Airplane transmission gear grinding device

A transmission gear and tooth grinding technology, which is applied to gear tooth manufacturing devices, belts/chains/gears, gear teeth, etc., can solve the problems of inability to grind the tooth surface and low processing precision of the grinding machine, and achieve the effect of convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

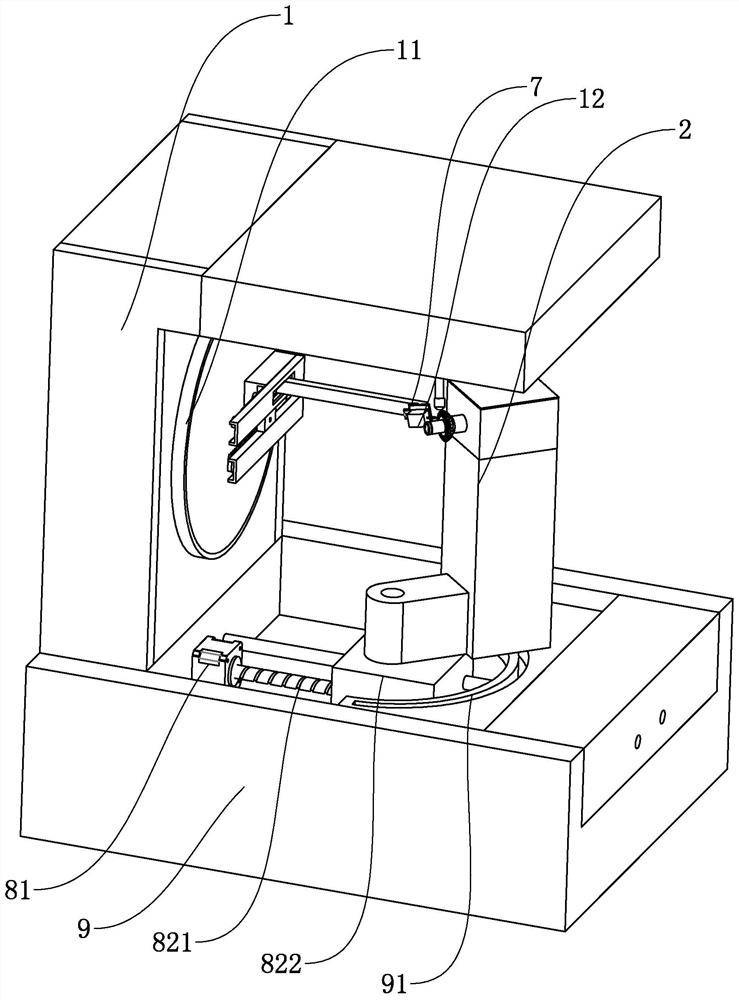

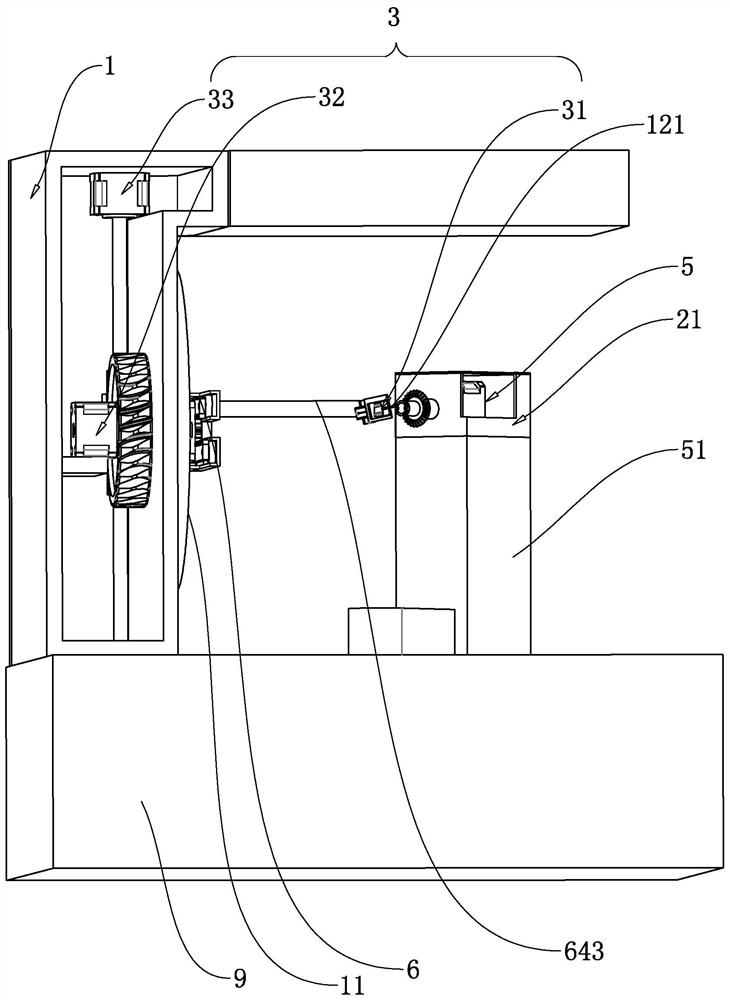

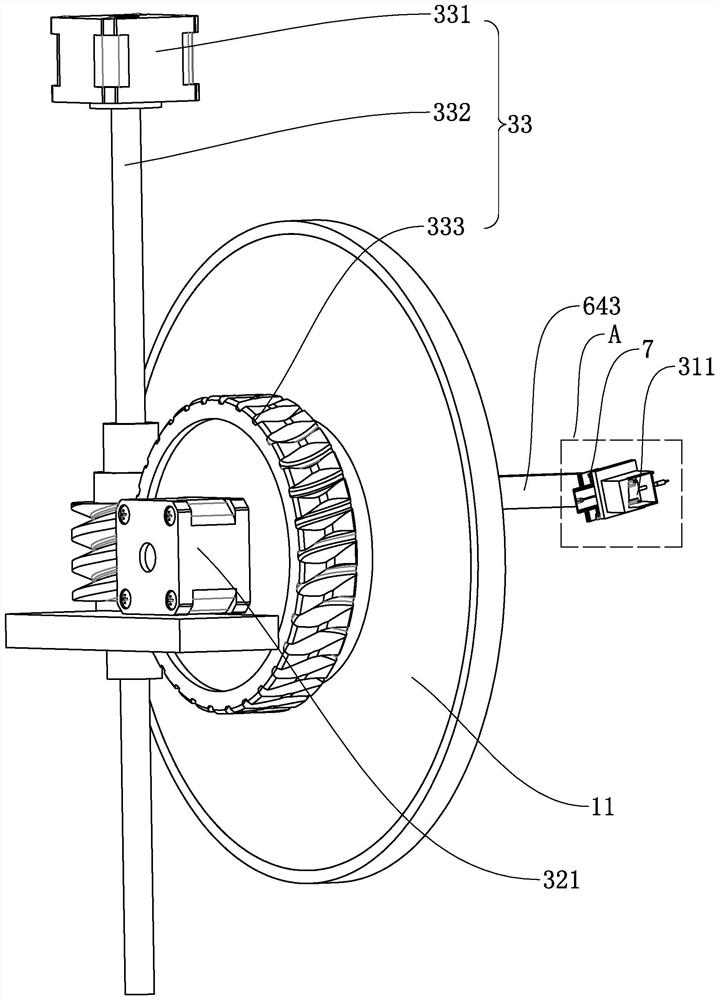

[0036] The following is attached Figure 1-7 The application is described in further detail.

[0037] The embodiment of the present application discloses an aircraft transmission gear grinding device. refer to figure 1 and 2 , The gear grinding device includes a grinding head lathe 1 and a workpiece lathe 2, the grinding head lathe 1 is connected with a sliding table 9, and the workpiece lathe 2 is slidably connected with the sliding table 9. Grinding head lathe 1 is fixed with adjusting mechanism, driving mechanism 3, cradle 11 and grinding head seat 12, and grinding head 121 is installed on the grinding head seat 12, and grinding head seat 12 is positioned at the end of cradle 11 close to workpiece lathe 2, and Fixedly connected with the adjustment mechanism. Before the grinding head 121 grinds a specific workpiece, the adjusting mechanism adjusts the position of the grinding head according to the model of the bevel gear part of the workpiece. When the grinding head 121...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com