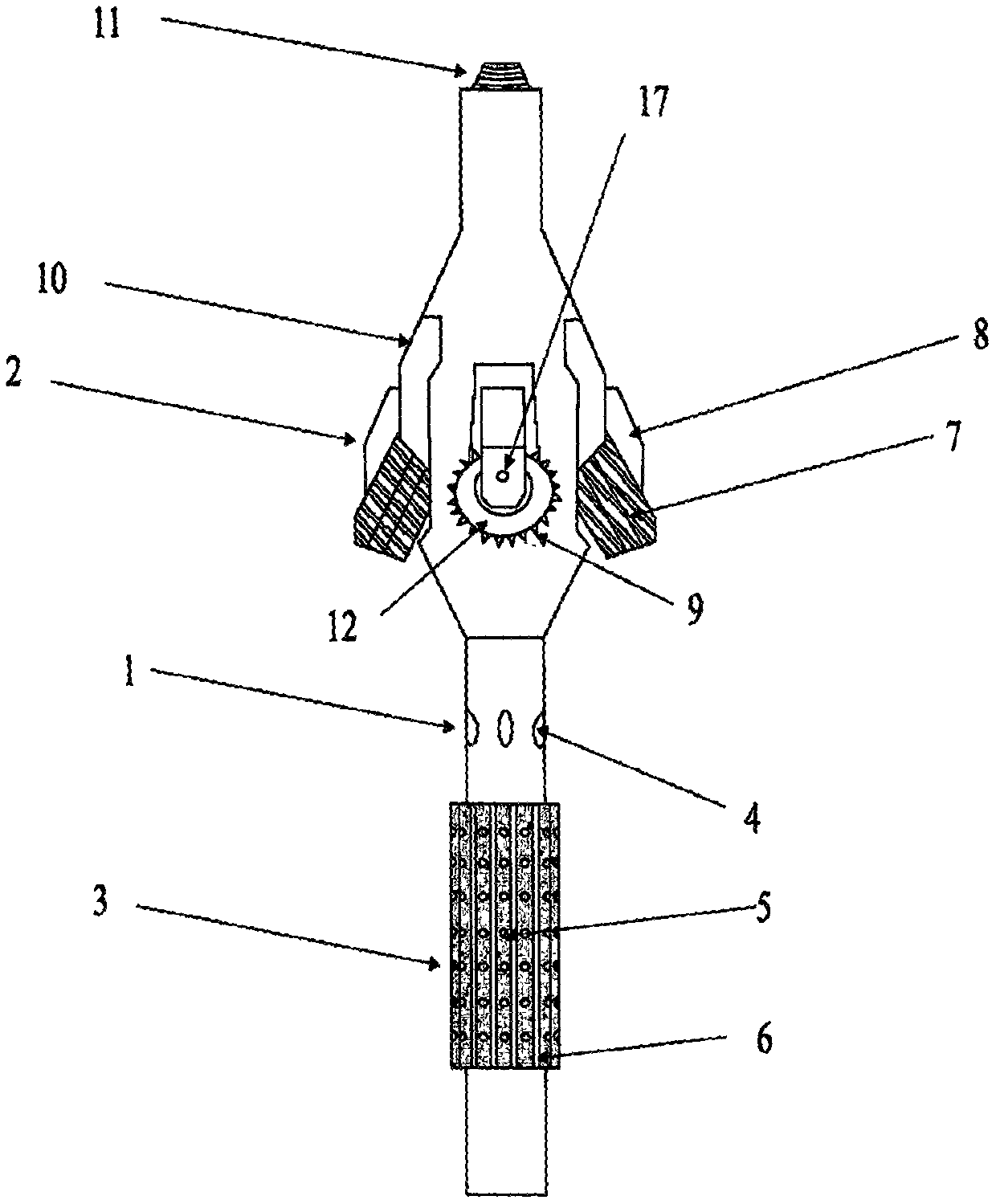

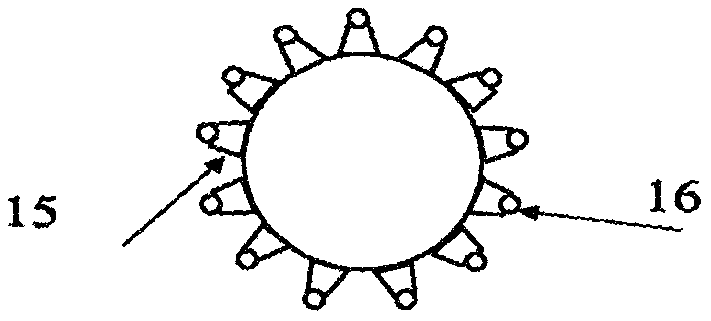

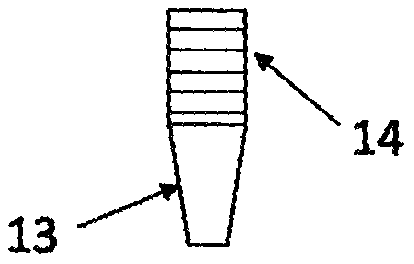

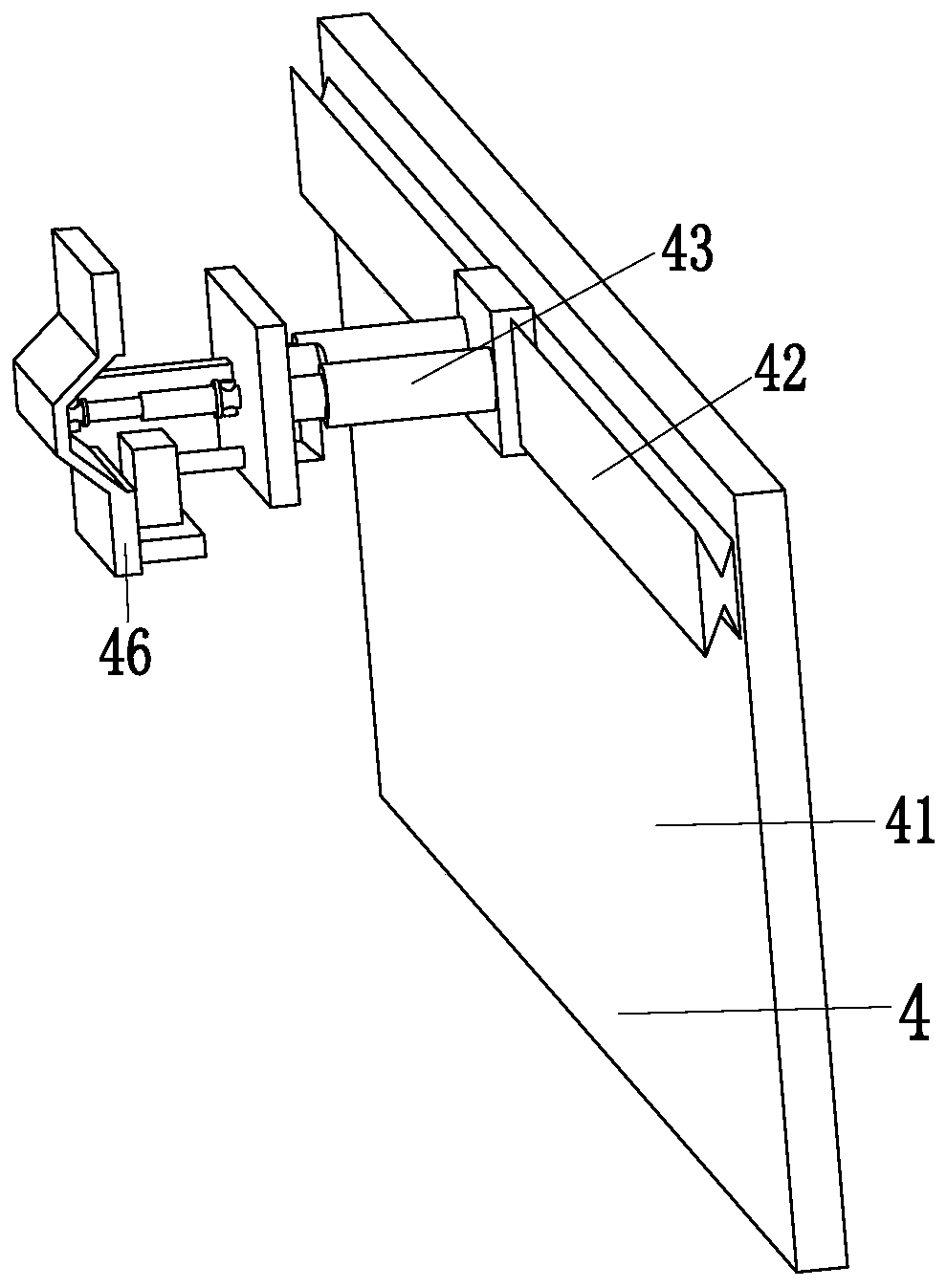

Stepped composite reaming and rock waste removal tool

The invention discloses a stepped composite reaming and rock waste removal tool which is a common tool in petroleum drilling and is particularly suitable for reaming and rock waste removal of a horizontal well and a large displacement well. When the horizontal well and the large displacement well are drilled, the situations that the rock waste of a horizontal section is difficult to remove and sometimes the driller encounters with a large section of gravel layer and an evaporite bed commonly exist, and the phenomena that the well wall is unstable and shrinks also exist. Therefore, the steppedcomposite reaming and rock waste removal tool is designed and mainly comprises a drill column body, a hydrophthalmia, a cone underreamer and a reamer underreamer, wherein the external diameter of thereamer underreamer is greater than that of the cone underreamer; the stepped composite reaming and rock waste removal tool is connected into a drill column through upper and lower threads and rotatesalong with rotation of the drill column, during the rotating process, the reaming cutter of the cone underreamer rotates to break rock, the hydrophthalmia at the lower part of the reaming cutter ejects high-pressure drilling fluid to flush the cutter; and when the cutter with a smaller diameter finishes reaming, the upper reamer underreamer with a larger diameter reams for a second time and trimsthe well wall to realize the purpose of removing the rock waste.

Owner:CNPC DRILLING RES INST

A kind of Portland cement preparation method

Owner:黑河关鸟河水泥有限责任公司

Concrete preparation system for recycling waste concrete

InactiveCN114734537AGrinding effectLow costSievingSolid waste managementGear wheelArchitectural engineering

The invention relates to the technical field of concrete preparation, in particular to a concrete preparation system for recycling waste concrete. Comprising a supporting seat, a rotating box is fixedly arranged on the left side of the upper end face of the supporting seat, a rotating box cavity with a rightward opening is formed in the right end face of the rotating box, and moving racks which can move left and right and are vertically symmetrical are arranged on the upper side wall and the lower side wall in the rotating box; according to the device, the stirring motor rotates forwards and the transmission motor rotates backwards to drive the stirring gear in the cavity of the stirring box body to rotate forwards and drive the fixed grinding block to rotate backwards to achieve the grinding effect, and the grinding effect is achieved through repeated cooperation, so that the effect that concrete stones are thoroughly separated into stones and building sand is achieved; the problems that a large amount of land is occupied by the waste concrete and resources are greatly wasted are solved, and the cost is greatly saved by using the waste concrete blocks.

Owner:褚思贝

Flattening device for road pavement concrete

InactiveCN109898393AImprove grinding effectDecrease productivityRoads maintainenceHandrailEngineering

The invention discloses a flattening device for road pavement concrete. The flattening device comprises a flattening plate, a bottom plate, a baffle, a motor shell, a vibration pump, a handrail, a control panel, a transverse rod, a pedal, supporting rods, a base plate, a pushing tip, transmission rods and a rubber pad. The transmission rod is respectively arranged at two ends of the flattening plate; the bottom plate is supported on the transmission rods, the vibration pump mounted on bottom plate; the vibration pump is not in direct contact with the flattening plate, instead, vibration is transmitted to the flattening plate through the two transmission rods; therefore, the pressure of the flattening plate on the road surface is uniform when the concrete road surface is flattened, the flattening effect can be improved, two ends of the flattening plate can be prevented from tilting after being used for a long time to influence the flattening of concrete, the working efficiency is improved, and the supporting rods are arranged at two ends of the motor shell and can rotate to flatten a curve part through the supporting rods. The flattening device has the characteristics that the flattening effect is enhanced, and the curve road surface can be flattened conveniently.

Owner:HUNAN JINGZHENG EQUIP MFG

A multifunctional biological material separation device

InactiveCN105420074BEasy to separateImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic beadBiochemical engineering

Owner:SHANXI ZDGSY BIO SCI CO LTD +1

An automatic sorting organic waste treatment system

ActiveCN105903754BAchieve separationPromote resource utilizationSolid waste disposalResource utilizationLitter

The invention provides an organic garbage treatment system with an automatic classification function. The organic garbage treatment system with the automatic classification function is used for carrying out classification treatment on kitchen garbage, and comprises a grinding-separating device, wherein the grinding-separating device comprises a cylinder block, a stirring device rotationally arranged in the cylinder block, and a spray device facing the interior of the cylinder block; a charge port is arranged in the upper part of the cylinder block; a discharge hole and an unloading port are arranged in the lower part of the cylinder block; the stirring device is used for grinding organic garbage into organic matter particles; a liquid sprayed by the spray device carries the organic matter particles and is rushed out from the discharge hole, and is subjected to resource utilization in the subsequent process; and massive garbage which is difficult to decompose or incapable of being decomposed is automatically discharged from the unloading port. The organic garbage treatment system with the automatic classification function, which is provided by the invention, has the advantages that the occupied space is less, the garbage treatment energy consumption is low, the system is simple to operate, the running cost is low, the generated odour is less, useful parts in the garbage can be effectively recycled, environment cannot be polluted, and the like. The organic garbage treatment system with the automatic classification function can be used as a front-end pre-treatment classification system in a process for treating garbage rich in organic matters, such as kitchen garbage, and can also be used for carrying out automatic garbage classification treatment in a municipal domestic garbage transfer station.

Owner:HONG KONG PRODUCTIVITY COUNCIL

Electric polishing device for beeswax raw stones

InactiveCN110815013AIncrease speedImprove sanding effectPolishing machinesGrinding drivesGear pumpSprayer

The invention discloses an electric polishing device for beeswax raw stones. The electric polishing device comprises a shell, wherein a working box and a collecting hopper are fixedly arranged at thetop of the shell; box doors are embedded in the front face of the shell; a filter box, a return pipe and a water tank are respectively embedded in the interior of the shell; a filter screen is embedded in the interior of the filter box; flow guide plates are embedded in the interiors of the water tank and the filter box; a pump is fixedly arranged at the top of the water tank; a water pumping pipeis fixedly arranged at the bottom of the pump; a water outlet pipe, a motor case and a protection plate are respectively embedded in the interior of the working box; a rotating shaft is movably connected to the inner side of the protection plate; a blade is fixedly connected to one side of the rotating shaft, and a driven gear is welded to the other side of the rotating shaft; a motor is embeddedin the interior of the motor case; a driving gear is welded to one side of the motor; and a sprayer is fixedly connected to one end of the water outlet pipe. According to the electric polishing device for the beeswax raw stones, the problem of poor polishing effect of an existing device is solved through arranging the sprayer, the driving gear, the pump and the water tank.

Owner:泰州市汇顶机械制造有限公司

Printing paint production grinding machine for advertisement manufacturing

InactiveCN111871508AEfficient grindingThere will be no incomplete grindingCombination devicesGas treatmentAir pollutionIndustrial engineering

The invention discloses a printing paint production grinding machine for advertisement manufacturing. The grinding machine comprises a closed grinding cylinder, a primary grinding box is mounted at the top end of the closed grinding cylinder, a peculiar smell removal mechanism is further mounted outside the primary grinding box, a roller grinding mechanism is arranged at an inlet of the primary grinding box, and an impact grinding assembly is arranged inside the closed grinding cylinder. The impact grinding assembly comprises a dispersing base plate installed in the closed grinding cylinder, aplurality of sets of impact media are arranged on the dispersing base plate, a vibration assembly is further installed on the surface of the dispersing base plate, the roller grinding mechanism comprises a plurality of grinding rollers arranged in parallel, temperature adjusting mechanisms are further arranged in the grinding rollers, and fine grinding assemblies are further arranged on the grinding rollers. The primary grinding box and the closed grinding cylinder are connected through a uniform dispersion hopper. According to the device, a printing paint raw material is further refined in astep-by-step grinding manner, the grinding effect is improved, meanwhile, in the grinding process, the temperature is convenient to adjust, the raw material is prevented from going bad, peculiar smell gas is absorbed in time, and air pollution is prevented.

Owner:郭晚春

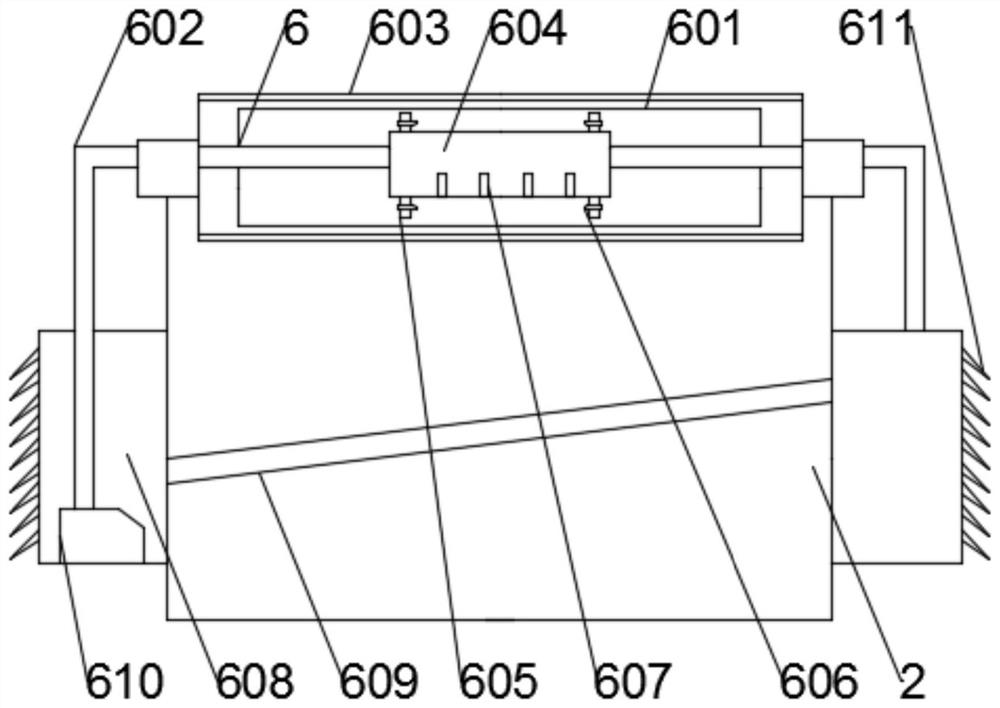

An automatic processing platform for polystyrene particle partition wall panels and an automatic processing method for partition wall panels

ActiveCN109015250BEfficient removalClean up thoroughlyGrinding drivesGrinding machinesEngineeringPolystyrene particle

The invention relates to a polystyrene particle partitioning wall plate automatic processing platform and a partitioning wall plate automatic processing method. The polystyrene particle partitioning wall plate automatic processing platform comprises a supporting bottom plate, a conveying bracket, a guide device and a polishing device. The conveying bracket is mounted at the top of the left end ofthe supporting bottom plate. The guide device is mounted at the upper end face of the middle of the supporting bottom plate. The polishing device is mounted at the top of the rear end of the supporting bottom plate. The polishing device comprises a polishing supporting plate, a polishing electric sliding block, polishing electric push rods, a polishing connecting plate, a guide connecting block, ascraper, an adjusting push rod, a dust suction pump, a sucking pipe and a sucking connecting block. The polystyrene particle partitioning wall plate automatic processing platform can solve the problems that when an existing polystyrene particle partitioning wall plate is fabricated, polystyrene particle partitioning wall plate conveying is difficult, during polystyrene particle partitioning wallplate polishing, effective fixing can not be achieved, shaking occurs after polystyrene particle partitioning wall plate fixation, and during polystyrene particle partitioning wall plate polishing, polystyrene particles can not be removed thoroughly, the polystyrene particle partitioning wall plate polishing effect is poor.

Owner:NANTONG YIHUA PLASTIC

Vanadium product raw material production integrated device

The invention discloses an integrated device for producing raw materials of vanadium products, which solves the problems of a mixing dead zone in a mixing agitator in the device, poor mixing and mixing effect, and low discharging efficiency. The integrated device for producing raw materials of vanadium products includes a frame, a mixing mixer, a pelletizing machine, and a baking device. Stirring, ball making, and baking are integrated into the production of raw materials for vanadium products; the mixing mixer includes a box body, a main drive shaft is set in the box, a support arm is set on the main drive shaft, hinged rollers are mounted on the support arm, and the main drive shaft The lower section is also equipped with an arc-shaped sweeping plate, which can push the material located in the middle of the bottom of the box to the roller, so that the effect of grinding and stirring is better, and the problem of the dead zone of stirring under the support arm is solved. , significantly improved the effect of stirring and mixing, and improved the efficiency of raw material production of vanadium products.

Owner:攀枝花市仁通钒业有限公司

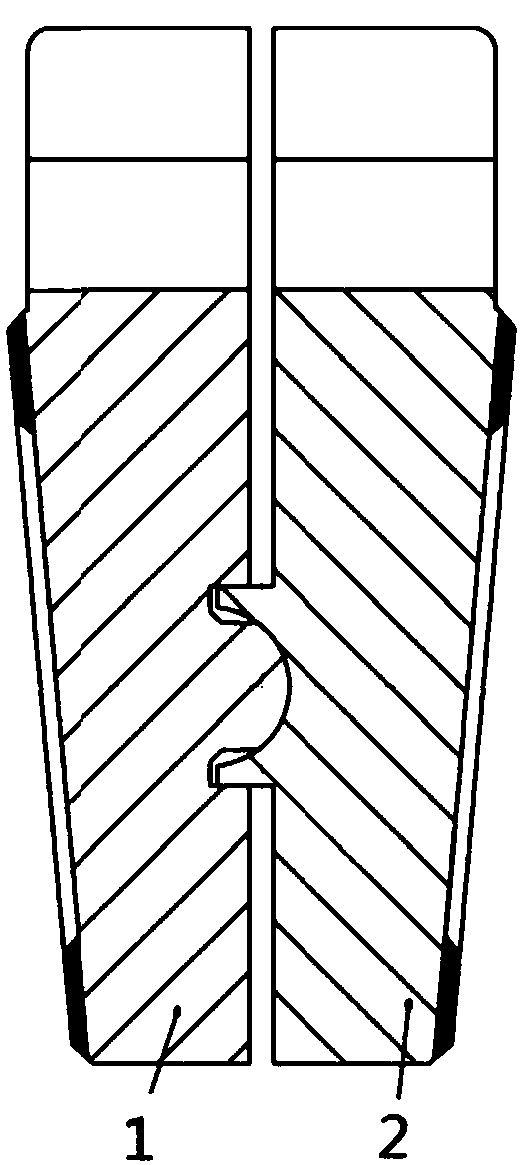

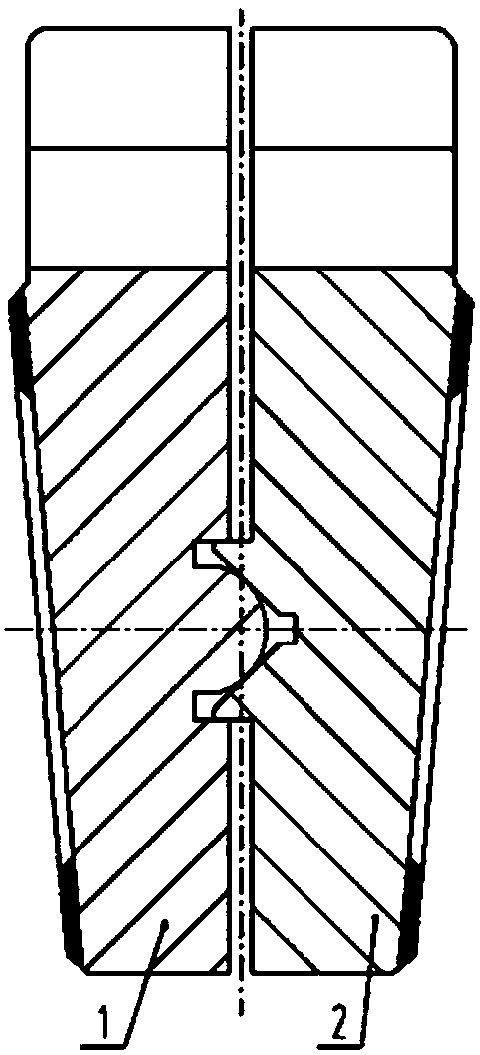

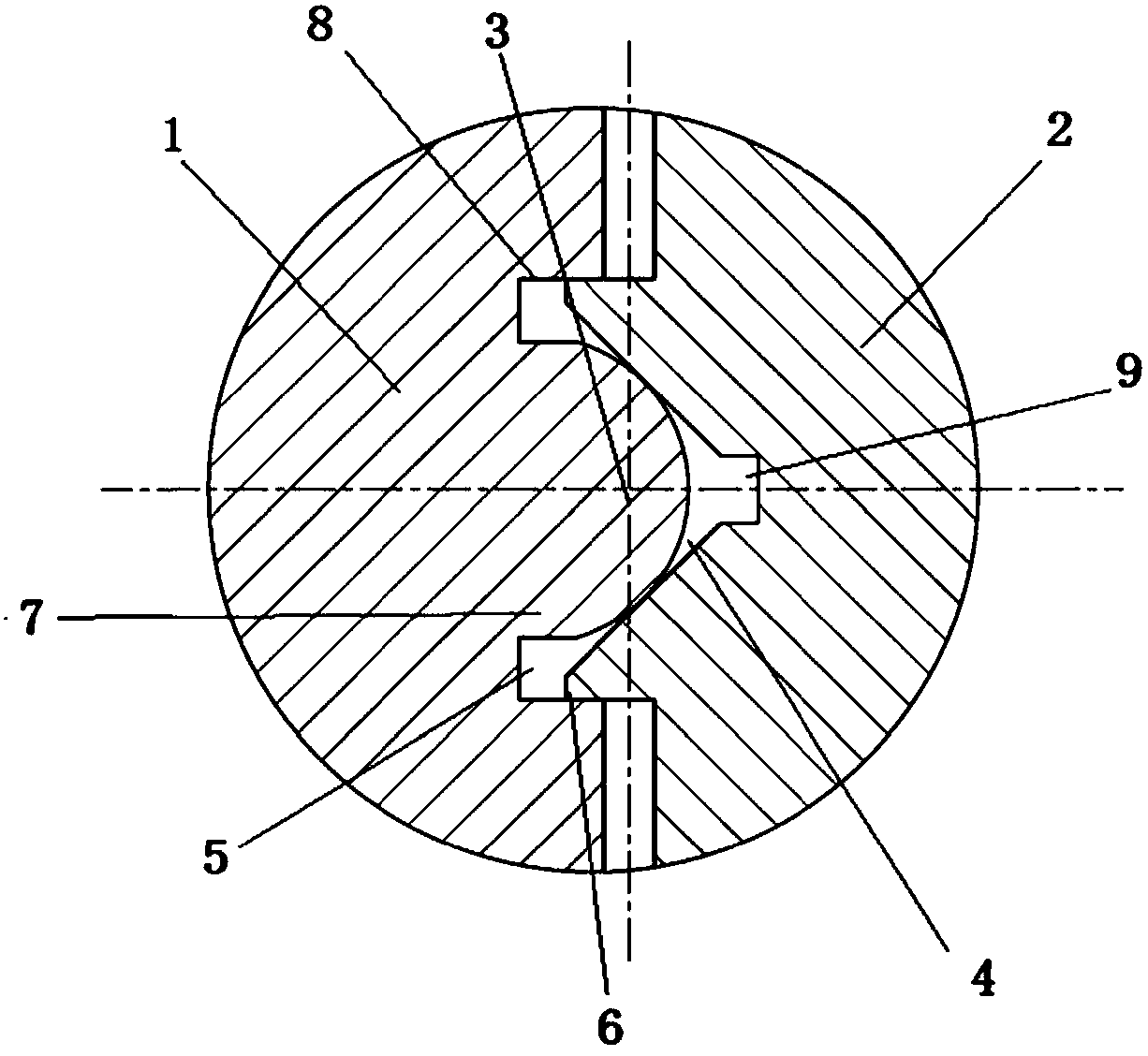

Wedge type double gate plate structure with V-shaped conical surface

The invention belongs to the technical field of valves, and particularly relates to a wedge type double gate plate structure with a V-shaped conical surface. The wedge type double gate plate structurecomprises a gate plate A and a gate plate B which are oppositely arranged, a semi-spherical protrusion is arranged on the butt joint surface of the gate plate A, the V-shaped conical surface is arranged on the butt joint surface of the gate plate B, the semi-spherical protrusion is positioned in the V-shaped conical surface, the vertex of the semi-spherical protrusion is located outside the buttjoint surface where the semi-spherical protrusion is located, namely the vertex of the semi-spherical protrusion is higher than the butt joint surface, and the edge of the V-shaped conical surface extends out of the butt joint surface of the gate plate B where the V-shaped conical surface is located. The convex spherical surface of the gate plate A always rolls on the V-shaped concave conical surface of the gate plate B, therefore, on one hand, the phenomenon that the two gate plates do not fit due to the processing size error can be avoided, the friction force between the two gate plates cannot be increased along with the increase of the running time, due to continuous grinding, the spherical surface can tend to be smooth, the friction force between the two gate plates is reduced, the motion of the spherical surface is facilitated, and the phenomenon that the gate plates are clamped can be prevented.

Owner:SUFA TECH IND CNNC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com